Page 1

SERVICE MANUAL

AV SELECTOR

XC03120053

JX-S333-J

POWER

SOURCE

SELECT

1

2

3

4

DUBBING LOCK

(MONITOR SELECT)

LINK

Model No.

ST

ANDBY/ON

1

SOURCE SELECT

2

3

4

DUBBING

(MONITOR SELECT)

LOCK

LINK

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

COPYRIGHT © 2005 Victor Company of Japan, Limited

No.XC031

2005/3

Page 2

SPECIFICATION

Product name AV selector

Input/output connectors Inputs:4 lines (Component, S-VIDEO, AUDIO L/R) x 4

Outputs:2 lines (S-VIDEO, AUDIO L/R) x 2

Monitor outputs:1 line (Component, S-VIDEO, AUDIO L/R) x 1

Video inputs Reference level

S-VIDEO Y:Vp-p = 1.0 V (75 Ω)

C: Vp-p = Burst 0.286 V/ Cyan 0.642 V (75 Ω)

Component signals

Y: Vp-p = 1.0 V (75Ω)

Cb/Pb: Vp-p = 0.7 V (75 Ω)

Cr/Pr: Vp-p = 0.7 V (75 Ω)

Maximum input

S-VIDEO V: Vp-p = 1.5 V (75Ω)

C: Vp-p = Burst 0.429 V/ Cyan 0.963 V (75Ω)

Component signals

Y: Vp-p = 1.5 V (75Ω)

Cb/Pb: Vp-p = 1.05 V (75Ω)

Cr/Pr: Vp-p = 1.05 V (75Ω)

Video outputs

(Reference level)

Video crosstalk 50 dB or more (45 dB or more between Y/C and Y/Pb/Pr in the same channel)

Video S/N ratio 50 dB or more

Video frequency response S-VIDEO: 10 MHz, Component signals: 30 MHz

Audio inputs Reference level: -10 dBV (47 kΩ)

Audio outputs -10 dBV (with reference input, 1 kHz)

Audio crosstalk 80 dB or more (1 kHz)

Audio S/N ratio 80 dB or more

Audio frequency response 5 Hz to 50 kHz

Distortion Less than 0.03% (with reference input, 1 kHz)

Power requirements AC 120 V ~, 60 Hz

Power consumption 6 W (less than 2.0 W in standby mode)

Dimensions (W) 435 mm x (H) 64 mm x (D) 282 mm (including knobs, jacks, and feet)

Main body weight 2.4 kg (5.3 lbs)

Accessories Remote control unit (RM-AJ333), “AA” (R6/UM-3) battery x 2 (for operation testing)

S-VIDEO Y: Vp-p = 1.0 V (75Ω)

C: Vp-p = Burst 0.286 V/ Cyan 0.642 V (75Ω)

Component signals

Y: Vp-p = 1.0 V (75Ω)

Cb/Pb: Vp-p = 0.7 V (75Ω)

Cr/Pr: Vp-p = 0.7 V (75Ω)

Maximum level:+6 dBV (1 kHz, 1% distortion)

(17-3/16" x 2-9/16" x 11-1/8")

1-2 (No.XC031)

Page 3

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

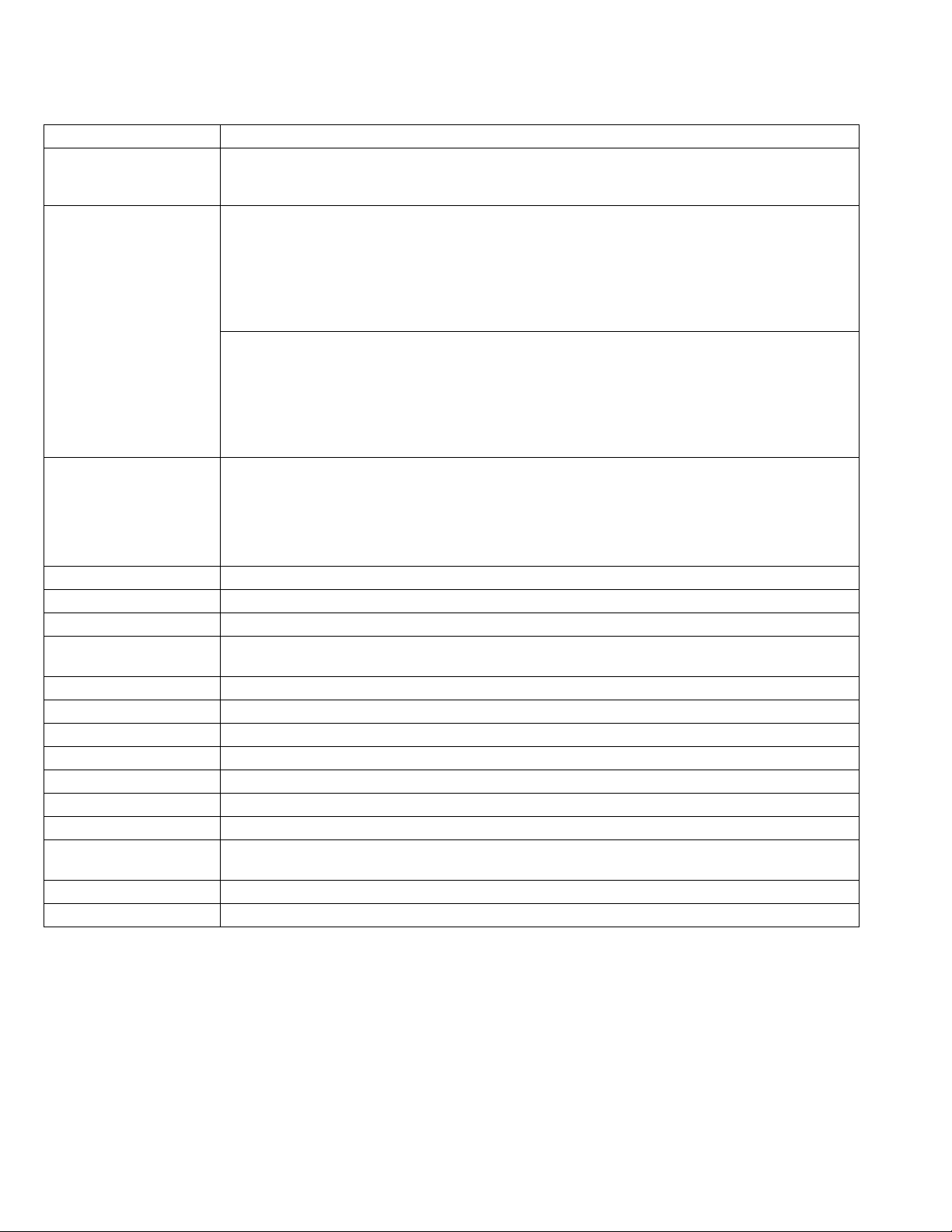

(5) Leakage shock hazard testing)

