Page 1

SERVICE MANUAL

COMPACT COMPONENT SYSTEM

MX-GT88

MX-GT88

B ------------------------ U.K.

E ---- Continental Europe

EN ----- Northern Europe

EV ------- Eastern Europe

CD

3

2

CD

CD

1

Area suffix

STANDBY

ECO

COMPACT COMPONENT SYSTEM MX-GT88

REC START

K

OC

R

/ STOP

CD REC

POP

START

DUBBING

CLASSIC

DISPLAY

MP3

PHONES

SOUND

TURBO

SUBWOOFER LEVEL

U

L

M

O

E

V

M

D

O

N

U

D

E

O

S

TUNING

BEEP

DISC CHANGE

REPEAT

DANCE

PROGRAM

HA

LL

RANDOM

STADIUM

CLOCK

/ TIMER

SET

PRESET

CANCEL

/ DEMO

TAPE A / B

SELECT

DISPLAY MODE

RDS MODE

TUNING

EJECTEJECT

SP-MXGT88 SP-MXGT88CA-MXGT88

Contents

Safety Precautions

Important for laser produbts

Preventing static electricity

Disassembly method

Wiring connection

Adjustment method

COPYRIGHT 2003 VICTOR COMPANY OF JAPAN, LTD.

1-2

1-4

1-5

1-6

1-19

1-20

Flow of functional operation

until TOC read

Maintenance of laser pickup

Replacement of laser pickup

Trouble shooting

Description of major ICs

1-24

1-25

1-25

1-26

1-30~44

No.22075

Jul. 2003

Page 2

MX-GT88

1. This design of this product contains special hardware and many circuits and components specially for safety

purposes. For continued protection, no changes should be made to the original design unless authorized in

writing by the manufacturer. Replacement parts must be identical to those used in the original circuits. Services

should be performed by qualified personnel only.

2. Alterations of the design or circuitr y of the product should not be made. Any design alterations of the product

should not be made. Any design alterations or additions will void the manufacturer`s warranty and will further

relieve the manufacture of responsibility for personal injury or property damage resulting therefrom.

3. Many electrical and mechanical parts in the products have special safety-related characteristics. These

characteristics are often not evident from visual inspection nor can the protection afforded by them necessarily

be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement par ts which

have these special safety characteristics are identified in the Parts List of Service Manual. Electrical

components having such features are identified by shading on the schematics and by ( ) on the Parts List in

the Service Manual. The use of a substitute replacement which does not have the same safety characteristics

as the recommended replacement parts shown in the Parts List of Service Manual may create shock, fire, or

other hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the like to be

separated from live parts, high temperature parts, moving parts and/or sharp edges for the prevention of

electric shock and fire hazard. When service is required, the original lead routing and dress should be

observed, and it should be confirmed that they have been returned to normal, after re-assembling.

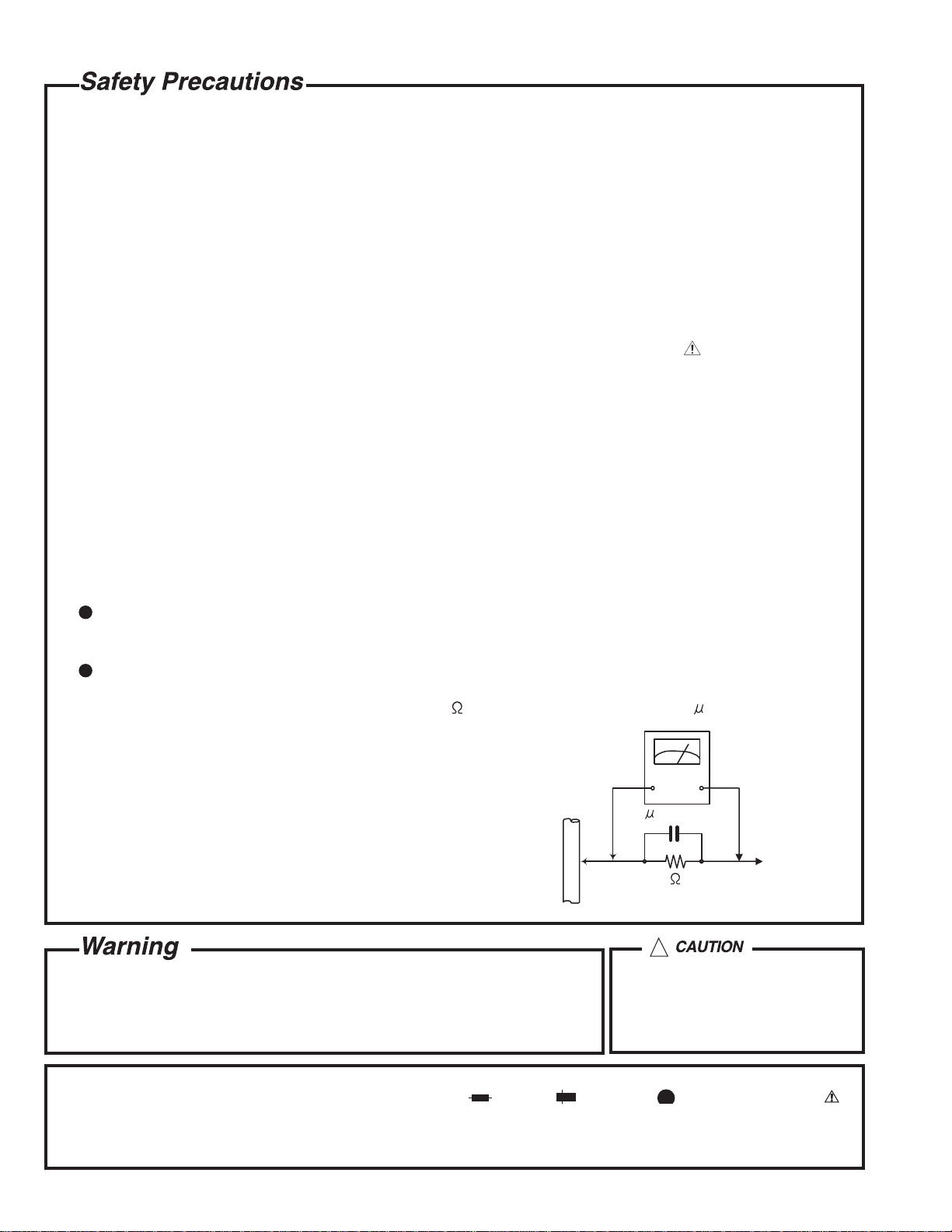

5. Leakage currnet check (Electrical shock hazard testing)

After re-assembling the product, always perform an isolation check on the exposed metal parts of the product

(antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control shafts, etc.) to be sure the

product is safe to operate without danger of electrical shock.

Do not use a line isolation transformer during this check.

Plug the AC line cord directly into the AC outlet. Using a "Leakage Current Tester", measure the leakage

current from each exposed metal parts of the cabinet, particularly any exposed metal part having a return

path to the chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having, 1,000 ohms per volt or more

sensitivity in the following manner. Connect a 1,500 10W resistor paralleled by a 0.15 F AC-type capacitor

between an exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal part,

particularly any exposed metal part having a return path to

the chassis, and meausre the AC voltage across the resistor.

Now, reverse the plug in the AC outlet and repeat each

measurement. Voltage measured any must not exceed 0.75 V

AC (r.m.s.). This corresponds to 0.5 mA AC (r.m.s.).

0.15 F AC TYPE

1500 10W

Good earth ground

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

Place this

probe on

each exposed

metal part.

!

1. This equipment has been designed and manufactured to meet international safety standards.

2. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

3. Repairs m ust be made in accordance with the relevant safety standards.

4. It is essential that safety critical components are replaced by approved parts.

5. If mains voltage selector is provided, check setting for local voltage.

Burrs formed during molding may

be left over on some parts of the

chassis. Therefore, pay attention to

such burrs in the case of

preforming repair of this system.

In regard with component parts appearing on the silk-screen pr inted side (parts side) of the PWB diagrams, the

parts that are printed over with black such as the resistor ( ), diode ( ) and ICP ( ) or identified by the " "

mark nearby are critical for safety.

(This regulation does not correspond to J and C version.)

1-2

Page 3

MX-GT88

(U.K only)

1. This design of this product contains special hardware and many circuits and components specially

for safety purposes. For continued protection, no changes should be made to the original

design unless authorized in writing by the manufacturer. Replacement parts must be identical to

those used in the original circuits.

2. Any unauthorised design alterations or additions will void the manufacturer's guarantee ; further more the

manufacturer cannot accept responsibility f or personal injury or property damage resulting therefrom.

3. Essential safety critical components are identified by ( ) on the Parts List and by shading on the

schematics, and must never be replaced by parts other than those listed in the manual. Please note

however that many electrical and mechanical parts in the product have special safety related

characteristics. These characteristics are often not evident from visual inspection. Parts other than

specified by the manufacturer may not have the same safety characteristics as the recommended

replacement parts shown in the Parts List of the Service Manual and may create shock, fire, or

other hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the

like to be separated from live parts, high temperature parts, moving parts and/or sharp edges

for the prevention of electric shock and fire hazard. When service is required, the or iginal lead

routing and dress should be observed, and it should be confirmed that they have been returned

to normal, after re-assembling.

1. Service should be performed by qualified personnel only.

2. This equipment has been designed and manufactured to meet international safety standards.

3. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

4. Repairs must be made in accordance with the relevant safety standards.

5. It is essential that safety critical components are replaced by approved parts.

6. If mains voltage selector is provided, check setting for local voltage.

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

1-3

Page 4

MX-GT88

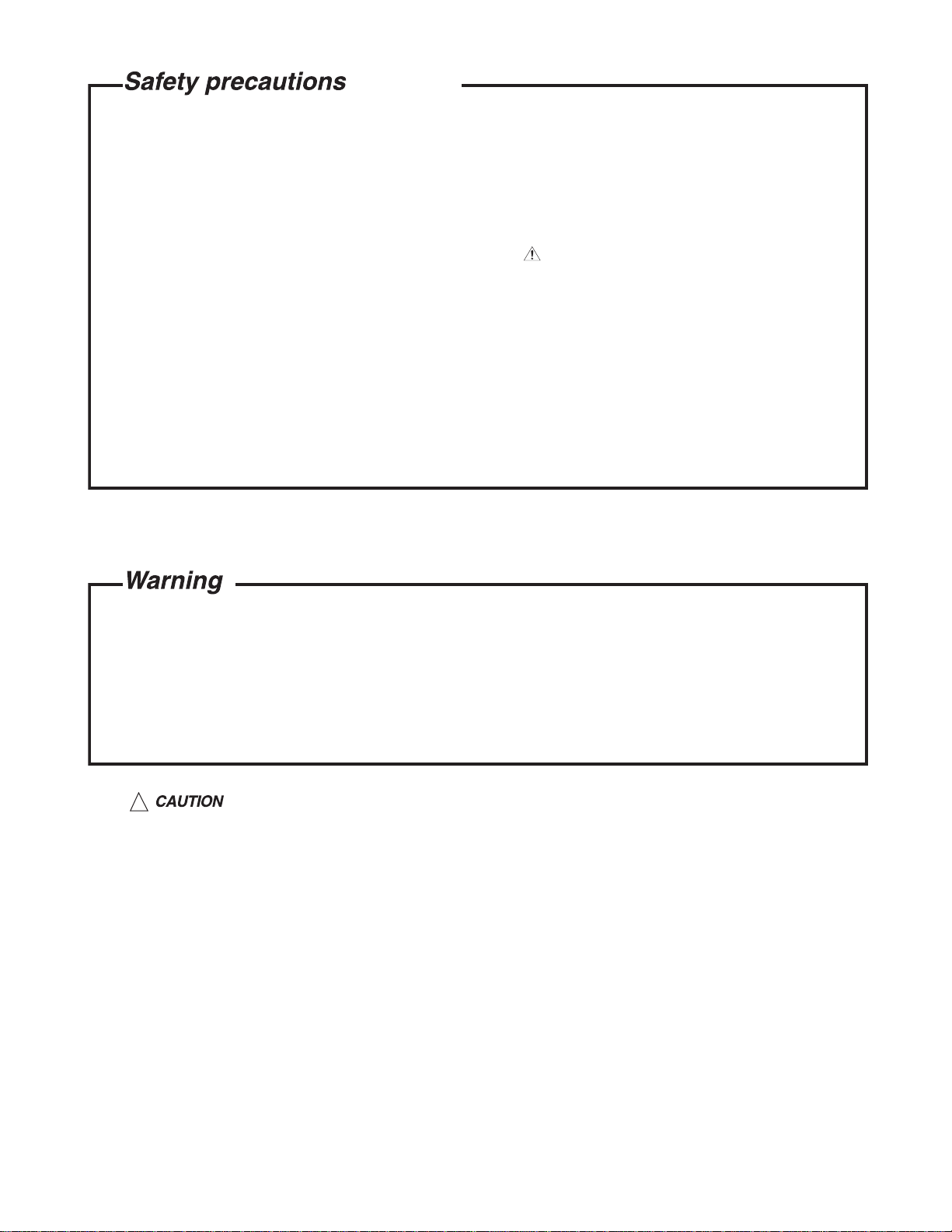

Important for laser products

1.CLASS 1 LASER PRODUCT

2.DANGER : Invisible laser radiation when open and inter

lock failed or defeated. Avoid direct exposure to beam.

3.CAUTION : There are no serviceable parts inside the

Laser Unit. Do not disassemble the Laser Unit. Replace

the complete Laser Unit if it malfunctions.

4.CAUTION : The compact disc player uses invisible

laserradiation and is equipped with safety switches

whichprevent emission of radiation when the drawer is

open and the safety interlocks have failed or are de

feated. It is dangerous to defeat the safety switches.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified herein may result in

hazardous radiation exposure.

CAUTION

!

REPRODUCTION AND POSITION OF LABELS

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

CLASS 1

LASER PRODUCT

WARNING LABEL

1-4

Page 5

Preventing static electricity

MX-GT88

1. Grounding to prevent damage by static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged,

can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

2. About the earth processing for the destruction prevention by static electricity

In the equipment which uses optical pick-up (laser diode), optical pick-up is destroyed by the static electricity of

the work environment.

