Page 1

PC-XC350

SERVICE MANUAL

CD PORTABLE COMPONEMT SYSTEM

PC-XC350

Unit No.

SP-PCXC350

contents

Safety precaution ------------------ 1-2 Block/Wiring Diagram ----------------- 1-16

Disassembly method -------------- 1-4 Circuit Diagram ------------------------- 1-18

Adjustment method ---------------- 1-6 PCB drawing ---------------------------- 1-20

TOC read ---------------------------- 1-11 Assembly -------------------------------- 1-22

Major IC Description ---------------1-12 Packing ----------------------------------- 1-32

COPYRIGHT © 2001 VICTOR COMPANY OF JAPAN,LTD (By JCA)

Unit No.

SP-PCXC350

Area Suffix

J-----USA

C-----CANADA

Unit No.

SP-PCXC350

No. xxxxx

OCT 2001

Page 2

PC-XC350

Safety Precautions

1. This design of this product contains special hardware and many circuits and components specially for

safety purposes. For continued protection, no changes should be made ti the original design unless

authorised in writing by the manufacturer. Replacement parts must be identical to those used in the

original circuits. Services should be performed by qualified personel only.

2. Alterations of the design or circuitry of the product should not be made. Any design alterations of the

product should not be made. Any design alterations or additions will void the manufacturer's warranty

and will further relieve the manufacturer of responsibility for personal injury or property damage

resulting therefrom.

3. Many eletrical and mechanical parts in the products have special safety-related characteristics.

These characteristics are often not evident from visual inspection nor can the protection afforded by

them necessarily be obtain by using replaement components rated for higher voltage, the Parts

List of Service manual. Electrical components having such features ate identified by the shading on the

schematics and by ( ) on the parts List in the Service Manual. The use of a substitute

repalcement which does not have the same safety characteristics as the recommended replacement

parts shown in the Parts List of Service manual may create shock, fire, or other hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubing's, barriers and the like to

be separated from live parts, high temperatures parts, moving parts and/or sharp edges for the

prevention of electric shcok and fire hazard. When service is required, the original leat routing and

dress should be observed, and it should be confirmed that they have been returned to normal, after

re-assembling.

5. Leakage current check (Electrical Shock hazard testing)

After re-assembling the product, always perform an isolation check on the exposed metap Parts of the

product (antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control shafts, etc.)

to be sure the product is safe to operate without danger of electrical shock.

Do not use a line isloation transformer during this check.

Plug the AC line cord directly into the AC outlet. Using a "Leakage Current Tester", measure the

leakage current from each ecposed metal parts of the cabinet, particularly and exposed metal

part having a return path to the chassis, to a known good earth ground. Any leakage current must

not exceed 0.5mA AC (r.m.s.)

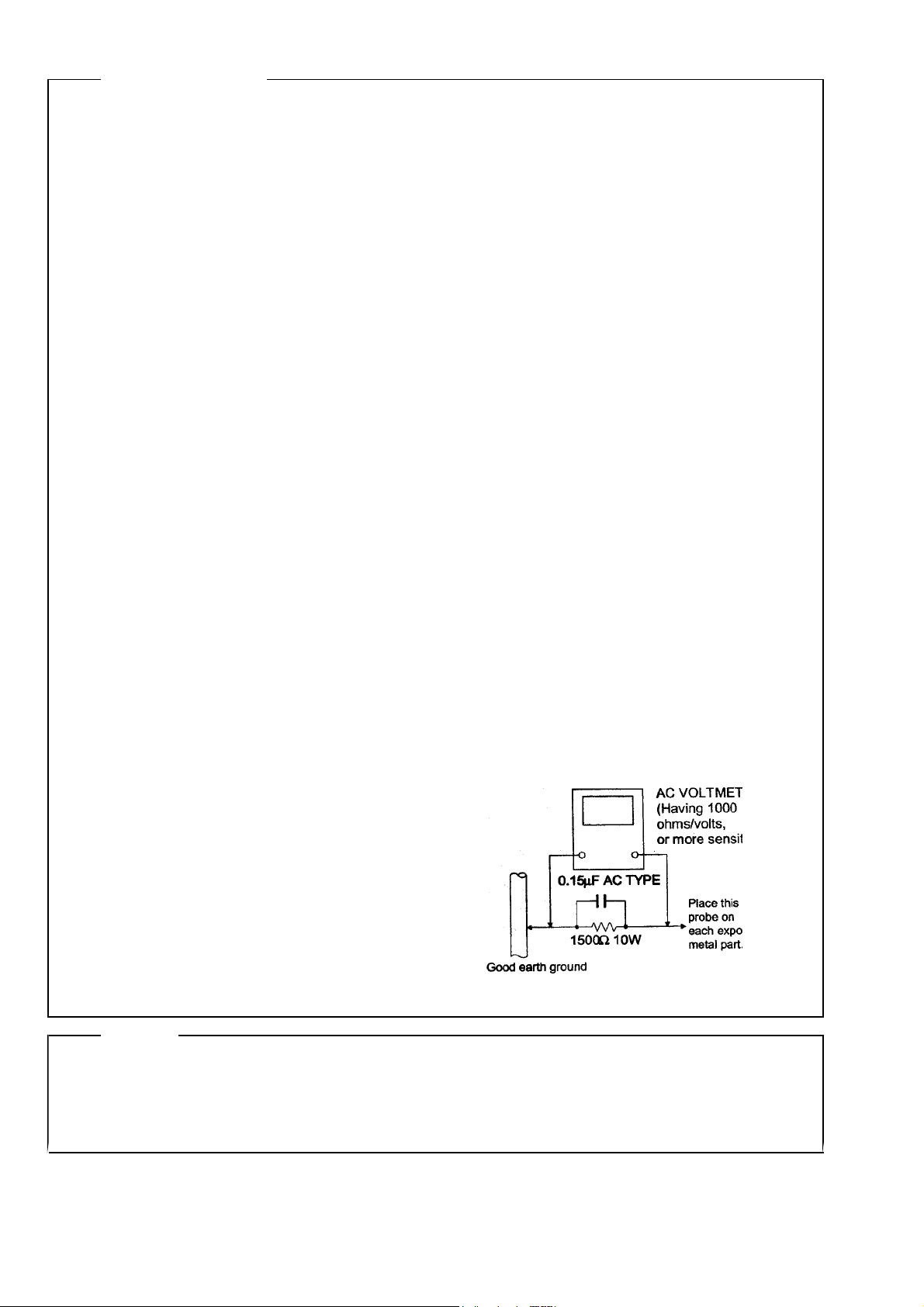

Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having, 1,000 ohms per

volt or more sensitvity in the following manner. Connect a 1,500 ohm 10W resistor paralleled by a

0.15uF AC-type capacitor between an exposed

metal part and a known good earth ground.

Measure the AC voltage across the resistor with

the AC voltmeter.

Move the resistor connection to each exposed

metal part, particularly and exposed metal part

having a return path to te chassis and

measure the AC voltage across the resistor. Now,

reverse the plug in the AC outlet and repeat

each measurement. Voltage measured Any must

not exceed 0.75 V AC (r.m.s.). This corresponds

to 0.5 mA AC (r.m.s.).

Warning

1. This equipment has been designed and manufactured to meet international safety standards.

2. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

3. repairs must be made in accordance with the relevant safety standards.

4. It is essential that safety critical components are replaced by approved parts.

5. It mains voltage selector is provided, check setting for local voltage.

CAUTION Burrs formed during moulding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of performing repair of this system.

1 - 2

Page 3

PC-XC350

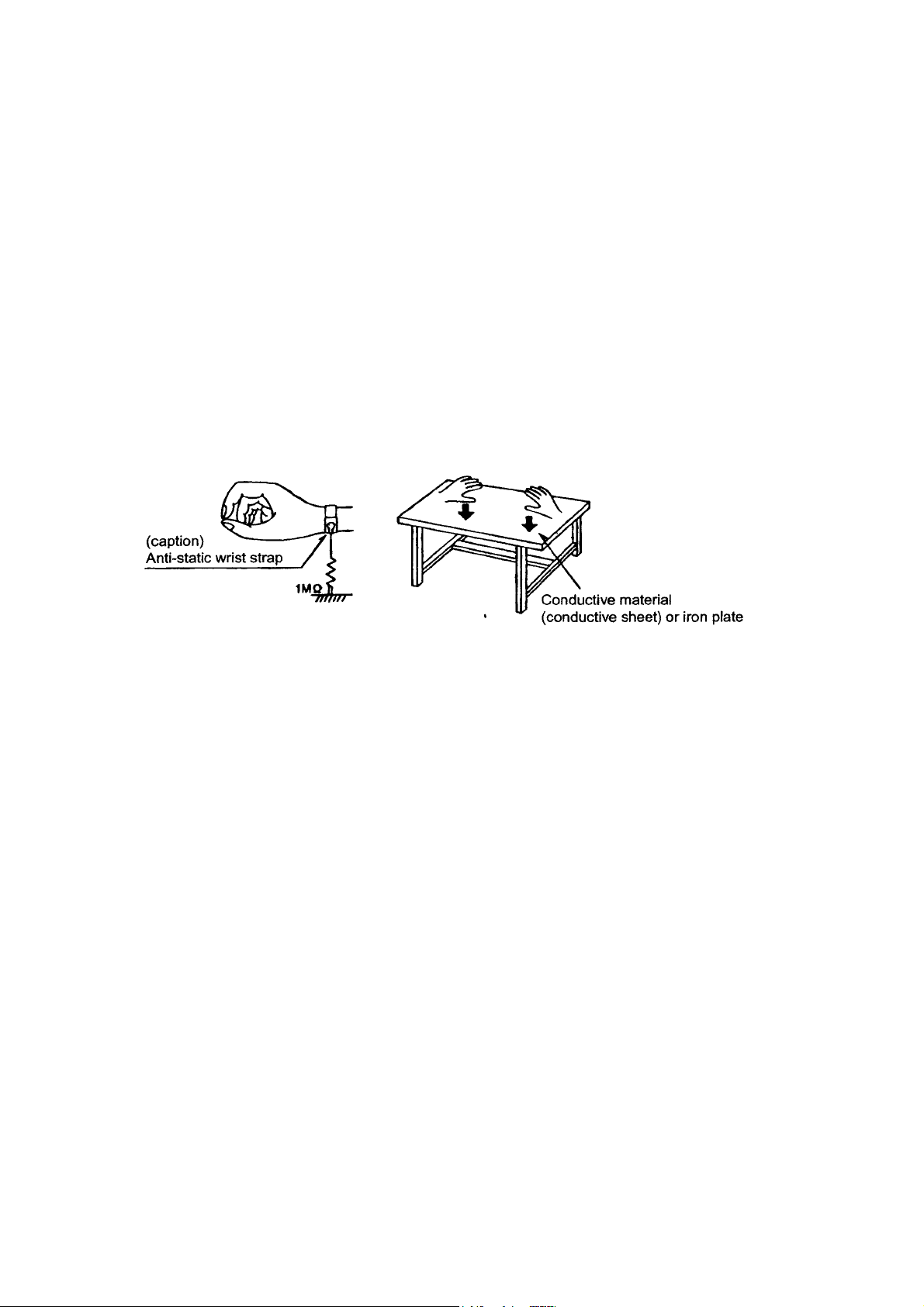

Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged,

can destroy the laser diode in the traverse unit (optical pcikup). Take care to prevent this when performing repairs.

1.1. Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devicessuch as DVD players.

Be careful to use proper grounding in the area where repairs are being performed.

1.1.1. Gound the workbench

1. Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over

it before placing the traverse unit (optical pickup) on it.

1.1.2. Ground yourself

Use an anti-static wrist starp to release and static electricity built up in your body.

1.

1.1.3. Handling the optical pcikup

1. In order to maintain quality during transport and before installation, both sides of the laser diode on the

replacement optical pickup are storted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

2. Do not use a tester to check the condition of the laserdiode in the optical pickup. The tester's internal power

source can easily destory the laser diode.

1.2. Handling the traverse unit (optical pickup)

Do not subject the traverse unit (optical pcikup) to strong shocks, as it is a sensitive, complex unit.

1.

Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific

2.

details, refer to the replacement procdeure in the text. Remove the anti-static pin when replacing the traverse

unit. Be careful not to take too long a time when attaching itto the connector.

3. Handle the flexible cable carefully as it may break when subjected to strong force.

It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not return it.

4.

1 - 3

Page 4

PC-XC350

Screw B.

