Page 1

49787200301

CH-X550

SERVICE MANUAL

CD CHANGER

CH-X550

Area Suffix

E ------- Continental Europe

TABLE OF CONTENTS

1 Important Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

2 Disassembly method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

3 Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

4 Description of major ICs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

COPYRIGHT © 2003 VICTOR COMPANY OF JAPAN, LTD.

No.49787

2003/01

Page 2

CH-X550

1.1 Safety Precautions

SECTION 1

Important Safety Precautions

!

!

Burrs formed during molding may be left over on some parts of the chassis. Therefore,

pay attention to such burrs in the case of preforming repair of this system.

Please use enough caution not to see the beam directly or touch it in case of an

adjustment or operation check.

1-2 (No.49787)

Page 3

1.2 Preventing static electricity

Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged,

can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs.

1.2.1 Grounding to prevent damage by static electricity

Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as DVD players.

Be careful to use proper grounding in the area where repairs are being performed.

(1) Ground the workbench

Ground the workbench by laying conductive material (such as a conductive sheet) or an iron plate over it before placing the

traverse unit (optical pickup) on it.

(2) Ground yourself

Use an anti-static wrist strap to release any static electricity built up in your body.

(caption)

Anti-static wrist strap

CH-X550

1M

Conductive material

(conductive sheet) or iron plate

(3) Handling the optical pickup

• In order to maintain quality during transport and before installation, both sides of the laser diode on the replacement optical

pickup are shorted. After replacement, return the shorted parts to their original condition.

(Refer to the text.)

• Do not use a tester to check the condition of the laser diode in the optical pickup. The tester's internal power source can easily

destroy the laser diode.

1.3 Handling the traverse unit (optical pickup)

(1) Do not subject the traverse unit (optical pickup) to strong shocks, as it is a sensitive, complex unit.

(2) Cut off the shorted part of the flexible cable using nippers, etc. after replacing the optical pickup. For specific details, refer to

the replacement procedure in the text. Remove the anti-static pin when replacing the traverse unit. Be careful not to take too

long a time when attaching it to the connector.

(3) Handle the flexible cable carefully as it may break when subjected to strong force.

(4) I t is not possible to adjust the semi-fixed resistor that adjusts the laser power. Do not turn it.

1.4 Attention when traverse unit is decomposed

*Please refer to "Disassembly method" in the text for the CD pickup unit.

• Apply solder to the short land before the flexible wire is disconnected from the connector on the CD pickup unit.

(If the flexible wire is disconnected without applying solder, the CDpickup may be destroyed by static electricity.)

• In the assembly, be sure to remove solder from the short land after connecting the flexible wire.

Short-circuit point

(Soldering)

Short-circuit point

Flexible wire

Pickup

Pickup

(No.49787)1-3

Page 4

CH-X550

Disassembly method

2.1 Replacement of the pickup

(1) After removing the exterior (top and bottom).

(2) Proceed to the pickup replacement section.

(3) When applying grease, refer to the exploded view.

Use new grease.

2.2 Mechanism section

(1) Remove the exterior (required section only).

(2) The mechanism section is designed so that each unit can

be removed separately.

(3) When reassembling, refer to the assembling precautions

(Use new grease when applying grease.)

2.3 Exterior section

2.3.1 Removing the bottom cover and front panel assembly

(See Fig.1 to 4)

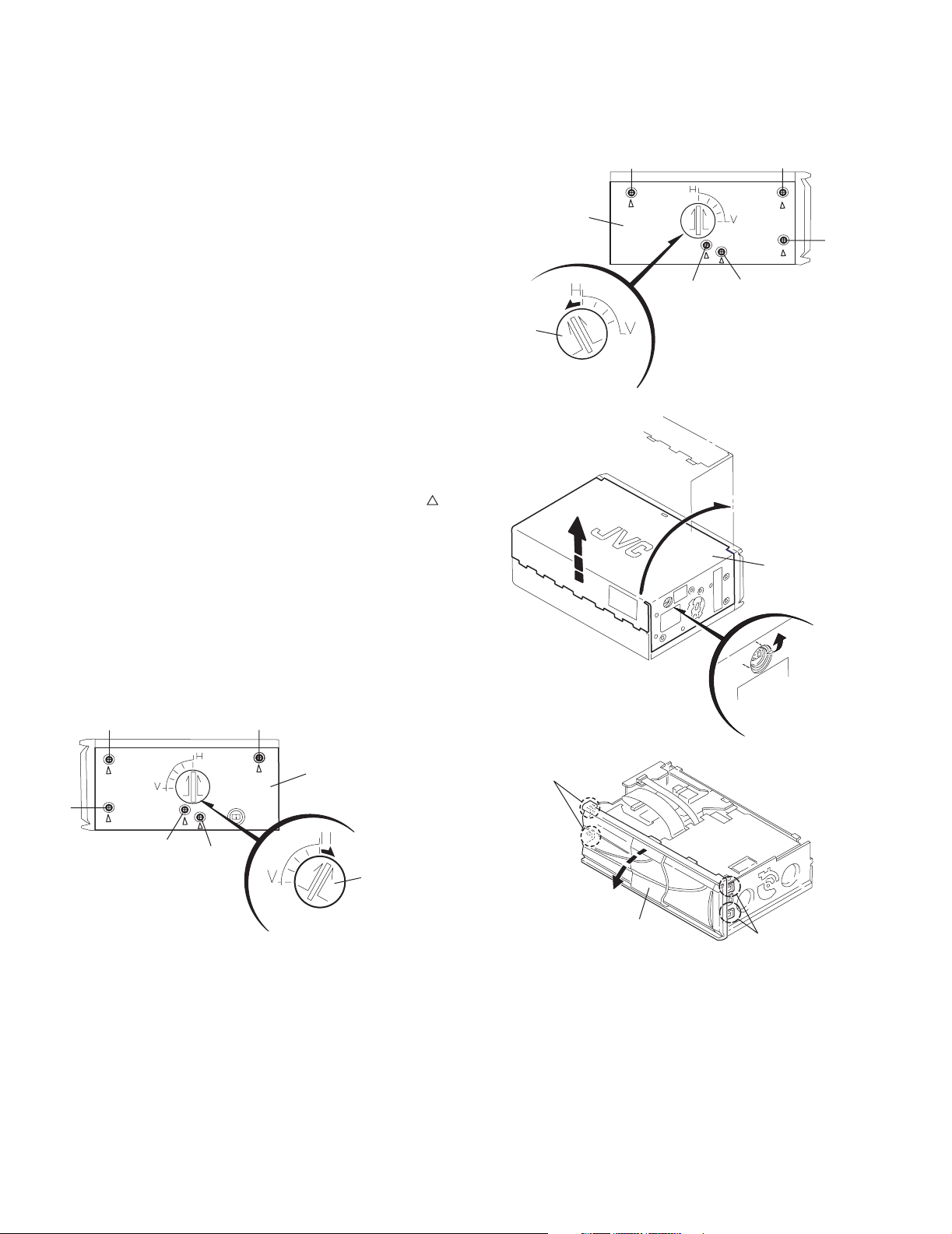

(1) Remove the two screw A to unlock the mounting direction

knob located on the side of the main unit.

(2) Turn the mounting direction knob in the direction of the ar-

row using a coin, etc. to remove it. (The knob can be removed only when it is set to this position.)

(3) Remove the four top cover fixing screws B at the triangle

marks on the side of the main unit. (Perform the same operation on both sides.)

(4) Turn the unit upside down so the bottom surface is facing

upward.

(5) Lift the rear edge of the bottom cover slightly and lift the

side by grasping the DIN jack section on the side panel,

then turn it toward the front (raise upward) to remove the

bottom cover.

(6) Unhook the four catches located on both sides of the front

panel, and turn the front panel toward the top cover (lower

down) to remove the front panel.

B

B

SECTION 2

Remove A and turn in

the direction of the arrow

The front panel can be

separated by raising the cover.

Bottom cover

Knob

Fig.2

Fig.3

A

BB

B

B

Bottom cover

Slightly lift the jack

section to remove.

B

1-4 (No.49787)

A

B

Bottom cover

Remove A and turn in

the direction of the arrow.

Fig.1

Unhook catches

Knob

Front panel

Unhook catches

Fig.4

Page 5

CH-X550

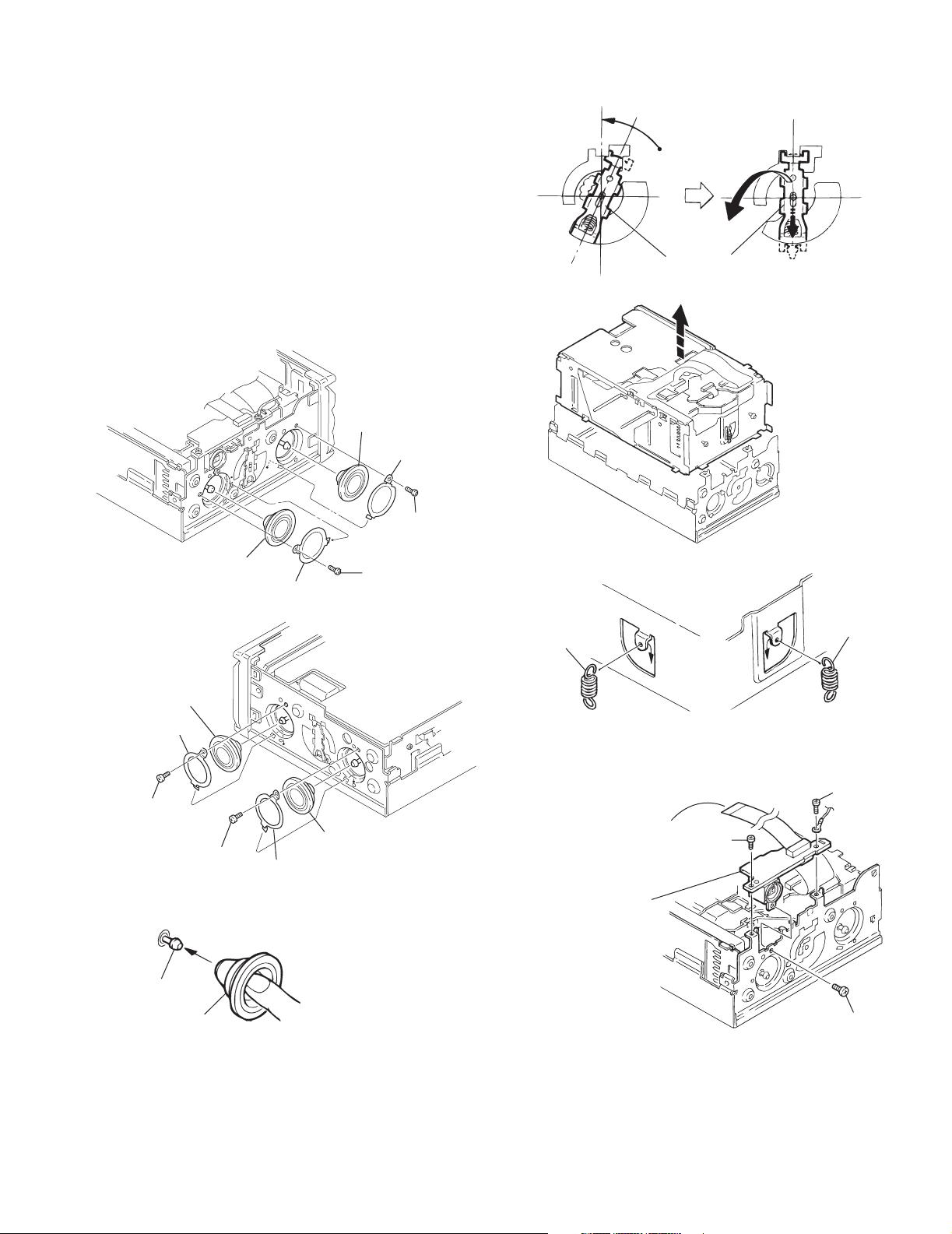

2.3.2 Removing the top cover

(See Fig.5 to 9)

(1) Remove the four damper bracket fixing screws C to re-

move the damper brackets.

