Page 1

SERVICE MANUAL

DVD/CD RECEIVER

MA17320053

KD-DV5188

ß®»¿ -«ºº·¨

ЛЪ уууууууууууууууууууууууууу Э¸·²¿

TABLE OF CONTENTS

1PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2SPECIFIC SERVICE INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

4ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

5TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

COPYRIGHT © 2005 Victor Company of Japan, Limited

No.MA173

2005/3

Page 2

SPECIFICATION

AUDIO AMPLIFIER SECTION

Maximum Power OutputFront50 W per channel

Rear50 W per channel

Continuous Power Output (RMS)Front19 W per channel into 4 , 40 Hz to 20 000 Hz at no more

than 0.8% total harmonic distortion.

Rear19 W per channel into 4 , 40 Hz to 20 000 Hz at no more

than 0.8% total harmonic distortion.

Load Impedance4 (4 to 8 allowance)

Equalizer Control RangeFrequencies60 Hz, 150 Hz, 400 Hz, 1 kHz, 2.4 kHz, 6 kHz, 15 kHz

Level±10 dB

Signal-to-Noise Ratio70 dB

Audio Output LevelDigital (DIGITAL OUT: Optical)Signal wave length : 660 nm

Output level : -21 dBm to -15 dBm

Line-Out Level/Impedance2.5 V/20 k load (full scale)

Output Impedance1 k

Color SystemPAL/NTSC

Video Output (composite)1 Vp-p/75

Other TerminalsLINE IN, CD changer

TUNER SECTION

Frequency RangeFM87.5 MHz to 108.0 MHz

AM531 kHz to 1 602 kHz

FM TunerUsable Sensitivity11.3 dBf (1.0 kV/75 )

50 dB Quieting Sensitivity16.3 dBf (1.8 kV/75 )

Alternate Channel Selectivity (400 kHz)65 dB

Frequency Response40 Hz to 15 000 Hz

Stereo Separation35 dB

Capture Ratio1.5 dB

AM TunerSensitivity20 kV

Selectivity35 dB

DVD/CD PLAYER SECTION

Signal Detection SystemNon-contact optical pickup (semiconductor laser)

Number of Channels2 channels (stereo)

Frequency ResponseDVD, fs=48 kHz/96 kHz16 Hz to 22 000 Hz

VCD, CD, MP3, WMA16 Hz to 20 000 Hz

Dynamic Range96 dB

Signal-to-Noise Ratio98 dB

Wow and FlutterLess than measurable limit

MP3 (MPEG Audio Layer 3)Max. Bit Rate: 320 kbps

WMA (Windows Media Audio)Max. Bit Rate: 192 kbps

GENERAL

Power RequirementOperating VoltageDC 14.4 V (11 V to 16 V allowance)

Grounding SystemNegative ground

Allowable Operating Temperature0pC to +40pC

Dimensions (W I H I D)Installation Size (approx.)182 mm I 52 mm I 158 mm

Panel Size (approx.)188 mm I 58 mm I 11 mm

Mass (approx.)1.7 kg (excluding accessories)

Design and specifications are subject to change without notice.

1-2 (No.MA173)

Page 3

1.1Safety Precautions

SECTION 1

PRECAUTIONS

ÿ

ÿ

Þ«®®- º±®³»¼ ¼«®·²¹ ³±´¼·²¹ ³¿§ ¾» ´»º¬ ±ª»® ±² -±³» °¿®¬- ±º ¬¸» ½¸¿--·-ò ̸»®»º±®»ô

°¿§ ¿¬¬»²¬·±² ¬± -«½¸ ¾«®®- ·² ¬¸» ½¿-» ±º °®»º±®³·²¹ ®»°¿·® ±º ¬¸·- -§-¬»³ò

д»¿-» «-» »²±«¹¸ ½¿«¬·±² ²±¬ ¬± -»» ¬¸» ¾»¿³ ¼·®»½¬´§ ±® ¬±«½¸ ·¬ ·² ½¿-» ±º ¿²

¿¼¶«-¬³»²¬ ±® ±°»®¿¬·±² ½¸»½µò

(No.MA173)1-3

Page 4

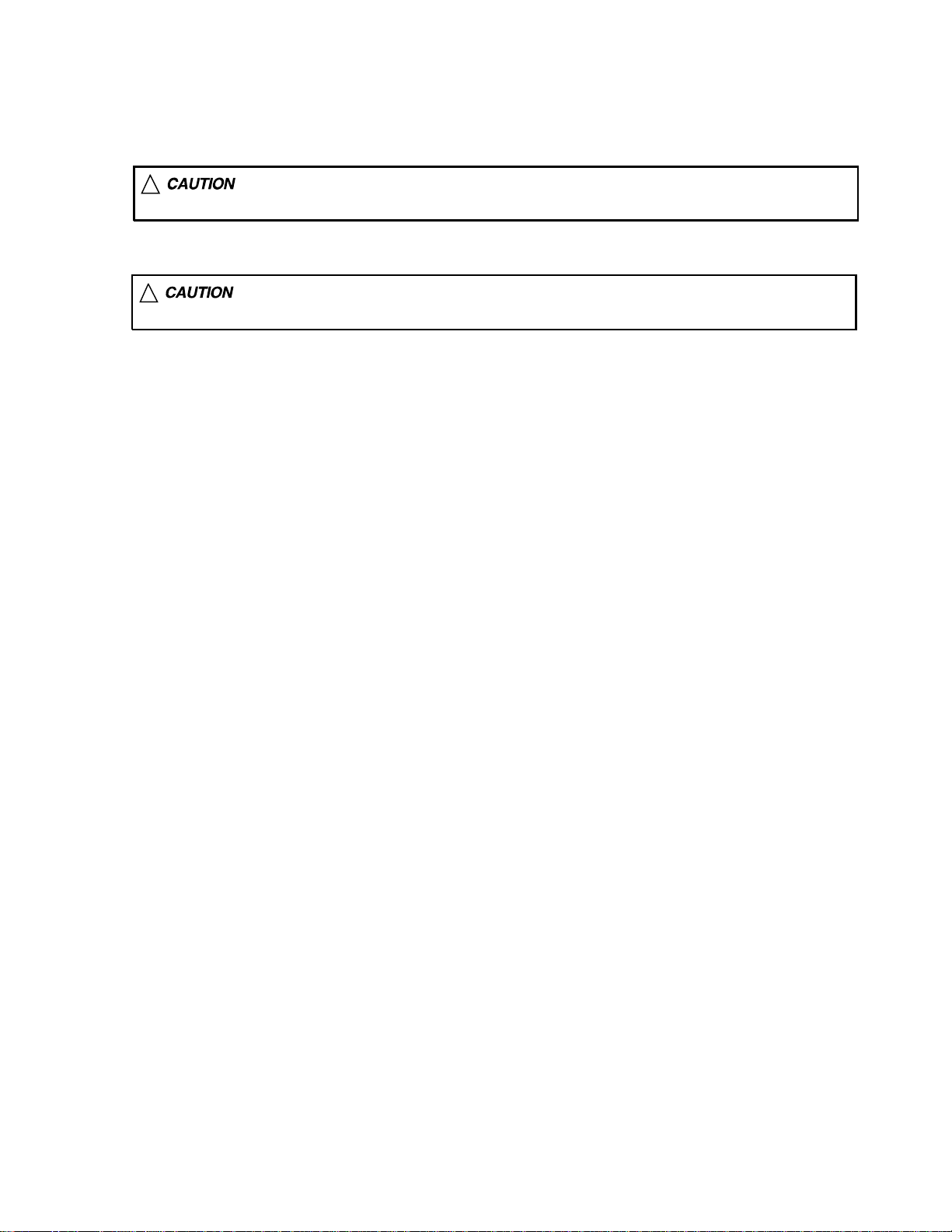

1.2Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser

diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.2.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as CD players.

Be careful to use proper grounding in the area where repairs are being performed.

(1)Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2)Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

ø½¿°¬·±²÷

ß²¬·ó-¬¿¬·½ ©®·-¬ -¬®¿°

ïÓ

ݱ²¼«½¬·ª» ³¿¬»®·¿´

ø½±²¼«½¬·ª» -¸»»¬÷ ±® ·®±² °´¿¬»

(3)Handling the optical pickup

In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.3Handling the traverse unit (optical pickup)

(1)Before disconnecting the flexible wire from the connector CN101 on the mechanism control board, solder the short-circuit points

on the flexible wire.

Caution:

If you do not follow this instruction, the DVD pickup may be damaged.

(2)Disconnect the flexible wire from the connector CN101 on the mechanism control board.

(3)Remove the solders from the short-circuit points on the flexible wire after replacing the DVD pickup.

(4)Connect the flexible wire to the connector CN101 on the mechanism control board.

Ú´»¨·¾´» ©·®»

ЭТпрп

1-4 (No.MA173)

͸±®¬ó½·®½«·¬ °±·²¬-

Ó»½¸¿²·-³ ½±²¬®±´ ¾±¿®¼

Page 5

1.4Important for laser products

птЭФЯНН п ФЯНЫО РОСЬЛЭМ

отЬЯТЩЫО ж ײª·-·¾´» ´¿-»® ®¿¼·¿¬·±² ©¸»² ±°»² ¿²¼ ·²¬»®

´±½µ º¿·´»¼ ±® ¼»º»¿¬»¼ò ߪ±·¼ ¼·®»½¬ »¨°±-«®» ¬± ¾»¿³ò

нтЭЯЛМЧСТ ж ̸»®» ¿®» ²± -»®ª·½»¿¾´» °¿®¬- ·²-·¼» ¬¸»

Ô¿-»® ˲·¬ò ܱ ²±¬ ¼·-¿--»³¾´» ¬¸» Ô¿-»® ˲·¬ò λ°´¿½»

¬¸» ½±³°´»¬» Ô¿-»® ˲·¬ ·º ·¬ ³¿´º«²½¬·±²-ò

мтЭЯЛМЧСТ ж М¸» ЭЬфУЬ ¿²¼ ЬКЬ °´¿§»® «-»- ·²ª·-·¾´»

´¿-»® ®¿¼·¿¬·±² ¿²¼ ·- »¯«·°°»¼ ©·¬¸ -¿º»¬§ -©·¬½¸»- ©¸·½¸

°®»ª»²¬ »³·--·±² ±º ®¿¼·¿¬·±² ©¸»² ¬¸» ¼®¿©»® ·- ±°»² ¿²¼

¬¸» -¿º»¬§ ·²¬»®´±½µ- ¸¿ª» º¿·´»¼ ±® ¿®» ¼»º»¿¬»¼ò ׬ ·-

¼¿²¹»®±«- ¬± ¼»º»¿¬ ¬¸» -¿º»¬§ -©·¬½¸»-ò

лтЭЯЛМЧСТ ж ׺ -¿º»¬§ -©·¬½¸»- ³¿´º«²½¬·±²ô ¬¸» ´¿-»® ·- ¿¾´»

¬± º«²½¬·±²ò

ктЭЯЛМЧСТ ж Ë-» ±º ½±²¬®±´-ô ¿¼¶«-¬³»²¬- ±® °»®º±®³¿²½» ±º

°®±½»¼«®»- ±¬¸»® ¬¸¿² ¬¸±-» -°»½·º·»¼ ¸»®» ·² ³¿§ ®»-«´¬ ·²

¸¿¦¿®¼±«- ®¿¼·¿¬·±² »¨°±-«®»ò

д»¿-» «-» »²±«¹¸ ½¿«¬·±² ²±¬ ¬±

-»» ¬¸» ¾»¿³ ¼·®»½¬´§ ±® ¬±«½¸ ·¬

·² ½¿-» ±º ¿² ¿¼¶«-¬³»²¬ ±® ±°»®¿¬·±²

½¸»½µò

ОЫРОСЬЛЭМЧСТ ЯТЬ РСНЧМЧСТ СЪ ФЯЮЫФН

ЙЯОТЧТЩ ФЯЮЫФ

ЭЯЛМЧСТ æ Ê·-·¾´» ¿²¼ ײª·-·¾´»

ЭФЯНН п

ФЯНЫО РОСЬЛЭМ

´¿-»® ®¿¼·¿¬·±² ©¸»² ±°»² ¿²¼

·²¬»®´±½µ º¿·´»¼ ±® ¼»º»¿¬»¼т

ЯКСЧЬ ЬЧОЫЭМ ЫИРСНЛОЫ МС

ЮЫЯУт ш»ч

ЯЬКЯОНЫФ æ ͧ²´·¹ ±¹ «-§²´·¹

´¿-»®-¬®;´·²¹ ²;® ³¿-µ·²»² »®

;¾»² »´´»® ·²¬»®´±½µ»² º»¶»´»®ò

˲¼¹; ¼·®»µ¬» »µ-°±²»®·²¹ ¬·´

-¬®;´·²¹ò ø¼÷

КЯОТЧТЩ æ ͧ²´·¹ ±½¸

±-§²´·²¹ ´¿-»®-¬®;´²·²¹ ²<®

¼»² *°°²¿- ±½¸ -°<®®»² <®

«®µ±°°´¿¼ò Þ»¬®¿µ¬¿ »¶

-¬®;´»²ò ø-÷

ÊßÎÑ æ ߪ¿¬¬¿»--¿ ¶¿ -«±¶¿´«µ·¬«±¸·¬»¬¬«²¿ ¬¿· ª·¿´´·-»²¿ ±´»¬ ¿´¬¬··²¿

²<µ§ª<´´» ¶¿ ²<µ§³<¬¬*³<´´»

´¿-»®-<¬»·´§´´»ò Ê<´¬< -<¬»»²

µ±¸¼·-¬«³·-¬¿ -«±®¿¿² ·¬-»»-·ò øº÷

(No.MA173)1-5

Page 6

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

1-6 (No.MA173)

