JVC HM-DH40000U Service Manual

82933200306

SERVICE MANUAL

D-VHS DIGITAL RECORDER

HM-DH40000U

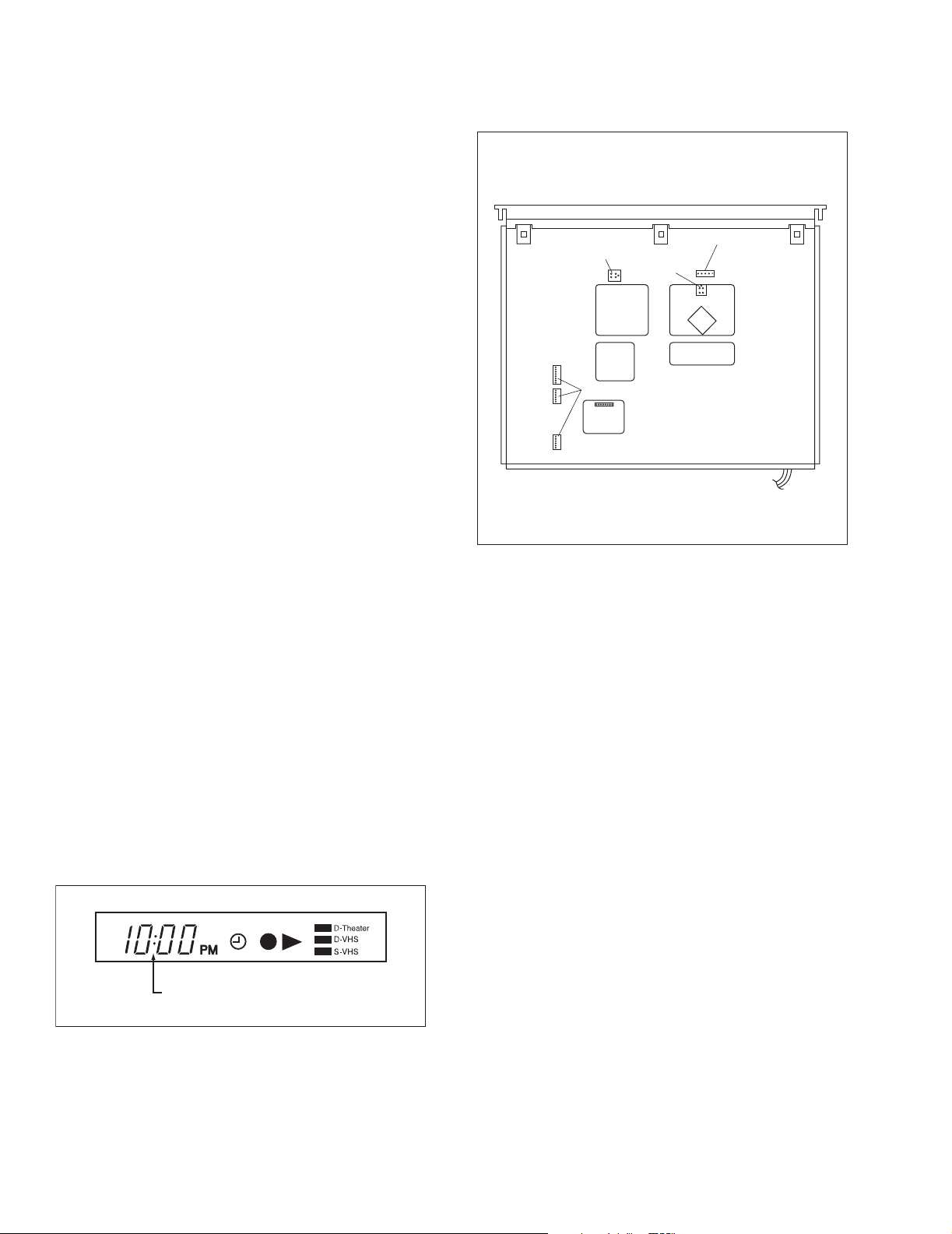

REMOTE

POWER

CODE

TV/VCR

A/B/C/D

VCR

CABLE

TV

/DBS

PROGRAM PROG.CHECK

TIMER

START STOP DATE

TV/VCR CH

REC

LINK

. , ?

ABC DEF

SUBTITLE

REC

SPEED

JKL MNO

GHI

DBS

DAILY

WEEKLY

ENTER

PQRS TUV WXYZ

AUX

C. RESET

SKIP

CANCEL

SEARCH

PLAY

F

F

REW

STOP

P

A

U

REC

S

E

MENU

TV

VOL

NAVI

R

O

T

I

N

O

M

.

A

E

N

TE

R

B

A

C

K

K

Y

O

A

S

PL

D

S

I

D

SPECIFICATION

GENERAL

Power requirement AC 120 V~, 60 Hz

Power consumption

Temperature

Operating position Horizontal only

Dimensions (W x H x D) 435 mm x 94 mm x 383 mm

Weight 5.5 kg (12.2 lbs)

Maximum recording time

VIDEO/AUDIO (D-VHS)

Video format MPEG2 standard

Audio format Encode MPEG1 Layer2

Track composition

Recording specification

Main data input rate 28.2 Mbps (HS mode)

Power on 42 W

Power off 18 W

Operating 5°C to 40°C (41°F to 104°F)

Storage -20°C to 60°C (-4°F to 140°F)

(17-3/16" x 3-3/4" x 15-1/8")

D-VHS (HS) 210 min. with DF-420 video cassette

D-VHS (STD) 420 min. with DF-420 video cassette

D-VHS (LS3) 1260 min. with DF-420 video cassette

D-VHS (LS5) 2100 min. with DF-420 video cassette

S-VHS/VHS (SP) 210 min. with ST-210 video cassette

S-VHS/VHS (EP) 630 min. with ST-210 video cassette

Decode MPEG1 Layer2/Dolby Digital

LINEAR PCM (HS/STD)

Tape speed 33.4 mm/sec (HS mode)

16.67 mm/sec (STD mode)

5.55 mm/sec (LS3 mode)

3.33 mm/sec (LS5 mode)

Head azimuth ±30 deg

Drum rotation 1800 rpm

Tracking system CTL track system

14.1 Mbps (STD mode)

4.7 Mbps (LS3 mode)

2.8 Mbps (LS5 mode)

MTP

NTSC

Interface IEEE1394 compliant DTCP digital copy

protection compatible

VIDEO/AUDIO (S-VHS/VHS)

Format S-VHS/VHS NTSC standard

Signal system NTSC-type color signal and

Recording/Playback

system

EIA monochrome signal, 525 lines/60 fields

DA-4 (Double Azimuth) head helical scan

system

Signal-to-noise ratio 45 dB

Frequency range

Normal audio 70 Hz to 10,000 Hz

Hi-Fi audio 20 Hz to 20,000 Hz

TUNER

Tuning system Frequency-synthesized tune r

Channel coverage

VHF Channels 2-13

UHF Channels 14-69

CATV 113 Channels

TIMER

Clock reference Quartz

Program capacity 1-year programmable timer/24 programs

Memory backup time Approx. 10 min.

CONNECTOR

Input/Output i.LINK IN/OUT (DV IN) x 2 (4-pin, S400)

RCA connectors (IN x 3, OUT x 2)

S-video connectors (IN x 3, OUT x 2)

Component video OUT (Y, PB/CB, PR/CR) x 1

Digital OUT (optical) x 1

ACCESSORIES

Provided accessories Infrared remote control unit, “AA” battery x 2,

Audio cable, RF cable (F-type),

S-video cable (4-pin), Controller

D2D4

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LTD.

No.82933

2003/06

TABLE OF CONTENTS

1 PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.1 SAFTY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 -3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

2.1 Disassembly flow chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

2.2 How to read the disassembly and assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

2.3 Disassembly/assembly method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 -5

2.4 Service position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

2.5 Mechanism service mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

2.6 Jig RCU mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

2.7 Opening on the chassis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

2.8 Emergency display function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

3 MECHANISM ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-15

3.1 Before starting repair and adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-15

3.2 Replacement of major parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-19

3.3 Compatibility adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-28

4 ELECTRICAL ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-31

4.1 Precaution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-31

4.2 Servo circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-32

4.3 Audio circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-34

4.4 Digital circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-34

CHARTS AND DIAGRAMS

BOARD INTERCONNECTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

SW.REG AND MAIN (REG) SCHEMATIC DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

MAIN (VIDEO/AUDIO) SCHEMATIC DIAGRAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

MAIN (SYNC DET) SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

MAIN (S-SUB) SCHEMATIC DIAGRAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

MAIN (FMA/DEMOD) SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

MAIN (SYSCON) SCHEMATIC DIAGRAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

MAIN (TUNER) SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

MAIN (TERMINAL) AND TERMINAL SUB SCHEMATIC DIAGRAMS. . . . . . . . . . . . . . . . . . . . . . . .2-19

RESET SW,REC SAFETY/D.CASS SW,DISPLAY AND JACK SCHEMATIC DIAGRAMS . . . . . . . .2-21

PRE/REC SCHEMATIC DIAGRAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-23

DIGITAL(SUB CPU) SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-25

DIGITAL(DMAIN) SCHEMATIC DIAGRAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-27

DIGITAL(DMAIN IF) SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-29

DIGITAL(E5) SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-31

DIGITAL(E5 DDR) SCHEMATIC DIAGRAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-33

DIGITAL(MEMORY) SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-35

DIGITAL(DIGITAL IF) SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-37

DIGITAL(VIDEO) SCHEMATIC DIAGRAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-39

DIGITAL(AUDIO) SCHEMATIC DIAGRAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-41

