Page 1

SERVICE MANUAL

HDD & S-VHS VIDEO RECORDER

VICTOR COMPANY OF JAPAN, LIMITED

VIDEO DIVISION

S40894

HM-HDS1EK/EU

SPECIFICATIONS

GENERAL

Power requirement : AC 220 V – 240 V ` , 50 Hz/60 Hz

Power consumption

Temperature

Operating position : Horizontal only

Dimensions (WxHxD) : 435 mm x 124 mm x 385 mm

Weight : 7.3 kg

Input/Output : 21-pin SCART connectors:

HDD DECK VIDEO/AUDIO

Video format : MPEG2 (VBR)

Audio format : MPEG1 Layer2

Maximum recording time (approx.)

VHS DECK VIDEO/AUDIO

No. 82887

Signal system : PAL-type colour signal and CCIR monochrome

Recording system :

Format : S-VHS/VHS PAL standard

Signal-to-noise ratio : 45 dB

Horizontal resolution

HM-HDS1EK/EU

1

2

123

4 56

789

0

<

ñ

(The specifications shown pertain specifically to the model HM-HDS1EU)

Power on : 41 W

Power off : 16 W

Operating : 5°C to 40°C

Storage : –20°C to 60°C

IN/OUT x 1, IN/DECODER x 1

RCA connectors:

VIDEO IN x 1, AUDIO IN x 1,

AUDIO OUT x 1

S-Video connectors: IN x 1, OUT x 1

(SP) : 14 hours

(LP) : 20 hours

(EP) : 28 hours

(SEP) : 40 hours

signal, 625 lines 50 fields

DA4 (Double Azimuth) head helical scan system

(SP/LP) : 250 lines (VHS)

(EP) : 220 lines (VHS)

400 lines (S-VHS)

350 lines (S-VHS)

3

4

>

+

Frequency range : 70 Hz to 10,000 Hz (Normal audio)

Maximum recording time

(SP) : 240 min. with E-240 video cassette

(LP) : 480 min. with E-240 video cassette

(EP) : 720 min. with E-240 video cassette

F - 1

20 Hz to 20,000 Hz (Hi-Fi audio)

TUNER/TIMER

TV channel storage capacity

Tuning system : Frequency synthesized tuner

Channel coverage : VHF 47 MHz – 89 MHz/

Aerial output : UHF channels 22 – 69 (Adjustable)

Memory backup time : Approx. 60 min.

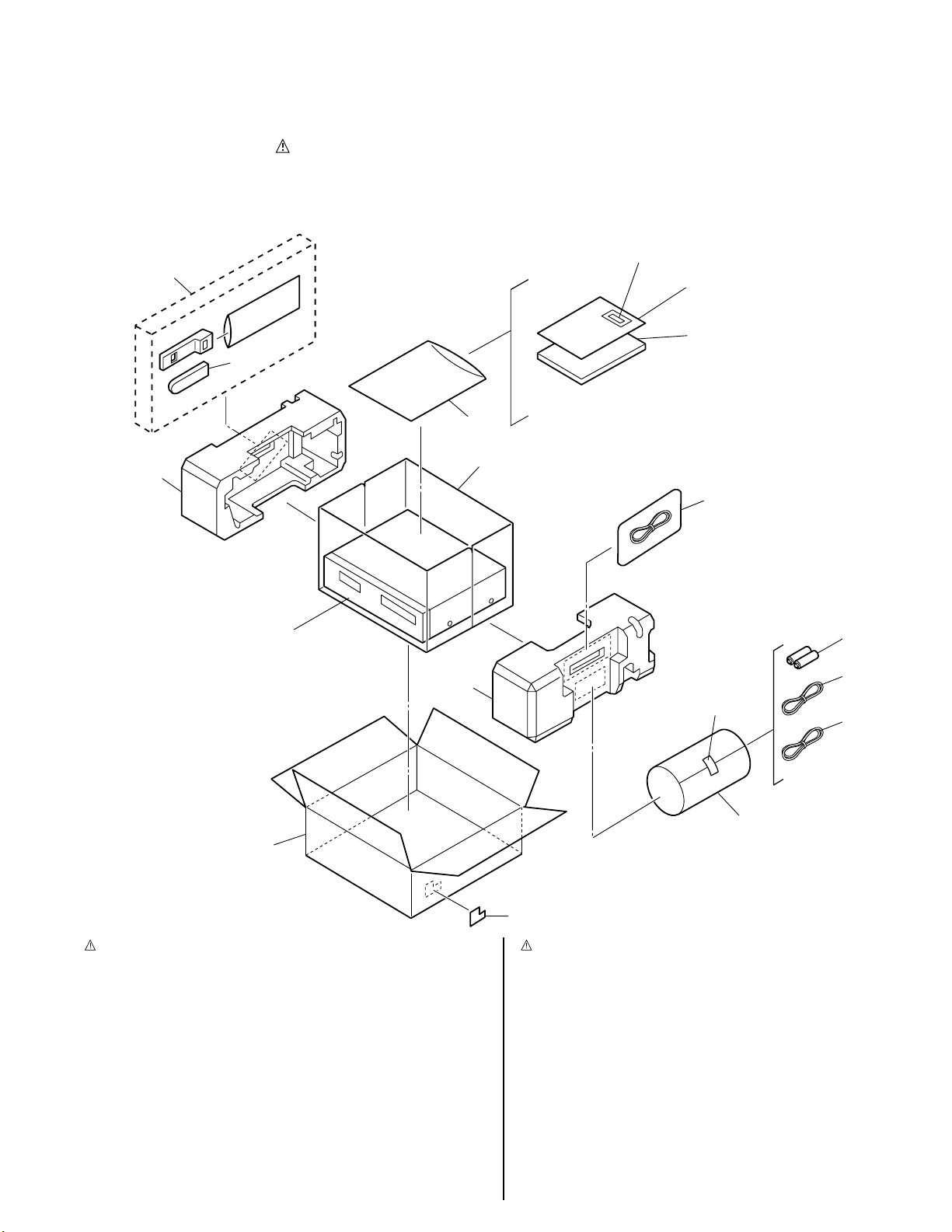

ACCESSORIES

Provided accessories : RF cable,

Specifications shown are for SP mode unless otherwise specified.

E. & O.E. Design and specifications subject to change without notice.

: 99 positions (+AUX position)

104 MHz – 300 MHz/

302 MHz – 470 MHz

UHF 470 MHz – 862 MHz

21-pin SCART cable,

Satellite Controller,

Infrared remote control unit,

“R6” battery x 2

Printed in Japan

This service manual is printed on 100% recycled paper.

COPYRIGHT © 2001 VICTOR COMPANY OF JAPAN, LTD.

No. 82887

July 2001

Page 2

Hard Disk Drive (HDD)

1. Hard Disk Drive (HDD) Handling Precautions

The HDD is a precision device for use in reading and writing a large amount of data on or from a disk rotating at

a high speed. If it is not handled carefully, either abnormal operation may result or it may not be possible to read

data. The HDD is sensitive to the following items and special care is required in safeguarding against them when

handling an HDD. Also take care in handling a set incorporating an HDD.

1. Vibrations and impacts

2. Static electricity

3. Rough handling

1.1 Handling in transport, etc.

s Be sure to place the HDD in the manufacturer's specified package

carton before transport.

s When receiving a package containing an HDD, check that the pack-

age carton is not damaged (such as having holes in the carton,

crushed corners, etc.).

s Do not impact the packaging carton when loading or unloading it.

s It is not permitted to use the inner package carton only for transport-

ing an HDD.

s Do not stack package cartons one upon another.

Be sure to package and

transport the HDDs correctly.

HDD

Do not throw or

drop packages.

1.2 Handling an HDD in the stand-alone status

s When handling an HDD on a hard workbench, place an antistatic

mat (rubber sheet) or similar object on the hard surface (to prevent

any impacts occurring between the HDD and bench).

s Do not stack the HDDs one upon another.

s Do not knock an HDD with a hard object (such as a screwdriver).

s Do not place an HDD on its side panel without using a support (do

not place an HDD in an unstable position).

1.3 Handling the installation of an HDD

s Place antistatic mats or similar sheets on all of the surfaces on which work is conducted or when the HDD

is transported.

s Do not permit the HDD to knock against the set's brackets.

s When screwing the brackets, be careful not to knock the HDD. When using a power screwdriver, use a low-

shock model and arrange the tightening torque properly.

s When mounting an HDD in a HDD/VHS DUAL RECORDER, take care not to apply excessive force to the

brackets.

1

Page 3

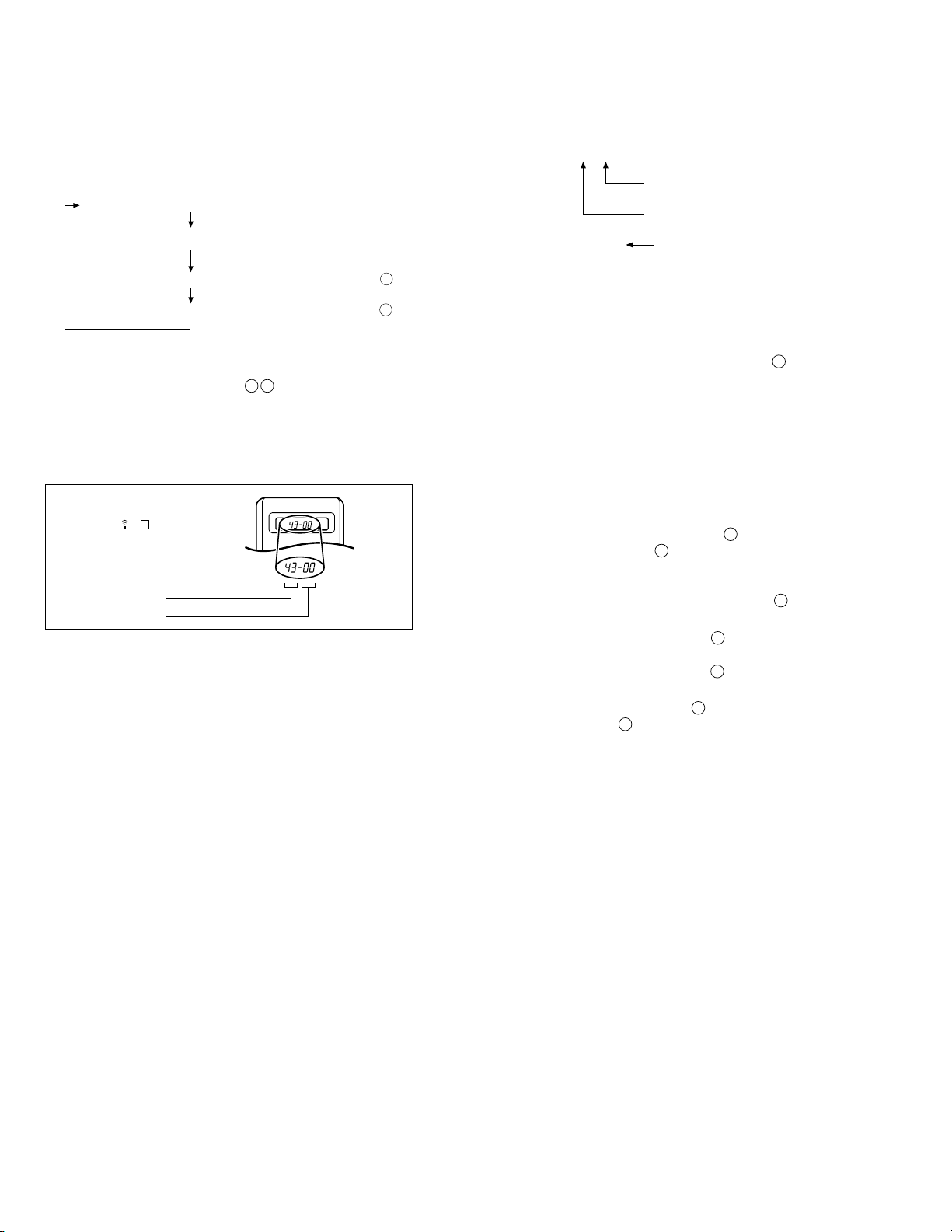

2. In Case of an HDD Failure

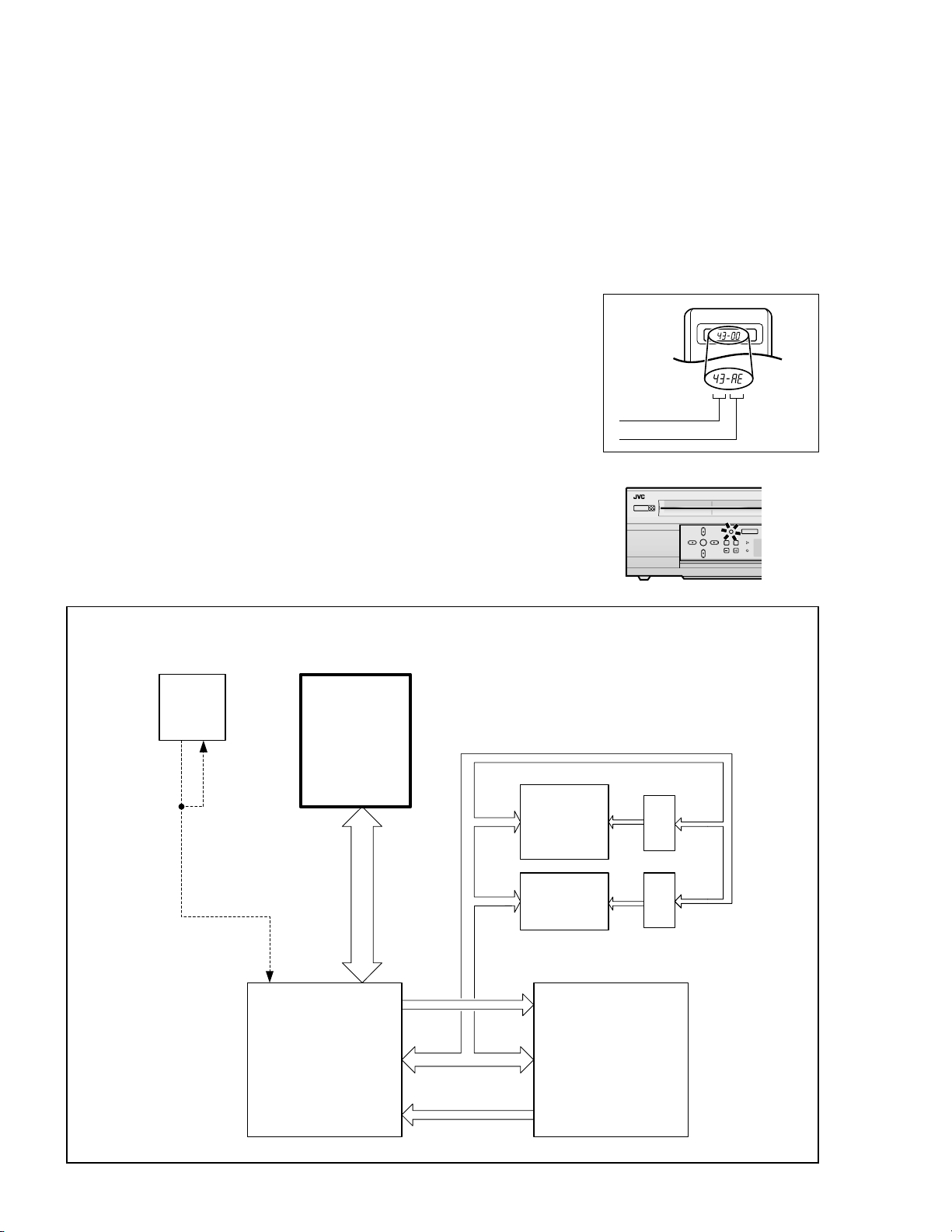

When a HDD/VHS DUAL RECORDER AC cord is plugged into a power outlet, the boot loader is read from the

IC8204 (8M FLASH ROM), which activates the HDD and reads the system files in the HDD before getting ready

for operation. In consequence, the HDD/VHS DUAL RECORDER cannot be turned on if the HDD fails.

In case a failure of the HDD is in doubt, use the following procedure to switch the main power of the set ON using

the VHS section alone, by bypassing the HDD operation check.

(1) With the HDD/VHS DUAL RECORDER in the remote control

standby status, transmit code AE from the remote jig for more

than 2 seconds.

(2) The REC LINK button on the HDD/VHS DUAL RECORDER

blinks, indicating that the power supply can be switched ON.

(3) When the code AE is transmitted again from the remote jig,

the button stops blinking and its function is canceled.

<Reference>

VHS

SYSCON

KBUS_IN

KBUS_OUT

E:08 is displayed in the

case of a

communication error

with the VHS SYSCON

HOSTDATA

40GB

HDD

AD 4:19

Firmware

HDD driver

Navigation information

AD 0:15

IDE 40PIN

AD 16:31

DVD 0_:7_

IC8204

8M FLASH

boot loader

VHS Navi

back up

OPEN

IC8205

Custom code

43: A code

52: B code

6F: C code

7F: D code

Data code

POWER

HM-HDS1

IC8206

LADO

4:11

LADO

12:19

IC8207

Latch

Address

Latch

Address

OK

AD 4:11

AD 12:19

Initial mode

BS DIGIATL

HDD

Blinks.

CHANNEL

AD 0:31

IC8201IC8001

ASIC_IF MPEG_DEC

VIO 0:7

2

Page 4

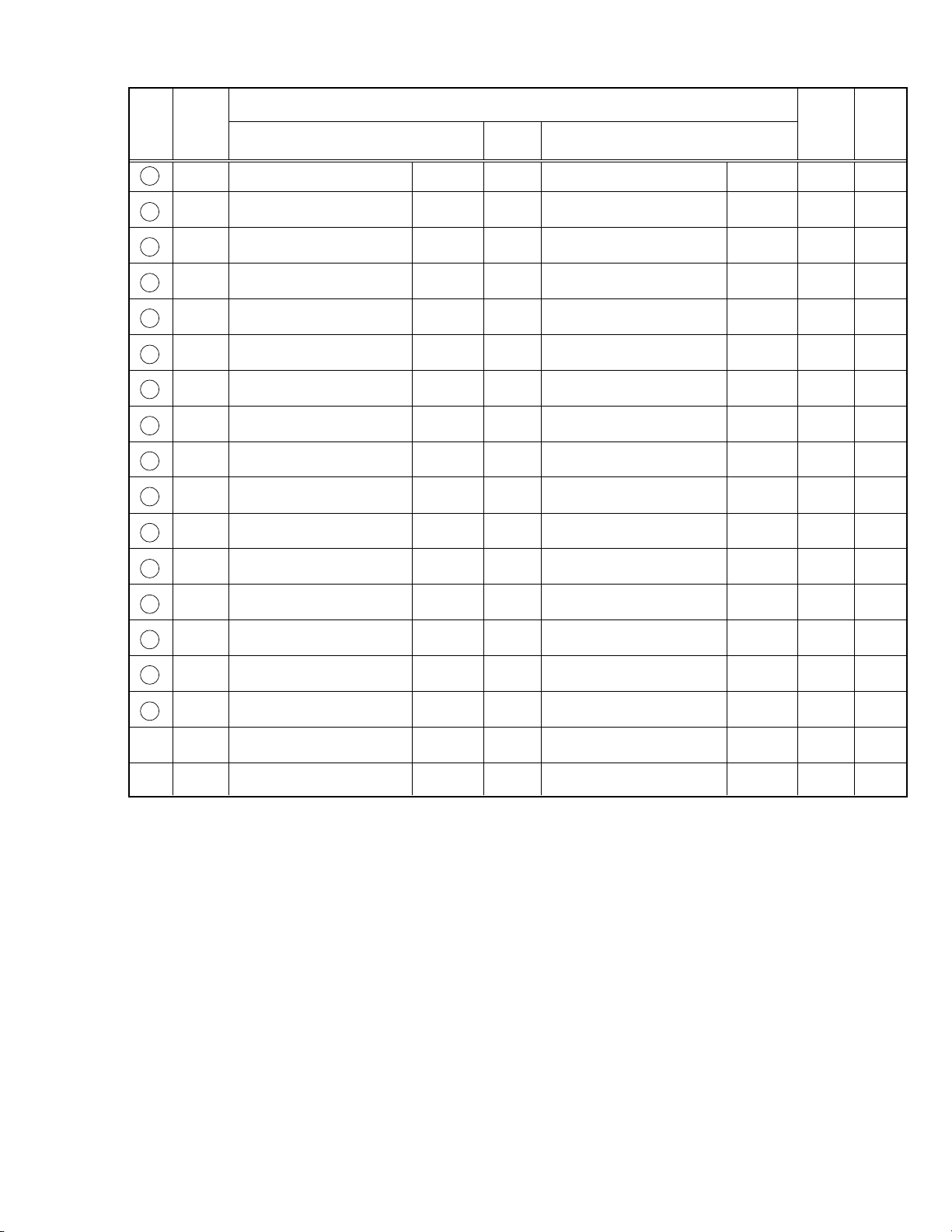

TABLE OF CONTENTS

Section Title Page Section Title Page

Hard Disk Drive (HDD)

Important Safety Precautions

INSTRUCTIONS

1. DISASSEMBLY

1.1 HOW TO REMOVE THE MAJOR PARTS ..................................................... 1-1

1.1.1 Introduction .................................................................................... 1-1

1.2 HOW TO READ THE DISASSEMBLY AND ASSEMBLY .............................. 1-1

1.3 DISCONNECTION OF CONNECTORS (WIRES) ........................................ 1-1

1.4 SCREWS USED CABINET COMPONENTS AND BOARD ASSEMBLIES .. 1-1

1.5 HOW TO REMOVE THE MAJOR PARTS <COM section> ........................... 1-2

1.5.1 Disassembly flow chart .................................................................. 1-2

1.5.2 Disassembly/assembly method <COM section>............................ 1-2

1.6 HOW TO REMOVE THE MAJOR PARTS <VHS section> ............................ 1-4

1.6.1 Disassembly flow chart .................................................................. 1-4

1.6.2 DIsassembly/assembly method <VHS section> ............................ 1-4

Hard Disk Drive (HDD) Handling Precautions ...................................................... 1-6

1.7 HOW TO REMOVE THE MAJOR PARTS <HDD section> ............................ 1-6

1.7.1 Disassembly flow chart .................................................................. 1-6

1.7.2 DIsassembly/assembly method <HDD section> ............................1-6

1.8 SERVICE POSITIONS .................................................................................. 1-7

1.8.1 Service position <VHS SIDE> ........................................................ 1-7

1.8.2 Service position <HDD SIDE> ....................................................... 1-8

1.9 MECHANISM SERVICE MODE .................................................................... 1-9

1.9.1 How to set the "MECHANISM SERVICE MODE" .......................... 1-9

1.10 CONNECTION ........................................................................................... 1-10

1.11 EMERGENCY DISPLAY FUNCTION ........................................................ 1-12

1.11.1 Displaying the emergency information ................................................. 1-12

1.11.2 Clearing the emergency history ........................................................... 1-12

1.11.3 Emergency content description ............................................................ 1-13

1.11.4 Emergency detail information 1 ......................................................... 1-14

1.11.5 Emergency detail information 2 ......................................................... 1-15

2. MECHANISM ADJUSTMENT (VHS)

2.1 Before starting repair and adjustment ............................................................ 2-1

2.1.1 Precautions .................................................................................... 2-1

2.1.2 Checking for proper mechanical operations ................................... 2-1

2.1.3 Manually removing the cassette tape............................................. 2-1

2.1.4 Jigs and tools required for adjustment ........................................... 2-2

2.1.5 Maintenance and inspection .......................................................... 2-3

2.2 Replacement of major parts .......................................................................... 2-6

2.2.1

Before starting disassembling (Phase matching between mechanical parts) ..

2.2.2 How to set the “Mechanism assembling mode” ............................. 2-6

2.2.3 Cassette holder assembly .............................................................. 2-6

2.2.4 Pinch roller arm assembly .............................................................. 2-8

2.2.5 Guide arm assembly and press lever assembly .............................2-8

2.2.6 A/C head ........................................................................................ 2-8

2.2.7 Loading motor ................................................................................ 2-8

2.2.8 Capstan motor................................................................................ 2-9

2.2.9 Pole base assembly (supply or take-up side) .................................2-9

2.2.10 Rotary encoder ............................................................................ 2-10

2.2.11 Clutch unit .................................................................................... 2-10

Change lever assembly, direct gear, clutch gear and coupling gear .

2.2.12

2.2.13 Link lever ......................................................................................2-11

2.2.14 Cassette gear, control cam and worm gear ................................. 2-11

2.2.15 Control plate .................................................................................2-11

Loading arm gear (supply or take-up side) and loading arm gear shaft ..

2.2.16

2.2.17 Take-up lever, take-up head and control plate guide .................... 2-13

2.2.18 Capstan brake assembly .............................................................. 2-13

2.2.19 Sub brake assembly (take-up side) .............................................. 2-13

2.2.20 Main brake assembly (take-up side), reel disk (take-up side) and

main brake assembly (supply side) ..............................................2-13

Tension brake assembly, reel disk (supply side) and tension arm assembly .

