Page 1

SERVICE MANUAL

MB593200612SERVICE MANUAL

CD PORTABLE SYSTEM

RC-EZ35SB,RC-EZ35SE,

RC-EZ35SEN,RC-EZ35SEV,

RC-EZ31BB,RC-EZ31BE,

RC-EZ31BEN,RC-EZ31BEV

SERVICE POLICY

No service part is available for this model.

Exchange only.

COPYRIGHT © 2006 Victor Company of Japan, Limited

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

COPYRIGHT © 2006 Victor Company of Japan, Limited

No.MB593

2006/12

Page 2

SPECIFICATION

RC-EZ35

Compact disc player section Type Compact disc player

Signal detection Non-contact optical pick-up (semicondicator lazer)

Number of channels 2 channels

Radio section Frequency ranges FM 87.5 MHz - 108.0 MHz

AM 522 kHz - 1 629 kHz

Antennas Telescopic antenna for FM

Ferrite core antenna for AM

Cassette deck section Track 4-track 2-channel stereo

Motor Electronic governor DC motor for capstan

Heads Hard permalloy head for recording/playback, magnetic head for erase

Fast wind time Approx. 120 sec. (C-60 cassette)

General Speaker 10 cm × 2 (4 Ω, 3 W)

Power output 4 W (2 W + 2 W) at 4 Ω (10% THD) (IEC268-3)

Output terminals PHONES × 1 (Ø 3.5 mm, stereo)

Power supply AC 230 V , 50 Hz

DC 12 V ("R20/D (13F)" cells × 8)

Power consumption 17 W (at operation)

1.5 W (at standby)

Dimentions 435 mm (W) × 156 mm (H) × 241 mm (D)

Mass Approx. 2.8 kg (without batteries)

RC-EZ31

Compact disc player section Type Compact disc player

Signal detection Non-contact optical pick-up (semicondicator lazer)

Number of channels 2 channels

Radio section Frequency ranges FM 88 MHz - 108.0 MHz

AM 530 kHz - 1 600 kHz

Antennas Telescopic antenna for FM

Ferrite core antenna for AM

Cassette deck section Track 4-track 2-channel stereo

Motor Electronic governor DC motor for capstan

Heads Hard permalloy head for recording/playback, magnetic head for erase

Fast wind time Approx. 120 sec. (C-60 cassette)

General Speaker 10 cm × 2 (4 Ω, 3 W)

Power output 4 W (2 W + 2 W) at 4 Ω (10% THD) (IEC268-3)

Output terminals PHONES × 1 (Ø 3.5 mm, stereo)

Power supply AC 230 V , 50 Hz

DC 12 V ("R20/D (13F)" cells × 8)

Power consumption 13 W (at operation)

1.5 W (at standby)

Dimentions 435 mm (W) × 156 mm (H) × 241 mm (D)

Mass Approx. 2.8 kg (without batteries)

Design and specifications are subject to change without notice.

1-2 (No.MB593)

Page 3

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

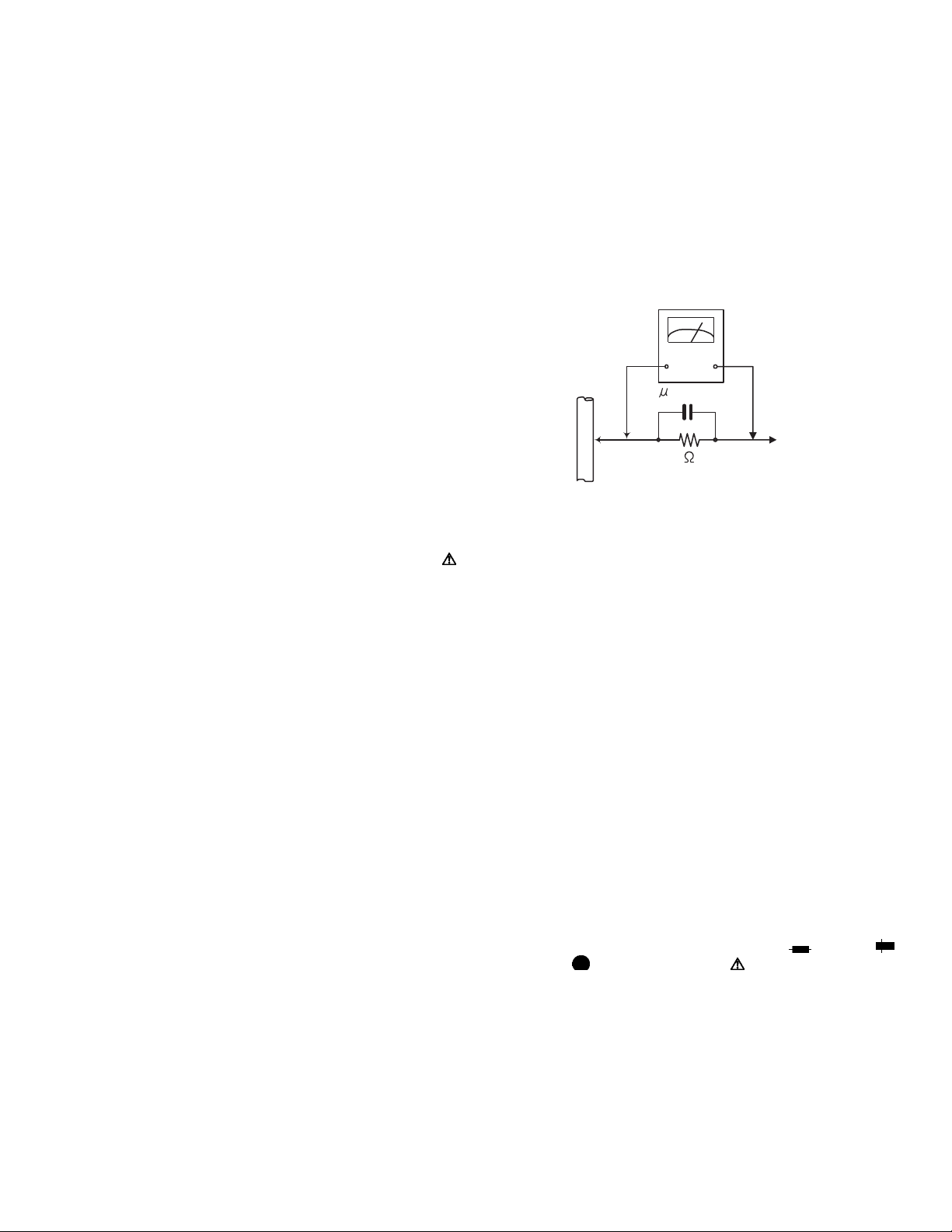

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following manner. Connect a 1,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an ex-

posed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

Good earth ground

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each exposed

metal part.