(2) Pull out the dampers, being careful not to damage them.

When reattaching a damper, insert your finger to push out

the center of the damper to mount it on the damper shaft,

as shown in Fig. 6-1.

(3) Turn the damper spring bracket toward the top at a right an-

gle as shown in Fig. 7, then push down the lower side of the

damper spring bracket to lift it off.

(4) Remove the three fixing screws D and E on the DIN jack

board assembly.

(5) Lift the changer unit upward.

(6) Remove the damper springs from the mechanism chassis

if required. To reassemble, refer to the diagram below.

Damper

Damper bracket

C

Turn to the top position (at a right angle),

then push down to lift off.

Damper spring bracket

Fig.7

Lift the changer unit upward

Damper

Damper bracket

C

Damper shaft

Damper

Damper

Damper bracket

Fig.5

Damper

C

Damper bracket

Fig.6

Apply alcohol to the shaft then immediately

attach the damper. (After attaching, check

that the shaft is correctly inserted.)

Push out with your finger

before attaching

Fig.6-1

C

Damper

spring

Silver

(mechanism

side)

Remove the flexible ribbon

wire if required

DIN jack board

How to attach the damper springs

Fig.8

Damper

spring

Mechanism

Chassis

Black

(magazine

side)

Fig.8-1

E

E

D

Fig.9

(No.49787)1-5

Page 6

CH-X550

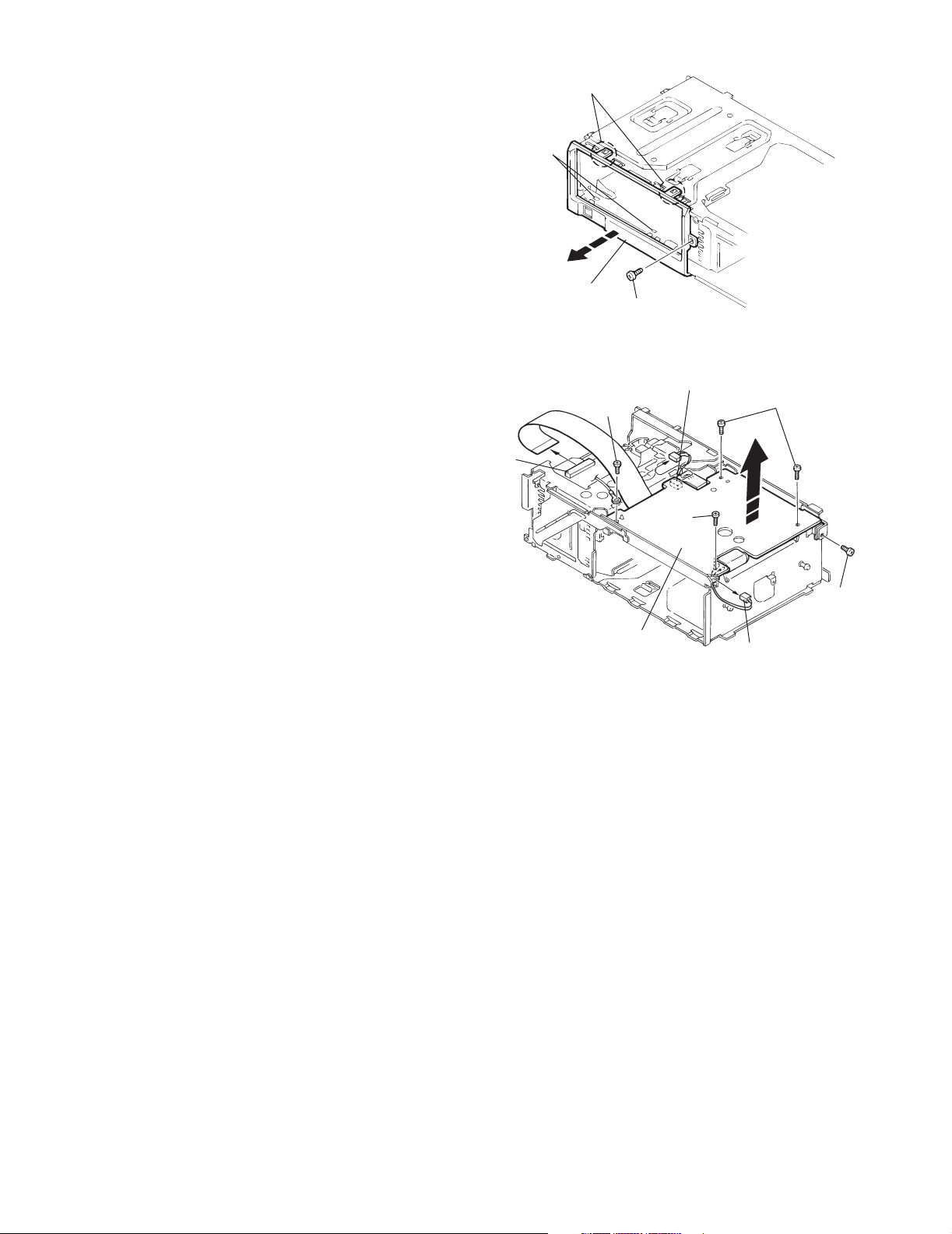

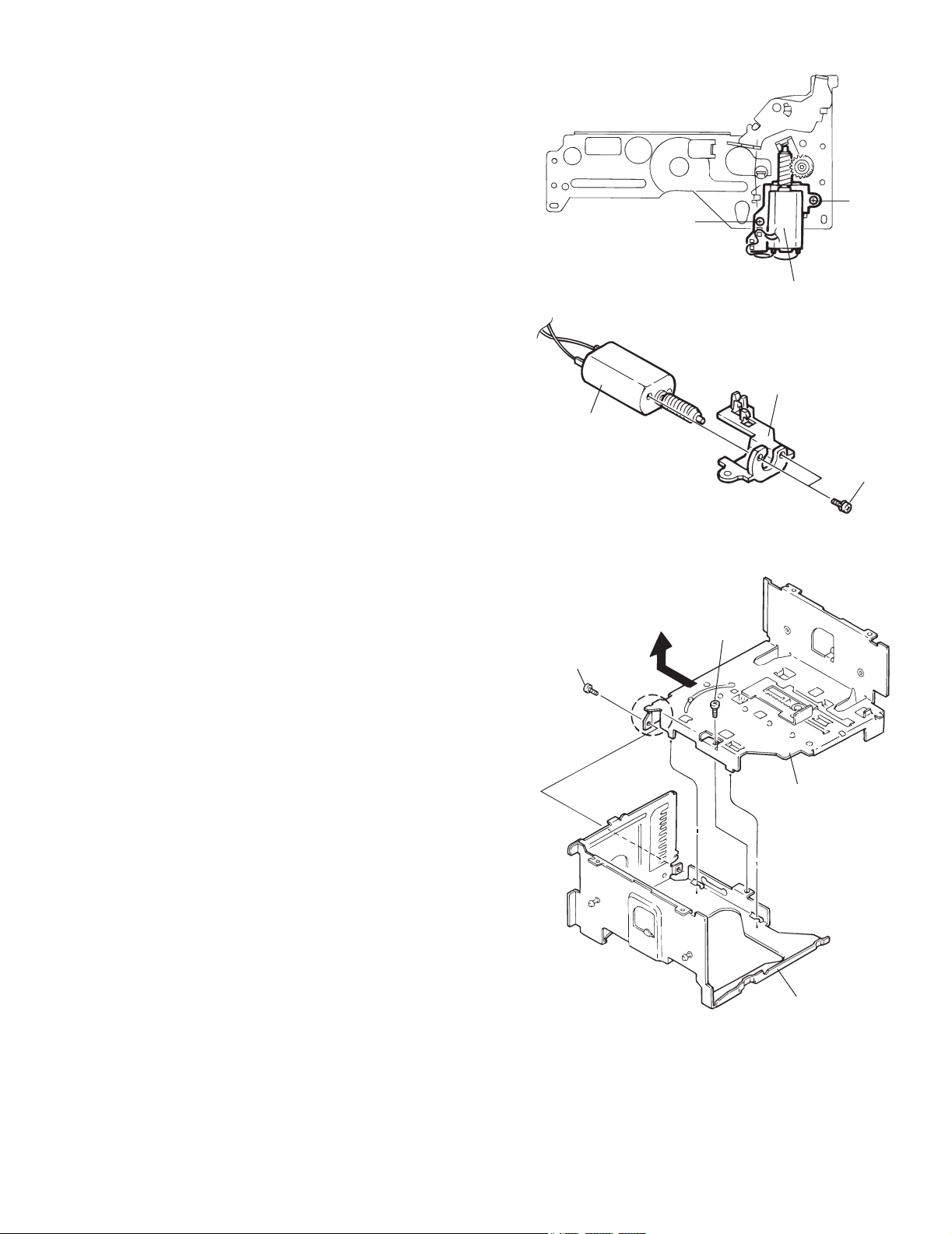

2.3.3 Removing the fittings

(See Fig.10)

(1) Remove the fixing screw F.

(2) Unhook the two catches a on the top edge of the fitting,

then unhook the two catches b at the left/right bottom edges.

2.3.4 Removing the main PCB assembly (See Fig.11)

(1) Remove the power IC fixing screw G.

