JVC KSAX-6700 Service manual

SERVICE MANUAL

POWER AMPLIFIER

KS-AX6700

KS-AX6700KS-AX6700

Caution

If electricity is connected during disassembly, it must be a no load current. If it is load

current, be sure to attach a heat sink to the power-amp IC. This will be damaged if the

above precautions are not followed, as it does not have a sub heat sink attached to it.

Contents

Safety Precaution

Location of main parts

Removal of main parts

Adjustment method

Wire connection diagram

1-2

1-3

1-5

1-8

1-9

Areas suffix

J -------- Nothem America

E ----- Continental Europe

This service manual is printed on 100% recycled paper.

COPYRIGHT 2000 VICTOR COMPANY OF JAPAN, LTD.

No. 49559

Jun. 2000

KS-AX6700

Safety precaution

CAUTION

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

1-2

KS-AX6700

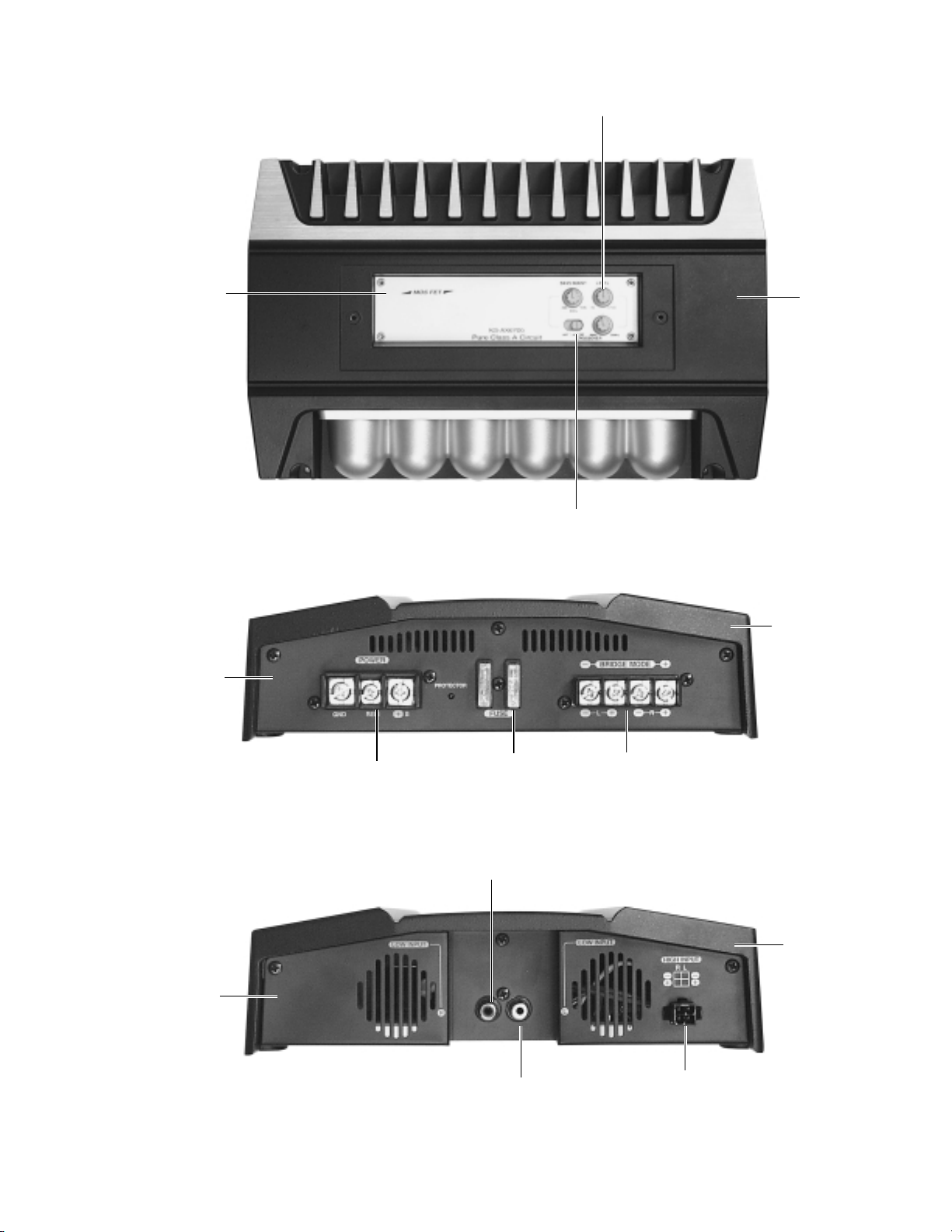

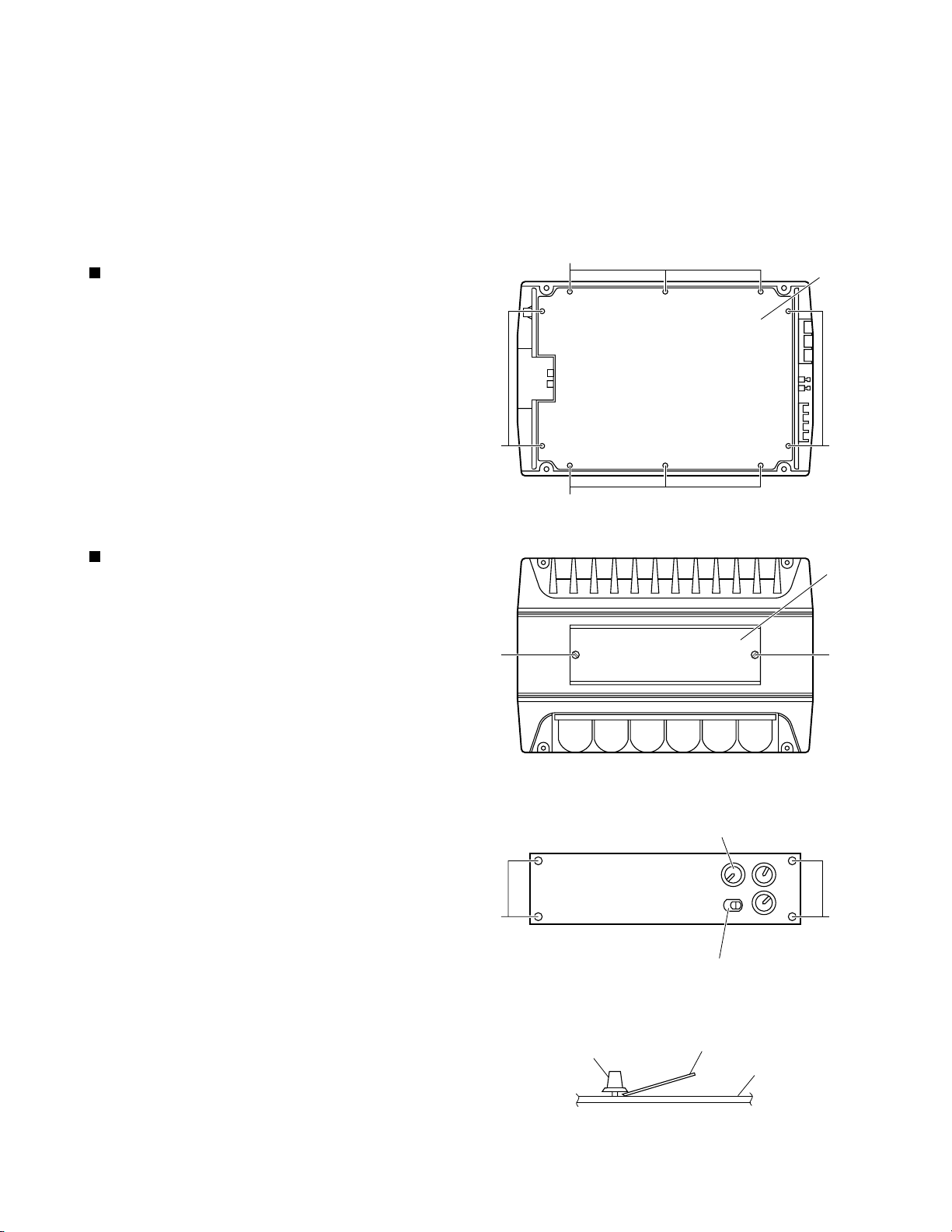

Location of main parts

Control panel

Volume knob

Heat sink

Switch knob

Rear panel

Front panel

Input for power

Fuse

Low input(R)

