Page 1

SERVICE MANUAL

D-ILA PROJECTOR

PA01820042

DLA-HX1U, DLA-HX1E

¨

OPERATE

PC VIDEO

W

DIGITAL

V-KEYSTONE H-KEYSTONE

SCREEN

ZOOM

S

FREEZE

VOLUME

FOCUS

QUICK ALIGN.

MENU EXIT

ENTER

PRESET HIDE

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-31

COPYRIGHT © 2004 VICTOR COMPANY OF JAPAN, LIMITED

No.PA018

2004/2

Page 2

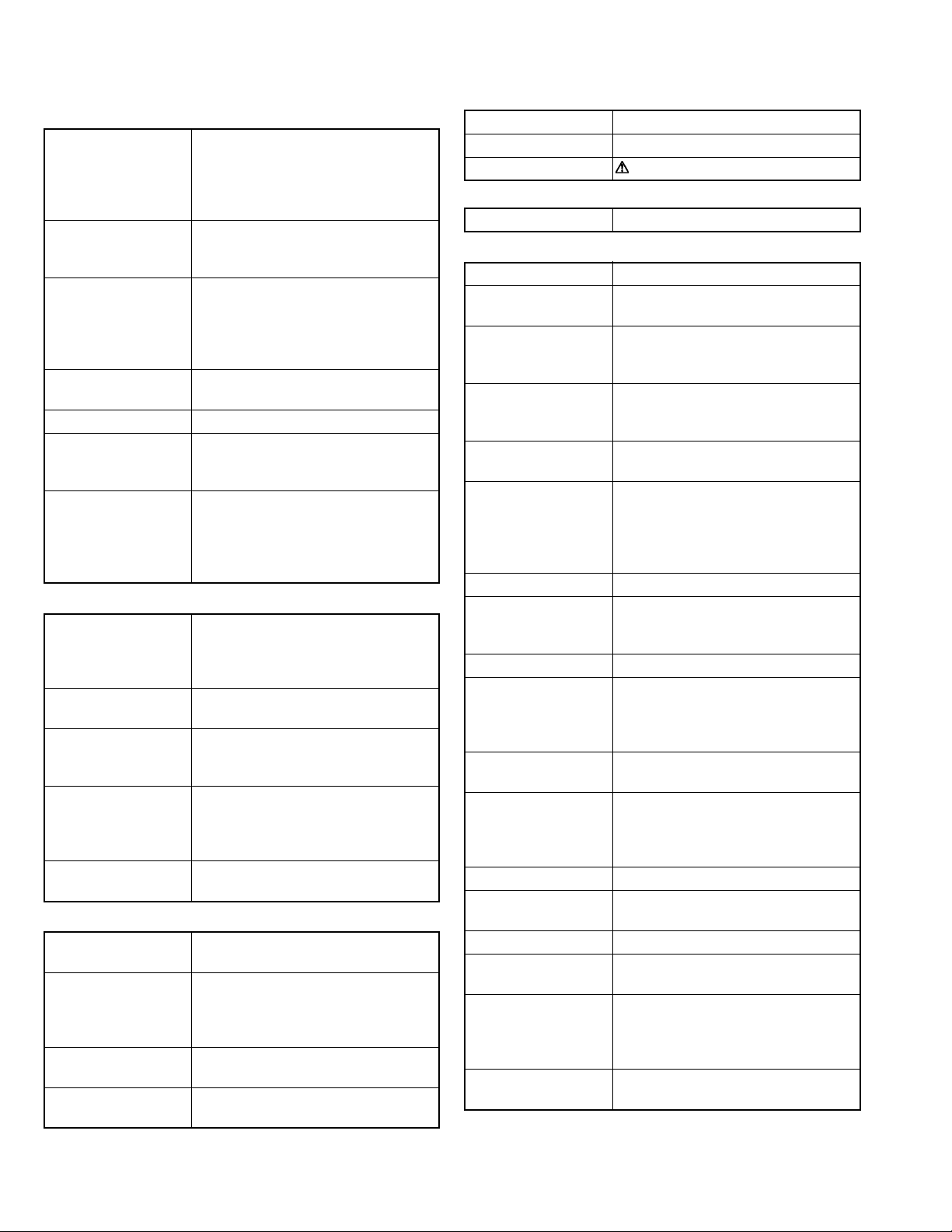

SPECIFICATION

GENERAL

Type

Dimensions

(W × H ×D)

Mass

Power requirements

Power Consumption

Operating temperature

Operating humidity

Storage temperature

Storage humidity

Projection angle

(Adjustable Foot)

Remote control unit RM-MSX21G

operation

Accessories Remote control unit (RM-MSX21) × 1

OPTIC

Projection system

D-ILA device

Projection lens 1.3times (2.1 : 1-2.6 : 1) manual ZOOM

Screen size 37" (94.3cm) [tele : min]-275" (698.5cm)

Projection distance Tele side :

Light lamp BHL5006-S

ELECTRIC

Color system NTSC3.58 / NTSC4.43 / PAL / SECAM

Resolution 1400 × 788 dots (during RGB input)

Scanning frequency Horizontal : 15kHz ~ 120kHz

Keystone distortion

correction

D-ILA PROJECTOR

Approx. 298 mm × 134 mm × 360 mm

(Approx. 11-7/8" × 5-3/10" × 14-1/5")

(Excluding handle, lens and protrusions)

Approx. 6.0kg (Approx.13.2lbs.)

AC 100-240V 50Hz/60Hz

3.4A (100VAC)~1.42A (240VAC)

+5°~+35°[41°F~95°F]

20%~80% (no-condensation)

-10°C~+60°C[14°F~140°F]

10%~90%

(Max. temp 40°C, no-condensation)

Vertical : max. +6° upper

Horizontal : max. 3° (±1.5°)

Distance : 7m

Angle: Horizontal =±30° Vertical =±20°

Mass

100g (includes dry cell battery)

Dry cell battery (size : UM-4/AAA/R02) × 2

PC Cable (D-sub 3-row 15pin : 2m) × 1

SCREEN TRIGGER terminal cable (1.8m)

Power code (2m) × 1

D-ILA(reflective-type active-matrix)system

0.64-inch(1.64cm) measured diagonally

[H:1400 pixels × V:788 pixels] × 3

< Total : 3,309,600 pixels >

lens [50% fix shift]

< recommended >

*measured diagonally with aspect 16:9

approx 2m (6.56ft)-11.5m(37.82ft)

wide side :

approx 1.6m (5.26ft)-12m(39.37ft)

UHP(Ultra High-Pressue mercury) lamp

(Automatic switching / Manual switching)

1000TV line

(Horizontal resolution aspect ratio 4:3,

during video input)

Vertical : 24Hz,25Hz,30Hz,50Hz~120Hz

Top-bottom tilt:

Horizontal=about 30°, Vertical=about 10°

× 1

Audio power output 1w(8Ω) : monaural

Speakers 4cm[1-5/8"] 8Ω round type × 1

Fuse QMF51D2-6R3J1(6.3A)

OUTPUT TERMINAL

SCREEN TRIGGER 12V, 100mA DC Power Jack × 1

INPUT CONNECTORS

VIDEO IN VIDEO signal

Y / C Luminance/Chroma separate video

signal mini DIN 4-pin × 1

Y

1.0V(p-p) 75Ω

C

0.286V(p-p)(burst) 75Ω [NTSC]

0.3V(p-p)(burst) 75Ω [PAL]

VIDEO Composite video signal

RCA, jack × 1

1.0V(p-p) 75Ω sync.

PC1 Analog RGB signal

D-sub 15-pin × 1

PC2 Component (B-Y,R-Y,Y) signal /

DTV (Pb,Pr,Y) format signal /

Analog RGB signal /

External sync. signal

BNC connector × 5

·Cb(B-Y)·Cr(R-Y) Component (Color Difference signal)

Y

Y

1.0V(p-p) 75Ω negative sync.

Cb

0.7V(p-p) 75Ω negative sync

Cr

0.7V(p-p) 75Ω negative sync

Y . Pb . Pr DTV format signal

[480i / 480p / 720p / 1080i]

Y

1.0V(p-p) 75Ω negative sync. [480i / 480p]

1.0V(p-p) 75Ω 3-value sync [720p / 1080i]

Pb / Pr

PC3 Digital RGB signal

AUDIO AUDIO signal

CONTROL Using external computer control

RS-232C RS-232C protocol

REMOTE For connecting an external sensor

0.7V(p-p) 75Ω

DVI-D 24-pin × 1

R

±0.5V(p-p) 50 Ω

G

±0.5V(p-p) 50 Ω

B

±0.5V(p-p) 50 Ω (Include H/V sync)

CLK

±0.5V(p-p) 50 Ω

RCA pin jack × 1

0.5V(rms), high impedance

D-sub 9-pin × 2 (in / out)

Baud rate : 9600bps / 19200bps

Data length : 8 bits (no parity)

Stop bit : 1 bit

Flow control : none

Ø3.5mm stereo mini-jack × 1

1-2 (No.PA018)

Page 3

SECTION 1

r

e

PRECAUTION

1.1 SAFTY PRECAUTIONS

Prior to shipment from the factory, JVC products are strictly inspected to conform with the recognized product safety and electrical codes of the countries in which they are to be

sold.However,in order to maintain such compliance, it is equally

important to implement the following precautions when a set is

being serviced.

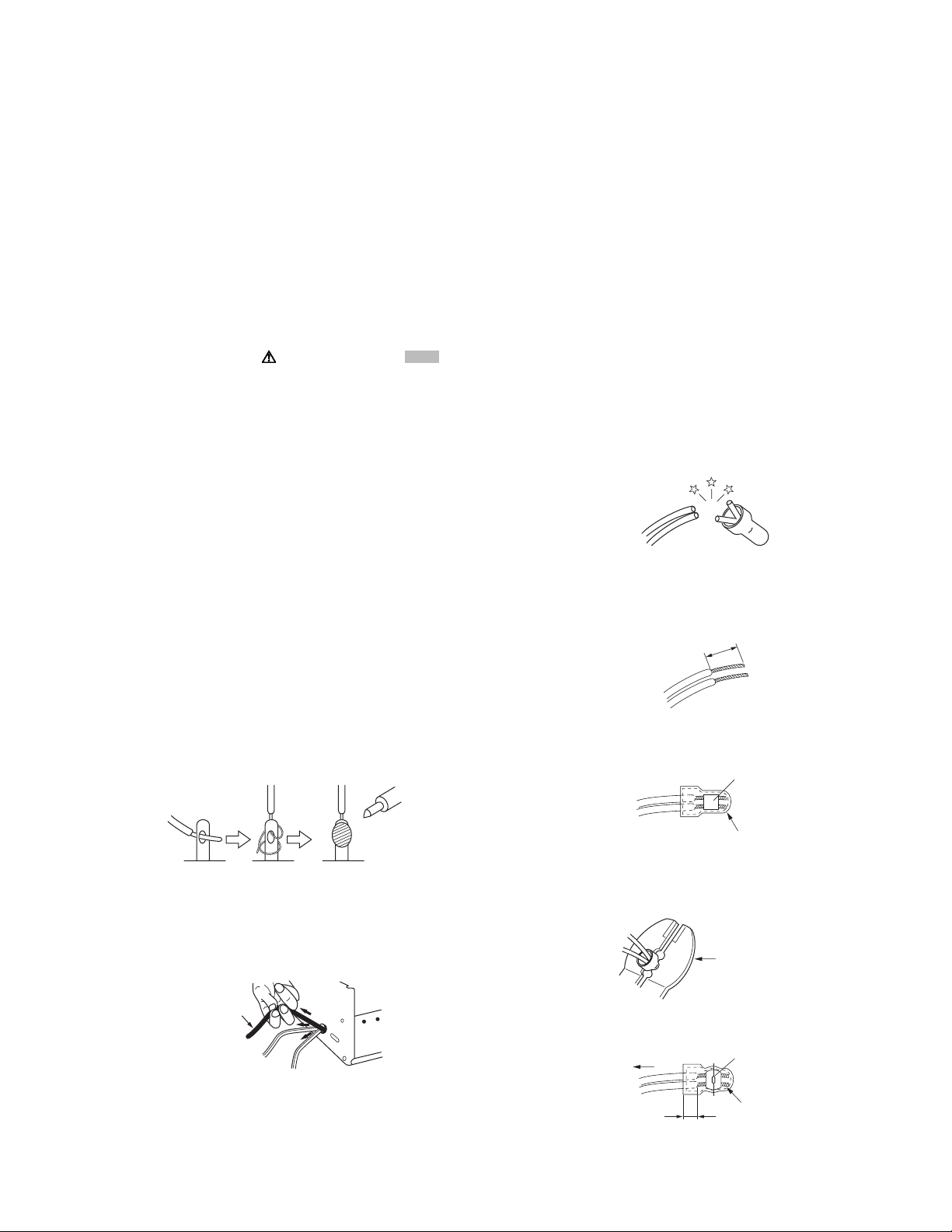

1.1.1 Precautions during Servicing

(1) Locations requiring special caution are denoted by labels

and inscriptions on the cabinet, chassis and certain parts of

the product.When performing service, be sure to read and

comply with these and other cautionary notices appearing

in the operation and service manuals.