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000 ohms per volt or more sensitivity in the following manner. Connect a 1,500 ohm 10W

resistor paralleled by a 0.15 F AC-type capacitor between an exposed metal part and a known good earth

ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical for

safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer. (Except

the JC version)

(No.XC031)1-3

Page 4

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

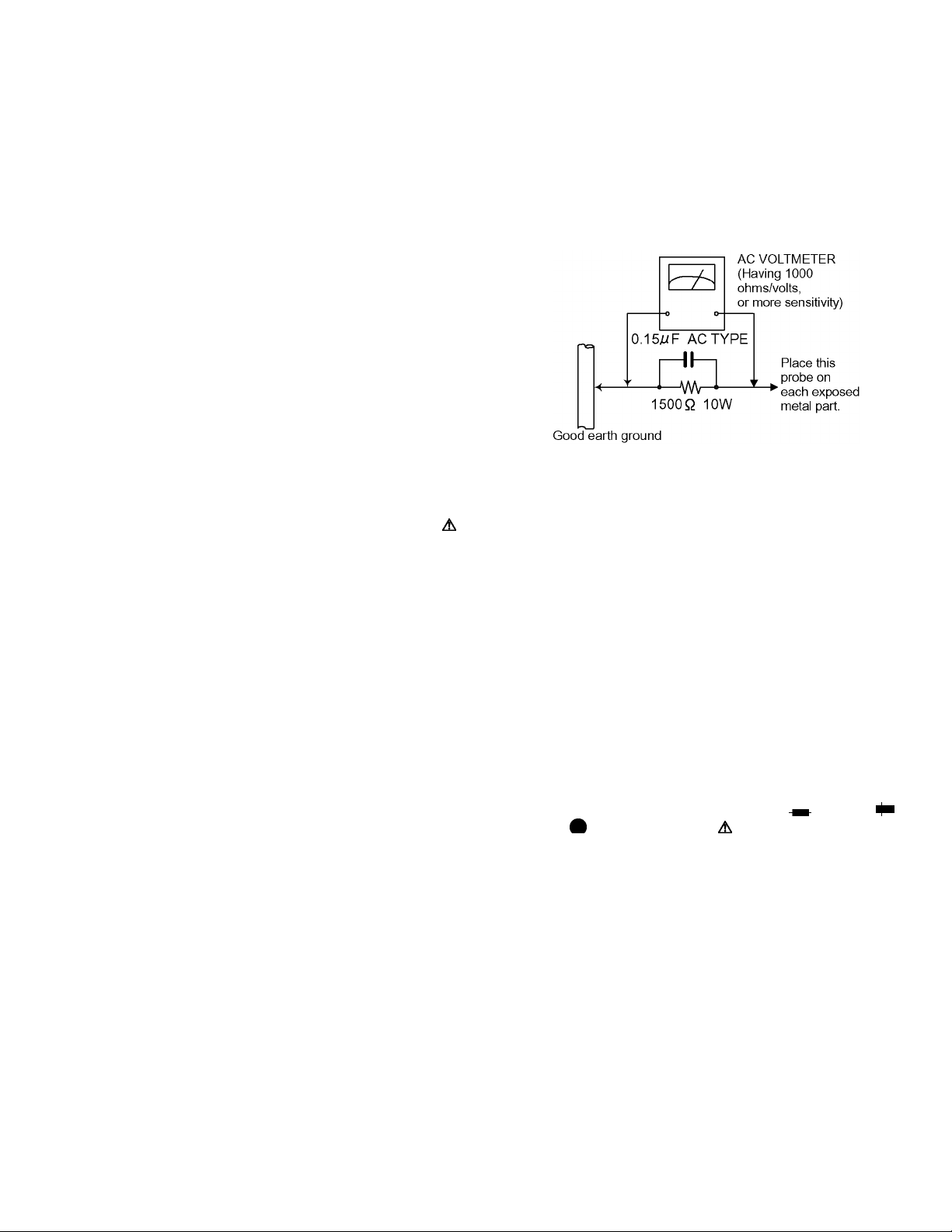

Location of major parts

Top cover

Front panel assembly

Main board

Rear panel

Switch board

Remote control board

Bottom chassis

1-4 (No.XC031)

Page 5

SECTION 3

TOP COVER

BOTTOM

DISASSEMBLY

3.1 Main body section

3.1.1 Removing the top cover (See Figure 1)

(1) Remove the four screws [A] attaching the top cover on

both sides of the main body.

(2) Remove the two screws [B] attaching the top cover on the

back of the main body.

(3) Raise the both sides and lower part of the rear of the top

cover, with opening them slightly in an outward direction.

And the top cover will be removed.

3.1.2 Removing the front panel assembly (See Figure 2, Figure 3)

• Prior to performing the following procedure, remove the top

cover.

(1) Disconnect the card wire and socket wire from connectors

, CN2 on the main board respectively.

CN1

(2) Remove the three screws [C] attaching the front panel as-

sembly on the bottom of the main body.

(3) Hook [a] is removed, and the front panel assembly is re-

moved.

