Page 1

SERVICE MANUAL

CAMCORDER

YF335<Rev.001>20102SERVICE MANUALEVERIO-S

GZ-MS110BEK, GZ-MS110BEU

SERIES

C0S3

GZ-MS110BEKM, GZ-MS110BEUM [C0S300]

COPYRIGHT © 2010 Victor Company of Japan, Limited

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

This service manual (No.YF335<Rev.001>) describes only the items which differ from those of already issued service manual

(No.YF334

For details other than those described in this manual, please refer to the service manuals which were already issued.

<Rev.001>)

TABLE OF CONTENTS

1 PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-28

5 TROUBLE SHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-32

COPYRIGHT © 2010 Victor Company of Japan, Limited

No.YF335<Rev.001>

2010/2

Page 2

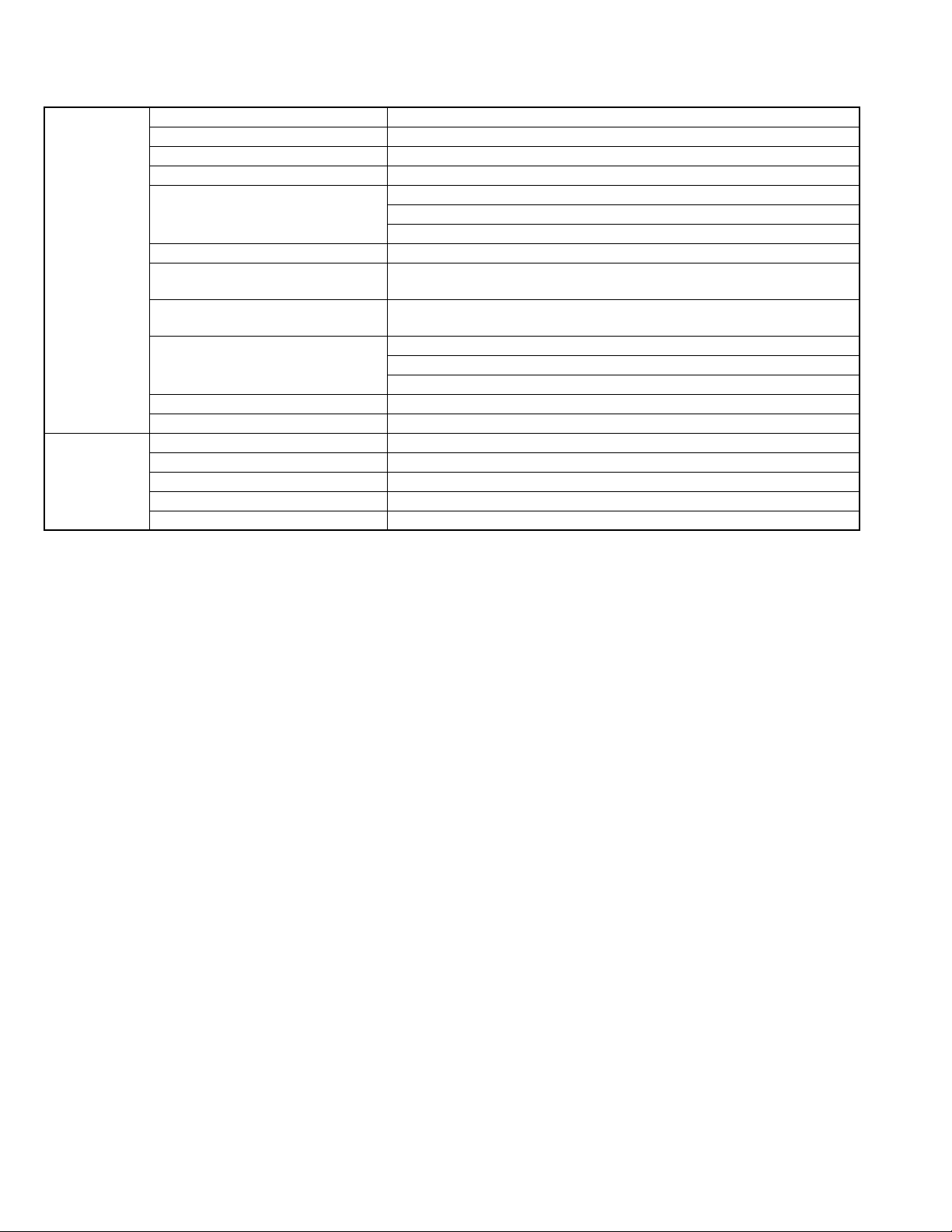

SPECIFICATION

Camera Power supply Using AC adapter: DC 5.2 V, Using battery pack: DC 3.6 V

Power consumption 1.5 W (when LCD backlight is set to “STANDARD”)

Dimensions (mm) 52 × 62 × 110 (W × H × D:excluding grip belt)

Mass Approx. 195 g (camera only), Approx. 220 g (including supplied battery pack)

Operating environment Allowable operating temperature:0°C to 40°C

Allowable storage temperature:-20°C to 50°C

Allowable operating humidity:35% to 80%

Image pickup device 1/6" 800,000 pixels

Recording area (Video) 410,000 pixels (optical zoom),

410,000 pixels to 550,000 pixels (dynamic zoom)

Lens F 1.8 to F 4.3, f = 2.2 mm to 85.8 mm

(35 mm conversion: 41.5 mm to 1619 mm)

Zoom (Video) Optical zoom: Up to 39×

Dynamic zoom: Up to 45×

Digital zoom: Up to 800×

Video recording format SD-VIDEO standard, Video: MPEG-2, Audio: Dolby Digital (2 ch)

Recording media Requires (×1) SDHC card ,sold separately

AC Adapter

(AP-V30M)*

*When using the AC adapter overseas, please prepare a commercially available converter plug for the country or region of visit.

• The specifications and appearance of this product are subject to changes for further improvement without prior notice.

Power supply AC 110 V to 240, 50 Hz/60 Hz

Output DC 5.2 V, 1.8 A

Allowable operating temperature 0°C to 40°C (10°C to 35°C during charging)

Dimensions (mm) 50 × 29 × 100 (W × H × D: excluding cord and AC plug)

Mass Approx. 112 g

1-2 (No.YF335<Rev.001>)

Page 3

SECTION 1

r

PRECAUTIONS

1.1 SAFETY PRECAUTIONS

Prior to shipment from the factory, JVC products are strictly

inspected to conform with the recognized product safety and

electrical codes of the countries in which they are to be

sold.However,in order to maintain such compliance, it is equally

important to implement the following precautions when a set is

being serviced.

1.1.1 Precautions during Servicing

(1) Locations requiring special caution are denoted by labels

and inscriptions on the cabinet, chassis and certain parts of

the product.When performing service, be sure to read and

comply with these and other cautionary notices appearing

in the operation and service manuals.

(2) Parts identified by the symbol and shaded ( ) parts

are critical for safety.

Replace only with specified part numbers.

NOTE :

Parts in this category also include those specified to

comply with X-ray emission standards for products

using cathode ray tubes and those specified for

compliance with various regulations regarding

spurious radiation emission.

(3) Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as

specified.

(4) Use specified internal wiring. Note especially:

• Wires covered with PVC tubing

• Double insulated wires

• High voltage leads

(5) Use specified insulating materials for hazardous live parts.

Note especially:

• Insulation Tape

• PVC tubing

•Spacers

• Insulation sheets for transistors

• Barrier

(6) When replacing AC primary side components (transformers,

power cords, noise blocking capacitors, etc.) wrap ends of

wires securely about the terminals before soldering.

emission. Consequently, when servicing these products,

replace the cathode ray tubes and other parts with only the

specified parts. Under no circumstances attempt to modify

these circuits.Unauthorized modification can increase the

high voltage value and cause X-ray emission from the

cathode ray tube.

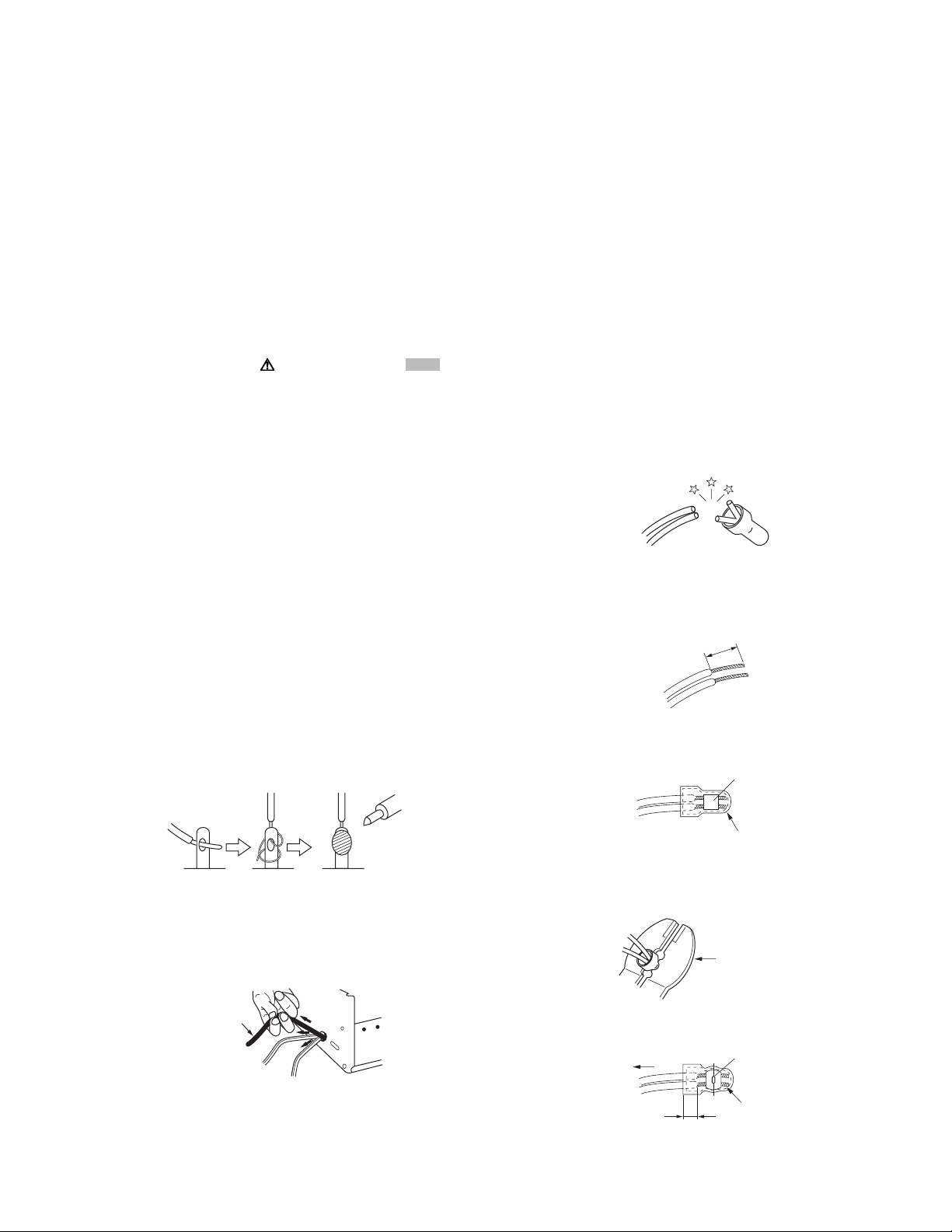

(12) Crimp type wire connectorIn such cases as when replacing

the power transformer in sets where the connections

between the power cord and power trans former primary

lead wires are performed using crimp type connectors, if

replacing the connectors is unavoidable, in order to prevent

safety hazards, perform carefully and precisely according

to the following steps.

• Connector part number :E03830-001

• Required tool : Connector crimping tool of the proper

type which will not damage insulated parts.

• Replacement procedure

a) Remove the old connector by cutting the wires at a

point close to the connector.Important : Do not

reuse a connector (discard it).

cut close to connector

Fig.1-1-3

b) Strip about 15 mm of the insulation from the ends

of the wires. If the wires are stranded, twist the

strands to avoid frayed conductors.

15 mm

Fig.1-1-4

c) Align the lengths of the wires to be connected.

Insert the wires fully into the connector.

Metal sleeve

Fig.1-1-1

(7) Observe that wires do not contact heat producing parts

(heatsinks, oxide metal film resistors, fusible resistors, etc.)

(8) Check that replaced wires do not contact sharp edged or

pointed parts.

(9) When a power cord has been replaced, check that 10-15

kg of force in any direction will not loosen it.

Power cord

Fig.1-1-2

(10) Also check areas surrounding repaired locations.

(11) Products using cathode ray tubes (CRTs)In regard to such

products, the cathode ray tubes themselves, the high

voltage circuits, and related circuits are specified for

compliance with recognized codes pertaining to X-ray

Connector

Fig.1-1-5

d) As shown in Fig.1-1-6, use the crimping tool to crimp

the metal sleeve at the center position. Be sure to

crimp fully to the complete closure of the tool.

1.2

5

2.0

5.5

Crimping tool

Fig.1-1-6

e) Check the four points noted in Fig.1-1-7.

Not easily pulled free

Wire insulation recessed

more than 4 mm

Crimped at approx. cente

of metal sleeve

Conductors extended

Fig.1-1-7

(No.YF335<Rev.001>)1-3

Page 4

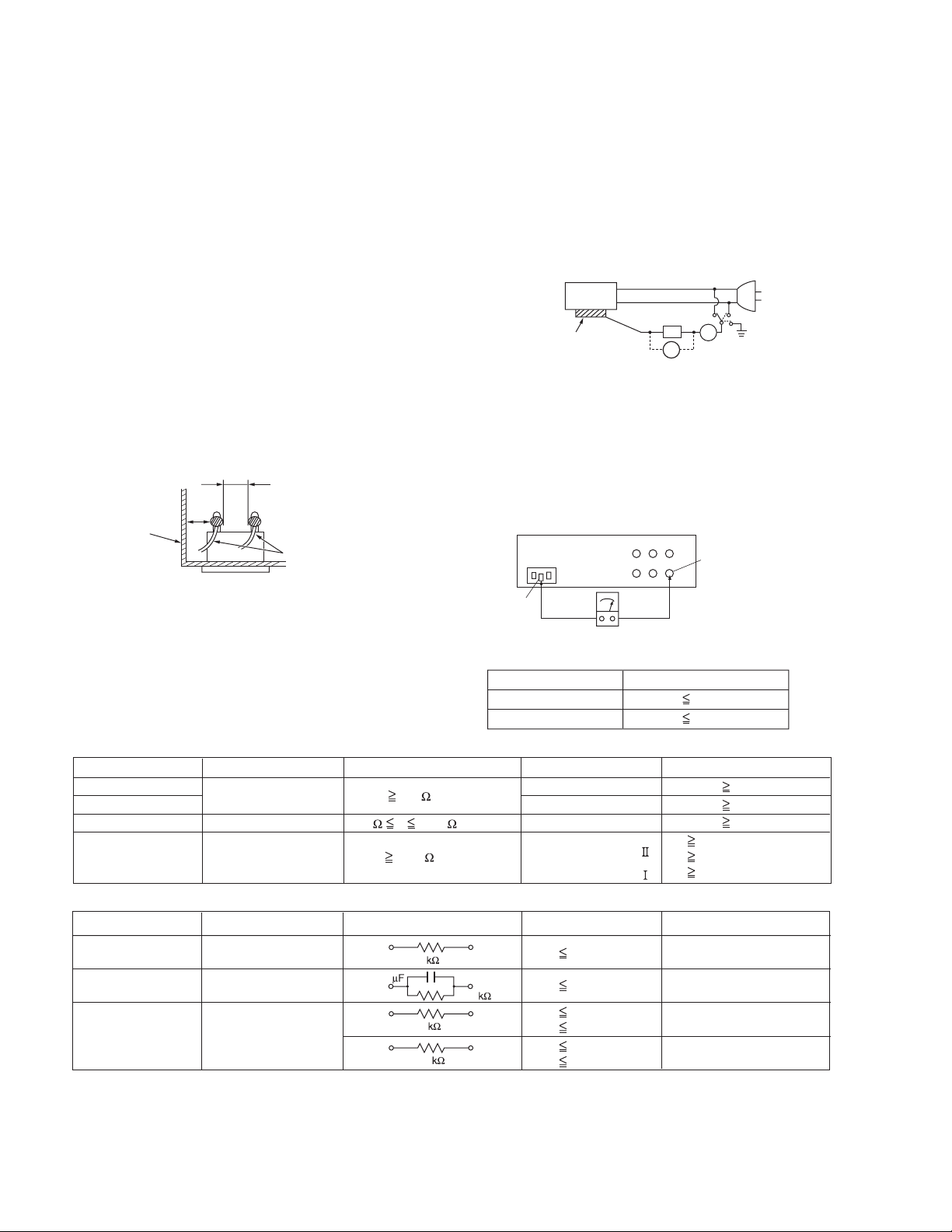

1.1.2 Safety Check after Servicing

Examine the area surrounding the repaired location for damage

or deterioration. Observe that screws, parts and wires have been

returned to original positions, Afterwards, perform the following

tests and confirm the specified values in order to verify

compliance with safety standards.

(1) Insulation resistance test

Confirm the specified insulation resistance or greater

between power cord plug prongs and externally exposed

parts of the set (RF terminals, antenna terminals, video and

audio input and output terminals, microphone jacks,

earphone jacks, etc.).See table 1 below.

(2) Dielectric strength test

Confirm specified dielectric strength or greater between

power cord plug prongs and exposed accessible parts of

the set (RF terminals, antenna terminals, video and audio

input and output terminals, microphone jacks, earphone

jacks, etc.). See Fig.1-1-11 below.

(3) Clearance distance

When replacing primary circuit components, confirm

specified clearance distance (d), (d') between soldered

terminals, and between terminals and surrounding metallic

parts. See Fig.1-1-11 below.

d

Chassis

d'

Power cord

primary wire

Fig.1-1-8

(4) Leakage current test

Confirm specified or lower leakage current between earth

ground/power cord plug prongs and externally exposed

accessible parts (RF terminals, antenna terminals, video

and audio input and output terminals, microphone jacks,

earphone jacks, etc.).

Measuring Method : (Power ON)Insert load Z between

earth ground/power cord plug prongs and externally

exposed accessible parts. Use an AC voltmeter to

measure across both terminals of load Z. See Fig.1-1-9

and following Fig.1-1-12.

ab

Externally

exposed

accessible part

Z

V

c

A

Fig.1-1-9

(5) Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between

earth pin in AC inlet and externally exposed accessible

parts (Video in, Video out, Audio in, Audio out or Fixing

screw etc.).Measuring Method:

Connect milli ohm meter between earth pin in AC inlet and

exposed accessible parts. See Fig.1-1-10 and grounding

specifications.