Be careful to use proper grounding in the area where repairs are being performed.

2-1 Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over

it before placing the traverse unit (optical pickup) on it.

2-2 Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

Conductive material

(conductive sheet) or iron plate

3. Handling the optical pickup

1. In order to maintain quality during transport and before installation, both sides of the laser diode on the

replacement optical pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

2. Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power

source can easily destroy the laser diode.

4. Handling the traverse unit (optical pickup)

1. Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

2. Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific

details, refer to the replacement procedure in the text. Remove the anti-static pin when replacing the traverse

unit. Be careful not to take too long a time when attaching it to the connector.

3. Handle the flexible cable carefully as it may break when subjected to strong force.

4. It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it

Attention when CD mechanism assembly is decomposed

*Please refer to "Disassembly method" in the text for pick-up and how to

detach the CD mechanism assembly.

1. Remove the CD changer unit.

2. Remove the CD changer mechanism.

3. Solder is put up before the card wire is removed from the pickup unit

connector on the CD mechanism assembly.

(When the card wire is removed without putting up solder, the CD pick-up

assembly might destroy.)

4. Please remove solder after connecting the card wire with the pickup unit

connector when you install picking up in the substrate.

Card wire

Picup unit

connector

Soldering

Fig.2

CD changer unit

Fig.1

Card wire

Picup unit

connector

CD changer

mechanism

1-5

Page 6

MX-GT88

Disassembly method

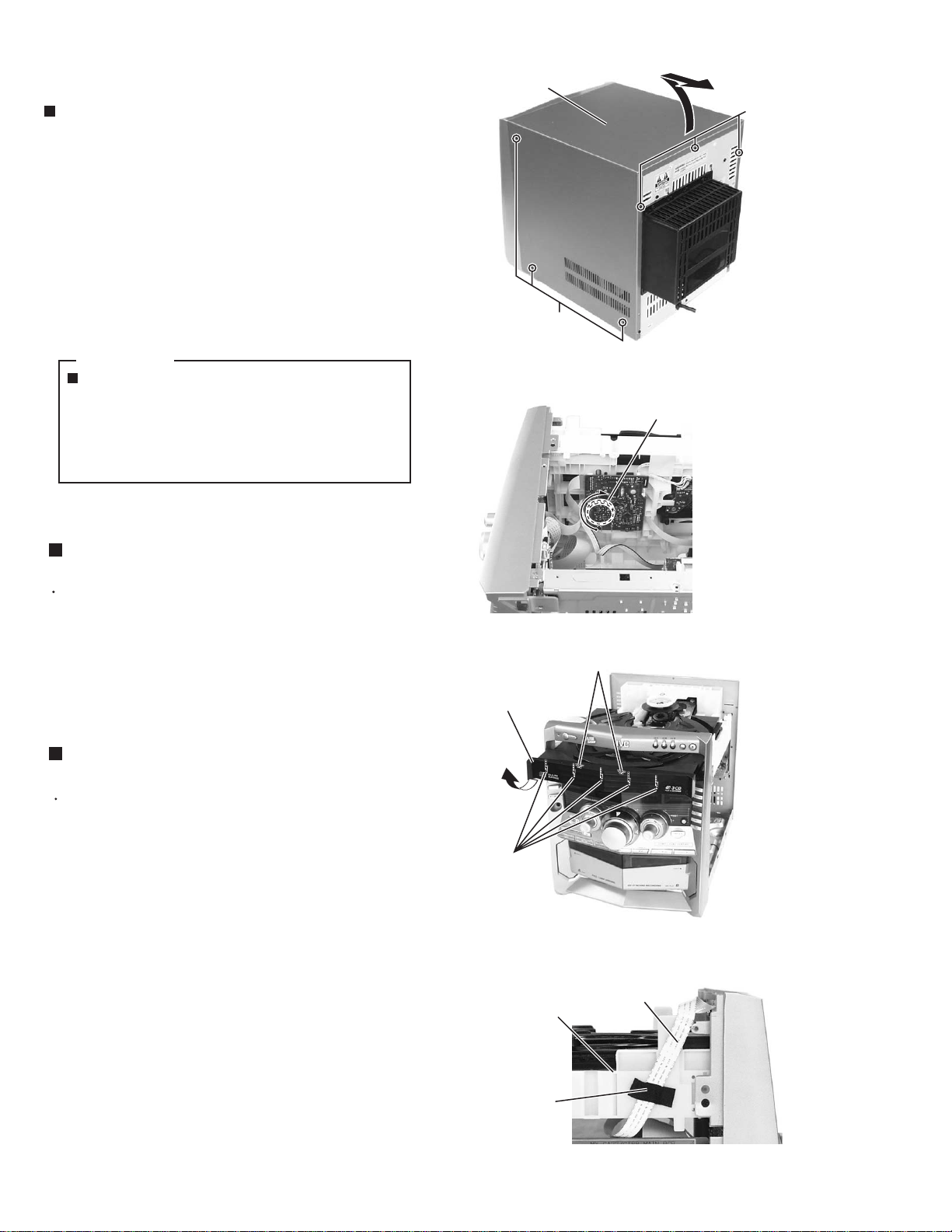

Removing the metal cover (See Fig.1)

1.

Remove the three screws A attaching the metal

cover on the back of the body.

2.

Remove the six screws B attaching the metal cover

on both sides of the body.

3.

Remove the metal cover from the body by lifting the

rear part of the cover.

ONE POINT

How to eject the CD tray manually

(see fig.2)

Turn the loading pulley gear at the bottom of

the CD changer unit as shown in Fig.2 and

draw the CD tray toward the front.

Metal cover

A

B

(both sides)

Fig.1

Loading pulley gear

(See <CD changer unit>fig.1)

Removing the CD tray fitting

(See Fig. 3)

Prior to performing the following procedure, eject the

CD tray.

After drawing the lower part of the tray fitting toward

1.

the front, remove the five claws. Then, while moving

the tray fitting upward, remove it.

Removing the CD changer unit

(See Fig.4 to 7)

Prior to performing the following procedure, remove

the metal cover and CD tray fitting.

1.

Remove the card wire attached to CD changer unit

on the adhesion tape.

2.

Disconnect the card wire from the connector CW105

on the CD board.

3.

Disconnect the harness from the connector CW104

on the main board.

4.

Remove the two screws C attaching the CD changer

unit to the rear panel.

Fig.2

Joint

CD tray fitting

Claw

Fig.3

Card wire

CD changer unit

5.

Remove the two screws D attaching the CD changer

unit to both sides of the front panel assembly.

6.

Draw the CD changer unit upward from behind while

pulling the rear panel outward.

1-6

Adhesion tape

Fig.4

Page 7

MX-GT88

CW105

CD board

CD changer unit

CW104

Main board

Fig.5

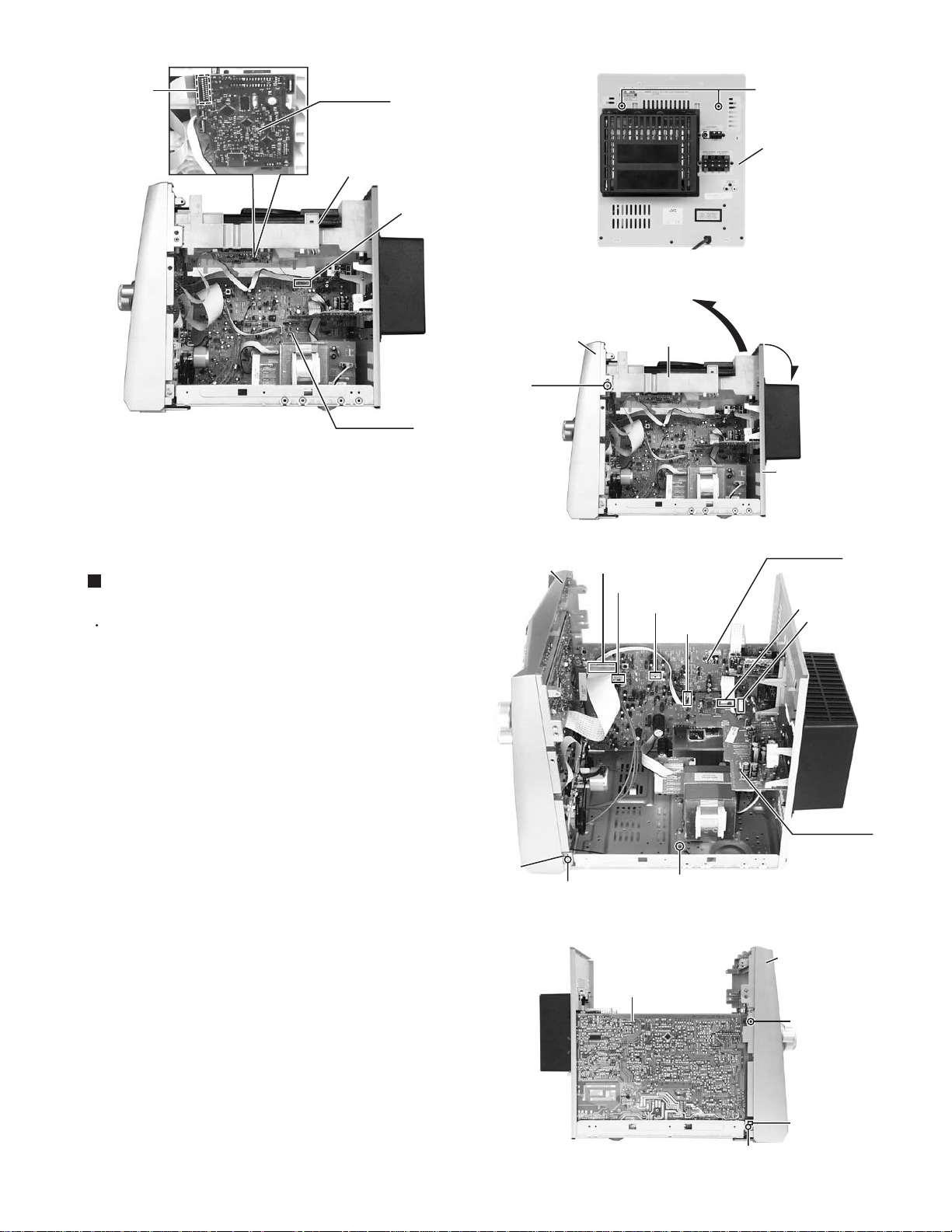

Removing the front panel assembly

(See Fig.8 to 10)

Prior to performing the following procedure, remove

the metal cover and CD changer unit.

Front panel

assembly

D

(both sides)

Front panel

assembly

Fig.6

CD changer unit

Fig.7

CW101

CW109

CW110

C

Rear panel

Rear panel

Main board

ACW1

ACW2

CW108

1.

Disconnect the card wire from the connector CW101

on the main board.

2.

Disconnect the harness from the connector CW108,

CW109 and CW110 on the main board.

3.

Remove the screw E fixiing the lug wire.

4.

Remove the two screws F attaching the front panel

assembly to both sides of the body.

5.

Remove the screw G attaching the main board to the

front panel assembly.

6.

Remove the screw H attaching the front panel

assembly to bottom of the body.

7.

Release the two joints1 and two joints2, and detach

the front panel assembly toward the front.

Joint1

(both sides)

(both sides)

F

Fig.8

Main board

Fig.9

E

(fixing the lug wire)

F

(both sides)

Amp. board

Front panel

assembly

G

Joint1

(both sides)

1-7

Page 8

MX-GT88

)

Removing the heat sink & amp. board

(See Fig.8, 11 and 12)

Prior to performing the following procedure, remove

the metal cover and CD changer unit.

1.

Disconnect the card wire from the connector ACW1

and the harness from the connector ACW2 on the

amp. board.

2.

Remove the four screws I attaching the heat sink

cover to the rear panel. Remove the heat sink cover.

3.

Remove the four screws J attaching the heat sink

and two screws K attaching the speaker terminal to

the rear panel.

4.

After moving the heat sink upward, remove the

claws. Then pull out the heat sink & amp. board

inward.

Heat sink

cover

H

Joint2

Fig.10

(Bottom side

Rear panel

I

I

Removing the tuner board

(See Fig.12 and 13)

Prior to performing the following procedure, remove

the metal cover.

1.

Disconnect the card wire from the connector CON01

on the tuner board.

2.

Remove the two screws L attaching the tuner board

to the rear panel.

Removing the rear panel (See Fig.12)

Prior to performing the following procedure, remove

the metal cover, CD changer unit, heat sink & amp.

board and tuner board.

1.

Remove the three screws M and three screws N

attaching the rear panel.

J

Claws

Heat sink

J

N

Main board

Fig.11

Rear panel

L

K

Speaker

terminal

M

Fig.12

CON01

Rear panel

1-8

Tuner board

Fig.13

Page 9

MX-GT88

3

Removing the main board (See Fig. 14)

Prior to performing the following procedure, remove

the metal cover, CD changer unit and rear panel.

1.

Disconnect the card wire from the connector CW101,

and the harness from the connector CW108,

CW109, CW110 and CW11, and the power cord

from the connector PW103 on the main board.

2.

Disconnect the harness from the connector PCW1

on the fuse board.

3.

Remove the screw G attaching the main board to the

front panel assembly. (See Fig.9)

4.

Remove the two screws O attaching the heat sink to

the bottom chassis.

Removing the power cord (See Fig. 14)

Prior to performing the following procedure, remove

the metal cover, CD changer unit and rear panel.

CW108

Fuse board

PCW1

PW102

Bottom chassis

Power supply board

Power ICs solder point

CW101

CW109

CW110

Main board

Heat sink

PW10

CW11

O

Power cord

Power cord stopper

Fig.14

Heat sink

1.

Disconnect the power cord from the connector

PW103 on the main board and pull up the power

cord stopper upward.

