Page 1

SERVICE MANUAL

CD PORTABLE SYSTEM

RC-BZ5LB/BZ5RD

RC-BZ6BU

RC-BZ5LB/BZ5RD

RC-BZ6BU

REMOTE CONTROL RM-SRCBZ5

RC-BZ5LB/BZ5RD

REMOTE CONTROL RM-SRCBZ6

RC-BZ6BU

Contents

Safety precautions

Importance administering point on the safety

Preventing static electricity

Important for laser products

Disassembly method

Adjustment method

Description of major ICs

1-2

1-3

1-4

1-5

1-6

1-15

1-18

Areas suffix

J ---------------- U.S.A.

C ------------- Canada

Comparison table

Item

Jog dial circuit Not used Used

Back light (LCD) Not used Used

Bass boost circuit Not used Used

Power amplifier 14W 18W

Electrical volume Not used Used

RC-BZ5LB/BZ5RD

RC-BZ6BU

COPYRIGHT 2000 VICTOR COMPANY OF JAPAN, LTD.

No.20819

July. 2000

Page 2

RC-BZ5LB/BZ5RD

RC-BZ6BU

Safety precautions

1. This design of this product contains special hardware and many circuits and components specially

for safety purposes. For continued protection, no changes should be made to the original design

unless authorized in writing by the manufacturer. Replacement parts must be identical to those

used in the original circuits. Services should be performed by qualified personnel only.

2. Alterations of the design or circuitry of the product should not be made. Any design alter ations of

the product should not be made. Any design alterations or additions will void the manufacturer`s

warranty and will further relieve the manufacture of responsibility for personal injury or property

damage resulting therefrom.

3. Many electrical and mechanical parts in the products have special safety-related characteristics.

These characteristics are often not evident from visual inspection nor can the protection afforded

by them necessarily be obtained by using replacement components rated for higher voltage,

wattage, etc. Replacement parts which have these special safety characteristics are identified in

the Parts List of Service Manual. Electrical components having such features are identified by

shading on the schematics and by ( ) on the Parts List in the Service Manual. The use of a

substitute replacement which does not have the same safety characteristics as the recommended

replacement parts shown in the Parts List of Service Manual may create shock, fire, or other

hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the

like to be separated from live parts, high temperature parts, moving parts and/or sharp edges

for the prevention of electric shock and fire hazard. When service is required, the original lead

routing and dress should be observed, and it should be confirmed that they have been returned

to normal, after re-assembling.

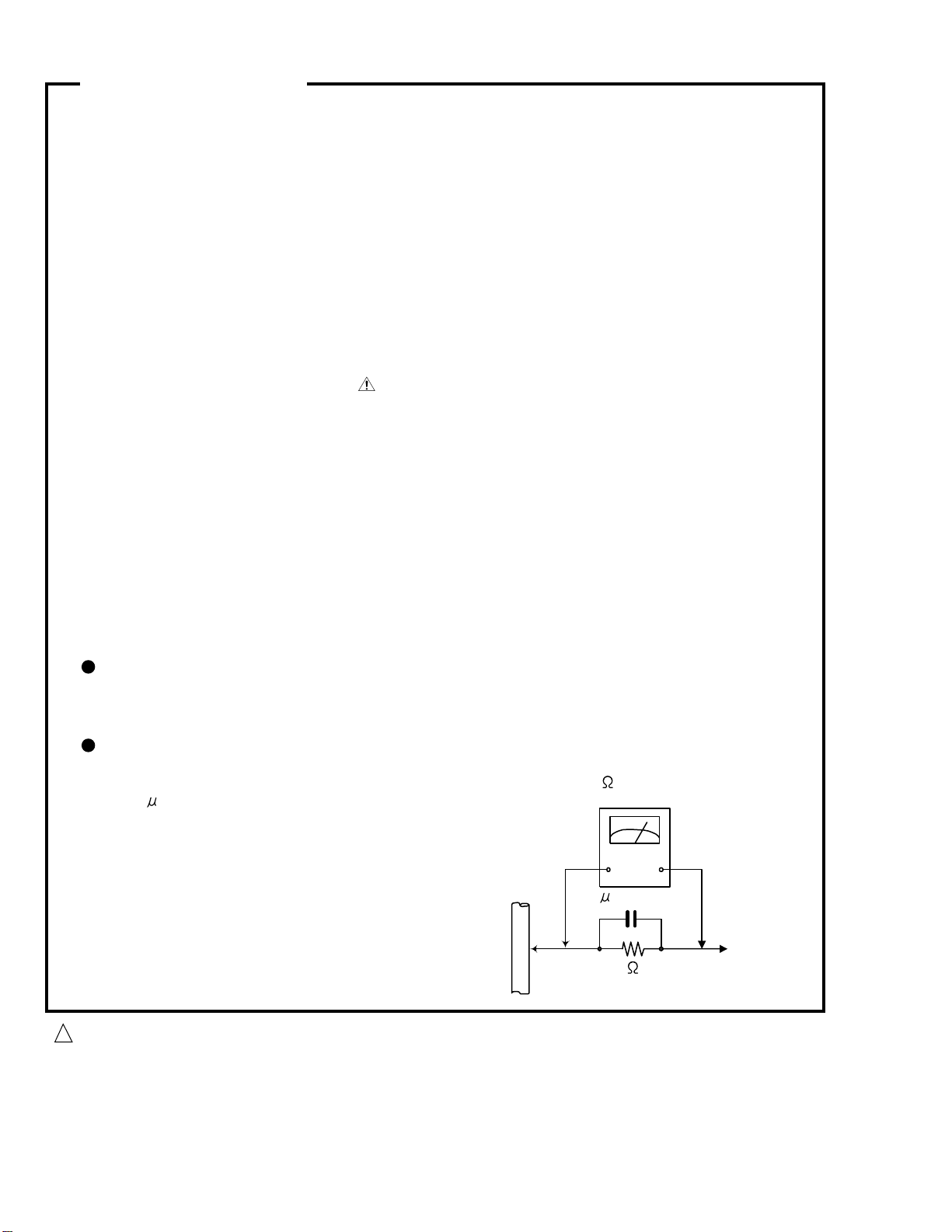

5. Leakage current check (Electrical shock hazard testing)

After re-assembling the product, always perfor m an isolation check on the exposed metal parts

of the product (antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control

shafts, etc.) to be sure the product is safe to operate without danger of electrical shock.

Do not use a line isolation transformer during this check.

Plug the AC line cord directly into the AC outlet. Using a "Leakage Current Tester", measure

the leakage current from each exposed metal parts of the cabinet , particularly any exposed

metal part having a return path to the chassis, to a known good earth ground. Any leakage

current must not exceed 0.5mA AC (r.m.s.)

Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having, 1,000 ohms

per volt or more sensitivity in the following manner. Connect a 1,500 10W resistor paralleled by

a 0.15 F AC-type capacitor between an exposed

metal part and a known good earth ground.

Measure the AC voltage across the resistor with the

AC voltmeter.

Move the resistor connection to each exposed metal

part, par ticularly any exposed metal part having a

return path to the chassis, and measure the AC

voltage across the resistor. Now reverse the plug in

the AC outlet and repeat each measurement voltage

measured any must not exceed 0.75 V AC (r.m.s.).

This corresponds to 0.5 mA AC (r.m.s.).

0.15 F AC TYPE

1500 10W

Good earth ground

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

Place this

probe on

each exposed

metal part.

1-2

CAUTION

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Page 3

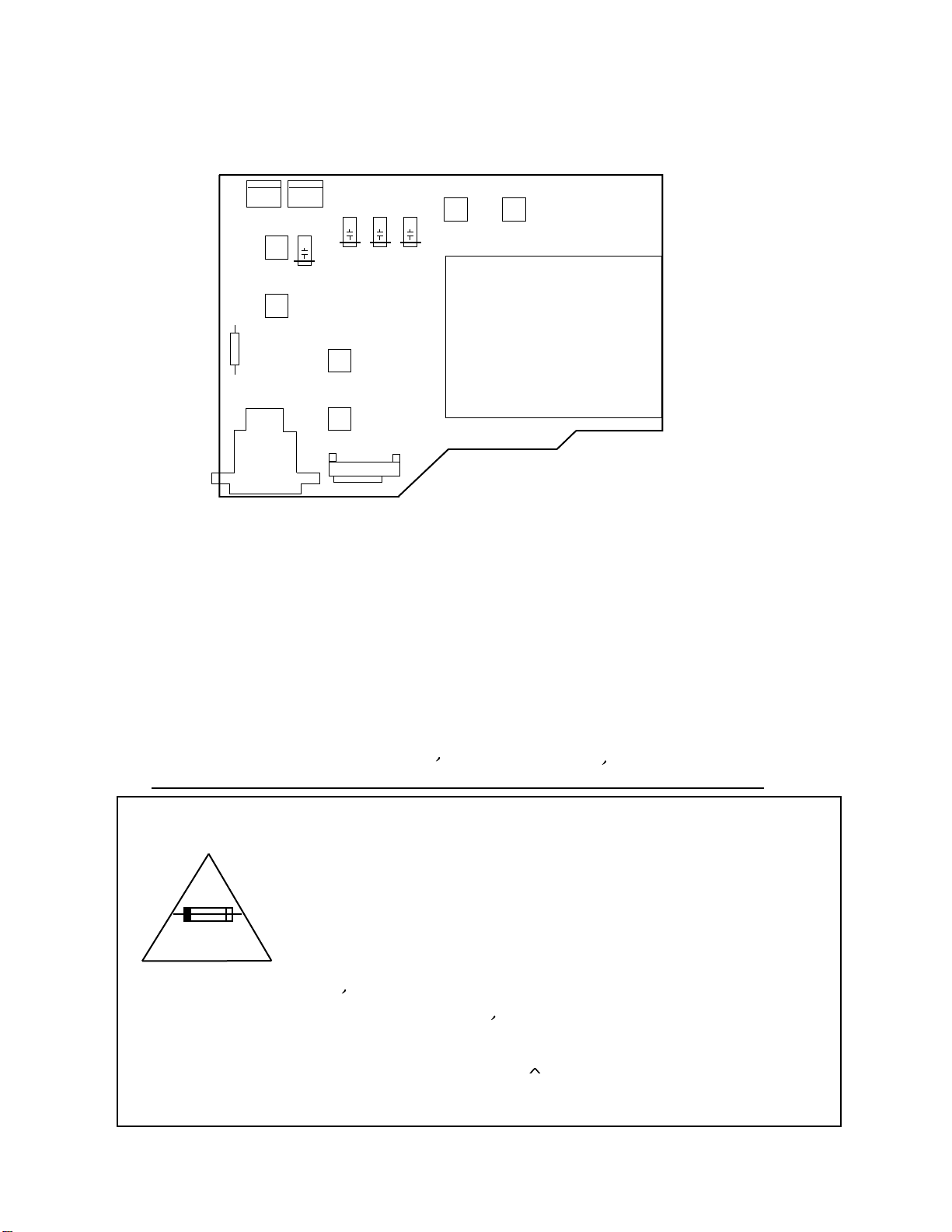

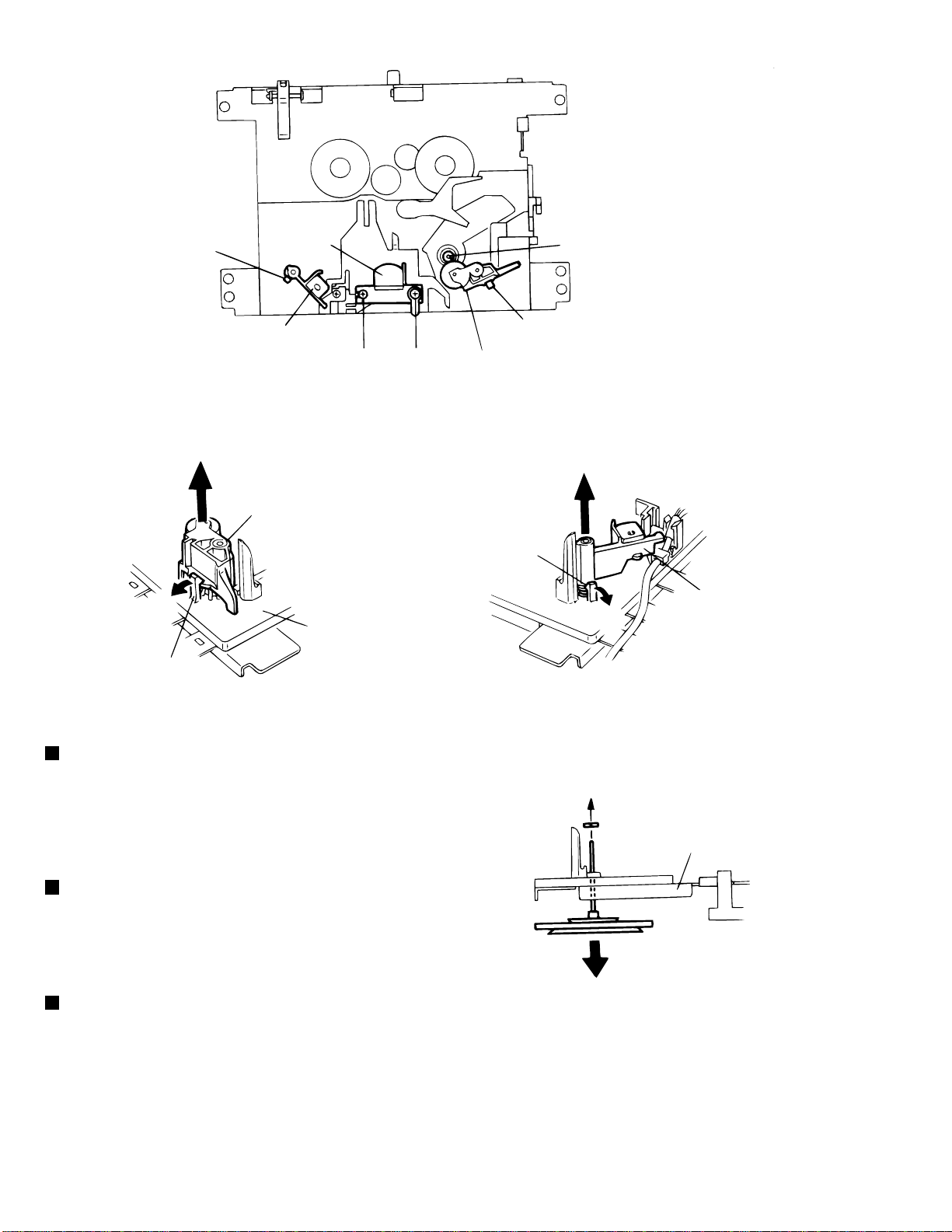

Importance administering point on the safety

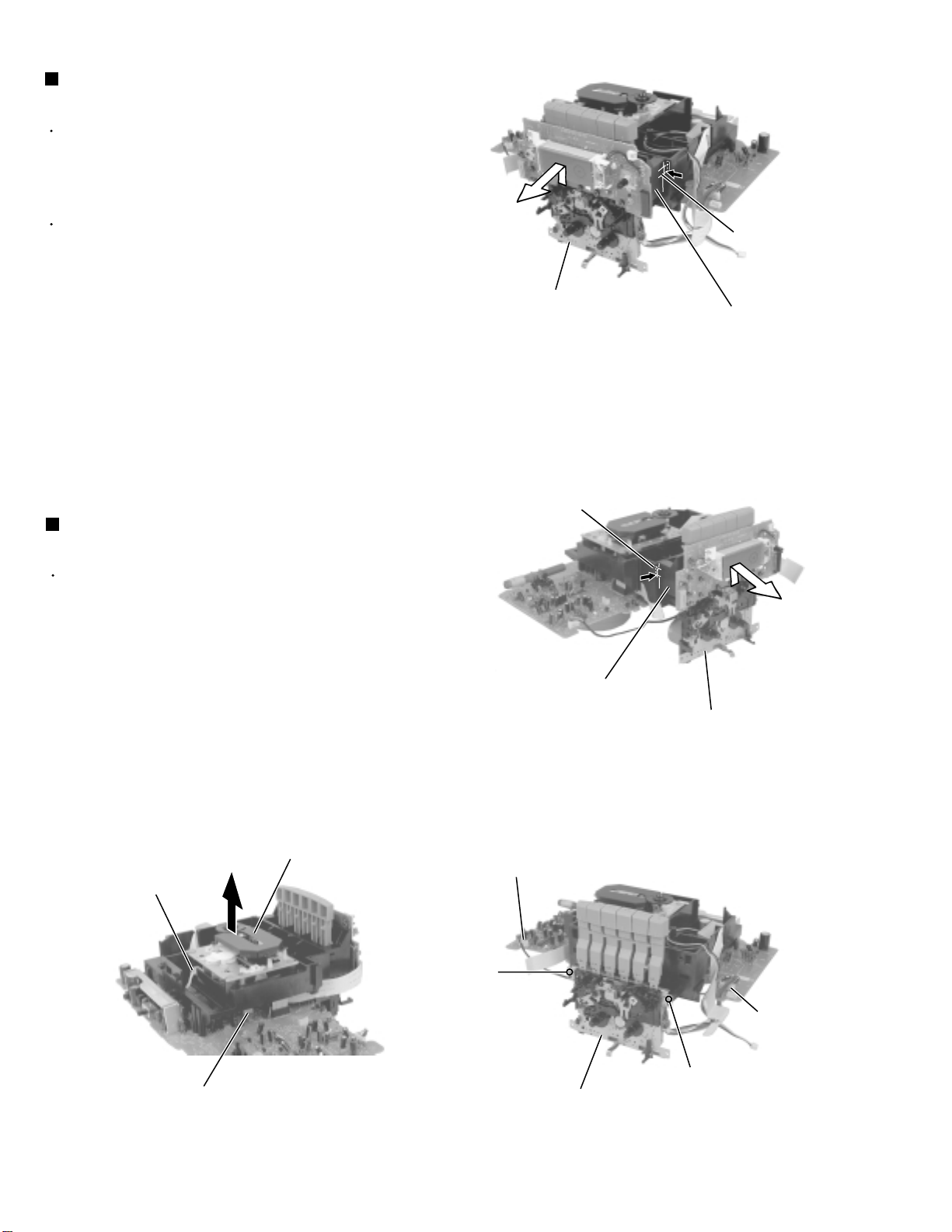

Power supply board

D902

D903

R998

CN307CN306

F903

D901

D904

F902

POWER TRANSFORMER

RC-BZ5LB/BZ5RD

RC-BZ6BU

J9

F901

Not used

S901

For USA and Canada / pour Etats - Unis d' Amerique et Canada

Caution: For continued protection against risk of

fire, replace only with same type 3A/125V for

F902 and F903. This symbol specifies type of fast

operating fuse.