(No.MB593)1-3

Page 4

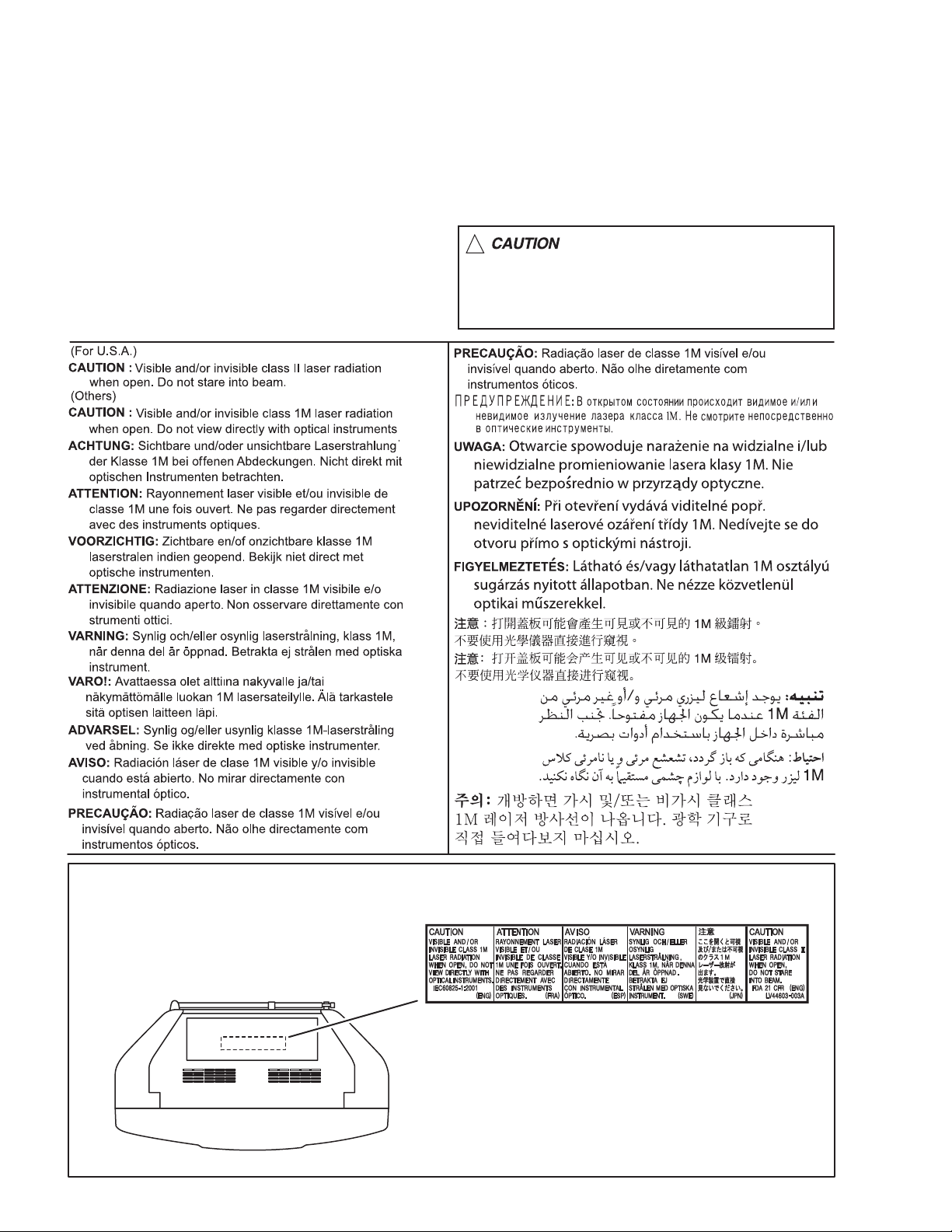

1.5 Important for laser products

1.CLASS 1 LASER PRODUCT

2.CAUTION :

(For U.S.A.) Visible and/or invisible class II laser radiation

when open. Do not stare into beam.

(Others) Visible and/or invisible class 1M laser radiation

when open. Do not view directly with optical instruments.

3.CAUTION : Visible and/or invisible laser radiation when

open and inter lock failed or defeated. Avoid direct

exposure to beam.

4.CAUTION : This laser product uses visible and/or invisible

laser radiation and is equipped with safety switches which

prevent emission of radiation when the drawer is open and

the safety interlocks have failed or are defeated. It is

dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified here in may result in

hazardous radiation exposure.

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

REPRODUCTION AND POSITION OF LABELS and PRINT

WARNING LABEL and PRINT

1-4 (No.MB593)

Page 5

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

(No.MB593)1-5

Page 6

SECTION 3

DISASSEMBLY

3.1 Main body

3.1.1 Removing the Rear cabinet assembly

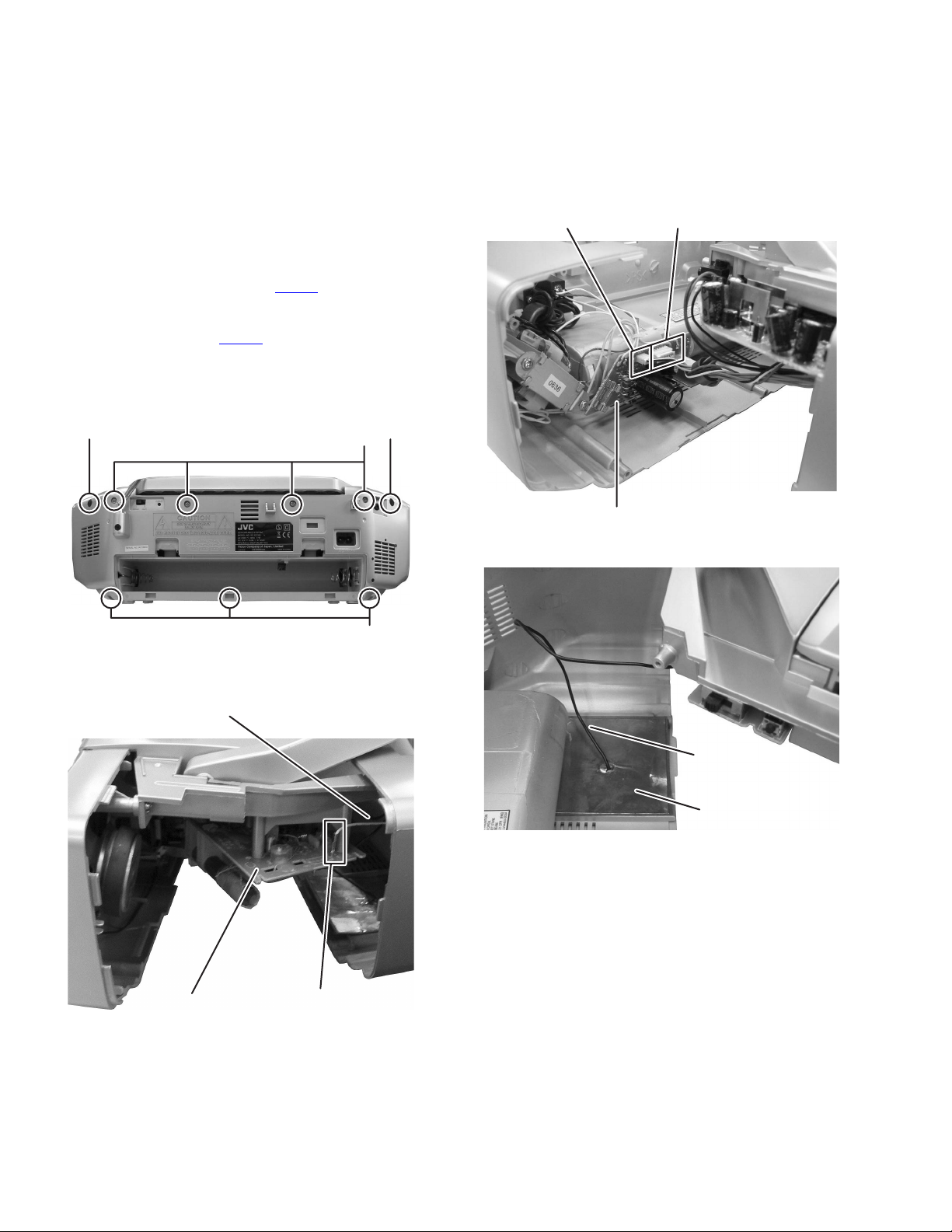

(See Fig.1 to 4)

(1) Remove the four screws A and five screws B attaching the

Rear cabinet assembly. (See Fig.1)

(2) Disconnect the Rod antenna wire from post pin of the Tun-

er board assembly. (See Fig.2)

(3) Disconnect the connector wire from Amplifier board as-

sembly connected to connector CN101

former board assembly. (See Fig.3)

(4) Disconnect the connector wire from Capstan motor con-

nected to connector CN102

board assembly. (See Fig.3)

(5) Remove the solder the grand wire from Tuner board sol-

dered to shield plate. (See Fig.4)

of the Power transformer

of the Power trans-

BB

A

CN101CN102

Power transformer board

Fig.1

Rod antenna wire

Fig.3

B

Ground wire

Shield plate

Fig.4

1-6 (No.MB593)

