Page 1

SECTION 5

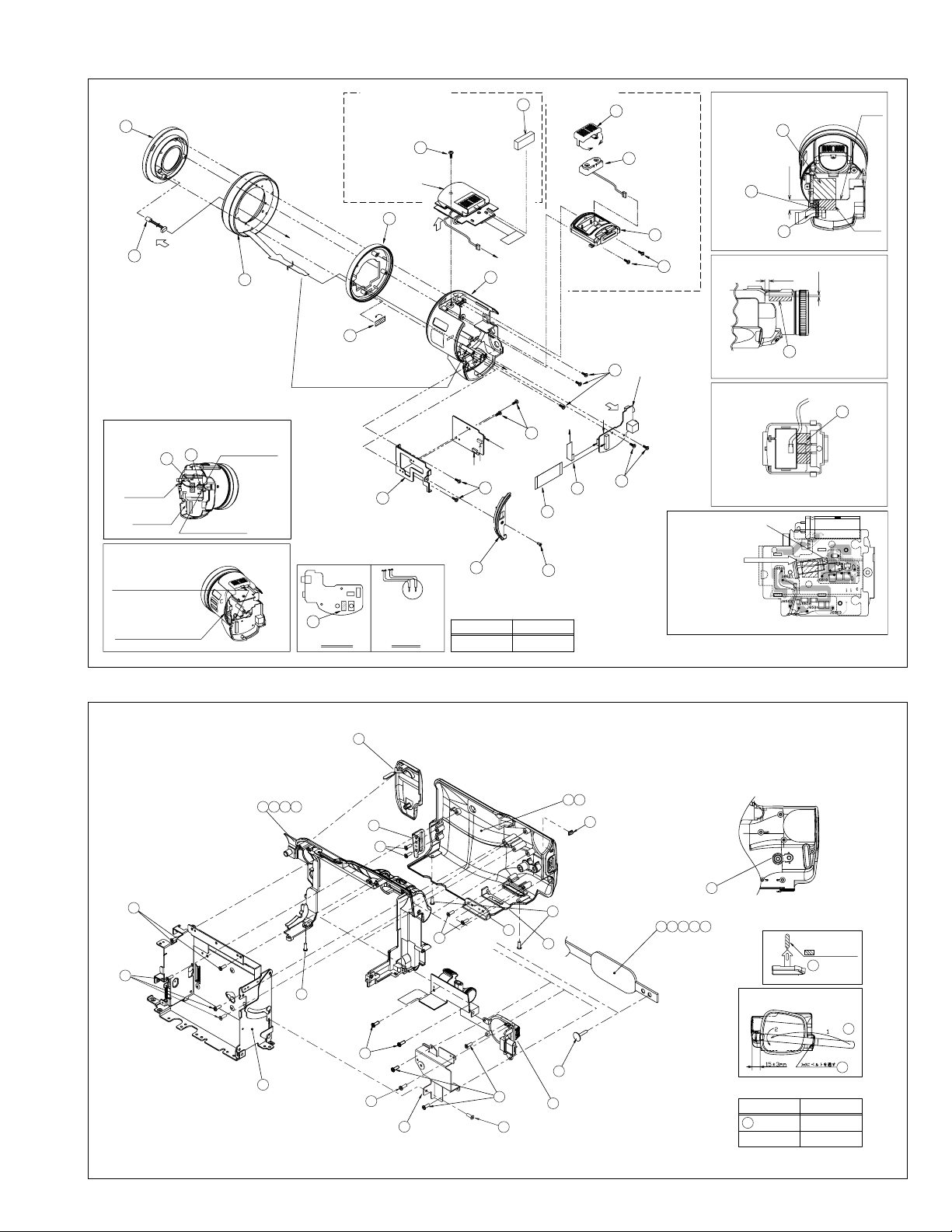

5.1 EXPLODED VIEW

SAFETY PRECAUTION

Parts identified by the symbol are critical for safety. Replace only with specified part numbers.

BEWARE OF BOGUS PARTS

Parts that do not meet specifications may cause trouble in regard to safety and performance. We

recommend that genuine JVC parts be used.

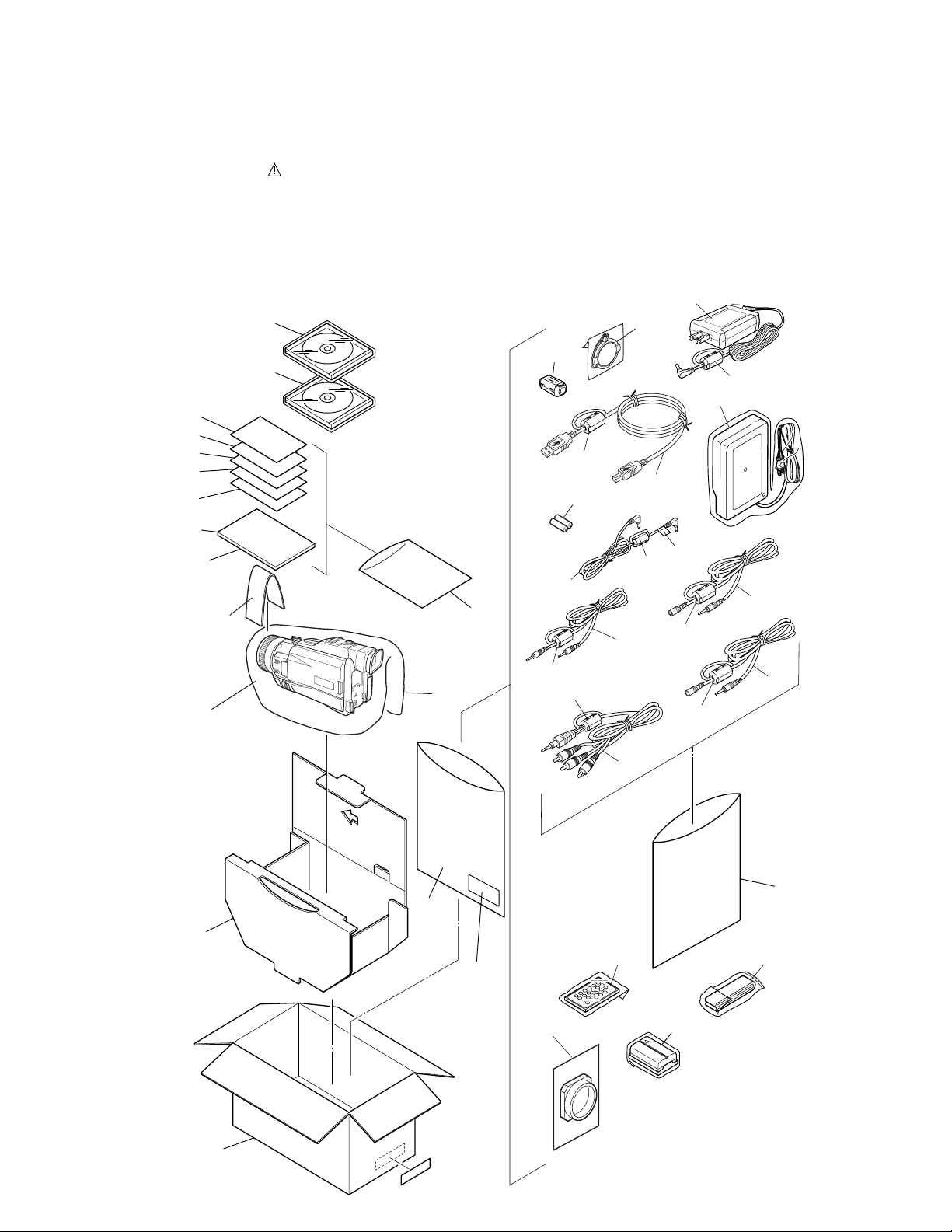

5.1.1 PACKING AND ACCESSORY ASSEMBLY <M1>

The instruction manual to be provided with this product will differ according to the destination.

008

PARTS LIST

075

074

051

050

048

047

046

043

042

024

FINAL ASSY

<M2>

007

014

041

094

080

081

086

073

078

079

072

077

093

076

085

087

091

092

082

083

003

002

009

(SERIAL,

LABEL

(SERIAL)

LABEL

ACC.)

022

006

071

005

004

5-1

Page 2

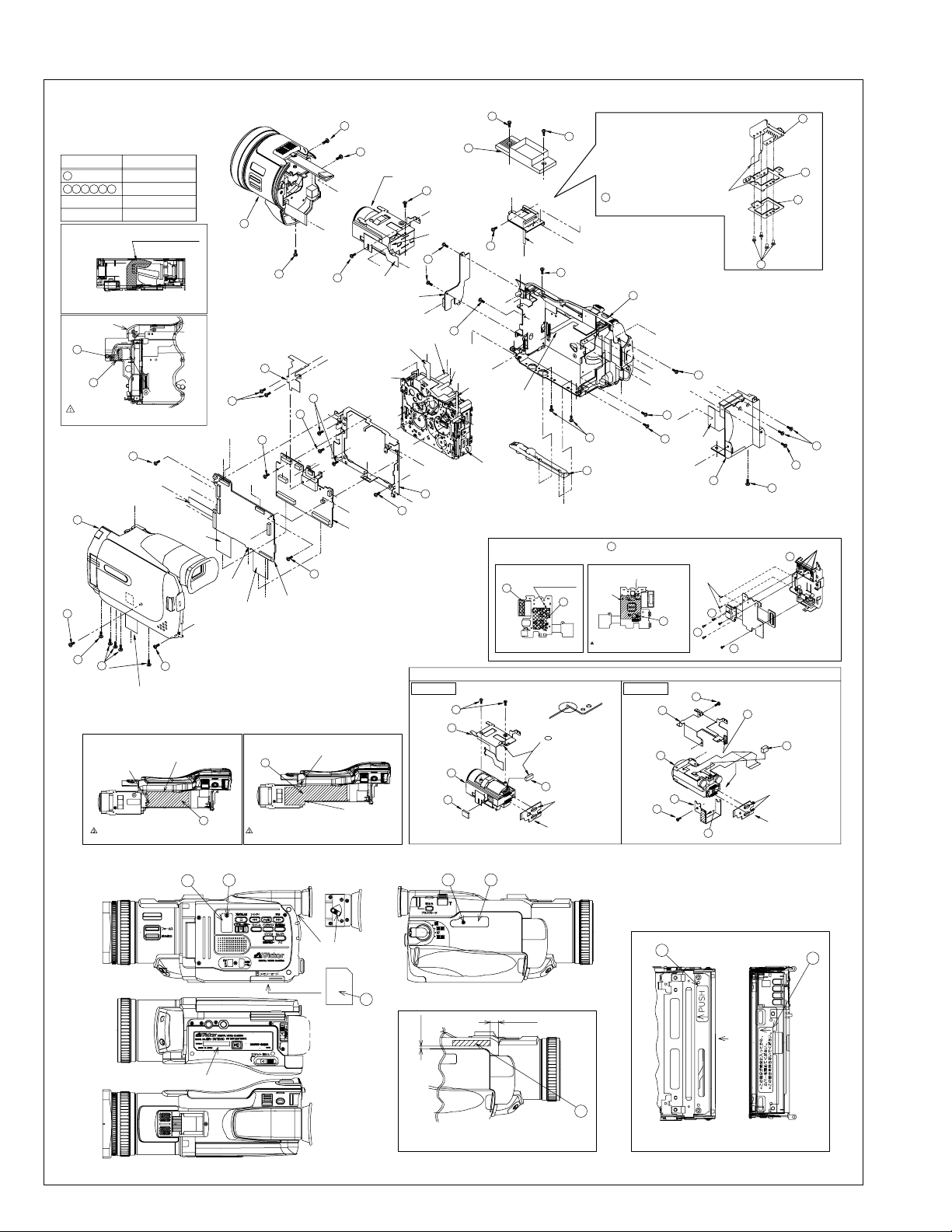

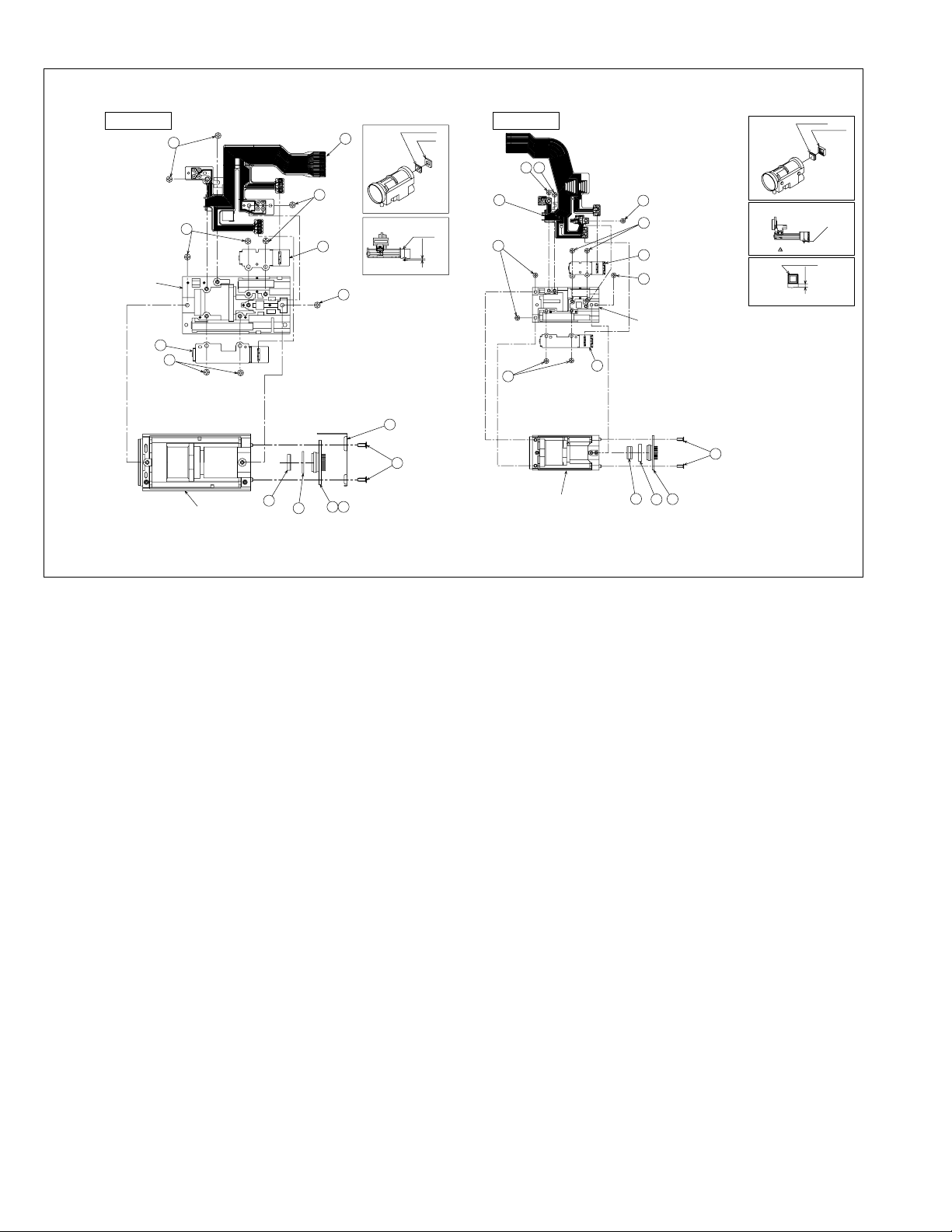

5.1.2 FINAL ASSEMBLY, REAR ASSEMBLY(G) AND SHOE ASSEMBLY(G) <M2>

<M2> FINAL ASS'Y

REAR ASS'Y(G)

SHOE ASS'Y(G)

OP FRAME ASS'Y

TABLE OF SETTING TORQUE FOR SCREW DRIVER

PART.NO

112

OTHER SCREW

FIG.1 DRUM MOTOR FPC PROCESSING CHART

LOWER CASE ASS'Y

152

FIG.2 STOPPER(JACK) INSTALLATION CHART

(Refer to the Exploded

view for this part.)

