Page 1

SERVICE MANUAL

COMPACT COMPONENT SYSTEM

HX-Z1R

HX-Z1R

HX-Z1R

Contents

Safety precautions

Preventing static electricity

Important for laser products

Disassembly method

Adjustment method

M

D

N

O

U

D

O

E

S

1-2

1-4

1-5

1-6

1-24

COMPACT

DIGITAL AUDIO

E

M

U

L

O

S

E

E

R

T

P

V

Flow of functional operation

until TOC read (CD)

Maintenance of laser pickup

Replacement of laser pickup

Description of major ICs

Area Suffix

B ----------------------- U.K.

E-------- Continental Europe

EN----------Northern Europe

EV------------Eastern Europe

1-29

1-30

1-30

1-31~41

COPYRIGHT 2002 VICTOR COMPANY OF JAPAN, LTD.

No.21114

1-1

Jul. 2002

Page 2

HX-Z1R

1. This design of this product contains special hardware and many circuits and components specially for safety

purposes. For continued protection, no changes should be made to the original design unless authorized in

writing by the manufacturer. Replacement parts must be identical to those used in the original circuits. Services

should be performed by qualified personnel only.

2. Alterations of the design or circuitry of the product should not be made. Any design alterations of the product

should not be made. Any design alterations or additions will void the manufacturer`s warranty and will further

relieve the manufacture of responsibility for personal injury or property damage resulting therefrom.

3. Many electrical and mechanical parts in the products have special safety-related characteristics. These

characteristics are often not evident from visual inspection nor can the protection afforded by them necessarily

be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in the Parts List of Service Manual. Electrical

components having such features are identified by shading on the schematics and by ( ) on the Parts List in

the Service Manual. The use of a substitute replacement which does not have the same safety characteristics

as the recommended replacement parts shown in the Parts List of Service Manual may create shock, fire, or

other hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the like to be

separated from live parts, high temperature parts, moving parts and/or sharp edges for the prevention of

electric shock and fire hazard. When service is required, the original lead routing and dress should be

observed, and it should be confirmed that they have been returned to normal, after re-assembling.

5. Leakage currnet check (Electrical shock hazard testing)

After re-assembling the product, always perform an isolation check on the exposed metal parts of the product

(antenna terminals, knobs, metal cabinet, screw heads, headphone jack, control shafts, etc.) to be sure the

product is safe to operate without danger of electrical shock.

Do not use a line isolation transformer during this check.

Plug the AC line cord directly into the AC outlet. Using a "Leakage Current Tester", measure the leakage

current from each exposed metal parts of the cabinet, particularly any exposed metal part having a return

path to the chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

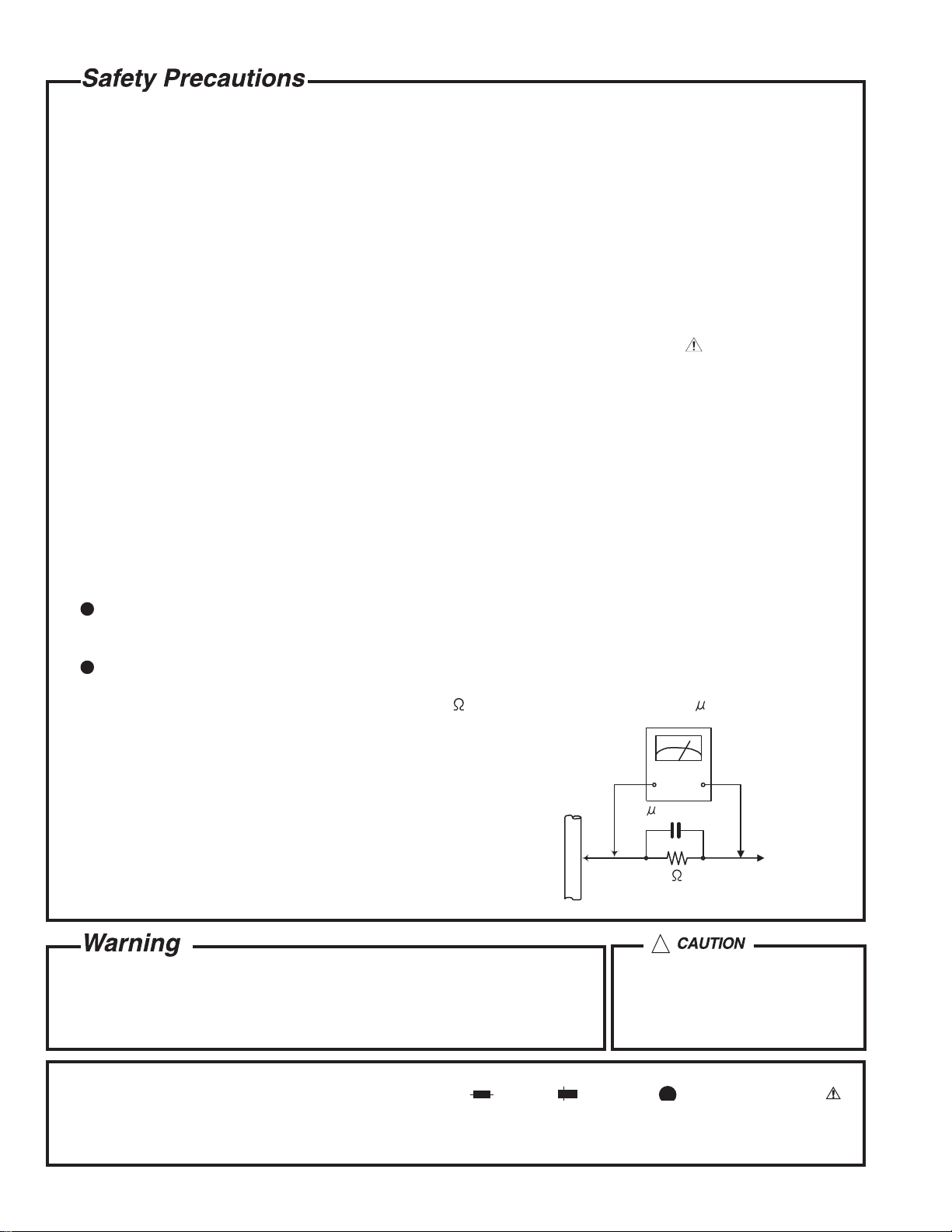

Alternate check method

Plug the AC line cord directly into the AC outlet. Use an AC voltmeter having, 1,000 ohms per volt or more

sensitivity in the following manner. Connect a 1,500 10W resistor paralleled by a 0.15 F AC-type capacitor

between an exposed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal part,

particularly any exposed metal part having a return path to

the chassis, and meausre the AC voltage across the resistor.

Now, reverse the plug in the AC outlet and repeat each

measurement. Voltage measured any must not exceed 0.75 V

AC (r.m.s.). This corresponds to 0.5 mA AC (r.m.s.).

0.15 F AC TYPE

1500 10W

Good earth ground

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

Place this

probe on

each exposed

metal part.

!

1. This equipment has been designed and manufactured to meet international safety standards.

2. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

3. Repairs must be made in accordance with the relevant safety standards.

4. It is essential that safety critical components are replaced by approved parts.

5. If mains voltage selector is provided, check setting for local voltage.

Burrs formed during molding may

be left over on some parts of the

chassis. Therefore, pay attention to

such burrs in the case of

preforming repair of this system.

In regard with component parts appearing on the silk-screen printed side (parts side) of the PWB diagrams, the

parts that are printed over with black such as the resistor ( ), diode ( ) and ICP ( ) or identified by the " "

mark nearby are critical for safety.

(This regulation does not correspond to J and C version.)

1-2

Page 3

HX-Z1R

(U.K only)

1. This design of this product contains special hardware and many circuits and components specially

for safety purposes. For continued protection, no changes should be made to the original

design unless authorized in writing by the manufacturer. Replacement parts must be identical to

those used in the original circuits.

2. Any unauthorised design alterations or additions will void the manufacturer's guarantee ; furthermore the

manufacturer cannot accept responsibility for personal injury or property damage resulting therefrom.

3. Essential safety critical components are identified by ( ) on the Parts List and by shading on the

schematics, and must never be replaced by parts other than those listed in the manual. Please note

however that many electrical and mechanical parts in the product have special safety related

characteristics. These characteristics are often not evident from visual inspection. Parts other than

specified by the manufacturer may not have the same safety characteristics as the recommended

replacement parts shown in the Parts List of the Service Manual and may create shock, fire, or

other hazards.

4. The leads in the products are routed and dressed with ties, clamps, tubings, barriers and the

like to be separated from live parts, high temperature parts, moving parts and/or sharp edges

for the prevention of electric shock and fire hazard. When service is required, the original lead

routing and dress should be observed, and it should be confirmed that they have been returned

to normal, after re-assembling.

1. Service should be performed by qualified personnel only.

2. This equipment has been designed and manufactured to meet international safety standards.

3. It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

4. Repairs must be made in accordance with the relevant safety standards.

5. It is essential that safety critical components are replaced by approved parts.

6. If mains voltage selector is provided, check setting for local voltage.

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

1-3

Page 4

HX-Z1R

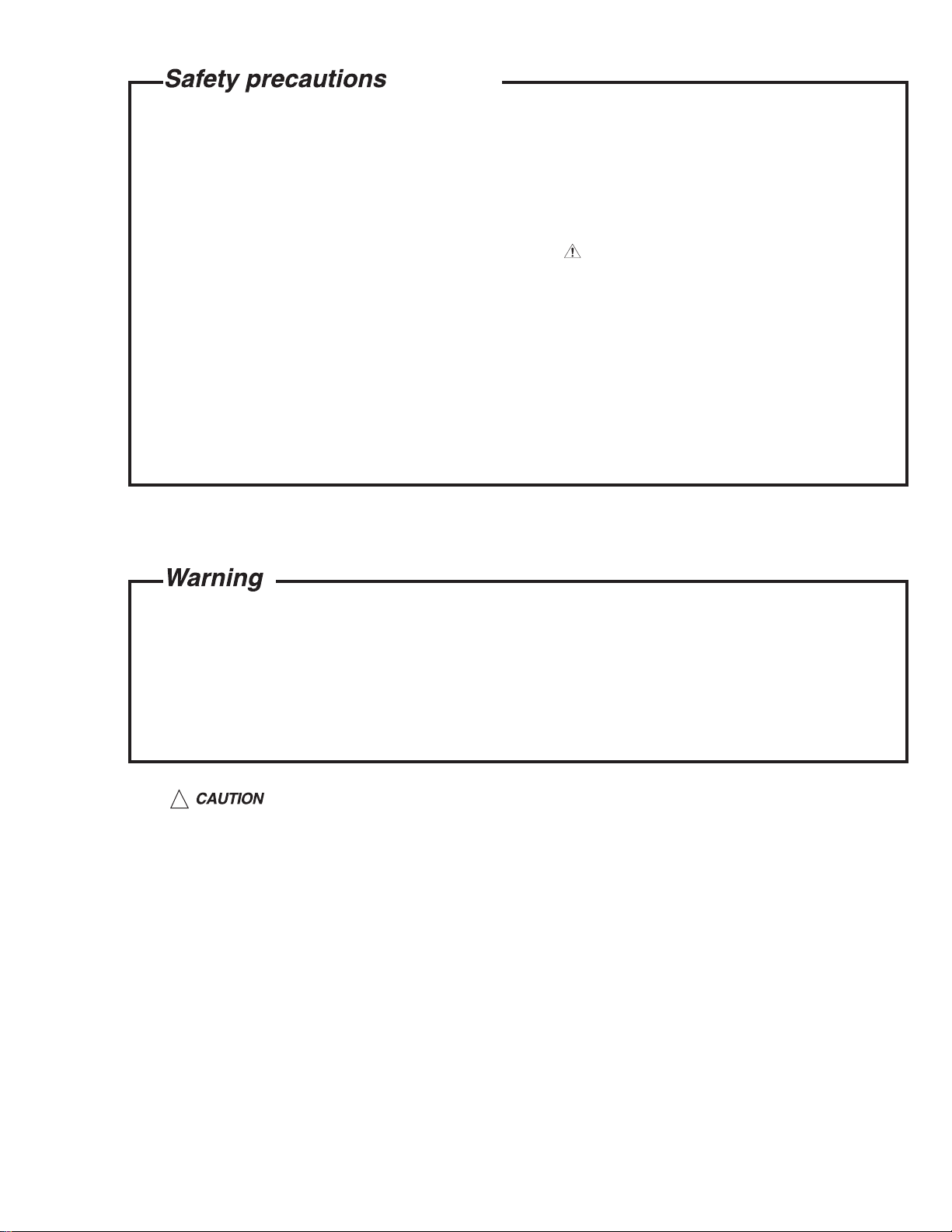

Preventing static electricity

1. Grounding to prevent damage by static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged,

can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

2. About the earth processing for the destruction prevention by static electricity

In the equipment which uses optical pick-up (laser diode), optical pick-up is destroyed by the static electricity of

the work environment.

Be careful to use proper grounding in the area where repairs are being performed.

2-1 Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over

it before placing the traverse unit (optical pickup) on it.

2-2 Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

Conductive material

(conductive sheet) or iron plate

3. Handling the optical pickup

1. In order to maintain quality during transport and before installation, both sides of the laser diode on the

replacement optical pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

2. Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power

source can easily destroy the laser diode.

4. Handling the traverse unit (optical pickup)

1. Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

2. Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific

details, refer to the replacement procedure in the text. Remove the anti-static pin when replacing the traverse

unit. Be careful not to take too long a time when attaching it to the connector.

3. Handle the flexible cable carefully as it may break when subjected to strong force.

4. It is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it

Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for pick-up and how to

detach the CD traverse mechanism.

1. Remove the disk stopper and T. bracket on the CD changer mechanism

assembly.

2. Disconnect the harness from connector on the CD motor board.

3. CD traverse unit is put up as shown in Fig.1.

4. Solder is put up before the card wire is removed from connector CN601

on the CD servo control board as shown in Fig. 2.

(When the wire is removed without putting up solder, the CD pick-up

assembly might destroy.)

5. Please remove solder after connecting the card wire with CN601 when

you install picking up in the substrate.