Page 7

SECTION 3

DISASSEMBLY

3.1Main body section

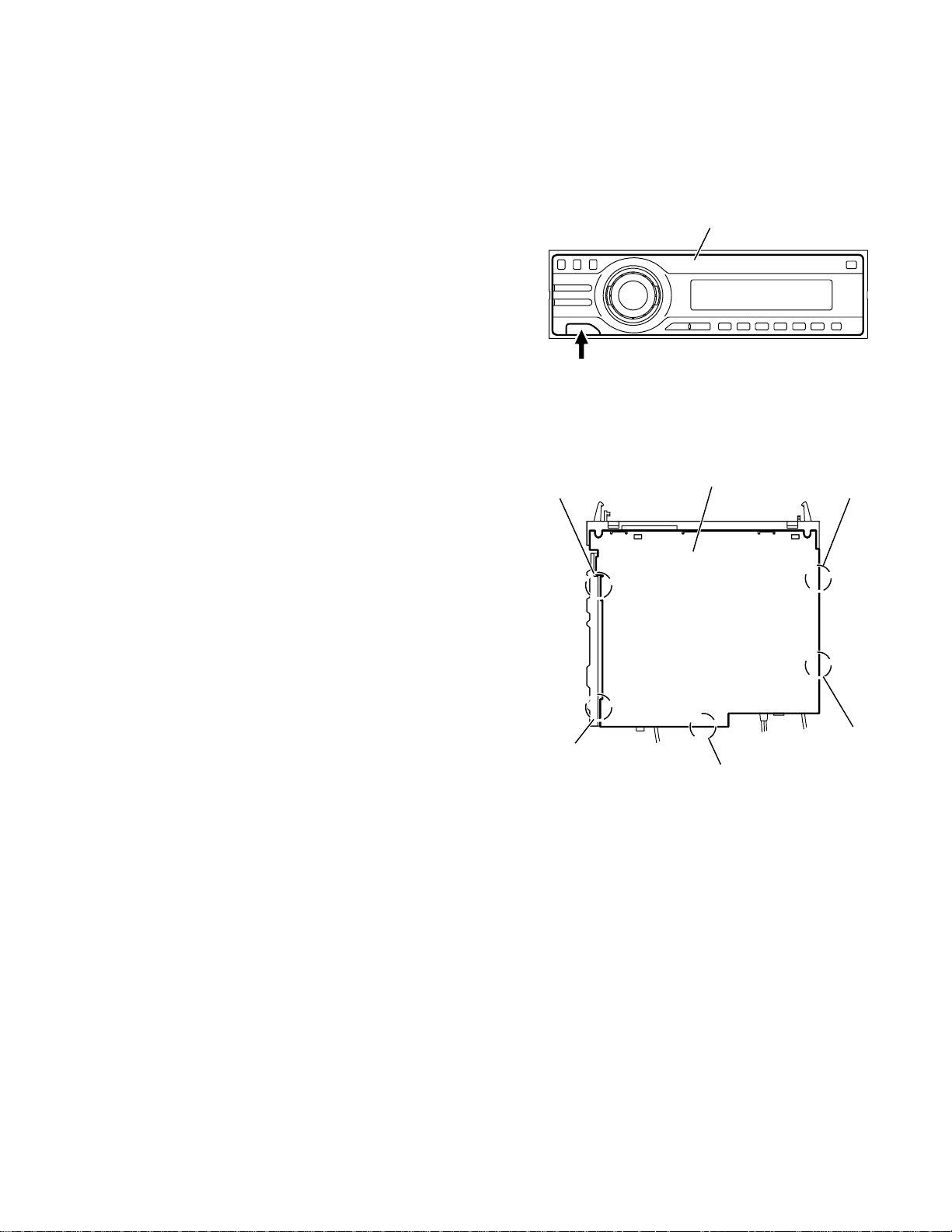

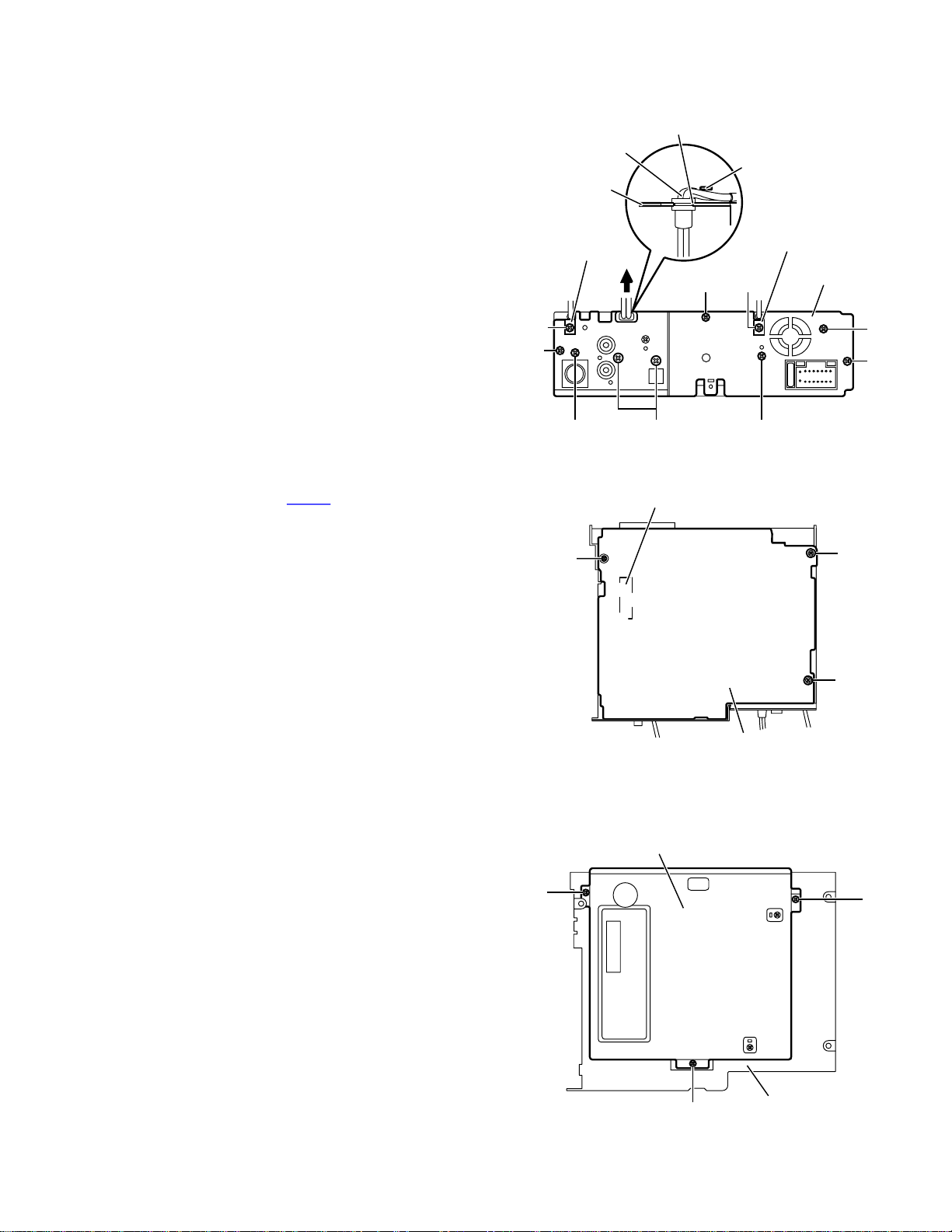

3.1.1Removing the front panel assembly

(See Fig.1)

Push the detach button in the lower left part of the front panel assembly and remove the front panel assembly.

3.1.2Removing the bottom cover

(See Fig.2)

Reference:

Remove the front panel assembly as required.

(1)Release the two joints a, two joints b and joint c.

(2)Remove the bottom cover from the main body.

Caution:

Do not damage the main board when releasing the joints using

a screwdriver or a similar tool.

Ú®±²¬ °¿²»´ ¿--»³¾´§

Ü»¬¿½¸ ¾«¬¬±²

¾

Fig.1

Þ±¬¬±³ ½±ª»®

¿

¿

¾

½

Fig.2

(No.MA173)1-7

Page 8

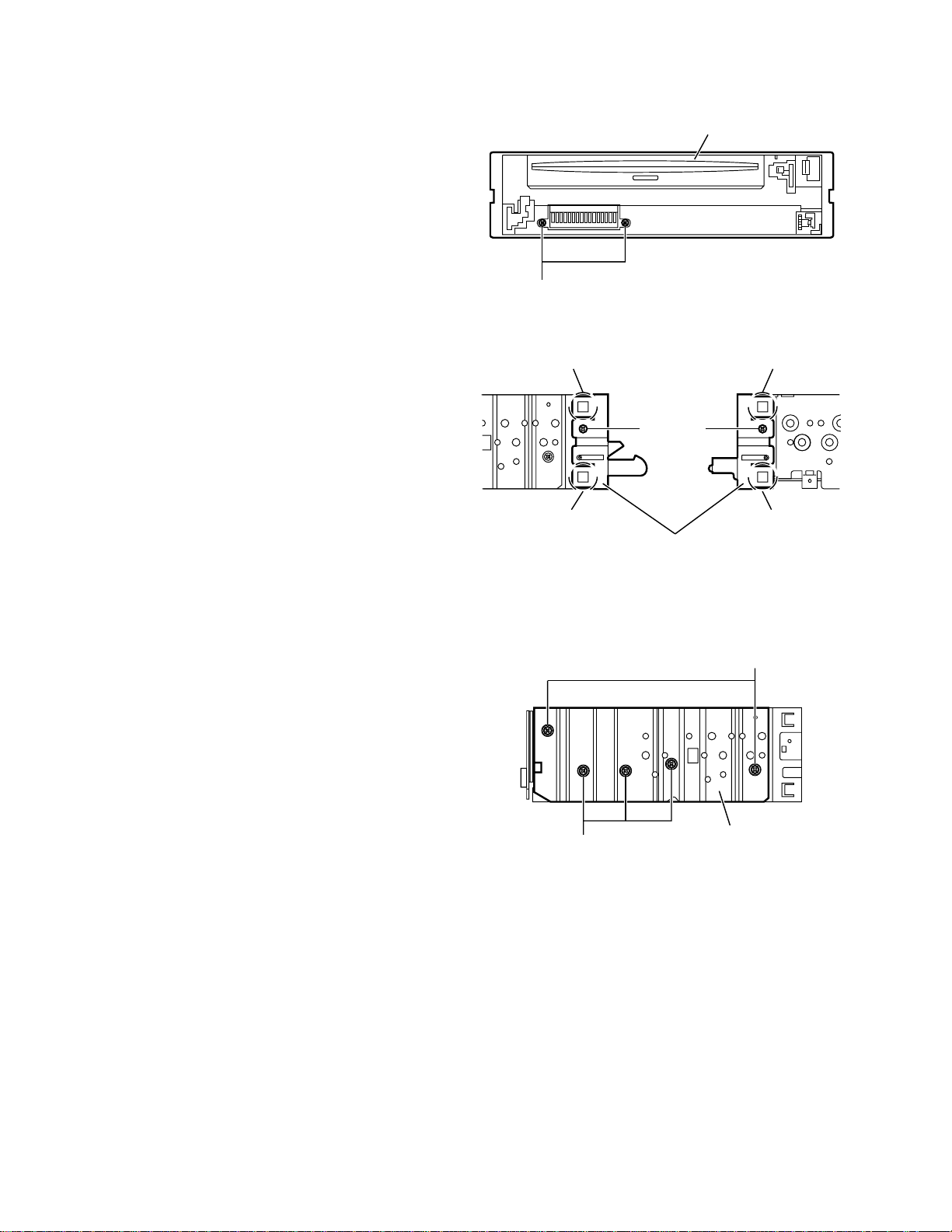

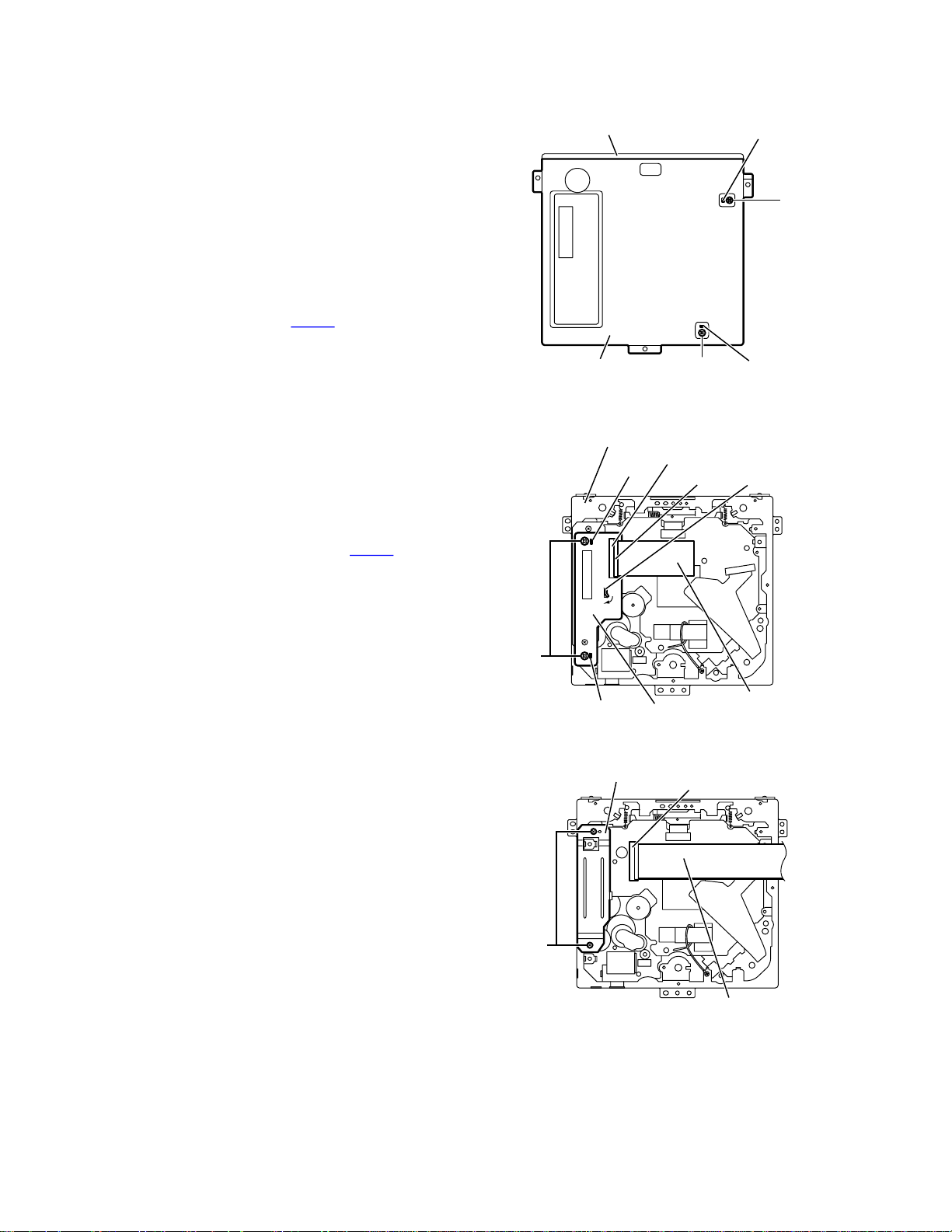

3.1.3Removing the front chassis assembly

(See Figs.3 and 4)

Remove the front panel assembly and bottom cover.

(1)From the front side of the main body, remove the two

screws A attaching the front chassis assembly. (See

Fig.3.)

(2)From the both sides of the main body, remove the two

screws B attaching the front chassis assembly. (See

Fig.4.)

(3)Release the two joints d and two joints e. (See Fig.4.)

Ú®±²¬ ½¸¿--·- ¿--»³¾´§

ß

Fig.3

3.1.4Removing the side heat sink

(See Fig.5)

Reference:

Remove the front panel and front chassis assemblies as re-

quired.

From the left side of the main body, remove the two screws C and

three screws D attaching the side heat sink.

¼

Þ

¼

Ú®±²¬ ½¸¿--·- ¿--»³¾´§

Fig.4

»

Þ

»

Ý

1-8 (No.MA173)

Ü

Í·¼» ¸»¿¬ -·²µ

Fig.5

Page 9

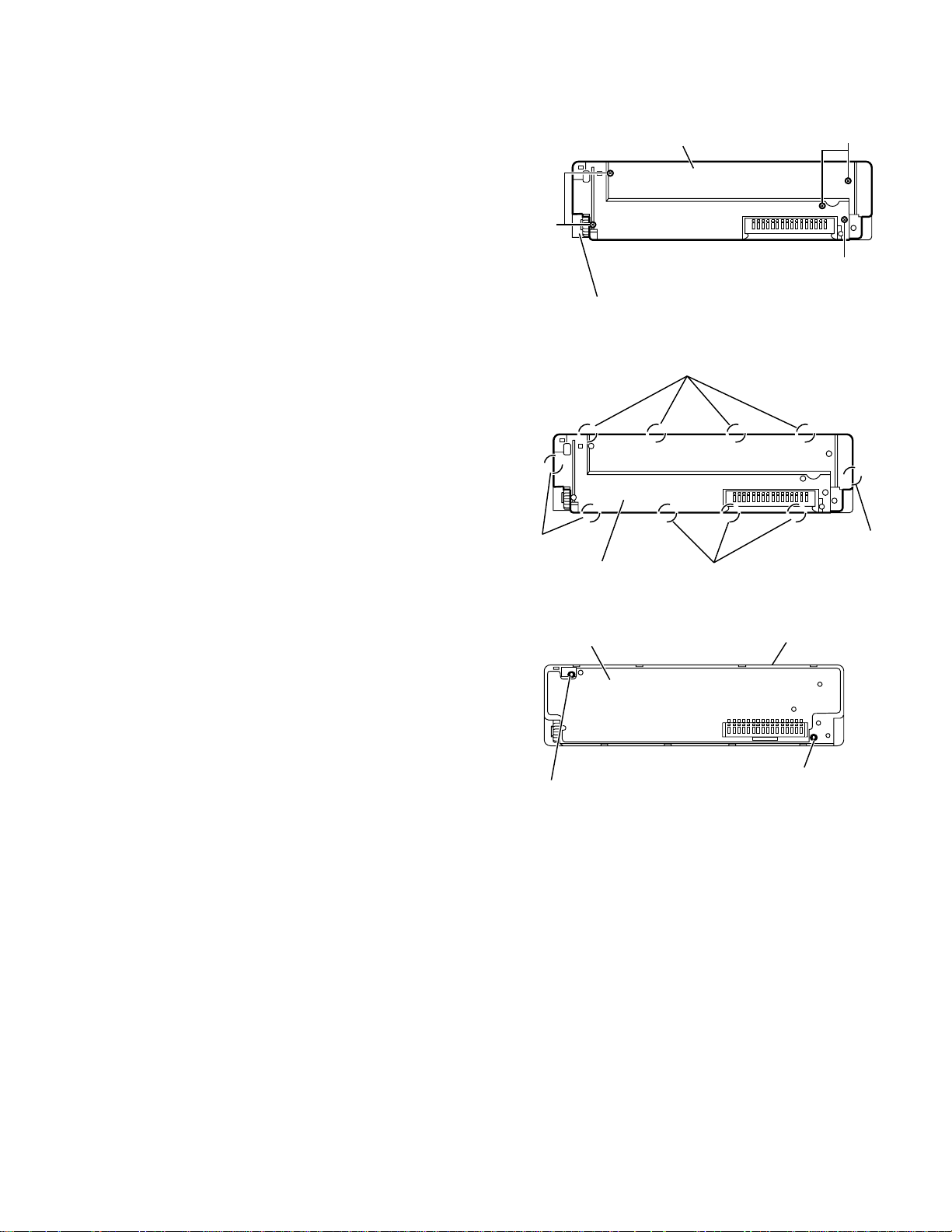

3.1.5Removing the rear bracket

(See Fig.6)

Remove the bottom cover.

(1)From the back side of the main body, remove the two

screws E, two screws E', screw F, two screws G and three

screws H attaching the rear bracket.

(2)Remove the LINE IN cable from the rear bracket in the di-

rection of the arrow.

Reference:

When attaching the LINE IN cable, insert it in a slot of the

rear bracket and hang it on a wire holder.

When attaching the screws E', attach the cable holders with

them.

Ô×ÒÛ ×Ò ½¿¾´»

λ¿® ¾®¿½µ»¬

Ý¿¾´» ¸±´¼»®

Í´±¬

É·®» ¸±´¼»®

ØÛÛù

Ý¿¾´» ¸±´¼»®

λ¿® ¾®¿½µ»¬

3.1.6Removing the main board

(See Figs.6 and 7)

Remove the front panel assembly, bottom cover, front chassis

assembly and side heat sink.

Reference:

Remove the rear bracket as required.

(1)From the back side of the main body, remove the three

screws H attaching the main board. (See Fig.6.)

(2)From the bottom side of the main body, remove the three

screws J attaching the main board. (See Fig.7.)

(3)Disconnect the connector CN961 on the main board from

the DVD mechanism assembly and take out the main

board from the main body. (See Fig.7.)

3.1.7Removing the DVD mechanism assembly

(See Fig.8)

Remove the front panel assembly, bottom cover, front chassis

assembly, side heat sink and main board.

(1)From the inside of the top chassis, remove the three

screws K attaching the DVD mechanism assembly.

(2)Take out the DVD mechanism assembly from the top cha

sis.