Precaution: Pour eviter risques de feux, remplacez

le fusible de surete de F902 et F903 comme le

meme type que 3A/125V.

Ce sont des fusibles suretes qui functionnes rapide.

1-3

Page 4

RC-BZ5LB/BZ5RD

RC-BZ6BU

Preventing static electricity

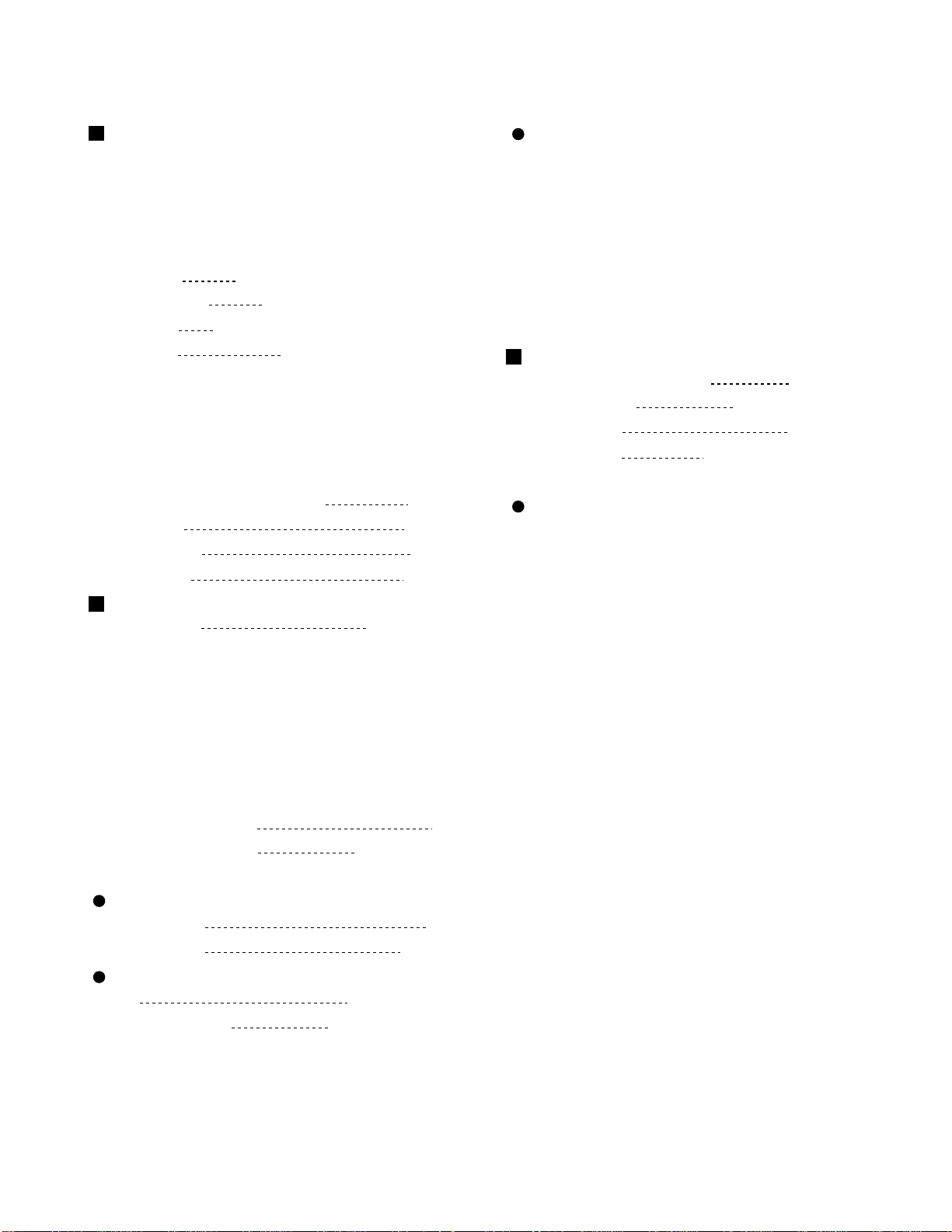

1.Grounding to prevent damage by static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged,

can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

2.About the earth processing for the destruction prevention by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as CD players.

Be careful to use proper grounding in the area where repairs are being performed.

2-1 Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over

it before placing the traverse unit (optical pickup) on it.

2-2 Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

Conductive material

(conductive sheet) or iron plate

3. Handling the optical pickup

1. In order to maintain quality during transport and before installation, both sides of the laser diode on the

replacement optical pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

2. Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power

source can easily destroy the laser diode.

4.Handling the traverse unit (optical pickup)

1. Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

2. Remove solder of the land on the flexible cable after replacing the optical pickup. For specific

details, refer to the replacement procedure in the text. Remove the anti-static pin when replacing the traverse

unit. Be careful not to take too long a time when attaching it to the connector.

3. Handle the flexible cable carefully as it may break when subjected to strong force.

4. It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it

CD Pick up

Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for pick-up and

how to detach the substrate.

1.Short the land before the card wire is removed from connector on

the Main board as shown in Figure.

(When the wire is removed without putting up solder, the CD pick-up

assembly might destroy.)

2.Please remove solder after connecting the card wire with

when you install picking up in the substrate.

1-4

Land

Page 5

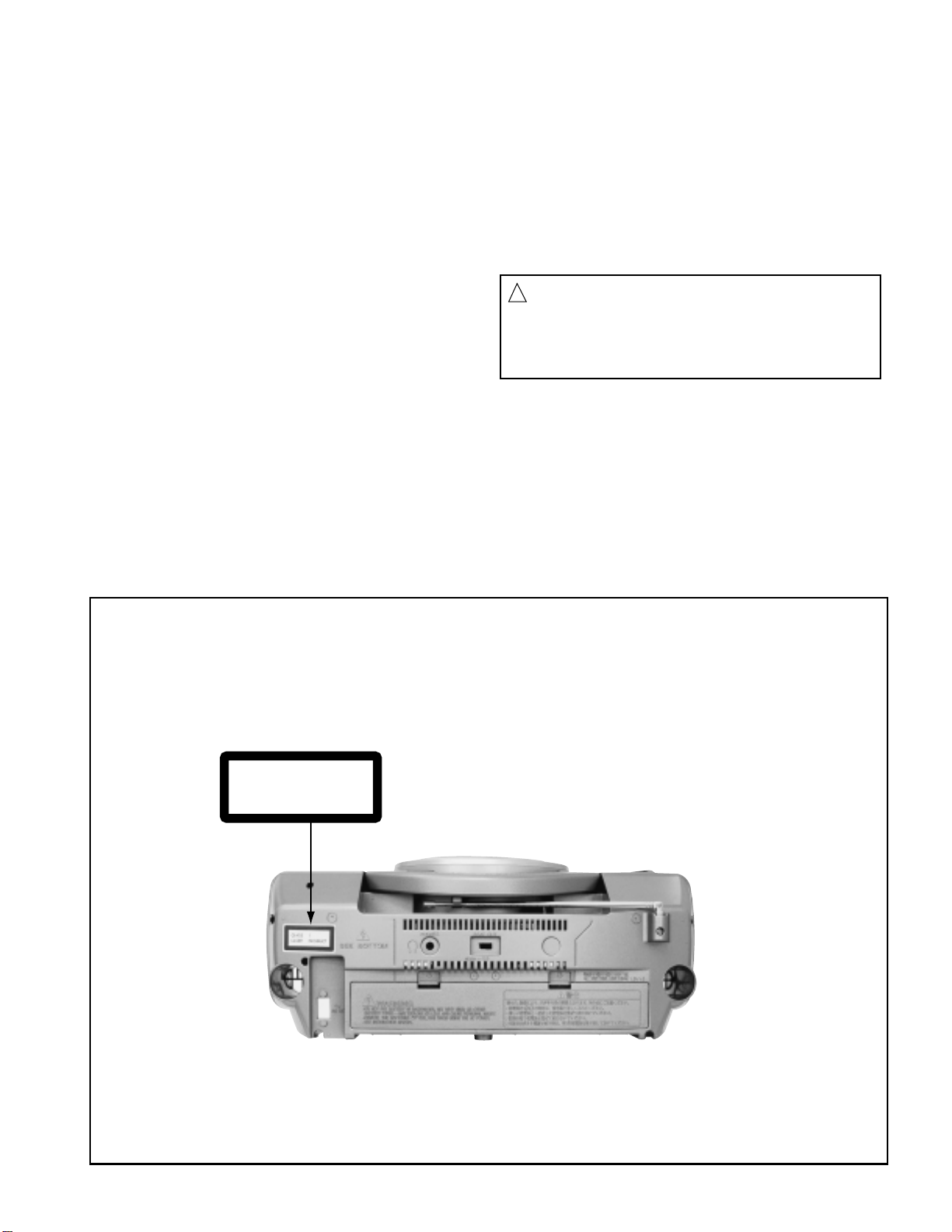

Important for laser products

RC-BZ5LB/BZ5RD

RC-BZ6BU

1.CLASS 1 LASER PRODUCT

2.DANGER : Invisible laser radiation when open and inter

lock failed or defeated. Avoid direct exposure to beam.

3.CAUTION : There are no serviceable parts inside the

Laser Unit. Do not disassemble the Laser Unit. Replace

the complete Laser Unit if it malfunctions.

4.CAUTION : The compact disc player uses invisible

laserradiation and is equipped with safety switches

whichprevent emission of radiation when the drawer is

open and the safety interlocks have failed or are de

feated. It is dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified herein may result in

hazardous radiation exposure.