2.2.21

2.2.22 Idler lever, idler arm assembly ..................................................... 2-14

2.2.23 Stator assembly ........................................................................... 2-14

2.2.24 Rotor assembly ............................................................................ 2-14

2.2.25 Upper drum assembly .................................................................. 2-15

2.3 Compatibility adjustment ............................................................................. 2-16

2.3.1 FM waveform linearity .................................................................. 2-16

2.3.2 Height and tilt of the A/C head ..................................................... 2-17

2.3.3 A/C head phase (X-value) ............................................................ 2-17

2.3.4 Standard tracking preset ..............................................................2-18

2.3.5 Tension pole position .................................................................... 2-18

3. ELECTRICAL ADJUSTMENT (VHS)

3.1 PRECAUTION............................................................................................... 3-1

3.1.1 Required test equipments .............................................................. 3-1

3.1.2 Required adjustment tools ............................................................. 3-1

3.1.3 Color (colour) bar signal,Color (colour) bar pattern ....................... 3-1

3.1.4 Switch settings and standard precautions...................................... 3-1

3.1.5 EVR Adjustment ............................................................................. 3-1

2-6

2-10

2-12

2-14

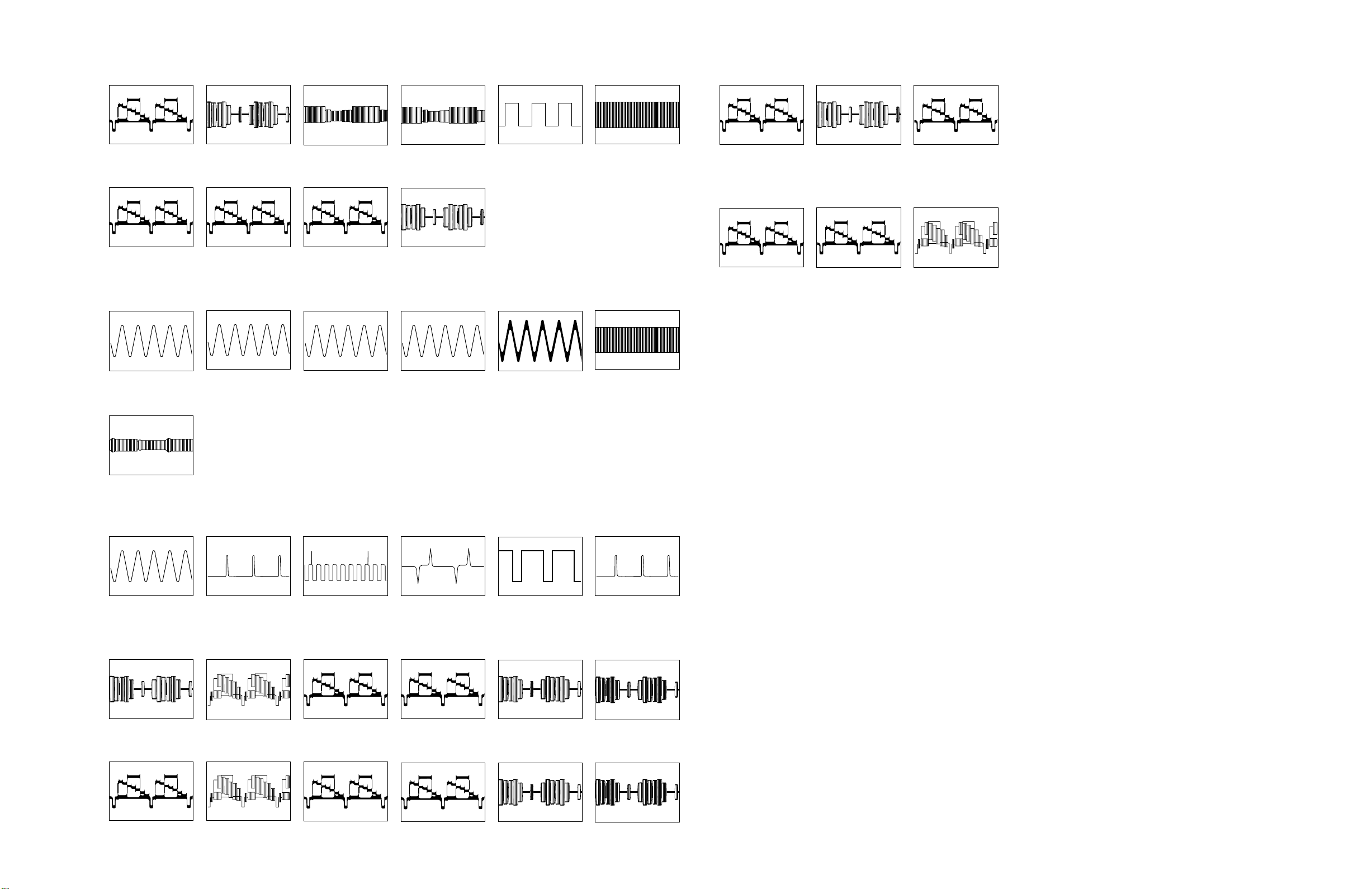

3.2 SERVO CIRCUIT .......................................................................................... 3-2

3.2.1 Switching point ...............................................................................3-2

3.2.2 Slow tracking preset ....................................................................... 3-2

3.3 VIDEO CIRCUIT ........................................................................................... 3-2

3.3.1 D/A level ......................................................................................... 3-2

3.3.2 EE Y level ....................................................................................... 3-3

3.3.3 PB Y level (S-VHS / VHS) .............................................................. 3-3

3.3.4 REC color (colour) level .................................................................3-3

3.3.5 Video EQ (Frequency response) .................................................... 3-4

3.3.6 AUTO PICTURE initial setting ........................................................ 3-4

3.4 DIGITAL CIRCUIT ......................................................................................... 3-4

3.4.1 HDD EE Y level .............................................................................. 3-4

3.4.2 HDD PB Y level .............................................................................. 3-5

3.4.3 HDD PB C burst level ..................................................................... 3-5

3.5 AUDIO CIRCUIT ........................................................................................... 3-5

3.5.1 Audio REC FM ...............................................................................3-5

3.6 SYSCON CIRCUIT [HM-HDS1EU] ............................................................... 3-6

3.6.1 Timer clock ..................................................................................... 3-6

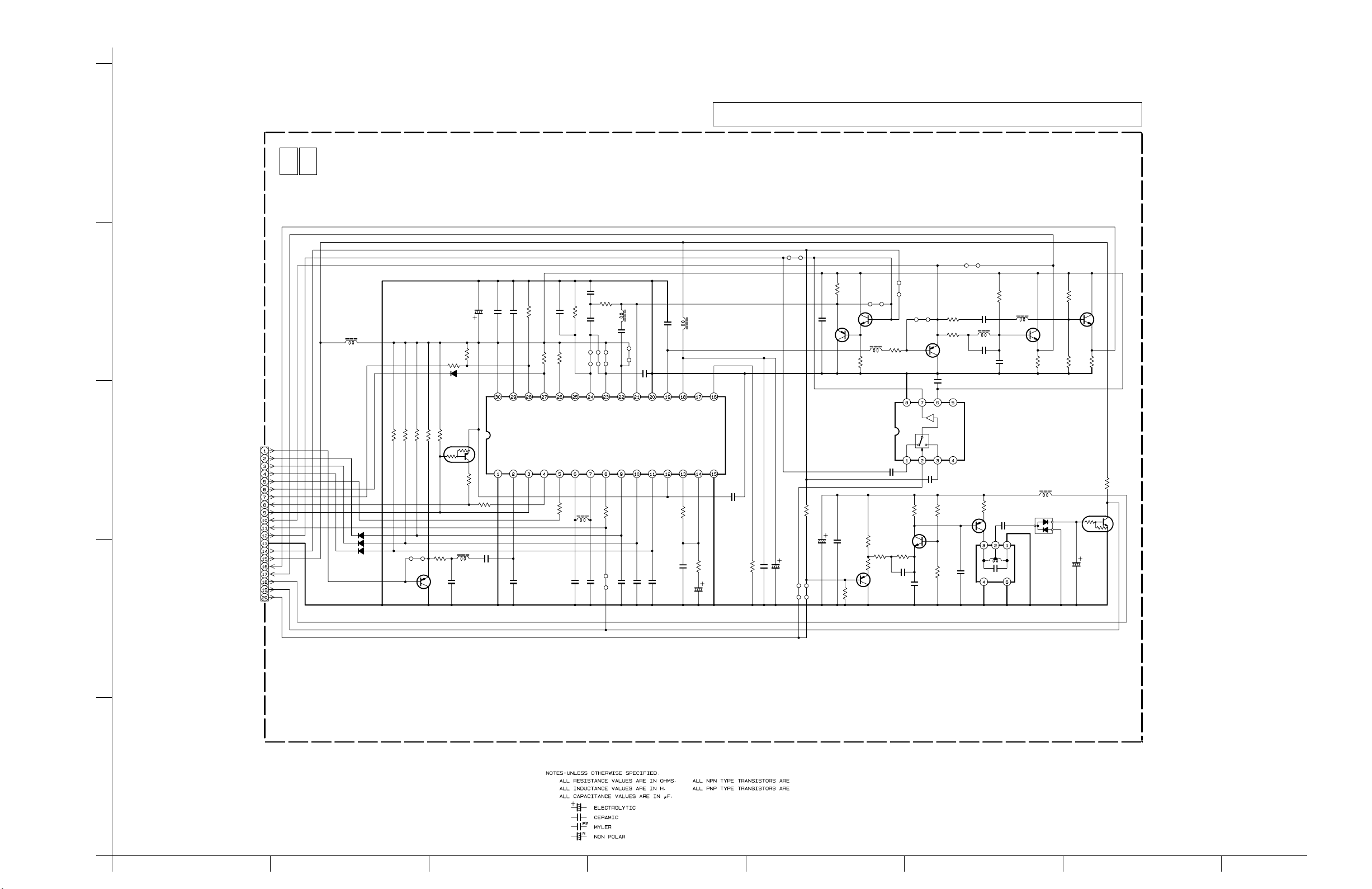

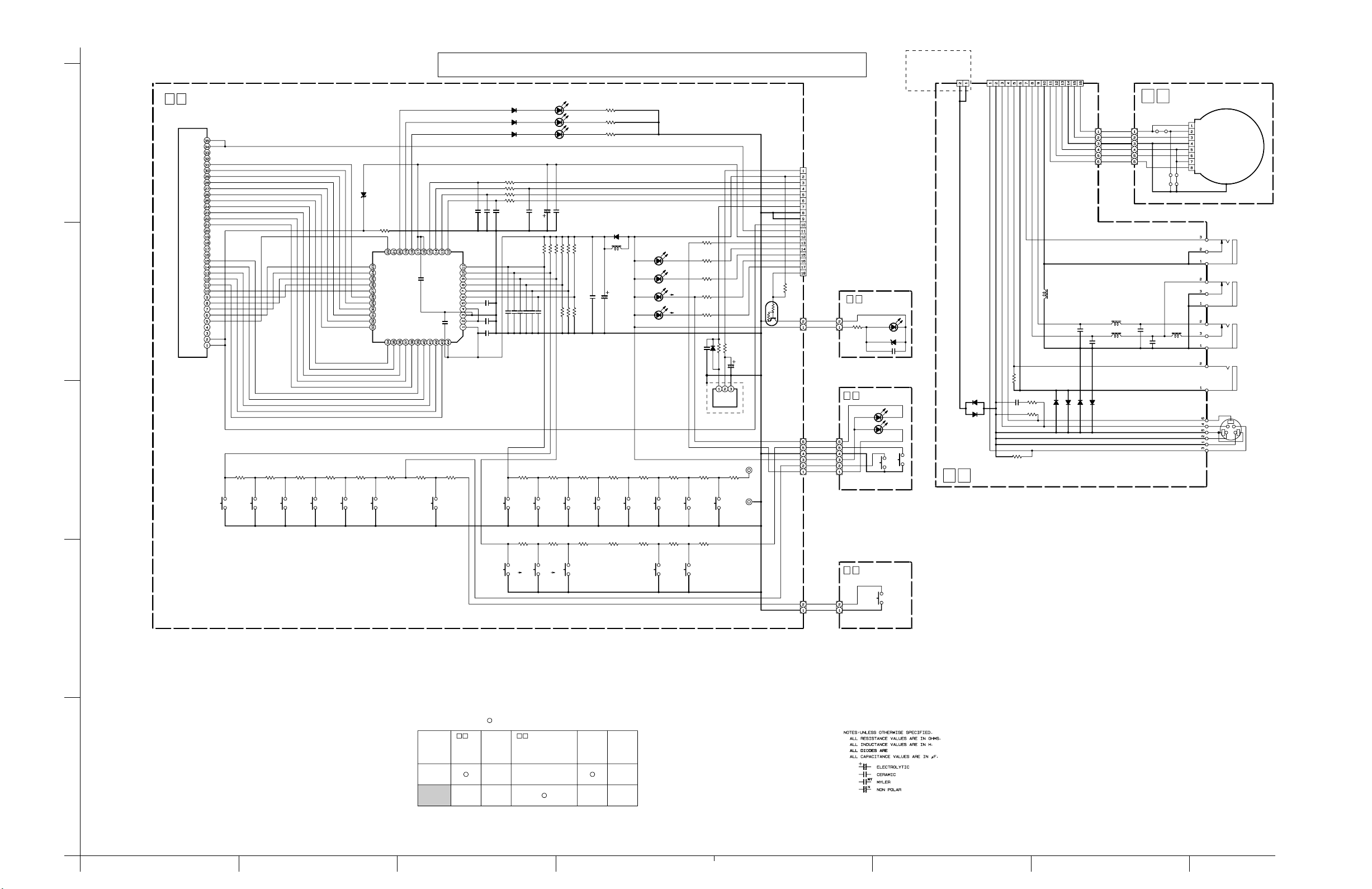

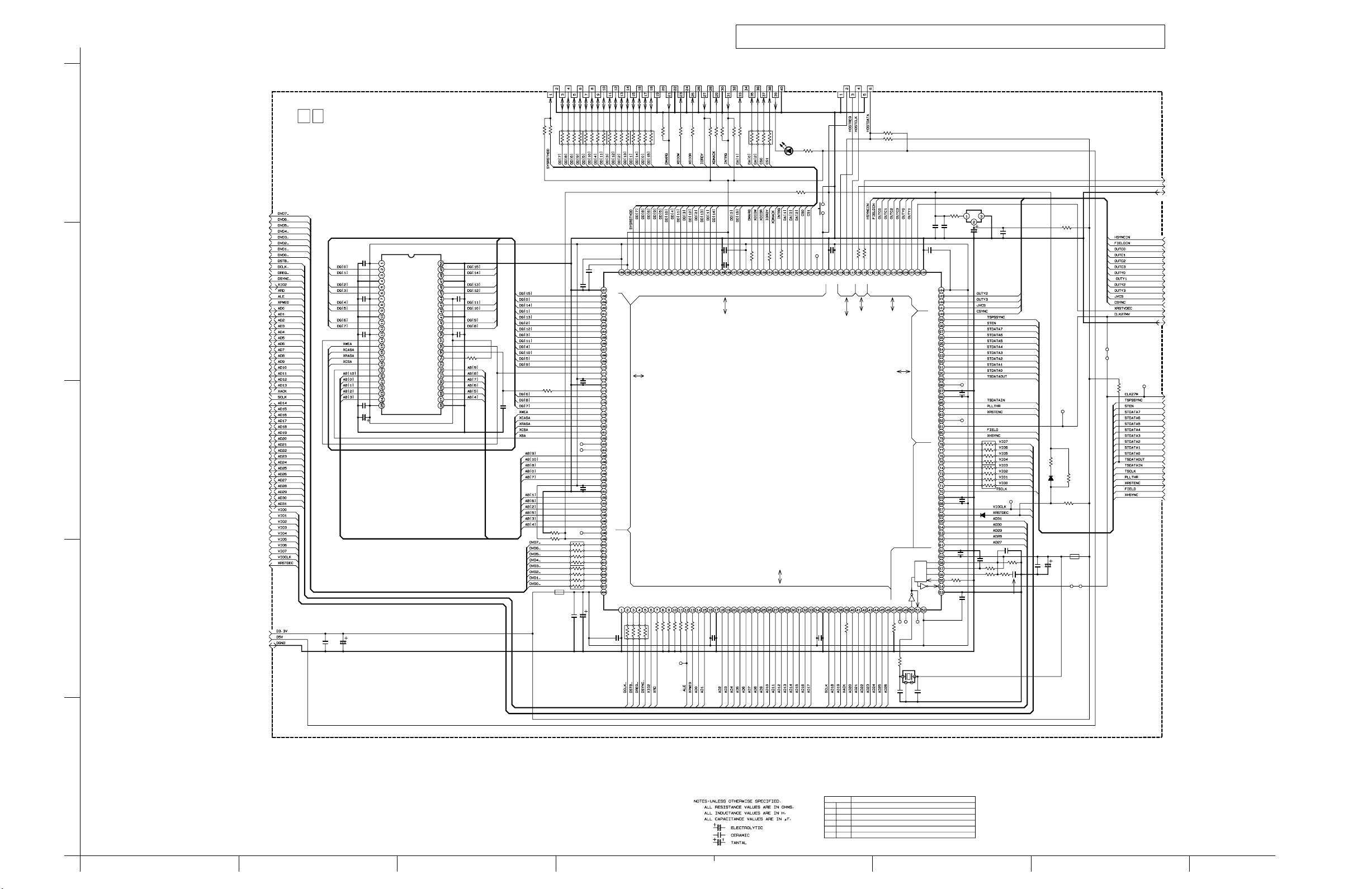

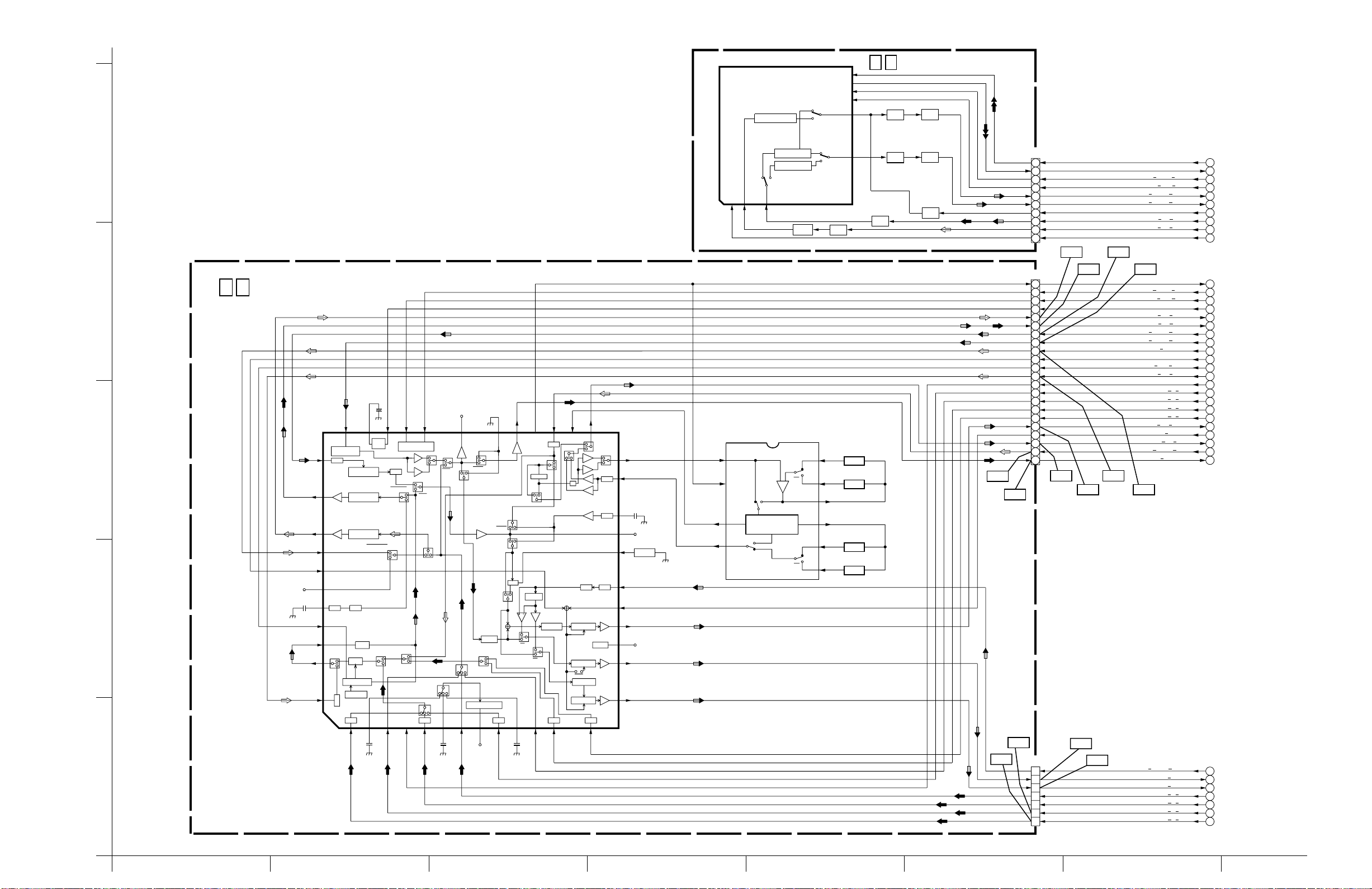

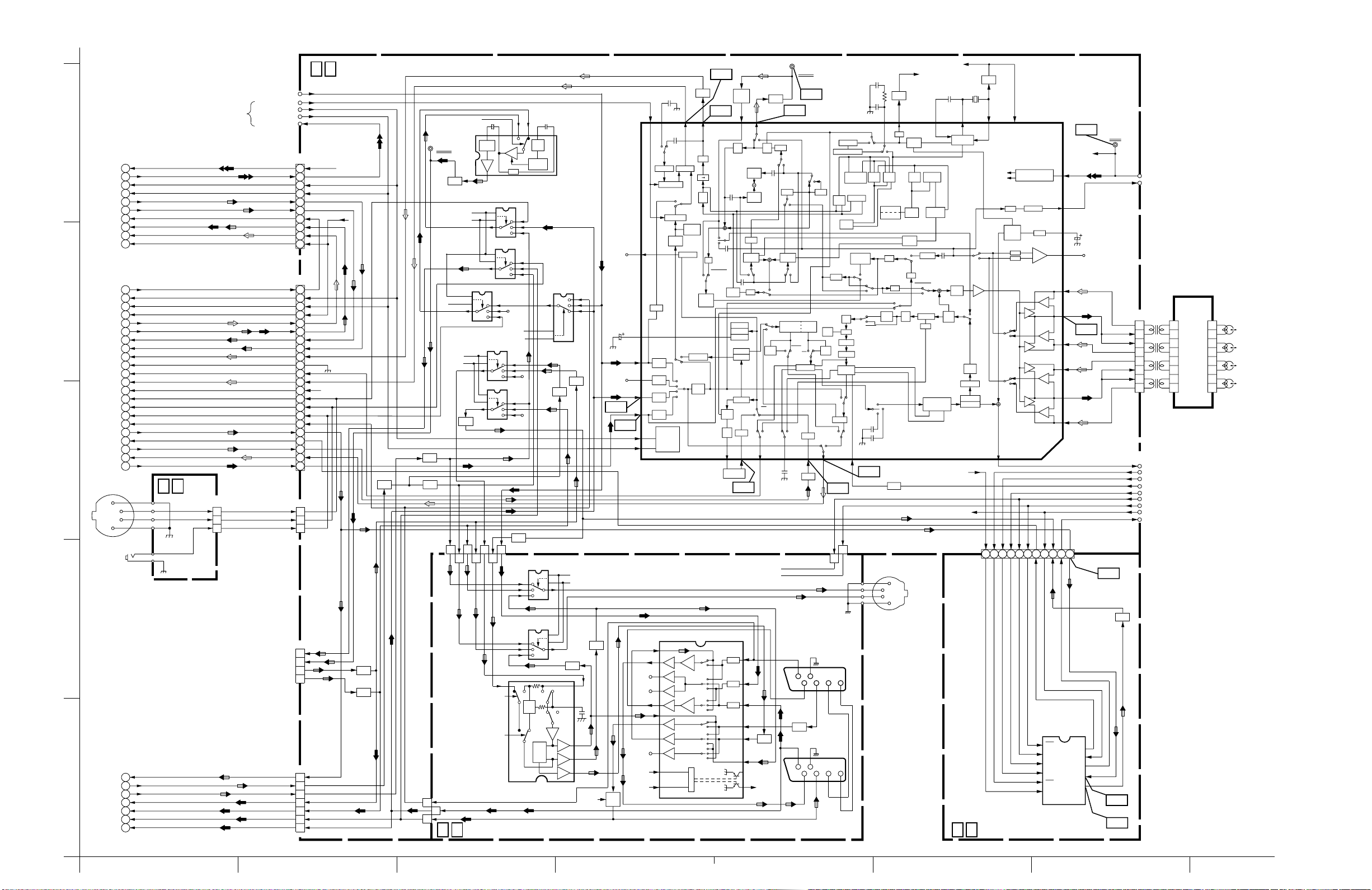

4. CHARTS AND DIAGRAMS

NOTES OF SCHEMATIC DIAGRAM ................................................................... 4-1

CIRCUIT BOARD NOTES .................................................................................... 4-2

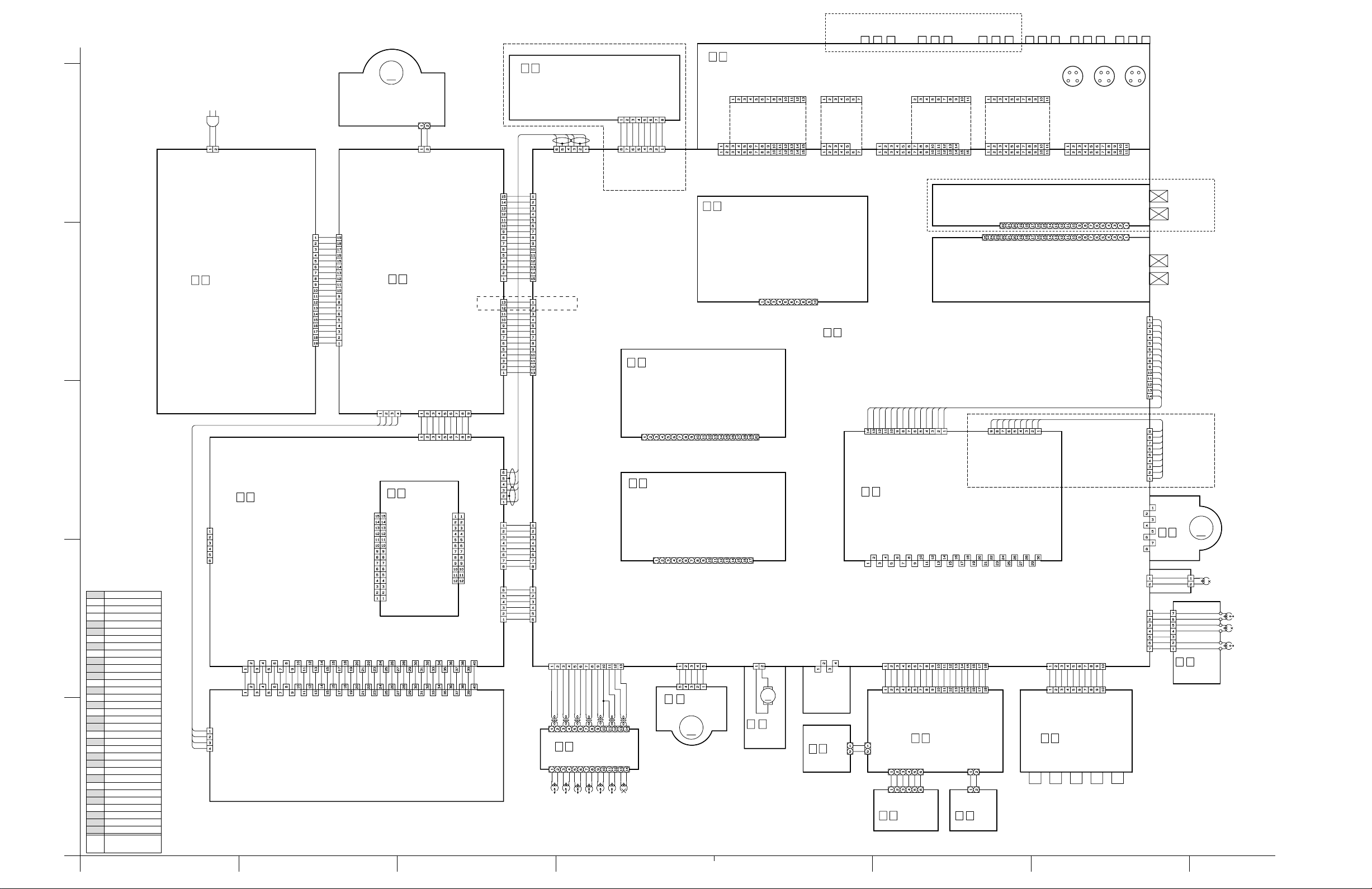

4.1 BOARD INTERCONNECTIONS ................................................................... 4-3

4.2

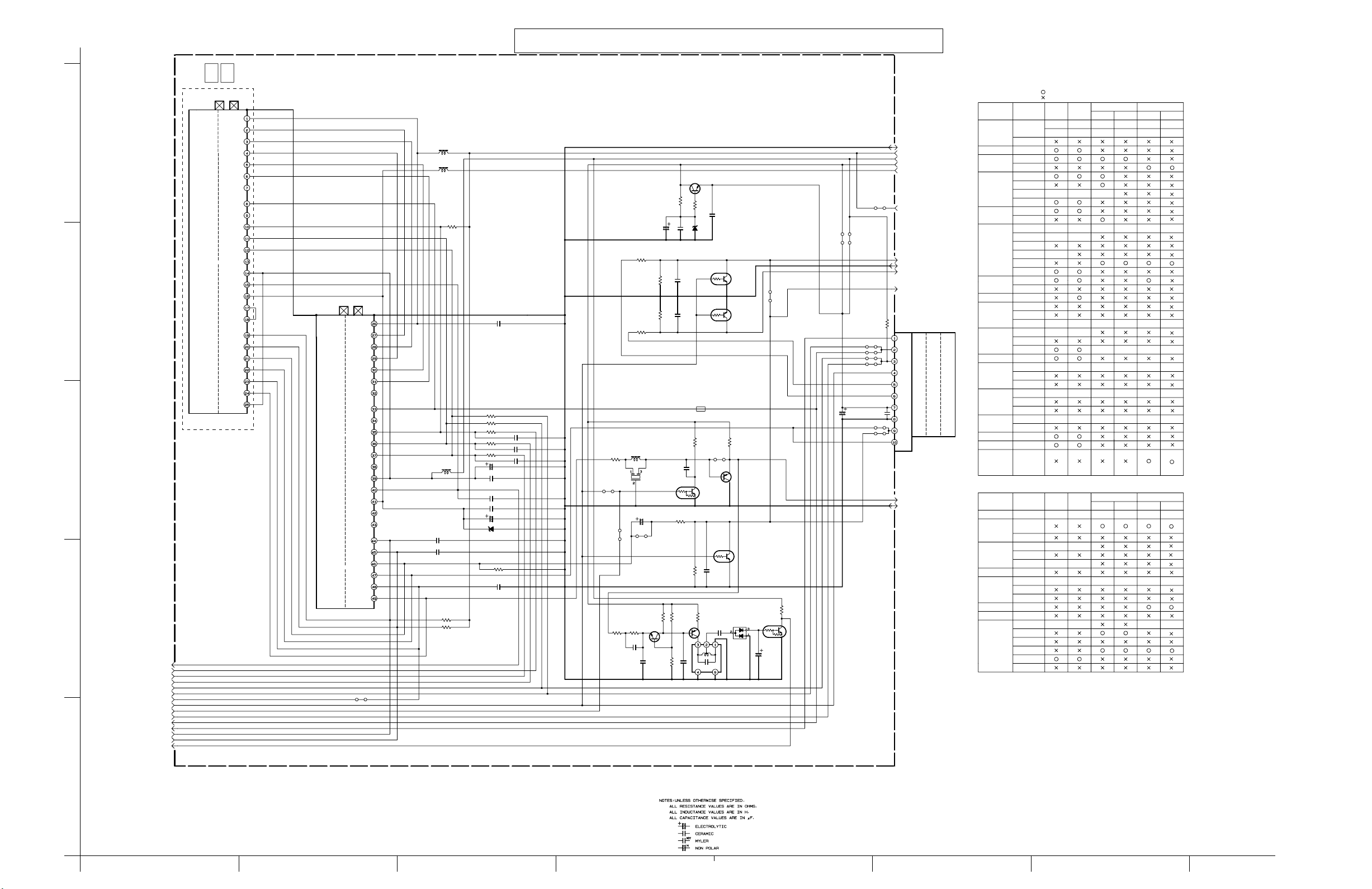

SWITCHING REGULATOR AND REGULATOR SCHEMATIC DIAGRAMS ...........