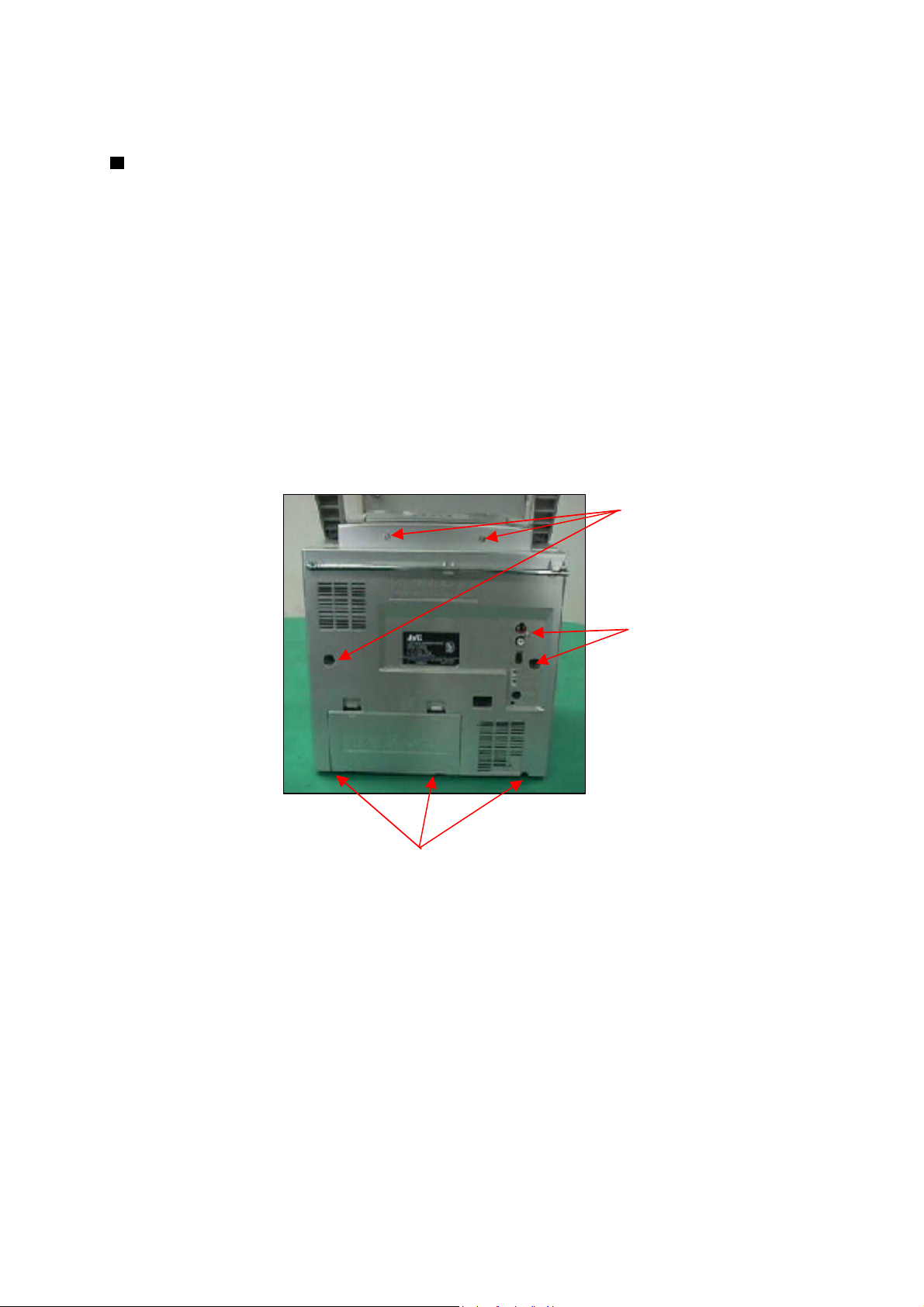

Disaeesmbly method

Removing the rear panel

1. From behind the body, remove the eight screws A

retaining the rear panel.

2. Then remove the two screws B retaining the rear panel.

3. Take out the rear panel from the body.

Note:

Be careful of the FM antenna white wire, it is connection with the tuner PCB up side.

You can directly take out from the tuner PCB.

When you re-assembly the product, plug the FM antenna white wire into the Tuner PCB's

"FM ANT" position.

Screw A.

Screw A.

1 - 4

Page 5

PC-XC350

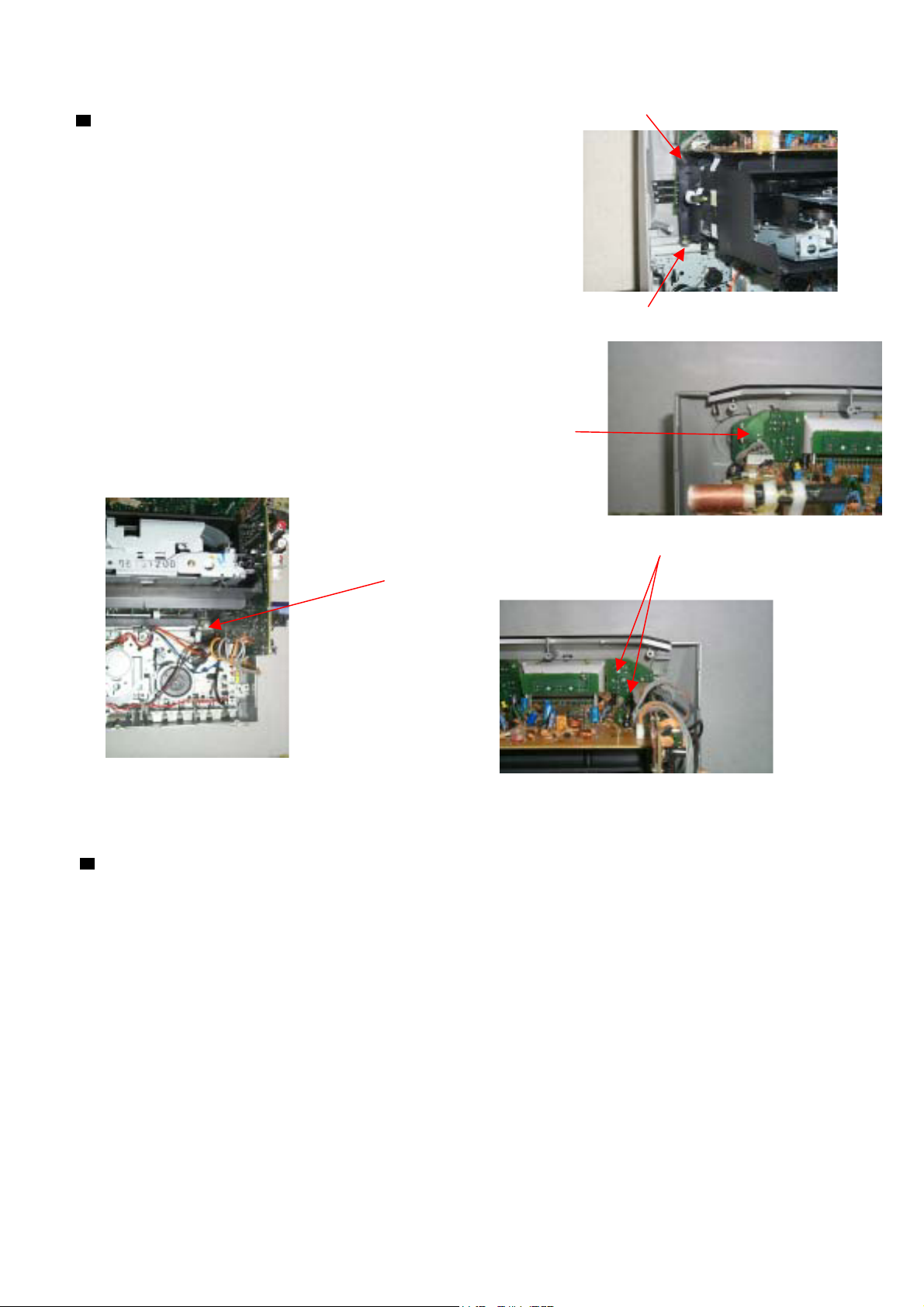

Removing the CD mechanism

1. Remove the rear panel

2. Removing the two screws E retaing the 3CD

mechanism cover.

3. Removing the crew F retaing the control PCB

left side.

4. Remove the srews G retaing on the 3CD mechanism cover

& the two screws H retaining on the control PCB

F

E

E

G

H

Removing the Main PCB

1. Remove rear panel

2. Remove the 3CD mechanism

3. Remove the four screws attaching the

main PCB.

1 - 5

Page 6

PC-XC350

Adjustment method

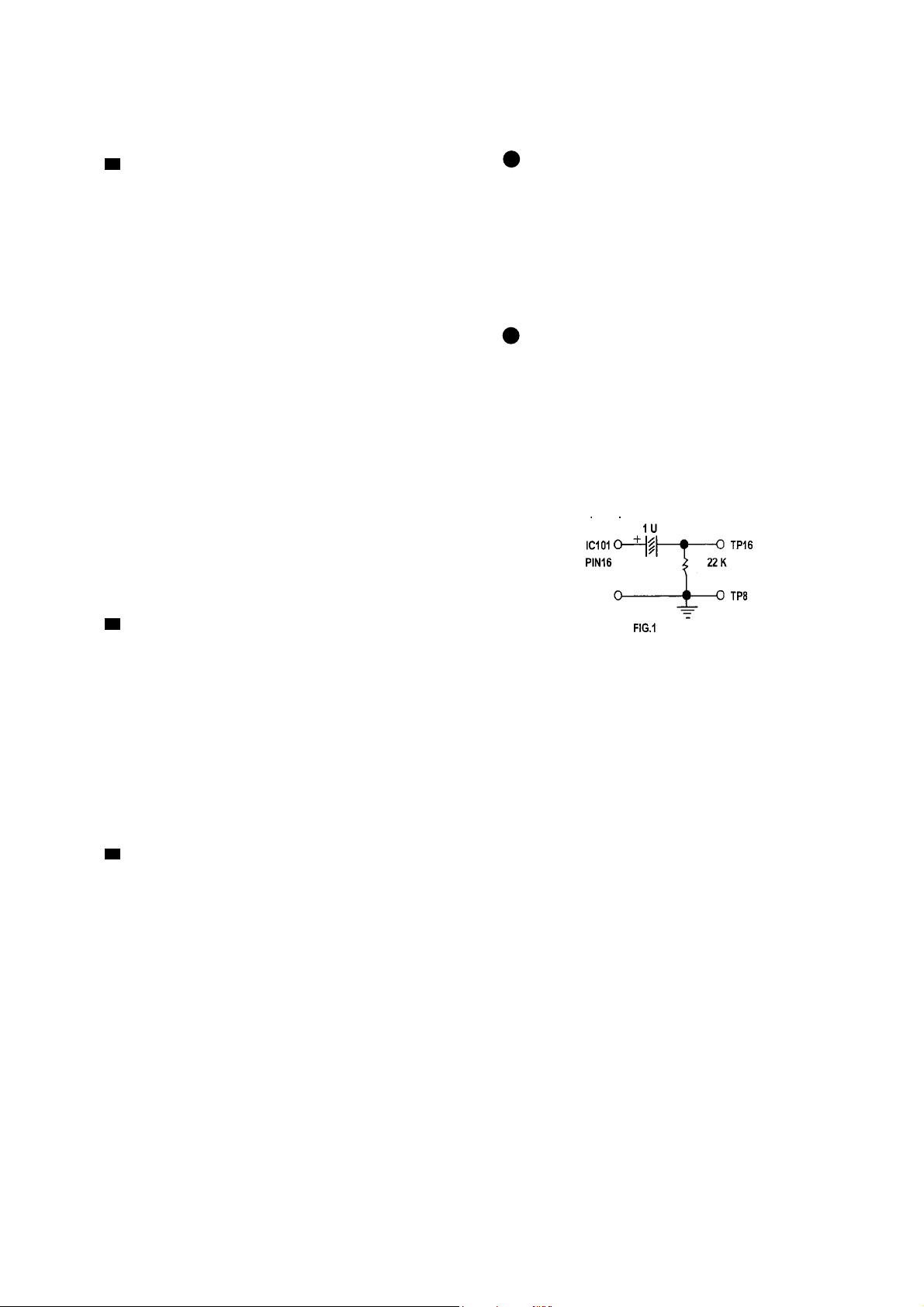

Measurement instruments required for Tuner section

adjustment

Voltage applied to tuner ----- +B:DC 5.7V

1. Low frequency oscillator VT: FM 2~5v / am 1.5~7.5v

This oscillator should have a capacity to output Reference measurement ----- 26.1mV(0.866/3

0dB to 600 at an oscillation frequency of output

50Hz-20KHz Input positions ----- AM : Standard loop antenna

FM : TP1 (hot) and TP2 (GND)

2. Electronic voltmeter

3. Distorion meter

4. Frequency counter Standard measurement position of volumett

5. Wow & flutter meter

6. Test tape Bass ---------------------- Off

TCC-112: tape speed and running unevenness (3KHz) EQ ----------------------- Flat

TCC-140: Reference level (1KHz) UP and down adjustment of volume ----- Vol : 16

TCC-182A: Head angle (8KHz), playback frequency

characteristics (1KHz) and dubbing frequency Precautions for measurement

charateristics (125Hz and 8KHz) 1. Direct connect to the IF sweeper output

side and 1 UF and 22 Kohm connect to the

7. Black tape sweeper input side. Same as FIG. 1.

TYPE I : TDK-D60

8. Torque gauge : For play and tension

FWD(CT-120m), and FF/REW(CT-F)

Measurement conditions

Power supply voltage----------AC 120V (60Hz)

Reference output----------Speaker : 0.866V/3 2. The IF sweeper output level should be made as

Headphone : 0.245V/32 low as possible within the adjusttable range.

