Page 1

SERVICE MANUAL

MICRO HD CAMERA

DZ-VCA3U

SPECIFICATIONS

Camera head section

L Image sensing device : 1/3-inch PS-CCD (350,000 pixels)

L Shooting system : 3-CCD system

L Color separation optical system : 1/3-inch F1.4 3-color separation prism

L Number of effective pixels : 659 (horizontal) x 494 (vertical), 330,000 pixels approximately

L Camera output : 19 pins

L Lens mount : Standard C mount ( flange back: 17.526 mm in air)

L Dimensions : Camera head; 44 (W) x 51.4 (H) x 57.7 (D) mm (1-6/8” x 2-1/16” x 2-2/8”) (not including

L Weight : Camera head; 100 g (0.22 lbs.)

L Classification : Type CF applied part

Camera control unit section

L Number of scanning lines : 1125 (980 effective)

L Scanning system : 2:1 interlace (HD output, NTSC output)

L Scanning frequency : HD OUT 33.71625kHz (horizontal), 59.94 Hz (vertical)

L Aspect ratio : 4:3

L Horizontal resolution (center) : 750 TV lines TYP. (HD Y output, SXGA output)

L Vertical resolution (center) : 700 TV lines TYP. (HD Y output, SXGA output)

L S/N : 52dB

L Sensitivity : F6.8, 2000 lx

L Minimum subject illuminance : 5 lx

L Sync system : Internal sync/external sync

L External sync signal input : Composite sync signal of ±0.3 Vp-p, 75 ohms, BNC x 1 (ITU-R Rec.BT .709-3 HDTV standard

L Color bar : Full color bar

L Contour correction : Horizontal dual-edged (7-step variable)

L Electronic shutter speed : 1/60 s (normal), 1/100 s, 1/175 s, 1/250 s, 1/375 s, 1/500 s, 1/1000 s, 1/2000 s,1/4000s,

protrusion and camera cable etc)

Progressive (SXGA output)

SXGA OUT 67.4325kHz(horizontal), 59.94 Hz (vertical)

NTSC OUT 15.73425kHz(horizontal), 59.94 Hz (vertical)

compliant)

Vertical dual-edged (7-step variable)

1/10000s

L Video output

• SXGA signal : R/G/B 0.7 Vp-p, 75 ohms HD/VD TTL D-Sub mini 15 pin

• HD signal : Y 1 Vp-p Pb/Pr 0.7 Vp-p 75 ohms BNC x 3

• NTSC signal : VBS 1 Vp-p 75 ohms BNC Y/C 1 Vp-p 75 ohms S terminal

• DV signal : IEEE1394 6 pins

L Camera input : 19 pins

L Date indication : Menu system 1) Year, month, day 2) Day , month, year 3) Month, day, year

L Time indication : Menu system, hour : minute: second

L Rating : 120V AC 60Hz, 0.7A

L Classification of insulation : Class I

L Operating environment :+5°C to +35°C (41°F to 95°F), 35 – 75%

L Storage environment : -20°C to +50°C (-4°F to 102°F), 35 – 80%

L Dimensions : 280 (W) x 140 (H) x 300 (D) mm

L Weight : 5.5 kg (12.1 lbs.)

L Accessories : Power cord x 1

(11-3/16” x 5-9/16” x 11-13/16”) (excluding the protrusion and switches etc)

Instruction manual x 1

Warranty card x 1

This service manual is printed on 100% recycled paper.

