JVC YF307 2009 6SERVICE MANUAL GZ-HD300AEK, GZ-HD300BEK, GZ-HD300AEU, GZ-HD300AEZ, GZ-HD300BER Service Manual

...

Page 1

SERVICE MANUAL

CAMCORDER

YF307<Rev.003>20096SERVICE MANUAL

GZ-HD300AEK, GZ-HD300AER, GZ-HD300AEU,

GZ-HD300AEZ, GZ-HD300BEK, GZ-HD300BER,

GZ-HD300BEU, GZ-HD300BEZ, GZ-HD300REK,

GZ-HD300RER, GZ-HD300REU, GZ-HD300REZ,

GZ-HD320BEK, GZ-HD320BER, GZ-HD320BEU,

GZ-HD320BEZ

COPYRIGHT © 2009 Victor Company of Japan, Limited

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

1 PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

5 TROUBLE SHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

COPYRIGHT © 2009 Victor Company of Japan, Limited

GZ-HD300AEKM,GZ-HD300AERM,GZ-HD300AEUM,GZ-HD300AEZM,

GZ-HD300BEKM,GZ-HD300BERM,GZ-HD300BEUM,GZ-HD300BEZM,

GZ-HD300REKM,GZ-HD300RERM,GZ-HD300REUM,GZ-HD300REZM, [M9H412]

GZ-HD320BEKM,GZ-HD320BERM,GZ-HD320BEUM,GZ-HD320BEZM [M9H416]

TABLE OF CONTENTS

No.YF307<Rev.003>

2009/7

Page 2

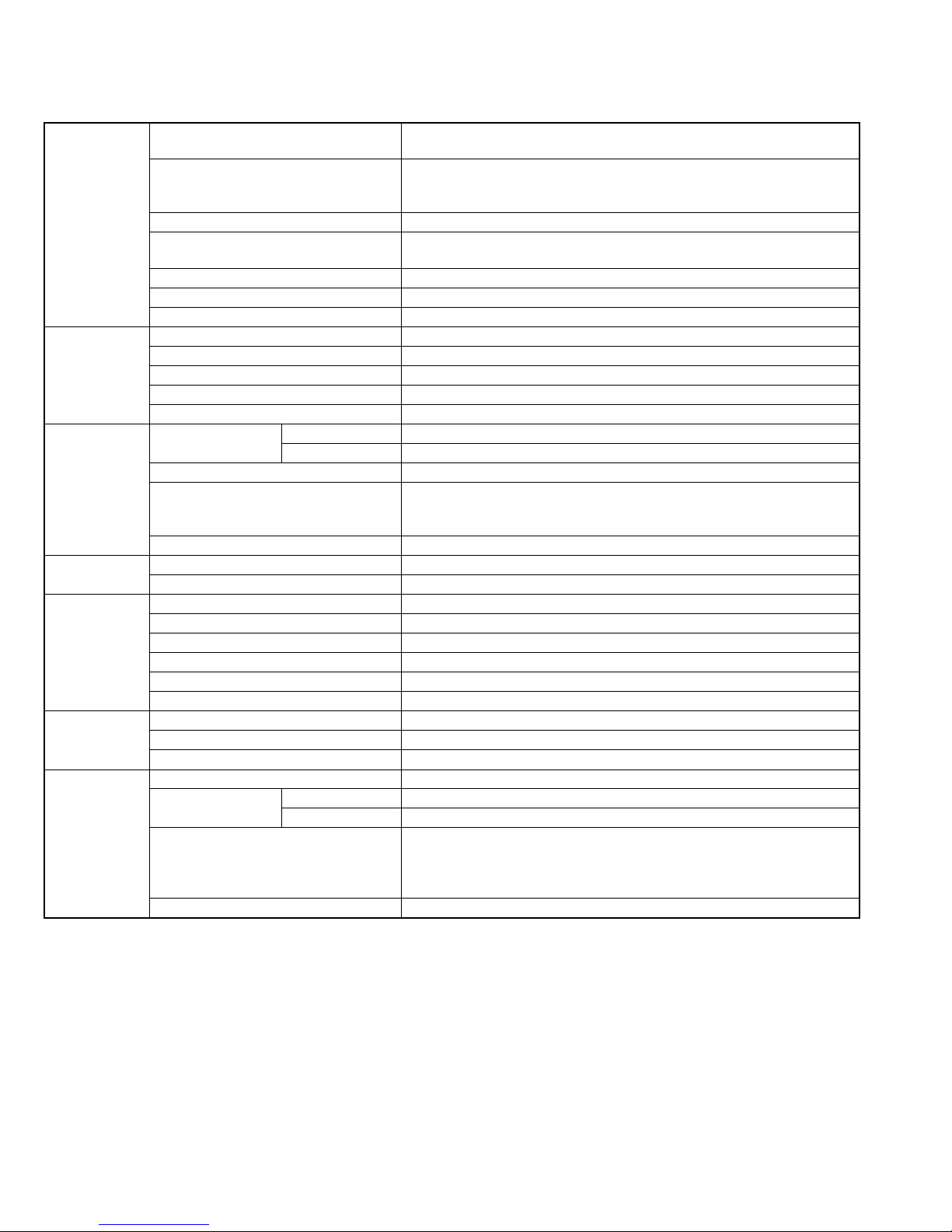

SPECIFICATION

General Power supply DC 11 V (Using AC adapter)

DC 7.2 V (Using battery pack)

Power consumption Approx. 3.5W*

* When the LED light is off and the monitor backlight is set to [STANDARD]

mode.

Dimensions (W × H × D) 53 mm × 68 mm × 113 mm

Weight Approx. 325 g

Approx. 370 g (incl. battery pack)

Operating temperature 0°C to 40°C

Storage temperature -20°C to 50°C

Operating humidity 35% to 80%

Camera/LCD

monitor

Connectors AV output Video output 1.0 V (p-p), 75 Ω

AC Adapter Power requirement AC 110 V to 240, 50 Hz/60 Hz

Remote Control Power supply DC 3 V

Still image Format JPEG

Video Signal format 1080/50i

Pickup 1/4.1" (3,050,000 pixels) progressive CMOS

Lens F 1.9 to 3.2, f = 2.9 mm to 58.0 mm, 20:1power zoom lens

Filter diameter Ø30.5 mm

LCD monitor 2.7" diagonally measured, LCD panel/TFT active matrix system

LED Light Within 1.5 m (recommended shooting distance)

Audio output 300 mV (rms), 1 kΩ

HDMI HDMI

Component output Y, Pb, Pr component output

USB Mini USB type A and type B,USB 2.0 compliant

Output DC 11 V, 1 A

Battery life Approx. 1 year (depending on the frequency of use)

Operating distance Within 5 m

Operating temperature 0°C to 40°C

Dimensions (W × H × D) 42 mm × 14.5 mm × 91 mm

Weight Approx. 30 g (incl. battery)

Image size 1920 × 1080, 1440 × 1080, 640 × 480

Image quality FINE/STANDARD

Recording/Playback

format

Recording mode (video) UXP: VBR, avarage of 24 Mbps

Recording mode (audio) 48 kHz, 256 kbps

Video MPEG-4 AVC/H.264

Audio Dolby Digital (2ch)

TM

(V.1.3 with x.v.ColorTM)

Y:1.0V (p-p), 75 Ω

Pb/Pr:700 mV (p-p), 75 Ω

XP: VBR, avarage of 17 Mbps

SP: VBR, avarage of 12 Mbps

EP: VBR, avarage of 5 Mbps

Design and specifications subject to change without notice.

1-2 (No.YF307<Rev.003>)

Page 3

SECTION 1

r

PRECAUTIONS

1.1 SAFETY PRECAUTIONS

Prior to shipment from the factory, JVC products are strictly

inspected to conform with the recognized product safety and

electrical codes of the countries in which they are to be

sold.However,in order to maintain such compliance, it is equally

important to implement the following precautions when a set is

being serviced.

1.1.1 Precautions during Servicing

(1) Locations requiring special caution are denoted by labels

and inscriptions on the cabinet, chassis and certain parts of

the product.When performing service, be sure to read and

comply with these and other cautionary notices appearing

in the operation and service manuals.

(2) Parts identified by the symbol and shaded ( ) parts

are critical for safety.

Replace only with specified part numbers.

NOTE :

Parts in this category also include those specified to

comply with X-ray emission standards for products

using cathode ray tubes and those specified for

compliance with various regulations regarding

spurious radiation emission.

(3) Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as

specified.

(4) Use specified internal wiring. Note especially:

• Wires covered with PVC tubing

• Double insulated wires

• High voltage leads

(5) Use specified insulating materials for hazardous live parts.

Note especially:

• Insulation Tape

• PVC tubing

•Spacers

• Insulation sheets for transistors

• Barrier

(6) When replacing AC primary side components (transformers,

power cords, noise blocking capacitors, etc.) wrap ends of

wires securely about the terminals before soldering.

emission. Consequently, when servicing these products,

replace the cathode ray tubes and other parts with only the

specified parts. Under no circumstances attempt to modify

these circuits.Unauthorized modification can increase the

high voltage value and cause X-ray emission from the

cathode ray tube.

