Page 1

SERVICE MANUAL

POWER AMPLIFIER

KS-AX4500

KS-AX4500KS-AX4500

Caution

If electricity is connected during disassembly, it must be a no load current. If it is load

current, be sure to attach a heat sink to the power-amp IC. This will be damaged if the

above precautions are not followed, as it does not have a sub heat sink attached to it.

Contents

Safety precaution

Location of main parts

Removal of main parts

Test method

Description of major ICs

1-2

1-3

1-5

1-7

1-8

Area Suffix

E

Continental Europe

J

Northern America

COPYRIGHT 2001 VICTOR COMPANY OF JAPAN, LTD.

No. 49622

Apr. 2001

Page 2

KS-AX4500

CAUTION

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

1-2

Page 3

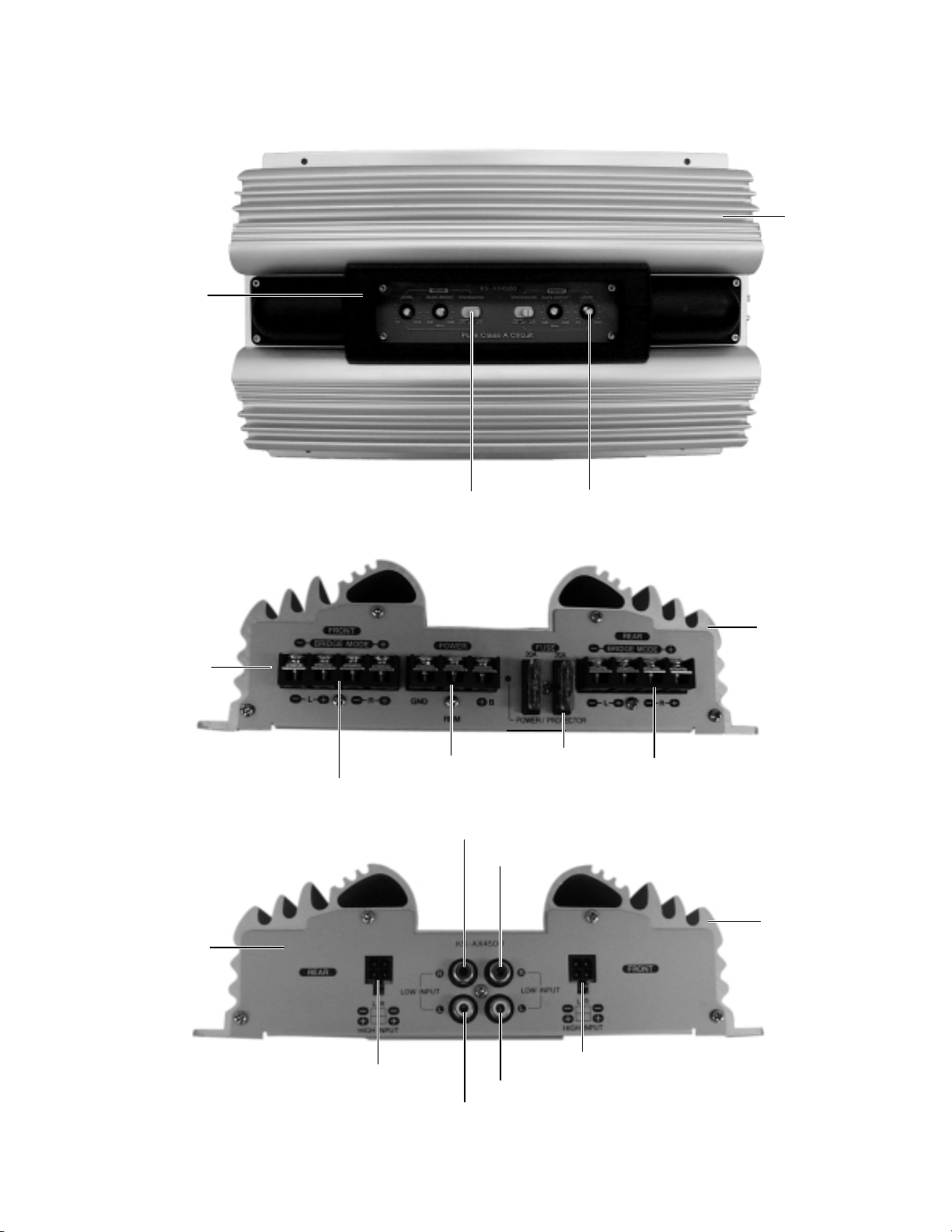

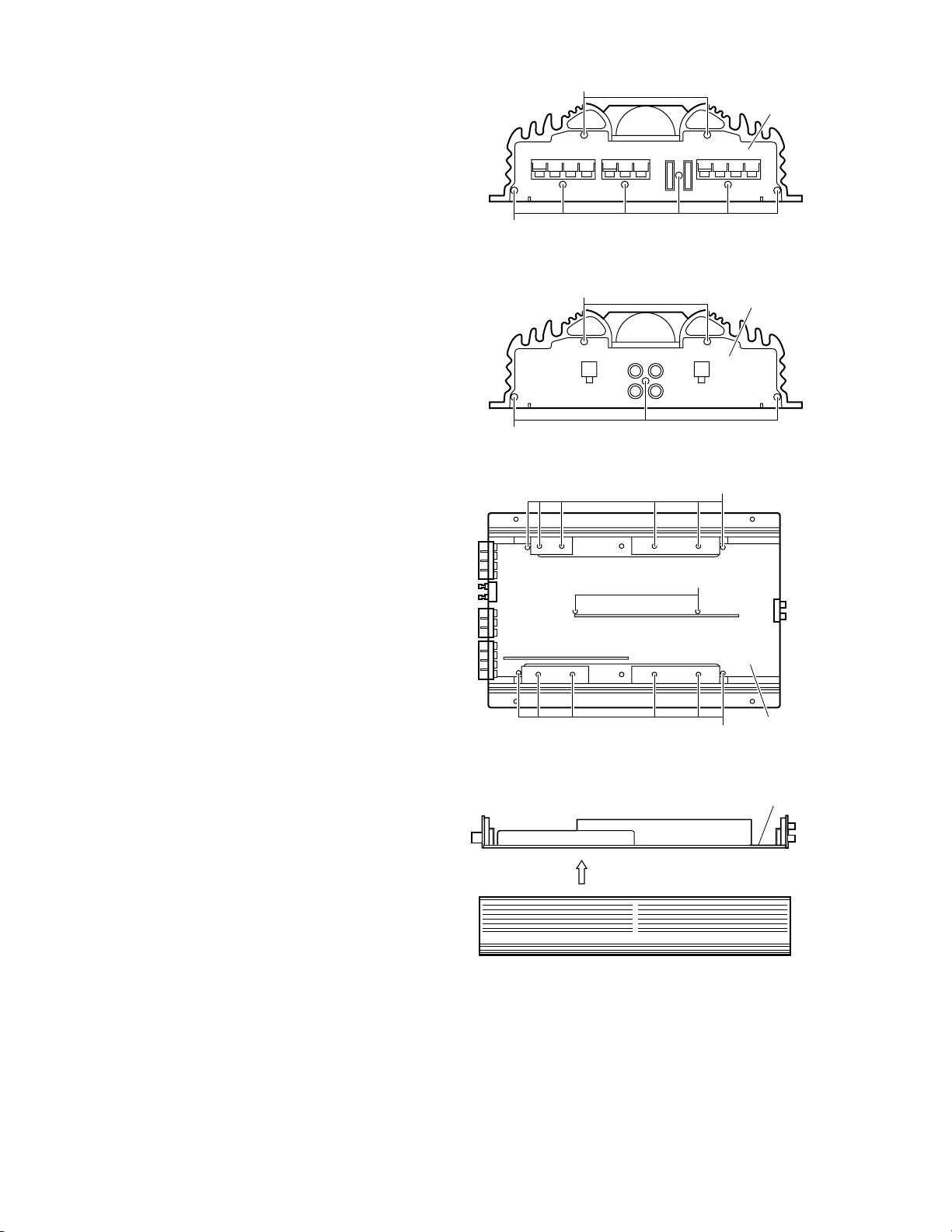

Location of main parts

CONTROL PANEL

KS-AX4500

HEAT SINK

REAR PANEL

OUTPUT TERMINAL for FRONT(L/R)

FRONT PANEL

SWITCH KNOB VOLUME KNOB

INPUT for POWER

LOW INPUT jack for REAR(R)

LOW INPUT jack for FRONT(R)

FUSE

HEAT SINK

OUTPUT TERMINAL for REAR(L/R)

HEAT SINK

HIGH INPUT connector for REAR

LOW INPUT jack for REAR(L)

HIGH INPUT connector for FRONT

LOW INPUT jack for FRONT(L)

1-3

Page 4

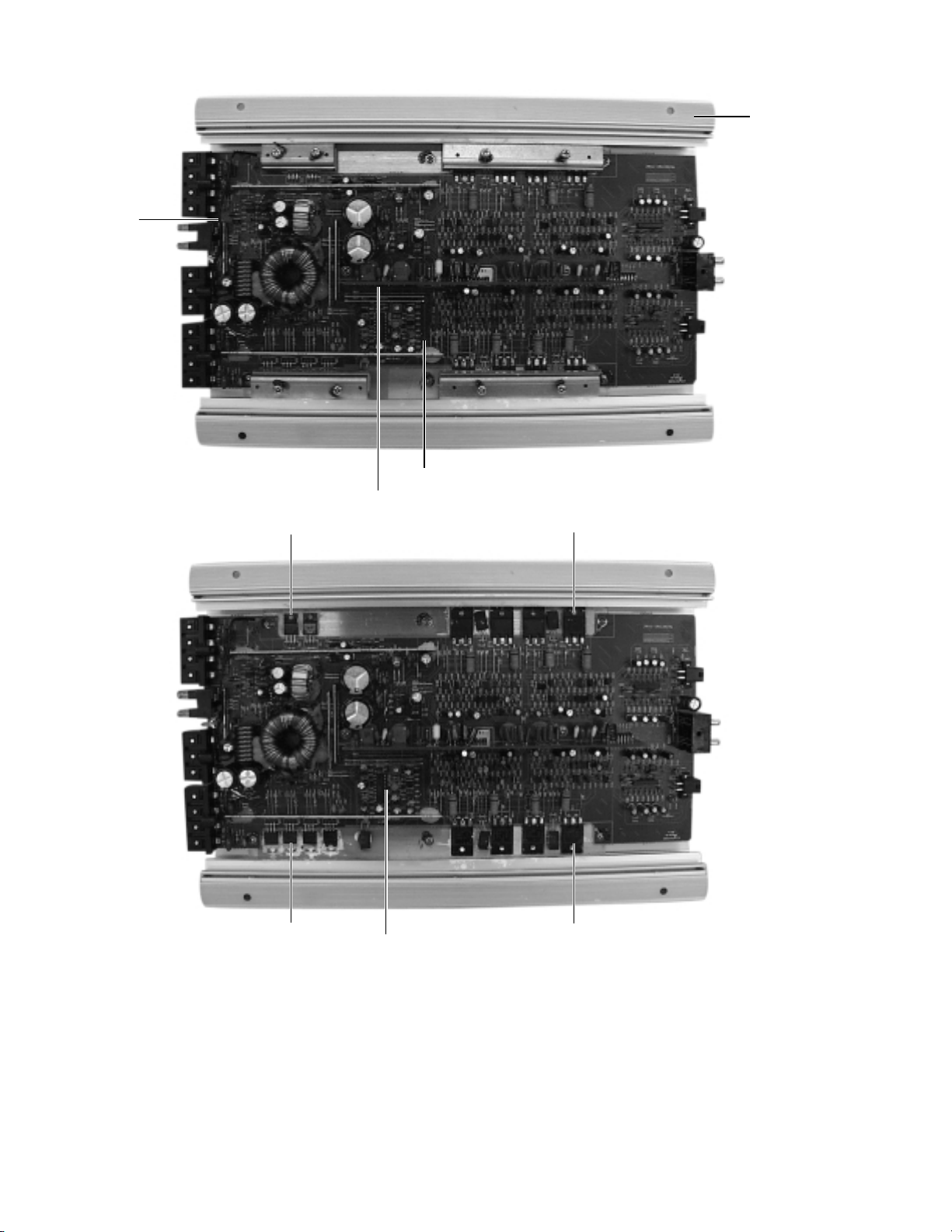

KS-AX4500

GND wire

DIODE

HEAT SINK

(Bottom view)