COPYRIGHT © 2002 VICTOR COMPANY OF JAPAN, LTD

DZ-VCA3U S14H42

No.86711

2002/12

Page 2

TABLE OF CONTENTS

Section Title Page Section Title Page

Important Safety Precautions

INSTRUCTIONS

1. PRECAUTIONS OF SERVICING

1.1

BEFORE DISASSEMBLING AND REASSEMBLING

1.1.1 Precautions ........................................................... 1-1

1.1.2 Disassembly of optical block assembly..................1-1

1.2 PREPARATION AND PRELIMINARY CHECK

REQUIRED FOR ADJUSTMENT ............................. 1-1

1.2.1 Before adjustment ................................................. 1-1

1.2.2

Tools and jigs required for repair and adjustment

1.3 Standard setup............................................................ 1-2

1.4 How to set the “ADJUSTNENT MODE” ...................... 1-2

1.5 How to set the “DEBUG MODE” ................................. 1-2

1.6 How to do “ALL RESET” ............................................. 1-2

Warnings for accident prevention in handking battery .......1-3

1.7 SERVICE CAUTIONS................................................. 1-4

1.7.1 Precautions ........................................................... 1-4

1.7.2 How to read the disassembly and assembly......... 1-4

1.7.3 Connection of the wires ........................................ 1-4

1.7.4 Disassembly procedure .........................................1-5

1.8 WIRING AND BOARD LAYOUT ..................................1-8

2. ELECTRICAL ADJUSTMENT

2.1 INITIAL SETTING ....................................................... 2-1

2.1.1 Functions and initial settings of

internal switches of boards ................................. 2-1

2.1.2 Adjustment procedure ........................................... 2-2

2.2 MTP BOARD ADJUSTMENT...................................... 2-3

2.2.1 Adjustment part(s) location guide...........................2-3

2.2.2 Input voltage check ............................................... 2-3

2.2.3 output voltage level ................................................2-3

2.2.4 output voltage check(1)..........................................2-3

2.2.5 output voltage check(2)..........................................2-3

2.2.6 output voltage check(3)..........................................2-3

2.3 MICOM BOARD ADJUSTMENT..................................2-4

2.3.1 Adjustment part(s) location guide...........................2-4

2.3.2 Main clock level......................................................2-4

2.3.3 GENLOCK output level ..........................................2-4

2.4 DSP BOARD ADJUSTMENT.......................................2-5

2.4.1 Adjustment part(s) location guide...........................2-5

2.4.2 HD OUT .................................................................2-5

2.4.2.1 Y signal ratio level ............................................. 2-5

2.4.2.2 Y signal level ..................................................... 2-5

2.4.2.3 Pr signal raio level.............................................2-6

2.4.2.4 Pr signal level....................................................2-6

2.4.2.5 Pb signal ratio level ........................................... 2-6

2.4.2.6 Pb signal level ................................................... 2-6

2.4.3 SXGA OUT.............................................................2-7

2.4.3.1 G gain level .......................................................2-7

2.4.3.2 B gain level .......................................................2-7

2.4.3.3 R gain level .......................................................2-7

2.5 NTSC BOARD ADJUSTMENT ....................................2-8

2.5.1 Adjustment part(s) locatio guide.............................2-8

2.5.2 INPUT SIGNAL ......................................................2-8

2.5.2.1 G gain level .......................................................2-8

2.5.2.2 B gain level .......................................................2-8

2.5.2.3 R gain level .......................................................2-9

2.5.3 OUTPUT SIGNAL ..................................................2-9

2.5.3.1 Video level (1) ...................................................2-9

2.5.3.2 Video level (2) ...................................................2-9

2.5.3.3 Y level ...............................................................2-9

2.5.3.4 Color level .......................................................2-10

2.5.3.5 DV signal check .............................................. 2-10

2.6 AD BOARD ASJUSTMENT ........................................ 2-11

2.6.1 Adjustment part(s) location guide.........................2-11

2.6.2 A/D AND AUTO GAIN .......................................... 2-11

2.6.2.1 A/D gain level .................................................. 2-11

2.6.2.2 AUTO gain level .............................................. 2-11

2.6.2.3 Color gain........................................................2-12

2.6.2.4 Color gain for tint adjustment ..........................2-12

2.6.2.5 White defect ....................................................2-12

... 1-1

... 1-1

3. INSTALLATION MANUAL

1. Precautions ....................................................................3-1

2. Connection of system components ................................ 3-1

3. Connection of each unit to the power supply unit .......... 3-1

4. Check of grounding (AA-V31U) .....................................3-2

5. Check of operation ......................................................... 3-2

6. Liaison slip of customer data .........................................3-2

7. Sterilization ....................................................................3-2

8. Report of complaints dealt with ...................................... 3-2

4. CHARTS AND DIAGRAMS

4.1 BOARD INTERCONNECTIONS ................................. 4-3

4.2 MTP SCHEMATIC DIAGRAM...................................... 4-5

4.3 AD IO SCHEMATIC DIAGRAM ....................................4-7

4.4 ANALOG SCHEMATIC DIAGRAM............................... 4-9

4.5 ADC SCHEMATIC DIAGRAM .................................... 4-11

4.6 SSG1 SCHEMATIC DIAGRAM..................................4-13

4.7 F MEN SCHEMATIC DIAGRAM ................................ 4-15

4.8 FLASH SCHEMATIC DIAGRAM................................4-17

4.9 AMDP IO SCHEMATIC DIAGRAM ............................4-19

4.10 AMDP G SCHEMATIC DIAGRAM ...........................4-21

4.11 AMDP B SCHEMATIC DIAGRAM ............................4-23

4.12 AMDP R SCHEMATIC DIAGRAM............................ 4-25

4.13 AMDP FM SCHEMATIC DIAGRAM ......................... 4-27

4.14 AMDP 01 SCHEMATIC DIAGRAM ..........................4-29

4.15 DSP-1 SCHEMATIC DIAGRAM...............................4-31

4.16 DSP-2 SCHEMATIC DIAGRAM...............................4-33

4.17 DSP-3 SCHEMATIC DIAGRAM...............................4-35

4.18 MICOM SCHEMATIC DIAGRAM.............................4-37

4.19 MICOM2 SCHEMATIC DIAGRAM...........................4-39

4.20 MICOM3 SCHEMATIC DIAGRAM...........................4-41

4.21 MICOM4 SCHEMATIC DIAGRAM...........................4-43

4.22 NTSC-2 SCHEMATIC DIAGRAM ............................4-45

4.23 NTSC-1 SCHEMATIC DIAGRAM ............................4-47

4.24 NTSC-5 SCHEMATIC DIAGRAM ............................4-48

4.25 NTSC-3 SCHEMATIC DIAGRAM ............................4-49

4.26 NTSC-4 SCHEMATIC DIAGRAM ............................4-51

4.27 NTSC-6 SCHEMATIC DIAGRAM ............................4-53

4.28 DV-1 SCHEMATIC DIAGRAM .................................4-55

4.29 DV-2 SCHEMATIC DIAGRAM .................................4-57

4.30 DV-3 SCHEMATIC DIAGRAM .................................4-59

4.31 FRT/LED SCHEMATIC DIAGRAM ..........................4-61

4.32 MTP CIRCUIT BOARD ............................................ 4-63

4.33 AD CIRCUIT BOARD...............................................4-67

4.34 AMDP CIRCUIT BOARD..........................................4-71

4.35 DSP CIRCUIT BOARD ............................................4-75

4.36 MICOM CIRCUIT BOARD .......................................4-79

4.37 NTSC CIRCUIT BOARD ..........................................4-83

4.38 DV CIRCUIT BOARD...............................................4-87

4.39 FRT & LED CIRCUIT BOARDS ............................... 4-89

4.40 CAMERA SYSTEM BLOCK DIAGRAM ...................4-91

5. PARTS LIST

5.1 PACKING AND ACCESSORY ASSEMBLY<M1> ....... 5-1

5.2 CAMERA CONTROL UNIT ASSEMBLY<M3> ............ 5-2

5.3 ELECTRICAL PARTS LIST......................................... 5-5

MTP BOARD ASSEMBLY<01>........................................ 5-5

AD BOARD ASSEMBLY<02> ..........................................5-6

AMDP BOARD ASSEMBLY<03> ................................... 5-11

DSP BOARD ASSEMBLY<04> ......................................5-15

MICOM BOARD ASSEMBLY<05> .................................5-18

NTSC BOARD ASSEMBLY<06> ...................................5-21

DV BOARD ASSEMBLY<07> ........................................5-25

FRT BOARD ASSEMBLY<08> ......................................5-26

LED BOARD ASSEMBLY<09> ......................................5-27

1

Page 3

Important Safety Precautions

Connector

Metal sleeve

Prior to shipment from the factory, JVC products are strictly inspected to conform with the recognized product safety and electrical codes

of the countries in which they are to be sold. However, in order to maintain such compliance, it is equally important to implement the

following precautions when a set is being serviced.

v

Precautions during Servicing

1. Locations requiring special caution are denoted by labels and

inscriptions on the cabinet, chassis and certain parts of the

product. When performing service, be sure to read and comply with these and other cautionary notices appearing in the

operation and service manuals.

2. Parts identified by the

such as fuses and circuit protectors are critical for safety.

Replace only with specified part numbers.

3. Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as specified.

4. Use specified internal wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

5. Use specified insulating materials for hazardous live parts.

Note especially:

1) Insulation Tape 3) Spacers 5) Barrier

2) PVC tubing 4) Insulation sheets for transistors

6. When replacing AC primary side components (transformers,

power cords, noise blocking capacitors, etc.) wrap ends of

wires securely about the terminals before soldering.

symbol and shaded ( ) parts

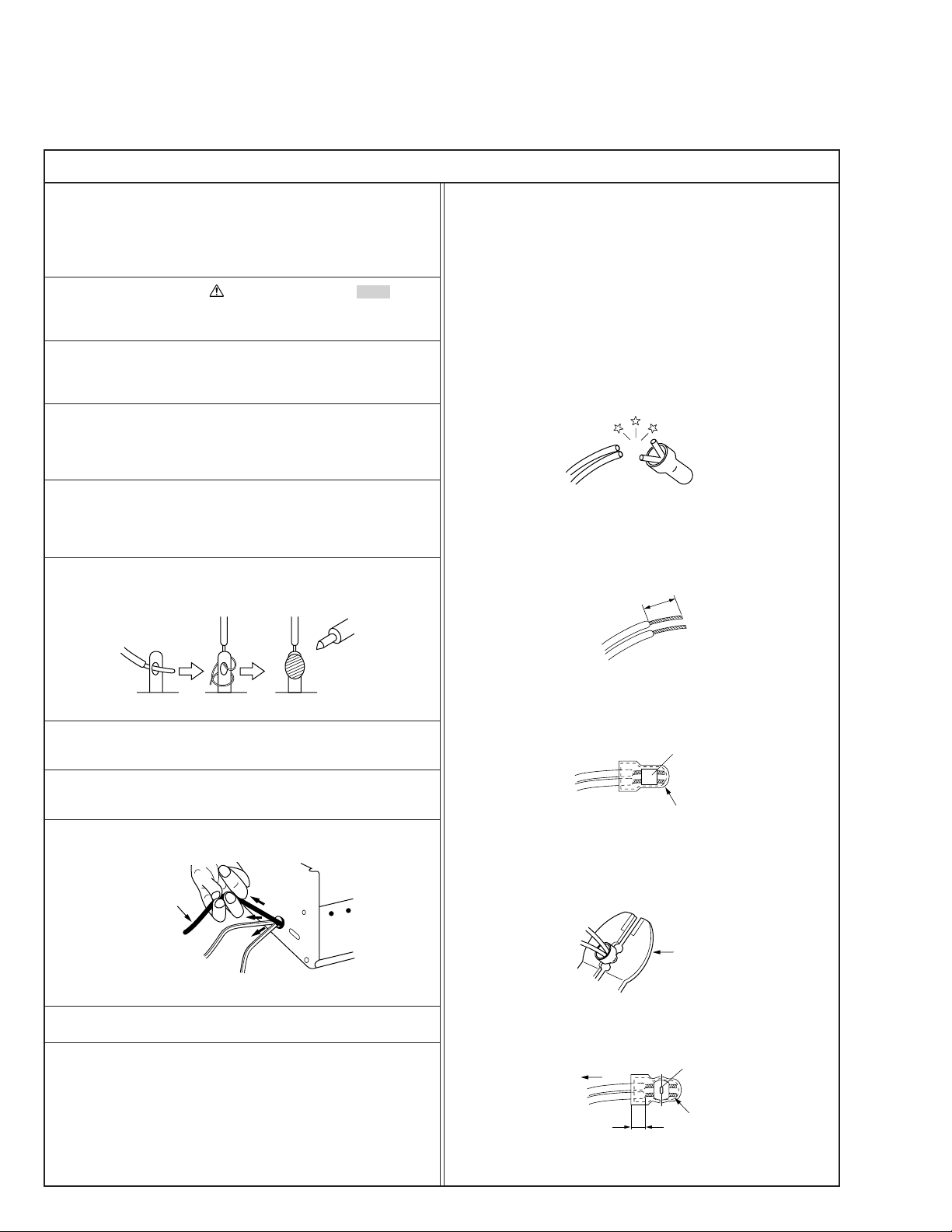

12. Crimp type wire connector

In such cases as when replacing the power transformer in sets

where the connections between the power cord and power

transformer primary lead wires are performed using crimp type

connectors, if replacing the connectors is unavoidable, in order to prevent safety hazards, perform carefully and precisely

according to the following steps.

1) Connector part number : E03830-001

2) Required tool : Connector crimping tool of the proper type

which will not damage insulated parts.

3) Replacement procedure

(1) Remove the old connector by cutting the wires at a point

close to the connector.

Important : Do not reuse a connector (discard it).

cut close to connector

Fig.3

(2) Strip about 15 mm of the insulation from the ends of

the wires. If the wires are stranded, twist the strands to

avoid frayed conductors.

15 mm

Fig.1

7. Observe that wires do not contact heat producing parts

(heatsinks, oxide metal film resistors, fusible resistors, etc.)

8. Check that replaced wires do not contact sharp edged or

pointed parts.

9. When a power cord has been replaced, check that 10-15 kg of

force in any direction will not loosen it.

Power cord

Fig.2

10. Also check areas surrounding repaired locations.

11. Products using cathode ray tubes (CRTs)

In regard to such products, the cathode ray tubes themselves,

the high voltage circuits, and related circuits are specified for

compliance with recognized codes pertaining to X-ray emission.

Consequently, when servicing these products, replace the cathode ray tubes and other parts with only the specified parts.

Under no circumstances attempt to modify these circuits.

Unauthorized modification can increase the high voltage value

and cause X-ray emission from the cathode ray tube.

Fig.4

(3) Align the lengths of the wires to be connected. Insert

the wires fully into the connector.

Fig.5

(4) As shown in Fig.6, use the crimping tool to crimp the

metal sleeve at the center position. Be sure to crimp fully

to the complete closure of the tool.

1.25

2.0

5.5

Fig.6

(5) Check the four points noted in Fig.7.

Not easily pulled free

Wire insulation recessed

more than 4 mm

Fig.7

Crimping tool

Crimped at approx. center

of metal sleeve

Conductors extended

1

Page 4

v

a, b, cLeakage Current ( i )AC Line Voltage

110 to 130 V

220 to 240 V

Japan

USA & Canada

i 1 mA rms Exposed accessible parts

Exposed accessible parts

Antenna earth terminals

Other terminals

i 0.5 mA rms

i 0.7 mA peak

i 2 mA dc

i 0.7 mA peak

i 2 mA dc

Europe & Australia

Region

Load Z

≤

≤

≤

≤

≤

≤

1 kØ

2 kØ

1.5 kØ

0.15 µF

50 kØ

100 V

110 to 130 V

a, b, cLeakage Current ( i )

AC Line Voltage

110 to 130 V

220 to 240 V

Japan

USA & Canada

Exposed accessible parts

Exposed accessible parts

Antenna earth terminals

Other terminals

Europe & Australia

Region Load Z

1 kØ

2 kØ

1.5 kØ

0.15 µF

50 kØ

100 V

110 to 130 V

i 0.1 mA

i 0.1 mA

i 0.1 mA

i 0.1 mA

Safety Check after Servicing

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts and wires have been

returned to original positions, Afterwards, perform the following tests and confirm the specified values in order to verify compliance with safety standards.

1. Leakage current test

Confirm specified or lower leakage current between earth ground/power cord plug prongs

and externally exposed accessible parts (RF terminals, antenna terminals, video and audio

input and output terminals, microphone jacks, earphone jacks, etc.).

Measuring Method : (Power ON)

Insert load Z between earth ground/power cord plug prongs and externally exposed accessible parts. Use an AC voltmeter to measure across both terminals of load Z. See figure 9 and

following table 2.

2. Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between earth pin and externally exposed accessible parts (Video in, Video out,

Audio in, Audio out or Fixing screw etc.).

Measuring Method:

Connect milli ohm meter between earth pin and exposed accessible parts. See figure 10 and grounding specifications.