SW.REG, DISPLAY, REC SAFETY, JACK AND TERMINAL SUB CIRCUIT BOARDS. . . . . . . . . . .2-43

MAIN CIRCUIT BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-45

COMPONENT PARTS LOCATION GUIDE <MAIN> LPB10177-001C. . . . . . . . . . . . . . . . . . . . . . . .2-47

PRE/REC CIRCUIT BOARD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-48

COMPONENT PARTS LOCATION GUIDE <PRE/REC> LPB10174-001B . . . . . . . . . . . . . . . . . . . .2-48

DIGITAL CIRCUIT BOARD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-49

COMPONENT PARTS LOCATION GUIDE <DIGITAL> LPB10175-001B . . . . . . . . . . . . . . . . . . . . .2-51

REMOTE CONTROLLER SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-53

FDP GRID ASSIGNMENT AND ANODE CONNECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-53

CPU PIN FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-54

VOLTAGE CHARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-55

WAVEFORMS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-56

VIDEO BLOCK DIAGRAM (1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-57

VIDEO BLOCK DIAGRAM (2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-59

AUDIO BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-61

SYSTEM CONTROL BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-63

D-VHS BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-65

PARTS LIST

1. EXPLODED VIEW

1.1 PACKING AND ACCESORY ASSEMBLY<M1> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

1.2 FINAL ASSEMBLY<M2>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

1.3 MECHANISM ASSEMBLY<M4> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

2. PARTS LIST

SWITCHING REGULATOR BOARD ASSEMBLY<01>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

MAIN BOARD ASSEMBLY<01> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

A/C HEAD BOARD ASSEMBLY<12> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

DISPLAY BOARD ASSEMBLY<28> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

REC SAFETY BOARD ASSEMBLY<32> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

JACK BOARD ASSEMBLY<36> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

PRE/REC BOARD ASSEMBLY<43>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

DIGITAL BOARD ASSEMBLY<50>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

TERMINAL SUB BOARD ASSEMBLY<52> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

LOADING MOTOR BOARD ASSEMBLY<55> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

1-2 (No.82933)

SECTION 1

r

e

PRECAUTIONS

1.1 SAFTY PRECAUTIONS

Prior to shipment from the factory, JVC products are strictly inspected to conform with the recognized product safety and electrical codes of the countries in which they are to be

sold.However,in order to maintain such compliance, it is equally

important to implement the following precautions when a set is

being serviced.

1.1.1 Precautions during Servicing

(1) Locations requiring special caution are denoted by labels

and inscriptions on the cabinet, chassis and certain parts of

the product.When performing service, be sure to read and

comply with these and other cautionary notices app earing in

the operation and service manuals.

(2) Parts identified by the symbol and shaded ( ) parts

are critical for safety.

Replace only with specified part numbers.

NOTE :

Parts in this category also include those specified to

comply with X-ray emission standards for products

using cathode ray tubes and those specified for compliance with various regulations regarding spurious

radiation emission.

(3) Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as specified.

(4) Use specified internal wiring. Note especially:

• Wires covered with PVC tubing

• Double insulated wires

• High voltage leads

(5) Use specified insulating materials for hazardous live parts.

Note especially:

• Insulation Tape

• PVC tubing

•Spacers

• Insulation sheets for transistors

• Barrier

(6) When replacing AC primary side components (transformers,

power cords, noise blocking capacitors, etc.) wrap ends of

wires securely about the terminals before soldering.

quently, when servicing these products, replace the cathode

ray tubes and other parts with only the specified parts. Under

no circumstances attempt to modify these circuits.Unauthorized modification can increase the high voltage value and

cause X-ray emission from the cathode ray tube.

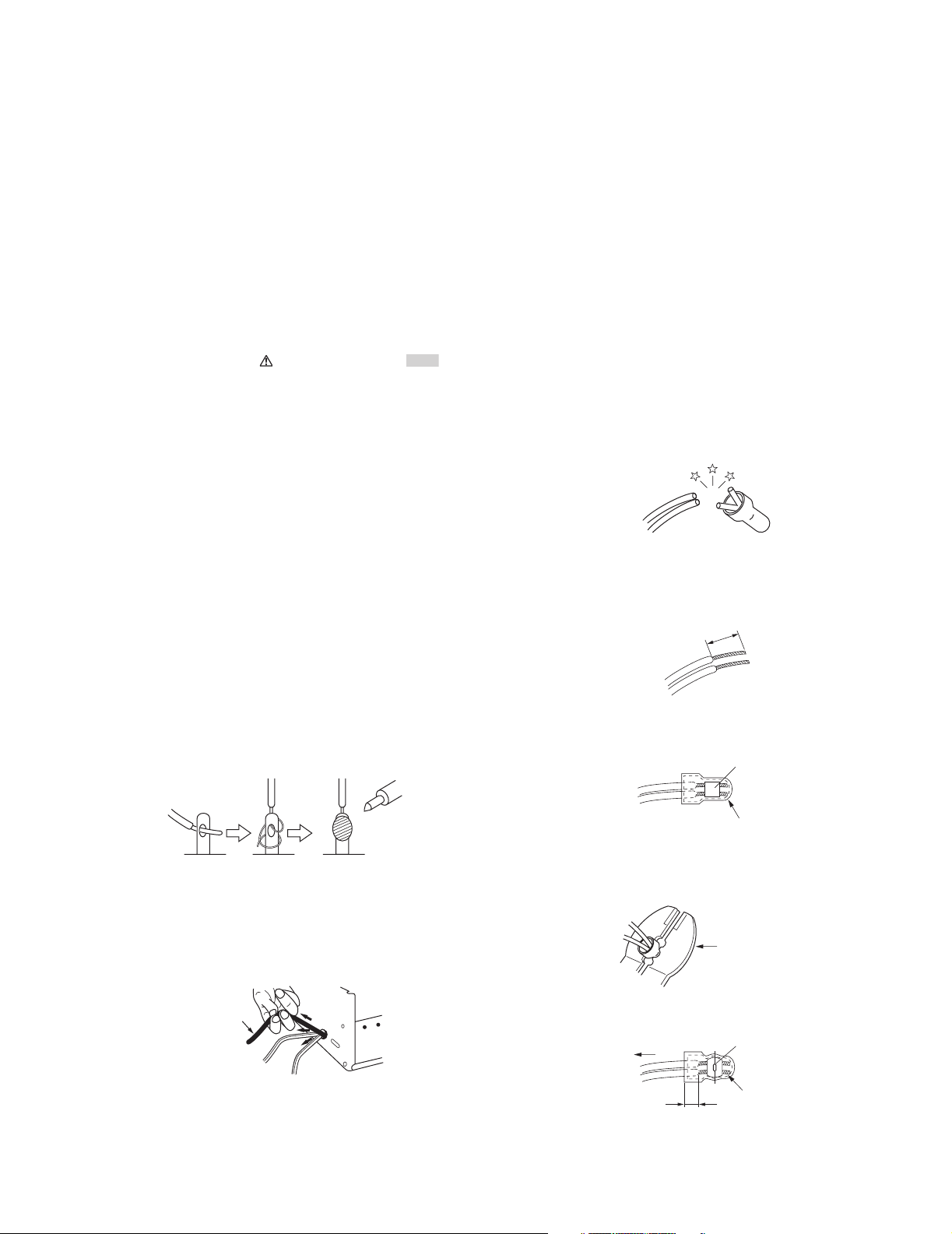

(12) Crimp type wire connector

In such cases as when replacing the power transformer in

sets where the connections between the power cord and

power trans former primary lead wires are performed using

crimp type connectors, if replacing the connectors is unavoidable, in order to prevent safety hazards, perfo rm carefully and precisely according to the following steps.

• Connector part number :E03830-001

• Required tool : Connector crimping tool of the proper

type which will not damage insulated parts.

• Replacement procedure

a) Remove the old connector by cutting the wires at a

point close to the connector.

Important : Do not reuse a connector (discard it).

cut close to connector

Fig.1-1-3

b) Strip about 15 mm of the insulation from the ends of

the wires. If the wires are stranded, twist the strands

to avoid frayed conductors.

15 mm

Fig.1-1-4

c) Align the lengths of the wires to be connected. Insert

the wires fully into the connector.

Metal sleeve

Fig.1-1-1

(7) Observe that wires do not contact heat producing parts

(heatsinks, oxide metal film resistors, fusible resistors, etc.)

(8) Check that replaced wires do not contact sharp edged or

pointed parts.

(9) When a power cord has been replaced, check that 10-15 kg

of force in any direction will not loosen it.

Power cord

Fig.1-1-2

(10) Also check areas surrounding repaired locations.

(11) Products using cathode ray tubes (CRTs)In regard to such

products, the cathode ray tubes themselves, the high voltage circuits, and related circuits are specified for compliance

with recognized codes pertaining to X-ray emission. Conse-

Connector

Fig.1-1-5

d) As shown in Fig.1-1-6, use the crimping tool to crimp

the metal sleeve at the center position. Be sure to

crimp fully to the complete closure of the tool.

1.2

5

2

.0

5.5

Crimping tool

Fig.1-1-6

e) Check the four points noted in Fig.1-1-7.

