Page 1

SERVICE MANUAL

CD PORTABLE SYSTEM

RC-BZ5LB/BZ5RD

RC-BZ6BU

RC-BZ5LB/BZ5RD

RC-BZ6BU

REMOTE CONTROL RM-SRCBZ5

RC-BZ5LB/BZ5RD

REMOTE CONTROL RM-SRCBZ6

RC-BZ6BU

Contents

Safety precautions

Importance administering point on the safety

Preventing static electricity

Important for laser products

Disassembly method

Adjustment method

Description of major ICs

1-2

1-3

1-4

1-5

1-6

1-15

1-18

Areas suffix

J ---------------- U.S.A.

C ------------- Canada

Comparison table

Item

Jog dial circuit Not used Used

Back light (LCD) Not used Used

Bass boost circuit Not used Used

Power amplifier 14W 18W

Electrical volume Not used Used

RC-BZ5LB/BZ5RD

RC-BZ6BU

COPYRIGHT 2000 VICTOR COMPANY OF JAPAN, LTD.

No.20819

July. 2000

Page 2

RC-BZ5LB/BZ5RD

RC-BZ6BU

Safety precautions

1. This design of this product contains special hardware and many circuits and components specially

for safety purposes. For continued protection, no changes should be made to the original design

unless authorized in writing by the manufacturer. Replacement parts must be identical to those

used in the original circuits. Services should be performed by qualified personnel only.

2. Alterations of the design or circuitry of the product should not be made. Any design alter ations of

the product should not be made. Any design alterations or additions will void the manufacturer`s

warranty and will further relieve the manufacture of responsibility for personal injury or property

damage resulting therefrom.

3. Many electrical and mechanical parts in the products have special safety-related characteristics.

These characteristics are often not evident from visual inspection nor can the protection afforded

by them necessarily be obtained by using replacement components rated for higher voltage,

wattage, etc. Replacement parts which have these special safety characteristics are identified in

the Parts List of Service Manual. Electrical components having such features are identified by

shading on the schematics and by ( ) on the Parts List in the Service Manual. The use of a

substitute replacement which does not have the same safety characteristics as the recommended

replacement parts shown in the Parts List of Service Manual may create shock, fire, or other

hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the

like to be separated from live parts, high temperature parts, moving parts and/or sharp edges

for the prevention of electric shock and fire hazard. When service is required, the original lead

routing and dress should be observed, and it should be confirmed that they have been returned

to normal, after re-assembling.

5. Leakage current check (Electrical shock hazard testing)

After re-assembling the product, always perfor m an isolation check on the exposed metal parts

of the product (antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control

shafts, etc.) to be sure the product is safe to operate without danger of electrical shock.

Do not use a line isolation transformer during this check.

Plug the AC line cord directly into the AC outlet. Using a "Leakage Current Tester", measure

the leakage current from each exposed metal parts of the cabinet , particularly any exposed

metal part having a return path to the chassis, to a known good earth ground. Any leakage

current must not exceed 0.5mA AC (r.m.s.)

Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having, 1,000 ohms

per volt or more sensitivity in the following manner. Connect a 1,500 10W resistor paralleled by

a 0.15 F AC-type capacitor between an exposed

metal part and a known good earth ground.

Measure the AC voltage across the resistor with the

AC voltmeter.

Move the resistor connection to each exposed metal

part, par ticularly any exposed metal part having a

return path to the chassis, and measure the AC

voltage across the resistor. Now reverse the plug in

the AC outlet and repeat each measurement voltage

measured any must not exceed 0.75 V AC (r.m.s.).

This corresponds to 0.5 mA AC (r.m.s.).

0.15 F AC TYPE

1500 10W

Good earth ground

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

Place this

probe on

each exposed

metal part.

