Page 1

SERVICE MANUAL

WIDE LCD TELEVISION

YA40120065

LT-Z32FX6, LT-Z32FX6/A,

LT-Z32FX6

/B, LT-Z32FX6/S

BASIC CHASSIS

FL3

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

COPYRIGHT © 2006 Victor Company of Japan, Limited

No.YA401

2006/5

Page 2

SPECIFICATION

Items Contents

Dimensions ( W × H × D ) 80.0 cm × 59.2 cm × 24.5 cm [Included stand]

80.0 cm × 54.5 cm × 12.7 cm [TV only]

Mass 17.0 kg [Included stand]

15.5 kg [TV only]

Power Input AC110V - AC240 V, 50 Hz / 60 Hz

Power Consumption 121 W (Standby:0.4 W)

TV RF System B, G, I, D, K, K1, M

Colour System PAL / SECAM / NTSC 3.58 / NTSC 4.43

Stereo System A2 (B/G, D/K), NICAM (B/G, I, D/K)

Teletext System FLOF (Fastext), WST (World Standard System)

Receiving

Frequency

Intermediate Frequency VIF

Colour Sub

Carrier

LCD panel 37V-inch wide aspect (16 : 9)

Screen Size

Display Pixels Horizontal : 1366 dots × Vertical : 768 dots (W-XGA)

Audio Power Output 10 W + 10 W

Speaker 5.0 cm, round type × 2 (Oblique corn)

Aerial terminal (VHF/UHF) 75 Ω unbalanced, coaxial

Video / Audio

Input-1/2/3

Component Video

625p / 525p / 625i / 525i

VHF Low

VHF High

SECAM

[Input-1/3]

750p / 1125i

S-Video

[Input-1/2]

Video / Audio Output S-Video

HDMI Input Video

PC (RGB) Input D-sub 15 pin × 1

Headphone 3.5 mm stereo mini jack × 1

Remote Control Unit RM-C1855 (AAA/R03 dry cell battery × 2)

Design & specifications are subject to change without notice.

46.25MHz - 140.25MHz

147.25MHz - 423.25MHz

431.25MHz - 863.25MHz

UHF

CATV

Mid (X - Z+2, S1 - S10) / Super (S11 - S20) / Hyper (S21 - S41) bands

38.0MHz (B, G, I, D, K, L)

SIF

32.26MHz (5.74MHz: B), 32.15MHz (5.85MHz: G), 31.45MHz (6.55MHz: I)

31.75MHz (6.25MHz: D), 32.15MHz (5.85MHz: K)

4.43MHz

PAL

4.40625MHz / 4.25MHz

3.58MHz / 4.43MHz

NTSC

Diagonal : 80.0 cm (H: 69.7 cm × V: 39.2 cm)

RCA pin jack × 3 (Input-3)

Y : 1V (p-p) (Sync signal: ±0.35V(p-p), 3-value sync.), 75 Ω

Pb/Pr : ±0.35V(p-p), 75 Ω

Y : 1V (p-p), Positive (Negative sync provided), 75 Ω

Pb/Pr : 0.7V(p-p), 75 Ω

Mini-DIN 4 pin connector × 2

Y: 1V (p-p), Positive (Negative sync provided), 75 Ω

C: 0.286V (p-p) (Burst signal), 75 Ω

1V (p-p), Positive (Negative sync provided), 75 Ω, RCA pin jack × 3

Video

500mV (rms), High impedance, RCA pin jack × 6

Audio

Mini-DIN 4 pin connector × 1

Y: 1V (p-p), Positive (Negative sync provided), 75 Ω

C: 0.286V (p-p) (Burst signal), 75 Ω

1V (p-p), Positive (Negative sync provided), 75 Ω, RCA pin jack × 1

Video

500mV (rms), Low impedance, RCA pin jack × 2

Audio

HDMI connector × 2

(Digital-input terminal is not compatible with picture signals of computer signal)

Digital: HDMI connector × 2

Audio

Analog: 500mV(rms) (-4dBs), high impedance, RCA pin jack × 2

R/G/B : 0.7 V (p-p), 75Ω

HD / VD : 1 V (p-p) to 5 V (p-p), high impedance

< Available signal >

VGA : 640 pixels × 480 pixels (Horizontal : 31.5 kHz / Vertical : 60 Hz)

XGA : 1024 pixels × 768 pixels (Horizontal : 48.4 kHz / Vertical : 60 Hz)

1-2 (No.YA401)

Page 3

SECTION 1

PRECAUTION

1.1 SAFETY PRECAUTIONS

(1) The design of this product contains special hardware,

many circuits and components specially for safety

purposes. For continued protection, no changes should be

made to the original design unless authorized in writing by

the manufacturer. Replacement parts must be identical to

those used in the original circuits. Service should be

performed by qualified personnel only.

(2) Alterations of the design or circuitry of the products should

not be made. Any design alterations or additions will void

the manufacturer's warranty and will further relieve the

manufacturer of responsibility for personal injury or

property damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These

characteristics are often not evident from visual inspection

nor can the protection afforded by them necessarily be

obtained by using replacement components rated for

higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in

the parts list of Service manual. Electrical components

having such features are identified by shading on the

schematics and by ( ) on the parts list in Service

manual. The use of a substitute replacement which does

not have the same safety characteristics as the

recommended replacement part shown in the parts list of

Service manual may cause shock, fire, or other hazards.

(4) Don't short between the LIVE side ground and

ISOLATED (NEUTRAL) side ground or EARTH side

ground when repairing.

Some model's power circuit is partly different in the GND.

The difference of the GND is shown by the LIVE : ( ) side

GND, the ISOLATED (NEUTRAL) : ( ) side GND and

EARTH : ( ) side GND.

Don't short between the LIVE side GND and ISOLATED

(NEUTRAL) side GND or EARTH side GND and never

measure the LIVE side GND and ISOLATED (NEUTRAL)

side GND or EARTH side GND at the same time with a

measuring apparatus (oscilloscope etc.). If above note will

not be kept, a fuse or any parts will be broken.

(5) When service is required, observe the original lead dress.

Extra precaution should be given to assure correct lead

dress in the high voltage circuit area. Where a short circuit

has occurred, those components that indicate evidence of

overheating should be replaced. Always use the

manufacturer's replacement components.

(6) Isolation Check (Safety for Electrical Shock Hazard)

After re-assembling the product, always perform an

isolation check on the exposed metal parts of the cabinet

(antenna terminals, video/audio input and output terminals,

Control knobs, metal cabinet, screw heads, earphone jack,

control shafts, etc.) to be sure the product is safe to operate

without danger of electrical shock.

a) Dielectric Strength Test

The isolation between the AC primary circuit and all metal

parts exposed to the user, particularly any exposed metal

part having a return path to the chassis should withstand a

voltage of 3000V AC (r.m.s.) for a period of one second. (.

. . . Withstand a voltage of 1100V AC (r.m.s.) to an

appliance rated up to 120V, and 3000V AC (r.m.s.) to an

appliance rated 200V or more, for a period of one second.)

This method of test requires a test equipment not generally

found in the service trade.

b) Leakage Current Check

Plug the AC line cord directly into the AC outlet (do not use

a line isolation transformer during this check.). Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal part of the cabinet, particularly

any exposed metal part having a return path to the chassis,

to a known good earth ground (water pipe, etc.). Any

leakage current must not exceed 0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.2mA AC

(r.m.s.).

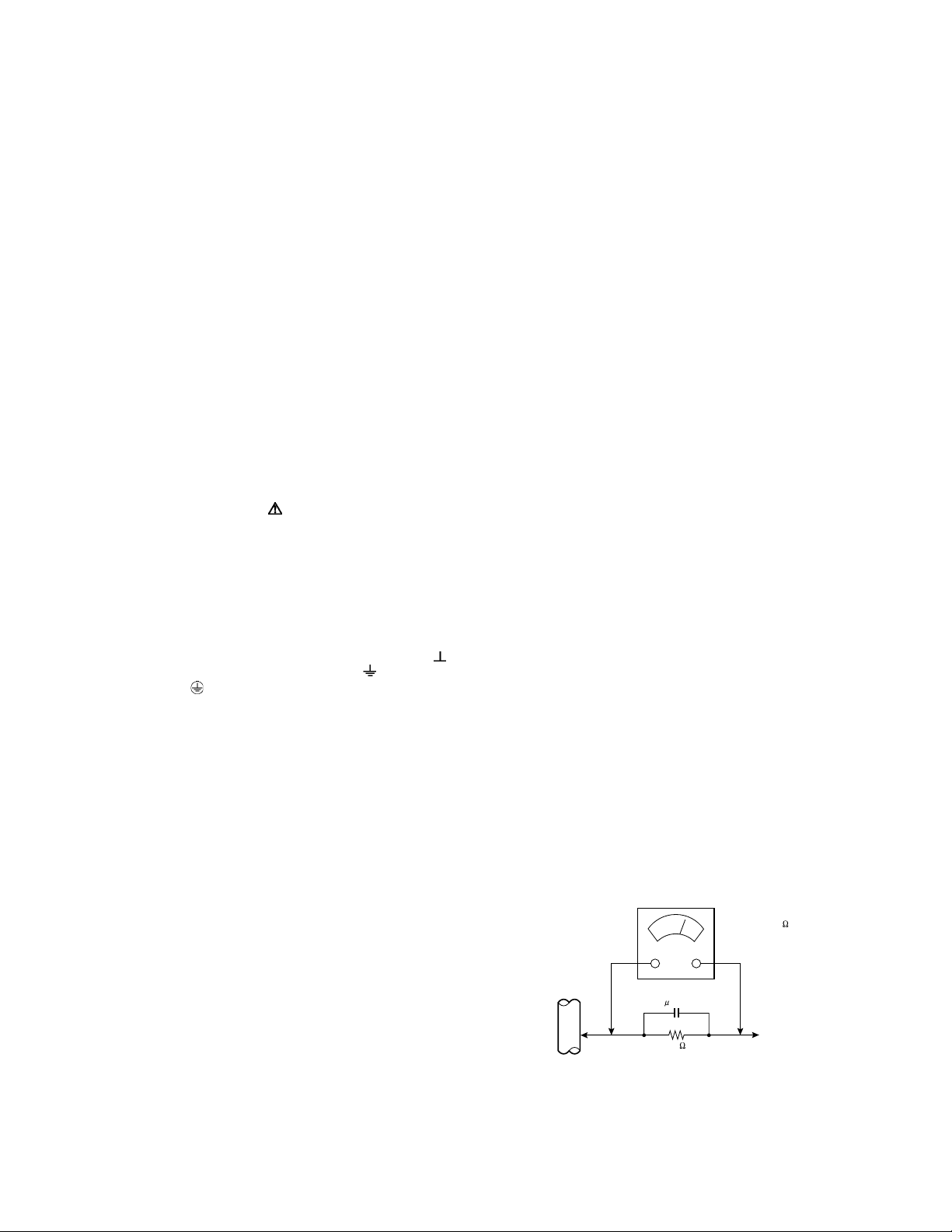

Alternate Check Method

Plug the AC line cord directly into the AC outlet (do not

use a line isolation transformer during this check.). Use

an AC voltmeter having 1000Ω per volt or more

sensitivity in the following manner. Connect a 1500Ω

10W resistor paralleled by a 0.15µF AC-type capacitor

between an exposed metal part and a known good earth

ground (water pipe, etc.). Measure the AC voltage

across the resistor with the AC voltmeter. Move the

resistor connection to each exposed metal part,

particularly any exposed metal part having a return path

to the chassis, and measure the AC voltage across the

resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Any voltage measured must

not exceed 0.75V AC (r.m.s.). This corresponds to

0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.3V AC

(r.m.s.). This corresponds to 0.2mA AC (r.m.s.).

