Page 1

SERVICE MANUAL

CASSETTE RECEIVER

KS-FX893

KS-FX893

KS-FX893

Contents

Safety precaution

Disassembly method

1-2

1-3

COPYRIGHT 2002 VICTOR COMPANY OF JAPAN, LTD.

Adjustment method

Description of major ICs

Area Suffix

UF China

1-11

1-15~24

No.49763

Nov. 2002

1-1

Page 2

KS-FX893

Safety precaution

!

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Please use enough caution not to see the beam directly or touch it in case of an

adjustment or operation check.

1-2

Page 3

KS-FX893

Disassembly method

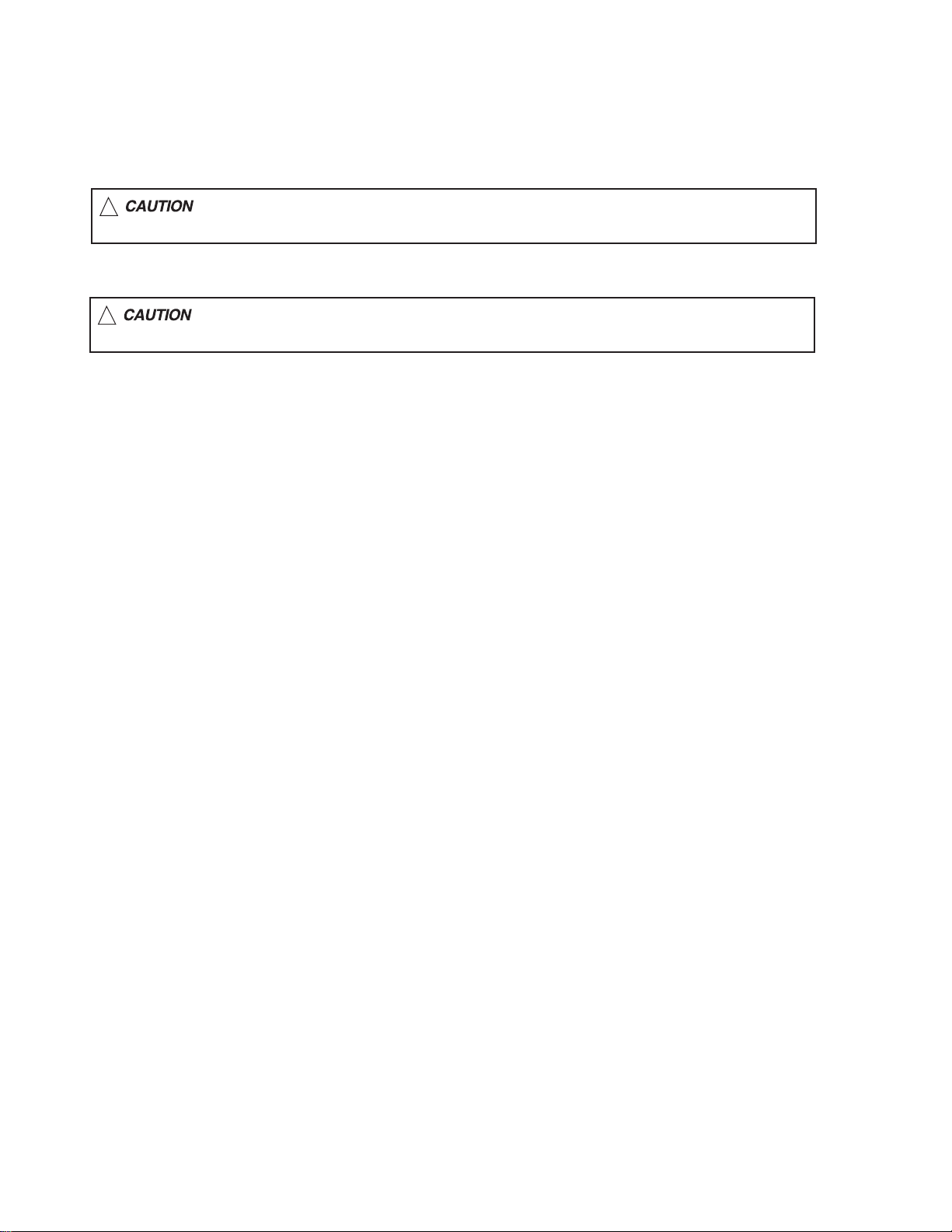

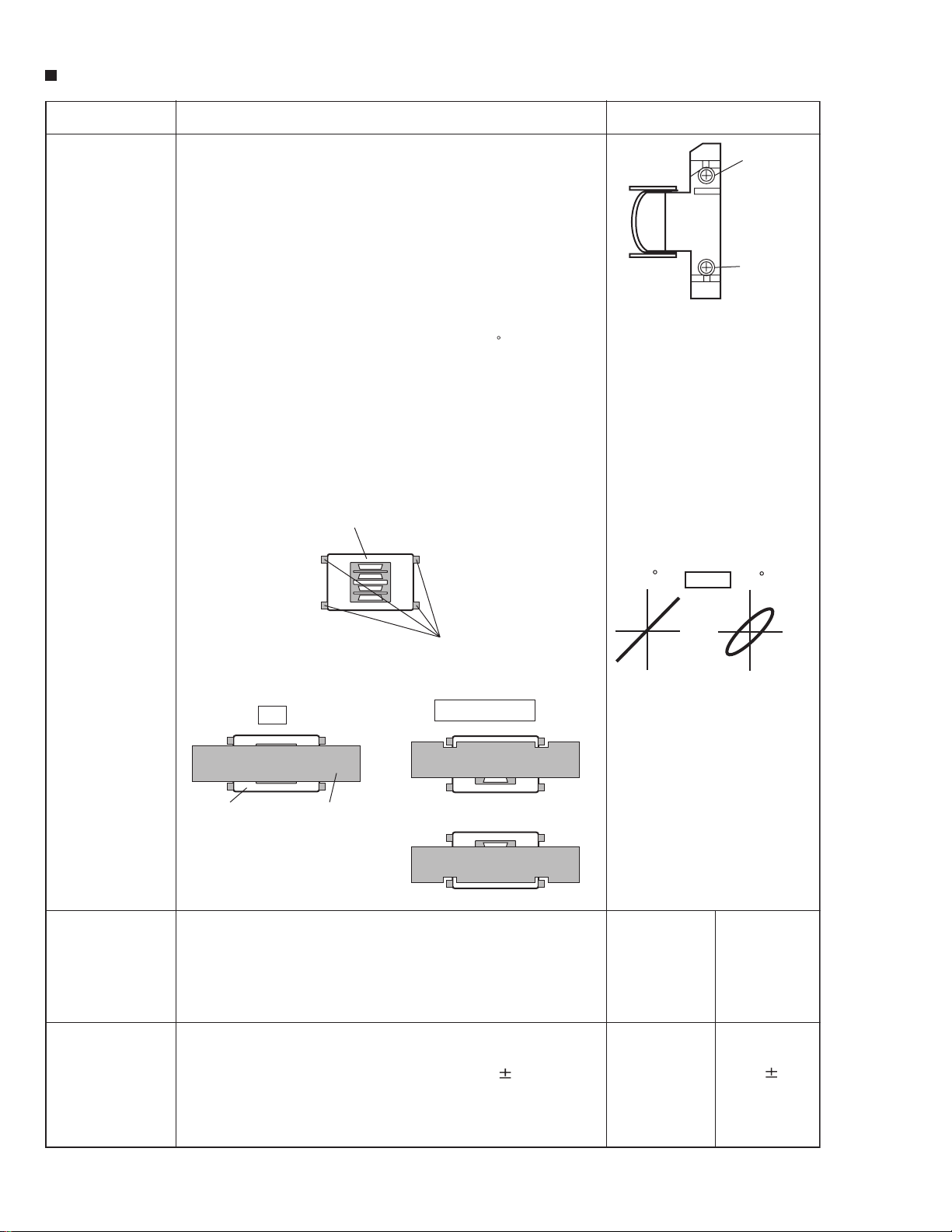

Removing the front chassis

1.2.Remove the two screws A attaching the front

chassis.

Insert a screwdriver to the two joints a on the side

of the front chassis, two joints b on the right side

and one joint c from upside, then detach the front

chassis toward the front side.

(See Fig.1~2)

A

c

Fig.1

a

b

Removing the heat sink

1. Remove the three screws B attaching the heat sink

on the left side of the body, and remove the heat

sink.

(See Fig.3)

B

a

Front chassis

B

b

Fig.2

B

Heat sink

Fig. 3

1-3

Page 4

KS-FX893

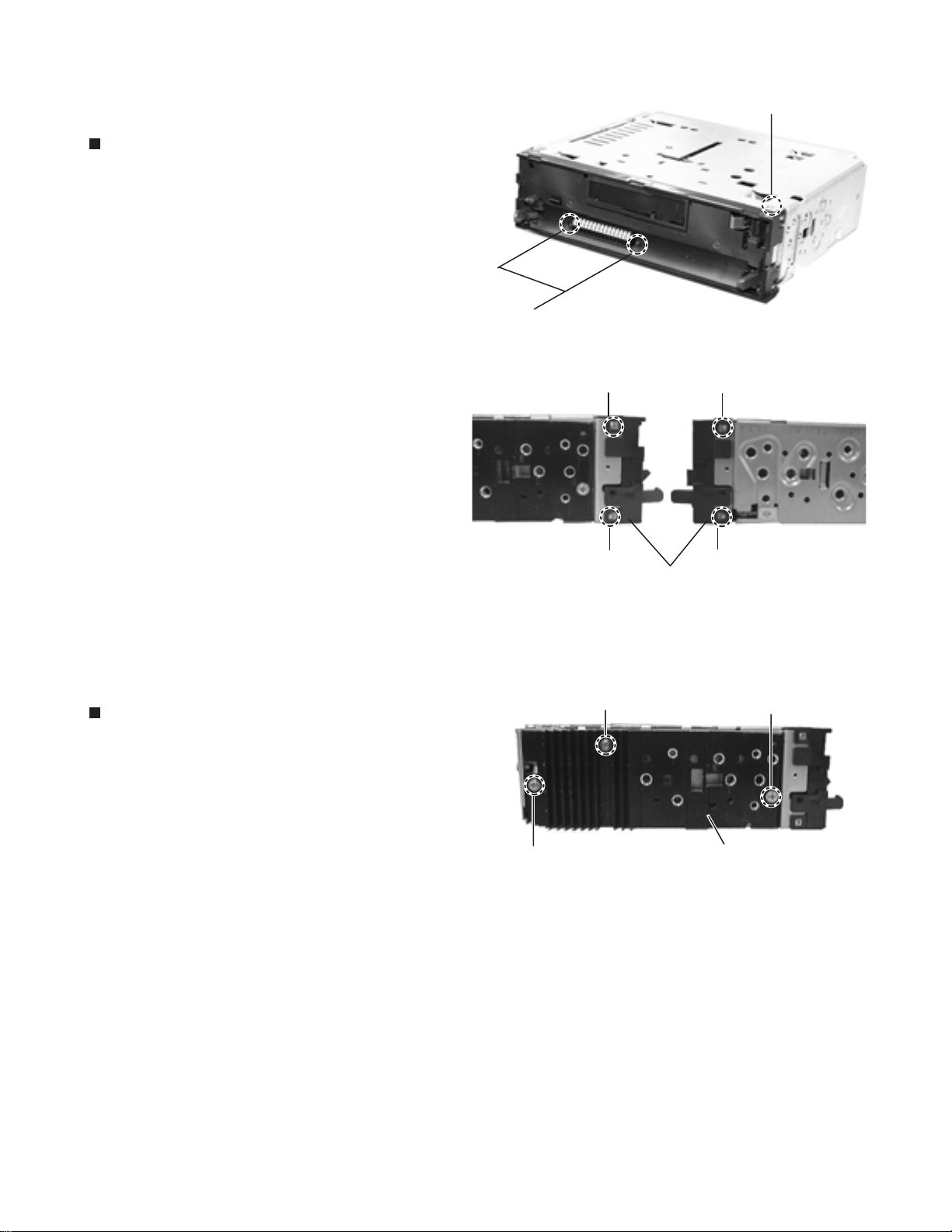

Removing the bottom cover

1.2.Turn the body upside down.

Insert a screwdriver to the two joints d and two

joints e on both sides of the body and the joint f on

the back of the body, then detach the bottom cover

from the body.

Removing the rear panel

1.

Remoe the front chassis.

2.

Remove the heat sink.

3.

Remove the bottom cover.

(See Fig.4)

(See Fig.5 )

B

d

Bottom cover

e

f

Fig. 4

C

B

B

4.

Remove the seven screws B attaching the rear

panel and one screw C attaching the pine jack on

the back of the body.

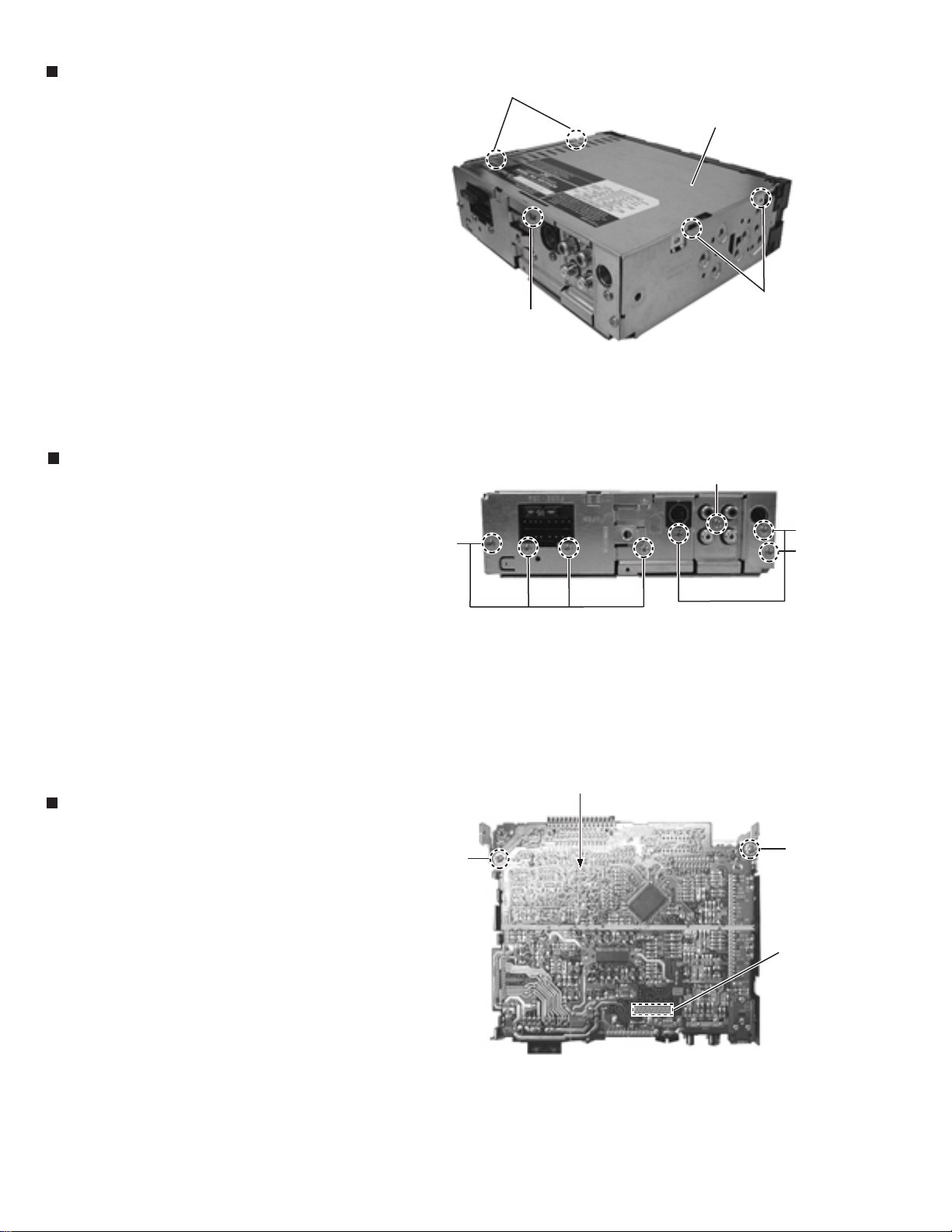

Removing the main amplifier board

assembly

1.