1-2

CAUTION

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Page 3

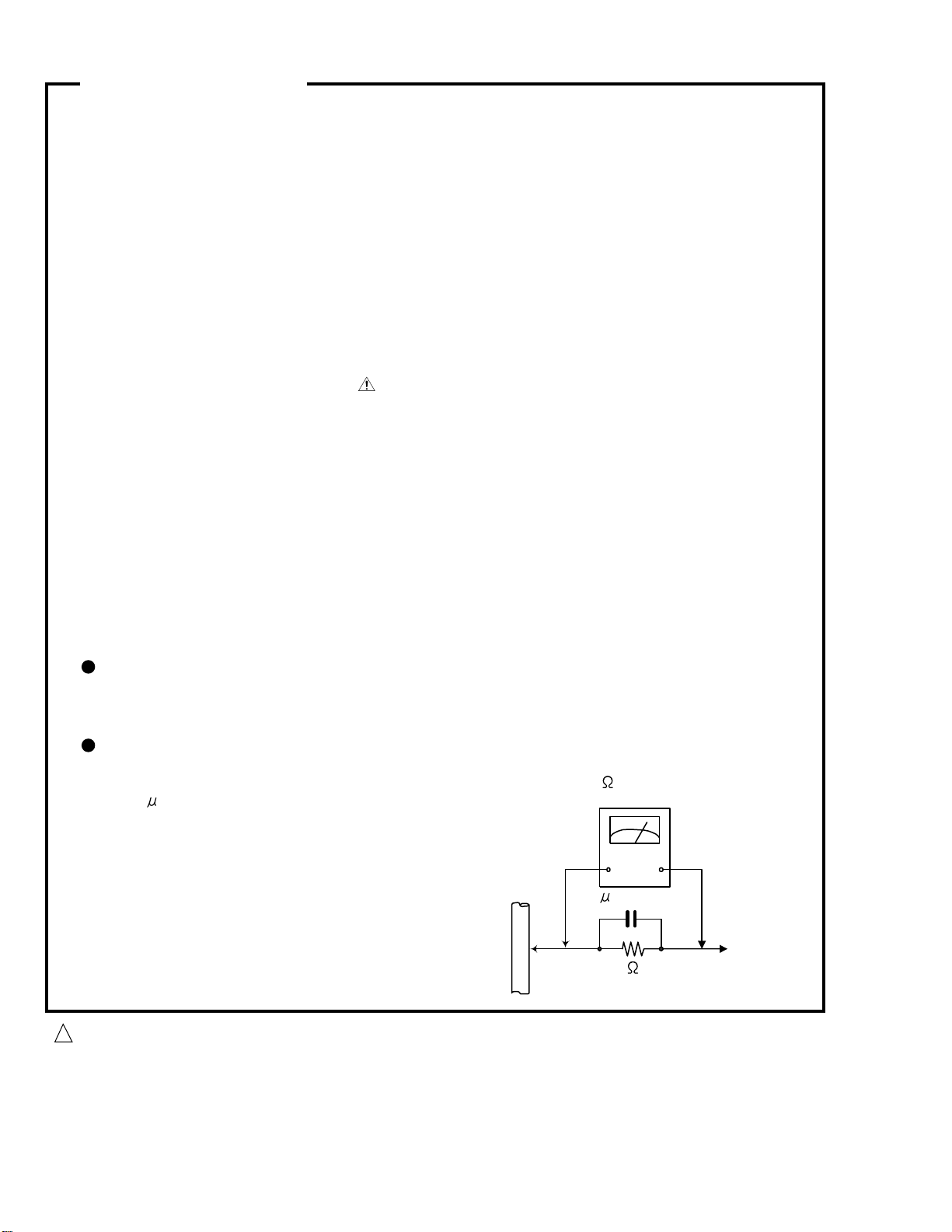

Importance administering point on the safety

Power supply board

D902

D903

R998

CN307CN306

F903

D901

D904

F902

POWER TRANSFORMER

RC-BZ5LB/BZ5RD

RC-BZ6BU

J9

F901

Not used

S901

For USA and Canada / pour Etats - Unis d' Amerique et Canada

Caution: For continued protection against risk of

fire, replace only with same type 3A/125V for

F902 and F903. This symbol specifies type of fast

operating fuse.

Precaution: Pour eviter risques de feux, remplacez

le fusible de surete de F902 et F903 comme le

meme type que 3A/125V.

Ce sont des fusibles suretes qui functionnes rapide.

1-3

Page 4

RC-BZ5LB/BZ5RD

RC-BZ6BU

Preventing static electricity

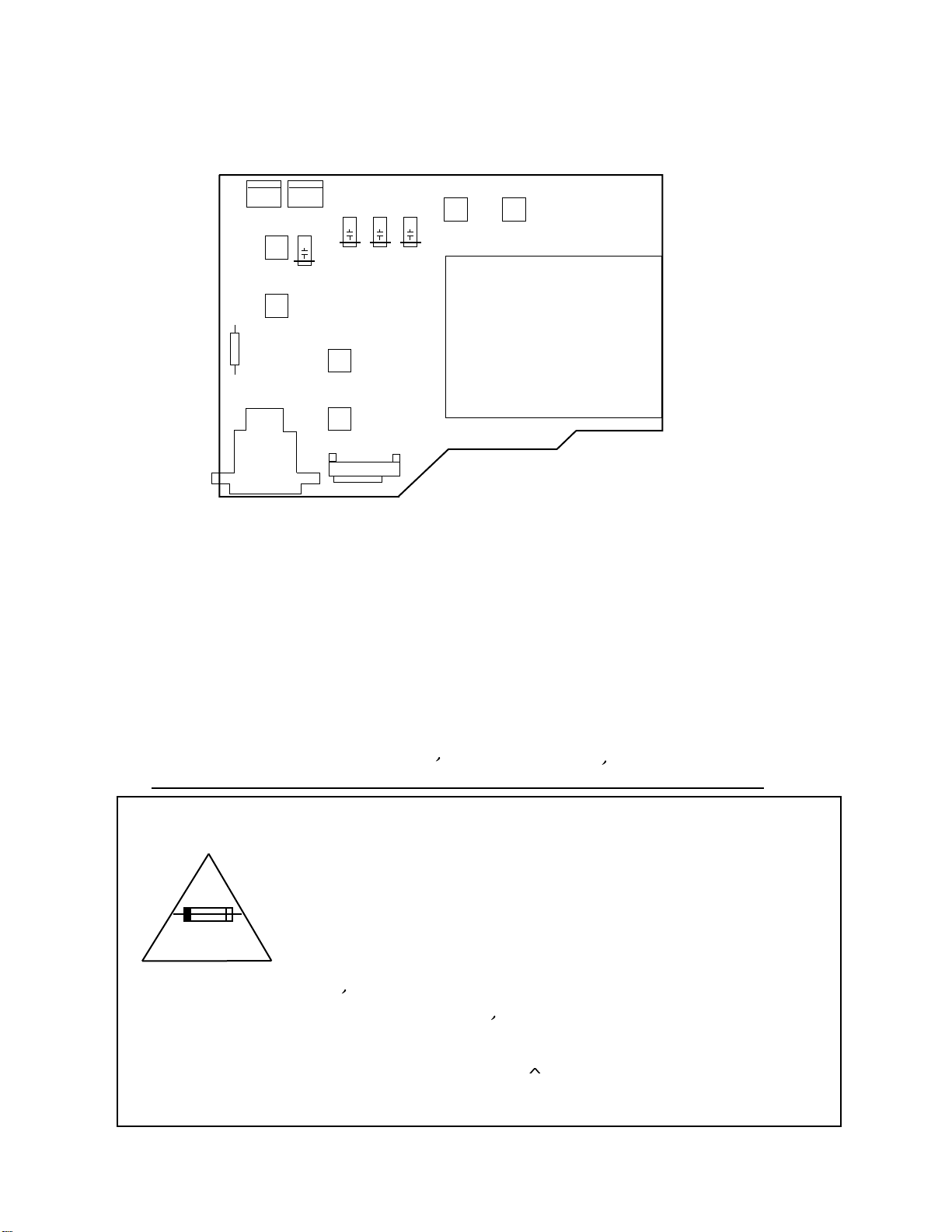

1.Grounding to prevent damage by static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged,

can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

2.About the earth processing for the destruction prevention by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as CD players.

Be careful to use proper grounding in the area where repairs are being performed.

2-1 Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over

it before placing the traverse unit (optical pickup) on it.

2-2 Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

Conductive material

(conductive sheet) or iron plate

3. Handling the optical pickup

1. In order to maintain quality during transport and before installation, both sides of the laser diode on the

replacement optical pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

2. Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power

source can easily destroy the laser diode.

4.Handling the traverse unit (optical pickup)

1. Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

2. Remove solder of the land on the flexible cable after replacing the optical pickup. For specific

details, refer to the replacement procedure in the text. Remove the anti-static pin when replacing the traverse

unit. Be careful not to take too long a time when attaching it to the connector.

3. Handle the flexible cable carefully as it may break when subjected to strong force.

4. It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it

CD Pick up

Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for pick-up and

how to detach the substrate.

1.Short the land before the card wire is removed from connector on

the Main board as shown in Figure.

(When the wire is removed without putting up solder, the CD pick-up

assembly might destroy.)

2.Please remove solder after connecting the card wire with

when you install picking up in the substrate.