UPPER

ASS'Y(G)

148

130

128

SETTING TORQUE

0.07 ±0.007 N•m

0.10 ±0.010 N•m

133132128127126121

0.08 ±0.008 N•m

PROCESS THIS PART OF DRUM MOTOR

FPC TO THE SHIELDING CASE .

151

127

S TERMINAL

116

b

r

e

q

z1

129

a2

a1

y

146

FRONT

ASS'Y(G)

(Refer to the Exploded

view for this part.)

SHIELD

COVER(PR)

108

112

u

111

m

c

d

t

g

125

j1

j2

h1

e

<01> MAIN

BOARD ASS'Y

q

h1

h2

110

s3

113

'h1

j3

j6

'h2

h2

117

FINAL ASS'Y LYH20608

THE INTERIOR SIDE IS A

THE INTERIOR SIDE IS ARM BKT MATCH.

EDGE MATCH OF SCREW.

153

FIG.3 SPACER(MECHA) INSTALLATION CHART (M3D6L) FIG.4 SPACER(MECHA) INSTALLATION CHART (M3D4L)

154

PEEL OFF,

PASTE A TWO SIDED TAPE,

AND APPLY IT.

CORNER HOLE MATCH OF OP BKT.

123

124

u

120

<02> JACK

BOARD ASS'Y

s4

t

j5

j4

<04> PRE/MDA

BOARD ASS'Y

MATCHING TO

EDGE FASE OF

MAIN PWB.

COVER(SHOE)

ASS'Y

OP FRAME ASS'Y

119

f

g

109

a2

a1

b

j2

j1

'h1

'h2

j5

s1

105

s2

BKT(MECHA) ASS'Y

110

J2G TYPE J7C TYPE

BKT

(OP-J2) ASS'Y

OP BLOCK

ASS'Y

(Refer to the

Exploded view for

this part.)

SPACER(A)

STICKING AS SHOWN IN FIGURE.

(MACHING TO LEFT EDGE.)

104

113

g

j3

j6

j4

<M3>

MECHANISM

ASS'Y

118

106

143

107

133

p1

p2

p1

n

126

m

g

n

f

r

s3

c

s4

REAR ASS'Y(G) LYH20611

PASTE ACCORDING

TO THE CORNER OF

THIS COIL AND APPLY IT.

283

FIG-1. SPACER AFFIXATION POSITION FIG-2. SHIELD AFFIXATION POSITION

SPACER DOSE NOT GO UP

PART OF BKT.

STICKING AS SHOWN IN

FIGURE.

(MACHING TO FRONT

EDGE.)

149

<10> CCD

BOARD ASS'Y

NOTES

1. BEND FPC , AND PASS THE CORNER

132

HOLE OF THE SHEET METAL .

2. BE CAREFUL NOT TO CUT FPC BY

THE SHEET METAL EDGE .

3. NOTE IT EXTERNALS WHERE THE DENT

IS NOT IN FPC WITH THE WOUND .

4. DO NOT TOUCH BY THE FINGER TERMINAL

AREA OF FPC .

147

SHOE ASS'Y(G) LYH20612

r

p2

131

102

s1

z3

s2

z2

z3

282

k3

115

103

BASE

145

IT MATCHES IT TO THE

END FACE OF C6202.

IT MATCHES IT

TO THE END FACE

OF THE PWB.

PUT IT SO THAT THE SHEET SHOULD

NOT FLOAT. ESPECIALLY, NOTE THE

PWB END FACE SIDE.

OP FRAME ASS'Y

BKT(OP-J7)

ASS'Y

OP BLOCK

ASS'Y

(Refer to the

Exploded view

SPACER(A)

SOLDERING

for this part.)

BKT(OP-J7)2

NOTES

LOWER CASE ASS'Y

(Refer to the Exploded view for this part.)

k1

SUPPRESS FROM BOTH SIDES

p2

p1

k2

113

d

114

REAR ASS'Y(G)

C6202

287

106

143

OF UPPER AND LOWER FIRMLY,

135

AND TIGHTEN FROM RIGHT SCREW.

p2

p1

k2

z2

z1

y

145

DO NOT PUT EXTERNAL

FORCE ON THE FPC

ROOT WHEN BENDING

IT.

285

284

285

118

w

t

w

k3

BEND

137

136

SPACER(A)

t

139

291

SHOE

ASS'Y

BKT(H.S)

294

BKT

(SHOE MIC)

293

122

134

REAR UNIT

281

<03> REG

BOARD ASS'Y

DO NOT PUT EXTERNAL

FORCE ON THE FPC ROOT.

SPACER(A)

150

STICKING AS SHOWN

IN FIGURE. (MACHING

TO FRONT EDGE.)

138

SPACER(A)

SOLDERING

<10> CCD

BOARD ASS'Y

292

121

SOLDERING

5-2

<M2>

185

RATING LABEL

188

THE KNOB IS C.COVER SIDE

AS SHOWN IN FIGURE.

190

189 184

9 mm

1 mm

IN WATCHING, THERE MUST BE NEITHER BENDING OF

THE STICKER NOR GREAT MISREGISTRATION.

DRAWING FOR STICKER(C) STICKING

192

186

CASSETTE HOUSING

A

LABEL AFFIXATION POSITION

CLEANER ASS'Y LYH20604

187

A SIDE

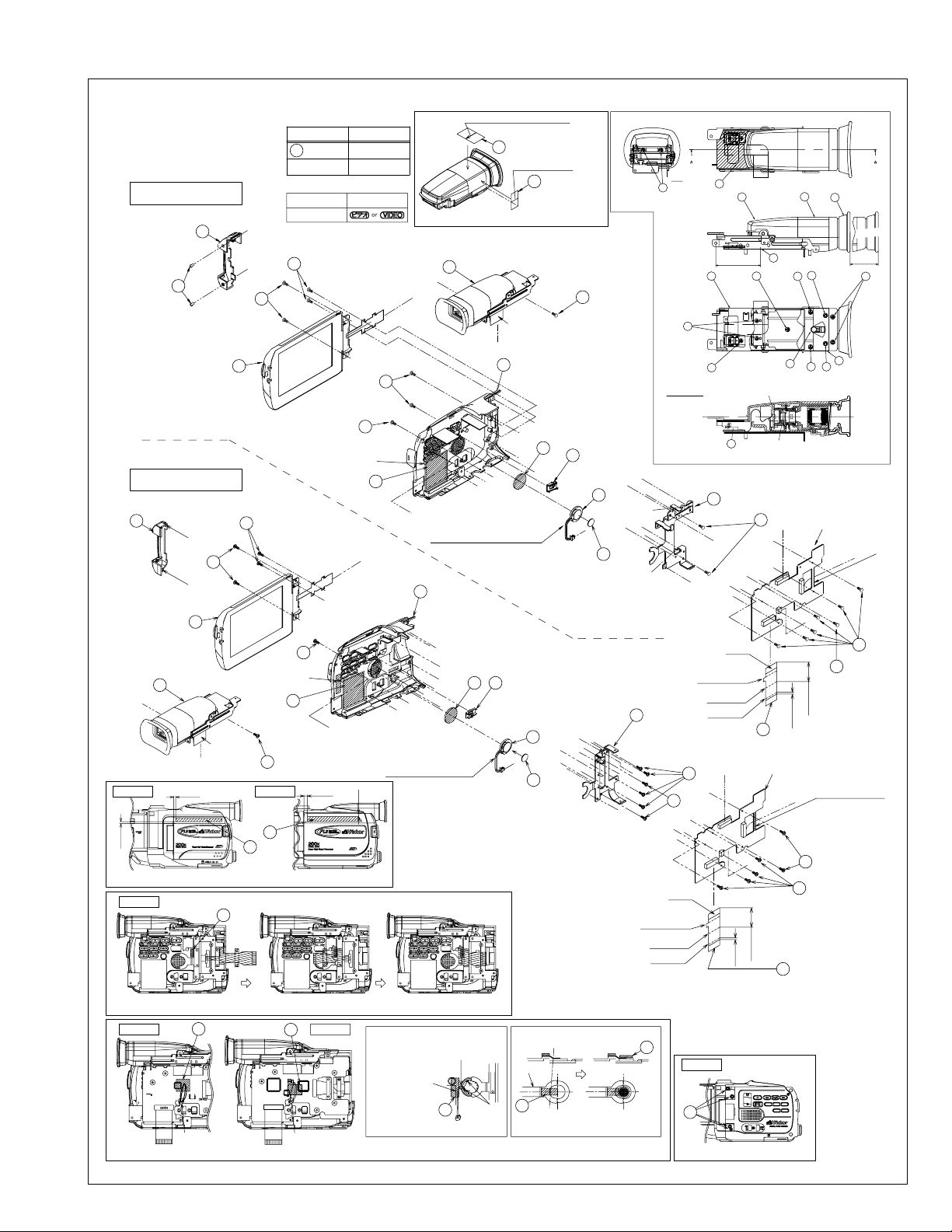

Page 3

a

B2

A3

A2

A1

d

A2

A1

a

F2

d

A4

A6

A5

B2

A4

A3

C1

C2

C1

C2

A5

D1

A6

D1

D2

D2

E1

E2

E1

E2

G1

G2

G1

G2

F1

F1

F2

b

b

3.5 INCH ASSEMBLY

UPPER ASS'Y(G) LYH20610

1

±

1mm

30

±

5mm

2.5 INCH ASSEMBLY

D2

C1

E1

D3

D1

D4

G1

G2

C2

F1

B1

B2

E2

1

±

1mm

30

±

5mm

a

B2

A3

A1

d

A4

A2

B1

b

F2

F1

b

E1

E2

C1

G1

G2

C2

a

A3

B2A4

A1

d

D1

D2

B1

D3

D4

F2

A2

3mm

1mm

2.5 INCH

2.5 INCH 3.5 INCH

4mm

4mm

3.5 INCH

CN702

CN701

IC7201

IC7101

IC7102

2.5 INCH

2.5 INCH

31.9±0.2 20(SLIDE)

VF ASS'Y LY21037

VIEW A-A

615

602

613

615

614

620

621

611

601

608

616

627

625

603

606

626

604

610

609

612

607

608

609

607

613

610

604

626

606

603625

601

611

621

627

620

614

615

602

616

618

619

622

622

628

624

623

905

931

908

902

901

912

910

904

928 913

903

932

909

906

928

913

907

911

626

631

632

629

PART.NO

0.08 ±0.01 N•m

0.12 ±0.02 N•m

VIDEO/MEMORY SW

MONITOR CLOSE

<M2> UPPER ASS'Y(G)

VF ASS'Y

U.CASE F(VF)

SHEET(HOLD)

U.CASE R(VF)

EYE CUP

B.CASE(VF)

LEVER

(LENS)

LCD MODULELEVER SWITCH

FPC

C VF BOARD ASS'Y

HOLDER(VF)

ASS'Y

KNOB(SLIDE)

SPEAKER

SPACER(A)

MONITOR

ASS'Y(G)

UPPER CASE ASS'Y

SPACER

COVER(UPPER) ASS'Y

VF ASS'Y

BKT(HINGE3.5)

<07> MONITOR

BOARD ASS'Y

UPPER CASE

ASS'Y

SPACER

SPACER

FPC

MONITOR

ASS'Y(G)

(WR103b)

COVER(UPPER) ASS'Y

VF ASS'Y

(WR102a)

KNOB(SLIDE)

SPEAKER

SPACER(A)

BKT(HINGE2.5)

SPACER

<07> MONITOR

BOARD ASS'Y

FPC

SHEET(CAUTION)1

LABEL(VF)

SPACER(A)

SPACER(A)

STICKER(A)

STICKER(E)

SPEAKER SPEAKER

FIG.1 VF INSTALLATION DETAIL DRAWING

IT SETS THE CORNER TO THE

POSITION OF FIGURE .

MOREOVER , BE CAREFUL NOT

TO RUN AGROUND IN THE BOSS.

ARROW DIRECTION

CHARACTER APRROVAL

ARROW DIRECTION CHARACTER APRROVAL

IT AFFIXES IT IN A

CENTRAL MATCH .

SCREW CONCLUSION TORQUE TABLE

TABLE OF SETTING SW

CONCLUSION TORQUE

OTHER SCREW

IT FIXES AS SHOWN DERECTION.

BECAUSE SOLDER IS NOT

TOUCHED WITH THE SHEET

METAL .

IT FIXES AS SHOWN DERECTION.

BECAUSE SOLDER IS NOT

TOUCHED WITH THE SHEET

METAL .

PLACE SW OF MONITOR

PWB AND ATTACH IT AT

THE CROWDED POSITION.

PLACE SW OF MONITOR PWB

AND ATTACH IT

AT THE CROWDED POSITION.

STIFFING PLATE SIDE

FPC MUST PASS

THIS PART UNDER .

FIG.2 SPEAKER WIRE PROCESSING DRAWING

PROCESS WIRE TO

THIS CUTTING LACK .

PROCESS WIRE TO

THIS CUTTING LACK .

IT MATCHES

THE CORNER

ON THIS DITCH.

IT MATCHES

THE CORNER

ON THIS DITCH.

MOUNTAIN FOLDING

AS SHOWN AT POSITION.

MOUNTAIN FOLDING

VALLEY FOLDING

PASS WIRE THROUGH

THIS CUTTING LACK .

SOLDERING

INSTALLATION CHART OF Sym. 623.

PROCESS IT SO THAT THE

WIRE SHOULD NOT ENTER

THIS DIFFERENCE PART.

FIG.4 DRAWING FOR STICKER(E) STICKING.

IN WATCHING, THERE MUST BE NEITHER BENDING

OF THE STICKER NOR GREAT MISREGISTRATION.

STIFFING PLATE SIDE

MOUNTAIN FOLDING

AS SHOWN AT POSITION.

MOUNTAIN FOLDING

VALLEY FOLDING

FPC MUST PASS

THIS PART UNDER .

A PUTTING STANDARD POSITION.

(THE EDGE OF POLON IS SET TO AN SIDE

(INSIDE) OF THE SHEET METAL.)

SHEET METAL.

MATCH AND PUT THE CENTER.

INSTALLATION CHART OF Sym. 626, 631. (2.5 & 3.5)

FIG.5 DRAWING FOR SPACER-B STICKING.

RIGHT AND LEFT MATCH: EDGE SIDE MATCH OF BKT(HINGE)

UPPER AND LOWER MATCH: END PART OF DIAMETER OF BKT(HINGE) PUTTING.

GET ON ON SPACER SURELY THE BEND PART OF FPC.

* BE NOT CAUGHT TO SPACER OF FPC.

INSTALLATION CHART OF Sym. 632. (ONLY 2.5 INCH MODEL.)

(Refer to the Exploded

view for this part.)

(Refer to the Exploded

view for this part.)

