Page 1

SERVICE MANUAL

HARD DISK CAMCORDER

YF16320068

GZ-MG47EX, GZ-MG47EY,

GZ-MG47EZ, GZ-MG57AA,

GZ-MG57AC, GZ-MG57AG,

GZ-MG57AH, GZ-MG57AS,

GZ-MG57EK, GZ-MG57EX,

GZ-MG57EY, GZ-MG57EZ

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

1 PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

5 TROUBLE SHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

COPYRIGHT © 2006 Victor Company of Japan, Limited

TABLE OF CONTENTS

GZ-MG47EXM, GZ-MG47EYM, GZ-MG47EZM [M6E355],

GZ-MG47EXM, GZ-MG47EYM, GZ-MG47EZM [M6E355],

GZ-MG57AAM, GZ-MG57ACM, GZ-MG57AGM,

GZ-MG57AAM, GZ-MG57ACM, GZ-MG57AGM,

GZ-MG57AH, GZ-MG57AS, GZ-MG57EKM,

GZ-MG57AH, GZ-MG57AS, GZ-MG57EKM,

GZ-MG57EXM, GZ-MG57EYM, GZ-MG57EZM [M6E357]

GZ-MG57EXM, GZ-MG57EYM, GZ-MG57EZM [M6E357]

No.YF163

2006/8

Page 2

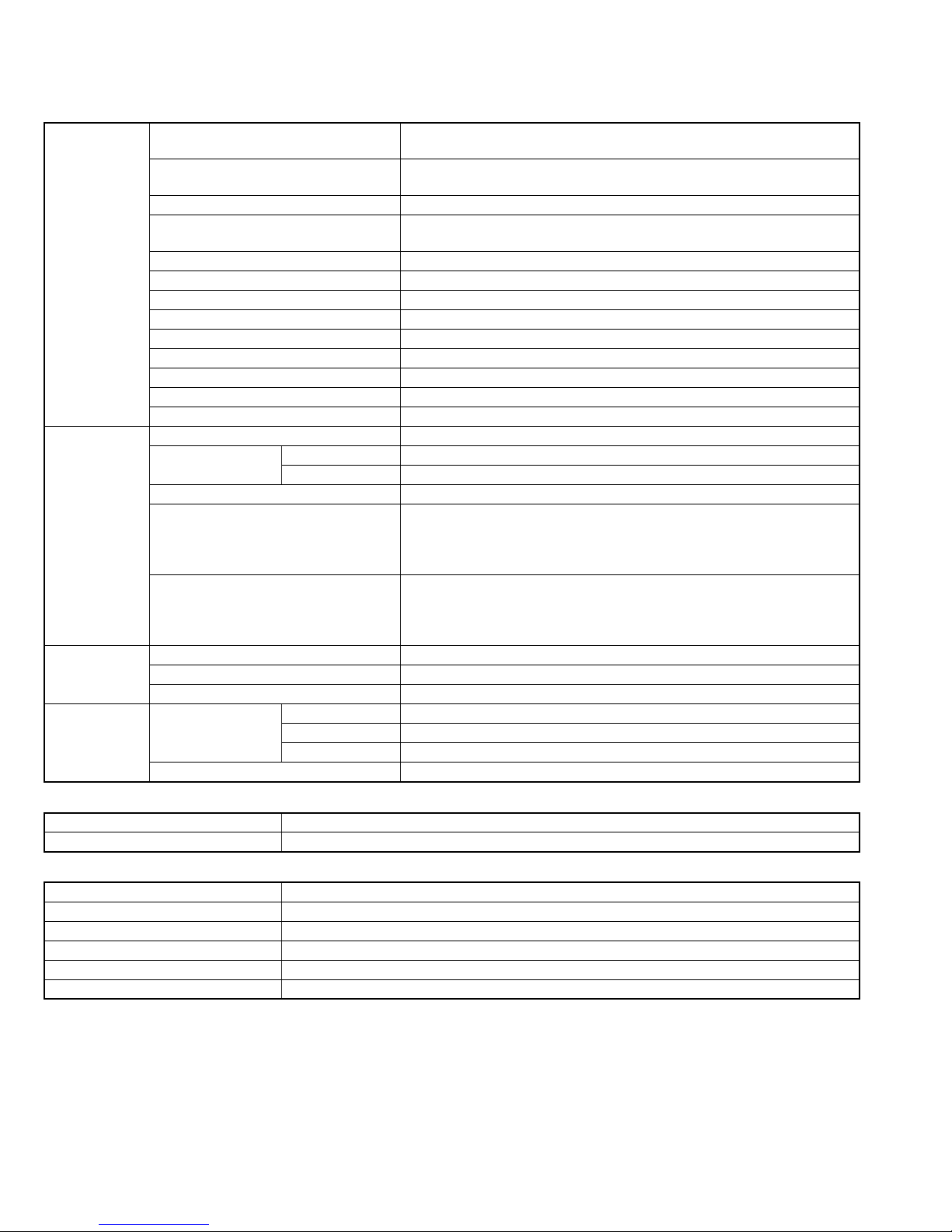

SPECIFICATION

Camcorder

For General Power supply DC 11 V (Using AC Adapter)

DC 7.2 V (Using battery pack)

Power consumption Approx. 3.9 (4.1)* W

* When using the LED light

Dimensions (W × H × D) 68 mm × 69 mm × 109 mm

Weight Approx. 340 g (without battery, lens cap and strap)

Approx. 400 g (incl. battery, lens cap and strap)

Operating temperature 0°C to 40°C

Operating humidity 35% to 80%

Storage temperature -20°C to 50°C

Pickup 1/6" (800,000 pixels) CCD

Lens F 2.0 to 4.5, f = 2.3 mm to 73.6 mm, 32:1 power zoom lens

Filter diameter Ø30.5 mm

LCD monitor 2.7" diagonally measured, LCD panel/TFT active matrix system

Speaker Monaural

Flash Within 1.5 m (recommended shooting distance)

For Video/Audio Format SD-VIDEO

Recording/Playback

format

Signal format PAL standard

Recording mode (video) ULTRA FINE: 720 × 576 pixels, 8.5 Mbps (VBR)

Recording mode (audio) ULTRA FINE: 48 kHz, 384 kbps

For Still image Format JPEG

Image size One mode (640 × 480)

Picture quality 2 modes (FINE/STANDARD)

For Connectors AV S-Video output Y:1.0 V (p-p), 75Ω, analogue, C:0.29V (p-p), 75Ω, analogue

USB Mini USB type A and B, USB 2.0 compliant

Video MPEG-2

Audio Dolby Digital (2 ch)

FINE: 720 × 576 pixels, 5.5 Mbps (VBR)

NORMAL: 720 × 576 pixels, 4.2 Mbps (VBR)

ECONOMY: 352 × 288 pixels, 1.5 Mbps (VBR)

FINE: 48 kHz, 384 kbps

NORMAL: 48 kHz, 256 kbps

ECONOMY: 48 kHz, 128 kbps

Video output 1.0 V (p-p), 75 kΩ, analogue

Audio output 300 mV (rms), 1 kΩ, analogue, stereo

AC Adapter

Power requirement AC 110 V to 240 V~, 50 Hz/60 Hz

Output DC 11 V, 1 A

Remote Control

Power supply DC 3 V

Battery life Approx. 1 year (depending on the frequency of use)

Operating distance Within 5 m

Operating temperature 0°C to 40°C

Dimensions (W × H × D) 45 mm × 13 mm × 105 mm

Weight Approx. 40 g (incl. battery)

Design and specifications subject to change without notice.

1-2 (No.YF163)

Page 3

SECTION 1

r

PRECAUTIONS

1.1 SAFTY PRECAUTIONS

Prior to shipment from the factory, JVC products are strictly

inspected to conform with the recognized product safety and

electrical codes of the countries in which they are to be

sold.However,in order to maintain such compliance, it is equally

important to implement the following precautions when a set is

being serviced.

1.1.1 Precautions during Servicing

(1) Locations requiring special caution are denoted by labels

and inscriptions on the cabinet, chassis and certain parts of

the product.When performing service, be sure to read and

comply with these and other cautionary notices appearing

in the operation and service manuals.

(2) Parts identified by the symbol and shaded ( ) parts

are critical for safety.

Replace only with specified part numbers.

NOTE :

Parts in this category also include those specified to

comply with X-ray emission standards for products

using cathode ray tubes and those specified for

compliance with various regulations regarding

spurious radiation emission.

(3) Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as

specified.

(4) Use specified internal wiring. Note especially:

• Wires covered with PVC tubing

• Double insulated wires

• High voltage leads

(5) Use specified insulating materials for hazardous live parts.

Note especially:

• Insulation Tape

• PVC tubing

•Spacers

• Insulation sheets for transistors

•Barrier

(6) When replacing AC primary side components (transformers,

power cords, noise blocking capacitors, etc.) wrap ends of

wires securely about the terminals before soldering.

emission. Consequently, when servicing these products,

replace the cathode ray tubes and other parts with only the

specified parts. Under no circumstances attempt to modify

these circuits.Unauthorized modification can increase the

high voltage value and cause X-ray emission from the

cathode ray tube.

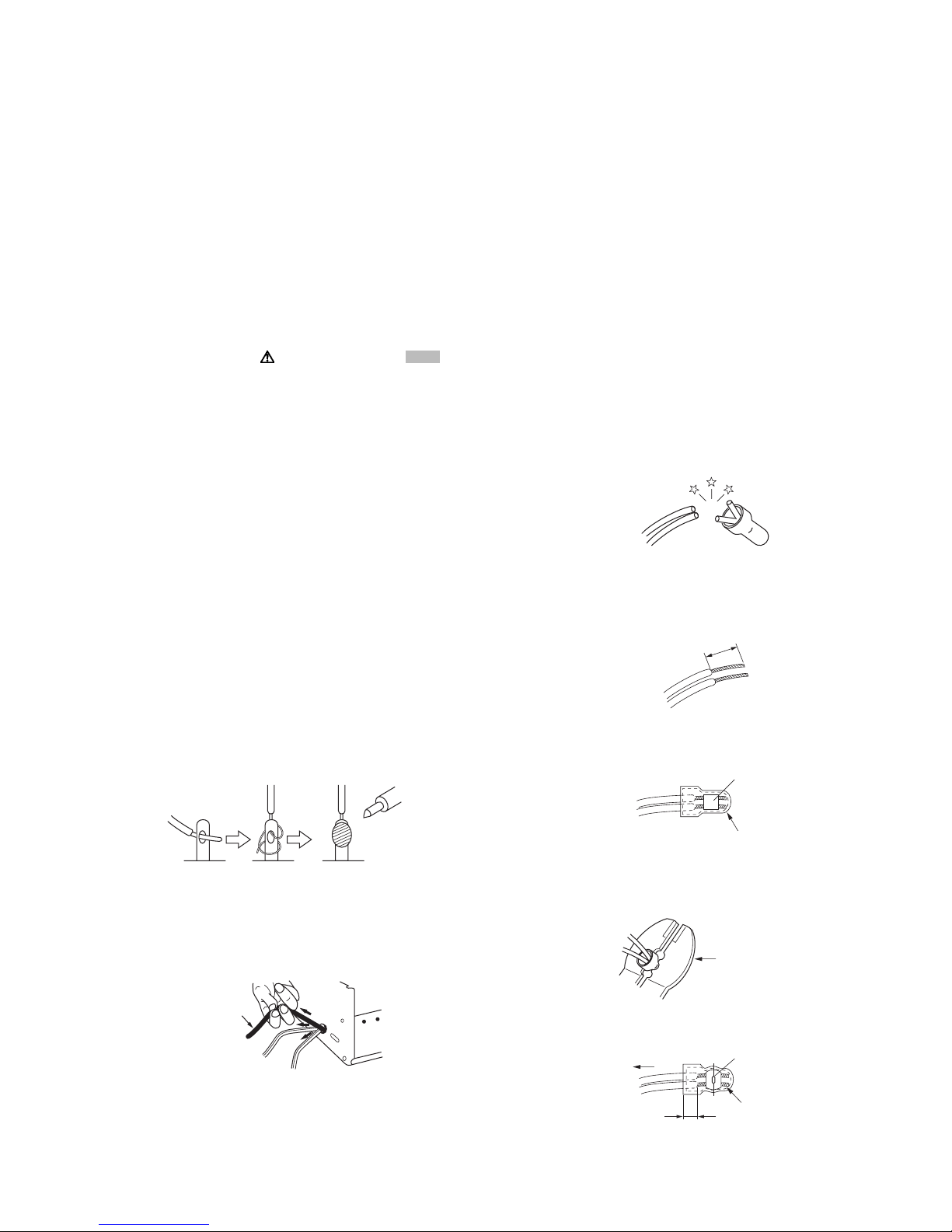

(12) Crimp type wire connectorIn such cases as when replacing

the power transformer in sets where the connections

between the power cord and power trans former primary

lead wires are performed using crimp type connectors, if

replacing the connectors is unavoidable, in order to prevent

safety hazards, perform carefully and precisely according

to the following steps.

• Connector part number :E03830-001

• Required tool : Connector crimping tool of the proper

type which will not damage insulated parts.

• Replacement procedure

a) Remove the old connector by cutting the wires at a

point close to the connector.Important : Do not

reuse a connector (discard it).

cut close to connector

Fig.1-1-3

b) Strip about 15 mm of the insulation from the ends

of the wires. If the wires are stranded, twist the

strands to avoid frayed conductors.

15 mm

Fig.1-1-4

c) Align the lengths of the wires to be connected.

Insert the wires fully into the connector.

Metal sleeve

Fig.1-1-1

(7) Observe that wires do not contact heat producing parts

(heatsinks, oxide metal film resistors, fusible resistors, etc.)

(8) Check that replaced wires do not contact sharp edged or

pointed parts.

(9) When a power cord has been replaced, check that 10-15

kg of force in any direction will not loosen it.

Power cord

Fig.1-1-2

(10) Also check areas surrounding repaired locations.

(11) Products using cathode ray tubes (CRTs)In regard to such

products, the cathode ray tubes themselves, the high

voltage circuits, and related circuits are specified for

compliance with recognized codes pertaining to X-ray

Connector

Fig.1-1-5

d) As shown in Fig.1-1-6, use the crimping tool to crimp

the metal sleeve at the center position. Be sure to

crimp fully to the complete closure of the tool.

1.2

5

2.0

5.5

Crimping tool

Fig.1-1-6

e) Check the four points noted in Fig.1-1-7.

Not easily pulled free

Wire insulation recessed

more than 4 mm

Crimped at approx. cente

of metal sleeve

Conductors extended

Fig.1-1-7

(No.YF163)1-3

Page 4

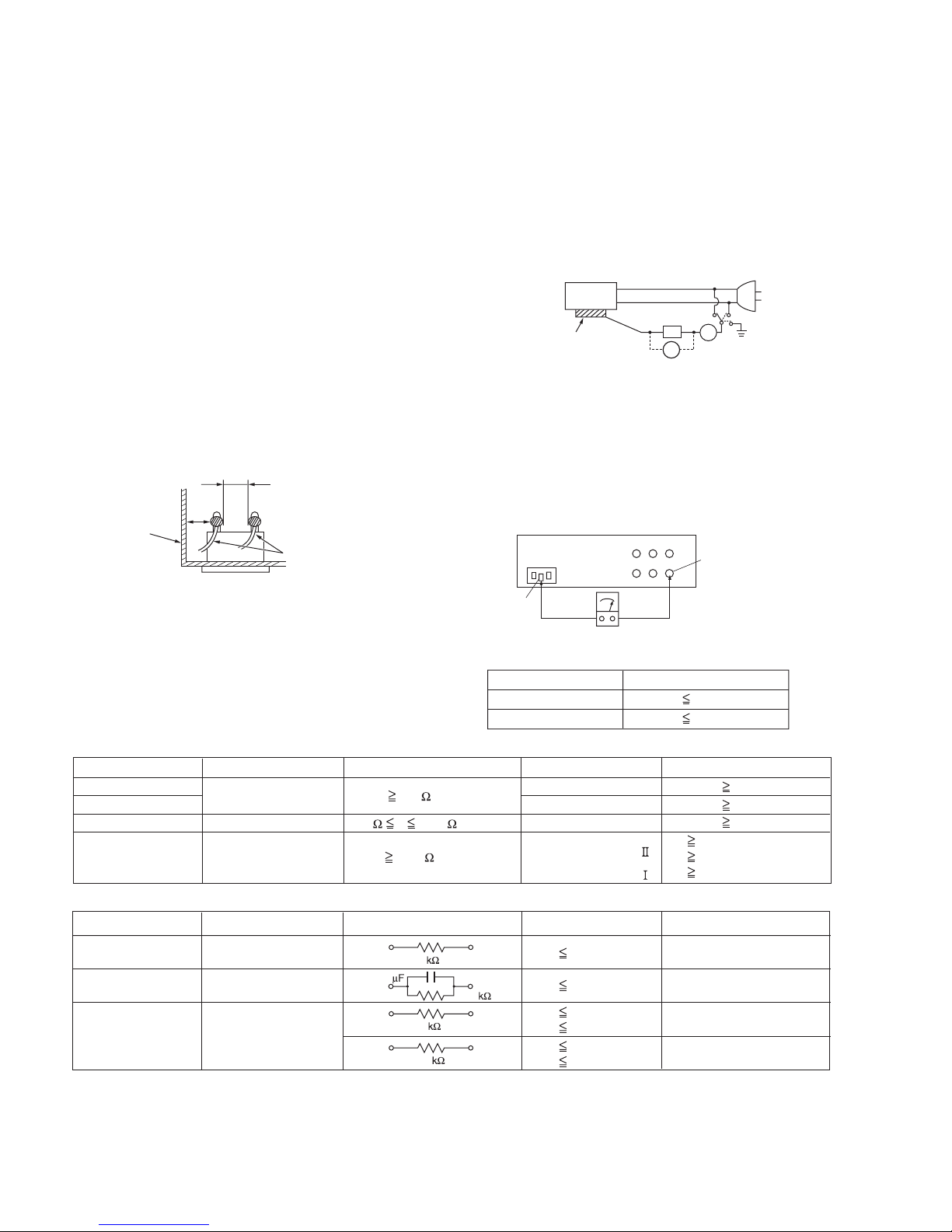

1.1.2 Safety Check after Servicing

Examine the area surrounding the repaired location for damage

or deterioration. Observe that screws, parts and wires have been

returned to original positions, Afterwards, perform the following

tests and confirm the specified values in order to verify

compliance with safety standards.