TOP COVER

TOP COVER

A

x 2

A

x 2

Front panel assembly

Main board

B

Fig.1

CN1 CN2

Fig.2

C

B

Hook a

Front panel assembly

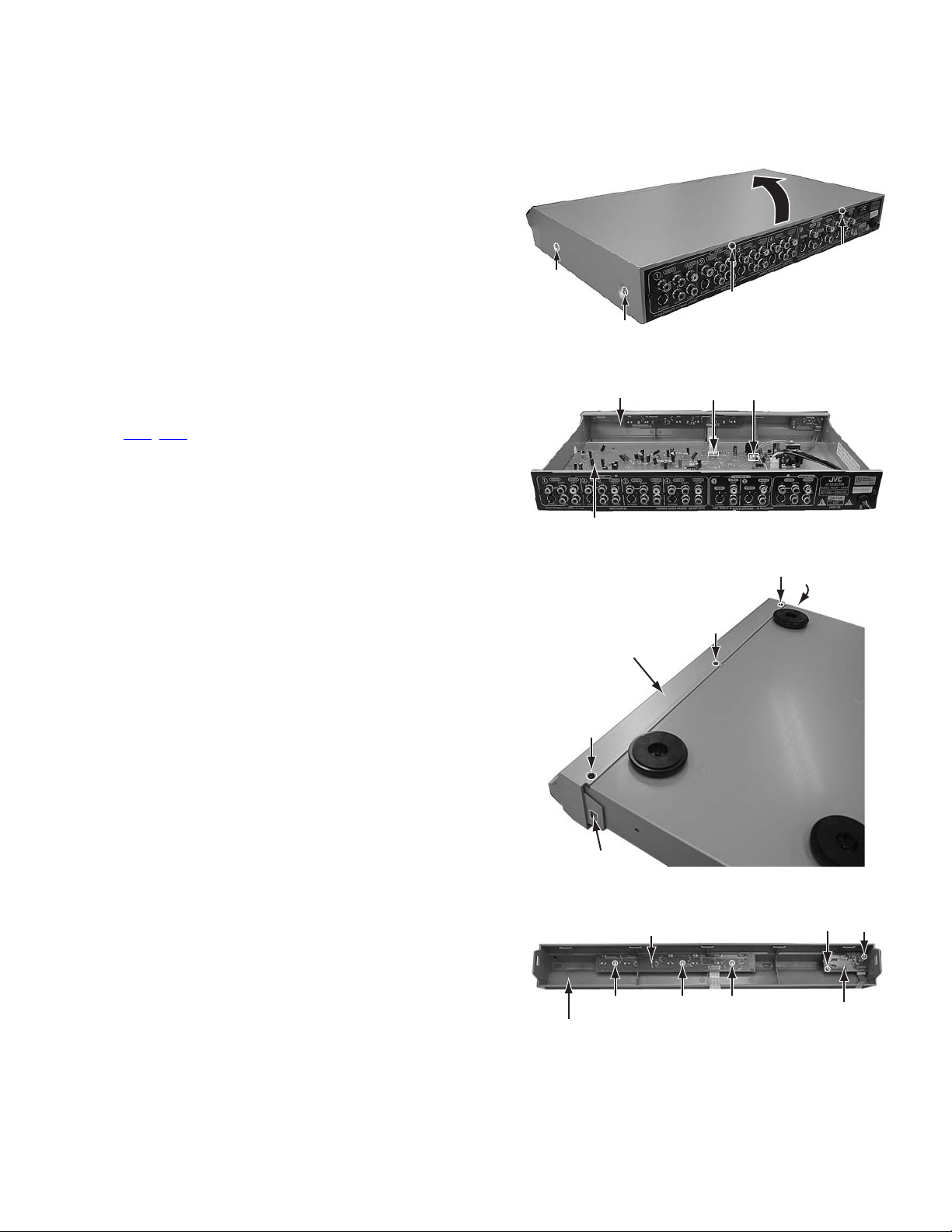

3.1.3 Removing the switch board and remote control board (See Figure 4)

• Prior to performing the following procedure, remove the top

cover, front panel assembly.

(1) Remove the five screws [D] attaching the switch board and

remote control board.

Front panel assembly

C

Hook a

Fig.3

Switch board

Fig.4

C

BOTTOM

DDD

DD

Remote control

board

(No.XC031)1-5

Page 6

3.1.4 Removing the rear panel and main board (See Figure 5, Figure 6)

• Prior to performing the following procedure, remove the top

cover.

(1) Disconnect the card wire and socket wire from connector

CN1, CN2 on the main board respectively.

(2) Disconnect the power cord from connector CN901

main board.

(3) Remove the twenty-two screws [E] attaching the rear pan-

el.

(4) Remove the two screws [F] attaching the main board.

(5) The fastener one place where the main board is fixed is re-

moved.

on the

F

F

CN1

CN2 CN901

Fastener

Main board

Fig.5

Main board Rear panel

Fig.6

SECTION 4

ADJUSTMENT

This service manual does not describe ADJUSTMENT.

Power cord

E

1-6 (No.XC031)

Page 7

SECTION 5

TROUBLESHOOTING

5.1 Circuit explanation

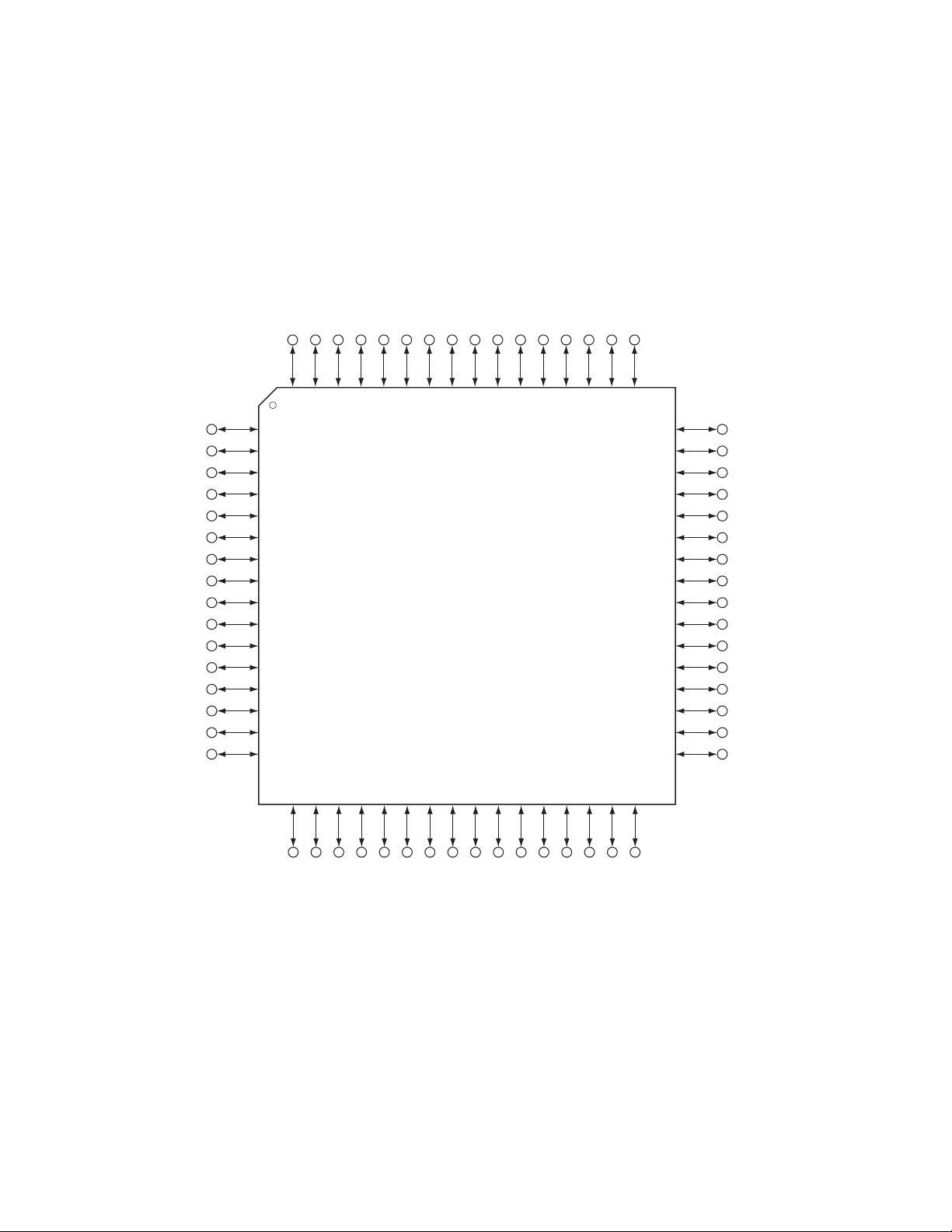

5.1.1 IC1(uPD780021AYGKN1)

uPD780021AYGKN1 is single chip microcomputer of 64 pin 8 bit equipped with the memory of ROM:8k byte / RAM:512 byte