Reference frequency and -----1KHz, AUX : 450mV 3. Since the IF sweeper is a fixed device, there is no

input level need to adjust this sweeper.

Input for confirming recording and-----CD : -10dB 4. Since a ceramic oscillator is used, there is no need

playback characteristics to perform and MIX adjustment.

Measurement output terminal-----Speaker CN301 5. Since a fixed coil is used, there is no need to

*Load resistance----------------------3 adjust the FM tracking.

6. The input and output earth systems are separated.

In case of simuitaneously measuring the voltage in

Radio Input signal both of the input and output systems with an

electronic voltmeter for two channels, therefore, the

AM frequency ----------------400Hz earth should be connected particularly carefully.

AM modulation-----------------30% 7. In the case of BTL connection amp., the minus

FM frequency -----------------1 KHz terminal of speaker is not for earthing. Therefore, be

FM frequency deviation --------22.5KHz sure not to connect any other earth terminal to this

terminal. This system is of an BTL system.

8. For connecting a dummy resistor when measuring

the output, use the wire with a greater code sze.

9. Whenever any mixed tape is used, use the band

pass filter (DV-12V)

1 - 6

Page 7

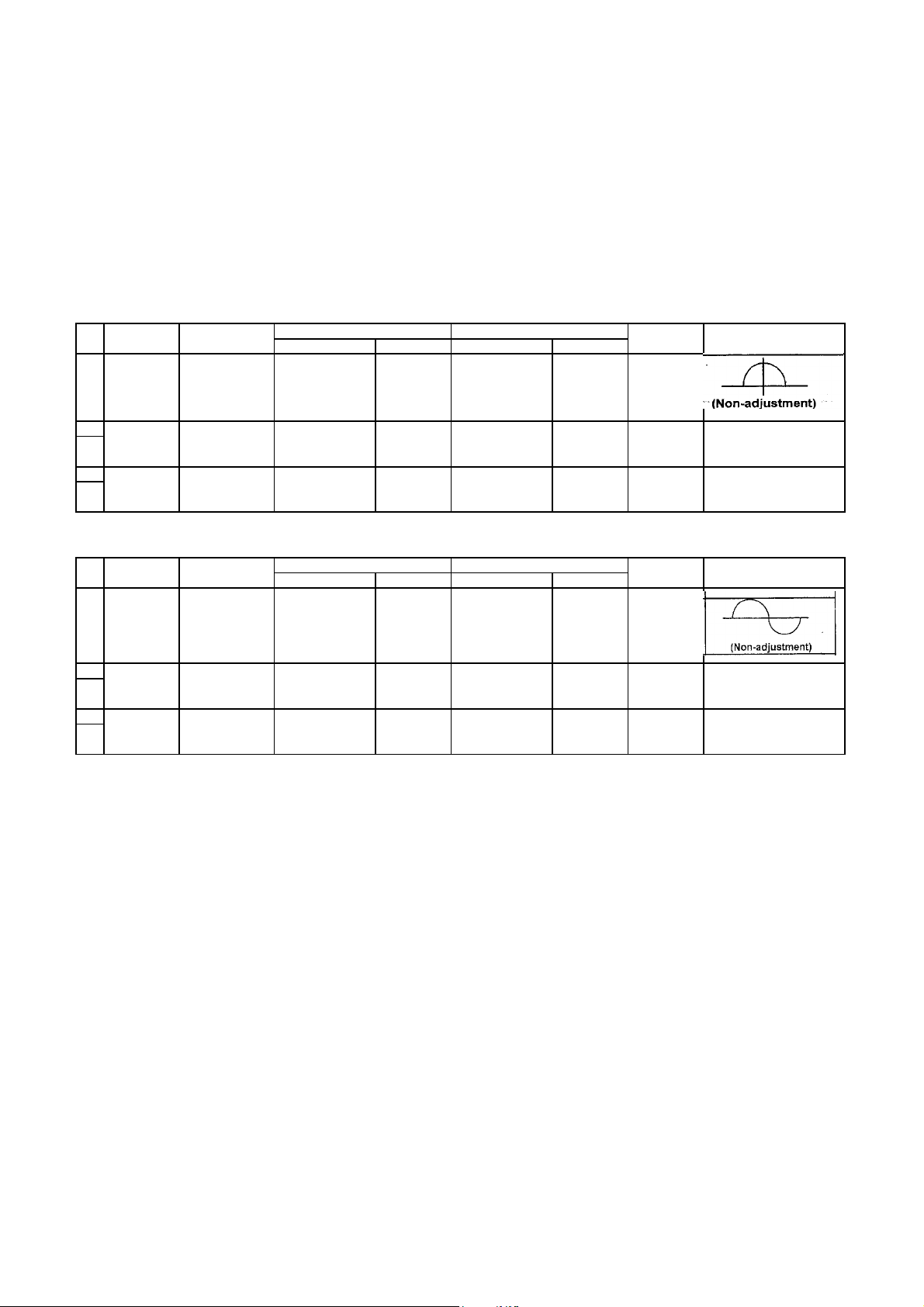

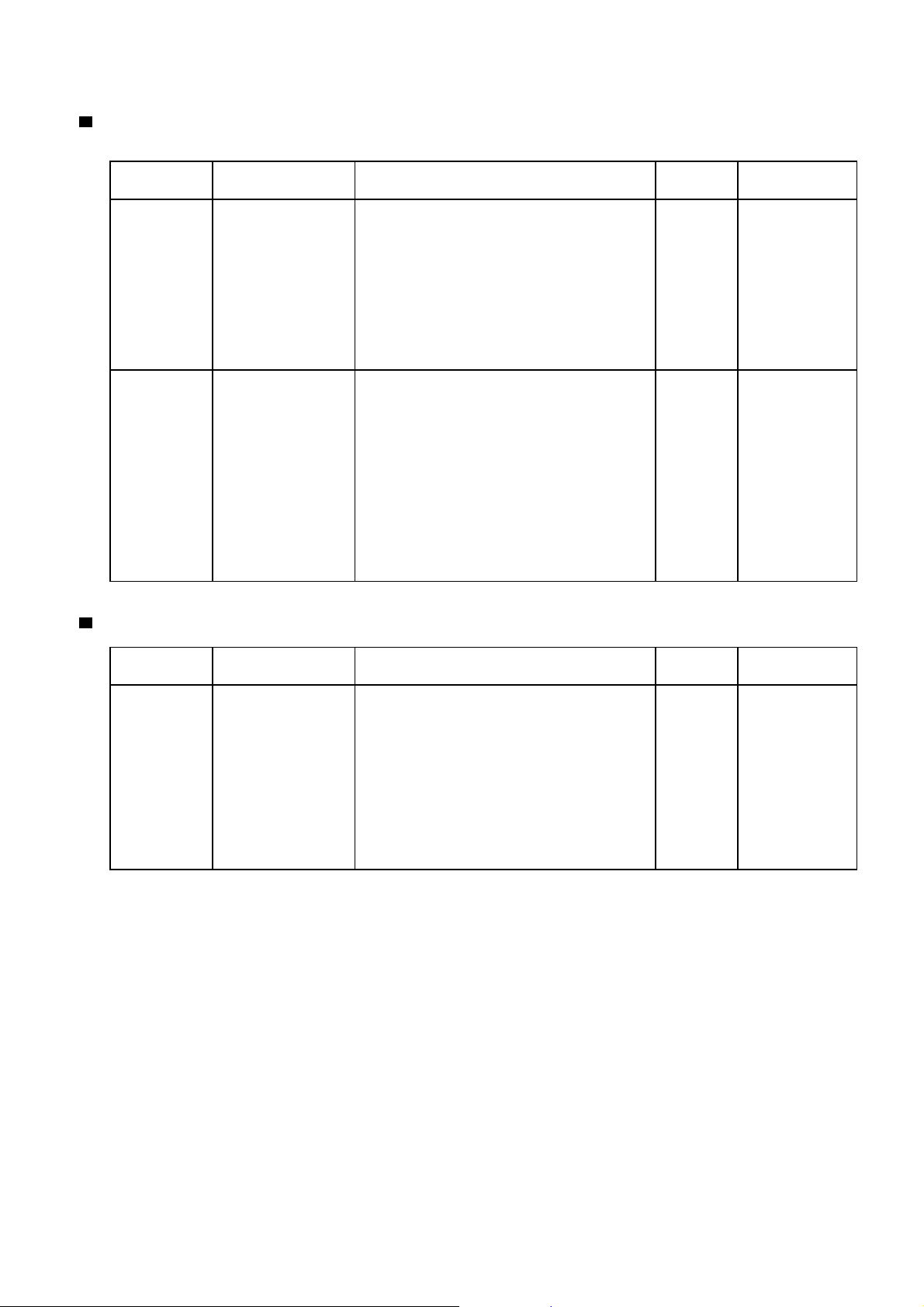

TUNER ADJUSTMENT

use a plastic screews driver for adjustments.

Adjust the intermediate frequency of AM and FM to the frequency of cermic filter.

Supply voltage: DC 12.0V

Speaker impedance: 3 OHMS

Function switch: RADIO

PC-XC350

a. AM adjustment BAND SELECT SWITCH : AM

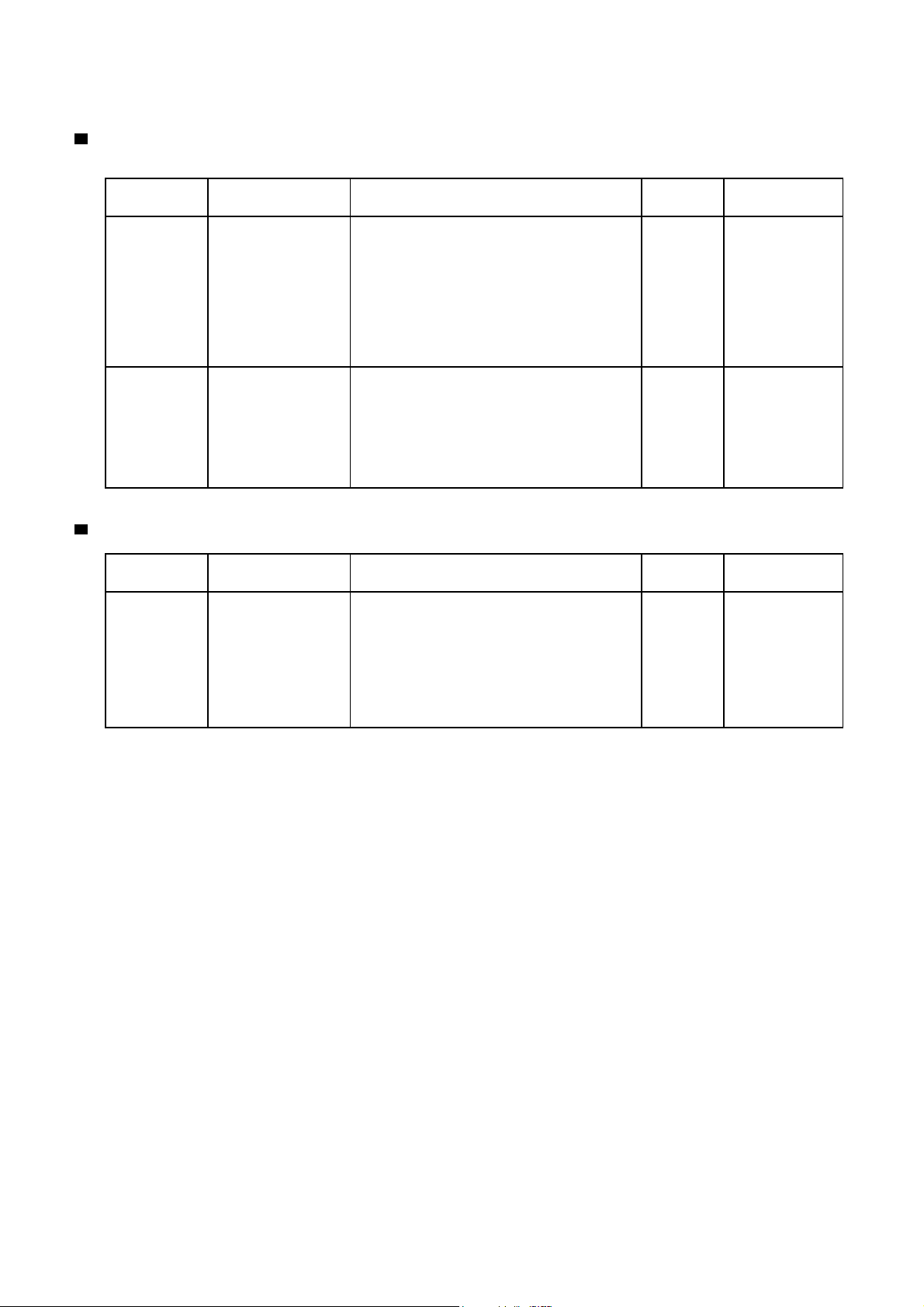

ste Adjusting Tuning Adjustment

circuit Frequency Measurement input Measurement output parts

1 IF 1000 KHz AM Sweep Loop VTVM TP16 (H) T103

(450 KHz) Generator ANT Oscilloscope TP 8 (E)