(1) Insulation resistance test

Confirm the specified insulation resistance or greater

between power cord plug prongs and externally exposed

parts of the set (RF terminals, antenna terminals, video and

audio input and output terminals, microphone jacks,

earphone jacks, etc.).See table 1 below.

(2) Dielectric strength test

Confirm specified dielectric strength or greater between

power cord plug prongs and exposed accessible parts of

the set (RF terminals, antenna terminals, video and audio

input and output terminals, microphone jacks, earphone

jacks, etc.). See Fig.1-1-11 below.

(3) Clearance distance

When replacing primary circuit components, confirm

specified clearance distance (d), (d') between soldered

terminals, and between terminals and surrounding metallic

parts. See Fig.1-1-11 below.

d

Chassis

d'

Power cord

primary wire

Fig.1-1-8

(4) Leakage current test

Confirm specified or lower leakage current between earth

ground/power cord plug prongs and externally exposed

accessible parts (RF terminals, antenna terminals, video

and audio input and output terminals, microphone jacks,

earphone jacks, etc.).

Measuring Method : (Power ON)Insert load Z between

earth ground/power cord plug prongs and externally

exposed accessible parts. Use an AC voltmeter to

measure across both terminals of load Z. See Fig.1-1-9

and following Fig.1-1-12.

ab

Externally

exposed

accessible part

Z

V

c

A

Fig.1-1-9

(5) Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between

earth pin in AC inlet and externally exposed accessible

parts (Video in, Video out, Audio in, Audio out or Fixing

screw etc.).Measuring Method:

Connect milli ohm meter between earth pin in AC inlet and

exposed accessible parts. See Fig.1-1-10 and grounding

specifications.

AC inlet

Earth pin

Exposed accessible part

MIlli ohm meter

Grounding Specifications

Region

USA & Canada

Europe & Australia

Grounding Impedance (Z

Z 0.1 ohm

Z 0.5 ohm

)

Fig.1-1-10

AC Line Voltage

100 V

100 to 240 V

110 to 130 V

110 to 130 V

200 to 240 V

Region

Japan

USA & Canada

Europe & Australia

Insulation Resistance (R

R 1 M /500 V DC

1 M R 12 M /500 V DC

R 10 M /500 V DC

)

Dielectric Strength

AC 1 kV 1 minute

AC 1.5 kV 1 minute

AC 1 kV 1 minute

AC 3 kV 1 minute

AC 1.5 kV 1 minute

(

Class

(

Class

Clearance Distance (d), (d'

d, d' 3 mm

d, d' 4 mm

d, d' 3.2 mm

d 4 m m

)

d' 8 m m (Power cord

d' 6 m m (Primary wire

)

Fig.1-1-11

AC Line Voltage

100 V

110 to 130 V

110 to 130 V

220 to 240 V

Region

Japan

USA & Canada

Europe & Australia

Load Z

1

0.15

1.5

2

50

Leakage Current (i)

i 1 mA rms

i 0.5 mA rms

i 0.7 mA peak

i 2 mA dc

i 0.7 mA peak

i 2 mA dc

a, b, c

Exposed accessible parts

Exposed accessible parts

Antenna earth terminals

Other terminals

Fig.1-1-12

NOTE :

These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

)

)

)

1-4 (No.YF163)

Page 5

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

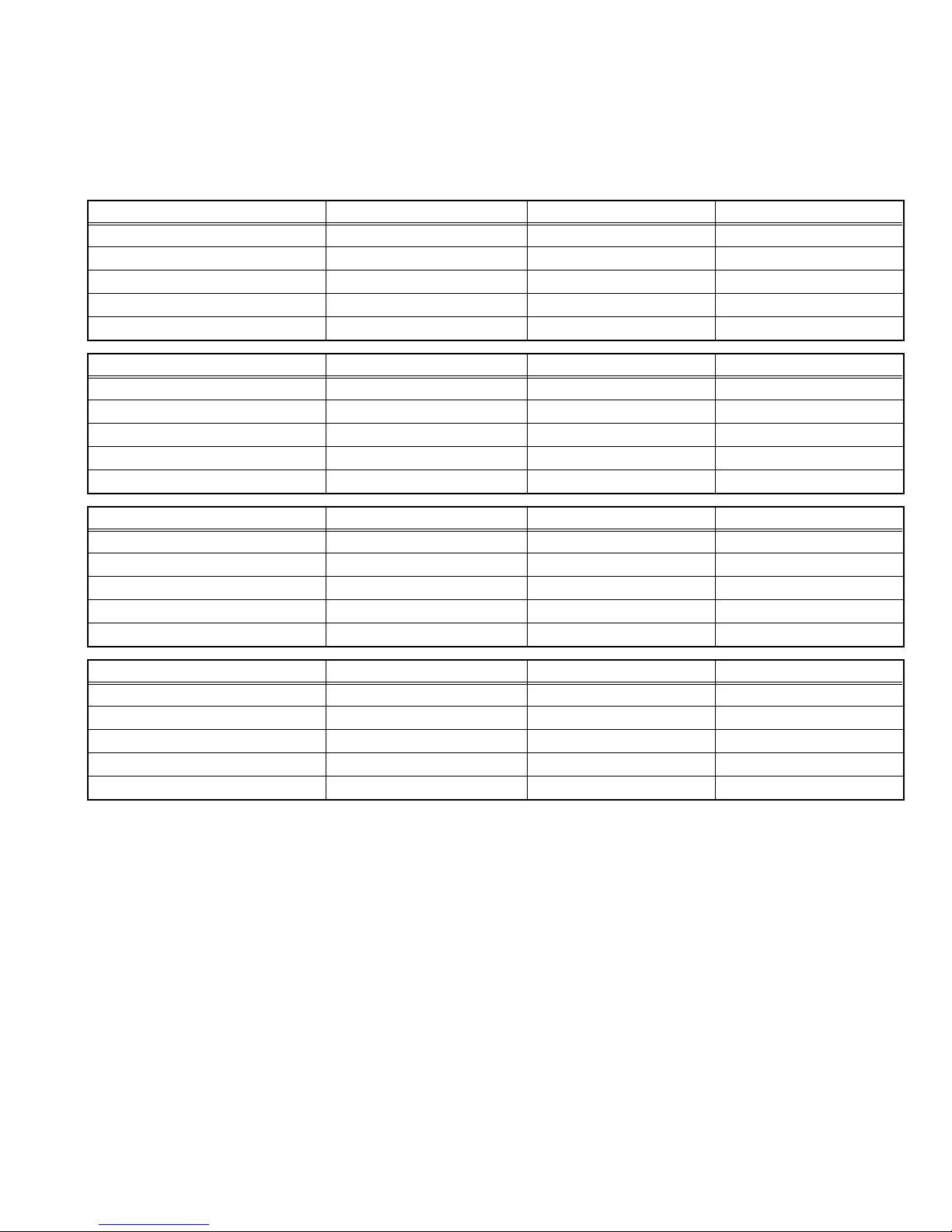

2.1 DIFFERENCE LIST

The following table indicate main different points between models GZ-MG47EX, GZ-MG47EY, GZ-MG47EZ, GZ-MG57AA,

GZ-MG57AC, GZ-MG57AG, GZ-MG57AH, GZ-MG57AS, GZ-MG57EK, GZ-MG57EX, GZ-MG57EY and GZ-MG57EZ.

MODEL NAME GZ-MG47EX GZ-MG47EY GZ-MG47EZ

HDD(BUILT-IN) 20GB 20GB 20GB

USB MASS STORAGE CLASS 2.0(OUT only) 2.0(OUT only) 2.0(OUT only)

AC ADAPTER AP-V17E AP-V17E AP-V17E

AC CORD NO NO NO

CONVERSION PLUG NO NO NO

MODEL NAME GZ-MG57AA GZ-MG57AC GZ-MG57AG

HDD(BUILT-IN) 20GB 30GB 30GB

USB MASS STORAGE CLASS 2.0 2.0 2.0

AC ADAPTER AP-V14E AP-V14AC AP-V17E

AC CORD YES(AS/NZS Plug) YES(CCC Plug) NO

CONVERSION PLUG NO NO NO

MODEL NAME GZ-MG57AH GZ-MG57AS GZ-MG57EK

HDD(BUILT-IN) 30GB 30GB 30GB

USB MASS STORAGE CLASS 2.0 2.0 2.0(OUT only)

AC ADAPTER AP-V14E AP-V14A AP-V14E

AC CORD YES(CEE Plug) YES(CEE Plug) YES(BS Plug)

CONVERSION PLUG YES(Fix to AC Cord) NO NO

MODEL NAME GZ-MG57EX GZ-MG57EY GZ-MG57EZ

HDD(BUILT-IN) 30GB 30GB 30GB

USB MASS STORAGE CLASS 2.0(OUT only) 2.0(OUT only) 2.0(OUT only)

AC ADAPTER AP-V17E AP-V17E AP-V17E

AC CORD NO NO NO

CONVERSION PLUG NO NO NO

(No.YF163)1-5

Page 6

SECTION 3

DISASSEMBLY

3.1 BEFORE ASSEMBLY AND DISASSEMBLY

3.1.1 Precautions

• Be sure to disconnect the power supply unit prior to mounting

and soldering of parts.

• Prior to removing a component part that needs to disconnect

its connector(s) and its screw(s), first disconnect the wire(s)

from the connector(s), and then remove the screw(s).

• When connecting/disconnecting wires, pay enough attention

not to damage the connectors.

• When inserting the flat wire to the connector, pay attention to

the direction of the flat wire.

• Be careful in removing the parts to which some spacer or

shield is attached for reinforcement or insulation.

• When replacing chip parts (especially IC parts), first remove

the solder completely to prevent peeling of the pattern.

• Tighten screws properly during the procedures. Unless

otherwise specified, tighten screws at a torque of 0.098N

·cm). However, as this is a required value at the time of

(1.0kgf

production, use the value as a measuring stick when

proceeding repair services. (See "SERVICE NOTE" as for

tightening torque.)

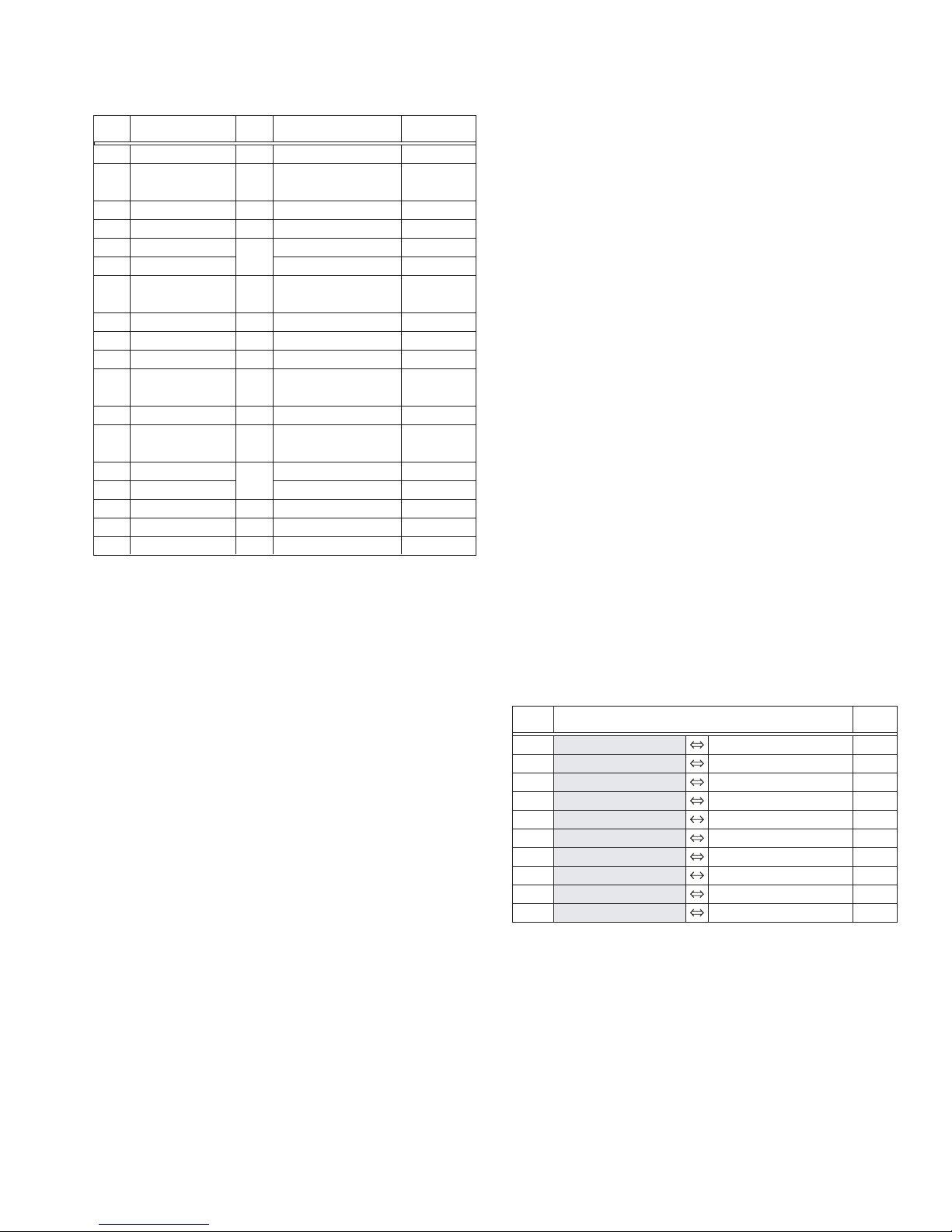

3.1.2 Destination of connectors

Two kinds of double-arrows in connection tables respectively

show kinds of connector/wires.

: Wire: Flat wire : Board to board (B-B)

: The connector of the side to remove

CONN. No. PIN No.CONNECTOR

CN2a

CN2b

MAIN CN101

MAIN CN103

MONI BW CN761

MINI BW CN762

3.1.3 Disconnection of connectors (Wires)

Wire

FPC Connector

· Pull both ends of the connector in the arrow

direction, remove the lock and disconnect the flat

wire.

Wire

FPC Connector

· Pull the both ends of the board in the direction of the

arrow, and remove the Connector.

Wire

Lock

FPC Connector

B-B Connector

B-B Connector

· Pull the both ends of the board in the direction of the arrow, and remove the B-B Connector.

· Extend the locks in the direction of the arrow for

unlocking and then pull out the wire. After

removing the wire, immediately restore the locks

to their original positions because the locks are

apt to come off the connector.

· Extend the locks in the direction of the arrow for

unlocking and then pull out the wire. After

removing the wire, immediately restore the locks

to their original positions because the locks are

apt to come off the connector.

· Extend the locks in the direction of the arrow for

unlocking and then pull out the wire. After

removing the wire, immediately restore the locks

to their original positions because the locks are

apt to come off the connector.