* Pin layout

P47/AD7

P46/AD6

P45/AD5

P44/AD4

P43/AD3

P42/AD2

P41/AD1

P40/AD0

P67/ASTB

P66/WAIT

P65/WR

P64/RD

P75/BUZ

P74/PCL

P73/TI51/TO51

P72/TI50/TO50

64 555657585960616263 54 4950515253

P50/A8

P51/A9

P52/A10

P53/A11

P54/A12

P55/A13

P56/A14

P57/A15

Vsso

Vddo

P30

P31

P32

P33

P34/SI31

P35/SO31

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17 262524232221201918 27 3231302928

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

P71/TI01

P70/TI00/TO00

P03/INTP3/ADTRG

P02/INTP2

P01/INTP1

P00/INTP0

Vss1

X1

X2

IC(Vpp)

XT1

XT2

RESET

AVdd

AVref

P10/ANI0

P20/SI30

P20/SO30

P36/SCK31

P24/TxD0

P23/RxD0

P22/SCK30

AVss

Vdd1

P25/ASCK0

P17/NI7

P16/AIN6

P14/ANI4

P13/ANI3

P15/ANIN5

P12/ANI2

P11/ANI1

(No.XC031)1-7

Page 8

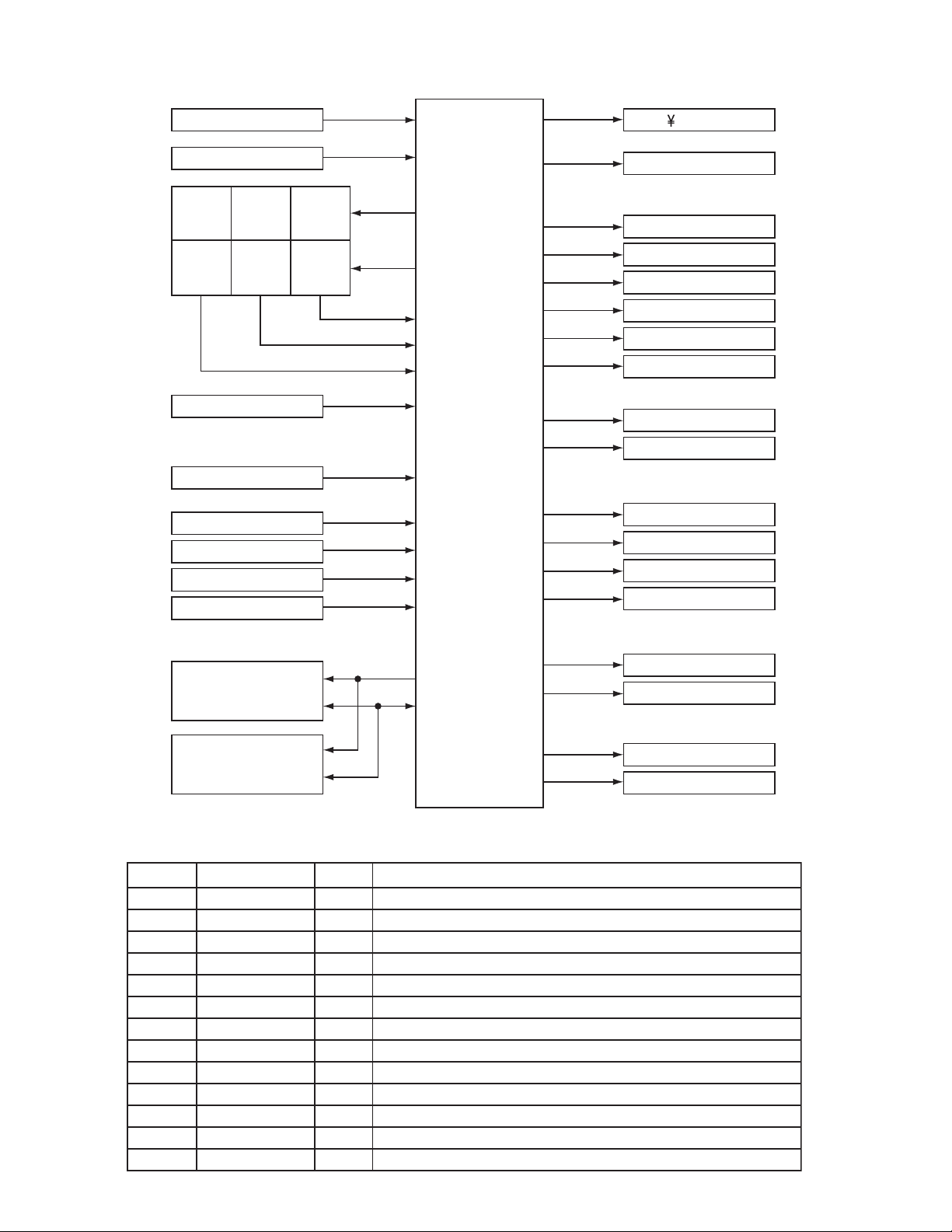

* Block diagram

KEY

1ch

KEY

2ch

P-SW

HD

KEY

3ch

KEY

4ch

REMO

D-SW

S-SW 1

S-SW 2

S-SW 3

S-SW 4

P-ON

P-ON

LOCK

LED_1CH

LED_2CH

LINK

LED_3CH

LED_4CH

LED_LOCK

LED_LINK

D-OFF1

D-OFF2

CH-SEL1

CH-SEL2

CH-SEL3

CH-SEL4

CXA2079Q

CXA2019Q

* Pin function (1/2)

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

SONY/

SONY/

Symbol

P50

P51

P52

P53

P54

P55

P56

P57

Vsso

Vddo

P30

P31

P32/SDA0

I/O

O

O

O

O

O

O

O

O

I/O

D-SELA

D-SELB

PCT1

PCT2

Description

LED lighting output

LED lighting output

LED lighting output

LED lighting output

LED lighting output

LED lighting output

Switch of D and S

Switch of D and S

-

-

-

-

Ground of port

Positive power supply of port

Not use

Not use

I2C Bus communication (data)

1-8 (No.XC031)

Page 9

* Pin f

(2/2)

unction

Pin No.