2 Tuning 530 KHz Digital TP16 (H) T102

3 Coverage 1710 KHz Voltmeter TP 8 (E)

4 Tracking 600 KHz Am signal Loop VTVM TP12 (L) MW COIL

5 1500 KHz Generator ANT Oscilloscope TP11 (R) CT102

b. FM Adjustment BAND SELECT SWITCH : FM FM Dummy Antenna : 75 ohm unbalance

ste Adjusting Tuning Adjustment

circuit Frequency Measurement input Measurement output parts

1 IF FM Sweep TP4 (H) VTVM TP16 (H)

(10.7 MHz) 98.0 MHz Generator TP8 (E) Oscilloscope TP8(E) T104

2 Tuning 87.5 MHz Digital TP16 (H)

3 Coversage 108 MHz -- -- Voltmeter TP8(E) L104

4 Tracking 90.0 MHz FM Signal FM ANT VTVM TP12 (L) L103

5 106.0 MHz Generator TP1(E) Oscilloscope TP11 (R)

Input Connection Output Connection VTVM Oscilloscope

Output ConnectionInput Connection VTVM Oscilloscope

1.2+/-0.05V

Confirm 7.0+/-0.5V

Maximum

Confirm 1.4+/-0.1V

5.6+/-0.5V

Confirm with being

near by effective

sensitvity

1 - 7

Page 8

PC-XC350

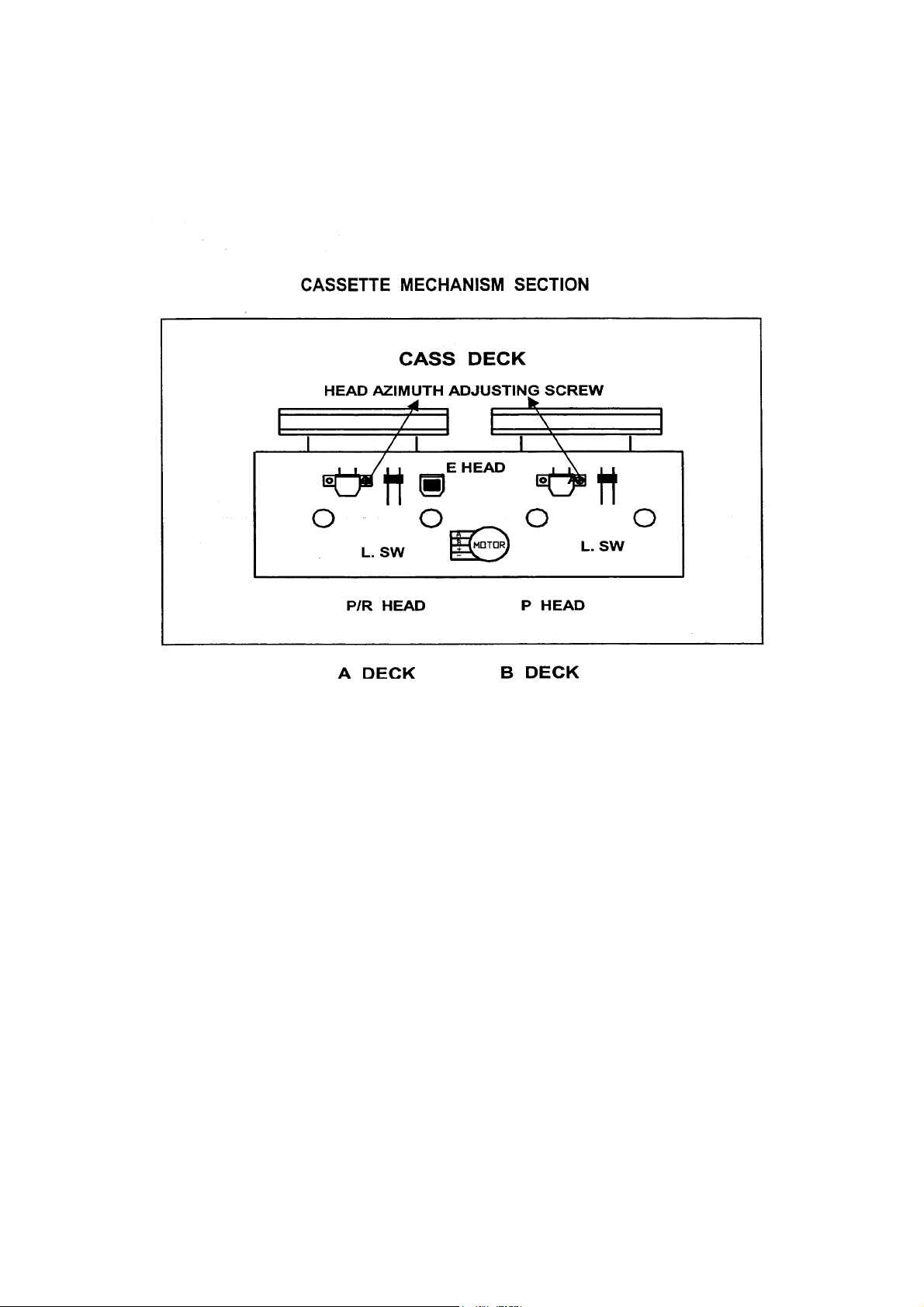

ARRANGEMENT OF ADJUSTMENTS POSITION

1 - 8

Page 9

PC-XC350

Tape recorder section

Items Measurement Measurement method Standard Adjusting

conditions Values position

Confirmation Test tape 1 Playback the test tape TCC-182A (8KHz) Maximum Adjust the head

of head angle : TCC-182A(8KHz) 2 With the recording & playback mechanism, output azimuth screw

Confirmation Test tape Adjust VR401 so that the frequency counter Tape speed VR401

of tape speed : TCC-112 (3KHz) reading becomes 3,010Hz +/-15Hz when of deck

Measurement output adjust the head azimuth screw so that the only

terminal left and right output leavers become

: Speaker terminal maximum, After adjustment, lock the head

Speaker R/L azimuth at least by half turn.

(Load resistance: 3

: Headphone terminal

playing back the test tape TCC-112 (3KHz) with :3,010Hz

playback and recording mechanism after +/-15Hz

Measurement output ending forward winding of the tape.

terminal

: Headphone terminal

Referemce Values for Confirmation Items

Items Measurement

conditions Values position

Wow & flutter Test tape When the test tape TCC-112 (3KHz) has been 0.25% or

:TCC-112(3KHz) played back with the recording and playback less

mechanism at the beginning of forward (WRMS)

winding, the frequency counter reading of

Measurement output wow & flutter should be 0.25% or less

terminal (WRMS).

:Headphone terminal

Measurement method

Standard Adjusting

1 - 9

Page 10

PC-XC350

Electrical Performance

Items Measurement Measurement method Standard Adjusting

conditions Values position

Adjustment of Mode: Playback 1 With the recording and playback

recording blas mode mechanism, load the test tapes TDK-D60

current Recording mode TDK-D60, and set the mechanism to the 4.5 u A

(Reference Test tape recording and pausing condition in advance. +/-0.5u A

Value) TDK-D60

Adjustment of Reference frequency 1 with the recording and playback Output

recording and :1KHz and 8KHz mechanism, load the test tapes (TDK-D60) deviation

palyback (REF.:-10dB) and set the mechanism to the between

frequency Test tape recording and pausing condition in 1KHz and

characteristics TDK-D60 advance 8KHz

Measurement output 2 After connecting 100 in series to the

terminal recorder head, measure the blas current

: Both recording and with a valve voltmeter at both of the

headphone terminals terminals

Measurement input 2 While repetitively inputting the reference :-1dB +/-2dB

terminal frequency signal of 1KHz and 8KHz from

: OSC IN OSC IN, record andplayback the tape.

3 While recording and playback the test tape

Lch and Rch so that the output

deviation between 1KHz and 8KHz from

-1dB +/-2dB

Reference Values for Electrical Function Confirmation Items

Items Measurement Measurement method Standard Adjusting

conditions Values position

Recording Playback 1 While changing over t and form BIAS 1 64KHz T201

blas Test tape and 2, confirm that the frequency is +/-6KHz

frequency TDK-D60 changed.

Measurement 2 With the recording and playback

terminal : BIAS TP on mechanism, load the test tape.

P.C. board (TDK-D60), and set the

mechanism to the recording and pausing

condition in advance.

