Page 1

SERVICE MANUAL

DIGITAL VIDEO CAMERA

JVC SERVICE & ENGINEERING COMPANY OF AMERICA

DIVISION OF JVC AMERICAS CORP.

Head office

East Coast

Midwest

West Coast

Atlanta

Hawaii

1700 Valley Road Wayne, New Jersey 07470-9976

:

10 New Maple Avenue Pine Brook, New Jersey 07058-9641

:

705 Enterprise Street Aurora, Illinois 60504-8149

:

5665 Corporate Avenue Cypress, California 90630-0024

:

1500 Lakes Parkway Lawrenceville, Georgia 30043-5857

:

2969 Mapunapuna Place Honolulu, Hawaii 96819-2040

:

(973)315-5000

(973)396-1000

(630)851-7855

(714)229-8011

(770)339-2582

(808)833-5828

JVC CANADA INC.

Head office

Montreal

Vancouver

:

21 Finchdene Square Scarborough, Ontario M1X 1A7

:

16800 Rte Trans-Canadienne, Kirkland, Quebec H9H 5G7

:

13040 Worster Court Richmond, B.C. V6V 2B3

(416)293-1311

(514)871-1311

(604)270-1311

S40895-03

GR-DVP3U

No. 86628

GR-DVP3U

SPECIFICATIONS

Camcorder

For General

Power supply : DC 6.3 V } (Using AC Power Adapter/Charger)

Power consumption

LCD monitor off, viewfinder on : Approx. 4.1 W

LCD monitor on, viewfinder off : Approx. 5.0 W

Dimensions (W x H x D) : 43 mm x 115 mm x 80 mm (1-3/4" x 4-9/16" x 3-3/16")

Weight : Approx. 340 g (0.75 lbs)

Operating temperature : 0°C to 40°C (32°F to 104°F)

Operating humidity : 35% to 80%

Storage temperature : –20°C to 50°C (–4°F to 122°F)

Pickup : 1/4" CCD

Lens : F 1.8, f = 3.7 mm to 37 mm, 10:1 power zoom lens

LCD monitor : 2" diagonally measured, LCD panel/TFT active matrix system

Viewfinder : Electronic viewfinder with 0.44" color LCD

Speaker : Monaural

For Digital Video Camera

Format : DV format (SD mode)

Signal format : NTSC standard

Recording/Playback format : Video: Digital component recording

Cassette : Mini DV cassette

Tape speed : SP: 18.8 mm/s

Maximum recording time : SP: 80 min.

(using 80 min. cassette) LP: 120 min.

For Digital Still Camera

Storage media : SD Memroy Card/MultiMediaCard

Compression system : Still image : JPEG (compatible)

File size : 2 modes (XGA: 1024 x 768 pixels/VGA: 640 x 480 pixels)

Picture quality : 2 modes (FINE/STANDARD)

Approximate number of storable images

(with the provided memory card [8 MB], with Sound Effects pre-stored)

FINE : 37 (VGA), 16 (XGA)

STANDARD : 105 (VGA), 51 (XGA)

For other memory cards, see pg. 17.

DC 7.2 V } (Using battery pack)

(with the LCD monitor closed and the viewfinder pushed back in)

(without grip belt, battery and cassette)

Approx. 410 g (0.91 lbs)

(incl. grip belt, battery and cassette)

(It is not possible to attach any lens filter or conversion lens.)

: Audio: PCM digital recording, 32 kHz 4-channel (12-bit),

48 kHz 2-channel (16-bit)

LP: 12.5 mm/s

Moving image : MPEG4 (compatible)

For Connectors

AV

Video output : 1 V (p-p), 75 Ω, analog

Audio output : 300 mV (rms), 1 kΩ, analog, stereo

DV

Input/output : 4-pin, IEEE 1394 compliant

Power requirement

U.S.A. and Canada : AC 120 V `, 60 Hz

Other countries : AC 110 V to 240 V `, 50 Hz/60 Hz

Power consumption : 23 W

Output

Charge : DC 7.2 V }, 1.2 A

VTR : DC 6.3 V }, 1.8 A

Dimensions (W x H x D) : 68 mm x 44 mm x 110 mm (2-11/16" x 1-3/4" x 4-3/8")

Weight : Approx. 255 g (0.57 lbs)

For General

Dimensions (W x H x D) : 48.4 mm x 36 mm x 79 mm (1-15/16" x 1-7/16" x 3-1/8")

Weight : Approx. 53 g (0.12 lbs)

For Connectors

PHONE

Headphone output : ø3.5 mm, stereo

USB : TYPE B

S-VIDEO OUT : Y: 1 V (p-p), 75 W, analog output

EDIT : ø3.5 mm, 2-pole

Specifications shown are for SP mode unless otherwise indicated. E & O.E. Design and specifications subject

to change without notice.

AC power adapter/charger AA-V100U

Docking Station CU-V507U

C: 0.29 V (p-p), 75 W, analog output

Printed in Japan

This service manual is printed on 100% recycled paper.

COPYRIGHT © 2001 VICTOR COMPANY OF JAPAN, LTD.

No. 86628

May 2001

Page 2

TABLE OF CONTENTS

Section Title Page Section Title Page

Important Safety Precautions

INSTRUCTIONS

1. DISASSEMBLY

1.1 BEFORE ASSEMBLY AND DISASSEMBLY ................... 1-1

1.1.1 Precautions ............................................................... 1-1

1.1.2 Assembly and disassembly ....................................... 1-1

1.1.3 Destination of connectors .......................................... 1-1

1.1.4 Disconnection of Connectors (Wires) ........................ 1-1

1.2 JIGS AND TOOLS REQUIRED FOR DISASSEMBLY,

ASSEMBLY AND ADJUSTMENT .................................... 1-2

1.2.1 Tools required for adjustments .................................. 1-2

1.3 DISASSEMBLY/ASSEMBLY OF CABINET PARTS AND

BOARD ASSEMBLY ........................................................ 1-2

1.3.1 Disassembly flow chart .............................................. 1-2

1.3.2 Disassembly method ................................................. 1-3

1.4 DISASSEMBLY OF 5 MONITOR ASSEMBLY ................ 1-8

1.4.1 5 Monitor assembly/Hinge assembly ........................ 1-8

1.4.2 Hinge assembly ......................................................... 1-8

1.5 DISASSEMBLY OF ! E. VF ASSEMBLY ........................ 1-9

1.5.1 !E. VF assembly ....................................................... 1-9

1.6 DISASSEMBLY OF # OP BLOCK ASSEMBLY/CCD

BOARD ASSEMBLY ...................................................... 1-10

1.6.1 Precautions ............................................................. 1-10

How to remove OP block assembly and CCD board assembly

1.6.2

How to install #

1.6.3

1.6.4 Replacement of service parts .................................. 1-10

1.7 EMERGENCY DISPLAY ............................................... 1-11

1.8 SERVICE KNOW-HOW ................................................. 1-12

1.9 SERVICE NOTE ............................................................ 1-14

2. MECHANISM ADJUSTMENT

PRELIMINARY REMARKS ON ADJUSTMENT AND REPAIR

2.1

2.1.1 Precautions ............................................................... 2-1

2.1.2 Notes on procedure for disassemby/assembly.......... 2-1

2.2 JIGS AND TOOLS REQUIRED FOR DISASSEMBLY,

ASSEMBLY AND ADJUSTMENT .................................... 2-2

2.2.1 Tools required for adjustments .................................. 2-2

DISASSEMBLY/ASSEMBLY OF MECHANISM ASSEMBLY .

2.3

2.3.1 General statement ..................................................... 2-3

2.3.2 Explanation of mechanism mode .............................. 2-3

2.3.3 Mechanism timing chart ............................................ 2-4

2.4 DISASSEMBLING PROCEDURE TABLE ....................... 2-5

2.4.1 Disassembly/assembly .............................................. 2-7

2.4.2 List of procedures for disassembly .......................... 2-13

CHECKUP AND ADJUSTMENT OF MECHANISM PHASE .

2.5

2.6 MECHANISM ADJUSTMENTS ..................................... 2-15

2.6.1 Adjustment of the slide guide plate ......................... 2-15

Adjustment of the Tension Arm and Pad Arm Assemblies .

