Page 1

SERVICE MANUAL

COMPACT COMPONENT SYSTEM

MB45520058

HX-D7

Area suffix

UJ ---------------------- U.S.Military

SP-HXD7

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

CA-HXD7 SP-HXD7

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

COPYRIGHT © 2005 Victor Company of Japan, Limited

No.MB455

2005/8

Page 2

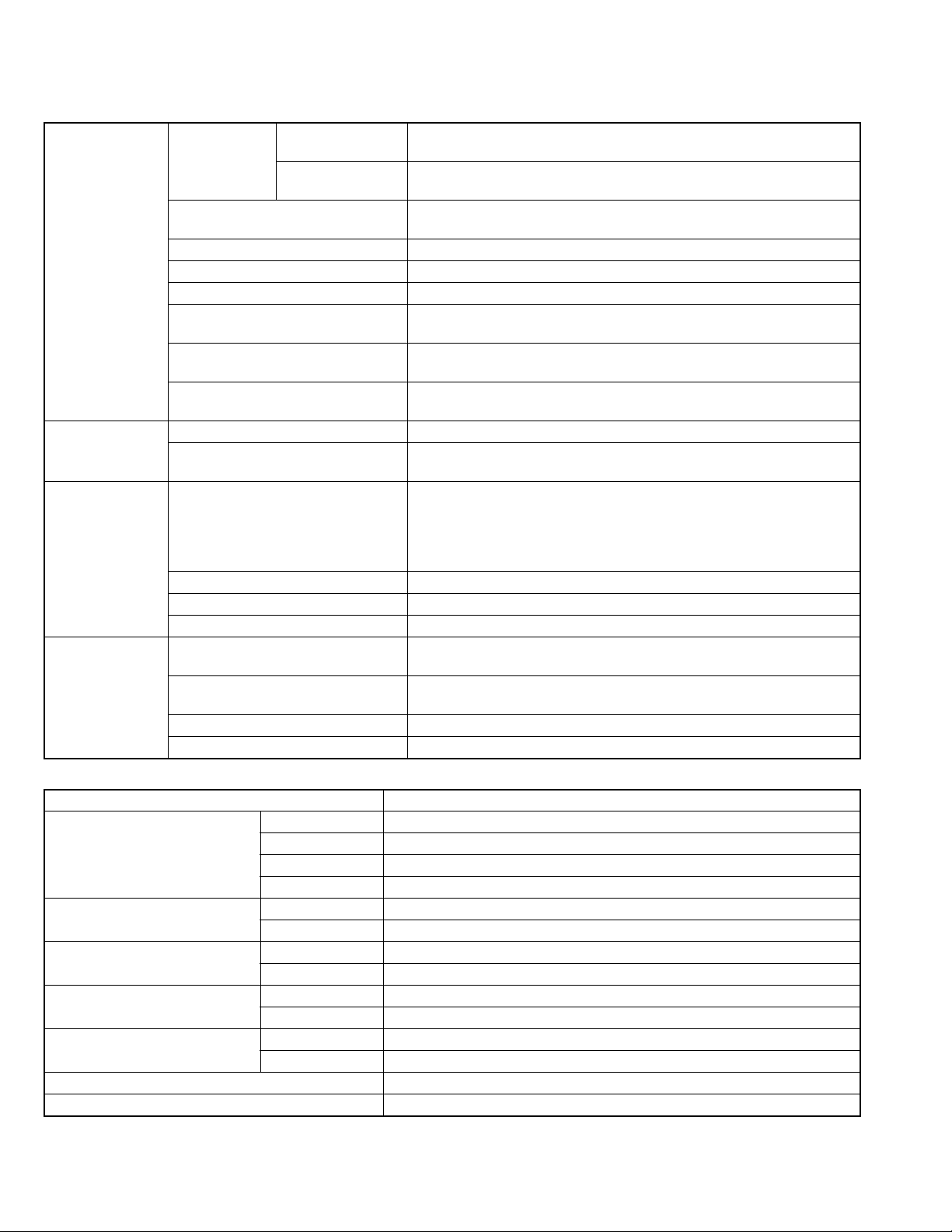

SPECIFICATION

CA-HXD7

Amplifier section Output Power SUBWOOFER 135 W per channel, min. RMS, driven into 6 Ω at 63 Hz with no more than

10% total harmonic distortion. (IEC268-3)

MAIN SPEAKER 60 W per channel, min. RMS, driven into 4 Ω at 1 kHz with no more than

10% total harmonic distortion. (IEC268-3)

Audio input sensitivity/impedance AUX:400 mV/47 kΩ

USB:USB Version 1.1

Digital output DIGITAL OUTPUT (OPTICAL):-21 dBm to -15 dBm (660 nm ±30 nm)

VIDEO OUT Color system:NTSC

VIDEO (composite) 1 V(p-p)/75 Ω

S-VIDEO Y (luminance):1 V(p-p)/75 Ω

C (chrominance, burst):0.286 V(p-p)/75 Ω

COMPONENT(interlace/ progressive) (Y):1 V(p-p)/75 Ω

(PB/PR):0.7 V(p-p)/75 Ω

Speaker Terminals 4 Ω - 8 Ω (main speakers)

6 Ω - 16 Ω (subwoofers)

Tuner section FM tuning range 87.50 MHz - 108.00 MHz

AM tuning range 531 kHz - 1 710 kHz (at 9 kHz interval)

530 kHz - 1 710 kHz (at 10 kHz interval)

Disc player section Playable disc DVD Video/DVD Audio

CD/VCD/SVCD

CD-R/CD-RW (recorded in Audio CD/Video CD/Super Video CD/MP3/

JPEG format)

DVD-R/DVD-RW (recorded in video format)

Dynamic range 90 dB

Horizontal resolution 500 lines

Wow and flutter Immeasurable

General Power requirement AC 110 V - AC 127 V/ AC 220 V - AC 240 V (adjustable with the voltage

selector), 50/60 Hz

Power consumption 160 W (at operation)

30 W (on standby)

Dimensions (approx.) 175 mm × 373 mm × 389 mm (W/H/D)

Mass (approx.) 10.1 kg

Speaker section-SP-HXD7

Type 4-Way Front Twin Woofer (Magnetically Shielded Type)

Speakers Subwoofer 16 cm cone × 1

Woofer 16 cm cone × 1

Mid range 7 cm cone × 1

Tweeter 2 cm piezo × 1

Power handling capacity Subwoofer 360 (180 + 180) W

Main speaker 160 (80 + 80) W

Impedance Subwoofer 6 Ω

Main speaker 4 Ω

Frequency range Subwoofer 30 Hz - 1 000 Hz

Main speaker 50 Hz - 20 000 Hz

Sound pressure level Subwoofer 74 dB/W·m

Main speaker 84 dB/W·m

Dimensions (approx.) 295 mm × 452 mm × 390 mm (W/H/D)

Mass (approx.) 8.9 kg each

Design and specifications are subject to change without notice.

1-2 (No.MB455)

Page 3

SECTION 1

PRECAUTION

1.1 Safety Precautions

(1) This design of this product contains special hardware and

many circuits and components specially for safety purposes. For continued protection, no changes should be made

to the original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to

those used in the original circuits. Services should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the product should

not be made. Any design alterations of the product should

not be made. Any design alterations or additions will void

the manufacturers warranty and will further relieve the

manufacture of responsibility for personal injury or property

damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in the Parts List of Service Manual. Electrical components having such features

are identified by shading on the schematics and by ( ) on

the Parts List in the Service Manual. The use of a substitute

replacement which does not have the same safety characteristics as the recommended replacement parts shown in

the Parts List of Service Manual may create shock, fire, or

other hazards.

(4) The leads in the products are routed and dressed with ties,

clamps, tubings, barriers and the like to be separated from

live parts, high temperature parts, moving parts and/or

sharp edges for the prevention of electric shock and fire

hazard. When service is required, the original lead routing

and dress should be observed, and it should be confirmed

that they have been returned to normal, after reassembling.

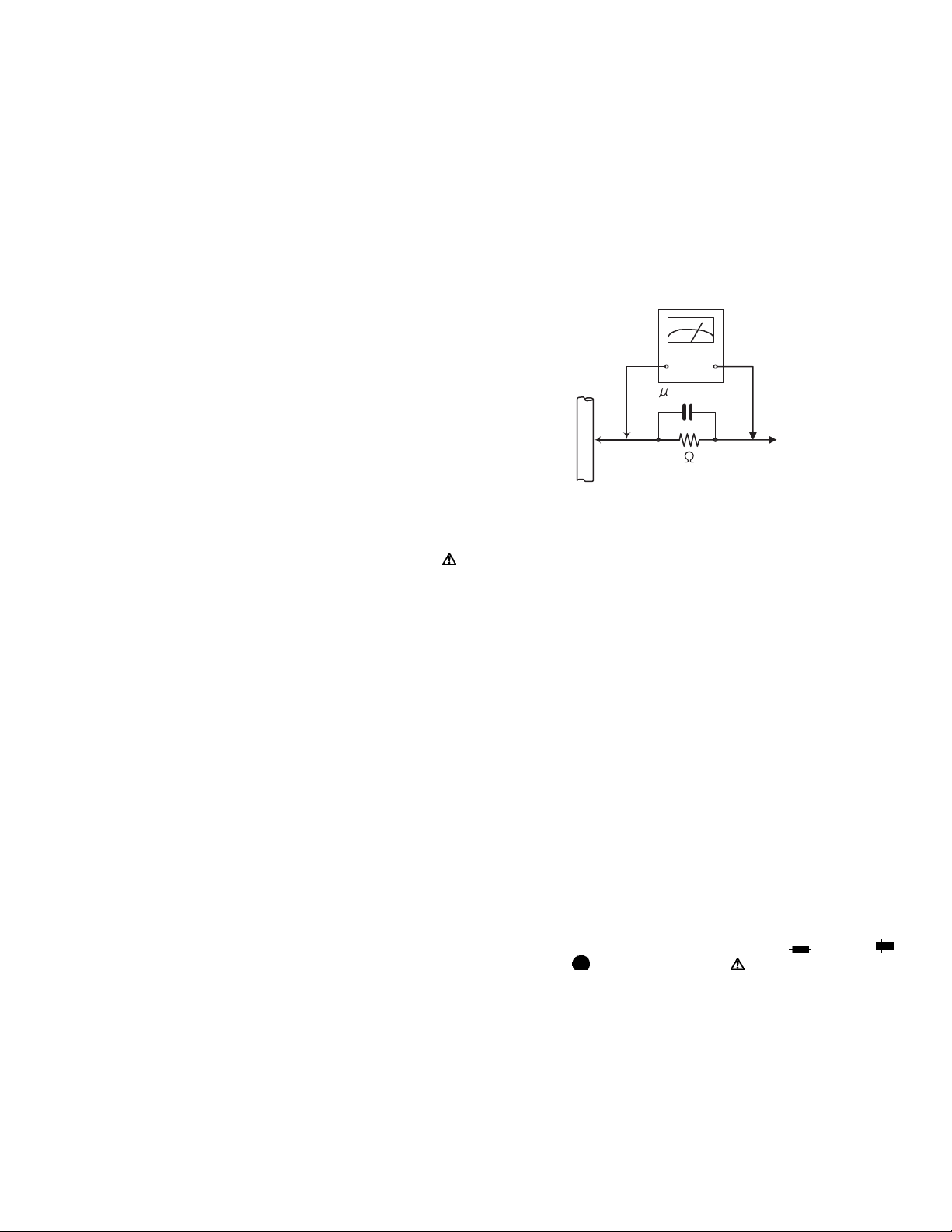

(5) Leakage shock hazard testing

After reassembling the product, always perform an isolation check on the exposed metal parts of the product (antenna terminals, knobs, metal cabinet, screw heads,

headphone jack, control shafts, etc.) to be sure the product

is safe to operate without danger of electrical shock.Do not

use a line isolation transformer during this check.

• Plug the AC line cord directly into the AC outlet. Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal parts of the cabinet, particularly any exposed metal part having a return path to the

chassis, to a known good earth ground. Any leakage current must not exceed 0.5mA AC (r.m.s.).

• Alternate check method

Plug the AC line cord directly into the AC outlet. Use an

AC voltmeter having, 1,000Ω per volt or more sensitivity

in the following manner. Connect a 1,500Ω 10W resistor

paralleled by a 0.15µF AC-type capacitor between an ex-

posed metal part and a known good earth ground.

Measure the AC voltage across the resistor with the AC

voltmeter.

Move the resistor connection to each exposed metal

part, particularly any exposed metal part having a return

path to the chassis, and measure the AC voltage across

the resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Voltage measured any must

not exceed 0.75 V AC (r.m.s.). This corresponds to 0.5

mA AC (r.m.s.).

AC VOLTMETER

(Having 1000

ohms/volts,

or more sensitivity)

0.15 F AC TYPE

Place this

probe on

1500 10W

Good earth ground

1.2 Warning

(1) This equipment has been designed and manufactured to

meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that

these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant

safety standards.

(4) It is essential that safety critical components are replaced

by approved parts.

(5) If mains voltage selector is provided, check setting for local

voltage.

1.3 Caution

Burrs formed during molding may be left over on some parts

of the chassis.

Therefore, pay attention to such burrs in the case of preforming repair of this system.

1.4 Critical parts for safety

In regard with component parts appearing on the silk-screen

printed side (parts side) of the PWB diagrams, the parts that are

printed over with black such as the resistor ( ), diode ( )

and ICP ( ) or identified by the " " mark nearby are critical

for safety. When replacing them, be sure to use the parts of the

same type and rating as specified by the manufacturer.

(This regulation dose not Except the J and C version)

each exposed

metal part.

(No.MB455)1-3

Page 4

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS.