3 Confirm that the BIAS TP frequency on the

P.C. board is 64KHz +/-6KHz

1-10

Page 11

PC-XC350

1-11

Page 12

PC-XC350

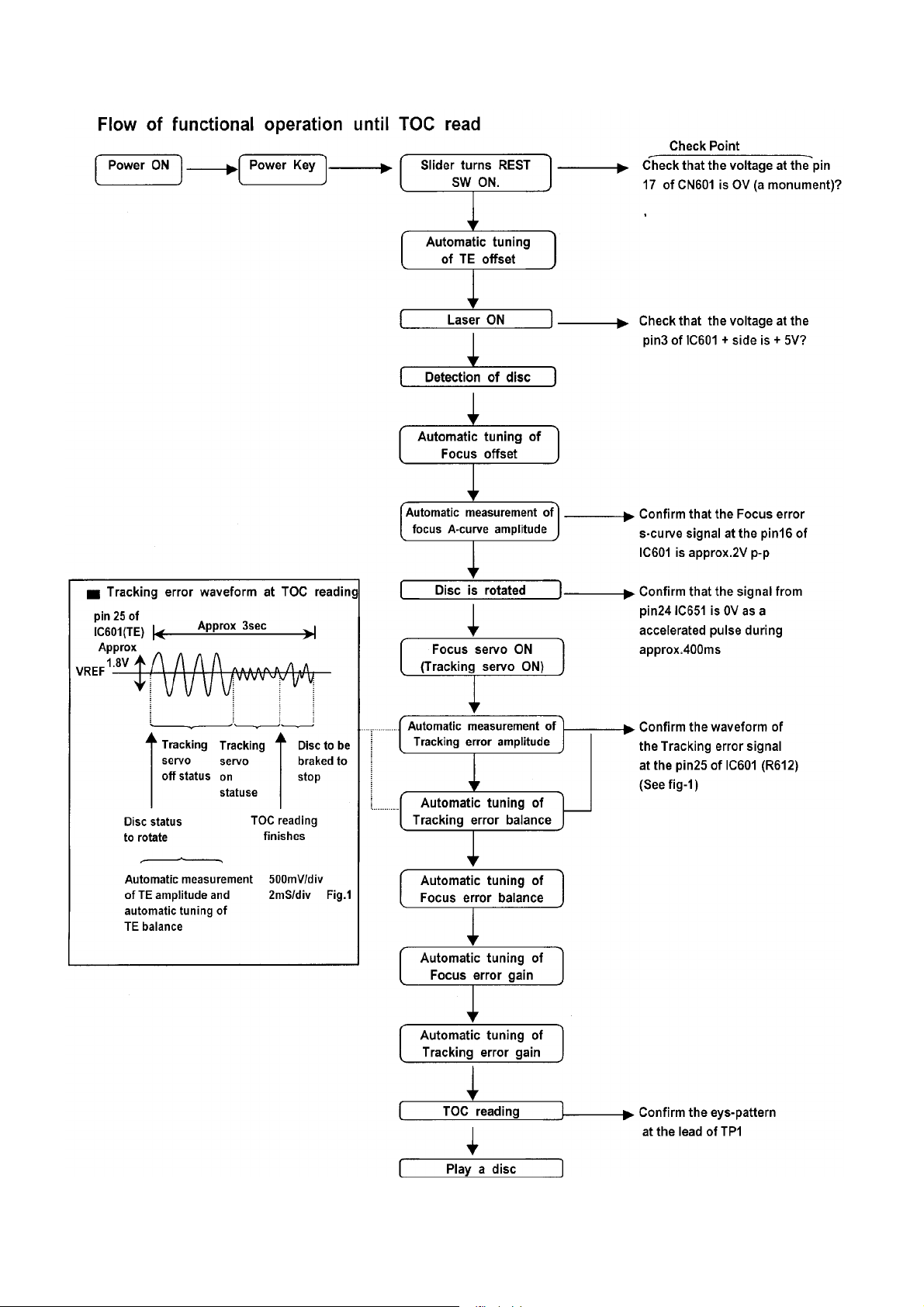

DESCRIPTION OF MAJOR IC

TA2104BN (IC101) AM/FM 1 CHIP TUNER

Block Diagram

1-12

Page 13

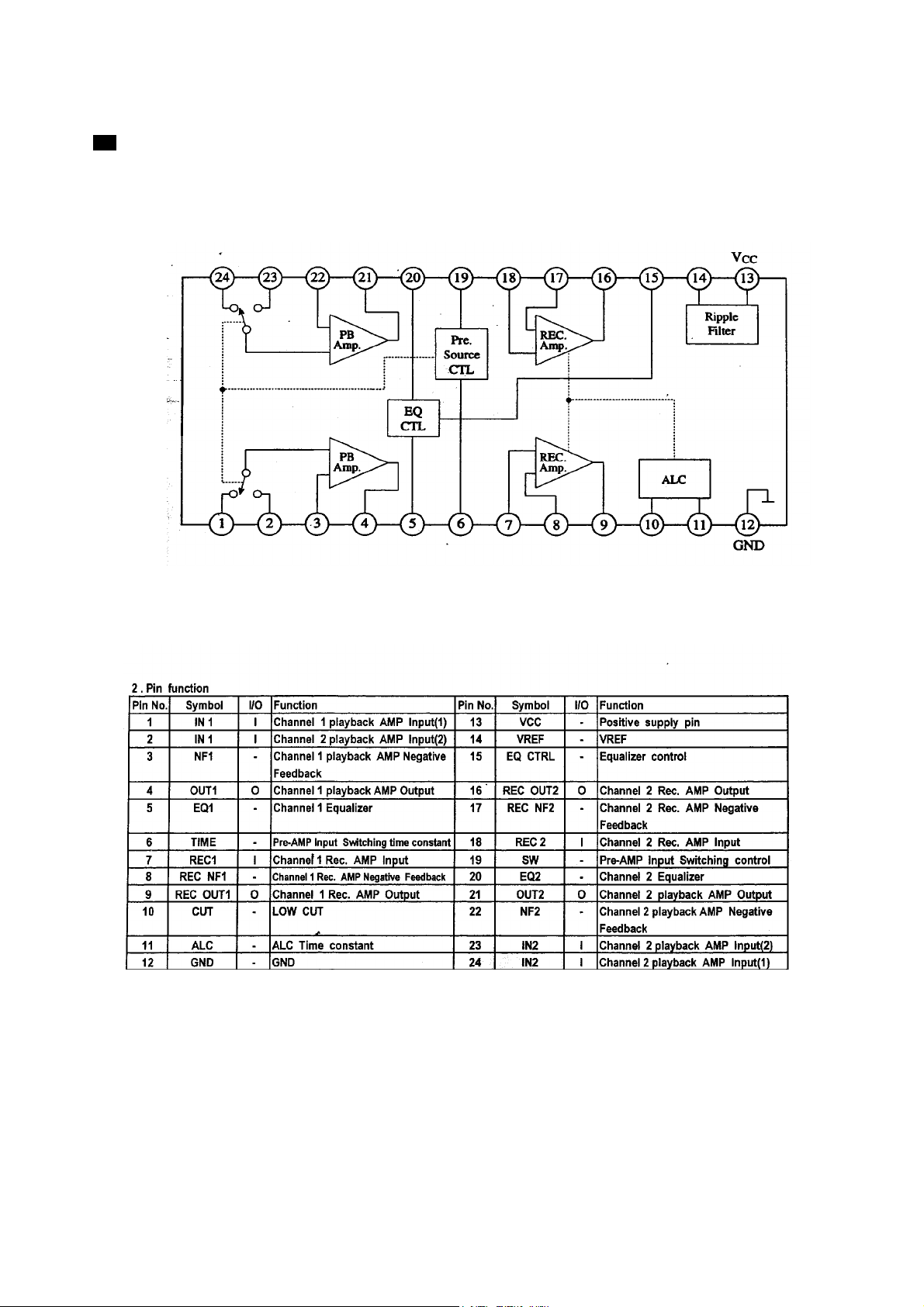

AN7345K (IC201) DUAL RECORD/PLAYBACK PRE-AMPLIFIER

Block Diagram

PC-XC350

1-13

Page 14

PC-XC350

1 - 14

Page 15

PC-XC350

1 - 15

Page 16

PC-XC350

BLOCK DIAGRAM

1 - 16

Page 17

WIRING DIAGRAM

PC-XC350

1-17

Page 18

PC-XC350

Circuit Diagram- 1

JACK2

JK301

R

7123654

L

L/SP.

GND

L.SPK

2

1

GND

R.SPK

R/SP.

2

1

!

CN1101

DC 12V

120

R341

C319

2200U/16V

C318

47U

1

2

3

4

5

6

7

8

9

270

10

R323

11

12

IC302 BA5417

13

14

15

4U7

C311

27k

R313

1

2

3

4

5

6

7

IC301 BA15218N

8

C337

R517

100K

BASS

TREBLE

R516

100K

VOL

R515

150K

9014

Q207

120

R342

C320

C321

154M

2200U/16V

C322

154M

4.7

R327

R328 4.7

C325 104M

R326 10K

R329 22K

1U

C324

R330 22K

C317

47U

270

R324

C314

500P

220

R317

Q303

1936

R315

10K

47U

1U

C305

R308

180K

C304

823M

C339

1U

C306

180K

R307

C302

823M

15K

R347

1.5K

R345

1U

C521

C514

4K7

R510

10K

R512

2K2

R519

1U

C519

0.1U

103M

C512

683M

C510

683M

C516

13

14

0.47U

15

C520

16

17

18

19

20

21

22

0.1U

C508

23

24

10U

C506

102M

500P

C313

4U7

C312

Q304

C303

823M

R349

10K

R301

R302

C301

823M

47U

C340

10K

R348

R309 100

R518

2K2

12

11

10

9

8

7

BH3852SIC502

6

5

4

3

2

1

D302

IN4148

C323

220U

47U

47U

C315

C316

220

R318

1936

27k

R314

R316

10K

2K2

R303

10k

R305

1.8K

1.8k

2K2

R304

470U

C307

R514

100K

0.1U

C507

C308 47U

1K

4V3

R310

D301

15K

R346

1U

C338

1.5K

R344

4U7

C518

C515

100U

100

R513

C513

103M

C511

683M

4K7

C509

683M

R509

10K

R511

C505

102M

1U

R331

470K

C326

2K7

R332

4U7

C329

104

C402

47U

C334

9014

Q306

R335

10K

22K

R333

R334

D303

IN4148

4K7

R312

4K7

R311

10k

R306

9014

Q301

C517 473M

9014

Q307

22K

R325

D305

IN4148

2K2

R339

9015

Q305

22K

9014

Q302

D304

IN4148

3K9

R336

R337

R338

9014

Q309

R343

100K

9015

Q308

R340 10

C327

33K

150K

10K

R478

9014

Q415

10K

4U7

R459

10U

C429

Q421

9014

D424

IN4148

D426

D425

IN4148

IN4148

C426 22U

C428

0.47U

22U

C427

R452

10K

R457

10K

Q424

9014

10K

R455

R450

R439 100

330

R438

8050

Q416

C410

6V8

D409

470U/25V

100U

C418

D412

IN4148

Q401

B764

R401

C404

100U/25V

D427

IN4148

10K

R464

R456

10K

R466

10K

B764

Q409

10K

R458

0.47U

C415

R428

47K

R449

10K

R453

2K2

R454

Q414

Q403

150

R418

10K

9014

C417

9014

27K

R404

22K

R405

4.7U

C331

103

C330

D310

IN4148

10 1/2W

100U

C408

330

R448

8050

Q408

!

9014

Q413

330

R430

27K

560P

R429

C416

22K

R434

1U

22K

R435

C424 100U/25V

R419

4.7 1/2W

13

!

10 1/2W

2

IC401

KIA7808

10K

R442

10V

D411

10K

R443

220U

C411

R446 1K5

9015

Q419

56K

R451

D407

IN4148

8050

Q420

D419

IN4148

120

R447

120

R445

47U

6V8

D420

47U

C421

C422

100U

C423

!

C401

4700U/25V

103

C406

1K

R407

9.1V

D403

R420

2.2 1/2W

10

R421

C412

560

100U/25V

R426

8050

Q411

R430

C413

4.71/4W

100U/25V

1K

R436

10K

R425

D413

C413

47K

R462

D418 IN4148

Q423 9015

100U/16V

D417

IN4148

!!

T1101

EI-48 POWER TF.

!

DC

223

223

AC

C1102

!

IN5401

D1102

D1104

IN5401

!

C1105 6800U/25V

223

C1104

*FS1101

C1101

C1103

T2.5A L 125V

!

D1101

IN5401

D1103

IN5401

!

223

123

GND

AC-(+)12V

DC-12V

GND

AC-(+)12V

DC-12V

123

10K

R422

C414

100U/25V

6V8

D405

6V2

D404

R423

100K

103

C425

9014

Q412

68K

R424

IN4148

47K

R539

LEAF SW. (B DECK)

MM+

A

MT1

B

DS-M

6

(+)12V

M(+)

5

GND

4

A

3

B

2

1

8

7

6

5

4

3

2

1

CD SIGNAL

TAPE MAIN SIGNAL

AUX SIGNAL

CN402

L.S.(B)

TO MAIN BOARD

GND

SAFETY

PWR.OUT

FUN.CD

BATT.

AC/DC

CN403

DC 6V

DC 12V

TO MI-COM BOARD

A DECK SIGNAL

B DECK SIGNAL

REC SIGNAL

MAIN SIGNAL

TUNER SIGNAL

D421 5V1

10K

R431

C223

470U

22K

R217

C217

332M

54123

GND

MU(1)-I/P

P/R CONT

R/B(+)-CONT

CN501

TO AUDIO BOARD

10K

9014

Q501

Q206

1K5

R503

C242

153M

C214

153M

220

R233

560

R231

R507

5K6

R230

1U

C602

100K

0.1U

C501

C225 102M

D201 IN4148

22K

R207

C213

222M

C219

1K5

R209

1U

22

C237

102M

4U7

Q201

A

C211

C209

3K9

R205 3K3

R201

R203

100U

C205

333M

C203

332M

332M

18K

R215

470

R213

1936

A

R437

9014

4K7

R505

10K

R463

120K

22U

C221

R237

22U

C215

0.1U

220P

C207

C201

R227 100

13

14

15

16

17

18

19

20

21

22

23

24

12

11

10

9

8

7

6

0.1U

5

C212

4

IC201 AN7345K

3

2

220P

C208

1

C239

9

8

7

6

5

C230

BA3126NIC202

4

3

2

1

4K7

R506

9014

Q502

R433 10K

C503

4.7U

220

C243

153M

393M

C222

R218 33K

R234

C227

22U

C244 153M

22U

C216

102M

C226

0.1U

C502

10U

C218

1K5

R210

1U

C210

100U

3K9

R202

C204

C206

333M

102M

332M

C202

220

R219

100U

R235 560

5K6

R502

22K

R208

3K3

R206

R204

22

C238

C240 332M

4U7

C220

R226

1K

R216 18K

8050

Q203

C232

1K

R221

1K

R220

1K5

R504

C504

120K

R508

8

7

332M

C224

C241

222M

6

5

4

3

IC501 BA15218N

2

1

D414 IN4148

4.7U

R533 100

C527

100U

100K

R530

10K

15P

C525

47U

R532

C526

R534

10K

1U

100U

C419

2K7

R440

5V6

D410

8050

Q417

22K

R441

D406

IN4148

D415

IN4148

VR401

10K

5K6

R417

C522

R531

15P

100K

C524

C523 1U

D416

IN4148

R212 6.8K

R211 6.8K

1936

Q202

R214

470

104

C236

390P(NPO)

500P

C229

500P

C228

3K3

R222

10K

R470

10U

C420

4.7

R224

8050

Q204

10K

R223

C234

C233

10

R225

3630

T201

103M

223M

C235

220U

C231

472M

9015

Q205

C246

10U

22K

R228

560

R237

68K

68K

6.8K

R521 6.8K

R536

R520

R535

R523 8.2K

R522 8.2K

9014

47K

R537

47K

R538

R526 30K

Q503

R527 30K

R468

2.2 1/2W

6

(+)12V

M(+)

5

GND

4

3

2

1

9

8

7

6

5

VOL

4

TRE

3

BASS

2

1

9014

Q505

150P

C528

2K2

R525

R524 2K2

9014

Q504

47K

R528

R529 47K

CN402

A

B

TO CASSETTE DECK

L.S.(B)

SMUTE

AHB

FUN.AUX

FUN.TU

REC B+

TRE

CN404

VOL

BASS

TO MI-COM BOARD

SW8V

HAVE CRITICAL

!

MU(2)-I/P

12345

678

9

10GND(2)

11

TU-5V

CD-RCH

LP-SW.

CD-5V

GND(1)

CONT.B+ 12

8V

JK501

PHOLEJACK2

3). COMPONENTS MARKED WITH

1).DISCONNECT POWER CORD BEFORE SERVING.

2). RECOMMEND THE UNIT BE OPERATED BY DC 12 VOLTS DURING TROUBLE SHOOTING.

CHARACTERISTICS. ONLY REPLACE WITH THE COMPONENT OF THE SAME TYPE NUMBER.

4). SUBJECT TO CHANGE WITHOUT NOTICE.