2.6.2

2.6.3 Adjustment of the Slide Lever 2............................... 2-16

2.7 JIG CONNECTOR CABLE CONNECTION ................... 2-17

2.8 SERVICE NOTE ............................................................ 2-18

3. ELECTRICAL ADJUSTMENT

3.1 PRECAUTION ................................................................. 3-1

3.2 SETUP ............................................................................ 3-2

OP block assembly and CCD board assembly

1-10

1-10

2-1

2-3

2-14

2-16

4. CHARTS AND DIAGRAMS

NOTES OF SCHEMATIC DIAGRAM .................................... 4-1

CIRCUIT BOARD NOTES ..................................................... 4-2

4.1 BOARD INTERCONNECTIONS ..................................... 4-3

4.2 SYSCON-CPU SCHEMATIC DIAGRAM ........................ 4-5

4.3 MSD-CPU SCHEMATIC DIAGRAM ............................... 4-7

4.4 MDA SCHEMATIC DIAGRAM ........................................ 4-9

4.5 DV MAIN SCHEMATIC DIAGRAM ............................... 4-11

4.6 PRE/REC SCHEMATIC DIAGRAM .............................. 4-13

4.7 VIDEO OUT SCHEMATIC DIAGRAM .......................... 4-15

4.8 CAM. DSP SCHEMATIC DIAGRAM ............................. 4-17

4.9 TG/VDR SCHEMATIC DIAGRAM ................................. 4-19

4.10 VF MAIN SCHEMATIC DIAGRAM ............................. 4-21

4.11 REG CON SCHEMATIC DIAGRAM ........................... 4-23

4.12 REG SCHEMATIC DIAGRAM .................................... 4-25

4.13 MONITOR MAIN SCHEMATIC DIAGRAM ................. 4-27

4.14 DSC SCHEMATIC DIAGRAM .................................... 4-29

4.15 AUDIO MP3 SCHEMATIC DIAGRAM ........................ 4-31

4.16 USBDRV SCHEMATIC DIAGRAM ............................. 4-33

4.17 W/B SCHEMATIC DIAGRAM ..................................... 4-35

4.18 CCD SCHEMATIC DIAGRAM .................................... 4-36

4.19 WBSE/SW SCHEMATIC DIAGRAM .......................... 4-37

4.20 AUDIO AD/DA SCHEMATIC DIAGRAM .................... 4-39

4.21 MAIN AUDIO SCHEMATIC DIAGRAM ...................... 4-41

4.22 OP DRIVE SCHEMATIC DIAGRAM........................... 4-43

4.23 BOTTOM SCHEMATIC DIAGRAM............................. 4-45

4.24 MONITOR SCHEMATIC DIAGRAM ........................... 4-47

4.25 OPE.COVER UNIT AND SUB OPE. UNIT

SCHEMATIC DIAGRAMS ........................................... 4-49

4.26 MAIN CIRCUIT BOARD ............................................. 4-51

4.27 AUDIO CIRCUIT BOARD ........................................... 4-57

4.28 BOTTOM CIRCUIT BOARD ....................................... 4-59

4.29 MONITOR CIRCUIT BOARD ..................................... 4-61

4.30 CCD AND EJECT CIRCUIT BOARDS ....................... 4-62

4.31 VOLTAGE CHARTS ................................................... 4-63

4.32 POWER SYSTEM BLOCK DIAGRAM ....................... 4-65

4.33 VIDEO SYSTEM BLOCK DIAGRAM .......................... 4-67

5. PARTS LIST

5.1 PACKING AND ACCESSORY ASSEMBLY <M1> .......... 5-1

5.2 FINAL ASSEMBLY <M2> ............................................... 5-3

5.3 MECHANISM ASSEMBLY <M3> ................................... 5-6

5.4 ELECTRONIC VIEWFINDER ASSEMBLY <M4> ........... 5-8

5.5 MONITOR ASSEMBLY <M5> ......................................... 5-9

5.6 ELECTRICAL PARTS LIST ........................................... 5-10

MAIN BOARD ASSEMBLY <01>. ...................................... 5-10

AUDIO BOARD ASSEMBLY <02> ..................................... 5-18

BOTTOM BOARD ASSEMBLY <03> ................................. 5-21

MONITOR BOARD ASSEMBLY <04> ............................... 5-21

CCD BOARD ASSEMBLY <05> ........................................ 5-21

EJECT BOARD ASSEMBLY <06> .................................... 5-21

6. AC POWER ADAPTER (AA-V100U)

6.1 CABINET ASSEMBLY <MA> .......................................... 6-1

6.2 SCHEMATIC DIAGRAM .................................................. 6-2

6.3 CIRCUIT BOARD ............................................................ 6-4

6.4 ELECTRICAL PARTS LIST ............................................. 6-5

Page 3

Important Safety Precautions

Prior to shipment from the factory, JVC products are strictly inspected to conform with the recognized product safety and electrical codes of the

countries in which they are to be sold. However, in order to maintain such compliance, it is equally important to implement the following precautions

when a set is being serviced.

Precautions during Servicing

•

1. Locations requiring special caution are denoted by labels and inscriptions on the cabinet, chassis and certain parts of the product.

When performing service, be sure to read and comply with these

and other cautionary notices appearing in the operation and service manuals.

2. Parts identified by the ! symbol and shaded ( ) parts are

critical for safety.

Replace only with specified part numbers.

Note: Parts in this category also include those specified to com-

ply with X-ray emission standards for products using

cathode ray tubes and those specified for compliance

with various regulations regarding spurious radiation

emission.

3. Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as specified.

4. Use specified internal wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

5. Use specified insulating materials for hazardous live parts. Note

especially:

1) Insulation Tape 3) Spacers 5) Barrier

2) PVC tubing 4) Insulation sheets for transistors

6. When replacing AC primary side components (transformers, power

cords, noise blocking capacitors, etc.) wrap ends of wires securely

about the terminals before soldering.

12. Crimp type wire connector

In such cases as when replacing the power transformer in sets

where the connections between the power cord and power transformer primary lead wires are performed using crimp type connectors, if replacing the connectors is unavoidable, in order to prevent

safety hazards, perform carefully and precisely according to the

following steps.

1) Connector part number : E03830-001

2) Required tool : Connector crimping tool of the proper type which

will not damage insulated parts.

3) Replacement procedure

(1) Remove the old connector by cutting the wires at a point

close to the connector.

Important : Do not reuse a connector (discard it).

cut close to connector

Fig.3

(2) Strip about 15 mm of the insulation from the ends of the

wires. If the wires are stranded, twist the strands to avoid

frayed conductors.

15 mm

Fig.1

7. Observe that wires do not contact heat producing parts (heatsinks,

oxide metal film resistors, fusible resistors, etc.)

8. Check that replaced wires do not contact sharp edged or pointed

parts.

9. When a power cord has been replaced, check that 10-15 kg of

force in any direction will not loosen it.

Power cord

Fig.2

10. Also check areas surrounding repaired locations.

11. Products using cathode ray tubes (CRTs)

In regard to such products, the cathode ray tubes themselves, the

high voltage circuits, and related circuits are specified for compliance with recognized codes pertaining to X-ray emission.

Consequently, when servicing these products, replace the cathode ray tubes and other parts with only the specified parts. Under

no circumstances attempt to modify these circuits.

Unauthorized modification can increase the high voltage value and

cause X-ray emission from the cathode ray tube.

Fig.4

(3) Align the lengths of the wires to be connected. Insert the

wires fully into the connector.

Metal sleeve

Connector

Fig.5

(4) As shown in Fig.6, use the crimping tool to crimp the metal

sleeve at the center position. Be sure to crimp fully to the

complete closure of the tool.

1

.2

5

2

.0

5

.5

Fig.6

(5) Check the four points noted in Fig.7.

Not easily pulled free

Wire insulation recessed

more than 4 mm

Fig.7

Crimping tool

Crimped at approx. center

of metal sleeve

Conductors extended

I

S40888-01

Page 4

Safety Check after Servicing

•

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts and wires have been returned

to original positions, Afterwards, perform the following tests and confirm the specified values in order to verify compliance with safety

standards.

1. Insulation resistance test

Confirm the specified insulation resistance or greater between power cord plug prongs and externally exposed parts of the set (RF terminals, antenna terminals, video and audio input and output

terminals, microphone jacks, earphone jacks, etc.). See table 1 below.

2. Dielectric strength test

Confirm specified dielectric strength or greater between power cord plug prongs and exposed accessible parts of the set (RF terminals, antenna terminals, video and audio input and output terminals,

microphone jacks, earphone jacks, etc.). See table 1 below.

3. Clearance distance

When replacing primary circuit components, confirm specified clearance distance (d), (d’) between soldered terminals, and between terminals and surrounding metallic parts. See table 1

below.

Fig. 8

4. Leakage current test

Confirm specified or lower leakage current between earth ground/power cord plug prongs and

externally exposed accessible parts (RF terminals, antenna terminals, video and audio input and

output terminals, microphone jacks, earphone jacks, etc.).

Measuring Method : (Power ON)

Insert load Z between earth ground/power cord plug prongs and externally exposed accessible

parts. Use an AC voltmeter to measure across both terminals of load Z. See figure 9 and following

table 2.

Externally

exposed

accessible part

Fig. 9

Z

V

ab

A

c

5. Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between earth pin in AC inlet and externally exposed accessible parts (Video in, Video out,

Audio in, Audio out or Fixing screw etc.).

Measuring Method:

Connect milli ohm meter between earth pin in AC inlet and exposed accessible parts. See figure 10 and grounding specifications.

Fig. 10

Table 1 Specifications for each region

Table 2 Leakage current specifications for each region

Note: These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

II

S40888-01

Page 5

SECTION 1

DISASSEMBLY

1.1 BEFORE ASSEMBLY AND DISASSEMBLY

1.1.1 Precautions

1. Be sure to remove the power supply unit prior to mounting and soldering of parts.

2. When removing a component part that needs to disconnect the connector and to remove the screw for removing itself, first disconnect the connecting wire from the

connector and then remove the screw beforehand.

3. When connecting and disconnecting the connectors, be

careful not to damage the wire.

4. Carefully remove and handle the part to which some

spacer or shield is attached for reinforcement or insulation.

5. When replacing chip parts (especially IC parts), desolder

completely first (to prevent peeling of the pattern).

6. Tighten screws properly during the procedures.

Unless specified otherwise, tighten screws at a torque

of 0.078N

•

m(0.8kgf•cm).

1.1.2 Assembly and disassembly

STEP

No.

1

2

3

PART

COVER(UNDER) Fig.1-3-1 (S1)—

COVER(SHOE) Fig.1-3-2 2(S2),(L2a),(L2b) —

MIC COVER ASSY

Fig.No.

POINT NOTE

(S3a),2(S3b) —

1.1.4 Disconnection of Connectors (Wires)

Connector

Pull both ends of the connector in the arrow direction, remove the lock and disconnect the flat wire.

Flat wire

Connector

Fig. 1-1-1 Connector 1

Extend the locks in the direction of the arrow for unlocking

and then pull out the wire. After removing the wire, immediately restore the locks to their original positions because

the locks are apt to come off the connector.