CD changer

mechanism

assembly

CD traverse

unit

Flexible cable

Fig.1

Soldering

Fig.2

1-4

Page 5

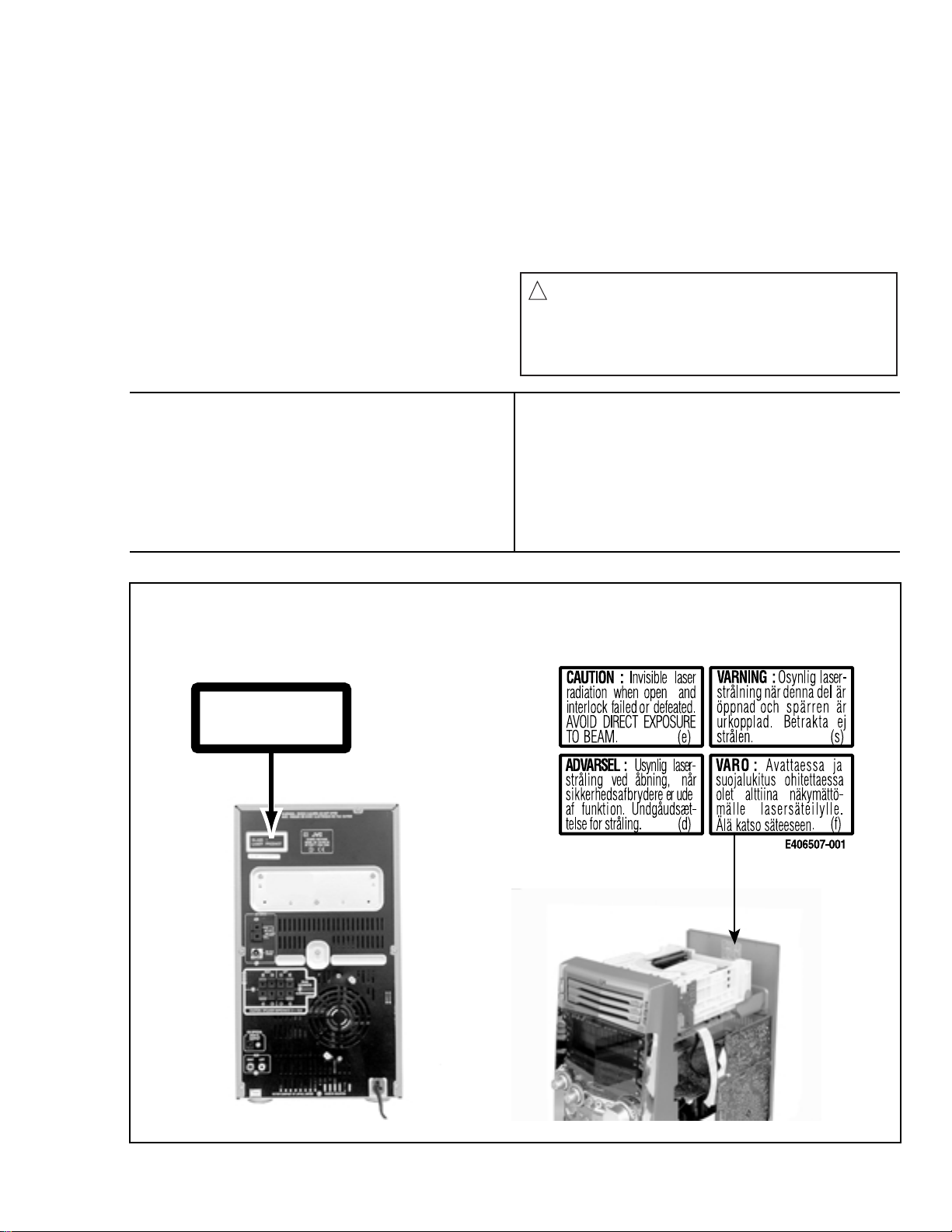

Important for laser products

HX-Z1R

1.CLASS 1 LASER PRODUCT

2.DANGER : Invisible laser radiation when open and inter

lock failed or defeated. Avoid direct exposure to beam.

3.CAUTION : There are no serviceable parts inside the

Laser Unit. Do not disassemble the Laser Unit. Replace

the complete Laser Unit if it malfunctions.

4.CAUTION : The compact disc player uses invisible

laserradiation and is equipped with safety switches

whichprevent emission of radiation when the drawer is

open and the safety interlocks have failed or are de

feated. It is dangerous to defeat the safety switches.

VARNING : Osynlig laserstrålning är denna del är öppnad

och spårren är urkopplad. Betrakta ej strålen.

VARO : Avattaessa ja suojalukitus ohitettaessa olet

alttiina näkymättömälle lasersäteilylle.Älä katso

säteeseen.

5.CAUTION : If safety switches malfunction, the laser is able

to function.

6.CAUTION : Use of controls, adjustments or performance of

procedures other than those specified herein may result in

hazardous radiation exposure.

CAUTION

!

Please use enough caution not to

see the beam directly or touch it

in case of an adjustment or operation

check.

ADVARSEL : Usynlig laserstråling ved åbning , når

sikkerhedsafbrydere er ude af funktion. Undgå

udsættelse for stråling.

ADVARSEL : Usynlig laserstråling ved åpning,når

sikkerhetsbryteren er avslott. unngå utsettelse

for stråling.

REPRODUCTION AND POSITION OF LABELS

WARNING LABEL

CLASS 1

LASER PRODUCT

1-5

Page 6

HX-Z1R

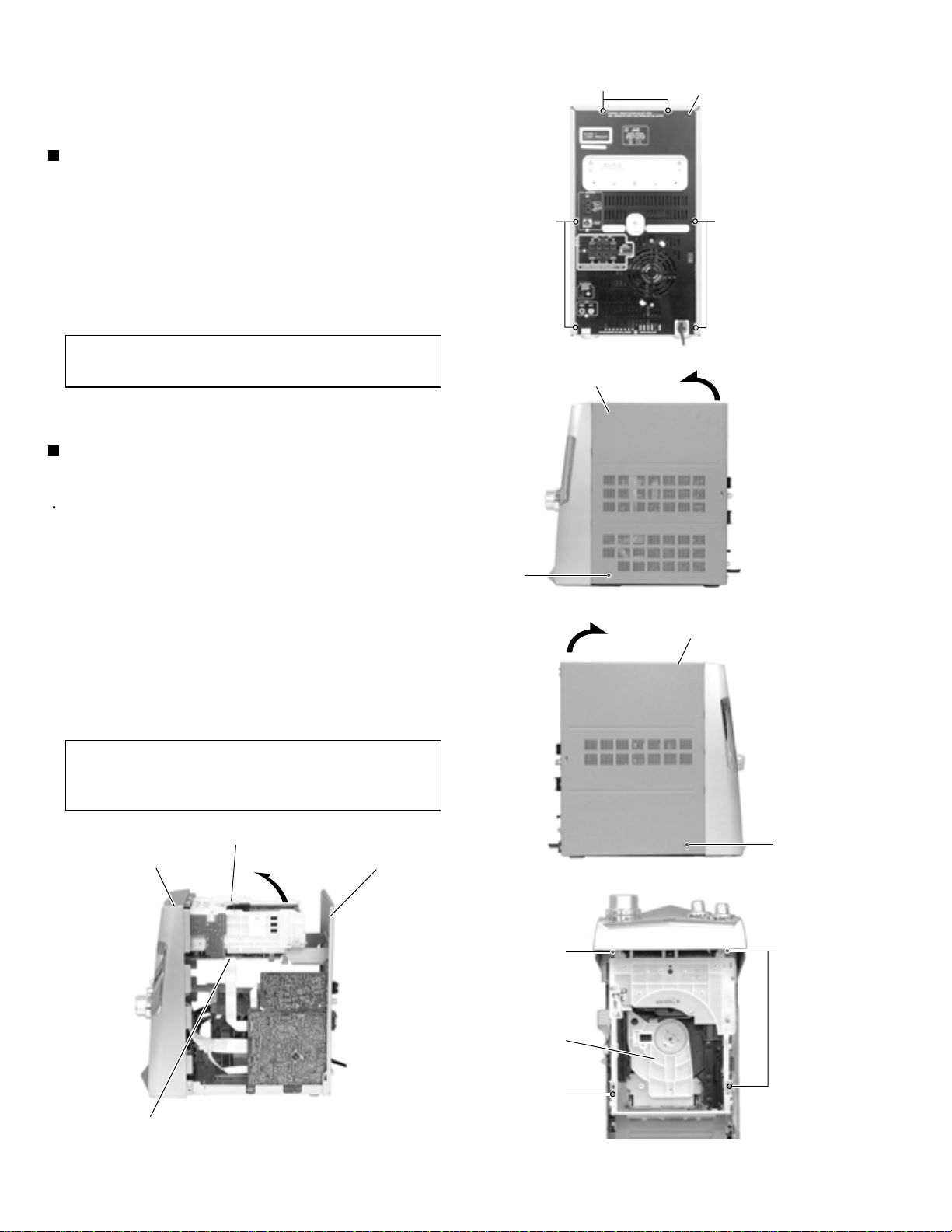

Disassembly method

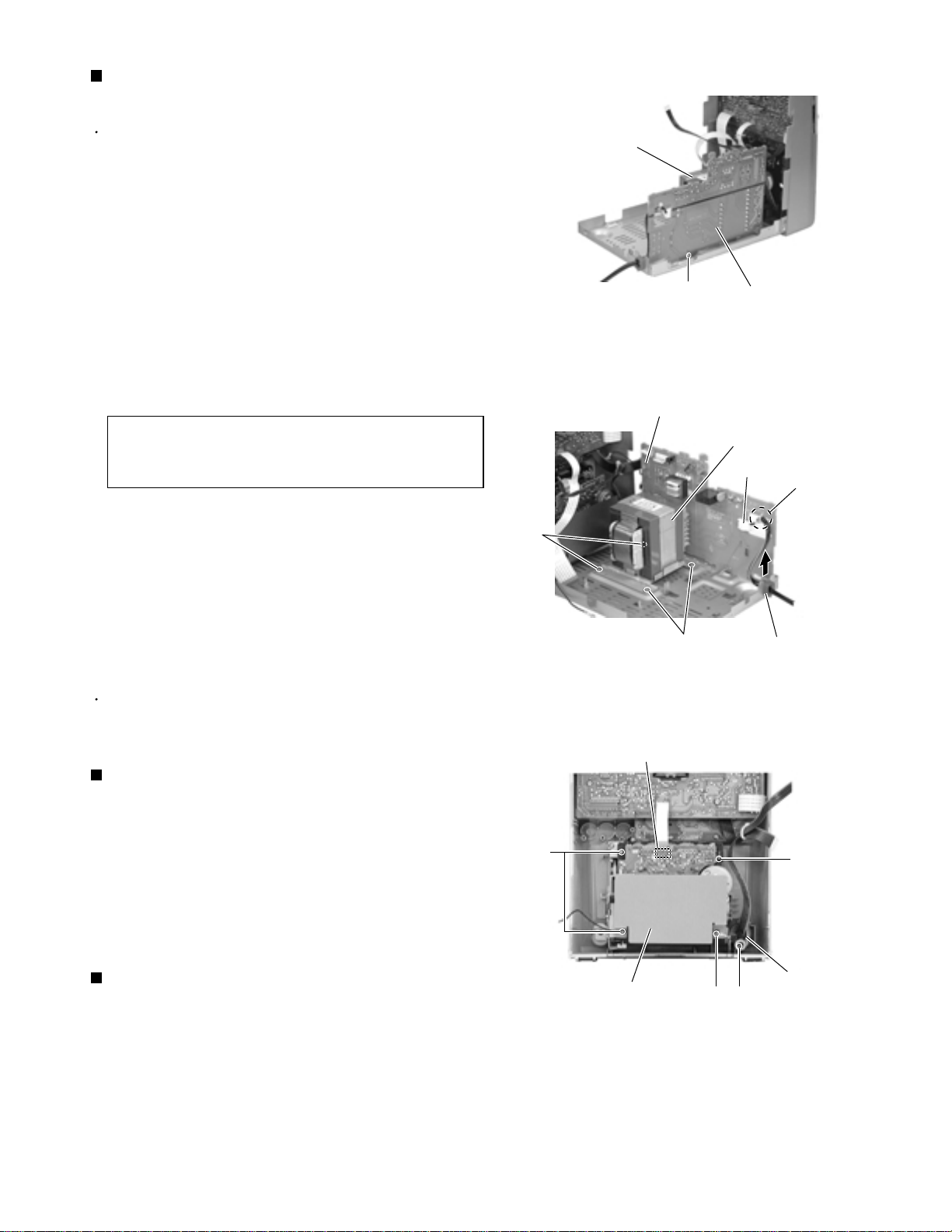

<Main board>

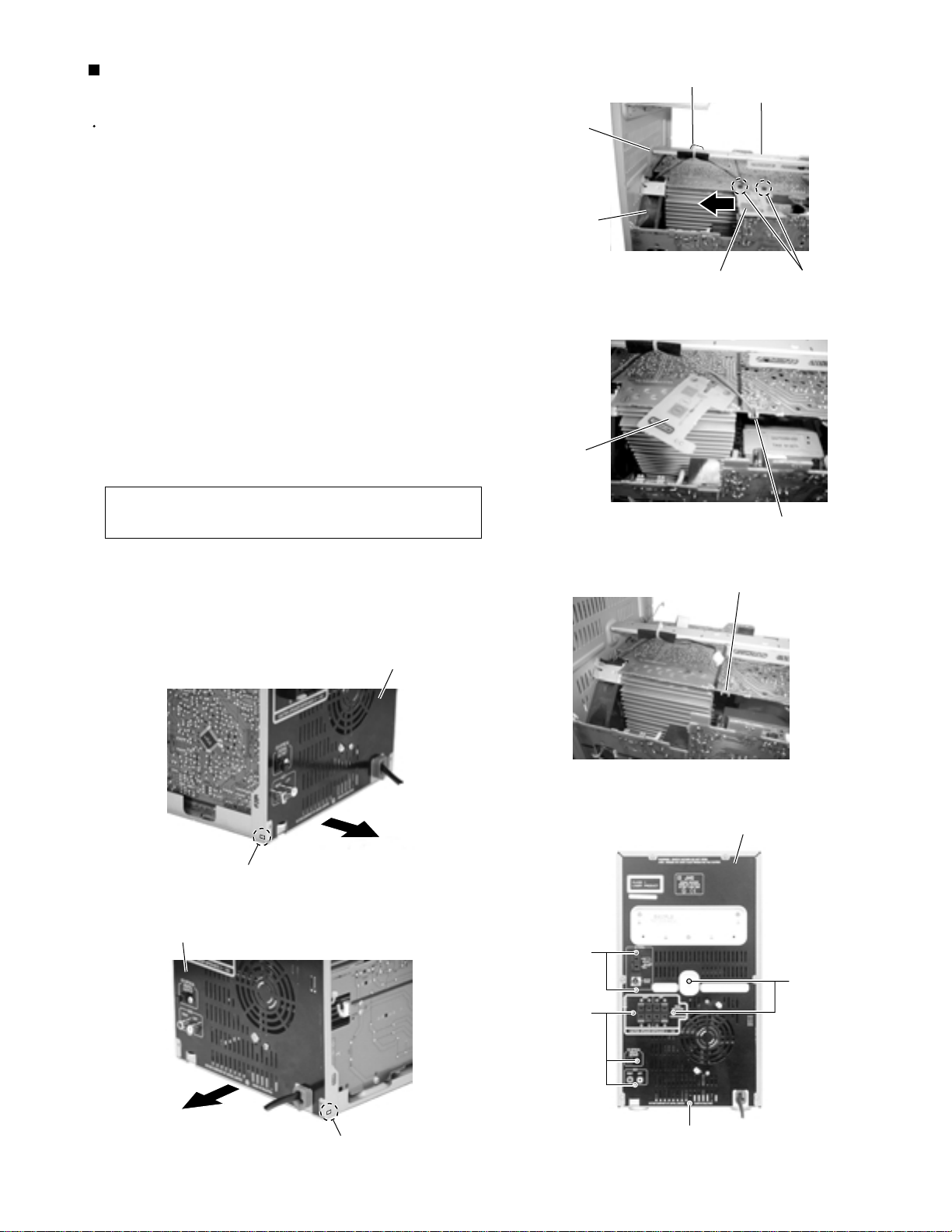

Removing the metal cover

(See Fig.1 ~ 3)

1.