Ûù

Ø

Õ

Ú

Ù

Fig.6

ЭТзкп

Ö

Fig.7

ÜÊÜ ³»½¸¿²·-³ ¿--»³¾´§

Û

Ø

Ö

Ö

Ó¿·² ¾±¿®¼

Õ

Õ

Fig.8

̱° ½¸¿--·-

(No.MA173)1-9

Page 10

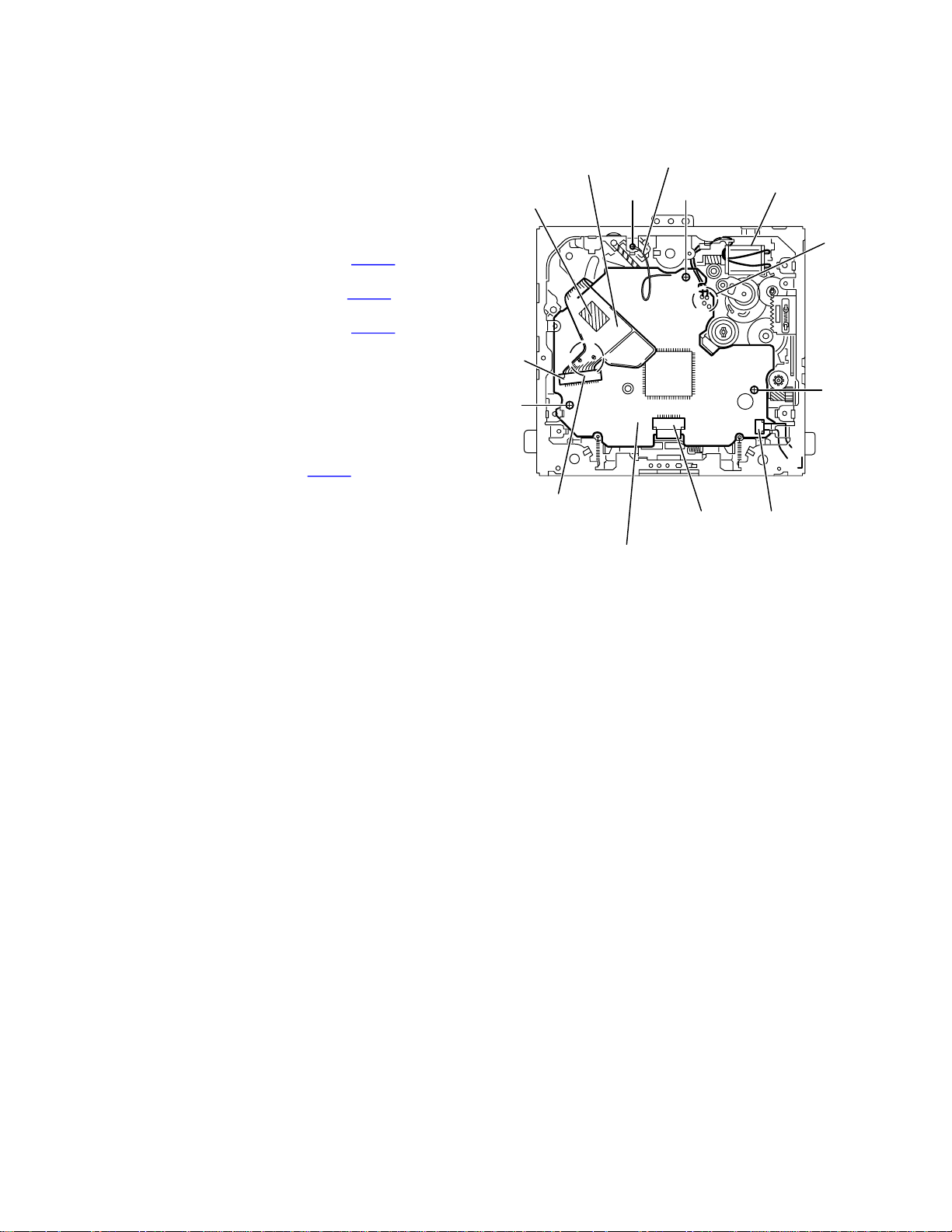

3.1.8Removing the main sub board

(See Figs.9 to 11)

Remove the front panel assembly, bottom cover, front chassis

assembly, side heat sink, main board and DVD mechanism assembly.

(1)From the top side of the DVD mechanism assembly, re-

move the two screws L attaching the dust cover. (See

Fig.9.)

(2)Remove the dust cover from the DVD mechanism assem-

bly. (See Fig.9.)

Reference:

When attaching the dust cover, align the joints f in the

holes of the dust cover before attaching the screws L.

(See Fig.9.)

(3)Release the lock of the connector CN962 on the main sub

board and disconnect the card wire. (See Fig.10.)

(4)Bend the joint g in the direction of the arrow. (See Fig.10.)

(5)Remove the two screws M attaching the main sub board

and remove the main sub board from the DVD mechanism

assembly. (See Fig.10.)

Reference:

When attaching the main sub board, align the joints h in the

holes of the main sub board before attaching the screws M.

(See Fig.10.)

When the resolution of DVD mechanism assembly is done

sequentially, remove the two screws N attaching the support

bracket. (See Fig.11.)

Remove the card wire from the connector CN401 as re-

quired. (See Fig.11.)

ÜÊÜ ³»½¸¿²·-³ ¿--»³¾´§

Ü«-¬ ½±ª»®

Fig.9

ÜÊÜ ³»½¸¿²·-³ ¿--»³¾´§

¸

ЭТзко

Ô±½µ

Ô

º

Ô

º

¹

Ó

Í«°°±®¬ ¾®¿½µ»¬

Ò

¸

Ó¿·² -«¾ ¾±¿®¼

Fig.10

Fig.11

Ý¿®¼ ©·®»

ЭТмрп

Ý¿®¼ ©·®»

1-10 (No.MA173)

Page 11

3.1.9Removing the switch board

(See Figs. 12 to 14)

Remove the front panel assembly.

(1)From the back side of the front panel assembly, remove the

five screws P attaching the rear cover. (See Fig.12.)

(2)Release the ten joints i attaching the rear cover to the front

panel assembly. (See Fig.13.)

(3)Take out the switch board while lifting the switch board

from the front panel assembly little by little. (See Fig.14.)

Reference:

Remove the volume knob from the front side of the front panel

assembly at the same time.

Note:

Do not lose the compression springs when removing the

switch board. (See Fig.14.)

λ¿® ½±ª»®

Ð

Ú®±²¬ °¿²»´ ¿--»³¾´§

Ð

Ð

Fig.12

·

·

λ¿® ½±ª»®

Í©·¬½¸ ¾±¿®¼

ݱ³°®»--·±² -°®·²¹

·

·

Fig.13

Ú®±²¬ °¿²»´ ¿--»³¾´§

ݱ³°®»--·±² -°®·²¹

Fig.14

(No.MA173)1-11

Page 12

3.2DVD mechanism assembly

3.2.1Removing the mechanism control board

(See Fig.1)

Caution:

Before disconnecting the flexible wire extending from the DVD

pickup, solder the short-circuit point on the flexible wire using

a grounding soldering iron. If you do not follow this instruction,

the DVD pickup may be damaged.

(1)Turn over the body, and solder the short-circuit points on

the flexible wire extending from the DVD pickup.

(2)Disconnect the flexible wire from connector CN101

mechanism control board.

(3)Disconnect the card wire from connector CN201 on the

mechanism control board.

(4)Disconnect the flexible wire from connector CN202 on the

mechanism control board.

(5)Unsolder two soldered points a on the mechanism control

board and remove the wire extending from the feed motor.

(6)Remove the screw A attaching the lug wire.

(7)Remove the two screws B and screw C attaching the

mechanism control board.

Caution:

As the flexible wire to be connected to CN101, make sure to

attach it to the mechanism control board using a double

tape.

After reassembling, unsolder the short-circuit points.

on the

Ú´»¨·¾´» ©·®»

ܱ«¾´» ¬¿°»

ЭТпрп

Ô«¹ ©·®»

ß

Þ

͸±®¬ó½·®½«·¬ °±·²¬-

Þ

ЭТорп

Ú»»¼ ³±¬±®

¿

Ý

ЭТоро

Ó»½¸¿²·-³ ½±²¬®±´ ¾±¿®¼

Fig.1

1-12 (No.MA173)

Page 13

3.2.2Removing the top cover

(See Fig.2)

(1)Remove the two screws D attaching the top cover on the

back of the body.

(2)Remove the top cover upward.

Reference:

When reassembling, set part b of the top cover under the

bending part c of the chassis frame.

3.2.3Removing the mechanism section

(See Fig.2 to 4)

Remove the top cover.

(1)From the bottom of the body, remove the screw E attaching

the lug wire. (See Fig.2.)

(2)Remove the two screws F attaching the right and left stop-

pers on the front side. (See Fig.2.)

(3)Remove the two floating springs on the bottom of the body.

(See Fig.3.)

(4)Move the mechanism section upward and remove from the

chassis frame.

The three damper springs come off from the dampers.

(See Fig.4.)

Caution:

When reassembling, reattach the damper spring to the

damper respectively and insert the three shafts on the bottom of the mechanism to the dampers.

Before inserting the shaft to the dampers, apply IPA to the

hole of damper.

Ú´±¿¬·²¹ -°®·²¹

Fig.3

Ó»½¸¿²·-³ -»½¬·±²

ͬ±°°»®

Ú

̱° ½±ª»®

ͬ±°°»®

Ú

Ü

Ü

¾

½

Û

Ô«¹ ©·®»

Ь¿³°»® НРтшЪч

øÍ·´ª»®÷

Ü¿³°»® øÚ÷

øÞ´¿½µ÷

Ь¿³°»® НРтшЪч

øÍ·´ª»®÷

Ü¿³°»® øÚ÷

øÞ´¿½µ÷

Fig.4

Ь¿³°»® НРтшОч

øλ¼÷

Ü¿³°»® øÎ÷

øЫ®°´»÷

ݸ¿--·- º®¿³»

Fig.2

(No.MA173)1-13

Page 14

3.2.4Removing the clamper unit

(See Fig.5 to 7)

Remove the top cover and the mechanism section.

(1)Remove the clamper2 spring on the bottom of the mecha-

nism section. (See Figs.5.and 6.)

(2)Release the part d of the clamper spring from the bending

part of the chassis base assembly. (See Fig.7.)

(3)Move the clamper unit in the direction of the arrow and turn.

Release the two joints e and f, then remove the clamper

unit upward. (See Fig.6.)

3.2.5Reattaching the clamper unit

(See Fig.5 to 9)

(1)Attach the clamper spring to the clamper unit. (See Fig.8.)

(2)Move the clamper unit to set the side joints e and f to each

boss of the chassis base assembly. Make sure that part g

is inserted to the notch of the chassis base assembly. (See

Figs.5 and 9.)

(3)Move the part d of the clamper spring to the outside of the

bending part of the chassis base assembly. (See Fig.7.)

(4)Attach the clamper2 spring to the chassis base assembly.

(See Figs.5 and 6.)

Caution:

When reattaching, temporarily hook the end of the clamper

spring as shown in the figure to make the work easy. (See

Fig.8.)

Ý´¿³°»® «²·¬

Ý´¿³°»®î -°®·²¹

ݸ¿--·- ¾¿-» ¿--»³¾´§

Fig.6

Ý´¿³°»® -°®·²¹

Ý´¿³°»® -°®·²¹

º

Ý´¿³°»®î -°®·²¹

ݸ¿--·- ¾¿-» ¿--»³¾´§

¹

¼

ݸ¿--·- ¾¿-» ¿--»³¾´§

Fig.7

»

Fig.5

1-14 (No.MA173)

Page 15

Ý´¿³°»® «²·¬

Ý´¿³°»® -°®·²¹

Ý´¿³°»® «²·¬

Fig.8

Fig.9

¹

Ò±¬½¸

(No.MA173)1-15

Page 16

3.2.6Removing the front unit

(See Fig.10 to 12)

Remove the top cover and the mechanism section.

(1)Disconnect the flexible wire from connector CN202 on the

mechanism control board at the bottom of the body. (See

Fig.10.)

(2)Remove the screw G attaching the front unit on the top of

the body. (See Fig.11.)

(3)Move the front unit toward the front to release joint h, and

release two joints i and j on the right side of the chassis

base assembly. Then remove the front unit upward. (See

Figs.11 and 12.)

(4)Remove the two screws H attaching the switch board. (See

Fig.12.)

Reference:

You can remove the switch board only without removing the

front unit.

Caution:

When reassembling, attach the flexible wire extending from

the switch board using the double tape. (See Figs.10 and 12.)

Ó»½¸¿²·-³ ½±²¬®±´ ¾±¿®¼

Ù

Ú®±²¬ «²·¬

¸

Fig.11

ЭТоро

ܱ«¾´» ¬¿°»

Fig.10

Ú´»¨·¾´» ©·®»

ܱ«¾´» ¬¿°»

¶

·

Ø

Í©·¬½¸ ¾±¿®¼

Ú®±²¬ «²·¬

Ù

1-16 (No.MA173)

¸

Fig.12

Page 17

3.2.7Removing the loading arm assembly

(See Fig.13 , 14)

Remove the top cover, the mechanism section and the front

unit.

(1)From the top of the body, move the loading arm assembly

from the front side upward, and release the bosses from

the right and left joints k and m of the chassis base assembly.

(2)Release the boss from notch n of the connect arm on the

right side of the body, and release the boss from notch p of

the slide cam assembly on the left side.

³

Ô±¿¼·²¹ ¿®³ ¿--»³¾´§

Í·¼» ½¿³

¿--»³¾´§

°

³

µ

Fig.13

Ô±¿¼·²¹ ¿®³ ¿--»³¾´§

µ

²

²

ݱ²²»½¬ ¿®³

Fig.14

(No.MA173)1-17

Page 18

3.2.8Removing the rod (L)(R)/roller assembly

(See Fig.15 and 16)

Remove the top cover, the mechanism section, the front unit

and the loading arm assembly.

(1)Release the rod (L) and (R) from the joints q at the bottom

of the loading arm assembly (See Fig.15.)

(2)Remove the roller assembly from the loading arm assem-

bly. (See Fig.16.)

(3)Remove the two collars and washer from the roller assem-

bly. (See Fig.16.)

Caution:

After attaching the loading arm assembly to the roller assembly, attach the rod (L) and (R). Attach the rods to the right and

left collars of the roller. (See Fig.15.)

When reattaching the rod (L) and (R) to the loading arm assembly, engage each joint as shown in Fig.15. As joints q of

the rod (L), let the rod through q before reattaching it.

ݱ´´¿®

α¼øÎ÷ α¼øÔ÷

¯

ݱ´´¿®

¯

¯

ݱ´´¿®

α¼øÔ÷

α¼øÎ÷

¯

Ô±¿¼·²¹ ¿®³ ¿--»³¾´§

Fig.15

α´´»® ¿--»³¾´§

Ô±¿¼·²¹ ¿®³ ¿--»³¾´§

¯

α¼øÔ÷

¯

ݱ´´¿®

É¿-¸»®

α¼øÎ÷

1-18 (No.MA173)

Fig.16

Page 19

3.2.9Removing the DVD pickup assembly

(See Fig.17 to 19)

Remove the mechanism control board.

(1)From the bottom of the body, turn the feed gear in the di-

rection of the arrow to move the DVD pickup outwards.

(See Fig.17.)

(2)Remove the screw J attaching the thrust spring. (See

Fig.17.)

(3)Remove the DVD pickup assembly upward on the L.S.gear

side and release from sub shaft at joint r. Move the lead

screw of the DVD pickup assembly in the direction of the

arrow to release from joint s. (See Fig.18.)

Caution:

When releasing the lead screw at joint s, the L.S.collar

comes off at the end of the lead screw. When reassembling, reattach the L.S.collar to the lead screw and

engage joint s. (See Fig.18.)

When reattaching the L.S.collar, reattach it to the point

s of the lead screw, and to the rod (M). Make sure that

the L.S.collar is set on the rod (M) spring. (See Fig.18.)

(4)Remove the screw K attaching the rack spring/ rack plate

on the DVD pickup. (See Fig.19.)

(5)Pull out the lead screw. (See Fig.19.)

Caution:

Perform adjustment after replacing the pickup.

ÜÊÜ Ð·½µ«° ¿--»³¾´§

ÜÊÜ Ð·½µ«° ¿--»³¾´§

Ú»»¼ ¹»¿®

Ö

̸®«-¬ -°®·²¹

Fig.17

-

ÔòÍò½±´´¿®

α¼øÓ÷

Ô»¿¼ -½®»©

Í«¾ -¸¿º¬

ÔòÍò½±´´¿®

®

ÔòÍò¹»¿®

Fig.18

Õ

ο½µ -°®·²¹

Ô»¿¼ -½®»©

ο½µ °´¿¬»

ÜÊÜ Ð·½µ«°

Fig.19

(No.MA173)1-19

Page 20

3.2.10Removing the spindle motor

®

(See Fig.20)

Remove the mechanism control board.

Remove the two screws L attaching the spindle motor on the

bottom of the body.

Caution:

Perform adjustment when reattaching the spindle motor.

3.2.11Removing the feed motor assembly

(See Fig.21 and 22)

Remove the mechanism control board.

(1)Remove the feed TRI. spring on the bottom of the body.

(See Fig.21.)

(2)Remove the two screws M attaching the feed motor as-

sembly. (See Fig.21.)

(3)Remove the slit washer from the motor H. assembly and

pull out the worm wheel. (See Fig.22.)

Remove the two screws N attaching the feed motor. (See

Fig.22.)

Í°·²¼´» ³±¬±®

Ô

Fig.20

Ú»»¼ ÌÎ×ò -°®·²¹

Ó

Ú»»¼ ³±¬±® ¿--»³¾´§

1-20 (No.MA173)

Í´·¬ ©¿-¸»®

ɱ®³ ©¸»»´

Ò

Ó±¬±® Øò ¿--»³¾´§

Fig.21

Ú»»¼ ³±¬±

Fig.22

Page 21

SECTION 4

ADJUSTMENT

4.1Test instruments required for adjustment

(1)Digital oscilloscope (100MHz)

(2)Jitter meter

(3)Digital tester

(4)Electric voltmeter

(5)Tracking offset meter

(6)Test Disc : VT501 or VT502

(7)Extension studs : STDV001-3P

(8)Extension cable : EXTDV002-30P

4.3Connection method

Connection procedure

(1)Attach the front chassis assembly to the main board.