5.1.3 UPPER ASSEMBL Y(G) AND VF ASSEMBLY<M2>

5-3

Page 4

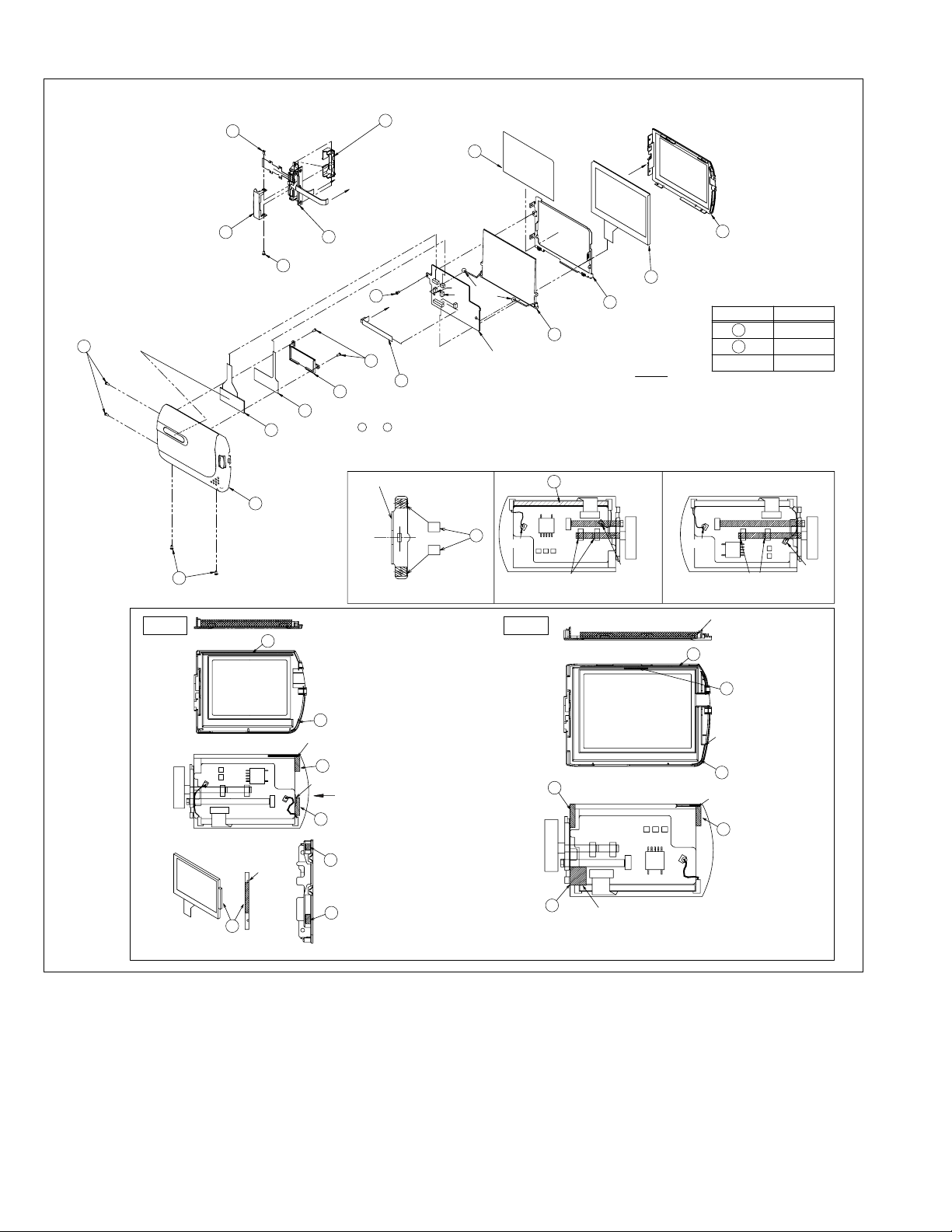

5.1.4 MONITOR ASSEMBLY(G) <M2>

<M2> MONITOR ASS'Y(G)

NEITHER GARBAGE

NOR MUST BE

IN WINDOW RESPECT .

818

2.5 INCH 3.5 INCH

815

806

HINGE

COVER(U)

LCD(SUB)

801

M.COVER(D6) ASS'Y

M.COVER(2.5) ASS'Y

M.COVER(3.5) ASS'Y

817

MONITOR ASS'Y(G) LYH20609

POSITIONING OF

THE UPPER PART.

BOSS MATCH.

PUTS AT THE STAGE

WHERE LCD IS BUILT

INTO THE MONITOR CASE.

823

HINGE COVER(L)

c

b

MONI HINGE

805

ASS'Y

815

816

814

804

HOLDER(LCD)

EL(WINDOW)

811

IT PEELS OFF THE FLAKING OFF SHEET,

IT PASTES TO

804

810

IT PEELS OFF THE SHEET PROTECTION.

(INSIDE AND OUT SIDE)

830

AND IT APPLIES IT.

830 IS PUT ON THE INNER WALL OF THE CASE.

LOWER MATCH AND LEFT WALL MATCH.

IT IS AFFIXATION ACCORDING TO THE

INSIDE OF THE CASE AS FOR 829.

THE RIB IN THE LEFT END IS MATCHED.

ATT.) DO NOT BEGIN TO SEE IN THE

CORNER HOLE PART OF THE SIDE.

829

PASTE SO AS NOT TO GENERATE THE SPACE

BETWEEN BLACK SEATS PASTED TO THE

MONITOR CASE ON THE SIDE.

834

THE EDGE SIDE MATCH ABOVE THE PWB.

UNDER THE PWB.

833

FIGURE SEEN FROM DIRECTION

OF ARROW OF A.

AND

MONITOR HINGE ASS'Y

FIG-3. DRAWING FOR 835 STICKING.

CONCEAL THE B/L SIDE.

FIGURE SEEN FROM DIRECTION

OF ARROW OF A.

CONCEAL THE B/L SIDE.

THE SPACE DO NOT BE IN THE

831

UPPER PART.

INSERTS IN THE CASE CORNER HOLE

PART OF THE SIDE, AND PUTS ON THE

LCD SIDE.

THE SPACE DO NOT BE IN THE

832

LOWER SIDE.

807

D BEF SHEET

c

a

812

810

.

b

FPC

IT PEELS OFF THE SHEET PROTECTION.

(INSIDE AND OUT SIDE)

820

SOLDERING

<06> BL3.5 BOARD ASS'Y

<06> BL2.5 BOARD ASS'Y

835

C RESPECT MATCH.

803

809

BACK LIGHT

SPACER(A)

SOLDERING

IT BENDS AND IT INSERTS IT .

FIG-1. INTERNAL PROCESSING DETAIL DRAWING (3.5 INCH)

TURNS TO THE SIDE, CROWS,

AND PASTES.

(HIDE THE BACK LIGHT SIDE)

PASTE ACCORDING TO THE

819

CORNER AND APPLY IT .

CN602

T7501

CN606

CN605

CN601

THERE MUST NOT

BE SOLDER HORN .

B/L LEFT END SIDE MATCH.

826

LINE OF WALL OUTSIDE CASE MATCH.

827

DO NOT COME IN SUCCESSION WITH SPACER

ON THE B/L LAMP TUBE.

OPTICAL LEAKAGE MEASURES SPACER STICKING DETAIL DRAWING.

a

MONI CASE(3.5)

802

MONI CASE(2.5)

LCD MODULE

808

BKT(FRM)3.5

BKT(FRM)2.5

NOTES

1. THING THAT GARBAGE AND DUST ARE NOT

BETWEEN LCD PANEL AND BACK LIGHT .

2. DO NOT TOUCH FPC TERMINAL AREA OF THE LCD PANEL .

3. Sym No. 17 AND 18 SCREWS MUST USE THE NEW ARTICLE

OF EACH REPAIR .

4. TIGHTENS THE SCREW OF Sym. 18 PREVIOUSLY

AFTER THE INSTALLATION OF M.COVER .

5. BACK LIGHT WIRE MUST NOT RUN AGROUND

ON THE TRANSFORMER .

SOLDERING

SCREW CONCLUSION TORQUE TABLE

PART.NO

OTHER SCREW

CN606

SOLDERING

T7501

IT BENDS AND IT INSERTS IT .

817

818

CN605

CONCLUSION TORQUE

0.12 ±0.01 N•m

0.20 ±0.02 N•m

0.08 ±0.01 N•m

CN602

CN601

SOLDERING

FIG-1. INTERNAL PROCESSING DETAIL DRAWING (2.5 INCH)

EDGE SIDE MATCH.

825 IS PUT ON THE INNER WALL OF THE CASE.

825

LOWER MATCH.

PUTS IN THE PENETRATION HOLE

836

OF THE CASE. (CENTER PART)

PASTE THE PILLING TO PUTTIN

RESPECT OF 825.

POSITION MATCH.

IT IS AFFIXATION ACCORDING TO THE

INSIDE OF THE CASE AS FOR 824.

824

PASTE SO AS NOT TO GENERATE THE SPACE

BETWEEN BLACK SEATS PASTED TO THE

MONITOR CASE ON THE SIDE.

828

5-4

Page 5

A

B

c

a

a

b

c

d

b

d

C

FRONT ASS'Y(G) LYH20613

10 ±2 mm

2mm

4mm

E.CAP

702

703

711

706

705

717

729

701

708

725

726

707

712

730

731

732

716

734

720

715

714

718

721

710

719

704

728

733

727

PART.NO

VIEW A VIEW B

[STROBE MODEL] [NON STROBE]

VIEW C

STROBE BOARD ASS'Y

0.08 ±0.01 N•m

<M2> FRONT ASS'Y(G)

SPACER(A)

P.T. UNIT

FOCUS UNIT

HOOD(D6)

<11>

STROBE

BOARD ASS'Y

F.COVER

ASS'Y

SPACER(A)

HOOD(SCREW) ASS'Y

<09>

SW BOARD

ASS'Y

COVER(MIC)

MIC ASS'Y

HOLDER

(MIC)

SPACER(FRONT PWB)

CORE FILTER

SPACER(A)

STICKER(D)

<05>

FRONT

BOARD

ASS'Y

SPACER(A)

BKT(FRONT)

RING

SPACER(A)

SPACER(A)

SPACER(A)

FIG.1 DRAWING FOR P.T ML WIRE AND

FFC WIRE ARRENGEMENT.

FIXED WITH SPACER.

FFC WIRE IS ALONG

THE EDGE OF PWB.

PWB END FACE MATCH 0mm -1.0mm

PWB CENTRAL MATCH ±1.0mm

FIG.2 DRAWING FOR MIC WIRE ARRENGEMENT.

MIC WIRE THROUGH

BETWEEN BKT AND F.COVER

AS SHOWN IN FIGURE.

PUSH A REMAING PART

INTO HERE.

FIG.3 INSTALLATION CHART OF SPACER & CORE FILTER.

FIG.4 DRAWING FOR STICKER(D) STICKING.

FIG.5 DRAWING FOR SPACER STICKING.

SHOULD BE BENDED BY THE EDGE OF PWB.

STICK TO PWB.

PASTE TO CONCEAL THE

POINT OF CORE FILTER

AND APPLY IT.

IT INSTALLS IN THE ROOT

OF CN501 THROUGH

A FLAT WIRE.

IN WATCHING, THERE MUST BE NEITHER BENDING OF

THE STICKER NOR GREAT MISREGISTRATION.

IT PASTES ACCORDING TO THE WALL OF HOLDER(MIC)

AFTER IT DOES THE MIC AND COVER(MIC) TO HOLDER(MIC)

IN ASS'Y AND IT APPLIES IT.

THE TERMINAL

PART DIRECTION

IS AS SHOWN IN

FIGURE.

SCREW CONCLUSION TORQUE TABLE

ALL SCREW

CONCLUSION TORQUE

THIS FFC PASSES

THROUGH UNDER

THE BOSS.

(ARROW INDICATION)

THE EDGE OF SPASER IS

MATCHED AS CONCEALING

THE BOSS'S HOLE. AND

THEN STICK IT AS WRAPPED

AROUND THE OTHER SIDE.

IT OPENS WHEN SCREW

TIGHTENINIG.

AND AFTER IT CLOSES. (VIEW C)

PUSH A REMAING

PART INTO HERE.

BEND INSIDE AFTER

ASSEMBLING IT.

THEN DON'T FLOAT

IT'S BODY.

TO HOLE.

[Method of opening STROBE]

Push the hook of the

solenoid in the direction

of the arrow.

Be careful not to damage

the STROBE wire.

Hook

(Refer to the Exploded view

for this part.)

LOWER CASE ASS'Y LY20987

531

521

532

529

527

528

501

526

504 505503502

518

517

524

509

508

530

523

506 507

519

511 512 513510 514

515

518

510

517

525

522

525

516

PART.NO

0.245 ±0.024 N•m

0.092 ±0.009 N•m

LOWER CASE

<M2> LOWER CASE ASS'Y

BKT(CASSETTE)

COVER(JACK)

COVER(JACK)

CASSETTE COVER

INDICATOR

GRIP BELT

CAP(GRIP BELT)

KNOB(LOCK)

ZOOM UNIT

ARM ASS'Y

HOOK

LOWER CASE

HOLDER

(LOCK)

CUT

Hook

GRIP BELT

CONCLUSION TORQUE

SCREW CONCLUSION TORQUE TABLE

OTHER SCREW

5.1.5 FRONT ASSEMBL Y(G)<M2>

5.1.6 LOWER CASE ASSEMBLY<M2>

5-5

Page 6

5.1.7 OP BLOCK ASSEMBLY<M2> [J2G(F1.2 LENS) / J7C(F1.8) LENS]

<M2> OP BLOCK ASS'Y <M2> OP BLOCK ASS'Y

OPTICAL LPF

SUB CASE

ZOOM

MOTOR

259

256

256

256

IRIS MOTOR UNIT

256

258

FOCUS

MOTOR

261

256

(fig2)

SPACER RUBBER

SOLDERING

BKT

(CCD BASE)

260

(fig1)

MOTOR

0 +1mm

IRIS

MOTOR

UNIT

209

244

J7C TYPEJ2G TYPE

209

208

209

ZOOM MOTOR

235

208

209

FOCUS

MOTOR

234

209

SUB CASE

OPTICAL LPF

SPACER RUBBER

(fig1)

(fig2)

SPACER RUBBER

0 -1mm

CUT

(fig3)

