Page 1

SERVICE MANUAL

CD PORTABLE SYSTEM

RC-BM5

Area suffix

J ----------------------------- U.S.A.

C -------------------------- Canada

RC-BM5

Contents

Safety precautions

Preventing static electricity

Important for laser products

Importance administering point

on the safety

Disassembly method

Adjustment method

1-2

1-3

1-4

1-5

1-6

1-16

Trouble shooting

Flow of functional operation

until TOC read

Maintenance of laser pickup

Replacement of laser pickup

Description of major ICs

Wiring connection

1-19

1-20

1-21

1-21

1-22

1-37

COPYRIGHT 2002 VICTOR COMPANY OF JAPAN, LTD.

No.21129

Oct. 2002

Page 2

RC-BM5

1. This design of this product contains special hardware and many circuits and components specially for safety

purposes. For continued protection, no changes should be made to the original design unless authorized in

writing by the manufacturer. Replacement parts must be identical to those used in the original circuits. Services

should be performed by qualified personnel only.

2. Alterations of the design or circuitry of the product should not be made. Any design alterations of the product

should not be made. Any design alterations or additions will void the manufacturer`s warranty and will further

relieve the manufacture of responsibility for personal injury or property damage resulting therefrom.

3. Many electrical and mechanical parts in the products have special safety-related characteristics. These

characteristics are often not evident from visual inspection nor can the protection afforded by them necessarily

be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in the Parts List of Service Manual. Electrical

components having such features are identified by shading on the schematics and by ( ) on the Parts List in

the Service Manual. The use of a substitute replacement which does not have the same safety characteristics

as the recommended replacement parts shown in the Parts List of Service Manual may create shock, fire, or

other hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the like to be

separated from live parts, high temperature parts, moving parts and/or sharp edges for the prevention of

electric shock and fire hazard. When service is required, the original lead routing and dress should be

observed, and it should be confirmed that they have been returned to normal, after re-assembling.

5. Leakage currnet check (Electrical shock hazard testing)

After re-assembling the product, always perform an isolation check on the exposed metal parts of the product

(antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control shafts, etc.) to be sure the

product is safe to operate without danger of electrical shock.

Do not use a line isolation transformer during this check.

Plug the AC line cord directly into the AC outlet. Using a "Leakage Current Tester", measure the leakage

current from each exposed metal parts of the cabinet, particularly any exposed metal part having a return

path to the chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

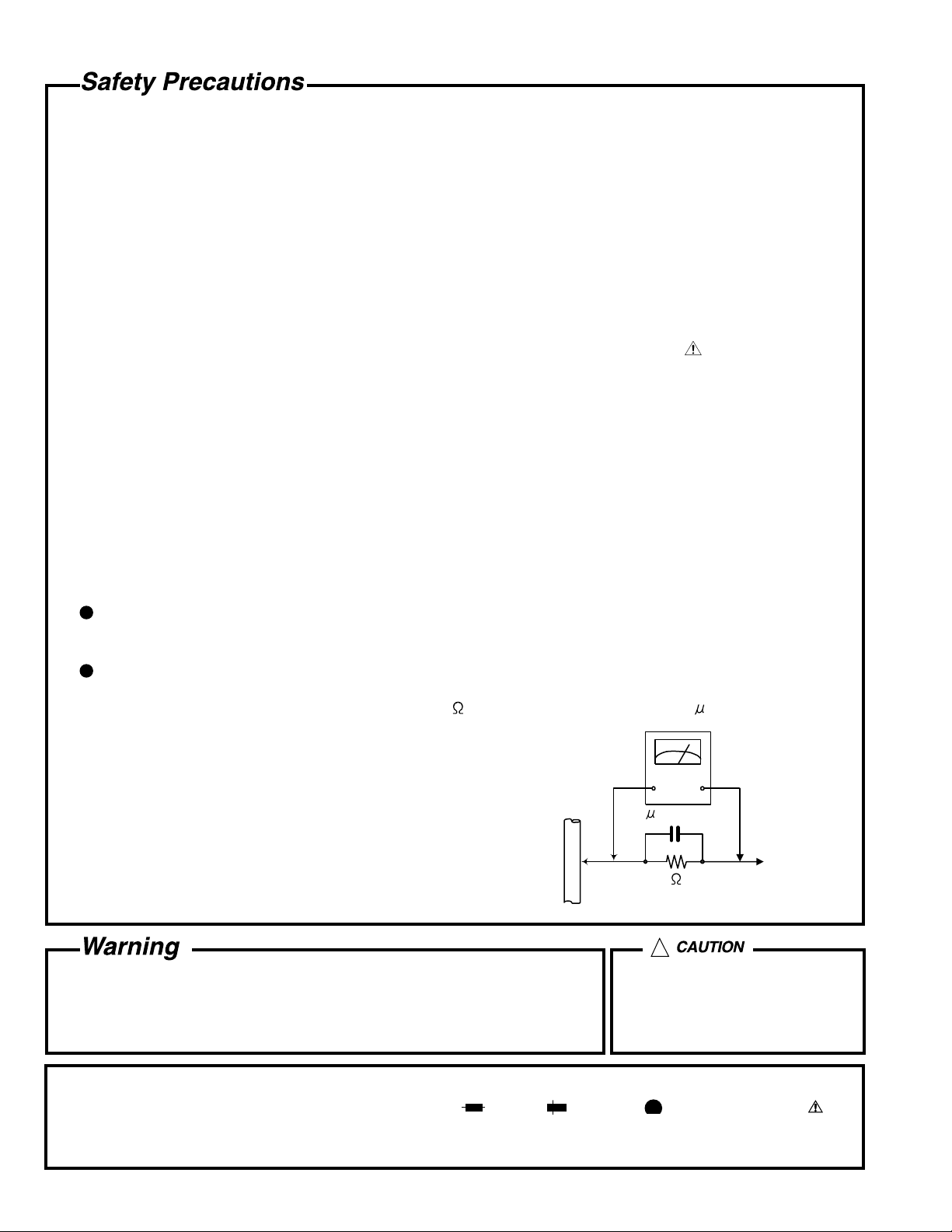

Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having, 1,000 ohms per volt or more

sensitivity in the following manner. Connect a 1,500 10W resistor paralleled by a 0.15 F AC-type capacitor

between an exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal part,

particularly any exposed metal part having a return path to

the chassis, and meausre the AC voltage across the resistor.

Now, reverse the plug in the AC outlet and repeat each

measurement. Voltage measured any must not exceed 0.75 V

AC (r.m.s.). This corresponds to 0.5 mA AC (r.m.s.).

0.15 F AC TYPE

1500 10W

Good earth ground

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

Place this

probe on

each exposed

metal part.

!

1. This equipment has been designed and manufactured to meet international safety standards.

2. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

3. Repairs must be made in accordance with the relevant safety standards.

4. It is essential that safety critical components are replaced by approved parts.

5. If mains voltage selector is provided, check setting for local voltage.

Burrs formed during molding may

be left over on some parts of the

chassis. Therefore, pay attention to

such burrs in the case of

preforming repair of this system.

In regard with component parts appearing on the silk-screen printed side (parts side) of the PWB diagrams, the

parts that are printed over with black such as the resistor ( ), diode ( ) and ICP ( ) or identified by the " "

mark nearby are critical for safety.

(This regulation does not correspond to J and C version.)

1-2

Page 3

RC-BM5

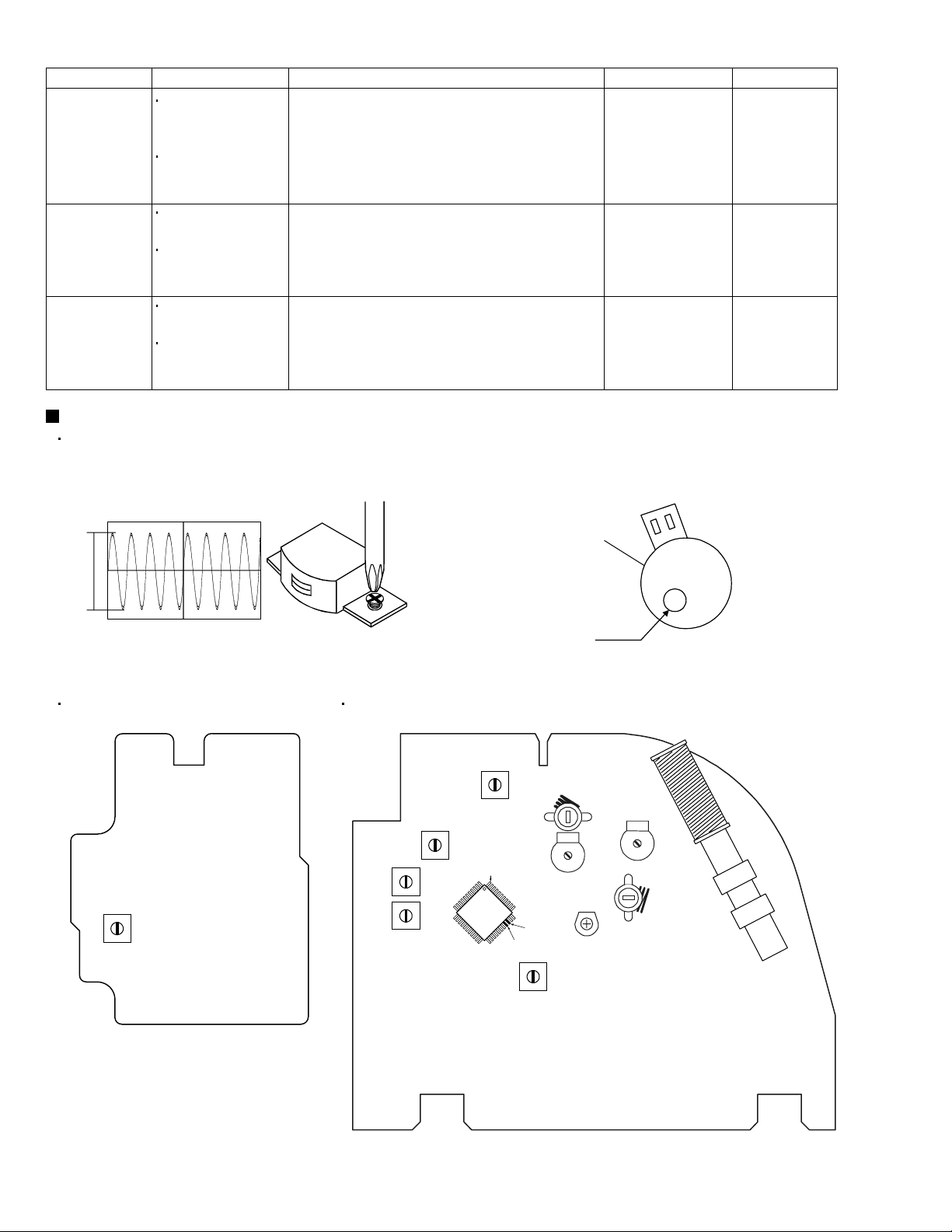

Preventing static electricity

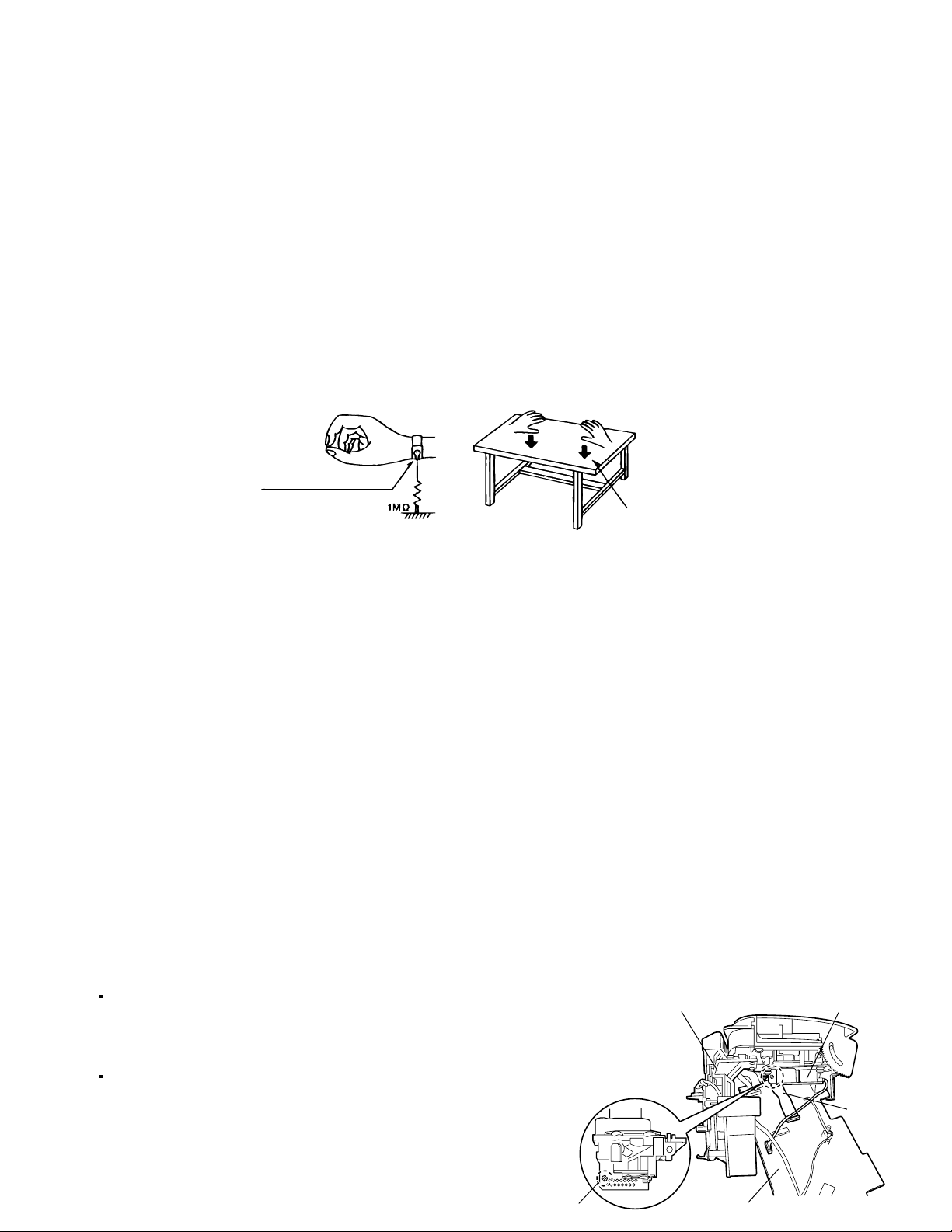

1. Grounding to prevent damage by static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged,

can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

2. About the earth processing for the destruction prevention by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as CD players.

Be careful to use proper grounding in the area where repairs are being performed.

2-1 Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it

before placing the traverse unit (optical pickup) on it.

2-2 Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

Conductive material

(conductive sheet) or iron plate

3. Handling the optical pickup

1.

In order to maintain quality during transport and before installation, both sides of the laser diode on the

replacement optical pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

2.

Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power

source can easily destroy the laser diode.

4. Handling the traverse unit (optical pickup)

1.

Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

2.

Remove solder of the short land on the flexible wire after replacing the optical pickup. For specific details, refer

to the replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit.

Be careful not to take too long a time when attaching it to the connector.

3.

Handle the flexible wire carefully as it may break when subjected to strong force.

4.

It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

5. Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the CD pickup unit.

Apply solder to the short land before the card wire is disconnected

from the connector on the main board.

(If the flexible wire is disconnected without applying solder, the CD

pickup may be destroyed by static electricity.)

In the assembly, be sure to remove solder from the short land after

connecting the card wire.

Short land

CD/Cassette mechanism

assembly

Main board

CD pickup unit

Card wire

1-3

Page 4

RC-BM5

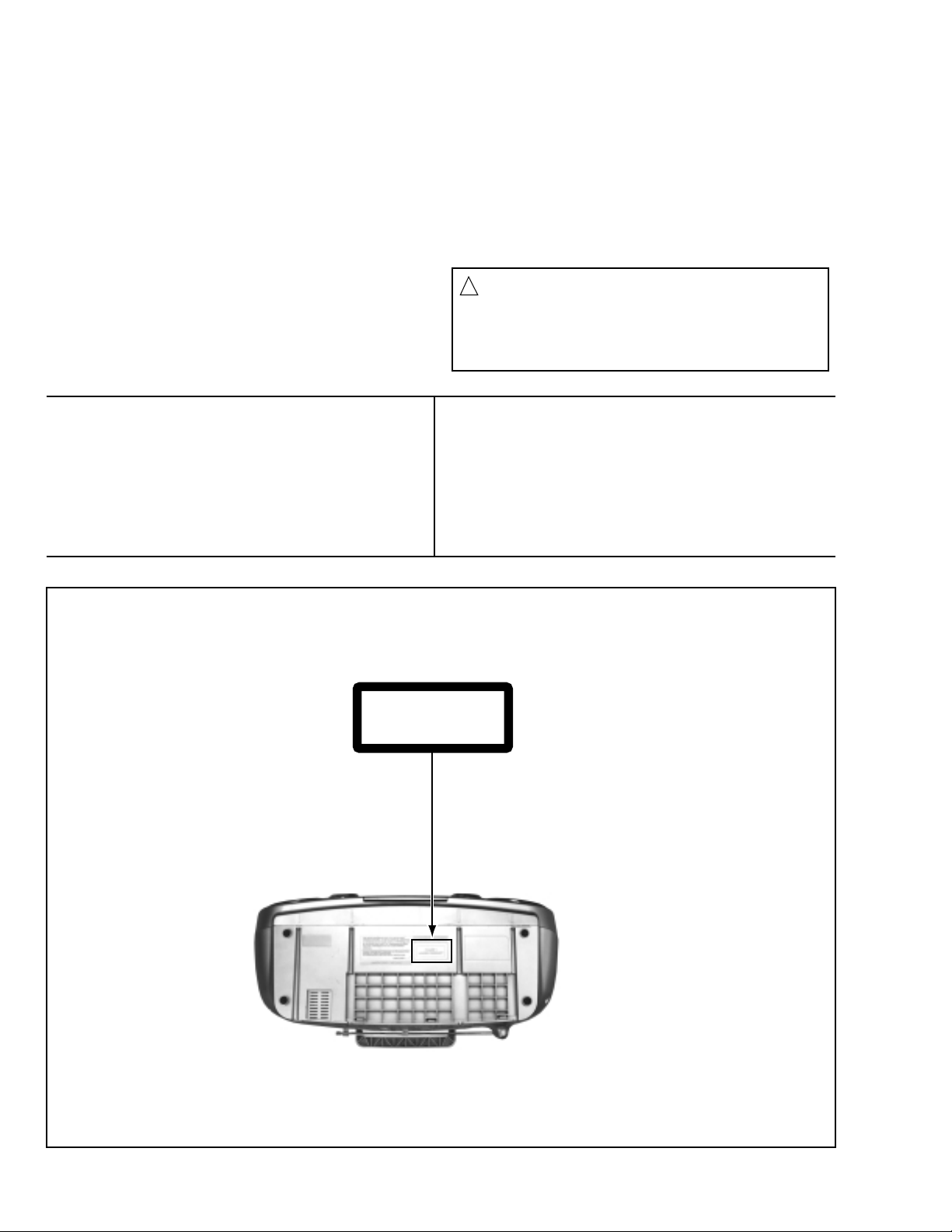

Important for laser products

1.CLASS 1 LASER PRODUCT

2.DANGER : Invisible laser radiation when open and inter

lock failed or defeated. Avoid direct exposure to beam.

