Page 1

COMPACT VHS CAMCORDER

VICTOR COMPANY OF JAPAN, LIMITED

VIDEO DIVISION

S40894

GR-FXM37EG, SXM607EG/EK

GR-FXM37EG, SXM607EG/EK

SPECIFICATIONS

Camcorder

General

No. 86589

Format : S-VHS (GR-SXM607)

Power source : DC 11 V

Power consumption

LCD monitor* off,

viewfinder on : 4.0 W

LCD monitor* on,

viewfinder off : 4.5 W

Video light** : 3.0 W

* Models equipped with LCD monitor only.

** GR-SXM607 only.

Signal system : PAL-type

Video recording system

Luminance : FM recording

Colour : Converted sub-carrier

Cassette :

Tape speed

SP : 23.39 mm/sec.

LP : 11.70 mm/sec.

Recording time (max.)

SP : 60 minutes

LP : 120 minutes

Operating

temperature :0°C to 40°C

VHS PAL standard

(Using AC Adapter)

DC 6 V

(Using battery pack)

direct recording

Conforms to VHS standard

(with EC-60 cassette)

VHS

PAL

625

(The specifications shown pertain specifically to the model GR-SXM607EG/FXM37EG)

/ cassette

Operating humidity : 35% to 80%

Storage temperature : –20°C to 50°C

Weight : Approx. 910 g (GR-SXM607)

Dimensions : 200 mm x 112 mm x 118 mm

(W x H x D)

* Models equipped with LCD monitor only.

Pickup : 1/4" format CCD

Lens : F1.6, f = 3.9 mm to 62.4 mm,

Viewfinder : Electronic viewfinder with 0.5"

White balance

adjustment : Auto/Manual adjustment

LCD monitor : 3" diagonally measured,

(models equipped with

LCD monitor only)

Speaker : Monaural

(models equipped with

LCD monitor only)

Connectors

JLIP/EDIT : ø3.5 mm, 4-pole, mini-head

Video : 1 V (p-p), 75 Ω unbalanced,

Approx. 900 g (GR-FXM37)

16:1 power zoom lens with

auto iris and macro control,

filter diameter 40.5 mm

black/white CRT

LCD panel/TFT active matrix

system (GR-SXM607)

: 2.5" diagonally measured, LCD

panel/TFT active matrix system

(GR-FXM37)

jack (compatible with

RC-5325 plug)

analogue output

(via Video output connector)

Audio : 300 mV (rms), 1 kΩ analogue

S-Video : Y : 1 V (p-p), 75 Ω,

output

(via Audio output connector)

analogue output

C : 0.29 V (p-p), 75 Ω,

analogue output

AC Adapter AP-V10EG

Power requirement : AC 110 V to 240 V`,

Power consumption : 23 W

Output : DC 11 V

Dimensions : 59 mm x 31 mm x 84 mm

(W x H x D)

Weight : Approx. 140 g

Optional Accessories

• Battery Packs BN-V12U, BN-V20U, BN-V400U

• Compact S-VHS (

• Compact VHS (

• Remote Control Unit RM-V700U

• Active Carrying Bag CB-V7U

• Cassette Adapter C-P7U

Some accessories are not available in some areas. Please

consult your nearest JVC dealer for details on accessories

and their availability.

Specifications shown are for SP mode unless otherwise

indicated. E & O.E. Design and specifications subject to

change without notice.

50 Hz/60 Hz

) Cassettes SE-C45/30

) Cassettes EC-60/45/30

, 1 A

Printed in Japan

This service manual is printed on 100% recycled paper.

COPYRIGHT

© 2000 VICTOR COMPANY OF JAPAN, LTD.