Tuner board assembly Post pin

Fig.2

Page 7

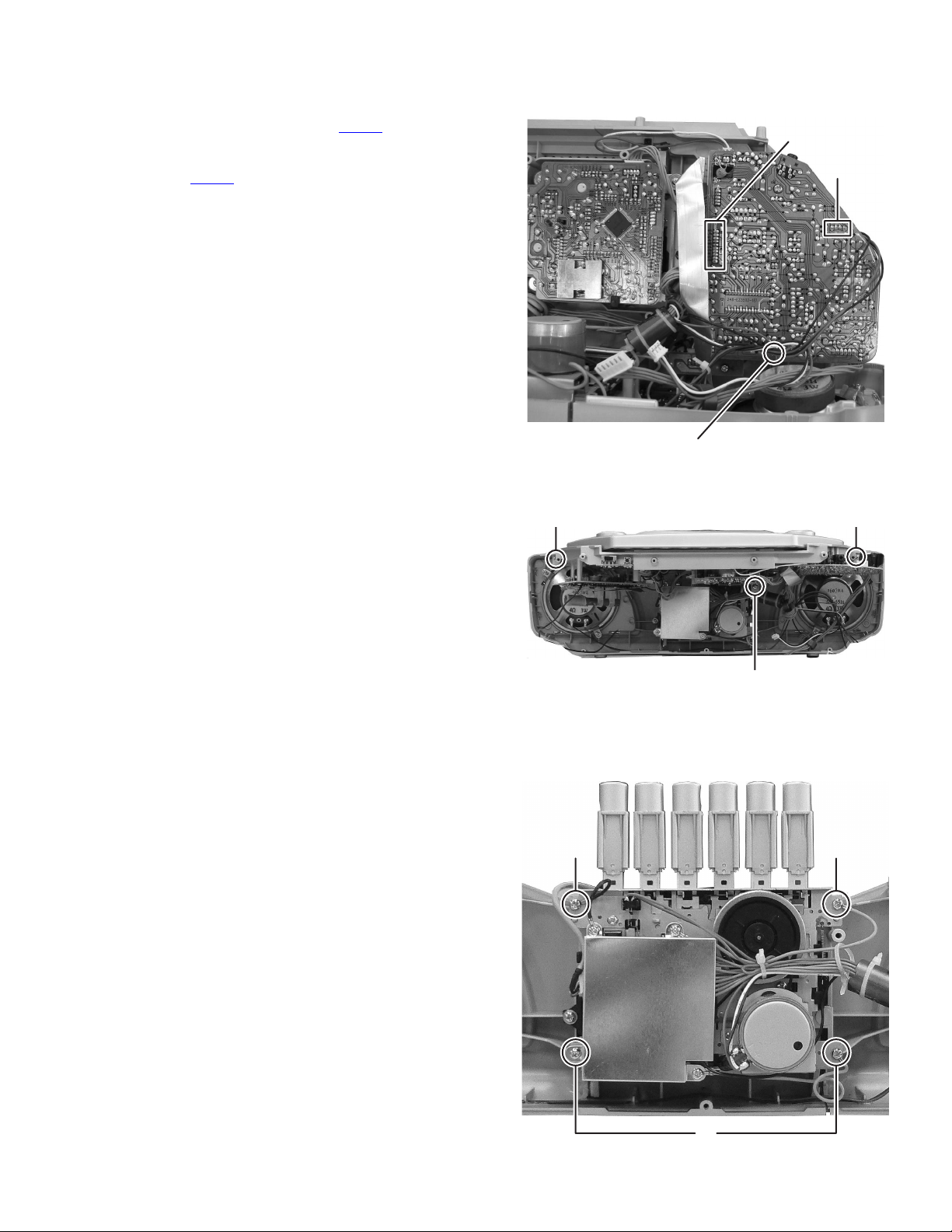

3.1.2 Removing the Top cabinet assembly

(See Fig.5, 6)

(1) Disconnect the connector wire from Cassette mechanism

assembly connected to connector CN205

board assembly. (See Fig.5)

(2) Disconnect the connector wire from speaker connected to

connector CN301

Fig.5)

(3) Remove the solder the grand wire from Cassette mecha-

nism assembly soldered to Amplifier board assembly. (See

Fig.5)

(4) Remove the three screws C attaching the Top cabinet as-

sembly. (See Fig.6)

of the Amplifier board assembly. (See

of the Amplifier

CN205

CN301

Ground wire

Fig.5

CC

3.1.3 Removing the Cassette mechanism assembly

(See Fig.7)

(1) Remove the four screws D attaching the Cassette mecha-

nism assembly.

C

Fig.6

DD

D

Fig.7

(No.MB593)1-7

Page 8

3.1.4 Removing the Amplifier board assembly

(See Fig.8, 9)

(1) Disconnect the card wire from LCD board assembly con-

nected to connector CN701 of the Amplifier board assembly. (See Fig.8)

(2) Disconnect the connector wire from Amplifier board as-

sembly connected to connector CN901

board assembly. (See Fig.8)

(3) Disconnect the connector wire from CD door switch con-

nected to connector CN906

bly. (See Fig.8)

(4) Disconnect the connector wire from Amplifier board as-

sembly connected to connector CN101

assembly. (See Fig.9)

(5) Disconnect the connector wire from Amplifier board as-

sembly connected to connector CN801

jack board assembly. (See Fig.9)

(6) Remove the three screws E attaching the Amplifier board

assembly. (See Fig.8)

of the Amplifier board assem-

of the CD servo

of the Tuner board

of the Headphone

CN701 CN906

Amplifier board

assembly

E

assembly

CN801

CN901CD servo board

Fig.8

E

1-8 (No.MB593)

