Page 1

Page 2

Removal of Main Parts

Disassembling Procedures

Perform operations according to the items to be disassembled.

Replacement of the Pickup

1. After removing the exterior (top and bottom)...

2. Proceed to the "Pickup Replacement" section.

3. When applying grease, refer to the Exploded View.

Use new grease.

Mechanism Section

1. Remove the exterior (required section only).

2. The mechanism section is designed so that each unit can be

removed separately.

3. When re-assembling, refer to the assembling precautions.

(Use new grease when applying grease.)

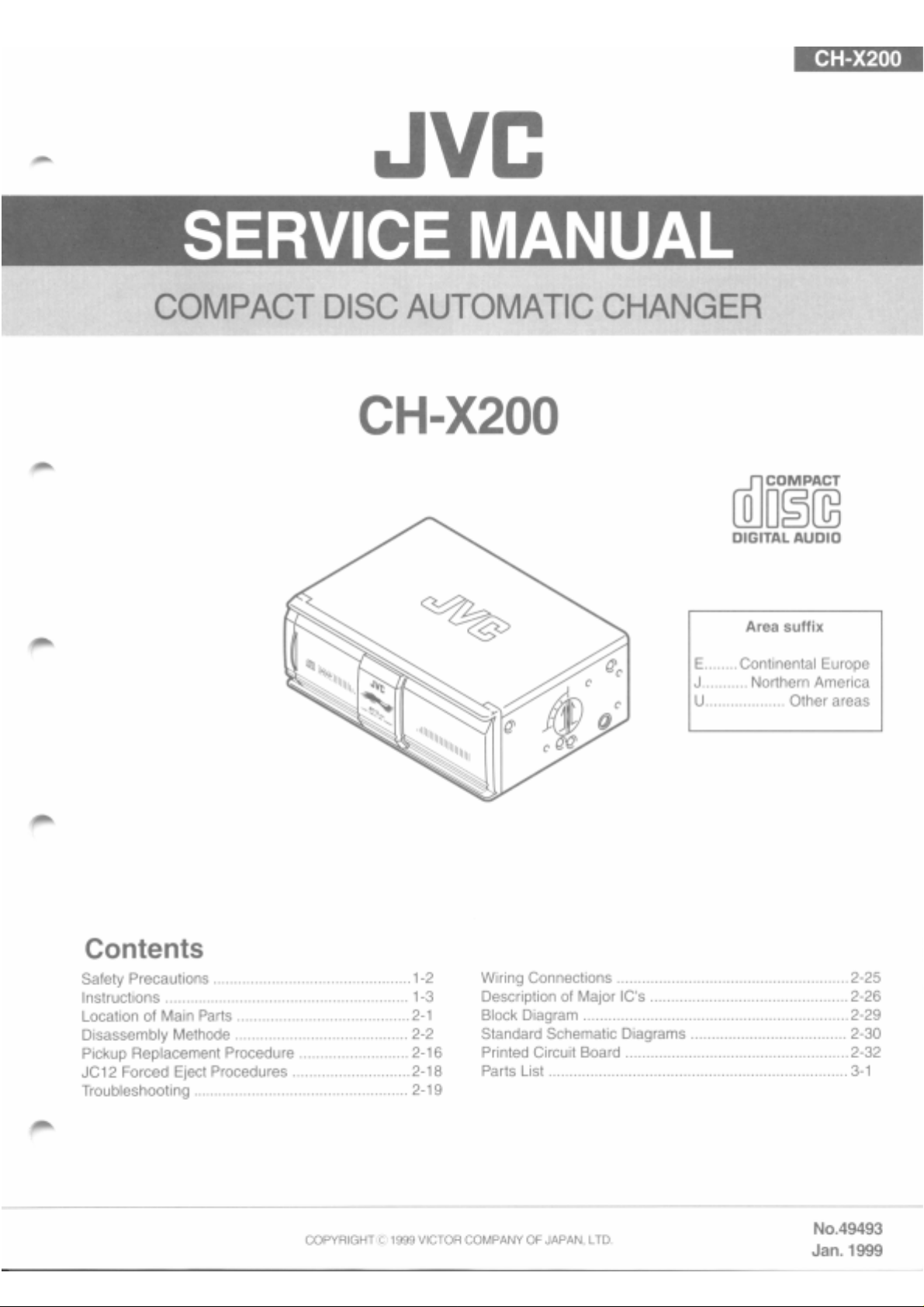

*Exterior Section

Removing the Bottom Cover and Front Panel

Assembly

1. Remove the screw (1-a) to unlock the mounting direction

knob located on the side of the main unit.

2. Turn the mounting direction knob in the direction of the arrow

using a coin, etc. to remove it. (The knob can be removed

only when it is set to this position.)

3. Remove the four top cover fixing screws (1) at the triangle

(A) marks on the side of the main unit. (Perform the same

operation on both sides.)

4. Turn the unit upside down so the bottom surface is facing

upward.

5. Lift the rear edge of the bottom cover slightly and lift the side

by grasping the DIN jack section on the side panel, then

turn it toward the front (raise upward) to remove the bottom

cover.

6. Unhook the four catches located on both sides of the front

panel, and turn the front panel toward the top cover (lower

down) to remove the front panel.

1 1

1

Remove 1-a and

turn in the

direction of the

arrow

1

1-a

Fig. 1

1 1

Fig. 2

Remove 1-a and

turn in the direction

of the arrow.

111-a

The front panel can be

separated by raising the

cover.

Fig. 3

Unhook catches

Unhook catches

Fig. 4

Slightly lift the

jack section to

remove.