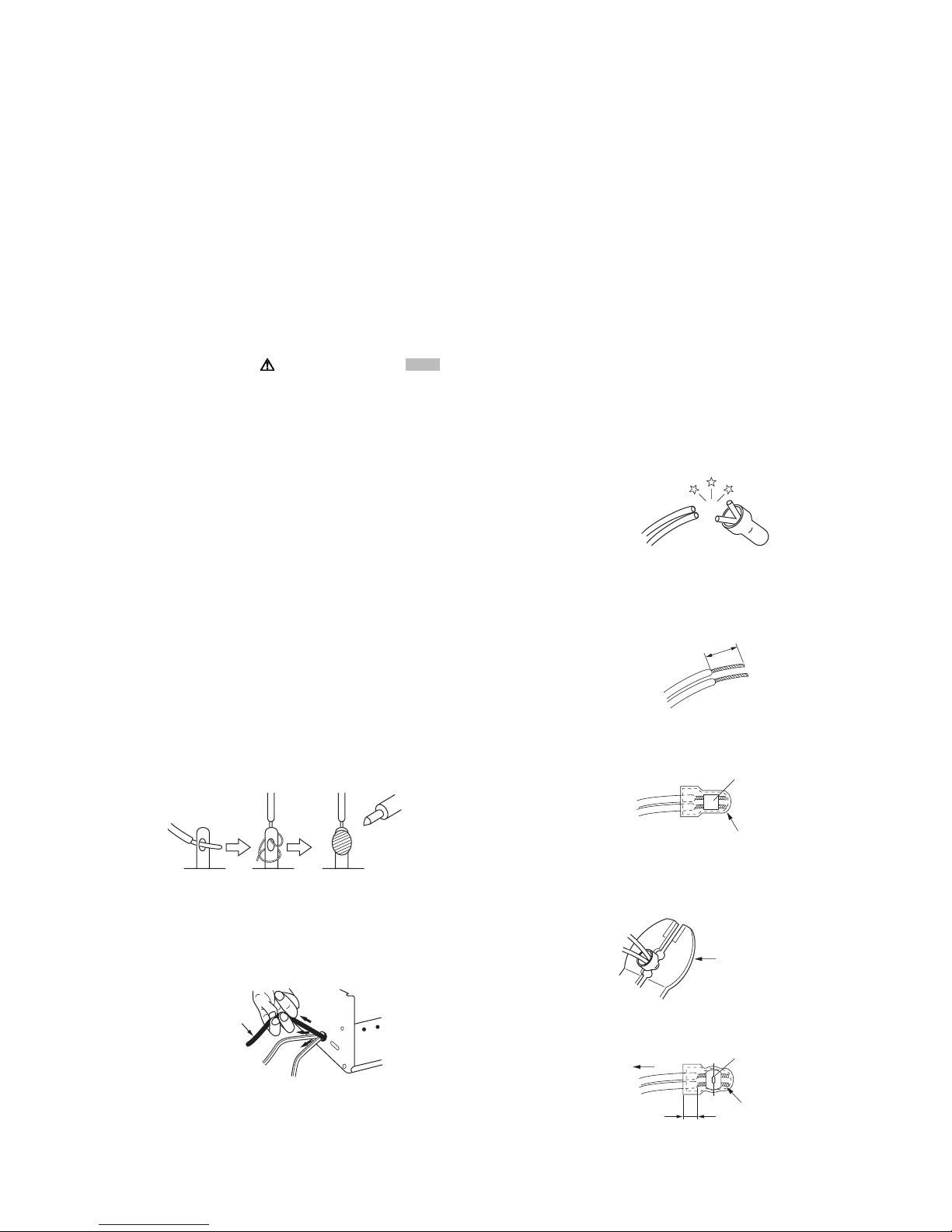

(12) Crimp type wire connectorIn such cases as when replacing

the power transformer in sets where the connections

between the power cord and power trans former primary

lead wires are performed using crimp type connectors, if

replacing the connectors is unavoidable, in order to prevent

safety hazards, perform carefully and precisely according

to the following steps.

• Connector part number :E03830-001

• Required tool : Connector crimping tool of the proper

type which will not damage insulated parts.

• Replacement procedure

a) Remove the old connector by cutting the wires at a

point close to the connector.Important : Do not

reuse a connector (discard it).

cut close to connector

Fig.1-1-3

b) Strip about 15 mm of the insulation from the ends

of the wires. If the wires are stranded, twist the

strands to avoid frayed conductors.

15 mm

Fig.1-1-4

c) Align the lengths of the wires to be connected.

Insert the wires fully into the connector.

Metal sleeve

Fig.1-1-1

(7) Observe that wires do not contact heat producing parts

(heatsinks, oxide metal film resistors, fusible resistors, etc.)

(8) Check that replaced wires do not contact sharp edged or

pointed parts.

(9) When a power cord has been replaced, check that 10-15

kg of force in any direction will not loosen it.

Power cord

Fig.1-1-2

(10) Also check areas surrounding repaired locations.

(11) Products using cathode ray tubes (CRTs)In regard to such

products, the cathode ray tubes themselves, the high

voltage circuits, and related circuits are specified for

compliance with recognized codes pertaining to X-ray

Connector

Fig.1-1-5

d) As shown in Fig.1-1-6, use the crimping tool to crimp

the metal sleeve at the center position. Be sure to

crimp fully to the complete closure of the tool.

1.2

5

2.0

5.5

Crimping tool

Fig.1-1-6

e) Check the four points noted in Fig.1-1-7.

Not easily pulled free

Wire insulation recessed

more than 4 mm

Crimped at approx. cente

of metal sleeve

Conductors extended

Fig.1-1-7

(No.YF307<Rev.003>)1-3

Page 4

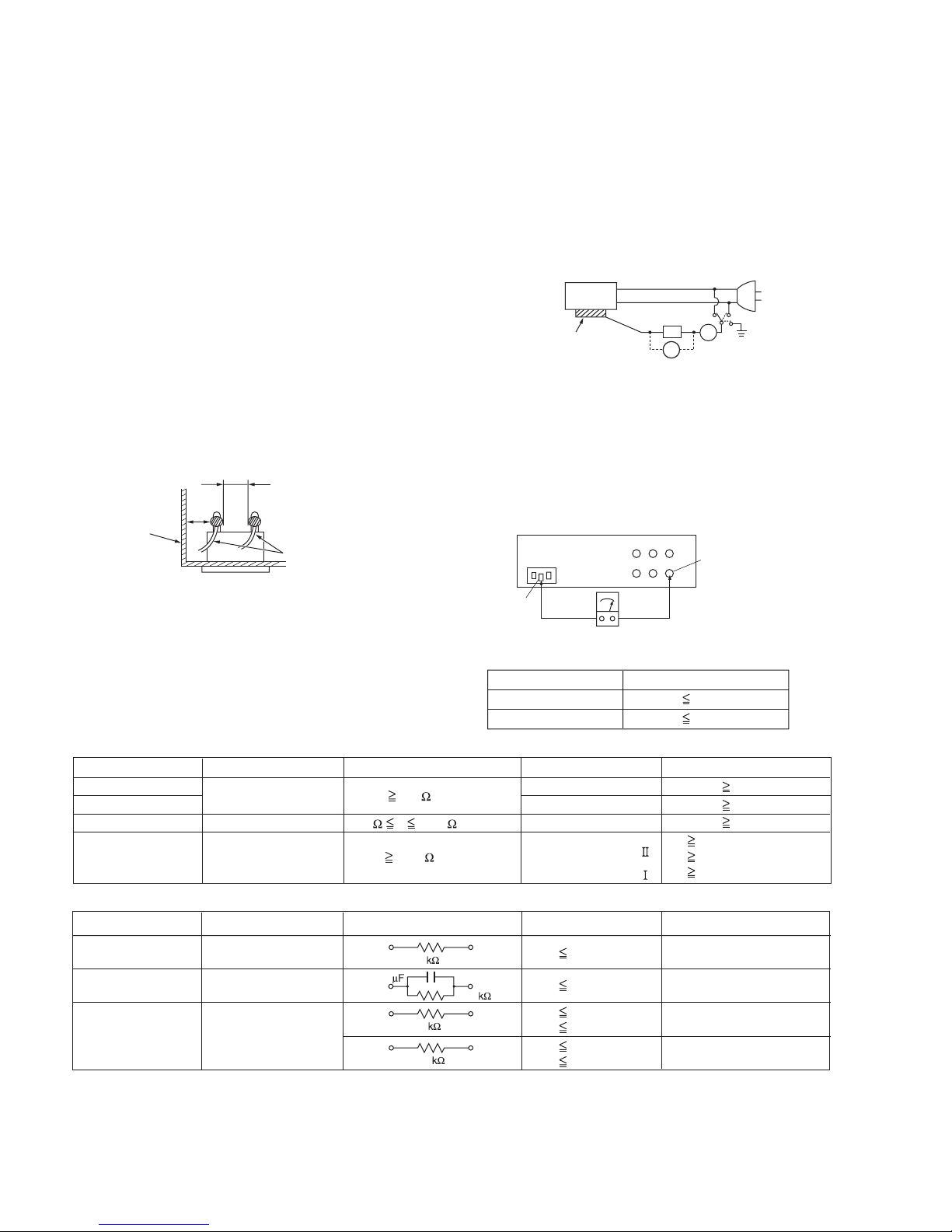

1.1.2 Safety Check after Servicing

Examine the area surrounding the repaired location for damage

or deterioration. Observe that screws, parts and wires have been

returned to original positions, Afterwards, perform the following

tests and confirm the specified values in order to verify

compliance with safety standards.