1-4 (No.MB455)

Page 5

SECTION 3

A

A

DISASSEMBLY

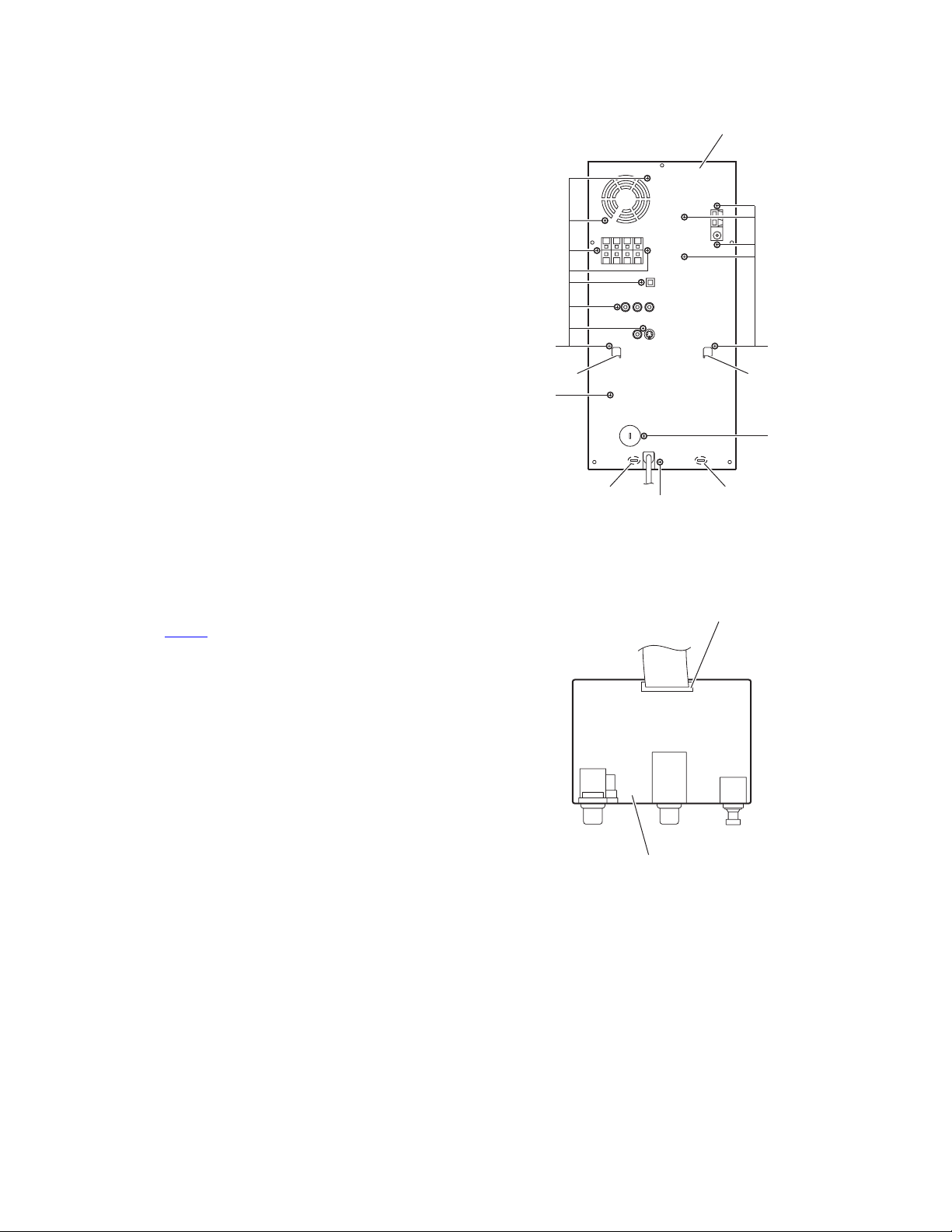

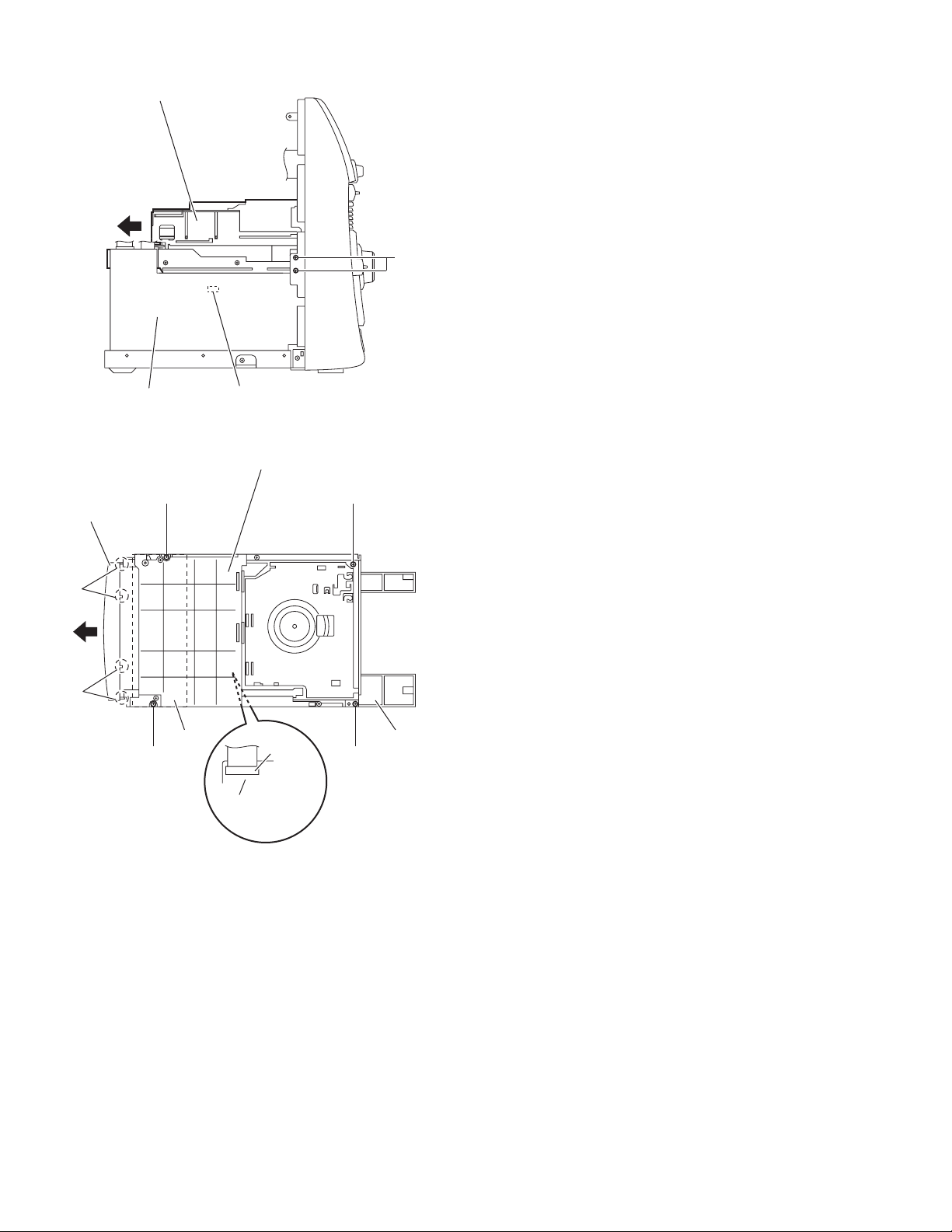

3.1 Main body section

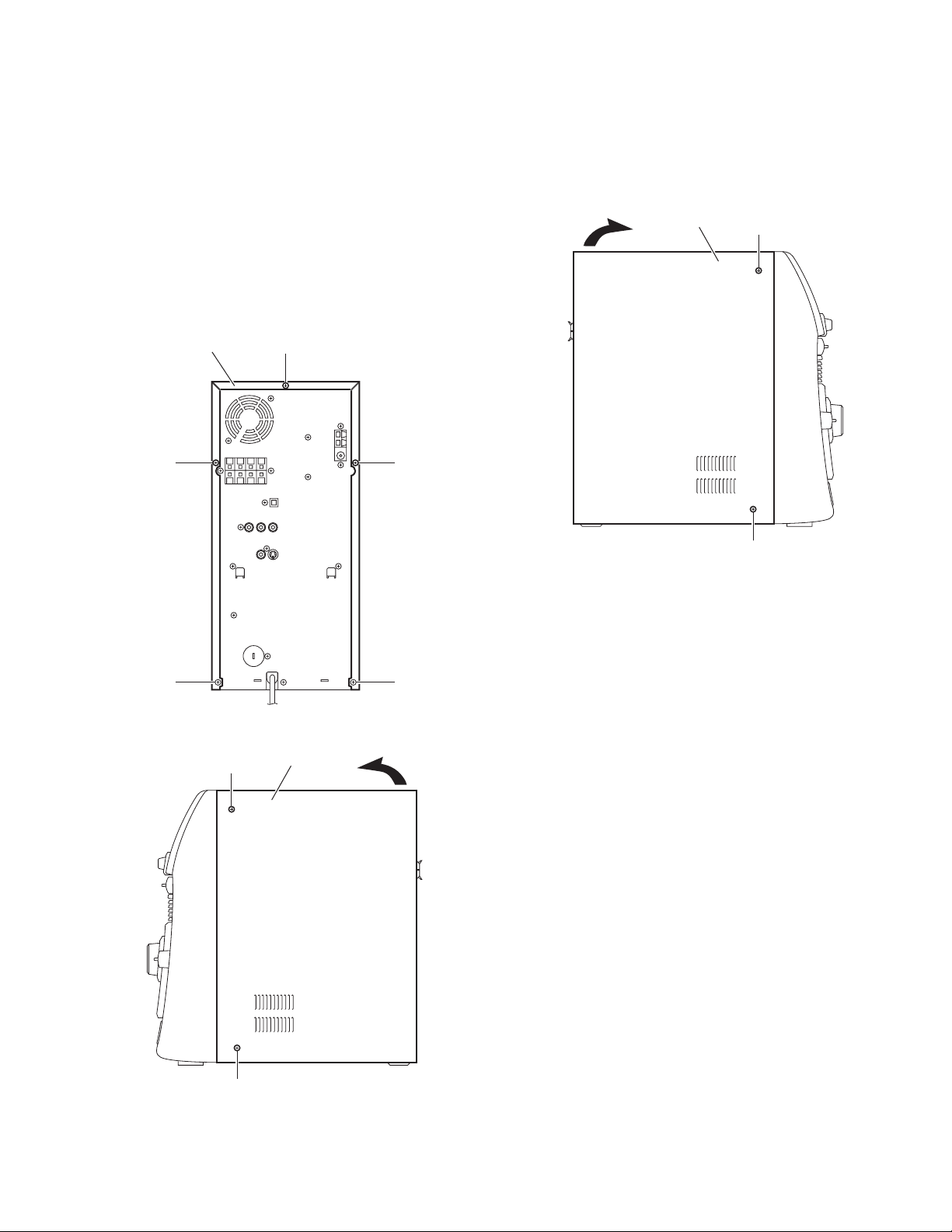

3.1.1 Removing the metal cover

(See Figs.1 to 3)

(1) From the back side of the main body, remove the five

screws A attaching the metal cover. (See Fig.1.)

(2) From the both sides of the main body, remove the four

screws A attaching the metal cover. (See Figs.2 and 3.)

(3) Remove the metal cover from the main body while lifting

the rear section of the metal cover in the direction of the arrow. (See Figs.2 and 3.)