Externally

exposed

accessible part

Z

V

Fig. 8

ab

c

A

Earth pin

Milli ohm meter

Earth

< MEDICAL USE >

< GENERAL USE >

AC Line Voltage

100 V

100 to 240 V

110 to 130 V

110 to 130 V

200 to 240 V

Exposed accessible part

Fig. 9

Table 1 Leakage current specifications for each region

Region

Japan

USA & Canada

Europe & Australia R 10 MØ/500 V DC

Insulation Resistance (R)

≤

R 1 MØ/500 V DC

≥≥

1 MØ R 12 MØ/500 V DC

≤

Table 2 Specifications for each region

Grounding Specifications

Region

USA & Canada

Europe & Australia

Dielectric Strength

AC 1 kV 1 minute

AC 1.5 kV 1 miute

AC 1 kV 1 minute

AC 3 kV 1 minute

AC 1.5 kV 1 minute

(Class 2)

(Class 1)

Grounding Impedance (Z)

≤

Z 0.2 ohm

≤

Z 0.2 ohm

Clearance Distance (d), (d')

≤

d, d' 3 mm

≤

d, d' 4 mm

≤

d, d' 3.2 mm

≤

d 4 mm

≤

d' 8 mm (Power cord)

≤

d' 6 mm (Primary wire)

Note: These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

Table 3 Leakage current specifications for each region

2

Page 5

SECTION 1

PRECAUTIONS FOR SERVICING

1.1 BEFORE DISASSEMBLING AND REASSEMBLING

1.1.1 Precautions

1. When disconnecting and reconnecting connectors, pay careful attention to their wirings not to damage them, particularly

to the wiring of the CCU’s camera connector that requires

the most meticulous care for disconnection and connection.

2. When unsoldering chip parts (IC in particular) for replacement, completely remove solder particles from them and their

surroundings beforehand. Moreover, pay heed to the circuit

pattern not to exfoliate it from the substrate during replacement of a chip part.

3. Don’t use any chip part that was once removed.

4. Handle the optical block assembly with meticulous care.

Don’t apply it a strong shock.

5. There is a lithium battery for backing up the timer on the

POWER board assembly. Pay careful attention to the lithium

battery for accident prevention.

1.1.2 Disassembly of optical block assembly

Since the CCD is precisely glued to the prism in the optical

block assembly, the CCD cannot be replaced individually if

it comes into failure. Therefore, the optical block assembly

is subject to repair by the JVC Home AV Network Business

Unit. If there is something wrong in the optical block assembly, send the camera head assembly whole with a written

request filled out with necessary matters to the Service Engineering Section, Home AV Network Business Unit, JVC.

1.2.2 Tools and jigs required for repair and adjustment

Use the following tools, jigs and test instruments to perform

check and adjustment properly.

1) Multiscan monitor and color monitor

For SXGA(G, B,R) signal : Flex Scan T962 (or equal)

For HD(Y,PB,PR) signal : DT-V1900CG(U) (or equal)

For NTSC siganl : DT-V1900CG(U) (or equal)

2) 1/2” professional zoom lens (Model No. YH13x7.5B12 or

YH13x7.5K12 is recommended by the Professional Video

Division)

3) C mount adapter (Model No. ACM-11)

4) Tripod

5) RCA cable

6) SXGA cable

7) Extension board

8) Resolution chart for HDTV

9) Gray scale chart (for NTSC, Part No. GS-2A)

10) Oscilloscope (for 300 MHz or more)

11) Wrench for removing connector ring

12) Illuminometer

13) Color temperature meter

14) Digital voltmeter

15) Lighting apparatus (3200 K halogen lamp)

C mount adapter (ACM-11)

1.2 PREP ARATION AND PRELIMINARY CHECK REQUIRED FOR ADJUSTMENT

1.2.1 Before adjustment

1. Use two or more lighting apparatuses whose color tempera-

ture is 3200K for illuminating the test pattern, and uniformly

light up the test pattern surface with illuminance of 4000 lx

approximately while checking it with an illuminometer. If the

pattern surface is unevenly illuminated, adjustment may result in failure. Carefully set up lighting apparatuses so that

the test pattern is illuminated uniformly. (It is desired to use

two or more light sources.)

2. Be sure to use a clean test pattern as far as circumstances

permit.

RCA - S Adapter (PTU93001A)

Extension board

1-1

Page 6

1.3 Standard setup

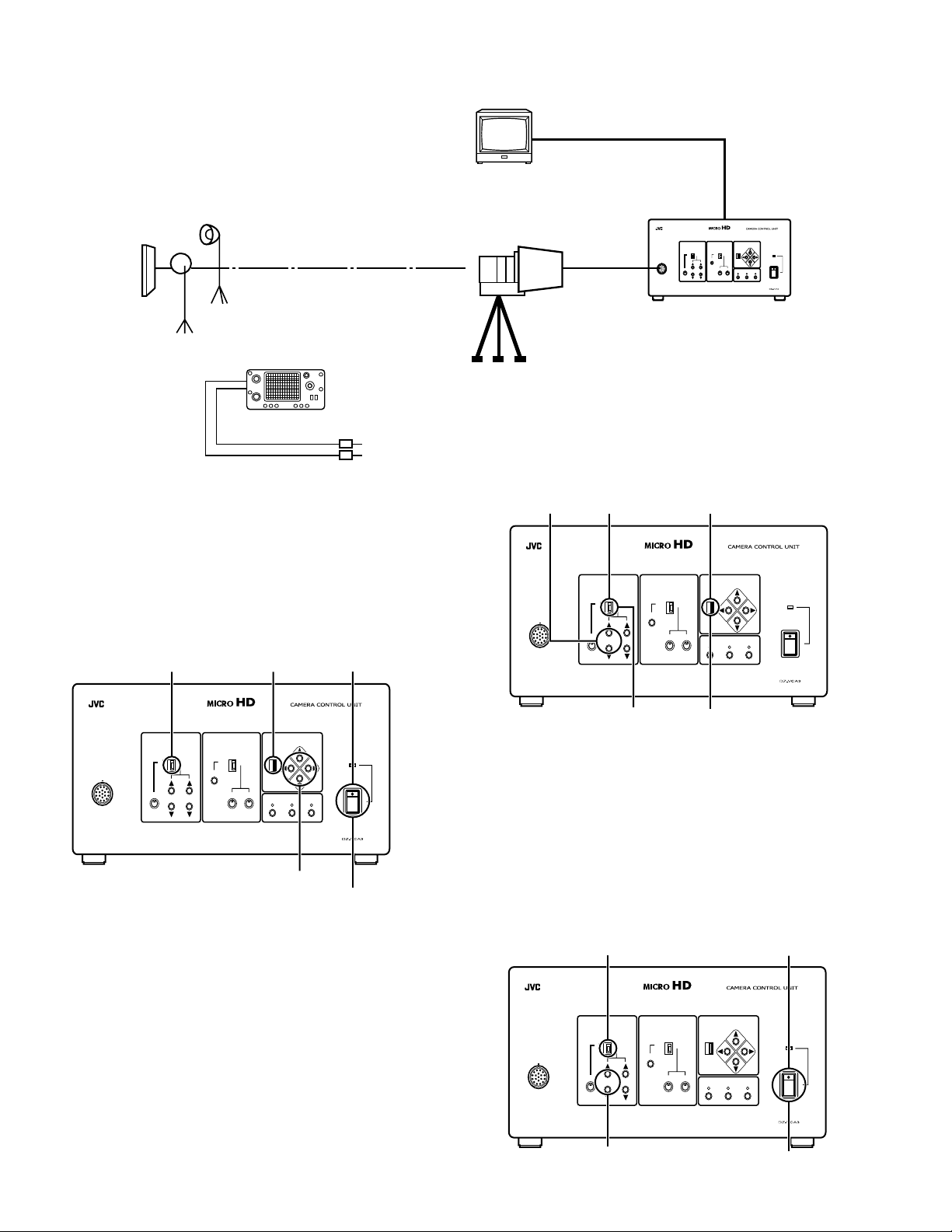

Monitor

Test pattern

Lighting of 3200 K

Oscilloscope

1.4 How to set the "ADJUSTMENT MODE"

1. Turn off the power of the CCU (Camera Control Unit).

2. Set the "MENU SETTING" switch to "OFF"

3. Set the "OUTPUT LEVEL" switch to "MANUAL"

4. Press and hold the "UP" and "DOWN" buttons of the

menu control button.

(The "UP" and "DOWN" buttons of the menu control button is pressing until picture comes to the monitor.)

5. Turn on the power of the CCU.

3. MANUAL 2. OFF 1. OFF

3-1.GAIN UP and

GAIN DOWN

CAMERA

ADJUST

2. AUTO

OUTPUT LEVEL

AUTO MANUAL

GAIN SHUTTER

CAMERA

ADJUST

CAMERA

WHITE BALANCE

AUTO MANU ON OFF

SETTING

RED BLUE

OUTPUT LEVEL

AUTO MANUAL

SETTING

GAIN SHUTTER

1. OFF

ENHANCE FREEZE BAR

WHITE BALANCE

AUTO MANU ON OFF

RED BLUE

MENU SETTING

MENU SETTING

ENHANCE FREEZE BAR

POWER

ON I

OFF

ON I

OFF

O

POWER

O

OUTPUT LEVEL

AUTO MANUAL

CAMERA

ADJUST

GAIN SHUTTER

WHITE BALANCE

AUTO MANU ON OFF

SETTING

RED BLUE

MENU SETTING

ENHANCE FREEZE BAR

POWER

ON I

OFF

O

4. UP and DOWN

5. ON

To release the "ADJUSTMENT MODE" as follows.