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62 to 64

Symbol

P33/SCL0

P34

P35

P36

P20

P21

P22

P23

P24

P25

Vdd1

AVss

P17/ANI7

P16/ANI6

P15/ANI5

P14/ANI4

P13/ANI3

P12/ANI2

P11/ANI1

P10/ANI0

AVr ef

AVdd

RESET

XT2

XT1

IC(Vpp)

X2

X1

Vss1

P00/INTP0

P01/INTP1

P02/INTP2

P03/INTP3

P70/TI00

P71

P72

P73

P74

P75

P64

P65

P66

P67

P40

P41

P42

P43

P44

P45 to P47

I/O

O

O

O

O

O

O

O

O

O

O

O

O

O

I/O

I/O

Description

I2C Bus communication (clock)

-

I

I

I

I

I

-

-

I

I

I

I

I

I

I

I

-

-

I

I

I

-

-

-

I

I

-

-

I

-

I

I

I

-

Not use

Power-ON output

Reversing of power-ON output

D detection input

S detection input

S detection input

S detection input

S detection input

Not use

Positive power supplies other than port

Ground terminal

Not use (Connect to Vsso)

Not use (Connect to Vsso)

Not use (Connect to Vsso)

Not use (Connect to Vsso)

Not use (Connect to Vsso)

Not use (Connect to Vsso)

Not use (Connect to Vsso)

Not use (Connect to Vsso)

Connect to Vsso (A/D Standard power supply)

Connect to Vddo (A/D power supply)

Reset

Open (Not use)

Connect to Vddo (Not use)

Connect to Vsso

Main clock 4MHz

Main clock 4MHz

Ground terminal other than port

Horizontal synchronizing signal detection input

Power ON/OFF input

Not use

Not use

Remote control reception

Not use

Output of input CH

Output of input CH

Output of input CH

Output of input CH

Output of input CH

Output of input CH

Output of protect CH CH1

Output of protect CH CH2

Key matrix (2 x 3) input

Key matrix (2 x 3) input

Key matrix (2 x 3) input

Key matrix (2 x 3) output

Key matrix (2 x 3) output

Not use

(No.XC031)1-9

Page 10

5.1.2 IC107(CXA2019AQ)

CXA2019AQ is bipolar IC that accumulates the brightness signal processing, the color signal processing, and the synchronous signal

processing of NTSC and PAL in single-chip. It corresponds to the I2C bus.

Various adjustments and the controls are possible according to two bus lines of SCL and SDA.

* Pin layout

SECAM REF

APC

X 443/358

X 358

X NTSC

SVcc

-(R_Y)OUT

-(B_Y)OUT

-(B_Y)IN

-(R_Y)IN

30 212223242526272829

S GND

CIN

A PED

CVBS/Y IN

ADRS

SCL

SDA

V SYNC

H SYNC

V HOLD

31

32

33

34

35

36

37

38

39

40

20

19

18

17

16

15

14

13

12

11

V OUT

U OUT

Y OUT

SGND2

SCP

H TIM

V TIM

V2 IN

U2 IN

Y2 IN

1 1098765432

AFC

JVcc

CREA

IREF

J GND

V2 OUT

Y2 OUT

U2 OUT

CP IN

ABLFILIN

* Block diagram

ADRS

SDA

SCL

IREF

H SYNC

J GND

J Vcc

AFC

CERA

SCP

H TIM

V SYNC

CVBS/Y IN

CIN

S GND

35 37 36 39 16 15 38 40 14

2

I C BUS

DECODER

CV/YC

SUB CONT

34

VIDEO

SW

32

ACC

31

45321 6 7 8

32/H

VCO

H.SYNC

IREF

SEP

SECAM

SUB

CONT

SUB COLOR

TRAP

ACC

DET.

TOT

DELAY

SECAM

30 25 29 28 27 26 33 23 24 22 21

TOT ON

KILLER

SECAM REF

TRAP

BST AMP

COLOR

KILLER

SVcc

PHASE

DET.

AFC HLOCK

TRAP ON

PHASE

DET.

LPF

APC

H.DRIVE

1/32

2/H

SHP 10

DELAY

PRE OVER

DELAY SHARPNESS CLAMP

SUB HUE

NT/PAL

HUE

PAL I D

ID AXIS

HUE

CHROMA

VCO

4.43/3.58

SW

X 358

X 443/358

X NTSC

V HOLD

V.S YN C

SEP

SHARPNESS

DC TRAN

NT/PAL

2fH

F.F

DEM

AXIS

PHASE

SHIFT

X'TAL PIN

V TIM

V.COUNT

DOWN

C MODE

V2 OUT

V2 PED

50/60

V2 PED V2 DRIVE

AUTO

PEDESTAL

CHROMA

DET.

A PED

(B_Y) OUT

V2 DRIVE

COLOR

CLAMP

(R_Y) OUT

U2 OUT

U2 PED

U2 DRIVE

U2 PED U2 DRIVE

Y DRIVE

Y DRIVE

COLOR

DET

SW

NT/PAL

EXT COLOR

(R_Y) IN

(B_Y) IN

U PED

U PED

Y2 OUT

Y2 DRIVE

Y2 DRIVE

V PED

V PED

ABL CENT

ABL

9

11

12

13

10

17

18

19

20

ABLFILIN

Y2 IN

U2 IN

V2 IN

CP IN

SGND2

Y OUT

U OUT

V OUT

* The sub picture bright and white balance can be adjusted

by receiving BGP or SCP output from the main picture Y/C/J,

clamping the PINP PROC. output, and varying the DC of the

clamped portion.

1-10 (No.XC031)

Page 11

5.1.3 IC101(CXA-2079Q)

CXA-2079Q is AV switch IC for I2CBus for TV of "Six video system input two outputs" and "Six audio system

stereo input two outputs". Four input corresponds to the S2 standard and S standard among six video system input.

Each output (The audio system treats Lch and Rch as a couple) can select an arbitrary independently input,

and this is done by the I2CBus control.

However, the output of the second system selects the same input system as the video system and the audio system.