(2)Connect the front panel assembly to the main board.

(3)Attach the heat sink and rear bracket to the main board.

(4)Attach the extension studs to the DVD mechanism assembly.

(5)Connect the DVD mechanism assembly and the main board with a extension cable.

4.2Standard measuring conditions

Power supply voltageDC14.4V(11 to 16V)

Load impedance4(2 Speakers connection)

Line Output20K

Caution:

Be sure to attach the heat sink and rear bracket onto the power

amplifier IC and regulator IC respectively, before supply the

power. If voltage is applied without attaching these parts, the

power amplifier IC and regulator IC will be destroyed by heat.

Ы¨¬»²-·±² ½¿¾´»

ЫИМЬКрроунрР

Ø»¿¬ -·²µ

λ¿® ¾®¿½µ»¬

Ó¿·² ¾±¿®¼

Ы¨¬»²-·±² -¬«¼

НМЬКррпунР

Ы¨¬»²-·±² -¬«¼НМЬКррпунР

(No.MA173)1-21

Page 22

After replacing the pickup, set the unit in the service mode to display a jitter value on the LCD. Confirm that the jitter value measured

with a jitter meter is within 12% of the jitter value displayed on the LCD. If it is within 12%, then adjustment is not necessary. Please

note that a jitter value displayed on the LCD is hex data. Refer to the corresponding decimal notation value using the Jitter Conversion

Table and confirm it with the measured value.

Fix the screws "a", "b" and "c" with screw lock paint.

If the measured jitter value is outside the 12% tolerance range, perform the following adjustments.

½

¾

¿

Jitter value adjustment procedure (Pickup horizontal level adjustment relative to the DVD recording surface)

(For the adjustment tool use a 3 mm wrench and not a screwdriver, this procedure will make the adjustment easier.)

í ³³ ©®»²½¸

(1)Set the unit to the service mode and display a jitter value (hex data) on the LCD.

(2)Turn each of the screws a, b and c, by a half-turn per step, in the direction that reduces the jitter value in order to minimize it.

(Do not turn a screw more than a half turn at a time, but adjust the screws in the cycle of a b c d a.)

(3)After completing the adjustment, secure the screws with screw lock paint.

1-22 (No.MA173)

Page 23

4.4Jitter value conversion table

Load the test DVD and set the unit to the service mode. A jitter value converted to the hex value is displayed on the LCD. Refer to the

corresponding decimal notation value shown in the following Jitter Conversion Table.

The adjustment is OK if the jitter value measured with a jitter meter is within 12% of the jitter value displayed on the LCD.

If the measured jitter value is outside the 12% tolerance range, adjust it to minimize the difference between the measured value and

the displayed value.

ײ¼·½¿¬»¼

±² ¬¸» ÔÝÜ

îðßé

îðéî

îðíÜ

îððè

ïÚÜî

ïÚçÜ

ïÚêè

ïÚíí

ïÛÚÛ

ïÛÝè

ïÛçí

ïÛëÛ

ïÛîç

ïÜÚì

ïÜÞÛ

ïÜèç

ïÜëì

ïÜïÚ

ïÝÛß

ïÝÞì

ïÝéÚ

ïÝìß

ïÝïë

ïÞÛð

ïÞßß

ïÞéë

ïÞìð

ïÞðÞ

ïßÜê

ïßßð

ïßêÞ

ïßíê

ïßðï

ïçÝÝ

ïççê

ïçêï

ïçîÝ

ïèÚé

Ö×Ì ÑËÌ

пзлйтзи

пзллтно

пзлоткк

пзлр

пзмйтнм

пзммтки

пзмотро

пзнзтнк

пзнктй

пзнмтрм

пзнптни

пзоитйо

пзоктрк

пзонтм

пзортйм

пзпитри

пзплтмо

пзпотйк

пзпртп

пзрйтмм

пзрмтйи

пзротпо

пиззтмк

пизкти

пизмтпм

пизптми

пииитио

пииктпк

пиинтл

пииртим

пийитпи

пийлтло

пийотик

пийрто

пикйтлм

пикмтии

пикотоо

пилзтлк

Ö·¬¬»® ª¿´«»

øû÷

ìòé

íèïè

ìòè

íèîë

ìòç

íèíî

ëòð

íèìð

ëòï

íèìÜ

ëòî

íèëß

ëòí

íèêé

ëòì

íèéë

ëòë

íèèî

ëòê

íèèÚ

ëòé

íèçÜ

ëòè

íèßß

ëòç

íèÞé

êòð

íèÝë

êòï

íèÜî

êòî

íèÜÚ

êòí

íèÛÝ

êòì

íèÚß

êòë

íçðé

êòê

íçïì

êòé

íçîî

êòè

íçîÚ

êòç

íçíÝ

éòð

íçìß

éòï

íçëé

éòî

íçêì

éòí

íçéï

éòì

íçéÚ

éòë

íçèÝ

éòê

íççç

éòé

íçßé

éòè

íçÞì

éòç

íçÝï

èòð

íçÝÚ

èòï

íçÜÝ

èòî

íçÛç

èòí

íçÚê

èòì

íßðì

ײ¼·½¿¬»¼

±² ¬¸» ÔÝÜ

ïèÝî

ïèèÝ

ïèëé

ïèîî

ïéÛÜ

ïéÞè

ïéèî

ïéìÜ

ïéïè

ïêÛí

ïêßÛ

ïêéè

ïêìí

ïêðÛ

ïëÜç

ïëßì

ïëêÛ

ïëíç

ïëðì

ïìÝÚ

ïìçß

ïìêì

ïìîÚ

ïíÚß

ïíÝë

ïíçð

ïíëß

ïíîë

ïîÚð

ïîÞÞ

ïîèê

ïîëð

ïîïÞ

ïïÛê

ïïÞï

ïïéÝ

ïïìê

ïïïï

Ö×Ì ÑËÌ

пилктз

пилмтом

пилптли

пимитзо

пимкток

пимнтк

пимртзм

пинитои

пинлтко

пинотзк

пинртн

пиойткм

пиомтзи

пиоотно

пипзткк

пипй

пипмтнм

пипптки

пирзтро

пирктнк

пирнтй

пирптрм

пйзитни

пйзлтйо

пйзнтрк

пйзртм

пйийтйм

пйилтри

пйиотмо

пййзтйк

пйййтп

пйймтмм

пййптйи

пйкзтпо

пйкктмк

пйкнти

пйкптпм

пйлитми

Ö·¬¬»® ª¿´«»

øû÷

èòë

íßïï

èòê

íßïÛ

èòé

íßîÝ

èòè

íßíç

èòç

íßìê

çòð

íßëì

çòï

íßêï

çòî

íßêÛ

çòí

íßéÞ

çòì

íßèç

çòë

íßçê

çòê

íßßí

çòé

íßÞï

çòè

íßÞÛ

çòç

íßÝÞ

ïðòð

íßÜç

ïðòï

íßÛê

ïðòî

íßÚí

ïðòí

íÞðð

ïðòì

íÞðÛ

ïðòë

íÞïÞ

ïðòê

íÞîè

ïðòé

íÞíê

ïðòè

íÞìí

ïðòç

íÞëð

ïïòð

íÞëÛ

ïïòï

íÞêÞ

ïïòî

íÞéè

ïïòí

íÞèë

ïïòì

íÞçí

ïïòë

íÞßð

ïïòê

íÞßÜ

ïïòé

íÞÞÞ

ïïòè

íÞÝè

ïïòç

íÞÜë

ïîòð

íÞÛí

ïîòï

íÞÚð

ïîòî

íÞÚÜ

ײ¼·½¿¬»¼

±² ¬¸» ÔÝÜ

ïðÜÝ

ïðßé

ïðéî

ïðíÝ

ïððé

ÚÜî

ÚçÜ

Úêè

Úíî

ÛÚÜ

ÛÝè

Ûçí

ÛëÛ

Ûîè

ÜÚí

ÜÞÛ

Üèç

Üëì

ÜïÛ

ÝÛç

ÝÞì

ÝéÚ

Ýìß

Ýïì

ÞÜÚ

Þßß

Þéë

Þìð

Þðß

ᚉ

ßßð

ßêÞ

ßíê

ßðð

çÝÞ

ççê

çêï

çîÝ

Ö×Ì ÑËÌ

пйллтио

пйлнтпк

пйлртл

пймйтим

пймлтпи

пймотло

пйнзтик

пйнйто

пйнмтлм

пйнптии

пйозтоо

пйоктлк

пйонтз

пйоптом

пйпитли

пйплтзо

пйпнток

пйпртк

пйрйтзм

пйрлтои

пйротко

пкззтзк

пкзйтн

пкзмткм

пкзптзи

пкизтно

пкикткк

пким

пкиптнм

пкйитки

пкйктро

пкйнтнк

пкйртй

пккитрм

пкклтни

пккотйо

пккртрк

пклйтм

Ö·¬¬»® ª¿´«»

øû÷

ïîòí

íÝðß

ïîòì

íÝïè

ïîòë

íÝîë

ïîòê

íÝíî

ïîòé

íÝìð

ïîòè

íÝìÜ

ïîòç

íÝëß

ïíòð

íÝêè

ïíòï

íÝéë

ïíòî

íÝèî

ïíòí

íÝèÚ

ïíòì

íÝçÜ

ïíòë

íÝßß

ïíòê

íÝÞé

ïíòé

íÝÝë

ïíòè

íÝÜî

ïíòç

íÝÜÚ

ïìòð

íÝÛÜ

ïìòï

íÝÚß

ïìòî

íÜðé

ïìòí

íÜïì

ïìòì

íÜîî

ïìòë

íÜîÚ

ïìòê

íÜíÝ

ïìòé

íÜìß

ïìòè

íÜëé

ïìòç

íÜêì

ïëòð

íÜéî

ïëòï

íÜéÚ

íÜèÝ

ïëòî

ïëòí

íÜçç

ïëòì

íÜßé

ïëòë

íÜÞì

ïëòê

íÜÝï

ïëòé

íÜÝÚ

ïëòè

íÜÜÝ

ïëòç

íÜÛç

ïêòð

íÜÚé

(No.MA173)1-23

Page 24

4.5Service mode

4.5.1Standard input/output conditions

Power supply voltageDC14.4V(11 to 16V)

Load impedance4(2 Speakers connection)

Line Output20K

4.5.2Service mode setting procedure

(The DVD does not need to be loaded before starting the following procedure.)

ЕНЫФГ ¾«¬¬±²

ЕНМЯТЬЮЗсСТ ЯММЫТЛЯМСОГ ¾«¬¬±²

ЕЬЧНЭ ЬСЙТГ ¾«¬¬±²

(1)Press a [STANDBY/ON ATTENUATOR] button on a main unit and switch it on.

(2)Keep this state more than 2 seconds while continuing pressing the [SEL] button, [STANDBY/ON ATTENUATOR] button and

[SOURCE] button sequentially.

(3)This unit is set by a service mode.

*Exchanging it operate a menu of a service mode with the [DISC UP] button and [DISC DOWN] button.

Operate choice of a menu with a [SEL] button.

ЕЬЧНЭ ЛРГ ¾«¬¬±²

ЕНСЛОЭЫГ ¾«¬¬±²

1-24 (No.MA173)

Page 25

4.5.3Operation procedures

Х»»° ¬¸·- -¬¿¬» ³±®» ¬¸¿² о -»½±²¼- ©¸·´»

½±²¬·²«·²¹ °®»--·²¹ ¬¸» ЕНЫФГ ¾«¬¬±²ф

ЕНМЯТЬЮЗсСТ ЯММЫТЛЯМСОГ ¾«¬¬±² ¿²¼

ЕНСЛОЭЫГ ¾«¬¬±² -»¯«»²¬·¿´´§т

̸» «²·¬ »²¬»®- ¬¸» -»®ª·½» ³±¼»ò

юЧТЧМ ЯФФю ·-

·²¼·½¿¬»¼ ±² ¬¸» ÔÝÜò

юКЫОНЧСТю ·-

·²¼·½¿¬»¼ ±² ¬¸» ÔÝÜò

юЯОЫЯсОЩТю ·-

·²¼·½¿¬»¼ ±² ¬¸» ÔÝÜò

юКЧЬЫСю ·-

·²¼·½¿¬»¼ ±² ¬¸» ÔÝÜò

Р®»-- ¬¸» ЕНЫФГ µ»§

Р®»-- ¬¸» ЕНЫФГ µ»§

Р®»-- ¬¸» ЕНЫФГ µ»§

Р®»-- ¬¸» ЕНЫФГ µ»§

Ч²·¬·¿´·¦» ¿´´ ¼¿¬¿ ¬± ¬¸» º¿½¬±®§ -»¬¬·²¹

ж М¸» -§-¬»³ ½±²¬®±´ ЫЫРОСУ ·- ·²·¬·¿´·¦»¼ »²¬·®»´§т

Ó·½®±½±³°«¬»® ª»®-·±² ¼·-°´¿§

цццццццццццц

цццццццццццц

ͧ-¬»³ ½±²¬®±´ ³·½®±½±³°«¬»® ª»®-·±²

ÜÊÜ ª»®-·±²

Ы¨½¸¿²¹·²¹ ·¬ ±°»®¿¬» »¿½¸ ·²¼·½¿¬·±² ©·¬¸ ¬¸»

ЕЬЧНЭ ЛРГ ¾«¬¬±² ¿²¼ ЕЬЧНЭ ЬСЙТГ ¾«¬¬±²т

Ü»-¬·²¿¬·±² ¿®»¿ñ®»¹·±² ¼·-°´¿§

цццццццццццц

цццццццццццц

цццццццццццц

ͧ-¬»³ ½±²¬®±´ ¼»-¬·²¿¬·±²

ÜÊÜ «²·¬ ¼»-¬·²¿¬·±²

ÜÊÜ «²·¬ ®»¹·±²

Ы¨½¸¿²¹·²¹ ·¬ ±°»®¿¬» »¿½¸ ·²¼·½¿¬·±² ©·¬¸ ¬¸»

ЕЬЧНЭ ЛРГ ¾«¬¬±² ¿²¼ ЕЬЧНЭ ЬСЙТГ ¾«¬¬±²т

Н»¬¬·²¹ ±º ТМНЭ ±® РЯФ

юТМНЭю ±® юРЯФю ¿®» ·²¼·½¿¬»¼ ±² ¬¸» ФЭЬт

Ы¨½¸¿²¹·²¹ ·¬ ±°»®¿¬» »¿½¸ ·²¼·½¿¬·±² ©·¬¸ ¬¸»

ЕЬЧНЭ ЛРГ ¾«¬¬±² ¿²¼ ЕЬЧНЭ ЬСЙТГ ¾«¬¬±²т

Ò±¬»æ

̸»®» ·- ¬¸» ³±¼»´ ¬¸¿¬ ·- ²±¬ »¯«·°°»¼ ©·¬¸

¬¸·- ³±¼» ¾§ ¿ ª»®-·±²ò

þÝÔÎ ÛÎÎþ ·-

·²¼·½¿¬»¼ ±² ¬¸» ÔÝÜò

ß Þ

Р®»-- ¬¸» ЕНЫФГ µ»§

Э´»¿® ´±¿¼·²¹с»¶»½¬·±² »®®±® ¸·-¬±®§

ж М¸» »®®±® ¸·-¬±®§ -¬±®»¼ ·² ¬¸» ЫЫРОСУ ·- ½´»¿®»¼т

(No.MA173)1-25

Page 26

ß Þ

юЭЬ ЫООСОю ·-

·²¼·½¿¬»¼ ±² ¬¸» ÔÝÜò

Ú®®±® ½±¼» øï ¾§¬»÷

Ú·®-¬ ¾§¬»Åðïà ۶»½¬ »®®±®

Ü»¬¿·´»¼ »®®±® ½±¼»- øî ¾§¬»-÷ Ü·-°´¿§»¼ ©·¬¸ ´±¿¼·²¹ñ»¶»½¬·±² »®®±®- ±²´§ò

Ú·®-¬ ¾§¬»

Í»½±²¼ ¾§¬»

Р®»-- ¬¸» ЕНЫФГ µ»§

λ¿¼ ´±¿¼·²¹ ¿²¼ »¶»½¬·±² »®®±® ¸·-¬±®§

æ ̸» »®®±® ¸·-¬±®§ -¿ª»¼ ·² ¬¸» -§-¬»³ ½±²¬®±´

·- ®»¿¼ ¿²¼ ¼·-°´¿§»¼ò

ÌÑÌ󨨨¨ æ ̱¬¿´ »®®±® ½±«²¬ò

М±¬¿´ »®®±® ½±«²¬

шЯ º·¹«®» ¾»¬©»»² р ¿²¼ зззз · ¼·-°´¿§»¼т прррр ±® ³±®» ·- ¿´-±

¼·-°´¿§»¼ ¿- ззззтч

Û²§§¦¦¦¦ æ Ô¿¬»-¬ ¬¸®»» »®®±® ½±¼»-ò

Ü»¬¿·´»¼ »®®±® ½±¼»

Û®®±® ½±¼»

ݱ«²¬»®

𲧧¦¦¦¦ æ Ú·®-¬ º·ª» »®®±® ½±¼»-

Ü»¬¿·´»¼ »®®±® ½±¼»

Û®®±® ½±¼»

ݱ«²¬»®

Ы¨½¸¿²¹·²¹ ·¬ ±°»®¿¬» »¿½¸ ·²¼·½¿¬·±² ©·¬¸ ¬¸»