AC inlet

Earth pin

Exposed accessible part

MIlli ohm meter

Grounding Specifications

Region

USA & Canada

Europe & Australia

Grounding Impedance (Z

Z 0.1 ohm

Z 0.5 ohm

)

Fig.1-1-10

AC Line Voltage

100 V

100 to 240 V

110 to 130 V

110 to 130 V

200 to 240 V

Region

Japan

USA & Canada

Europe & Australia

Insulation Resistance (R

R 1 M /500 V DC

1 M R 12 M /500 V DC

R 10 M /500 V DC

)

Dielectric Strength

AC 1 kV 1 minute

AC 1.5 kV 1 minute

AC 1 kV 1 minute

AC 3 kV 1 minute

AC 1.5 kV 1 minute

(

Class

(

Class

Clearance Distance (d), (d'

d, d' 3 mm

d, d' 4 mm

d, d' 3.2 mm

d 4 m m

)

d' 8 m m (Power cord

d' 6 m m (Primary wire

)

Fig.1-1-11

AC Line Voltage

100 V

110 to 130 V

110 to 130 V

220 to 240 V

Region

Japan

USA & Canada

Europe & Australia

Load Z

1

0.15

1.5

2

50

Leakage Current (i)

i 1 mA rms

i 0.5 mA rms

i 0.7 mA peak

i 2 mA dc

i 0.7 mA peak

i 2 mA dc

a, b, c

Exposed accessible parts

Exposed accessible parts

Antenna earth terminals

Other terminals

Fig.1-1-12

NOTE :

These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

)

)

)

1-4 (No.YF335<Rev.001>)

Page 5

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

2.1 DIFFERENCE LIST The following table indicate main different points between models GZ-MS110BUS, GZ-MS110BEK and GZ-MS110BEU.

MODEL GZ-MS110BUS GZ-MS110BEK GZ-MS110BEU

SIGNAL FORMAT NTSC PAL PAL

USB TERMINAL IN/OUT OUT ONLY OUT ONLY

AC ADAPTER AP-V30U AP-V30M AP-V30E

AC CORD NO YES(BS) NO

BATTERY BN-VG107US BN-VG107EU BN-VG107EU

2.2 CHECKING THE CPU VERSION

To check the CPU version of the model, display the firmware update screen.

Note) Before checking the version, connect both a fully

charged battery and a DC cord to the model.

Procedure

(1) Open the MONITOR ASSY to turn ON the power.

(2) Press the [MENU] button to display the menu screen, se-

lect BASIC SETTINGS > with the SELECT lever, and then

press the [OK] button. Next, select UPDATE with the SELECT lever, and press the [OK] button.

(3) On the monitor screen, CURRENT VERSION: *.** is dis-

played.

(4) After checking the display, press the [MENU] button to exit

from the menu screen.

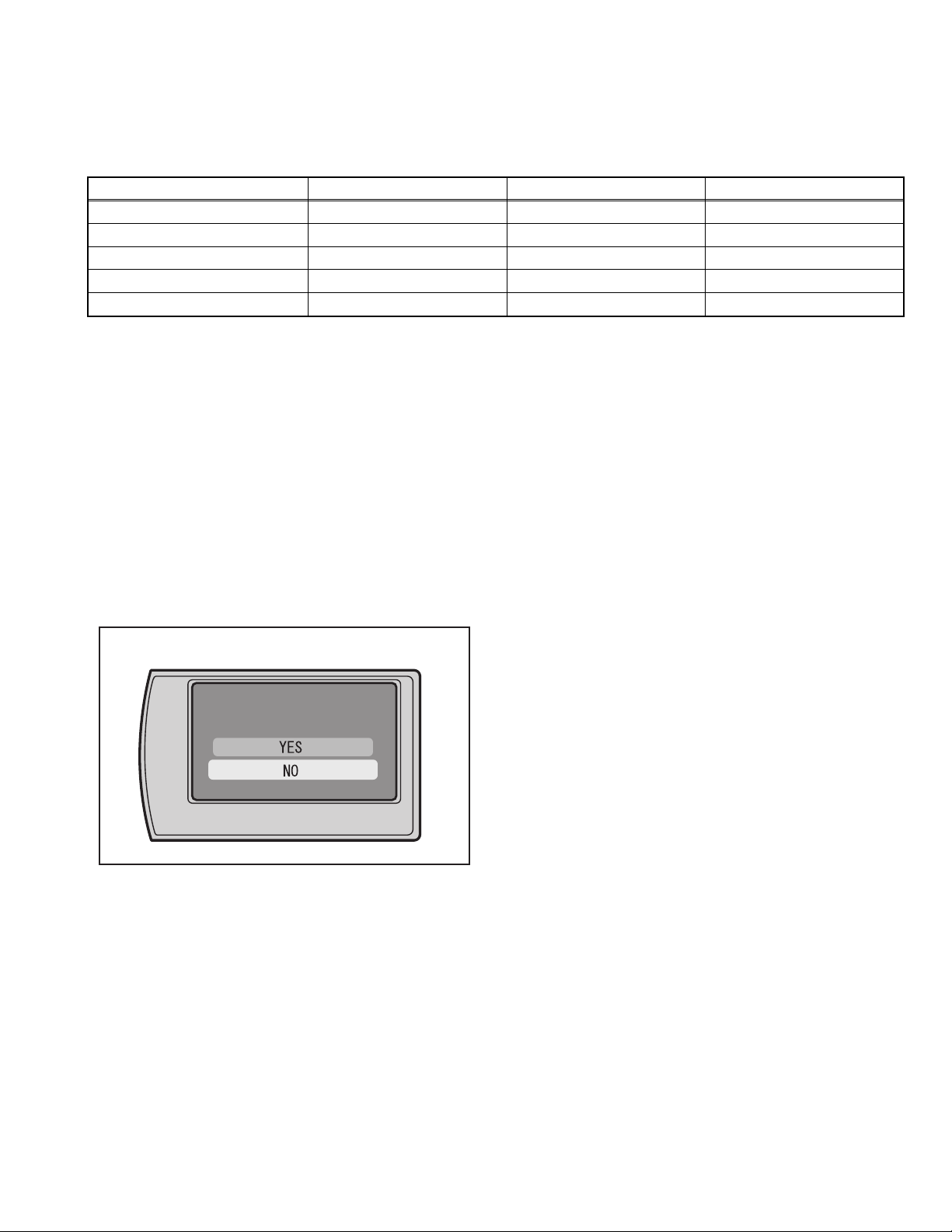

<Checking screen>

LCD MONITOR

CURRENT VERSION : 1.01

START UPDATE?

Fig.2-1-1

(No.YF335<Rev.001>)1-5

Page 6

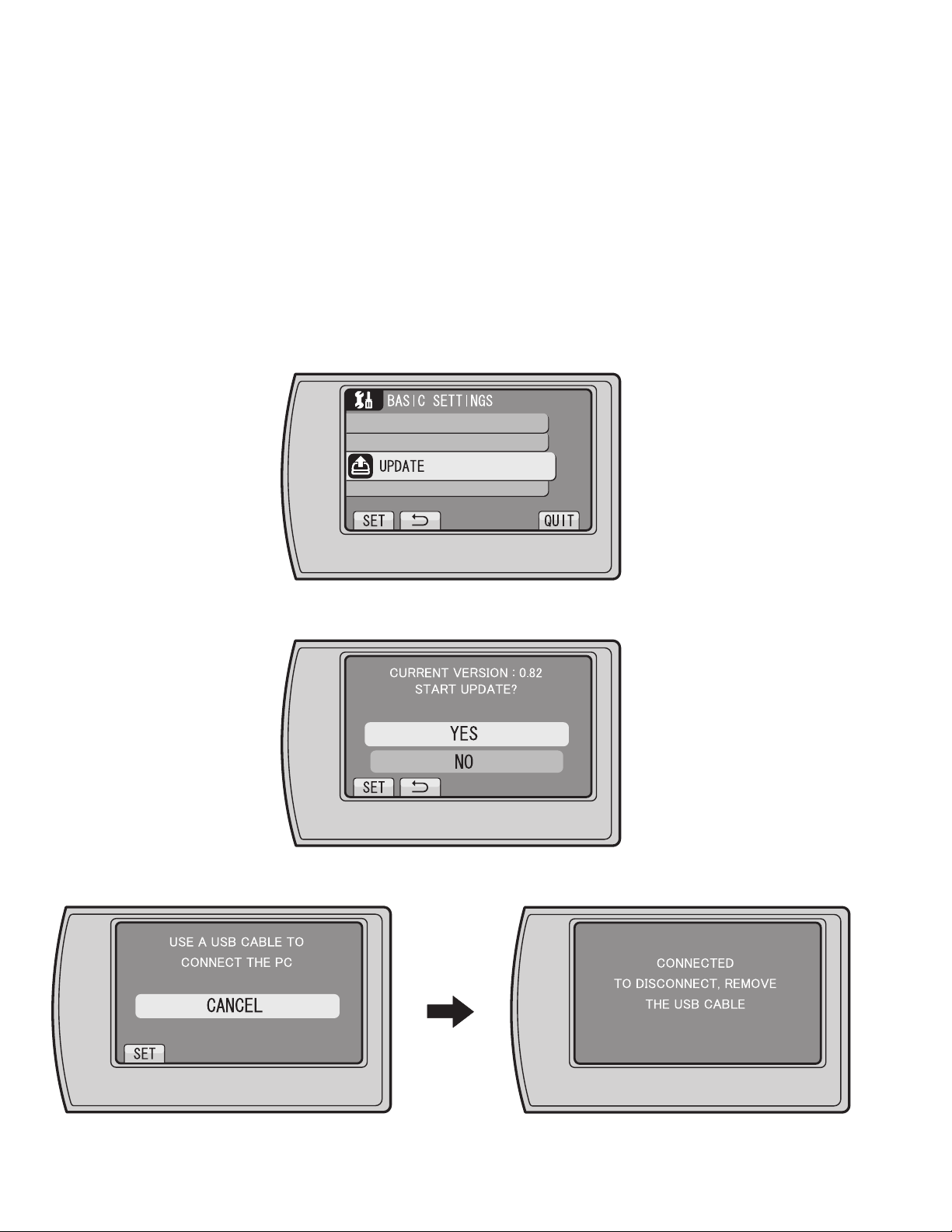

2.3 FIRMWARE UPDATE

Connecting Everio to a PC via USB cable enables firmware update.

Connect a battery, capable of operating for 30 minutes or longer, and an AC adapter to Everio for update.

* The following procedure shows the monitor displays of the firmware update from ver. 0.82 to ver. 1.55.

* Use Windows XP or Windows Vista.

1.Preparation

(1)Preparation

Download the firmware update application software from JS-NET.

(2)Connection

Connect a battery that is capable of operating for 30 minutes or longer and an AC adapter to Everio.

* To ensure secure power supply during the update, update is disabled if either of them is not available.

2.Firmware transfer

(1) Select "UPDATE" in the main menu of Everio.

MENU > BASIC SETTINGS > UPDATE

Fig.2-2-1

(2)When the displayed current version is an old one, select "YES", and then press (OK).

Fig.2-2-2

(3)Follow the directions on the monitor to connect Everio to the PC via USB cable.

1-6 (No.YF335<Rev.001>)

Fig.2-2-3

Page 7

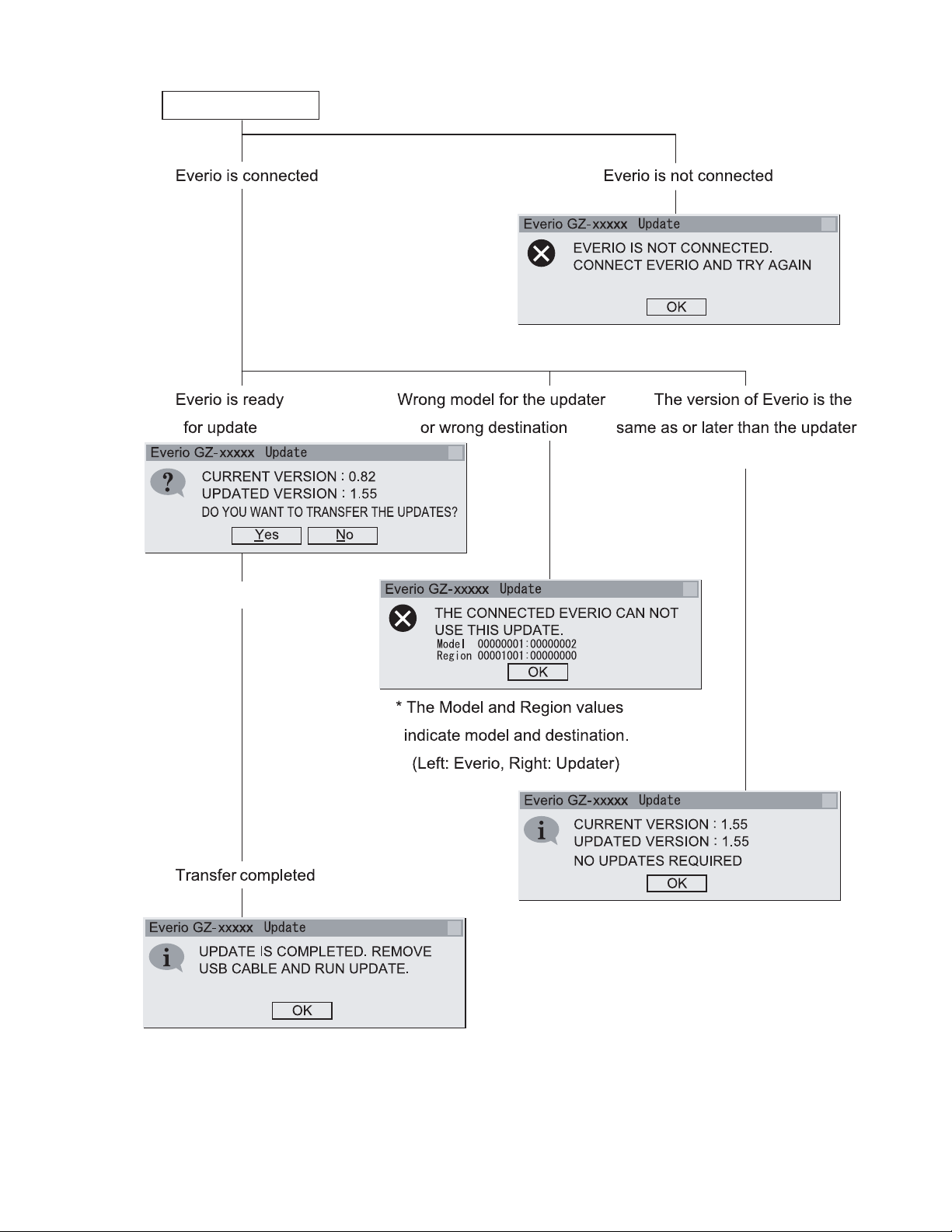

(4)Double click the downloaded file to execute it. (The following shows the screen display of the PC.)

Execute the file

㬍

㬍

Click "YES"

㬍

㬍

㬍

Click "OK" to finesh the file.

Fig.2-2-4

(No.YF335<Rev.001>)1-7

Page 8

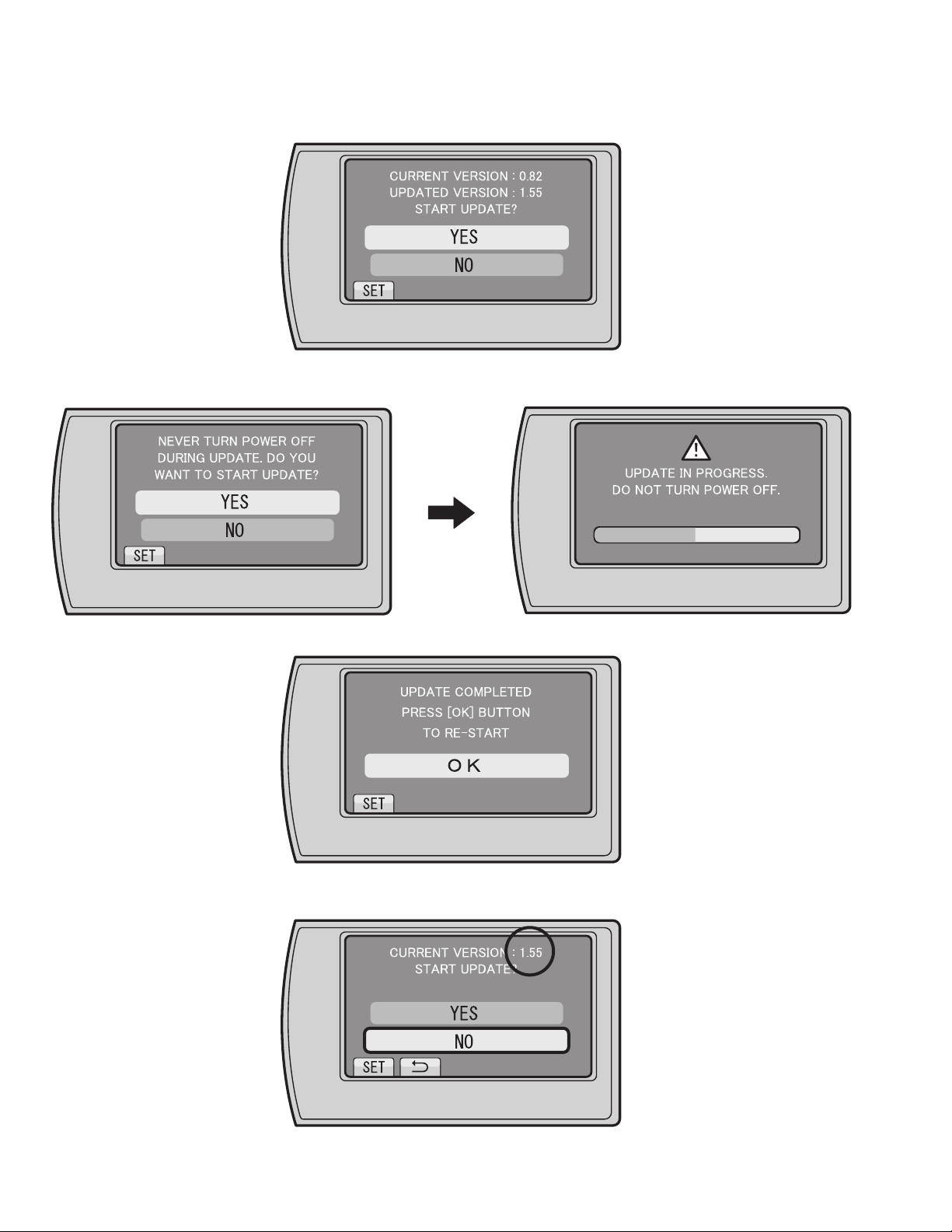

3.Execute update

(1)Disconnect the USB cable, and remove Everio from the PC.

