Page 1

LT-22HG45E

22" LED TV

SERVICE MANUAL

Design and specifications are subject to change without notice.

ORIGINAL

MFR'S VERSION A

Page 2

IMPORTANT SERVICE SAFETY INFORMATION

not be attempted by anyone not familiar with the

If available, measure current using an accurate leakage

Operating the receiver outside of its cabinet or with its Before returning the receiver to the user, perform the

back removed involves a shock hazard. Work on following safety checks:

these models should only be performed by those who 1. Inspect all lead dress to make certain that leads are

are thoroughly familiar with precautions necessary not pinched or that hardware is not lodged between

when working on high voltage equipment. the chassis and other metal parts in the receiver.

2. Replace all protective devices such as nonmetallic

Exercise care when servicing this chassis with power control knobs, insulating fishpapers, cabinet backs,

applied. Many B plus and high voltage RF terminals are adjustment and compartment covers or shields,

exposed which, if carelessly contacted, can cause isolation resistor-capacitor networks, mechanical

serious shock or result in damage to the chassis. insulators, etc.

Maintain interconnecting ground lead connections 3. To be sure that no shock hazard exists, a check for

between chassis, escutcheon, picture tube dag and the presence of leakage current should be made at

tuner cluster when operating the chassis. each exposed metal part having a return path to the

chassis (antenna, cabinet metal, screw heads,

These receivers have a "polarized" AC line cord. The AC knobs and/or shafts, escutcheon, etc.) in the

plug is designed to fit into standard AC outlets in one following manner.

direction only. The wide blade connects to the "ground

side" and the narrow blade connects to the "hot side" of Plug the AC line cord directly into a 120V AC receptacle.

the AC line. This assures that the TV receiver is properly (Do not use an Isolation Transformer during these

grounded to the house wiring. If an extension cord must checks.) All checks must be repeated with the AC line

be used, make sure it is of the "polarized" type. cord plug connection reversed. (If necessary, a

nonpolarized adapter plug must be used only for the

Since the chassis of this receiver is connected to one purpose of completing these checks.)

side of the AC supply during operation, service should

precautions necessary when working on these types current tester. Any reading of 0.35mA or more is

of equipment. excessive and indicates a potential shock hazard which

must be corrected before returning the receiver to the

When it is necessary to make measurements or tests with owner.

AC power applied to the receiver chassis, an Isolation

Transformer must be used as a safety precaution and to If a reliable leakage current tester is not available, this

prevent possible damage to transistors. The Isolation alternate method of measurement should be used.

Transformer should be connected between the TV line Using two clip leads, connect a 1500 ohm, 10 watt

cord plug and the AC power outlet.

resistor paralleled by a 0.15µF capacitor in series with

a known earth ground, such as a water pipe or conduit

When removing springs or spring mounted parts from the and the metal part to be checked. Use a VTVM or

tuner, tuner cluster or chassis, shatterproof goggles must VOM with 1000 ohms per volt, or higher, sensitivity to

be worn. Keep others without shatterproof goggles away. measure this AC voltage drop across the resistor. Any

reading of 0.35 volt RMS or more is excessive and

indicates a potential shock hazard which must be

corrected before returning the receiver to the owner.

VT VM

AC SCALE

0.15K OHMS

10W

TO EXPOSED

METAL PARTS

10µF

TEST PROBE

TO KNOWN

EARTH GROUND

Page 3

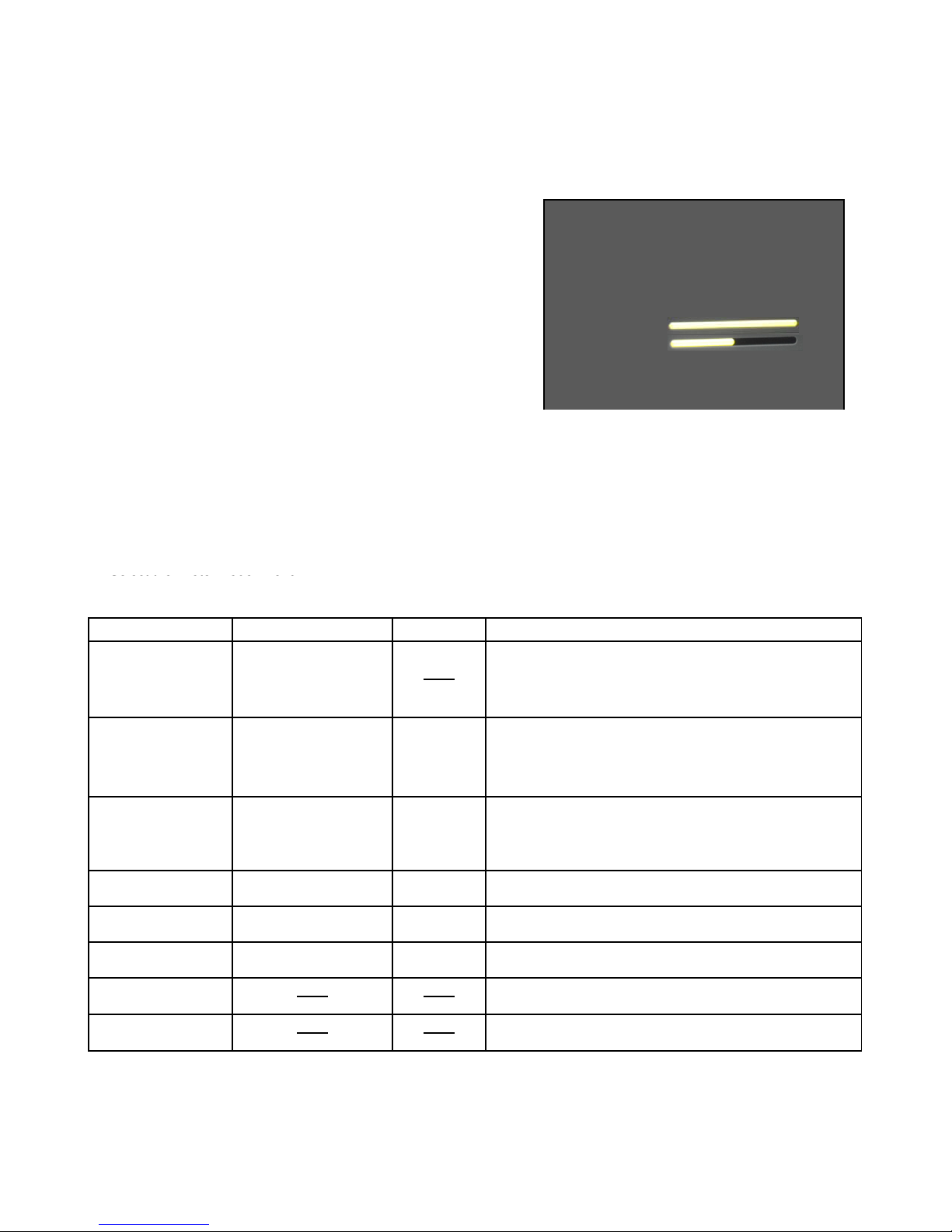

ABOUT LEAD FREE SOLDER (PbF)

Distinction of PbF PCB:

PCBs (manufactured) using lead free solder will have a PbF printing on the PCB.

(Please refer to figures.)

Caution:

• Pb free solder has a higher melting point than standard solder;

Typically the melting point is 86oF~104oF(30oC~40oC) higher.

Please use a soldering iron with temperature control and adjust it to 650oF ± 20oF (350oC ± 10oC).

In case of using high temperature soldering iron, please be careful not to heat too long.

•

Pb free solder will tend to splash when heated too high (about 1100oF/ 600oC).

• All products with the printed circuit board with PbF printing must be serviced with lead free solder.

When soldering or unsoldering, completely remove all of the solder from the pins or solder area,

and be sure to heat the soldering points with the lead free solder until it melts sufficiently.

Recommendations

Recommended lead free solder composition is Sn-3.0Ag-0.5Cu.

Page 4

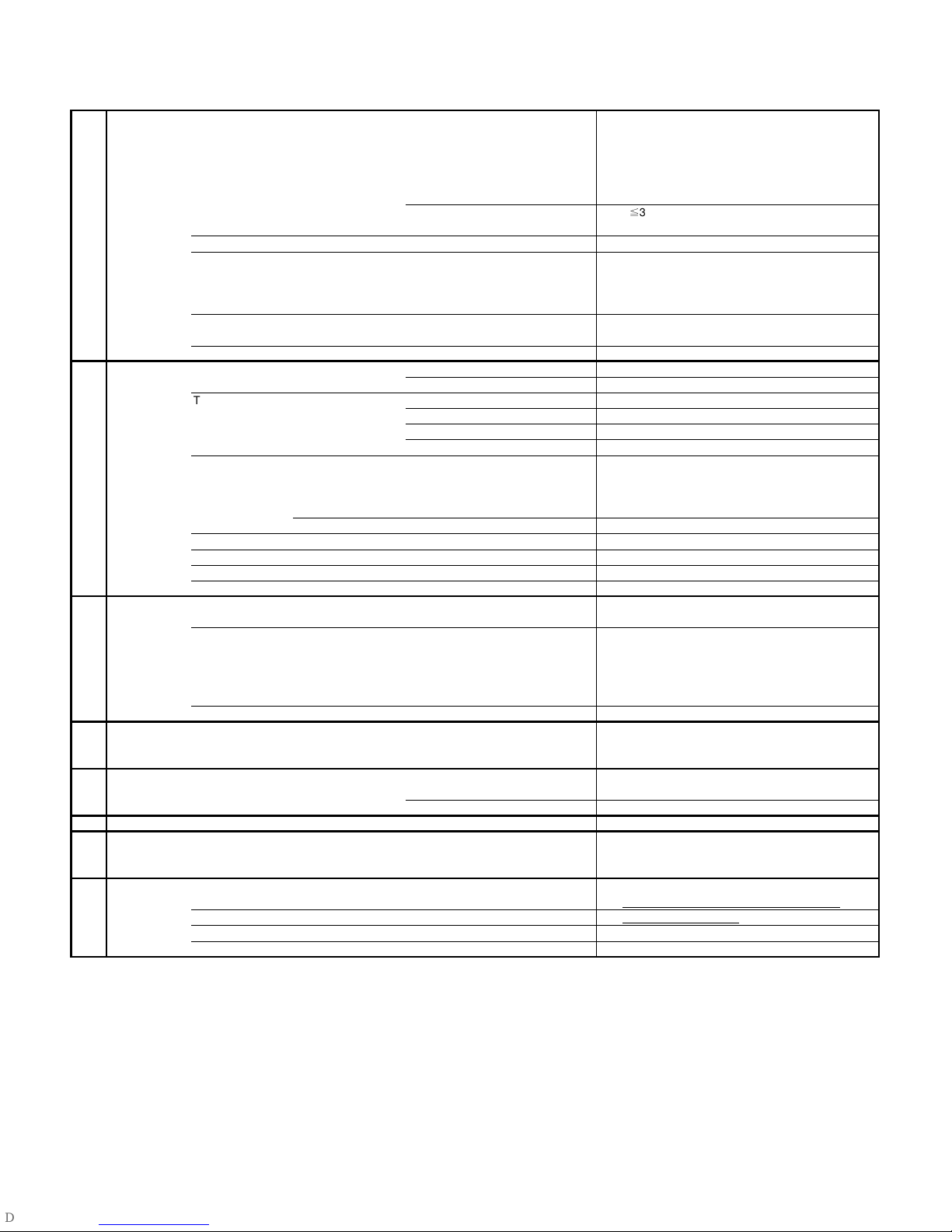

HOTEL MODE FUNCTION

To set the Hotel mode, please follow the steps below.

1. Press the MENU ---> 1147 button on the remote control.

4.

Select the "Hotel Mode" menu.

2. Press the DOWN button on the remote control,

3. Select the "Setup" menu , then press ENTER button.

4. Select the "Hotel Mode" menu, Select "ON".

5. The Hotel mode setting menu will appear.

6. Using the UP/DOWN button on the remote control,

select the desired mode. Then press the ENTER button

Using the LEFT/RIGHT button on the remote control,

7.

set the mode to desired setting.

8. The Hotel mode has now been set up.

.

Hotel mode On <>

Source Lock >>

Default Source Off <>

Channel Type All <>

Default Program 1 <>

Max Volume

Default Volume

Clone to USB >>

Restore from USB >>

To reset the Hotel mode, please follow the steps below.

1. Press the MENU ---> 1147 button on the remote control.

2. Press the DOWN button on the remote control,

3. Select the "Setup" menu , then press ENTER button.

5. The setting items has now been returned to initial value.

100

50

Setting item Setting value

ANTENNA/CABLE/AV

Source Lock

Channel Type

Default Program

Max volume 0~100

Default Volume

Clone to USB

Restore from USB

COMPONENT/SCART/

PC/HDMI/USB

ANTENNA/CABLE/AV

COMPONENT/SCART/

PC/HDMI/USB

ANTENNA/CABLE/AV

COMPONENT/SCART/ 1 Setting of the CH if select "Default Source" to TV input.

PC/HDMI/USB

1~21

0~50

Initial value

Setting Input skip, combine with "Default Source".

OFFDefault Source

21 Setting of the CH if select "Default Source" to TV input.

100 Setting of the maximum volume value.

50 Setting volume at Power on.

Setting Input Source, combine with "Source Lock"

If select "Source Lock" for this function disappear.