Metal cover

A

Metal cover

A

A

A

A

Fig.3

A

Fig.1

Metal cover

A

Fig.2

(No.MB455)1-5

Page 6

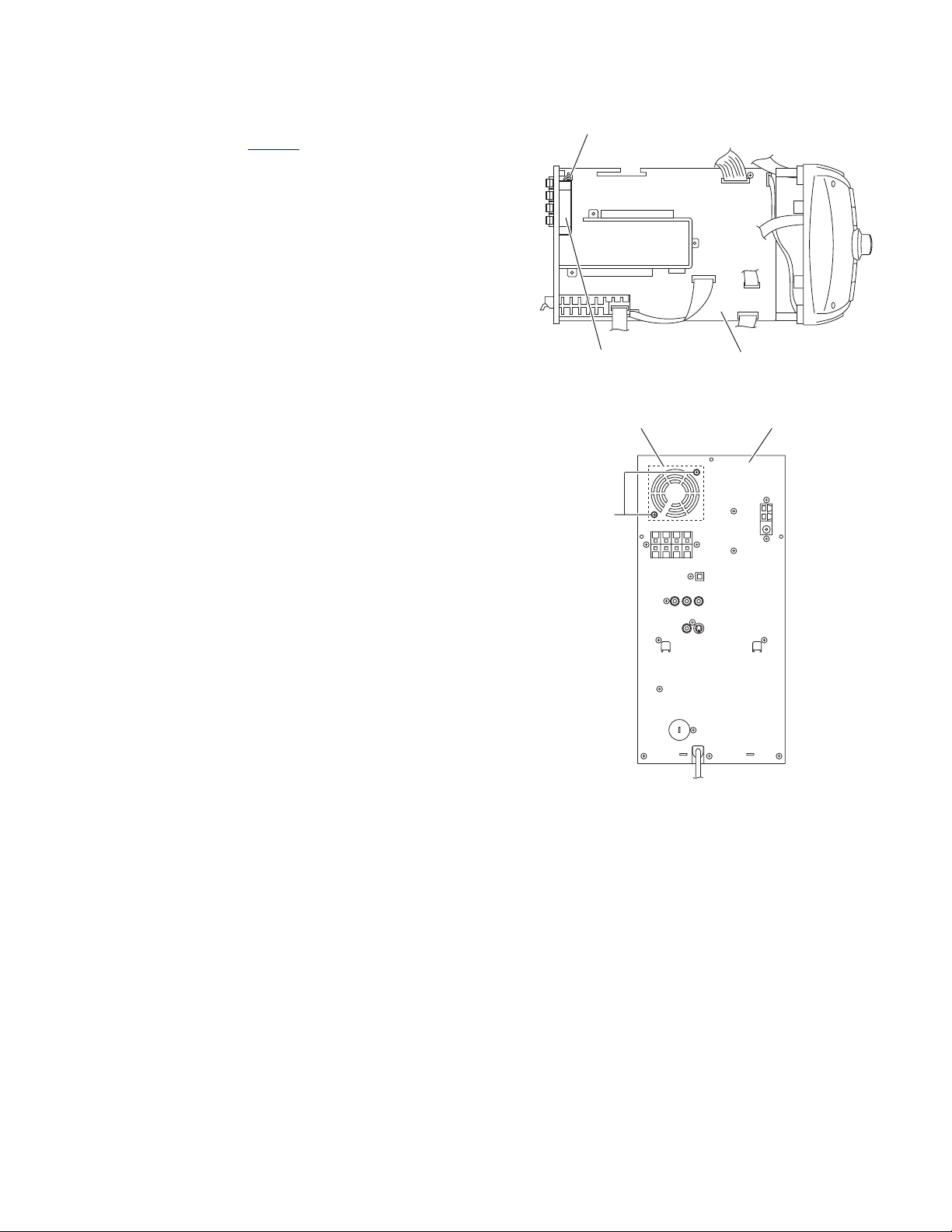

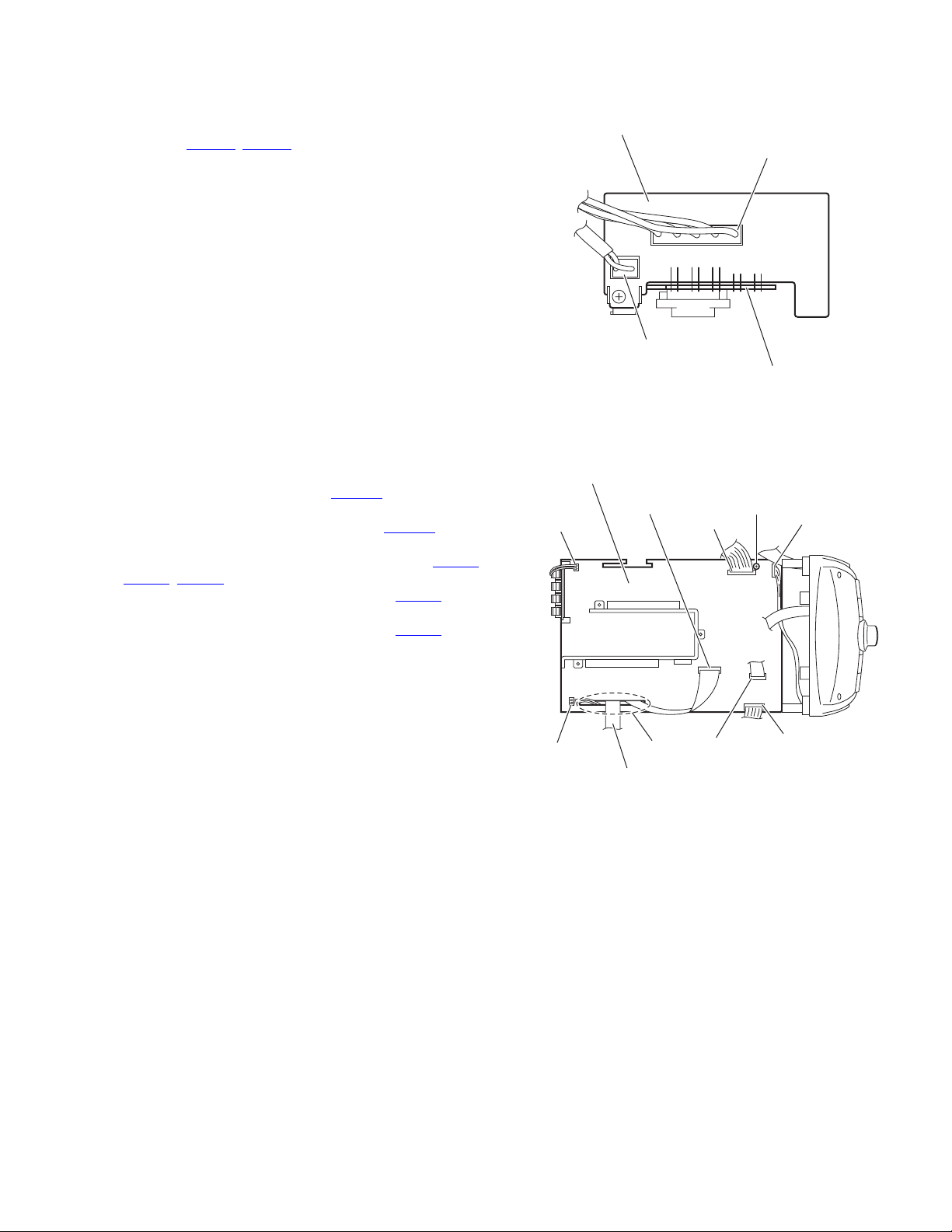

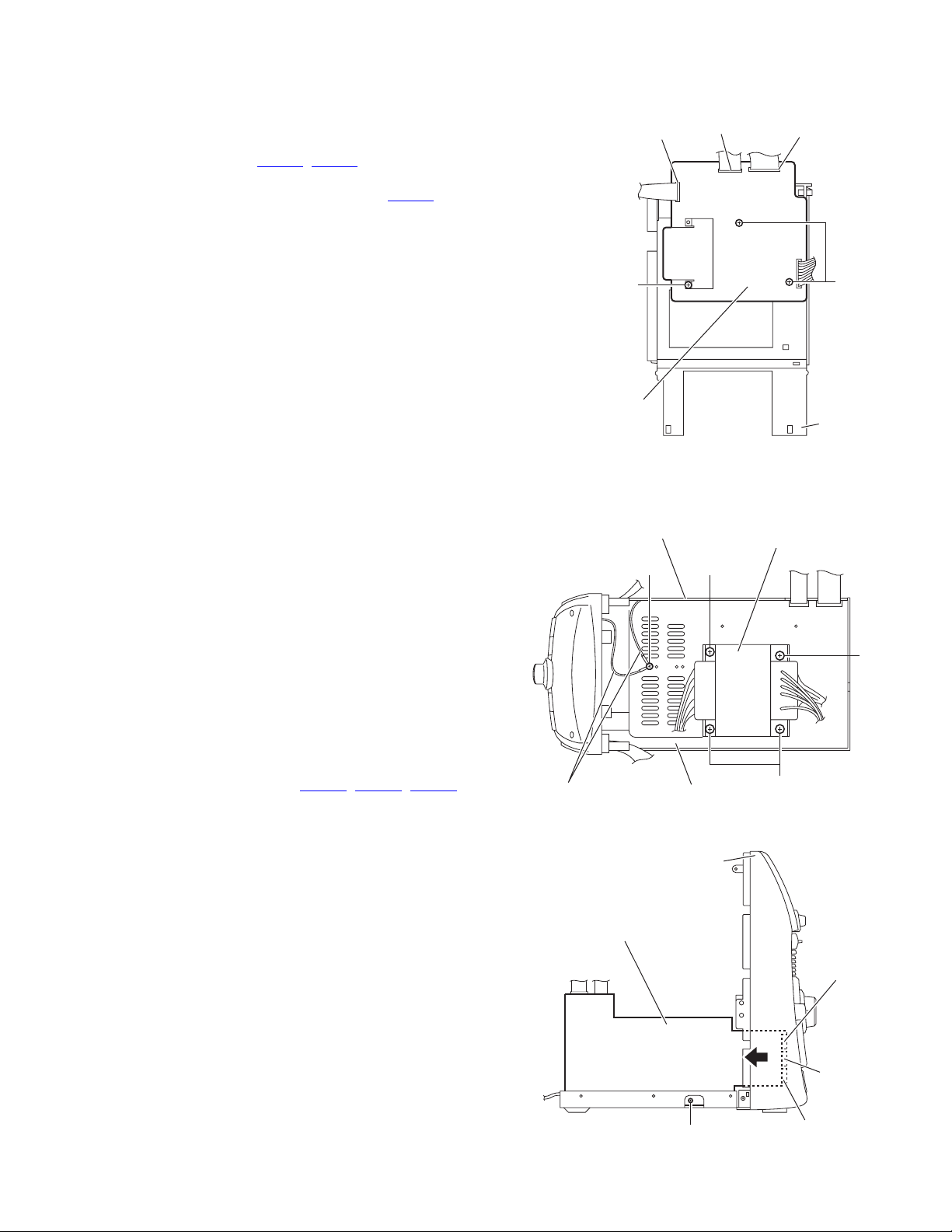

3.1.2 Removing the tuner

(See Figs.4 and 5)

• Remove the metal cover.

(1) From the left side of the main body, disconnect the card

wire from the connector on the tuner. (See Fig.4.)

(2) From the back side of the main body, remove the two

screws B attaching the tuner to the rear panel. (See Fig.5.)

Tuner

Connector

Fig.4

Rear panel

Tuner

B

Fig.5

1-6 (No.MB455)

Page 7

3.1.3 Removing the fan motor

(See Figs.6 and 7)

• Remove the metal cover.

(1) From the top side of the main body, disconnect the wire

from the connector FAN101

Fig.6.)

(2) From the back side of the main body, remove the two

screws C attaching the fan motor to the rear panel. (See

Fig.7.)

(3) Take out the fan motor from the main body.

on the amplifier board. (See

FAN101

Fan motor

Fan motor

C

Amplifier board

Fig.6

Rear panel

Fig.7

(No.MB455)1-7

Page 8

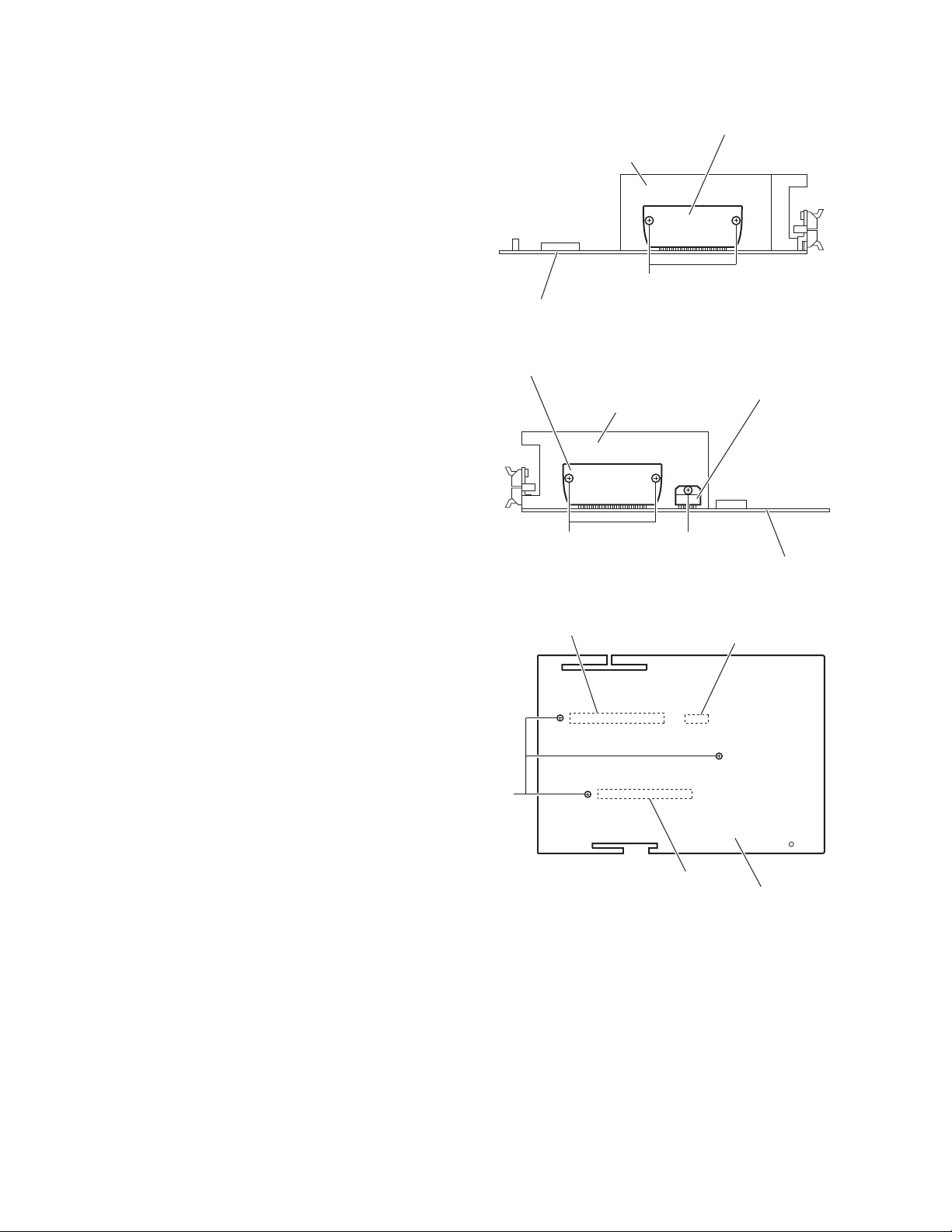

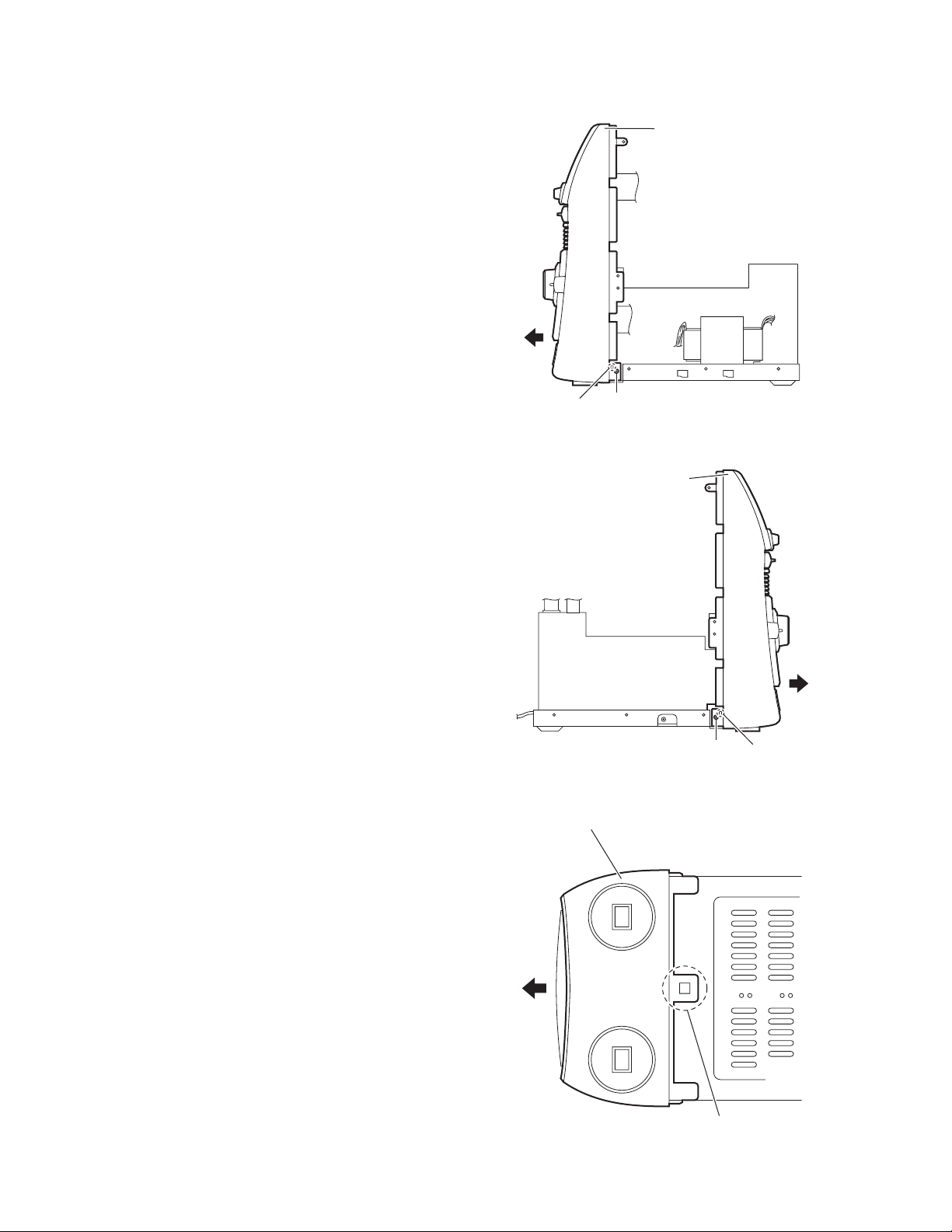

3.1.4 Removing the rear panel

(See Fig.8)

• Remove the metal cover.

(1) From the back side of the main body, remove the fifteen

screws D and screw E attaching the rear panel.

(2) Remove the sections a toward this side and remove the

rear panel from the sections b.

Rear panel

3.1.5 Removing the video board

(See Fig.9)

• Remove the metal cover and rear panel.

From the back side of the main body, disconnect the card wire

from the connector CN101

on the video board.