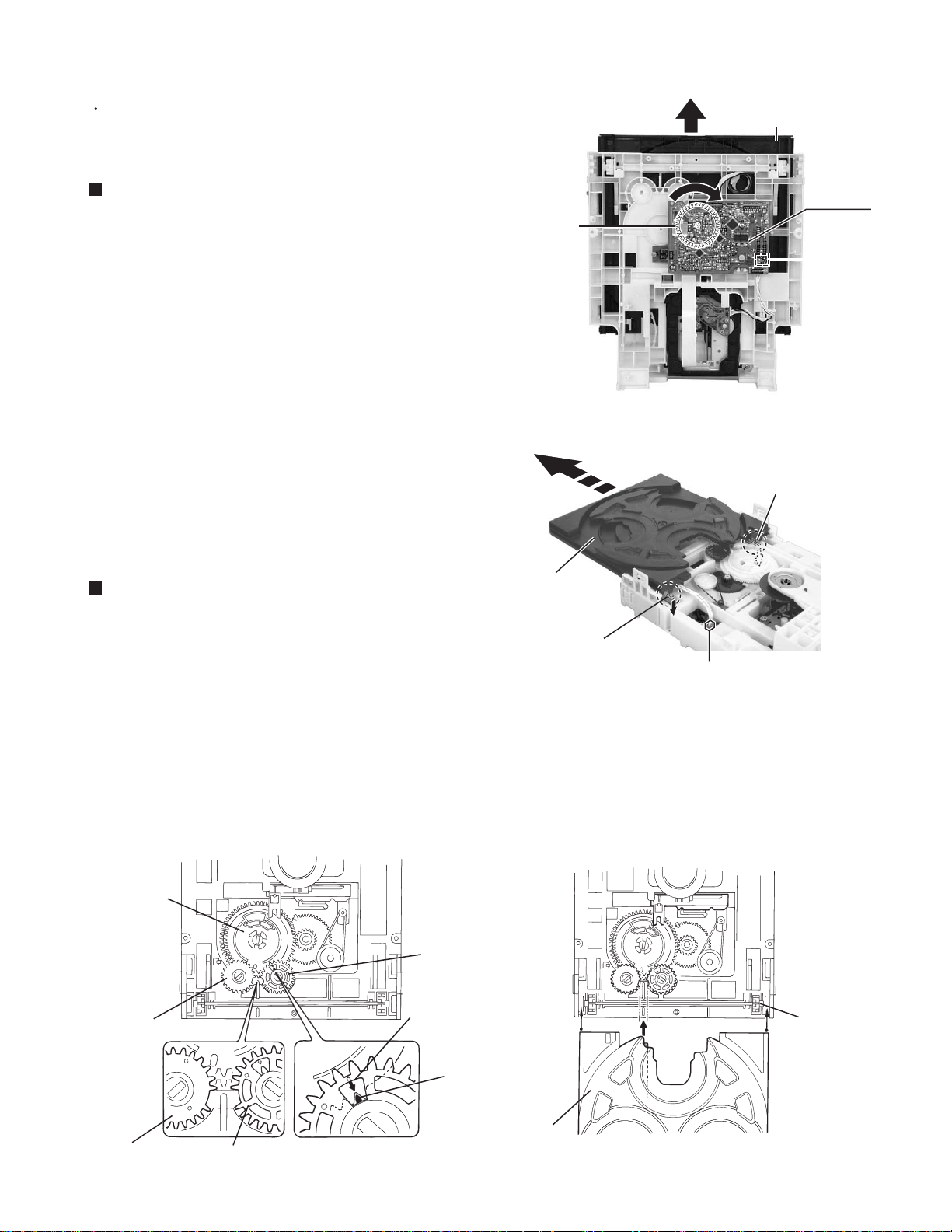

Removing the power ICs

(See Fig.15 and 16)

Prior to performing the following procedure, remove

the metal cover, CD changer unit and heat sink &

amp. board.

1.

Unsolder the power ICs solder points.

2.

Remove the four screws P attaching the power ICs

to the heat sink.

Removing the power transformer

(See Fig .17)

Prior to performing the following procedure, remove

the metal cover, CD changer unit and heat sink &

amp. board.

1.

Disconnect the harness from the connector PW102

on the power supply board.

Fig.15

Fig.16

Power transformer

P

Amp. board

(reverse side)

Heat sink

Amp. board

Fuse board

PCW1

2.

Disconnect the harness from the connector PCW1 on

the fuse board.

3.

Remove the four screws Q attaching the power

transformer on the bottom chassis.

Bottom

chassis

Q

Power supply board

PW102

Fig.17

1-9

Page 10

MX-GT88

<Front panel assembly>

Prior to performing the following procedure, remove

the front panel assembly.

Removing the CD switch board (See Fig.1)

1.

Disconnect the card wire from the connector UCW03

on the CD switch board.

2.

Remove the five screws A attaching the CD switch

board.

Removing the front board

(See Fig.1 and 2)

1.

Pull out the sound mode knob, volume knob, and

preset knob from the front side of front panel

assembly.

2.

Disconnect the card wire from the connector UCW02

on the front board and the connector on the mecha.

board.

3.

Remove the fifteen screws B attaching the front

board.

B

B

Connector

Mecha.

board

Front panel assembly (inner side)

A

Fig.1

CD switch board

UCW03

Front board

UCW02

UCW01

4.

Disconnect the card wire from the connector UCW01

on the front board.

Removing the headphone jack board

(See Fig.3)

Prior to performing the following procedure remove

the front board.

1.

You can pull out the headphone jack board.

Removing the cassette mechanism

assembly (See Fig.3)

1.

Disconnect the card wire from the connector on the

mecha. board.

2.

Remove the six screws C attaching the cassette

mechanism assembly.

Connector

C

Mecha.

board

Sound mode knob

Volume knob

Preset knob

Fig.2

Front panel assembly (inner side)

Headphone

jack board

C

1-10

C

(fixing the lug wire)

Fig.3

Cassette mechanism

assembly

Page 11

MX-GT88

<CD changer unit>

Prior to performing the following procedure, remove

the CD changer unit.

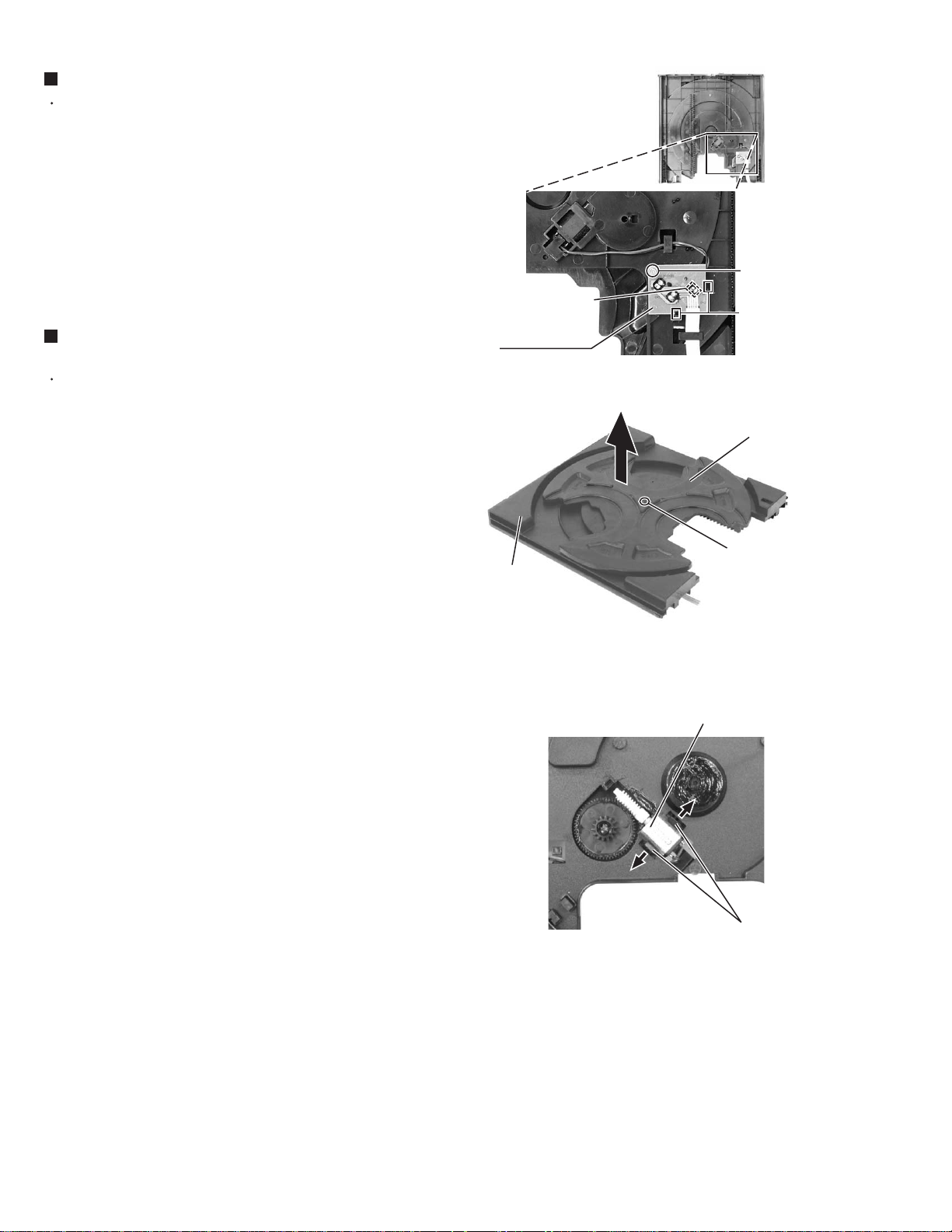

Removing the CD tray (See Fig.1 and 2)

1.

Turn the black loading pulley gear on the under side

of the CD changer unit in the direction of the arrow

and draw the CD tray toward the front until it stops.

2.

Disconnect the card wire from connector CW103 on

the CD board.

3.

Push down the two tray stoppers marked a and pull

out the CD tray.

Loading pulley

gear

CD changer uint (reverse side)

CD tray

CD board

CW103

Fig.1

a (Tray stopper)

Reinstall the CD tray (See Fig.3 and 4)

1.

Align the gear-cam with the gear-tray as shown fig.3,

then mount the CD tray.

2.

When assembling the CD tray, take extreme care not

engage with gear - synchro.

Gear-cam

Gear-convert

Gear-cam

timing point

CD tray

a

(Tray stopper)

CW103

(on the CD board)

Fig.2

Gear-tray

Gear-synchro

Gear-convert

Gear-tray

CD tray

Gear-tray

Fig.3 Fig.4

1-11

Page 12

MX-GT88

Removing the sensor board (See Fig.5)

Prior to performing the following procedure, remove

the CD tray.

1.

Remove the screw A attaching the sensor board on

the CD tray.

2.

Remove the sensor board releasing the two tabs a.

3.

Disconnect the harness from the connector CW1 on

the sensor board.

Removing the turn tray motor

(See Fig.6 and 7)

Prior to performing the following procedure, remove

the CD tray and sensor board.

1.

Remove the screw B attaching the turn tray. Detach

the turn tray from the base tray.

2.

Pull outward the tab b attaching the turn tray motor

on the base tray and detach the turn tray motor.

CD tray (reverse side)

A

CW1

Tab a

Sensor board

Fig.5

Turn tray

Introductory notes:

Base tray + Turn tray = CD tray

Base tray

B

Fig.6

Turn tray motor

Base tray (upper side)

Tab b

Fig.7

1-12

Page 13

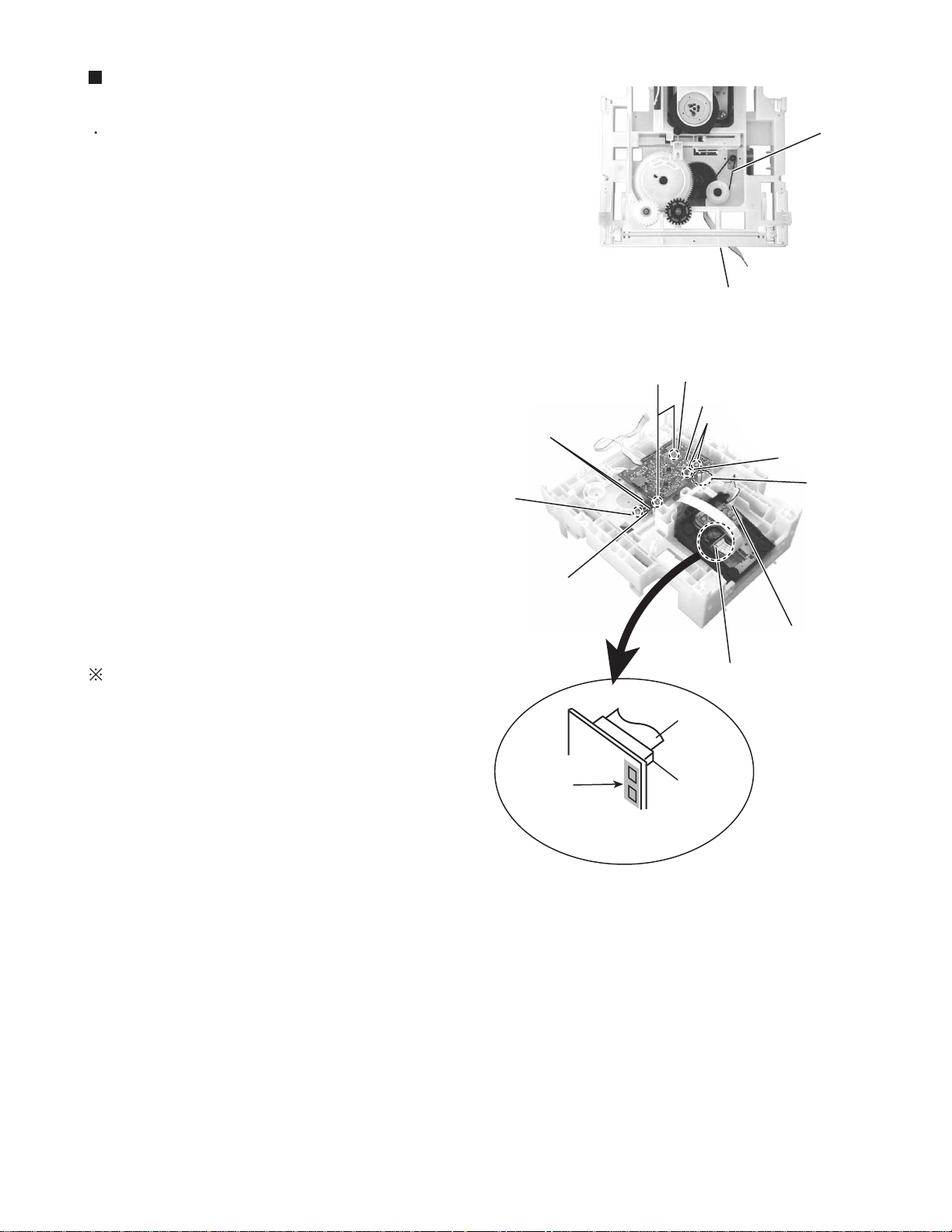

Removing the belt, the CD board and the

switch board (See Fig.8 and 9)

Prior to performing the following procedure, remove

the CD tray.