Remove the six screws A on the back of the body.

2.

Remove the screw B on each side of the body.

3.

Remove the metal cover from the body by lifting the

rear part of the cover.

CAUTION:

Removing the CD changer mechanism

assembly (See Fig.4, 5)

Prior to performing the following procedure, remove

the metal cover.

Do not break the front panel tab fitted to

the metal cover.

A

Metal cover

A

Metal cover

A

Fig.1

1.

Disconnect the card wire from connector CN651 on

the CD servo control board on the right bottom of the

CD changer mechanism assembly.

2.

Remove the four screws C attaching the CD

changer mechanism assembly on top of the body.

3.

Remove the CD changer mechanism assembly while

lifting the rear part.

CAUTION:

Front panel assembly

Do not damage the CD fitting when

removing the CD changer mechanism

assembly.

CD changer mechanism assembly

Rear part

B

C

Fig.2

Metal cover

B

Fig.3

C

CD servo control board

CN651

1-6

CD changer

mechanism assembly

C

Fig.5Fig.4

Page 7

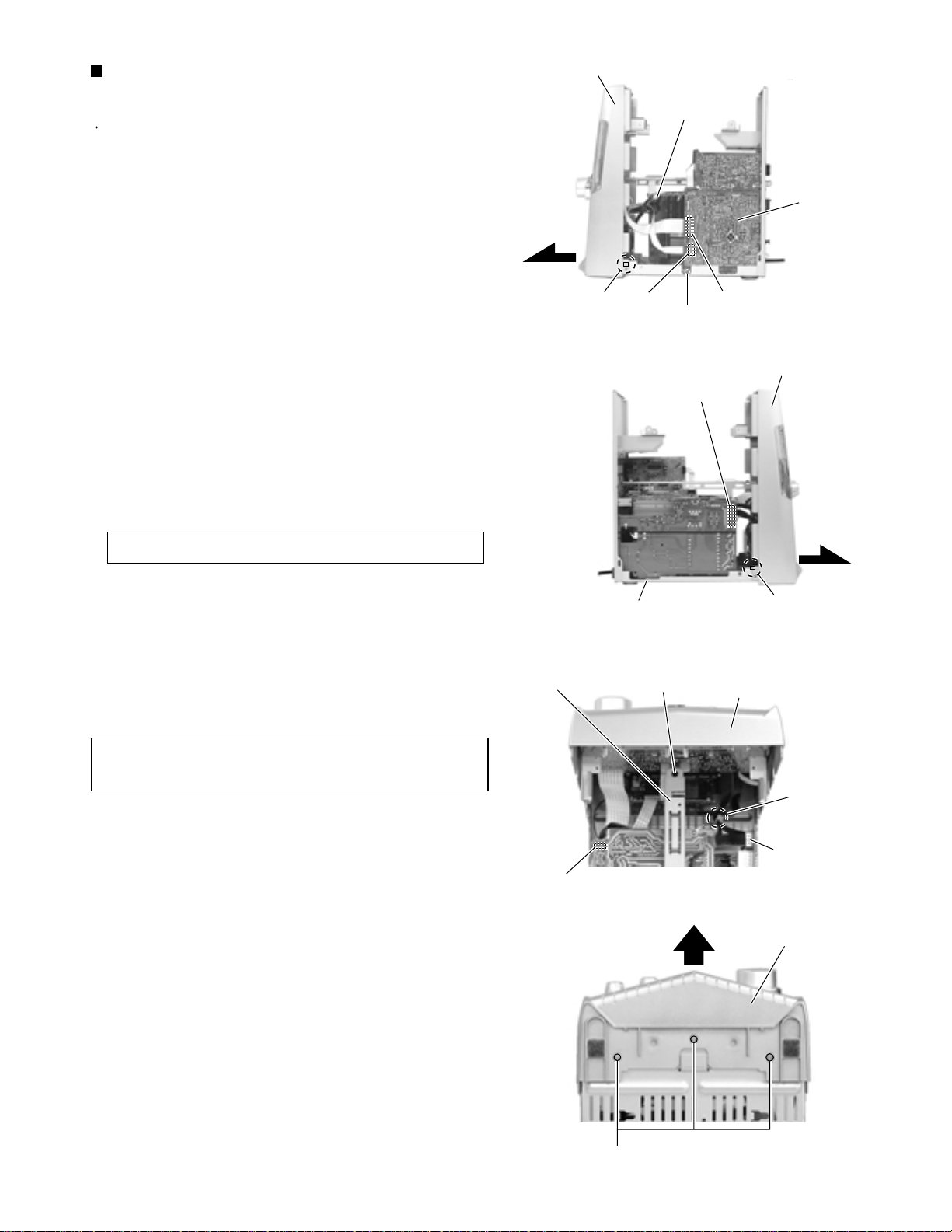

HX-Z1R

Removing the front panel assembly

(See Fig.6 ~ 9)

Prior to performing the following procedure, remove

the metal cover and the CD changer mechanism

assembly.

1.

Disconnect the card wire from connector CN44 and

CN870 on the main board on the right side of the

body. Remove the screw D attaching the wire from

extending from the underside of the front panel

assembly.

2.

Disconnect the wire from connector CN701 on the

bridge board.

3.

Cut the tie band.

4.

Disconnect the wire from connector CN231 and

CN232 on the primary board on the left side of the

body and remove the band fixing the wire.

5.

Remove the plastic rivet attaching the inner bar in

the center of the front panel assembly.

Front panel assembly

Joint a

CN44

Bridge board

CN701

D

Fig.6

Primary board

CN231, CN232

Main board

CN870

Front panel assembly

REFERENCE:

6.

Remove the three screws E attaching the front

Keep the plastic rivet for reuse.

panel assembly at the bottom of the body.

7.

Release the two joints a on the lower left and right

sides of the front panel assembly using a

screwdriver, and remove the front panel assembly

toward the front.

REFERENCE:

Front panel need to be tilt a little bit as release

from bottom chassis.

Inner bar

Bridge board

CN701

Bottom chassis

Plastic rivet

Joint a

Fig.7

Front panel assembly

Band

Primary board

CN231, CN232

Fig.8

Front panel assembly

E

Fig.9

1-7

Page 8

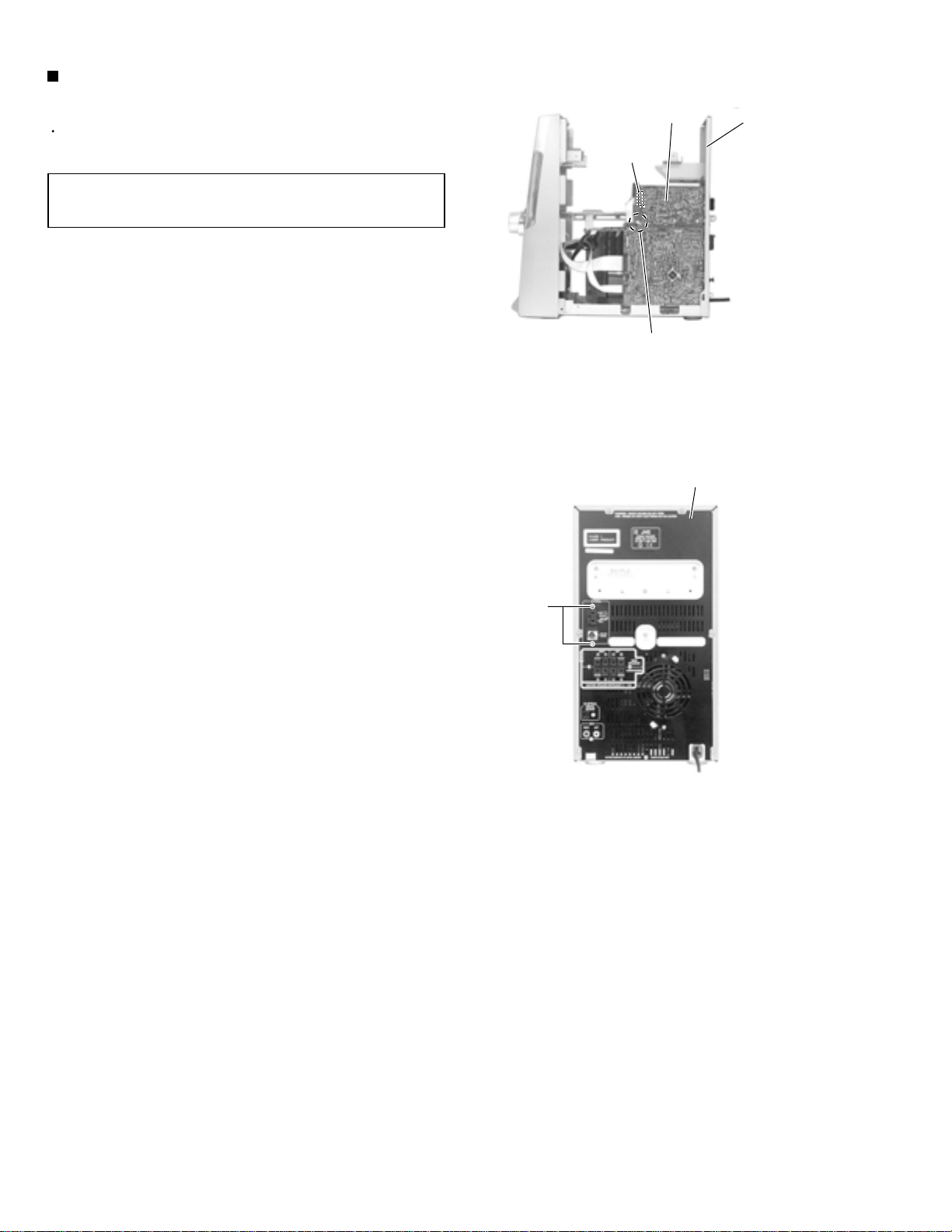

HX-Z1R

Removing the antenna board

(See Fig.10, 11)

Prior to performing the following procedure, remove

the metal cover.

Antenna board

CN1

Rear panel

REFERENCE:

1.

Disconnect the card wire from connector CN1 on the

antenna board on the right side of the body.

2.

Remove the band attaching the antenna board.

3.

Remove the two screws F on the rear panel on the

back of the body.

There is no need to remove the CD

changer mechanism assembly.

Band

Fig.10

Rear panel

F

1-8

Fig.11

Page 9

HX-Z1R

Removing the rear panel

(See Fig.12 ~ 17)

Prior to performing the following procedure, remove

the metal cover and the CD changer mechanism

assembly.

1.

Remove holding board by remove two plastic rivets

and then slide out the holding board as shown in fig.

12.

2.

Disconnect fan wire from connector CN206.

3.

Cut off the tie band that tied fan wire on inner bar.

4.

Remove eight screws F from rear panel.

5.

Detach joint b to release rear panel from inner bar.

6.

Release joints c which on right bottom and left

bottom of rear panel. The joint can be release by pull

outward the side of rear panel.

REFERENCE:

Fan assembly will come off with rear

panel.