(2) Parts identified by the symbol and shaded ( ) parts

are critical for safety.

Replace only with specified part numbers.

NOTE :

Parts in this category also include those specified to

comply with X-ray emission standards for products

using cathode ray tubes and those specified for

compliance with various regulations regarding spurious radiation emission.

(3) Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as specified.

(4) Use specified internal wiring. Note especially:

• Wires covered with PVC tubing

• Double insulated wires

• High voltage leads

(5) Use specified insulating materials for hazardous live parts.

Note especially:

• Insulation Tape

• PVC tubing

•Spacers

• Insulation sheets for transistors

•Barrier

(6) When replacing AC primary side components (transformers,

power cords, noise blocking capacitors, etc.) wrap ends of

wires securely about the terminals before soldering.

Consequently, when servicing these products, replace the

cathode ray tubes and other parts with only the specified

parts. Under no circumstances attempt to modify these circuits.Unauthorized modification can increase the high voltage value and cause X-ray emission from the cathode ray

tube.

(12) Crimp type wire connectorIn such cases as when replacing

the power transformer in sets where the connections between the power cord and power trans former primary lead

wires are performed using crimp type connectors, if replacing the connectors is unavoidable, in order to prevent safety hazards, perform carefully and precisely according to the

following steps.

• Connector part number :E03830-001

• Required tool : Connector crimping tool of the proper

type which will not damage insulated parts.

• Replacement procedure

a) Remove the old connector by cutting the wires at a

point close to the connector.Important : Do not reuse a connector (discard it).

cut close to connector

Fig.1-1-3

b) Strip about 15 mm of the insulation from the ends

of the wires. If the wires are stranded, twist the

strands to avoid frayed conductors.

15 mm

Fig.1-1-4

c) Align the lengths of the wires to be connected. In-

sert the wires fully into the connector.

Metal sleeve

Fig.1-1-1

(7) Observe that wires do not contact heat producing parts

(heatsinks, oxide metal film resistors, fusible resistors, etc.)

(8) Check that replaced wires do not contact sharp edged or

pointed parts.

(9) When a power cord has been replaced, check that 10-15

kg of force in any direction will not loosen it.

Power cord

Fig.1-1-2

(10) Also check areas surrounding repaired locations.

(11) Products using cathode ray tubes (CRTs)In regard to such

products, the cathode ray tubes themselves, the high voltage circuits, and related circuits are specified for compliance with recognized codes pertaining to X-ray emission.

Connector

Fig.1-1-5

d) As shown in Fig.1-1-6, use the crimping tool to crimp

the metal sleeve at the center position. Be sure to

crimp fully to the complete closure of the tool.

1.2

5

2

.0

5.5

Crimping tool

Fig.1-1-6

e) Check the four points noted in Fig.1-1-7.

Not easily pulled free

Wire insulation recessed

more than 4 mm

Crimped at approx. cente

of metal sleev

Conductors extended

Fig.1-1-7

(No.PA018)1-3

Page 4

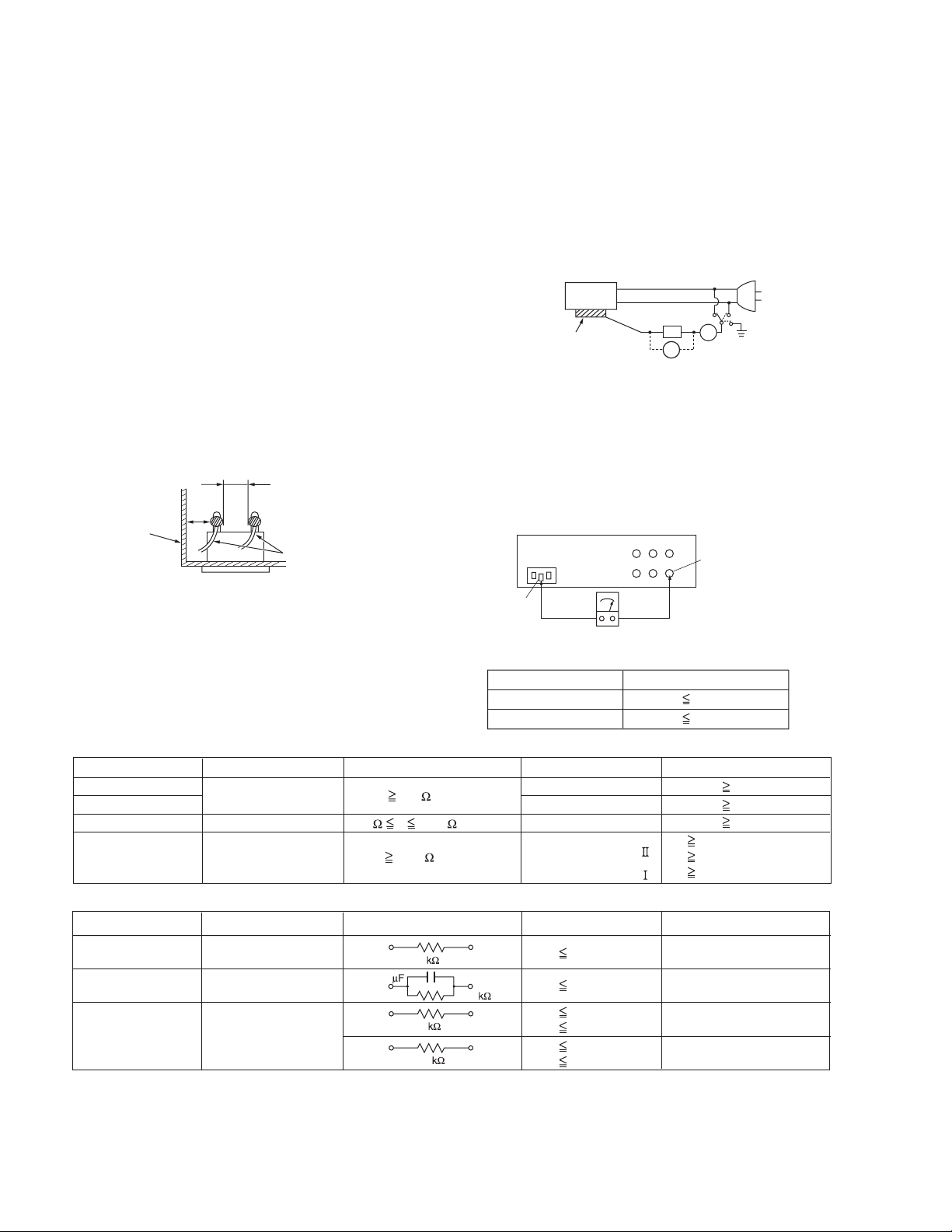

1.1.2 Safety Check after Servicing

Examine the area surrounding the repaired location for damage

or deterioration. Observe that screws, parts and wires have been

returned to original positions, Afterwards, perform the following

tests and confirm the specified values in order to verify compliance with safety standards.

(1) Insulation resistance test

Confirm the specified insulation resistance or greater between power cord plug prongs and externally exposed

parts of the set (RF terminals, antenna terminals, video and

audio input and output terminals, microphone jacks, earphone jacks, etc.).See table 1 below.

(2) Dielectric strength test

Confirm specified dielectric strength or greater between

power cord plug prongs and exposed accessible parts of

the set (RF terminals, antenna terminals, video and audio

input and output terminals, microphone jacks, earphone

jacks, etc.). See Fig.1-1-11 below.

(3) Clearance distance

When replacing primary circuit components, confirm specified clearance distance (d), (d') between soldered terminals, and between terminals and surrounding metallic

parts. See Fig.1-1-11 below.

d

Chassis

d'

Power cord

primary wire

Fig.1-1-8

(4) Leakage current test

Confirm specified or lower leakage current between earth

ground/power cord plug prongs and externally exposed accessible parts (RF terminals, antenna terminals, video and

audio input and output terminals, microphone jacks, earphone jacks, etc.).

Measuring Method : (Power ON)Insert load Z between

earth ground/power cord plug prongs and externally exposed accessible parts. Use an AC voltmeter to measure

across both terminals of load Z. See Fig.1-1-9 and following Fig.1-1-12.

ab

Externally

exposed

accessible part

Z

V

c

A

Fig.1-1-9

(5) Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between

earth pin in AC inlet and externally exposed accessible

parts (Video in, Video out, Audio in, Audio out or Fixing

screw etc.).Measuring Method:

Connect milli ohm meter between earth pin in AC inlet and

exposed accessible parts. See Fig.1-1-10 and grounding

specifications.

AC inlet

Earth pin

Exposed accessible part

MIlli ohm meter

Grounding Specifications

Region

USA & Canada

Europe & Australia

Grounding Impedance (Z

Z 0.1 ohm

Z 0.5 ohm

)

Fig.1-1-10

AC Line Voltage

100 V

100 to 240 V

110 to 130 V

110 to 130 V

200 to 240 V

Region

Japan

USA & Canada

Europe & Australia

Insulation Resistance (R

R 1 M /500 V DC

1 M R 12 M /500 V DC

R 10 M /500 V DC

)

Dielectric Strength

AC 1 kV 1 minute

AC 1.5 kV 1 minute

AC 1 kV 1 minute

AC 3 kV 1 minute

AC 1.5 kV 1 minute

(

Class

(

Class

Clearance Distance (d), (d'

d, d' 3 mm

d, d' 4 mm

d, d' 3.2 mm

d 4 m m

)

d' 8 m m (Power cord

d' 6 m m (Primary wire

)

Fig.1-1-11

AC Line Voltage

100 V

110 to 130 V

110 to 130 V

220 to 240 V

Region

Japan

USA & Canada

Europe & Australia

Load Z

1

0.15

1.5

2

50

Leakage Current (i)

i 1 mA rms

i 0.5 mA rms

i 0.7 mA peak

i 2 mA dc

i 0.7 mA peak

i 2 mA dc

a, b, c

Exposed accessible parts

Exposed accessible parts

Antenna earth terminals

Other terminals

Fig.1-1-12

NOTE :

These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

)

)

)

1-4 (No.PA018)

Page 5

1.1.3 Warning and caution labels

• Labels advising of warning and caution are affixed on and in various locations of the product.

• Take careful notice of these during service and inspection.

WARNING Risk of lethal or otherwise serious personal injury.

CAUTION Risk of personal injury and damage to the product.

Class Pictorial Label advisory Location

WARNING

WARNING

Hot, breakable This projector lamp emits high heat and contains high-pressure during use.

If touched, the lamp (bulb) may rupture and burns may result. Before

attempting to replace the lamp, remove the power cord plug from the outlet and

wait for the lamp (bulb) to cool (at least one hour). Then proceed to replace the

lamp.

High voltage Never open any cover on the projector except the lamp and filter covers.

Dangerous electrical voltage inside the projector.

Bottom chassis

Bottom chassis

WARNING

CAUTION

CAUTION

CAUTION

High brightness Never look into the lens while the projector is on.

There is danger of eye damage.

Hot, shock hazard

High voltage

Hot Caution, high temperature Lamp unit

Do not insert foreign objects into the ventilation holes as this can result in fire or

electrical hazards.

Do not block the ventilation holes as this may cause the internal temperature to

rise and possibly result fire.

When the inside of the unit requires cleaning, consult your nearest JVC dealer

or service center.

Turn off before opening this lamp cover. See user's manual for replacing the

lamp. Replace with the same type (BHL5006-S) lamp rated 250W.

Top cover

Bottom chassis

Bottom chassis

1.1.4 Additional cautionary items

• High voltage is applied for lighting the lamp. During adjustments and other work with the cover removed, extreme care is needed to

avoid electric shock.

• Use care to avoid touching the fan or safety switch terminals during work with the cover removed.

• Select a stable, horizontal work site to prevent dropping the product and components.

• Use the power cord and interface cable supplied with the product.

Before starting work, be sure to also check the safety notices contained in the instruction manual.

(No.PA018)1-5

Page 6

1.2 INSTALLATIONS

1.2.1 Installation method

The D-ILA system (reflecting type active matrix liquid crystal system) does not require convergence adjustment. Note the following

when placed on a floor (refer to OPERATING INSTRUCTIONS for actual operating method).

(1) Place the projector at the position needed for the required image size observe the projector is not tilted horizontally.