1.

Detach the belt from the pulley on the upper side of

the CD changer unit (Do not stain the belt with

grease).

2.

Disconnect the card wire from the pickup unit

connector on the under side of the CD changer unit.

Attention : Solder is put up before the card wire is

removed from the pick-up unit

connector on the CD mechanism

assembly.

(When the card wire is removed without

putting up solder, the CD pick-up unit

assembly might destroy.)

3.

Disconnect the motor wire harness from connector

on the CD board.

4.

Remove the screw C attaching the switch board and

release the two tabs e attaching the switch board

outward and detach the switch board.

5.

Remove the two screws D attaching the CD board.

First release the two tabs f and two tabs g attaching

the motor, then release the CD board.

If the tabs f and g are hard to release, it is

recommendable to unsolder the two soldered parts

on the motor terminal of the CD board.

Tabs e

C

Switch board

CW3

CD changer unit

Fig.8

CD board

D

Tabs g

Soldered parts

CD mechanism board

motor connecter

Pickup unit connector

Card wire

MX-GT88

Belt

Motor

Tabs f

Soldering

Picup unit

connector

Fig.9

1-13

Page 14

MX-GT88

Removing the CD mechanism holder

assembly (mechanism included)

(See Fig.10 to 13)

1.

Disconnect the harness from connector on the CD

mechanism board in the CD mechanism assembly

on the under side of the CD changer unit. Disconnect

the card wire from the pickup unit connector.

Attention : Solder is put up before the card wire is

removed from the pick-up unit

connector on the CD mechanism

assembly. (Refer to Fig.9)

(When the card wire is removed without

putting up solder, the CD pick-up unit

assembly might destroy.)

Motor connecter

CD changer unit

CD mechanism holder assembly

Pickup unit connector

2.

Remove the screw E attaching the shaft on the right

side of the CD mechanism holder assembly. Pull

outward the stopper fixing the shaft on the left side

and remove the CD mechanism holder assembly

from behind in the direction of the arrow y.

3.

Turn the CD mechanism holder assembly half

around the lift up slide shaft h of the CD mechanism

holder assembly until the turn table is reversed, and

pull out the CD mechanism holder assembly.

Lift up slide shaft

Fig.10

E

Stopper

CD mechanism holder assembly

Fig.11

Lift up slide shaft n

1-14

CD mechanism holder assembly

Fig.13

y

CD mechanism holder assembly

Fig.12

Page 15

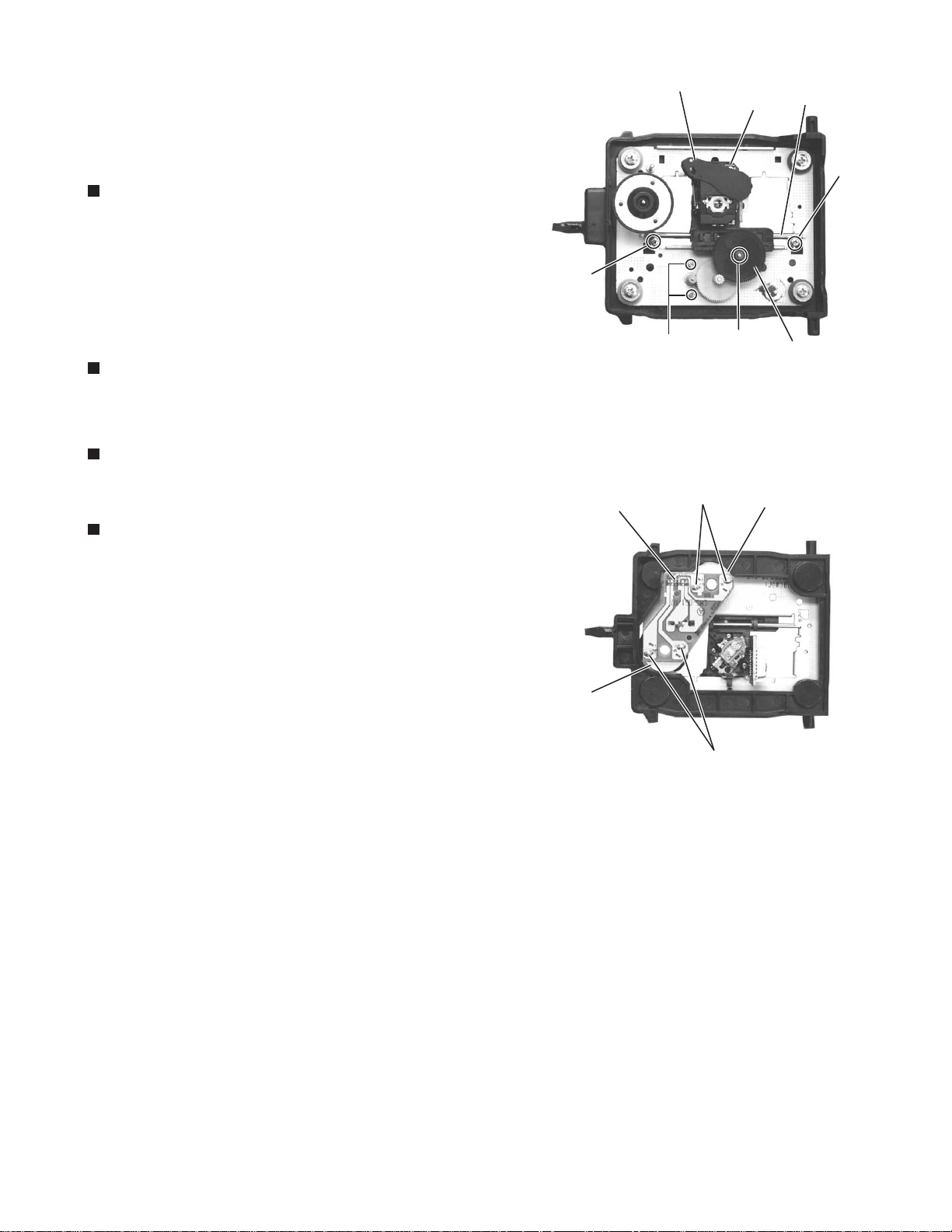

MX-GT88

<CD mechanism section>

•

Removing the CD mechanism holder from the CD

chager unit.

(Refer to "Removing the CD mechanism holder

assembly" )

Removing the pickup unit (

1. Removing the cut washer on the feed gear

sleeve and pull out the feed gear.

2. Remove the two screws A fixing the pickup

shaft.

3. Removing the pickup unit.

Removing the motor board

1. Unsolder the motor terminal on the motor board.

2. Remove the moter board.

Removing the feed motor (

Remove the two motor fixing screws at B and

removing the feed motor.

See Fig.1)

(See Fig.2)

See Fig.1)

A

Motor board

Shutter

Cut washer

B

Fig.1

Unsolder

Pickup unit

Feed Gear

Feed motor

Shaft

A

Removing the spindle motor

The spindle motor cannot be removed as a single

unit.

When removing the spindle motor, change the chasis

and turntable together as aunit.

Spindle motor

Unsolder

Fig.2

1-15

Page 16

MX-GT88

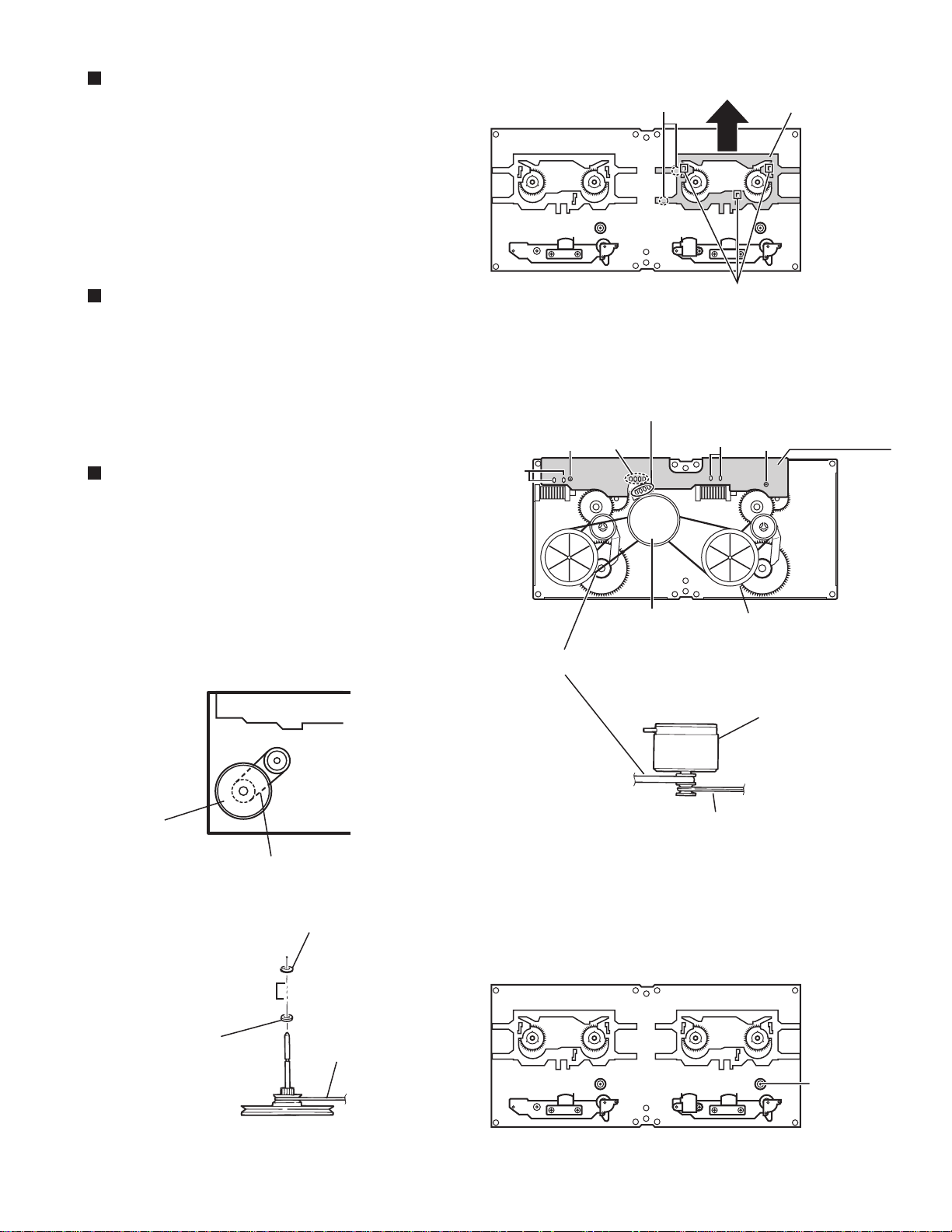

<Cassette mechanism section>

Prior to performing the following procedure, remove

the

cassette mechanism assembly.

Removing the R/P head.

(See Fig.1 and 2)

1.

Remove the screw A on the right side of the R/P

head.

2.

Remove the screw B on the left side of the R/P

head.

Remove the erase head.

1.

Remove the screw C fixing the erase head.

(See Fig.1)

E. Head

R/P Head

C

B

B

Pinch roller

A

Fig.1

A

Remove the pinch roller.

Pull out the pinch roller stopper.

1.

Pull out the pinch roller.

2.

(See Fig.3)

Spring

Pinch roller

R/P Head

Fig.2

Pinch roller

stopper

Fig.3

1-16

Page 17

MX-GT88

Removing the motor

1.

Slide the plastic cover in the direction of the arrow,

and remove the three claws. Then remove the

plastic cover.

2.

Remove the two screws D fixing the motor.

Be careful to grease's splash when the drive belt

comes off.

3.

Unsolder the motor terminal.

(See Fig. 4 to 6)

Removing the mechanism board

1.

Unsolder the four solder parts a and the four solder

parts b.

2.

Remove the two screws E attaching the mecha.

board.

(See Fig. 5)

Removing the flywheel

1.

Remove the cut-washer at c from the capstan shaft,

then remove the flywheel.

When reassembling the flywheel, be sure to use new

washers as they cannot be reused.

(See Fig. 7 and 9)

Solder

part

D

Claw

Fig.4

Motor

b

terminal

Solder

part

a

Solder

part

E

a

Plastic cover

Mecha. board

E

Flywheel

Washer

FR belt

Fig.8

Sleeve

c

FR belt

Drive belt

Motor

Drive belt

Fig.5

Motor

Drive belt

Fig.6

Fig.9

Capstan

washer

Fig.7

1-17

Page 18

MX-GT88

< Speaker section >

It is exchange in a unit.

Please do not decompose as much as possible.

Removing the duct (See Fig. 1)

1.

Remove the foru screws A and two screws B

attaching the duct, and remove the duct.

Duct

B

(both sides)

A

(both sides)

Fig.1

1-18

Page 19

MX-GT88

Wiring connection

Amp. board

0

9

Front board

UCW02

AH39-00295A

3809-001413

ACW2

ACW1

CD switch board

3809-001228

UCW03

UCW04

UCW05

UCW01

9

Power transformer

0

PW102

PCW1

9

0

3809-001121

AH39-00338A

AH39-00466A

CD mechanism

AH39-20561P

CW2

AAN1

CW1

CW3

AH38-12001A

9

0

Color codes are shown below.