No. 86589

November 2000

Page 2

TABLE OF CONTENTS

Section Title Page

Important Safety Precautions

INSTRUCTIONS

1. DISASSEMBLY

1.1 SERVICE CAUTIONS .......................................................... 1-1

1.1.1 Precautions .................................................................. 1-1

1.1.2 How to read the disassembly and assembly ................ 1-1

1.1.3 Connection of the wires................................................1-1

1.2 TOOLS REQUIRED FOR ADJUSTMENTS ......................... 1-2

1.3 DISASSEMBLY/ASSEMBLY OF CABINET PARTS ............. 1-3

1.3.1 Disassembly flow chart.................................................1-3

1.3.2 Disassembly method .................................................... 1-4

1.4 DISASSEMBLY/ASSEMBLY OF CAMERA SECTION

AND DECK SECTION ........................................................ 1-10

1.4.1 Flowchart of disassembly ........................................... 1-10

1.4.2 Disassembly method .................................................. 1-10

1.5 REPLACEMENT OF CCD IMAGE SENSOR ..................... 1-12

1.5.1 Removal of CCD image sensor ..................................1-12

1.5.2 Installation of new CCD image sensor ....................... 1-12

1.5.3 Replacement of CCD board assy...............................1-12

1.6 TAKE OUT CASSETTE TAPE ............................................ 1-13

1.7 EMERGENCY DISPLAY..................................................... 1-14

1.8 DEMONSTRATION MODE ................................................ 1-14

2. MECHANISM ADJUSTMENT

2.1 SERVICE CAUTIONS ............................................................ 2-1

2.1.1 Precautions .................................................................... 2-1

2.1.2 How to read the disassembly and assembly

(For Mechanism Parts) .................................................. 2-1

2.1.3 Required adjustment tools ............................................. 2-1

2.2 DISASSEMBLY/ASSEMBLY OF MECHANISM PARTS ........ 2-2

2.3 CHECKUP AND ADJUSTMENT OF MECHANISM

PHASE ................................................................................. 2-6

2.4 TAPE TRANSPORT ADJUSTMENT .................................... 2-7

2.4.1 Back tension.................................................................2-7

2.4.2 Tape pattern ................................................................. 2-7

2.4.3 A/CTL head height & azimuth ...................................... 2-8

2.4.4 Phase of control head (X value) ................................... 2-9

2.5 REMARKS ............................................................................ 2-9

2.5.1 Cleaning ....................................................................... 2-9

2.5.2 Applying oil and grease ................................................ 2-9

2.5.3 Checkup ....................................................................... 2-9

2.6 JIG CONNECTOR CABLE CONNECTION ........................2-10

3. ELECTRICAL ADJUSTMENT

3.1 ELECTRICAL ADJUSTMENT...............................................3-1

3.1.1 PREPARATION ............................................................ 3-1

3.2 MONITOR ADJUSTMENT .................................................... 3-3

3.2.1 V COM.......................................................................... 3-3

3.3 ELECTRONIC VIEWFINDER (E. VF) ADJUSTMENT ......... 3-4

3.3.1 Horizontal sync.............................................................3-4

Section Title Page

3.3.2 PLL adjustment ............................................................ 3-4

3.3.3 Centering ...................................................................... 3-4

3.3.4 Focus ............................................................................3-5

3.3.5 Brightness .................................................................... 3-5

3.4 SERVICE NOTE................................................................... 3-6

4. CHARTS AND DIAGRAMS

NOTES OF SCHEMATIC DIAGRAM ................................... 4-1

CIRCUIT BOARD NOTES.................................................... 4-2

4.1 BOARD INTERCONNECTIONS .......................................... 4-3

4.2 CPU SCHEMATIC DIAGRAM .............................................. 4-5

4.3 VTR ASP SCHEMATIC DIAGRAMS .................................... 4-7

4.4 MECHA MDA SCHEMATIC DIAGRAM ................................ 4-9

4.5 VTR DSP SCHEMATIC DIAGRAM .................................... 4-11

4.6 DSP SCHEMATIC DIAGRAM............................................. 4-13

4.7 IRIS & AF/ZOOM SCHEMATIC DIAGRAMS ......................4-15

4.8 VIDEO OUT SCHEMATIC DIAGRAM ................................4-17

4.9 REGULATOR SCHEMATIC DIAGRAM.............................. 4-19

4.10 LCD CTL SCHEMATIC DIAGRAM ..................................... 4-21

4.11 JACK AND CCD SCHEMATIC DIAGRAMS ....................... 4-23

4.12 SPEAKER AND MONITOR

SCHEMATIC DIAGRAMS .................................................. 4-25

4.13 TOP OPE UNIT, ZOOM UNIT, REAR UNIT

AND SENSOR SCHEMA TIC DIAGRAMS ........................... 4-27

4.14 ELECTRONIC VIEWFINDER SCHEMA TIC DIAGRAM ......... 4-29

4.15 MAIN CIRCUIT BOARD ..................................................... 4-31

4.16 CCD CIRCUIT BOARD ...................................................... 4-37

4.17 MONITOR CIRCUIT BOARD ............................................. 4-39

4.18 ELECTRONIC VIEWFINDER CIRCUIT BOARD ............... 4-41

4.19 POWER SYSTEM BLOCK DIAGRAM ............................... 4-43

4.20 CAMERA BLOCK DIAGRAM ............................................. 4-45

4.21 Y/C BLOCK DIAGRAM....................................................... 4-49

4.22 MONITOR BLOCK DIAGRAM ............................................ 4-51

4.23 CPU/MDA BLOCK DIAGRAM ............................................ 4-53

4.24 WAVEFORMS .................................................................... 4-55

4.25 VOLTAGE CHARTS ........................................................... 4-56

5. PARTS LIST

5.1 PACKING ASSEMBLY <M1>................................................ 5-1

5.2 FINAL ASSEMBL Y <M2> ..................................................... 5-3

5.3 MECHANISM ASSEMBLY <M3> ......................................... 5-6

5.4 ELECTRONIC VIEWFINDER ASSEMBLY <M4>................. 5-8

5.5 MONITOR ASSEMBL Y <M5>............................................... 5-9

5.6 ELECTRICAL PARTS LIST ................................................ 5-10

MAIN BOARD ASSEMBLY <01>........................................ 5-10

CCD BOARD ASSEMBLY <02> .........................................5-17

MONITOR BOARD ASSEMBLY <07> ................................ 5-17

E. VF BOARD ASSEMBLY <50>........................................ 5-18

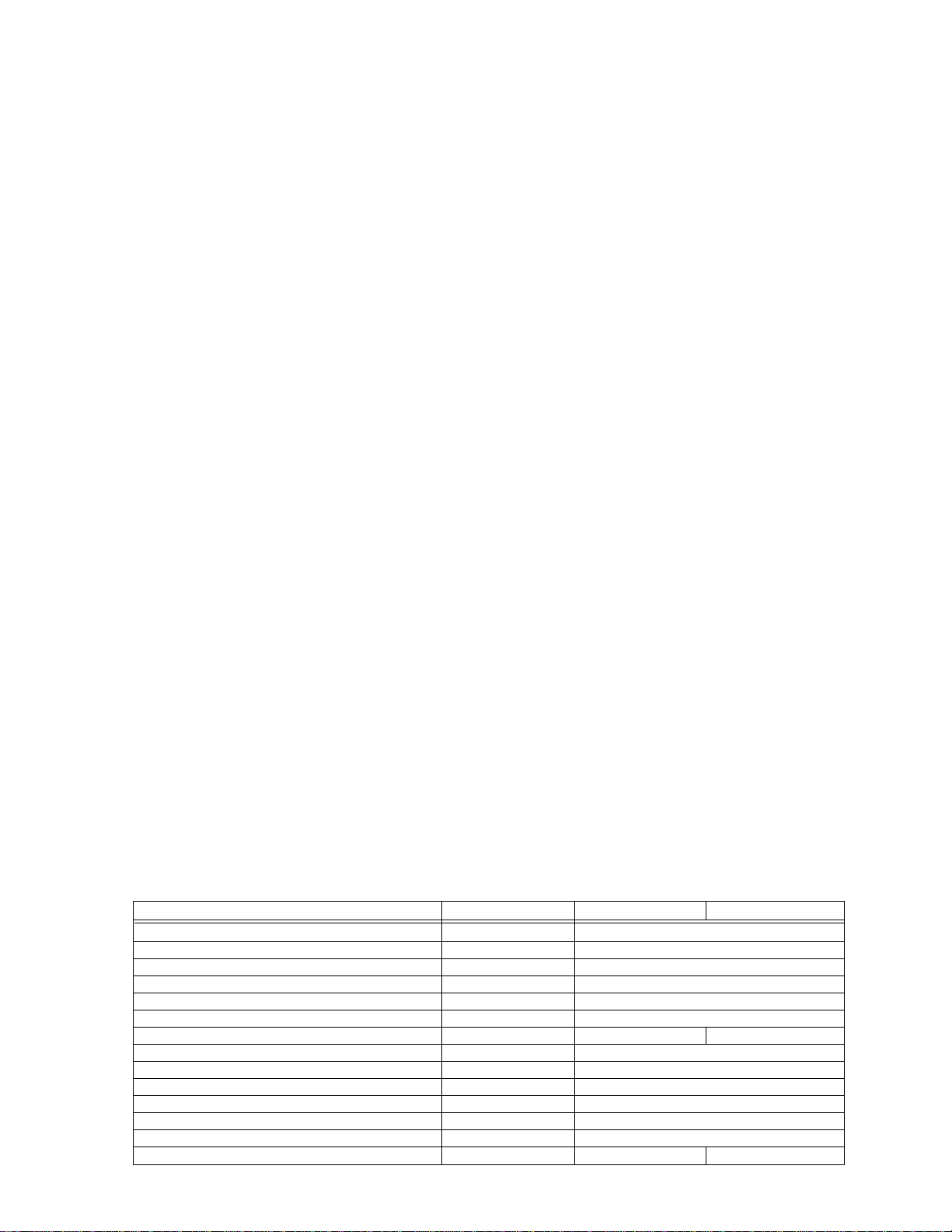

The following table lists the differing points between Models GR-FXM37EG and GR-SXM607EG/EK in this series.

GR-FXM37EG GR-SXM607EG GR-SXM607EK

VIDEO LIGHT NOT USED USED

IR RECEIVER NOT USED USED

LCD MONITOR 2.5” 3”

BODY COLOR Mold Black Silver

IMAGE SENSOR 1/4” 320K 1/4” 470K

HORIZONTAL RESOLUTION 300LINES 400LINES

AC CORD CEE TYPE CEE TYPE UK TYPE

BA TTERY PACK BN-BV11U BN-20BU

RCU UNIT NOT USED PROVIDE

SNAP SHOT NOT USED USED (FULL ONLY)

NIGHT SCOPE NOT USED USED

5 SEC REC SW USED NOT USED

S-VHS ON/OFF NOT USED USED

VIDEO OUT SELECT PAL/SECAM NOT USED USED NOT USED

Page 3

SECTION 1

DISASSEMBLY

1.1 SERVICE CAUTIONS

1.1.1 Precautions

1. Before disassembling/re-assembling the set as well as

soldering parts, make sure to disconnect the power

cable.

2. When disconnecting/connecting connectors, pay enough

attention to wiring not to damage it.

3. In general, chip parts such as resistor, shorting jumpers

(0-ohm resistor), ceramic capacitors, diodes, etc. can not

be reused after they were once removed.

4. When installing parts, be careful not to do with other parts

as well as not to damage others.

5. When removing ICs, be careful not to damage circuit

patterns.

6. Tighten screws properly during the procedures. Unless

specified otherwise, tighten screws at torque of 0.196 N·m

(2.0 kgf·cm).

1.1.2 How to read the disassembly and assembly

(For Cabinet Parts)

STEP

/LOC PART

NO.

Fig.

No.

REMOVAL

*UNLOCK/RELEASE/

UNPLUG/UNCLAMP/

UNSOLDER

1 CASSETTE C1 2(S1)

COVER ASSEMBLY

1.1.3 Connection of the wires

1. Pull the connector structure upward to release the clamp

when removing or inserting the flat wire cable.

Wire

Connector

Fig. 1-1-1

Wire

2

UPPER CASE C2 2(S2), (L2)

LOWER CASE C3 9(S3), (L3a), (L3b)

3 ASSEMBLY(INCL. *CN 3a 3b

E. VF. ASSEMBLY) CAP (RCA jack)

▲▲

(1) (2) (3) (4)

(1) Order of steps in Procedure

When reassembling, preform the step(s) in the reverse

order. These numbers are also used as the identifica-

tion (location) No. of parts Figures.

(2) Part to be removed or installed.

(3) Fig. No. showing Procedure or Part Location.

C = Cabinet

CA = Camera

D = Deck

(4) Identification of part to be removed, unhooked, unlocked,

released, unplugged, unclamped or unsoldered.

P = Spring

W = Washer

S = Screw

* = Unhook, unlock, release, unplug or unsolder.

2(S3) = 2 Screws (S3)

CN = Connector

(5) Adjustment information for installation.

▲

▲

NOTE:

Connector

After removing the wire, return the stopper to

its original position, because it is apt to come

off if it is left open.

Fig. 1-1-2

1-1

Page 4

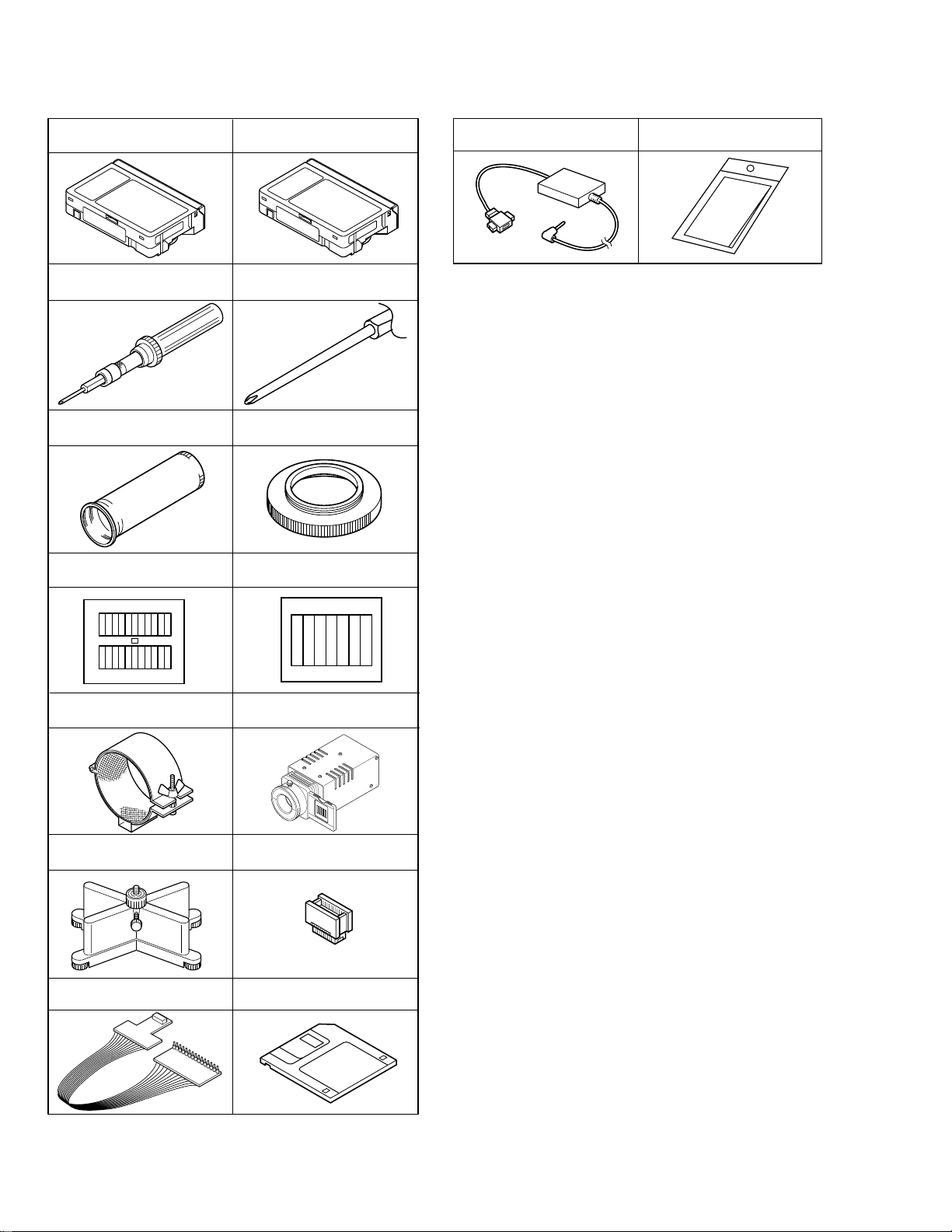

1.2 TOOLS REQUIRED FOR ADJUSTMENTS

Alignment tape

(for SP interchangeability)

1

3

5

78

MHP-C

Torque driver

YTU94088

INF adjustment lens

YTU92001B

Gray Scale Chart

YTU94133A

Alignment tape

(for N. SP PB Y/C level)

2

4

6

MHV-2C

YTU94088-003

Conn. ring

YTU92001-111

Color Bar Chart

YTU94133C

Bit

15 16

PC cable

QAM0099-002

Table 1-2-1

Cleaning cloth

KSMM-01

INF lens holder

910

11 12

13

YTU94087

Camera stand

YTU93079

Jig connector cable

YTU93106A

Light box Assembly

YTU93096A

Extension connector

YTU94145B-30

Service support system software

14

YTU94057-51

1-2

Page 5

1,2. Alignment tape

To be used for check and adjustment of interchangeability

of the mechanism.

(Video: Color bar signal, Audio: Non-signal)

3. Torque driver

Be sure to use to fastening the mechanism and exterior

parts because those parts must strictly be controlled for

tightening torque.

4. Bit

This bit is slightly longer than those set in conventional

torque drivers.

5. INF adjustment lens

To be used for adjustment of the camera system.

6. Conn. ring

The connector ring to attach the INF. lens to the head of

the OP lens.

7. Color bar chart

To be used for adjustment of the camera system.

8. Gray scale chart

To be used for adjustment of the camera system.

9. INF lens holder

To be used together with the camera stand (11) for

operating the VideoMovie in the stripped-down condition

such as the status without the exterior parts or for using

commodities that are not yet conformable to the

interchangeable ring.

10. Light box

To be used for adjustment of the camera system.

11. Camera stand

To be used together with the INF adjustment lens holder.

12. Extention connector

To be used to JIG connector cable

13. JIG connector cable

Connected to CN25 of the main board and used for

measuring error rates, etc.

14. Service support software

To be used for adjustment with a personal computer.