3.CAUTION : There are no serviceable parts inside the

Laser Unit. Do not disassemble the Laser Unit. Replace

the complete Laser Unit if it malfunctions.

4.CAUTION : The compact disc player uses invisible

laserradiation and is equipped with safety switches

whichprevent emission of radiation when the drawer is

open and the safety interlocks have failed or are de

feated. It is dangerous to defeat the safety switches.

VARNING : Osynlig laserstrålning när denna del är öppnad

och spårren är urkopplad. Betrakta ej strålen.

VARO : Avattaessa ja suojalukitus ohitettaessa olet

alttiina näkymättömälle lasersäteilylle.Älä katso

säteeseen.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified herein may result in

hazardous radiation exposure.

CAUTION

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

ADVARSEL : Usynlig laserstråling ved åbning , når

sikkerhedsafbrydere er ude af funktion.

Undgåudsættelse for stråling.

ADVARSEL : Usynlig laserstråling ved åpning,når

sikkerhetsbryteren er avslott. unngå utsettelse

for stråling.

REPRODUCTION AND POSITION OF LABELS

CLASS 1

LASER PRODUCT

1-4

Page 5

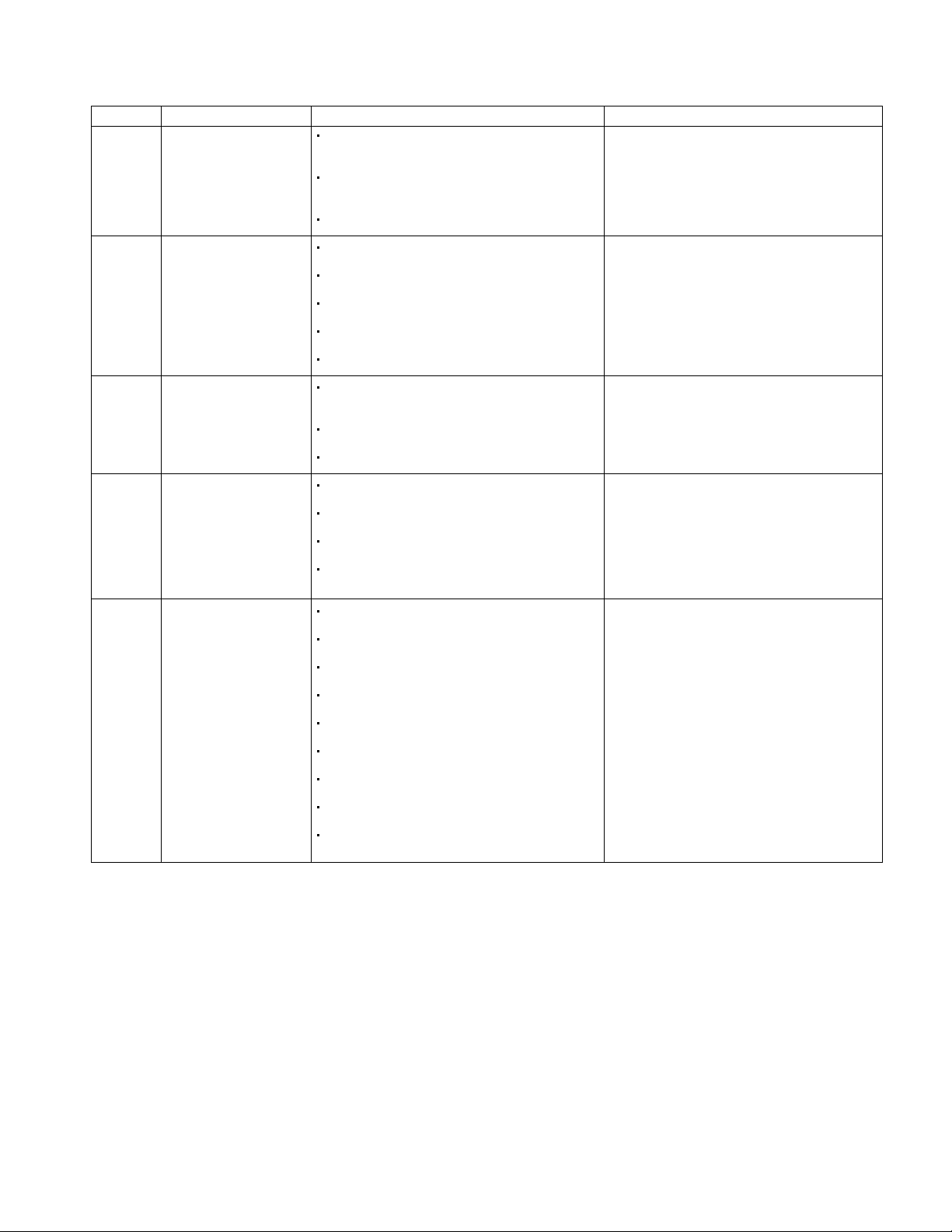

Importance administering point on the safety

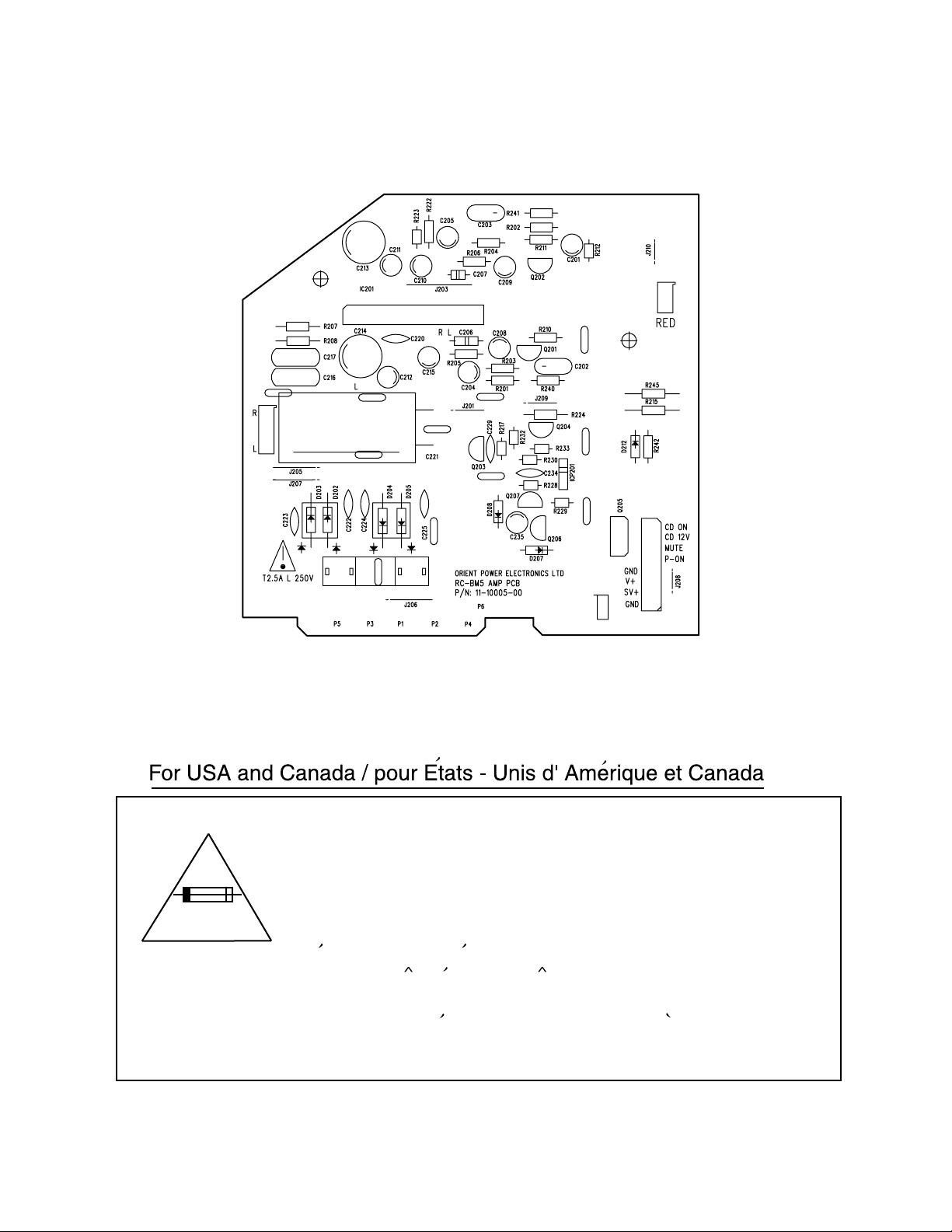

CN204

CN203

RC-BM5

CN206

F201

Power amplifier board

Caution: For continued protection against risk of fire,

replace only with same type: 2.5A/250V for F201.

This symbol specifies type of fast operating fuse.

Precaution: Pour eviter les risques de feu, remplacez le

fusible de surete par le meme type: 2,5A/250V pour

F201.

Ce symbole specifie le type du fusible a fonctionnement

rapide.