Fig.9

Page 9

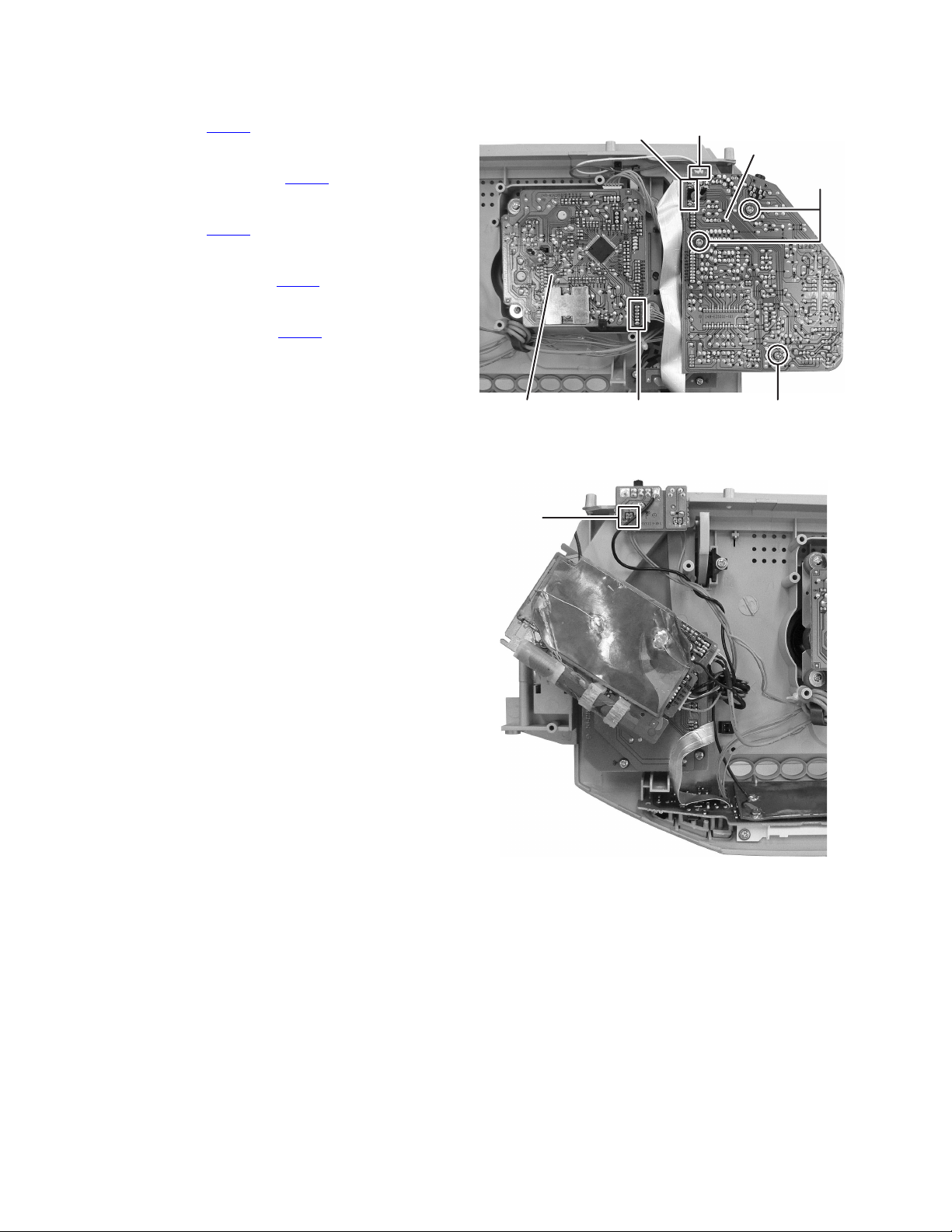

3.1.5 Removing the Headphone jack board assembly

(See Fig.10)

(1) Remove the solder the grand wire from LCD board assem-

bly soldered to Headphone jack board assembly.)

(2) Remove the one screw F attaching the Headphone jack

board assembly.)

(3) Disconnect the connector wire from Function board assem-

bly connected to connector CN707

board assembly.

3.1.6 Removing the Tuner board assembly

(See Fig.11)

(1) Remove the solder of the grand wire from Function board

assembly soldered to Tuner board assembly.

(2) Disconnect the connector wire from Function board assem-

bly connected to connector CN102

sembly.

(3) Remove the tree screws G attaching the Tuner board as-

sembly.

of the Headphone

of the Tuner board as-

G

F

Solder point

Ground wire

CN707

Fig.10

Fig.11

G

Solder point

CN102

(No.MB593)1-9

Page 10

3.1.7 Removing the Function board assembly

(See Fig.12)

(1) Disconnect the card wire from LCD board assembly con-

nected to connector CN103 of the Function board assembly.

(2) Remove the four screws H attaching the Function board

assembly.

HH

3.1.8 Removing the Power switch board assembly

(See Fig.13)

(1) Disconnect the connector wire from LCD board assembly

connected to connector CN709

assembly.

(2) Remove the three screws J attaching the Power switch

board assembly.

of the Power switch board

H

CN103

Fig.12

Fig.13

H

J

J

CN709

1-10 (No.MB593)

Page 11

3.1.9 Removing the LCD board assembly

(See Fig.14)

(1) Remove the two screws K attaching the LCD board assem-

bly.

3.1.10 Removing the CD mechanism assembly

(See Fig.15)

(1) Removing the four screws L attaching the CD mechanism

assembly.

KK

Fig.14

L

L

SECTION 4

ADJUSTMENT

L

L

Fig.15

This service manual does not describe ADJUSTMENT.

(No.MB593)1-11

Page 12

< MEMO >

Page 13

SECTION 5

TROUBLESHOOTING

5.1 BLOCK DIAGRAM

5.1.1 Block diagram for RC-EZ35

FM ANT.

AM ANT.

CD DOOR SW.

BPF

FM RF FM OSC

IC101

FM F/E, IF/DET/MPX

AM RF/IF/DET

AM OSC

IC102

PLL

+8V

TU SW.

IC501

FUNCTION SELECT

EQ/BASS/VOL CONTROL

RESET

PLAY OUT

REC IN

IC201

R/P AMP

+8V

TA SW.

DECK SW

BIAS OSC

R/P HEAD

+

M

-

TAPE MOTOR

DISC

PICKUP

+

M

-

SPINDLE MOTOR

+

M

-

SLED MOTOR

IC901

RF + D-SERVO +

MP3 DECODER+1M DRAM

IC902

SERVO DRIVER

Q902

+8V

CD SW.

+8V

Q401

D2061

IC701

MCU

P-CON

POWER

SW.

LCD

KEY

R.C.

+5V

Q411

L SPEAKER BOX

IC301

POWER AMP.

R SPEAKER BOX

RECTIFIER

AC IN

2-13

Page 14

5.1.2 Block diagram for RC-EZ31

R/P HEAD

IC201

FM ANT.

FM RF

BPF

AM ANT

IC501

SIGNAL SELECT SW.

FM OSC.

IC101

FM F/E, IF/DET/MPX

AM RF/IF/DET.

AM OSC

VOL

TU-5V

REG.

L SPEAKER

IC301

POWER AMP.

DISC

PICKUP

SPINDLE

MOTOR

SLED

MOTOR

CD DOOR

LEAF SW

R SPEAKER

M+

LCD

IC901

DSP

M

IC903

MOTOR/ACTUATOR

DRIVER

M

Q902

IC902

MCU

KEY

TU SW.

TA SW.

CD SW.

Q401

DC SUP

SW

M-

RECTIFIER

CASS MOTOR

AC INPUT

TRANSFORMER

2-14

Page 15

5.2 STANDARD SCHEMATIC DIAGRAMS for RC-EZ35

5.2.1 Primary and Amplifier section

CN906

Q412

9014

TO CD DOOR LEAF SW.