D

a a

D

b

D

Fig.8

D

E

b

CN101

1-8 (No.MB455)

Video board

Fig.9

Page 9

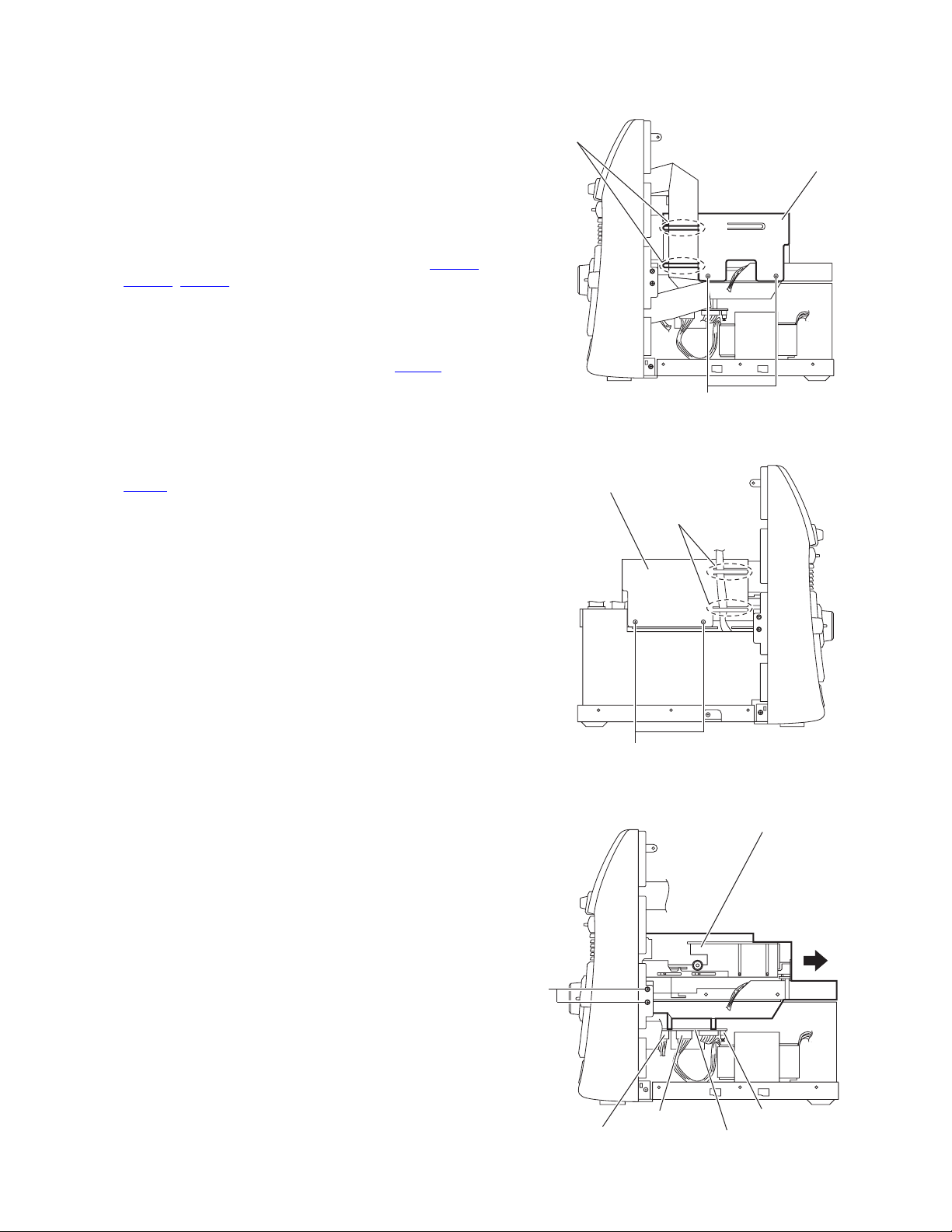

3.1.6 Removing the fuse board and voltage selector board

(See Fig.10)

• Remove the metal cover and rear panel.

From the back side of the main body, disconnect the wires from

the connectors (DCW06

the fuse board with the voltage selector board.

3.1.7 Removing the amplifier board

(See Fig.11)

• Remove the metal cover and rear panel.

(1) From the top side of the main body, disconnect the wire of

the fan motor from the connector FAN101

board.

(2) Disconnect the wire from the connector FAN102

amplifier board and remove the wire from the slot c.

(3) Disconnect the wires from the connectors (AW102,

, CW108) on the amplifier board.

AW105

(4) Disconnect the card wire from the connector AW104 on the

amplifier board.

(5) Disconnect the card wire from the connector AW101

amplifier board and remove the card wire from the slot c.

(6) Remove the card wire of the tuner from the slot c.

Reference:

• Remove the tuner as required.

• When connecting the each wire, pass them through

the slot c as before.

(7) Remove the screw F and take out the amplifier board from

the main body.

, DCW07) on the fuse board and remove

on the amplifier

on the

on the

Fuse board

DCW07

Amplifier board

AW101

FAN101

FAN102

Card wire (for the tuner)

DCW06

Voltage selector board

Fig.10

F

CW108

c

AW104

AW102

AW105

Fig.11

(No.MB455)1-9

Page 10

3.1.8 Removing the power amplifier ICs

(See Figs.12 to 14)

• Remove the metal cover, rear panel and amplifier board.

(1) From the forward side of the amplifier board, remove the

four screws G and screw H attaching the power amplifier

ICs to the heat sink. (See Figs.12 and 13.)

(2) From the reverse side of the amplifier board, remove the

three screws J attaching the heat sink. (See Fig.14.)

(3) Remove the soldered sections (d, e, f) and remove the

power amplifier ICs from the forward side of the amplifier

board. (See Fig.14.)

Power amplifier IC (AIC01)

Heat sink

G

Amplifier board

Fig.12

Power amplifier IC (AIC02)

Power amplifier IC (PIC02)

Heat sink

G H

Amplifier board

Fig.13

d

e

J

f

Amplifier board

Fig.14

1-10 (No.MB455)

Page 11

3.1.9 Removing the 5DVD changer mechanism assembly

(See Figs.15 to 19)

• Remove the metal cover, rear panel, video board and amplifier

board.

(1) From the right side of the main body, remove the card wire

from the sections g of the shield. (See Fig.15.)

(2) From the left side of the main body, remove the wire from

the sections h of the shield. (See Fig.16.)

(3) From the both sides of the main body, remove the four

screws K and remove the shield from the main body. (See

Figs.15 and 16.)

(4) Disconnect the wires from the connectors (DCW02

DCW04

(5) From the both sides of the main body, remove the four

screws M and remove the 5DVD changer mechanism assembly from the main body in the direction of the arrow.

(See Figs.17 and 18.)

(6) Disconnect the card wire from the connector CW104

forward side of the main board. (See Fig.18.)

(7) From the top side of the 5DVD changer mechanism as-

sembly, remove the four screws N and remove the base 1

and base 2. (See Fig.19.)

(8) From the bottom side of the 5DVD changer mechanism as-

sembly, disconnect the card wire from the connector

CN701

Reference:

When removing the tray panels, release the claws j of the tray

panel and remove the five tray panels from the 5DVD changer

mechanism assembly. (See Fig.19.)

Note:

When releasing the claws j, take care not to break them. (See

Fig.19.)

, DCW05) on the DVD power board. (See Fig.17.)

on the

on the DVD servo control board. (See Fig.19.)

g

Shield

,

K

Fig.15

Shield

h

M

DCW02

K

Fig.16

5DVD changer mechanism assembly

DCW05

DVD power board

Fig.17

DCW04

(No.MB455)1-11

Page 12

5DVD changer mechanism assembly

M

Main board

Tray panels

j

j

CW104

Fig.18

5DVD changer mechanism assembly

NN

Base 1

CN701

NN

DVD servo

control board

Base 2

1-12 (No.MB455)

Fig.19

Page 13

3.1.10 Removing the DVD power board

(See Fig.20)

• Remove the metal cover, rear panel, video board, amplifier

board and 5DVD changer mechanism assembly.

(1) From the back side of the base 2, disconnect the card wires

from the connectors (AW103

board.

(2) Disconnect the wire from the connector AW104

DVD power board.

(3) Remove the three screws P attach the DVD power board

on the base 2.

, AW106) on the DVD power

on the

AW104

AW106

AW103

3.1.11 Removing the power transformer

(See Fig.21)

• Remove the metal cover, rear panel, video board, fuse board,

voltage selector board, amplifier board and 5DVD changer

mechanism assembly.

(1) Remove the four screws Q attaching the power transformer

on the bottom chassis.

(2) Take out the power transformer.

3.1.12 Removing the main board

(See Figs.21 and 22)

• Remove the metal cover, rear panel, video board, amplifier

board and 5DVD changer mechanism assembly.

(1) From the top side of the main body, remove the screw R at-

taching the earth wires on the bottom chassis. (See

Fig.21.)

(2) Remove the screw S attaching the main board. (See

Fig.22.)

(3) Disconnect the connectors (CW101

the main board from the front panel assembly in the direction of the arrow. (See Fig.22.)

, CW102, CW105) on

P

DVD power board

Main board

Earth wires

Fig.20

R

Bottom chassis

Q

Fig.21

P

Base 2

Power transformer

Q

Q

Front panel assembly

Main board

S

Fig.22

CW105

CW102

CW101

(No.MB455)1-13

Page 14

3.1.13 Removing the front panel assembly

(See Figs.21, 23 to 25)

• Remove the metal cover, rear panel, video board, amplifier

board and 5DVD changer mechanism assembly.

(1) From the top side of the main body, remove the screw R at-

taching the earth wires on the bottom chassis. (See

Fig.21.)

(2) From the both sides of the main body, remove the two

screws T attaching the front panel assembly. (See Figs.23

and 24.)

(3) From the both and bottom sides of the main body, release

the joints (k, m) and remove the front panel assembly from

the main body in the direction of the arrow. (See Figs.23 to

25.)

Front panel assembly

k

T

Fig.23

Front panel assembly

1-14 (No.MB455)

Fig.24

Front panel assembly

Fig.25

T

k

m

Page 15

3.1.14 Removing the FL board

(See Fig.26)

• Remove the metal cover, rear panel, video board, amplifier

board, 5DVD changer mechanism assembly and front panel

assembly.

(1) From the inside of the front panel assembly, remove the

four screws U attaching the FL board.

(2) Take out the FL board from the front panel assembly and

disconnect the card wire from the connector FW102

forward side of the FL board.

on the

Front panel assembly

U

U

FW102

Fig.26

FL board

(No.MB455)1-15

Page 16

3.1.15 Removing the switch board

(See Figs.27 and 28)

• Remove the metal cover, rear panel, video board, amplifier

board, 5DVD changer mechanism assembly, front panel assembly and FL board.

(1) From the inside of the front panel assembly, remove the

spacer on the switch board.

(2) Remove the five screws U attaching the switch board. (See

Fig.27.)

(3) Take out the switch board while lifting it from the front panel

assembly little by little.

Reference:

The preset knob is removed from the front side simultaneously. (See Fig.28.)

(4) Take out the switch board from the front panel assembly

and disconnect the card wire from the connector FW201

the forward side of the switch board. (See Fig.27.)

on

FW201

U

Spacer

3.1.16 Removing the volume board

(See Figs.28 and 29)

• Remove the metal cover, rear panel, video board, amplifier

board, 5DVD changer mechanism assembly and front panel

assembly.

(1) From the front side of the front panel assembly, pull out the

volume knob in the direction of the arrow. (See Fig.28.)

(2) From the inside of the front panel assembly, disconnect the

card wire from the connector FW301

(See Fig.29.)

(3) Remove the seven screws U attaching the volume board.

(See Fig.29.)

(4) Take out the volume board from the front panel assembly

and disconnect the wires from the connectors (FW307

FW308) on the forward side of the volume board. (See

Fig.29.)

3.1.17 Removing the jack board

(See Fig.29)

• Remove the metal cover, rear panel, video board, amplifier

board, 5DVD changer mechanism assembly, front panel as-

sembly and volume board.

Remove the three screws U and take out the jack board from the

front panel assembly.

on the volume board.

U

Fig.27

Preset knob

,

Volume knob

Fig.28

Volume board

Switch board

Front panel assembly

U

1-16 (No.MB455)

FW301

FW307

Jack board

Fig.29

U

FW308

UU

UU

Page 17

SECTION 4

ADJUSTMENT

This service manual does not describe ADJUSTMENT.

SECTION 5

TROUBLESHOOTING

This service manual does not describe TROUBLESHOOTING.

(No.MB455)1-17

Page 18

Victor Company of Japan, Limited

AV & MULTIMEDIA COMPANY AUDIO/VIDEO SYSTEMS CATEGORY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MB455)

Printed in Japan

VPT

Page 19

SCHEMATIC DIAGRAMS

COMPACT COMPONENT SYSTEM

HX-D7

SP-HXD7

CD-ROM No.SML200508

CA-HXD7 SP-HXD7

Area suffix

UJ ---------------------- U.S.Military

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

Contents

Block diagram

Standard schematic diagrams

Printed circuit boards

COPYRIGHT 2005 Victor Company of Japan, Limited.

2-1

2-2

2-7 to 11

No.MB455SCH

2005/8

Page 20

In regard with component parts appearing on the silk-screen printed side (parts side) of the PWB diagrams, the

parts that are printed over with black such as the resistor ( ), diode ( ) and ICP ( ) or identified by the " "

mark nearby are critical for safety.

Page 21

Block diagram

TUNER

RHYTHM AX

JCV8011

CD/MP3

DVD

AUX

VIDEO

HEADPHONE

USB

VIDEO DRIVER

MM1623XFBE

DIGITAL SIG.

INPUT1

INPUT2

INPUT3

INPUT4

USB AUDIO IC

CM102

FUNCTION

TDA7442D

BUFFER

4558

HP AMP

4556

H.P.F

4558

L.P.F

324

AMP IC

STK428-610

FRONT CH

AMP IC

STK428-640

SUB-WOOFER CH

L.P.F

L.P.F

L.P.F

L.P.F

MAIN

SUB WOOFER

KEY COMAND

FRONT PCB ASS'Y

USB ON

u-COM

V.F.DISPLAY

DATA/CLK COMMAND

REMOCON

5V

5V REG. IC

78L05

P.SENS

POWER ON

SIGNAL 12V

DVD 8.6V

L4959

5.6V

MOTOR 12V

PE202

PE201

VFD

-VP

PBD01

1N5402

PE212

PE205

PE203PE204

PBD02

1N5402

PD202

VFD

AC

PD211-214

1N5392

Voltage

selector

AC INPUT

2-1

Page 22

Standard schematic diagrams

Main section

2-2

Page 23

Amp section

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified one.

2-3

Page 24

FL & Key control section

2-4

Page 25

DVD primary section

Parts are safety assurance parts.

When replacing those parts make

sure to use the specified one.

2-5

Page 26

Vide section

2-6

Page 27

Printed circut boards

Main board

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

(Forward sde)

2-7

Page 28

Main board

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

(Reverse sde)

2-8

Page 29

Amp board

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

(Forward side) (Reverse side)

2-9

Page 30

Front board

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

(Forward side) (Reverse side)

2-10

Page 31

Power board

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

2-11

Page 32

Victor Company of Japan, Limited

AV & MULTIMEDIA COMPANY AUDIO/VIDEO SYSTEMS CATEGORY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.MB455SCH)

Printed in Japan

VPT

Page 33

PARTS LIST

[ HX-D7 ]

* All printed circuit boards and its assemblies are not available as service parts.

Area suffix

UJ --------------------- U.S.Military

MB455

- Contents -

Exploded view of general assembly and parts list (Block No.M1)

Electrical parts list (Block No.01~06)

Packing materials and accessories parts list (Block No.M3)

3- 2

3- 5

3-12

3-1

Page 34

Exploded view of general assembly and parts list

m

Block No.

58

Front board

M

M

1

M

A

58

4

51

54

59

VFD

10

13

14

57

58

22

23

20

24

2

25

21

1

31

VFD board

57

58

Front board

5

19

16

8

9

7

17

15

58

18

USB board

6

11

5858

Main boardMain board

3-2

3

Page 35

61

5858

58

4

51

54

Amp board

58

60

32

53

52

29

47

58

58

30

46

5858

58

SB board

1

5858

in board

in board

18

45

34

Video jack

69

66

RFS6

70

DF102

58

RFS9

board

50

Voltage

board

64

RFS4

27

BKT. board

58

63

RFS3

58

12

6

33

Power

board

55

26

RFS7

71

DF103

67

44

68

RFS8

65

RFS5

56

58

43

RFS1

62

72

28

The parts without symbol number are not service.