SOLDERING

MAIN CASE

OPTICAL

LPF

262

210

243

CCD BASE ASS'Y

263

SPACER

RUBBER

SHEET

264

265

CCD BASE ASS'Y

257

MAIN CASE

OPTICAL

LPF

223

SPACER

RUBBER

SHEET

224

OP BLOCK ASS'Y LYH20637 OP BLOCK ASS'Y LYH20156

5-6

Page 7

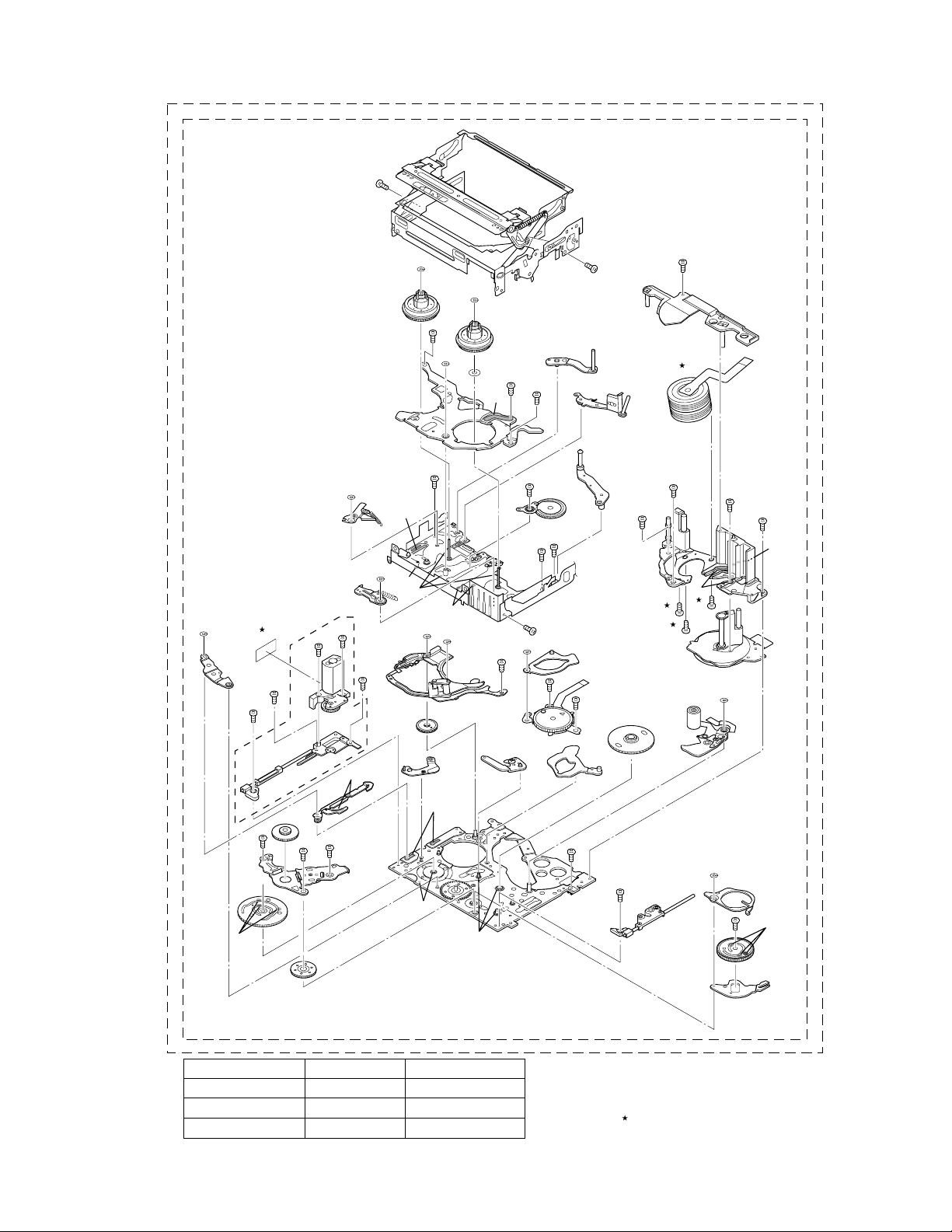

5.1.8 MECHANISM ASSEMBLY <M3>

900

900A

901

902

976

930

963

946

906

962

963

906

904

905

932

903

965

963

CC

CC

907

964

933

945

944

959

AA

958

960

910

977

908

913

938

909

978

912

913

CC

911

919

918

921

920

902

943

939

950

941

956

966

AA

914

922

925

924

CC

929

AA

935

BB

AA

940

940

949

CC

AA

928

936

957

936B

953

936B

937

936A

AA

934

954

952

979

937

937

931

953

955

AA

902

915

916

917

921

942

951

951

961

948

947

Classification Part No. Symbol in drawing

Grease KYODO-SH-JB AA

Oil YTU94027 BB

Grease (HANARL)

RX-410R CC

NOTE1: The section marked in AA and BB, CC

indicate lubrication and greasing areas.

NOTE2: Mark is not contained in 900A.

5-7

Page 8

MODEL MARK MODEL MARK

5.2 PARTS LIST

# REF No. PART No. PART NAME, DESCRIPTION # REF No. PART No. PART NAME, DESCRIPTION

---------------- ----------------------- ----------------------------------------------------- ----------------- ----------------------- -----------------------------------------------------

******************************

P ACKING AND ACCESSOR Y ASSEMBLY<M1>

002 LY33421-002A PACKING CASE,A

002 LY33421-003A PACKING CASE,B,C

002 LY33421-001A PACKING CASE,D

003 LY20995-001A CUSHION

! 004 L Y32566-001A BA TT.PACK ASSY,BN-V408U-B

005 LY20186-004A SHOULDER STRAP

006 LY21020-001A REMOTE CTL UNIT,RM-V718U,A,B

006 LY20750-001A REMOTE CTL UNIT,RM-V717U,C,D

007 LY32210-053A CD ROM ASSY

008 LY32210-043A CD ROM ASSY

009 QPA02503505P POLY BAG,ACC.

014 LY30023-028A POLY BAG

041 QPA02003506 POLY BAG,DOCUMENT

! 042 LYT1106-001B IB(EN),A,B

! 042 LYT1106-002B IB(FR),A,B

! 042 LYT1106-003B IB(SP),A,B

! 042 LYT1107-001B IB(EN),C

! 042 LYT1107-002B IB(FR),C

! 042 LYT1107-003B IB(SP),C

! 042 LYT1106-001C IB(EN),D

! 042 LYT1106-002C IB(FR),D

! 042 LYT1106-003C IB(SP),D

043 LYT1108-004A SHEET(CORRECT.),A

046 LYT1111-001A IB(SOFT.EN)

046 LYT1111-003A IB(SOFT.FR)

046 LYT1111-005A IB(SOFT.SP)

047 BT-51005-5 WARRANTY INF.

048 BT-51028-2 REGIST.CARD

051 BT-52006-2 WARRANTY CARD

071 QPA01703005 POLY BAG,CABLE

072 QAM0346-001 A/V CABLE

073 QQR0918-002 CORE FILTER,AV 1T

074 LY32430-004A HOOD CAP ASSY

! 075 L Y20968-001B AC ADAPTER,AP-V13U

076 QQR0917-002 CORE FILTER

077 QAM0451-001 USB CABLE,USB

078 QQR0491-002 CORE FILTER,USB 1T

079 PEAC0428-150 CABLE ASSY,EDIT 2-2,C,D

080 QQR0491-002 CORE FILTER,EDIT 2T,C,D

081 ——— BATTERY,X2,C,D

082 QAM0213-001 AUDIO CABLE,HP

083 QQR0917-002 CORE FILTER,HP 2TURN

091 QAM0213-001 AUDIO CABLE,MIC

092 QQR0917-002 CORE FILTER,MIC 2TURN

094 QQR0491-002 CORE FILTER,EDIT 2T,A,B

115 LY30018-006B SPECIAL SCREW,X2,ARM-BASE

116 LY42424-001A SPECIAL SCREW,MAINP-BKT

117 LY30019-014A SPECIAL SCREW,MAINP-BKT

118 LY30019-029B SPECIAL SCREW,OPBKT-OP,A,B,C

118 LY30019-029B SPECIAL SCREW,X2,OPBKT-OP,D

119 LY30018-091A SPECIAL SCREW,OPBKT-ARM

120 LY30018-084A SPECIAL SCREW,OPBKT-LC

121 LY30018-0J9A SPECIAL SCREW,X2,RC-ARM

122 LY30018-0G6A SPECIAL SCREW,RC-LC

123 LY30018-0G6A SPECIAL SCREW,FC-LC

124 LY30018-059A SPECIAL SCREW,COVIR-LC

125 LY30018-006B SPECIAL SCREW,COVIR-ARM

126 LY30018-059A SPECIAL SCREW,BKTSHOE-LC

127 LY30018-047A SPECIAL SCREW,X4,UC-BASE

128 LY30018-0A1A SPECIAL SCREW,UC-BKTHIN

129 LY30018-032A SPECIAL SCREW,UC-RC

130 LY30018-006B SPECIAL SCREW,UC-DV

131 LY30018-006B SPECIAL SCREW,LC-BKTSHOE

132 LY30018-075A SPECIAL SCREW,COVSH-BKTS

133 LY30018-084A SPECIAL SCREW,COVSH-FC

134 LY30018-0G6A SPECIAL SCREW,REAR-LOWER

135 LY30018-0G6A SPECIAL SCREW,LOWER-REAR

136 LY30018-070A SPECIAL SCREW,BKT-BKTOP,A,B,C

137 LY33391-001A BKT(OP-J7)2,A,B,C

138 LY30030-070A SPACER(A),A,B,C

139 LY30030-055A SPACER(A),A,B,C

143 J7C-117A OP BLOCK ASS'Y,A,B,C

143 J2G-301A OP BLOCK ASS'Y,D

145 L YH2061 1-002B REAR ASSY(G),A,B

145 L YH2061 1-002C REAR ASSY(G),C,D

146 L YH20613-003A FRONT ASSY(G),A,B,C

146 L YH20613-002A FRONT ASSY(G),D

147 L YH20612-001A SHOE ASSY(F)

148 LYH20610-003A UPPER CASE ASSY(G),A

148 LYH20610-002A UPPER CASE ASSY(G),B,C

148 LYH20610-004A UPPER CASE ASSY(G),D

149 LY30030-079A SPACER(A),D

150 LY30030-054A SPACER(A),A,B,C

151 LY33451-001B STOPPER(JACK)

152 LY30018-084A SPECIAL SCREW,STP-LC

154 LY44285-001A SPACER(MECHA)

184 LY33213-001A COVER(ADJUST)

185 LY33214-001A COVER(JIG)

186 LY40699-002A LABEL(PUSH)

187 LY32001-002A LABEL(HOUSING)

188 LY30018-0J8A SPECIAL SCREW,JIG

189 LY30018-0J8A SPECIAL SCREW,COVAD-CASS

190 QAM0404-002 MEMORY CARD,MMC 8MB*

192 LY44205-001A STICKER(C)

GR-DV500US A GR-DV801US C

GR-DV800US B GR-DV900US D

******************************

FINAL ASSEMBL Y<M2>

102 LY20987-004A LOWER CASE ASSY

103 LY31984-001B BASE

104 LY33209-001A COVER(SHOE)

105 LY33215-001A BKT(MECHA)ASSY

106 LY33218-001B BKT(OP-J7)ASSY,A,B,C

106 LY33216-001A BKT(OP-J2)ASSY,D

107 LY30030-053A SPACER(A),D

108 LY33220-001A SHIELD COVER(PR

109 LY30018-006B SPECIAL SCREW,X2,JACK-ARM

110 LY30019-028A SPECIAL SCREW,X3,BKTME-MECH

111 LY30018-006B SPECIAL SCREW,MDA-BKTME

112 QYSPSPT1414M SCREW,X2,MECHA-PRE 1.4mmx1.4mm

113 LY30018-006B SPECIAL SCREW,X3,BKTME-ARM

114 LY30018-017A SPECIAL SCREW,LC-BKTME

5-8

*NOTE :

DATA FILE is not contained in MEMORY CARD of the service part.

OP BLOCK ASSEMBLY<M2>

208 LY30727-001A TAP SCREW,X2,A,B,C

209 LY30727-002A TAP SCREW,X8,A,B,C

210 QYSPSGU1750Z TAP SCREW,X2,A,B,C

223 LY43384-001A OP LPF,A,B,C

224 LY43494-001A SHEET,A,B,C

234 LY31571-001A FOCUS MOTOR,A,B,C

235 LY31572-001A ZOOM MOTOR,A,B,C

243 LYH30375-009A CCD BASE ASS’Y,A,B,C

244 LY33430-001A IRIS MOTOR UNIT,A,B,C

256 LY30727-002A TAP SCREW,X9,D

257 QYSPSGU1750Z TAP SCREW,X2,D

Page 9

MODEL MARK MODEL MARK

GR-DV500US A GR-DV801US C

GR-DV800US B GR-DV900US D

# REF No. PART No. PART NAME, DESCRIPTION # REF No. PART No. PART NAME, DESCRIPTION

---------------- ----------------------- ----------------------------------------------------- ----------------- ----------------------- -----------------------------------------------------