AC VOLTMETER

(HAVING 1000 /V,

OR MORE SENSITIVITY)

0.15 F AC-TYPE

GOOD EARTH GROUND

1500 10W

PLACE THIS PROBE

ON EACH EXPOSED

ME TAL PAR T

(No.YA401)1-3

Page 4

1.2 INSTALLATION

1.2.1 HEAT DISSIPATION

If the heat dissipation vent behind this unit is blocked, cooling

efficiency may deteriorate and temperature inside the unit will

rise. The temperature sensor that protects the unit will be

activated when internal temperature exceeds the pre-determined

level and power will be turned off automatically.Therefore,

please make sure pay attention not to block the heat dissipation

vent as well as the ventilation outlet behind the unit and ensure

that there is room for ventilation around it.

Ventilation hole

1.2.3 INSTALLATION REQUIREMENTS

To ensure safety in an emergency such as an earthquake, and

to prevent accidents, ensure that measures are taken to prevent

the TV dropping or falling over.

Tie commercially available tough cord(s) to the hooks in the back

of the TV, and fix the TV to solid walls or columns.

< FRONT VIEW >

WALL

*Diagram differs from actual appearance.

1.2.2 INSTALLATION REQUIREMENTS

Ensure that the minimal distance is maintained, as specified

below, between the unit with and the surrounding walls, as well

as the floor etc.Install the unit on stable flooring or stands.Take

precautionary measures to prevent the unit from tipping in order

to protect against accidents and earthquakes.

HOOK

HOOK

*Diagram differs from actual appearance.

< SIDE VIEW >

It fixes in a band.

TV STAND

*Diagram differs from actual appearance.

200mm

*Diagram differs from actual appearance.

50mm150mm 150mm 50mm

1-4 (No.YA401)

1.2.4 NOTES ON HANDLING

(1) WHEN TAKING UNIT OUT OF A PACKING CASE

When taking the unit out of a packing case, do not grasp

the upper part of the unit. If you take the unit out while

grasping the upper part, the LCD PANEL may be damaged

because of a pressure. Instead of grasping the upper part,

put your hands on the lower backside or sides of the unit.

(2) AS FOR PRESSING OR TOUCHING A SPEAKER

Be careful not to press the opening of the speaker in the

lower part of the unit and around them since the decorative

sheet on the surface of the openings may be deformed.

Page 5

1.3 HANDLING LCD PANEL

1.3.1 PRECAUTIONS FOR TRANSPORTATION

When transporting the unit, pressure exerted on the internal LCD

panel due to improper handling (such as tossing and dropping)

may cause damages even when the unit is carefully packed. To

prevent accidents from occurring during transportation, pay

careful attention before delivery, such as through explaining the

handling instructions to transporters.

Ensure that the following requirements are met during

transportation, as the LCD panel of this unit is made of glass and

therefore fragile:

(1) USE A SPECIAL PACKING CASE FOR THE LCD PANEL

When transporting the LCD panel of the unit, use a special

packing case (packing materials). A special packing case

is used when a LCD panel is supplied as a service spare

part.

(2) ATTACH PROTECTION SHEET TO THE FRONT

Since the front (display part) of the panel is vulnerable,

attach the protection sheet to the front of the LCD panel

before transportation. Protection sheet is used when a LCD

panel is supplied as a service spare part.

(3) AVOID VIBRATIONS AND IMPACTS

The unit may be broken if it is toppled sideways even when

properly packed. Continuous vibration may shift the gap of

the panel, and the unit may not be able to display images

properly. Ensure that the unit is carried by at least 2

persons and pay careful attention not to exert any vibration

or impact on it.

(4) DO NOT PLACE EQUIPMENT HORIZONTALLY

Ensure that it is placed upright and not horizontally during

transportation and storage as the LCD panel is very

vulnerable to lateral impacts and may break. During

transportation, ensure that the unit is loaded along the

traveling direction of the vehicle, and avoid stacking them

on one another. For storage, ensure that they are stacked

in 2 layers or less even when placed upright.

1.3.2 OPTICAL FILTER (ON THE FRONT OF THE LCD PANEL)

(1) Avoid placing the unit under direct sunlight over a

prolonged period of time. This may cause the optical filter

to deteriorate in quality and COLOUR.

(2) Clean the filter surface by wiping it softly and lightly with a

soft and lightly fuzz cloth (such as outing flannel).

(3) Do not use solvents such as benzene or thinner to wipe the

filter surface. This may cause the filter to deteriorate in

quality or the coating on the surface to come off. When

cleaning the filter, usually use the neutral detergent diluted

with water. When cleaning the dirty filter, use water-diluted

ethanol.

(4) Since the filter surface is fragile, do not scratch or hit it with

hard materials. Be careful enough not to touch the front

surface, especially when taking the unit out of the packing

case or during transportation.

1.3.3 PRECAUTIONS FOR REPLACEMENT OF EXTERIOR

PARTS

Take note of the following when replacing exterior parts (REAR

COVER, FRONT PANEL, etc.):

(1) Do not exert pressure on the front of the LCD panel (filter

surface). It may cause irregular COLOUR.

(2) Pay careful attention not to scratch or stain the front of the

LCD panel (filter surface) with hands.

(3) When replacing exterior parts, the front (LCD panel) should

be placed facing downward. Place a mat, etc. underneath

to avoid causing scratches to the front (filter surface).

(No.YA401)1-5

Page 6

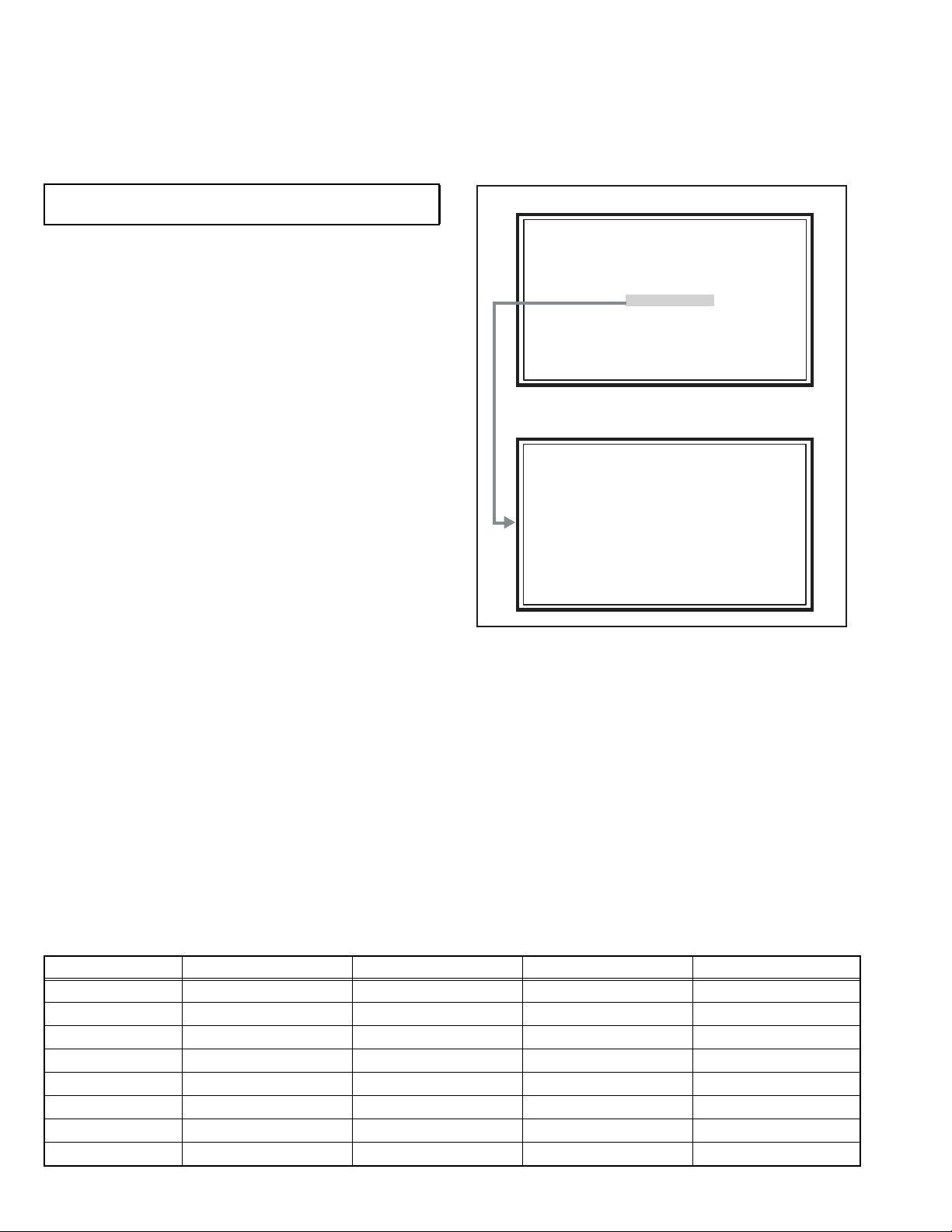

2.1 SYSTEM SETTEING

SERVICE MENU

1. ADJUST

2. SELF CHECK

3. I2C STOP

LOB 0 FAN 0

AUD 0

ANA 9 DIG 9

0000 00

00

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

Be sure to carry out the following operation at the end of

the procedure.

(1) Press the [DISPLAY] key and [MUTING] key

simultaneously, then enter the SERVICE MODE.

(2) When the Main Menu is displayed, press [2] key to enter

the self check mode.

(3) Turn off the power by pressing the [POWER] key on the

remote control unit.

SERVICE MENU SCREEN

SERVICE MENU

1. ADJUST

2. SELF CHECK

3. I2C STOP

SELF CHECK MODE SCREEN

LOB 0 FAN 0

AUD 0

ANA 9 DIG 9

0000 00

00

2.2 FEATURES

D.I.S.T. (Digital Image Scaling Technology)

This system uses line interpolation to double the number of

scanning lines and achieve high resolution, flicker-free picture.

Colour Management

This function ensures dull colours are compensated to

produce natural hues.

Picture Management

This function makes it easier to see the dark areas when a

picture has many dark areas, and makes it easier to see the

bright areas when a picture has many bright areas.

Smart Picture

This function detects the APL (Average Picture Level) and

adjusts the contrast suitable for what you are watching.

DIGITAL VNR

This function cuts down the amount of noise in the original

picture.

MPEG Noise Reduction

This function effects the block noise removal and mosquito NR

simultaneously.

MaxxBass

This function emphasizes the bass sound.

2.3 MAIN DIFFERENCE LIST

Item LT-Z32FX6 LT-Z32FX6/A LT-Z32FX6/S LT-Z32FX6/B

POWER CORD EU Type (2 Pins) AU Type (2 Pins) UK Type (3 Pins) Flat type (2 Pins)

ANALOG PWB SFL-1231A-H2 ←←SFL-1231A-BK

D-AMP PWB SFL-6231A-H2 ←←SFL-6231A-BK

SW PWB SFL-7202A-H2 ←←SFL-7202A-BK

LED PWB SFL-8706A-H2 ←←SFL-8706A-BK

POWER PWB SFL-9044A-H2 ←←SFL-9044A-BK

DC-DC PWB SFL-9145A-H2 ←←SFL-9145A-BK

DIGITAL PWB SFL0D355A-H2 SFL0D356A-H2 ← SFL0D355A-BK

1-6 (No.YA401)

Page 7

2.4 TECHNICAL INFORMATION

2.4.1 LCD PANEL

This unit uses the flat type panel LCD (Liquid Crystal Display) panel that occupies as little space as possible, instead of the

conventional CRT (Cathode Ray Tube), as a display unit.