MAIN PCB

SUB PCB

POWER TRANSISTER

1-4

POWER FET

MAIN PCB

POWER TRANSISTER

Page 5

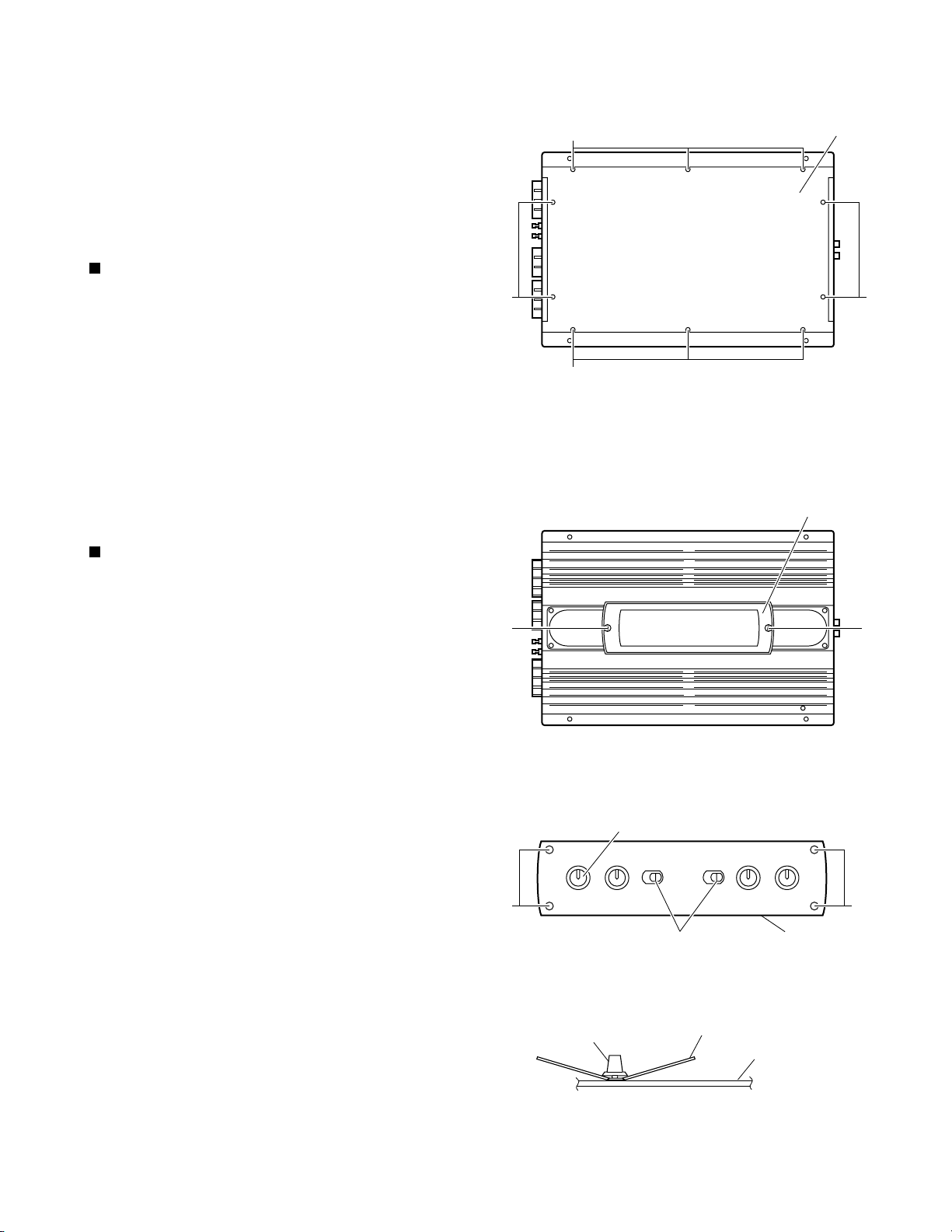

Removal of main parts

KS-AX4500

CAUTION:

If electricity is connected during disassembly,

it must be a no load current. If it is load

current, be sure to attach a heat sink to the

power-amp IC. This will be damaged if the

above precautions are not followed, as it

does not have a sub heat sink attached to it.

Removing the bottom cover (see Fig. 1)

1.

From the bottom side of the main unit, remove the 4

screws A retaining the bottom cover.

2.

Then remove the 6 screws B retaining the bottom

cover.

3.

Remove the bottom cover.

Removing the MAIN PCB

(see Fig. 2 to 8)

1.

Remove the bottom cover from the main unit.

A

B

B

Bottom cover

A

Fig. 1

Top panel

2.

Loosen and remove the 2 screws C retaining the top

plate on the main unit. (Stoppers are attached to the

backs of the C screws so that they cannot be

removed easily.)

3.

Remove the 4 volume knobs on top of the control

panel. If it cannot be pulled out easily, insert a rope

or wire between the base of the volume knob and the

control panel so that the volume knob is raised a little

above the surface and then remove it.

(Be careful when inserting a lever etc. not to

scratch the surface of the control panel).

4.

Remove the 4 screws D retaining the control panel.

Then detach the control panel and the switch knobs.

C

Fig. 2

Volume knob

D D

Volume knob

Switch knob

Fig. 3

Rope or wire

Control panel

Control panel

C

(Side view)

Fig. 4

1-5

Page 6

KS-AX4500

5.

Remove the 13 screws E retaining the panels on

both sides of the main unit.

E

Rear panel

6.

Remove the 14 screws F attaching the MAIN PCB to

the bottom of the main unit.

E

E

E

Fig. 5

Front panel

Fig. 6

F

F

7.

Remove the MAIN PCB by lift up the arrow mark.

MAIN PCB

F

Fig. 7

MAIN PCB

(Side view)

Fig. 8

1-6

Page 7

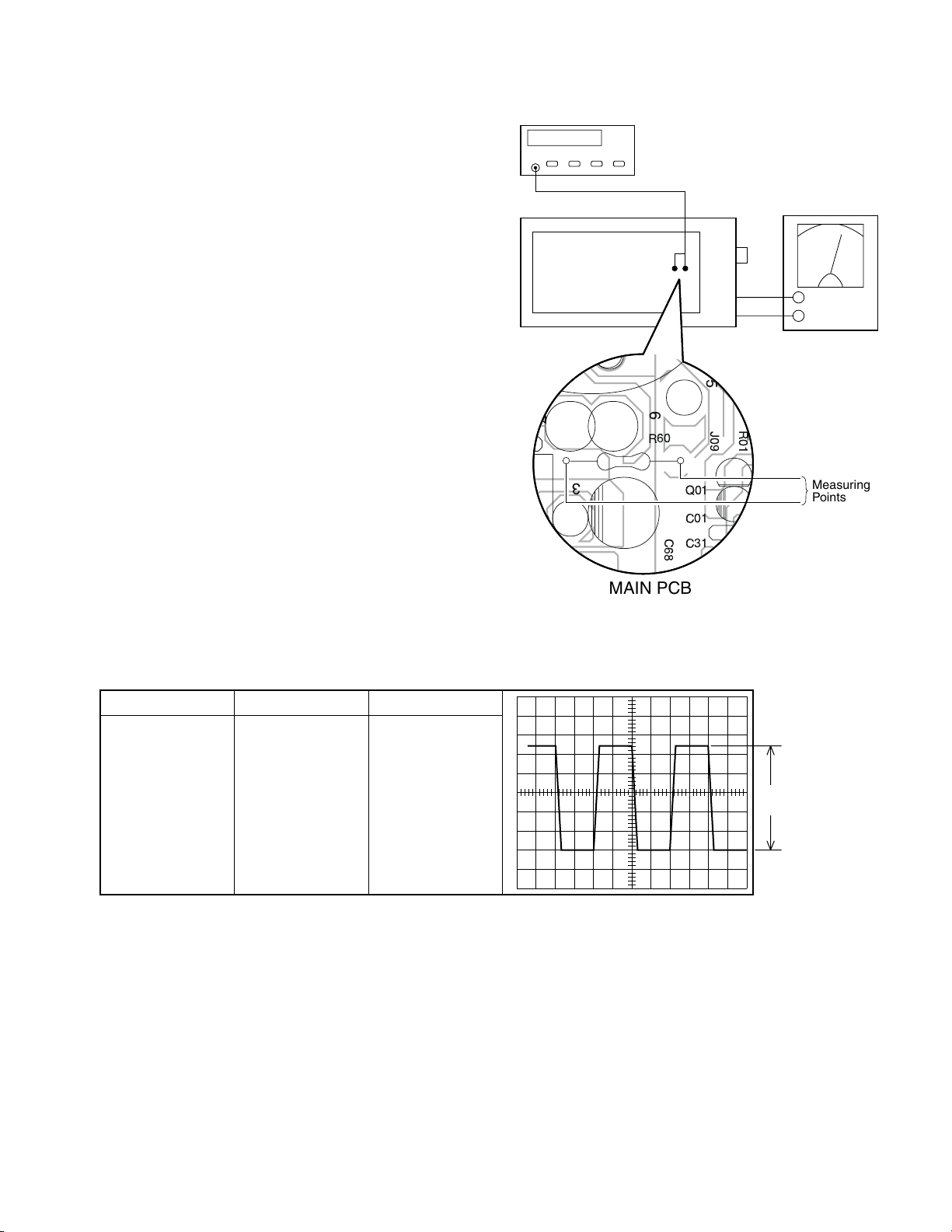

Test method

5

6

7

3

R01

R60

C01

J09

Q01

C31

C68

Check the voltage and frequency of the secondary

1.

toroidal coil.

KS-AX4500

FREQUENCY COUNTER

.

Measure the secondary toroidal coil, if the standard

2.

FREQUENCY:22.87kHz ± 50Hz

VOLTAGE VALUE:60Vp-p ± 2.5V

frequency value of 22.87 kHz ± 50 Hz is not attained,

measure the R60 terminal, then adjust the SV01 so

that the R60 terminal becomes 22.87 kHz ± 50Hz.

Note:

When measuring, adjust and apply power

with no signal or load on each board.

TEST SET

MAIN PCB

MAIN PCB

(+)

(

POWER SUPPLY

14.4V

-

)

Measuring

Points

DC/DC CONVERTER SECOND GENERATOR SWITCHING

TEST ITEM

VOLTAGE TEST

FREQUENCY CHECK

SPECIFICATION CONDITION

60Vp-p±2.5V

22.87KHz±50Hz

OSCILLOSCOPE

VOLT/DIV: 10

TIME/DIV: 10mcec

60Vp-p

±2.5V

1-7

Page 8

KS-AX4500

Description of major ICs

PIN CONNECTIONS

Noninv

Input

Inv

Input

Compen/PWN

Comp Input

Dead Time

Control

C

R

Ground

C1

1

2

3

4

5

T

6

T

7

8

(TOP View)

16

15

14

13

12

11

10

9

Noninv

Input

Inv

Input

V

ref

Output

Control

V

CC

C2

E2

E1

TL494

6

5

4

1

Oscillator

0.12V

0.7V

0.7mA

Dead-Time

Comparator

PWM

Comparator

2

FlipFlop

Ck Q

UV

Lockout

QD

3.5V

13

8

Q1

9

11

Q2

10

12

4.9V

Reference

Regulator

7141615321

1-8

Page 9

VICTOR COMPANY OF JAPAN, LIMITED

MOBILE ELECTRONICS DIVISION

PERSONAL & MOBILE NETWORK B.U. 10-1,1Chome,Ohwatari-machi,Maebashi-city,Japan

(No. 49622)

Printed in Japan

200104(S)

Page 10

PARTS LIST

KS-AX4500

* All printed circuit boards and its assemblies are not available as service parts.