* In about 30 seconds after the removal, the update start screen appears.

(2)When the displayed current version is an old one, select "YES", and then press (OK).

Fig.2-2-5

(3)When the displayed current version is an old one, select "YES", and then press (OK).

* It takes about 4 minutes and 30 seconds to complete the update.

Fig.2-2-6

(4)Select "OK", and then re-start Everio.

Fig.2-2-7

(5)After the re-start, check that the current firmware is updated in UPDATE.

MENU > BASIC SETTINGS > UPDATE

When the updated firmware version is confirmed, select "NO", and then press (OK).

The firmware update is completed.

1-8 (No.YF335<Rev.001>)

Fig.2-2-8

Page 9

2.4 EMERGENCY DISPLAY FUNCTION

This model has a function to save emergency information in a flash ROM (IC3003).

To obtain the emergency information, read the data using terminal software.

There are types of terminal software including Windows HyperTerminal and freeware Tera Term.

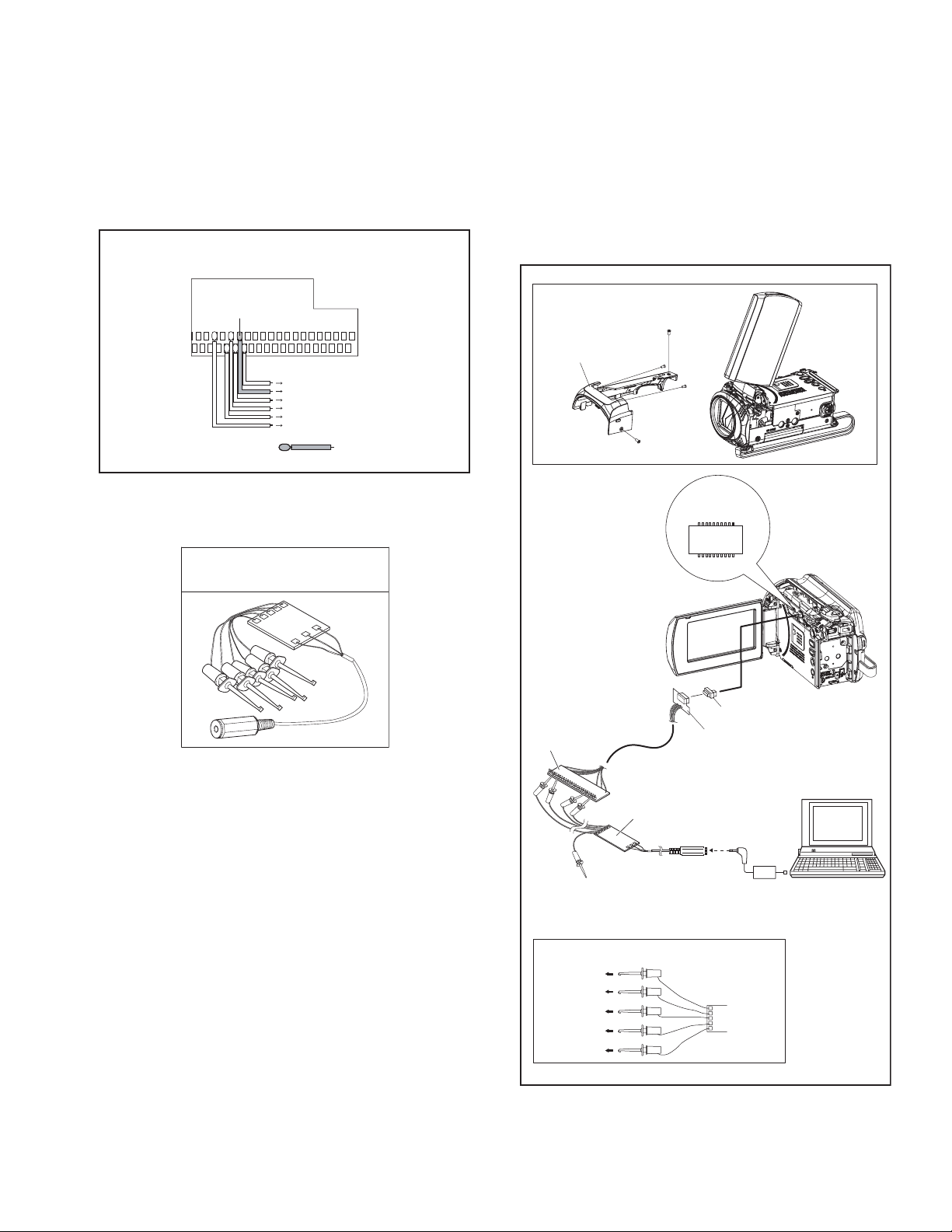

2.4.1 Jig connector cable

Connect the model to the serial port of the PC using the jig connector cable and the serial update jig (or communication cable).

Note) As the jig connector cable (Part No.: YTU93106B) is not extended, adding a wire is required.

How to work on the jig connector cable (YTU93106B)

Connection procedure

·Remove the 4 screws (1-4), and then remove the COV-

<Soldered side>

ER(HIN) ASSY.

11

12 RKPNOT USE

11 RKPUA_TXD0

10 RKPGND

9 RKPGND

8 RKPNOT USE

5 RKPNOT USE

Additional wire

Serial Update Jig

To be used to connect the PC cable and the Jig connector cable for firmware repair and various analyses.

Serial Update Jig

YTU93113A

COVER(HIN) ASSY

JIG CONNECTOR CABLE

(YTU93106B)

1

3

4

2

JIG CONNECTOR

(MAIN CN110)

10

20

JIG CONNECTOR

1

11

CONVERSION CONNECTOR

(YTU94145K-20)

SERIAI UPDATE JIG

(YTU93113A)

NC

(NOT USED)

JIG CONNECTOR

TO AL_2.83V

TO UA_RXD0

TO UA_TXD0

NC(NOT USED)

TO GND

WHITE

YELLOW

BLACK

BLUE

RED

RS232C

COM PORT

PC CABLE

SERIAI UPDATE JIG

(No.YF335<Rev.001>)1-9

TERMINAL

SOFTWARE

PC

Page 10

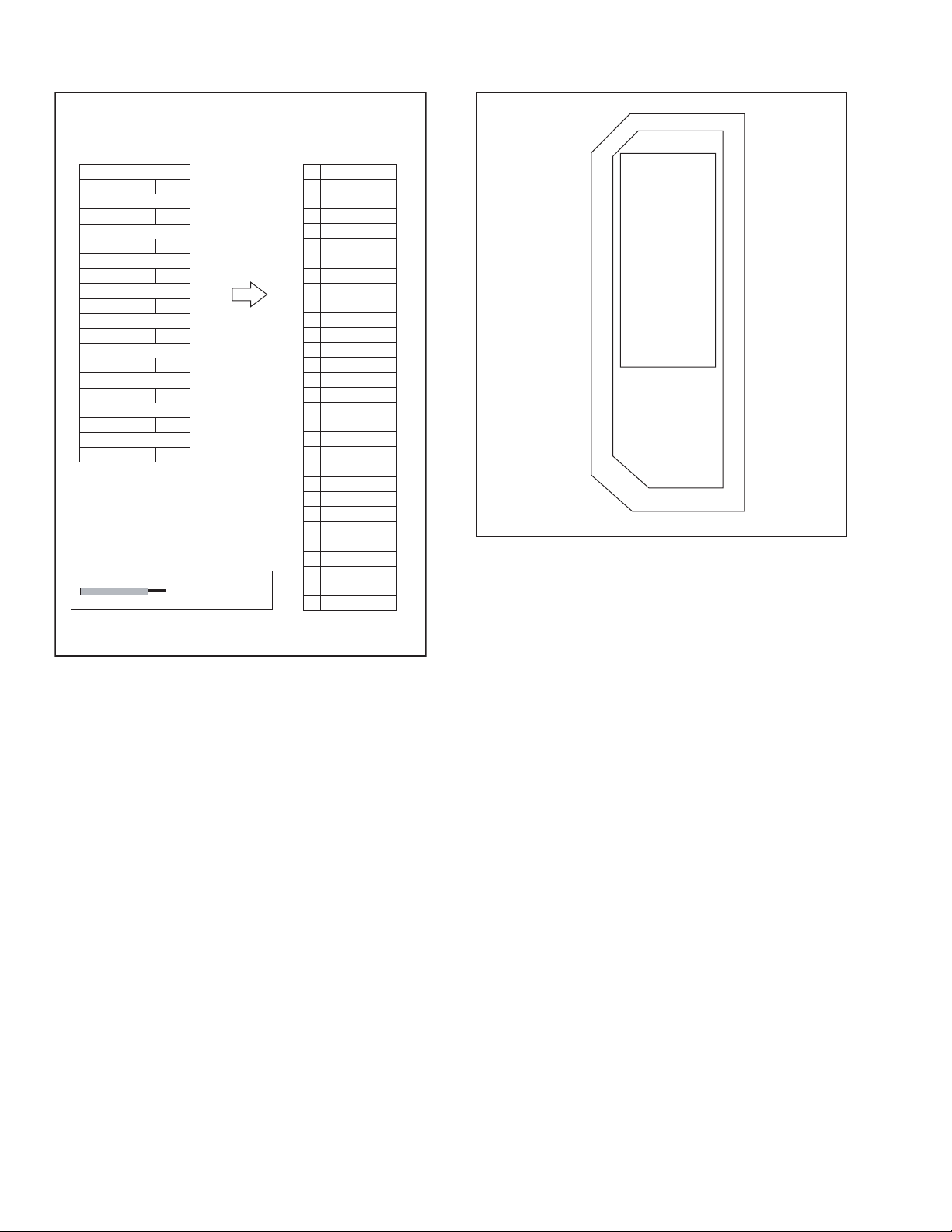

Jig connector diagrams Conversion Connector

JIG CONNECTOR CABLE (YTU93106B)

JIG CONN. BOARD

MAIN CN110

DSP_RTCK

DSP_TMS

DSP_RST

XDSPTRST

REG_2.83V

OCD_SDA

SYS_RSTL

GND

DSP_TDI

GND

UA_RXD0

UA_TXD0

DSP_TCK

OCD_SCL

IF_RX

IF_TX

AL_2.83V

IRU

KENTO

DSP_TDO

ADDITIONAL WIRE

10

9

8

7

6

5

4

3

2

1

20

19

18

17

16

15

14

13

12

11

11. UA_TXD0

(PIN NO.)

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

-

AL_2.83V

-

-

UA_RXD0

-

-

-

-

NC

NC

NC

NC

NC

-

-

-

-

UA_TXD0

GND

GND

-

-

NC

NC

NC

NC

NC

KENTO*

AL_2.83V

IF_RX*

DSP_TCK*

UA_RXD0

DSP_TDI*

SYS_RSTL*

REG_2.83V*

DSP_RST*

DSP_RTCK*

NC

NC

NC

NC

NC

*NC

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

11

12

13

14

15

16

17

18

19

20

10

DSP_TDO*

1

2

3

4

5

6

7

8

9

15

IRU*

14

IF_TX*

13

OCD_SCL*

12

UA_TXD0

11

GND

10

GND

9

OCD_SDA*

8

XDSPTRST

7

DSP_TMS*

6

NC

5

NC

4

NC

3

NC

2

NC

1

*

1-10 (No.YF335<Rev.001>)

Page 11

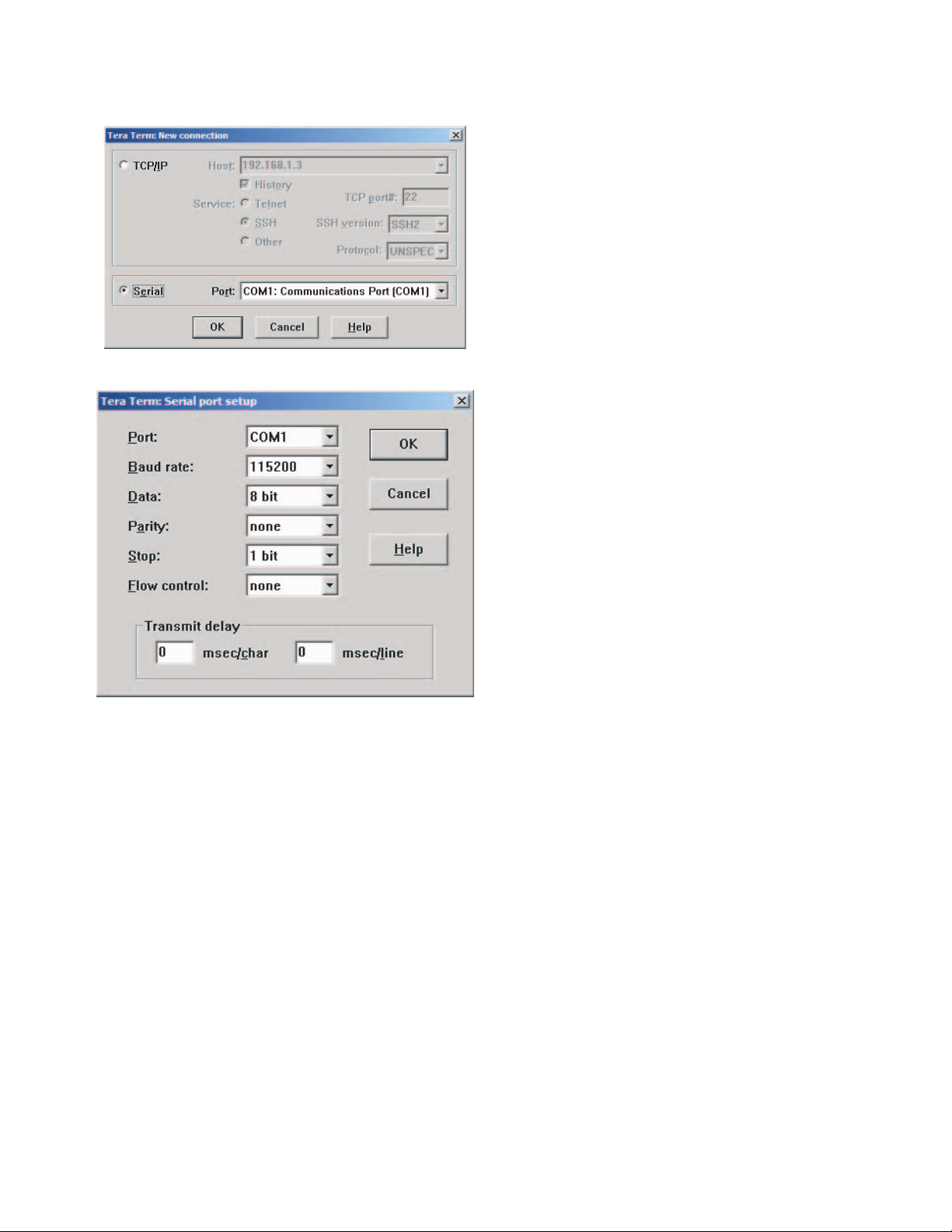

2.4.2 Starting the terminal software

Before starting the terminal software, install the terminal software.

(1) Start Tera Term, select "Serial", and then click "OK".

(2) Select Setup > Serial port. Set each item, and then click "OK".

* Maximizing terminal window size enables better viewing of

output data.

(No.YF335<Rev.001>)1-11

Page 12

2.4.3 Obtaining the emergency information

(1) Turning on the power of the model starts data reading, and the data is displayed in the terminal window. Wait until the data read-

ing finishes.

(2) When the data reading finishes, press Enter. "DBG>" is displayed in the window.

(3) Input the terminal command, and then press Enter.

* Terminal command

DBG>meid 81

The emergency information is displayed in the terminal window.

Note) There are three types of emergency information. (emgergency1/emgergency2/emgergency3)

< Display window >

Note) When emergency information is saved, [data*] is displayed in eight-digit alphanumeric characters.

These 8-digit characters are 4-bit hexadecimal numbers comprising 32-bit data.

As an exception, some product names in emergency2 are indicated using ASCII code.

There are up to four types of data: [data0]/[data1]/[data2]/[data3], and displayed number of data varies depending on the type of

emergency.

[emgergency1] displays [data0] only, and [data1]-[data3] are reserved (not used).

[emgergency2] displays [data0]-[data3].

[emgergency3] displays [data0] and [data2]. [data2] and [data3] are reserved (not used).

Refer to emergency information for data reading.

Display example 1: No Emergency Information

DBG>meid 81

0 emgergency1 data saved

0 emgergency2 data saved

0 emgergency3 data saved

Display example 2: Single Emergency Information for each item

DBG>meid 81

1 emgergency1 data saved

2009/12/11 05:16 ********

1 emgergency2 data saved

2009/01/06 16:02 ******** ******** ******** ********

1 emgergency3 data saved

2009/01/13 14:26 ******** ********

Display example 3: Multiple Emergency Information

DBG>meid 81

2 emgergency1 data saved

2009/12/11 05:16 ********

2009/12/12 06:20 ********

8 emgergency2 data saved

2009/01/06 16:02 ******** ******** ******** ********

2009/01/06 16:05 ******** ******** ******** ********

2009/01/06 17:37 ******** ******** ******** ********

2009/01/06 17:38 ******** ******** ******** ********

2009/01/13 14:02 ******** ******** ******** ********

2009/01/13 14:22 ******** ******** ******** ********

2009/01/13 14:24 ******** ******** ******** ********

2009/01/13 14:26 ******** ******** ******** ********

2 emgergency3 data saved

2009/01/13 14:26 ******** ********

2009/01/15 17:26 ******** ********

1-12 (No.YF335<Rev.001>)

Page 13

2.4.4 Obtaining and reading data written in flash ROM

zemergency1

Note) emergency1 can save up to 32 pieces of data.

When the data exceeds 32 pieces, the data will be erased from the oldest one.