Not easily pulled free

Wire insulation recessed

more than 4 mm

Crimped at approx. cente

of metal sleev

Conductors extended

Fig.1-1-7

(No.82933)1-3

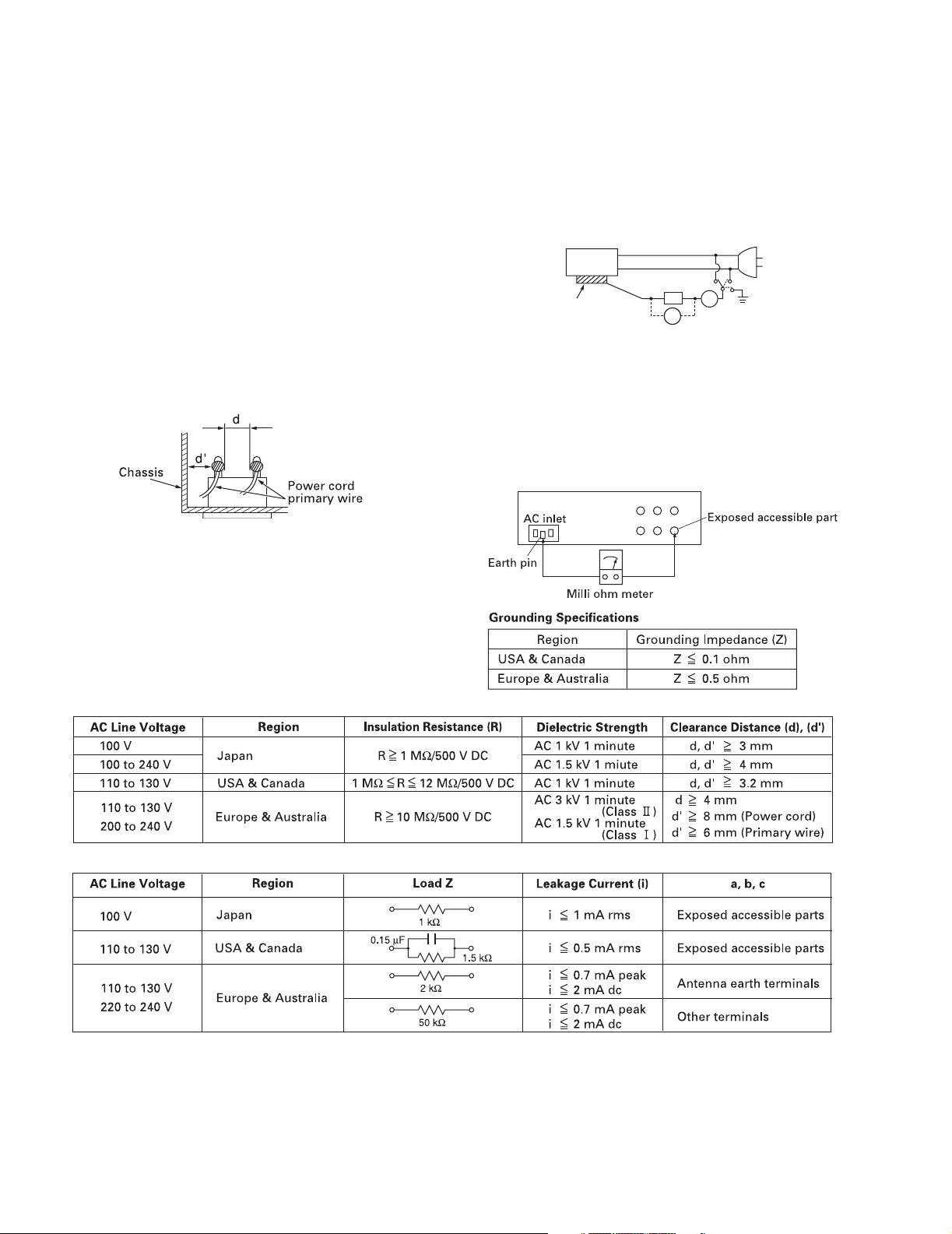

1.1.2 Safety Check after Servicing

Examine the area surrounding the repaired location for d amage

or deterioration. Observe that screws, parts and wires have been

returned to original positions, Afterwards, perform the following

tests and confirm the specified values in order to verify compliance with safety standards.

(1) Insulation resistance test

Confirm the specified insulation resistance or greater between power cord plug prongs and externally exposed

parts of the set (RF terminals, antenna terminals, video and

audio input and output terminals, microphone jacks, earphone jacks, etc.).

See table 1 below.

(2) Dielectric strength test

Confirm specified dielectric strength or greater between

power cord plug prongs and exposed accessible parts of

the set (RF terminals, antenna terminals, video and audio

input and output terminals, microphone jacks, earphone

jacks, etc.). See Fig.1-1-11 below.

(3) Clearance distance

When replacing primary circuit components, confirm specified clearance distance (d), (d') between soldered terminals, and between terminals and surrounding metallic

parts. See Fig.1-1-11 below.

(4) Leakage current test

Confirm specified or lower leakage current between earth

ground/power cord plug prongs and externally exposed accessible parts (RF terminals, antenna terminals, video and

audio input and output terminals, microphone jacks, earphone jacks, etc.).

Measuring Method : (Power ON)

Insert load Z between earth ground/power cord plug

prongs and externally exposed accessible parts. Use an

AC voltmeter to measure across both terminals of load Z.

See Fig.1-1-9 and following Fig.1-1-12.

ab

Externally

exposed

accessible part

Z

V

c

A

Fig.1-1-9

(5) Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between

earth pin in AC inlet and externally exposed accessible

parts (Video in, Video out, Audio in, Audio out or Fixing

screw etc.).

Measuring Method:

Connect milli ohm meter between earth pin in AC inlet and

exposed accessible parts. See Fig.1-1-10 and grounding

specifications.

Fig.1-1-8

Fig.1-1-11

Fig.1-1-10

Fig.1-1-12

NOTE :

These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

1-4 (No.82933)