* Pin layout * Block diagram

VGND

57

27

S2-4

YOUT1

TRAP1

55

56

29

28

NC

S-4

ROUT1

54

30

NC

NC

VOUT1

LOUT1

52

53

32

31

ADR

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

CIN1

BIAS

YIN1

MUTE

NC

NC

YIN2

AGND2

CIN2

CC

V

VOUT2

ROUT2

YOUT2

LOUT2

COUT2

DC OUT

AGND

SDA

SCL

TV

V1

V2

V3

V4

V5

Y1

Y2

Y3

Y4

C1

C2

C3

C4

LTV

LV1

LV2

LV3

LV4

LV5

63

1

8

15

22

60

3

10

17

24

5

12

19

26

62

2

9

16

23

59

LV1

RV1

S2-1

S-1

LV2

RV2

S2-2

S-2

LV3

RV3

RV5

61

23

LV4

COUT1

LV5

V5

59

58

60

26

25

24

C4

RV4

Y4

RTV

LTV

TV

62

64

63

1

V1

2

3

Y1

4

5

C1

6

7

8

V2

9

10

Y2

11

12

C2

13

14

15

V3

16

17

Y3

18

19

C3

20

21

22

V4

S-3

S2-3

6dB

6dB

6dB

6dB

6dB

6dB

BIAS

6dB

0dB

6dB

0dB

53

49

56

55

58

51

41

45

39

37

43

57

50

42

35

44

52

54

38

VOUT1

YIN1

YOUT1

TRAP1

COUT1

CIN1

VOUT2

YIN2

YOUT2

COUT2

CIN2

VGND

BIAS

V

CC

AGND

AGND2

LOUT1

ROUT1

LOUT2

RTV

RV1

RV2

RV3

RV4

RV5

NC

NC

NC

NC

NC

40

36

33

34

32

7

14

21

28

6

13

20

27

48

ROUT2

DC OUT

SCL

SDA

ADR

S-1

S-2

S-3

S-4

S2-1

S2-2

S2-3

S2-4

MUTE

6dB

64

4

6dB

11

18

25

61

Logic

29

30

31

46

47

(No.XC031)1-11

Page 12

5.2 Troubleshooting

5.2.1 Standard input signal

Vedeo signal

V→Full field color bar(White100%)1.0Vp-p

Y→1.0Vp-p(With synchronous signal)

C→Burst level 0.286Vp-p Only chroma signal

Pb / Pr →0.7Vp-p

Audio signal

1kHz,- 10dBV Sine wave

YES→Normality

NO→Neither the voltage nor the shape of waves are nomal.

Symptom Check point Voltage and shape of waves

Check and locating fault

when it is normal

1.The power supply

doesn't enter

1 Between C903+ and C903- Approx DC 164V NO→Check of power cord and

CN901

Please check Q901,T901,D901

surrounding enough when the

fuse has been disconnected.

YES →Check of 2

2 Cathode of D906

Anode of D908

DC + 9.4 V

DC - 9.8 V

NO→The IC905 surrounding is

checked. or Defect of PC901

YES →Check of 3

3 Emitter of Q904

Emitter of Q905

3 pin of IC902

2 pin of IC903

DC + 6.4 V

DC - 6.4 V

DC + 5 V

DC +9 V

NO→Defective IC902 and IC903.

Defective Q904 to Q906.

YES→Check of CN1, CN2 and

wire

2.Lighting failure LED 4 1 pin to 6 pin of CN1 DC 0 V or + 5 V NO→Defective Q1 to Q6.

YES→Check of CN1, CN701 and

wire

3.Defective operation of

switch

5 8 pin to 12 pin of CN1 DC 0 V or + 5 V NO→Defective IC2.

YES→Check of CN1, CN701 and

wire Defective tact switch

4.The remote control

operation is abnormal

6 47 pin of IC1 DC + 5 V Remote control code

(Refer to TM.)

NO→Defective IC701, CN1,

CN701 and wire.

YES →Defective IC1.

5.Link function defective

operation

7 8 pin of IC106 DC + 5 V NO→Check of 8

YES→IC1, Q909, and the circum-

ference circuit are checked.

8 2 pin of IC106 NO→IC105 and the circumfer-

ence circuit are checked.

1.0 Vp-p

YES→IC106 and the circumfer-

ence circuit are checked.

Notice (When component terminals are used)

When S-Video signals are input to the JX-S333 from VCR and Video Camcorder, and JX-S333 is connected to TV through component output terminals, the phenomena of distortions or image disorders may occur on some TV sets.

As the phenomena are caused by specifications of the TV, when these are occurred, they cannot be avoid or improved.

Please note that the JX-S333 does not have functions of stabilizing or improving video image although JX-S333 can convert video

signal formats.

When these phenomena happen, connection by S Video cord between JX-S333 and TV is recommended without a component signal line..

1-12 (No.XC031)

Page 13

Symptom Check point Voltage and shape of waves

when it is normal

6.The S-VIDEO signal

input from 1 to 4CH is

not output from terminal

S-VIDEO.

9 (Y) Base of Q110, Q114

(C) Base of Q108, Q112

(Y)

2.0 Vp-p

(C)

1.28 Vp-p

Check and locating fault

NO→Check of 10

YES→Output buffer and the cir-

cumference circuit are checked.

7.The S-VIDEO signal

input from 1 to 4CH is

not output from terminal

monitor.

10 (Y) Emitter of Q103

(C) Emitter of Q104

11 (Y) Emitter of Q101

(C) Emitter of Q102

(Y)

(C)

(Y)

(C)

2.0 Vp-p

1.28 Vp-p

2.0 Vp-p

1.28 Vp-p

NO→IC101 and the circumfer-

ence circuit are checked.

YES→Defective IC103, IC108.

NO→IC101 and the circumfer-

ence circuit are checked.

YES→Output buffer and the cir-

cumference circuit are checked.

(No.XC031)1-13

Page 14

Symptom Check point Voltage and shape of waves

when it is normal

8.The component signal

conversion function

doesn't operate.

12 (Y) 6 pin of IC206

(Pb) 5 pin of IC206

(Pr) 3 pin of IC206

(Y)

1.0 Vp-p

(Pb)

0.7 Vp-p

(Pr)

0.7 Vp-p

Check and locating fault

NO→Check of 13

YES→IC207 and the circumfer-

ence circuit are checked.

13 (Y) Emitter of Q124

(Pb) Emitter of Q123

(Pr) Emitter of Q122

14 (Y) Emitter of Q126

(C) Emitter of Q125

(Y)

(Pb)

(Pr)

(Y)

(C)

1.0 Vp-p

0.7 Vp-p

0.7 Vp-p

2.0 Vp-p

1.28 Vp-p

NO→Check of 14

YES→IC206 and the circumfer-

ence circuit are checked.

NO→IC101 and the circumfer-

ence circuit are checked.

YES→IC107, Q122 to Q124 and

the circumference circuit are

checked.

1-14 (No.XC031)

Page 15

Symptom Check point Voltage and shape of waves

when it is normal

9.The component signal

is not output.

15 (Y) 6 pin of IC206

(Pb) 5 pin of IC206

(Pr) 3 pin of IC206

(Y)

1.0 Vp-p

(Pb)

0.7 Vp-p

(Pr)

0.7 Vp-p

Check and locating fault

NO→Check of 16

YES→IC207 and the circumfer-

ence circuit are checked.

16 (Y) 13 pin of IC201

(Pb) 3 pin of IC202

(Pr) 13 pin of IC202

17 (Y) Emitter of Q201,204,207,210

(Pb)Emitter of Q203,206,209,212

(Pr) Emitter of Q202,205,208,211

(Y)

(Pb)

(Pr)

(Y)

(Pb)

1.0 Vp-p

0.7 Vp-p

0.7 Vp-p

1.0 Vp-p

0.7 Vp-p

NO→Check of 17

YES→IC206 and the circumfer-

ence circuit are checked.

NO→Q201 to Q212 and the cir-

cumference circuit are checked.

YES→IC201 to IC202 and the cir-

cumference circuit are checked.