15. PC cable

To be used to connect the VideoMovie and a personal

computer with each other when a personal computer is

used for adjustment.

16. Cleaning cloth

Recommended cleaning cloth to wipe down the video

heads, mechanism (tape transport system), optical lens

surface.

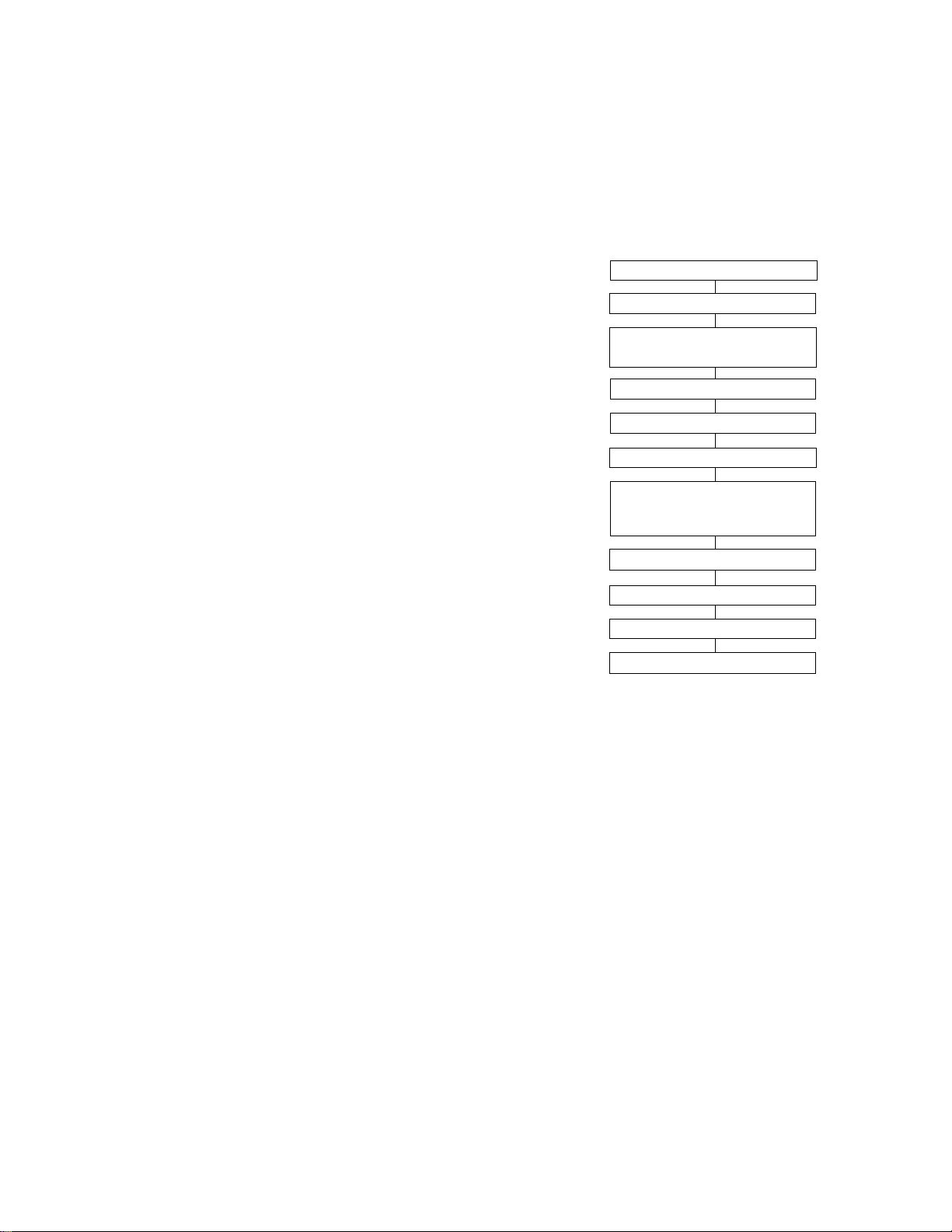

1.3 DISASSEMBLY/ASSEMBLY OF CABINET PARTS

1.3.1 Disassembly flow chart

This flowchart indicates the disassembly step for the cabinet parts and board assembly in order to gain access to

item(s) to be serviced. When reassembling, perform the

step(s) in reverse order. Bend, route and dress the flat cables as they were originally.

1 Cassette cover assembly

2 Upper case

▼

▼

3 Lower case assembly

(Incl. E. VF assembly)

▼

4 E. VF assembly

▼

5 Top operation unit

6 Rear unit

▼

▼

7 Front cover assembly

(Incl. Microphone,

DC light assembly)

▼

8 Microphone

9 DC light assembly

▼

▼

▼

0 Monitor assembly

- Front frame assembly

▼

Note:

For screw management, refer to the table appearing

in the section "3.4 SERVICE NOTE" (page 3-6).

1-3

Page 6

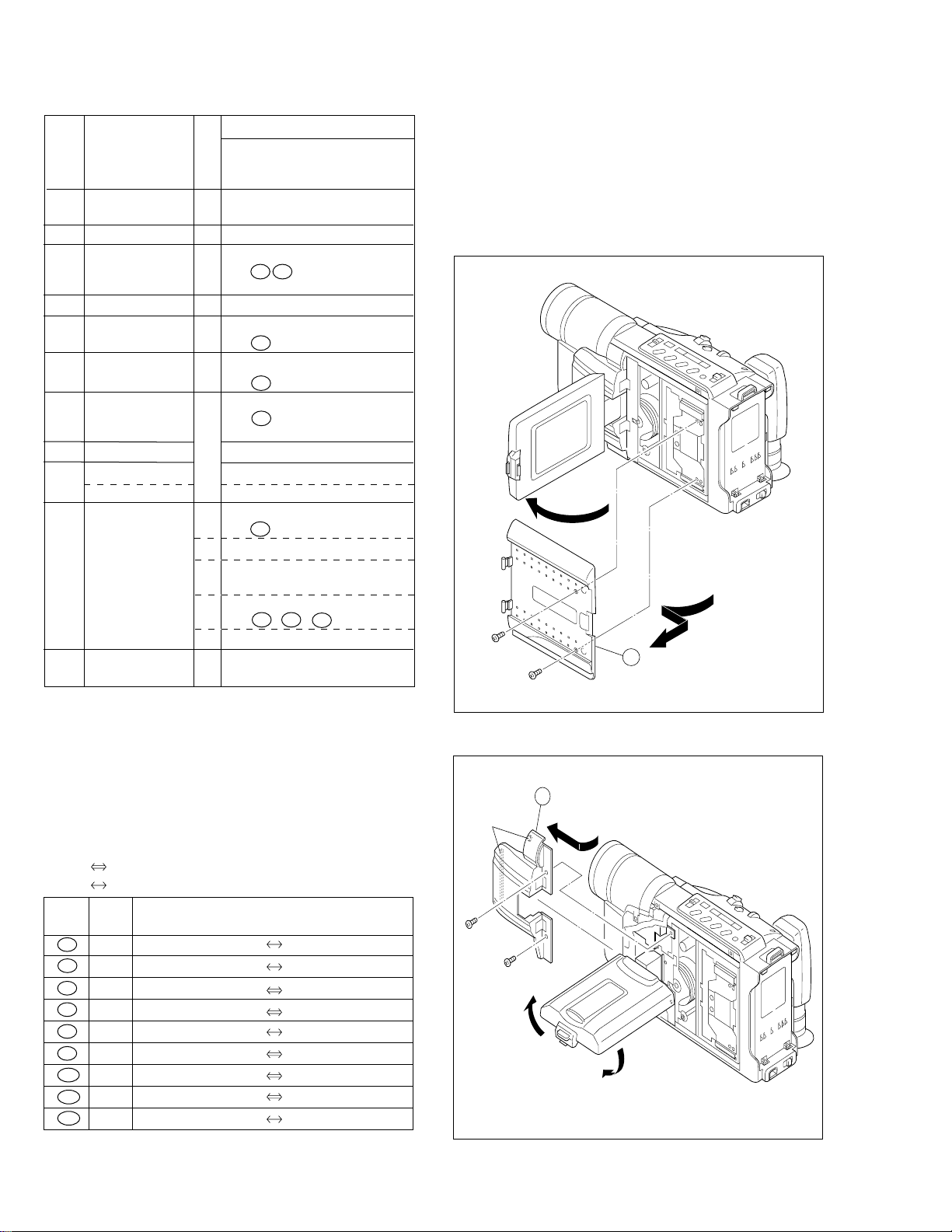

1.3.2 Disassembly method

2

(L2)

3

(S2)

4

(S2)

STEP

/LOC PART

NO.

1 CASSETTE C1 2(S1)

COVER ASSEMBLY

2

UPPER CASE C2 2(S2), (L2)

3 LOWER CASE C3 9(S3), (L3a), (L3b)

ASSEMBLY (INCL. *CN 3a 3b

E. VF ASSEMBLY) CAP (RCA jack)

4 E. VF ASSEMBLY C4 3(S4)

5 TOP OPERATION C5 2(S5), (L5a), (L5b), (L5c)

UNIT *CN 5a

6 REAR UNIT C6 3(S6), (L6a), (L6b)

7 FRONT COVER C7 2(S7a), (S7b), (L7a), (L7b)

ASSEMBLY (INCL. MIC *CN 7a

DC LIGHT ASSEMBLY)

8 MICROPHONE (S7a)

DC LIGHT ASSEMBLY 2(L7c)

9

COVER (LIGHT) 2(L7c)

0 MONITOR ASSEMBLY C8 2(S8a), (S8b)

- FRONT FRAME C13 2(S13)

ASSEMBLY

List of Abbreviations:

2(S1)=2 screws (S1)

4(L1a)=4 Locking Tabs

CN=Connector

Reference Notes:

<NOTE 1>

Destination of connectors

Note:

Two kinds of double-arrows in connection tables

respectively show kinds of connector/wires.

: Flat wire

: Wire

Con- No. of

nector Pins

3a 2 SPEAKER MAIN CN27

3b 5 E. VF (B/W) MAIN CN12

5a 12 TOP OPERATION UNIT MAIN CN18

6a 13 REAR UNIT MAIN CN28

7a 2 MIC MAIN CN8

8a 33 MONITOR ASSEMBLY MAIN CN16

11a 28 MONITOR CN7501 T. HINGE

11b 24 MONITOR CN7502 LCD MODULE

11c 2 MONITOR CN7503 BACK LIGHT

REMOVAL

Fig.

No.

C9 2(S9a), (S9b), (S9c), (S9d)

C10 2(S10a), 2(S10b), 2(S10c),

C11 (L11a), (L11b), (L11c)

C12 2(S12a), (S12b), 2(L12a)

*UNLOCK/RELEASE/

UNPLUG/UNCLAMP/

UNSOLDER

*CN 6a

*CN 8a

(L10a), (L10b), (L10c)

*CN 11a , 11b , 11c

Connector

<NOTE 2, 3>

(1) The FPC assembly should be winded around the hinge

assembly by two and half turns so that the wire to be

connected to the monitor board assembly is positioned

inside.

(2) The upper and lower hinge covers should be mounted so

carefully the any wire is not caught into either of the

covers.