[The image size is 37 to 275(wide side) inches diagonal (16:9), requiring a projection distance of 2m to 12m (tele side).]

(2) Adjust the placement site and screen tilt so that the projection angle is perpendicular to the screen.

(3) Adjust the placement site and screen position (height) so that the projection lens center is at the lower edge of the screen.

(4) Project an image on the screen. (Connect video equipment and power source, switch power on and select the input.)

(5) Fine adjust the projected image position and angle. If adjusting the placement site and screen cannot correct the projected po-

sition (too low) or angle (lower part of image widened), adjust the front foot.

(6) Turn the lens ZOOM ring by hand and adjust for suitable image size.

(7) Turn the lens FOCUS ring by hand and adjust to correct image blur.

(8) Adjust [KEYSTONE] if the image appears expanded or contracted at the top or bottom edge.

(9) Adjust < Image adj. > - [Brightness], [Contrast], [Sharpness], [Color] and [Tint] for optimum picture.

1.2.2 Installation site and status

• The projector contains a fan for cooling. Obstruction of the ventilation openings can lead to internal overheating, abnormal operation

and failure. Also observe there is plenty of free space between the projector and adjacent walls, ceiling and other equipment.

Note that excess heat can cause failure and damage to both the projector and nearby equipment.

Required spacing :

Front = 15cm / left and right sides = 30cm / rear = 50cm (When the unit is enclosed with block according to the required spacing

on the left side, provide the unit with adequate ventilation so that the temperature inside of the enclosed area is kept at the same

temperature in the open space in the room.)

• Avoid locations that are wobbly or inclined. If the setting site floor has protrusions or horizontal cannot be maintained, there is risk

the projector may drop, fall over, etc. If located in a site where left to right tilt is greater than ±5° and front to rear tilt greater than

±20°, particularly the optical system components can be severely affected and there is risk basic performance and quality of the

projector cannot be maintained.

• Observe the site can stably bear the weight (approx. 6kg) of the projector over a long period of time.

• If mounted on a stand with casters, observe the casters are securely braked to prevent movement.

• Avoid suspending in a location subject to vibration. Both the projector and mounting fixture can be damaged.

• Do not place in the following types of locations.

Especially, Avoid locations subject to dust, grit, smoke or other airborne contaminants. Use adequate caution when providing external ventilation, filters and dust protection.

Near water or in humid sites Near heaters or heat generating equipment

Dust or grit Direct sunlight

Oily or tobacco smokes Very high or very low temperature

1-6 (No.PA018)

Page 7

SPECIFIC SERVICE INSTRUCTIONS

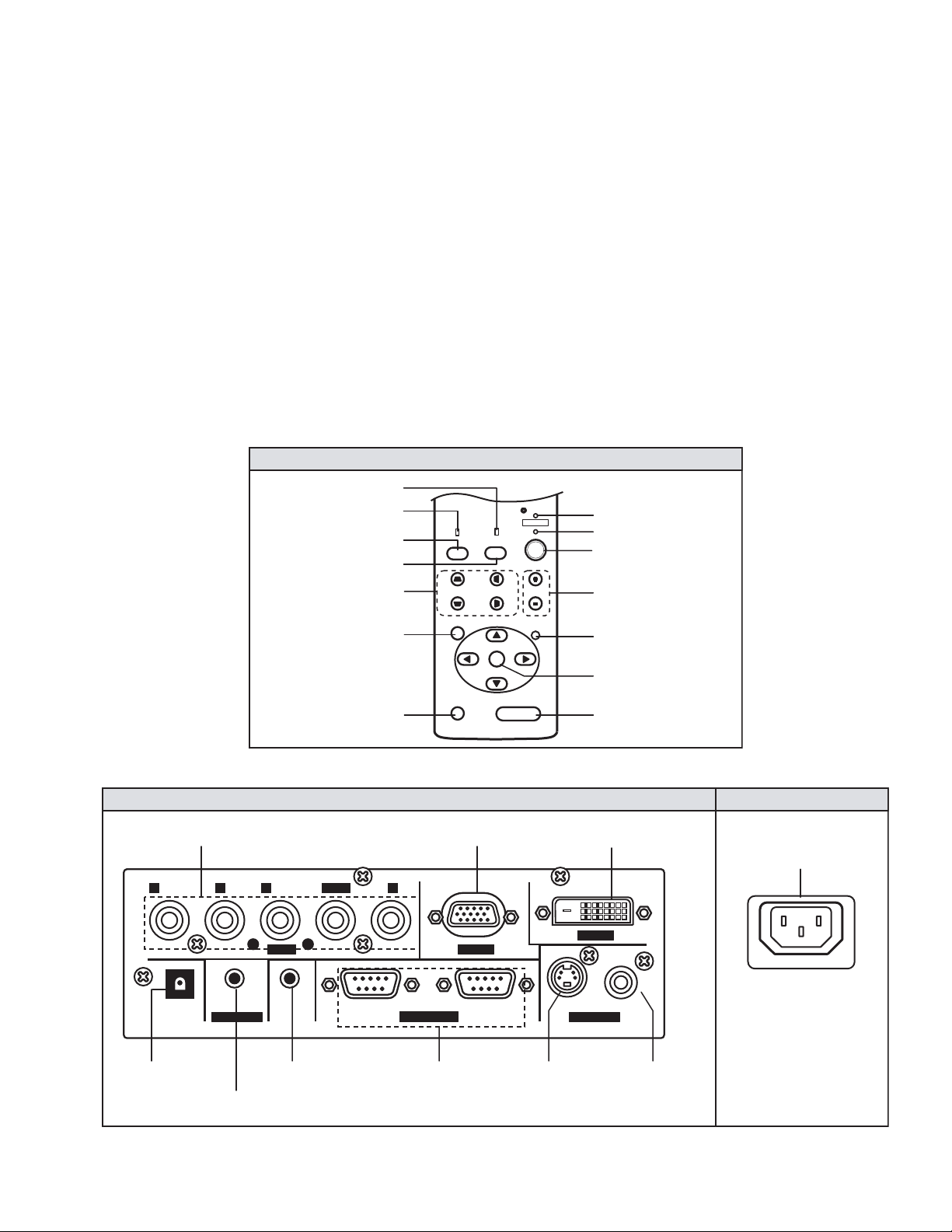

TOP VIEW (Operation Panel)

2.1 FUNCTIONS

2.1.1 LED indications

The LED operations are as follows.

OPERATE LED

Lighted : Power on mode in progress.

Extinguished : Mode other than above.

STAND-BY LED

Lighted : Stand-by mode in progress.

Flashing : Cool down mode in progress.

Extinguished : Mode other than above.

TEMP LED

Flashing : Internal temperature abnormally high

(shift to emergency mode) .

Extinguished : Internal temperature normal.

2.1.2 Operation button & LED location

TOP VIEW (Operation Panel)

TEMP LED

LAMP LED

PC BUTTON

VIDEO BUTTON

KEYSTONE BUTTON

SECTION 2

LAMP LED

Lighted : Lamp replacement time near (used approx.1900

Flashing : Lamp end of life (approx. 2000 hours), power

Extinguished : Mode other than above

NOTE :

Please refer to troubleshooting about the warning display by

LED.

STAND BY

OPERATE

TEMP

LAMP

VIDEO

PC

H-KEYSTONEV-KEYSTONE

VOL.

hours) At power on, message appears by the onscreen display for advising to "LAMP REPLACE".

on inhibited.

(lamp abnormally absent) .

STAND BY LED

OPERATE LED

OPERATE BUTTON

VOLUME BUTTON

MENU BUTTON

PRESET BUTTON

2.1.3 Input / output terminal location

PC2 INPUT

PB/CBPR/CR Y

TRIGGER

SCREEN TRIGGER

OUTPUT

AUDIO IN

AUDIO INPUT

REMOTOSCREEN

REMOTE

INPUT / OUTPUT

MENU

PRESET

RIGHT SIDE

H/Cs VBGR

RS-232C OUT RS-232C IN

INPUT / OUTPUT

PC1 INPUT DVI INPUT

PC 1PC 2

CONTROL

RS-232C

EXIT

ENTER

HIDE

EXIT BUTTON

ENTER BUTTON

HIDE BUTTON

DVI

PC 3

VIDEO Y/C

VIDEO IN

Y/C INPUT VIDEO INPUT

LEFT SIDE

POWER INPUT

(No.PA018)1-7

Page 8

2.2 LAMP UNIT INSTRUCTIONS

Refer to the OPERATING INSTRUCTIONS for a detailed operating description.

2.2.1 Lamp life

Life of the projector lamp (time to reach 1/2 average brightness)

is about 2000 hours.

∗ Lamp use time can be checked at the menu < Information > -

[Lamp time].

LAMP UNIT : BHL5006-S

2.2.2 Operation when lamp use time exceeds 1900 hours

z 1900 to 2000 HOURS

• Power on : LAMP LED lights.

• Operation : Lamp replacement lamp message appears on

screen (∗press any button to extinguish).

z 2000 to 2010 HOURS

• Power on : LAMP LED flashes.

• Operation : "Warning" and "Lamp replacement" messages

appear on screen, and "Warning" flashes.

∗Press [EXIT] button to extinguish the display. But after 1

hour, "Warning" and "Lamp replacement" again appear.

NOTE:

At power off, the stand-by mode is produced and further operation is prevented.

∗To again use the projector, replace the lamp unit and reset

the lamp use time indication.

z AFTER 2010 HOURS

• Power on : Power is cut and cool-down mode entered,

LAMP and OPERATE LEDs flash.

2.2.3 Handling cautions

• Use a cross-head screwdriver to take out and reinstall the lamp

cover (2 screws) and lamp unit (2 screws). Refer to the OPERATING INSTRUCTIONS.

• Observe the following cautions.

- Be sure to disconnect the power cord from the AC power

source.

- The lamp remains quite hot after power off. Be sure to allow

plenty of time (30 minutes to 1 hour) to cool before proceeding.

- The lamp can break if dropped or subjected to physical

shock.

- Use care not to directly touch or soil the lamp projecting

(glass) face.

• When installing the lamp unit, observe the interior projections

of the lamp cover are securely inserted into the holes of the

projector. Since the lamp cover projections engage the interlock switch part of the protector circuit (normal operating state),

be sure the cover is properly positioned and secure with

screws.

• The replaced old lamp (depleted lamp unit) can be discarded

in the same manner as a fluorescent lamp. Check local ordinances and dispose of the used lamp as prescribed.

2.2.4 Lamp use time reset

• Be sure to reset the Lamp use time after replacing the lamp

unit. Unless reset, the projector will cease operation (lamp will

not light) when 2000 hours are reached.

∗Conversely, reset the use time only after replacing the lamp.

• RESETTING

(1) Set for stand-by mode.

(2) In sequence, press the [EXIT], [HIDE] and [PRESET]

buttons.

(3) Press the [VOL+] button for more than 2 seconds.

∗The STAND-BY and OPERATE LEDs alternately flash

for about 3 seconds, then only the STAND-BY LED

lights steadily.

• RESET AFTER REPLACING MAIN PWB ASS'Y

The lamp use time data are stored in memory on the MAIN

PWB ASS'Y and need to be reentered after replacing the

MAIN PWB ASS'Y. Use the special software and a personal

computer to reenter the data. Afterwards, confirm the mode

has been returned to that prior to board replacement.

1-8 (No.PA018)

Page 9

2.3 PROJECTION SPECIFICATIONS AND NOTES

2.3.1 Projection distance

• The usable projection distance (focus obtainable) is tele side :

approx. 2m to 11.5m / wide side : approx. 1.6m to 12m. The

picture size (16:9) is 37 to 275 inches.

• Use the wide side for sizes bigger than 200 inches.

• If picture edge distortion occurs at the minimum distance

(1.6m), increase the distance slightly.

• The guaranteed projection distance range is from 2m to 10m.

2.3.2 Projection image and image size

• The projection distances and image size relationship given in

the operation manual is approximate for general reference.

The actual values may vary due to lens tolerance and other

factors.

• A distance between a horizontal line that passes a center of

the projection lens of this model and a bottom of the projection

screen is one-thirtieth of the vertical size of the screen. (See

the Instruction Manual.)

• The projector a horizontal (vertical line) "keystone (trapezoid

distortion)" due to projection angle wavering corrective function. Keystone compensation yields a smaller image than the

uncompensated picture. When the image is important, to the

extent possible, correct by selecting the projector position,

screen front to rear tilt and projection angle (perpendicular) to

the screen.

2.3.3 Other cautions

• Use care not to directly touch the lens. Clear soiling from the

lens with optical lens paper or a photographer's blower.

• Check the lens cap is removed before projecting. If left installed the projector can overheat and the lens cap can be deformed.