CN710

1

2

3

4

5

6

7

8

9

10

11

12

13

TO MCU BOARD CN701

14

15

CN105

4

3

2

1

TO TUNER BOARD CN101

TO CD BOARD CN901

R509

CN905

1

2

3

4

5

R523

15K

C534

OPEN

CN205

10

9

8

7

GND

6

5

4

TO P / R BOARD CN202

GND

3

2

1

CN206

TO CN801

4.7K

R418

10K

R421

10K

C523

R519

3.3K

153M

C533

OPEN

R522

2.7K

ZD404

R520

15K

R411

10K

5V6

R419

R413

R510

R517

R514

3.3K

150

10K

15K

4.7K

C529

C525

R521

2.7K

100P

Q406

9014

153M

R507

Q503

15K

9014

+

C518

C406

100P

Q403

8050

47U

R513

4. 7K

R410

330

Q50 2

9014

R412

470

C405

+

330U

R409

D405

IN4148

R515

1.2K

L SPEAKER

4

3

1

R SPEAKER

JK301

HEADPHONES JACK

ACINPUT

11

2

Q304

8550

B+

R402

22K

DC+

C1105

220U / 16V

R309

2.2

+

C312

1000U

12

1

C311

1000U

+

R308

2.2

403

C1104

403

+

C1102

6800U / 25V

D1104

IN4001

D1102

IN4001

BATT

C1103

C1101

D1103

IN4001

403

403

R310

D1101

R311

100

L302

FX1101

2A

IN4001

100

125V

L303

15UH

15UH

AC-IN1

AC-IN2

BT -

CN301

4

3

22

1

15UH

L301

POWER / TRANSFORMER

CW301

C310

IC301

C307

100U

+

13

14

+

C308

100U

C316

470U / 25V

R314

10K

Q402

9014

D401

IN4148

223

C401

0.1M

10

3

+

C309

0.1M

+

C404

C302

100U

+

C303

100U

R307

7

6

R306

+

+

+

33K

C403

470U / 16V

C306

100U

+

120

8

5

120

C407

1000U / 25V

Q303

9014

C315

470U / 25V

R401

330

Q401

D2061

+

8V2

ZD401

9

UTC8227

4

1 / 4W

C313

+

22

R405

Q404

9014

10K

R404

10K

Q408

9014

R414

470

Q409

8550

R425

Q407

8550

D404

IN4148

Q415

9014

SHORT

R508

68K

C520

R503

500P

3.9K

C507

+

C508

1U

+

13

15

14

R1

NC

R2

C521

1U

+

C504

9

+

C505

1U

8

RIN

LC75342

272M

0.1M

C503

7

RTRE

RBASS1

1U

C506

+

1U

10

12

11

R3

R4

RSEL0

IC501

R406

470

R415

10K

1 / 4W

9014

Q410

C402

22U

+

R408

10K

R407

47K

3V

ZD403

D402

IN4148

Q411

8050

R417

3.3K

R416

5.6

1 / 4W

6V2

ZD402

C408

100U

+

R302

1K

R303

1K

D302

15K

D406

IN4148

R501

15K

Q405

A928A

R301

+

100U

C409

8.2K

R427

1K

R304

18K

0.1M

+

C501

4.7U

C502

6

RBASS2

3

2

4

5

CE

VSS

TEST

ROUT

C532

102

C531

102

1

DI

R502

R315

IN4148

+

47K

C301

3.3U

Q301

1936

Q302

1936

CN401

LBASS1

25

0.1M

R506

3.9K

LBASS2

C511

LOUTNCVREF

27

26

+

C509

4.7U

0.1M

R305

18K

VDD

CL

29

30

28

C510

+

22U

+

C519

100U

R428

68K

R504

15K

C530

102

R505

100

CW1102

+

-

C410

220U / 25V

+

R317

+

47U

C412

4.7K

M

MOTOR

CASSETTE DECK

Q413

9014

R423

10K

D403

IN4148

R403

10K

C411

10UF

+

R420

5.6K

16

R518

4. 7K

NC

L2

L1

L3

17

R512

1.2K

+

C516

C517

Q501

9014

1U

1U

R516

22K

18 19

+

20

+

C515

1U

Q414

9014

R426

+

C528

22U

LIN

LESL0

L4

21

C527

1U

R511

1K

R422

2.2K

22

+

68K

R424

SHORT

C514

1U

C513

272M

C526

500P

LTRE

24

23

C512

1U

102

C304

102

C305

C314

+

1U

R316

4.7K

D301

R312

IN4148

10K

6

6

5

5

4

4

3

3

2

2

1

1

3

3

22

1

1

CN1102

R313

CN1101

CN801

TO AUDIO BOARD CN206

TO CONTROL BOARD CN707

1

2

CN711

R805

10

SW801- A

SW719

Rese t

2-15

Page 16

5.2.2 Front section

CN702

5

4

3

2

1

TO CD BOARD CN903

CN701

15

14

13

12

11

10

9

8

7

6

5

4

3

TO AUDIO BOARD CN710

2

1

B03

R722

R701

27K

R726

1K

R728

100

R710

R725

10K

100

R727

1K

R702

100

MP3MP3

TRACK

FOLDER

REPEAT

ALL

RANDOM

PROGRAM

INTRO

CLASSIC

4

5

6

S7

S6S5S4

1

2

3

4

5

6

7

8

9

10

1

2

CN704

SLEEP

kHz

MHz

2

3

S3

10

9

8

7

6

5

4

3

2

1

CN706

1

2

CN709

1

S1

S2

S[1: 34]

B01

B02

B03

B04

B05

B06

B[01:06]

R785 R783

2.2K

SW714

PRESER UP

REPEAT

SW709

STANDBY

CN708

TO TUNER BOARD CN102

3

2

5

4

B02

B03

B04

B01

R786

SW713

R781

1.2K

SW710

VOL UP

390

SW716

TUNER

3.9K

FM MODE

R782

3.3K

CN707

TO BEAT CUT BOARD CN711

R784

1.2K

SW717

TAP E

2

B06

R787

4.7K

SW718

PROGR

/CLK

1

B05

R780

4.7K

SW711

VOL DOWN

1

SW712

HBS

SW715

EQ

LCD701

USB

33

34

COM03

COM01

COM02

COM04

S23

47

48

S23

S22

OPT_SYS1(I, - )

IF_ RST(0,Nch)

14

13

102

C704

R705

R706

104

C703

S21

S22

464544

S21

KEY0( I,- )

15

56K

4.7K

R707

68K

D701

R720

S20

S20

KEY1( I,- )

16

4.7K

R708

C720

-

+

C714

2.2UF

IN4148

S19

S19

KEY2( I,- )

17

R711

4.7K

102

1K

D705

IN4148

S18

S17

42

43

S17

S18

VSS2

VDD2

IR(I,-)

ST(I,-)

V_GND(0,CM)

V_CHK( I,-)

SW_CD( I,-)

18

19

6.8K

R750

R714

10K

R718

S16

41

40

S16

39

38

S15

37

S14

36

S13

35

S12

34

S11

33

S10

32

S9

31

S8

30

S7

29

S6

28

S5

27

S4

26

S3

25

S2

24

S1

23

22

21

IF_REQ( I,-)

20

R751

5.6K

C707

47K

Q703

9015

R719

100K

L701

100UH

ZD701

102

C713

3.9V

R736

390

+

-

2200UF

Q704

9015

S26

IC701

8MHz

X702

C711

R715

51

S26

CF2( 0)

10

22P

S25

50 49

S25

VDD1

11

S24

OPT_CT (I, - )

12

C702

10K

S24

102

S30

S28

S27

S29

60

59 58

57

56

54

55

53 52

COM01

47K

47K

R753

R754

C701

100P

C724

102

680P

C716

R744

100

1K

47K

47K

47K

R745

R731

R732

D704

L702

IN4148

100UH

47K

R752

47K

R721

R735

R729

47K

COM02

COM03

COM[01:04]

COM04

1K

1K

R730

680P

C723

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

680P

C722

COM1

COM2

JOG-(I,ex-PU)

JOG+(I,ex-PU)

COM3

COM4

P_ PCON(0 ,CM)

VSS3

VDD3

AMUTE(0,CM)

P_ TU( 0 ,Nch)

P_ CD( 0 ,Nch)

IF_ IN(0 ,Nch)

TR_ M- ( 0 ,Nch)

TR_ M+ ( 0 ,Nch)

CD_ RST( 0 ,Nch)

CD_ CE( 0 ,Nch)

TUEV_ CE( 0 ,Nch)

CD_ CMD(0 ,CM)

CD_ DATA ( I,-)

CD_ CLK

IF_ CLK( 0 ,CM) / TX

(I, -) / RX

TUEV_DI(0,CM)

IF_OUT

2

1

100

100

R741

R742

680P

C721

S31

S32

SYN_REC(I,ex-PU)

/RES(I,ex- PU)

TUEV_CL(0,CM)

TUEV_D0( I, -)

5

4

3

100

X701

R743

32.768KHz

C709

15P

S30

XT1(I)

6

R723

4.7M

S29

S27

S28

LC877C64C-57K1

VSS1

XT2( 0)

CF1(I)

8

7

9

R724

680K

C710

15P

C708

22P

D702

IN4148

R717

100K

LED702

Amber Back Light

LED701

Standby

R733

10K

C715

102

Q702

9014

R716

47K

R734

3.3K

D703

IN4148

B02

B01

B04

32

S15

S14

S13

S12

S11

S10

S9

S8

S7

S6

S5

S4

S3

S2

S1

WMA

31

292827

30

S30

S29

S28

26

S27

STEREO

23

25

24

S26

S24

S23

S25

S12

POP

9

8

S10

7

S9

S8

11

10

S11

HBS

21

22

20

S22

S21

S20

ROCK

19

17

16

18

S17

S19

S18

S16

JAZZ

13

12

15

14

S14

S15

S13

B[ 01:06]

CN703

C712

104

REM701

B01

B02

B03

B04

B05

B06

R749

R747

SW707

F.B .

1.2K

B05

B06

R748

SW706

F.F.