Heat sink

Output terminal

Heat sink

Low input(L)

High input connector

1-3

KS-AX6700

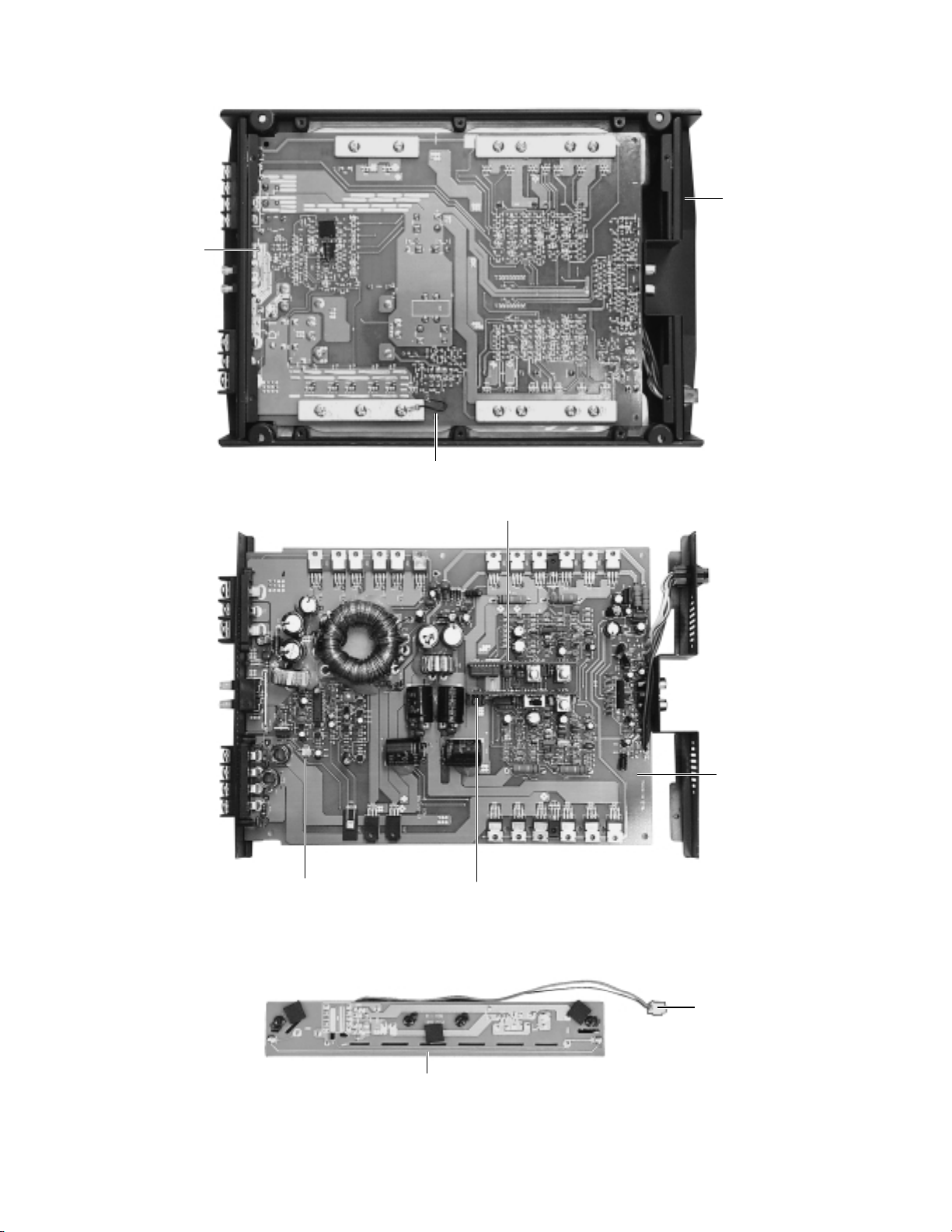

Main P.C. board

Heat sink

(Bottom view)