Remove the front chassis.

2.

Remove the bottom cover.

3.

Remove the rear panel.

4.

Remove the two screws D attaching the main

amplifier board assembly on the top cover.

5.

Disconnect connector CP701 on the main amplifier

board assembly from the cassette mechanism

assembly.

(See Fig.6)

D

Fig. 5

Main board assembly

D

CP701

Fig. 6

1-4

Page 5

KS-FX893

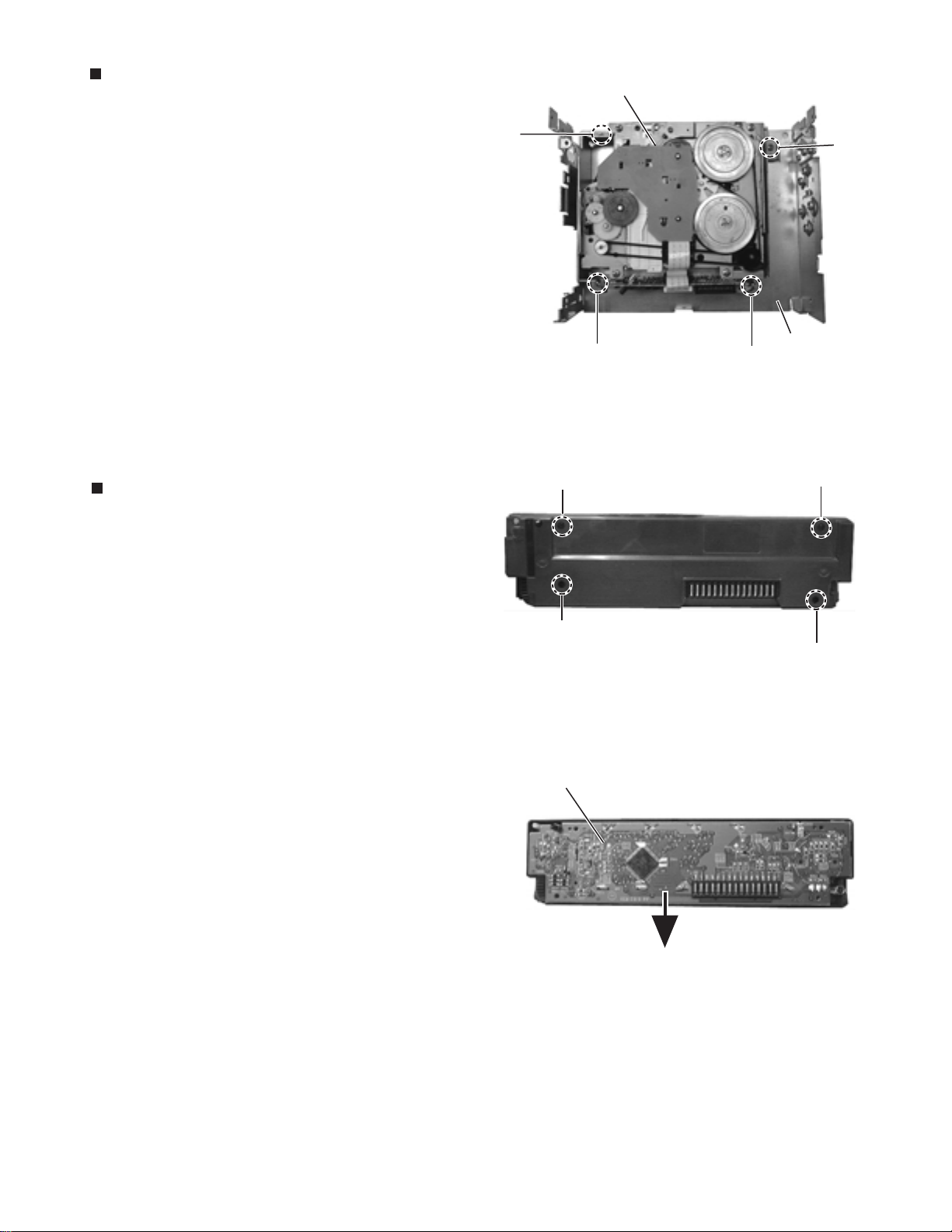

Removing the Cassette mechanism

assembly

1.

Remove the front chassis.

2.

Remove the bottom cover.

3.

Remove the main amplifier board assembly.

4.

Remove the fore screws F attaching the cassette

mechanism assembly from the top cover.

(See Fig.7)

Removing the control switch board

(See Fig.8 and 9 )

Cassette mechanism assembly

F

F

Fig. 7

G

F

Top cover

F

G

1.

Remove the front panel unit from the main body.

2.

Remove the four screws G attaching the rear cover

on the back of the front panel unit.

3.

Remove the control switch board from the front

panel unit.

G

LCD & Key control board

Fig. 8

Fig. 9

G

1-5

Page 6

KS-FX893

y

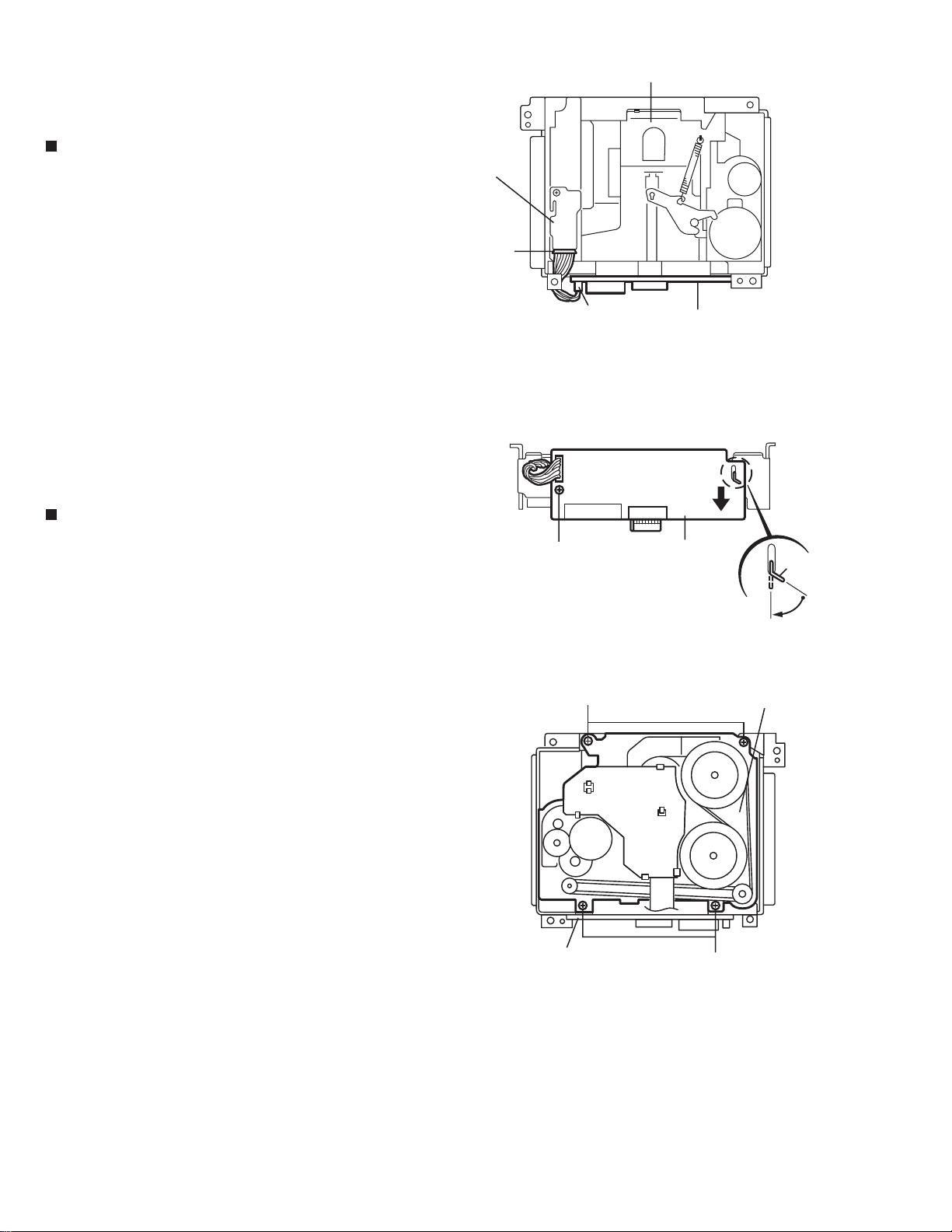

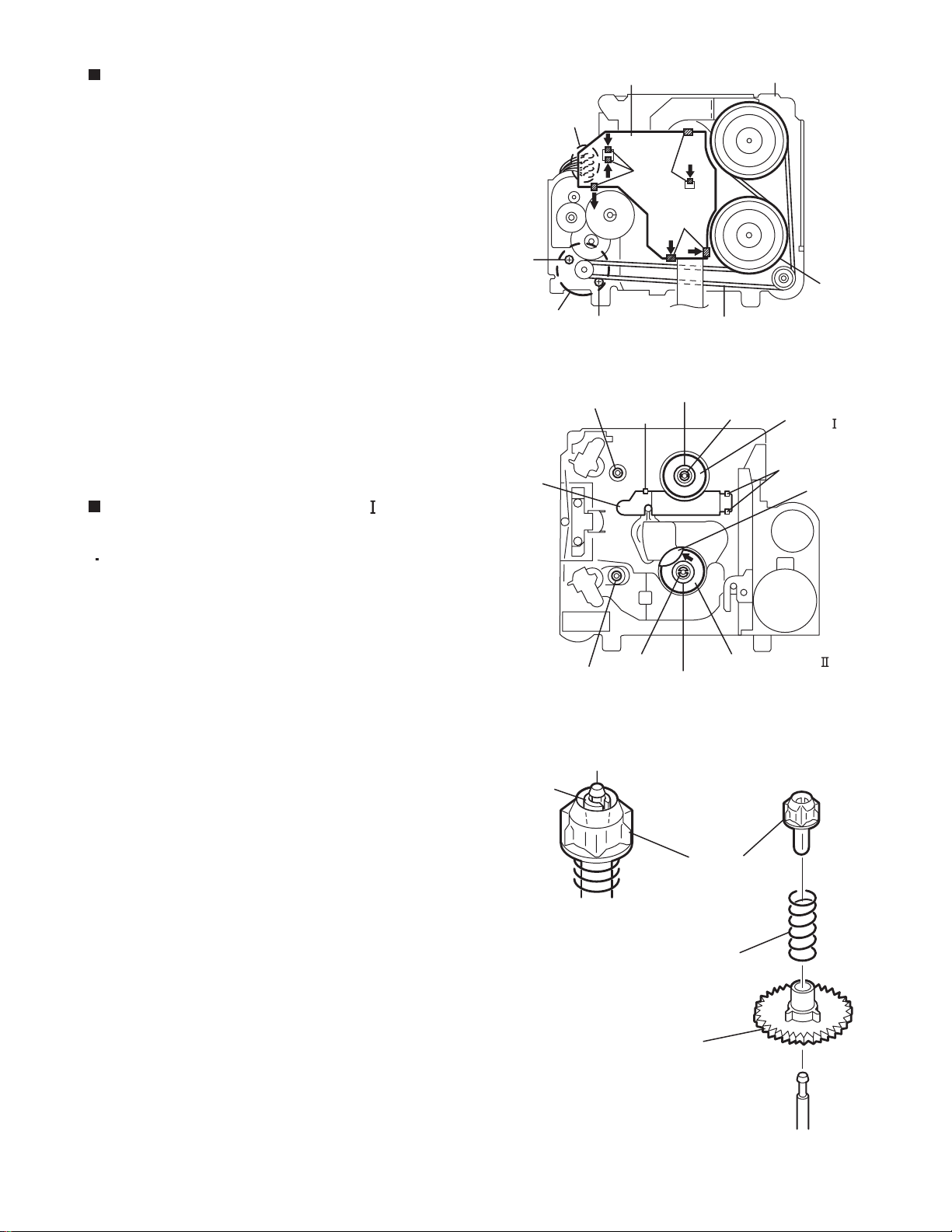

<Removal of the cassette mechanism>

Cassette mechanism ass’y

Removing the head amplifier board.

(See Fig.1 and 2)

1.

For the 6pin wire extending from connector CN402

on the head amplifier board, disconnect it from the

head relay board.

2.

Disconnect the card wire from connector CN403 on

the head amplifier board.

3.

Remove the screw A attaching the head amplifier

board.

4.

Move the tab a as shown in Fig.2 and remove the

head amplifier board while moving it in the direction

of the arrow.

Removing the cassette mechanism

assembly (See Fig.1 to 3)

1.

Disconnect the 6pin wire from connector CN402 and

the card wire from CN403 on the head amplifier

board (Refer to Fig.1 and 2).