258 LY33303-001A FOCUS MOTOR,D

259 LY33302-001A ZOOM MOTOR,D

260 LY33410-001A BKT(CCD BASE),D

261 LY33304-001B IRIS MOTOR UNIT,D

262 LY44069-001A OPTICAL LPF,D

263 LY43494-001A SHEET,D

264 LYH30375-009A CCD BASE ASS’Y,D

REAR ASSEMBL Y(G)<M2>

281 LY21007-002C REAR UNIT

282 LY30030-065A SPACER(A),REG PWB(R

283 L Y30030-058B SPACER(A),B TO B

284 LY30018-006B SPECIAL SCREW,X2,PWB-REAR

285 LY30018-084A SPECIAL SCREW,X3,PWB-REAR

287 LY44264-001A SHIELD(REG),REG PWB

SHOE ASSEMBL Y(G)<M2>

291 L Y33207-001B SHOE ASSY

292 L Y33208-001A BKT(H.S),A

292 L Y33208-001B BKT(H.S),B,C,D

293 LY30018-006B SPECIAL SCREW,X4,BKT-SHOE

******************************

LOWER CASE ASSEMBLY<M2>

501 L Y20988-001B ARM ASSY

502 LY10433-004A LOWER CASE

506 LY10434-002A CASSETTE COVER

508 LY33369-001A KNOB(LOCK)

509 LY33370-001A HOLDER(LOCK)

510 LY20991-004A GRIP BELT

515 LY40592-001A CAP(GRIP BELT)

516 LY10435-001A ZOOM UNIT

517 LY44037-001A HOOK

518 LY33178-001A COVER(JACK)

519 ——— INDICATOR

521 LY33443-001A BKT(CASSETTE)

522 LY30018-0G2A SPECIAL SCREW,X3,ZOOM-CASS

523 LY30018-084A SPECIAL SCREW,X2,HOLD-CASS

524 QYSLSF2055D TAP SCREW,X2,HOOK-CASS

525 LY30018-0D1A SPECIAL SCREW,GRIP-CASS

526 LY30018-084A SPECIAL SCREW,X2,ZOOM-LOWER

527 LY30018-0G2A SPECIAL SCREW,X2,ARM-LOWER

528 LY30018-056A SPECIAL SCREW,LOWER-ARM

529 LY30018-084A SPECIAL SCREW,X3,ARM-CASS

530 LY30018-056A SPECIAL SCREW,X2,CASS-ARM

531 LY30018-092A SPECIAL SCREW,BKT-ZOOM

532 LY30018-056A SPECIAL SCREW,BKT-ARM

******************************

UPPER ASSEMBL Y(G)<M2>

601 LY20997-002C UPPER CASE ASSY,A

601 LY20999-002B UPPER CASE ASSY,B,C,D

602 LY33230-001A COVER(UPPER2.5),A

602 LY33231-002B COVER(UPPER)AS,B,C,D

603 LY33048-001A KNOB(SLIDE)

604 LY20998-001A BKT(HINGE2.5),A

604 LY33181-001A BKT(HINGE3.5),B,C,D

606 QAS0127-001 SPEAKER

607 QAL0468-001 FPC,MPWB-MAIN

608 LY30018-087A SPECIAL SCREW,X2,UC-BKT-P,A

608 LY30018-057A SPECIAL SCREW,X2,UC-BKTHIN,B,C,D

609 LY30018-087A SPECIAL SCREW,X4,MPWB-UC,A

609 LY30018-063A SPECIAL SCREW,X6,MPWB-UC,B,C,D

610 LY30018-087A SPECIAL SCREW,X4,BKTHIN-UC,A

610 LY30018-063A SPECIAL SCREW,X2,BKTHIN-UC,B,C,D

611 LY30018-070A SPECIAL SCREW,VF-BKTHIN

612 LY30018-070A SPECIAL SCREW,MPWB-BKTHI,B,C,D

613 LY30018-087A SPECIAL SCREW,X2,COVUP-BKT,A

613 LY30018-070A SPECIAL SCREW,X2,COVUP-BKT,B,C,D

614 LY30018-070A SPECIAL SCREW,X2,FPC-UC,A

614 LY30018-063A SPECIAL SCREW,X2,FPC-UC,B,C,D

615 LY30018-028A SPECIAL SCREW,X2,HIN-BKTHIN

616 LY30018-032A SPECIAL SCREW,UC-VF

618 LY41701-004A SHEET(CAUTION)1

619 LY43041-001A LABEL(VF)

620 L YH20609-004A MONITOR ASSY(G),A

620 L YH20609-003A MONITOR ASSY(G),B,C

620 L YH20609-002A MONITOR ASSY(G),D

621 L Y21037-001C VF ASSY

622 L Y30029-0W4A SPACER(A),SPEAKER2

623 L Y30029-0W4A SPACER(A),SPEAKER

624 L Y44203-001A STICKER(A),B,C,D

625 L Y44241-001A SP ACER

626 L Y44259-001A SP ACER

627 L Y30030-0E8A SPACER(A)

628 L Y44294-001A STICKER(E),A

629 L Y30017-022A SP ACER-B,X4,A

632 L Y30030-0V7A SPACER(A)

******************************

FRONT ASSEMBL Y(G)<M2>

701 L Y33180-002D F.COVER ASSY,A,B,C

701 L Y33180-003E F.COVER ASSY ,D

702 LY33187-001A HOOD(SCREW J7),A,B,C

702 LY33193-001A HOOD(SCREW J2),D

704 LY33189-001B RING

705 LY33188-001A HOOD(J7),A,B,C

705 LY33195-001A HOOD(J2),D

707 LY33191-001A COVER(MIC)

708 L Y33400-001B MIC ASSY

710 L Y33192-001A BKT(FRONT)

712 LY44231-001A SPACER,FRONT PWB

714 WJT0092-001A E-CARD WIRE,FRONT-MAIN

715 WJT0093-001A E-CARD WIRE,FRONT-SW

716 LY30018-0J7A SPECIAL SCREW,X3,FRT-HOOD,A,B,C

716 LY30018-0J6A SPECIAL SCREW,X3,FRT-HOOD,D

718 LY30018-006B SPECIAL SCREW,X2,SPWB-BKTF

719 LY30018-059A SPECIAL SCREW,X2,BKTF-FRT

720 LY30018-059A SPECIAL SCREW,X2,FPWB-COV

721 LY30018-006B SPECIAL SCREW,RING-BKTF

725 LY30018-059A SPECIAL SCREW,X2,HOLD-FRT

726 LY33190-001A HOLDER(MIC)

730 QQR1290-001 CORE FILTER,FRONT-MAIN

731 LY30029-0W4A SPACER(A),FRONT-MAIN

733 LY33030-0F1A SPACER(A),D

734 LY30030-0L1A SPACER(A),MIC

******************************

MONITOR ASSEMBLY(G)<M2>

801 L Y21001-001C M.COVER(2.5)AS,A

801 L Y21003-001C M.COVER(3.5)AS,B,C

801 L Y21003-003C M.COVER(3.5)AS,D

802 L Y10439-001B MONI.CASE(2.5),A

802 L Y10443-001B MONI.CASE(3.5),B,C,D

803 L Y21002-001A BKT(FRM)2.5,A

5-9

Page 10

MODEL MARK MODEL MARK

GR-DV500US A GR-DV801US C

GR-DV800US B GR-DV900US D

# REF No. PART No. PART NAME, DESCRIPTION # REF No. PART No. PART NAME, DESCRIPTION

---------------- ----------------------- ----------------------------------------------------- ----------------- ----------------------- -----------------------------------------------------

803 LY21004-001A BKT(FRM)3.5,B,C,D

805 LY33236-001B MONI HINGE ASSY

806 LY33237-001B HINGE COVER(U),A

806 LY33237-002B HINGE COVER(U),B,C,D

807 LY33238-001A HINGE COVER(L)

808 QLD0271-001 LCD MODULE,A

808 QLD0268-001 LCD MODULE,B,C,D

809 QLL0149-001 BACK LIGHT,A

809 QLL0148-001 BACK LIGHT,B,C,D

812 QAL0483-001 FPC

815 LY30018-060A SPECIAL SCREW,X2,HC-HINGE

816 LY30018-056A SPECIAL SCREW,PWB-BKT

817 LY30018-056A SPECIAL SCREW,X2,CO-CA-BKT

818 LY30018-028A SPECIAL SCREW,X2,MON-HINGE

819 LY30030-075A SPACER(A),B,C,D

820 LY44197-001A D BEF SHEET,B,C,D

823 LY30030-0J1A SPACER(A),A

824 LY30030-0H1A SPACER(A),B,C,D

825 LY30030-0M2A SPACER(A),B,C,D

826 LY30030-0G4A SPACER(A),B,C,D

827 LY30030-0G6A SPACER(A),B,C,D

828 LY30030-0K4A SPACER(A),B,C,D

829 LY30030-0H7A SPACER(A),A

830 LY30030-0K1A SPACER(A),A

831 LY30030-0J2A SPACER(A),A

832 LY30030-0J3A SPACER(A),A

833 LY30030-0G4A SPACER(A),A

834 LY30030-0K4A SPACER(A),A

835 LY30030-0K3A SPACER(A),X2

******************************

VF ASSEMBLY<M2>

901 L Y21009-001A U.CASE.F(VF)

902 L Y21010-001A U.CASE.R(VF)

903 L Y21008-001A B.CASE(VF)

904 L Y33006-001C LEVER(LENS)

905 LY33250-001A EYE CUP

906 LY33255-001C HOLDER(VF)ASSY

907 LY30019-050A SPECIAL SCREW,X2,EYE CUP

908 LY30018-059A SPECIAL SCREW,B.C-H.LCD2

909 LY30018-0K4A SPECIAL SCREW,FPC-HOLDER

910 QAL0469-001 FPC

911 NSW0200-001X LEVER SWITCH,TEZUKE

912 LY44144-001A SHEET(HOLD)

913 LY30018-0K5A SPECIAL SCREW,X2,B.C-G.LENS

928 LY30018-0G6A SPECIAL SCREW,X2,B.C-U.C(R)

931 LY30018-0K4A SPECIAL SCREW,X2,U.C-HINGE

932 LY30018-0G6A SPECIAL SCREW,X2,B.C-U.C(F)

******************************

MECHANISM

900 YMA0029H MECHA(A)ASSY

900A YMA0029D MECHA(A)ASSY

901 L Y32870-001G CASSETTEHOUSING ASSY

902 YQ43893-8 MINI SCREW (x3)

903 LYH30420-001A UPPER BASE ASSY

904 QYSPSPU1425M SCREW

905 YDV2102B DRUM ASSY

906 L Y42820-001A DAMP.SCREW ASSY (x2)

907 L Y42820-002A DAMP.SCREW ASSY

908 LY31538-001F REEL DISK ASSY

909 LY31538-002H REEL DISK ASSY

910 YQ44246 SLIT WASHER

911 LY10372-001D REEL COVER ASSY

PARTS LIST

<M3>

912 LY42120-002A MINI SCREW

913 LY41945-003A MINI SCREW (x2)

914 YQ44246 SLIT WASHER

915 L Y43725-001D TENSION ARM ASSY

916 LYH40269-001A SLANT POLE ARM ASSY

917 L Y43731-001F TU ARM ASSY

918 L Y31531-001D SWING ARM ASSY

919 YQ43893 MINI SCREW

920 LYH30424-001A SLIDE DECK FINAL ASSY

921 YQ43893 MINI SCREW (x2)

922 LY43023-001A MINI SCREW

924 L YH30419-001A PAD ARM ASSY

925 YQ44246 SLIT WASHER

928 LYH40270-001A TU BRAKE ASSY

929 YQ44246 SLIT WASHER

930 LY43684-001A TENSION CONTROL LEVER ASSY

931 LY32861-001A CENTER GEAR

932 LY31516-001F PINCH ROLLER ARM FINAL ASSY

933 YQ44246 SLIT WASHER

934 LY43681-001A TENSION CONTROL PLATE ASSY

935 LY43687-001A BRAKE CONTROL LEVER ASSY

936 LYH30421-001A MOTOR BRACKET ASSY

936A QAR0138-001 LOADING MOTOR

936B LY41940-001A TAPPING SCREW (x2)

937 YQ43893 MINI SCREW (x3)

938 LYH30422-001A GUIDE RAIL ASSY

939 YQ43893 MINI SCREW

940 YQ44246 SLIT WASHER (x2)

941 LY32843-001A SLIDE LEVER2 ASSY

942 LY43690-001A LOADING PLATE ASSY

943 YQ44246 SLIT WASHER

944 LY32858-001A EJECT LEVER

945 YQ44246 SLIT WASHER

946 LYH40271-001A BASE R ASSY

947 YQ43893 MINI SCREW

948 LY41945-001B MINI SCREW

949 LY43665-001A MODE GEAR

950 QSW0876-003 ROTARY ENCODER

951 YQ43893 MINI SCREW (x2)

952 LY32860-001A GEAR COVER ASSY

953 YQ43893 MINI SCREW (x2)

954 YQ43893-4 MINI SCREW

955 LY43676-001A MAIN CAM ASSY

956 L Y41941-001B SLIDE ARM ASSY

957 LY43678-001A CONNECT GEAR 2

958 LY41954-001C SUB CAM ASSY

959 LY42120-001A MINI SCREW

960 L Y43692-001A CONTROL ARM ASSY

961 LY32859-001A REEL GEAR 1

962 LY31508-002B DRUM BASE ASSY

963 QYSPSPU1425M SCREW 1.4mm x 2.5mm(x3)

964 QAR0142-001 CAPSTAN MOTOR

965 YQ43893 MINI SCREW

966 LY10367-001D MAIN DECK ASSY

976 YQ44246 SLIT WASHER

977 YQ44246-6 SLIT WASHER

978 LY42047-005A WASHER

979 LY43987-001B SPACER

5-10

Page 11

MODEL MARK MODEL MARK

GR-DV500US A GR-DV801US C

GR-DV800US B GR-DV900US D

# REF No. PART No. PART NAME, DESCRIPTION # REF No. PART No. PART NAME, DESCRIPTION

---------------- ----------------------- ----------------------------------------------------- ----------------- ----------------------- -----------------------------------------------------

******************************

MAIN BOARD ASSEMBLY <01>

PW1 YB10434B MAIN PWB ASS'Y,A,B

PW1 YB10434B-01 MAIN PWB ASS'Y,C

PW1 YB10434A-01 MAIN PWB ASS'Y,D

IC1001 UPD703038F1-A12 IC(MICRO C ROM),CAM CPU,A,B,C

IC1001 UPD703038F1-A11 IC(MICRO C ROM),CAM CPU,D

IC1001 or UPD70F3038F1A12 IC(MICRO C ROM),CAM CPU,A,B,C

IC1001 or UPD70F3038F1A11 IC(MICRO C ROM),CAM CPU,D

IC1002 RS5C314-X IC

IC1003 X25330S8I-2.5-X IC

IC1003 or 25LC320-I/SN-X IC

IC1003 or AT25320N-10SI-X IC

IC1003 or CAT25C32SI-X IC

IC1003 or M95320-WMN6-X IC

IC1004 NJU7108F3-X IC

IC1005 74HC1G00GW-X IC

IC1005 or MC74HC1G00DF-X IC

IC1005 or SN74AHC1G00K-X IC

IC1006 MB90097PFV149-X IC(MICRO C ROM),MB90099

IC1007 SN74AHC1G08K-X IC

IC1008 74HC2G08DP-X IC

IC1009 IC-PST3423U-X IC

IC1009 or S-80823CNNB-X IC

IC1401 UPD703040YF-M20 IC(MICRO C ROM),DECK MASK

IC1401 or UPD70F3040YFM20 IC(MICRO C ROM),DECK FLASH

IC1401 or UPD703040YFM20A IC(MICRO C ROM),PP ONLY

IC2101 AK4550VT-X IC

IC2201 AK4564VQ IC,48P0.5

IC3001 JCY0152 IC

IC3002 JCY0174-X IC

IC3003 SN74AHC1G04K-X IC

IC3701 BA7665FS-X IC

IC3701 or BA7665AFS-X IC,B

IC3731 MM1504XN-X IC

IC3801 JCP8045 IC(DIGITAL)