1 Brown

2 Red

3 Orange

4 Yellow

5 Green

6 Blue

7 Violet

0

9

8 Gray

9 White

0 Black

0

2

0

2

3809-001034

CW102

CW103

CW105

CW106

9

0

CD board

CW107

CW101

CW104

CW3

AH39-00060A

3809-001211

3809-001434

CON01

0

0

9

3809-001259

9

0

9

0

9

0

CW103

9

0

CW105

CW104

PW103

CW11

CW106

9

0

9

AH39-00247A

0

CW108

Main board

CW110

Tuner board

CW101

CW111

CW109

CW107

9

0

0

9

2

2

0

CW01B

9

0

Headphone J.board

9

AH39-00022A

0

9

2

0

88

9

9

0

9

2

0

AH39-20002D

8

2

8

2

1-19

Page 20

MX-GT88

Adjustment method

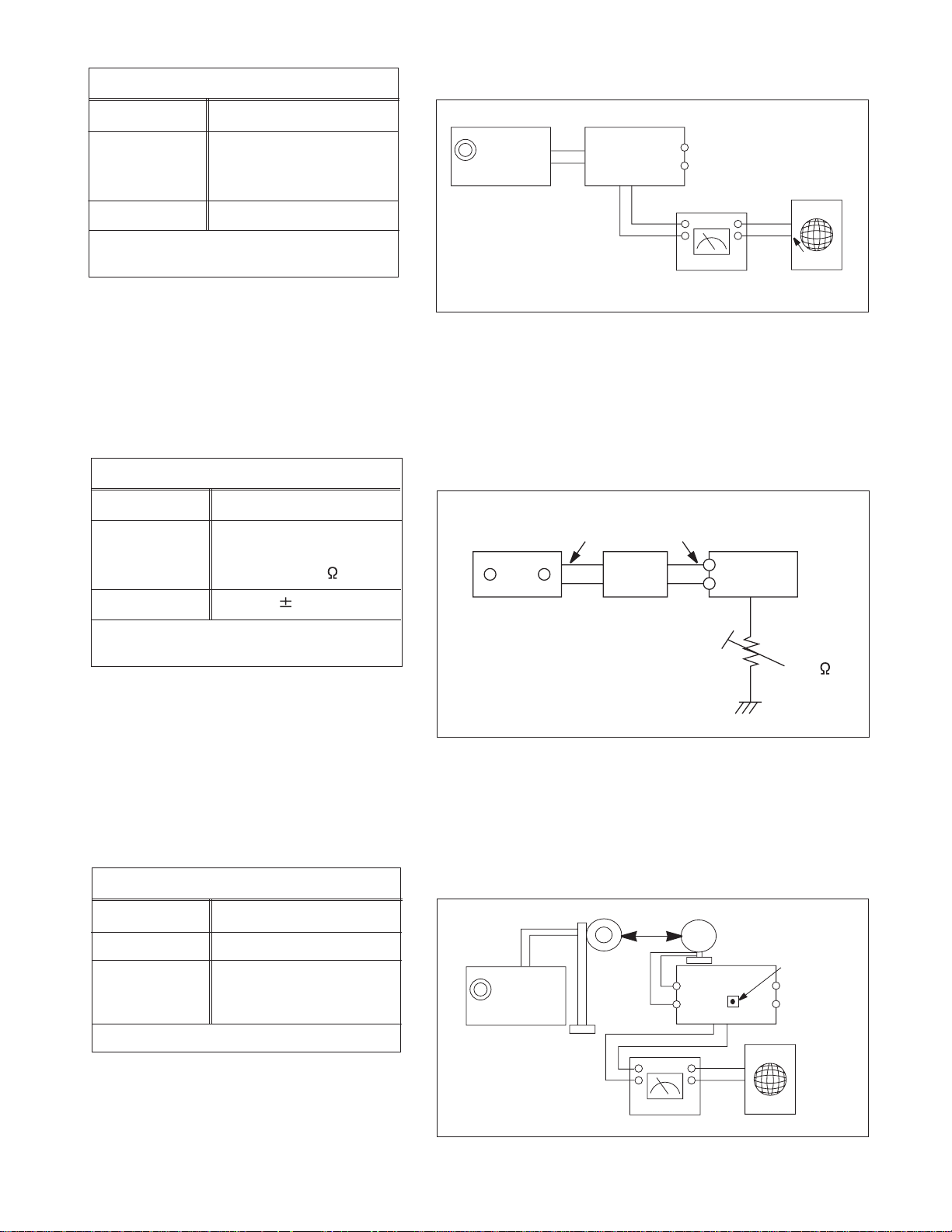

1. Tuner

ITEAM

Received FREQ.

Adjustment

point

Output

* Adjustment Location of Tuner PCB

AM(MW) OSC

Adjustment

522~1629 KHz

MO

1~7.0 0.5V

MAIN

PCB

AM(MW) RF

Adjustment

594 KHz

MA

Maximum

Output(Fig.1)

VT GND

TESTER

1-20

Fig.1 OSC Voltage

Page 21

FM THD Adjustment

MX-GT88

SSG FREQ.

98 MHz

Adjustment

point

FM DETECTOR COIL

(FM DET)

Output

60 dB

Minumum Distortion (0.4% below)

(Fig.2)

FM Search Level Adjustment

SSG FREQ.

Adjustment

point

(SVR1)

BEACON

SENSITIVITY

SEMI-VR(10K )

98 MHz

Output

GND

FM

Antenna

Terminal

SET

FM S.S.G

Speaker

Terminal

output

Distortion Meter

Fig.2 IF CENTER and THD Adjustment

28 dB

FM Antenna

Input

Oscilloscope

Input

SET

Output

28 dB(

2dB)

Adjust SVR1 (Fig.3)

*Adjust FM S.S.G level to 28dB

AM(MW) I.F Adjustment

SSG FREQ.

Frequency

450 kHz

522 kHz

Adjustment

point

AM IF

Maximum output (Fig.4)

FM S.S.G

GND

FM IN

Fig.3 FM Auto Search Level Adjustment

60cm

OUTPUT

AM SSG

450KHZ

AM ANT

IN

20 k

AM IF

Speaker Terminal

INPUT

VTVM Oscilloscope

OUTPUT

Fig.4 AM I.F Adjustment

1-21

Page 22

MX-GT88

2. Cassette Deck

To adjust tape speed

Notes

1) Measuring tape:

i) VT-712/MTT-111(or equivalent)

(Tapes recorded with 3kHz)

ii) AC-225/MTT-5512(or equivalent)

2) Connect the cassette deck to the frequency counter

as in fig.1.

Cassette Deck

SPK OUT

Frequency Counter

output

Fig.1

Pre-Setup

Condition

NOR

1 3KHz

SPEED

Control

SPK OUT

(connected to the

frequency counter)

1) Deck 1:VT-712

2) Press PLAY

SW button

To Adjust

Turn VSR1 to

left and right

(FRONT PCB)

3) Deck 2:Same

as above

To adjust plabyback level/REC

Notes

1) Before the actual adjustment, clean the play/recording head.

2) Measuring tape :

i) VT-703/MTT-114N(or equivalent 10kHz AZIMUTH control)

ii) AC-225/MTT-5512(or equivalent)

3) The cassette deck is connections as shown in fig.2.

MAIN PCB

SPK OUT

(GND)

Fig.2

VTVM

In Out

RemarkStandardPre-SetupItemStep

1%

range

Oscilloscope

1. Adjust Deck 1 Play Level

Pre-Setup

Condition

AZIMUTH1 SPK OUT

(VTVM is

connected to

the scope)

1-22

After putting VT-703

into Deck 1

- Press FWD PLAY

button.

To Adjust

Turn the control

screw to as

shownin Fig.3.

Max output

and same phase

(both channels)

RemarkStandardPre-SetupItemStep

After

adjustment

secure it with

REGION

LOCK.

Page 23

2. Adjust Deck 2 Play Level/REC BIAS

MX-GT88

2

AZIMUTH1

Recording

Bias

Voltage

Pre-Setup

Condition

SPK OUT

(VTVM is

connected to

the scope)

Fig.4

Recording /Play head

AZIMUTH control screw

(FWD Play)

After putting VT-703

into Deck 2

1)Press FWD PLAY

button.

After putting AC-225

into Deck 2

1)Press REC PLAY

button.

2)TAPE PCB JCW3,

connectted to VTVM

To Adjust

Turn the control

screw to as

shown in Fig.3.

Turn JSR2L,

JSR2R to the

right and left

Max output

and same phase

(both channels)

CHECK TO

7mV(

0.5mV)

RemarkStandardPre-SetupItemStep

After

adjustment

secure it with

REGION

LOCK.

AZIMUTH control screw

(RVS Play)

Audio OSC.

Fig.3

AUX IN

SET

(MAIN PCB)

IN

TP

SPK OUT

Fig.4

VTVM

IN OUT

Oscilloscope

1-23

Page 24

MX-GT88

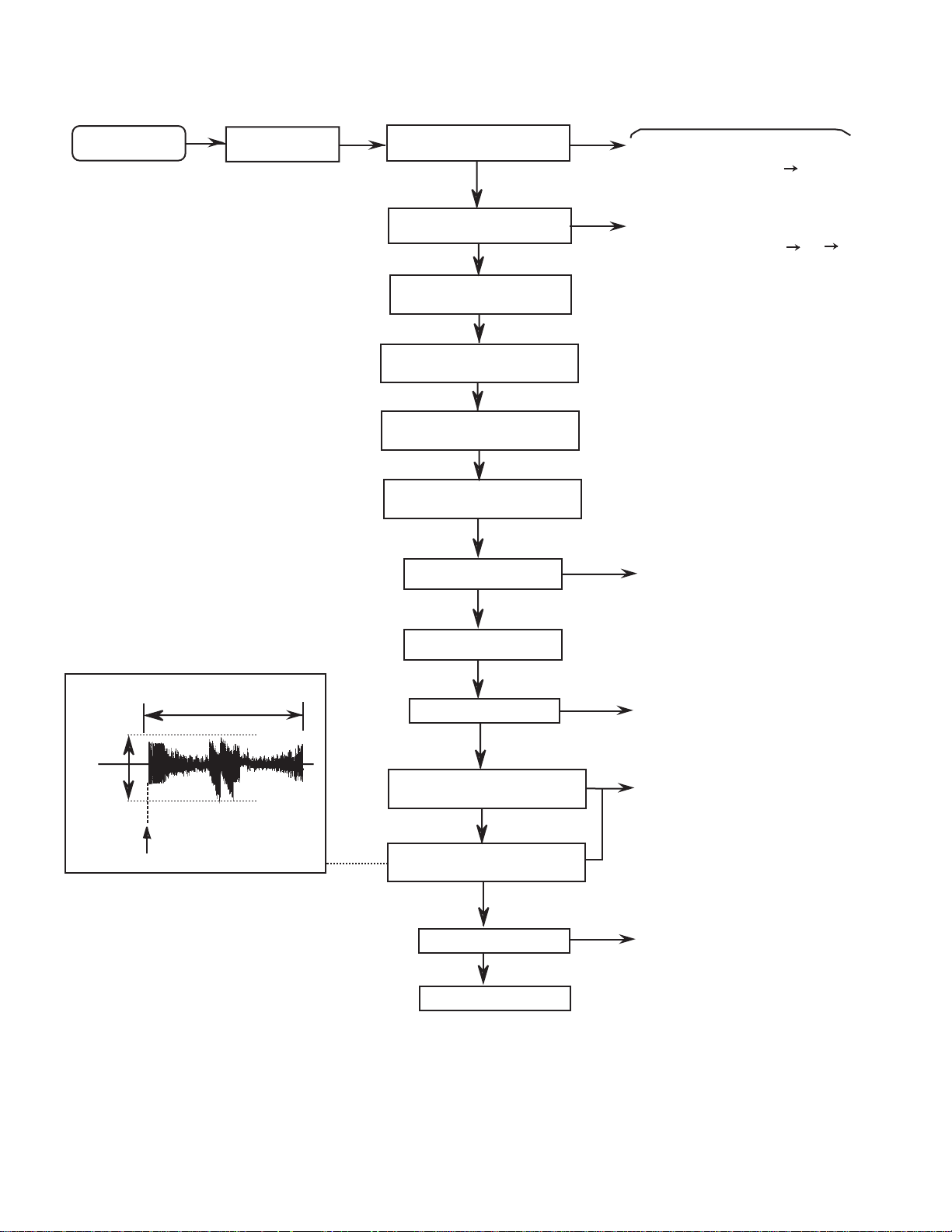

Flow of functional operation until TOC read

Power ON

Play Key

RESET a CD LSI

Check Point

Confirm that the voltage at the pin17

of KB9226(IC101) is "L" "H".

LIMIT SW ON

SET Default value of

TE gain, TE balance

Automatic adjusting of

focus bias

Automatic adjusting of

FE offset

Automatic adjusting of

TE offset

LASER power ON

Detection of disk

Confirm that the voltage at the pin33

of KB9226(IC101) is "H" "L" "H".

Confirm that the voltage at the

pin37 of KB9226(IC101) is 3.5V.

Tracking error waveform at TOC reading

Pin 34 of

KB9226

(IC101)

Approx

0.4V

2.50V

Disc states

to rotate

Approx.3.7sec

Disc is rotated

Automatic adjusting of

TE balance

Automatic adjusting of

TE gain

TOC reading

Play a disc

Confirm that the signal from pin24

of KB9226(IC101) is 3.5V as a

accelerated pulse during

approx.1.96s.

Confirm the waveform of

the Tracking error signal

at the pin 34 of KB9226(IC101).

Confirm the eye-pattern

at the pin2 of KB9226(IC101).