Head relay

board

6pin

wire

CN402

A

CN403

CN402

Fig.1

CN403

Head amplifier board

Fig.2

Head amplifier board

Tab a

2.

Remove the four screws B on the bottom of the

cassette mechanism.

Head amplifier board

B

Cassette mechanism ass’

B

Fig.3

1-6

Page 7

KS-FX893

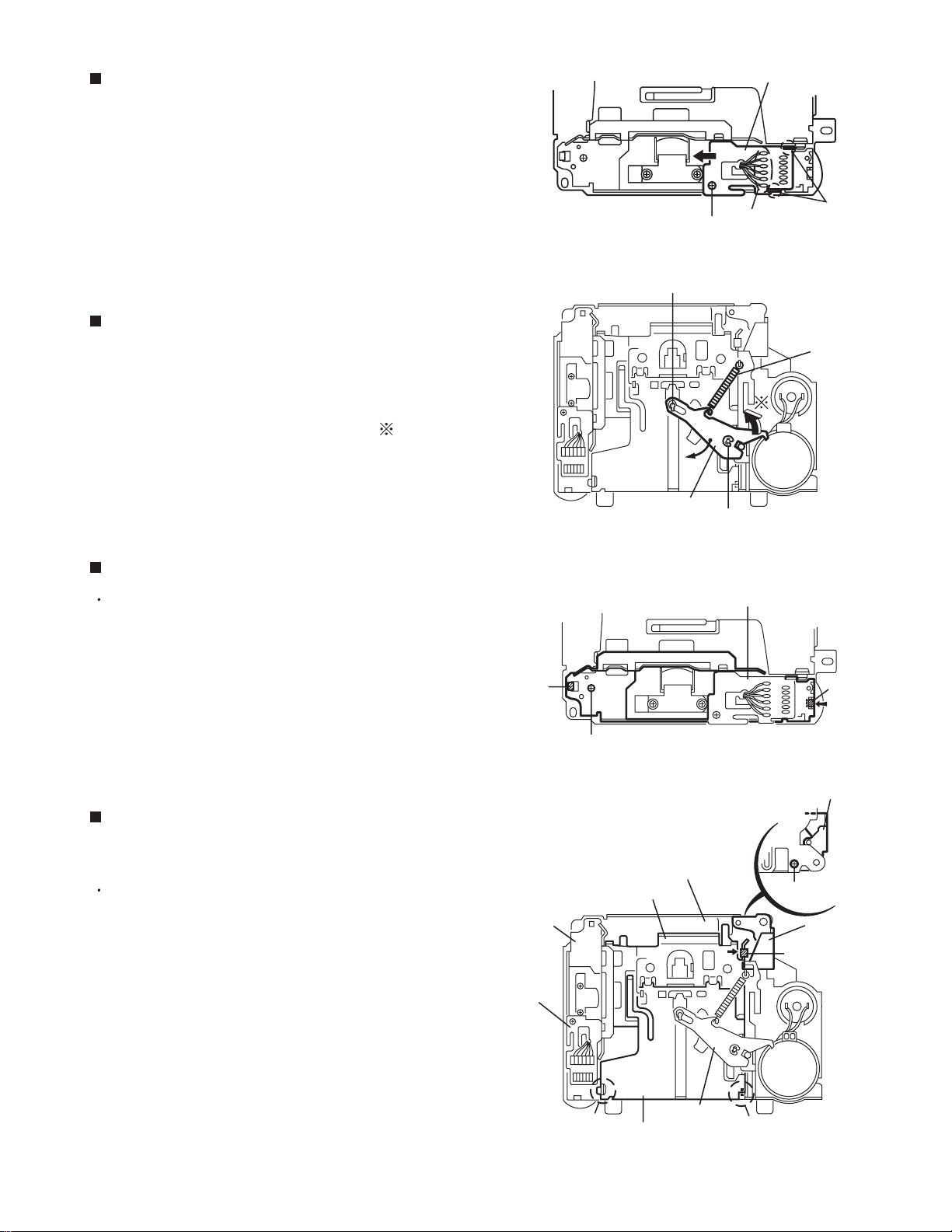

Removing the head relay board

(See Fig.4)

1.

Unsolder the soldering b on the head relay board.

2.

Remove the screw C attaching the head relay board.

3.

Remove the head relay board in the direction of the

arrow while releasing the two joints c.

Removing the load arm (See Fig.5)

1.

Remove the E washer attaching the load arm using

a pincette or something like that and remove the

spring d.

2.

Move the part of the load arm marked upwards to

release it from the axis of rotation. Then rotate the

load arm in the direction of the arrow to remove it

from the cach.

Fig.4

Cach

Load arm

Fig.5

Head relay board

Soldering b

C

E washer

Joint c

Spring d

Removing the sub chassis (See Fig.6)

Prior to performing the following procedure, remove

the head relay board.

1.

Remove the screw D attaching the sub chassis.

2.

Push the tab e in the direction of the arrow to detach

the one side of the sub chassis. Then release the

sub chassis from the tab f.

Removing the cassette holder and the

holder arm in the eject mode

(See Fig.7 and 8)

Prior to performing the following procedure, remove

the head relay board, the load arm and the sub

chassis.

1.

Remove the screw E attaching the reinforce bracket.

2.

Remove the reinforce bracket.

Tab f

Sub chassis

Head relay

board

D

Cassette mecha chassis

Cassette holder

Fig.6

Head relay board

Tab e

Reinforce bracket

E

Reinforce

bracket

tab g

3.

Push the tab g fixing the cassette holder in the

direction of the arrow and open the cassette holder

and the holder arm upward until they stop at an

angle of 45 degrees. Move the two joints h to the

side and remove the cassette holder and the holder

arm from the shaft.

Joint h

Load arm

Holder arm

Fig.7

Joint h

1-7

Page 8

KS-FX893

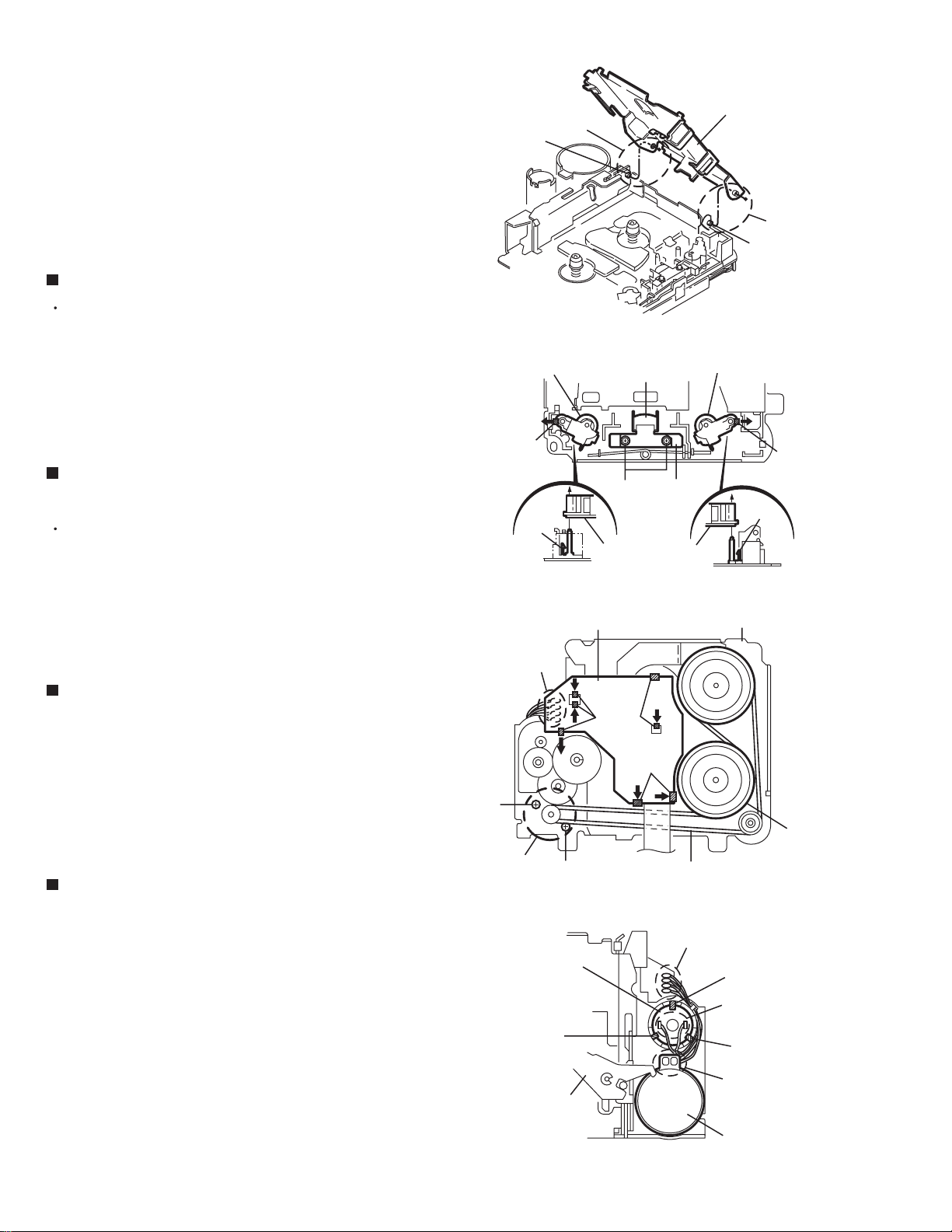

Removing the play head (See Fig.9)

Prior to performing the following procedure, remove

the head relay board and the sub chassis.

1.

Remove the two screws F attaching the play head

(The spring under the play head comes off at the

same time).

Shaft

Joint h

Pinch roller ass’y

Fig.8

Play head

Cassette holder

and holder arm

Joint h

Shaft

Pinch roller ass’y

Removing the pinch roller ass’y

(See Fig.9)

Prior to performing the following procedure, remove

the head relay board and the sub chassis.

1.

Push each tab i in the direction of the arrow and pull

out the pinch rollers on both sides.

Removing the reel disc board

(See Fig.10)

1.

Unsolder the soldering j on the reel disc board.

2.

Push the seven tabs k on the bottom of the cassette

mechanism assembly in the direction of the arrow.

Removing the motor and the sub motor

(See Fig.10 and 11)

Tab i

Tab i

Soldering j

G

Motor

F

Pinch roller ass’y

Fig.9

Reel disc board

Tabs k

Tabs k

G

Tab i

Spring

Tab i

Cassette mechanism ass’y

Flyhwheel

Belt

Fig.10

1.

Unsolder the two soldering l of the motor and the sub

motor.

2.

Release the sub motor from the three tabs m. Push

the sub motor upward and pull out it.

3.

Remove the belt on the bottom of the cassette

mechanism assembly and remove the two screws G

attaching the motor.

ATTENTION:

The motors can be detached before

removing the load arm.

1-8

Sub motor

Tab m

Load arm

Soldering j

Tab m

Soldering l

Tab m

Soldering l

Motor

Fig.11

Page 9

KS-FX893

Removing the flywheel

(See Fig.10 and 12)

1.

Prior to performing the following procedure, remove

the head relay board, the load arm, the sub chassis,

the cassette holder, the holder arm and the reel disc

board.

2.

Remove the belt on the bottom of the cassette

mechanism ass’y.

3.

Remove the slit washer attaching the flywheel on the

upper side of the cassette mechanism ass’y and pull

out the flywheel downward. Then remove another

flywheel in the same way.

ATTENTION:

When reassembling, make sure to use

a new slit washer.

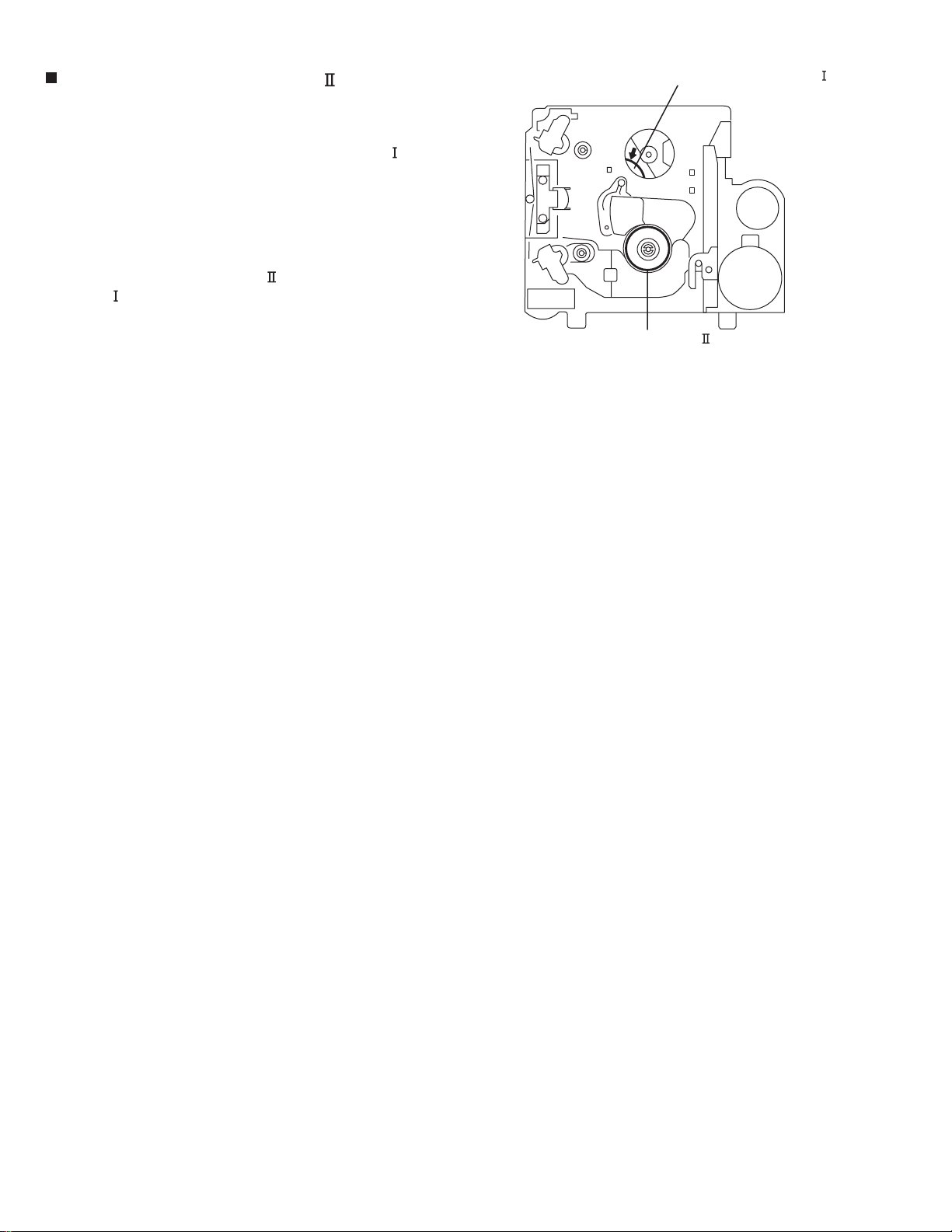

Removing the reel disc ass’y( )

(See Fig.12 to 14)

Soldering j

G

Motor

Plate

Reel disc board

G

Slit washer

Tab k

Tab o

Cassette mechanism ass’y

Tab k

Belt

Fig.10

Reel driver

The part n

Tabs o

Flyhwheel

Reel disc

ass’y( )

Push aside

the gear

Prior to performing the following procedure, remove

the head relay board, the load arm, the sub chassis,

the cassette holder and the holder arm.