Areas suffix

KS-AX4500

- Contents -

Exploded view of enclosure assembly and parts list

Electrical parts List

Packing and accessories

E ------------ Continental Europe

J -------------- Northern America

3-2

3-4

3-9

3-1

Page 11

KS-AX4500

Exploded view of enclosure assembly and parts list

7

28

Block No.

M

1

M

M

21

28

30

24

5

24

2

8

9

9

11

30

24

20

2/4

24

6

21

21

3

21

1

16

13

12

17

15

14

21

21

23

23

21

20

1/4

18

26

19

18

26

19

17

15

27

14

23

25

13

20

19

22

3/4

27

23

29

18

16

12

10

20

26

26

19

4/4

22

4

22

22

22

3-2

22

22

Page 12

KS-AX4500

Parts list ( Enclosure assembly )

Item Parts number Parts name Area

A

MA-HS-IT-1123-1

1

MA-FP-IT-6411-1

2

MA-RP-IT-6412-1

3

MA-BC-IT-6415-2

4

MA-SD-06-1924-0

5

MA-TC-03-1122-0

6

MA-TC-04-1922-0

7

MO-KB-07-6023-2

8

MO-KB-07-6024-1

9

MA-SH-IT-6416-1

10

MA-SH-IT-6417-1

11

MA-BR-03-4116-0

12

MA-BR-03-4117-0

13

MA-BR-03-4180-0

14

MA-BR-03-4181-0

15

MO-CU-02-4866-1

16

MO-CU-02-4195-1

17

MO-CU-01-4097-1

18

MO-CU-01-4097-0

19

MA-SP-02-1901-0

20

MNSC-04-3-30-08

21

MNSC-04-2-30-06

22

MNC-00-3-40-14

23

MNSC-04-6-30-06

24

MZSC-04-5-30-08

25

MZSC-04-5-30-13

26

MZSC-04-5-30-10

27

MNSC-00-1-40-7

28

MNSC-04-3-30-06

29

MOWA-05-8085-0

30

MAIN HEAT SINK

FRONT PANEL

REAR PANEL

BOTTOM COVER

CONTROL PANEL

PIPE

TOP PANEL

VOLUME KNOB

SWITCH KNOB

SUB HEAT SINK-A

SUB HEAT SINK-B

TR BRACKET-C

TR BRACKET-D

TR BRACKET-E

TR BRACKET-F

TR/BKT CUSHION-B

TR/BKT CUSHION-C

RUBBER CUSH.-A

RUBBER CUSH.-B

SILICON PAD

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW (SPECIFIC)

SCREW

POLY WASHER

Q'ty Description

1

1

1

1

1

1

1

4

2

1

1

2

2

2

2

2

2

5

4

1

13

10

8

8

2

4

2

2

4

2

430mm(107.5mm 4)

Block No. M1MM

3-3

Page 13

KS-AX4500

Electrical parts list

Electrical parts list (P.C.board)

Item

A

C 01 ELE10UF/16V E.CAPACITOR ELECTROLYTIC

C 03 MAL105J/50V M.CAPACITOR MYLAR 63V 5%

C 09 MAL104J/50V M.CAPACITOR MYLAR 50V 5%

C 11 ELE2200UF/25V E.CAPACITOR ELECTROLYTIC

C 12 ELE2200UF/25V E.CAPACITOR ELECTROLYTIC

C 13 CER104PF/50V C.CAPACITOR CERAMIC DISK 50

C 15 CER104PF/50V C.CAPACITOR CERAMIC DISK 50

C 16 MAL334J/50V M.CAPACITOR MYLAR 50V 5%

C 17 ELE47UF/16V E.CAPACITOR ELECTROLYTIC

C 18 ELE100UF/16V E.CAPACITOR ELECTROLYTIC

C 19 ELE100UF/16V E.CAPACITOR ELECTROLYTIC

C 20 CER104PF/50V C.CAPACITOR CERAMIC DISK 50

C 21 ELE10UF/25V E.CAPACITOR ELECTROLYTIC

C 22 ELE47UF/25V E.CAPACITOR ELECTROLYTIC

C 23 ELE100UF/16V E.CAPACITOR ELECTROLYTIC

C 24 MAL103M/50V M CAPACITOR MYLAR 50V 5%

C 25 MAL103M/50V M CAPACITOR MYLAR 50V 5%

C 27 CER473PF/50V C.CAPACITOR CERAMIC DISK 50

C 31 MAL104J/50V M.CAPACITOR MYLAR 50V 5%

C 40 MAL102G S.CAPACITOR STYCON

C 41 ELE100UF/16V E.CAPACITOR ELECTROLYTIC

C 60 MAL222J/50V M.CAPACITOR MYLAR 50V 5%

C 61 ELE2.2UF/50V E.CAPACITOR ELECTROLYTIC

C 62 ELE2.2UF/50V E.CAPACITOR ELECTROLYTIC

C 63 ELE220UF/16V E.CAPACITOR ELECTROLYTIC

C 64 ELE220UF/16V E.CAPACITOR ELECTROLYTIC

C 65 CER104PF/50V C.CAPACITOR CERAMIC DISK 50

C 66 CER104PF/50V C.CAPACITOR CERAMIC DISK 50

C 67 ELE470UF/35V E.CAPACITOR ELECTROLYTIC

C 68 ELE470UF/35V E.CAPACITOR ELECTROLYTIC

C 69 ELE3300UF/35V E.CAPACITOR ELECTROLYTIC

C 70 ELE3300UF/35V E.CAPACITOR ELECTROLYTIC

C 73 CER473PF/50V C.CAPACITOR CERAMIC DISK 50

C 74 CER473PF/50V C.CAPACITOR CERAMIC DISK 50

C 80 CER22PF/50V C.CAPACITOR CERAMIC DISK 50

C 81 ELE10UF/50V E.CAPACITOR ELECTROLYTIC

C 91 CER104PF/50V C.CAPACITOR CERAMIC DISK 50

C 92 CER104PF/50V C.CAPACITOR CERAMIC DISK 50

C 93 CER104PF/50V C.CAPACITOR CERAMIC DISK 50

C 100 ELE330UF/25V(NP E CAPACITOR ELECTROLYTIC(NP

C 101 ELE4.7UF/50V E.CAPACITOR ELECTROLYTIC

C 102 ELE4.7UF/50V E.CAPACITOR ELECTROLYTIC

C 104 CER22PF/50V C.CAPACITOR CERAMIC DISK 50

C 105 CER100PF/50V C.CAPACITOR CERAMIC DISK 50

C 106 CER22PF/50V C.CAPACITOR CERAMIC DISK 50

C 107 ELE4.7UF/50V E.CAPACITOR ELECTROLYTIC

C 108 SMD68PF/50V CAPACITOR SMD 0805 50V 5

C 111 SMD47PF/50V CAPACITOR SMD 0805 50V 5

C 112 MAL224J/50V M.CAPACITOR MYLAR 50V 5%

C 113 MAL183J/50V M.CAPACITOR MYLAR 50V 5%

C 114 MAL104J/50V M.CAPACITOR MYLAR 50V 5%

C 115 MAL473J/50V M.CAPACITOR MYLAR 50V 5%

C 116 MAL473J/50V M.CAPACITOR MYLAR 50V 5%

C 117 MAL473J/50V M.CAPACITOR MYLAR 50V 5%

C 130 ELE4.7UF/50V E.CAPACITOR ELECTROLYTIC

C 131 ELE4.7UF/50V E.CAPACITOR ELECTROLYTIC

C 132 CER68PF/50V C.CAPACITOR CERAMIC DISK 50

C 133 ELE22UF/16V E.CAPACITOR ELECTROLYTIC

C 134 ELE22UF/16V E.CAPACITOR ELECTROLYTIC

C 135 CER150PF/50V C.CAPACITOR CERAMIC DISK 50

C 136 MAL473J/50V M.CAPACITOR MYLAR 50V 5%

C 137 CER150PF/50V C.CAPACITOR CERAMIC DISK 50

C 138 CER56PF/50V C.CAPACITOR CERAMIC DISK 50

Parts number Parts name Area

Remarks

Block No. 01

Item

A

C 139 ELE100UF/16V E.CAPACITOR ELECTROLYTIC

C 140 CER150PF/50V C.CAPACITOR CERAMIC DISK 50

C 141 MAL104J/50V M.CAPACITOR MYLAR 50V 5%

C 142 CER104PF/50V C.CAPACITOR CERAMIC DISK 50

C 151 ELE220UF/16V E.CAPACITOR ELECTROLYTIC

C 161 ELE4.7UF/50V E.CAPACITOR ELECTROLYTIC

C 162 ELE4.7UF/50V E.CAPACITOR ELECTROLYTIC

C 163 CER102PF/50V C.CAPACITOR CERAMIC DISK 50

C 164 CER102PF/50V C.CAPACITOR CERAMIC DISK 50

C 191 CER104PF/50V C.CAPACITOR CERAMIC DISK 50

C 192 SMD473PF/50V CAPACITOR SMD 0805 50V 5

C 193 SMD473PF/50V CAPACITOR SMD 0805 50V 5

C 194 SMD473PF/50V CAPACITOR SMD 0805 50V 5

C 195 SMD473PF/50V CAPACITOR SMD 0805 50V 5

C 196 SMD473PF/50V CAPACITOR SMD 0805 50V 5

C 201 ELE4.7UF/50V E.CAPACITOR ELECTROLYTIC

C 202 ELE4.7UF/50V E.CAPACITOR ELECTROLYTIC

C 204 CER22PF/50V C.CAPACITOR CERAMIC DISK 50

C 205 CER100PF/50V C.CAPACITOR CERAMIC DISK 50

C 206 CER22PF/50V C.CAPACITOR CERAMIC DISK 50

C 207 ELE4.7UF/50V E.CAPACITOR ELECTROLYTIC

C 208 SMD36PF/50V CAPACITOR SMD 0805 50V 5

C 211 SMD47PF/50V CAPACITOR SMD 0805 50V 5

C 212 MAL224J/50V M.CAPACITOR MYLAR 50V 5%

C 213 MAL183J/50V M.CAPACITOR MYLAR 50V 5%

C 214 MAL104J/50V M.CAPACITOR MYLAR 50V 5%

C 215 MAL473J/50V M.CAPACITOR MYLAR 50V 5%

C 216 MAL473J/50V M.CAPACITOR MYLAR 50V 5%

C 217 MAL473J/50V M.CAPACITOR MYLAR 50V 5%

C 230 ELE4.7UF/50V E.CAPACITOR ELECTROLYTIC

C 231 ELE4.7UF/50V E.CAPACITOR ELECTROLYTIC

C 232 CER68PF/50V C.CAPACITOR CERAMIC DISK 50

C 233 ELE22UF/16V E.CAPACITOR ELECTROLYTIC

C 234 ELE22UF/16V E.CAPACITOR ELECTROLYTIC

C 235 CER150PF/50V C.CAPACITOR CERAMIC DISK 50

C 236 MAL473J/50V M.CAPACITOR MYLAR 50V 5%

C 237 CER150PF/50V C.CAPACITOR CERAMIC DISK 50

C 238 CER56PF/50V C.CAPACITOR CERAMIC DISK 50

C 239 ELE100UF/16V E.CAPACITOR ELECTROLYTIC

C 240 CER150PF/50V C.CAPACITOR CERAMIC DISK 50

C 241 MAL104J/50V M.CAPACITOR MYLAR 50V 5%

C 261 ELE4.7UF/50V E.CAPACITOR ELECTROLYTIC

C 262 ELE4.7UF/50V E.CAPACITOR ELECTROLYTIC

C 263 CER102PF/50V C.CAPACITOR CERAMIC DISK 50

C 264 CER102PF/50V C.CAPACITOR CERAMIC DISK 50

C 291 CER104PF/50V C.CAPACITOR CERAMIC DISK 50

C 292 SMD473PF/50V CAPACITOR SMD 0805 50V 5

C 293 SMD473PF/50V CAPACITOR SMD 0805 50V 5

C 294 SMD473PF/50V CAPACITOR SMD 0805 50V 5

C 295 SMD473PF/50V CAPACITOR SMD 0805 50V 5

C 296 SMD473PF/50V CAPACITOR SMD 0805 50V 5

C 301 ELE4.7UF/50V E.CAPACITOR ELECTROLYTIC

C 302 ELE4.7UF/50V E.CAPACITOR ELECTROLYTIC

C 304 CER22PF/50V C.CAPACITOR CERAMIC DISK 50

C 305 CER100PF/50V C.CAPACITOR CERAMIC DISK 50

C 306 CER22PF/50V C.CAPACITOR CERAMIC DISK 50

C 307 ELE4.7UF/50V E.CAPACITOR ELECTROLYTIC

C 308 SMD68PF/50V CAPACITOR SMD 0805 50V 5

C 311 SMD47PF/50V CAPACITOR SMD 0805 50V 5

C 312 MAL224J/50V M.CAPACITOR MYLAR 50V 5%

C 313 MAL183J/50V M.CAPACITOR MYLAR 50V 5%

C 314 MAL104J/50V M.CAPACITOR MYLAR 50V 5%

C 315 MAL473J/50V M.CAPACITOR MYLAR 50V 5%

Parts number Parts name Area

Remarks

3-4

Page 14

KS-AX4500

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Electrical parts list (P.C.board)

