Page 1

SERVICE MANUAL

DIGITAL VIDEO CAMERA

GR-DX75EX, GR-DX75EY, GR-DX75EZ, GR-DX75EK,

GR-DX95E

X, GR-DX95EY, GR-DX95EZ, GR-DX95EK

For disassembling and assembling of MECHANISM ASSEMBLY, refer to the SERVICE MANUAL No.86700(MECHANISM ASSEMBLY).

SPECIFICATIONS

General

Power supply :

Power consumption

LCD monitor off,

viewfinder on : Approx. 3.4 W

LCD monitor on,

viewfinder off : Approx. 4.6 W

Dimensions

(W x H x D) : 55 mm x 102 mm x 96 mm

Weight : Approx. 440 g (GR-DX300/DX100)

Operating

temperature :0°C to 40°C

Operating

humidity : 35% to 80%

Storage

temperature : –20°C to 50°C

Pickup : 1/4" CCD (GR-DX300/DX100)

Lens : F 1.8, f = 3.8 mm to 38 mm,

Filter diameter : ø30.5 mm

LCD monitor : 3" diagonally measured, LCD

Viewfinder : Electronic viewfinder with 0.24"

Speaker : Monaural

DC 11.0 V (Using AC Adapter)

DC 7.2 V

(with the LCD monitor closed and

the viewfinder pushed back in)

(without grip belt)

: Approx. 450 g (GR-DX95/DX75)

(without grip belt)

1/6" CCD (GR-DX95/DX75)

10:1 power zoom lens

(GR-DX300/DX100)

F1.6, f =2.7 mm to 43.2 mm,

16:1 power zoom lens

(GR-DX95/DX75)

panel/TFT active matrix system

(GR-DX300/DX95)

2.5" diagonally measured, LCD

panel/TFT active matrix system

(GR-DX100/DX75)

black/white LCD

(The specifications shown pertain specifically to the model GR-DX75EX, GR-DX95EX, GR-DX100EX and GR-DX300EX.)

(Using battery pack)

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LTD

Digital Video Camera

Format : DV format (SD mode)

Signal format : PAL standard

Recording/

Playback format : Video:

Cassette : Mini DV cassette

Tape speed : SP : 18.8 mm/s

Maximum

recording time : SP : 80 min.

(using 80 min. LP : 120 min.

cassette)

Digital Still Camera Function

Storage media : SD Memory Card/MultiMediaCard

Compression

system : Still image : JPEG

File size : 4 modes (1600 x 1200 pixels*,

Picture quality : 2 modes (FINE/STANDARD)

Approximate

number of

storable images :

* GR-DX300/DX100 only.

Specifications shown are for SP mode unless otherwise indicated. E & O.E. Design and specifications subject

to change without notice.

Digital component

recording

: Audio: PCM digital recording,

32 kHz 4-channel (12-bit),

48 kHz 2-channel (16-bit)

LP : 12.5 mm/s

Moving image : MPEG4

1280 x 960 pixels*,

1024 x 768 pixels,

640 x 480 pixels)

(compatible)

(compatible)

Z pg. 18.

Connectors

S/AV

S-Video output : Y : 1 V (p-p), 75 Ω, analogue

S-Video input : Y : 0.8 V (p-p) – 1.2 V (p-p), 75 Ω,

Video output : 1 V (p-p), 75 Ω, analogue

Video input : 0.8 V (p-p) – 1.2 V (p-p), 75 Ω,

Audio output : 300 mV (rms), 1 kΩ, analogue,

Audio input : 300 mV (rms), 50 kΩ, analogue,

Edit : ø3.5 mm, 2-pole

DV

Output : 4-pin, IEEE 1394 compliant

Input : 4-pin, IEEE 1394 compliant

USB : 5-pin

Power requirement

Output : DC 11 V

C : 0.29 V (p-p), 75 Ω, analogue

analogue

C : 0.2 V (p-p) – 0.4 V (p-p), 75 Ω,

analogue

analogue

stereo

stereo

AC Adapter

: AC 110 V to 240 V`, 50 Hz/60 Hz

, 1 A

GR-DX75EK M3D327

GR-DX75EX M3D327

GR-DX75EY M3D327

GR-DX75EZ M3D327

GR-DX95EK M3D337

GR-DX95EX M3D337

GR-DX95EY M3D337

GR-DX95EZ M3D337

No.86740

2003/06

Page 2

CONTENTS

Important Safety Precautions

1. DISASSEMBLY............................................................................................................................................................... 1-1

3. ADJUSTMENT................................................................................................................................................................ 3-1

4. CHARTS AND DIAGRAMS ............................................................................................................................................ 4-1

5. PARTS LIST.................................................................................................................................................................... 5-1

DIFFERENT LIST

DIFFERENT TABLE OF FEATURE

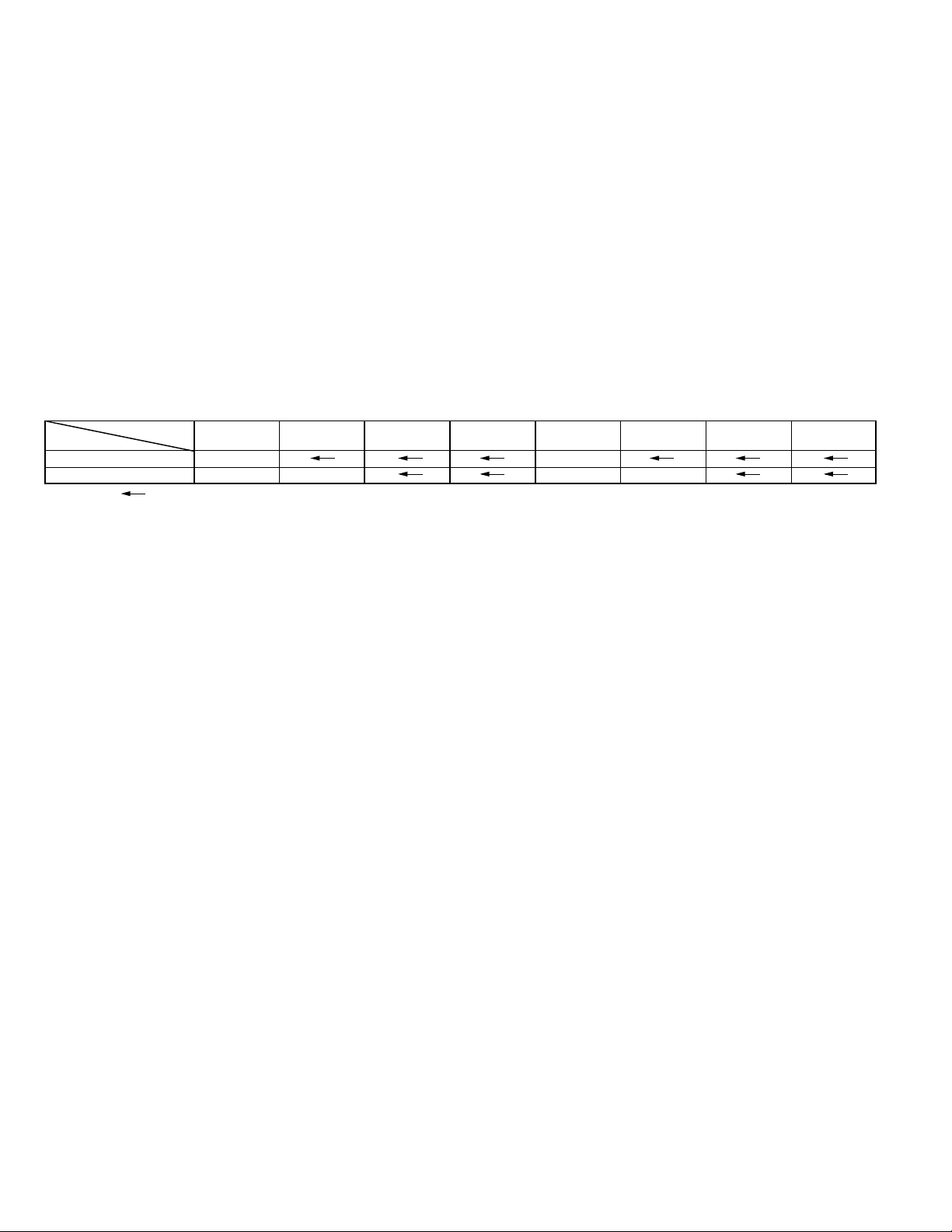

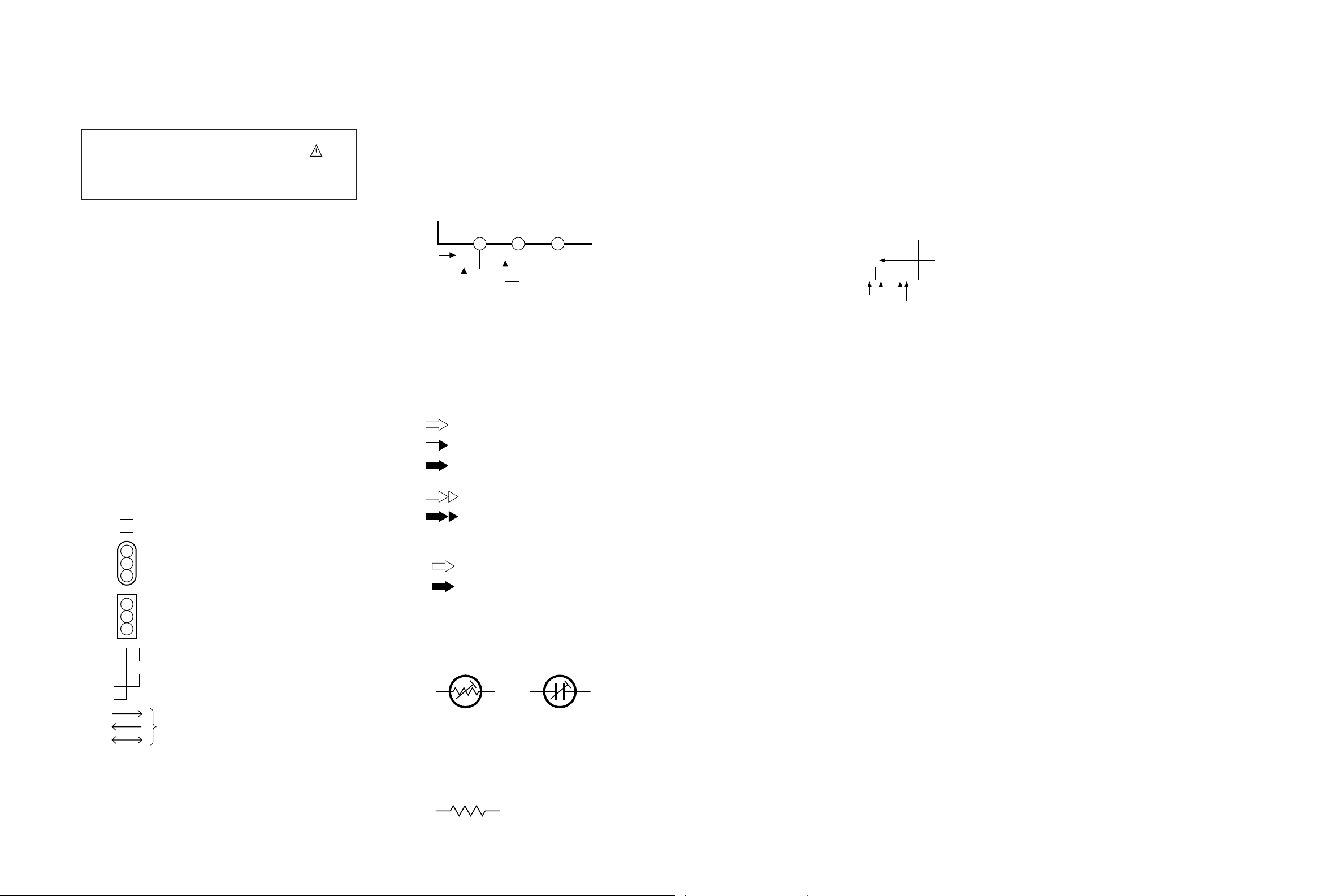

The following table indicate main different points between models GR-DX75EK, GR-DX75EX, GR-DX75EY, GR-DX75EZ, GR-

DX95EK, GR-DX95EX, GR-DX95EY and GR-DX95EZ.

ITEM

LCD MONITOR 2.5 INCH 3.0 INCH

AC CORD BS PLUG CEE PLUG BS PLUG CEE PLUG

Notes: Mark is same as left.

MODEL

GR-DX75EK

GR-DX75EX GR-DX75EY GR-DX75EZ GR-DX95EK GR-DX95EX GR-DX95EY GR-DX95EZ

Page 3

Important Safety Precautions

Connector

Metal sleeve

Prior to shipment from the factory, JVC products are strictly inspected to conform with the recognized product safety and electrical codes

of the countries in which they are to be sold. However, in order to maintain such compliance, it is equally important to implement the

following precautions when a set is being serviced.

v

Precautions during Servicing

1. Locations requiring special caution are denoted by labels and

inscriptions on the cabinet, chassis and certain parts of the

product. When performing service, be sure to read and comply with these and other cautionary notices appearing in the

operation and service manuals.

2. Parts identified by the symbol and shaded ( ) parts are

critical for safety.

Replace only with specified part numbers.

Note: Parts in this category also include those specified to com-

ply with X-ray emission standards for products using

cathode ray tubes and those specified for compliance

with various regulations regarding spurious radiation

emission.

3. Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as specified.

4. Use specified internal wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

5. Use specified insulating materials for hazardous live parts.

Note especially:

1) Insulation Tape 3) Spacers 5) Barrier

2) PVC tubing 4) Insulation sheets for transistors

6. When replacing AC primary side components (transformers,

power cords, noise blocking capacitors, etc.) wrap ends of

wires securely about the terminals before soldering.

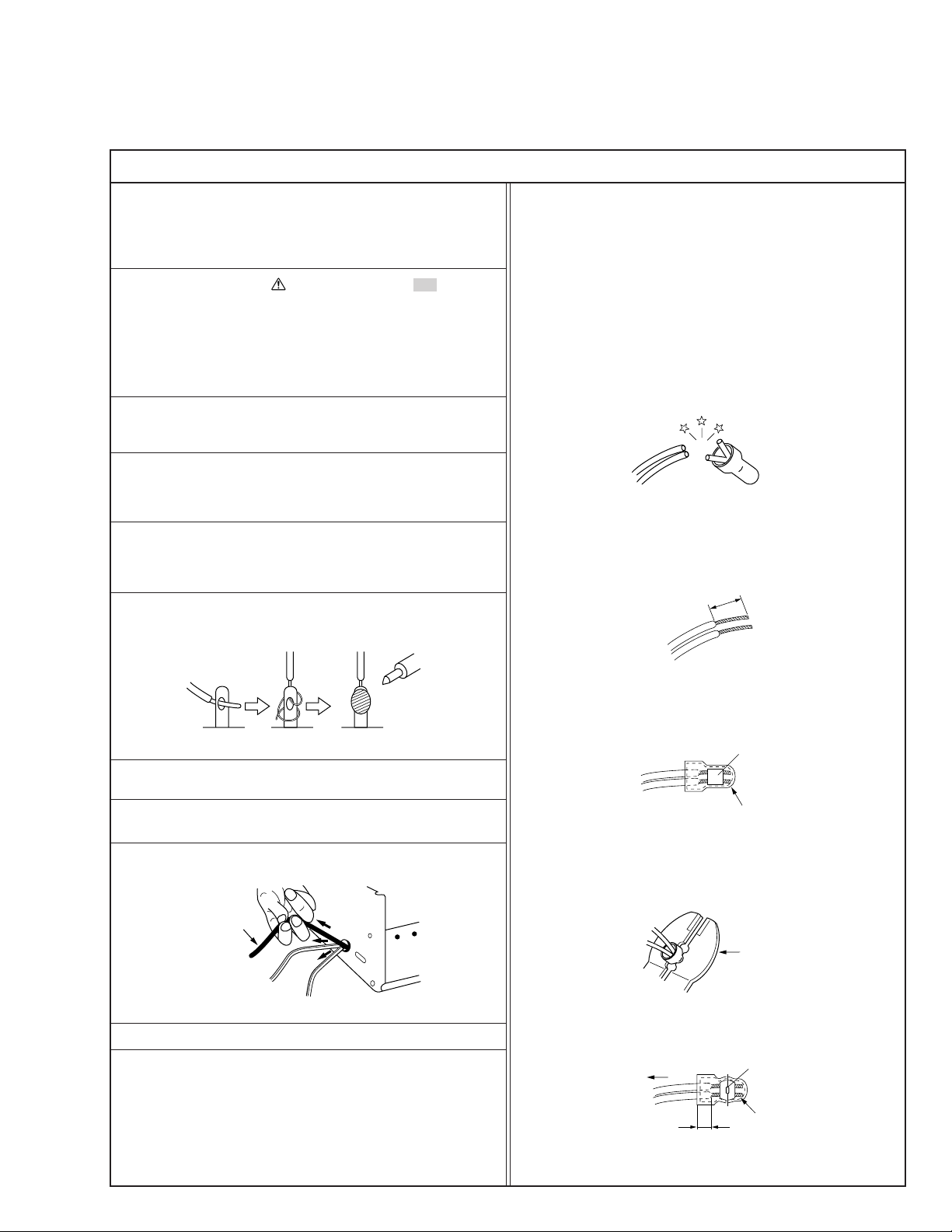

12. Crimp type wire connector

In such cases as when replacing the power transformer in sets

where the connections between the power cord and power

transformer primary lead wires are performed using crimp type

connectors, if replacing the connectors is unavoidable, in order to prevent safety hazards, perform carefully and precisely

according to the following steps.