3-3

Page 36

General Assembly

Symbol No. Part No. Part Name Description Local

1 AH64-03278D FRONT CABINET MIPS

2 AH64-03279C VFD WINDOW PMMA VIS GS-15C

3 AH64-03280B USB WINDOW PMMA VIS GS-15C

4 AH64-03283B DVD DOOR ABS L/GRAY

5 AH64-03284B SOUND MODE KNOB ABS 94HB

6 AH64-03285B SUBWOOFER KNOB ABS 94HB

7 AH64-03286B DEMO KNOB ABS 94HB

8 AH64-03282A WINDOW RING PMMA VIS GS-15C

9 AH67-00336B LENS RING PMMA MILKY

10 AH61-01831A VFD HOLDER ABS BLACK

11 AH61-01834A VOLUME HOLDER ABS WHITE

12 AH61-01835A DECK HOLDER ABS WHITE

13 AH61-01833A DISC HOLDER ABS BLACK

14 AH67-00335B DISC LENS ABS CLEAR

15 AH67-00339A USB LENS PMMA MILKY

16 AH67-00334A FUNCTION LENS PMMA VIS GS-15C

17 AH67-00338B RHYTHM AX LENS ABS CLEAR

18 AH67-00340A DECK CAP ABS

19 AH61-01832D FUNCTION HLDR ABS BLACK

20 AH64-03289C JOG KNOB ABS 94HB

21 AH64-03290C VOLUME KNOB ABS 94HB

22 AH67-00337A VOLUME LENS PMMA MILKY

23 AH67-00341C JOG CAP ABS NATURAL

24 AH67-00342B VOLUME CAP ABS NATURAL

25 AH63-00913A MIRROR SHEET PC T0.5

26 AH63-00278L PCB COVER PC T0.5

27 AH64-03293D REAR CABINET SECC T0.8

28 AH64-03292A BOTTOM CABINET SECC T1.0

29 AH63-00912A DECK COVER SECC T0.8

30 AH64-03291B TOP CABINET SECC T0.6

31 AH69-20031A FOOT (x2)

32 AH62-00137A HEAT SINK AL T3.0

33 AH62-00129C HEAT SINK AL T3.0

34 AH63-01063A SHIELD SPTE T0.3

43 AH26-00329B POWER TRANS

44 AH39-00257A POWER CORD 250V 2.5A 1830MM

45 AH31-00044A FAN ASSY

46 AH40-00097A TUNER PACK

47 AH59-01514A 5DVD MECHA ASSY FMU-SM2-15PM

50 AH63-00278M PROTECT SHEET PC T0.5

51 AH64-03283C DVD DOOR DISC2 ABS L/GRAY

52 AH64-03283D DVD DOOR DISC3 ABS L/GRAY

53 AH64-03283E DVD DOOR DISC4 ABS L/GRAY

54 AH64-03283F DVD DOOR DISC5 ABS L/GRAY

55 6003-001463 SCREW TH 4X6 YEL(x4)

56 6003-001561 SCREW BH 2S M3X6 YEL

57 6002-000126 SCREW M3X10 BLACK(x4)

58 6003-000276 SCREW M3X10 YEL(x60)

59 AH64-01106G SCREW M3X10 SILVER(x4)

60 6003-000109 SCREW M2.6XL8(x4)

61 6003-001375 SCREW M3XL8(x3)

62 3601-000414 FUSE RFS1 250V 5A

63 3601-000281 FUSE RFS3 250V 4A

64 3601-000281 FUSE RFS4 250V 4A

65 3601-001007 FUSE RFS5 250V 6.3A

66 3601-001007 FUSE RFS6 250V 6.3A

67 3601-001277 FUSE RFS7 250V 8A

68 3601-001277 FUSE RFS8 250V 8A

69 3601-000281 FUSE RFS9 250V 4A

70 3601-000216 FUSE DF102 250V 2.5A

71 3601-000216 FUSE DF103 250V 2.5A

72 AH68-50282D CAUTION LABEL

Block No. [M][1][M][M]

3-4

Page 37

Electrical parts list

Main board

Block No. [0][1]

Symbol No.

AIC01 324 IC 1201-000471

AIC02 324 IC 1201-000471

AIC03 4558 IC 1201-000461

CIC01 78R05 IC 1203-001006

EIC01 TDA7442D IC 1204-001776

EIC02 4558 IC 1201-000461

HIC01 4556 IC 1201-001285

SIC01 JCV8011-TLM-E IC 1204-002268

SIC02 4558 IC 1201-000461

AQ101 KTC945B TRANSISTOR 0501-002409

AQ102 KTC945B TRANSISTOR 0501-002409

AQ103 KTC945B TRANSISTOR 0501-002409

CQ01L KTC2874-B TRANSISTOR 0501-002436

CQ01R KTC2874-B TRANSISTOR 0501-002436

EQ02 KSR2003 TRANSISTOR 0504-000145

EQ03 KSR1003 TRANSISTOR 0504-000118

EQ04 KSR2003 TRANSISTOR 0504-000145

EQ01L KTC2874-B TRANSISTOR 0501-002436

EQ01R KTC2874-B TRANSISTOR 0501-002436

EQ02L KTC2874-B TRANSISTOR 0501-002436

EQ02R KTC2874-B TRANSISTOR 0501-002436

EQ101 KTC945B TRANSISTOR 0501-002409

FQ101 KSC2331-Y TRANSISTOR 0501-000369

FQ102 KTA1273 TRANSISTOR 0501-000422

HQ02 KTC2874-B TRANSISTOR 0501-002436

HQ01L KTC2874-B TRANSISTOR 0501-002436

HQ01R KTC2874-B TRANSISTOR 0501-002436

PQ109 KSD1691 TRANSISTOR 0502-001048

SQ01 KTC2874-B TRANSISTOR 0501-002436

SQ02 KRA104M TRANSISTOR 0504-001175

AD101 1N4148 DIODE 0401-000005

AD102 1N4148 DIODE 0401-000005

AD103 1N4148 DIODE 0401-000005

AD104 1N4148 DIODE 0401-000005

CD101 1N4148 DIODE 0401-000005

CD102 1N4148 DIODE 0401-000005

ED101 1N4148 DIODE 0401-000005

ED102 1N4148 DIODE 0401-000005

EZD01 MTZJ9.1C Z DIODE 0403-001170

SZD01 MTZJ9.1C Z DIODE 0403-001170

AC01L 2202-000263 C CAPACITOR 470pF 50V

AC01R 2202-000263 C CAPACITOR 470pF 50V

AC101 2301-000216 M CAPACITOR 220nF 50V

AC102 2301-000474 M CAPACITOR 8.2nF 50V

AC103 2301-000390 M CAPACITOR 15nF 50V

AC104 2201-000021 C CAPACITOR 100nF 50V

AC105 2301-000419 M CAPACITOR 27nF 50V

AC106 2301-000449 M CAPACITOR 47nF 50V

AC107 2301-000375 M CAPACITOR 100nF 50V

AC108 2301-000375 M CAPACITOR 100nF 50V

AC109 2301-000419 M CAPACITOR 27nF 50V

AC110 2301-000216 M CAPACITOR 220nF 50V

AC111 2201-000146 C CAPACITOR 0.1nF

AE101 2401-000042 E CAPACITOR 100uF 16V

AE102 2401-000042 E CAPACITOR 100uF 16V

AE103 2401-000027 E CAPACITOR 4.7uF 50V

AE104 2401-000027 E CAPACITOR 4.7uF 50V

AE107 2401-000042 E CAPACITOR 100uF 16V

AE109 2401-001975 E CAPACITOR 47uF 16V

AE110 2401-000027 E CAPACITOR 4.7uF 50V

AE111 2401-001912 E CAPACITOR 1uF 50V

AE112 2401-000042 E CAPACITOR 100uF 16V

AE114 2401-001975 E CAPACITOR 47uF 16V

AE115 2401-001975 E CAPACITOR 47uF 16V

AE116 2401-000651 E CAPACITOR 2.2uF 50V

AE117 2401-000027 E CAPACITOR 4.7uF 50V

CE101 2401-000042 E CAPACITOR 100uF 16V

EC07L 2301-000454 M CAPACITOR 5.6nF 50V

EC07R 2301-000454 M CAPACITOR 5.6nF 50V

Part No. Part Name Description Local

Symbol No.