Setting of the Hotel Mode return factory setting.

Setting of the Password.

FUNCTION

Page 5

GENERAL SPECIFICATIONS

+5oC ~ +40

C

-20oC ~ +60

C

G-1 TV

System

G-2 Tuning

System

G-3 Power

G-4 Regulation

G-5 Temperature

G-6 Operating Humidity

G-7 OSD Language

G-8 Clock and

Timer

LCD LCD Size / Visual Size 21.53 inch / 546.8mmV

Color System PAL / SECAM

Speaker 2 Speaker

Sound Output MAX 2.0W + 2.0W

NTSC3.58+4.43 /PAL60Hz Yes

Broadcasting System Analog

Tuner and System 1Tuner (Analog+Digital)

Receive CH Destination UK, I.R., CCIR Hyper+France CATV

CH Coverage Analog 45.75~858MHz

Intermediate Analog

Frequency Picture(FP) 38.9 / 38.9 / 38.9MHz

Auto Tuning Method

Preset CH 4000 Service in total of Analog and Digital.

Stereo/Dual TV Sound Nicam/A2 Dual

Tuner Sound Muting Yes

Power Source AC 220-240V AC 50Hz

Power Consumption at AC 31 W at AC 230 V 50 Hz

Protector Power Fuse Yes

Sleep Timer Max Time 120 Min

On/Off Timer Program(On Timer / Off Timer) 1 Program / 1 Program

Timer Back-up (at Power Off Mode) more than -- Min Sec

EPG Timer Events --

LCD Type Color TFT LCD

Number of Pixels 1920(H) x 1080(V)

Double Scan No

View Range Left/Right 85/85 degree

Up/Down 80/80 degree

Bright Dot

Zero Bright Dot Ratio 70% above

Position Bottom

Size 1.0 x 2.7 inch

Impedance 8 ohm

10%(Typical) ---

Digital

Digital E2~E69

Sound(FS)

FP-FS

Digital

DC ---

at DC --

Stand by (at AC) w/ EPG Timer --

w/o EPG Timer 0.49 W at AC 230 V 50 Hz

Per Year -- kWh/Year

Safety CE(EN60065:2002+AMD.11:2008)

Radiation CE

X-Radiation --Operation

Storage

Space Around Unit 100mm (4inch)

Step 10 / 20 / 30 / 40 / 50 / 60 / 90 / 120 Min

n≦3

PAL(B/G, D/K, I), SECAM(B/G, D/K)

DVB-T

BG / II / DK

33.4 / 32.9 / 32.4MHz

5.5 / 6.0 / 6.5MHz

DVB-T 36.167MHz

ALL Band (Not C.C.I.R. CH Plan)

o

o

Less than 80% RH

English, Spanish, German, French, Italian, Swedish

Dutch, Russian, Portuguese, Turkish, Greek, Finnish

Hungarian, Polish, Danish, Norwegian, Czech, Slovak

Page 6

GENERAL SPECIFICATIONS

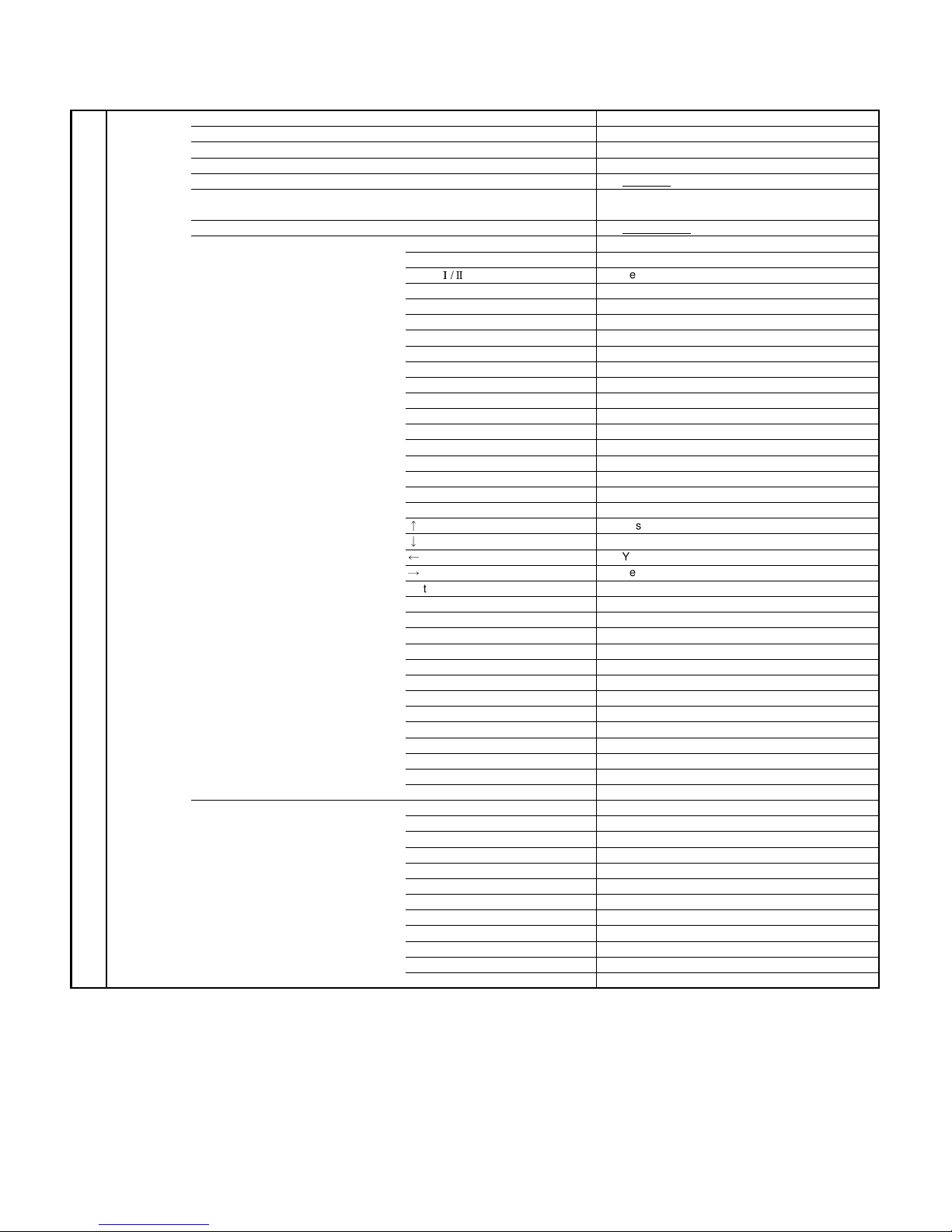

G-9 Remote

Control

Unit RC-TR

Glow in Dark Remocon Yes

Remocon Format ORION

Format NEC

Custom Code 71-8E h

Power Source Voltage(D.C) 3V

UM size x pcs UM-4 x 2 pcs

Total Keys 41 Keys

Keys Power (Stand By) Yes

Information Yes

Ⅰ/Ⅱ

Audio

1 Yes

2 Yes

3 Yes

4 Yes

5 Yes

6 Yes

7 Yes

8 Yes

9 Yes

0 Yes

Input Select Yes

Guide(EPG) Yes

Menu Yes

Return Yes

Enter / CH List Yes

↑

↓

←

→

Mute Yes

Picture Size Yes

Volume Up Yes

Volume Down Yes

TV Yes

MEDIA Yes

Freeze No

Quick View No

Play No

Stop No

Pause No

Play Mode Yes

Rec No

T-Rec No

T'TEXT Keys Subtitle Yes

CH Up / Page Up Yes

CH Down / Page Down Yes

Freeze / Hold Yes

Quick View / Sub Page Yes

Search- / Teletext Yes

Play / Reveal Yes

Search+ / F.T.B Yes

Red/Skip- Yes

Green/Pause Yes

Yellow/Stop Yes

Cyan/Skip+ Yes

Yes

Yes

Yes

Yes

Yes

Page 7

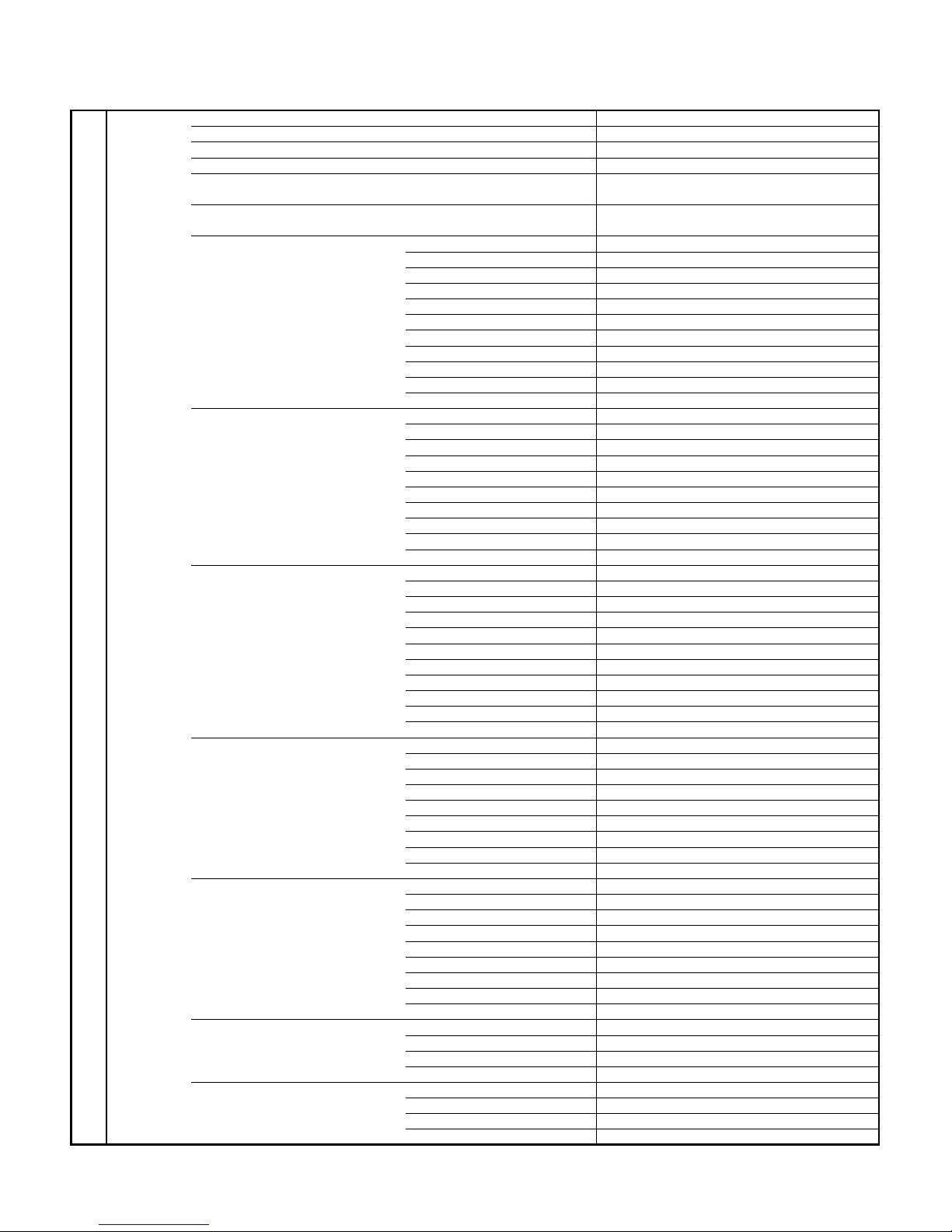

GENERAL SPECIFICATIONS

G-10 Features

Power On Memory Yes

Auto Shut Off Yes

Just Clock Function No

Game Position No

DNR Yes

3D

Comb Filter Yes

3D

Auto Set Up (Fast installation) Language Yes

Country Yes

TV Location Yes

Auto Power Off Yes

E-POP Demo No

Tuner Mode Yes

Auto Tuning (Analog/DVB-T, DVB-C) Yes

CH sort Yes

ATS Yes

Auto clock (Digital tuner) Yes

Plug in start Yes

Picture Setting(TV) Picture Mode Yes

Brightness , Contrast , Color Yes

Tint Yes

Sharpness Yes

DNR Yes

Color Temperature Yes

Backlight Control Yes

MPEG NR Yes

DBC (Dynamic Backlight Control) No

Film Mode No

Picture Setting(PC) Picture Mode Yes

Brightness , Contrast , Color Yes

HOR POSITION , VER POSITION Yes

PHASE , CLOCK Yes

AUTO ADJUST Yes

RED , GREEN , BLUE No

DNR No

Color Temperature Yes

Backlight Yes

WXGA INPUT No

WVGA INPUT No

Audio Sound Mode No

Tone Control (Bass/Treble/Balance) Yes

Surround Yes

Equalizer Yes

Speaker No

Stable Sound Yes

BBE No

SRS WOW (SRS 3D/Focus/Tru Bass)