• Sunlight or other illumination can render the image difficult to

see. Use a curtain or other means to shield the screen from

stray light.

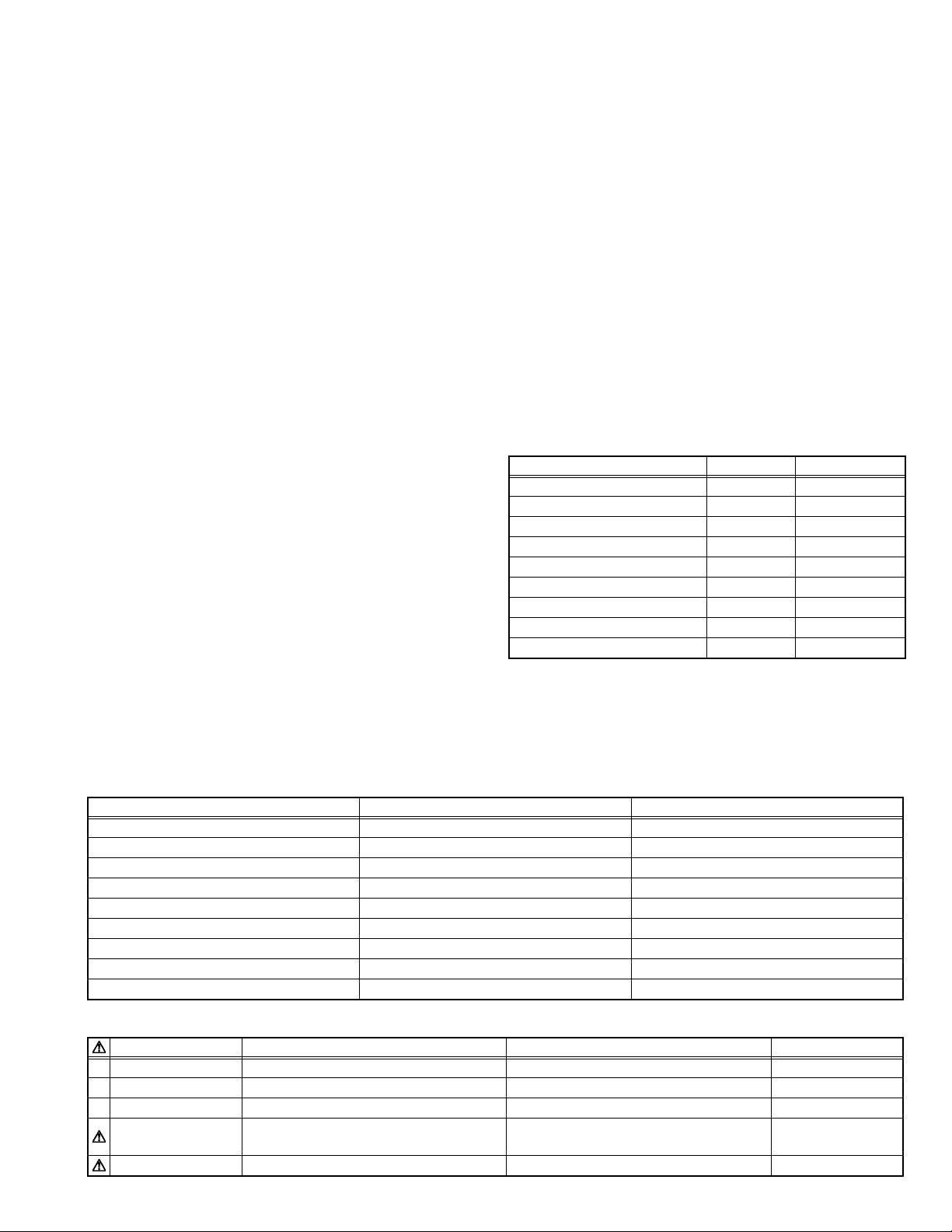

2.5 SERVICE POLICY

The following service policy is being utilized.

Item Parts number Service method

MAIN PWB ASS'Y SXZ-1006A Replace parts

DD SUB PWB ASS'Y SXZ-3002A Replace parts

POWER PWB ASS'Y SXZ-9001A Replace parts

TERMINAL PWB ASS'Y SXZ-0J003A Replace parts

IR PWB ASS'Y SXZ-0R001A Replace parts

CONT. & 3.3V PWB ASS'Y SXG-0P002A Replace parts

OPTICAL BLOCK ASS'Y HX1OP-S Replace (module)

LAMP BALLAST UNIT QAL0435-002 Replace (module)

LAMP UNIT BHL5006-S Replace (module)

2.4 CONNECTION AND OPERATION CAUTIONS

• The projector can function with fH 15 to 120 kHz, fV 24Hz,

25Hz, 30Hz, 50Hz to 120 Hz signal input, but even within this

range, partial picture loss, fold-over at the top and bottom picture edges and other effects can occur according to signal type

and conditions to prevent a normal projected image (see "Signals that can be input the projector" of the OPERATING INSTRUCTION).

• The projector is compatible with UXGA input (H : 1600 ~ V :

1200 dots).

• VGA computer signal may be detected and displayed as 480p

mode of the video system. Select the video system input at the

menu.

• If the video signal from a VTR or other source contains a large

jitter component, distortion, blurring or instability can occur in

the picture. In this case, use a TBC (time base corrector) or

video equipment (e.g., VTR) that contains a TBC.

• The digital zoom and still picture (freeze) functions do not operate with UXGA signal input. When these functions are desired, use another signal input.

• The menu indication differs when the input is selected for video

system or computer system. See below.

Item VIDEO COMPUTER

< Image adj. > Sharpness Present Present ∗1

< Set up > Decoder Present Absent

< Set up > Deinterlace Present Absent

< Set up > Aspect ratio Present Absent

< Set up > HDTV Present Absent

< Set up > Tracking Absent Present

< Setting > Resize Absent Present

< Set up > Clamp Absent Present

< Set up > Sync level Absent Present ∗2

∗1 : If the "Resize" function is the PC submenu is set to "1:1", the

image quality will not change even if the value is changed.

(No adjustment)

∗2 : This will be displayed at the no-signal status when PC1 and

PC2 is selected.

2.6 MAIN DIFFERENCE LIST

Part name DLA-HX1U DLA-HX1E Remark

PACKING CASE LC21468-003A LC21468-004A

POLY BAG QPA01503005 -------- For Warranty card

WARRANTY CARD BT-51030-2 -------- Accessory

POWER CORD QMPE320-200-R

INST. BOOK LCT1511-001A (ENG/FRA) LCT1512-001A (

QMPL280-200-R (for EU)

QMPP220-200-R (for UK)

ENG/FRA/GER/ITA/SPA/KOR

Accessory

) Accessory

(No.PA018)1-9

Page 10

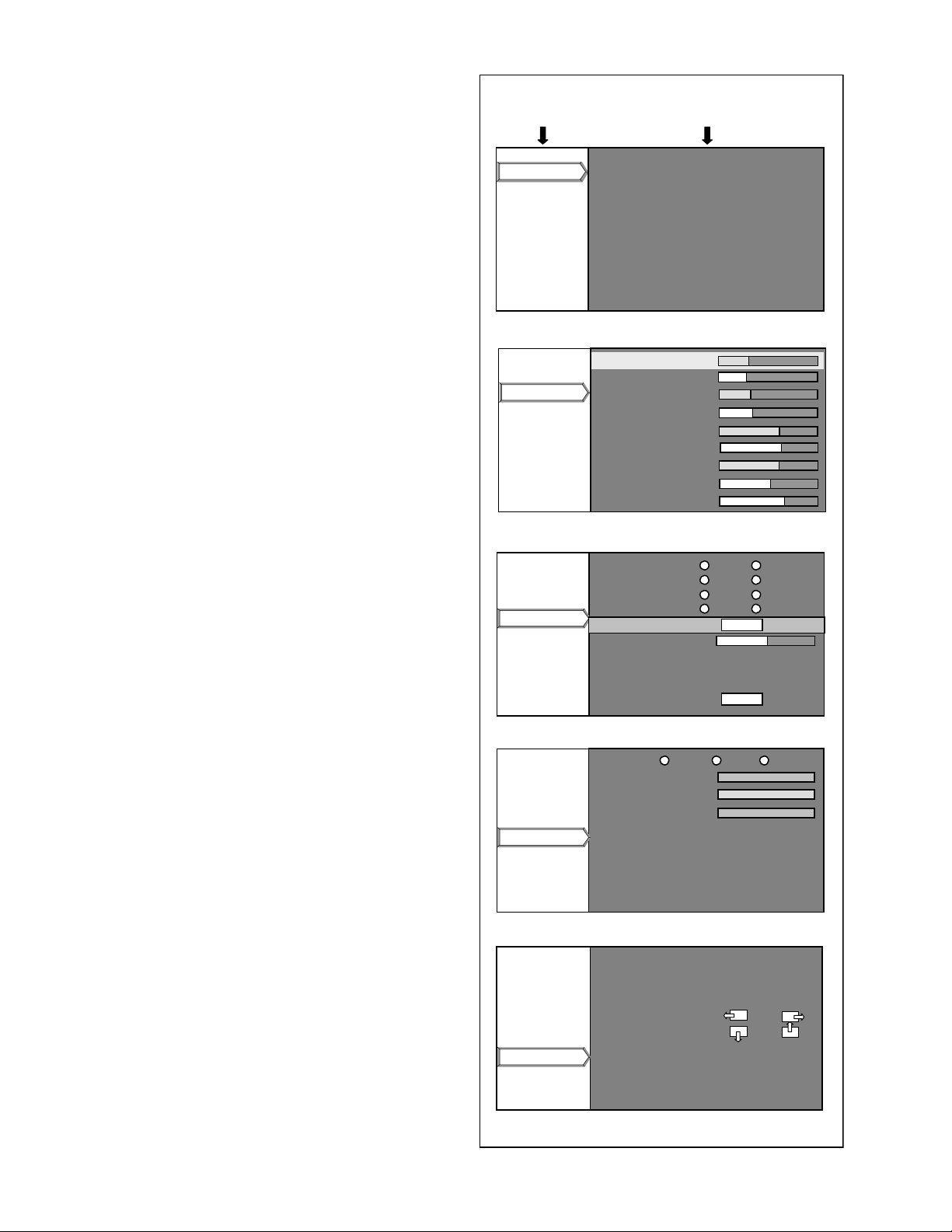

2.7 SERVICE MENU

Horizontal resolution

Vertical resolution

Tracking

Position of Horizontal display

Position of Vertical display

The service menu contains items not ordinarily needed by the user. Use these as necessary during service.

2.7.1 Enter

(1) No menu shown.

(2) Press the [] button.

(3) Within press the [] button.

(4) Within press the [] button.

(5) Within press the [] button.

(6) Within press the [ENTER] button to display the service

menu.

NOTE:

When the Service Menu Screen is not displayed, go back to

the beginning. It is recommended that you press the buttons a

little earlier and steadily.

2.7.2 Release

Press the [MENU] button to exit the menu indication.

2.7.3 Basic operation

Use the following buttons to operate the service menu.

(1) Choose the SETTING MENU with the [/] button.

(2) When the [] button is pressed after choosing the SET-

TING MENU, the cursor will shift to the SETTING / ADJUSTMENT ITEMS of each SETTING MENU.

(3) When the cursor is shifted, choose the SETTING / AD-

JUSTMENT ITEMS with the [/] button.

(4) Using the [/] button, change the setup values and ad-

justment values, respectively.

(5) When the [EXIT] button is pressed, the cursor will return to

the SETTING MENU.

(6) When the [MENU] button is pressed, the SERVICE MENU

will go out of the screen.

NOTE:

The SERVICE MENU will go out of the screen automatically

after 10 seconds if you do not press the [MENU] button.

SETTING NENU

Software version

Cont. / Bright

Option

Color temp

Resolution

Software version

Cont. / Bright

Option

Color temp

Resolution

Software version

Cont. / Bright

Option

Color temp

Resolution

SERVICE MENU

SETTING / ADJUSTMENT ITEM

MODEL NAME : DL

PR OGRAM : 7

OSD : 3

DLAHX1_00003_2003_0826_01

Software version SCREEN

Contrst_R 80

Contrast_R 80

Contrast_G

Contrast_B

Contrast_Main

Brightness_R

Brightness_G

Brightness_B

Cb

Cr

Cont. / Bright SCREEN

VGA mode VGA

Back color Black

Auto shutdown OFF

Over scan

Test pattern

Sharp ness

All reset

A-HX1

HDCP

72

87

90

166

167

165

33

41

480p

Blue

ON

Normal

ENTER

0

ENTER

Overscan

Software version

Cont. / Bright

Option

Color temp

Resolution

Software version

Cont. / Bright

Option

Color temp

Resolution

Option SCREEN

Color temp 6500 STD User

RED

GREEN

BLUE

0

0

0

Color temp SCREEN

Horizontal resolution

Vertical resolution

Tracking

Position of Horizontal display

Position of Vertical display

Resolution adjustment SCREEN

1234

1234

123

12

12

1-10 (No.PA018)

Page 11

2.7.4 Setting items

Item Initial value

Adjustment

range

Description

Software version

Software version ------ ------ Information of PROGRAM -----Cont. / Bright

Contrast

R / G / B / Main

Brightness

R / G / B

[Service adjust.

value]

[Service adjust.

value]

0 ~ 255 Main contrast adjustment. Common

0 ~ 255 Main brightness adjustment. Common

Cb / Cr 31 0 ~ 31 Component signal adjustment. AV system

Option

VGA mode* 480p [Select 2 items] Sets processing for VGA signal input (H : 31.5 kHz / V : 60 Hz).