(1) Insulation resistance test

Confirm the specified insulation resistance or greater

between power cord plug prongs and externally exposed

parts of the set (RF terminals, antenna terminals, video and

audio input and output terminals, microphone jacks,

earphone jacks, etc.).See table 1 below.

(2) Dielectric strength test

Confirm specified dielectric strength or greater between

power cord plug prongs and exposed accessible parts of

the set (RF terminals, antenna terminals, video and audio

input and output terminals, microphone jacks, earphone

jacks, etc.). See Fig.1-1-11 below.

(3) Clearance distance

When replacing primary circuit components, confirm

specified clearance distance (d), (d') between soldered

terminals, and between terminals and surrounding metallic

parts. See Fig.1-1-11 below.

d

Chassis

d'

Power cord

primary wire

Fig.1-1-8

(4) Leakage current test

Confirm specified or lower leakage current between earth

ground/power cord plug prongs and externally exposed

accessible parts (RF terminals, antenna terminals, video

and audio input and output terminals, microphone jacks,

earphone jacks, etc.).

Measuring Method : (Power ON)Insert load Z between

earth ground/power cord plug prongs and externally

exposed accessible parts. Use an AC voltmeter to

measure across both terminals of load Z. See Fig.1-1-9

and following Fig.1-1-12.

ab

Externally

exposed

accessible part

Z

V

c

A

Fig.1-1-9

(5) Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between

earth pin in AC inlet and externally exposed accessible

parts (Video in, Video out, Audio in, Audio out or Fixing

screw etc.).Measuring Method:

Connect milli ohm meter between earth pin in AC inlet and

exposed accessible parts. See Fig.1-1-10 and grounding

specifications.

AC inlet

Earth pin

Exposed accessible part

MIlli ohm meter

Grounding Specifications

Region

USA & Canada

Europe & Australia

Grounding Impedance (Z

Z 0.1 ohm

Z 0.5 ohm

)

Fig.1-1-10

AC Line Voltage

100 V

100 to 240 V

110 to 130 V

110 to 130 V

200 to 240 V

Region

Japan

USA & Canada

Europe & Australia

Insulation Resistance (R

R 1 M /500 V DC

1 M R 12 M /500 V DC

R 10 M /500 V DC

)

Dielectric Strength

AC 1 kV 1 minute

AC 1.5 kV 1 minute

AC 1 kV 1 minute

AC 3 kV 1 minute

AC 1.5 kV 1 minute

(

Class

(

Class

Clearance Distance (d), (d'

d, d' 3 mm

d, d' 4 mm

d, d' 3.2 mm

d 4 m m

)

d' 8 m m (Power cord

d' 6 m m (Primary wire

)

Fig.1-1-11

AC Line Voltage

100 V

110 to 130 V

110 to 130 V

220 to 240 V

Region

Japan

USA & Canada

Europe & Australia

Load Z

1

0.15

1.5

2

50

Leakage Current (i)

i 1 mA rms

i 0.5 mA rms

i 0.7 mA peak

i 2 mA dc

i 0.7 mA peak

i 2 mA dc

a, b, c

Exposed accessible parts

Exposed accessible parts

Antenna earth terminals

Other terminals

Fig.1-1-12

NOTE :

These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

)

)

)

1-4 (No.YF307<Rev.003>)

Page 5

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

2.1 DIFFERENCE LIST

The following table indicate main different points between models GZ-HD300AEK, GZ-HD300AER, GZ-HD300AEU, GZ-HD300AEZ,

GZ-HD300BEK, GZ-HD300BER, GZ-HD300BEU, GZ-HD300BEZ, GZ-HD300REK, GZ-HD300RER, GZ-HD300REU, GZ-HD300REZ,

GZ-HD320BEK, GZ-HD320BER, GZ-HD320BEU and GZ-HD320BEZ .

MODEL GZ-

HD300AEK

GZ-

HD300AER

GZ-

HD300AEU

GZ-

HD300AEZ

GZ-

HD300BEK

GZ-

HD300BER

GZ-

HD300BEU

BODY COLOR BLUE BLUE BLUE BLUE BLACK BLACK BLACK

HDD 60GB 60GB 60GB 60GB 60GB 60GB 60GB

AC ADAPTER AP-V20M AP-V20E AP-V20E AP-V20E AP-V20M AP-V20E AP-V20E

AC CORD YES(BS) NO NO NO YES(BS) NO NO

MODEL GZ-

HD300BEZ

GZ-

HD300REK

GZ-

HD300RER

GZ-

HD300REU

GZ-

HD300REZ

GZ-

HD320BEK

GZ-HD320BER

BODY COLOR BLACK RED RED RED RED BLACK BLACK

HDD 60GB 60GB 60GB 60GB 60GB 120GB 120GB

AC ADAPTER AP-V20E AP-V20M AP-V20E AP-V20E AP-V20E AP-V20M AP-V20E

AC CORD NO YES(BS) NO NO NO YES(BS) NO

MODEL GZ-HD320BEU

BODY COLOR BLACK BLACK

HDD 120GB 120GB

AC ADAPTER AP-V20E AP-V20E

AC CORD NO NO

GZ-

HD320BEZ

2.3 CHECKING THE CPU VERSIONS

Procedure

(1) Open the MONITOR ASSY to turn the power ON.

(2) While halfway pressing and holding the [SNAPSHOT] but-

ton, repeat touching the buttons [A] and [B] 3 times in order:

[A]→[B]→[A]→[B]→[A]→[B].

2.2 REPLACING HDD

NOTE1) After HDD replacement, format the HDD first.

When the power is turned on after the HDD replacement, the

below "Warning screen" is displayed.

Be sure to format the HDD following the messages.

Be sure to turn off the power once after the formatting.

If the HDD recording is started without being turned off the power, normal recording cannot be performed although the recording will start.

NOTE2)

The picture title data needs to be written in the HDD.

Download the data and writing procedure from JS-NET.

Note that the picture title is a thumbnail image used in Creating Playlist including Titles and saved in the space where users cannot see.

(3) Release the halfway pressed [SNAPSHOT] button.

NOTE)

[VERSION INFO] is displayed on the monitor for about 5 seconds.

(4) Release the pressed [MENU] button, and the mode is

made clear.

NOTE)

When the mode is not canceled and the button is not operable, disconnect the battery or the DC cable to reset the power.

Even when the mode is canceled, resetting the power is

recommended.

Example:For GZ-HD320

LCD MONITOR

< "Warning screen">

VERSION INFO.

0''&61(14/#6*#4&&+5-

&4+8'

#..#9+..$''4#5'&

&1;179#0661(14/#6!

Fig.2-2-1

Model

Current Ver

EEPROM Ver

CAMCPU Ver 0.16

OK

Button[B]

NOTECurrent

CAMCPU Ver : CAMERA CPU VERSION

Ver : ELISE CPU VERSION

Name

GZ-HD320

1.05

12

Button[A]

NOTE

MENU

Fig.2-3-1

NOTE) Display of CAMCPU Ver: Camera CPU Version

As the Camera CPU Version cannot be displayed correctly,

check the version using Service Support System.