1. Turn off the power of the CCU.

2. Turn on the power of the CCU in the usual steps.

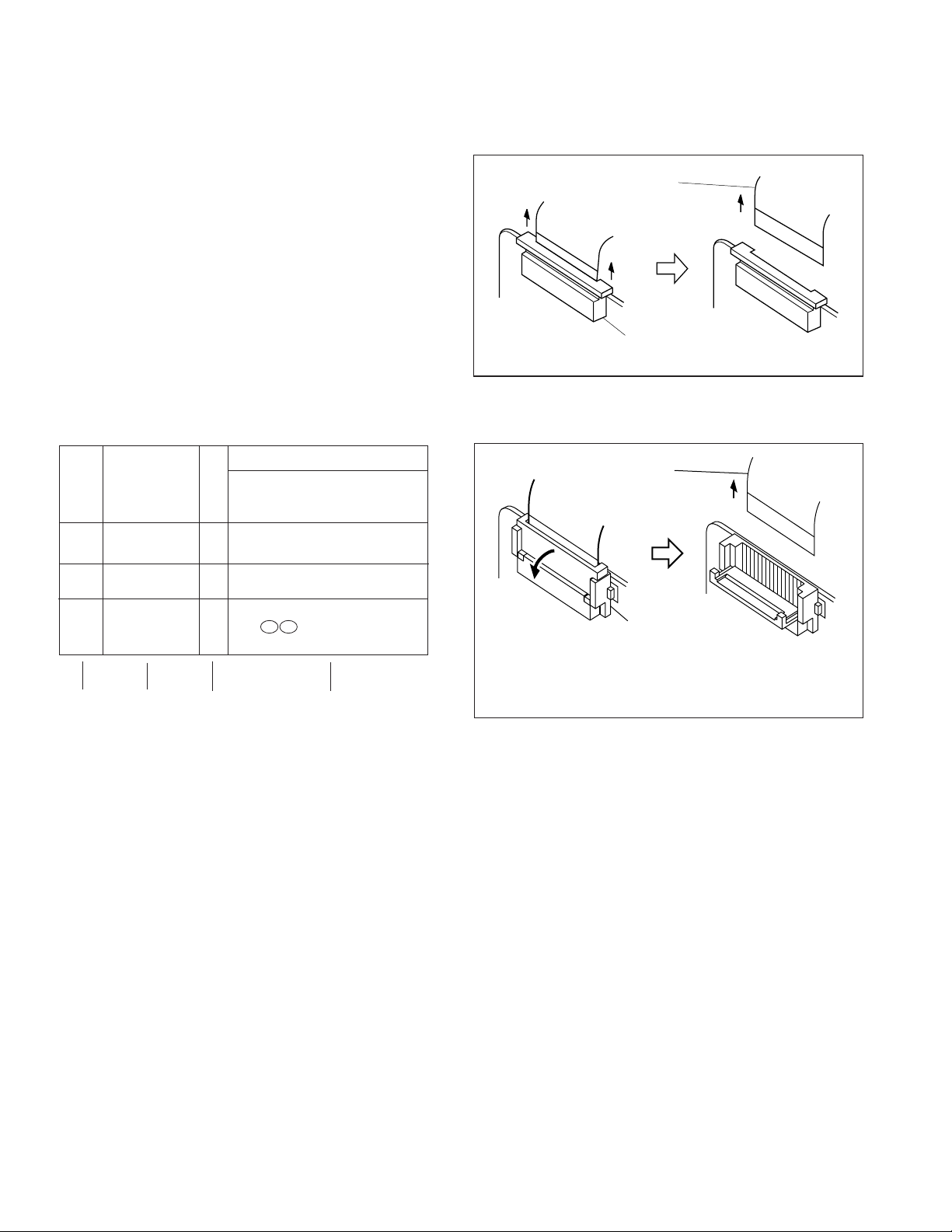

1.5 How to set the "DEBUG MODE"

1. Set the "MENU SETTING" switch to "OFF".

2. Set the "OUTPUT LEVEL" switch to "AUTO".

3. Press and hold the "GAIN UP" and "GAIN DOWN" buttons, and set the "MENU SETTING" switch to "ON".

4. Set the "OUTPUT LEVEL" switch to "MANUAL".

4. MANUAL 3-2. ON

To release the "DEBUG MODE" as follows.

1. Run the "RETURN"

1.6 How to do "ALL RESET"

1. Turn off the power of the CCU.

2. Set the "OUTPUT LEVEL" switch to "AUTO".

3. Press and hold the "GAIN UP" and "GAIN DOWN" buttons.

(The "GAIN UP" and "GAIN DOWN" buttons is pressing

until picture comes to the monitor.)

4. Turn on the power of the CCU.

2. AUTO

CAMERA

ADJUST

3.GAIN UP and

GAIN DOWN

OUTPUT LEVEL

AUTO MANUAL

GAIN SHUTTER

WHITE BALANCE

AUTO MANU ON OFF

SETTING

RED BLUE

MENU SETTING

ENHANCE FREEZE BAR

1. OFF

POWER

ON I

OFF

4. ON

O

1-2

Page 7

Warnings for accident prevention in handling battery

WARNING: Fire, Explosion, Leakage and Burn Hazard. Do not recharge, Disassemble, Heat Above

212°F , Incinerate, Or Expose Contents T o Water. Be Sure The Battery Is Inserted In The Right Direction.

The lithium battery incorporates inflammable substances such as lithium and organic solvent, etc.

inside.

If the lithium battery is handled in a wrong way, it may cause injury, fire and other dangerous

accident caused by heating, bursting, firing, etc. Be sure to follow the instructions mentioned below

to prevent you from an unexpected accident before unpacking, in and after using the battery.

1. Be careful of short-circuit.

If the positive (+) and negative (-) terminals come into contact with each other or with other metallic

material, the battery is shortcircuited. If many batteries are left disorderly and their terminals are in contact

with others, some of the batteries may generate heat, burst or fire and resultingly cause accident.

2. Neither immerse battery in water nor throw it into fire.

If the lithium battery is immersed in water or thrown into fire, it may fire or burst violently.

3. Avoid heating the battery.

If the lithium battery is heated at a temperature of 100°C or more, the electrolyte may leak from the battery

because the plastic materials such as gasket and separator are damaged or the battery may burst or fire

because the battery is heated by internal shortcircuit.

4. Avoid directly soldering the battery.

If the lithium battery is directly soldered, the electrolyte may leak from it because the plastic materials such

as the gasket and separator are damaged or the battery may burst or fire because it is heated by internal

shortcircuit.

5. Avoid charging the battery.

If the primary battery is charged, the battery may generate gas inside and it may resultingly cause

expansion, burst or fire of the battery.

6. Avoid dismantling the battery.

If the lithium battery is dismantled, some kind of gas is generated and it stimulates the throat or the

dismantled battery may fire because the negative lithium reacts on water and generates heat.

7. Avoid deformation with pressure.

If the lithium battery is deformed with pressure, the electrolyte may leak from it because of warp or

damage in the sealing, or the battery may burst or fire because it is heated by internal shortcircuit.

8. Don’t use batteries of different types or old ones mixedly.

If batteries of different brands/types are mixedly used or new and old batteries are mixedly used, it may

cause expansion, burst or fire of the batteries because they are over-discharged by difference in their

characteristics of voltage, capacitance, etc.

9. Avoid setting of the battery in wrong polarities.

If the battery is set in wrong polarities (+ and - poles are set reversely), the battery may be shortcircuited

and it may resultingly cause heating, bursting or firing in the battery.

1-3

Page 8

1.7 SERVICE CAUTIONS

1.7.1 Precautions

1. Before disassembling/re-assembling the set as well as soldering parts, make sure to disconnect the power cable.

2. When disconnecting/connecting connectors, pay enough attention to wiring not to damage it.

3. In general, chip parts such as resistor, shorting jumpers (0ohm resistor), ceramic capacitors, diodes, etc. can not be

reused after they were once removed.

4. When installing parts, be careful not to do with other parts

as well as not to damage others.

5. When removing ICs, be careful not to damage circuit patterns.

6. Tighten screws properly during the procedures. Unless specified otherwise, tighten screws at torque of 0.196 N·m (2.0

kgf·cm).

1.7.3 Connection of the wires

1. Pull the connector structure upward to release the clamp

when removing or inserting the flat wire cable.

Wire

Connector

1.7.2 How to read the disassembly and assembly

(For Cabinet Parts)

STEP

/LOC PART

NO.

Fig.

No.

REMOVAL

*UNLOCK/RELEASE/

UNPLUG/UNCLAMP/

UNSOLDER

1 CASSETTE C1 (S1),3(L1a),(L1b),(L1c)

COVER ASSEMBLY Push button, spring

2

UPPER CASE C2 2(S2), (L2)

LOWER CASE C3 9(S3), (L3a), (L3b)

3 ASSEMBLY(INCL. *CN 3a 3b

E. VF. ASSEMBLY) CAP (RCA jack)

▲

▲

(1) (2) (3) (4)

(1) Order of steps in Procedure

When reassembling, preform the step(s) in the reverse order. These numbers are also used as the identification (lo-

cation) No. of parts Figures.

(2) Part to be removed or installed.

(3) Fig. No. showing Procedure or Part Location.

C = Cabinet

CA = Camera

D = Deck

(4) Identification of part to be removed, unhooked, unlocked, re-

leased, unplugged, unclamped or unsoldered.

P = Spring

W = Washer

S = Screw

* = Unhook, unlock, release, unplug or unsolder.

2(S3) = 2 Screws (S3)

CN = Connector

(5) Adjustment information for installation.

▲

▲

NOTE:

Fig. 1-7-1

Wire

Connector

After removing the wire, return the stopper to

its original position, because it is apt to come

off if it is left open.

