Page 1

SERVICE MANUAL

HD HARD DISK CAMERA

YF289<Rev.003>20096SERVICE MANUAL

GZ-HD300AUS, GZ-HD300BUS,

GZ-HD300RUS, GZ-HD310BUC,

GZ-HD320BUS

GZ-HD300AUSM, GZ-HD300BUSM, GZ-HD300RUSM[M9H413]

GZ-HD310BUCM[M9H415]

GZ-HD320BUSM [M9H417]

COPYRIGHT © 2009 Victor Company of Japan, Limited

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

TABLE OF CONTENTS

1 PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

5 TROUBLE SHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

COPYRIGHT © 2009 Victor Company of Japan, Limited

No.YF289<Rev.003>

2009/7

Page 2

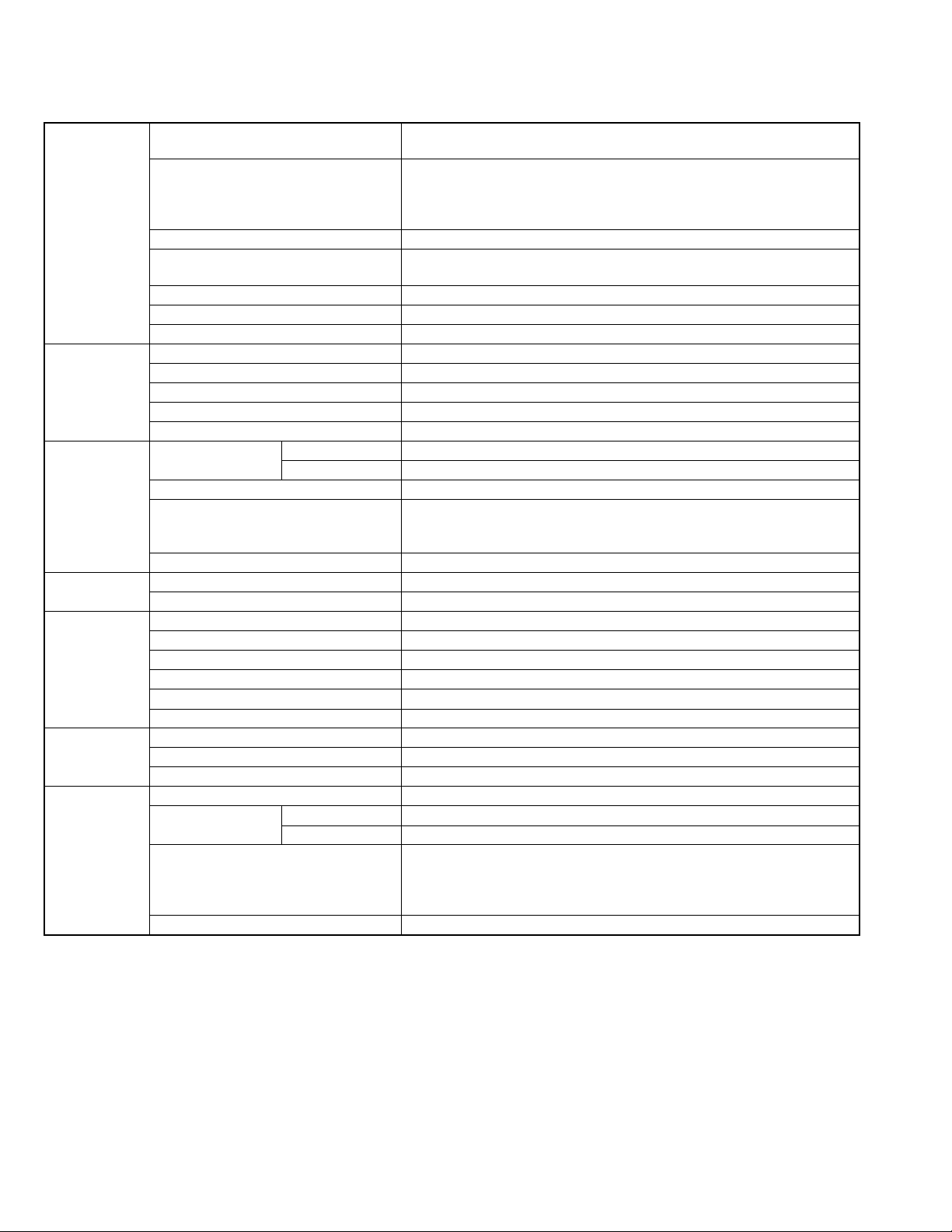

SPECIFICATION

General Power supply DC 11 V (Using AC adapter)

DC 7.2 V (Using battery pack)

Power consumption Approx. 3.5W*

* When the LED light is off and the monitor backlight is set to [STANDARD]

mode.

Rated Current Consumption: 1A

Dimensions (W × H × D) 53 mm × 68 mm × 113 mm (2-1/8" × 2-11/16" × 4-1/2")

Weight Approx. 325 g (0.7 lbs)

Approx. 370 g (0.8 lbs) (incl. battery pack)

Operating temperature 0°C to 40°C (32°F to 104°F)

Storage temperature -20°C to 50°C (-4°F to 122°F)

Operating humidity 35% to 80%

Camera/LCD

monitor

Connectors AV output Video output 1.0 V (p-p), 75 Ω

AC Adapter Power requirement AC 110 V to 240, 50 Hz/60 Hz

Remote Control Power supply DC 3 V

Still image Format JPEG

Video Signal format 1080/60i

Pickup 1/4.1" (3,050,000 pixels) progressive CMOS

Lens F 1.9 to 3.2, f = 2.9 mm to 58.0 mm, 20:1power zoom lens

Filter diameter Ø30.5 mm

LCD monitor 2.7" diagonally measured, LCD panel/TFT active matrix system

LED Light Within 1.5 m (4.9 ft) (recommended shooting distance)

Audio output 300 mV (rms), 1 kΩ

HDMI HDMI

Component output Y, Pb, Pr component output

USB Mini USB type A and type B,USB 2.0 compliant

Output DC 11 V, 1 A

Battery life Approx. 1 year (depending on the frequency of use)

Operating distance Within 5 m (16.4 ft)

Operating temperature 0°C to 40°C (32°F to 104°F)

Dimensions (W × H × D) 42 mm × 14.5 mm × 91 mm (1-11/16" × 5/8" × 3-5/8")

Weight Approx. 30 g (0.07 lbs) (incl. battery)

Image size 1920 × 1080, 1440 × 1080, 640 × 480

Image quality FINE/STANDARD

Recording/Playback

format

Recording mode (video) UXP: VBR, avarage of 24 Mbps

Recording mode (audio) 48 kHz, 256 kbps

Video MPEG-4 AVC/H.264

Audio Dolby Digital (2ch)

TM

(V.1.3 with x.v.ColorTM)

Y:1.0V (p-p), 75 Ω

Pb/Pr:700 mV (p-p), 75 Ω

XP: VBR, avarage of 17 Mbps

SP: VBR, avarage of 12 Mbps

EP: VBR, avarage of 5 Mbps

Design and specifications subject to change without notice.

1-2 (No.YF289<Rev.003>)

Page 3

SECTION 1

r

PRECAUTIONS

1.1 SAFETY PRECAUTIONS

Prior to shipment from the factory, JVC products are strictly

inspected to conform with the recognized product safety and

electrical codes of the countries in which they are to be

sold.However,in order to maintain such compliance, it is equally

important to implement the following precautions when a set is

being serviced.

1.1.1 Precautions during Servicing

(1) Locations requiring special caution are denoted by labels

and inscriptions on the cabinet, chassis and certain parts of

the product.When performing service, be sure to read and

comply with these and other cautionary notices appearing

in the operation and service manuals.

(2) Parts identified by the symbol and shaded ( ) parts

are critical for safety.

Replace only with specified part numbers.

NOTE :

Parts in this category also include those specified to

comply with X-ray emission standards for products

using cathode ray tubes and those specified for

compliance with various regulations regarding

spurious radiation emission.

(3) Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as

specified.

(4) Use specified internal wiring. Note especially:

• Wires covered with PVC tubing

• Double insulated wires

• High voltage leads

(5) Use specified insulating materials for hazardous live parts.

Note especially:

• Insulation Tape

• PVC tubing

•Spacers

• Insulation sheets for transistors

• Barrier

(6) When replacing AC primary side components (transformers,

power cords, noise blocking capacitors, etc.) wrap ends of

wires securely about the terminals before soldering.

emission. Consequently, when servicing these products,

replace the cathode ray tubes and other parts with only the

specified parts. Under no circumstances attempt to modify

these circuits.Unauthorized modification can increase the

high voltage value and cause X-ray emission from the

cathode ray tube.

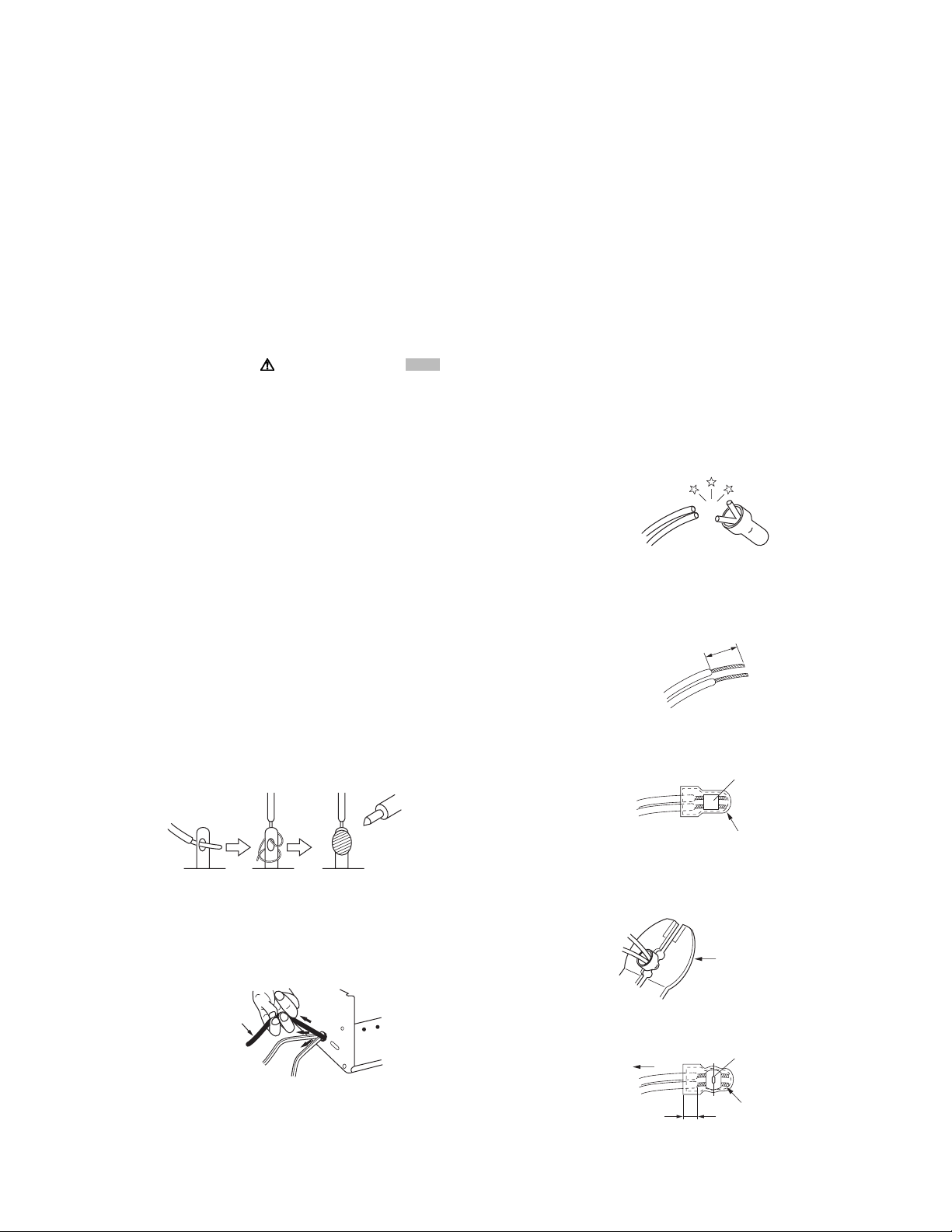

(12) Crimp type wire connectorIn such cases as when replacing

the power transformer in sets where the connections

between the power cord and power trans former primary

lead wires are performed using crimp type connectors, if

replacing the connectors is unavoidable, in order to prevent

safety hazards, perform carefully and precisely according

to the following steps.

• Connector part number :E03830-001

• Required tool : Connector crimping tool of the proper

type which will not damage insulated parts.

• Replacement procedure

a) Remove the old connector by cutting the wires at a

point close to the connector.Important : Do not

reuse a connector (discard it).

cut close to connector

Fig.1-1-3

b) Strip about 15 mm of the insulation from the ends

of the wires. If the wires are stranded, twist the

strands to avoid frayed conductors.

15 mm

Fig.1-1-4

c) Align the lengths of the wires to be connected.

Insert the wires fully into the connector.

Metal sleeve

Fig.1-1-1

(7) Observe that wires do not contact heat producing parts

(heatsinks, oxide metal film resistors, fusible resistors, etc.)

(8) Check that replaced wires do not contact sharp edged or

pointed parts.

(9) When a power cord has been replaced, check that 10-15

kg of force in any direction will not loosen it.

Power cord

Fig.1-1-2

(10) Also check areas surrounding repaired locations.

(11) Products using cathode ray tubes (CRTs)In regard to such

products, the cathode ray tubes themselves, the high

voltage circuits, and related circuits are specified for

compliance with recognized codes pertaining to X-ray

Connector

Fig.1-1-5

d) As shown in Fig.1-1-6, use the crimping tool to crimp

the metal sleeve at the center position. Be sure to

crimp fully to the complete closure of the tool.

1.2

5

2.0

5.5

Crimping tool

Fig.1-1-6

e) Check the four points noted in Fig.1-1-7.