1.

Disengage the part n inside of the reel driver which

engages with the shaft, using a pincette or

something like that. Then remove the reel driver from

the shaft.

2.

Remove the reel driver spring and the reel table.

The part n

Slit washer

Shaft

Fig.13

The part n

Reel driver

Fig.12

Reel driver

Reel driver spring

Reel disc ass’y( )

Reel table

Fig.14

1-9

Page 10

KS-FX893

Removing the reel disc ass’y( )

(See Fig.12 to 15)

ATTENTION:

1.

Release the plate from the three tabs o.

2.

Push aside the gear over the reel table using a

pincette or something like that.

3.

Remove the reel disc ass’y ( ) as with the reel disc

ass’y ( ).

ATTENTION:

Prior to performing the following

procedure, remove the reel disc ( ).

Do not break the front panel tab fitted

to the metal cover.

Push aside the gear and reattach the reel disc Ass’y( ).

Reel disc ass’y( )

Fig.15

1-10

Page 11

Adjustment method

KS-FX893

Test instruments required for adjustment

1. Digital oscilloscope(100MHz)

2. Frequency Counter meter

3. Electric voltmeter

4. Wow & flutter meter

5. Test Tapes

MC-109C

VT724

VT739 ............ For playback frequency measurement

VT712 ....For wow flutter & tape speed measurement

VT703 ..................... For head azimuth measurement

6. Torque gauge .................... Cassette type for CTG-N

...................

.......................

For TAPA CURL confirmation

(without Padd type)

For DOLBY level measurement

(mechanism adjustment)

Measuring conditions(Amplifier section)

Power supply voltage .............. DC14.4V (10.5 - 16V)

Load impedance ........... 4 (2Speakers connection)

Line out............................................................ 20k

Standard volume position

Balance and Bass,Treble volume .Fader

:Center(Indication"0")

Loudness,Dolby NR,Sound,Cruise:Off

Volume position is about 2V at speaker output with

following conditions. Playback the test tape VT721.

AM mode 1000kHz/62dB,INT/400Hz,30%

modulation signal on receiving.

FM mono mode 97.5MHz/66dB,INT/400Hz,22.5kHz

deviation pilot off mono

FM stereo mode 1kHz,67.5kHz dev. pilot7.5kHz dev.

Output level 0dB(1 V,50 /open terminal)

1-11

Page 12

KS-FX893

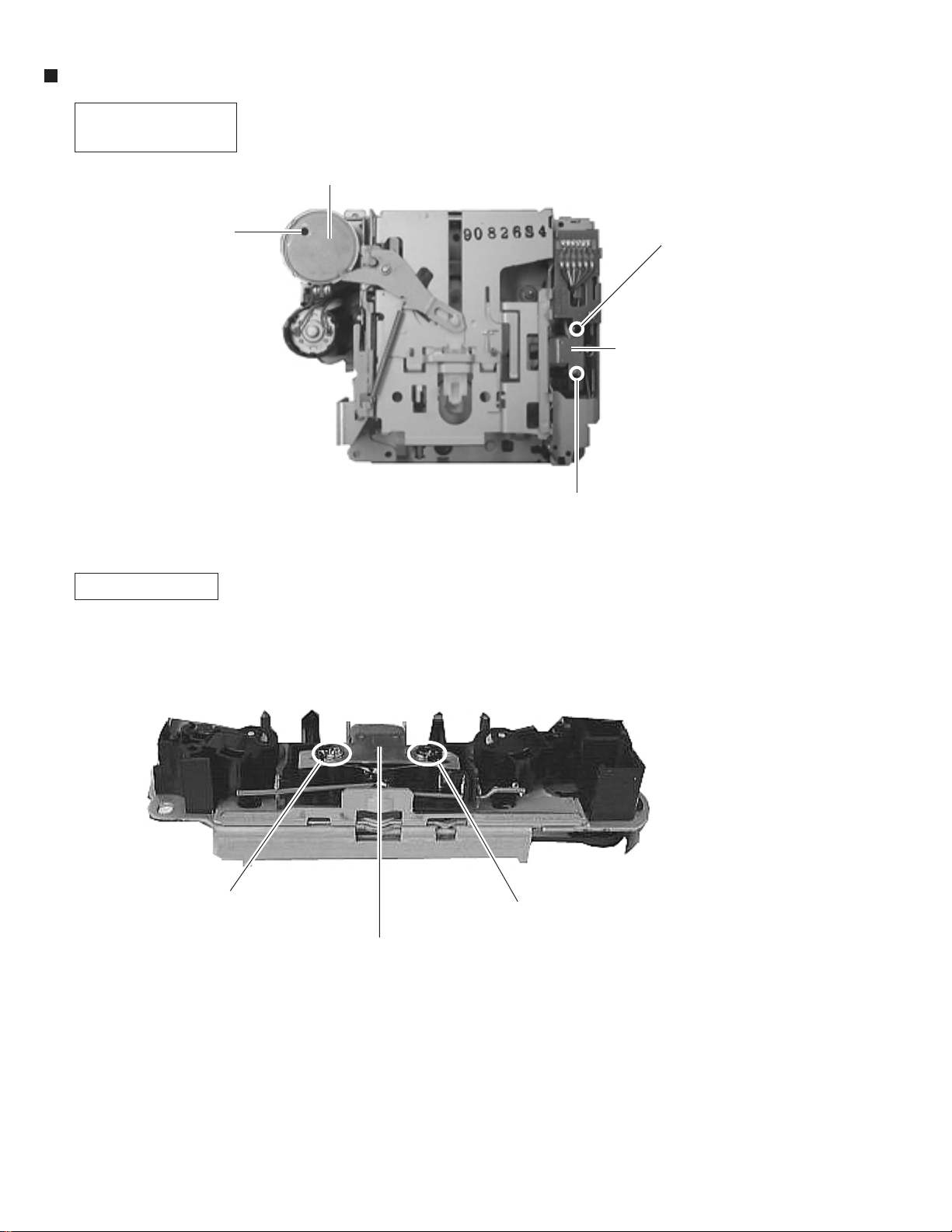

Arrangement of adjusting & test points

Cassette mechanism

(Surface)

Motor assembly

Tape speed adjust

Head section view

Azimuth screw A

(Forward)

Playback head

Azimuth screw B

(Reverse)

1-12

Azimuth screw B

(Reverse)

Azimuth screw A

(Forward)

Playback Head

Page 13

KS-FX893

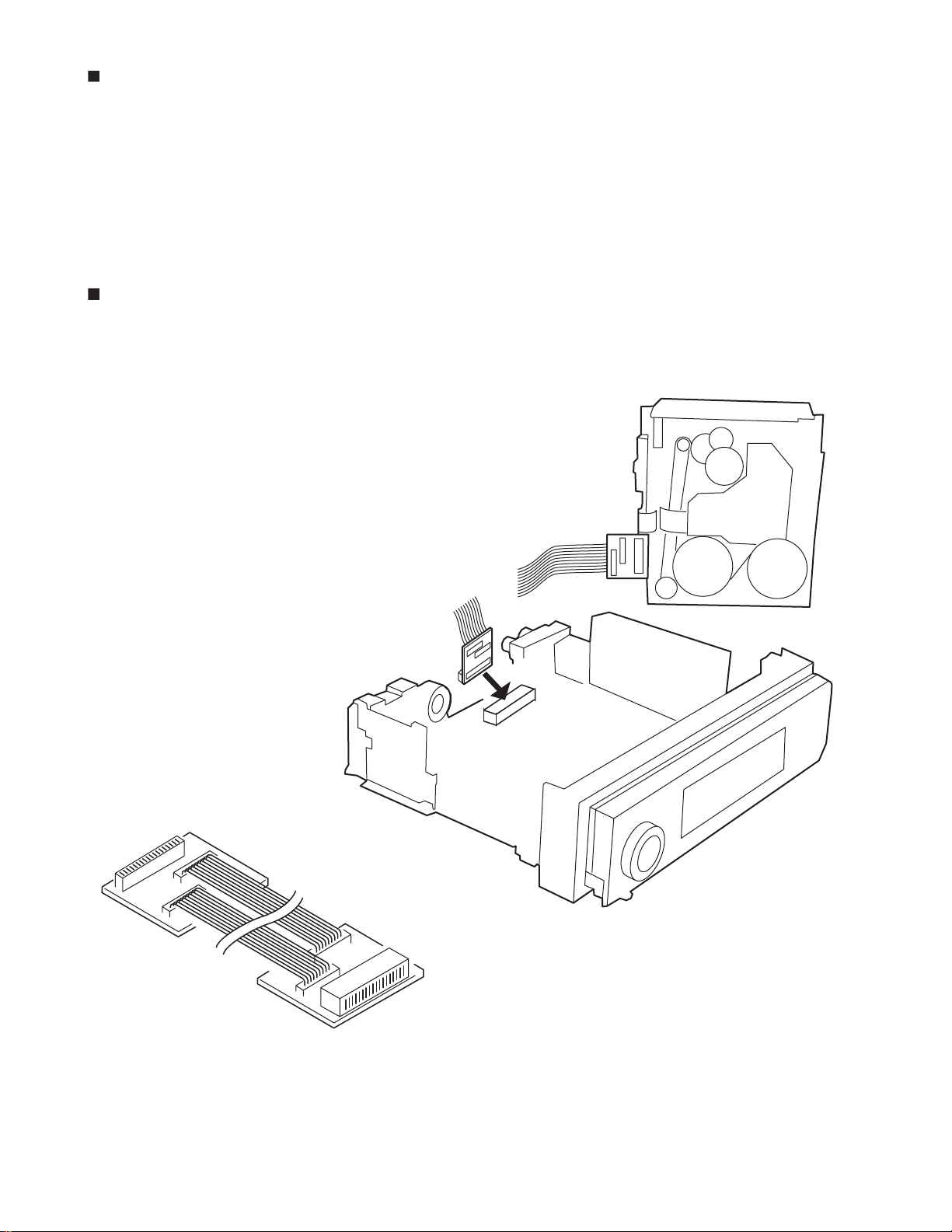

y

Information f

1. We're advancing efforts to make our extension cords common for all car audio products.

Please use this type of extension cord as follows.

2. As a U-shape type top cover is employed, this type of extension cord is needed to check operation of the

mechanism assembly after disassembly.

3. Extension cord : EXTKSRT002-18P ( 18 pin extension cord ) For connection between mechanism assembly

and main board assembly.

Check for mechanism driving section such as motor ,etc..

or using a car audio service jig

Disassembly method

1. Remove the bottom cover.

2. Remove the front panel assembly.

3. Remove the top cover .

4. Install the front panel.

5. Confirm that current is being carried by connecting

an extension cord jig.

Note

Available to connect to the CP701 connector when in-

stalling the front panel.

Cassette mechanism

to Cassette mechanism

Extension cord

EXTKSRT002-18P

Main board

to Main board

CP701

Front panel assembl

EXTKSRT002-18P

1-13

Page 14

KS-FX893

Mechanism adjustment section

Item Adjusting & Confirmation Methods Adjust Std. Value

1. Tape running

adjustment

2. Azimuth

adjustment

confirmation

a) At Forward playmode, using mirror tape, make adjustment

with Azimuth screw A and Azimuth screw B, without curl of 4

parts of head tape guide.

b) At Reverse play mode, using mirror tape, make adjustment

with Azimuth screw A and Azimuth screw B, without tape

curl of 4 parts of head guide.

c) At Forward / Reverse play mode, make confirmation of no

tape curl of 4 parts of head tape guide.

a) At forward play mode, make adjustment of peak of Lch / Rch

output with Azimuth screw A.

* For Oscilloscope litharge corrugation, set 45 as standard.

b) At Reverse play mode, make adjustment of peak of Lch / Rch

output with Azimuth screw B.

* For Oscilloscope litharge corrugation, set 45 as standard.

c) With AC volt meter confirm the difference of output for 4ch

between Lch / Rch at forward play mode and Lch / Rch

Reverse play mode being within 3.0dB.

d) After operation, make confirmation of Lch / Rch azimuth

output being within 1.0dB from adjustment value.

Azimuth

screw A

Azimuth

screw B

2.Tape Speed and

Wow & Flutter

HEAD

Tape guide

OK

HEAD TAPE

1.Check to see if the reading of the frequency counter & W ow

flutter meter is within 2940-3090 Hz( FWD/REV ), and less

than 0.35% ( JIS RMS ).

2.In case of out of specification, adjust the motor with a builtin volume resistor .

Tape curl NG

0

Phase

Built-in

volume resistor

45

Tape Speed

2940-3090Hz

Wow&Flutter

Less than

0.35%

(JIS RMS)

3.Playback

Frequency

response

1-14

1.Play the test tape ( VT724 : 1kHz ) back and set the volume

position at 2V .

2.Play the test tape ( VT739 )back and confirm 0 3dB at1kHz/

10kHz and -4+2dB at 1kHz/63Hz.

3.When 10kHz is out of specification, it will be necessary to

read adjust the azimuth.