[480p] : Process as 480p (video system) signal

[VGA] : Process as VGA (PC system) signal

Back color Blue [Select 2 items] "Sets no signal background color to blue or black.

[Blue] : Blue color [Black] :Black color"

Auto shutdown ON [Select 2 items] If POWER OFF is selected, no warning will be displayed on and after 1900

hours of the lamp operating time. However, POWER ON is also available

after 2000 hours of the lamp operating time.

Over scan* Over scan [Select 2 items] Sets scan size for video signal.

[Normal] : Under scan (100%) [Over scan] : Normal (95%)

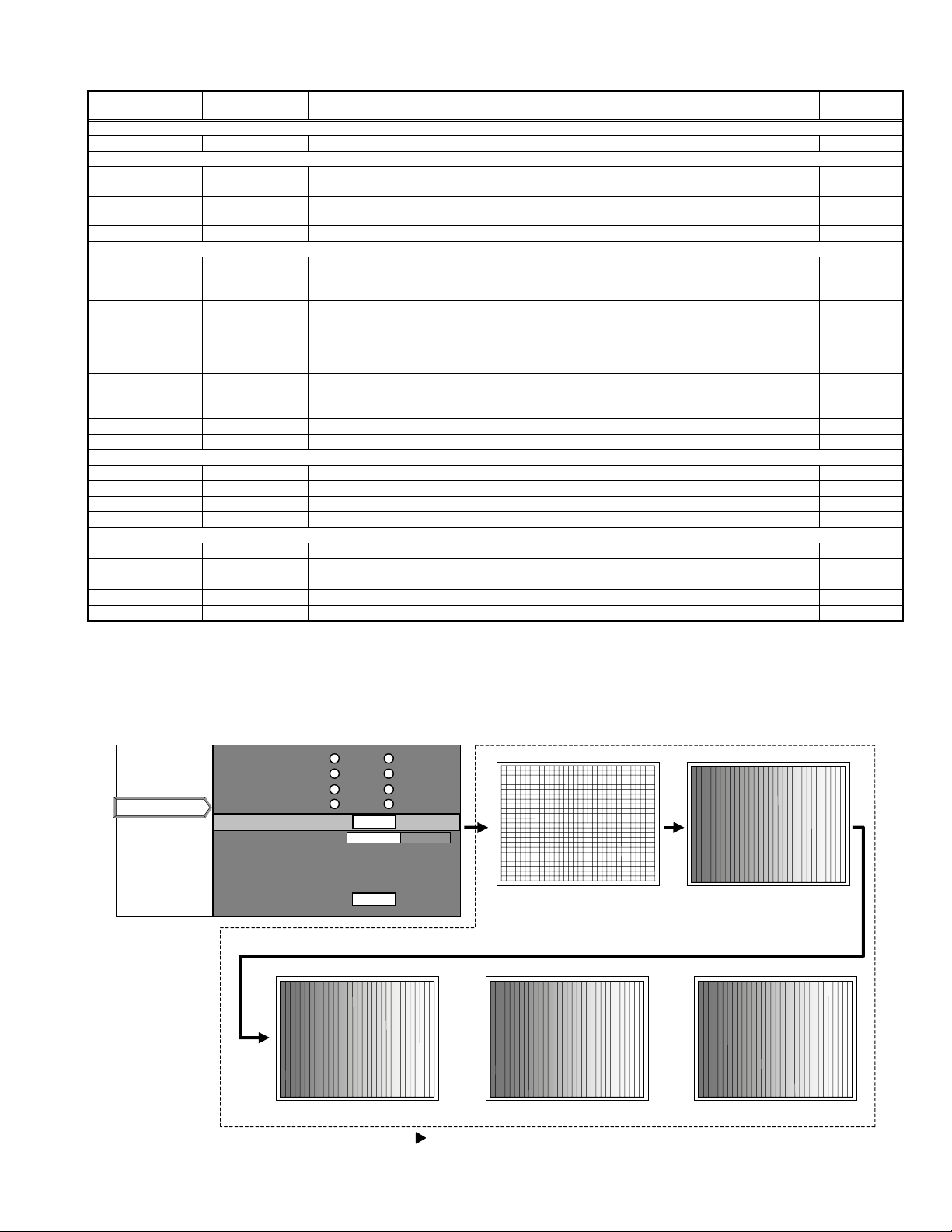

Test pattern ------ [Select 5 items] Press [ENTER] then Test pattern appear. (Refer to following Fig.1) Common

Sharpness 0 -3~3 Main sharpness adjustment. Common

All reset ------ ------ Press [ENTER] then all reset. Common

Color temp

Color temp User Select 3 items Setting of [6500] [Normal] [User] Common

R 0 -255~0 Setting color temp of red Common

G 0 -255~0 Setting color temp of green Common

B 0 -255~0 Setting color temp of blue Common

Resolution

Horizontal resolution

Vertical resolution

Tracking

Position of Horizontal display

Position of Vertical display

Depending on signals

Depending on signals

Depending on signals

Depending on signals

Depending on signals

← Set the horizontal resolution

← Set the vertical resolution

← Same as for the tacking in the User Menu

← Same as for the display of the horizontal position in the User Menu

← Same as for the display of the vertical position in the User Menu

Setting

object

Each signal

(VGA)

Common

Common

Each signal

(AV system)

Analog PC signal

Analog PC signal

Analog PC signal

Analog PC signal

Analog PC signal

∗ : When these items are set, the service menu is automatically closed.

Notice on items in relation to resolution

(1) These functions may sometimes not project some types of signals properly.

(2) These functions cannot set resolution of signals that are input from DVI terminal and video signals (displayed in video menu).

(3) Method of changing the resolution (See the next page.)

Test patter Screen

Software version

Cont. / Bright

Option

Option

Color temp

SERVICE MENU Screen

VGA mode 480p VGA

Back color Blue Black

Auto shutdown ON OFF

Over scan Normal Over scan

Test pattern

Test pattern

Sharp ness 0

ENTER

All reset

ENTER

cross-hatch Gray scale

Red Green Blue

(When the key is pressed, the screen is changed one after the other as shown in the above.)

(No.PA018)1-11

Page 12

HOLIZONTAL RESOLUTION CHANGE PROCEDURE

Start

Set the horizontal position

to the minimum value.

Set the tracking value in

accordance with the Formula1

on the right side.

Change the horizontal

resolution.

Is it changed?

Yes

Formula1

...

New tracking = Previous tracking New horizontal resolution Previous horizontal resolution

No

Previous resolution>New resolution?

Yes

Decrease the tracking value.

No

Increase the tracking value.

Quick Alignment

Check it by referring to

the information in Menu.

1-12 (No.PA018)

End

Yes

Change the horizontal resolution.

Is it changed?

No

This signal cannot be changed.

Page 13

VERTICAL RESOLUTION CHANGE PROCEDURE

Start

Set the vertical position to

the minimum value.

Change the vertical resolution.

Is it changed?

Yes

Quick Alignment

Check it by referring to

the information in Menu.

End

No

This signal cannot be changed.

(No.PA018)1-13

Page 14

2.8 FACTORY SHIPPING SETTING

SET (PROJECTOR) / REMOTE CONTROL UNIT

Switch / Item

MAIN POWER

VIDEO

PC

MENU

Item

Image adj. (VIDEO INPUT/ COMPUTER INPUT)

Contrast

Brightness

Color

Tint

Sharpness

Color temp.

Color temp.

RED

GREEN

BLUE

Reset

Set up

Position

Menu pos.

Horiz. disp. pos.

Vert. pos.

Horiz. DIST pos. *

2

Film*

2

HDTV*

Aspect ratio*

2

Aspect ratio

2

Color*

Tracking *

1

Phase

Resize *

1

Resize

Clamp *

Sync level *

1

3

2

Position

OFF

VIDEO

PC1

Position

0

0

0

0

0

ENTER

6500

0

This adjustment is only

available when the USER is

0

selected for color temperature.

0

ENTER

ENTER

4

351*

4

42*

0

AUTO

1080i

ENTER

4

16:9*

ENTER

4

1688*

4

20*

ENTER

Aspect

BP

Std

Switch / Item

VOLLUME

FREEZE

HIDE

Item Position

Logo

Logo disp.

Logo pos.

Back color

Logo delete

Capture menu

Option

( Page1 )

Color profile

Menu display

Line display

Flip H

Flip V

( Page2 )

Sleep time [min]

Menu color

PC2(BNC)

DET

SCART

RS-232C[bps]

SXGA

PC3

Language

Position

0

OFF (moving picture)

OFF (display)

ON

Center

Black

ENTER

ENTER

ENTER

15sec

5sec

OFF

OFF

OFF

OFF

YPbPr

ON

OFF

19200

1280

HDCP

English

*1 : Only when PC system signal selected

*2 : Only when VIDEO system signal selected

*3 : Only non signal

*4 : It changes with input signals.

1-14 (No.PA018)

Page 15

SECTION 3

DISASSEMBLY

Notes:

• Confirm that the power cord is unplugged from the AC outlet before proceeding.

• The lamp remains quite hot after turning the power off. Allow sufficient time to cool before starting work.

3.1 LENS COVER

(1) Rotate the LENS COVER on the front of the main frame

counterclockwise and release the lock. Then pull out the

LENS COVER toward you. (Fig.1)

3.2 LAMP UNIT COVER

(1) Loosen the 2 screws marked A on the right side of the main

frame and pull out the LAMP UNIT COVER toward you.

(Fig.2)

These 2 screws are not removed from the LAMP UNIT

COVER.

3.3 TOP COVER

• Remove the LENS COVER.

• Remove the LAMP UNIT COVER.

(1) Remove the 1 screw marked B and the 3 screws marked C

on the right side of the main frame. (Fig.2)

(2) Remove the 3 screws marked D on the left side of the main

frame. (Fig.2)

(3) Remove the 1 screw marked E on the rear side of the main

frame. (Fig.2)

(4) Remove the harness from the connector CN701

CONTROL UNIT which is secured to the back of the TOP

COVER.

(5) Lift up the TOP COVER to remove it.

3.4 PROTECT COVER

• Remove the LENS COVER.

• Remove the LAMP UNIT COVER.

• Remove the TOP COVER.

(1) Remove the 1 screw marked E' fixing the PROTECT COV-

ER, and lift up the PROTECT COVER to remove it. (Fig.2)

3.5 CONTROL UNIT

• Remove the LENS COVER.

• Remove the LAMP UNIT COVER.

• Remove the TOP COVER.

(1) Remove the 5 screws marked F fixing the CONTROL UNIT

from the back of the TOP COVER. (Fig.2)

(2) Remove the CONTROL UNIT. (Fig.2)

of the

LENS COVER

Fig. 1

D

(x3)

(x1)

CN710

TOP COVER

E'

F

(x5)

CONTROL UNIT

C

(x1)

E

(x1)

A

(x2)

LAMP UNIT COVER

BOTTOM CHASSIS

Fig.2

C

(x2)

B

(x1)

(No.PA018)1-15

Page 16

3.6 TERMINAL PWB ASS'Y AND MAIN PWB ASS'Y

• Remove the LENS COVER.

• Remove the LAMP UNIT COVER.

• Remove the TOP COVER.

(1) Remove the 6 screws marked J fixing the MAIN PWB

ASS'Y. (Fig.3)

(2) Remove the harness from the connectors CN710

, and CN001.

CN701

, CN711,

(3) Remove the cord wire from the connector CN801.

(4) Remove the harness from the connectors CN800

, CN706, CN705, CN713, CN704, and CN708.

CN707

, CN714,

3.7 TERMINAL BOARD AND SHIELD SHEET

• Remove the LENS COVER.

• Remove the LAMP UNIT COVER.

• Remove the TOP COVER.