GND wire

2pin connector

(to CCFL P.C. board)

Sub1 P.C. board

Main P.C. board

Sub2 P.C. board

1-4

Wire assemb'y

(from Main)

CCFL P.C. board

Removal of main parts

KS-AX6700

CAUTION:

If electricity is connected during

disassembly, it must be a no load current. If

it is load current, be sure to attach a heat

sink to the power-amp IC. This will be

damaged if the above precautions are not

followed, as it does not have a sub heat

sink attached to it.

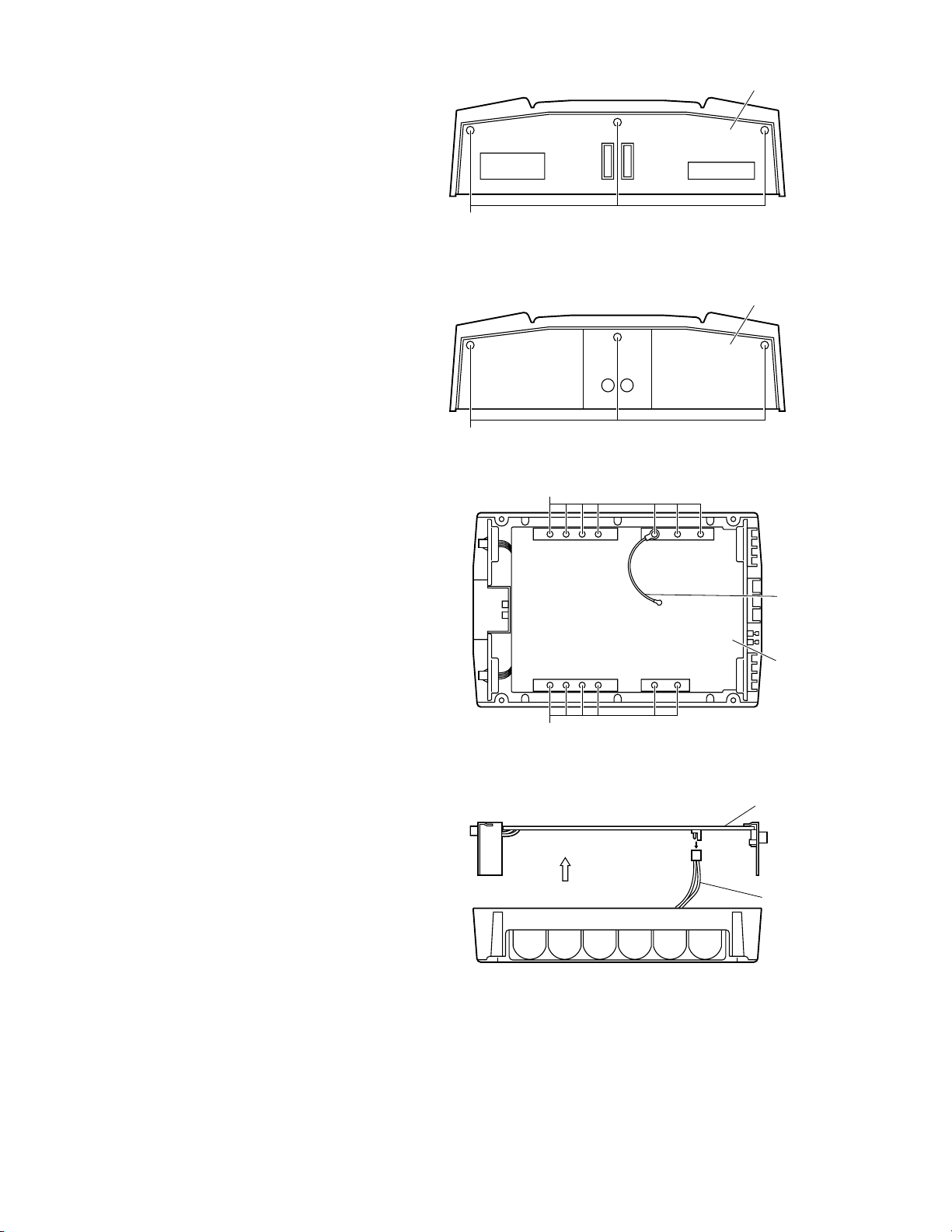

Removing the bottom cover (see Fig. 1)

1.

From the bottom side of the main unit, remove the 4

screws A retaining the bottom cover.

2.

Then remove the 6 screws B retaining the bottom

cover.

3.

Remove the bottom cover.

Removing the main P.C. board

(see Fig. 2 to 8)

1.

Remove the bottom cover from the main unit.

A

B

B

Bottom cover

A

Fig. 1

Top plate

2.

Loosen and remove the 2 screws C retaining the top

plate on the main unit. (Stoppers are attached to the

backs of the C screws so that they cannot be

removed easily.)

3.

Remove the 3 volume knobs on top of the control

panel. If it cannot be pulled out easily, insert a scale

or suitable lever between the base of the volume

knob and the control panel so that the volume knob is

raised a little above the surface and then remove it.

(Be careful when inserting a lever etc. not to

scratch the surface of the control panel).

4.

Remove the 4 screws D retaining the control panel.

Then detach the control panel and the switch knob.

C

D

Volume knob

C

Fig. 2

Volume knob

D

Switch knob

Fig. 3

Scale or suitable lever

Control panel

(Side view)