Not easily pulled free

Wire insulation recessed

more than 4 mm

Crimped at approx. cente

of metal sleeve

Conductors extended

Fig.1-1-7

(No.YF289<Rev.003>)1-3

Page 4

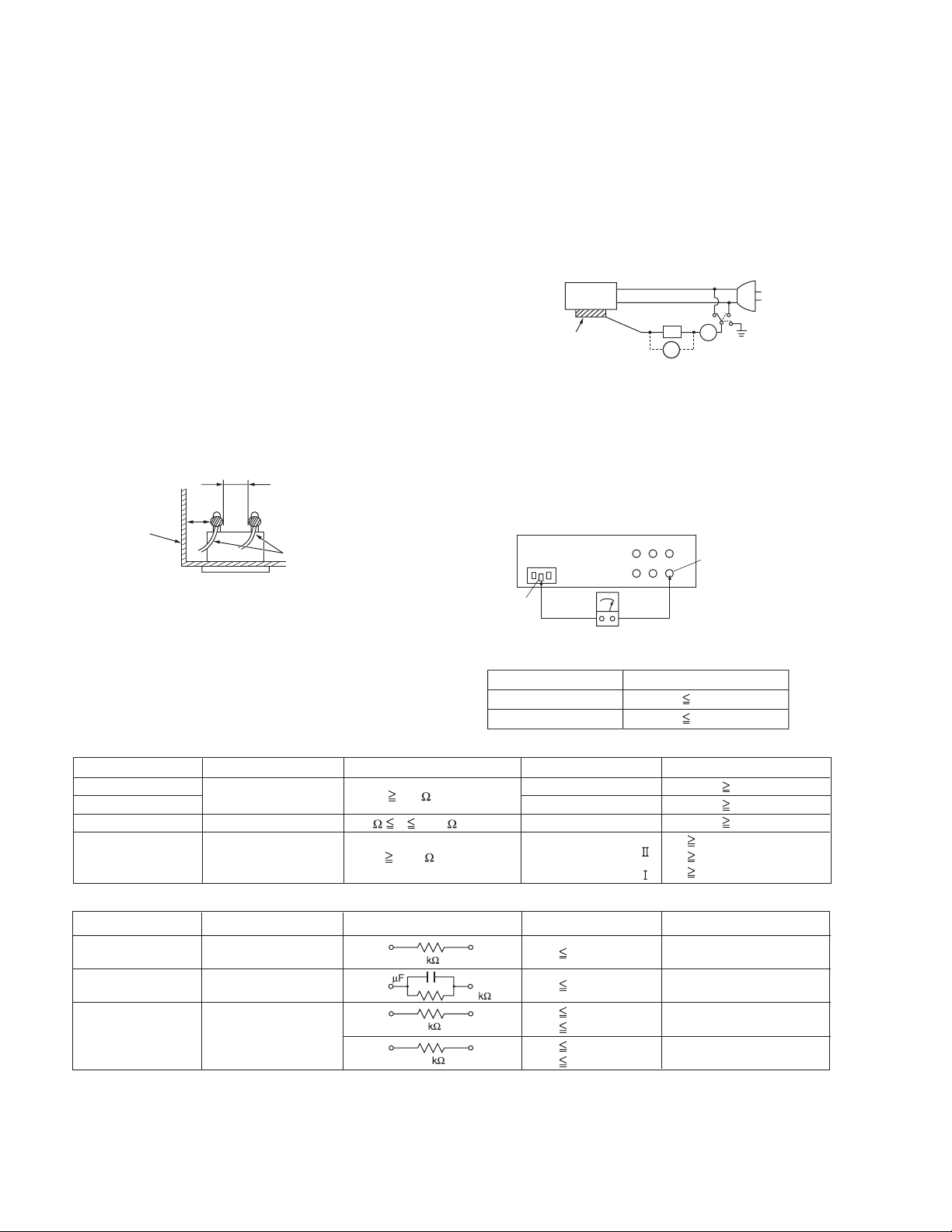

1.1.2 Safety Check after Servicing

Examine the area surrounding the repaired location for damage

or deterioration. Observe that screws, parts and wires have been

returned to original positions, Afterwards, perform the following

tests and confirm the specified values in order to verify

compliance with safety standards.

(1) Insulation resistance test

Confirm the specified insulation resistance or greater

between power cord plug prongs and externally exposed

parts of the set (RF terminals, antenna terminals, video and

audio input and output terminals, microphone jacks,

earphone jacks, etc.).See table 1 below.

(2) Dielectric strength test

Confirm specified dielectric strength or greater between

power cord plug prongs and exposed accessible parts of

the set (RF terminals, antenna terminals, video and audio

input and output terminals, microphone jacks, earphone

jacks, etc.). See Fig.1-1-11 below.

(3) Clearance distance

When replacing primary circuit components, confirm

specified clearance distance (d), (d') between soldered

terminals, and between terminals and surrounding metallic

parts. See Fig.1-1-11 below.

d

Chassis

d'

Power cord

primary wire

Fig.1-1-8

(4) Leakage current test

Confirm specified or lower leakage current between earth

ground/power cord plug prongs and externally exposed

accessible parts (RF terminals, antenna terminals, video

and audio input and output terminals, microphone jacks,

earphone jacks, etc.).

Measuring Method : (Power ON)Insert load Z between

earth ground/power cord plug prongs and externally

exposed accessible parts. Use an AC voltmeter to

measure across both terminals of load Z. See Fig.1-1-9

and following Fig.1-1-12.

ab

Externally

exposed

accessible part

Z

V

c

A

Fig.1-1-9

(5) Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between

earth pin in AC inlet and externally exposed accessible

parts (Video in, Video out, Audio in, Audio out or Fixing

screw etc.).Measuring Method:

Connect milli ohm meter between earth pin in AC inlet and

exposed accessible parts. See Fig.1-1-10 and grounding

specifications.

AC inlet

Earth pin

Exposed accessible part

MIlli ohm meter

Grounding Specifications

Region

USA & Canada

Europe & Australia

Grounding Impedance (Z

Z 0.1 ohm

Z 0.5 ohm

)

Fig.1-1-10

AC Line Voltage

100 V

100 to 240 V

110 to 130 V

110 to 130 V

200 to 240 V

Region

Japan

USA & Canada

Europe & Australia

Insulation Resistance (R

R 1 M /500 V DC

1 M R 12 M /500 V DC

R 10 M /500 V DC

)

Dielectric Strength

AC 1 kV 1 minute

AC 1.5 kV 1 minute

AC 1 kV 1 minute

AC 3 kV 1 minute

AC 1.5 kV 1 minute

(

Class

(

Class

Clearance Distance (d), (d'

d, d' 3 mm

d, d' 4 mm

d, d' 3.2 mm

d 4 m m

)

d' 8 m m (Power cord

d' 6 m m (Primary wire

)

Fig.1-1-11

AC Line Voltage

100 V

110 to 130 V

110 to 130 V

220 to 240 V

Region

Japan

USA & Canada

Europe & Australia

Load Z

1

0.15

1.5

2

50

Leakage Current (i)

i 1 mA rms

i 0.5 mA rms

i 0.7 mA peak

i 2 mA dc

i 0.7 mA peak

i 2 mA dc

a, b, c

Exposed accessible parts

Exposed accessible parts

Antenna earth terminals

Other terminals

Fig.1-1-12

NOTE :

These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

)

)

)

1-4 (No.YF289<Rev.003>)

Page 5

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

2.1 DIFFERENCE LIST The following table indicate main different points between models GZ-HD300AUS, GZ-HD300BUS, GZ-HD300RUS, GZ-HD310BUC and GZ-HD320BUS.

MODEL GZ-

HD300AUS

GZ-

HD300BUS

GZ-

HD300RUS

GZ-

HD310BUC

GZ-

HD320BUS

BODY COLOR BLUE BLACK RED BLACK BLACK

HDD 60GB 60GB 60GB 80GB 120GB

2.2 REPLACING HDD NOTE1) After HDD replacement, format the HDD first.

When the power is turned on after the HDD replacement, the

below "Warning screen" is displayed.

Be sure to format the HDD following the messages.

Be sure to turn off the power once after the formatting.

If the HDD recording is started without being turned off the power, normal recording cannot be performed although the recording will start.

NOTE2)

The picture title data needs to be written in the HDD.

Download the data and writing procedure from JS-NET.

Note that the picture title is a thumbnail image used in Creating Playlist including Titles and saved in the space where users cannot see.

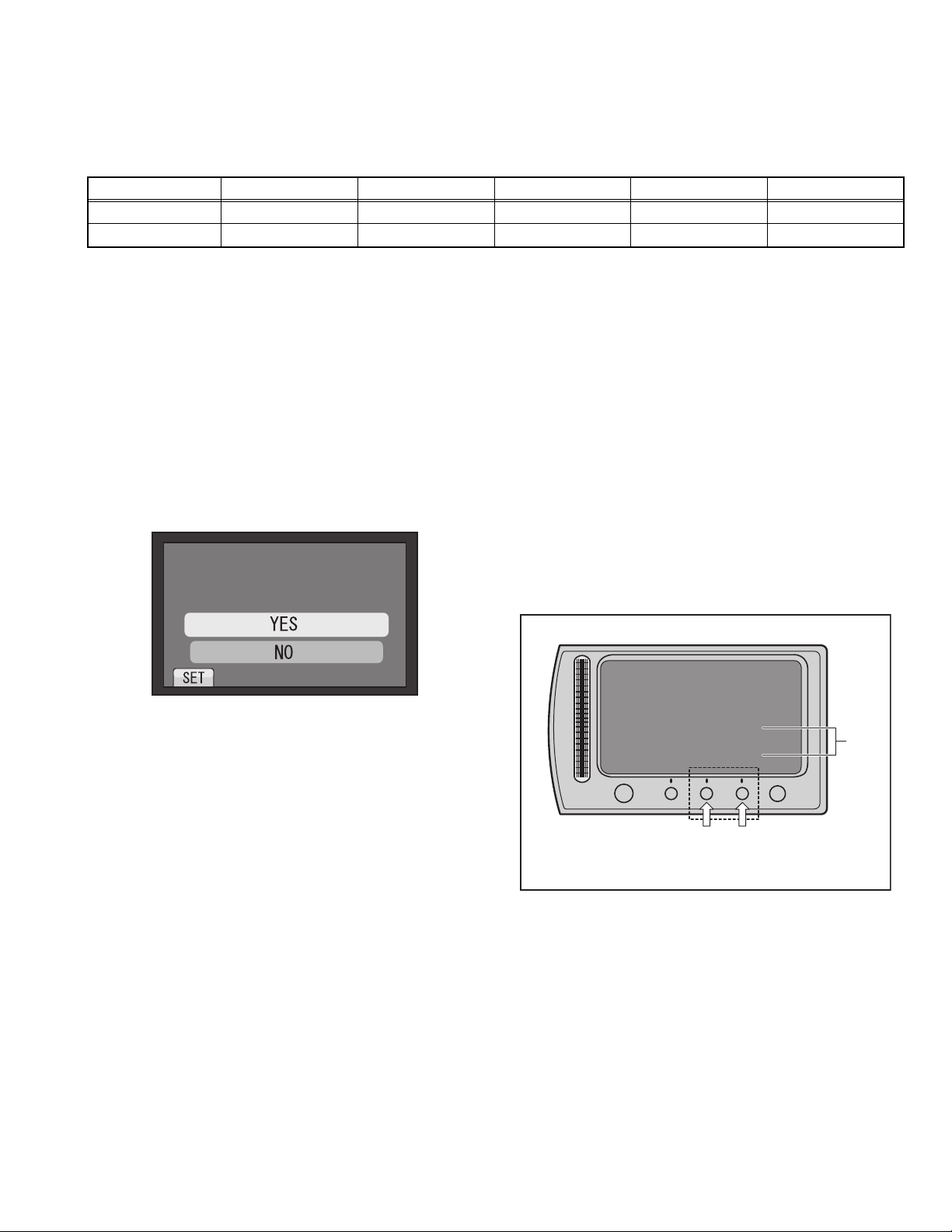

< "Warning screen">

2.3 CHECKING THE CPU VERSIONS Procedure

(1) Open the MONITOR ASSY to turn the power ON.

(2) While halfway pressing and holding the [SNAPSHOT] but-

ton, repeat touching the buttons [A] and [B] 3 times in order:

[A]→[B]→[A]→[B]→[A]→[B].

(3) Release the halfway pressed [SNAPSHOT] button.

NOTE)

[VERSION INFO] is displayed on the monitor for about 5

seconds.

(4) Release the pressed [MENU] button, and the mode is

made clear.

NOTE)

When the mode is not canceled and the button is not operable, disconnect the battery or the DC cable to reset

the power.

0''&61(14/#6*#4&&+5-

&4+8'

#..#9+..$''4#5'&

&1;179#0661(14/#6!

Example:For GZ-HD320

Even when the mode is canceled, resetting the power is

recommended.

LCD MONITOR

Fig.2-2-1

VERSION INFO.

Model

Current Ver

EEPROM Ver

CAMCPU Ver 0.16

OK

Button[B]

NOTECurrent

CAMCPU Ver : CAMERA CPU VERSION

Ver : ELISE CPU VERSION

Name

GZ-HD320

1.05

12

Button[A]

NOTE

MENU

Fig.2-3-1

NOTE) Display of CAMCPU Ver: Camera CPU Version

As the Camera CPU Version cannot be displayed correctly,

check the version using Service Support System.

(No.YF289<Rev.003>)1-5

Page 6

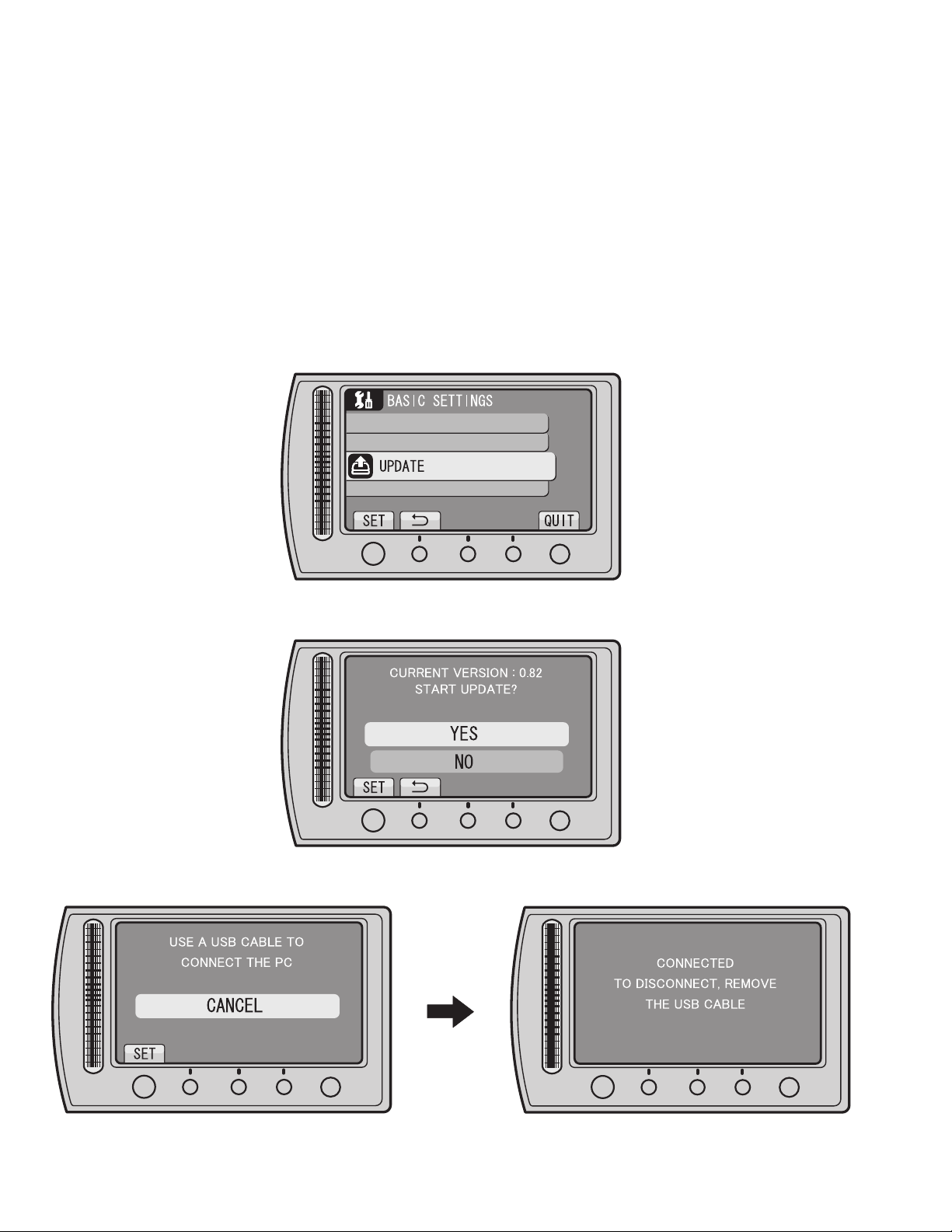

2.4 FIRMWARE UPDATE

Connecting Everio to a PC via USB cable enables firmware update.