(2) Remove the four screws H securing the main board as-

sembly.

(3) Disconnect position motor wire connector CN504 from the

main board assembly.

(4) Disconnect sensor board assembly wire connector CN601

from the main board assembly.

(5) Remove the flexible ribbon wire from CN502 on the

traverse mechanism board assembly. When reinstalling

the board boards, refer to the reassembling procedures for

protecting switches, etc.

Catches b

CN502

Catches a

Fitting

H

F

Fig.10

CN601

H

H

Main board

Fig.11

G

CN504

1-6 (No.49787)

Page 7

CH-X550

2.4 CD mechanism assembly

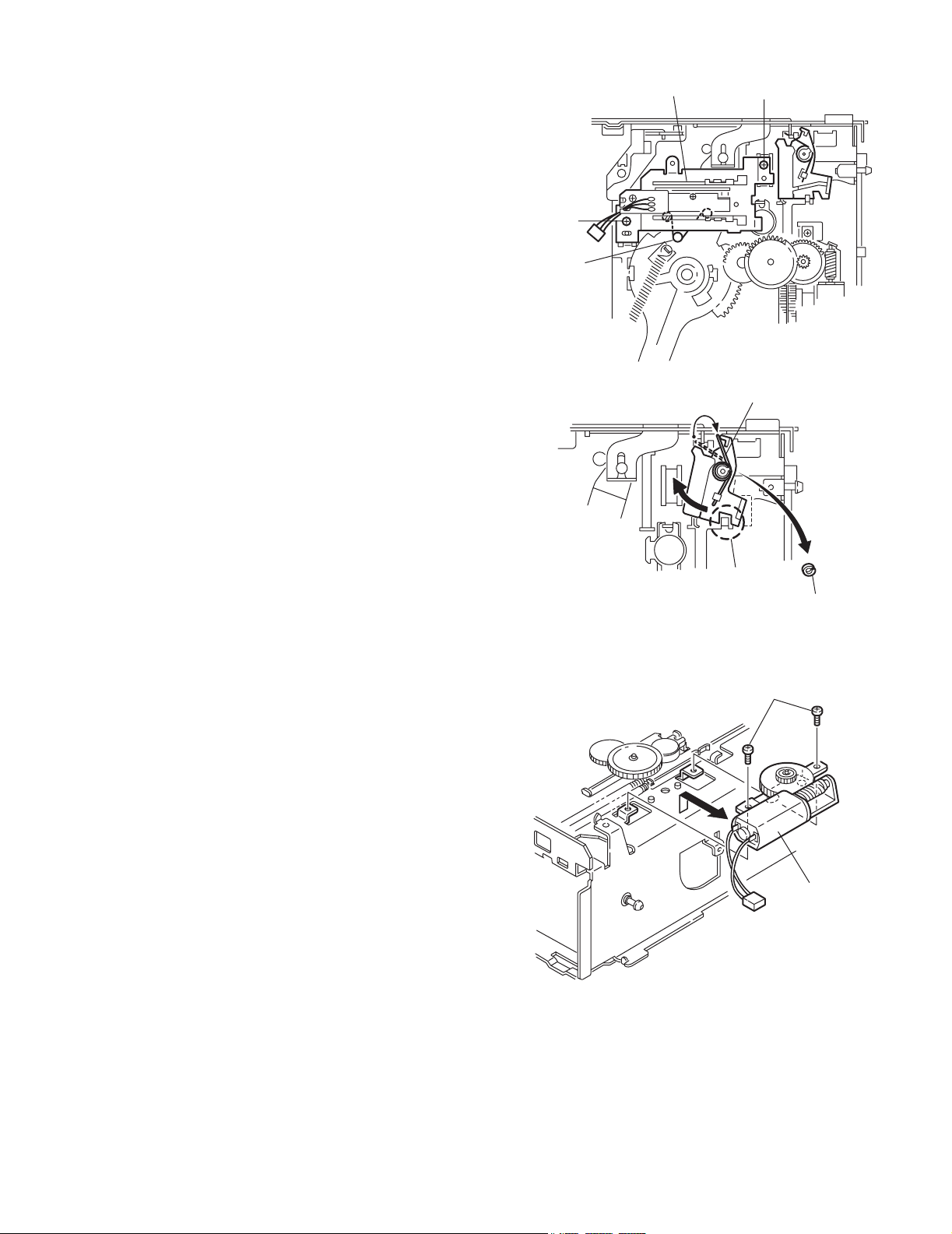

2.4.1 Sensor assembly unit

(See Fig.1)

(1) Remove the two screws I securing the sensor assembly

unit.

(2) Unhook the spring on the back of the sensor assembly unit

from the holes on the chassis.

2.4.2 Magazine lock arm

(See Fig.1 and 2)

(1) Remove the magazine lock spring from the front side of the

chassis.

(2) Remove the poly-washer c securing the magazine lock

arm.

(3) Turn the magazine lock arm in the direction of the arrow un-

til the notch is at the d position to remove it from the chassis.

I

Spring

Rear

Sensor assembly

Fig.1

I

Magazine lock spring

2.4.3 Positioning motor assembly

(See Fig.3)

(1) Remove the two screws J securing the positioning motor.

(2) Slightly lift the positioning motor assembly to remove it

from the two burrs on the chassis.

d

Poly-washer c

Fig.2

J

Positioning

motor assembly

Fig.3

(No.49787)1-7

Page 8

CH-X550

r

r

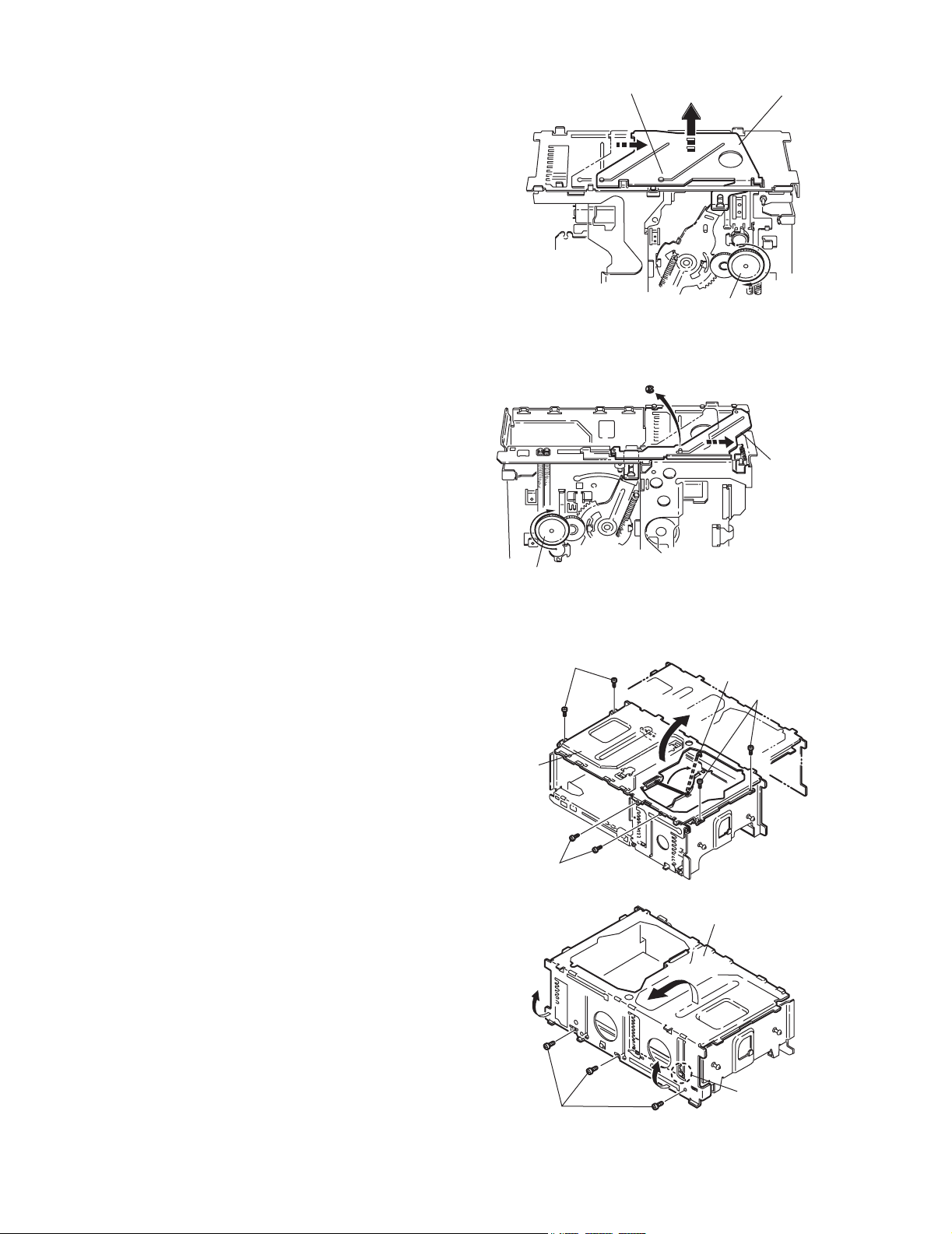

2.4.4 Rear slider

(See Fig.4)

(1) Position the unit with the front section facing down. Rotate

the third gear located on the back of the main unit in the direction of the arrow (clockwise).

(2) Shift the rear slider in the direction of the arrow and remove

it at the rear slider mounting position (at the widest hole).

2.4.5 Front slider

(See Fig.5)

(1) Position the unit with the rear section facing down. Rotate

the third gear located on the bottom of the unit in the direction

of the arrow (clockwise) until the front slider is shifted to the

outermost position.

(2) Remove the E-washer securing the front slider to remove

the front slider from the chassis

Can be removed at the stud position

(at the widest hole)

Shift

Fig.4

Remove

Third gear

Remove the E-washer

Rear slide

Front slide

2.4.6 Top plate

(See Fig.6 and 7)

(1) Remove the nine screws K securing the top plate.

(2) Disconnect the section e attached to the rear of the unit,

then lift the top plate slightly.

(3) Slide the top plate toward the rear of the unit to remove the

upper rod from the top plate.