1

(S1)

2

(S1)

1

Fig. C1

1-4

Fig. C2

Page 7

5

5a

18

(S5)

17

(S5)

(L5c)

(L5a)

(L5b)

8

(S3)

6

(S3)

7

(S3)

9

(S3)

CAP

(RCA jack)

13

(S3)

5

(S3)

(L3b)

10

(S3)

12

(S3)

3b

3a

(L3a)

3

11

(S3)

4

16

(S4)

Fig. C3

14

(S4)

15

(S4)

Fig. C4

Fig. C5

1-5

Page 8

6a

(L6a)

Fig. C6

(L6b)

20

(S6)

19

(S6)

6

21

(S6)

(L7c)

9

NO.VIDEO

LIGHT MODEL

(L7c)

9

VIDEO LIGHT

USED MODEL

(L7a)

7

8

(L7b)

22

(S7a)

23

(S7a)

(S7a)

24

(S7b)

25

7a

1-6

Fig. C7

Page 9

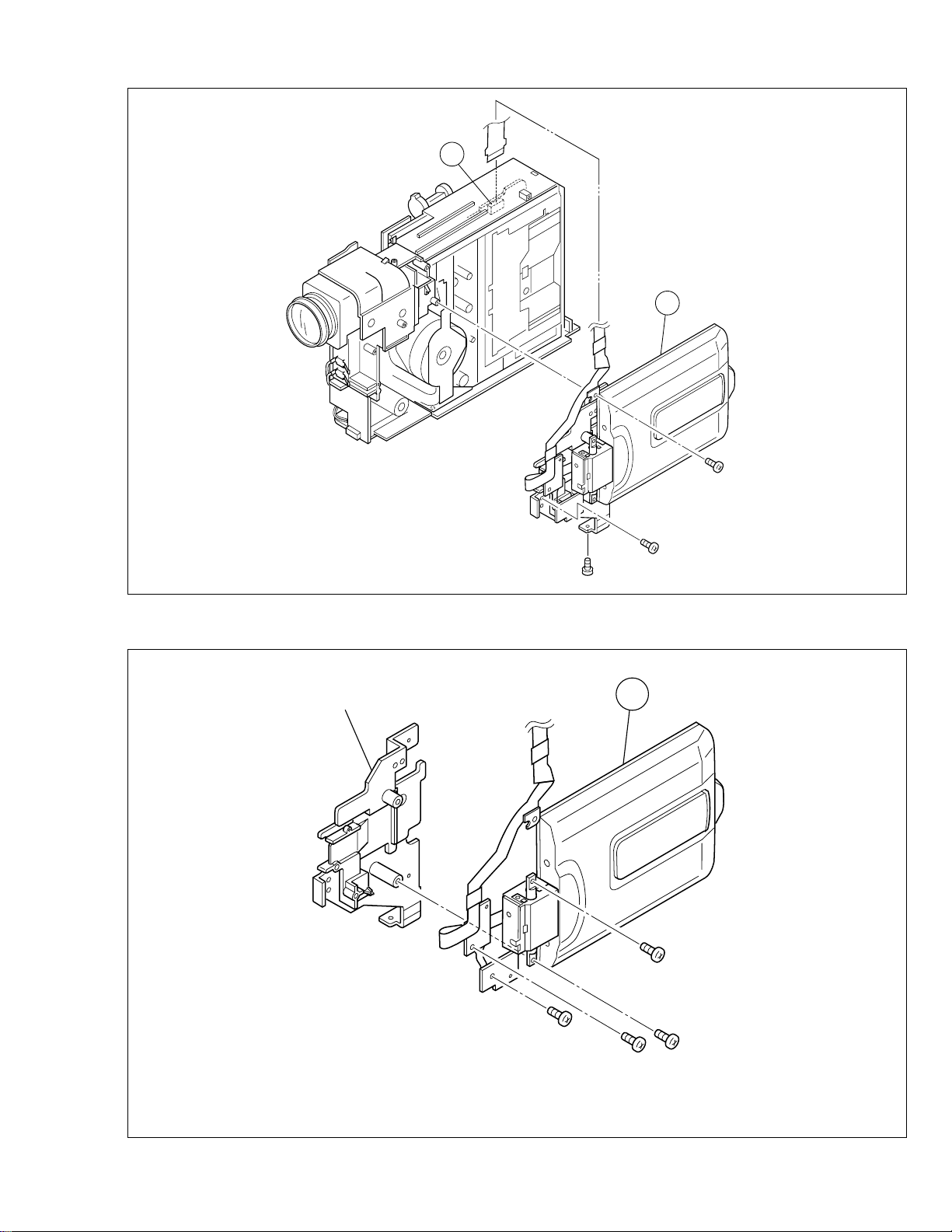

8a

10

26

(S8a)

Fig. C8

Bracket (Upper) ASSY

28

(S8b)

27

(S8a)

10

29

(S9a)

32

(S9c)

Fig. C9

31

(S9b)

30

(S9a)

1-7

Page 10

37

(S10c)

(L10c)

38

(S10c)

33

(S10a)

34

(S10a)

Upper case assy

Monitor cover

(L10a)

(L10b)

36

(S10b)

35

(S10b)

: 0.118 N·m (1.2 kgf·cm)

Monitor case

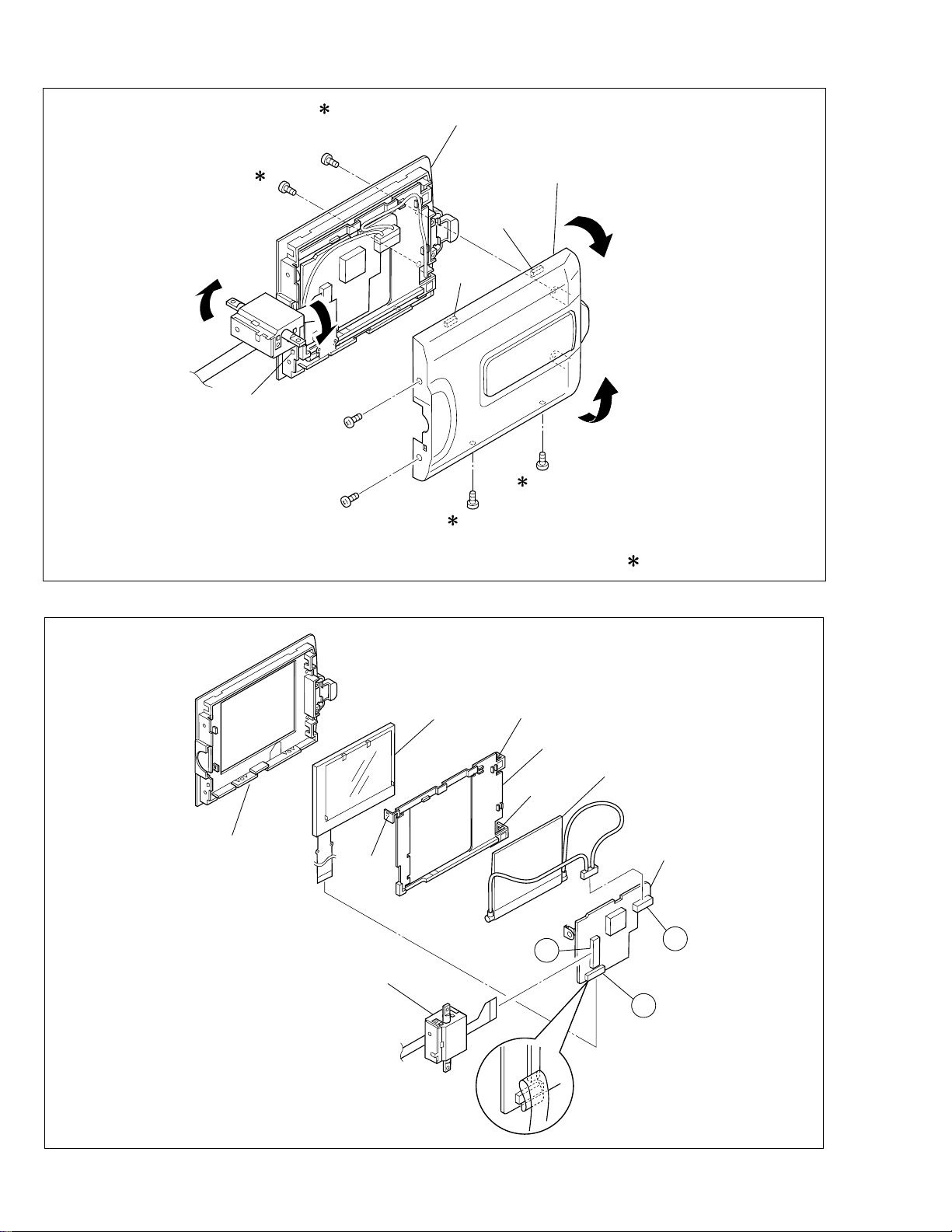

Fig. C10

LCD module

(L11a)

T.Hinge assy

(L11b)

Holder

(L11c)

11a

Back light

Monitor

<07>

11c

11b

1-8

Fig. C11

Page 11

Reinforced

(

)

surface

FPC

Cover (Hinge U)

39

(S12a)

Hinge

(L12a)

Cover (Hinge L)

40

(S12a)

Plate (SW)

41

S12b

Push switch

Reinforced

surface

Reinforced

surface

Hinge

Note 2,3

FPC

Fig. C12

42

(S13)

11

43

: 0.098 N·m (1.0 kgf·cm)

Fig. C13

(S13)