Since the unit has the two polarizing filter that are at right angles to each other, the unit adopts "normally black" mode, where light

does not pass through the polarizing filter and the screen is black when no voltage is applied to the liquid crystals.

2.4.1.1 SPECIFICATIONS

The following table shows the specifications of this unit.

Item Specifications

Maximum dimensions ( W × H × D )

Weight 7.0 kg

Effective screen size Diagonal: 800 mm (H: 697 mm × V: 392 mm)

Aspect ratio 16 : 9

Drive device / system a-Si-TFT active matrix system

Resolution Horizontally 1366 × Vertically 768 × RGB < W-XGA > 3147264 dots in total

Pixel pitch (pixel size) Horizontally: 0.51075 mm, Vertically: 0.51075mm

Displayed colour 16777216 colours 256 colours for R G and B

Brightness 500cd/m2

Contrast ratio 1200 : 1

Response time (Tr + Tf) less than 14 ms

View angle (Horizontally) 178°

View angle (Vertically) 178°

Surface polarizer Anti-Glare type Low reflective coat

Colour filter Vertical stripe

Backlight Direct-type Cold cathode fluorescent lamp ×16

Power supply voltage in LCD 6.5 V

Power supply voltage in inverter

Panel interface system LVDS (Low Voltage Differential Signaling)

760 mm × 450 mm × 50 mm

24 V

2.4.1.2 PIXEL FAULT

There are three pixel faults - bright fault , dark fault and flicker fault - that are respectively defined as follows.

BRIGHT FAULT

In this pixel fault, a cell that should not light originally is lighting on and off.

For checking this pixel fault, input ALL BLACK SCREEN and find out the cell that is lighting on and off.

DARK FAULT

In this pixel fault, a cell that should light originally is not lighting or lighting with the brightness twice as brighter as originally lighting.

For checking this pixel fault, input 100% of each R/G/B colour and find out the cell that is not lighting.

FLICKER FAULT

In the pixel fault, a cell that should light originally or not light originally is flashing on and off.

For checking this pixel fault, input ALL BLACK SCREEN signal or 100% of each RGB colour and find out the cell that is flashing on

and off.

(No.YA401)1-7

Page 8

2.4.2 MAIN CPU PIN FUNCTION [IC7301

Pin Pin name I/O Function Pin Pin name I/O Function

1 TCK O Test purpose 65 D2 I/O Program ROM data for main CPU

2 TMS I Test purpose 66 D12 I/O Program ROM data for main CPU

3 TDI I Test purpose 67 D10 I/O Program ROM data for main CPU

4 TDO O Test purpose 68 VSS33 - GND

5 P2.8 O TV, Subtitle/OTHER 69 VDD33 I 3.3V

6 P2.9 O Blue for OSD 70 D4 I/O Program ROM data for main CPU

7 P2.10 O Blue for OSD 71 D3 I/O Program ROM data for main CPU

8 P2.11 O Blue for OSD 72 D11 I/O Program ROM data for main CPU

9 P2.12 O Blue for OSD 73 RSTIN I Reset

10 P2.13 O Blue for OSD 74 POWER O Sleep state release for chassis CPU [Relese : L]

11 P2.14 I Not used 75 P3.1 O DM_RESET(IDTV)

12 P2.15 O Request for chassis CPU communication 76 REMOCON I Remote control

13 VSS33 - GND 77 P3.3 I Clock for OSD

14 VDD33 I 3.3V 78 P3.4 O Red for OSD

15 P4.5 O Not used 79 P3.5 O Red for OSD

16 A20 O Program ROM address for main CPU 80 P3.6 O Red for OSD

17 A19 O Program ROM address for main CPU 81 P3.7 O Red for OSD

18 A18 O Program ROM address for main CPU 82 MTST I/O Data transmission for chassis CPU communication

19 A17 O Program ROM address for main CPU 83 MTSR I/O Data receive for chassis CPU communication

20 VSS25 - GND 84 VSS33 - GND

21 VDD25 I 2.5V 85 VDD33 I 3.3V

22 A16 O Program ROM address for main CPU 86 VSS25 - GND

23 A8 O Program ROM address for main CPU 87 VDD25 I 2.5V

24 A7 O Program ROM address for main CPU 88 TXD0 I/O Communication for adjustment

25 A9 O Program ROM address for main CPU 89 RXD0 I/O Communication for adjustment

26 A6 O Program ROM address for main CPU 90 P3.12 O Red for OSD

27 A5 O Program ROM address for main CPU 91 CLK O Clock for chassis CPU communication

28 A10 O Program ROM address for main CPU 92 P3.15 O Green for OSD

29 A11 O Program ROM address for main CPU 93 P5.14 O Green for OSD

30 A12 O Program ROM address for main CPU 94 P5.15 O Green for OSD

31 VSS33 - GND 95 TRIG_IN O Green for OSD

32 VDD33 I 3.3V 96 TRIG_OUT O Green for OSD

33 A4 O Program ROM address for main CPU 97 P6.2 O Green for OSD

34 A3 O Program ROM address for main CPU 98 P6.3 I/O I

35 A2 O Program ROM address for main CPU 99 P6.4 I/O I

36 A1 O Program ROM address for main CPU 100 P6.5 O Teletext signal select [Analog RGB : H / Digital RGB : L]

37 A0 O Program ROM address for main CPU 101 IRQ O IRQ(IDTV)

38 A13 O Program ROM address for main CPU 102 VSYNC I/O Vertical sync

39 ARAS/A14 O Program ROM address for main CPU 103 HSYNC I/O Horizontal sync

40 CAS/A15 O Program ROM address for main CPU 104

41 VSS33 - GND 105 BLANK O Ys for OSD / Teletext

42 VDD33 I 3.3V 106 VDD33 I 3.3V

43 MEMCLK O Clock for memory 107 VSS33 - GND

44 CSSDRAM O Chip select for memory 108 XTAL1 I 6MHz for system clock

45 CLKEN O Clock enable for memory 109 XTAL2 O 6MHz for system clock

46 CSROM O Chip select for memory 110 VSSA - GND

47 RD O Read for memory 111 VDDA I 2.5V

48 UDQM O Control buffer of memory 112 R O R for OSD / Teletext

49 LDQM O Control buffer of memory 113 G O G for OSD / Teletext

50 WR O Write for memory 114 B O B for OSD / Teletext

51 D15 I/O Program ROM data for main CPU 115 VSSA - GND

52 VSS33 - GND 116 VDDA I 2.5V

53 VDD33 I 3.3V 117 CVBS2 I Video for Teletext

54 D7 I/O Program ROM data for main CPU 118 VSSA - GND

55 D0 I/O Program ROM data for main CPU 119 VDDA I 2.5V

56 D14 I/O Program ROM data for main CPU 120 CVBS1B I Video for Teletext

57 D8 I/O Program ROM data for main CPU 121 CVBS1A I Video for Teletext

58 D6 I/O Program ROM data for main CPU 122 VSSA - GND

59 D1 I/O Program ROM data for main CPU 123 VDDA I 2.5V

60 VSS33 - GND 124 KEY1 I Key scan data 1 [ON : H]

61 VDD33 I 3.3V 125 KEY2 I Key scan data 2 [ON : H]

62 D13 I/O Program ROM data for main CPU 126 MECA_SW I Main power ON / OFF control [ON : L]

63 D9 I/O Program ROM data for main CPU 127

64 D5 I/O Program ROM data for main CPU 128 TMODE I Test purpose

: DIGITAL PWB]

COR/RSTOUT

(KEYP2)P5.3

2

C bus clock (for main memory)

2

C bus Data (for main memory)

O Not used

I Not used

1-8 (No.YA401)

Page 9

SECTION 3

DISASSEMBLY

3.1 DISASSEMBLY PROCEDURE

CAUTION AT DISASSEMBLY:

• Be sure to perform the SYSTEM SETTEING, at the end of the procedure.

• Make sure that the power cord is disconnected from the outlet.

• Pay special attention not to break or damage the parts.

• When removing each board, remove the connectors as required. Taking notes of the connecting points (connector numbers)

makes service procedure manageable.

• Make sure that there is no bent or stain on the connectors before inserting, and firmly insert the connectors.

3.1.1 REMOVING THE STAND (Fig.1)

(1) Remove the 2 screws [A].

(2) Remove the STAND COVER.

(3) Remove the 4 screws [B].

(4) Remove the STAND.

3.1.2 REMOVING THE REAR COVER (Fig.1)

• Remove the STAND.

(1) Remove the JACK COVER (L/R).

(2) Remove the 7 screws [C], the 5 screws [D], and the 1

screw [E].

(3) Remove the REAR COVER.

3.1.3 REMOVING THE POWER PWB (Fig.1)

• Remove the STAND.

• Remove the REAR COVER.

(1) Remove the 1 screw [F].

(2) Remove the POWER CORD HOLDER.

(3) Remove the POWER CORD.

(4) Remove the 4 screws [G].

(5) Remove the POWER PWB.

3.1.4 REMOVING THE D-AMP PWB (Fig.1)

• Remove the STAND.

• Remove the REAR COVER.

(1) Remove the 2 screw [H].

(2) Remove the D-AMP PWB.

3.1.6 REMOVING THE DC-DC PWB (Fig.1)

• Remove the STAND.

• Remove the REAR COVER.

(1) Remove the 4 screws [Q].

(2) Remove the BACK BRACKET.

(3) Remove the 2 screws [R].

(4) Remove the DC-DC PWB.

3.1.7 REMOVING THE DIGITAL PWB (Fig.1)

• Remove the STAND.

• Remove the REAR COVER.

• Remove the BACK BRACKET.

• Remove the 7 hooks of the SHIELD COVER.

(1) Remove the SHIELD COVER by sliding it in the direction of

the arrow.

(2) Remove the 2 screws [S] and 2 screws [T].

(3) Remove the SHIELD TERMINAL.

(4) Remove the 9 screws [U].

(5) Remove the DIGITAL PWB.

CAUTION :

Make sure to perform the "SYSTEM SETTEING", when

DIGITAL PWB is replaced.

3.1.5 REMOVING THE ANALOG PWB (Fig.1)

• Remove the STAND.

• Remove the REAR COVER.

• Remove the D-AMP PWB.

(1) Remove the 3 screws [J] and 2 screws [K].

(2) Remove the TERMINAL BASE.

(3) Remove the 1 screw [L].

(4) Remove the TUNER BASE.

(5) Remove the 2 screws [M].

(6) Remove the D-AMP BRACKET.

(7) Remove the 2 screws [N] and 2 screws [P].

(8) Remove the ANALOG PWB.

(No.YA401)1-9

Page 10

㧯

JACK COVER

D

E

STAND COVER

A

A

B

REAR COVER

STAND

SHIELD COVER

Hook

Hook

Hook

Hook

Hook

Hook

Hook

BACK BRACKET

Q

M

D-AMP PWB

BRACKET

H

U

DIGITAL PWB

U

S

D-AMP PWB

SHIELD COVER

SHIELD TERMINAL

SHIELD TERMINAL

T

ANALOG PWB

N

TUNER BASE

K

TERMINAL BASE

SHIELD BASE

L

R

R

POWER PWB

DC-DC PWB

POWER CORD HOLDER

POWER CORD

F

G

J

1-10 (No.YA401)

P

FRONT

Fig.1

Page 11

3.1.8 REMOVING THE SW PWB (Fig.2)

• Remove the STAND.

• Remove the REAR COVER.

(1) Remove the 2 screws [A].

(2) Remove the CONTROL ASS’Y with SW PWB.

(3) Remove the 2 screws [B].

(4) Remove the SW PWB from the CONTROL ASS’Y.

3.1.11 REMOVING THE ILLUMINATE LENS (Fig.2)

• Remove the STAND.