ЕЬЧНЭ ЛРГ ¾«¬¬±² ¿²¼ ЕЬЧНЭ ЬСЙТГ ¾«¬¬±²т

Åðçà Ա¿¼·²¹ »®®±®

Ø·¹¸»® ì ¾·¬-

Ô±©»® ì ¾·¬Åïà ̷³» ±«¬

Åîà ͩ·¬½¸ -¬¿¬«- »®®±®

Åíà ͩ·²¹·²¹ »®®±®

¾·¬é

¾·¬êôë

¾·¬ì

¾·¬í

¾·¬î

¾·¬ï

¾·¬ð

шЫ¨¿³°´»ч Й¸»² ¿ -©·¬½¸ -¬¿¬«- »®®±® ±½½«®- ¼«®·²¹ ´±¿¼·²¹ ®±«¬» н ¿²¼

¬¸» -©·¬½¸ -¬¿¬«- ·- ФсФсШсШсШ шррпппЮ г рйШчф ¬¸» »®®±® ½±¼»

¿²¼ ¼»¬¿·´»¼ »®®±® ½±¼» ¾»½±³»ж Ерз норйГт

О±«¬» Т±т шЫЦЫЭМ ®±«¬» Т±тч

ó

ïøî÷

ïøî÷

᫬» Ò±ò øЮ±½»-- ±º »®®±® ±½½«®®»²½»÷

λº»® ¬± ½¸¿®¬- ïòï ¿²¼ ïòîò

Û®®±® ¬§°»

Ü·-½ ¬§°» øðæ ïî ½³ò ïæ è ½³÷

Ú·¨»¼ ¿¬ ð

ÍÉï -¬¿¬«ÍÉî -¬¿¬«ÍÉí -¬¿¬«ÍÉì -¬¿¬«ÎÛÍÌ ÍÉ -¬¿¬«-

НЙпсоснсм

пфпфпфп

рфпфпфп

рфрфпфп

Åλ-¬ ÍÉÃ

ÅðÃ

ÅðÃ

ÅðÃ

Ô±¿¼·²¹

Ò± Ü·-½

Ü·-½ ·²-»®¬

¼»¬»½¬·±²

Û¶»½¬

Ò± Ü·-½

Û¶»½¬

½±³°´»¬·±²

λ´±¿¼

Ü·-½ °«-¸ ·²

Ý Ü

1-26 (No.MA173)

îøî÷

îøî÷

îøî÷

îøî÷

íøï÷

íøï÷

рфрфрфп

рфрфпфп

рфпфпфп

пфпфпфп

пфпфпфр

пфпфпфр

ÅðÃ

ÅðÃ

ÅðÃ

ÅðÃ

ÅðÃ

ÅïÃ

Ô±¿¼ ½±³°´»¬·±²

ݸ¿®¬ ïòï ïî½³ Ü·-½ -©·¬½¸ -¬¿¬«- ¬®¿²-·¬·±²

О±«¬» Т±т шЫЦЫЭМ ®±«¬» Т±тч

ó

ïøî÷

ïøî÷

îøî÷

îøî÷

íøï÷

íøï÷

Ì®¿²-·¬·±² ·² ¬¸» ½»²¬»® ´±¿¼·²¹ øÍ·³·´¿® ¬± ïî½³ ·² ¬¸» -·¼» ´±¿¼·²¹÷

НЙпсоснсм

пфпфпфп

рфпфпфп

рфрфпфп

рфпфпфп

пфпфпфп

пфпфпфр

пфпфпфр

Åλ-¬ ÍÉÃ

ÅðÃ

ÅðÃ

ÅðÃ

ÅðÃ

ÅðÃ

ÅðÃ

ÅïÃ

Ô±¿¼·²¹

Ò± Ü·-½

Ü·-½ ·²-»®¬

¼»¬»½¬·±²

Ô±¿¼ ½±³°´»¬·±²

ݸ¿®¬ ïòî è½³ Ü·-½ -©·¬½¸ -¬¿¬«- ¬®¿²-·¬·±²

Û¶»½¬ -¬¿®¬

Û¶»½¬

Ò± Ü·-½

Û¶»½¬

½±³°´»¬·±²

Û¶»½¬ -¬¿®¬

λ´±¿¼ -¬¿®¬

Ô±¿¼ ½±³°´»¬·±²

λ´±¿¼

Ü·-½ °«-¸ ·²

λ´±¿¼ -¬¿®¬

Ô±¿¼ ½±³°´»¬·±²

Page 27

Ý Ü

юНЗНуМЫУРю ·-

·²¼·½¿¬»¼ ±² ¬¸» ÔÝÜò

юЭШХ УСЬЫю ·-

·²¼·½¿¬»¼ ±² ¬¸» ÔÝÜò

юОЛТТЧТЩю ·-

·²¼·½¿¬»¼ ±² ¬¸» ÔÝÜò

юУЫУЭШЫЭХю ·-

·²¼·½¿¬»¼ ±² ¬¸» ÔÝÜò

юЧТЧМю ·-

·²¼·½¿¬»¼ ±² ¬¸» ÔÝÜò

Р®»-- ¬¸» ЕНЫФГ µ»§

Р®»-- ¬¸» ЕНЫФГ µ»§

Р®»-- ¬¸» ЕНЫФГ µ»§

Р®»-- ¬¸» ЕНЫФГ µ»§

Р®»-- ¬¸» ЕНЫФГ µ»§

̸»®³·-¬±®ù- ¬»³°»®¿¬«®» ¼¿¬¿ ®»¿¼±«¬

æ Ü¿¬¿ ·² ¬¸» ¬»³°»®¿¬«®» -»²-±® ·² ¬¸» -§-¬»³ ½±²¬®±´

·- ®»¿¼ »ª»®§ ë -»½±²¼- ¿²¼ ¼·-°´¿§»¼ ·² ¸»¨ ²«³¾»®-ò

ЬКЬ «²·¬ ½¸»½µ ³±¼»

шН»» -»½¬·±² юлтптм ЬКЬ «²·¬ ½¸»½µ ³±¼»ю º±® ¼»¬¿·´-тч

Ϋ²²·²¹ ³±¼»æ Ú±® «-» ·² ®«²²·²¹ ¬»-¬-ò

Ó»³±®§ ½¸»½µ

æ ̸» ®»³¿·²·²¹ ¼¿¬¿ ½¿°¿½·¬§ ±º ¬¸» ¼·-½ ·- ¼·-°´¿§»¼ ±² ¬¸» ÔÝÜò

Ч²·¬·¿´·¦» «-»® -»¬ ¼¿¬¿

ж М¸» -§-¬»³ ½±²¬®±´ ЫЫРОСУ ·- ·²·¬·¿´·¦»¼ »¨½»°¬ º±® ¬¸»

´±¿¼·²¹с»¶»½¬·±² »®®±® ¸·-¬±®§т

(No.MA173)1-27

Page 28

4.5.4DVD unit check mode

ݸ¿²¹» ÔÝÜ ·²¼·½¿¬·±² ©·¬¸ ¿ ÅÚÚ Ã ¾«¬¬±² ¿²¼ ¿ ÅÎÛÉ Ã ¾«¬¬±²ò

ݸ»½µ ·¬»³ ´·-¬

Ò±òßñÜ µ»§ ÜÊÜ «²·¬ ±°»®¿¬·±²

ï

ÅïÃ

î

ÅîÃ

í

ÅíÃ

ì

ÅìÃ

ë

ÅëÃ

ê

ÅêÃ

ЕЬЧНРГ

é

è

ЕНСЛОЭЫГ

ç

ЕНЫФГ

ïð

ЕУСЬЫГ

ïï

ЕЮЯТЬГ

ïî

ЕЬЧНЭ ЛР Г

ïí

ЕЬЧНЭ ЬЙ Г

ïì

ЕЫЦЫЭМГ

Н¬¿®¬ ¿¬ ²±®³¿´ -°»»¼

шЯº¬»® -¬¿®¬ф ·¬ ·- ³»¿-«®»¼ ЦЧММЫО ±² ¬¸»

·²¬»®²¿´ °±-·¬·±²÷

Ì®¿½µ·²¹ ±ºº ±² ¬¸» ±«¬»®³±-¬ °±-·¬·±² ±º ÝÜ

Ì®¿½µ·²¹ ±ºº ±² ¬¸» ·²²»®³±-¬ °±-·¬·±² ±º ÝÜ

ЭЬБФЬ ´·¹¸¬- ¿²¼ ´¿-»® ½«®®»²¬ ·- ¼·-°´¿§»¼

ЬКЬБФЬ ´·¹¸¬- ¿²¼ ´¿-»® ½«®®»²¬ ·- ¼·-°´¿§»¼

ÜÊÜ ¨ï ¶·¬¬»® ³»¿-«®·²¹ ³±¼»

øº±® «-» ·² ³»½¸¿²·-³ ³»¿-«®»³»²¬÷

Ч²¼·½¿¬·±² ±º ЫЫРОСУ ½±²¬»²¬-

Ч²·¬·¿´·¦¿¬·±² ±º ЫЫРОСУ ½±²¬»²¬Ч²¼·½¿¬·±² ±º ¬»³°»®¿¬«®»

Í»¿®½¸ ú ¶·¬¬»® ³»¿-«®»³»²¬ ¬± ¿² ¿°°±·²¬»¼

°±-·¬·±² ±º ÜÊÜ

Н»¬¬·²¹ ±º УСТЧМСО ¬»®³·²¿´

ЬКЬ¨п ¼±«¾´» -°»»¼ -¬¿®¬

шЯº¬»® -¬¿®¬ф ·¬ ·- ³»¿-«®»¼ ЦЧММЫО ±² ¬¸»

·²¬»®²¿´ °±-·¬·±²ч

Ь·-½ -¬±°°»¼ ъ ФЬуСЪЪ

СРЫТ

Û¨¿³°´» ±º

ÔÝÜ ·²¼·½¿¬·±²

ТСОУРФЯЗ

ЭЛО

ЦЧМ

ЫЪуЮЯФ

СЛМОХСЪЪ

ЫЪуЮЯФ

ЧТМОХСЪЪ

ЭЬФЬ СТ

ЭЛО

ЦЧМ

ЬКЬФЬ СТ

ЭЛО

ЦЧМ

ЬКЬ ЦЧМО

ЭЛО

ЦЧМ

ОСУ ЬЯМЯ

ЯЬЬО

ЬЯМЯ

ОСУЭФЫЯО

ЦЬмуМЫУР

МЫУ

ЬКЬуЬФ

РФЭ

ЦЧМ

УСТЧМСО

Уп

Уо

РФЯЗ

ЭЛО

ЦЧМ

НМСР

ЬНЭ СРЫТ

Ô¿-»® ½«®®»²¬ ª¿´«»

Ö·¬¬»® ª¿´«»

Ú±® ÛÚ °¸¿-» »®®±®

Ú±® ÛÚ °¸¿-» »®®±®

Ô¿-»® ½«®®»²¬ ª¿´«»

Ö·¬¬»® ª¿´«»

Ô¿-»® ½«®®»²¬ ª¿´«»

Ö·¬¬»® ª¿´«»

Ô¿-»® ½«®®»²¬ ª¿´«»

Ö·¬¬»® ª¿´«»

ЫЫРОСУ ¿¼¼®»-ЫЫРОСУ ½±²¬»²¬-

Ì»³°»®¿¬«®»

шР±-·¬·±² ³»¿-«®»¼ ©·¬¸ КМулрпч

Ц·¬¬»® ª¿´«»

Ô¿-»® ½«®®»²¬ ª¿´«»

Ö·¬¬»® ª¿´«»

ײ¼·½¿¬·±² ½±²¬»²¬-

Ò±¬»

Р®»-- µ»§ ЕпГ ±º Т±тп ¾»º±®» ¿² ·¬»³ ·² ©¸·½¸ ¬¸» Т±то ±® н µ»§ ·- °®»--»¼т

Р®»-- µ»§ ЕпГ ±º Т±тп ±® µ»§ ЕпоГ ±º Т±тпо ¾»º±®» ¿² ·¬»³ ·² ©¸·½¸ ¬¸» Т±т пр µ»§ ·- °®»--»¼ ¿²¼ ½±²º·®³

¬¸» ·²¼·½¿¬·±² ±º ¶·¬¬»® ª¿´«» ±² ¬¸» ФЭЬт

Т±тк -¬¿®¬- ±²´§ ¿ ЬКЬп ´¿§»® ¼·-µт Ыª»² ±¬¸»® ¼·-µ- -¬¿®¬ ЬКЬп ´¿§»®т

Й¸»² Т±тп ¿²¼ Т±тпо ¿®» °«-¸»¼ ¿º¬»® ¶·¬¬»® ·²¼·½¿¬·±²ф ¿ º±½«- ¶«³° ·- »¨»½«¬»¼т ш±²´§ ЬКЬо ´¿§»®ч

Н¬±° ¿ ¼·-µ ¾»º±®» СРЫТф ЭФСНЫ ¾§ ¿´´ ³»¿²-т шСРЫТ ¿²¼ ЭФСНЫ ¿®» ²±¬ »¨»½«¬»¼ ·² ¿ ¼·-µ ¬«®²тч

М¸» ½¸»½µ ³±¼» ½¿² ¾» »¨·¬»¼ »·¬¸»® ¾§ °®»--·²¹ ¬¸» ЕРСЙЫОГ µ»§ ±® ¾§ ®»-»¬¬·²¹ ¬¸» «²·¬т

1-28 (No.MA173)

Page 29

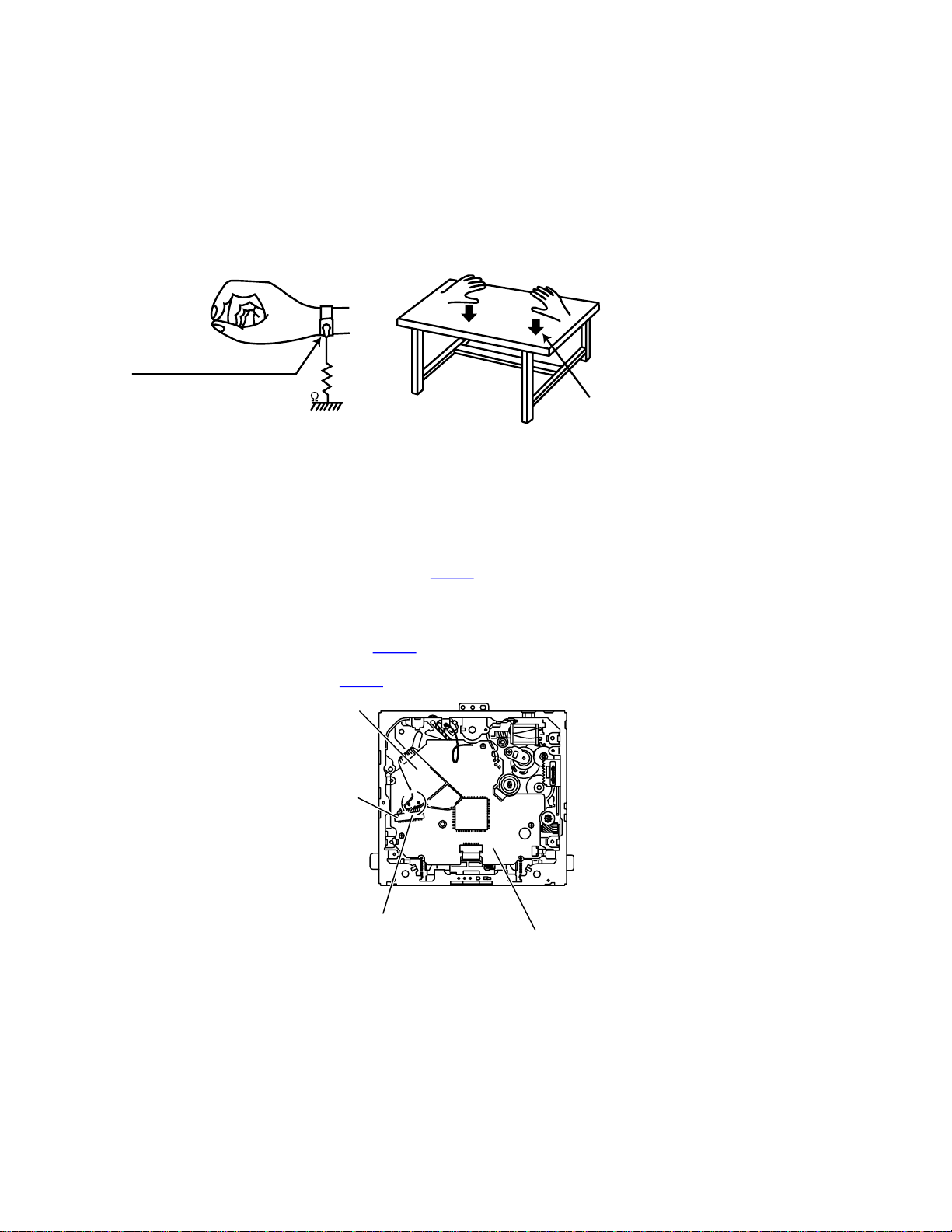

5.116 PIN CORD DIAGRAM

8

GN

WH

GN/BK

7

6

5

4

3

2

1

VI/BK

VI

NC

BL/WH

RD

BK

WH/BK

GY/BK

GY

BR

YG

OR/WH

YL

10

11

12

13

14

15

16

SECTION 5

TROUBLESHOOTING

BK

RD

BL

WH

BR

Black

Red

Blue

White

Brown

9

YG Yellow Green

GN

VI

GY

YL

OR

Green

Violet

Gray

Yellow

Orange

RD

1

3

5

7

NCBR

NC

BL/WH

RD

YL

OR/WH

BK

2

4

6

8

2 RD

16 YL

1 BK

3 BL/WH

13 BR

15 OR/WH

6 GN

7 GN/BK

5 VI

6 VI/BK

9 WH

10 WH/BK

12 GY

11 GY/BK

14 YG

ACC

MEMORY

GND

REMOTE

TEL

ILL

RL+

RL-

RR+

RR-

FL+

FL-

FR+

FR-

PARKING

TEL MUTING

ILLUMINATION

CONTROL

1

3

5

7

RD 7

YL 4

WH

VI

GY

GN

8

5

2

6

7

8

1

2

5

6

3

4

PARKING

BRAKE

VI/BK

2

GY/BK

4

WH/BK

6

GN/BK

8

RR

Rear Right

FR Front Right

FL

RL

REMOTE

ILL

Front Left

Rear Left

Remote

Illuminations Control

ANT

ACC

TEL

GND

MEMORY

PARKING

Auto Antenna

ACC Line

Telephone Muting

Ground

Memory Backup Battery+

Parking Brake

(No.MA173)1-29

Page 30

Victor Company of Japan, Limited

AV & MULTIMEDIA COMPANY CAR ELECTRONICS CATEGORY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MA173)