1 emgergency1 data saved

2009/12/11 05:16 90000000

ޓdata[0] data[1]ޓޓdata[2]ޓdata[3]

[data0] bit31-bit28

Example: When [data0] is 9*******

[9] in 9******* is <1001> in binary number.

data[0]

data[0]

bitψ

9*******

1010

31 30 28 27 0

The allocation table below shows the drop detection setting is ON and the drop distance is 21-40 cm.

data[0]

bit31 Drop detection setting

bit28-bit30 Drop distance

Unit:cm

bit0-bit27 Reserved

0: OFF / 1: ON (Indicates the status set on the menu setting screen on the main unit)

0: Drop distance 0-20 / 1: Drop distance 21-40 / 2: Drop distance 41-60 /

3: Drop distance 61-80 / 4: Drop distance 81-100 / 5: Drop distance 101 or more

Reserved/Not used

data[1] Reserved/Not used

data[2] Reserved/Not used

data[3] Reserved/Not used

Hexadecimal number

Binary number

(No.YF335<Rev.001>)1-13

Page 14

zemergency2

Note) Combined with emergency3, emergency2 can save up to 32 pieces of data.

When the data exceeds 32 pieces, the data will be erased from the oldest one.

1 emgergency2 data saved

2009/01/06 16:02 ******** ******** ******** ********

data[1] data[2] data[3]data[0]

[data0] bit31-bit24

Example: When [data0] is 02******

[02] in 02****** is <00000010> in binary number.

data[0]

data[0]

bitψ

The allocation table below shows the media type is NAND.

[data0] bit15-[data2] bit16

[data0] bit15-bit8 save the media manufacturer ID.

[data0] bit15-[data2] bit24 save the media product name in 6-byte ASCII code.

The display varies depending on the manufacturer. Details have not been confirmed.

[data2] bit23-bit16 save the media revision number. The display varies depending on the manufacturer. Details have not been confirmed.

data[0]

bitψ

data[1]

bitψ

data[2]

bitψ

[data2] bit15-[data3] bit8

Example: [data2] is ****09C2, and [data3] is 002004**

[09C2] in ****09C2 is <0000100111000010> in binary number. [002004] in 002004** is <000000000010000000000100> in binary number.

data[2]

data[2]

bitψ

data[3]

data[3]

bitψ

The allocation table below shows the media production date (year/month) is December, 2009; the SD card is inserted in slot A; and the card capacity unit is GB.

The SD card capacity is 32 GB in speed class 4.

data[0]

data[1]

data[2]

data[3]

0

0

0 0 0 0 10 0

31 24 23 16 15 8 7 0

Various displays exist and the display varies depending on the manufacturer. Details have not been confirmed.

31 16 15 8 7 0

31 0

31

****

31

002004

31 16 15 8 7 0

bit24-bit31 Media type

bit16-bit23 Reserved

bit8-bit15

bit0-bit7

bit24-bit31

bit16-bit23

bit4-bit15 Production date (year/month)

bit3

bit2-bit1 Card capacity unit

bit0

bit16-bit31 Card capacity

bit8-bit15 Speed class

bit0-bit7 Reserved

2***

24 23

24 23

0 100000000000000 00001000

Manufacturer ID

Product namebit0-bit31

Product revision number

SD card slot

Reserved

16 15

0 0010001

16 15

0

0: HDD / 1: SDCard / 2: NAND

Reserved/Not used

The upper 8 bits indicate the bottom 2 digits of the year (western calendar). The lower 4 bits indicate the month.

0: A / 1: B (Card slot position)

0: MB / 1: GB / 2: TB

Reserved/Not used

0-1023

Reserved/Not used

***

09C

1000011

31024

**

0

2

0

Hexadecimal number

Binary number

Hexadecimal number

Binary number

Hexadecimal number

Binary number

1-14 (No.YF335<Rev.001>)

Page 15

zemergency3

Note) Combined with emergency2, emergency3 can save up to 32 pieces of data.

When the data exceeds 32 pieces, the data will be erased from the oldest one.

data[0]

bitψ

31 28 27 25 24 23 12 11 0

SDVideo

[data0]

bit28-bit31

bit25-bit27

bit24

bit12-bit23

bit0-bit11

Error type 0: HDD error / 1: Unsupported file / 3: Failed playback file / 4: Unknown error

Media type 0: HDD or NAND / 1: SD card

SDVideo / User MPEG 0: SD Video / 1: User MPEG

Folder number 1-0xFFF

File number 1-0xFFF

User MPEG

Note) User MPEG is the data handled as another file due to no management file.

[data0]

bit28-bit31

bit25-bit27

bit24

bit0-bit23

Error type 0: HDD error / 1: Unsupported file / 3: Failed playback file / 4: Unknown error

Media type 0: HDD or NAND / 1: SD card

SDVideo / User MPEG 0: SD Video / 1: User MPEG

File number 1-9999

data[1]

bitψ

31 0

bit0-bit31 Indicates GOP on the error point only with SDVideo with undefined user MPEG value.

data[2] Reserved

data[3] Reserved

(No.YF335<Rev.001>)1-15

Page 16

SECTION 3

DISASSEMBLY

3.1 BEFORE ASSEMBLY AND DISASSEMBLY

3.1.1 Precautions

• Be sure to disconnect the power supply unit prior to mounting

and soldering of parts.

• Prior to removing a component part that needs to disconnect

its connector(s) and its screw(s), first disconnect the wire(s)

from the connector(s), and then remove the screw(s).

• When connecting/disconnecting wires, pay enough attention

not to damage the connectors.

• When inserting the flat wire to the connector, pay attention to

the direction of the flat wire.

• Be careful in removing the parts to which some spacer or

shield is attached for reinforcement or insulation.

• When replacing chip parts (especially IC parts), first remove

the solder completely to prevent peeling of the pattern.

• Tighten screws properly during the procedures. Unless

otherwise specified, tighten screws at a torque of 0.088N

·cm). However, as this is a required value at the time of

(0.9kgf

production, use the value as a measuring stick when

proceeding repair services. (See "SERVICE NOTE" as for

tightening torque.)

3.1.2 Destination of connectors

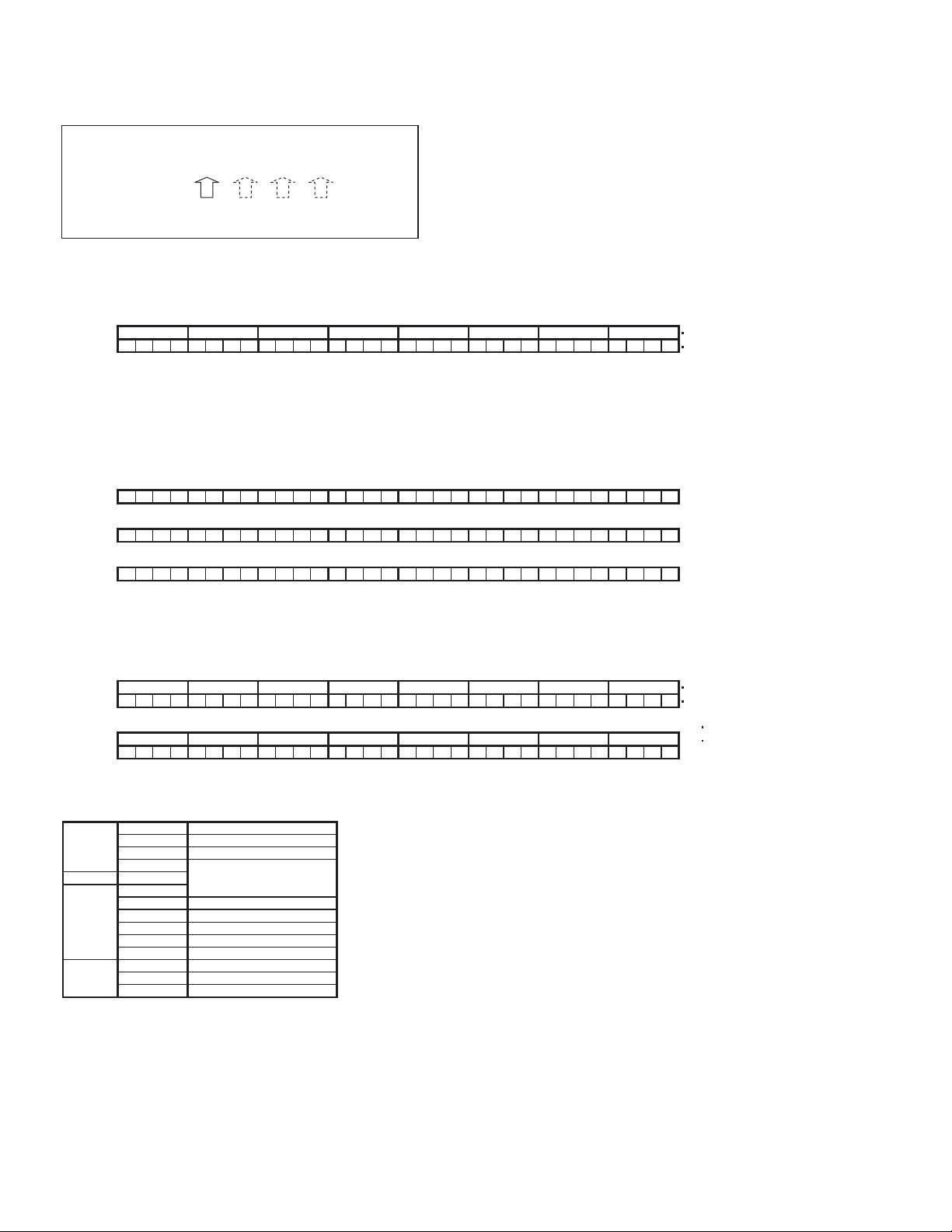

Two kinds of double-arrows in connection tables respectively

show kinds of connector/wires.

: Wire: Flat wire : Board to board (B-B)

: The connector of the side to remove

CONN. No. PIN No.CONNECTOR

CN2a

CN2b

MAIN CN101

MAIN CN103

MONI BW CN761

MINI BW CN762

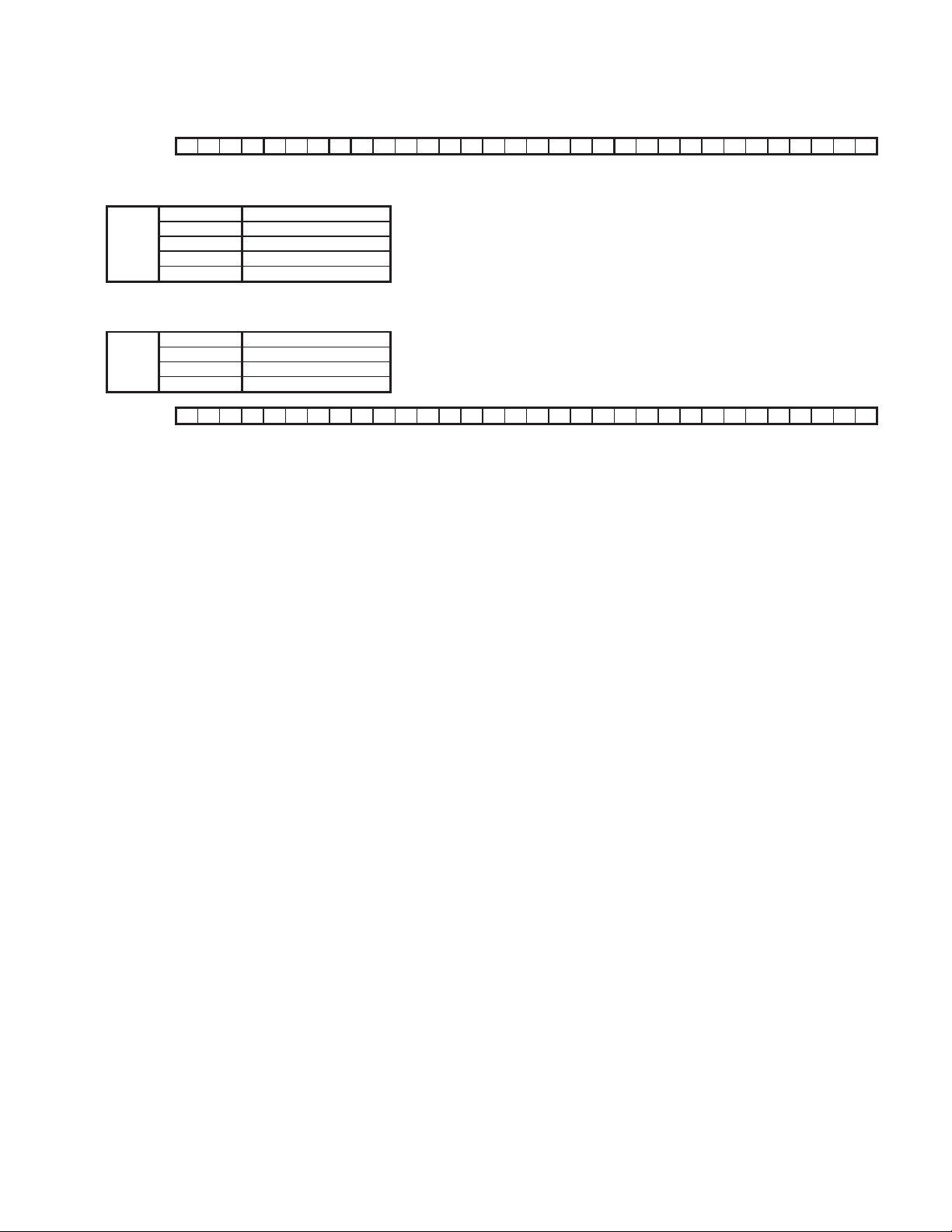

3.1.3 Disconnection of connectors (Wires)

Wire

· Pull both ends of the connector in the arrow

direction, remove the lock and disconnect the flat

wire.

· Pull the both ends of the board in the direction

of the arrow, and remove the B-B Connector.

· Extend the locks in the direction of the arrow for

unlocking and then pull out the wire. After

removing the wire, immediately restore the locks

to their original positions because the locks are

apt to come off the connector.

B-B Connector

B-B Connector

· Pull the both ends of the board in the direction of the arrow, and remove the B-B Connector.

FPC Connector

Wire

FPC Connector

Wire

Lock

FPC Connector

· Extend the locks in the direction of the arrow for

unlocking and then pull out the wire. After

removing the wire, immediately restore the locks

to their original positions because the locks are

apt to come off the connector.

· Extend the locks in the direction of the arrow for

unlocking and then pull out the wire. After

removing the wire, immediately restore the locks

to their original positions because the locks are

apt to come off the connector.

· Extend the locks in the direction of the arrow for

unlocking and then pull out the wire. After

removing the wire, immediately restore the locks

to their original positions because the locks are

apt to come off the connector.

Wire

FPC Connector

FPC

Connector

Wire

FPC Connector

Lock

Lock

Lock

B-B Connector

Fig.3-1-1

·m

40

10

Lock

Wire

3.1.4 Tools required for disassembly and assembly

Torque driver

YTU94088

Chip IC replacement jig

PTS40844-2

Bit

YTU94088-003

Cleaning cloth

KSMM-01

Tweezers

P-895

Fig.3-1-2

• Torque driver

Be sure to use to fastening the mechanism and exterior parts

because those parts must strictly be controlled for tightening

torque.

• Bit

This bit is slightly longer than those set in conventional torque

drivers.

• Tweezers

To be used for removing and installing parts and wires.

• Chip IC replacement jig

To be used for replacement of IC.

• Cleaning cloth

Recommended cleaning cloth to wipe down the video heads,

mechanism (tape transport system), optical lens surface.

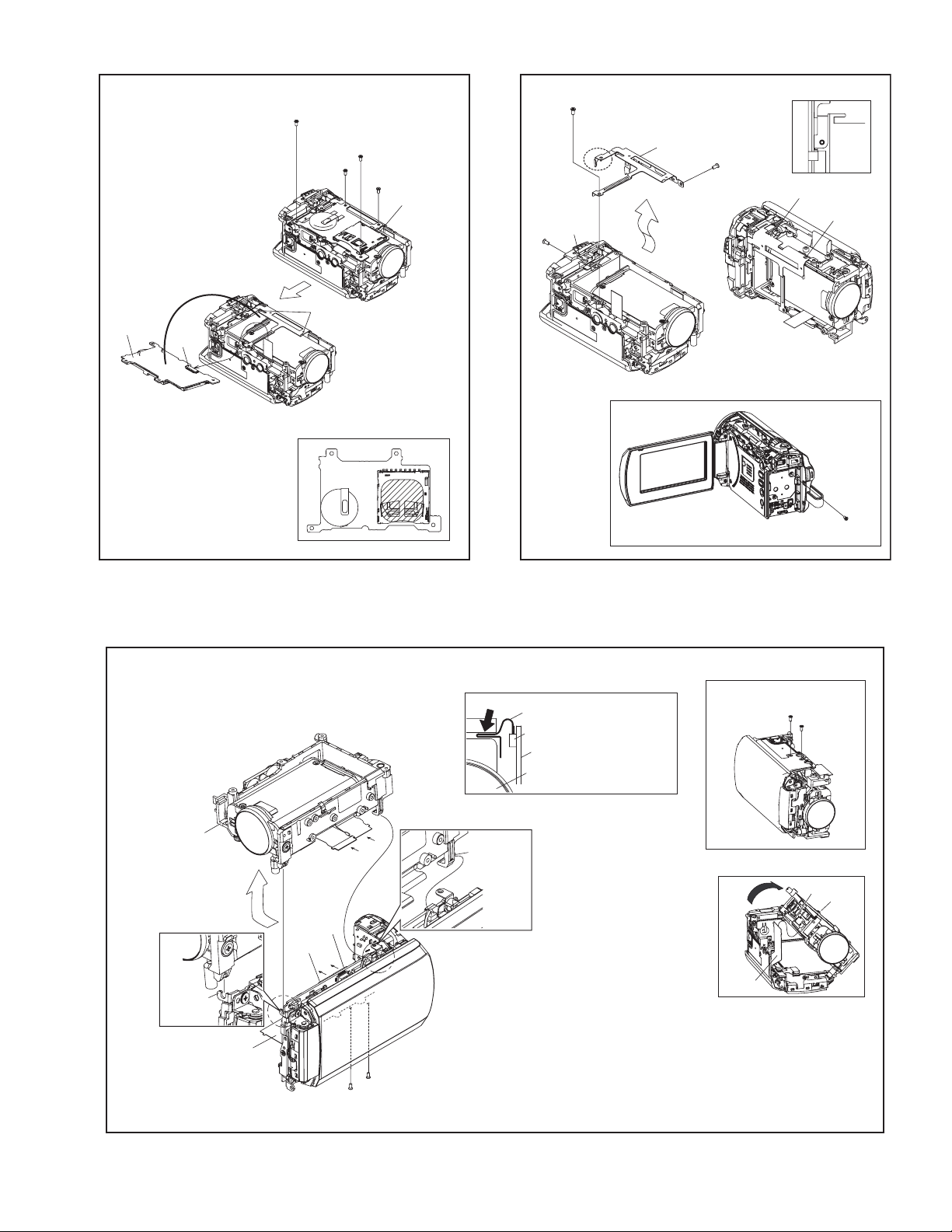

3.2 ASSEMBLY AND DISASSEMBLY OF MAIN PARTS

3.2.1 Assembly and disassembly

When reassembling, perform the step(s) in reverse order.