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

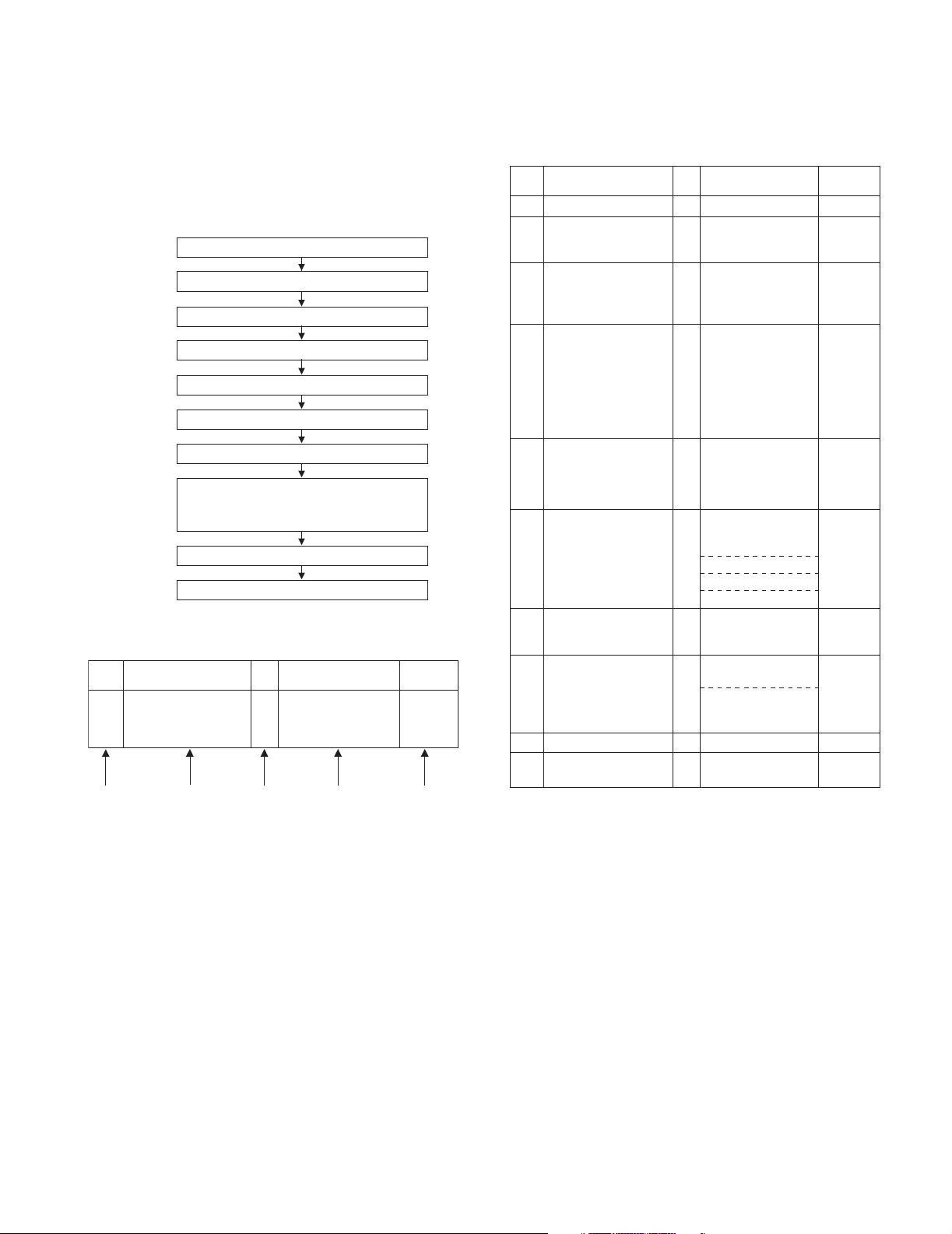

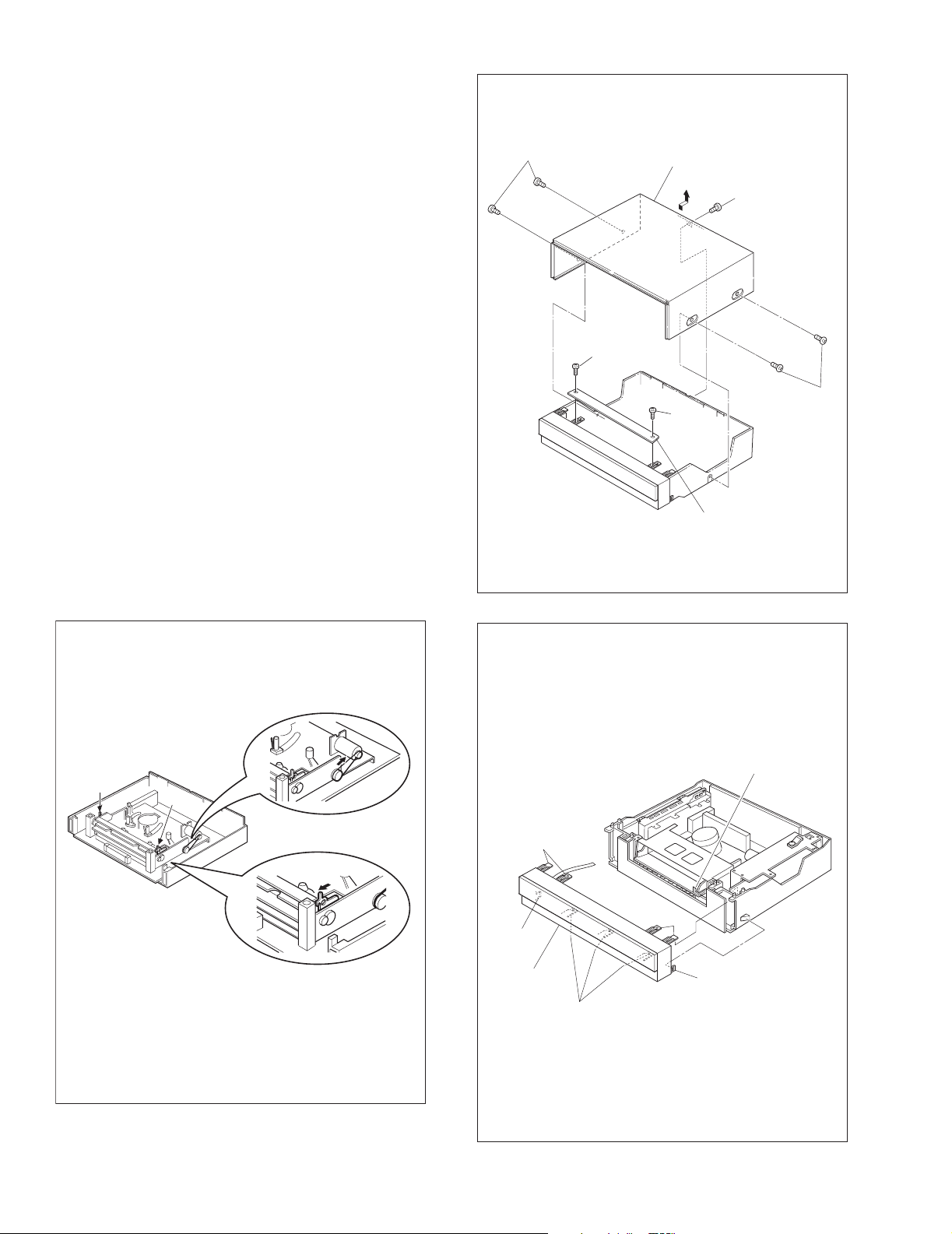

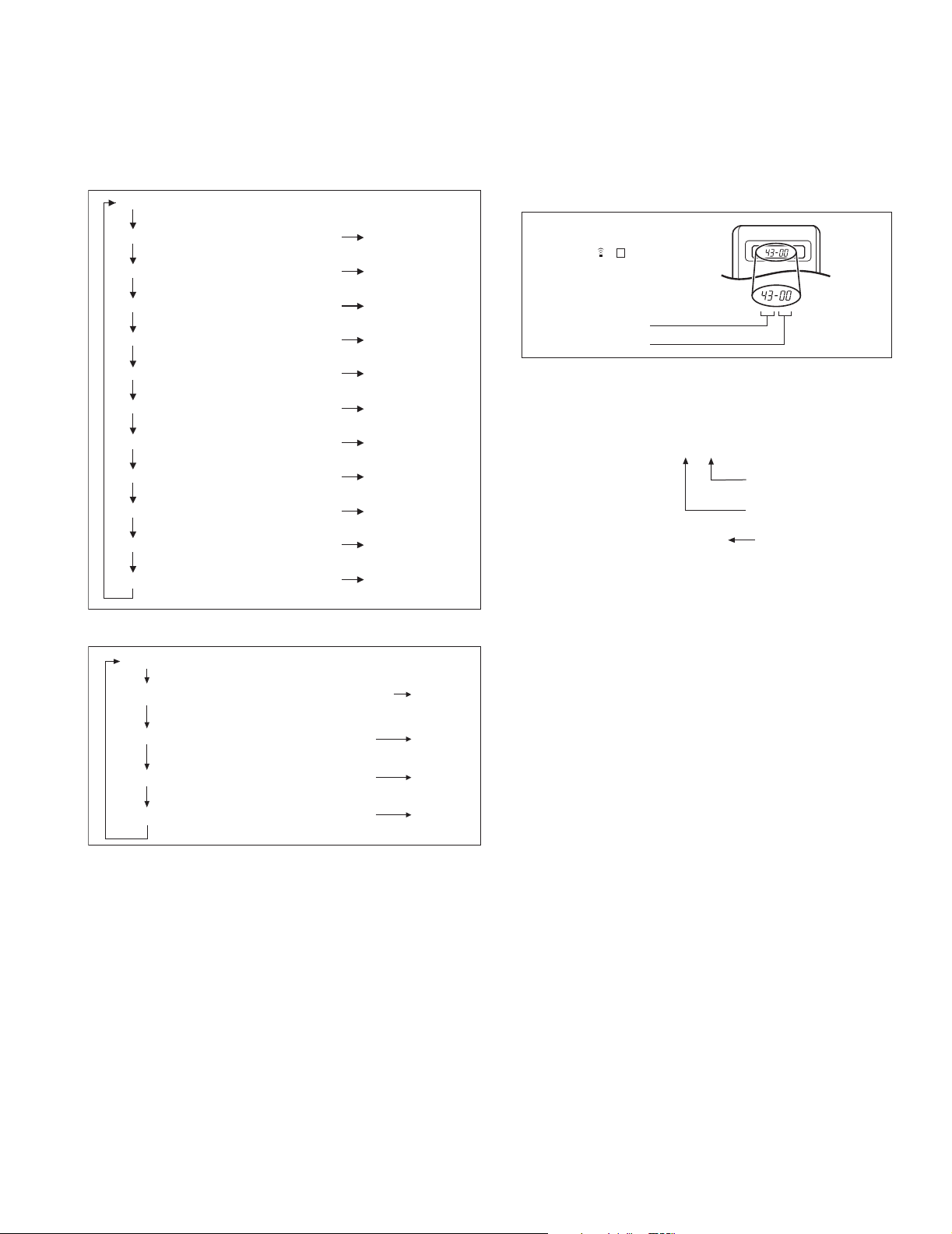

2.1 Disassembly flow chart

This flowchart lists the disassembling steps for the cabinet parts

and P.C. boards in order to gain access to item(s) to be serviced.

When reassembling, perform the step(s) in reverse order. Bend,

route and dress the flat cables as they were originally laid.

[1]

[2]

[3]

[4]

[5]

[6]

[7]

Switching regulator board assembly

Top cover, Bracket

Front panel assembly

Digital board assembly

PRE/REC board assembly

Drum assembly

Mechanism assembly

REC safety board assembly,

[8]

Display board assembly,

Jack board assembly

[9]

[10]

Main board assembly

Bottom cover

2.2 How to read the disassembly and assembly

<Example>

Step/

Loc No.

[1] Top cover, D1

(1) (2) (3) (4) (5)

Part Name

Bracket 2(S1c)

Fig.

No.