Printed in Japan

VPT

Page 31

НЭШЫУЯМЧЭ ЬЧЯЩОЯУН

ЬКЬсЭЬ ОЫЭЫЧКЫО

ХЬуЬКлпии

ЭЬуОСУ Т±тНУФоррлрн

ß®»¿ -«ºº·¨

ЛЪ уууууууууууууууууууууууууу Э¸·²¿

ݱ²¬»²¬-

Þ´±½µ ¼·¿¹®¿³

ͬ¿²¼¿®¼ -½¸»³¿¬·½ ¼·¿¹®¿³Ð®·²¬»¼ ½·®½«·¬ ¾±¿®¼-

îóï

îóî

îóë ¬± é

ЭСРЗОЧЩШМ оррл К·½¬±® Э±³°¿²§ ±º Ц¿°¿²ф Ф·³·¬»¼т

Т±тУЯпйнНЭШ

оррлсн

Page 32

Í¿º»¬§ °®»½¿«¬·±²

ÿ

ÿ

Þ«®®- º±®³»¼ ¼«®·²¹ ³±´¼·²¹ ³¿§ ¾» ´»º¬ ±ª»® ±² -±³» °¿®¬- ±º ¬¸» ½¸¿--·-ò ̸»®»º±®»ô

°¿§ ¿¬¬»²¬·±² ¬± -«½¸ ¾«®®- ·² ¬¸» ½¿-» ±º °®»º±®³·²¹ ®»°¿·® ±º ¬¸·- -§-¬»³ò

д»¿-» «-» »²±«¹¸ ½¿«¬·±² ²±¬ ¬± -»» ¬¸» ¾»¿³ ¼·®»½¬´§ ±® ¬±«½¸ ·¬ ·² ½¿-» ±º ¿²

¿¼¶«-¬³»²¬ ±® ±°»®¿¬·±² ½¸»½µò

Page 33

Þ´±½µ ¼·¿¹®¿³

ЪСЭЛН

ú

МОЯЭХЧТЩ

ÝÑ×Ô

Ð×ÝÕ ËÐ

ФСЯЬъЪЫЫЬ

УСМСО

НРЧТЬФЫ

УСМСО

ꃕ ± ꃒ

ÜÊÜ -»½¬·±²

ЯфЮфЭфЬфЫфЪ

ЪпЭЬфЪоЭЬ

ЪпЬКЬфЪоЬКЬ

ФРЭСп

ÔÜõ

Ïïðï

ЬКЬФЬЭЛО

Ïïðî

ФРЭСо

ÔÜõ

Ïïðí

ЭЬФЬЭЛО

Ïïðì

сЬОКУЛМЫ

МОЬОК

ЪСЬОК

ЪхфЪу

МхфМу

ÚÔÓõ

Ó

ÚÔÓó

ШпхфШпу

ШохфШоу

ШнхфШну

НУп ¬± НУн

Ó

ЧЭорп

ЬОЧКЫО

ЧЭолп

НР УСМСО

КШЯФЪ

МОНЬОК

ЬОКЭСТМ

ФУ

НРЬОК

сНРУЛМЫ

ЪЩ

ЧЭнрп

ЬКотп

ЬОЧКЫО

УЯ𠬱 УЯпп

УЬП𠬱 УЬПпл

ЬПУрфЬПУп

ЮЯрфЮЯпфУЭХ

ТЙЫфТЭНУ

ЧЭнзз

ТЭЯНфТОЯН

НЬОЯУ

ꃕ ± ꃒ

НЙмфМОКНЙ

НЙмфНЙл

ÛÐÜ×

ÛÐÜÑ

ÛÐÍÕ

ÛÐÝÍ

ЧЭмип

ЫРОСУ

ЯСЛМн

ЮЭХ

ФОЭХ

РЭУЭФХ

ЬЯЭРЬТ

ЬЯЭСЭН

ЬЭФХ

ЬЬЯМЯ

ЧЭмрп

Üñß

ЯСЛМФх

ЯСЛМФу

ЯСЛМОх

ЯСЛМОу

ЧЭмпп

ßÓÐ

ЬЯЭмСЛМфЧЫЭСЛМ

ФОУЛМЫфЛЭНфНЭН

НЭФХфЛоНЬМфНоЛЬМ

ЫИЯЬМ𠬱 ЫИЯЬМпл

ЫИЯЬОпк ¬± ЫЖЯЬОор

ЫИЬЯМ𠬱 ЫИЬЯМпл

ТЫИСЫфТЫИЭЫ

ТЫИЙЫ

сЪФБОНМ

ÒÎÍÌ

ÔóÝØ

ÎóÝØ

ЧЭнзи

ЪФЯНШ ОСУ

ЭРЛОНМ

ЧЭнрм

ОЫНЫМ

НЙпфНЙм

ßÒÌ

Ô×ÒÛ ×Ò

ЭШЯТЩЫО

ÔÝÜ ú Õ»§ -©·¬½¸ -»½¬·±²

ОЫУСЭСТ

ОЫУСЭСТ

ЧЭкро

ÕÛÇð

ÕÛÇï

ÕÛÇî

Íêðï ¬± Íêïì

НкпкфНкпй

ХЫЗ УЯМОЧИ

ÔÝÜï

ФЭЬ ЬЧНРФЯЗ

Íï ¬± Íëî

ÝÑÓï ¬± ÝÑÓí

ЧЭкрп

ФЭЬ ЬОЧКЫО

Üêðï ¬± Üêïç

ФЧЩШМЧТЩ

ЬЧНРФЯЗ

ФЭЬЬЯ

ФЭЬЭФ

ФЭЬЭЫ

ПкмрфПкмп

ЬЧУУЫО

ÝÑÒÌ

ЫТкрп

ЫТЭСЬЫО

ÛÒÝï

ÛÒÝî

ЬЧУБЭСТ

Ó¿·² ¿³°´·º·»® -»½¬·±²

ÌËîï

ЪУсЯУ МЛТЫО

НЫЫХ

УСТС

ЪУсЯУ

Ì«òÔ

ÜÊÜÔ

ÜÊÜÎ

Ì«òÎ

ÝØÔ

ÝØÎ

НЭХ

НЧсНС

ÖÊÝ ÞËÍ

ЮЛННС

ЮЛННЭХ

ЮЛНЧТМ

ЧсСфНЧсНС

ЧЭирп

ФЧТЫуФ

ФЧТЫуО

ХЫЗ𠬱 ХЫЗо

ЬЧУСЛМ

ФЭЬЭФ

ФЭЬЬЯ

ФЭЬЭЫ

ЫТЭпфЫТЭо

ОЫУСЭСТ

НтУЫМЫО

ЧЪЭЭСТМфНЬсНМ

×Ýíï

ÐÔÔ

ЧЭпкп

ЫтКСФЛУЫ

ФОУЛМЫ

ЛЭНфНЭН

НЭФХ

ЛоНЬМфНоЛЬМ

ЭРЛОНМ

ЧЭзкп

ЧЭзко

ФЫКЫФ

ЭСТКт

ХЫЗ𠬱 ХЫЗофЬЧУСЛМ

ФЭЬЭФфФЭЬЬЯфФЭЬЭЫ

ЫТЭпфЫТЭофОЫУСЭСТ

ЮЛННСфЮЛННЭХ

ЮЛНЧТМфЧсСфНЧсНС

РФФЬЧфРФФЬС

РФФЭЫфРФФЭХ

КСФЬЯ

КСФЭХ

КСФУЛМЫ

НЯЭФХ

НЯСЛМ

ФОУЛМЫ

ЛЭНфНЭН

НЭФХ

ЛоНЬМфНоЛЬМ

ЭРЛОНМ

ЧЭйоп

ÝÐË

ÐÑÒ

ßÒÌ

СЛМФЪ

СЛМОЪ

СЛМФО

СЛМОО

ЫРЬЯЧ

ЫРЬЯС

ЫРЭФХ

ОЫНЫМ

ЧЭнрп

РСЙЫО

ßÓÐ

ЧЭзрп

ОЫЩЛФЯМСО

ЭСУРСНЧМЫ

ÌÈ

ЧЭйоо

ЫРОСУ

ЧЭйон

ОЫНЫМ

Íéîí

ОЫНЫМ

ÍÉ

ЪОСТМ Фх

ЪОСТМ Фу

ЪОСТМ Ох

ЪОСТМ Оу

ОЫЯО Фх

ОЫЯО Фу

ОЫЯО Ох

ОЫЯО Оу

ЯЭЭ

ОЫУСМЫ

ЧЭмпп

КЧЬЫС

ßÓÐ

СЛМФО

СЛМОО

ÚßÒ

ÊÑËÌ

Ô×ÒÛ ÑËÌ

НРЫЯХЫО

ъ

ЮЯММЫОЗ

КЧЬЫС

СЛМ

ЬЧЩЧМЯФ

СЛМ

ЪЯТ

УСМСО

Ó

2-1

Page 34

Edited by Foxit PDF Editor

Copyright (c) by Foxit Software Company, 2004

For Evaluation Only.