CAUTION

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

REPRODUCTION AND POSITION OF LABELS

WARNING LABEL

CLASS 1

LASER PRODUCT

1-5

Page 6

RC-BZ5LB/BZ5RD

RC-BZ6BU

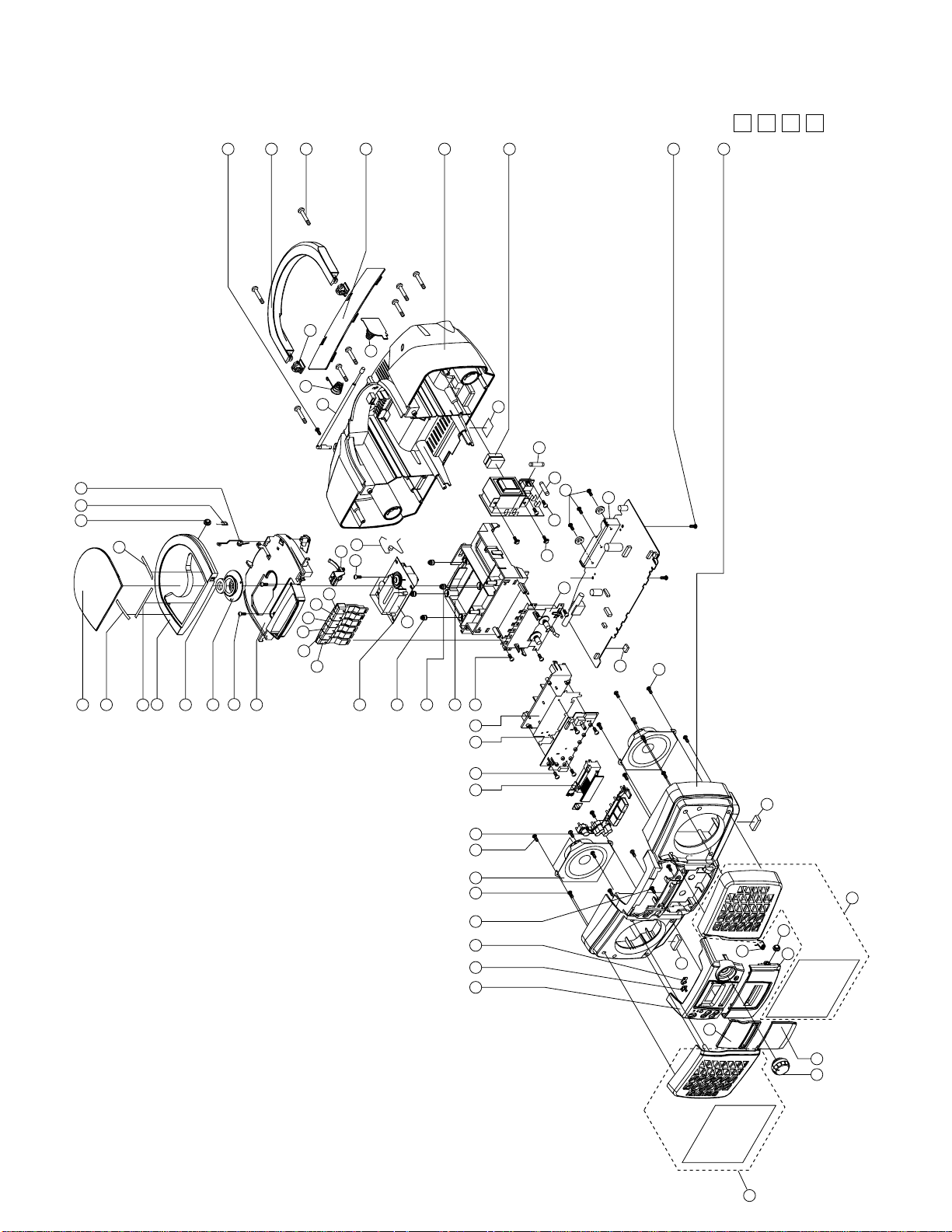

Disassembly method

<Main body>

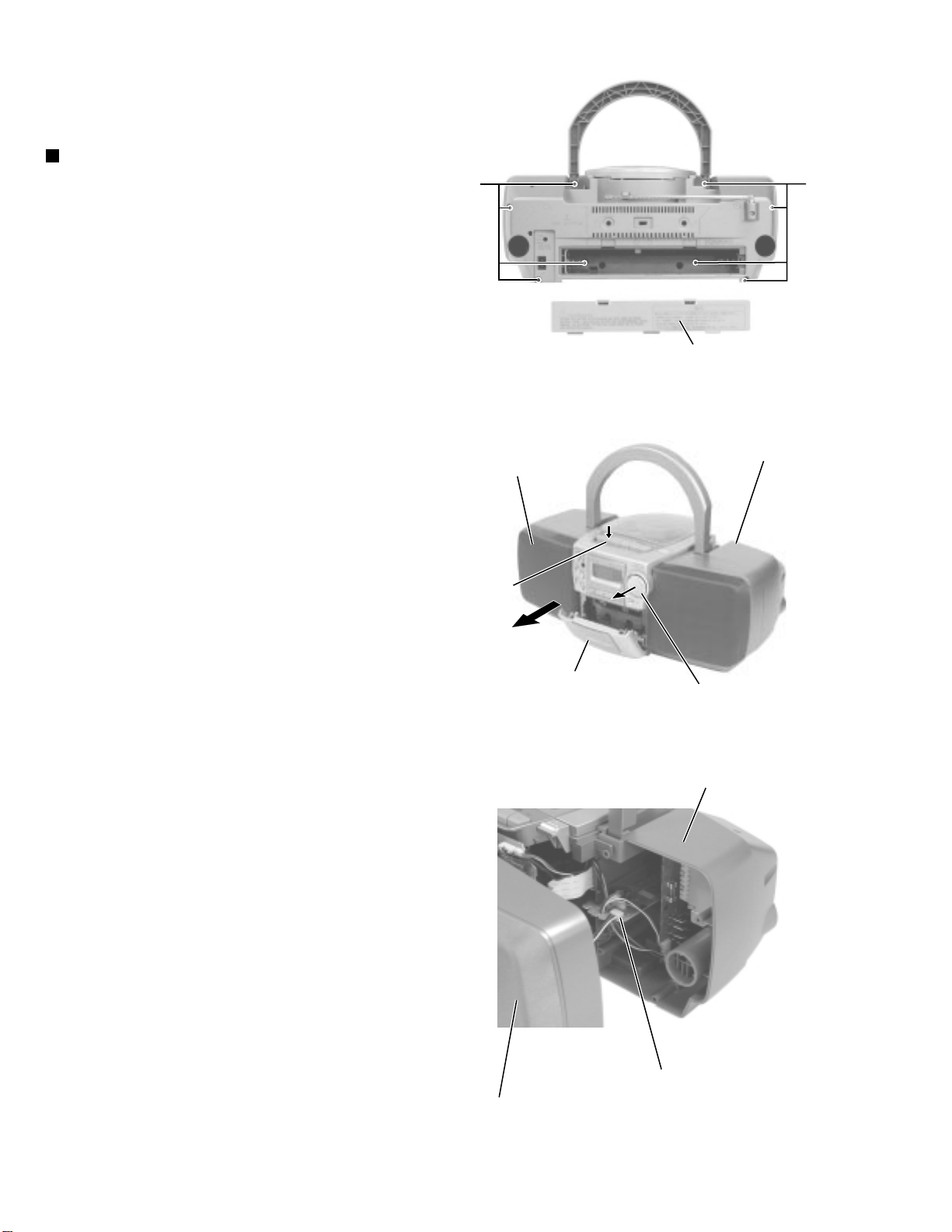

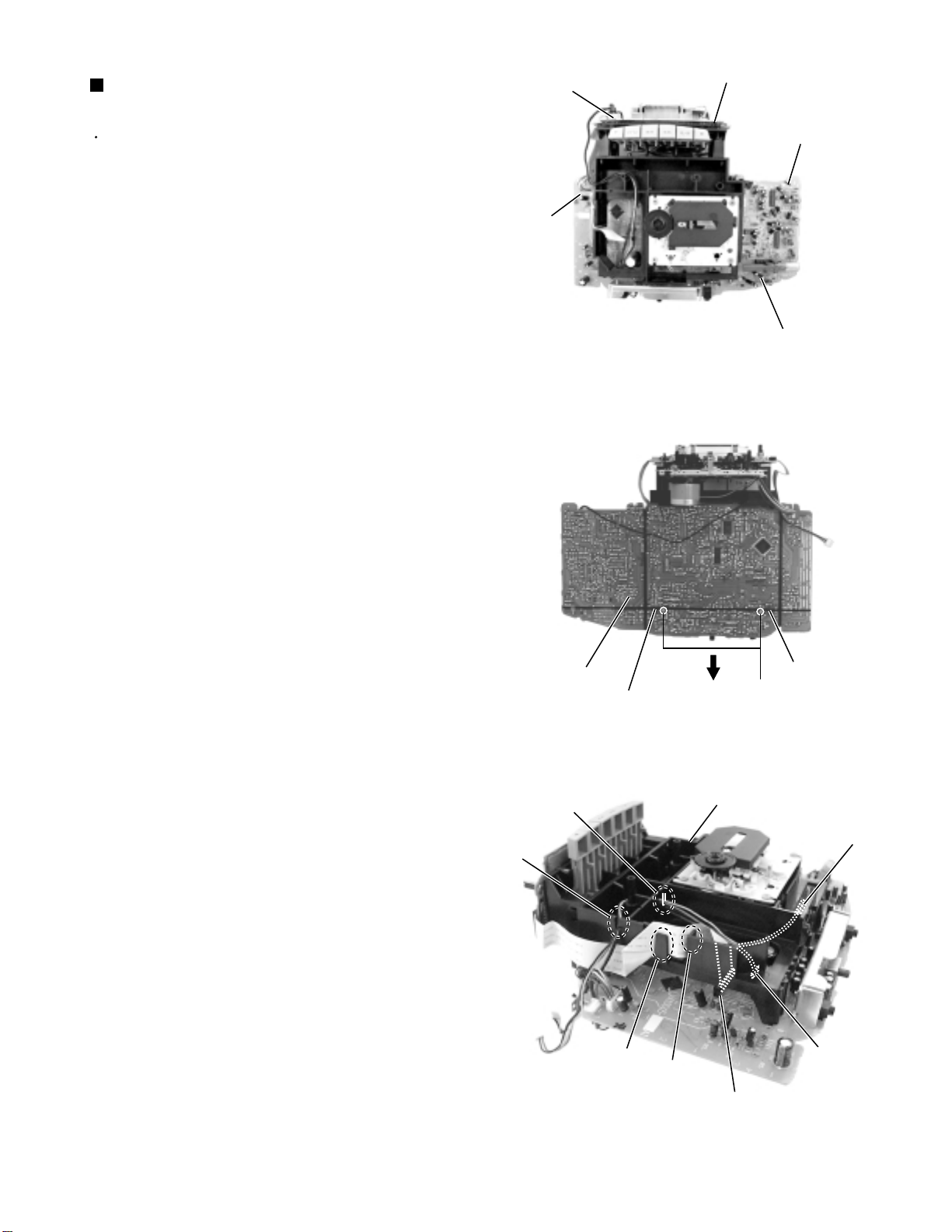

Removing the front cabinet assembly /

rear cabinet assembly (See Fig.1 to 3)

1.

Detach the battery cover on the back of the body.

Remove the eight screws A attaching the front

cabinet assembly and the rear cabinet assembly.

2.

Press STOP / EJECT button on the upper side of the

body to open the cassette door.

3.

Remove the front cabinet assembly toward the front

and pull out the volume knob at the same time.

4.

Disconnect the speaker harness from connector

CN309 on the main board in the rear cabinet

assembly.

A

Front cabinet assembly

A

Battery cover

Fig.1

Rear cabinet assembly

STOP / EJECT button

assembly /

Cassette door

Volume knob

Fig.2

Rear cabinet assembly

1-6

Main board

CN309

Front cabinet assembly

Fig.3

Page 7

<Front cabinet assembly>

RC-BZ5LB/BZ5RD

RC-BZ6BU

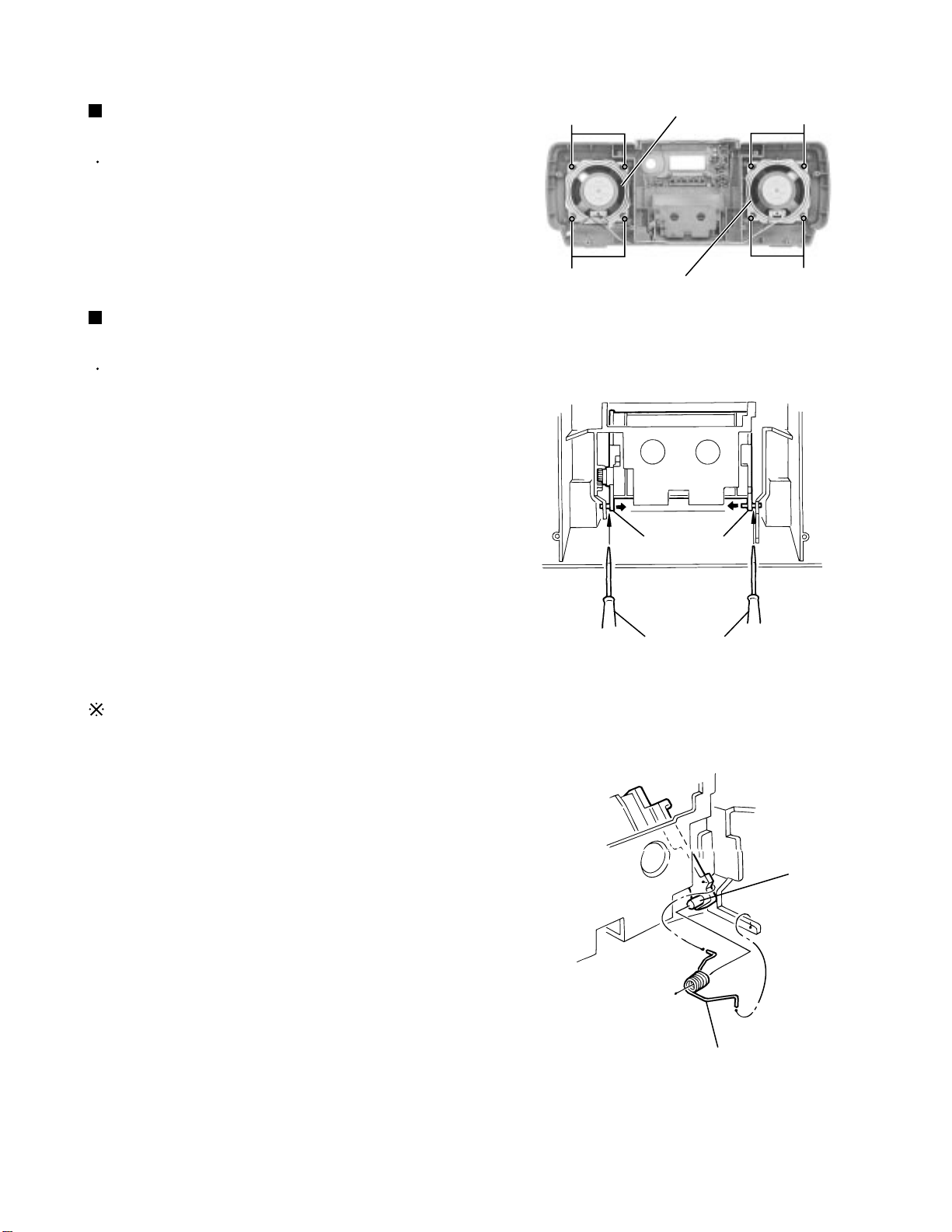

Removing the speaker (L) and (R)

(See Fig.4)

Prior to performing the following procedure, remove

the front cabinet assembly.

1.

Remove the eight screws B in the front cabinet.

Removing the cassette door

(See Fig.5 and 6)

Prior to performing the following procedure, remove

the front cabinet assembly.

1.

Remove the door spring in the front cabinet

assembly.

2.

Insert a screwdriver between the door arm and the

front cabinet and slide the door arms inward, then

detach the cassette door from the front cabinet.

B

B

Speaker (L)

Speaker (R)

Fig.4

Door arms

B

B

Reattaching the door spring

1.

Reattach the door spring to the cassette door shaft

with opening the cassette door.

2.

Fit another end of the door spring to the front cabinet

rib.

3.

Fit the shorter end of the door spring to the cassette

door.