Point Note

4(S1a),(S1b),3(L1a), <Note 1a>

2(SD1a),(P1a),(W1a),

CN1(WR1a),

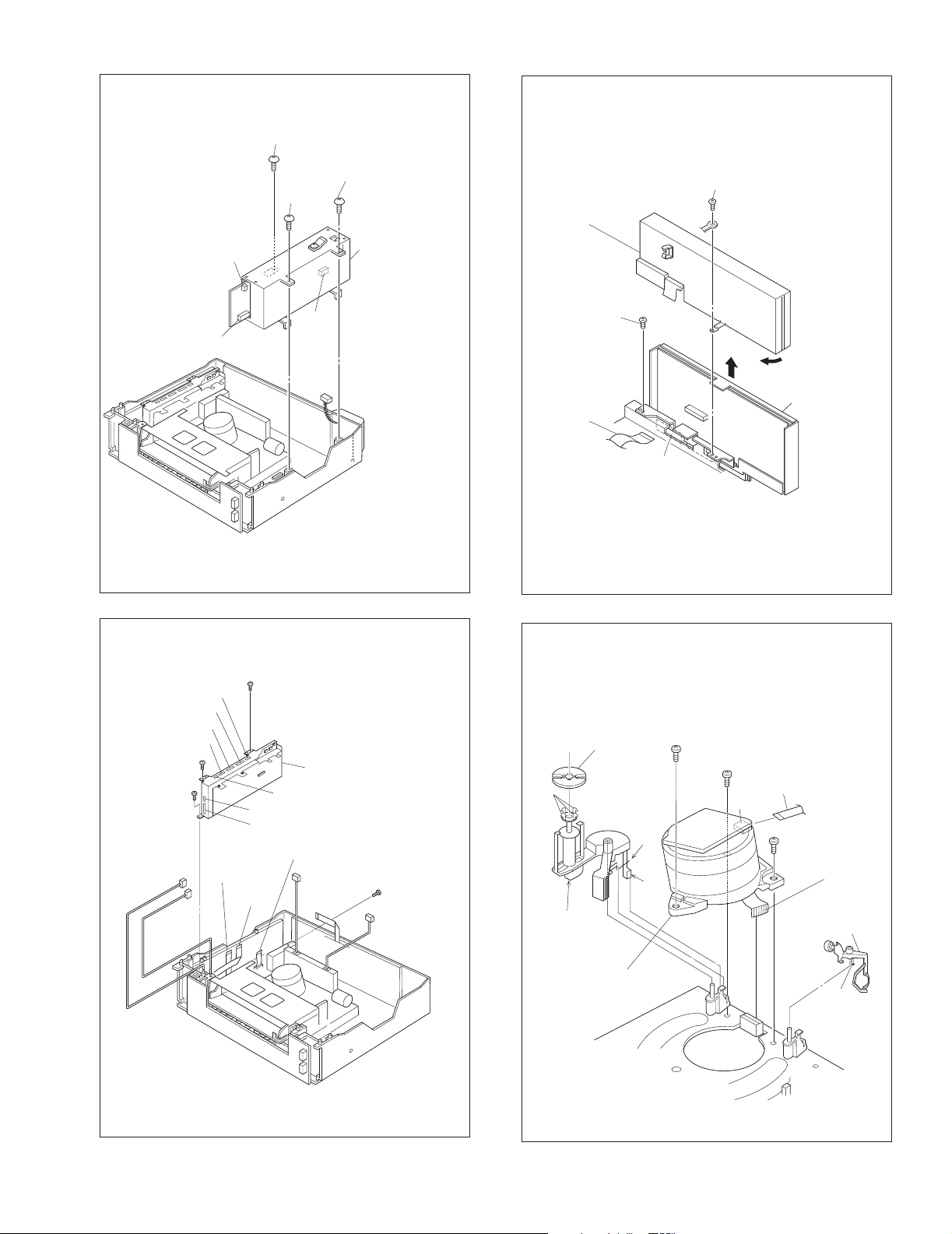

2.3 Disassembly/assembly method

Step/

Loc No.

[1] Top cover, Bracket D1

[2] Front panel assembly D2 CN901(WR2a),

[3] Switching regulator

[4]

[5] PRE/REC board

[6] Drum assembly, D6 CON1(WR6a), <Note 2a>

[7] Mechanism assembly D7 CN1(WR7a), (S7a),

[8] REC safety board

[9] Main board assembly D9 2(S9a)

[10] Bottom cover D10

Part Name

board assembly

Digital board assembly

assembly

(Inertia plate), 4(L6a)

(Roller arm assembly),

(Cleaner assembly) (L6c)

assembly,

Display board assembly

Fig.

No.

D3 CN5303(WR3a),

D4 CN401(WR4a),

D5 (S5a), (S5b),

D8 (S8a) <Note 2a>

Point Note

4(S1a), (S1b), 2(S1c)

4(L2a), 2(L2b),

3(L2c)

CN5301

CN5305

3(S3a)

CN402(WR4b),

CN8003(WR4c),

CN9301(WR4d),

CN9001(WR4e),

CN8001(WR4f),

CN8002(WR4g)

3(S4a), (S4b),

L5a(WR5a),

Shield case(PRE),

CN604(WR5b),

CN603

CN1(WR6b),

(S6a), (S6b), (S6c)

(P6a), (L6b)

(S7b), (S7c), (S7d),

S7e(WR7b), 2(L7a)

CN7002(WR8a),

CN7005(WR8b)

4(L8a)

(S10a), 2(S10b),

4(L10a), 3(L10b)

<Note 2a>

<Note 2b>

<Note 2a>

<Note 2a>

<Note 2a>

<Note 4a>

<Note 5a>

<Note 2a>

<Note 6a>

<Note 7a>

(1) Order of steps in Procedure

When reassembling, perform the step(s) in the reverse order.

These numbers are also used as the identification (loca-

tion) No.of parts Figures.

(2) Part na me to be removed or installed.

(3) Fig. No. showi ng procedure or part location.

(4) Identification of part to be remo ved, unhooked, unlocked,

released, unplugged, unclamped or unsoldered. P= Spring,

W= Washer, S= Screw, L= Locking tab, SD= Solder,

CN**(WR**) = Remove the wire (WR**) from the connector

(CN**).

Note:

• The bracketed ( ) WR of the connector symbol are

assigned nos. in priority order and do not correspond to those on the spare parts list.

(5) Adjustment information for installation

(No.82933)1-5

<Note 2a>

• Be careful not to damage the connector and wire etc. during

connection and disconnection.

• When connecting the flat wire to the connector, be careful

with the wire direction.

<Note 2b>

• When reattaching the Front panel assembly, make sure that

the door opener “a” of the Cassette holder assembly is lowered in position prior to the reinstallation.

<Note 4a>

• When securing the screw (S5a), be sure to connect the lug

wire (WR5a) together it.

<Note 5a>

• When installing the drum assembly, secure the screws (S6a

to S6c) in the order of a,b,c.

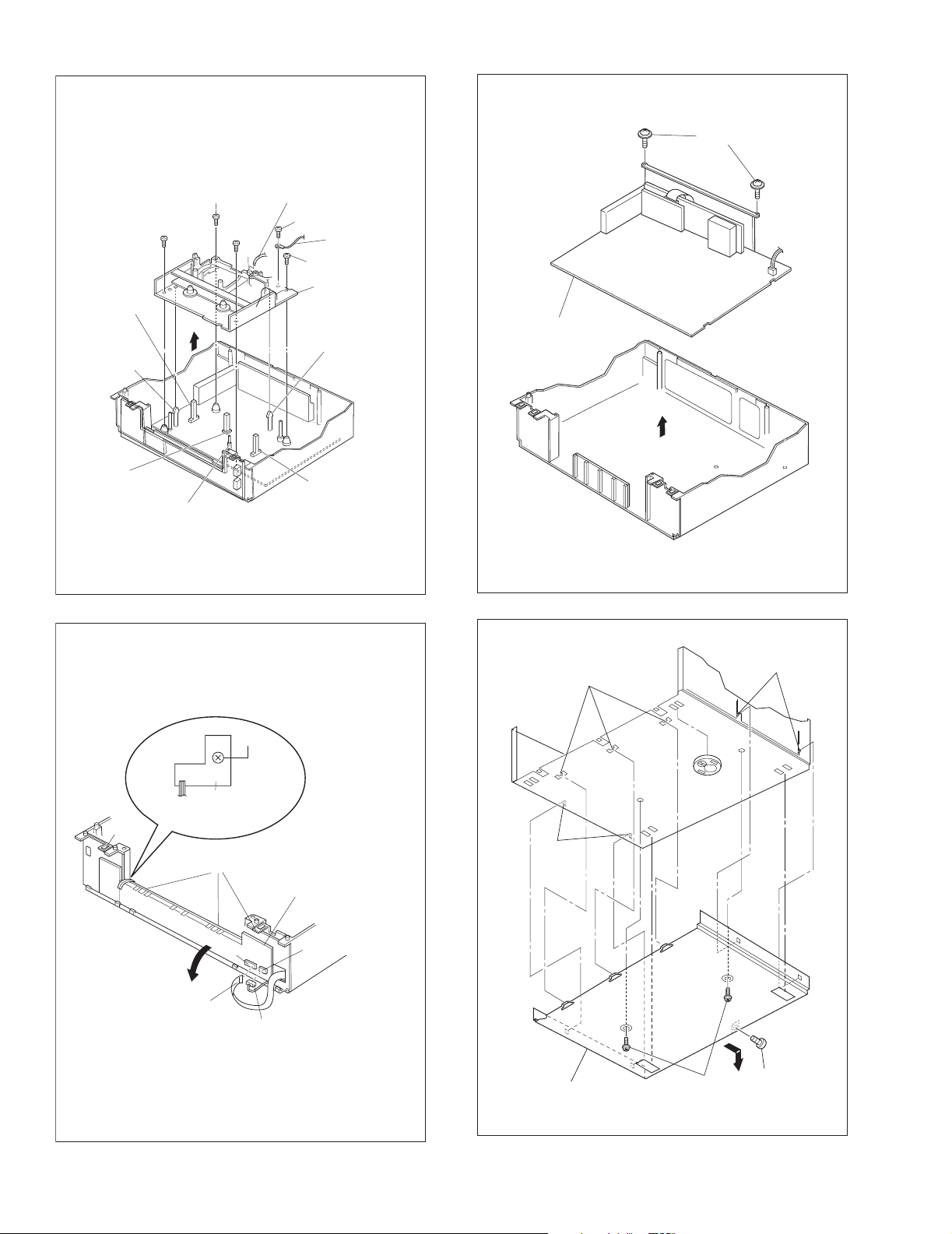

<Note 6a>

• When it is required to remove the screws (S7a to S7b) re-

taining the Mechanism assembly, please refer to the “Procedures for Lowering the Cassette holder assembly” (See on

page 1-6).

• When reattaching the Mechanism assembly to the Main

board assembly, take care not to damage the sensors and

switch on the Main board assembly.

• When removing the Mechanism assembly only, unhook the

two spacers connecting it with the Main board assembly with

pliers from the back side of the Main board assembly first,

and then remove the Mechanism assembly.

<Note 7a>

• After removing the REC safety board assembly, remove the

display board assembly.