Variable Audio Out No

Tuning Auto Tuning (Analog/Digital) Yes

Manual Tuning (Analog/Digital) Yes

Update Scan (Analog/Digital) No

TV Connection Yes

CH Skip (Analog/Digital) Yes

CH Sort (Analog/Digital) Yes

CH Edit (Analog/Digital) Yes

Clean CH List (Analog/Digital) Yes

Fine Tuning (Analog) Yes

Lock System Lock Yes

Channel Lock Yes

Parental Lock (Digital) Yes

Hotel Lock Yes

Screen Saver

Inversion No

Full White No

Screen Saver Yes

Static Image No

No

Page 8

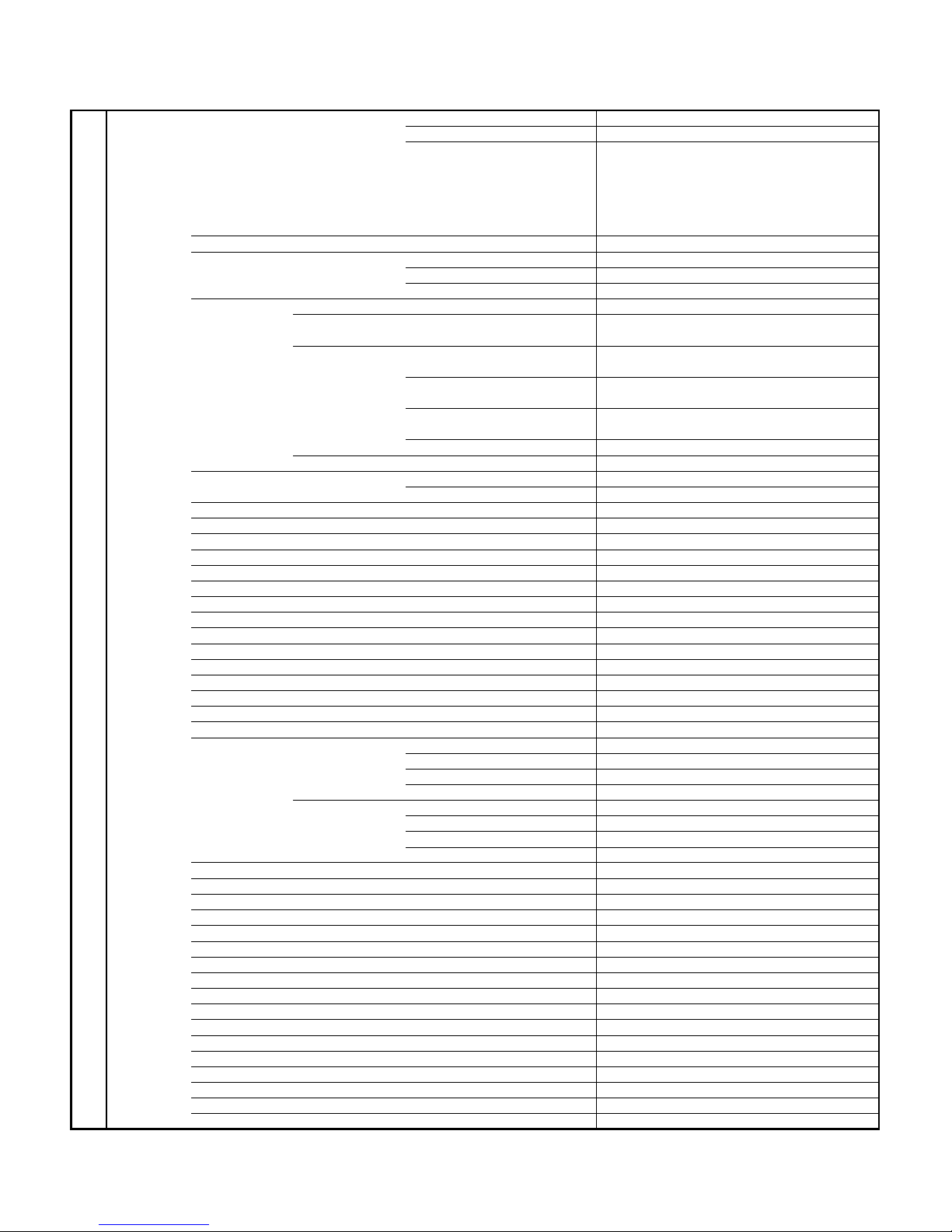

GENERAL SPECIFICATIONS

T'Text Yes

Text type Fastext / Toptext

Text Language English, German, Swedish, Finnish, Hungarian,

Italian, French, Portuguese, Spanish, Czech,

Slovak, Polish, Estonian, Lettish, Lithuanian,

Slovenian, Rumanian, Russian,

Ukrainian, Turkish, Greek, Hebrew, Farisi

Arabic, Danish, Flemish, Icelandic, Byelorussian

Text and Picture No

PVR Timeshift No

Timer Recording No

EPG Recording No

USB Media Player Photo JPEG (.jpg/.jpeg), BMP (.bmp), PNG (.png)

Music WMA (.wma), WAVE (.wav), AAC-LC (.m4a)

HE-AAC (.m4a), MPEG1 (.mp2), MPEG4 (.m4a)

Video Container AVI (.avi), MKV (.mkv), MP4 (.mp4/,m4v),

PS (.mpg/.mpeg), TS (.ts/.tp/.trp), VOB (.vob)

Video Codec Xvid, MPEG1, MPEG2, MPEG4 SP/ASP, H.264

MJPEG

Audio Codec MPEG1, MPEG2, MPEG4, AAC, AAC-LC

HE-AAC, PCM/ADPCM, AC3

DivX DMF Support No

Text Text (.txt)

Internet Hbb TV No

BBC iPLAYER No

Wide Mode (AUTO/4:3/16:9/Zoom1/Zoom2/1:1) Yes

CH Label Yes

Reset TV Setting Yes

HD Zoom Yes

Picture Scroll (Vertical Position) No

PFC(Power Factor circuit) No

Freeze frame Yes

Plug and Play No

Power Management Yes

Hearing Impaired Yes

Audio Description Yes

Power On LED No

HDMI Mode Yes

PC Mode Yes

Blue Back Yes

Scart Spec Scart1 AV in Yes

AV out Yes (A.Tuner/D.Tuner)

S-Video in Yes

RGB in Yes

Scart2 AV in No

AV out No

S-Video in No

Digital Text (VBI teletext)

MHEG-5

MHP

EPG (BBC type 8Days Digital tuner only)

OAD (Over Air Download)

CI+

Common Interface (Digital tuner only)

Rec Screen Status

Ch sorting based on Ch List (Digital/Germany only)

Rename Carrier (Digital)

Edit Event Timer

Software Update via CI Slot

Preference Language (Audio/Subtitle/Digital Service)(Digital)

DVB Subtitle (Digital)

Clock

DST

Signal Status

RGB in No

Yes

No

No

Yes

Yes

No

Yes

No

Yes

No

No

No

Yes

Yes

Yes

No

Yes

Page 9

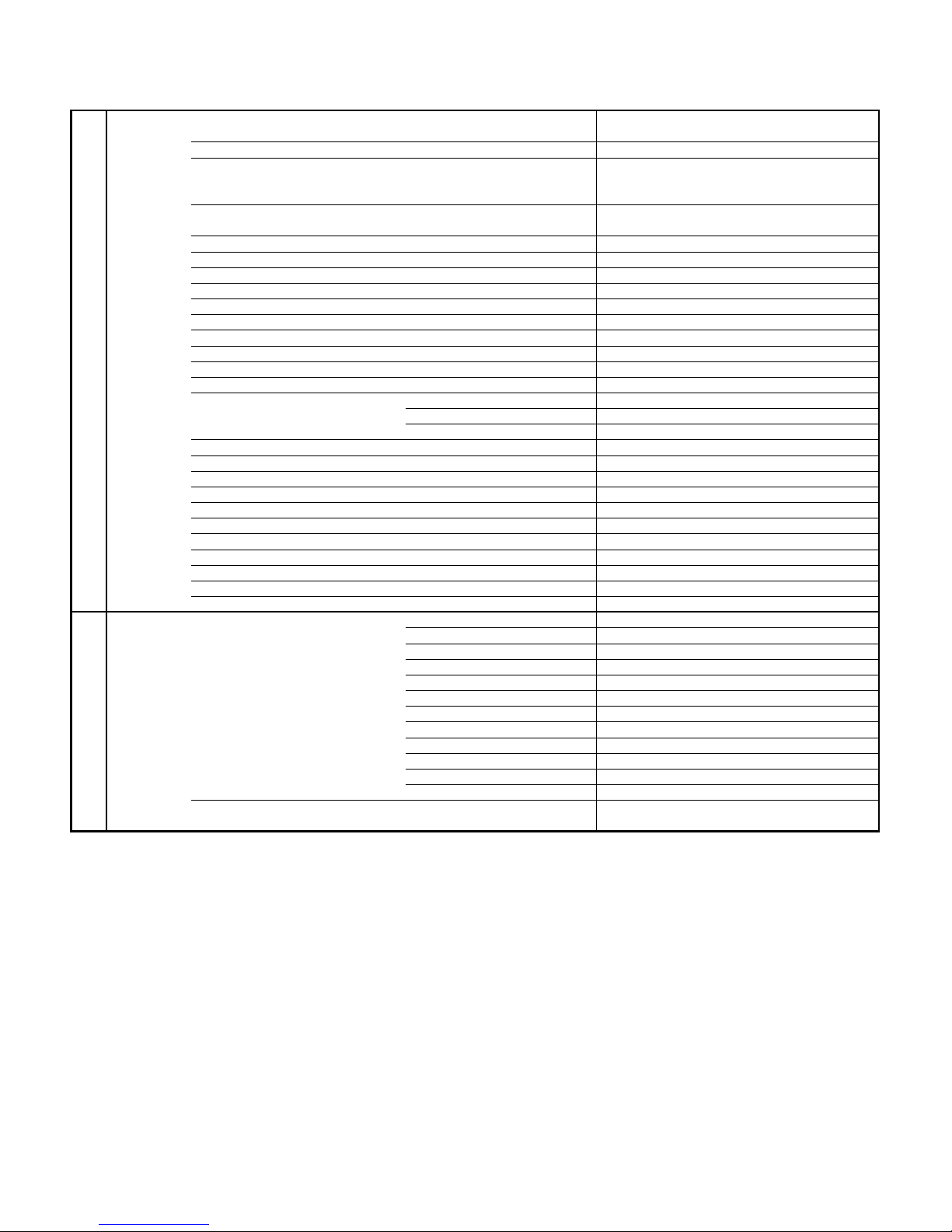

GENERAL SPECIFICATIONS

Digital Out Dolby Digital Dolby Digital

Dolby Digital Plus Dolby Digital

MPEG PCM

HE AAC PCM

Decode(Down Mix) Dolby Digital Yes

Dolby Digital Plus Yes

MPEG Yes

HE AAC Yes

PC Monitor Input Yes

VGA (640x480) Yes (60Hz)

VGA (720x400) No (Possible to Display)

WVGA (848x480) No

SVGA (800x600) Yes (60Hz)

XGA (1024x768) Yes (60Hz)

WXGA (1280x768) Yes (60Hz)

WXGA (1280x720) Yes (60Hz)

WXGA (1360x768) Yes (60Hz)

SXGA (1280x1024) Yes (60Hz)

WXGA+ (1440x900) Yes (60Hz)

WSXGA+ (1680x1050) No (Possible to Display)

FULL HD (1920x1080) Yes (60Hz)

HDMI Input Yes

VGA (640×480) Yes (60Hz)

VGA (720x400) No (Possible to Display)

WVGA (848x480) No

SVGA (800x600) Yes (60Hz)

XGA (1024x768) Yes (60Hz)

WXGA (1280x768) Yes (60Hz)

WXGA (1280x720) Yes (60Hz)

WXGA (1360x768) Yes (60Hz)

SXGA (1280x1024) Yes (60Hz)

WXGA+ (1440x900) Yes (60Hz)

WSXGA+ (1680x1050) No (Possible to Display)

FULL HD (1920x1080) Yes (60Hz)

720×480i (4:3) Yes (60Hz)

720×480i (16:9) Yes (60Hz)

720×480p (4:3) Yes (60Hz)

720×480p (16:9) Yes (60Hz)

720×576i (4:3) Yes (50Hz)

720×576i (16:9) Yes (50Hz)

720×576p (4:3) Yes (50Hz)

720×576p (16:9) Yes (50Hz)

1280×720p Yes (50/60Hz)

1920×1080i Yes (50/60Hz)

1920×1080p Yes (24/50/60Hz)

CEC(ORION Standard) No

Deep Color No

xvYCC No

Component Input Yes

720×480i (4:3) Yes (60Hz)

720×480i (16:9) Yes (60Hz)

720×480p (4:3) Yes (60Hz)

720×480p (16:9) Yes (60Hz)

720×576i (4:3) Yes (50Hz)

720×576i (16:9) Yes (50Hz)

720×576p (4:3) Yes (50Hz)

720×576p (16:9) Yes (50Hz)

1280×720p Yes (50/60Hz)

1920×1080i Yes (50/60Hz)

1920×1080p No (Possible to Display)

Wall Mount Size W x H(mm) Yes (75 x 75)