1-4

Land

Page 5

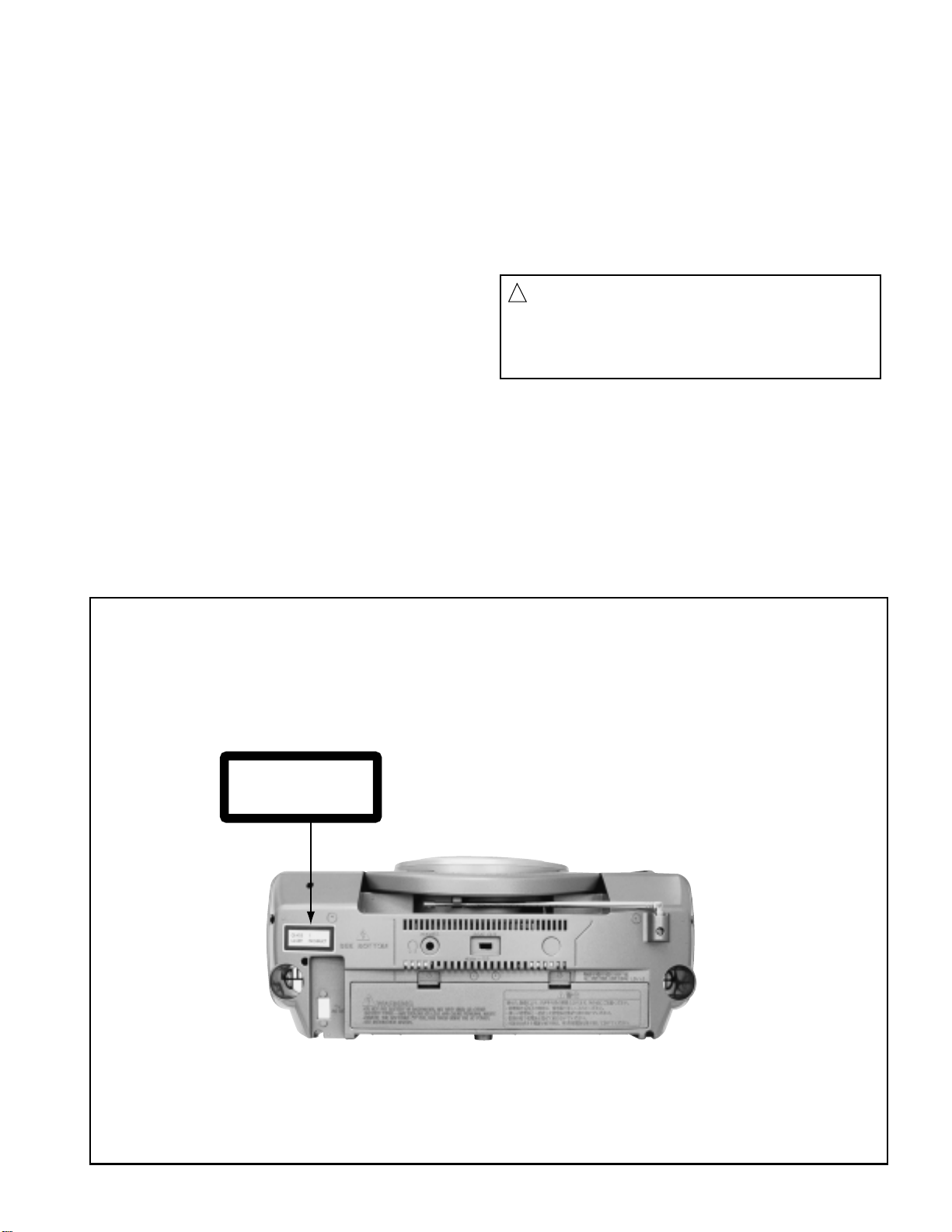

Important for laser products

RC-BZ5LB/BZ5RD

RC-BZ6BU

1.CLASS 1 LASER PRODUCT

2.DANGER : Invisible laser radiation when open and inter

lock failed or defeated. Avoid direct exposure to beam.

3.CAUTION : There are no serviceable parts inside the

Laser Unit. Do not disassemble the Laser Unit. Replace

the complete Laser Unit if it malfunctions.

4.CAUTION : The compact disc player uses invisible

laserradiation and is equipped with safety switches

whichprevent emission of radiation when the drawer is

open and the safety interlocks have failed or are de

feated. It is dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified herein may result in

hazardous radiation exposure.