Connect a battery, capable of operating for 10 minutes or longer, and an AC adapter to Everio for update.

* The following procedure shows the monitor displays of the firmware update from ver. 0.82 to ver. 1.55.

* Use Windows XP or Windows Vista.

1.Preparation

(1)Preparation

Download the firmware update application software from JS-NET.

(2)Connection

Connect a battery that is capable of operating for 10 minutes or longer and an AC adapter to Everio.

* To ensure secure power supply during the update, update is disabled if either of them is not available.

2.Firmware transfer

(1) Select "UPDATE" in the main menu of Everio.

MENU > BASIC SETTINGS > UPDATE

OK

Fig.2-4-1

(2)When the displayed current version is an old one, select "YES".

OK

Fig.2-4-2

(3)Follow the directions on the monitor to connect Everio to the PC via USB cable.

MENU

MENU

OK

1-6 (No.YF289<Rev.003>)

MENU

Fig.2-4-3

OK

MENU

Page 7

(4)Execute the downloaded application software.

×

×

×

×

×

Fig.2-4-4

(No.YF289<Rev.003>)1-7

Page 8

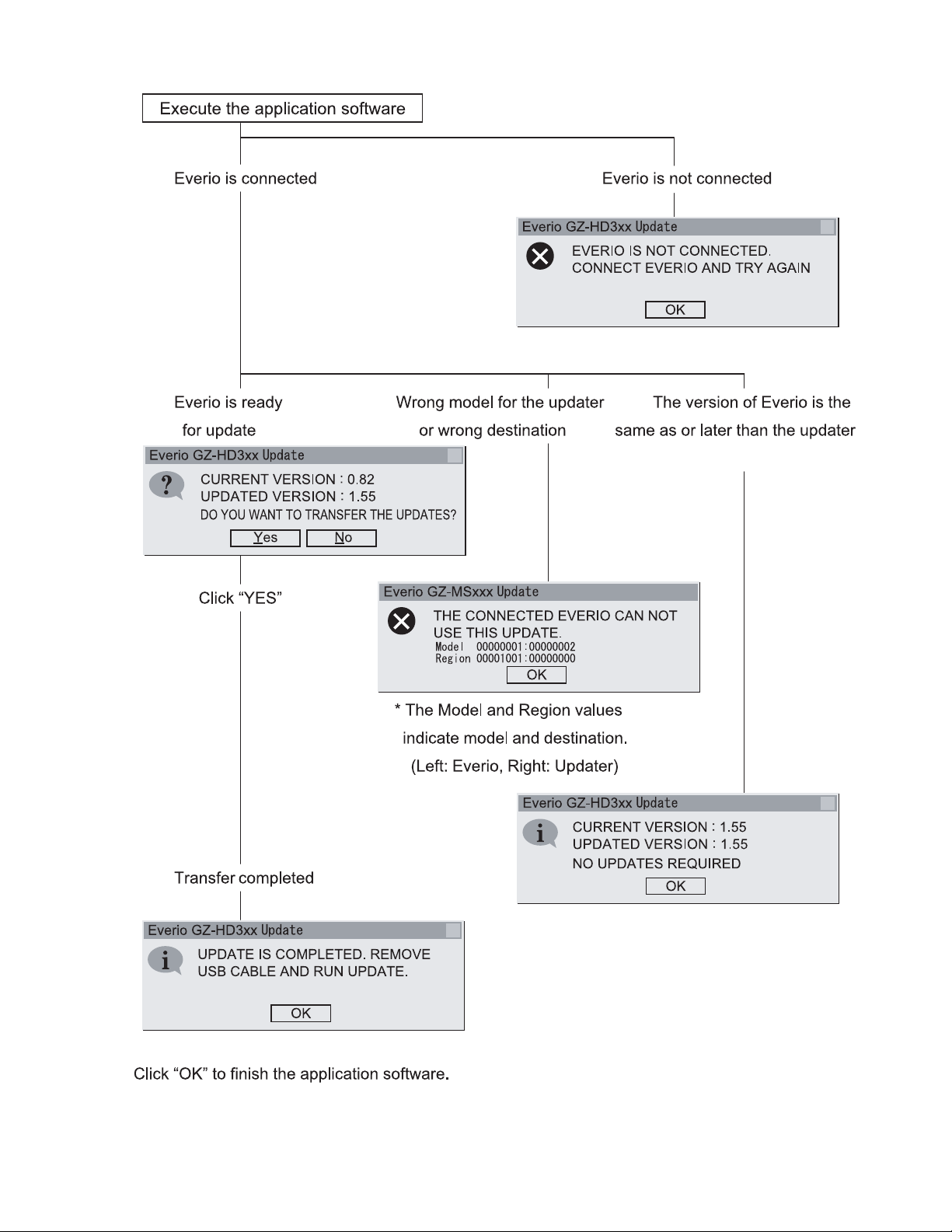

3.Execute update

(1)Disconnect the USB cable, and remove Everio from the PC.

(2)Check the current and updated versions, and then select "YES".

OK

Fig.2-4-5

(3)Carefully read and understand the warning, and then select "YES".

* It takes about 1 minutes and 30 seconds to complete the update.

OK

MENU

Fig.2-4-6

(4)Select "OK", and then re-start Everio.

MENU

OK

MENU

OK

Fig.2-4-7

(5)After the re-start, check that the current firmware is updated in UPDATE.

MENU > BASIC SETTINGS > UPDATE

OK

Fig.2-4-8

When the updated firmware version is confirmed, select "NO".

1-8 (No.YF289<Rev.003>)

MENU

MENU

Page 9

SECTION 3

DISASSEMBLY

3.1 BEFORE ASSEMBLY AND DISASSEMBLY

3.1.1 Precautions

• Be sure to disconnect the power supply unit prior to mounting

and soldering of parts.

• Prior to removing a component part that needs to disconnect

its connector(s) and its screw(s), first disconnect the wire(s)

from the connector(s), and then remove the screw(s).

• When connecting/disconnecting wires, pay enough attention

not to damage the connectors.

• When inserting the flat wire to the connector, pay attention to

the direction of the flat wire.

• Be careful in removing the parts to which some spacer or

shield is attached for reinforcement or insulation.

• When replacing chip parts (especially IC parts), first remove

the solder completely to prevent peeling of the pattern.

• Tighten screws properly during the procedures. Unless

otherwise specified, tighten screws at a torque of 0.088N

·cm). However, as this is a required value at the time of

(0.9kgf

production, use the value as a measuring stick when

proceeding repair services. (See "SERVICE NOTE" as for

tightening torque.)

3.1.2 Destination of connectors

Two kinds of double-arrows in connection tables respectively

show kinds of connector/wires.

: Wire: Flat wire : Board to board (B-B)

: The connector of the side to remove

CONN. No. PIN No.CONNECTOR

CN2a

CN2b

MAIN CN101

MAIN CN103

MONI BW CN761

MINI BW CN762

3.1.3 Disconnection of connectors (Wires)

Wire

FPC Connector

· Pull both ends of the connector in the arrow

direction, remove the lock and disconnect the flat

wire.

Wire

FPC Connector

· Pull the both ends of the board in the direction of the

arrow, and remove the Connector.

Wire

Lock

FPC Connector

B-B Connector

B-B Connector

· Pull the both ends of the board in the direction of the arrow, and remove the B-B Connector.

· Extend the locks in the direction of the arrow for

unlocking and then pull out the wire. After

removing the wire, immediately restore the locks

to their original positions because the locks are

apt to come off the connector.

· Extend the locks in the direction of the arrow for

unlocking and then pull out the wire. After

removing the wire, immediately restore the locks

to their original positions because the locks are

apt to come off the connector.

· Extend the locks in the direction of the arrow for

unlocking and then pull out the wire. After

removing the wire, immediately restore the locks

to their original positions because the locks are

apt to come off the connector.

Wire

FPC Connector

FPC

Connector

Lock

B-B Connector

Fig.3-1-1

·m

40

10

Lock

Wire

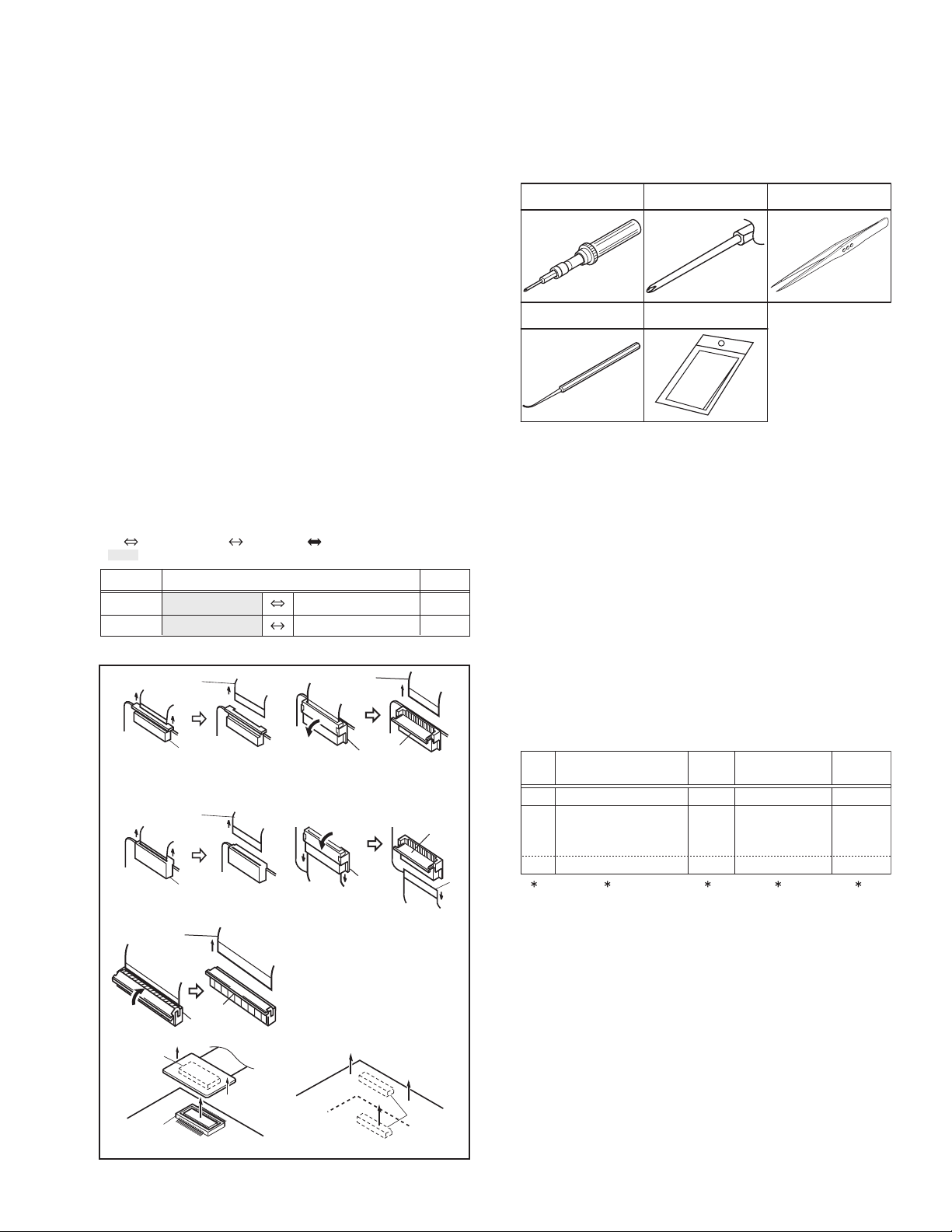

3.1.4 Tools required for disassembly and assembly

Torque driver

YTU94088

Chip IC replacement jig

PTS40844-2

Bit

YTU94088-003

Cleaning cloth

KSMM-01

Tweezers

P-895

Fig.3-1-2

• Torque driver

Be sure to use to fastening the mechanism and exterior parts

because those parts must strictly be controlled for tightening

torque.

• Bit

This bit is slightly longer than those set in conventional torque

drivers.

• Tweezers

To be used for removing and installing parts and wires.

• Chip IC replacement jig

To be used for replacement of IC.

• Cleaning cloth

Recommended cleaning cloth to wipe down the video heads,

mechanism (tape transport system), optical lens surface.

3.2 ASSEMBLY AND DISASSEMBLY OF MAIN PARTS

3.2.1 Assembly and disassembly

When reassembling, perform the step(s) in reverse order.

STEP

No.

[1]

[2]

PART

TOP COVER ASSY

UPPER ASSY

(Inc. VF ASSY,

SPEAKER/MONITOR)

[8]

E.VF UNIT(B/W)

(∗1) Order of steps in Procedure

When reassembling, preform the step(s) in the reverseorder.

These numbers are also used as the identification (location)

No. of parts Figures.

(∗2) Part to be removed or installed.

(∗3) Fig. No. showing Procedure or Part Location.

(∗4) Identification of part to be removed, unhooked, unlocked,

released, unplugged, unclamped or unsoldered.

S = Screw L = Lock, Release, Hook

SD = Solder CN = Connector

[Example]

• 4 (S1a) = Remove 4 S1a screws.

• 3 (L1a) = Disengage 3 L1a hooks.

• 2 (SD1a) = Unsolder 2 SD1a points.

• CN1a = Remove a CN1a connector.

(∗5) Adjustment information for installation.

Fig.

No.