Screwdriver

Fig.5

Shaft

Door spring

Fig.6

1-7

Page 8

RC-BZ5LB/BZ5RD

RC-BZ6BU

<Rear cabinet assembly>

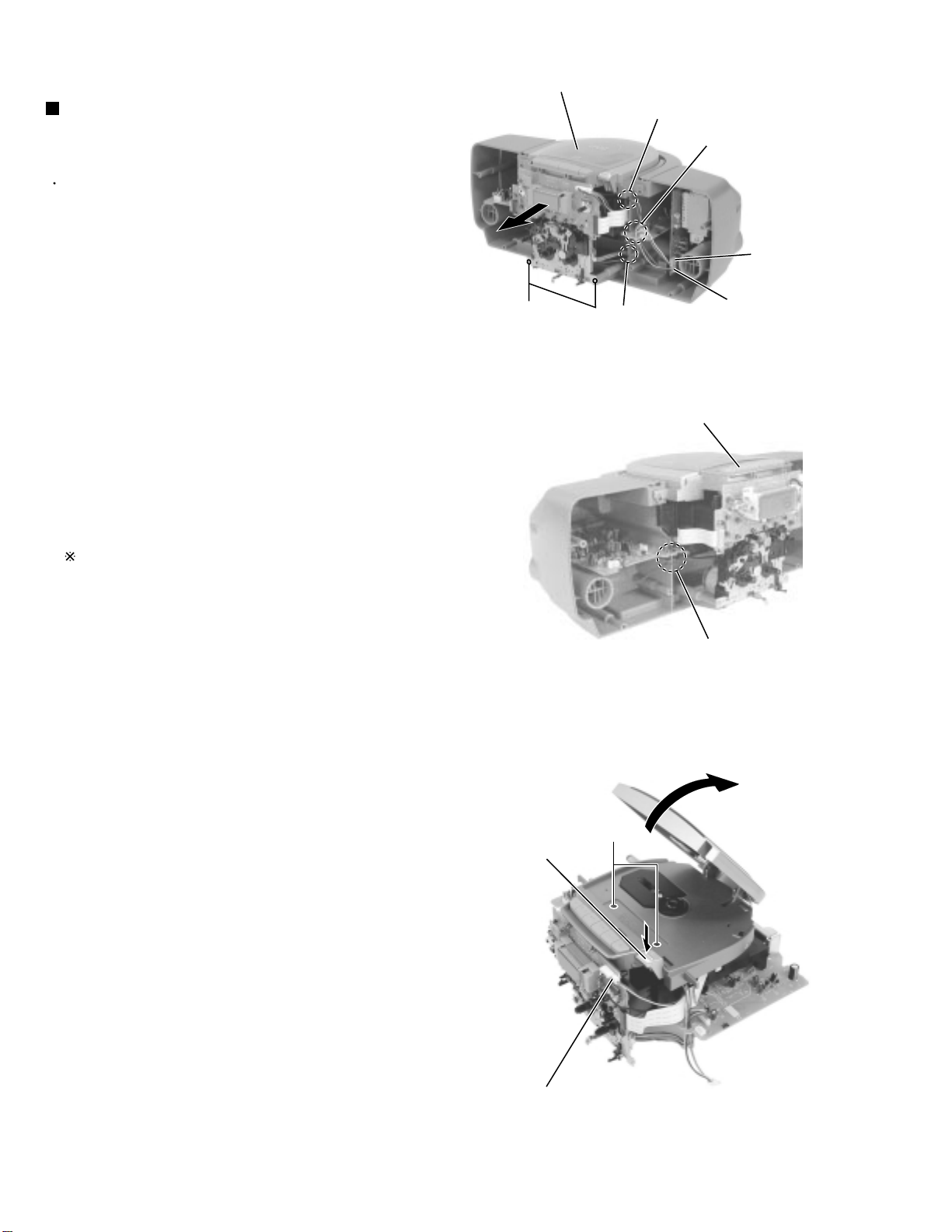

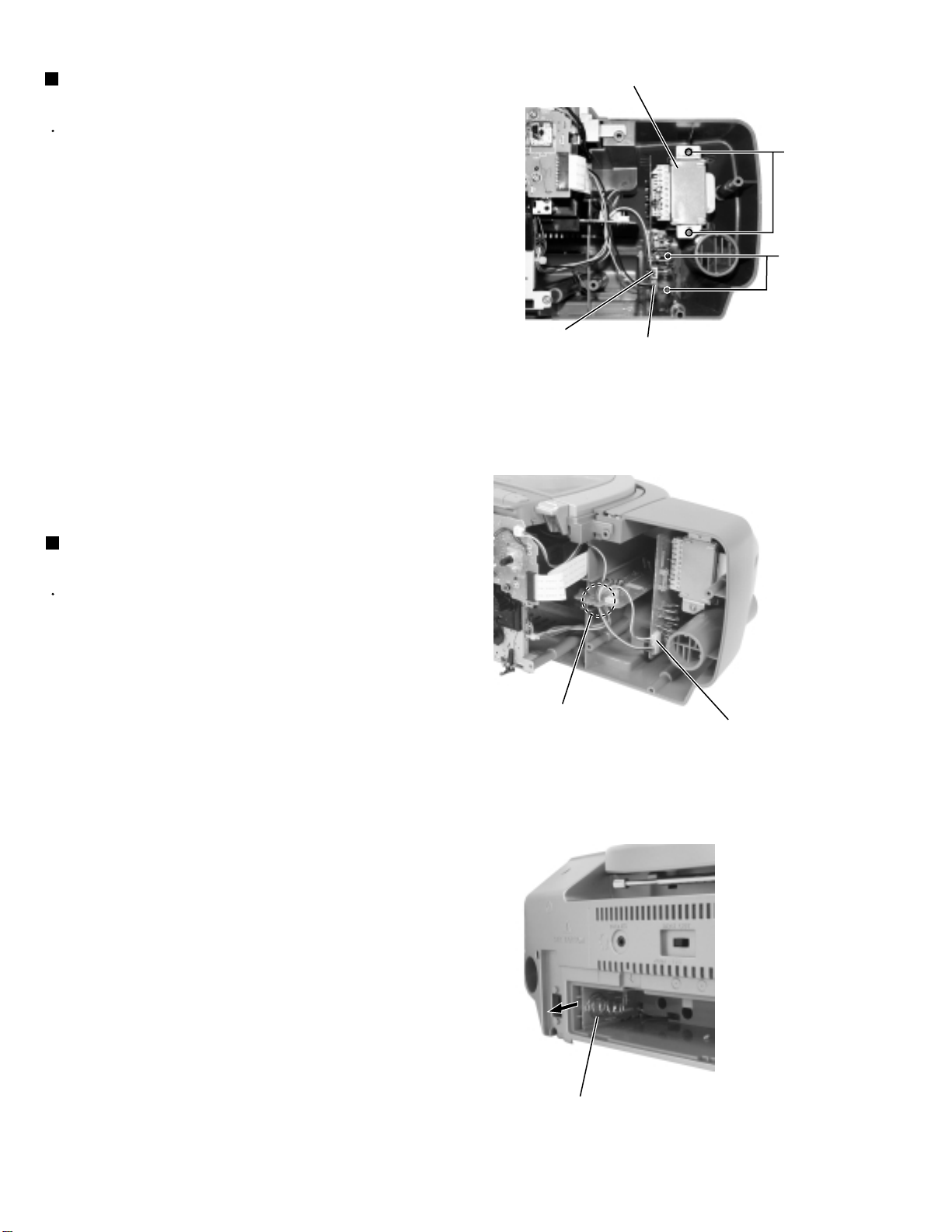

Removing the CD / cassette and amplifier

assembly from the rear cabinet

(See Fig.7 and 8)

Prior to performing the following procedure, remove

the front cabinet assembly and the rear cabinet

assembly.

1.

For the harness connecting the amplifier board with

the power board, disconnect it from connector

CN306 on the power board in the right rear cabinet

assembly. For the harness connecting the battery

terminal wire with the power board, disconnect it

from CN307 on the power board.

2.

Remove the two screws C on the bottom of the

cassette mechanism unit.

3.

Release the harnesses from the slot a, b and c and

the notch of the main board in the rear cabinet.

4.

Remove the CD / cassette and amplifier assembly

from the rear cabinet.

CD / cassette and amplifier assembly

Slot a

Release the hornese

C

CD / cassette and amplifier assembly

Slot c

Fig.7

Power board

CN307

CN306

Now the CD / cassette and amplifier assembly is

ready to conduct burn-in.

Slot b

Fig.8

D

CD door eject button

1-8

Key switch / display board

CN704

Fig.9

Page 9

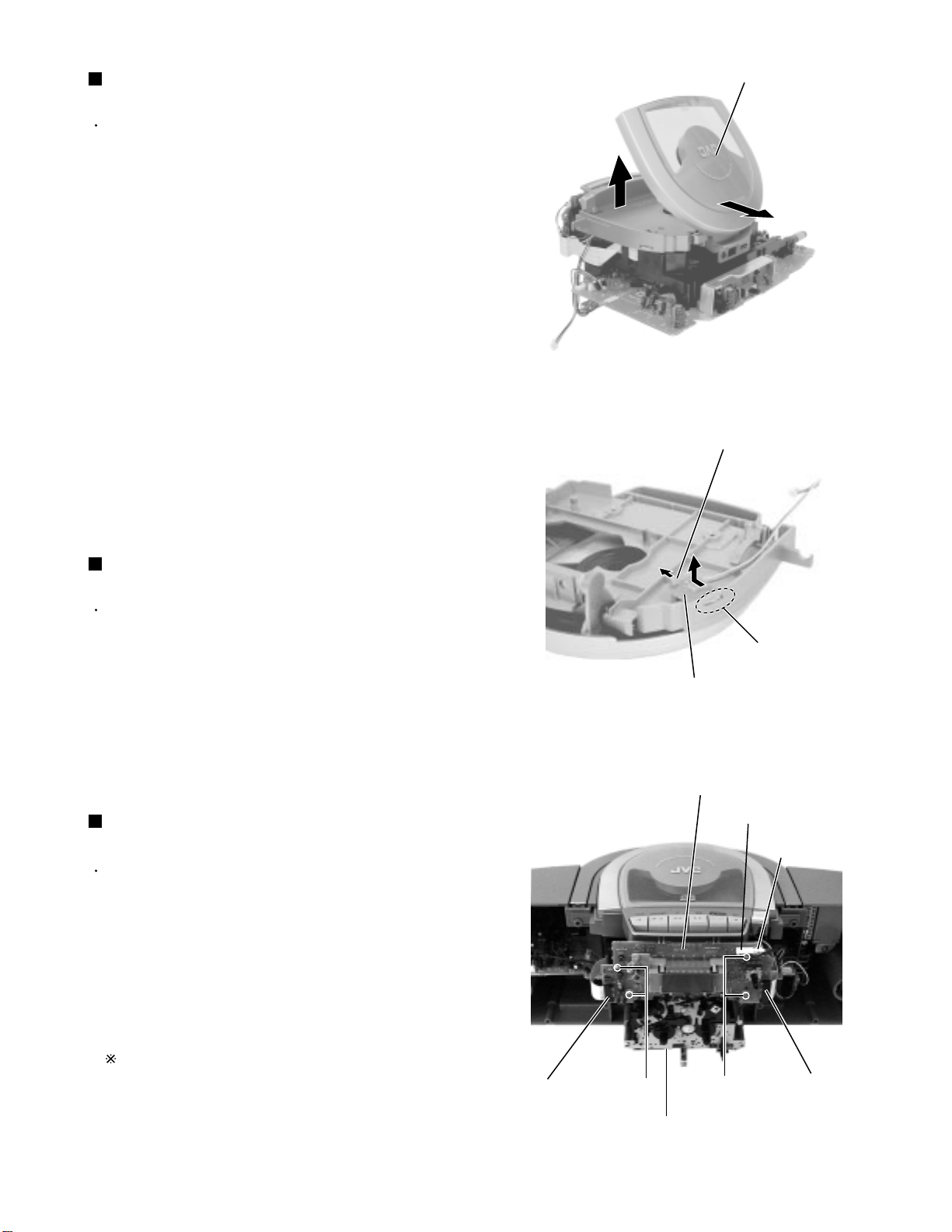

Removing the CD cover and door unit

(See Fig.9 and 10)

Prior to performing the following procedure, remove

the CD / cassette and amplifier assembly.

1.

Disconnect the harness from connector CN704 on

the key switch / display board (The harness is

extending from the door switch board).

2.

Press EJECT button to open the CD door.

3.

Remove the two screws D on the front of the CD

cover and door unit.

4.

Raise the front part of the CD cover and door unit

and detach upward. Then push the whole unit

backward until it comes off.

RC-BZ5LB/BZ5RD

RC-BZ6BU

CD cover and door unit

Fig.10

ATTENTION:

At this point, the CD mechanism unit

will become removable. So handle the

rear cabinet with care.

Removing the CD door switch board

(See Fig.11)

Prior to performing the following procedure, remove

the CD cover and door unit.

1.

Turn over the CD cover and door unit and gently

spread apart the locking tab. Then remove the CD

door switch board in the direction of the arrow while

releasing it from joint d.

Removing the key switch / display board

(See Fig.12)

Prior to performing the following procedure, remove

the front cabinet assembly and the rear cabinet

assembly.

Tab

Joint d

CD door switch board

Fig.11

Key switch / display boardKey switch / display board

CN702(RC-BZ5 only)

CN704

1.

Disconnect the card wires from connector CN701,

CN702 and CN703, then the harness from CN704

on the key switch / display board.

2.

Remove the four screws E attaching the key switch /

display board.

The key switch / display board can be removed

even if the mechanism cover is attached.

CN703

E

Cassette mechanism assembly

Fig.12

E

CN701

1-9

Page 10

RC-BZ5LB/BZ5RD

RC-BZ6BU

Removing the cassette mechanism

assembly (See Fig.13 to 15)

Prior to performing the following procedure, remove

the CD / cassette and amplifier assembly, the CD

cover and door unit and disconnect the harnesses

connected to the key switch / display board.

The cassette mechanism cover is still attached.

1.

Push inward the locking tabs e on both sides of the

cassette mechanism cover and remove the

mechanism cover in the direction of the arrow.

2.

Disconnect the harnesses from connector CN301

and CN308 on the main board.

3.

Remove the upper two screws F and the cassette

mechanism assembly toward the front.

Removing the CD mechanism assembly

(See Fig.16)

Prior to performing the following procedure, remove

the CD / cassette and amplifier assembly, the CD

cover and door unit.

1.

Disconnect the harness from connector P011 on the

motor board in the lower part of the CD mechanism

assembly. Then disconnect the pickup card wire

from CN601 on the main board.

2.

Remove the CD mechanism assembly upward.

Cassette mechanism assembly

Fig.13

Locking tab e

Cassette mechanism cover

Fig.14

Locking tab e

Cassette mechanism

Cassette mechanism assembly

cover

1-10

Motor board

P011

Main board

CN601

CD mechanism assembly

CN301

F

Cassette mechanism assembly

Fig.15Fig.16

Main board

CN308

F

Page 11

RC-BZ5LB/BZ5RD

RC-BZ6BU

Removing the main board

(See Fig.17 to 19)

Prior to performing the following procedure, remove

the CD / cassette and amplifier assembly, the CD

cover and door unit and the CD mechanism

assembly.

1.

Disconnect the harnesses from connector CN301

and CN308 on the main board (The harnesses are

extending from the cassette mechanism assembly).

2.

Disconnect the harness from connector CN702 on

the key switch/display board (RC-BZ5 only).

3.

Remove the two screws G on the underside of the

main board and release the two joint tabs f from the

chassis in the direction of the arrow.

ATTENTION:

When reassembling, get the harness

extending from FW301 and FW302

on the m a i n board through the two

slots g of the chassis. Get the card

wire extending from CN304 on the

main board through the hook h

and the slot i.

CN308

CN702

Key switch/display bord

CN301

Main board

Fig.17

g

Main board

Joint tab f

g

Joint tab f

G

Fig.18

Chassis

FW302(RC-BZ5 only)

h

i

CN304

FW301

Fig.19

1-11

Page 12

RC-BZ5LB/BZ5RD

RC-BZ6BU

Removing the power transformer

assembly (See Fig.20)

Prior to performing the following procedure, remove

the front cabinet assembly and the rear cabinet

assembly.

1.

Disconnect the harnesses from connector CN306

and CN307 on the power board in the power

transformer assembly.

2.

Remove the two screws H attaching the AC jack of

the power board and the two screws I attaching the

power transformer.

Remove the power transformer assembly toward the

front.

Power transformer assembly

Power board

CN307

I

H

CN306

Fig.20

Removing the battery board

(See Fig.21 and 22)

Prior to performing the following procedure, remove

the front cabinet assembly and the rear cabinet

assembly.

1.

Disconnect the battery terminal wire from connector

CN307 on the power board.

2.

Remove the battery board on the back of the rear

cabinet.

Release the hornese

Power board

CN307

Fig.21

1-12

Battery board

Fig.22

Page 13

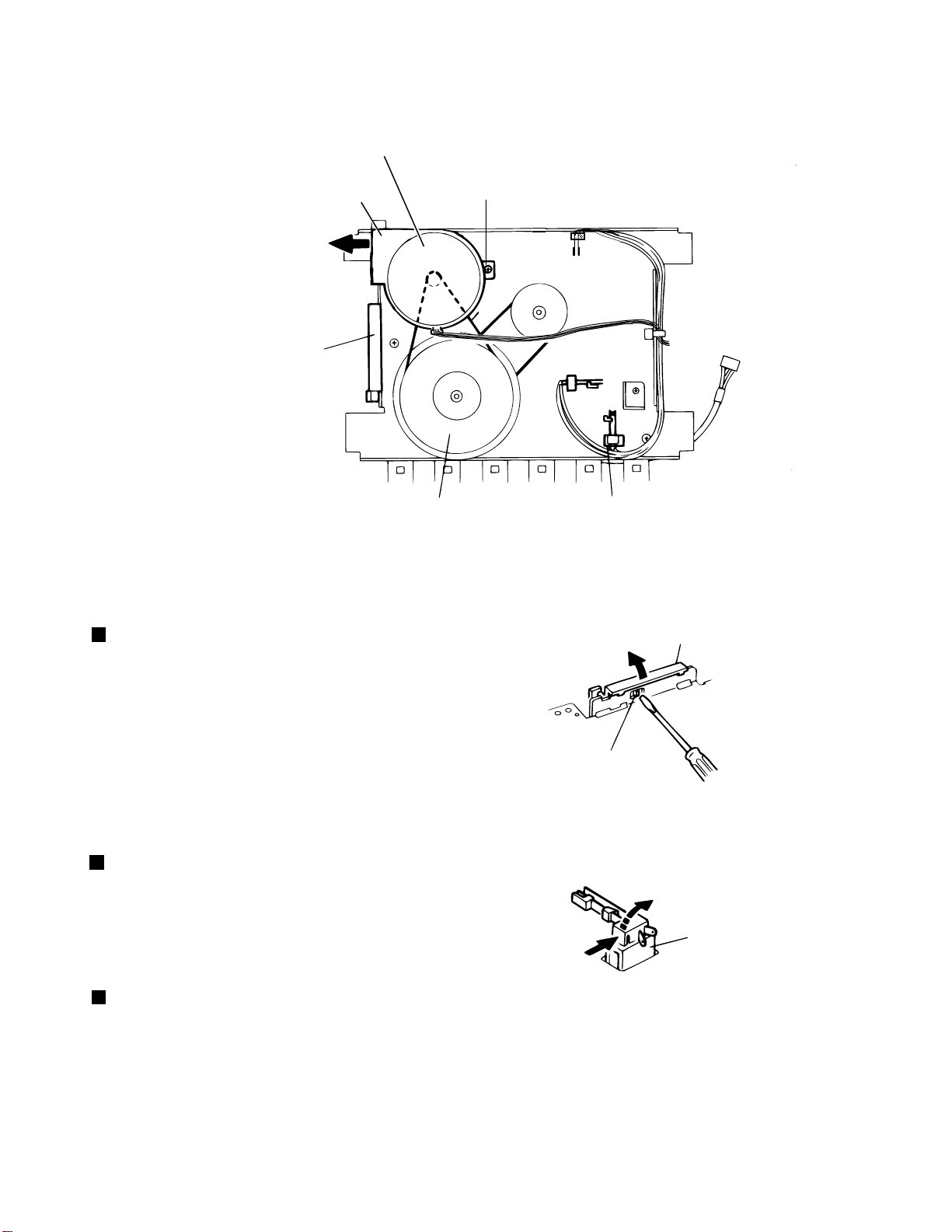

<Cassette mechanism section>

Capstan motor ass’ y

RC-BZ5LB/BZ5RD

RC-BZ6BU

Motor bracket

a

Eject slide

lever

Flywheel ass’ y Leaf switch

Fig.1

Capstan motor

1. Remove the cassette mechanism assembly. (Refer

to the article “Cassette mechanism assembly”

appearing on a previous page.)