Fig. 1-7-2

1-4

Page 9

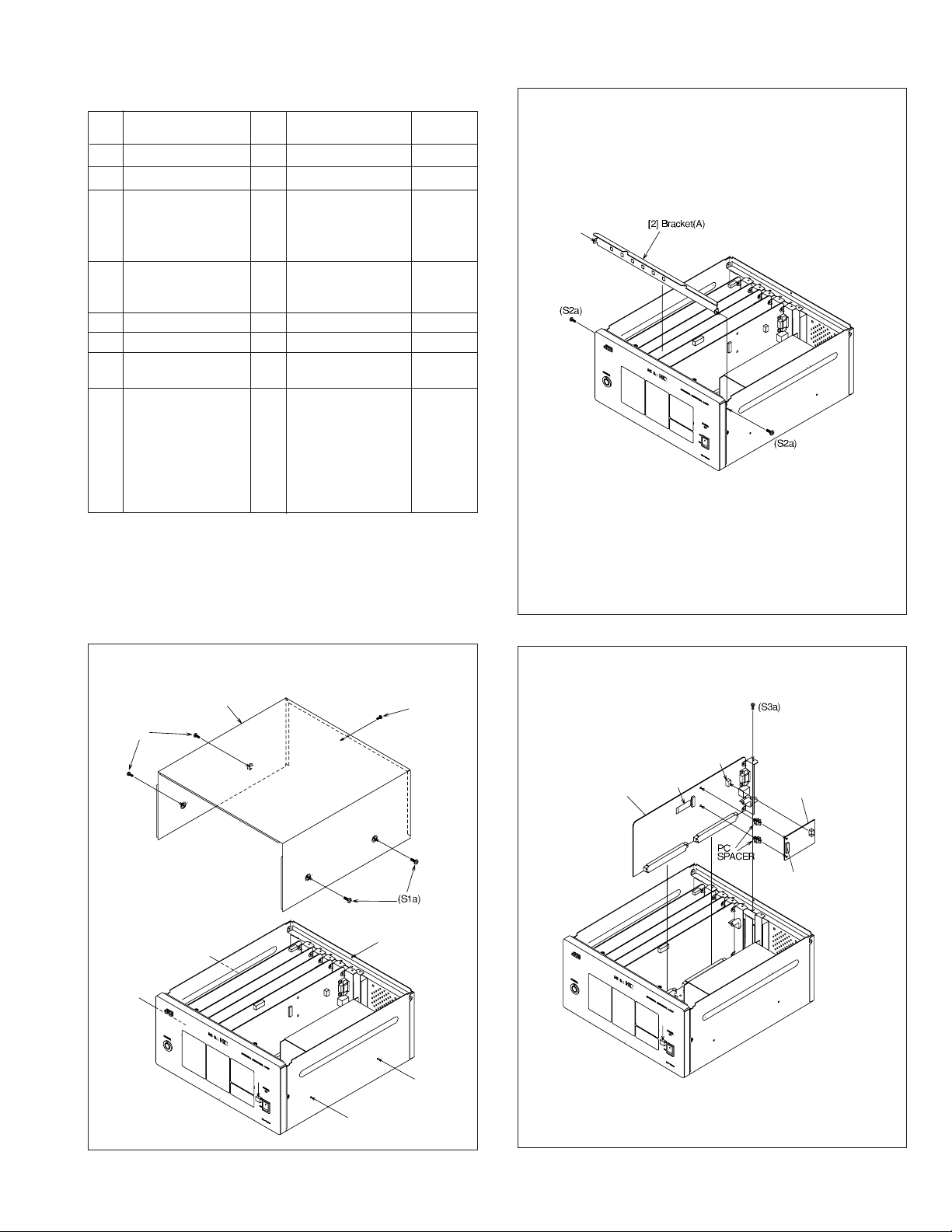

1.7.4

Disassembly procedure

Step/

Loc No.

Part Name

[1] TOP COVER

[2] BRACET(A)

[3]

NTSC board assembly

--------------------------------------------------------------------------

DV board assembly

Fig.

No.

1-7-4a

1-7-4b

1-7-4c

1-7-4c

Point Note

4(S1a), (S1b)

2(S2a)

(S3a),(L3a)

CN5501(WR3a), <Note 3a>

(CN3a),

PC SPACER,x2

MICOM board assembly1-7-4d

[4]

(S4a),(L4a) <Note 3a>

CN4004(D CONNECTOR ASSEMBLY),

CN4005(WR4b)

[5] DSP board assembly

[6]

AMDP board assembly

[7] AD board assembly

1-7-4e

(S5a),(L5a)

1-7-4f

(S6a),(L6a)

1-7-4g

(S7a),(L7a) <Note 3a>

CN1003(D CONNECTOR ASSEMBLY)

[8] FRONT PANEL

1-7-4h

6(S8a),(S7b), <Note 3a>

assembly CN615(WR8a),

CN616(D CONNECTOR ASSEMBLY),

CN617(D CONNECTOR ASSEMBLY)

--------------------------------------------------------------------------

FRT board assembly

--------------------------------------------------------------------------

LED board assembly

1-7-4i

1-7-4i

(WR8b),(WR8c)

7(S8c),3(S8d)

2(S8e)

<Note 3a>

• Be careful not to damage the connector and wire etc. during

connection and disconnection.

• When connecting the flat wire to the connector, be careful with

the flat wire direction.

• When removing or attaching the WIRE/FPC, refer to “1.8 WIRING AND BOARD LAYOUT” at same time.

Fig. 1-7-4b

(S1a)

[1] TOP COVER

(S1b)

[3] NTSC BOARD ASSY

(WR3a)

<Note 3a>

(CN3a)

[3] DV BOARD ASSY

CN5501

Fig. 1-7-4a

Fig. 1-7-4c

1-5

Page 10

To CN4004

(3pin)

D CONNECTOR

ASSEMBLY

(WR4a)

[4] MICOM BOARD ASSY

CN4004

CN4003

(S4a)

(S6a)

[6] AMDP BOARD ASSY

Fig. 1-7-4d

[5] DSP BOARD ASSY

(S5a)

CN1003

D CONNECTOR

ASSEMBLY

Fig. 1-7-4f

[7] AD BOARD ASSY

To CN1003

(8pin)

(S7a)

1-6

Fig. 1-7-4e

Fig. 1-7-4g

Page 11

D CONNECTOR

ASSEMBLY

(S8a)

(S8a)

[8] FRONT PANEL

ASSEMBLY

(S8a)

DETAIL "A"

The wire connection of the power switch.

Note : Confirm the following items when reattaching.

To CN617

(2pin)

To CN616

(4pin)

CN617

(S8a)

CN616

"A"

(WR8a)

(S8a)

FRONT PANEL

ASSEMBLY

POWER

SWITCH

1. The direction of the power switch.

2. The color of the wire(s).

3. The connected location (SW.REG or AC

INLET) of the wire(s).

(brown)

(blue)

(WR8c)

(To SW.REG)

(S8a)

(brown)

(blue)

(WR8b)

(To AC INLET)

CN615

FRONT PANEL

ASSEMBLY

Fig. 1-7-4h

[8] FRT board assembly

Fig. 1-7-4i

(S8c)

(S8d)

(S8c)

(S8e)

[8] LED board

assembly

(S8c)

1-7

Page 12

1.8 WIRING AND BOARD LAYOUT

AMDP board

assembly

AD board

assembly

DSP board

assembly

MICOM board

assembly

NTSC board

assembly

DV board

assembly

MTP board

assembly

NUT

WASHER

SCREW

WIRE CLAMP

Attach the WIRE CLAMP to the

center between CORE FILTER

of the wire which has connected

D CONNECTOR with AD board

assembly.

D CONNECTOR

assembly

A part of number of the CORE FILTER

in the figure is omitted.

CN617

CN1003

CN4004

Process the sag of the wire which

has connected CN4004 of the

MICOM board assembly with D

CONNECTOR, between the

MICOM board assembly and the

DSP board assembly.

(see the figure)

CN613

Fix the wire which has connected

the MTP board assembly with

SW.REG assembly, through the

hole (the 4th hole from the left) of

SW.REG assembly.

(see the figure)

Fix the wire which has

connected to CN615 and

CN616 of the MTP board

assembly at this position.

CN616

CN615

Process the wire which has connected

CN616 of the MTP board assembly with

D CONNECTOR, under each B to B

board assembly, being cautious of

interference of CORE FILTER.

(see the figure)

Attach the CORE FILTER to come to

each edge of the SW.REG assembly.

(see the figure)

Soldering of D. CONNECTOR ASSEMBLY

11

10

9

8

D.CONNECTOR

Parts Number

Connector Pin No.

WIRE color

Pin No. of

D. CONNECTOR

WJM0254

-001A

12123 1234 123456789101112

brown red green blue brown red orange brown red orange yellowred white brown red black

GND 13 14 11 3 4 512 8 9 7 1015161718126–

WJM0255

-001A

STEP. 1 STEP. 2 STEP. 3

Coil the UL TAPE(about 19mm

width) around the wire 1 round

and a half.

(For insulation of GND terminal)

SHIELD

TAPE

Cut the SHIELD TAPE

into 30mm and coil

the SHIELD TAPE around the wire.

The edge of the

SHIELD TAPE

of the wire.

Detail of coiling the shield tape to the D.CONNECTOR.

1

12

2

13

3

14

18

19

4

15

17

16

5

67

GND

WJM0256

-001A

Cut SHIELD TAPE into 80mm, and coil

SHIELD

the SHIELD TAPE around the wire so

TAPE

that each SHIELD section certainly

overlaps. (refer to the figure)

WJM0257

-001A

The edge of the

STEP 2.

Fig. 1-8-1

Fig. 1-8-2

Detail of installation of the CORE FILTER(s).

Attach the CORE FILTER(s) after attaching the D.CONNECTOR

ASSEMBLY to the FRONT PANEL ASSEMBLY.

CORE FILTER "A"

To

MTP

To

MICOM

To

MTP

To

AD

CORE FILTER "B"

20±5mm

On the basis of this position, put

six CORE FILTERs side by side.

30±5mm

On the basis of this position, put

five CORE FILTERs side by side.

30±5mm

On the basis of this position, put

two CORE FILTERs side by side.

CORE FILTER "A"

• The dimension is a straight

line dimension (no sag).

• Certainly lock a claw.

CORE FILTER "A" : QQR0490-002

CORE FILTER "B" : QQR0917-002

CORE FILTER "C" : QQR0942-001

CORE FILTER "C"

20±5mm

50±5mm

CORE FILTER "B"