CAUTION

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

REPRODUCTION AND POSITION OF LABELS

WARNING LABEL

CLASS 1

LASER PRODUCT

1-5

Page 6

RC-BZ5LB/BZ5RD

RC-BZ6BU

Disassembly method

<Main body>

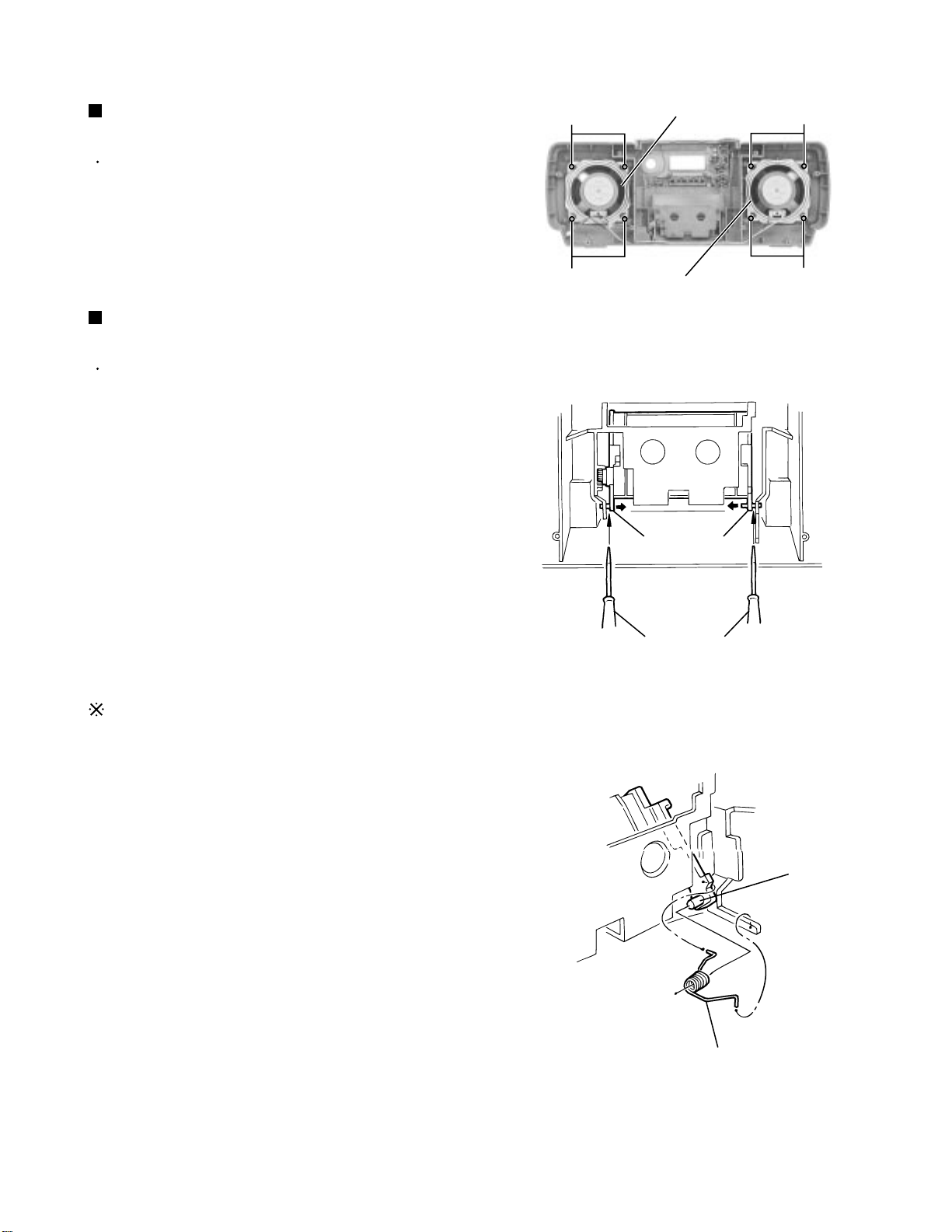

Removing the front cabinet assembly /

rear cabinet assembly (See Fig.1 to 3)

1.

Detach the battery cover on the back of the body.

Remove the eight screws A attaching the front

cabinet assembly and the rear cabinet assembly.

2.

Press STOP / EJECT button on the upper side of the

body to open the cassette door.

3.

Remove the front cabinet assembly toward the front

and pull out the volume knob at the same time.

4.

Disconnect the speaker harness from connector

CN309 on the main board in the rear cabinet

assembly.

A

Front cabinet assembly

A

Battery cover

Fig.1

Rear cabinet assembly

STOP / EJECT button

assembly /

Cassette door

Volume knob

Fig.2

Rear cabinet assembly

1-6

Main board

CN309

Front cabinet assembly

Fig.3

Page 7

<Front cabinet assembly>

RC-BZ5LB/BZ5RD

RC-BZ6BU

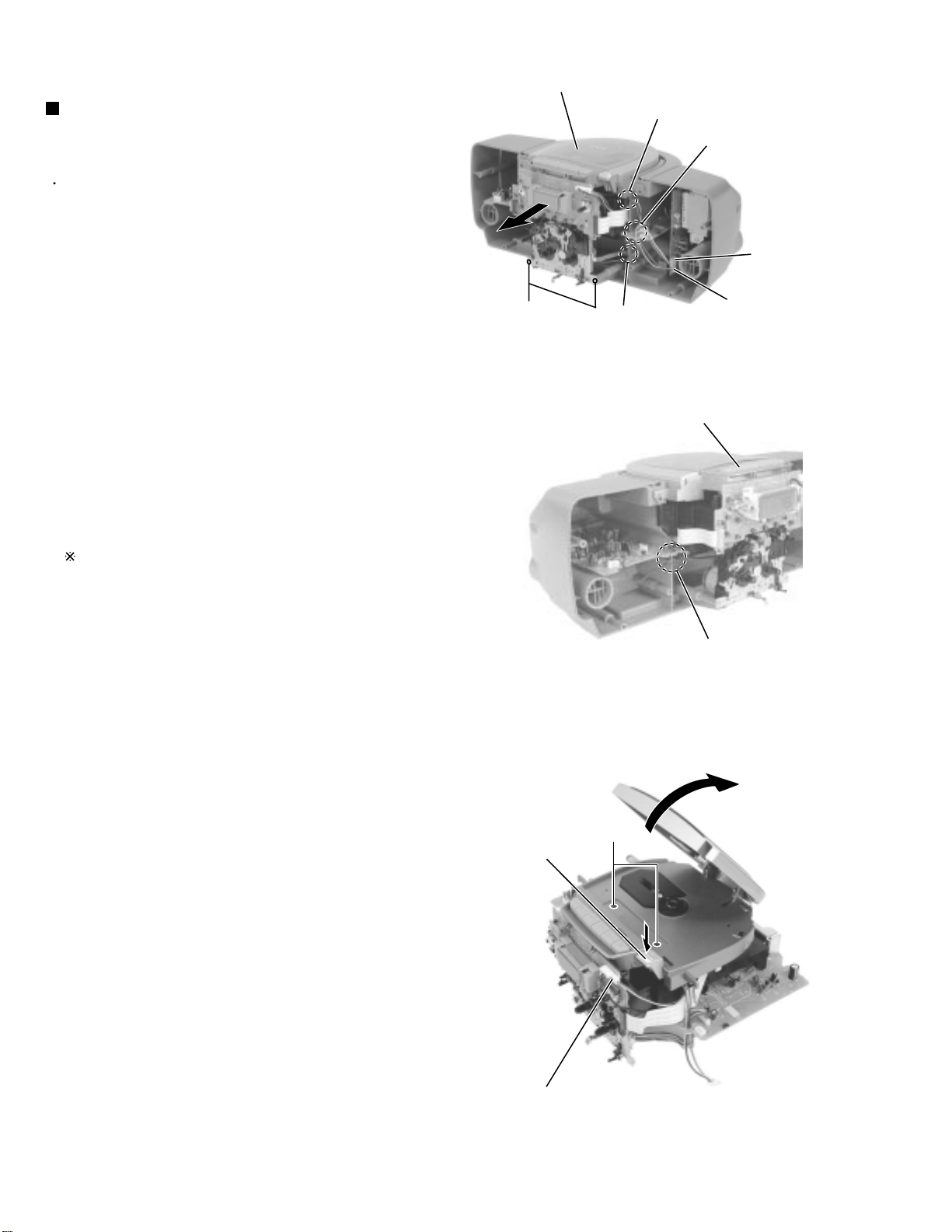

Removing the speaker (L) and (R)

(See Fig.4)

Prior to performing the following procedure, remove

the front cabinet assembly.

1.

Remove the eight screws B in the front cabinet.

Removing the cassette door

(See Fig.5 and 6)

Prior to performing the following procedure, remove

the front cabinet assembly.

1.

Remove the door spring in the front cabinet

assembly.

2.

Insert a screwdriver between the door arm and the

front cabinet and slide the door arms inward, then

detach the cassette door from the front cabinet.