2. Remove one screw A retaining the capstan motor

assembly from the back of the cassette mechanism

assembly.

3. Disengage the main belt from the flywheel assembly.

Then slide the capstan motor slightly in the direction

of the arrow a while lifting it upwards to remove

together with the main belt.

(Fig.1)

A

Main belt

b

Stopper arm

Fig.2

Eject slide lever

Eject slide lever

1. Place the cassette mechanism back side frontward

and disengage the stopper arm b of the Eject slide

lever by pressing it inwards through the opening of

the chassis with a small screwdriver as shown in

Fig.2.

Leaf switch

1. Press the leaf switch in the direction of the arrow c

and then remove it in the direction of the arrow d

referring to Fig.3.

(Fig.2)

(Fig.3)

d

Leaf switch

c

Fig.3

1-13

Page 14

RC-BZ5LB/BZ5RD

RC-BZ6BU

Stopper

Rec/PB

head

Capstan shaft

Erase head

B

C

Fig.4

f

Pinch roller arm ass’y

e

Base ass’y

Stopper

Fig.5 Fig.6

Pinch roller arm assembly

1. Pull out the stopper protruding from the base assembly

in the direction of the arrow e to remove it from the

pinch roller arm assembly.

2. Then, pull out the pinch roller arm assembly in the

direction of the arrow f.

(Fig.4 to 5)

Stopper

Pinch roller arm ass’y

h

Stopper

Erase head

g

i

P washer

Base ass’y

Rec/PB head and erase head

1. Remove two screws B, C retaining the Rec/PB head.

2. Pull out the stopper of the erase head in the direction of

the arrow g.

3. Pull out the erase head in the direction of the arrow h.

Flywheel assembly

1. Remove the split washer retaining the flywheel

assembly in the direction of the arrow i.

2. Pull the flywheel assembly out of the back side of the

cassette mechanism assembly in the direction of the

arrow j.

1-14

(Fig.7)

(Fig.4 to 6)

Flywheel

j

Fig.7

Page 15

Adjustment method

RC-BZ5LB/BZ5RD

RC-BZ6BU

Test Instruments required for adjustment

1. Low frequency oscillator

(Frequency range: 50Hz to 20kHz)

(Output: 0 dBs across 600 Ω terminating resistor)

2. Attenuator(Impedance: 600 Ω)

3. T est Tapes

VT712 For tape speed, wow & flutter check

VT722, 724 For playback, output level check

VT738 For playback frequency response check

VT702 For head azimuth adjustment

4. Blank tape TYPE1:AC–225

5. Electronic voltmeter

6. Distortion meter

7. Frequency counter

8. Wow and flutter meter

9. Torque gauge(Cassette type) CTG – N

10. Test disc CTS1000

11. Jitter meter NJM631

12. TE Offset LTM9055

Measuring conditions(Amplifier section)

Supply voltage AC120V(60Hz)

DC12V(UM–1 x 8)

Reference output level Speaker

: 0 dBs(0.775V) / 3 Ω

Headphone

: –10 dBs(0.245V) / 32 Ω

Reference input level

: –20 dBs supplied to test point CN1

Standard test frequency 1kHz

Output measuring point Speaker terminal

:Dummy load 3 Ω

Standard position of switches

Function switch TAPE

Beat cut switch NORMAL

Standard position of controls

Tone Maximum position

Main volume adjust 0 dBs output position

Test remarks

1. Negative side of the input and output terminals of the

testing set, shall be isolated from each other. The

negative side should not be commonly connected

when a 2channel electronic voltmeter is connected.

2. A dummy load shall be connected to the output

terminal and the lead wires of dummy load shall be

as thick as possible.

Measuring condition(Tuner section)

Power supply voltage to tuner Vcc: DC 6V

Reference output Speaker: 0.245V/3 Ω

AM modulation 400Hz, 30%

FM modulation 400Hz, deviation 22.5kHz

Remarks for alignment

1. Connect 30 pF capacitor and 33k Ω resistor to the

output terminal of the IF sweeper in series while

0.082 µ F capacitor and 100k Ω resistor to the input

terminal in series.

2. Set the output level of the IF sweeper as low as

adjustable.

3. IF alignment is not necessary for both AM and FM

MPX alignment is not necessary either. All IFTs and

MPX coil are non-adjusting type.

1-15

Page 16

RC-BZ5LB/BZ5RD

RC-BZ6BU

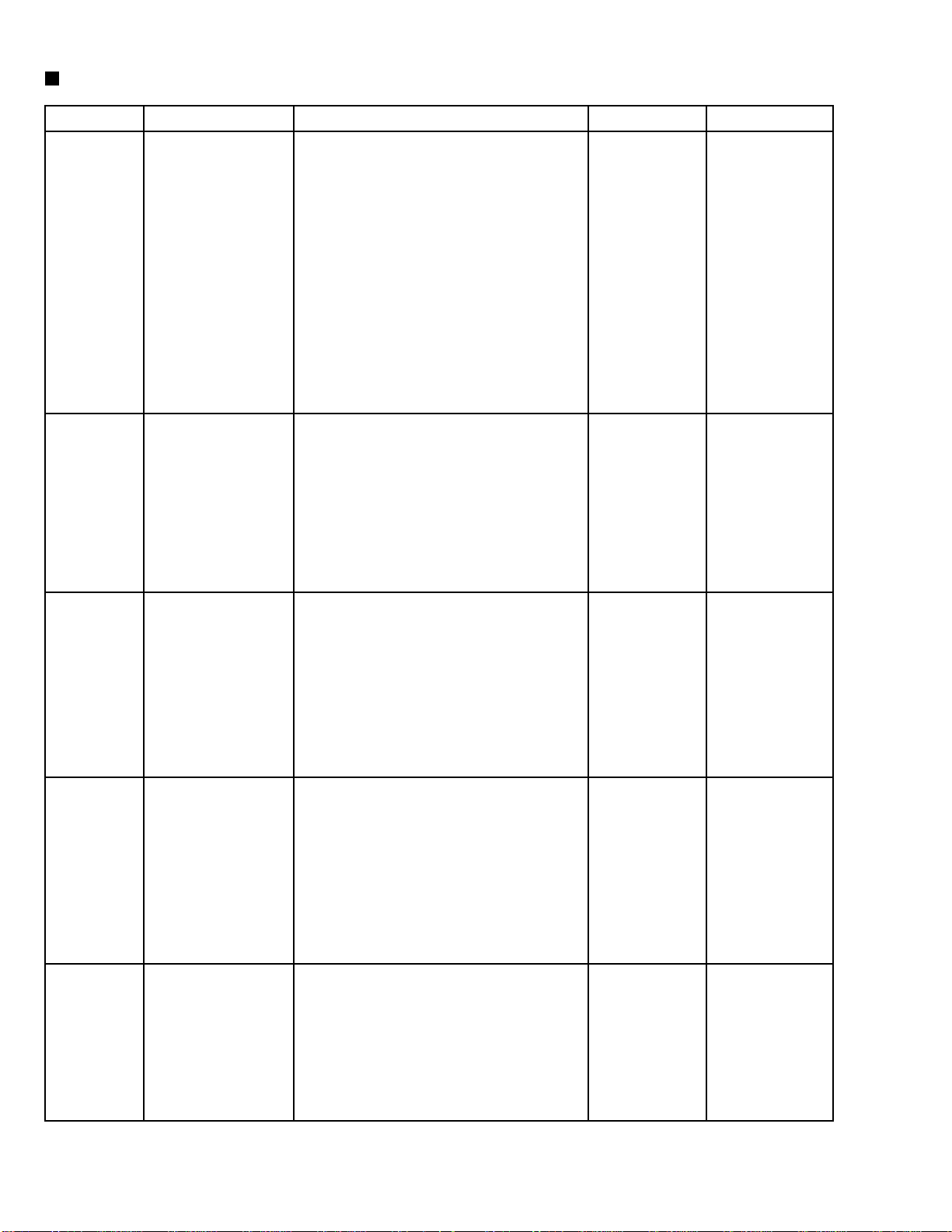

Cassette amplifier section

Item

Head azimuth

adjustment

Tape speed,

Wow & flutter

check

Conditions Adjustment & Confirmation Method Standard Value Adjusting Point

• Test tape:

VT702(8 kHz)

• Test output from:

Speaker terminal

(with 3 Ω load)

• Function selector:

TAPE

• Test tape:

VT712 (3 kHz)

•Test output from:

Speaker terminal

(with 3 Ω load)

1. Play back the test tape VT702 (8 kHz signal).

2. Adjust the azimuth adjusting screw so that

phase difference between R and L channels is minimum with the output level that

is the maximum level plug less than 2 dB

in the FWD and REV mode.

After the adjustment apply screw sealant

onto the azimuth adjusting screw for more

than half the screw head.

3. If the head azimuth is still maladjusted, readjust it with the azimuth adjusting screw

alternately in the FWD and REV modes.

1. Play back the end portion of the test tape

VT712 (3 kHz signal).

2. At that time check to see if the frequency

counter reads 2940 to 3090 Hz. If not,

adjust the semi-fixed resistor inside the

motor to obtain the specified frequency.

3. Wow and flutter must be 0.38 % or less

(unweighted).

• Output: Max.

level plus less

than 2 dB

• Phase difference between

R & L ch:

Minimum

Frequency:

2940-3090 Hz

0.38 % or less

(unweighted)

Azimuth adjusting

screw (after head

replacement only)

Tape speed (with

semi-fixed resistor

inside motor)

Playback

output check

Playback

frequency

response

check

REC/PB

sensitivity

check

• Function selector:

TAPE

• Test tape: VT722,

VT724 (1 kHz)

• Test output from:

Speaker terminal

(with 3 Ω load)

• Function selector:

TAPE

• Test tape: VT738

• Test output from:

Speaker terminal

(with 3 Ω load)

• Function selector:

TAPE

• Mode: Recording

• Test input to:

CN301

1. With the test tape VT722 (1 kHz signal)

being played back, confirm that the speaker

output is 2.1 W or more with 10 % distortion.

2. With the test tape VT724 being played

back, confirm that the deviation between

R-ch and L-ch outputs is less than 3 dB.

With the test tape VT738 being played back,

confirm that the deviation between 1 kHz and

125 Hz signals is 6 ± 3 dB and that between

the 1 kHz and 8 kHz signals is 0 ± 4 dB.

With the input of 1 kHz, –20 dBs signal to the

test point CN301, confirm that the level difference between the recording and playback

is 0 ± 3 dB or less.

• Speaker output

with 10 %

distortion:

2.1W or more

• Deviation between R & L ch

outputs:

3 dB or less

• Deviation

between 1 kHz

& 125 Hz:

6 ± 3 dB

• Deviation

between 1 kHz

& 8 kHz:

0 ± 4 dB

• Level difference

between

REC & PB:

0 ± 3 dB or less

1-16

Page 17

RC-BZ5LB/BZ5RD

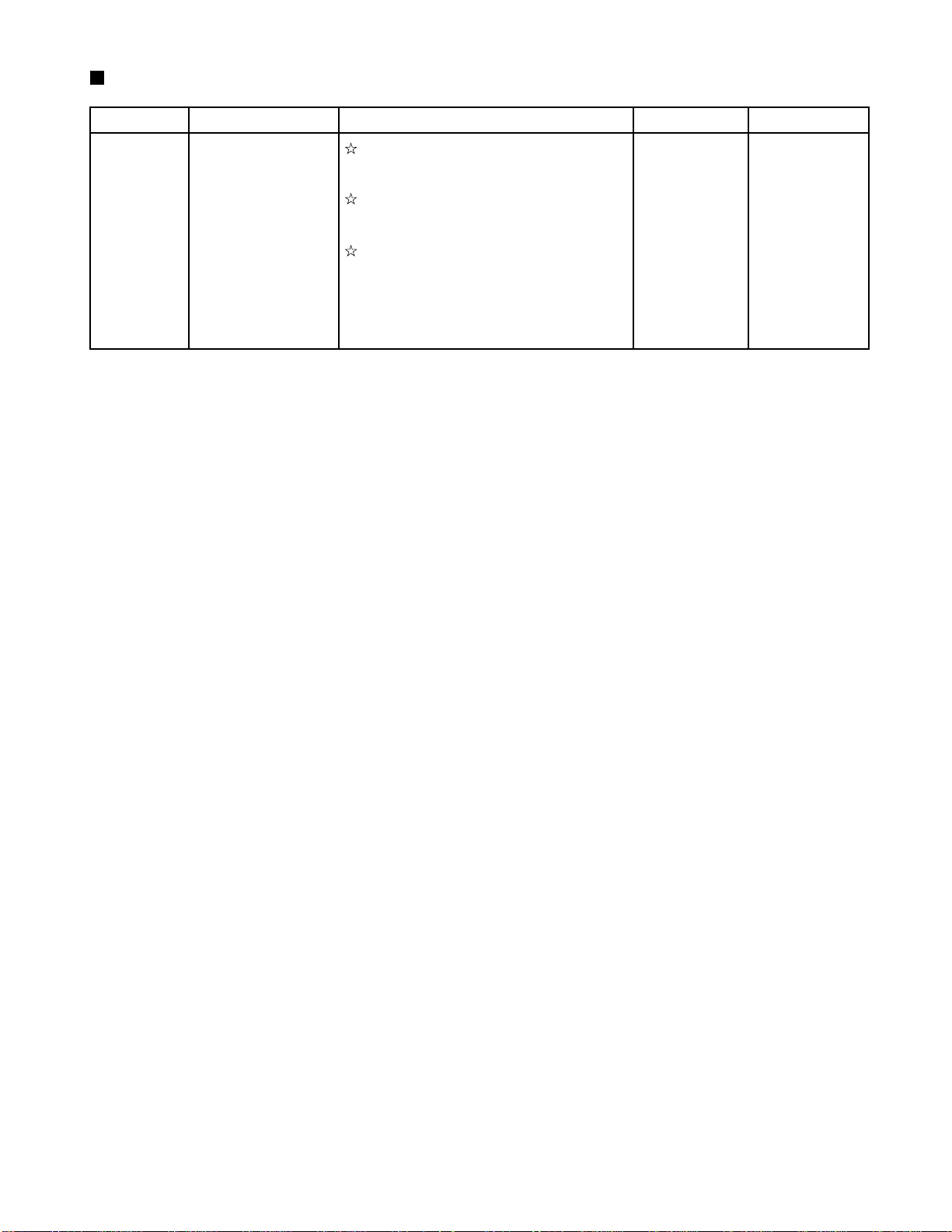

Tuner sections

Item Conditions Adjustment & Confirmation Methods Stand. values Adjust

RC-BZ6BU

FM, AM IF

adjustment

MPX

adjustment

FM tracking

adjustment

Since a solid IF is being used, no

adjustment is required.

Since a ceramic resonator is being used,

no adjustment is required.

Since a fixed coil is being used, no

adjustment is required.