10.The audio signal is

not output.

11.The audio signal is

not output to the monitor

output terminal.

18 (L) 9, 11 pin of IC104

(R) 2, 3 pin of IC104

19 (L) 52 pin of IC101

(R) 54 pin of IC101

(Pr)

–10 dBV

(0.32 Vrms)

–10 dBV

(0.32 Vrms)

0.7 Vp-p

NO→IC101 and the circumfer-

ence circuit are checked.

YES→Defective IC104.

NO→IC101 and the circumfer-

ence circuit are checked.

YES→The substrate pattern

around PJ117 is checked.

(No.XC031)1-15

Page 16

5.3 Description of major ICs

5.3.1 IC107(CXA-2019AQ)

* Pin layout

SECAM REF

APC

X 443/358

X 358

30 212223242526272829

S GND

31

CIN

32

A PED

ADRS

SCL

SDA

V SYNC

H SYNC

V HOLD

33

34

35

36

37

38

39

40

CVBS/Y IN

1 1098765432

AFC

JVcc

IREF

CREA

* Block diagram

ADRS

SDA

SCL

IREF

45321 6 7 8

IREF

SUB

CONT

TRAP

ACC

DET.

TOT

DELAY

SECAM

30 25 29 28 27 26 33 23 24 22 21

SECAM REF

CVBS/Y IN

CIN

S GND

35 37 36 39 16 15 38 40 14

2

I C BUS

DECODER

CV/YC

SUB CONT

34

VIDEO

SW

32

SUB COLOR

ACC

31

X NTSC

SVcc

J GND

V2 OUT

H SYNC

H.SYNC

SEP

SECAM

TOT ON

KILLER

-(R_Y)OUT

-(B_Y)OUT

-(B_Y)IN

Y2 OUT

U2 OUT

ABLFILIN

J GND

AFC HLOCK

TRAP

BST AMP

COLOR

KILLER

SVcc

-(R_Y)IN

20

19

18

17

16

15

14

13

12

11

CP IN

J Vcc

AFC

PHASE

DET.

TRAP ON

PHASE

DET.

LPF

APC

V OUT

U OUT

Y OUT

SGND2

SCP

H TIM

V TIM

V2 IN

U2 IN

Y2 IN

CERA

SCP

H TIM

32/H

VCO

H.DRIVE

1/32

2/H

SHP 10

NT/PAL

PAL I D

ID AXIS

X NTSC

SHARPNESS

NT/PAL

PHASE

SHIFT

X'TAL PIN

DELAY

PRE OVER

DELAY SHARPNESS CLAMP

SUB HUE

HUE

HUE

CHROMA

VCO

4.43/3.58

SW

X 358

X 443/358

V SYNC

V HOLD

V.S YN C

SEP

DC TRAN

2fH

F.F

DEM

AXIS

V TIM

V.COUNT

DOWN

C MODE

V2 OUT

V2 PED

50/60

V2 PED V2 DRIVE

AUTO

PEDESTAL

CHROMA

DET.

A PED

(B_Y) OUT

V2 DRIVE

COLOR

CLAMP

(R_Y) OUT

U2 OUT

U2 PED

U2 DRIVE

U2 PED U2 DRIVE

Y DRIVE

Y DRIVE

COLOR

DET

SW

NT/PAL

EXT COLOR

(R_Y) IN

(B_Y) IN

U PED

U PED

Y2 OUT

Y2 DRIVE

Y2 DRIVE

V PED

V PED

ABL CENT

ABL

9

11

12

13

10

17

18

19

20

ABLFILIN

Y2 IN

U2 IN

V2 IN

CP IN

SGND2

Y OUT

U OUT

V OUT

* The sub picture bright and white balance can be adjusted

by receiving BGP or SCP output from the main picture Y/C/J,

clamping the PINP PROC. output, and varying the DC of the

clamped portion.

1-16 (No.XC031)

Page 17

5.3.2 IC101 CXA-2079Q [SONY]

* Pin layout

COUT1

YOUT1

VGND

LV5

V5

59

58

57

60

24

Y4

25

RV4

56

26

27

28

S-4

S2-4

C4

LV1

RV1

S2-1

S-1

LV2

RV2

S2-2

S-2

LV3

RV3

RTV

RV5

LTV

TV

62

64

63

61

1

V1

2

3

Y1

4

5

C1

6

7

8

V2

9

10

Y2

11

12

C2

13

14

15

V3

16

17

Y3

18

19

C3

20

23

21

22

LV4

V4

S-3

S2-3

TRAP1

55

29

NC

ROUT1

VOUT1

53

54

30

31

NC

NC

LOUT1

52

32

ADR

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

CIN1

BIAS

YIN1

MUTE

NC

NC

YIN2

AGND2

CIN2

CC

V

VOUT2

ROUT2

YOUT2

LOUT2

COUT2

DC OUT

AGND

SDA

SCL

* Block diagram

TV

63

V1

1

V2

8

V3

15

V4

22

V5

60

Y1

3

Y2

10

Y3

17

Y4

24

C1

5

C2

12

C3

19

C4

26

LTV

62

LV1

2

LV2

9

LV3

16

LV4

23

LV5

59

6dB

6dB

6dB

6dB

6dB

6dB

BIAS

6dB

0dB

6dB

0dB

53

49

56

55

58

51

41

45

39

37

43

57

50

42

35

44

52

54

38

VOUT1

YIN1

YOUT1

TRAP1

COUT1

CIN1

VOUT2

YIN2

YOUT2

COUT2

CIN2

VGND

BIAS

V

CC

AGND

AGND2

LOUT1

ROUT1

LOUT2

RTV

RV1

RV2

RV3

RV4

RV5

NC

NC

NC

NC

NC

40

36

33

34

32

7

14

21

28

6

13

20

27

48

ROUT2

DC OUT

SCL

SDA

ADR

S-1

S-2

S-3

S-4

S2-1

S2-2

S2-3

S2-4

MUTE

6dB

64

4

6dB

11

18

25

61

Logic

29

30

31

46

47

(No.XC031)1-17

Page 18

5.3.3 IC106,IC205 LA7217M [SANYO]

* Pin layout and block diagram

NC

14

Vcc AFC CTL VCO OUT VCO IN HD OUT DET OUT

13 12 11 10 89

12

NC VIDEO IN F.B CLAMP SYNC OUT VD OUT GND EXC

5.3.4 IC2 M51957AL [MITSUBISHI]

* Pin layout * Block diagram

M51957A/BL

AFC

SYNC

SEP

5

Output

4

Delay capacity

3

Ground

2

Input

1

Power supply

COUNT

DOWN

34

Input

32fH

VCO

Power supply

-

+

1.25V

LOCK

DET

V.SE P

5

A : With fixed current load

B : Open corrector

5 A

Standard Standard

25 A

-

76

Output

5.3.5 IC207 NJM2581D

* Pin layout and block diagram

1

VIN1

BIAS

VIN2

2

3

VEE1

BIAS

VIN3

4

5

VEE2

BIAS

VEE3

Power Save

6

7

6dB

AMP

6dB

AMP

6dB

AMP

75

Driver

75

Driver

75

Driver

REF

Delay capacityGround

14

V+1

13

VOUT1

12

V+2

11

VOUT2

10

V+3

9

VOUT3

8

GND

1-18 (No.XC031)