Wire

FPC Connector

FPC

Connector

Lock

B-B Connector

Fig.3-1-1

·m

40

10

Lock

Wire

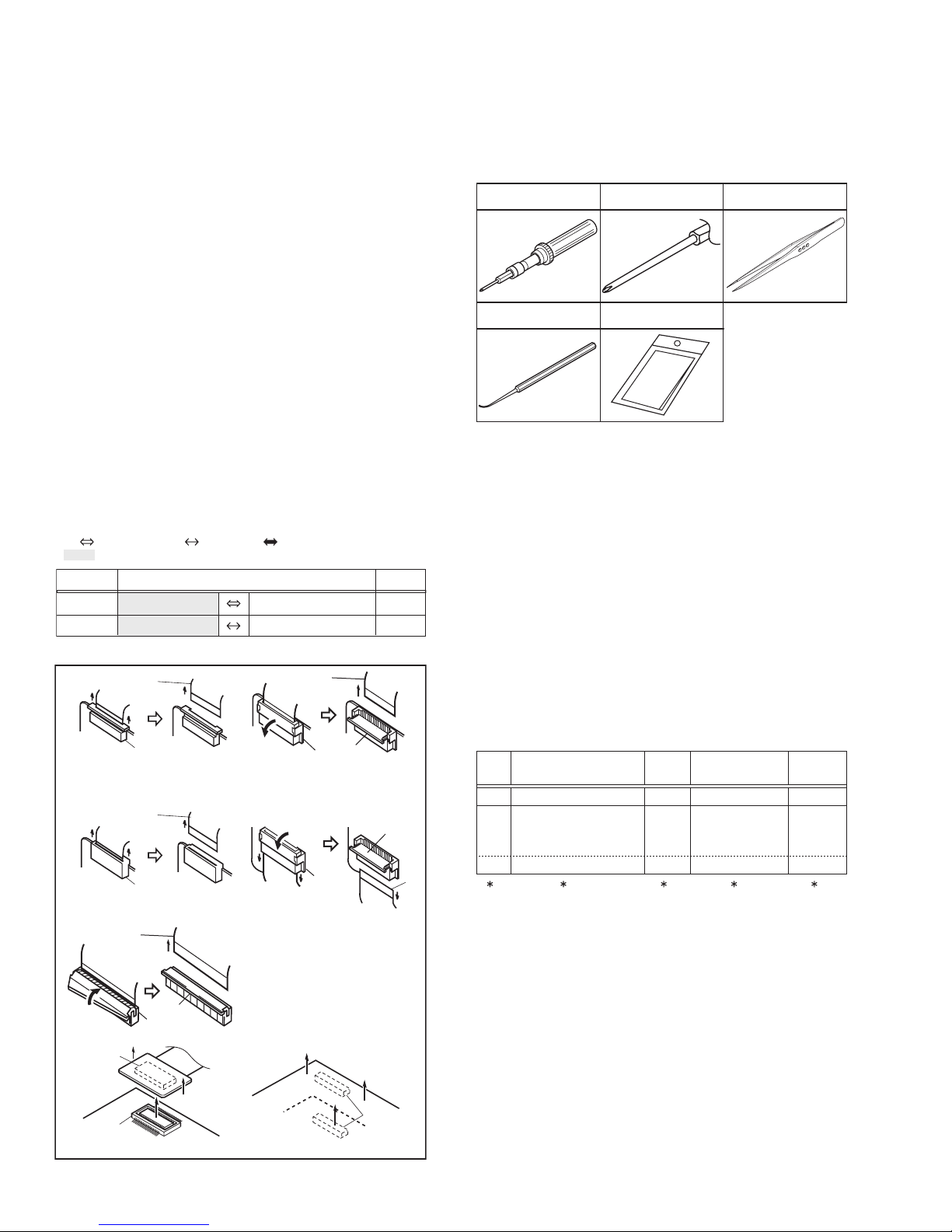

3.1.4 Tools required for disassembly and assembly

Torque driver

YTU94088

Chip IC replacement jig

PTS40844-2

Bit

YTU94088-003

Cleaning cloth

KSMM-01

Tweezers

P-895

Fig.3-1-2

• Torque driver

Be sure to use to fastening the mechanism and exterior parts

because those parts must strictly be controlled for tightening

torque.

• Bit

This bit is slightly longer than those set in conventional torque

drivers.

• Tweezers

To be used for removing and installing parts and wires.

• Chip IC replacement jig

To be used for replacement of IC.

• Cleaning cloth

Recommended cleaning cloth to wipe down the video heads,

mechanism (tape transport system), optical lens surface.

3.2 ASSEMBLY AND DISASSEMBLY OF MAIN PARTS

3.2.1 Assembly and disassembly

When reassembling, perform the step(s) in reverse order.

STEP

No.

[1]

[2]

PART

TOP COVER ASSY

UPPER ASSY

(Inc. VF ASSY,

SPEAKER/MONITOR)

[8]

E.VF UNIT(B/W)

(∗1) Order of steps in Procedure

When reassembling, preform the step(s) in the reverseorder.

These numbers are also used as the identification (location)

No. of parts Figures.

(∗2) Part to be removed or installed.

(∗3) Fig. No. showing Procedure or Part Location.

(∗4) Identification of part to be removed, unhooked, unlocked,

released, unplugged, unclamped or unsoldered.

S = Screw L = Lock, Release, Hook

SD = Solder CN = Connector

[Example]

• 4 (S1a) = Remove 4 S1a screws.

• 3 (L1a) = Disengage 3 L1a hooks.

• 2 (SD1a) = Unsolder 2 SD1a points.

• CN1a = Remove a CN1a connector.

(∗5) Adjustment information for installation.

Fig.

No.

4(S1a), 3(L1a),CN1a

C1

(S2a),2(S2b),3(S2c)

C2-1

2(SD1a),

L2,CN2a,b

2(S8),L8,CN8a

C2-2

POINT

( 4) ( 5)( 2) ( 3)( 1)

NOTE

-

-

NOTE 8

1-6 (No.YF163)

Page 7

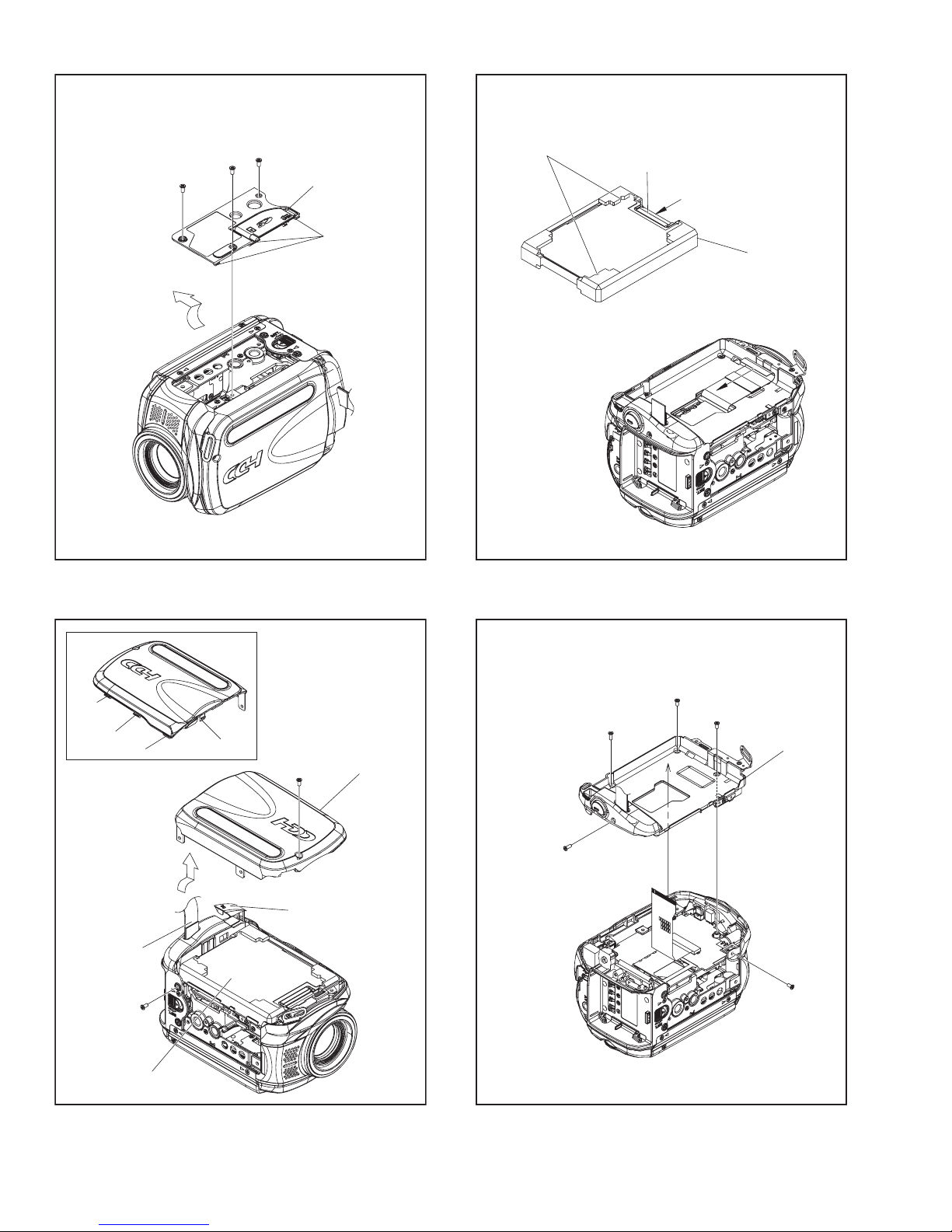

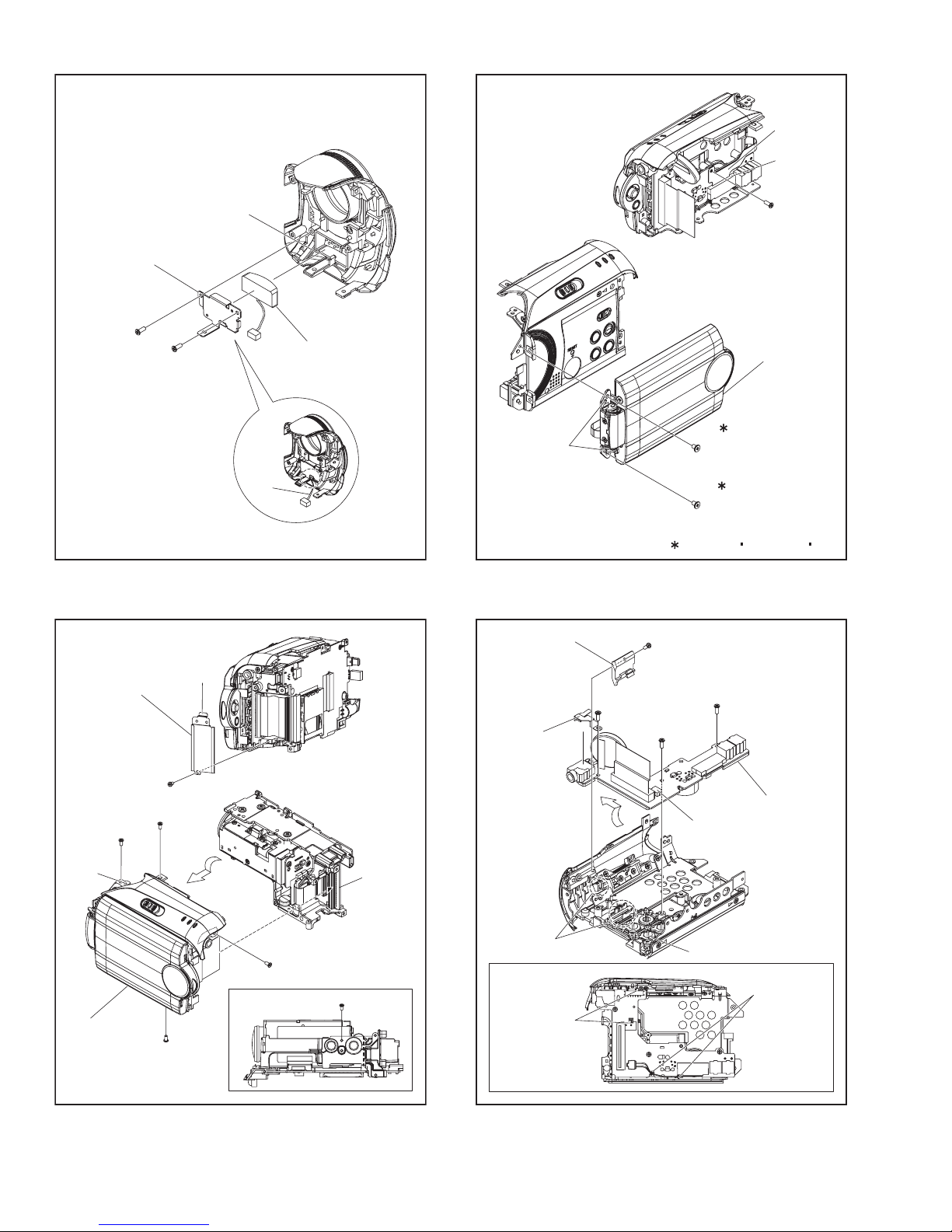

3.2.2 ASSEMBLY/DISASSEMBLY OF CABINET PARTS AND ELECTRICAL PARTS

z Disassembly procedure

STEP

PART NAME

No.

[1]

BOTTOM COVER ASSY

[2]

HDD COVER ASSY

[3]

HDD

[4]

HDD CASE ASSY

[5]

TOP COVER(ZOOM)

[6]

ZOOM UNIT

[7]

REAR BOARD ASSY

[8]

MONI. LOCK CASE ASSY

[9]

FRONT COVER ASSY

[10]

MIC

[11]

UPPER ASSY

[12]

MONITOR ASSY

[13]

OPE BOARD ASSY

[14]

TOP COVER(U) ASSY

[15]

POWER SW ASSY

[16]

SPEAKER

[17]

MAIN BOARD ASSY

[18]

OP BLOCK ASSY

Fig.

No.

CA1

FA1

FA2

FA3

FA4

FA5

FA6

FA7

FA8

FA9

UA1

UA2

UA3

UA4

FA10

FA11

POINT NOTE

3(S1),3(L1)

GRIP BELT,2(S2),

JACK COVER(DC),L2a,b,c,d

CN3

3(S4a),2(S4b)

CN5,JACK COVER(REAR),S5,L5a,b

SHIELD(ZOOM),2(S6),2(L6)

4(S7),2(L7a),JACK COVER(REAR),

CN7a,b,L7b,REAR UNIT

2(S8),2(L8)

2(S9a),S9b,CN9

2(S10),L10,BKT(MIC)

S11,L11a,SHIELD(FRAME),

4(S11),L11b,CN11

S12a,CN12,2(S12b),2(L12)

S13,INTER RUPTER,S13

EARTH PLATE OPE,2(S13),CN13,L13

2(S14),2(L14)

2(S15),2(L15)

4(S16),L16a,b,BKT(UPPER)

CN17a,b,2(S17)

3(S18)

NOTE2a,b,c,d

NOTE3a,b

NOTE5

NOTE6

NOTE7

NOTE10

NOTE12a,b

NOTE13a,b,c

NOTE16

NOTE17

NOTE18a,b

NOTE2a:

During the procedure, leave the GRIP BELT removed from

the hook.

NOTE2b:

When removing the HDD COVER ASSY, leave the JACK

COVER (DC) released.

NOTE2c:

During the procedure, be careful not to damage the tabs.

NOTE2d:

When removing the HDD COVER ASSY, be careful in handling as the HDD may come off.

NOTE3a:

During the procedure, be careful in handling the HDD. Make

sure not to give any shock to the HDD.

NOTE3b:

When attaching the HDD, check the positions of the marks,

and be careful with the GEL lift.

NOTE5:

The screw (No.11) is located under the JACK COVER

-

-

-

-

-

-

-

NOTE12b:

Refer to 3.2.3 ASSEMBLY/DISASSEMBLY OF [12] MONITOR ASSEMBLY for the disassembly of the MONITOR ASSY.

NOTE13a:

During the procedure, be careful in handling the EARTH

PLATE OPE.

NOTE13b:

When attaching the two switches (POWER, MODE), be

careful with the attachment locations. Attach the levers and

switches fixed to one direction as they can be fixed (except

the MODE switch lever). After the attachment, check the operation by moving the switch levers.

NOTE13c:

When attaching the SPEAKER WIRE, be careful in the wiring and not to catch the WIRE in between.

NOTE16:

When attaching the SPEAKER, be careful with the attachment location. Attach the OPE BOARD ASSY first, and then

follow the figure for the SPKEAKER wiring.

NOTE17:

When attaching the MAIN BOARD ASSY, make sure to insert the corner of the MAIN BOARD ASSY into the slit of the

FRAME ASSY.

NOTE18a:

During the procedure, be careful not to damage the EARTH

TERMINAL.