• Remove the REAR COVER.

• Remove the LED PWB.

• Remove the STAND BRACKET.

(1) Remove the 2 screws [F].

(2) Remove the ILLUMINATE LENS.

3.1.9 REMOVING THE SPEAKER (Fig.2)

• Remove the STAND.

• Remove the REAR COVER.

(1) Remove the 6 screws [C].

(2) Remove the SPEAKER (L /R).

NOTE:

• Since the speaker is attached in a certain direction, attach

the speaker in the same correct direction as it has been

attached.

• When the speaker is decomposed, the performance cannot

be kept.

3.1.10 REMOVING THE LED PWB (Fig.2)

• Remove the STAND.

• Remove the REAR COVER.

(1) Remove the 2 screws [D].

(2) Remove the STAND BRACKET.

(3) Remove the 2 hooks [E].

(4) Remove the LED PWB.

MAIN BASE

G

G

3.1.12 REMOVING THE LCD PANEL UNIT (Fig.2)

• Remove the STAND.

• Remove the REAR COVER.

• Remove the BACK BRACKET.

• Remove the STAND BRACKET.

• Remove the POWER CORD HOLDER.

(1) Remove the 2 screws [G].

(2) Remove the MAIN BASE.

(3) Remove the 2 screws [H] and 2 screw [J].

(4) Remove the LCD PANEL UNIT with TOP/BOTTOM

FRAME.

(5) Remove the 2 screws [K].

(6) Remove the TOP FARAME from the LCD PANEL UNIT.

(7) Remove the 2 screws [L].

(8) Remove the BOTTOM FARAME from the LCD PANEL

UNIT.

D

STAND

BRACKET

C

SPEAKER

SW PWB

A

CONTROL ASS'Y

ILLUMINATE LENS

F

LCD PANEL UNIT

SPEAKER

H

K

TOP FRAME

G

H

K

E

J

C

B

A

FRONT PANEL

FRONT

LED PWB

J

BOTTOM FRAME

L

L

Fig.2

(No.YA401)1-11

Page 12

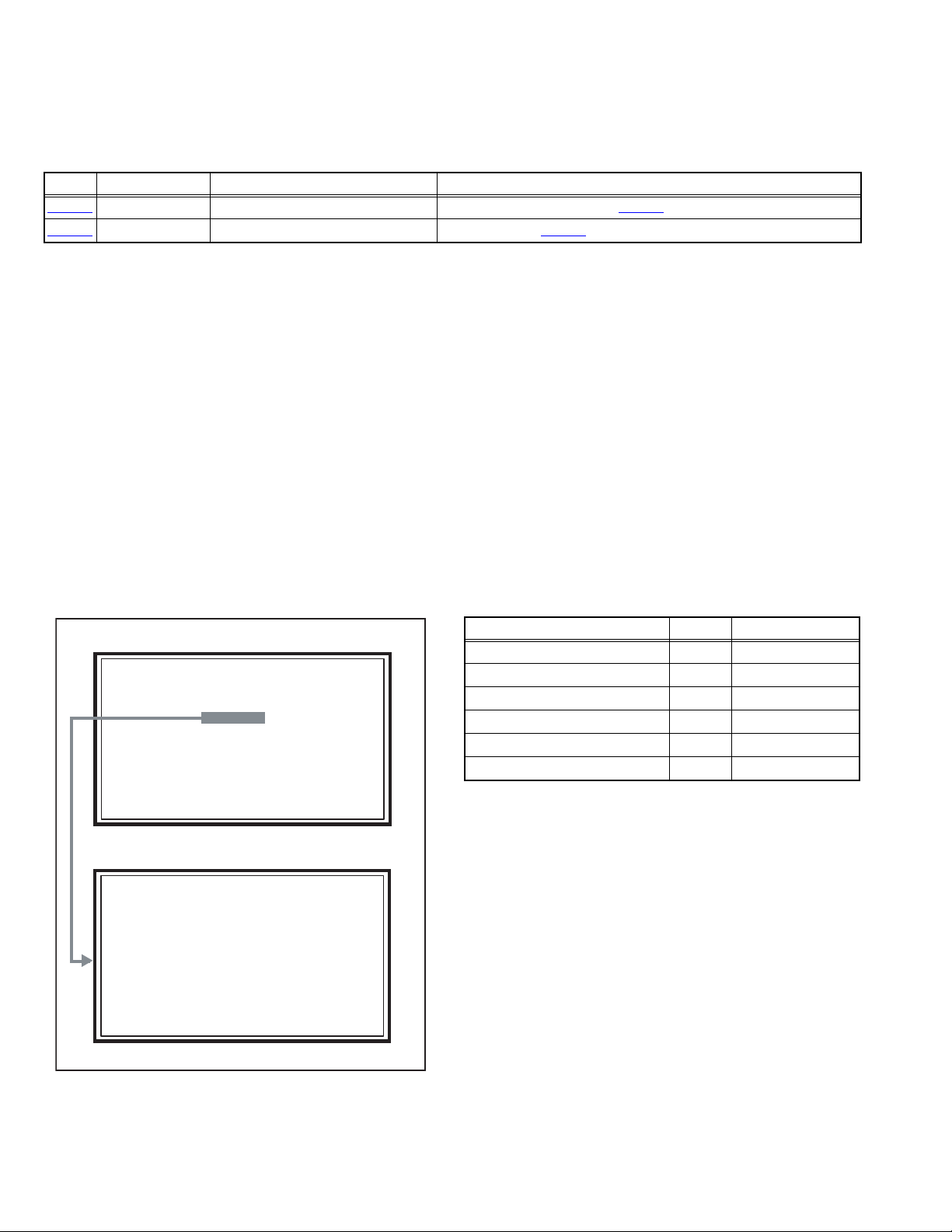

3.2 MEMORY IC REPLACEMENT

SERVICE MENU

1. ADJUST

2. SELF CHECK

3. I2C STOP

S001 R DRIVE 137

PAL50 FULL STD H

• This model uses the memory IC.

• This memory IC stores data for proper operation of the video and drive circuits.

• When replacing, be sure to use an IC containing this (initial value) data.

3.2.1 MEMORY IC TABLE

Simbol Number of pins Mounting PWB Main content of data

IC7201

IC7602

48-pin DIGITAL PWB Progaram(Video process) of IC6001(System CPU) is memorized.

8-pin DIGITAL PWB Setting value of IC7301(MAIN CPU) is memorized.

3.2.2 MEMORY IC REPLACEMENT PROCEDURE

1. Power off

Switch off the power and disconnect the power plug from the AC outlet.

2. Replace the memory IC

Be sure to use the memory IC written with the initial setting values.

3. Power on

Connect the power plug to the AC outlet and switch on the power.

4. Receiving channel setting

Refer to the OPERATING INSTRUCTIONS and set the receive channels (Channels Preset) as described.

5. User setting

Check the user setting items according to the given in page later. Where these do not agree, refer to the OPERATING

INSTRUCTIONS and set the items as described.

6. SERVICE MODE setting

Verify what to set in the SERVICE MODE, and set whatever is necessary (Fig.1). Refer to the SERVICE ADJUSTMENT for setting.

3.2.3 SERVICE MODE SETTING

SERVICE MODE SCREEN

MAIN MENU SCREEN

SERVICE MENU

1. ADJUST

2. SELF CHECK

3. I2C STOP

ADJUSTMENT MODE SCREEN

S001 R DRIVE 137

PAL50 FULL STD H

SETTING ITEM

Setting items Settings Item No.

Video system setting Adjust S001 - S009

Audio system setting Adjust T001 - T003

Main CPU system setting Fixed M001 - M224

Drive system setting Fixed F001 - F002

(Not used) Fixed D001

(Not used) Fixed Z001

1-12 (No.YA401)

Fig.1

Page 13

3.2.4 SETTINGS OF FACTORY SHIPMENT

3.2.4.1 BUTTON OPERATION 3.2.4.2 REMOTE CONTROL DIRECT OPERATION

Setting item Setting position

POWER Off

CHANNEL PR01

VOLUME 10

TV/AV TV

3.2.4.3 REMOTE CONTROL MENU OPERATION

(1) PICTURE

Setting item Setting position

Picture Mode Bright

White Balance Cool

Features

Super Digipure Auto

Pull Down Auto

Colour Management On

Picture Management On

Smart Picture Off

MPEG Noise Reduction On

Colour System Main Depends on PR

Sub Auto

4:3 Auto Aspect Panoramic

(2) SOUND

Setting item Setting position

Stereo / I•II Stereo Sound

Bass Centre

Treble Centre

Balance Centre

Cinema Sound Off

Maxx Bass Low

Voice Enhancer Off

CHANNEL PR01

VOLUME 10

ZOOM Panoramic

(4) FEATURES

Sleep Timer Off

Appearance Type A

Blue Back On

Favourite Setting Blank

Child Lock Off

Auto Shutoff Off

Illumination Bright

Power Lamp On

(5) SET UP

Auto Program Tv Channel Automatically Set

Edit/manual Preset Ch Only

Language English

VIDEO-1 Setting Component

VIDEO-3 Setting Component

AI Volume On

Teletext Language Group-1

Hdmi Setting Auto

Setting item Setting position

Setting item Setting position

Setting item Setting position

(No.YA401)1-13

Page 14

3.3 REPLACEMENT OF CHIP COMPONENT

3.3.1 CAUTIONS

(1) Avoid heating for more than 3 seconds.

(2) Do not rub the electrodes and the resist parts of the pattern.

(3) When removing a chip part, melt the solder adequately.

(4) Do not reuse a chip part after removing it.

3.3.2 SOLDERING IRON

(1) Use a high insulation soldering iron with a thin pointed end of it.

(2) A 30w soldering iron is recommended for easily removing parts.

3.3.3 REPLACEMENT STEPS

1. How to remove Chip parts

2. How to install Chip parts

[Resistors, capacitors, etc.]

(1) As shown in the figure, push the part with tweezers and

alternately melt the solder at each end.

(2) Shift with the tweezers and remove the chip part.

[Transistors, diodes, variable resistors, etc.]

(1) Apply extra solder to each lead.

SOLDER

SOLDER

[Resistors, capacitors, etc.]

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the

solder. Then heat and melt the solder at both ends of the

chip part.

[Transistors, diodes, variable resistors, etc.]

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the

solder.

(3) First solder lead A as indicated in the figure.

(2) As shown in the figure, push the part with tweezers and

alternately melt the solder at each lead. Shift and remove

the chip part.

NOTE :

After removing the part, remove remaining solder from the

pattern.

1-14 (No.YA401)

A

B

C

(4) Then solder leads B and C.

A

B

C

Page 15

SECTION 4

SERVICE MENU

1. ADJUST

2. SELF CHECK

3. I2C STOP

ADJUSTMENT

4.1 ADJUSTMENT PREPARATION

(1) There are 2 ways of adjusting this TV : One is with the

REMOTE CONTROL UNIT and the other is the

conventional method using adjustment parts and

components.

(2) The adjustment using the REMOTE CONTROL UNIT is

made on the basis of the initial setting values. The

setting values which adjust the screen to the optimum

condition can be different from the initial setting

values.

(3) Make sure that connection is correctly made AC to AC

power source.

(4) Turn on the power of the TV and measuring instruments for

warming up for at least 30 minutes before starting

adjustments.

(5) If the receive or input signal is not specified, use the most

appropriate signal for adjustment.

(6) Never touch the parts (such as variable resistors,

transformers and condensers) not shown in the adjustment

items of this service adjustment.

4.2 PRESET SETTING BEFORE ADJUSTMENTS

Unless otherwise specified in the adjustment items, preset the

following functions with the REMOTE CONTROL UNIT.