B

B

Speaker (L)

Speaker (R)

Fig.4

Door arms

B

B

Reattaching the door spring

1.

Reattach the door spring to the cassette door shaft

with opening the cassette door.

2.

Fit another end of the door spring to the front cabinet

rib.

3.

Fit the shorter end of the door spring to the cassette

door.

Screwdriver

Fig.5

Shaft

Door spring

Fig.6

1-7

Page 8

RC-BZ5LB/BZ5RD

RC-BZ6BU

<Rear cabinet assembly>

Removing the CD / cassette and amplifier

assembly from the rear cabinet

(See Fig.7 and 8)

Prior to performing the following procedure, remove

the front cabinet assembly and the rear cabinet

assembly.

1.

For the harness connecting the amplifier board with

the power board, disconnect it from connector

CN306 on the power board in the right rear cabinet

assembly. For the harness connecting the battery

terminal wire with the power board, disconnect it

from CN307 on the power board.

2.

Remove the two screws C on the bottom of the

cassette mechanism unit.

3.

Release the harnesses from the slot a, b and c and

the notch of the main board in the rear cabinet.

4.

Remove the CD / cassette and amplifier assembly

from the rear cabinet.

CD / cassette and amplifier assembly

Slot a

Release the hornese

C

CD / cassette and amplifier assembly

Slot c

Fig.7

Power board

CN307

CN306

Now the CD / cassette and amplifier assembly is

ready to conduct burn-in.

Slot b

Fig.8

D

CD door eject button

1-8

Key switch / display board

CN704

Fig.9

Page 9

Removing the CD cover and door unit

(See Fig.9 and 10)

Prior to performing the following procedure, remove

the CD / cassette and amplifier assembly.

1.

Disconnect the harness from connector CN704 on

the key switch / display board (The harness is

extending from the door switch board).

2.

Press EJECT button to open the CD door.

3.

Remove the two screws D on the front of the CD

cover and door unit.

4.

Raise the front part of the CD cover and door unit

and detach upward. Then push the whole unit

backward until it comes off.

RC-BZ5LB/BZ5RD

RC-BZ6BU

CD cover and door unit

Fig.10

ATTENTION:

At this point, the CD mechanism unit

will become removable. So handle the

rear cabinet with care.

Removing the CD door switch board

(See Fig.11)

Prior to performing the following procedure, remove

the CD cover and door unit.

1.

Turn over the CD cover and door unit and gently

spread apart the locking tab. Then remove the CD

door switch board in the direction of the arrow while

releasing it from joint d.

Removing the key switch / display board

(See Fig.12)

Prior to performing the following procedure, remove

the front cabinet assembly and the rear cabinet

assembly.

Tab

Joint d

CD door switch board

Fig.11

Key switch / display boardKey switch / display board

CN702(RC-BZ5 only)

CN704

1.

Disconnect the card wires from connector CN701,

CN702 and CN703, then the harness from CN704

on the key switch / display board.

2.

Remove the four screws E attaching the key switch /

display board.

The key switch / display board can be removed

even if the mechanism cover is attached.

CN703

E

Cassette mechanism assembly

Fig.12

E

CN701

1-9

Page 10

RC-BZ5LB/BZ5RD

RC-BZ6BU

Removing the cassette mechanism

assembly (See Fig.13 to 15)

Prior to performing the following procedure, remove

the CD / cassette and amplifier assembly, the CD

cover and door unit and disconnect the harnesses

connected to the key switch / display board.

The cassette mechanism cover is still attached.

1.

Push inward the locking tabs e on both sides of the

cassette mechanism cover and remove the

mechanism cover in the direction of the arrow.

2.

Disconnect the harnesses from connector CN301

and CN308 on the main board.

3.

Remove the upper two screws F and the cassette

mechanism assembly toward the front.

Removing the CD mechanism assembly

(See Fig.16)

Prior to performing the following procedure, remove

the CD / cassette and amplifier assembly, the CD

cover and door unit.

1.

Disconnect the harness from connector P011 on the

motor board in the lower part of the CD mechanism

assembly. Then disconnect the pickup card wire

from CN601 on the main board.

2.

Remove the CD mechanism assembly upward.

Cassette mechanism assembly

Fig.13

Locking tab e

Cassette mechanism cover

Fig.14

Locking tab e

Cassette mechanism

Cassette mechanism assembly

cover

1-10

Motor board

P011

Main board

CN601

CD mechanism assembly

CN301

F

Cassette mechanism assembly

Fig.15Fig.16

Main board

CN308

F

Page 11

RC-BZ5LB/BZ5RD

RC-BZ6BU

Removing the main board

(See Fig.17 to 19)

Prior to performing the following procedure, remove

the CD / cassette and amplifier assembly, the CD

cover and door unit and the CD mechanism

assembly.

1.

Disconnect the harnesses from connector CN301

and CN308 on the main board (The harnesses are

extending from the cassette mechanism assembly).

2.

Disconnect the harness from connector CN702 on

the key switch/display board (RC-BZ5 only).

3.

Remove the two screws G on the underside of the

main board and release the two joint tabs f from the

chassis in the direction of the arrow.

ATTENTION:

When reassembling, get the harness

extending from FW301 and FW302

on the m a i n board through the two

slots g of the chassis. Get the card

wire extending from CN304 on the

main board through the hook h

and the slot i.

CN308

CN702

Key switch/display bord

CN301

Main board

Fig.17

g

Main board

Joint tab f

g

Joint tab f

G

Fig.18

Chassis

FW302(RC-BZ5 only)

h

i

CN304

FW301

Fig.19

1-11

Page 12

RC-BZ5LB/BZ5RD

RC-BZ6BU

Removing the power transformer

assembly (See Fig.20)

Prior to performing the following procedure, remove

the front cabinet assembly and the rear cabinet

assembly.

1.

Disconnect the harnesses from connector CN306

and CN307 on the power board in the power

transformer assembly.

2.

Remove the two screws H attaching the AC jack of

the power board and the two screws I attaching the

power transformer.

Remove the power transformer assembly toward the

front.

Power transformer assembly

Power board

CN307

I

H

CN306

Fig.20

Removing the battery board

(See Fig.21 and 22)

Prior to performing the following procedure, remove

the front cabinet assembly and the rear cabinet

assembly.

1.

Disconnect the battery terminal wire from connector

CN307 on the power board.

2.

Remove the battery board on the back of the rear

cabinet.

Release the hornese

Power board

CN307

Fig.21

1-12

Battery board

Fig.22

Page 13

<Cassette mechanism section>

Capstan motor ass’ y

RC-BZ5LB/BZ5RD

RC-BZ6BU

Motor bracket

a

Eject slide

lever

Flywheel ass’ y Leaf switch

Fig.1

Capstan motor

1. Remove the cassette mechanism assembly. (Refer

to the article “Cassette mechanism assembly”

appearing on a previous page.)