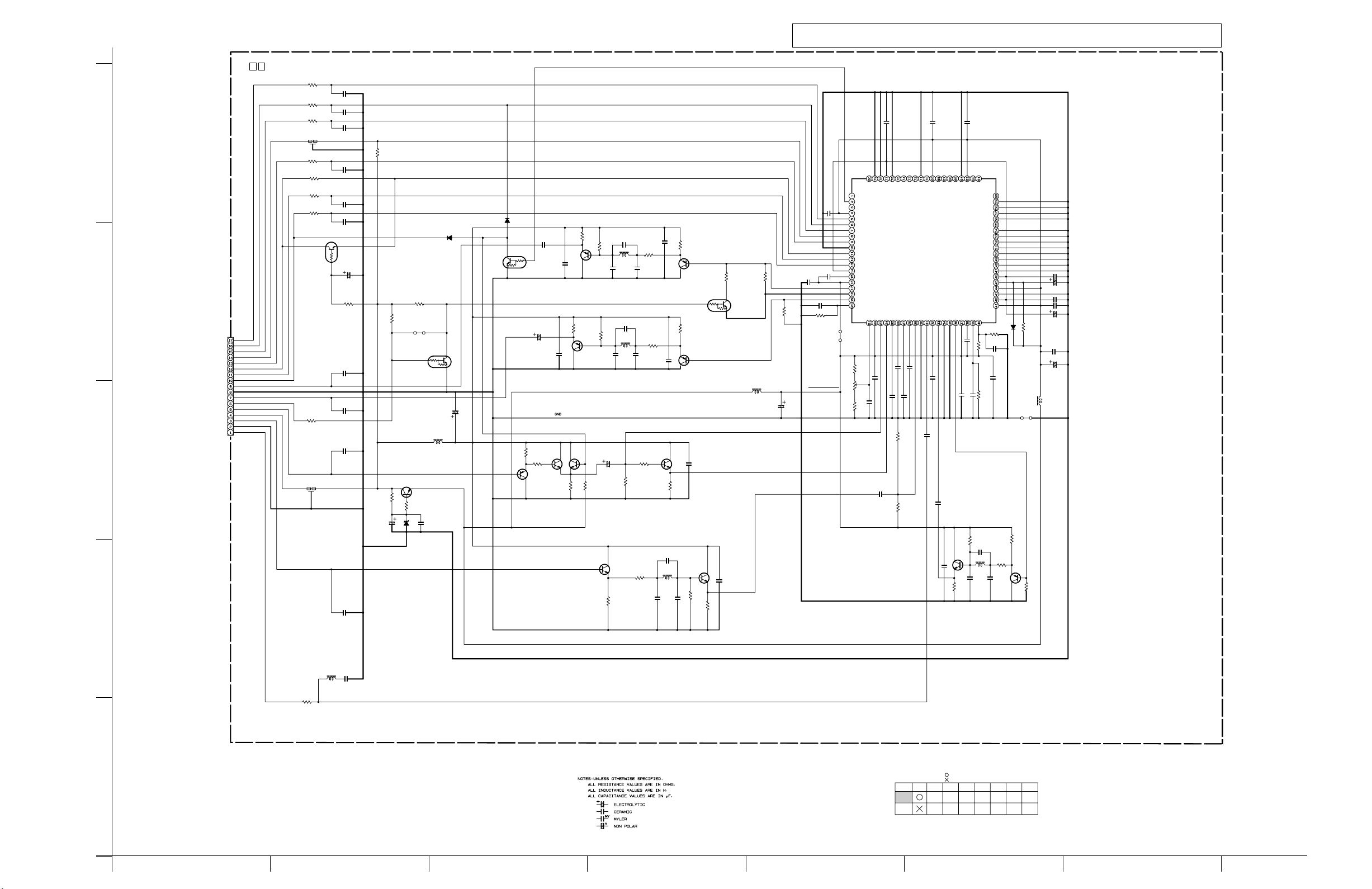

4.3 VIDEO/AUDIO SCHEMATIC DIAGRAM ....................................................... 4-7

4.4 SYSTEM CONTROL SCHEMATIC DIAGRAM ............................................. 4-9

4.5 VIDEO I/O SWITCH SCHEMATIC DIAGRAM ............................................ 4-13

4.6 AUDIO I/O SCHEMATIC DIAGRAM ............................................................ 4-15

4.7 CONNECTION SCHEMATIC DIAGRAM .................................................... 4-17

4.8 TUNER SCHEMATIC DIAGRAM ................................................................ 4-19

4.9 3D DIGITAL/2M SCHEMATIC DIAGRAM ................................................... 4-21

4.10 TERMINAL SCHEMATIC DIAGRAM ........................................................ 4-23

4.11 DEMODULATOR SCHEMATIC DIAGRAM ............................................... 4-25

4.12 S-SUB SCHEMATIC DIAGRAM ............................................................... 4-27

4.13 ON SCREEN SCHEMATIC DIAGRAM ..................................................... 4-29

EJECT SW, DISPLAY, JACK, LED/SW AND LED SCHEMATIC DIAGRAMS ..

4.14

4.15 DIGITAL P.SUP SCHEMATIC DIAGRAM .................................................. 4-33

4.16 DIGITAL VIDEO SCHEMATIC DIAGRAM ................................................. 4-35

4.17 DIGITAL AUDIO SCHEMATIC DIAGRAM ................................................ 4-37

4.18 DIGITAL MPEG DEC SCHEMATIC DIAGRAM ......................................... 4-39

4.19 DIGITAL MPEG ENC SCHEMATIC DIAGRAM ......................................... 4-41

4.20 DIGITAL ASIC IF SCHEMATIC DIAGRAM ............................................... 4-43

4.21 SWITCHING REGULATOR AND REGULATOR CIRCUIT BOARDS ....... 4-45

4.22 3D DIGITAL/2M AND S-SUB CIRCUIT BOARDS .................................... 4-47

4.23 TERMINAL CIRCUIT BOARD .................................................................. 4-48

4.24 EJECT SW, DISPLAY, JACK, LED/SW, AND LED CIRCUIT BOARDS .... 4-49

4.25 MAIN CIRCUIT BOARD ........................................................................... 4-51

4.26 DEMODULATOR AND ON SCREEN CIRCUIT BOARDS........................ 4-54

4.27 DIGITAL CIRCUIT BOARD ....................................................................... 4-55

4.28 FDP GRID ASSIGNMENT AND ANODE CONNECTION ........................ 4-58

4.29 DIGITAL SUB SCHEMATIC DIAGRAM .................................................... 4-59

4.30 DIGITAL SUB CIRCUIT BOARD .............................................................. 4-61

4.31 REMOTE CONTROL SCHEMATIC DIAGRAM ........................................ 4-62

4.32 WAVEFORMS ........................................................................................... 4-63

4.33 VOLTAGE CHARTS .................................................................................. 4-65

4.34 CPU PIN FUNCTION................................................................................ 4-68

4.35 SYSTEM CONTROL BLOCK DIAGRAM (VHS) ....................................... 4-69

4.36 AUDIO BLOCK DIAGRAM ........................................................................ 4-71

4.37 VIDEO BLOCK DIAGRAM(VHS) .............................................................. 4-73

4.38 VIDEO/AUDIO BLOCK DIAGRAM (HDD) ................................................ 4-77

5. PARTS LIST

5.1 PACKING AND ACCESSORY ASSEMBLY <M1> ....................................... 5-1

5.2 FINAL ASSEMBLY <M2> ............................................................................. 5-2

5.3 MECHANISM ASSEMBLY <M4> .................................................................. 5-4

5.4 ELECTRICAL PARTS LIST ........................................................................... 5-6

SW.REG BOARD ASSEMBLY <01> ......................................................... 5-6

REG BOARD ASSEMBLY <02> ............................................................... 5-7

MAIN BOARD ASSEMBLY <03> .............................................................. 5-8

3D DIGITAL/2M BOARD ASSEMBLY <05> ............................................ 5-15

TERMINAL BOARD ASSEMBLY <06> ................................................... 5-17

A/C HEAD BOARD ASSEMBLY <12> .................................................... 5-18

DEMOD BOARD ASSEMBLY <14> ........................................................ 5-18

S-SUB BOARD ASSEMBLY <15> .......................................................... 5-19

ON SCREEN BOARD ASSEMBLY <17> ................................................ 5-20

EJECT SW BOARD ASSEMBLY <27> ................................................... 5-20

SW/DISPLAY BOARD ASSEMBLY <28> ................................................ 5-20

JACK BOARD ASSEMBLY <36> ............................................................ 5-21

LED/SW BOARD ASSEMBLY <47> ....................................................... 5-22

DIGITAL SUB BOARD ASSEMBLY <49> ............................................... 5-22

DIGITAL BOARD ASSEMBLY <50> ........................................................ 5-22

LOADING MOTOR BOARD ASSEMBLY <55> ....................................... 5-27

LED BOARD ASSEMBLY <90> .............................................................. 5-27

4-5

4-31

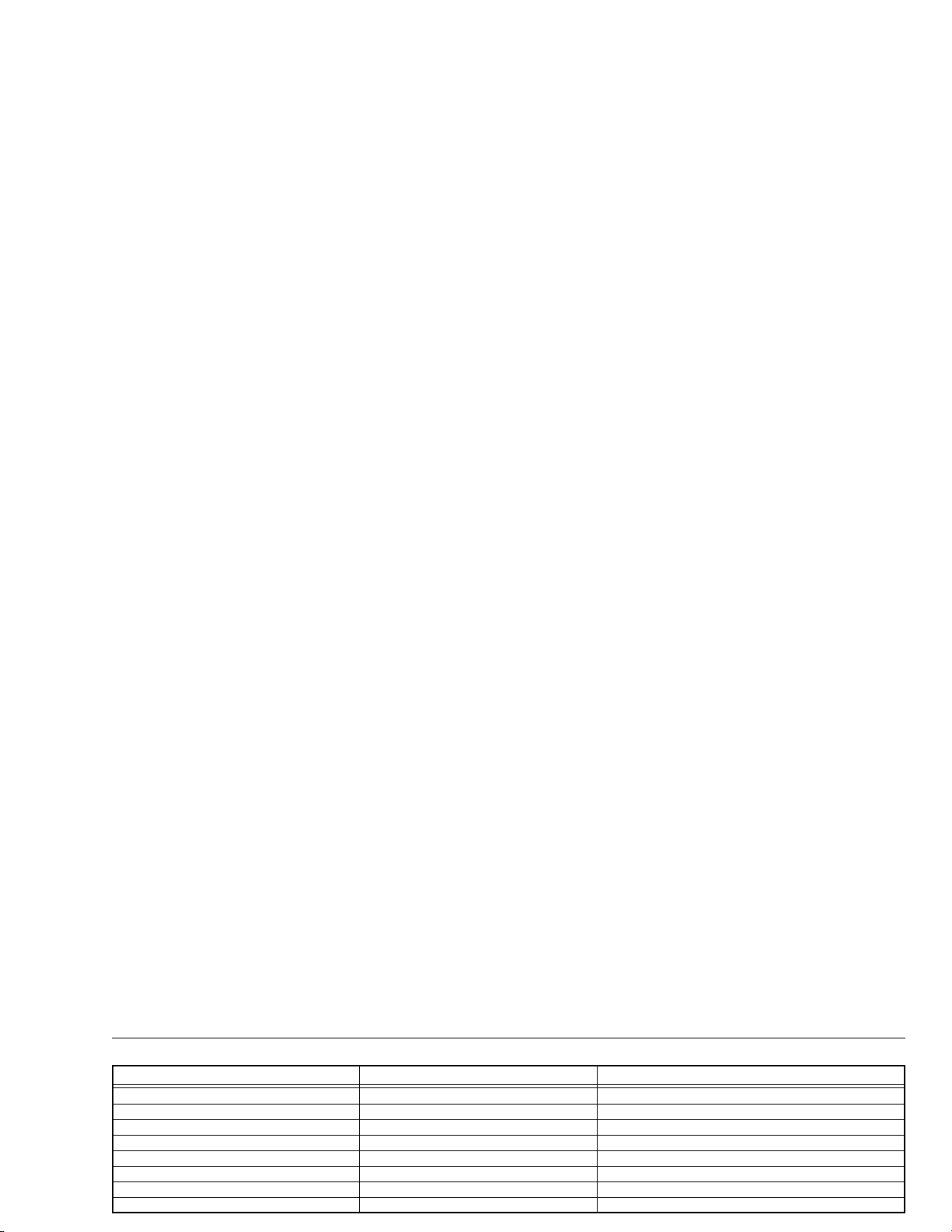

The following table lists the differing points between Models ( HM-HDS1EK and HM-HDS1EU) in this series.

HM-HDS1EK HM-HDS1EU

VIDEO SYSTEM PAL/NTSC ON PAL TV PAL/MESECAM(MANUAL)/NTSC ON PAL TV

BROADCASTING STANDARD I B/G,D/K

STEREO DECODER NICAM NICAM/A2

VCR PLUS+ VIDEOPLUS+ DELUXE SHOWVIEW DELUXE

VPS(AUTO) NOT USED USED

INITIAL (TIMER) OFF GER,AUS,SWISS:ON, OTHER:OFF

LANGUAGE [INITIAL] (ON SCREEN DISPLAY)

POWER PLUG 3PIN CEE

ENG 10 LANG. [E]

Page 5

Important Safety Precautions

Prior to shipment from the factory, JVC products are strictly inspected to conform with the recognized product safety and electrical codes of the

countries in which they are to be sold. However, in order to maintain such compliance, it is equally important to implement the following precautions

when a set is being serviced.

Precautions during Servicing

•

1. Locations requiring special caution are denoted by labels and inscriptions on the cabinet, chassis and certain parts of the product.

When performing service, be sure to read and comply with these

and other cautionary notices appearing in the operation and service manuals.

2. Parts identified by the ! symbol and shaded ( ) parts are

critical for safety.

Replace only with specified part numbers.

Note: Parts in this category also include those specified to com-

ply with X-ray emission standards for products using

cathode ray tubes and those specified for compliance

with various regulations regarding spurious radiation

emission.

3. Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as specified.

4. Use specified internal wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

5. Use specified insulating materials for hazardous live parts. Note

especially:

1) Insulation Tape 3) Spacers 5) Barrier

2) PVC tubing 4) Insulation sheets for transistors

6. When replacing AC primary side components (transformers, power

cords, noise blocking capacitors, etc.) wrap ends of wires securely

about the terminals before soldering.

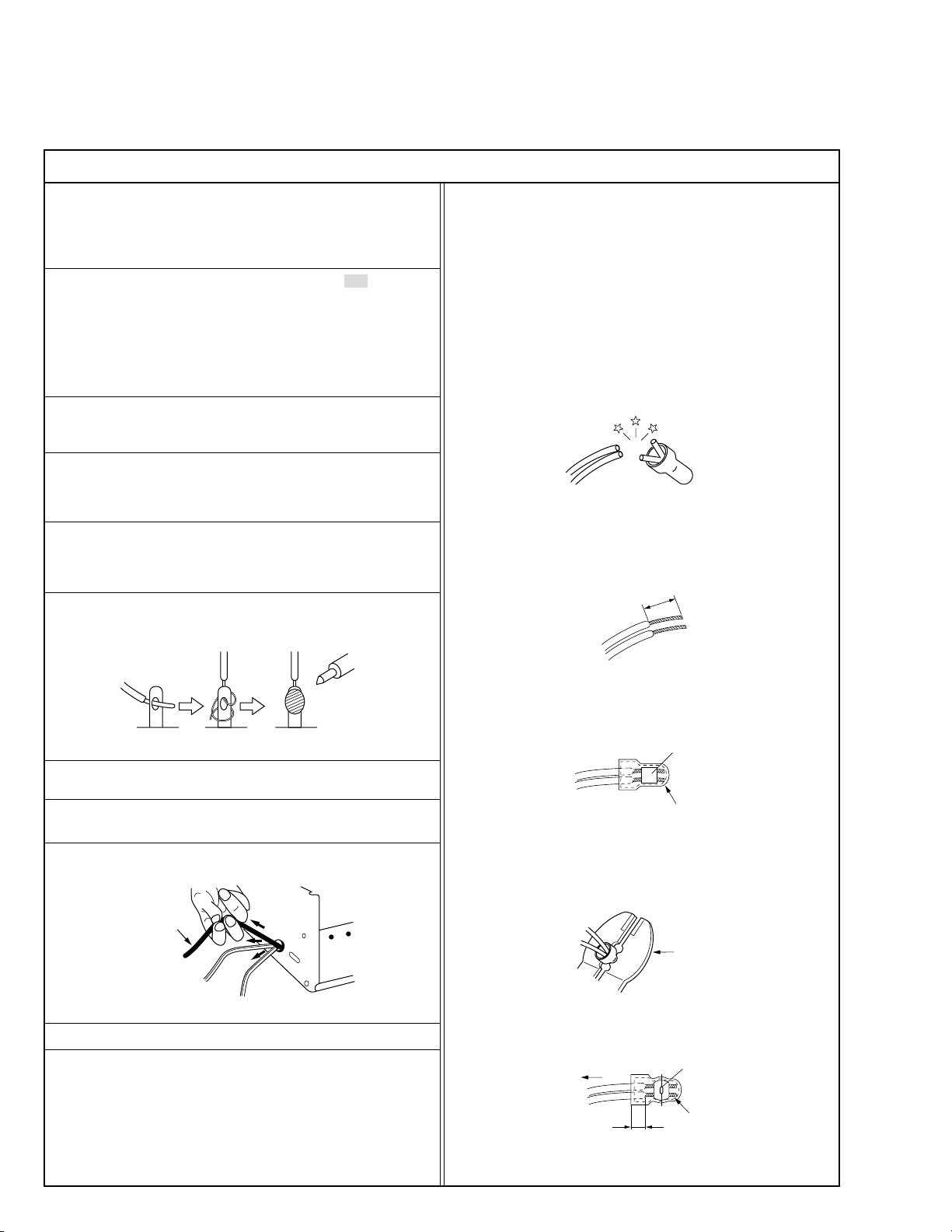

12. Crimp type wire connector

In such cases as when replacing the power transformer in sets

where the connections between the power cord and power transformer primary lead wires are performed using crimp type connectors, if replacing the connectors is unavoidable, in order to prevent

safety hazards, perform carefully and precisely according to the

following steps.

1) Connector part number : E03830-001

2) Required tool : Connector crimping tool of the proper type which

will not damage insulated parts.

3) Replacement procedure

(1) Remove the old connector by cutting the wires at a point

close to the connector.

Important : Do not reuse a connector (discard it).

cut close to connector

Fig.3

(2) Strip about 15 mm of the insulation from the ends of the

wires. If the wires are stranded, twist the strands to avoid

frayed conductors.

15 mm

Fig.1

7. Observe that wires do not contact heat producing parts (heatsinks,

oxide metal film resistors, fusible resistors, etc.)

8. Check that replaced wires do not contact sharp edged or pointed

parts.

9. When a power cord has been replaced, check that 10-15 kg of

force in any direction will not loosen it.

Power cord

Fig.2

10. Also check areas surrounding repaired locations.

11. Products using cathode ray tubes (CRTs)

In regard to such products, the cathode ray tubes themselves, the

high voltage circuits, and related circuits are specified for compliance with recognized codes pertaining to X-ray emission.

Consequently, when servicing these products, replace the cathode ray tubes and other parts with only the specified parts. Under

no circumstances attempt to modify these circuits.

Unauthorized modification can increase the high voltage value and

cause X-ray emission from the cathode ray tube.

Fig.4

(3) Align the lengths of the wires to be connected. Insert the

wires fully into the connector.

Metal sleeve

Connector

Fig.5

(4) As shown in Fig.6, use the crimping tool to crimp the metal

sleeve at the center position. Be sure to crimp fully to the

complete closure of the tool.

1

.2

5

2

.0

5

.5

Fig.6

(5) Check the four points noted in Fig.7.

Not easily pulled free

Wire insulation recessed

more than 4 mm

Fig.7

Crimping tool

Crimped at approx. center

of metal sleeve

Conductors extended

I

S40888-01

Page 6

Safety Check after Servicing

•

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts and wires have been returned

to original positions, Afterwards, perform the following tests and confirm the specified values in order to verify compliance with safety

standards.

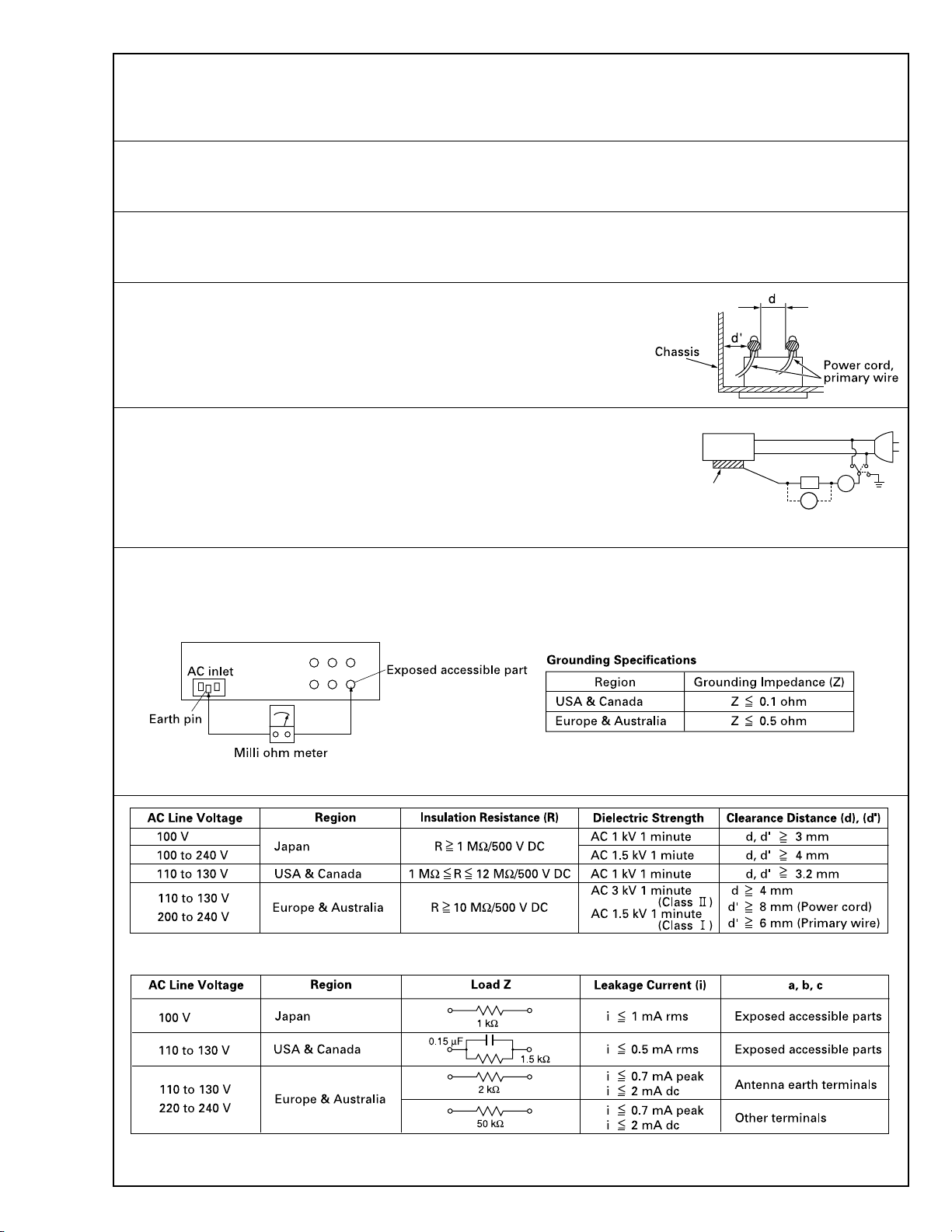

1. Insulation resistance test

Confirm the specified insulation resistance or greater between power cord plug prongs and externally exposed parts of the set (RF terminals, antenna terminals, video and audio input and output

terminals, microphone jacks, earphone jacks, etc.). See table 1 below.