Flat wire

(1) (2) (3) (4) (5)

(1) Indicate the disassembly steps. When assembling, per-

form in the reverse order of these steps. This number

corresponds to the number in the disassembly diagram.

(2) Indicates the name of disassembly/assembly parts.

(3) Indicates the number in the disassembly diagram.

(4) Indicates parts and points such as screws, washers,

springs which must be removed during disassembly/

assembly.

Symbol Name, Point

S Screw

L Lock, Pawl, Hook

SD Soldering

CN Connector

(Example)

• 2 (S1) : Remove the two screws (S1) for removing the

part 1.

• CN 1a: Disconnect the connector 1a.

• SD1 : Unsolder at the point SD1.

(5) Precautions on disassembly/assembly.

1.1.3 Destination of connectors

Note:

Three kinds of double-arrows in connection tables respectively show kinds of connector/wires.

↔ : Wire

⇔ : Flat wire (FPC, FFC)

: Board to Board connector

[Example]

NOTE:

Remove the parts marked in

CONN.

No.

a MAIN CN111 BOTTOM CN301 50

4

b MAIN CN112 ⇔ SUB OPE UNIT CN112 7

4

CONNECTOR

.

Pin No.

Connector

Fig. 1-1-2 Connector 2

B-B connector

Pull the board by both the sides in the direction of the arrow for disconnecting the B-B connector.

Connector

Connector

Fig. 1-1-3 Connector 3

Connector

Fig. 1-1-4 Connector 4

1-1

Page 6

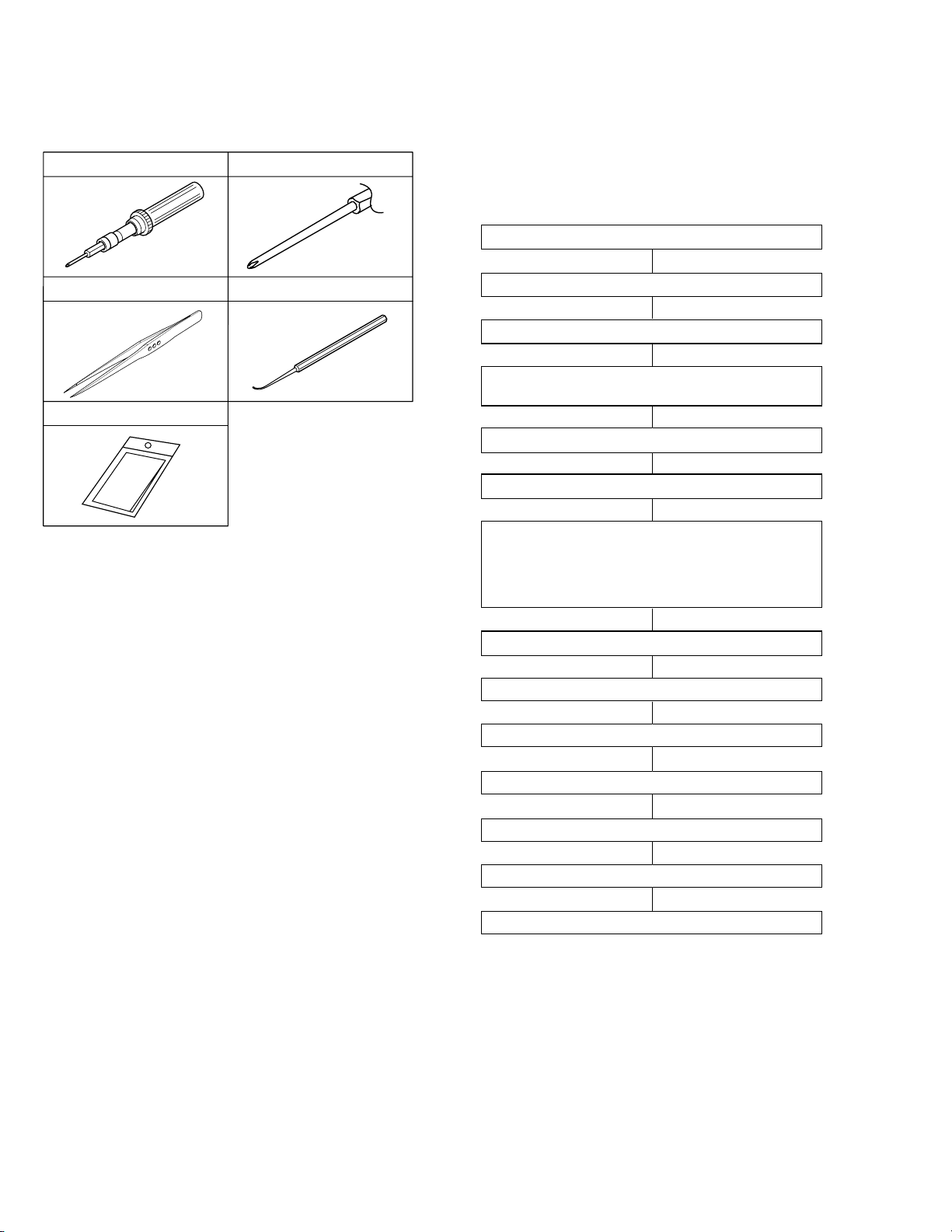

1.2 JIGS AND TOOLS REQUIRED FOR DISASSEMBLY, ASSEMBLY AND ADJUSTMENT

1.2.1 Tools required for adjustments

1

Torque Driver

YTU94088

2

Bit

YTU94088-003

1.3 DISASSEMBLY/ASSEMBLY OF CABINET PARTS AND BOARD ASSEMBLY

1.3.1 Disassembly flow chart

This flowchart indicates the disassembly step for the cabinet parts and board assembly in order to gain access to

item(s) to be serviced. When reassembling, perform the

step(s) in reverse order.

3

5

Tweezers

P-895

Cleaning Cloth

KSMM-01

Chip IC Replacement Jig

4

PTS40844-2

Table 1-2-1

1. Torque driver

Be sure to use to fastening the mechanism and exterior

parts because those parts must strictly be controlled for

tightening torque.

2. Bit

This bit is slightly longer than those set in conventional

torque drivers.

3. Tweezers

To be used for removing and installing parts and wires.

4. Chip IC replacement jig

To be used for adjustment of the camera system.

5. Cleaning cloth

Recommended cleaning cloth to wipe down the video

heads, mechanism (tape transport system), optical lens

surface.

1

2

3

4

5

6

7

8

9

0

!

@

COVER (UNDER)

COVER (SHOE)

MIC COVER ASSY

UPPER CASE ASSY

(Inc.MONITOR ASSY)

MONITOR ASSY

SHUTTER ASSY

LOWER CASE ASSY

(Inc.MICROPHONE

/E.VF UNIT

/AUDIO BOARD ASSY

/OP BLOCK ASSY)

MAIN BOARD ASSY

MECHANISM ASSY

MICROPHONE

E VF UNIT

AUDIO BOARD ASSY

1-2

#

$

OP BLOCK ASSY

SHOE ASSY

Table 1-3-1

Page 7

1.3.2 Disassembly method

STEP

No.

1

2

3

4

5

6

7

8

9

0

!

@

#

$

PART

COVER (UNDER) Fig.1-3-1 (S1) —

COVER (SHOE) Fig.1-3-2 2(S2), (L2a), (L2b) —

MIC COVER ASSY

UPPER CASE ASSY

MONITOR ASSY Fig.1-3-4 2(S5a), GUIDE(MONI), 2(S5b) NOTE5

SHUTTER ASSY FIig.1-3-5(S6

LOWER CASE ASSY

(

Inc.MICROPHONE,

E VF UNIT,

AUDIO BOARD ASSY,

OP BLOCK ASSY)

MAIN BOARD ASSY

MECHANISM ASSY

MICROPHONE Fig.1-3-8a HOOD, SPACER, (S#), (S@) NOTE0a

E VF UNIT (S!), SPACER, CN!a NOTE!a

AUDIO BOARD ASSY

OP BLOCK ASSY

SHOE ASSY CN $a NOTE$

Fig.No.

(S3a), 2(S3b) —

Fig.1-3-3a (SD CARD) NOTE4a

Fig.1-3-3b 2(S4b), (S4c), 2(S4b), (S4d) NOTE4c

Fig.1-3-6

Fig.1-3-7 SHEET(SHUTTER), 2(S8) —

Fig.1-3-8b 2(S@b), SPACER, 3(S$) NOET@

(S4a), COVER (JIG) NOTE4b

CN 4a

2(S4b), (S4e)

CN 4b, CN4c

CN 7a,CN 7b,SHEET(SHUTTER)

CN 7c, CN7d, 4(S7)

(L8a), SHIELD ASSY, CN 8a,

CN 8b, CN 8c, CN 8d

2(L8b), (L8c)

CN 8e, CN 8f

3(S9),BRACKET(MECHA) ASSY

CN0a NOTE0b

CN #a NOTE#a

POINT NOTE

)

Table 1-3-2

NOTE

6

NOTE7

NOTE!b

NOTE#b

NOTE 4a:

NOTE 4b:

NOTE 4c:

NOTE 5:

NOTE 6:

NOTE 7:

NOTE 0a:

NOTE 0b:

NOTE !a:

NOTE !b:

NOTE @, #a, $ :

NOTE #b:

If a card is installed, remove it in advance.

Be careful not to damage the battery removal switch.

When disassembling, ensure that the lock lever is in the

low position and set the battery removal switch only to

the up position.

Take care of the removed screws.

Refer to Fig. 1-4-1 for the disassembly method.

Be careful not to damage or lose the parts.

For the disassembly/assembly of the EVF unit, AUDIO

board assembly, and OP block assembly, see section

1.8, “SERVICE KNOW-HOW”.

Take care not to damage the switch.