NOTE18b:

Refer to 3.2.4 ASSEMBLY/DISASSEMBLY OF [18] OP

BLOCK ASSEMBLY/CCD BOARD ASSEMBLY.

z Destination of connectors

CN.

No.

CN3 HDD - MAIN CN102 40

CN5 MAIN CN104 ZOOM UNIT - 6

CN7a MAIN CN103 REAR CN6001 53

CN7b REAR CN6002 TRIG SW - 6

CN9 MAIN CN107 MIC - 4

CN11 MAIN CN101 OPERATION CN401 50

CN12 OPERATION CN402 MONI-BL CN7601,7602 24/12,12

CN13 OPERATION CN403 SPEAKER - 2

CN17a MAIN CN105 CCD CN5201 24

CN17b MAIN CN106 OP BLOCK - 22

(REAR).

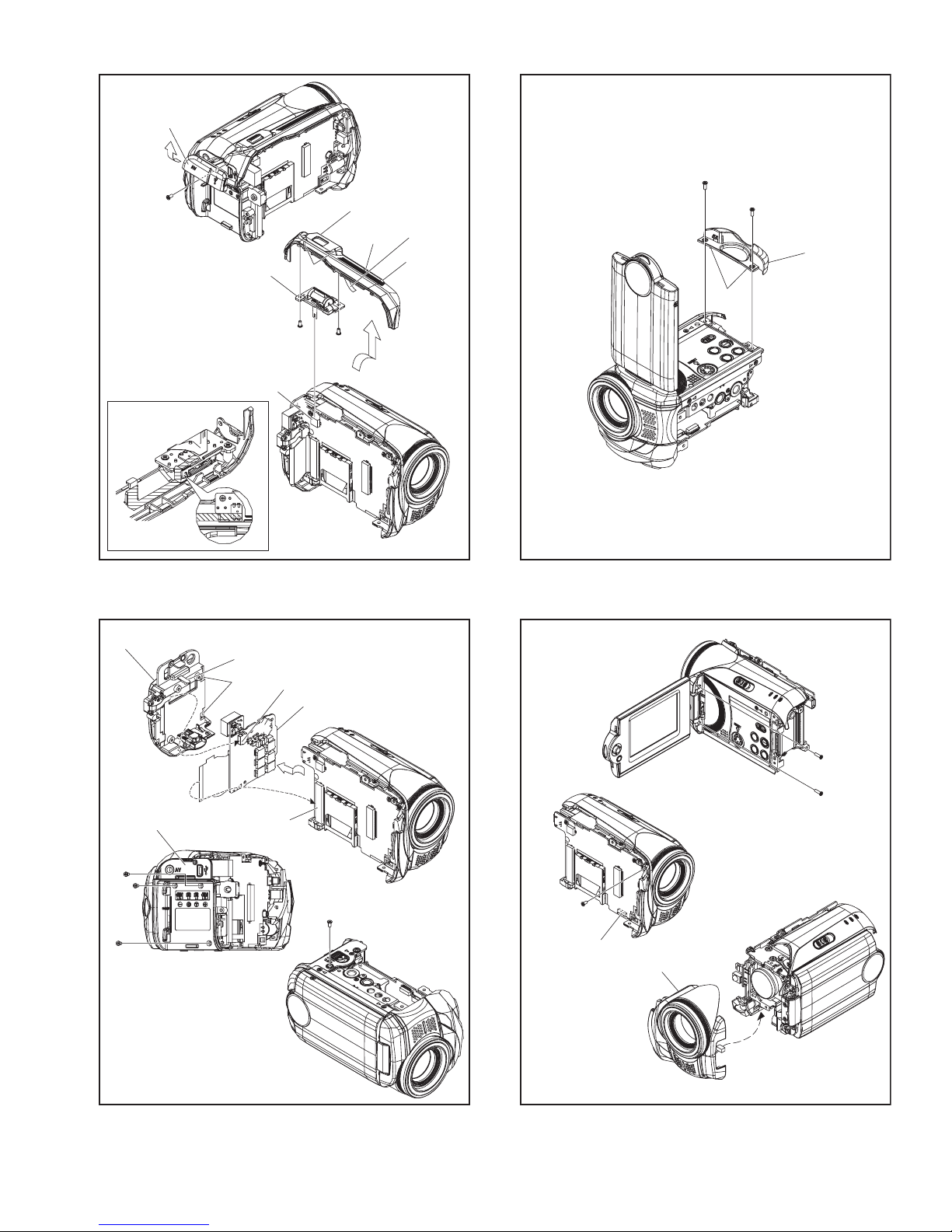

NOTE6:

Do not disassemble the ZOOM UNIT if not needed as the

SHIELD (ZOOM) is attached to the terminals.

NOTE7:

When removing the REAR UNIT, be careful in handling as

the JACK COVER (REAR) comes off together.

NOTE10:

When attaching the MIC, be careful with the MIC wiring.

NOTE12a:

Remove the screw (No.30), which tightens up the FPC, before connecting/ disconnecting the FPC to/ from the connector.

CONNECTOR

PIN

No.

(No.YF163)1-7

Page 8

1

(S1)

2

(S1)

3

(S1)

[1]

NOTE3b

MARK

CN3

a

L2d

L2d

L2c

L2c

L2b

L2b

Fig.CA1

L2a

L2a

4

4

(S2)

(S2)

L1

NOTE2c

NOTE2c

[2]

[2]

10

(S4b)

Fig.FA2

(S4a)

NOTE3a

[3]

a

7

8

(S4a)

[4]

NOTE2b

NOTE2b

JACK COVER(DC)

JACK COVER(DC)

NOTE2a

NOTE2a

GRIP BELT

GRIP BELT

5

5

(S2)

(S2)

NOTE2d

NOTE2d

Fig.FA1

1-8 (No.YF163)

9

(S4b)

6

(S4a)

Fig.FA3

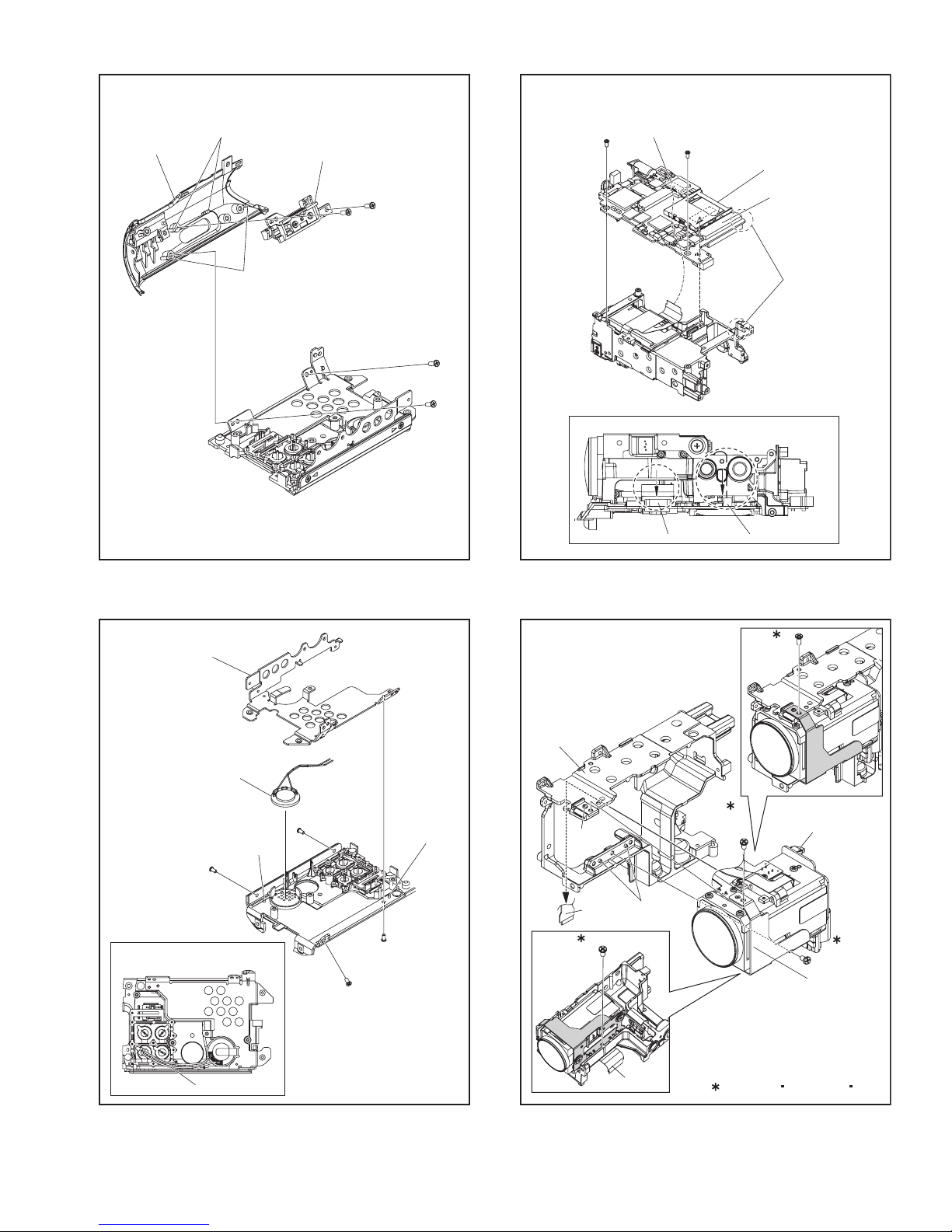

Page 9

JACK COVER

(REAR)

11

(S5)

NOTE5

<NOTE6>

[6]

NOTE6

CN5

12

(S6)

L6

13

(S6)

[5]

L5b

SHIELD

(ZOOM)

L5a

18

(S8)

19

(S8)

[8]

L8

REAR UNIT

NOTE7

JACK COVER

(REAR)

15

(S7)

16

(S7)

17

(S7)

L7b

L7a

Fig.FA4

CN7b

CN7a

[7]

(S7)

14

22

22

(S9b)

(S9b)

CN9

CN9

[9]

[9]

Fig.FA6

(S9a)

(S9a)

21

21

(S9a)

(S9a)

20

20

Fig.FA5

Fig.FA7

(No.YF163)1-9

Page 10

FPC

CN12

BKT(MIC)

23

(S10)

24

(S10)

SHIELD(FRAME)

25

(S11)

L11a

L10

WIRE

Fig.FA8

[10]

NOTE10

L12

INTERRUPTER

EARTH

PLATE OPE

NOTE13a

34

(S13)

Fig.UA1

33

(S13)

35

(S13)

30

(S12a)

NOTE12a

NOTE12b

[12]

31

(S12b)

32

(S12b)

:

0.245N m(2.5kgf cm)

36

(S13)

29

(S11)

28

(S11)

L11b

27

(S11)

[11]

26

(S11)

Fig.FA9

1-10 (No.YF163)

CN11

26

(S11)

NOTE13b

NOTE13b

[13]

CN13

L13

NOTE13c

Fig.UA2

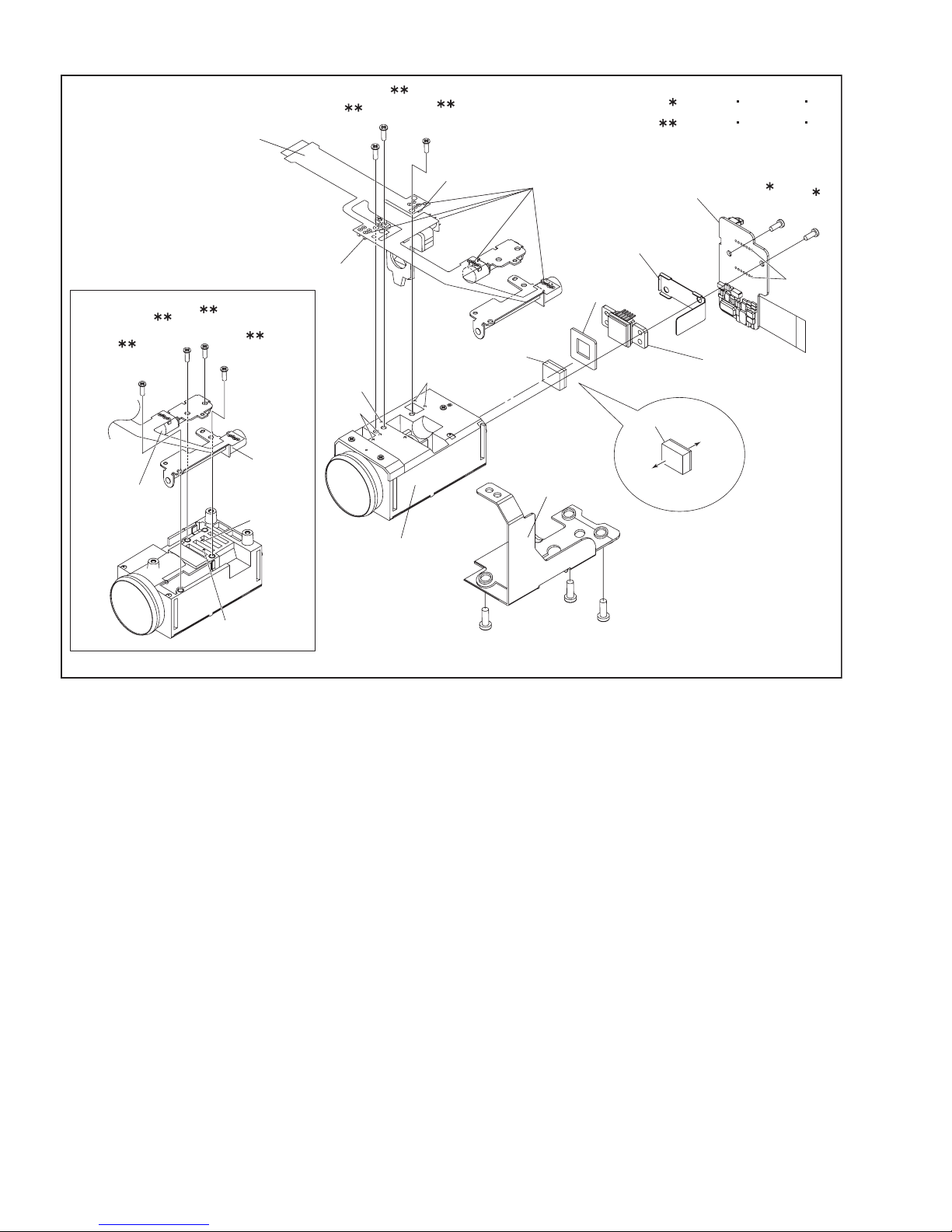

Page 11

[14]

L15

[15]

45

(S17)

CN17b

46

(S17)

[17]

BKT(UPPER)

L14

Fig.UA3

39

(S15)

40

(S15)

38

(S14)

37

(S14)

CN17b

Fig.FA10

CN17a

NOTE17

CN17a

47

(S18)

(S16)

NOTE16

42

[16]

WIRE

L16a

Fig.UA4

41

(S16)

43

(S16)

44

(S16)

L16b

FRAME ASSY

L18b

FPC

48

(S18)

L18a

FPC

47

(S18)

:

Fig.FA11

NOTE18a

EARTH TERMINAL

48

(S18)

[18]

NOTE18b

0.118N m(1.2kgf cm)

(No.YF163)1-11

Page 12

3.2.3 ASSEMBLY/DISASSEMBLY OF [12] MONITOR ASSEMBLY

zCAUTIONS

(1) Remove the MONITOR ASSEMBLY from the UPPER

ASSEMBLY first, as they are removed together in main

parts disassembly, and then proceed to the disassembly

procedure.

(2) During the procedure, be careful in handling the LCD

MODULE and other parts. Pay special attention not to

damage or soil the monitor screen.If fingerprints are left

on the screen, wipe them with clean chamois leather or

a cleaning cloth.

zRemoving MONITOR ASSEMBLY

(1) Turn the HINGE UNIT ASSEMBLY 90°, and remove the

three screws (1-3). Remove the MONITOR COVER ASSEMBLY by removing the six hooks (L12a-f).

(2) Pull out the U/D SWITCH BOARD from the MONITOR

CASE ASSEMBLY.

NOTE12a:

During the procedure, be careful in handling the FPC.

(3) Release the lock of the connector (CN12a,b), and re-

move the HINGE UNIT by lifting it up.

(4) Release the lock of the connector (CN12c,d), and pull

out the FPC.

(5) Remove the two screws (4,5), and Remove the MONI-

BL BOARD ASSEMBLY by removing the hook (L12h).

(6) Remove the BACK LIGHT.

(7) Remove the LCD MODULE.

(8) Remove the LCD BKT.

zRemoving HINGE UNIT ASSEMBLY

(1) Remove the two screws (6,7), and then remove the

HINGE COVER (U,L).