2. Dielectric strength test

Confirm specified dielectric strength or greater between power cord plug prongs and exposed accessible parts of the set (RF terminals, antenna terminals, video and audio input and output terminals,

microphone jacks, earphone jacks, etc.). See table 1 below.

3. Clearance distance

When replacing primary circuit components, confirm specified clearance distance (d), (d’) between soldered terminals, and between terminals and surrounding metallic parts. See table 1

below.

Fig. 8

4. Leakage current test

Confirm specified or lower leakage current between earth ground/power cord plug prongs and

externally exposed accessible parts (RF terminals, antenna terminals, video and audio input and

output terminals, microphone jacks, earphone jacks, etc.).

Measuring Method : (Power ON)

Insert load Z between earth ground/power cord plug prongs and externally exposed accessible

parts. Use an AC voltmeter to measure across both terminals of load Z. See figure 9 and following

table 2.

Externally

exposed

accessible part

Fig. 9

Z

V

ab

A

c

5. Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between earth pin in AC inlet and externally exposed accessible parts (Video in, Video out,

Audio in, Audio out or Fixing screw etc.).

Measuring Method:

Connect milli ohm meter between earth pin in AC inlet and exposed accessible parts. See figure 10 and grounding specifications.

Fig. 10

Table 1 Specifications for each region

Table 2 Leakage current specifications for each region

Note: These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

II

S40888-01

Page 7

SECTION 1

DISASSEMBLY

1.1 HOW TO REMOVE THE MAJOR PARTS

1.1.1 Introduction

This set is a double-deck video recorder integrating a HDD

(Hard Disk Drive) and a VHS deck. Its internal structure is divided into three sections that include the power supply, VHS

and HDD sections. Therefore, the removal of major parts will

also be described under three separate sections as listed below.

1. COMMON section

2. VHS section

3. HDD section

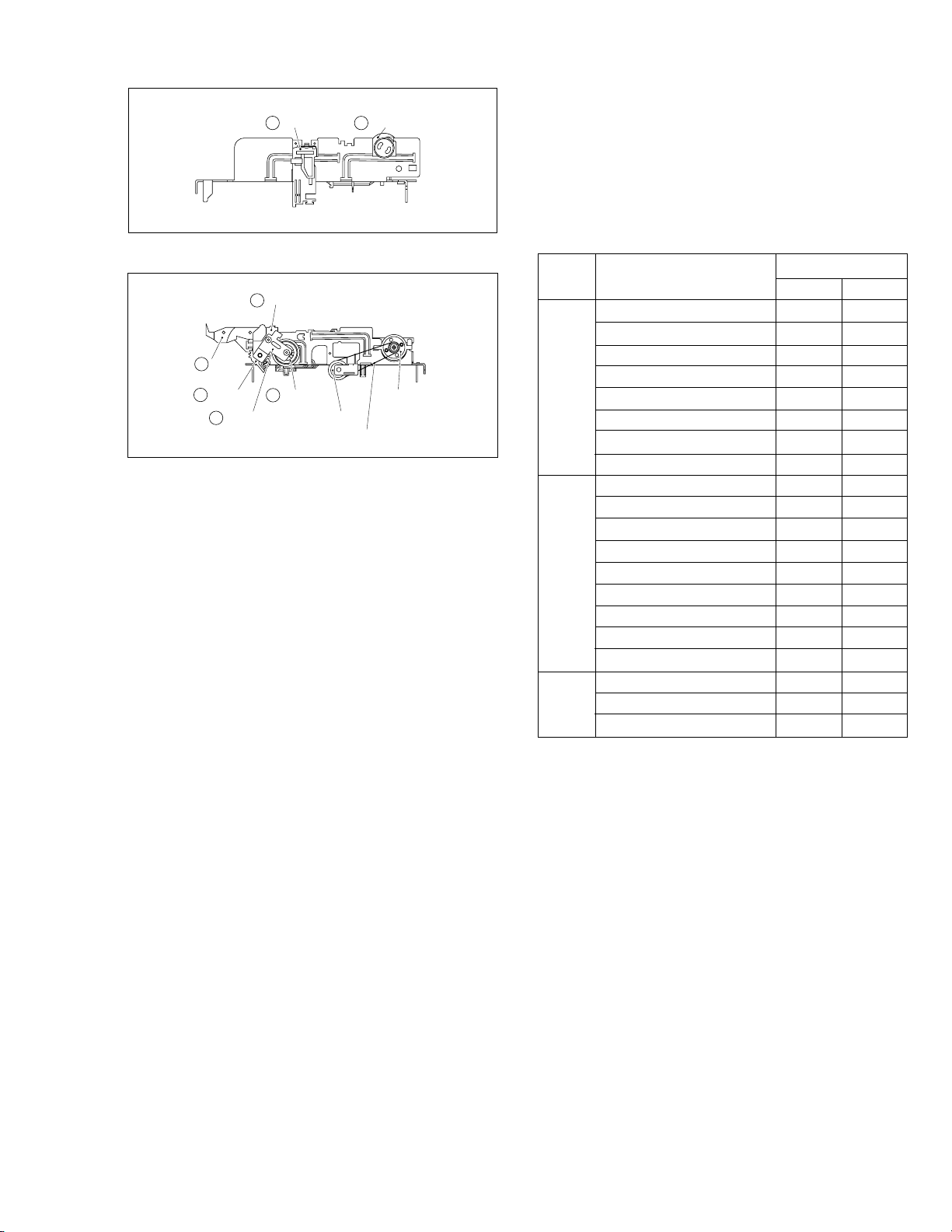

< TOP VIEW >

1. COMMON section

3. HDD section

2. VHS section

Fig. 1-1-1

1.2 HOW TO READ THE DISASSEMBLY AND ASSEMBLY

Step/

Loc No.

1

Top cover, Bracket COM1

Front panel

2

assembly

Fig. No.

4(S1), 3(S2), 2(L1), (L2)

2(S3)

COM2 8(L3),

CN7507(WR1),

CN3011(WR2)

Point NotePart name

—

<Note

1,2,3,4>

§§ §§ §

(1) (2) (3) (4) (5)

(1) Order of steps in Procedure

When reassembling, perform the step(s) in the reverse order.

These numbers are also used as the identification (location) No.

of parts Figures.

(2) Part name to be removed or installed.

(3) Fig. No. showing procedure or part location.

(4) Identification of part to be removed, unhooked, unlocked,

released, unplugged, unclamped or unsoldered.

P= Spring, W= Washer, S= Screw, L= Locking tab, SD= Solder,

CN**(WR**)= Remove the wire (WR**) from the connector

(CN**).

Note:

• The bracketed ( ) WR of the connector symbol are as-

signed nos. in priority order and do not correspond to

those on the spare parts list.

(5) Adjustment information for installation

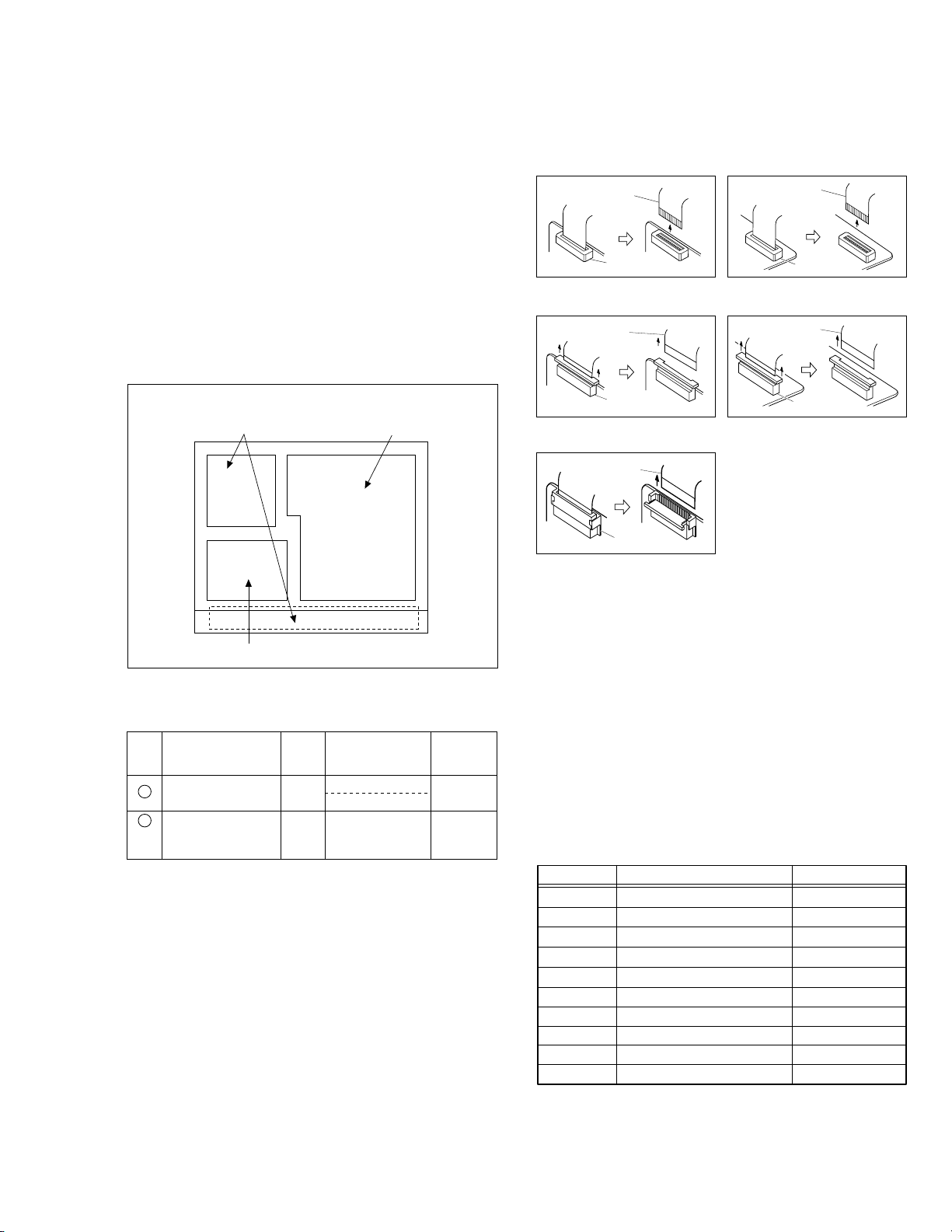

1.3 DISCONNECTION OF CONNECTORS (WIRES)

FPC

CONNECTOR

FPC

CONNECTOR

Fig. 1-3-1 Fig. 1-3-2

FPC

CONNECTOR

FPC

CONNECTOR

Fig. 1-3-3 Fig. 1-3-4

FPC

CONNECTOR

Fig. 1-3-5

1.4 SCREWS USED CABINET COMPONENTS AND

BOARD ASSEMBLIES

Table 1-4-1 below shows the symbols, shapes, colors and

part numbers of screw that are used in the cabinet components and board assemblies and are appearing in the disassembling/reassembling diagrams in this manual.

When screwing them again in reassembling, be sure to use

them correctly referring to the following table.

Notes:

• Screw that are asterisked (marked with*) in the shape col-

umn are fixed with screw lock agent. If such the screw is

once removed, never use it again.

• The Screw symbols are assigned nos. in priority order and

do not correspond to those on the spare parts list.

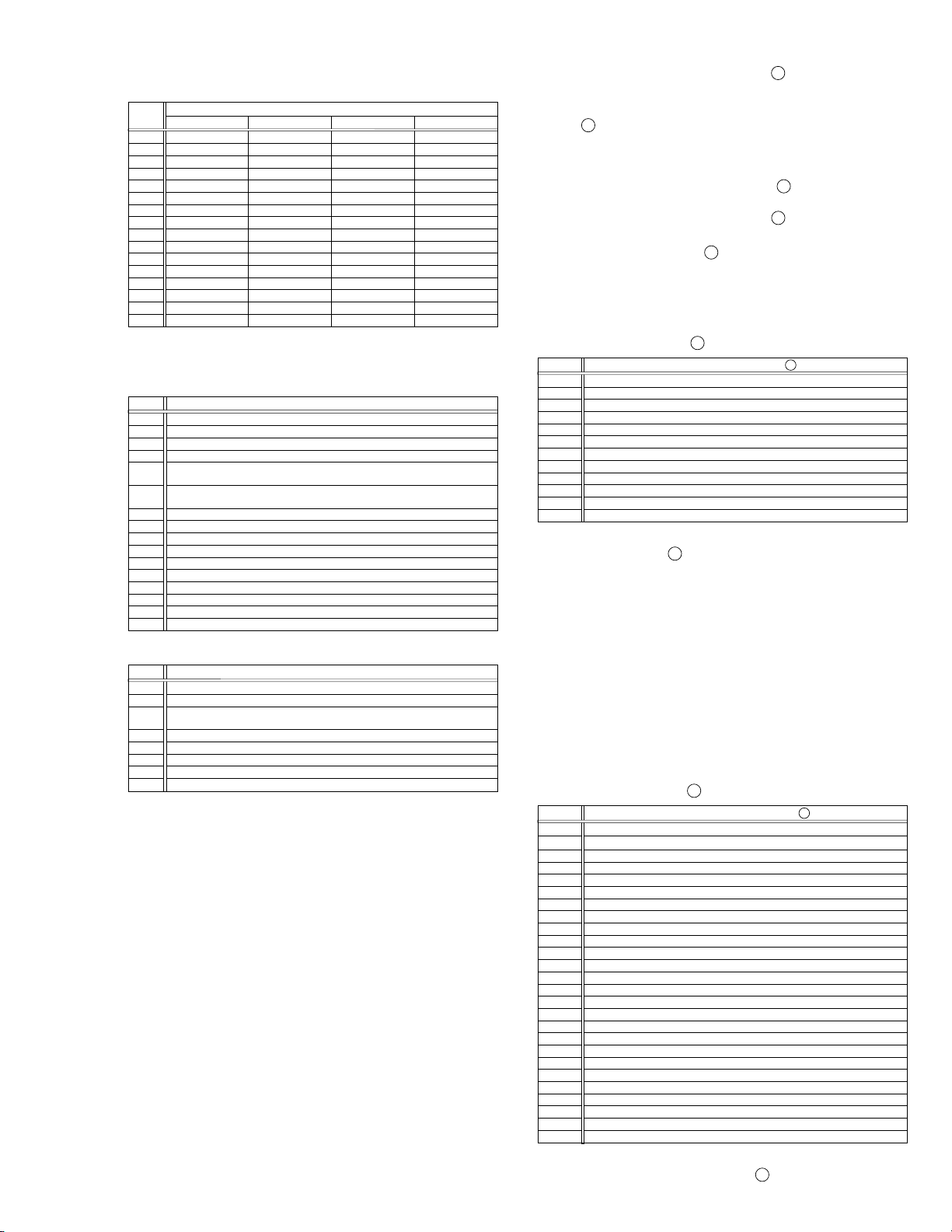

SYMBOL PARTS NO. COLOR

S1 QYTDST3006R SILVER BLACK

S2 QYTDST3006M BLACK

S3 QYTDSF3010Z GOLD

S4 QYTDSF2606Z GOLD

S5 QYTDST3006Z GOLD

S6 QYTDSF3008M BLACK

S7 QYTDST2610Z GOLD

S8 PQ40413 BLACK

S9 LP40700-001A BLACK

S10 LP40738-001A GOLD

Table 1-4-1

1-1

Page 8

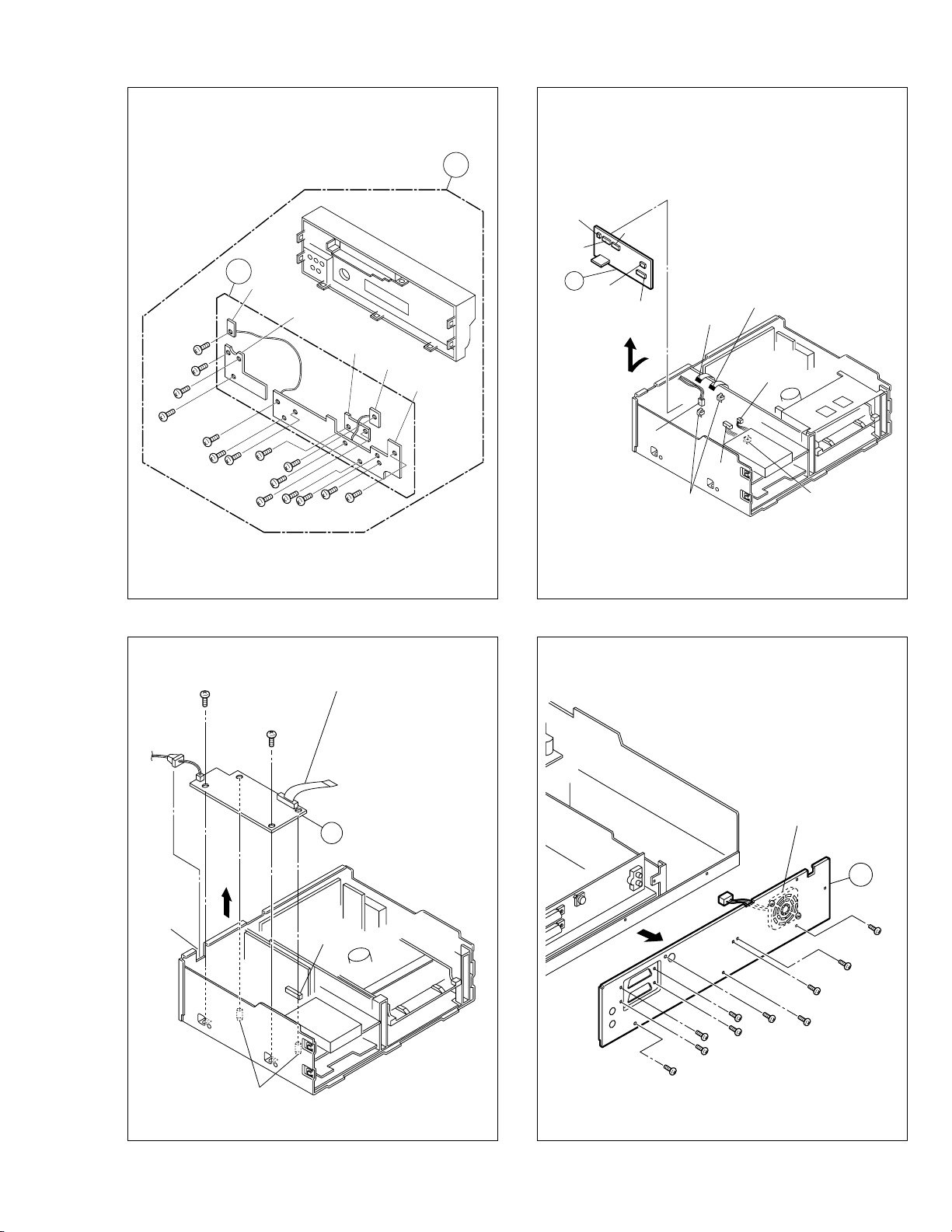

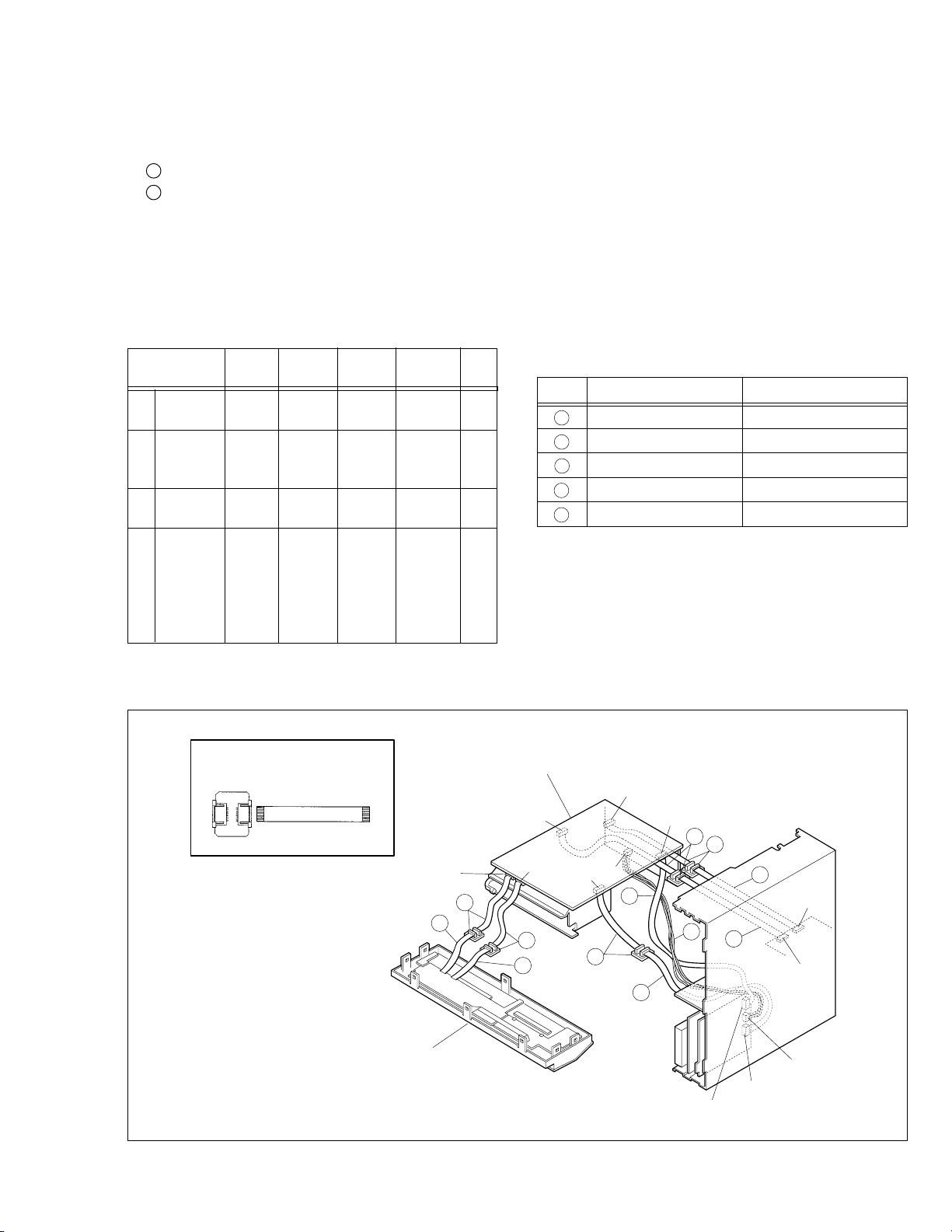

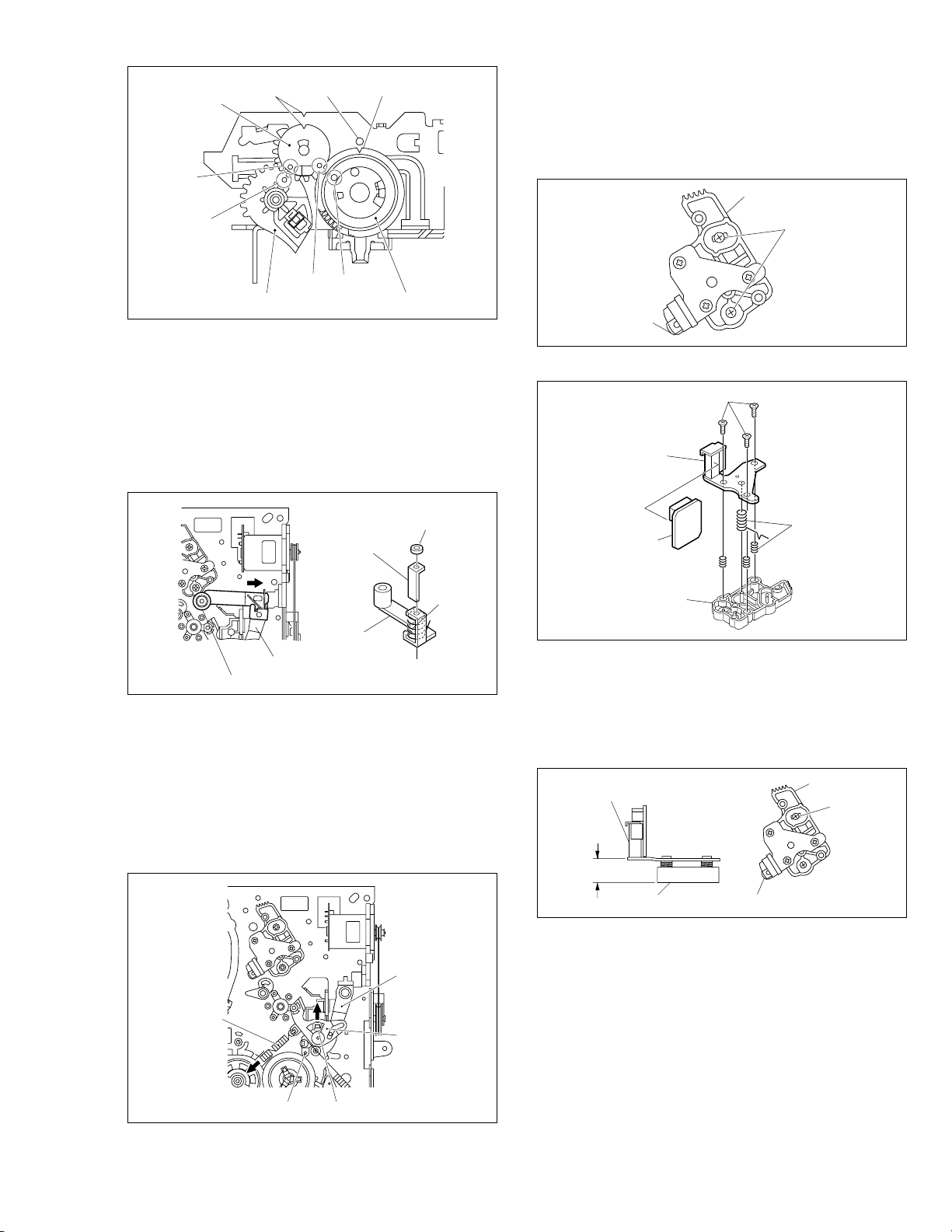

HOW TO REMOVE THE MAJOR PARTS <COM section>

1.5

1.5.1 Disassembly flow chart

This flowchart shows the disassembly procedure for the exterior parts and electrical parts.

Basically, reverse this procedure when assembling them.

1 Top cover, Bracket

2 Front panel assembly

Display board assembly, LED/SW board assembly,

3

Eject SW board assembly, Jack board assembly,

LED board assembly

4 SW REG board assembly

5 Regulator board assembly

6 Rear cover

Disassembly/assembly method <COM section>

1.5.2

Step/

Loc No.

Top cover, Bracket COM1

1

Front panel

2

assembly

Fig. No.