Leave the OP block assembly connected to the audio

board and locate it in a vacant space.

Be careful not to cut the FPC wire or damage any of

the switches during work.

Refer to Fig. 1-5-1 for the disassembly method.

When assembling, attach the OP block assembly and

the shoe assembly on the AUDIO board assembly and

install them together in the lower case assembly.

Refer to Fig. 1-6-1 for the disassembly method.

Note:

Remove the parts marked in .

CONN.

No.

CN4a MAIN CN111 BOTTOM CN301 50

CN4b MAIN CN112 ⇔ SUB OPE UNIT - 7

CN4c MAIN CN113 ⇔ MONITOR CN401 39

CN7a MAIN CN110 AUDIIO CN201 120

CN7b MAIN CN111 ⇔ CCD - 20

CN7c MAIN CN107 ⇔ ZOOM OPE UNIT - 13

CN7d MAIN CN108 ←→ EJECT SW - 2

CN8a MAIN CN102 ⇔ LOADING MOTOR - 6

CN8b MAIN CN103 ⇔ ROTARY ENCODER - 6

CN8c MAIN CN101 ⇔ HEAD - 8

CN8d MAIN CN106 ⇔ SENSOR - 16

CN8e MAIN CN105 ⇔ CAPSTAN MOTOR - 18

CN8f MAIN CN104 ⇔ DRUM MOTOR - 11

CN0a AUDIO CN203 ←→ MICROPHONE - 4

CN!a AUDIO CN204 ⇔ VF BL CN7551 20

CN#a AUDIO CN205 ⇔ OP BLOCK ASSY - 24

CN$a AUDIO CN202 ⇔ SHOE ASSY - 16

CONNECTOR

Table 1-3-3

Pin No.

1-3

Page 8

3

5

3

(S b)

6

3

(S b)

2

(L a)

2

1

1

1

(S )

Fig. 1-3-1

4

3

(S a)

Fig. 1-3-2

2

(L b)

2

2

(S )

3

2

(S )

NOTE a

4

COVER

(SD)

4

CN a

NOTE b

4

4

(S a)

COVER

(JIG)

BATT. RELEASE

SWITCH

LOCK LEVER

7

4

1-4

Fig. 1-3-3a

Page 9

Fig. 1-3-3b

4

(S d)

13

4

(S b)

8

4

(S b)

15

4

(S d)

14

4

(S e)

17

4

NOTE c

4

CN b

4

CN c

4

(S e)

17

4

(S c)

10

4

(S b)

16

4

(S b)

12

4

(S b)

11

4

(S b)

9

4

GUIDE

(MONI)

18

5

(S a)

19

5

(S a)

4

20

(S b)

21

5

(S b)

5

NOTE

5

5

22

6

(S )

6

NOTE

6

: 0.98N·m (1.0kgf·cm)

Fig. 1-3-4

Fig. 1-3-5

1-5

Page 10

CASS.

COVER

SPACER

NOTE

7

7

(S )

SHEET

(SHUTTER)

23

7

24

7

(S )

7

CN a

(S )

26

7

CN b

CN c

25

(S )

7

CN d

7

7

7

SHEET

(SHUTTER)

27

8

(S )

28

8

(S )

9

(L a)

SHIELD

ASSY

Fig. 1-3-6

29

(S )

8

(L b)

9

BRACKET

8

CN a

8

30

9

(S )

8

8

CN c

(L c)

31

9

(S )

8

8

CN e

CN f

CN d

8

8

CN b

8

1-6

Fig. 1-3-7

Page 11

Fig. 1-3-8a

10

7

13

14

11

CN a

13

NOTE b

10

NOTE

AUDIO

PWB

SW

a

10

NOTE a

10

CN a

11

CN a

10

(S )

32

13

(S )

34

SPACER

11

(S )

33

HOOD

SPACER

12

12

37

14

(S )

SPACER

KNOB

(VIDEO

/DSC)

12

Fig. 1-3-8b

(S )

CN a

CN a

(S b)

SPACER

14

35

12

14

39

13

14

38

14

(S )

(S b)

13

36

12

1-7

Page 12

1.4 DISASSEMBLY OF 5 MONITOR ASSEMBLY

1.4.1 5 Monitor assembly/Hinge assembly

1. Remove the three screws (1 to 3) and then remove the

monitor cover by disengaging the two hooks (L5a, L5b)

at the top and bottom.

Note

a:

Be careful not to lose part (Lib).

5

2. Pull out the part (sensor) from the monitor case assembly.

3. Disconnect FPC from the connector CN5a and then remove the MONITOR board assembly and backlight.

Note

b:

When removing the parts out of the monitor case

5

assembly, be very careful not to damage the FPC

and parts.

Note5c:

Remove the MONITOR board assembly and

backlight together unless it is needed to separate

them from each other for part replacement, etc.,

because the two are soldered to each other.

4. Take out the LCD module, back light and monitor board

assembly from the monitor case assembly. Be careful

with the hooks (L5e, L5f) on the two sides.

Disconnect the FPC assembly from the connector

(CN5b) and remove the LCD module. Be careful with the

hooks (L5g ,L5h) on the two sides.

1.4.2 Hinge assembly

1. Remove the two screws (4,5) to take out the FPC assembly while removing the hinge cover.

Note

d:

Be careful not to lose any part during the above-

5

mentioned process.

2. Remove the hinge cover (U) from hinge assembly.

e:

Note

Be careful not to lose any part during the abobe

5

mentioned process.

Note5f:

When reassembling, wind the FPC assembly

around the hinge assembly by three turns and a

half.

Be careful not to break the FPC wire during the

work.

MONITOR

CASE ASSY

5

(L f)

HINGE

COVER(L)

5

NOTE e

HINGE

ASSY

FPC ASSY

5

NOTE b,d,e,f

a

5

(L b)

b

b

(L e)

LCD

MODULE

SENSOR

5

(L c)

NOTE d

5

MAGNET

5

(L g)

c

(S c)

(S c)

5

4

5

5

5

NOTE c

BACK LIGHT

HINGE

COVER(U)

5

CN b

5

(L h)

CN a

c

NOTE a

5

1

5

(S a)

2

5

(S a)

NOTE c

MONITOR

5

5

RIB

5

<04>

5

(L b)

a

5

(L b)

NOTE

<WIRING>

MONITOR

COVER

3

5

(S b)

5

c

BROWN

5

CN

b

5

CN

5

NOTE f

FPC ASSY

HINGE

ASSY

ORANGE

a

BLACK

RED

1-8

5

NOTE d

MARKING

Fig. 1-4-1

Page 13

1.5 DISASSEMBLY OF

1.5.1

Note

Note!b:

1. Draw the frame (VF) out of the case assembly.

2. Remove the eyecup and pull out the guide (VF).

<Case assembly>

3. While holding the guide (VF), pull out the case assem-

4. Remove the three screws (3-5) and draw out the eye-

5. Draw out the guide (VF).

Note

E. VF assembly

!

a:

When disassembling the E VF assembly, remove

!

the frame (VF) from the case/cap assembly depending on the situation.

Be very careful not to get the inside of the VF

soiled or dusty during and after disassembling the

E. VF assembly.

bly, remove the two screws (1, 2) and remove the cap

(VF).

piece sub assembly.

c:

A lens assembly and a lever are mounted on the

!

eye-piece sub assembly. When removing this assembly, be careful not to damage them.

E. VF ASSEMBLY

!

<Frame (VF)>

6. Remove the screw (6) first and then LCD module/holder

(LCD).

7. Get the two hooks (L!a, L!b) disengaged and then remove the holder (LCD)

Note

d:

Carefully proceed with the above-mentioned work

!

not to damage any part.

8. Disconnect the connector (CN!a) and remove the LCD

module.

Note!e:

Pay heed the parts not to damage any thing.

: 0.069N·m (0.7kgf·cm)

FPC ASSY

B/L PWB

11

(L

a)

11

CN a

11

CN b

(L b)

LCD MODULE

(S a)

2

11

(S a)

3

11

(S b)

NOTE d

11

HOLDER

(LCD)

11

NOTE b,e

11

1

CAP(VF)

11

6

11

(S c)

FRAME(VF)

NOTE a,b

11

LENS ASSY

(S b)

4

11

(S b)

CASE ASSY

NOTE a,c

11

GUIDE(VF)

5

11

EYE PIECE

SUB ASSY

NOTE c

NOTE c

LENS ASSY

LEVER

CASE ASSY

EYE CUP

11

11

Fig. 1-5-1

1-9

Page 14

1.6 DISASSEMBLY OF # OP BLOCK ASSEMBLY/CCD

BOARD ASSEMBLY

1.6.1 Precautions

1. Carefully handle the CCD image sensor, optical LPF,

lens, etc. during the disassembly work. Pay the most

careful attention to the surface of those parts not to get

it soiled, scratched or dusty. If some of those surfaces

gets soiled with fingerprints, etc., wipe it out with silicone

paper, clean chamois, cleaning cloth or the like.

2. The new CCD image sensor is occasionally shipped from

the factory as a protection seal is applied onto its transparent glass. If so, leave the protection seal as it is and

remove it just before installing the CCD image sensor in

the OP block assembly.

1.6.2 How to remove OP block assembly and CCD

board assembly

1. Remove the spacer.

2. Unsolder at the fourteen points (SD1) and remove the

CCD board assembly.

3. Remove the two screws (1, 2) and then remove the CCD

base assembly.

Note

a:

Carefully remove the CCD base assembly, be-

#

cause the space rubber and optical LPF may be

removed together with the CCD image sensor.

Note#b:

When replacing the CCD image sensor, don’t replace it individually but replace the CCD base assembly in whole with a new one.