Speaker out

1kHz/10kHz

: 0dB 3dB,

63Hz/1kHz

: -4dB+2dB,

Page 15

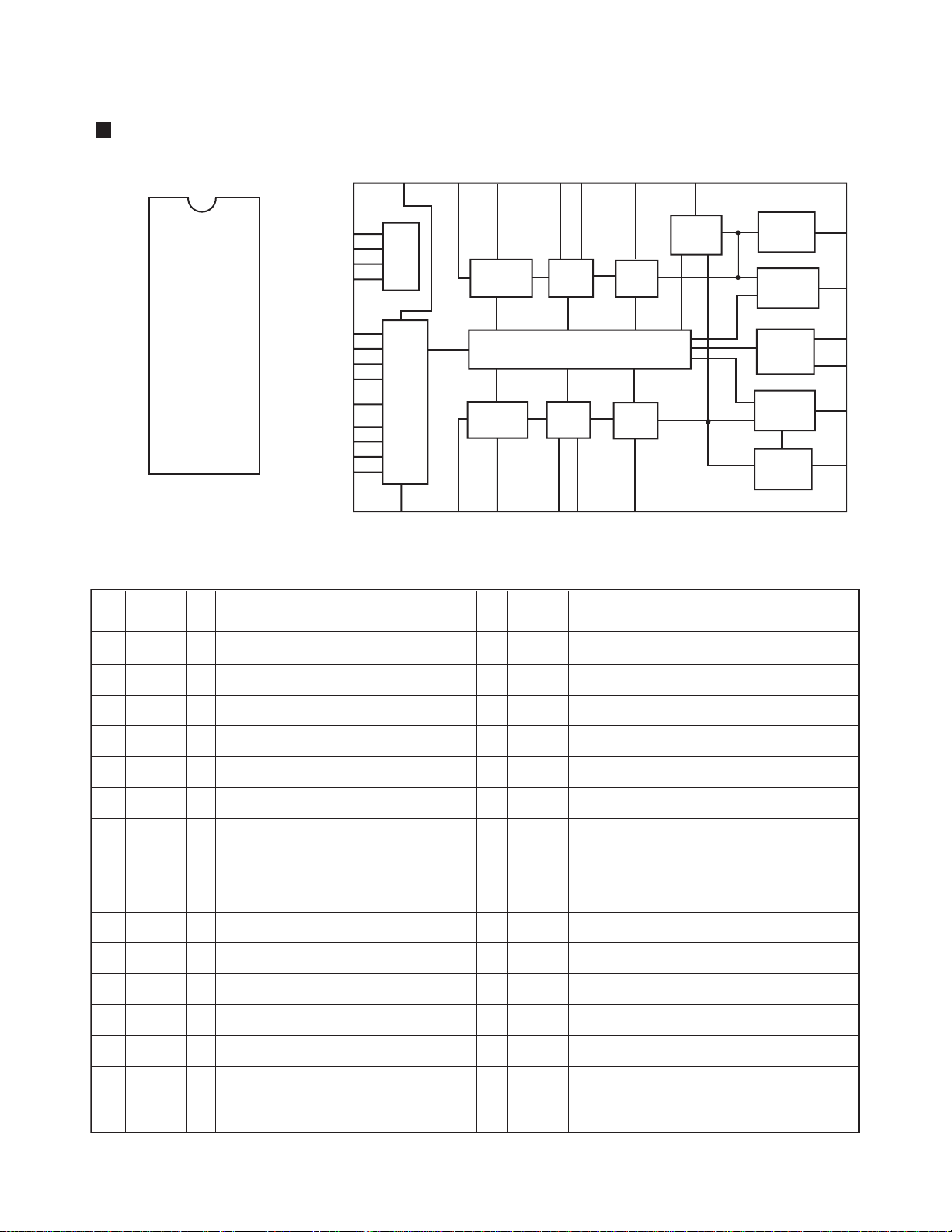

Description of major ICs

TEA6320T-X (IC161) : E. volume

1. Pin layout

2. Block diagram

10 8 9 7 6

KS-FX893

5

12

SDA

1

GND

2

OUTLR

OUTLF

MUTE

TL

B2L

B1L

IVL

ILL

QSL

IDL

ICL

IMD

IBL

IAL

3

4

5

6

7

8

9

10

11

12

13

14

15

16

3. Pin functions

Pin

Symbol

No.

SDA

1

SCL

32

VCC

31

OUTRR

30

OUTRF

29

TR

28

B2R

27

B1R

26

IVR

25

ILR

24

QSR

23

IDR

22

Vref

21

ICR

CD-CH

TAPE

TUNER

20

19

18

17

CAP

IBR

IAR

I/O

Serial data input/output.

I/O

MUTE

21

31

2

19

16

15

13

11

14

22

20

18

17

Functions Functions

POWER

SUPPLY

SOURCE

SELECTOR

23 25 24 26 27 28

VOLUM E 1

+20 to -31 dB

LOUDNESS

LEFT

VOLUM E 1

+20 to -31 dB

LOUDNESS

RIGHT

Pin

No.

17

Symbol

IAR

BASS

LEFT

+15 dB

LOGIC

BASS

RIGHT

+15 dB

I/O

I

Input A right source.

TREBLE

LEFT

+12 dB

TREBLE

RIGHT

+12 dB

FUNCTION

ZERO CROSS

DETECTOR

VOLUM E 2

0 to 55 dB

BALANCE

FENDER REAR

VOLUM E 2

0 to 55 dB

BALANCE

FENDER FRONT

HC BUS

REC

VOLUM E 2

0 to -55dB

BALANCE

FENDER FRONT

VOLUM E 2

0 to -55dB

BALANCE

FENDER REAR

3

4

32

1

29

30

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

GND

OUTLR

OUTLF

TL

B2L

B1L

IVL

ILL

QSL

IDL

MUTE

ICL

IMO

IBL

IAL

Ground.

-

output left rear.

O

output left front.

O

Treble control capacitor left channel or

I

input from an external equalizer.

Bass control capacitor left channel or

output to an external equalizer.

Bass control capacitor left channel.

-

Input volume 1. left control part.

I

Input loudness. left control part.

I

Output source selector. left channel.

O

Not used

-

Not used

-

Input C left source.

I

Not used

-

Input B left source.

I

Input A left source.

I

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

IBR

CAP

ICR

Vref

IDR

QSR

ILR

IVR

B1R

B2R

TR

OUTRF

OUTRR

Vcc

SCL

I

Input B right source.

-

Electronic filtering for supply.

I

Input C right source.

-

Reference voltage (0.5Vcc)

-

Not used

O

Output source selector right channel.

I

Input loudness right channel.

I

Input volume 1. right control part.

-

Bass control capacitor right channel

Bass control capacitor right channel or

O

output to an external equalizer.

Treble control capacitor right channel or

I

input from an external equalizer.

O

Output right front.

O

Output right rear.

-

Supply voltage.

I

Serial clock input.

1-15

Page 16

KS-FX893

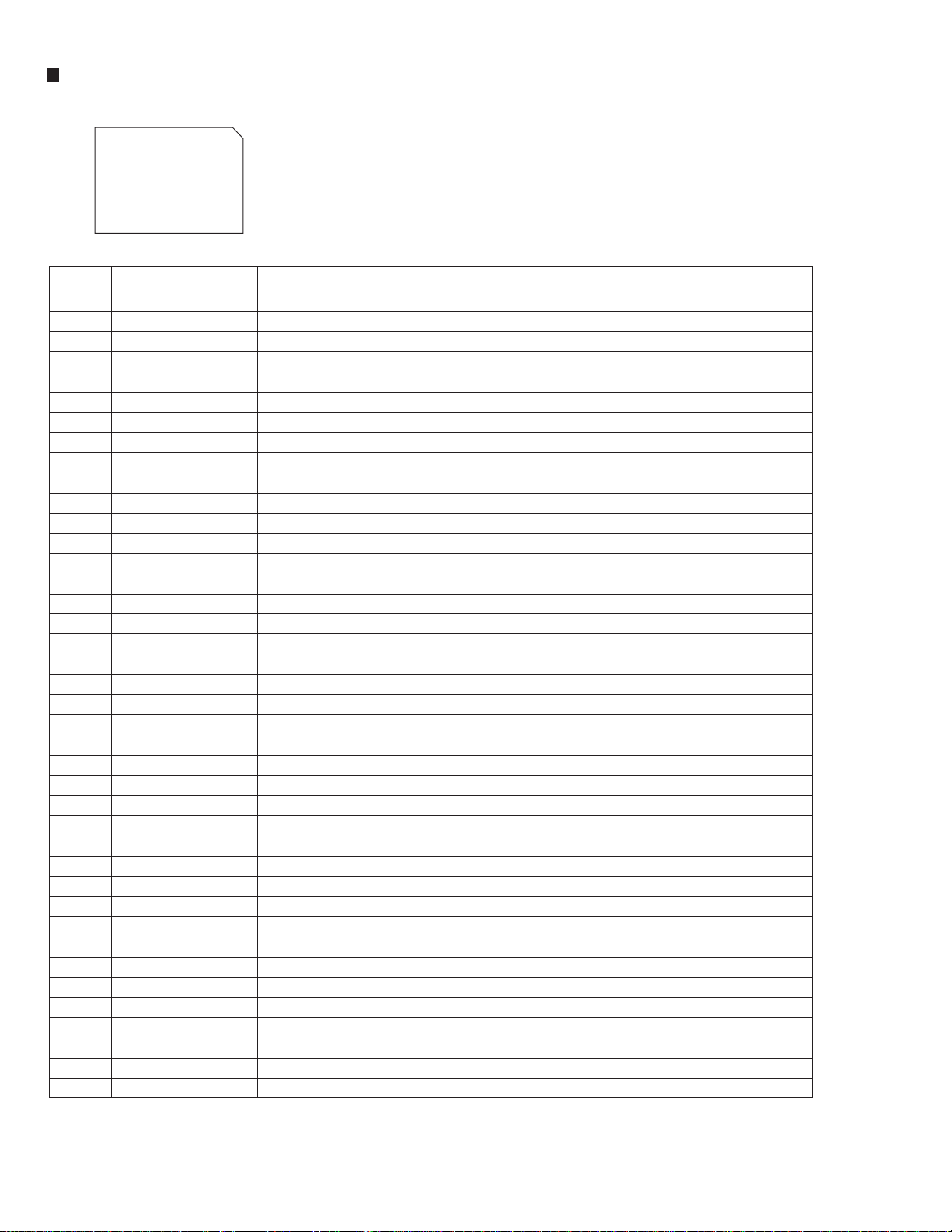

LC72366-9987 (IC701) : System CPU

1. Pin layout

24 ~ 1

25

80

~

40

41 ~ 64

2. Pin function

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

J-BUS SCK

TEL-MUTE

DIMMER IN

EVOL SCK

POWER ANT

DEMEROUT

FF/REW MODE

SEEK/STOP

RADIO/TAPE

BEEP LEVEL

Symbol FunctionPin No.

XIN

GND

J-BUS SI

J-BUS SO

J-BUS I/O

LCD SO

LCD SCK

LCD CE

EVOL SO

OPEN

MUTE

CD ILLUM

NC

NC

NC

NC

NC

NC

KS1

KS0

K3

K2

K1

K0

Vdd

TEST

MONO

PWR-CNT

ACC

KICK

65

~

I/O

I

Crystal oscillator input port

-

Connect to GND

I

Data input for J-BUS information

O

Data output for J-BUS information

O

Clock output for J-BUS information

O

Switching signal output for J-BUS information I/O, H:Out L:In

I

Telephone mute signal input

O

Data output for LCD driver

O

Information clock output for LCD driver data

O

Chip enable output for LCD driver

-

None connection

O

Data output for electrical volume

O

Clock output for electrical volume information

I

Door open detect input

I

Power ant ON signal input

I

Mute signal input

-

Non connection

O

DIMMER control signal output

-

Non connection

-

Non connection

-

Non connection

-

Non connection

-

Non connection

-

Non connection

-

Non connection

O

Diode matrix output port for initial establishing

I

Diode matrix output port for initial establishing

I

Diode matrix output port for initial establishing

-

Non connection

I

Diode matrix output port for initial establishing

-

5V power supply port (+B)

I

Turn on all light indicator of LCD, L: All light a LED indicator

O

FF/REW mode select signal output

O

H:Auto seek, L: Stop Use both as IF count REQ and Seek/Stop

O

Forced monaural output port, H:Turn on Forced monaural

-

Non connection

-

Non connection

O

"H" : Turn on power

-

Non connection

-

Non connection

1-16

Page 17

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

LEVELMETER

63

64

65

66

67

68

69

AM IF COUNT

70

FM IF COUNT

71

72

73

74

75

76

77

78

79

80

MOTOR

SUBMO+

SUBMO-

BEEP

TAPE IN

STANDBY

REEL

MODE

F/R

MS

SD/ST

DETACH

ENC1

ENC2

J-BUS INT

REMOCON

FM/AM

DOLBY

NC

NC

MEM DET

S.METER

KEY2

KEY1

KEY0

ACCDET

SENSE

NC

NC

Vdd

AM OSC

FM OSC

VSS

NC

E0

TEST1

XOUT

I/OPort Name FunctionPin No.

Main motor output, H:Transport L: Stop

O

Sub-motor output(+), Loading direction to transport output

O

Sub-motor output(-), Eject direction to transport output

O

Non connection

Switch for detecting to input cassette, L: Cassette in

I

Switch for detecting standby position

I

Switch for detecting tape end position

I

Detecting mode position input

I

Switch for detecting forward/reverse , H:FWD L:REV

I

MS input port,

I

Station detector, Stereo signal input, H:SD

I

Front panel detect

O

Connect to encoder 1

I

Connect to encoder 2

I

Cut in signal detecting port from J-Bus information

I

Non connection

FM/AM mode switching signal port, H:FM L:AM

O

Non connection

Non connection

Non connection

Back-up power supply detecting port, H:input L:no input

I

Pressure voice level voltage input for level meter.