1-17

Page 18

RC-BZ5LB/BZ5RD

RC-BZ6BU

Description of major IC's

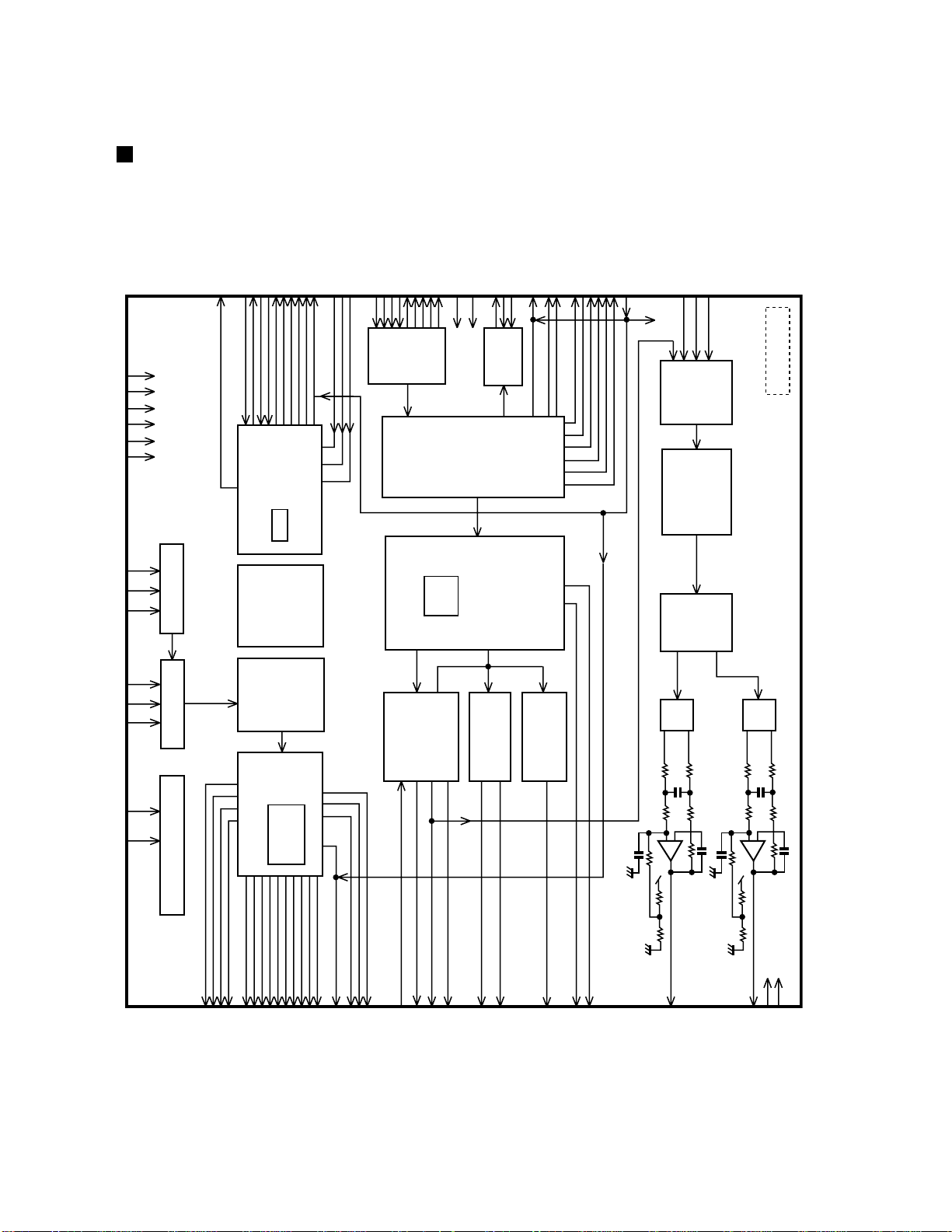

MN35510 (IC603) : Digtal servo & digtal signal processor

1. Block diagram

BYTCK

SMCK

PMCK

VDD

VSS

DVDD1

VDSS1

/RST

/TEST

MSEL

STAT

X2

X1

CSEL

PITCH CONTROL

FCLK

GENERATOR

VCOF

TIMING

CK384(EFM)

MDATA

MCLK

MLD

PSEL

RSEL

ARF

DRF

DSLF

PLLF

IREF

PLL VCO

DSL

DEMODULATION

AVDD2

EFM

PCK

SUBCODE

AVSS2

INTERPOLATION

SYNC

SQCK

SUBQ

SUBCODE

BUFFER

DEMODULATION

SSEL

EFM

FLAG5(RESY)

DEMPH

RESY

SUBC

SBCK

/CLDCK

BLKCK

CRC

SRDATAIN(PSEL)

LRCKIN(MSEL)

BCLKIN(SSEL)

IOSEL

CLVS

MN35510

DEEMPHSIS

DIGITAL

8TIMES

OVER SAMPPUNG

DIGITAL FILTER

RFENV

TRCRS

VDET

BDO

/RFDET

OFT

VCO

A/D CONVERTER

FE

TE

INPUT PORT

SERVO

TIMING GENERATOR

MICRO COMPUTER

INTERFACE

SERVO

CPU

OUTPUT

PORT

D/A

CONVERTER

ATTENUATION

PEAK DETCT

AUTO CUE

SRAM

SOFT MUTING

DIGITAL

15K

INTER POLATION

DEINTERLEVE

CORRECTION

CIRC ERROR

SERVO

CLV

1BIT DAC

LOGIS

PWM

INTERFACE

DIGITAL

AUDIO

(L)

–

+

PWM

(R)

–

+

1-18

SENSE

WVEL

LDON

PLAY

TES

/TLOCK

/FLOCLK

TOFS

FBAL

TBAL

FOD

TRD

TVD

ECS

(BYTCK)TRVSTR

VREF

KICK

TRV

DMUTE

BCLK

SRDATA

LRCK

PC

ECM

TX

FLAG

IPFLAG

OUTL

OUTR

AVDD1

AVSS1

Page 19

BA6897FP (IC602) : 4channel driver

1.Terminal layout & Block diagram

RC-BZ5LB/BZ5RD

RC-BZ6BU

CH1-OUTA

CH1-OUTB

CH1-INA

CH1-INB

TEST1

TEST2

MUTE

CH2-INB

CH2-INA

CH2-OUTB

CH2-OUTA

GND

D.BUF

1

2

D.BUF

- +

D.BUF

D.BUF

Level

shift

+-

Level

shift

- +

-+

3

4

5

6

7

8

9

10

11

12

13

T.S.D

DRIVER

MUTE

+ Level

shift

+-

-+

Level

shift

+ -

-+

D.BUF

D.BUF

D.BUF

D.BUF

28

GND

CH4-OUTA

27

CH4-OUTB

26

CH4-INA

25

CH4-INB

24

BIAS IN

23

Vcc

22

Vcc

21

CH3-INB

20

19

CH3-INA

18

CH3-OUTB

17

CH3-OUTA

16

OP IN(+)

OP-OUT

14

-+

15

OP IN(-)

1-19

Page 20

RC-BZ5LB/BZ5RD

RC-BZ6BU

LC72136N (IC2) : PLL Frequency sinsesizer

1.Terminal layout

1

FM/AM

CLOCK

DO1

FM ST VCO STOP

AM/FM

SDIN

2. Block diagram

XT

CE

DI

NC

NC

2

3

4

5

6

7

8

9

10

11

22

21

20

19

18

17

16

15

14

13

12

XT

GND

LPFOUT

LPFIN

PD

VCC

FMIN

AMIN

NC

IFCONT

IFIN

1-20

1

22

16

15

3

4

5

6

17

21

3. Pin function

Pin

Symbol

No.

1

2

3

4

5

6

7

8

9

10

11

XT

FM/AM

CE

DI

CLOCK

DO1

FM ST

VCO STOP

AM/FM

NC

NC

SDIN

Reference

Driver

Swallow Counter

1/2

2

B

C

I/F

Power

on

Reset

Function

I/O

X'tal oscillator connect (75KHz)

I

LOW:FM mode (Not use)

O

When data output/input for 4pin(input) and

I

Swallow Counter

1/16,1/17 4bit

1/16,1/17 4bit

12bit

Programmable

DriverS

Data Shift Register & Latch

7821113

6pin(output): H

Input for receive the serial data from

I

controller

Sync signal input use

I

Data output for Controller

O

Output port

"Low": MW mode

O

O

Not use

Not use

Data input/output (Not use)

I/O

Phase

Detector

Charge Pump

Unlock

Detector

Universal

Counter

Pin

No.

12

13

14

15

16

17

18

19

20

21

22

Symbol

IFIN

IFCONT

NC

AMIN

FMIN

VCC

PD

LPFIN

LPFOUT

GND

XT

18

19

20

12

I/O

Function

IF counter signal input

I

IF signal output

O

Not use

-

AM Local OSC signal output

I

FM Local OSC signal input

I

Power supply(VDD=4.5 5.5V)

When power ON:Reset circuit move

PLL charge pump output(H: Local OSC

O

frequency Height than Reference frequency.

L: Low Agreement: Height impedance)

Input for active lowpassfilter of PLL

I

Output for active lowpassfilter of PLL

O

Connected to GND

X'tal oscillator(75KHz)

I

Page 21

TA2104AN (IC1) : AM/FM 1 chip tuner IC

1.Terminal layout & Block diagram

RC-BZ5LB/BZ5RD

RC-BZ6BU

FM

RF OUTRFVcc

GNDFMRF INAMLOW CUT

2.Pin function

FMRF

AM

RF IN

222324

AM

MIX

FM

OSC

21

FM

OSC

FM

MIX

4 6 9

MIX

OUT

AM

OSC

20

AM

OSC

BUFF

BUFF

521 3 7 8

Vcc

OSC

OUT

19 18 17 16

LEVEL

DET

AMIF FMIF

IF INFMIF IN

ST

LED

SW

ST

IF

BUFF

1 / 8

IF

REQ

IF

REQ

AM

DET

GNDRF

AF

BUFF

AGC

DET

OUT

AGC QUAD R-OUT L-OUTAM

FM

DET

MPX

IN LPF1 LPF2

15

AF

10 11 12

14 13

VCO

DIVIDE

ST / MO

FM / AM

DECODE

MUTE

Pin

Pin Name

1

RF GND

2

FM RF IN

3

AM LOW CUT

4

MIX OUT

5

Vcc

6

AM IF IN

7

FM IF IN

8

GND

9

AGC

QUAD

10

R-OUT

11

L-OUT

12

LPF2

13

LPF1

14

MPX IN

15

DET OUT

16

IF REQ

17

ST LED

18

OSC OUT

19

AM OSC

20

FM OSC

21

AM RF IN

22

RF Vcc

23

FM RF OUT

24

Function

RF Stage ground

FM RF Input

AM Low Frequency Cut Filter External Component

Mixer Output

Power Supply

AM IF Amplifier Input

FM IF Amplifier Input

Ground

AM AGC External Capacitor

FM Quadrature Detector Terminal

Audio output CH-R

Audio output CH-L

LPF Terminal for Phase Detector / AM, FM Switching

LPF Terminal for Synchronous Detector / VCO Stop

FM MPX Input

AM/FM Detector Output

IF Output / IF Request control

FM Stereo Indicator Output

Local Oscillator Output

AM Oscillator

FM Oscillator

AM RF Input

RF Stage Vcc

FM RF Amplifier Output

1-21

Page 22

RC-BZ5LB/BZ5RD

RC-BZ6BU

AN8806SB (IC601) : RF & Servo amplifier

1.Treminal layout

PD

LD

LDON

LDP

VCC

RF-

RFOUT

RFIN

C.AGC

ARF

C.ENV

C.EA

CSBDO

BDO

CSBRT

OFTR

/NRFDET

GND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

PDAC

PDBD

PDF

PDE

PDER

PDFR

TBAL

FBAL

FE FEOUT

TE TEOUT

CROSS

TEBPF

VDET

LDOFF

VREF

ENV

2.Block diagram

36

35

31

34

32

6

VCBA

29

728

VCBA

VCBA

VCBA

8

27

EQ

OFTR

910 17

AGC

RF

DET

BDO

11

12 19

ENV CIRCUIT

13

14

15

16

20

1-22

21

33

24 25

30

23

26

22

14

3

2

Page 23

3. Pin function

RC-BZ5LB/BZ5RD

RC-BZ6BU

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

Symbol

PD

LD

LDON

LDP

VCC

RF-

RFOUT

RFIN

C.AGC

ARF

C.ENV

C.EA

CSBDO

BDO

CSBRT

OFTR

/NRFDET

GND

ENV

VREF

LDOFF

VDET

TEBPF

CROSS

TEOUT

TE-

FEOUT

FEFBAL

TBAL

PDFR

PDER

PDE

PDF

PDBD

PDAC

I/O

I

APC amp input terminal

APC amp output terminal

O

APC ON/OFF control terminal

I

--

Connect to ground

Power supply

-Inverse input pin for RF amp

I

RFamp output

O

RF input

I

Connecting pin of AGC loop filter

I/O

RF output

O

I/O

A capacitor is connected to this terminal to detect the envelope of RF signal

I/O

A capacitor is connected to this terminal to detect the envelope of RF signal

A capacitor is connected to detect the lower envelope of RF signal

I/O

BDO output pin

O

A capacitor is connected to detect the lower envelope of RF signal

I/O

O

Of-track status signal output

RF detection signal output

O

--

Ground

O

Envelope output

Reference voltage output

O

Function

I

O

Vibration detection signal output

I

Input pin of tracking error through BPF

O

Tracking error cross output

O

Tracking error signal output

Inverse input pin for tracking error amp

I

O

Output pin of focus error

Inverse input pin for focus error amp

I

I

Focus balance control

I

Tracking balance control

F I-V amp gain control

I/O

E I-V amp gain control

I/O

I

I-V amp input

I-V amp input

I

I

I-V amp input

I I-V amp input

1-23

Page 24

RC-BZ5LB/BZ5RD

RC-BZ6BU

TA2068N (IC301) : Rec/PB. amplifier

1. Terminal layout

1

AGC

2

PBO1

REC1

VREF

VSS

REC2

PBO2

3

4

5

6

7

8

9

10

11

12

PBNF1

PBIN1

PBIN2

PBNF2

MICNF

2. Block diagram

24

23

22

21

20

19

18

17

16

15

14

13

RAIN1

MICSEL

CDIN1

P/R

OUT1

VCC

OUT2

SEL

CDIN2

TAPE

RAIN2

MICIN

22

24235

19

13

12

6

7

REF. AMP

RADIO

TAPE

NAB AMP1

–

46.5

+

MIC AMP1

–

19.5

+

NAB AMP2

+

2.1V

8 10 11 14 16 15 17

46.5

–

LINE

TAPE

BUF. AMP A1BUF. AMP A1

MUTE

ON

BUF. AMP A2

TAPE

LINE

TAPE

RADIO

+

–

BUF. AMP B1

+

–

BUF. AMP B2

MUTE

ALC1

DET

ALC2

MUTE

LOGIC

MONITOR AMP 1

7

ON

REC AMP1

26

REC AMP2

26

MONITOR AMP

ON

7

21

20

4

1

9

2

18

23

1-24

Page 25

RC-BZ5LB/BZ5RD

RC-BZ6BU

VICTOR COMPANY OF JAPAN, LIMITED

AUDIO & COMMUNICATION BUSINSS DIVISION

PERSONAL & MOBILE NETWORK B.U. 10-1,1Chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.20819)

Printed in Japan

200007(S)

Page 26

Block diagrams (RC-BZ5LB/BZ5RD)

RC-BZ5LB/BZ5RD

RC-BZ6BU

R/P HEAD

L3

AM

BPF

BP1

CN301

IC2

PLL

L1

L4

FM RF/IF/DET/MPX

AM RF/IF/DET

IC1

CF1

Q101

REC

PB

Bias

+B

T2

Tuner

L&R

IC301

R/P Amp.

Main Volume

FW302

RCH

LCH

Q112

Q212

CN702

Q101

Q201

Q302

SMUTE

EQ

Power Amp.

LCH

RCH

RCH

LCH

CN309

IC302

J301

R-CH / L-CH

SPEAKER

CD Pickup

F/T

Coil

SPINDLE / FEED

MOTOR

M

M

CN601

RF/Servo amp.

IC601

Forcus

Spindle

Tracking

IC602

BTL Driver

Feed

IC603

Digital servo

Digital signal

Processor

SMUTE

CN303

CN703

IC701

SYSTEM

CONT.

2-1

Page 27

RC-BZ5LB/BZ5RD

RC-BZ6BU

Block diagrams (RC-BZ6BU)

L4

L3

AM

L.OSC

FM RF/IF/DET/MPX

AM RF/IF/DET

+B

R/P HEAD

CD Pickup

BPF

BP1

CN301

CN601

IC2

PLL

L1

REC

PB

Bias

RF/Servo amp.

IC1

CF1

Q101

T2

Tuner

L&R

IC301

R/P Amp.

Bass

Boost

Amp.

IC304

E.VOL

IC303

RCH

LCH

Q101

Q201

Q302

SMUTE

Power Amp.

LCH

RCH

RCH

IC302

LCH

CN309

J301

R-CH / L-CH

SPEAKER

F/T

Coil

SPINDLE / FEED

MOTOR

M

M

IC601

Spindle

Forcus

BTL Driver

IC602

Tracking

Feed

IC603

Digital servo

Digital signal

Processor

SMUTE

CN303

CN703

IC701

SYSTEM

CONT.