2. Remove one screw A retaining the capstan motor

assembly from the back of the cassette mechanism

assembly.

3. Disengage the main belt from the flywheel assembly.

Then slide the capstan motor slightly in the direction

of the arrow a while lifting it upwards to remove

together with the main belt.

(Fig.1)

A

Main belt

b

Stopper arm

Fig.2

Eject slide lever

Eject slide lever

1. Place the cassette mechanism back side frontward

and disengage the stopper arm b of the Eject slide

lever by pressing it inwards through the opening of

the chassis with a small screwdriver as shown in

Fig.2.

Leaf switch

1. Press the leaf switch in the direction of the arrow c

and then remove it in the direction of the arrow d

referring to Fig.3.

(Fig.2)

(Fig.3)

d

Leaf switch

c

Fig.3

1-13

Page 14

RC-BZ5LB/BZ5RD

RC-BZ6BU

Stopper

Rec/PB

head

Capstan shaft

Erase head

B

C

Fig.4

f

Pinch roller arm ass’y

e

Base ass’y

Stopper

Fig.5 Fig.6

Pinch roller arm assembly

1. Pull out the stopper protruding from the base assembly

in the direction of the arrow e to remove it from the

pinch roller arm assembly.

2. Then, pull out the pinch roller arm assembly in the

direction of the arrow f.

(Fig.4 to 5)

Stopper

Pinch roller arm ass’y

h

Stopper

Erase head

g

i

P washer

Base ass’y

Rec/PB head and erase head

1. Remove two screws B, C retaining the Rec/PB head.

2. Pull out the stopper of the erase head in the direction of

the arrow g.

3. Pull out the erase head in the direction of the arrow h.

Flywheel assembly

1. Remove the split washer retaining the flywheel

assembly in the direction of the arrow i.

2. Pull the flywheel assembly out of the back side of the

cassette mechanism assembly in the direction of the

arrow j.

1-14

(Fig.7)

(Fig.4 to 6)

Flywheel

j

Fig.7

Page 15

Adjustment method

RC-BZ5LB/BZ5RD

RC-BZ6BU

Test Instruments required for adjustment

1. Low frequency oscillator

(Frequency range: 50Hz to 20kHz)

(Output: 0 dBs across 600 Ω terminating resistor)

2. Attenuator(Impedance: 600 Ω)

3. T est Tapes

VT712 For tape speed, wow & flutter check

VT722, 724 For playback, output level check

VT738 For playback frequency response check

VT702 For head azimuth adjustment

4. Blank tape TYPE1:AC–225

5. Electronic voltmeter

6. Distortion meter

7. Frequency counter

8. Wow and flutter meter

9. Torque gauge(Cassette type) CTG – N

10. Test disc CTS1000

11. Jitter meter NJM631

12. TE Offset LTM9055

Measuring conditions(Amplifier section)

Supply voltage AC120V(60Hz)

DC12V(UM–1 x 8)

Reference output level Speaker

: 0 dBs(0.775V) / 3 Ω

Headphone

: –10 dBs(0.245V) / 32 Ω

Reference input level

: –20 dBs supplied to test point CN1

Standard test frequency 1kHz

Output measuring point Speaker terminal

:Dummy load 3 Ω

Standard position of switches

Function switch TAPE

Beat cut switch NORMAL

Standard position of controls

Tone Maximum position

Main volume adjust 0 dBs output position

Test remarks

1. Negative side of the input and output terminals of the

testing set, shall be isolated from each other. The

negative side should not be commonly connected

when a 2channel electronic voltmeter is connected.

2. A dummy load shall be connected to the output

terminal and the lead wires of dummy load shall be

as thick as possible.

Measuring condition(Tuner section)

Power supply voltage to tuner Vcc: DC 6V

Reference output Speaker: 0.245V/3 Ω

AM modulation 400Hz, 30%

FM modulation 400Hz, deviation 22.5kHz

Remarks for alignment

1. Connect 30 pF capacitor and 33k Ω resistor to the

output terminal of the IF sweeper in series while

0.082 µ F capacitor and 100k Ω resistor to the input

terminal in series.

2. Set the output level of the IF sweeper as low as

adjustable.

3. IF alignment is not necessary for both AM and FM

MPX alignment is not necessary either. All IFTs and

MPX coil are non-adjusting type.

1-15

Page 16

RC-BZ5LB/BZ5RD

RC-BZ6BU

Cassette amplifier section

Item

Head azimuth

adjustment

Tape speed,

Wow & flutter

check

Conditions Adjustment & Confirmation Method Standard Value Adjusting Point

• Test tape:

VT702(8 kHz)

• Test output from:

Speaker terminal

(with 3 Ω load)

• Function selector:

TAPE

• Test tape:

VT712 (3 kHz)

•Test output from:

Speaker terminal

(with 3 Ω load)

1. Play back the test tape VT702 (8 kHz signal).

2. Adjust the azimuth adjusting screw so that

phase difference between R and L channels is minimum with the output level that

is the maximum level plug less than 2 dB

in the FWD and REV mode.

After the adjustment apply screw sealant

onto the azimuth adjusting screw for more

than half the screw head.

3. If the head azimuth is still maladjusted, readjust it with the azimuth adjusting screw

alternately in the FWD and REV modes.

1. Play back the end portion of the test tape

VT712 (3 kHz signal).

2. At that time check to see if the frequency

counter reads 2940 to 3090 Hz. If not,

adjust the semi-fixed resistor inside the

motor to obtain the specified frequency.

3. Wow and flutter must be 0.38 % or less

(unweighted).

• Output: Max.

level plus less

than 2 dB

• Phase difference between

R & L ch:

Minimum

Frequency:

2940-3090 Hz

0.38 % or less

(unweighted)

Azimuth adjusting

screw (after head

replacement only)

Tape speed (with

semi-fixed resistor

inside motor)

Playback

output check

Playback

frequency

response

check

REC/PB

sensitivity

check

• Function selector:

TAPE

• Test tape: VT722,

VT724 (1 kHz)

• Test output from:

Speaker terminal

(with 3 Ω load)

• Function selector:

TAPE

• Test tape: VT738

• Test output from:

Speaker terminal

(with 3 Ω load)

• Function selector:

TAPE

• Mode: Recording

• Test input to:

CN301

1. With the test tape VT722 (1 kHz signal)

being played back, confirm that the speaker

output is 2.1 W or more with 10 % distortion.