ͬ¿²¼¿®¼ -½¸»³¿¬·½ ¼·¿¹®¿³-

Ó¿·² ¿³°´·º·»® -»½¬·±²

ÌËîï

ПЯЛрнпоурро

Ôï

ìòé

Éîï

ПЯУрпрлуррн

Инп

ПЯИркпкуррпЖ

éÐïðÐ

ÝîèÝîç

×Ýíï

ïðµ

Îìì

Îßíï

ТОЖррклуоооИ

РФФЭЫ

РФФЬС

РФФЭХ

РФФЬЧ

ÍÛÛÕ

ÓÑÒÑ

ЪУсЯУ

ïðÕ

ïðÕ

ïðÕ

Îìí

Îìî

Îìï

ЭТзко

ЭТзкн

ПЩЪрлнмЪп умлИ

ПЩЮоройФи унрИ

МЮоппиЪуИ

ìòéµ

Îíç

êòîµ

ìéÐ

Ýìè

Îìð

ЭТзкп

ПЩЮоройУнун рН

Ýçç

Ò×

Ò×

ооспк

Ýìé

Ýìê

Ýìë

ðòðï

Ýëð

ïððÐ

Ýçêï

оорспр

Îçêî

ÌÈ

ïðð

ÊÙÒÜ

ртрмй

ЭСУРСНЧМЫ

Ýçêç

Ýçêì

оорспр

пррспк

Ýçðç

Ýçïì

Ýçïë

ðòï

ïððÐ

Îíè

Эзки

ртрмй

ÜÊÜÔ

ÜÊÜÎ

Ýçêë

ЛЬЖНлтпЮуИ

ЛЬЖНлтпЮуИ

ïðÐ

Ýíð

прспк

ртрмй

Ò×

Ýìì

Îç

ïð

Ôíï

ТПФппмХумйрИ

ð

оорспр

Îçêï

Üéïí

Üéïë

Ýìï

Ýìî

ïð

ÍÉï

ÍÉì

ð

Îçêé

оорспр

Ýíè

ðòðï

оорспр

Ýìí

Ýìç

Фзоо

ТПФлкЭХуоорИ

Фзоп

ТПФйзЩУупррИ

ЮЯннЮЭрЪРуИ

Ýçîï

ïððÐ

ðòìé

ïððÐ

Îéðï

Ýíí

Îíë

Ýíë

ЯЛИЧТФ

ð

Îíí

ртррп

Ýíï

ðòðï

Ýíî

ðòðï

Ò×

ртпспк

ЧЭзоп

ïðð

ртрмй íçµ

Ýìð

Ýçêê

ЯЛИЧТЩ

ð

Îéðî

ЛЬЖНлтпЮуИ

Îíî

Ýíé

Îíì

ïðµ

Ýíì

ðòðï

Îíé

ìéð

ìéÐ

Ïíï

ЛТооппуИ

ÍÝÍ

НТймФКЭноЯРЙуИ

Îçîï

ð

Îçêç

ð

Îçêè

ð

пЯнЩуМп

Ýçîî

пррспр

ЯЛИЧТО

УЯиркосУсуИ

ð

Îéðí

Üéïî

ЛЬЖНлтпЮуИ

Ýéðí

Ýéðì

Ýéðë

Üéïì

Ïé

Îì

ìéÕ

ð

Îè

НоЛЬМ

ЭРЛОНМ

Îçéí

Îçéì

Îçéë

Ôçîé

ТПФЮйЩУуп ррИ

Ôçîë

ТПФйпЫУуннрИ

ÛÒÝî

ФЭЬЭЫ

îéð

îéð

Îéðì

оНЮйрзЯсОсуИ

Îé

ìéÕ

Ïì

оНЮкомсмсуИ

Üí

Îë

ìòéÕ

Ïë

Îê

íòíÕ

ЛТооппуИ

Îëè

ìéð

Îëç

Ïëí

Ýëë

ртмйслр

ÍÏ

ФОУЛМЫ

ïðÕ

ïðÕ

Ýçêé

ртпспк

ïðÕ

Îçïì

îîð

Ýçêî

оорспр

Üçðê

ЛЬЖНлтпЮуИ

Îçîí

íçÕ

íçðµ

ðòï

ðòï

ОЮрлпФумруИ

Üçîî

Îçîê

Ýçíð

Ýçîè

ÛÒÝï

ОЫУСЭСТ

ïðÕ

Îéðé

Îéðê

îéð

Îéðë

Üéðì

Üéðë

Üéðê

Üéðé

Üéðç

Üéïð

Ýéðï

Ýéðî

Üéïï

ЭТйрп

ПТЖркрлуррп

ð

îî

îî

Îî

ртррой

Ýíç

Üçîï

оорспр

Üéðí

Îí

Ýíê

ртррп

îîð

Îíê

ïððÐ

ïðµ

Îïì

Ïïì

ЛТооппуИ

ЪУсЯУ

ЧЪЭЭСТМ

ЧЭзкп

Ýçêí

оорспр

Ýçïï

ртррп

ð

Þçîî

Ôçîì

ТПФлкЭХуоорИ

Ýçîé

мйрсол

Ýçîë

Ýçîê

ПЫИФпЯУумйкЖ

ÕÛÇî

ÕÛÇï

ФЭЬЭФ

ÕÛÇð

ФЭЬЬЯ

УЯиркосУсуИ

УЯиркосУсуИ

Üéðï

Üéðî

МС ЭТкрп

шНШЫЫМ оч

УЯплоЙХуИ

ïëµ

оНЬкрпЯсОс уИ

ËÝÍ

НТймШЭМноЯРЙуИ

Ïçðì

ЛТооппуИ

мйррР

ïëðÕ

Îçîë Ýçîç

Îçîì

УЯиркосУсуИ

УЯиркосУсуИ

УЯиркосУсуИ

УЯиркосУсуИ

УЯиркосУсуИ

УЯиркосУсуИ

ðòðï

ðòï

УЯиркосУсуИ

Îëé

ïðÕ

УЯпппуИ

УЯпппуИ

Üî

Üï

ïðÕ

ЧЭзко

Îçïð

ЮЬзйипШЪРуЙ

мйспк

ртрмй

Ýë

Ýê

оНЬкрпЯсОсуИ

Ýëì

ðòï

Ýëí

ртррмй

Ïçðí

оНЮйрзЯсОсуИ

Îçðç

îòîÕ

ЧЭзоо

Ýçíï

Ò×

Ýï

ðòðï

Ýé

ïðÕ

Îëê

Ïëî

Îëì

ìéÕ

Îçîé

ð

Îçîè

Îçîç

ìéµ

ðòï

Ýìîè

мтйсол

ÜÊÜÎ

ÜÊÜÔ

Ýìíè

мтйсол

Ýéèï

ртррпл

ííÕ

ííÕ

ртррпл

ртррпл

Îïéï

îòîµ

Пйип

ЛТопппуИ

ШРЬЯМЯ

ØÐÝÕ

ШРНМЮ

Îìëî

îîµ

Ýìëï

îîµîîµ

мйсктн

ÎìëïÎììï

мйсктн

Ýììï

Îììî

îîµ

ïð

ííÕ

ííÕ

Îìêï

ЧЭнйп

пррспр

Ýíéç

Ýíèð

пррспр

ЧЭнип

Ýíçð

пррспр

Ýíèç

пррспр

ð

Þïðî

ÝØÎ

отослр

Ýïèé

ÝØÔ

ðòðï

Ýïêç

Îïéí

ð

Ýïéð

прспк

Îèçï

ìéÕ

ÓËÌÛ

Îçéê

ëêµ

Îèçî

ïÕ

Пизп

ЛТооппуИ

Ïèçî

ЛТооппуИ

МЫФУЛМЫ

МЫФЭСТМ

Ò×

пррспр

прспк

Ýçðí

Ýçðì

Ýçðë

Îçéé

ïèµ

Ьизп

УЯплоЙЯуИ

Îèçí

íòíµ

ðòï

Ýçðê

Ýìêï

ооспк

Ýíëê

мтйсол

ìéµ

Îíëí

ìéµ

Ýíîê

мтйсол

Îíìí

Ýíìê

мтйсол

ð

ð

ð

ð

Þïðì

Þïðê

Þïðí

Þïðë

Îííé

ð

ð

Îíëé

Îíìé

ð

Îíîé

ð

Îíðì

Üíðî

УЯпппуИ

ìéµ

Îíðè

îòîµ

ïð

Îíðé

Ýíïë

ооспк

Ïíðì

ЛТооппуИ

ЯУРХЧФФ

×ÔÔ

ÌÛÔ

Îèèî

ïðÕ

Îèèï

Îèèë

ìéµ

ìéµ

Ýèçï

ðòï

ðòï

ßÒÌ

Ýèèï

Ïèèï

ооспк

ЬЧУУЫО

Ýèçî

оорспр

ðòðï

Ýçðé

Ýçðè

ÐÑÒ

Îèðî

ìéÕ

Ýèðî

îîÐ

оНЬкрпЯсОсуИ

Ôçðî

ТПФлкЭХуоо рИ

НЧсНС

ÐÞÎÕ

ЧЭзрп

ШЯпнпкмЯ

ïðµ

Îçðë

ëòêÕ

Пзрп

ЛТопппуИ

Îçðê

Пзпо

ЛТооппуИ

ïÕ

Îçðé

×ñÑ

ЮЛННС

Îèðì

ïððµ

Îèðí

îîÕ

Îèðï

ïðð

ШЬймШЭпокЪРуИ

ЭТпмп

ПЩЯорркЭпурм

Ýïëë

ðòìé

ìéÕìéÕ

ÎïìïÎïëï

ртррмйртррмй

Îï

ìéµ

Ýèí

ïñëð

ðòðï

оорспр

Ýì

Ýí

ртпслр

ХМЬпнрмуИ

Üë

ЧЭйоп

ЛРЬйимопйЯЩЭнпр

КСФУЛМЫ

Îéîê

Îéíë

ЯУРХЧФФ

Îéîè

ïðÕ

îòîÕ

îòîÕ

ÊÐÐ

ìòéÕ

ìòéÕ

ìéµ

ìéµ

Îéðè

ííð

НФОулкКЭнЪ

ïñëð

ðУЯпппуИ

ßÚÝÕ

ïðÕ

ð

ëòêµ

ìòéµ

ð

îòîµ

îòîµ

ìéÕ

Îéïð

оНЮйрзЯсОсуИ

Îèï

ïëÕ

Îçï

Ýçí

ïëÕ

Îçí

ìòéÕ

Îèí

Ïçï

ìòéÕ

Îïí

Ïïí

Ýïí

ðòï

Ýéë

ëêðÐ

Ïç

ЛТопппуИ

Îéîí

ìéÕ

Îéîì

Îéðç

ïµ

ëòêµ

Ïéðï

ìé

Îíï

ртррп

Ýî

ооспк

Ýè

Îëë

ìéÕ

Ýëî

ðòðï

ìéµ

Îëí

îòîÕ

ìéµ

ðòðï

ðòðï

ртрпо

ртрпо

Ýçï

Ýèï

Ýèî

Ýçî

Ýïî

Ïïï

ЛТооппуИ

ðòðï

ð

Ýç

Îïî

îéÕ

Îëî

Ýëï

ííðÐ

ÍÝÔÕ

ЛоНЬМ

Îéîë

ртрмй

Ýéîî

оорспр

Ýéîí

ìéðÐ

ФОУЛМЫ

ÍÝÍ

ЭРЛОНМ

Ïïî

ìòéµ

Îïï

Ïïð

ЛТопппуИ

Îëï

ìéÕ

Ïëï

ЛТооппуИ

Üì

Îïð

îéÕ

УЯпппуИ

НтУЫМЫО

ÍÛÛÕ

ÓÑÒÑ

Ýççç

Ýççé

ðòðï

ïððÐ

ШРУЛМЫ

ЬСЛМУЛМЫ

КУЛМЫ

ìéÕ

ÓËÌÛ

Ýéîï

ЬЧУУЫО

ÐÞÎÕ

ßÒÌ

Îéîé

ÐÑÒ

Îéîç

ЬЧУСЛМ

МЫФУЛМЫ

Îéíï

МЫФЭСТМ

Îéíî

Îéíí

Îéíì

ÚßÒ

Îéíê

Îéíé

Îéíè

Îéíç

Îéëè

Îéëç

Üéïç

НЬсНМ

îéÕ

поррР

ХМЬпнрмуИ

ЛТопппуИ

ðòðï

Ýéî

Ýçì

Îçî

Ïèï

ХМЬпнрмуИ

ОЬНЬЯ

отослр

Ýéé

Ýéê

Îéë

ртроо

îòîµ

НЯЯклйзМуИ

×Ýéï

Îéí

Îéì

îòîµ

îòîµ

ОЬННЭХ

Èéï

мйсктн

Ò×

ПЯИрокнурр пЖ

Ýéï

ð

Îéî

Îéï

ìéÐ

èîÐ

Ýéí

Ýéì

ШРНМЮ

НЯЭФХ

КСФЬЯ

КСФЭХ

ШРЬЯМЯ

ЙуУЛМЫ

îòîµ

îòîµ

îòîµ

îòîµ

Îéíð

Îéîî

Îéîï

Îéèì

ïðµ

ïðµ

Îéêí

Îéêë

Ôéîï

ÍÉï

ÍÉì

ÛÒÝï

ÛÒÝî

ìéµ

ìéµ

ìéµ

ìéµ

ìéµ

ìéµ

Îéìí

Îéìç

Îéëð

Îéìè

Îéìé

Îéìî

оорспр

ìéðÐ

Ýéîë

Ýéîê

Ýéîì

Ì«òÔ

Ì«òÎ

îéÕ

поррР

Ýèì

Îèî

Эпкк

прспк

Ýïéï

Ýïèï

Ýïéî

ÜÊÜÔ

Ýïèî

ÜÊÜÎ

ФЧТЫуФ

ФЧТЫуЩ

ФЧТЫуО

ЯЛИЧТФ

ЯЛИЧТЩ

ЯЛИЧТО

ØÐÝÕ

ìéµ

ìéµ

Îèìì

ßÚÝÕ

Îèìí

НЬсНМ

ОЬНЬЯ

ïµ

îòîµ

ïÕ

Îèìë

ТОЖррклуоооИ

Îéïç

Îéîð

ОЯйоп

Îéìì

ТПФниЬХунн рИ

èÐ

ïðµ

Îéïè

îòîµ

èîð

ïðÓ

Îéìë

îòîµ

Îéìð

Îéëí

ËÝÍ

ìéÕ

Îéìê

ОЫНЫМ

Èéîï

ííµ

ÈéîîÝéîç

ПЯИркпйурр пЖ

ПЯИрмрпурр п

Îéëï

îéÐ

îîÐ

îéÐ

ЮЛНЧТМ

Ýéîè

Ýéîé

ÝïìïÝïëï

ФЧТЫуФ

ФЧТЫуЩ

ФЧТЫуО

Ýïêï

пррспр

Эпко

ртрмй

Ýïêì

ï

отослр

отослр

отослр

отослр

Ýïéë

ìéðÐ

Ýïèë

ìéðÐ

Ýïðî

ооспк

Ýïðï

прспк

ìéµìéµ

ÎïðïÎïïï

Ýïïï

прспк

Ýïïî

ооспкр

ìéµ

ìéµ

Îèìî

Îèìï

РФФЬЧ

РФФЭХ

îòîµ

Îéëì

ОЫУСЭСТ

Îéëë

ïðµ

ÊÜÜ

ÙÒÜ

îîµ

Îéëî

ШТЬФЫОЫУ

РФФЬС

Ýïêí

ï

Ýïéì

Ýïêè

Ýïèì

РФФЭЫ

ОЫНЫМ

отослр

отослр

отослр

ïðµ

Îïðí

Îïïí

ïðµ

ïðµïðµ

Îïïî

ïðµ

Îéïé

Íéîí

ПНЙпрмзуррп Ж

Ýïêë

ï

ÎïðìÎïðî

ïðµïðµ

Îïïì

ЯЛИсЭШ

Îéïë

îéð

îéð

Îéïê

ÌÜ

ÎÜ

Îïëë

Îïêî

ÍÝÕ

Îééç

Îéçç

Îééè

Îééé

Îééê

Îééë

Îééì

Îééí

Îééî

Îééï

Îééð

Îéêç

Îéêè

Îéêé

Îéêê

ТОЖррклупрнИ

ЧЭйон

Îéëê

ìéð

Эплк

ртрмй

ìéÕ

Îïðë

ïðµ

Îïïë

ïðµ

Эпрз

ртроо

Ýéíí

Îéïï

Îéèð

ОЯйон

îòîµ

ЛТоппнуИ

Îïêí

ìéÕ

ЧЭпрп

ЮОомФпкЪуЙуИ

ìéðÐ

Îéïí

îòîµ

îòîµ

îòîµ

ìéÕ

ïµ

ìòéµ

ìòéµ

ìòéµ

íòçµ

íòçµ

íòçµ

ïµ

ïðÕ

ïðÕ

ìéÕ

ЧЭуРНМнмннЛуИ

Ýéíð

мйсктн

ПЩЯолрпЭнурнЖ

ХМЬпнрмуИ

Ïïçî

Ýïçï

мйсктн

Üïçî

УЯпппуИ

ð

Îïêï

ТЦУмлклКуИ

ЧЭйоо

ïðµ

ïðµ

ìéµ

ТЯЬрроиупрнИ

ìòéÕ

Îéêð

ЭТпзп

Îïçí

ïðð

Ïïçï

Îïçî

Îïçï

ìòéµ

èîð

Îíéë

Îíéé

Îíéì

ïððÕ

Îíèì

ïððÕ

Îíéí

ïððÕ

Îíèí

ïððÕ

ð

РЬЫМЯЭШ

УЯплоЙЯуИ

ЭнйлЭнйй

Ýíéí

мтйсол

Ýíçï

мйсктн

Энйм

мтйсол

Ýíéê

Îíéê

Îíèê

Ýíèê

Ýíèì

мтйсол

Ýíçî

мйсктн

Ýíèí

мтйсол

Ýíèë

Îíèë

ЭЬмрккЮРЙуИ

ЯЛИсЭШ

Îéèî

Îéèï

Üéèî

Ïéèî

ЛТопппуИ

ШРУЛМЫ

УЯиркосУсуИ

ПНЙрмлпуррп

Üéïê

Íéðî

ЛТоопнуИ

îîÕ

ðòï ртррпл

ТЦУопкрЮКуИ

ðòï

Ýíéè

Îíéè

îîÕ

Îíèè

îîÕ

Ýíèè

ðòï

ТЦУопкрЮКуИ

ðòï

Ýíèé

îîÕ

Îíèé

ЧЭпко

Îïéî

îòîµ

ìéð

ìéð

Üéèï

УЯплоЙЯуИ

Ýéèî

мйсктн

УЯиркосУсуИ

Üéïé

Üçðí

УЯпппуИ

Эзпр

ртррп

ÞßÌÌ

оНЮйрзЯсОсуИ

Ïçéê

мйсктн

Ïçéé

ЙуУЛМЫ

Îíéï

ïµ

Îíéî

ìéÕ

Îïêë

ìéÕ

Îïêì

Ýîêé

прспк

îîð

Îïêê

НЯСЛМ

Îïêé

îòîÕ

КСФУЛМЫ

Îïêè

îòîÕ

НЯЭФХ

îòîÕ

Îïêç

КСФЭХ

îòîÕ

Îïéð

КСФЬЯ

ЧЭпкп

МЬЯймпк

Ýïðí

мйсктн

Îïðé

ïðµ

ïðµ

Îïðê

Ýïïí

ïðµ

ïðµ

Îïïé

Îïïê

мйсктн

Îïïð

Эппр

мйспк

ïððµ

Îéïì

Îéïî

ïððµ

ÍÝÔÕ

НоЛЬМ

ЛоНЬМ

×ñÑ

ЮЛННЭХ

ЮЛННС

НЧсНС

ФЭЬЭФ

ФЭЬЬЯ

Ýéíî

ФЭЬЭЫ

ЧЪЭЭСТМ

НтУЫМЫО

ÍÏ

МШйоп

ÕÛÇî

ÕÛÇï

ÕÛÇð

ìòéÕ

ìòéÕ

Îéêï

Îéêî

ОЬННЭХ

Üéíï

ìéµ

ðòðï

УЯпппуИ

Ýéíï

Îéëé

ïµ

Îíèî

ïµ

Îíèï

ïµ

Эпйк

отослр

ЯЛИтФ

Þïðï

Ýïéé

отослр

Эпик

отослр

Ïïêï

ЛТооппуИ

ЯЛИтО

Ïïêî

ЛТооппуИ

НЯСЛМ

Ïéèí

ЛТопппуИ

ЭйинЬйин

мйспкЛЬЖНппЮуИ

РСРЫТ

ПНЙрмлпуррп

Íéðï

оорспр

Ôéîî

ТПФппмХумйрИ

Ýéíì

ðòï

ïððÕïððÕ

Îìíç

Ýìíé

Îìíè

ìòéÕ

мтйсол

ЧЭмнп

ФЭйлнммУуИ

Ýìîê Ýìíê

Ýìîé

мтйсол

Îìîè

ìòéÕ

пррспр

ðòï

Îìîç

ïð

Îìêî

Ýìêî

Ýìêí

Îííë

Ýííê

ïÕ

мтйсол

Îííí

УЯпппуИ

ìéµ

УЯпппуИ

УЯпппуИ

Îíîí

УЯпппуИ

ìéµ

Îíîë

ïÕ

ЧЭнрп

МЮозркШП