4(S1a), 3(L1a),CN1a

C1

(S2a),2(S2b),3(S2c)

C2-1

2(SD1a),

L2,CN2a,b

2(S8),L8,CN8a

C2-2

POINT

( 4) ( 5)( 2) ( 3)( 1)

NOTE

-

-

NOTE 8

(No.YF289<Rev.003>)1-9

Page 10

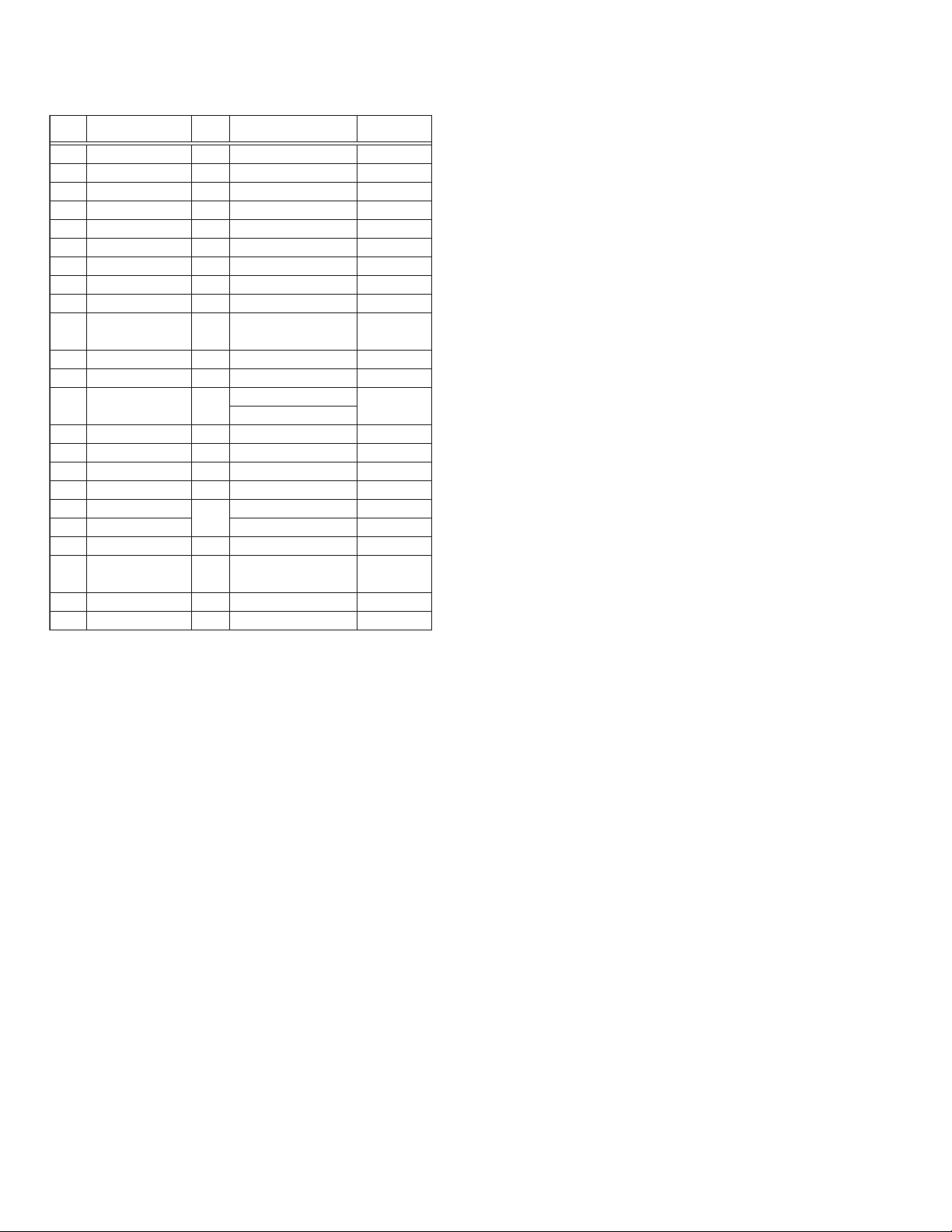

3.2.2 Assembly/Dissambly of cabinet parts and electrical parts

z Disassembly procedure

STEP

PART NAME

No.

[1]

B.COVER(N)ASSY

[2]

COVER (HINGE) ASSY

[3]

HDD COVER ASSY

[4]

TOP COVER

[5]

HDD

[6]

HDD CASE ASSY

[7]

BKT(O.TOP)

[8]

ORNAMENT(TOP)

[9]

UPPER ASSY

REAR COVER ASSY

[10]

(Inc.REAR BOARD ASSY,ZOOM UNIT)

[11]

ZOOM UNIT

[12]

REAR BOARD ASSY

[13]

JACK BOARD ASSY

[14]

FRONT ASSY

[15]

MAIN BOARD ASSY

[16]

FRAME (PLATE) ASSY

[17]

OP BLOCK ASSY

[18]

BARRIER UNIT

[19]

HOOD(SCERW)

[20]

MIC

[21]

OPE BOARD ASSY

[22]

SPEAKER

[23]

MONITOR ASSY

Fig.

No.

3-2-1

3-2-2

3-2-3

3-2-4

3-2-5

3-2-6

3-2-7

3-2-8

3-2-9

3-2-10

3-2-11

3-2-12

3-2-13

3-2-14

3-2-15

3-2-16

3-2-17

3-2-18

3-2-19

3-2-20

3-2-21

3-2-22

POINT NOTE

3(S1),2(L1a), 2(L1b)

2(S2),2(L2)

4(S3a),S3b,L3a,b,4(L3c)

2(S4a),2(S4b),L14a,2(L4b),L4c

CN5

3(S6),L6a,b,c

2(S7),L7a,b,2(L7c),L7d

L8a,b,c,d,e

CN9,S9a,b,L9

CN10a,b,2(S10),L10a,b

S11,L11a,b

S12,L12a,b

CN13,2(S13),2(L13a)

S13,L13b,BKT(HDMI),PLATE(HDMI)

CN14a,b.L14a,b,c

2(S15),L15,CN15a,b

2(S16),L16a,b,c

3(S17),FRAME ASSY

S18a,2(S18b)

L19a,b

S20,L20a,b,PLATE(MIC)

S21a,CN21a,2(L21a),L21b,

CN21b,2(S21b),L21c,d

S22,BKT(SPEAKER),SPACER(SPK)

2(S23),L23

NOTE1

NOTE2

NOTE3

NOTE4

NOTE5a,b,c,d,e,f

-

-

NOTE8

NOTE9

-

-

-

NOTE13

-

NOTE14a,b

NOTE15

-

NOTE17a,b

NOTE18

-

NOTE20

NOTE21a,b,c,d,e

NOTE22a,b

NOTE23

NOTE1:

When removing the BOTTOM COVER ASSY, open and pull

up the COVER (SD).

NOTE2:

When removing the COVER (HINGE) ASSY, open the

MONITOR ASSY, remove the 2 screws, rotate the MONI-

TOR ASSY 90°, tilt it to the rear side, and then pull out the

COVER (HINGE) ASSY.

NOTE3:

Screw No.8 is located under the JACK COVER (USB). Remove or slide the JACK COVER (USB) to remove the screw.

NOTE4:

Screw No.11 is located under the JACK COVER (AV). Remove or slide the JACK COVER (AV) to remove the screw.

NOTE5a:

During the procedure, be careful in handling the parts. Pay

special attention not to give any external shock to the HDD.

NOTE5b:

When the HDD is replaced, be sure to refer to Replacing

HDD in "SECTION2 SPECIFIC SERVICE INSTRUCTIONS"

for the procedure after HDD replacement.

NOTE5c:

Be careful as the RUBBER SPACERS on both sides are

easily come off when the HDD is removed from the main

unit.

If the RUBBER SPACERS come off, be sure to attach them

in the correct direction shown in the figure.

NOTE5d:

When connecting the FPC to the connector, insert the FPC

straight into the connector. When locking the connector, be

careful not to give so much load that it bends the board.

NOTE5e:

In this procedure, the FPC connected to the HDD connector

is not removed. If the FPC is removed due to broken wire,

be careful in attachment direction.

Be sure to connect the STOPPER side to the HDD.

Pay attention as wrong attachment could damage the HDD.

NOTE5f:

Be careful with the wiring.

NOTE8:

During the procedure, be careful not to break the parts.

NOTE9:

Please refer to Fig.3-2-20 and the following procedure for removing the UPPER ASSY.

NOTE13:

The JACK BOARD ASSY is attached between the PLATE

(HDMI) and the BRACKET (HDMI). For replacement, remove the screw (No.28) and disassemble them if necessary.

NOTE14a:

When attaching the FRONT ASSY, be careful in handling

the wire and the FPC.

NOTE14b:

Please refer to Fig.3-2-18 and the following procedure for removing the FRONT ASSY.

NOTE15:

When attaching the MAIN BOARD ASSY, be careful in handling

the WIRE (CMOS).

NOTE17a:

Refer to 3.2.3 Assembly/Disambly of [17] OP BLOCK ASSY/

CMOS BOARD ASSY of OP BLOCK ASSY.

NOTE17b:

When attaching the OP BLOCK ASSY, be careful in handling the WIRE (CMOS).

NOTE18:

When attaching the BARRIER UNIT, be careful in handling

the WIRE (MIC).

NOTE20:

When attaching the MIC, attach the BARRIER UNIT before

handling the WIRE (MIC). (Refer to NOTE 18.)

NOTE21a:

When removing, remove the screw No.40 first to release the

FPC, and then pull out the FPC from the connector.

NOTE21b:

When removing the OPE BOARD ASSY, release the WIRE

(SPK) from the HOOK (L21b) first, and then pull out the

WIRE (SPK) from the connector.

NOTE21c:

When attaching, make sure that the LEVER of the

SW(S408) interlocks with the KNOB (SLIDE).

1-10 (No.YF289<Rev.003>)

Page 11

NOTE21d:

When attaching, be careful with the wiring.

NOTE21e:

During the procedure, be careful not to damage the parts.

When attaching the OPE BOARD ASSY with the MONITOR

ASSY closed, be especially careful not to break the

SWITCH (S401).

NOTE22a:

When removing the SPEAKER, be careful in handling as the

SPACER (SPK) may come off with the SPEAKER.

NOTE22b:

When attaching, be careful with the wiring.

As the final wiring is performed when attaching the OPE

BOARD ASSY, leave the wire as shown in the drawing.

NOTE23:

Refer to 3.2.4 Disassembly of [23] MONITOR ASSY.

z Destination of connectors

CN.

No.

CN5 MAIN CN102 HDD - 40

CN9 MAIN CN101 OPE CN401 36/40

CN10a MAIN CN104 OPE UNIT

CN10b MAIN CN103 REAR CN602 32/36

CN13 MAIN CN114 JACK - 40

CN14a MAIN CN111 LENS BARRIER - 6

CN14b MAIN CN107 MIC - 4

CN15a MAIN CN105 CMOS CN4001 22

CN15b MAIN CN106 OP BLOCK - 25

CN21a OPE CN402 MONITOR CN703 28/29

CN21b OPE CN401 SPEAKER - 2

CONNECTOR

PIN

No.

- 12

L2

[2]

a

b

4

(S2)

5

(S2)

Fig.3-2-2

a

b

NOTE2

1

(S1)

2

(S1)

L1a

3

(S1)

[1]

NOTE1

COVER(SD)

L1b

6

(S3a)

10

(S3b)

9

(S3a)

(S3a)

[3]

9

(S3a)

NOTE3

(S3a)

(S3b)

7

8

10

(S3a)

6

8

(S3a)

L3c

(S3a)

NOTE3

JACK

COVER

(USB)

L3b

L3a

7

8

(S3a)

Fig.3-2-1

Fig.3-2-3

(No.YF289<Rev.003>)1-11

Page 12

NOTE4

14

(S4b)

L4a

11

(S4a)

11

(S4a)

JACK

COVER

(AV)

L4c

13

(S4b)

12

(S4a)

[4]

L4b

L4a

14

(S4b)

12

(S4a)

NOTE4

11

(S4a)

15

(S6)

16

(S6)

17

(S6)

[6]

L6a

L6b

L6c

NOTE5f

FPC

MAIN BOARD ASSY

NOTE5e

FPC

NOTE5d

CN5

HDD

STOPPER

Fig.3-2-4

NOTE5a,b

NOTE5c

RUBBER SPACER

[5]

[7]

L7d

L7b

Fig.3-2-6

18

(S7)

19

(S7)

L7c

L7a

1-12 (No.YF289<Rev.003>)

Fig.3-2-5

Fig.3-2-7

Page 13

NOTE8

L8c

L8b

[10]

CN10a

L10b

L8d

L8e

[8]

Fig.3-2-8

CN9

L8a

CN10b

L10a

22

(S10)

23

(S10)

Fig.3-2-10

24

(S11)

[11]

20

(S9a)

[9]

NOTE9

L9

Fig.3-2-9

L11b

21

(S9b)

CN9

L11a

Fig.3-2-11

(No.YF289<Rev.003>)1-13

Page 14

[10]

NOTE14b

[14]

L14c

L14b

L14a

L12b

L12a

NOTE13

GASKET

28

(S13)

[12]

Fig.3-2-12

25

(S12)

FPC(LENS BARR.)

NOTE14a

WIRE(MIC)

30

(S15)

29

(S15)

CN14a(FPC)

WIRE(MIC)

FPC(LENS BARR.)

Fig.3-2-14

[15]

CN14b(WIRE)

L13b

GASKET

[13]

26

(S13a)

27

(S13a)

1-14 (No.YF289<Rev.003>)

Fig.3-2-13

CN13

L13a

GASKET

L15

CN15b

CMOS WIRE

Fig.3-2-15

NOTE15

CN15a

NOTE15

MAIN PWB

Page 15

L16b

32

(S16)

L16c

31

(S16)

[16]

L16a

[18]

(S18b)

37

(S18b)

38

NOTE18

WIRE(MIC)

NOTE18

WIRE(MIC)

36

(S18a)

NOTE17b

Fig.3-2-16

(S17)

34

(S17)

35

33

(S17)

[19]

L19a

L19b

Fig.3-2-18

39

(S20)

PLATE(MIC)

[20]

NOTE20

WIRE(MIC)

FRME ASSY

0.118Nm (1.2kgfcm)

Fig.3-2-17

NOTE17a

[17]

FRONT COVER ASSY

L20b

L20a

Fig.3-2-19

(No.YF289<Rev.003>)1-15

Page 16

[21]

41

(S21b)

42

(S21b)

CN21b

CN21a

NOTE21e

SW(S401)

WIRE(SPK)

a

L21b

L21a

NOTE21a

40

(S21a)

FPC

NOTE21c

[21]

CN21b

WIRE(SPK)

L21b

NOTE21eNOTE21b,d

SW(S401)

L21d

L21c

NOTE22b

WIRE(SPK)

NOTE22b

WIRE(SPK)

40

(S21a)

NOTE21a

BKT(SPACER)

[22]

a

FPC

43

(S22)

Fig.3-2-20

SW(S408)

KNOB(SLIDE)

SW(S408)

LEVER

[21]

44

(S23)

45

(S23)

[23]

NOTE23

NOTE22a

SPACER(SPK)

1-16 (No.YF289<Rev.003>)

L23

Fig.3-2-21 Fig.3-2-22

Page 17

3.2.3 Assembly/Disambly of [17] OP BLOCK ASSY/CMOS BOARD ASSY

zPrecautions

(1) Be careful in handling the LENS components.

Pay special attention to the surfaces to protect them from

stains, dust, or scratches.

If the surfaces are soiled with finger prints or other stains,

wipe them off with silicon paper, clean chamois leather,

or recommended cleaning cloth.

zDisassembly of OP BLOCK ASSY / CMOS BOARD ASSY

(1) Remove the screw (1), and then remove the

SHIELD(CMOS).