I

S meter voltage input

I

Key 2 input port

I

Key 1 input port

I

Key 0 input port

I

Hold port for Acc detecting, L: Hold mode

I

Voltage sensor port

I

Non connection

FM frequency detecting

I

Non connection

Non connection

5V power supply (+B)

Non connection

I

FM limited signal input

I

Ground port for power supply

Non connection

Error signal output port for PLL

O

Test port for LSI, To connect ground

-

4.5MHz crystal oscillator output

O

KS-FX893

LC72366-9987(2/2)

1-17

Page 18

KS-FX893

F

LA4743K (IC301) : Power amp

1.Block diagram

IN 1

TA B

IN 2

+

0.22 F

+

0.22 F

11

1

12

Vcc 1/2 Vcc 3/4

6 20

-

+

Protective

circuit

-

+

2200 F 0.022

+

9

7

+

OUT 1+

OUT 1-

PWR GND1

8

+

OUT 2+

5

-

OUT 2-

3

PWR GND2

2

ST BY

R.F

47 F

IN 3

PRE GND

IN 4

+5V

ST ON

+

0.22 F

N.C

+

0.22 F

4

Stand by

Switch

Mute

10

+

Ripple

Filter

Mute

22

circuit

3.3 F

+

15

-

+

-

17

19

10K

+

OUT 3+

OUT 3-

Low Level

Mute ON

25

18

21

23

PWR GND3

OUT 4+

OUT 4-

13

14

Protective

circuit

-

+

+

-

1-18

ON TIME C

22 F

Muting &

16

+

ON Time Control

Circuit

PWR GND4

24

Page 19

2.Terminal layout

KS-FX893

3.Pin function

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

SymbolPin No. Function

TA B

GND

OUTRRSTBY

OUTRR+

VCC1/2

OUTRFGND

OUTRF+

RIPPLE

INRF

INRR

SGND

INLR

INLF

ONTIME

OUTLF+

GND

OUTLFVCC3/4

OUTLR+

MUTE

OUTLRGND

NC

Header of IC

Power GND

Outpur(-) for front Rch

Stand by input

Output (+) for front Rch

Power input

Output (-) for rear Rch

Power GND

Output (+) for rear Rch

Ripple filter

Rear Rch input

Front Rch input

Signal GND

Front Lch input

Rear Lch input

Power on time control

Output (+) for rear Lch

Power GND

Output (-) for rear Lch

Power input

Output (+) for front

Muting control input

Output (-) for front

Power GND

Non connection

LA4743B

LB1641 (IC402) : DC motor driver

1. Pin layout

1 2 3 4 5 6 7 8 9

GND OUT1 P1

VZ IN1 IN2

VCC1

VCC2 P2

10

OUT2

2. Pin function

Input Output

IN1 IN2 OUT1 OUT2

0 0 0 0

1 0 1 0

0 1 0 1

1 1 0 0

Mode

Brake

CLOCKWISE

COUNTER-CLOCKWISE

Brake

1-19

Page 20

KS-FX893

CXA2560Q (IC401) : Dolby B type noise reduction system with play back equalizer amp.

1. Pin layout & Block diagram

PBTC2

PBFB2

PBRIN2

PBGND

PBFIN2

VCT

PBREF

PBFIN1

PBGND

PBRIN1

PBFB1

2. Pin function

PBOUT2

30 29 28

7k/12k

31

32

300k

33

34

35

36

37

38

39

40

+

F2

30k

45k

30k

F1

+

-

300k

7k/12k

12345

PBTC1

PBOUT1

OUTREF2

27

70 /120

70 /120

OUTREF1

TAPEIN2

100k

1

1

100k

TAPEIN1

GND

26

25

T2

TAP E E Q

FWD/RVS

LPF

T1

6

Vcc

DIREF

BIAS

MUTE

Vcc

NC

24

+

+

-

F3

+

7

TCH2

LINEOUT2

23 22 21

NR

OFF/B

-

MS MODE

NR MODE

DET

OFF/B

-

NR

8910

TCH1

LINEOUT1

NC

MS ON/

NC

OFF

MSSW

MSLPF

20

19

18

17

16

15

14

13

12

11

MSMODE

DRSW

TAPESW

MUTESW

NRSW

NC

MSOUT

MSTC

G1FB

G2FB

Pin No. Symbol

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

PBTC1

PBOUT1

OUTREF1

TAPEIN1

Vcc

NC

LINEOUT1

TCH1

NC

MSLPF

G2FB

G1FB

MSTC

MSOUT

NC

NRSW

MUTESW

TAPESW

DRSW

MSMODE

MSSW

NC

TCH2

LINEOUT2

I/O Function

Playback equalizer amplifier

capacitance

Playback equalizer amplifier

O

output

Output reference

O

TAPE input

I

Power supply

Non connection.

Line output

O

Time constant for the HLS

Non connection.

Cut-off frequency adjustment

of the music sensor LPF

Music signal interval detection

Music signal interval detection

Time constant for detecting

music signal interval

Music sensor out

O

No use

Dolby NR control

I

Mute function control

I

Playback equalizer amplifier

I

control

Head select control

I

Music sensor mode control

I

Music sensor control

I

-

Non connection.

-

Time constant for the HLS

O

Line output

Pin No. Symbo l

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

DIREF

GND

TAPEIN2

OUTREF2

PBOUT2

PBTC2

PBFB2

PBRIN2

PBGND

PBFIN2

VCT

PBREF

PBFIN1

PBGND

PBRIN1

PBFB1

I/O Function

-

Resistance for setting the

reference

-

Ground

I

TAPE input

O

Output reference

O

Playback equalizer amplifier

output

-

Playback equalizer amplifier

capacitance

I

Playback equalizer amplifier

feedback

I

Playback equalizer amplifier

input

-

Playback equalizer amplifier

ground

I

Playback equalizer amplifier

input

O

Center

O

Playback equalizer amplifier

reference

I

Playback equalizer amplifier

input

-

Playback equalizer amplifier

ground

I

Playback equalizer amplifier

input

I

Playback equalizer amplifier

feedback

1-20

Page 21

HD74HC126P (IC801) : Changer control

1. Pin arrangement 2. Pin function

KS-FX893

11C

21A

31Y

42C

52A

62Y

7GND

3. Block diagram

( TOP VIEW )

1A

14

13

12

11

10

Vcc

4C

4A

4Y

3C

9

3A

8

3Y

Input Output

CA

X

LLH

HH H

Y

ZL

1Y

1C

2A

2C

3A

3C

4A

2Y

3Y

4Y

4C

1-21

Page 22

KS-FX893

AN80T05 (IC901) : Regulator

1. Terminal layout & Block diagram

Reference Voltage

Thermal

Protection

ASO & Peak

Current Protection

Pre

Drive

1 2 3 4 5 6 7 8 9 10 11 12

ILL

10V

2. Pin function

Pre

Drive

MODE2 MODE1 STB VDD

Pin

Symbol Function

No.

1

2

3

4

5

6

7

8

9

10

11

12

ILL

MODE2

MODE1

STB

VDD

AMP

VCC

ANT

COM

AM

FM

GND

10V power supply for illumination.

When 5V is input,becomes AM. and the antenna output is turned on.

When 5V is input,becomes AM. and the output of FM is switched.

When 5V is input, outputs to ILL,COM,and AMP. It is 0V usually.

5.6V power supply.

Power supply supply to remote amplifier

Back up. connects with ACC with it.

Power supply supply to auto antenna.

8.7V power supply.

The power supply of 8.7V to AM.

The power supply of 8.7V to FM.

Ground

5.6V

AMP

Out

AMP VCC ANT COM

AMP

Out

Pre

Drive

Pre

Drive

8.7VAM8.7VFM8.7V

Pre

Drive

GND

1-22

Page 23

KIA7810PI (IC902) : Regulator

t

1. Pin layout 2. Block diagram

KS-FX893

1 INPUT

1 2 3

R4 R18

Q12

R5

Z1

R6

R7

R1

Q1

Q13

R10 R3

Q8

Q10

Q5

Q7

R8

R2

Q6

Q2

R15

Q14

C1

R14

Q4

Q9

R16

R9

Q15

Q3

Q11

R13

R21

R17

Q16

R12

Q17

R11

3 OUTPUT

R20

R19

2 GND

RPM6938-SV4 (IC602) : Remote control receiver

AGC

AMP

I/V

conversion

PD

magnetic shield

BPF

for

trimming

circuit

Detector

Vcc

Comp

Vcc

22k

ohm

Rou

GND

1-23

Page 24

KS-FX893

LC75873NW (IC601) : LCD driver

1.Block diagram

COM3

COM2

COM1

S68

S67

S5

S4/P4

S3/P3

S2/P2

S1/P1

VDD1

VDD2

INH

OSC

VDD

VSS

COMMOM

DRIVER

CLOCK

GENERATOR

SEGMENT DRIVER

SHIFT REGISTER

ADDRESS

DETECTOR

2.Pin functions

Pin No. Symbol Description

1~66

67~69

70

71

S3~S68

COM1~3

VDD

VDD1

I/O

Segment Output.

O

Common Driver Output.

O

Power Supply Connection.

-

Used for applying the LCD drive 2/3 bias voltage externally.

I

Must be connected to VDD2 when a 1/2 bias drive scheme in used.

72

VDD2

Used for applying the LCD drive 1/3 bias voltage externally.

I

Must be connected to VDD1 when a 1/2 bias drive scheme in used.

73

74

VSS

OSC

Power supply connection.

-

Oscillator connection. An oscillator circuit is formed by connecting an

I/O

external resistor and capacitor to this pin.

75

76

77

78

79

80

INH

CE

CLOCK

DI

DIMMER

NC

Display off control input.

I

Chip enable input.

I

Synchronization clock input.

I

Serial data input.

I

DIMMER Control signal output.

O

Non connect.

-

1-24

Page 25

< MEMO >

KS-FX893

1-25

Page 26

KS-FX893

(

)

KS-FX893

VICTOR COMPANY OF JAPAN, LIMITED

MOBILE ELECTRONICS DIVISION

PERSONAL & MOBILE NETWORK BUSINESS UNIT. 10-1,1Chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

No.49763

1-26

Printed in Japan

200211

Page 27

KS-FX893

SCHEMATIC DIAGRAMS

CASSETTE RECEIVER

KS-FX893

CD-ROM No.SML200211

Contents

Block diagram

Standard schematic diagrams

Printed circuit boards

COPYRIGHT 2002 VICTOR COMPANY OF JAPAN, LTD.

Area Suffix

UF China

2-1

2-2

2-5~7

No.49763SCH

Nov. 2002

Page 28

Safety precaution

!

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Please use enough caution not to see the beam directly or touch it in case of an

adjustment or operation check.

Page 29

Block diagram

KS-FX893

FSMW1093

GEB10002A

5

MAIN MOTOR

MM

TAPE IN

STANDBY

MODE

REEL

PULSE

SUB MOTOR

SUBMO+

SUBMO-

CN403

4

F/R

HEAD

COMMON-L

FWD-L

CN402

FWD-R

REW-L

REW-R

COMMON-R

3

2

MOTOR DRIVER

IC402

MODE

STANDBY

TAPEIN

MOTOR

REEL

14V

HEAD AMP

IC401

FF/REW

F/R

DOLBY

GND

MSOUT

Rch

S-GND

Lch

9V

10V

SUBMO+

SUBMO-

CN401

REGULATOR

IC902

ILL10V

CP701

FF/REW

F/R

DOLBY

MSOUT

MODE

STANDBY

TAPEIN

MOTOR

REEL

DIMMEROUT

KEY0

KEY1

KEY2

LCDSCK

LCDSO

LCDCE

ENC1

ENC2

REMOCON

SUBMO+

SUBMO-

TAPE_L

TAPE_R

-COM

IC701

EVOLCLK

EVOLDA

E.VOLUME

IC161

FM OSC

IFC

S. METER

SD/ST

IFREQ

TUL

TUR

OUTLF

OUTLR

OUTRF

OUTRR

JBUS_SO

JBUS_IO

JBUS_INT

JBUS_SCK

POWER ANT

PWR_CNT

POWER AMP.