Setting item Settings position

Picture Mode Standard

Picture Adjustments Centre

White Balance Mid

Super Digipure Auto

Pull Down Auto

Colour Management On

Picture Management On

Zoom Full

4.3 MEASURING INSTRUMENT AND FIXTURES

• Signal generator (Pattern generator) [PAL]

• Remote control unit

4.5 BASIC OPERATION OF SERVICE MODE

4.5.1 HOW TO ENTER THE SERVICE MODE

(1) Press [DISPLAY] key and [MUTING] key on the remote

control unit simultaneously to enter the SERVICE MODE

SCREEN.

(2) In the SERVICE MENU, press the [1] key to display

ADJUSTMENT MODE SCREEN.

SERVICE MENU SCREEN

SERVICE MENU

1. ADJUST

2. SELF CHECK

3. I2C STOP

NOTE:

• Before enter the SERVICE MODE, press the [MODE] key to

confirm that "TV" position is indicated. If it is in a wrong

position, the SERVICE MODE operation cannot be

performed.

• When a number key other than the [1] key is pressed in the

SERVICE MODE SCREEN, the other relevant screen may

be displayed.

This is not used in the adjustment procedure. Press the

[MENU] key to return to the SERVICE MODE SCREEN.

4.5.2 HOW TO EXIT THE SERVICE MODE

Press the [MENU] key to exit the Service mode.

4.5.3 SERVICE MODE SELECT KEY LOCATION

[MUTING] key

[Nunber] key

4.4 ADJUSTMENT ITEMS

VIDEO CIRCUIT

• WHITE BALANCE (HIGH LIGHT) adjustment

[RETURN+] key

[Red] key

[MODE] key

[Function/] key

[DISPLAY] key

[Green] key

[MENU] key

[FUNCTION

/] key

(No.YA401)1-15

Page 16

4.5.4 ADJUSTMENT MODE

S001 R DRIVE 137

PAL50 FULL STD H

This mode is used to adjust the VIDEO CIRCUIT and the MTS CIRCUIT.

4.5.4.1 HOW TO ENTER THE ADJUSTMENT MODE

When the SERVICE MENU SCREEN of SERVICE MODE is displayed, press [1] key to enter the ADJUSTMENT MODE.

4.5.5 DESCRIPTION OF STATUS DISPLAY

(3) PICTURE MODE

SOFT : SOFT

ADJUSTMENT MODE

STD : STANDARD

BRI : BRIGHT

SETTING ITEM No.

SETTING ITEM

SETTING VALUE (DATA)

(4) WHITE BALANCE

H: COOL

M: MID

S001 R DRIVE 137

PAL50 FULL STD H

L: WARM

(5) SETTING ITEM NAME

Setting item name are displayed. For the setting item names

to be displayed, refer to "INITIAL SETTING VALUES IN THE

SERVICE MODE".

SIGNAL SYSTEM

ZOOM MODE

PICTURE MODE

WHITE BALANCE

(1) SIGNAL SYSTEM

The signal displayed on the screen is displayed.

PAL50 : PAL50Hz (Composite / S-video)

PAL60 : PAL60Hz (Composite / S-video)

SECAM : SECAM

NTSC3 : NTSC3.58

NTSC4 : NTSC4.43

525I : 525i (Component)

525P : 525p

625I : 625i (Component)

625P : 625p

750P : 750p

1125I5 : 1125i 50Hz

1125I6 : 1125i 60Hz

RGB5 : RGB 525i

RGB6 : RGB 625i

PCVGA : PC (VGA)

PCXGA : PC (XGA)

H525I : HDMI 525i

H525P : HDMI 525p

H625I : HDMI 625i

H625P : HDMI 625p

H750P : HDMI 750p

H125I5 : HDMI 1125i 50Hz

H125I6 : HDMI 1125i 60Hz

--- : OTHER

(2) ZOOM MODE

State of the SCREEN SIZE or MULTI PICTURE is displayed.

SINGLE SCREEN

FULL : FULL

PANO : PANORAMIC

1609 : 16:9 ZOOM

1609S : 16:9 ZOOM SUBTITLE

1409 : 14:9 ZOOM

REGU : REGULAR

MULTI SCREEN

M2 : 2-pictures multi

M12 : 12-pictures multi

(6) SETTING ITEM NO.

Setting item numbers are displayed. The setting item numbers

to be displayed are listed below.

Item No. Setting item

S001 - S009 Video system setting

T001 - T003 Audio system setting

M001 - M224 Main CPU system setting

F001 - F002 Drive system setting

D001 (NOT USED)

Z001 (NOT USED)

(7) SETTING VALUE (DATA)

The SETTING VALUE is displayed.

4.5.6 CHANGE AND MEMORY OF SETTING VALUE

SELECTION OF SETTING ITEM

• [FUNCTION /] key.

For scrolling up / down the setting items.

S001...S009 ↔ T001...T003 ↔ M001...M224 ↔

F001...F002 ↔ D001 ↔ Z001↔return to S001

CHANGE OF SETTING VALUE (DATA)

• [FUNCTION /] key.

For scrolling up / down the setting values.

MEMORY OF SETTING VALUE (DATA)

Changed setting value is memorized by pressing [MUTING]

key.

1-16 (No.YA401)

Page 17

4.6 INITIAL SETTING VALUES IN THE SERVICE MODE

• Perform fine-tuning based on the "initial values" using the remote control when in the Service mode.

• The "initial values" serve only as an indication rough standard and therefore the values with which optimal display can be achieved

may be different from the default values. But, don't change the values that are not written in "ADJUSTMENT PROCEDURE". They

are fixed values.