1-9

Page 12

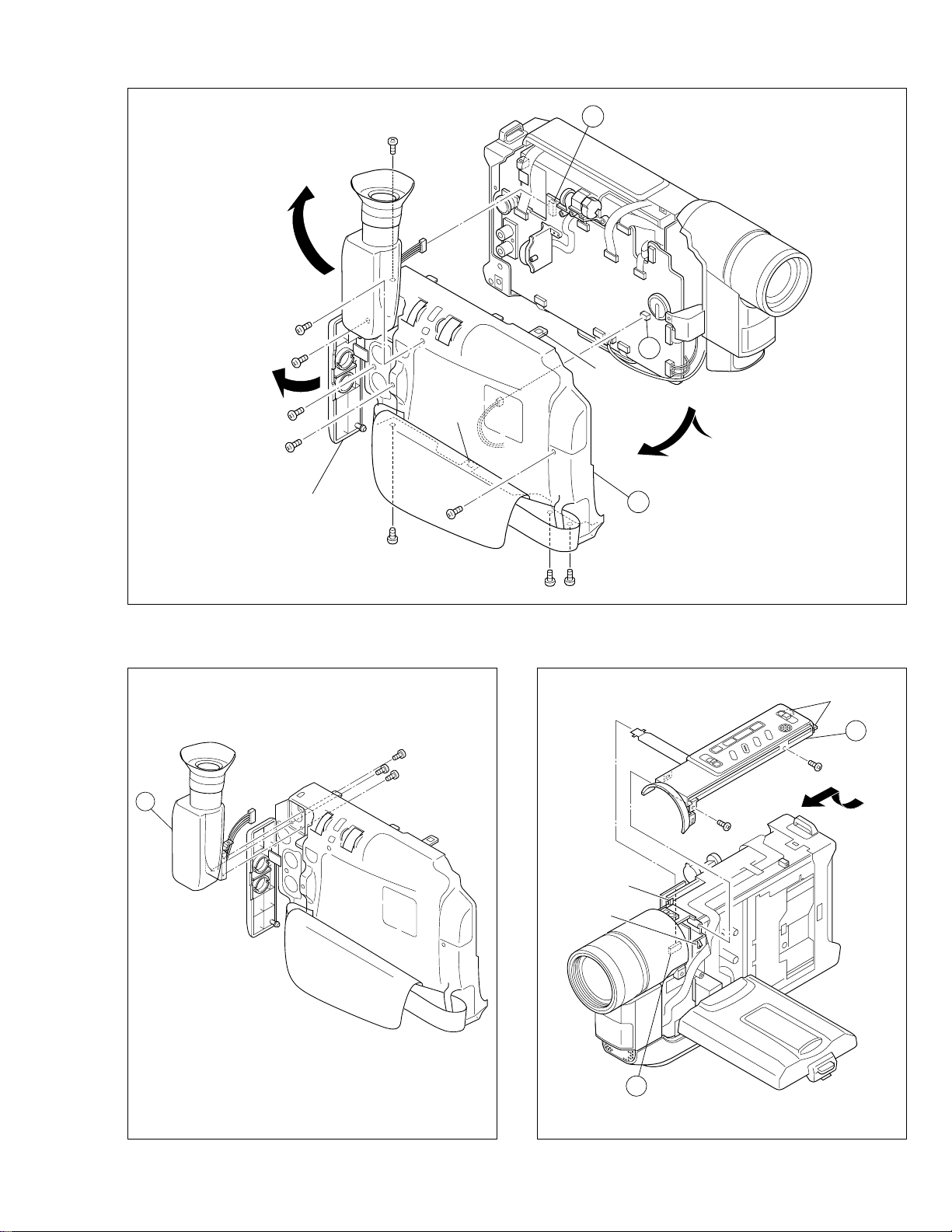

1.4 DISASSEMBLY/ASSEMBLY OF CAMERA SECTION AND DECK SECTION

1.4.1 Flowchart of disassembly

The following flowchart shows the disassembly of the camera

section and deck section. When assembly of the camera

section and deck section, follow this flowchart in the reverse

order.

<Camera section/Deck section>

1

Zoom unit assembly

▼

2 Main board assembly

3 OP block assembly

▼

(Incl. CCD board assembly)

▼

3 OP block assembly

3

CCD board assembly

For details of disassembly of

manner, refer to page 1-12,

“1.5 REPLACEMENT OF

CCD IMAGE SENSOR.

▼

▼

4 Frame assembly

5 Cassette housing assembly

▼

Reference Notes:

<NOTE 1>

Open two pins of the cennter and connect CN4 as shown in

Fig.

<NOTE 2>

Destination of connectors

Two kinds of double-arrows in connection tables re-

Note:

spectively show kinds of connector/wires.

: Flat wire

: Wire

Con- No. of

nector Pins

Connector

1a 14 MAIN CN13 ZOOM UNIT

2a 14 MAIN CN2 SENSOR

2b 11 MAIN CN5 VIDEO/FLY. E HEAD

2c 10 MAIN CN1 DRUM MOTOR

2d 6 MAIN CN4 (PIN 1,2)

MAIN CN4 (PIN 5,6)

LOADING MOTOR

DC LIGHT

(OPEN TWO PINS OF

THE CENTER AND

CONNECT)

2e 22 MAIN CN15 OP BLOCK

2f 18 MAIN CN3 CAPSTAN MOTOR

2g 11 MAIN CN7 A/C HEAD

2h 14 MAIN CN22

CCD

1.4.2 Disassembly method

STEP

/LOC PART

NO.

Fig.

No.

*UNLOCK/RELEASE/

UNPLUG/UNCLAMP/

1 ZOOM UNIT D1 4(S1)

ASSEMBLY *CN 1a

2 MAIN BOARD D2 (S2), (L2a), (L2b)

*CN 2a , 2b , 2c , 2d , 2e

2f , 2g , 2h

3 OP BLOCK D3 2(S3)

ASSEMBLY CUSHION (OP)

4 FRAME ASSEMBLY D4 (S4a), 2(S4b), (S4c)

5 CASSETTE D5 4(S5)

HOUSING

ASSEMBLY

List of Abbreviations:

2(S1) = 2 Screws (S1)

4(L1a)=4 Locking Tabs (L1a)

CN=Connector

REMOVAL

UNSOLDER

1

(S1)

2

(S1)

4

(S1)

1

1a

3

(S1)

Fig. D1

1-10

Page 13

2

c

10

(S4b)

9

(S4b)

11

(S4c)

4

8

(S4a)

)

2h

(L2a)

3

2a

5

(S2)

2b

2c

2g

2e

2d

White

Fig. D2

2f

Note1

Red

Red

(L2b)

✽ : 0.108 N·m (1.1 kgf·cm)

Fig. D4

14

(S5)

5

12

(S5)

15

(S5)

13

(S5)

Cushion (OP

6

(S3)

Fig. D3

7

(S3)

Fig. D5

1-11

Page 14

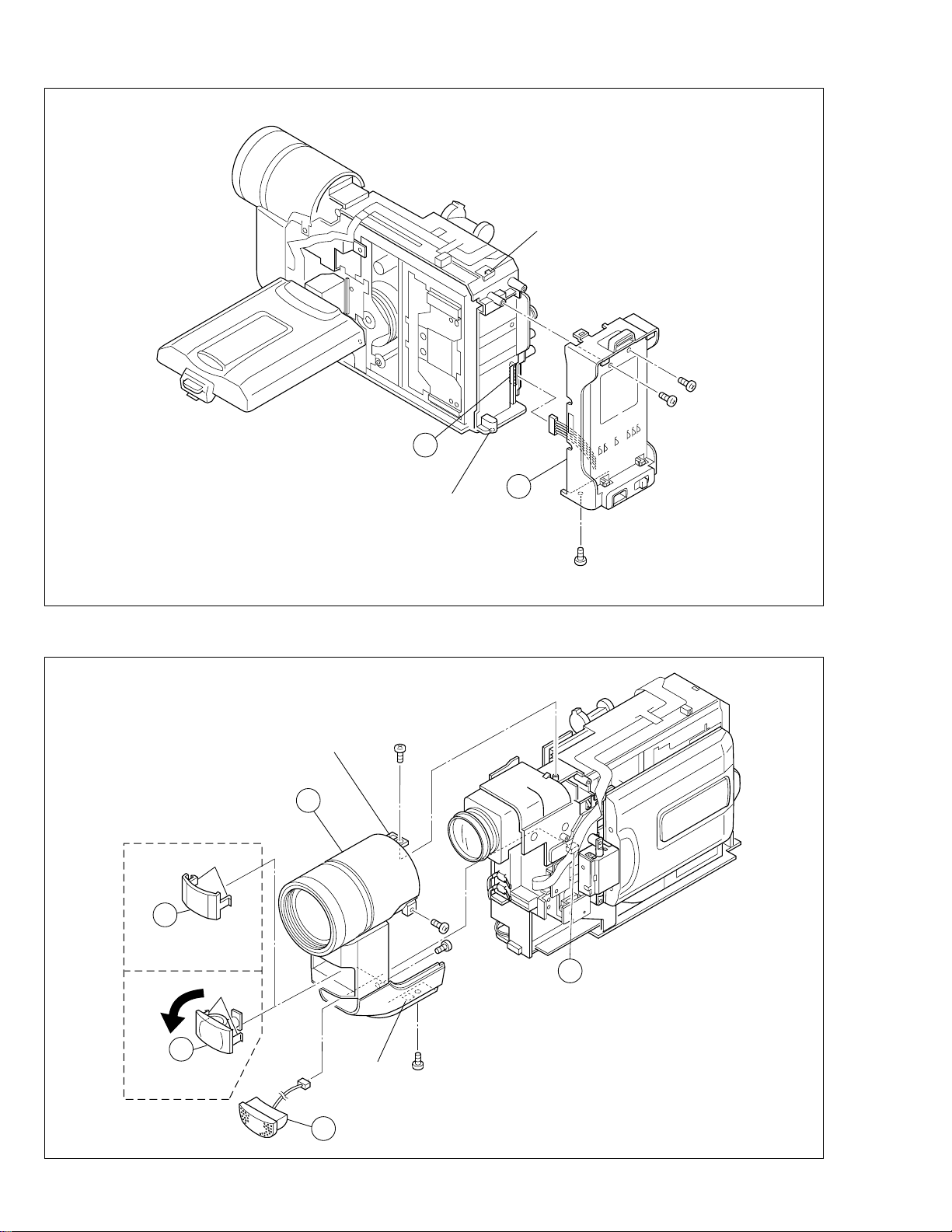

1.5 REPLACEMENT OF CCD IMAGE SENSOR Notes:

•

Pay the most careful attention to the transparent glass

and optical LPF of the CCD image sensor so a not the

soil and damage them. If something is soiled with finger-prints, etc., gently clean it with silicon-processed

paper/cloth or chamois.

• When the CCD image sensor is shipped from the fac-

tory, there are protection seals applied onto the transparent glass. Leave the protector as it is, and take it off just

before assembling the CCD image sensor to the OP

block.

1.5.1 Removal of CCD image sensor

1. Remove two screws (1, 2) securing the CCD base assy,

and disassemble the CCD spacer, the optical LPF,

spacer rubber.

1.5.2 Installation of new CCD image sensor

1. Remove the protection seal from a new CCD image sensor. Next, put the optical LPF, spacer rubber, CCD spacer

on the CCD image sensor as they are piled up in this

order. At that time, make sure of orientation of each item

refering to the following table (see Fig. 1-5-1).

Part Name Orientation

CCD image sensor Mark is on the right viewed as indi-

cated by the arrow a .

Spacer rubber IC side is horizontal.

Optical LPF Marks are on the left and bottom

viewed as indicated by the arrow

a .

2. Fix the CCD base assy to OP block with the two screws

(1, 2) . At that time, be careful of the orientation.

3. After completion of all P.C. boards to the camera section, observe the monitor to confirm no vignetting caused

by the bodytube, rings, lens hood, etc. If no vignetting is

observed, it can be said that image's parallel, horizontality

and centering are correct.

1.5.3 Replacement of CCD board assy

1. Remove one screw (3).

2. Unsolder at the fourteen points on the CCD board assy.

1. Remove the screw (3) only when the CCD board

Note:

assy needs replacement.

2. When installing a new CCD board assy, carry out the

above-mentioned procedure in the reverse order.

Optical LPF

Blue

OP

side

CCD

side

(S1a)

CCD base assembly

CCD spacer

Spacer rubber

a

3

1

2

(S1a)

(S1b)

CCD board

assembly

1-12

Fig. 1-5-1

Page 15

1.6 TAKE OUT CASSETTE TAPE

In the event that the set enters the emergency mode as it is

loaded with a cassette tape and the cassette tape cannot

be ejected with the EJECT button, manually, take it out of

the set according to the following procedure.

Note:

If the mechanism comes into the unloading mode as

the cassette tape is not held by hand, it results in tape

damage.