Joint b

Fan assembly

Holding board

Tie band

Holding board

Fig.12

Fig.13

Inner bar

Plastic Rivets

CN206

Rear panel

CN206

Rear panel

Fig.14

Rear panel

Joint c

Fig.16

F

F

F

Fig.17

Joint c

F

Fig.15

1-9

Page 10

HX-Z1R

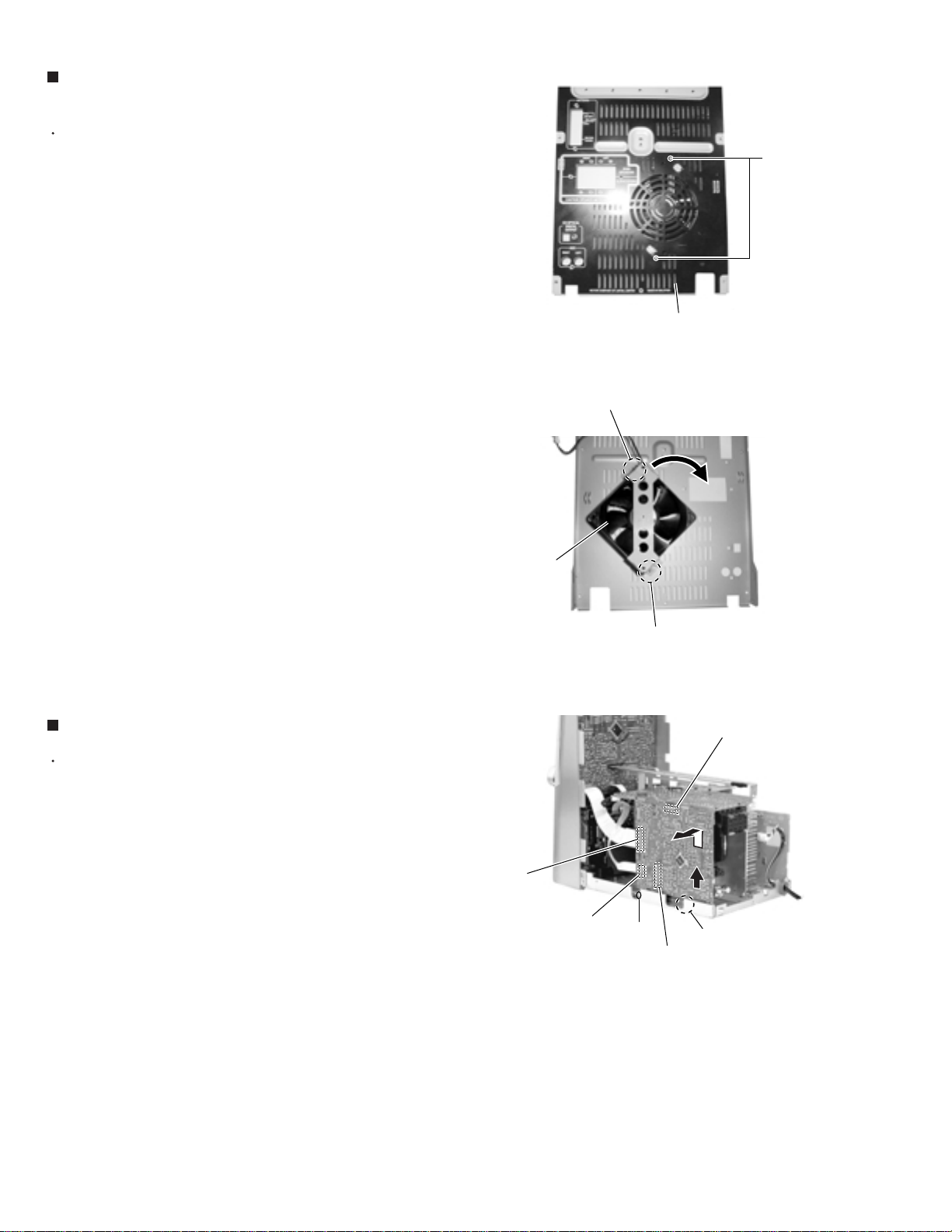

Removing the fan assembly

(See Fig.18, 19)

Prior to performing the following procedure, remove

the metal cover and the CD changer mechanism

assembly and the rear panel.

1.

Remove two screws G on the rear panel.

2.

Rotate fan assembly in clockwise direction to release

fan assembly from rear panel (joint d).

G

Rear panel

Fig.18

Joint d

Removing the main board (See Fig.20)

Prior to performing the following procedure, remove

the metal cover, the CD changer mechanism

assembly, the antenna board and the rear panel.

1.

Disconnect the card wire from connector CN44 and

CN870 on the main board.

2.

Remove the screw D attaching the board.

3.

Disconnect connector CN217 and CN311 on the

main board outward and release from the base

chassis (joint e) upward.

Fan assembly

Main board

CN870

CN44

Joint d

Fig.19

D

CN311

Fig.20

CN217

Joint e

1-10

Page 11

HX-Z1R

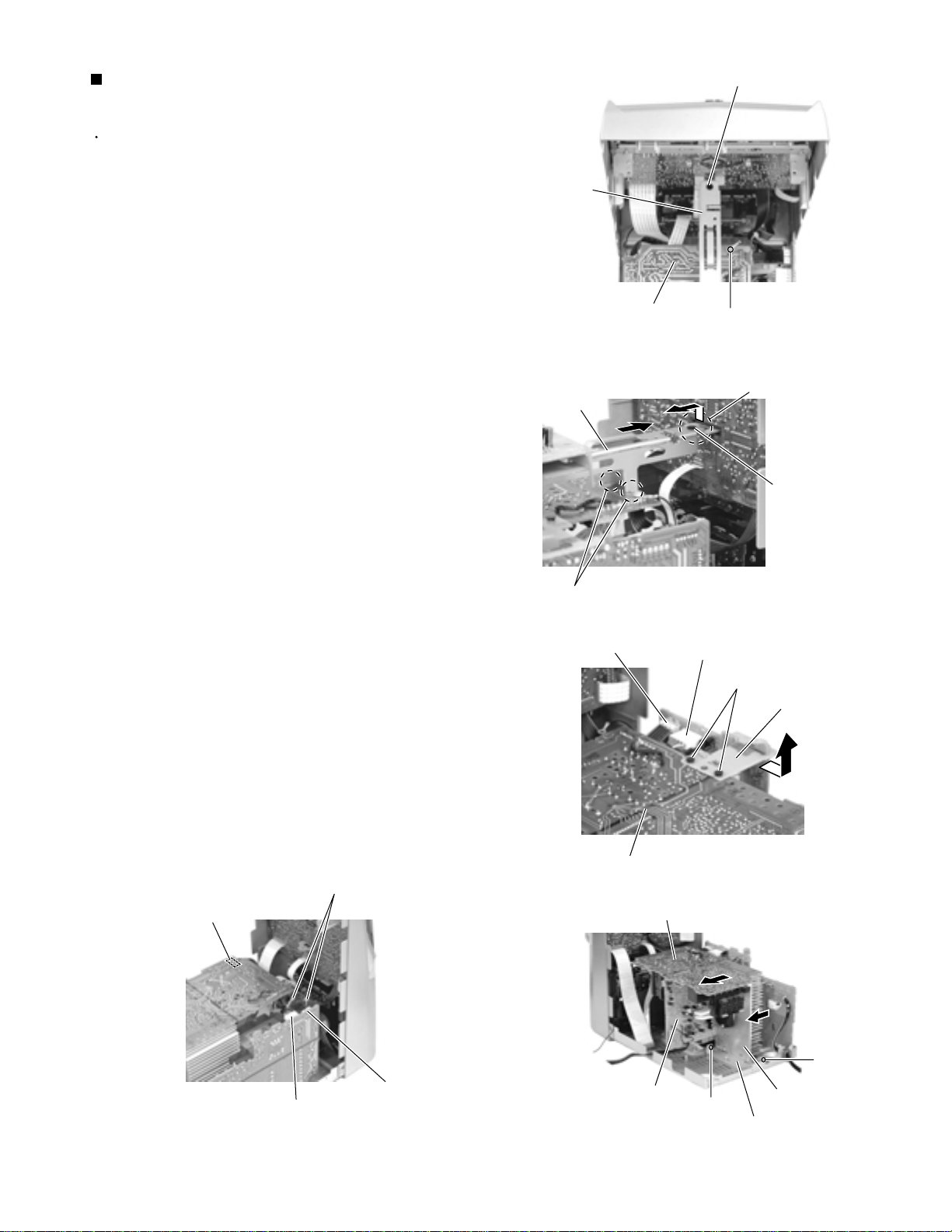

Removing the bridge board / regulator

board / heat sink (See Fig.21 ~ 27)

Prior to performing the following procedure, remove

the metal cover, the CD changer mechanism

assembly, the rear panel, the antenna board and

main board.

1.

Remove the plastic rivet attaching the stay inner bar

and remove the screw H on the bridge board.

2.

Move the inner bar forward and upward to release

from the front section (joint f) and from the bridge

board (two joints h) respectively.

3.

Remove the two plastic rivets setting the holding

board fixing the bridge board and the primary board.

Move the bracket board in the direction of the arrow.

4.

Disconnect the wire from connector CN212, CN213

and CN214 on the primary board respectively and

remove the band attaching the wires.

5.

Disconnect the wire from connector CN701 on the

bridge board.

Inner bar

Inner bar

Bridge board

Fig.21

Plastic rivet

H

Joint f

Plastic rivet

6.

Remove the two screws I attaching the heat sink

bracket and move the heat sink in the direction of the

arrow to release from the base chassis. The bridge

board and the regulator board come off with the heat

sink.

Bridge board

CN701

Band

Joint g

CN212, CN213

Bridge board

Fig.22

Primary board

CN214

Plastic rivets

Holding board

Fig.23

Bridge board

Primary board

CN214

CN212, CN213

Regulator board

Fig.25Fig.24

Heat sink

I

Heat sink bracket

I

1-11

Page 12

HX-Z1R

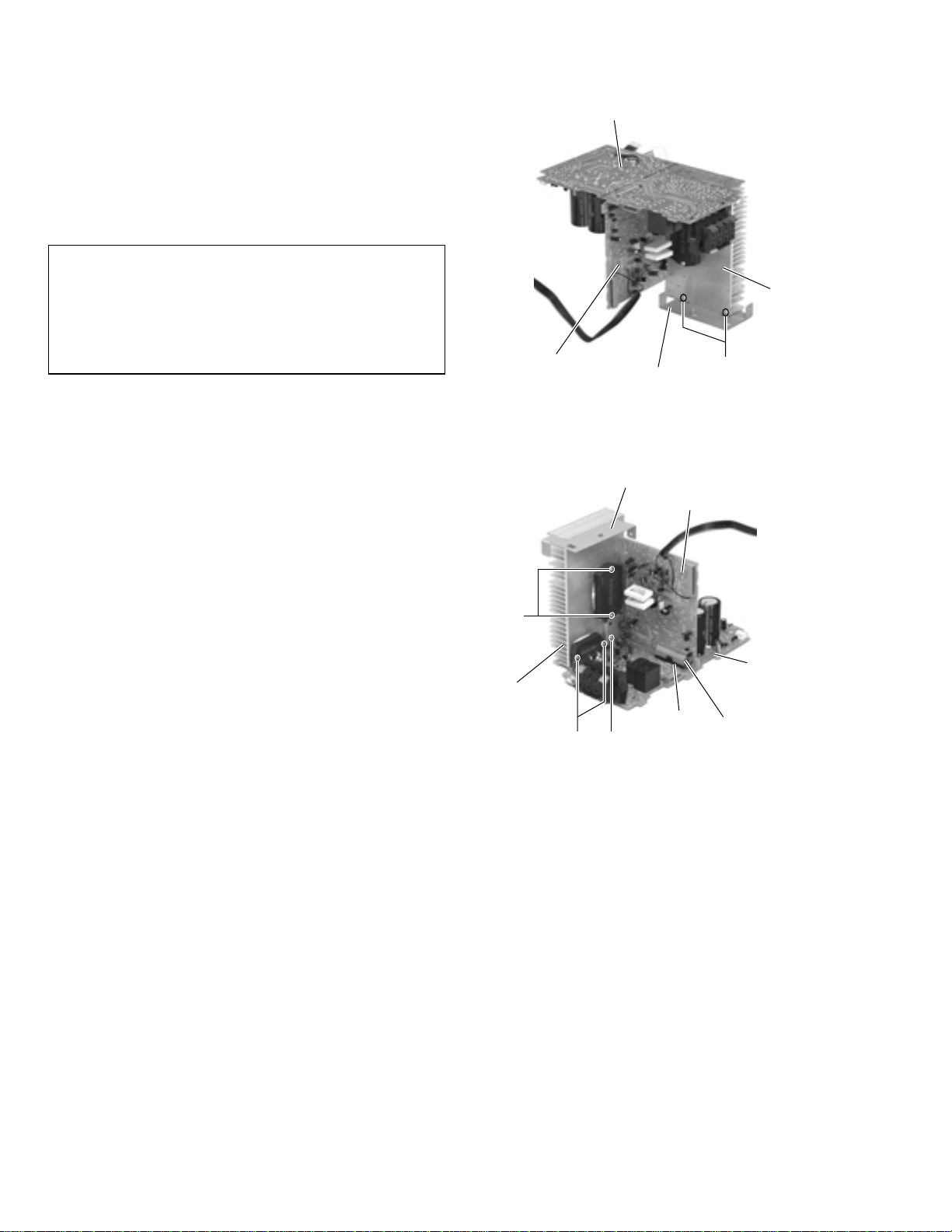

7.

Remove the two screws J attaching the heat sink

bracket.

8.

Remove the two screws M, detach bridge board from

regulator board by disconnect connector CN205.

9.

Remove the screws K and L to detach regulator

board from heat sink.

Bridge board

CAUTION:

As assembly back the regulator board and

bridge board to heat sink.

Regulator board MUST be assembly to heat

sink first and screw K and L MUST be

screwed before bridge board attach to

regulator board.

Regulator board

Heat sink

K

Heat sink bracket

Fig.26

Heat sink bracket

Regulator board

Heat sink

J

Bridge board

ML

Fig.27

CN205

CN215

1-12

Page 13

Removing the power transformer

assembly (See Fig.28, 29)

HX-Z1R

Prior to performing the following procedure, remove

the metal cover, the CD changer mechanism

assembly, the rear panel, the main board and the

bridge board / regulator board.

1.

Remove the screw N attaching the primary board.

2.

Disconnect the wire from connector CN231 and

CN232 on the primary board.

3.

Remove the four screws O attaching the power

transformer assembly.

4.

Cut the tie band and detach power cord from primary

board.

REFERENCE:

When disconnecting the power cord

from connector CN250 on the primary

board, remove the fixing band.

Power transformer assembly

Primary board

CN231, CN232

O

Primary board

N

Fig.28

Power transformer assembly

CN250

Band

<Front panel assembly>

Prior to performing the following procedure, remove

the metal cover, the CD changer mechanism

assembly and the front panel assembly.

Removing the cassette mechanism

assembly (See Fig.30)

1.

Disconnect the card wire from connector CN33 on

the head amplifier & mechanism control board.

2.

Remove the two screws P, and the screw Q

attaching the cassette mechanism assembly.

Removing the headphone board

(See Fig.30)

1.

Remove the screw Q attaching the wire extending

from the headphone board.

2.

Remove the screw R and pull out the headphone

board backward.

O

Fig.29

Head amplifier & mechanism control board

CN33

P

Cassette mechanism assembly

QR

Fig.30

Cord stopper

Q

Headphone board

1-13

Page 14

HX-Z1R

Removing the display system control

board (See Fig.31, 32)

1.

Remove the four screws S attaching the stay

bracket (1).

2.

Disconnect the card wire from connector CN43 and

CN880 on the display system control board.

Remove the ten screws T attaching the display

system control board.