4.6.1 VIDEO SYSTEM SETTING

Item No. Item Variable range Setting value

S001 R DRIVE 0 - 255 137

S002 G DRIVE 0 - 255 120

S003 B DRIVE 0 - 255 104

S004 RESREV 0 - 255 0

S005 RESREV 0 - 255 2

S006 RESREV 0 - 255 2

S007 RESREV 0 - 255 2

S008 RESREV 0 - 255 2

S009 RESREV 0 - 255 2

4.6.2 AUDIO SYSTEM SETTING

Item No. Item Variable range Setting value

T001 RESREV 0 - 15 2

T002 RESREV 0 - 63 2

T003 RESREV 0 - 63 2

4.6.3 MAIN CPU SYSTEM SETTING (Fixed values)

Item No. Item Variable range Setting value

M001 1E00 00 - FF 00

M002 1E01 00 - FF 00

M003 1E02 00 - FF 05

M004 1E03 00 - FF 01

M005 1E04 00 - FF 00

M006 1E05 00 - FF 00

M007 1E06 00 - FF 00

M008 1E07 00 - FF 00

M009 1E08 00 - FF 00

M010 1E09 00 - FF 00

M011 1E0A 00 - FF 01

M012 1E0B 00 - FF 00

M013 1E0C 00 - FF 01

M014 1E0D 00 - FF 00

M015 1E0E 00 - FF 00

M016 1E0F 00 - FF 00

M017 1E10 00 - FF 01

M018 1E11 00 - FF 00

M019 1E12 00 - FF 00

M020 1E13 00 - FF 01

M021 1E14 00 - FF 10

M022 1E15 00 - FF 01

M023 1E16 00 - FF 00

M024 1E17 00 - FF 00

M025 1E18 00 - FF 00

M026 1E19 00 - FF 00

M027 1E1A 00 - FF 00

M028 1E1B 00 - FF 00

M029 1E1C 00 - FF 00

M030 1E1D 00 - FF 00

M031 1E1E 00 - FF 00

M032 1E1F 00 - FF 00

M033 1E20 00 - FF 00

M034 1E21 00 - FF 00

Item No. Item Variable range Setting value

M035 1E22 00 - FF 00

M036 1E23 00 - FF 00

M037 1E24 00 - FF 00

M038 1E25 00 - FF 00

M039 1E26 00 - FF 00

M040 1E27 00 - FF 00

M041 1E28 00 - FF 00

M042 1E29 00 - FF 00

M043 1E2A 00 - FF 00

M044 1E2B 00 - FF 00

M045 1E2C 00 - FF 00

M046 1E2D 00 - FF 00

M047 1E2E 00 - FF 00

M048 1E2F 00 - FF 00

M049 1E30 00 - FF 00

M050 1E31 00 - FF 02

M051 1E32 00 - FF 01

M052 1E33 00 - FF 00

M053 1E34 00 - FF 00

M054 1E35 00 - FF 00

M055 1E36 00 - FF 01

M056 1E37 00 - FF 00

M057 1E38 00 - FF C8

M058 1E39 00 - FF 0A

M059 1E3A 00 - FF 00

M060 1E3B 00 - FF 20

M061 1E3C 00 - FF 00

M062 1E3D 00 - FF 00

M063 1E3E 00 - FF 00

M064 1E3F 00 - FF 00

M065 1E40 00 - FF 00

M066 1E41 00 - FF 00

M067 1E42 00 - FF 04

M068 1E43 00 - FF 20

M069 1E44 00 - FF 00

M070 1E45 00 - FF 20

M071 1E46 00 - FF 04

M072 1E47 00 - FF 00

M073 1E48 00 - FF 00

M074 1E49 00 - FF 00

M075 1E4A 00 - FF 04

M076 1E4B 00 - FF 04

M077 1E4C 00 - FF 03

M078 1E4D 00 - FF 03

M079 1E4E 00 - FF 03

M080 1E4F 00 - FF 00

M081 1E50 00 - FF 06

M082 1E51 00 - FF 00

M083 1E52 00 - FF 22

M084 1E53 00 - FF 00

M085 1E54 00 - FF 00

M086 1E55 00 - FF 00

M087 1E56 00 - FF 00

(No.YA401)1-17

Page 18

Item No. Item Variable range Setting value

M088 1E57 00 - FF 00

M089 1E58 00 - FF 00

M090 1E59 00 - FF 00

M091 1E5A 00 - FF 00

M092 1E5B 00 - FF 00

M093 1E5C 00 - FF 00

M094 1E5D 00 - FF 00

M095 1E5E 00 - FF 00

M096 1E5F 00 - FF 00

M097 1E60 00 - FF 00

M098 1E61 00 - FF 00

M099 1E62 00 - FF 00

M100 1E63 00 - FF 00

M101 1E64 00 - FF 00

M102 1E65 00 - FF 00

M103 1E66 00 - FF 00

M104 1E67 00 - FF 00

M105 1E68 00 - FF 00

M106 1E69 00 - FF 00

M107 1E6A 00 - FF 02

M108 1E6B 00 - FF 00

M109 1E6C 00 - FF 00

M110 1E6D 00 - FF 00

M111 1E6E 00 - FF 00

M112 1E6F 00 - FF 00

M113 1E70 00 - FF 00

M114 1E71 00 - FF 00

M115 1E72 00 - FF 00

M116 1E73 00 - FF 00

M117 1E74 00 - FF 00

M118 1E75 00 - FF 00

M119 1E76 00 - FF 00

M120 1E77 00 - FF 0F

M121 1E78 00 - FF 00

M122 1E79 00 - FF 00

M123 1E7A 00 - FF 00

M124 1E7B 00 - FF 00

M125 1E7C 00 - FF 00

M126 1E7D 00 - FF 00

M127 1E7E 00 - FF 02

M128 1E7F 00 - FF 00

M129 1E80 00 - FF 01

M130 1E81 00 - FF 00

M131 1E82 00 - FF 01

M132 1E83 00 - FF 00

M133 1E84 00 - FF 00

M134 1E85 00 - FF 00

M135 1E86 00 - FF 00

M136 1E87 00 - FF 00

M137 1E88 00 - FF 00

M138 1E89 00 - FF 00

M139 1E8A 00 - FF 00

M140 1E8B 00 - FF 00

M141 1E8C 00 - FF 00

M142 1E8D 00 - FF 00

M143 1E8E 00 - FF 00

M144 1E8F 00 - FF 00

M145 1E90 00 - FF 00

Item No. Item Variable range Setting value

M146 1E91 00 - FF 00

M147 1E92 00 - FF 00

M148 1E93 00 - FF 00

M149 1E94 00 - FF 00

M150 1E95 00 - FF 00

M151 1E96 00 - FF 00

M152 1E97 00 - FF 00

M153 1E98 00 - FF 00

M154 1E99 00 - FF 00

M155 1E9A 00 - FF 01

M156 1E9B 00 - FF 00

M157 1E9C 00 - FF 03

M158 1E9D 00 - FF 00

M159 1E9E 00 - FF 00

M160 1E9F 00 - FF 00

M161 1EA0 00 - FF 00

M162 1EA1 00 - FF 00

M163 1EA2 00 - FF 01

M164 1EA3 00 - FF 00

M165 1EA4 00 - FF 00

M166 1EA5 00 - FF 00

M167 1EA6 00 - FF 00

M168 1EA7 00 - FF 00

M169 1EA8 00 - FF 00

M170 1EA9 00 - FF 00

M171 1EAA 00 - FF 00

M172 1EAB 00 - FF 00

M173 1EAC 00 - FF 1B

M174 1EAD 00 - FF 00

M175 1EAE 00 - FF 00

M176 1EAF 00 - FF 00

M177 1EB0 00 - FF 00

M178 1EB1 00 - FF 00

M179 1EB2 00 - FF 00

M180 1EB3 00 - FF 00

M181 1EB4 00 - FF 00

M182 1EB5 00 - FF 00

M183 1EB6 00 - FF 00

M184 1EB7 00 - FF 00

M185 1EB8 00 - FF 00

M186 1EB9 00 - FF 00

M187 1EBA 00 - FF 00

M188 1EBB 00 - FF 00

M189 1EBC 00 - FF 01

M190 1EBD 00 - FF 00

M191 1EBE 00 - FF 00

M192 1EBF 00 - FF 00

M193 1EC0 00 - FF 00

M194 1EC1 00 - FF 00

M195 1EC2 00 - FF 01

M196 1EC3 00 - FF 00

M197 1EC4 00 - FF 00

M198 1EC5 00 - FF 00

M199 1EC6 00 - FF 00

M200 1EC7 00 - FF 00

M201 1EC8 00 - FF 01

M202 1EC9 00 - FF 00

M203 1ECA 00 - FF 00

1-18 (No.YA401)

Page 19

Item No. Item Variable range Setting value

M204 1ECB 00 - FF 00

M205 1ECC 00 - FF 02

M206 1ECD 00 - FF 00

M207 1ECE 00 - FF 00

M208 1ECF 00 - FF 00

M209 1ED0 00 - FF 10

M210 1ED1 00 - FF 00

M211 1ED2 00 - FF 00

M212 1ED3 00 - FF 00

M213 1ED4 00 - FF 00

M214 1ED5 00 - FF 00

M215 1ED6 00 - FF 00

M216 1ED7 00 - FF 00

M217 1ED8 00 - FF 00

M218 1ED9 00 - FF 00

M219 1EDA 00 - FF 00

M220 1EDB 00 - FF 00

4.7 ADJUSTMENT PROCEDURE

4.7.1 VIDEO CIRCUIT

Item

WHITE

BALANCE

(HIGHLIGHT)

Measuring

instrument

Remote

control unit

Signal

generator

Test point Adjustment part Description

[1.ADJUST]

S001: R DRIVE (Red drive)

S002: G DRIVE (Green drive)

S003: B DRIVE (Blue drive)

Item No. Item Variable range Setting value

M221 1EDC 00 - FF 00

M222 1EDD 00 - FF 00

M223 1EDE 00 - FF 00

M224 1EDF 00 - FF 00

4.6.4 DRIVE SYSTEM SETTING (Fixed values)

Item No. Item Variable range Setting value

F001 DD 0 - 1 0

F002 RAM REF 0 - 1 0

4.6.5 NOT USED (Fixed values)

Item No. Item Variable range Setting value

D001 RESREV 0 - 255 2

4.6.6 NOT USED (Fixed values)

Item No. Item Variable range Setting value

Z001 RESREV 0 - 255 2

(1) Receive a PAL 75% all white signal.

(2) Set PICTURE MODE to "STANDARD".

(3) Set ZOOM to "FULL".

(4) Set WHITE BALANCE to "MID".

(5) Select "1.ADJUST" from the SERVICE MODE.

(6) Adjust to Keep one of < S001 > (Red drive),

< S002 > (Green drive) or < S003 > (Blue drive)

unchanged, then lower the other two so that the

all-white screen is equally white throughout.

NOTE:

Set one or more of < S001 >, < S002 >, and

< S003 > to "137".

(7) Check that white balance is properly tracked

from low light to high light. If the white balance

tracking is deviated, adjust to correct it.

(8) Press the [MUTING] key to memoirze the set

value.

(No.YA401)1-19

Page 20

SECTION 5

SERVICE MENU

1. ADJUST

2. SELF CHECK

3. I2C STOP

LOB 0 FAN 0

AUD 0

ANA 9 DIG 9

0000 00

00

TMP 0 L 1 0

L 2 0 DDT 0

FAN 0 L C 0

IRS 0

TROUBLESHOOTING

5.1 SELF CHECK FEATURE

5.1.1 OUTLINE

This unit comes with the "Self check" feature, which checks the

operational state of the circuit and displays/saves it during

failure.Diagnosis is performed when power is turned on, and

information input to the main microcomputer is monitored at all

time.Diagnosis is displayed in 2 ways via screen display and LED

flashes. Failure detection is based on input state of I

2

C bus and

the various control lines connected to the main microcomputer.

5.1.2 HOW TO ENTER THE SELF CHECK MODE

Before enter the SELF CHECK MODE, press the [MODE] key to

confirm that "TV" position is indicated. If it is in a wrong position,

the SELF CHECK MODE operation cannot be performed.

(1) Press the [DISPLAY] key and [MUTING] key

simultaneously, then enter the SERVICE MODE.

(2) Press the [2] key SELF CHECK MODE.

(3) Press the [RED] key to enter Page 2 of the SELF CHECK

MODE.

*Use the [GREEN] key to toggle between Page 1 and Page 2.

NOTE:

When a number key other than the [2] key is pressed in the

SERVICE MODE screen, the other relevant screen may be

displayed.

This is not used in the SELF CHECK MODE. Press the

[MENU] key to return to the MAIN MENU SCREEN.

5.1.3 HOW TO EXIT THE SELF CHECK MODE

To Save Failure History:

Turn off the power by unplugging the AC power cord plug when

in the Self check display mode.

To Clear (Reset) Failure History:

Turn off the power by pressing the [POWER] key on the remote

control unit when in the Self check display mode.

5.1.4 FAILURE HISTORY

Failure history can be counted up to 9 times for each item. When

the number exceeds 9, display will remain as 9. Failure history

will be stored in the memory unless it has been deleted.

NOTE:

Only SYNC (with/without sync signals) will be neither counted

nor stored.

5.1.5 POINTS TO NOTE WHEN USING THE SELF CHECK

FEATURE

In addition to circuit failures (abnormal operation), the following

cases may also be iagnosed as "Abnormal" and displayed and

counted as "NG".

(1) Temporary defective transmissions across circuits due to

pulse interruptions

(2) Misalignment in the on/off timing of power for I

2

C bus

(VCC) when turning on/off the main power.

Diagnosis may be impeded if a large number of items are

displayed as "NG". As such, start Self check check only after 3

seconds in the case of receivers and 5 seconds in the case of

panels upon turning on the power. If recurrences are expected,

ensure to clear (reset) the failure history and record the new

diagnosis reults.

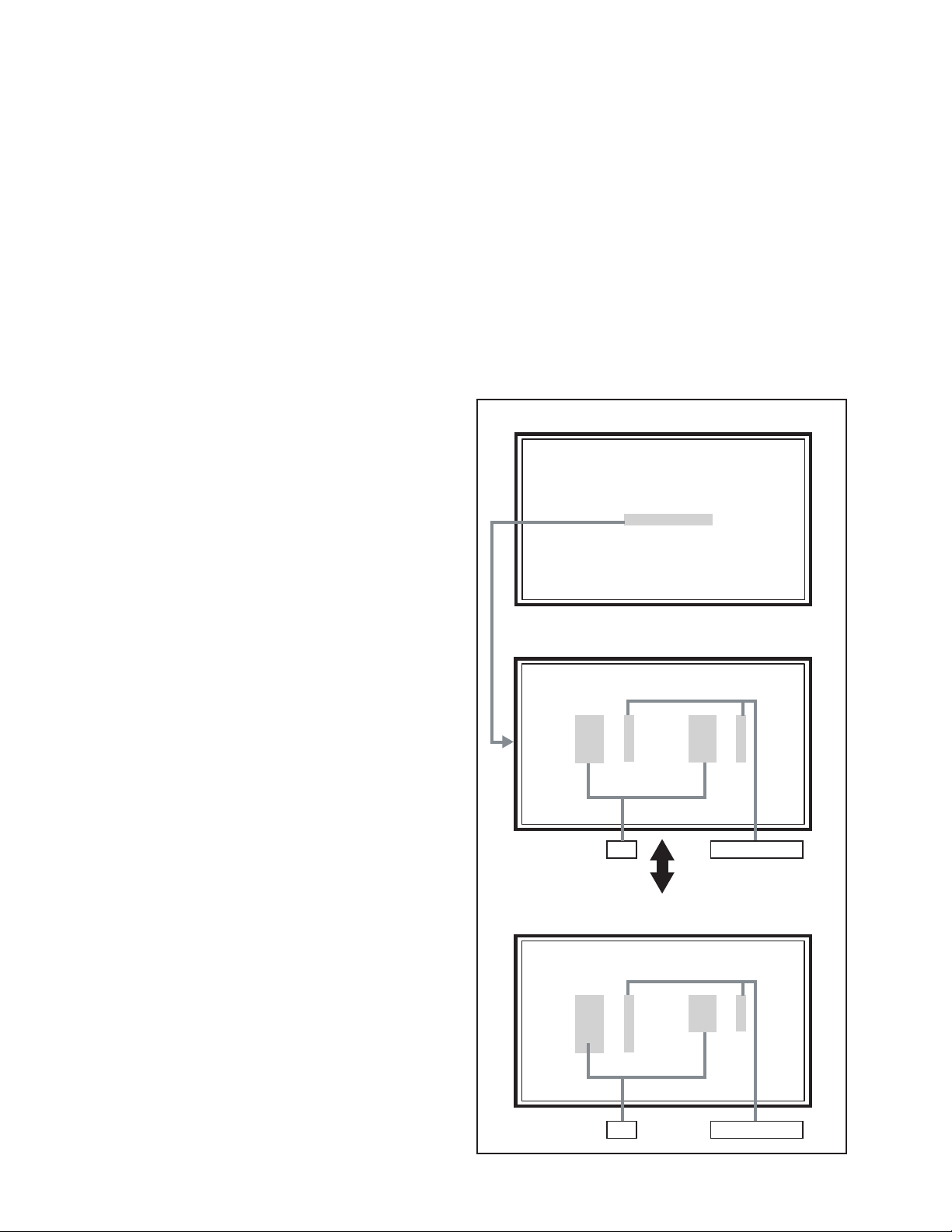

SERVICE MENU SCREEN

SERVICE MENU

1. ADJUST

2. SELF CHECK

3. I2C STOP

SELF CHECK MODE SCREEN (Page 1)

LOB 0 FAN 0

AUD 0

ANA 9 DIG 9

0000 00

00

Item Failure history

1-20 (No.YA401)

SELF CHECK MODE SCREEN (Page 2)

TMP 0 L 1 0

L 2 0 DDT 0

FAN 0 L C 0

IRS 0

Item Failure history

Fig.1

Page 21

5.1.6 DETAILS

Self check is performed for the following items:

< Page 1 of screen >

Detection item Display Detection content

Low bias line short

protection

Fan lock FAN Not used ---- ----

Abnormal rise of

temperature in audio

circuit

Devices on the ANALOG

PWB

Devices on the DIGITAL

PWB

< Page 2 of screen >

Detection item Display Detection content

Temp. sensor TEM Not used ---- ----

Lamp does not light up L1 Not used ---- ----

Lamp goes out L2 Not used ---- ----

Abnormal DD CPU

circuit

Fan lock FAN Not used ---- ----

Lamp cover open LC Not used ---- ----

Abnormal of optical iris IRS Not used ---- ----

LOB Confirm the operation of the low bais (16V / 5V /

LCD5V / 3.3V / 1.2V) protection circuit.