CN203

54123

P/R CONT

TO R/P SW. BOARD

CN502

TU-RCH

TU-LCH

CD-LCH

GND

MU(1)-I/P

MU(2)-I/P

R/B(+)-CONT

P-GND

TO TUNER BOARD

5PIN

3 PIN

CN201

R/CH

P/B HEAD

R/CH

L/CH

R/P HEAD

P/B HEAD

B DECK

CN202

L/CH

R/P HEAD

A DECK

1 - 18

Page 19

Circuit Diagram- 2

PC-XC350

1 - 19

Page 20

PC-XC350

Printed Circuit Board- 1

1 - 20

Page 21

PC-XC350

Assembly- 1

09

S4

01

05

S3

02

04

S2

06

08

S5

07

S1

03

1 - 22

Page 22

Assembly- 1

PC-XC350

ITEM Q'TY

!

01 535-026800-000 REMOTE RECEIVER BRACKET 1

02 248-350003-103 CONTROL BOARD 1

03 357-000033-123 CD DECK 1

04 408-146395-150 HEAT SINK 1

05 454-000030-050 NUT M3 1

06 248-350001-104 TUNER BOARD 4

07 535-147000-000 CD TRAY 1

08 248-350008-100 LIGHT BOARD 1

09 535-131064-000 DISPLAY BRACKET 1

S1 238-130150-602 SCREW 3 x 15 PB 7 FROM CD TRAY TO FRONT CABINET

S2 238-230080-203 SCREW 3 x 8 BM 4 FIX THE TUNER BOARD

S3 238-130086-202 SCREW 3 X 8 BB ( HARD ) 1 FIX HEAT SINK

S4 238-130080-602 SCREW 3 X 8 PB 4 FIX THE TUNER BOARD

S5 238-130100-602 SCREW 3 x 10 PB 4 FROM CD DECK TO CD TRAY

PARTS NAME DESCRIPTION/LOCALITYPART NO.

1 - 23

Page 23

PC-XC350

Assembly- 2

S9

S8

31

25

26

27

28

24

S7

30

29

S5

22

S6

20

12

23

17

S3

21

19

S1

S4

16

05

18

S2

07

08

15

14

13

04

1 - 24

06

11

01

03

09

02

10

Page 24

R

Assembly- 2

PC-XC350

ITEM Q'TY

!

PARTS NUMBER PARTS NAME DESCRIPTION/LOCALITY

01 525-073030-011 RIGHT CASS DOOR LENS 1

02 525-072030-011 LEFT CASS DOOR LENS 1

03 525-0030S3-012 LEFT CASS DOOR 1

04 525-0130S3-012 RIGHT CASS DOOR 1

05 766-250000-000 LEFT CASS DOOR SPRING 1

06 525-029300-000 LEFT CASS TAPE BRACKET 1

07 766-250000-000 RIGHT CASS DOOR SPRING 1

08 525-029300-000 RIGHT CASS TAPE BRACKET 1

09 525-080400-013 CD DISPLAY LENS 1

10 500-810200-011 "JVC" NAME PLATE 1

11 535-145430-012 DISPLAY PANEL 1

12 535-1010S3-012 FRONT CABINET 1

13 535-149017-012 CD DOOR 1

14 535-1803S3-000 CD DOOR LENS 1

15 535-1074S3-000 VOLUME KNOB 1

16 539-121200-000 LEFT CASS DOOR GEAR HOLDER 1

17 539-121100-000 LEFT CASS DOOR GEAR 1

18 539-121200-000 RIGHT CASS DOOR GEAR HOLDE

19 539-121100-000 RIGHT CASS DOOR GEAR 1

20 525-0102S3-012 LEFT CASS KNOB 1

21 525-0108S3-012 RIGHT CASS KNOB 1

22 463-380000-000 LEFT CASS KNOB PLATE 1

23 463-380000-000 RIGHT CASS KNOB PLATE 1

24 535-150417-012 CD DOOR OPEN KNOB 4pcs/KIT

25 535-1510S3-000 POWER KNOB 1

26 535-1520S3-000 TIMER CONTROL KNOB 4pcs/KIT

27 535-1516S3-013 FUNCTION KNOB 6pcs/KIT

28 535-1060S3-000 TURNER CONTROL KNOB 4pcs/KIT

29 535-150317-011 CD PLAY KNOB 3pcs/KIT

30 248-250813-000 RECORDING BOARD 1

31 156-255609-254 CASS DECK 1

S1 238-120060-602 SCREW 2 X 6 PB 1 FIX LEFT TAPE BRACKET

S2 238-120060-602 SCREW 2 X 6 PB 1 FIX RIGHT TAPE BRACKET

S3 238-130080-632 SCREW 3 X 8 PWB 1 FIX LEFT CASS DOOR GEAR

S4 238-130080-632 SCREW 3 X 8 PWB 1 FIX RIGHT CASS DOOR GEAR

S5 238-130060-602 SCREW 3 X 6 PB 3 FIX LEFT CASS KNOB PLATE

S6 238-130060-602 SCREW 3 X 6 PB 3 FIX RIGHT CASS KNOB PLATE

S7 238-220050-903 SCREW 2 X 5 MC 2 FIX THE RECORDING BOARD

S8 238-130100-602 SCREW 3 X 10 PB 6 FIX CASS DECK

S9 238-130100-632 SCREW 3 X 10 PWB 4 CD DOOR TRAY TO FRONT CABINET

1

1 - 25

Page 25

PC-XC350

Assemly- 3

S2

S3

02

04

01

S1

03

05

S4

12

08

S5

07

13

06

11

09

10

1 - 26

Page 26

Assembly- 3

PC-XC350

ITEM Q'TY

!

!

!

!

01 158-000117-622 AC SOCKET 1

02 500-025100-000 AC SOCKET COVER 1

03 152-112560-225 POWER TRANSFORMER 1

04 248-250812-100 RECTIFIER BOARD 1

05 525-0020S3-012 BACK CABINET 1

06 763-250000-000 BATTERY SPRING ( +/-- ) 1

07 764-701300-000 BATTERY SPRING ( +) 1

08 765-901000-000 BATTERY SPRING ( -- ) 1

09 763-455000-000 BATTERY SPRING ( +/-- ) 1

10 763-331800-000 BATTERY SPRING ( +/-- ) 1

11 525-0040S3-000 BATTERY DOOR 1

12 466-756350-050 1 COVER THE VOLTAGE SELECTOR HOLE

PART NO.

PARTS NAME DESCRIPTION/LOCALITY

PVC PLATE FOR VOLTAGE

SELECTOR HOLE

13 155-420026-238 RADIO ANTENNA 1

S1 238-130200-632 SCREW 3 X 20 PWB 2 FIX POWER TRANSFORMER

S2 238-128120-602 SCREW 2.8 X 12 PB 2 FIX AC SOCKET COVER

S3 238-130080-602 SCREW 3 X 8 PB 1 FIX RECTIFIER BOARD

S4 238-128120-602 SCREW 3 X 10 PB 1 FIX AUX JACK

S5 238-130100-203 SCREW 3 X 10 BM ( BLACK ) 1 FIX RADIO ANTENNA

1 - 27

Page 27

PC-XC350

Assembly- 4

01

S2

S1

1 - 28

Page 28

Assembly- 4

PC-XC350

ITEM Q'TY

!

1 525-0050S3-000 HANDLE 1

S1 238-130250-602 SCREW 3 X 25 PB 8 FROM FRONT CABINET TO BACK CABINET

S2 238-130100-602 SCREW 3 X 10 PB 1 FIX THE AUX JACK

PARTS NAME DESCRIPTION/LOCALITYPART NO.

1 - 29

Page 29

PC-XC350

Assembly- 5

02

S1

07

04

S2

03

06

S3

01

Assembly- 6

05

1- -30

Page 30

Assembly- 5

FOR RIGHT SPEAKER BOX ASSEMBLY

PC-XC350

ITEM Q'TY

!

01 500-810200-011 "JVC" NAME PLATE 1

02 525-040000-000 SPEAKER NET HOLDER 1

03 525-0410S3-010 SPEAKER BOX PANEL 1

04 154-178450-329 LOUD SPEAKER 1

05 154-508380-609 SPEAKER 1

06 525-026900-000 SPEAKER CORD HOLDER 1

07 525-0390S3-008 RIGHT SPEAKER BOX BACK 1

S1 238-130300-602 SCREW 3 X 30 PB 6

S2 238-130080-632 SCREW 3 X 8 PWB 4 FIX THE SPEAKER

S3 238-130080-632 SCREW 3 X 8 PWB 2

FOR LEFT SPEAKER BOX ASSEMBLY

ITEM Q'TY

!

01 500-810200-011 "JVC" NAME PLATE 1

PART NO.

PART NO. PARTS NAME DESCRIPTION/LOCALITY

NAME DESCRIPTION/LOCALITY

PARTS

FROM SPEAKER PANEL TO SPEAKER BOX BACK

FIX THE LOUD SPEAKER

02 525-040000-000 SPEAKER NET HOLDER 1

03 525-0410S3-010 SPEAKER BOX PANEL 1

04 154-508380-609 SPEAKER 1

05 154-178450-329 LOUD SPEAKER 1

06 525-026900-000 SPEAKER CORD HOLDER 1

07 525-0390S3-002 LEFT SPEAKER BOX BACK 1

S1 238-130300-602 SCREW 3 X 30 PB 6

S2 238-130080-632 SCREW 3 X 8 PWB 4 FIX THE SPEAKER

S3 238-130080-632 SCREW 3 X 8 PWB 2

FROM SPEAKER PANEL TO SPEAKER BOX BACK

FIX THE LOUD SPEAKER

1 - 31

Page 31

PC-XC350

Packing

MADE IN CHINA

P.14

P.15

P.2

P.1

P.12

P.13

P.3

P.4

P.5

P.6

P.7

P.11P.10

P.8

P.9

P.16

P.17

P.18

1 - 32

P.20

P.19

P.21

P.22

Page 32

Packing List

Item Part's Name Parts No.

PC-XC350

P.1 Poly Bag

RC37-400S3-010

P.2 Remote Control Unit

P.3 Instruction Manual

P.4 Warranty Card

P.5

Registration card

601-351000-010

602-700339-000

602-700337-000

P.6 Safety Instruction Sheet 602-900276-000

P.7 Poly Bag 676-070100-040

P.8 Poly Bag 676-040130-040

P.9 Power Cord Set 151-117117-612

P.10 Poly Form, Top Left

875-351000-000

P.11 Poly Form, Top Right

P.12 Poly Bag 676-215240-040

P.13 Main Unit

-

P.14 Speaker Unit, Left AS00-25002

P.15 Poly Bag 676-180240-040

P.16 Speaker Unit, Right AS00-25008

P.17 Poly Bag 676-180240-040

POP Label-Left

629-080097-000

P.18

POP Label-Right

629-080096-000

P.19 Poly Form, Bottom Right

875-351000-000

P.20 Poly Form, Bottom Left

P.21 Gift Box 891-351100-010

P.22 Bar Code Label 612-080132-000

1-33

Page 33

PC-XC350

VICTOR COMPANY OF JAPAN, LIMITED. (By JCA)

AUDIO & COMMUNICATION BUSINESS DIVISION (By JCA)

PERSONAL & MOBILE NETWORK BUSINESS UNIT. 10-1, 1 Chome, Ohwatari-machi, Maebashi-city, 371-8543, Japan. (By JCA)

No. 28xxx

Page 34

PC-XC350

PARTS LIST

[ PC-XC350 ]

* All printed circuit boards and its assemblies are not available as service parts.