Page 3

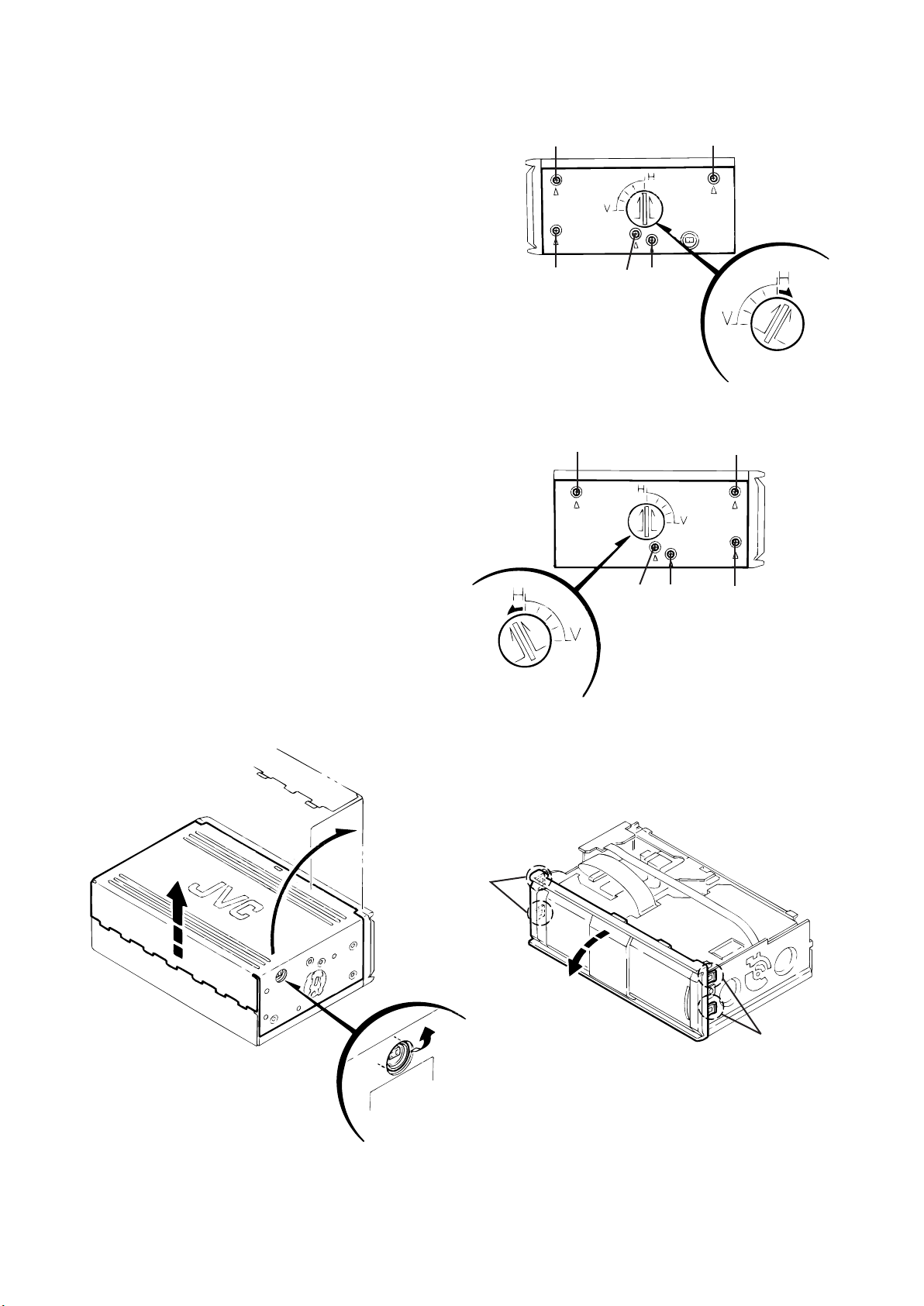

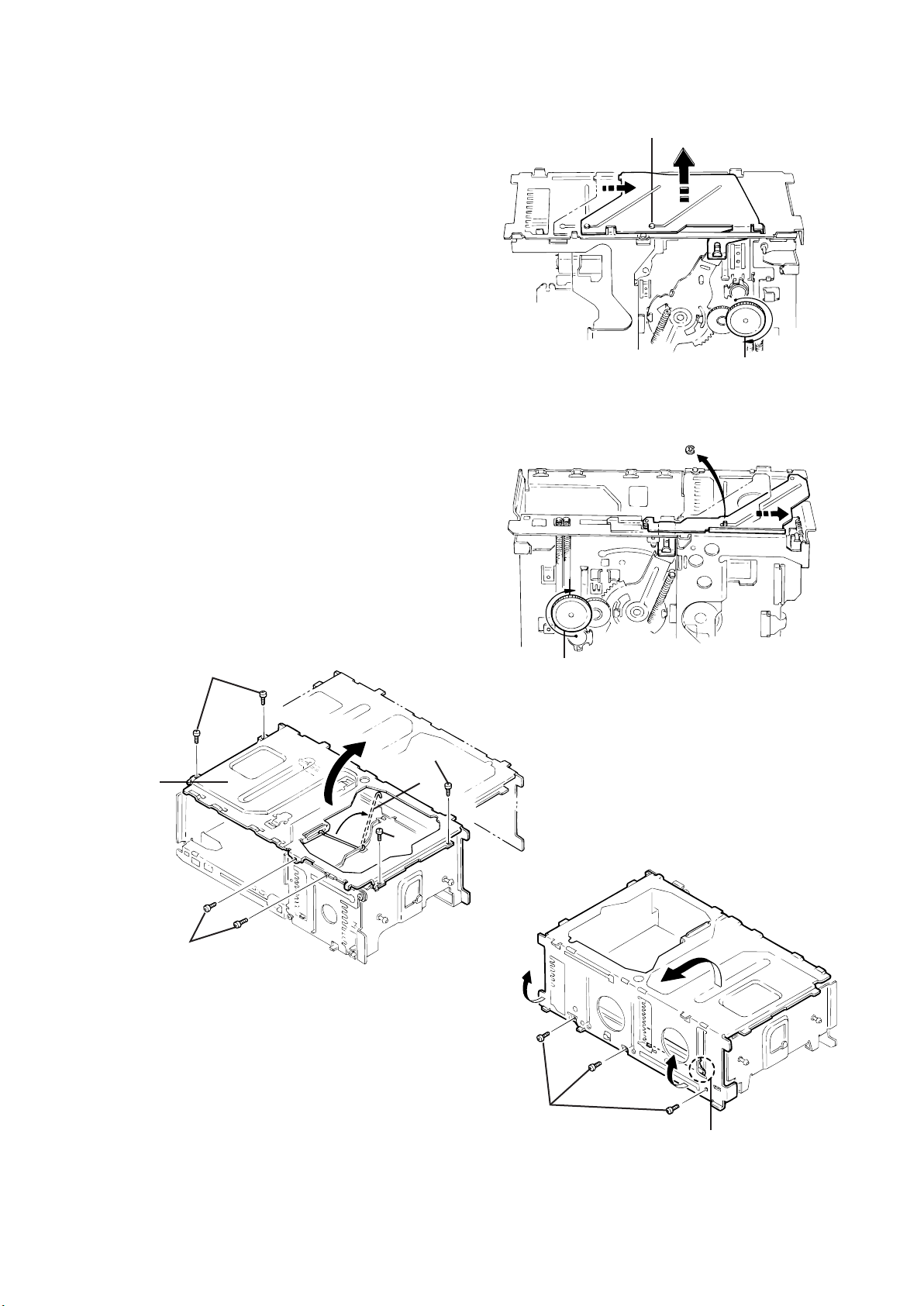

Removing the Top Cover

1. Remove the four damper bracket fixing screws (2) to remove

the damper brackets.

2. Pull out the dampers, being careful not to damage them.

When re-attaching a damper, insert your finger to push out the

center of the damper to mount it on the damper shaft, as

shown in Fig. 6-1.

3. Turn the damper spring bracket toward the top at a right angle

as shown in Fig. 7, then push down the lower side of the

damper spring bracket to lift it off.

4. Remove the three fixing screws (3) and (4) on the DIN jack

PCB assembly.

5. Lift the changer unit upward.

6. Remove the damper springs from the mechanism chassis if

required. To reassemble, refer to the diagram below.

Apply alcohol to the shaft then

immediately attach the damper. (After

attaching, check that the shaft is

correctly inserted.)

Fig. 5

2

2

Fig. 6-1

Lift the changer unit upward

Fig. 8

Push out with your

finger before

attaching

2

2

Turn to the top position (at a right angle),

Remove the flexible ribbon

wire if required

Fig 6

then push down to lift off.