1-24

Page 25

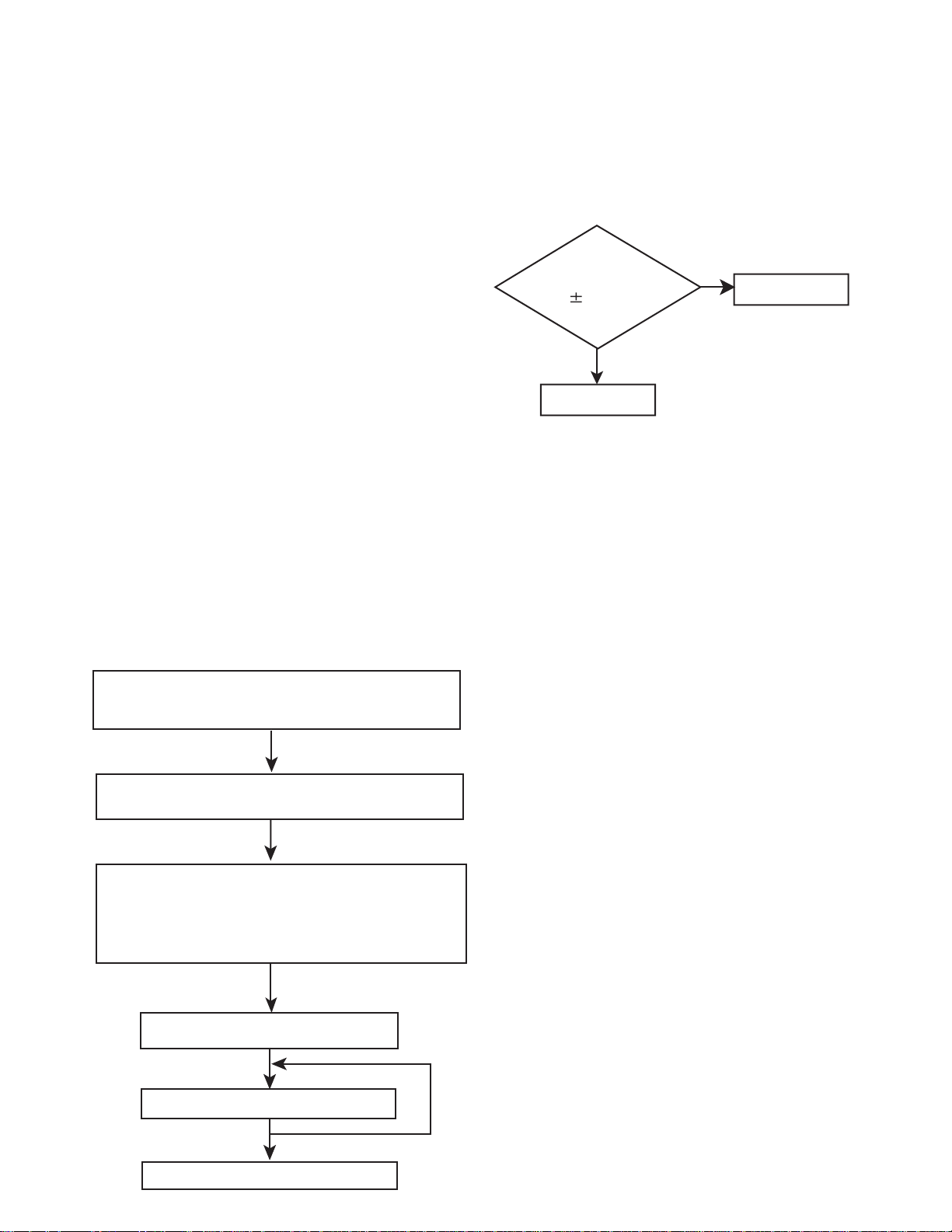

Maintenance of laser pickup

MX-GT88

(1) Cleaning the pick up lens

Before you replace the pick up, please try to

clean the lens with a alcohol soaked cotton

swab.

(3) Semi-fixed resistor on the APC PC board

The semi-fixed resistor on the APC printed circuit board which is attached to the pickup is used to adjust the

laser power. Since this adjustment should be performed to match the characteristics of the whole optical block,

do not touch the semi-fixed resistor.

If the laser power is lower than the specified value, the laser diode is almost worn out, and the laser pickup

should be replaced.

If the semi-fixed resistor is adjusted while the pickup is functioning normally, the laser pickup may be damaged

due to excessive current.

(2) Life of the laser diode

When the life of the laser diode has expired,

the following symptoms will appear.

1. The level of RF output (EFM output :

amplitude of eye pattern) will below.

Is the level of

RF OUT under

1.1V 0.2Vp-p?

YES

O.K

NO

Replace it.

Replacement of laser pickup

Turn off the power switch and,disconnect the

power cord from the ac outlet.

Replace the pickup with a normal one.(Refer

to "Pickup Removal" on the previous page)

Plug the power cord in,and turn the power on.

At this time,check that the laser emits for

about 3seconds and the objective lens moves

up and down.

Note: Do not observe the laser beam directly.

Play a disc.

Check the eye-pattern at TP1.

Finish.

1-25

Page 26

MX-GT88

Troubleshooting

1. Amplifier

Power malfunction

No output

1-26

Page 27

2.Tuner malfunction (FM/AM)

MX-GT88

3.Tape

1-27

Page 28

MX-GT88

4.CD

1-28

Page 29

5.CD - MP3 parts

MX-GT88

1-29

Page 30

MX-GT88

Description of major ICs

LC876764 (UIC1) : Microcontroller

1.Pin layout

S47/PF7

S46/PF6

S45/PF5

S44/PF4

S43/PF3

S42/PF2

S41/PF1

S40/PF0

VDD4

S39/PE7

S38/PE6

S37/PE5

S36/PE4

S35/PE3

S34/PE2

S33/PE1

S32/PE0

S31/PD7

S30/PD6

S29/PD5

S28/PD4

S27/PD3

S26/PD2

S25/PD1

S24/PD0

S23/PC7

S22/PC6

S21/PC5

S20/PC4

FIX0

2.Block diagram

8079787776757473727170696867666564636261605958575655545352

P00

P01

P02

P03

P04

P05

P06

P07

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

1234567891011121314151617181920212223242526272829

CF1

RES

VSS1

XT1/AN10

P16/T1PWML

P30/INT4/T1IN

P31/INT4/T1IN

P32/INT4/T1IN

P33/INT4/T1IN

P17/T1PWMH/BUZ

P34/INT5/T1IN

P35/INT5/T1IN

XT2/AN11

P36/INT5/T1IN

P37/INT5/T1IN

IR PLA

S48/PG0

S49/PG1

S50/PG2

S51/PG3

VSS2

VDD2

P10/SO0

P11/SI0/SB0

P12/SCK0

P13/SO1

P14/SI1/SB1

P15/SCK1

Interrupt Control

Stand-by Control ROM

CF2

VDD1

P80/AN0

P81/AN1

P82/AN2

P83/AN3

P84/AN4

P85/AN5

P86/AN6

P87/AN7/MICIN

51

S19/PC3

50

S18/PC2

49

S17/PC1

48

S16/PC0

47

VDD3

46

S15/T15

45

S14/T14

44

S13/T13

43

S12/T12

42

S11/T11

41

S10/T10

40

S9/T9

39

S8/T8

38

S7/T7

37

S6/T6

36

S5/T5

35

S4/T4

34

S3/T3

33

S2/T2

32

S1/T1

31

30

S0/T0

P73/INT3/T0IN/AN13

P70/INT0/T0LCP/AN8

P71/INT1/T0HCP/AN9

P72/INT2/T0IN/NKIN/AN12

SIO0

SIO1

Timer 0

(High speed clock counter)

Timer 1

Base Timer

VFD Controller

INT 0 - 5

Noise Rejection

CF

RC

MRC

X’ tal

Clock

Generator

Bus Interface

Port 0

Port 1

Port 3

Port 7

Port 8

ADC

Weak Signal

Detector

PC

ACC

B Register

C Register

ALU

PSW

RAR

RAM

1-30

Timer 4

Timer 5

Timer 6

Timer 7

Stack Pointer

Watch Dog Timer

Page 31

MX-GT88

3. Pin function (1/2)

Pin name

VSS1, 2

VDD1,2,3,4

FIX0

PORT0

P00 to P07

PORT1

P10 to P17

PORT3

P30 to P37

PORT7

P70 to P73

PORT8

P80 to P87

S0/T0 to

S8/T8

S9/T9 to

S15/T15

S16 to S23

S24 to S31

-

-

-

I/O

I/O

I/O

I/O

I/O

O

O

I/O

I/O

Power supply (-)

Power supply (+)

Test pin

Set as VSS with the user’s option. (see Note 1)

• 8bit input/output port

• Data direction programmable in nibble units

• Use of pull-up resistor can be specified in nibble units

• Input for HOLD release

• Input for port 0 interrupt

• 15V withstand at N-channel open drain output

• 8bit input/output port

• Data direction programmable for each bit

• Use of pull-up resistor can be specified for each bit

• Other pin functions

P10: SIO0 data output

P11: SIO0 data input / bus input / output

P12: SIO0 clock input / output

P13: SIO1 data output

P14: SIO1 data input / bus input / output

P15: SIO1 clock input / output

P16: Timer 1 PWML output

P17: Timer 1 PWMH output / Buzzer output

• 8bit input/output port

• Data direction can be specified for each bit

• Use of pull-up resistor can be specified for each bit

• 15V withstand at N-channel open drain output

• Other functions:

P30 to P33: INT4 input / HOLD release input / Timer 1 event input / Timer 0L

capture input / Timer 0H capture input

P34 to P37: INT5 input / HOLD release input / Timer 1 event input / Timer 0L

capture input / Timer 0H capture input

• 4bit input/output port

• Data direction can be specified for each bit

• Use of pull-up resistor can be specified for each bit

• Other functions

P70: INT0 input / HOLD release input / Timer0L capture input / Output for watchdog timer

P71: INT1 input / HOLD release input / Timer0H capture input

P72: INT2 input / HOLD release input / Timer 0 event input / Timer0L capture input

/ High speed clock counter input

P73: INT3 input(noise rejection filter attached input) / Timer 0 event input

/ Timer 0H capture input

AD input port: AN8(P70), AN9(P71), AN12(P72), AN13(P73)

• 8bit input/output port

• Input/output can be specified in a bit unit

• Other functions:

AD input port: AN0 to AN7

Weak signal detector input port: MICIN(P87)

• Large current output for VFD display controller digit (can be used for segment)

• Large current output for VFD display controller segment/digit

• Output for VFD display controller segment/digit

• Other functions:

High voltage input port: PC0 to PC7

• Output for VFD display controller segment

• Other functions:

High voltage input port: PD0 to PD7

Function I/O

1-31

Page 32

MX-GT88

3. Pin function (2/2)

Pin name

S32 to S39

S40 to S47

S48 to S51

RES

XT1

XT2

CF1

CF2

I/O

I/O

I/O

I

I

I/O

I

O

Function I/O

• Output for VFD display controller segment

• Other functions

High voltage input port: PE0 to PE7

• Output for VFD display controller segment

• Other functions:

High voltage input/output port: PF0 to PF7

• Output for VFD display controller segment

• Other functions:

High voltage input/output port: PG0 to PG3

Reset terminal

• Input for 32.768kHz crystal oscillation

• Other functions:

General purpose input port

When not in use, connect to VDD1.

AD input port: AN10

• Output for 32.768kHz crystal oscillation

• Other functions:

General purpose input port

When not in use, set to oscillation mode and leave open circuit.

AD input port: AN11

Input terminal for ceramic oscillator

Output terminal for ceramic oscillator

KA9258D (IC301) : 4-ch Motor driver

1.Block diagram

28 27 26 25 24 23 22 21 20 19 18 17 16 15

10K

T • S • D

+-

LEVEL SHIFT

VCC VCC

10K

REGULATOR

10K

10K

GND

10K

10K

10K

50K

MUTE

LEVEL SHIFT

-+

1-32

10K

1 2 3 4 5 6 7 8 9 10 11 12 13 14

GND

Page 33

HA12237 (JIC01) : Audio signal processor

1. Block diagram

TEST

(Open for normal use)

IREF

GND

ALCDET

20

19

18

17

Vcc

16

A

MUTE ON/OFF

REC MUTE OFF/ON

15

14

(REC RETURN ON/OFF)

A/B

13

ALC ON/OFF

High/Normal

11

12

MX-GT88

REC OUT(L)

NC

ALC(L)

REC IN(L)

NC

PB OUT(L)

TAI(L)

EQOUT(L)

PB-EQ(L)

PB-NF2(L)

21

22

23

24

2526

27

28

29

30

EQ

120/60

(Norm/High)

+

31

MUTE

AB

32

33

34

Return SW

35

ALC

Return SW

36

37

38

MUTE

AB

39

EQ

120/60

(Norm/High)

+

40

REC OUT(R)

10

9

NC

8

ALC(R)

7

REC IN(R)

6

NC

5

PB OUT(R)

4

TAI(R)

3

EQOUT(R)

2

PB-EQ(R)

1

PB-NF2(R)

2. Pin function

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Symbol

PB-NF2(R)

PB-EQ(R)

EQOUT(R)

TAI(R)

PBOUT(R)

NC

RECIN(R)

NC

RECOUT(R)

ALC ON/OFF

High/Norm

A/B

MUTE ON/OFF

PB-NF1(L)

Function

PB EQ feed back

NAB output

EQ output

Tape input

PB output

NC pin

REC-EQ input

NC pin

REC output

Mode control input

Mode control input

Mode control input

Mode control input

AIN(L)

Pin No.

RIP

15

16

17

18

19

20

21

22

23

24

25

26

REC

IN(L)

Symbol

REC MUTE

OFF/ON

Vcc

GND

IREF

Test mode

RECOUT(L)

NC

RECIN(L)

NC

PBOUT(L)

GND

Return

Function

Mode control input

Vcc pin

GND pin

Equalizer reference

current input

Test mode pin

REC output

NC pin

REC-EQ input

NC pin

PB output

IN(R)

NC

AIN(R)

Pin No.