IC3802 SN74AHC1G04K-X IC

IC3901 BU2501FV-X IC

IC4201 HD49340HNP-X IC,CDS/AD

IC4202 MM1613BN-X IC,REG3.1V

IC4301 JCY0183 IC,CAMERA DSP

IC4302 R1160N121B-X IC,REG1.2V

IC4802 NJM2143R-X IC,HALL AMP+

IC4803 NJM2143R-X IC,HALL AMPIC4804 NJM3414AV -X IC,DRIVE AMP

IC4805 MM6564XFBE-X IC,DAMPER

IC4851 UPD16879GS-X IC,F/Z_MDA

IC5001 CXD3602AR IC,TG/VDR

IC5002 W194-70G-X IC,CLK72

IC5003 MM1613DN-X IC,REG3.3V

IC8001 TMS320DSC24GHKL IC,DSC24

IC8002 K4S643233F-SE75 IC,64MSDRAM

IC8003 MBV160TE90PBA06 IC(MICRO C ROM),16MFLASH

IC8003 or MBV160TE90PBA08 IC(MICRO C ROM),16MFLASH

IC8004 BU2288FV-X IC,FS PLL

IC8301 ISP1181ABS IC,USBQNF,2.6

IC8302 S-80842CNNB-W IC

Q1001 DTC124EE-X DIGI TRANSISTOR

Q1002 2SC4617/QR/-X TRANSISTOR

Q1003 DTC143EE-X DIGI TRANSISTOR

Q1004 DTC143XE-X DIGI TRANSISTOR

Q1005 2SJ347-X MOS FET

Q1006 DTC143XE-X DIGI TRANSISTOR

Q1007 DTC143XE-X DIGI TRANSISTOR

Q1401 DTA114EE-X DIGI TRANSISTOR,MIC CTL

Q1401 or RN2102-X DIGI TRANSISTOR

Q1401 or PDTA1 14EE-X DIGI TRANSISTOR

Q1401 or UN9111J-X DIGI TRANSISTOR

Q1402 UMC3N-W DIGI TRANSISTOR,REEL LED

Q1403 UMC3N-W DIGI TRANSISTOR,TAPE LED

Q2901 2SB1188/QR/-W TRANSISTOR

Q2902 DTC144EE-X DIGI TRANSISTOR

Q2902 or UN9213J-X DIGI TRANSISTOR

Q2902 or RN1104-X DIGI TRANSISTOR

Q2902 or PDTC144EE-X DIGI TRANSISTOR

Q2903 2SD1759-X TRANSISTOR

Q2904 CPH3314-X MOS FET

Q2905 DTC144EE-X DIGI TRANSISTOR

Q2905 or UN9213J-X DIGI TRANSISTOR

Q2905 or RN1104-X DIGI TRANSISTOR

Q2905 or PDTC144EE-X DIGI TRANSISTOR

Q2202 DTC144EE-X DIGI TRANSISTOR

Q2202 or UN9213J-X DIGI TRANSISTOR

Q2202 or PDTC144EE-X DIGI TRANSISTOR

Q2401 2SC4617/QR/-X TRANSISTOR

Q2402 2SC4617/QR/-X TRANSISTOR

Q2403 2SC4617/QR/-X TRANSISTOR

Q2601 2SC5585-X TRANSISTOR,ZMIC_ATT

Q2602 2SC5585-X TRANSISTOR,ZMIC_ATT

Q2701 UMX1N-W PAIR TRANSISTOR

Q2702 UMX1N-W PAIR TRANSISTOR

Q3701 UMT1N-W PAIR TRANSIST OR

Q3701 or XP4401-W TRANSISTOR

Q3702 UMZ1N-W PAIR TRANSIST OR

Q3702 or XP4601-W TRANSISTOR

Q3704 2SA1774/RS/-X TRANSISTOR

Q3705 UMT1N-W PAIR TRANSIST OR

Q3705 or XP4401-W TRANSISTOR

Q3731 2SC4617/RS/-X TRANSISTOR

Q3731 or 2SD2216J/RS/-X TRANSISTOR

Q3732 DTC144EE-X DIGI TRANSISTOR

Q3732 or UN9213J-X DIGI TRANSISTOR

Q3732 or RN1104-X DIGI TRANSISTOR

Q3732 or PDTC144EE-X DIGI TRANSISTOR

Q3733 UMZ1N-W PAIR TRANSIST OR

Q3733 or XP4601-W TRANSISTOR

Q3734 2SC4617/RS/-X TRANSISTOR

Q3734 or 2SD2216J/RS/-X TRANSISTOR

Q3735 UMZ1N-W PAIR TRANSIST OR

Q3735 or XP4601-W TRANSISTOR

Q4801 2SC4655/BC/-X TRANSISTOR,HALL DRIVE

Q4802 2SC4617/RS/-X TRANSISTOR,DRIVEQ4803 DTC144EE-X DIGI TRANSISTOR,SS MINI

Q4803 or RN1104-X DIGI TRANSISTOR,SS MINI

Q4803 or PDTC144EE-X DIGI TRANSISTOR,SS MINI

Q4803 or UN9213J-X DIGI TRANSISTOR,SS MINI

Q4804 DTA144EE-X DIGI TRANSISTOR,SS MINI

Q4804 or RN2104-X DIGI TRANSISTOR,SS MINI

Q4804 or PDTA144EE-X DIGI TRANSISTOR,SS MINI

Q4804 or UN9113J-X DIGI TRANSISTOR,SS MINI

Q4805 2SC4617/RS/-X TRANSISTOR,SS MINI

Q4806 2SA1774/QR/-X TRANSISTOR

Q4851 2SC4617/RS/-X TRANSISTOR

Q8001 2SA1774/RS/-X TRANSISTOR,2SA1774

5-11

Page 12

MODEL MARK MODEL MARK

GR-DV500US A GR-DV801US C

GR-DV800US B GR-DV900US D

# REF No. PART No. PART NAME, DESCRIPTION # REF No. PART No. PART NAME, DESCRIPTION

---------------- ----------------------- ----------------------------------------------------- ----------------- ----------------------- -----------------------------------------------------

D1001 DA221-X SI DIODE

D1002 1SS376-X SI DIODE

D2901 UMZ6.8EN-W Z DIODE

D2903 EMZ6.8N-X Z DIODE

D2903 or DF3A6.8FE-X Z DIODE

D3001 EC2C01C-X VARI CAP DIODE

D3002 EC2C01C-X VARI CAP DIODE

D3003 EC2C01C-X VARI CAP DIODE

D3004 MA2Z720-X SB DIODE

D5001 1SS355-X SI DIODE

D5001 or MA111-X SI DIODE

D8301 1SS355-X SI DIODE

D8301 or MA111-X SI DIODE

R1001 NRSA6AJ-104W MG RESISTOR 100kØ,1/16W

R1002 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R1003 NRSA6AJ-472W MG RESISTOR 4.7kØ,1/16W

R1004 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R1005 NRSA6AJ-153W MG RESISTOR 15kØ,1/16W

R1006 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R1007 NRSA6AJ-333W MG RESISTOR 33kØ,1/16W

R1009 NRSA6AJ-471W MG RESISTOR 470Ø,1/16W

R1010 NRSA6AJ-471W MG RESISTOR 470Ø,1/16W

R1015 NRSA6AJ-474W MG RESISTOR 470kØ,1/16W

R1017 NRSA6AJ-102W MG RESISTOR 1kØ,1/16W

R1018 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R1019 NRSA6AJ-623W MG RESISTOR 62kØ,1/16W

R1020 NRSA6AJ-331W MG RESISTOR 330Ø,1/16W

R1021 NRSA6AJ-331W MG RESISTOR 330Ø,1/16W

R1022 NRSA6AJ-331W MG RESISTOR 330Ø,1/16W

R1023 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R1024 NRSA6AJ-823W MG RESISTOR 82kØ,1/16W

R1025 NRSA6AJ-473W MG RESISTOR 47kØ,1/16W

R1026 NRSA6AJ-472W MG RESISTOR 4.7kØ,1/16W

R1027 NRSA6AJ-104W MG RESISTOR 100kØ,1/16W

R1028 NRSA6AJ-185W MG RESISTOR 1.8MØ,1/16W

R1029 NRSA6AJ-473W MG RESISTOR 47kØ,1/16W

R1030 NRSA6AJ-104W MG RESISTOR 100kØ,1/16W

R1031 NRSA6AJ-102W MG RESISTOR 1kØ,1/16W

R1032 NRSA6AJ-104W MG RESISTOR 100kØ,1/16W

R1033 NRSA6AJ-102W MG RESISTOR 1kØ,1/16W

R1034 NRSA6AJ-102W MG RESISTOR 1kØ,1/16W

R1035 NRSA6AJ-473W MG RESISTOR 47kØ,1/16W

R1036 NRSA6AJ-102W MG RESISTOR 1kØ,1/16W

R1037 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R1038 NRSA6AJ-104W MG RESISTOR 100kØ,1/16W

R1039 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R1040 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R1041 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R1042 NRSA6AJ-102W MG RESISTOR 1kØ,1/16W

R1044 NRSA6AJ-123W MG RESISTOR 12kØ,1/16W

R1045 NRSA6AJ-822W MG RESISTOR 8.2kØ,1/16W

R1046 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R1047 NRSA6AJ-473W MG RESISTOR 47kØ,1/16W

R1048 NRSA6AJ-104W MG RESISTOR 100kØ,1/16W

R1049 NRSA6AJ-393W MG RESISTOR 39kØ,1/16W

R1050 NRSA6AJ-223W MG RESISTOR 22kØ,1/16W

R1051 NRSA6AJ-272W MG RESISTOR 2.7kØ,1/16W

R1052 NRSA6AJ-183W MG RESISTOR 18kØ,1/16W

R1053 NRSA6AJ-154W MG RESISTOR 150kØ,1/16W

R1054 NRSA6AJ-473W MG RESISTOR 47kØ,1/16W

R1055 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R1056 NRSA6AJ-472W MG RESISTOR 4.7kØ,1/16W

R1058 NRSA6AJ-222W MG RESISTOR 2.2kØ,1/16W

R1060 NRSA6AJ-473W MG RESISTOR 47kØ,1/16W

R1063 NRSA6AJ-102W MG RESISTOR 1kØ,1/16W

R1064 NRSA6AJ-102W MG RESISTOR 1kØ,1/16W

R1065 NRSA6AJ-102W MG RESISTOR 1kØ,1/16W

R1066 NRSA6AJ-473W MG RESISTOR 47kØ,1/16W

R1071 NRSA6AJ-474W MG RESISTOR 470kØ,1/16W

R1072 NRSA6AJ-104W MG RESISTOR 100kØ,1/16W

R1076 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R1077 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R1081 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R1083 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R1084 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R1085 NRSA6AJ-102W MG RESISTOR 1kØ,1/16W

R1086 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R1088 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R1089 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R1090 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R1091 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R1092 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R1093 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R1107 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R1109 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R1111 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R1112 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R1115 NRSA6AD-102W MG RESISTOR 1kØ,1/16W

R1116 NRSA6AD-102W MG RESISTOR 1kØ,1/16W

R1401 NRSA6AJ-105W MG RESISTOR 1MØ,1/16W

R1402 NRSA6AJ-102W MG RESISTOR 1kØ,1/16W

R1403 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R1404 NRSA6AJ-472W MG RESISTOR 4.7kØ,1/16W

R1405 NRSA6AJ-332W MG RESISTOR 3.3kØ,1/16W

R1406 NRSA6AJ-332W MG RESISTOR 3.3kØ,1/16W

R1407 NRSA6AJ-332W MG RESISTOR 3.3kØ,1/16W

R1408 NRSA6AD-753W MG RESISTOR 75kØ,1/16W

R1409 NRSA6AJ-334W MG RESISTOR 330kØ,1/16W

R1411 NRSA6AJ-332W MG RESISTOR 3.3kØ,1/16W

R1412 NRSA6AJ-332W MG RESISTOR 3.3kØ,1/16W

R1413 NRSA6AJ-332W MG RESISTOR 3.3kØ,1/16W

R1414 NRSA6AJ-332W MG RESISTOR 3.3kØ,1/16W

R1415 NRSA6AJ-472W MG RESISTOR 4.7kØ,1/16W

R1416 NRSA6AJ-472W MG RESISTOR 4.7kØ,1/16W

R1417 NRSA6AJ-101W MG RESISTOR 100Ø,1/16W

R1427 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R1428 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R1429 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R1430 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R1431 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R1432 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R2001 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R2002 NRSA6AJ-152W MG RESISTOR 1.5kØ,1/16W

R2003 NRSA6AJ-182W MG RESISTOR 1.8kØ,1/16W

R2004 NRSA6AJ-272W MG RESISTOR 2.7kØ,1/16W

R2005 NRSA6AJ-392W MG RESISTOR 3.9kØ,1/16W

R2006 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R2012 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R2013 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R2014 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R2015 NRSA63J-0R0X MG RESISTOR 0Ø,1/16W

R2016 NRSA63J-0R0X MG RESISTOR 0Ø,1/16W

R2017 NRSA02J-0R0X MG RESISTOR 0Ø,1/10W

R2101 NRSA6AJ-471W MG RESISTOR 470Ø,1/16W

R2102 NRSA6AJ-471W MG RESISTOR 470Ø,1/16W

R2110 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

5-12

Page 13

MODEL MARK MODEL MARK

GR-DV500US A GR-DV801US C

GR-DV800US B GR-DV900US D

# REF No. PART No. PART NAME, DESCRIPTION # REF No. PART No. PART NAME, DESCRIPTION

---------------- ----------------------- ----------------------------------------------------- ----------------- ----------------------- -----------------------------------------------------

R2111 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R2112 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R2201 NRSA6AJ-224W MG RESISTOR 220kØ,1/16W

R2202 NRSA6AJ-564W MG RESISTOR 560kØ,1/16W

R2203 NRSA6AJ-393W MG RESISTOR 39kØ,1/16W

R2204 NRSA6AJ-154W MG RESISTOR 150kØ,1/16W

R2206 NRSA6AJ-333W MG RESISTOR 33kØ,1/16W

R2207 NRSA6AJ-333W MG RESISTOR 33kØ,1/16W

R2208 NRSA6AJ-223W MG RESISTOR 22kØ,1/16W

R2209 NRSA6AJ-223W MG RESISTOR 22kØ,1/16W

R2210 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R2211 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R2212 NRSA6AJ-2R7W MG RESISTOR 2.7Ø,1/16W

R2213 NRSA6AJ-2R7W MG RESISTOR 2.7Ø,1/16W

R2217 NRSA6AJ-100W MG RESISTOR 10Ø,1/16W

R2218 NRSA6AJ-100W MG RESISTOR 10Ø,1/16W

R2219 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R2220 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R2221 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R2222 NRSA6AJ-100W MG RESISTOR 10Ø,1/16W

R2223 NRSA6AJ-100W MG RESISTOR 10Ø,1/16W

R2224 NRSA6AJ-100W MG RESISTOR 10Ø,1/16W

R2225 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R2226 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R2227 NRSA6AJ-821W MG RESISTOR,A,B 820Ø,1/16W

R2227 NRSA6AJ-822W MG RESISTOR,C,D 8.2kØ,1/16W

R2228 NRSA6AJ-821W MG RESISTOR,A,B 820Ø,1/16W

R2228 NRSA6AJ-822W MG RESISTOR,C,D 8.2kØ,1/16W

R2231 NRSA6AJ-102W MG RESISTOR 1kØ,1/16W

R2233 NRSA6AJ-332W MG RESISTOR,A,B 3.3kØ,1/16W

R2233 NRSA6AJ-333W MG RESISTOR,C,D 33kØ,1/16W

R2234 NRSA6AJ-332W MG RESISTOR,A,B 3.3kØ,1/16W

R2234 NRSA6AJ-333W MG RESISTOR,C,D 33kØ,1/16W

R2401 NRSA6AJ-472W MG RESISTOR 4.7kØ,1/16W

R2402 NRSA6AJ-472W MG RESISTOR 4.7kØ,1/16W

R2403 NRSA6AJ-183W MG RESISTOR 18kØ,1/16W

R2404 NRSA6AJ-472W MG RESISTOR 4.7kØ,1/16W

R2405 NRSA6AJ-123W MG RESISTOR 12kØ,1/16W

R2407 NRSA6AJ-100W MG RESISTOR 10Ø,1/16W

R2601 NRSA6AJ-222W MG RESISTOR 2.2kØ,1/16W

R2602 NRSA6AJ-222W MG RESISTOR 2.2kØ,1/16W

R2603 NRSA6AJ-682W MG RESISTOR 6.8kØ,1/16W

R2604 NRSA6AJ-682W MG RESISTOR 6.8kØ,1/16W

R2605 NRSA6AJ-332W MG RESISTOR 3.3kØ,1/16W

R2606 NRSA6AJ-332W MG RESISTOR 3.3kØ,1/16W

R2607 NRSA6AJ-222W MG RESISTOR 2.2kØ,1/16W

R2608 NRSA6AJ-222W MG RESISTOR 2.2kØ,1/16W

R2609 NRSA6AJ-223W MG RESISTOR 22kØ,1/16W

R2610 NRSA6AJ-223W MG RESISTOR 22kØ,1/16W

R2611 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R2612 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R2613 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R2614 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R2701 NRSA6AJ-821W MG RESISTOR 820Ø,1/16W

R2702 NRSA6AJ-821W MG RESISTOR 820Ø,1/16W

R2703 NRSA6AJ-564W MG RESISTOR 560kØ,1/16W

R2704 NRSA6AJ-564W MG RESISTOR 560kØ,1/16W

R2705 NRSA6AJ-332W MG RESISTOR 3.3kØ,1/16W

R2706 NRSA6AJ-221W MG RESISTOR 220Ø,1/16W

R2707 NRSA6AJ-221W MG RESISTOR 220Ø,1/16W

R2708 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R2709 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R2710 NRSA6AJ-332W MG RESISTOR 3.3kØ,1/16W

R2711 NRSA6AJ-104W MG RESISTOR 100kØ,1/16W

R2901 NRSA6AJ-472W MG RESISTOR 4.7kØ,1/16W

R2902 NRSA6AJ-105W MG RESISTOR 1MØ,1/16W

R2903 NRSA6AJ-105W MG RESISTOR 1MØ,1/16W

R2905 NRSA6AJ-102W MG RESISTOR 1kØ,1/16W

R2906 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R2907 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R2908 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R2909 NRSA6AJ-122W MG RESISTOR 1.2kØ,1/16W