Screw Size M4 x 10

Stand Tilt No

Swievel No

Page 10

GENERAL SPECIFICATIONS

G-11 Accessories

G-12 Interface

Owner's Manual Language English/Czech/Slovak/Hungarian/Polish

w/Guarantee Card Yes

Remote Control Unit Yes

Rod Antenna No

Poles -

Terminal Loop Antenna (W/ Antenna Change Plug) No

Terminal DVB-T Antenna No

U/V Mixer No

DC Car Cord (Center+) No

Guarantee Card No

Warning Sheet No

Circuit Diagram No

Antenna Change Plug No

Service Facility List No

Important Safeguard No

Quick Set-up Sheet Yes

Battery Yes

UM size x pcs UM-4 x 2 pcs

OEM Brand No

AC Adapter No

AC Cord (for AC Adapter) No

AC Cord Yes

AV Cord (2Pin-1Pin) No

HDMI-DVI Cable No

3 in 1Mini Pin Cable (Y(CVBS)/Pb/Pr) Yes

Registration Card No

300 ohm to 75 ohm Antenna Adapter No

Stand Screw Yes (2pcs)

Stand Yes

Frame Stand No

Switch Power Yes

System Select No

Main Power SW No

Channel Up / Menu Up Yes

Channel Down / Menu Down Yes

Volume Up / Menu > Yes

Volume Down / Menu < Yes

Menu Yes

Play No

Stop No

Eject No

Input Select/Enter Yes

Indicator Power/Stand-by Yes (Blue / Red)

On Timer No

Page 11

GENERAL SPECIFICATIONS

G-13 Set Size

G-14 Weight

G-15 Carton

G-16 Material

G-17 Environment

Terminals Side Video Input 1

Audio Input 1

S- Input 1 No

Video Input 2 No

Audio Input 2 No

S- Input 2 No

Video Output No

Audio Output No

Digital Audio Out (Coaxial)

Euro Scart (21Pin) No

Component In

Audio Input (Component In use) Composite Audio Input Alternative

HDMI Input 1

Audio Input (HDMI/DVI In use) PC Monitor Audio Input Alternative

USB (Media) Yes

Sub Woofer Output No

Diversity No

Ext Speaker No

DC Jack 12V(Center +) No

VHF/UHF Antenna Input No

Headphone Yes

CI Card Slot Yes

AC Inlet Yes

PC Monitor Input (D-Sub) No

Audio Input No

Rear Euro Scart (21Pin)

Digital Audio Out (Coaxial) No

VHF/UHF Antenna Input

PC Monitor Input (D-Sub)

Audio Input

Approx. W x D x H (mm) 533.2 x 143.0 x 381.2

w/o Stand,Handle Approx. W x D x H (mm)

Net Approx. 3.5kg (7.7 lbs)

Net w/o Stand,Handle Approx. 3.3kg (7.3 lbs)

Gross Approx. 4.5kg (9.9lbs)

Gross w/Master Carton (Approx.) --- kg ( --- lbs)

Master Carton No

Content ---- Sets

Material -- /--

Dimensions W x D x H(mm) -- x -- x --

Description of Origin No

Gift Box Yes

Material Single/White

Dimensions W x D x H(mm) 620 x 129 x 452

Design As per Buyer's

Description of Origin No

Drop Test

Height (cm) 80

Container Stuffing 1650 Sets/45' Trailer

w/Pallet Yes

w/Wrapping Yes

Cabinet Cabinet Front PC+ABS 94V0 NON-HALOGEN

Cabinet Rear PS 94V0 NON-DECABROM

Stand PC+ABS 94V0 NON-HALOGEN

PCB Non-Halogen No

Eyelet Yes

Environmental standard requirement Green procurement of JVC

Pb- Free Phase3(PHASE3A)

Measures for Whisker Yes

WEEE Yes

Mini Pin Jack(φ3.5)

RCA x 2(L, R)

Yes

Mini Pin Jack(φ3.5) (CVBS Mini Pin Jack Alternative)

Yes

Yes

DIN Type

Yes

Mini Pin Jack(φ3.5), STEREO

533.2 x 48.5 x 353.2

Natural Dropping At 1 Corner / 3 Edges / 6 Surfaces

Page 12

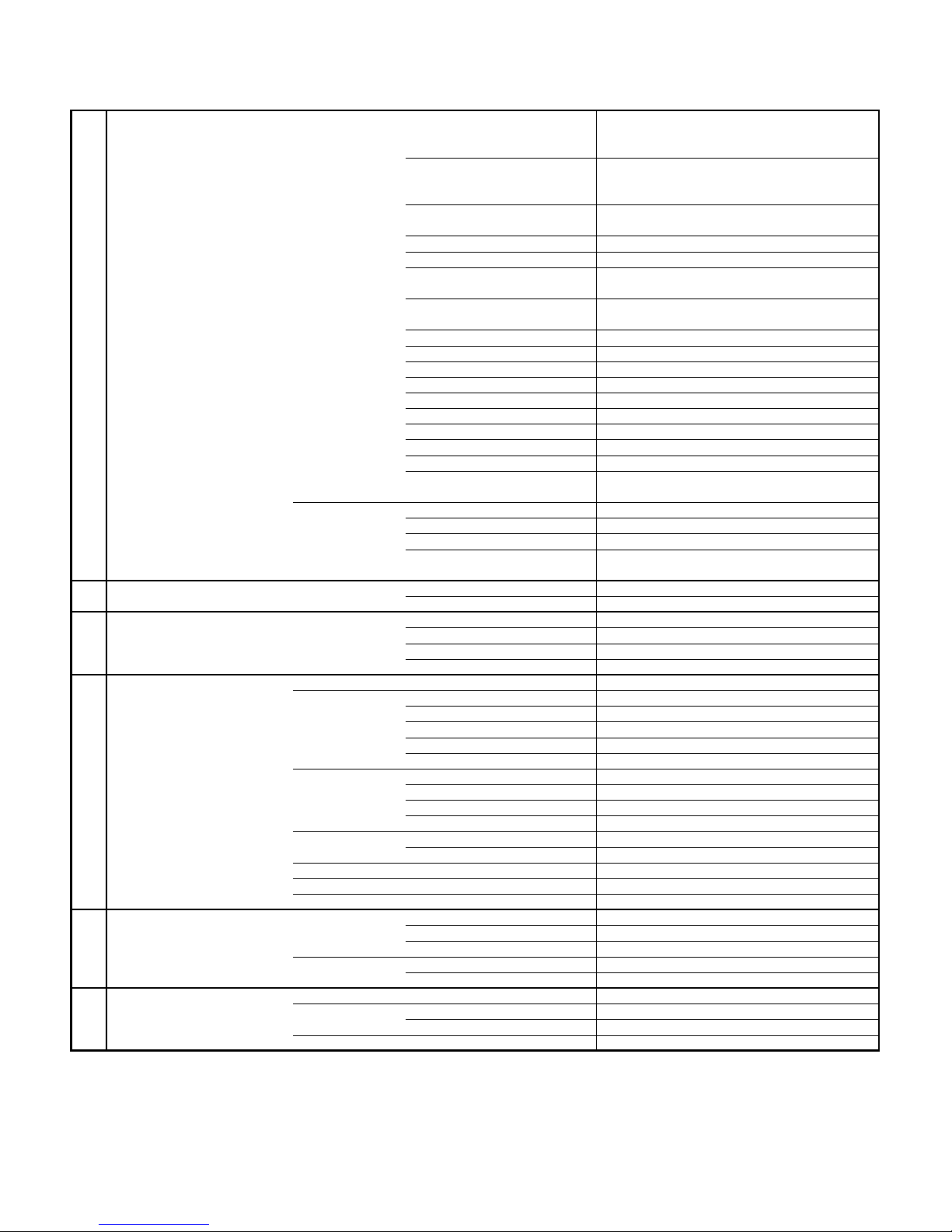

1. REMOVAL OF MECHANICAL PARTS

1.

Disconnect the following connectors:

(CN2, CN3, CN5, CN6, CN11 and CN17)

.

CAUTION

2.

Remove the screw (1).

3.

Remove the 2 screws (2).

4.

Remove the Plate Jack in the direction of arrow (A).

5.

Remove the Shield Jack in the direction of arrow (B).

6.

Remove the 4 screws (3).

1-1: STAND ASS'Y (Refer to Fig. 1-1)

7.

Remove the Main Unit in the direction of arrow (C).

1.

Remove the 3 screws (1).

2.

Remove the Stand Ass'y in the direction of arrow.

DISASSEMBLY INSTRUCTIONS

1-2: BACK CABI ASS'Y (Refer to Fig. 1-2)

1.

Remove the screw (1).

1-4: POWER PCB (Refer to Fig. 1-4)

2.

Remove the 3 screws (2).

3.

Remove the Back Cabi Ass'y in the direction of arrow.

1.

Disconnect the following connector:

(CP7001)

.

2.

Remove the 6 screws (1).

AND P.C. BOARDS

Be careful not to remove the LVDS cable forcibly, because

the LVDS cable may be damaged.

(1)

(1)

(1)

Stand Ass'y

1-3: MAIN PCB (Refer to Fig. 1-3)

(2)

(1)

(2)

(A)

Plate Jack

(B)

(3)

CN11

Shield Jack

CN2

CN17

(C)

CN5

CN3

(3)

(3)

(3)

CN6

Main Unit

(1)

(2)

(2)

(2)

Fig. 1-1

3. Remove the Power PCB in the direction of arrow.

(1)

(1)

(1)

CP7001

(1)

(1)

Power PCB

Fig. 1-3

Fig. 1-4

Fig. 1-2

Page 13

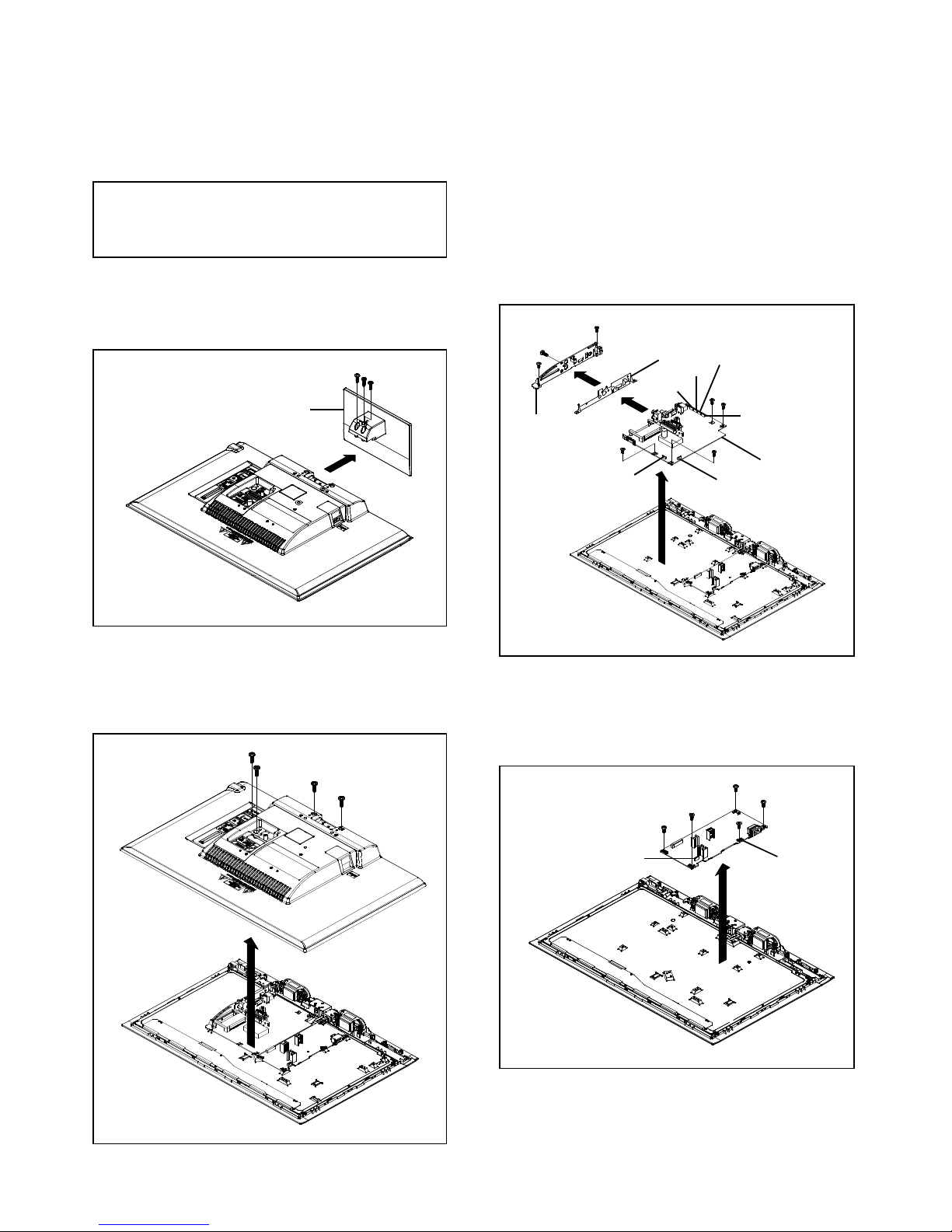

1-5: REMOCON PCB / LED PCB / OPERATION PCB

(Refer to Fig. 1-5)

2.

Remove the screw (1).

3.

Remove the Angle Hinge in the direction of arrow (B).

6.