NOTE12b:

During the procedure, be careful in handling the MAGNET and be careful with its attachment direction. Make

sure to attach the MAGNET with its mark facing inward.

NOTE12c:

During the procedure, be careful in handling the FPC.

NOTE12d:

The FPC, with its connection to the MONITOR BOARD

ASSEMBLY facing inward, is rolled around the axis

(shaft) of the HINGE ASSEMBLY rotation 2.5 rounds

(2.5times).

<NOTE12a>

MONI BOARD

ASSY

BACK LIGHT

BL FPC

LCD MODULE

LCD FPC

LCD BKT

U/D SWITCH

FPC

L12h

4

(S12c)

5

(S12c)

MONI.COVER

ASSY

1

(S12a)

HINGE COVER(U)

NOTE12b

MAGNET

NOTE12d

HINGE UNIT

HINGE COVER(L)

6

(S12d)

L12a

2

(S12a)

7

(S12d)

L12c

L12b

FPC

L12g

NOTE12c,d

L12d

3

(S12b)

L12e

L12f

<NOTE12b>

Marking in this side.

HINGE

COVER(U)

b

a

<NOTE12c,d>

MAGNET

MONI.CASE

ASSY

1-12 (No.YF163)

NOTE12a

U/D SWITCH

CN12c

Fig.3-2-3

CN12a

CN12b

CN12d

b

a

0.245N m(2.5kgf cm)

Page 13

3.2.4 ASSEMBLY/DISASSEMBLY OF [18] OP BLOCK ASSEMBLY/CCD BOARD ASSEMBLY

zPrecautions

(1) Take care in handling the CCD IMAGE SENSOR, OPTICAL

LPF and lens components when performing maintenance

etc., especially with regard to surface contamination, attached dust or scratching. If fingerprints are present on

the surface they should be wiped away using either a silicon paper, clean chamois or the cleaning cloth.

(2) The CCD IMAGE SENSOR may have been shipped with

a protective sheet attached to the transmitting glass.

When replacing the CCD IMAGE SENSOR, do not peel

off this sheet from the new part until immediately before

it is mounted in the OP BLOCK ASSEMBLY.

(3) As the attachment direction of the OPTICAL LPF is im-

portant, be careful when removing it. Make sure to reattach the OP LPF in its original direction.

zDisassembly of OP BLOCK ASSEMBLY / CCD BOARD AS-

SEMBLY

(1) Remove the three screws (1-3),and remove the BKT

(OP) ASSEMBLY.

(2) Unsolder the fourteen soldered points (SD18a) of the

CCD BOARD ASSEMBLY.

(3) Remove the two screws (4, 5), and then remove the CCD

BOARD ASSEMBLY ,BKT(HEAT SINK)MEGA, SHEET,

OPTICAL LPF and the CCD BASE ASSEMBLY.

NOTE18a:

Be careful in handling as there are only the OPTICAL

LPF and the SHEET stored inside the OP BLOCK

ASSY when the CCD BASE ASSY is removed.

NOTE18b:

zAssembly of OP BLOCK ASSEMBLY / CCD BOARD AS-

SEMBLY

(1) Set the OPTICAL LPF first, and then the SHEET to the

OP BLOCK ASSEMBLY.

NOTE18c:

Pay careful attention to the orientation of the OPTICAL

LPF.

(2) Attach the CCD BASE ASSEMBLY first then the

BKT(HEAT SINK)MEGA, CCD BOARD ASSEMBLY so

that the SHEET stays in place, and tighten with the two

screws (4, 5).

(3) Solder the 14 points (SD18a) on the CCD BOARD AS-

SY.

(4) Attach the BKT (OP) ASSEMBLY,and tighten with the

three screws(1-3).

zReplacement of service repair parts

The service repair parts for the OP BLOCK ASSEMBLY are as

listed below.Take special care not to disconnect any of the FPC

wires or cause any damage due to soldering (excessive heating).

(1) FOCUS MOTOR UNIT

(2) ZOOM MOTOR UNIT

(3) AUTO IRIS UNIT

NOTE18d:

When replacing the FOCUS MOTOR UNIT or the ZOOM

MOTOR UNIT, solder the FPC at a space of about 0.5 mm

above the terminal pin.

NOTE 18e:

The AUTO IRIS UNIT includes the FPC ASSEMBLY and

two sensors.

Replace the CCD IMAGE SENSOR as a CCD BASE

ASSEMBLY, not as a single part replacement.

(No.YF163)1-13

Page 14

NOTE18d,e

AUTO IRIS UNIT

10

(S18c)

12

(S18c)

11

(S18c)

0.147N m(1.5kgf cm)

0.078N m(0.8kgf cm)

7

(S18c)

6

(S18c)

FOCUS MOTOR

UNIT

NOTE18d

8

(S18c)

(S18c)

ZOOM MOTOR

UNIT

NOTE18d

L18b

9

L18a

SENSOR

L18e

L18c

OP BLOCK ASS'Y

SENSOR

NOTE18a

OPTICAL LPF

L18d

1

(S18a)

SD18b

CCD BOARD ASS'Y

BKT

(HEAT SINK)MEGA

NOTE18a

SHEET

BKT (OP ASSY)

2

(S18a)

(S18a)

NOTE18c

Blue

OP

side

3

4

(S18b)

(S18b)

SD18a

NOTE18a,b

CCD BASE ASS'Y

CCD

side

5

Fig.3-2-4

1-14 (No.YF163)

Page 15

SECTION 4

ADJUSTMENT

4.1 PREPARATION

4.1.1 Precaution

Camera system and deck system of this model are specially

adjusted by using PC.

However, if parts such as the following are replaced, an

adjustment is required. The adjustment must be performed in a

Service Center equipped with the concerned facilities.

• OP BLOCK ASSEMBLY

• MONITOR ASSEMBLY

• EEP ROM (IC4502 of MAIN board)

In the event of malfunction with electrical circuits, first find a

defective portion with the aid of proper test instruments as shown

in the following electrical adjustment procedure, and then

commence necessary repair/ replacement/adjustment.

• In observing chip TP, use IC clips, etc. to avoid any stress.

Prior to replacement of chip parts (especially IC), remove the

solder completely to prevent peeling of the pattern.

• Use a patch cord if necessary. As for a patch cord, see the

BOARD INTERCONNECTIONS.

• Since connectors are fragile, carefully handle them in

disconnecting and connecting the FPC.

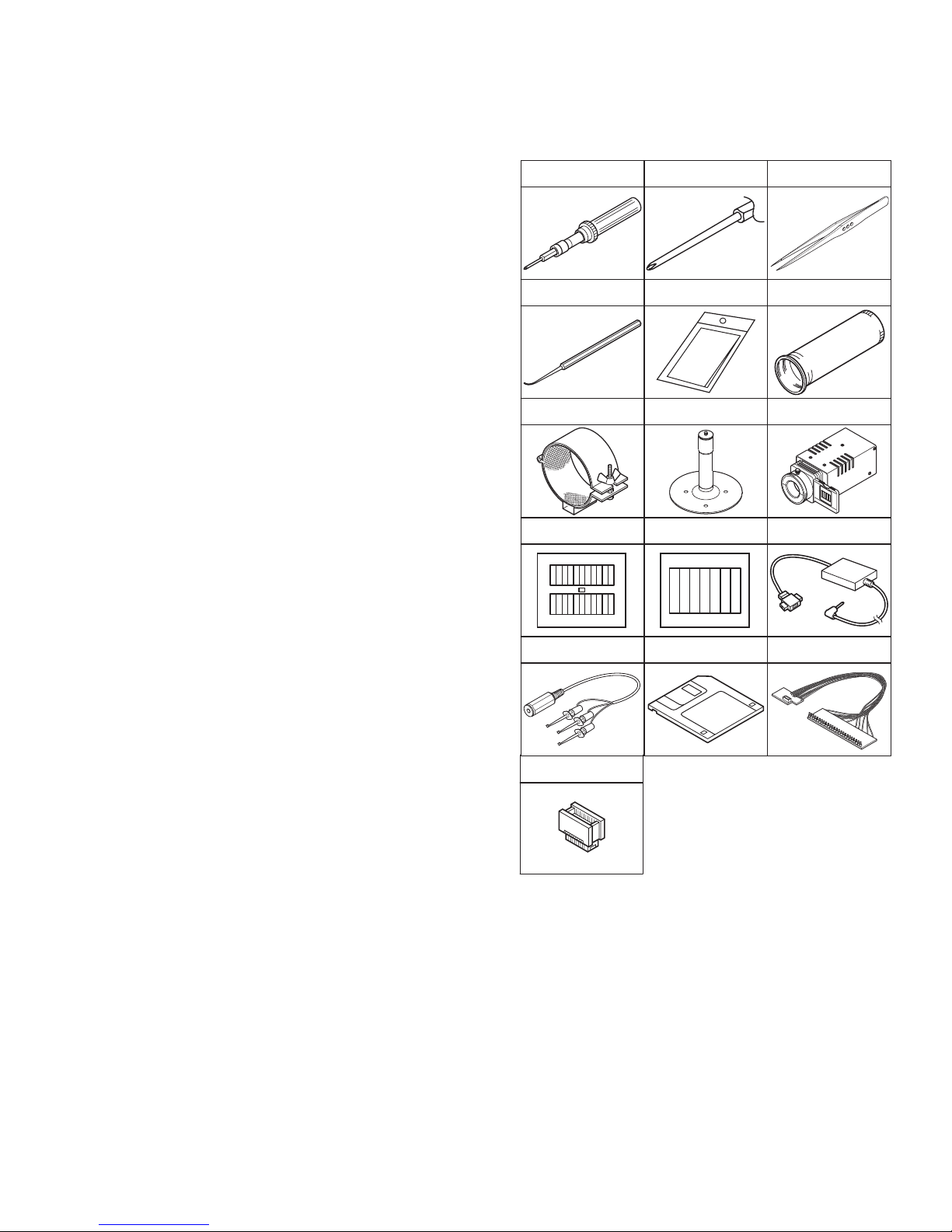

4.1.2 REQUIRED TEST EQUIPMENT

• Personal computer (for Windows)

• Color TV monitor

• Oscilloscope (dual-trace type, observable 100MHz or higher

frequency). The one observable 300 MHz or higher frequency

is recommended.

• Digital voltmeter

• DC power supply or AC adapter

• Frequency counter (with threshold level adjuster)

4.1.3 TOOLS REQUIRED FOR ADJUSTMENT

Torque Driver

YTU94088

Chip IC Replacement Jig

PTS40844-2

INF Adjustment Lens Holder

YTU94087

Gray Scale Chart

YTU94133A

Communication Cable

YTU93107B

Service Support System

Bit

YTU94088-003

Cleaning Cloth

KSMM-01

Mini Stand

YTU93108

Color Bar Chart

YTU94133C

YTU94057-97

INF Adjustment Lens

YTU92001B

Light box Assembly

YTU93096A

QAM0099-005

Jig Connector Cable

YTU93106A

Tweezers

P-895

PC Cable

Conversion Connector

YTU94145L-30

• Torque driver

Be sure to use to fastening the mechanism and exterior parts

because those parts must strictly be controlled for tightening

torque.

• Bit

This bit is slightly longer than those set in conventional torque

drivers.

• Tweezers

To be used for removing and installing parts and wires.

• Chip IC replacement jig

To be used for adjustment of the camera system.

• Cleaning cloth

Recommended the Cleaning cloth to wipe down the video

heads, mechanism (tape transport system), optical lens surface.

(No.YF163)1-15

Page 16

• INF adjustment lens

To be used for adjustment of the camera system. For the

usage of the INF adjustment lens, refer to the Service Bulletin

No. YA-SB-10035.

• INF adjustment lens holder

To be used together with the Camera stand for operating the

Videocamera in the stripped-down condition such as the status without the exterior parts or for using commodities that are

not yet conformable to the interchangeable ring. For the usage

of the INF lens holder, refer to the Service Bulletin No. YA-SB-

10035.

• Mini stand

To be used together with the INF adjustment lens holder. For

the usage of the Mini stand, refer to the Service Bulletin No.

YA-SB-10035.

• Light box assembly

To be used for adjustment of the camera system. For the

usage of the Light box assembly, refer to the Service Bulletin

No. YA-SB-10035.

• Gray scale chart

To be used for adjustment of the camera system. For the

usage of the INF adjustment lens, refer to the Service Bulletin

No. YA-SB-10035.

• Color bar chart

To be used for adjustment of the camera system. For the

usage of the INF adjustment lens, refer to the Service Bulletin

No. YA-SB-10035.

• PC cable

To be used to connect the Videocamera and a personal computer

with each other when a personal computer issued for adjustment.

• Communication cable

Connect the Communication cable between the PC cable and

Jig connector cable when performing a PC adjustment.

• Service support system

To be used for adjustment with a personal computer. Software

can be downloaded also from JS-net.

• Jig connector cable

Connected to JIG CONNECTOR of the main board and used

for electrical adjustment, etc.

• Conversion connector

Conversion connector is used to convert the connector part of

the JIG connector cable.

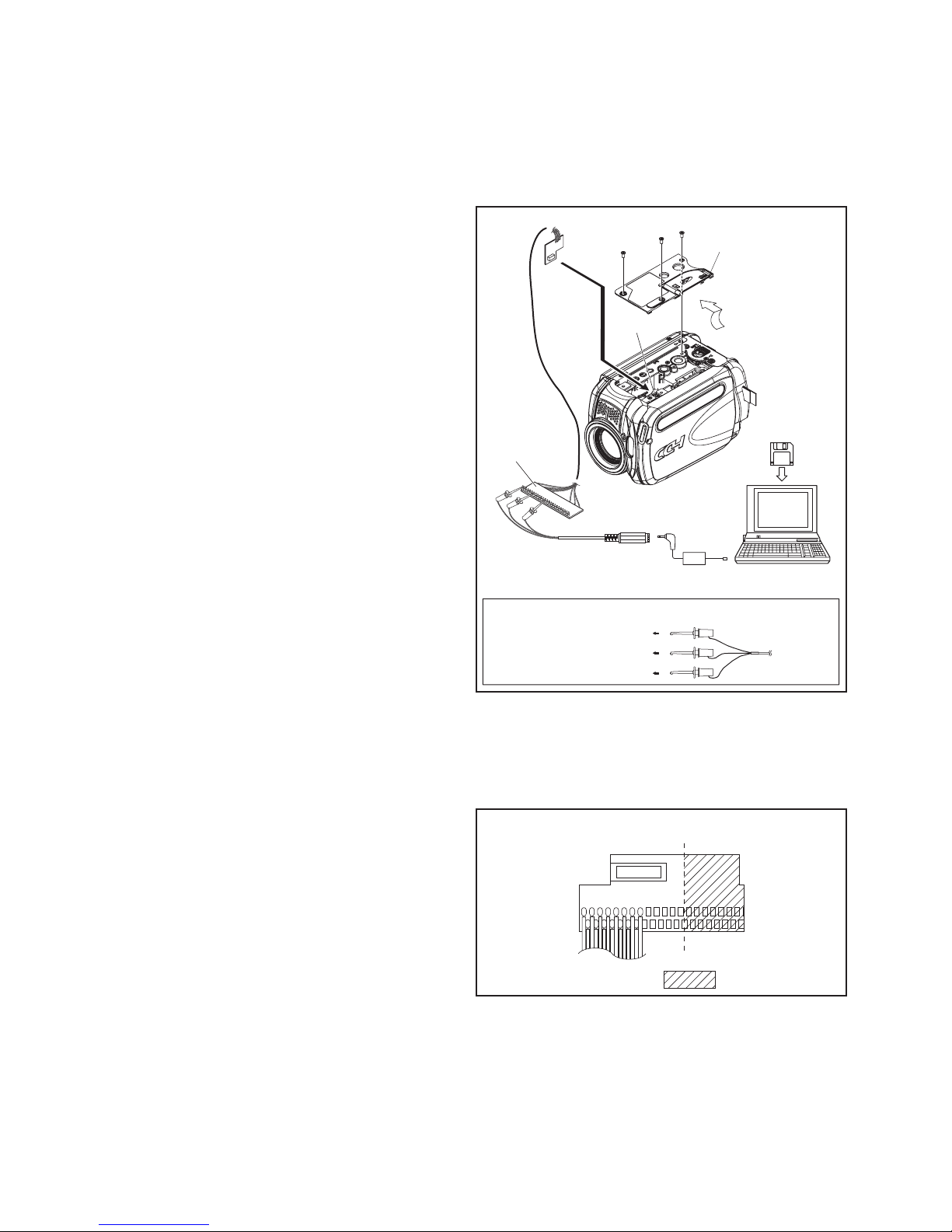

4.2 JIG CONNECTOR CABLE CONNECTION

Connection procedure

NOTE

Be sure to turn the power “OFF”, when connecting the JIG

CONNECTOR CABLE.