(No.YF307<Rev.003>)1-5

Page 6

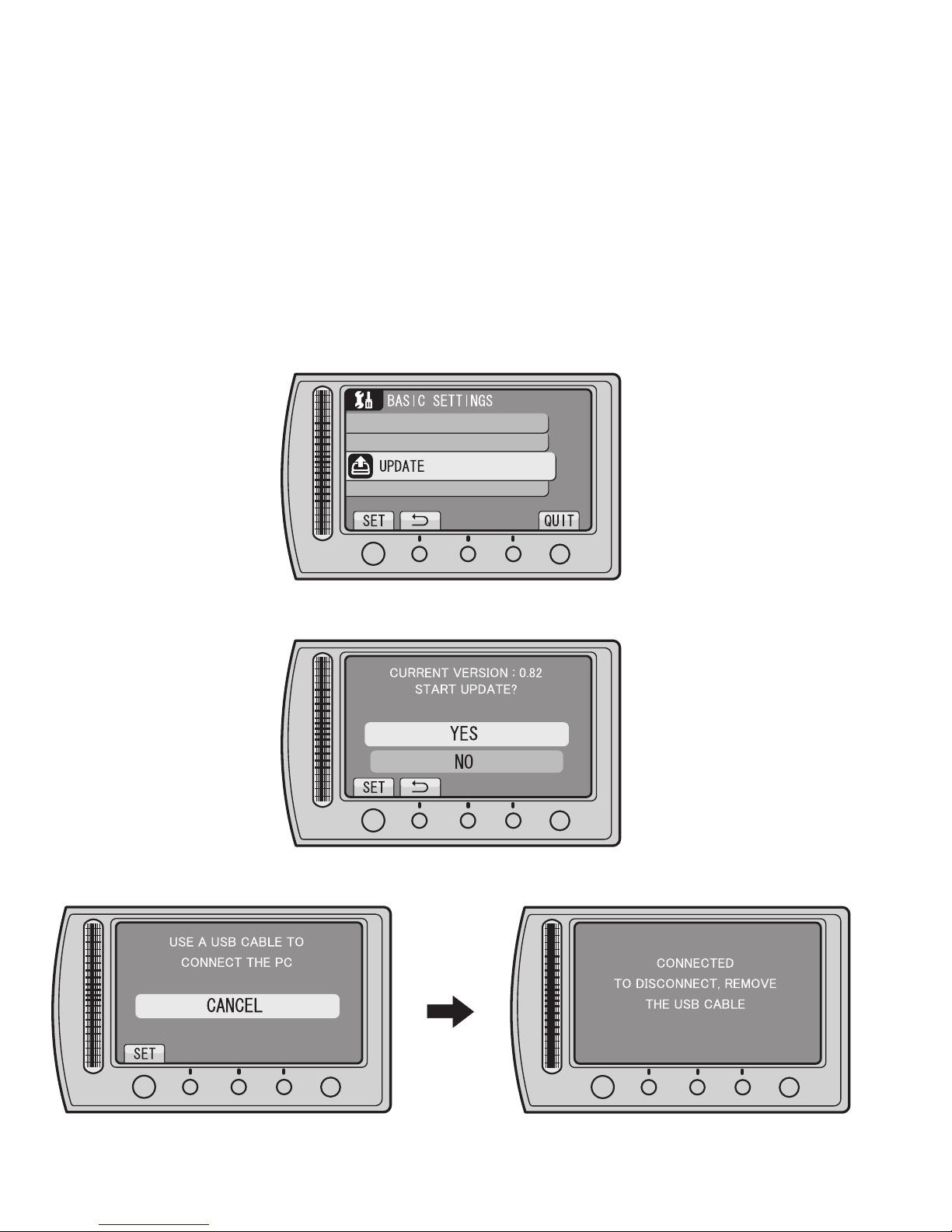

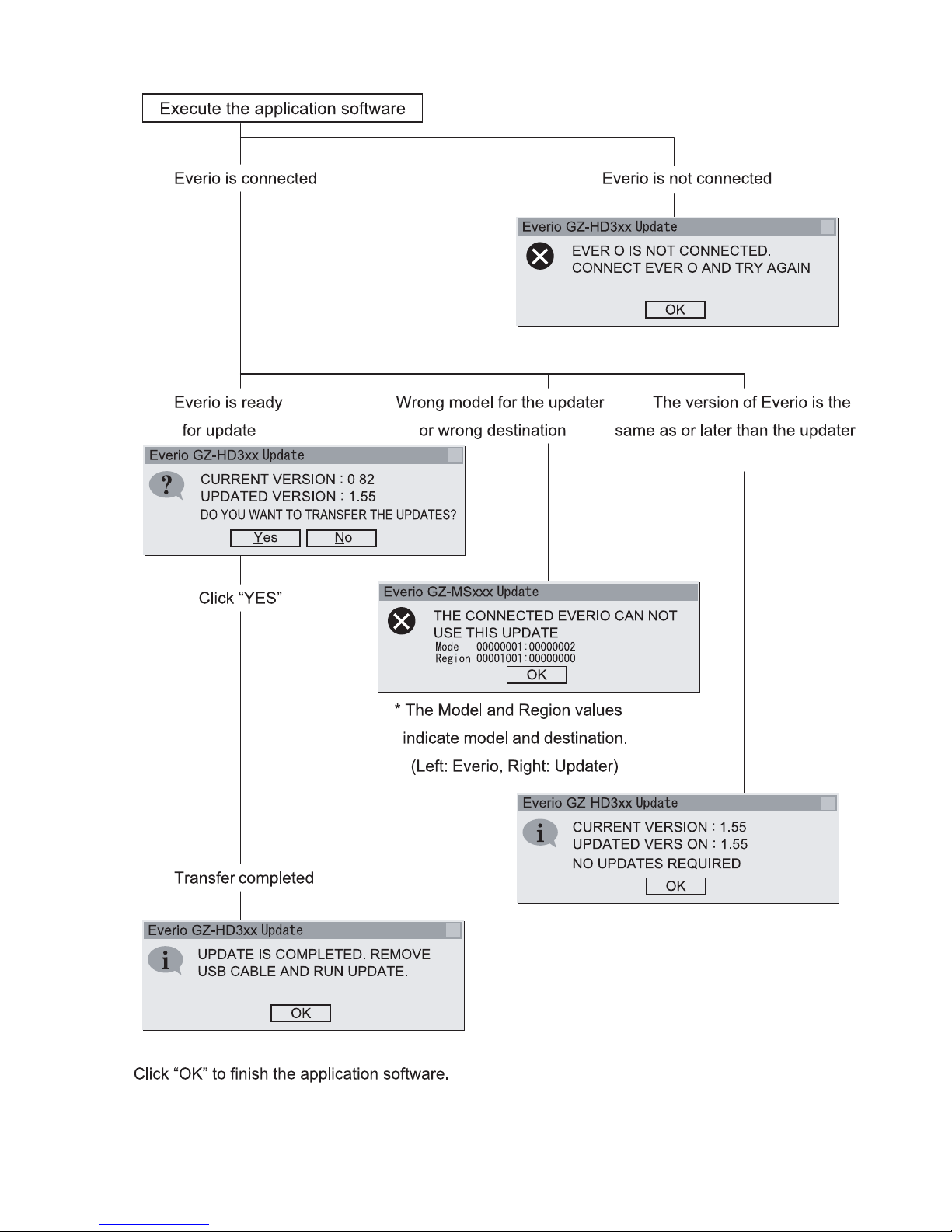

2.4 FIRMWARE UPDATE

Connecting Everio to a PC via USB cable enables firmware update.

Connect a battery, capable of operating for 10 minutes or longer, and an AC adapter to Everio for update.

* The following procedure shows the monitor displays of the firmware update from ver. 0.82 to ver. 1.55.

* Use Windows XP or Windows Vista.

1.Preparation

(1)Preparation

Download the firmware update application software from JS-NET.

(2)Connection

Connect a battery that is capable of operating for 10 minutes or longer and an AC adapter to Everio.

* To ensure secure power supply during the update, update is disabled if either of them is not available.

2.Firmware transfer

(1) Select "UPDATE" in the main menu of Everio.

MENU > BASIC SETTINGS > UPDATE

OK

Fig.2-4-1

(2)When the displayed current version is an old one, select "YES".

OK

Fig.2-4-2

(3)Follow the directions on the monitor to connect Everio to the PC via USB cable.

MENU

MENU

OK

1-6 (No.YF307<Rev.003>)

MENU

Fig.2-4-3

OK

MENU

Page 7

(4)Execute the downloaded application software.

×

×

×

×

×

Fig.2-4-4

(No.YF307<Rev.003>)1-7

Page 8

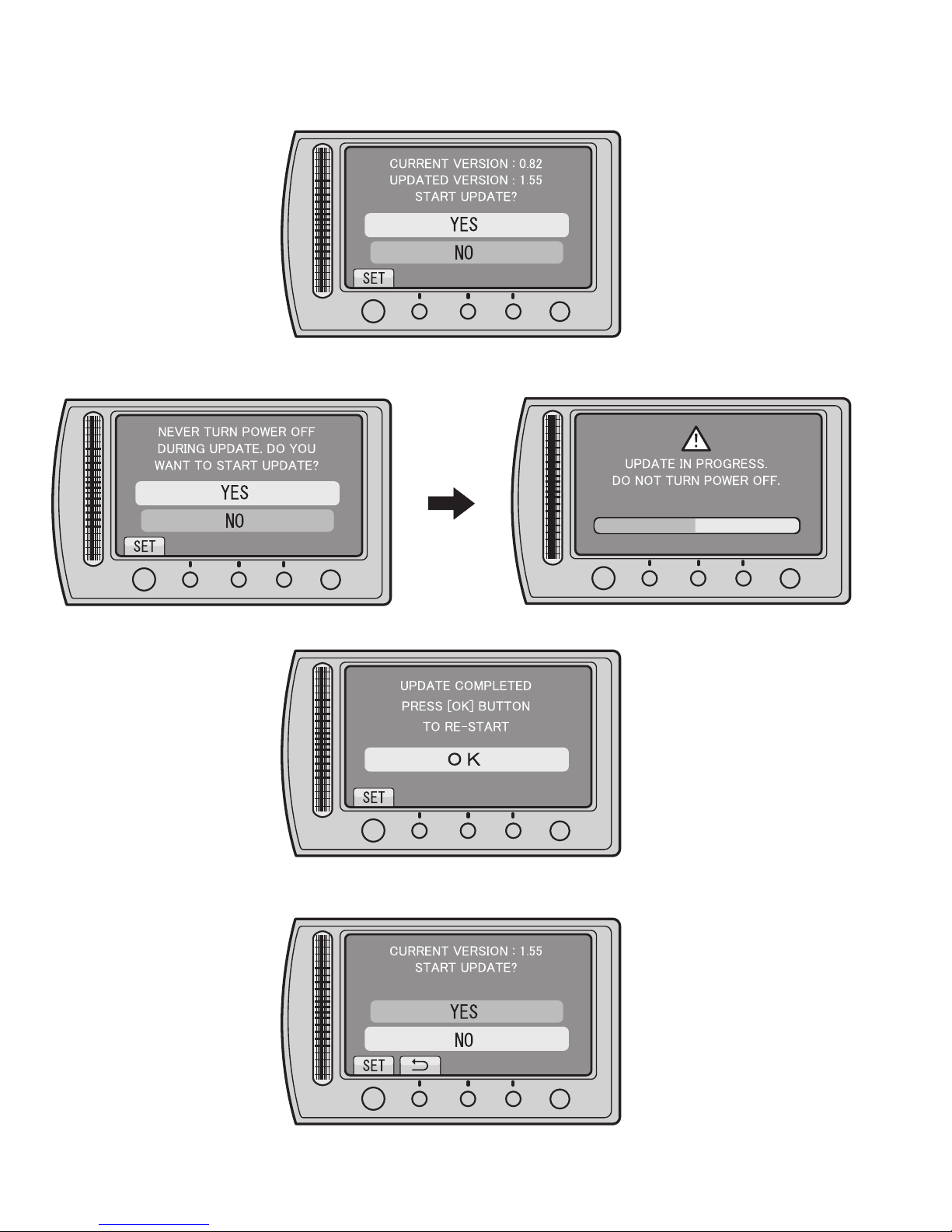

3.Execute update

(1)Disconnect the USB cable, and remove Everio from the PC.