EC08L 2301-000216 M CAPACITOR 220nF 50V

EC08R 2301-000216 M CAPACITOR 220nF 50V

EC09L 2301-000216 M CAPACITOR 220nF 50V

EC09R 2301-000216 M CAPACITOR 220nF 50V

EC101 2301-000361 M CAPACITOR 1.2nF 50V

EC102 2301-000375 M CAPACITOR 100nF 50V

EC103 2201-000021 C CAPACITOR 100nF 50V

EC11L 2201-000573 C CAPACITOR 0.047nF 50V

EC11R 2201-000573 C CAPACITOR 0.047nF 50V

EC12L 2201-000379 C CAPACITOR 22nF 50V

EC12R 2201-000379 C CAPACITOR 22nF 50V

EC13L 2201-000379 C CAPACITOR 22nF 50V

EC13R 2201-000379 C CAPACITOR 22nF 50V

EE25 2401-001912 E CAPACITOR 1uF 50V

EE01L 2401-001912 E CAPACITOR 1uF 50V

EE01R 2401-001912 E CAPACITOR 1uF 50V

EE02L 2401-001912 E CAPACITOR 1uF 50V

EE02R 2401-001912 E CAPACITOR 1uF 50V

EE03L 2401-001912 E CAPACITOR 1uF 50V

EE03R 2401-001912 E CAPACITOR 1uF 50V

EE04L 2401-001912 E CAPACITOR 1uF 50V

EE04R 2401-001912 E CAPACITOR 1uF 50V

EE05L 2401-001912 E CAPACITOR 1uF 50V

EE05R 2401-001912 E CAPACITOR 1uF 50V

EE06L 2401-000651 E CAPACITOR 2.2uF 50V

EE06R 2401-000651 E CAPACITOR 2.2uF 50V

EE07L 2401-000651 E CAPACITOR 2.2uF 50V

EE07R 2401-000651 E CAPACITOR 2.2uF 50V

EE08L 2401-001912 E CAPACITOR 1uF 50V

EE08R 2401-001912 E CAPACITOR 1uF 50V

EE09L 2401-000455 E CAPACITOR 10uF 35V

EE09R 2401-000455 E CAPACITOR 10uF 35V

EE101 2401-000480 E CAPACITOR 10uF 50V

EE102 2401-001975 E CAPACITOR 47uF 16V

EE103 2401-000832 E CAPACITOR 220uF 25V

EE104 2401-000042 E CAPACITOR 100uF 16V

EE105 2401-000042 E CAPACITOR 100uF 16V

EE106 2401-000048 E CAPACITOR 47uF 25V

EE107 2401-000027 E CAPACITOR 4.7uF 50V

EE108 2401-000027 E CAPACITOR 4.7uF 50V

EE109 2401-000759 E CAPACITOR 220nF 50V

EE110 2401-000048 E CAPACITOR 47uF 25V

FC101 2401-001975 E CAPACITOR 47uF 16V

FC102 2401-000048 E CAPACITOR 47uF 25V

HC01L 2201-000863 C CAPACITOR 0.68nF 50V

HC01R 2201-000863 C CAPACITOR 0.68nF 50V

HC02L 2201-000146 C CAPACITOR 0.1nF

HC02R 2201-000146 C CAPACITOR 0.1nF

HC03L 2201-000389 C CAPACITOR 0.022nF

HC03R 2201-000389 C CAPACITOR 0.022nF

HE01L 2401-001912 E CAPACITOR 1uF 50V

HE01R 2401-001912 E CAPACITOR 1uF 50V

HE02L 2401-001164 E CAPACITOR 33uF 16V

HE02R 2401-001164 E CAPACITOR 33uF 16V

HE101 2401-000832 E CAPACITOR 220uF 25V

HE102 2401-000832 E CAPACITOR 220uF 25V

HE103 2401-001975 E CAPACITOR 47uF 16V

PE215 2401-002042 E CAPACITOR 220uF 10V

SC01 2301-000419 M CAPACITOR 27nF 50V

SE04 2401-000651 E CAPACITOR 2.2uF 50V

SE05 2401-000651 E CAPACITOR 2.2uF 50V

SE08 2401-000480 E CAPACITOR 10uF 50V

SE09 2401-000027 E CAPACITOR 4.7uF 50V

SE10 2401-000480 E CAPACITOR 10uF 50V

SE11 2401-000480 E CAPACITOR 10uF 50V

SE12 2401-000480 E CAPACITOR 10uF 50V

SE13 2401-000027 E CAPACITOR 4.7uF 50V

SE14 2401-000759 E CAPACITOR 220nF 50V

SE15 2401-000651 E CAPACITOR 2.2uF 50V

SE16 2401-001645 E CAPACITOR 0.68uF 50V

SE17 2401-000048 E CAPACITOR 47uF 25V

SE01L 2401-000027 E CAPACITOR 4.7uF 50V

SE01R 2401-000027 E CAPACITOR 4.7uF 50V

SE02L 2401-000048 E CAPACITOR 47uF 25V

SE02R 2401-000048 E CAPACITOR 47uF 25V

SE03L 2401-000480 E CAPACITOR 10uF 50V

Part No. Part Name Description Local

3-5

Page 38

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

SE03R 2401-000480 E CAPACITOR 10uF 50V

SE06L 2401-001938 E CAPACITOR 22uF 25V

SE06R 2401-001938 E CAPACITOR 22uF 25V

SE07L 2401-000480 E CAPACITOR 10uF 50V

SE07R 2401-000480 E CAPACITOR 10uF 50V

Ω

AR01L 2001-000522 C RESISTOR 22K

AR01R 2001-000522 C RESISTOR 22K

AR02L 2001-000786 C RESISTOR 47K

AR02R 2001-000786 C RESISTOR 47K

AR03L 2001-000508 C RESISTOR 220K

AR03R 2001-000508 C RESISTOR 220K

AR101 2001-000563 C RESISTOR 27K

AR102 2001-000563 C RESISTOR 27K

AR103 2001-000548 C RESISTOR 270K

AR104 2001-000273 C RESISTOR 100K

AR105 2001-000273 C RESISTOR 100K

AR106 2001-000522 C RESISTOR 22K

AR107 2001-000522 C RESISTOR 22K

AR108 2001-000281 C RESISTOR 100

AR109 2001-000281 C RESISTOR 100

AR10L 2001-000793 C RESISTOR 47

AR10R 2001-000793 C RESISTOR 47

AR110 2001-000273 C RESISTOR 100K

AR111 2001-000273 C RESISTOR 100K

AR112 2001-000273 C RESISTOR 100K

AR114 2001-000864 C RESISTOR 56K

AR115 2001-000258 C RESISTOR 1.8K

AR116 2001-000977 C RESISTOR 8.2K

AR118 2001-000508 C RESISTOR 220K

AR119 2001-000281 C RESISTOR 100

AR11L 2001-000290 C RESISTOR 10K

AR11R 2001-000290 C RESISTOR 10K

AR121 2001-000802 C RESISTOR 5.6K

AR122 2001-000522 C RESISTOR 22K

AR123 2001-000258 C RESISTOR 1.8K

AR124 2001-000331 C RESISTOR 12K

AR125 2001-000522 C RESISTOR 22K

AR126 2001-000522 C RESISTOR 22K

AR127 2001-000890 C RESISTOR 6.8K

AR128 2001-000563 C RESISTOR 27K

AR129 2001-000281 C RESISTOR 100

AR130 2001-000281 C RESISTOR 100

AR131 2001-000281 C RESISTOR 100

AR132 2001-000508 C RESISTOR 220K

AR133 2001-000449 C RESISTOR 2.2K

AR134 2001-001000 C RESISTOR 82K

AR135 2001-000273 C RESISTOR 100K

AR136 2001-000273 C RESISTOR 100K

AR137 2001-000786 C RESISTOR 47K

AR138 2001-000786 C RESISTOR 47K

AR139 2001-000554 C RESISTOR 270

AR140 2001-000802 C RESISTOR 5.6K

AR141 2001-000027 C RESISTOR 100

AR142 2001-000027 C RESISTOR 100

CR01L 2001-000864 C RESISTOR 56K

CR01R 2001-000864 C RESISTOR 56K

CR02L 2001-000411 C RESISTOR 18K

CR02R 2001-000411 C RESISTOR 18K

CR03L 2001-000591 C RESISTOR 3.3K

CR03R 2001-000591 C RESISTOR 3.3K

ER25 2001-000290 C RESISTOR 10K

ER02L 2001-000591 C RESISTOR 3.3K

ER02R 2001-000591 C RESISTOR 3.3K

ER05L 2001-000515 C RESISTOR 220

ER05R 2001-000515 C RESISTOR 220

ER06L 2001-000786 C RESISTOR 47K

ER06R 2001-000786 C RESISTOR 47K

ER07L 2001-000734 C RESISTOR 4.7K

ER07R 2001-000734 C RESISTOR 4.7K

ER08L 2001-000786 C RESISTOR 47K

ER08R 2001-000786 C RESISTOR 47K

ER09L 2001-000331 C RESISTOR 12K

ER09R 2001-000331 C RESISTOR 12K

ER101 2001-000515 C RESISTOR 220

ER102 2001-000515 C RESISTOR 220

ER103 2001-000023 C RESISTOR 47

ER104 2001-000022 C RESISTOR 33

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

1/8W

Ω

1/8W

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

1/4W

Ω

1/2W

1/8W

1/8W

1/8W

1/8W

Ω

1/8W

Ω

1/8W

1/8W

1/8W

Ω

1/8W

Ω

1/8W

Ω

1/8W

1/8W

1/8W

1/8W

1/8W

Ω

1/8W

Ω

1/8W

Ω

1/8W

1/8W

Ω

1/8W

Ω

1/8W

Ω

1/8W

1/8W

1/8W

1/8W

Ω

1/8W

1/8W

Ω

1/8W

1/8W

1/8W

1/8W

Ω

1/8W

1/8W

1/8W

1/8W

1/8W

Ω

1/8W

Ω

1/8W

1/8W

Ω

1/8W

Ω

1/8W

1/8W

1/8W

1/8W

Ω

1/8W

1/4W

1/4W

1/8W

1/8W

1/8W

1/8W

Ω

1/8W

Ω

1/8W

1/8W

Ω

1/8W

Ω

1/8W

1/8W

1/8W

1/8W

1/8W

Ω

1/8W

Ω

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

ER105 2001-000591 C RESISTOR 3.3KΩ 1/8W

ER109 2001-000290 C RESISTOR 10K

ER10L 2001-000273 C RESISTOR 100K

ER10R 2001-000273 C RESISTOR 100K

ER110 2001-000773 C RESISTOR 470K

ER111 2001-000515 C RESISTOR 220

ER112 2001-000645 C RESISTOR 330K

ER113 2001-000989 C RESISTOR 820K

ER114 2001-000786 C RESISTOR 47K

ER13L 2001-000356 C RESISTOR 150K

ER13R 2001-000356 C RESISTOR 150K

ER14L 2001-000008 C RESISTOR 15K

ER14R 2001-000008 C RESISTOR 15K

ER15L 2001-000290 C RESISTOR 10K

ER15R 2001-000290 C RESISTOR 10K

ER16L 2001-000003 C RESISTOR 330

ER16R 2001-000003 C RESISTOR 330

ER17L 2001-000003 C RESISTOR 330

ER17R 2001-000003 C RESISTOR 330

ER19L 2001-000591 C RESISTOR 3.3K

ER19R 2001-000591 C RESISTOR 3.3K

ER20L 2001-000864 C RESISTOR 56K

ER20R 2001-000864 C RESISTOR 56K

ER21L 2001-001000 C RESISTOR 82K

ER21R 2001-001000 C RESISTOR 82K

ER22L 2001-000522 C RESISTOR 22K

ER22R 2001-000522 C RESISTOR 22K

ER23L 2001-000429 C RESISTOR 1K

ER23R 2001-000429 C RESISTOR 1K

ER24L 2001-000786 C RESISTOR 47K

ER24R 2001-000786 C RESISTOR 47K

ER25L 2001-000591 C RESISTOR 3.3K

ER25R 2001-000591 C RESISTOR 3.3K

FR101 2001-000429 C RESISTOR 1K

FR102 2001-000449 C RESISTOR 2.2K

FR103 2001-000025 C RESISTOR 75

FR104 2001-000522 C RESISTOR 22K

FR222 2001-000855 C RESISTOR 560

HR01L 2001-000449 C RESISTOR 2.2K

HR01R 2001-000449 C RESISTOR 2.2K

HR02L 2001-000449 C RESISTOR 2.2K

HR02R 2001-000449 C RESISTOR 2.2K

HR03L 2001-000734 C RESISTOR 4.7K

HR03R 2001-000734 C RESISTOR 4.7K

HR04L 2001-000290 C RESISTOR 10K

HR04R 2001-000290 C RESISTOR 10K

HR05L 2001-000019 C RESISTOR 10

HR05R 2001-000019 C RESISTOR 10

HR06L 2001-000591 C RESISTOR 3.3K

HR06R 2001-000591 C RESISTOR 3.3K

HR101 2001-000028 C RESISTOR 100

HR102 2001-000028 C RESISTOR 100

PR222 2001-000273 C RESISTOR 100K

PR223 2001-000062 C RESISTOR 470

SR01 2001-000773 C RESISTOR 470K

SR02 2001-000773 C RESISTOR 470K

SR03 2001-000281 C RESISTOR 100

SR04 2001-000008 C RESISTOR 15K

SR05 2001-000802 C RESISTOR 5.6K

SR06 2001-000723 C RESISTOR 4.3K

SR07 2001-000273 C RESISTOR 100K

SR08 2001-000290 C RESISTOR 10K

SR09 2001-000734 C RESISTOR 4.7K

SR12 2001-000591 C RESISTOR 3.3K

SR13 2001-000023 C RESISTOR 47

SR18 2001-000281 C RESISTOR 100

SR19 2001-000281 C RESISTOR 100

SR20 2001-000244 C RESISTOR 1.5M

SR21 2001-000290 C RESISTOR 10K

SR10L 2001-000331 C RESISTOR 12K

SR10R 2001-000331 C RESISTOR 12K

SR11L 2001-000449 C RESISTOR 2.2K

SR11R 2001-000449 C RESISTOR 2.2K

SR14L 2001-000290 C RESISTOR 10K

SR14R 2001-000290 C RESISTOR 10K

SR15L 2001-000290 C RESISTOR 10K

SR15R 2001-000290 C RESISTOR 10K

SR16L 2001-000802 C RESISTOR 5.6K

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

1/4W

Ω

Ω

Ω

Ω

Ω

1/2W

Ω

1/2W

Ω

Ω

Ω

Ω

Ω

Ω

Ω

1/4W

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

1/8W

Ω

1/8W

Ω

1/8W

Ω

1/8W

1/8W

Ω

1/8W

Ω

1/8W

1/8W

Ω

1/8W

Ω

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

Ω

1/8W

Ω

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

Ω

1/8W

Ω

1/8W

1/8W

Ω

1/8W

1/8W

1/4W

Ω

1/8W

Ω

1/8W

Ω

1/8W

Ω

1/8W

Ω

1/8W

Ω

1/8W

1/8W

1/8W

Ω

1/8W

Ω

1/8W

1/2W

1/2W

Ω

1/8W

1/4W

Ω

1/8W

Ω

1/8W

1/8W

1/8W

Ω

1/8W

Ω

1/8W

Ω

1/8W

1/8W

Ω

1/8W

Ω

1/8W

1/8W

1/8W

Ω

1/8W

1/8W

1/8W

1/8W

Ω

1/8W

Ω

1/8W

1/8W

1/8W

1/8W

1/8W

Ω

1/8W

3-6

Page 39

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

SR16R 2001-000802 C RESISTOR 5.6KΩ 1/8W

SR17L 2001-000734 C RESISTOR 4.7K

SR17R 2001-000734 C RESISTOR 4.7K

AW104 AH39-00791A CONNECTOR WIRE

CW101 3711-005905 CONNECTOR 2P

CW102 3710-002254 CONNECTOR 12P 2mm

CW103 3708-000412 CONNECTOR 12P 1.25mm

CW104 3708-000347 CONNECTOR 10P 1MM

CW105 3711-005905 CONNECTOR 2P

CW106 3708-000189 CONNECTOR 17P 1.25mm

FW101 AH39-20008Q CONNECTOR WIRE

GND1 AH39-50001K HARNESS WIRE 140mm BLK

GND2 AH65-30013A CLAMP CORD

XXXXX 3811-000122 PVC WIRE 300V 150mm

XXXXX 6003-001375 SCREW M3XL8

XXXXX AH61-40014A SUPPORT RIVET (x2)

XXXXX AH62-00099A HEAT SINK

XXXXX AH62-00147A HEAT SINK

Ω

1/8W

Ω

1/8W

10P for AMP

AW105

2P for AMP

FAN 102

Front board

Block No. [0][2]

Symbol No.