Page 19

5.3.6 IC206 NJM2584D

* Pin layout and block diagram

1

IN1B

2

NC

NC

IN3A

3

4

5

6

7

8

OUT1

GND2

OUT2

OUT3

5.3.7 IC103, IC104, IC108, IC109 TC74HC4066AFEL [TOSHIBA]

* Pin layout

11I/O

1O/I

14

13

Vcc

1C

BIAS

CLAMP

BIAS

16

15

14

13

12

11

10

9

IN1A

GND1

IN2B

V+

CTL

IN2A

GND3

IN3B

2O/I23

2I/O

4

2C

5

3C

6

GND

7

* Truth table

CONTROL SWITCH FUNCTION

(TOP VIEW)

H

L

ON

OFF

12

11

10

9

8

4C

4I/O

4O/I

3O/I

3I/O

(No.XC031)1-19

Page 20

5.3.8 IC903 PQ09RD08 [SHARP]

* Pin layout * Block diagram

2

1 43

5.3.9 IC701 RPM7138 [ROHM]

* Block diagram

1

DC Input (Vin)

2

DC Output (Vo)

3

Ground

ON/OFF Control terminal (Vc)

4

1 2

Special IC

4

3

VCC

LimiterAMP

I/V

5.3.10 IC105, IC201, IC202 TC74HC4052AFEL [TOSHIBA]

* Pin layout

0Y 1

2Y 2

Y - COM 3

3Y 4

1Y 5

INH 6

EE 7

V

GND 8

16 V

cc

15 2X

14 1X

13 X - COM

12 0X

11 3X

10 A

9 B

* Truth table

INHIBIT

* Block diagram

BPF

L

L

L

L

L

L

L

L

H

Demodulator

and integrator

C*

L

L

L

L

H

H

H

H

X

I / OCO / I

Comparator

B

L

L

H

H

L

L

H

H

X

X-COM

0X

A

L

H

L

H

L

H

L

H

X

22K

R

OUT

"ON" CHANNELCONTROL INPUTS

HC4052A

0X, 0Y

1X, 1Y

2X, 2Y

3X, 3Y

-- --

-- --

-- --

-- --

NONE

A

B

INH

1-20 (No.XC031)

Logic Level Converter

I / OCO / I

1X

2X

3X

0Y

1Y

2Y

3Y

Y-CO M

Page 21

5.3.11 IC905 uPC1093J [NEC]

* Pin layout * Block diagram

12 3

1 : REF

2 : A

3 : K

REF

D

K

Q

12

R

5

Q

1

R

1

1

R

2

R

3

Q

5

Q

2

C

1

R

6

Q

13

Q

14

C

15

2

Q

10

R

9

R

10

Q

11

Q

6

Q

7

R

7

Q

8

Q

Q

16

Q

17

5.3.12 IC902 uPC7805AHF [NEC]

* Pin layout * Block diagram

R4 R18

IN GND OUT

D1

Q13

R5

R6

R7

Q

3

R8 R9

Q8 Q9

Q10

Q6

Q5

R1

R2

Q12

R10

Q7

Q1

R3 R14

Q2

C1

Q

4

R

4

R

8

Q

9

A

INPUT

OUTPUT

GND

Q4

Q14

R16

Q15

Q3

R13

Q11

Q16

R15

R12R17

Q17

R11

R20

R19

(No.XC031)1-21

Page 22

5.3.13 IC1 uPD780021AYGKN1

* Pin layout

* Block diagram

P50/A8

P51/A9

P52/A10

P53/A11

P54/A12

P55/A13

P56/A14

P57/A15

Vsso

Vddo

P30

P31

P32

P33

P34/SI31

P35/SO31

P47/AD7

P46/AD6

P45/AD5

P44/AD4

P43/AD3

P42/AD2

P41/AD1

P40/AD0

P67/ASTB

64 555657585960616263 54 4950515253

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17 262524232221201918 27 3231302928

AVss

Vdd1

P20/SI30

P36/SCK31

P23/RxD0

P20/SO30

P22/SCK30

P24/TxD0

P25/ASCK0

P66/WAIT

P65/WR

P64/RD

P17/NI7

P16/AIN6

P15/ANIN5

P75/BUZ

P74/PCL

P14/ANI4

P13/ANI3

P73/TI51/TO51

P72/TI50/TO50

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

P12/ANI2

P11/ANI1

P71/TI01

P70/TI00/TO00

P03/INTP3/ADTRG

P02/INTP2

P01/INTP1

P00/INTP0

Vss1

X1

X2

IC(Vpp)

XT1

XT2

RESET

AVdd

AVref

P10/ANI0

TI00/TO0/P70

TI01/P71

TI50/TO50/P72

TI51/TO51/P73

SI30/P20

SO30/P21

SCK30/P22

RxD0/P23

TxD0/P24

ASCK0/P25

SDA0/P32

SCL0/P33

ANI0/P10-

ANI7/P17

INTP0/P00-

INTP3/P03

BUZ/P75

PCL/P74

1-22 (No.XC031)

AVd d

AVs s

AVr ef

16-bit TIMER/

EVENT COUNTER0

8-bit TIMER/

EVENT COUNTER50

8-bit TIMER/

EVENT COUNTER51

WATCHDOG TIMER

WATCH TIMER

SERIAL

INTERFACE SIO30

UART0

I2C BUS

8

A/D CONVERTER

4

INTERRUPT

CONTROL

CLOCK/BUZZER

OUTPUT CONTROL

78K/0

CPU

CORE

ROM

(FLASH

MEMORY)

RAM

Vdd0 Vdd1 Vss0 Vss1 IC

(Vpp)

PORT0

PORT1

PORT2

PORT3

PORT4

PORT5

PORT6

PORT7

EXTERNAL

ACCESS

SYSTEM

CONTROL

8

4

6

7

8

8

4

6

8

8

P00-P03

P10-P17

P20-P25

P30-P36

P40-P47

P50-P57

P64-P67

P70-P75

AD0/P40AD7/P47

A8/P50A15/P57

RD/P64

WR/P65

WAIT/P66

ASTB/P67

RESET

X1

X2

XT1

XT2

Page 23

(No.XC031)1-23

Page 24

Victor Company of Japan, Limited

AV & MULTIMEDIA COMPANY ACCESSORIES CATEGORY 1644, Shimotsuruma, Yamato, Kanagawa 242-8514, Japan

(No.XC031)

Printed in Japan

VPT

Loading...

Loading...