(2)Check the current and updated versions, and then select "YES".

OK

Fig.2-4-5

(3)Carefully read and understand the warning, and then select "YES".

* It takes about 1 minutes and 30 seconds to complete the update.

OK

MENU

Fig.2-4-6

(4)Select "OK", and then re-start Everio.

MENU

OK

MENU

(5)After the re-start, check that the current firmware is updated in UPDATE.

MENU > BASIC SETTINGS > UPDATE

When the updated firmware version is confirmed, select "NO".

1-8 (No.YF307<Rev.003>)

OK

OK

MENU

Fig.2-4-7

MENU

Fig.2-4-8

Page 9

SECTION 3

DISASSEMBLY

3.1 BEFORE ASSEMBLY AND DISASSEMBLY

3.1.1 Precautions

• Be sure to disconnect the power supply unit prior to mounting

and soldering of parts.

• Prior to removing a component part that needs to disconnect

its connector(s) and its screw(s), first disconnect the wire(s)

from the connector(s), and then remove the screw(s).

• When connecting/disconnecting wires, pay enough attention

not to damage the connectors.

• When inserting the flat wire to the connector, pay attention to

the direction of the flat wire.

• Be careful in removing the parts to which some spacer or

shield is attached for reinforcement or insulation.

• When replacing chip parts (especially IC parts), first remove

the solder completely to prevent peeling of the pattern.

• Tighten screws properly during the procedures. Unless

otherwise specified, tighten screws at a torque of 0.088N

·cm). However, as this is a required value at the time of

(0.9kgf

production, use the value as a measuring stick when

proceeding repair services. (See "SERVICE NOTE" as for

tightening torque.)

3.1.2 Destination of connectors

Two kinds of double-arrows in connection tables respectively

show kinds of connector/wires.

: Wire: Flat wire : Board to board (B-B)

: The connector of the side to remove

CONN. No. PIN No.CONNECTOR

CN2a

CN2b

MAIN CN101

MAIN CN103

MONI BW CN761

MINI BW CN762

3.1.3 Disconnection of connectors (Wires)

Wire

FPC Connector

· Pull both ends of the connector in the arrow

direction, remove the lock and disconnect the flat

wire.

Wire

FPC Connector

· Pull the both ends of the board in the direction of the

arrow, and remove the Connector.

Wire

Lock

FPC Connector

B-B Connector

B-B Connector

· Pull the both ends of the board in the direction of the arrow, and remove the B-B Connector.

· Extend the locks in the direction of the arrow for

unlocking and then pull out the wire. After

removing the wire, immediately restore the locks

to their original positions because the locks are

apt to come off the connector.

· Extend the locks in the direction of the arrow for

unlocking and then pull out the wire. After

removing the wire, immediately restore the locks

to their original positions because the locks are

apt to come off the connector.

· Extend the locks in the direction of the arrow for

unlocking and then pull out the wire. After

removing the wire, immediately restore the locks

to their original positions because the locks are

apt to come off the connector.

Wire

FPC Connector

FPC

Connector

Lock

B-B Connector

Fig.3-1-1

·m

40

10

Lock

Wire

3.1.4 Tools required for disassembly and assembly

Torque driver

YTU94088

Chip IC replacement jig

PTS40844-2

Bit

YTU94088-003

Cleaning cloth

KSMM-01

Tweezers

P-895

Fig.3-1-2

• Torque driver

Be sure to use to fastening the mechanism and exterior parts

because those parts must strictly be controlled for tightening

torque.

• Bit

This bit is slightly longer than those set in conventional torque

drivers.

• Tweezers

To be used for removing and installing parts and wires.

• Chip IC replacement jig

To be used for replacement of IC.

• Cleaning cloth

Recommended cleaning cloth to wipe down the video heads,

mechanism (tape transport system), optical lens surface.

3.2 ASSEMBLY AND DISASSEMBLY OF MAIN PARTS

3.2.1 Assembly and disassembly

When reassembling, perform the step(s) in reverse order.

STEP

No.

[1]

[2]

PART

TOP COVER ASSY

UPPER ASSY

(Inc. VF ASSY,

SPEAKER/MONITOR)

[8]

E.VF UNIT(B/W)

(∗1) Order of steps in Procedure

When reassembling, preform the step(s) in the reverseorder.

These numbers are also used as the identification (location)

No. of parts Figures.

(∗2) Part to be removed or installed.

(∗3) Fig. No. showing Procedure or Part Location.

(∗4) Identification of part to be removed, unhooked, unlocked,

released, unplugged, unclamped or unsoldered.

S = Screw L = Lock, Release, Hook

SD = Solder CN = Connector

[Example]

• 4 (S1a) = Remove 4 S1a screws.

• 3 (L1a) = Disengage 3 L1a hooks.

• 2 (SD1a) = Unsolder 2 SD1a points.

• CN1a = Remove a CN1a connector.

(∗5) Adjustment information for installation.

Fig.

No.

4(S1a), 3(L1a),CN1a

C1

(S2a),2(S2b),3(S2c)

C2-1

2(SD1a),

L2,CN2a,b

2(S8),L8,CN8a

C2-2

POINT

( 4) ( 5)( 2) ( 3)( 1)

NOTE

-

-

NOTE 8

(No.YF307<Rev.003>)1-9

Page 10

3.2.2 Assembly/Dissambly of cabinet parts and electrical parts

z Disassembly procedure

STEP

PART NAME

No.

[1]

B.COVER(N)ASSY

[2]

COVER (HINGE) ASSY

[3]

HDD COVER ASSY

[4]

TOP COVER

[5]

HDD

[6]

HDD CASE ASSY

[7]

BKT(O.TOP)

[8]

ORNAMENT(TOP)

[9]

UPPER ASSY

REAR COVER ASSY

[10]

(Inc.REAR BOARD ASSY,ZOOM UNIT)

[11]

ZOOM UNIT

[12]

REAR BOARD ASSY

[13]

JACK BOARD ASSY

[14]

FRONT ASSY

[15]

MAIN BOARD ASSY

[16]

FRAME (PLATE) ASSY

[17]

OP BLOCK ASSY

[18]

BARRIER UNIT

[19]

HOOD(SCERW)

[20]

MIC

[21]

OPE BOARD ASSY

[22]

SPEAKER

[23]

MONITOR ASSY

Fig.

No.

3-2-1

3-2-2

3-2-3

3-2-4

3-2-5

3-2-6

3-2-7

3-2-8

3-2-9

3-2-10

3-2-11

3-2-12

3-2-13

3-2-14

3-2-15

3-2-16

3-2-17

3-2-18

3-2-19

3-2-20

3-2-21

3-2-22

POINT NOTE

3(S1),2(L1a), 2(L1b)

2(S2),2(L2)

4(S3a),S3b,L3a,b,4(L3c)

2(S4a),2(S4b),L14a,2(L4b),L4c

CN5

3(S6),L6a,b,c

2(S7),L7a,b,2(L7c),L7d

L8a,b,c,d,e

CN9,S9a,b,L9

CN10a,b,2(S10),L10a,b

S11,L11a,b

S12,L12a,b

CN13,2(S13),2(L13a)

S13,L13b,BKT(HDMI),PLATE(HDMI)

CN14a,b.L14a,b,c

2(S15),L15,CN15a,b

2(S16),L16a,b,c

3(S17),FRAME ASSY

S18a,2(S18b)

L19a,b

S20,L20a,b,PLATE(MIC)

S21a,CN21a,2(L21a),L21b,

CN21b,2(S21b),L21c,d

S22,BKT(SPEAKER),SPACER(SPK)

2(S23),L23

NOTE1

NOTE2

NOTE3

NOTE4

NOTE5a,b,c,d,e,f

-

-

NOTE8

NOTE9

-

-

-

NOTE13

-

NOTE14a,b

NOTE15

-

NOTE17a,b

NOTE18

-

NOTE20

NOTE21a,b,c,d,e

NOTE22a,b

NOTE23

NOTE1:

When removing the BOTTOM COVER ASSY, open and pull

up the COVER (SD).

NOTE2:

When removing the COVER (HINGE) ASSY, open the

MONITOR ASSY, remove the 2 screws, rotate the MONI-

TOR ASSY 90°, tilt it to the rear side, and then pull out the

COVER (HINGE) ASSY.

NOTE3:

Screw No.8 is located under the JACK COVER (USB). Remove or slide the JACK COVER (USB) to remove the screw.

NOTE4:

Screw No.11 is located under the JACK COVER (AV). Remove or slide the JACK COVER (AV) to remove the screw.

NOTE5a:

During the procedure, be careful in handling the parts. Pay

special attention not to give any external shock to the HDD.