NOTE17a:

When reMmoving the SHIELD(CMOS), be careful in

handling as the SHIELD(CMOS) or CMOS BOARD

ASSY may be removed together with the HEAT

SHEET attached.

(2) Remove the 2 screws (2,3), and then remove the CMOS

FRAME ASSY.

NOTE17b:

When removing the CMOS FRAME ASSY, be careful

in handling as the CMOS FRAME ASSY may be removed together with the SHEET attached.

zAssembly of OP BLOCK ASSY / CMOS BOARD ASSY

zReplacement of service repair parts

NOTE17c:

(1) The SHEET is set in the OP BLOCK ASSY.

(2) Attach the CMOS FRAME ASSY first,so that the SHEET

stays in place, and tighten with the 2 screws (2,3).

(3) Attach the SHIELD(CMOS) first, and tighten with the

screw (1).

The service repair parts for the OP BLOCK ASSY are as listed below.

When replacing parts, be careful not to cut the FPCs or damage any parts by soldering (excessive heat).

(1) FOCUS MOTOR UNIT

(2) ZOOM MOTOR UNIT

(3) AUTO IRIS UNIT

NOTE 17d:

When replacing the FOCUS MOTOR UNIT or the ZOOM

MOTOR UNIT, solder the FPC at a space of about 0.1

mm above the terminal pin.

NOTE 17e:

The AUTO IRIS UNIT includes the FPC ASSY and two sensors.

The CMOS BOARD ASSY is included in CMOS

FRAME ASSY.

Replace the CMOS BOARD ASSY as a CMOS

FRAME ASSY, not as a single part replacement.

SD17b

6

(S17b)

ZOOM MOTOR

UNIT

7

(S17b)

10

(S17b)

8

(S17b)

9

(S17b)

NOTE17d

AUTO IRIS UNIT

4

(S17b)

FOCUS MOTOR

UNIT

5

(S17b)

SHIELD(CMOS)

NOTE17a

HEAT SHEET

NOTE17c

CMOS FRAME ASSY

CMOS BOARD ASSY

is contained.

NOTE17b

SHEET

2

(S17b)

1

(S17a)

3

(S17b)

OP BLOCK ASSY

OP BLOCK ASSY

0.078Nm (0.8kgfcm)

0.147 Nm (1.5kgfcm)

Fig.3-2-23

(No.YF289<Rev.003>)1-17

Page 18

3.2.4 Disassembly of [23] MONITOR ASSY

zCAUTIONS

(1) During the procedure, be careful in handling the LCD

MODULE and other parts. Pay special attention not to

damage or stain the monitor screen.

If fingerprints are left on the screen, wipe them with clean

chamois leather or a cleaning cloth.

z Removing MONITOR ASSY

(1) Remove the 2 screws (1,2).

(2)

Turn the HINGE UNIT ASSY 90°, and remove the 2 screws

(3,4).

(3) Remove the MONI.COVER ASSY by removing the 8

hooks (L23a-h).

(4) Release the lock of the connector (CN23a), and remove

ASSY

the HINGE UNIT

NOTE23a:

During the procedure, be careful in handling the FPC.

(5) Release the lock of the connectors (CN23b,c), and pull

out the FPC.

Remove the screw (5), and remove the MONITOR BOARD

(6)

ASSY .

NOTE23b:

During the procedure, be careful in handling the FPC.

(7) Remove the SHEET (M.REF), LIGHT GUIDE, SHEET(M/

DIFF), and the SHEET(BEF).

NOTE23c:

When attaching, insert one side of the SHEET (M/

DIFF) under the LCD CASE RIB.

NOTE23d:

When attaching, insert each tab on both sides of the

SHEET (M.REF) into the LCD CASE notch.

(8) Remove the LCD CASE, SHEET(COVER), LCD MOD-

ULE, SPACER(LCD) and the LCD BKT.

NOTE23e:

During the procedure, handle the five parts (LCD

CASE, SHEET(COVER), LCD MODULE, SPACER(LCD) and the LCD BKT) together.

NOTE23f:

The SENSOR BOARD ASSY is originally affixed to the

MONI.CASE ASSY using jigs and they have structures difficult to replace.

If replacement is required, please refer to the NOTE

and follow the operation procedure.

Assembly/Disambly of MONITOR CASE ASSY/SENSOR BOARD ASSY

z

Operation procedure

• Removing the part which is to be reused

Remove the SENSOR BOARD ASSY from the MONI.CASE

(1)

ASSY by gradually peeling off from the HINGE UNIT ASSY side.

NOTE23g:

During the procedure, be careful not to break.

Prepare the new SENSOR BOARD ASSY and D.FACE

TAPE and use them in place of the removed parts.

•

Completely peel off the remaining tape pieces of the D. FACE

TAPE left on the part to be reused (MONI.CASE ASSY).

NOTE23h:

Make sure that there are no D. FACE TAPE pieces or

foreign substances left on the surfaces. If necessary,

clean the surfaces using alcohol etc.

• Affixing the D. FACE TAPE to the SENSOR BOARD

(1) Affix the D. FACE TAPE to the SENSOR BOARD ASSY.

NOTE23j:

Securely fix the D. FACE TAPE, and then affix the SENSOR BOARD ASSY to the D. FACE TAPE by adjusting

the four frames of the SENSOR BOARD ASSY to the

1-18 (No.YF289<Rev.003>)

by lifting it up.

frame of the D. FACE TAPE. Evenly press over the paper backing of each long / short side of the L shape.

(2) Peel off the paper backing.

NOTE23k:

When removing the paper backing, check that there

are no foreign substances or air bubbles on the tape.

If there are foreign substances etc., completely remove them and continue the affixing procedure.

• Affixing the SENSOR BOARD ASSY to the MONI. CASE

(1) Affix the SENSOR BOARD ASSY to the MONI. CASE

NOTE23m:

When affixing, adjust the position of the long side of the

L shape to avoid misalignment, and then press evenly.

Be sure to press hard for 10 seconds or more on each

long/ short side of the L shape for even adhesion.

During the procedure, be careful to prevent foreign

substances or air bubbles from entering.

(2) After the replacement, make sure that there are no bro-

ken or deformed parts or any abnormalities.

Use the service software for the operation check of the

touch sensor sensitivity.

NOTE23g,j,k

SENSOR BOARD ASSY

NOTE23j,k

D.FACE TAPE

DETACHMENT PAPER

NOTE23j,k

SENSOR BOARD ASSY

D.FACE TAPE

Fig.3-2-24

zRemoving HINGE UNIT ASSY

(1) Remove the HINGE COVER(U).

(2) Remove the HINGE COVER(L).

(3) Remove the MAGNET.

NOTE23n:

During the procedure, be careful in handling the FPC.

During the procedure, be careful in handling the MAGNET.

When attaching, set the N pole outside as shown in the

figure. Be careful when removing as there is no marking.

NOTE23p:

During the procedure, be careful in handling the FPC.

NOTE23q:

The FPC, with its connection to the MONITOR BOARD

ASSY facing inward, is rolled around the axis (shaft) of

the HINGE UNIT ASSY rotation 2.5 rounds (2.5times).

Page 19

0.118 Nm (1.2kgfcm)

NOTE23p

FPC

<NOTE23p,q>

FPC

HINGE UNIT

HINGE COVER(U)

L23n

L23m

L23q

HINGE COVER(L)

HINGE UNIT

L23p

NOTE23n

MAGNET

3

(S23a)

NOTE23a

HINGE UNIT

ASSY

CN23a

L23a

4

(S23a)

L23k

L23e

CN23b

1

(S23a)

L23c

b

L23j

L23h

L23e

L23d

CN23c

MONI. COVER

ASSY

MONI. COVER

ASSY

L23g

L23f

2

(S23a)

<MONI. CASE SIDE>

NOTE23e

(REINFORCED SIDE)

LCD BKT

SPACER(LCD)

LCD MODULE

SHEET(COVER)

LCD CASE

CN20b

NOTE23d

NOTE23c

NOTE23c

LCD CASE

LIB

CN23c

g

b

f

c

j

h

f,h

c

FPC

NOTE23b

g,j

5

(S23b)

MONI. BOARD

ASSY

d

e

SHEET(M.REF)

m

k

LIGHT GUIDE

SHEET(M/DIFF)

SHEET(BEF)

e

m

k

d

NOTE23b

FPC

<MONI. COVER SIDE>

SENSOR BOARD

Fig.3-2-25

ASSY

NOTE23f,j

MONI. CASE ASSY

NOTE23f,g,h,m

(No.YF289<Rev.003>)1-19

Page 20

SECTION 4

ADJUSTMENT

4.1 PREPARATION

4.1.1 Precaution

Camera system and deck system of this model are specially

adjusted by using PC.

However, if parts such as the following are replaced, an

adjustment is required. The adjustment must be performed in a

Service Center equipped with the concerned facilities.

• EEP ROM (IC1005 of MAIN board)

• OP BLOCK ASSY

• MONITOR ASSY

In the event of malfunction with electrical circuits, first find a

defective portion with the aid of proper test instruments as shown

in the following electrical adjustment procedure, and then

commence necessary repair/ replacement/adjustment.

• In observing chip TP, use IC clips, etc. to avoid any stress.

Prior to replacement of chip parts (especially IC), remove the

solder completely to prevent peeling of the pattern.

• Use a patch cord if necessary. As for a patch cord, see the

BOARD INTERCONNECTIONS.

• Since connectors are fragile, carefully handle them in

disconnecting and connecting the FPC.

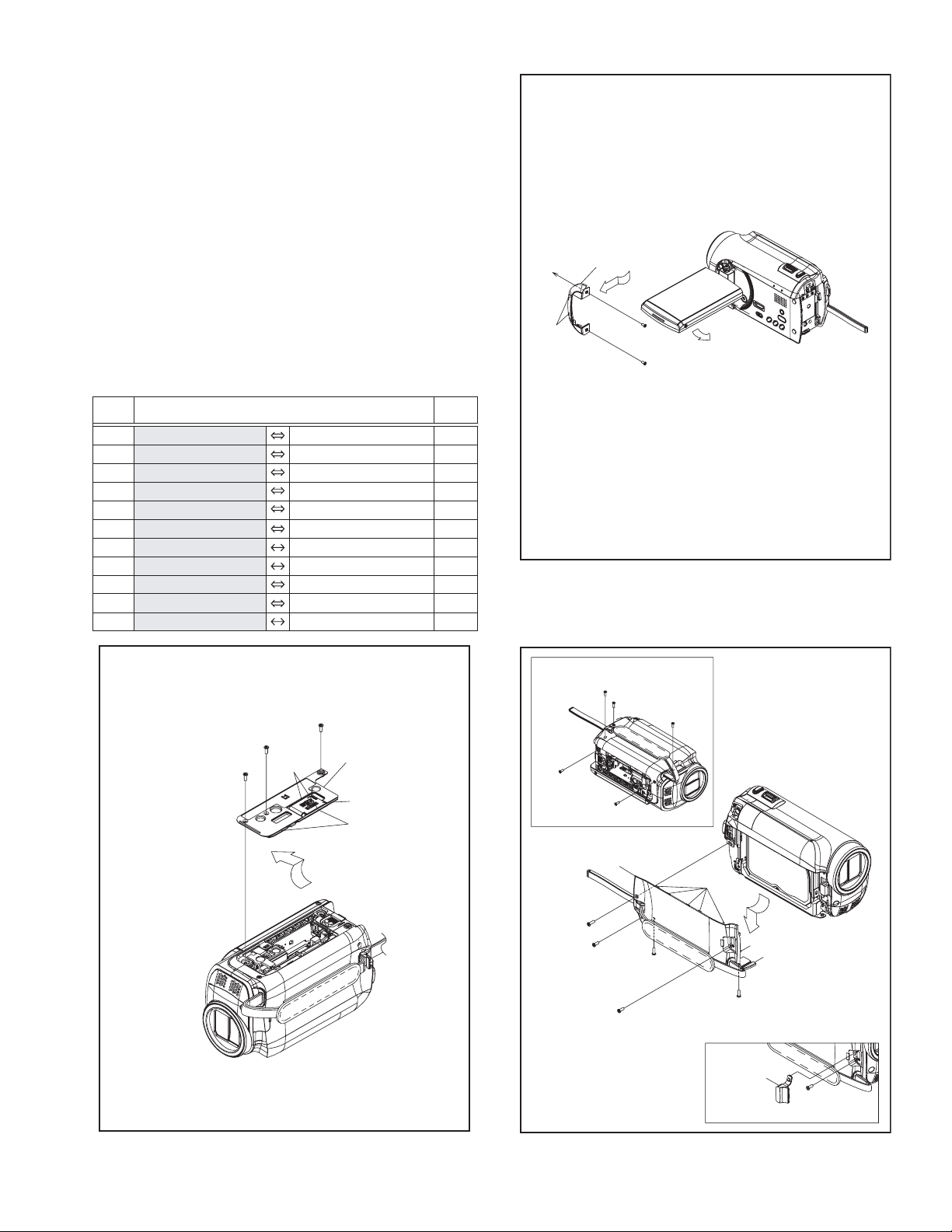

4.1.2 Required test equipment

• Personal computer (for Windows)

• Color TV monitor

• Oscilloscope (dual-trace type, observable 100MHz or higher

frequency). The one observable 300 MHz or higher frequency

is recommended.

• Digital voltmeter

• DC power supply or AC adapter

• Frequency counter (with threshold level adjuster)

4.1.3 Tools required for adjustment

Torque Driver

YTU94088

Chip IC Replacement Jig

PTS40844-2

INF Adjustment Lens Holder

YTU94087

Gray Scale Chart

YTU94133A

Service Support System

YTU94057-117

Bit

YTU94088-003

Cleaning Cloth

KSMM-01

Mini Stand

YTU93108

Color Bar Chart

YTU94133C

Communication Cable

YTU93111-1

Tweezers

P-895

INF Adjustment Lens

YTU92001D

Light Box Assembly

YTU93096B

Focus Chart

YTU92001-018

1-20 (No.YF289<Rev.003>)

PC Cable

QAM0099-002

IDE Adapter

YTU96041

Jig Connector Cable

YTU93106D

IDE Adapter

YTU96043

Charing Battery Adjuatment Jig

YTU93112A

FPC Wire

YTU94165-40

• Torque Driver

Be sure to use to fastening the mechanism and exterior parts

because those parts must strictly be controlled for tightening

torque.

• Bit

This bit is slightly longer than those set in conventional torque

drivers.

• Tweezers

To be used for removing and installing parts and wires.

Page 21

• Chip IC Replacement Jig

To be used for adjustment of the camera system.

• Cleaning Cloth

Recommended the Cleaning cloth to wipe down the video

heads, mechanism (tape transport system), optical lens surface.

• INF Adjustment Lens

To be used for adjustment of the camera system. For the

usage of the INF adjustment lens, refer to the Service Bulletin

No. YA-SB-10035.

• INF Adjustment Lens Holder

To be used together with the Camera stand for operating the

Videocamera in the stripped-down condition such as the status without the exterior parts or for using commodities that are

not yet conformable to the interchangeable ring. For the usage

of the INF lens holder, refer to the Service Bulletin No. YA-SB-

10035.