Area suffix

- Contents -

Electrical Parts List (Tuner circuit pcb)

Electrical Parts List (Audio circuit pcb)

Electrical Parts List (Rectifier circuit pcb)

Electrical Parts List (Control circuit pcb)

J ------------------------------- USA

C -------------------------- Canada

2 - 2

2 - 5

2 - 10

2 - 11

2 - 1

Page 35

Tuner pcb

y

2 - 2

Parts No. Material Qt

199-741005-000 GOLD CAP DX-5R5H104 0.1 F/5.5V 1 PCS C725

201-000220-125 RESISTOR 2.2 OHM +-5% 1/2W 1 PCS R427

201-001000-185 RESISTOR 10 OHM +-5% 1/8W 1 PCS R136

201-004700-185 RESISTOR 47 OHM +-5% 1/8W 1 PCS R113

201-011000-185 RESISTOR 100 OHM +-5% 1/8W 3 PCS R122,R123,R701

201-013300-185 RESISTOR 330 OHM +-5% 1/8W 6 PCS R116,R120,R428,R429,R430,R431

201-016800-185 RESISTOR 680 OHM +-5% 1/8W 2 PCS R748,R751

201-021000-185 RESISTOR 1 KOHM +-5% 1/8W 17 PCS R104,R106,R117,R119,R121,R128,R129,R130,R133,R134,R735,R736,

201-022200-185 RESISTOR 2.2 KOHM +-5% 1/8W 22 PCS R105,R126,R703,R704,R705,R706,R707,R708,R725,R726,R727,R728,

201-023300-185 RESISTOR 3.3 KOHM +-5% 1/8W 3 PCS R118,R124,R721

201-024700-185 RESISTOR 4.7 KOHM +-5% 1/8W 2 PCS R125,R764

201-026800-185 RESISTOR 6.8 KOHM +-5% 1/8W 1 PCS R723

201-028200-185 RESISTOR 8.2 KOHM +-5% 1/8W 2 PCS R749,R750

201-031000-185 RESISTOR 10 KOHM +-5% 1/8W 31 PCS R114,R131,R132,R135,R761,R762,R763,R765,R752,R755,R759,R722,

201-032200-185 RESISTOR 22 KOHM +-5% 1/8W 2 PCS R719,R720

201-033000-185 RESISTOR 30 KOHM +-5% 1/8W 1 PCS R776

201-033300-185 RESISTOR 33 KOHM +-5% 1/8W 1 PCS R768

201-034700-185 RESISTOR 47 KOHM +-5% 1/8W 4 PCS R101,R102,R127,R767

201-036800-185 RESISTOR 68 KOHM +-5% 1/8W 1 PCS R770

201-038200-185 RESISTOR 82 KOHM +-5% 1/8W 1 PCS R777

201-041000-185 RESISTOR 100 KOHM +-5% 1/8W 9 PCS R110,R112,R137,R716,R717,R718,R740,R746,R766

201-041500-185 RESISTOR 150 KOHM +-5% 1/8W 2 PCS R301,R724

201-042200-185 RESISTOR 220 KOHM +-5% 1/8W 1 PCS R747

201-043300-185 RESISTOR 330 KOHM +-5% 1/8W 1 PCS R771

202-101205-505 I CERAMIC CAP 12 PF/50V SL 2 PCS C139,C140

202-101805-505 G CERAMIC CAP 18 PF/50V SL 1 PCS C101

202-102005-505 H CERAMIC CAP 20 PF/50V SL 1 PCS C125

202-102205-505 I CERAMIC CAP 22 PF/50V SL 2 PCS C714,C715

202-102405-505 A CERAMIC CAP 24 PF/50V SL 2 PCS C716,C719

202-103005-505 H CERAMIC CAP 30 PF/50V SL 3 PCS C102,C103,C109

202-104705-505 H CERAMIC CAP 47 PF/50V SL 3 PCS C119,C717,C718

202-211005-101 G CERAMIC CAP 100 PF/50V 5 PCS C153,C706,C707,C708,C709

202-211505-101 A CERAMIC CAP 150 PF/50V 11 PCS C720,C721,C723,C724,C732,C152,C712,C713,C711,C710,C740

202-221005-802 G CERAMIC CAP 0.001 UF/50V B 7 PCS C107,C120,C130,C131,C132,C137,C156

Position

R738,R739,R760,R779,R780

R737,R741,R742,R743,R753,R754,R756,R757,R758,R777

R729,R730,R731,R732,R733,R734,R709,R710,R711,R712,R713,R714,

R715,R744,R745,R769,R774,R775,R778

PC-XC350

Page 36

Tuner pcb

(

(

(

(

)

202-500505-505 G CERAMIC CAP 5 PF/50V NPO 1 PCS C108

202-501005-505 I CERAMIC CAP 10 PF/50V NPO 1 PCS C117

202-631002-802 G CERAMIC CAP 0.01 UF/25V F 9 PCS C106,C112,C114,C127,C136,C141,C154,C156,C730

202-632202-802 G CERAMIC CAP 0.022 UF/25V F 1 PCS C113

202-634702-802 G CERAMIC CAP 0.047 UF/25V F 1 PCS C129

202-641002-802 G CERAMIC CAP 0.1 UF/25V F

203-041050-202 ELECT CAP 0.1 UF/50V +-20% 3 PCS C123,C144,C145

203-042250-202 ELECT CAP 0.22 UF/50V +-20% 1 PCS C122

203-044750-202 ELECT CAP 0.47 UF/50V +-20% 2 PCS C124,C128

203-051050-202 ELECT CAP 1 UF/50V +-20% 1 PCS C726

203-052250-202 ELECT CAP 2.2 UF/50V +-20% 1 PCS C134

203-053350-202 ELECT CAP 3.3 UF/50V +-20% 1 PCS C133

203-054750-202 ELECT CAP 4.7 UF/50V +-20% 2 PCS C121,C126

203-061050-202 ELECT CAP 10 UF/50V +-20% 4 PCS C703,C704,C705,C727

203-064710-202 ELECT CAP 47 UF/10V +-20% 1 PCS C728

203-071010-202 ELECT CAP 100 UF/10V +-20% 4 PCS C138,C150,C151,C413

203-072210-202 ELECT CAP 220 UF/10V +-20% 1 PCS C729

204-022299-101 MYLAR CAP 0.0022 UF/100V +-10% 3 PCS C135,C146,C147

204-023399-101 MYLAR CAP 0.0033 UF/100V +-10% 2 PCS C142,C143

204-031599-101 MYLAR CAP 0.015 UF/100V +-10% 2 PCS C148,C149

205-013950-505 POLY CAP 390 PF/50V +-5% 1 PCS C118

206-100101-000 DIODE ISV101

206-100149-000 DIODE ISV149

206-104148-000 DIODE IN-4148 38.39.4630.63. 8 PCS D101,D102,D103,D104,D701,D702,D703,D705

206-106938-000 DIODE RPM-6938-V4

206-200051-102 ZENER 5.1V 1/2W #73/AMR209.309 1 PCS D704

206-200082-102 ZENER 8.2V 1/2W #CD32.42.72.76 1 PCS D407

207-000114-009 TRANSISTOR DTC-114TS #DS802/ 1 PCS Q707

207-000114-059 260X TRANSISTROR DTC-114ES 1 PCS Q704

207-000114-109 TRANSISTOR DTA-114TS CD9788 1 PCS Q701

207-008550-020 TRANSISTOR 8550B/C #38/39/4630 1 PCS Q412

207-009014-030 TRANSISTOR 9014C #38/39/4630/ 7 PCS Q103,Q411,Q702,Q703,Q705,Q706,Q708

207-009015-030 TRANSISTOR 9015C #38/39/4630/ 1 PCS Q709

207-009018-080 TRANSISTOR 9018-H 38/39/63/731 1 PCS Q104

207-182159-050 TRANSISTOR 2SD-2159E 1 PCS Q410

208-010730-018 CERAMIC FILTER 10.7 MHz 3 PINS 1 PCS CF102

2 - 3

208-045030-400 CERAMIC FILTER 450 KHz 3 PINS 1 PCS CF101

209-160380-010 I.F.T. IF 0380 PINK 10 mm 1 PCS T104

209-181612-010 I.F.T. OSC 1A612R RED 10 mm MW 1 PCS T101

209-252070-010 I.F.T. IF 2070 YELLOW 10 mm 1 PCS T103

210-002104-014 I.C. TOSHIBA TA2104AN CHP-38 1 PCS IC101

TOSHIBA) #7318. 2 PCS VD101,VD102

TOSHIBA) #7318. 2 PCS VD104,VD106

ROHM

Y5V 5 PCS C110,C155,C701,C702,C733

1 PCS

PC-XC350

Page 37

Tuner pcb

p

(

)

210-072136-000 I.C. SANYO LC-72136N NSX2700 1 PCS IC102

210-171603-086 B I.C. SANYO MN171603Hz CHP-38 1 PCS IC701

2 - 4

212-065025-100 AM COIL 65:25T WIRE 4 x 100mm 1 PCS

213-035045-070 FM COIL 3.5T 4.5 x 0.7 mm 1 PCS L104

213-045045-070 FM COIL 4.5T 4.5 x 0.7 mm 1 PCS L103

213-055045-070 FM COIL 5.5T 4.5 x 0.7 mm 2 PCS L101,L102

216-000010-018 TRIMMER 10 PF RED 1 PCS TC101

220-207634-281 LCD DISPLAY 76x34.5 mm 28 PINS 1 PCS

222-010070-000 FERRITE BAR 10 x 70 mm 1 PCS

226-010000-000 CHOKE COIL 100 uH #38.7017.801 2 PCS L701,L702

226-393000-000 CHOKE COIL 39 mH 2 PCS L105,L106

227-020302-860 LIGHT BULB 8V 60 mA DIA=3 mm 3 PCS LAMP701,LAMP702,LAMP703

228-041900-002 B RESONATOR 4.19 MHz 2 PINS 1 PCS CF702

229-000075-000 CRYSTAL 2C 75KHz 20PF +-20PM 1

229-327680-200 CRYSTAL 32.768KHz 20PPM

HOORAY

232-070130-110 FFC HEADER 7 PINS 1.0mm R- 1 PCS CN703

232-110130-210 I FFC HEADER 11 PINS 1.0mm R 1 PCS CN708

233-020200-025 HEADER 2 PINS "JST" 2.5mm V 1 PCS CN707

233-030200-020 HEADER 3 PINS "JST" 2.0mm V 1 PCS CN704

233-080200-020 HEADER 8 PINS "JST" 2.0mm V 1 PCS CN705

233-090200-020 HEADER 9 PINS "JST" 2.0 mm V 2 PCS CN702,CN706

233-120200-020 I HEADER 12 PINS "JST" 2.0 mm 1 PCS CN101

248-350001-104 I P.C.B. PC-X350 TUNER BD. W/ 1 PCS

401-101045-000 ANTENNA BAR HOLDER H=45 mm 2 PCS

402-030070-021 LIGHT BULB COVER 3 mm

403-000050-000 COPPER JUMPER WIRE 5 mm 6 PCS JW712,JW722,JW724,JW104,JW708

403-000075-000 COPPER JUMPER WIRE 7.5 mm 4 PCS JW710,JW709,JW704,JW729

403-000100-000 COPPER JUMPER WIRE 10 mm 17 PCS JW102,JW103,JW104,JW701,JW702,JW703,JW705,JW706,JW711,J

BLUE

cs CF103

1 PCS CF701

3 PCS LAMP701-LAMP703

W713,JW714,JW715,JW716,JW717,JW718,JW719,JW720

PC-XC350

410-100000-001 CONTACT PIN RT-01T-1.0B 1mm 1 PCS FM ANT.