NOTE5b:

When the HDD is replaced, be sure to refer to Replacing

HDD in "SECTION2 SPECIFIC SERVICE INSTRUCTIONS"

for the procedure after HDD replacement.

NOTE5c:

Be careful as the RUBBER SPACERS on both sides are

easily come off when the HDD is removed from the main

unit.

If the RUBBER SPACERS come off, be sure to attach them

in the correct direction shown in the figure.

NOTE5d:

When connecting the FPC to the connector, insert the FPC

straight into the connector. When locking the connector, be

careful not to give so much load that it bends the board.

NOTE5e:

In this procedure, the FPC connected to the HDD connector

is not removed. If the FPC is removed due to broken wire,

be careful in attachment direction.

Be sure to connect the STOPPER side to the HDD.

Pay attention as wrong attachment could damage the HDD.

NOTE5f:

Be careful with the wiring.

NOTE8:

During the procedure, be careful not to break the parts.

NOTE9:

Please refer to Fig.3-2-20 and the following procedure for removing the UPPER ASSY.

NOTE13:

The JACK BOARD ASSY is attached between the PLATE

(HDMI) and the BRACKET (HDMI). For replacement, remove the screw (No.28) and disassemble them if necessary.

NOTE14a:

When attaching the FRONT ASSY, be careful in handling

the wire and the FPC.

NOTE14b:

Please refer to Fig.3-2-18 and the following procedure for removing the FRONT ASSY.

NOTE15:

When attaching the MAIN BOARD ASSY, be careful in handling

the WIRE (CMOS).

NOTE17a:

Refer to 3.2.3 Assembly/Disambly of [17] OP BLOCK ASSY/

CMOS BOARD ASSY of OP BLOCK ASSY.

NOTE17b:

When attaching the OP BLOCK ASSY, be careful in handling the WIRE (CMOS).

NOTE18:

When attaching the BARRIER UNIT, be careful in handling

the WIRE (MIC).

NOTE20:

When attaching the MIC, attach the BARRIER UNIT before

handling the WIRE (MIC). (Refer to NOTE 18.)

NOTE21a:

When removing, remove the screw No.40 first to release the

FPC, and then pull out the FPC from the connector.

NOTE21b:

When removing the OPE BOARD ASSY, release the WIRE

(SPK) from the HOOK (L21b) first, and then pull out the

WIRE (SPK) from the connector.

NOTE21c:

When attaching, make sure that the LEVER of the

SW(S408) interlocks with the KNOB (SLIDE).

1-10 (No.YF307<Rev.003>)

Page 11

NOTE21d:

When attaching, be careful with the wiring.

NOTE21e:

During the procedure, be careful not to damage the parts.

When attaching the OPE BOARD ASSY with the MONITOR

ASSY closed, be especially careful not to break the

SWITCH (S401).

NOTE22a:

When removing the SPEAKER, be careful in handling as the

SPACER (SPK) may come off with the SPEAKER.

NOTE22b:

When attaching, be careful with the wiring.

As the final wiring is performed when attaching the OPE

BOARD ASSY, leave the wire as shown in the drawing.

NOTE23:

Refer to 3.2.4 Disassembly of [23] MONITOR ASSY.

z Destination of connectors

CN.

No.

CN5 MAIN CN102 HDD - 40

CN9 MAIN CN101 OPE CN401 36/40

CN10a MAIN CN104 OPE UNIT

CN10b MAIN CN103 REAR CN602 32/36

CN13 MAIN CN114 JACK - 40

CN14a MAIN CN111 LENS BARRIER - 6

CN14b MAIN CN107 MIC - 4

CN15a MAIN CN105 CMOS CN4001 22

CN15b MAIN CN106 OP BLOCK - 25

CN21a OPE CN402 MONITOR CN703 28/29

CN21b OPE CN401 SPEAKER - 2

CONNECTOR

PIN

No.

- 12

L2

[2]

a

b

4

(S2)

5

(S2)

Fig.3-2-2

a

b

NOTE2

1

(S1)

2

(S1)

L1a

3

(S1)

[1]

NOTE1

COVER(SD)

L1b

6

(S3a)

10

(S3b)

9

(S3a)

(S3a)

[3]

9

(S3a)

NOTE3

(S3a)

(S3b)

7

8

10

(S3a)

6

8

(S3a)

L3c

(S3a)

NOTE3

JACK

COVER

(USB)

L3b

L3a

7

8

(S3a)

Fig.3-2-1

Fig.3-2-3

(No.YF307<Rev.003>)1-11

Page 12

NOTE4

14

(S4b)

L4a

11

(S4a)

11

(S4a)

JACK

COVER

(AV)

L4c

13

(S4b)

12

(S4a)

[4]

L4b

L4a

14

(S4b)

12

(S4a)

NOTE4

11

(S4a)

15

(S6)

16

(S6)

17

(S6)

[6]

L6a

L6b

L6c

NOTE5f

FPC

MAIN BOARD ASSY

NOTE5e

FPC

NOTE5d

CN5

HDD

STOPPER

Fig.3-2-4

NOTE5a,b

NOTE5c

RUBBER SPACER

[5]

[7]

L7d

L7b

Fig.3-2-6

18

(S7)

19

(S7)

L7c

L7a

Fig.3-2-5

1-12 (No.YF307<Rev.003>)

Fig.3-2-7

Page 13

NOTE8

L8c

L8b

[10]

CN10a

L10b

L8d

L8e

[8]

Fig.3-2-8

CN9

L8a

CN10b

L10a

22

(S10)

23

(S10)

Fig.3-2-10

24

(S11)

[11]

20

(S9a)

L9

[9]

NOTE9

Fig.3-2-9

L11b

21

(S9b)

CN9

L11a

Fig.3-2-11

(No.YF307<Rev.003>)1-13

Page 14

[10]

NOTE14b

[14]

L14c

L14b

L14a

L12b

L12a

NOTE13

GASKET

28

(S13)

[12]

Fig.3-2-12

25

(S12)

FPC(LENS BARR.)

NOTE14a

WIRE(MIC)

30

(S15)

29

(S15)

CN14a(FPC)

WIRE(MIC)

FPC(LENS BARR.)

Fig.3-2-14

[15]

CN14b(WIRE)

L13b

GASKET

[13]

26

(S13a)

27

(S13a)

Fig.3-2-13

1-14 (No.YF307<Rev.003>)

CN13

L13a

GASKET

L15

CN15b

CMOS WIRE

Fig.3-2-15

NOTE15

CN15a

NOTE15

MAIN PWB

Page 15

L16b

32

(S16)

L16c

31

(S16)

[16]

L16a

[18]

(S18b)

37

(S18b)

38

NOTE18

WIRE(MIC)

NOTE18

WIRE(MIC)

36

(S18a)

NOTE17b

Fig.3-2-16

(S17)

34

(S17)

35

33

(S17)

[19]

L19a

L19b

Fig.3-2-18

39

(S20)

PLATE(MIC)

[20]

NOTE20

WIRE(MIC)

FRME ASSY

0.118Nm (1.2kgfcm)

Fig.3-2-17

NOTE17a

[17]

FRONT COVER ASSY

L20b

L20a

Fig.3-2-19

(No.YF307<Rev.003>)1-15

Page 16

[21]

41

(S21b)

42

(S21b)

CN21b

CN21a

NOTE21e

SW(S401)

WIRE(SPK)

a

L21b

L21a

NOTE21a

40

(S21a)

FPC

NOTE21c

[21]

CN21b

WIRE(SPK)

L21b

NOTE21eNOTE21b,d

SW(S401)

L21d

L21c

NOTE22b

WIRE(SPK)

NOTE22b

WIRE(SPK)

40

(S21a)

NOTE21a

BKT(SPACER)

[22]

a

FPC

43

(S22)

Fig.3-2-20

SW(S408)

KNOB(SLIDE)

SW(S408)

LEVER

[21]

44

(S23)

45

(S23)

[23]

NOTE23

NOTE22a

SPACER(SPK)

Fig.3-2-21 Fig.3-2-22

1-16 (No.YF307<Rev.003>)

L23

Page 17

3.2.3 Assembly/Disambly of [17] OP BLOCK ASSY/CMOS BOARD ASSY

zPrecautions

(1) Be careful in handling the LENS components.

Pay special attention to the surfaces to protect them from

stains, dust, or scratches.

If the surfaces are soiled with finger prints or other stains,

wipe them off with silicon paper, clean chamois leather,

or recommended cleaning cloth.

zDisassembly of OP BLOCK ASSY / CMOS BOARD ASSY

(1) Remove the screw (1), and then remove the

SHIELD(CMOS).

NOTE17a:

When reMmoving the SHIELD(CMOS), be careful in

handling as the SHIELD(CMOS) or CMOS BOARD

ASSY may be removed together with the HEAT

SHEET attached.

(2) Remove the 2 screws (2,3), and then remove the CMOS

FRAME ASSY.

NOTE17b:

When removing the CMOS FRAME ASSY, be careful

in handling as the CMOS FRAME ASSY may be removed together with the SHEET attached.

zAssembly of OP BLOCK ASSY / CMOS BOARD ASSY

zReplacement of service repair parts

NOTE17c:

(1) The SHEET is set in the OP BLOCK ASSY.

(2) Attach the CMOS FRAME ASSY first,so that the SHEET

stays in place, and tighten with the 2 screws (2,3).