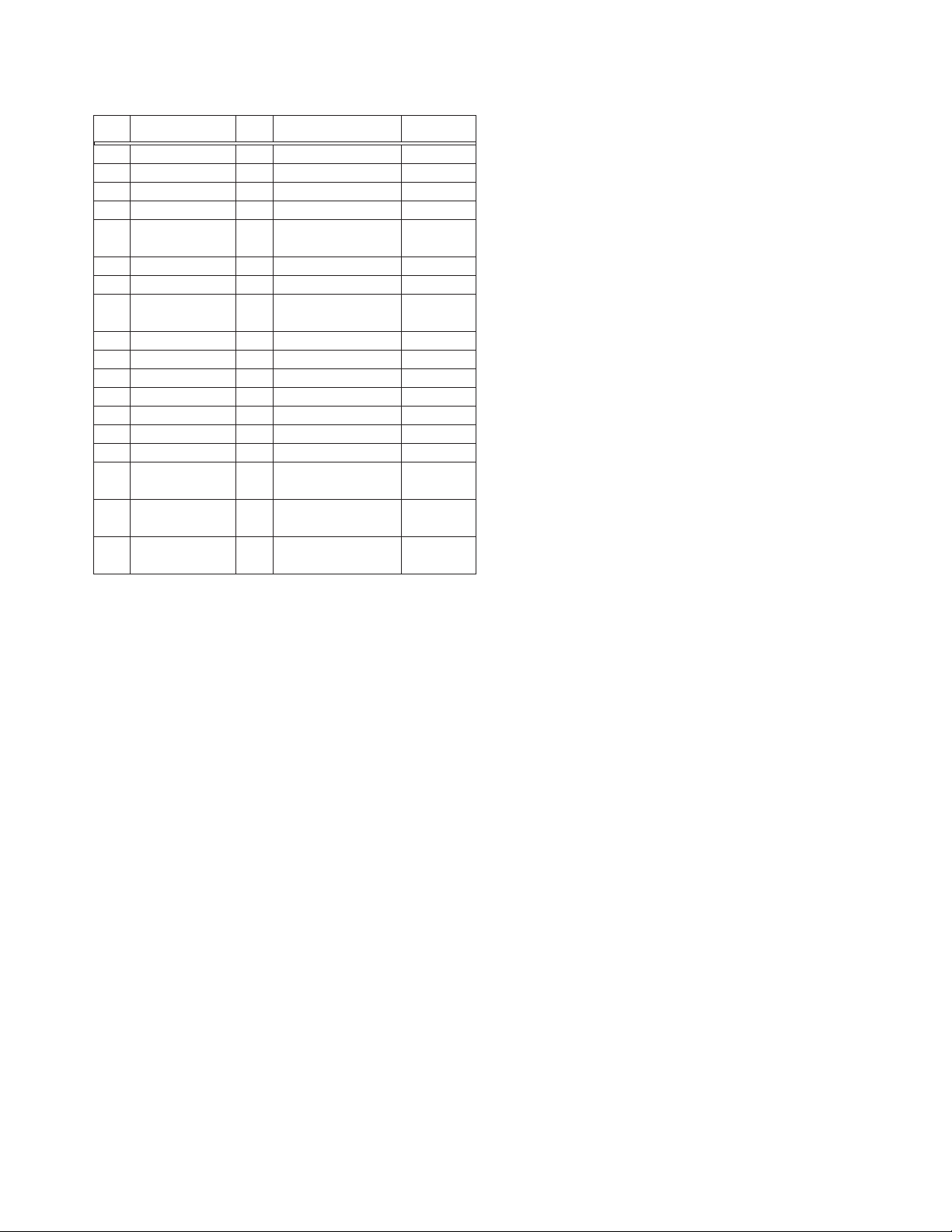

STEP

No.

[1]

[2]

PART

TOP COVER ASSY

UPPER ASSY

(Inc. VF ASSY,

SPEAKER/MONITOR)

[8]

E.VF UNIT(B/W)

(∗1) Order of steps in Procedure

When reassembling, preform the step(s) in the reverseorder.

These numbers are also used as the identification (location)

No. of parts Figures.

(∗2) Part to be removed or installed.

(∗3) Fig. No. showing Procedure or Part Location.

(∗4) Identification of part to be removed, unhooked, unlocked,

released, unplugged, unclamped or unsoldered.

S = Screw L = Lock, Release, Hook

SD = Solder CN = Connector

[Example]

• 4 (S1a) = Remove 4 S1a screws.

• 3 (L1a) = Disengage 3 L1a hooks.

• 2 (SD1a) = Unsolder 2 SD1a points.

• CN1a = Remove a CN1a connector.

(∗5) Adjustment information for installation.

Fig.

No.

4(S1a), 3(L1a),CN1a

C1

(S2a),2(S2b),3(S2c)

C2-1

2(SD1a),

L2,CN2a,b

2(S8),L8,CN8a

C2-2

POINT

( 4) ( 5)( 2) ( 3)( 1)

NOTE

-

-

NOTE 8

1-16 (No.YF335<Rev.001>)

Page 17

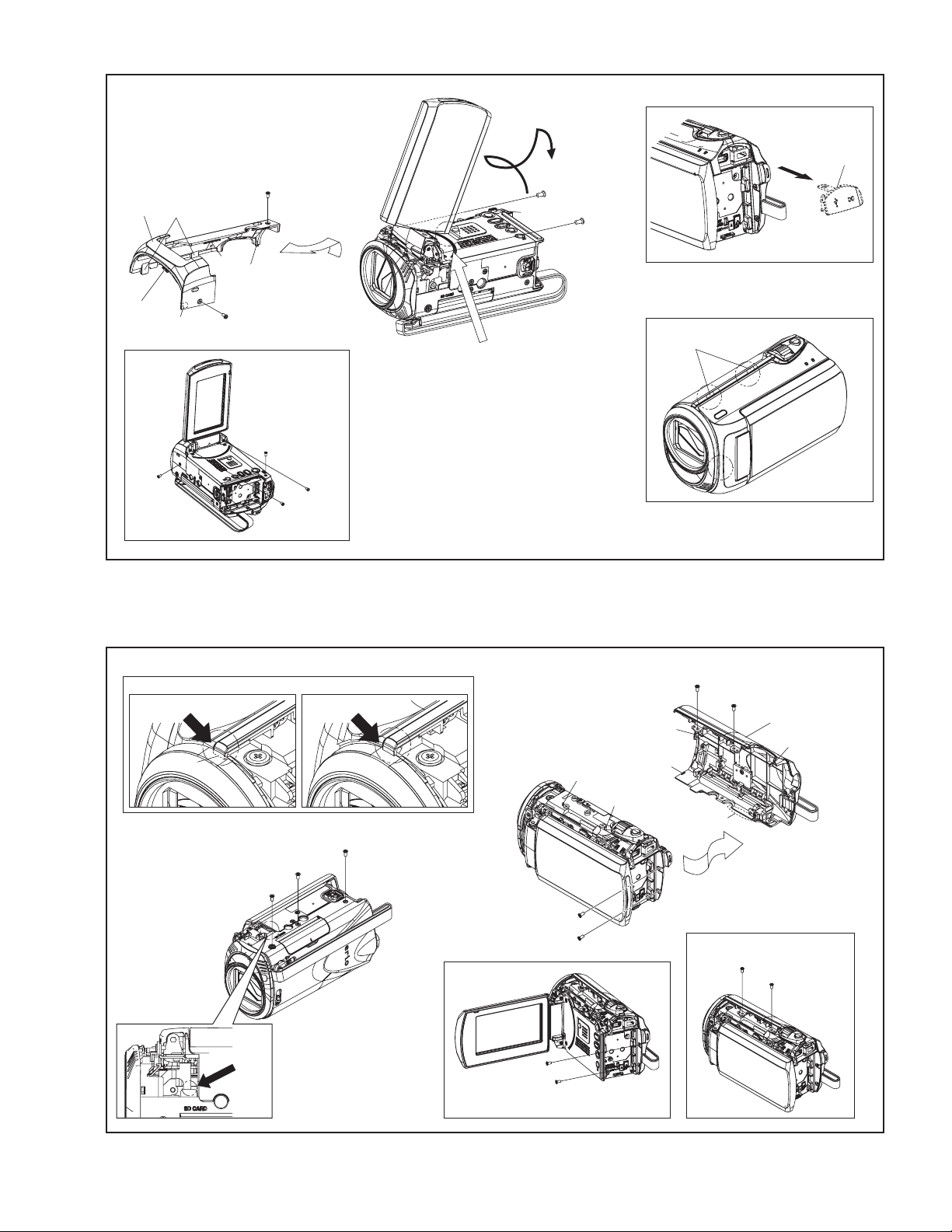

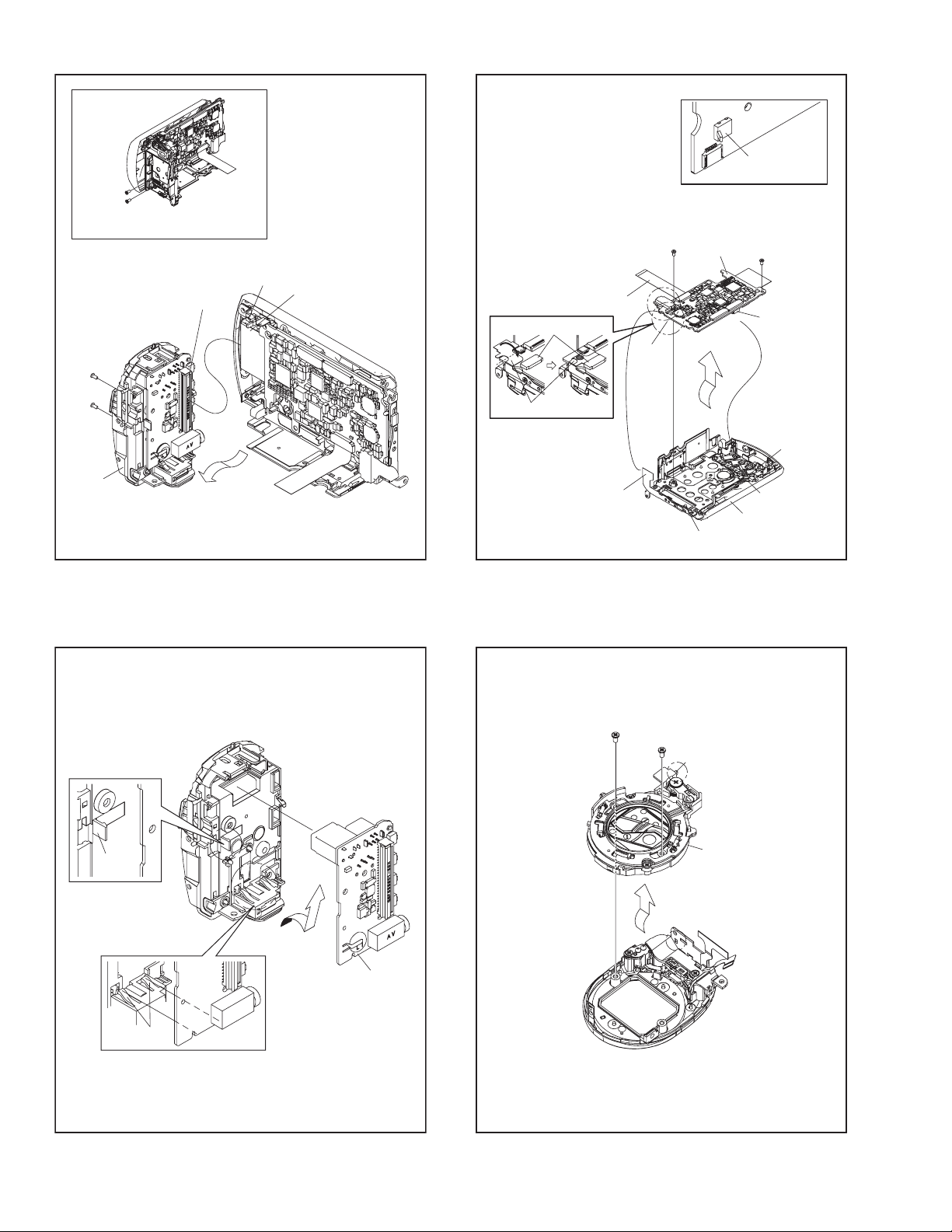

3.2.2 Assembly/Dissambly of cabinet parts and electrical parts

z Disassembly procedure

STEP

PART NAME

No.

[1]

COVER(HIN) ASSY

[2]

LOWER CASE ASSY(S3)

[3]

HOLDER(IND) ASSY

[4]

OPE UNIT

FRONT ASSY

[5]

(Incl. MIC & SHUTTER ASSY)

[6]

SD BOARD ASSY

[7]

SHIELD

OP BLOCK ASSY

[8]

(Incl. CCD BOARD ASSY & HOLDER)

[9]

REAR ASSY

[10]

REAR BOARD ASSY

[11]

MAIN BOARD ASSY

[12]

SHUTTER ASSY

[13]

PLATE(MIC) SD

[14]

MICROPHONE UNIT

[15]

OP BLOCK ASSY

[16]

CCD BOARD ASSY

[17]

MONITOR ASSY

[18]

SPEAKER

Fig.

No.

3-2-1

3-2-2

3-2-3

3-2-4

3-2-5

3-2-6

3-2-7

3-2-8

3-2-9

3-2-10

3-2-11

3-2-12

3-2-13

3-2-14

3-2-15

3-2-16

3-2-17

3-2-18

POINT NOTE

4(S1),L1a,b,c,2(L1d),L1e,f

7(S2),L2a,b,c,d,e,f

S3

CN4,S4,2(L4a),L4b,c,d

CN5,2(S5a),S5b,L5a,b

2(S6a),2(S6b),2(L6),CN6

3(S7),L7a,b,c

2(S8),L8a,b,c,CN8a,b

S9a,b,L9,CN9

L10a,2(L10b)

CN11a,2(S11),L11a,b,CN11b

2(S12),L12

S13,L13a,b

-

3(S15),HOLDER(OPSD) ASSY

2(S16),2(L16),CCD BASE ASSY,

SHEET,OP LPF

S17a,2(L17a),2(S17b),L17b,

2(L17c),UPPER CASE ASSY(SD)

L18a,S18,L18b,BKT(SPK),

2(L18c)

NOTE1a,b,c

NOTE2a,b

-

NOTE4

NOTE5a,b,c

NOTE6

NOTE7a,b

NOTE8a,b,c

-

-

NOTE11a,b,c

NOTE12

NOTE16a,b,c

NOTE17a,b,c

NOTE18a,b,c,d

-

-

-

NOTE1a:

Although the JACK COVER (SD) can be left attached to the

main unit during the procedure, remove the JACK COVER

(SD) if it interferes with the operation.

NOTE1b:

During the procedure, be careful in handling the parts. Be

especially careful as the edge of the tilted MONITOR ASSY

could damage the UPPER CASE surface.

NOTE1c:

Be sure to attach the COVER (HIN) ASSY firmly so that

there is no gap or lift between the parts.

NOTE2a:

When attaching the LOWER CASE ASSY (S3), be careful

not to catch the FPC (MIC) in between.

NOTE2b:

Be sure to attach the LOWER CASE ASSY firmly so that

there is no gap or lift between the parts.

NOTE4:

To remove the OPE UNIT, pull out the FPC from the connector, release the SWITCH (TRIG), and then slide the

SWITCH (ZOOM) toward the OP BLOCK.

NOTE5a:

During the procedure, be careful in handling the parts.

Be very careful not to break the FPC.

When attaching, the FRONT ASSY, be careful in handling

the WIRE (MIC).

NOTE5b:

When the FRONT ASSY is removed, be careful not to bend

or damage the exposed FPC (HINGE).

NOTE5c:

Refer to Fig.3-2-12 and the procedures that follow for disassembly of FRONT ASSY.

NOTE6:

During the procedure, be careful in handling the SD

SLOT(s).

Loading too much weight on the SD SLOT(s) or the SD

BOARD ASSY/NAND BOARD ASSY may cause soldering

points peel off.

NOTE7a:

During the procedure, be careful in handling the parts.

Be very careful not to bend or deform the SHIELD (HDD).

NOTE7b:

To attach the SHIELD, insert the SHIELD between the

REAR BOARD ASSY and the OP HOLDER.

NOTE8a:

During the procedure, be careful in handling the parts.