1.6.3 How to install # OP block assembly and CCD

board assembly

1. Install the optical LPF with the # OP block assembly.

2. With the spacer rubber left attached to the CCD base

assembly, install the assembly in the OP block assembly and clamp it using the two screws (1, 2).

3. Set the CCD board assembly in the CCD base assembly, and fasten it by soldering at the fourteen points

(SD1).

1.6.4 Replacement of service parts

Service parts to be supplied for the OP block assembly are

as follows.

When replacing a part, be very careful not to get the FPC

wire broken or damaged by soldering (overheating).

1. Focus motor

2. Zoom motor

3. Iris motor unit

Note

c:

When soldering the FPC wire of the focus motor

#

or zoom motor during the replacement work, be

sure to keep the tip of a soldering iron approximately 1 mm above the terminal.

Note#d:

The iris motor unit includes one FPC assembly

and two sensors.

(S b)

ZOOM MOTOR

NOTE c

13

8

13

(S c)

4

13

(S b)

3

13

9

13

(S c)

5

13

(S c)

6

13

(S c)

NOTE d

13

IRIS MOTOR

UNIT

CCD

OP

SIDE

SIDE

BLUE

OPTICAL

LPF

NOTE c

13

OP BLOCK

FOCUS MOTOR

NOTE c

13

7

13

(S c)

1

13

(S a)

(SD1)

(S a)

CCD BASE

ASSY

NOTE a,b

13

SPACER

RUBBER

: 0.118N·m (1.2kgf·cm)

SPACER

2

13

CCD

<05>

1-10

Fig. 1-6-1

Page 15

1.7 EMERGENCY DISPLAY

Whenever some abnormal signal is input to the syscon CPU,

an error number (E01, as an example) is displayed on the

LCD monitor or (in the electronic view finder).

In every error status, such the message as shown below

alternately appear over and over.

• In an emergency mode, all operations except turning on/

off the POWER switch are ineffectual.

LCD

display

E01 LOADING

E02 UNLOADING

E03 TU & SUP REEL

Emergency

mode

FG

Details

In the case the encoder position is not shifted

to the next point though the loading motor has

rotated in the loading direction for 4 seconds

or more. This error is defined as [E01].

In the case the encoder position is not shifted

to the next point though the loading motor has

rotated in the unloading direction for 4 seconds

or more. This error is defined as [E02].

In the case no REEL FG is produced for 4 seconds or more in the capstan rotation mode after loading was complete, the mechanism mode

is shifted to STOP with the pinch roller set off.

This error is defined as [E03].

However, no REEL EMG is detected in the

SLOW/STILL mode.

Example (in case of the error number E01):

E01

UNIT IN

SAFEGUARD MODE

E01

REMOVE AND

REATTACH BATTERY

Possible cause

1. The mechanism is locked during mode shift.

2. The mechanism is locked at the mechanism loading

end, because the encoder position is skipped during

mechanism mode shift.

3. No power is supplied to the loading MDA.

1. The mechanism is locked during mode shift.

2. The mechanism is locked at the mechanism loading

end, because the encoder position is skipped during

mechanism mode shift.

1. The idler gear does not engage with the reel disk well.

2. Though the idler gear and reel disk are engaged with

each other, the tape is not wound because of overload to the mechanism.

3. No FG pulse is output from the reel sensor.

4. No power is supplied to the reel sensor.

5. Tape transport operation takes place with a cassette

having no tape inside.

6. The tape slackens and no pulse is produced until the

slack is taken up and the tape comes into the normal

status.

E04 DRUM FG

E05 –

E06 CAPSTAN FG

In the case there is no DRUM FG input in the

drum rotation mode for 4 seconds or more. This

error is defined as [E04], and the mechanism

mode is shifted to STOP with the pinch roller

set off.

–

In the case no CAPSTAN FG is produced in

the capstan rotation mode for 2 seconds or

more. This error is defined as [E06], and the

mechanism mode is shifted to STOP with the

pinch roller set off.

However, no CAPSTAN EMG is detected in the

STILL/FF/REW mode.

Table 1-7-1

1. The drum cannot be started or drum rotation is stopped

because tape transport load is too high.

1) Tape tension is extremely high.

2) The tape is damaged or soiled with grease, etc.

2. The DRUM FG signal is not received by the syscon

CPU.

1) Disconnection in the middle of the signal line.

2) Failure of the DRUM FG pulse generator (hall ele-

ment).

3. No drum control voltage is supplied to the MDA.

4. No power is supplied to the DRUM MDA.

–

1. The CAPSTAN FG signal is not received by the syscon

CPU.

1) Disconnection in the middle of the signal line.

2) Failure of the CAPSTAN FG pulse generator (MR

element).

2. No capstan control voltage is supplied to the MDA.

3. No power is supplied to the CAPSTAN MDA.

4. The capstan cannot be started or capstan rotation is

stopped because tape transport load is too high.

1) Tape tension is extremely high. (Mechanical lock-

ing)

2) The tape is damaged or soiled with grease, etc.

(Tape tangling occurs, etc.)

(DVC_03)

1-11

Page 16

1.8 SERVICE KNOW-HOW

When performing disassembly/assembly work to this model,

the parts that are most complicated and require special attention are the EVF unit and the AUDIO board, OP block and

shoe assemblies, all of which are mounted inside the lower

case assembly.

Care should be taken in handling these parts as they are

mounted inside the lower case assembly (except the E.VF

unit) and there is a lack of adequate space to work conveniently. This section gives further details regarding the disassembly procedures, although they have been described in

previous sections.

1. See Fig. 1-8-1.

(1) Remove the hood by moving the 0 microphone out of

way.

(2) Peel off the spacer, remove the screw (32) and take out

the # OP block assembly by moving the 0 microphone

out of the way.

(3) Remove the screw (33) and, while opening the @ AU-

DIO board assembly, disconnect the wire from the connector (CN203) and remove the 0 microphone.

(4) Remove the screw (34), peel off the spacer, take out

the ! E.VF assembly by moving the $ shoe assembly

out of way, disconnect the FPC from the connector

(CN204).

Note:

Be careful not to damage the FPC or the switches

when carrying out this work.

NOTE a

10

AUDIO

PWB

CN a

32

(S )

SW

10

13

CN a

13

CN a

(S )

11

33

12

NOTE

10

a

14

11

SPACER

34

11

(S )

10

1-12

SPACER

7

12

Fig. 1-8-1

13

NOTE b

10

HOOD

Page 17

2. See Fig. 1-8-2.

(1) Remove the two screws (35,36) in order to free the @

AUDIO board assembly.

(2) Remove the three screws (37 to 39), peel off the spacer

and take out the @ AUDIO board assembly together with

the # OP block assembly and the $ shoe assembly.

Note:

Be careful not to lose the VIDEO and DSC knobs,

which may slip out during the disassembly.

(3) Disconnect the FPCs from the connectors on the # OP

block assembly and the $ shoe assembly.

37

14

(S )

SPACER

KNOB

(VIDEO

/DSC)

12

(S )

14

CN a

CN a

(S b)

SPACER

14

39

35

12

14

13

38

14

(S )

(S b)

13

36

12

Fig. 1-8-2

1-13

Page 18

1.9 SERVICE NOTE

1 2 3 4 5 6 7 8 9 11 12 13 14 16 17 18

19 20 21

12 3

67 8 90!

!5

#

@# $

45

Fig.1-3-1

Fig.1-3-2

Fig.1-3-3a Fig.1-3-3b Fig.1-3-4

I

I

II

22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39

MONITOR ASSY

Fig.1-3-5

Fig.1-3-6 Fig.1-3-7 Fig.1-3-8a Fig.1-3-8b

–

Fig. 1-4-1

I

Symbol No.

Removing order of screw

Place to stick screw

Reference drawing

Screw tightening torque

Symbol No.

Removing order of screw

Place to stick screw

Reference drawing

Screw tightening torque

Removing order of screw

Place to stick screw

Reference drawing

Screw tightening torque

Removing order of screw

Place to stick screw

Reference drawing

Screw tightening torque

Removing order of screw

Place to stick screw

Reference drawing

Screw tightening torque

1 2 3 4 5 1 2 3 4 5 6

E VF UNIT

OP BLOCK ASSY

Fig.1-6-1

III

IV

1234 56789

< NOTE >

1) : : Don’t reuse the screw, because screw lock bond was applied to them.

2) Pay careful attention to tightening torque for each screw.

I : 0.078N·m (0.8kgf·cm)

II : 0.098N·m (1.0kgf·cm)

III : 0.118N·m (1.2kgf·cm)

IV : 0.069N·m (0.7kgf·cm)

Fig.1-5-1

Table 1-9-1

1-14

Page 19

SECTION 2

MECHANISM ADJUSTMENT

2.1 PRELIMINARY REMARKS ON ADJUSTMENT AND REPAIR

2.1.1 Precautions

1. When fastening parts, pay careful attention to the tight-

ening torque of each screw. Unless otherwise specified,

tighten a screw with the torque of 0.039 N

2. Be sure to disconnect the set from the power supply be-

fore fastening and soldering parts.

3. When disconnecting/connecting wires, be careful not to

get them and their connectors damaged. (Refer to the

Section 1.)

4. When replacing parts, be very careful neither to dam-

age other parts nor to fit wrong parts by mistake.

2.1.2 Notes on procedure for disassemby/assembly

The disassembling procedure table (Table 2-4-1 on page

2-5,a part of the table is shown below for reference)shows

the procedure to disassemble/reassemble mechanism

parts.

Carefully read the following explanation before starting actual disassembling/reassembling work. The item numbers

(circled numbers)in the following explanation correspond

to those appearing under respective columns of the table.

(1) Circled numbers appearing in this column indicate the

order to remove parts. When reassembling, follow these

numbers in the reverse order. Circled numbers in this

column correspond to those appearing in drawings of

this section.