IC301

FM/AM TUNER

TU1

JVC BUS

IC801

REGULATOR

IC901

MEMORY

ILLUM CONTROL

TEL-MUTE

FLRLRRFRGND

ACC

POWER ANTENNA

REMOTE

FL+

RL+

RR+

FR+

CH_L

CH_R

CONTROL

SCK

SI/SO

MEMORY

CP981

CP801

CHANGER CONTROL

CJ701

CN601

KEY0

KEY1

KEY2

10V

ACC5V

REMOCON

ENC1

ENC2

D601~D623

1

S601~S620

KEY MATRIX

D629

LIGHTING DISPLAY

REMOCON

IC602

ENCODER

EN601

LCDCL

LCDDA

LCDCE

LCD DRIVER

IC601

LCD DISPLAY

LCD1

AB CD E F G

GEB10013A

2-1

Page 30

Standard schematic diagrams

Main amp. section

TU1

L1

4.7uH

1SS133-T2

D1

R31

1K 10K

R32

1K

0.1/50

0.1/50

C32

C31

DIMMEROUT

D711

D712

D713

D714

MTZJ5.6B-T2

MTZJ5.6B-T2

MTZJ5.6B-T2

MTZJ5.6B-T2

R801

R802

R803

6.8K

R814

CH.R

A.GND

CH.L

1SS133-T2

D2

R33

1K

C34

0.001

Q32

KTC3199/GL/-TKTC3199/GL/-T

STDBY

TAPEIN

MODE

SUBMO+

SUBMO-

TAPE.L

A.GND

TAPE.R

REEL

MS

DOLBY

F/R

FF/REW

MOTOR

KEY0

KEY1

KEY2

LCDSCK

LCDSO

LCDCE

ENC2

ENC1

REMOCON

100K

100K

100

R804

QAU0205-001

C33

2.2/50

330K

0.022

10/16

10

10/16

C3

C2

C4

R1

150p

C16

KTA1267/YG/-T

Q1

R34

Q31

MTZJ9.1C-T2

220/10

C35

D31

R35

1.5K

EO

10V

9V

PCNT14V

C707

C706

D715

0.1

0.1

MTZJ5.6B-T2

C801

R809

IC801

HD74HC126P

0.047

R36D32

PCNT14V

10K

R2

1SS133-T2

1SS133-T2

D3B

R4

2.2K

470

1SS133-T2

ANALOGUE.BUS

PCNT14V

R753

750

D753

SLR-56MC3F

10K

D3A

ILL10V

MEMORY

PCNT14V

100

R807

ACC5V

Vdd5V

2SA1706/ST/-T

R5

Q3

22K

R808

330K

R805

Q2

1K

R810

R3

Vdd5V

JBUS.SO

JBUS.IO

JBUS.INT

JBUS.SCK

100K

R806

5

QNB0100-002

J1

4

QGB1214J1-18S

CP701

3

QNZ0007-002

CJ701

D705

D706

D707

D708

D709

D710

2

CP801

QNZ0095-001

R811

6.8K

MTZJ5.6B-T2

MTZJ5.6B-T2

R812

MTZJ5.6B-T2

MTZJ5.6B-T2

2.4K

MTZJ5.6B-T2

MTZJ5.6B-T2

R813

2.4K

1

BAND

100K

10K

KRC102M-T

KS-FX893

R91

2.7K

R81

KRC102M-T

JBUS.SI

0.001

C10

TUNER.BUS

2.7K

0.1/50

10

C9

C13

C11

220/10

Q701

MOTOR

KTC3199/GL/-T

REEL

82

R6

C12

0.01

R10

J.BUS

10/16

C1

TUNER9V

10K

0.022

0.022

120p

C8

R7

C81

C91

6.8

IFREQ

IFC

IFREQ

MONO

S702

QSW0451-001

R749

FF/REW

Q4

R8R9

8.2k

0.01

C6

22k

MONO

SD/ST

S.METER

D702

1SS133-T2

47K

R727

2.2K

R728

2.2K

R729

47K

R701

47K

R714

56K

R713

47K

R712

47K

R702

4.7K

R703

4.7K

R704

4.7K

R705

47K

c14

56p

SUBMO+

4.7K

R82

SUBMO-

1/50

C92

1/50

C82

TU.R

TU.L

4.7K

R92

4.7K

R706

0.1

C709

DIMMEROUT

3.3K

3.3K

3.3K

2.2K

R724

R725

R748

R739

IC701

LC72366-9987

2.2K

2.2K

10K

10K

R743

R730

R741

R742

MS

MODE

F/R

ENC1

ENC2

SD/ST

DETACH

S701

QSW0451-001

TAPEIN

STDBY

3.3K

R746

EVOLCLK

EVOLDA

A.GND

C196

27p

C701

1SS133-T2

R162

C165

IC161

TEA6320T-X

C175

C174 C164

0.0082 0.0082

22K 22K

R171 R161

R172

100/10

0.0047

C17

C705

0.22

C704

100/6.3

C708

47K

R716

0.01

C703

10/16

47K

R707

4.7K

R708

47K

R709

47K

R710

47K

R711

47K

R747

24K

R750

1.2K1.2K

R164

A.GND

CH.L

TAPE.L

R163

3.9K

TU.L

TU.R

TAPE.R

R173

3.9K 1SS133-T2

CH.R

LCDCE

LCDSO

LCDSCK

JBUS.IO

JBUS.SO

JBUS.SI

JBUS.SCK

2.2K

2.2K

2.2K

4.7K

4.7K

4.7K

R722

4.7K

R732

REMOCON

4.7K

R721

R720

R719

R718

R717

10K

10K

2.2K

R734

R733

R738

DOLBY

BAND

S.METER

R723

4.7K

R731

JBUS.INT

C163

1/50

C162

1/50

C172

C173

C195

1/50

1/50

47/16

R174

X701

22p

C702

QAX0406-001Z

D704

10K

10K

R736

10K

R735

KEY2

R737

KEY1

KEY0

C167

0.033

0.15

C177

C176 C166

0.15

0.22 0.22

0.033

2.2K 2.2K

KS-FX893

C181

C182

1/50

1/50

1/50

C178 C168

C191

C192

1/50

0.0056 0.0056

47K

C197

R195

R175

10

9V

PCNT14V

ILL10V

EO

TUNER9V

10V

Vdd5V

PCNT5V

9V

Vdd5V

IFC

PCNT5V

ACC5V

MEMORY

QNN0170-001

CJ321

IC301

LA4743K

C361

56K

QSQ1A11-V06Z

22k

0.22

2.2/50

C332

27K

R331

27K

R351

27K

R341

27K

R321

Q782

D321

C199

470p

2SA1706/ST/-T

Q905

47K

R908

R909

1K

Q906

470p

KRC102M-T

Q901

R930

47k

1K

R905

Q902

S930

KRA102M-T

C882

1SS133-T2

1SS133-T2

1SS133-T2

C782

R904

KRC102M-T

C352

C342

C322

D310

47/16

D782

R892Q891

KRC102M-T

KTC3199/GL/-T

47K

2200/6.3

C912

47K

1SS133-T2

C15

R979

D902B

Q781

MTZJ11B-T2

D892

Q977

47K

D902A

2.2/50

2.2/50

2.2/50

470p

470p

470p

470p

C321

C341

C351

C331

KRA102M-T

D781

C781

1SS133-T2

220/10

PCNT5V

PCNT5V

PCNT5V

1K

47K

R891

R882

Q881

KRC102M-T

D891

1SS133-T2

C891

0.1

1200p

Q976

R978

KTA1267/YG/-T

27K

AN80T05

IC901

10/16

10/16

10/16

C907

C906

C905

R305

4.7K

R302

27K

KRC102M-T

C881

220/10

C904

Q301

22/16

R977

220/10

C903

4.7/25

C303

C319

0.1

R303

1K

R881

4.7K

R976

43K

68K

D903

1A3G-T1 1A3G-T1

C318

0.1

2200/16

1N5401-TU-15

QQR0703-001

L901

R901

R902

C909

D904

10/16

0.022

C301

C304

C901

D901

100

C902

10/16

6.8K

R903

11K

0.22

2.2/50

22/16

C302

C315

0.1

0.1

C317

C316

CP981

QNZ0002-001

QMFZ047-150-T

TAPE PLAY SIGNAL

TUNER SIGNAL

1K

R353

1K 100

R176

47K

R166

C241

1/50

47K

R243

Q241

R244

R343 R344

9V

R245R247

180K

12K1K

C243 D242

0.047

47

R246

22K

C242

IC902

KIA7810PI

Q903

1K

R907

Q904

Q351 Q321

KTC3199/GL/-T

L902

KRA102M-T

KRC102M-T

47K

R165

0.01

C198

100/10

150K

150K

R241

R242

R911

100

100

R354

2SD2144S/VW/-T

2.2K

R325

2.2K

R355

RB721Q-T2

D241

C244

R248

RB721Q-T2

0.47/50

22/16

0.1

C910

C911

0.33

47uH KTA1267/YG/-T

Q930

47K

R906

KTA1267/YG/-T

R931

CHANGER SIGNAL

KTA1267/YG/-T

Q907

MAIN SIGNAL

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified one.

AB CD E F G

2-2

Page 31

Mecha control section

KS-FX893

C415

0.01

5

390

100p

C401

100K

R402

R401

100p

C402

100K

R403

100p

C403

100K

R404

100p

C404

100K

R405

C409

100P

100P

22/16

100P

100P

C408

C407

C406

C405

180 180

R406 R407

0.015

C411

0.015

C410

33K

VR402

33K

VR401

0.10.1

CXA2560Q

22/16

C414

C413C412

IC401

100

R412

18K

R413

0.1

C417

0.1

C416

220P

C418

R414

3.9K

0.47/50

C419

R417

10K

CN403

QGF1219F1-10S

4

CN402

VMP3501-001

3

2

Q403

2SB1322/RS/-T

1A3G-T1

D402

R418

15K

22K

R415

0.01

C421

R422

3.3K

Q402

DTC114EKA-X

R416

910K

0.1

C422

47K

R423

IC402

LB1641

D401

MA3047/H/-X

3.3K

R424

10/16

C423

C425

0.01

0.1

C424

33

R425

QGB1214K1-18S

CN401

TAPE PLAY SIGNAL

1

AB CD E F G

2-3

Page 32

KS-FX893

KS-FX893

LCD & Key switch section

5

4

S28

S27

S26

S34

S33

S32

S31

S30

S29

S40

S39

S38

S37

S36

S35

3

R601R602R603R604R605

1212121212

6805606809101.2K

S603S604S605S606

1212

12

12

12

12

R611

12

1.2K

S613

R617

12

1.5K

S620

12

12

12

2

12

12

R614R615R616

121212

6809101.2K

S617S618S619

12

12

S609S610S611

12

R613

12

560

S616

12

R606R607R609 R608

121212 12

680560910 680

S608

R612

12

680

S615

12

QNZ0449-001

S68

S67

S66

S65

S64

S63

S62

S61

S60

S59

S58

S57

S56

S55

S54

S53

S52

S51

S50

S49

S48

S47

S46

S45

S44

S43

S42

S41

S14

S10

S11

S12

S13

S15

S16

S17

S18

S19

S20

S21

S22

S23

S24

S25

S601S602

12

12

R621

S607

12

S614

12

D601

R620

12

820( 1/8W)

12

470( 1/8W)

12

D602

12

D603

12

D604

R622

12

270( 1/8W)

QNZ0450-001

R623

12

270( 1/8W)

12

D605

12

D606

12

D607

12

12

12

R624

D608

D609

D610

12

390( 1/8W)

12

D611

12

D612

R625

470( 1/8W)

12

12

12

12

R626

D628

D614

D615

COM1

S2S1S3S4S5S6S7S8S9

12

390( 1/8W)

1212

D616D618

12

D617

COM3S3COM2

R627

330( 1/8W)

LCD1

R628

12

12

D619

12

D620

12

560( 1/8W)

12

12

12

R629

D629

D622

D623

12

390( 1/8W)

12

D621

R630

12

470( 1/8W)

12

12

B604

D613

R641

430( 1/8W)

12

D641

NSPW310BS/BRS/

R642

430( 1/8W)

12

D642

NSPW310BS/BQ/

EN601

QSW0793-001

1

R643

430( 1/8W)

12

121212

D643

NSPW310BS/BRS/

23

R650

100

12

R644

470( 1/8W)

12

231

Q641

2SB815/7/-X

R646

2

UN2211

Q642

1

R652

47K

12

12

R651

47K

1K( 1/8W)

12

3

ENC2

ENC1

KEY1

KEY2

KEY0

ACC5V

47K

R645

12

IC602

RPM6938-SV4

CN601

R661

3.3K

12

3.3K

R662

12

3.3K

R663

12

QNZ0006-001

R657

10K

REMOCON

12

ACC5V

12

10V

C606

UDZS5.6B-X

4.7/6.3

R658

470

2

1

ENC1

ENC2

LCDCE

LCDDA

LCDCL

KEY2

KEY1

DIMMER

GND

S44

S45

S46

S47

S48

S49

S50

S51

S52

S53

S54

S55

S56

S57

S58

S59

S60

S61

S62

R653

R654

12 12

1K( 1/8W)

220

2

D651

UDZS5.1B-X

1

10V

2

2

1

D654

121

1SS355-X

1SS355-X

D659

LCDCE

LCDCL

LCDDA

2

2

D653

D658

1SS355-X

1

121

1SS355-X

1SS355-X

1SS355-X

D656

D655

R655

R656

390K

12

2

1

C601

2

330K

1

12

1

2

R669

10K

12

2

D652

1

1SS355-X

4.7/6.3

C604

0.01220P

C602C603

R670 R671

10K 10K

12

12

2

2

1

1

0.22

C605

S64

S65

S66

S67

S68

COM1

COM2

COM3

0.22

S2

S1

S4S5S6S7S8S9S10

IC601

LC75873NW

S11

S12

S13

S14

S15

S16

S17

S18

S19

S20

S21

S22 S43

2

D657

1

S42S63

S41 KEY0

S40

S39

S38

S37

S36

S35

S34

S33

S32

S31

S30

S29

S28

S27

S26

S25

S24

S23

1

AB CD E F G

2-4

Page 33

Printed circuit boards

Main board

C901

KS-FX893

(Forward side)

R712

R724

R727

D703

D701

R701

R714

R713

R806

C166 C167

R172

R719

CJ701

R171

D702

R746

C175

R162

R718

B904

R725

R739

R161

C196

R747

R717

L902

C907

C174

R748

R803

R729

R728

B905

CP701

C903

R804

C163

C164 C165

R163

R812

R814

C172 C173

X701

C702

C701

B802

D753

R753

R164

R811

R813

R174

R173

B801

R810

C162

R706

R734

C705

IC801

R707

R709

R730

R710

R708

R809

C704

R711

R732

CP801

B906

R702

R705

R704

C35

R716

D704

R741

R335

C703

CJ321

C362

C361

R343

R323

R324

D32

R36

Q2

R3

R2

C708

R703

R742

R723

C801

S930

R743

R721

Q331

Q32

D31

C92

R333

R334

R355

Q341

R345

Q31

C34

R33

R31

R34

R32

R35

C4

R1

C5

Q3

R6

R5

R4

D3A

Q1

D3B

C82

C83

R82

R91

R92

C93

R7

Q4

C8

C7

R9

R8

C10

C6

R722

R737

R735

R736

R801

R802

J1

R354

R353

R344

Q321

Q351

R325

D2

L1

D321 D341

C33

C31

C32

C12

R81

C81

C91

R10

R11

S702

C13

D1

C3

C2

C1

TU1

C11

C9

C14

5

4

IC301

3

S701

B301

C341

R342

R341

R248

B303

C321

R322

R321

D242

R246

C15

C244

C304

R247

C17

D241

R245

C243

C315

B302

Q891

C912

CP981

R243

C316

C317

C302

C241

C891

D892

C911

R891

Q241

C303

C301

R892

D891

C242

IC902

C351

C331

R882

Q881

C910

C902

R352

R244

C322

C318

R332

R351

Q902

R905

R979

R911

R331

C881

C332

C352

R977

C319

Q903

B902

C342

R903

B901

R976

R902

R906

D907

R302

R303

R301

R305

R881

Q901

R978

R904

R907

R901

C882

Q977

D705

D902A

D902B

D901

D903

D904

C909

C913

R910

Q301

C182

C198

D310

R195

R166

R176

R165

R738

R733

C197

C192 C195

C191

C178

R241

Q905

Q782

R908

R909

Q781

C781

D781

C199

Q907

C707

R930

D706

D707

R931

R750

D708

Q930

D709

Q701

R805

D710

Q906

D715

D906

R175

Q976

Q904

C706

C181

R242

R807

D711

L901

C905 C906

C709

B903

D712

C177

C168

C782

D782

R808

R731

D713

IC901

C914

C904

C176

R749

R720

D714

2

Front board

1

D613

D601

S614

(Forward side)

IC602

S607

R606

B601

D602

B602

D603

B603

D604

R607

R650

D624

S608

EN601

D612

D611

S616

D616

D618

S615

D617

S609

D605

R614

S617

D606

R615

R616

D607

S618 S619

R617

D608

S620

D609

S601

D610

S610

D619

S611

D620

D641

D642

D643

LCD1

D621

S605

S604

D628

D614

D615

S602

AB C

S603

D629

R605

R604

D622

S613

D623

S606

2-5

Page 34

KS-FX

893

Main board

(Reverse side)