Item

A

C 316 MAL473J/50V M.CAPACITOR MYLAR 50V 5%

C 317 MAL473J /50V M CAPACITOR MYLAR 50V 5%

C 330 ELE4.7UF/50V E.CAPACITOR ELECTROLYTIC

C 331 ELE4.7UF/50V E.CAPACITOR ELECTROLYTIC

C 332 CER68PF/50V C.CAPACITOR CERAMIC DISK 50

C 333 ELE22UF/16V E.CAPACITOR ELECTROLYTIC

C 334 ELE22UF/16V E.CAPACITOR ELECTROLYTIC

C 335 CER150PF/50V C.CAPACITOR CERAMIC DISK 50

C 336 MAL473J/50V M.CAPACITOR MYLAR 50V 5%

C 337 CER150PF/50V C.CAPACITOR CERAMIC DISK 50

C 338 CER56PF/50V C.CAPACITOR CERAMIC DISK 50

C 339 ELE100UF/16V E.CAPACITOR ELECTROLYTIC

C 340 CER150PF/50V C.CAPACITOR CERAMIC DISK 50

C 341 MAL104J/50V M.CAPACITOR MYLAR 50V 5%

C 342 CER104PF/50V C.CAPACITOR CERAMIC DISK 50

C 361 ELE4.7UF/50V E.CAPACITOR ELECTROLYTIC

C 362 ELE4.7UF/50V E.CAPACITOR ELECTROLYTIC

C 363 CER102PF/50V C.CAPACITOR CERAMIC DISK 50

C 364 CER102PF/50V C.CAPACITOR CERAMIC DISK 50

C 391 CER104PF/50V C.CAPACITOR CERAMIC DISK 50

C 392 SMD473PF/50V CAPACITOR SMD 0805 50V 5

C 393 SMD473PF/50V CAPACITOR SMD 0805 50V 5

C 394 SMD473PF/50V CAPACITOR SMD 0805 50V 5

C 395 SMD473PF/50V CAPACITOR SMD 0805 50V 5

C 396 SMD473PF/50V CAPACITOR SMD 0805 50V 5

C 401 ELE4.7UF/50V E.CAPACITOR ELECTROLYTIC

C 402 ELE4.7UF/50V E.CAPACITOR ELECTROLYTIC

C 403 CER103PF/50V C CAPACITOR CERAMIC DISK 50

C 404 CER22PF/50V C.CAPACITOR CERAMIC DISK 50

C 405 CER100PF/50V C.CAPACITOR CERAMIC DISK 50

C 406 CER22PF/50V C.CAPACITOR CERAMIC DISK 50

C 407 ELE4.7UF/50V E.CAPACITOR ELECTROLYTIC

C 408 SMD36PF/50V CAPACITOR SMD 0805 50V 5

C 411 SMD47PF/50V CAPACITOR SMD 0805 50V 5

C 412 MAL224J/50V M.CAPACITOR MYLAR 50V 5%

C 413 MAL183J/50V M.CAPACITOR MYLAR 50V 5%

C 414 MAL104J/50V M.CAPACITOR MYLAR 50V 5%

C 415 MAL473J/50V M.CAPACITOR MYLAR 50V 5%

C 416 MAL473J/50V M.CAPACITOR MYLAR 50V 5%

C 417 MAL473J/50V M.CAPACITOR MYLAR 50V 5%

C 430 ELE4.7UF/50V E.CAPACITOR ELECTROLYTIC

C 431 ELE4.7UF/50V E.CAPACITOR ELECTROLYTIC

C 432 CER68PF/50V C.CAPACITOR CERAMIC DISK 50

C 433 ELE22UF/16V E.CAPACITOR ELECTROLYTIC

C 434 ELE22UF/16V E.CAPACITOR ELECTROLYTIC

C 435 CER150PF/50V C.CAPACITOR CERAMIC DISK 50

C 436 MAL473J/50V M.CAPACITOR MYLAR 50V 5%

C 437 CER150PF/50V C.CAPACITOR CERAMIC DISK 50

C 438 CER56PF/50V C.CAPACITOR CERAMIC DISK 50

C 439 ELE100UF/16V E.CAPACITOR ELECTROLYTIC

C 440 CER150PF/50V C.CAPACITOR CERAMIC DISK 50

C 441 MAL104J/50V M.CAPACITOR MYLAR 50V 5%

C 461 ELE4.7UF/50V E.CAPACITOR ELECTROLYTIC

C 462 ELE4.7UF/50V E.CAPACITOR ELECTROLYTIC

C 463 CER102PF/50V C.CAPACITOR CERAMIC DISK 50

C 464 CER102PF/50V C.CAPACITOR CERAMIC DISK 50

C 491 CER04PF/50V C CAPACITOR CERAMIC DISK 50

C 492 SMD473PF/50V CAPACITOR SMD 0805 50V 5

C 493 SMD473PF/50V CAPACITOR SMD 0805 50V 5

C 494 SMD473PF/50V CAPACITOR SMD 0805 50V 5

C 495 SMD473PF/50V CAPACITOR SMD 0805 50V 5

C 496 SMD473PF/50V CAPACITOR SMD 0805 50V 5

D 01 1N5404 DIODE RECTIFIER

Parts number Parts name Area

Remarks

Block No. 01

Item

A

D 02 1N4004 DIODE RECTIFIER

D 05 1N4148 GE DIODE SWITCHING SIGNA

D 10 1N4148 GE DIODE SWITCHING SIGNA

D 11 1N4148 GE DIODE SWITCHING SIGNA

D 31 FR154 DIODE FAST RECOVERY

D 32 FR154 DIODE FAST RECOVERY

D 34 FR154 DIODE FAST RECOVERY

D 35 FR154 DIODE FAST RECOVERY

D 51 YG225D2 DIODE(BRIDGE) FAST RECOVERY

D 52 YG225D2 DIODE(BRIDGE) FAST RECOVERY

D 53 1N4744 ZENER DIODE

D 54 1N4744 ZENER DIODE

D 70 1N4148 GE DIODE SWITCHING SIGNA

D 71 1N4148 GE DIODE SWITCHING SIGNA

D 101 1N4148 GE DIODE SWITCHING SIGNA

D 201 1N4148 GE DIODE SWITCHING SIGNA

D 301 1N4148 GE DIODE SWITCHING SIGNA

D 401 1N4148 GE DIODE SWITCHING SIGNA

F 1 FUSE20A/32V AUTO FUSE

A

F 01 FH-9604 FUSE HOLDER

HP 01 2X8P HEADER PIN GOLD PLATED

HP 02 2X2P HEADER PIN GOLD PLATED

HP 03 5P HEADER PIN GOLD PLATED

HP 04 4P HEADER PIN GOLD PLATED

JA 01 SY-SW0406G RCA JACK

JA 02 LAD-1140-04 WAFER

JA 03 LAD-1140-04 WAFER

LED01 SAM3270 LED

P 01 TM0006-00 TERMINAL

P 02 TM0009-00 TERMINAL

P 03 TM0009-00 TERMINAL

Parts number Parts name Area

01 KTA1023Y TRANSISTOR SMALL SIGNAL PN

02 KTC3198GR TRANSISTOR SMALL SIGNAL NP

05 KTA1266GR TRANSISTOR SMALL SIGNAL PN

06 KTA1266GR TRANSISTOR SMALL SIGNAL PN

07 KTC3198BL TRANSISTOR SMALL SIGNAL NP

08 KTA1268GR TRANSISTOR SMALL SIGNAL PN

31 KTC3198GR TRANSISTOR SMALL SIGNAL NP

32 KTC3198GR TRANSISTOR SMALL SIGNAL NP

40 KTA1266GR TRANSISTOR SMALL SIGNAL PN

41 KTA1266GR TRANSISTOR SMALL SIGNAL PN

45 FQP50N06 FET N-CH POWER MOSF

46 FQP50N06 FET N-CH POWER MOSF

55 FQP50N06 FET N-CH POWER MOSF

56 FQP50N06 FET N-CH POWER MOSF

80 KTK117 FET N-CH JFET

100 J108 FET MUTING JFET

101 KTC3198GR TRANSISTOR SMALL SIGNAL PN

102 KTA1266GR TRANSISTOR SMALL SIGNAL PN

103 KTA1266GR TRANSISTOR SMALL SIGNAL PN

104 KTA1266GR TRANSISTOR SMALL SIGNAL PN

105 KTA1268GR TRANSISTOR SMALL SIGNAL PN

106 KTC3200GR TRANSISTOR SMALL SIGNAL NP

107 KTC3200GR TRANSISTOR SMALL SIGNAL NP

108 KTC1027Y TRANSISTOR SMALL SIGNAL NP

109 KTA1023Y TRANSISTOR SMALL SIGNAL PN

110 KTD998 TRANSISTOR AUDIO POWER NPN

111 KTB778 TRANSISTOR AUDIO POWER PNP

112 KTC3200GR TRANSISTOR SMALL SIGNAL NP

113 KTC3198GR TRANSISTOR SMALL SIGNAL NP

200 J108 FET MUTING JFET

201 KTC3198GR TRANSISTOR SMALL SIGNAL NP

202 KTC3198GR TRANSISTOR SMALL SIGNAL NP

Remarks

3-5

Page 15

KS-AX4500

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Electrical parts list (P.C.board)