Remove the Operation PCB in the direction of arrow (D).

DISASSEMBLY INSTRUCTIONS

1. Remove the Remocon PCB in the direction of arrow (A).

4. Unlock the 2 supports (1).

5. Remove the LED PCB in the direction of arrow (C).

(1)

Angle Hing

Remocon PCB

(B)

(A)

LED PCB

(C)

Operation PCB

(2)

(D)

Fig. 1-5

Page 14

2. REMOVAL AND INSTALLATION OF

3. When IC starts moving back and forth easily after

FLAT PACKAGE IC

desoldering completely, pickup the corner of the IC using

DISASSEMBLY INSTRUCTIONS

Fig. 2

-

1

tweezers and remove the IC by moving with the IC

REMOVAL desoldering machine. (Refer to Fig. 2-3.)

1. Put Masking Tape (cotton tape) around the Flat Package

IC to protect other parts from any damage.

(Refer to Fig. 2-1.)

NOTE

Masking is carried out on all the parts located within

10 mm distance from IC leads.

Masking Tape

(Cotton Tape)

IC

2. Heat the IC leads using a blower type IC desoldering

machine. (Refer to Fig. 2-2.)

NOTE

NOTE

Some ICs on the PCB are affixed with glue, so be

careful not to break or damage the foil of each IC

leads or solder lands under the IC when removing it.

Blower type IC

desoldering machine

Tweezers

IC

Fig. 2-3

Do not rotate or move the IC back and forth , until IC 4. Peel off the Masking Tape.

can move back and forth easily after desoldering the

leads completely. 5. Absorb the solder left on the pattern using the Braided

Shield Wire. (Refer to Fig. 2-4.)

Blower type IC

desoldering machine

NOTE

Do not move the Braided Shield Wire in the vertical

direction towards the IC pattern.

Braided Shield Wire

Soldering Iron

IC

Fig. 2-2

IC pattern

Fig. 2-4

Page 15

INSTALLATION

DISASSEMBLY INSTRUCTIONS

damaged. So, always be sure to replace the IC in this

4. When bridge-soldering between terminals and/or the

soldering amount are not enough, resolder using a

1. Take care of the polarity of new IC and then install the

Thintip Soldering Iron. (Refer to Fig. 2-8.)

new IC fitting on the printed circuit pattern. Then solder

each lead on the diagonal positions of IC temporarily.

(Refer to Fig. 2-5.)

Thin-tip Soldering Iron

Soldering Iron

IC

5. Finally, confirm the soldering status on four sides of the

IC using a magnifying glass.

Confirm that no abnormality is found on the soldering

Solder temporarily

Solder temporarily

Fig. 2-5

position and installation position of the parts around the

IC. If some abnormality is found, correct by resoldering.

NOTE

2. Supply the solder from the upper position of IC leads

sliding to the lower position of the IC leads. When the IC leads are bent during soldering and/or

(Refer to Fig. 2-6.)

repairing, do not repair the bending of leads. If the

bending of leads are repaired, the pattern may be

case.

Solder

Fig. 2-8

Soldering Iron

Supply soldering

IC

from upper position

to lower position

Fig. 2-6

3. Absorb the solder left on the lead using the Braided

Shield Wire. (Refer to Fig. 2-7.)

NOTE

Do not absorb the solder to excess.

Soldering Iron

IC

Braided Shield Wire

Fig. 2-7

Page 16

This unit is provided with the following SERVICE MODES so you can repair, examine and adjust easily.

1-1:

1-2:

1-3:

SERVICE MODE LIST

CAUTION

Do not feel after other MENU.

1. Check of the SUM DATA and MICON VERSION on the screen.

Press the MENU ---> 1147 button on the remote control to select "Setup".

Press the DOWN button on the remote control to select "Version Info".

On the screen as shown in Fig. 1-1.

Model Name : mt5365_eu_dvbs_cIplus_verf

Version : IDTV0801_002114_8_001_70

OUl Code : 0x000C3B

H/W Model ID : 0x0D12

H/W Version ID : 0x0001

S/W Model ID : 0x0D12

S/W Version ID : 0x0001

Checksum : C7C6

Serial Number : 2012-03-19 16:15:59

Fig. 1-1

Page 17

2. BASIC ADJUSTMENTS

ELECTRICAL ADJUSTMENTS

1. ADJUSTMENT PROCEDURE

G Offset

0

color is achieved.

Prepare the following measurement tools for electrical

2-1: WHITE BALANCE

adjustments.

1. Place the set in Aging Test for more than 15 minutes.

1. Pattern Generator 2. Please select input About mode to adjust W/B.

3. Receive the gray scale pattern from the Pattern

On-Screen Display Adjustment

Generator.

4. Press the INPUT SELECT button on the remote control

1. Press the MENU---> 1147 button on the remote control. to set to the AV mode.

2. Press the DOWN button on the remote control. 5. Using the remote control, set the brightness and

3. Select the "Video" menu, then press contrast to normal position.

ENTER button on the remote control. 6. Press the MENU---> 1147 button on the remote control.

4. Select the "Color Temperature" menu , then press 7. Press the DOWN button on the remote control.

ENTER button on the remote control. 8. Select the "Video" menu, then press

5.

On the screen as shown in Fig. 1-1.

ENTER button on the remote control.

9. Select the "Color Temperature" menu , then press

ENTER button on the remote control.

10. Press the UP/DOWN button on the remote control

Color Temperature Cool

<>

to select the "R Gain", "G Gain", "B Gain", "R Offset",

"G Offset", "B Offset.

R Gain -37

G Gain 0

B Gain 102

R Offset -2

B Offset -1

11. Adjust the LEFT/RIGHT button on the remote control

to whiten the R Gain, G Gain, B Gain, R Offset, G Offset,

B Offset at each step tone sections equally..

12. Perform the above adjustments 10 and 11 until the white

Fig 1-1

Page 18

ELECTRICAL ADJUSTMENTS

3. ELECTRICAL ADJUSTMENT PARTS LOCATION GUIDE (WIRING CONNECTION)

LCD PANEL

POWER PCB

CP7001

J502

CD2801

MAIN UNIT

CD3004

CN3

CP501

CN11

CN13

CN25

CN2

CN7

CN9

CN14

CN8

CN27

CN23

CN26

CN17

T1

CN24

CN5

CN6

CP2204

OPERATION PCB

CD805

CD7602

LED PCB

SPEAKER

CP7601

OS7601

REMOCON PCB

Page 19

(LCD SECTION)

POWER DOES NOT TURN ON

Yes

TROUBLESHOOTING GUIDE

Is F501 broken?

No

Is there voltage C502

305VDC?

Yes

Is there voltage at pin6

of IC501 21VDC?

Is there voltage Q501

169VDC?

Yes

Yes

No

No

Yes

Change F501.

Check D507, D508, D518, D510

and peripheral circuit.

Check IC501 and peripheral

circuit.

Change R510 and peripheral

circuit.

Is there voltage at pin5

of IC501 21VDC?

Yes

Is there voltage at pin 8

of IC501 169VDC?

Yes

Is there voltage at

pin1 of IC501 5.7VDC?

Yes

Change POWER PCB.

Yes

No

No

Check IC501 and peripheral

circuit.

Check D505 and peripheral

circuit.

Check R516, R534 and

peripheral circuit.

Page 20

TROUBLESHOOTING GUIDE

and 9 of IC YD

1517

(F)?

peripheral circuit.

THE PICTURE APPEARS,

BUT THE AUDIO DOES NOT

APPEARS.

Is SP WIRE CONNECTOR

connected?

Yes

Is there signal at wave

(SP.Lift) and wave

(SP.Right)?

No

Is there signal at pins 1

Yes

Is there signal at pins 4

and 6 of IC YD1517(F)?

No

Yes

Yes

Yes

Connect SP WIRE

CONNECTOR.

Change SPEAKER.

Check IC YD1517(F) and

Check IC YD1517(F) and

peripheral circuit.

Yes

Is there voltage at pin 7

of IC YD1517(F)

+12VDC?

Yes

Change IC YD1517(F).

Yes

Check D514 and peripheral

circuit.

Page 21

THE PICTURE DOES NOT

APPEAR

TROUBLESHOOTING GUIDE

Does backlight shine?

Yes

Is there voltage at

pin2 12VDC?

Yes

Is there voltage at pin7

of IC 7001 5VDC?

Yes

Change IC 7001.

No

No

No

Check IC7001 and peripheral

circuit.

Check D514 and L503 and

peripheral circuit.

Check R7003 and peripheral

circuit.

Page 22

THE COLOR DOES NOT

APPEAR

TROUBLESHOOTING GUIDE

Is Setting of color

Normal?

Yes

Is the color signal

received?

Yes

Is there color signal at

IC MT5310CHHU?

Yes

Change IC MT5310CHHU.

No

No

No

Adjust the color.

Receive the color signal.

Check IC MT5310CHHU and

peripheral circuit.

Page 23

SEMICONDUCTOR BASE CONNECTIONS

DIODE

1N4006-A5 1F5 HZS33NB2 RB056L-40TE25 S14K385E2S5M4

IC

TRANSISTOR

ANODE

8

B

1SS133T-77 FCHS10A08

FCF10A20 HZS12NB2

SARS01 ZRM11C

CATHODE

ANODE

BA36-PUR1DCB549T1/470 UDZSNP11B TE-17 MA111-(TX) ATTINY48-MU NR887D

1

1

FA5640N-D1-TE1 KIA431A-AT PS2561AL1-1-V(W) KRC103SRTK FMV09N90E

2

3

1

1

E

C

KTA1504S_Y_RTK

1

G

D

S

Page 24

<Remonon PCB>

<Operation PCB>

<DVD PCB>

<LCD

PANEL>

BLOCK DIAGRAM

DVB-T/C TUNER

MPEG/SCALER

TDTK-G941D

DEMOD.

MT5310 (MEDIATEK)

BUS SW

Y/C

SPDIF

PCMCIA

TS

MT5135AE

LVDS

Bus

SPDIF

SPI FLASH

64Mbit

EN25Q64-104HIP

【【【【

HDMI-1

】】】】

(EON)

(MTK)

【【【【

AV2/Comp A-in

】】】】

AUDIO L/R

【【【【

AV2/Component

】】】】

CVBS/Y,

Pb, Pr

Mini

【【【【

PC/Comp

Audio IN

】】】】

AUDIO L/R

【【【【

SCART1

】】】】

D-sub

【【【【PC】】】】

CVBS_In/Out

15pin

RGB

RGB

SCART

Side

Audio_In/Out

SPDIF Out

(Coaxial) Side

HP Jack

5V

USB

FUSE

USB

Sound AMP

Side

YD1517P

Main Speaker

(YD)

2W + 2W

DDR3-1333 1Gb

NT5CB64M16DP-CF

(NANYA)

Page 25

L501_1

C508

W847

C

5

3

4

W810

C507

W812

TH501

C502

D508

D510

D507

D518

D505

R

5

1

0

W823

R505

IC505

R512

Q501

D527

R534

D511

C

5

1

3

R501

R502

D528

D512

SH502

SH505

C516

HS501

D514

HS503

F501

C514

D504_1

R503

T501_1

R511_1

J502_1

D513

D506

R507

D523

HS502

C512

C520

IC502

L504

W008

C522

CP501

L503

W814

W007

D516

R518

SH503

SH507

C506

W009

C511

C7010

CP7001

L7002

C7001

IC7001

B7001

W004

C527

C524

C504

W001

W003

W803

W802

W845

C542_1

POWER (INSERTED PARTS)

SOLDER SIDE

R526

R528

R514

R506

C509

C505

R516

C503

C501

R520

R504

IC501

C536

R529

Q502

R522

R515

C523

C521

R523

R525

R519

R524

R513

Q504

W852

R532

Q503

W807

D517

R7001

R7002

R7008

R7012

R7011

R7010

R7009

C7013

C7012

C7015

R7017

R7013

C7016

R7005

C7002

R7003

C7004

R7004

C7005

C7017

D7003

C517

B7002

R7014

W806

C7011_2

POWER (CHIP MOUNTED PARTS)

SOLDER SIDE

PRINTED CIRCUIT BOARDS

CEL788A

CEL788A

RISKOFFIRE

-REPLACEASMARKED.