• Mini Stand

To be used together with the INF adjustment lens holder. For

the usage of the Mini stand, refer to the Service Bulletin No.

YA-SB-10035.

• Light Box Assembly

To be used for adjustment of the camera system. For the

usage of the Light box assembly, refer to the Service Bulletin

No. YA-SB-10035.

• Gray Scale Chart

To be used for adjustment of the camera system. For the

usage of the INF adjustment lens, refer to the Service Bulletin

No. YA-SB-10035.

• Color Bar Chart

To be used for adjustment of the camera system. For the

usage of the INF adjustment lens, refer to the Service Bulletin

No. YA-SB-10035.

• Focus Chart

To be used for adjustment of the camera system. For the

usage of the INF adjustment lens, refer to the Service Bulletin

No. YA-SB-10035.

• Service Support System

To be used for adjustment with a personal computer. Software

can be downloaded also from JS-net.

• Communication Cable

Connect the Communication cable between the PC cable and

Jig connector cable when performing a PC adjustment.

• PC Cable

To be used to connect the Videocamera and a personal computer

with each other when a personal computer issued for adjustment.

• Jig Connector Cable

Connected to JIG CONNECTOR of the main board and used

for electrical adjustment, etc.

• Charging Battery Adjustment Jig

This Jig is used for the adjustment of the camcorders that have

Main Body battery charging function.

• IDE Adapter(YTU96041)

To be used for HDD test.

• IDE Adapter(YTU96043)

To be used for HDD test.

• FPC Wire

To be used for connecting the HDD to the IDE adapter.

4.2 JIG CONNECTOR CABLE CONNECTION

Connection procedure

NOTE

• Be sure to turn the power “OFF”, when connecting the JIG

CONNECTOR CABLE.

If the JIG CONNECTOR CABLE is connected with the power “ON”, communication error may occur.

• Remove the 3 screws (1-3), and then remove the B.COV-

ER ASSY.

3

B.COVER ASSY

2

1

JIG

CONNECTOR

JIG CONNECTOR

CABLE

SERVICE

SUPPORT

SYSTEM

RS232C

COMMUNICATION

CABLE

JIG CONNECTOR

TO AL_2.8V

TO IF_RX

TO IF_TX

TO GND

BLUE

WHITE

BLACK

or

COMMUNICATION

CABLE

RED

COM PORT

PC CABLE

MENU

PERSONAL COMPUTER

Fig.4-2-1

JIG CONNECTOR CABLE [YTU93106D]

1630

115

Fig.4-2-2

(No.YF289<Rev.003>)1-21

Page 22

Jig connector diagrams

JIG CONNECTOR CABLE (YTU93106D)

MAIN CN110

DSP_TDO

DSP_TCK

DSP_TMS

DSP_TDI

XDSPTRST

XDSPSRST

REG_2.83V

UARXD0

UATXD0

AL_2.8V

IF_TX

IF_RX

NC

SYS_RSTL

OCD_SCL

CAPSENS_DT

NC

GND

OCD_SDA

GND

MVD

IRU

ISSP_DATA

NC

NC

EXTRG0

DSP_RTCK

KENTO

GND

KENTO2

JIG CONN. BOARD

(PIN NO.)

1

16

2

17

3

18

4

19

5

20

6

21

7

22

8

23

9

24

10

25

11

26

12

27

13

28

14

29

15

30

1

2

XDSPTRST

3

REG_2.83V

4

5

6

7

8

9

10

11

ISSP_DATA

12

13

DSP_RTCK

14

15

16

17

XDSPSRST

18

19

20

21

SYS_RSTL

22

CAPSENS_DT

23

24

25

26

27

28

29

30

DSP_TDO

DSP_TMS

UATXD0

IF_TX

NC

OCD_SCL

NC

OCD_SDA

MVD

NC

GND

DSP_TCK

DSP_TDI

UARXD0

AL_2.8V

IF_RX

GND

GND

IRU

NC

EXTRG0

KENTO

KENTO2

Fig.4-2-3

1-22 (No.YF289<Rev.003>)

Page 23

4.3 IDE ADAPTER AND FPC WIRE

• IDE ADAPTER and FPC WIRE are used for HDD test.

Check with the NOTE, and then refer to the below figure (Fig. 4-3-1, Fig.4-3-2) for the connection procedure.

<TYPE-T>

FPC WIRE(Parts No.:YTU94165-40)

<BACK SIDE><FRONT SIDE>

HDD HDD

IDE ADAPTER CONNECTOR

<TYPE-S>

LABEL

Fig.4-3-1

FPC WIRE(Parts No.:YTU94165-40)

<BACK SIDE><FRONT SIDE>

HDD HDD

CONNECTOR

Fig.4-3-2

<NOTE>

• During the procedure, be careful in handling the parts. Pay special attention not to give any external shock to the HDD.

• There are two types of IDE ADAPTER (Parts Number: YTU96041, YTU96043). Either type can be used.

• Using the FPC WIRE originally used with this unit will damage the HDD.

Use the FPC WIRE (Parts Number: YTU94165-40) to connect the IDE ADAPTER and the HDD.

Connecting the FPC WIRE upside-down will damage the HDD.

LABELIDE ADAPTER

(No.YF289<Rev.003>)1-23

Page 24

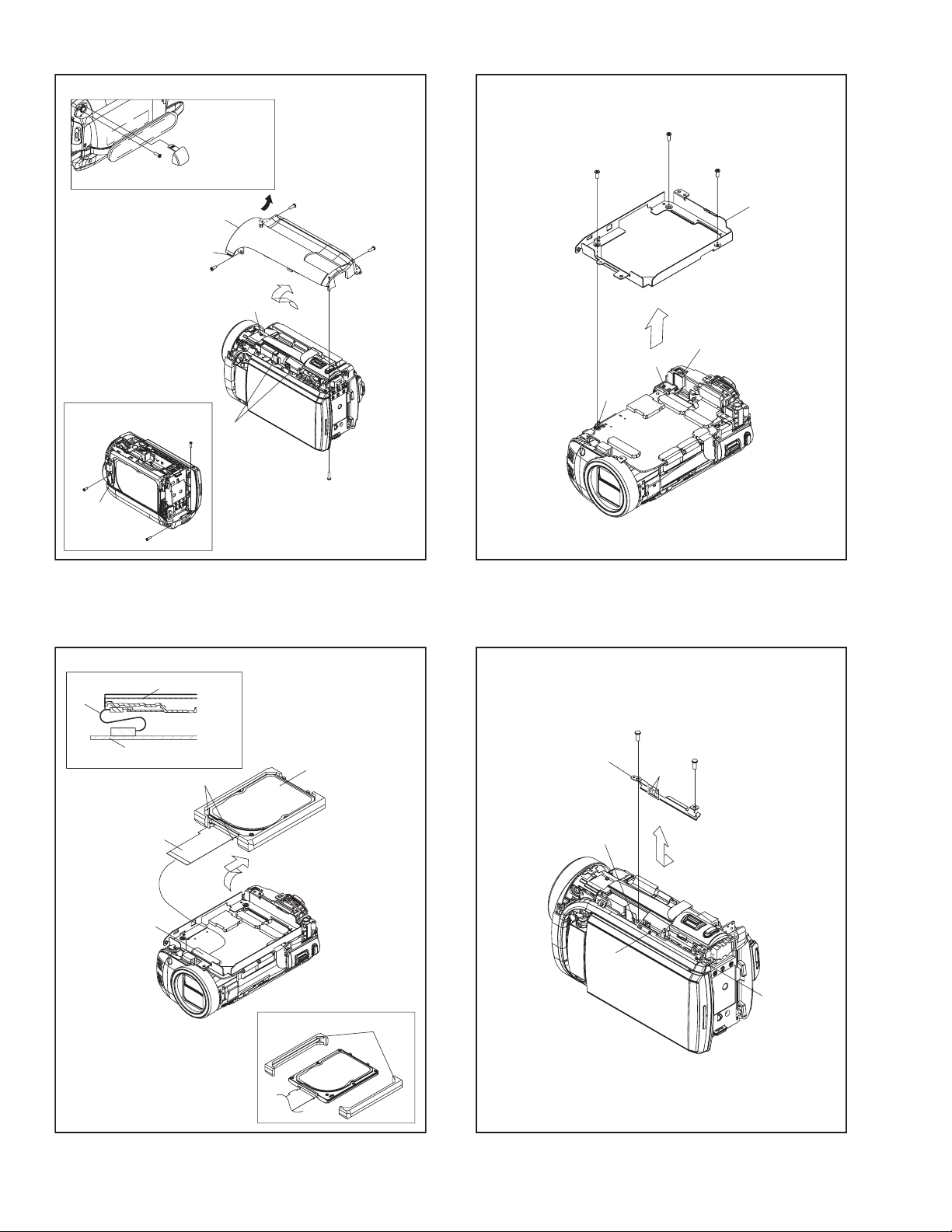

5.1 SERVICE NOTE

SECTION 5

TROUBLE SHOOTING

[12][11]

-

-

3-2-123-2-11

aa

3-2-10

-

3-2-8

3-2-6 3-2-7 3-2-9

-

3-2-5

ab

[23]

-

-

[20]MONITOR ASSY

3-2-24

1 2 3 4 5

b-

a

aaa

3-2-15 3-2-16 3-2-183-2-17 3-2-20 3-2-22

-

[14]

[1] [2] [4][3] [5] [6] [7] [8] [9] [10]

CABINET PARTS AND ELECTRICAL PARTS(1)

Symbol No.

3-2-1 3-2-2 3-2-3 3-2-4

1 2 3 4 5 6 7 8 9 10 11 12 13 14 - 15 16 17 18 19 - 20 21 22 23 24 25

Place to stick screw

Removing order of screw

Screw tightening torque

Reference drawing (Fig.No.)

[13] [15] [16] [17] [18] [19] [20] [21] [22] [23]

CABINET PARTS AND ELECTRICAL PARTS(2)

Symbol No.

3-2-14 3-2-19 3-2-21

a

3-2-13

26 27 28 - 29 30 31 32 33 34 35 36 37 38 - 39 40 41 42 43 44 45

Place to stick screw

Removing order of screw

Screw tightening torque

Reference drawing (Fig.No.)

[17]

[14]OP BLOCK ASSY/CCD BOARD ASSY

Symbol No.

3-2-23

cd

1 2 3 4 5 6 7 8 9 10

Place to stick screw

Removing order of screw

Screw tightening torque

Reference drawing (Fig.No.)

Prepare the specified screws and use them in place of the removed screws.

Be careful not to break either the screws or the screw holes.

and tighten the screw manually.

The specified torque value is a recommended value of the initial assembly. Therefore, set the value below the specified torque value in the assembling procedure.

There are setting limits of the torque value for the torque driver. If the value exceeds the setting value, take it as a rough measurement (reference value),

㧞)Tightening torque for the screws

㧝)㧖and㧖㧖 (This mark shows where to attach the screws) : Do not reuse the screws because the screw lock bond was applied to prevent the screws from loosening.

NOTE:

a㧦0.088N㨯m (0.9kgf㨯cm) b㧦0.118N㨯m (1.2kgf㨯cm) c㧦0.147N㨯m (1.5kgf㨯cm) d㧦0.078N㨯m (0.8kgf㨯cm)

1-24 (No.YF289<Rev.003>)

Page 25

Victor Company of Japan, Limited

Camcorder Division 12, 3-chome, Moriya-cho, Kanagawa-ku, Yokohama-city, Kanagawa-prefecture, 221-8528, Japan

(No.YF289<Rev.003>)

Printed in Japan

VSE

Page 26

PARTS LIST

SAFETY PRECAUTION

Parts identified by the symbol are critical for safety. Replace only with specified part numbers.

BEWARE OF BOGUS PARTS

Parts that do not meet specifications may cause trouble in regard to safety and performance. We recommend that genuine

JVC parts be used.

1. EXPLODED VIEW

1.1 FINAL ASSEMBLY <M1>

The instruction manual to be provided with this product will differ according to the destination.

126

F1

106

107

108

125

129

130

129

a

a

GZ-HD300AUS A

GZ-HD300BUS B

GZ-HD300RUS

GZ-HD310BUC

GZ-HD320BUS

MODEL

112

126

150

107

125

125

F1

134

134

205

205

205

211

MARK

C

D

E

128

143

144

b

b

142

145

109

133

140

127

141

127

201

202

203

(No.YF289<Rev.001>)3-1

Page 27

512

512

502

121

121

503

510

e

504

505

W1

F5

e

501

511

FRONT ASSEMBLY

114

124

113

UPPER ASSEMBLY

F5

137

W1

137

F2

MAIN BOARD ASSEMBLY

F2

123

122

123

<01>

138

F6

120

W2

138

120

105

F6

120

W2

d

F3

132

d

110

REAR BOARD

ASSEMBLY

<05>

JACK BOARD

ASSEMBLY

<07>

104

103

111

F4

131

135

136

104

102

F4

101

F3

OP BLOCK ASSEMBLY

F8

136

F8

3-2(No.YF289<Rev.001>)

Page 28

611

OP BLOCK ASSEMBLY

601D

601D

601B

601D

601D

601D

601C

601D

601D

601A

699

603

606

605

610

610

602

601

604

(No.YF289<Rev.001>)3-3

Page 29

UPPER ASSEMBLY

321

320

322

337

318

F11

j

324

306

MONITOR BOARD ASSEMBLY

<06>

F10

n

p

323

316

308

312

m

k

314

313

316

337

317

h

F9

317

309

307

311

g

305

310

j

F9

h

n

p

m

k

332

333

331

W3

g

334

335

335

W3

330

NOTE)

When attaching the SENSOR BOARD ASSY

to the MONI. CASE ASSY,

be sure to remove the paper backing.

For details, please refer to SECTION 3.

F12

OPE BOARD

ASSEMBLY

<04>

F12

F10

302

SENSOR BOARD

ASSEMBLY

<03>

F11

301

3-4(No.YF289<Rev.001>)

336

Page 30

1.2 PACKING AND ACCESSORY ASSEMBLY <M5>

101

FINAL ASSEMBLY

<M1>

111

102

106

103

105

104

005

011

003

013

016

019

002

020

025

001

005

LABEL

(SERIAL)

(No.YF289<Rev.001>)3-5

Page 31

2. PARTS LIST

FINAL ASSEMBLY <M1>

Symbol No.