Page 38

Audio pcb

Parts No. Material Qty Circuit ID

200-000220-125 FUSE RESISTOR 2.2OHM 1/2W +-5% 1 PCS R420

201-000470-125 RESISTOR 4.7 OHM +-5% 1/2W 1 PCS R419

201-000470-185 RESISTOR 4.7 OHM +-5% 1/8W 2 PCS R327,R328

201-000560-185 RESISTOR 5.6 OHM +-5% 1/8W 1 PCS R224

201-001000-125 RESISTOR 10 OHM +-5% 1/2W 2 PCS R418,R450

201-001000-185 RESISTOR 10 OHM +-5% 1/8W 2 PCS R340,R421

201-002200-185 RESISTOR 22 OHM +-5% 1/8W 2 PCS R203,R204

201-004700-185 RESISTOR 47 OHM +-5% 1/8W 1 PCS R225

201-011000-185 RESISTOR 100 OHM +-5% 1/8W 6 PCS R227,R309,R409,R439,R513,R533

201-011200-185 RESISTOR 120 OHM +-5% 1/8W 4 PCS R341,R342,R445,R447

201-011500-185 RESISTOR 150 OHM +-5% 1/8W 1 PCS R401

201-012200-185 RESISTOR 220 OHM +-5% 1/8W 5 PCS R219,R233,R234,R323,R324

201-013300-185 RESISTOR 330 OHM +-5% 1/8W 3 PCS R430,R438,R448

201-015600-185 RESISTOR 560 OHM +-5% 1/8W 1 PCS R426

201-021000-185 RESISTOR 1 KOHM +-5% 1/8W 8 PCS R220,R221,R226,R310,R407,R416,R436,R444

201-021200-185 RESISTOR 1.2 KOHM +-5% 1/8W 2 PCS R231,R235

201-021500-185 RESISTOR 1.5 KOHM +-5% 1/8W 7 PCS R209,R210,R301,R302,R446,R503,R504

201-021800-185 RESISTOR 1.8 KOHM +-5% 1/8W 2 PCS R303,R304

201-022200-185 RESISTOR 2.2 KOHM +-5% 1/8W 8 PCS R305,R306,R339,R454,R518,R519,R524,R525

201-022700-185 RESISTOR 2.7 KOHM +-5% 1/8W 2 PCS R332,R440

201-023300-185 RESISTOR 3.3 KOHM +-5% 1/8W 8 PCS R205,R206,R213,R214,R222,R232,R236,R410

201-023900-185 RESISTOR 3.9 KOHM +-5% 1/8W 3 PCS R201,R202,R336

201-024700-185 RESISTOR 4.7 KOHM +-5% 1/8W 9 PCS R311,R312,R317,R318,R408,R505,R506,R509,R510

201-025600-185 RESISTOR 5.6 KOHM +-5% 1/8W 5 PCS R417,R501,R502,R511,R512

201-026800-185 RESISTOR 6.8 KOHM +-5% 1/8W 2 PCS R321,R322

2 - 5

201-031000-185 RESISTOR 10 KOHM +-5% 1/8W 41 PCS R211,R212,R223,R229,R230,R319,R320,R326,R333,R41

1R414,R422,R425,R427,R428,R431,R432,R433,R437,R44

3,R452,R453,R455R461,R463,R464,R466,R520,R521,R523,R532,R534,R54

PC-XC350

Page 39

Audio pcb

201-031200-185 RESISTOR 12 KOHM +-5% 1/8W 2 PCS R329,R330

2 - 6

201-031800-185 RESISTOR 18 KOHM +-5% 1/8W 4 PCS R215,R216,R313,R314

201-032200-185 RESISTOR 22 KOHM +-5% 1/8W 15 PCS R207,R208,R217,R228,R315,R316,R325,R334,R335,R40

5,R434,R435,R441,R442,R465

201-032700-185 RESISTOR 27 KOHM +-5% 1/8W 2 PCS R404,R429

201-033300-185 RESISTOR 33 KOHM +-5% 1/8W 2 PCS R218,R337

201-034700-185 RESISTOR 47 KOHM +-5% 1/8W 7 PCS R449,R462,R528,R529,R537,R538,R539

201-035600-185 RESISTOR 56 KOHM +-5% 1/8W 2 PCS R507,R508

201-036800-185 RESISTOR 68 KOHM +-5% 1/8W 4 PCS R424,R451,R535,R536

201-041000-185 RESISTOR 100 KOHM +-5% 1/8W 8 PCS R343,R415,R423,R514,R516,R517,R530,R531

201-041200-185 RESISTOR 120 KOHM +-5% 1/8W 2 PCS R526,R527

201-041500-185 RESISTOR 150 KOHM +-5% 1/8W 2 PCS R338,R515

201-041800-185 RESISTOR 180 KOHM +-5% 1/8W 2 PCS R307,R308

201-044700-185 RESISTOR 470 KOHM +-5% 1/8W 1 PCS R331

202-101505-505 H CERAMIC CAP 15 PF/50V SL 2 PCS C524,C525

202-211505-101 A CERAMIC CAP 150 PF/50V B(X7R 1 PCS C528

202-212205-101 I CERAMIC CAP 220 PF/50V B(X7R 2 PCS C207,C208

202-213305-101 G CERAMIC CAP 330 PF/50V B(X7R 2 PCS C228,C229

PC-XC350

202-215005-101 H CERAMIC CAP 500 PF/50V B(X7R 2 PCS C313,C314

202-215605-101 I CERAMIC CAP 560 PF/50V B(X7R 2 PCS C407,C416

202-631002-802 G CERAMIC CAP 0.01 UF/25V F 2 PCS C406,C425

202-641002-802 G CERAMIC CAP 0.1 UF/25V F(Y5V 2 PCS C236,C402

203-041050-202 ELECT CAP 0.1 UF/50V +-20% 3 PCS C211,C212,C403

203-051050-202 ELECT CAP 1 UF/50V +-20% 9 PCS C209,C210,C324,C326,C405,C417,C519,C520,C521

203-054750-202 ELECT CAP 4.7 UF/50V +-20% 14 PCS C219,C220,C311,C312,C327,C328,C329,C501,C502,C50

3,C504,C507,C508,C518

203-061016-202 ELECT CAP 10 UF/16V +-20% 8 PCS C215,C216,C218,C420,C516,C522,C523,C540

203-062210-202 ELECT CAP 22 UF/10V +-20% 4 PCS C221,C227,C305,C306

203-064710-202 ELECT CAP 47 UF/10V +-20% 9 PCS C308,C315,C316,C415,C422,C426,C427,C428,C526

Page 40

Audio pcb

203-071010-202 ELECT CAP 100 UF/10V +-20% 12 PCS C203,C204,C230,C235,C408,C411,C414,C418,C419,C42

3,C515,C527

203-071016-202 ELECT CAP 100 UF/16V +-20% 1 PCS C413

203-071025-202 ELECT CAP 100 UF/25V +-20% 3 PCS C404,C412,C424

203-072210-202 ELECT CAP 220 UF/10V +-20% 3 PCS C317,C318,C323

203-073310-202 ELECT CAP 330 UF/10V +-20% 1 PCS C421

203-074710-202 ELECT CAP 470 UF/10V +-20% 2 PCS C223,C307

203-074725-202 ELECT CAP 470 UF/25V +-20% 1 PCS C410

203-082216-202 ELECT CAP 2200 UF/16V +-20% 2 PCS C319,C320

203-084725-202 ELECT CAP 4700 UF/25V +-20% 1 PCS C401

204-021099-101 MYLAR CAP 0.001 UF/100V +-10% 11 PCS C201,C202,C225,C226,C232,C237,C238,C239,C240,C50

5,C506

204-022299-101 MYLAR CAP 0.0022 UF/100V +-10% 2 PCS C213,C241

204-023399-101 MYLAR CAP 0.0033 UF/100V +-10% 2 PCS C217,C224

204-024799-101 MYLAR CAP 0.0047 UF/100V +-10% 1 PCS C231

204-031099-101 MYLAR CAP 0.01 UF/100V +-10% 3 PCS C234,C513,C514

204-031599-101 MYLAR CAP 0.015 UF/100V +-10% 4 PCS C214,C242,C243,C244

204-032299-101 MYLAR CAP 0.022 UF/100V +-10% 1 PCS C233

204-033399-101 MYLAR CAP 0.033 UF/100V +-10% 2 PCS C205,C206

204-033950-101 MYLAR CAP 0.039 UF/50V +-10% 1 PCS C222

204-034799-101 MYLAR CAP 0.047 UF/100V +-10% 1 PCS C517

204-036899-101 MYLAR CAP 0.068 UF/100V +-10% 4 PCS C509,C510,C511,C512

204-038299-101 MYLAR CAP 0.082 UF/100V +-10% 4 PCS C301,C302,C303,C304

204-041099-101 MYLAR CAP 0.1 UF/100V +-10% 3 PCS C309,C310,C325

204-041599-101 MYLAR CAP 0.15 UF/100V +-10% 2 PCS C321,C322

206-104148-000 DIODE IN-4148 38.39.4630.63. 22 PCS D201,D202,D302-D305,D401,D406,D407,D412-

2 - 7

206-200043-102 ZENER 4.3V 1/2W CH818RC 1 PCS D301

206-200051-102 ZENER 5.1V 1/2W #73/AMR209.309 1 PCS D421

206-200056-102 ZENER 5.6V 1/2W CD82/CD978/CH 1 PCS D410

D418,D423-D427

PC-XC350

Page 41

Audio pcb

206-200062-102 ZENER 6.2V 1/2W #826/AMR209. 2 PCS D404,D405

2 - 8

206-200068-102 ZENER 6.8V 1/2W #38/39/63/7013 2 PCS D409,D420

206-200082-102 ZENER 8.2V 1/2W #CD32.42.72.76 1 PCS D403

206-200100-102 ZENER 10V 1/2W CD46.82.86.96. 2 PCS D402,D411

206-305401-000 RECTIFIER IN-5401 #AMR209.309L 1 PCS D422

207-008050-030 TRANSISTOR 8050C/D #38/39/63/ 6 PCS Q204,Q408,Q411,Q416,Q417,Q420

207-009014-030 TRANSISTOR 9014C #38/39/4630/ 28 PCS Q201-Q203,Q207-Q208,Q210,Q301-

Q304,Q306,Q307,Q309,Q402-Q404,Q410Q412,Q415,Q421,Q422,Q424,Q501-Q505

207-009015-030 TRANSISTOR 9015C #38/39/4630/ 6 PCS Q205,Q305,Q308,Q318,Q419,Q423

207-190764-040 TRANSISTOR 2SB-764-D CD85.97 2 PCS Q401,Q409

209-223630-010 I.F.T. AC BIAS 3630 BLACK 10mm 1 PCS T201

210-003126-014 G I.C. ROHM BA3126N PC-X250 1 PCS IC202

210-003852-019 I.C. ROHM BH-3852S CHP-38 1 PCS IC502

210-005417-000 I.C. ROHM BA-5417 AMR209/M9010 1 PCS IC302

210-007345-011 I I.C. AN7345K PANASONIC PC350 1 PCS IC201

PC-XC350

210-007808-000 I.C. KEC KIA-7808P CD32.72.84. 1 PCS IC401

210-015218-014 I.C. ROHM BA-15218N CHP-38 2 PCS IC301,IC501

215-810000-000 SEMI-FIXED FRB-085-10 KOHM 1 PCS VR401

217-040707-000 TACT SWITCH H=4mm W=7x7mm V 1 PCS SW501

219-122335-506 SLIDE SW. SK22F03G6 0306 1 PCS SW201

233-020200-020 HEADER 2 PINS "JST" 2.0mm V 1 PCS CN504

233-020200-025 HEADER 2 PINS "JST" 2.5mm V 2 PCS CN301,CN302

233-030200-025 3 3 PCS CN201,CN401,CN503

233-050200-025 HEADER 5 PINS "JST" 2.5mm V 1 PCS CN202

233-060200-025 HEADER 6 PINS "JST" 2.5 mm V 1 PCS CN402

237-260050-080 JUMPER WIRE #26 50 mm RED 1 PCS Q421 "B" PIN Q415 "C" PIN

240-004000-000 DC JACK DC-400 1 PCS JK401

240-035200-902 STEREO EARPHONE JACK MSJ2000 1 PCS JK301

241-000252-638 G RCA JACK MSP-252V-04 NI PC-X 1 PCS JK501

Page 42

Audio pcb

243-000032-098 DIGITAL OUT JACK GPIF-32T 1 PCS JK502

248-350002-117 I P.C.B. PC-X350 AUDIO BD. 1 PCS

403-000050-000 COPPER JUMPER WIRE 5 mm 13 PCS JP208,JP213,JP219,JP302,JP416,JP417,JP419,JP420,J

P422,JP440,JP442,JP444,JP470

403-000075-000 COPPER JUMPER WIRE 7.5 mm 15 PCS JP201,JP209,JP211,JP214,JP301,JP303,JP304,JP305,J

P306,JP307,JP308,JP412,JP418,JP427,JP436

403-000100-000 COPPER JUMPER WIRE 10 mm 14 PCS JP204,JP205,JP206,JP207,JP403,JP404,JP411,JP415,J

P421,JP423,JP433,JP437,JP438,JP439

403-000125-000 COPPER JUMPER WIRE 12.5 mm 9 PCS JP202,JP203,JP210,JP212,JP401,JP413,JP414,JP430,J

403-000150-000 COPPER JUMPER WIRE 15 mm 3 PCS JP407,JP409,JP410

PC-XC350

2 - 9

Page 43

Rectifier pcb

Parts No. Material Qty Position / ECN

202-632202-802 G CERAMIC CAP 0.022 UF/25V F 4 PCS C1101-C1104

2 - 10

206-305401-000 RECTIFIER IN-5401 #AMR209.309L 4 PCS D1101-D1104

231-220000-250 GLASS TUBE FUSE 2A 250V 5T 1 PCS FUSE1101

233-030200-025 HEADER 3 PINS"JST" 2.5mm V 1 PCS CN1101

248-350012-100 I P.C.B. PC-X350 RECTIFIER BD. 1 PCS

405-002040-000 EYELET 2 x 4 mm 7 PCS

406-050090-000 FUSE HOLDER 5 x 9 mm MW1010K 2 PCS FUSE1101

PC-XC350

Page 44

Control pcb

Parts No. Material Qty Circuit ID

201-021000-185 RESISTOR 1 KOHM +-5% 1/8W 6 PCS R769,R770,R771,R772,R780,R781

201-021200-185 RESISTOR 1.2 KOHM +-5% 1/8W 2 PCS R773,R782

201-021500-185 RESISTOR 1.5 KOHM +-5% 1/8W 2 PCS R774,R783

201-022200-185 RESISTOR 2.2 KOHM +-5% 1/8W 4 PCS R711,R712,R775,R784

201-022700-185 RESISTOR 2.7 KOHM +-5% 1/8W 2 PCS R776,R785

201-023900-185 RESISTOR 3.9 KOHM +-5% 1/8W 2 PCS R777,R786

201-025600-185 RESISTOR 5.6 KOHM +-5% 1/8W 2 PCS R778,R787

201-031000-185 RESISTOR 10 KOHM +-5% 1/8W 1 PCS R779

201-034700-185 RESISTOR 47 KOHM +-5% 1/8W 1 PCS R714

201-041000-185 RESISTOR 100 KOHM +-5% 1/8W 1 PCS R762

201-042700-185 RESISTOR 270 KOHM +-5% 1/8W 1 PCS R763

203-051050-202 ELECT CAP 1 UF/50V +-20% 1 PCS C728

203-054750-202 ELECT CAP 4.7 UF/50V +-20% 1 PCS C731

207-009014-030 TRANSISTOR 9014C #38/39/4630/ 2 PCS Q708,Q710

217-060650450

270-162012-122 ROTARY ENCODER R162EC-AD1- 1 PCS VR701

TACT SWITCH H=5mm W=6x6mm 22 PCS TIMER,SUPER/BASS,POWER,CD,STOP,TAPE,TUNER,MONO/ST(BEAT),C

LOCK,TUNING/PRESET,DISK3/EJECT,DISK2/EJECT,DISK1/EJECT,ALL/EJ

ECT,LONG/PLAY,SEARCH/DOWN,SEARCH/UP,PRESET

EQ,DISK3,DISK2,DISK1

PC-XC350

2 - 11

Loading...

Loading...