Fig. 7

4

4

Mechanism

Chassis

Silver

(mechanism side)

How to Attach the Damper Springs

Fig. 8-1

Black

(magazine side)

3

Fig. 9

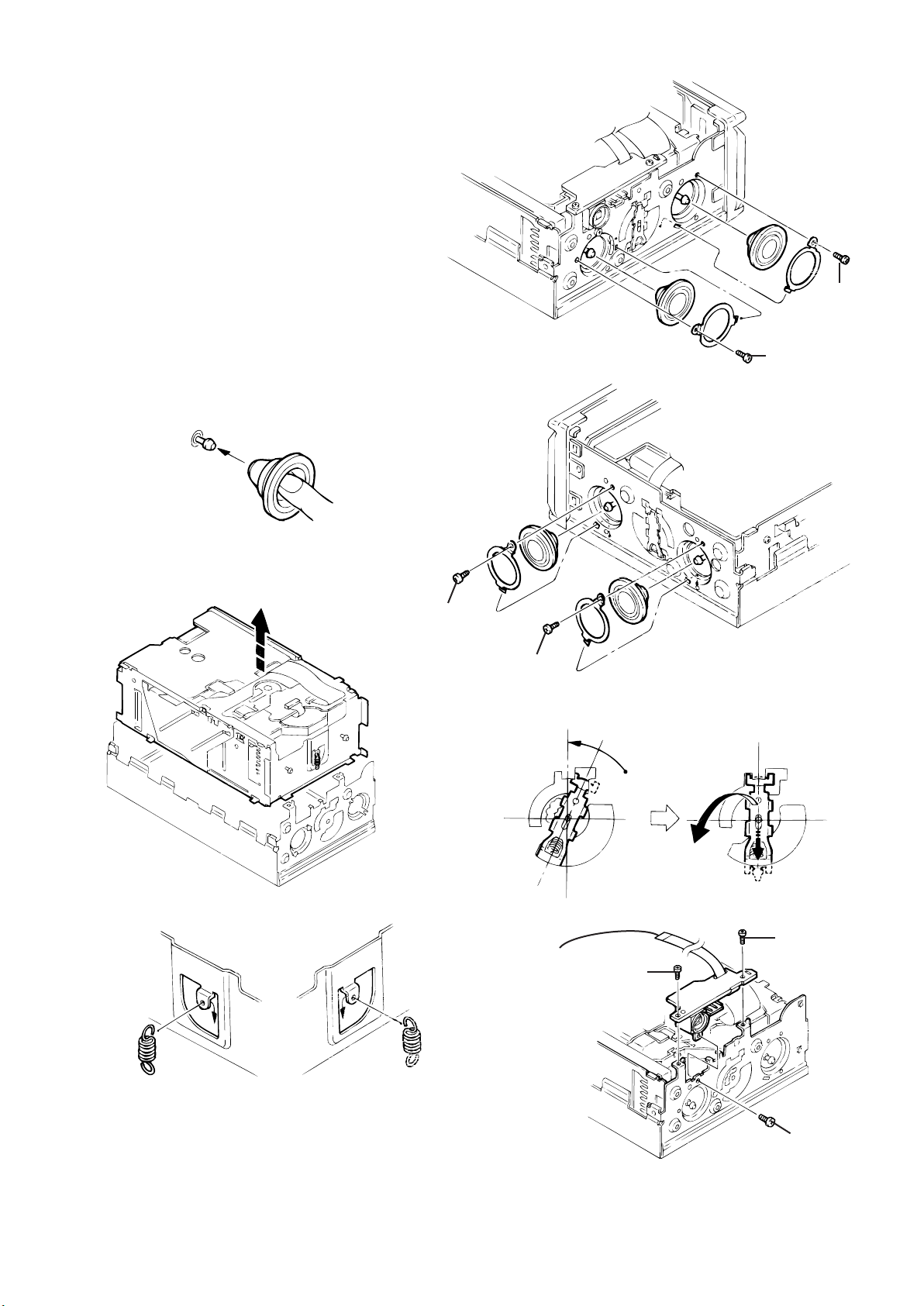

Page 4

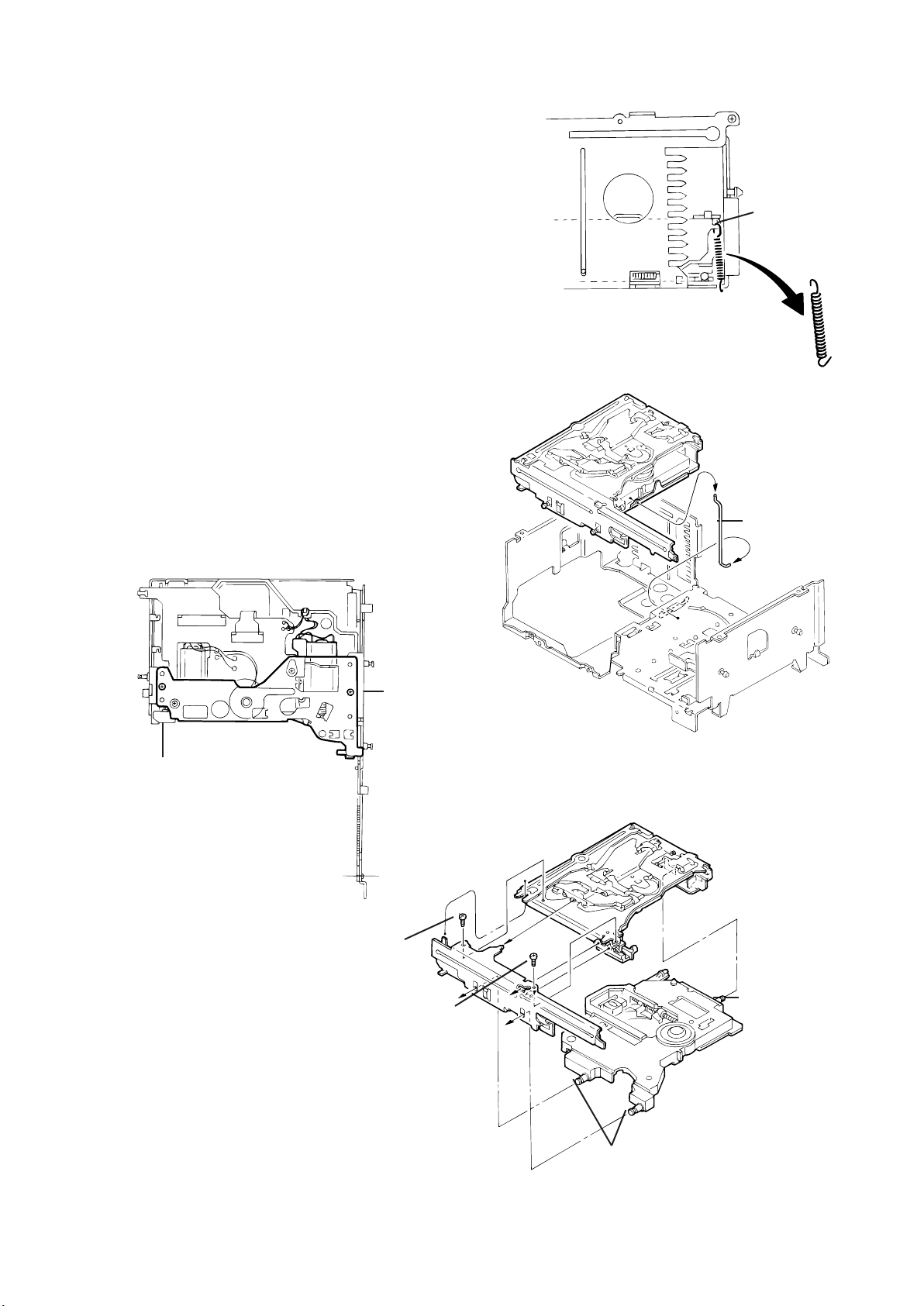

Removing the Fittings

1. Remove the fixing screw (5).

2. Unhook the two catches (a) on the top edge of the fitting,

then unhook the catches (b) at the left/right bottom edges.