1-5

Page 6

RC-BM5

Disassembly method

<Main body section>

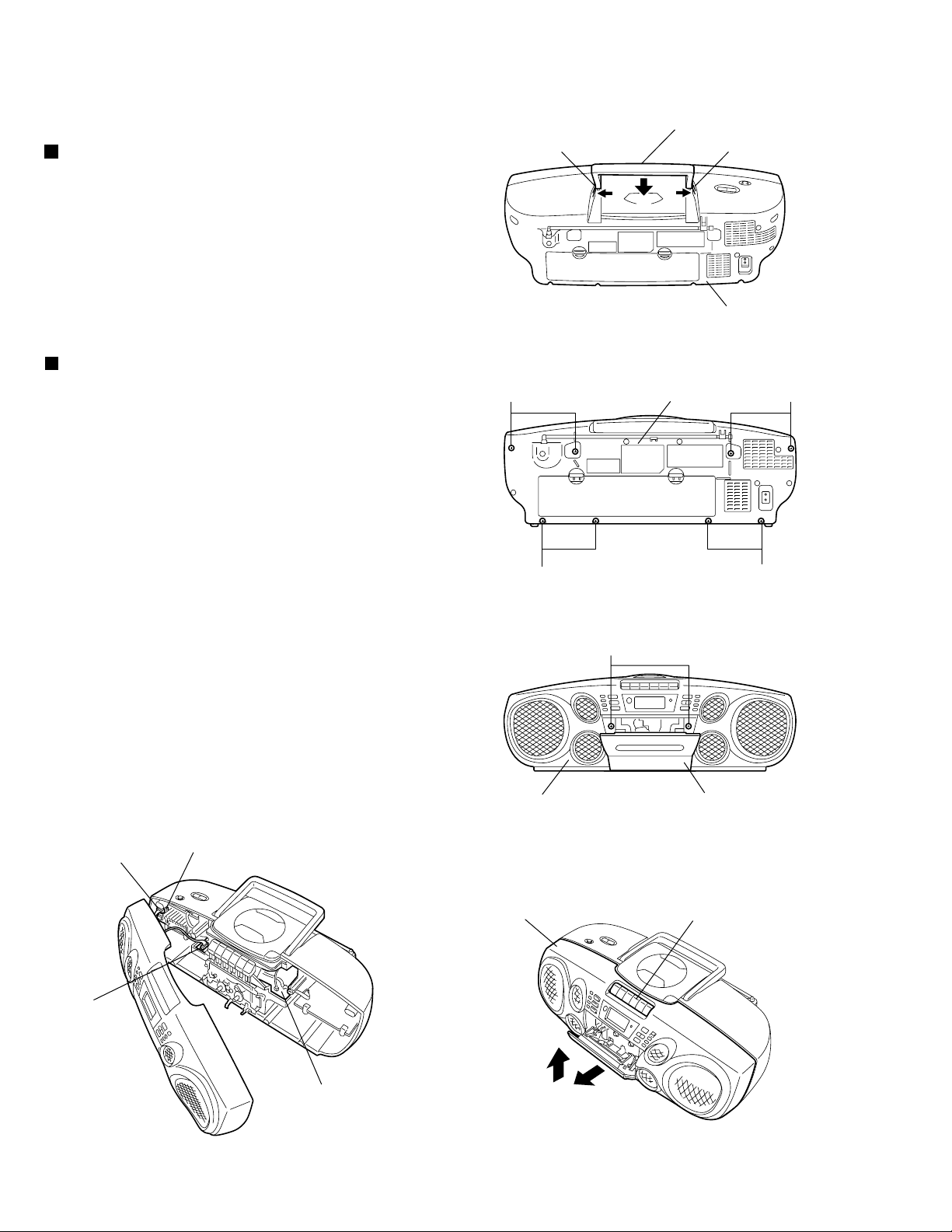

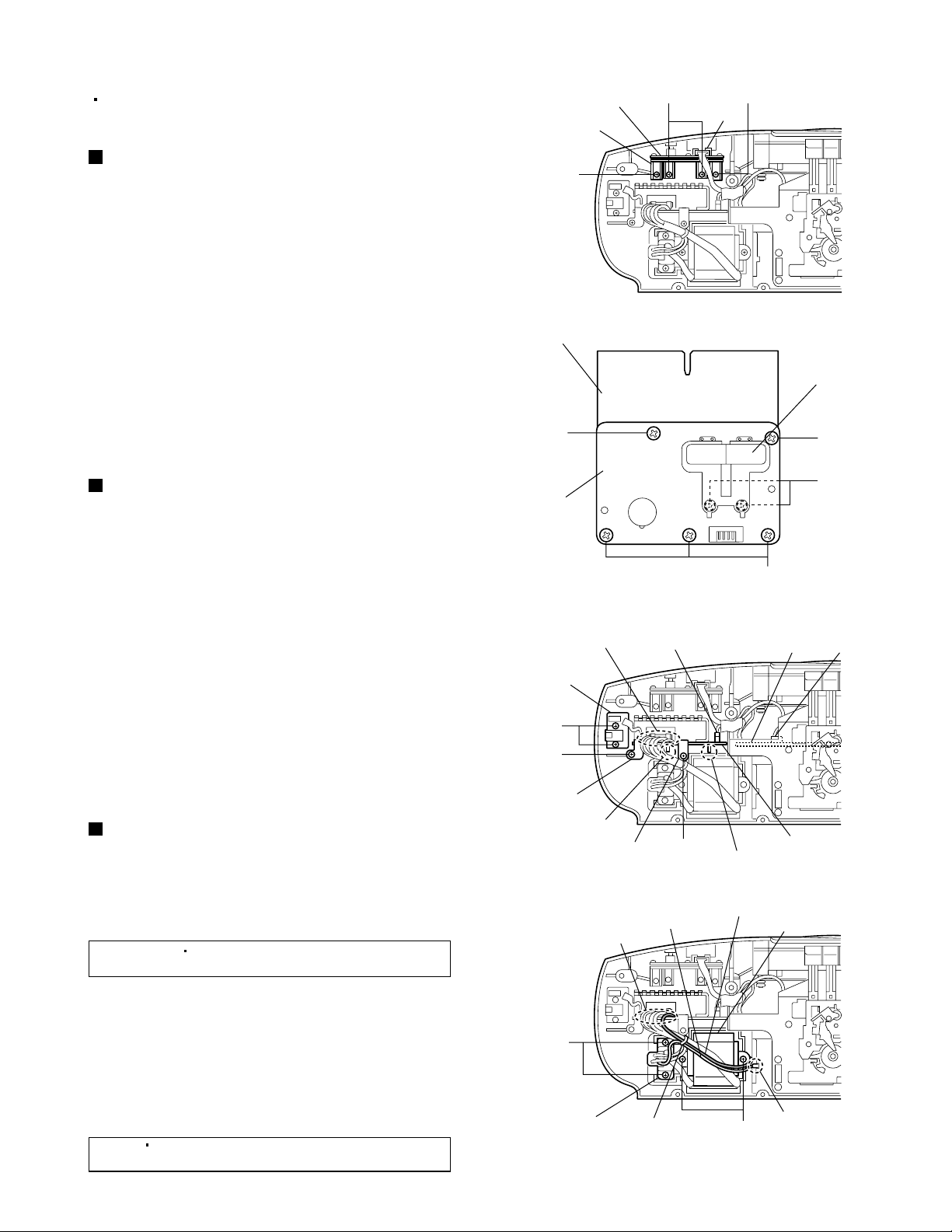

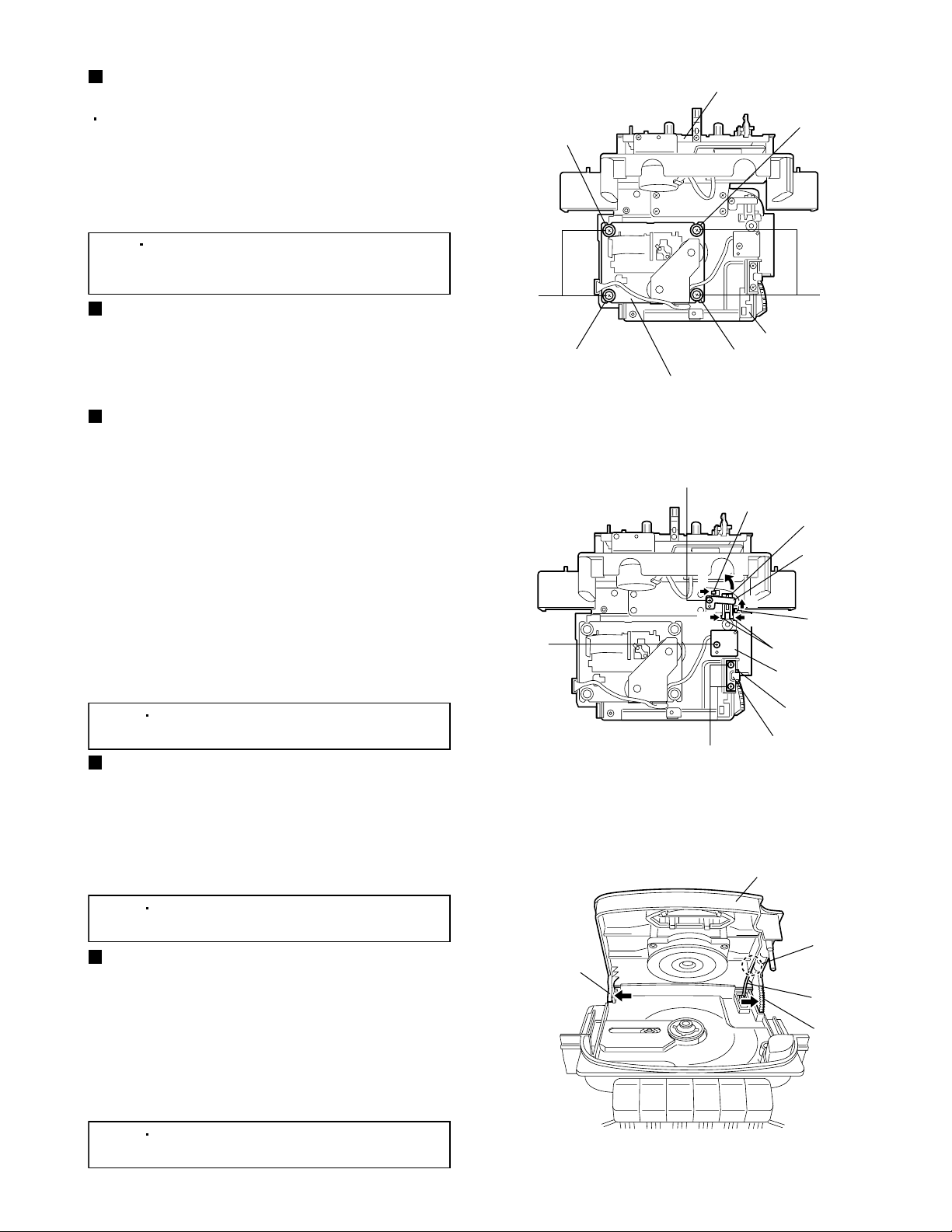

Removing the handle (See Fig. 1.)

Lift the handle slightly.

1.

While pressing the claws a of the rear cabinet

2.

assembly in the direction of the arrow 1, slide the

handle in the direction of the arrow 2.

Removing the front cabinet assembly

and rear cabinet assembly

(See Figs. 2 to 5.)

1.

Remove the eight screws A retaining the front

cabinet and rear cabinet assemblies from the rear

of the main body. (See Fig.2.)

2.

Open the cassette door. (See Fig.3.)

3.

Remove the two screws B retaining the front

cabinet assembly. (See Fig.3.)

4.

Slide the lower part of the front cabinet slightly in

the direction of the arrow 1. (See Fig.4.)

5.

While removing the front cabinet assembly from the

cassette knobs and remove it in the upward

direction 2. (See Fig.4.)

Handle

Claw aClaw a

2

Fig.1

1

Rear cabinet assembly

1

AA

Rear cabinet assembly

AA

Fig.2

B

6.

Disconnect the speaker wire from the connector

CN205 on the phone jack board. (See Fig.5.)

7.

Disconnect the parallel wire from the connector

CN302 on the main board. (See Fig.5.)

CN205

CN302

Phone jack board

Main board

Fig.5

Front cabinet assembly Cassette door

Fig.3

Front cabinet assembly

2

1

Fig.4

Cassette knobs

1-6

Page 7

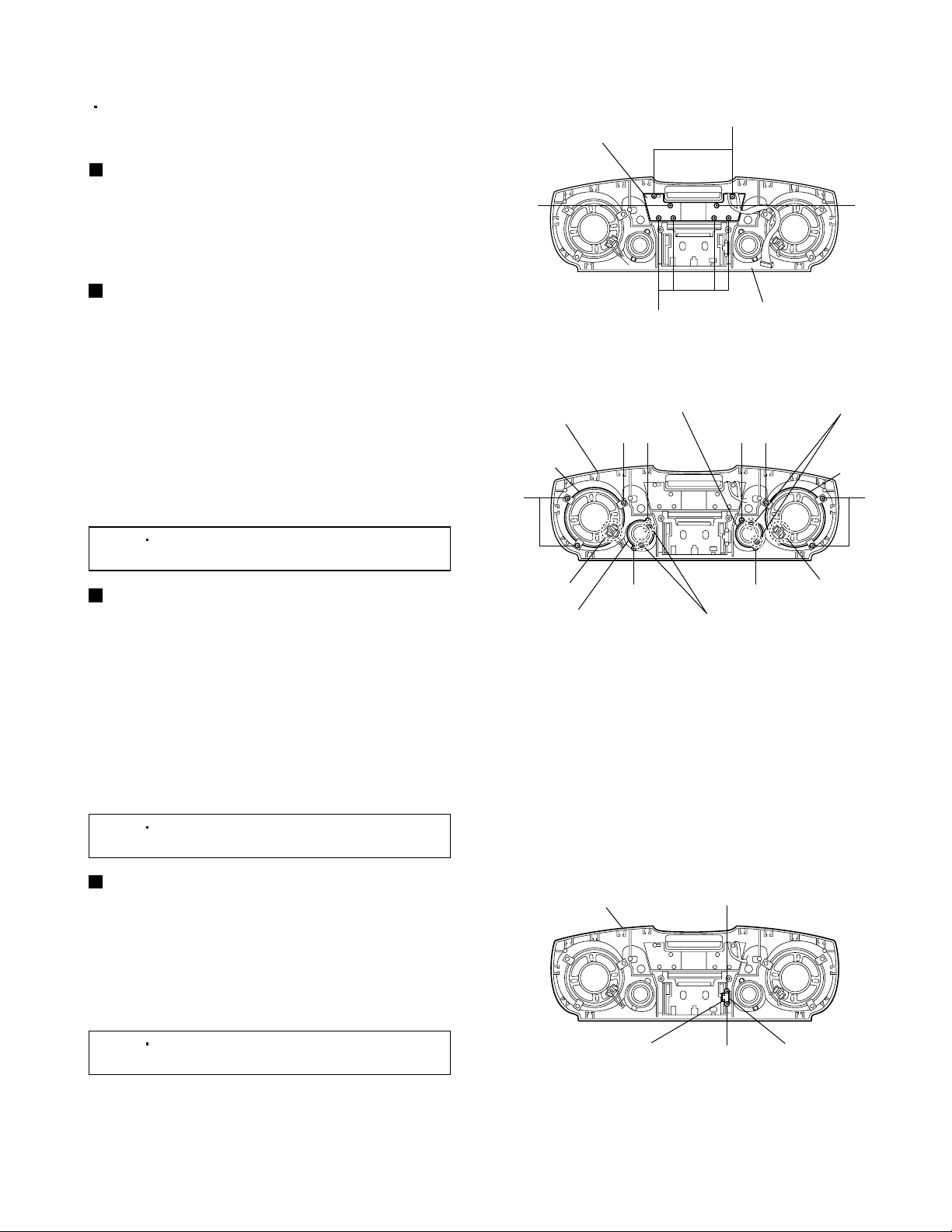

<Front cabinet section>

Prior to performing the following procedures,

remove the front cabinet assembly from the rear

cabinet assembly.

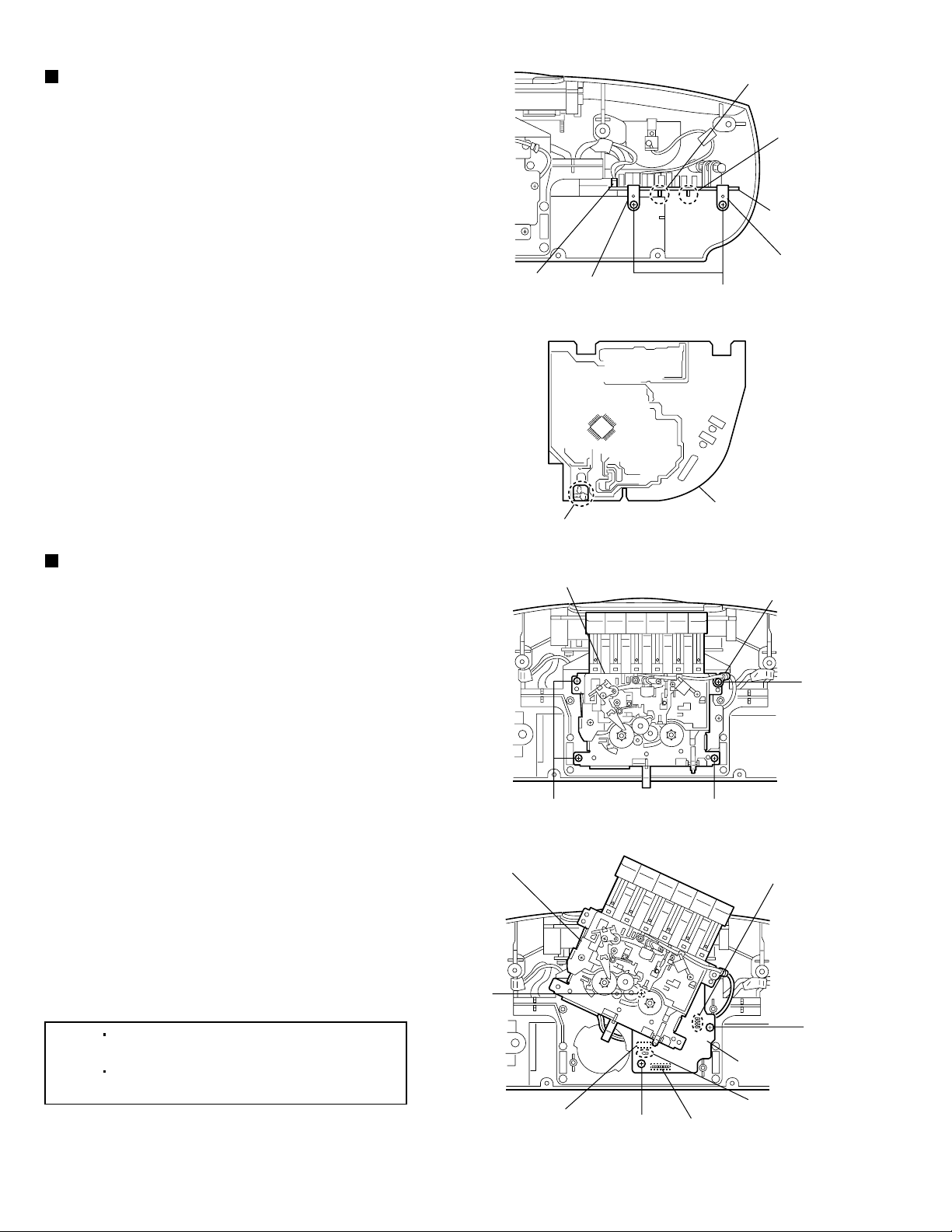

Removing the display board

(See Fig. 6.)

From the inside of the front cabinet assembly,

remove the eight screws C retaining the display

board and then take out the display board.

Removing the right and left main

speaker assemblies (See Fig. 7.)

1.

From the inside of the front cabinet assembly,

remove the six screws D retaining the right and left

main speaker assemblies.

2.

Remove the solders from the soldered sections b

and c of the right and left main speaker

assemblies, remove the wires.

3.

Take out the right and left main speaker

assemblies.

Display board

Front cabinet

assembly

Right main

speaker

C

Front cabinet assembly

Fig.6

Left sub speaker

C

Soldered sections e

EE

DD

RC-BM5

CC

Left main

speaker

DD

[Note]

After assembly, apply a locking agent to

the screws D.

Removing the right and left sub

speaker assemblies (See Fig. 7.)

1.

From the inside of the front cabinet assembly,

remove the four screws E retaining the right and

left sub speaker assemblies.

2.

Remove the solders from the soldered sections d

and e of the right and left sub speaker assemblies,

remove the wires.

3.

Take out the right and left sub speaker assemblies.

[Note]

After assembly, apply a locking agent to

the screws E.

Removing the cassette door damper

(See Fig. 8.)

1.2.From the inside of the front cabinet assembly,

remove the two screws F retaining the bracket of

the cassette door damper.

Soldered

section b

Right sub speaker

Front cabinet assembly

EE

Soldered sections d

Fig.7

F

Soldered

section c

Take out the cassette door damper.

[Note]

After assembly, apply a locking agent to

the screws F.

Cassette door damper Bracket

F

Fig.8

1-7

Page 8

RC-BM5

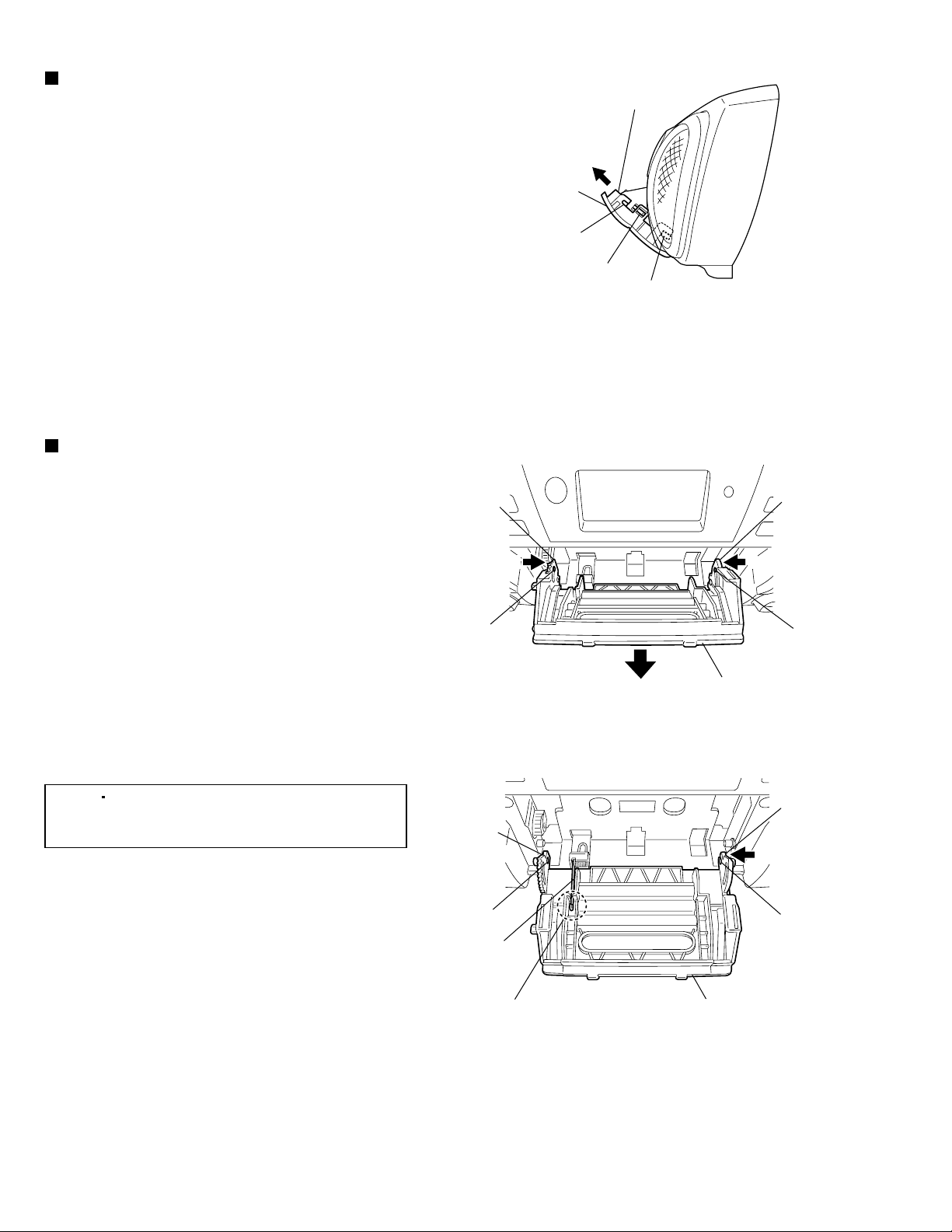

Removing the cassette door

(See Fig. 9.)