101 LY36913-002A FRAME ASSY

102 LY36910-001A PLATE(HDMI)

103 LY36911-001A BKT(HDMI)

104 LY45291-051A GASKET (x2)

105 LY37035-001A FRM(PLATE)ASSY

106 LY37015-001C HDD CASE ASSY

107 LY37032-001A GEL (x2)

108 QAL0906-003 FPC

109 LY22003-003D TOP COVER A

109 LY22003-001D TOP COVER B,D,E

109 LY22003-004D TOP COVER C

110 LY21938-001C REAR COVER ASSY

111 LY21940-007C ZOOM UNIT A

111 LY21940-005C ZOOM UNIT B,D,E

111 LY21940-008C ZOOM UNIT C

112 LY36761-003C COVER(HINGE)ASY A

112 LY36761-001B COVER(HINGE)ASY B,D,E

112 LY36761-004C COVER(HINGE)ASY C

113 LY21998-002C ORNAMENT(TOP) A,C

113 LY21998-001C ORNAMENT(TOP) B,D,E

114 LY36915-001A BKT(O.TOP)

120 LY30032-021A SPECIAL SCREW OP-FRAME(x3)

121 LY30031-0D5A SPECIAL SCREW MAIN.P-FRM(x2)

122 LY30031-0D5A SPECIAL SCREW REAR-FRAM

123 LY30031-0D5A SPECIAL SCREW REAR-FRAM(x2)

124 LY30031-0D4A SPECIAL SCREW UPPER-FRAM

125 LY30031-0D5A SPECIAL SCREW

126 LY30031-0D5A SPECIAL SCREW

127 LY30031-0L8B SPECIAL SCREW TOP-REAR(x2)

128 LY30031-0D5A SPECIAL SCREW UPPER-FRAM

129 LY30031-0D5A SPECIAL SCREW

130 LY30031-0L8B SPECIAL SCREW HDDCV-REAR

131 LY30031-0L8B SPECIAL SCREW ZOOM-BATTP

132 LY30031-0L8B SPECIAL SCREW ZOOM-REAR

133 LY30031-0D5A SPECIAL SCREW TOP-BAR

134 LY30031-0D4A SPECIAL SCREW CV.HI-HING(x2)

135 LY30031-0D5A SPECIAL SCREW BKTHDM-PLT

136 LY30031-0D5A SPECIAL SCREW

137 LY30031-0L8B SPECIAL SCREW UPPER-BKT(x2)

138 LY30031-0D5A SPECIAL SCREW

140 LY36996-003F HDD COVER ASSY A

140 LY36996-001F HDD COVER ASSY B,D,E

140 LY36996-004F HDD COVER ASSY C

141 LY21941-001C GRIP BELT ASSY

142 LY36629-001B HOLDER(G.B)

143 LY36630-001A SHAFT(G.B)

144 LY30031-0L8B SPECIAL SCREW HLDGB-HDDC

145 LY30031-0L8B SPECIAL SCREW GRPADJ-HDD

150 QAL1139-003 HDD 60G A,B,C

150 QAL1140-001 HDD 80G D

150 QAL1161-003 HDD 120G E

201 LY36631-001A JACK COVER(USB)

202 LY36632-001C JACK COVER(DC)

203 LY36633-001C JACK COVER(AV)

205 LY30031-0D5A SPECIAL SCREW

211 LY21972-001E B.COVER(N)ASSY

301 LY36637-001D MONI.CASE ASSY

302 LY36638-001B D FACE TAPE

305 LY21965-001A LCD CASE

306 LY21945-001B LCD BKT

307 LY36124-001A SHEET (COVER) (x2)

308 LY36702-001A SPACER (LCD)

309 QLD0538-001 LCD MODULE

310 LY36703-001A SHEET (BEF)

311 LY35480-001A SHEET(M/DIFF)

312 LY35481-001A SHEET(M.REF)

313 LY36668-001A LIGHT GUIDE

314 LY36916-007C MONI.COVER ASSY A

314 LY36916-005B MONI.COVER ASSY B,D,E

314 LY36916-008C MONI.COVER ASSY C

316 LY30031-079A SPECIAL SCREW M.C-LCDBKT(x2)

317 LY30031-079A SPECIAL SCREW M.CO-HINGE(x2)

318 LY30031-0D4A SPECIAL SCREW M.PWB-LCDB

320 LY36640-001C HINGE UNIT

Part No. Part Name Description Local

HDDCS-FRAM(x3)

HDDCV-FRAM(x2)

HDDCV-HDDC(x2)

HDMIP-FRAM(x2)

FRMPLT-FRM(x2)

BTMCV-FRAM(x3)

Symbol No.

MODEL MARK

GZ-HD300AUS

GZ-HD300BUS

GZ-HD300RUS

Part No. Part Name Description Local

A

B

C

MODEL MARK

GZ-HD310BUC

GZ-HD320BUS

321 LY21994-003A HINGE COVER(U) A

321 LY21994-001A HINGE COVER(U) B,D,E

321 LY21994-004A HINGE COVER(U) C

322 LY21952-001C HINGE COVER(L)

323 LY45427-001A P.C.MAGNET

324 QAL1149-001 FPC

330 LY21995-003E U.CASE ASSY A

330 LY21995-001E U.CASE ASSY B,D,E

330 LY21995-004E U.CASE ASSY C

331 LY36645-001B BKT(SPEAKER)

332 QAS0543-001 SPEAKER

333 LY45709-001B SPACER(SPK)

334 LY30031-0L8B SPECIAL SCREW SPK BKT-UP

335 LY30031-0L8B SPECIAL SCREW

OPE PWB-UP(x2)

336 LY30031-0K7A SPECIAL SCREW FPC-UPPER

337 LY30031-0K7A SPECIAL SCREW HIN-BKT(UP)(x2)

501 LY36649-001C F.COVER ASSY

502 LY21958-001P BARRIER UNIT

503 LY36659-003C HOOD(SCREW)

504 LY36660-001A PLATE(MIC)

505 LY36139-001A MIC

510 LY30031-0L8B SPECIAL SCREW PLMIC-CVMI

511 LY30031-0D4A SPECIAL SCREW BARU-FRCV

512 LY30031-0L8B SPECIAL SCREW

HDSCR-BARU(x2)

601 LY36922-001A OP BLOCK

601A PTY36134-101 MOTOR UNIT FOCUS

601B PTY36134-101 MOTOR UNIT ZOOM

601C PTY36922-106 AUTO IRIS UNIT

601D PTY36134-530 SCREW (x7)

602 LY45766-001A SHEET

603 LY36776-001A SHIELD(CMOS)

604 LY45801-001A HEAT SHEET

605 LY45801-002A HEAT SHEET

606 LY45291-050A GASKET

610 QYSPSGU1740ZA TAP SCREW M1.7 x 4mm(x2)

611 QYSPSGU1745MA TAP SCREW M1.7 x 4.5mm

699 JVP5-101 CMOS FRM ASSY

PACKING AND ACCESSORY ASSEMBLY <M5>

Symbol No.

Part No. Part Name Description Local

001 LY36957-005A PACKING CASE A,B,C

001 LY36957-007A PACKING CASE D

001 LY36957-006A PACKING CASE E

002 LY21961-001C CUSHION

003 LY30023-054A POLY BAG

005 LY36917-002B LABEL(COLOR) (x2) A

005 LY36917-004A LABEL(COLOR) (x2) B

005 LY36917-003B LABEL(COLOR) (x2) C

011 QAM0509-001 A/V CABLE

013 QAM1112-001 USB CABLE

016 QAL1151-001 AC P ADAPTOR AP-V20U

019 LY21805-002A REMOTE CTL UNIT RM-V751US

020 LY35320-002D BATTERY PACK BN-VF808U

025 QAM1179-001 D CABLE RCA

101 LY34452-001B POLY BAG

102 LY35273-056A CD ROM ASSY

103 LYT2043-001B INST BOOK

103 LYT2043-002B INST BOOK (FRENCH) A,B,C,E

103 LYT2044-001B INST BOOK

(ENGLISH/SPANISH)

(ENGLISH/FRENCH)

104 LYT2045-001B SHEET(QSG) A,B,C,E

105 ------------ WARRANTY CARD BT-51005-9

106 ------------ WARRANTY CARD BT-52008-1

111 BT-51044-1 REGISTRATION CARD

MAIN BOARD ASSEMBLY <01>

Symbol No.

PW1 LYA10165-01C MAIN BOARD ASSY

Part No. Part Name Description Local

D

E

A,B,C,E

D

3-6(No.YF289<Rev.001>)

Page 32

Symbol No.

Part No. Part Name Description Local

Symbol No.

MODEL MARK

GZ-HD300AUS

GZ-HD300BUS

GZ-HD300RUS

A

B

C

GZ-HD320BUS

MODEL MARK

GZ-HD310BUC

D

E

Part No. Part Name Description Local

IC82 NAL0068-001X SHOCK SENSOR

IC1001 MN103SD0QGF IC(MICRO C ROM)

IC1001 or MN103SFD0RGF IC(MICRO C ROM)

IC1001 or MN103SFD0RGFA IC(MICRO C ROM)

IC1002 NJU7108F3-X IC

IC1005 LE25LB1282TT-X IC

IC1006 S-35190A-G-X IC

IC1007 IC-PST8223U-W IC

IC1007 or S-80823CNNB-G-W IC

IC1009 R5G05001N302N-X IC(MICRO C ROM)

IC1009 or YCBCJVSNS8031-X IC(MICRO C ROM)

IC2201 AK4669EN-W IC

IC3001 JCY0243 IC

IC3002 S-1112B31MC-W IC

IC3010 TPS2051BDBV-X IC

IC3101 HY5MS7B2BLFP6E IC

IC3102 HY5MS7B2BLFP6E IC

IC3201 SG64N90BFI030H0 IC(MICRO C ROM)

IC3201 or SG64N90BFI030H1 IC(MICRO C ROM)

IC3201 or SG64N90BFI030H2 IC(MICRO C ROM)

IC3721 LY36351-001A CSP IC ASSY SERVICE

IC4501 JCY0245 IC

IC4502 H55S1222EFP-60M IC

IC4507 S-1112B31MC-W IC

IC4508 NJM2872BF05-X IC

IC4901 AN41905A-X IC

IC4904 GP1UF311Y-X IR DETECT UNIT

IC4905 NJM2143R-X IC

IC5701 LV8075LP-W IC

IC6001 FA7736AF IC

IC6002 MAX8792ETD-X IC

IC6003 NJM2872BF05-X IC

IC6004 S-1112B28MC-W IC

IC6005 S-1112B18MC-W IC

IC6006 R1172N271D-X IC

Q421 UMZ1N-W PAIR TRANSISTOR

Q421 or XP4601-W TRANSISTOR

Q421 or PUMZ1-W PAIR TRANSISTOR

Q422 DTC143XE-X DIGI TRANSISTOR

Q422 or RT1N432U-X DIGI TRANSISTOR

Q422 or UN921FJ-X DIGI TRANSISTOR

Q422 or SRC1219EF-X DIGI TRANSISTOR

Q422 or KRC419E-X DIGI TRANSISTOR

Q651 2SC4617/QR/-X TRANSISTOR

Q651 or 2SC5383/E/-X TRANSISTOR

Q651 or 2SD2216J/QR/-X TRANSISTOR

Q651 or 2SC4617/RS/-X TRANSISTOR

Q651 or 2SC5383/F/-X TRANSISTOR

Q651 or 2SD2216J/RS/-X TRANSISTOR

Q1002 DTC143XE-X DIGI TRANSISTOR

Q1002 or UN921FJ-X DIGI TRANSISTOR

Q1002 or RT1N432U-X DIGI TRANSISTOR

Q1002 or SRC1219EF-X DIGI TRANSISTOR

Q1002 or KRC419E-X DIGI TRANSISTOR

Q1007 DTC143XE-X DIGI TRANSISTOR

Q1007 or UN921FJ-X DIGI TRANSISTOR

Q1007 or RT1N432U-X DIGI TRANSISTOR

Q1007 or SRC1219EF-X DIGI TRANSISTOR

Q1007 or KRC419E-X DIGI TRANSISTOR

Q2401 2SC4617/RS/-X TRANSISTOR

Q2401 or 2SC5383/F/-X TRANSISTOR

Q2402 2SC4617/RS/-X TRANSISTOR

Q2402 or 2SC5383/F/-X TRANSISTOR

Q2701 UMX18N-W PAIR TRANSISTOR

Q2702 DTA143ZE-X DIGI TRANSISTOR

Q3001 DTC144EE-X DIGI TRANSISTOR

Q3001 or RT1N441U-X DIGI TRANSISTOR

Q3001 or KRC404E-P-X DIGI TRANSISTOR

Q3001 or UN9213J-X DIGI TRANSISTOR

Q3001 or PDTC144EE-X DIGI TRANSISTOR

Q3002 3LN01SS-X MOS FET

Q3003 DTA144EE-X DIGI TRANSISTOR

Q3003 or KRA304E-X DIGI TRANSISTOR

Q3003 or PDTA144EE-X DIGI TRANSISTOR

Q3003 or UN9113J-X DIGI TRANSISTOR

Q3751 XP4312-W DIGI TRANSISTOR

Q4502 UMT1N-W PAIR TRANSISTOR

Q4502 or XP4401-W TRANSISTOR

Q4502 or KTA701U/G/-X PAIR TRANSISTOR

Q4502 or PUMT1-W PAIR TRANSISTOR

Q4502 or BC856S-X PAIR TRANSISTOR

Q6001 SP8J5-X MOS FET

Q6201 RSR025P03-X MOS FET

Q6202 RSR025N03-X MOS FET

Q6504 2SA1577/QR/-X TRANSISTOR

Q6505 UMX1N-W PAIR TRANSISTOR

Q6505 or KTC801U/G/-X PAIR TRANSISTOR

Q6505 or RT3CLLM/EF/-X TRANSISTOR

Q6505 or XP4501-W TRANSISTOR

Q6505 or PUMX1-W PAIR TRANSISTOR

Q6701 RSR025P03-X MOS FET

Q6702 RSR025P03-X MOS FET

Q6703 RSR025P03-X MOS FET

Q6801 RSR025N03-X MOS FET

Q6802 RSR025N03-X MOS FET

Q7802 UMX1N-W PAIR TRANSISTOR

Q7802 or KTC801U/G/-X PAIR TRANSISTOR

Q7802 or RT3CLLM/EF/-X TRANSISTOR

Q7802 or XP4501-W TRANSISTOR

Q7802 or PUMX1-W PAIR TRANSISTOR

Q7803 UMX1N-W PAIR TRANSISTOR

Q7803 or KTC801U/G/-X PAIR TRANSISTOR

Q7803 or RT3CLLM/EF/-X TRANSISTOR

Q7803 or XP4501-W TRANSISTOR

Q7803 or PUMX1-W PAIR TRANSISTOR

Q7804 UMX1N-W PAIR TRANSISTOR

Q7804 or KTC801U/G/-X PAIR TRANSISTOR

Q7804 or RT3CLLM/EF/-X TRANSISTOR

Q7804 or XP4501-W TRANSISTOR

Q7804 or PUMX1-W PAIR TRANSISTOR

D181 EMZ6.8N-X Z DIODE

D191 MA111-X SI DIODE

D191 or SDS511-X SI DIODE

D191 or 1SS355-X SI DIODE

D191 or 1SS352-X SI DIODE

D421 NSPW300DS/C0VW/ LED

D4501 RB751V-40-X SB DIODE

D6101 MA22D23-X SB DIODE

D6201 MA22D23-X SB DIODE

D6301 MA22D23-X SB DIODE

D6401 MA22D23-X SB DIODE

D6501 RB481K-X SB DIODE

D6502 RB481K-X SB DIODE

D6701 MA22D23-X SB DIODE

D6702 MA22D23-X SB DIODE

D6801 MA22D28-X SB DIODE

D6901 RB551V-30-X SB DIODE

C82 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C112 NCBA1CK-103W C CAPACITOR 0.01uF 16V K

C141 NCB20JM-475X C CAPACITOR 4.7uF 6.3V M

C142 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C601 NCB31EK-104X C CAPACITOR 0.1uF 25V K

C1009 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C1011 NCBA1CK-103W C CAPACITOR 0.01uF 16V K

C1013 NCB30JK-105X C CAPACITOR 1uF 6.3V K

C1015 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C1016 NCB30JK-105X C CAPACITOR 1uF 6.3V K

C1030 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C1031 NCBA1CK-103W C CAPACITOR 0.01uF 16V K

C1032 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C1033 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C1035 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C1036 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C1037 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C1038 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C1039 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C1040 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C1061 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C1064 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C1065 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C1076 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C2201 NCB31CK-105X C CAPACITOR 1uF 16V K

(No.YF289<Rev.001>)3-7

Page 33

Symbol No.