R718

C904

R171

R701

R714

R713

R739

R172

D701

R719

C914

R725

C166

R806

R748

R720

D703

R749

IC901

C167

C176

R727

C709

D714

D702

R731

C905

C168

IC161

R712

C782

Q701

R808

D713

C181

C177

R807

C198

D782

D712

C178

C781

Q930

D901

C906

R242

R241

C191

R750

D711

R805

D710

C182

C192

Q782

R733

L901

D709

C197

D708

R176

C909

C913

Q905

R931

R195

R930

D707

R165

R166

D781

C199

D904

R910

Q781

R738

D310

D706

R908

Q907

R909

Q976

D906

Q301

C707

Q906

R175

C706

D903

R901

Q901

Q977

D902A

D902B

Q904

D715

D907

R302

R303

R301

R305

C882

D705

C319

R881

R902

R904

R978

R907

C352

R906

C881

R976

Q903

R977

CJ701

C332

R331

C902

R903

Q902

R351

C342

R905

C322

Q881

R911

C318

R332

R352

R979

C910

C316

D891

C331

R882

R244

C242

IC902

Q241

CP981

C303

C351

C341

R342

R341

R892

C317

C302

C911

R891

R247

C241

D892

C301

C891

R243

R246

C912

C10

R354

C4

R1

C5

R6

R91

R7

C8

C81

R92

D321

C93

C91

C33

C31

C32

C13

R10

R11

R81

C361

Q351

R33

R4

C6

R737

CJ321

D341

C34

R35

R5

D3B

R9

R8

R345

R355

D3A

R802

C7

C362

R32

R743

R736

Q31

C82

C92

R324

R801

Q32

CP801

R323

CP701

R335

X701

D753

R811

R164

C164

C702

C903

C907

R161

R162

C165

C196

C195

C174

C175

C172 C173

R729

R728

R746

R747

R724

R717

R803

R804

L902

R334

Q331

R343

R333

R344

C35

D31

R36

R34

R3

Q2

R2

Q1

C703

C708

R82

C83

R734

R716

D704

R702

R705

R704

R703

R721

R722

R742

R741

R723

C801

S930

D32

R732

R809

R711

R710

R707

R709

R730

C704

IC801

R708

R706

C705

R812

R814

R813

R174

R173

R810

C162

IC701

C163

R163

C701

R753

,

Q341

R31

Q3

Q4

R735

5

R353

R325

J1

D2

L1

D1

C3

4

C2

C1

TU1

C11

C9

Q321

C12

3

S702

C14

R245

C17

R248

C304

C315

Q891

C321

R322

R321

C243

C244

D241

C901

IC301

C15

D242

S701

2-6

2

Front board

1

Q642

R645

D656

(Reverse side)

IC602

R627

R626

D657

R658

R657

R608

R622

R621

B604

R603

R646

R644

D659

D654

Q641

R669

D658

D653

R602

D652

R601

D655

D641

R611

R629

R643

D642

D643

C601

R642

C602

R609

R641

R655

R671

C603

R656

R670

C604

C605

IC601

CN601

R663

R662

R654

R661

R653

D651

C606

R613

R612

AB C

R624

R625

R623

R651 R652

R628

R620

R630

Page 35

Cassette mecha control board

KS-FX893

(Forward side)

5

C409

VR401

C410

B442

B441

C411

B471

B421

CN403

B422

B431

CN402

CN401

4

B423

C416

C417

C414

B451

Q403

B432

B433

B443

B434

C419

B436

B435

D402

IC402

VR402

B461

R426

C423

(Reverse side)

3

R411

VR402

B409

R426

2

C423

D401

R425

C413

B407

R424

IC402

C425

R410

Q401

C424

B406

D402

R416

R401

C419

C422

C414

B408

C416

C421

B403

R420

Q403

B413

R415

R417

B410

C415

C418

B411

R414

R418

R413

C417

B404

R412

CJ403

C412

B412

IC401

B405

R409

C411

B402

R423

VR401

CJ401

R408

C410

B401

C409

C405

C406

R407

C408

C402

R406

C407

R403

R405

C403

R402

C404

R404

C401

R422

Q402

1

AB C

2-7

Page 36

KS-FX893

VICTOR COMPANY OF JAPAN, LIMITED

MOBILE ERECTRONICS DIVISION

PERSONAL & MOBILE NETWORK BUSINESS UNIT. 10-1,1Chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

No.49763SCH

Printed in Japan

200211

Page 37

PA RTS LIST

[ KS-FX893 ]

* All printed circuit boards and its assemblies are not available as service parts.

KS-FX893

Areas suffix

UF ----------------------------- China

- Contents -

Exploded view of general assembly and parts list (Block No.M1)

Cassette mechanism assembly and parts list (Block No.MP)

Electrical parts list (Block No.01~03)

Packing materials and accessories parts list (Block No.M3,M5)

3- 2

3- 5

3-10

3-14

3-1

Page 38

KS-FX893

Exploded view of general assembly and parts list

Block No.

13

74

75

76

73

73

13

71

72

A

67

66

10

M

M

1

M

65

68

70

8

12

15

12

A

7

a

69

14

21

9

Main board

35

24

29

34

Mecha

22

19

14

18

36

37

17

20

a

5

28

32

16

57

11

4

11

control board

6

2

6

B

C

25

33

23

30

26

31

59

27

56

57

50

64

55

77

43

Front board

41

81

47

49

45

48

54

40

53

60

78

62

80

63

58

61

46

52

44

51

3-2

11

B

C

3

11

6

42

1

38

6

39

Page 39

KS-FX893

Parts list (General assembly)

Item

A

1

2

3

4

5

6

7

8

9

10 FSMA3005-001

11 QYSDST2604Z

12 FSKZ4005-001

13 QYSDST2604Z

14 QYSDST2606Z SCREW 2 CHASSIS+MAIN PWB

15 FSKZ4005-001

16 QYSDSF2006M

17 FSJC1060-002

18 VJK3707-001

19 QYSPSGU1745N

20 FSYH4036-046

21 FSKS3014-001 OPEN LEVER 1

22 FSKS3015-001

23 VKS3798-002

24 VKS3793-001

25 VKS3794-003

26 VKS3795-002

27 VKS5563-001

28 VKZ4786-002 OIL DAMPER 1

29 FSKW4012-001

30 VKW5264-005

31 VKW5262-001 T.SPRING 1 FOR L.LEVER(R)

32 QYSDSF2006M

33 VKW5263-002

34 VKZ4777-001

35 FSKW4013-002

36 FSJC3014-001

37 VKW4947-002

38 GE10005-006B FRONT PANEL 1

39 GE30113-016B

40 FSJK4009-001

41 GE20104-002A

42 GE30105-002B

43 GE30106-001A

44 GE20110-001C

45 GE20103-001A PUSH BUTTON(3) 1

46 GE20109-001C

47 GE30546-002A

48 GE30366-001A

Parts number Parts name Area

---------------

FSYH4036-050

FSKL2001-004

FSKL2002-002 MECHA BRACKET(R)

QYSDST2606Z

QYSDST2606Z

FSJC1056-001 TOP CHASSIS

FSMH3001-204

FSKM3011-002SSF

CASSETTE MECHA

SHEET

MECHA BRACKET(L)

SCREW

SCREW

HEAT SINK

BOTTOM COVER

INSULATOR

SCREW

SCREW

SCREW

SCREW

SCREW

FRONT CHASSIS

LIGHT LENS

MINI SCREW

SHEET

LOCK LEVER(O.L)

RELEASE LEVER

LOCK LEVER(TOP)

LOCK LEVER(L)

LOCK LEVER(R)

GEAR

T.SPRING

T.SPRING

SCREW

T.SPRING

MINI SCREW

T.SPRING

CASS.LID

DOOR SPRING

FINDER ASSY

REMOTE LENS

PRESET BUTTON

POWER BUTTON

SND FUNC BUTTON

D.FUNCT BUTTON

UP DOWN BUTTON

KNOB

SEL BUTTON

Q'ty

1

CDS-801

1

1

1

1

4

1

1

1

1

4

CHASSIS+MECHA BKT

2

CHASSIS+SIDE PANEL

2

CHASSIS+REAR BKT

1

SIDE PANEL+IC BKT

2

F.CHASSIS+CONNECTOR

1

1

2

FOR LIGHT LENS

1

1

1

1

1

1

1

1

FOR L.LEVER(TOP)

1

FOR RELEASE LEVER

1

DAMPER+L.LEVER(R)

1

FOR L.LEVER(L)

1

LOCK LEVER(O.L.)

1

FOR OPEN LEVER

1

NO PRINTING

1

1

1

FOR REMOTE CON.

1

1-6 (2 COLOUR)

1

1

RPT,RND,SCM

1

TAPE,F/A,CD-CH

1

1

JOG DIAL

1

Block No. M1MM

Description

3-3

Page 40

KS-FX893

Parts list (General assembly)

Item

A

49 FSYH4036-032

50 GE30104-001A

51 GE30115-002A

52 VKW3001-330 COMP.SPRING 1 FOR EJECT BUTTON

53 GE30116-001A

54 VKW3001-330

55 GE10006-001B REAR COVER 1

56 FSYH4036-035

57 VKZ4777-001

58 QLD0164-001

59 QNZ0449-001

60 QNZ0450-001

61 GE30114-001A

62 FSJK3028-001 LCD LENS 1

63 FSYH4061-001

64 FSKS3013-001

65 GE30846-001A

66 GE40103-002A

67 GE40107-002A

68 QMFZ047-150-T

A

69 VMA4652-001SS EARTH PLATE 1

70 FSKL4024-001

71 FSKM3010-017SSF

72 QYSDST2606Z

73 QYSDST2606Z

74 QYSDSF3006Z

75 QYSDST2606Z

76 QYSDST2606Z SCREW 1 REAR BKT+REG BKT

77 FSKS3017-002

78 FSYH4036-087

80 FSYH4061-002 LIGHTNG SHEET 1

81 FSYH4036-031

Parts number Parts name Area

SHEET

RIM LENS

EJECT BUTTON

DETACH BUTTON

COMP.SPRING

SHEET

MINI SCREW

LCD MODULE

RUBBER CONNECTOR

RUBBER CONNECTOR

LCD CASE

LIGHTNG SHEET

LENS CASE

NAME PLATE

REG BRACKET

HEAT SINK

FUSE

IC BRACKET

REAR BRACKET

SCREW

SCREW

SCREW

SCREW

LED HOLDER

SHEET

SHEET

Q'ty

1

SEL BUTTON

1

FOR KNOB

1

1

1

FOR DETACH BUTTON

1

REAR COVER

4

FRONT PANEL+REAR COVER

1

1

1

1

1

1

1

1

1

1

1

1

1

REAR BKT+ANT JACK

2

REAR BKT+16P CN

1

REAR BKT+PIN JACK

1

REAR BKT+CD IN

1

1

1

PRESET BUTTON

Block No. M1MM

Description

3-4

Page 41

Cassette mechanism assembly and parts list

CDS-801

Block No.

M

P

KS-FX893

M

M

28

63

64

27

LEN-315Y2

30

85

c

d

82

48

50

84

5

68

4

SW-522B

LEN-315Y2

107

3

86

67

LEN-315Y2

33

111

87

CFD-409

16

SW-522B

25

12

FG-84M

114

95

FG-84M

45

22

A

94

c

d

117

CFD-409

106

FG-84M

38

93

96

FG-84M

CFD-409

FG-84M

49

108

55

FG-84M

17

SW-902

CFD-409

42

40

75

34

FG-84M

FG-84M

41

46

C

44

113

SW-522B

10

39

21

65

C

66

43

FG-84M

D

105

24

SW-902

CFD-409

109

D

110

113

111

71

40

66

39

FG-84M

75

FG-84M

A

B

32

76

91

26

FG-84M

11

1

107

73

LEN-315Y2

106

51

61

37

74

B

23

FG-84M

FG-84M

103

99

47

2

100

FG-84M

13

104

35

60

36

9

97

101

72

98

102

59

3-5

Page 42

KS-FX893

Parts list (Cassette mechanism)

Item

A

1 X-0801-1003S

2 X-0801-1002S

3 X-0801-1008S

4 X-0801-1010S EJECT CAM LIMIT 1

5 X-0801-1013S

9 1-0801-6002S

10 X-0801-2003S GEAR BASE ASS'Y 1

11 X-0801-2021S

12 X-0801-2022S

13 1-0801-6003S

16 X-0801-7006S

17 X-0801-7057S

21 1-0801-1003S

22 1-0801-1004S DIRECTION LINK 1

23 1-0801-1005S

24 1-0801-1006S

25 1-0801-1007S

26 1-0801-1009S

27 1-0801-1011S

28 1-0801-1012S

30 1-0801-1020S REINFORCE BRKT 1

32 1-0101-2056S

33 1-0801-2004S

34 1-0801-2005S

35 1-0801-2006S

36 1-0801-2007S

37 1-0801-2008S

38 1-0801-2009S MODE GEAR 1

39 1-0801-2010S

40 1-0801-2011S

41 1-0801-2014S GEAR BASE ARM 1

42 1-0801-2015S

43 1-0801-2016S

44 1-0801-2017S

45 1-0801-2018S

46 1-0801-2019S

47 1-0801-2020S

48 1-0801-2023S LOAD RACK 1

49 1-0801-2024S

50 1-0801-2025S

51 1-0801-2030S

55 1-0801-3005S

59 1-0801-4001S

60 1-0801-4002S

61 1-0801-4003S FF SPG 1

63 1-0801-4005S

64 1-0801-4006S

65 1-0801-4007S

Parts number Parts name Area

MAIN CHASSIS AS

SLIDE CHASSIS A

SIDE BKT ASS'Y

CASSETTE HANGER

FLYWHEEL ASSY F

PINCH ARM F ASS

PINCH ARM R ASS

FLYWHEEL ASSY R

SUB MOTOR ASS'Y

MAIN MOTOR ASSY

DIRECTION PLATE

PINCH SPG ARM

CASSETTE GUIDE

LOAD ARM

HEAD SUPT SPG

EJECT CAM PLATE

CASSETTE HOLDER

IDLE PULLEY(A1)

REDUCTION GEARA

REDUCTION GEARB

SPG HOLDER F

FRICTION GEARPL

FRICTION GEARFF

REEL SPINDLE

REEL DRIVER

GEAR BASE LINK

TAKE UP GEAR

REFLECTOR GEAR

MODE RACK

MODE SW ACTUATR

TAPE GUIDE

RACK LINK

CASSETTE CATCH

SPG HOLDER R

RACK COLLAR

PINCH ARM SPG

TU SPG

EJECTCAM PLT SP

HOLDER CUSH SPG

GEAR BASE SPG

Q'ty

Block No. MPMM

Description

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

3-6

Page 43

KS-FX893

Parts list (Cassette mechanism)

Item

A

66 1-0801-4008S

67 1-0801-4009S

68 1-0801-4011S

71 1-0801-5001S BELT 1

72 1-0801-5002S

73 1-0801-5003S

74 1-0801-5004S FELT 1 11*18.5*1.0

75 1-0801-5005S

76 21732-6280-36S

82 1-0801-7001S

84 1-0801-7003S

85 1-0801-7005S

86 1-0801-7024S

87 1-0801-7026S FLAT CABLE 10P 1

91 1-0801-7014S