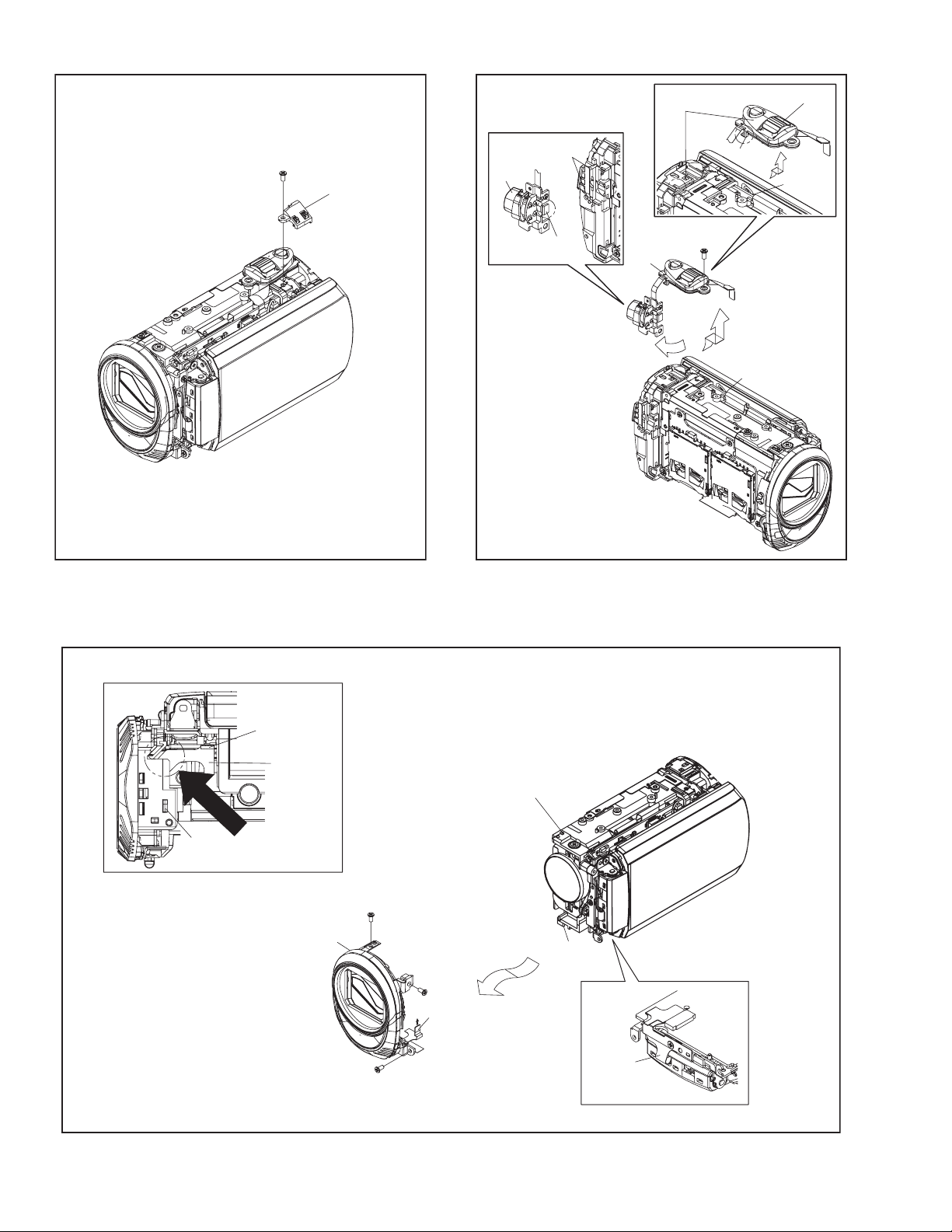

Disassembly procedure

(1) Remove the 2 screws (24, 25).

(2) Turn open the OP BLOCK ASSY from the bottom as

shown in the figure, and pull out the FPCs.

(3) When the OP BLOCK ASSY is turned 90°, lift and re-

lease the OP BLOCK ASSY from the HOOK (L8b),

and then slide and pull out the STUD (L8c).

(4) Pull out each FPC from the connectors (CN8a, b) in

turn.

NOTE8b:

To attach the OP BLOCK ASSY, insert the FPCs (OP

BLOCK ASSY) into the gap between the HOLDER (OP) before connecting the FPCs to the connector.

NOTE8c:

Refer to Fig. 3-2-15 and the procedures that follow for disassembly of OP BLOCK ASSY.

NOTE11a:

During the procedure, be careful in handling the FPC.

NOTE11b:

During the procedure, be careful not to damage the parts.

Be very careful in handling the SWITCH (MONI SW) lever as

it can easily be damaged.

When attaching the MAIN BOARD ASSY, leave the MONITOR ASSY open to prevent the lever from being damaged.

NOTE11c:

Refer to Fig. 3-2-17 and the procedures that follow for disassembly of UPPER ASSY.

NOTE12:

During the procedure, be careful not to touch the shutter

opening. Opening the shutter during the procedure is recommended.

NOTE16a:

Replace the CCD IMAGE SENSOR as a CCD BASE ASSY,

not as a single part replacement.

For replacement procedure, a 17W soldering iron with the tip

°

temperature around 330

centigrade is recommended.

(No.YF335<Rev.001>)1-17

Page 18

NOTE16b:

When removing the CCD BASE ASSY, be careful in handling as the CCD IMAGE SENSOR may be removed together with the SHEET and the OP LPF attached.

NOTE16c:

Be careful with the attachment direction of the OP LPF.

NOTE17a:

During the procedure, be careful with the wiring of the FPC.

Be very careful not to bend or damage the FPC.

NOTE17b:

To attach the MONITOR ASSY, first, set the screws L17b

and 2 × L17c to the correct positions. Next, tighten the screw

40 first, and then tighten the screw 39.

NOTE17c:

Refer to 3.2.3 DISASSEMBLY OF Disassembly of [17]

MONITOR ASSY.

NOTE18a:

During the procedure, be careful in handling the parts.

NOTE18b:

During the procedure, hold the outer rim of the SPEAKER.

NOTE18c:

When attaching the SPEAKER, be careful so that the

SPEAKER terminal and the BKT (SPK) do not contact.

NOTE18d:

When attaching the SPEAKER, be careful in handling the

WIRE (SPK).

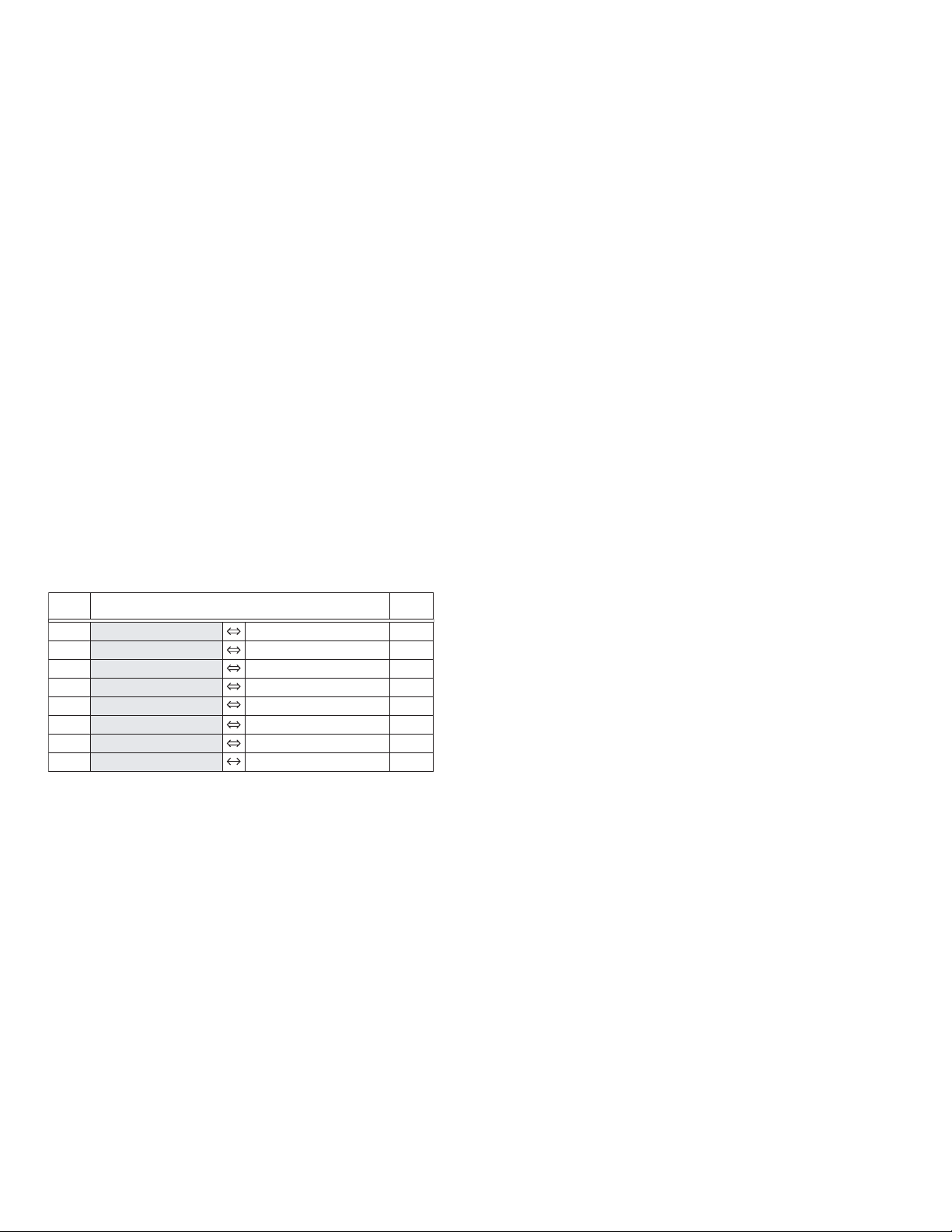

z Destination of connectors

CN.

No.

CONNECTOR

PIN

No.

CN4 MAIN CN104 OPE UNIT - 6

CN5 MAIN CN211 MIC

- 6

CN6 SD CN851 MAIN CN102 40

CN8a MAIN CN4201 CCD CN5001 22

CN8b MAIN CN106 OP BLOCK ASSY - 25

CN9 REAR CN601 MAIN CN103 45

CN11a MAIN CN101 MONITOR CN703 20

CN11b MAIN CN281 SPEAKER - 2

1-18 (No.YF335<Rev.001>)

Page 19

NOTE1a

[1]

L1f

(S1)

L1d

L1e

L1c

L1b

1

(S1)

2

(S1)

L1a

JACK COVER

3

(S1)

4

(S1)

NOTE1c

L1d

(SD)

NOTE1b

2

(S1)

1

4

(S1)

3

(S1)

Fig.3-2-1

NOTE2b

OK

Firmly attached hook Misaligned hook

HOOK

10

(S2)

9

(S2)

NOTE2a

NOTE2a

11

(S2)

NG

7

(S2)

(S2)

(S2)

8

(S2)

5

(S2)

6

(S2)

5

(S2)

[2]

L2a

6

(S2)

L2f

L2c

7

8

L2d

L2b

L2e

Fig.3-2-2

(No.YF335<Rev.001>)1-19

Page 20

12

(S3)

[3]

NOTE4

SW

(TRIG)

L4a

L4b

[4]

L4c

SW(ZOOM)

L4d

CN4

13

(S4)

CN4

NOTE5a

Fig.3-2-3 Fig.3-2-4

CN5

FPC(MIC)

L5b

L5a

NOTE5a

14

(S5a)

[5]

NOTE5c

L5a

15

(S5a)

FPC(MIC)

NOTE5a

NOTE5b

1-20 (No.YF335<Rev.001>)

16

(S5b)

FPC

(HINGE)

Fig.3-2-5

Page 21

19

(S6b)

17

(S6a)

20

(S6b)

(S6a)

18

[6]

NOTE6

21

(S7)

23

(S7)

NOTE7b

L7a

NOTE7a

[7]

NOTE7b

22

(S7)

L7b

L7c

NOTE6

[6]

CN6

L6

Fig.3-2-6 Fig.3-2-7

NOTE8b

FPC(OP BLOCK ASSY)

CN8b

MAIN BOARD ASSY

OP BLOCK ASSY

25

(S8)

21

(S7)

24

(S8)

[8]

NOTE8c

HOOK

(L8b)

FPC

CN8a

CN8b

a

b

a

b

25

(S8)

24

(S8)

STUD

(L8c)

Fig.3-2-8

NOTE8a

L8a

FPC

(No.YF335<Rev.001>)1-21

Page 22

26

(S9a)

26

(S9a)

27

(S9b)

CN9

L9

FPC

NOTE11a

CN11a

FPC

28

(S11)

CN11a

NOTE11b

S101

SW

(MONI SW)

29

(S11)

[11]

CN11b

27

(S9b)

[9]

L10a

Fig.3-2-9

FPC

FPC

30

(S12)

Fig.3-2-11

31

(S12)

L11a

L12

L11b

WIRE(SPK)

UPPER ASSY

NOTE11c

NOTE12

[12]

L10b

1-22 (No.YF335<Rev.001>)

Fig.3-2-10

[10]

Fig.3-2-12

Page 23

[13]

(S13)

L13a

32

35

(S15)

34

(S15)

HOLDER(OPSD)

ASSY

[14]

Fig.3-2-13

FPC

L13b

33

(S15)

[15]

FPC

FPC

0.118 Nm (1.2kgfcm)

Fig.3-2-15

FPC

Fig.3-2-14

(No.YF335<Rev.001>)1-23

Page 24

[15]

CCD BASE ASSY

NOTE16a,b

NOTE16b

OP LPF

NOTE16b,c

L16

SHEET

36

(S16)

[16]

37

(S16)

L16

0.147 Nm (1.5kgfcm)

NOTE17b

39

(S17b)

(S17a)

38

40

(S17b)

[17]

NOTE17c

NOTE17a

38

(S17a)

OP LPF

(OP LENS SIDE)

TRANSPARENT

(CCD BASE SIDE)

BLUE

NOTE16c

Fig.3-2-16

NOTE18c

BKT(SPK)

NOTE18b

41

(S18)

OK NG

NOTE18d

L18c

FPC

NOTE17a

NOTE17b

L17b

L17a

L17c

1-24 (No.YF335<Rev.001>)

L17a

FPC

[18]

NOTE18

a,b,c,d

L18a

UPPER CASE ASSY(SD)

UPPER CASE

ASSY(SD)

0.196 Nm (2.0kgfcm)

Fig.3-2-17 Fig.3-2-18

L18b

NOTE18c,d

WIRE(SPK)

L18a

L18b

NOTE18c

Page 25

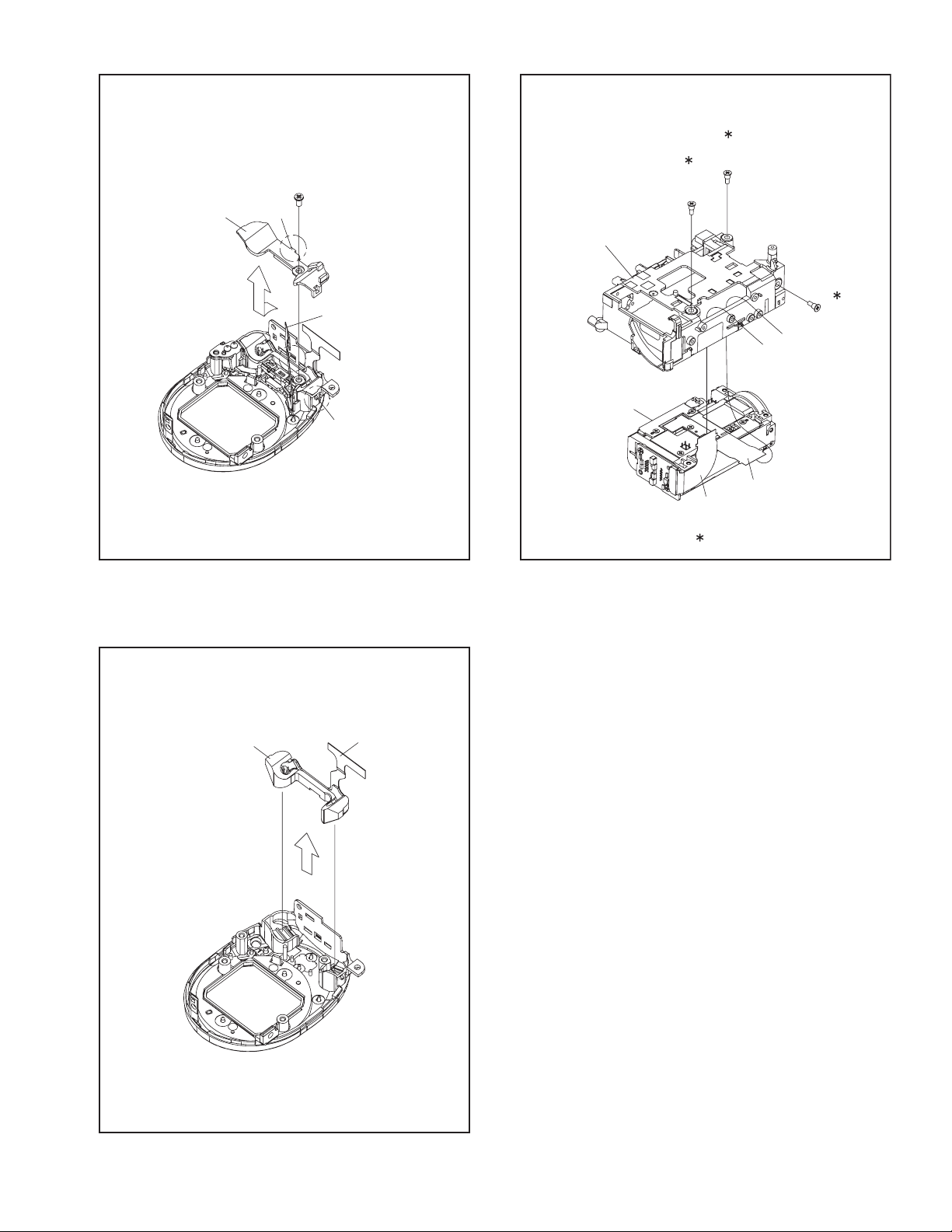

3.2.3 Disassembly of [17] MONITOR ASSY

zCAUTIONS

(1) During the procedure, be careful in handling the parts.

Be very careful not to damage or stain the LCD screen.

If fingerprints are left on the screen, wipe them off with

clean chamois leather or a cleaning cloth.

z Removing MONITOR ASSY

(1) Remove the 2 screws (1, 2).

Turn the HINGE UNIT ASSY 90°, and remove the 2 screws

(2)

(3, 4).

(3) Remove the MONI.COVER ASSY by releasing the 7

hooks (L17a-g).

(4) Release the lock of the connector (CN17a), and remove

the HINGE UNIT ASSY by lifting it up.

During the procedure, be careful in handling the FPC.

(5) Remove the MONITOR BOARD ASSY and the BRACK-

ET (LCD) as one unit.

(6) Release the lock of the connector (CN17b), and pull out

the FPC.

(7) Remove the 2 screws (5,6), and remove the MONITOR

BOARD ASSY .

(8) Refer to the drawing for disassembly of MONI SA.

NOTE17a:

MONI SA consists of the parts on both sides of the

LCD CASE.

On one side of the LCD CASE, the SHEET (BEF),

SHEET (M/DIFF), LIGHT GUIDE, and the SHEET

(M.REF) are assembled toward the MONITOR

BOARD ASSY. On the other side, the SHEET LCD,

LCD MODULE, and the SPACER LCD are assembled

in order between the LCD CASE and the BRACKET

(LCD).

NOTE17b:

During the procedure, be careful in handling the parts.

Be very careful not to damage the FPC.