If the JIG CONNECTOR CABLE is connected with the power “ON”, communication error may occur.

3

2

JIG CONNECTOR

CABLE

COMMUNICATION CABLE

1

JIG

CONNECTOR

JIG CONNECTOR

TO NU_RX

TO NU_TX

TO GND

PC CABLE

RS232C

COM PORT

COMMUNICATION

CABLE

RED

WHITE

BLACK

COVER(JIG)

SERVICE

SUPPORT

SYSTEM

MENU

PERSONAL COMPUTER

Fig.4-2-1

CAUTION

The JIG CONNECTOR CABLE cannot be connected with

the COVER (JIG) removed because of its structure. It is necessary to cut a part of the connector board as shown below.

Pay special attention during the procedure.

JIG CONNECTOR CABLE [YTU93106A]

1-16 (No.YF163)

: The part to be cut

Page 17

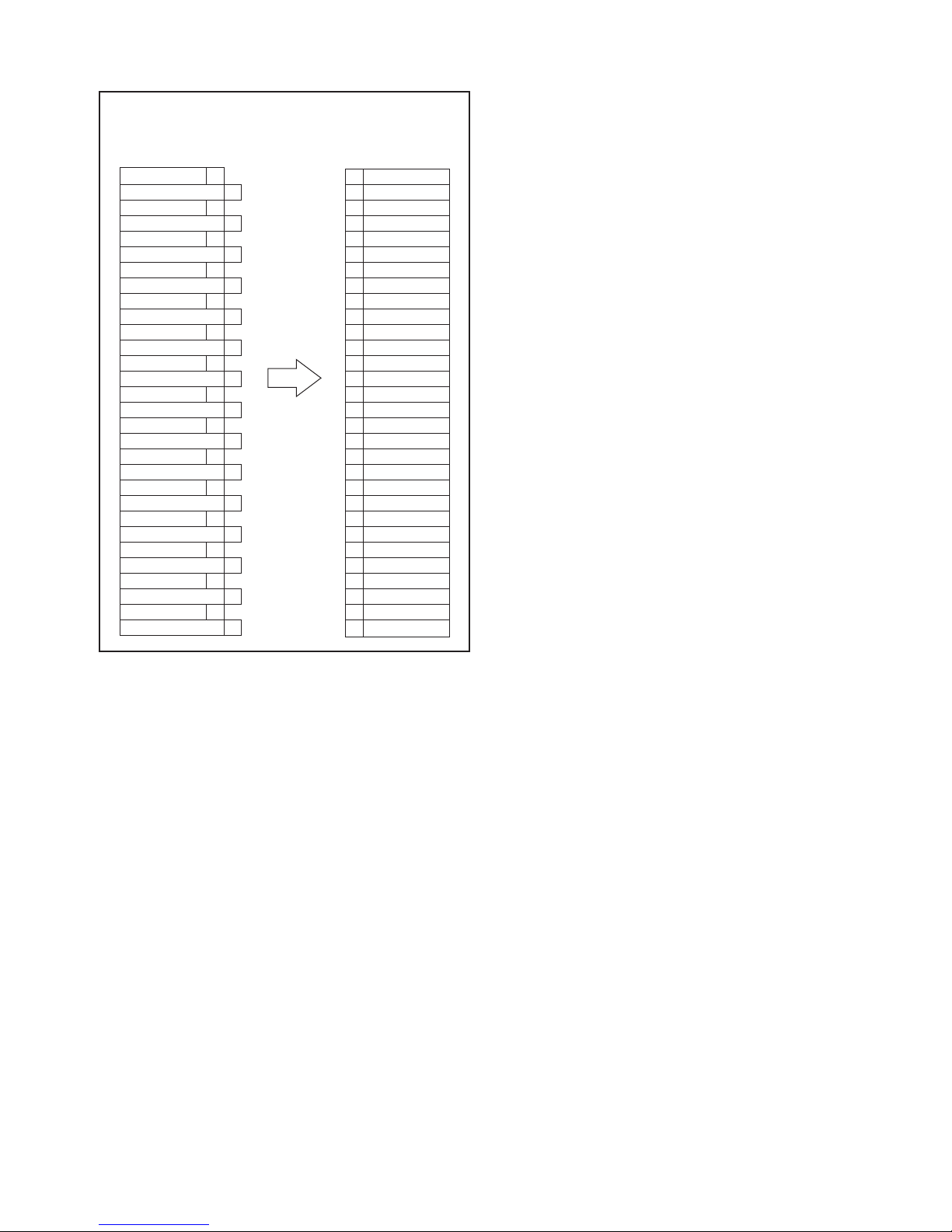

Jig connector diagrams

JIG CONNECTOR CABLE (YTU93106A)

MAIN CN110

ARMTDO

ARMTCK

ARMTMS

ARMTDI

XARMTRST

XJRESET

REG_3.1V

NU_RX

NU_TX

AL_3.1V

SJIG_TX

SJIG_RX

MOD0

SJIG_RST

NC

GND

MON_B

HRP

MON_R

GND

MON_G

NC

VDCVF

NC

NC

ZGH_OUT

ZGH_THRU

SBD5

SBT5

WORD

JIG CONN. BOARD

(PIN NO.)

1

16

2

17

3

18

4

19

5

20

6

21

7

22

8

23

9

24

10

25

11

26

12

27

13

28

14

29

15

30

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

ARMTDO

ARMTMS

XARMTRST

REG_3.1V

NU_TX

SJIG_TX

MOD0

NC

MON_B

MON_R

MON_G

VDCVF

NC

ZGH_THRU

SBT5

ARMTCK

ARMTDI

XJRESET

NU_RX

AL_3.1V

SJIG_RX

SJIG_RST

GND

HRP

GND

NC

NC

ZGH_OUT

SBD5

WORD

Fig.4-2-2

(No.YF163)1-17

Page 18

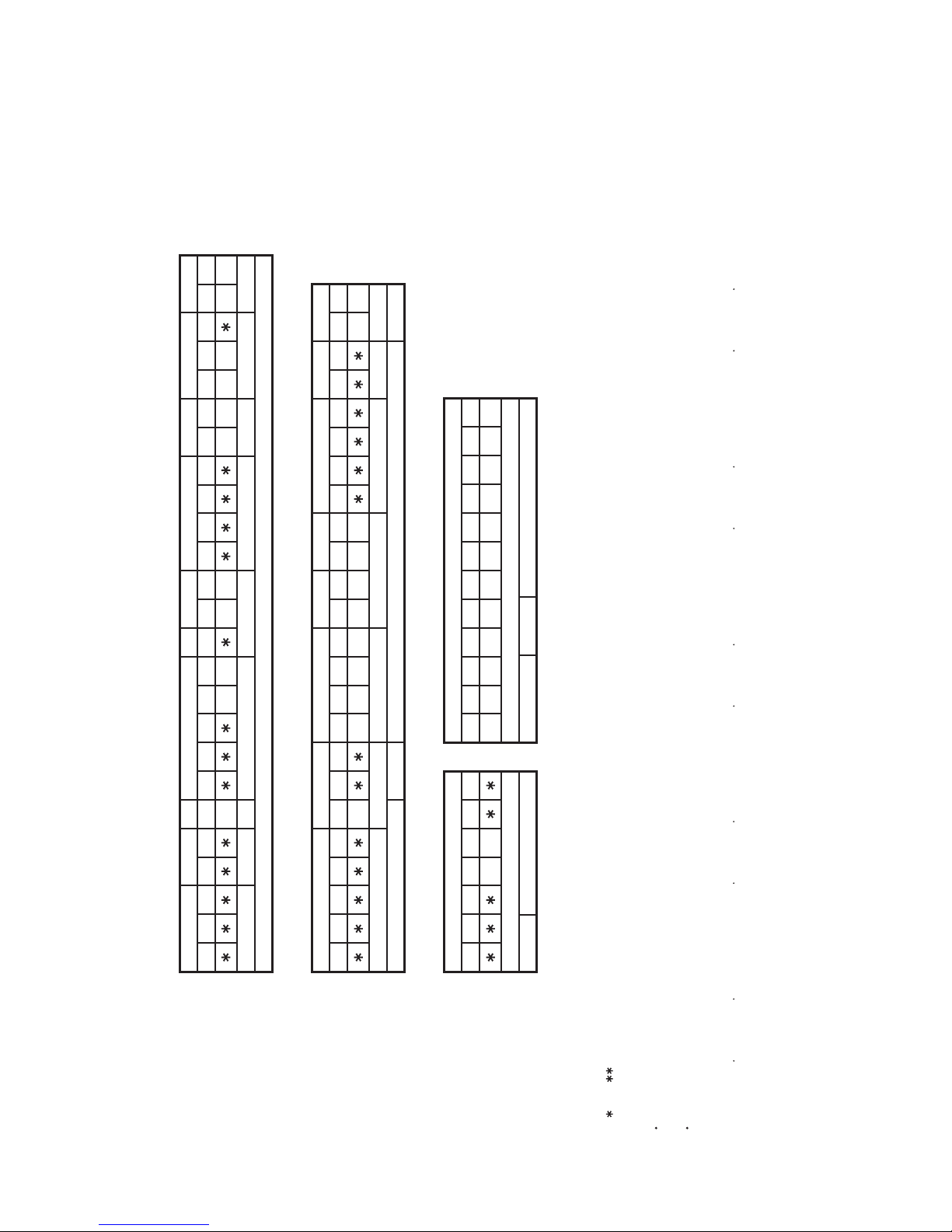

5.1 SERVICE NOTE

SECTION 5

TROUBLE SHOOTING

FA6 FA7 FA8

FA4

FA3 FA5

[18]

c

FA11

eda

aab

a

UA3 UA4 FA10

[18]

3-2-4

UA2

[18]OP BLOCK ASSY/CCD BOARD ASSY

1 2 3 4 5 6 7 8 9 10 11 12

-

[1] [2] [3] [4] [5] [6] [7] [8] [9] [10]

CABINET PARTS AND ELECTRICAL PARTS(1)

Symbol No.

CA1 FA1 FA2

1 2 3 4 5 - 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

Place to stick screw

Removing order of screw

Reference drawing (Fig.No.)

CABINET PARTS AND ELECTRICAL PARTS(2)

Screw tightening torque

1-18 (No.YF163)

[11] [12] [13] [14] [15] [16] [17]

FA9 UA1

25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

Symbol No.

Place to stick screw

Removing order of screw

Screw tightening torque

Reference drawing (Fig.No.)

ab

[12]

[12]MONITOR ASSY

Symbol No.

3-2-3

1 2 3 4 5 6 7

Place to stick screw

Removing order of screw

Screw tightening torque

Reference drawing (Fig.No.)

NOTE:

1 ) and (This mark shows where to attach the screws) : Do not reuse the screws because the screw lock bond was applied to prevent the screws from loosening.

Prepare the specified screws and use them in place of the removed screws.

2 )Tightening torque for the screws

There are setting limits of the torque value for the torque driver. If the value exceeds the setting value, take it as a rough measurement (reference value),

and tighten the screw manually.

The specified torque value is a recommended value of the initial assembly. Therefore, set the value below the specified torque value in the assembling procedure.

Be careful not to break either the screws or the screw holes.

a : 0.098N m (1.0kgf cm) b : 0.245N m (2.5kgf cm) c : 0.118N m (1.2kgf cm) d : 0.147N m (1.5kgf cm) e : 0.078N m (0.8kgf cm)

Page 19

Victor Company of Japan, Limited

Camcorder Category 12, 3-chome, Moriya-cho, kanagawa-ku, Yokohama, kanagawa-prefecture, 221-8528, Japan

(No.YF163)

Printed in Japan

VPT

Page 20

SCHEMATIC DIAGRAMS

HARD DISK CAMCORDER

YF02620042

GZ-MG47EX, GZ-MG47EY,

GZ-MG47EZ, GZ-MG57AA,

GZ-MG57AC, GZ-MG57AG,

GZ-MG57AH, GZ-MG57AS,

GZ-MG57EK, GZ-MG57EX,

GZ-MG57EY, GZ-MG57EZ

CD-ROM No.SML200608

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

COPYRIGHT © 2006 Victor Company of Japan, Limited

GZ-MG47EXM, GZ-MG47EYM, GZ-MG47EZM [M6E355],

GZ-MG47EXM, GZ-MG47EYM, GZ-MG47EZM [M6E355],

GZ-MG57AAM, GZ-MG57ACM, GZ-MG57AGM,

GZ-MG57AAM, GZ-MG57ACM, GZ-MG57AGM,

GZ-MG57AH, GZ-MG57AS, GZ-MG57EKM,

GZ-MG57AH, GZ-MG57AS, GZ-MG57EKM,

GZ-MG57EXM, GZ-MG57EYM, GZ-MG57EZM [M6E357]

GZ-MG57EXM, GZ-MG57EYM, GZ-MG57EZM [M6E357]

No.YF163SCH

2006/8

Page 21

(No.YF163)2-1 2-2(No.YF163)

!

CHARTS AND DIAGRAMS

NOTES OF SCHEMATIC DIAGRAM

Safety precautions

The Components indentified by the symbol are

critical for safety. For continued safety, replace safety

critical components only with manufacturer's recommended parts.

1. Units of components on the schematic diagram

Unless otherwise specified.

1) All resistance values are in ohm. 1/6 W, 1/8 W (refer to

parts list).

Chip resistors are 1/16 W.

K: KΩ(1000Ω), M: MΩ (1000KΩ)

2) All capacitance values are in µF, (P: PF).

3) All inductance values are in µH, (m: mH).

4) All diodes are 1SS133, MA165 or 1N4148M (refer to parts

list).

2. Indications of control voltage

AUX : Active at high.

AUX or AUX(L) : Active at low.

3. Interpreting Connector indications

Note: If the voltages are not indicated on the schematic

diagram, refer to the voltage charts.

123

2.5

(5.0)

1.8

PB and REC modes

(Voltage of PB and REC modes

are the same)

PB mode

REC mode

4. Voltage measurement

1) Regulator (DC/DC CONV) circuits

REC : Colour bar signal.

PB : Alignment tape (Colour bar).

— : Unmeasurable or unnecessary to measure.

2) Indication on schematic diagram

Voltage indications for REC and PB mode on the schematic diagram are as shown below.

5. Signal path Symbols

The arrows indicate the signal path as follows.

NOTE : The arrow is DVC unique object.

Playback signal path

Playback and recording signal path

Recording signal path

(including E-E signal path)

Capstan servo path

Drum servo path

(Example)

R-Y

Y

Playback R-Y signal path

Recording Y signal path

6. Indication of the parts for adjustments

The parts for the adjustments are surrounded with the circle

as shown below.

7. Indication of the parts not mounted on the circuit board

“OPEN” is indicated by the parts not mounted on the circuit

board.

R216

OPEN

1

2

3

1

2

3

1

2

3

1

4

2

3

Removable connector

Wire soldered directly on board

Non-removable Board connector

Board to Board

Connected pattern on board

The arrows indicate signal path

Note: The Parts Number, value and rated voltage etc. in

the Schematic Diagram are for references only.

When replacing the parts, refer to the Parts List.

Note: For the destination of each signal and further line

connections that are cut off from the diagram,

refer to "BOARD INTERCONNECTIONS"

CIRCUIT BOARD NOTES

1. Foil and Component sides

1) Foil side (B side) :

Parts on the foil side seen from foil face (pattern face)

are indicated.

2) Component side (A side) :

Parts on the component side seen from component face

(parts face) indicated.

2. Parts location guides

Parts location are indicated by guide scale on the circuit board.

rts location are indicated by guide scale on the circuit board.

Note: For general information in service manual, please

refer to the Service Manual of GENERAL INFORMATION Edition 4 No. 82054D (January 1994).

LOCATION

REF No.