Item

A

R 01 CAR1/4WJ10 RESISTOR CARBON FILM 1/4

R 02 CAR1/5WJ4.7K RESISTOR CARBON FILM 1/5

R 03 CAR1/5WJ4.7K RESISTOR CARBON FILM 1/5

R 04 CAR1/5WJ4.7K RESISTOR CARBON FILM 1/5

R 05 CAR1/5WJ10K RESISTOR CARBON FILM 1/5

R 15 MET1/5WF130K RESISTOR METAL FILM 1/5W

R 16 MET1/5WF51K RESISTOR METAL FILM 1/5W

R 17 CAR1/5WJ4.7K RESISTOR CARBON FILM 1/5

R 18 CAR1/5WJ4.7K RESISTOR CARBON FILM 1/5

R 19 CAR1/5WJ10K RESISTOR CARBON FILM 1/5

R 20 CAR1/5WJ10K RESISTOR CARBON FILM 1/5

R 25 CAR1/5WJ10 RESISTOR CARBON FILM 1/5

R 26 CAR1/5WJ1K RESISTOR CARBON FILM 1/5

R 30 CAR1/5WJ1K RESISTOR CARBON FILM 1/5

R 31 CAR1/5WJ22K RESISTOR CARBON FILM 1/5

R 32 CAR1/5WJ33K RESISTOR CARBON FILM 1/5

R 33 CAR1/5WJ15K RESISTOR CARBON FILM 1/5

R 34 CAR1/5WJ15K RESISTOR CARBON FILM 1/5

R 35 CAR1/5WJ1.2K RESISTOR CARBON FILM 1/5

R 36 CAR1/5WJ51K RESISTOR CARBON FILM 1/5

R 37 CAR1/5WJ1.2K RESISTOR CARBON FILM 1/5

R 38 CAR1/5WJ10K RESISTOR CARBON FILM 1/5

R 39 CAR1/5WJ68K RESISTOR CARBON FILM 1/5

R 40 CAR1/5WJ27K RESISTOR CARBON FILM 1/5

R 41 MET1/5WF24K RESISTOR METAL FILM 1/5W

R 42 CAR1/4WJ220 RESISTOR CARBON FILM 1/4

Parts number Parts name Area

203 KTA1266GR TRANSISTOR SMALL SIGNAL PN

204 KTA1266GR TRANSISTOR SMALL SIGNAL PN

205 KTA1268GR TRANSISTOR SMALL SIGNAL PN

206 KTC3200GR TRANSISTOR SMALL SIGNAL NP

207 KTC3200GR TRANSISTOR SMALL SIGNAL NP

208 KTC1027Y TRANSISTOR SMALL SIGNAL NP

209 KTA1023Y TRANSISTOR SMALL SIGNAL PN

210 KTD998 TRANSISTOR AUDIO POWER NPN

211 KTB778 TRANSISTOR AUDIO POWER PNP

212 KTC3200GR TRANSISTOR SMALL SIGNAL NP

213 KTC3198GR TRANSISTOR SMALL SIGNAL NP

300 J108 FET MUTING JFET

301 KTC3198GR TRANSISTOR SMALL SIGNAL NP

302 KTC3198GR TRANSISTOR SMALL SIGNAL NP

303 KTA1266GR TRANSISTOR SMALL SIGNAL PN

304 KTA1266GR TRANSISTOR SMALL SIGNAL PN

305 KTA1268GR TRANSISTOR SMALL SIGNAL PN

306 KTC3200GR TRANSISTOR SMALL SIGNAL NP

307 KTC3200GR TRANSISTOR SMALL SIGNAL NP

308 KTC1027Y TRANSISTOR SMALL SIGNAL NP

309 KTA1023Y TRANSISTOR SMALL SIGNAL PN

310 KTD998 TRANSISTOR AUDIO POWER NPN

311 KTB778 TRANSISTOR AUDIO POWER PNP

312 KTC3200GR TRANSISTOR SMALL SIGNAL NP

400 J108 FET MUTING JFET

401 KTC3198GR TRANSISTOR SMALL SIGNAL NP

402 KTC3198GR TRANSISTOR SMALL SIGNAL NP

403 KTA1266GR TRANSISTOR SMALL SIGNAL PN

404 KTA1266GR TRANSISTOR SMALL SIGNAL PN

405 KTA1268GR TRANSISTOR SMALL SIGNAL PN

406 KTC3200GR TRANSISTOR SMALL SIGNAL NP

407 KTC3200GR TRANSISTOR SMALL SIGNAL NP

408 KTC1027Y TRANSISTOR SMALL SIGNAL NP

409 KTA1023Y TRANSISTOR SMALL SIGNAL PN

410 KTD998 TRANSISTOR AUDIO POWER NPN

411 KTB778 TRANSISTOR AUDIO POWER PNP

412 KTC3200GR TRANSISTOR SMALL SIGNAL NP

Remarks

Block No. 01

Item

A

R 43 CAR1/4WJ220 RESISTOR CARBON FILM 1/4

R 44 CAR1/5WJ1K RESISTOR CARBON FILM 1/5

R 45 CAR1/5WJ47 RESISTOR CARBON FILM 1/5

R 46 CAR1/5WJ47 RESISTOR CARBON FILM 1/5

R 47 MET2W10 RESISTOR METAL FILM 2WJ

R 54 CAR1/5WJ1K RESISTOR CARBON FILM 1/5

R 55 CAR1/5WJ47 RESISTOR CARBON FILM 1/5

R 56 CAR1/5WJ47 RESISTOR CARBON FILM 1/5

R 57 MET2W10 RESISTOR METAL FILM 2WJ

R 60 MET2W100 RESISTOR METAL FILM 2WJ

R 70 MET2W220 RESISTOR METAL FILM 2WJ

R 71 MET2W220 RESISTOR METAL FILM 2WJ

R 77 MET1/2WJ10K RESISTOR METAL FILM 1/2W

R 78 MET1/2WJ10K RESISTOR METAL FILM 1/2W

R 80 CAR1/5WJ220K RESISTOR CARBON FILM 1/5

R 81 CAR1/5WJ10K RESISTOR CARBON FILM 1/5

R 82 CAR1/5WJ2.2M RESISTOR CARBON FILM 1/5

R 90 CAR1/5WJ10K RESISTOR CARBON FILM 1/5

R 101 MET1/5WF22K RESISTOR METAL FILM 1/5W

R 102 MET1/5WF21.5K RESISTOR METAL FILM 1/5W

R 103 MET1/5WF22K RESISTOR METAL FILM 1/5W

R 105 MET1/5WF33K RESISTOR METAL FILM 1/5W

R 106 MET1/5WF33K RESISTOR METAL FILM 1/5W

R 108 SMD1/5WJ1K RESISTOR SMD 0805 1/5WJ

R 109 SMD1/5WF1.3K RESISTOR SMD 0805 1/5WF

R 110 SMD1/5WF15K RESISTOR SMD 0805 1/5WF

R 111 SMD1/5WF11K RESISTOR SMD 0805 1/5WF

R 112 SMD1/5WF30K RESISTOR SMD 0805 1/5WF

R 113 SMD1/5WJ1K RESISTOR SMD 0805 1/5WJ

R 114 SMD1/5WJ1K RESISTOR SMD 0805 1/5WJ

R 115 SMD1/5WJ1K RESISTOR SMD 0805 1/5WJ

R 116 SMD1/5WJ20K RESISTOR SMD 0805 1/5WJ

R 117 SMD1/5WJ100K RESISTOR SMD 0805 1/5WJ

R 118 SMD1/5WJ5.6K RESISTOR SMD 0805 1/5WJ

R 119 SMD1/5WJ470K RESISTOR SMD 0805 1/5WJ

R 121 SMD1/5WJ30K RESISTOR SMD 0805 1/5WJ

R 122 SMD1/5WJ30K RESISTOR SMD 0805 1/5WJ

R 123 SMD1/5WJ30K RESISTOR SMD 0805 1/5WJ

R 124 SMD1/5WJ62K RESISTOR SMD 0805 1/5WJ

R 130 CAR1/5WJ10K RESISTOR CARBON FILM 1/5

R 131 MET1/5WF5.6K RESISTOR METAL FILM 1/5W

R 132 MET1/5WF22K RESISTOR METAL FILM 1/5W

R 133 CAR1/5WJ1K RESISTOR CARBON FILM 1/5

R 134 CAR1/5WJ5.6K RESISTOR CARBON FILM 1/5

R 135 CAR1/5WJ5.6K RESISTOR CARBON FILM 1/5

R 136 CAR1/5WJ1K RESISTOR CARBON FILM 1/5

R 137 CAR1/5WJ1K RESISTOR CARBON FILM 1/5

R 138 CAR1/5WJ22 RESISTOR CARBON FILM 1/5

R 139 CAR1/5WJ22 RESISTOR CARBON FILM 1/5

R 140 CAR1/5WJ22 RESISTOR CARBON FILM 1/5

R 141 CAR1/5WJ22 RESISTOR CARBON FILM 1/5

R 142 CAR1/5WJ1K RESISTOR CARBON FILM 1/5

R 143 CAR1/5WJ 47 RESISTOR CARBON FILM 1/5

R 144 CAR1/5WJ 3.9K RESISTOR CARBON FILM 1/5

R 145 CAR1/5WJ2.7K RESISTOR CARBON FILM 1/5

R 146 CAR1/5WJ47 RESISTOR CARBON FILM 1/5

R 147 MET1/5WF12K RESISTOR METAL FILM 1/5W

R 148 MET1/5WF1K RESISTOR METAL FILM 1/5W

R 149 CAR1/5WJ220 RESISTOR CARBON FILM 1/5

R 150 MET3W0.1 RESISTOR

R 151 MET3W0.1 RESISTOR

R 152 CAR1/5WJ1.5K RESISTOR CARBON FILM 1/5

R 153 CAR1/5WJ15K RESISTOR CARBON FILM 1/5

Parts number Parts name Area

Remarks

3-6

Page 16

KS-AX4500

Electrical parts list (P.C.board)