NOTE17c:

To attach the SHEET (M/DIFF), insert the SHEET (M/

DIFF) under the ribs on the LCD CASE.

zRemoving HINGE UNIT ASSY

(1) Remove the HINGE COVER(U).

(2) Remove the HINGE COVER(L).

NOTE17d:

During the procedure, be careful in handling the FPC.

The FPC, with its connection to the MONITOR BOARD

ASSY facing inward, is rolled around the axis (shaft) of the

HINGE UNIT ASSY rotation 2.5 rounds (2.5times).

(3) Remove the MAGNET.

NOTE17e:

The FPC, with its connection to the MONITOR

BOARD ASSY facing inward, is rolled around the axis

(shaft) of the HINGE UNIT ASSY rotation 2.5 rounds

(2.5times).

During the procedure, be careful in handling the MAGNET.

When attaching, set the N pole outside as shown in

the figure. Be careful when removing as there is no

marking.

(No.YF335<Rev.001>)1-25

Page 26

:0.245 Nm (2.5kgfcm)

3

(S17b)

4

(S17b)

4

(S17b)

3

(S17b)

L17c

L17d

HINGE UNIT ASSY

L17j

L17e

L17h

L17g

L17f

1

(S17a)

MONITOR

COVER ASSY

2

(S17a)

NOTE17d

HINGE UNIT

HINGE UNIT

L17m

L17n

L17p

FPC

FPC

NOTE17d

FPC

L17m

L17n

L17p

L17q

L17r

L17q

HINGE COVER(U)

HINGE UNIT

NOTE17d

HINGE COVER(L)

L17r

MAGNET

NOTE17e

S

L17j

L17h

6

CN17a

L17k

CN17b

N

d

e

f

(S17a)

c

g

h

(S17a)

5

MONITOR

COVER ASSY

MONI SA

NOTE17a,b,c

a

b

j

NOTE17d

<OK> <NG>

1-26 (No.YF335<Rev.001>)

MONITOR CASE ASSY

Fig.3-2-19

Page 27

<MONITOR BOARD ASSY SIDE>

SHEET(B LIGHT)

<BKT(LCD) SIDE>

NOTE17c

c

d

ef

c

d

e f g h j

efg hj

v

w

x

u

g

h

j

a

b

ts

SHEET(M.REF)

a

b

LIGHT GUIDE

SHEET(M/DIFF)

SHEET(BEF)

BKT(LCD)

NOTE17b

r

q

MONI SA

NOTE17a

w

x

w

x

kmn

v

kmn

v

u

u

p

ts

p

ts

BKT(LCD)

r

q

SPACER LCD

LCD MODULE

SHEET LCD

LCD CASE

r

q

kmn

p

Fig.3-2-20

(No.YF335<Rev.001>)1-27

Page 28

SECTION 4

ADJUSTMENT

4.1 PREPARATION

4.1.1 Precaution

Camera system and deck system of this model are specially

adjusted by using PC.

However, if parts such as the following are replaced, an

adjustment is required. The adjustment must be performed in a

Service Center equipped with the concerned facilities.

• OP BLOCK ASSEMBLY

• MONITOR ASSEMBLY

• EEP ROM (IC1005 of MAIN board)

In the event of malfunction with electrical circuits, first find a

defective portion with the aid of proper test instruments as shown

in the following electrical adjustment procedure, and then

commence necessary repair/ replacement/adjustment.

• In observing chip TP, use IC clips, etc. to avoid any stress.

Prior to replacement of chip parts (especially IC), remove the

solder completely to prevent peeling of the pattern.

• Use a patch cord if necessary. As for a patch cord, see the

BOARD INTERCONNECTIONS.

• Since connectors are fragile, carefully handle them in

disconnecting and connecting the FPC.

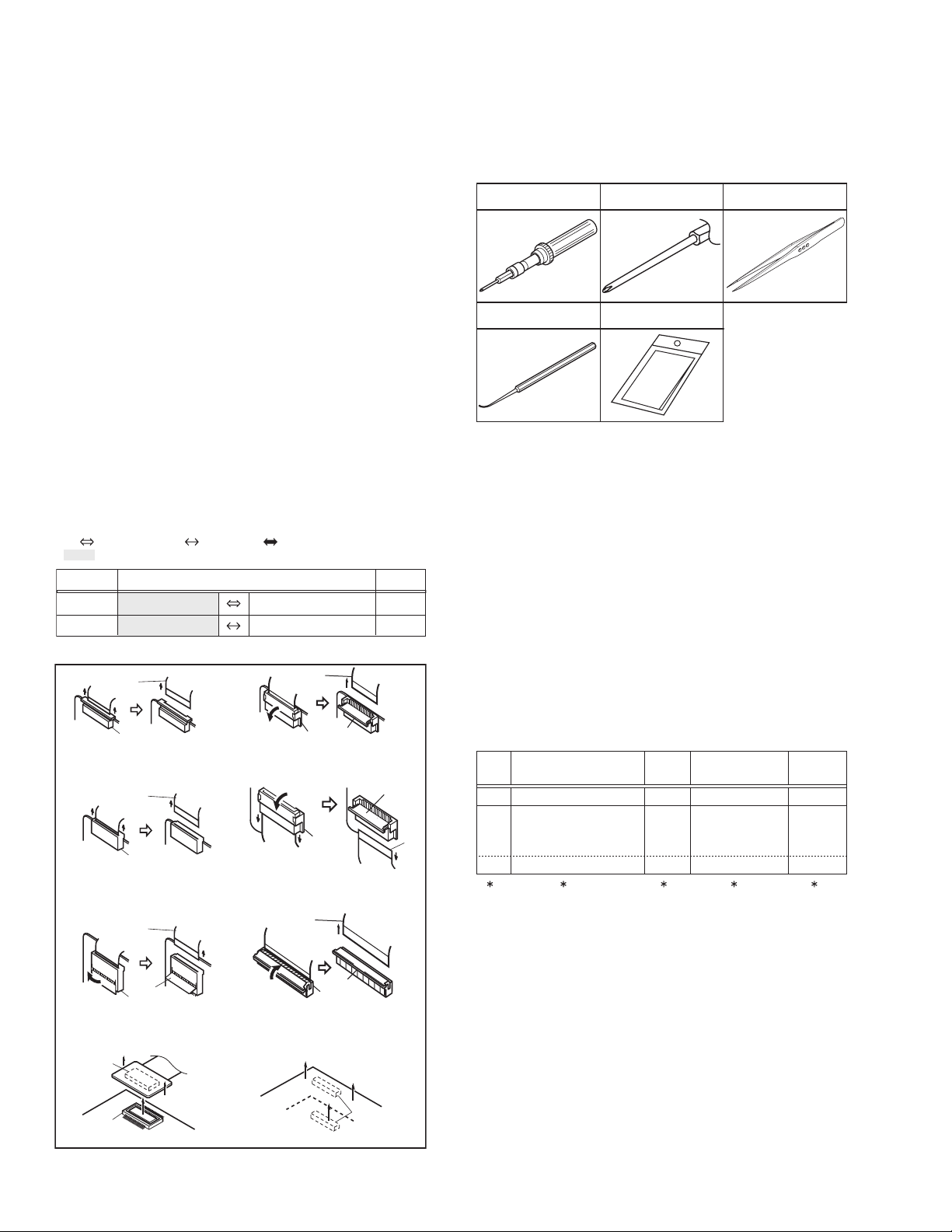

4.1.3 Tools required for adjustment

Torque Driver

YTU94088

Chip IC Replacement Jig

PTS40844-2

INF Adjustment Lens Holder

YTU94087

Bit

YTU94088-003

Cleaning Cloth

KSMM-01

Mini Stand

YTU93108

Tweezers

P-895

INF Adjustment Lens

YTU92001D

Light Box Assembly

YTU93096B

4.1.2 Required test equipment

• Personal computer (for Windows)

• Color TV monitor

• Oscilloscope (dual-trace type, observable 100MHz or higher

frequency). The one observable 300 MHz or higher frequency

is recommended.

• Digital voltmeter

• DC power supply or AC adapter

• Frequency counter (with threshold level adjuster)

Color Bar Chart

YTU94133C

Communication Cable

YTU93111-1

Jig Connector Cable

YTU93106B

Focus Chart

YTU92001-018

Conversion Connector

YTU94145K-20

Service Support System

YTU94057-122

PC Cable

QAM0099-005

Charing Battery Adjuatment Jig

YTU93112A

1-28 (No.YF335<Rev.001>)

Page 29

• Torque Driver

Be sure to use to fastening the mechanism and exterior parts

because those parts must strictly be controlled for tightening

torque.

• Bit

This bit is slightly longer than those set in conventional torque

drivers.

• Tweezers

To be used for removing and installing parts and wires.

• Chip IC Replacement Jig

To be used for adjustment of the camera system.

• Cleaning Cloth

Recommended the Cleaning cloth to wipe down the video

heads, mechanism (tape transport system), optical lens surface.

• INF Adjustment Lens

To be used for adjustment of the camera system. For the

usage of the INF adjustment lens, refer to the Service Bulletin

No. YA-SB-10035 and No. YA-SB-10223.

• INF Adjustment Lens Holder

To be used together with the Camera stand for operating the

Videocamera in the stripped-down condition such as the status without the exterior parts or for using commodities that are

not yet conformable to the interchangeable ring. For the usage

of the INF lens holder, refer to the Service Bulletin No. YA-SB-

10035.

• Mini Stand

To be used together with the INF adjustment lens holder. For

the usage of the Mini stand, refer to the Service Bulletin No.

YA-SB-10035.

• Light Box Assembly

To be used for adjustment of the camera system. For the

usage of the Light box assembly, refer to the Service Bulletin

No. YA-SB-10035 and No. YA-SB-10218.

• Color Bar Chart

To be used for adjustment of the camera system. For the

usage of the INF adjustment lens, refer to the Service Bulletin

No. YA-SB-10035.

• Focus Chart

To be used for adjustment of the camera system. For the

usage of the INF adjustment lens, refer to the Service Bulletin

No. YA-SB-10035.

• Service Support System

To be used for adjustment with a personal computer. Software

can be downloaded also from JS-net.

• Communication Cable

Connect the Communication cable between the PC cable and

Jig connector cable when performing a PC adjustment.

• PC Cable

To be used to connect the Videocamera and a personal computer

with each other when a personal computer issued for adjustment.

• Jig Connector Cable

Connected to JIG CONNECTOR of the main board and used

for electrical adjustment, etc.

• Conversion Connector

Conversion connector is used to convert the connector part of

the JIG connector cable.

• Charging Battery Adjustment Jig

This Jig is used for the adjustment of the camcorders that have

Main Body battery charging function.

(No.YF335<Rev.001>)1-29

Page 30

4.2 JIG CONNECTOR CABLE CONNECTION

4.2.1 Cautions

(1) Only 9 of 30pins of JIG CONNECTOR CABLE(PN:YTU93106B)

are extended with wires. Additional 2pins (13 and 28) need

to be soldered and extended with the wires for adjustment

and checking.

See Fig. 4-2-1 for details.

Connection procedure

·Remove the 4 screws (1-4), and then remove the COV-

ER(HIN) ASSY.

<COMPONENT SIDE>

29pin AL_2.83V

28pin IF_RX

26pin NOT USED

23pin NOT USED

22pin NOT USED

<FOIL SIDE>

13

1

COVER(HIN) ASSY

3

2

28

4

JIG CONNECTOR

JIG CONNECTOR CABLE

(MAIN CN110)

10

20

JIG CONNECTOR

1

11

CONVERSION CONNECTOR

SERVICE SUPPORT SYSTEM

Fig.4-2-1

13pin IF_TX

12pin NOT USED

10pin GND

9pin GND

8pin NOT USED

5pin NOT USED

: ADDITIONAL WIRE

COMMUNICATION

CABLE

JIG CONNECTOR

TO AL_2.83V

TO IF_RX

TO IF_TX

TO GND

COMMUNICATION

CABLE

BLUE

RED

WHITE

BLACK

or

PC CABLE

Fig.4-2-2

RS232C

COM PORT

MENU

PERSONAL COMPUTER

1-30 (No.YF335<Rev.001>)

Page 31

Jig connector diagrams

JIG CONNECTOR CABLE (YTU93106B)

MAIN CN110

DSP_RTCK

DSP_TMS

DSP_RST

XDSPTRST

REG_2.83V

OCD_SDA

SYS_RSTL

GND

DSP_TDI

GND

UA_RXD0

UA_TXD0

DSP_TCK

OCD_SCL

IF_RX

IF_TX

AL_2.83V

IRU

KENTO

DSP_TDO

ADDITIONAL WIRE

20

10

19

9

18

8

17

7

16

6

15

5

14

4

13

3

12

2

11

1

13. IF_TX

28. IF_RX

JIG CONN. BOARD

(PIN NO.)

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

-

AL_2.83V

IF_RX

-

-

-

-

-

-

NC

NC

NC

NC

NC

-

-

IF_TX

-

-

GND

GND

-

-

NC

NC

NC

NC

NC

4.3 ELECTRICAL ADJUSTMENT

Electrical adjustment is performed by using a personal computer

and software for SERVICE SUPPORT SYSTEM. Read

README.TXT file to use the software properly.

As for the connection of cables, see "4.2 JIG CONNECTOR

CABLE CONNECTION".

Conversion Connector

KENTO*

AL_2.83V

DSP_TCK*

UA_RXD0*

DSP_TDI*

SYS_RSTL*

REG_2.83V*

DSP_RST*

DSP_RTCK*

IF_RX

NC

NC

NC

NC

NC

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

Fig.4-2-3

11

12

13

14

15

16

17

18

19

20

10

DSP_TDO*

1

2

3

4

5

6

7

8

9

15

IRU*

14

IF_TX

13

OCD_SCL*

12

UA_TXD0*

11

GND

10

GND

9

OCD_SDA*

8

XDSPTRST

7

DSP_TMS*

6

NC

5

NC

4

NC

3

NC

2

NC

1

*

*NC

Fig.4-2-4

(No.YF335<Rev.001>)1-31

Page 32

5.1 SERVICE NOTE

3-2-10

3-2-6

SECTION 5

TROUBLE SHOOTING

-

a

3-2-5 3-2-83-2-7 3-2-9

3-2-3 3-2-4

3-2-163-2-15

a

-

-

[14][11] [13][12] [15] [16] [17] [18]

[1] [2] [4][3] [5] [6] [7] [8] [9] [10]

CABINET PARTS AND ELECTRICAL PARTS(1)

3-2-1 3-2-2

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 -

CABINET PARTS AND ELECTRICAL PARTS(2)

28 29 30 31 32 - 33 34 35 36 37 38 39 40 41

3-2-14 3-2-183-2-13

acdaab

3-2-123-2-11 3-2-17

[17]

[17]MONITOR ASSY

Prepare the specified screws and use them in place of the removed screws.

aae

3-2-19

1 2 3 4 5 6

Symbol No.

Place to stick screw

Removing order of screw

1-32 (No.YF335<Rev.001>)

Screw tightening torque

Reference drawing (Fig.No.)

Symbol No.

Place to stick screw

Removing order of screw

Screw tightening torque

Reference drawing (Fig.No.)

Symbol No.

Place to stick screw

Removing order of screw

Screw tightening torque

Reference drawing (Fig.No.)

and tighten the screw manually.

The specified torque value is a recommended value of the initial assembly. Therefore, set the value below the specified torque value in the assembling procedure.

There are setting limits of the torque value for the torque driver. If the value exceeds the setting value, take it as a rough measurement (reference value),

㧞)Tightening torque for the screws

㧝)㧖and㧖㧖 (This mark shows where to attach the screws) : Do not reuse the screws because the screw lock bond was applied to prevent the screws from loosening.

NOTE:

Be careful not to break either the screws or the screw holes.

a㧦0.088N㨯m (0.9kgf㨯cm) b㧦0.118N㨯m (1.2kgf㨯cm) c㧦0.147N㨯m (1.5kgf㨯cm) d㧦0.196N㨯m (2.0kgf㨯cm)

e㧦0.245N㨯m (2.5kgf㨯cm)

Page 33

Victor Company of Japan, Limited

Digital Imaging Products Business Division Imaging Products Operation 12, 3-chome, Moriya-cho, Kanagawa-ku, Yokohama-city, Kanagawa-prefecture, 221-8528, Japan

(No.YF335<Rev.001>)

Printed in Japan

VSE

Page 34

SCHEMATIC DIAGRAMS

30

CAMCORDER

GZ-MS110BEK GZ-MS110BEU

(No.YF335<Rev.001>)1/

Page 35

■ PRECAUTIONS ON SCHEMATIC DIAGRAMS

z Due to the improvement in performance, some part numbers shown in the circuit diagrams

may not agree with those indicated in the Parts List.

z The parts numbers, values and rated voltage etc. in the Schematic Diagrams are for

reference only.

z Since the circuit diagrams are standard ones, the circuits and circuit constants may be

subject to change for improvement without any notice.

■ PRECAUTIONS ON PARTS LIST

z

The parts identified by the symbol are critical for safety. Whenever replacing these parts, be sure to

use specified ones to secure the safety.

z

The parts not indicated in this Parts List and those which are filled with lines --- in the Parts No.

columns will not be supplied.

z

P.W. BOARD Ass'y will not be supplied, but those which are filled with the Parts No. in the Parts No.

columns will be supplied.

z

When ordering chips, screws etc., place bulk orders (unit of tens) whenever possible to improve

shipping efficiency.

z

There are cases where the actual implemented parts in the sets and the service parts are different.

When ordering parts, make sure to refer to the Parts List.

■

PRECAUTIONS ON SERVICE

Certain parts of the power circuits and the GNDs differ according to the models. Care must be

taken for the following points as the differences are indicated separately in the LIVE GND ( ) and

the ISOLATED (NEUTRAL) GND ( ).

1. Do not touch the LIVE GND, or do not touch the LIVE GND and the ISOLATED (NEUTRAL)

GND at the same time. It may cause an electric shock.

Before pulling out the chassis or other parts, make sure to pull out the power cord from the

wall outlet first.

2. Do not short circuit between the LIVE GND and ISOLATED (NEUTRAL) GND, or never

measure the LIVE GND and ISOLATED (NEUTRAL) GND at the same time using measuring

instruments (oscilloscope, etc.). It may blow fuses or damage other parts.