IC101 B C 6 A

IC

Category : IC

Horizontal “A” zone

Vertical “6” zone

B : Foil side

(A : Component side)

C : Chip component

D : Discrete component)

Page 22

2-4(No.YF163)(No.YF163)2-3

CCD

GYRO

MAIN IF

TG

CDS

OP DRV

AUDIO

MPEG2 CODEC

3D NR/VIDEO OUT

PREPRCS

DSP

SUB CPU

MONI BL

OPE IF

REAR IF

REG

YTU94074-24

YTU94077-24

YTU94105-40

YTU94077-40

YTU94074-6

YTU94077-6

YTU94074-22

YTU94077-22

YTU94074-24

YTU94077-24

YTU94074-6

YTU94077-6

YTU94074-6

YTU94077-6

YTU94128-4

SIGN00155

VDCPU

DV2OUT3

ANA_IN

MPGFLD

SDR_DQ8

SDR_A8

PMA12

SDR_CS0

ACES_LED

PMA9

SDR_DQ17

PMD14

SDR_DQ3

FOCUS04

XVOEN

DC_CHEK

PMD1

SCPU_CS

REG_1.2V

LCD_RVS

PMA5

SUB

SDR_DQ15

MPGFLD

CDS_CS

PMD11

PMD3

PMA1

SDR_DQ13

PMA20

NCFD7

PMD10

AOBD

GND

PMA0

PMD15

SDR_DQ31

KEY_C

GND

ACHI3

XPMBLS1

DV2OUT0

SDR_A1

PMA13

SDR_DQ30

SDR_DQ3

SDR_A4

SDR_BA1

SDR_CLK

PMA13

SDR_DQ16

BUZZER

PMD13

SDR_DQ2

REG_3.1V

VI1

PMA14

NXCFCE1

REG_4.9V

PMA9

XJRESET

HGout+

SDR_A10

MPGVSYNC

PMA8

PMD4

PMA2

PMD9

PMA16

REG_3.1V

H2

PMA21

NCFD6

AIOBCK

AIOBCK

TG_CS

PMA19

PMA1

ACHI5

GND

PMA0

SDR_DQ26

DV2CKOUT

FLDCPU

ACHI6

SDR_A1

DV2OUT2

SDR_DQ29

SDR_A12

SDR_BA0

F_PTR_AD

SDR_DQM3

SDR_A5

SDR_DQ24

SDR_DQ14

XPMOE

PMA17

SDR_DQ1

CAM_VD

GND

VI0

PMINT

PMD11

V_BATT

VI4

NXCFCE0

CAM_OUT

PMA12

SDR_A3

PMD11

DMACLR

CAM_CLK

SDR_A9

ASPECT

PMA9

PMD3

GND

V2

PMA15

CAM_IN

PMD2

GND

INT_L

SCPU_CS

ARMTMS

VI3

ACHI2

KEY_A

TG_VD

PMA7

SPK-

SDR_DQ25

CN107

123

4

SDR_A3

SDR_DQ28

ACHI7

DV2OUT4

XCACK

SDR_DQ31

SDR_DQM2

PMD14

SDR_WE

SDR_A6

SDR_DQ22

PMA16

SDR_DQ0

SDR_DQ9

PMD12

MPGHSYNC

ZOOM04

PMD2

DV2OUT4

SDR_BA0

PMA18

SDR_CLK

GND

SDR_A8

PMD2

PMD1

GND

REG_4.9V

PMD15

PMD0

SREG_2.5V

NCFD4

AUDIO_CS

TG_HD

ARMTDO

P_GYAMP

CLK27A

VI5

DATA_OUT

ZOOM02

REG_3.1V

PMA6

S_SHUT

SDR_DQ30

SDR_A2

SDR_DQ27

ACHI1

SDR_CKE

SDR_DQ13

DV2OUT5

PMD9

NCFRESET

POFF_SW

SDR_DQM3

SDR_DQM0

SDR_A7

PMA15

PMA1

IR_OUT

PSCTL

ACHI4

CAM_IN

SDR_DQ4

PMD3

REG_4.9V

SDR_A7

PMD1

PMA2

OSD_CS

TG_CS

3AAZEROG

H1

NCFD11

PMD1

SDR_DQM1

ANA_CLK

ACHI6

AOBD

CLK27A

PMD0

PMA5

MPGHSYNC

SDR_DQ26

SDR_DQ28

DMABREQ

SDR_DQ12

VI2

PMD7

CLK27_AT

PMA5

DV2OUT7

SDR_DQM1

PMA5

PMA14

CLK27B

OP_CS

ACHI8

PMA8

REG_3.1V

DV2OUT2

CAM_CLK

CAM_OUT

SDR_DQ10

HGVss-

PMA20

NXCFIORD

PMD8

PMA3

V_OUT

XPMCS7

AIBD

SDR_RAS

REG_1.5V

SDR_A4

5049484746454443424140393837363534333231302928272625242322

21

PMD7

TG_VD

HDCVF

ACHI7

PMA3

SDR_DQ25

PMA4

VI4

SDR_DQ7

SDR_DQ11

SREG2.5V

PMD10

M_REG4.9

PMA6

SDR_DQ27

ACHI4

CN101

2019181716151413121110

987

6

NXCFWAIT

CLK48

REG_4.9V

PMA18

XCREQ

FOCUS02

SDR_DQM2

PMD6

PMA7

DV1IN0

SDR_DQ2

DMASREQ

SDR_A6

NU_TX

PMD12

PMA4

ANA_CLK

C_OUT

XPMWE

V4

OP_CS

GND

SDR_DQM0

ZOOM03

NCFBVD1

CLK27_AT

PMD6

LCD_OPEN

INT_R

VDCVF

PMA2

SDR_DQ24

SDR_DQ10

NXCFIOWR

VI6

VI3

REG_1.5V

SDR_DQ20

DRIVE+

PMA7

A_MUTE

NCFD10

SDR_DQ23

ACHI8

PMA8

SREG2.5V

XPMWE

ASPECT

PMA13

DV1CLKIN

IR_RMC

DV1IN4

AU_SIG/R

CAM_3.1V

SDR_A5

HDIRS

SDR_DQ5

PMD13

PMD3

AIOLRCK

AUDIO_CS

Y_OUT

XPMOE

TG_HD

XPMBLS0

IR_OUT

SDR_WE

MON_B

NCFD15

MCLKI

PMA1

MCLKI

SDR_DQ23

SDR_DQ9

VI7

PMD6

VI2

DMASREQ

SDR_DQ21

PMA10

PMD8

NCFD8

SDR_DQ18

PMD9

PMA15

REG_3.1V

DV1IN2

MOD0

SDR_A0

SCPU_SCK

F_VCC

PMD7

PMD4

SDR_BA1

SDR_DQ11

ANA_OUT

PMD12

ARMTCK

SCPU_SI

PMD5

MON_G

PMA0

NCFBVD2

REG_CS

V1

SDR_DQ22

L_MUTE

SDR_DQ8

PMD5

DV2OUT0

PMD4

NCFRDY

G_RST

VI1

REG_3.1V

CAM_VD

SDR_A2

SDR_CAS

PMD4

NCFD3

PMD11

PMA10

PMA10

DV1IN5

SDR_DQ16

T_BATT

VDCPU

PMA14

ACHI3

SSGFLD

PMD10

FOCUSO3

PMD5

AIBD

SCPU_SI

S_SHUT

DV2CKOUT

VI5

SDR_A10

SDR_DQ12

ANA_CS

AOMCLK

SCPU_SO

SDR_CAS

ACHI0

PMA7

FLSH_RST

TG2_RST

SPK+

NCFD14

MON_R

SDR_DQ21

HDIRS

RG

XPMDE

SDR_DQ7

XCINT

DV2OUT5

PMD15

DV1IN1

SCPU_SCK

MPEG_RST

PMA4

PMD5

PMA6

NCFD9

DV1IN3

I_MTR

FLDCPU

PMA8

SDR_DQ19

PMA21

PMD14

PMD6

VI7

HGout-

AL_3.1V

SCPU_SO

BUZZER

REG_3.1V

VI0

SDR_A9

SDR_DQ1

ANA_RST

AIOLRCK

SDR_RAS

PMA11

SJIG_RST

SDR_DQ20

NCFD12

ZOOM01

SDR_DQ6

DMACLR

XPMWE

XPMCS1

DV2OUT6

PLLSTOP

PLAY_SW

PMD13

PMA11

REG_3.1V

SDR_A11

XPMOE

PMA2

OSD_VD

SDR_DQ29

NCFD2

SDR_A11

PMA3

ACHI9

PMA17

PMD7

DV2CKOUT

ACHI5

DV2OUT6

CLK27B

AU_SIG/L

VI6

SDR_DQ0

SDR_CS0

XCREQ

XARMTRST

PMA10

PMA12

SDR_DQ19

DMABREQ

PMD15

NCFD13

SDR_DQ5

ACHI1

DV2OUT1

Z_PTR_AD

XPMWE

DV1IN6

CHRG_EVR

DRIVE-

SSGFLD

PMD0

L_MUTE

PMD14

PMD10

PMA3

PMA19

A_MUTE

XPMBLS0

ID_LAT

NCFD0

PMD0

PMA9

PMD8

SDR_DQ15

PD_L

XPMCS1

PD_L

HGVcc+

ACHI2

ID_LAT

DV2OUT1

MPGVSYNC

SDR_DQ6

SDR_CKE

LCD_CS

DV2OUT7

ARMTDI

PMA11

CHRG_LED

PMA6

SDR_DQ18

PMD13

SDR_DQ4

ACHI0

FOCUS01

DV2OUT3

XCACK

PMINT

DV1IN7

NU_RX

OP_THRMO

ADP_L

V3

PMA11

ACHI9

DUMP+

REC_SW

GND

PMA4

PMD12

PMD8

SDR_DQ17

SDR_A0

XPMBLS1

SDR_A12

NCFD1

IRIS_PS

PMD9

AOMCLK

PMA2

XPMCS7

SDR_DQ14

REG_3.1V

REG_3.1V

P_GYAMP

Y_GYAMP

GND

G_RST

CN5201

123456789

101112131415161718192021222324

CCD_15V

CCD_-7.5VRGGND

H2

CCD_OUTV1SUBH1V2V3V4

F/Z_RST

CCD__CTL

CCD_CTL

CCD_OUT

CAM_OUT

CAM_CLK

CCD_CTL

REG+CCD

ANA_OUT

INT_GND

ANA_CLK

ANA_OUT

M_REG4.9

XPMWAIT

XPMWAIT

XPMWAIT

HRP

DSP_RST

ANA_IN

OSD_CS

DSP_RST

ANA_RST

OSD_VD

ANA_CS

PSCTL

DSP_RST

CN7601

123456789

101112

CN7602

123456789

101112

CN402

123456789

101112131415161718192021222324

JP7601

JP7602

JP7603

CN103

9

1011121314151617181920212223242526272829303132333435363738

39

40414243444546474849505152

53

CN6001

123456789

101112131415161718192021222324252627282930

31

32333435363738394041424344

45

CN110

30

15

29

14

28

13

27

12

26

11

25

10

24

9

23

8

22

7

21

6

20

5

19

4

18

3

17

2

16

1

CN102

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

NCFA2

NCFA1

NCFA0

NCFD5

V27_OUT

V27_OUT

TVSEL

EEPRM_CK

EEPRM_DI

EEPRM_CS

EEPRM_DO

EEPRM_DO

EEPRM_DI

HOST_LED

TVSEL

AFE_RST

AFE_RST

LAMP_ON

SDWP

SDWP

SDR_VDD SDR_VDD

DV1CLKIN

DV1IN7

DV1IN5

DV1IN0

DV1IN3

PLLSTOP

DV1IN4

DV1IN6

MPEG_RST

NOT USED

NOT USED

(NOT USED)

NOT USED

XCINT

XPMCS0

DV1IN1

DV1IN2

XVOEN

SDDAT0

SDDAT1

SDDAT2

SDDAT3

SDCD

SDCLK

SDCMD

USBDP

USBDN

XCFIORD

XCFIOWR

3AAZEROG

P_DET

S_DET

LITHIUM

INFO_SW

SET_SW

P_MEDIA

LCD_CTL

BL_POWER

UNREGCHK

CLK_OUT

D_BATT

KEY_B

IR_RMC

LIT_3V

LIT_3V

PS_ZEROG

PS_ZEROG

SBT5

SBD5

SJIG_RX

SJIG_TX

WORD

ZEROG_H

ZEROG_H

ZGH_OUT

ZGH_THRU

ZOOM_SW

CN104

12345

6

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

Y_GYAMP

8765432

1

46474849505152

53

54321

54321

2019181716151413121110

987

6

CN401

5049484746454443424140393837363534333231302928272625242322

21

CN7701

12345

6

CN7603

123456789

10111213141516171819202122232425262728293031323334353637383940

3132333435

36

CN7603

123456789

101112131415161718192021222324252627282930

DUMP-

Z_VCC

F_LED

CN403

1

2

SREG1.8V

PPRO8

PPRO4

PPRO1

PPRO11

SOF

PPRO3

PPRO0

PPRO6

PPRO2

PPRO10

VLD_PIX

PPRO5

PPRO9

PPRO7

VCLK

CN6002

12345

6

PMA4

PMA6

PMA2

PMA5

PMA1

PMA8

PMA7

PMA9

PMA3

PMD14

PMD7

PMD13

PMD0

PMD8

PMD11

PMD1

PMD10

PMD4

PMD9

PMD5

PMA2

PMD15

PMD3

PMD12

PMD6

CFBVD1

CFRDY

CFBVD2

PMA20

PMA21

XPMCS0

CLK24_ON

XUSB_CS1

XUSB_CS0

XUSB_RST

NXCFIOWR

NCFA1

NCFD6

NCFD13

NCFD14

NCFD4

NXCFCE0

NCFD7

NCFD9

NCFD3

NCFD11

NCFD0

NCFD12

NXCFCE1

NXCFWAIT

NCFD5

NCFD10

NCFD1

NCFD15

NXCFIORD

NCFD8

NCFD2

NCFA2

NCFA0

NCFRESET

NCFBVD2

NCFBVD1

NCFRDY

SDDAT0

SDCLK

SDDAT2

SDDAT1

SDCMD

SDDAT3

SDCD

SDWP

XCFIOWR

CFA0

CFD4

CFD14

CFD0

CFD5

XCFCE0

CFD11

CFD12

CFD9

CFD13

CFD7

CFD1

XCFCE1

CFRESET

CFD10

CFD2

CFD8

CFD15

XCFIORD

CFD3

CFD6

CFA2

CFA1

CN111

111213

8

7

6

5

4

3

2

1

9

14

10

XBRDMACK

XCFWAIT

BRDMARQ

AL_3.1V

XUSB_INT

CLK48

XPMOE

XPMWE

REG_3.1V

GND

XUSB_CS1

XUSB_CS0

FLSH_RST

SREG1.8V

REG_4.9V

XUSB_RST

XUSB_INT

NTXD_IN

NTXD_OUT

NTXD_IN

NTXD_OUT

VBUS

VBUS

XUSBHOST

XUSBHOST

REG_4.9V

LAMP_ON

LAMP_ON

REG_15V

SDDAT3

SDCD

SDWP

SDDAT2

SDDAT0

SDDAT1

SDCLK

SDCMD

CFA0

CFD8

CFD5

CFRDY

CFRESET

CFD12

CFD7

CFD11

CFBVD2

CFA2

CFD15

XCFWAIT

CFD3

XCFCE0

CFBVD1

CFD0

CFD9

XCFCE1

CFD6

CFD13

CFD2

CFD4

CFD10

CFA1

CFD1

CFD14

USBDN

USBDP

USBDN

USBDP

EEPRM_CS

EEPRM_CK

IRIS_PS

F/Z_RST

CN106

1 F_LED

2 F_PTR_AD

3 F_VCC

4 OP_THRMO

5 GND

6 DRIVE-IS

7 DRIVE+IS

8 HGOUT-IS

9 HGOUT+IS

10 HGVSS-IS

11 HGVCC+IS

12 FOCUS2

13 FOCUS3

14 FOCUS4

15 FOCUS1

16 ZOOM1

17 ZOOM2

18 ZOOM3

19 ZOOM4

20 Z_LED

21 Z_PTR_AD

22 Z_VCC

CN105

1

CCD+15V2CCD+15V3CCD-7.5V4GND5GND6GND7CCD_OUT8GND9GND10GND11GND12RG13H114H215SUB16CCD_CTL17V118V219V320V421Y_GYAMP22G_RST23REG_3.1V24P_GYAMP

PPRO11

SOF

PPRO3

PPRO0

PPRO6

PPRO2

PPRO10

VLD_PIX

PPRO8

PPRO5

PPRO4

PPRO9

PPRO7

PPRO1

VCLK

CAM_CLK

CAM_OUT

CCD_CTL

REG_4.9V

REG_-7.5V

REG+CCD

CAM_3.1V

GND

SHD

TG2_RST

SHP

CPOB

PBLK

ADCLK

PBLK

CPOB

SHD

CDS_CS

SHP

ADCLK

REG_3.1V

REG_14V

REG_14V

ANA_CLK

SUB

ANA_OUT

Vout

GND

DC JACK

REG_1.5V

JIG CONNECTOR

REG_1.5V

123456

REG_1.5V

INT_GND

7

8

INT_L9INT_R

1011121314

BATT_TERM

V4V3V2V1GND

Vdd

RG

TEST

H2

H1

VL

INT_GND

RESET_SW

AU_SIG/L

AU_SIG/R

C_OUT

V_OUT

Y_OUT

MON_B

MON_G

MON_R

HDCVF

B/L(LED)SMS

HRP

SIG_GND

BL_GND

VDCVF

BL_POWER

BL_GND

LCD_CS

LCD_CTL

MON_R

MON_G

HDCVF

REG_4.9V

MON_B

ANA_CLK

ANA_OUT

LCD_RVS

SIG_GND

SIG_GND

BL_POWER

LCD HINGE

REV

SW

M_RVS

REG_3.1V

SIG_GND

LCD_RVS

LCD_CS

LCD_CTL

VDCVF

BL_POWER[15V]