(2) This column shows part names corresponding to circled

numbers in the left column.

(3) The symbol (T or B)appearing in this column shows the

side which the objective part is mounted on.

T =the upper side, B =the lower side

(4) Symbols appearing in this column indicate drawing

numbers.

Step Part Name Fig. Point Note Remarks

•

m (0.4 kgf•cm).

(5) This column indicates parts and points such as screws,

washers,springs,and others to be removed/fitted for disassembling/reassembling the mechanism. Besides such

the parts, this column occasionally indicates working

points.

P = Spring

W = Washer

S = Screw

* = Lock (L),soldering (SD),shield,connector (CN),

etc.

Example • Remove ((W1)=Washer W1.

• **Remove the solder at (SD1)=Point SD1.

• **Disconnect

(6) Numbers in this column represent the numbers of notes

in the text.

(For parts that need phase adjustment after reassembling, refer to “2.6 MECHANISM ADJUSTMENTS”.)

(7) This column indicates required after-disassembling/-re-

assembling work such as phase adjustment or mechanism adjustment.

=Connector Å .

Å

NO. PART NAME FIG. POINT NOTE REMARKS

1 CASSETTE HOUSING ASSY T Fig.2-4-3 3(S1),(L1a)-(L1e)

2 UPPER BASE ASSY T Fig.2-4-4 (S2),(L2a),(L2b)

3 DRUM ASSY T (S3a),2(S3b)

4 REEL DISK ASSY(SUP) T Fig.2-4-5 (W4)

5 REEL DISK ASSY(TU) T (W5)

6 REEL COVER ASSY T 2(W6),(S6a),2(S6b)

(1) (2) (3) (4) (5) (6) (7)

NOTE1a,b,c,d

NOTE

2

NOTE3a,b

NOTE4a

NOTE

5

NOTE

6

ADJUSTMENT

ADJUSTMENT

2-1

Page 20

2.2 JIGS AND TOOLS REQUIRED FOR DISASSEMBLY, ASSEMBLY AND ADJUSTMENT

2.2.1 Tools required for adjustments

1

3

5

7

9

11

13

15

Torque Driver

YTU94088

Tweezers

P-895

Guide Driver (Hexagonal)

D-770-1.27

Slit Washer Installation Jig

YTU94121A

Jig Connector cable

YTU93106C

PC cable

QAM0099-002

Service Support System

YTU94057-54

Cleaning Cloth

KSMM-01

2

Chip IC Replacement Jig

4

6

Slit Washer Installation Jig

8

10

12

Cassette Torque Meter

14

Bit

YTU94088-003

PTS40844-2

Adjustment Driver

YTU94028

YTU94121B

Communication cable

YTU93107A

Alignment Tape

MC-1

YTU94151A

1. Torque Driver

Be sure to use to fastening the mechanism and exterior

parts because those parts must strictly be controlled for

tightening torque.

2. Bit

This bit is slightly longer than those set in conventional

torque drivers.

3. Tweezers

To be used for removing and installing parts and wires.

4. Chip IC Replacement Jig

To be used for adjustment of the camera system.

5. Guide Driver (Hexagonal)

To be used to turn the guide roller to adjustment of the

linarity of playback envelope.

6. Adjustment Driver

To be used for adjustment.

7. Slit Washer Installation Jig

To be used to install slit washers.

8. Slit Washer Installation Jig (NEW TYPE)

To be used to install slit washers.

9. Jig Connector Cable

Connected to CN114 of the main board and used for

electrical adjustment, etc.

10. Communication Cable

Connect the Communication cable between the PC cable and Jig connector cable when performing a PC adjustment.

11. PC Cable

To be used to connect the VideoMovie and a personal

computer with each other when a personal computer is

used for adjustment.

12. Alignment Tape

To be used for check and adjustment of interchangeability of the mechanism.

13. Service Support System

To be used for adjustment with a personal computer.

14. Cassette Torque Meter

This is used to cheek the back tension and play torque

during mechanism adjustment.

When using the cassette torque meter, install the

Note:

service support system software in advance.

•

LED : Forced to ON

•

EJECT SW : OFF (Cancel)

The above setting is required to prevent any tape

damage that may occur because the cassette

torque meter cannot detect the leading/trailing sections of the tape.

15. Cleaning Cloth

Recommended cleaning cloth to wipe down the video

heads, mechanism (tape transport system), optical lens

surface.

2-2

Table 2-2-1

Page 21

2.3 DISASSEMBLY/ASSEMBLY OF MECHANISM AS-

<SUB CAM GEAR>

TOP VIEW BOTTOM VIEW

<C IN mode>

<SHORT FWD mode>

<STOP mode>

<REV mode>

<PLAY mode>

SEMBLY

2.3.1 General statement

The mechanism should generally be disassembled/assembled in the C.IN mode (ASSEMBLY mode). (Refer to Fig.

2-3-1,2.)

However, when the mechanism is removed from the main

body, it is set in the STOP mode. Therefore, after the

mechanism is removed from the main body, supply 3 V DC

to the electrode on the top of the loading motor to enter

the mechanism mode into the C,IN mode compulsory.

<Mechanism assembly/Cassette housing assembly>

DC3V

2.3.2 Explanation of mechanism mode

The mechanism mode of this model is classified into five

modes as shown in Table 2-3-1. Each mechanism mode

can be distinguished from others by the relative position

”, “Q”, “Q” “ ” marks on the sub cam gear to the in-

of “

ner or outer protrusion on the main deck.

Refer to Fig. 2-3-3 to 2-3-8 below.

Fig. 2-3-3

<Back side of the mechanism assembly>

C IN mode

LOADING MOTOR

Fig. 2-3-4

Fig. 2-3-5

Fig. 2-3-1

Fig. 2-3-6

Back side of deck

Fig. 2-3-2

Fig. 2-3-7

Fig. 2-3-8

2-3

Page 22

2.3.3 Mechanism timing chart

PARTS

MAIN CAM

SUB CAM

ROTARY

ENCODER

EJECT LEVER

TENSION ARM

TU ARM

SLIDE DECK

BRAKE (S)

BRAKE (T)

MODE

OFF

L. END

LOCK

L. END

OFFPAD ARM

OFF

LOAD

L. END

LOADSUP. L. ARM

L. END

LOADTU. L. ARM

PRESS

LOADP. ROLLER

OFF

OFF

SHORT

EJECT

CAS. IN

-12.40° (22.44°) (69.53°) (80.5°) (150.58°) (153.5°)58.71°0° 177.79° 212.77° 243.94°

-16.97° (30.71°) (95.14°) (110.06°) (206.06°) (210.05°)80.34°0° 243.29° 291.16° 333.82°

-15° (27.14°) (84.08°) (97.35°) (182.10°) (185.63°)71°0°

-13°-3° 3° 68°

a

b

c

ON

UL

UL

ON

UL

UL

UL

UL

ON

ON

R

RELEASE

TU. P. B

START

SLIDE SLIDE

START

TU. P. B

END END

STOP PLAYREVFWD

215°

212° 218°

257.3°

254.3° 260.3°

295°

292° 310°74°

CTL PLATE

RELEASE

LEVER

2-4

C

L

ON

OFF

Table 2-3-1

Page 23

2.4 DISASSEMBLING PROCEDURE TABLE

MARK: 夝 After assembly, perform adjustments.

NO. PART NAME FIG. POINT NOTE REMARKS

1 CASSETTE HOUSING ASSY T Fig.2-4-3 3(S1),(L1a)-(L1e)

2 UPPER BASE ASSY T Fig.2-4-4 (S2),(L2a),(L2b)

3 DRUM ASSY T (S3a),2(S3b)

4 REEL DISK ASSY(SUP) T Fig.2-4-5 (W4)

5 REEL DISK ASSY(TU) T (W5)

6 REEL COVER ASSY T 2(W6),2(S6a),(S6b)

7 TENSION ARM ASSY T Fig.2-4-6 —

8 SLANT POLE ARM ASSY T —

9 TU ARM ASSY T —

10 SWING ARM ASSY T (S0)

11 SLIDE DECK ASSY T Fig.2-4-7a 2(S!a),(S!b),2(L!a),

2(L!b),(L!c)

12 PAD ARM ASSY T Fig.2-4-7b (P@),(L@),(W@)

13 SUP BRAKE ASSY T (P#),(L#),(S#)

14 TU BRAKE ASSY T (P$),(L$),(W$)

15 TENSION CTL LEVER ASSY T Fig.2-4-8 —

16 CENTER GEAR T —

17 PINCH ROLLER ARM F. ASSY T (W&)

18 TENSION CTL PLATE ASSY T —

19 BRAKE CTL LEVER ASSY T —

20 MOTOR BRACKET ASSY T Fig.2-4-9 3(S)),(L)a),2(L)b)

21 GUIDE RAIL ASSY T

22 SLIDE LEVER 2 ASSY T —

23 LOADING PLATE ASSY T (W‹)

24 MODE GEAR T —

25 EJECT LEVER T (Wfi)

26 BASE R ASSY T Fig.2-4-10 (Sfla),(Sflb),2(Lfl)

27 ROTARY ENCODER T 2(S‡)

28 GEAR COVER ASSY T (S°a),2(S°b)

29 MAIN CAM ASSY T —

30 SLIDE ARM ASSY T Fig.2-4-11 —

31 CONNECT GEAR 2 T —

32 SUB CAM ASSY T (S™)

33 CONTROL ARM ASSY T —

34 REEL GEAR 1 T —

35 / 36

DRUM BASE ASSY/ T Fig.2-4-12 3(S∞)