470

R712

3.3K

Q701

9015

R713

47K

R704

C706

47K

JP1

C718

220UF

102

R703

3.9K

+

-

R737

R738

C705

820

US1

102

3.3K

SW701

PLAY

R791

4.7K

C719

104

R709R709

R792

6.8K 8.2K

US2

390

SW702

RANDOM

EU1

SW703

DISPLAY

R793

C717

3K

R740

R739

SW708 SW704

FOLDER+ FOLDER-

R794

10K

EU3

EU2

680P

1.2K

R795

12K

R746

AS

100

2K

SW705

STOP

2-16

Page 17

5.2.3 CD servo section

CN902

PICKUP

SW901

Limit Switch

MOTOR1

SLED

M

M

MOTOR2

SPINDLE

VC

VCC

GND

LD

VR

PD

F+

T-

T+

F-

C936

-

+

4.7UF

R938

33

R939

150

R941

150

78

77

79

SLC0

AVDD

RCH0

LRVSS

TD0

FD0

AVDD

SLD0

2324252627

22

15K

R907

R940

767574

LCH0

LRVDD

SPD0

VVSS1

6.8K

R908

-

C916

C939

C903

-

C908

103

+

R901

330

C907

10UF

+

C901

472

683

104

C914

104

80

1

EFMIN

2

RFOUT

3

LPF

45

PHLPF

AIN

6

CIN

7

BIN

8

DIN

9

FEC

10

RFMON

11

VEEF

12

JITTC

13

EIN

14

FIN

15

TEC

16

TE

17

TEIN

18

LDD

19

LDS

20

AVSS

21

C940

473

C945

104

1

2

E

3

D

4

A

5

B

6

C

7

F

8

9

10

R949

11

100

12

13

14

15

16

R946

33

L902

22uH

R903

R904

3.3

470

C909

104

-

+

C910

100UF

Q901

2SA608NF

C911

103

C912

104

+

C943

33UF

C944

-

R948

100

104

R925

8.2K

C906

102

C946

100UF

R947

100K

R902

+

C947

104

-

8.2K

C902

103

100UF

C905

C913

C904

473

103

47

R909

+

1UF

R910

C932

104

C933

-

+

330UF

R937

73

XIN

XVDD

PDOUT0

PDOUT1

282930

680

R911

2.2M

C935

-

+

4.7UF

16.9344MHz

220

72

XOUT

LC78690W

PCKIST

R912

680

C915

-

+

-

+

28 27 26 25

VIN4

VREF

VCC2

VG4

24 23

V04+

V04-

30

22

NC

GND

IC902

LA6548NH

21

NC

20

V03-

19

V03+

18

VIN3G

17

VIN3

16

C950

-

2.2UF

+

CD

15

RESET

X901

71

IC901

6.8K

C917

473

C934

104

XVSS

VVDD1

31

104

70

AMUTEB

DMUTEB

+

-

69

32

R942

100

DOUT

PUIN

C920

68

DVDD

DEFECT

33

100UF

C931

104

C930

67

DVSS

FSEQ

34

C918

104

R906

+

100UF

66

DVDD1.8

C2F

35

12K

R943

100

22K

R935

656463

VVSS2

VPDOUT2

DVDD

DVSS

373839

36

104

C949

R933

VCOC2

VPREF2

DVDD1.8

+

-

C921

100UF

62

VVDD2

DATACK

TEST1

STDATA

STREQ

TEST0

CONT0

CONT1

CONT2

INTB0

DVSS

DVDD

VVDD3

-

C948

3.3K

61

LRSY

DATA

STCK

INTB1

RESB

DO

DI

CL

CE

VVSS3

40

+

100UF

R936

150

C928

104

C927

60

59

58

5756

5554

53

52

51

50

49

48

47

4645

44

43

42

41

C919

104

L903

100uH

R926

150

104

C929

R924

10K

R950

10K

+

1UF

R934

22

C926

104

C938

102

C937

102

-

R932

0

R930

0

R928

0

C922

104

R922

27K

C925

104

R920

100K

C924

68P

R918

Open

R916

5.6K

R921

1K

R917

C923

R919

R913

1K

1K

1K

68P

R914

27K

R915

2.2K

CN903

1

2

3

4

5

TO MCU BOARD CN702

CN901

1

2

3

4

5

TO AUDIO BOARD CN905

Q902

B764

C942

104

+

-

C941

470UF

L901

26UH

VCC1

1

MUTE

2

VG1

VIN1

34

V01+

5

V01-

NC

67

GND

29

R905

10K

VIN2

V02+

NC

V02-

9

8

VG2

11

10

REG_G

REG_B

14

12

13

2-17

Page 18

5.2.4 Cassette mechanism section

L / CH.

L / CH

R / CH

AC / B

R / CH.

GND

1

2

3

4

CW201

1

2

3

4

CN201

L / CH

GND

R / CH

AC / B

SW201 - 1 - A

4

SW201-1 -B

10

C209

5

222M

6

11

12

R209

C211

SW201 - D - A

7

C201

222M

SW201- 5 -A

13

14

8K2

222M

8

9

C202

15

R225

IC201

BA3308

C216

7P

102M

3K9

R229

3K9

R211

C227

7P

5K6

1

C259

100P

C203

R210

R204

+

100U

27

8K2

C208

222M

2

R201

47K

3

R208

+

C204

6k8

4

4U7

C205

10U

R202

470K

+

5

Q201

9014

C217

7P

6

R216

C207

22K

R206

7

8

9

C258

100P

R203

47K

+

4U7

C206

+

100U

+

C226

7P

6K8

102M

C212

R205

C213

5K6

333M

C215

27

R207

1000U

C214

104

R219

100

Q801

9014

R804

15K

C219

103

C801

500P

SW201- 6- A

1

2

C210

333M

3

C806

103M

R803

10K

100

Q802

8050

R802

5.6

R214

1.5K

R220

10K

R215

1.5K

C220

+

10U

16

SW201- 5 - B

10K

R221

17

R222

10k

18

MUTE

Beat Cut

Mic Rec.

Rec.R In

R Out

GND

+8V

Rec. L In

L Out

SYNC

TO MAIN BD.CN305

10

9

8

7

6

5

4

3

2

1

CN202

C803

332M

T801

3630

223

C225

C260

223

+

C804

223M

220U

C805

R801

24 8 - STDS13- 108

BIAS =80 KHz

2-18

Q203

9014

Q202

9014

Page 19

5.2.5 Tuner section

FM-ANT

CT102

10P

VD103

SVC348

223

C151

R101

47K

R144

15p

IN4148

C159

D102

AM COIL ANT

C104

10U

10K

C150

BPF 87~108MHz

IN4148

D101

GND

65 : 25

+

-

104

GND

CF101

1K

R102

C148

223

C91

GND

18p

C101

C105

223

102

GND

L100

102

C145

3.5MM

4.5T

10

R122

C108

C132

18p

R140

R142

+

C152

-

100U

C138

104

C157

R128

10

C126

104

C122

102

L101

390P(P)

C107

56p

2K2

R141

4K7

2K7

C100

223

104

6p

C103

4.5MM

3.5T

C139

R145

C158

104

C154

20P

30p

R126

100K

CT101

102

C135

C147

C153

R125

10P

VD101

SVC201

IC101

LA1823

T101

612R

C137

102

220

+

R146

20P

100K

C134

VD102

SVC201

1U

2K2

7.2MHz

X101

6p

24

1

R139

R127

220

102

C133

23

FMRF1

AMRF

2

R117

10

C113

100U

2K7

20

XOUT

XIN

1

C94

GND2

REG

+

-

19

VSS

CE

2

102

5MM

L102

2T5

22

FMRF2

AMOSC

3

18

AOUT

IC102

DI

3

R124

220K

21

VCC2

VCC1

4

C163

104

103

C146

17

AIN

CL

4

Q107

9018H

103

820

20P

C131

R100

10

R121

20

FMOSC

FMIFOUT

5

10. 7MA5 - A

CF102

2K2

R138

16

PD

D0

5

C156

19

DETOUT

GND1

6

15

VDD

B01

6

R120

1K2

222

C130

TP16(H)

+

4U7

C129

181716

ROUT

MPXIN

ST

IFBUFF

7

8

27K

R104

R153

Q110

9018F

R154

22

100P

100P

C142

C143

13

14

FMIN

LC72131

B02

7

8

C96

9

R111

1M

AMIN

B03

12P

+

0.22U

-

C121

15

LOUT

AMIFOUT

FMIFIN

101112

150K

T103

2070

4.7k

R123

100K

12

NC

B04

9

10

11

FM / AM

IF

I01

+

-

0.22U

C120

3K3

R119

14

ST / MONO

AMIFIN

C160

104

R152

330

R151

C162

223

100P

C140

8p

C155

+

3U3

-

C118

13

DET

AGG

CF105

450KHz

C114

330

R103

C141

47P

CF104

10

R118

223

CF103

10.7MA5 - A

C149

104

R110

R143

10K

C164

104

CDA10.7MC1- A

+

47U

-

C144

680

C93

102

R150

C102

GND

10K

*

TP8 (E)