Item

A

R 154 CAR1/5WJ56K RESISTOR CARBON FILM 1/5

R 155 MET1/2WJ4.7 RESISTOR METAL FILM 1/2W

R 156 MET2W680 RESISTOR METAL FILM 2WJ

R 161 MET1/5WF68K RESISTOR METAL FILM 1/5W

R 162 MET1/5WF68K RESISTOR METAL FILM 1/5W

R 163 CAR1/5WJ15K RESISTOR CARBON FILM 1/5

R 201 MET1/5WF22K RESISTOR METAL FILM 1/5W

R 202 MET1/5WF21.5K RESISTOR METAL FILM 1/5W

R 203 MET1/5WF22K RESISTOR METAL FILM 1/5W

R 205 MET1/5WF33K RESISTOR METAL FILM 1/5W

R 206 MET1/5WF33K RESISTOR METAL FILM 1/5W

R 208 SMD1/5WJ1K RESISTOR SMD 0805 1/5WJ

R 209 SMD1/5WF1.3K RESISTOR SMD 0805 1/5WF

R 210 SMD1/5WF15K RESISTOR SMD 0805 1/5WF

R 211 SMD1/5WJ12K RESISTOR SMD 0805 1/5WJ

R 212 SMD1/5WF56K RESISTOR SMD 0805 1/5WF

R 213 SMD1/5WJ1K RESISTOR SMD 0805 1/5WJ

R 214 SMD1/5WJ1K RESISTOR SMD 0805 1/5WJ

R 215 SMD1/5WJ1K RESISTOR SMD 0805 1/5WJ

R 216 SMD1/5WJ20K RESISTOR SMD 0805 1/5WJ

R 217 SMD1/5WJ100K RESISTOR SMD 0805 1/5WJ

R 218 SMD1/5WJ5.6K RESISTOR SMD 0805 1/5WJ

R 219 SMD1/5WJ470K RESISTOR SMD 0805 1/5WJ

R 221 SMD1/5WJ30K RESISTOR SMD 0805 1/5WJ

R 222 SMD1/5WJ30K RESISTOR SMD 0805 1/5WJ

R 223 SMD1/5WJ30K RESISTOR SMD 0805 1/5WJ

R 224 SMD1/5WJ62K RESISTOR SMD 0805 1/5WJ

R 230 CAR1/5WJ10K RESISTOR CARBON FILM 1/5

R 231 MET1/5WF5.6K RESISTOR METAL FILM 1/5W

R 232 MET1/5WF22K RESISTOR METAL FILM 1/5W

R 233 CAR1/5WJ1K RESISTOR CARBON FILM 1/5

R 234 CAR1/5WJ5.6K RESISTOR CARBON FILM 1/5

R 235 CAR1/5WJ5.6K RESISTOR CARBON FILM 1/5

R 236 CAR1/5WJ1K RESISTOR CARBON FILM 1/5

R 237 CAR1/5WJ1K RESISTOR CARBON FILM 1/5

R 238 CAR1/5WJ22 RESISTOR CARBON FILM 1/5

R 239 CAR1/5WJ22 RESISTOR CARBON FILM 1/5

R 240 CAR1/5WJ22 RESISTOR CARBON FILM 1/5

R 241 CAR1/5WJ22 RESISTOR CARBON FILM 1/5

R 242 CAR1/5WJ1K RESISTOR CARBON FILM 1/5

R 243 CAR1/5WJ47 RESISTOR CARBON FILM 1/5

R 244 CAR1/5WJ3.9K RESISTOR CARBON FILM 1/5

R 245 CAR1/5WJ2.7K RESISTOR CARBON FILM 1/5

R 246 CAR1/5WJ47 RESISTOR CARBON FILM 1/5

R 247 MET1/5WF12K RESISTOR METAL FILM 1/5W

R 248 MET1/5WF1K RESISTOR METAL FILM 1/5W

R 249 CAR1/5WJ220 RESISTOR CARBON FILM 1/5

R 250 MET3W0.1 RESISTOR

R 251 MET3W0.1 RESISTOR

R 252 CAR1/5WJ1.5K RESISTOR CARBON FILM 1/5

R 253 CAR1/5WJ15K RESISTOR CARBON FILM 1/5

R 254 CAR1/5WJ56K RESISTOR CARBON FILM 1/5

R 255 MET1/2WJ4.7 RESISTOR METAL FILM 1/2W

R 256 MET2W680 RESISTOR METAL FILM 2WJ

R 261 MET1/5WF68K RESISTOR METAL FILM 1/5W

R 262 MET1/5WF68K RESISTOR METAL FILM 1/5W

R 263 CAR1/5WJ15K RESISTOR CARBON FILM 1/5

R 301 MET1/5WF22K RESISTOR METAL FILM 1/5W

R 302 MET1/5WF21.5K RESISTOR METAL FILM 1/5W

R 303 MET1/5WF22K RESISTOR METAL FILM 1/5W

R 305 MET1/5WF33K RESISTOR METAL FILM 1/5W

R 306 MET1/5WF33K RESISTOR METAL FILM 1/5W

R 308 SMD1/5WJ1K RESISTOR SMD 0805 1/5WJ

Parts number Parts name Area

Remarks

Block No. 01

Item

A

R 309 SMD1/5WF1.3K RESISTOR SMD 0805 1/5WF

R 310 SMD1/5WF15K RESISTOR SMD 0805 1/5WF

R 311 SMD1/5WF11K RESISTOR SMD 0805 1/5WF

R 312 SMD1/5WF30K RESISTOR SMD 0805 1/5WF

R 313 SMD1/5WJ1K RESISTOR SMD 0805 1/5WJ

R 314 SMD1/5WJ1K RESISTOR SMD 0805 1/5WJ

R 315 SMD1/5WJ1K RESISTOR SMD 0805 1/5WJ

R 316 SMD1/5WJ20K RESISTOR SMD 0805 1/5WJ

R 317 SMD1/5WJ100K RESISTOR SMD 0805 1/5WJ

R 318 SMD1/5WJ5.6K RESISTOR SMD 0805 1/5WJ

R 319 SMD1/5WJ470K RESISTOR SMD 0805 1/5WJ

R 321 SMD1/5WJ30K RESISTOR SMD 0805 1/5WJ

R 322 SMD1/5WJ30K RESISTOR SMD 0805 1/5WJ

R 323 SMD1/5WJ30K RESISTOR SMD 0805 1/5WJ

R 324 SMD1/5WJ62K RESISTOR SMD 0805 1/5WJ

R 330 CAR1/5WJ10K RESISTOR CARBON FILM 1/5

R 331 MET1/5WF5.6K RESISTOR METAL FILM 1/5W

R 332 MET1/5WF22K RESISTOR METAL FILM 1/5W

R 333 CAR1/5WJ1K RESISTOR CARBON FILM 1/5

R 334 CAR1/5WJ5.6K RESISTOR CARBON FILM 1/5

R 335 CAR1/5WJ5.6K RESISTOR CARBON FILM 1/5

R 336 CAR1/5WJ1K RESISTOR CARBON FILM 1/5

R 337 CAR1/5WJ1K RESISTOR CARBON FILM 1/5

R 338 CAR1/5WJ22 RESISTOR CARBON FILM 1/5

R 339 CAR1/5WJ22 RESISTOR CARBON FILM 1/5

R 340 CAR1/5WJ22 RESISTOR CARBON FILM 1/5

R 341 CAR1/5WJ22 RESISTOR CARBON FILM 1/5

R 342 CAR1/5WJ1K RESISTOR CARBON FILM 1/5

R 343 CAR1/5WJ47 RESISTOR CARBON FILM 1/5

R 344 CAR1/5WJ3.9K RESISTOR CARBON FILM 1/5

R 345 CAR1/5WJ2.7K RESISTOR CARBON FILM 1/5

R 346 CAR1/5WJ47 RESISTOR CARBON FILM 1/5

R 347 MET1/5WF12K RESISTOR METAL FILM 1/5W

R 348 MET1/5WF1K RESISTOR METAL FILM 1/5W

R 349 CAR1/5WJ220 RESISTOR CARBON FILM 1/5

R 350 MET3W0.1 RESISTOR

R 351 MET3W0.1 RESISTOR

R 352 CAR1/5WJ1.5K RESISTOR CARBON FILM 1/5

R 353 CAR1/5WJ15K RESISTOR CARBON FILM 1/5

R 354 CAR1/5WJ56K RESISTOR CARBON FILM 1/5

R 355 MET1/2WJ4.7 RESISTOR METAL FILM 1/2W

R 356 MET2W680 RESISTOR METAL FILM 2WJ

R 361 MET1/5WF68K RESISTOR METAL FILM 1/5W

R 362 MET1/5WF68K RESISTOR METAL FILM 1/5W

R 363 CAR1/5WJ15K RESISTOR CARBON FILM 1/5

R 401 MET1/5WF22K RESISTOR METAL FILM 1/5W

R 402 MET1/5WF21.5K RESISTOR METAL FILM 1/5W

R 403 MET1/5WF22K RESISTOR METAL FILM 1/5W

R 404 CAR1/5WJ470 RESISTOR CARBON FILM 1/5

R 405 MET1/5WF33K RESISTOR METAL FILM 1/5W

R 406 MET1/5WF 33K RESISTOR METAL FILM 1/5W

R 408 SMD 1/5WJ1K RESISTOR SMD 0805 1/5WJ

R 409 SMD1/5WF1.3K RESISTOR SMD 0805 1/5WF

R 410 SMD1/5WF15K RESISTOR SMD 0805 1/5WF

R 411 SMD1/5WJ12K RESISTOR SMD 0805 1/5WJ

R 412 SMD1/5WF56K RESISTOR SMD 0805 1/5WF

R 413 SMD1/5WJ1K RESISTOR SMD 0805 1/5WJ

R 414 SMD1/5WJ1K RESISTOR SMD 0805 1/5WJ

R 415 SMD1/5WJ1K RESISTOR SMD 0805 1/5WJ

R 416 SMD1/5WJ20K RESISTOR SMD 0805 1/5WJ

R 417 SMD1/5WJ100K RESISTOR SMD 0805 1/5WJ

R 418 SMD1/5WJ5.6K RESISTOR SMD 0805 1/5WJ

R 419 SMD1/5WJ470K RESISTOR SMD 0805 1/5WJ

Parts number Parts name Area

Remarks

3-7

Page 17

KS-AX4500

Electrical parts list (P.C.board)

Item

A

R 421 SMD1/5WJ30K RESISTOR SMD 0805 1/5WJ

R 422 SMD1/5WJ30K RESISTOR SMD 0805 1/5WJ

R 423 SMD1/5WJ30K RESISTOR SMD 0805 1/5WJ

R 424 SMD1/5WJ62K RESISTOR SMD 0805 1/5WJ

R 430 CAR1/5WJ10K RESISTOR CARBON FILM 1/5

R 431 MET1/5WF5.6K RESISTOR METAL FILM 1/5W

R 432 MET1/5WF22K RESISTOR METAL FILM 1/5W

R 433 CAR1/5WJ1K RESISTOR CARBON FILM 1/5

R 434 CAR1/5WJ5.6K RESISTOR CARBON FILM 1/5

R 435 CAR1/5WJ5.6K RESISTOR CARBON FILM 1/5

R 436 CAR1/5WJ1K RESISTOR CARBON FILM 1/5

R 437 CAR1/5WJ1K RESISTOR CARBON FILM 1/5

R 438 CAR1/5WJ22 RESISTOR CARBON FILM 1/5

R 439 CAR1/5WJ22 RESISTOR CARBON FILM 1/5

R 440 CAR1/5WJ22 RESISTOR CARBON FILM 1/5

R 441 CAR1/5WJ22 RESISTOR CARBON FILM 1/5

R 442 CAR1/5WJ1K RESISTOR CARBON FILM 1/5

R 443 CAR1/5WJ47 RESISTOR CARBON FILM 1/5

R 444 CAR1/5WJ3.9K RESISTOR CARBON FILM 1/5

R 445 CAR1/5WJ2.7K RESISTOR CARBON FILM 1/5

R 446 CAR1/5WJ47 RESISTOR CARBON FILM 1/5

R 447 MET1/5WF12K RESISTOR METAL FILM 1/5W

R 448 MET1/5WF1K RESISTOR METAL FILM 1/5W

R 449 CAR1/5WJ220 RESISTOR CARBON FILM 1/5

R 450 MET3W0.1 RESISTOR

R 451 MET3W0.1 RESISTOR

R 452 CAR1/5WJ1.5K RESISTOR CARBON FILM 1/5

R 453 CAR1/5WJ15K RESISTOR CARBON FILM 1/5

R 454 CAR1/5WJ56K RESISTOR CARBON FILM 1/5

R 455 MET1/2WJ4.7 RESISTOR METAL FILM 1/2W

R 456 MET2W680 RESISTOR METAL FILM 2WJ

R 461 MET1/5W 68K RESISTOR METAL FILM 1/5W

R 462 MET1/5WF68K RESISTOR METAL FILM 1/5W

R 463 CAR1/5WJ15K RESISTOR CARBON FILM 1/5

SV 01 GF06P-202 SEMI VOLUME 2K OHM

SW101 JSS-2319 SWITCH SLIDE SW

SW301 JSS-2319 SWITCH SLIDE SW

T 01 TF137061201 TRANS FORMER

TH 01 FTD5-350 THERMISTOR 50KNTC

U 01 TL494CN I.C PWM IC

U 101 NJM2068LD I.C DUAL OP AMP

U 102 KIA4558F I.C DUAL OP AMP

U 103 KIA4558F I.C DUAL OP AMP

U 104 KIA4558F I.C DUAL OP AMP

U 105 KIA4558F I.C DUAL OP AMP

U 106 KIA4558F I.C DUAL OP AMP

U 301 NJM2068LD I.C DUAL OP AMP

U 302 KIA4558F I.C DUAL OP AMP

U 303 KIA4558F I.C DUAL OP AMP

U 304 KIA4558F I.C DUAL OP AMP

U 305 KIA4558F I.C DUAL OP AMP

U 306 KIA4558F I.C DUAL OP AMP

VR101 RK0971220-20KB2 VOLUME

VR102 RK0971220-20KB2 VOLUME

VR301 RK0971220-20KB2 VOLUME

VR302 RK0971220-20KB2 VOLUME

W 01 150M/M 1007 AWG#22

Parts number Parts name Area

Remarks

Block No. 01

3-8

Page 18

Packing and accessories

P7

P7

P3

P8

Block No.

Block No.