Third gear

Top plate

K

K

Fig.5

Slide and remove the rod inside

Rod

K

Slide

Fig.6

Top plate

Remove

1-8 (No.49787)

After lifting

K

Fig.7

e

Page 9

CH-X550

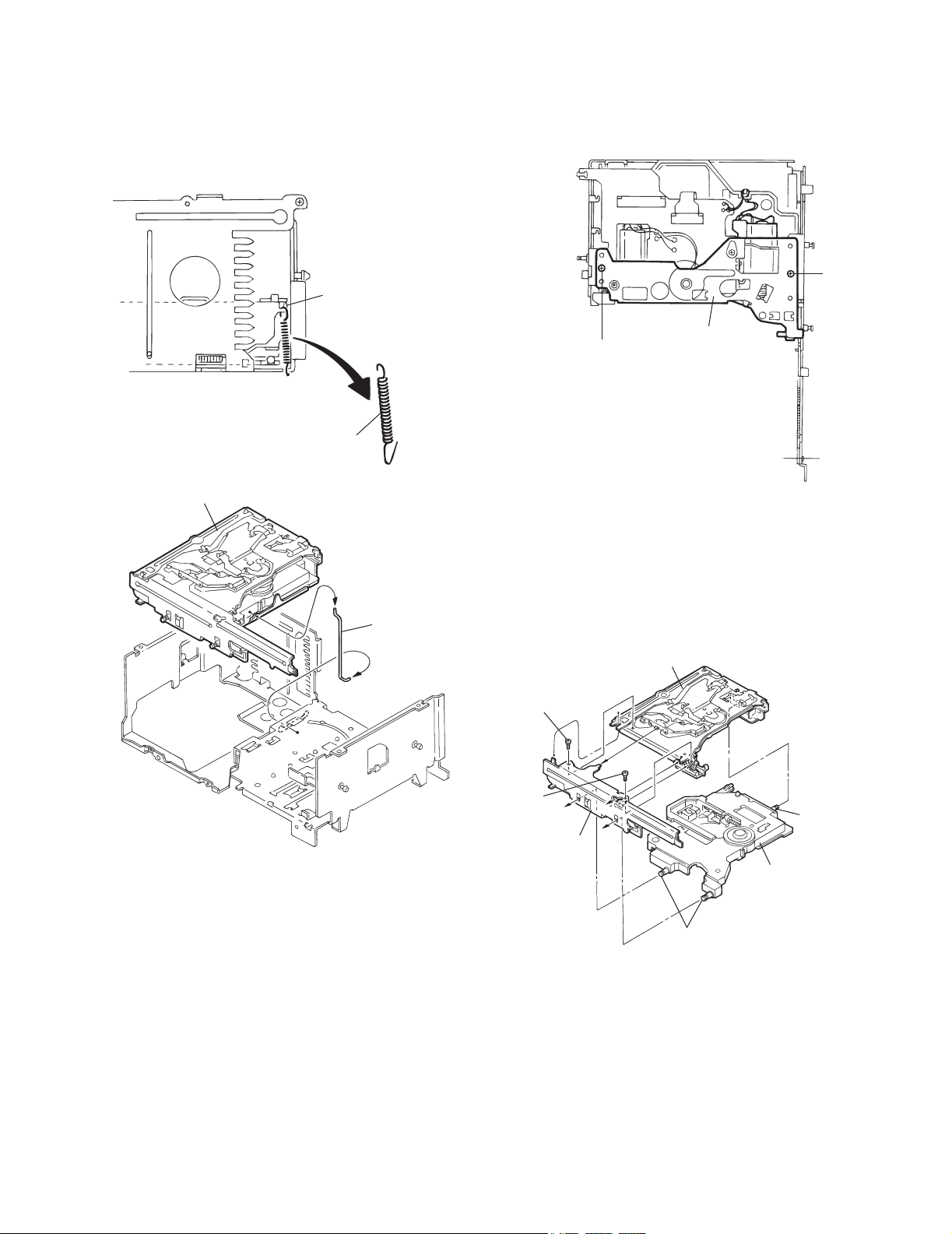

2.4.7 Lifter unit

(See Fig.8 and 9)

(1) Unhook the elevator spring located on the front side of the

unit. (Be sure to first unhook the spring from the lifter side

as shown in the upper part of the diagram.)

(2) Lift the lifter unit upward, then remove the lower rod to re-

move the lifter unit from the chassis.

Unhook this part first

Proper

orientation

Spring

Fig.8

Lifter unit

Lift up the lifter unit

Lower rod

2.4.8 Lifter bracket

(See Fig.10)

(1) Remove the two lifter bracket fixing screws L located on the

back of the lifter unit.

(2) Remove the lower rod.

L

Lifter bracket

L

Fig.10

2.4.9 Side bracket and traverse mechanism assembly

(See Fig.11)

(1) Remove the two side bracket unit fixing screws M to dis-

connect the side bracket unit from the lifter unit.

(2) Remove the three shafts on the traverse mechanism as-

sembly from the lifter unit.

CAUTION:

For reassembling, refer to the reassembling procedures.

Lifter unit

Fig.9

M

M

Side bracket

Traverse mechanism

assembly

Remove from the lifter unit

Fig.11

Remove from the

lifter unit

(No.49787)1-9

Page 10

CH-X550

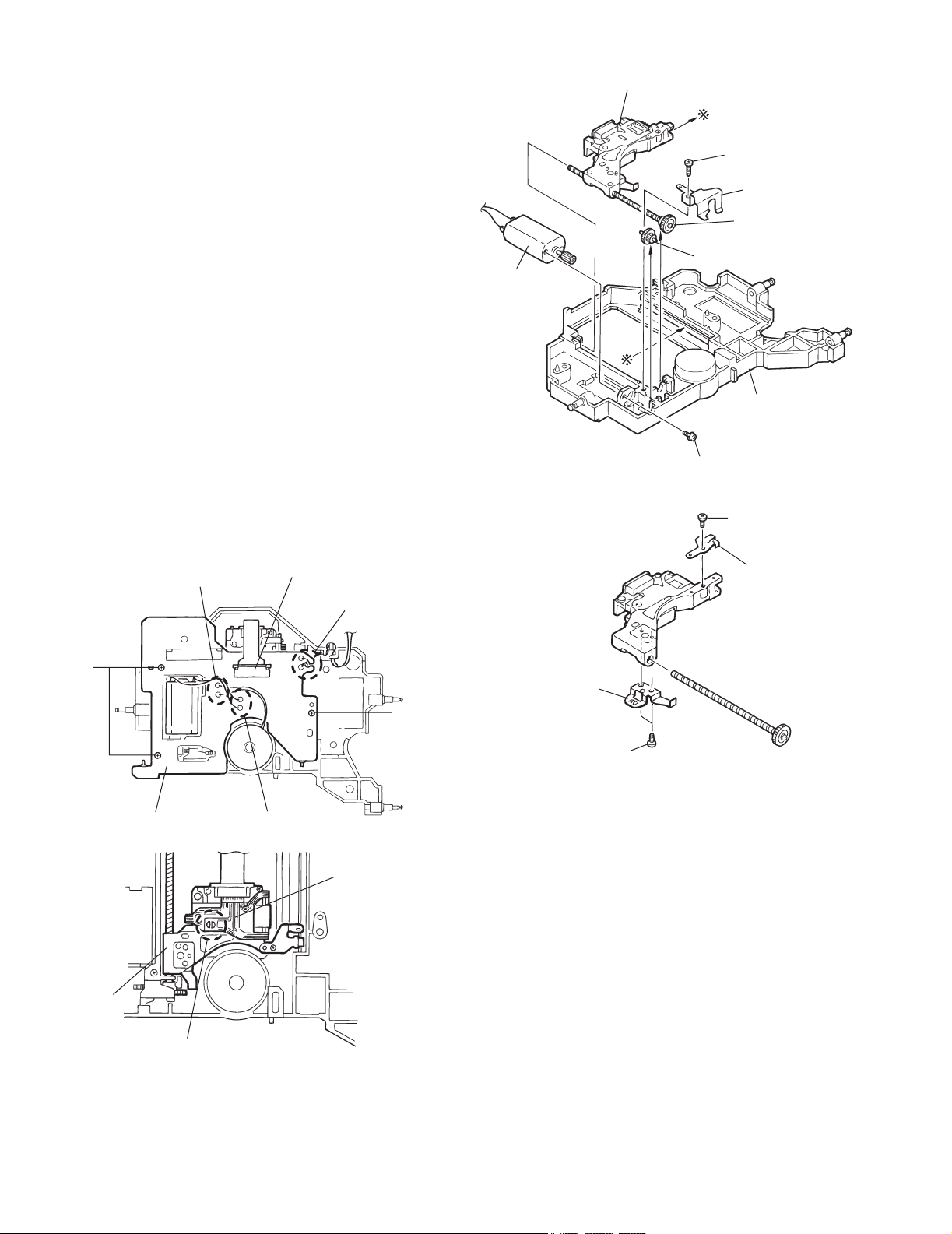

2.4.10 Removing the mechanism board / pickup assembly

(See Fig.12 to 15)

(1) Remove the three screws N fixing the mechanism board on

the back of the traverse mechanism.

(2) Disconnect the two feed motor wires (blue and white), two

spindle motor wires (red and black) and two tray motor wires

(brown and black) that are soldered to the mechanism

board.

(3) Short-circuit the grounding point on the mechanism board.

Move the mechanism board without disconnecting the wire

from connector CN501. Solder the short circuit round on

the pickup assembly.

(4) Disconnect the wire from connector CN501 on the mech-

anism board.

(5) Remove the screw O to remove the feed motor assembly.

(6) Remove the screw P to remove the shaft holder retaining

the feed slide shaft assembly and the middle gear.

(7) Move the middle gear.

(8) Move the pickup assembly upward from the gear section

and remove it from the traverse chassis assembly.

(9) Remove the two screws Q to remove the rack arm.

(10) Pull out the feed slide shaft assembly.

(11) Remove the screw R to remove the spring.

CAUTION:

To reattach the mechanism board, connect the pickup flexible wire to connector CN501 on the mechanism board before unsoldering the short circuit round. Subsequently, fix

the mechanism board using screws.

Red and black

CN501

Brown and black

Grounding point

Feed motor

Remove gears and

motors only when

required.