C117

4U7

100UH

L105

R109

R108

+

-

220U

+

-

C125

R135

18K

R134

18K

27K

33K

R107

100K

Q109

104

C165

C124

103

C123

103

8050

5V6

ZD101

FMVT: L=1.8+ - / 0.1V

AMVT:

C127

C128

TP12(L)

Q108

2SC3330U

R147

R106

680

+

C116

-

100U

103

C115

L=1.4+ - / 0.1V

L=1.0+ - / 0.1V

TP11(R)

104

104

102

C92

47

H=7. 2+ - / 0. 5V(ALL)

H=7. 2+ - / 0. 5V(XE / UK)

H=7. 2+ - / 0. 5V(CA / KR / AU)

1

2

3

4

TO AUDIO BOARD CN105

CN102

TO CONTROL BOARD CN708

100P

103

C99

C97

100P

C95

GND

CN101

ST

ST

D0

CE

DI

CL

TU- R

GND

TU- L

+8V

1K

R129

R130

1K

1K

R131

R132

10K

D104

IN4148

2-19

Page 20

5.3 STANDARD SCHEMATIC DIAGRAMS for RC-EZ31

5.3.1 Primary and Amplifier section

5

B/C

4

Rch

3

Lch

2

GND

1

+8V

CN201

(TO:CN101)

CN307 TO Rec BD CN202

10

0.01

C327

CD-L

AGND

CD-R

MUTE

CDGND

CD+8V

SYNC

SYNC

LED-

LED+

CN307

R374

9

8

7

6

5

4

3

2

1

Q371

S8050

100

3.3U

C392

3.3U

C391

4K7

R378

C372

47UF

R373

18K

R392

C371

C376

100UF

18K

R393

330

R372

3.3K

0.1UF

4K7

R398

R394

3.9K

5.1V

DZ301

R391

9014

Q391

C393

103M

3.9K

C326

47UF

47UF

C378

C377

47UF

C394

103M

R399

10K

B/C

TA

R/R

R/O

GND

+8V

R/L

L/O

SYNC

TO CN204

CN309

CN305

CN906

4K7

R368

4K7

R367

R389 10K

Q369

9014C

Q329

9014C

9014C

Q392

3.2k

C369

R369

R222

R381

R396

10K

R375

2K2

100U / 10V

R502

C501

102PF

1K

10K

1.2K

R331

1k

1K

1UF

R501

C508

16

15

X2

VDD

IC501 TC4052

Y0Y2Y

1

2

1UF

1UF

C507

C506

1.2K

R328

R333

1k

1UF

1UF

C502

C395

14

13

X

X1

Y3

3

4

C503 C510

1UF 1UF

500P

C374

12

5

X0

Y1

120K

R380

1UF

C509

11

6

X3

INH

500P

C373

10

A

VEE

7

120K

R379

9

B

VSS

8

10K

R503

D306

1UF

C504

10K

R504

IN4148

IN4148

D307

1UF

C505

C311

102M

R322

C312C322C321

R324R323R321

8.2K

R370

10K

R506

10K

102M

5.6K

473M473M

5.6K

10K

C317

100UF

C323

10K

R505

R327

VR301-B

50KA

VR301-A

50KA

R326

8.2K

R371

C318

15K

C325

15K

100UF

47UF

5K6

R312

CD

TAP E

TUN

SW301-B

C324

1UF

D1936

5K6

R311

1UF

Q302

D311

IN4148

D314

IN4148

Q301

D1936

C302

1UF

C316

5K6

R332

SW301-A

CD

TAP E

TUN

C301

1UF

1UF

R303

4.7K

R304

D310

IN4148

7.5K

R305

R301

4.7K

5.6K

R316

D309

IN4148

2.2K

67

2.2K

R302

7.5K

R306

100UF/10V

C329

+12V

TO CN303

DC+

+8V

GND

GND

C309

180K

R307

100uF

4

154M

R309

4.7K

C307

1413

3

152M

C303

C319

5

IC301 UTC8227

8

9

10

47uF

180K

R308

152M

C304

D301

IN4001

CN1101

LFSW

CN303

C305

100uF/16V

C306

R320

10K

R300

9015C

LFSW

DC+

+12V

+8V

GND

GND

TO CN1101

100uF

C308

C310

154M

100K

Q303

C403

2200UF / 25V

1. DISCONNECT POWER CORD BEFORE SERVING

2. RECOMMEND THE UNIT BE OPERATED BY DC 12V VOLTS DURING

TROUBLE SHOOTING

3. COMPONENTS MARKED WITH

CHARACTERISTICS.ONLY REPLACE WITH THE COMPONENT OF THE SAME

TYPE NEMBER.

4. SUBJECT TO CHANGE WITHOUT NOTICE

1K

R315

C315

220UF/25V

470uF/16V

100uF

D302

1

8550

Q306

12

C320

2200UF/25V

27k

Q401

2SD2061

IN4148

D401

C404

IN4001

10K

47UF

R328

R330

R401

C401

Q305

10K

C1105

330 1/2W

0.022

2

11

R310

IN4148

R319

8.2V

4.7K

D308

DZ401

C313

470uF/16V

C314

9014C

IN4148

D300

AC

3300UF / 25V

HAVE CRITICAL

R329

33K

120

120

C1

102P

C2

102P

L303

L302

L301

10T

CN332

CN1102

C4C3

102P102P

R313

R314

470uF/25V

C330

REMARK

JP

VERSION :F110 1 2A125V

XE

VERSION :F1101 T2AL250V

DC

C1102

0.04

D1102

IN4001

D1104

IN4001

0.04

C1104

IN4001

D1101

C1103

0.04

IN4001

D1103

C1101

0.04

10T

10T

JK301 HEAD

SP301

+

-

+

-

SP302

C402

220U/25V

+

MOTOR

-

LEAF-SW

*

AC LINE

CN1101

T1101

F1101

BATT 12V

R395

2.2K

D305

IN4148

2-20

Page 21

5.3.2 Front sction

REP

M

LCD701

1

2

3

4

5

6

7

8

9

R706

SW704SW706 REPEAT P/P

SW703SW701 MEMORY STOP

Q702

2.7K

9014

SW705 F.F

SW702 F.B

REM701

R702

1.5K

LED701

R703

CN702

2.7K

TO CN203

18PINS

CN701

1

REM

2

3

KEY02

KEY11

4

5

KEY12

6

KEY13

KEY14

7

COM1

8

COM2

9

101112

COM3

SEG1

SEG2

1314151617

SEG3

SEG4

+5V

SEG5

GND

18

S6

KEY01

2-21

Page 22

5.3.3 CD servo section

VREF

1

2

COM*

3

E

4

D

A

5

6

B

7

C

F

8

GND

9

LD

10

VR

11

MD

12

F+

13

14

T-

15

T+

16

F-

CN901

TO CD DECK

+

C934

10U 103

C935

C902

473M

R907

C938

C950

104 104

+

2SA1342

C936

Q903

1U

C949

100P

C940

104

X901

16.934MHz

C962

XIN

DRF

RES

XOUT

XVDD

PMTSL1

CLOSE

ROUT

IC902

LC78601RE

(DSP)

PLK

CLOCK

3.3VDD

CDIN

RWC

JP-

JP+

TGL

C924

104

R944

100K

C923

330P

R935

R936

10K

+

C939

100U

C944

680P

64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49

1

DEF1

2

4.2M

R937

3

PDO

470

4

VVSS

10K

5

ISET

6

VVDD

7

FR

VSS

8

9

EFMO

10

EFMIN

11

TMDO

12

CLV+

CLV-

13

14

HFL

TES

15

TOFF

16

10K

C937

104

C942

104

L/RVSS

SLO-

+

220U

L/RVDD

SLEO+

R957

LOUT

SLEO-

C951

103

220

RW

PUIN

C933

473M

1K5

R923

C912

+

C930

100U

PHI

FE-

153M

15K

LF2

LA9242M

AGND

C918

100U

+

VR2

IC901

(ASP)