, Q9651[DC-DC PWB]

Q9601

AUD Confirmation of the temperature of audio circuit.

TH6401

ANA Confirmation of reply of ACK signal which uses

I2C communication.

IC101

[ANALOG PWB]

DIG Confirmation of reply of ACK signal which uses

I2C communication.

IC6401

DDT Not used ---- ----

[D-AMP PWB]

, IC102, IC381, IC601, IC606, TU3001

[DIGITAL PWB]

Diagnosis

signal (line)

LB_PRO Detection starts 3 seconds after

the power is turned on. If error

continues between 200 ms the

power is turned off.

---- Detection starts 3 seconds after

the power is turned on.

If the temperture of 90°C is

detected for 3 seconds the power

is turned off.

SDA If it checks whenever I2C

communication is performed and

no reply of ACK signal an error

will be counted.

SDA If it checks whenever I2C

communication is performed and

no reply of ACK signal an error

will be counted.

Diagnosis

signal (line)

Detection timing

Detection timing

5.1.7 METHOD OF DISPLAY WHEN A RASTER IS NOT OUTPUT

In the state where a raster is not output by breakdown of the set, an error is displayed by blink of the POWER LED.

Type of error POWER LED flash cycle

Low bias line short protection Blue turnig on and off at 1 second intervals.

Abnormal rise of temperature in audio circuit Blue turnig on and off at 0.5 second intervals.

< Explanation of operation >

If error is detected, the power is turned off.

Shortly after a power is turned off, POWER LED will be blinked.

Power cannot be turned on until the power cord takes out and inserts, after a power is turned off.

(No.YA401)1-21

Page 22

Victor Company of Japan, Limited

Flat Panel Display Category 12, 3-chome, Moriya-cho, Kanagawa-ku, Yokohama-city, Kanagawa-prefecture, 221-8528, Japan

(No.YA401)

Printed in Japan

VPT

Page 23

LT-Z32FX6

WIDE LCD PANEL TV INSTRUCTIONS

ENGLISH

LCT2025-001A-H

Page 24

I

Page 25

1

2

3

4

II

Page 26

Expanding the world of

ENGLISH

1

Page 27

beautiful images

Contents

Enjoy rich multi-media with JVC

VHF/UHF

Digital camera

Video camera

First things fi rst!

Warning ············································ 3

ENGLISH

IMPORTANT! PREPARE USE

Audio components

VCR DVD player

DVD recorder

Game console

Personal

Computer

Getting started

Names of all the parts ······················ 5

Basic connections ···························· 7

Initial settings ··································· 9

Editing channels ····························· 11

· Registering channels

Connecting external devices ·········· 13

Let’s try it out

Enjoying your new TV! ··················· 15

· TV / Teletext / Video / etc.

Watching TV ···································17

Viewing teletext ······························ 19

Watching videos / DVDs ················ 21

Try the advanced features

Useful functions ······························23

· Take a snapshot

· View and search in multi-picture mode

· “Sleep Timer” / “Channel Guard”

Operate JVC recorders and other devices

··· 27

Just the way you like it

Customising your TV ······················ 29

Advanced picture adjustment ········· 31

·

Reduce noise / Watch a more natural picture

· Set the aspect ratio, etc.

When you have trouble

Troubleshooting ····························· 33

Technical information ····················· 37

“CH/CC” List ··································· 39

Specifi cations ································· 40

SETTINGS

TROUBLE?

2

Page 28

First things fi rst!

Warning

ENGLISH

Follow this manual

regarding setup!

Connect only to a 110-240V, 50/60Hz

AC outlet.

Make enough room for

inserting and removing

the power plug!

Place the TV as

close to the outlet as

possible!

The main power supply for this TV is

controlled by inserting or removing the

power plug.

Never cut or damage

the power cord!

Please follow all the guidelines below

Do not allow the TV

to fall!

Do not rest your elbows on, or allow

children to hang from the TV.

There is a risk that the TV will fall and

cause injuries.

Never try to repair

the TV yourself!

If the problem cannot be solved in

“Troubleshooting” (P. 33), unplug

the power cord and contact your

retailer.

If the AC plug is not the

right shape, or the power

cord is not long enough,

use an appropriate plug

adapter or extension cable.

(Consult your retailer.)

Unplug the power cord

when going out!

The power buttons on

the remote control and

the TV unit cannot

completely turn off the

TV. (Make appropriate

arrangements for

bedridden people.)

For more details on installation, usage and safety

For more details on installation, usage and safety

3

Consult your retailer

Consult your retailer

Page 29

When attaching the TV to

the wall, use the optional

JVC wall mounting unit!

Consult a qualifi ed technician.

See the included manual on mounting

procedures.

JVC assumes no responsibility for

damage due to improper mounting.

If the TV is damaged

or behaving strangely,

stop using it at once!

Unplug the power cord and contact

your retailer.

Never place anything on

the TV!

Placing liquids, naked

fl ames, cloths, paper,

etc. on the TV may

cause a fi re.

Never expose to rain or

moisture!

To prevent fi re or electric

shock, never allow

liquids to enter the unit.

Never insert objects into

the cabinet openings!

It may cause a fatal

electric shock. Take care

when children are near.

Never listen to

headphones at high

volume!

ENGLISH

IMPORTANT! PREPARE USE

Never dismantle the

rear panel!

It may cause an electric shock.

Never obstruct the

ventilation holes!

It may cause overheating or a fi re.

Handle LCD panel

with care!

Use a soft, dry cloth when cleaning.

It may damage your hearing.

Hold the TV so as not to

scratch the screen!

Do not touch the screen when carrying the

TV.

Do not carry the

TV on your own!

In order to prevent accidents,

ensure that the TV is carried

by two or more people.

SETTINGS

TROUBLE?

4

Page 30

Getting started

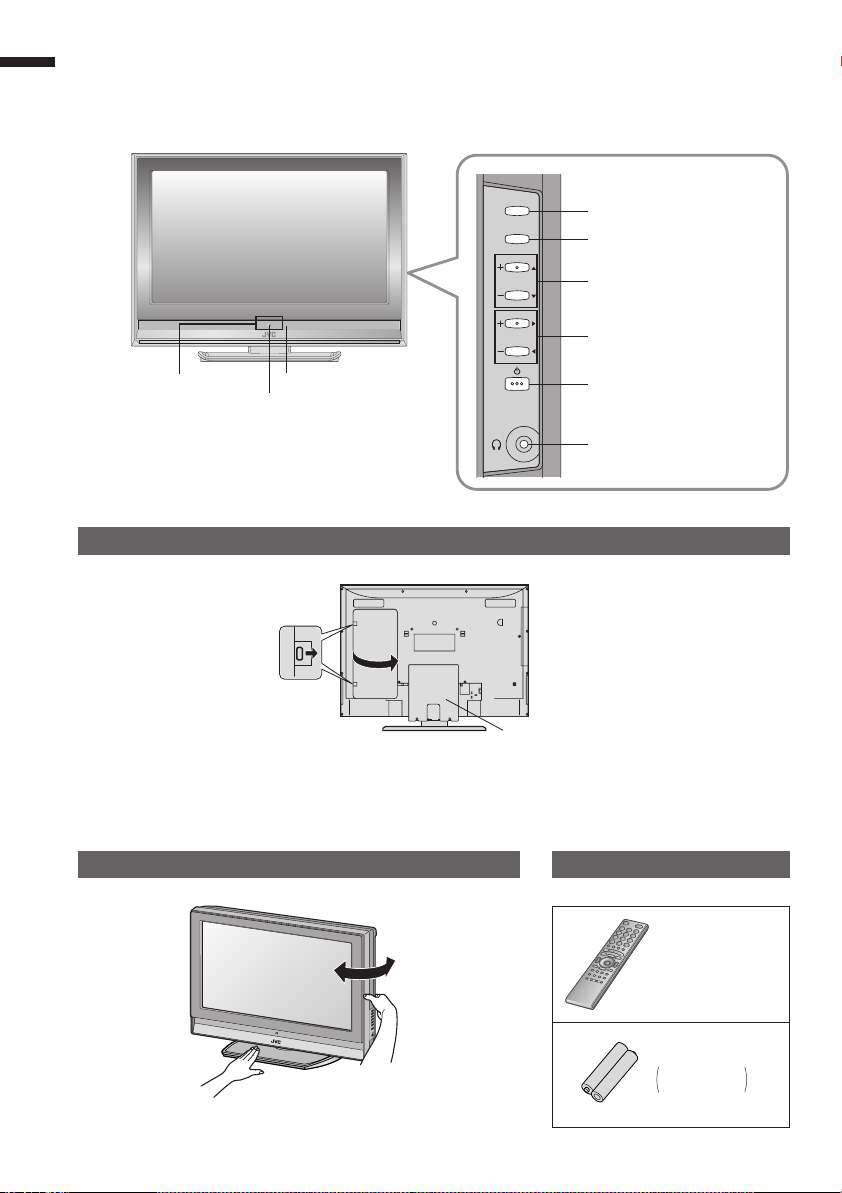

ENGLISH

Names of all the parts

TV/VIDEO

MENU

/OK

CHANNEL

Switch between

TV / AV devices

Display on-screen

menu / set

Change channel / page

VOLUME

Illumination lamp

Illumination lamp lights

while the TV is on.

“Illumination”

(P. 30)

Remote control sensor

Power lamp

ON: Lit (Blue)

OFF: Unlit

Power lamp lights while

the TV is on.

“Power Lamp” (P. 30)

Remove the terminal cover

Press to

remove.

Cable cover

If the cover cannot be closed due to the cables being in the way

Do not force the cover to close (leave it open).

Connecting terminals on the back of the TV Connecting External devices (P. 13)

Change the direction of TV

Check accessories

Volume

Power On / Off

To headphones (P. 13)

5

Remote control

(RM-C1855)

“AAA/R03” Batteries

For confi rming

the TV works

Page 31

Mute

Power On / Off

Change channel / page

ENGLISH

Return to channel

you want to view

Colour buttons

Return to TV

/ Watch video, etc. (P. 21)

Volume

Channel information

(P. 17)

When watching TV / Video

Change the aspect ratio (P. 17)

Turn on “Cinema Surround” (P. 17)

Take a snapshot of the

screen (P. 23)

View in multi-picture

mode (P. 23)

To teletext

(P. 19)

Switch between

“TV / VCR / DVD / AUDIO” (P. 27)

Display on-screen menu

(P. 29)

Select and

confi rm settings in menus

Change channel / page

To previous screen

When viewing teletext (P. 19)

Hold the current page

Bookmark pages

Reveal hidden pages

Enlarge the text

IMPORTANT! PREPARE USE

SETTINGS

Insert the batteries

Use two “AAA/R03” dry cell batteries.