(S1a)

[1] Top cover

(S1b)

(S1c)

(S1a)

(S1c)

[1] Bracket

Fig.D1

Procedures for Lowering the Cassette holder assembly

As the mechanism of this unit is integrated with the Housing

assembly, the holder must be lowered and the two screws

unscrewed when removing the Mechanism assembly.

(A)

Fig. 1

(B)

Fig. 2

Fig. 3

Turn the loading motor pulley in the direction as indicated by

Fig.2. As both (A) and (B) levers are lodged twice, push

thelevers in the direction as indicated by Fig.3 to release

them. When pushing the levers, do it in the order of (A), (B),

(B), (A). When the holder has been lowered, turn the pulley

untilthe cassette holder is securely in place without allowing

any up/down movement.

(L2a)

(L2b)

[2] Front panel

assembly

(

WR2a

<Note 2a>

(L2c)

<Note 2b>

a

)

(L2a)

(L2b)

Fig.Procedures for Lowering the Cassette holder assembly

1-6 (No.82933)

Fig.D2

(S3a)

CN5303

CN5301

(S3a)

<Note 2a>

Fig.D3

CN5305

WR3a

(S3a)

[3]

Switching regulator

board assembly

Shield case (PRE)

(S5b)

WR5b

<Note 2a>

(L5a)

CN604

CN603

(CN3011)

(S5a)

Fig.D5

WR5a

<Note 4a>

[5]

PRE/REC

board assembly

CN9301

(S4a)

(S4a)

(WR4f)

<Note 2a>

(WR4g)

<Note 2a>

CN8003

CN402

CN401

<Note 2a>

(S4a)

WR4d

<Note 2a>

CN8001

CN8002

WR4c

[4]Digital board assembly

CN9001

WR4a

<Note 2a>

WR4b

<Note 2a>

WR4e

<Note 2a>

(S4b)

WR4a

<Note 2a>

Note :

When installing Drum assembly,

secure the screws (S6a to S6c) in the order of a, b, c.

(S6a)

Inertia plate

(L6a)

<Note 5a>

(P6a)

(S6c)

<Note 5a>

CON1

WR6a

<Note 2a>

(S6b)

<Note 5a>

(L6b)

Roller arm

assembly

Cleaner assembly

[6]Drum assembly

CN1

WR6b

<Note 2a>

(L6c)

Fig.D4

Fig.D6

(No.82933)1-7

Note :

When installing the Mechanism assembly,

secure the screws (S7a to S7b) in order of a, b.

CN1

WR7a

<Note 2a>

(S7e)

(S7c)

(S7b)

<Note 6a>

(S7d)

<Note 6a>

(S7a)

Q3003

End sensor

<Note 6a>

(L7a)

Spacer

<Note 6a>

(S9a)

WR7b

[7] Mechanism

assembly

[9] Main board assembly

(L7a)

Spacer

<Note 6a>

D3001

LED

<Note 6a>

(L8a)

S3002

S cassette switch

<Note 6a>

Fig.D7

(S8a)

REC safety

board assembly

<Note 7a>

(L8a)

Q3002

Start sensor

<Note 6a>

Fig.D9

(L10a)

(L10b)

(L10a)

[8] Display board assembly

1-8 (No.82933)

WR8a

<Note 2a>

CN7002

<Note 2a>

Fig.D8

WR8b

CN7005

[10]

Bottom cover

Fig.D10

(S10b)

(S10a)

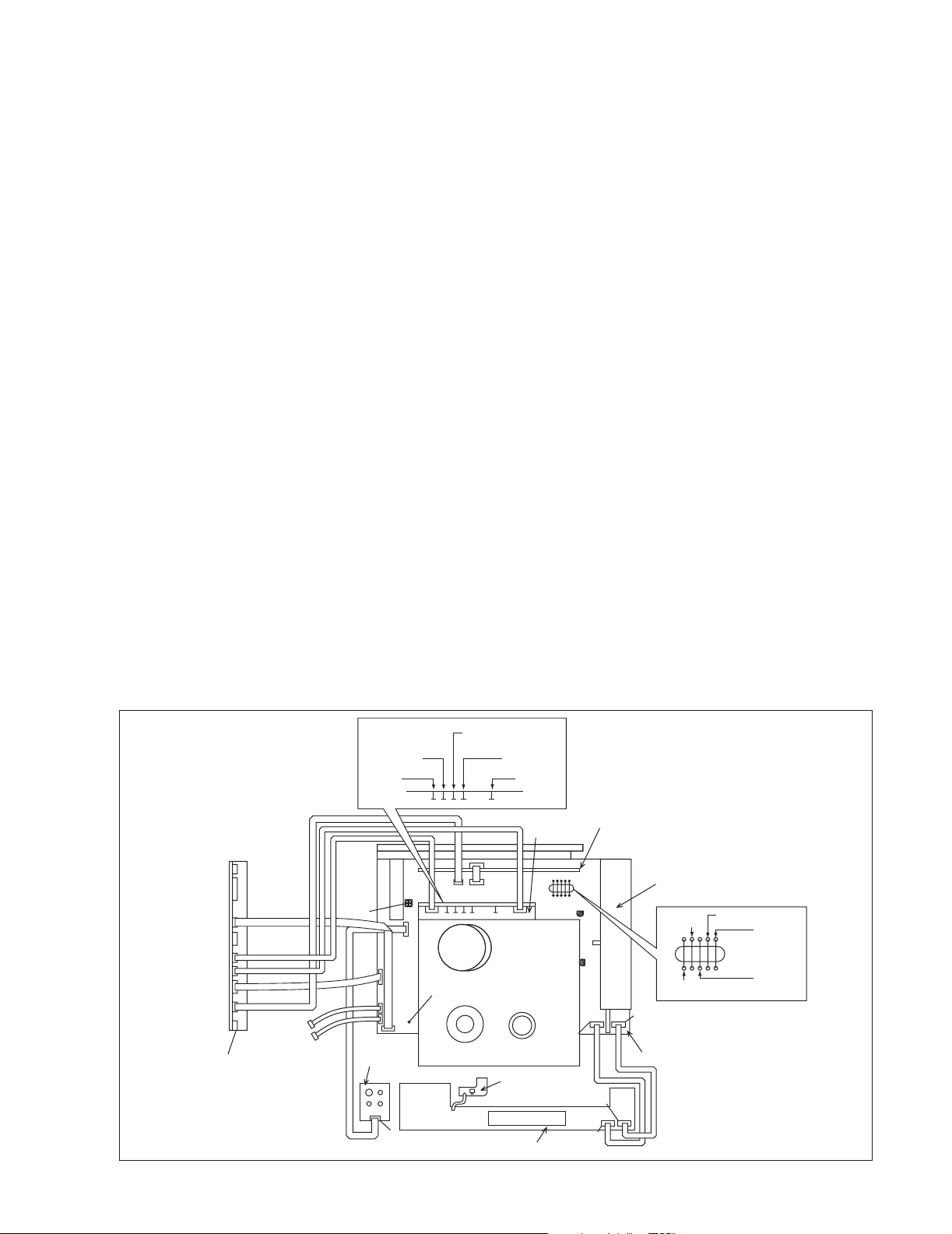

2.4 Service position

This unit has been designed so that the Mechanism an d Main

board assemblies can be removed together from the chassis assembly. Before diagnosing or servicing the circuit boards, take

out the major parts from the chassis assembly.

2.4.1 How to set the “Service position”

(1) Refer to the disassembly procedure and perform the disas-

sembly of the major parts before removing the PRE/REC

board assembly.

(2) Remove the screws attaching the mechanism assembly

with the chassis assembly. Remove the screws attaching

the board assembly, if necessary.

(3) Remove the combined Mechanism and Main board assem-

blies.

(4) Connect the wires and connectors of the major parts that

have been removed in step (1). (Refer to Fig.2-4-1a.)

(5) Place the combined Mecha nism and Main board assem-

blies upside down.

(6) Insert the power cord plug into the power outlet and then-

proceed with the diagnostics and servicing of the board assembly.

Notes:

• Before inserting the power cord plug into the power out-

let, make sure that none of the electrical parts are able

to short-circuit between the workbench and the board

assembly.

• For the disassembly procedure of the major parts and

details of the precautions to be taken, see “2.3 Disassembly/assembly method”.

• If there are wire connections from the Main board and

Mechanism assemblies to the other major parts, besure

to remove them ( including wires connected to the major

parts ) first before performing step (2).

• When carrying out diagnosis and repair of the Main

board assembly in the “Service position”, be sure to

ground both the Main board and Mechanism assem-

blies. If they are improperly grounded, there may

benoise on the playback picture or F DP counter displaymay move even when the mechanism is kept in an inoperative status.

• In order to diagnose the playback or recording of the-

cassette tape, set the Mechanism assembly to the required mode before placing it upside down. If the

mechanism mode is changed (including e jection) while

it is in an upside down position the tape inside may be

damaged.

2.4.2 Precautions for cassette loading in the “Service position”

The REC safety board assembly detects cassette loading as well

as cassette tabs. Therefore, after the assembly has been removed in the “Service position”, it is required to set the switch

manually on the REC safety board assembly when a cassette is

loaded.

2.4.3 Cassette loading and ejection methods in the “Service position”

(1) Insert a cassette halfway in the Cassette holder assembly.

(2) Set the switch on the REC safety board assembly to on (by

pressing the switch).

(3) As soon as the cassette starts to be loaded, set the switch

on the REC safety board assembly to off (by releasing the

switch).

(4) Now the desired o peration (recording, playback, fast for-

ward, rewind, etc.) is possible in this status.

(5) The switch on the REC safety board assembly does

nothave to be operated when ejecting a tape. But be sure

to turn the set to the normal position before ejecting the

tape.

Note:

• In the “Service position”, the cassette tabs cannot be detected and recording becomes possible even with a cassette

with broken tabs such as the alignment tape. Be verycareful

not to erase important tapes.