Ýííè

Îííç

ïñïê

ëïµ

Îíëç

Ýíëè

ëïµ

ïñïê

ìéÕ

ìéÕìé Õ

ïððÐ

ïððÐ

Îíëè

ЧЭирп

ìéÕ

Îíîè

Îíðê

ЬЧУСЛМ

Îèðë

ïðµ

ÎííèÎíìè

îéµ

УЯпппуИ

Ïèèë

ЛТооппуИ

Ýííç

Ýíëç

ïððÐ

ïððÐ

Ýíìè

Ýíìç

Ýíîç

Îíìç

ïñïê

ëïµ

Îíîç

Ýíîè

ëïµ

ïñïê

Îíðí

ð

Îíðë

ïðµ

Ïíðí

ЛТооппуИ

ÐßÎÕ

Üèèë

Îèèè

ð

Îèèê

ìòéµ

Îèèé

ïðµ

Ýèèë

прспк

ртрмй

ооспк

Ýçïî

Ýçïí

Îèðé

ííð

Îèðç

ïðð

Îèïð

Ýèðí

ìéÕ

ртрмй

Îìíê

ïèÕ

êòèÕ

Îìíé

ЧЭмоп

ТЦУмлирКуИ

îîðÐ îîðÐ

Ýìîë

ïððÐ

Îìîé

Îíëë

Üíëì

Üííì

Üíîì

Üíìì

Îíìë

Îíìð

ïµ

Îíêð

ïµ

Îíëð

ïµ

Îííð

ïµ

Ýííð

ðòï

Îíðî

ð

Ýíïì

отослр

Îçðí

ЮЛННЭХ

ЮЛНЧТМ

Îèðê

ïððÕ

Îèðè

îîµ

Ýèðì

îîÐ

êòèÕ

Ýìíë

ïððÐ

ïÕ

ïÕ

ìéð°

Ýíðí

ìòéÕ

ÍÝÕ

Ýìîì

ïëðÐ

Îìîê

ïèÕ

ЭОНрнуЙ

Üíðí

Üçèï

ОЮпкрУунруИ

ОЮпкрУунруИ

Îçðî

çòïÕ

ïðÊ

Ýìíì

ïëðÐ

Îìêí

ïð

ðòï

Ýìêë

Îíëì

îòîµ

Îííì

îòîµ

Îíîì

îòîµ

Îíìì

îòîµ

Ýíïí

ðòðï

ЭОНрнуЙ

ìéð°

ìéð°

Ýíðì

Ýíðë

Üíðì

Üçèî

КУЛМЫ

Ýìíí

Îìíì

íçîî

оорспр

ïµ

Îìíë

ïµ

Îìîë

Ýìîî

Ýìîí

Îìîì

оорспр

пррспр

Ýìêì

Пнлм

ХМЬпнрмуИ

ХМЬпнрмуИ

ХМЬпнрмуИ

Ïíìì

ХМЬпнрмуИ

Ýíïî

мйспк

Ýíëð

ðòï

Üíðë

ОЮпкрУунру И

ìéð°

ЭОНрнуЙ

Ýíðê

Üíðê

Ýçèï

ðòï

Üèëï

Ò×ìéÕ

ÚßÒ

ШТЬФЫОЫУ

ЬСЛМУЛМЫ

ÌÈ

Îìïí

ïð

ЭСУРСНЧМЫ

Îìïï

ÊÙÒÜ

ð

ðòðï

Ýìíî

ðòðï

Ïííì

Ïíîì

Ýíïï

мтйспк

Üíðè

ОЮпкрУунру И

ìéð°

Ýíðé

Îçèï

Üèëî

Ò×

НТймЯШЭМпЩриКуИ

Îìðï

ìéð

ТПФппмХумйрИ

Îìïî

Îìíí

Îìîí

ïÕ

Üìîï

Üìíï

УЯпппуИ

УЯпппуИ

Ýíêð

ðòï

ìéð°

ЭОНрнуЙ

Ýíðè

Üíðé

Ýèëï

Îèîï

ïð

Ýèîí

Ïèîï

ЛТооппуИ

Ôìïï

ЧЭмпп

УУплпрИТуИ

Ýìïí

ïòë

êòèÕ

Îìïé

ïèð

ïµ

Ýíïê

ðòðï

Ýíìð

ðòï

ìéð°

Ýíðç

Ò×

оНЬпззмЯсОНсуМ

ðòðï

Üèîï

îéð

ЧЭмрп

ХМЬпнрмуИ

ХМЬпнрмуИ

ХМЬпнрмуИ

ХМЬпнрмуИ

Îìíï

Ïìíî

Ïìîî

Îíëê

ïðð

Îííê

ïðð

Îíîê

ïðð

Îíìê

ìéð°

ЭОНрнуЙ

Ýíïð

Üíðç

Îçèî

îòîÕîòîµ

ЛЬЖНпоЮуИ

Îèëï

Ýèîï

ЭОНрнуЙ

Üíïð

Îìíî

ïÕ

Îìîî

ïµ

ïðð

Ò×

Ïèîí

Ïèîî

прспк

ТПОрррйурроИ

УЯиркосУсуИ

îî°

Ýìðï

Îìîï

îîíç

ЛТоопнуИ

ЛТопппуИ

Оиоо

ìéð

ðòðï

Ýìðî

ïððÐ

Ýííë

ïððÐ

Ýíîë

Ïíðï

Õèíï

Üèíï

Ýìïë

ïððÐ

Ïìíï

Ïìîï

ðòðï

Ýíðî

Ýçðî

отослр

Эиоо

прспк

ðòðï

Ýìðí

оорспр

Ýìïï

ïððÐ

Ýíëë

ïððÐ

Ýíìë

Ïíðî

ЛТоппнуИ

Ýèðï

Ò×

ОЮпкрУунруИ

ïð

Îìðî

Õìðï

ТПОрррйурроИ

Üìðï

ОЮпкрУунруИ

Ôìðï

ТПОрррйурроИ

ТПОрррйурроИ

ннрсктн

ртрмй

Ýìïî

Ýìïê

ðòðï

ìéðÐìéðÐ

ÝìíïÝìîï

Üíðï

ЛЬЖНппЮуИ

Îçðï

ÌÛÔ

ÐßÎÕ

×ÔÔ

Ò×

Ýèèç

ÝØÎ

Îìðí

ìéð

Õìðî

Ýìïì

Þçîï

ТПОрорпуррмИ

Ýíðï

ïµ

Îèèç

Õçîî

мйспк

Îèèí

Îìðì

ï

Ýìðì

Îìïì

ïÕ

ртроо

Ýííï

Îèçì

ïððµ

Ýçðï

ннррспк

ÝØÔ

Üèðï

ПЩЯоррпЭпуро

ПЩЯорркЪпуро

Ýèíï

ïððÐ

МСМИпййФ

пррсктн

ð

Ôìíï

ТПОрррйурроИ

ТПОрррйурроИ

Ôìîï

ТПОрррйурроИ

ртроо

Ýìíð

ð

ð

Ôçðï

ППОпнйиурро

Üçðï

пТлмрпуЪкм

Öèðï

ПТЖррзлуррп

НЧсНС

ЧЭмро

îî°

Ýìðê

Ýìðë

ÊÑËÌ

éë

Îìïë

Îìïê

ð

ТПОрорпуррмИ

Ôìíð

ПТТрлпзуррп

ÍÝÕ

ЭТиоп

ЭТинпÎèíî

Îèíï

ð

ðòðï

Õìïï

ПЩЯолрпЭнур нЖ

ЭТмоп

Öííï

ЭТзрп

ПТЖркрйурр п

ЭТмпп

ПЩЯолрпЪпуро

ﮬ- ¿®» -¿º»¬§ ¿--«®¿²½» °¿®¬-ò

ɸ»² ®»°´¿½·²¹ ¬¸±-» °¿®¬- ³¿µ»

-«®» ¬± «-» ¬¸» -°»½·º·»¼ ±²»ò

SHEET 1

2-2

Page 35

ÔÝÜ ú Õ»§ -©·¬½¸ -»½¬·±²

Edited by Foxit PDF Editor

Copyright (c) by Foxit Software Company, 2004

For Evaluation Only.

ЧЭкро

ОРУйнниуКм

ртроо

Ýêèï

ртроо

Ýêèî

íòçÕ

íòçÕ

Îêðê

Îêïî

Îêðë

îòéÕ

ЫТкрп

ПНЙппплурро

ð

Îêéð

Öêðï

ПТНромлуррп

ЬЧУСЛМ

ОЫУСЭСТ

ïðÊ

ÛÒÝï

ÛÒÝî

ФЭЬЭЫ

ФЭЬЬЯ

ФЭЬЭФ

ÕÛÇî

ХЫЗп

ХЫЗр

ЯЛИтО

ЯЛИтЩТЬ

ЯЛИтФ

ÙÒÜ

МС ЭТйрп

шНШЫЫМ пч

ЬЧУБЭСТ

ÔÝÜï

ПФЬрнмзуррп

ЧЭкрп

РМклонФПуФ

Îêðï

ÎêðîÎêðíÎêðì

èîð

èîðïòîÕïòèÕ

ÎêðéÎêðèОкппОкпрОкрз

èîðèîðотйХптиХптоХ

Îêïì

èîð

Îêïí

èîð

ÕÛÇî

ÕÛÇï

ÕÛÇð

Üêðï

Üêðî

Üêðí

Üêðì

Üêðë

Üêðê

Üêðé

Üêðè

Üêìð

УЯплоЙХуИ

Üêðç

Üêïð

Üêïï

Üêïî

Üêïí

Üêïì

Üêïë

Üêïê

Üêïé

Üêïè

Üêïç

Ïêìï

ЛТооппуИ

Îêéî

Îêéï

ìéð

Îêëï

îòîµ

ìéð

Îêëî

îòîµ

Îêëí

ïðµ

Îêëè

ïèðµ

Üêìî

УЯпппуИ

ртроо

Ýêðï

Ííî

Ííï

Ííð

Íîç

Íîè

Íîé

Íîê

Íîë

Íîì

Íîí

Íîî

Íîï

Íîð

Íïç

Íïè

Íïé

Îêîî

ìéµ

Îêîí

ìéµ

SHEET 2

2-3

Page 36

Edited by Foxit PDF Editor

Copyright (c) by Foxit Software Company, 2004

For Evaluation Only.

ÜÊÜ -»½¬·±²

Ýïðé

ртпспк

Ýïïî

ртпспк

Ýïïí

ртпспк

Îïðî

ð

ртпспк

Ýïðí

Îïðï

ð

Ýïðì

ртпспк

ÌÐëï

МРорп

МРоро

ÌÐëî

ЭТорп

ПЩЪпрниЪпуппИ

Þîðï

Þîðî

Þîðí

Þîðì

Þîðë

ÜÙÒÜ

РнтнК

ТПОрлроуррпИ

Õíçç

ЧЭнзи

НЩноУзрМЪЧОн

ЫИЯЬМпл

ЫИЯЬМпм

ЫИЯЬМпн

ЫИЯЬМпо

ЫИЯЬМпп

ЫИЯЬМпр

ЫИЯЬМз

ЫИЯЬМи

ЫИЯЬОпз

ЫИЯЬОор

ТЫИЙЫ

сЪФБОНМ

Ò×

Îíçè

Îíçê

ìéµ

ЫИЯЬОпи

ЫИЯЬОпй

ЫИЯЬМй

ЫИЯЬМк

ЫИЯЬМл

ЫИЯЬМм

ЫИЯЬМн

ЫИЯЬМо

ЫИЯЬМпЫИЯЬМр

ÚïÝÜ

Ú

Û

ÚîÝÜ

ß

Îïîî

Þ

ð

Ý

ÔÐÝî

Ü

ÔÐÝï

Îïïç

Õïðï Îïðì

Ýïðï

Ýïðî

КОЫЪШ

ртпспк

ртпспк

ЪпЬКЬ

ЪоЬКЬ

ШЯЩЛР

Õïðî

ТПОрррйурроИ

Îïîê

íí

Úó

Ìó

Ìõ

Úõ

ÍÓí

ÍÓî

ÍÓï

Øíó

Øíõ

ÊØ

Øïõ

Øïó

Øîõ

Øîó

Ò×

ÍÉï

Ò×

ÍÉî

Ò×

ÍÉí

Ò×

ÍÉì

Ò×

МОКНЙ

ÎÚõ

ÎÚó

ÜëÊ

ТПОрррйурроИ

Üïðï

Ò×

ÓëÊ

ÓçÊ

Îîíï

отйµ

ОонлОонм

êòèµíçðµ

ÍÞÎÕ

ÍÞÎÕ

ÓçÊ

ÓÙÒÜ

НРЬОК

ð

ЬМЯппмЫЫуИ

Ò×

Ýîðç

Îîíî

Ïîíï

ЬМЭппмЫЫуИ

ÓÙÒÜ

ЫИЯЬОпк

Îíçç

ð

ЫИЬЯМпл

ЫИЬЯМй

ЫИЬЯМпм

ЫИЬЯМк

ЫИЬЯМпн

ЫИЬЯМл

ЫИЬЯМпо

ЫИЬЯМм

ЫИЬЯМпп

ЫИЬЯМн

ЫИЬЯМпр

ЫИЬЯМо

ЫИЬЯМз

ЫИЬЯМп

ЫИЬЯМи

ЫИЬЯМр

ТЫИСЫ

Îíçé

Ò×

ТЫИЭЫ

Ýíçê

ртпспк

Îïîí

ð

Îïîð

ð

íðµíðµ

оНЮпмомсОсуЙоНЮпмомсОсуЙ

оНЭмкпйсОсуИ

НнтнК

Ïïðë

ЭорнЭорм

ойр°плр°

Îîðí

íðµ

ЧЭорп

ЮЯлинлЪУуИ

ÓÙÒÜ

Ýîîï

ЮЬккйпЪУуИ

Îîëç

сНРУЛМЫ

ртроо

ЧЭолп

ïðÕ

ïëµ

Îîëî

ïðµ

Ýíçç

ртпспк

ÓÜÏð

ртпспк

УЬПп

Ýíçî

ÓÜÏî

ÓÜÏí

ÓÜÏì

ртпспк

УЬПл

Ýíçï

ÓÜÏê

ÓÜÏé

Ýíçè

ÜÏÓð

ртпспк

ÒÉÛ

ÒÝßÍ

ÒÎßÍ

ÒÝÍÓ

Þßð

Þßï

Óßïð

Óßð

Óßï

Óßî

Ýíçë

ртпспк

ÜÙÒÜ

Îïïî

Îïðé Îïïë

пррпрр

Ïïðï Ïïðí

Ïïðî

Îîðë

îéµ

Îîðì

îéµ

Îîðî

ìéµ

ïëµ

Îîïç

Îîîð

ïèµ

МОНЬОК

Îîîï

ïðµ

Îîîí

Îîîî

ïðµ

ð

Îîëê

ìé

Îîëì

ïðµ

ХмНоипкноЪуЛЭйл

ЧЭнзз

УЬПпл

УЬПпм

УЬПпн

Ýíçí

УЬПпо

ртпспк

УЬПпп

УЬПпр

ÓÜÏç

Ýíçì

ÓÜÏè

Ò×

Ýíèì

ÜÏÓï

ртпспк

ÓÝÕ

Óßïï

Óßç

Óßè

Óßé

Óßê

Óßë

Óßì

Óßí

ÍëÊ

Ïïðì

оНЭмкпйсОсуИ

ÜÙÒÜ

сШЪУСТ

ÌÜÎÊ

Îîðé

ð

ÚÜÎÊ

Îîðê

ð

КШЯФЪо

ÊØ

ÍÓï

ÍÓî

ÍÓí

сЬОКУЛМЫ

МОЬОК

ЪСЬОК

КШЯФЪ

Ò×

Îîïð

ð

Îîïï

МОНЬОК

ЬОКЭСТМ

ÔÓ

ÚÙ

ÚÙ

ЫИЯЬОор

ТЫИЙЫ

ЫИЯЬМр

ЫИЯЬМм

ЫИЯЬМи

ЫИЯЬМпо

ЫИЯЬОпк

ЫИЯЬОпи

ЫИЯЬМпм

ЫИЯЬМпр

ЫИЯЬМк

ЫИЯЬМо

ТЫИЭЫ

ЫИЯЬМп

ЫИЯЬМл

ЫИЯЬМз

ЫИЯЬМпн

ЫИЯЬОпй

ЫИЯЬОпз

ЫИЯЬМпл

ЫИЯЬМпп

ЫИЯЬМй

ЫИЯЬМн

ТЫИСЫ

сЪФБОНМ

ТЫИЙЫ

ÓÜÏç

ÓÜÏë

УЬПпр

ÓÜÏì

УЬПпп

ÓÜÏí

УЬПпо

ÓÜÏî

УЬПпн

ÓÜÏï

УЬПпм

ÓÜÏð

УЬПпл

ЬЯЭРЬТ

ЬЯЭСЭН

ÜÝÔÕ

ЬЬЯМЯ

РнтнК

Ýï

ртпспк

Ýî

ртпспк

Ýíðé

ртпспк ртпспк

Îíîï

ð

Ýí

ртпспк

Ýì

ртпспк

Ýë

ртпспк

ртпспк

Ýê

Ýé

ртпспк

Îíîî

ð

ííð

Îíéî

ííð

Îíéí

ÛÐÝÍ

ÛÐÍÕ

ÛÐÜÑ

Îíðì

Ò×

ÜÙÒÜ

ЧЭнрм

НуириойЭТТЮуЩуЙ

Îíîí

ð

Ïíðî

РЭУЭФХ

ÛÐÜÑ

ÛÐÝÍ

ÛÐÍÕ

ЧЭмип

ЮОзнФккЪуЙуИ

ÞÝÕ

ÛÐÜ×

ЯСЛМн

ФОЭФХ

ЬЯЭРЬТ

ÛÐÜ×

ЬЯЭСЭН

ÜÝÔÕ

ЬЬЯМЯ

ЧЭмрп

ЯХмнилЫМуИ

ЧЭнрп

УТоЬНрррнЯЯуШ

РнтнК

ÜÙÒÜ

Ïíðï

ЬМЭпммЫЫуИЬМЭпммЫЫуИ

îîµ

Îëíë

Ýëíï

ìòéÕ

ннррР

ОлнпОлнм

мтйХорр

Ýìðî

мйспр

Эмрп

ртпспк

ÜÙÒÜ

ЧЭмпп

ТЦУмлклКуИ

Îìíì

Îìíï

мтйХорр

Ýìíï

Îìíë

ннррР

мтйХмтйХ

Îëíè

ìòéÕ

Îëíé

Îëíê

Ýëíí

îðð

ìéðÐ

Ýìíí

Îìíê

ìéðÐ

îðð

Îìíé

Îìíè

îîµ

ртпспк

ртпспк

КШЯФЪ

ФОУЛМЫ

ßëÊ

ÔóÝØ

ßÙÒÜ

Îìïï

ßçÊ

ïð

ÎóÝØ

РнтнК

ЬптоК

Ýïð

ЫИЬЯМи

МРнол

Ýíïë

Ýíïï

ТПФрзнХупОиИ

ТПФрзнХупОиИ

Îíðë

Ò×

ртпспк

Ýç

Ôíðë

ТПФрзнХупОиИ

Ýíïí

Ýííç

Îíîë

ïêð

Ýíìï

Îíìð

Îíëð

Îíëç

Îíêð

Îîðè

Îîðç

Ýíëê

Ýíïé

Ýíïê

Îíêç

Ôíðê

Ôíðé

ртпспк

ртпспк

Îíêî

Îíìì

Ýíìî

Ò×

Ýíïè

ïñïê

Îíìî

íðµ

éë

Ýíïî

éë

ïñïê

éë

îðµ

îîµ

Îííí

ïñïê

ртпспк

ртпспк

ïêµ

Îííì

Îííë

Îííê

Îííé

Îííè

Îííç

Îíçì

Îíçí

Îíçî

Îíçï

ìòéµ

Ýíìí

Ýíìì

Ýíìë

Ýíìê

Ýîðë

Эмзп

ртпспк

Ò×

Ò×

Ò×

Ò×

ТПОрлроуррпИ

Ò×

Õìîë

Õìîé

Õìîè

Õìîç

Îíëé

Îíëï

ð

Ò×

ртпспк

Ò×

Ýîðê

ëêð°

êèð°

ïëð

ïëð

ïëð

ïëð

ð

ð

ïîð

ïîð

МШмзп

ТЯЬрролупрнИ

МРмзп

Õíðï

ïµ

ð

ð

Îíêé

Õíïï

ТПОрпозурроИ

Îíìï

Ò×

ТПФрммХупррИ

Îíðð

Îíðï

Ò×

ТПФрзнХупОиИ

Ò×

Ò×

Ò×

ТПФрзнХупОиИ

Îíêï

Îíëè

ð

Ýíîë

Инлп

ТЯИрйнруррпИ

Ýíîê

Îíìë

ð

Îíïë

ð

Îíïê

ð

Ôíðí

Îíïè

ííµ

Ôíðì

Ò×

ÎìçïÎìçî

ïðÕ

ïð°

ïð°

ð

ð

Îííî

ïµ

РЭУЭФХ

ЬКЬФЬЭЛО

ЭЬФЬЭЛО

НнтнК

МРнпи

ЪпЬКЬ

ЪоЬКЬ

ÜÙÒÜ

ð

ЪСЬОК

МОЬОК

ÚïÝÜ

ÚîÝÜ

ЧЭнрн

Ò×

ЧЭнро

ЮЯррШЭлЙЪуИ

ЯСЛМн

ÞÝÕ

ФОЭФХ

ÍëÊ

ß

Þ

Ý

Ü

Û

Ú

МРнпк

ЫЦОЫП