UIC01 AH11-00167A MASK ROM LC876B64C-56L0

UIC02 LC709006A IC 1205-002632

UIC03 CM102 IC 0904-001968

FQ301 KTC8050 TRANSISTOR 0501-002375

FQ302 KTC8050 TRANSISTOR 0501-002375

FQ303 KSD1691 TRANSISTOR 0502-001048

FQ304 KSR1003 TRANSISTOR 0504-000118

UQ101 KTC945B TRANSISTOR 0501-002409

FD201 1N4002 DIODE 0402-000127

FD204 1N4002 DIODE 0402-000127

FD301 1N4002 DIODE 0402-000127

FZ301 MTZJ5.6B Z DIODE 0403-000509

LD201 0601-001739 LED RED

LD202 0601-001739 LED RED

LD203 0601-001739 LED RED

LD204 0601-001739 LED RED

LD205 0601-001739 LED RED

LD206 0601-001739 LED RED

LD207 0601-001739 LED RED

LD208 0601-001739 LED RED

LD209 0601-001739 LED RED

LD301 0601-001739 LED RED

LD302 0601-001739 LED RED

LD303 0601-001739 LED RED

LD304 0601-001739 LED RED

LD305 0601-001739 LED RED

LD306 0601-001739 LED RED

LD307 0601-001739 LED RED

LD308 0601-001739 LED RED

LD309 0601-001739 LED RED

LD310 0601-001739 LED RED

LD311 0601-001739 LED RED

LED12 0601-001739 LED RED

LED13 0601-001739 LED RED

UD02 1N4148 DIODE 0401-000005

UD101 1N4148 DIODE 0401-000005

UD102 1N4148 DIODE 0401-000005

UD103 1N4002 DIODE 0402-000127

UD104 1N4002 DIODE 0402-000127

UD105 1N4148 DIODE 0401-000005

FC01L 2202-000806 C CAPACITOR 220pF 50V

FC01R 2202-000806 C CAPACITOR 220pF 50V

FC02L 2202-000806 C CAPACITOR 220pF 50V

FC02R 2202-000806 C CAPACITOR 220pF 50V

FC201 2201-000982 C CAPACITOR 10nF

Part No. Part Name Description Local

FC204 2201-000565 C CAPACITOR 47nF 50V

FC301 2202-000121 C CAPACITOR 0.1nF 50V

FC302 2202-000121 C CAPACITOR 0.1nF 50V

FC303 2202-000786 C CAPACITOR 0.01nF 50V

FC304 2202-000786 C CAPACITOR 0.01nF 50V

FE200 2401-000240 E CAPACITOR 100uF 10V

FE301 2401-000832 E CAPACITOR 220uF 25V

FE302 2401-001952 E CAPACITOR 4.7uF 50V

FE303 2401-000480 E CAPACITOR 10uF 50V

FE304 2401-000414 E CAPACITOR 10uF 16V

FE305 2401-000414 E CAPACITOR 10uF 16V

FE30L 2401-002042 E CAPACITOR 220uF 10V

FE30R 2401-002042 E CAPACITOR 220uF 10V

UC101 2201-000982 C CAPACITOR 10nF

UC102 2201-000565 C CAPACITOR 47nF 50V

UC103 2201-000389 C CAPACITOR 0.022nF

UC104 2201-000389 C CAPACITOR 0.022nF

UC105 2201-000565 C CAPACITOR 47nF 50V

UC106 2201-000565 C CAPACITOR 47nF 50V

UC107 2201-000017 C CAPACITOR 1nF 50V

UE101 2401-000651 E CAPACITOR 2.2uF 50V

UE102 2401-000759 E CAPACITOR 220nF 50V

UE103 2401-000118 E CAPACITOR 1000uF 10V

UE104 2401-000240 E CAPACITOR 100uF 10V

Ω

FR01L 2001-000290 C RESISTOR 10K

FR01R 2001-000290 C RESISTOR 10K

FR201 2001-000995 C RESISTOR 820

FR202 2001-000429 C RESISTOR 1K

FR203 2001-000221 C RESISTOR 1.2K

FR204 2001-000241 C RESISTOR 1.5K

FR205 2001-000258 C RESISTOR 1.8K

FR206 2001-000449 C RESISTOR 2.2K

FR207 2001-000591 C RESISTOR 3.3K

FR208 2001-000734 C RESISTOR 4.7K

FR209 2001-000890 C RESISTOR 6.8K

FR210 2001-000995 C RESISTOR 820

FR211 2001-000429 C RESISTOR 1K

FR212 2001-000221 C RESISTOR 1.2K

FR213 2001-000241 C RESISTOR 1.5K

FR214 2001-000258 C RESISTOR 1.8K

FR215 2001-000449 C RESISTOR 2.2K

FR216 2001-000591 C RESISTOR 3.3K

FR217 2001-000034 C RESISTOR 220

FR218 2001-000034 C RESISTOR 220

FR219 2001-000034 C RESISTOR 220

FR220 2001-000034 C RESISTOR 220

FR221 2001-000034 C RESISTOR 220

FR222 2001-000855 C RESISTOR 560

FR223 2001-000034 C RESISTOR 220

FR224 2001-000034 C RESISTOR 220

FR225 2001-000034 C RESISTOR 220

FR301 2001-000034 C RESISTOR 220

FR302 2001-000034 C RESISTOR 220

FR303 2001-000034 C RESISTOR 220

FR304 2001-000034 C RESISTOR 220

FR305 2001-000034 C RESISTOR 220

FR306 2001-000034 C RESISTOR 220

FR307 2001-000034 C RESISTOR 220

FR308 2001-000034 C RESISTOR 220

FR309 2001-000034 C RESISTOR 220

FR30L 2001-000411 C RESISTOR 18K

FR30R 2001-000411 C RESISTOR 18K

FR310 2001-000034 C RESISTOR 220

FR311 2001-000995 C RESISTOR 820

FR312 2001-000429 C RESISTOR 1K

FR313 2001-000221 C RESISTOR 1.2K

FR314 2001-000241 C RESISTOR 1.5K

FR315 2001-000258 C RESISTOR 1.8K

FR316 2001-000449 C RESISTOR 2.2K

FR317 2001-000734 C RESISTOR 4.7K

FR318 2001-000734 C RESISTOR 4.7K

FR319 2001-000119 C RESISTOR 680

FR320 2001-000241 C RESISTOR 1.5K

FR321 2001-000527 C RESISTOR 22

FR322 2001-000527 C RESISTOR 22

FR323 2001-000435 C RESISTOR 1M

FR324 2001-000290 C RESISTOR 10K

Ω

Ω

Ω

1/8W

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

1/8W

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

1/8W

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

1/8W

Ω

1/8W

Ω

Ω

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/4W

1/4W

1/4W

1/4W

1/4W

1/4W

1/4W

1/4W

1/4W

1/4W

1/4W

1/4W

1/4W

1/4W

1/4W

1/4W

1/4W

1/4W

1/8W

1/8W

1/4W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/4W

1/8W

1/8W

1/8W

3-7

Page 40

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

FR325 2001-000034 C RESISTOR 220Ω 1/4W

FR326 2001-000034 C RESISTOR 220

FR327 2001-000034 C RESISTOR 220

UR001 2001-000290 C RESISTOR 10K

UR101 2001-000734 C RESISTOR 4.7K

UR102 2001-000734 C RESISTOR 4.7K

UR103 2001-000734 C RESISTOR 4.7K

UR104 2001-000734 C RESISTOR 4.7K

UR105 2001-000734 C RESISTOR 4.7K

UR106 2001-000734 C RESISTOR 4.7K

UR107 2001-000734 C RESISTOR 4.7K

UR108 2001-000734 C RESISTOR 4.7K

UR109 2001-000734 C RESISTOR 4.7K

UR110 2001-000734 C RESISTOR 4.7K

UR111 2001-000734 C RESISTOR 4.7K

UR112 2001-000734 C RESISTOR 4.7K

UR113 2001-000786 C RESISTOR 47K

UR114 2001-000786 C RESISTOR 47K

UR115 2001-000786 C RESISTOR 47K

UR116 2001-000786 C RESISTOR 47K

UR117 2001-000786 C RESISTOR 47K

UR118 2001-000786 C RESISTOR 47K

UR119 2001-000786 C RESISTOR 47K

UR120 2001-000786 C RESISTOR 47K

UR121 2001-000786 C RESISTOR 47K

UR122 2001-000786 C RESISTOR 47K

UR123 2001-000786 C RESISTOR 47K

UR124 2001-000786 C RESISTOR 47K

UR125 2001-000786 C RESISTOR 47K

UR126 2001-000786 C RESISTOR 47K

UR127 2001-000786 C RESISTOR 47K

UR128 2001-000786 C RESISTOR 47K

UR129 2001-000786 C RESISTOR 47K

UR130 2001-000786 C RESISTOR 47K

UR131 2001-000786 C RESISTOR 47K

UR132 2001-000786 C RESISTOR 47K

UR133 2001-000786 C RESISTOR 47K

UR134 2001-000786 C RESISTOR 47K

UR135 2001-000786 C RESISTOR 47K

UR136 2001-000786 C RESISTOR 47K

UR137 2001-000786 C RESISTOR 47K

UR138 2001-000786 C RESISTOR 47K

UR139 2001-000786 C RESISTOR 47K

UR140 2001-000786 C RESISTOR 47K

UR141 2001-000786 C RESISTOR 47K

UR142 2001-000786 C RESISTOR 47K

UR143 2001-000786 C RESISTOR 47K

UR144 2001-000786 C RESISTOR 47K

UR145 2001-000786 C RESISTOR 47K

UR146 2001-000786 C RESISTOR 47K

UR147 2001-000786 C RESISTOR 47K

UR148 2001-000786 C RESISTOR 47K

UR149 2001-000786 C RESISTOR 47K

UR150 2001-000429 C RESISTOR 1K

UR151 2001-000290 C RESISTOR 10K

UR152 2001-000290 C RESISTOR 10K

UR153 2001-000290 C RESISTOR 10K

UR154 2001-000290 C RESISTOR 10K

UR155 2001-000290 C RESISTOR 10K

UR156 2001-000290 C RESISTOR 10K

UR157 2001-000290 C RESISTOR 10K

UR158 2001-000290 C RESISTOR 10K

UR159 2001-000290 C RESISTOR 10K

UR160 2001-000290 C RESISTOR 10K

UR161 2001-000429 C RESISTOR 1K

UR162 2001-000429 C RESISTOR 1K

UR163 2001-000429 C RESISTOR 1K

UR172 2001-000027 C RESISTOR 100

UR173 2001-000281 C RESISTOR 100

UR174 2001-000027 C RESISTOR 100

UR175 2001-000281 C RESISTOR 100

UR176 2001-000027 C RESISTOR 100

UR177 2001-000295 C RESISTOR 10M

UR178 2001-000850 C RESISTOR 560K

UR179 2001-000435 C RESISTOR 1M

UR180 2001-000449 C RESISTOR 2.2K

UR181 2001-000734 C RESISTOR 4.7K

UR182 2001-000508 C RESISTOR 220K

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

1/8W

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

1/8W

Ω

1/8W

Ω

1/8W

Ω

Ω

Ω

Ω

Ω

Ω

Ω

1/4W

1/4W

1/8W

Ω

1/8W

Ω

1/8W

Ω

1/8W

Ω

1/8W

Ω

1/8W

Ω

1/8W

Ω

1/8W

Ω

1/8W

Ω

1/8W

Ω

1/8W

Ω

1/8W

Ω

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/4W

1/8W

1/4W

1/8W

1/4W

1/8W

Ω

1/8W

1/8W

Ω

1/8W

Ω

1/8W

Ω

1/8W

UR183 2001-000793 C RESISTOR 47Ω 1/8W

UR184 2001-000734 C RESISTOR 4.7K

UR186 2001-000780 C RESISTOR 470K

UR187 2001-000780 C RESISTOR 470K

AJACK1 3722-001588 PHONE JACK 7P 3.6PI AG BLK

BEAD1 3301-000297 FERRITE BEADS

BEAD2 3301-000297 FERRITE BEADS

BZ101 3002-001134 BUZZER 85DB 12V

FL301 3301-000297 FERRITE BEADS

FL302 3301-000297 FERRITE BEADS

FW101 3708-000492 CONNECTOR 9P 1.25mm

FW102 3708-001696 CONNECTOR 24P

FW201 3708-001577 CONNECTOR 30P 1.25mm

FW202 3708-001696 CONNECTOR 24P

FW301 3708-001488 CONNECTOR 30P 1.25mm

FW302 3710-002050 CONNECTOR 12P

FW303 3710-002050 CONNECTOR 12P

FW304 3710-002050 CONNECTOR 12P

FW305 3722-002292 USB JACK 4P/1P

FW306 AH39-00096D CONNECTOR WIRE

FW307 3711-000906 CONNECTOR 3P 1R 2mm

FW308 3711-001136 CONNECTOR 8P

FW309 AH39-00060C CONNECTOR WIRE

GND2 AH39-50001L HARNESS WIRE

HJACK1 3722-001588 PHONE JACK 7P 3.6PI AG BLK

PS102 3406-001050 ROTARY SWITCH

REYE1 0609-001189 REMOCON MODULE

SW201 3404-000165 TACT SWITCH 12V 50mA

SW202 3404-000165 TACT SWITCH 12V 50mA

SW203 3404-000165 TACT SWITCH 12V 50mA

SW204 3404-000165 TACT SWITCH 12V 50mA

SW205 3404-000165 TACT SWITCH 12V 50mA

SW206 3404-000165 TACT SWITCH 12V 50mA

SW207 3404-000165 TACT SWITCH 12V 50mA

SW208 3404-000165 TACT SWITCH 12V 50mA

SW209 3404-000165 TACT SWITCH 12V 50mA

SW210 3404-000165 TACT SWITCH 12V 50mA

SW211 3404-000165 TACT SWITCH 12V 50mA

SW212 3404-000165 TACT SWITCH 12V 50mA

SW213 3404-000165 TACT SWITCH 12V 50mA

SW214 3404-000165 TACT SWITCH 12V 50mA

SW215 3404-000165 TACT SWITCH 12V 50mA

SW216 3404-000165 TACT SWITCH 12V 50mA

SW217 3404-000165 TACT SWITCH 12V 50mA

SW218 3404-000165 TACT SWITCH 12V 50mA

SW310 3404-000165 TACT SWITCH 12V 50mA

SW311 3404-000165 TACT SWITCH 12V 50mA

SW312 3404-000165 TACT SWITCH 12V 50mA

SW313 3404-000165 TACT SWITCH 12V 50mA

SW314 3404-000165 TACT SWITCH 12V 50mA

SW315 3404-000165 TACT SWITCH 12V 50mA

SW316 3404-000165 TACT SWITCH 12V 50mA

UW002 AH39-00249A CONNECTOR WIRE 5P for AMP AW102

UW003 3711-003408 CONNECTOR 2P

UW004 AH39-00342A CONNECT WIRE Z510S 2P

UW103 3708-000448 CONNECTOR 6P 1.25mm

UX101 2801-001394 CRYSTAL 32.768KHz

UX102 2802-001198 C.RESONATOR 10MHz

UX103 2801-004396 CRYSTAL UNIT 12.0MHz 30ppm

VFD1 AH07-00152A VFD DISPLAY WHITE

VR101 3406-001047 ROTARY SWITCH 5V DC 0.5mA

XXXXX 6003-001375 SCREW M3XL8

XXXXX AH61-01831A VFD HOLDER ABS BLACK

XXXXX AH61-01834B LED HOLDER ABS

XXXXX AH62-00099A HEAT SINK

XXXXX AH63-01033A USB SHIELD

Ω

1/8W

Ω

1/8W

Ω

1/8W

3P for FRONT

FW307

8P for FRONT

FW308

RING4 200MM

BLK

5V DC 0.5mA

12mm

HORIZONTAL

16.4mm

3-8

Page 41

Amp board

Block No. [0][3]

Symbol No.

AIC01 STK428-610 IC 1201-002207

AIC02 STK428-640 IC 1201-002208

AIC03 KIA7812PI IC AH14-10003E

AIC04 KIA7812PI IC AH14-10003E

PIC02 4959 IC 1203-001653

PQ001 78L05A IC 1203-000429

XXXXX 78R05 IC 1203-001006

AQ201 KSC1008 TRANSISTOR 0501-000010

AQ202 KTA1281 TRANSISTOR 0501-002228

AQ203 KSR2003 TRANSISTOR 0504-000145

AQ204 KSC1008 TRANSISTOR 0501-000010

AQ205 KSB1366 TRANSISTOR 0502-001138

AQ301 KSC1008 TRANSISTOR 0501-000010

AQ302 KTA1281 TRANSISTOR 0501-002228

AQ303 KTC2874-B TRANSISTOR 0501-002436

AQ304 KSR2002 TRANSISTOR 0504-000144

AQ305 KTD2058 TRANSISTOR 0502-000465

PQ102 KSR2002 TRANSISTOR 0504-000144

PQ103 KSR1003 TRANSISTOR 0504-000118

PQ104 KSC1009-Y TRANSISTOR 0501-000331

PQ105 KTA1046 TRANSISTOR 0502-001177

PQ105 KTA1281 TRANSISTOR 0501-002228

PQ106 KSA708-Y TRANSISTOR 0501-000294

AD201 1N4002 DIODE 0402-000127

AD202 1N4002 DIODE 0402-000127

AW133 1N4002 DIODE 0402-000127

AW173 1N4002 DIODE 0402-000127

AZ201 UZ5.1BSB Z DIODE 0403-000355

PBD01 1N5402 DIODE 0402-000157

PBD02 1N5402 DIODE 0402-000157

PBD03 1N5402 DIODE 0402-000157

PBD04 1N5402 DIODE 0402-000157

PBD05 1N5402 DIODE 0402-000157

PBD06 1N5402 DIODE 0402-000157

PBD07 1N5402 DIODE 0402-000157

PBD08 1N5402 DIODE 0402-000157

PD001 1N4002 DIODE 0402-000127

PD002 1N4148 DIODE 0401-000005

PD201 1N4002 DIODE 0402-000127

PD202 1N4002 DIODE 0402-000127

PD204 1N4002 DIODE 0402-000127

PD207 1N4002 DIODE 0402-000127

PD210 1N4002 DIODE 0402-000127

PD211 1N5392 DIODE 0402-000151

PD212 1N5392 DIODE 0402-000151

PD213 1N5392 DIODE 0402-000151

PD214 1N5392 DIODE 0402-000151

PD401 1N4002 DIODE 0402-000127

PZ104 1N4733A Z DIODE 0403-000525

PZ105 1N4743A Z DIODE 0403-000150

PZ401 UZ5.1BSB Z DIODE 0403-000355

PC201 2201-000161 C CAPACITOR 10nF

PC202 2201-000161 C CAPACITOR 10nF

PC203 2201-000161 C CAPACITOR 10nF

AC201 2201-000161 C CAPACITOR 10nF

AC204 2201-000338 C CAPACITOR 2.2nF 50V

AC205 2201-000338 C CAPACITOR 2.2nF 50V

AC206 2201-000161 C CAPACITOR 10nF

AC209 2305-001039 M CAPACITOR 270nF 63V

AC210 2301-001074 M CAPACITOR 680nF 63V

AC211 2305-000412 M CAPACITOR 470nF

AC212 2305-000412 M CAPACITOR 470nF

AC301 2201-000161 C CAPACITOR 10nF

AC304 2201-000338 C CAPACITOR 2.2nF 50V

AC305 2201-000338 C CAPACITOR 2.2nF 50V

AC306 2201-000161 C CAPACITOR 10nF

AC309 2301-001074 M CAPACITOR 680nF 63V

AC310 2305-001039 M CAPACITOR 270nF 63V

AC311 2305-000412 M CAPACITOR 470nF

AC312 2305-000412 M CAPACITOR 470nF

Part No. Part Name Description Local

Symbol No.