Fig. 4

1-5

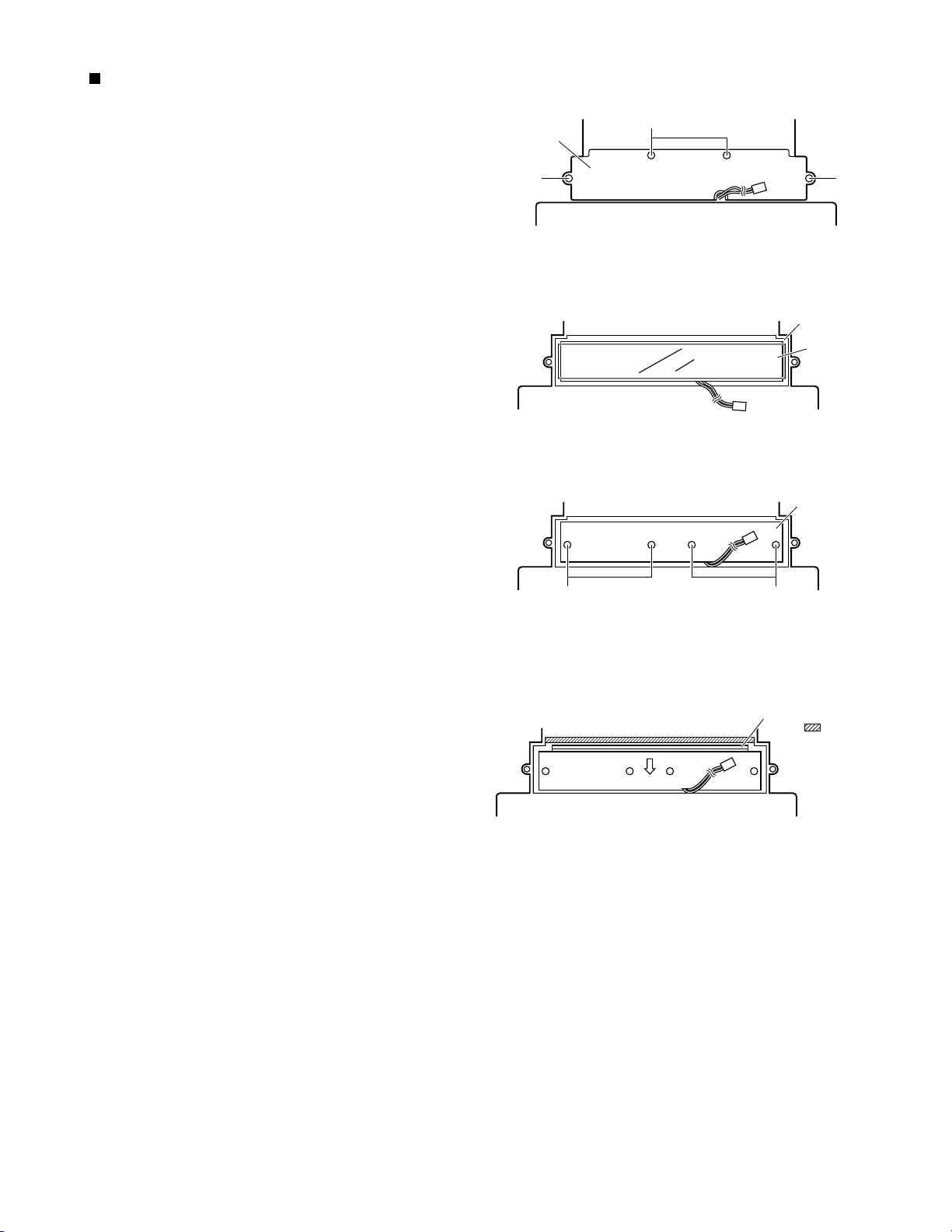

KS-AX6700

5.

Remove the 6 screws E retaining the panels on both

sides of the main unit.

Rear panel

6.

Remove the 13 screws F attaching the main P.C.

board to the bottom of the main unit.

(The GND wire that protrudes from the main

P.C.board must be re-installed to its original

position during re-assembly.)

E

Fig. 5

Front panel

E

Fig. 6

F

GND wire

Main P.C. board

7.

To remove the wire ass'y, lift up the main P.C. board

a little.

F

Fig. 7

Main P.C. board

Wire assemb'y

(Side view)

Fig. 8

1-6

Removing the CCFL board

(see Fig. 9 to 12)

1.

Remove the bottom cover.

2.

Then remove the Main P.C. board.

3.

From the bottom side of the main unit, remove the 4

screws G retaining the CCFL cover.

4.

Then remove the insulation sheet on top of the CCFL

P.C. board.

KS-AX6700

G

CCFL cover

G G

Fig. 9

CCFL P.C. board

Insulation sheet

Fig. 10

5.

Remove the 4 screws H retaining the CCFL P.C.

board.

6.

Remove the CCFL P.C. board by sliding it a little

towards the arrow mark.

H

CCFL P.C. board

H

Fig. 11

This section is cought

by the portion.