1) Connector part number : E03830-001

2) Required tool : Connector crimping tool of the proper type

which will not damage insulated parts.

3) Replacement procedure

(1) Remove the old connector by cutting the wires at a point

close to the connector.

Important : Do not reuse a connector (discard it).

cut close to connector

Fig.3

(2) Strip about 15 mm of the insulation from the ends of

the wires. If the wires are stranded, twist the strands to

avoid frayed conductors.

15 mm

7. Observe that wires do not contact heat producing parts

8. Check that replaced wires do not contact sharp edged or

9. When a power cord has been replaced, check that 10-15 kg of

10. Also check areas surrounding repaired locations.

11. Products using cathode ray tubes (CRTs)

Fig.1

(heatsinks, oxide metal film resistors, fusible resistors, etc.)

pointed parts.

force in any direction will not loosen it.

Power cord

Fig.2

In regard to such products, the cathode ray tubes themselves,

the high voltage circuits, and related circuits are specified for

compliance with recognized codes pertaining to X-ray emission.

Consequently, when servicing these products, replace the cathode ray tubes and other parts with only the specified parts.

Under no circumstances attempt to modify these circuits.

Unauthorized modification can increase the high voltage value

and cause X-ray emission from the cathode ray tube.

Fig.4

(3) Align the lengths of the wires to be connected. Insert

the wires fully into the connector.

Fig.5

(4) As shown in Fig.6, use the crimping tool to crimp the

metal sleeve at the center position. Be sure to crimp fully

to the complete closure of the tool.

1.25

2.0

5.5

Fig.6

(5) Check the four points noted in Fig.7.

Not easily pulled free

Wire insulation recessed

more than 4 mm

Fig.7

Crimping tool

Crimped at approx. center

of metal sleeve

Conductors extended

1

S40888-01

Page 4

v

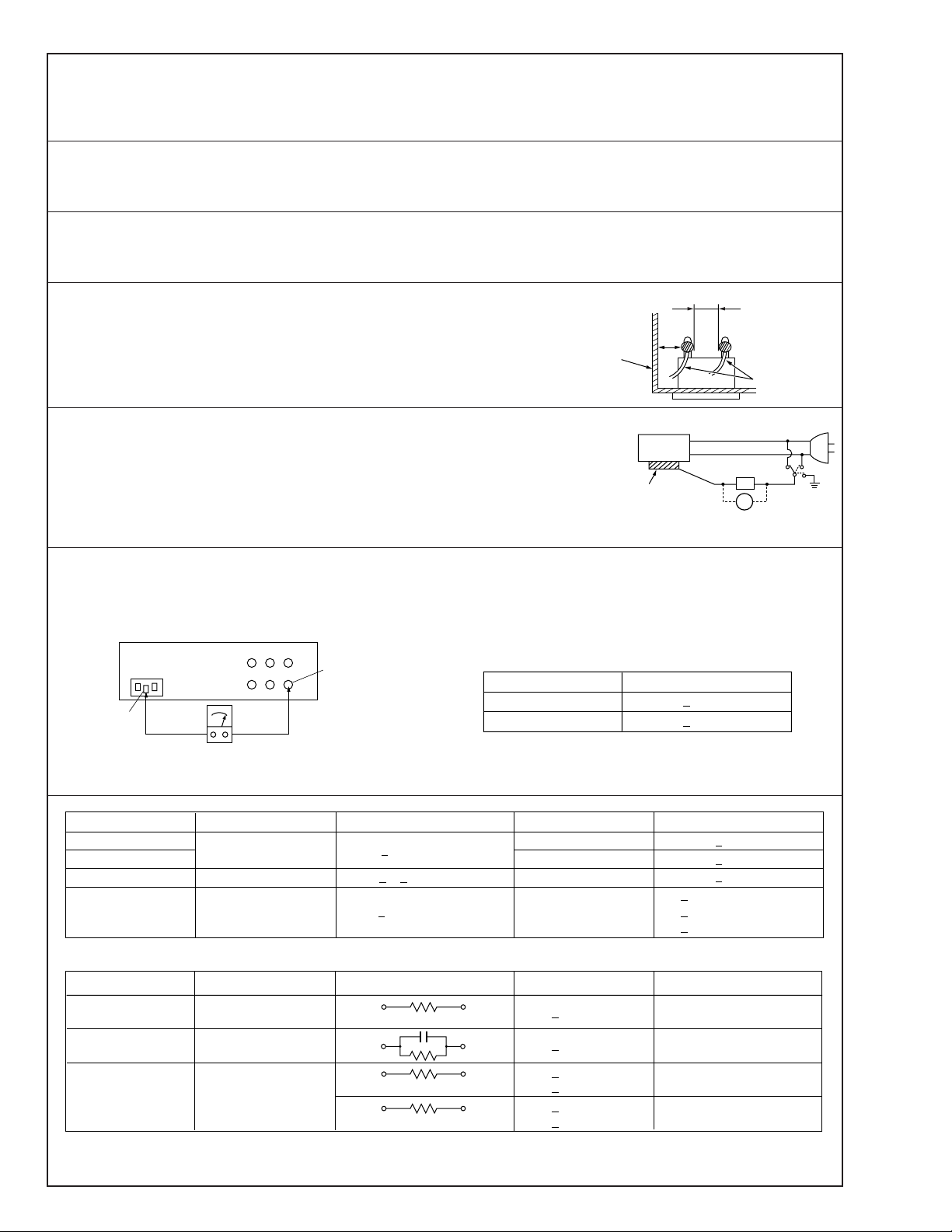

Safety Check after Servicing

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts and wires have been

returned to original positions, Afterwards, perform the following tests and confirm the specified values in order to verify compliance with safety standards.

1. Insulation resistance test

Confirm the specified insulation resistance or greater between power cord plug prongs and

externally exposed parts of the set (RF terminals, antenna terminals, video and audio input

and output terminals, microphone jacks, earphone jacks, etc.). See table 1 below.

2. Dielectric strength test

Confirm specified dielectric strength or greater between power cord plug prongs and exposed

accessible parts of the set (RF terminals, antenna terminals, video and audio input and output

terminals, microphone jacks, earphone jacks, etc.). See table 1 below.

3. Clearance distance

When replacing primary circuit components, confirm specified clearance distance (d), (d’) between soldered terminals, and between terminals and surrounding metallic parts. See table 1

below.

Chassis

Fig. 8

4. Leakage current test

Confirm specified or lower leakage current between earth ground/power cord plug prongs

and externally exposed accessible parts (RF terminals, antenna terminals, video and audio

input and output terminals, microphone jacks, earphone jacks, etc.).

Measuring Method : (Power ON)

Insert load Z between earth ground/power cord plug prongs and externally exposed accessible parts. Use an AC voltmeter to measure across both terminals of load Z. See figure 9 and

following table 2.

5. Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between earth pin in AC inlet and externally exposed accessible parts (Video in,

Video out, Audio in, Audio out or Fixing screw etc.).

Measuring Method:

Connect milli ohm meter between earth pin in AC inlet and exposed accessible parts. See figure 10 and grounding specifications.

AC inlet

Earth pin

Exposed accessible part

Grounding Specifications

Region

USA & Canada

Europe & Australia

Externally

exposed

accessible part

Grounding Impedance (Z)

d

d'

≤

Z 0.1 ohm

≤

Z 0.5 ohm

Power cord,

primary wire

Z

V

Fig. 9

ab

c

Milli ohm meter

Fig. 10

AC Line Voltage

100 V

100 to 240 V

110 to 130 V

110 to 130 V

200 to 240 V

100 V

110 to 130 V

110 to 130 V

220 to 240 V

Note: These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

Region

Japan

USA & Canada

Europe & Australia R 10 MΩ/500 V DC

Region Load Z

Japan

USA & Canada

Europe & Australia

Table 2 Leakage current specifications for each region

Insulation Resistance (R)

≤

R 1 MΩ/500 V DC

≥≥

1 MΩ R 12 MΩ/500 V DC

≤

Table 1 Specifications for each region

1 kΩ

0.15 µF

1.5 kΩ

2 kΩ

50 kΩ

Dielectric Strength

AC 1 kV 1 minute

AC 1.5 kV 1 miute

AC 1 kV 1 minute

AC 3 kV 1 minute

AC 1.5 kV 1 minute

i 1 mA rms Exposed accessible parts

i 0.5 mA rms

i 0.7 mA peak

i 2 mA dc

i 0.7 mA peak

i 2 mA dc

2

≤

≤

≤

≤

≤

≤

(Class 2)

(Class 1)

Clearance Distance (d), (d')

≤

d, d' 3 mm

≤

d, d' 4 mm

≤

d, d' 3.2 mm

≤

d 4 mm

≤

d' 8 mm (Power cord)

≤

d' 6 mm (Primary wire)

a, b, cLeakage Current (i)AC Line Voltage

Exposed accessible parts

Antenna earth terminals

Other terminals

S40888-01

Page 5

SECTION 1

DISASSEMBLY

1.1 Before disassembling

1.1.1 Precaution

• Be sure to disconnect the power supply unit prior to mounting and soldering of parts.

• Prior to removing a component part that needs to disconnect its connector(s) and its screw(s), first disconnect the

wire(s) from the connector(s), and then remove the screw(s).

• Be careful not to damage the connector and wire etc. during connection and disconnection.

• When connecting the flat wire to the connector, be careful

with the flat wire direction.

• Be careful in removing or handling the part to which some

spacer or shield is attached for reinforcement or insulation.

• When replacing chip parts (especially IC parts), first remove

the solder completely to prevent peeling of the pattern.

• Tighten screws properly during the procedures. Unless

specified otherwise, tighten screws at a torque of 0.078Nom

(0.8kgfocm).

• The bracketed ( ) WR of the connector symbol are assigned

nos. in priority order and do not correspond to those on the

spare parts list.

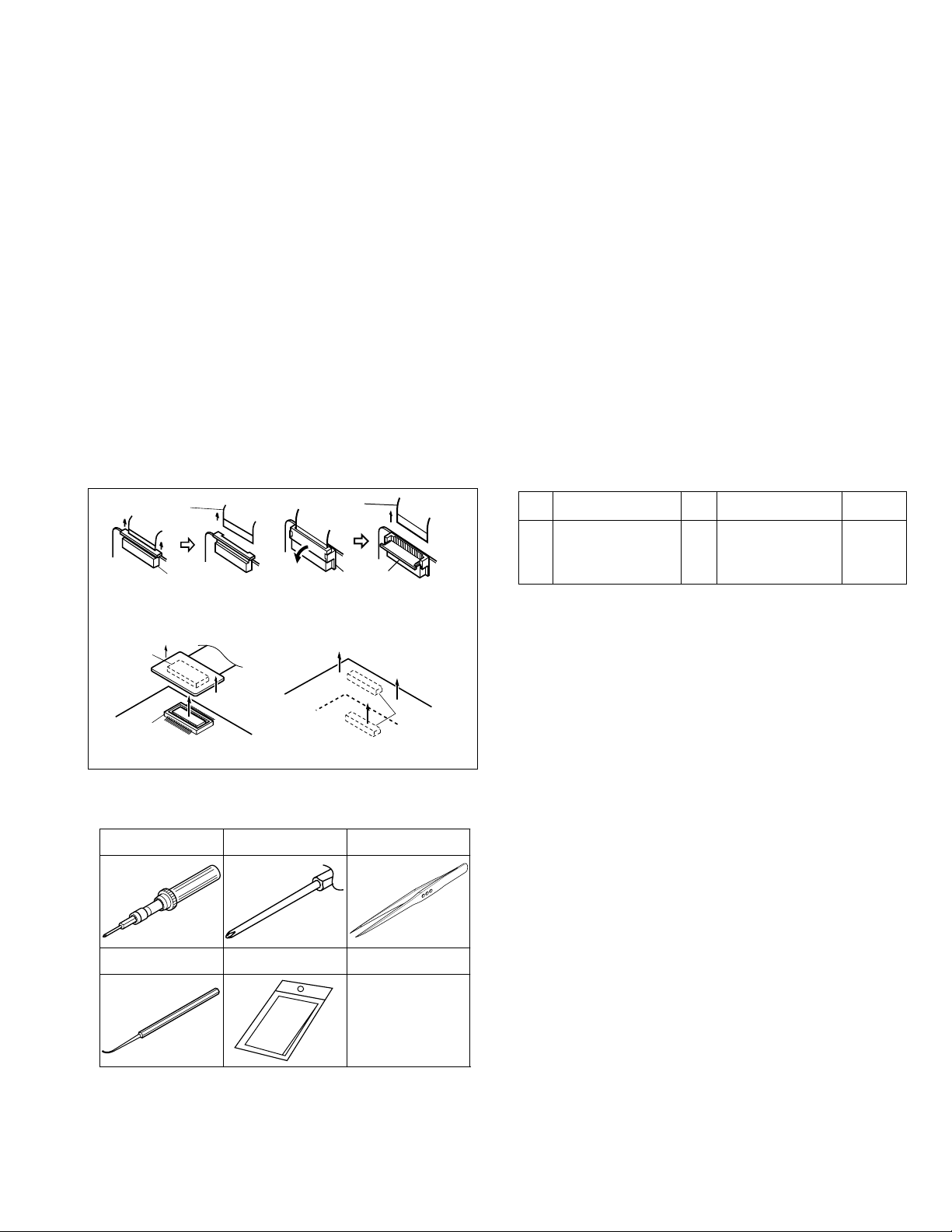

1.1.2 Disconnection of connectors (wires)

Flat wire

• Pull both ends of the connector in the arrow

B-B connector

B-B connector

FPC connector

direction, remove the lock and disconnect

the flat wire.

• Pull the board by both the sides in the direction of

the arrow for disconnecting the B-B connector.

• Extend the locks in the direction of the arrow for

unlocking and then pull out the wire. After removing the wire, immediately restore the locks

to their original positions because the locks are

apt to come off the connector.

Fig. 1-1-2a CONNECTOR

1.1.3 Required disassembling tools

Torque driver

YTU94088

Bit

YTU94088-003

Flat wire

FPC connector

lock

B-B connector

Tweezers

P-895

• Torque driver

Be sure to use to fastening the mechanism and exterior parts

because those parts must strictly be controlled for tightening torque.

• Bit

This bit is slightly longer than those set in conventional torque

drivers.

• Tweezers

To be used for removing and installing parts and wires.

• Chip IC replacement jig

To be used for replacement of IC.

• Cleaning cloth

Recommended the Cleaning cloth to wipe down the video

heads, mechanism (tape transport system), optical lens surface.

1.2 Removing the major parts

1.2.1 How to read the procedure table

This table shows the steps for disassembly of the major parts.

Reverse these steps when re-assembling them.

<Example>

Step

No.

[1] Top cover, 1-3a

(*1) (*2) (*3) (*4) (*5)

Part Name

Bracket 2(S1c)

Fig. No.

--------------------------

Point Note

4(S1a),(S1b),3(L1a), <Note 1a>

2(SD1a),(P1a),(W1a),

CN1(WR1a),

(*1) Order of steps in Procedure

When reassembling, perform the step(s) in the reverse or-

der.

(*2) Part name to be removed or installed.

(*3) Fig. No. showing procedure or part location.

(*4) Identification of part to be removed, unhooked, unlocked,

released, unplugged, unclamped or unsoldered.

P= Spring, W= Washer, S= Screw, L= Locking tab, SD=

Solder, CN**(WR**)= Remove the wire (WR**) from the con-

nector (CN**).

(*5) Adjustment information for installation

Chip IC replacement jig

PTS40844-2

Cleaning cloth

KSMM-01

Fig. 1-1-3a

1-1

Page 6

1.2.2 Disassembly procedure

[FINAL ASS'Y]

Step

No.

Part Name

Fig. No.