Digital

board assembly

CN8004

CN8801

CN8003

CN8005

CN402

CN401

CN9301

CN9001

CN8001

CN8002

TO CN8001

TO CN8002

VR2251

FMA

REC

LEVEL

TP602

A/HS2_FF

TP622

PB_DATA2

CN901

CN7017

CN3009

Jack board

assembly

CN7191

CN7102

TP501

Y TO SE

TP612

REC_LEVEL2

TP611

REC_LEVEL1

CN7104

CN7101

TP622 TP612

TP621 TP602 T611

CN601CN602

REC Safety

board assembly

Display board assembly

Fig.2-4-1a

TP621

PB_DATA1

PRE/REC

board assembly

CP4001

CP3002

CN3008

Terminal sub board assembly

CN5603

Main board assembly

CN7005

CN7002

Switching regulator

board assembly

TP106

PB FM

TP2254

A.REC FM

TP4001

CTL P

TP111

D.FF

TP2253

A.PB FM

(No.82933)1-9

2.5 Mechanism service mode

This model has a unique function to enter the mechanisminto every operation mode without loading of any cassette tape. This

function is called the “Mechanism service mode”.

2.5.1 How to set the “Mechanism service mode”

(1) Set the VCR to the Jig RCU mode (the mode in which

codes from the Jig RCU can be received).

(2) Transmit the code “E5” from the Jig RCU.

(3) With lock levers (A) (B) on the left and right of the Cassette

holder assembly pulled toward the front, slide the holder in

the same direction as the cassette insertion directi on. (For

the positions of lock levers (A) (B), refer to the “Procedures

for Lowering the Cassette holder assembly” of 2.3 Disas-

sembly/assembly method.)

(4) The cassette holder lowers and, when the loading has

completed, the mechanism enters the desired mode.

2.6 Jig RCU mode

This unit uses the following two modes for receiving remote control codes.

1) User RCU mode : Ordinary mode for use by the user.

2) Jig RCU mode : Mode for use in production and servicing.

When using the Jig RCU, it is required to set the VCR to the Jig

RCU mode (the mode in which codes from the Jig RCU can be

received). As both of the above two modes are stored in the EEPROM, it is required to set the VCR back to the User RCU mode

each time that an adjustment is made or to check that the necessary operations have been completed. These modes can be set

by the operations described below.

Note:

• Confirm the RCU mode when exchanged parts. Since

some SERVICE PARTS set the VCR to the Jig RCU mode

as initial setting.

2.6.1 Setting the Ji g RCU mode

(1) Unplug the power cord plug from the power outlet.

(2) Press and hold the “REC” and “PAUSE” buttons on the

VCR simultaneously, while plugging the power cord plugin-

to the power outlet. When the VCR is set to the Jig RCU

mode, the symbols ( “ : ” ) in the time display of the FDP are

blinking.

2.6.2 Setting the User RCU mode

(1) Turn off the power.

(2) Press the “REC” and “PAUSE” buttons of the VCR simulta-

neously. Alternatively, transmit the code “80” from the Jig

RCU.

2.7 Opening on the chassis

The chassis of this VCR has openings for diagnosis of some

parts on the board assembly.

Reel sensor

(Supply)

TU6001

CN3011

Reel sensor

(Take-up)

Rotary encoder

IC3001

Fig.2-7-1a

1-10 (No.82933)

Blink

Fig.2-6-2a User/Jig RCU mode

2.8 Emergency display function

This unit has a function for storing the history of the past two

emergencies (EMG) and displaying them on each FDP (or OSD).

With the status of the VCR and mechanism at the moment an

emergency occurred can also be confirmed.

FDP display model [FDP display]

0: 00

E: **

1E: **

1: *1

2: *2

3: 34

4: *5

5: *6

6: *7

7: *8

8: *9

9: *10

Normal display

EMG content display (Latest) See 2.8.3

EMG content display (Previous) See 2.8.3

EMG detail information <1> See 2.8.4

[Deck operation mode]

EMG detail information <1> See 2.8.4

[Mechanism operation mode]

EMG detail information <1> See 2.8.4

[Mechanism sensor information and Mechanism mode position]

EMG detail information <2> See 2.8.5

[Type of the cassette tape in use <1>]

EMG detail information <2> See 2.8.5

[Winding position of the cassette tape in use]

EMG detail information <2> See 2.8.5

[Type of the cassette tape in use <2> (Winding area)]

EMG detail information <3> See 2.8.6

[Previous deck operation mode]

EMG detail information <3> See 2.8.6

[The deck operation mode of the one before the last]

EMG detail information <3> See 2.8.6

[The deck operation mode of the one prior to one above]

FDP (7segment LED) display model [FDP display]

0 : 00 : 00

E:** :**

*1 : *2 : 34

*5: *6 : *7

*8: *9 : *10

Normal display (Counter or clock)

EMG content display (E:Latest:Previous) See 2.8.3

[EMG code display mode]

EMG detail information <1> display See 2.8.4

[Deck and other mode display mode]

EMG detail information <2> display See 2.8.5

[Cassette display mode]

EMG detail information <3> display See 2.8.6

[Deck mode history dispaly mode]

Notes:

• The EMG detail information <1><2> show the informa-

tion on the latest EMG.

It becomes “ - - : - - : - -” when there is no latest EMG

record.

• When using the Jig RCU, it is required to set the VCR to

the Jig RCU mode (the mode in which codes from the

Jig RCU can be received).

Jig RCU

[Data transmitting method]

Depress the “ ” ( 3 ) button

after the data code is set.

CUSTOM CODE

43: A CODE

53: B CODE

DATA CODE

INITIAL MODE

Fig.2-8a Jig RCU [PTU94023B]

2.8.1 Displaying the EMG info rmati on

(1) Trans mit the code “59” from the Jig RCU.

The FDP shows the EMG content in the form of “E: * * : * * ”.

<Example 1> E : 01 : 03

Previous EMG

Latest EMG

<Example 2> E : – – : – –

No EMG record

(2) Transmi t the code “59” from the Jig RCU again.The FDP

shows the EMG detail information <1> in the form of “ * 1 :

* 2 : 34 ”.

* 1 : Deck operation mode at the moment of EMG

* 2 : Mechanism operation mode at the moment of EMG

3- : Mechanism sensor information at the moment of EMG

-4 : Mechanism mode position at the moment of EMG

(3) Transmit the code “59” from the Jig RCU once again.

The FDP shows the EMG detail information <2> in the form

of “ * 5 : * 6 : * 7 ”.

* 5 : Type of the cassette tape in use <1>.

* 6 : Winding position of the cassette tape in use

* 7 : Type of the cassette tape in use <2> (Winding area)

(4) Transmi t the code "59" from the Jig RCU once again. The

FDP shows the EMG detail information <3> in the form of

"*8 : *9 : *10".

* 8 :Previous deck operation mode at the moment of EMG

* 9 :The deck operation mode of the one before the last at

the moment of EM G

* 10:The deck operation mode of the one prior to one

above at the moment of EMG

(5) Transmit the code “59” from the Jig RCU once again to re-

set the display.

Notes:

• For the EMG content, see “2.8.3 EMG content description”.

• For the EMG detail information <1> , see “2.8.4 EMG detail

information <1> ”.

• For the EMG detail information <2> , see “2.8.5 EMG detail

information <2>”.

2.8.2 Clearing the EMG history

(1) Display the EMG history.

(2) Trans mit the code “36” from the Jig RCU.

(3) Reset the EMG display.