2. With the test tape VT724 being played

back, confirm that the deviation between

R-ch and L-ch outputs is less than 3 dB.

With the test tape VT738 being played back,

confirm that the deviation between 1 kHz and

125 Hz signals is 6 ± 3 dB and that between

the 1 kHz and 8 kHz signals is 0 ± 4 dB.

With the input of 1 kHz, –20 dBs signal to the

test point CN301, confirm that the level difference between the recording and playback

is 0 ± 3 dB or less.

• Speaker output

with 10 %

distortion:

2.1W or more

• Deviation between R & L ch

outputs:

3 dB or less

• Deviation

between 1 kHz

& 125 Hz:

6 ± 3 dB

• Deviation

between 1 kHz

& 8 kHz:

0 ± 4 dB

• Level difference

between

REC & PB:

0 ± 3 dB or less

1-16

Page 17

RC-BZ5LB/BZ5RD

Tuner sections

Item Conditions Adjustment & Confirmation Methods Stand. values Adjust

RC-BZ6BU

FM, AM IF

adjustment

MPX

adjustment

FM tracking

adjustment

Since a solid IF is being used, no

adjustment is required.

Since a ceramic resonator is being used,

no adjustment is required.

Since a fixed coil is being used, no

adjustment is required.

1-17

Page 18

RC-BZ5LB/BZ5RD

RC-BZ6BU

Description of major IC's

MN35510 (IC603) : Digtal servo & digtal signal processor

1. Block diagram

BYTCK

SMCK

PMCK

VDD

VSS

DVDD1

VDSS1

/RST

/TEST

MSEL

STAT

X2

X1

CSEL

PITCH CONTROL

FCLK

GENERATOR

VCOF

TIMING

CK384(EFM)

MDATA

MCLK

MLD

PSEL

RSEL

ARF

DRF

DSLF

PLLF

IREF

PLL VCO

DSL

DEMODULATION

AVDD2

EFM

PCK

SUBCODE

AVSS2

INTERPOLATION

SYNC

SQCK

SUBQ

SUBCODE

BUFFER

DEMODULATION

SSEL

EFM

FLAG5(RESY)

DEMPH

RESY

SUBC

SBCK

/CLDCK

BLKCK

CRC

SRDATAIN(PSEL)

LRCKIN(MSEL)

BCLKIN(SSEL)

IOSEL

CLVS

MN35510

DEEMPHSIS

DIGITAL

8TIMES

OVER SAMPPUNG

DIGITAL FILTER

RFENV

TRCRS

VDET

BDO

/RFDET

OFT

VCO

A/D CONVERTER

FE

TE

INPUT PORT

SERVO

TIMING GENERATOR

MICRO COMPUTER

INTERFACE

SERVO

CPU

OUTPUT

PORT

D/A

CONVERTER

ATTENUATION

PEAK DETCT

AUTO CUE

SRAM

SOFT MUTING

DIGITAL

15K

INTER POLATION

DEINTERLEVE

CORRECTION

CIRC ERROR

SERVO

CLV

1BIT DAC

LOGIS

PWM

INTERFACE

DIGITAL

AUDIO

(L)

–

+

PWM

(R)

–

+

1-18

SENSE

WVEL

LDON

PLAY

TES

/TLOCK

/FLOCLK

TOFS

FBAL

TBAL

FOD

TRD

TVD

ECS

(BYTCK)TRVSTR

VREF

KICK

TRV

DMUTE

BCLK

SRDATA

LRCK

PC

ECM

TX

FLAG

IPFLAG

OUTL

OUTR

AVDD1

AVSS1

Page 19

BA6897FP (IC602) : 4channel driver

1.Terminal layout & Block diagram

RC-BZ5LB/BZ5RD

RC-BZ6BU

CH1-OUTA

CH1-OUTB

CH1-INA

CH1-INB

TEST1

TEST2

MUTE

CH2-INB

CH2-INA

CH2-OUTB

CH2-OUTA

GND

D.BUF

1

2

D.BUF

- +

D.BUF

D.BUF

Level

shift

+-

Level

shift

- +

-+

3

4

5

6

7

8

9

10

11

12

13

T.S.D

DRIVER

MUTE

+ Level

shift

+-

-+

Level

shift

+ -

-+

D.BUF

D.BUF

D.BUF

D.BUF

28

GND

CH4-OUTA

27

CH4-OUTB

26

CH4-INA

25

CH4-INB

24

BIAS IN

23

Vcc

22

Vcc

21

CH3-INB

20

19

CH3-INA

18

CH3-OUTB

17

CH3-OUTA

16

OP IN(+)

OP-OUT

14

-+

15

OP IN(-)

1-19

Page 20

RC-BZ5LB/BZ5RD

RC-BZ6BU

LC72136N (IC2) : PLL Frequency sinsesizer

1.Terminal layout

1

FM/AM

CLOCK

DO1

FM ST VCO STOP

AM/FM

SDIN

2. Block diagram

XT

CE

DI

NC

NC

2

3

4

5

6

7

8

9

10

11

22

21

20

19

18

17

16

15

14

13

12

XT

GND

LPFOUT

LPFIN

PD

VCC

FMIN

AMIN

NC

IFCONT

IFIN

1-20

1

22

16

15

3

4

5

6

17

21

3. Pin function

Pin

Symbol

No.

1

2

3

4

5

6

7

8

9

10

11

XT

FM/AM

CE

DI

CLOCK

DO1

FM ST

VCO STOP

AM/FM

NC

NC

SDIN

Reference

Driver

Swallow Counter

1/2

2

B

C

I/F

Power

on

Reset

Function

I/O

X'tal oscillator connect (75KHz)

I

LOW:FM mode (Not use)

O

When data output/input for 4pin(input) and

I

Swallow Counter

1/16,1/17 4bit

1/16,1/17 4bit

12bit

Programmable

DriverS

Data Shift Register & Latch

7821113

6pin(output): H

Input for receive the serial data from

I

controller

Sync signal input use

I

Data output for Controller

O

Output port

"Low": MW mode

O

O

Not use

Not use

Data input/output (Not use)

I/O

Phase

Detector

Charge Pump

Unlock

Detector

Universal

Counter

Pin

No.

12

13

14

15

16

17

18

19

20

21

22

Symbol

IFIN

IFCONT

NC

AMIN

FMIN

VCC

PD

LPFIN

LPFOUT

GND

XT

18

19

20

12

I/O

Function

IF counter signal input

I

IF signal output

O

Not use

-

AM Local OSC signal output

I

FM Local OSC signal input

I

Power supply(VDD=4.5 5.5V)

When power ON:Reset circuit move

PLL charge pump output(H: Local OSC

O

frequency Height than Reference frequency.