(3) Attach the SHIELD(CMOS) first, and tighten with the

screw (1).

The service repair parts for the OP BLOCK ASSY are as listed below.

When replacing parts, be careful not to cut the FPCs or damage any parts by soldering (excessive heat).

(1) FOCUS MOTOR UNIT

(2) ZOOM MOTOR UNIT

(3) AUTO IRIS UNIT

NOTE 17d:

When replacing the FOCUS MOTOR UNIT or the ZOOM

MOTOR UNIT, solder the FPC at a space of about 0.1

mm above the terminal pin.

NOTE 17e:

The AUTO IRIS UNIT includes the FPC ASSY and two sensors.

The CMOS BOARD ASSY is included in CMOS

FRAME ASSY.

Replace the CMOS BOARD ASSY as a CMOS

FRAME ASSY, not as a single part replacement.

SD17b

6

(S17b)

ZOOM MOTOR

UNIT

7

(S17b)

10

(S17b)

8

(S17b)

9

(S17b)

NOTE17d

AUTO IRIS UNIT

4

(S17b)

FOCUS MOTOR

UNIT

5

(S17b)

SHIELD(CMOS)

NOTE17a

HEAT SHEET

NOTE17c

CMOS FRAME ASSY

CMOS BOARD ASSY

is contained.

NOTE17b

SHEET

2

(S17b)

1

(S17a)

3

(S17b)

OP BLOCK ASSY

OP BLOCK ASSY

0.078Nm (0.8kgfcm)

0.147 Nm (1.5kgfcm)

Fig.3-2-23

(No.YF307<Rev.003>)1-17

Page 18

3.2.4 Disassembly of [23] MONITOR ASSY

zCAUTIONS

(1) During the procedure, be careful in handling the LCD

MODULE and other parts. Pay special attention not to

damage or stain the monitor screen.

If fingerprints are left on the screen, wipe them with clean

chamois leather or a cleaning cloth.

z Removing MONITOR ASSY

(1) Remove the 2 screws (1,2).

(2)

Turn the HINGE UNIT ASSY 90°, and remove the 2 screws

(3,4).

(3) Remove the MONI.COVER ASSY by removing the 8

hooks (L23a-h).

(4) Release the lock of the connector (CN23a), and remove

ASSY

the HINGE UNIT

NOTE23a:

During the procedure, be careful in handling the FPC.

(5) Release the lock of the connectors (CN23b,c), and pull

out the FPC.

Remove the screw (5), and remove the MONITOR BOARD

(6)

ASSY .

NOTE23b:

During the procedure, be careful in handling the FPC.

(7) Remove the SHEET (M.REF), LIGHT GUIDE, SHEET(M/

DIFF), and the SHEET(BEF).

NOTE23c:

When attaching, insert one side of the SHEET (M/

DIFF) under the LCD CASE RIB.

NOTE23d:

When attaching, insert each tab on both sides of the

SHEET (M.REF) into the LCD CASE notch.

(8) Remove the LCD CASE, SHEET(COVER), LCD MOD-

ULE, SPACER(LCD) and the LCD BKT.

NOTE23e:

During the procedure, handle the five parts (LCD

CASE, SHEET(COVER), LCD MODULE, SPACER(LCD) and the LCD BKT) together.

NOTE23f:

The SENSOR BOARD ASSY is originally affixed to the

MONI.CASE ASSY using jigs and they have structures difficult to replace.

If replacement is required, please refer to the NOTE

and follow the operation procedure.

Assembly/Disambly of MONITOR CASE ASSY/SENSOR BOARD ASSY

z

Operation procedure

• Removing the part which is to be reused

Remove the SENSOR BOARD ASSY from the MONI.CASE

(1)

ASSY by gradually peeling off from the HINGE UNIT ASSY side.

NOTE23g:

During the procedure, be careful not to break.

Prepare the new SENSOR BOARD ASSY and D.FACE

TAPE and use them in place of the removed parts.

•

Completely peel off the remaining tape pieces of the D. FACE

TAPE left on the part to be reused (MONI.CASE ASSY).

NOTE23h:

Make sure that there are no D. FACE TAPE pieces or

foreign substances left on the surfaces. If necessary,

clean the surfaces using alcohol etc.

• Affixing the D. FACE TAPE to the SENSOR BOARD

(1) Affix the D. FACE TAPE to the SENSOR BOARD ASSY.

NOTE23j:

Securely fix the D. FACE TAPE, and then affix the SENSOR BOARD ASSY to the D. FACE TAPE by adjusting

the four frames of the SENSOR BOARD ASSY to the

1-18 (No.YF307<Rev.003>)

by lifting it up.

frame of the D. FACE TAPE. Evenly press over the paper backing of each long / short side of the L shape.

(2) Peel off the paper backing.

NOTE23k:

When removing the paper backing, check that there

are no foreign substances or air bubbles on the tape.

If there are foreign substances etc., completely remove them and continue the affixing procedure.

• Affixing the SENSOR BOARD ASSY to the MONI. CASE

(1) Affix the SENSOR BOARD ASSY to the MONI. CASE

NOTE23m:

When affixing, adjust the position of the long side of the

L shape to avoid misalignment, and then press evenly.

Be sure to press hard for 10 seconds or more on each

long/ short side of the L shape for even adhesion.

During the procedure, be careful to prevent foreign

substances or air bubbles from entering.

(2) After the replacement, make sure that there are no bro-

ken or deformed parts or any abnormalities.

Use the service software for the operation check of the

touch sensor sensitivity.

NOTE23g,j,k

SENSOR BOARD ASSY

NOTE23j,k

D.FACE TAPE

DETACHMENT PAPER

NOTE23j,k

SENSOR BOARD ASSY

D.FACE TAPE

Fig.3-2-24

zRemoving HINGE UNIT ASSY

(1) Remove the HINGE COVER(U).

(2) Remove the HINGE COVER(L).

(3) Remove the MAGNET.

NOTE23n:

During the procedure, be careful in handling the FPC.

During the procedure, be careful in handling the MAGNET.

When attaching, set the N pole outside as shown in the

figure. Be careful when removing as there is no marking.

NOTE23p:

During the procedure, be careful in handling the FPC.

NOTE23q:

The FPC, with its connection to the MONITOR BOARD

ASSY facing inward, is rolled around the axis (shaft) of

the HINGE UNIT ASSY rotation 2.5 rounds (2.5times).

Page 19

0.118 Nm (1.2kgfcm)

NOTE23p

FPC

<NOTE23p,q>

FPC

HINGE UNIT

HINGE COVER(U)

L23n

L23m

L23q

HINGE COVER(L)

HINGE UNIT

L23p

NOTE23n

MAGNET

3

(S23a)

NOTE23a

HINGE UNIT

ASSY

CN23a

L23a

4

(S23a)

L23k

L23e

CN23b

1

(S23a)

L23c

b

L23j

L23h

L23e

L23d

CN23c

MONI. COVER

ASSY

MONI. COVER

ASSY

L23g

L23f

2

(S23a)

<MONI. CASE SIDE>

NOTE23e

(REINFORCED SIDE)

LCD BKT

SPACER(LCD)

LCD MODULE

SHEET(COVER)

LCD CASE

CN20b

NOTE23d

NOTE23c

NOTE23c

LCD CASE

LIB

CN23c

g

b

f

c

j

h

f,h

c

FPC

NOTE23b

g,j

5

(S23b)

MONI. BOARD

ASSY

d

e

SHEET(M.REF)

m

k

LIGHT GUIDE

SHEET(M/DIFF)

SHEET(BEF)

e

m

k

d

NOTE23b

FPC

<MONI. COVER SIDE>

SENSOR BOARD

Fig.3-2-25

ASSY

NOTE23f,j

MONI. CASE ASSY

NOTE23f,g,h,m

(No.YF307<Rev.003>)1-19

Page 20

SECTION 4

ADJUSTMENT

4.1 PREPARATION

4.1.1 Precaution

Camera system and deck system of this model are specially

adjusted by using PC.

However, if parts such as the following are replaced, an

adjustment is required. The adjustment must be performed in a

Service Center equipped with the concerned facilities.

• EEP ROM (IC1005 of MAIN board)

• OP BLOCK ASSY

• MONITOR ASSY

In the event of malfunction with electrical circuits, first find a

defective portion with the aid of proper test instruments as shown

in the following electrical adjustment procedure, and then

commence necessary repair/ replacement/adjustment.

• In observing chip TP, use IC clips, etc. to avoid any stress.

Prior to replacement of chip parts (especially IC), remove the

solder completely to prevent peeling of the pattern.

• Use a patch cord if necessary. As for a patch cord, see the

BOARD INTERCONNECTIONS.

• Since connectors are fragile, carefully handle them in

disconnecting and connecting the FPC.

4.1.2 Required test equipment

• Personal computer (for Windows)

• Color TV monitor

• Oscilloscope (dual-trace type, observable 100MHz or higher

frequency). The one observable 300 MHz or higher frequency

is recommended.