R2910 NRSA6AJ-332W MG RESISTOR 3.3kØ,1/16W

R2911 NRSA6AJ-104W MG RESISTOR 100kØ,1/16W

R3002 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R3004 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R3006 NRSA6AJ-100W MG RESISTOR 10Ø,1/16W

R3007 NRSA6AJ-562W MG RESISTOR 5.6kØ,1/16W

R3008 NRSA6AJ-222W MG RESISTOR 2.2kØ,1/16W

R3009 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R3010 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R3011 NRSA6AJ-224W MG RESISTOR 220kØ,1/16W

R3012 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R3013 NRSA6AJ-242W MG RESISTOR 2.4kØ,1/16W

R3014 NRSA6AJ-392W MG RESISTOR 3.9kØ,1/16W

R3015 NRSA6AJ-392W MG RESISTOR 3.9kØ,1/16W

R3016 NRVA6AD-560W CMF RESISTOR 56Ø,1/16W

R3017 NRVA6AD-560W CMF RESISTOR 56Ø,1/16W

R3018 NRVA6AD-560W CMF RESISTOR 56Ø,1/16W

R3019 NRVA6AD-560W CMF RESISTOR 56Ø,1/16W

R3020 NRVA6AD-512W CMF RESISTOR 5.1kØ,1/16W

R3021 NRSA6AJ-100W MG RESISTOR 10Ø,1/16W

R3022 NRSA6AJ-100W MG RESISTOR 10Ø,1/16W

R3027 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R3028 NRSA6AJ-822W MG RESISTOR 8.2kØ,1/16W

R3029 NRSA6AJ-105W MG RESISTOR 1MØ,1/16W

R3030 NRSA6AJ-224W MG RESISTOR 220kØ,1/16W

R3031 NRSA6AJ-224W MG RESISTOR 220kØ,1/16W

R3032 NRSA6AJ-105W MG RESISTOR 1MØ,1/16W

R3033 NRSA6AJ-222W MG RESISTOR 2.2kØ,1/16W

R3034 NRSA6AJ-823W MG RESISTOR 82kØ,1/16W

R3035 NRSA6AJ-123W MG RESISTOR 12kØ,1/16W

R3036 NRSA6AJ-122W MG RESISTOR 1.2kØ,1/16W

R3037 NRSA6AJ-152W MG RESISTOR 1.5kØ,1/16W

R3038 NRSA6AJ-561W MG RESISTOR 560Ø,1/16W

R3039 NRSA6AJ-561W MG RESISTOR 560Ø,1/16W

R3040 NRSA6AJ-222W MG RESISTOR 2.2kØ,1/16W

R3045 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R3046 NRSA6AJ-681W MG RESISTOR 680Ø,1/16W

R3049 NRSA6AJ-560W MG RESISTOR 56Ø,1/16W

R3051 NRSA6AJ-101W MG RESISTOR 100Ø,1/16W

R3058 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R3059 NRSA6AJ-100W MG RESISTOR 10Ø,1/16W

R3701 NRSA6AJ-271W MG RESISTOR 270Ø,1/16W

R3702 NRSA6AJ-271W MG RESISTOR 270Ø,1/16W

R3703 NRSA6AJ-332W MG RESISTOR 3.3kØ,1/16W

R3704 NRSA6AJ-301W MG RESISTOR 300Ø,1/16W

R3705 NRSA6AJ-301W MG RESISTOR 300Ø,1/16W

R3706 NRSA6AJ-332W MG RESISTOR 3.3kØ,1/16W

R3707 NRSA6AJ-680W MG RESISTOR 68Ø,1/16W

R3708 NRSA6AJ-680W MG RESISTOR 68Ø,1/16W

R3709 NRSA6AJ-680W MG RESISTOR 68Ø,1/16W

R3710 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R3711 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R3712 NRSA6AJ-105W MG RESISTOR 1MØ,1/16W

R3713 NRSA6AJ-104W MG RESISTOR 100kØ,1/16W

5-13

Page 14

MODEL MARK MODEL MARK

GR-DV500US A GR-DV801US C

GR-DV800US B GR-DV900US D

# REF No. PART No. PART NAME, DESCRIPTION # REF No. PART No. PART NAME, DESCRIPTION

---------------- ----------------------- ----------------------------------------------------- ----------------- ----------------------- -----------------------------------------------------

R3714 NRSA6AJ-823W MG RESISTOR 82kØ,1/16W

R3715 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R3721 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R3722 NRSA6AD-121W MG RESISTOR 120Ø,1/16W

R3724 NRSA6AJ-332W MG RESISTOR 3.3kØ,1/16W

R3725 NRSA6AD-121W MG RESISTOR 120Ø,1/16W

R3726 NRSA6AJ-472W MG RESISTOR 4.7kØ,1/16W

R3727 NRSA6AJ-472W MG RESISTOR 4.7kØ,1/16W

R3728 NRVA6AD-121W CMF RESISTOR 120Ø,1/16W

R3730 NRSA6AJ-472W MG RESISTOR 4.7kØ,1/16W

R3731 NRSA6AJ-472W MG RESISTOR 4.7kØ,1/16W

R3732 NRSA6AJ-101W MG RESISTOR 100Ø,1/16W

R3733 NRSA6AJ-561W MG RESISTOR 560Ø,1/16W

R3734 NRSA6AJ-822W MG RESISTOR 8.2kØ,1/16W

R3735 NRSA6AJ-182W MG RESISTOR 1.8kØ,1/16W

R3736 NRSA6AJ-183W MG RESISTOR 18kØ,1/16W

R3737 NRSA6AJ-183W MG RESISTOR 18kØ,1/16W

R3738 NRSA6AJ-681W MG RESISTOR 680Ø,1/16W

R3739 NRSA6AJ-821W MG RESISTOR 820Ø,1/16W

R3740 NRSA6AJ-821W MG RESISTOR 820Ø,1/16W

R3741 NRSA6AJ-102W MG RESISTOR 1kØ,1/16W

R3742 NRSA6AJ-104W MG RESISTOR 100kØ,1/16W

R3743 NRSA6AJ-104W MG RESISTOR 100kØ,1/16W

R3744 NRSA6AJ-561W MG RESISTOR 560Ø,1/16W

R3745 NRSA6AJ-152W MG RESISTOR 1.5kØ,1/16W

R3746 NRSA6AJ-222W MG RESISTOR 2.2kØ,1/16W

R3747 NRSA6AJ-102W MG RESISTOR 1kØ,1/16W

R3748 NRSA6AJ-474W MG RESISTOR 470kØ,1/16W

R3801 NRSA6AJ-101W MG RESISTOR 100Ø,1/16W

R3802 NRSA6AD-821W MG RESISTOR 820Ø,1/16W

R3803 NRSA6AD-273W MG RESISTOR 27kØ,1/16W

R3804 NRSA6AD-153W MG RESISTOR 15kØ,1/16W

R3805 NRSA6AD-821W MG RESISTOR 820Ø,1/16W

R3809 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R4201 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R4202 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R4203 NRSA6AJ-333W MG RESISTOR 33kØ,1/16W

R4204 NRSA6AJ-101W MG RESISTOR 100Ø,1/16W

R4205 NRSA6AJ-101W MG RESISTOR 100Ø,1/16W

R4301 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R4303 NRSA6AJ-220W MG RESISTOR 22Ø,1/16W

R4304 NRSA6AJ-220W MG RESISTOR 22Ø,1/16W

R4306 NRSA6AJ-220W MG RESISTOR 22Ø,1/16W

R4307 NRSA6AJ-220W MG RESISTOR 22Ø,1/16W

R4308 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R4310 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R4311 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R4312 NRSA6AJ-220W MG RESISTOR 22Ø,1/16W

R4313 NRSA6AJ-220W MG RESISTOR 22Ø,1/16W

R4314 NRSA6AJ-102W MG RESISTOR 1kØ,1/16W

R4315 NRSA6AJ-101W MG RESISTOR 100Ø,1/16W

R4316 NRSA6AJ-101W MG RESISTOR 100Ø,1/16W

R4317 NRSA6AJ-101W MG RESISTOR 100Ø,1/16W

R4318 NRSA6AJ-101W MG RESISTOR 100Ø,1/16W

R4319 NRSA6AJ-101W MG RESISTOR 100Ø,1/16W

R4320 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R4321 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R4322 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R4323 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R4324 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R4325 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R4326 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R4327 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R4328 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R4804 NRSA6AJ-564W MG RESISTOR 560kØ,1/16W

R4805 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R4806 NRSA6AJ-683W MG RESISTOR 68kØ,1/16W

R4807 NRSA6AJ-683W MG RESISTOR 68kØ,1/16W

R4808 NRSA6AJ-243W MG RESISTOR 24kØ,1/16W

R4809 NRSA6AJ-331W MG RESISTOR 330Ø,1/16W

R4810 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R4811 NRSA6AJ-564W MG RESISTOR 560kØ,1/16W

R4812 NRSA6AJ-153W MG RESISTOR 15kØ,1/16W

R4814 NRSA6AJ-105W MG RESISTOR 1MØ,1/16W

R4815 NRSA6AJ-472W MG RESISTOR 4.7kØ,1/16W

R4816 NRSA6AJ-105W MG RESISTOR 1MØ,1/16W

R4817 NRSA6AJ-472W MG RESISTOR 4.7kØ,1/16W

R4818 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R4819 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R4820 NRSA6AJ-104W MG RESISTOR 100kØ,1/16W

R4821 NRSA6AJ-104W MG RESISTOR 100kØ,1/16W

R4822 NRSA6AJ-473W MG RESISTOR 47kØ,1/16W

R4823 NRSA6AJ-102W MG RESISTOR 1kØ,1/16W

R4824 NRSA6AJ-472W MG RESISTOR 4.7kØ,1/16W

R4825 NRSA6AJ-222W MG RESISTOR 2.2kØ,1/16W

R4826 NRSA6AJ-473W MG RESISTOR 47kØ,1/16W

R4828 NRSA6AJ-183W MG RESISTOR 18kØ,1/16W

R4829 NRSA6AJ-122W MG RESISTOR 1.2kØ,1/16W

R4830 NRSA6AJ-222W MG RESISTOR 2.2kØ,1/16W

R4831 NRSA6AJ-473W MG RESISTOR 47kØ,1/16W

R4832 NRSA6AJ-333W MG RESISTOR 33kØ,1/16W

R4833 NRSA6AJ-104W MG RESISTOR 100kØ,1/16W

R4834 NRSA6AJ-104W MG RESISTOR 100kØ,1/16W

R4836 NRSA6AJ-561W MG RESISTOR 560Ø,1/16W

R4841 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R4842 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R4854 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R4856 NRSA63J-6R8X MG RESISTOR 6.8Ø,1/16W

R4857 NRSA63J-6R8X MG RESISTOR 6.8Ø,1/16W

R4858 NRSA6AJ-333W MG RESISTOR 33kØ,1/16W

R4859 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R4860 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R4862 NRSA63J-6R8X MG RESISTOR 6.8Ø,1/16W

R4863 NRSA63J-6R8X MG RESISTOR 6.8Ø,1/16W

R4864 NRSA6AJ-102W MG RESISTOR 1kØ,1/16W

R4865 NRSA6AJ-102W MG RESISTOR 1kØ,1/16W

R4866 NRSA6AJ-102W MG RESISTOR 1kØ,1/16W

R4867 NRSA6AJ-102W MG RESISTOR 1kØ,1/16W

R4868 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R4870 NRSA6AJ-271W MG RESISTOR 270Ø,1/16W

R4871 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R4874 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R5002 NRSA6AJ-100W MG RESISTOR 10Ø,1/16W

R5003 NRSA6AJ-100W MG RESISTOR 10Ø,1/16W

R5004 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R5005 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R5006 NRSA6AJ-100W MG RESISTOR 10Ø,1/16W

R5009 NRSA6AJ-100W MG RESISTOR 10Ø,1/16W

R5010 NRSA6AJ-100W MG RESISTOR 10Ø,1/16W

R5017 NRSA6AJ-101W MG RESISTOR 100Ø,1/16W

R5020 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R5021 NRSA6AJ-104W MG RESISTOR 100kØ,1/16W

R5023 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R8001 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R8002 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R8003 NRSA6AJ-220W MG RESISTOR 22Ø,1/16W

5-14

Page 15

MODEL MARK MODEL MARK

GR-DV500US A GR-DV801US C

GR-DV800US B GR-DV900US D

# REF No. PART No. PART NAME, DESCRIPTION # REF No. PART No. PART NAME, DESCRIPTION

---------------- ----------------------- ----------------------------------------------------- ----------------- ----------------------- -----------------------------------------------------

R8004 NRSA6AJ-220W MG RESISTOR 22Ø,1/16W

R8005 NRSA6AJ-220W MG RESISTOR 22Ø,1/16W

R8007 NRSA6AJ-102W MG RESISTOR 1kØ,1/16W

R8008 NRSA6AJ-561W MG RESISTOR 560Ø,1/16W

R8009 NRSA6AJ-105W MG RESISTOR 1MØ,1/16W

R8011 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R8012 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R8014 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R8015 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R8016 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R8017 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R8019 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R8020 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R8021 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R8022 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R8023 NRSA6AJ-472W MG RESISTOR 4.7kØ,1/16W

R8025 NRSA6AJ-472W MG RESISTOR 4.7kØ,1/16W

R8027 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R8028 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R8029 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R8030 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R8031 NRSA6AJ-100W MG RESISTOR 10Ø,1/16W

R8032 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R8033 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R8034 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R8035 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R8036 NRSA6AJ-220W MG RESISTOR 22Ø,1/16W

R8039 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R8302 NRS181J-220X MG RESISTOR 22Ø,1/8W

R8303 NRS181J-220X MG RESISTOR 22Ø,1/8W

R8305 NRSA6AJ-105W MG RESISTOR 1MØ,1/16W

R8306 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R8307 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R8308 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R8309 NRSA6AJ-103W MG RESISTOR 10kØ,1/16W

R8310 NRSA6AJ-153W MG RESISTOR 15kØ,1/16W

R8313 NRSA6AJ-0R0W MG RESISTOR 0Ø,1/16W

R8314 NRSA6AJ-105W MG RESISTOR 1MØ,1/16W

R8315 NRSA6AJ-105W MG RESISTOR 1MØ,1/16W

RA1008 NRZ0034-103W NET RESISTOR 10kØ,1/32W

RA1009 NRZ0034-104W NET RESISTOR 100kW

RA1010 NRZ0034-104W NET RESISTOR 100kW

RA1401 NRZ0034-473W NET RESISTOR,CAM

RA3001 NRZ0034-101W NET RESISTOR

RA3002 NRZ0034-101W NET RESISTOR

RA3003 NRZ0040-0R0X NET RESISTOR,3216

RA3004 NRZ0034-103W NET RESISTOR 10kØ,1/32W

RA4201 NRZ0034-101W NET RESISTOR,(1005X4)

RA4202 NRZ0034-101W NET RESISTOR,(1005X4)

RA4301 NRZ0034-101W NET RESISTOR,(1005X4)

RA4302 NRZ0034-101W NET RESISTOR,(1005X4)

RA4303 NRZ0034-101W NET RESISTOR,(1005X4)

RA4304 NRZ0034-101W NET RESISTOR,(1005X4)

RA4305 NRZ0034-100W NET RESISTOR,(1005X4) 10Ø

RA4306 NRZ0034-100W NET RESISTOR,(1005X4) 10Ø

RA4307 NRZ0034-100W NET RESISTOR,(1005X4) 10Ø

RA4308 NRZ0034-100W NET RESISTOR,(1005X4) 10Ø

RA8001 NRZ0034-101W NET RESISTOR,(1005X4)