Page 26

POWER (INSERTED PARTS)

SOLDER SIDE

POWER (CHIP MOUNTED PARTS)

SOLDER SIDE

PRINTED CIRCUIT BOARDS

Page 27

CEJ570A

CEJ572A

CEJ570A

CEJ572A

OS7601

CD7602

D7602_1

CP7601

C7602

R7605

W801

W804

W803

LED (INSERTED PARTS)

SOLDER SIDE

PRINTED CIRCUIT BOARDS

LED (CHIP MOUNTED PARTS)

SOLDER SIDE

REMOCON (INSERTED PARTS)

SOLDER SIDE

REMOCON (CHIP MOUNTED PARTS)

SOLDER SIDE

D2204

C2225

R2267

R2266_1

R2271

R2272

R2273_1

R2274_1

R2269

R2268

R2278

R2284

R2283

R2282

R2281

R2279

R2280

C2226

C2227

C2228

C2229

R2265_1

C2230

C2232

C2231

CP2204

IC2204

B2204

B2203

C2203

B2202

C2202

B2201

C2201

R2264

OPERATION (TOP SIDE)

CEK600A

2

OPE

25

1

9

17

Page 28

LED (INSERTED PARTS)

SOLDER SIDE

PRINTED CIRCUIT BOARDS

LED (CHIP MOUNTED PARTS)

SOLDER SIDE

REMOCON (INSERTED PARTS)

SOLDER SIDE

REMOCON (CHIP MOUNTED PARTS)

SOLDER SIDE

OPERATION (TOP SIDE)

Page 29

ABC D E F GH

ABC D E F GH

2

1

3

4

5

6

7

8

2

1

3

4

5

6

7

8

CAUTION: DIGITAL TRANSISTOR

C536

0.00150V B

C542_1

0.022

630V

ECWF(L)

C508

0.1310V LE-MX

C507

0.001

250V

E

C534

0.001250V E

C513

330P2KV R

C503

330P

50V

CH

C505

10P50V CH

C509 0.150V

B

C506

0.22

310V

LE-MX

C501 0.015

50V

B

C514

470P250V E

C517

0.00150V B

C524

0.001 B

C527

0.001 B

C521

0.047

50V

B

C523

470P

50V

CH

C520

4.750V YXF

C516

22

50V

2.5mm

YXF

C502

82400V GJ

N’UTILISER QUE DES FUSIBLE DE MEME TYPE

:POUR UNE PROTECTION CONTINUE LES RISQUES D’INCEIE

ATTENTION

REPLACE ONLY WITH THE SAME TYPE FUSE

:FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,

CAUTION

TH501

B57153S0479A001

WAS RECEIVED IN GOOD CONDITION AND PICTURE IS NORMAL.

WITH THE DIGITAL TESTER WHEN THE COLOR BROADCAST

NOTE:THE DC VOLTAGE AT EACH PART WAS MEASURED

OF PRINTING AND SUBJECT TO CHANGE WITHOUT NOTICE

NOTE:THIS SCHEMATIC DIAGRAM IS THE LATEST AT THE TIME

W807

W803

W812

W810

W847

W814

W823

W845

W852

W802

:SINCE THESE PARTS MARKED BY

CAUTION

DESCRIBED IN PARTS LIST ONLY

CRITICAL FOR SAFETY,USE ONES

ARE

DANS LA NOMENCLATURE DES PIECES

N’UTILISER QUE CELLS DECRITES

DANGEREUSES AN POINT DE VUE SECURITE

:LES PIECES REPAREES PAR UN ETANT

ATTENTION

R505

0.27 1W

D513

SARS01

D505

1N4006-A5

D511

1F5

D518

ZRM11C

D508

ZRM11C

D506

1F5

D516

1SS133

D507

ZRM11C

D510

ZRM11C

D504_1

S14K385E2S5M4

IS THE LIVE CONNECTIONCAUTION:

L501_1

JLB24123

LINE FILTER

12

34

IC505

PS2561AL1-1-V(W)

FEED BACK IC

1

2

34

R511_1

220K 1W RCR

R520

330K 1/8W

(32-16)

R504

330K 1/8W

(32-16)

R526

330K

1/8W

(32-16)

R528

330K

1/8W

(32-16)

R503

12M1W

RCR

R522

2.2K 1/10W

R514

33

1/16W

R524

910 1/16W

+-1%

R515

1K 1/16W

R525

2.2K 1/16W

+-1%

R516

100K

1/16W

R506

33K 1/16W

R501

5.6K 1/2W

R512

5.6K

1/2W

R518

100 1/4W

R529

10K 1/16W

R523

2.2K 1/16W

+-1%

R507

100 1/4W

R513

220 1/16W

R502

330 1/4W

R532

10K 1/16W

R519

10K 1/16W

R534

15 1/4W

D517

UDZSNP11B

D512 HZS12NB2

D528

HZS33NB2

D527

HZS33NB2

IC501

FA5640N-D1-TE1

POWER CONTROL IC

1234

56

78

IS NON POLAR ONE.

THE ALUMI ELECTROLYTIC CAPACITOR MARKED NP

THE RESISTOR MARKED F IS FUSE RESISTOR.NOTE:

IC502

KIA431A-AT

REGULATOR IC

123

D523

FCHS10A08

1

2

3

D514

FCF10A20

1

2

3

L504

10uH

TSL0808

L503

10uH

TSL0808

SH505

YQ-12

SH502

YQ-12

SH503

YQ-12

SH507

YQ-12

C512

22025V YXF_P

C511

47025V ZLH

C504

100010V ZLH

C522

100025V ZLJ

F501

SCT_2.5A250V

USA:4A(T)250V/EU:2.5A(T)250V

HS502

763WAAA120

FOR D523

HS503

763WAAA198

FOR D514

HS501

763WAAA120

FOR Q501

2.5A 250V

2.5A 250V

R510

0.22 1W

S

D

G

Q501

FMV09N90E

SWITCHING

CP501

00_6216_016_000_808+

1

10

11

12

13

14

15

16

2

3

4

5

6

7

8

9

T501_1 8128042Z

1

11

12

3

5

67

8

J502_1

CCT2302-0721C

12

Q503

KRC103SRTK

P.FAIL_SW

Q504

KRC103SRTK

P.FAIL_SW

Q502

KTA1504S_Y_RTK

POWER FAIL SW

FRAMEGND1 FRAMGND3

LED+12V

SOUND_GND

LIGHT_CTL

GND

SOUND+B

AT+12V

SOUND_GND

LED+12V

GND

AT+5.8V

POWER_FAIL

GND

AT+5.8V

AT+12V

SOUND+B

SOUND_GND

LIGHT_CTL

4A 125V4A 250V

4A 250V (F501)

, 4A 250V (F502) AND 4A 125V (F503)

2.5A 250V (F501)

, 2.5A 250V (F502) AND 4A 125V (F503)

4A 250V (F501)

2.5A 250V (F501)

, 4A 250V (F502)

, 2.5A 250V (F502)

ET 4A 125V (F503)

ET 4A 125V (F503)

:F501 IS MANUFACTURED BY SKYGATE CO.,LTD., TYPE SCT.

:F502 IS MANUFACTURED BY SKYGATE CO.,LTD., TYPE SCT.

:F503 IS MANUFACTURED BY SKYGATE CO.,LTD., TYPE 20N.

CAUTION

FROM/TO BACKLIGHT INVERTER

PCB240

CEL788

(CN3)

FROM/TO MAIN UNIT

5.8

5.8

5.8

NC

OUT

VCC

NC

VH

GND

IS

FB

ZCD

21.0

21.30

1.8

2.8

5.7

169.0

1.8

12.0

11.0

2.8

0

AC REF

2.5

0

11.0

IC PIN

169.0

20.0

4A 250V

PRI

SEC

(SOUND GND)

POWER SCHEMATIC DIAGRAM

(POWER PCB)

GND

LIGHT_CTL

SOUND_GND

SOUND+B

GND

AT+5.8V

AT+5.8V

GND

SW+12V/GND

SW+12V

SOUND+B

SOUND_GND

POWER_ON_H

INVERTER_H

POWER_FAIL

AT+5.8V

NC.

NC.

5.8

0

0

0

0

3.3

Page 30

ABC D E F GH

ABC D E F GH

2

1

3

4

5

6

7

8

2

1

3

4

5

6

7

8

B7001

W4BRH3.5X6X1.0

B7002

HCB3216KF-391T20

CP7001

00_6232_007_006_800+

1

2

3

4

5

6

7

C7011_2

0.150V 1608B

C7005

0.150V B

C7015

0.002250V B

C7013

0.00150V B

C7017

0.0150V B

C7002

0.1

50V

B

C7004

0.001550V B

C7016

470P50V CH

C7012

0.4725V B

C7010

10025V ZLG

C7001

10016V ML

WAS RECEIVED IN GOOD CONDITION AND PICTURE IS NORMAL.

WITH THE DIGITAL TESTER WHEN THE COLOR BROADCAST

NOTE:THE DC VOLTAGE AT EACH PART WAS MEASURED

OF PRINTING AND SUBJECT TO CHANGE WITHOUT NOTICE

NOTE:THIS SCHEMATIC DIAGRAM IS THE LATEST AT THE TIME

W806

D7003

RB056L-40

R7014

47 1/10W

R7013

47 1/10W

R7004

100 1/10W

R7008

3.9 1/4W +-1%

R7009

3.9 1/4W +-1%

R7010

3.9 1/4W +-1%

R7012

3.9 1/4W +-1%

R7011

3.9 1/4W +-1%

R7001

1K 1/16W

R7017

47K 1/16W

R7003

10 1/16W

R7002

22K 1/16W

R7005

10K 1/16W

+-1%

IC7001 NR887D

INVERTER DRIVE

1234

5

678

L7002

22uH PF13

LED+12V

LIGHT_CTL

SOUND_GND

GND

(POWER PCB)

BACKLIGHT INVERTER SCHEMATIC DIAGRAM

PCB240

CEL788

FROM/TO LED PCB

ILED2

ILED2

ILED2

ILED1

VLED

VLED

VLED

10V 960mA

960mA

(CD2003)

FB

GND

BS

VIN

SW

SS

EN

NC NC

FROM/TO POWER

VFB

0.8V

5.0

5.0

12.7

0

0

4.8

5.0

PATTERN

GNDPATTERN

Page 31

ABC D E F GH

ABC D E F GH

2

1

3

4

5

6

7

8

2

1

3

4

5

6

7

8

CD7601_2

E8232206

B

R

D7602_1

BA36-PUR1DCB549T1/470

ST-BY/POWER

1

2

3

CD7602

E8231204

1

2

3

CP7601

A2001WV-3A

1

2

3

OS7601

KSM-603LM2M(OR)

1

2

3

C7602

4.76.3V

1608

B

WAS RECEIVED IN GOOD CONDITION AND PICTURE IS NORMAL.

WITH THE DIGITAL TESTER WHEN THE COLOR BROADCAST

NOTE:THE DC VOLTAGE AT EACH PART WAS MEASURED

OF PRINTING AND SUBJECT TO CHANGE WITHOUT NOTICE

NOTE:THIS SCHEMATIC DIAGRAM IS THE LATEST AT THE TIME

W804

W803

W801

R7605

100

1/16W

1608

(CN2)

FROM/TO MAIN UNIT

(CN6)

FROM/TO MAIN UNIT

HEAD PHONE/REMOCON/LED SCHEMATIC DIAGRAM

PCBDT0

CEJ572

POWER ON LED

GND

STAND_BY LED

(LED PCB)

(REMOCON/LED PCB)

AT+3.3V

GND

REMOCON IN

CEJ570

PCBDA0

(HEAD PHONE/REMOCON PCB)

GND

Vout

B+

Page 32

ABC D E F GH

ABC D E F GH

2

1

3

4

5

6

7

8

2

1

3

4

5

6

7

8

IC2204

ATTINY48-MU

KEY_SENSOR_IC

1

10111213141516

17181922021222324

25 26 27 28 29

3

30 31 32

45678

9

JG2231 VCC

JG2232 GND

JG2230 RST

JG2229 SCK

JG2228 MISO

JG2227 MOSI

JG2226

JG2225

CP2204

A2001WR-S04-T

1

2

3

4

CD805

CH243303

B2203

FCM1608KF-102T02

B2204

FCM1608KF-102T02

B2202

FCM1608KF-102T02

B2201

FCM1608KF-102T02

C2225

0.1

10V

B

C2202

0.01

25V

B

C2203 0.01

25V

B

C2201

10

6.3V

B

C2231

0.02225V

B

C2232 0.02225V B

C2230 0.02225V

B

C2229 0.022

25V

B

C2228

0.022

25V

B

C2227 0.02225V

B

C2226

0.022

25V B

WAS RECEIVED IN GOOD CONDITION AND PICTURE IS NORMAL.