[1] FRONT ASS’Y(G) 1-2-2a (S132), 2(S131),

[2] UPPER ASS’Y(G) 1-2-2a 2(S124), COVER(DV),

[3] LOWER ASS’Y(F) 1-2-2a

[4] MAIN BOARD ASS’Y 1-2-2a 2(S117),

[5] MECHANISM ASS’Y 1-2-2a (S116),

Point Note

(S133), (S130),

TOP COVER, MIC COVER,

(S125), (S126), 2(S129),

MAIN CN115(WR101a),

HOLDER(DV/USB)

(S128), (S127),

BRACKET(TOP),

(S120), (S122), (S121),

3(S123),

MAIN CN112(WR102a),

MAIN CN113(WR102b)

MAIN CN114(WR103a),

MIC ASS’Y,

MAIN CN111(WR103b),

MAIN CN102(WR103c),

MAIN CN101(WR103d),

MAIN CN109(WR103e),

(S119), 3(S118)

SHIELD PLATE,

MAIN CN106(WR104a),

MAIN CN110(WR104b),

MAIN CN107(WR104c),

MAIN CN103(WR104d),

(L104a),

MAIN CN108(WR104e),

MAIN CN104(WR104f)

BKT(PRE-REC),

3(S115),

MECHA BKT ASS’Y

[WIRE CONNECTION]

WR No. CONNECTION

WR101a FRONT ASS’Y(G) STROBE CN6501 MAIN CN115

WR102a UPPER ASS’Y(G) SUB OPE UNIT — MAIN CN112

WR102b UPPER ASS’Y(G) MONITOR CN7601 MAIN CN113

WR103a — MIC ASS’Y — MAIN CN114

WR103b LOWER ASS’Y(F) C. OPE UNIT — MAIN CN111

WR103c LOWER ASS’Y(F) CCD — MAIN CN102

WR103d LOWER ASS’Y(F) BATT. TERM. — MAIN CN101

WR103e LOWER ASS’Y(F) SD CN301 MAIN CN109

WR104a MECHA ASS’Y SENSOR — MAIN CN106

WR104b MECHA ASS’Y HEAD — MAIN CN110

WR104c MECHA ASS’Y R. ENCODER — MAIN CN107

WR104d MECHA ASS’Y LOAD. MOTOR — MAIN CN103

WR104e MECHA ASS’Y CAP. MOTOR — MAIN CN108

WR104f MECHA ASS’Y DRUM MOTOR — MAIN CN104

[LOWER ASS’Y(F), LOWER ASS’Y(G)]

Step

No.

Part Name

Fig. No.

[1] OP F. ASS’Y (S560),

(OP ASS’Y) (SD551a),

--------------------------

[2] VF ASS’Y(G) 2(S559),

[3] SD BOARD ASS’Y (S557),

[4]

SIDE OPE BOARD ASS’Y

[5] CASS.COVER ASS’Y 4(S515)

(ARM ASS’Y) 2(S513),

--------------------------

Point Note

SD CN302(WR551a),

(S558), BKT(OP)

CCD BOARD ASS’Y

SD CN304(WR552a)

SD CN303(WR553a)

2(S512),

CAMERA OPE UNIT,

(S522),

HOLDER(G.OUTER),

2(S514),

BKT(S.COVER/VF),

(S521),

SIDE COVER ASS’Y,

KNOB(DSC)

BATT.TERM.

[UPPER ASS’Y(G)]

Step

No.

Part Name

Fig. No.

[1] MONITOR ASS’Y(G) (S614)*, (*601a)

--------------------------

[2] U.CASE ASS’Y (S610),

Point Note

BKT(SPEAKER)*,

(S617), 2(S616),

2(S611), (WR601a)

2(S612),

COVER(TOP/UPP)L,

COVER(TOP/UPP)R

FRAME(UPPER) ASS’Y

(*601a) Mark*: This part was deleted on the way of production.

[MONITOR ASS’Y(G)]

Step

No.

Part Name

Fig. No.

[1] M.COVER ASS’Y 3(S815), 2(S814)

[2]

MONITOR BOARD ASS’Y

[3] HINGE UNIT ASS’Y (S813)

[4] MONITOR CASE(3) BACK LIGHT,

Point Note

(WR802a),

MONITOR CN7601(WR802b),

MONITOR CN7602(WR802c),

2(SD802a),

(S812), 2(L802a)

LCD BKT(3INCH)2,

LCD MODULE,

LCD BKT(3INCH)1

[VF ASS’Y(G)]

Step

No.

Part Name

Fig. No.

[1] VFBW BOARD ASS’Y FRAME(VF)2

[2] GUIDE(OUTER) ASS’Y 2(S871),

Point Note

VFBW CN7002(WR851a),

2(S875)

(L852a),

COVER(VF) ASS’Y

1-2

Page 7

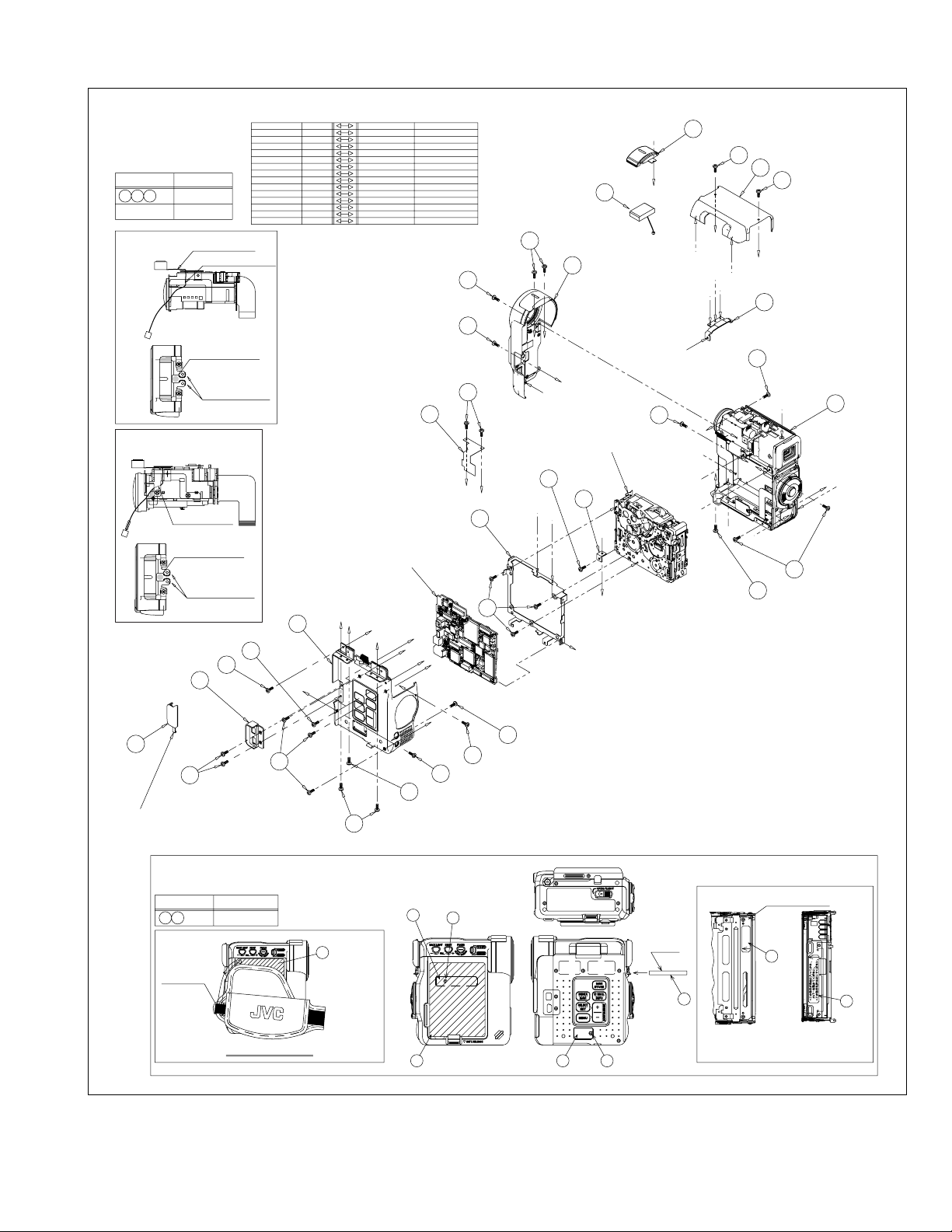

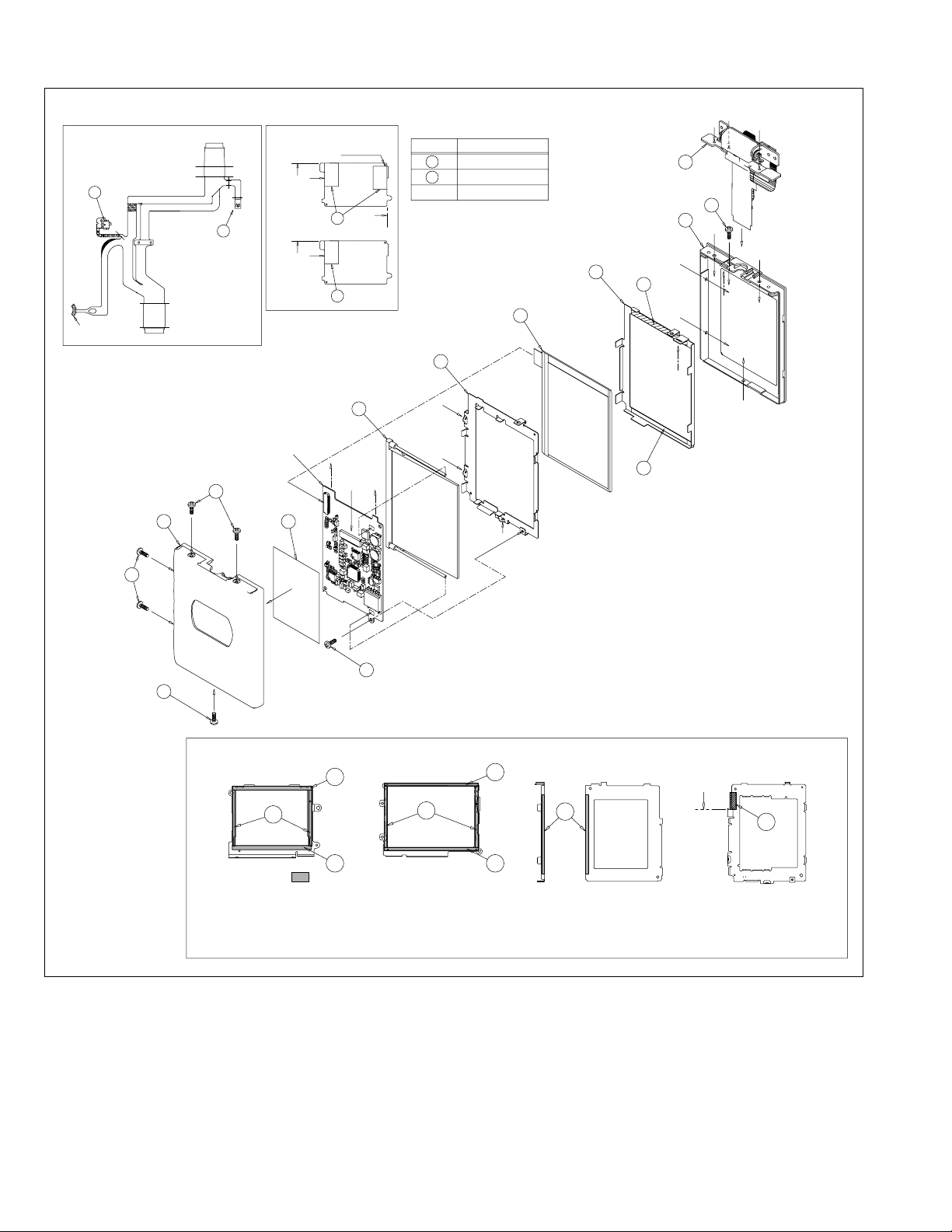

<M2> FINAL ASS'Y

TABLE OF SETTING TORQUE FOR SCREW DRIVER

PART NO.

115 116 117

OTHER SCREW

PROCESSING J7C MIC WIRE.

[J7C: Megapixel CCD MODEL]

PROCESSING K185 MIC WIRE.

[K185: Non Megapixel CCD MODEL]

SETTING TORQUE

0.07 ±0.01 N•m

0.09 ±0.01 N•m

THIS MIC WIRE PASS ON SPACER.

THIS MIC WIRE PASS OUTSIDE BKT(OP).

PROCESSING MIC WIRE TO THIS AREA

WHEN BUILT IN OF FRONT ASS'Y(F).

THIS AREA DON'T BITE ON MIC WIRE.

PASS MIC WIRE INSIDE BKT(OP).

PROCESSING MIC WIRE TO THIS AREA

WHEN BUILT IN OF FRONT ASS'Y(F).

THIS AREA DON'T BITE ON MIC WIRE.

Table.1 WIRE(FPC) CONNECTION TABLE

PWB NAME

MAIN PWB ASS'Y

MAIN PWB ASS'Y

MAIN PWB ASS'Y

MAIN PWB ASS'Y

MAIN PWB ASS'Y

MAIN PWB ASS'Y

MAIN PWB ASS'Y

MAIN PWB ASS'Y

MAIN PWB ASS'Y

MAIN PWB ASS'Y

MAIN PWB ASS'Y

MAIN PWB ASS'Y

MAIN PWB ASS'Y

MAIN PWB ASS'Y

132

COVER(DV)

127

111

HOLDER(DV/USB)

CN No.

CN101

CN102

CN103

CN104

CN106

CN107

CN108

CN109

CN110

CN111

CN112

CN113

CN114

CN115

UPPER ASS'Y(G)

U.CASE ASS'Y(G)

(Refer to the Exploded

view for this part.)

104

U

J

P

ASS'Y NAME

LOWER ASS'Y(F)

LOWER ASS'Y(F)

MECHA(A) ASS'Y

MECHA(A) ASS'Y

MECHA(A) ASS'Y

MECHA(A) ASS'Y

MECHA(A) ASS'Y

LOWER ASS'Y(F)

MECHA(A) ASS'Y

LOWER ASS'Y(F)

UPPER ASS'Y(G)

UPPER ASS'Y(G)

MIC ASS'Y

FRONT ASS'Y(G)

WIRE(FPC)NAME

BATT.TERM.

CCD

LOAD.MOTOR

DRUM MOTOR

SENSOR

R.ENC

CAPSTAN

SD PWB ASS'Y (CN301)

HEAD

CAMERA OPE

SUB OPE

MONI PWB

MIC WIRE

STROBE PWB

134

126

117

109

SHIELD PLATE

A

B1

MECHA BKT ASS'Y

108

<01> MAIN BOARD ASS'Y

115

R

N

V

K

R

L

G

[For Megapixel CCD MODEL]

MIC ASS'Y

135

129

102

FRONT ASS'Y(G)

F.COVER ASS'Y

(Refer to the Exploded

view for this part.)

T

S

Q

P

<M3> MECHANISM ASS'Y

BKT

116

(PRE-REC)

110

A

B2

B1

B2

(L104a)

MIC COVER

106

X1

TOP COVER

130

113

V

128

C

M

133

W

BRACKET(TOP)

114

W

D

LOWER ASS'Y(F)

(Refer to the Exploded

view for this part.)

103

E

H

X2

X1

U

X2

S

T

R

118

Q

J

K

L

118

119

NOTES

- While assembling the SET, don't touch CLEANER ROLLER portion of MECHA ASS'Y.

- PREVENT THE MOTOR FPC FROM ENTERING IN FERNALLY IN THE DRUM UPPER BASE.

- OPEN CASSETTE CAVER AND ASSEMBLE UPPER ASS'Y(G) AND FRONT ASS'Y(G).

112

123

124

HOOK THIS PART BETWEEN COVER(DV) AND FRONT COVER ASS'Y.

TABLE OF SETTING TORQUE FOR SCREW DRIVER

PART NO.

188 189

STRING IS CONNECTED

TO GRIP BELT.

SETTING TORQUE

0.069 ±0.007 N•m

FIG. PROCESSING TAG

H

122

131

COVER(ADJ)

183

191

TAG

A AFTER BERAKING INTO DOUBLE

FOLD PUT IN BETWEEN GRIP BELT

AND DUMMY(BATT.).

M

121

120

125

188

DUMMY BATT.

185

DUMMY BATTERY

COVER(JIG CONN)

Fig. 1-2-2a FINAL ASS’Y

RATING LABEL

184 189

LABEL SIDE

190

MEMORY CARD

FINAL ASS'Y LYH20619

CLEANER ASS'Y LYH20615

CASSETTE HOUSING

PUSH

187

LABEL(PUSH)

186

LABEL(HOUSING)

NOTE THE DIRECTION WHERE LABELS ARE STICKED.