Pickup assembly

P

Shaft holder

Feed slide

shaft assembly

Middle gear

Chassis

O

Fig.14

R

Spring

N

Mechanism board

Pickup

Short circuit round

(Grounding point)

Blue and white

Fig.12

Fig.13

N

Flexible wire

Rack arm

Pull out

Q

Fig.15

1-10 (No.49787)

Page 11

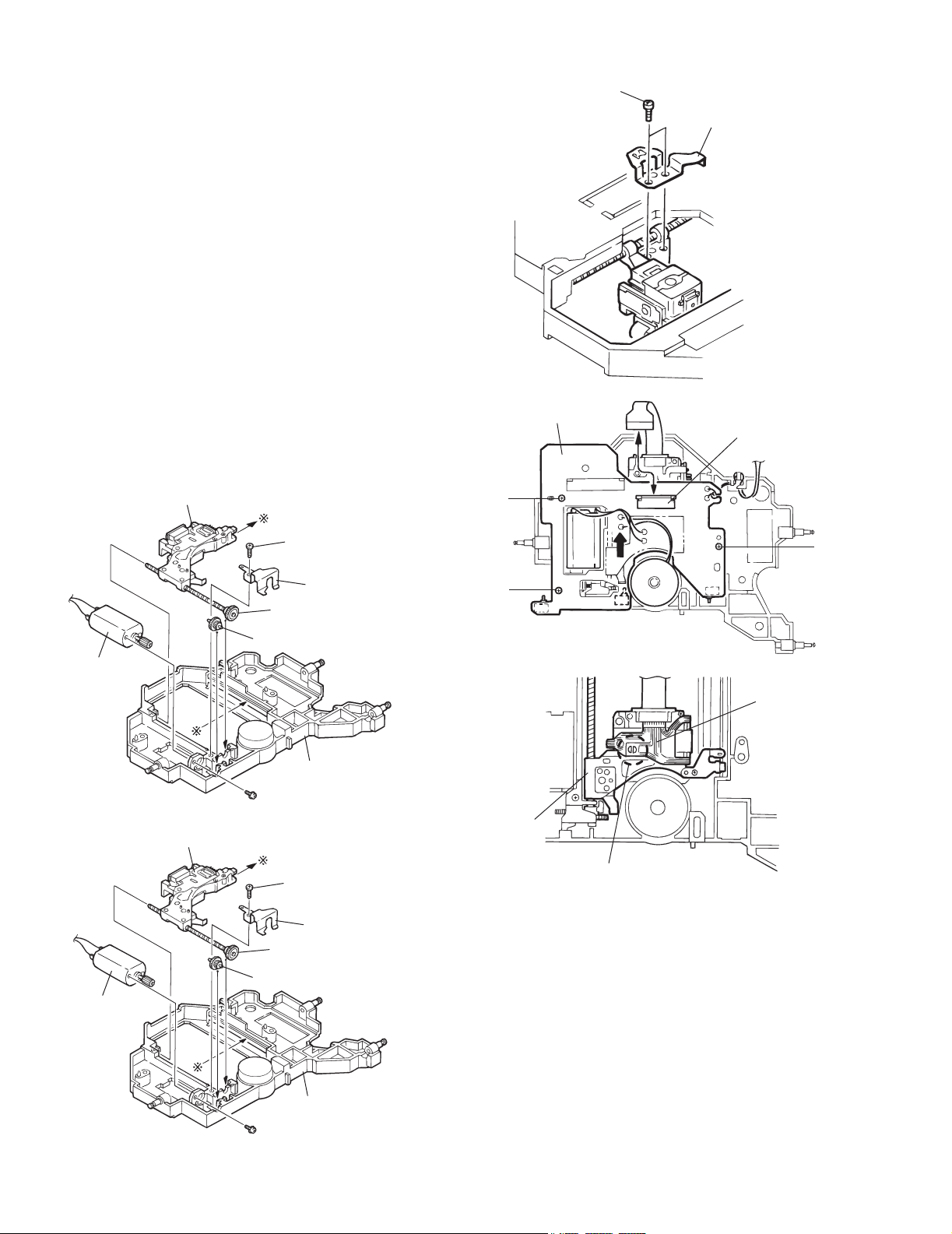

2.4.11 Tray motor

(See Fig.16 and 17 )

(1) Remove the two screws S securing the tray motor.

(2) Remove the two screws T to remove the tray motor as-

sembly from the tray motor holder.

CH-X550

S

S

Tray motor

2.4.12 Separation of the chassis (L) assembly and chassis (R) assembly

(See Fig.18 )

(1) Remove the two screws U retaining the chassis (L) and (R)

assemblies.

(2) Slide the chassis (L) assembly toward the front and detach

it, then remove the chassis (L) upward.

Slide and remove upward

as shown by the arrow

U

Fig.16

Tray motor assembly

Tray motor holder

T

Fig.17

U

Front side

Chassis (L) assembly

Chassis (R) assembly

Fig.18

(No.49787)1-11

Page 12

CH-X550

2.4.13 Precautions on reassembling

CAUTION:

When reassembling, also refer to the disassembling procedures.

2.4.13.1 Mounting the traverse mechanism

(See Fig.19 to 23)

(1) When mounting the pickup assembly, attach the feed slide

shaft assembly to the traverse chassis.Apply E-JC-525

grease to the shaft.

(2) Mount the middle gear and the feed slide shaft to the

traverse chassis and secure them with the screw P through

the shaft holder.

(3) Before mounting the mechanism board, move the pickup to

the outer edge position, then secure the board assembly

using the screw N.

At this time, check that the rest switch is correctly placed.

(4) To mount the rack arm, first move the pickup to the middle

position and secure it with the screws Q.

CAUTION:

To reattach the mechanism board, connect the pickup flexible

wire to connector CN501 on the mechanism board before unsoldering the short circuit round. Subsequently, fix the mechanism board using screws.

Pickup assembly

Attached to chassis

P

Q

Rack arm

Move the pickup to

the middle position

Fig.21

Mechanism board

CN501

N

N

Motor

Motor

Pickup assembly

Fig.19

Shaft holder

Feed slide shaft

(half coated with grease)

Middle gear

Chassis

Mounting the

feed motor assembly

Attached to chassis

P

Shaft holder

Feed slide shaft

(half coated with grease)

Middle gear

N

Fig.22

Flexible wire

Pickup

Short circuit round

(Grounding point)

Fig.23

1-12 (No.49787)

Fig.20

Chassis

Mounting the

feed motor assembly

Page 13

2.4.13.2 Mounting the lifter unit

(See Fig.24 to 26)

(1) Insert the shafts f of the traverse mechanism assembly into

the slide grooves g on the lifter unit.

(2) Shift the hook of the lifter unit to the edge, and shift the slid-

ing lever inside the side bracket unit to the edge as well.

(3) With each hole and lever shifted to the edge, mount the lift-

er unit and side bracket unit from the side.

(Check each attached section, and check that the two

shafts h of the lifter unit are correctly inserted into the holes

i of the side bracket unit. After mounting, check that the levers move together. )

(4) Turn the lifter unit upside down.

As shown in Fig. 35, slide the lever 30mm away from the

edge, then mount the lifter bracket assembly.

Attach

Fig.24

Lifter unit

h

CH-X550

f

g

f

M

Side bracket

Lifter bracket

g

g

i

f

Traverse mechanism

assembly

Fig.25

Shift inside by approx. 30 mm

Fig.26

Expanded view

(No.49787)1-13

Page 14

CH-X550

2.4.13.3 Connection of the chassis (L) assembly and chassis (R) assembly

(See Fig.27 to 29)

(1) Attach the lower rod to the chassis (R) assembly. While

shifting the rod toward the front side, mount the rod on the

lifter unit.

With the rod mounted, place the lifter unit on the chassis

(R) assembly.

(2) Combine the chassis (L) and (R) assemblies so that the

hook section j of the chassis (L) assembly is inserted into

the notch of the chassis (R) assembly by sliding it from the

front side.

(3) After engaging, secure with the two screws U.

(4) Attach the tension spring between the lifter unit and the

chassis.

Lifter unit

j

Lower Rod

Fig.27

Notch

Attached

Set first

(chassis side)

Tension spring

Set last (lifter side)

Proper

orientation

Slide to engage

U

Chassis (R) assembly

Fig.29

Fig.28

Chassis (L) assembly

U

Combine with (R) chassis

1-14 (No.49787)

Page 15

2.4.13.4 Mounting the top plate

r

(See Fig.30 to 33)

(1) Mount the upper rod on the lifter side l and set it on the rear

of the top plate, then mount the other end of the upper rod

to m.

(2) Check that the five points (n, o, p, s and r) are correctly po-

sitioned.

When mounting section s, set it so that section t of the lifter

unit is pinched by the bending section of the top plate.

(3) Secure the top plate with six fixing screws K.

CH-X550

m

Upper rod

l

Fig.30

K

K

Top plate

K

Fig.31

Expanded view of mounting s

Section t

Lifter Unit

Point r

Fig.32

n

o

Fig.33

p

s

(No.49787)1-15

Page 16

CH-X550

2.4.13.5 Mounting the front slider and rear slider (See Fig.45 and 46)

(1) Position the unit with the rear side facing down, then rotate

the third gear in the direction of the arrow (clockwise) until

the lift arm comes to the position at which the holes are exposed, as shown in Fig. 34

(2) Mount the front slider from the top.

Rotate the third gear counterclockwise until the hole of the

slider is lined up with the right hole of the stud, as shown in

Fig. 34

(3) Mount the E-washer on the shaft.

(4) Position the unit with the front side facing down, then

mount the rear slider. Check that the u, v and w positions

are correctly mounted as shown in Fig. 35.

(5) Rotate the third gear in the direction of the arrow (counter-

clockwise) until the lifter unit is at the top position.

Front slider

Check after mounting

Rotate the third gear

to move the slider

u

E-Washer

Set so the holes

are exposed

Rotate until the

holes are lined up

Fig.34

v

Stud

Position so

that the stud

and right hole

are lined up

w

1-16 (No.49787)

Rotate the third gear

to move the slider

Fig.35

Page 17

2.4.13.6 Mounting the sensor board assembly

A

(See Fig.36)

(1) Attach the longer spring to the white resin, and attach the

shorter spring temporarily to the sensor assembly bracket.

(2) Mount the sensor assembly so that the shaft of the lift arm

is inserted into the longer hole on the white resin located on

the back of the sensor board assembly.

(3) Attach the shorter spring to the hook of the lift arm.

2.4.13.7 Mounting the main PC board assembly

(See Fig.37)

(1) Rotate the third gear clockwise until section x of the front

slider and the third hole from the right are lined up.

(Be sure to set properly. If incorrectly set, the switches on

the board assembly may be damaged.)

(2) After they are correctly positioned, mount the main board

assembly.

ttach

temporarily

Shorter spring

Sensor assembly fixing screws

I

Longer spring

Fig.36

Position so that the slider hole and

third hole from the right are lined up

x

I

Shorter

spring

CH-X550

Fig.37

(No.49787)1-17

Page 18

CH-X550

r

2.4.13.8 Pickup replacement procedure

(See Fig.38 to 44)

(1) Remove the bottom cover, front panel and top cover from

the exterior section.

(2) Unplug the flexible ribbon wire from connector CN502 on

the traverse mechanism PC board assembly.

(3) Turn the rear slider and third gear in the lifter section coun-

terclockwise until the traverse mechanism assembly is in

the lowermost (bottom) position.

(4) Unsolder the two wires (black and brown) connected to the

tray motor.

(5) Remove the two screws M from the round holes on the

chassis (R) assembly to remove the lifter bracket (L).