Part No. Part Name Description Local

Symbol No.

MODEL MARK

GZ-HD300AUS

GZ-HD300BUS

GZ-HD300RUS

A

B

C

MODEL MARK

GZ-HD310BUC

GZ-HD320BUS

D

E

Part No. Part Name Description Local

C2203 NCB31CK-105X C CAPACITOR 1uF 16V K

C2205 NCB31CK-105X C CAPACITOR 1uF 16V K

C2206 NCBA1CK-104W C CAPACITOR 0.1uF 16V K

C2208 NCB31CK-105X C CAPACITOR 1uF 16V K

C2209 NCBA1EK-682W C CAPACITOR 6800pF 25V K

C2210 NCBA1CK-153W C CAPACITOR 0.015uF 16V K

C2401 NCB20JK-106X C CAPACITOR 10uF 6.3V K

C2402 NCB20JK-106X C CAPACITOR 10uF 6.3V K

C2403 NCB20JK-106X C CAPACITOR 10uF 6.3V K

C2404 NCB20JK-106X C CAPACITOR 10uF 6.3V K

C2405 NCB20JK-106X C CAPACITOR 10uF 6.3V K

C2406 NCB20JK-106X C CAPACITOR 10uF 6.3V K

C2407 NCBA1CK-104W C CAPACITOR 0.1uF 16V K

C2603 NCBA1AK-683W C CAPACITOR 0.068uF 10V K

C2604 NCBA1AK-683W C CAPACITOR 0.068uF 10V K

C2605 NCBA1CK-223W C CAPACITOR 0.022uF 16V K

C2606 NCBA1CK-223W C CAPACITOR 0.022uF 16V K

C2607 NCB30JK-105X C CAPACITOR 1uF 6.3V K

C2608 NCB30JK-105X C CAPACITOR 1uF 6.3V K

C2609 NCB31CK-105X C CAPACITOR 1uF 16V K

C2651 NCBA1CK-103W C CAPACITOR 0.01uF 16V K

C2652 NCBA1CK-103W C CAPACITOR 0.01uF 16V K

C3003 NCBA1CK-103W C CAPACITOR 0.01uF 16V K

C3005 NCB30JK-105X C CAPACITOR 1uF 6.3V K

C3006 NCB20JK-475X C CAPACITOR 4.7uF 6.3V K

C3007 NCB30JK-105X C CAPACITOR 1uF 6.3V K

C3012 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C3019 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C3024 NCB20JK-475X C CAPACITOR 4.7uF 6.3V K

C3027 NCBA1CK-103W C CAPACITOR 0.01uF 16V K

C3029 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C3031 NBE41AM-476X TA E CAPACITOR 47uF 10V M

C3032 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C3034 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C3038 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C3041 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C3056 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C3101 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C3102 NCBA1CK-103W C CAPACITOR 0.01uF 16V K

C3103 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C3104 NCBA1CK-103W C CAPACITOR 0.01uF 16V K

C3105 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C3106 NCBA1CK-103W C CAPACITOR 0.01uF 16V K

C3107 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C3108 NCBA1CK-103W C CAPACITOR 0.01uF 16V K

C3201 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C3721 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C3722 NCB30JK-105X C CAPACITOR 1uF 6.3V K

C3723 NCB30JK-105X C CAPACITOR 1uF 6.3V K

C3724 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C3725 NCB30JK-105X C CAPACITOR 1uF 6.3V K

C3726 NCB30JK-105X C CAPACITOR 1uF 6.3V K

C3727 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C3729 NBE20JM-106X TA E CAPACITOR 10uF 6.3V M

C3730 NBE20JM-107X TA E CAPACITOR 100uF 6.3V M

C3731 NCB11AK-106X C CAPACITOR 10uF 10V K

C3732 NBE20JM-107X TA E CAPACITOR 100uF 6.3V M

C3733 NBE20JM-226X TA E CAPACITOR 22uF 6.3V M

C3734 NCB11AK-106X C CAPACITOR 10uF 10V K

C3735 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C3736 NBE20JM-107X TA E CAPACITOR 100uF 6.3V M

C3737 NBE20JM-107X TA E CAPACITOR 100uF 6.3V M

C3738 NCB11AK-106X C CAPACITOR 10uF 10V K

C3740 NCB30JK-105X C CAPACITOR 1uF 6.3V K

C3741 NCB30JK-105X C CAPACITOR 1uF 6.3V K

C4502 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C4503 NCB20JK-475X C CAPACITOR 4.7uF 6.3V K

C4505 NCB20JK-475X C CAPACITOR 4.7uF 6.3V K

C4506 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C4507 NCB20JK-475X C CAPACITOR 4.7uF 6.3V K

C4508 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C4511 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C4515 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C4518 NCBA1CK-103W C CAPACITOR 0.01uF 16V K

C4519 NCB30JK-105X C CAPACITOR 1uF 6.3V K

C4520 NCB30JK-105X C CAPACITOR 1uF 6.3V K

C4522 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C4524 NCB30JK-105X C CAPACITOR 1uF 6.3V K

C4525 NCB30JK-105X C CAPACITOR 1uF 6.3V K

C4526 NCB30JK-105X C CAPACITOR 1uF 6.3V K

C4527 NCBA1CK-103W C CAPACITOR 0.01uF 16V K

C4529 NCB20JK-475X C CAPACITOR 4.7uF 6.3V K

C4533 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C4535 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C4538 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C4539 NCB20JK-475X C CAPACITOR 4.7uF 6.3V K

C4541 NCB20JK-475X C CAPACITOR 4.7uF 6.3V K

C4542 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C4544 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C4546 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C4547 NCB30JK-105X C CAPACITOR 1uF 6.3V K

C4548 NCB30JK-105X C CAPACITOR 1uF 6.3V K

C4549 NCB30JK-105X C CAPACITOR 1uF 6.3V K

C4554 NCB20JK-475X C CAPACITOR 4.7uF 6.3V K

C4555 NCB20JK-475X C CAPACITOR 4.7uF 6.3V K

C4558 NCB20JK-475X C CAPACITOR 4.7uF 6.3V K

C4560 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C4561 NCB30JK-105X C CAPACITOR 1uF 6.3V K

C4562 NCBA1CK-103W C CAPACITOR 0.01uF 16V K

C4563 NCB30JK-105X C CAPACITOR 1uF 6.3V K

C4565 NCB30JK-105X C CAPACITOR 1uF 6.3V K

C4566 NCB20JK-475X C CAPACITOR 4.7uF 6.3V K

C4567 NCB20JK-475X C CAPACITOR 4.7uF 6.3V K

C4569 NCB31EK-104X C CAPACITOR 0.1uF 25V K

C4570 NCB30JK-105X C CAPACITOR 1uF 6.3V K

C4571 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C4575 NCB30JK-105X C CAPACITOR 1uF 6.3V K

C4576 NCB30JK-105X C CAPACITOR 1uF 6.3V K

C4901 NCB20JK-106X C CAPACITOR 10uF 6.3V K

C4902 NCB20JK-106X C CAPACITOR 10uF 6.3V K

C4903 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C4904 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C4905 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C4906 NCBA1CK-103W C CAPACITOR 0.01uF 16V K

C4907 NDCA1HJ-101W C CAPACITOR 100pF 50V J

C4908 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C4909 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C4910 NCBA1HK-102W C CAPACITOR 1000pF 50V K

C4916 NCB20JK-106X C CAPACITOR 10uF 6.3V K

C4921 NCB30JK-105X C CAPACITOR 1uF 6.3V K

C4922 NCBA1AK-104W C CAPACITOR 0.1uF 10V K

C5701 NCB20JK-106X C CAPACITOR 10uF 6.3V K

C6002 NCB21CK-105X C CAPACITOR 1uF 16V K

C6003 NCB21CK-105X C CAPACITOR 1uF 16V K

C6004 NCB31CK-105X C CAPACITOR 1uF 16V K

C6005 NCB31CK-105X C CAPACITOR 1uF 16V K

C6006 NCB31EK-104X C CAPACITOR 0.1uF 25V K

C6008 NCB31EK-473X C CAPACITOR 0.047uF 25V K

C6081 NCB20JK-106X C CAPACITOR 10uF 6.3V K

C6101 NCBA1HK-221W C CAPACITOR 220pF 50V K

C6102 NCBA1HK-152W C CAPACITOR 1500pF 50V K

C6103 NCB31CK-105X C CAPACITOR 1uF 16V K

C6104 NCB20JK-106X C CAPACITOR 10uF 6.3V K

C6201 NCBA1HK-221W C CAPACITOR 220pF 50V K

C6202 NCBA1HK-152W C CAPACITOR 1500pF 50V K

C6203 NCB31CK-105X C CAPACITOR 1uF 16V K

C6204 NCB20JK-106X C CAPACITOR 10uF 6.3V K

C6301 NCBA1HK-221W C CAPACITOR 220pF 50V K

C6302 NCBA1HK-152W C CAPACITOR 1500pF 50V K

C6303 NCB31CK-105X C CAPACITOR 1uF 16V K

C6304 NCB20JK-106X C CAPACITOR 10uF 6.3V K

C6305 NCB21AK-475X C CAPACITOR 4.7uF 10V K

C6306 NCB21AK-475X C CAPACITOR 4.7uF 10V K

C6401 NCBA1HK-221W C CAPACITOR 220pF 50V K

C6402 NCBA1HK-102W C CAPACITOR 1000pF 50V K

C6403 NCB31CK-105X C CAPACITOR 1uF 16V K

C6404 NCB20JK-106X C CAPACITOR 10uF 6.3V K

C6501 NCBA1AK-473W C CAPACITOR 0.047uF 10V K

C6502 NCBA1AK-333W C CAPACITOR 0.033uF 10V K

C6503 NCB31CK-105X C CAPACITOR 1uF 16V K

C6504 NCB31CK-105X C CAPACITOR 1uF 16V K

C6505 NCB31CK-105X C CAPACITOR 1uF 16V K

C6506 NCB21CK-105X C CAPACITOR 1uF 16V K

C6507 NCB21CK-105X C CAPACITOR 1uF 16V K

C6510 NCB21CK-105X C CAPACITOR 1uF 16V K

C6512 NCB31CK-105X C CAPACITOR 1uF 16V K

3-8(No.YF289<Rev.001>)

Page 34

Symbol No.

Part No. Part Name Description Local

Symbol No.

MODEL MARK

GZ-HD300AUS

GZ-HD300BUS

GZ-HD300RUS

A

B

C

GZ-HD320BUS

MODEL MARK

GZ-HD310BUC

D

E

Part No. Part Name Description Local

C6701 NCBA1EK-472W C CAPACITOR 4700pF 25V K

C6702 NCBA1CK-103W C CAPACITOR 0.01uF 16V K

C6704 NCB31CK-105X C CAPACITOR 1uF 16V K

C6705 NCB11AK-106X C CAPACITOR 10uF 10V K

C6706 NCBA1HK-152W C CAPACITOR 1500pF 50V K

C6707 NDCA1HJ-151W C CAPACITOR 150pF 50V J

C6708 NCB10JK-106X C CAPACITOR 10uF 6.3V K

C6801 NCB21CK-105X C CAPACITOR 1uF 16V K

C6802 NCB11AK-106X C CAPACITOR 10uF 10V K

C6804 NCBA1CK-104W C CAPACITOR 0.1uF 16V K

C6805 NCB31CK-105X C CAPACITOR 1uF 16V K

C6806 NCBA1HK-102W C CAPACITOR 1000pF 50V K

C6807 NCB31CK-105X C CAPACITOR 1uF 16V K

C6808 NCB31CK-105X C CAPACITOR 1uF 16V K

C6809 NCB31CK-105X C CAPACITOR 1uF 16V K

C6810 NCBA1EK-472W C CAPACITOR 4700pF 25V K

C6811 NCBA1HK-102W C CAPACITOR 1000pF 50V K

C6813 NCBA1CK-104W C CAPACITOR 0.1uF 16V K

C6901 NCBA1HK-102W C CAPACITOR 1000pF 50V K

C6902 NCBA1HK-392W C CAPACITOR 3900pF 50V K

C6903 NCB21CK-105X C CAPACITOR 1uF 16V K

C6904 NCB20JK-106X C CAPACITOR 10uF 6.3V K

C6905 NCB31CK-105X C CAPACITOR 1uF 16V K

C6906 NCB31CK-105X C CAPACITOR 1uF 16V K

C6907 NCB31CK-105X C CAPACITOR 1uF 16V K

C6908 NCB31CK-105X C CAPACITOR 1uF 16V K

C7801 NCB11CK-225X C CAPACITOR 2.2uF 16V K

C7803 NCB31CK-105X C CAPACITOR 1uF 16V K

Ω

R82 NRSA6AJ-103W MG RESISTOR 10k

R120 NRSA6AD-680W MG RESISTOR 68

R121 NRSA6AD-680W MG RESISTOR 68

R122 NRSA6AD-680W MG RESISTOR 68

R123 NRSA6AD-680W MG RESISTOR 68

R142 NRSA6AJ-221W MG RESISTOR 220

R143 NRSA6AJ-473W MG RESISTOR 47k

R144 NRSA6AJ-473W MG RESISTOR 47k

R145 NRSA6AJ-473W MG RESISTOR 47k

R146 NRSA6AJ-473W MG RESISTOR 47k

R147 NRSA6AJ-103W MG RESISTOR 10k

R148 NRSA6AJ-680W MG RESISTOR 68

R149 NRSA6AJ-680W MG RESISTOR 68

R150 NRSA6AJ-680W MG RESISTOR 68

R151 NRSA6AJ-680W MG RESISTOR 68

R181 NRSA6AJ-682W MG RESISTOR 6.8k

R184 NRSA6AJ-104W MG RESISTOR 100k

R185 NRSA6AJ-104W MG RESISTOR 100k

R191 NRSA6AJ-102W MG RESISTOR 1kΩ 1/16W J

R421 NRSA6AJ-392W MG RESISTOR 3.9k

R422 NRSA6AJ-183W MG RESISTOR 18k

R423 NRSA6AJ-392W MG RESISTOR 3.9k

R424 NRSA6AJ-220W MG RESISTOR 22

R601 NRSA6AJ-0R0W MG RESISTOR 0