27

28

29

30

31

32

33

34

35

36

37

38

39

40

PB-NF1(R)

Symbol

TAI(L)

EQOUT(L)

PB-EQ(L)

PB-NF2(L)

PB-NF(L)

AIN(L)

RIP

BIN(L)

REC-RETURN

GND

BIN(R)

NC

AIN(R)

PB-NF1(R)

Function

Tape input

EQ output

NAB output

PB EQ feed back

PB EQ feed back

PB A deck input

Ripple filter

PB B deck input

REC Return

GND pin

PB B deck input

NC pin

PB A deck input

PB EQ feed back

1-33

Page 34

MX-GT88

KB9226 (IC101) : RF amp. & servo signal processor

1. Pin layout

36 35 34 33 32 31 30 29 28 27 26 25

SLP

FEO

VCC

FEM

FRSH

TEO

FSET

TEM

FLB

FGD

2. Block diagram

37

LD

PD

38

39

PDAC

40

PDBD

PDF

41

42

PDE

43

DCB

MCP

44

45

DCCI

46

DCCO

47

VREF

48

EQC

LPFT

ATSC

RFO

RFM

1 2 3 4 5 6 7 8 9 10 11 12

TEIO

TZC/SSTOP

S1L9226X

EQO

EQI

GND

EFMI

FSI

SLO

SLM

SPO

SPM

ASY

EFM

LOCK

WDCK

CLVI

RESET

MLT

MDATA

MCK

ISTAT

TGU

24

23

22

21

20

19

18

17

16

15

14

13

EQO

EFMI

DCCI

DCC0

MCP

DCB

VCC/

VDD

FRSH

FSET

FLB

FGD

FSI

45

46

44

43

10

11

EQI

RFO

RFM

4

5

RF AGC & EQ

Control

Focus OK Detect

Defect Detect Mirror

Gen

Focus Servo Loop

- Gain & Phase

Compensation

- Focus Search

- Offset Adjust

- FZC Gen.

6

7

8

9

EQC

Center

Voltage

APC. Laser

Control &

LPC

Tracking Servo Loop

- Gain & Phase

Compensation

- Track Jump

- Offset Adjust

- TZC Gen.

Hardware Logic

- Auto-Sequencer

- Fast Search

- Febias, Focus Servo,

Tracking Offset ADJ.

VREF

Tracking Error

PDE

(RW)

I/V AMP

PDF

41 40424748123

PDBD

39

RF & Focus

Error (CD-RW)

I/V AMP

Sled Servo &

Kick Gen

PDAC

38

37

35

34

33

36

29

28

27

26

25

PD

LD

LPFT

TEIO

TZC&

SSTOP

ATSC

TEO

TEM

SLP

SLO

SLM

- Tracking Balance & Gain

Adjust

- Interruption Detect

29

FEO

- EFM Muting System

30

FEM

1-34

TGU

12

Micom Data Interface Logic Decoder

1413 15 16 17 19 18 20 22 21

ISTAT

MCK

MDATA

MLT

RESET

WDCK

CLVI

LOCK

EFM

Comparator

ASY

EFM

Spindle

Servo LPF

23

24

SPDLO

SPDLM

Page 35

3. Pin function

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

Symbol

RFM

RFO

EQI

EQO

EFMI

VCC

FRSH

FSET

FLB

FGD

FSI

TGU

ISTAT

MCK

MDATA

MLT

RESET

CLVI

WDCK

LOCK

EFM

ASY

SPM

SPO

SLM

SLO

SLP

TEM

TEO

FEM

FEO

GND

TZC/

SSTOP

TEIO

LPFT

ATSC

LD

PD

PDAC

PDBD

PDF

PDE

DCB

MCP

DCCI

DCCO

VREF

EQC

Function

I/O

RF summing amp. inverting input

I

RF summing amp. output

O

RFO DC eliminating input(use by MIRROR, FOK ,AGC & EQ terminal)

I

RF equalizer output

O

EFM slice input. (input impedance 47K)

I

Main power supply

P

Capcitor connection to focus search

I

Filter bias for focus,tracking,spindle

I

Capacitor connection to make focus loop rising band

I

Terminal to change the hign frequency gain of focus loop

I

Focus servo input

I

Connect the component to change the high frequency of tracking Loop

I

Internal status output

O

Micom clock

I

Data input

I

Data latch input

I

Reset input

I

Input the spindle control output from DSP

I

88.2KHz input terminal from DSP

I

Sled run away inhibit pin (L: sled off & tracking gain up)

I

EFM output for RFO slice(to DSP)

O

Auto asymmetry control input

I

Spindle amp. inverting input

I

Spindle amp. output

O

Sled servo inverting input

I

Sled servo output

O

Sled servo noninverting input

I

Tracking servo amp.inverting input

I

Tracking servo amp. output

O

Focus servo amp. inverting input

I

Focus servo amp. output pin

O

Main ground

P

Tracking zero crossing input & Check the position of pick-up wherther inside or not

I

Tracking error output & Tracking servo input

B

Tracking error integration input (to automatic control)

I

Anti-shock input

I

APC amp. output

O

APC amp. input

I

Photo diode A & C RF I/V amp. inverting input

I

Photo diode B & D RF I/V amp. inverting input

I

Photo diode F & tracking(F) I/V amp. inverting input

I

Photo diode E & tracking(E) I/V amp. inverting input

I

Capacitor connection to limit the defect detection

I

Capacitor connection to mirror hold

I

Output pin to connect the component for defect detect

O

Input pin to connect the component for defect detect

I

(VCC+GND)/2 Voltage reference output

O

AGC_equalize level control terminal & capacitor terminal to input in to VCA

I

MX-GT88

1-35

Page 36

MX-GT88

5L9290 (IC201) : Digital signal processor for CDP

1. Pin layout

RCHOUT

VSSA_DAC

VREF

VHALF

VDDA_DAC

LRHOUT

VDDA_PLL

48 47 46 45 44 43 42 41 40 39 38 37

VSSD_DAC

VDDD_DAC

SADTI

LRCKI

BCKI

2. Block diagram

VSSA_PLL

VCO1LF

VSSD_PLL

VDDD_PLL

VDDD1_5V

XIN

XOUT

VSSD1_5V

EFMI

LOCK

SMEF

SMON

1

2

3

4

5

6

7

8

9

10

11

12

13 14 15 16 17 18 19 20 21 22 23 24

SMDS

WDCK

S5L9290X

DSP+DAC

48-LQFP-0707

LKFS

TESTV

LKFS

RESETB

MLT

MDAT

SOS1

SQCK

SBCK

SQDT

SBDT

MCK

ISTAT

C2PO

S0S1

SQCK

36

35

34

33

32

31

30

29

28

27

26

25

DATX

BCKO

LRCKO

SADTO

DATX

C2PO

JITB

SBCK

VDDD3-5V

VSSD2-3V

VDDD2-3V

MUTE

SQDT

VCO1LF

EFMI

LOCK

SMEF

SMDP

SMDS

WDCK

WFCK

RFCK

C4M

XIN

ISTAT

MLT

MDAT

MCK

MUTE

DPLL

CLV

Servo

Timing

Generator

Micom

Interface

Subcode

Out

EFM

Demodulator

ECC

16K

SRAM

Address

Generator

JITB

Interpolator

Interface

SADTO

LRCKO

BCKO

I/O

Digital

Out

SADTI

LRCKI

BCKI

Digital

Filter

1-bit

DAC

PWM

LPF

LCHOUT

RCHOUT

VHALF

VREF

1-36

Page 37

3. Pin function

MX-GT88

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

28

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

Symbol

VSSA_PLL

VCO1LF

VSSD_PLL

VDDD_PLL

VDDD1-5V

XIN

XOUT

VSSD1

EFMI

LOCK

SMEF

SMDP

SMDS

WDCK

TESTV

LKFS

C4M

RESETB

MLT

MDAT

MCK

ISTAT

S0S1

SQCK

SQDT

MUTE

VDDD2-3V

VSSD2

VDDD3-5V

SBCK

JITB

C2PO

DATX

SADTO

LRCKO

BCKO

BCKI

LRCKI

SADTI

VSSD_DAC

VDDD_DAC

RCHOUT

VSSA_DAC

VREF

VHALF

VDDA_DAC

LCHOUT

VDDA_PLL

I/O

-

O

-

-

I

O

-

I

O

O

O

O

O

I

O

O

I

I

I

I

O

O

I

O

I

-

-

-

I

O

O

O

O

O

O

I

I

I

-

-

O

O

O

O

-

Function

Analog Ground for DPLL

Pump out for VCO1

Digital Ground Separated Bulk Bias for DPLL

Digital Power Separated Bulk Bias for DPLL (3V Power)

Digital Power (5V Power, I/O PAD)

X'tal oscillator input (16.9344MHz)

X'tal oscillator output

Digital Ground (I/O PAD)

EFM signal input

CLV Servo locking status output

LPF time constant control of the spindle servo error signal

Phase control output for Spindle Motor drive

Speed control output for Spindle Motor drive

Word clock output (Normal Speed : 88.2KHz, Double Speed : 176.4KHz)

Various Data/Clock Input

The Lock status output of frame sync

4.2336MHz clock output

System Reset at 'L'

Latch signal input from Micom

Serial data input from Micom

Serial data receiving clock input from Micom

The internal status output to Micom

Subcode sync signal(S0+S1) output

Subcode-Q data transfering bit clock input

Subcode-Q data serial output

System mute at 'H'

Digital Power (3V Power, Internal Logic)

Digital Ground (Internal Logic)

Digital Power (5V Power, I/O PAD)

Subcode data transfering bit clock

Internal SRAM jitter margin status output

C2 pointer output

Digital audio data output

Serial audio data output (48 slot, MSB first)

Channel clock output

Bit clock output

Bit clock input

Channel clock input

Serial audio data input (48 slot, MSB first)

Digital Ground for DAC

Digital Power for DAC (3V Power)

Right-Channel audio output through DAC

Analog Ground for DAC

Referance Voltage output for bypass

Referance Voltage output for bypass

Analog Power for DAC (3V Power)

Left-Channel audio output through DAC

Analog Power for PLL (3V Power)

1-37

Page 38

MX-GT88

KS9274 (IC601) : CD-MP3 decoder

1.Block diagram

2.Pin function

5

6

10

14

15

20

21

22

24

25

26

27

35

36

37

38

39

44

45

46

47

50

51

52

53-62

63

CD-ROM Decoder MP3 Decoder

DRAM CONTROLLER

44-63 35-39

1M 4bits DRAM

CLK

RESETB

FILTER_0

FILTER_1

PLL_BYPASS

CD_DATA

CD_LRCK

CD_BCK

ACLK

BCLK

LRCK

ADAT

MDAT

MCK

MLAT

MDOUT

MINT

DDAT0

DDAT1

WEB

RASB

DDAT2

DDAT3

CASB

DA9-DA0

OEB

I

System clock input

I

System reset actibe LOW

O

820uF to GND940uF to GND

O

When "HIGH" PLL is bypassed, Tied to LOW in normal operation

I

I

I

I

O

O

O

O

I

Write/Read data from MCU to CD-MP3

I

Data strobe signal from MCU

I

Micom command identifier from MCU to CD-MP3

O

Data from CD-MP3 to MCU

O

Intertupt output to MCU

Data BUS

Data BUS

O

Wtite enable

O

Row address strobe

Data BUS

Data BUS

O

Colume address strobe

O

Address output

O

Control output to make data output to "High-Z" at DRAM

DAC

INTERFACE

HOST MCU INTERFACE

HOST MCU

24-2720-22

KA3082 (IC401, IC402) : DC motor driver

1.Pin layout 2.Pin function

Pin No.

BIAS

1234

GND

V

O1

1-38

DRIVER OUT

PRE DRIVER

LOGIC SWITCH

678910

V

V

Z1

CTL

5

V

IN1VIN2

SV

CC

TSD

PV

CC

V

V

O2

Z2

1

2

3

4

5

6

7

8

9

10

Symbol

GND

VO1

VZ1

VCTL

VIN1

VIN2

SVCC

PVCC

VZ2

VO2

Function

I/O

Ground

Output 1

O

Phase compensation

Motor speed control

I

Input 1

I

Input 2

I

Supply voltage (Signal)

Supply voltage (Power)

Phase compensation

Output 2

O

Page 39

TDA7442D (EIC01) : Audio processor

1.Pin layout

MX-GT88

R_IN3

R_IN2

R_IN1

L_IN1

L_IN2 V

L_IN3

L_IN4

MUXOUTL

IN(L)

MUXOUT(R)

IN(R)

BIN(R)

BOUT(R)

BIN(L)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

2.Block diagram

MUXOUT(L)

0.47 F

0.47 F

0.47 F

0.47 F

0.47 F

0.47 F

0.47 F

0.47 F

L-IN1

L-IN2

L-IN3

L-IN4

R-IN1

R-IN2

R-IN3

R-IN4

4

50K

5

50K

6

50K

7

50K

3

50K

2

50K

1

50K

28

50K

31.5dB

control

31.5dB

control

MUXOUT(R)

+

2.2 F

+

2.2 F

28

R_IN4

27

LOUT

26

ROUT

25

AGND

24

S

CREF23

SDA

22

SCL

21

DIG-GND

20

TREBLE(R)

19

TREBLE(L)

18

PS1

17

LP

16

15

BOUT(L)

100nF

IN(L)

98

30K

SYMULATED

L+R

30K

1110

IN(R)

PS1

17

RPS1

PS1

90Hz

MUSIC/

SYMULATED

SUPPLY

AGND

CREF

MIXING

AMP

MIXING

AMP

22 F

MUSIC

-

L-R

+

OFF

LPF

EFFECT

9KHz

CONTROL

24 25 2316

LP

V

S

1.2nF

5.6nF

TREBLE-L

18

OFF

SURR

TREBLE

TREBLE

SURR

OFF

Vref

TREBLE-R

5.6nF

5.6K

100nF

100nF

BIN(L)

BOUT(L)

15

14

RB

FIX

BASS

I2C BUS DECODER + LATCHES

BASS

12

BIN(R) BOUT(R)

100nF 100nF

5.6K

FIX

VAR

RB

1319

79dB CONTROL

-

VAR

+

FIX

+

-

SPKR

ATT

MUTE

SPKR

ATT

MUTE

79dB CONTROL

D98AU947A

27

LOUT

21

SCL

22

SDA

20

DIG GND

26

ROUT

BA4560 (FIC02) : Dual op amp.