Catches (a)

Catches (b)

Fitting

Removing the Main PCB Assembly

1. Remove the power IC fixing screw (6).

2. Remove the four screws (7) securing the main PCB

assembly.

3. Disconnect position motor wire connector CN504 from the

main PCB assembly.

4. Disconnect sensor PCB assembly wire connector CN601

from the main PCB assembly.

5. Remove the flexible ribbon wire from CN502 on the traverse

mechanism PCB assembly.

When re-installing the PC boards, refer to the reassembling

procedures for protecting switches, etc.

CN502

7 CN601

5

Fig. 10

7

7

Fig. 11

CN504

6

Page 5

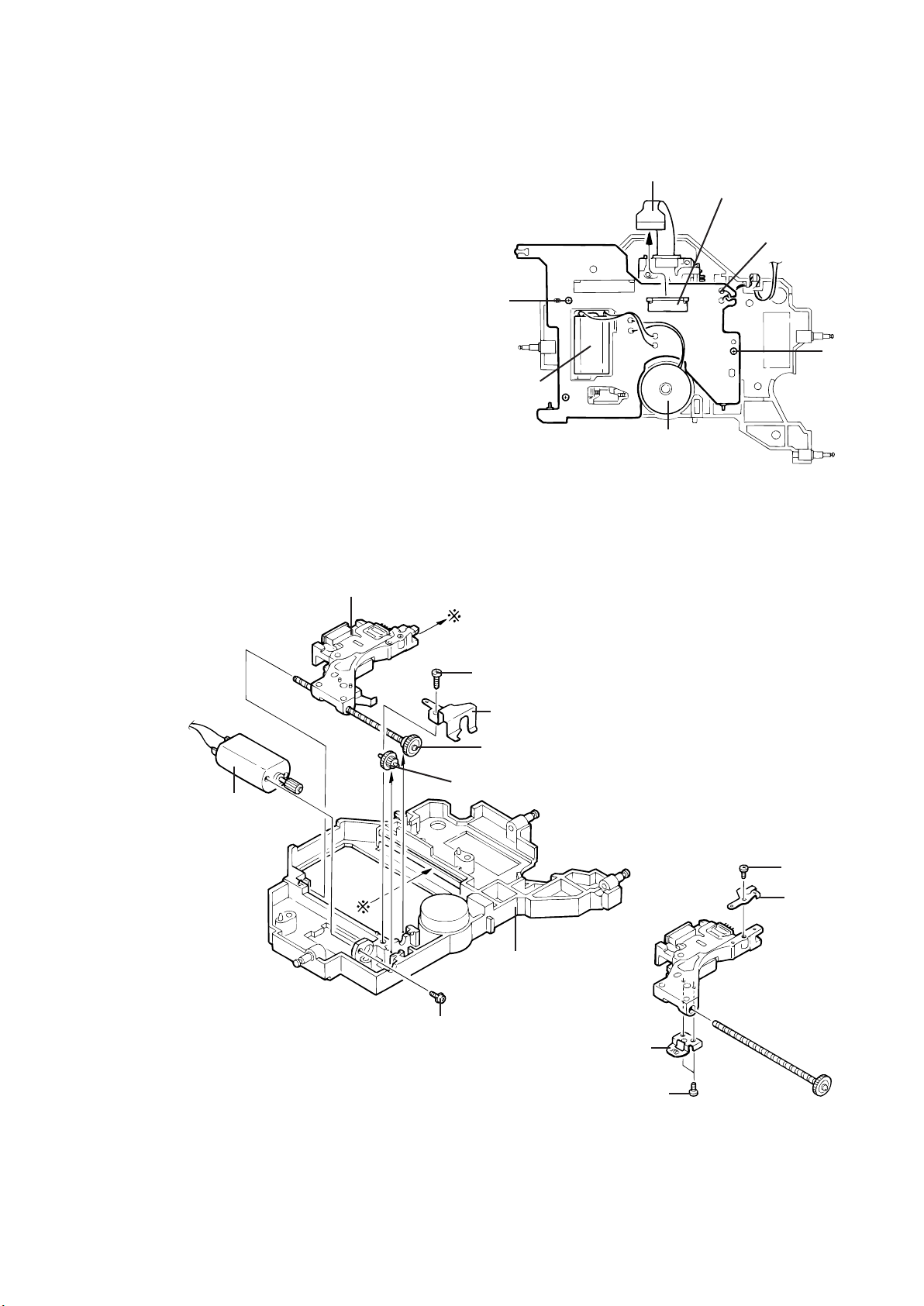

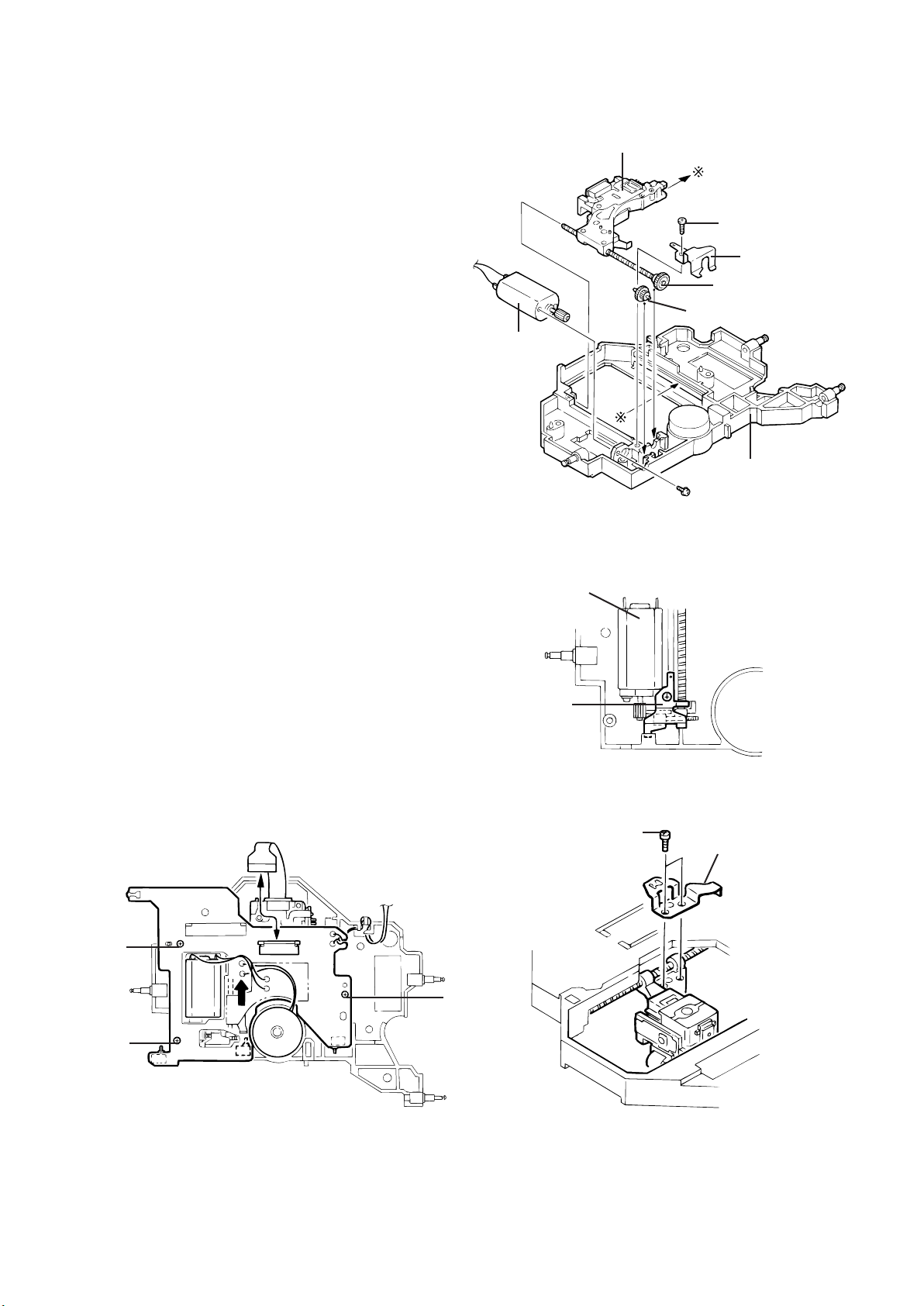

*Changer Mechanism Section

Sensor Assembly Unit

1. Remove the two screws (1) securing the sensor assembly

unit.

2. Unhook the springs on the back of the sensor assembly unit

from the holes on the chassis.

1

Sensor

Assembly

Magazine Lock Arm

1. Remove the magazine lock spring from the front side of the

chassis.

2. Remove the poly-washer (b) securing the magazine lock arm.

3. Turn the magazine lock arm in the direction of the arrow until

the notch is at the "C" position to remove it from the chassis.

Positioning Motor Assembly

1. Remove the two screws (2) securing the positioning motor.

2. Slightly lift the positioning motor assembly to remove it from

the two burrs on the chassis.

1

a

Fig. 14

Magazine Lock Spring

Rear

c

Fig. 15

Poly-Washer (b)