Fig. 12

1-7

KS-AX6700

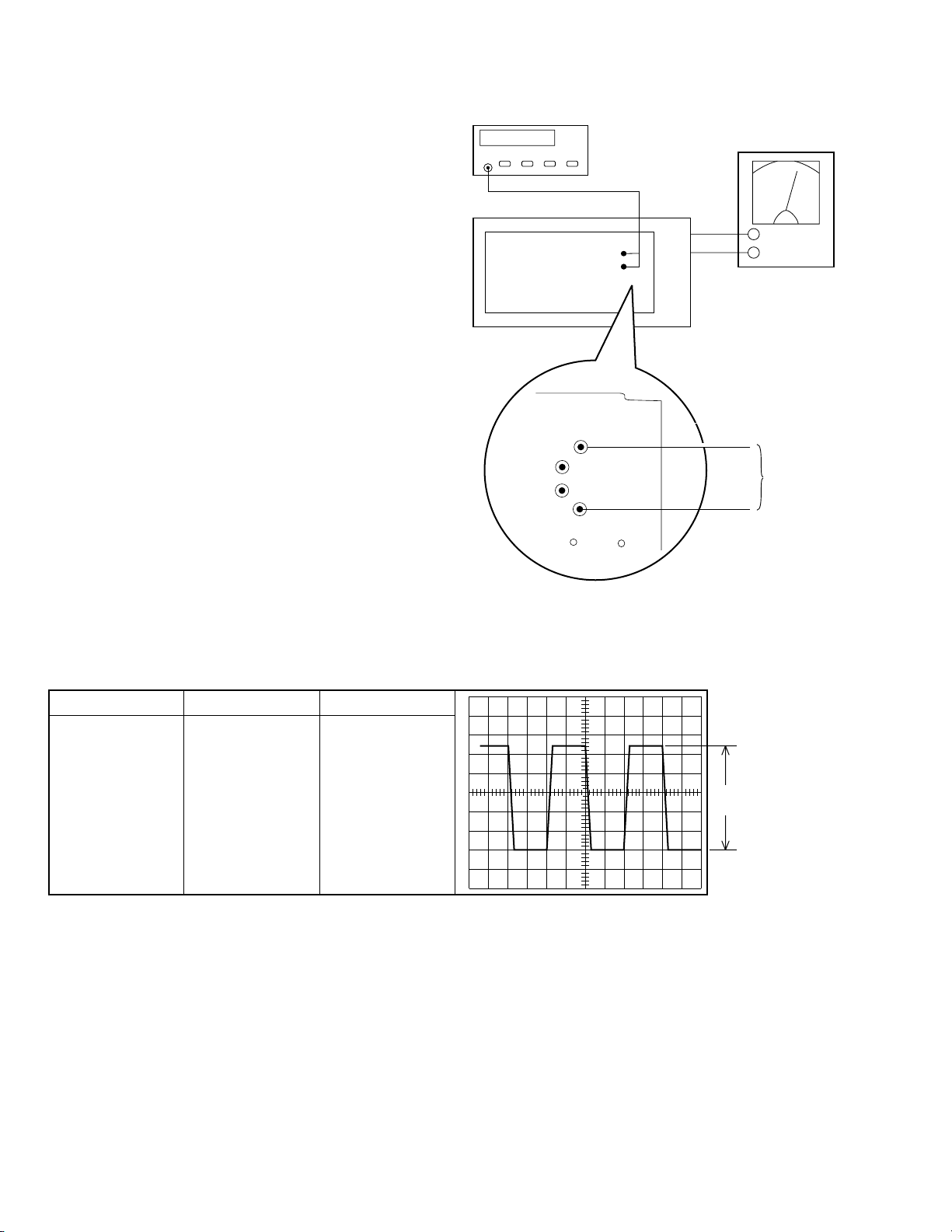

Adjustment method

Check the voltage and frequency of the secondary

1.

toroidal coil.

.

Measure the secondary toroidal coil, if the standard

2.

frequency value of 24.35 kHz ± 10 Hz is not attained,

measure the R760 terminal, then adjust the VR701

so that the R760 terminal becomes 24.25 kHz ± 10Hz.

FREQUENCY:24.35kHz ±10Hz

VOLTAGE VALUE:55Vp-p

FREQUENCY COUNTER

TEST SET

MAIN PCB

R760

(+)

(

POWER SUPPLY

14.4V

-

)

Measuring

Points

Note:

When measuring, adjust and apply power

with no signal or load on each board.

DC/DC CONVERTER SECOND GENERATOR SWITCHING

TEST ITEM

VOLTAGE TEST

FREQUENCY CHECK

SPECIFICATION CONDITION

88Vp-p±2.5V

24.350KHz±10Hz

OSCILLOSCOPE

VOLT/DIV: 10

TIME/DIV: 10mcec

VARIABLE: MINIMUM

88Vp-p

±2.5V

1-8

Loading...

Loading...