1-3

Page 8

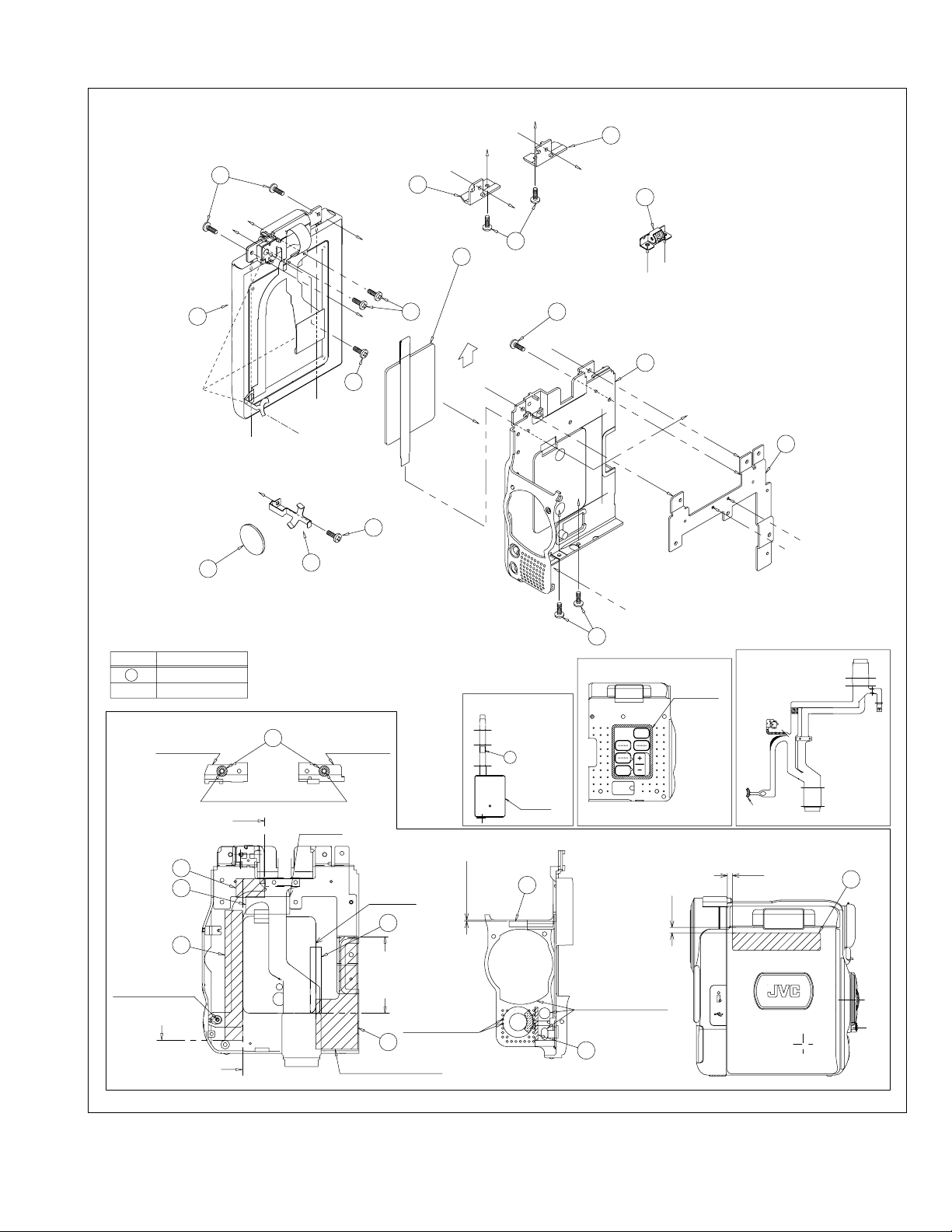

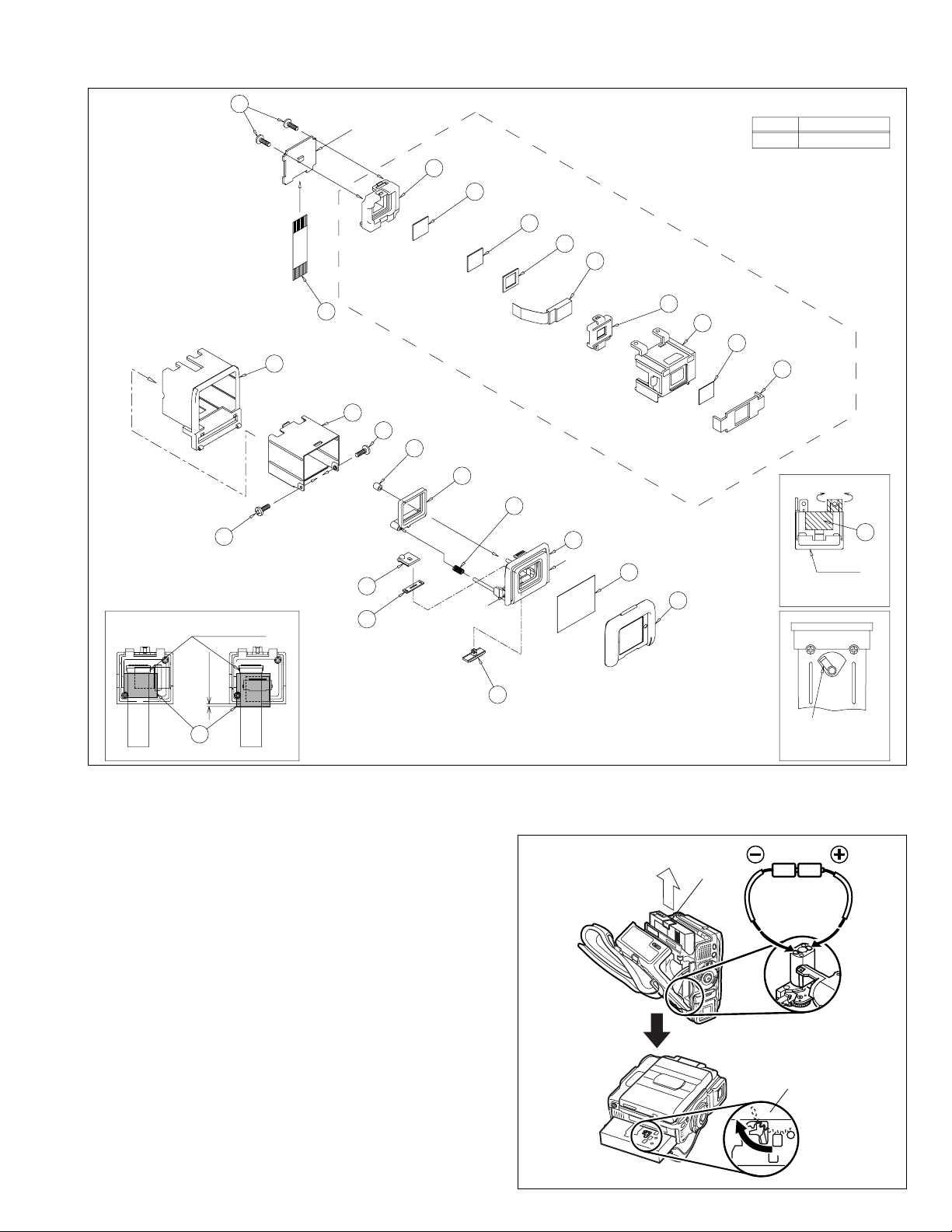

<M2> LOWER ASS'Y(F)

BKT(OP)

555

E

A

558

A

CONNECT

556

E-CARD WIRE

[K185: Non Megapixel CCD MODEL]

(WR551a)

CONCLUSION SCREW TORQUE TABLE

PART.NO

ALL SCREW

TORQUE

0.09 ±0.009 N•m

<M2> LOWER ASS'Y(G)

FPC

508

BATT.TERMINAL

507

A

BKT(OPJ7C)

555

G

OP F. ASS'Y

[K185]

(Refer to the

Exploded view

for this part.)

BENT 180" TO SIDE OF

REIN FOR CEMENT BOARD

OF CCD PWB ASS'Y

(WR551a)

(SD551a)

F

F

CONCLUSION SCREW TORQUE TABLE

PART.NO

514

ANOTHER SCREW

TORQUE

0.07 ±0.009 N•m

0.12 ±0.01 N•m

513

B

513

[J7C: Megapixel CCD MODEL]

558

G

F

<03>

SD BOARD ASS'Y

557

559

(WR553a)

(WR552a)

B

559

OP F. ASS'Y

[J7C]

(Refer to the

Exploded view

for this part.)

(SD551a)

E

D

HOLDER

(G.OUTER)

515

[For Non Megapixel CCD MODEL]

LOWER ASS'Y(G)

(Refer to the Exploded

view for this part.)

552

B

MIC ASS'Y

D

562

560

C

BE CAREFUL NOT TO TOUCH BY THE FINGER, AND BE CAREFUL

NOT TO BEND THE TERMINAL FPC OF CAMERA OPE UNIT.

(USE TWEEZERS OR FINGER STALL)

(COUNTERMEASURE OF MIGRATION)

553

VF ASS'Y(G)

(Refer to the Exploded

view for this part.)

LOWER ASS'Y(F) LYH20622

502

SIDE COVER ASS'Y

E

<04>

SIDE OPE

BOARD ASS'Y

519

KNOB(DSC)

503

PROCESSING E-CARD WIRE (ONLY THE MODEL OF OP ASS'Y OF K185).

[K185: Non Megapixel CCD MODEL]

AFTER ASSEMBLY

BENT 180" PART

OF E-CARD WIRE.

PROCESSING J7C OP ASS'Y.

[J7C: Megapixel CCD MODEL]

BENT

PASTE

567

SHEET(SHIELD)

PROCESSING K185 OP ASS'Y AND MIC WIRE.

[K185: Non Megapixel CCD MODEL]

SPACER(A)

SPACER(A)

563

SPACER(A)

564

PASTE SO THAT SIDE OF

BKT(OP) MAYBE HIDDEN.

PASTE TO CORNER OF OP ASS'Y.

565

SPACER(A)

565

SPACER(A)

DRAWING FOR SPACER STICKING.

LESS THAN 1 mm.

570

PASTE

SPACER

SPACER(A)

561

PASTE SPACER

TO COVER FPC OF OP ASS'Y.

PASTE ALONG THIS LINE.

PASTE SPACER TO COVER

FPC OF OP ASS'Y.

INSID BRACKET PART

OF OP ASS'Y.

PASTE TO

ACCORD.

566

SPACER IS TWISTED AND

WIRE CAN'T BE SEEN.

LESS THAN 1 mm.

PASTE

PASTE SHIELD INSIDE FPC.

DON'T PASS MIC WIRE ON THIS SCREW.

PASS MIC WIRE INSIDE BKT(OP).

DRAWING FOR AFTER ASSEMBLY BKT(OP).

SPACER IS NOT

PROTRUDED FROM

ARM BRACKET.

SHIELD(CCD)

568

561

SPACER(A)

BENT

LOWER ASS'Y(G) LYH20620

PROCESSING GRIP BELT.

514

521

522

ARM ASS'Y

504

SOLDERING

D

BKT(S.COVER/VF)

510

E

A

D

B

515

C

BE CAREFUL NOT TO TOUCH BY THE FINGER, AND BE CAREFUL

NOT TO BEND THE TERMINAL FPC OF CAMERA OPE UNIT.

(USE TWEEZERS OR FINGER STALL)

(COUNTERMEASURE OF MIGRATION)

Fig. 1-2-2b LOWER ASS’Y(F), LOWER ASSY(G)

C

512

(WR553a)

515

505

CASS.COVER ASS'Y

506

CAMERA OPE UNIT

E-CARD WIRE

509

PROCESSING BATT. FPC

SHEET(BAT.FPC)

SHOULD BE COVERED

TERMINAL PART.

516

SHOULD NOT BE

COVERED SCREW HOLE.

520

SPACER(A)

DRAWING FOR SPACER STICKING.

PASTE SPACER AFTER ATTACHING BATT. TERMINAL.

STICK ALONG

SPACER(A) SPACER(A)

THE EDGE OF ARM.

518

STICK ALONG

THE EDGE

OF ARM.

DON'T STICK OUT

BATT. FPC IN

ARM BRACKET.

GRIP BELT

511

PROCESSING CAP(GRIP BELT).

PROCESSING STICKER.

518

STICK ALONG

THE EDGE

OF ARM.

ATTACHING

CAP(GRIP BELT)

523

ATTACH

CAP(GRIP BELT)

THAT WIDTH IS WIDER

BECOME REAR SIDE.

LABEL(C.COVER)

517

1 ±1 mm

2 ±1 mm

1-4

Page 9

611

601

610

602

609

603

604

612

606

605

611

607

613

616

617

622

620

618

623

621

624

625

619

626

615

608

614

<M2> UPPER ASS'Y(G)

0.2 ±0.01 N•m

0.08 ±0.01 N•m

PART.NO

UPPER ASS'Y(G) LYH20626

3 ±1 mm

3 ±1 mm

E

F

D2

D1

C2

C1

D1

C1

E

F

J

H

A

B

D2

C2

A

B

J

H

G

G

MONITOR ASS'Y(G)

COVER(TOP/UPP)R

COVER(TOP/UPP)L

SUB OPE UNIT

MONI.LOCK ASS'Y

U.CASE ASS'Y

SPEAKER

FRAME(UPPER) ASS'Y

BRACKET(SPEAKER) *

SCREW *

COVER(TOP/UPP)R COVER(TOP/UPP)L

SPACER(A)

SPACER(A)

SPACER(A)

SPACER(A)

SPACER(A)

SPACER(A)

SPACER(A)

SHEET(SHIELD)

STICKER

(WR601a)

ANOTHER SCREW

TORQUE

CONCLUSION SCREW TORQUE TABLE

PASTE

UPWARDS

SHEET STICK ALONG

THE REINFORCEMENT

BOARD OF FPC.

SHEET STICK ALONG

THE CORNER OF FRAME.

DON'T SEPARATE.

DRAWING FOR SPACER STICKING.

LESS THAN 0.5mm

DON'T STICK OUT SPACER

IN UPPER CASE.

PASTE SPACER THIS CONVEX

IN UNDER SIDE.

PASTE SPACER

INSIDE BKT(UPPER).

STICK FPC SO THAT THERE

MAY BE NO CREVICE BET MEEN

THE HOLE OF IT IN THE RIGHT

SIDE OF THE HOLE RING.

THE SIDE OF THE

HOLE RING IS MET.

DON'T RUN A GROUND

OF UPPER CASE.

SHOULD BE COVERED

THIS CONVEX.

DON'T BE SEEN SPACER OUTSIDE

OF UPPER CASE.

STICK SPACER THAT FPC

MAY BE PRESSED DOWN.

PASTE SPACERS NOT TO COVER THESE HOLES.

THESE HOLES CAN BE SSEN.

PROCESSING MONITOR FPC.

SOLDER

2 POINT

SOLDERING

2 POINT

MOUNTAIN FOLDING

VALLEY FOLDING

MOUNTAIN FOLDING

VALLEY FOLDING

PROCESSING SUB OPE.

AFTER PASTING SUB OPE

PUSH TO THIS SLASH PART.

DON'T RUN A GROUND TO A LEVEL DIFFERENCE OF UPPER CASE.

PROCESSING SUB OPE FPC.

MOUNTAIN FOLDING

VALLEY FOLDING

VALLEY FOLDING

DON'T STICK OUT

SPACER IN

SUB OPE FPC.

STICK TO U.CASE.

(Refer to the Exploded

view for this part.)

Mark*: This part was deleted on the way of production.

Fig. 1-2-2c UPPER ASS’Y(G)

1-5

Page 10

<M2> MONITOR ASS'Y(G)

PROCESSING MONITOR FPC.

VALLEY FOLDING

DETECT SWITCH

SOLDER

808

4 POINT

SOLDER

2 POINT

MOUNTAIN FOLDING

VALLEY FOLDING

MOUNTAIN FOLDING

(WR802b)

IC

809

SOLDER

3 POINT

PUTTING OF SPACER(A).

MONITOR P. ASS'Y

THE END OF PWB IS

NOT OVER FLOWED.

(WR802a)

MONITOR P. ASS'Y

THE END OF PWB IS

NOT OVER FLOWED.

(2.5 INCH)

SPACER(A)

(3.0 INCH)

SPACER(A)

THIS HOLE IS NOT

PLUGGED UP.

819

THE END OF PWB IS

NOT OVER FLOWED.

819

CONCLUSION SCREW TORQUE TABLE

PART NO.

814

815

OTHER SCREW

LCD BKT(2.5)2

LCD BKT(3INCH)2

806

SETTING TORQUE

0.2 ±0.02 N•m

0.055 ±0.01 N•m

0.07 ±0.01 N•m

LCD MODULE

(WR802c)

LCD BKT(2.5)1

LCD BKT(3INCH)1

810

805

HINGE UNIT ASS'Y

807

MONITOR CASE(25)

MONITOR CASE(3)

SPACER(A)

816

802

C1

PASTE

D1

X

813

F

A2

B2

A1

a

B1

A2

F

C2

Z

B2

D2

E2

815

811

BACK LIGHT

<06> MONITOR BOARD ASS'Y

Z

(L802a)

814

a

I.SHEET(M.COVER)M.COVER ASS'Y

803

804

A1

C1

D1

815

B1

PASTE

E1

LCD MODULE S.A.

1. PUTTING OF SPACER(A)

LCD BKT(2.5INCH)2 LCD BKT(3INCH)2

SPACER(A)

818

SPACER(A)

817

SPACER(A)

818

RANGE OF PUTTING

MASKING AREA IN ENGRAVE LINE CETAINLY.

DON'T STICK OUT SPACER(A) IN LCD DISPLAY FACE.

2. PUTTING OF LCD MODULE (2.5 & 3.0 INCH)

- PEEL OFF PROTECTION SHEET OF SPACER(A) ON LCD BKT2.