WITH THE DIGITAL TESTER WHEN THE COLOR BROADCAST

NOTE:THE DC VOLTAGE AT EACH PART WAS MEASURED

OF PRINTING AND SUBJECT TO CHANGE WITHOUT NOTICE

NOTE:THIS SCHEMATIC DIAGRAM IS THE LATEST AT THE TIME

D2204 MA111

R2274_1 22K 1/16W +-1%

R2273_1 5.6K 1/16W +-1%

R2272 560 1/16W

R2271 3.9K 1/16W

R2269 8.2K 1/16W

R2267 33K 1/16W

R2266_1 18K 1/16W +-1%

R2265_1 10K 1/16W +-1%

R2280 1K 1/16W

R2281 1K 1/16W

R2282 1K 1/16W

R2283 1K 1/16W

R2279 1K 1/16W

R2278 1K 1/16W

R2268 10K 1/16W

R2264 330 1/16W

R2284 1K 1/16W

(CN6)

FROM/TO MAIN UNIT

CEK600

PCB270

NC

NC

NC

AT+3.3V

KEY_A

KEY_B

GND

NC

JG2205 KEY6/MENU

JG2207 KEY8/VOL+

JG2208 KEY1/CH+

JG2209 KEY2/INPUT

JG2210 KEY3/VOL-

JG2211 KEY4/POWER

JG2212 KEY5/CH-

PD5

PD6

PD7

PB0

PB1

PB2

PB3

PB4

PB5AVCC

PB7PB6PA3GNDVCC

PA0PC7GNDPA1PC0PC1

PC2

PC3

PC4

PC5

PC6

PD0

PD1

PD2

PD3 PD4 PA2

OUT3

OUT4

OUT5

OUT2

OUT6

OUT1

IC

OUT8

OUT7

NC

3.36

3.36

3.28

3.28

3.36

NCNC0

0

3.36

0

3.36 3.36 0 3.36 3.36 3.28

0

3.28

0

3.28

3.28

3.36

3.28

3.28

3.28

3.28 3.28 3.36 3.3603.28 0

3.28

NC

OPERATION SCHEMATIC DIAGRAM

(OPERATION PCB)

Page 33

ABC D E F GH

ABC D E F GH

2

1

3

4

5

6

7

8

2

1

3

4

5

6

7

8

J4208

1

10

11

12

13

14

15

16

17

18

19

2

20

213

4

5

6

7

8

9

CN13

1

10

11

12

13

14

15

16

17

18

19

2

20

21

3

4

5

6

7

8

9

CN23

1

2

3

4

5

6

7

8

CN5

1

2

3

4

CN17

1

2

3

4

CN12

1

2

3

4

5

6

CN10

1

10

11

12

13

14

15

16

17

18

19

2

20

21

22

23

24

3

4

5

6

7

8

9

Vout

B+

GND

OS7601

1

2

3

CD501

230V AC 50Hz

CN11

1

10

11

12

13

14

15

16

17

18

19

2

20

21

22

23

24

25

26

27

28

29

3

30

4

5

6

7

8

9

CP2204

1

2

3

4

B

R

D7602_1

ST-BY/POWER

1

2

3

CP7601

1

2

3

CN4

1

2

3

CN6

1

2

3

CN2

1

2

3

CD7602

1

2

3

CD2003

1

2

3

4

5

6

7

CP7001

1

2

3

4

5

6

7

WAS RECEIVED IN GOOD CONDITION AND PICTURE IS NORMAL.

WITH THE DIGITAL TESTER WHEN THE COLOR BROADCAST

NOTE:THE DC VOLTAGE AT EACH PART WAS MEASURED

:SINCE THESE PARTS MARKED BY

CAUTION

DESCRIBED IN PARTS LIST ONLY

CRITICAL FOR SAFETY,USE ONES

ARE

DANS LA NOMENCLATURE DES PIECES

N’UTILISER QUE CELLS DECRITES

DANGEREUSES AN POINT DE VUE SECURITE

:LES PIECES REPAREES PAR UN ETANT

ATTENTION

CP501

1

10

11

12

13

14

15

16

2

3

4

5

6

7

8

9

CN3

1

10

11

12

13

14

15

16

2

3

4

5

6

7

8

9

J3801

1 2

CEJ572

CEJ570

AT+3.3V

GND

REMOCON IN

4

3

2

1

4

3

2

1AT+3.3V

KEY_A

KEY_B

GND

NC

NC

CEK600

PCB270

OPERATION PCB

INTERCONNECTION DIAGRAM

3

2

1

3

2

1

GND

LIGHT_CTL

SOUND_GND

SOUND+B

GND

AT+5.8V

AT+5.8V

GND

SW+12V/GND

SW+12V

SOUND+B

SOUND_GND

POWER_ON_H

INVERTER_H

POWER_FAIL

AT+5.8V

NC.

NC.

5

5

1

2

3

4

6

1

2

3

4

6

7

8

9

10

11

12

13

14

15

16

7

8

9

10

11

12

13

14

15

16

3

3

212

1

MAIN UNIT

MAIN001

POWER ON LED

GND

STAND_BY LED

LED PCB

PCBDT0

PCBDA0

REMOCON PCB

TM101

COMMAND TRANSMITTER

VLED

VLED

VLED

N1

N2

N2

N2

CEL789

5

1

2

3

4

6

751

2

3

4

6

7

PCBFM0

LED PCB

ILED2

ILED2

ILED2

ILED1

VLED

VLED

VLED

CEL788

POWER PCB

PCB240

Page 34

SCALER VIDEO/AUDIO

20µs/div 2ms/div

500mV/div 200mV/div

AV IN PC AUDIO L

10µs/div 2ms/div

200mV/div 200mV/div

PY PC AUDIO R

10µs/div 1ms/div

100mV/div 500mV/div

WAVEFORMS

PR AUDIO OUT L

10µs/div 1ms/div

200mV/div 500mV/div

PB AUDIO OUT R

1ms/div 1ms/div

200mV/div 2V/div

AU AUDIO IN L SPEAKER L

1ms/div 1ms/div

200mV/div 2V/div

AU AUDIO IN R SPEAKER R

NOTE : Main Board Signal Input/Output.

Page 35

MECHANICAL EXPLODED VIEW

103B

103A

103B

103B

103B

103

110

110

110

102A

102

205

205

206

102B

102B

112

113

114

207

111

205

204

204

205

106

108

203

203

203

PCB240

(POWER PCB ASS'Y)

202

202

202

203

203

203

203

203

105

109

107

115

PCB270

(OPERATION PCB ASS'Y)

PCBDA0

(REMOCON PCB ASS'Y)

PCBDT0

(LED PCB ASS'Y)

101A

101

101C

101B

201

101D

101D

101D

101D

101D

101D

201

104

MAIN001

(MAIN UNIT)

Page 36

MECHANICAL EXPLODED VIEW

(PACKING DIAGRAM)

11

3

2

1

8

6, 12, 13, 14, 15

7

9

4

10

5

Page 37

REF. NO.

PART NO.

DESCRIPTION

QUANTITY

101 X-7A708A911A FRONT CABI ASS'Y 1

MECHANICAL REPLACEMENT PARTS LIST

114

X-723000F826

SHEET JACK 2

1

REF. NO.

PART NO.

DESCRIPTION

QUANTITY

ACCESSORY REPLACEMENT PARTS LIST

101A X-708WPDA718 CABINET FRONT 1

101B X-711WPAA316 FRONT PLATE 1

101C X-713WPD0028 GUIDE REMOCON 1

101D X-800WQ00181 FELT SHEET 6

102A X-702WPAC014 CABINET BACK 1

102B X-800WQ0A312 FELT SHEET 2

103 X-7A704A375A STAND ASS'Y 1

103A X-704WPA0161 STAND 1

103B X-800SRA0002 CUSHION LEG VEB1349-A 4

104 X-7290000210 DOUBLE FACE TAPE 1

105 X-709WPA0051 HOLDER WIRE 1

106 X-752WUAA016 SHIELD JACK 1

107 X-759WNAA043 SHEET PC 1

108 X-761WPAA430 PLATE JACK 1

109 X-761WSAA217 ANGLE HINGE 1

110 X-769WSA0022 VESA SHAFT 4

111 X-704WPA0162 STAND FRAME 1

112 X-722538A287 SHEET RATING 1

113 X-723000F825 SHEET JACK 1 1

115 X-800WQ0A266 FELT SHEET 1

201 X-8110K2660U SCREW TAP TITE(P) LAMI HEAD 2.6x6 2

202 X-8109I30A0U SCREW TAP TITE(B) WH7 3x10 3

203 X-810722660U SCREW TAP TITE(S) BIND 2.6x6 10

204 X-810722680U SCREW,TAP TITE(S) BIND M2.6x8 2

205 X-8109230A0S SCREW TAP TITE(B) BIND 3x10 6

206 X-8107K2660S SCREW TAP TITE(S) LAMI HEAD 2.6x6 1

207 X-810722680S SCREW TAP TITE(S) BIND M2.6x8 1

1 X-120A155811 CORD SET AC O27-007BK 1

2 X-06EYB18003 CORD,RCA PIN 06.03.02.0176 1

3 X-076R0TR021 TRANSMITTER R56-2294 1

4 X-791WHA0173 FILM BAG 1

5 X-723000F778 SHEET CARTON 1

6 X-723000F779 ENERGY LABEL 1

7 X-791WHAA322 FILM BAG 1

8 X-792PHAA067 PACKAGE TOP 1

9 X-792PHAA068 PACKAGE BOTTOM 1

10 X-793PCDA452 GIFT BOX 1

11 X-795PCA0001 SHEET PROTECTION 1

12 X-8905000013 SCREW 1

13 X-JB5PD000 POLYBAG INSTRUCTION(RED CAUTION) 1

14 X-J3LJ0307A QUICK SET UP SHEET 1

15 X-J3LJ0351A INSTRUCTION BOOK(EN/CZ/SK/HU/PL) 1

Page 38

ELECTRICAL REPLACEMENT PARTS LIST

REF. NO.

PART NO.

DESCRIPTION

QUANTITY

*** DIODES ***

REMOCON PCB ASS'Y

*** PCB ***

PCBDA0 X-A3LJ03WDA0P REMOCON PCB ASS'Y CEJ570A 1

*** RESISTORS ***

R7605 X-R803R9101J RC 100 OHM 1/16W HPWGJ101T50 1

*** CAPACITORS ***

C7602 X-CS0PB0PQ6K CC 4.7 UF 6.3V B GRM188B30J475KE18D 1

*** OTHERS ***

CP7601 X-06GG230029 CONNECTOR PCB SIDE A2001WV-3A 1

OS7601 X-077Q038012 REMOTE RECEIVER KSM-603LM2M(OR) 1

LED PCB ASS'Y

*** PCB ***

PCBDT0 X-A3LJ03WDT0P LED PCB ASS'Y CEJ572A 1

D7602 X-0021991050 LED BA36-PUR1DCB549T1/470 1

*** OTHERS ***

CD7602 X-06E8231204 CORD CONNECTOR E8231204 1

*** OTHERS ***

! V7201 X-A3LJ03WFM0P LED MODULE ASS'Y M215HGE-P02-LED OR7A 1

POWER PCB ASS'Y

*** PCB ***

PCB240 X-A3LJ03W240P POWER PCB ASS'Y CEL788A 1

*** RESISTORS ***

R501 X-R002T2562J RC 5.6K OHM 1/2W CR1/2W-SS562JT/B 1

R502 X-R002T4331J RC 330 OHM 1/4W BCS4J0331A10 1

! R503 X-RC31X1126J RC 12M OHM 1W RCR60CT52A126J 1

! R504 X-R8X2R8334J RC 330K OHM 1/8W 1206W8J0334T5E 1

! R505 X-R3K781R27J R,METAL OXIDE 0.27 OHM 1W ERX1FJR27H 1

! R506 X-R803R9333J RC 33K OHM 1/16W HPWG J 333 T50 1

R507 X-R002T4101J RC 100 OHM 1/4W BCS4J0101A10 1

! R510 X-R63881R22J R,FUSE 0.22 OHM 1W RF1CL15AR22J 1

! R511 X-RC31X1224J RC 220K OHM 1W RCR60CT52A224J 1

R512 X-R002T2562J RC 5.6K OHM 1/2W CR1/2W-SS562JT/B 1

R513 X-R803R9221J RC 220 OHM 1/16W HPWGJ221T50 1

R514 X-R803R9330J RC 33 OHM 1/16W HPWG J 330 T50 1

R515 X-R803R9102J RC 1K OHM 1/16W HPWGJ102T50 1

R516 X-R803R9104J RC 100K OHM 1/16W HPWGJ104T50 1

! R518 X-R002T4101J RC 100 OHM 1/4W BCS4J0101A10 1

Page 39

ELECTRICAL REPLACEMENT PARTS LIST

R519

X-R803R9103J

RC 10K OHM 1/16W

HPWGJ103T50

1

!