1-8

Page 13

SECTION 2

ELECTRICAL ADJUSTMENT

2.1 INITIAL SETTING

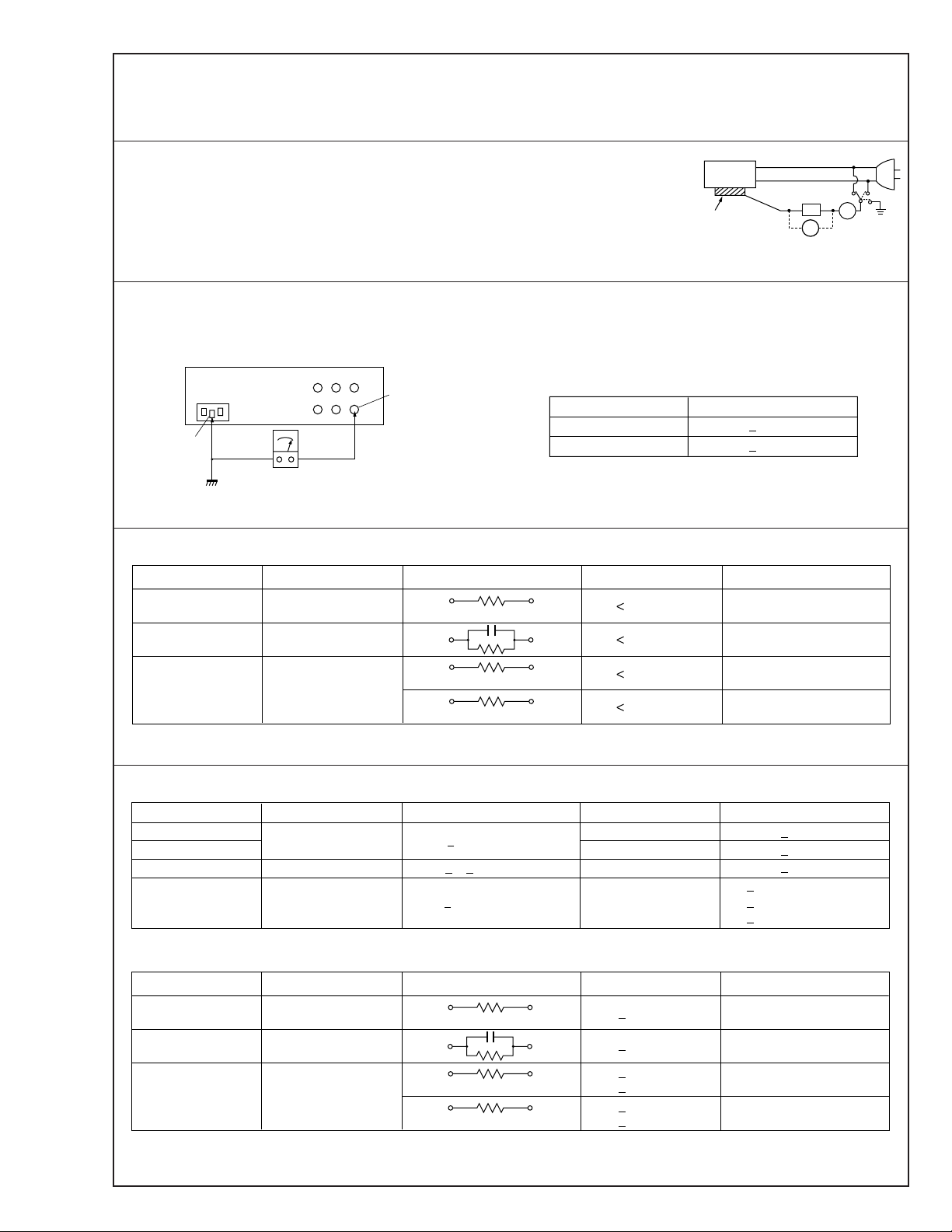

2.1.1 Functions and initial settings of internal switches of boards

Board assembly Switch Function Initial setting

AMDP SW2101 1 : Don’t care 1 : ON

MICOM SW4304 1 : DIN(SG2_DATA) 1 : ON

SW4305 1 : Don’t care 1 : ON

AD SW1501 1 : DIAG (ON : VD2 lock) 1 : ON

SW1502 1 : T. GEN (ON : TEST GAN) 1 : OFF

DSP SW3002 1 : I/O 1 : OFF

SW3003 1 : I/O 1 : OFF

NTSC SW5001 1 : I/O 1 : OFF

2 : XRST 2 : ON

3 : DSCLK 3 : ON

4 : DSDT0 4 : ON

2 : DONE(SG2_DONE) 2 : ON

3 : INIT(SG2_INI) 3 : ON

4 : PROGRAM(SG2_PRG) 4 : ON

2 : Don’t care 2 : ON

3 : Don’t care 3 : ON

4 : DCLK(SG2_CLK) 4 : ON

2 : GAMMA (ON : GAMMA ON) 2 : ON

3 : Don’t care 3 : OFF

4 : Program write 4 : ON

2 : T. SEL0 (GENERATOR MODE 1) 2 : OFF

3 : T. SEL1 (GENERATOR MODE 2) 3 : OFF

4 : Don’t care 4 : OFF

2 : I/O 2 : OFF

3 : I/O 3 : ON

4 : I/O 4 : ON

2 : I/O 2 : ON

3 : I/O 3 : ON

4 : I/O 4 : OFF

2 : I/O 2 : OFF

3 : I/O 3 : OFF

4 : I/O 4 ; OFF

OFFON1234

OFFON1234

OFFON1234

OFFON1234

OFFON1234

OFFON1234

OFFON1234

OFFON1234

SXGA OUT

GENLOCK

NTSC OUT SXGA OUT

HD OUT

IN/OUT

DV Y

GBR

Y/C

(S)

VBS

PB

PR

D-SUB 15pin ⇔ BNC CABLE.

Y/C(S) OUT

S CABLE

GENLOCK

NTSC OUT SXGA OUT

IN/OUT

DV Y

Y/C

(S)

VBS

HD OUT

GBR

PB

PR

RCA ⇔ BNC CABLE

Oscilloscope

PTU93001A

Connection of SXGA terminal to Oscilloscope

Connection of Y/C(S) terminal to oscilloscope

Fig. 2.1.1 Connection (SXGA) Fig. 2.1.2 Connection (Y/C(S))

DV OUT

GENLOCK

NTSC OUT SXGA OUT

HD OUT

IN/OUT

DV Y

GBR

PB

Y/C

(S)

PR

VBS

DV CABLE

AV CABLE

Oscilloscope

Extension board

VTR MONITOR

Connection of DV terminal to Monitor

Fig. 2.1.3 Connection (DV) Fig. 2.1.4 Extension Board

2-1

Page 14

2.1.2 Adjustment procedure

1. Standard adjustment procedure

2.1

Initial setting

2.2

MTP board adjustment

2.3

MICOM board adjustment

2.4

DSP board asjustment

2.5

NTSC board adjustment

2.6

AD board adjustment

2. Adjustment procedure at camera head replacement

2.6

AD board asjustment

2-2

Page 15

2.2 MTP BOARD ADJUSTMENT

2.2.1 Adjustment part(s) location guide

CN602

CN601

CN617

12

CN604

CN603

CN606

CN605

CN608

CN607

CN610

CN609

TP601

CN612

CN611

TP610

3

CN614

TP604

TP605

TP603

TP602

TP607

TP606

CN616

1

VR601

CP611

TP609

TP608

41

10

1

CN613

CN615

12

Fig. 2.2.1 Adjustment part(s) location of MTP board assembly

2.2.2 Input voltage check

Signal • (None)

Mode • Power ON

Equipment • Digital voltmeter

Test points • CN613 (1)pin • CN613 (10)pin

External trigger • Use TP601(or TP610) as the ground

Specified value • +6.20±0.30V • –6.20±0.30V

(1) Each test point to check is measured using Digital voltmeter.

2.2.3 output voltage level

Signal • (None)

Mode • Power ON

Equipment • Digital voltmeter

Test points • TP603

External trigger • Use TP601(or TP610) as the ground

Adjustment part • VR601

Specified value • +2.5±0.05V

(1) Adjust part is adjusted and output voltage level is set as

Specified value.

2.2.4 output voltage check (1)

Signal • (None)

Mode • Power ON

Equipment • Digital voltmeter

Test points •

External trigger • Use TP601(or TP610) as the ground

Specified value • +5.00±0.20V • –5.00±0.20V

TP604,TP605,TP606

• TP607

(1) Each test point to check is measured using Digital voltmeter.

2.2.5 output voltage check (2)

Signal • (None)

Mode • Power ON

Equipment • Digital voltmeter

Test points • TP602 • TP609

External trigger • Use TP601(or TP610) as the ground

Specified value • +3.30±0.15V • +15.00±0.50V

(1) Each test point to check is measured using Digital voltmeter.

2.2.6 output voltage check (3)

Signal • (None)

Mode • Power ON

Equipment • Digital voltmeter

Test points • TP608 • CP611

External trigger • Use TP601(or TP610) as the ground

Specified value • –7.50±0.50V • More than 3V

(1) Each test point to check is measured using Digital voltmeter.

2-3

Page 16

2.3 MICOM BOARD ADJUSTMENT

2.3.1 Adjustment part(s) location guide

When adjusting or checking the MICOM board assembly, use the extension board. (Be careful of board direction)

SW4302

SW4303

Fig. 2.3.1a Adjustment part(s) location of MICOM board assembly

2.3.2 Main clock level

Signal • (None)

Mode • Power ON

Equipment • Frequency couter

Test points • TP4413

External trigger • Use TP601(or TP610) as the ground

Adjustment part • VR4401

Specified value • 101.1480MHz

(1) The test point to check is measured using frequency counter.

(2) Adjustment part is adjusted and main clock level is set as

Specified value.

TP4413

VR4401

GENLOCK

IN/OUT

2.3.3 GENLOCK output level

Note :

• Connect with Oscilloscope directly through a 75

Ω

terminus using a coaxial cable.

• Measure the range of an oscilloscope by 0.1V.

Signal • (None)

Mode • SYNC OUT(MENU)

Equipment • Oscilloscope

Test points • GENLOCK terminal (75Ω terminated)

Specified value • 600mV±60mVp-p

(1) The test point to check is measured using Oscilloscope.

(2) It checks that measured value is Specified value.

2-4

Page 17

2.4 DSP BOARD ADJUSTMENT

TP3005

TP3007

VR3002

VR3001

VR3003

VR3006

VR3007

VR3005

VR3009

VR3008

VR3010

SW3002SW3003

SXGA

OUT

2.4.1 Adjustment part(s) location guide

When adjusting or checking the DSP board assembly, use the extension board. (Be careful of board direction)

Fig. 2.4.1 Adjustment part(s) location of DSP board assembly

2.4.2 HD OUT

Note :

• Connect with Oscilloscope directly through a 75

Ω

terminated using a coaxial cable.

• Measure the range of an oscilloscope by 0.2V or 0.1V.

2.4.2.1 Y signal ratio level

Signal • Built-in color bar signal

Mode • BAR(LED lighting)

Equipment • Oscilloscope

Test points • Y OUT terminal (75Ω teminated)

AMDP board assembly

External trigger • TP3005

Adjustment part • VR3002

Specified value • A:B = 7:6 (Signal ratio)

2.4.2.2 Y signal level

Signal • Built-in color bar signal

Mode • BAR(LED lighting)

Equipment • Oscilloscope

Test points • Y OUT terminal (75Ω teminated)

AMDP board assembly

External trigger • TP3005

Adjustment part • VR3009

Specified value • 1.0V

(1) The test point to check is measured using Oscilloscope.

(2) Adjustment part is adjusted and Y signal is set as Specified

value.

(1) The test point to check is measured using Oscilloscope.