AC321 2301-000302 M CAPACITOR 680nF 100V

AC322 2301-000302 M CAPACITOR 680nF 100V

AC323 2301-000302 M CAPACITOR 680nF 100V

AC324 2301-000302 M CAPACITOR 680nF 100V

AC325 2201-000806 C CAPACITOR 1nF 400V

AC326 2201-000806 C CAPACITOR 1nF 400V

AC327 2201-000806 C CAPACITOR 1nF 400V

AC328 2201-000806 C CAPACITOR 1nF 400V

AC405 2201-000021 C CAPACITOR 100nF 50V

AC406 2201-000021 C CAPACITOR 100nF 50V

AC407 2201-000021 C CAPACITOR 100nF 50V

AC408 2201-000021 C CAPACITOR 100nF 50V

AE201 2401-000303 E CAPACITOR 100uF 25V

AE202 2401-002335 E CAPACITOR 1000uF 63V

AE203 2401-002335 E CAPACITOR 1000uF 63V

AE204 2401-000303 E CAPACITOR 100uF 25V

AE205 2401-000303 E CAPACITOR 100uF 25V

AE206 2401-002335 E CAPACITOR 1000uF 63V

AE207 2401-002335 E CAPACITOR 1000uF 63V

AE208 2401-000650 E CAPACITOR 2.2uF 50V

AE209 2401-000650 E CAPACITOR 2.2uF 50V

AE301 2401-000303 E CAPACITOR 100uF 25V

AE302 2401-004153 E CAPACITOR 1000uF 100V

AE303 2401-004153 E CAPACITOR 1000uF 100V

AE304 2401-000303 E CAPACITOR 100uF 25V

AE305 2401-000303 E CAPACITOR 100uF 25V

AE306 2401-004153 E CAPACITOR 1000uF 100V

AE307 2401-004153 E CAPACITOR 1000uF 100V

AE308 2401-000650 E CAPACITOR 2.2uF 50V

AE309 2401-000650 E CAPACITOR 2.2uF 50V

PE201 2401-002592 E CAPACITOR 2200uF 50V

PE202 2401-002592 E CAPACITOR 2200uF 50V

PE203 2401-003385 E CAPACITOR 3300uF 80V

PE204 2401-003385 E CAPACITOR 3300uF 80V

PE205 2401-003116 E CAPACITOR 4700uF 35V

PE206 2401-000832 E CAPACITOR 220uF 25V

PE207 2401-000909 E CAPACITOR 22uF 16V

PE208 2401-000027 E CAPACITOR 4.7uF 50V

PE209 2401-001912 E CAPACITOR 1uF 50V

PE210 2401-000970 E CAPACITOR 22uF 50V

PE211 2401-000970 E CAPACITOR 22uF 50V

PE212 2401-000230 E CAPACITOR 100uF 100V

PE213 2401-000027 E CAPACITOR 4.7uF 50V

PE214 2401-000480 E CAPACITOR 10uF 50V

PE221 2401-000480 E CAPACITOR 10uF 50V

PE401 2401-001625 E CAPACITOR 6.8uF 50V

PE402 2401-001938 E CAPACITOR 22uF 25V

AR201 2003-000689 METAL RESISTOR 4.7

AR202 2001-001015 C RESISTOR 9.1K

AR203 2001-000734 C RESISTOR 4.7K

AR204 2001-000290 C RESISTOR 10K

AR205 2001-000010 C RESISTOR 68K

AR206 2001-000010 C RESISTOR 68K

AR207 2001-000290 C RESISTOR 10K

AR208 2001-000290 C RESISTOR 10K

AR209 2001-000734 C RESISTOR 4.7K

AR210 2001-000290 C RESISTOR 10K

AR211 2001-000449 C RESISTOR 2.2K

AR212 2001-000449 C RESISTOR 2.2K

AR213 2001-001015 C RESISTOR 9.1K

AR214 2003-000429 METAL RESISTOR 100

AR215 2003-000429 METAL RESISTOR 100

AR216 2003-000690 METAL RESISTOR 4.7

AR217 2003-000690 METAL RESISTOR 4.7

AR218 2001-000411 C RESISTOR 18K

AR219 2001-000411 C RESISTOR 18K

AR220 2001-000522 C RESISTOR 22K

AR221 2001-000522 C RESISTOR 22K

AR222 2001-001107 C RESISTOR 220

AR225 2001-000008 C RESISTOR 15K

AR226 2001-000008 C RESISTOR 15K

AR250 2001-000456 C RESISTOR 2.2

AR301 2003-000429 METAL RESISTOR 100

AR301 2003-000689 METAL RESISTOR 4.7

AR302 2001-000522 C RESISTOR 22K

AR303 2001-000734 C RESISTOR 4.7K

AR304 2001-000290 C RESISTOR 10K

Part No. Part Name Description Local

Ω

1W

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

2W

Ω

2W

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

1/4W

Ω

Ω

1W

Ω

Ω

Ω

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

1/8W

2W

2W

1/8W

1/8W

1/8W

1/8W

1/2W

1/8W

1/8W

2W

1/8W

1/8W

1/8W

3-9

Page 42

Symbol No.

Part No. Part Name Description Local

Symbol No.

Part No. Part Name Description Local

AR305 2001-000273 C RESISTOR 100KΩ 1/8W

AR306 2001-000273 C RESISTOR 100K

AR307 2001-000290 C RESISTOR 10K

AR308 2001-000290 C RESISTOR 10K

AR309 2001-000734 C RESISTOR 4.7K

AR311 2001-000591 C RESISTOR 3.3K

AR312 2001-000591 C RESISTOR 3.3K

AR313 2001-000522 C RESISTOR 22K

AR314 2003-000429 METAL RESISTOR 100

AR315 2003-000429 METAL RESISTOR 100

AR316 2003-000690 METAL RESISTOR 4.7

AR317 2003-000690 METAL RESISTOR 4.7

AR318 2001-000563 C RESISTOR 27K

AR319 2001-000563 C RESISTOR 27K

AR320 2001-000429 C RESISTOR 1K

AR321 2001-000429 C RESISTOR 1K

AR322 2001-000591 C RESISTOR 3.3K

AR325 2001-000429 C RESISTOR 1K

AR326 2001-000008 C RESISTOR 15K

AR327 2001-000008 C RESISTOR 15K

AR350 2001-000456 C RESISTOR 2.2

JW183 2001-000022 C RESISTOR 33

PF101 2001-000016 C RESISTOR 1Ω 1/2W

PR003 2001-000009 C RESISTOR 20K

PR004 2001-000009 C RESISTOR 20K

PR201 2001-000052 C RESISTOR 3.3K

PR202 2001-000055 C RESISTOR 4.7K

PR203 2001-000429 C RESISTOR 1K

PR204 2001-000786 C RESISTOR 47K

PR205 2001-000290 C RESISTOR 10K

PR206 2003-000455 METAL RESISTOR 100

PR208 2001-000734 C RESISTOR 4.7K

PR209 2001-000111 C RESISTOR 150

PR210 2001-000055 C RESISTOR 4.7K

PR211 2001-000038 C RESISTOR 390

PR216 2003-000701 METAL RESISTOR 470

PR217 2001-001153 C RESISTOR 47

PR218 2001-001153 C RESISTOR 47

PR219 2001-000290 C RESISTOR 10K

PR221 2001-000660 C RESISTOR 33K

PR401 2001-001168 C RESISTOR 6.8K

PR402 2001-001099 C RESISTOR 2.7K

R207 2001-000563 C RESISTOR 27K

AL201 2702-001129 COIL 20uH

AL202 2702-001129 COIL 20uH

AL301 2702-001132 COIL 20uH

AL302 2702-001132 COIL 20uH

AW101 3708-000193 CONNECTOR 17P

AW102 3711-001011 CONNECTOR 5P 1R 2.5mm

AW104 3708-001029 CONNECTOR 9P

AW105 3711-000596 CONNECTOR 10P

CW108 3711-000631 CONNECTOR

FAN101 3711-000820 CONNECTOR 2P 1R 2.5mm

FAN102 3711-000820 CONNECTOR 2P 1R 2.5mm

SP101 3716-001208 TERMINAL BLOCK 8P

XXXXX 6003-001230 SCREW M3X16 YEL(x4)

XXXXX 6003-001375 SCREW M3XL8(x5)

XXXXX AH62-00062D HEAT SINK (x2)

XXXXX AH62-00137A HEAT SINK AL T3.0

Ω

Ω

1/8W

Ω

1/8W

Ω

1/8W

Ω

1/8W

Ω

1/8W

Ω

1/8W

Ω

2W

Ω

2W

Ω

2W

Ω

2W

Ω

1/8W

Ω

1/8W

Ω

1/8W

Ω

1/8W

Ω

1/8W

Ω

1/8W

Ω

1/8W

Ω

1/8W

Ω

1/4W

Ω

1/2W

Ω

1/8W

Ω

1/8W

Ω

1/2W

Ω

1/4W

Ω

1/8W

Ω

1/8W

Ω

1/8W

Ω

2W

Ω

1/8W

Ω

1/4W

Ω

1/4W

Ω

1/4W

Ω

2W

Ω

1/2W

Ω

1/2W

Ω

1/8W

Ω

1/8W

Ω

1/2W

Ω

1/2W

Ω

1/8W

BOX 11P 1R

2.5mm

1/8W

VC105 2203-000595 CHIP CAPACITOR 0.22nF 50V

VC106 2203-000595 CHIP CAPACITOR 0.22nF 50V

VC107 2203-000595 CHIP CAPACITOR 0.22nF 50V

VC108 2203-000408 CHIP CAPACITOR 0.18nF 50V

VC109 2203-000206 CHIP CAPACITOR 100nF 50V

VE101 2401-000042 E CAPACITOR 100uF 16V

VE102 2401-001912 E CAPACITOR 1uF 50V

VE103 2401-001975 E CAPACITOR 47uF 16V

VE104 2401-001912 E CAPACITOR 1uF 50V

VE105 2401-001912 E CAPACITOR 1uF 50V

VE106 2401-001912 E CAPACITOR 1uF 50V

VE107 2401-001102 E CAPACITOR 330uF 16V

VE108 2401-001102 E CAPACITOR 330uF 16V

VE109 2401-001102 E CAPACITOR 330uF 16V

VE111 2401-001102 E CAPACITOR 330uF 16V

J13 2007-000033 CHIP RESISTOR 0

J19 2007-000029 CHIP RESISTOR 0

J21 2007-000029 CHIP RESISTOR 0

J22 2007-000029 CHIP RESISTOR 0

J25 2007-000033 CHIP RESISTOR 0

J26 2007-000033 CHIP RESISTOR 0

J28 2007-000033 CHIP RESISTOR 0

J29 2007-000033 CHIP RESISTOR 0

J30 2007-000033 CHIP RESISTOR 0

J31 2007-000033 CHIP RESISTOR 0

VR101 2007-000766 CHIP RESISTOR 330

VR102 2007-000766 CHIP RESISTOR 330

VR103 2007-000766 CHIP RESISTOR 330

VR104 2007-000766 CHIP RESISTOR 330

VR105 2007-000766 CHIP RESISTOR 330

VR106 2007-000766 CHIP RESISTOR 330

VR107 2007-000026 CHIP RESISTOR 200Ω 1/8W

VR108 2007-000023 CHIP RESISTOR 120

VR109 2007-000026 CHIP RESISTOR 200Ω 1/8W

VR110 2007-000023 CHIP RESISTOR 120

VR111 2007-000290 CHIP RESISTOR 100

VR112 2007-000290 CHIP RESISTOR 100

VR113 2007-001166 CHIP RESISTOR 75Ω 1/8W

VR114 2007-001166 CHIP RESISTOR 75

VR115 2007-001166 CHIP RESISTOR 75

VR116 2007-001166 CHIP RESISTOR 75

VR117 2007-001166 CHIP RESISTOR 75

VR118 2007-001166 CHIP RESISTOR 75

VR119 2007-000290 CHIP RESISTOR 100

CN101 3708-000172 CONNECTOR 15P

OJ101 3707-001060 CONNECTOR

VJ101 3722-002145 PIN JACK 1P VHS+PIN

VJ102 3722-002224 PIN JACK 3P

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

1/8W

Ω

1/8W

Ω

1/8W

Ω

1/8W

Ω

1/8W

Ω

Power board

Block No. [0][5]

Symbol No.

DIC02 KIA378R09PI IC 1203-003743

DIC03 278R05 IC 1203-001589

DIC04 78R05 IC 1203-001006

DIC05 78R33 IC 1203-001543

Part No. Part Name Description Local

1/10W

1/10W

Jack board

Block No. [0][4]

Symbol No.

VIC01 MM1623XFBE IC 1201-002085

VC101 2203-000206 CHIP CAPACITOR 100nF 50V

VC102 2203-000206 CHIP CAPACITOR 100nF 50V

VC103 2203-000595 CHIP CAPACITOR 0.22nF 50V

VC104 2203-000595 CHIP CAPACITOR 0.22nF 50V

3-10

Part No. Part Name Description Local

DP103 1N4002 DIODE 0402-000127

DPD02 PBL403 DIODE 0402-000450

DPD03 PBL403 DIODE 0402-000450

PD203 1N4148 DIODE 0401-000005

PC103 2201-002128 C CAPACITOR 4.7nF 400V

PC104 2201-001005 C CAPACITOR 2.2nF 400V

DC102 2201-002128 C CAPACITOR 4.7nF 400V

DC103 2201-002128 C CAPACITOR 4.7nF 400V

DC105 2201-000565 C CAPACITOR 47nF 50V

DC106 2201-000565 C CAPACITOR 47nF 50V

DC107 2201-000565 C CAPACITOR 47nF 50V

Page 43

Symbol No.

DC108 2201-000565 C CAPACITOR 47nF 50V

DE102 2401-003116 E CAPACITOR 4700uF 35V

DE103 2401-001883 E CAPACITOR 1000uF 25V

DE105 2401-000303 E CAPACITOR 100uF 25V

DE106 2401-001364 E CAPACITOR 470uF 16V

DE107 2401-000303 E CAPACITOR 100uF 25V

DE108 2401-000303 E CAPACITOR 100uF 25V

DE109 2401-001355 E CAPACITOR 470uF 10V

DE110 2401-000303 E CAPACITOR 100uF 25V

DE111 2401-002042 E CAPACITOR 220uF 10V

DR101 2003-000629 METAL RESISTOR 3.3

Part No. Part Name Description Local

Ω

2W

AW103 3708-001761 CONNECTOR 28P

AW104 AH39-00791A CONNECTOR WIRE

AW106 3708-000172 CONNECTOR 15P

DCW02 3711-005949 CONNECTOR 5P

DCW03 AH39-00539A CONNECTOR WIRE

DCW04 3711-000820 CONNECTOR 2P 1R 2.5mm

DCW05 3711-004848 CONNECTOR 3P 1R 7.92mm

DCW07 3711-000190 CONNECTOR 2P 1R 7.92mm

PL104 2901-001341 FILTER

VS101 3408-000177 SLIDE SWITCH 250V 5A DPDT

XXXXX AH61-40014A SUPPORT RIVET (x2)

XXXXX AH62-00129C HEAT SINK

10P for AMP

AW105

11P for AMP

CW108

Wiring

Block No. [0][6]

Symbol No.

XXXXX 3301-000132 FERRITE BEADS

XXXXX AH63-00075B SHEET CUSHION

XXXXX 3809-001298 FLAT CABLE

XXXXX 3809-001327 FLAT CABLE

XXXXX 3809-001452 FLAT CABLE

XXXXX 3809-001468 FLAT CABLE

XXXXX 3809-001707 FLAT CABLE

XXXXX 3809-001718 FLAT CABLE

XXXXX 3809-001719 FLAT CABLE

XXXXX 3809-001720 FLAT CABLE

Part No. Part Name Description Local

12P for MAIN

CW103 to TUNER

17P for MAIN

CW106 to AMP

AW101

24P for FRONT

FW102 to FW202

9P for AMP AW104

to FRONT FW101

30P for FRONT

FW201 to FW301

10P for MAIN

CW104 to DVD

15P for JACK

CN101 to POWER

CW106

28P for POWER

AW103 to DVD

3-11

Page 44

Packing materials and accessories parts list

P6

Block No.

M

3

M

M

A8

P7

P8

P8

A9

P2

P4

A1

A4

A7

P5

A2

A3

A5 A6

P3

3-12

P1

Page 45

Packing and Accessories

Symbol No. Part No. Part Name Description Local

A 1 AH68-01704C INST BOOK ENG LVT1351-003B

A 2 AH59-01539A REMOTE CONTROL

A 3 AH39-00320C FM WIRE

A 4 AH42-00019A ANT LOOP

A 5 ------------ BATTERY (x2)

A 6 AH39-40001V RCA CABLE

A 7 3721-000117 CONVERSION PLUG

A 8 AH81-01691A SPEAKER BOX L

A 9 AH81-01691B SPEAKER BOX R

P 1 AH69-01408F CARTON FOR SET

P 2 AH69-01405A CUSHION L FOR SET

P 3 AH69-01406A CUSHION R FOR SET

P 4 6902-000068 POLY BAG FOR SET

P 5 6902-000385 POLY BAG FOR ACCESSORIES

P 6 AH81-01691V CUSHION TOP

P 7 AH81-01691W CUSHION BOTTOM

P 8 AH81-00631U POLY BAG FOR SPEAKER(x2)

Block No. [M][3][M][M]

3-13

Loading...

Loading...