(6) Remove the lower rod.

(7) Disconnect the two feed motor wires (blue and white), two

spindle motor wires (red and black) and two tray motor

wires (brown and black) that are soldered to the mecha-

nism board.

(8) Short-circuit the grounding point on the mechanism board.

Move the mechanism board without disconnecting the wire

from connector CN501. Solder the short circuit round on

the pickup assembly.

(9) Disconnect the wire from connector CN501 on the mecha-

nism board.

(10) Remove the three fixing screws N from the round holes on

the chassis (R) assembly to remove the traverse mecha-

nism board assembly.

(11) Remove the pickup shaft holder fixing screw P to remove

the pickup assembly.

CAUTION:

When replacing the pickup, be sure to apply countermeasures against static electricity (grounding the operation table, wrist band and soldering iron). To remove it,

first short-circuit the grounding point on the mechanism

board, then lift the mechanism board assembly with

CN501 connected. Next, short-circuit the grounding

point on the pickup main unit, then unplug the pickup

flexible board from connector CN501.

CAUTION:

When reassembling, perform in the reverse order.

(12) Remove the two rack arm fixing screws Q.

Pull out the feed slide shaft.

Remove the shaft holder fixing screw R.

(13) When mounting the lifter bracket after replacing the pickup,

shift the lifter unit lever approx. 30 mm towards the inside,

then mount the lifter bracket.

Main PCB assembly

M

Lifter bracket (L)

N

Tray motor

assembly

Traverse mechanism

board assembly

Spindle motor

Unsolder

Grounding point

CN502

Fig.38

Fig.39

Third gear

Unsolder

CN501

Shaft holder

M

Feed moto

assembly

N

N

P

1-18 (No.49787)

Pickup assembly

Fig.40

Flexible wire

Pickup

Short circuit round

(Drounding point)

Fig.41

Page 19

R

CH-X550

Pickup

Rack arm

Pickup

Middle gear

Feed slide shaft

Q

Fig.42

P

Shaft Holder

Middle gear

Chassis

Fig.43

Shift approx. 30 mm

Shift approx. 30 mm

Enlarged diagram

Lifter unit lever

Fig.44

(No.49787)1-19

Page 20

CH-X550

3.1 Forced eject procedures

SECTION 3

Adjustment

Magazine eject does not function.

RESET (Press EJECT for 3 sec.)

YES

Completed

Check that the trays remain no more

than 10 mm inside the magazine.

Improperly positioned

Remove the dampers and the top

cover to take out the mechanism.

Remove the item(s) causing the

disc-jam through the clearance at

the top of the lifter.

Are trays stored in

the magazine?

Check visually.

Remove the bottom cover

NO

Rotate the third gear clockwise and

Is the disc set in the

playing position?

unchuck the disc.

Disconnect the tray from the hook.

NO

NO

YES

YES

Peel off the sticker on the left side

of the unit. Insert a screwdriver

and press the internal lever to

forcibly eject the magazine.

Completed

Remove the lifter bracket (L) and

return the tray to the magazine.

1-20 (No.49787)

Place the unit with its left side

facing down and apply a slight

shock, then return the tray to the

magazine.

Rotate the third gear clockwise

until the lifter level is below the 9th

tray position.

Press the magazine lock lever to

eject the magazine.

Completed

Page 21

3.2 Troubleshooting

3.2.1 Servicing procedures for CH-X550 error displays

Error display Servicing procedure

CH-X550

E1: Eject error

E2: Position

motor error

E3: Tray motor

error

The magazine cannot be ejected until S601 (magazine switch) turns off.

Can the magazine be ejected? YES

1. The magazine switch (S601) does not turn off even though the magazine is completely ejected.

2. Check that the magazine is not engaged with the mechanism assembly.

The lifter does not move up and down when exchanging or ejecting discs.

After resetting, check whether or not the lifter moves.YES

3. If the lifter exceeds the required disc position, check the lift position input. (IC601 pin 76)

If the lifter does not reach the required disc position, check the mechanism (mainly the lifter

elevation mechanism)

4. Check that voltage is present at the motor terminal.

If voltage is present, check the lifter elevation mechanism. If voltage is not present, separate

the motor from the circuit and check again whether or not voltage is present.

If voltage is present, next check that the armature resistance of the position motor (resistance

between motor terminals) is approx. 12Ω.

If the resistance is excessively low (1 - 2Ω), the motor is defective.

Trays cannot be opened or closed when exchanging or ejecting discs.

Does the tray move when changing or ejecting discs? YES

5. Check that TRAY OUT SW (S602) and TRAY IN SW (S603) function correctly.

S602 & IC601 pin (46) S603 & IC601 pin (45)

When opening

→

H

1, NO → 2

→

3, NO → 4

→

5, NO → 6

L

E4: Pick

returning

When closing

6. Check that the drive voltage is applied to the motor terminal.

If the voltage is present, check the tray mechanism.

If the voltage is not present, separate the motor from the circuit and check again whether or

not the voltage is present.

Does the feed (pickup unit) return to the inner area of the disc when ejecting?

→

7, NO → 8, 9

YES

7. Check the rest switch.

8. If the feed gear is rotated, check the feed transfer mechanism

9. If the feed gear is not rotated, check the motor driver and the pattern.

HL

Other errors occurring in the receiver or controller.

E8: Connection

error

The E1 ~ E8 error displays described above may appear as E-1 ~ E-8, 1E1 ~ 1E8, R-1 ~ R-8, or RST1 ~ RST8,

depending on the product.

When selecting the CD Changer mode using function keys, etc., the unit does not enter the CD

changer mode, or the E8 error display appears. This signifies trouble relating to communications.

a. Check the connection cables between the CD changer and the receiver (CD changer controller).

b. Check the CD changer power cord and the fuse (including F901 on the PC board).

c. Check IC651 and its peripheral circuits.

(No.49787)1-21

Page 22

CH-X550

3.2.2 Error code

The following error codes can be displayed and stored in up to 3 memories when the KD-MX3000 is used with the controller. Refer

to the KD-MX3000 service manual regarding error code indication.

The error code indication when using the earlier controller is the same as the CH-X99, KD-MK88 and other 12CD changer models.

CH-1 error code table

Generating condition Description Error code

Tray extension error Tray-in switch time out

(Tray-in switch Low, Tray-out switch High)

Tray-out switch time out

(Tray-in switch High, Tray-out switch High)

Tray-in switch time out

(Tray-in switch Low, Tray-out switch Low)

MAG-in switch Low to High Magazine removed when tray partly extende E1 03 00 14

Tray retraction error Tray-in switch time out

(Tray-in switch Low, Tray-out switch Low)

Tray-out switch time out

(Tray-in switch High, Tray-out switch High)

Tray-in switch time out

(Tray-in switch Low, Tray-out switch Low)

MAG-in switch Low to High Magazine removed when tray partly retracted E1 03 00 19

Lifter raise error Wait position time out Position motor inoperative E1 02 00 21

Wait position time out Position not stable in fine adjust mode E1 02 00 22

Wait position time out Other fault E1 02 00 23

Lifter lower error Wait position time out Position motor inoperative E1 02 00 26

Wait position time out Position not stable in fine adjust mode E1 02 00 27

Wait position time out Other fault E1 02 00 28

Chuck error Play position time out Position motor inoperative E1 02 00 31

Play position time out Position not stable in fine adjust mode E1 02 00 32

Play position time out Other fault E1 02 00 33

Unchuck error Wait position time out Position motor inoperative E1 02 00 36

Wait position time out Position not stable in fine adjust mode E1 02 00 37

Wait position time out Other fault E1 02 00 38

Eject error Eject position time out Position motor inoperative E1 02 00 41

Eject position time out Eject position not attained E1 02 00 42

MAG in switch time out Magazine not ejected E1 02 00 43

Initialize error Mechanism switch time out21 Both Tray-in and Tray-out Low E1 03 00 46

Absolute position time out Not stable at absolute position E1 03 00 47

Tray stops part way E1 03 00 11

Tray stops part way E1 03 00 12

Tray-in switch faulty or other defect E1 03 00 13

Tray motor inoperative E1 03 00 16

Tray retraction stops part way E1 03 00 17

Tray-in switch faulty or other defect E1 03 00 18

Note:

The 1st error code is indicated by E1, while the 2nd and 3rd error codes are respectively indicated by E2 and E3.

1-22 (No.49787)

Page 23

3.3 Flow of functional operation until TOC read

Acceleration

CH-X550

• When the pickup correctly moves

to the inner area of the disc

Microprocessor

commands

FMO

TC9462

FEED MOTOR

IC581

RESET SW

53

TERMINAL

20

$ 83

$ 82 $81

5V

Hi-Z

0V

6V

4V

2V

OFF

ON

• When correctly focused

FSO

TA2109

14

2.2V

Focus Servo Loop ON

Power ON

Set Function to CD

Disc inserted

Pickup feed to the inner area

YES

Laser emitted

Focus search

YES

Disc rotates

RF signal eye-pattern

remains closed

Tracking loop closed

RF signal eye-pattern

opens

TOC readout

Jump to the first track

• When the laser diode correctly

emits

Microprocessor

commands

SEL

TC9462

LD

CN502

or

CN503

57

5

22

$ 84

"No disc"

display

• When the disc correctly rotates

Microprocessor

commands

DMO

TC9462

Spindle

motor (+)

IC581

$ 8A $ 86 $ A200

55

1

Acceleration

Acceleration

0.2Sec 0.5Sec

Rough

Servo

Tracking Servo Loop ON

5V

0V

4V

0V

5V

2.2V

0V

6V

3.2V

2V

Servo CLV

Play

• RF signal

Rough Servo Mode

CLV Servo Mode

(ProgramArea)

CLV Servo Mode

(Lead-In Area;

Digital: 0)

(No.49787)1-23

Page 24

CH-X550

3.3.1 General section

Turn the power on with

no magazine loaded.

Reset

Move the lifter until it

comes to the STOP

position

(shipping position).

YES

Connect the receiver,

etc. and turn the power

on.

Set to the changer

mode.

CD changer indication

appears on the receiver,

etc.

YES

Load the magazine.

Is the disc pulled out to

start play?

NO

NO

NO

The lifter moves up or

down and stops.

NO

The position motor does

not function.

NO

The tray motor goes

forward and back

several times.

Check the connections

to the receiver or the

circuits in the vicinity of

IC651.

YES

Check the linear position

sensor (VR601).

YES

Check the wiring of the

CD 9 V power supply

position motor.

Check the TRAY-IN and

TRAY-OUT switches.

Proceed to the Focus

Exchange discs, then

check whether or not the

feed motor moves.

section.

YES

Check the RESET

switch and feed

section

(Refer to the Feed section).