Insert the batteries from the - end, making

sure the + and - polarities are correct.

Switch briefl y

between teletext and TV

To index page

TROUBLE?

6

Page 32

Basic connections

Please read the user manuals of each device carefully before setup.

It is necessary to connect an aerial to watch TV.

ENGLISH

Connect with other devices “Connecting external devices” (P. 13)

Connect the aerial

AERIAL

After all the connections have been made, insert the plug into an AC outlet.

Power requirements

Connect the power cord only to a 110-240V,

50/60Hz AC outlet.

When attaching the TV to the wall, use the

optional JVC wall mounting unit

Consult a qualifi ed technician.

See the included manual on mounting procedures.

JVC assumes no responsibility for damage due to

improper mounting.

200mm × 200mm mount which conforms to VESA

standards.

7

Care when setting

Installation requirements

To avoid overheating, ensure the unit has ample

room.

200mm

50mm150mm 150mm 50mm

Page 33

Connect a VCR / DVD recorder

(Y)

(Pr)

(Pb)

VIDEO-1

(R)

(L)

VCR / DVD recorder

ENGLISH

IMPORTANT! PREPARE USE

AERIAL

After all the connections have been made, insert the plug into an AC outlet.

If both composite and S-VIDEO cables are connected, S-VIDEO will be enable.

Tidying the cables

To remove the cable cover, refer to back of the cover.

SETTINGS

TROUBLE?

8

Page 34

Initial settings

Set the menu language, installation location and automatically register the TV channels.

These channels can be edited later in “Editing channels” (P. 11).

ENGLISH

9

To the previous screen

Exit

If the “JVC” logo does not appear or

if you wish to make changes later

“Language”, “Teletext language” and

“Auto Program”

(P. 30)

TV

MENU

BACK

Page 35

ENGLISH

ge

01

AV

PR

02

03

04

05

06

07

08

09

CH/CC

CH

21

CH

22

CH

23

CH

24

CH

25

CC

02

CC

CC

04

CC

05

03

> Edit

ID

1

2

3

4

Begin

Shown only when

powering on for the fi rst time.

The power on the unit can also be used.

Select a language

Langua

1 select

2 set

Select the teletext language group

>

Teletext Language

Group-1

Group-2

Group-3

Group-4

Group-5

select

Automatically register channels

>>

Auto Program

CH

14%

28

The remote control doesn’t

work

Confi rm the mode is set to “TV”.

For the teletext language group

“Language group for teletext”

(P. 37)

If the characters are unreadable.

“Language group for teletext”

(P. 37)

IMPORTANT! PREPARE USE

Check what was registered

5

Edit channels

⁄ in “Editing channels” (P. 11)

Confi rm

SETTINGS

TROUBLE?

6

10

Page 36

Editing channels

Edit the channels registered with “Auto Program” in “Initial settings” (P. 9).

ENGLISH

When coming from “Initial settings” (P. 9), skip to ⁄.

Display the menu bar

1

Select “Set Up”

2

Set Up

Select “Edit / Manual”

Set Up

Auto Program

Edit/Manual

Language

Video-1 Setting

Video-3 Setting

AI Volume

Teletext Language

HDMI Setting

PC Position

Select a row

> Edit

ID

PR

AV

01

02

03

04

05

06

07

08

09

Edit

Finish

CH/CC

CH

CH

CH

CH

CH

CC

CC

CC

CC

Video

Video

Off

21

22

23

24

25

02

03

04

05

To the previous

screen

Exit

3

4

5

6

1 select

2 next

1 select

2 next

select

Move a

channel’s

position

MOVE

Edit a

channel

name

ID

Insert a

channel

INSERT

Delete a

channel

DELETE

11

Register a

new channel

MANUAL

· Registering channels

Page 37

1 Begin 2 Select a destination 3 Finish

>Edit

PR

AV

01

02

03

04

05

06

07

move out move in

08

09

CH/CC

ID

CH

21

CH

22

CH

24

CH

25

CC

02

CC

03

CC

04

CC

05

23

CH

select

> Edit

PR

AV

01

02

03

04

05

06

07

08

09

CH/CCID

CH

21

CH

22

CH

24

CH

25

CH

23

CC

03

CC

04

CC

05

1 Begin 2 Enter a channel name

(red)

>Edit

PR

AV

01

02

03

04

05

06

07

08

09

CH/CC

ID

CH

21

CH

22

CH

23

CH

24

CH

25

CC

02

CC

A

03

CC

04

CC

05

1 enter the fi rst

character

2

next column

>Edit

PR

AV

01

02

03

04

05

06

07

JVC

08

09

ENGLISH

IMPORTANT! PREPARE USE

CH/CCID

CH

21

CH

22

CH

23

CH

24

CH

25

CC

02

CC

03

CC

04

CC

05

set

1 Begin

(green)

1 Delete

(yellow)

1 Begin

(blue)

3 Set

2 Select a “CH / CC” 3 Enter a number

>Edit

PR

AV

01

02

03

04

05

06

07

08

09

CH/CC

ID

CH

CH

CH

CH

CH

CC

CC

CC

CC

“CH/CC” List (P. 39)

>

Edit

ID

CH/CC

CC

CH

06

02 (B/G

CH/CC

CH

CH

CH

CH

CC

CC

CC

)

PR

AV

01

02

03

04

05

06

07

Beginning channel search

2

>

Manual

ID

PR

10

11

12

13

14

15

16

17

If you can not receive the

channel you want to view,

press 3 to change the sound

system.

“Sound system in your

country or region” (P. 37)

>

Edit

ID

PR

10

11

12

13

14

15

16

17

CH/CC

CC

CH

06

08

21

22

23

24

25

02

03

04

22

23

24

25

02

03

04

From high

frequencies

(red)

or

select

From low

frequencies

(green)

>Edit

PR

AV

01

02

03

04

05

06

07

08

09

Adjust

Channel fi ne tuning

If the picture or sound is unnatural

>Manual

>Manual

PR

10

11

12

13

14

15

16

17

PR

10

11

12

13

14

15

16

CH/CCID

CH

21

CH

22

CH

23

CH

24

CH

25

CC

02

12

CC

CC

03

CC

04

CH/CC

ID

06

CC

)

CH

08 (B/G

Receives the

broadcast

signal.

Auto-search begins,

and the nearest

frequency is imported.

SETTINGS

Repeat the previous

steps until the

desired channel is

)

(yellow)

displayed

(blue)

/

TROUBLE?

CH/CC

ID

06

CC

CH

08 (I

select a system

12

Page 38

Connecting external devices

You can connect many different devices to the rear panel of the TV.

Please read the user manuals of each device before setting up.

ENGLISH

(Connecting cables are not supplied with this TV.)

PC

To “VIDEO-3” R/L

“Technical information” (P. 37)

Set-top box / Digital

broadcast tuner

Game consoles

Video camera

VCR / DVD recorder

VCR / DVD recorder

Amplifi er

(L) (R)

Headphone

PC IN

(Y)

(Pr)

(Pb)

VIDEO-3

(R)

(L)

(R) (L)

VIDEO-2

(Y)

(Pr)

(Pb)

VIDEO-1

(R)

(L)

(R)

(L)

IN HDMI-1

(R)

(L)

OUT

13

Headphones

Page 39

VCR / DVD / other devices

: signal direction

HDMI-2 HDMI-1

IN HDMI-1

VIDEO-1

Output Input

Use Component signal

“Switch between video and

component signal” (P. 22)

Use S-VIDEO

“Using S-VIDEO” (P. 22)

VIDEO-2

Output Input

Use S-VIDEO

“Using S-VIDEO” (P. 22)

VIDEO-3

Output Input

Use Component signal

“Switch between video and

component signal” (P. 22)

HDMI-1

HDMI-2

Output Input

“HDMI Setting” (P. 30)

HDMI-2 input does not support

analogue sound.

Watching videos

·

Composite signal /

Component signal

/ S-VIDEO

· Sound L / R

Watching videos

·

Composite signal /

S-VIDEO

· Sound L / R

Watching DVDs

·

Composite signal /

Component signal

· Sound L / R

Connecting

HDMI devices

· HDMI signal

(P. 38)

OUT

Video and sound signal of a TV channel

you are viewing outputs from this

terminal

Output

·

Composite signal /

S-VIDEO

· Sound L / R

“Using OUT terminal”. (P. 22)

ENGLISH

IMPORTANT! PREPARE USE

SETTINGS

TROUBLE?

DVD player

(HDMI compatible)

DVD player

(HDMI compatible)

Connect a “DVI” device to

“HDMI-1”

(P. 38)

14

Page 40

Let’s try it out

ENGLISH

Enjoying your new TV!

Watching TV

PAGE

17

View channel information

Change the aspect ratio

Enjoy “Cinema Surround”

Register your favourite channels

15

PAGE

Watching

21

· TV / Teletext / Video / etc.

videos / DVDs

Watch high quality video (S-VIDEO)

Switch between video and component signal

PC position adjustment

Page 41

TV mode TV and Text mode

Text mode

Viewing teletext

ENGLISH

IMPORTANT! PREPARE USE

PAGE

19

Enlarge the text

To the index page

Hold the current page

Switch briefl y between teletext and TV

Bookmark your favourite pages

Reveal hidden pages

Personal preferences

Adjust the picture

Adjust the sound

Advanced settings

(sleep-timer / channel guard, etc.)

Basic settings

(channel settings, etc.)

Picture

PAGE

29

SETTINGS

TROUBLE?

16

Page 42

Watching TV

ENGLISH

Mute

Volume

Set to “TV”

1

Power on

2

Press again to turn the screen off

Select a channel

3

Move up or down a channel

Switch between mono / stereo /

bilingual broadcasting

“Stereo / t·u” ( P. 30)

Note

To completely turn off the TV, unplug

the AC plug.

The blue

power lamp

on the TV lights

and put the TV into standby mode.

E.g.

1 :

15 :

up

down

Channel

information

DISPLAY

Change the aspect

ratio

ZOOM

Enjoy ambient

sound

CINEMA SURROUND

Emphasize bass

sound

MAXXBASS

17

Basic operations using the side buttons

1

Power on

CHANNEL

2

Volume

Change

the channel

TV/VIDEO

MENU

/OK

CHANNEL

VOLUME

Always return to

the channel you

want to view

RETURN PLUS

Return to the

last channel you

were viewing

RETURN

Page 43

PR List

AV

01

02

03

04

05

06

07

08

09

Select a page

PR List

Channels

registered in

“Initial settings” will

appear here.

select

AV

Channel information

(No indication)

Select and view a channel

1 select

2 view

ENGLISH

IMPORTANT! PREPARE USE

Zoom

Auto

Regular

Panoramic

14:9 Zoom

16:9 Zoom

16:9 Zoom Subtitle

Full

HighCinema Surround

“MENU” “

” “Sound” “MaxxBass”

High

Registered as return channel

While the channel

is displayed

Hold down

for 3 seconds

1 select

2 set

High

Low

Mono

Off

1 select

2 set

When set to “Auto”, the aspect ratio

will turn to the ratio obtained from

16 : 9 Zoom

the information the TV received.

Without receiving aspect information,

it will be the setting in “4:3 Auto

Move the picture with

1 or 4 while this bar is

displayed

Aspect” (P. 32)

Not available in 1080i (1125i) /

720p (750p) signals.

In PC mode, “Regular” and “Full” can

be selected.

: For stereo sound

: For stereo sound (when the sound distorts in “High” mode)

: For mono sound (emulates a stereo-like sound)

: Turns off “Cinema Surround”

level

Off Low High

Cancel

While the channel

is displayed

Hold down