4(S1), 3(S2), 2(L1), (L2)

2(S3)

COM2 8(L3),

CN7507(WR1),

Point NotePart name

—

<Note

1,2,3,4>

CN3011(WR2)

Display board assembly,

3

LED/SW board assembly,

Eject SW board assembly,

COM3 15(S4)

—

Jack board assembly,

LED board assembly

SW REG board

4

assembly

Regulator board

5

assembly

COM4 2(S5), 2(L4), (L5)

CN5301(WR3),

COM5 3(L6),

CN5322(WR4),

CN5321(WR5),

<Note 1,

4>

<Note 1,

4>

CN5325(WR6),

CN5326(WR7),

CN5323(WR8)

6

COM6 4(S2), 6(S6),

Fan motor

<Note 5>Rear cover

<Note 1>

When attaching the FPC, be sure to connect it in the correct orientation.

<Note 2>

When attaching the front panel assy, make sure that the

door openers of cassette housing assembly is in the down

position.

<Note 3>

When attaching the FPC take care that it is not caught.

Pass the two VHS-side FPCs below the base (1).

<Note 4>

When removing the SW REG board assembly or Regulator board assembly, unhook the several spacers connecting it with pliers from the top side.

<Note 5>

Perform the work by leaving fan motor attached to the rear

cover except when replacing the fan motor.

When attaching the rear cover, please be careful with the

wiring.

1

(S1)

(L3)

(L1)

(L3)

2

(S1)

Digital board

assembly

Base (1)

(L3)

(L2)

8

(S3)

Top cover

1

CN3011

<Note 3>

WR2

(S2)

9

(S3)

1

Fig. COM1

Fig. COM2

6

Bracket

WR1

(L3)

2

5

(S2)

3

(S1)

CN7507

<Note 1>

Supporing

tape side

(S2)

4

(S1)

<Note 2>

7

1-2

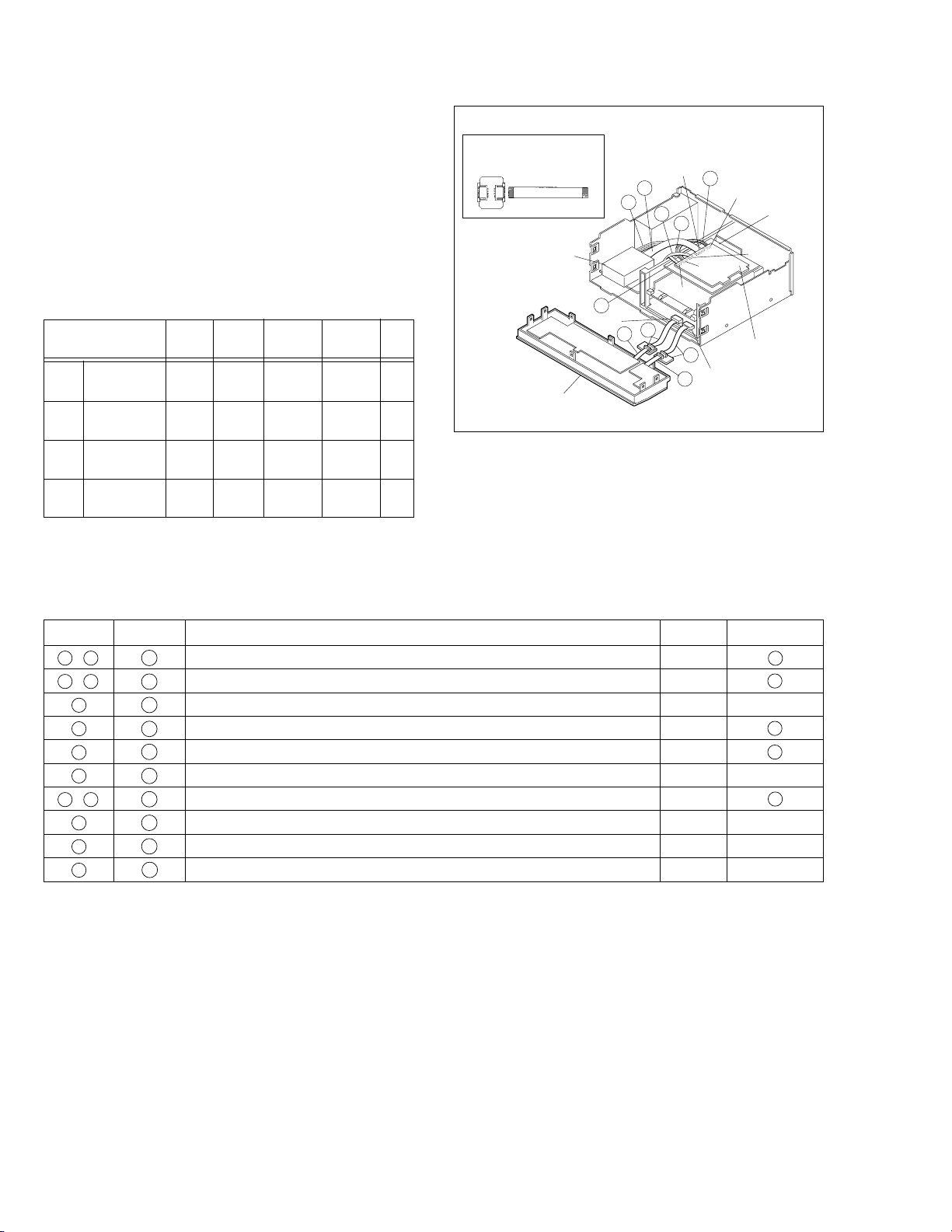

Page 9

24

5

CN5325

CN5326

WR8

WR5

Foil side

<Note 1>

WR4

Foil side

<Note 1>

WR6

WR7

CN5321

CN5322

(L6)

Spacer

<Note 4>

(L6)

Spacer

<Note 4>

CN5323

(S4)

23

(S4)

(S4)

22

(S4)

2

3

Eject SW

board assembly

Jack

board assembly

12

(S4)

LED/SW

board assembly

11

10

(S4)

(S4)

LED board assembly

Display board

assembly

21

17

(S4)

16

(S4)

15

(S4)

(S4)

18

(S4)

19

20

(S4)

14

(S4)

13

(S4)

(L5)

26

(S5)

Spacer

<Note 4>

(L4)

Fig. COM3

27

(S5)

Fig. COM4

WR3

Supporting

tape side

<Note 1>

4

CN5301

28

(S2)

Fig. COM5

32

(S6)

(S6)

33

(S6)

Fig. COM6

35

34

(S6)

36

(S6)

<Note 5>

Fan Motor

37

(S6)

29

(S2)

30

(S2)

6

31

(S2)

1-3

Page 10

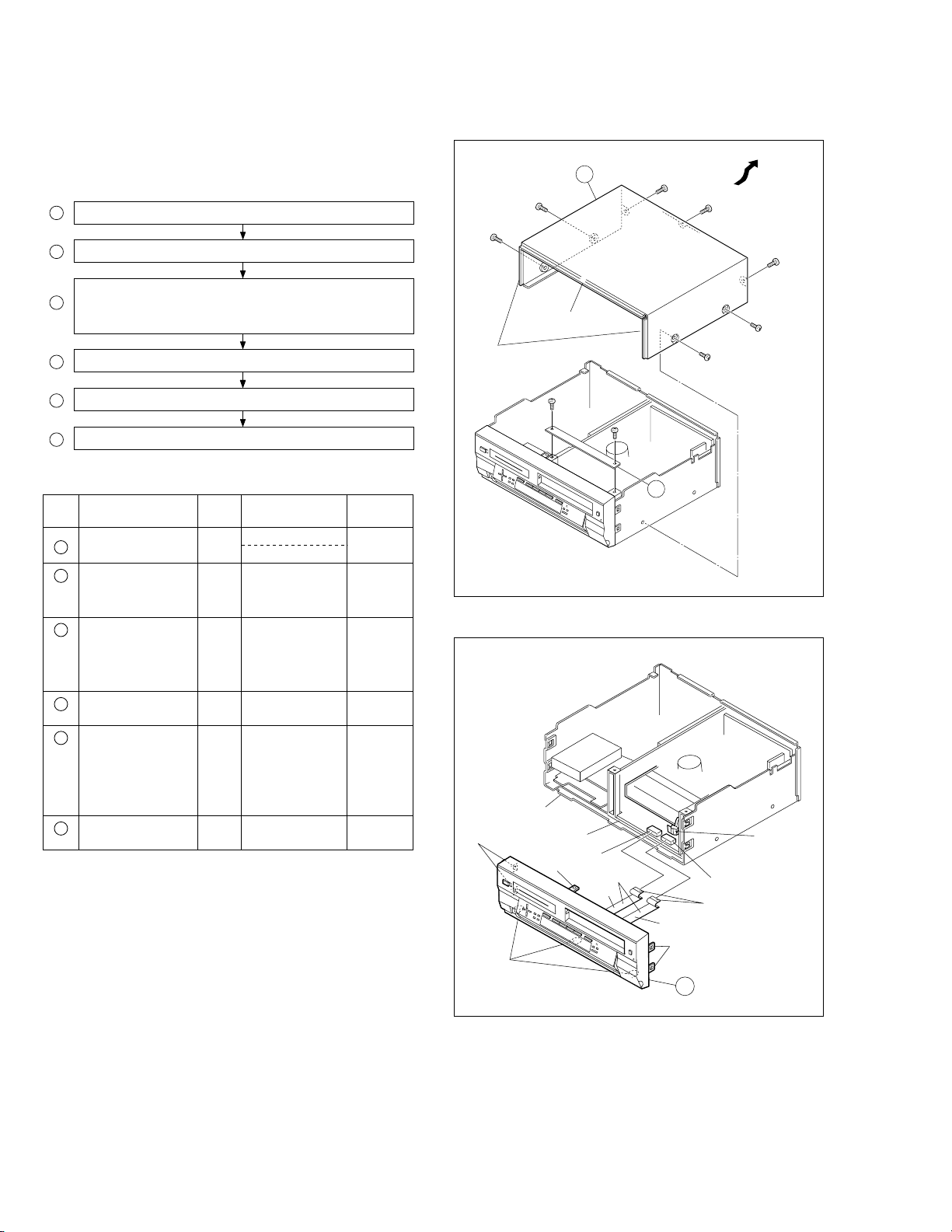

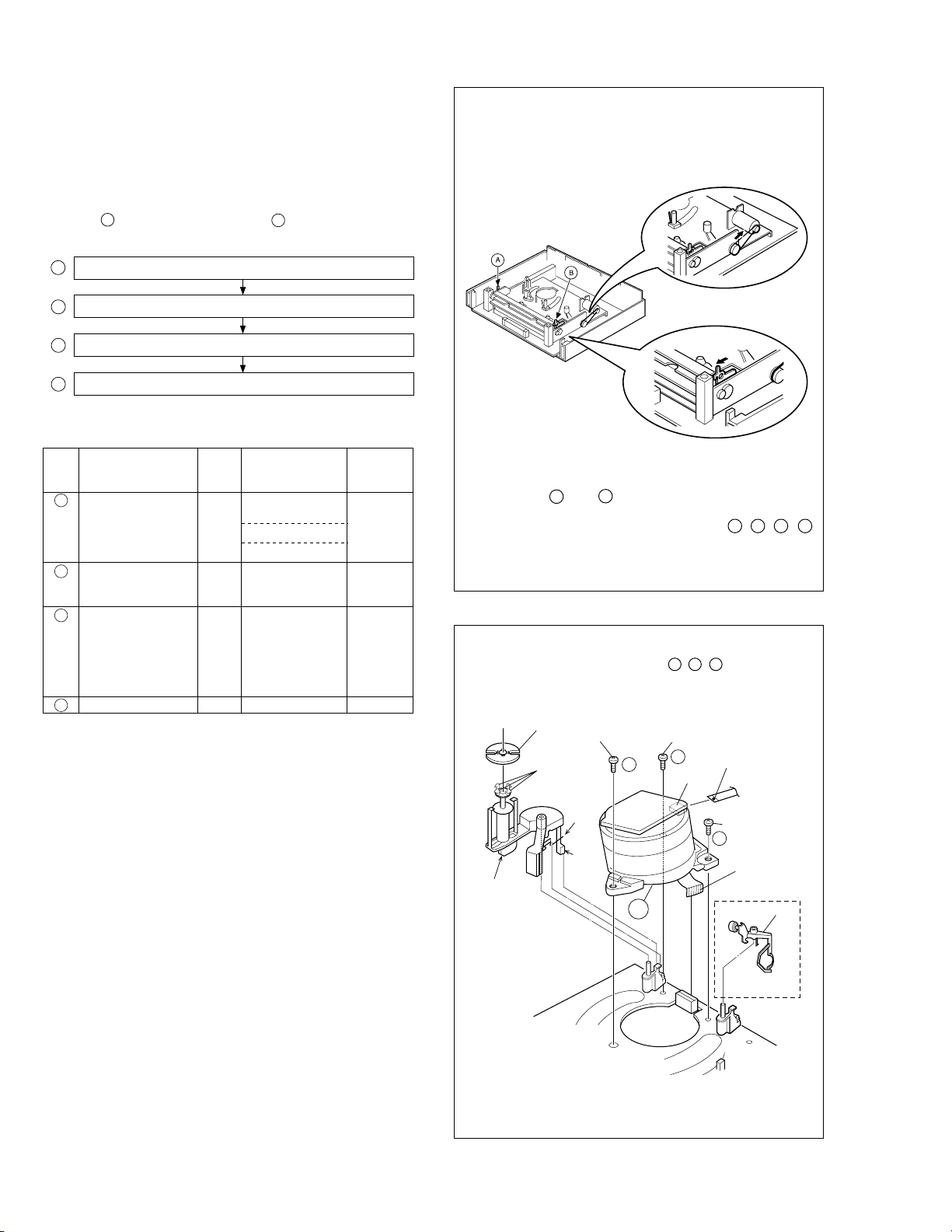

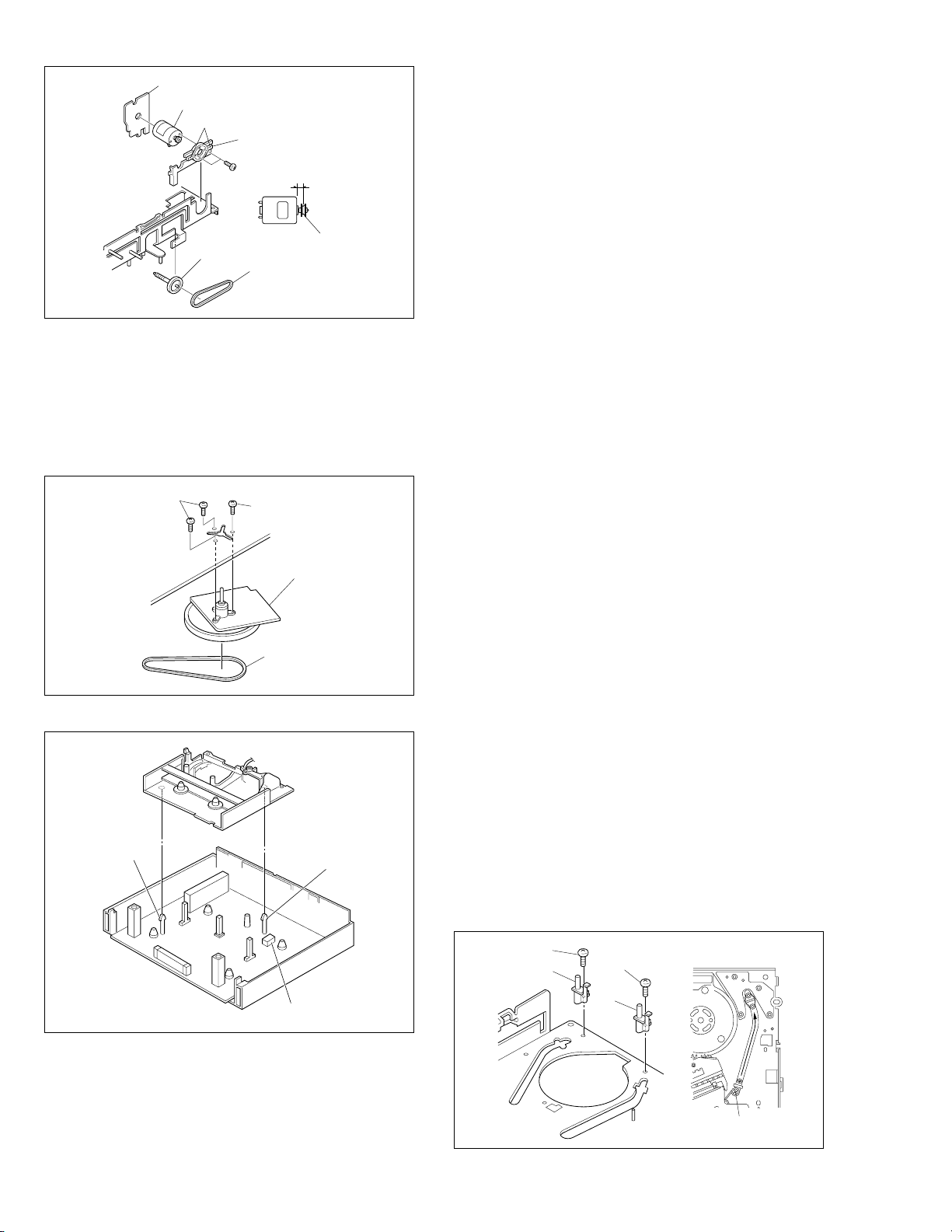

HOW TO REMOVE THE MAJOR PARTS <VHS section>

1.6

1.6.1 Disassembly flow chart

This flowchart shows the disassembly procedure for the exterior parts and electrical parts.

Basically, reverse this procedure when assembling them.

However, it is required to remove the common section parts

as far as 1 “Top cover Bracket” and 2 “Front panel assembly” in advance. (See section 1.5.)

1 Drum assembly

2 Mechanism assembly

3 Main board assembly

4 Base (1)

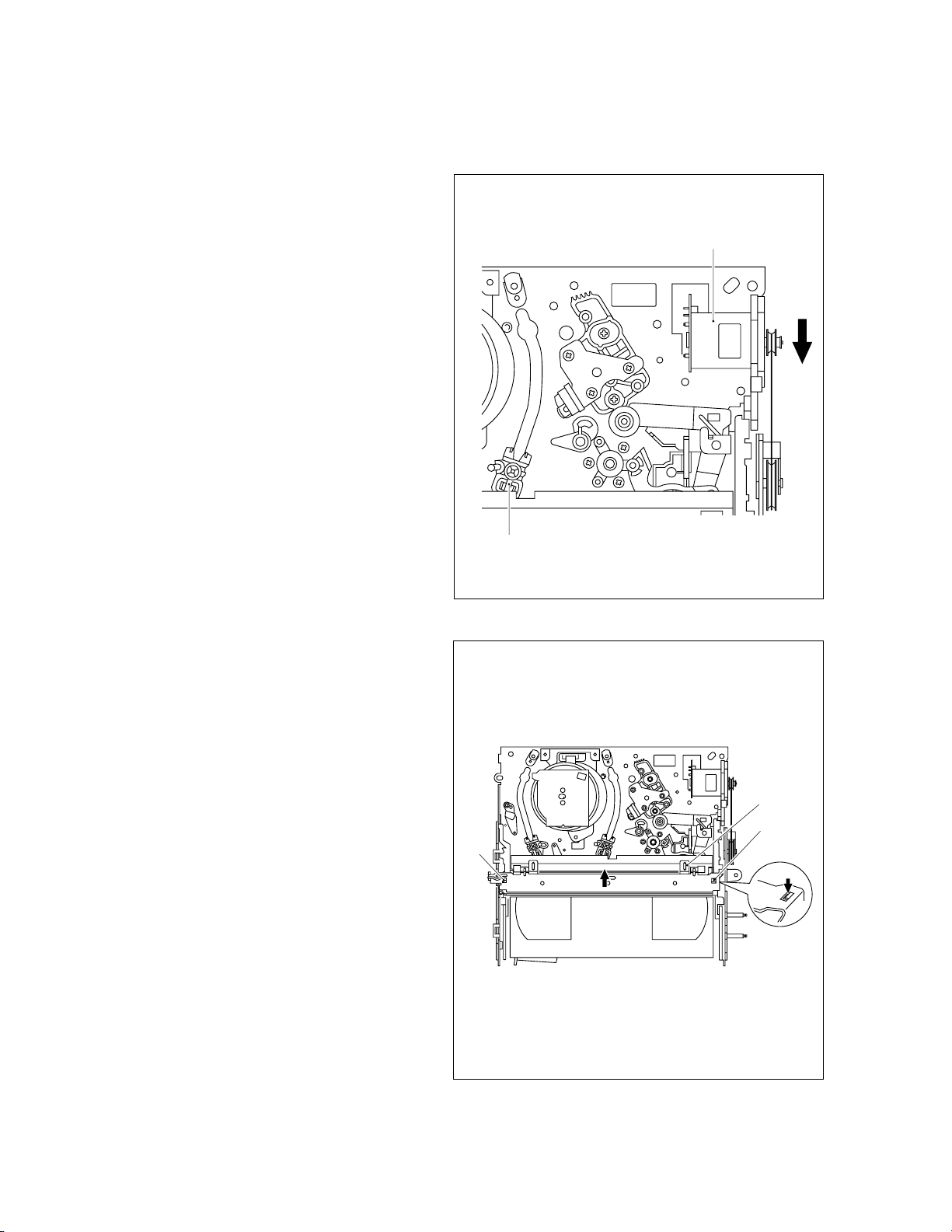

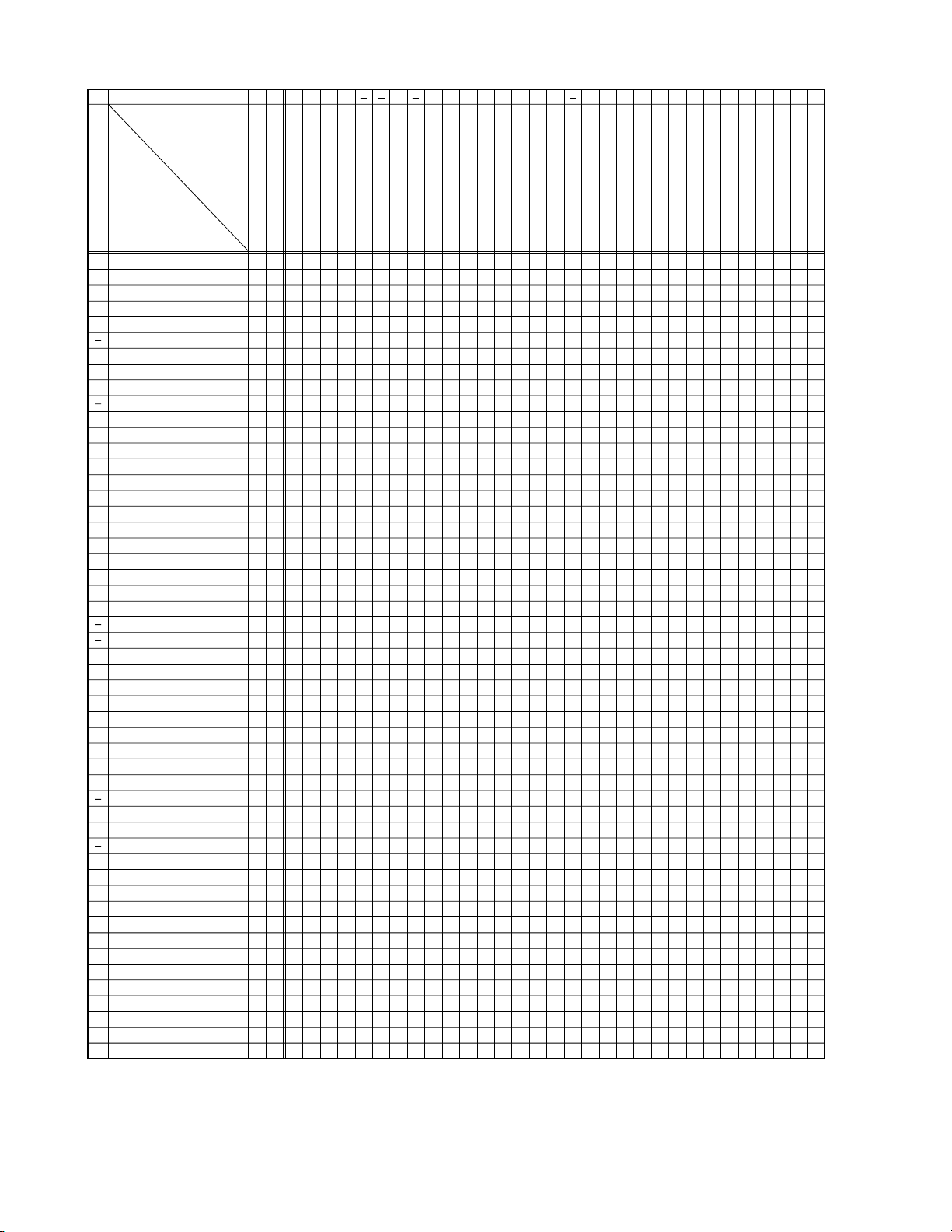

Procedures for Lowering the Cassette holder assembly

As the mechanism of this unit is integrated with the Housing

assembly, the holder must be lowered and the two screws unscrewed when removing the Mechanism assembly.

Fig. 2

Fig. 1

1.6.2 DIsassembly/assembly method <VHS section>

Step/

Loc No.

Drum assembly

1

(Inertia plate)

(Roller arm assy)

2

Mechanism

assembly

Main board

3 <Note 2>

assembly

Base (1) V4 (S3), 3(S5)4 —

Fig. No.

V1

3(S7), CON1(WR9),

CN1(WR10)

4(L1)

(P1), (L2)

V2

2(S3), (S8), (S9),

(L3), (L4),

CN1(WR11),

V3 2(S3), (S5),

CN5321(WR5),

CN5322(WR4),

CN3014(WR14),

CN703(WR15),

CN2601(WR16)

Point NotePart name

<Note 1,2>

<Note 2,4>

<Note 1>

When attaching or removing the FPC, take care not to disconnect any of the wires.

<Note 2>

When attaching the FPC, be sure to connect it in the correct orientation.

<Note 3>

When attaching wires, connect them in the correct orientation.

Fig. 3

Turn the loading motor pulley in the direction as indicated by

Fig.2. As both A and B levers are lodged twice, push the

levers in the direction as indicated by Fig.3 to release them.

When pushing the levers, do it in the order of A , B , B , A .

When the holder has been lowered, turn the pulley until the

cassette holder is securely in place without allowing any up/

down movement.

Procedures for Lowering the Cassette holder assembly

Note: When installing the Drum assembly, secure the

screws (S7) in the order of a , b , c .

Roller arm

assy

Inertia plate

(L1)

(P1)

(L2)

(S7)

1

a

2

(S7)

WR9

Foil side

c

<Note 2>

CON1

3

(S7)

b

WR10

Foil side

<Note 1,2>

1

Cleaner assy

<Note 4>

• When it is required to remove the screws (S3) retaining the

Mechanism assembly, please refer to the “Procedures for

Lowering the Cassette holder assembly”(See on page 1-5).

• When removing the Mechanism assembly only, unhook the

two spacers connecting it with the Main board assembly with

pliers from the back side of the Main board assembly first,

and then remove the Mechanism assembly.

• When reattaching the Mechanism assembly to the Main

board assembly, take care not to damage the sensors on

the Main board assembly (D3001: LED, Q3002: Start sensor, Q3003: End sensor, S3002: S cassette switch).