Fig. 16

2

Positioning

Motor Assembly

Page 6

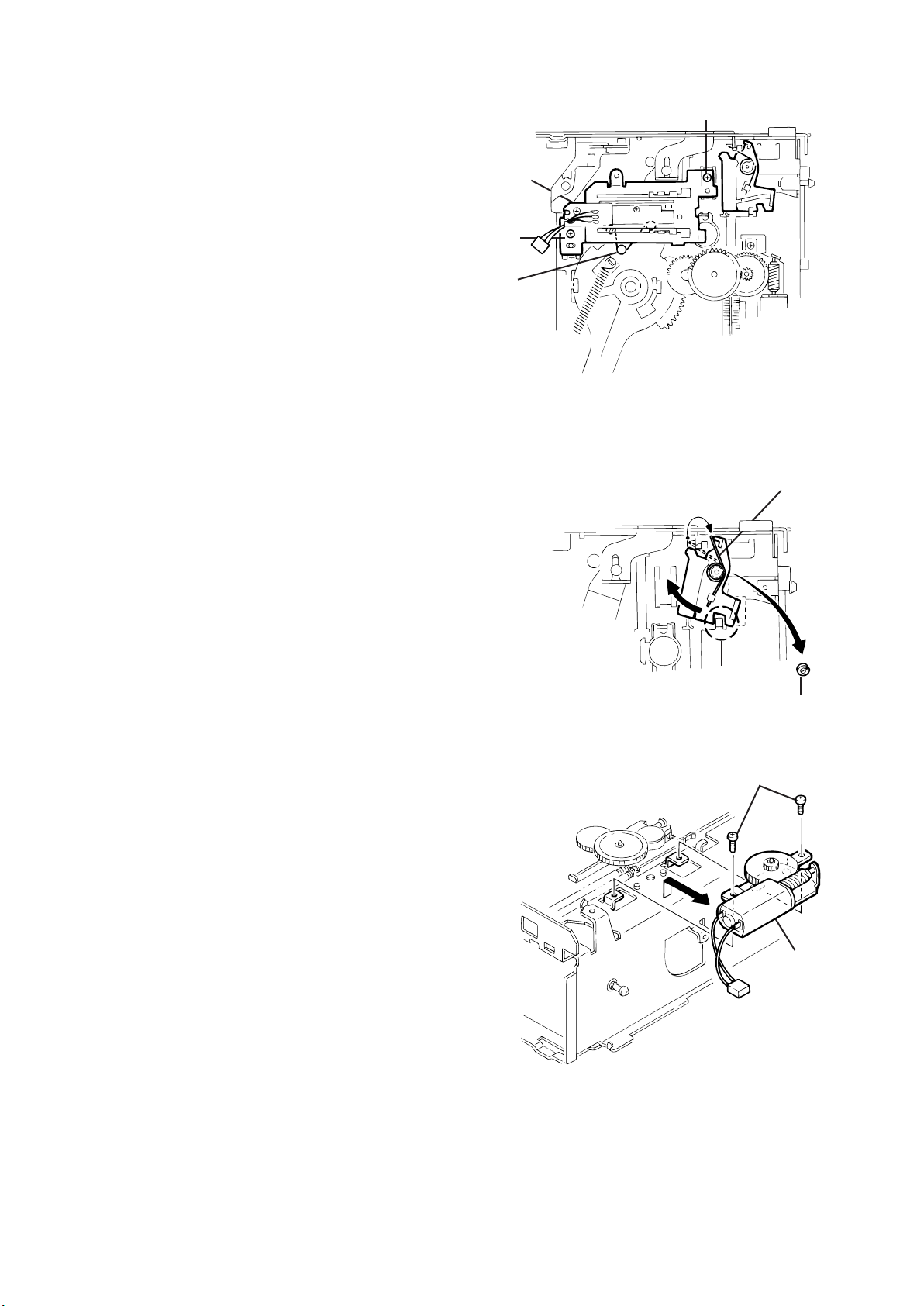

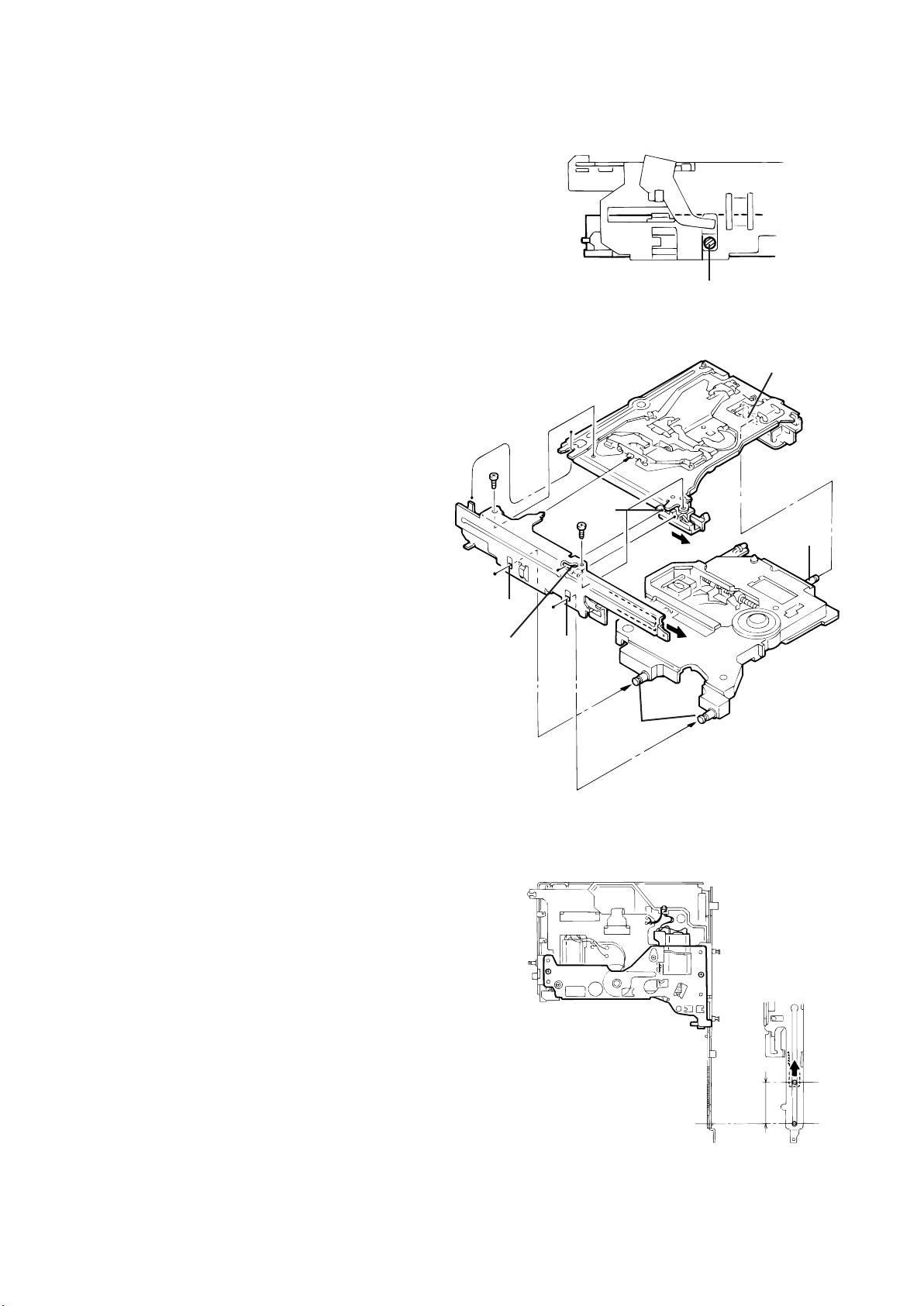

Rear Slider

1. Position the unit with the front section facing down. Rotate

the third gear located on the back of the main unit in the

direction of the arrow (clockwise).

2. Shift the rear slider in the direction of the arrow and remove it

at the rear slider mounting position (at the widest hole).

Front Slider

1. Position the unit with the rear section facing down. Rotate the

third gear located on the bottom of the unit in the direction of

the arrow (clockwise) until the front slider is shifted to the

outermost position.

2. Remove the E-washer securing the front slider to remove the

front slider from the chassis.

Can be removed at the stud position

(at the widest hole)

Shift

Fig. 17

Remove

Third Gear

Top Plate

1. Remove the nine screws (3) securing the top plate.

2. Disconnect the section (e) attached to the rear of the unit,

then lift the top plate slightly.

3. Slide the top plate toward the rear of the unit to remove the

upper rod from the top plate.