■ DEVIATION TOLERANCE RANGE

DEVIATION TOLERANCE RANGE

F G J K M N R H Z P

± 1% ± 2% ± 5% ±10% ±20% ±30%

+30%

-10%

+50%

-10%

+80%

-20%

+100%

-0%

30

(No.YF335<Rev.001>)2/

Page 36

MONITOR60

SD40

MAIN10

REAR

50

CCD20

REG+CCD

REG

REG+CCD

AUDIO

MONI RGB

CN102/SD PWB

MAIN IF

ELISE

CPU

AU_SIG/LR

SPK+

CN281/SPEAKER

REG

CN211/MIC

AUDIO

CN103/REAR

MONI RGB

CN101/MONITOR

ELISE

AUDIO

LITHIUM

MONI SW

REG

ELISE

CN103/REAR

BATT+

CN103/REAR

CN101/MONITOR

CN110/JIG

CN104/OPE UNIT

OP DRV

ELISE

AUDIO

CPU

MAIN IF

CN101/MONITOR

AEF/TG

OP DRV

ELISE

AUDIO

CN101/MONITOR

ELISE

CN4201/CCD

AEF/TG

REG

REG+CCD

CN110/JIG

CN103/REAR

MAIN IF

CPU

CPU

CPU

CN104/OPE UNIT

CN106/OP BLOCK

REG

CN103/REAR

MAIN IF

CN110/JIG

CN101/MONITOR

LCD_RGT/DWN

ELISE

ELISE

AEF/TGOP DRV

ELISE

REG

CN101/MONITOR CN110/JIG

CN103/REAR

CPU

CPU

AEF/TG

CDS/TG

OPDRV

MAIN IF

REG

CPU ELISE

AEF/TG

CPU

CN4201/CCD

ELISE

REG

ELISE

CPU

CN106/OP BLOCK

OP DRV

HGVCC+

HGOUT+

DRIVE+

JIG CONNECTOR

MIC

LCD MODULE

LED LED

USB

DC

AV JACK

BATTERY TERMINAL

OPE UNIT

TRIG

PHOTO

ZOOM

T

W

SPEAKER

OP BLOCK

AUDIO_CLK

GOUT

REG_2.83V

GND

BOUT

ROUT

REG_8.5V

GIN

RIN

XDSPTRST

AUDIO_CS

AUDIO_OUT

IR_DC

IR_DC

VIDEO_PS

REG_2.83V

REG_1.8V

GND

REG_4.9V

REG-7.5V

AL_2.83V

UNREGCHK

V_BATT

REG_D_IN

REG_CS

REG_D_OUT

REG_RSTL

REG_CLK

DC_CHECK

ADP_L

CH3_CTL

I_MTR

CHRG_EVR

REG_8.5V

F_PTR_AD

Z_PTR_AD

OP_THRMO

GND

REG_2.83V

V_BATT

TRIG_SW

I_MTR

REG_RSTL

KEY_B

CH3_CTL

REG_CS

REG_D_OUT

DC_CHECK

ADP_L

REG_D_IN

UNREGCHK

AL_2.83V

ZOOM_SW

LIT_2.8V

REG_CLK

CHRG_EVR

PWR_LED

ACES_LED

KEY_A

MONI_SW

KENTO

PWR_SW

T_BATT

P_DET

BATT_L

D_BATT

OCD_SCL

OCD_SDA

M_RVS

SYS_RSTL

IF_TX

IF_RX

IRU

LCD_XDSG_CPU

BUZZER

L_MUTE

ADDT15

ADDT14

ADDT13

ADDT12

ADDT11

ADDT10

ADDT09

ADDT08

ADDT07

ADDT06

ADDT05

ADDT04

ADDT03

ADDT02

ADDT01

ADDT00

XDSPTRST

DSP_RST

MOD0

CDWE

CDAS

CDRE

VDIN

OMT

MFLD

MVD

INT_TO_CAM

DSP_CS

FLSH_RST

TVSEL

VBUS1DET

SDWP

REG_DCHG

EEP_CS_INT

EEP_IN

EEP_OUT

EEP_CLK

CDSTG_RST

CAM_CLK

CAM_OUT

CDSTG_CS

OPDRV_RST

VD_FZ

OPDRV_OUT

OPDRV_IN

OPDRV_CLK

OPDRV_CS

REG_1.05V

REG_2.83V

GND

REG_4.9V

BL_CTL

LCD_STH

LCD_ENB

LCD_CKH2

LCD_STV

LCD_CKV

LCD_CKH1

DSP_TCK

LCD_DSG

DSP_TDI

DSP_TDO

DSP_TMS

DSP_RTCK

ADDT01

ADDT02

ADDT13

ADDT10

ADDT14

ADDT00

ADDT04

ADDT15

ADDT03

ADDT09

ADDT06

ADDT11

ADDT05

ADDT08

ADDT07

ADDT12

VBUS1

USBDP

USBDN

REG_1.8V

REG_DCHG

CDWE

TVSEL

DSP_CS

CDAS

CDRE

OMT

MFLD

MVD

VIDEO_PS

FLSH_RST

DSP_RST

VDIN

HDIN

MCLKI

ACHI11

ACHI10

ACHI9

ACHI8

ACHI7

ACHI6

ACHI5

ACHI4

ACHI3

ACHI2

ACHI1

ACHI0

MCLKI

SDWP1

VDIRS

CLK27O

SDDAT1

SDDAT0

SDDAT3

SDDAT2

SDCD1

SDCMD1

SDCLK1

USB_SEL

UA_RXD0

UA_TXD0

DA_AOUT_ENCO

GIN

BIN

RIN

AIBD

AOBD

AIOLRCK

AIOBCK

AOMCLK

INT_TO_CAM

EEP_IN

EEP_CS_INT

EEP_OUT

EEP_CLK

MOD0

SD_WP

GND

REG_2.83V

USB_SEL

AL_2.83V

VBUS1DET

MCLKI

MONI_SW

CDSTG_RST

HDIN

CAM_CLK

CDSTG_CS

CAM_OUT

VDIN

GND

REG_2.83V

REG-7.5V

REG-CCD

V2H2V5

V6

SUB

H1

V1RGV4

V3

CCD_OUT

ACHI5

ACHI8

UNREG

ACHI10

ACHI7

ACHI2

BATT_CHK

ACHI4

ACHI3

VADP

REG_1.05V

MCLKI

ACHI6

GBAT

ACHI0

GADP

ACHI9

ACHI11

ACHI1

GND

REG_4.9V

REG_2.83V

VDIRS

CLK27O

OPDRV_OUT

OPDRV_CLK

OPDRV_CS

VD_FZ

OPDRV_IN

OPDRV_RST

HGVSS-

FOCUS03

HGOUT-

ZOOM01

ZOOM03

Z_LED

FOCUS04

FOCUS02

ZOOM04

F_VCC

DRIVE-

F_LED

ZOOM02

FOCUS01

Z_VCC

LCD_PSIG

BIN

GND

LCD_COM

AUDIO_OUT

REG_4.9V

INT_L

AIOBCK

AUDIO_CLK

AOBD

SPK-

AIOLRCK M_GND

L_MUTE

DA_AOUT_ENCO

AOMCLK

V_OUT

AIBD

AUDIO_CS

BUZZER

REG_2.83V

VBUS145

GND44

USBDN43

USBDP42

GND41

ACES_LED40

PWR_LED39

AL_2.83V38

REG_2.83V37

KEY_A36

BATT_L35

D_BATT34

T_BATT33

BATT_CHK32

BATT+31

BATT+30

BATT+29

BATT+28

BATT+27

UNREG26

UNREG25

UNREG24

UNREG23

UNREG22

UNREG21

UNREG20

UNREG19

UNREG18

UNREG17

GADP16

GBAT15

VADP14

PWR_SW13

GND12

GND11

GND10

GND9

GND8

GND7

GND6

AU_SIG/LR5

AU_SIG/LR4

GND3

V_OUT2

P_DET1

CN103

QGF0534F2-45X

COM 24

CS 23

VST 22

VCK 21

EN 20

DWN 19

VDD 18

VSS 17

NC 16

VSSG 15

XSTBY 14

PCG 13

HST 12

REF 11

TEST1 10

NRW 9

HCK2 8

HCK1 7

PSIG 6

GREEN 5

RED 4

BLUE 3

RGT 2

TEST2 1

CN701

QGF0534F2-24X

22212019181716151413121110

987654321

CN5001

QGF0543F3-22X

GND22

GND21

H120

H219

SUB18

RG17

CCD_CTL16

V615

V514

V413

V212

V311

V110

REG-CCD9

REG+CCD8

GND7

GND6

GND5

CCD_OUT4

GND3

GND2

GND1

CN4201

QGF0543F3-22X

2019181716151413121110

987654321

CN703

QGF0534F2-20X

GND 20

M_RVS 19

REG_2.83V 18

LCD_PSIG 17

LCD_CKH1 16

LCD_CKH2 15

REG_8.5V 14

LCD_STH 13

LCD_DSG 12

LCD_XDSG_CPU

11

LCD_RGT/DWN

10

LCD_ENB 9

LCD_CKV 8

VCD_STV 7

LCD_COM 6

BL_CTL 5

BOUT 4

ROUT 3

GOUT 2

REG_4.9V 1

CN101

QGF0534F2-20X

REG_2.83V 18

REG_2.83V 17

SDCMD1 16

SDCD1 15

SDDAT2 14

SDWP1 13

SDDAT3 12

GND 11

SDDAT0 10

GND 9

SDDAT1 8

GND 7

GND 6

SDCLK1 5

GND 4

GND 3

LIT_2.8V 2

GND 1

CN102

QGF0543F3-18X

181716151413121110

987654321

CN851

QGF0543F3-18X

GND6

HALF_SW5

FULL_SW4

REG_2.83V3

ZOOM_SW2

TRIG_SW1

CN104

QGF0534F3-06X

M_GND 6

M_GND 5

M_GND 4

INT_L 3

M_GND 2

M_GND 1

CN211

QGF0543F3-06X

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

QGF0566C1-45X

CN601

ZOOM0225

ZOOM0324

ZOOM0423

ZOOM0122

F_VCC21

F_LED20

F_PTR_AD19

OP_THRMO18

GND17

DUMP+16

HGVCC+15

HGOUT+14

DRIVE+13

DRIVE-12

HGVSS-11

HGOUT-10

DUMP-9

GND8

FOCUS027

FOCUS036

FOCUS045

FOCUS014

Z_VCC3

Z_LED2

Z_PTR_AD1

QGF0543F3-25X

CN106

DSP_RTCK 20

DSP_RST 19

REG_2.83V 18

SYS_RSTL 17

DSP_TDI 16

UA_RXDO 15

DSP_TCK 14

IF_RX 13

AL_2.83V 12

KENTO 11

DSP_TMS 10

XDSPTRST 9

OCD_SDA 8

GND 7

GND 6

UA_TXDO 5

OCD_SCL 4

IF_TX 3

IRU 2

DSP_TDO 1

QGB0519J1-20X

CN110

SPK-2

SPK+1

QGA1001F1-02X

CN281

<BOARD INTERCONNECTIONS>

**<FPC or WIRE - 03 -WR1>

(**) indicates the block No. and symbol No. of the WIRE or the FPC.

NOTES: The number of patch cords (*) are indicated by interconnected.

Symbol No.

Block No.

yf335_y10878001a_ver0.1

*

YTU94077-6

YTU94074-6

<FPC-M1-604>

**

*

YTU94077-22

YTU94074-22

<FPC-M1-102>

**

YTU94077-24

YTU94074-24

<FPC-M1-327>

**

*

YTU94077-20

YTU94074-20

*

*

YTU94077-6

YTU94074-6

<FPC-M1-101>

**

*

YTU94077-18

YTU94074-18

created date:2010-02-19No.YF335

30

(No.YF335<Rev.001>)3/

Page 37

SW

Q6701

REG

Q6604

SW

Q6601

Q6404

Q6401

SW

Q601

ADP_L

LOUT82

DOUT22

GADP

GBAT

OUT6

IC6001

DOUT1

LOUT5

OUT4

BATT+

VADP

VPIN22

VPIN32

VPIN5

VPIN82

CH1VDD

VPIN1

OUTA7

VPIN21

PVDD

VPIN31

VPIN81

AVDD

<POWER SYSTEM BLOCK DIAGRAM>

AL_2.83V

REG_2.83V

REG_1.8V

REG_2.83V

BATT+

VADP

BATT_CHK

VADP

REG_1.05V

REG_2.83V

REG_2.83V

LIT_2.8V

REG_2.83V

REG_2.83V

REG_4.9V

REG_2.83V

ADP_L

V_BATT

REG_4.9V

AL_2.83V

REG_2.83V

F_VCC

Z_VCC

REG_2.83V

T_BATT

REG_4.9V

REG_2.83V

REG_4.9V

V_BATT

REG-7.5V

REG+CCD

REG-CCD

REG+CCD

LIT_2.8V

REG+CCD

REG_4.9V

REG_4.9V

REG_2.83V

REG_2.83V

LIT_2.8V

AL_2.83V

REG_2.83V

[-]

AL_2.83V

REG_2.83V

UNREG

F601

GADP

GBAT

GADP

UNREG

ACES_LED

PWR_LED

2

KEY_A

PWR_SW

UNREG

GBAT

BATT+

F602

VBUS1

UNREGCHK

-

REG-7.5V

AL_2.83V

BATT+

BATT_L

REG_2.83V

REG_8.5V

REG_2.83V

REG_8.5V

ADP_L

REG_8.5V

REG+CCD

REG_4.9V

REG_2.83V

REG_1.8V

REG_1.05V

[-]

[D]

[T]

[+]

BT602

SDREG2.83V

4

CN852

LIT_2.8V

REG_2.83V

REG_2.83V

D_BATT

REG_8.5V

REG_8.5V

REG_2.83V

REG_4.9V

REG_4.9V

BATT_L

D_BATT

T_BATT

BATT+/

BATT_CHK

SD/MMC

CONNECTOR

18

JIG CONNECTOR

12

CN110

3

LITTIUM

BATTERY

CN104

172

REG_1.05V

317

OPE UNIT

218

REG_1.8V

CN851CN102

REG_2.83V

REG_4.9V

ELISE

183

REG_2.83V

14

7

18

VDD

REG_2.83V

CN701

VDD

REG_2.83V

REG+CCD

120

REG_4.9V

REG_4.9V

CN101CN703

LCD MODULE

MONI RGBAUDIO

4040

3939

RED

GREEN

D612D611

3838

3737

LIT_2.8V

D603

POWER SWMOVIE/STILL

REG_8.5V

S694S693

REG_4.9V

REG_2.83V

3636

1313

PLAY/REC

MAIN IF

S691

UPLOAD/TITLE

S692

4545

1

J611

REG_2.83V

USB CONNECTOR

REG_4.9V

ADP_L

212

3

T_BATT

35351

CN106

34343

OP DRV

V_BATT

3333

4

3232

5

D_BATT

3131

BT601

BATT_L

BATTERY

TERMINAL

2727

UNREGCHK

1515

REG_2.83V

2626

1

REG_2.83V

LIT_2.8V1717

REG+CCD

REG-7.5V

AL_2.83V

4

1616

3

J602

REG-CCD

99

DC JACK

REG+CCD

88

CPU

1414

CN5001CN4201

AEF/TGREG

CN103CN601

OP BLOCK

0 6

MONITOR

0

4

SD

0 2

CCD

0 1

MAIN

0

5

REAR

created date:2010-02-19No.YF335

30

(No.YF335<Rev.001>)4/

Page 38

MDA

FOCUS/ZOOM

IC4901

AEF/TG

IC4201

(64M)

FLASH ROM

IC3003

(512M)

SDRAM

IC3002

(DSP)

ELISE

IC3001

DSP

VIDEO/AUDIO

IC2201

RTC

IC1006

EEPROM

IC1005

CPU

IC1001

SD CARD

MIC IN

(MONO)

(27MHz)

USB CONNECTOR

SD

4

0

SPEAKER

OP BLOCK

0 6

MONITOR

0

5

REAR

0 1

MAIN

0 2

CCD

(1/6 inch)

CCD

MIC IN

L/R OUT

V OUT,

R/G/B

X4202

(48MHz)

X3001

(32.768kHz)

X1002

(20MHz)

X1001

LCD MODULE

J611

J601

AV JACK

IC5001

<VIDEO/AUDIO SYSTEM BLOCK DIAGRAM>

created date:2010-02-19No.YF335

30

(No.YF335<Rev.001>)5/

Page 39

MAIN(MAIN IF)10

USB SELECT

MONI SW

192~195

SYMBOL NO. 191~

VACANT NO. VACANT NO.

166~168R 198

LAST NO.

R

101

VACANT NO.

SYMBOL NO. 101~

LAST NO.

J

LAST NO.

105,106,108

SYMBOL NO. 161~

ONBOARD CONTACT

D162Q

C

111CN

162

169

191

LIT_2.8V

UNREG

T_BATT

ZOOM_SW

V_OUT

TRIG_SW

KEY_B

BATT_L

P_DET

ACES_LED

PWR_LED

GBAT

GADP

VADP

VBUS1

D_BATT

USBDN

GND

SDWP1

XDSPTRST

REG_2.83V

GND

REG_2.83V

SDCD1

SDDAT1

SDDAT3

AL_2.83V

SDCMD1

GND

AL_2.83V

GND

SDCLK1

LCD_CKH1

REG_8.5V

LCD_CKH2

LCD_PSIG

LCD_STV

LCD_DSG

LCD_RGT/DWN

BL_CTL

LCD_XDSG_CPU

LCD_STH

LCD_ENB

LCD_COM

LCD_CKV

GOUT

BOUT

ROUT

AU_SIG/LR

BATT_CHK

REG_2.83V

REG_2.83V

KENTO

PWR_SW

IRU

SDDAT0

IF_RX

DSP_RST

UA_RXD0

UA_TXD0

GND

IF_TX

REG_2.83V

DSP_RTCK

M_RVS

AL_2.83V

OCD_SCL

SYS_RSTL

DSP_TMS

DSP_TDO

OCD_SDA

DSP_TCK

DSP_TDI

REG_4.9V

SDDAT2

USB_SEL

REG_2.83V

GND

GND

USBDP

MONI_SW

GND

KEY_A

BATT+

!

!

sure to use the specified one.

When replacing those parts make

Parts are safety assurance parts.!

OPEN

NNZ0194-001X

TP6

OPEN

NNZ0194-001X

TP7

43

21

NSW0322-001X

S101

1k

R601

47k

R302

OPEN

R301

OPEN

R184

OPEN

R185

0Ω

R181

3

2

1

OPEN

D601

3

2

1

OPEN

D181

OPEN

D602

MA111-X

D603

OPEN

D604

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19