1-4

Not use

CN1

Fig. V1

Page 11

8

(S3)

10

(S5)

9

(S3)

WR16 Foil side

<Note 2>

CN5322

CN703

WR15

CN2601

CN3014

WR4

Foil side

<Note 2>

WR5

Foil side

<Note 2>

WR14

Foil side

<Note 2>

CN5321

3

Note: When installing the Mechanism assembly, secure

the screws (S8) in the order of a , b .

6

5

(S3)

<Note 4>

(S8)

4

(S3)

<Note 4>

WR11

Foil side

<Note 2>

(S9)

7

2

(L4)

Spacer

<Note 4>

12

(S5)

Fig. V3

13

(S5)

4

14

(S5)

Mechanism assy

<Note 4>

Spacer

(L3)

Spacer

<Note 4>

Fig. V2

S3002

S cassette switch

<Note 4>

11

(S3)

Fig. V4

1-5

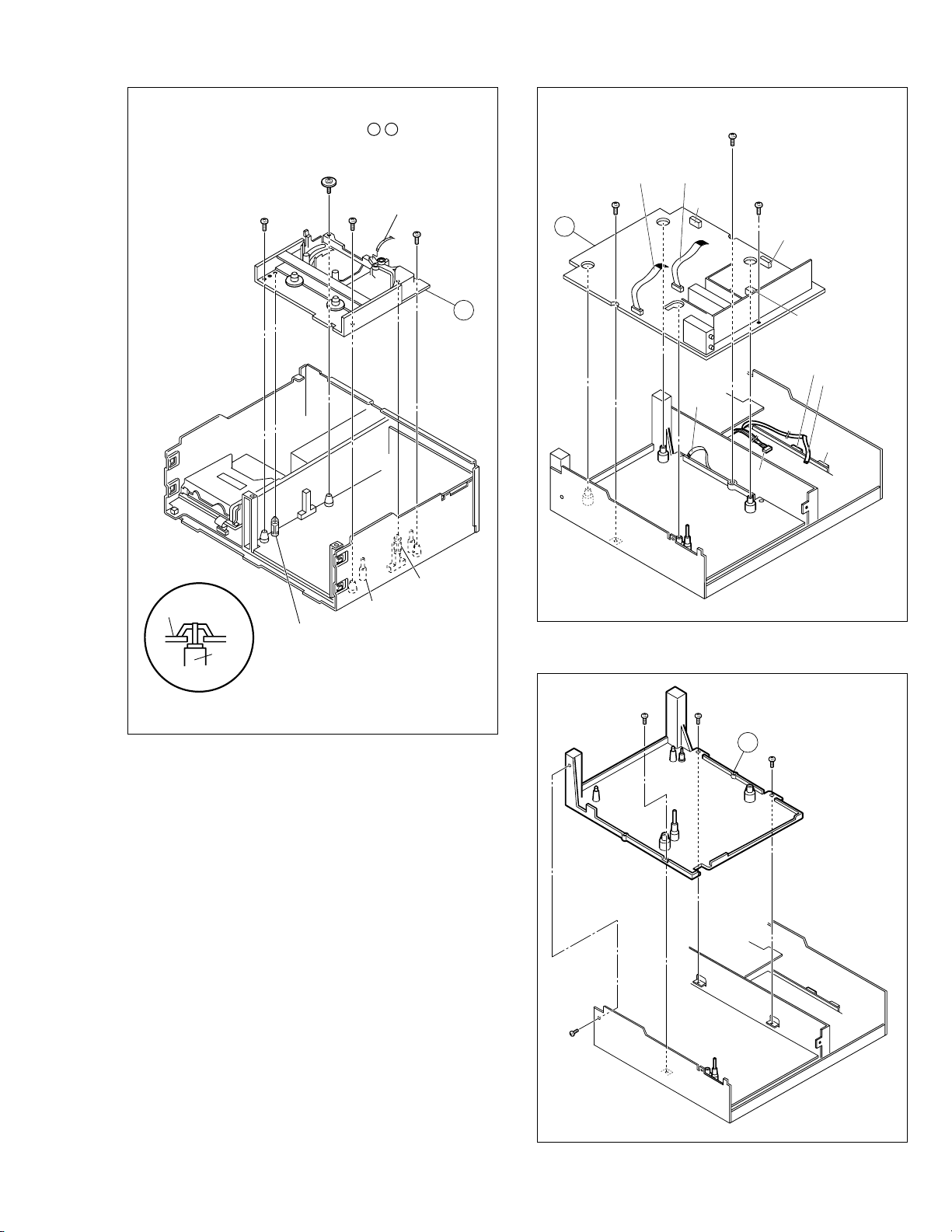

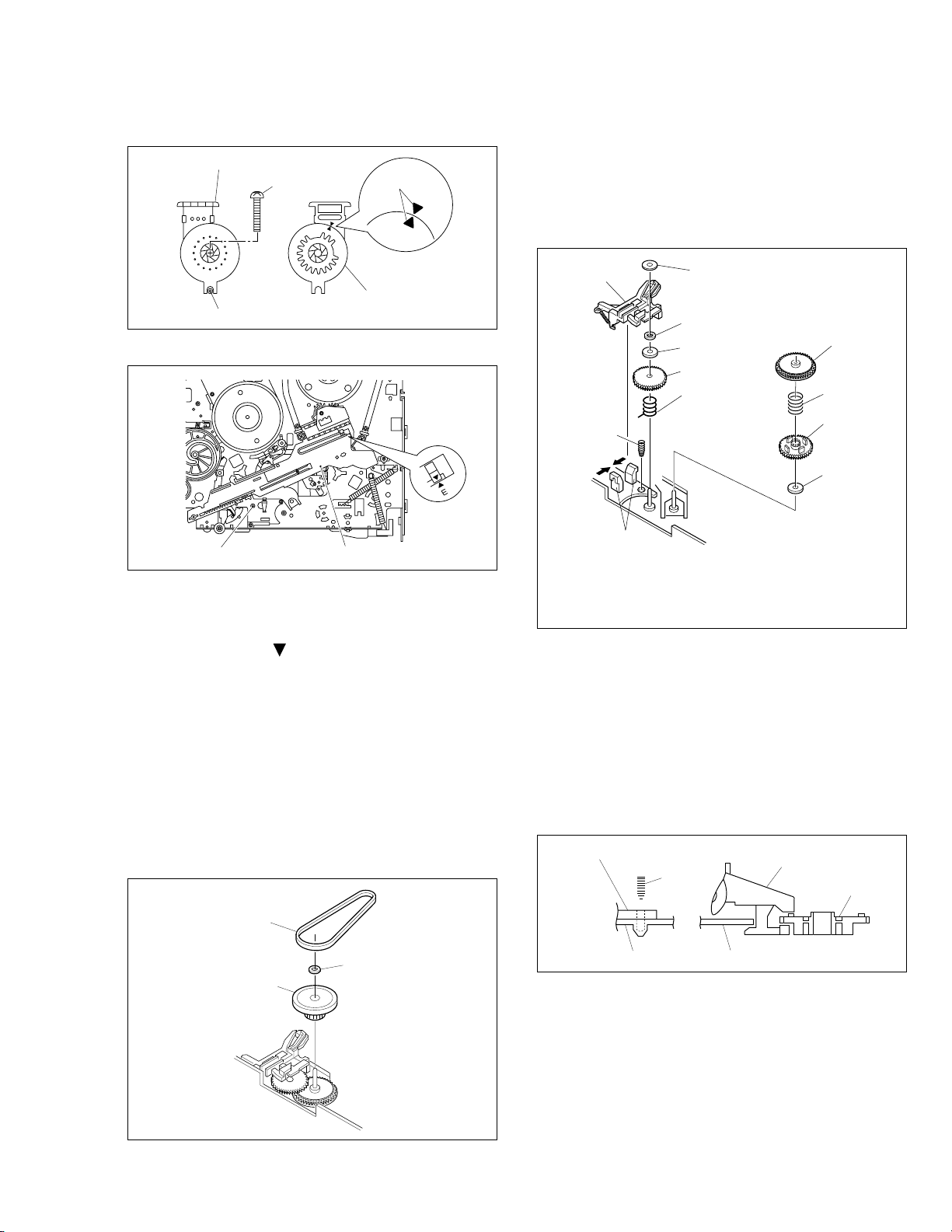

Page 12

Hard Disk Drive (HDD) Handling Precautions

The HDD is a precision device for use in reading and writing

a large amount of data on or from a disk rotating at a high

speed. If it is not handled carefully, either abnormal operation may result or it may not be possible to read data. The

HDD is sensitive to the following items and special care is

required in safeguarding against them when handling an

HDD. Also take care in handling a set incorporating an HDD.

1 Hard disk drive assembly

2 Hard disk

3 Digital board assembly

1.7

HOW TO REMOVE THE MAJOR PARTS <HDD section>

1.7.1 Disassembly flow chart

This flowchart shows the disassembly procedure for the exterior parts and electrical parts.

Basically, reverse this procedure when assembling them.

However, it is required to remove the common section parts

as far as 1 “Top cover” and 2 “Front panel assembly” in advance. (See section 1.5.)

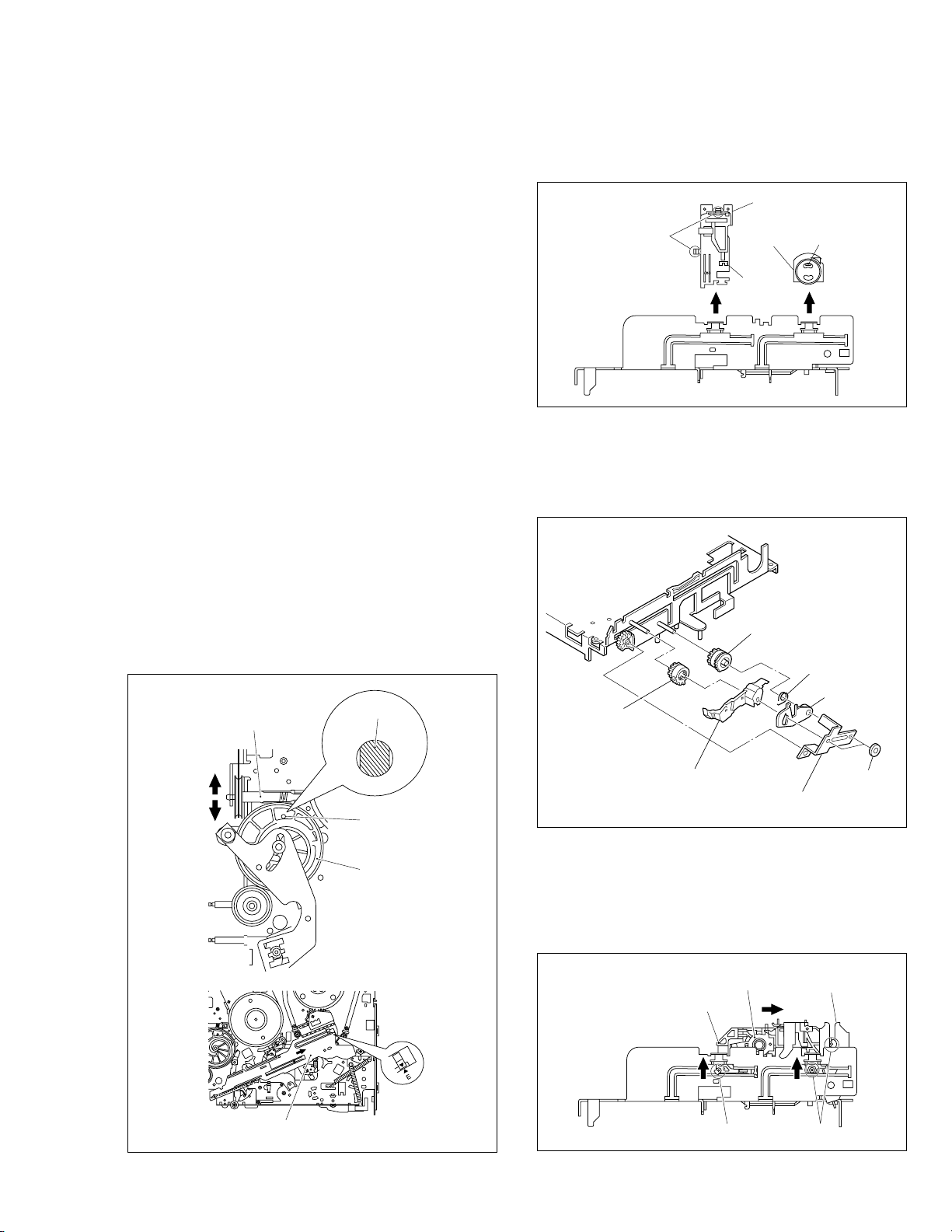

1 Hard disk drive assembly

1

(S5)

1

<Note 1>

(S5)

2

WR7

Frame

CN8001

3

(S5)

Fig. H1

(S5)

4

WR15

Earth

wire

<Note 2>

CN5326

2 Hard disk drive

3 Digital board assembly

1.7.2 DIsassembly/assembly method <HDD section>

Step/

Loc No.

1

Hard disk drive

assembly

2

Hard disk drive H2

3

Digital board

assembly

Fig. No.

H1 4(S5),

H3 4(S5),

Point NotePart name

<Note 1,2>

CN5326(WR15)

4(S10)

<Note 3,4>

CN8901(WR8),

CN8002(WR12),

CN8601(WR13),

CN8801(WR14)

<Note 1>

With due regard to operational considerations, remove the

parts located on the frame (Hard disk drive) together before removing the major parts.

<Note 2>

When attaching the hard disk drive assembly, be sure to

connect the earth wire.

<Note 3>

• When connecting or disconnecting the connector or wire,

take care not to damage them.

• When connecting the flat wire to the connector, be sure

to connect it in the correct orientation.

<Note 4>

When removing the board assembly, take care not to damage it.

(S5)

9

3

10

(S5)

CN8901

CN8002

Frame

CN8601

<Note 4>

12

(S5)

CN8801

2

5

(S10)

11

(S5)

6

(S10)

Fig. H2

7

(S10)

8

(S10)

WR13

WR8

WR12

Foil side

<Note 3>

WR14

Supporting

tape side

<Note 3>

1-6

Fig. H3

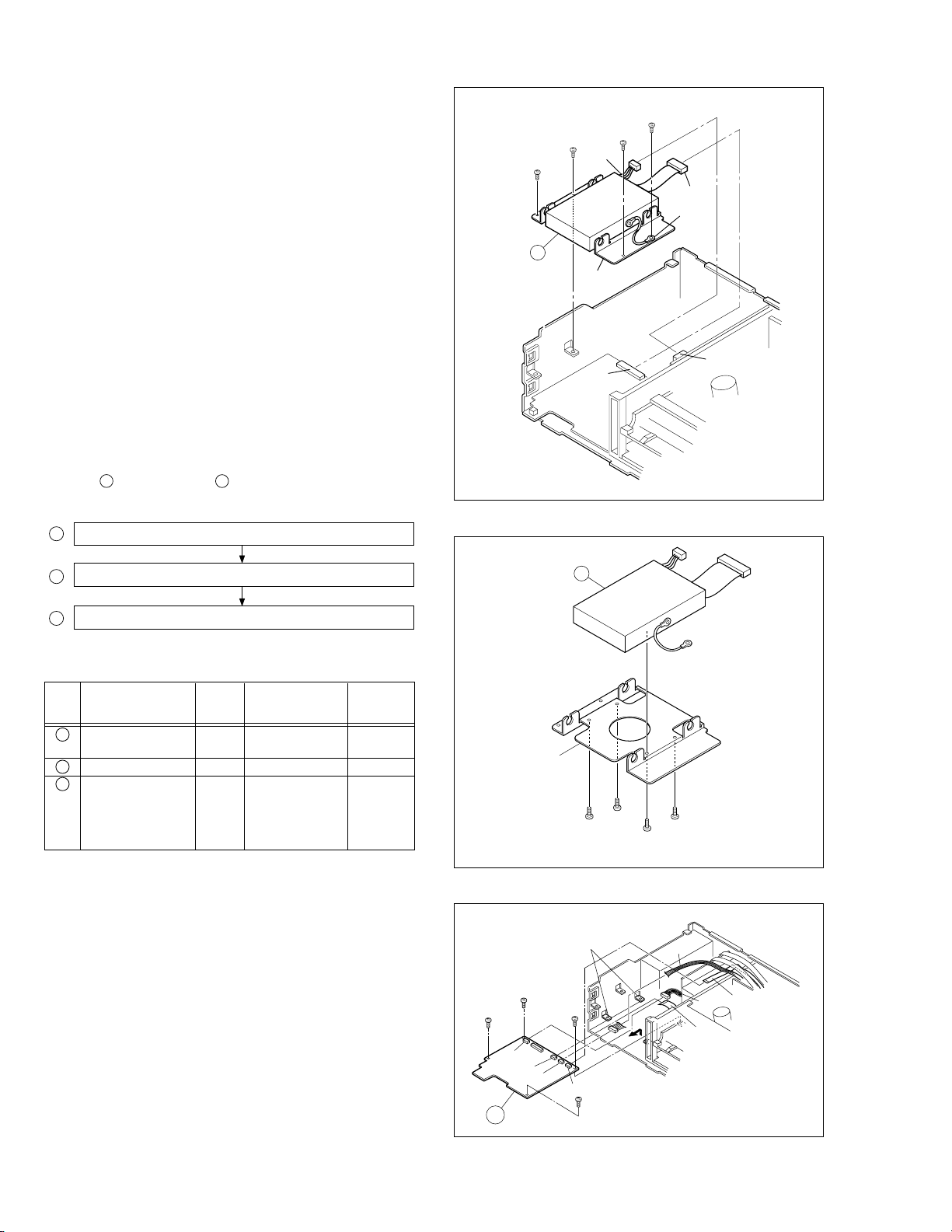

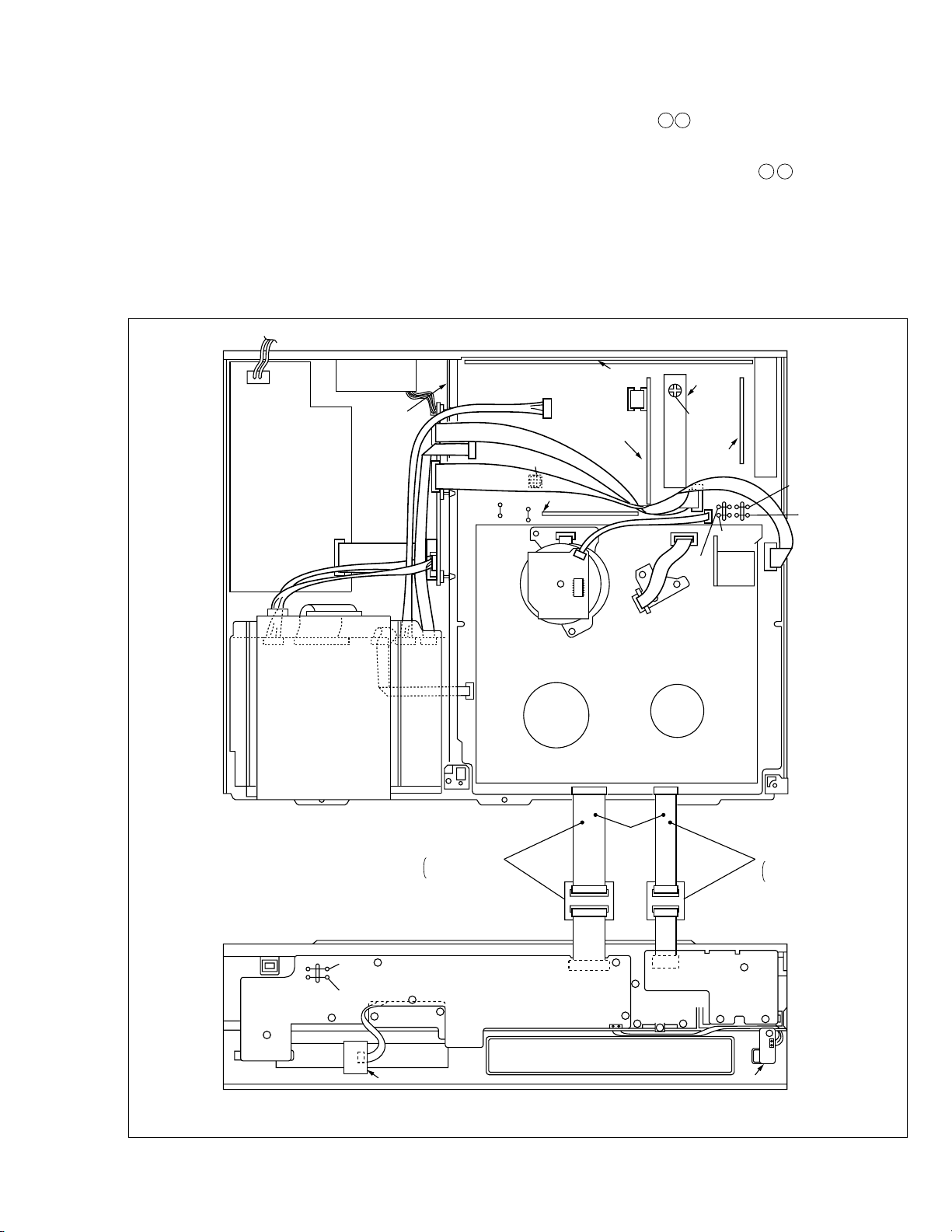

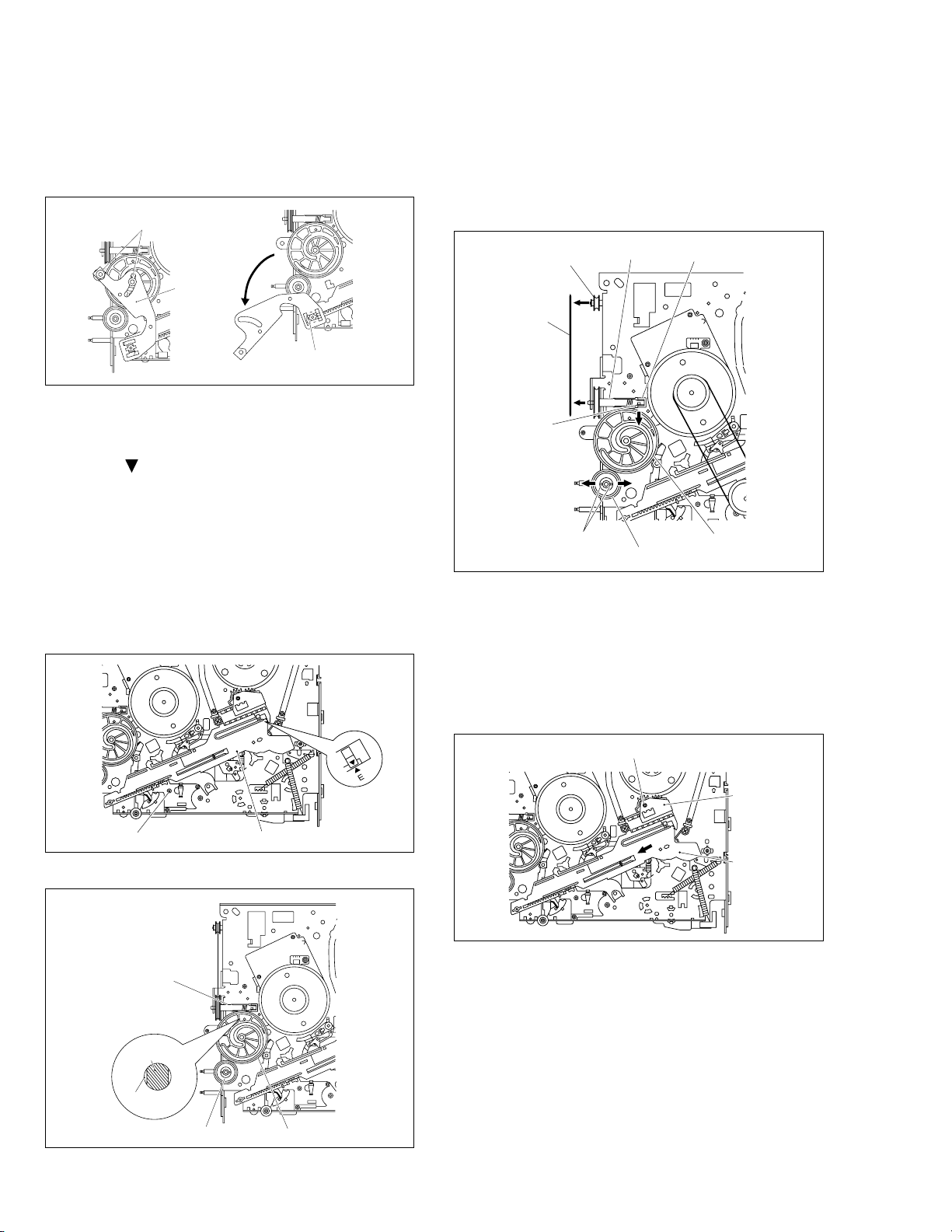

Page 13

1.8 SERVICE POSITIONS

The servicing locations for use in troubleshooting or servicing of the set are provided separately for the VHS and HDD.

I SERVICE POSITIONS <VHS SIDE>

II SERVICE POSITIONS <HDD SIDE>

1.8.1 Service position <VHS SIDE>

<Removal>

(1) Remove the top cover and bracket.

(2) Remove the front panel assembly.

(3) Remove the MAIN board assembly together with the

mechanism assembly.

Fig. No.

(Page)

(1)

Top cover,

COM1 9 2 + 1

Bracket (1-3) (No.1-9) (L1,2)

(2) Front

panel

COM2 0 8 2

(1-3) (L3) (CN7507/ —

assembly

(3) Rear

cover

(4) Main

board

COM6 10 0 1

(1-3)

V2, V3 7 0 5

(1-6) (No.4-10) (CN5321/

assembly

(etc.)

Screw Hook, etc. Connector Note

0 —

CN3011)

(No.28-37)

(CN5325)

CN5322/

CN3014/

—

—

CN703/

CN2601)

< Installation >

(1) Stand up the bottom chassis assembly so that the Regu-

lator side is in the lower position.

(2) Connect the PATCH CORD to the three FPCs then con-

nect CN3014, CN7508 and CN7509.

(3) By connecting a total of two FPCs and wires (CN703/

CN2601), carry out the installation so that the Main board

assembly comes in the upper position.

Point: • Take care that the FPCs and wires are not

subjected to stress in this positioning.

(4) Connect the PATCH CORDS to the two FPCs of the front

panel assembly, then connect the CORDS to the

CN7507/CN3011.

For the PATCH CORD is required, see Table 1-8-2.