1. Disconnect the set from the power source.

2. Remove the cassette cover assembly, Cover (VF), top

cover, (See Fig. C1, C2 and C3, Page 1-1, 2, 3 and 4)

3. Connect a jumper wire to each pole of the loading motor

as shown by the magnified view b (Fig. 1-6-1)

Battery

4. While holding down the cassette housing by hand, connect the jumper wires to a battery to run the mechanism

to the EJECT position four unloading. If this unloading

operation is performed as the cassette housing is not

held down by hand, the front lid of the cassette may

damage the tape when it is ejected.

5. For taking in the slack of the tape, run the mechanism

to the EJECT position as the front lid of the cassette is

left open, and turn the take-up gear in the forward direction to wind up the tape. After confirming that the tape

has completely been wound up and the supply reel is

idling, take the cassette tape out of the cassette housing.

Magnified view

Top view

b

Take-up gear

Fig. 1-6-1

1-13

Page 16

1.7 EMERGENCY DISPLAY

䊳

R

D

N

E

.

ECXZT

M

O

S

O

O

Y

D

M

SETEM ME

S

5

N

P

0

U

x

䊳

F

E

M

T

O

X

.

O

C

P

W

U

O

.

S

S

S

B

C

Y

U

.

A

S

R

M

T

E

EERMAMMEE

N

A

A

A

N

U

U

U

U

U

T

T

T

O

O

O

Whenever some abnormal signal is input to the

mechacon CPU, an error number (E01, as an exam-

• In an emergency mode, all operations except

turning on/off the POWER switch are ineffectual.

ple) is displayed in the electronic view finder.

In every error status, such the message as shown below alternately appear over and over.

Example (in case of the error number E01):

E01

UNIT IN

SAFEGUARD MODE

E01

REMOVE AND

REATTACH BATTERY

E. VF Symptom Mode when observed Resulting mode

E07 Short circuit of capstan MDA Power ON Power OFF

E06 CAPSTAN FG input absent EDIT Power OFF

E04 DRUM FF input absent DRUM rotation Power OFF

E03 SUPPLY REEL FG input absent REC, PLAY, SEARCH, FF

E02

Mode control motor rotates for more than 10

UNLOADING Power OFF

UNLOADING

[Power OFF

sec without shift to next mode.

E01

Mode control motor rotates for more than 10

LOADING Power OFF

sec without shift to next mode.

E00 Overtime the programming transaction REC, PLAY Power OFF

1.8 DEMONSTRATION MODE

This model has the DEMONSTRATION mode.

1) How to set the DEMONSTRATION mode.

The camera can be entered into the DEMONSTRATION mode by setting on the DISPLAY screen appearing in the viewfinder.

When entering the camera into the DEMONSTRA TION

mode, pay heed to the following matters.

1. Set the POWER switch to turn on

the "M".

Press the MENU WHEEL once. The

first page of the DISPLAY appears

on the LCD monitor (or in the

MENU Wheel

M

A

F

F

O

Y

A

L

P

Recording Start/Stop Button

viewfinder).

No cassette is set in the camcorder or a cassette is set

in the camcorder but it is protected from recording.

Note 1)

The indications of the DISPLAY page very

depending on the setting.

2) How to cancel the DEMONSTRATION mode.

To cancel the DEMONSTRATION mode, turn the

POWER switch off (“POWER OFF”).

2. Turn the MENU WHEEL in the

direction of the arrow to set the

cursor at “NEXT”.

Press the MENU WHEEL once.

The second page of the DISPLAY

appears on the LCD monitor (or in

the viewfinder).

E

T

N

S

Y

S

䊳

T

E

O

M

A

C

E

R

E

M

C

I

T

M

I

N

I

T

.

T

C

T

E

A

L

E

M

A

T

I

L

T

L

E

M

D

A

I

T

T

E

/

D

D

E

O

M

M

O

䊳

R

N

R

E

T

U

U

A

MMEEN

R

U

O

F

F

E

O

F

F

O

R

O

F

F

N

GM.

F

R

EFNCH

E

E

O

F

See to

next page

1-14

Fig. 1-8-1

Display 1

Display 2

Page 17

Refer to Fig. 1-9-2.

While the DEMONSTRATION

mode is activated, a word of

DEMONSTRATION is

appearing on the screen

scrolling from right to left.

DENO MODE

OFF

ON

EXIT

䊳

R

I

T

T

D

J

D

V

䊳

T

E

N

E

I

A

L

E

I

R

O

C

T

L

T

T

I

M

D

E

.

E

L

E

P

O

E

T

C

T

E

/

O

U

S

A

I

T

M

T

I

M

R

Y

M

M

I

A

L

I

D

O

O

N

S

E

E

M

C

A

M

D

U

T

R

E

R

N

E

N

E

T

E

A

O

G

O

M

.

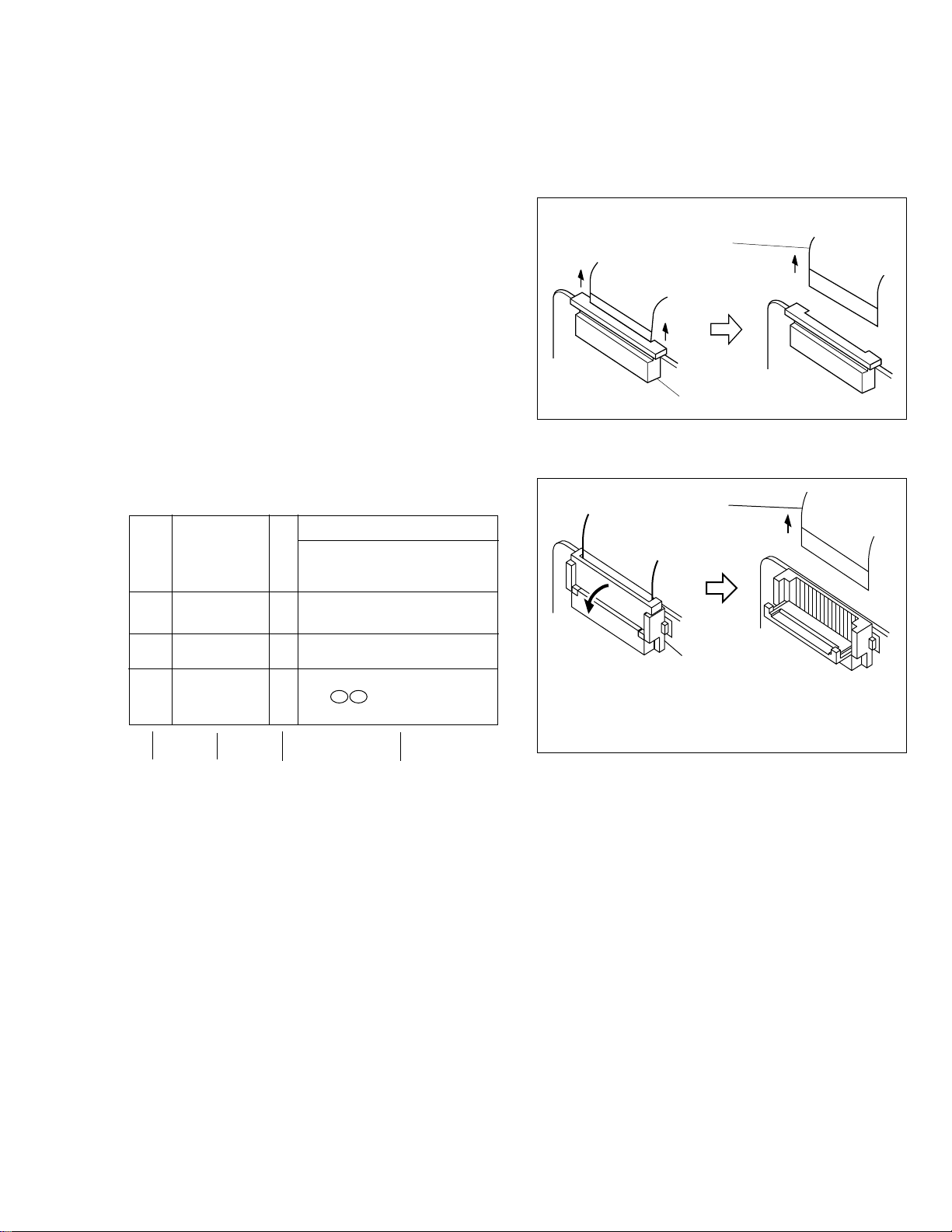

.

M

MEE

N

O

O

O

F

0

O

S

N

U

F

F

F

R

6

N

E

U

F

F

F

ENACMH

Note 2)

As the “DEMO MODE” is executed, the

camcoder enters the DEMONSTRATION mode

after the title screen of “TITLE CALL” and

“FUTURE” appear in this order.

<Flow chart>

1. TITLE CALL and FUTURE

2. FOG

3. ND EFFECT

4. FADER/WIPE (BLACK)

5. MOSAIC

6. SHUTTER

7. SLIDE

8. DOOR

9. CORNER

10. WINDOW

11. NEGA/POSI

12. STRETCH

13. MOSAIC

14. SEPIA

15. B/W

16. STROBE

17. CLASSIC

18. VIDEO ECHO

35. PIN UP SNAPSHOP

34. WIDE ANGLE

33. 30 ~ 32 (For DSC MODEL ONLY)

32. D.S.C. 9 FRAME

31. D.S.C. 4 FLAME

30. D.S.C. INDEX

29. NIGHT ALIVE 10X

28. NIGHT ALIVE OFF

27. S-VHS (For S-VHS MODEL ONLY)

26. VHS

25. P. STABILIZER OFF

24. P. STABILIZER OFF

23. P. STABILIZER ON

22. P. STABILIZER OFF

21. WIDE OFF

19. WIDE OFF

3. Turn the MENU WHEEL in the

direction of the arrow to set the

cursor at “DEMO MODE”. Then,

press the MENU WHEEL once.

The third page of the DEMO

MODE appears on the LCD

monitor (or in the viewfinder).

20. WIDE ON

Fig. 1-8-2

4. Turn the MENU WHEEL in the direction of the arrow to set the cursor at

“ON”. Then, press the MENU WHEEL

once.

The fourth page of the DISPLAY

appears on the LCD monitor (or in the

viewfinder).

(“DEMO MODE” is switched “ON” from

“OFF” status.)

Display 4Display 3

5. Press the MENU WHEEL once.

The camcorder automatically

enters the DEMONSTRATION

mode and it repeats demonstration operation.

While the camcorder is performing demonstration, all operations

except turning on/off the POWER

switch are ineffectual.

1-15

Page 18

SECTION 2

MECHANISM ADJUSTMENT

2.1 SERVICE CAUTIONS

2.1.1 Precautions

1. Before disassembling/re-assembling the set as well as

soldering parts, make sure to disconnect the power

cable.

2. When disconnecting/connecting connectors, pay enough

attention to wiring not to damage it.

3. When installing parts, be careful not to do with other parts

as well as not to damage others. (Pay the most careful

attention to the upper drum assy and tape transport

mechanism.)

2.1.2 How to read the disassembly and assembly

(For Mechanism Parts)

(1) Order of steps in Procedure

When reassembling, perform the step(s) in the reverse

order. These numbers are also used as the identification (location) No. of parts Figures.

(2) Part to be removed or installed.

(3) Location of part.

T = Top

B = Bottom

(4) Fig. No. showing Procedure or Part Location.

M = Mechanism

(5) Identification of part to be removed, unhooked, un-

locked, released, unplugged, unclamped or unsoldered.