RA8002 NRZ0034-101W NET RESISTOR,(1005X4)

RA8003 NRZ0034-101W NET RESISTOR,(1005X4)

RA8004 NRZ0034-101W NET RESISTOR,(1005X4)

C1004 NCFA1AZ-104W C CAPACITOR 0.1µF,10V

C1005 NBE90JM-106X TA E CAPACITOR 10µF,6.3V

C1006 NDCA1HJ-9R0W C CAPACITOR 9pF,50V

C1007 NCFA1HZ-103W C CAPACITOR 0.01µF,50V

C1009 NCFA1HZ-103W C CAPACITOR 0.01µF,50V

C1010 NCFA1HZ-103W C CAPACITOR 0.01µF,50V

C1011 NCFA1HZ-103W C CAPACITOR 0.01µF,50V

C1012 NCFA1HZ-103W C CAPACITOR 0.01µF,50V

C1013 NCFA1HZ-103W C CAPACITOR 0.01µF,50V

C1014 NCFA1HZ-103W C CAPACITOR 0.01µF,50V

C1015 NCFA1HZ-103W C CAPACITOR 0.01µF,50V

C1016 NCFA1HZ-103W C CAPACITOR 0.01µF,50V

C1017 NCFA1HZ-103W C CAPACITOR 0.01µF,50V

C1018 NCFA1HZ-103W C CAPACITOR 0.01µF,50V

C1019 NCFA1HZ-103W C CAPACITOR 0.01µF,50V

C1020 NCFA1HZ-103W C CAPACITOR 0.01µF,50V

C1021 NCFA1HZ-103W C CAPACITOR 0.01µF,50V

C1023 NCFA1AZ-104W C CAPACITOR 0.1µF,10V

C1026 NCFA1AZ-104W C CAPACITOR 0.1µF,10V

C1027 NCFA1HZ-103W C CAPACITOR 0.01µF,50V

C1028 NCFA1HZ-103W C CAPACITOR 0.01µF,50V

C1029 NCFA1HZ-103W C CAPACITOR 0.01µF,50V

C1030 NCFA1HZ-103W C CAPACITOR 0.01µF,50V

C1031 NCF31AZ-105X C CAPACITOR 1µF,10V

C1034 NCFA1HZ-103W C CAPACITOR 0.01µF,50V

C1036 NCFA1HZ-103W C CAPACITOR 0.01µF,50V

C1037 NCFA1HZ-103W C CAPACITOR 0.01µF,50V

C1038 NCFA1HZ-103W C CAPACITOR 0.01µF,50V

C1041 NCFA1HZ-103W C CAPACITOR 0.01µF,50V

C1401 NDCA1HJ-100W C CAPACITOR 10pF,50V

C1402 NDCA1HJ-220W C CAPACITOR 22pF,50V

C1403 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C1404 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C1405 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C1406 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C1407 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C1409 NCBA1EK-682W C CAPACITOR 0.0068µF,25V

C1410 NCBA1EK-682W C CAPACITOR 0.0068µF,25V

C1411 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C1412 NCBA1CK-223W C CAPACITOR 0.022µF,16V

C1413 NCBA1CK-223W C CAPACITOR 0.022µF,16V

C1414 NCBA1CK-223W C CAPACITOR 0.022µF,16V

C1415 NCBA1CK-223W C CAPACITOR 0.022µF,16V

C1416 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C2040 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C2101 NCB30JK-105X C CAPACITOR 1µF,6.3V

C2102 NCB30JK-105X C CAPACITOR 1µF,6.3V

C2105 NCBA1HK-222W C CAPACITOR 0.0022µF,50V

C2106 NCBA1HK-222W C CAPACITOR 0.0022µF,50V

C2107 NBE20JM-106X TA E CAPACITOR 10µF,6.3V

C2108 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C2109 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C2110 NBE20JM-475X TA E CAPACITOR 4.7µF,6.3V

C2201 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C2202 NCB30JK-105X C CAPACITOR 1µF,6.3V

C2203 NCB30JK-105X C CAPACITOR 1µF,6.3V

C2204 NCB30JK-105X C CAPACITOR 1µF,6.3V

C2205 NCB30JK-105X C CAPACITOR 1µF,6.3V

C2206 NBE20GM-476X TA E CAPACITOR 47µF,4V

C2207 NBE20GM-476X TA E CAPACITOR 47µF,4V

C2209 NCB30JK-105X C CAPACITOR 1µF,6.3V

C2210 NCB30JK-105X C CAPACITOR 1µF,6.3V

C2211 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C2212 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C2213 NCBA1AK-104W C CAPACITOR 0.1µF,10V

5-15

Page 16

MODEL MARK MODEL MARK

GR-DV500US A GR-DV801US C

GR-DV800US B GR-DV900US D

# REF No. PART No. PART NAME, DESCRIPTION # REF No. PART No. PART NAME, DESCRIPTION

---------------- ----------------------- ----------------------------------------------------- ----------------- ----------------------- -----------------------------------------------------

C2214 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C2215 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C2216 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C2217 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C2218 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C2223 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C2224 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C2401 NBE20JM-106X TA E CAPACITOR 10µF,6.3V

C2402 NBE20JM-106X TA E CAPACITOR 10µF,6.3V

C2403 NBE20JM-106X TA E CAPACITOR 10µF,6.3V

C2404 NBE20JM-106X TA E CAPACITOR 10µF,6.3V

C2405 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C2406 NBE20JM-106X TA E CAPACITOR 10µF,6.3V

C2603 NCBA1CK-223W C CAPACITOR 0.022µF,16V

C2604 NCBA1CK-223W C CAPACITOR 0.022µF,16V

C2605 NCBA1EK-472W C CAPACITOR 0.0047µF,25V

C2606 NCBA1EK-472W C CAPACITOR 0.0047µF,25V

C2607 NCBA1AK-473W C CAPACITOR 0.047µF,10V

C2608 NCBA1AK-473W C CAPACITOR 0.047µF,10V

C2609 NCBA1HK-102W C CAPACITOR 0.001µF,50V

C2610 NCBA1HK-102W C CAPACITOR 0.001µF,50V

C2611 NCB30JK-105X C CAPACITOR 1µF,6.3V

C2612 NCB30JK-105X C CAPACITOR 1µF,6.3V

C2613 NCB30JK-105X C CAPACITOR 1µF,6.3V

C2614 NDCA1HJ-101W C CAPACITOR 100pF,50V

C2615 NDCA1HJ-101W C CAPACITOR 100pF,50V

C2616 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C2901 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C2903 NCB30JK-105X C CAPACITOR 1µF,6.3V

C2904 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C3001 NBE20JM-106X TA E CAPACITOR 10µF,6.3V

C3003 NCB30JK-105X C CAPACITOR 1µF,6.3V

C3005 NBE20JM-106X TA E CAPACITOR 10µF,6.3V

C3007 NCB10JK-106X C CAPACITOR 10µF,6.3V

C3008 NBE20JM-106X TA E CAPACITOR 10µF,6.3V

C3010 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C3011 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C3012 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C3013 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C3015 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C3016 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C3017 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C3020 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C3021 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C3022 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C3023 NDCA1HJ-330W C CAPACITOR 33pF,50V

C3024 NCBA1HK-102W C CAPACITOR 0.001µF,50V

C3025 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C3026 NCB30JK-105X C CAPACITOR 1µF,6.3V

C3027 NCBA1EK-472W C CAPACITOR 0.0047µF,25V

C3028 NDCA1EJ-271W C CAPACITOR 270pF,25V

C3029 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C3030 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C3031 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C3032 NCBA1HK-102W C CAPACITOR 0.001µF,50V

C3033 NDCA1HJ-220W C CAPACITOR 22pF,50V

C3036 NDCA1HJ-6R0W C CAPACITOR 6pF,50V

C3037 NDCA1HJ-6R0W C CAPACITOR 6pF,50V

C3038 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C3039 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C3042 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C3043 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C3044 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C3045 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C3046 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C3047 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C3048 NCB31CK-473X C CAPACITOR 0.047µF,16V

C3049 NCBA1HK-222W C CAPACITOR 0.0022µF,50V

C3050 NCBA1HK-102W C CAPACITOR 0.001µF,50V

C3055 NCB30JK-105X C CAPACITOR 1µF,6.3V

C3056 NCB30JK-105X C CAPACITOR 1µF,6.3V

C3058 NCBA1AK-473W C CAPACITOR 0.047µF,10V

C3059 NCBA1HK-102W C CAPACITOR 0.001µF,50V

C3061 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C3062 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C3701 NBE20JM-106X TA E CAPACITOR 10µF,6.3V

C3702 NDCA1HJ-560W C CAPACITOR 56pF,50V

C3703 NDCA1HJ-270W C CAPACITOR 27pF,50V

C3704 NDCA1HJ-680W C CAPACITOR 68pF,50V

C3705 NDCA1HJ-270W C CAPACITOR 27pF,50V

C3706 NCB30JK-105X C CAPACITOR 1µF,6.3V

C3707 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C3708 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C3709 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C3710 NBE20GM-226X TA E CAPACITOR 22µF,4V

C3711 NBE20GM-226X TA E CAPACITOR 22µF,4V

C3712 NBE40GM-107X TA E CAPACITOR 100µF,4V

C3713 NBE40GM-107X TA E CAPACITOR 100µF,4V

C3715 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C3731 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C3732 NCBA1HK-102W C CAPACITOR 0.001µF,50V

C3733 NDCA1HJ-3R0W C CAPACITOR 3pF,50V

C3734 NDCA1HJ-5R0W C CAPACITOR 5pF,50V

C3735 NDCA1HJ-330W C CAPACITOR 33pF,50V

C3736 NCBA1HK-102W C CAPACITOR 0.001µF,50V

C3738 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C3739 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C3740 NCB30JK-105X C CAPACITOR 1µF,6.3V

C3741 NCB30JK-105X C CAPACITOR 1µF,6.3V

C3742 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C3743 NDCA1HJ-3R0W C CAPACITOR 3pF,50V

C3744 NDCA1HJ-5R0W C CAPACITOR 5pF,50V

C3745 NDCA1HJ-330W C CAPACITOR 33pF,50V

C3746 NCB20JM-475X C CAPACITOR 4.7µF,6.3V

C3747 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C3801 NCB30JK-105X C CAPACITOR 1µF,6.3V

C3802 NCB30JK-105X C CAPACITOR 1µF,6.3V

C3803 NBE20JM-106X TA E CAPACITOR 10µF,6.3V

C3804 NBE20GM-476X TA E CAPACITOR 47µF,4V

C3805 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C3806 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C3807 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C3808 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C3809 NCB31CK-104X C CAPACITOR 0.1µF,16V

C3810 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C3811 NCB31CK-104X C CAPACITOR 0.1µF,16V

C3812 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C3813 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C3814 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C3815 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C3816 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C3817 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C3818 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C3819 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C3820 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C3901 NBE90GM-226X TA E CAPACITOR 22µF,4V

5-16

Page 17

MODEL MARK MODEL MARK

GR-DV500US A GR-DV801US C

GR-DV800US B GR-DV900US D

# REF No. PART No. PART NAME, DESCRIPTION # REF No. PART No. PART NAME, DESCRIPTION

---------------- ----------------------- ----------------------------------------------------- ----------------- ----------------------- -----------------------------------------------------

C3902 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C4201 NCB30JK-105X C CAPACITOR 1µF,6.3V

C4202 NBZ0015-106X TA E CAPACITOR 10µF,6.3V

C4203 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C4204 NBE20GM-107X TA E CAPACITOR 100µF,4V

C4205 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C4206 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C4207 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C4208 NCBA1CK-123W C CAPACITOR 0.012µF,16V

C4209 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C4210 NCB30JK-105X C CAPACITOR 1µF,6.3V

C4211 NCB21CK-105X C CAPACITOR 1µF,16V

C4213 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C4214 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C4215 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C4216 NCB30JK-105X C CAPACITOR 1µF,6.3V

C4219 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C4220 NCB30JK-105X C CAPACITOR 1µF,6.3V

C4221 NCB30JK-105X C CAPACITOR 1µF,6.3V

C4222 NCB30JK-105X C CAPACITOR 1µF,6.3V

C4301 NBZ0015-106X TA E CAPACITOR 10µF,6.3V

C4302 NBZ0015-106X TA E CAPACITOR 10µF,6.3V

C4303 NBZ0015-106X TA E CAPACITOR 10µF,6.3V

C4304 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C4305 NCB30JK-105X C CAPACITOR 1µF,6.3V

C4306 NBZ0015-106X TA E CAPACITOR 10µF,6.3V

C4307 NBZ0015-106X TA E CAPACITOR 10µF,6.3V

C4308 NBZ0015-106X TA E CAPACITOR 10µF,6.3V

C4309 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C4310 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C4311 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C4312 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C4803 NBE20JM-106X TA E CAPACITOR 10µF,6.3V

C4804 NCFA1AZ-104W C CAPACITOR 0.1µF,10V

C4806 NCFA1AZ-104W C CAPACITOR 0.1µF,10V

C4808 NCB30JK-105X C CAPACITOR 1µF,6.3V

C4809 NCFA1AZ-104W C CAPACITOR 0.1µF,10V

C4810 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C4811 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C4812 NCFA1AZ-104W C CAPACITOR 0.1µF,10V

C4813 NCFA1AZ-104W C CAPACITOR 0.1µF,10V

C4814 NCFA1AZ-104W C CAPACITOR 0.1µF,10V

C4815 NCB31HK-152X C CAPACITOR 0.0015µF,50V

C4816 NCFA1AZ-104W C CAPACITOR 0.1µF,10V

C4819 NCF31EZ-104X C CAPACITOR 0.1µF,25V

C4851 NBE20JM-106X TA E CAPACITOR 10µF,6.3V

C4852 NCFA1AZ-104W C CAPACITOR 0.1µF,10V

C4853 NBE21AM-335X TA E CAPACITOR 3.3µF,10V

C4854 NBE21AM-106X TA E CAPACITOR 10µF,10V

C4855 NCB31CK-104X C CAPACITOR 0.1µF,16V

C4858 NDCA1HJ-680W C CAPACITOR 68pF,50V

C4859 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C4860 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C4861 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C4862 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C4864 NBE20JM-106X TA E CAPACITOR 10µF,6.3V

C4865 NCFA1AZ-104W C CAPACITOR 0.1µF,10V

C5001 NCB30JK-105X C CAPACITOR 1µF,6.3V

C5002 NCBA1CK-103W C CAPACITOR 0.01µF,16V

C5003 NBE20JM-226X TA E CAPACITOR 22µF,6.3V

C5004 NCB30JK-105X C CAPACITOR 1µF,6.3V

C5005 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C5006 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C5008 NBE20GM-476X TA E CAPACITOR 47µF,4V

C5009 NBZ0015-106X TA E CAPACITOR 10µF,6.3V

C5010 NBP21DM-475X TA E CAPACITOR 4.7µF,20V

C5011 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C5012 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C5013 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C5014 NCBA1AK-104W C CAPACITOR 0.1µF,10V

C5017 NBE41AM-476X TA E CAPACITOR 47µF,10V

C5019 NCF31EZ-104X C CAPACITOR 0.1µF,25V

C5021 NBP21DM-475X TA E CAPACITOR 4.7µF,20V

C5022 NCF31EZ-104X C CAPACITOR 0.1µF,25V

C5023 NCBA1AK-104W C CAPACITOR 0.1µF,10V