(2) Adjustment part is adjusted so that the ratio of a luminosity

signal and a synchronized signal may become Specified

value.

A

B

Fig. 2.4.2.1

1.0V

Fig. 2.4.2.2

2-5

Page 18

2.4.2.3Pr signal ratio level

Signal • Built-in color bar signal

Mode • BAR(LED lighting)

Equipment • Oscilloscope

Test points • Pr OUT terminal (75Ω teminated)

AMDP board assembly

External trigger • TP3005

Adjustment part • VR3003

Specified value • A:B = 7:6 (Signal ratio)

2.4.2.5 Pb signal ratio level

Signal • Built-in color bar signal

Mode • BAR(LED lighting)

Equipment • Oscilloscope

Test points • Pb OUT terminal (75Ω teminated)

AMDP board assembly

External trigger • TP3005

Adjustment part • VR3001

Specified value • A:B = 7:6 (Signal ratio)

(1) The test point to check is measured using Oscilloscope.

(2) Adjustment part is adjusted so that the ratio of a Pr signal

and a synchronized signal may become Specified value.

B

A

Fig. 2.4.2.3

2.4.2.4 Pr signal level

Signal • Built-in color bar signal

Mode • BAR(LED lighting)

Equipment • Oscilloscope

Test points • Pr OUT terminal (75Ω teminated)

AMDP board assembly

External trigger • TP3005

Adjustment part • VR3010

Specified value • 700mV

(1) The test point to check is measured using Oscilloscope.

(2) Adjustment part is adjusted and Pr signal is set as Specified

value.

(1) The test point to check is measured using Oscilloscope.

(2) Adjustment part is adjusted so that the ratio of a Pb signal

and a synchronized signal may become Specified value.

B

A

Fig. 2.4.2.5

2.4.2.6 Pb signal level

Signal • Built-in color bar signal

Mode • BAR(LED lighting)

Equipment • Oscilloscope

Test points • Pb OUT terminal (75Ω teminated)

AMDP board assembly

External trigger • TP3005

Adjustment part • VR3008

Specified value • 700mV

(1) The test point to check is measured using Oscilloscope.

(2) Adjustment part is adjusted and Pb signal is set as Specified

value.

2-6

700mV

Fig. 2.4.2.4

700mV

Fig. 2.4.2.6

Page 19

2.4.3 SXGA OUT

Note :

• Since a signal is outputted from SXGA OUT, a D-SUB 15

⇔

BNC cable is used.

• Connect with Oscilloscope directly through a 75

Ω

terminated using a coaxial cable.

• Measure the range of an oscilloscope by 0.2V or 0.1V.

2.4.3.1G gain level

Signal • Built-in color bar signal

Mode • BAR(LED lighting)

Equipment • Oscilloscope

Test points • G OUT terminal (75Ω teminated)

External trigger • TP3007

Adjustment part • VR3006

Specified value • 700mV

• D-SUB15 ⇔ BNC cable

(1) Since a G OUT signal is outputted from SXGA OUT, a D-

SUB15 ⇔ BNC cable is used. The test point to check is

measured using Oscilloscope.

(2) Adjustment part is adjusted and G gain is set as Specified

value.

TP3007

2.4.3.3 R gain level

Signal • Built-in color bar signal

Mode • BAR(LED lighting)

Equipment • Oscilloscope

• D-SUB15 ⇔ BNC cable

Test points • R OUT terminal (75Ω teminated)

External trigger • TP3007

Adjustment part • VR3005

Specified value • 700mV

(1) Since a R OUT signal is outputted from SXGA OUT, a D-

SUB15 ⇔ BNC cable is used. The test point to check is

measured using Oscilloscope.

(2) Adjustment part is adjusted and R gain is set as Specified

value.

TP3007

700mV

Fig. 2.4.3.3

700mV

Fig. 2.4.3.1

2.4.3.2B gain level

Signal • Built-in color bar signal

Mode • BAR(LED lighting)

Equipment • Oscilloscope

Test points • B OUT terminal (75Ω teminated)

External trigger • TP3007

Adjustment part • VR3007

Specified value • 700mV

(1) Since a B OUT signal is outputted from SXGA OUT, a D-

SUB15 ⇔ BNC cable is used. The test point to check is

measured using Oscilloscope.

(2) Adjustment part is adjusted and B gain is set as Specified

value.

• D-SUB15 ⇔ BNC cable

TP3007

Fig. 2.4.3.2

700mV

2-7

Page 20

2.5 NTSC BOARD ADJUSTMENT

2.5.1 Adjustment part(s) location guide

When adjusting or checking the NTSC board assembly, use the extension board. (Be careful of board direction)

VR5101

VR5201 VR5301

VR5003 VR5002 VR5001

TP5102

SW5001

TP5202

TP5302

Fig. 2.5.1 Adjustment part(s) location of NTSC board assembly

2.5.2 INPUT SIGNAL

2.5.2.1G gain level

Signal • Built-in color bar signal

Mode • BAR(LED lighting)

Equipment • Oscilloscope

Test points • TP5102

External trigger • TP5013

Adjustment part • VR5101

Specified value • 1.49V

(1) The test point to check is measured using Oscilloscope.

(2) Adjustment part is adjusted and G gain is set as Specified

value.

DV OUT

TP5001

TP5013

S OUT

VBS OUT

2.5.2.2 B gain level

Signal • Built-in color bar signal

Mode • BAR(LED lighting)

Equipment • Oscilloscope

Test points • TP5202

External trigger • TP5013

Adjustment part • VR5201

Specified value • 1.49V

(1) The test point to check is measured using Oscilloscope.

(2) Adjustment part is adjusted and B gain is set as Specified

value.

2-8

Fig. 2.5.2.1

1.49V

TP5013

TP5013

1.49V

Fig. 2.5.2.2

Page 21

2.5.2.3R gain level

Signal • Built-in color bar signal

Mode • BAR(LED lighting)

Equipment • Oscilloscope

Test points • TP5302

External trigger • TP5013

Adjustment part • VR5301

Specified value • 1.49V

(1) The test point to check is measured using Oscilloscope.

(2) Adjustment part is adjusted and R gain is set as Specified

value.

TP5013

1.49V

2.5.3.2Video level (2)

Signal • Built-in color bar signal

Mode • BAR(LED lighting)

Equipment • Oscilloscope

Test points • VBS terminal (75Ω terminated)

External trigger • TP5001

Adjustment part • VR5002

Specified value • 0.714V

(1) The test point to check is measured using Oscilloscope.

(2) Adjustment part is adjusted and Y signal is set as Specified

value.

0.714V

Fig. 2.5.2.3

2.5.3 OUTPUT SIGNAL

Note :

• Connect with Oscilloscope directly through a 75

Ω

terminated using a coaxial cable.

• Measure the range of an oscilloscope by 0.2V or 0.1V.

2.5.3.1Video level (1)

Signal • Built-in color bar signal

Mode • BAR(LED lighting)

Equipment • Oscilloscope

Test points • VBS terminal (75Ω terminated)

External trigger • TP5001

Adjustment part • VR5201, VR5301

Specified value • Minimum signal level

(1) The test point to check is measured using Oscilloscope.

(2) Adjustment part is fine-adjusted and the signal waveform

level of the white portion of a color bar is made into the

minimum.

minimum

Fig. 2.5.3.2

2.5.3.3Y level

Signal • Built-in color bar signal

Mode • BAR(LED lighting)

Equipment • Oscilloscope

• PTU93001A(RCA-S ADAPTER)

Test points • S OUT terminal (75Ω terminated)

External trigger • TP5001

Adjustment part • VR5001

Specified value • 0.714V

(1) The test point to check is measured using Oscilloscope.

PTU93001A is used for changing S terminal into a RCA

terminal.

(2) Adjustment part is adjusted and Y level is set as Specified

value.

0.714V

white portion

Fig. 2.5.3.1

Fig. 2.5.3.3

2-9

Page 22

2.5.3.4Color level

Signal • Built-in color bar signal

Mode • BAR(LED lighting)

Equipment • Oscilloscope

Test points • C OUT terminal (75Ω terminated)

External trigger • TP5001

Adjustment part • VR5003

Specified value • 286mV

• PTU93001A(RCA-S ADAPTER)

(1) The test point to check is measured using Oscilloscope.

PTU93001A is used for changing S terminal into a RCA

terminal.

(2) Adjustment part is adjusted and burst level is set as Specified

value.

286mV

Fig. 2.5.3.4

2.5.3.5DV signal check

Signal • Built-in color bar signal

Mode • BAR(LED lighting)

Equipment • apparatus with DV input Monitor

Test points • DV terminal

(1) It checks that connect apparatus with DV INPUT and a color

bar signal is reflected in a monitor.

2-10

Page 23

2.6 AD BOARD ADJUSTMENT

1.8V

TP1002

1.8V

signal line

Note :

• A camera head is attached.

• Shoot the gray scale chart under the standard shooting condition, an iris is set as F8.

• Standard shooting conditions

1) Ambient temperature : +20° to +25°C

2) Standard lighting : 3200 K, 4000 lx

3) Lens : YH13x7.5B12 or YH13x7.5K12

2.6.1 Adjustment part(s) location guide

When adjusting or checking the AD board assembly, use the extension board. (Be careful of board direction)

TP1102

VR1101

VR1103

TP1202

VR1201

SW1501 SW1502

VR1203

VR1303

TP1002

TP1001

VR1301

TP1010

VR1001

TP1302

Fig. 2.6.1 Adjustment part(s) location of AD board assembly

2.6.2 A/D AND AUTO GAIN

Note :

• A/D adjustment and AUTO adjustment are performed

continuously.

2.6.2.1A/D gain level

Perform this adjustment at ADJUSTMENT MODE.

After adjustment, turn off and turn on the power again.

Signal • Shot the gray scale chart

Mode • Adjustment mode

Equipment • Oscilloscope

Test points • TP1102, TP1202, TP1302

External trigger • TP1001

Adjustment part • VR1101, VR1201, VR1301

Specified value • 1.61V

(1) The test point to check is measured using Oscilloscope.

(2) Adjustment part is adjusted and A/D gain is set as Speci-

fied value. It measures in the bottom position of a signal line.

2.6.2.2AUTO gain level

Signal • Shot the gray scale chart

Mode • Adjustment mode

Equipment • Oscilloscope

Test points • TP1010

External trigger • TP1002

Adjustment part • VR1001

Specified value • 1.8V

(1) Adjustment parts is adjusted and AUTO gain is set as Speci-

fied value. It is measured in the center position of a signal

line.