1.

Open the cassette.

2.

While pressing the claws f on the left and right of

the cassette door bracket, slide the cassette door.

3.

Disengage the hooks g and h on the left and right

of the cassette door bracket, and remove the

cassette door.

Removing the cassette door bracket

(See Figs. 10 and 11.)

1.

While pressing the sections i on the left and right of

the cassette door bracket in the direction of the

arrow 1, remove the cassette door bracket from the

bosses j of the front cabinet assembly and then

open the cassette door bracket in the direction of

the arrow 2.

Section i

Cassette door bracket

Cassette door

Hook h

Claw f

Hook g

Fig.9

Section i

11

2.

Press the section k of the cassette door bracket

and remove the cassette door bracket from the

boss m of the front cabinet assembly.

3.

Disengage the section n of the cassette door

bracket from the boss p of the front cabinet

assembly and remove the cassette door bracket.

[Note]

Be sure to hang the spring to the

section q before attaching the cassette

door bracket.

Boss j

Section n

Boss p

Spring

Section q

2

Fig.10

Fig.11

Boss j

Cassette door bracket

Section k

Boss m

Cassette door bracket

1-8

Page 9

RC-BM5

<Rear cabinet section>

Prior to performing the following procedures,

remove the front cabinet assembly from the rear

cabinet assembly.

Removing the volume switch board

(See Fig. 12 and 13.)

1.

Disconnect the wire from the connector H402 on

the volume switch board.

2.

Remove the four screws G retaining the control

bracket of the volume switch board.

3.

While pressing the power and volume buttons of

the volume switch board, take out the volume

switch board.

4.

From the forward side of the volume switch board,

remove the five screws H retaining the volume

switch board to the control bracket. (See Fig.13.)

5.

From the bottom side of the control bracket,

remove the two screws J retaining the volume

switch board and volume button to the control

bracket. (See Fig.13.)

Removing the power amplifier board

and phone jack board (See Fig. 14.)

1.

Disconnect the wire from the connector CN206 on

the power amplifier board.

Volume switch board

Control bracket

G

Control bracket

H

Volume switch

board

GG

H402

Fig.12

Volume switch

H

J

(Bottom side)

2.

Disconnect the wire from the connector CN801 on

the main board.

3.

Remove the wire from the soldered section r on the

power amplifier board.

4.

Remove the two screws K and board holders

(A)/(B) retaining the power amplifier board.

5.

Remove the two screws L retaining the phone jack

board.

6.

Pull out the power amplifier board from notches s

and t, and then take out the power amplifier board

together the phone jack board.

Removing the power transformer

(See Fig. 15.)

1.2.Remove the tie band bundling the wires from the

power transformer and battery plate.

Remove the wire from the soldered section u on

the power amplifier board.

[Reference]

3.

Remove the wire(blue) from the soldered section v

of the battery plate.

It is not necessary to remove the

wire(black) from the battery plate.

Soldered section r

Phone jack

board

L

K

Board holder (A)

Notch s

Board holder (B)

Soldered section u

Fig.13

CN206

K

Fig.14

Wire(blue)

H

Main board

Power amplifier board

Notch t

Wire(black)

Power transformer

CN801

4.

Remove the two screws M retaining the power

transformer.

5.

Remove the two screws N retaining the AC jack.

6.

Take out the power transformer together the AC

jack.

[Note]

After assembly, apply a locking agent to

the screws M.

N

AC jack

Tie band

Fig.15

Soldered section v

M

1-9

Page 10

RC-BM5

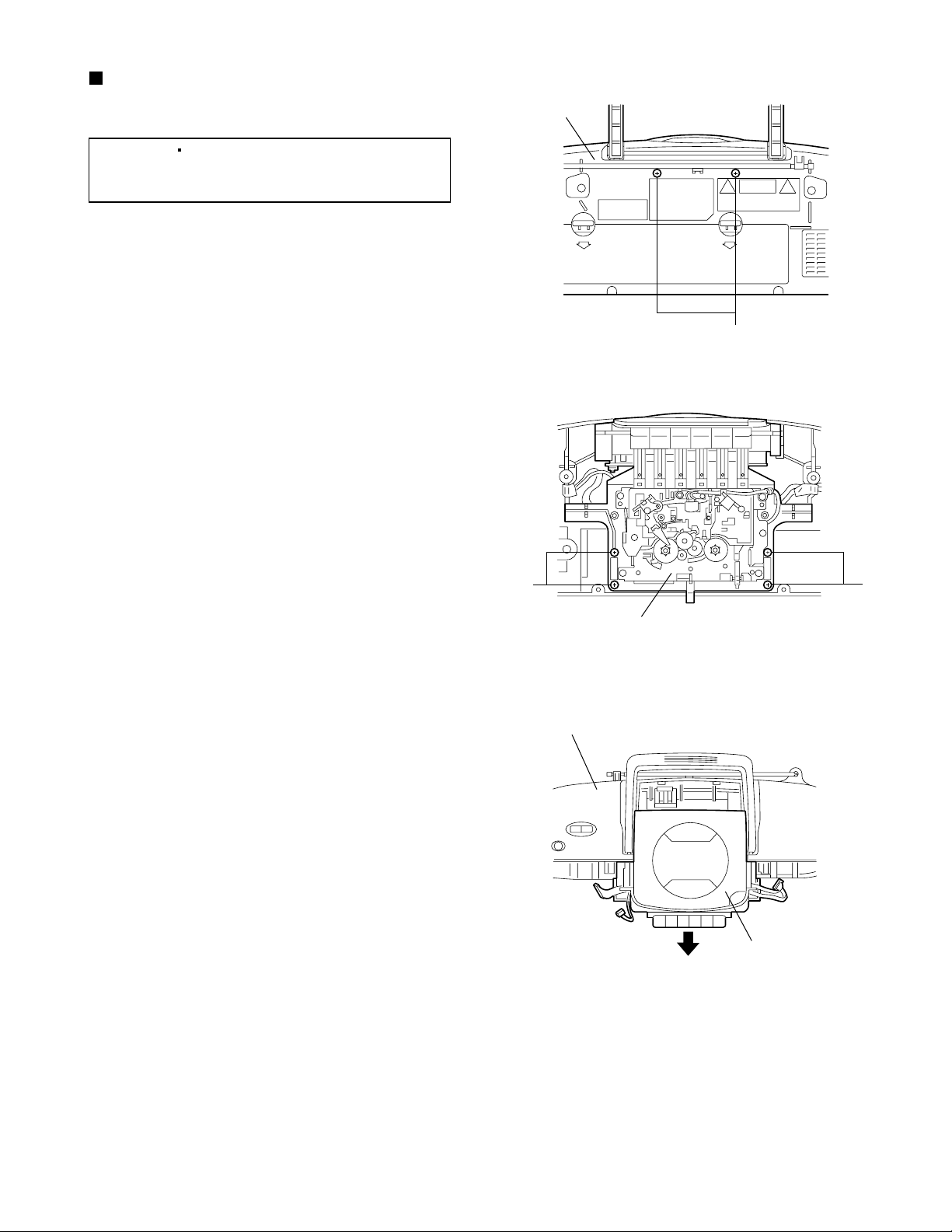

Removing the tuner board

(See Figs. 16 and 17.)

1.

Remove the wire from the connector H801 on the

tuner board.

2.

Remove the two screws P and board holders (B)

retaining the tuner board.

3.

Pull out the tuner board from the notches w and x

of the rear cabinet assembly.

4.

Remove the FM antenna wire from the soldered

section y on the reverse side of the tuner board.

(See Fig.17.)

Removing the cassette deck

mechanism assembly and cassette

board (See Figs. 18 and 19.)

1.

Remove the three screws Q and screw Q' retaining

the cassette deck mechanism assembly.

H801

Board holder (B)

Fig.16

Soldered section y

Fig.17

Cassette deck mechanism assembly

Notch w

Notch x

Tuner board

Board holder (B)

P

Tuner board

(Reverse side)

Wire clamp

2.

Lift the cassette deck mechanism assembly slightly

and move it as shown in Fig.19.

3.

Remove the three screws R retaining the cassette

board.

4.

Lift the cassette board slightly, remove the capstan

motor wire and REC/PB head wire from the

soldered sections z and aa on the cassette board.

5.

From the forward side of the cassette board,

disconnect the wire from the connector CN602 and

then remove the cassette deck mechanism

assembly.

6.

From the forward side of the cassette board,

disconnect the wire from the connector H602 and

then remove the cassette board.

[Notes]

When attaching the screw Q', attach the

wire at the same time.

After assembly, apply a locking agent to

the screws Q and Q'.

Cassette deck mechanism

assembly

R

CN602 (Forward side)

Fig.18

H602 (Forward side)

R

Fig.19

Q'

QQ

Soldered section aa

R

Cassette board

Soldered section z

1-10

Page 11

RC-BM5

Removing the CD/Cassette mechanism

assembly

(See Figs. 12,14,16 and 20 to 22.)

[Reference]

1.

From the back side of the rear cabinet assembly,

remove the two screws S retaining the

CD/Cassette mechanism assembly. (See Fig.12.)

2.

Disconnect the wire from the connector H402 on

the volume switch board. (See Fig.12.)

3.

Disconnect the wire from the connector CN206 on

the power amplifier board. (See Fig.14.)

4.

Disconnect the wire from the connector CN801 on

the main board. (See Fig.14.)

5.

Disconnect the wire from the connector H801 on

the tuner board. (See Fig.16.)

6.

Remove the four screws T retaining the

CD/Cassette mechanism assembly. (See Fig.21.)

It is not necessary to remove the

cassette deck mechanism assembly

from the rear cabinet assembly.

Rear cabinet

assembly

S

Fig.20

7.

Slide the CD/Cassette mechanism assembly in the

direction of the arrow and take out it. (See Fig.22.)

TT

CD/Cassette mechanism assembly

Fig.21

Rear cabinet assembly

CD/Cassette mechanism

assembly

Fig.22

1-11

Page 12

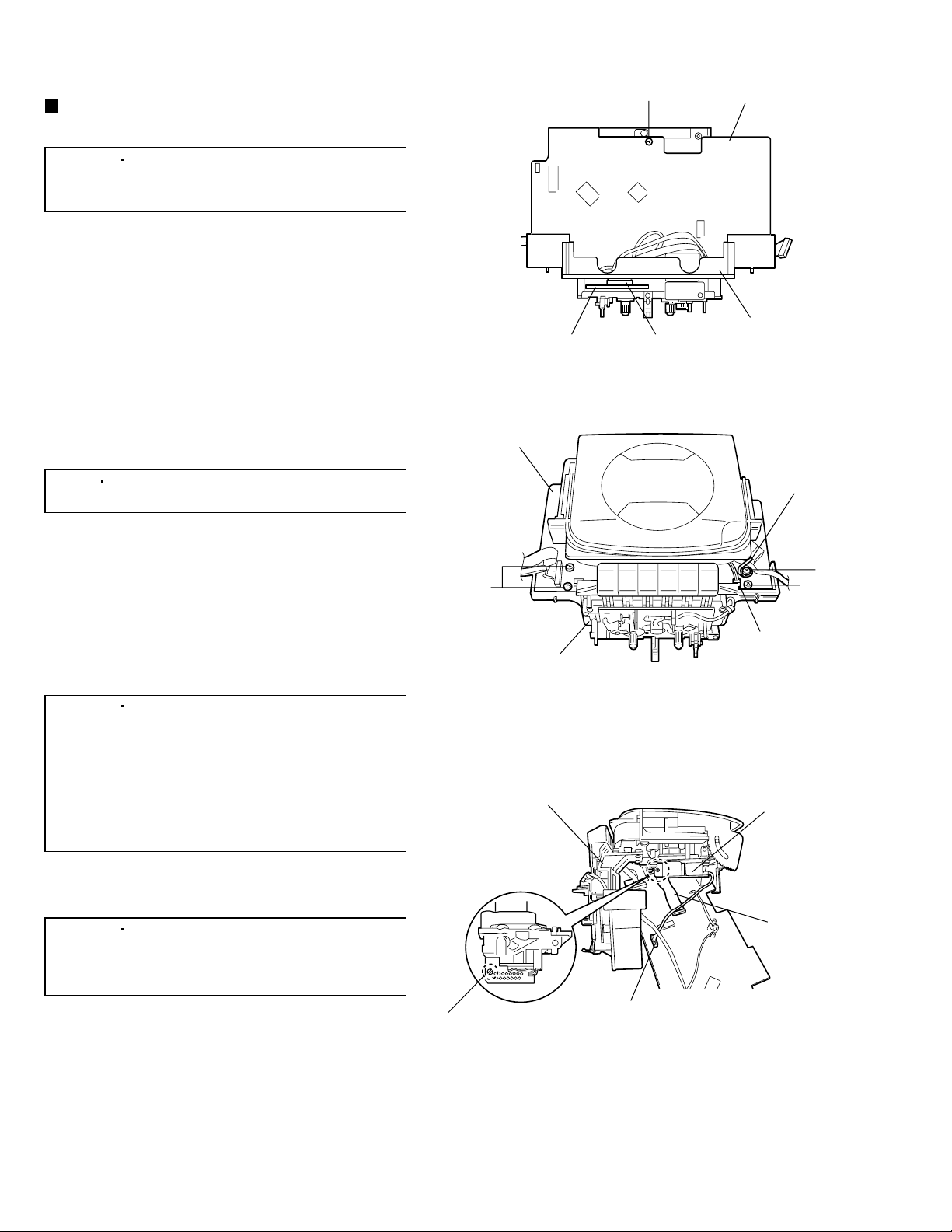

RC-BM5

<CD/Cassette mechanism section>

Removing the main board

(See Figs. 23 to 25.)

[Caution]

1.

From the bottom side of the CD/Cassette

mechanism assembly, remove the screw U

retaining the main board.

2.

Disconnect the wire from the connector H602 on

the cassette board. (See Fig.23.)

3.

Disconnect the wire from the connector H302 on

the main board. (See Fig.24.)

4.

From the top side of the CD/Cassette mechanism

assembly, remove the three screws V and screw V'

retaining the main board. (See Fig.24.)

[Note]

5.

Remove the main board from the CD/Cassette

mechanism assembly, lift the CD/Cassette

mechanism assembly as shown in Fig.25.

6.

Disconnect the wire from the connector H502 on

the main board. (See Fig.25.)

7.

Apply solder to the short land section ab on the CD

pickup unit. (See Fig.25.)

[Caution]

When removing the main board, be

careful not to scratch or damage the

CD door.

When attaching the screw V', attach the

wire at the same time.

Be sure to solder the short land

section ab on the CD pickup unit

before disconnecting the card wire

from the CD pickup unit.

If the card wire is disconnected

without applying solder, the CD

pickup may be destroyed by static

electricity.

Main board

V

CD/Cassette

mechanism assembly

CD/Cassette mechanism

assembly

U

H602Cassette board

Fig.23

Fig.24

Main board

CD/Cassette

mechanism assembly

Wire clamp

V'

V

H302

CD pickup unit

8.After soldering, disconnect the card wire from the

CD pickup unit and then remove the main board.

(See Fig.25.)

[Caution]

1-12

In the assembly, be sure to remove

solder from the short land section ab

on the CD pickup unit after

connecting the card wire.

Short land section ab

Card wire

H502

Fig.25

Page 13

RC-BM5

Removing the CD mechanism

assembly (See Fig. 26.)

Prior to performing the following procedures,

remove the main board from the CD/Cassette

mechanism assembly.

From the bottom side of the CD/Cassette

mechanism assembly, remove the four screws W

retaining the CD mechanism assembly.

[Note]

When attaching the CD mechanism

assembly, be sure not to mistake the

positions of the pink and orange rubbers.

Removing the CD door switch board

(See Fig. 27.)

From the bottom side of the CD/Cassette

mechanism assembly, remove the screw X

retaining the CD door switch board.

Removing the hanger and CD door

button (See Fig. 27.)

1.

From the bottom side of the CD/Cassette

mechanism assembly, loosen the screw Y of the

spring plate holding the hanger and then move the

spring plate in the direction of the arrow 1.

Rubber (Orange)

W

Rubber (Orange)

Cassette mechanism assembly

Rubber (Pink)

CD mechanism assembly

Fig.26

Y

(To be loosened)

Claw ad

Rubber (Pink)

W

CD tray assembly

Hanger

2.

While pressing the claws ac of the hanger in the

direction of the arrow 2, remove the hanger from

the CD tray assembly.

3.

Press the claws ad of the CD open knob in the

direction of the arrow 3 and then take out the CD

open knob from the top side of the CD tray

assembly.

[Note]

After assembly, apply a locking agent to

the screw Y.

Removing the CD door damper

(See Fig. 27.)

1.2.From the bottom side of the CD/Cassette

mechanism assembly, remove the two screws Z

retaining the CD door damper holder.

Take out the CD door damper.

[Note]

After assembly, apply a locking agent to

the screws Z.

Removing the CD door (See Fig. 28.)

1.

Open the CD door.

2.

While pressing the arm section ae of the CD door

in the direction of the arrow, remove the arm

section.

X

Arm af

Fig.27

1

3

3

2

2

Claws ac

CD door switch

board

CD door damper

CD door damper holder

Z

CD door

Spring plate

Claw ad

Section ag

Spring

Arm ae

3.

While pressing the arm section af of the CD door in

the direction of the arrow, remove the CD door.

[Note]

When attaching the CD door, hang the

spring to the section ag of the CD door.