- CONFORM THAT LCD MODULE IS SUITABLE FOR POSITION OF

LCD BKT2 AND PUT TWO PARTS.

(L802a)

812

X

(SD802a)

(SD802a)

SPACER(A)

817

C2

D2

816

SPACER(A)

PASTE

E1

E2

NOTES

- SHOULD BE NO SCRATCHES, NO DUSTS AND OTHER ON COSMETIC COMPONENTS.

- SHOULD BE NO FLOATAGE, MISSING PARTS OF THE SCREW.

- BE GODS ALL-IN WHEN M.COVER ASS'Y IS BUILT IN OF FPC AND WIRE, ETC.

- SHOULD BE PASTE SYMBOL"804" OF THE REVERSE SIDE OF M.COVER.

MONITOR ASS'Y(G) LYH20625

SPACER(A)

818

818

SPACER(A)

LCD BKT(2.5INCH)2

& LCD BKT(3INCH)2 LCD BKT(2.5INCH)2

SPACER(A)

STICK ACCORDING

TO THE END OF

THIS LCD BKT2

820

TURN UP

821

SPACER(A)

TURN UP

1-6

Fig. 1-2-2d MONITOR ASS’Y(G)

Page 11

<M2> VF ASS'Y(G)

PROCESSING SPACER(A)

875

GUIDE SCREW

871

DON'T RUN A GROUND ON

THIS CONNECTOR.

E-CARD WIRE

GUIDE(OUTER)

861

GUIDE(OUTER) ASS'Y

A

872

860

B

V.ADJ.PLATE

S.PLATE

VFBW BOARD ASS'Y

VFCL BOARD ASS'Y

CASE(VF) ASS'Y

GUIDE SCREW

871

870

865

866

B.LIGHT CASE

B.LIGHT CASE

BLOW OUT AIR.

852

STP RING

BLOW OUT AIR.

SHEET(DIFF)

853

(WR851a)

LENS HOLDER ASS'Y

868

869

(L852a)

A

SHEET(POLA)

CUSHION(LCD)

CUSHION(LCD)3

854

BLOW OUT AIR.

857

COMPRES.SPRING

862

B

LCD MODULE

BLOW OUT AIR.

PASTE TAPE TO LCD RESPECT,

856

AND PEEL OFF TAPE.

S.GUIDE ASS'Y

SHEET(LENS)

864

LCD HOLDER

LCD HOLDER2

BLOW OUT AIR.

855

EYE CUP

863

FRAME(VF)

FRAME(VF)2

BLOW OUT AIR.

858

CONCLUSION SCREW TORQUE TABLE

PART.NO

ALL SCREW

SHEET(POLA)

PASTE INSIDE THAT EXFOLIATION

854

PAPER'S COLOR IS TRANSPARENT.

TORQUE

0.09 ±0.009 N•m

859

SHEET HOLD

BLOW OUT AIR.

TURN TURN

FRAME(VF)2

DRAWING FOR EARTH SHEET STICKING.

EARTH SHEET

876

PASTE

LESS THAN 1mm.

874

B/W VF COLOR VF

SPACER(A)

V.ADJ.KNOB

Fig. 1-2-2f STROBE BOARD ASS’Y

1.3 Manually removing the cassette tape

The following procedure describes a simplified method of ejecting the cassette tape in case it is not possible to eject it, due

to an electrical failure.

Be careful not to damage any of the parts or the tape when

performing repairs or maintenance work.

(1) Remove the Power Unit (battery, DC code, etc.) from the

main unit.

(2) Open the Cassette cover.

(3) Attach a piece of PVC tape at the front of the Cassette hous-

ing.

This helps prevent the tape from being damaged when the

Cassette housing assembly is moved upward at the unload-

ing end.

(4) Apply DC3V to the electrode on the top surface of the Load-

ing motor assembly to set the Mechanism assembly to the

eject mode.

Unloading end is eject mode.

(5) If there is any slack tape in the tape transport system, wind

it inside the cassette tape by turning the Reel disk (SUP)

from the backside of the Slide deck assembly.

(6) Peel off the PVC tape and take out the cassette tape from

the Cassette housing.

Make sure that grease or a similar substance is not attached

to the surface of the tape.

Similarly, also make sure that grease or a similar substance

is not attached on the Mechanism assembly.

867

VF ASS'Y(G) LYH20621

PVC TAPE

REEL DISK

ASSY (SUP)

Fig. 1-3a

SHUOLD BE MATCHED KNOB

TO FULL LEFT SIDE.

(REFER TO THE CHART)

DIOPTER ADJUSTMENT CONTROL

(DC3V)

1-7

Page 12

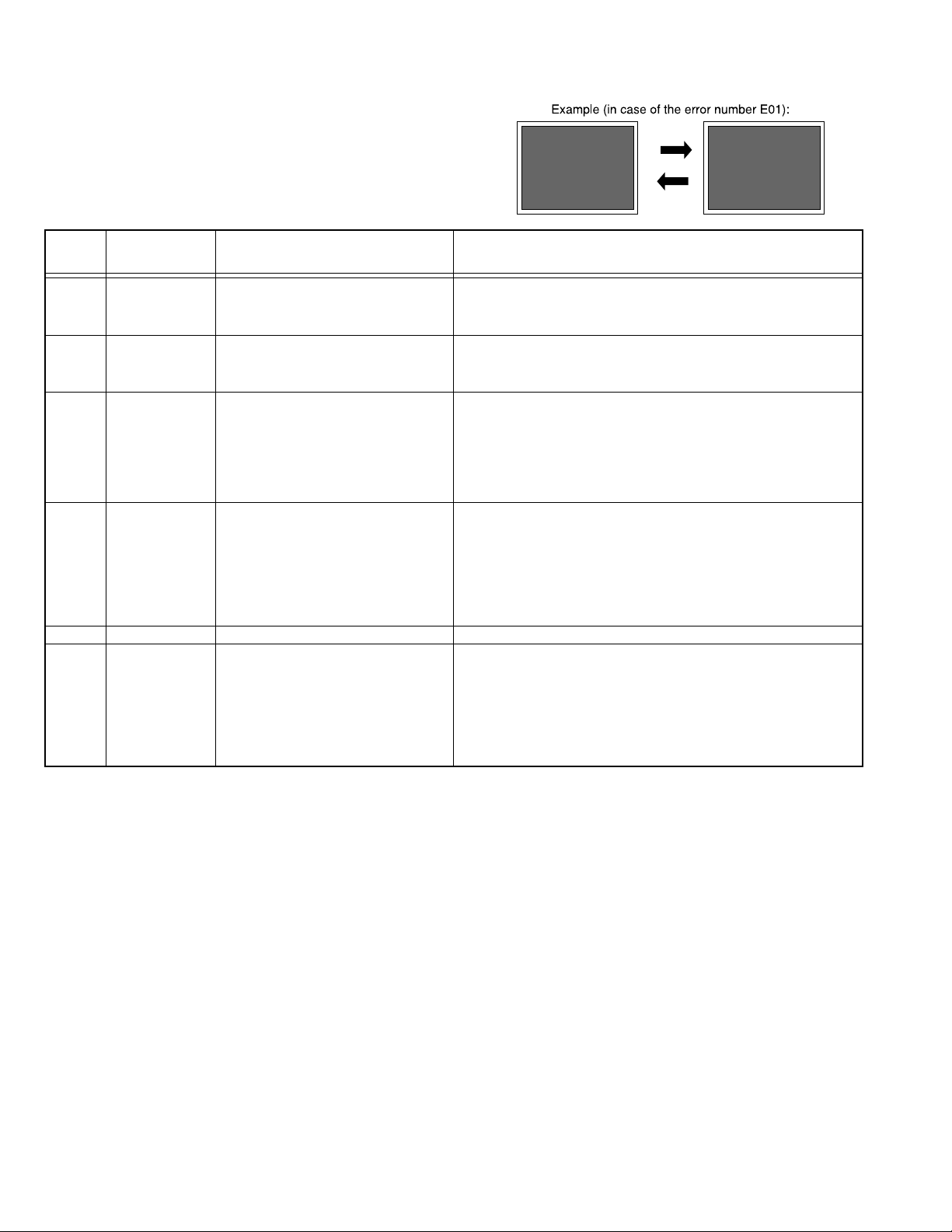

1.4EMERGENCY DISPLAY

Whenever some abnormal signal is input to the syscon CPU,

an error number (E01, as an example) is displayed on the LCD

monitor or (in the Electronic view finder).

In every error status, such the message as shown below alternately appear over and over.

In an emergency mode, all operations except turning on/off the

Power switch are ineffectual.

E01

UNIT IN

SAFEGUARD MODE

E01

REMOVE AND

REATTACH BATTERY

LCD

display

E01 LOADING In the case the encoder position is not shifted to

E02 UNLOADING In the case the encoder position is not shifted to

E03 TU & SUP REEL FG In the case no REEL FG is produced for 4 sec-

E04 DRUM FG In the case there is no DRUM FG input in the

E05 — — —

E06 CAPSTAN FG In the case no CAPSTAN FG is produced in the

Emergency

mode

Details Possible cause

the next point though the loading motor has rotated in the loading direction for 4 seconds or

more. This error is defined as [E01].

the next point though the loading motor has rotated in the unloading direction for 4 seconds or

more. This error is defined as [E02].

onds or more in the capstan rotation mode after

loading was complete, the mechanism mode is

shifted to STOP with the pinch roller set off. This

error is defined as [E03].

However, no REEL EMG is detected in the SLW/

STILL mode.

drum rotation mode for 4 seconds or more.

This error is defined as [E04], and the mechanism mode is shifted to STOP with the pinch roller

set off.

capstan rotation mode for 2 seconds or more.

This error is defined as [E06], and the mechanism mode is shifted to STOP with the pinch roller

set off.

However, no CAPSTAN EMG is detected in the

STILL/FF/ REW mode.

1. The mechanism is locked during mode shift.

2. The mechanism is locked at the mechanism loading end, because the encoder

position is skipped during mechanism mode shift.

3. No power is supplied to the loading MDA.

1. The mechanism is locked during mode shift.

2. The mechanism is locked at the mechanism loading end, because the encoder

position is skipped during mechanism mode shift.

1. The idler gear does not engage with the reel disk well.

2. Though the idler gear and reel disk are engaged with each other, the tape is not

wound because of overload to the mechanism.

3. No FG pulse is output from the reel sensor.

4. No power is supplied to the reel sensor.

5. Tape transport operation takes place with a cassette having no tape inside.

6. The tape slackens and no pulse is produced until the slack is taken up and the

tape comes into the normal status.

1. The drum cannot be started or drum rotation is stopped because tape transport

load is too high.

1) Tape tension is extremely high.

2) The tape is damaged or soiled with grease, etc.

2. The DRUM FG signal is not received by the syscon CPU.

1) Disconnection in the middle of the signal line.

2) Failure of the DRUM FG pulse generator (hall element).

3. No drum control voltage is supplied to the MDA.

4. No power is supplied to the DRUM MDA.

1. The CAPSTAN FG signal is not received by the syscon CPU.

1) Disconnection in the middle of the signal line.

2) Failure of the CAPSTAN FG pulse generator (MR element).

2. No capstan control voltage is supplied to the MDA.

3. No power is supplied to the CAPSTAN MDA.

4. The capstan cannot be started or capstan rotation is stopped because tape

transport load is too high.

1) Tape tension is extremely high. (Mechanical locking)

2) The tape is damaged or soiled with grease, etc. (Tape tangling occurs, etc.)

Fig. 1-4a

1-8

Page 13

SECTION 3

ADJUSTMENT

3.1 Before adjustment

3.1.1 Precaution

This model does not contain adjustment controls (VR).

General deck system, camera system and monitor system adjustment are not required. However, if circuit board mounting

the EEPROM needs replacement, please use original EEPROM

on to new board. Then adjustment are not required. And if parts

such as the following need replacement, special computerized

adjustment are required. Electrical adjustment with personal

computer is setup and it adjusts using a service support system. Please contact to JVC Service for detail information.

• OP BLOCK ASSEMBLY

•

EEPROM (IC1003 of MAIN board) [Megapixel CCD MODEL]

•

EEPROM (IC1005 of MAIN board) [Non Megapixel CCD MODEL]

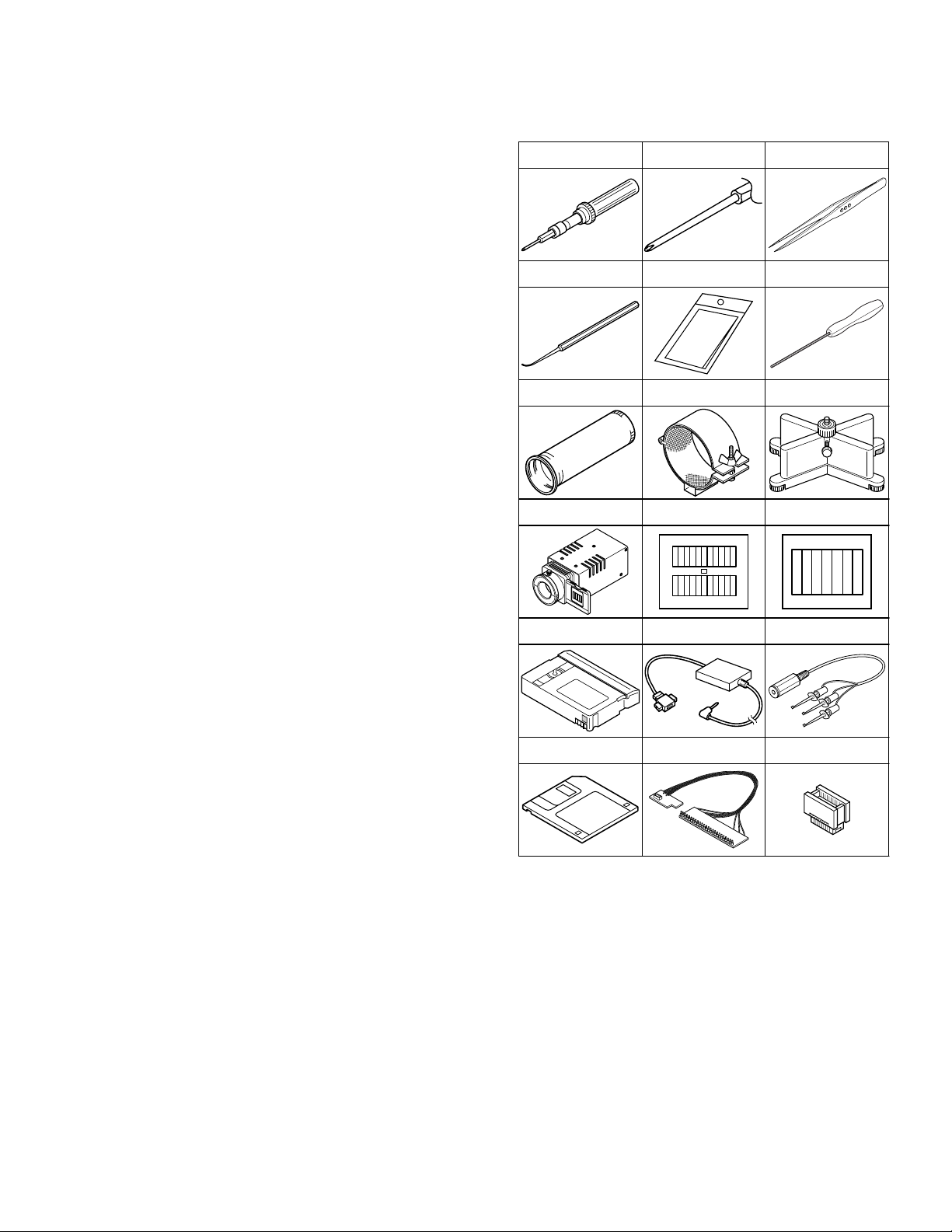

3.1.3 Required adjustment tools

Torque driver

YTU94088

Chip IC replacement jig

PTS40844-2

Bit

YTU94088-003

Cleaning cloth

KSMM-01

Tweezers

P-895

Guide driver (Hexagonal)

D-770-1.27

In the event of malfunction with electrical circuits, troubleshooting with the aid of proper test instruments most be done first,

and then commence necessary repair, replacement and adjustment, etc.

• In case of wiring to chip test points for measurement, use IC

clips, etc. to avoid any stress.

• Since connectors are fragile, carefully handle them in discon-

necting and connecting.

• In the following work, use the patch cords as required. For

details of the patch cords, see the "BOARD INTERCONNECTIONS" (CHARTS AND DIAGRAMS).

3.1.2 Required test equipments

• AC power adapter

• Color television or monitor

• Oscilloscope

(dual-trace type, observable 100 MHz or higher frequency)

It is recommended to use one observable 300 MHz or higher

frequency.