Removing the bottom board

(See Fig.33 ~ 35)

Prior to performing the following procedure, remove

the display system control board.

Stay bracket (1)

T

T

CN43

S

Display system

control board

Fig.31

T

CN880

Display system control board

T

1.

Pull out preset knob, sound mode knob on the front

panel toward the front.

2.

Remove the nut at volume knob encoder from front

panel.

3.

Remove the four screws U attaching the stay

bracket (2).

4.

Remove the eight screws V attaching the bottom

board.

Sound mode knob

CN43

Front panel

Preset knob

T

Fig.32

Fig.33

T

CN880

Volume knob

1-14

U

Bottom board

Stay bracket (2)

U

V

Bottom board

Fig.35Fig.34

V

V

Page 15

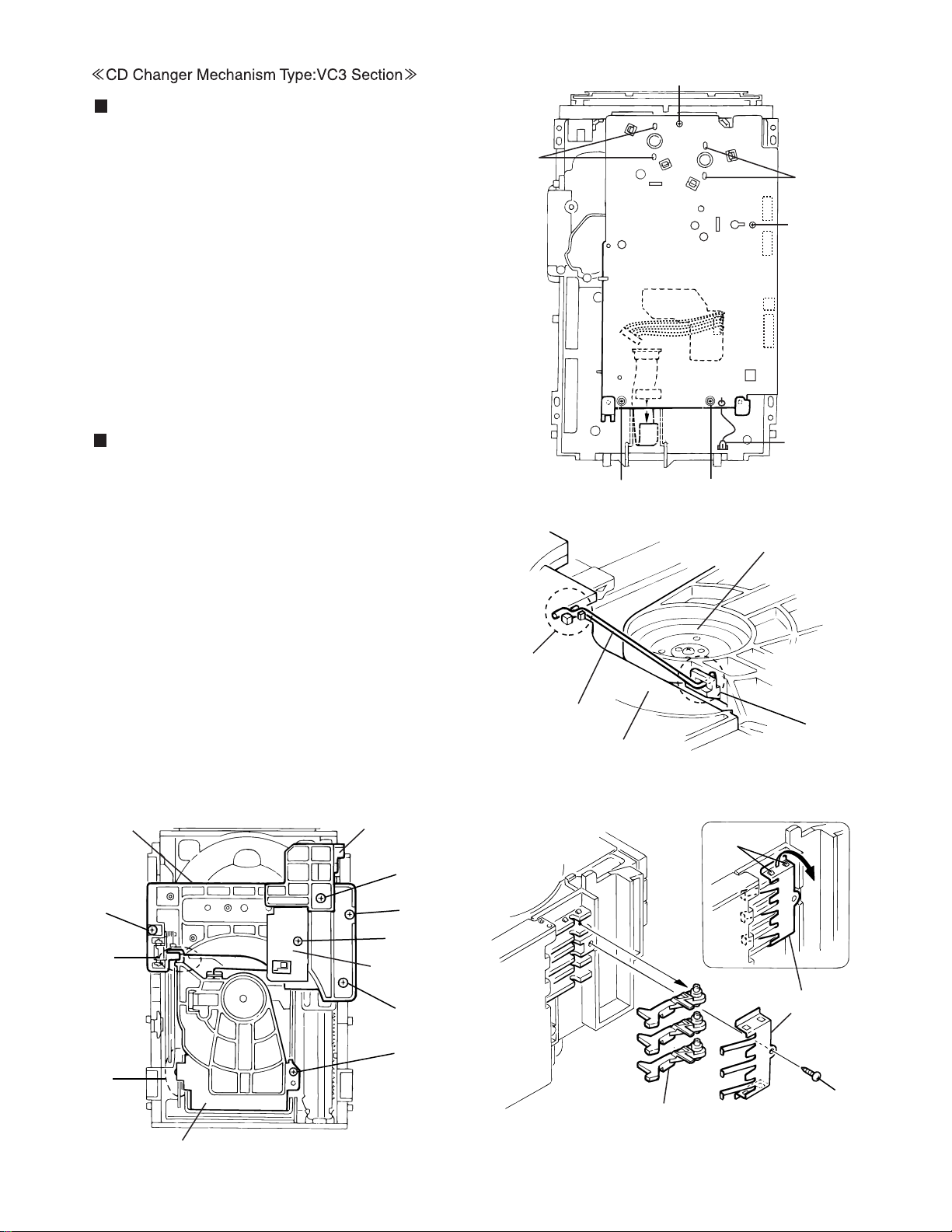

Removing the CD Servo control board

(See Fig.1)

1.Remove the metal cover.

2.Remove the CD changer mechanism assembly.

3.From bottom side the CD changer mechanism assembly,

remove the four screws A retaining the CD servo control

board.

4.Absorb the four soldered positions "a" of the right and

left motors with a soldering absorber.

5.Pull out the earth wire on the CD changer mechanism

assembly.

6.Disconnect the connector CN854 on the CD servo

control board.

7.Disconnect the card wire CN601 and the connector

CN801 on the CD servo control board.

HX-Z1R

A

a

a

CN854

A

CN651

CD servo control board

CN652

CN801

CN601

CN151

Removing the CD tray assembly

(See Fig.2~4)

Remove the front panel assembly.

1.

Remove the CD changer mechanism assembly.

2.

Remove the CD Servo control board.

3.

Remove the screw B' retaining the lod stopper.

4.

From the T.bracket section "b" and clamper base

5.

section "c" , remove both of the edges fixing the

rod(See Fig.2 and 3).

Remove the screw B retaining the disc stopper

6.

(See Fig.3).

Remove the three screws C retaining the T.bracket

7.

(See Fig.3).

Remove the screw D retaining the clamper assembly

8.

(See Fig.3).

From the left side face of the chassis assembly, remove

9.

the one screw E retaining both of the return spring and

lock lever(See Fig. 4).

10.

By removing the pawl at the section "d" fixing the return

spring, dismount the return spring(See Fig.4).

11.

Remove the three lock levers(See Fig.4).

T.Braket

Disc stopper

B

Earth

wire

Fig.1

A

Clamper base

A

b

Rod

c

T.Braket

Fig.2

d

CC

B'

a

Lod stopper

(C/J version only)

C

D

b

Lock lever

Clamper ass'y

Fig.3

Fig.4

Return spring

E

1-15

Page 16

HX-Z1R

11.

Check whether the lifter unit stopper has been caught

into the hole at the section "e" of CD tray assembly as

shown in Fig.5.

Make sure that the driver unit elevator is positioned as

12.

shown in Fig.6 from to the second or fifth hole on the

left side face of the CD changer mechanism assembly.

[Caution]

13.

14.

15.

Chassis assembly

In case the driver unit elevator is not at above

position, set the elevator to the position as

shown in Fig.7 by manually turning the pulley

gear as shown in Fig.8.

Manually turn the motor pulley in the clockwise

direction until the lifter unit stopper is lowered from the

section "e" of CD tray assembly(See Fig.8).

Pull out all of the three stages of CD tray assembly in

the arrow direction "f" until these stages stop

(See Fig.6).

At the position where the CD tray assembly has

stopped, pull out the CD tray assembly while pressing

the two pawls "g and g' " on the back side of CD tray

assembly(See Fig.9). In this case, it is easy to pull out

the assembly when it is pulled out first from the stage

CD tray assembly.

Stopper

e

CD tray

assembly

Fig.5

Refer to Fig.7

Pulley gear

Pawl

Fig.6

CD tray assembly

g

CD

CD

CD

f

Drive unit of elevator

Fig.7

3

2

1

CD tray assembly

1-16

Motor pulley

Fig.8

Pawl ,

g

Fig.9

g'

Page 17

HX-Z1R

Removing the CD loading mechanism

assembly(See Fig.10)

1.2.While turning the cams R1 and R2 assembly in the

arrow direction "h" ,align the shaft "i" of the CD loading

mechanism assembly to the position shown in Fig.10.

Remove the four screws F retaining the CD loading

mechanism assembly.

Removing the CD traverse mechanism

(See Fig.11 and 12 )

For dismounting only the CD traverse mechanism

1.

without removing the CD loading mechanism assembly,

align the shaft "j" of the CD loading mechanism

assembly to the position shown Fig.11 while turning the

cam R1 and R2 assembly in the arrow direction "k" .

By raising the CD loading mechanism assembly in the

2.

arrow direction "l", remove the assembly from the lifter

unit

Cam R1, R2 assembly

Cams R1, R2 assembly

Arrow

h

i

F

F

CD loading mechanism assembly

Fig.10

F

F

CD traverse mechanism

Arrow

k

j

Fig.11

Removing the CD pick unit

(See Fig.13 )

1.

Move the cam gear in the arrow direction "m" . Then,

the CD pickup unit will be moved in the arrow direction

"n" .

According to the above step, shift the CD pickup unit to

2.

the center position.

While pressing the stopper retaining the shaft in the

3.

arrow direction "o" , pull out the shaft in the arrow

direction "p".

After dismounting the shaft from the CD pickup unit,

4.

remove the CD pickup unit

Lifter unit

o

Stopper

Shaft

Fig.12

CD Pickup unit

n

m

Shaft

p

Stopper

Fig.13

Arrow

CD loading

mechanism

Shaft

Cam gear

l

1-17

Page 18

HX-Z1R

Removing the try select switch board

(See Fig.14)

1.2.Remove the two screws G retaining the tray select

switch board.

Disconnect the tray select switch board from connector

CN804 on the CD servo control board.

Removing the cam unit

(See Fig.15 ~17 )

1.

Remove the CD loading mechanism assembly.

2.

While turning the cam gear "q", align the Paul "r"

position of the drive unit to the notch position(Fig.16) on

the cam gear "q".

Pull out the drive unit and cylinder gear(See Fig.17).

3.

While turning the cam gear "q", align the Paul "s"

4.

position of the select lever to the notch position(Fig.18)

on the cam gear "q".

Remove the four screws H retaining the cam unit(cam

5.

gear "q" and cams R1/R2 assembly)(See Fig.18).

Chassis assembly

Drive unit

CN851

CN854

Fig.14

Cam gear

Tray select

switch board

CN804

q

G

Drive unit

Cylinder gear

r

Cam gear

H

s

Fig.15

H

q

Cams R1, R2 assembly

Cam unit

J

1-18

Fig.16

Select lever

Fig.17

Page 19

HX-Z1R

Fig.18

Fig.20

Fig.19

Fig.21

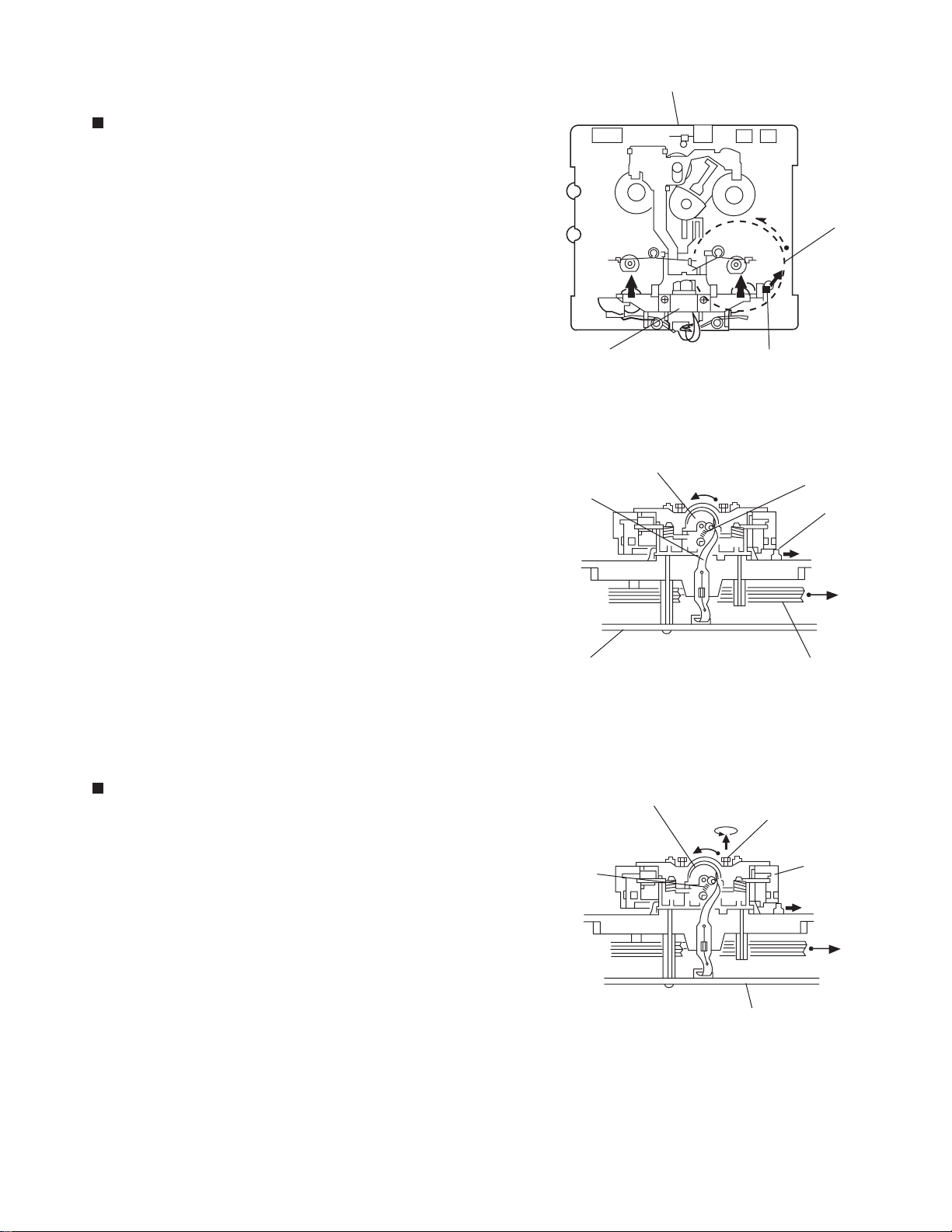

[Note]

When the chassis assembly is turned over under

the conditions wherein the gear bracket and belt

have been removed, then the pulley gear as well

as the gear, etc. constituting the gear unit can

possibly be separated to pieces. In such a case,

assemble these parts by referring to the assembly

and configuration diagram in Fig. 21.

Removing the actuator motor and belt

(See Fig.18~21)

1.

2.

3.

4.

5.