3

Slide

3

Top Plate

Rod

3

Remove the E-washer

Third gear

Slide and remove the rod inside

Fig. 18

3

Remove

Fig. 19

After Lifting

3

e

Fig. 20

Page 7

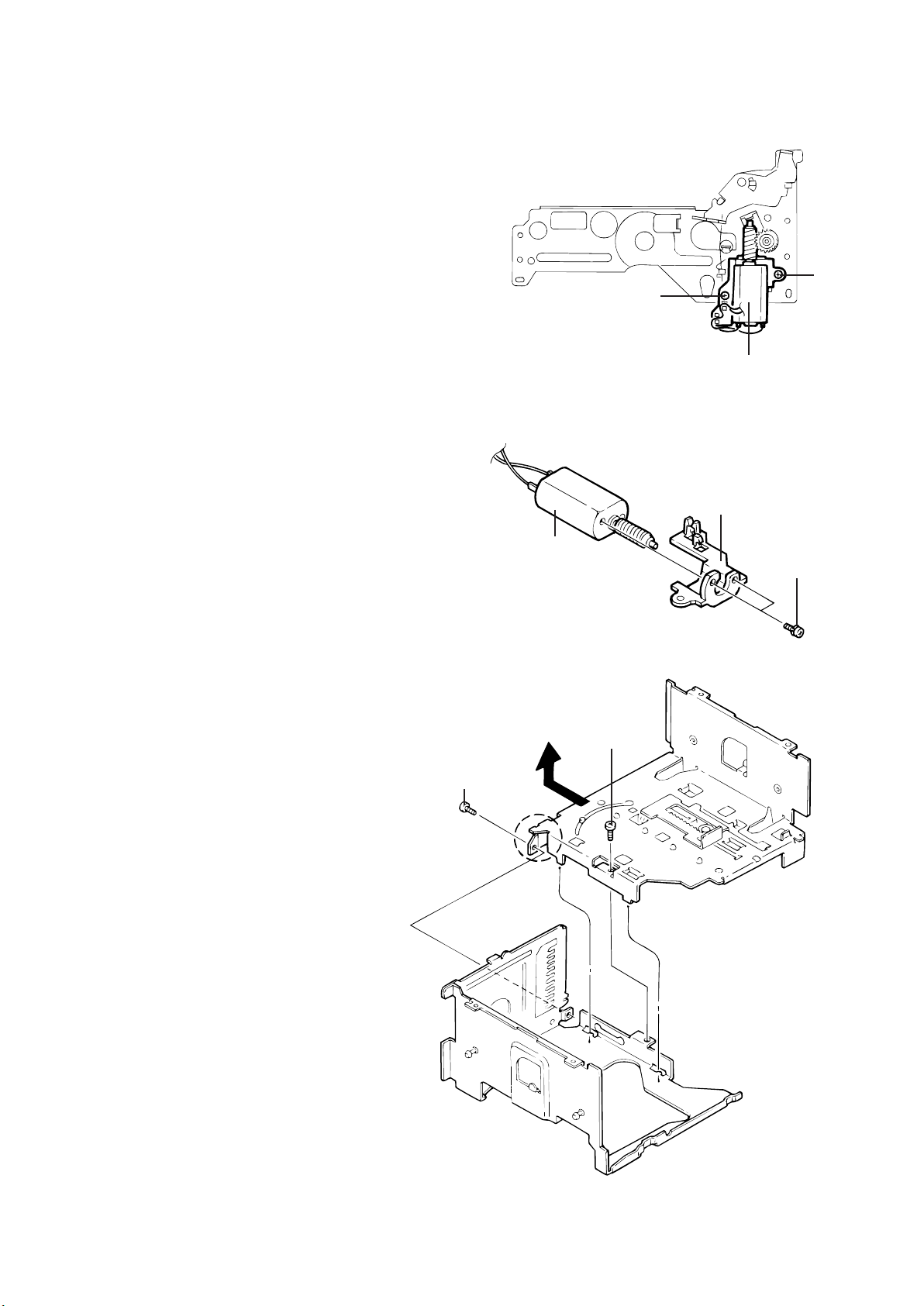

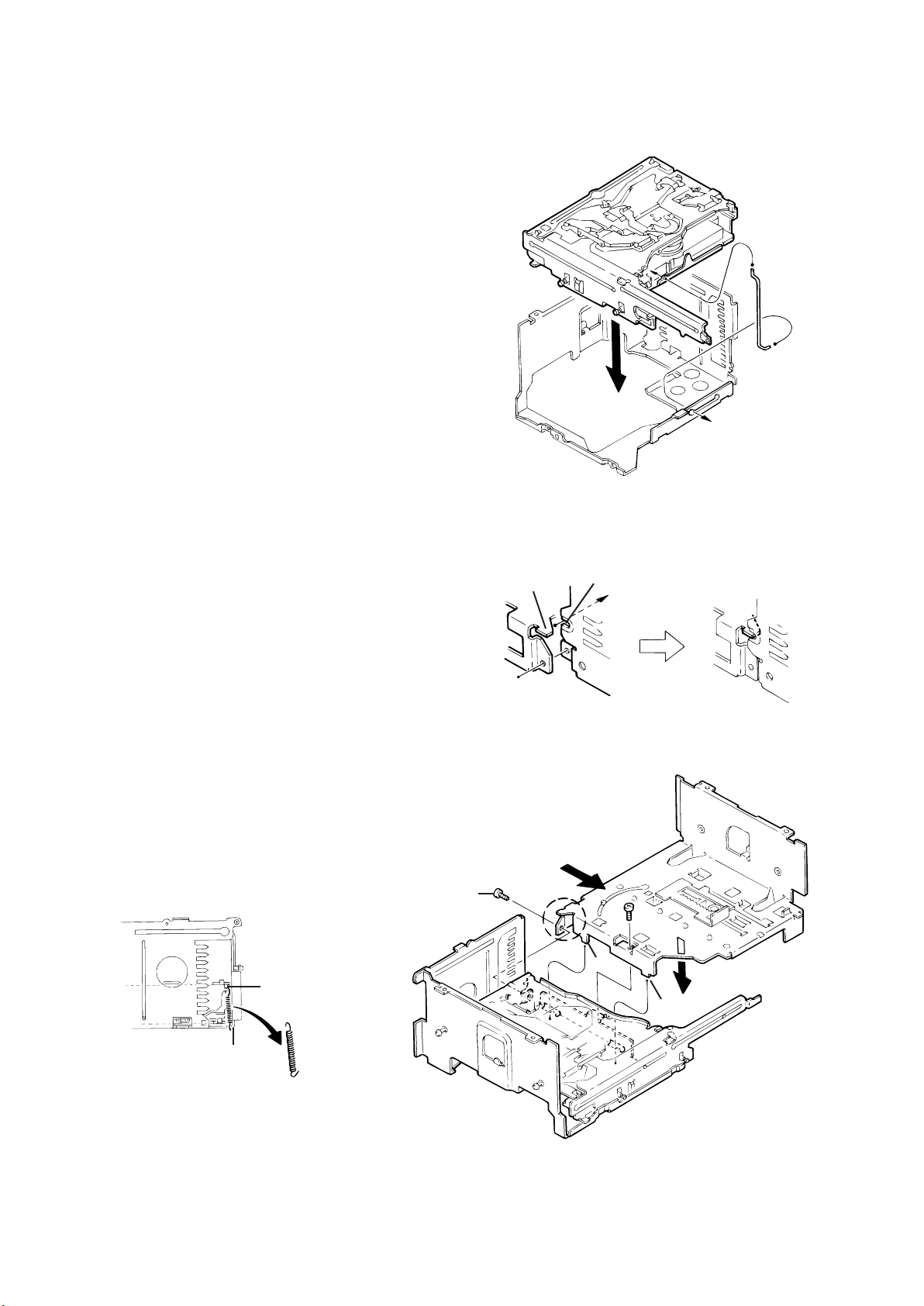

Lifter Unit

1. Unhook the elevator spring located on the front side of the

unit.

(Be sure to first unhook the spring from the lifter side as

shown in the upper part of the diagram.)

2. Lift the lifter unit upward, then remove the lower rod to

remove the lifter unit from the chassis.

Lifter Bracket

1. Remove the two lifter bracket fixing screws (4) located on the

back of the lifter unit.

2. Remove the lower rod.

Side Bracket and Traverse Mechanism

1. Remove the two side bracket unit fixing screws (5) to

disconnect the side bracket unit from the lifter unit.

2. Remove the three shafts on the traverse mechanism

assembly from the lifter unit.

For reassembling, refer to the reassembling

procedures.