• Remove the TERMINAL PWB ASS'Y AND MAIN PWB ASS'Y. *1

(1) Remove the 5 screws marked G fixing the TERMINAL

BOARD. (Fig.3)

(2) Remove the TERMINAL BOARD.

(3) Using a nut driver and the like, remove the 8 screws

marked H fixing the D-SUB connector and DVI connector.

(Fig.3)

(4) Pull out the SHIELD SHEET toward you to remove it.

*1

After (2) in the procedure above, the TERMINAL BOARD and

the SHIELD SHEET can be replaced. However, be careful

about the cord wire and the harness that are not replaced.

3.8 TERMINAL PWB ASS'Y

• Remove the LENS COVER.

• Remove the LAMP UNIT COVER.

• Remove the TOP COVER.

• Remove the TERMINAL PWB ASS'Y AND MAIN PWB ASS'Y.

• Remove the TERMINAL BOARD and the SHIELD SHEET.

(1) Remove the 1 screw L fixing the TERMINAL PWB ASS'Y.

(2) Disconnect the connector CN010

that connects the TER-

MINAL PWB ASS'Y and the MAIN PWB ASS'Y.

(3) Remove the 1 screw marked L' fixing the bracket, and the

TERMINAL PWB ASS'Y is removed.

3.9 MAIN PWB ASS'Y

• Remove the LENS COVER.

• Remove the LAMP UNIT.

• Remove the TOP COVER.

• Remove the TERMINAL PWB ASS'Y AND MAIN PWB ASS'Y.

• Remove the TERMINAL BOARD and the SHIELD SHEET.

(1) Remove the 1 screw market K fixing the MAIN PWB

ASS'Y.

(2) Disconnect the connector CN010

that connects the MAIN

PWB ASS'Y and the TERMINAL PWB ASS'Y.

CN714

CN707

CN706

CN705

CN713

CN704

CN708

CN701

CN801

CN001

K

CN800

(x1)

L'

(x1)

L

(x1)

CN711

CN010

CN710

J

(x6)

TERMINAL PWB ASS'Y

MAIN PWB ASS'Y

TERMINAL BOARD

SHIELD SHEET

(x4)

H

(x4)

G

(x5)

H

1-16 (No.PA018)

Fig.3

Page 17

3.10 LAMP UNIT UPPER BRACKET

• Remove the LENS COVER.

• Remove the LAMP UNIT.

• Remove the TOP COVER.

• Remove the TERMINAL PWB ASS'Y AND MAIN PWB ASS'Y.

(1) Remove the 2 screws marked M fixing the LAMP UNIT UP-

PER BRACKET. (Fig.4)

(2) Pull out the LAMP UNIT UPPER BRACKET in the direction

of the arrow.

3. 11 POWER SUPPLY SHIELD CASE(1) and LAMP BALLAST UNIT

• Remove the LENS COVER.

• Remove the LAMP UNIT.

• Remove the TOP COVER.

• Remove the TERMINAL PWB ASS'Y AND MAIN PWB ASS'Y.

• Remove the LAMP UNIT UPPER BRACKET.

(1) Remove the 5 screws marked N fixing the POWER SUP-

PLY SHIELD CASE(1). (Fig.4)

(2) Disconnect the connectors CN1

and CN2.

(3) Remove the 1 screw marked O fixing the LAMP POWER

SUPPLY CORD SUPPRESSION BRACKET. (Fig.4)

(4) Lift up the LAMP POWER SUPPLY CORD SUPPRES-

SION BRACKET to remove it, and remove the LAMP

POWER SUPPLY CORD.

(5) After setting up the POWER SUPPLY SHIELD CASE(1),

remove the 4 claws marked a which secure the LAMP BALLAST UNIT to the back of the POWER SUPPLY SHIELD

CASE. (Fig.4)

(x5)

LAMP BALLAST UNIT

POWER SUPPLY SHIELD CASE(1)

CN2

CN1

M

(x2)

a

N

LAMP UNIT UPPER BRACKET

O

(x1)

LAMP POWER SUPPLY CORD

SUPPRESSION BRACKET

LAMP POWER SUPPLY CORD

Fig.4

(No.PA018)1-17

Page 18

3.12 POWER SUPPLY PWB ASS'Y

• Remove the LENS COVER.

• Remove the LAMP UNIT.

• Remove the TOP COVER.

• Remove the TERMINAL PWB ASS'Y AND MAIN PWB ASS'Y.

• Remove the LAMP UNIT UPPER BRACKET.

• Remove the POWER SUPPLY SHIELD CASE(1).

(1) Remove the 4 screws marked P fixing the POWER SUP-

PLY PWB ASS'Y. (Fig.5)

(2) Disconnect the POWER SUPPLY CORD from the connec-

tor CN001

.

(3) Pull out the harness from the THERMOSTAT PROTEC-

TOR.

(4) Pull out the POWER SUPPLY CONTROL MODULE PWB

ASS'Y from CN005. (Fig.5)

3.13 POWER SUPPLY CONTROL MODULE PWB ASS'Y

• Remove the LENS COVER.

• Remove the LAMP UNIT.

• Remove the TOP COVER.

• Remove the TERMINAL PWB ASS'Y AND MAIN PWB ASS'Y.

• Remove the LAMP UNIT UPPER BRACKET.

• Remove the POWER SUPPLY SHIELD CASE(1).

(1) Pull out the POWER SUPPLY CONTROL MODULE PWB

ASS'Y from the connector CN005

of the POWER SUPPLY

PWB ASS'Y. (Fig.5)

3.14 POWER SUPPLY SHIELD CASE(2), RADIATION FAN, INTERLOCK SWITCH, COOLING FAN1, DUCT1

• Remove the LENS COVER.

• Remove the LAMP UNIT.

• Remove the TOP COVER.

• Remove the TERMINAL PWB ASS'Y AND MAIN PWB ASS'Y.

• Remove the POWER SUPPLY SHIELD CASE(1).

• Remove the POWER SUPPLY PWB ASS'Y.

(1) Remove the 4 screws marked Q fixing the POWER SUP-

PLY SHIELD CASE(2). (Fig.5)

(2) Lift up the POWER SUPPLY SHIELD CASE(2) to remove

it.

(3) Remove the 2 screws marked R fixing the RADIATION

FAN to the POWER SUPPLY SHIELD CASE(2). (Fig.5)

(4) Remove the 1 screw marked S fixing the INTERLOCK

SWITCH to the POWER SUPPLY SHIELD CASE(2), and

remove the INTERLOCK SWITCH. (Fig.5)

(5) Remove the 2 screws marked b fixing the DUCT1. (Fig.5)

(6) Remove the 2 screws marked c fixing the COOLING

FAN1. (Fig.5)

b

(x2)

c

(x2)

COOLING FAN1

POWER SUPPLY CONTROL MODULE PWB ASS'Y

CN005

DUCT1

POWER SUPPLY SHIELD CASE(2)

CN001

P

(x4)

R

(x2)

Q

(x4)

RADIATION FAN

S

(x1)

INTERLOCK SWITCH

THERMOSTAT PROTECTOR

1-18 (No.PA018)

Fig.5

Page 19

3.15 IR PWB ASS'Y

• Remove the LENS COVER.

• Remove the LAMP UNIT.

• Remove the TOP COVER.

• Remove the TERMINAL PWB ASS'Y AND MAIN PWB ASS'Y.

(1) Remove the 1 screw marked T fixing the IR PWB ASS'Y.

(Fig.6)

(2) Lift up the IR PWB ASS'Y to remove it.

3.16 OPTICAL BLOCK, INTAKE FAN

• Remove the LENS COVER.

• Remove the LAMP UNIT COVER.

• Remove the TOP COVER.

• Remove the TERMINAL PWB ASS'Y AND MAIN PWB ASS'Y.

(1) Remove the 1 screw marked o fixing the LAMP POWER

SUPPLY CORD SUPPRESSION BRACKET. (Fig.4)

(2) Pull out the LAMP POWER SUPPLY CORD

(3) Remove the 2 screws marked j fixing the THERMOSTAT

PROTECTOR. (Fig.6)

(4) Remove the 2 screws U and 3 screws v fixing the OPTICAL

BLOCK. (Fig.6)

(5) Remove the 1 screw k fixing the EARTH BRACKET that

connects the OPTICAL BLOCK and the CHASSIS. (Fig.6)

(6) Lift up the OPTICAL BLOCK to remove it. (Fig.6)

(7) Remove the 2 screws d fixing the INTAKE FAN. (Fig.6)

3.17 DD SUB PWB ASS'Y

• Remove the LENS COVER.

• Remove the LAMP UNIT.

• Remove the TOP COVER.

• Remove the TERMINAL PWB ASS'Y AND MAIN PWB ASS'Y.

• Remove the PROTECT COVER.

• Remove the OPTICAL BLOCK (for easier operation).

(1) Remove the 3 screws w fixing the DD SUB PWB ASS'Y.

(Fig.6)

(2) Remove the cord wire from the connectors CN101

and CN301

.

, CN201,

3.18 COOLING FAN2, DUCT2, COOLING FAN3, DUCT3,

DUCT4

• Remove the LENS COVER.

• Remove the LAMP UNIT COVER.

• Remove the TOP COVER.

• Remove the TERMINAL PWB ASS'Y AND MAIN PWB ASS'Y.

• Remove the PROTECT COVER.

• Remove the OPTICAl BLOCK.

(1) Remove the 2 screws marked e fixing the DUCT2. (Fig.6) *2

(2) Remove the 2 screws marked f fixing the COOLING FAN2.

(Fig.6) *2

(3) Remove the 3 screw marked i fixing the DUCT4. (Fig.6) *2

(4) Remove the 1 screw marked g fixing the DUCT3. (Fig.6)

(5) Remove the 1 screw marked h fixing the COOLING FAN3.

(Fig.6)

*2

This operation is easier if OPTICAL BLOCK is removed.

CN301

CN101

CN201

INTAKE FAN

DD SUB PWB ASS'Y

w

(x3)

d

(x2)

OPTICAL BLOCK

DUCT4

(x3)

i

(x3)

COOLING FAN2

f

(x2)

v

DUCT2

COOLING FAN3

(x2)

(x1)

g

(x1)

h

U

(x2)

k

(x1)

DUCT3

T

(x1)

IR PWB ASS'Y

j

(x2)

THERMOSTAT PROTECTOR

LAMP UNIT

FIXING SCREWS (x2)

e

Fig.6

BOTTOM CHASSIS

(No.PA018)1-19

Page 20

SECTION 4

ADJUSTMENT

4.1 BEFORE STARTING ADJUSTMENT

(1) Adjustment items utilize a personal computer.

This instruction is for HX1 PSA CONTROL PROGRAM

Program. Use the latest version program.

(2) Data back up is required before adjustments.

(3) Allow the equipment and test instruments adequate time

(at least 30 minutes) to warm-up.

(4) Confirm the set is properly connected to the specified AC

power source.

(5) Use care not to disturb internal controls and parts not spe-

cifically mentioned.

(6) Unless specifically mentioned in the "ADJUSTMENT PRO-

CEDURE" steps, do not change any data.

4.2 INSTRUMENTS AND TOOLS

• Oscilloscope

• PAL signal generator : composite output, Y/C output

Gray scale : 0IRE-100IRE

Color bar : include 75% white peak

• NTSC signal generator : composite output [Y / CB / CR]

Flat (raster) pattern : 10%

• HDTV signal generator : composite output [Y / PB / PR]

Flat (raster) pattern : 10%

• PC signal generator

Signal : VGA / SXGA

Gray scale : 0.7V (p-p) [include 100% White / 0% Black]

∗Show at least 2 images on 1 screen (Upper scale and Lower

scale must be reversed)

Cross-hatch

Flat (raster) pattern : 100%, 93%, 13%, 0%

• Light meter [for example: Minolta T-10]

• Color-meter [CL-200]

• Remote control unit [RM-MSX21G]

• Personal computer

Operating system Windows 98 ME 2000 XP

Memory More than 16 Mbytes

Hard disk free space More than 5 Mbytes

RS-232C interface At least 1 port

Display resolution Minimum : 800 × 600 pixels

Recommended : 1024 × 768 pixels or better

Display colors Minimum : 8 bits/pixel

Recommended : 16 bits/pixel or better

Input devices Keyboard and mouse

• Adjustment software : HX1 PSA CONTROL PROGRAM

• RS-232C 9pin NULL-MODEM (cross) cable

• Photoelectric conversion device (one of these)

Light meter [Minolta T-10] A-out (Analog output)

Photoelectric conversion device (for example: HAMAMAT-

SU PHOTONICS S1226-8BK)

Phototransistor or CdS photoconductor with amplifier

• Color filters

G color filter (ex. MELLES GRIOT 03 FIV 044)

R color filter (ex. MELLES GRIOT 03 FIB 014)

B color filter (ex. MELLES GRIOT 03 FIV 028)

• Screen

• Darkroom (illumination less than 0.03 lx)

1-20 (No.PA018)

Page 21

4.3 REQUIRED ADJUSTMENTS BY REPLACING COMPONENTS

The following adjustment procedure is required after replacing PWB ASS'Ys, LAMP BALLAST UNIT and OPTICAL BLOCK.