Fig.28

1-13

Page 14

RC-BM5

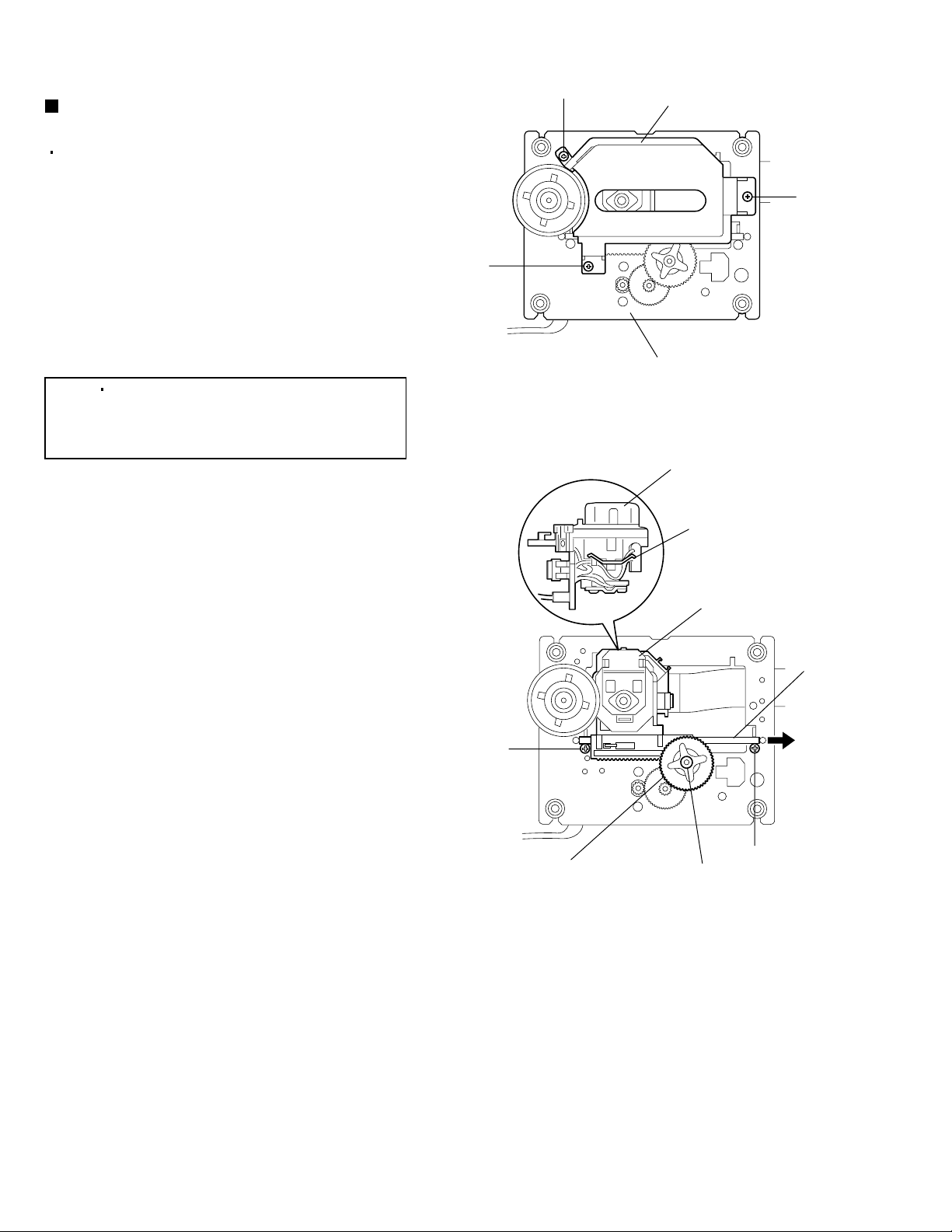

<CD mechanism section>

Removing the CD pickup unit

(See Figs. 1 to 2.)

Prior to performing the following procedures,

remove the CD mechanism assembly.

1.

Remove the three screws A retaining the CD

pickup cover.

2.

Remove the slit washer retaining the feed middle

gear and take out the feed middle gear.

3.

Loosen the two screws B retaining the shaft and

pull out the shaft in the direction of the arrow.

4.

Take out the CD pickup unit.

[Note]

In the assembly, be sure to attach the

sliding spring in the correct orientation

before attaching the CD pickup unit.

(See Fig.2.)

A

A

CD pickup cover

A

CD mechanism assembly

Fig.1

CD pickup unit

Sliding Spring

B

Feed middle gear

Fig.2

CD pickup unit

Slit washer

Shaft

B

1-14

Page 15

RC-BM5

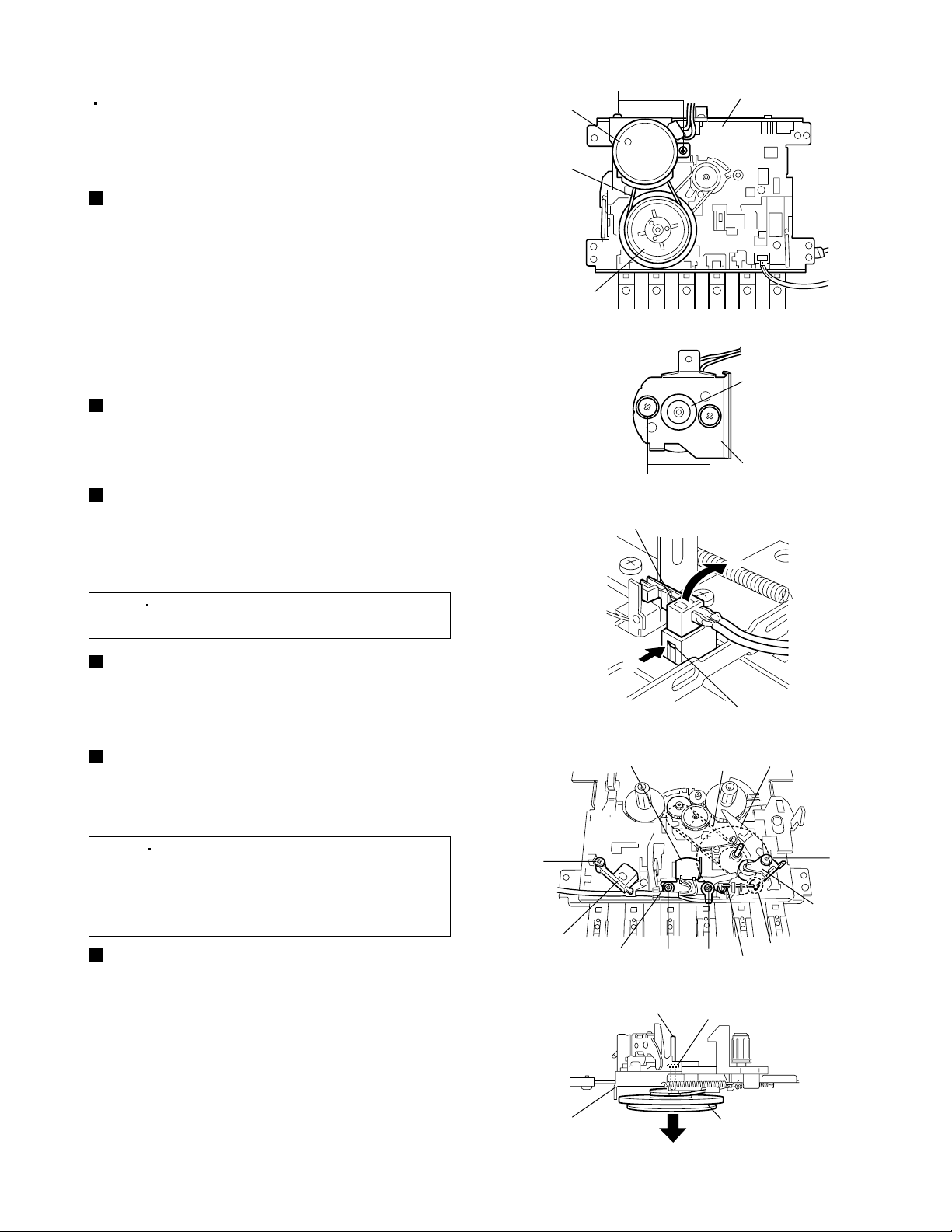

<Cassette mechanism section>

Prior to performing the following procedures,

remove the cassette mechanism assembly from

the rear cabinet assembly.

(See Fig.17 and 18 of "Rear cabinet section" on

page 1-10.)

Removing the capstan motor

(See Figs.1 and 2.)

1.

Remove the capstan motor belt.

2.

Remove the two screws A retaining the bracket of

the capstan motor from the cassette mechanism

assembly.

3.

Remove the two screws B retaining the bracket

from the capstan motor. (See Fig.2.)

Removing the leaf switch (See Fig.3.)

Pressing the claw a of the leaf switch in the

direction of the arrow 1 and take out the leaf switch

in the direction of the arrow 2.

Removing the pinch roller arm

assembly (See Fig.4.)

Remove the screw C retaining the pinch roller arm

assembly and remove the pinch roller arm

assembly in an upward direction.

[Note]

In the assembly, hang the notch b of the

pinch roller arm assembly to the spring.

Capstan motor

Capstan motor

belt

Flywheel assembly

Leaf switch

A

Cassette mechanism assembly

Fig.1

Capstan motor

Bracket

B

Fig.2

2

Removing the erase head

(See Fig.4.)

Remove the screw D retaining the erase head and

remove the erase head in an upward direction.

Removing the REC/PB head

(See Fig.4.)

Remove the screw E, washer and screw F retaining

the REC/PB head and remove the REC/PB head.

[Notes]

When removing or replacing the

REC/PB head, perform the REC/PB head

adjustment. (See "Adjustment method".)

After adjusting the REC/PB head, apply

a locking agent to the screws F.

Removing the flywheel assembly

(See Figs. 4 and 5.)

1.

From the bottom side of the cassette mechanism

assembly, remove the main belt.

2.

From the top side of the cassette mechanism

assembly, remove the slit washer retaining the

shaft of the flywheel assembly.

D

Erase head

1

REC/PB head

Washer

Shaft

Fig.3

Main belt

FE

Fig.4

Slit washer

Claw a

Flywheel assembly

Notch b

Spring

C

Pinch roller

arm

assembly

3.

Pull out the flywheel assembly in the direction of

the arrow. (See Fig.5.)

Cassette mechanism

assembly

Flywheel assembly

Fig.5

1-15

Page 16

RC-BM5

Adjustment method

Measuring instructions required for

adjustment

1. AM signal generator

2. FM signal generator

3. Inter mediate frequency sweep generator

4. FM stereo signal generator

5. Low-frequency oscillator

(oscillation frequency 50Hz-20kHz, 0dB output

with 600 ohm impedance)

6. Attenuator (600 ohm impedance)

7. Electronic voltmeter

8. Distortion meter

9. Torque gauge (cassette for CTG-N)

10. Wow & flutter meter

11. Frequency counter meter

12. Test tape

VT712 : For tape speed and wow flutter

VT724 : For reference level

VT702 : For playback frequency

VT702 : For head azimuth adjustment

13. Blank tape

TAPE : AC-225

Measuring instruments

Radio section

FM 1kHz, 22.5kHz deviation

FM STEREO : 1kHz, 67.5kHz deviation

pilot signal 7.5kHz

AM : 1kHz, 30% modulation

Reference output :

Speaker output 0.5W(1.2V) 3.2 ohm

Standard mode of function knob :

Selects FM or AM in tuner mode

Bass boost: OFF

Preset EQ: Flat

Main volume: Reference output

Cassette amplifier section

Reference output :

Speaker output 0.5W(1.2V) 3.2 ohm

Standard mode of function knob :

Press TAPE knob of select TAPE mode

CD section

CD test disc : CTS-1000

Measurement conditions

Power supply voltage

AC120V/60Hz

1-16

Page 17

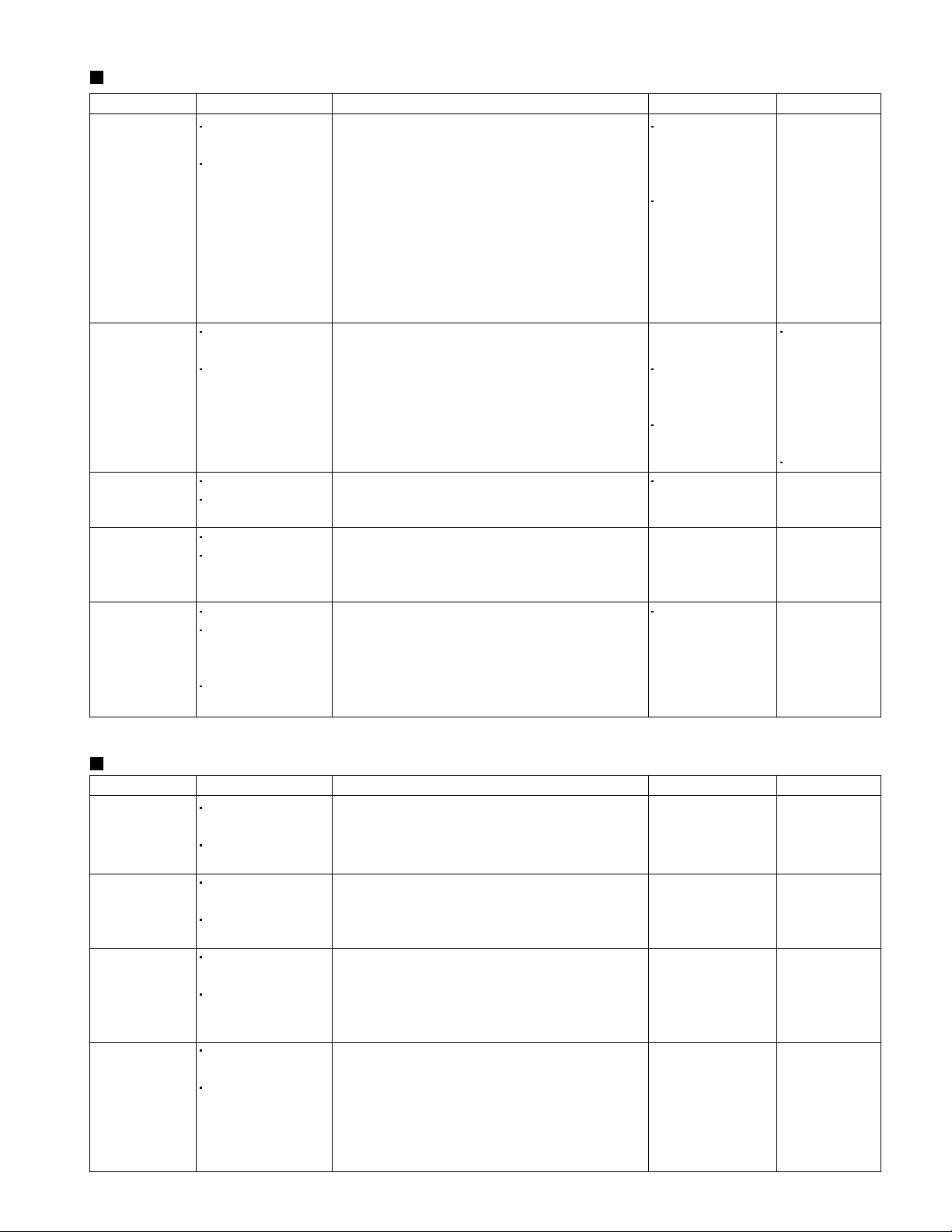

Cassette amplifier section

Item Measuring condition Check and adjustment procedure Standard value Adjusting part

Head azimuth

adjustment

Tape speed and

wow/flutter check

and adjustment

PB frequency

response check

Bias frequency

check

REC and PB

frequency

response

adjustment

Test tape:

VT702 (8kHz)

Signal output terminal:

Speakers

Test tape:

VT712 (3kHz)

Signal output terminal:

Speakers

Test tape: VT702

Signal output terminal:

Speakers

Tape: Normal

Signal output terminal:

Cassette REC./PLAY

HEAD

Test tape: AC225

Signal input:

SG 1kHz -20dBs

with emphasis

Signal output terminal:

Speakers

Play back the test tape VT702 (8kHz).

1.

Adjust the head azimuth adjusting screw so that the

2.

phase difference between the R and L channels is

minimized at an output level that is within (+2dB-2dB)

of the maximum output level in the FWD and REV

operations. After this adjustment, lock the head

azimuth adjusting screw with screw sealant to cover

more than a half of the screw head.

When the head azimuth is maladjusted, correct it with

3.

the head azimuth adjusting screw in the FWD and

REV operations alternately.

Play back the test tape VT712 (3kHz) by the end

1.

portion.

Connect a frequency counter and check that it reads

2.

between 2940 and 3090Hz. If not, adjust the

frequency with the motor semifixed resistor.

Check that the wow/flutter is within 0.38%

3.

(unweighted).

Play back the test tape VT702 while con-firming that

deviation between the 1kHz signal and 8kHz signal

should be (0+3dB-6dB).

While recording, check to see if the frequency at the

measuring point is (75+2kHz-2kHz) if not adjust T605

until the frequency counter indicates (75+2kHz-2kHz).

In recording FM mode, and record the reference 1kHz

signal and 8kHz signal alternately repeatedly. While

playing back the recorded signal of the 1kHz signal

differ from that of the 8kHz signal by within (0+4dB4dB).

Output level:

Within (+2dB-2dB) of

maximum output

level

Phase difference R

and L channels:

Minimum

2940 to 3090Hz

Within 0.38%

(unweighted)

Deviation between

1kHz and 8kHz:

(0+3dB-6dB)

Level difference for

1kHz singnal: Within

(0+4dB-4dB)

RC-BM5

Head azimuth

adjusting screw

(To be used only

after head

replacement)

See Fig.1 on

page 1-18.

Tape speed:

Motor semifixed

resistor

See Fig.2 on

page 1-18.

Check only

T605

See Fig.3 on

page 1-18.