P2

KS-AX4500

2

M

M

M

M

3

M

M

A3

A3

P2

P8

P5

P4

A1,A2,A7,A8

A4

P6

A5

A6

P1

3-9

Page 19

KS-AX4500

Packing parts list

Item Parts number Parts name Area

A

P 1

P 2

P 3

P 4

P 5

P 6

P 7

P 8

MA-GB-02-6419-0

MA-SN-07-1116-0

MA-PB-01-1039-0

MA-PB-01-1524-1

MA-PB-01-1715-0

MA-PB-01-4101-0

MO-FI-01-8087-0

MA-IN-02-8090-0

GIFT BOX

CUSHION

POLY BAG-A

POLY BAG-D

POLY BAG-B

POLY BAG-C

PAPER SPACER

FLAT PAD

Q'ty Description

1

2

1

1

1

1

2

2

Accessories parts list

Item Parts number Parts name Area

A

A 1

A 2

A 3

A 4

A 5

A 6

A 7

A 8

KIT 1

LVT0727-001A

BT-52004-1

BT-51018-2

BT-54013-1

CHD114-N

FUSE20A/32V

MO-CU-01-4167-0

MNSC-05-2-40-20

BT-51020-2

BT-20071B

KSAX4700-SCREW

INST BOOK

WARRANTY CARD

WARRANTY CARD

WARRANTY CARD

CONNECTOR ASS'Y

AUTO FUSE

RUBBER CUSHION

SCREW

REGIST CARD

SERVICE CECTER LIST

SCREW PARTS LIST

Q'ty Description

1

1

1

1

2

2

4

4

1

1

1

A5, A6, P6

Block No. M2MM

Block No. M3MM

J

J

E

J

J

3-10

Page 20

Circuit block diagram

KS-AX4500

R-OUT

FRONT

AMP

Q101~

LPF

U104

-A

OFF

Q111

HPF

5

U104

CROSS OVER

POWER

3

80Hz 12dB/OCT FIXED

L-OUT

-B

3

LPF

U106

-A

Q201~

Q211

OFF

HPF

5

U106

-B

Q100

Q200

MUTE

CONTROL

TRANS

Q80

T01

+/- 15V

VCC

PROTECT

VEE

Q112,Q212

Q113,Q213

Q312,Q412

MUTE

CONTROL

Q300

REAR

R-OUT

AMP

POWER

Q400

SW301A

LPF

OFF

U305

-A

3

Q301~

Q311

HPF

5

L-OUT

U305

-B

SW301B

LPF

OFF

U306

-A

3

Q401~

Q411

HPF

5

U306

-B

CROSS OVER

80Hz 12dB/OCT FIXED

U103

-A

3

BASS BOOST

50Hz 0~12dB VARIABLE

U102

-A

3

U101

-A

AMP

INPUT

5

R-IN

FRONT

VR102A

VR101A

L-IN

3

6

3

U105

-A

U102

-B

U101

-B

VR102B

VR101B

R

FRONT

HI-INPUT

U303

POWER

REGULATOR

Q40,Q41

Q45,Q46

Q55,Q56

-A

3

BASS BOOST

VR302A

3

U305

-A

VR302B

50Hz 0~12dB VARIABLE

U302

-A

AMP

INPUT

R-IN

REAR

3

5

U301

-A

VR301A

SV01

Q01

F01

INPUT

+12V

D.C.

U701

Q02

REM

Q05

R

REAR

HI-INPUT

~Q08

L

POWER

CONTROL

L

POWER

L-IN

6

3

U302

-B

U301

-B

VR301B

2-1

Page 21

KS-AX4500

MEMO

2-2

Page 22

Standard schematic diagrams

MAIN PCB [1/3] and SUB PCB circuit diagrams

7

Q01

A1023Y

R01

10/0.25W

L01

CL-310

UC400962

F01

20Ax2

KS-AX4500

P1

TM0006-00

C67

470/35V

C68

470/35V

R70

220/2W

C61

2.2/50V

C62

2.2/50V

R71

220/2W

L10

CL-1113

C80

22P

C09

104(M)

Q80

K117

C69

3300/35V

C70

3300/35V

D53

1N4744

D54

1N4744

C81

10/50V

CHASSIS

C73

473P

C74

473P

C03

105(M)

C63

220/16V

C64

220/16V

MUTE

+15V

C65

104P

C66

104P

-15V

VCC

R77

10K/0.5W

R78

10K/0.5W

VEE

CHASSIS

6

R90

10K

C93

104P

C91

104P

C92

104P

C15

104P

R15

130KF

R16

51KF

Q02

C3198GR

Q31

C3198GR

C01

10/16V

R35 1.2K

R36

51K

5

R37

R38

1.2K

10K

10111213141516

9

4

R17

4.7K

C17

47/16V

UC000242

C23

100/16V

R20

10K

Q06

A1266GR

R25

10

U01

TL494CN

234567

1

8

SV01

2K

3

R41

24KF

C40

102(M)"STYCON"

R18

4.7K

C16

334(M)

Q05

A1266GR

R19

10K

R39

68K

D05

1N4148

R26

1K

TH01

50KTH

C18

100/16V

C19

100/16V

R40

27K

2

Q08

A1268GR

R32

33K

Q07

C3198BL

C20

104P

R30

1K

R31

22K

C21

10/25V

1

R03

4.7K

C41

100/16V

R02

4.7K

SAM3270

R33

15K

C27

473P

LED01

C31

104(M)

1N4148

A1266GR

R42

220/0.25W

R43

220/0.25W

1N4148

R04

4.7K

D10

Q40

Q41

A1266GR

D11

C22

47/25V

R34

15K

R05

10K

Q32

C3198GR

R46

47

R45

47

G

R44

1K

R54

1K

G

R55

47

R56

47

PROTECTION

D

FQP50N06

S

D

S

G

Q55

FQP50N06

G

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified one.

Q45

D

S

D

S

D02

1N4004

Q46

FQP50N06

Q56

FQP50N06

C11

2200/25V"RX"

C12

2200/25V"RX"

C13

104P

D01

1N5404

D31 FR154

D32 FR154

D34 FR154

D35 FR154

D70

1N4148

D71

1N4148

D51

YG225D2

UC000235

D52

YG225D2

UC000236

R80

220K

R81

10K

R82

2.2M

C24

103(M)

R47

10/2W

R57

10/2W

C25

103(M)

12T

6T

6T

12T

T01

37 PHI

R60

100/2W

C60

222(M)

Caution

If electricity is connected during disassembly, it must be a no load current. If it is load

current, be sure to attach a heat sink to the power-amp IC. This will be damaged if the

above precautions are not followed, as it does not have a sub heat sink attached to it.

BCDEFGH I JA

2-3

Page 23

MAIN PCB [2/3] and SUB PCB circuit diagrams

7

+15V

C391

104P

R309

1.3KF

VR301-A

20KB

4.7/50V

C407

R310

15K

C392

473P

C307

4.7/50V

R410

15KF

R411

12K

R311

11KF

3

2

5

6

C301

R302

C361

4.7/50V

4.7/50V

C363

102P

C463

102P

4.7/50V

C461

4.7/50V

R305

33KF

C362

C462

21.5KF

R402

21.5KF

R403

22KF

R405

33KF

C305

U301-A

8

100P

NJM2068LD

5

+

-

6

-15V

U301-B

NJM2068LD

3

2

R406 33KF

C406

22P

7

4

R306

33KF

C306

22P

C491

104P

8

1

R308

1K

R408

1K

VR301-B

20KB

R409

1.3KF

R303

22KF

C304

22P

R361

68KF

R362

68KF

R462

68KF

R461

68KF

A

C405

100P

C404

22P

JA01-C

6

SY-SW0406G

R301

22KF

4.7/50V

C302

4.7/50V

R-IN

5

JA03

LAD1140-04

+

-

HI-INPUT

-

+

R463

R363

15K

C364

102P

C464

102P

15K

4

L-IN

R401

22KF

C401

4.7/50V

C402

4.7/50V

JA01-D

SY-SW0406G

3

R404

C100

330/25V

C403

470

103P

2

+15V +15V

C393

R313

1K

VR302-A

20KB

C312

224(M)

C313

183(M)

R319

470K

R314

1K

473P

R315

1K

3

2

R318

5.6K

5

6

U302-A

4558F

8

1

4

R312

30KF

C308

68P

C492

473P

-15V

BASS BOOST(50Hz,0-12dB/oct)

C408 36P

R412 56KF

U302-B

4

4558F

7

R413

1K

VR302-B

20KB

C412

224(M)

C413

183(M)

R419

470K

R414

1K

C395

473P

R415

1K

5

6

3

2

C411 47P

R418

5.6K

4

-15V

U303-A

8

4558F

C311 47P

R316

20K

U303-B

4558F

4

-15V

+15V

8

U305-A

4558F

R416

20K

U305-B

4558F

7

C495

473P

C493

473P

KS-AX4500

+15V

R337

R333

1K

1K

C333

R331

5.6KF

R332

22KF

Q300

Q400

J108

J108

C331

4.7/50V

C431

4.7/50V

R432

22KF

22/16V

22/16V

C334

22/16V

C434

C433

22/16V

+15V

C314

104(M)

8

3

R322

R321

30K

1

R317

C316 C317

100K

473(M)

7

30K

R323 30K

473(M)

473(M)

R324

62K

2

C315

U304-B

5

6

-15V

LPF-FLAT-HPF

(80Hz,12dB/oct)

+15V

104(M)

C414

8

3

R422

R421

30K

1

R417

100K

473(M)473(M)

30K

R423 30K

C417C416

C415

473(M)

R424

62K

2

U306-B

4558F

5

6

4

-15V

4558F

4

U304-A

4558F

1

U306-A

4558F

7

C496

473P

C394

473P

1

SW301-A

JSS2319

MUTE

4.7/50V

C430

4.7/50V

C330

R330

10K

R430

10K

R431

5.6KF

LPF

FLAT

HPF

7

C494

473P

C396

473P

SW301-B

JSS2319

LPF

FLAT

HPF

C332

68P

C432

68P

R335

5.6K

R336

1K

R435

5.6K

R436

1K

R334

5.6K

R433

1K

R434

5.6K

Q301

C3198GR

R338

22

R34022R341

Q303

A1266GR

R342

1K

-15V

+15V

R437

1K

Q401

C3198GR

R438

22

R440

22

Q403

A1266GR

R442

1K

-15V

R339

22

22

Q304

A1266GR

R348

1KF

C339

100/16V

Q402

C3198GR

R439

22

R441

22

Q404

A1266GR

R448

1KF

C439

100/16V

Q302

C3198GR

C335

150P

C336

473(M)

C337

150P

R347 12KF

C338 56P

C435

150P

C436

473(M)

C437

150P

R447 12KF

C438 56P

Q305

A1268GR

R344

3.9K

R345

2.7K

C3200GR

R346

47

R443

47

Q405

A1268GR

R444

3.9K

R445

2.7K

Q406

C3200GR

R446

47

R343

47

Q306

Q307

C3200GR

Q407

C3200GR

Q308

C1027Y

R349

220

Q309

A1023Y

Q408

C1027Y

R449

220

Q409

A1023Y

Q310

D998

R350

0.1/3W

R351

0.1/3W

Q311

B778

Q410

D998

R450

0.1/3W

R451

0.1/3W

Q411

B778

R352

1.5K

R452

1.5K

R353

15K

D301

1N4148

R453

15K

D401

1N4148

Q312

C3200GR

Q412

C3200GR

C340

150P

C440

150P

R354

56K

R454

56K

OFFSET

R356

680/2W

R456

680/2W

PROTECTION

R355

4.7/0.5W

C341

104(M)

C342

104P

CHASSIS

R455

4.7/0.5W

C441

104(M)

P03

TM0009-00

Indicates main signal path

Caution

1

BCDEFGH I JA

If electricity is connected during disassembly, it must be a no load current. If it is load

current, be sure to attach a heat sink to the power-amp IC. This will be damaged if the

above precautions are not followed, as it does not have a sub heat sink attached to it.