• Digital voltmeter

• DC power supply or AC adapter

• Frequency counter (with threshold level adjuster)

4.1.3 Tools required for adjustment

Torque Driver

YTU94088

Chip IC Replacement Jig

PTS40844-2

INF Adjustment Lens Holder

YTU94087

Gray Scale Chart

YTU94133A

Service Support System

YTU94057-117

Bit

YTU94088-003

Cleaning Cloth

KSMM-01

Mini Stand

YTU93108

Color Bar Chart

YTU94133C

Communication Cable

YTU93111-1

Tweezers

P-895

INF Adjustment Lens

YTU92001D

Light Box Assembly

YTU93096B

Focus Chart

YTU92001-018

1-20 (No.YF307<Rev.003>)

PC Cable

QAM0099-005

IDE Adapter

YTU96041

Jig Connector Cable

YTU93106D

IDE Adapter

YTU96043

Charing Battery Adjuatment Jig

YTU93112A

FPC Wire

YTU94165-40

• Torque Driver

Be sure to use to fastening the mechanism and exterior parts

because those parts must strictly be controlled for tightening

torque.

• Bit

This bit is slightly longer than those set in conventional torque

drivers.

• Tweezers

To be used for removing and installing parts and wires.

Page 21

• Chip IC Replacement Jig

To be used for adjustment of the camera system.

• Cleaning Cloth

Recommended the Cleaning cloth to wipe down the video

heads, mechanism (tape transport system), optical lens surface.

• INF Adjustment Lens

To be used for adjustment of the camera system. For the

usage of the INF adjustment lens, refer to the Service Bulletin

No. YA-SB-10035.

• INF Adjustment Lens Holder

To be used together with the Camera stand for operating the

Videocamera in the stripped-down condition such as the status without the exterior parts or for using commodities that are

not yet conformable to the interchangeable ring. For the usage

of the INF lens holder, refer to the Service Bulletin No. YA-SB-

10035.

• Mini Stand

To be used together with the INF adjustment lens holder. For

the usage of the Mini stand, refer to the Service Bulletin No.

YA-SB-10035.

• Light Box Assembly

To be used for adjustment of the camera system. For the

usage of the Light box assembly, refer to the Service Bulletin

No. YA-SB-10035.

• Gray Scale Chart

To be used for adjustment of the camera system. For the

usage of the INF adjustment lens, refer to the Service Bulletin

No. YA-SB-10035.

• Color Bar Chart

To be used for adjustment of the camera system. For the

usage of the INF adjustment lens, refer to the Service Bulletin

No. YA-SB-10035.

• Focus Chart

To be used for adjustment of the camera system. For the

usage of the INF adjustment lens, refer to the Service Bulletin

No. YA-SB-10035.

• Service Support System

To be used for adjustment with a personal computer. Software

can be downloaded also from JS-net.

• Communication Cable

Connect the Communication cable between the PC cable and

Jig connector cable when performing a PC adjustment.

• PC Cable

To be used to connect the Videocamera and a personal computer

with each other when a personal computer issued for adjustment.

• Jig Connector Cable

Connected to JIG CONNECTOR of the main board and used

for electrical adjustment, etc.

• Charging Battery Adjustment Jig

This Jig is used for the adjustment of the camcorders that have

Main Body battery charging function.

• IDE Adapter(YTU96041)

To be used for HDD test.

• IDE Adapter(YTU96043)

To be used for HDD test.

• FPC Wire

To be used for connecting the HDD to the IDE adapter.

4.2 JIG CONNECTOR CABLE CONNECTION

Connection procedure

NOTE

• Be sure to turn the power “OFF”, when connecting the JIG

CONNECTOR CABLE.

If the JIG CONNECTOR CABLE is connected with the power “ON”, communication error may occur.

• Remove the 3 screws (1-3), and then remove the B.COV-

ER ASSY.

3

B.COVER ASSY

2

1

JIG

CONNECTOR

JIG CONNECTOR

CABLE

SERVICE

SUPPORT

SYSTEM

RS232C

COMMUNICATION

CABLE

JIG CONNECTOR

TO AL_2.8V

TO IF_RX

TO IF_TX

TO GND

BLUE

WHITE

BLACK

or

COMMUNICATION

CABLE

RED

COM PORT

PC CABLE

MENU

PERSONAL COMPUTER

Fig.4-2-1

JIG CONNECTOR CABLE [YTU93106D]

1630

115

Fig.4-2-2

(No.YF307<Rev.003>)1-21

Page 22

Jig connector diagrams

JIG CONNECTOR CABLE (YTU93106D)

MAIN CN110

DSP_TDO

DSP_TCK

DSP_TMS

DSP_TDI

XDSPTRST

XDSPSRST

REG_2.83V

UARXD0

UATXD0

AL_2.8V

IF_TX

IF_RX

NC

SYS_RSTL

OCD_SCL

CAPSENS_DT

NC

GND

OCD_SDA

GND

MVD

IRU

ISSP_DATA

NC

NC

EXTRG0

DSP_RTCK

KENTO

GND

KENTO2

JIG CONN. BOARD

(PIN NO.)

1

16

2

17

3

18

4

19

5

20

6

21

7

22

8

23

9

24

10

25

11

26

12

27

13

28

14

29

15

30

1

2

XDSPTRST

3

REG_2.83V

4

5

6

7

8

9

10

11

ISSP_DATA

12

13

DSP_RTCK

14

15

16

17

XDSPSRST

18

19

20

21

SYS_RSTL

22

CAPSENS_DT

23

24

25

26

27

28

29

30

DSP_TDO

DSP_TMS

UATXD0

IF_TX

NC

OCD_SCL

NC

OCD_SDA

MVD

NC

GND

DSP_TCK

DSP_TDI

UARXD0

AL_2.8V

IF_RX

GND

GND

IRU

NC

EXTRG0

KENTO

KENTO2

Fig.4-2-3

1-22 (No.YF307<Rev.003>)

Page 23

4.3 IDE ADAPTER AND FPC WIRE

• IDE ADAPTER and FPC WIRE are used for HDD test.

Check with the NOTE, and then refer to the below figure (Fig. 4-3-1, Fig.4-3-2) for the connection procedure.

<TYPE-T>

FPC WIRE(Parts No.:YTU94165-40)

<BACK SIDE><FRONT SIDE>

HDD HDD

IDE ADAPTER CONNECTOR

LABEL

Fig.4-3-1

<TYPE-S>

FPC WIRE(Parts No.:YTU94165-40)

<BACK SIDE><FRONT SIDE>

HDD HDD

CONNECTOR

LABELIDE ADAPTER

Fig.4-3-2

<NOTE>

• During the procedure, be careful in handling the parts. Pay special attention not to give any external shock to the HDD.

• There are two types of IDE ADAPTER (Parts Number: YTU96041, YTU96043). Either type can be used.

• Using the FPC WIRE originally used with this unit will damage the HDD.

Use the FPC WIRE (Parts Number: YTU94165-40) to connect the IDE ADAPTER and the HDD.

Connecting the FPC WIRE upside-down will damage the HDD.

(No.YF307<Rev.003>)1-23

Page 24

5.1 SERVICE NOTE

SECTION 5

TROUBLE SHOOTING

[12][11]

-

-

3-2-123-2-11

aa

3-2-10

-

3-2-8

3-2-6 3-2-7 3-2-9

-

3-2-5

ab

[23]

-

-

[20]MONITOR ASSY

3-2-24

1 2 3 4 5

b-

a

aaa

3-2-15 3-2-16 3-2-183-2-17 3-2-20 3-2-22

-

[14]

[1] [2] [4][3] [5] [6] [7] [8] [9] [10]

CABINET PARTS AND ELECTRICAL PARTS(1)

Symbol No.

3-2-1 3-2-2 3-2-3 3-2-4

1 2 3 4 5 6 7 8 9 10 11 12 13 14 - 15 16 17 18 19 - 20 21 22 23 24 25

Place to stick screw

Removing order of screw

Screw tightening torque

Reference drawing (Fig.No.)

[13] [15] [16] [17] [18] [19] [20] [21] [22] [23]

CABINET PARTS AND ELECTRICAL PARTS(2)

Symbol No.

3-2-14 3-2-19 3-2-21

a

3-2-13

26 27 28 - 29 30 31 32 33 34 35 36 37 38 - 39 40 41 42 43 44 45

Place to stick screw

Removing order of screw

Screw tightening torque

Reference drawing (Fig.No.)

[17]

[14]OP BLOCK ASSY/CCD BOARD ASSY

Symbol No.

3-2-23

cd

1 2 3 4 5 6 7 8 9 10

Place to stick screw

Removing order of screw

Screw tightening torque

Reference drawing (Fig.No.)

Prepare the specified screws and use them in place of the removed screws.

Be careful not to break either the screws or the screw holes.

and tighten the screw manually.

The specified torque value is a recommended value of the initial assembly. Therefore, set the value below the specified torque value in the assembling procedure.

There are setting limits of the torque value for the torque driver. If the value exceeds the setting value, take it as a rough measurement (reference value),

㧞)Tightening torque for the screws

㧝)㧖and㧖㧖 (This mark shows where to attach the screws) : Do not reuse the screws because the screw lock bond was applied to prevent the screws from loosening.

NOTE:

a㧦0.088N㨯m (0.9kgf㨯cm) b㧦0.118N㨯m (1.2kgf㨯cm) c㧦0.147N㨯m (1.5kgf㨯cm) d㧦0.078N㨯m (0.8kgf㨯cm)

1-24 (No.YF307<Rev.003>)

Page 25

Victor Company of Japan, Limited

Camcorder Division 12, 3-chome, Moriya-cho, Kanagawa-ku, Yokohama-city, Kanagawa-prefecture, 221-8528, Japan

(No.YF307<Rev.003>)

Printed in Japan

VSE

Loading...

Loading...