• Digital voltmeter

• Frequency counter (with threshold level adjuster)

• Personal computer

INF adjustment lens

YTU92001B

Light box assembly

YTU93096A

Alignment tape

MC-*

Service support system

YTU94057-**

INF lens holder

YTU94087

Gray scale chart

YTU94133A

PC cable

QAM0099-***

Jig connector cable

YTU93106B

Camera stand

YTU93079

Color bar chart

YTU94133C

Communication cable

YTU93107A

Extension connector

YTU94145C-30

Table 3-1-3a

3-1

Page 14

• Torque driver

Be sure to use to fastening the mechanism and exterior parts

because those parts must strictly be controlled for tightening

torque.

• Bit

This bit is slightly longer than those set in conventional torque

drivers.

• Tweezers

To be used for removing and installing parts and wires.

• Chip IC replacement jig

To be used for replacement of IC.

• Cleaning cloth

Recommended the Cleaning cloth to wipe down the video

heads, mechanism (tape transport system), optical lens surface.

• Guide driver (Hexagonal)

To be used for mechanism compatibility adjustment.

• INF adjustment lens

To be used for adjustment of the camera system.

For the usage of this tool, refer to the Service Bulletin No. YASB-10035.

• INF lens holder

To be used together with the Camera stand for operating the

Videocamera in the stripped-down condition such as the status without the exterior parts or for using commodities that

are not yet conformable to the interchangeable ring.

For the usage of this tool, refer to the Service Bulletin No. YASB-10035.

• Camera stand

To be used together with the INF adjustment lens holder.

For the usage of this tool, refer to the Service Bulletin No. YASB-10035.

• Light box assembly

To be used for adjustment of the camera system.

For the usage of this tool, refer to the Service Bulletin No. YASB-10035.

• Gray scale chart

To be used for adjustment of the camera system.

For the usage of this tool, refer to the Service Bulletin No. YASB-10035.

• Color bar chart

To be used for adjustment of the camera system.

For the usage of this tool, refer to the Service Bulletin No. YASB-10035.

• Alignment tape

To be used for mechanism compatibility adjustment.

MC-1 [For NTSC model]

MC-2 [For PAL model]

• PC cable

To be used to connect the Videocamera and a personal computer with each other when a personal computer is used for

adjustment.

QAM0099-001 [For J* model]

QAM0099-002 [For U* and K* models]

QAM0099-003 [For E* models]

QAM0099-005 [For A* models]

• Communication cable

Connect the Communication cable between the PC cable and

Jig connector cable when performing a PC adjustment.

• Service support system

To be used for adjustment with a personal computer. Software can be downloaded also from JS-net.

• Jig connector cable

Connected to CN for Jig of the circuit board and used for electrical adjustment, etc.

• Extension connector

Connect this extension connector to the connector of the Jig

connector cable for extending the cable connector.

3-2

Page 15

3.1.4 Jig connector cable connection

ENV_OUT

HID1

Flatten the waveform.

Misalignment of guide roller

height on the take-up side

Misalignment of guide

roller height on the

supply side

3.1.4.1 Preparation

The Jig connector cable (YTU93106B) has been provided for

GR-DV2000 series. And it has been connected only 9 terminals for low cost, although it has 30 terminals.

Now it can be used another series camcorder, but all the

terminals have to be connected by soldering wires. Refer to

the Service Bulletin (No. YA-SB-10082), and connect all the

terminals.

3.1.4.2 Connection

GUIDE ROLLER (SUP)

GUIDE ROLLER (TU)

CJIG_RST

AL_3VSYS

B

CJIG_RST

AL_3VSYS

A

REG_3V

SRV_RX

MAIN CN105

JIG CONN.

NCNCNC

NCNCNC

DRST

SRV_TX

TXD2

CVF_B

CVF_R

VPL

VCK

SPA

RXD2

GND

GND

GND

PB_CLK

JLIP_TX

PB_CLK

JLIP_TX

PB_CLK

JLIP_TX

HID1

HID1

HID1

GND

GND

GND

ATFI

ATFI

GND

V_OUT

GND

V_OUT

GND

V_OUT

VIDL

VIDL

VIDL

CVF_G

MON_G

VIDH

MON_G

CVF_G

MON_G

MON_B

JLIP_RX

MONI_CHG

MON_B

JLIP_RX

MONI_CHG

MON_B

JLIP_RX

MONI_CHG

A : Mega pixel with DSC model

B : Non Mega pixel with DSC model

ATFI

ENV_OUT

ENV_OUT

ENV_OUT

I_MTR

DISCRI

MAIN_VCO

I_MTR

DISCRI

MAIN_VCO

DISCRI

AL_3VSYS

MAIN_VCO

IF_TX

EXMOD_1

IF_TX

EXMOD_1

VPPC

VPPD

FS_PLL

MMOD_1

MMOD_0

FS_PLL

MMOD_1

MMOD_0

IF_TX

FS_PLL

CJING_RST

C

C : Non Mega pixel without DSC model

Fig. 3-1-4-2b Schematic diagram of Jig CN

3.2 Mechanism compatibility adjustment

3.2.1 Tape pattern check

(1) Play back the tape for compatibility adjustment.

(2) Apply the external trigger signal to HID1, to observe the

waveform of the ENV_OUT.

(3) Set to the manual tracking mode (ATF OFF).

(4) Make sure that there is no significant level drop of the

waveform caused by the tracking operation, with its gen-

erally parallel and linear variation ensured. Perform the fol-

lowing adjustments when required.

(5) Reduce the waveform by the tracking operation. If a drop

in level is found on the left side, turn the guide roller (sup-

ply side) to make the waveform linear.

If a drop in level is on the right side, likewise turn the guide

roller (take-up side) to make it linear.

(6) Unload the cassette tape once, play back the tape again

and confirm that the waveform is flat.

(7) Record at the recording tape, and play back the recorded

signal.

(8) Confirm that the waveform is flat.

TO JIG CONNECTOR

JIG

CONNECTOR

CABLE

COMMUNICATION

CABLE

RED

WHITE

BLACK

COMMUNICATION

CABLE

JIG CONNECTOR

TO JLIP_RX

TO JLIP_TX

TO GND

Fig. 3-1-4-2a Cable connection

JIG CONNECTOR

SERVICE SUPPORT SYSTEM

PC CABLE

TO COMMUNICATION

CABLE

RS232C

COM PORT

TO ENV_OUT

MENU

Fig. 3-2-1a

PERSONAL COMPUTER

OSCILLOSCOPEJIG CONNECTOR

TO HID1

Fig. 3-2-1b

3.3 Electrical adjustment

Adjustment is performed by using personal computer. Read

README.TXT file to use the software for Service support system properly.

As for the connection of cables, see Fig. Cable connection.

3-3

Page 16

4-2

S40889-01

CIRCUIT BOARD NOTES

1. Foil and Component sides

1) Foil side (B side) :

Parts on the foil side seen from foil face (pattern face)

are indicated.

2) Component side (A side) :

Parts on the component side seen from component face

(parts face) indicated.

2. Parts location guides

Parts location are indicated by guide scale on the circuit board.

Note: For general information in service manual, please

refer to the Service Manual of GENERAL INFORMATION Edition 4 No. 82054D (January 1994).

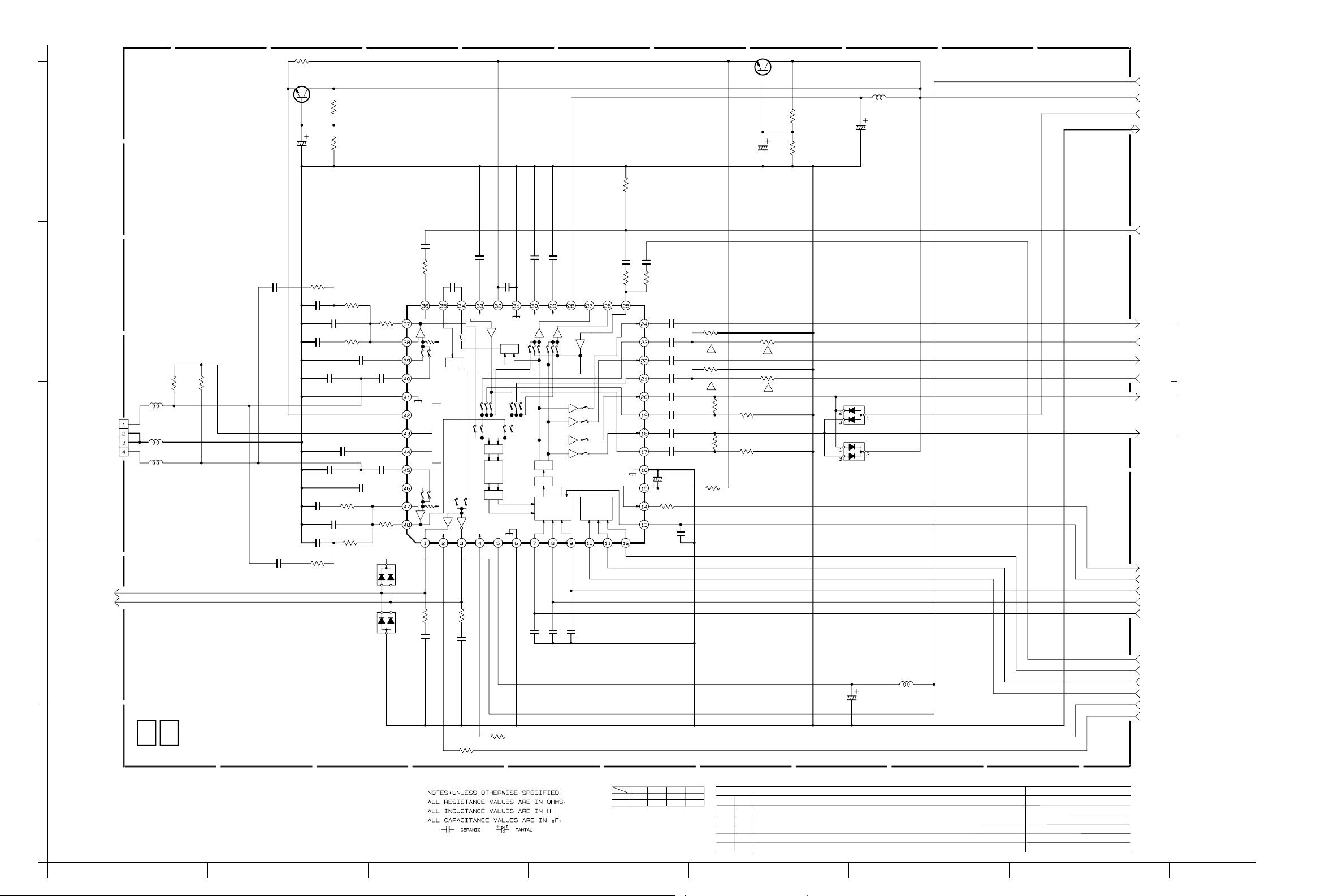

NOTES OF SCHEMATIC DIAGRAM

Safety precautions

The Components identified by the symbol are

critical for safety. For contin ued saf ety, replace safety

critical components only with manufacturer's recommended parts.

1. Units of components on the schematic diagram

Unless otherwise specified.

1) All resistance values are in ohm. 1/6 W, 1/8 W (refer to

parts list).

Chip resistors are 1/16 W.

K: KØ (1000Ø), M: MØ (1000KØ)

2) All capacitance values are in µF, (P: PF).

3) All inductance values are in µH, (m: mH).

4) All diodes are 1SS133, MA165 or 1N4148M (refer to parts

list).

Note: The Parts Number, value and rated voltage etc. in

the Schematic Diagram are for references only.

When replacing the parts, refer to the Parts List.

2. Indications of control voltage

AUX : Active at high.

AUX or AUX(L) : Active at low.

CHARTS AND DIAGRAMS

SECTION 4

4. Voltage measurement

1) Regulator (DC/DC CONV) circuits

REC : Colour bar signal.

PB : Alignment tape (Colour bar).

— : Unmeasurable or unnecessary to measure.

4) Indication on schematic diagram

Voltage Indications for REC and PB mode on the schematic diagram are as shown below.

REC mode

Note: If the voltages are not indicated on the schematic

5. Signal path Symbols

The arrows indicate the signal path as follows.

NOTE : The arrow is DVC unique object.

123

2.5

(5.0)

PB mode

1.8

PB and REC modes

(Voltage of PB and REC modes

are the same)

diagram, refer to the voltage charts.

Playback signal path

Playback and recording signal path

(A : Component side)

D : Discrete component)

B : Foil side

C : Chip component

REF No.

IC101 B C 6 A

LOCATION

IC

Category : IC

Horizontal “A” zone

Vertical “6” zone

3. Interpreting Connector indications

1

2

Removable connector

3

1

2

Wire soldered directly on board

3

1

Non-removable Board connector

2

3

1

2

4

Board to Board

3

Connected pattern on board

The arrows indicate signal path

Note: For the destination of each signal and further line

connections that are cut off from the diagram,

refer to "BOARD INTERCONNECTIONS"

Recording signal path

(including E-E signal path)

Capstan servo path

Drum servo path

(Example)

R-Y

Playback R-Y signal path

Y

Recording Y signal path

6. Indication of the parts for adjustments

The parts for the adjustments are surrounded with the circle as

shown below.

7. Indication of the parts not mounted on the circuit board

“OPEN” is indicated by the parts not mounted on the circuit

board.

R216

OPEN

4-1

Page 17

NOTE ) :