CAPSTAN MOTOR

36 CAPSTAN MOTOR T (S§)

37 MAIN DECK ASSY T —

2(W⁄),(S⁄),2(L⁄a),(L⁄b)

NOTE1a,b,c,d

NOTE

2

NOTE3a,b

NOTE

4

NOTE

5

NOTE

6

NOTE

7

NOTE

8

NOTE

9

NOTE

0

NOTE!a,b

NOTE

@

NOTE

#

NOTE

$

NOTE

%

NOTE

^

NOTE

&

NOTE

*

NOTE

(

NOTE

)

NOTE

⁄

NOTE

¤

NOTE

‹

NOTE

›

NOTE

fi

NOTE

fl

NOTE

‡

—

NOTE

·

NOTE

‚

NOTE

¡

NOTE

™

NOTE

£

NOTE

¢

NOTE∞a,b

NOTE

§

—

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT / 夝

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT / 夝

ADJUSTMENT / 夝

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT / 夝

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT

PHASE ADJUSTMENT

PHASE ADJUSTMENT

ADJUSTMENT

PHASE ADJUSTMENT

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT

Table 2-4-1

2-5

Page 24

< TOP VIEW >

24 27 2 3 36 3521

17

< BOTTOM VIEW >

20

23

18

8

7

22

12

4

29

19

34

143128161530

13

Fig. 2-4-1

5

36 3 22

26

34

9

10

33

26

6

37

25

32

11

26

32

25

31 16 6

Fig. 2-4-2

37

11

27

20

30

18

19

29

30

2-6

Page 25

2.4.1 Disassembly/assembly

1

(S )

1

2

(S )

1

1

NOTE d

1

NOTE c

1

NOTE b

1

NOTE a

1

(S )

1

3

(L d)

LOCK

LEVER

1

(L a)

1

(L e)

1

(L c)

1

(L b)

1

NOTE d

1

2

3

(S )

2

4

(S b)

7

3

(S b)

6

3

(S a)

5

3

(L b)

2

(L a)

2

NOTE

2

NOTE

3

NOTE b

3

NOTE

2

a

CASSETTE HOUSING ASSY

1.

1

NOTE1a:

Be careful not to damage any of the

parts during work.

NOTE1b:

Special care is required in mounting.

1

NOTE b

NOTE1c:

NOTE c

When mounting, the CASSETTE

HOUSING ASSY should be attached in the Eject status. Pay

heed to the positions of the LOCK

LEVER and EJECT LEVER during

mounting.

NOTE1d:

When mounting, be sure to locate the

FPC in the gap.

2.

UPPER BASE ASSY

2

DRUM ASSY

3

NOTE

NOTE2:

When mounting, be sure to insert

the FPC reinforcing sheet.

1

EJECT

LEVER

NOTE d

LOCK

LEVER

1

Fig. 2-4-3

2

NOTE3a:

Be mindful of scratches or damage

during work.

NOTE3b:

Be careful not to attach screws incorrectly.

3

NOTE

b

5

7

6

Fig. 2-4-4

2-7

Page 26

REEL DISK ASSY(SUP)

3.

4

REEL DISK ASSY(TU)

5

REEL COVER ASSY

6

NOTE4:

Be careful not to attach the REEL DISK wrongly. The Supply side can be identified by the white color at the center.

4 5

NOTE5:

Be careful not to attach the

REEL DISK wrongly. The

NOTE ,

REEL DISK ASSY

WHITE

BLACK

Take-up side can be identified by the black color at

the center.

NOTE

6

SUP

:

TU

Perform the following steps for mounting.

1. Align the 2 holes with the pins.

2. Attach the PINCH ROLLER ARM ASSY by aligning the

positions.

3. Attach the SUB DECK

ASSY by aligning the

positions.

4. Check that the parts

NOTE

6

53

2,6

below them are located in the correct

positions.

5. Tighten the 2 screws.

4

6. Tighten the screw.

7. Attach the 2 SLIT

WASHER parts.

1, 7

NOTE

4

NOTE

(W )

4

8

6

(S a)

6

(W )

6

6

4

(W )

5

(W )

6

Fig. 2-4-5

NOTE

5

10

6

(S b)

5

9

6

(S a)

4.

TENSION ARM ASSY

7

SLANT POLE ARM ASSY

8

TU ARM ASSY

9

SWING ARM ASSY

0

NOTE7:

When detaching, remove the spring

of the @ PAD ARM ASSY in advance.

Pay attention to the attachment position.

NOTE8:

Be careful not to lose any parts

(such as a spring).

NOTE9:

Pay attention to the

mounting position.

9

NOTE

7

NOTE

SPRING

8

NOTE

SPRING

10

NOTE

TOP SIDE

NOTE

7

NOTE

7

(P )

NOTE

NOTE

7

10

8

NOTE

8

8

10

11

10

(S )

9

9

NOTE0:

When detaching, remove the

screw then remove the SWING

ARM ASSY by pulling it up and

turning it.

2-8

Fig. 2-4-6

Page 27

5.

11

(S b)

14

11

(S a)

12

11

(S a)

13

11

(L b)

11

(L a)

11

(L c)

11

NOTE a

11

NOTE b

11

SLIDE DECK ASSY

!

NOTE!a:

Each of the parts on the SLIDE DECK ASSY can be replaced separately.

When detaching the assembly, if there is no need to replace

any of its parts, remove the SLIDE DECK ASSY as it is.

NOTE!b:

When mounting, pay attention to the positions of the

¤

SLIDE LEVER (2) studs and the BRAKE CONTROL LEVER

ASSY.

When mounting, position the CONTROL PLATE on the left

side.

Pay attention to the position of the SLIDE GUIDE PLATE

during mounting.

11

NOTE

b

6.

PAD ARM ASSY

@

SUP BRAKE ASSY

#

TU BRAKE ASSY

$

NOTE@:

The spring may have already been disengaged when the

8

SLANT POLE ARM ASSY was removed.

NOTES#/$:

When mounting, pay attention to the correct positioning.

Mount the CONTROL PLATE by moving it fully toward the

left side.

12 13 14

NOTE

12

SPRING

CONTROL

PLATE

13 14

12

(W )

NOTE

(L )

13

13

12

15

(S )

13

NOTE

12

(P )

13

Fig. 2-4-7a

12

13

(P )

(W )

12

(L )

14

14

NOTE

(L )

14

(P )

14

14

Fig. 2-4-7b

2-9

Page 28

TENSION CTL LEVER ASSY

7.

%

CENTER GEAR

^

PINCH ROLLER ARM F. ASSY

&

TENSION CTL PLATE ASSY

*

BRAKE CTL LEVER ASSY

(

NOTES%/^:

When mounting, pay attention to the correct positioning.

15

NOTE

NOTE

16

(TOP)

(BOTTOM)

NOTES*/(:

When mounting, pay at-

NOTE&:

Take care against grease

attachment during work.

17

NOTE

tention to the correct positioning.

19

NOTE

18

NOTE

NOTE

15

NOTE

19

15

19

NOTE

18

18

NOTE

17

16

17

NOTE

17

(W )

16

MOTOR BRACKET ASSY

8.

)

GUIDE RAIL ASSY

⁄

SLIDE LEVER 2 ASSY

¤

LOADING PLATE ASSY

‹

MODE GEAR

›

EJECT LEVER

fi

NOTE):

When mounting, pay attention to the positioning of the sliding parts.

21

NOTE

NOTE⁄:

When mounting, take care

that no part is allowed to

float or rattle.

NOTES¤/‹/›/fi:

NOTE

When mounting, pay attention to the

correct positioning.

23

NOTE

22

NOTE

NOTE

24

Fig. 2-4-8

20

21

(W )

(W )

23

22

21

NOTE

19

21

(S )

22

(L a)

21

(L b)

21

NOTE

18

20

(S )

20

20

17

20

(S )

NOTE

16

20

(S )

21

21

NOTE

23

23

(L b)

25

(W )

(L a)

20

(W )

20

NOTE

24

24

25

25

NOTE

2-10

NOTE

25

Fig. 2-4-9

Page 29

BASE R ASSY

9.

fl

ROTARY ENCODER

‡

GEAR COVER ASSY

°

MAIN CAM ASSY

·

NOTEfl:

When mounting, fold the sliding

part to the inner side.

NOTE

22

27

(S )

27

NOTE

26

27

23

27

(S )

25

26

28

24

28

(S a)

21

26

(S b)

28

(S b)

(S b)

NOTE‡:

When mounting, pay attention to

the correct positioning and the

FPC layout.

NOTE

·

:

When mounting, pay attention to

the correct positioning.

SLIDE ARM ASSY

10.

‚

CONNECT GEAR 2

¡

SUB CAM ASSY

™

CONTROL ARM ASSY

£

REEL GEAR 1

¢

NOTE

‚

:

When mounting, pay attention to the

correct positioning and the FPC layout.

NOTE

NOTE

NOTE

20

26

27

(S a)

28

29

29

NOTE

29

26

NOTE

26

26

(L )

Fig. 2-4-10

30

30

NOTE

30

27

32

(S )

NOTE

32

32

NOTE

34

34

NOTE¡:

When mounting, pay attention to the position of the front and back.

NOTE

(BOTTOM)

31

(TOP)

NOTES™/£/¢:

When mounting, pay attention to the correct positioning and

the FPC layout.

34

32 33

NOTE /

33

32

NOTE

NOTE

31

31

Fig. 2-4-11

33

NOTE

33

2-11

Page 30

11.

DRUM BASE ASSY

∞

CAPSTAN MOTOR

§

MAIN DECK ASSY

¶

NOTES

∞

a /§:

When detaching, remove them together and then separate

from ∞a.

§

∞

b:

NOTE

When mounting, attach the DRUM BASE ASSY so that the

screw hole is located at the center of the ellipse.