P = Spring

W = Washer

S = Screw

* = Unhook, unlock, release, unplug or unsolder.

2.1.3 Required adjustment tools

Alignment tape

MHPE-C

Jig connector cable

YTU93106A

Cassette torque meter

PUJ50431-2

Table 2-1-1

Alignment tape

MHPE-LC

Extension connector

YTU94145B-30

Roller Driver

PTU94002-2

(6) Adjustment information for installation.

(+) = Refer to Exploded Views for Lubrication information.

(For Mechanism Parts)

STEP/LOC.

No.

PART

Fig.

No.

REMOVAL INSTALLATION

*UNHOOK/UNLOCK ADJUSTMENT

/RELEASE/UNPLUG CONDITION

/UNSOLDER NOTE

1 ROLLER BASE ASSEMBLY T M1 (S1) –

2 TENSION ARM ASSEMBLY T M1 (P1), (W1a) –

3 REEL DISC (SUP) T M1 (W1a), (W1b) _

4 SLANT ARM ASSEMBLY T M1 (W1a) –

5 CANCEL LEVER ASSEMBLY T M2 (W2) _

6 EJECT LEVER ASSEMBLY T M2 (W2) –

7 CASSETTE GUIDE (L) ASSEMBLY T M2 (S2) –

5

(1) (2) (3) (4) (5) (6)

2-1

5

5

5

5

5

Page 19

2.2 DISASSEMBLY/ASSEMBLY OF MECHANISM PARTS

This procedure starts with the condition that the cabinet parts and deck parts. Also, all the following procedures for adjustment

and parts replacement should be performed in STOP mode. When reassembling, perform the step(s) in the reverse order.

REMOVAL INSTALLATION

*UNHOOK/UNLOCK ADJUSTMENT

/RELEASE/UNPLUG CONDITION

/UNSOLDER NOTE

STEP/LOC.

No.

PART

Fig.

No.

1 ROLLER BASE ASSEMBLY T M1 (S1) –

2 TENSION ARM ASSEMBLY T M1 (P1), (W1a) –

3 REEL DISC (SUP) T M1 (W1a), (W1b) –

4 SLANT ARM ASSEMBLY T M1 (W1a) –

5 CANCEL LEVER ASSEMBLY T M2 (W2) –

6 EJECT LEVER ASSEMBLY T M2 (W2) –

7 CASSETTE GUIDE (L) ASSEMBLY T M2 (S2) –

8 SUPPLY CLUTCH ASSEMBLY T M2 (W2) –

9 WHEEL GEAR T M2 (W2) See, Adjustment procedure for

Section 1.3

0 ROTARY ENCODER B M3 4(S3a)

The function of this part varies according to the assembly (YMA0030A-E/

YMA0031A-E) which this part is incorporated in.

! TIMING BELT B M3 ––

@ CENTER PULLEY UNIT T/B M3 2(S3a) –

# CASSETTE GUIDE (R) ASSEMBLY T M3 (S3b), (P3) (Only use YMA0031A-E)

$ TU GEAR T M3 (W3a) –

% BRAKE SUB GEAR T M3 (W3a) –

^ P.R ARM ASSEMBLY T M3 (W3b) –

& TU GUIDE ARM ASSEMBLY T M3 (W3b) –

* LINK ARM ASSEMBLY T M4 (W4) –

( LED GUIDE T M4 (S4a) –

) A/C HEAD UNIT T M4 2(S4b) –

q SLANT POLE BASE ASSEMBLY T M5 (S5a) –

w CAP MOTOR ASSEMBLY T M5 3(S5a) –

e MOTOR BASE T M5 2(S5b), (S5c) –

r BRUSH B M6 (S6a) –

t DRUM FINAL T/B M6

2(S6b), 2(S6c) *CATCHER

–

y GUIDE RAIL T M6 8(S6d) –

u POLE BASE (SUP) T M6 ––

i POLE BASE (TU) T M6 ––

o COVER PLATE T M7 ––

p DRIVE LEVER ASSEMBLY T M7 ––

Q MOTOR BRACKET ASSEMBLY T M7 3(S7) –

W CONTROL CAM T M8 (W8a) See, Adjustment procedure for

Section 1.3

E LINK LEVER T M8 ––

R MIDDLE GEAR T M8 ––

T LOADING GEAR(T) ASSEMBLY T M8 (W8b) See, Adjustment procedure for

Section 1.3

Y LOADING GEAR(S) ASSEMBLY T M8 (W8b) –

U LOADING RING ASSEMBLY T M8 4(S8) See, Adjustment procedure for

Section 1.3

Table 2-2-1

2-2

Page 20

<TOP VIEW>

31

37

25

26

<BOTTOM VIEW>

1

29

28

27

4

36

2

5

9

3

34

Fig. 2-2-1 TOP VIEW

20

21

19

22

23

17

16

14

15

18

12

33326830357

13

Note:

When reinstalling the cassette housing to

the set, pay careful attention to the switch

not to damage it.

2-3

24

11

10

Fig. 2-2-2 BOTTOM VIEW

Page 21

2

16

12

17

14

11

(W3a)

15

(W3a)

(W3a)

(W3b)

(S3a)

(S3b)

(P3)

(S3a)

(S3a)

(S3a)

(S3a)

10

13

(W1a)

(S1)

1

(W1a)

(P1)

(W1a)

3

4

(W1b)

Fig. M1 Fig. M3

5

(W2)

9

(S2)

(W2)

6

(W2)

7

8

18

(S4a)

(W4)

19

(S4b)

20

(S4b)

Fig. M4Fig. M2

2-4

Page 22

22

(S5a)

(S5a)

21

(S5a)

31

(S7)

27

(S5b)

Catcher

28

(S6b)

Fig. M5

(S6d)

25

(S5c)

23

(S8)

29

30

Fig. M7

(S8)

37

2-5

(S6d)

(S6c)

(S6c)

Fig. M6

(S6d)

26

24

(S6a)

(S6d)

36

(W8a)

32

(W8b)

(W8b)

35

33

34

Fig. M8

Page 23

2.3 CHECKUP AND ADJUSTMENT OF MECHANISM PHASE

Note:

Pay careful attention to the installing order and

phase of mechanism parts of the loading system.

Align the hole of the Loading gear

(T) assembly to that of the deck.

Align the two holes of the Loading

ring assembly to those of the deck.

Align the hole of the

link lever assembly to

the deck hole.

Align one of the three holes of

wheel gear to the deck hole.

lign this part to each

Triangle" mark.

Align each one link lever

assembly hole and deck

hole to the hole at the

control cam position.

Fig. 2-3-1 Top of main deck

Align this part to each

"Triangle" mark.

Fig. 2-3-2 Rotary encoder

2-6

Page 24

2.4 TAPE TRANSPORT ADJUSTMENT

In most cases the deck section is in need electrical adjustment, it results from replacement of worm mechanical parts

or video heads. In the event of malfunction with electrical

circuits, troubleshouting with the aid of proper test instruments most be done first, and then commence necessary

repair, replacement and adjustment, etc.

2.4.1 Back tension

1. Set a cassette torque meter onto the deck and measure

the back tension in standard REC mode to confirm that

the back tension is 7 – 14 gf

•cm.

2. If not, replace the tension band.

When the value widely fluctuates in the measurement,

replace the supply reel disk.

3. With the cassette torque meter, confirm that the play

torque is 15 – 25 gf

•cm.

If necessary, replace the center pully unit.

8. When the FM waveform breaks in the level varying process, subtly adjust the height of guide rollers at every

breaking point so that the waveform varies as flat as possible.

Repeat the above steps 6. and 7. several times to confirm that the waveform is flat as a whole.

9. Playback the LP stairstep signal of alighment tape and

adjust the tracking control to maximize the FM waveform, confirm that FM waveform variation is always

flat.

10. Record the signal and play it back in both of the SP and

LP modes, and confirm that the FM waveform is flat in

both modes.

Note:

Among the above-mentioned adjustment steps,

the items of No. 9 and No. 10 are needed for the

LP model only.

CH-2

1 field

Back tension

-3

0.7x10

(7-14gf·cm)

-1.37x10-3 N•cm

Play torque

1.47x10

-3

-2.45x10-3 N·m

(15-25gf·cm)

Fig. 2-4-1 Cassette torque meter

2.4.2 Tape pattern

1. Remove the Cover (JIG) shwon on Fig. 2-6-1 (Page 2-10).

2. Connect the jig connector cable to CN25 on the MAIN

board as shwon on Fig. 2-6-1 (Page 2-10).

3. Observe signal at V. TP FM with external trigger from V.

FF on the jig connector cable.

4. Playback the SP stairstep signal of the alignment tape

and maximize the FM waveform by the tracking button.

5. Set the tracking control to the center position by simultaneously pressing the tracking (-) and (+) buttons and

maximize the FM waveform by the tracking button.

6. If the observed FM waveform is not flat, adjust the height

of the supply of take-up guide roller with the roller driver.

Causer by wrong height

of supply guide roller

Flatten waveform.

Caused by wrong height

of take-up guide roller

Fig. 2-4-2 FM waveform-1

Correct variation of waveform

Bad variation of waveform

Fig. 2-4-3 FM waveform-2

To prevent the tape from damage, turn the guide

Note:

rollers slowly.

7. By operating the tracking button (both in + and – directions) in the manual tracking mode, vary the output level

of the FM waveform from maximum to minimum and

vice versa to confirm that the waveform varies nearly in

a flat shape.

2-7

Page 25

11. Through the above steps, confirm that there occur no

A/C head

Screw C

Screw B

Screw A

g

wrinkling and damage in the tape around the pinch roller

and TU guide pole whenever the deck is in operation of

Loading/Unloading, Search Rewind and at mode change

from Search Rewind to play mode. If wrinkling or damage in the tape occurs around the TU guide pole, adjust

the angle (slant) of the A/C head to the tape. So that the

tape normally runs along the lower flange of the guide

pole.

Pole base (SUP)

(Guide roller)

Pole base (TU)

(Guide roller)

TU guide

pole

2.4.3 A/CTL head height & azimuth

1. Connect the jig connector cable to CN25 on the MAIN

board.

2. Connect the channel-1 scope probe to the audio output

and connect the channel-2 scope probe to PB CTL.

3. Playback the alignment tape.

4. Set the tracking to its center range by pressing the (+)

and (–) tracking controls simultaneously.

5. Adjust screws A , B and C approximately 45 degrees

in the same direction to obtain maximum audio output

and CTL signal levels.

6. As a final fine adjustment, adjust screw B for minimum

signal level fluctuation and screw C for maximum output signal level.

Tension

pole

Fig. 2-4-4 Tape transport system

Pinch

roller

Fig. 2-4-5 A/C head

Audio

signal

Control

pulse

si

nal

Fig. 2-4-6 Audio and CTL signal

2-8

Page 26

2.4.4 Phase of control head (X value)

1. Connect the jig connector cable to CN25 on the MAIN

board.

2. Playback the SP stairstep signal of the alignment tape

and observe signal at V.TP FM with external trigger from

V.FF on the jig connector cable.

3. Operate the tracking button in the center and manual

tracking mode by pressing the tracking (+) and (–) buttons and confirm that the FM output level is maximum

at the center position as shown in Fig. 2-4-8.