Tuner section

Item Measuring condition Check and adjustment procedure Standard value Adjusting part

FM VT

adjustment

AM VT

adjustment

FM IF adjustment

AM IF adjustment

Signal input:

FM antenna

VT test point:

IC101 pin8

Signal input:

AM loop antenna

VT test point:

IC101 pin8

Signal input:

IC101 pin3

Voltage test point:

IC101 pin19 and pin20

Signal input:

IC101 pin2

Signal output:

IC101 pin10

Set the FM signal generator at 108MHz and output

1.

level at 60dBu.

Adjust L102, so that the VT is within (8+0.2V-0.2V).

2.

Set the AM signal generator at 1710kHz and output

1.

level at 100dBu.

Adjust T102, so that the VT is within (8V+0.1V-0.1V).

2.

Set the FM signal generator at 10.7MHz with no

1.

signal deviation and output level at 90dBu.

Short IC101 pin21 to GND.

2.

Adjust T103 so that the voltage between IC101 pin19

3.

and pin20 is within (0+3mV-3mV).

Set the intermediate frequency sweep generator to

1.

AM 450kHz.

Adjust T104 and T105 for maximum and center

2.

output.

Adjust T106 so that the voltage between IC101 pin19

3.

and pin20 is within (0+2mV-2mV).

VT=8+0.2V-0.2V

VT=8+0.1V-0.1V

0+3mV-3mV

L102

See Fig.4 on

page 1-18.

T102

See Fig.4 on

page 1-18.

T103

See Fig.4 on

page 1-18.

T104

T105

T106

See Fig.4 on

page 1-18.

1-17

Page 18

RC-BM5

Item Measuring condition Check and adjustment procedure Standard value Adjusting part

AM tracking

adjustment

FM tracking

adjustment

FM stereo

separation

adjustment

Signal input:

AM ANT. COIL

antenna

Signal output:

IC101 pin14 or

IC101 pin15

Signal input:

FM antenna

Signal output:

IC101 pin14 or

IC101 pin15

Signal input:

FM antenna

Signal output:

IC101 pin14 or

IC101 pin15

Location of adjusting parts

Cassette mechanism section

(Caution) For adjusting any head, be sure to use a screw driver degaussed.

Set the AM signal generator at 600kHz and the unit

1.

receiving 600kHz, adjust L105(AM ANT. COIL) for

maximum output.

Set the AM signal generator at 1400kHz and the unit

2.

receiving 1400kHz, adjust TC101 for maximum output.

Set the FM signal generator at 90MHz and the unit

1.

receiving 90MHz, adjust L101 for maximum output.

Set the FM signal generator at 106MHz and the unit

2.

receiving 106MHz, adjust TC102 for maximum output.

Set the AM signal generator at 98MHz with stereo

1.

deviation and the unit receiving 98kHz.

Adjust VR101, so that the separation between the R

2.

and L channels for maximum.

L105

TC101

See Fig.4 on

page 1-18.

L101

TC102

See Fig.4 on

page 1-18.

VR101

See Fig.4 on

page 1-18.

max

Cassette board

T605

Head

Azimuth adjustment screw

Fig.1 Head output signal

Adjustment

Tuner board

T105

T106

CASSETTE MOTOR

T102

T104

1pin

IC101

15pin

T103

Tape Speed Adj.

L2

L101

TC1

TC102

VR101

14pin

TC10

TC101

L102

L1

-

+

Fig.2

L105

(AM ANT. COIL)

1-18

Fig.3

Fig.4

Page 19

Trouble shooting

RC-BM5

Circuit Symptom Cause

General

AM

FM

Tape

No sound

No sound, weak

sound

(Low sensitivity)

No sound, weak

sound

(Low sensitivity)

No sound/recording,

unsteady tape sound,

weak sound

The unit is on STANDBY mode.

Defective volume control

The unit is on MUTE mode.

Adjust the set position for the best reception.

AM VT faulty

Intermediate frequency tuning faulty

RF tracking faulty

Defective IC101

Adjust FM antenna position for the best

reception.

Defective IC101

Intermediate frequency tuning faulty

Dirty capstan or head

Irregular cassette tape winding

Defective IC202

Remedy

Press STANDBY/ON button to turn on the

unit.

Set the volume control to a proper sound

level.

Press MUTE on the remote control.

Readjust (see "Adjustment method").

Readjust (see "Adjustment method").

Readjust (see "Adjustment method").

Check voltages. Replace if necessary.

Check voltages. Replace if necessary.

Readjust (see "Adjustment method").

Clean the capstan or head with alcohol.

Replace tape.

Check voltages. Replace if necessary.

CD

CD-R

CD-RW

MP3-CD

Cannot read the table

of content.

No display, no sound

Cassette erasure prevention tabs broken out

Disc is inserted upside down.

Disc is dirty.

Disc is scratched.

Disc is seriously warped.

A non-standard disc has been inserted.

Moisture has formed inside the CD deck.

Defect in the servo control board

Defect in the CD pickup mechanism

MP3 formats not supported.

Replace tape or cover tab openings with

adhesive tape.

Insert disc correctly.

Wipe clean with a soft cloth.

Use a new disc.

Use a new disc.

Use only a brand name disc.

Wait about 20 to 30 minutes.

Replace or repair as required.

Replace as required.

Use MP3-CD formats supported on this

unit

1-19

Page 20

RC-BM5

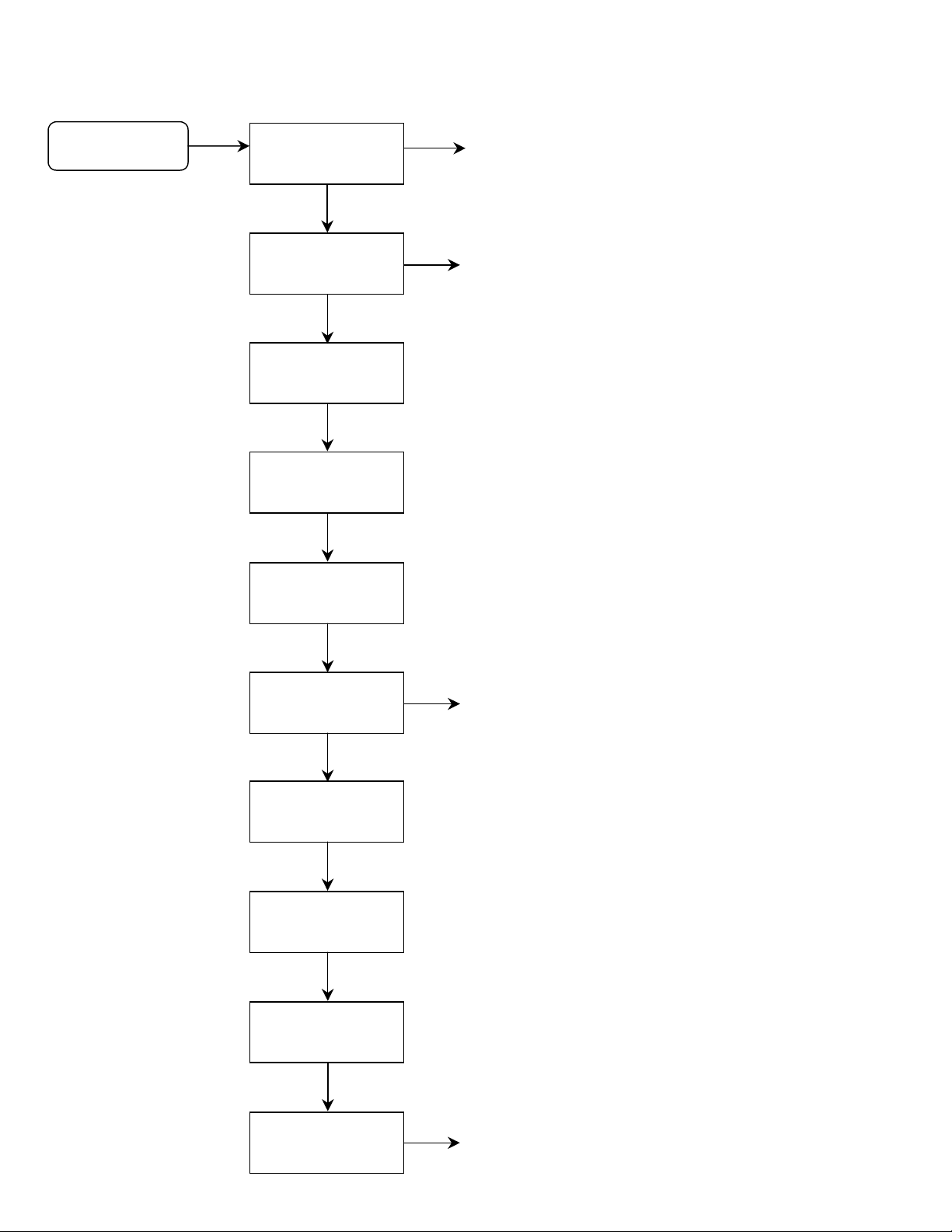

Flow of functional operation until TOC read

Power ON

Slider turns REST

SW ON.

Laser ON

Focus start

FOK

Turn on focus

servo

Confirm that the voltage at the pin5 of CN502 is

"H"/"L"/"H"

Check that the voltage at the pin64(LD) of

IC501 is +3.3V.

Disc spinning

Radial_error

scaling

PLL Lock

Turn on radial

servo

Read TOC

Check that the voltage at the pin1 and pin2 of

CN502 is +0.78V.

Confirm the eye-pattern at the "RF" test point.

1-20

Page 21

RC-BM5

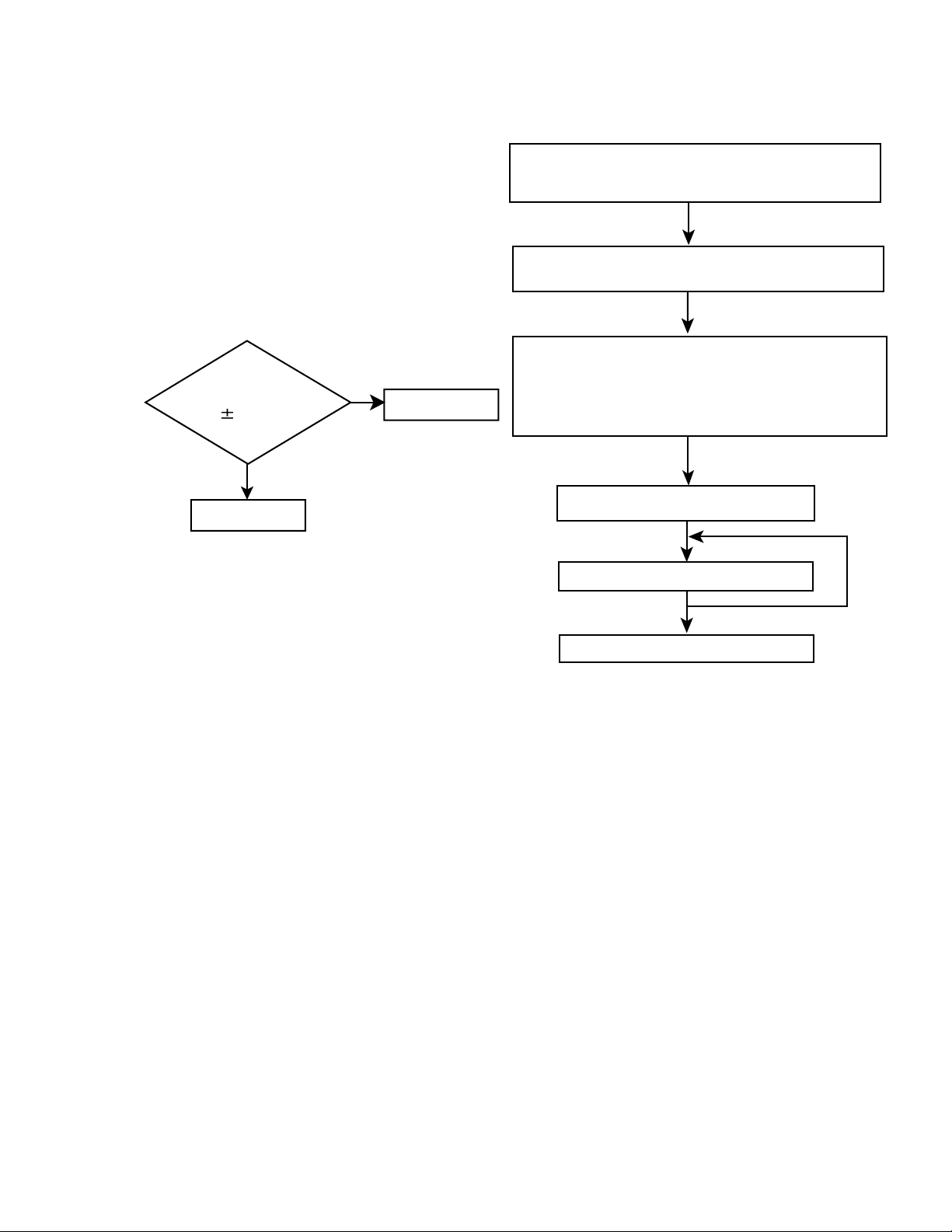

Maintenance of laser pickup

(1) Cleaning the pick up lens

Before you replace the pick up, please try to

clean the lens with a alcohol soaked cotton

swab.

(2) Life of the laser diode

When the life of the laser diode has expired,

the following symptoms will appear.

The level of RF output (EFM output:ampli tude of eye pattern) will below.

Is the level of

RF OUT under

1.25V 0.22Vp-p?

YES

O.K

NO

Replace it.

Replacement of laser pickup

Turn off the power switch and,disconnect the

power cord from the AC OUTLET.

Replace the pickup with a normal one.(Refer

to "Removing the CD pickup" on the previous page)

Plug the power cord in,and turn the power on.

At this time,check that the laser emits for

about 3 seconds and the objective lens moves

up and down.

Note: Do not observe the laser beam directly.

Play a disc.

Check the eye-pattern at the "RF" test point.

Finish.

(3) Semi-fixed resistor on the APC PC board

The semi-fixed resistor on the APC printed circuit board which is attached to the pickup is used to adjust the laser

power.

Since this adjustment should be performed to match the characteristics of the whole optical block, do not touch the

semi-fixed resistor.

If the laser power is lower than the specified value,the laser diode is almost worn out, and the laser pickup should

be replaced.

If the semi-fixed resistor would be adjusted when the pickup operates normally,the laser pickup may be damaged

due to excessive current.

1-21

Page 22

RC-BM5

Description of major ICs

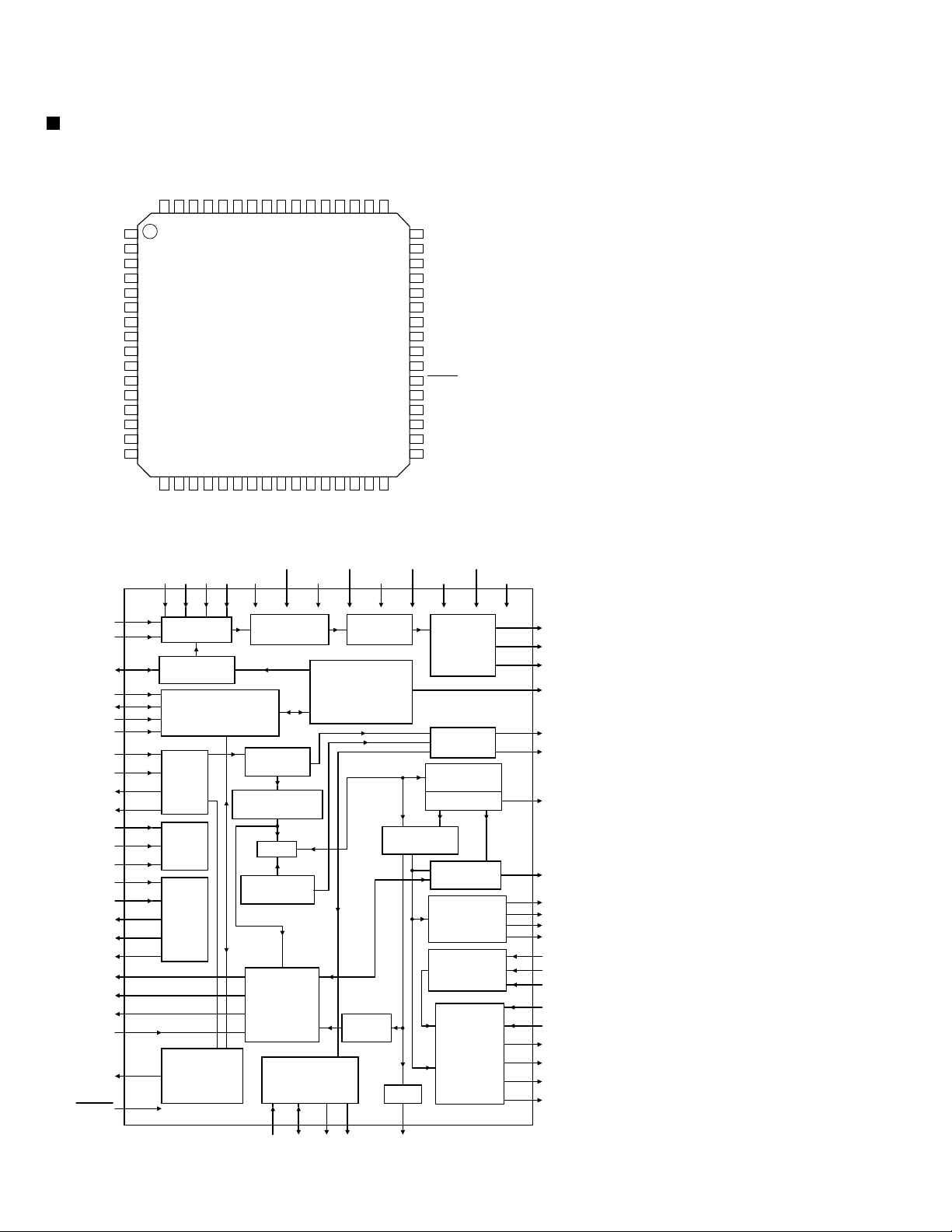

SAA7324 (IC501) : Digital servo processor & compact disc decoder

1. Terminal layout

1

HFREF

2

HFIN

3

ISLICE

4

V

SSA1

5

V

DDA1

6

I

ref

7

V

RIN

8

D1

9

D2

10

D3

11

D4

12

R1

13

R2

14

V

SSA2

15

CROUT

16

CRIN

2. Block diagram

12

R1

13

R2

SCL

SDA

RAB

SILD

HFIN

Iref

SUB

RCK

7

40

39

41

42

2

1

3

6

25

31

44

24

16

15

26

49

48

47

46

45

43

38

VRIN

HFREF

ISLICE

TEST1

TEST2

TEST3

SELPLL

CRIN

CROUT

CL16

CL11/4

SBSY

SFSY

STATUS

RESET

LDONV1V5V4MOTO2

646362616059585756555453525150

171819202122232425262728293021

LP

LN

V

DDA2

V

D1 D2 D3 D4

8 91011

ADC

SSD3VDDD2(C)

MOTO1

V

SLFORA

SAA7324H

RP

RN

pos

neg

V

TEST1

SELPLL

V

SS

A2

VSSA1

4 14 5 17 33 50 58 52 57

PRE.