(No.82933)1-11

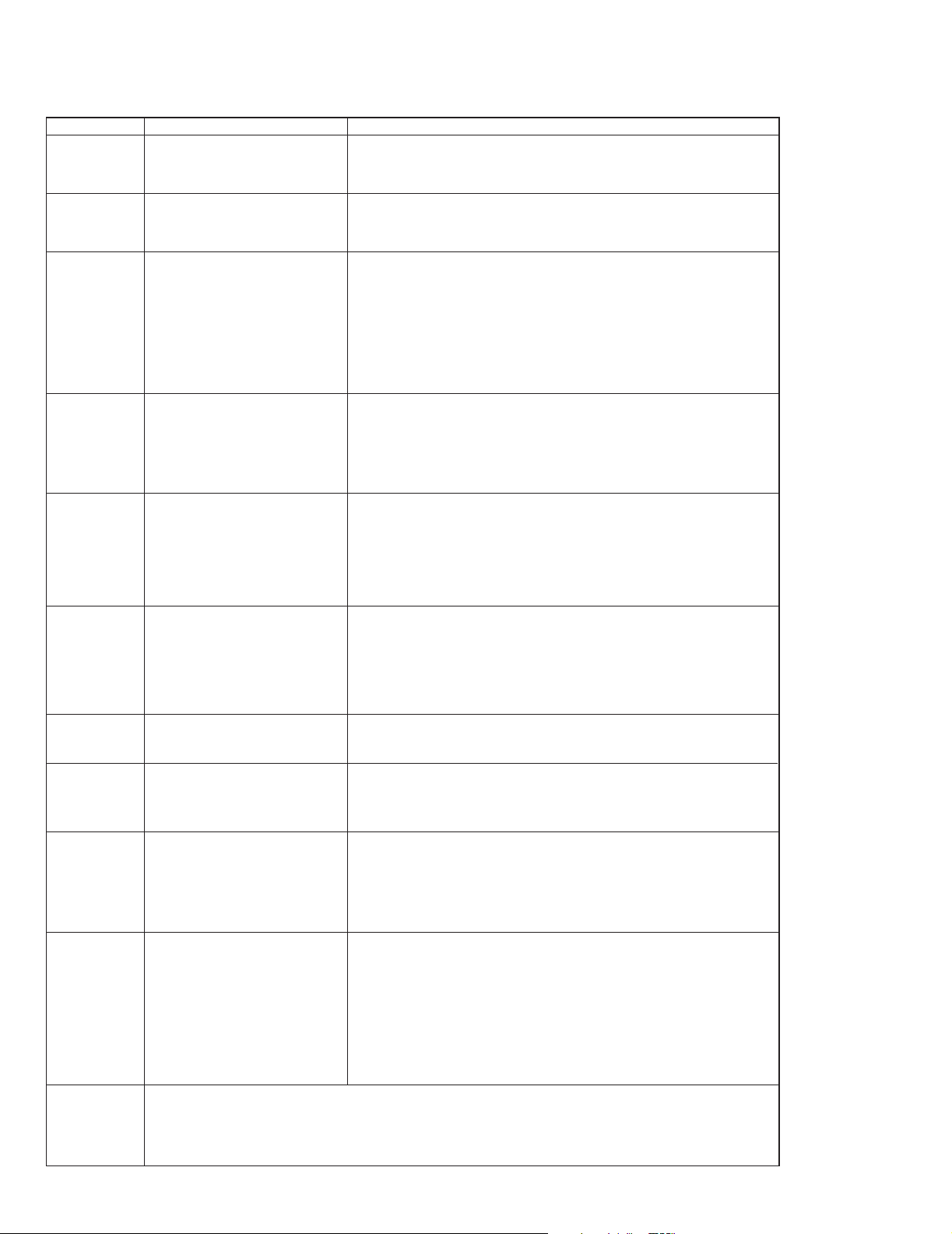

2.8.3 EMG content description

Note: EMG contents “E08/E09” are for the model with Dynamic Drum (DD).

FDP CONTENT CAUSE

E01: Loading EMG

E02: Unloading EMG

E03: Take Up Reel

Pulse EMG

E04: Drum FG

EMG

E05: Cassette Eject

EMG

E06: Capstan FG

EMG

E07: SW Power

Short-Circuit

EMG

E08: DD Initialized

(Absolute

Position

Sensor)

EMG

E09: DD FG EMG

E0A: Supply Reel

Pulse EMG

EC1 or EU1:

Head clog warning

When the mechanism mode cannot be

changed to another mode even when the

loading motor has rotatedfor more than 4 seconds in the loading direction, [E:01] is identified and the power is turned off.

When the mechanism mode cannot be

changed to an-other mode even when the

loading motor has rotatedfor more than 4 seconds in the unloading direction, [E:02] is identified and the power is turned off.

When the take-up reel pulse has not been

generated for more than 4 seconds in the capstan rotating mode, [E:03] is identified, the

pinch rollers are turned off and stopped,and

the power is turned off. However, the reel

EMG isnot detected in STILL/SLOW modes.

When the drum FG pulse has not been input

for more than 3 seconds in the drum rotating

mode, [E:04] is iden-tified, the pinch rollers are

turned off and stopped, and the power is

turned off.

When the eject operation does not complete in

3 seconds after the start, [E:05] is identified,

the pinch rollers are turned off and stopped,

and the power is turned off. When the cassette insertion operation does not complete in

3 seconds after the start, the cassette is ejected. In addition, when the operation does not

complete within 3 seconds after the start,

[E:05] is also identified and the power is

turned off immediately.

When the capstan FG pulse has not been

generated for more than 1 second in the capstan rotating mode, [E:06] is identified, the

pinch rollers are turned off and stopped, and

the power is turned off. However, the capstan

EMG is not detected in STILL/SLOW/FF/REW

modes.

When short-circuiting of the SW power supply

with GND has lasted for 0.5 second or more,

[E:07] is identified, all the motors are stopped

and the power is turned off.

When DD tilting does not complete in 4 seconds, [E:08] is identified, the tilt motor is stopped and the power is turned off.

When the DD FG pulse is not generated within

2.5 seconds, [E:09] is identified, the tilt motor

is stopped and the power is turned off.

When the supply reel pulse has not been generated for more than 10 seconds in the capstan rotating mode, [E:0A] is identified and the

cassette is ejected (but the power is not

turned off). However, note that the reel EMG

is not detected in the SLOW/STILL mode.

Presupposing the presence of the control pulse output in the PLAY mode, when the value obtained by mixing the two V.FM output channels (without

regard to the A.FM output) has remained below a certain threshold level for more than 10 seconds, [E:C1] or [E:U1] is identified and recorded in the

emergency history. During the period in which a head clog is detected, the FDP and OSD repeat the "3-second warning display" and "7-second noise

picture display" alternately.

EMG code : "E:C1" or "E:U1" / FDP : "U:01" / OSD : "Try cleaning tape." or "Use cleaning cassette."

The head clog warning is reset when the above-mentioned threshold has been exceeded for more than 2 seconds or the mode is changed to another

mode than PLAY.

1. The mechanism is locked in the middle of mode transition.

2. The mechanism is locked at the loading end due to the encoder position reading error during mode

transition.

3. Power is not supplied to the loading MDA.

1. The mechanism is locked in the middle of mode transition.

2. The mechanism is locked at the unloading end due to the encoder position reading error during

mode transition.

3. Power is not supplied to the loading MDA.

1. The take-up reel pulse is not generated in the FWD transport modes (PLAY/FWD SEARCH/FF,

etc.) because;

1) The idler gear is not meshed with the take-up reel gear;

2) The idler gear is meshed with the take-up reel gear, but incapable of wind-ing due to too large

mechanical load (abnormal tension);

3) The take-up reel sensor does not output the FG pulse.

2. The supply reel pulse is not generated in the REV transport modes (REVSEARCH/REW, etc.) because;

1) The idler gear is not meshed with the supply reel gear.

2) The idler gear is meshed with the supply reel gear, but incapable of wind-ing due to too large a

mechanical load (abnormal tension);

3) The supply reel sensor does not output the FG pulse.

3. Power is not supplied to the reel sensors.

1. The drum could not start or the drum rotation has stopped due to too large a load on the tape, because;

1) The tape tension is abnormally high;

2) The tape is damaged or a foreign object (grease, etc.) adheres to the tape.

2. The drum FG pulse did not reach the System controller CPU because;

1) The signal circuit is disconnected in the middle;

2) The FG pulse generator (hall device) of the drum is faulty.

3. The drum control voltage (DRUM CTL V) is not supplied to the MDA.

4. Power is not supplied to the drum MDA.

1. The cassette cannot be ejected due to a failure in the drive mechanism of the housing.

2. When the housing load increases during ejection, the loading motor is stopped because of lack of

headroom in its drive torque.

Housing load increasing factors: Temperature environment (low temperature, etc.), mechanism

wear or failure.

3. The sensor/switch for detecting the end of ejection are not functioning normally.

4. The loading motor drive voltage is lower than specified or power is not sup-plied to the motor

(MDA).

5. When the user attempted to eject a cassette, a foreign object (or perhaps the user's hand) was

caught in the opening of the housing.

1. The capstan could not start or the capstan rotation has stopped due to too large a load on the tape,

because;

1) The tape tension is abnormally high (mechanical lock);

2) The tape is damaged or a foreign object (grease, etc.) is adhered to the tape (occurrence of

tape entangling, etc.).

2. The capstan FG pulse did not reach the System controller CPU because;

1) The signal circuit is disconnected in the middle;

2) The FG pulse generator (MR device) of the capstans is faulty.

3. The capstan control voltage (CAPSTAN CTL V) is not supplied to the MDA.

4. Power is not supplied to the capstan MDA.

1. The SW 5 V power supply circuit is shorted with GND.

2. The SW 12 V power supply circuit is shorted with GND.

1. The absolute value sensor is defective. (The soldered parts have separated.)

2. The pull-up resistor at the absolute sensor output is defective. (The soldered parts have separated.)

3. Contact failure or soldering failure of the pins of the connector (board-to-board) to the absolute value sensor.

4. The absolute value sensor data is not sent to the System Controller CPU.

1. The FG sensor is defective. (The soldered parts have separated.)

2. The pull-up resistor at the FG sensor output is defective. (The soldered parts have separated.)

3. Contact failure or soldering failure of the pins of the connector (board-to-board) to the FG sensor.

4. The power to the sensor is not supplied. (Connection failure/soldering failure)

5. The FG pulse is not sent to the System Controller CPU.

6. The tilt motor is defective. (The soldered parts have separated.)

7. The drive power to the tilt motor is not supplied. (Connection failure/soldering failure)

8. The tilt motor drive MDA - IC is defective.

9. Auto-recovery of the DD tilting cannot take place due to overrun.

1. The supply reel pulse is not generated in the FWD transport mode (PLAY/FWD SEARCH/FF, etc.)

because;

1) PLAY/FWD or SEARCH/FF is started while the tape in the inserted cassette is cut in the middle;

2) A mechanical factor caused tape slack inside and outside the supply reel side of the cassette

shell. In this case, the supply reel will not rotate until the tape slack is removed by the FWD

transport, so the pulse is not generated until then;

3) The FG pulse output from the supply reel sensor is absent.

2. The take-up reel pulse is not generated in the REV transport mode (REVSEARCH/REW, etc.).

1) REV SEARCH/REW is started when the tape in the inserted cassettehas been cut in the middle;

2) A mechanical factor caused tape slack inside and outside the take-up reel side of the cassette

shell. In this case, the supply reel will not rotate until the tape slack is removed by the REV

transport, so the pulse will not be generated until that time;

3) The FG pulse output from the take-up reel sensor is absent.

3. The power to a reel sensor is not supplied.

1-12 (No.82933)

Loading...

Loading...