REG_3.1V

REG_3.1V

HRP

GND

LAMP_ON

P_MEDIA

LCD_OPEN

KEY_A

SET_SW

KEY_C

INFO_SW

ACES_LED

CHRG_LED

PLAY_SW

REC_SW

POFF_SW

LITHIUM

S_DET

P_DET

REG_4.9V

REG_4.9V

REG_4.9V

GND

GND

GND

GND

GND

GND

UNREGCHK

I_MTR

V_BATT

CLK_OUT

AL_3.1V

REG_CS

DRV_3.3V

DRV_3.3V

DRV_3.3V

DC_CHEK

REG_1.2V

REG_1.2V

REG_1.2V

D_BATT

GND

GND

GND

GND

GND

GND

GND

GND

GND

T_BATT

ADP_L

REG_4.9V

REG_4.9V

REG_4.9V

CHRG_EVR

CAM_3.1V

CAM_3.1V

DATA_OUT

REG_3.1V

REG_3.1V

REG_3.1V

SJIG_RST

-+TD

XARMTRST

SJIG_RST

XJRESET

GND

REG_3.1V

SBT5

GND

NU_RX

NU_TX

MON_B

HRP

WORD

MON_R

AL_3.1V

MON_G

SJIG_TX

VDCVF

NC

ARMTDO

NC

ARMTCK

ZGH_OUT

ZGH_THRU

ARMTMS

SJIG_RX

ARMTDI

SBD5

MOD0

INT MIC

OP BLOCK

DRV_3.3V

CFBVD2

XCFCE1

XCFCE0

CFA2

CFA0

CFBVD1

CFA1

CFRDY

DMACK-

GND

XCFWAIT

GND

DIOR-

DIOW-

GND

DMARQ

GND

CFD15

CFD0

CFD14

CFD1

CFD13

CFD2

CFD12

CFD3

CFD11

CFD4

CFD10

CFD5

CFD9

CFD6

CFD8

CFD7

GND

CFRESET

HDD

NC

NC

ZOOM_SW

ZOOM_SW

GND

GND

REG_3.1V

REG_3.1V

ZOOM UNIT

WT

OFF

PLAY

REC

TRASH

SW

MENU

SW

LIGHT

SW

INFO

SW

LED RED

POW/CHRG

LED BLUE

ACCESS

LCD OPEN

SW

/DASP-

/CS1-

/CS0-

/DA2

/DA0

/PDIAG-

/GROUND

/GROUND

/GROUND

/DD15

/DD0

/DD14

/DD1

/DD13

/DD2

/DD12

/DD3

/DD11

/DD4

/DD10

/DD5

/DD9

/DD6

/DD8

/DD7

/GROUND

/DA1

/NC

/INTRQ

/GROUND

/IOROY

/RESET-

/NC

/NC

A/V JACK

GND

GND

REG+CCD

GND

GND

REG-CCD

GND

GND

GND

GND

GND

GND

GND

KEY_B

GND

GND

HOST_LED

SPK+

SPK-

KEY_A

INFO_SW

SET_SW

CAM_3.1V

CAM_3.1V

LED GREEN

HOST

CROSS KEY

S JACK

VIDEO

DSC

LITHIUM

AUTO

SW

BL_REGA

NC

LCD_BLK

BL_REGA

LCD_BLK

NC

VB

C12-

C8-V3C1-

AGND

GRB

HSYNC

SCL

VGH

VGoffL

C31+

VCAC

VSYNC

VCCVCC12+

NCNCPGND

VGoffH

NC

C1+

CSB

DFAP

GND1

PVDD

VCOMR

APOL

NC

NC

VA

4:3 LCD MODULE

C8+

ADJ0

VGL

SDA

VCIOUT

ADJ1

NC

C31-

POL

VSS1

C21P

VCOML

VSS

VB[G]

VGL

GCS

VDDA0

VS

C41N

PDO

VCIOUT

VCOMH

C12N

VDD1

C41P

VC[B]

VDD

C21N

GCL

C22P

VA[R]

16:9 LCD MODULE

C31P

HS

GDA

C22N

C11P

C12P

VGH

VDDA1

VCL

VCOIN

C11N

VDDA

C31N

SPEAKER

SPK-

SPK+

USB

LOCK

CU-SD008U

ٕ

SD CARD

XBRDMACK

XCFIORD

XCFIOWR

BRDMARQ

GND

GND

HARF_SW

FULL_SW

GND

GND

TRIG SW

WB_SENS

RMC

MB

SD

8

CCD

20

MAIN

10

USB HOST

DSP MEM

REAR

50

OPERATION

40

MONITOR

60

CLK24_ON

(Page2-35)

(Page2-29)

(Page2-5)

(Page2-27)

(Page2-19)

(Page2-25)

(Page2-17)

(Page2-23)

(Page2-9)

(Page2-11)

(Page2-13)

(Page2-21)

(Page2-15)

(Page2-7)

(Page2-41)

(Page2-41)

(Page2-36)

(Page2-37)

(Page2-31)

(Page2-39)

(Page2-33)

yf163_y10653001a_rev0.1

BOARD INTERCONNECTION

NOTES: The number of patch cords ( ) are indicated by interconnected.

Page 23

(No.YF163)2-5 2-6(No.YF163)

!

!

V_OUT

AU_SIG/L

TO AUDIO

TO 3D NR

TO SUB CPU

TO SUB CPU

TO SUB CPU

P_DET

C_OUT

Y_OUT

S_DET

AU_SIG/R

GND

D191

RB715W-X

2

1

3

R191

1k

LIT_3V

CHRG_LED

PLAY_SW

SET_SW

SJIG_RST

LCD_OPEN

REC_SW

POFF_SW

INFO_SW

KEY_C

LCD_RVS

ACES_LED

KEY_A

P_MEDIA

REG_4.9V

HRP

REG_3.1V

MON_R

MON_B

MON_G

VDCVF

HDCVF

ANA_OUT

LCD_CS

ANA_CLK

LCD_CTL

AL_3.1V

USBDN

VBUS

USBDP

GND

L131

NQR0506-002X

1

43

2

IC171

KSM-2003SN2E

RMC

1

OUT2GND3VCC

R171

IR_RMC

REG_3.1V

GND

T

C171

10/6.3

R172

1.5k

L171

NQR0129-002X

GND

REG_4.9V

T

C172

10/6.3

IR_OUT

CN102

QGF0508F1-40X

TO HDD

USB TERM

0.5mm_FPC_BOTTOM

1

3.3V23.3V33.3V4DASP-5CS1-6CS0-7DA28DA09PDIAG-10DA111INTRQ12DMACK-13GROUND14IORDY15GROUND16DIOR-17DIOW-18GROUND19DMARQ20GROUND21GROUND22DD1523DD024DD1425DD126DD1327DD228DD1229DD330DD1131DD432DD1033DD534DD935DD636DD837DD738GROUND39GROUND40RESET-

C122

0.1

C121

OPEN

[2125]

IC121

NAL0035-001X

1

GND2Tout3AGND4AOZ5AOY

21

6

AOX

7

NC

8

NC

9

NC

10

NC

22

11

STBYB

12

GND

13

AVCC14VREF15DVCC

23

16

GND

17

GND

18

GND

19

ZeroG

20

DGND

24

3AAZEROG

GND

AL_3.1V

L121

SHORT

SDDAT3

R145 47k

R141 47k

REG_3.1V

SDCD

SDDAT1

R148 22

R142

47k

L141

NQR0129-002X

SDCMD

SDCLK

C142 0.1

SDDAT0

GND

R147 10k

R144 47k

R143 47k

R150 22

CN111

NNZ0134-001X

9

SD_DATA2

1

SD_DATA3

2

SD_CMD

3

VSS(GND)

4

VDD(DSC_3V)

5

SD_CLK

6

VSS2

7

SD_DATA0

8

SD_DATA1

R149 22

SDDAT2

R151 22

SDWP

CN104

QGF0508F1-06X

TO ZOOM UNIT

0.5mm_FPC_BOTTOM

1

TELE

234

WIDE

56

WORD

GND

MON_R

SBD5

REG_3.1V

MON_G

R197

MON_B

NU_RX

HRP

ARMTDO

NU_TX

XARMTRST

ARMTDI

TO DSP

TO AUDIO

TO DSP

TO SUB CPU

TO SUB CPU

SUB CPU

TO MAIN IF(CN101,103),

3D NR

TO MAIN IF(CN101,)

ARMTCK

AL_3.1V

XJRESET

ARMTMS

CN110

QGB0512L1-30X

TO JIG CONNECTOR

0.5mm_BtoB

1162173184195206217228239241025112612271328142915

30

R196

R198

SJIG_TX

MOD0

VDCVF

SJIG_RX

SBT5

SJIG_RST

ZOOM_SW

TO SUB CPU

BL_POWER

J101

QNZ0497-001

2

3

4

5

6

7

1

T

C111

47/6.3

L111

SHORT

[2125]

DRV_3.3V

CN107

QGA1001F1-04X

TO MIC

1mm_ML

1234

CFD11

CFBVD2

CFD10

CFD15

TO USB HOST

TO USB HOST

TO DSP,USB HOST

TO PREPRCS,USB HOST

XCFIOWR

CFA1

CFD14

CFD9

CFD4

CFA2

CFD5

XCFCE1

CFD13

CFD3

CFD8

CFRDY

CFD2

XCFCE0

CFD1

CFD7

CFD12

XCFIORD

CFD6

CFD0

CFRESET

CFBVD1

XCFWAIT

CFA0

GND

INT_R

INT_GND

INT_L

REG_3.1V

GND

T

C141

10/6.3

D141

OPEN

123

45

CN111

NNZ0134-001X

10

CARD_DET

CN111

NNZ0134-001X

11

TERMINAL12WP_SW13GND

CN111

NNZ0134-001X

14

GND

D142

OPEN

123

45

R146 47k

Q162

OPEN

R165

OPEN

Q161

OPEN

5412

63

REG_15V

C161

OPEN

[2125]

R163

OPEN

C162

OPEN

R162

OPEN

R164

OPEN

REG+CCD

GND

R161

OPEN

R169

ZGH_OUT

ZGH_THRU

PS_ZEROG

ADP_L

GND

REG_1.2V

KEY_B

CAM_3.1V

REG_1.5V

M_REG4.9

REG_-7.5V

AL_3.1V

CHRG_EVR

L161

NQL38DK-100X

UNREGCHK

DRV_3.3V

REG_CS

SJIG_RST

T_BATT

V_BATT

I_MTR

CLK_OUT

REG_4.9V

REG_3.1V

D_BATT

TO SUB CPU

TO SUB CPU

TO SUB CPU

TO OP DRV

TO CDS,TG

TO TG

TO MAIN IF(CN101,CN110),

SUB CPU

REG_15V

DATA_OUT

CAM_3.1V

R166 OPEN

R167

XUSBHOST

TO USB HOST

TO DSP

46

CAM_3.1V

47 CAM_3.1V

48 GND

49

REG_3.1V

50 REG_3.1V

51 REG_3.1V

52 GND

53 GND

CN103

QGF0508F1-45X

(CN6001)

(CN401)

TO REAR

0.5mm_FPC_BOTTOM

1 GND

2 GND

3

D_BATT

4

KEY_B

5

DC_CHEK

6

CHRG_EVR

7

REG_CS

8 GND

9

CLK_OUT

10 DATA_OUT

11 GND

12 SJIG_RST

13 I_MTR

14 GND

15

V_BATT

16

T_BATT

17 GND

18

ADP_L

19 GND

20

REG-CCD

21 GND

22

REG+CCD

23 GND

24

UNREGCHK

25 GND

26

AL_3.1V

27 GND

28

DRV_3.3V

29 DRV_3.3V

30 DRV_3.3V

31 GND

32

REG_1.2V

33 REG_1.2V

34 REG_1.2V

35 GND

36

GND

37

REG_1.5V

38

REG_1.5V

39

REG_1.5V

40

GND

41

GND

42

REG_4.9V

43

REG_4.9V

44

REG_4.9V

45

GND

DC_CHEK

BL_POWER

R170

R173

OPEN

CN101

QGF0547C2-50X

TO OPE

0.5mm_FPC_VERTICAL

1 GND

2 GND

3

AU_SIG/L

4

AU_SIG/R

5

P_DET

6

V_OUT

7

C_OUT

8

S_DET

9

Y_OUT

10 GND

11 GND

12 LITHIUM

13

POFF_SW

14

REC_SW

15

PLAY_SW

16

CHRG_LED

17

ACES_LED

18

KEY_C

19

INFO_SW

20

SET_SW

21

KEY_A

22

P_MEDIA

23

LCD_OPEN

24

RESET_SW

25 LAMP_ON

26

GND

27 GND

28 GND

29 GND

30

HRP

31

REG_3.1V

32

REG_3.1V

33

REG_4.9V

34 REG_4.9V

35 REG_4.9V

36

BL_POWER

37

MON_B

38

MON_G

39

MON_R

40

HDCVF

41

VDCVF

42

LCD_CTL

43

ANA_CLK

44

ANA_OUT

45

LCD_CS

46

LCD_RVS

47

SPK+

48

SPK-

49

HOST_LED

50 GND

SPK+

SPK-

HOST_LED

XBRDMACK

BRDMARQ

Q422

DTC143XE-X

3

2

1

LAMP_ON

D421

EW5806X/3LMH/

LED_4.9V

GND

R421

1.5k

R101

LED_4.9V

Q171

RPM-22PB

W/B

GND

TP1

NNZ0159-001X

TP2

NNZ0159-001X

TP3

NNZ0159-001X

Q421

UMZ1N-W

5462

13

R424

24

R422

1.8k

R423

391

TL1

STRB_ENV

D181

2

3

GND

Q202

UMX1N-W

5412

63

R206

OPEN

R201

OPEN

C201

1

R205

24k

REG_14V

TO 3D NR

TO MAIN IF

(CN101)

TO TG

R202

27k

R204

1.8k

REG_15V

C202

1

Q201

2SA1577/QR/-X

R203

8.2k

0Ω

0Ω0Ω0Ω

0Ω

0Ω

0Ω

0Ω

_0.5%

_0.5%

110

140,150

190

ONBOARD CONTACT

MAIN(MAIN IF)

10

yf163_y10654001a_rev0.1

TO MAIN IF(CN103,CN110),

TO MAIN IF(CN110),

TO MAIN IF(R170)

TO CDS,TG

SUB CPU

3D NR

TO MAIN IF(CN110),

3D NR

TO MAIN IF(CN110),

3D NR

TO 3D NR

TO SUB CPU

TO SUB CPU

TO SUB CPU

TO SUB CPU,AUDIO,3D NR

TO AUDIO

TO SUB CPU

TO SUB CPU

TO OP DRV

TO PREPRCS

TO DSP

MAIN(MAIN IF) SCHEMATIC DIAGRAM

NOTES: 1. For the destination of each signal and further line connections that are cut off from this diagram, refer to "BOARD INTERCONNECTIONS".

2. The parts with marked ( ) is not used.

Page 24

(No.YF163)2-7 2-8(No.YF163)

PSCTL

EEPRM_CS

TVSEL

SYSSEL1

PD_L

DC_CHEK

SETSW

SCPU_SCK

DIAL_OFF

ACESLED

DC_CHEK

SCPU_SO

FLSH_RST

LCD_CS

CHRG_EVR

SCPU_CS

UNREGCHK

ANA_CLK

SYSSEL0

ZGH_OUT

ZGH_OUT

ZOOMSW

EEPRM_DO

OSD_CS

SCPU_CS

T_BATT

PD_L

PS_ZEROG

EEPRM_DO

ADP_L

A_MUTE

SDET

EEPRM_DI

SCPU_SI

LCD_CS

SCPU_SO

SETSW

ANA_CS

LCD_CTL

DIAL_REC

ANA_IN

T_BATT

KEY_ACH

ANA_OUT

ADP_L

DBATT

CHRGLED

PMEDIA

HOSTLED

BATT_H

ANA_CLK

3AAZEROG

AUDIO_CS

FLSH_RST

BATT_H

LCDRVS

L_MUTE

INFOSW

SCPU_SI

TG2_RST

ANA_RST

AVREF_OF

DIAL_OFF

EEPRM_CK

SBD5

ANA_OUT

CHRGLED

T_BATT

ACESLED

SYSSEL1

V_BATT

V27_OUT

KEY_CCH

UNREGCHK

HOSTLED

INFOSW

ANA_IN

ANA_CLK