2-2

Page 28

Standard schematic diagrams

System control circuit (RC-BZ5LB/BZ5RD only)

TO MAIN AMP SECTION

TO D-1 on page 2-7

RC-BZ5LB/BZ5RD

RC-BZ6BU

CN701

7

SW8V

CD+B

FCD

AC/DC

TAPE

REC

SAFETY

REST

MLD

MDATA

MCLK

DG

XRST

STAT

SQCK

TO MAIN AMP SECTION

TO A-1 on page 2-7

SUBQ

DG

6

5

CD DOOR SW

S866

VMW14774 D

4

FW701

2

2

1

1

P8-22F23-A3.3NS

3

2

1

QGF1212F1-17

17

8.3V

16

6.8V

15

0.7V

14

2.1V

13

5.7V

12

0V

11

5.0V

10

4.6V

9

R774

5.1V

8

R775

4.8V

7

R776

5.0V

6

0V

5

R777

6.1V

4

R778

0.1V

3

R772

5.1V

2

R779

5.0V

1

0V

CN704

EMV5133-002KR OR TIP-X02P-MI

2

1

CN703

QGF1212F1-12

1K

1K

1K

1K

1K

1K

1K

SW8V

CD+B

D706

SAFETY

FCD

MLD

XRST

TAPE

REC

AC/DC

1SS133-T2

TUST

22K

0V

R709

5.1V

0V

5.1V 5.1V

R796 100K

BASS

POUT

SMUTE

FTU

TRE

C725

100P

Q704

DTC144EKA-X

+

C711

10/16

BCTL

4.4V

Q705

R738 10K

R735 10K

R746

R767

R768

R741

R739 22K

R758 2.2K

R761

C722

100P

AC/DC

R719 100K

RESET

Q706

0V

1SS133-TE

R706 10K

D707

2SA1037AK/RS/-X

22K

4.7K

10K

10K

2.2K

R708 10K

5.0V

DTC143TKA-X

0V

0V

5.0V

0V

0V

0V

0V

5.0V

6.0V

+

0V

0V

2.2K

R721

2.2/50

C712

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

R707

L701

3AB39N

SDATA

TUST

SCK

MPX

POUT

BASS

FTU

TPEDGBUC

SMUTE

US6V

123456789

0.9V0V0V0V1.1V0V0V0V0V

42

NC

NC

NC

NC

NC

NC

NC

NC

NC

BASS

POUT

SMUTE

+BCTL

FTU

NC

NC

TPE

FCD

MLD

XRST

BEAT

AC/DC64TAPE65STAT66REC67RESET68NC69NC70VSS71OSC272OSC173VDD74TUST75SQCK76SUBQ77MCLK78MDATA79SCK80SI81SO82PIN83PEN

5.1V0V0V0V5.4V0V5.4V0V2.0V

10K

R729

47K

10K

K701

VQZ0048-009

R740

K703

2.2K

R762

STAT

101112

5.1V

3.1V

VQZ0048-009

10K

R723

C710 0.01

220/10

+

C708

5.9V

33

34

35

36

2.6V

2.6V

2.6V

NC37NC38NC39NC40NC41NC

SEG16

SEG15

SEG14

SEG13

IC701

MN171603JACA

SYSTEM

CONTROLLER

2.4V

2.2K

R742

0.1

2SC2714/O/-X

R701

C707

30

31

32

2.6V

2.6V

2.6V

SEG11

SEG12

5.4V0V0V0V0V0V0V

R752 10K

C702

24P

Q701

1K

0V

2.2K

R753

0V

0V

2.6V

SEG10

29

R763 2.2K

2.6V

SEG9

28

R760 1K

8.2K

R702

SEG8

2.5V

27

1K

R759

C703 36P

25

26

2.5V

2.6V

SEG5

SEG6

SEG7

R751 10K

X701

QAX0410-001Z

CLOCK

23

24

2.6V

2.6V

SEG4

AVDD VREF+

CLOSE/REST

CD+B SAFETY

SW5V SAFETY

AVSS VREF-

0V0V5.4V

5.4V

R730 10K

R750 10K

C704 36P

2.6V

MODEL

8.2K

R703

SEG222SEG3

SEG1

SEG0

COM0

COM1

COM2

COM3

VLCD3

VLCD2

VLCD1

KEY1

BUP

MPX

VER

84

NC

NC

DI701

QLD0046-001

2.6V

21

2.6V

20

2.5V

19

18

17

2.5V

16

15

14

13

12

11

10

9

8

7

5.1V

6

5

3.7V

3.5V

4

3

2

1

C703

24P

2SC2714/O/-X

0V

0V

0V

2.5V

2.5V

0V

1.7V

3.3V

5.1V

4.6V

5.0V

0V

0V

0V

0V

0V

0V

C719

C720

0.001

0.001

C724

C723

C738

R748 22K

R749 47K

Q702

R704

1K

COM31COM22COM13COM0

R734

100K

R726

R725

R728 10K

R754 10K

R724 2.2K

R727

R785

R789

*

100P

100P

150P

C706

0.001

4

SEG05SEG16SEG27SEG38SEG49SEG510SEG611SEG712SEG813SEG9

REC BASS

TRACK

STEREO MONO

R733

R732

100K

100K

2.2K

2.2K

C732

0.1

2.2K

*

R773

10K

REST

MDATA

MCLK

SUBQ

SQCK

VQZ0048-009

R756 22K

SDATA

SCK

MPX

0.01

C721

R770

K702

L702

3AB39N

2.2K

14

SEG1015SEG1116SEG1617SEG1218SEG1319SEG1420SEG15

ALLSLEEP

KHz MHz

D702

1SS133-T2

R711 22K

39K

R714

R720 100K

+

C727 47/10

LIST

EE.EV

E.B.EN

U.UP.US.UT.UX.UY.UZ

J.C

PARTS NAME CONSTRUCTION

DTC143TKA

R718

10K

4.7K

R797

R712 10K

5.0V

3

5.0V

2

0V

1

R789 R785

10K

10K

10K

4.7K

LCD HOLDER

D703

UZ5.16SC-T2

47K

R716

0.6V

0V

R710

R715

OUT

VCC

GND

REMOCON

NOTES:

150K

22K

8.2K

2.2K-------

21

REPEAT

S858

R857

39K

R856

12K

R855

6.8K

R854

3.9K

R853

2.7K

R852

1.8K

R851

1.5K

R717 33K

BACK UP

Q703

2SC2412K/R/-X

0V

UP/

S857

CD/

S856

STOP/

S855

TUNER/BAND

S854

DOWN/

S853

PRESET

S852

SOUND

S851

S851---S858

QSW0707-001Z

QSW0707-001Z

POWER

S865

100K

33K

IC703

GP1U281X

VMW2422 A

1. VOLTAGES ARE DC-MEASURED WITH A DIGITAL VOLT METER OR OSCILOSCOPE

WITHOUT INPUT SIGNAL.

CONDITION ---- CD STOP AT DC SUPLLY

2. UNLESS OTHERWISE SPECIFIED,RESISTORS ARE 1/6W 5% CAPBON RESISTOR.

ALL RESISTANCE VALUES ARE IN OHM(s)

ALL CAPACITORS ARE CERAMIC CAPACITOR OR MYLAR CAPACITOR.

ALL CAPACITANCE VALUES ARE IN uF(p*pF).

ALL INDUCTANCE VALUES ARE IN uH(m*mH).

ALL E.CAPACITORS ARE SHOWN IN THE FORM OF CAPACITANCE(uF)/RATED VOLTAGE (V).

ALL DIODES ARE 1SS254T-77 OR 1N4148M

ALL TRANSISTORS ARE 2SC2785(F.E). OR 2SC3330(S.T). OR KTC3199(GL).

R864

5.6K

POWER

D708

1SS133-T2

R858

5.6K

R859

18K

R860

LED

D852

LTD321-41

0.7V

4.0V

0V

D851

LTD3116-41

STANBY

LED

R861

680

330

Q851

2SA1037AK/RS/-X

DTC144EKA

47K

47K

BCDEFGH I JA

2-3

Page 29

7

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

CN701

QGF1212F1-17

R738 10K

R735 10K

R745

22K

R767

4.7K

R768

10K

R739

22K

R758

2.2K

R761 2.2K

R721

2.2K

R729

47K

R740 10K

R762 2.2K

R723 10K

R752 10K

R751 10K

R759 1K

R760 1K

R763 2.2K

R753

2.2K

R750 10K

R730 10K

R746 22K

R749

47K

R734

100K

R733

100K

R732

100K

R726

2.2K

R725

2.2K

R728

10K

R754

10K

R724

2.2K

R727 2.2K

R785

*

R789

*

R773

10K

R756

22K

R770

2.2K

R715 33K

R720

100K

R797

4.7K

R712

10K

R718

10K

R714

39K

R710 100K

1K

R704

R703 8.2K

R702

8.2K

R701 1K

R742 2.2K

R707

10K

R708

10K

R706

10K

R719

100K

C710

0.01

C707

0.1

C702

24P

C701 36P

C703

24P

C706

0.001

C738

150P

C723

100P

C724

100P

C719

0.001

C720

0.001

C721

0.01

K701

VQZ004B-009

L701 3AB39N

+

C708 220/10

X701

QAX0410-001Z

Q701

2SC2714/O/-X

Q702

2SC2714/O/-X

C704

36P

+

C712

2.2/50

C725 100P

C722 100P

D707

1SS133-T2

Q706

DTC143TKA-X

Q704

DTC144EKA-X

+

C711

10/16

R709 22K

K702 VQZ0048-009

L702

3AB39N

C732

0.1

+

C727

47/10

D702

1SS133-T2

R711 22K

Q703

2SC2412K/R/-X

R716

47K

R717

33K

D703

UZ5.1BSC-T2

Q705

2SA1037AK/RS/-X

R796

100K

K703

VQZ0046-009

R776 1K

R775 1K

R774 1K

R779 1K

R772 1K

R778 1K

R777 1K

D706

1SS133-T2

D708

1SS133-T2

1

2

CN704

EMV5133-002KR OR TIP-X02P-MI

S858

CLOCK/METER

S857

UP/

S856

CD/

S855

STOP/PRESET

S854

TUNER/BAND

S853

DOWN/

S852

BASS

S851

SOUND

S865

QSW0707-001Z

R858

5.6K

R859

18K

R860

330

R861

680

R864 5.6K

Q851

2SA1037AK/RS/-X

D851

LTD3116-41

D852

LTD321-41

R851

1.5K

R852

1.8K

R853

2.7K

R854

3.9K

R855

6.8K

R856

12K

R857

39K

1

2

S866

VMW1474 D

1

2

FW701

P8-22F23-A3.3NS

TO MAIN AMP SECTION

TO A-1 on page 2-8

8.3V

6.8V

0.7V

2.1V

5.7V

0V

5.0V

4.5V

5.1V

4.8V

5.0V

5.1V

0.1V

5.1V

5.0V

0V

CD DOOR SW

CD+B

SAFETY

FCD

MLD

XRST

TAPE

REC

AC/DC

TO D-1 on page 2-8

TO MAIN AMP SECTION

0.9V0V0V

1.1V

5.0V0V5.0V0V5.1V

3.1V

5.9V

5.1V

5.1V

4.4V

BCTL

AHB

POUT

SMUTE

FTU

0V

5.0V

0V

0V

0V

0V

5.0V

5.0V

5.0V

0V

AC/DC

TUST

0V

5.1V

0V

CLOCK

5.1V

5.6V

0V

0V

5.1V

2.0V

2.6V

0V

2.3V

2.2V

4.9V

5.1V

5.1V

5.0V

4.8V

0V

0V

0V0V5.0V

5.0V

SCK

MDATA

MCLK

SUBQ

SQCK

MPX

REST

2.6V

2.6V

2.6V

2.5V

2.5V

2.5V

0V

1.7V

3.3V

5.1V

4.5V

5.0V

0V

0V

0V

5.1V

3.7V

3.5V

0V

0V

5.0V

LCD HOLDER

S851--- S858

QSW0707-001Z

POWER

0V

0.7V

4.0V

POWER

LED

STANBY

LED

REMOCON

BACK UP

VMW2422 A

NOTES: 1. VOLTAGES ARE DC-MEASURED WITH A DIGITAL VOLT METER OR OSCILOSCOPE

WITHOUT INPUT SIGNAL

2. UNLESS OTHERWISE SPECIFIED,RESISTORS ARE 1/6W 5% CAPBON RESISTOR.

ALL RESISTANCE VALUES ARE IN OHM(s)

ALL CAPACITORS ARE CERAMIC CAPACITOR OR MYLAR CAPACITOR.

ALL CAPACITANCE VALUES ARE IN uF(p*pF).

ALL INDUCTANCE VALUES ARE IN uH(m*mH).

ALL E.CAPACITORS ARE SHOWN IN THE FORM OF CAPACITANCE(uF)/RATED VOLTAGE (V).

LIST

U.UP.US.UT.UX.UY.UZ

E.B.EN

J.C

R789

R785

10K

10K

22K

8.2K

2.2K

-------

PARTS NAME CONSTRUCTION

DTC143TKA

DTC144EKA

4.7K

47K

47K

RESET

123456789

101112

13

CN703

QGF1212F1-13

0V

0V

1 2

1

2

FW702

Q852

2SC2412K/R/-X

Q709

2SC2412K/R/-X

R790

4.7K

R865 2.2K

5.7V

6.3V

5.7V

4.3V

4.9V

0V

0V

4.3V

R769

10K

R737 10K

VOLCLK

VOLDATA

D704

1SS133-T2

C716

150P

C714 150P

R731

1K

R713 10K

R755

10K

X702

QAX0401-001

R722

100K

C717

22P

C718

27P

R862 10K

R863 10K

C801

0.01

C802

0.01

SDATA

2.6V

2.6V

2.6V

2.6V

2.6V

2.6V

2.6V

2.5V

2.6V

2.6V

2.6V

2.6V

2.6V

2.5V

2.6V

2.6V

2.6V

2.6V

2.6V

2.6V

2.6V

2.6V

2.6V

2.6V

2.6V

2.6V

2.6V

2.6V

2.6V

2.6V

0V

0V

5.0V

0V

0V

5.0V

5.0V

JOG1

1

JOG2

2

AVSS VREF-

3

VER

4

SWBY SAFETY

5

CD+B SAFETY

6

MPX

7

MODEL

8

BUP

9

KEY1

10

CLOSE/REST

11

AVDD VREF+

12

VLCD1

13

VLCD2

14

VLCD3

15

COM3

16

COM2

17

COM1

18

COM0

19

SEG0

20

SEG1

21

SEG222SEG323SEG4

24

SEG525SEG6

26

SEG7

27

SEG828SEG9

29

SEG10

30

SEG11

31

SEG12

32

SEG13

33

SEG14

34

SEG15

35

SEG16

36

SEG17

37

SEG18

38

SEG19

39

SEG20

40

SEG21

41

SEG22

42

SEG23

43

SEG24

44

SEG25

45

SEG26

46

SEG27

47

SEG28

48

NC

49

NC

50

NC

51

AHB

52

POUT

53

SMUTE

54

+BCTL

55

FTU

56

VOLCK

57

VOLDATA

58

KILL

59

FCD

60

MLD

61

XRST

62

BEAT

63

AC/DC64TAPE65STAT66REC67RESET68X169X270VSS71OSC272OSC173VDD74TUST75SQCK76SUBQ77MCLK78MDATA79SCK80SI81SO82PIN83PEN

84

SYSTEM

CONTROLLER

IC701

MN171603JACA

0V

0V

0V

0V

0V

0V

5.4V

5.4V

5.4V

0V 0V

0.6V

12

FW703

PL701

BACK LIGHT

CONDITION ----- CD STOP AT DC SUPLLY

SOUND.FLAT AHB.ON

0V

STAT

STEREO

KHz MHz

ALL MONO

ON

OFF

COM31COM22COM13COM0

4

SEG05SEG16SEG27SEG38SEG49SEG510SEG611SEG712SEG813SEG9

14

SEG1015SEG1116SEG1217SEG1318SEG1419SEG1520SEG1621SEG1722SEG1823SEG1924SEG2025SEG2126SEG2227SEG2328SEG2429SEG2530SEG2631SEG2732SEG28

33

SLEEP

CLOCK

REC

AHB PRO

TRACK

DI701

QLD0045-001

123

JS801

QSW0705-001

GND

1

VCC

2

OUT

3

IC703

GP1U281X

SW8V

CD+B

FCD

AC/DC

TAPE

REC

SAFETY

REST

MLD

MDATA

MCLK

DG

XRST

STAT

SQCK

SUBQ

DG

AHB

SDATA

TUST

SCK

MPX

POUT

VOLCK

FTU

VOLDATADGBUC

SMUTE

US6V

1

2

3

4

5

6

7

8

9

10

11

12

13

14

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

15

16

17

18

19

202122

23

24

19

20

21

22

23

24

252627282930313233343536373839404142434445464748495051525354555657

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

EE.EV

10K 150K

System control circuit (RC-BZ6BU only)

6

5

4

3

2

1

BCDEFGH I JA

RC-BZ5LB/BZ5RD

RC-BZ6BU

2-4

Page 30

CD amplifire circuit

RC-BZ5LB/BZ5RD

RC-BZ6BU

7

6

PICKUP ASS'Y

OPTIMA-7B

HQ100008

2K

HDU-100

1

2

3

4

56

VR001

5

4

3

2

1. VOLTAGES ARE DC-MEASURED WITH A DIGITAL VOLT METER.

2.UNLESS OTHERWISE SPECIFIED,RESISTORS ARE 1/6W +/-5%

CARBON RESISTOR.