Items noted as "Check" means check the condition, then adjust if required.

4.3.1 Component required adjustment at replacing

Adjustment items MAIN TERMINAL DD SUB POWER

1. D-ILA COMMON DC Check Required Check Check Required

2. GAMMA (GRADATION / WHITE BALANCE) Check Required Check Check Required

3. SHADING (UNIFORMITY) Check Check Check Required

4. 8 - PHASE VERTICAL BARS Check Required Required

5. A-D CONVERTER APERTURE Required

6. COLOR TEMPERATURE Check Check Required

7. COLOR PROFILE Check Required

8. GHOST Check Required

9. FRAME Check Required

4.3.2 List of required instruments and tools (except those related to the personal computer)

LAMP

BALLAST

OPTICAL

BLOCK

Adjustment items

1. D-ILA COMMON DC Required (Required)

2. GAMMA (

3. SHADING (UNIFORMITY) Required Required Required

4. 8 - PHASE VERTICAL BARS Required Required

5. A-D CONVERTER APERTURE Required Required Required

6. COLOR TEMPERATURE Required Required

7. COLOR PROFILE Required Required

8. GHOST Required

9. FRAME Required

4.3.3 Data backup

Before replacing major components such as PWB ASS'Ys, UNIT or BLOCK, be sure to backup the data contained in the set.

In absence of data backup, complete adjustment becomes necessary.

z PREPARATION

(1) Make sure that Version.ini file is located in the same folder of the PSA controller.

(2) Remove all signal cables except for the interface cable to the PC from the main body.

z DATA SAVE

(1) Enter Stand-by mode and open the PSA controller on the PC.

(2) Click [System] in the main menu. When the pull down menu is displayed, click [Backup ROM Data] and open ROM Data Up

(3) Tick [Main EEPROM] and [Sub EEPROM] in [Target EEPROM].

(4) When [Down Load] is selected, data will be downloaded in the order of EEPROM → EEPROM2 → SUB EEPROM.

(5) When the download has completed, Save Data with File Name dialog box will be displayed. Then save the data with a file

z DATA ENTRY

(1) Enter Stand-by mode and open the PSA controller on the PC.

(2) Click [System] in the main menu. When the pull down menu is displayed, click [Backup ROM Data] and open ROM Data Up

(3) Tick [Main EEPROM] in [Target EEPROM].

(4) When [Down Load] is selected, Open dialog box will be displayed. Then select a file which you want to upload.

(5) The data will be downloaded in the order of EEPROM → EEPROM2 → SUB EEPROM.

GRADATION / WHITE BALANCE

Load/Down

Load.

name.

Load/Down Load.

OSCILLOSCOPE

) Required Required Required Required

PC signal

generator

NTSC

signal

generator

HDTV

signal

generator

Light meter Color filter Color meter

(No.PA018)1-21

Page 22

4.4 ADJUSTMENT PROCEDURE

4.4.1 D-ILA COMMON DC adjustment

Instruments REPLACING COMPONENTS

Test point

Adjustment menu < DDIC >

Preparation Running the unit enough before adjustment

Note :

Large deviation of this adjustment can cause image flicker.

Residual image or element burn can occur when out of adjustment.

WATCHING ADJUSTMENT

(1) Open Menu [DDIC] [Flat Field / DD Ctrl], and set [Dual Scan] to [Off].

(2) Set [R Mute], [G Mute] and [B Mute] to [On].

(3) Set [R] Flat Field level to 512, and set [G] and [B] Flat Field level to 0.

(4) Open Menu [DDIC] [EVR], then adjust [R Com] to minimize the flickers with watching. If there is unevenness with the flickers,

try to manage the balance of flickers by reducing the high-visibility portions of the flickers as much as possible.

Note :

Do not adjust under the lamp have flickers.

(5) Open Menu [DDIC] [Flat Field / DD Ctrl], and set block [R] Flat Field level to 0.

(6) Set [G] Flat Field level to 512.

(7) Open Menu [DDIC] [EVR], then adjust [G Com] to minimize the flickers with watching. If there is unevenness with the flickers,

try to manage the balance of flickers by reducing the high-visibility portions of the flickers as much as possible.

(8) Open Menu [DDIC] [Flat Field / DD Ctrl], and set block [G] Flat Field level to 0.

(9) Set [B] Flat Field level to 512.

(10) Open Menu [DDIC] [EVR], then adjust [B Com] to minimize the flickers with watching. If there is unevenness with the flickers,

try to manage the balance of flickers by reducing the high-visibility portions of the flickers as much as possible.

(11) Open Menu [DDIC] [Flat Field / DD Ctrl], and set block [B] Flat Field level to 0.

(12) When all of the adjustments are finished, set [R Mute] [G Mute] [B Mute] to [Off].

(13) Set [Dual Scan] to [On].

z DD SUB PWB ASS'Y

z OPTICAL BLOCK

1-22 (No.PA018)

Page 23

4.4.2 GAMMA adjustment

Instruments SVGA signal generator [Gray scale]

Light-meter

Color-meter (CL-200)

Color filter (R / G / B)

Test point

Adjustment menu < DDIC > < Gamma >

Preparation Completed D-ILA COMMON DC adjustment

PREPARATION

(1) Set to ZOOM at Wide end, if a zoom lens is installed.

(2) Measure the lightness in the room with a proofread light-meter and set the lightness to below 0.03lx.

(3) Set the light-meter on the center of image.

(The distance from the projection lens to the light-meter is approximate 30cm, then don't move them.)

(4) Open Menu [Gamma] and click [Default], then make sure that the Gamma line is linear. After a check, click the [Transmit] and

transmit data.

(5) Open Menu [DDIC] and set [LUMDAT] to [Off].

(6) Open Menu [DDIC] [Flat Field / DD Ctrl], and set [R Mute], [G Mute] and [B Mute] to [On].

(7) Allow the unit adequate time (more than 10 minutes) to warm-up.

(8) After installing the top cover, adjust the unit.

(9) Open Menu [User Adjust] [Image] tab, and set [Color Temp] to [6500K].

OFFSET GAIN ADJUSTMENT

(1) Set the G color filter in front of the light-meter, and measure the luminance of the center of the screen.

(2) Open Menu [DDIC] [EVR], then set [R OFFSET] and [B OFFSET] to 255. (Record the data before adjustment)

(3) Open Menu [DDIC] [Flat Field / DD Ctrl] and set [R], [G] and [B] Flat Field level to 0 similarly.

(4) Open Menu [DDIC] [EVR] and set [G OFFSET] to 255, then record the illumination intensity (the lowest illumination intensity)

at this time.

(5) Open Menu [DDIC] [Flat Field / DD Ctrl], and set [G] Flat Field level to 1023.

(6) Open Menu [DDIC] [EVR], and adjust [G OFFSET] so that the illumination intensity becomes the highest. Record the illumi-

nation intensity (the highest illumination intensity) at this time.

(7) The target of the 0 IRE adjustments should be the higher illumination intensity between the value 1 (1.05 times of the lowest

illumination intensity) and the value 2 (the highest illumination intensity × 0.95 / 1000).

(8) Open Menu [DDIC] [Flat Field / DD Ctrl], and set the Flat Field level of [G] to 64. Under this condition, open Menu [DDIC] [EVR]

and adjust [G OFFSET] so that the illumination intensity falls within the target value of the 0 IRE adjustments in 7) above.

(9) Open Menu [DDIC] [Flat Field / DD Ctrl],and set the Flat Field level of [G] to 960. At this time, click [Gain/Setup] of [Gain] and

adjust the illumination intensity with the cursor so that it becomes 95% of the highest illumination intensity.

(10) Repeat the adjustment so that the requirements in step 8) and 9) are met together.

(11) Adjust [R], [B] in the same way with [R], [B] color filter.

(12) Open Menu [DDIC] [Flat Field / DD Ctrl], and set the Flat Field level of [R], [G] and [B] to 960, respectively. Then measure the

uv value using a color-meter. If the uv value exceeds +0.025, open [Gain/Setup] and lower the [Gain] value so that the

uv value falls within +0.025. In case where the uv value is less than +0.025, no adjustment is required. (By clicking [ALL],

adjust the eight phases together.

G GAMMA & COMPUTATION OF ADJUSTMENT TARGET LUMINANCE

(1) Open Menu [Gamma] and set the control point to [VGP].

(2) Put [G] color filter in front of the light-meter and measure the illumination intensity at the center of the screen.

(3) Open Menu [DDIC] [Flat Field / DD Ctrl], and adjust the Flat field level of [G] to 960, [R] and [B] to 0. Then measure the 100

IRE illumination intensity of [G].

(4) Based on the calculating table for target illumination intensity and the measurement results obtained in 3) above, calculate the

target illumination intensity of the control points 14-2.

(5) By adjusting the Flat Field level of each control point, adjust the illumination intensity of the screen so that it falls within the

values calculated in accordance with the calculating table.

REPLACING COMPONENTS

z DD SUB PWB ASS'Y

z OPTICAL BLOCK

(No.PA018)1-23

Page 24

< ADJUSTMENT TARGET ILLUMINATION TABLE >

Control point FLAT FIELD ADJUSTMENT TARGET

coefficient

14 896 0.850 92.86

13 800 0.649 82.14

12 704 0.477 71.43

11 608 0.334 60.71

10 512 0.218 50.00

9 416 0.128 39.29

8 320 0.064 28.57

7 256 0.034 21.43

6 224 0.023 17.86

5 192 0.0151 14.29

4 160 0.0096 10.71

3 128 0.0056 7.14

2 96 0.00280 3.57

< The computation type >

• ADJUSTMENT TARGET ILLUMINANCE = 100 IRE ILLUMINANCE × ADJUSTMENT TARGET coefficient

• 0 IRE ILLUMINANCE = MAXIMUM ILLUMINANCE × 0.95 / 1000 or 1.05 times of the lowest illumination intensity

R and B GAMMA ADJUSTMENT

(1) Set the color-meter at the center of the screen.

(2) Open Menu [DDIC] [Flat Field / DD Ctrl], then set [R], [G] and [B] Flat Field level to 960, respectively. Then record the points

of chromaticity (X, Y) at this time.

(3) Open Menu [DDIC] [Flat Field / DD Ctrl] and adjust [R], [G] and [B] Flat Field level to the value as shown in the control point

14 in the calculating table for target illumination intensity.

(4) Open Menu [Gamma]. Then click [Option] at the lower right of the Gamma screen to display the sub-screen.

(5) Then adjust the gamma adjustment point 14 of [R] and [B] so that the points of chromaticity become the values measured in

2) above. (In case where you choose the Flat Field level of [R] and [B] in the sub-screen, click [R] and [B] at the higher right

on the screen, respectively.)

(6) Adjust the control point 13~2 like above 5).

(7) If the gamma at the control points 2 and 3 show discontinuous curve or the target points of chromaticity cannot be obtained,

adjust the curve as if it looks like a smooth curve visibly.

(8) Repeat the adjustment until all of the control points obtain the requirements together.

SIGNAL LEVEL

1-24 (No.PA018)

Page 25

4.4.3 SHADING adjustment

Instruments SVGA signal generator

Light-meter

Test point

Adjustment menu < DDIC > < Area Shading >

Preparation Completed GAMMA adjustment

REPLACING COMPONENTS

z DD SUB PWB ASS'Y

z OPTICAL BLOCK

PREPARATION

(1) When the reverse shading function is used, open Menu

[DDIC] [Flat Field / DD Ctrl], and set [Left side Right] and

[Up Side Down] to [Off].

(2) Open Menu [Area Shading] and, after clicking [LUM]. Set

each [R], [G] and [B] to [Default] respectively, then click

[Transmit].

(3) Click [DYN] or [STC] and set [R], [G] and [B] to [Default]

respectively in the same way, then click [Transmit].

SHADING ADJUSTMENT

(1) Open Menu [DDIC] [Flat Field / DD Ctrl], and set [R

Mute], [G Mute] and [B Mute] to [On].

(2) Set [R], [G] and [B] Flat Field level to 204, respectively.

(3) Open Menu [Area Shading] and click [STC]. Then adjust

the screen with the slide bar for adjustment level setting

so that the screen is evenly colored.

(4) Open Menu [DDIC] [Flat Field / DD Ctrl] and set [R], [G]

and [B] Flat Field level to 614, respectively.