YES

Is the disc taken out?

Is the disc rotated?

Is voltage present at

IC521 pin z 2.5 V while

Proceed to the Tracking

Is track selection or

search performed

correctly?

YES

10. Is the playback

sound normal?

YES

Normal

YES

YES

the disc rotates?

YES

section.

NO

NO

NO

NO

NO

Proceed to the Signal

Processing section.

Check the MAG SW,

TRAY-IN, and TRAY-

Proceed to

the Signal

Processing

section.

OUT switches.

NO

Set from the STOP to

PLAY mode, then check

that the triangle wave

appears at IC581 pins H

and I .

YES

Does the laser emit?

YES

Proceed to the Focus

section.

NO

Check the vicinity of

IC501 6and 7.

1-24 (No.49787)

Page 25

3.3.2 Feed section

CH-X550

Is the voltage output at

IC521 pin u 5V or 0V?

Is 4V present at both

sides of the feed motor?

Check the feed motor

3.3.3 Focus section

YES

YES

NO

YES

Is 5V present at IC581

Check the vicinity of

YES

Check the feed motor

connection wiring.

Check the circuits in

the vicinity of IC581

pin 6?

YES

IC521.

Is the wiring for IC521

(90) ~ (100) correct?

NO

Is 6V or 2V present at

IC581 Q and R?

NO

.

Check IC581.

When the lens is

moving:

NONO

Check CD 9V

and 5V.

pins H ~ K.

4V

Does the S-search

waveform appear at

IC581 pins H and I?

YES

Check the pickup and

its connections

YES

.

3.3.4 Spindle section

Is the disk rotated?

YES

Does the RF signal

appear at TP1?

YES

Is the RF waveform at

TP1 distorted?

YES

Proceed to the Tracking

section

3.3.5 Tracking section

When the disc is rotated

at first:

Approx. 1.2V

NO

NO

Is 4V present between

IC581 pins 1 and 2?

Check the spindle motor

and its wiring.

NO

Check the circuits in the

vicinity of IC501 J ~ O

or the pickup

NO

Check the circuit in the

vicinity of IC501 pins

~ 2C.

Is 4V present at IC521

pin x ?

YES

Check the vicinity of

IC581.

YESYES

Check the pickup and

NO

Check IC501 and

its connections

IC521.

Is the tracking error

signal output at TP3 ?

YES

Check IC521.

(No.49787)1-25

Page 26

CH-X550

3.3.6 Signal processing section

Is the sound output from

both channels (L, R)?

YES

Normal

NO

No sound from either

channel.

Is 9V present at IC101 pin

Is the audio signal

(including sampling output

components) output to

IC521 pins ^and | during

Is the audio signal output

at IC101 pins 1

and 7 during playback?

Check the muting circuit.

(8)?

YES

YES

YES

YES

NO

Compare the L-ch and R-ch

to locate the defective point.

NO

Check the vicinity of the

Q981 audio power supply.

NO

Check IC521 and its

peripheral circuits

NO

Check IC101 and its

peripheral circuits

YES

1-26 (No.49787)

Page 27

Description of major ICs

4.1 BA15218F-XE (IC101) : Dual operation amplifier

•Pin layout

CH-X550

SECTION 4

OUT1 1

+IN1 3

• Block diagram

Vcc

-IN

+IN

-IN1 2

VEE 4

1

R1

Q5

Q1

Q2

D1

Q3 Q4

8 Vcc

7 OUT2

6 -IN2

2

5 +IN2

Q8

Q19

Q17Q16

C2

R5

Q6

Q9

Q10

Q7

Q18Q13

Q11

R6

OTHER

CH

R7

R8

Q12

VEE

C1

R3R2

R4

OUTPUT

Q14 Q15Q114

R9

(No.49787)1-27

Page 28

CH-X550

A

4.2 BR24C01AF-W-X (IC604) : EEPROM

• Pin layout • Pin function

Vcc WP SCL SDA

A0, A1, A2 I Slave address setting terminal

A0 A1 A2 GND

• Block diagram

Symbol I/O Description

Vcc - Power supply

GND - GND

SCL I Serial clock input terminal

SDA I/O Slave/word address serial data input/output

WP I Write protect terminal

A0 1

A1 2

A2 3

GND 4

7bit

Address

decoder

7bit

Control circuit

High voltage circuit

1kbit EEPROM

Slave/Word

Address register

START

Voltage detection

STOP

ACK

8bit

Data

register

8 Vcc

7 WP

6 SCL

5 SD

1-28 (No.49787)

Page 29

4.3 FAN8037 (IC581) : CD driver

• Pin layout & Block diagram

CH-X550

48 47 46 45 44 43 42 41 40 39 38 37

1

2

3

4

5

6

7

8

9

10

11

12

13 14 15 16 17 18 19 20 21 22 23 24

• Pin function

Pin No. Symbol I/O Function

1 IN2+ I CH2 op-amp input(+)

2 IN2- I CH2 op-amp input(-)

3 OUT2 O CH2 op-amp output

4 IN3+ I CH3 op-amp input(+)

5 IN3- I Ch3 op-amp input(-)

6 OUT3 O CH3 op-amp output

7 IN4+ I CH4 op-amp input(+)

8 IN4- I CH4 op-amp input(-)

9 OUT4 O CH4 op-amp output(+)

10 CTL1 I CH5 motor speed control

11 FWD1 I CH5 forward input

12 REV1 I CH5 reverse input

13 CTL2 I CH6 motor speed control

14 FWD2 I CH6 forward input

15 REV2 I CH6 reverse input

16 SGND - Signal ground

17 FWD3 I CH7 forward input

18 REV3 I CH7 reverse input

19 CTL3 I CH7 motor speed control

20 SB I Stand by

21 PS I Power save

22 MUTE I All mute

23 PVCC2 - Power supply voltage

24 DO7- O CH7 drive output(-)

36

35

34

33

32

31

30

29

28

27

26

25

T.S.D

D

D

D

D

D

D

STAND BY

ALL MUTE

POWER SAVE

M

s

S

w

C

M

s

S

w

C

M

s

S

w

C

Pin No. Symbol I/O Function

25 DO7+ O CH7 drive output(+)

26 DO6- O CH6 drive output(-)

27 DO6+ O CH6 drive output(+)

28 PGND2 - Power ground2

29 DO5- O CH5 drive output(-)

30 DO5+ O CH5 drive output(+)

31 DO4- O CH4 drive output(-)

32 DO4+ O CH4 drive output(+)

33 DO3- O CH3 drive output(-)

34 DO3+ O CH3 drive output(+)

35 PGND1 - Power ground1

36 DO2- O CH2 drive output(-)

37 DO2+ O CH2 drive output(+)

38 DO1- O CH1 drive output(-)

39 DO1+ O CH1 drive output(+)

40 PVCC1 - Power supply voltage

41 REGOX I Regulator feedback input

42 REGX O Regulator output

43 RESX I Regulator reset input

44 VREF I Bias voltage input

45 SVCC - Signal supply voltage

46 IN1+ I CH1 op-amp input(+)

47 IN1- I CH1 op-amp input(-)

48 OUT1 O CH1 op-amp output

(No.49787)1-29

Page 30

CH-X550

4.4 HD74HC126FP-X (IC651) : Buffer

• Pin layout • Pin function

• Block diagram

1C

1A

1Y

2C

2A

2Y

GND

1

2

3

4

5

6

7

14

13

12

11

10

9

8

VCC

4C

4A

4Y

3C

3A

3Y

Vcc Vcc

Input Output

CA Y

LX Z

HL H

HH L

Note:

H:High level

L:Low level

X:Irrelevant

Z:Off(High-impedance)

State a 3-state input

1k

Input

Note:

CL includes probe and jig capacitance

See Function Table

1A

2A

3A

4A

1C

2C

3C

4C

1Y

2Y

3Y

4Y

Output

Output

Output

Output

S1

CL

1k

Sample as Load Circuit 1

Sample as Load Circuit 1

Sample as Load Circuit 1

1-30 (No.49787)

Page 31

4.5 IC-PST9333U-X (IC602) : Regulator

• Pin layout • Block diagram

CH-X550

NC 1

GND 2

• Pin function

Pin No. Symbol Function

1 NC Non connect

2 GND GND terminal

3 VOUT Reset signal output terminal

4 Vcc Vcc terminal/Voltage detect terminal

4 Vcc

3 VOUT

Vcc 4

NC 1

3 VOUT

2 GND

(No.49787)1-31

Page 32

CH-X550

4.6 TA2147F-X (IC501) : RF amp.

• Terminal layout

• Block diagram

VRO

FEO

FEN

RFRP

RFRPIN

RFGO

RFGC

AGCIN

RFO

RFN

13GVSW

14

15

16

17

18

19

20

21

22

23

10pF

40k

30k

20k 20k

20k

20k

BOTTOM

3k

15k

50 A

12k

12k

PEAK

20k

180k

40pF

20k

20k

PEAK

1.3V

240k

180k

40k

40k

240k

15pF

15pF

40pF

60k

60k

50k

2k

20 A

20k

60 A

50k

14k

k

1

80k

x0.5

x0.5

80k

20k

20k

15k

x2

x2

1k

2k

1.75k

10pF

12 RFDC

11

TEO

10

TEN

TEBC

9

8

SEL

7

LDO

MDI

6

5

TNI

4

TPI

3

FPI

2

FNI

1-32 (No.49787)

GND

24

3k

1

Vcc

Page 33

• Pin function

Pin

Symbol I/O Function

No.

1 Vcc - 3.3V Power supply pin

2 FNI I Main-beam amp input pin

3 FPI I Main-beam amp input pin

4 TPI I Sub-beam amp input pin

5 TNI I Sub-beam input pin

6 MDI I Monitor photo diode amp input pin

7 LDO O Laser diode amp output pin

8 SEL I "APC circuit ON/OFF control signal laser diode (LDO) control signal, input or bottom/peak detection frequency

change pin."

CH-X550

APC

circuit

GND OFF

Connected to Vcc

LDOSEL

through 1k resistor

HIZ

Vcc

9 TEBC I "Tracking error balance adjustment signal pin Adjusts TE signal balance by eliminating carrier component

from PWM signal(3-state output, PWM carrier = 88.2kHz) output from TC9490F/FA TEBC pin using RC-LPF

and inputting DC. TEBC input voltage:GND~Vcc"

10 TEN I Tracking error signal generation amp negative-phase input pin

11 TEO O Tracking error signal generation amp output pin.Combining TEO signal and RFRP signal with TC9490F/FA

configures tracking search system.