1

ALL RESISTANCE VALUES ARE IN OHM( )

ALL CAPACITORS ARE CERAMIC CAPACITOR OR MYLAR CAPACITOR.

ALL CAPACITANCE VALUES ARE IN uF(P=pF).

ALL E.CAPACITORS ARE SHOWN IN THE FORM OF CAPACITANCE

(uF)/RATED VOLTAGE (V).

NOTES

10

9

8

7

REST SW

C001

1

FOCUS COIL

TRACKING COIL

SPINDLE

+

+

FEED

R605 270K

R606 150K

27K

F

E

C606

C607

0.001

0.001

D

A

2.4V

2.4V

2.4V

2.4V

34

36

35

PDE33PDF

PDAC

PDBD

AN8806SB

0.022

C641

P001

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

-

M

-

M

CN601

HQMV7102-015

A

B

F

C

D

K

E

MD

LD

VR

G

F+

T+

TF-

CN602

QGF1025C1-15

1

2.4V

2

2.4V

3

2.4V

4

5

D

2.4V

6

5.0V

7

E

2.4V

8

0V

9

0.8V

R615 12

10

0V

R616 91

11

0V

12

F+

3.1V

13

T+

3.1V

14

T-

3.1V

15

F-

3.1V

FM+

6

3.1V

5

4.6V

SM-

4

3.1V

3

3.1V

SM+

2

0V

1

FM-

3.1V

A

F

R613

120

PD1LD2LDON3LDP4VCC5RF-6RFOUT7RFIN8C.AGC9ARF10C.ENV11C.EA12CSBDO13BDO

C622 47/10

IC601

0V

0V

4.5V0V4.9V

LDON

1.0V

4.5V

Q601

2SA952/LK/-T

OR 2SB698/EF/-T

C605

10/25

R622 33

R621 33

C631

470/10

BTL DRIVER

0.0082

T+

0V

3.1V

28

27

GND

OUT4+

OUT1+1OUT1-2IN1/R3IN14TR-B5REG-OUT6MUTE

IC602 BA6897FP

3.1V

3.1V

C698

100P

F-

F+

R696

2.2K

6.8V

C640

R614

5.0V

10

C619 270P

C615 0.022

C616 0.022

2.4V

2.4V

2.4V

2.4V

2.4V

29

31

32

PDER

PDFR

28

30

FE-

FBAL

TBAL

RF&SERVO AMP

2.4V

2.4V

2.4V

3.4V

1/50

C614 0.1

C608

R601 11K

C628 0.047

C629 100/10

R623 33

T-

C696

100P

2.4V

2.4V

2.4V

25

2.4V

IN4/R

24

IN4

6.0V

6.1V

6.8V

22

23

VCC

VREF

7

5.0V

3.6V0V0V

R633

5.0V

OR 2SB8698/EF/-T

3.1V

26

OUT4-

2.4V

R631

330

Q631 2SA952/LK/-T

27K

R607

R632

100

2.4V

27

FEOUT

1.5V

ARF

TAB

TAB

2.4V

26

TE-

3.7V

C609 100P

R610

470K

TEBPF

IN3/R

150K

C618

0.0022

SM-

C617

0.022

R697

21

22

VDET

LDOFF

OSBRT15OFTR 0V

16

4.8V

OFT

R603 1.2M

C612 0.01

FM-

3.1V

3.1V

17

18

OUT3-

OUT3+

3.1V

3.1V0V6.3V

L602

100uH

2.4V

20

17

0V

RFDET

FM+

C699

100P

0.9V

16

C697

100P

R612

1K

VREF

OP-IN+

R609

100K

C620

180P

2.4V

4.8V

1.7V0V0V

25

24

23

CROSS

TEOUT

14

3.0V

3.3V0V3.3V

BDO

C610 0.027

C611 0.0047

2.4V

6.8V

2.4V

21

19

20

IN3

VCC

GND8IN29IN2/R10OUT2-11OUT2+12GND13OP-OUT

2.4V

2.4V

C632

100/10

C623 0.1

2.4V

19

ENV

GND18NRFDET 0V

C613

330P

0V

R641 56K

R642 12K

R643 8.2K

R644 22K

0.8V

15

OP-IN-

14

SM+

R645 22K

R646

R647 4.7K

TP601

(GND)

C604

100/10

2.2K

KICK

TRD

TVD

TRV

ECM

FOD

ECS

TBAL

FBAL

RFENV

TRCRS

VDET

FE

TE

OFT

RFDET

BDO

LDON

ARF

FBAL

TBAL

FE

TE

RFENV

VDET

TRCRS

K601

QQR0779-001Z

TRV

TVD

ECM

ECS

KICK

TRD

FOD

TP602

(ARF)

L601 10uH

21

TRV

2.4V

22

TVD

2.4V

23

PC

5.0V

24

ECM

2.4V

25

ECS

2.3V

26

KICK

2.4V

27

TRD

2.4V

28

FOD

2.4V

29

VREF

2.4V

30

FBAL

2.4V

31

TBAL

2.5V

32

FE

2.4V

33

TE

2.4V

34

RFENV

0.0V

35

VDET

0.0V

36

OFT

0.0V

37

TRCRS

4.8V

38

RFDET

4.8V

39

BDO

0.0V

40

LDON

0.0V

C661 470P

C676

0.001

C691 150P

C692 150P

C693 150P

11

12

0.0V

0.0V

TLOCK

FLOCLK

10

SENSE

0.0V

MLD

9

MLD

5.1V

MDATA

8

4.8V

MDATA

MCLK

7

5.0V

MCLK

6

3

5

4

0.0V

0.0V

5.0V

TX

DVSS1

DVDD1

C653

0.022

20

5.4V

PMCK

19

5.1V

SMCK

XRST

1K

R651

18

RST

5.1V

STAT

R652 1K

17

STAT

0.1V

16

DMUTE

0.0V

SUBQ

R653 1K

15

SUBQ

0.0V

SQCK

R654 1K

C694

150P

14

SQCK

5.1V

13

BLKCK

0.0V

IC603

MN35510

DIGITAL SERVO

&

DIGITAL SIGNAL

PROCESSOR

TES41PLAY42WVEL43ARF44IREF45DRF46DSLF47PLLF48VCOF49AVDD250AVSS251EFM52PCK53TOFS54SUBC55SBCK56VSS57X158X259VDD

0.0V

0.0V

2.5V

5.0V

R661 68K

0.022

0.022

C562

TO MAIN SECTION

TO A-2 on page 2-7 or 2-8

C663

L

R

+B

AG

DG

MG

1.3V

0.022

C664

0.0V

2.5V

R663 120K

0.7V

0.1

C665

470

R664

5.0V

5.0V

0.0V

2.4V

2.4V

2.2V

3.1V

C651

22P

C652

22P

CD SIGNAL

0.0V

5.0V

X651

16.9344MHZ

QAX0369-001Z

2

0.0V

SRDATA

2.6V

2.5V

LRCK

2.6V

R659

270

1

BCLK

SSEL

MSEL

PSEL

CSEL

RSEL

OUTR

AVSS1

OUTL

AVDD1

TEST

IOSEL

RESY

DEMPH

CRC

CLVS

FLAG

IPFLAG

FCLK

CLDCK

BYTCK

60

2.5V

5.0V

C671

0.0022

C655

0.047

5.0V

0.0V

0.0V

0.0V

5.0V

2.5V

0.0V

2.5V

4.9V

5.0V

5.0V

0.0V

0.0V

0.0V

0.0V

0.2V

2.5V

0.0V

5.0V

4.7V

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

C672

0.0022

C674

C673

R666 22

K602

QQR0779-001Z

C675

0.001

0.022

220/10

D661

1SS133-T2

DG

SUBQ

SQCK

STAT

XRST

DG

MCLK

MDATA

MLD

REST

TO MAIN SECTION

TO B-1 on page 2-7 or 2-8

SAFETY

R671 1K

R672 1K

BCDEFGH I JA

2-5

Page 31

RC-BZ5LB/BZ5RD

RC-BZ6BU

Tuner circuit

NOTES

1. VOLTAGES OF THE TABLE ARE DC-MEASURED WITH A DIGITAL VOLT METER.

7

BP1 QQR0768-001Z

PIN NO.

FM NO SIGNAL

IC1

FM 60dB STEREO

AM NO SIGNAL

IC2

FM NO SIGNAL

PIN NO.

FM NO SIGNAL

IC1

FM 60dB STEREO

AM NO SIGNAL

IC2

FM NO SIGNAL

123456789101112

0.8

00.7

1.1

5.0 5.0

1.9

1.3

5.0

16

1.5

1.4

1.4

2.5 5.0

5.0

5.0

5.0

4.000

5.0

5.0

5.0

0

5.0

5.0

3.6

3.6

17

18

19

20

1.4

3.6

4.0

5.0

1.6

3.6

4.0

5.0

1.4

3.6

4.1

5.0

1.0 1.0

0.8 0

0.8

0

2.4

13

4.4

4.4

4.5

3.6 0.1

0

0.7

0

0.3

0

0

14

15

3.6

3.6

3.6

3.6

0

0

0

3.6 5.0

3.6

4.1

0.1

21

5.0

5.0

5.0

1.5

1.6

1.5

5.0

1.6

1.5

4.3

1.6

0

0.1

0.1

22

23

24

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

5.0

2.3

BAR ANT

L3

VQB008M-506T

TC2 QAT7002-200Z

R20

22K

D8

C21

0.047

SVC344

CC

R13

100K

C22

430P

PP

C23

12P

CH

L4

QQR0723-001

(MW OSC)

R18

1K

R37

56

6

TO ROD.ANT

L12

QQR0756-001

(FM OSC)

R44

2.2K

14

NC

C16

0.01

1K

13

IF CONT

R47

22

R48

1K

K1

QR0779-001Z

R63

47K

C37

0.001

12

IF IN

11

0.1/50

C32

0.01

R30

18K

C35

24

FM RF OUT

IC1

TA2104AN

GND11FM RF IN2AM LOW CUT3MIX OUT4VCC25AM IF IN6FM IF IN7GND 28AGC9QUAD10R-CH OUT11L-CH OUT

(FM IF)

CF1

QAX0403-001

(FM IF)

TP1

FM GND

D5

D6

L2

(FM RF)

C52

QQR0769-001

0.001

3.9P

D1.2 SVC203SPA-JVKV1370N

D1

C3

5

TP2

100K

R7

100K

R1

CC

C13

0.022

R2

47K

4

C60

0.001

CH

C64

3

12P

CH

C62 12P

X1

QAX0402-001

L7

QQL231K-221

C61

100/10

IC2

LC72136N

2

C63 0.001

R42

L10

QQL231K-4R7Y

C6

0.01

D2

R9

4.7K

22

21

XT

GND

XT1NC2CE3DI4CLOCK5D016FM ST 7AM/FM8NC9NC10NC

R61

1K

47K

47K

R4

R54

2.2K

R56 3.3K

C69

R55

2.2K

20

19

LPF IN

LPF OUT

PLL

R59

1K

C7

0.001

12P

C9

0.0022

R52

10K

18

PD

R3 27

C77

0.001

C71

10/16

C70

2.2/50

17

VCC

R60

16

FM IN

VCO STOP

1K

15

AM IN

L1

R57

C65

0.001

QQR0772-001

23

VCC1

R25

1K

C31

0.001

20

22

21

FM OSC

AM OSC

AM RF IN

FM RF/IF/EDT/MPX AM RF/IF/DET

CC

C42

0.047

T2(AM IF)

QAX0540-001

R33

330

Q1

2SC2668/0/-T

18

19

ST LED

OSC OUT

C45

C51

330P

0.1/50

R24

680

C41

4.7/50

15

17

IF REQ

16

DET OUT

C36

4.7/50

C38

0.01

MPX IN

CF3

R38

100

ZD1

MTZJ3.08

14

LPF1

0.01

QAX0538-001Z

C40

2. ALL RESISTORS ARE 1/6W +/-5% CARBON RESISTOR.

3.ALL RESISTANCE VALUES ARE IN OHM

4. ALL CAPACITANCE VALUES ARE IN uF(P=pF).

5. ALL E.CAPACITORS ARE SHOWN IN THE FORM OF CAPACITANCE (uF)/RATED VOLTAGE(V).

6. ALL INDUCTANCE VALUES ARE IN uH(m=mH).

7. SI.DIODES( ) ARE ALL 1SS133T

C44

1/50

R32

3.3K

C43

0.1/50

13

LPF2

12

CC

C47

0.015

CC

C33

100/10

1K

R64

R31 100K

120

R39

IN4001

C48

0.015

R49

18K

C50

0.1/50

R50

18K

D12

R35

27K

R36

27K

C49

0.1/50

ANT GND

GND

TUR

TUL

TUSW6V

MPX

SDATA

SCK

TUST

TO A-5 on page 2-7 or 2-8TO C-1 on page 2-7 or 2-8

TO MAIN SECTION

1

AM SIGNAL

J/C/B/E/EN/U/UP/US/UT/UX/UY/UZ

FM SIGNAL

RADIO MAIN SIGNAL

BCDEFGH I JA

2-6

Page 32

Amplifier circuit (RC-BZ5LB/BZ5RD only)

7

6

5

TO TUNER SECTION

TO J-2 on page 2-6

R/P HEAD

MS15R-AA2N1

R

4

3

2

1

L

MG E.HEAD

PH-K380-MS1-6A

NOTES

1. VOLTAGES ARE DC-MEASURED WITH A DEGITAL

VOLT METER OR OSCILLOSCOPE WITHOUT

INPUT SIGNAL.

CONDITION--- CD STOP MODE AT DC SUPLLY

( )IS INVERT MODE SOUND FLAT AHB.ON

2. UNLESS ( )THEAWISE SPECIFIED.RESISTORS

ARE 1/6W 15% CARBON RESISTOR.

ALL RESISTANCE VALUCE ARE IN OHM(s)

ALL CAPACITORS ARE CERAMIC CAPACITOR OR

MYLAR CAPACITOR

ALL CAPACITANCE VALUES ARE IN uF(P=pF)

ALL INDUCTANCE VALUES ARE IN uH(m=mH)

ALL E.CAPACITORS ARE SHOWN IN THE FORM

OF CAPACITANCE (uF)/RATEO VOLTAGE (V)

ALL DIODES ARE 1SS133-T2

ALL NPN TRANSISTORS ARE 2SC2458/YG/-T

TO CD SECTION

TO U-COM

ANTGND

GND

TUL

TUSW6V

TUR

1

2

3

4

BIAS

CDR

GND

CDL

CD+B

MG

DG

TO G-1 on page 2-5

SW8V

CD+B

FCD

AC/DC

TAPE

REC

SAFETY

REST

MLD

MDATA

MCLK

DG

XRST

STAT

TO A-7 on page 2-3

SQCK

SUBQ

DG

CN301

DGA2501C4-04

(TIP-X04P-82)

2.3V

1

2.3V

2

2.3V

3

0V

4

GND

17

8.3V

16

6.8V

15

0.7V

14

2.1V

13

5.7V

12

0V

11

5.0V

10

4.6V

9

5.1V

8

4.8V

7

5.0V

6

0V

5

5.1V

4

0.1V

3

5.1V

2

5.0V

1

0V

CN304

QGF1212C1-17

TP301

R361 470K

C203

22/16

R305

1.8K

2SC2001/LK/-T

R306

1.8K

2SC2001/LK/-T

DG

SUBQ

TO CD SECTION