1.Pin layout

OUT1

– IN1

+ IN1

V

1

2

1ch

+

–

3

EE

4

+

2ch

8

7

6

–

5

V

CC

OUT2

– IN2

+ IN2

1-39

Page 40

MX-GT88

L4959 (PIC02) : Voltage regulator

1.Pin layout

TAB CONNECTED TO PIN 6

2.Block diagram

2/10

V

S

EN 8V

EN 12V(a)

EN 12V(b)

8

7

5

REF

GEN

11

10

9

8

7

6

5

4

3

2

1

D97AU716A

OUT 12V(a)

V

S

OUT 8.6V

EN 8.6V

EN 12V(a)

GND

EN 12V(b)

N.C.

OUT 5.6V

V

S

OUT 12V(b)

5.6V, 250mA

3

OUT 5.6V

REGULATOR

8.6V, 600mA

REGULATOR

9

OUT 8.6V

SWITCHED

12V, 800mA

REGULATOR

11

OUT 12V(a)

SWITCHED

12V, 1.3A

REGULATOR

1

OUT 12V(b)

SWITCHED

1-40

D97AU569C

3.Pin function

Pin Pins Description

1 OUT 12V (b) 12V/1.3A SWITCHED OUTPUT VOLTAGE

2V

S

3 OUT 5.6V 5.6V/250mA OUTPUT VOLTAGE

4 N.C. not connected

5 EN 12V (b) Enable 12V/1.3A SWITCHED OUTPUT VOLTAGE

6 GND Ground

7 EN 12V (a) Enable 12V/0.8A SWITCHED OUTPUT VOLTAGE

8 EN 8.6V Enable 8.6V/0.6A SWITCHED OUTPUT VOLTAGE

9 OUT 8.6 8.6V/0.6A SWITCHED OUTPUT VOLTAGE

10 V

S

11 OUT 12V (a) 12V/0.8A SWITCHED OUTPUT VOLTAGE

Supply Voltage

Supply Voltage

GND

6

Page 41

M11L1644 (IC602) : DRAM

1. Block diagram

MX-GT88

WE

RAS

CAS

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

CONTROL

CLOCK

GENERATOR

COLUMN

11

ADDRESS

BUFFER

REFRESH

CONTROLLER

REFRESH

COUNTER

11

ADDRESS

BUFFERS(11)

LOGIC

11

ROW

DATA-IN BUFFER

I/O0

.

.

4

I/O3

DATA-OUT

11

COLUMN

BUFFER

CE

DECODER

2048

4

4

SENSE AMPLIFIERS

I/O RATING

2048 x 4

2048 x 2048 x 4

2048

ROW

11

DECODER

MEMORY

ARRAY

2. Pin function

Pin No.

3~11, 14~19, 7

5

21

4

20

2, 3,22, 23

1, 12

13, 24

6

Symbol

A0~A10

RAS

CAS

WE

OE

I/O0~I/O3

Vcc

Vss

NC

I/O

I/O

Vdd GENERATOR

Function

Address Input

Row Address : A0~A10

I

Column Address : A0~A10

Row Address Strobe

I

Column Address Strobe

I

Write Enable

I

Output Enable

I

Data Input/ Ountput

Power (5V or 3.3V)

Ground

-

No Connect

Vcc

Vss

1-41

Page 42

MX-GT88

STK403-070 (FIC01) : Power amp.

1.Pin layout

Ch1

+Vcc

2

2.Block diagram

2

out

Ch1

out

41

3

Ch2

out

5

Ch2

out

6

Ch1

10

Ch1

IN

NF

11

+TRE8SUB9GND-Vcc

7

ST-BY

12

Ch2

NF

13

Ch2

IN

14

7

10

11

Pre Driver IC

CH1

R1

R2

C1

1

SUB

STK412-020 (WIC01) : Power amp.

1.Block diagram

13

TR1 TR4

R5

TR3

R6

TR2

3489 6 125

R8

TR5

R7

TR6

R3

R4

C2

Bias Circuit

1817

Pre Driver IC

CH2

TR41

R41

14

13

1

1-42

14

15

16

TR1

TR3

C2

R4

R5

D1

TR6

R6

R3

R7

TR8

TR7

TR9

TR10

9 118

TR19

TR18

TR20

1012

D2

TR2 TR12

R1

C1

TR4

TR5

R2

TR17

R17

R13

TR16

R16

R14

R15

C12

D12

R11

TR14

TR11

C11

TR13

TR15

R12

D41

D51

TR51

Comaprator

SUB

Comaprator

R51

D42

D43

D53

D52

3

2

7

5

4

6

Page 43

PT8300 (UIC03, UIC04) : DRAM

1.Pin layout

MX-GT88

1

VSS

CLK

LATCH

P15

P14

P13

P12

P11

P10

P9

P8

CLK0

2

3

4

5

6

7

8

9

10

11

12

13

14

/RESET

LATCH0

2.Block diagram

PULLUP

27

28

VDD

VSS

1

4

LATCH

CLK

3

26

DI1

/RESET

2

/RESET

CLKO

14

16

DI2

LATCH0

DO2

DO1

13

25

15

28

27

26

25

24

23

22

21

20

19

18

17

16

15

VDD

PULLUP

DI1

DO2

P0

P1

P2

P3

P4

P5

P6

P7

DI2

DO1

LATCH

RESET

P0 P1 P2 P3 P4 P5 P6 P7 P8 P9 P10 P11 P12 P13 P14 P15

CLK

DI

CLK

DI

O0

I0

Q0

RESET

D0

LATCH 16-BIT

SHIFT REGISTER1: 16-BIT SHIFT REGISTER SERIAL TO PARALLEL

SHIFT REGISTER2: 16-BIT SHIFT REGISTER SERIAL TO PARALLEL

O7 O8

I7 I8

O15

I15

Q15

DO

D15

DO

3. Pin function

Pin No.

Pin Name

1

2

/RESET

3

4

5-12

13

14

15,25

26,17

17-24

27

LATCH

P15~P8

LATCHO

CLKO

DO1, DO2

DI1, DI2

P7~P0

PULLUP

28

VSS

CLK

VDD

I/O

Function

-

Ground

I

Reset pin

I

Clock input pin

I

Latch input pin

I/O

Parallel data I/O pins

O

Latch output pin

O

Clock output pin

O

Serial data output pins

I

Serial data input pins

O

Parallel data output pin

I

P8 to P15 control pin for internal pull-up resistor

When P8 to P15 are in the output state, the PULLUP pin must be connected to VDD.

When P8 to P15 are in the input state, the PULLUP pin must be connected to VSS.

-

Power supply pin

1-43

Page 44

MX-GT88

LA72723(IC03) : RDS demodulation

1. Pin layout

VREF

MPXIN

Vdda

Vssa

FLOUT

CIN

TES

XOUT

1

2

3

4

5

6

7

8

2. Block Diagram

Vdda

REFERENCE

VOLTAGE

Vssa

MPXIN

ANTI ALIASING

FILTER

RDS-ID/READY

16

RDCL

15

RDDA

14

RST

13

MODE

12

Vddd

11

Vssd

10

XIN

9

57kHz

BPF

(SCF)

FLOUTVREF

VREF

SMOOTHING

FILTER

CIN

+

-

PLL

(57kHz)

CLOCK

RECOVERY

(1187.5Hz)

DATA

DECODER

RAM

(128-bits)

Vddd

Vssd

RDDA

RDCL

MODE

TEST

3. Pin functions

Pin

Symbol

No.

1

VREF

2

MPXIN

Vdda

3

4

Vssa

5

FLOUT

6

CIN

TEST

7

8

XOUT

9

XIN

10

Vssd

11

Vddd

12

MODE

13

14

15

16

RST

RDDA

RDCL

RDS-ID

READY

TEST

I/O

O

O

O

O

I/O

O

CLK(4.332MHz)

OSC

XIN XOUT

RDS-ID

DETECT

RST

RDS-ID/

READY

Function

Reference voltage output (Vdda/2)

I

Baseband (multiplexed) signal input

Analog power supply (+5V)

Analog ground

Subcarrier input (filter output)

I

I

Subcarrier input (comparator input)

Test input

Crystal oscillator output (4.332MHz)

I

Crystal oscillator input (exeternal reference input)

Digtal ground

Digtal power supply

I

I

Read mode setting (0:master,1:slave)

RDS-ID/RAM reset (positive polarity)

RDS data output

RDS clock output (master mode)/RDS clock input (slave mode)

RDS-ID/READY output (negative polarity)

1-44

Page 45

MX-GT88

SCHEMATIC DIAGRAMS

COMPACT COMPONENT SYSTEM

MX-GT88

CD-ROM No.SML200307

B ------------------------ U.K.

Area suffix

E ---- Continental Europe

EN ----- Northern Europe

EV ------- Eastern Europe

CD

3

2

CD

CD

1

STANDBY

ECO

COMPACT COMPONENT SYSTEM MX-GT88

REC START

CK

O

R

/ STOP

CD REC

P

PO

START

DUBBING

CLASSIC

DISPLAY

MP3

PHONES

SOUND

TURBO

SUBWOOFER LEVEL

U

L

M

O

E

V

M

D

O

N

U

D

E

O

S

TUNING

BEEP

DISC CHANGE

REPEAT

DANCE

PROGRAM

HA

LL

RANDOM

STADIUM

CLOCK

/ TIMER

SET

PRESET

CANCEL

/ DEMO

TAPE A / B

SELECT

DISPLAY MODE

RDS MODE

TUNING

EJECTEJECT

SP-MXGT88 SP-MXGT88CA-MXGT88

Contents

Block diagram

Standard schematic diagrams

Printed circuit boards

COPYRIGHT 2003 VICTOR COMPANY OF JAPAN, LTD.

2-1

2-2

2-7~10

No.22075SCH

Jul. 2003

Page 46

MX-GT88

In regard with component parts appearing on the silk-screen pr inted side (par ts side) of

the PWB diagrams, the parts that are printed over with black such as the resistor ( ),

diode ( ) and ICP ( ) or identified by the " " mark nearby are critical for safety.

(This regulation does not correspond to J and C version.)

Page 47

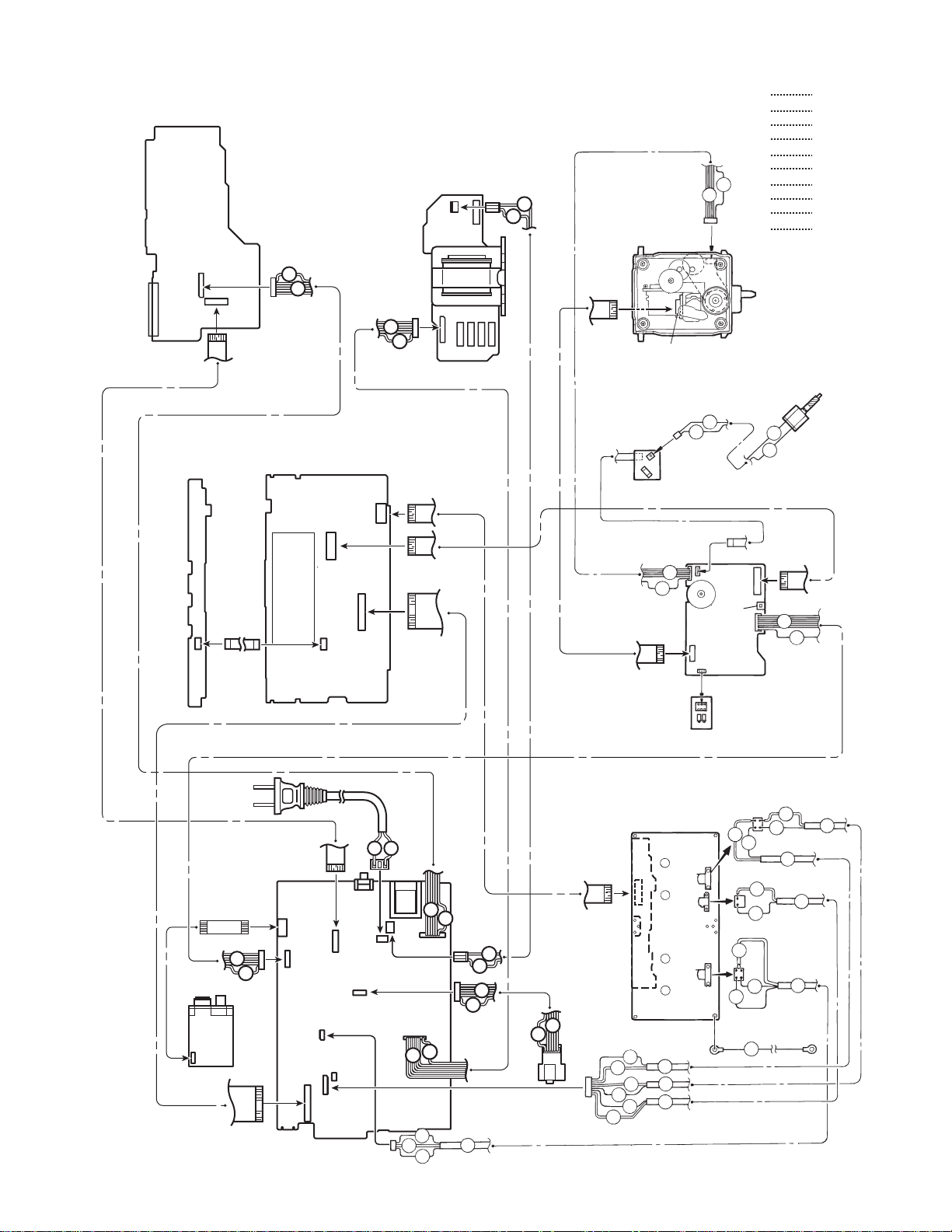

Block diagram

MX-GT88

H/P

TUNER

5

AUDIO

4