SP

C959

+

C919

103

10U

C929

FSS

DRF

REFI

VCC2

SPO

SP-

SPG

SPI

C957

100P

56K

R929

R930

1K

332M

56K

R928

R924

+++

33K

C914

0.33U

R926

DE

SLEO

R958

10K

CL

DAT

CLK

DEF

NC

TBC

FSC

DGND

SLI

SLC

RFS

RFSM

CV+

CV-

RW

HFL

TES

TOFF

TGL

JP+

JP-

SL+

SL-

SLD

32313029282726252423222120191817

C958

332

R927

6K8

10K

C913

22U

C915

4U7

R943

270K

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

C926

R945

4K7

+

C927

2U2

333M

R942

R941

12K

10K

R940

22K

R933

R934

C961

15P(N)

C925

222M

150K

150K

R938

R939

330

1K

+

C953

C960

220U

100K

100K

100K

100K

104M

R959

10K

R917

R913

15K

R910

2K2

3K3

104p

R908

C906

330P

C903

C907

104M

R925

R946

10

Q901

2SA608NF

1

2

3

4

5

R909

150K

333M

C906

0.1U

R921

27K

3K3

C908

R914

R920

5K6

100K

6

7

8

9

+

10

11

332

12

13

14

15

16

22K

C911

104M

C956

332M

100

R901

R902

R903

R904

180K

R905

180K

R906

C901

R911

330

R916

27K

C928

103

C932

47U

+

C955

64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49

CC1

FIN2

FIN1

E

F

TB

TE-

TE

TESI

SCH

TH

TA

TD-

TD

JP

TO

FD-

FD

15K

R919

C910

333M

C941

682M

102

0.33U

C931

+

BHI

LDS

LDD

FE

FA-

FA

68K

R918

R922

MUTE

REMOTE

RANDOM/KEY02

KEYIN/KEY11

PROG/KEY12

DIG1/KEY13

DIG2/KEY14

SEG1/COM1

SEG2/COM2

SEG3/COM3

SEG5/S2

SEG6/S3

NC/S6

DOUT

SEG8/S5

D901

D902

C2F

DMUTE

FSEO

NC/KEY01

VSS

SEG4/S1

SEG7/S4

32313029282726252423222120191817

IN4148

10K

Q904

IN4148

VDD

48

47

46

45

44

43

42

41

40

NC

39

38

37

36

35

34

33

2SA1342

C964

+

R956

220

+

C945

3U3

3U3

R955

R960

5.6K

R961

5.6K

220

C968

104

C947

102M

C948

102M

CLOSE

GND

CN902

6

5

4

3

2

1

TO CN906

CN903

16 PINS

16

REM

15

RANDOM/KEY02

14

KEYIN/KEY11

13

PROG/KEY12

12

DIGI/KEY13

11

DIGI/KEY14

10

SEG1/COM1

9

SEG2/COM2

8

SEG3/COM3

7

SEG4/S1

6

SEG5/S2

5

SEG6/S3

4

SEG7/S4

3

SEG8/S5

2

GND

1

+5V

TO CN701

CN904

+8V

AGND

ROUT

AMUTE

GND

LOUT

SW902

CW904

CD DOOR SW

M

-+

SP

SL

-

+

M

C954

2U2

+

24 23 22 21 20 19 18 17 16 15 14 13

V08

VCC2

V01

VIN1

MUTE

VCC1

1

1

SPIN+

SPIN-

2

2

SL+

3

3

4

4

SL-

P-SW

5

5

GND

6

6

V01

IC903

CSC1469XH

V02

V07

VG4

VIN4

VREF

V06

V05

V03

V04

7123456 89

VG3

VG2

10 11 12

VUN3

VIN2

CD

REG-OUT

RES

REG-IN

R931

R932

10K

2K2

Q902

B764

C916C917

220U104

C963

++

C952

104

470U

L901

26uHX2

2-22

Page 23

5.3.4 Cassette mechanism section

1

2

3

4

CN201

L/CH.

R/CH.

L/CH.

AGND

R/CH

AC/B

AGND

R265

R264

L/CH.

AGND

R/CH

AC/B

1

2

3

4

CN203

820

820

C209

222M

S201-1-A

456

GND

S201-1-B

C202

102M

S201-D-A

789

222M

C201

7P

C216

GND

S201-5-A

13121110

14

15

C227

7P

R225

IC201

BA3308

R229

R211

3K9

C210

L204

15UH

3K9

C203

5K6

333M

100U

R210

1

C262

+

47P

L203

15UH

C208

222M

27

R204

8K2

R209

8K2

C211

222M

2

R201

47K

C259

100P

R208

1. DISCONNECT POWER CORD BEFORE SERVING

2. RECOMMEND THE UNIT BE OPERATED BY DC 12V

3

4

5

6

7

8

9

C205

+

10U

R202

470K

+

4U7

C204

6k8

Q201

9014

C207

4U7

R206

C261

47P

C258

100P

R203

47K

R205

333M

102M

+

C206

5K6

+

C213

L202

15UH

6K8

C212

L201

15UH

100U

C215

27

R207

+

C226

7P

1000U

C214

104

R219

100

VOLTS DURING TROUBLE SHOOTING

3. COMPONENTS MARKED WITH

HAVE CRITICAL

CHARACTERISICS. ONLY REPLACE WITH THE COMPONENT

OF THE SAME TYPE NUMBER

4. SUBJECT TO CHANGE WITHOUT NOTICE

R804

C219

Q801

9014

15K

103

C801

500P

S201-6-A

123

AGND

C803

C225

223

T801-A

3630

332M

C260

223

+

220U

C804

223M

C805

R801

100

C806

103M

R803

10K

Q802

8050

R802

5.6

R214

1.5K

R220

10K

R215

1.5K

R216

C220

22K

+

Q202

9014

10U

S201-5-B

16 17 18

10K

R221

R222

10K

Q203

9014

R224

10K

AGND

CN204

SYNC

B / C

TA

R / R

R / O

AGND

+8V

R / L

L / O

9

8

7

6

5

4

3

2

CN202

TO CN304

SYNC

1

2-23

Page 24

5.3.5 Tuner section

VC2

3.5T

L102

22P

C114

NC

L101

2.5T

VC1

15

R110

C115

2P

R117

47K

AM ANT

120T:15T

R109

10K

330P

C104

1010T103

120P

C118

VC4

680P

C106

R108

3.9K

C105

C103

1UF

473M

C111M

Q101

R107

12K

C113

823M

C112

0.22UF

R106

22K

AM

FM

SW102B

SW101

MONO

ST

FM ANT

473P

C127

IN4148

D102

IN4148

D101

VC3

102P

C117

473P

C109

IC101

2111A

473P

24

1

C125

23

22

AM RFIN

FMRF OUT

FM RFIN

RF GND

2

3

C119

21

20

RF VCC

FM OSC

AM LOW

MIX OUT

4

5

C120

0.47UF

473P

C126

19

AFC

AM OSC

VGC

VCC

6

22UF

10002

T101

DZ101

18

17

MPX IN

DET-OUT

AMIF IN

FMIF IN

7

8

5.6V

16

LPF2

GND

9

68P

C121

15

14

LPF1

L-OUT

TUN LED

ST LED

11

10

13

R-OUT

QUAD

12

CF101

465KHz

CF103

10.7M

C123

5P

10.7MHZ

R116

10

CF102

C108

153M

100K

R102

C111

100K

473P

220UF

R104

R101

C110

18K

C101

1UF

C102

1UF

R103

150

18K

R105

B / C

GND

Rch

Lch

+8V

C107

153M

SW102A

TO CN201

CN101

2-24

Page 25

< MEMO >

Page 26

Victor company of Japn, Limited

Audio/Video Systems category 10-1,1chome,Ohwatari-machi,Maebashi-city,Gumma-ken, 371-8543,Japan

(No.MB593)

Printed in Japan

VPT

Loading...

Loading...