C502

X-E83FHH820D

CE 82 UF 400V

LGJ2G820MELB

1

! R520 X-R8X2R8334J RC 330K OHM 1/8W 1206W8J0334T5E 1

R522 X-R801R7222J RC 2.2K OHM 1/10W HMWAJ0222T50 1

R523 X-R803R9222F RC 2.2K OHM 1/16W HPWGF222T50 1

R524 X-R803R9911F RC 910 OHM 1/16W HPWGF911T50 1

R525 X-R803R9222F RC 2.2K OHM 1/16W HPWGF222T50 1

! R526 X-R8X2R8334J RC 330K OHM 1/8W 1206W8J0334T5E 1

! R528 X-R8X2R8334J RC 330K OHM 1/8W 1206W8J0334T5E 1

R529 X-R803R9103J RC 10K OHM 1/16W HPWGJ103T50 1

R532 X-R803R9103J RC 10K OHM 1/16W HPWGJ103T50 1

R534 X-R002T4150J RC 15 OHM 1/4W BCS4J0150A10 1

R7001 X-R803R9102J RC 1K OHM 1/16W HPWGJ102T50 1

R7002 X-R803R9223J RC 22K OHM 1/16W HPWG J 223 T50 1

R7003 X-R803R9100J RC 10 OHM 1/16W HPWGJ100T50 1

R7004 X-R801R7101J RC 100 OHM 1/10W HMWAJ0101T50 1

R7005 X-R803R9103F RC 10K OHM 1/16W HPWGF103T50 1

R7008 X-R861R43R9F RC 3.9 OHM 1/4W MCR10EZHFL3R9 1

R7009 X-R861R43R9F RC 3.9 OHM 1/4W MCR10EZHFL3R9 1

R7010 X-R861R43R9F R 3.9 OHM 1/4W MCR10EZHFL3R9 1

R7011 X-R861R43R9F R 3.9 OHM 1/4W MCR10EZHFL3R9 1

R7012 X-R861R43R9F RC 3.9 OHM 1/4W MCR10EZHFL3R9 1

R7013 X-R801R7470J RC 47 OHM 1/10W HMWAJ0470T50 1

R7014 X-R801R7470J RC 47 OHM 1/10W HMWAJ0470T50 1

R7017 X-R803R9473J RC 47K OHM 1/16W HPWG J 473 T50 1

*** CAPACITORS ***

! C501 X-CS0PB04E4K CC 0.015 UF 50V B C0603X7R153K500NT 1

! C503 X-CS0PCH4L2J CC 330 PF 50V CH C0603C0G331J500NT 1

! C504 X-E8E101102M CE 1000 UF 10V 10ZLH1000MEFC10*12.5 1

! C505 X-CS0PCH411D CC 10 PF 50V CH GRM1882C1H100JA01D 1

! C506 X-P4K12D224K CMPP 0.22 UF 310V LE224-MX-C3.5 1

! C507 X-CE39E0M13M CC 0.001 UF 250V E DE1E3KX102MB4BL01 1

! C508 X-P4K12D104K CMPP 0.1 UF 310V LE104-MX-C3.5 1

! C509 X-CS0PB0415K CC 0.1 UF 50V B C0603X7R104K500NT 1

! C511 X-E8E1T3471M CE 470 UF 25V 25ZLH470MEFCT8 10*12.5 1

! C512 X-E8E2T3221D CE 220 UF 25V 25YXF220MEFCTA 8*11.5 1

C513 X-C03L0R7L2K CC 330 PF 2KV R DEHR33D331KB3B 1

! C514 X-CE39E0MQ2K CC 470 PF 250V E DE1B3KX471KB4BL01 1

C516 X-E8E2U5220D CE 22 UF 50V 50YXF22MEFCT1 5*11 1

C517 X-CS0PB0413K CC 0.001 UF 50V B C0603X7R102K500NT 1

C520 X-E8E2U54R7D CE 4.7 UF 50V 50YXF4.7MEFCT1 5*11 1

C521 X-CS0PB04Q4K CC 0.047 UF 50V B GRM188B11H473KA01D 1

! C522 X-E9E8F3102D CE 1000 UF 25V 25VZLJ1000MKC10*20 1

C523 X-CS0PCH4Q2J CC 470 PF 50V CH C0603CG471J500NT 1

C524 X-CRGTB0413K CC 0.001 UF 50V B UP025B102K-A-BZ 1

C527 X-CRGTB0413K CC 0.001 UF 50V B UP025B102K-A-BZ 1

! C534 X-CE39E0M13M CC 0.001 UF 250V E DE1E3KX102MB4BL01 1

C536 X-CS0PB0413K CC 0.001 UF 50V B C0603X7R102K500NT 1

! C542 X-P416F5223J CMPP 0.022 UF 630V ECWF(L) ECWF6223JLB 1

C7001 X-E9EGU2101M CE 100 UF 16V 16ML101MEFCT5 6.3*7 1

C7002 X-CS0PB0415K CC 0.1 UF 50V B C0603X7R104K500NT 1

C7004 X-CS0PB04E3K CC 0.0015UF 50V B C0603X7R152K500NT 1

C7005 X-CS0PB0415K CC 0.1 UF 50V B C0603X7R104K500NT 1

C7010 X-E8EMU3101D CE 100 UF 25V 25ZLG100MEFC6.3*11 1

C7011 X-CQGTB0415K CC 0.1 UF 50V B UP050B104K-A-BZ 1

C7012 X-CS0PB03Q5K CC 0.47 UF 25V B GRM188B31E474KA75D 1

C7013 X-CS0PB0413K CC 0.001 UF 50V B C0603X7R102K500NT 1

C7015 X-CS0PB04H3K CC 0.0022UF 50V B C0603X7R222K500NT 1

C7016 X-CS0PCH4Q2J CC 470 PF 50V CH C0603CG471J500NT 1

C7017 X-CS0PB0414K CC 0.01 UF 50V B C0603X7R103K500NT 1

Page 40

ELECTRICAL REPLACEMENT PARTS LIST

*** DIODES ***

! D504 X-D7KZ385E20 DIODE VARISTA S14K385E2S5M4 1

! D505 X-D4CTN40060 DIODE SILICON 1N4006-A5 1

D506 X-D4JX001F50 DIODE SILICON 1F5 1

! D507 X-D4JXRM11C0 DIODE SILICON ZRM11C 1

! D508 X-D4JXRM11C0 DIODE SILICON ZRM11C 1

! D510 X-D4JXRM11C0 DIODE SILICON ZRM11C 1

! D511 X-D4JX001F50 DIODE SILICON 1F5 1

D512 X-DJBUA12012 DIODE ZENER HZS12NB2 1

! D513 X-D4JXARS010 DIODE SILICON SARS01 1

! D514 X-D28A10A200 DIODE SILICON FCF10A20 1

! D516 X-D1VT001330 DIODE,SILICON 1SS133T-77 1

D517 X-DE7RB1102B DIODE ZENER UDZSNP11B TE-17 1

! D518 X-D4JXRM11C0 DIODE SILICON ZRM11C 1

! D523 X-D28A10A080 DIODE SCHOTTKY BARRIER FCHS10A08 1

! D527 X-DJBUA33012 DIODE ZENER HZS33NB2 1

! D528 X-DJBUA33012 DIODE ZENER HZS33NB2 1

D7003 X-D27RB056L0 DIODE SCHOTTKY RB056L-40TE25 1

*** ICS ***

! IC501 X-ICAJ056400 POWER IC CONTROL FA5640N-D1-TE1 1

! IC502 X-I1KJ9A431A VARIABLE SHUNT REGULATOR TAPE KIA431A-AT 1

! IC505 X-000220002W PHOTO COUPLER PS2561AL1-1-V(W) 1

IC7001 X-ILYD0887D0 LED DRIVER IC NR887D 1

*** TRANSISTORS ***

! Q501 X-TK1009N900 FET FMV09N90E 1

Q502 X-TAAA1504SY TRANSISTOR SILICON KTA1504S_Y_RTK 1

Q503 X-TNAAC05002 COMPOUND TRANSISTOR KRC103SRTK 1

Q504 X-TNAAC05002 COMPOUND TRANSISTOR KRC103SRTK 1

*** COILS ***

B7001 X-024HT03564 CORE,BEADS W4BRH3.5X6X1.0 1

B7002 X-024HC13914 CORE,BEADS HCB3216KF-391T20 1

! L501 X-029B000187 COIL,LINE FILTER JLB24123 1

L503 X-02167E100K COIL 10 UH TSL0808RA-100K2R 1

L504 X-02167E100K COI 10 UH TSL0808RA-100K2R 1

L7002 X-021D0N220M COIL 22 UH PF13-220-OS 1

*** TRANSFORMERS ***

! T501 X-048128042Z TRANSFORMER,SWITCHING 8128042Z 1

*** JACKS ***

! J502 X-064Q2A0004 JACK,AC CCT2302-0721C 1

*** CONNECTORS ***

CP501 X-069E7G0630 CONNECTOR PCB SIDE 00_6216_016_000_808+ 1

CP7001 X-069EV73030 CONNECTOR PCB SIDE 00_6232_007_006_800+ 1

*** FUSES ***

! F501 X-0805T02501 FUSE SCT 2.5A 1

*** THERMISTOR ***

! TH501 X-DSVD8E4R7M THERMISTOR B57153S0479A001 1

Page 41

ELECTRICAL REPLACEMENT PARTS LIST

R2274

X-R808R9223F

RC 22K OHM 1/16W

0402WGF2202TCE

1

*** OTHERS ***

EL2401 X-124116281A EYE LET EYE LET XRY16X28BD 9

EL2402 X-124120301A EYE LET EYE LET XRY20X30BD 2

SH502 X-126D000045 TERMINAL PIN YQ-12 1

SH503 X-126D000045 TERMINAL PIN YQ-12 1

SH505 X-126D000045 TERMINAL PIN YQ-12 1

SH507 X-126D000045 TERMINAL PIN YQ-12 1

OPERATION PCB ASS'Y

*** PCB ***

PCB270 X-A3LJ03W270P OPERATION PCB ASS'Y CEK600A 1

*** RESISTORS ***

R2264 X-R808R9331J RC 330 OHM 1/16W 0402WGJ0331TCE 1

R2265 X-R808R9103F RC 10K OHM 1/16W 0402WGF0103TCE 1

R2266 X-R808R9183F RC 18K OHM 1/16W 0402WGF1802TCE 1

R2267 X-R808R9333J RC 33K OHM 1/16W 0402WGJ0333TCE 1

R2268 X-R808R9103J RC 10K OHM 1/16W 0402WGJ0103TCE 1

R2269 X-R808R9822J RC 8.2K OHM 1/16W 0402WGJ0822TCE 1

R2271 X-R808R9392J RC 3.9K OHM 1/16W 0402WGJ0392TCE 1

R2272 X-R808R9561J RC 560 OHM 1/16W 0402WGJ0561TCE 1

R2273 X-R808R9562F RC 5.6K OHM 1/16W 0402WGF5601TCE 1

R2278 X-R808R9102J RC 1K OHM 1/16W 0402WGJ0102TCE 1

R2279 X-R808R9102J RC 1K OHM 1/16W 0402WGJ0102TCE 1

R2280 X-R808R9102J RC 1K OHM 1/16W 0402WGJ0102TCE 1

R2281 X-R808R9102J RC 1K OHM 1/16W 0402WGJ0102TCE 1

R2282 X-R808R9102J RC 1K OHM 1/16W 0402WGJ0102TCE 1

R2283 X-R808R9102J RC 1K OHM 1/16W 0402WGJ0102TCE 1

R2284 X-R808R9102J RC 1K OHM 1/16W 0402WGJ0102TCE 1

*** CAPACITORS ***

C2201 X-CS0PB0P17M CC 10 UF 6.3V B GRM188B30J106ME69D+A01 1

C2202 X-CS0UB0314K CC 0.01 UF 25V B GRM155B11E103KA01D 1

C2203 X-CS0UB0314K CC 0.01 UF 25V B GRM155B11E103KA01D 1

C2225 X-CS0UB0N15K CC 0.1 UF 10V B C0402X5R104K100NY 1

C2226 X-CS0UB03H4K CC 0.022 UF 25V B C0402X7R223K250NY 1

C2227 X-CS0UB03H4K CC 0.022 UF 25V B C0402X7R223K250NY 1

C2228 X-CS0UB03H4K CC 0.022 UF 25V B C0402X7R223K250NY 1

C2229 X-CS0UB03H4K CC 0.022 UF 25V B C0402X7R223K250NY 1

C2230 X-CS0UB03H4K CC 0.022 UF 25V B C0402X7R223K250NY 1

C2231 X-CS0UB03H4K CC 0.022 UF 25V B C0402X7R223K250NY 1

C2232 X-CS0UB03H4K CC 0.022 UF 25V B C0402X7R223K250NY 1

*** DIODES ***

D2204 X-DGERMA1110 DIODE SILICON MA111-(TX) 1

*** ICS ***

IC2204 X-IG6N0AT480 MCU 8BIT W/4K FLASH Q-TOUCH ATTINY48-MU 1

Page 42

ELECTRICAL REPLACEMENT PARTS LIST

*** COILS ***

CD2801

X-06EH2U1011

CORD CONNECTOR

EH2U1011

1

RC……………………

CC……………………

CE……………………

CP……………………

CPP………………….

CPL………………….

CMP………………….

CMPL………………..

CMPP……………….

B2201 X-024HC51023 CORE,BEADS FCM1608KF-102T02FCM1608KF-102T02 1

B2202 X-024HC51023 CORE,BEADS FCM1608KF-102T02 1

B2203 X-024HC51023 CORE,BEADS FCM1608KF-102T02 1

B2204 X-024HC51023 CORE,BEADS FCM1608KF-102T02 1

*** OTHERS ***

CP2204 X-06GG240059 CONNECTOR PCB SIDE A2001WR-S04-T 1

AND OTHERS

*** CONNECTORS ***

CD805 X-06CH242503 CORD CONNECTOR CH242503 1

CD805 X-06E8242501 CORD CONNECTOR E8242501 1

CD3004 X-122H0G0501 CORD JUMPER 2H0G0501 1

*** TUNER ***

TU001 X-0164E03021 DIGITAL TUNER TDTK-G731D(A) 1

*** OTHERS ***

BT001 X-141U004021 BATTERY,MANGAN AAA(R03) 1

BT002 X-141U004021 BATTERY,MANGAN AAA(R03) 1

CD7601 X-06E8232206 CORD CONNECTOR E8232206 1

MAIN001 X-1564Y00005 MAIN UNIT T.MT5310.91A 1

SP301 X-070Y433020 SPEAKER S0307F08-F 1

RESISTOR

CARBON RESISTOR

CAPACITORS

CERAMIC CAPACITOR

ALUMI ELECTROLYTIC CAPACITOR

POLYESTER CAPACITOR

POLYPROPYLENE CAPACITOR

PLASTIC CAPACITOR

METAL POLYESTER CAPACITOR

METAL PLASTIC CAPACITOR

METAL POLYPROPYLENE CAPACITOR

Page 43

SPEC.NO. M3LJ-03W

O/R NO. F233167

Loading...

Loading...