12 RFDC O RF signal peak detection output pin

13 GVSW I AGC/FE/TE amp gain change pin

Control signal output

ON

Control signal output

ON

ModeGVSW

GND

HIZ

Vcc

14 VRO O Reference voltage (VRO) output pin *VRO = 1/2 Vcc when Vcc = 3.3V

15 FEO O Focus error signal generation amp output pin

16 FEN I Focus error signal generation amp negative-phase input pin

17 RFRP O Signal amp output pin for track count Combining RFRP signal TEO signal with TC9490F/FA configures track-

ing search system.

18 RFRPIN I Signal generation amp input pin for track count

19 RFGO O RF signal amplitude adjustment amp output pin

20 RFGC I "RF amplitude adjustment control signal input pin Adjusts RF signal amplitude by eliminating carrier compo-

nent from PWM signal (3-state output, PWM carrier = 88.2kHz) output from TC9490F/FA RFGC pin using

RC-LPF and inputting DC.*RFGC input voltage : GND-Vcc"

21 AGCIN I RF signal amplitude adjustment amp input pin

22 RFO O RF signal generation amp output pin

23 RFN I RF signal generation amp input pin

24 GND - GND pin

CD-RW

CD-DA

CD-DA

(No.49787)1-33

Page 34

CH-X550

4.7 TC9490FA (IC521) : DSP & DAC

• Pin layout & Block daiagram

DVSS3

RO

DV

DD3

DVR

LO

DV

SS3

ZDET

V

SS5

BUS0

BUS1

BUS2

BUS3

BUCK

/CCE

/RST

VXDD3XOXI

SS3

XV

TEIN

DD3

V

VSS3

DMO

FMO

DD3

AV

SEL

TEBC

RFGC

48 47 46 45 44 43 42 41 40 39 38 37 36 35 34 33

49

50

51

52

LPF

Clock

generator

1-bit

DAC

PWM

Servo control

A/D

53

54

55

56

Address

circuit

ROM

RAM

Digital equalizer

automatic

adjustment circuit

57

58

59

60

61

62

Micro-

controller

interface

circuit

Correction

Audio output

circuit

16k

RAM

Digital output

CLV servo

Sync signal

protection

EFM

Sub code

detector

TMAX

63

VCO

PLL

REF

V

D/A

Data

slicer

TRO

FOO

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

TEZI

TEI

SBAD

FEI

RFRP

RFZI

RFCT

AV

DD3

RFI

SLCO

AV

SS3

VCOF

RV

REF

LPFO

LPFN

V

DD5

1-34 (No.49787)

64

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

DD3

BCK

LRCK

AOUT

DOUT

IPF

VSS3

V

SBOK

CLCK

DATA

SFSY

SBSY

/HSO

UHSO

DD3

PV

PDO

17

TMAX

Page 35

• Pin function

Pin

Symbol I/O Function

No.

1 BCK O Bit clock outputpin 32fs, 48fs, or 64fs selectable by command.

2 LRCK O L/R channel clock output pin."L" for L channe and "H" for R channel. Output polarity can be inverted by

command.

3 AOUT O Audio data output pin. MSB-first or LSB-first selectable by command.

4 DOUT O Digital data output pin. Outputs up to double-speed playback.

5 IPF O Correction flag output pin.When set to "H", AOUT output cannot be corrected by C2 correction processing.

6 VDD3 - Digital 3.3V power supply voltage pin.

7 VSS3 - Digital GND pin.

8 SBOK O Subcode Q data CRCC result output pin."H" level when result is OK.

9 CLCK I/O Subcode P-W data read clockI/O pin. I/O polarity selectable by command.

10 DATA O Subcode P-W data output pin.

11 SFSY O Playback frame sync signal output pin.

12 SBSY O Subcode block sync signal output pin. "H" level at S1 when subcode sync is detected.

13 /HSO O Playback speed mode flag output pins.

14 /UHSO O

/HSO

Playback speed/UHSO

CH-X550

H

H

L

--

15 PVDD3 - PLL-only 3.3V power supply voltage pin.

16 PDO O EFM and PLCK phase difference signal output pin.

17 TMAX O TMAX detection result output pin.

H

L

L

--

Normal

Double

4 times

---

TMAX OutputTMAX Detection result

Longer than fixed period

Within fixed period

Shorter than fixed period

18 LPFN I Inverted input pin for PLL LPF amp.

19 LPFO O Output oin for PLL LPF amp.

20 PVREF - PLL-only VREF pin.

21 VCOF O VCO filter pin.

22 AVSS3 - Analog GND pin.

23 SLCO O DAC output pin for data slice level generation.

24 RFI I RF signal input pin.Zin selectable by command.

25 AV - Analog 3.3V power supply voltage pin.

26 RFCT I RFRP signal center level input pin.

27 RFZI I RFRP signal zero-cross input pin.

28 RFRP I RF ripple signal input pin.

29 FEI I Focus error signal input pin.

30 SBAD I Sub-beam adder signal input pin.

31 TEI I Tracking error input pin. Inputs when tracking servo is on.

32 TEZI I Tracking error signal zero-cross input pin.

33 FOO O Focus equalizer output pin.

"PVDD3"

"HIZ"

SS3"

"AV

(No.49787)1-35

Page 36

CH-X550

Pin

Symbol I/O Function

No.

34 TRO O Tracking equalizer output pin.

35 VREF - Analog reference power supply voltage pin.

36 RFGC O RF amplitude adjustment control signal output pin.

37 TEBC O Tracking balance control signal output pin.

38 SEL O APC circuit ON/OFF signal output pin. At laser on, high impedance with

UHS="L", H output with UHS="H".

39 AVDD3 - Analog 3.3V power supply voltage pin.

40 FMO O Feed equalizer output pin.

41 DMO O Disc equalizer output pin.

42 VSS3 - Digital GND pin.

43 VDD3 - Digital 3.3V power supply voltage pin.

44 TESIN I Test input pin. Normally, fixed to "L".

45 XVSS3 - System clock oscillator GND pin.

46 XI I System clock oscilatoe input pin.

47 XO O System clock oscillator output pin.

48 XVDD3 - System clock oscillator 3.3V power supply voltage pin.

49 DVSS3 - DA converter GND pin.

50 RO O R-channel data forward output pin.

51 DVDD3 - DA converter 3.3V power supply pin.

52 DVR - Reference voltage pin.

53 LO O L-channel data forward output pin.

54 DVSS3 - DA converter GND pin.

55 ZDET O 1 bit DA converter zero data detection flag output pin.

56 VSS5 - Microcontroller interface GND pin.

57

58

59

60

61 BUCK I Microcontroller interface clock input pin.

62 /CCE I Microcontroller interface chip enable signal input pin.At "L".

63 /RST I Reset signal input pin. At reset, "L".

64 VDD5 - Microcontroller interface 5V power supply pin.

BUS0

BUS1

BUS2

BUS3

I/O Microcontroller interface data I/O pins.

Bus0 to BUS3 are active.

1-36 (No.49787)

Page 37

4.8 UPD780058GC-291(IC601):CPU

• Terminal layout

80 61

1

CH-X550

60

20

41

21 40

• Pin function

Pin

PORT Name I/O Function

No.

1 LCDDA O LCD driver data output

2 LCDSCK O LCD driver clock output

3 LCDCE O LCD driver chip enable output

4 GND - Connect to ground

5 VREF - Reference voltage output

6 POSCON O Position control output

7 AVREF1 - Connect to 5V

8 NC - Unused output port

9 NC - Unused output port

10 CDCHECK I CD check mode input. Reset only.

11 EPROMDI I/O EEPROM data input

12 EOROMDO O EEPROM data output.

Hi durring input.

13 EPROMCK I/O EEPROM clock input/output

14 NC - Unused output port

15 BUS I/O O JVC bus input/output control(Lo:input)

16 BUS SI I JVC bus data input

17 BUS SO O JVC bus data output

18 BUS SCK I/O JVC bus clock input/output

19 NC - Unused output port

20 NC - Unused output port

21 NC - Unused output port

22 NC - Unused output port

23 NC - Unused output port

24 NC - Unused output port

25 NC - Unused output port

26 CD ON O CD power control Hi:on

27 PWR CONT O Power supply control output Hi:on

28 POSMO+ O Position motor control output

29 POSMO- O Position motor control output

30 TRAYMO+ O Tray motor control output

31 TRAYMO- O Tray motor control output

32 BUCK - CD LSI data clock

33 GND - Connect to ground

34 LSI RESET O CD LSI reset

35 CCE I/O CD LSI chip enable

36 BUS0 I/O CD LSI data 0(open drain)

37 BUS1 I/O CD LSI data 1 (open drain)

38 BUS2 I/O CD LSI data 2 (open drain)

39 BUS3 O CD LSI data 3 (open drain)

40 NC - Unused output port

41 CD RW O CD-RW Detect signal output

42 NC - Unused output port

Pin

PORT Name I/O Function

No.

43 NC - Unused output port

44 MAG IN - Magazine switch

Lo:magazine inserted

45 TRAY OUT O Tray extend switch

Lo:extension complete

46 TRAY IN O Tray retract switch

Lo:retraction complete

47 REST I Resr switch

48 DISC SEL O Disc select output

49 EMPH O Emphasis select output Hi:on

50 NC - Unused output port

51 OE - Unused output port

52 SHOCK SW I Shock proof switch signal input

53 SHOCK O Shock proof output

54 NC - Unused output port

55 A.MUTE - Unused output port

56 MUTE PWR O Power supply for mute

57 STAGE I LCD,AD key,remote inhibit selector

Low:inhidit

58 STAGE2 - Unused output port

59 EPROM CLR I EEPROM clear input Functional only

dunng reset

60 RESET I Reset input

(includes flash write in function)

61 REMOCON I Remote controller signal input

62 PWR DET I Memory power detect input

63 PWR SW I CRTL+B detect input

64 BUS INT I JVC bus com start interrupt input

65 EJECT I Eject key input

66 NC - Unused output port

67 GND - Connect to ground

68 VDD0 - Conneto to VDD

69 X2 O Oscillater (4.19430 MHz)

70 X1 I Oscillater (4.19430 MHz)

71 GND - Connect to ground

72 XT2 O Open

73 XT1 I Connect to VDD

74 VDD - Connect to 5V

75 AVREF0 - Connect to ADCONT

76 L SENSOR I Linear sensor input(8 bit A/D input)

77 KEY1 I Key input 1 (8 bit A/D input)

78 KEY2 I Key input 2 (8 bit A/D input)

79 KEY3 I Key input 3 (8 bit A/D input)

80 KEY0 I Key input 0 (8 bit A.D input)

(No.49787)1-37

Page 38

CH-X550

VICTOR COMPANY OF JAPAN, LIMITED

AV & MULTIMEDIA COMPANY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan

(No.49787)

Printed in Japan

200301WPC

Loading...

Loading...