PROCESSING

CL16

V

DD1(P)

CFLG

V

DATA

SCLK

WCLK

V

DD

DD

A1

Vref

GENERATOR

MICROCONTROLLER

CONTROL

PART

INTERFACE

DIGITAL

FRONT-

END

PLL

EFM

DEMODULATOR

TEST

SRAM

RAM

ADDRESSER

TIMING

SUBCODE

PROCESSOR

DETECT

DECODER

MICRO-

CONTROLLER

INTERFACE

VERSATILE PINS

INTERFACE

63 34 61 62

V1 V2/V3 V4 V5 KILL

SSD2

DOBM

V

CL11/4

49

32

EF

KILL

TEST2

A2

SS

D1

V

CONTROL

FUNCTION

PROCESSOR

PEAK

KILL

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

V

SS

AUDIO

32

D2

SBSY

SFSY

SUB

RCK

TEST3

STATUS

SILD

RAB

SCL

SDA

RESET

SCLI

SDI

WCLI

V2/V3

V

SSD1

DDD1(P)

V

SS

D3

V

OUTPUT

STAGES

MOTOR

CONTROL

ERROR

CORRECTOR

FLAGS

EBU

INTERFACE

SERIAL DATA

INTERFACE

SERIAL DATA

(LOOPBACK)

INTERFACE

BITSTREAM

DAC

V

DDD2(C)

54

RA

55

FO

56

SL

64

LDON

59

MOTO1

60

MOTO2

53

CFLG

51

DOBM

30

EF

29

SCLK

28

WCLK

27

DATA

37

SCLI

35

WCLI

36

SDI

20

Vneg

21

VPOS

18

LN

19

LP

22

RN

23

RP

1-22

Page 23

3. Pin function

Pin No. Symbol I/O Function

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

HFREF

HFIN

ISLICE

SSA1

V

V

DDA1

Iref

V

RIN

D1

D2

D3

D4

R1

R2

SSA2

V

CROUT

CRIN

V

DDA2

LN

LP

V

neg

V

pos

RN

RP

SELPLL

TEST1

CL16

DATA

WCLK

SCLK

EF

TEST2

KILL

V

SSD1

V2/V3

WCLI

SDI

SCLI

RESET

SDA

SCL

RAB

SILD

STATUS

TEST3

RCK

SUB

SFSY

SBSY

CL11/4

I

Comparator common mode input

I

Comparator signal input

O

Current feedback output from data slicer

-

Analog ground 1

-

Analog supply voltage 1

O

Reference current output

-

Reference voltage for servo ADCs

I

Unipolar current input 1 (central diode signal input)

I

Unipolar current input 2 (central diode signal input)

I

Unipolar current input 3 (central diode signal input)

I

Unipolar current input 4 (central diode signal input)

I

Unipolar current input 1 (satellite diode signal input)

I

Unipolar current input 2 (satellite diode signal input)

-

Analog ground 2

O

Crystal/resonator output

I

Crystal/resonator input

-

Analog supply voltage 2

O

DAC left channel differential negative output

O

DAC left channel differential positive output

I

DAC negative reference input

I

DAC positive reference input

O

DAC right channel differential negative output

O

DAC right channel differential positive output

-

Selects whether internal clock multiplier PLL is used

I

Test control input 1 (this pin should be tied LOW)

O

16.9344MHz system clock output

O

Serial d4(1) data output (3-state)

O

Word clock output (3-state)

O

Serial bit clock output (3-state)

O

C2 error flag output (3-state)

I

Test control input 2 (this pin should be tied LOW)

O

Kill output (programmable;open-drain)

-

Digital ground 1

I/O

Versatile I/O:versatile input 2 or versatile output 3 (open-drain)

I

Word clock input (for data loopback to DAC)

I

Serial data input (for data loopback to DAC)

I

Serial bit clock input (for data loopback to DAC)

I

Power-on reset input (active LOW)

I/O

Microcontroller interface data I/O line (IIC-bus;open-drain output)

I

Microcontroller interface clock line input (IIC-bus)

I

Microcontroller interface R/W and load control line input (4-wire bus mode)

I

Microcontroller interface R/W and load control line input (4-wire bus mode)

O

Servo interrupt request line/decoder status register output (open-drain)

I

Test control input 3 (this pin should be tied LOW)

I

Subcode clock input

O

P-to-W subcode bits output (3-states)

O

Subcode frame sync output (3-sates)

O

Subcode block sync output (3-sates)

O

11.2896 or 4.2336MHz (for microcontroller) clock output

RC-BM5

1-23

Page 24

RC-BM5

Pin No. I/O FunctionSymbol

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

AN7312 (IC601) : Dual recording/Playback pre-amplifier circuit with ALC

1. Terminal layout

14 8

SSD2

V

DOBM

V

DDD1(P)

CFLG

RA

FO

SL

V

DDD2(C)

V

SSD3

MOTO1

MOTO2

V4

V5

V1

LDON

~

-

Digital ground 2

O

Bi-phase mark output (externally buffered;3-state)

-

Digital supply voltage 1 for periphery

O

Correction flag output (open-drain)

O

Radial actuator output

O

Focus actuator output

O

Sledge control output

-

Digital supply voltage 2 for core

-

Digital ground 3

O

Motor output 1;versatile (3-state)

O

Motor output 2;versatile (3-state)

O

Versatile output 4

O

Versatile output 5

I

Versatile input 1

O

Laser drive on output (open-drain)

2. Block diagram

Vcc

14 13 12 11 10

8

9

Ripple Filter

17

~

1 2 3 4 5 6

GND

ALC

3. Pin function

Pin No. Symbol Function

1

GND

2

ALC time constant

3

ALC input Ch.1

4

Output Ch.1

5

Phase compensation Ch.1

6

N.E.B. Ch.1

7

Input Ch.1

8

Input Ch.2

9

N.E.B. Ch.2

10

Phase compensation Ch.2

11

Output Ch.2

12

ALC input Ch.2

13

Ripple filter

14

Vcc

I/O

GND

ALC time constant by resistance and capacitor

Right channel ALC input

I

Right channel output

O

Not connect

Right channel negative feed back input

I

Right channel signal input

I

Left channel signal input

I

Left channel negative feed back input

I

Not connect

Left channel output

O

Left channel ALC input

I

Ripple filter

Power supply

-

Amp.

Ch2

Amp.

Ch1

7

1-24

Page 25

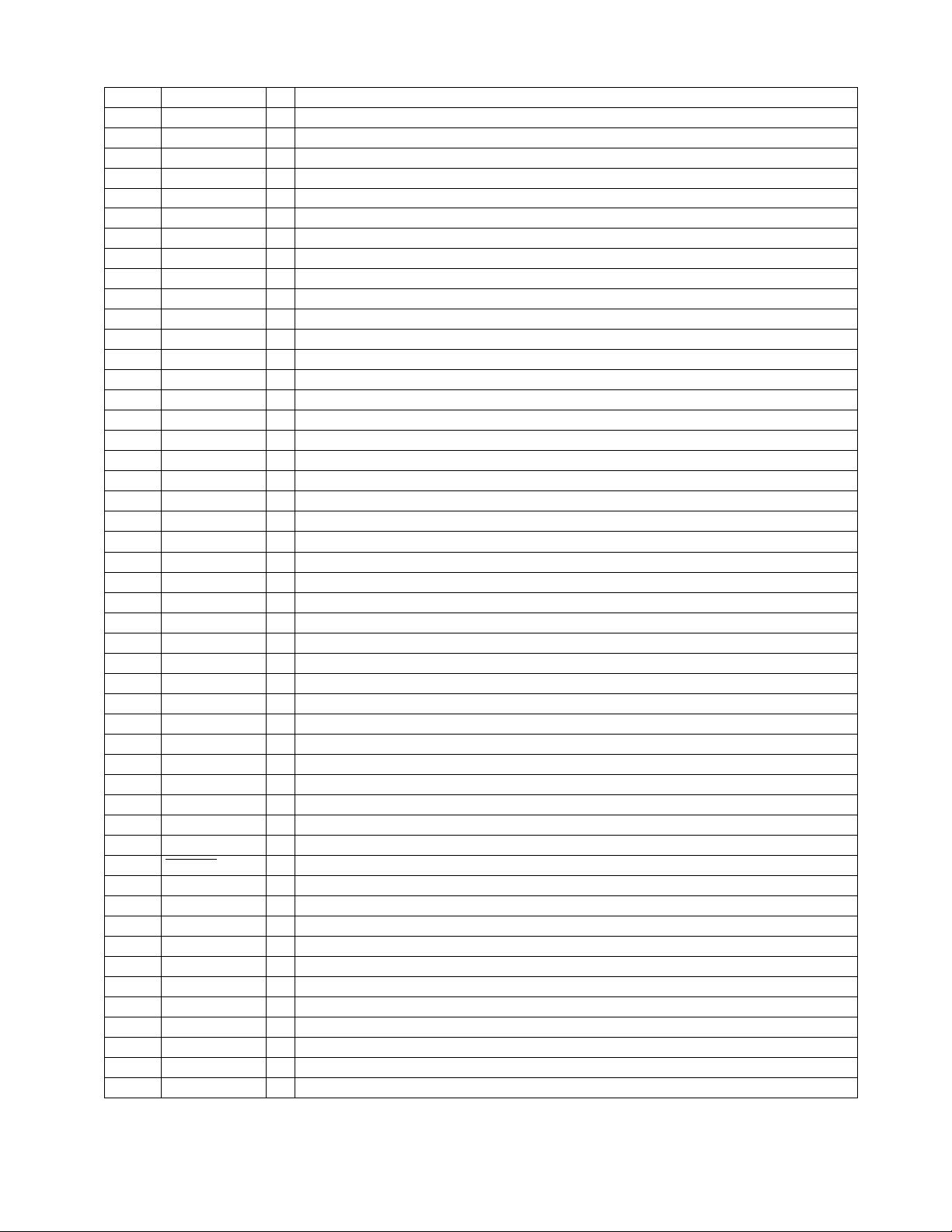

MX10FLCDPC (IC301) : MCU

1.Terminal layout

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

2. Block diagram

Vcc

Vss

REGISTER

RAM ADDR.

B

REGISTER

PSEN

ALE

EA

RST

TIMING

AND

CONTROL

P0.0-P0.7 P2.0-P2.7

PORT 0

DRIVERS

ALU

PSW

PORT1

LATCH

PORT 0

LATCH

RAM

ACC

TMP2 TMP1

REGISTER

INSTRUCTION

STACK

POINTER

T0/T1/T2

TIMERS

PORT2

DRIVERS

PORT 2

LATCH

WATCHDOG

SFRs

T3

TIMER

PORT1

LATCH

ROM

PROGRAM

REGISTER

INCREMENTER

PROGRAM

COUNTER

RC-BM5

ADDR.

BUFFER

PC

DPTR

3.Pin function

Pin No.

P1.0 to P1.7

P2.0 to P2.5,P3.4 to P3.5

P0.0 to P0.7

P3.3

P2.7

ALE

EA

P3.7,P3.1,P3.0

VDD

GND

Symbol I/O

A0 to A7

A8 to A13,A14 to A15

Q0 to Q7

CE

OE

WE

Vpp

MS2 to MS0

VDD

GND

osc

XTAL2XTAL1

PORT1

DRIVERS

DRIVERS

P3.0-P3.7P1.0-P1.7

Function

I

Input low order address bits

I

Input high order address bits

I/O

Data input/output

I

Chip enable input

I/O

Output enable input

I

Write enable input

-

Program supply voltage, 12.5-13volts

-

Flash mode selection

-

Power supply voltage (+5V)

-

Ground pin

PORT1

1-25

Page 26

RC-BM5

PT2314 (IC801) : 4ch input audio processor

1. Terminal layout

1 28

2

3

4

6

7

8

9

10

11

12

13

14

2. Block diagram

LOUT

LIN

LOUD_L

BOUT_L

BIN_L

27

26

25

245

23

22

21

20

19

18

17

16

15

LIN1

LIN2

LIN3

LIN4

RIN4

RIN3

RIN2

RIN1

LIN1

LIN2

LIN3

LIN4

RIN4

RIN3

RIN2

RIN1

Supply

Volume &

Loudness

Volume&

Loudness

RB

Bass Treble

Serial Bus Decoder & Latches

Bass Treble

RB

TREBLE_L

Speaker

ATT

OUT_L

CLK

DATA

DGND

OUT_R

Speaker

ATT

Mute

Mute

VDD

REF

AGND

ROUT

RIN

LOUD_R

BOUT_R

3. Pin function

Pin No. Symbol I/O Function

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

VDD

AGND

TREB_L

TREB_R

RIN

ROUT

LOUD_R

RIN4

RIN3

RIN2

RIN1

LOUD_L

LIN4

LIN3

LIN2

LIN1

LIN

LOUT

BIN_L

BOUT_L

BIN_R

BOUT_R

OUT_R

OUT_L

DGND

DATA

CLK

REF

-

Supply input voltage

-

Analog ground

I

Left channel input for treble controller

I

Right channel input for treble controller

I

Audio processor right channel input

O

Gain output and input selector for right channel

I

Right channel loudness input

I

Right channel input 4

I

Right channel input 3

I

Right channel input 2

I

Right channel input 1

I

Left channel loudness input

I

Left channel input 4

I

Left channel input 3

I

Left channel input 2

I

Left channel input 1

I

Audio processor left channel input

O

Gain output and input selector for left channel

I

Left channel input for bass controller

O

Left channel output for bass controller

I

Right channel input for bass controller

O

Right channel output for bass controller

O

Right speaker output

O

Left speaker output

-

Digital ground

I

Control data input

I

Clock input for serial data transmission

-

Analog reference voltage (1/2 VDD)

BIN_R

TREBLE_R

1-26

Page 27

AS4C256KEO (IC701) : DRAM

1. Termianl layout

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

2. Block diagram

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

WE

RAS

CASL

CASH

A0

A1

A2

A3

A4

A5

A6

A7

A8

CONTROL

LOGIC

CLOCK

GENERATOR

COLUMN

ADDRESS

BUFFER

REFRESH

CONTROLER

REFRESH

COUNTER

ROW.

ADDRESS

BUFFERS<9>

ROW

DECODER

512

COLUMN

DECODER

512

SENSE AMPLIFIERS

I/O GATING

512 X 16

512 x 512 x 16

MEMORY

ARRAY

DATA-IN

BUFFER

DATA-OUT

BUFFER

OE

IO0

.

IO15

RC-BM5

3. Pin function

Pin No. Symbol Function

1

2 to 5

6

7 to 10

11,12

13

14

15

16 to 19

20

21

22 to 26

27

28

29

30

31 to 34

35

36 to 39

40

VCC

I/O0 to I/O3

Vcc

I/O4 to I/O7

NC

WE

RAS

NC

A0 to A3

Vcc

GND

A4 to A8

OE

UCAS

LCAS

NC

I/O8 to I/O11

GND

I/O12 to I/O15

GND

I/O

Power (5V 0.5V)

Input/output

I/O

Power (5V 0.5V)

Input/output

I/O

Not connect

Read/write control

Row address strobe

Not connect

Address inputs

I

Power (5V 0.5V)

Ground

Address inputs

I

Output enable

O

Column address strobe,upper byte

Column address strobe,lower byte

Not connect

Input/output

I/O

Ground

Input/output

I/O

Ground

-

V

BB

GENERATOR

V

CC

V

SS

1-27

Page 28

RC-BM5

LS188 (IC703) : VCD decoder

1. Terminal layout 2. Block diagram

102 65

103

128

1 38

3. Pin function

Pin No.