4. If necessary, slightly loosen the setscrews D and E and

insert the Tweezers into the notch and guide hole to

move the A/C head fully in the direction of the capstan

to the extent.

5. Gradually move the A/C head toward the drum to find

the position where the FM output level maximum for the

first time (a' – b' in Fig. 2-4-8).

6. Fine adjust the phase of the A/C head and tighten the

screws D and E at the point a.

A/C head

Insert the

Tweezers

2.5 REMARKS

2.5.1 Cleaning

1. For cleaning of the upper drum (particularly video heads),

use fine-woven cotton cloth or Kimwipe with alcohol

soaks through. Do not move the cloth but turn the upper

drum counterclockwise.

Make sure not to move the cloth in the vertical

Note:

direction to the video head, since it may cause

damage of the video heads.

2. For cleaning of parts of the tape transport system except

the upper drum, use fine-woven cotton cloth or cotton

swab soaked alcohol.

3. After cleaning, confirm that the cleaned parts are completely dry before loading the deck with cassette tape.

2.5.2 Applying oil and grease

1. Periodical oiling and greasing are not required but should

be done to new parts when replacing. If oil and grease

on the other parts of the other party are old and dirty,

wipe them clean and apply new oil or grease.

2. For parts and points to apply oil and grease, refer to the

exploded view of the mechanism assembly (M3).

Table 1-5-1 specifies oil and grease to be used.

3. When oiling, clean the objective parts with alcohol first

and apply one or two drop(s) of oil. Too much oiling

causes rotary parts to slip because of oil leakage.

Screw D

Screw E

Fig. 2-4-7 Phase of control head

a

FM output

Direction of capstan

Adjusting

point

A/C head phase

b

Direction of drum

Fig. 2-4-8 Phase adjustment point of control head

Max

Classification Name Symbol in drawing

Grease KYODO-SH-P AA

Oil YTU94027 BB

Table 2-5-1 Specific oil and grease to be used

2.5.3 Checkup

After replacement of the supply reel disk and tension band,

make sure to inspect back tension according to the adjustment procedure of MECHANISM ADJUSTMENT section.

Zero

2-9

Page 27

2.6 JIG CONNECTOR CABLE CONNECTION

Remove the cover (JIG).

Jig connector cable

Extention connector

Fig. 2-6-1 Jig connector cable connection

CN25

Cover(JIG)

MAIN BOARD CN25 Jig BOARD

MON_B

CVF_B

MON_G

CVF_G

MON_R

CVF_R

VF_PRO

VPP_7.8

MON_HD

DISCHG_L

MCU_RST

V_TP_FM

V_OUT

V_OVL

AO_SIG_J

PB_CTL

AL_J3.2V

JIG_TX

EJECT_SW

GND

I_MTR

GND

GND

GND

TXD

V_FF

RXD

NC

NC

NC

1

16

2

17

3

18

4

19

5

20

6

21

7

22

8

23

9

24

10

25

11

26

12

27

13

28

14

29

15

30

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

1

MON_B

CVF_B

2

MON_G

CVF_G

3

MON_R

CVF_R

4

GND

I_MTR

5

GND

VF_PRO

6

GND

VPP_7.8

7

MON_HD

DISCHG_L

8

GND

MCU_RST

9

TXD

V_FF

10

RXD

V_TP_FM

11

V_OUT

V_OVL

12

AO_SIG_J

PB_CTL

13

AL_J3.2V

JIG_TX

14

EJECT_SW

NC

15

NC

NC

Fig. 2-6-2 Jig connector cable schematic diagram

2-10

Page 28

SECTION 3

p

ELECTRICAL ADJUSTMENT

3.1 ELECTRICAL ADJUSTMENT

3.1.1 PREPARATION

1. Precaution

This model does not contain adjustment controls (VR).

General deck system, camera system and monitor system

adjustment are not required. However, if MAIN board and

MONITOR board need replacement, please use original

2

E

PROM on to new board. Then adjustment are not required.

And if parts such as the following need replacement, special

computerized adjustment are required (Refer to sec. 3.1.1-

4). Please contact to JVC Service for detaile information.

• OP block

2

• E

PROM (IC104 of MAIN board)

• MONITOR

In the event of malfunction with electrical circuits, troubleshooting with the aid of proper test instruments most be

done first, and then commence necessary repair, replacement and adjustment, etc.

1. In case of wiring to chip test points for measurement, use

IC clips, etc. to avoid any stress.

2. Since connectors are fragile, carefully handle them in

disconnecting and connecting.

3. Shortcircuit between operation un it and DECK chassis.

2. Required test equipment

1. Color TV monitor.

2. AC power adapter

3. Oscilloscope (dual-trace type, observable 100 MHz or

higher frequency)

* It is recommended to use one observable 300 MHz or

higher frequency.

4. Digital voltmeter

5. Frequency counter (with threshold level adjuster)

6. Personal computer

3. Required adjustment tools

For detsails of special jigs necessary for adjustment, refer to

page 1-2 and 1-3 of the Section 1.

4. Setup for E. VF section adjustment

Referring to “SEC. 1 DISASSEMBLY” and connect the E.VF

WIRE to CN12 of the MAIN board.

(LY20686)

Bottom case assy

Parts No.

LY20686

Adjustment ltem : 3.3

Note:

•

This adjustmentalls into a special adjustment that requires

a personal computer.

For details, refer to “3.1.1 Preparation”.

Serial No.

label

Screw

5. Connection for Service support system

Fig. 3-1-1 Connection for Service support system

3-1

PC CABLE

RS232C

COM Port

Service Support

System software

MENU

Personal Com

uter

Page 29

7 FUSE LOCATION FOR MAIN BOARD ASSEMBLY

60

61

41

IC1601

80

120

17

IC2001

IC2401

4

85

IC4251

1

85

14

38 20

IC4501

119

IC105

9

8

16

1

IC107

5

4

8

1

24

13

FOIL SIDE

14

IC7005

CN12

14

8

5

F6002

F6003

0 1 MAIN PWB

YB10310-01-01

5

4

8

1

IC7006

CN28

113

13

24

2536

IC5202

40

21

157

148

37

IC5201

48

112

2536

112

37

48

24

13

105156

104

37

48

IC7001

1

2536

12

IC4001

208

152

43

IC106

IC104

1

5

8

4

4

2

3

1

56

53

2942

28

IC3501

15

114

0 1 MAIN PWB

YB10310-01-01

CN16

25

36

IC4702

95

17

IC6001

32

33

F6001

Fig. 3-1-2 FUSE location for MAIN board assembly (FOIL SIDE)

COMPONENT SIDE

8

13

24

37

14

116

48

1

29

114

CN2

IC7002

48

64

49

CN25

9

12

1

2

30

CN11

1

16

1

20

IC7008

IC7009

85

14

110

146

CN13

114

IC3003

3

4

5

IC3001

1

73

1

72

19

39

37

36

1

5

1

3

4

IC3002

IC102

1

5

3

4

111

176

1

44

109

1

12

CN19

CN18

IC4002

45

CN22

115

1

38

20

38

2

20 11

110

IC101

1

10

CN1CN5

11

IC4003

CN7

CN3

18 1

1

17

IC4202

148

IC4201

4

85

1

22

133

132

89

88

CN15

1

CN4

16

Fig. 3-1-3 FUSE location for MAIN board assembly (COMPONENT SIDE)

3-2

Page 30

7 FUSE LOCATION FOR MONITOR BOARD ASSEMBLY

COMPONENT SIDE

1

CN7502

28 1

24

R7516

0 7 MONITOR PWB

YB20900-01-01

CN7501

F7501

IC7501

14

85

21

CN7503

Fig. 3-1-4 FUSE location for MAIN board assembly (COMPONENT SIDE)

3.2 MONITOR ADJUSTMENT

Notes:

Unless otherwise specified, all measurement points

and adjustment parts are located on MONITOR board.

COMPONENT SIDE (A)

1

CN7502

CN7501

28 1

24

R7516

V COM

0 7 MONITOR PWB

YB20900-01-01

F7501

IC7501

14

85

21

CN7503

3.2.1 V COM

Signal •Alignment tape

•Stairstep

Mode •PB

Equipment • LCD MONITOR

Measurement point •–

Adjusting part • R7516 (V COM)

Specification • Black level must correctly be

reproduced on the LCD MONITOR.

(There is a sharp contrast

between black and white parts.)

(1) Adjust R7516 to make sharp contrast between black and

white parts on the LCD MONITOR screen.

(2) Adjust R7516 so that black and white levels (patticularly

black level in the contour) is sharply reproduced on the

LCD MONITOR screen.

3-3

Page 31

3.3 ELECTRONIC VIEWFINDER (E. VF) ADJUSTMENT

Notes:

Unless otherwise specified, all measurement points

and adjustment parts are located on E. VF board.

CRT

CENTERING

MAGNET

FOCUS

MAGNET

F.B.T

Fig. 3-3-1 E. VF

CRT-CN

VR4

BRIGHT

VR1

V. SIZE

50E. VF PWB ASSY

VR2

H. HOLD

CN2

CN1

(a)

Fig. 3-3-3 Horizontal sync. 1

(b)

Fig. 3-3-4 Horizontal sync. 2

3.3.2 PLL adjustment

Subject •Camera picture

Fig. 3-3-2 E. VF board

3.3.1 Horizontal sync.

Subject • Alignment tape

• Stairstep

Mode • PB

Equipment • E. VF

Measurement point • E. VF screen

Adjusting part • VR2 (H. HOLD)

Specification • The midpoint of the two

markings

1) Observing the viewfinder screen, turn VR2 fully clockwise

to make the picture unstable.

2) Slowly return VR2 counterclockwise to find a point where

the picture becomes stable, and mark this position.

3) Turn VR2 fully counterclockwise to make the picture

unstable in the same manner as 1) above.

4) Slowly return VR2 clockwise until the picture becomes

stable, and mark this position.

5) Finally set VR2 to the midpoint between the two markings

of 2) and 4).

Mode • EE

Equipment •E. VF

Measurement point • E. VF screen

Adjusting part •VR1 (V. SIZE)

Specification • Normal picture amplitude

1) Observing the viewfinder screen, adjust VR1 for normal

picture amplitude.

3.3.3 Centering

Subject •Alignment tape

•Stairstep

Mode • PB

Equipment •E. VF

Measurement point • E. VF screen

Adjusting part •Centering magnet (CRT assy)

Specification • The center of the E. VF screen

1) While observing the viewfinder screen, adjust the centering

magnet to locate the stairstep in the center of the viewfinder screen.

3-4

Page 32

3.3.4 Focus

Subject • Camera picture

Mode •EE

Equipment •E. VF

Measurment point •E. VF screen

Adjustment part •Focus magnet (CRT assy)

Specification •

1) While observing the viewfinder screen, adjust the focus

magnet for the deflecting yoke so that the picture at the

central area of the screen is clear and defined.

3.3.5 Brightness

Subject • -

Mode • EE

Equipment • E. VF

Measurment point • E. VF screen

Adjustment part • VR4 (BRIGHT)

Specification •

1) Close the lens with the cap and adjust VR4 so that the

raster of the CRT is just visible in the E. VF.

The center area is clear and defined

• Lens closed

The CRT raster is just barely visible

3-5

Page 33

3.4 SERVICE NOTE

3-6

Loading...

Loading...