(2) Adjustment mode will be canceled if a power supply is

switched on again.

TP1001

1.61V

Fig. 2.6.2.1

signal line

1.61V

Fig. 2.6.2.2

2-11

Page 24

2.6.2.3Color gain

Signal •

Mode • CAMERA

Equipment • Oscilloscope

Test points • TP1102, TP1202, TP1302

External trigger • TP1001

Adjustment part • VR1103, VR1203, VR1303

Specified value • Minimum siganl level

An iris is closed and GAIN is set as +24dB.

(1) The test point to check is measured using Oscilloscope.

(2) Adjustment part is adjusted to minimize deflection of the sig-

nal level in the “A” and “B” sides of the waveform.

It is changing into the state where volume had been turned,

when it cannot adjust to minimum.

(3) GAIN is returned to +0dB and an iris is set as F8.

TP1001

A

B

A

B

Fig. 2.6.2.3

2.6.2.5White defect

Note :

• Connect to the monitor by SXGA or HD(Y, Pb, Pr), when

checking WHITE DEFECT.

• Perform this adjustment at DEBUG MODE.

• After adjustment, turn off and turn on the power again.

Signal •

Mode • DEBUG

Equipment • Monitor

Setup • GAIN : 18dB, SHUT : 1/60

Specified value • Minimum signal level

(1) An iris is closed.

(2) It is made DEBUG MODE. And WHITE DEFECT is chosen

using UP and DOWN of MENU operation.

(3) It changes into STANDBY state using → of MENU opera-

tion. And a setup is checked.

DEBUG PAGE RETURN

S/N MODE NO

M.BLACK

ALC

AUTO DEBUG

WHITE DEF. STANDBY

2.6.2.4Color gain for tint adjustment

Signal • Shot the gray scale chart

Mode • CAMERA

Equipment • Oscilloscope

Test points • Pb OUT, Pr OUT

External trigger • TP1002

Adjustment part • VR1201, VR1301

Specified value • Minimum signal level

(1) The test point to check is measured using Oscilloscope di-

rectly uses with a coaxial cable.

(2) Adjustment part is adjusted to minimize deflection of the sig-

nal level of the waveform.

(4) Detection of WHITE DEFECT carries out START by “DOWN”

of MENU operation. After detection of WHITE DEFECT is

completed, it is automatic to STANDBY and returns to it.

DEBUG PAGE RETURN

S/N MODE

M.BLACK

ALC

AUTO DEBUG

WHITE DEF.

(5) MENU is operated and DEBUG mode is ended.

2-12

Page 25

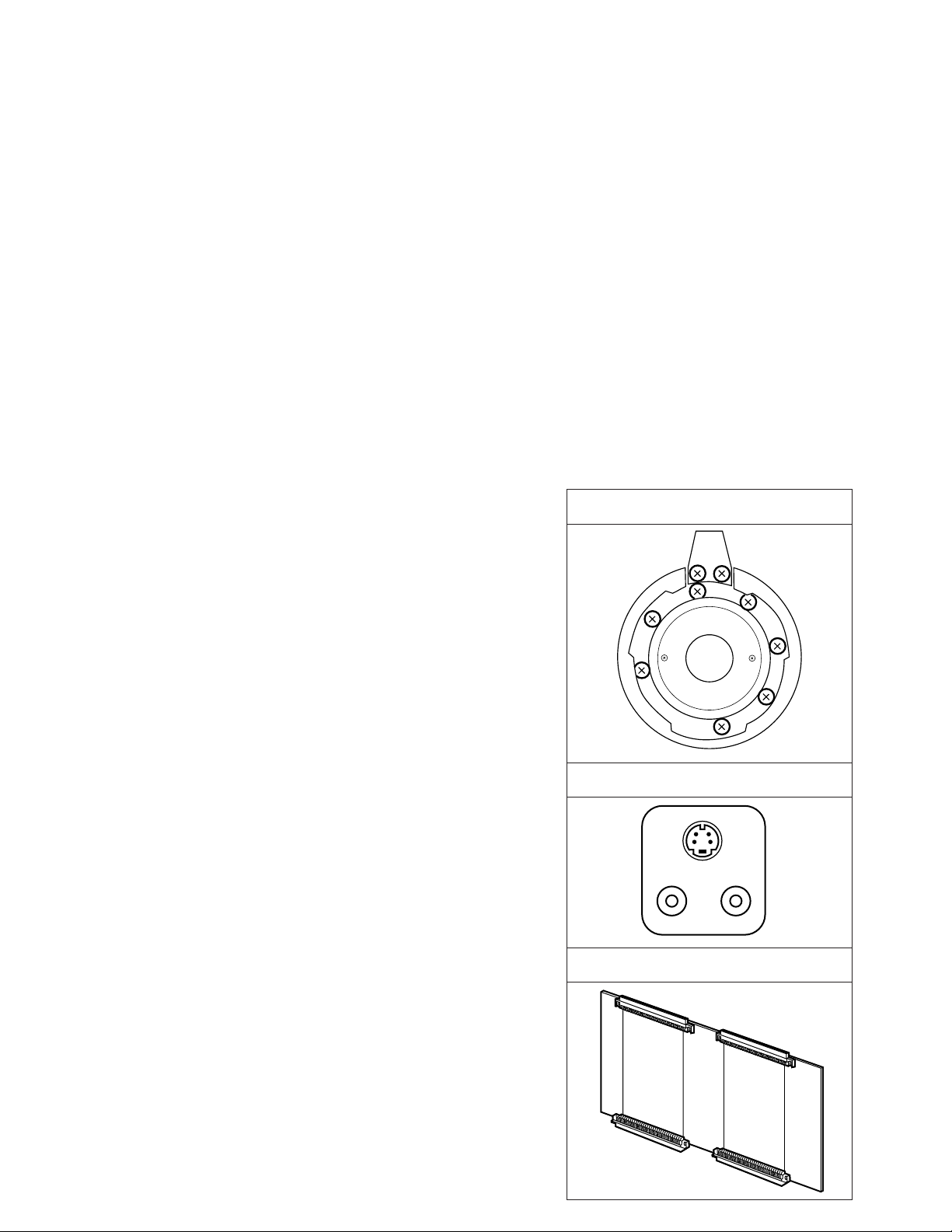

SECTION 3

INSTALLATION MANUAL

For installing and operating the system which this camera is incorporated in, be sure to follow the instructions

mentioned below.

1. Use the AA-V31U isolation transformer to supply the power to every unit of the system.

2. Ground the AA-V31U. (Please refer to “4. Check of grounding (AA-V31U)”)

3. Cover disused power outlets of the AA-V31U with protection brackets respectively.

1. Safety precautions

• Before starting installation, carefully read “Safety precautions” appearing on pages 4 to 8 of the instructions.

2. Connection of system components

• Connect each unit referring to “Connection” appearing on page 9 of the instructions.

• Please install isolation transformer near the equipotential terminal of video cart.

• When installing the system, power supply cords should be routed so that they are not pinched by items placed upon

or against them. Besides that, when moving the system, please pay special attention to power cords as the cart will

not be fallen down.

Please do not connect other equipment to the signal in - or outputs during use of the system at the patient - unless

you are using facility for galvanic separation, e.g. electro-optical transimitter.

The system may not be changed without additional checking of the safety provisions of EN 60601-1-1. Please note

that the party (person or company) which is assembling, installing or modifying a medical sytstem is responsible that

it complies with all relevant requirements of that standard.

3. Connection of each unit to the power supply unit

• Connect the power cable of each unit to the isolation transformer (AA-V31U) referring to the following figure.

The plug of each power cable must be fastened by a band and a holder, which needs to be fastened with a screwdriver.

Washer

Use exclusive screws to fasten

the plug and tighten the screws

with the special screwdriver.

(Pay need to the orientation of

each screw.)

Cover disused power outlets of the

AA-V31U with exclusive protection

brackets,

and fasten each protection bracket

with exclusive screws that need the

special screwdriver for tightening.

When fastening the band to the AA-V31U with an exclusive screw, be sure to put two washers (two different

types) on the screw so that they are inserted between the band and the AA-V31U.

• When fitting the cover to the DZ-VCA3U for medical use, be sure to disconnect the power cord from the AC outlet in

the hospital/clinic to avoid getting an electric shock.

• Be careful not to insert a screwdriver or the like into the AC outlet.

3-1

Page 26

4. Check of grounding (AA-V31U)

• If the AA-V31U is connected to an AC outlet that is not grounded or is poorly grounded, the indicator lamp of the AAV31U goes on. In such a case, reconnect the AA-V31U to another AC outlet that is perfectly grounded.

5. Check of operation

• Check main operations of the system referring to the instructions.

6. Liaison slip of customer data

• When all the above-mentioned work is complete, fill out the liaison slip of customer data and send it to the sales office

concerned.

7. Sterilization

When returnings to repair this camera, the camera head must be sterilized by following the instructions of the sterilizing app aratus referring to the following example of sterilization.

Example of sterilization

• Sterilization by ethylene oxide gas

Gas composition : Ethylene oxide gas 20%

Carbon dioxide 80%

Temperature : 104 to 140 F

Humidity : 40 to 60% RH

EO density : 500 to 600 mg/liter

Action time : 4 hours

Degassing method : Aeration

Shelf condition : By aerator, 122 F

Shelf time : 18 hours or more

(48 hours or more at the room temperature and a general atmospheric pressure)

This equipment is not waterproof.

Don't sterilize the equipment and accessories in a way other than the above-mentioned condition, otherwise

it may cause a failure in the equipment.

8. Report of complaints dealt with

When a complaint about the system is settled on the spot (except rapair of system failure), write details of dealing

with the complaint in the part of “Details of complaint and progress to settlement ” of the “Complaint reception slip

about medical instrument GMP (Good Manufacturing Practice) ”, and send the slip to the following addresses.

JVC Professional Product Company

1700 Vallay Road,Wayne NJ 07470

TEL:(973)317-5000

FAX:(973)317-5030

3-2

Page 27

JVC SERVICE & ENGINEERING COMPANY OF AMERICA

DIVISION OF JVC AMERICAS CORP.

www.jvcservice.com(US Only)

JVC CANADA INC.

Head office

:

21 Finchdene Square Scarborough, Ontario M1X 1A7

(416)293-1311

Printed in Japan

0212 VP

Loading...

Loading...