Board to Board WIRE

A PTU94022-10 QUQ112-1040CG

B PTU94022-18 QUQ112-1840CG

C PTU94022-13 QUQ212-1340CG

D PTU94022-15 QUQ212-1540CG

E YTU94072-06 QUQ210-0640CG

Table 1-8-2

Table 1-8-1

PATCH CORD

PTU94017B

Front panel assembly

Main board assembly

CN7509

CN7507

A

1

CN3011

CN3014

B

2

CN703

E

CN7508

CN2601

6

7

D

C

3

CN8801

4

CN5322

5

CN5321

CN8601

CN8002

Fig. 1-8-1 Service position <VHS side>

1-7

Page 14

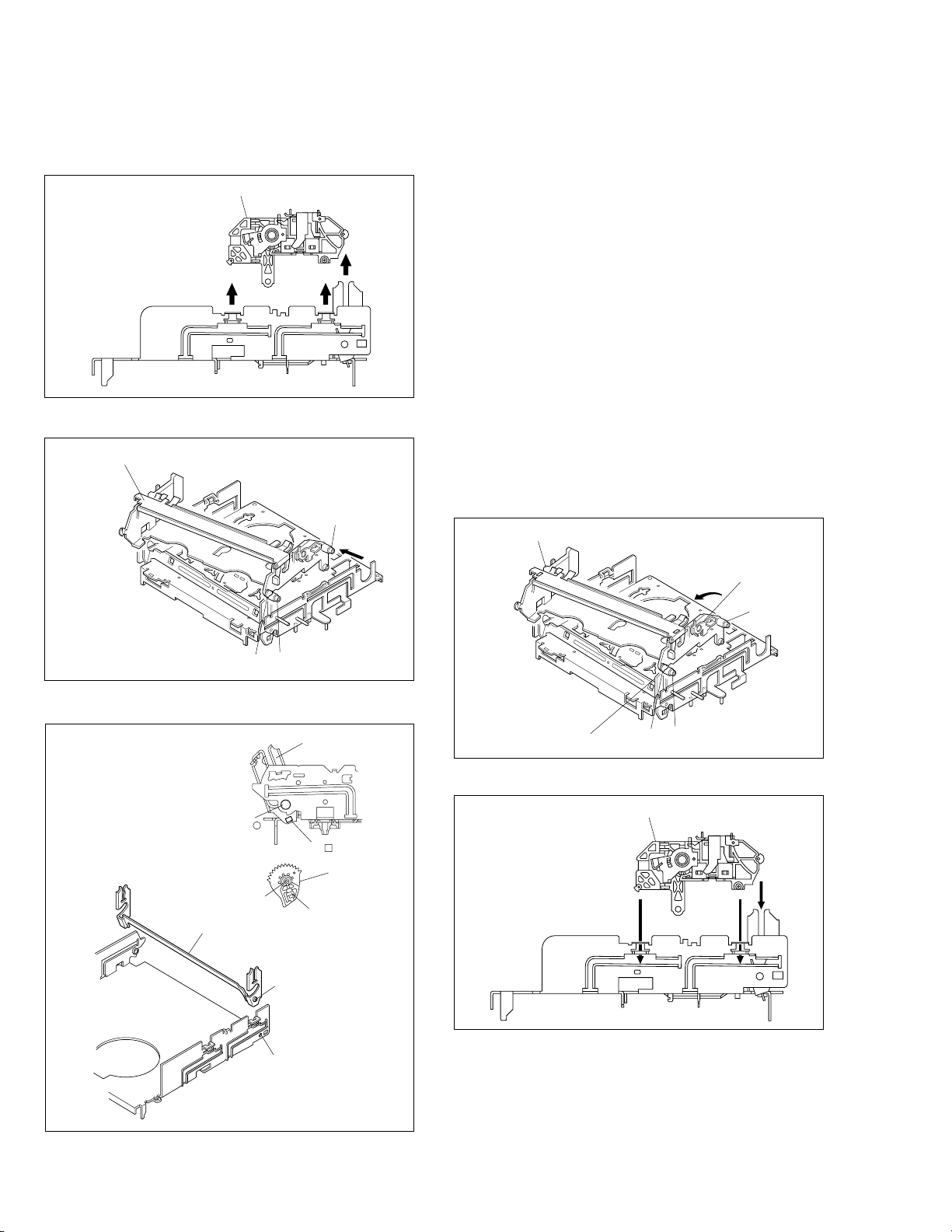

1.8.2 Service position <HDD SIDE>

(1) Remove the exterior parts (Top cover and front panel as-

sembly).

(2) Remove the hard disk drive(HDD) together with the frame.

(3) Remove the digital board assembly together with the wires

attached to it, and place the assembly upside down on

an insulated mat that is placed on the mechanism (VHS)

assembly.

(4) Mount the HDD that was removed in (2) to its original

position on the bottom chassis assembly, and connect

the wires to the connector CN8001 on the digital board

assembly and to the connector CN5326 on the regulator

board assembly.

Fig. No.

(Page)

Screw

(No.)

Hooks,

etc. (No.)

Connectors

Note

(1) Top cover, COM1 9 2 + 1 0 —

Brackets (1-3) (No.1-9) (L1, L2)

(2) Front panel COM2 0 8 (L3)

2(CN7507,

—

assembly (1-3) CN3011)

Hard disk drive

(3)

H1 4 0

2 (CN8001,

—

assembly (1-6) (No.1-4) CN5326)

(4) Digital board H3 4 0 0 —

assembly

(No.9-12)

Table 1-8-3

PATCH CORD

PTU94017B

Hard disk drive

assembly

Front panel assembly

6

CN3011

CN8001

7

CN8801

3

A

1

10

CN8601

CN7507

8

9

B

2

Fig. 1-8-2 Service position <HDD side>

CN8901

Insulation sheet

CN8002

Digital board

assembly

Note :

•

The symbol numbers in the following table are special numbers indicating the service positions. They do not coincide with the symbol numbers used in Fig. 1-10-1 (1-10) or Table 1-10-1 (1-11).

SYMBOL CONNECTOR (WIRE) CONNECTIONS

PIN No

PATCH CORD

I / II 1 MAIN CN7507 — JACK CN7002 10 A

I / II 2 MAIN CN3011 — DISPLAY CN7001 18 B

I 3 TERMINAL CN703 — DIGITAL CN8601 6 —

I 4 MAIN CN7508 — REGULATOR CN5322 13 C

I 5 MAIN CN7509 — REGULATOR CN5321 15 D

I 6 MAIN CN2601 — DIGITAL CN8801 8 —

I / II 7 MAIN CN3014 — DIGITAL CN8002 6 E

II 8 DIGITAL CN8001 — HARD DISK DRIVE 40 —

II 9 REGULATOR CN5326 — HARD DISK DRIVE 4 —

II 10 REGULATOR CN5323 — DIGITAL CN8901 9 —

Table 1-8-4 Connection of Connectors

1-8

Page 15

1.9 MECHANISM SERVICE MODE

This model has a unique function to enter the mechanism

into every operation mode without loading of any cassette

tape. This function is called the “MECHANISM SERVICE

MODE”.

1.9.1 How to set the "MECHANISM SERVICE MODE"

(1) Disconnect VCR from AC.

(2) Connect TPGND and TP7001 (TEST) on the Display

board assembly with a jump wire.

(3) Connect VCR to AC.

(4) Press the POWER button.

(5) With lock levers A B on the left and right of the Cassette

holder assembly pulled toward the front, slide the holder

in the same direction as the cassette insertion direction.

(For the positions of lock levers A B , refer to the “Pro-

cedures for Lowering the Cassette holder assembly” on

page 1-5 of 1.6 HOW TO REMOVE THE MAJOR PARTS

<VHS section>

(6) The cassette holder lowers and, when the loading has

completed, the mechanism enters the desired mode.

Swithing regulator

board assembly

Hard disk drive

(HDD)

Fan motor

Regulator

board assembly

Main board assembly

TPGND

Terminal board assembly

S-Sub

board assembly

VR701

DV AG C

TP701

On screen

D AGC

board assembly

TP106

PB FM

VHS mechanism

CN3011 CN7507

3D Digital

/2M board

assembly

VR1401

D/A

LEVEL ADJ

Demodulator

board

assembly

TP2253

A.PB FM

TP4001

CTL.P

TP111

D.FF

TP7001

TEST

TPGND

PATCH CORD

PTU94022-18

QUQ112-1840CG

LED SW

board assembly

LED board assembly

<Front panel assembly>

Display board assembly

Fig. 1-9-1

Supporting

tape side

PATCH CORD

PTU94022-10

QUQ112-1040CG

Jack board assembly

Eject SW board assembly

1-9

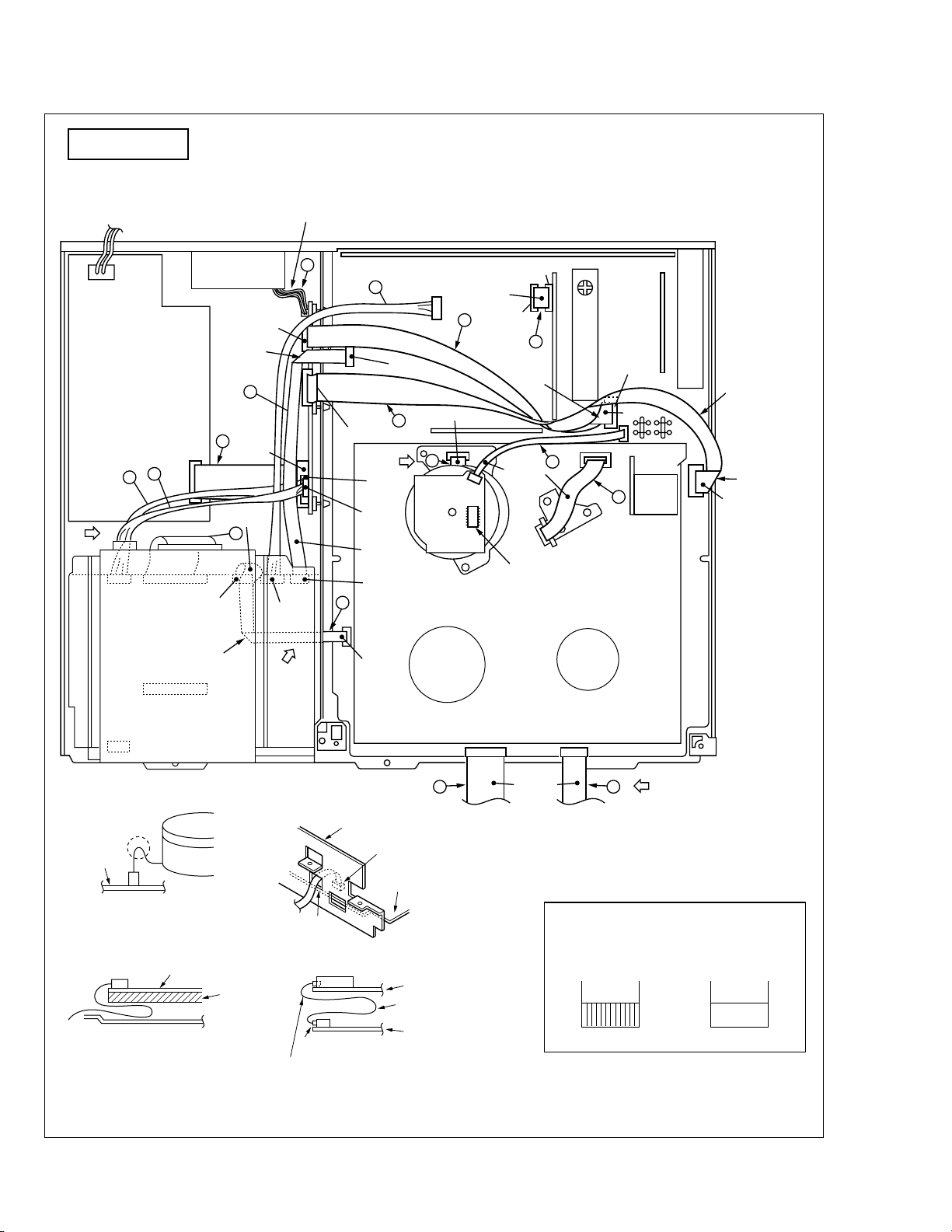

Page 16

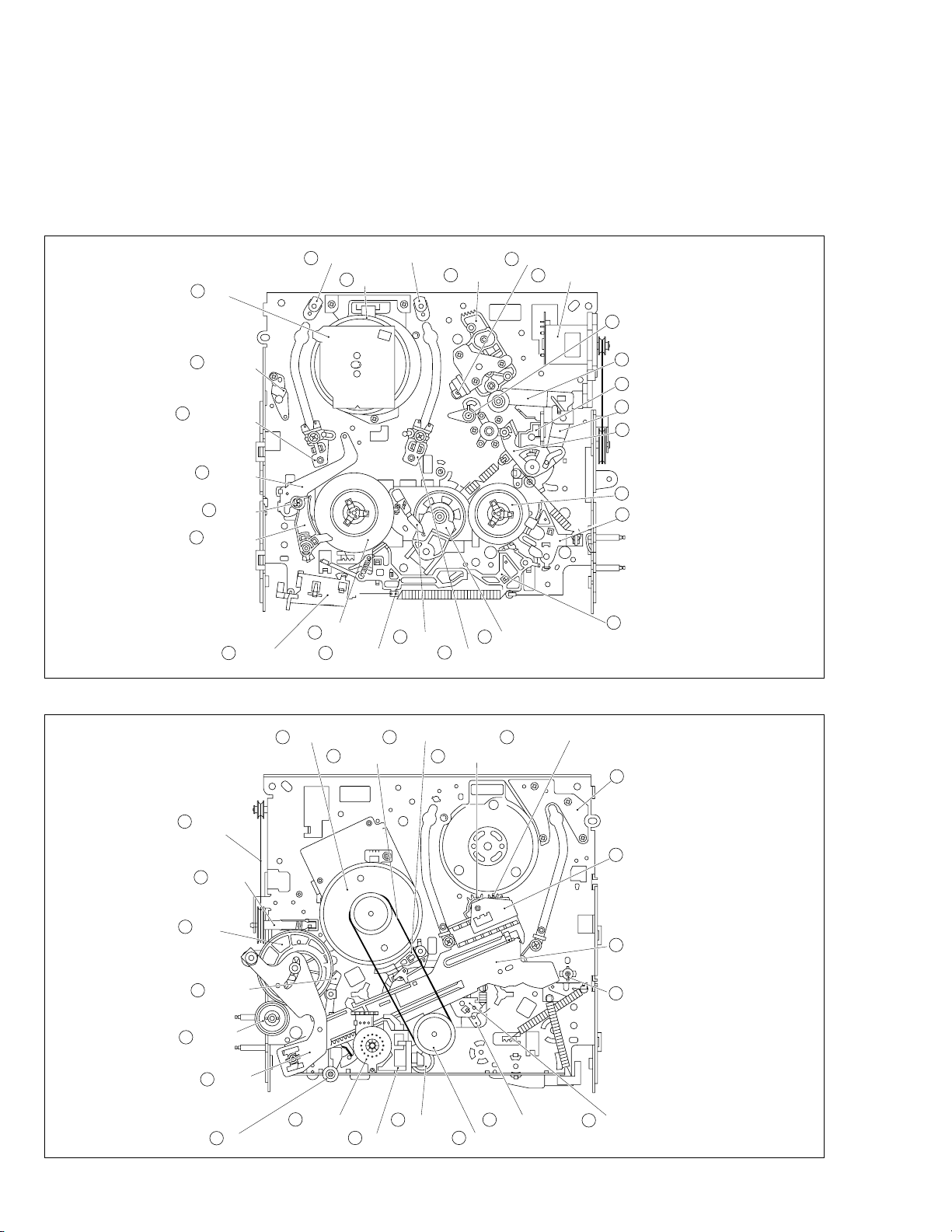

1.10 CONNECTION

TOP VIEW

Treat wire so as not to come to the FAN motor.

CN5325

CN8601

C

6

Foil side

Foil side

CN5321

Foil side

Make a

crease.

12

CN3014

13

CN5323

(Middle)

CN5326

(Upper)

Foil side

CN8801

Foil side

CN2601

Supporting

5

tape side

A

CN703

10

DRUM

Supporting

tape side

4

CON1

FAN motor

CN5322

Make a

crease.

14

3

CN5301

Supporting

tape side

Supporting

tape side

Supporting

tape side

CN8002

(Lower)

15

CN5201

7

8

D

CN8901

CN8001

Make a crease.

CN8201

CN512

CN7506

16

Make a

crease.

CN1

Foil side

CN1

A/C HEAD

Should be confirmed that wire

not touch to IC of the Stator

board assembly.

CN7508

Treat the wire

CN7509

Supporting

tape side

according to the

figure not to

overlap in TP.

Make a crease.

Foil side

CN2001

9

CN3001

11

CN8202

DETAIL "A" DETAIL "C"

DRUM

Chassis

B

Main board

assembly

Absorb the looseness of

the wire in the B part.

DETAIL "B"

Treat the front wires

according to the figure.

CN1

Main board assembly

Base(1)

Treat the wire

through the hole.

DETAIL "D"

HDD

CN8001

The wire should be

does not touch from edge.

CN3011 CN7507

CN3014

Main board

assembly

Frame

The excessive length portion of

wire should be treat as figure.

Digital board

assembly

Fig. 1-10-1 Top view

Foil side

12

B

[CAUTION]

Insert the FPC wires as shown below.

Foil side Supporting tape side

1-10

Page 17

Fig.

No.

Symbol

Connection

Pin No.

Connected point ←→ Connected point

Type

(FPC/

WIRE)

1 WR1 MAIN CN7507 ←→ JACK CN7002 10 FPC

2 WR2 MAIN CN3011 ←→ DISPLAY CN7001 18 FPC

3 WR3 REGULATOR CN5301 ←→ SW REG CN5201 19 FPC

4 WR4 REGULATOR CN5322 ←→ MAIN CN7508 13 FPC

5 WR5 REGULATOR CN5321 ←→ MAIN CN7509 15 FPC

6 WR6 REGULATOR CN5325 ←→ FAN MOTOR — 2 WIRE

7 WR7 REGULATOR CN5326 ←→ HDD — 4 WIRE

8 WR8 REGULATOR CN5323 ←→ DIGITAL CN8901 9 WIRE

9 WR9 DRUM MOTOR CON1 ←→ MAIN CN3001 5 FPC

10 WR10 MAIN CN1 ←→ UPPER DRUM — 11 FPC

11 WR11 A/C HEAD CN1 ←→ MAIN CN2001 7 FPC

12 WR12 MAIN CN3014 ←→ DIGITAL CN8002 6 FPC

13 WR13 MAIN CN703 ←→ DIGITAL CN8601 6 WIRE

14 WR14 MAIN CN2601 ←→ DIGITAL CN8801 8 FPC

15 WR15 DIGITAL CN8001 ←→ HDD — 40 WIRE

16 — MAIN CN7506 ←→ S-SUB CN512 14 FPC

—— DIGITAL CN8201 ←→ Jig CONN. CABLE — 100 WIRE

—— DIGITAL CN8202 ←→ Jig CONN. CABLE — 6 FPC

Table 1-10-1 Connection

1-11

Page 18

1.11 EMERGENCY DISPLAY FUNCTION

This unit has a function for storing the history of the past two

emergencies (EMG) and displaying them on each FDP. With

the status of the VCR and mechanism at the moment an emergency occurred can also be confirmed.

FDP display switching

FDP display

Notes:

•

The emergency detail display

on the latest emergency.

It becomes “ – – : – – : – –” when there is no latest emergency record.

•

When using the Jig RCU, set its custom code to match

the custom code of the VCR.

Jig RCU

[Data transmitting method]

Depress the “ ” ( 3 ) button

after the data code is set.

0 : 00 : 00

E: **:

1: *2 : 34

*

5: *6 :

*

CUSTOM CODE

43: A CODE

53: B CODE

6F: C CODE

7F: D CODE

DATA CODE

Fig. 1-11-1 Jig RCU [PTU94023B]

Normal display

Emergency content display

**

(E:Latest:Previous)

Emergency detail display

Emergency detail display

7

*

1 2

show the information

1

2

INITIAL MODE

1.11.1 Displaying the emergency information

(1) Transmit the code “59” from the Jig RCU.

The FDP shows the emergency content in the form of

“E:

:**”.

**

Example 1 E : 01 :

Example 2 E : –– :

Note:

For the emergency content, see “1.11.3 Emergency content description”.

(2) Transmit the code “59” from the Jig RCU again.

The FDP shows the emergency detail information 1 in the

form of “

*

*

3 – : Mechanism sensor information at the moment of

– 4 : Mechanism mode position at the moment of emer-

Note:

•

For the emergency detail information

Emergency detail information

(3) Transmit the code “59” from the Jig RCU once again.

The FDP shows the emergency detail information 2 in the

form of “

*

*

*

Note:

•

For the emergency detail information 2 , see “1.11.5 Emergency detail information

1 : *2 : 34”.

*

1 : Deck operation mode at the moment of emergency

2 : Mechanism operation mode at the moment of emer-

gency

emergency

gency

5 : *6 :

*

5 : Type of the cassette tape in use 1 .

6 : Winding position of the cassette tape in use

7 : Type of the cassette tape in use 2 (Winding area)

03

Previous emergency

Latest emergency

––

No emergency record

1

, see “1.11.4

1

”.

7 ”.

*

2

”.

1-12

(4) Transmit the code “59” from the Jig RCU once again to re-

set the display.

1.11.2 Clearing the emergency history

(1) Display the emergency history.

(2) Transmit the code “36” from the Jig RCU.

(3) Reset the emergency display.

Page 19

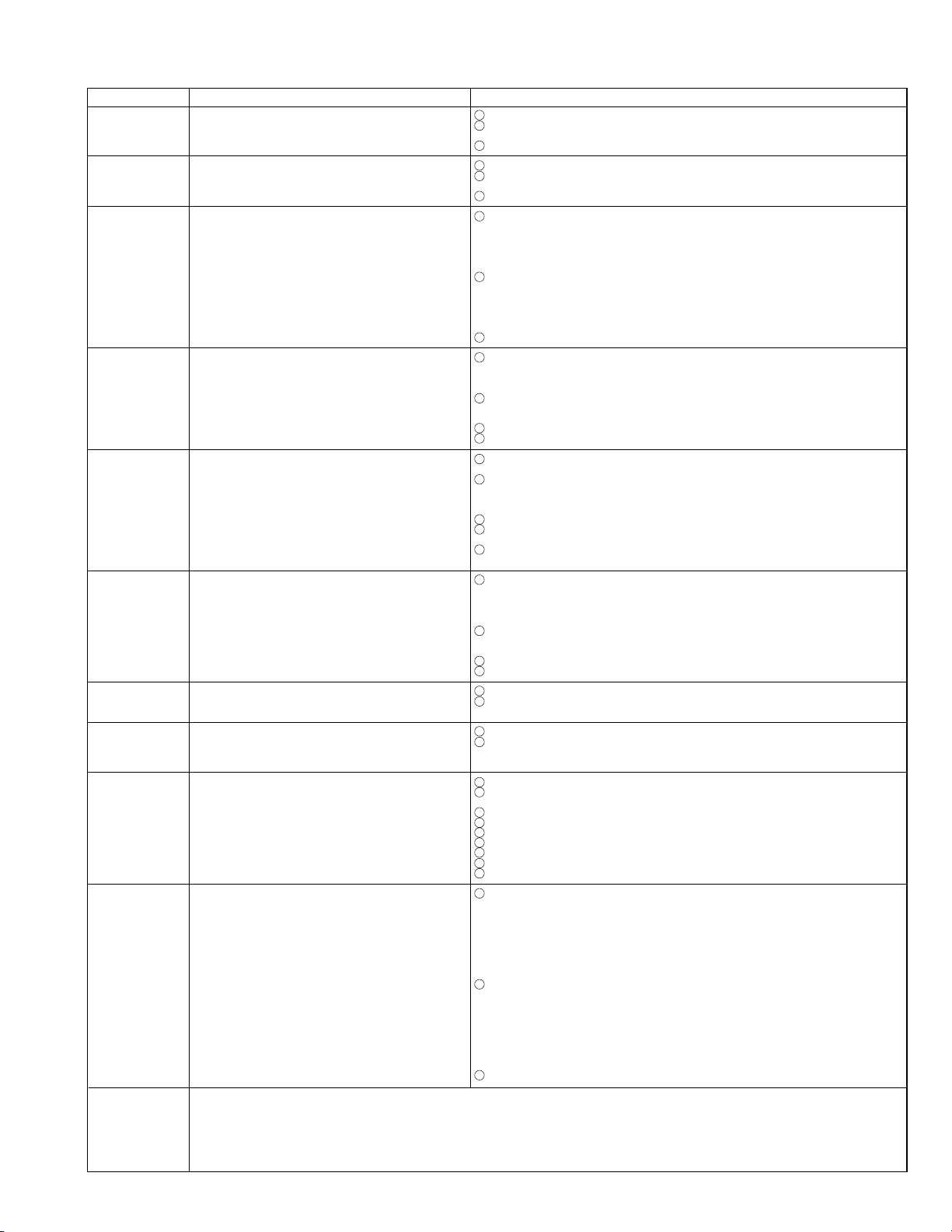

1.11.3 Emergency content description

Emergency contents “E08/E09” are for the model with Dynamic Drum (DD).

Note:

FDP CONTENT CAUSE

1

E01: Loading EMG

E02:

Unloading EMG

E03: Take Up Reel

Pulse EMG

E04: Drum FG

EMG

E05: Cassette Eject

EMG

E06: Capstan FG

EMG

E07: SW Power

Short-Circuit

EMG

E08:

HDD

Communication EMG

E09: DD FG EMG

E0A:Supply Reel

Pulse EMG

EC1 or EU1:

Head clog warning

When the mechanism mode cannot be changed to another mode even when the loading motor has rotated

for more than 4 seconds in the loading direction, [E:01]

is identified and the power is turned off.

When the mechanism mode cannot be changed to another mode even when the loading motor has rotated

for more than 4 seconds in the unloading direction, [E:02]

is identified and the power is turned off.

When the take-up reel pulse has not been generated for

more than 4 seconds in the capstan rotating mode, [E:03]

is identified, the pinch rollers are turned off and stopped,

and the power is turned off. However, the reel EMG is

not detected in STILL/SLOW modes.

When the drum FG pulse has not been input for more

than 3 seconds in the drum rotating mode, [E:04] is identified, the pinch rollers are turned off and stopped, and

the power is turned off.

When the eject operation does not complete in 3 seconds after the start, [E:05] is identified, the pinch rollers

are turned off and stopped, and the power is turned off.

When the cassette insertion operation does not complete

in 3 seconds after the start, the cassette is ejected. In

addition, when the operation does not complete within

3 seconds after the start, [E:05] is also identified and the

power is turned off immediately.

When the capstan FG pulse has not been generated for

more than 1 second in the capstan rotating mode, [E:06]

is identified, the pinch rollers are turned off and stopped,

and the power is turned off.However, the capstan EMG

is not detected in STILL/SLOW/FF/REW modes.

When short-circuiting of the SW power supply with GND

has lasted for 0.5 second or more, [E:07] is identified,

all the motors are stopped and the power is turned off.

When the KBUS_DATA signal did not reach the pin-46

of the System controller CPU (IC3001) on the main board

assembly, [E:08] is identified, "POWER ON" operation

is rejected.

When the DD FG pulse is not generated within 2.5 seconds, [E:09] is identified, the tilt motor is stopped and

the power is turned off.

When the supply reel pulse has not been generated for

more than 10 seconds in the capstan rotating mode,

[E:0A] is identified and the cassette is ejected (but the

power is not turned off). However, note that the reel EMG

is not detected in the SLOW/STILL mode.

Presupposing the presence of the control pulse output in the PLAY mode, when the value obtained by mixing the two V.FM output

channels (without regard to the A.FM output) has remained below a certain threshold level for more than 10 seconds, [E:C1] or [E:U1]

is identified and recorded in the emergency history. During the period in which a head clog is detected, the FDP and OSD repeat the

“3-second warning display” and “7-second noise picture display” alternately.