L: Low Agreement: Height impedance)

Input for active lowpassfilter of PLL

I

Output for active lowpassfilter of PLL

O

Connected to GND

X'tal oscillator(75KHz)

I

Page 21

TA2104AN (IC1) : AM/FM 1 chip tuner IC

1.Terminal layout & Block diagram

RC-BZ5LB/BZ5RD

RC-BZ6BU

FM

RF OUTRFVcc

GNDFMRF INAMLOW CUT

2.Pin function

FMRF

AM

RF IN

222324

AM

MIX

FM

OSC

21

FM

OSC

FM

MIX

4 6 9

MIX

OUT

AM

OSC

20

AM

OSC

BUFF

BUFF

521 3 7 8

Vcc

OSC

OUT

19 18 17 16

LEVEL

DET

AMIF FMIF

IF INFMIF IN

ST

LED

SW

ST

IF

BUFF

1 / 8

IF

REQ

IF

REQ

AM

DET

GNDRF

AF

BUFF

AGC

DET

OUT

AGC QUAD R-OUT L-OUTAM

FM

DET

MPX

IN LPF1 LPF2

15

AF

10 11 12

14 13

VCO

DIVIDE

ST / MO

FM / AM

DECODE

MUTE

Pin

Pin Name

1

RF GND

2

FM RF IN

3

AM LOW CUT

4

MIX OUT

5

Vcc

6

AM IF IN

7

FM IF IN

8

GND

9

AGC

QUAD

10

R-OUT

11

L-OUT

12

LPF2

13

LPF1

14

MPX IN

15

DET OUT

16

IF REQ

17

ST LED

18

OSC OUT

19

AM OSC

20

FM OSC

21

AM RF IN

22

RF Vcc

23

FM RF OUT

24

Function

RF Stage ground

FM RF Input

AM Low Frequency Cut Filter External Component

Mixer Output

Power Supply

AM IF Amplifier Input

FM IF Amplifier Input

Ground

AM AGC External Capacitor

FM Quadrature Detector Terminal

Audio output CH-R

Audio output CH-L

LPF Terminal for Phase Detector / AM, FM Switching

LPF Terminal for Synchronous Detector / VCO Stop

FM MPX Input

AM/FM Detector Output

IF Output / IF Request control

FM Stereo Indicator Output

Local Oscillator Output

AM Oscillator

FM Oscillator

AM RF Input

RF Stage Vcc

FM RF Amplifier Output

1-21

Page 22

RC-BZ5LB/BZ5RD

RC-BZ6BU

AN8806SB (IC601) : RF & Servo amplifier

1.Treminal layout

PD

LD

LDON

LDP

VCC

RF-

RFOUT

RFIN

C.AGC

ARF

C.ENV

C.EA

CSBDO

BDO

CSBRT

OFTR

/NRFDET

GND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

PDAC

PDBD

PDF

PDE

PDER

PDFR

TBAL

FBAL

FE FEOUT

TE TEOUT

CROSS

TEBPF

VDET

LDOFF

VREF

ENV

2.Block diagram

36

35

31

34

32

6

VCBA

29

728

VCBA

VCBA

VCBA

8

27

EQ

OFTR

910 17

AGC

RF

DET

BDO

11

12 19

ENV CIRCUIT

13

14

15

16

20

1-22

21

33

24 25

30

23

26

22

14

3

2

Page 23

3. Pin function

RC-BZ5LB/BZ5RD

RC-BZ6BU

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

Symbol

PD

LD

LDON

LDP

VCC

RF-

RFOUT

RFIN

C.AGC

ARF

C.ENV

C.EA

CSBDO

BDO

CSBRT

OFTR

/NRFDET

GND

ENV

VREF

LDOFF

VDET

TEBPF

CROSS

TEOUT

TE-

FEOUT

FEFBAL

TBAL

PDFR

PDER

PDE

PDF

PDBD

PDAC

I/O

I

APC amp input terminal

APC amp output terminal

O

APC ON/OFF control terminal

I

--

Connect to ground

Power supply

-Inverse input pin for RF amp

I

RFamp output

O

RF input

I

Connecting pin of AGC loop filter

I/O

RF output

O

I/O

A capacitor is connected to this terminal to detect the envelope of RF signal

I/O

A capacitor is connected to this terminal to detect the envelope of RF signal

A capacitor is connected to detect the lower envelope of RF signal

I/O

BDO output pin

O

A capacitor is connected to detect the lower envelope of RF signal

I/O

O

Of-track status signal output

RF detection signal output

O

--

Ground

O

Envelope output

Reference voltage output

O

Function

I

O

Vibration detection signal output

I

Input pin of tracking error through BPF

O

Tracking error cross output

O

Tracking error signal output

Inverse input pin for tracking error amp

I

O

Output pin of focus error

Inverse input pin for focus error amp

I

I

Focus balance control

I

Tracking balance control

F I-V amp gain control

I/O

E I-V amp gain control

I/O

I

I-V amp input

I-V amp input

I

I

I-V amp input

I I-V amp input

1-23

Page 24

RC-BZ5LB/BZ5RD

RC-BZ6BU

TA2068N (IC301) : Rec/PB. amplifier

1. Terminal layout

1

AGC

2

PBO1

REC1

VREF

VSS

REC2

PBO2

3

4

5

6

7

8

9

10

11

12

PBNF1

PBIN1

PBIN2

PBNF2

MICNF

2. Block diagram

24

23

22

21

20

19

18

17

16

15

14

13

RAIN1

MICSEL

CDIN1

P/R

OUT1

VCC

OUT2

SEL

CDIN2

TAPE

RAIN2

MICIN

22

24235

19

13

12

6

7

REF. AMP

RADIO

TAPE

NAB AMP1

–

46.5

+

MIC AMP1

–

19.5

+

NAB AMP2

+

2.1V

8 10 11 14 16 15 17

46.5

–

LINE

TAPE

BUF. AMP A1BUF. AMP A1

MUTE

ON

BUF. AMP A2

TAPE

LINE

TAPE

RADIO

+

–

BUF. AMP B1

+

–

BUF. AMP B2

MUTE

ALC1

DET

ALC2

MUTE

LOGIC

MONITOR AMP 1

7

ON

REC AMP1

26

REC AMP2

26

MONITOR AMP

ON

7

21

20

4

1

9

2

18

23

1-24

Page 25

RC-BZ5LB/BZ5RD

RC-BZ6BU

VICTOR COMPANY OF JAPAN, LIMITED

AUDIO & COMMUNICATION BUSINSS DIVISION

PERSONAL & MOBILE NETWORK B.U. 10-1,1Chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.20819)

Printed in Japan

200007(S)

Loading...

Loading...