5

4

3

2

1

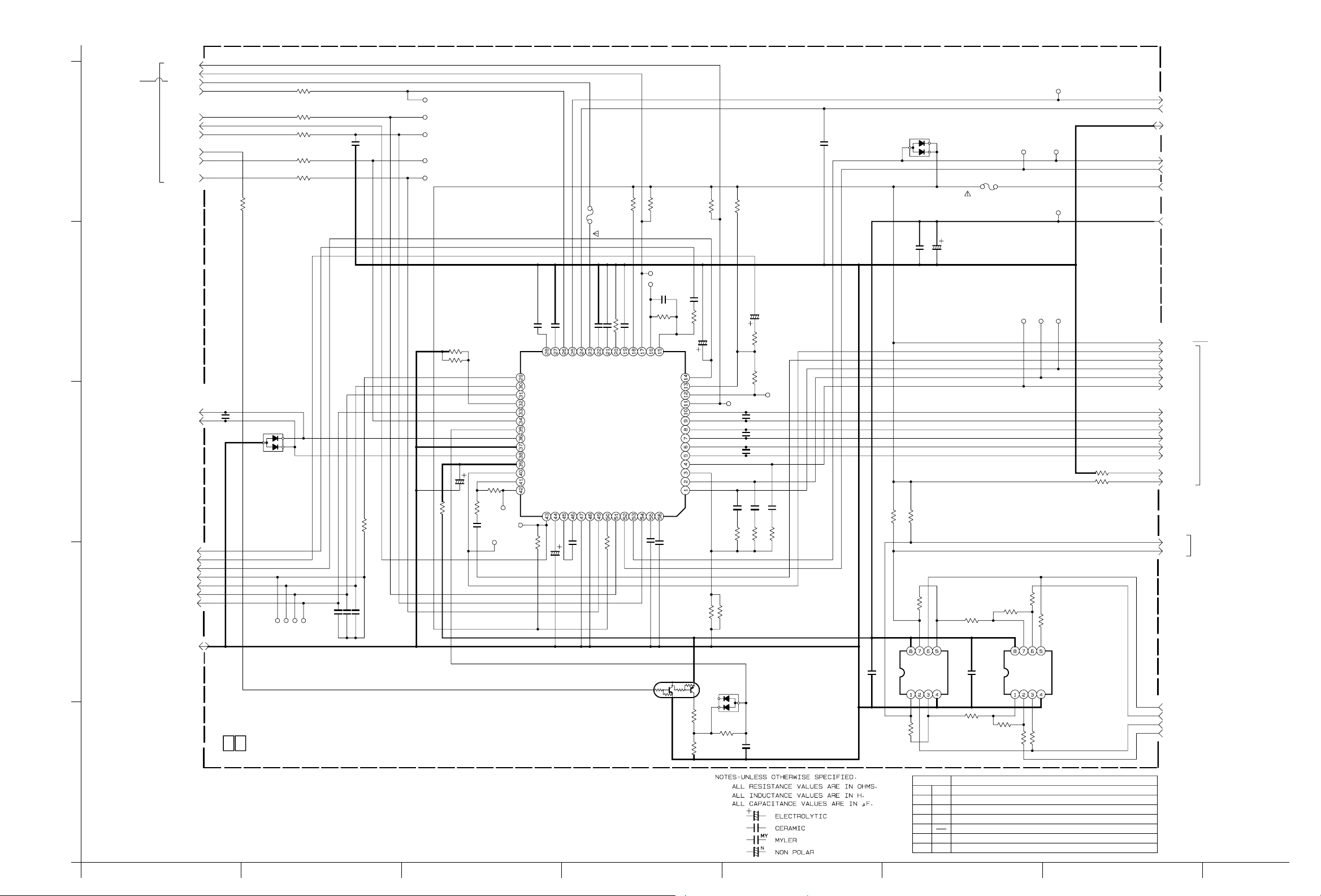

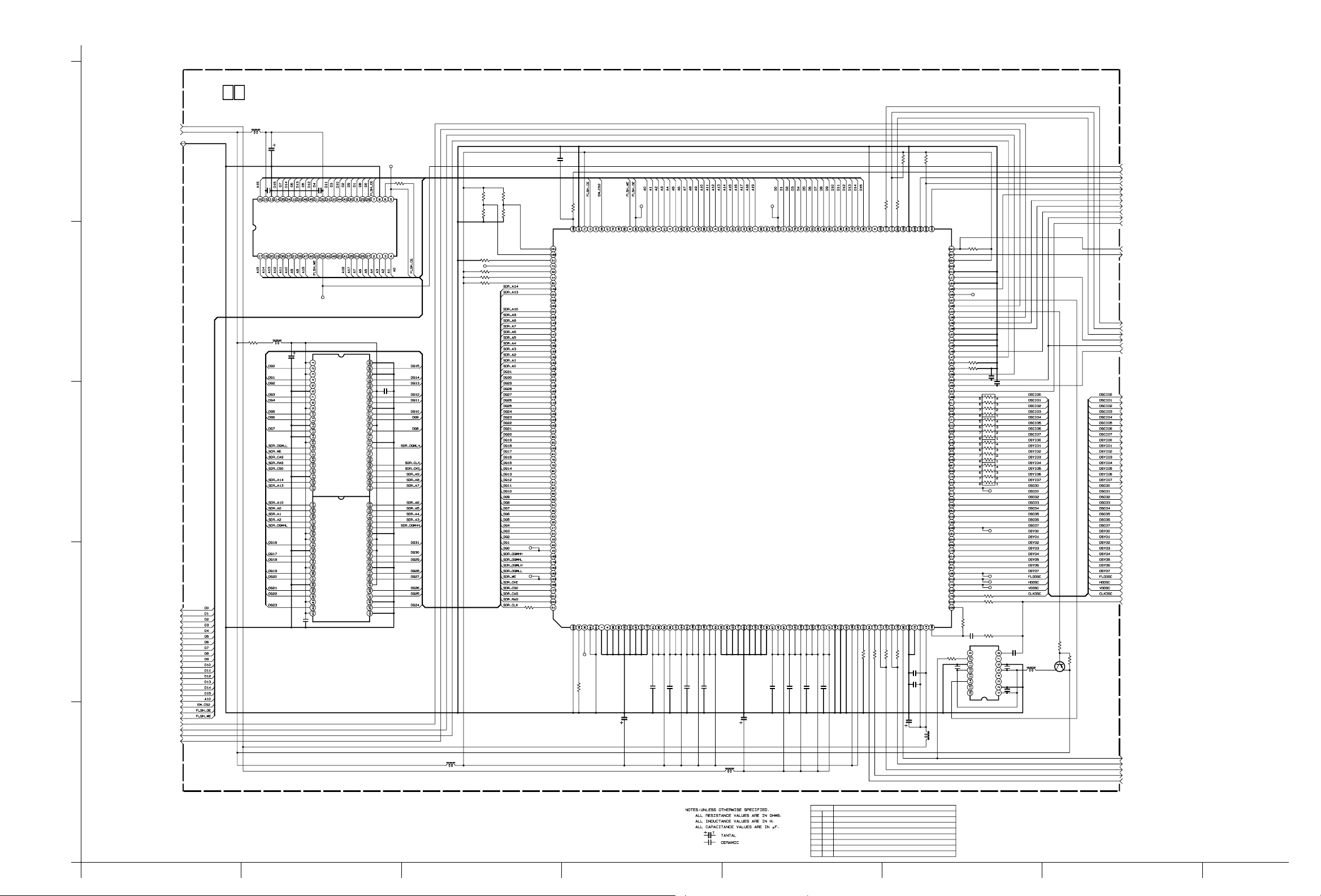

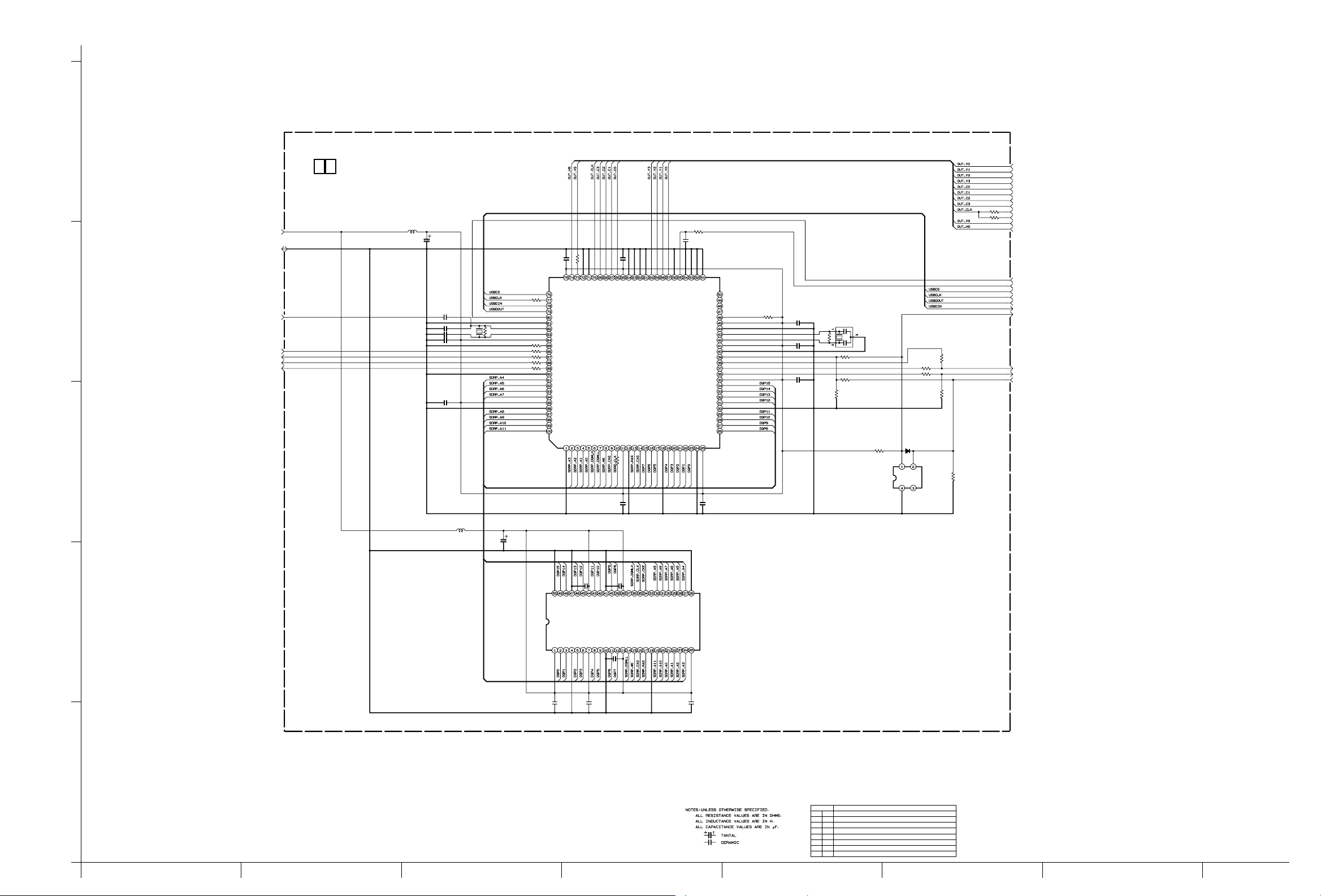

4.1 BOARD INTERCONNECTIONS [FOR MEGA PIXEL with DSC MODEL]

The number of patch cords are

∗

indicated by interconnected.

YTU94074-18

∗

YTU94077-18

CN7001

THH

PDR

VIDH

VCK

VPL

HODL

HLTOR

VF_COM

VF_VEE2V

VF_VDD9V

GND

VREF

HPL

HCK

RENEN

RENON

VIDL

TCL

THL

TV

LCD(VF BW)PANEL

CN7002

VF_COM

CVF_G

CVF_R

CVF_B

GND

HCK1

HCK2

HST

VDD

VDD

EN

STB

VCK2

VST

GND

VDD(12V)

CN7002

LCD(CVF)PANEL

INT MIC

VF_COM

VF_VEE2V

VF_VDD9V

(Page 4-70)

VF BW

VFREG4.8

08

OR

CN7001

VF_COM

VF_VEE2V

CVF

VF_VDD9V

08

VFREG4.8

VIDH

HODL

HLTOR

VREF

RENEN

RENON

CVF_G

CVF_R

CVF_B

HODL

HLTOR

VREF

RENEN

RENON

PDR

VCK

VPL

HPL

HCK

VIDL

GND

GND

CN304

PDR

HPL

HCK

VIDL

GND

GND

CN301

H_GAIN

F_PTR_AD

CN109

CN114

MIC/L

MIC_GND

MIC_GND

MIC/R

STO_E

STO_C

REG_4.8V

STO_OFF

GATE

CHG_ON

DTRB_AD

GND

(Page 4-73)

GND

GND

M_REG4.8

M_REG4.8

CN115

CN6501

STROBE

07

HV

YTU94074-12

∗

YTU94077-12

M_RVS

REG_3V

GND

SENSOR

SPEAKER

BL_GND

BL

NC/-15V

STV1

OEV

STV2

VDD

VGH

LCD_COM

LCD_VEE

STH2

LCD_RVS

NC/VB

MON_R

MON_G

MON_B

CLK3

CLK2

CLK1

OEH

LCD(MONITOR) PANEL

STH1

SPK-

SPK+

VGL

UD

CPV

GND

Q2H

0

SIDE OPE

(Page 4-69)

CLK4M5

F/Z_RST

IRIS_O/C

HALL_AD

DATA_OUT

Z_PTR_AD

OP_THRMO

STROBE

STO_E

STO_C

STO_OFF

GATE

CHG_ON

DTRB_AD

0

CN7602

OP BLOCK

4

LITHIUM

CN401

GND

KEY_A

VF_SW

EJT_SW

REG_3V

LITHIUM

P_MEDIA

CN303

0

3

SD

(Page 4-66)

IRIS_C

F/Z_CS

CAM_VD

IRIS_PWM

6

REG_4.8

CLK_OUT

M_REG4.8

M_REG4.8

H_OFFSET

M_REG4.8

STROBE

SENSOR

(Page 4-9)

MONITOR

BL_4.8V

CN7602

VGL

NC/-15V

STV1

UD

MONITOR

CPV

OEV

STV2

(Page 4-71)

VDD

VGH

LCD_COM

LCD_VEE

STH2

LCD_RVS

NC/VB

MON_R

MON_G

MON_B

CLK3

CLK2

CLK1

Q2H

OEH

STH1

REG_4.8

∗

GND

REG_3V

DV_MAIN

SYSCON

YTU94074-24

YTU94077-24

GND

GND

GND

REG_3V

REG_3V

REG

REG_3V

REG_4.8V

REG_12V

GND

SENS_EVR

STRB_AD

SENSPULS

GATEPULS

STRB_CHG

STO_OFF

CN7601

VF_LCD

LCD_CTL

MON_G

MON_B

HDCVF

ROM_CS

LV_CLK

LV_OUT

RENON

RENEN

VF_VDD9V

VF_VEE2V

VF_COM

REG_15V

REG_-15V

REG_12V

REG_4.8V

GND

VDCVF

LV_IN

M_CS

LCD_B

LCD_R

LCD_G

VREF

HLTOR

HODL

CVF_B

CVF_R

CVF_G

REG

CN302

GND

HRP

VIDL

HCK

HPL

PDR

GND

8MB

CN305

GND

GND

GND

GND

Vout

GND

GND

V1

R

PT

SUB

VDD

Z_LED

Z_VCC

DRIVE-

DRIVE+

Z_PTR_AD

OP

DAMP-

HGout-

DAMP+

HGout+

HGVss-

HGVcc+

OP_DRV

SYSCON

HALL_AD

CAM_CLK

IRIS_O/C

TG_RST

F/Z_CS

CAM_OUT

MultiMediaCard

CU-MMC04

Victor

PDR

CVF_B

HLTOR

CVF_R

CVF_G

CN7601

V3

V2

V4

CCD

(Page 4-65)

HL

H1

H2

DAMP-

HGout-

DAMP+

HGout+

HGVss-

HGVcc+

GND

Z_LED

Z_VCC

DRIVE+

FOCUS04

FOCUS03

FOCUS02

Z_PTR_AD

(Page 4-67)

F_PTR_AD

Z_PTR_AD

OP_THRMO

SD_DATA2

MMC_CS

Dat2MMC

VSS(GND)

VDD(DSC_3V)

MMC_CLK

VSS2/CD

Dat2Host

SD_DATA1

CARD_DET

SD_WP

HCK

VREF

HODL

VF_COM

VF_VEE2V

VF_VDD9V

GND

GND

GND

VF_LCD

LCD_CTL

REG_-15V

REG_15V

MON_G

MON_B

REG_4.8V

REG_4.8V

REG_4.8V

REG_4.8V

HRP

VDCVF

HDCVF

ROM_CS

LV_IN

M_CS

LV_CLK

LV_OUT

GND

GND

GND

GND

LCD_B

LCD_R

LCD_G

REG_12V

VIDL

RENON

RENEN

HCK

HPL

VREF

VF_VDD9V

VF_VEE2V

VF_COM

HLTOR

HODL

CVF_B

CVF_R

CVF_G

PDR

GND

0

ZOOM01

FOCUS01

HPL

2

ZOOM02

ZOOM03

F_VCC

F_PTR_AD

OP_THRMO

DV_MAIN

SD/

MMC

RENEN

RENON

F_LED

ZOOM04

F_LED

ZOOM04

H_GAIN

H_OFFSET

VIDL

VFREG4.8

F_VCC

ZOOM03

REG

SD_WP

OP_THRMO

ZOOM02

ZOOM01

CAM_DSP

M32_MMC_CS

GND

REG_3V

MMC_CD

GND

FOCUS01

F_PTR_AD

REG

M_REG4.8

DRIVE-

REG_4.8V

REG_3V

CAM_VD

CLK4M5

IRIS_PWM

IRIS_C

MMC_CMD

MMC_CLK

MMC_CD

MMC_DATA

SD_WP

MMC_CMD

MMC_DATA

M32_MMC_CS

USB

J102

USB_DP

USB_DN

USBSENS

SYSCON

USBDOWN

DSC_RST

FOCUS02

GND

MMC_CLK

SPKSPKSPK+

SPK+

MONI_SW

GND

GND

VF_LCD

M_BL_ON

REG_-15V

REG_15V

MON_G

MON_B

REG_4.8V

REG_4.8V

REG_4.8V

REG_4.8V

HRP

VDCVF

HDCVF

ROM_CS

S_DT_IN

M_CS

S_CLK

S_DT_OUT

GND

GND

GND

LCD_B

LCD_R

LCD_G

REG_12V

VIDL

RENON

RENEN

HCK

HPL

VREF

VF_VDD9V

VF_VEE2V

VF_COM

HLTOR

HODL

CVF_B

CVF_R

CVF_G

PDR

REG_3V

M_RVS

FOCUS03

FOCUS04

EJT_SW

P_MEDIA

CN102

KEY_A

VF_SW

LITHIUM

(Page 4-64)

DSC

GI03

GI015

GI06

USB DOWN

EM_CS2

FLSH_OE

FLSH_WE

D[0-15]

A10

REG_4.8V

GND

REG

CN113

YTU94074-16

∗

YTU94077-16

YTU94074-11

∗

YTU94077-11

MECHA

CAPSTAN MOTOR DRUM MOTOR HEAD

YTU94074-18

∗

YTU94077-18

V1

V3

V2

V4

SUBSW2

GND

GND

CCD_OUT

HL

SUBSW2

CN102

TG/VDR

(Page 4-49)

HDIN

CAM_DSP

REG

REG_3V

REG_1.8V

GND

OP_DRV

CAM_VD

CLK4M5

IRIS_PWM

IRIS_C

SERVO

CAM_VD

REG

SD/MMC

REG

REG_3V

GND

D_GAIN

GND

GND

V1

V2

VDIN

CLK9A

DSC

GND

REG_1.8V

MMC_DATA

MMC_CLK

CAM_DSP

GND

V3

V4

CPOB

TG_36M

DSYIO[0-7]

DSCIO[0-7]

REG_3V

DSC

MMC_CMD

MMC_CD

CAM_VD

SUB

CCD+12V

CCD+12V

H2

H1

RG

SUB

PBLK

SYSCON

FLDDSC

DSCO[0-7]

DSYO[0-7]

USB

M32_MMC_CS

SD_WP

JIG

H1

H2

CCD-8V

CCD-8V

REG

REG_3V

REG-CCD

REG_4.8V

CDS/AD

CCD_CTL

CLK_OUT

DATA_OUT

TG_RST

VDIN

HDIN

CLK9A

TG/VDR

HDDSC

CLK27B

CLKDSC

VDDSC

A10

D[0-15]

EM_CS2

FLSH_OE

FLSH_WE

USBDOWN

(Page 4-57)