1 to 3,22

4 to 11

12 to15

16

17,18,20,21

19

23,24

25

26

27

28

29

30

31

32

33

34

35

36

37 to 42

43

44,45

46

47

48

49

50

51

52 to 55

56

57,58

59

60,61

EMI_A_9 to EMI_A_12

EMI_D_7 to EMI_D_0

EMI_A_0 to EMI_A_3

VDD_IO_00

EMI_A_4 to EMI_A_7

VSS_IO_00

EMI_A_15 to EMI_A_16

EMI_A_18

I2C_CLK

I2C_DAT

VSS_OSC_0

XTLCLK_I

XTLCLK_O

VDD_OSC_0

TEST_H

RESET_L

HSYNC_L

VSYNC_L

CLK27_O

VDAT_7 to VDAT_2

VSS_CORE_00

VDAT_1 to VDAT_0

VDD_CORE_00

AUD_XCK

AUD_BCK

AUD_LRCK

AUD_DOUT

AUD_DIN

GPIO_23 to GPIO_20

VDD_IO_10

GPIO_19,GPIO_18

VSS_CORE_10

GPIO_17,GPIO_16

DRAM

64

ROM/SRAM

Panel and

keypad

39

Symbol Function

Host

I/O

O

I

O

-

O

O

O

O

-

-

I

O

-

I

I

I

I

O

O

-

O

-

O

O

O

I

-

-

-

-

-

DRAM

Interface

EMI

Interface

Prog.I/O

Interface

CD

Host/CD

Interface

RISC

Processor

DSP

Core

EMI address bus

EMI data bus

EMI address bus

+3.3V

EMI address bus

+3.3V

EMI address bus

EMI address bus

I2C clock

I2C data

GND

Crystal input

Crystal output

+3.3V

Test

Hardware reset

Horizontal sync

Vertical sync

CLK 27MHz output

Luminance output

GND

Luminance output

+2.5V

External audio clock

Audio bit clock

Audio left/right clock

Audio data output

Audio data input

Programmable I/O

+3.3V

Programmable I/O

GND

Programmable I/O

Video

Processor

On Screen

Display

Video

Decoder

Audio

Decoder

Audio

Interface

Register

Bank

NTSC/PAL

Encoder

Audio

DAC

Audio

ADC

1-28

Page 29

RC-BM5

Pin No.

62

63,64

65

66 to 79

80

81

82

83

84

85

86

87

88

89

90,91

92

93

94

95

96

97

98

99

100

101

102

103,104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119,120

121

122,123

124

125

126

127

128

Symbol FunctionI/O

VDD_CORE_10

GPIO_15,GPIO_14

VSS_IO_10

GPIO_13 to GPIO_0

IR_IN

CD_DATA

CD_LRCK

CD_BCK

CD_C2P0

DR_D_0

DR_D_15

DR_D_1

DR_D_14

VDD_IO_20

DR_D_2,DR_D_13

VSS_IO_20

DR_D_3

DR_D_12

DR_D_4

DR_D_11

DR_D_5

DR_D_10

VSS_PLL_0

VDD_PLL_0

DR_D_6

DR_D_9

DR_D_7,DR_D_8

VSS_CORE_20

LCAS_L

DR_WE_L

VDD_IO_30

UCAS_L

URAS_L

VDD_CORE_20

LRAS_L

DR_A_8

DR_A_0

DR_A_7

DR_A_1

DR_A_6

VSS_IO_30

DR_A_2,DR_A_5

VSS_CORE_30

DR_A_3,DR_A_4

VDD_CORE_30

EMI_A_17

EMI_A_14

EMI_A_13

EMI_A_8

-

+2.5V

-

Programmable I/O

-

GND

-

Programmable I/O

I

IR input

I

CD serial data

I

CD left/right clock

I

CD bit clock

I

CD data error flag

-

DRAM data bus

-

DRAM data bus

-

DRAM data bus

-

DRAM data bus

-

+2.5V

-

DRAM data bus

-

GND

-

DRAM data bus

-

DRAM data bus

-

DRAM data bus

-

DRAM data bus

-

DRAM data bus

-

DRAM data bus

-

GND

-

+2.5V

-

DRAM data bus

-

DRAM data bus

-

DRAM data bus

-

GND

O

Lower column address strobe

O

Memory write enable

-

+3.3V

O

Upper column address strobe

O

Upper row address strobe

-

+2.5V

O

Lower row address strobe

O

DRAM address bus

O

DRAM address bus

O

DRAM address bus

O

DRAM address bus

O

DRAM address bus

-

GND

O

DRAM address bus

-

GND

O

DRAM address bus

-

+2.5V

O

EMI address bus

O

EMI address bus

O

EMI address bus

O

EMI address bus

1-29

Page 30

RC-BM5

BA5417 (IC201) : Dual power amplifier

1. Terminal layout & Block diagram 2. Pin function

Pin No. Symbol I/O Function

1

T.S.D.

30K

30K

2

3

4

5

RF2

30K

GND1

Pre

Pre

PRE GND1

PRE GND2

GND2

6

7

8

9

30K

BS

ST.BY

GND

Power

ST.BY

45

FILTERBS

FILTER

RF1

IN2

45

IN1

Vcc

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

N.C.

BS

OUT1

Vcc

OUT2BSPOWER GND

10

11

12

13

14

15

NJM7805FA (IC505) : Regulator

1. Terminal layout

2. Block diagram

1

INPUT

NC

BS

OUT1

VCC

OUT2

BS

GND

ST.BY

FILTER

RF1

IN2

IN1

RF2

PRE GND1

PRE GND2

-

Not connect

-

BS

O

Output terminal

O

Power supply

O

Output terminal

O

BS

O

Power GND

I

ST.BY

I

Filter

-

RF1

-

Input terminal

-

Input terminal

-

RF2

I/O

PRE GND

O

PRE GND

Q1

2

OUTPUT

THERMAL SHUTDOWN

1.INPUT

2.OUTPUT

3.GND

BANDGAP REFERENCE

123

RPM6938-V4 (IC402) : Remote control receiver

1. Block diagram

I/V

conversion

PD

AMP

for

trimming circuit

magnetic shield

BPF

AGC

Vcc

Comp

Detector

22k

ohm

3

1

2

OVER VOLTAGE PROTECTION

SOA PROTECTION

SHORT CIRCUIT

PROTECTION

VDD

OUT

GND

R1

R2

3

GND

1-30

Page 31

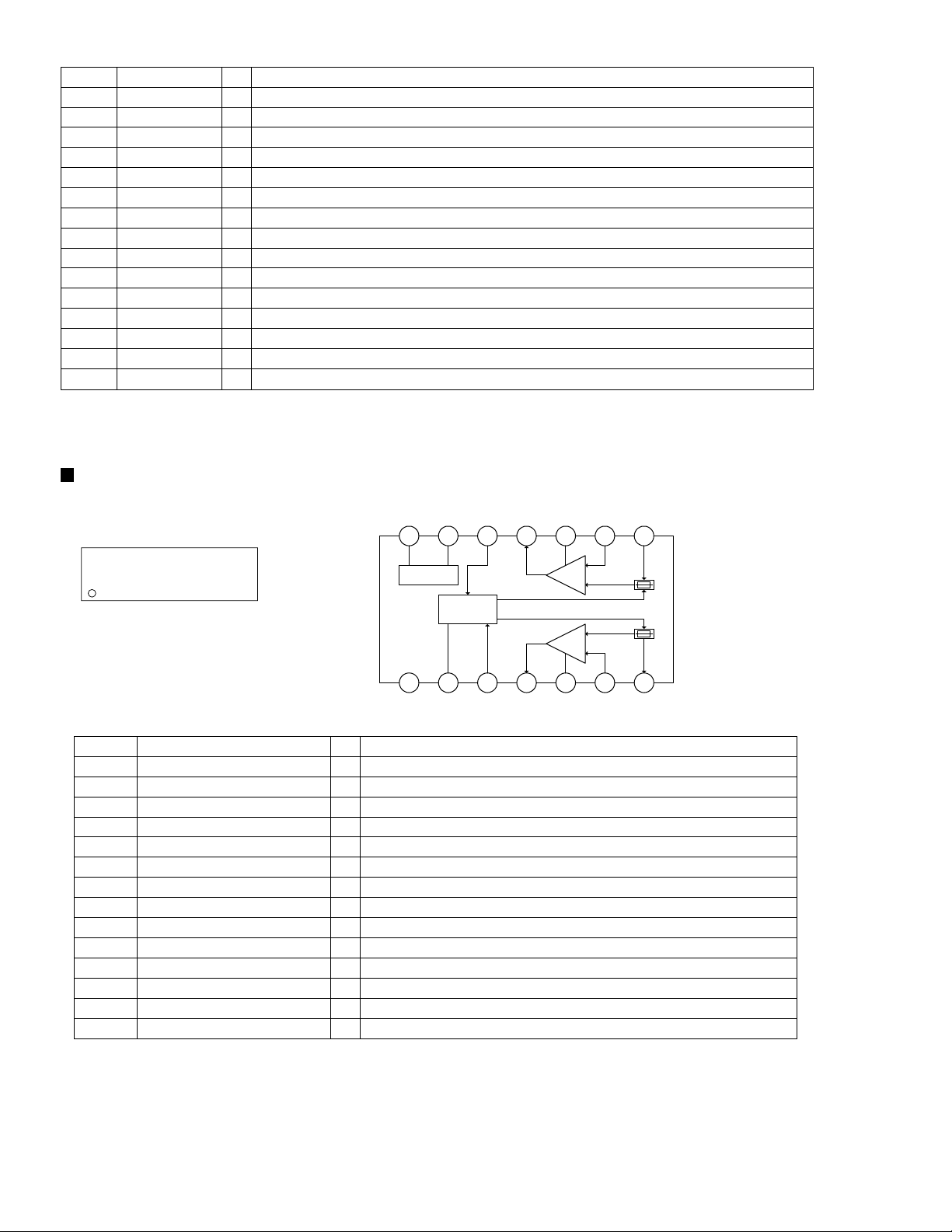

PT6553 (IC401) : LCD driver with key input function

1. Terminal layout

KO5

KO4

KO3

KO2/SG42

KO1/SG41

COM3

COM2

COM1

SG40

SG39

SG38

SG37

SG36

SG35

SG34

SG33

KO6

K11

K12

K13

K14

K15

TEST

VDD

VDD1

VDD2

VSS

OSC

CLK

DO

CE

484746454443424140393837363534

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

DI

33

SG32

32

SG31

31

SG30

30

SG29

29

SG28

28

SG27

27

SG26

26

SG25

25

SG24

24

SG23

23

SG22

22

SG21

21

SG20

20

SG19

19

SG18

18

SG17

17

2. Block diagram

COM1

COM2

COM3

DO

CE

DI

COMMON

DRIVER

CLOCK

GENERATOR

INTERFACE

VDET

TEST

OSC

CLK

VDD

VDD1

VDD2

VSS

SG40

SG5

SG4/P4

SG3/P3

SEGMENT DRIVER & LATCH

SHIFT REGISTER

CONTROL

REGISTER

KEY BUFFER

KEY SCAN

SG2/P2

RC-BM5

SG1/P1

1

2

3456789

P1/SG1

P2/SG2

P3/SG3

P4/SG4

SG5

SG6

SG7

10111213141516

SG8

SG9

SG10

SG11

SG12

SG13

SG14

SG15

SG16

3. Pin function

Pin No. Symbol I/O Function

1 to 4

SG1/P1 to SG4/P4

O

Segment output general purpose output pins under serial data control

these pins may be used a general purpose output parts.

5 to 40

41,42,43

44

45

46 to 49

50 to 54

55

56

57

58

59

60

61

62

63

64

SG5 to SG40

COM1,COM2,COM3

KO1/SG41

KO2/SG42

KO3 to KO6

K11 to K15

Test

VDD

VDD1

VDD2

VSS

OSC

DO

CE

CLK

DI

O

Segment output pins

O

Common driver output pins

O

Key scan output segment output pin

O

Key scan output segment output pin

O

Key scan output pins

I

Key scan input pins

I

Test pin

-

Power supply

-

Power supply

-

Power supply

-

Ground

I/O

Oscillator pin

O

Data output pin

I

Chip enable pin

I

Synchronization clock input pin

I

Din transistor input pin

K15

K11

K05

K03

SG42/KO2

SG41/KO1

1-31

Page 32

RC-BM5

ST24C01 (IC302) : Serial access 1K(128x8) EEPROM

1. Terminal layout

A0

A1

A2

V

SS

1

2

3

4

V

8

CC

7

WC

6

SCL

5

SDA

2. Pin function

Pin No. Symbol I/O Function

1

2

3

4

5

6

7

8

A0

A1

A2

Vss

SDA

SCL

WC

VCC

TDA1308 (IC704) : Class AB stereo headphone driver

1. Terminal layout

I

Chip enable input

I

Chip enable input

I

Chip enable input

-

Ground

I/O

Serial data adress input/output

-

Serial clock

-

Write control (W version)

-

Supply voltage

3. Pin function2. Block diagram

OUTA

INA(neg)

INA(pos)

V

SS

1

2

3

4

TDA 1308

8

7

6

5

V

DD

OUTB

INB(neg)

INB(pos)

OUTA

INA(neg)

INA(pos)

V

SS

1

2

3

4

8

7

6

5

V

DD

OUTB

INB(neg)

INB(pos)

TDA7073 (IC502/IC503) : Dual BTL power driver

1. Terminal layout

IN1-

IN1+

n.c.

n.c.

Vp

IN2+

IN2-

n.c.

1

2

3

4

5

6

7

8

OUT1+

16

n.c.

15

GND1

14

OUT1-

13

OUT2-

12

n.c.

11

GND2

10

OUT2+

9

1

2

3

4

5

6

7

8

DISC MOTOR

VDD

SLIDE MOTOR

16

15

14

13

12

11

10

9

Pin No. Symbol I/O Function

OUTA

1

2

3

4

5

6

7

8

INA(neg)

INA(pos)

Vss

INB(pos)

INB(neg)

OUTB

VDD

Output A

O

Inverting input A

I

Non-inverting input A

I

Negative supply

Non-inverting input B

I

Inverting input B

I

Output B

O

Positive supply

-

3. Pin function2. Block diagram

Pin No. Symbol I/O Function

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

IN1IN1+

n.c.

n.c.

Vp

IN2+

IN2n.c.

OUT2+

GND2

n.c.

OUT2OUT1GND1

n.c.

OUT1+

Negative input 1

I

Positive input 1

I

Not connect

Not connect

Positive supply voltage

Positive input 2

I

Negative input 2

I

Not connect

Positive output 2

O

Ground 2

Not connect

Negative output 2

O

Negative output 1

O

Ground 1

Not connect

Positive output 1

O

1-32

Page 33

TZA1024 (IC504) : Data amplifier and laser supply

1. Terminal Layout

2. Pin function

RC-BM5

LD

1

V

PWRON

DD(L)

CFIL

MON

DIN

GND

2

3

4

5

6

7

TZA1024

3. Block diagram

DIN

11

5

CDRW

14

RGADJ

V

13

DD

12

EQSEL

11

CDRW

10

RFEQO

9

RFFB

8

CMFB

V

DD

13

1

4

Pin No. Symbol I/O Function

LD

1

2

3

4

5

6

7

8

9

10

11

12

13

14

V

DD(L)

CFIL

MON

DIN

GND

PWRON

CMFB

RFFB

RFEQO

CDRW

EQSEL

V

DD

RGADJ

V

DD

Current output to laser diode

O

Laser supply voltage

External filter capacitor

Laser monitor diode input

I

Central diode input

I

Ground

Power-on select input

I

Common mode feedback voltage input

I

External RF feedback resistor

RF amplifier output

O

Gain select input for CD-A/V, CD-R/W

I

Equalizer/speed select input (n=1,2 or 4)

I

Supply voltage

External laser supply gain adjust resistor

-

12

EQSEL

9

RFFB

10

RFEQO

MON

2

250

kHz

V/I

4

GND

V

GAP

(1)

V

DD(L)

V/I

V

26

DD

14

MGR517

8

CMFB

1

LD

RGADJ

3

CFIL

7

PWRON

1-33

Page 34

RC-BM5

TEA5757(IC101): Self tuner radio (STR)

1. Terminal layout

2. Block diagram

DATA

STAB(A)

STAB(B)

V

CC1

V

DDD

XTAL

DGND

P1

P0

43

42

28

27

29

38

34

7

23

1

25

26

31

30

2

FM-RFI

RFGND

BUS-CLOCK

WRITE-ENABLE

V

V

RIPPLE

AM-RFI

RIPPLE

1

2

AM-RFI

RFGND

FMOSC

V

CC1

TUNE

VCO

AFO

MPXI

3

3

4

5

6

7

8

9

10

11

OSCILLATOR

OSCILLATOR

FM-FRO

AM-OSC

FM-RFO FMOSC

FM

FRONT-END

STABILIZER

PRESCALER

MULTIPLEXER

CRYSTAL

OSCILLATOR

AM

FRONT-END

AGC

FM-RFI

44

43

12

13

LFI

MUTE

5

FM

SHIFT REGISTER

LAST-STATION

MEMORY

PROGRAMMABLE

COUNTER

WINSOW

DETECTOR

AM

RF GND

AM-IFI1

42

41

14

15

AFLO

AFRO

FM-MIXER

39 37

FM

MIXER

AM

MIXER

AM-MIXER

40

TEA5757

16

PILFIL

FM-IFI1

REGISTER

SEQUENTIAL

FM

AM

STAB(A)

FM-MIXER

V

39

38

17

18

IFGND

FMFEM

FM-IFO1

35 33

FM

IF1

STATUS

CIRCUIT

AM

IF

FM-IFI1

37

19

(n)

AFC

FM-IFI2

Up

Down

Level

AGC

AM-IFI/O2

36

20

(p)

AFC

STAB(B)

FM-IFO1

V

35

34

33

32

31

30

29

28

27

26

25

24

23

21

22

FSI

CC2

V

IFGND

FMDEM

17 18

FM

IF2FMDETECTOR

AM/FM

INDICATOR

IN-LOCK

DETECTOR

CHARGE

PUMP

Hard mute

AFC

AM

DETECTOR

FM-IFI2

AFC

P1

P0

WRITE-ENABLE

DATA

BUS-CLOCK

DGND

XTAL

MO/ST

V

DDD

FSI

21

PILOT

DETECTOR

19 kHz

38 kHz

DECODER

MATRIX

Stereo Mono

SDS

level

CONVERTER

PLL

V/I

Stereo

MUTE

16

PILFIL

24

MO/ST

12

LFI

9

VCO

14

AFLO

AFRO

15

13

MUTE

19

AFC

AFC

AFC

(n)

(p)

20

32

1-34