Remove the two screws I retaining the gear bracket

(See Fig.18).

While pressing the pawl "t" fixing the gear bracket in the

arrow direction, remove the gear bracket

(See Fig.18).

From the notch "u section" on the chassis assembly

fixing the edge of gear bracket, remove and take out the

gear bracket(See Fig. 19).

Remove the belts respectively from the right and left

actuator motor pulleys and pulley gears(See Fig. 18).

After turning over the chassis assembly, remove the

actuator motor while spreading the four pawls "v" fixing

the right and left actuator motors in the arrow

direction(See Fig. 20).

Pulley gear

Belt

Motor pulley

Belt

Pulley gear

Motor pulley

Gear bracket

t

I

I

Pawl

v

Actuator motor

v

Chassis assembly

u

Gear bracket

Pulley gear

Gear B

Cylinder gear

Gross gear U

Gear C

Gross gear L

Select gear

Gear B

Gear C

Pulley gear

Assembly and Configuration Diagram

1-19

Page 20

HX-Z1R

Removing the cams R1/R2 assembly

and cam gear q(See Fig.22)

Remove the slit washer fixing the cams R1 and R2

1.

assembly.

By removing the two pawls "w" fixing the cam R1,

2.

separate R2 from R1.

Remove the slit washer fixing the cam gear "q".

3.

Pull out the cam gear "q" from the C.G. base assembly.

4.

Removing the C.G. base assembly

(See Fig.22 and 23)

Remove the three screws J retaining the C.G. base

assembly.

[Caution]

To reassemble the cylinder gear, etc.with the

cam unit (cam gear and cans R1/R2 assembly),

gear unit and drive unit, align the position of the

pawl "x" on the drive unit to that of the notch on

the cam gear "q". Then, make sure that the

gear unit is engaged by turning the cam gear

"q" (See Fig. 24).

Slit washer

Cam gear q

J

Slit washer

Cam R2

Pawl

w

Cam R1

Cam switch board

C.G. base assembly

Pawl

w

Notch

Pawl

x

Cylinder

gear

Drive unit

Fig.22

Cam gear q

Cam R1, R2 assembly

Gear unit

Gear bracket

Fig.23

1-20

Page 21

HX-Z1R

<Cassette mechanism section>

Removing the playback / recording &

eraser head (See Fig. 1 ~ 3)

1.

While shifting the trigger arms seen on the right side

of the head mount in the arrow direction, turn the

flywheel R in counterclockwise direction until the

head mount has gone out with a click (See Fig. 1).

2.

When the flywheel (R) is rotated in counterclockwise

direction, the playback / recording & eraser head will

be turned in counterclockwise direction from the

position in Fig. 2 to that in Fig. 3.

3.

At this position, disconnect the flexible P.C. board

(outgoing from the playback / recording & eraser

head) from the connector CN31 on the head

amplifier & mechanism control P.C. board.

4.

Remove the flexible P.C. board from the chassis

base.

5.

Remove the spring a from behind the playback /

recording & eraser head.

Head mount

Flexible board

Cassette mechanism

Flywheel (R)

Trigger arm

Fig. 1

Playback / recording &

eraser head

Spring a

Trigger arm

6.

Loosen the reversing azimuth screw retaining the

playback / recording & eraser head.

7.

Take out the playback / recording & eraser head from

the front of the head mount.

8.

The playback / recoring & eraser head should also

be removed similarly according to steps 1 to 7 above.

Reassembling the playback / recording &

eraser head (See Fig.2, 3)

1.

Reassemble the playback head from the front of the

head mount to the position as shown in Fig. 3.

2.

Fix the reversing azimuth screw.

3.

Set the spring 1 from behind the playback / recording

& eraser head.

4.

Attach the flexible P.C. board to the chassis base, as

shown in Fig. 3.

5.

The playback / recording & eraser head should also

be reassembled similarly to step 1 to 4 above.

CN31

Head amplifier & mechanism

control P.C. board

Fig. 2

Playback / recording & eraser head

Spring 1

Head amplifier & mechanism control

P.C. board

Fig. 3

Flywheel (R)

Reversing azimuth screw

Head mount

Flexible

board

1-21

Page 22

HX-Z1R

Removing the head amplifier & mechanism

control board (See Fig. 4)

1.

Remove the cassette mechanism assembly.

2.

After turning over th cassette mechanism assembly,

remove the three screws A retaining the head

amplifier & mechanism control board.

3.

Disconnect the connector CN32 on the board

including the connector CN1 on the reel pulse P.C.

board.

4.

When necessary, remove the 4 pin parallel wire

soldered to the main motor.

Removing the main motor assembly

(See Fig.4 ~ 6)

1.

Remove the two screws B retaining the main motor

assembly (See Fig. 4 and 4a).

2.

While raising the main motor, remove the capstan

belt from the motor pulley (See Fig. 4a).

A

Head amplifier &

mechanism control

board

Flexible board

Capstan belt

CN32

CN31

A

Main motor

assembly

A

Belt

Main motor

assembly

B

B

4pin parallel wire

Main motor

assembly

Fig. 4

CAUTION:

Capstan

belt

Be sure to handle the capstan belt so

carefully that this belt will not be stained

by grease and other foreign matter.

Moreover, this belt should be hanged

while referring to the capstan belt

hanging method in Fig. 5 and 6.

Mechanism motor

assembly

Motor

pulley

Fig. 5

Main motor

assembly

Flywheel

Capstan belt

Motor

pulley

Fig. 4a

Motor pulley

Fig. 6

1-22

Page 23

Removing the flywheel (See Fig. 7, 8)

1.

Remove the head amplifier & mechanism control P.C.

board.

2.

Remove the main motor assembly.

3.

After turning over the cassette mechanism, remove

the two slit washers and fixing the capstan shafts R

and L, and pull out the flywheel (R) and (L)

respectively from behind the cassette mechanism.

HX-Z1R

Flywheel (R) Flywheel (L)

Flywheel R Flywheel L

Fig. 8

Removing the reel pulse P.C. board and

solenoid (See Fig. 9)

1.

Remove the five pawls a to e reattaining the reel

pulse board.

2.

From the surface of the reel pulse board parts,

remove the two pawls f and g retaining the solenoid.

a b c d e

g

f

Solenoid

Capstan shaft (R)

Slit washer

Capstan shaft (L)

Slit washer

Fig. 7

Reel pulse board

Fig. 9

1-23

Page 24

HX-Z1R

Adjustment method

Measurement Instruments Required for

Adjustment

1. Low frequency oscillator

This oscillator should have a capacity to output

0dBs to 600 at an oscillation frequency of

50Hz-20kHz.

2. Attenuator impedance : 600

3. Electronic voltmeter

4. Distortion meter

5. Frequency counter

6. Wow & flutter meter

7. Test tape

VTT703L : Head azimuth

VT712 : Tape speed and running unevenness

(3kHz)

VT724 : Reference level (1kHz)

8. Blank tape

TYPE : AC-225

TYPE : AC-514

9. Torque gauge : For play and back tension

FWD(TW2111A), REV(TW2121a) and

FF/REW(TW2231A)

10. Test disc: CTS-1000

Measurement conditions

Power supply voltage

AC120V (60Hz) : Ver.J,C

Reference output : Speaker : 0.775V/4

: Headphone : 0.077V/32

Reference frequency and

input level ------------------------------ 1kHz, AUX : -8dBs

Measurement output terminal ------- at Speaker J3002

Load resistance --------------------------- 4

Radio Input signal

AM frequency --------------------------------------- 400Hz

AM modulation ---------------------------------------- 30%

FM frequency --------------------------------------- 400Hz

FM frequency deviation ------------------------ 22.5kHz

Tuner section

FM Band cover: 87.5 108MHz

MW Band cover: 522 1,629kHz

LW Band cover: 144 288kHz

Voltage applied to tuner +B : DC5.7V

VT : DC 12V

Reference measurement

output 26.1mV(0.28V)/3

Input positions AM : Standard loop antenna

FM : TP1 (hot) and TP2 (GND)

Standard measurement position of volume

Function switch to Tape

Beat cut switch to Cut

Super Bass/Active hyper Bass to OFF

Bass Treble to Center

Adjustment of main volume to reference output

VOL : 28

Precautions for measurement

1. Apply 30pF and 33k to the IF sweeper output

side and 0.082 F and 100k in series to the

sweeper input side.

2. The IF sweeper output level should be made as

low as possible within the adjustable range.

3. Since the IF sweeper is a fixed device, there is no

need to adjust this sweeper.

4. Since a ceramic oscillator is used, there is no need

to perform any MIX adjustment.

5. Since a fixed coil is used, there is no need to adjust

the FM tracking.

6. The input and output earth systems are separated.

In case of simultaneously measuring the voltage in

both of the input and output systems with an

electronic voltmeter for two channels, therefore, the

earth should be connected particularly carefully.

7. In the case of BTL connection amp., the minus

terminal of speaker is not for earthing. Therefore, be

sure not to connect any other earth terminal to this

terminal. This system is of an BTL system.

8. For connecting a dummy resistor when measuring

the output, use the wire with a greater code size.

9. Whenever any mixed tape is used, use the band

pass filter (DV-12).

1-24

Page 25

<<

Arrangement of Adjusting Position

HX-Z1R

>>

Cassette mechanism section

Head azimuth

adjusting screw

(Forward side)

Cassette AMP board

VR37

C308

R314

MOTOR SPEED

VR37

L301

B155

VR31

BIAS ADJ

VR31

Head azimuth

adjusting screw

(Reverse side)

MB

PBRAGPBL

RECRAGRECL

MS

SW8V

MG

1

CN34

C307

R313

C310

R315

C314

Q302

R327

C317

C319

C221

B112

C313

C121

L303

C316

R310

R335

B198

R353

Q305

C106

Q103

R305

R303

R122

Q101

C103

B163

Q321

R221

10

B156

C303

R115

R101

B157

R108

C113

R110

R109

R102

C110

C104

R301

R121

1

C108

C107

9

B151

R112

R111

C102

R107

B152

C302

R103

1

C301

C111

C306

B164

Cassette mechanism section (Back side)

Head azimuth

adjusting screw

(Forward side)

Playback/Recording &

eraser head

R304

B158

C101

C109

6

8

B106

B166

R116

R212

R211

C211

R216

IC32

9

9

C201

B101

CN33

B109B108

C209

R342

C213

R210

R209

C207

B159

16

B102

R341

C208

R207

1

CN31

B200

B110

1

R208

R340

R205

R105

C105

B160

NC

R343

C305

C206

R345

TAP

R201

1IC31

B113

C304

C202

C210

Q331

RRE

C375

C205

R215

C203

B161

R339

C334

R106

R206

R203

5VMGSOL

R204

R222

C204

B168

PHO

B153

R104

R202

C333

C332

PLA

R375

Q201

Q203

C331

Q372

R331

B167

FRE

R371

C376

10

70u

Q375

CN32

R376

R372

R373

B162

C371

16

1

C374

R338

B

E

D375

Q376

B

Q371

E

R337

R336

9

IC33

8

Head azimuth

adjusting screw

(Reverse side)

1-25

Page 26

HX-Z1R

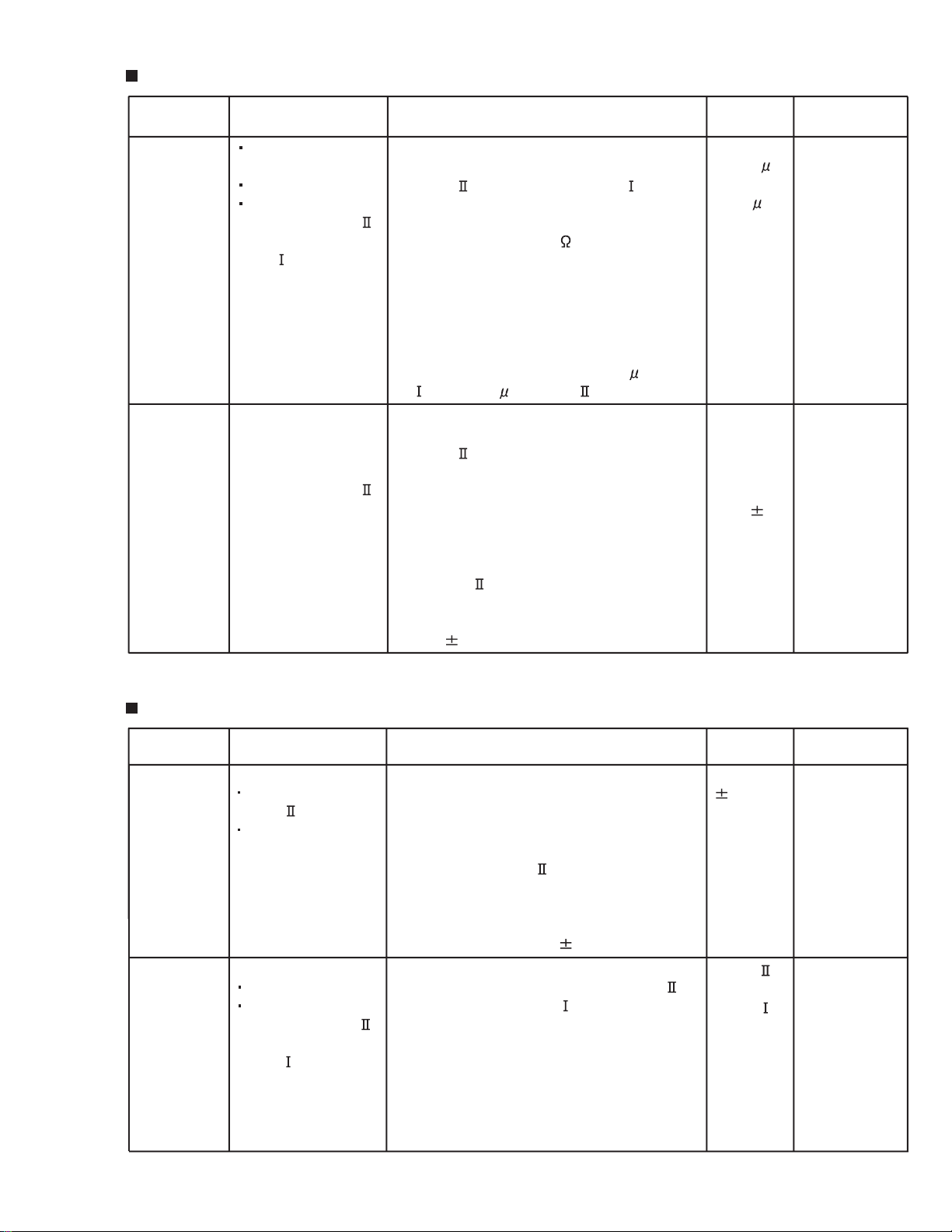

Tape Recorder Section

Items

Confirmation

of head angle

Measurement

conditions

Test tape

: VTT703L (8kHz)

Measurement output

terminal

: Speaker terminal

Speaker R

(Load resistance: 4 )

: Headphone terminal

Measurement method

1 Playback the test tape VTT703L (8kHz)

2 With the recording & playback mechanism,

adjust the head azimuth screw so that the

forward and reverse output levels become

maximum. After adjustment, lock the head

azimuth at least by half turn.