DOBCL2

A_AD/DA

AIDAT2

TXD2

RXD2

SERVO

HL

RG

GND

REG_12V

PBLK

SHD

SHP

CPOB

ADCLK

TG_CS

PBLK

CPOB

TG_36M

CAM_DSP

(Page 4-43)

S_SHUT

AUDIO

GI03

GI06

GI015

CAM_DSP

SYSCON

DSC_WKUP

DOMCK2

DOLRCK2

DODAT2

S_CLK

SRV_CS

S_DT_IN

SRV_RST

SRV_RDY

S_DT_OUT

SYSCON

HG_U[-]

CLK27B

CLKDSC

CAPT_REQ

DSC_STS

MXDT_OUT

EEP_IN

HG_V[-]

HDDSC

FLDDSC

DSC_CS

EEP_DT_CLK

EEP_DT_OUT

(Page 4-19)

MDA

T_REEL

REEL_VCC

S_REEL

CAS_SW

TAPE_LED

S_SENS

E_SENS

REC_SAFE

01

MIC_1

MIC_2

MIC_3

DRUM_PG

DRUM_FG

DRUM_REF

MAIN

L_FRB

LD_ON

C_FRB

MDA_PS

CAP_FG

CAP_REF

HID3

HID1

PRE/REC

MM

GND

C_FG[-]

HG_W[-]

HG_BS[-]

TG/VDR

DV_MAIN

DSYO[0-7]

DSCO[0-7]

DSYIO[0-7]

DSC_DT_IN

DSC_CLK

DSC_DT_OUT

CAS_SW

EEPROM_CS

DV_MAIN

RECH

MONI_CHG

PBH

HG_V[+]

HG_U[+]

HG_W[+]

HG_BS[+]

CN102

CCD_OUT

PBLK

SHD

SHP

CPOB

ADCLK

CAM_DSP

CDS

DCI[0-3]

DYI[0-3]

DCO[0-3]

DYO[0-3]

OUTV

CLK27A

VDDSC

DSCIO[0-7]

DSC_RST

FLSH_RST

SD0CD

JIG

SRV_RX

DRST

SRV_TX

MONI_CHG

HID1

VPPD

ADDT[00-15]

DRE

DRWSEL

DALE

DWE

DV_WAIT

CLK27SEL

DV_RST

SRV_TRK

HID1

OUTV

TSR

FRP

SPA

CAM_SW_A

CAM_SW_B

CAM_SW_C

DEW_SENS

CN107, CN103

C_COIL_V

C_COIL_V

101112131415161718

REG

REG_4.8V

ADIN[0-9]

ADIN[0-9]

INV

OUTH

CAM_DSP

CN113

C_COIL_U

GND

SYSCON

SYSCON

INH

S_SHUT

SPK+

MDA_2.9V

C_COIL_U

C_COIL_W

C_COIL_W

CDS/AD

(Page 4-63)

DATA_OUT

CLK_OUT

CDS_CS

MVD

OMT

CALE

MFLD

CDSTB

CRWSEL

BUS[0-15]

DSP_RST

OUT_HS

OUT_C[0-3]

OUT_VS

OUT_Y[0-3]

VIDEO_I/O

TBCCTL

AUDIO

DSC

AD/DA

AIDAT2

DOBCK2

(Page 4-23)

DOMCK2

DOLRCK2

DODAT2

EM_AU/L

MD_AU/L

EM_AU/R

A_AD/DA

AUDIO

(Page 4-25)

MIC/R

CN114

SPK-

MIC/L

MIC_GND

CLK27A

MD_AU/R

C_FG[+]

123456789

CN106

CLK27B

AUDIO

MULTI

SYSCON

PD_L

MD_AU/L

MD_AU/R

AU_SIG/R

CLK_OUT

SYSCON

EM_AU/L

EM_AU/R

AU_SIG/L

AUDIO_CS

DATA_OUT

A_MUTE

BUZZER

AUDIO

BUZZER

CLK_OUT

AUDIO_CS

DATA_OUT

PD_L

A_MUTE

A_ADDA

PWDA2

PWAD2

MD_DEM1

CAM_DSP

BUS[0-15]

CDSTB

CRWSEL

CALE

MVD

MFLD

OMT

DSP_RST

OP_DRV

HALL_AD

IRIS_O/C

F/Z_CS

DATA_OUT

CLK_OUT

F/Z_RST

Z_PTR_AD

F_PTR_AD

OP_THRMO

SIDE OPE

EJT_SW

P_MEDIA

KEY_A

VF_SW

STO_SENS

STO_OFF

STRB_AD

GATEPULS

SENSPULS

STRB_CHG

SERVO

SRV_RDY

S_DT_OUT

S_DT_IN

S_CLK

SRV_CS

SRV_RST

EEP_IN

EEP_DT_OUT

EEP_DT_CLK

EEPROM_CS

CAS_SW

VF_CTL

SENSOR

GND

MIC3

S_SENS

MDA_2.9V

REG

REG_3V

GND

PWAD2

PWDA2

MD_DEM1

DV_MAIN

AIMCK

AILRCK

AIBCK

AODAT

AIDAT

REG

REG_3V

REG_4.8V

REG_CCD

CDS/AD

MIC2

GND

DATA_OUT

DSC

REC_SAFE

CDS_CS

CLK_OUT

FLSH_RST

MIC1

CN108

TG/VDR

DSC_RST

DSC_CLK

S_RL[-]

E_SENS

CAS_SW

C_FG[-]

C_FG[+]

C_COIL_V

TG_RST

CCD_CTL

DATA_OUT

DSC_DT_OUT

DSC_DT_IN

DSC_CS

T_RL[-]

S_RL[+]

TAPE_LED

REEL_VCC

HG_V[-]

HG_U[-]

HG_V[+]

HG_BS[+]

C_COIL_U

C_COIL_W

MDA

S_REEL

T_REEL

DRUM_PG

DRUM_FG

DRUM_REF

SERVO

CAM_DSP

CN113

TG_CS

CLK_OUT

VIDEO_I/O

SYSCON

(Page 4-15)

USB

MXDT_OUT

DSC_STS

CAPT_REQ

DSC_WKUP

SD0CD

GND

T_RL[+]

S_RL[-]

S_RL[+]

HG_W[-]

HG_U[+]

HG_W[+]

HG_BS[-]

MDA_2.9V

CN106

(Page 4-21)

MDA_PS

L_FRB

CAP_FG

LD_ON

C_FRB

CAP_REF

CLK27B

CLK27A

TBCCTL

OUT_VS

OUT_HS

DCO[0-3]

OUT_Y[0-3]

OUT_C[0-3]

DV_MAIN

VIDEO_I/O

(Page 4-39)

VDCVF

HDCVF

HRP

LCD_G

LCD_B

LCD_R

S_IN_L

TBC_CS

TBC_DTI

S_DC_IN

TBC_CLK

TBC_RST

EXT_IN_L

TBC_DTO

CN113

USBDOWN

DSC_RST

VF_LCD

M_BL_ON

D_FG[-]

D_PFG[+]

11

10

T_RL[-]

T_RL[+]

MDA_2.9V

REG

CAP_PWR

CAP_ERR

INH

DYO[0-3]

SYSCON

EXT_IN_L

S_DC_IN

VC[0-3]

BLK[A-C]

A_CSYNC

MONI_SW

ROM_CS

S_DT_OUT

D_COIL_U

DRUM_PWR

INV

S_IN_L

OSD_HD

S_CLK

D_COIL_V

D_COIL_V

D_COIL_U

6

789

D_PFG[+]

CN104

D_COIL_W

COIL_COM

DRUM_ERR

GND

V_OUT

Y_OUT

MULTI

TBC_DTO

TBC_CLK

TBC_CS

TBC_DTI

OSD_VD

ASPECT1

ASPECT2

DOT_CLK

CAMERA_OPE

S_DT_IN

M_CS

M_RVS

YTU94074-6

∗

YTU94077-6

D_PG[-]

D_COIL_W

D_COIL_W

COIL_COM

D_FG[-]

D_PG[-]

D_COIL_V

D_COIL_U

CN103

LOAD_FWD

LOAD_REV

M_REG4.8

M_UNREG

REG_3V

JIG

C_OUT

V_OUT

BLK[A-C]

VC[0-3]

OSD_HD

OSD_VD

TBC_RST

TO DV_MAIN

DATA_OUT

CLK_OUT

DAC_CS

CJIG_RST

AL_3VSYS

JLIP_TX

JLIP_RX

MULTI

REM_OUT

PWR_LED

TRIG_SW

DIAL_MANU

DIAL_AUTO

DIAL_OFF

DIAL_PB

ZOOM_SW

PHOTO SW

STOP SW

SUB_OPE

NAVI_SW

CJIG_RST

AREG_SO

AREG_CLK

T_BATT

REG_CS

V_BATT

VF_CTL

CHRG_EVR

LIT_3V

AL_3V

REG_3V

REG

DOT_CLK

JIG

IF_TX

VPPC

P_DET

REG

I_MTR

ADP_H

GND

12345

REG_3V

REG_4.8V

ASPECT1

GND

LOADING MOTOR

GND

REG_1.8V

ASPECT2

A_CSYNC

M

GND

DEW_SENS

6

LOAD_FWD

LOAD_FWD

JIG

ENV_OUT

ATFI

LOAD_REV

LOAD_REV

12345

SYSCON

CHRG_EVR

I_MTR

V_BATT

AREG_SO

AREG_CLK

REG_CS

CJIG_RST

VF_CTL

SERVO

D_GAIN

CN110

GND

HEAD

PRE/REC

HID3

PBH

SERVO

RECH

HID1

AUDIO

AODAT

AIDAT

AIMCK

AIBCK

AILRCK

CAM_DSP

V_I/O

INV

INH

OUTV

OUTH

DCO[0-3]

DYO[0-3]

DCI[0-3]

DYI[0-3]

CLK27A

OP_DRV

H_OFFSET

H_GAIN

STO_SENS

SENS_EVR

TO SYSCON

DATA_OUT

CLK_OUT

DAC_CS

MDA

CAP_ERR

CAP_PWR

DRUM_ERR

DRUM_PWR

∗

1F

1S

GND

GND

GND

2F

1F

2S

1S

(Page 4-37)

DUMP_CTL

MONI_CHG

ATF_GAIN

NOSIG_LV

DV_MAIN

VREF_1.1

VRB_AGC

AGC_OUT

REC_DATA

PRE/REC

DV_MAIN

(Page 4-31)

SERVO

ADDT[00-15]

DV_WAIT

DRWSEL

CDDSTB

REG_3V

REG_1.8V

REG_2.5V

M_UNREG

REG

(Page 4-53)

YTU94074-8

YTU94077-8

2F

2S

GND

CN107CN103CN104CN108

REG_4.8V

REG_2.5V

VREF_1.1

RECCADJ

AGC_OUT

REC_CLK

VRB_AGC

VRB_ATF

ATFI

VRB_ATF

REF_CLK

REC_CTL

REC_CLK

DUMP_CTL

TSR

DV_RST

CLK27SEL

SRV_TRK

DWE

DALE

REG_12V

REG_15V

REG-CCD

REG_4.8V

VFREG4.8

M_REG4.8

ROTARY

ENCODER

SW

REG

GND

REG_3V

REF_CLK

REC_DATA

REC_CTL

ATFI

RECCADJ

ATF_GAIN

NOSIG_LV

MAIN_VCO

REG_2.5V

REG_1.8V

HID1

FRP

SPA

AL_3V

LIT_3V

LITHIUM

REG_-15V

JIG

I_MTR

CN101

ADP_DC

J104

BATT_+

JIG

FS_PLL

PB_CLK

DISCRI

J101

REG

REG_3V

GND

R.E.SW

YTU94074-6

∗

CAM_SW_A

CAM_SW_B

65432

YTU94077-6

USB

J102

DV

J101

JIG

CONN.

CN105

MONI_CHG

ENV_OUT

MAIN_VCO

AL_3VSYS

CJING_RST

CN111

PWR_LED

GND

REG_3V

ZOOM_SW

TRIG_SW

DIAL_MANU

DIAL_AUTO

DIAL_OFF

DIAL_PB

STOP_SW

PHOTO_SW

CN112

GND

NC

INDEX_SW

SELCT_SW

MENU_SW

MINUS_SW

PLUS_SW

INFO_SW

NAVI_SW

MULTI

J103

Y_OUT

C_OUT

V_OUT

REM_OUT

GND

GND

GND

P_DET

AU_SIG/R

AU_SIG/L

CN101

GND

GND

GND

GND

GND

GND

GND

GND

T_BATT

ADP_DC

ADP_DC

ADP_DC

ADP_DC

ADP_DC

ADP_DC

ADP_DC

ADP_DC

DC JACK

J104

USB_DP_TX

USB_DN_RX

USBSENSE

TPA+

TPATPB+

TPB-

SRV_RX

REG_3V

DRST

SRV_TX

TXD2

RXD2

SPA

V_OUT

GND

VIDL

MON_G

CVF_G

MON_B

JLIP_RX

GND

JLIP_TX

PB_CLK

HID1

GND

ATFI

DISCRI

VPPD

VPPC

FS_PLL

IF_TX

YTU94074-11

∗

YTU94077-11

CAMERA OPE

SUB OPE

+

∗

-

T

YTU94074-9

YTU94077-9

BATT.TERM.

NC

NC

GND

CAM_SW_C

1

SPA

TPA+

TPATPB+

TPB-

GND

4-3 4-4

y10371001a_rev0

HGFEDCBA

Page 18

4.2 BOARD INTERCONNECTIONS [FOR NON-MEGA PIXEL with DSC MODEL]

NOTE ) :

5

4

3

2

1

The number of patch cords

∗

are indicated by interconnected.

YTU94074-18

∗

YTU94077-18

CN7001

THH

PDR

VIDH

VCK

VPL

HODL

HLTOR

VF_COM

VF_VEE2V

VF_VDD9V

GND

VREF

HPL

HCK

RENEN

RENON

VIDL

TCL

THL

TV

LCD(VFBW)PANEL

CN7002

VF_COM

CVF_G

CVF_R

CVF_B

GND

HCK1

HCK2

HST

VDD

VDD

EN

STB

VCK2

VST

GND

VDD(12V)

CN7002

LCD(CVF)PANEL

(Page 4-70)

VFBW

08

CN7001

CVF

08

PDR

VIDH

VCK

VPL

HODL

HLTOR

VF_COM

VF_VEE2V

VF_VDD9V

VREF

HPL

HCK

RENEN

RENON

VIDL

VFREG4.8

GND

GND

PDR

CVF_G

CVF_R

CVF_B

HODL

HLTOR

VF_COM

VF_VEE2V

VF_VDD9V

VREF

HPL

HCK

RENEN

RENON

VIDL

VFREG4.8

GND

GND

OPEN

INT MIC

MIC/L

MIC_GND

MIC_GND

MIC/R

STO_E

STO_C

REG_4.8V

STO_OFF

GATE

CHG_ON

DTRB_AD

GND

(Page 4-73)

GND

GND

M_REG4.8

M_REG4.8

YTU94074-12

∗

CN6501

YTU94077-12

STROBE

07

M_RVS

REG_3V

GND

SENSOR

CN304

CN301

H_GAIN

CLK4M5

F_PTR_AD

IRIS_O/C

CN109

CN114

CN115

SPEAKER

CAM_OUT

Z_PTR_AD

0

HALL_AD

OP_THRMO

STROBE

STO_E

STO_C

STO_OFF

GATE

CHG_ON

DTRB_AD

4

GND

REG_3V

CAM_VD

TG_RST

IRIS_PWM

BL

LCD(MONITOR) PANEL

SPK-

SPK+

OP BLOCK

YTU94074-24

∗

YTU94077-24

SIDE OPE

(Page 4-69)

LITHIUM

CN401

KEY_A

VF_SW

EJT_SW

P_MEDIA

LITHIUM

CN303

0

3

SD

(Page 4-66)

CAM_CLK

M_REG4.8

CN7602

REG_4.8

REG_4.8

M_REG4.8

0

REG_3V

GND

REG_3V

REG_4.8V

REG_12V

DVMAIN

SENS_EVR

SYSCON

STRB_AD

SENSPULS

GATEPULS

STRB_CHG

STO_OFF

6

IRIS_C

F/Z_CS

M_REG4.8

H_OFFSET

STROBE

SENSOR

(Page 4-11)

HV

BL_GND

VGL

NC/-15V

STV1

UD

CPV

OEV

STV2

VDD

VGH

LCD_COM

LCD_VEE

STH2

LCD_RVS

NC/VB

MON_R

MON_G

MON_B

GND

CLK3

CLK2

CLK1

Q2H

OEH

STH1

CN302

8MB

CN305

GND

GND

GND

GND

GND

GND

GND

GND

REG

REG_3V

REG_3V

GND

MONITOR

BL_4.8V

CN7602

VGL

NC/-15V

STV1

UD

CPV

OEV

STV2

VDD

MONITOR

VGH

LCD_COM

LCD_VEE

STH2

LCD_RVS

NC/VB

MON_R

MON_G