2-4

Page 24

MAIN PCB [3/3] circuit diagrams

7

+15V

C191

104P

C101

R102

C161

4.7/50V

4.7/50V

4.7/50V

C261

4.7/50V

C162

C262

R105

33KF

C263

102P

21.5KF

R103

22KF

C163

102P

C104

22P

R161

68KF

R261

68KF

R262

68KF

C105

100P

JA01-A

SY-SW0406G

6

R101

22KF

4.7/50V

C102

4.7/50V

R-IN

JA02

+

-

-

+

HI INPUT

LAD1140-04

R163

15K

C164

102P

C264

102P

R263

15K

5

4

L-IN

R202

R201

22KF

C201

4.7/50V

C202

4.7/50V

21.5KF

R203

22KF

R205

33KF

A

JA01-B

SY-SW0406G

3

2

C205

100P

R162

68KF

C204

22P

8

5

+

-

6

-15V

NJM2068LD

3

2

R206 33KF

4

U101-B

8

U101A

NJM2068LD

7

R106

33KF

C106

22P

C291

104P

1

C206

22P

R108

1K

VR101-A

20KB

R208

1K

R209

1.3KF

R109

1.3KF

VR101-B

20KB

4.7/50V

R110

15KF

C207

4.7/50V

C107

C192

473P

R210

15KF

R211

12K

8

3

2

R111

11KF

-15V

C208 36P

R212 56KF

6

5

C193

473P

C108

68P

R113

1K

1

R112

30KF

C292

473P

VR102A

20KB

C112

224(M)

C113

183(M)

R119

470K

R114

1K

R115

1K

3

2

5

6

U102A

4558F

4

BASS BOOST(50Hz,0-12dB/oct)

C195

R215

1K

473P

3

2

C211 47P

5

6

-15V

4

U102B

4558F

R213

1K

7

R214

1K

VR102B

20KB

C212

224(M)

C213

183(M)

R219

470K

+15V+15V

8

C111 47P

R118

5.6K

U103B

4558F

4

-15V

+15V

U105A

8

4558F

R216

20K

R218

5.6K

U105B

4558F

4

R116

20K

U103A

4558F

7

7

C295

473P

KS-AX4500

+15V

C135

150P

C136

473(M)

C137

150P

R147 12KF

C138 56P

C235

150P

C236

473(M)

C237

150P

R247 12KF

C238 56P

R143

47

Q105

A1268GR

R144

3.9K

R145

2.7K

Q106

C3200GR

R146

47

R243

47

Q205

A1268GR

R244

3.9K

R245

2.7K

Q206

C3200GR

R246

47

Q107

C3200GR

Q207

C3200GR

Q108

C1027Y

R149

220

Q109

A1023Y

Q208

C1027Y

R249

220

Q209

A1023Y

Q110

D998

R150

0.1/3W

R151

0.1/3W

Q111

B778

Q210

D998

R251

0.1/3W

Q211

B778

R152

1.5K

R250

0.1/3W

R252

1.5K

R153

15K

D101

1N4148

R253

15K

D201

1N4148

Q112

C3200GR

Q212

C3200GR

C140

150P

C240

150P

OFFSET

R254

56K

R154

56K

Q113

C3198GR

C151

220/16V

R156

680/2W

R256

680/2W

C3198GR

PROTECTION

R155

4.7/0.5W

C141

104(M)

Q213

C142

104P

CHASSIS

TM0009-00

R255

4.7/0.5W

C241

104(M)

P02

R137

R133

1K

1K

R235

5.6K

R236

1K

R135

5.6K

R136

1K

R234

5.6K

R134

5.6K

R233

1K

Q101

C3198GR

R138

22

R140

22

Q103

A1266GR

R142

1K

-15V

+15V

R237

1K

Q201

C3198GR

R238

22

R24022R241

Q203

A1266GR

R242

1K

-15V

Q102

C3198GR

R139

22

R141

22

Q104

A1266GR

R148

1KF

C139

100/16V

C3198GR

R239

22

22

Q204

A1266GR

R248

1KF

C239

100/16V

Q202

C133

R232

22KF

C131

4.7/50V

Q100

J108

Q200

J108

C231

4.7/50V

R132

22KF

C234

22/16V

22/16V

C134

22/16V

C233

22/16V

C132

68P

C232

68P

+15V

104(M)

C293

473P

C114

8

3

R122

R121

30K

1

R117

100K

473(M)

473(M)

30K

R123 30K

C117C116

C115

473(M)

R124

62K

2

5

6

LPF-FLAT-HPF

U104B

4558F

4

-15V

U104A

4558F

C194

473P

1

C130

SW101A

LPF

JSS2319

FLAT

HPF

7

C294

473P

MUTE

4.7/50V

R131

5.6KF

R130

10K

R230

10K

(80Hz,12dB/oct)

+15V

C214

104(M)

R222

30K

R223 30K

473(M)

R224

62K

C215

3

2

U106B

4558F

5

6

-15V

R221

30K

1

R217

C216 C217

100K

473(M)473(M)

C196

473P

8

1

FLAT

SW101B

LPF

JSS2319

HPF

C230

4.7/50V

R231

5.6KF

U106A

4558F

7

4

C296

473P

Indicates main signal path

1

Caution

If electricity is connected during disassembly, it must be a no load current. If it is load

current, be sure to attach a heat sink to the power-amp IC. This will be damaged if the

above precautions are not followed, as it does not have a sub heat sink attached to it.

BCDEFGH I JA

2-5

Page 25

Caution

If electricity is connected during disassembly, it must be a no load current. If it is load

current, be sure to attach a heat sink to the power-amp IC. This will be damaged if the

above precautions are not followed, as it does not have a sub heat sink attached to it.

Printed circuit boards

MAIN PCB

7

KS-AX4500

Surface side view

KS-AX4500

PPM028-01

REV.0

6

J77

R263

C262

C261

C161

R163

C162

C164

C101

R162

C105

C104

R101

R106

R105

C102

C106

C191

C291

R103

l-gnd

f-15v

COMPONENT

C163

C206

RL RL

- --

R206

R262

R261

R161

U101

R203

C202

R202

R201

C205

C204

C201

R205

R102

5

JA02

C263

C264

FRONT REAR

JA01

R401

C402

R403

R405

C404

C401

R402

4

C100

C403

J103

R404

R302

C301

C304

R301

R305

C302

r-gndr-gnd

R303

l-gnd

r-15v

bip

C405

C461

R461

R361

C361

C305

R362

R363

C364

C363

-

3

JA03

C464

J76

++ ++

C463

C406

U301

R406

C462

R462

R463

C362

R306

C491

C391

C306

2

f+15v

r+15v

fr-in

rr-in

R146

R142

R130

fl-in

rl-in

R330

R342

R346

gnd

COMPONENT

Q106

C132

Q100

muting

muting

Q300

C332

Q306

C137

C131

R131

rrfr

R331

C331

C337

COMPONENT

J29

J30

D35

D34

D31

D32

J40

J41

J28

J116

J32

J33

J31

J27

D51

R44

J115

4

J39

J38

Q46

COMPONENT

J114

8

4

Q55

Q56

J19

J110

J20

J15

J14

C11

R46

J113

J26

C24

J24

J23

J22

C25

R56

R54

J21

J111

2

R55

J25

R47

R57

3

1

COMPONENT

COMPONENT

T01

L01

COMPONENT

5

C60

7

L10

J37

D52

6

J09

R60

3

1 2

J34

C68

C67

Q01

C01

C31

R03

Q02

C27

J35

R01

R35

R36

Q32

R18

Q05

C16

R04

R02

J08

J07

R38

R37

Q31

D02

R17

R05

J36

C342

COMPONENT

J98

C62

C92

C91

Q45

R45

C93

BJ03

R90

J100

BJ04

Q107

R145

Q110

Q211

Q111

J84

C140

R143

R134

J85

Q112

D101

C133

R152

R153

R133

R150

J86

R246

R242

R230

Q206

C232

Q200

J87

J104

C237

C231

R231

J78

R132

C130

Q109

Q103

R140

J80

R149

Q101

R138

C136

Q104

R141

R144

Q102

R139

R151

C138

R148

C139

R147

R137

R135

J81

J79

C135

C134

J82

J83

Q108

Q105

R136

J65

J66

C330

R332

J75

R340

Q303

Q309

R338

Q301

R349

R341

Q304

C336

R339

Q302

R344

C339

R348

C338

R335

R337

R347

C334

C335

J74

R336

Q305

Q308

R334

R343

C340

C333

D301

Q312

R333

R353

R352

C430

R442

R446

R430

C432

Q406

R431

C431

C437

R350

R351

Q311

J72

J71

J73

R345

Q307

ENT

ON

COMP

J70

Q310

J69

J68

J67

R451

Q411

J88

J89

R232

C230

Q400

R432

J63

J62

J102

R251

Q209

Q203

R240

R440

Q403

Q409

J61

Q201

R238

R438

Q401

R449

R445

Q407

Q207

R245

J90

C236

J60

Q204

R241

R441

Q404

J91

C436

J59

J92

R244

Q202

R239

R439

Q402

R444

J58

R249

C238

R248

C239

C439

R448

C438

Q210

R450

Q410

J93

R247

R237

R235

R435

R437

R447

J107

J94

C235

C234

C434

C435

J64

J57

J106

Q208

Q205

R236

J52

R436

Q405

Q408

J56

R250

NETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNET

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENTCOMPONENTCOMPONENT

COMPONENT

COMPONENT

COMPONENTCOMPONENTCOMPONENTCOMPONENTCOMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENTCOMPONENT

COMPONENTCOMPONENTCOMPONENTCOMPONENT

COMPONENT

COMPONENTCOMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENTCOMPONENTCOMPONENTCOMPONENTCOMPONENTCOMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

C

COMPONENT

C

C

C

C

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENTCOMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENTCOMPONENTCOMPONENTCOMPONENTCOMPONENTCOMPONENTCOMPONENTCOMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

COMPONENT

OM

OM

OM

OM

OM

NETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNET

COMPONENTCOMPONENTCOMPONENTCOMPONENTCOMPONENTCOMPONENT

COMPONENTCOMPONENTCOMPONENTCOMPONENTCOMPONENTCOMPONENTCOMPONENT

C74

R78

J43

C70

C69

R26

R25

C17

C15

R16

R15

C41

D10

Q40

Q41

D11

TH01

BJ05

BJ06

D05

R19

C23

Q06

R20

C18

R40

C40

R41

SV01

R81

R80

POLYGONSOLIDPOLYGONSOLID

R42

R43

C81

R82

Q80

C80

R39

C19

J49

U01

22.87KHz

J48

J42

C73

R77

R30

C21

R31

J97

C20

Q07

R32

R252

J95

C240

J96

R254

Q212

Q08

R243

R253

D201

R233

C233

R234

P

P

P

P

P

ONENT

ONENT

ONENT

ONENT

ONENT

J50

J101

J51

R434

C433

R433

R154

Q213

Q113

R33

C22

R34

J47

C151

R453

R443

C440

D401

Q412

R452

C64

J46

R354

J99

R454

C66

J45

D54

D70

J55

J54

J53

POLYGONSOLIDPOLYGONSOLID

C63

D53

C65

D71

R70

COMPONENT COMPONENT

C61

R71

W02

C12

J06

J12

C02

C09

J17

D01

C142

C341

C141

C13

J03

J04

J05

R155

R455

C441

R355

R255

C241

J18

BJ01

F01

R356

J02

C03

R456

R256

R156

P01

RCG

J01

P02

COMPONENT

W01

COMPONENT

LED01

P03

COMPONENT

NETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETNETPOLYGONSOLIDPOLYGONSOLIDPOLYGONSOLIDPOLYGONSOLIDPOLYGONSOLIDPOLYGONSOLIDPOLYGONSOLIDPOLYGONSOLIDPOLYGONSOLIDPOLYGONSOLIDPOLYGONSOLIDPOLYGONSOLIDPOLYGONSOLIDPOLYGONSOLIDPOLYGONSOLIDPOLYGONSOLIDPOLYGONSOLIDPOLYGONSOLIDPOLYGONSOLIDPOLYGONSOLIDPOLYGONSOLIDPOLYGONSOLIDPOLYGONSOLIDPOLYGONSOLIDPOLYGONSOLIDPOLYGONSOLIDPOLYGONSOLID

COMPONENTCOMPONENTCOMPONENTCOMPONENTCOMPONENTCOMPONENT

COMPONENTCOMPONENTCOMPONENT

COMPONENT

COMPONENTCOMPONENT

COMPONENTCOMPONENTCOMPONENT

COMPONENT

COMPONENTCOMPONENT

COMPONENT

COMPONENT

COMPONENTCOMPONENTCOMPONENTCOMPONENTCOMPONENTCOMPONENTCOMPONENT

COMPONENTCOMPONENTCOMPONENTCOMPONENTCOMPONENTCOMPONENTCOMPONENT

1

BCDEFGH I JA

2-6

Page 26

KS-AX4500

Caution

If electricity is connected during disassembly, it must be a no load current. If it is load

current, be sure to attach a heat sink to the power-amp IC. This will be damaged if the

above precautions are not followed, as it does not have a sub heat sink attached to it.

Bottom side view

7

W02

C342

D52

Q407

Q411

R445

J62

J102

J60

Q409

R449

J63

Q403

Q401

R432

Q400

R440

R438

Q410

C63

D54

C64

J56

J55

R447