3 In either case, this adjustment should be

performed in both the forward and reverse

directions with the head azimuth screw.

Confirmation

of tape speed

Test tape

: VT712 (3kHz)

Measurement output

terminal

: Headphone terminal

Adjust VR37 so that the frequency counter

reading becomes 2,940~3,090Hz when

playing back the test tape VT712 (3kHz) with

playback and recording mechanism after

ending forward winding of the tape.

Reference Values for Confirmation Items

Standard

Values

Maximum

output

Tape speed

of deck

: 2,940 ~

3,090Hz

Adjusting

positions

Adjust the head

azimuth screw

only when the

head has been

changed.

VR37

Items

Difference

between the

forward and

reverse speed

Measurement

conditions

Test tape

: VT712 (3kHz)

Measurement output

terminal

: Speaker terminal

Speaker R

(Load resistance: 4 )

Measurement output

terminal

: Headphone

Wow & flutter Test tape

: VT712 (3kHz)

Measurement output

terminal

: Headphone terminal

Measurement method

Standard

Values

When the test tape VT712 (3kHz) has been

played back with the recording and playback

mechanism at the beginning of forward

winding, the frequency counter reading of the

difference between both of the mechanism

should be 6.0Hz or less.

When the test tape VT712 (3kHz) has been

played back with the recording and playback

mechanism at the beginning of forward

winding, the frequency counter reading of

wow & flutter should be 0.25% or less

(WRMS).

6.0Hz or

less

0.25% or

less

(WRMS)

Adjusting

positions

Head azimuth

screw

1-26

Page 27

Electrical Performance

HX-Z1R

Items

Adjustment of

recording bias

current

(Reference

Value)

Adjustment of

recording and

playback

frequency

characteristics

Measurement

conditions

Mode: Forward or

reverse mode

Recording mode

Test tape

: AC-514 to TYPE

and AC-225 to

TYPE

Measurement output

terminal

: Both recording and

headphone terminals

Reference frequency

: 1kHz and 10kHz

(REF.: -20dB)

Test tape

: AC-514 to TYPE

Measurement input

terminal

: OSC IN

Measurement method

Standard

Values

1 With the recording and playback

mechanism, load the test tapes (AC-514 to

TYPE

and AC-225 to TYPE ), and set

the mechanism to the recording and

pausing condition in advance.

2 After connecting 100

in series to the

recorder head, measure the bias current

with a valve voltmeter at both of the

terminals.

3 After resetting the [PAUSE] mode, start

recording. At this time, adjust VR31 for Lch

and VR32 for Rch so that the recording

bias current values become 4.0

A (TYPE

) and 4.20 A (TYPE ).

1 With the recording and playback

mechanism, load the test tapes (AC-514 to

TYPE

), and set the mechanism to the

recording and pausing condition in

advance.

2 While repetitively inputting the reference

frequency signal of 1kHz and 10kHz from

OSC IN, record and playback the rape.

3 While recording and playback the test tape

in TYPE , adjust VR31 for Lch and VR32

for Rch so that the output deviation

between 1kHz and 10kHz becomes

-1dB 2dB.

AC-225

: 4.20

A

AC-514

: 4.0 A

Output

deviation

between

1kHz and

10kHz

: -1dB 2dB

Adjusting

positions

VR31

VR31

Reference Values for Electrical Function Confirmation Items

Items

Recording

bias

frequency

Measurement

conditions

Forward or reverse

Test tape

: TYPE (AC-514)

Measurement

terminal : BIAS TP on

P.C. board

Measurement method

1 While changing over to and from BIAS 1

and 2, confirm that the frequency is

changed.

2 With the recording and playback

mechanism, load the test tape.

(AC-514 to TYPE ), and set the

mechanism to the recording and pausing

condition in advance.

3 Confirm that the BIAS TP frequency on the

P.C. board is 100kHz 6kHz.

Eraser

current

(Reference

value)

Forward or reverse

Recording mode

Test tape

: AC-514 to TYPE

and AC-225 to

TYPE

Measurement

terminal : Both of the

eraser head terminals

1 While recording and playback mechanism,

load the test tapes (AC-514 to TYPE

and AC-225 to TYPE ), and set the

mechanism to the recording and pausing

conditions in advance.

2 After setting to the recording conditions,

connect 1W in series to the eraser head on

the recording and playback mechanism

side, and measure the eraser current from

both of the eraser terminals.

Standard

Values

100 kHz

6 kHz

TYPE

: 120 mA

TYPE

: 75 mA

Adjusting

positions

1-27

Page 28

HX-Z1R

Extension code connecting method

CD servo

control board

CN651

Main board

CN661

1-28

Page 29

Flow of functional operation until TOC read

Power ON

Play Key

Slider turns REST

SW ON.

Automatic tuning

of TE offset

Confirm that the voltage at the pin5

of CN801 is "H"\"L"\"H".

HX-Z1R

Check Point

Tracking error waveform at TOC reading

Approx.3sec

Tracking

servo

off states

Automatic measurement

of TE amplitude and

automatic tuning of

TE balance

VREF

pin 25 of

IC601(TE)

Approx

1.8V

Disc states

to rotate

Tracking

servo

on states

Disc to be

braked to stop

TOC reading

finishes

500mv/div

2ms/div

Fig.1

Laser ON

Detection of disc

Automatic tuning of

Focus offset

Automatic measurement of

Focus S-curve amplitude

Disc is rotated

Focus servo ON

(Tracking servo ON)

Automatic measurement of

Tracking error amplitude

Automatic tuning of

Tracking error balance

Check that the voltage at the

pin40 of IC651 is + 5V?

Confirm that the Focus error

S-cuve signal at the pin28 of

IC651 is approx.2Vp-p

Confirm that the signal from

pin24 IC651 is 0V as a

accelerated pulse during

approx.400ms.

Confirm the waveform of

the Tracking error signal.

at the pin 25 of IC601 (R604)

(See fig-1)

Automatic tuning of

Focus error balance

Automatic tuning of

Focus error gain

Automatic tuning of

Tracking error gain

TOC reading

Play a disc

Confirm the eys-pattern

at the lead of TP1

1-29

Page 30

HX-Z1R

Maintenance of laser pickup

(1) Cleaning the pick up lens

Before you replace the pick up, please try to

clean the lens with a alcohol soaked cotton

swab.

(2) Life of the laser diode

When the life of the laser diode has expired,

the following symptoms will appear.

1. The level of RF output (EFM output : ampli

tude of eye pattern) will below.

Is the level of

RFOUT under

1.25V 0.22Vp-p?

YES

O.K

NO

Replace it.

Replacement of laser pickup

Turn off the power switch and, disconnect the

power cord from the ac outlet.

Replace the pickup with a normal one.(Refer

to "Pickup Removal" on the previous page)

Plug the power cord in, and turn the power on.

At this time, check that the laser emits for

about 3seconds and the objective lens moves

up and down.

Note: Do not observe the laser beam directly.

Play a disc.

Check the eye-pattern at TP1.

Finish.

(3) Semi-fixed resistor on the APC PC board

The semi-fixed resistor on the APC printed circuit board which is attached to the pickup is used to adjust the laser

power. Since this adjustment should be performed to match the characteristics of the whole optical block, do not

touch the semi-fixed resistor.

If the laser power is lower than the specified value, the laser diode is almost worn out, and the laser pickup should

be replaced.

If the semi-fixed resistor is adjusted while the pickup is functioning normally, the laser pickup may be damaged

due to excessive current.

1-30

Page 31

Description of major ICs

BU2092 (IC642) : Port expander

1.Pin Layout

HX-Z1R

Vss

DATA

CLOCK

LCK

Q0

Q1

Q2

Q3

Q4

1

2

3

4

5

6

7

8

9

CONTROL

CIRCUIT

12BIT SHIFT RESISTER

12BIT STRAGE RESISTER

OUTPUT BUFFER(OPEN DRAIN)

18

17

16

15

14

13

12

11

10

Vdd

OE

Q11

Q10

Q9

Q8

Q7

Q6

Q5

2.Pin function

Pin No.

1

2

3

4

5~16

17

18

Symbol

Vss

DATA

CLOCK

LCK

Q0~Q11

OE

Vdd

I/O

-

I

I

I

O

I

-

Function

Connect to GND

Serial Data input

Shift Clock of Data

Latch Clock of Data

Parallel Data Output

Latch Data L H

OUTPUT ON OFF

Output Enable

Power Supply

1-31

Page 32

HX-Z1R

BH3874AKS (IC434) : Audio sound processor

1.

Pin

layout

48 ~ 33

49

~

64

1 ~ 16

2. Block diagram

VFC1

-9dB

47INLD

INLC

45

INLB

43

INLA

INRA

INRB

INRC

INRD

RECR

41

42

44

46

48

-9dB

52

MODE SELECTOR

VFC2

MIC

11dB

+

-

+

-

11dB

+

-

+

19dB

+

+

-

32

~

17

+

-

+

DPLR2

DPLR1

DPLL2

+

+

EFFECT

-

+

DPLL1

+

+

F2L2

F2L1

F1L2

F1L1

5 BAND EQ

5 BAND EQ

F3L1

F3L2

F4L1

F4L2

F5L

-30dB~-

+

RECL

PS1

PS2

0~30dB

+

10K

+

10K

+

L-R

+

+

+

L+R

+

PS

PS

10.5Hz

HPFL1

HPP

VCA

HPFL2

HPFL3

1918171563 64 3 4 7 8 11 1258576059626151565553

BASS1

FILTER

26252423

Vcc

1

Vcc

2

+

+

-

+

+

-

VCC

30

-

+

FILTER

28

GND

54

OUTL

32

BASS5

27

CAP

29

OUTR

31

BASS4

BASS3

BASS2

DET

10.5Hz

10.5Hz

10.5Hz

DET

DET

MPX

HPP

DIGITAL

CONTROL

SCK

35

SI

34

DET

10.5Hz

DET

ALC

33

STEPC

1-32

22K

40 36 37 38 39 1 2 5 6 9 10 13 14 16 20 21 22 50 49

BPNF

BPOUT

C

B

A

F1R1

F1R2

F2R1

F2R2

F3R1

F3R2

F4R1

F4R2

F5R

HPFR1

HPFR2

HPFR3

ALCB

ALCC

Page 33

3. Pin function

Pin NO. Name Function

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

1

2

3

4

5

6

7

8

9

F1R1

F1R2

F2L1

F2L2

F2R1

F2R2

F3L1

FAL2

F3R1

F3R2

F4L1

F4L2

F4R1

F4R2

F5L

F5R

HPFL1

HPFL2

HPFL3

HPFR1

HPFR2

HPFR3

BASS1

BASS2

BASS3

BASS4

BASS5

FILTER

CAP

VCC

OUTR

OUTL

STEPC

Rch GREQ f1 filter setting pin

Rch GREQ f1 filter setting pin

Lch GREQ f2 filter setting pin

Lch GREQ f2 filter setting pin

Rch GREQ f2 filter setting pin

Rch GREQ f2 filter setting pin

Lch GREQ f3 filter setting pin

Lch GREQ f3 filter setting pin

Rch GREQ f3 filter setting pin

Rch GREQ f3 filter setting pin

Lch GREQ f4 filter setting pin

Lch GREQ f4 filter setting pin

Rch GREQ f4 filter setting pin

Rch GREQ f4 filter setting pin

Lch GREQ f5 filter setting pin

Rch GREQ f5 filter setting pin

Lch high-pass filter setting pin

Lch high-pass filter setting pin

Lch high-pass filter setting pin

Rch high-pass filter setting pin

Rch high-pass filter setting pin

Rch high-pass filter setting pin

Dynamic bass filter setting pin

Dynamic bass filter setting pin

Dynamic bass filter setting pin

Dynamic bass filter setting pin

Biamp output pin

VCC/2 pin

ALC trap frequency setting pin

Power supply pin

Rch output pin

Lch output pin

Time conatant attachment for

switching shook protection

Pin NO.