(5) Open Menu [Area Shading] and click [DYN]. Then adjust

the screen with the slide bar for adjustment level setting

so that the screen is evenly colored.

(6) Open Menu [DDIC], and set [DYNDAT] [STCDAT] to

[Off].

(7) Open Menu [Flat Field / DD Ctrl] and set [R] Flat Field

level to 204, [G] and [B] Flat Field level to 0, respectively.

Record the brightness of the screen at this time

(8) Set [R] Flat Field to 614 and record the brightness of the

screen at this time.

(9) Return [DYNDAT] and [STCDAT] to [On].

(10) Open Menu [EVR] and adjust [R OFFSET] so that the

brightness of the screen become the same value as

those of the recorded value.

(11) Open Menu [DDIC] [Gain/Setup] and click [Gain]. Adjust

[DDIC] [GAIN] so that the brightness of the screen at the

[R] Flat Field level of 614 become the same value re-

corded in 8) above.

(12) In the same manner as for the above steps, also adjust

[G] and [B] Flat Field level.

(13) Adjust [LUM], if necessary. Keep the Flat Field level at

1023 at the center of the screen as much as you can.

(14) After adjustment, transfer the data to the reverse shad-

ing adjustment memory by clicking [Copy Shading Data

to Reverse Shading Data] on the bottom of the Area

Shading screen. At this time, open [Shading] on [Config-

uration] tool bar and set the values according to the table

on the right side so as to compensate the vertical reverse

shading gradient.

∗If necessary, adjust Up Side Down position. When adjusting

the Up Side Down position, hang the unit from the ceiling.

Open Menu [DDIC] [Flat Field DD/Ctrl] and set [Left Side

Right] and [Up Side Down] to [On]. For the adjustment, follow

the same manner as for the steps 1)~14) above.

LUM DYN STC Vcom

R G B

button

button

Default

button

<Area Shading> Menu

[Offset] : Presetting

[Copy Shading Data to Reverse Shading Data] :

Revers shading adjustment memory setting

[Cursor size] : Adjustment area setting

[Slide bar] : Adjustment level setting

STC Shading DYN Shading

Red 63 0.1

Green 63 0.1

Blue 63 0.1

< Compensate the vertical reverse shading gradient >

(No.PA018)1-25

Page 26

4.4.4 8-PHASE VERTICAL BARS adjustment

Instruments Oscilloscope

Light-meter (Analog output terminal)

Test point

REPLACING COMPONENTS

z OPTICAL BLOCK

z DD SUB PWB ASS'Y

Adjustment menu < DDIC >

Preparation Completed GAMMA adjustment

DC SETUP ADJUSTMENT

[ Method of signal waveform observation ]

(1) Open Menu [DDIC] [EVR] and save the data at [EVR R OFFSET], then set the value to 255. Turn [DCS DAT] on the right

of [EVR] to [ON].

(2) Open Menu [Flat Field / DD Ctrl] and, after turning [R MUTE] to [ON], set [R] Flat Field level to zero.

(3) Connect an oscilloscope to the TEST PIN (See the table given below) on the DD SUB PWB, observe the DC level of the 0-

PHASE signal through seven phase signal. Then record the target value for adjustment which shall be an approximate in-

termediate value between the maximum and minimum of the DC level.

(4) Open Menu [DDIC] [Gain/Setup] and click [DC Setup]. Observe the DC level of the 0-PHASE signal and adjust [DC Setup]

for the 0-PHASE of [DDIC] [Gain/Setup] so that the DC level of the 0-PHASE signal falls within the target value recorded in

3) above.

Note :

Click [Separate A and B], then adjust [A-line] and [B-line], respectively. When the A-line is made larger, the DC level increases. On the other hand, when the B-line is made larger, the DC level decreases. Either A-line or B-line or both should

be 0.

(5) In the same manner as for above, adjust the 1-PHASE to 7-PHASE.

(6) Return [EVR] [R OFFSET] to its original value recorded in 1) above.

(7) Also adjust [G] and [B] in the same manner as for the steps 1) - 5) above.

Test pin for observation of DD SUB PWB

RGB

0-PHASE TP 101 TP 201 TP 301

1-PHASE TP 102 TP 202 TP 302

2-PHASE TP 103 TP 203 TP 303

3-PHASE TP 104 TP 204 TP 304

4-PHASE TP 105 TP 205 TP 305

5-PHASE TP 106 TP 206 TP 306

6-PHASE TP 107 TP 207 TP 307

7-PHASE TP 108 TP 208 TP 308

TOP

1-26 (No.PA018)

DD SUB PWB TEST POINT LOCATION

CN800

CN801

DD SUB PWB

CN301

TP308

TP304

TP307

TP303

TP306

TP305

TP302

TP301

CN101

CN201

CN899

TP206

TP203

TP108

TP105

TP102

TP207

TP204

TP201

TP106

TP103

TP101

TP208

TP205

TP202

TP107

TP104

Page 27

[ Method using light-meter ]

(1) Adjust [V-COM] again.

(2) Set a light-meter with analog output terminal at the screen center and observe waveform of the analog output using an os-

cilloscope.

(3) Open Menu [DDIC] [Flat Field / DD Ctrl], and turn [R Mute], [G Mute], [B Mute] to [On].

(4) Open Menu [Gain/Setup] and click [Gain]. Record the data of [R], [G] and [B] at this time.

(5) Set all phases of [R], [G] and [B] of [Gain] to 0.

(6) Open Menu [Flat Field / DD Ctrl] and set [R] Flat Field level to 500, then [G] and [B] to 0, respectively.

(7) Open Menu [Gain/Setup] and click [Gain]. Return the 0-PHASE of [Gain] to the data recorded in 4) above.

(8) Click [DC Setup]. Using an oscilloscope, observe the waveform of the flicker. Then adjust the 0-PHASE so that the ampli-

tude of the flicker is reduced to a minimum.

(9) Click [GAIN] and set the 0-PHASE to 0.

(10) In the same manner as for above, adjust 1-PHASE to 7-PHASE.

(11) In the same manner as for the steps 6)-10) above, adjust [G] and [B].

(12) Open [DDIC] [GAIN] and return the value of [GAIN] to the value recorded in 4) above.

(13) Adjust V-COM again.

G BLACK 8 BARS ADJUSTMENT

(1) Supply a G gray-scale signal.

(2) Open Menu [DDIC] [Gain/Setup], then click [G] and [Setup].

(3) Observe the darkest gradation with vertical stripes and the lighter portions (1-2 lighter gradations) from the darkest gradation.

Then adjust the phase with the adjustment cursor so that the vertical stripes are reduced to a minimum. (Adjust each phase

separately after turning [ALL] off.)

Note :

Set [Separate A and B] to off, then adjust [A-line] and [B-line] at the same time.

G WHITE 8 BARS ADJUSTMENT

(1) Supply a G gray-scale signal.

(2) Open Menu [DDIC] [Gain/Setup], then click [G] and [Gain].

(3) Observe the lightest gradation with vertical stripes and the darker portions (1-2 darker gradations) from the lightest gradation.

Then adjust the phase with the adjustment cursor so that the vertical stripes are reduced to a minimum. (Adjust each phase

separately after turning [ALL] off.)

Note :

Set [Separate A and B] to off, then adjust [A-line] and [B-line] at the same time.

R ADJUSTMENT

(1) In the same manner as for G Black 8 bars and G white 8 bars adjustments, adjust R.

B ADJUSTMENT

(1) In the same manner as for G Black 8 bars and G white 8 bars adjustments, adjust B.

(No.PA018)1-27

Page 28

4.4.5 A-D CONVERTER APERTURE adjustment

Instruments SVGA signal generator [Gray scale (include : white100% & black 0%)]

NTSC signal generator

HDTV signal generator color-meter

Test point

Adjustment menu < User Adjustment >

Preparation

ADJUSTMENT OF RGB SYSTEM

(1) Open Menu [Gamma] and click [Receive], then perform

asking of the Gamma data.

(2) Open Main screen of PSA controller. Save the data by

[File] → [Save].

(3) Open Menu [Gamma] and set the control point to [128

Points].

(4) Select the Point No.8, and set Y Position to 2047.

(5) Select the Point No.120, and set Y Position to 2047.

(6) Supply a SVGA 0% signal from the D-SUB terminal.

(7) Open Menu [User Adjust] [Adjustment] and adjust [Sub-

BRT G] so that the screen becomes brightest.

(8) Supply SVGA green 100% luster signal from D-SUB ter-

minal.

(9) Open Menu [User Adjust] [Adjustment] and adjust [Sub-

CNT G] so that the screen becomes darkest.

(10) Return the value of the Gamma carve to the value saved

in (2) above.

(11) Adjust [R] and [B] according to the same order of (1)-(7)

above.

REPLACING COMPONENTS

z MAIN PWB ASS'Y

ADJUSTMENT OF COMPONENT (COLOR DIFFERENCE) SYSTEM

• Please carry out this adjustment after completing the adjustment of RGB system.

[ Watching adjustment ]

(1) Supply a component gray scale signal of NTSC.

(2) Open Menu [User Adjust] [Adjustment] and adjust [Cb

Offset] and [Cr Offset] so that the white balance at the

dark gradation becomes same gradation as those at

the screen center.

(3) Supply a component gray scale signal of HDTV.

(4) Open Menu [User Adjust] [Adjustment] and adjust [Cb

Offset] and [Cr Offset] so that the white balance at the

dark gradation becomes same gradation as those at

the screen center.

[ Adjustment by the color meter ]

(1) Open Menu [DDIC] [Flat Field / DD Ctrl] and set [R

Mute], [G Mute] and [B Mute] to [On].

(2) Set [R], [G] and [B] Flat Field level to 154 and measure

the color point of the screen center, then record the

value.

(3) Supply a component white 10% flat signal of NTSC

from the component terminal.

(4) Measure the color point of the screen center.

(5) Open Menu [User Adjust] [Adjustment] and adjust [Cb

Offset] and [Cr Offset] so that the color point becomes

the same as measured in (4) above.

(6) Supply a component gray scale signal of HDTV.

(7) Measure the color point of the screen center.

(8) Open Menu [User Adjust] [Adjustment] and adjust [Cb

Offset] and [Cr Offset] so that the color point becomes

the same as measured in (7) above.

(9) Open Menu [DDIC] [Flat Field / DD Ctrl], then set [R

Mute], [G Mute] and [B Mute] to [Off].

Sub-CNT R / G / B

Sub-BRT R / G / B

Cr Offset / Cb Offset Adjustment

User Adjust MENU

1-28 (No.PA018)

Page 29

4.4.6 COLOR TEMPERATURE adjustment

Instruments SVGA signal generator

Color-meter (CL-200)

Test point

Adjustment menu < User adjust >

Preparation Completed GAMMA adjustment , SHADING adjustment ,

A-D CONVERTER APERTURE adjustment

• Open Menu [User Adjust], and set [Color Temp] to 6500K after set the initial value of [R-Temp] [G-Temp] and [B-Temp] to 0.

(1) Supply a white 50% signal of SVGA.

(2) Adjust [G-Temp] so that the deviation [duv] at the screen center falls within +0.01±0.001.

(3) After adjustment in (3) above, check the color temperature at the screen center. If the temperature is more than 6500K, adjust

[B-Temp] so that it falls within 6500K±100K. At the same time, adjust [G-Temp] so that the deviation [duv] falls within

+0.01±0.001.

* At this time, set [R-Temp] to 0.

(4) After adjustment in (3) above, check the color temperature at the screen center. If the temperature is less than 6500K, adjust

[R-Temp] so that it falls within 6500K±100K. At the same time, adjust [G-Temp] so that the deviation [duv] falls within

+0.01±0.001.

* At this time, set [B-Temp] to 0.

4.4.7 COLOR PROFILE adjustment

Instruments SVGA signal generator (include : white 505)

Color-meter (CL-200)

Test point

Adjustment menu < CMS >

Preparation Completed GAMMA adjustment , SHADING adjustment

A-D CONVERTER APERTURE adjustment,

COLOR TEMPERATURE adjustment

REPLACING COMPONENTS

z OPTICAL BLOCK

REPLACING COMPONENTS

z OPTICAL BLOCK

PREPARATION

(1) Open Menu [CMS].

(2) Prepare COLOR PROFILE DATA (acr_r, acr_g, acr_b).

(3) Install a color-meter.

ADJUSTMENT OF COLOR PROFILE

(1) Open Menu [CMS] and select [ACR] tab at the lower part of [CMS Control] screen.

(2) Select [sRGB] tab located on the third column from the top of the screen.

(3) Click [sRGB] button located on the second column from the top of the screen and enter [sRGB] operation mode.

(4) Supply a R 50% raster signal of SVGA.

(5) Click [R] button on the left column of the data sheet of [CMS Control] screen.