EMG code : “E:C1” or “E:U1” / FDP : “U:01” / OSD : “Try cleaning tape.” or “Use cleaning cassette.”

The head clog warning is reset when the above-mentioned threshold has been exceeded for more than 2 seconds or the mode is

changed to another mode than PLAY.

The mechanism is locked in the middle of mode transition.

2

The mechanism is locked at the loading end due to the encoder position

reading error during mode transition.

3

Power is not supplied to the loading MDA.

1

The mechanism is locked in the middle of mode transition.

2

The mechanism is locked at the unloading end due to the encoder position reading error during mode transition.

3

Power is not supplied to the loading MDA.

1

The take-up reel pulse is not generated in the FWD transport modes (PLAY/

FWD SEARCH/FF, etc.) because;

1) The idler gear is not meshed with the take-up reel gear;

The idler gear is meshed with the take-up reel gear, but incapable of wind-

2)

ing due to too large mechanical load (abnormal tension);

3) The take-up reel sensor does not output the FG pulse.

2

The supply reel pulse is not generated in the REV transport modes (REV

SEARCH/REW, etc.) because;

1) The idler gear is not meshed with the supply reel gear.

2) The idler gear is meshed with the supply reel gear, but incapable of wind-

ing due to too large a mechanical load (abnormal tension);

3) The supply reel sensor does not output the FG pulse.

3

Power is not supplied to the reel sensors.

1

The drum could not start or the drum rotation has stopped due to too large

a load on the tape, because;

1) The tape tension is abnormally high;

2)

The tape is damaged or a foreign object (grease, etc.) adheres to the tape.

2

The drum FG pulse did not reach the System controller CPU because;

1) The signal circuit is disconnected in the middle;

2) The FG pulse generator (hall device) of the drum is faulty.

3

The drum control voltage (DRUM CTL V) is not supplied to the MDA.

4

Power is not supplied to the drum MDA.

1

The cassette cannot be ejected due to a failure in the drive mechanism of

the housing.

2

When the housing load increases during ejection, the loading motor is

stopped because of lack of headroom in its drive torque.

Housing load increasing factors: Temperature environment (low temperature, etc.), mechanism wear or failure.

3

The sensor/switch for detecting the end of ejection are not functioning normally.

4

The loading motor drive voltage is lower than specified or power is not supplied to the motor (MDA).

5

When the user attempted to eject a cassette, a foreign object (or perhaps

the user's hand) was caught in the opening of the housing.

1

The capstan could not start or the capstan rotation has stopped due to too

large a load on the tape, because;

1) The tape tension is abnormally high (mechanical lock);

2) The tape is damaged or a foreign object (grease, etc.) is adhered to the

tape (occurrence of tape entangling, etc.).

2

The capstan FG pulse did not reach the System controller CPU because;

1) The signal circuit is disconnected in the middle;

2) The FG pulse generator (MR device) of the capstans is faulty.

3

The capstan control voltage (CAPSTAN CTL V) is not supplied to the MDA.

4

Power is not supplied to the capstan MDA.

1

The SW 5 V power supply circuit is shorted with GND.

2

The SW 12 V power supply circuit is shorted with GND.

1 HDD is defective

2 KBUS_DATA signal is disconnected in the middle.

1 The FG sensor is defective. (The soldered parts have separated.)

2 The pull-up resistor at the FG sensor output is defective. (The soldered parts have

separated.)

3 Contact failure or soldering failure of the pins of the connector (board-to-board) to the FG sensor.

4 The power to the sensor is not supplied. (Connection failure/soldering failure)

5 The FG pulse is not sent to the System Controller CPU.

The tilt motor is defective. (The soldered parts have separated.)

6

7 The drive power to the tilt motor is not supplied. (Connection failure/soldering failure)

8 The tilt motor drive MDA - IC is defective.

9 Auto-recovery of the DD tilting cannot take place due to overrun.

1

The supply reel pulse is not generated in the FWD transport mode (PLAY/

FWD SEARCH/FF, etc.) because;

1) PLAY/FWD or SEARCH/FF is started while the tape in the inserted cassette is cut in the middle;

2) A mechanical factor caused tape slack inside and outside the supply

reel side of the cassette shell. In this case, the supply reel will not rotate

until the tape slack is removed by the FWD transport, so the pulse is not

generated until then;

3) The FG pulse output from the supply reel sensor is absent.

2

The take-up reel pulse is not generated in the REV transport mode (REV

SEARCH/REW, etc.).

1) REV SEARCH/REW is started when the tape in the inserted cassette

has been cut in the middle;

2) A mechanical factor caused tape slack inside and outside the take-up

reel side of the cassette shell. In this case, the supply reel will not rotate

until the tape slack is removed by the REV transport, so the pulse will

not be generated until that time;

3) The FG pulse output from the take-up reel sensor is absent.

3

The power to a reel sensor is not supplied.

Table 1-11-1

1-13

Page 20

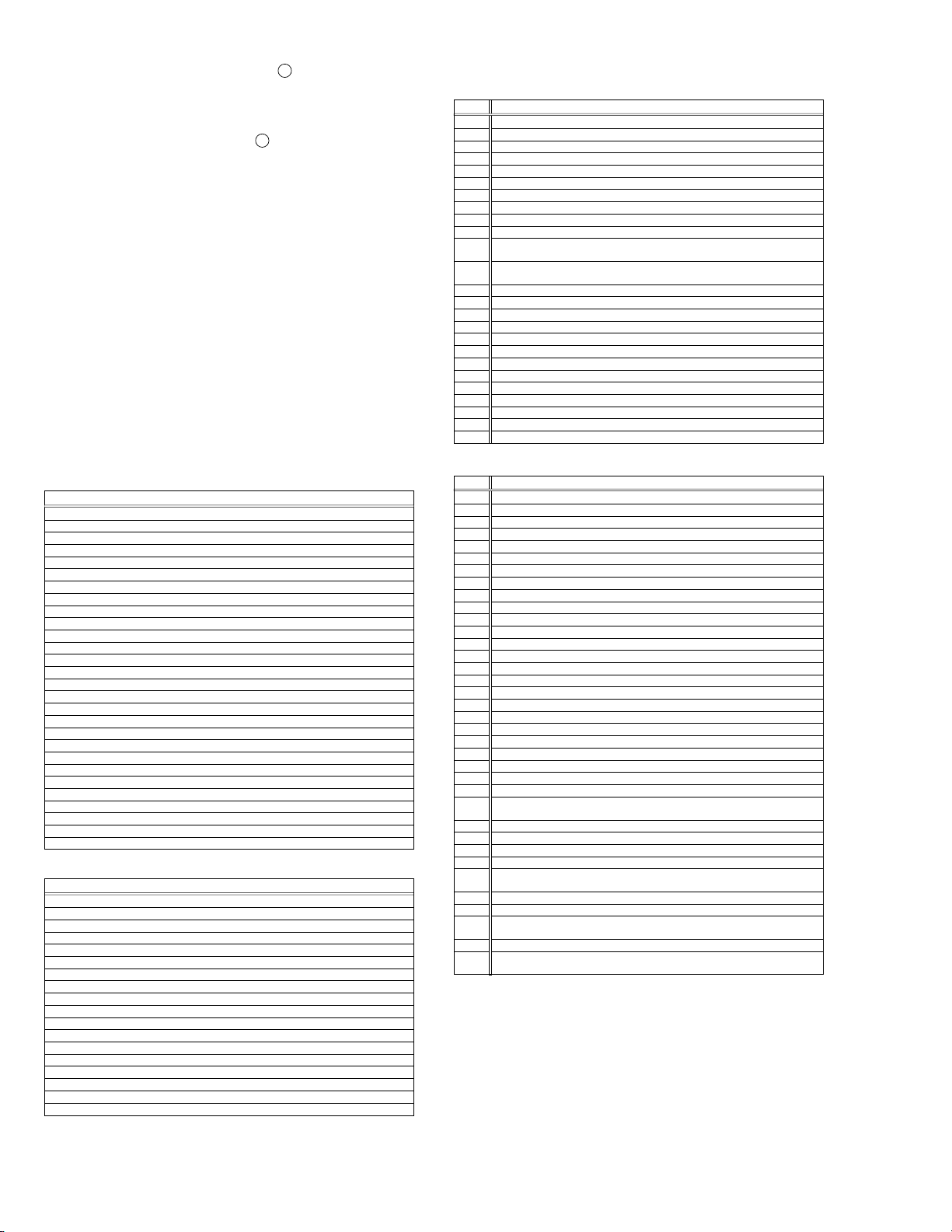

1.11.4 Emergency detail information 1

The status (electrical operation mode) of the VCR and the status (mechanism operation mode/sensor information) of the

mechanism in the latest emergency can be confirmed based on

the figure in EMG detail information 1 .

[FDP display]

1 : *2 : 34

*

1 : Deck operation mode at the moment of emergency

*

2 :

Mechanism operation mode at the moment of emergency

*

3 –

: Mechanism sensor information at the moment of emergency

– 4 :

Mechanism mode position at the moment of emergency

Note:

•

In the Deck operation mode/Mechanism operation mode/

Mechanism mode position, the contents of the code that

is shown on the FDP differs depending on the parts

number of the System Control microprocessor (IC3001)

of the VCR.

For the microprocessor parts number that starts with the

two letters “MN”, refer to the Table of MN and for parts

number with “HD”, refer to the Table of HD.

2 : Mechanism Operation Mode

*

[Table of MN]

Display

00 Command standby (Status without executing command)

02 POWER OFF by EMG occurrence

04 Moving to the adjacent position in the LOAD direction

06 Moving to the adjacent position in the UNLOAD direction

08 Cassette ejection being executed

0A Cassette insertion being executed

0C Tape being loaded

0E Tape being unloaded

10 Mode transition to STOP with pinch roller compression ON

12 Mode transition to STOP with pinch roller compression OFF

14 Mode transition to STOP with pinch roller compression OFF as a result

of POWER OFF

16 Mode transition to STOP with pinch roller compression ON as a result of

POWER ON

18 Mode transition to PLAY

1A Mode transition to FWD SEARCH

1C Mode transition to REC

1E Mode transition to FWD STILL/SLOW

20 Mode transition to REV STILL/SLOW

22 Mode transition to REV SEARCH

24 Mode transition from FF/REW to STOP

26 Mode transition to FF

28 Mode transition to REW

2A 4 sec. of REV as a result of END sensor going ON during loading

2C Short FF/REV as a result of tape sensor going ON during unloading

2E Mechanism position being corrected due to overrun

80 Mechanism in initial position (Dummy command)

Mechanism Operation Mode

1 : Deck Operation Mode

*

[Table of MN]

Display

00 Mechanism being initialized

01 STOP with pinch roller pressure off (or tape present with P.OFF)

02 STOP with pinch roller pressure on

03 POWER OFF as a result of EMG

04 PLAY

0C REC

10 Cassette ejected

20 FF

21 Tape fully loaded, START sensor ON, short FF

22

Cassette identification FWD SEARCH before transition to FF (SP x7-speed)

24 FWD SEARCH (variable speed) including x2-speed

2C INSERT REC

40 REW

42

Cassette identification REV SEARCH before transition to REW (SP x7-speed)

44 REV SEARCH (variable speed)

4C AUDIO DUB

6C INSERT REC (VIDEO + AUDIO)

84 FWD STILL/SLOW

85 REV STILL/SLOW

8C REC PAUSE

8D Back spacing

8E Forward spacing (FWD transport mode with BEST function)

AC INSERT REC PAUSE

AD INSERT REC Back spacing

CC AUDIO DUB PAUSE

CD AUDIO DUB Back spacing

EC INSERT REC (VIDEO + AUDIO) PAUSE

ED INSERT REC (VIDEO + AUDIO) Back spacing

Deck Operation Mode

[Table of HD]

Display

00 STOP with pinch roller pressure off (or tape present with P.OFF)

01 STOP with pinch roller pressure on

04 PLAY

0E REC

11 Cassette ejected

22 FF

26 FWD SEARCH (variable speed) including x2-speed

2E INSERT REC

43 REW

47 REV SEARCH (variable speed)

4C AUDIO DUB

6E INSERT REC (VIDEO+AUDIO)

84 FWD STILL/SLOW

85 REV STILL/SLOW

8F REC PAUSE

AF INSERT REC PAUSE

CD AUDIO DUB PAUSE

EF INSERT REC (VIDEO+AUDIO) PAUSE

Deck Operation Mode

[Table of HD]

Display

00 STOP with pinch roller pressure off

01 STOP with pinch roller pressure on

02 U/L STOP (or tape being loaded)

04 PLAY

05 PLAY (x1-speed playback using JOG)

0E REC

11 Cassette ejected

22 FF

26 FWD SEARCH (variable speed) including x2-speed

2E INSERT REC

43 REW

47 REV SEARCH

4C AUDIO DUB

6E INSERT REC (VIDEO + AUDIO)

84 FWD STILL/SLOW

85 REV STILL/SLOW

8F REC PAUSE

AF INSERT REC PAUSE

C7 REV SEARCH (x1-speed reverse playback using JOG)

CD AUDIO DUB PAUSE

EF INSERT REC (VIDEO + AUDIO) PAUSE

F0 Mechanism being initialized

F1 POWER OFF as a result of EMG

F2 Cassette being inserted

F3 Cassette being ejected

F4 Transition from STOP with pinch roller pressure on to STOP with pinch

roller pressure off

F5 Transition from STOP with pinch roller pressure on to PLAY

F6 Transition from STOP with pinch roller pressure on to REC

F7 Cassette type detection SEARCH before FF/REW is being executed

F8 Tape being unloaded

F9 Transition from STOP with pinch roller pressure off to STOP with pinch

roller pressure on

FA Transition from STOP with pinch roller pressure off to FF/REW

FB Transition from STOP with pinch roller pressure off to REC.P (T.REC,etc.)

FC Transition from STOP with pinch roller pressure off to cassette type de-

tection SEARCH

FD Short REV being executed after END sensor on during unloading

FE Tension loosening being executed after tape loading (STOP with pinch

roller pressure on)

Mechanism Operation Mode

1-14

Page 21

3 – : Mechanism Sensor Information

[Common table of MN and HD]

Display

0– VHS Tab broken ON ON

1– VHS Tab broken ON OFF

2– VHS Tab broken OFF ON

3– VHS Tab broken OFF OFF

4– VHS Tab present ON ON

5– VHS Tab present ON OFF

6– VHS Tab present OFF ON

7– VHS Tab present OFF OFF

8– S-VHS Tab broken ON ON

9– S-VHS Tab broken ON OFF

A– S-VHS Tab broken OFF ON

B– S-VHS Tab broken OFF OFF

C– S-VHS Tab present ON ON

D– S-VHS Tab present ON OFF

E– S-VHS Tab present OFF ON

F– S-VHS Tab present OFF OFF

– 4 : Mechanism Mode Position

Mechanism Sensor Information

S-VHS SW

REC SAFETY SW

START SENSOR

END SENSOR

[Table of MN]

Display

-0 Initial value

-1 EJECT position

-2 Housing operating

-3 U/L STOP position

Tape being loaded/unloaded (When the pole base is located on the front

-4

side of the position just beside the drum)

-5 Tape being loaded/unloaded (When the pole base is located on the rear

side of the position just beside the drum)

-6 Pole base compressed position

-7 FF/REW position

-8 Between FF/REW and STOP with pinch roller compression ON

-9 STOP with pinch roller compression OFF

-A Between STOP with pinch roller compression OFF and REV

-B REV (REV STILL/SLOW) position

-C Between REV and FWD

-D FWD (FWD STILL/SLOW) position

-E Between FWD and PLAY

-F PLAY position

Mechanism Mode Position

[Table of HD]

Display

–0 EJECT position

–1 U/L STOP position

–2 Tape being loaded/unloaded (When the pole base is located on the rear

side of the position just beside the drum)

–3 FF/REW position

–4 STOP with pinch roller pressure off

–5 REV (REV STILL/SLOW) position

–6 FWD (FWD STILL/SLOW) position, PLAY position

–7 Intermediate position during transition between other mechanism modes

Mechanism Mode Position

Note:

As the display is always “–7” at any intermediate position

•

between mechanism modes, the position of transitory

EMG may sometimes not be locatable.

1.11.5 Emergency detail information 2

The type of the cassette tape and the cassette tape winding position can be confirmed based on the figure in EMG detail information 2 .

[FDP display]

5 : *6 :

*

*

*

*

Note:

•

EMG detail information 2 is the reference information

7

*

5 : Type of the cassette tape in use 1

6 : Winding position of the cassette tape in use

7 :

Type of the cassette tape in use

2

(Winding area)

stored using the remaining tape detection function of the

cassette tape. As a result, it may not identify cassette correctly when a special cassette tape is used or when the

tape has variable thickness.

5 : Cassette tape type 1

*

Display Cassette Tape Type 1

00 Cassette type not identified

16

Large reel/small reel (T-0 to T-15/T-130 to T-210) not classified

82 Small reel, thick tape (T-120) identified/thin tape (T-140) identified

84 Large reel (T-0 to T-60) identified

92

Small reel, thick tape (T-130) identified/thin tape (T-160 to T-210) identified

93

Small reel, thick tape/C cassette (T-0 to T-100/C cassette) not classified

C3

Small reel, thick tape/C cassette (T-0 to T-100/C cassette) being classified

D3

Small reel, thick tape/C cassette (T-0 to T-100/C cassette) being classified

E1 C cassette, thick tape (TC-10 to TC-20) identified

E2 Small reel, thick tape (T-0 to T-100) identified

E9 C cassette, thin tape (TC-30 to TC-40) identified

C cassette, thick tape/thin tape (TC-10 to TC-40) not classified

F1

Notes:

Cassette tape type 1 is identified a few times during mode

•

transition and the identification count is variable depending on

the cassette tape type. If an EMG occurs in the middle of identification, the cassette tape type may not be able to be identified.

•

If other value than those listed in the above table is displayed,

the cassette tape type is not identified.

6 : Cassette tape winding position

*

The cassette tape winding position at the moment of EMG is

displayed by dividing the entire tape (from the beginning to the

end) in 22 sections using a hex number from “00” to “15”.

“00” : End of winding

“15” : Beginning of winding

“FF” : Tape position not identified

7 : Cassette tape type 2 (Winding area)

*

Display Cassette Tape Type 2

00

Cassette type not identified

07

08 - 0E

0A - 0B

0A - 16

0A - 16

0D - 0F

17 - 1A

19 - 1D

1D - 21

1E - 1F

1F - 23

29 - 2B

2D - 2F

Small reel, thick tape T-5

C cassette, thick tape TC-10

09 - 15

C cassette, thick tape TC-20P

Small reel, thick tape T-20

C cassette, thin tape TC-30

C cassette, thin tape TC-40

Small reel, thick tape T-40

11 - 14

Small reel, thick tape T-60

15 - 18

Small reel, thick tape T-80/DF-160

Small reel, thick tape T-80/DF-180

Small reel, thick tape T-100

Small reel, thick tape T-120/DF-240

Small reel, thin tape T-140

Small reel, thick tape T-130

21 - 23

Small reel, thin tape T-160

21 - 23

Small reel, thin tape T-168

22 - 24

Small reel, thick tape DF-300

22 - 24

Small reel, thin tape T-180/DF-380

22 - 24

Small reel, thin tape T-210/DF-420

22 - 23

Large reel T-5

23 - 24

Large reel T-10

25 - 26

Large reel T-20

27 - 29

Large reel T-30

Large reel T-40

Large reel T-60

Note:

•

The values of cassette tape type 2 in the above table are

typical values with representative cassette tapes.

1-15

Page 22

SECTION 2

MECHANISM ADJUSTMENT

2.1 Before starting repair and adjustment

2.1.1 Precautions

(1) Unplug the power cord plug of the VCR before using your

soldering iron.

(2) Take care not to cause any damage to the conductor

wires when plugging and unplugging the connectors.

(3) Do not randomly handle the parts without identifying

where the trouble is.

(4) Exercise enough care not to damage the lugs, etc. dur-

ing the repair work.

(5) When reattaching the front panel assembly, make sure

that the door opener of the cassette holder assembly is

lowered in position prior to the reinstallation. (See SECTION 1 DISASSEMBLY.)

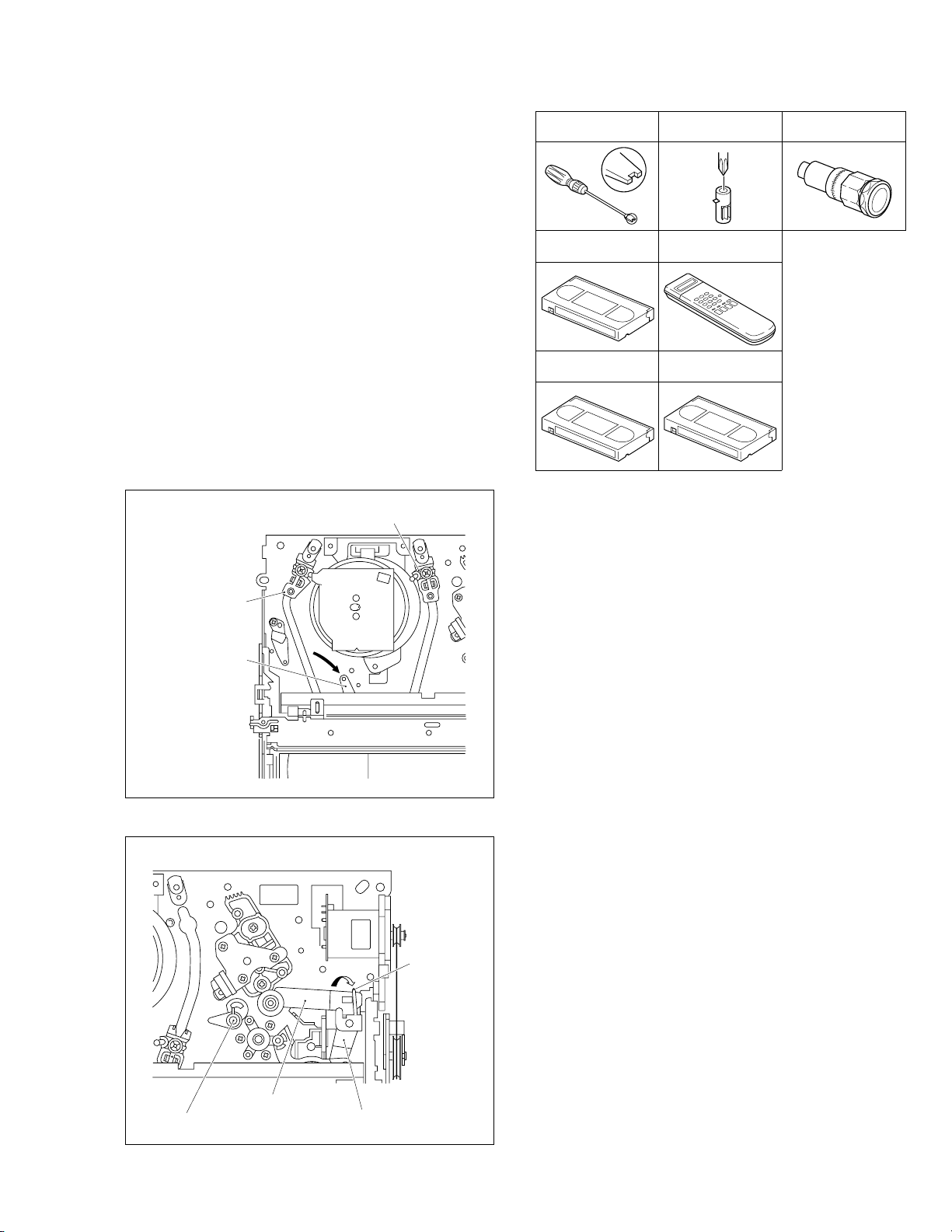

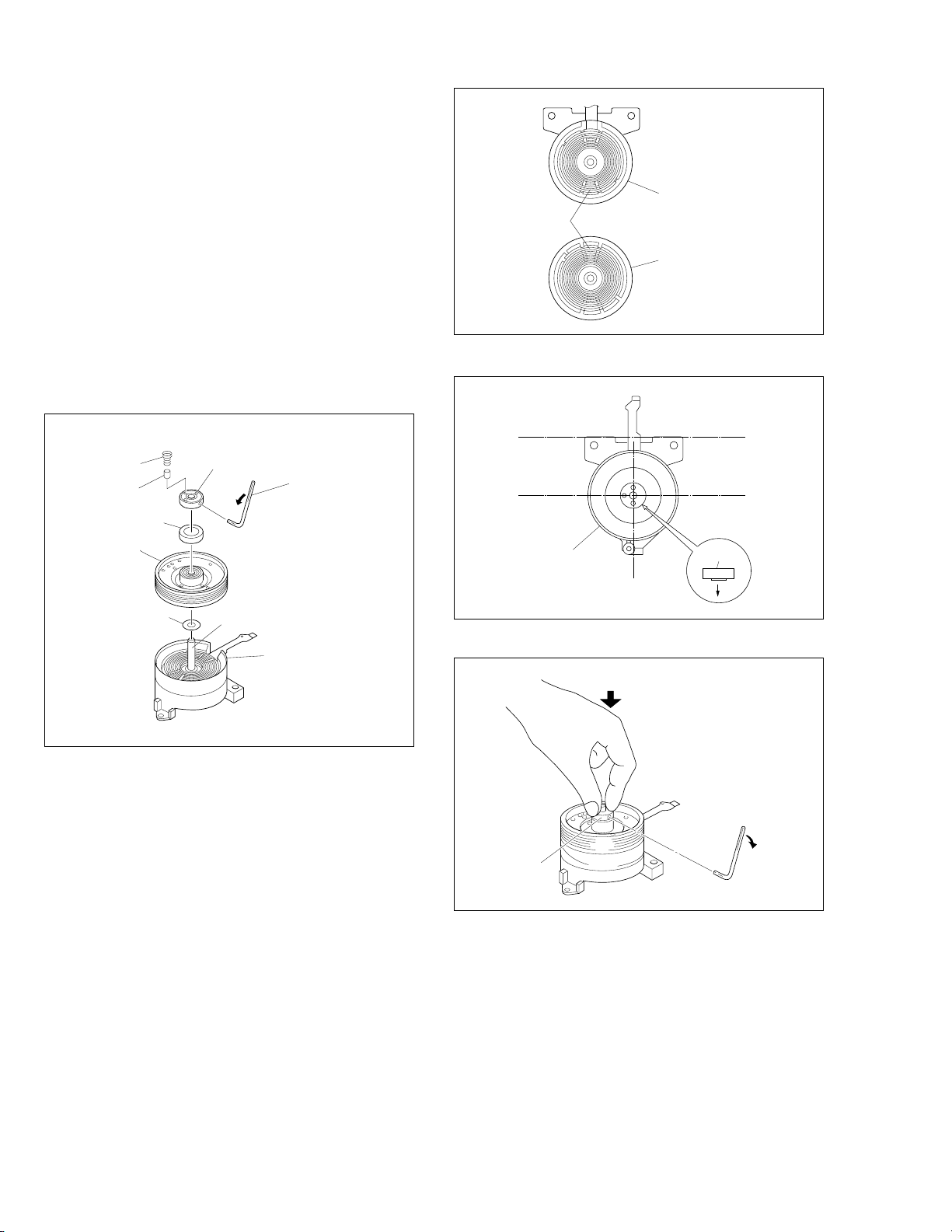

(6) When using the Jig RCU, it is required to set the VCR to