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

Name Function

SI

SCK

A

B

C

BPOUT

BPNF

INLA

INRA

INLB

INRB

INLC

INRC

INLD

INRD

ALCC

ALCR

RECL

REOR

VFC1

GND

VFC2

MIC

DPLL1

DPLL2

DPLR1

DPLR2

PS1

PS2

F1L1

F1L2

Serial data larch receiving pin

Serial clook receiving pin

Parallel data receiving pin

Parallel data receiving pin

Parallel data receiving pin

Output pin for spectrum analyzer

Spectrum analyzer level setting pin

Lch input pin A

Rch input pin A

Lch input pin B

Rch input pin B

Lch input pin C

Rch input pin C

Lch input pin D

Rch input pin D

Time constant of ALC setting pin

ALC level setting pin

Lch RECOUT output pin

Rch RECOUT output pin

Vocal fade filter setting pin

Ground pin

Vocal fade filter setting pin

Input pin for microphone

Lch output pin for DPL

Lch input pin for DPL

Rch output pin for DPL

Rch input pin for DPL

Surround setting pin

Surround setting pin

Lch GREQ f1 filter setting pin

Lch GREQ f1 filter setting pin

HX-Z1R

1-33

Page 34

HX-Z1R

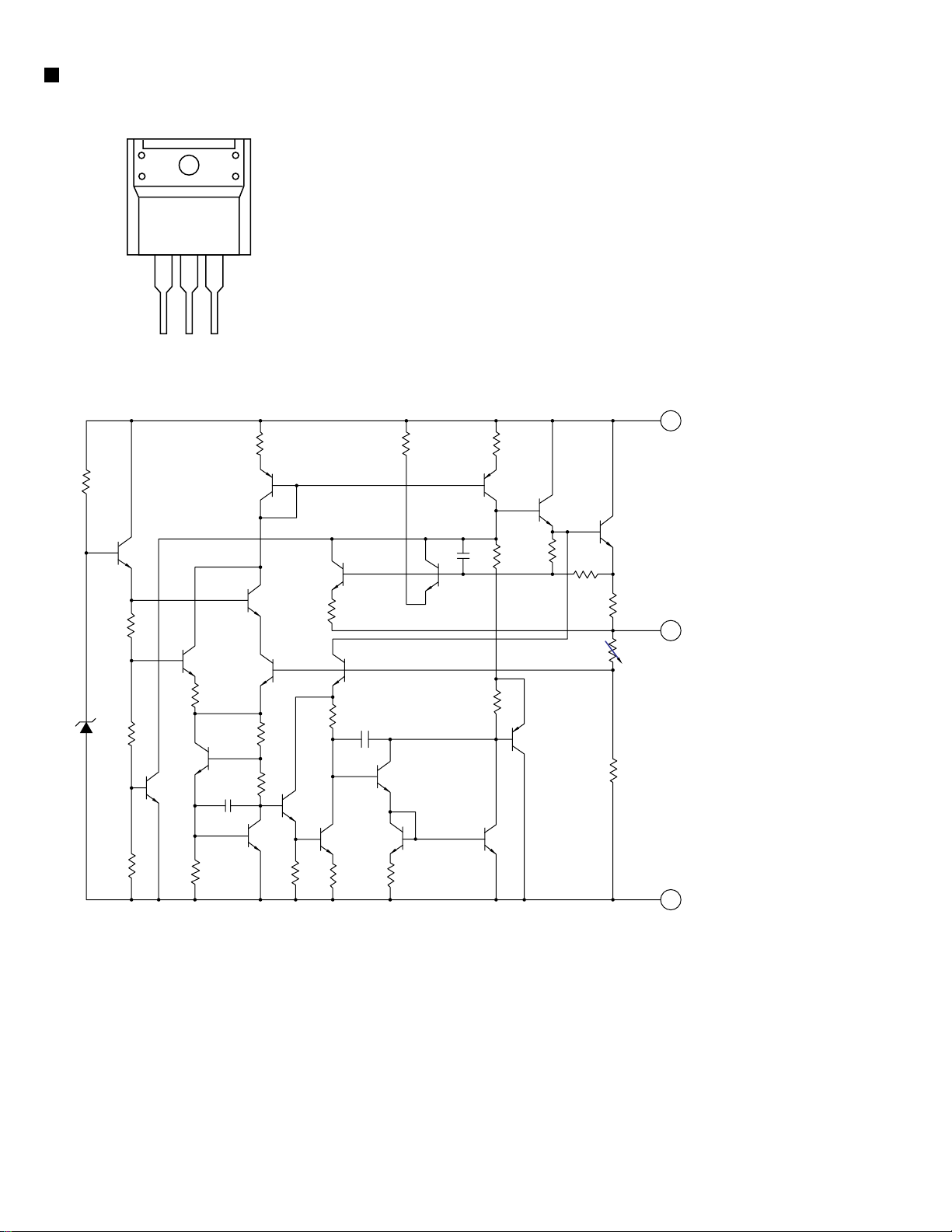

KIA7805API (IC360) : Regulator

1.

Pin

layout

1 2 3

2.Block diagram

1.VCC

2.GND

3.OUTPUT

1

INPUT

Z1

R1

Q12

R12

R11

R13

Q13

Q2

Q18

R18

R4

R22

Q11

Q1

Q17

R2

R3

Q3

Q4

R5

Q14

Q6

R19

R7

Q5

R6

C1

Q9

Q7

R8

R17

Q19

R26

Q11-1

R10

R9

Q8

Q10

Q15

R15

R14

Q16

R16

R20

R21

3

OUTPUT

2 COMMON (GND)

1-34

Page 35

KIA7808API (IC303) : Regulator

1.

Pin

layout

1.VCC

2.GND

3.OUTPUT

1 2 3

2.Block diagram

1

HX-Z1R

INPUT

Z1

R1

Q12

R12

R11

R13

Q13

Q2

Q18

R18

R4

R22

Q11

Q1

Q17

R2

R3

Q3

Q4

R5

Q14

Q6

R19

R7

Q5

R6

C1

Q9

Q7

R8

R17

Q19

R26

Q11-1

R10

R9

Q8

Q10

Q15

R15

R14

Q16

R16

R20

R21

3

OUTPUT

2 COMMON (GND)

1-35

Page 36

HX-Z1R

KIA7812API (IC240) : Regulator

1.

Pin

layout

1.VCC

2.GND

3.OUTPUT

1 2 3

2.Block diagram

1

INPUT

Z1

R1

Q12

R12

R11

R13

Q13

Q2

Q18

R18

R4

R22

Q11

Q1

Q17

R2

R3

Q3

Q4

R5

Q14

Q6

R19

R7

Q5

R6

C1

Q9

Q7

R8

R17

Q19

R26

Q11-1

R10

R9

Q8

Q10

Q15

R15

R14

Q16

R16

R20

R21

3

OUTPUT

2 COMMON (GND)

1-36

Page 37

KIA7042AP-T (IC830) : Regulator

HX-Z1R

1. Pin layout

2. Block diagram

1 2 3

1.VCC

2.GND

3.OUT

NJM4580D (IC501, IC502, IC571) : LPF, Mic and H.phone amp.

1. Pin layout

A OUT

1

+

8

V

2. Block diagram

+

V

INPUT

+

A -IN

A +IN

V

2

A

3

-

4

(TOP VIEW)

B

7

6

5

B OUT

B -IN

B +IN

OUTPUT

-

V

1-37

Page 38

HX-Z1R

GP1U271XK (IC951) : Receiver for remote

+

–

Amp.

Limiter Integrator Comparator

STK402-050 (IC602) : 2ch AF power amp.

Pin

layout

1.

B.P.F

Demodulator

GND

VCC Vout

1 ~ 15

2.Block diagra

4

R1

1

2

TR3

R2

8

TR7

TR4

C1

TR5

TR2TR1

D1

R3

R4

R5

R6

TR8

TR6

R7

TR9

TR10

R8

TR12

TR13

R9

R13

TR1E

C2

R15R14

R11

R12

R10

TR16

R14

1-38

9

SUB

151411106712513

Page 39

STK402-010 (IC701) : 2ch AF power amp.

Pin

layout

1.

1 ~ 18

HX-Z1R

2.Block diagra

R1 C1

14

TR3

15

16

TR5

R2

TR2TR1

TR4

D2

C2

D1

R4

R5

TR6

R6

R3

TR7

R7

TR8

TR9

TR10

13 18 17

D12R13

TR11TR12

TR16

TR19

TR20

TR18

C12

R14

R15

R16

TR17

R17

R11C11

TR13TR14

TR15

R12

TR41

TR51

D41

D51

R41

Comparator

Comparator

R51

D42

SUB

D53

D52

1

3

D43

2

7

5

4

6

12

9 8 11 10

1-39

Page 40

HX-Z1R

UPD784975AGF303 (IC810) : Main micon

1.

Pin

layout

100 ~ 81

1

~

30

31 ~ 50

80

~

51

2. Pin function

Pin NO. Name Function

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

AVDD

SPIDTI

MSI

MPX

H/P

KEY1

KEY2

KEY3

VOL-

VOL+

SLCPLAY

SLCKEY

PHOTO A

AVSS

VSS1

X1

X2

VDD1

IC(VPP)

VC3RESET

M STAT

KCMND

RDS DATA

RDS CK

BUZZER

REMIN

SMUTE

SLCCE

CK

DATA OUT

DATA I N

SM-

SM+

ECHO1

ECHO2

I/O

AD VDD, same as VDD1

SPI analog input

I

Music scan input

I

Tuner stereo indicator

I

I

SW vol IC btw bi-amp & dyn & off relay

I

Key 1 input

I

Key 2 input

I

Key 3 input

I

Volume decrease

I

Volume increase

I

SLC detect play

I

SLC key input

I

SLC photo A

-

AD VDD, same as VSS1

-

GND

I

Oscillation

-

Oscillation

-

-

Connect to VSS1

I/O

VC3 reset

I/O

VC3 status input

I/O

VC3 KCMND(serial data)

I/O

RDS data

INT

RDS clock

I/O

Buzzer on

INT

Remocon input

I/O

System mute

I/O

SLC chip enable

I/O

SLC / tuner clock

I/O

SLC / tuner data out

I/O

Tuner data in

I/O

Soundmode reverse

I/O

Soundmode forward

I/O

Echo 1 data

I/O

Echo 2 data

Pin NO.

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62~78

79

80

81~84

85~100

Name Function

SPI A

SPI B

SPI C

PBMUTE

VSS0

VDD0

RESET

INH

LATCH

VOLCK

VOLDA

RELAY

POUT

ECON

PRT

AUXMUTE

TUCE

EXTDA

EXTCK

EXTCE

OEEXT

VOLLED

FSEARCH

RSEARCH

S21~S5

VDD2

VLOAD

S4~S1

G16~G1

I/O

I/O

SPI A data

I/O

SPI B data

I/O

SPI C data

I/O

Playback mute

-

I

Micom reset

I/O

Back-up mode detect

I/O

Latch for vol IC

I/O

Volume clock

I/O

Volume data

I/O

Relay out

I/O

Power on

I/O

Ecology mode

I/O

Protector in

O

Auxmute

O

Tuner chip enable

O

Available pin

O

Available pin

O

External IC data

O

External IC clock

O

External IC strobe

O

Output enable for external IC

I/O

Volume led

I/O

Forward skip

I/O

Reverse skip

I/O

FL segment

I/O

I/O

Negative power supply(-30V)

I/O

FL segment

I/O

FL display grid

1-40

Page 41

HX-Z1R

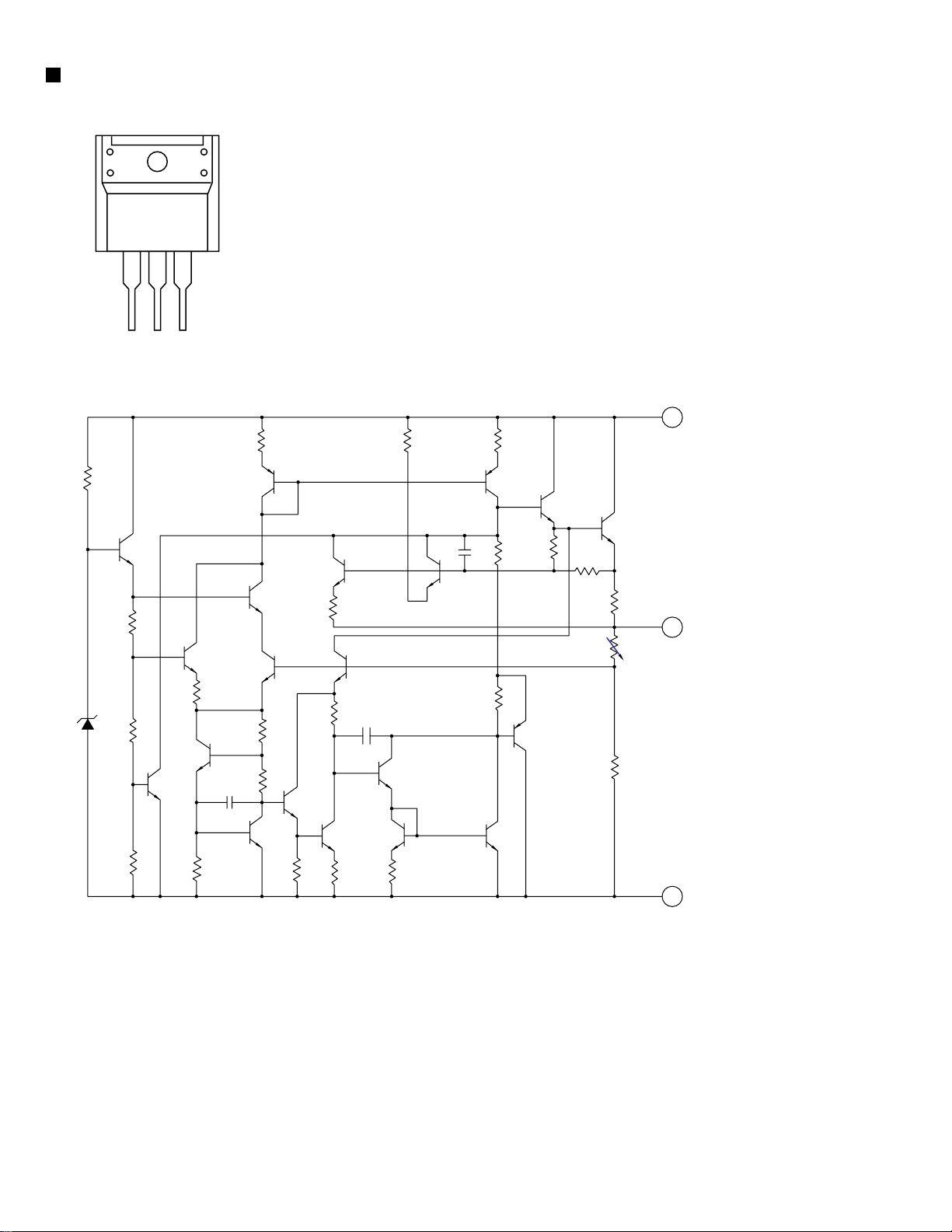

KIA7809API (IC305) :

1.Pin layout

1 2 3

2.Block diagram

Regulator

1.INPUT

2.COMMON

3.OUTPUT

R22

R17

R23

1

INPUT

Z1

R1

Q12

R12

R11

R13

Q13

Q2

Q18

R18

R4

Q11

Q1

Q17

R2

R3

Q3

Q4

R5

Q14

Q6

R19

R7

Q5

R6

C1

Q9

Q7

R8

Q19

Q11-1

R10

R9

Q8

Q10

Q15

R15

R14

Q16

R16

R20

R21

3

OUTPUT

2 COMMON (GND)

1-41

Page 42

HX-Z1R

HX-Z1R

VICTOR COMPANY OF JAPAN, LIMITED

AUDIO & COMUNICATION BUSINESS DIVISION

PERSONAL & MOBILE NETWORK BUSINESS UNIT. 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

1-42

(No.21114)

Printed in Japan

200207

Loading...

Loading...