35

NOTE b

NOTE

35

35

28

35

(S )

a

29

35

(S )

31

36

(S )

30

35

(S )

NG

OK

NG

NOTE

36

36

Fig. 2-4-12

37

NOTE

35

b

2-12

(Z27 Ver.2)

Page 31

2.4.2 List of procedures for disassembly

(S15 )

13

13

(P )

18

20

(S )

(W )

13

12

14

17

20

(S )

20

12

(S b)

8

(P )

14

(W )

14

(P )

8

(S )

14

11

(P )

(S )

2

1

12

16

20

4

(W )

4

8

6

(S a)

6

(W )

6

7

23

(W )

22

27

(S )

18

27

(W )

6

(W )

30

23

5

(S b)

11

(S )

23

27

(S )

5

10

6

10

13

11

(S a)

3

1

(S )

34

1

9

6

(S a)

10

12

11

(S a)

11

21

(W )

1

(S )

22

21

(W )

19

(S )

21

1

9

(S b)

21

(S )

28

35

(S )

35

7

3

(S b)

5

3

(S a)

6

3

(S )

29

35

17

36

4

2

2

3

31

36

(S )

30

35

(S )

17

(W )

25

28

(S b)

15

29

16

31

26

28

(S b)

28

24

28

(S a)

19

24

37

Fig. 2-4-13

21

26

(S b)

20

26

(S a)

26

25

(W )

(S )

25

27

32

32

33

2-13

Page 32

2.5 CHECKUP AND ADJUSTMENT OF MECHANISM PHASE

MODE GEAR

24

Align the MODE GEAR with the Main Deck

Assembly hole.

Note:

The MODE GEAR may

be displaced during the

mechanism operation,

however it can be

checked from the rear

and realigned during

manual assembly.

27

ROTARY ENCODER

Mount the ROTARY ENCODER by aligning its mark ( )

and the mark ( ) of the Main Deck Assembly.

Note:

Be careful when handling the FPC during mounting.

34

REEL GEAR 1

Align the REEL GEAR 1 with

the Main Deck Assembly hole.

Note:

The REEL GEAR 1 may be

displaced during mechanism

operation, however this can

be checked from the rear and

realigned during manual

assembly.

MAIN CAM ASSY/ 30 SLIDE ARM ASSY

29 32

When mounting the SLIDE ARM ASSY align it with the

Main Deck Assembly and MAIN CAM ASSY holes.

Note:

During the mounting procedure, make sure that the 32 .

SUB CAM ASSY is in the correct mounting position.

Fig. 2-5-1

SUB CAM ASSY/ 33 CONTROL ARM ASSY

Mount the SUB CAM ASSY hole to align with the CONTROL

ARM ASSY and Main Deck Assembly holes and then tighten

them all together with a screw.

The screw tightening torque should be 0.039 N•m (0.4 kgf•cm)

Note:

When mounting it, make sure that the 29 MAIN CAM ASSY is

in the correct mounting position.

2-14

Page 33

2.6 MECHANISM ADJUSTMENTS

2.6.1 Adjustment of the slide guide plate

Use Fig. 2-6-1 as the reference unless otherwise specified.

1. Set the PLAY mode.

See Fig. 2-3-8.

2. Loosen the screws ( A , B ).

3. With the Main Deck and Slide Deck Assemblies pushed

into the unit, tighten the screws ( A , B ) while applying

pressure to the stud (shaft) on the Slide Guide plate.

The pressure applied should be enough to enable utilization of the rebounding force of the springs.

The tightening torque should be 0.069 N

•

m (0.7 kgf•cm).

4. Check the operation.

Repeat unloading and loading several times and make

sure that these operations can be performed smoothly

without producing rattles.

3

2, 3

SCREW

3

STUD

(SHAFT)

3

3

A

2,3

SCREW

B

3

Fig. 2-6-1

2-15

Page 34

2.6.2 Adjustment of the Tension Arm and Pad Arm Assemblies

Use Fig. 2-6-2 as the reference unless otherwise specified.

1. Set the PLAY mode.

Se Fig. 2-3-8.

2. Loosen the screw A .

3. With the take-up side at the bottom, align the extreme

end of the Tension Arm Assembly with the crossed

grooves on the screw B that retains the Loading Motor

Assembly and then tighten the screw A .

The tightening torque should be 0.069 N

•

m (0.7 kgf•cm).

4. Check the operation.

Repeat unloading and loading several times and make

sure that the Tension Arm Assembly is located within the

normal range.

Note :

With the above checking method, a Torque Meter is not used.

When a Torque meter is used, the following are

the reference values:

2, 3

SCREW

SCREW

A

TENSIOM

ARM ASSY

B

Back Tension : 2.0 to 6.0 g•cm

Play Torque : 8.3 to 12.5 g

•

cm

2.6.3 Adjustment of the Slide Lever 2

Use Fig. 2-6-3 as the reference unless otherwise specified.

1. Set the C IN mode.

See Fig. 2-3-4.

2. Loosen the screw A .

3. Set the Main Deck and Slide Deck Assemblies apart so

that they do not rattle, then tighten the screw A by

screwing it fully toward the Drum Assembly.

The tightening torque should be 0.069 N

•

m (0.7 kgf•cm).

4. Check the operation.

Repeat unloading and loading several times and make

sure that these operations can be performed smoothly

without producing rattles.

2, 3

SCREW

Fig. 2-6-2

3

A

2-16

3

Fig. 2-6-3

Page 35

2.7 JIG CONNECTOR CABLE CONNECTION

Remove one screw (1) first and the cover (JIG) next.

GUIDE ROLLER

(SUP) ASSY

COVER

(M.ADJ)

MAIN

CN114

VF_RPD 40

CVF_G 20

CVF_R 39

CVF_B 19

VF_COM 38

MT_RPD 18

MT_G 37

MT_R 17

MT_B 36

MT_COMCS 16

MT_PSIG 35

GND 15

GND 34

MONI_CHG 14

SBE 33

SPA 13

FRP 32

FS_PLL 12

DISCRI 31

HID1 11

ATFI 30

MAIN_VCO 10

ENV_OUT 29

PB_CLK 9

TRST 28

TCMK 8

TMS 27

TDO 7

TDI 26

JLIP_RX 6

JLIP_TX 25

IF_TX 5

AL_3VSYS 24

RST 4

VPPC 23

SRV_RX 3

SRV_TX 22

REG_3V 2

DRST 21

VPPD 1

JIG CONNECTOR CABLE

Fig. 2-7-1

JIG CONN. BOARD

(PIN NO.)

40 VF_RPD

39 CVF_R

38 VF_COM

37 MT_G

36 MT_B

35 MT_PSIG

33 SBE

32 FRP

31 DISCRI

30 ATFI

29 ENV_OUT

28 TRST

27 TMS

26 TDI

25 JLIP_TX

20 CVF_G

19 CVF_B

18 MT_RPD

17 MT_R

16 MT_COMCS

15 GND

14 MONI_CHG

13 SPA

12 FS_PLL

11 HID1

10 MAIN_VCO

9 PB_CLK

8 TCMK

7 TDO

6 JLIP_RX

NOTE)

The JIG connector board uses 30 of the 40 pins of CN114 on

the Main board.

Pins 1 to 5, 21 to 24 and 34 of CN114 on the Main board are

not used.

1

COVER

(JIG)

GUIDE ROLLER

(TU) ASSY

Fig. 2-7-2

2-17

Page 36

2.8 SERVICE NOTE

Use the following chart to manage mechanism parts that are removed for disassembling the mechanism.

Fig.

1

CASSETTE HOUSING ASSY UPPER BASE ASSY

Fig.

2

2

I

4

I

3

Fig. Fig.

3

DRUM ASSY

2

I

4

I

4

2

I

4

I

5

REEL DISK ASSY(SUP)

4

REEL DISK ASSY(TU)

5

2

I

4

I

4

REEL COVER ASSY

6

Fig.

TENSION ARM ASSY

7

SLANT POLE ARM ASSY SWING ARM ASSYTU ARM ASSY

8 9

2

I

4

I

6

Fig. Fig.

2

I

4

I

7

a

SLIDE DECK ASSY

11

2

I

4

I

7

b

PAD ARM

ASSY

1312

10

SUP

BRAKE

ASSY

14

TU BRAKE

ASSY

2-18

Table 2-8-1a

Page 37

Fig.

2

I

4

I

8

TENSION CTL

15

LEVER ASSY

CENTER GEAR

16

PINCH ROLLER

17

ARM F. ASSY

TENSION

18

CTL PLATE

ASSY

BRAKE CTL

19

LEVER

ASSY

Fig.

2

I

4

I

9

Fig.

2

I

4

I

10

Fig.

MOTOR

20

BRACKET

ASSY

BASE R ASSY ROTARY

26

SLIDE ARM

30

ASSY

31

27

CONNECT

GEAR 2

GUIDE

21

RAIL ASSY

ENCODER

32

28

SUB CAM

ASSY

22

24

GEAR COVER

ASSY

33

SLIDE LEVER 2

ASSY

MODE GEAR EJECT LEVER

MAIN CAM ASSY

29

CONTROL

ARM ASSY

LOADING

23

PLATE ASSY

25

REEL GEAR 1

34

2

I

4

I

11

Fig.

2

I

4

I

12

DRUM BASE ASSY

35

CAPSTAN MOTOR MAIN DECK ASSY

36

Table 2-8-1b

37

2-19

Page 38

SECTION 3

ELECTRICAL ADJUSTMENT

3.1 PRECAUTION

1. Precaution

Both the camera and deck sections of this model needs a

personal computer for adjustment except simple adjustment

with potentiometers. If some of the following parts is replaced

for repair or other reason, the repaired set must be adjusted