Fig. 21

Unhook this

part first

Proper

orientation

Lift up the lifter unit

Lower Rod

4

Fig. 22

4

Fig. 23

5

Remove from the

5

lifter unit

Fig. 24

Remove from the

lifter unit

Page 8

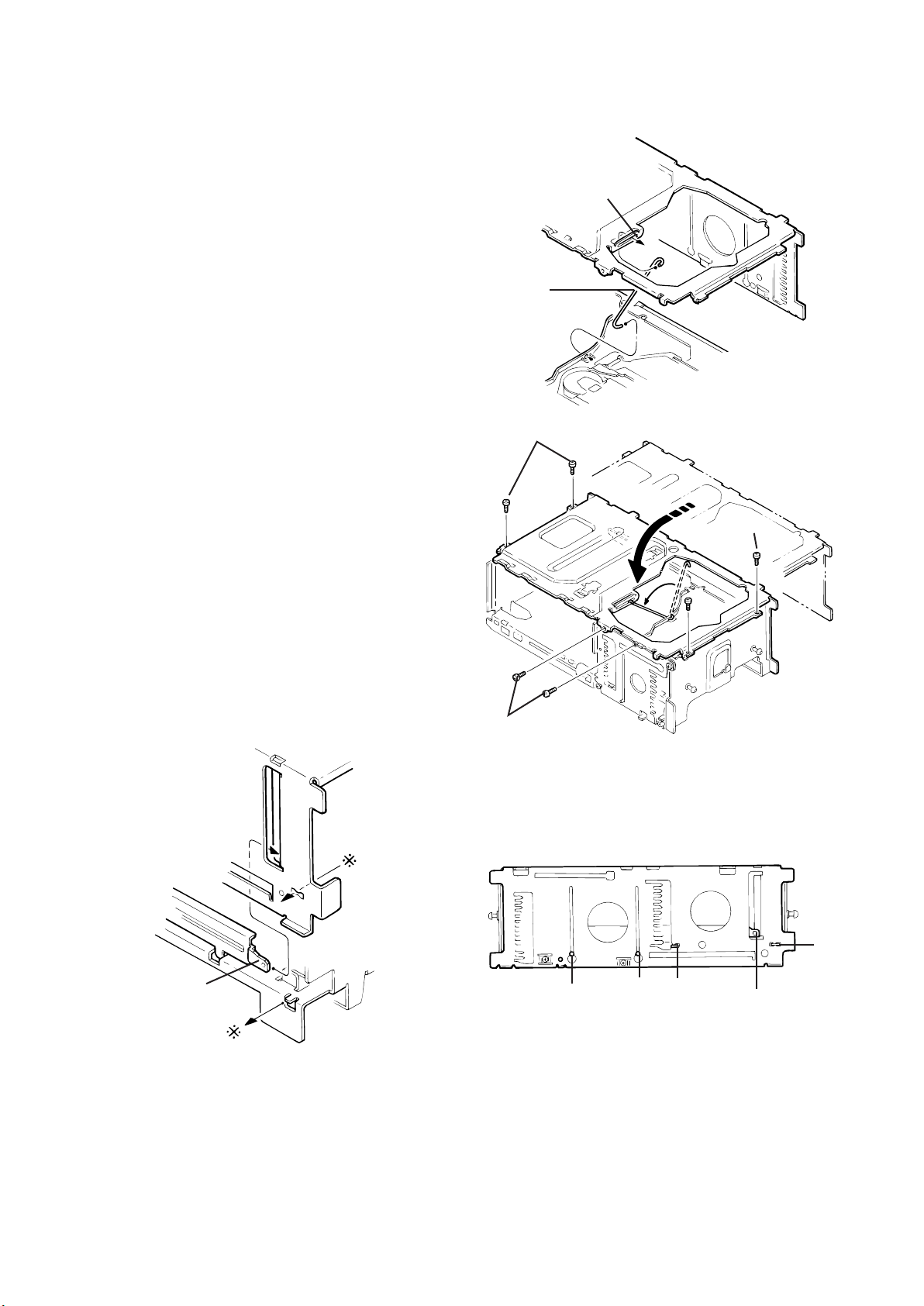

Pickup Assembly

1. Remove the three mechanism PCB fixing screws (6) located

on the back of the traverse mechanism.

2. Disconnect the two feed motor wires (blue and white), two

spindle motor wires (red and black) and two tray motor

wires (brown and black) that are soldered to the mechanism

PCB assembly.

3. Short-circuit the grounding point on the mechanism PCB

assembly, and lift it with the flexible PCB attached to

connector CN501.

Next, short-circuit the grounding point on the pickup unit

and disconnect CN501.

4. Remove the screw (7) to remove the feed motor assembly.

5. Remove the screw (8) to remove the shaft holder retaining

the feed slide shaft assembly and the middle gear.

6. Remove the middle gear.

7. Move the pickup assembly upward from the gear section

and remove it from the traverse chassis assembly.

8. Remove the two screws (9) to remove the rack arm.

9. Pull out the feed slide shaft assembly.

10. Remove the screw (10) to remove the spring.

Note: Before replacing the pickup, be sure to short-circuit the

grounding points. First short-circuit the PCB section and

then immediately short-circuit the pickup section.

Pickup: Remove

after shorting

6

Feed Motor

Pickup Flexible PCB

CN501

Tray Motor Wire

6

Spindle Motor

Grounding Point

Fig. 25

Grounding Point

Feed Motor

Remove gears and

motors only when

required.

Fig. 26

Pickup Assembly

Middle Gear

7

8

Shaft Holder

Feed Slide Shaft Assembly

10

Chassis

Pull out

Rack Arm

9

Fig. 27

Page 9

Tray Motor

1. Remove the two screws (11) securing the tray motor.

2. Remove the two screws (12) to remove the tray motor

assembly from the tray motor holder.

Separation of the Chassis L Assembly and

Chassis R Assembly

1. Remove the two screws (13) retaining the chassis "L" and

"R" assemblies.

2. Slide the chassis L assembly toward the front and detach it,

then remove the chassis "L" upward.

11

11

Fig. 28

Tray Motor

Slide and remove upward as

shown by the arrow

13

Tray Motor Assembly

Tray Motor Holder

12

Fig. 29

13

Front side

Fig. 30.

Page 10

Precautions On Reassembling

When reassembling, also refer to the

disassembling procedures.

Pickup Assembly

Mounting the Traverse Mechanism

1. When mounting the pickup assembly, attach the feed slide

shaft assembly to the traverse chassis.

Apply E-JC-525 grease to the shaft.

2. Mount the middle gear and the feed slide shaft to the traverse

chassis and secure them with the screw (14) through the

shaft holder.

3. Before mounting the mechanism PCB assembly, move the

pickup to the outer edge position, then secure the PCB

assembly using the screw (15).

At this time, check that the rest switch is correctly placed.

4. To mount the rack arm, first move the pickup to the middle

position and secure it with the screws (16).

Motor

Feed Motor

Fig. 31

Attached to chassis

14

Shaft Holder

Feed Slide Shaft (half

coated with grease)

Middle Gear

Chassis

Mounting the

Feed Motor Assembly

Mechanism PCB Assembly

15

15

Fig. 33

15

Shaft Holder

Spindle Motor

Fig. 32

16

Rack Arm

Move the pickup to the

middle position

Fig. 34

Page 11

Mounting the Lifter unit

1. Insert the shafts (B) of the traverse mechanism assembly into

the slide grooves (F) on the lifter unit.

2. Shift the hook of the lifter unit to the edge, and shift the

sliding lever inside the side bracket unit to the edge as well.

3. With each hole and lever shifted to the edge, mount the lifter

unit and side bracket unit from the side.

(Check each attached section, and check that the two shafts

(C) of the lifter unit are correctly inserted into the holes (g) of

the side bracket unit. After mounting, check that the levers

move together. )

4. Turn the lifter unit upside down.

As shown in Fig. 37, slide the lever 30 mm away from the

edge, then mount the lifter bracket L assembly.

Attach

(C)

Fig. 35

(B)

(F)

(B)

(F)

(g)

(F)

(B)

Fig. 36

Fig. 37

Shift inside by approx. 30 mm

Expanded View

Page 12

Connection of the Chassis "L" Assembly

and Chassis "R" Assembly

1. Attach the lower rod to the chassis "R" assembly. While

shifting the rod toward the front side, mount the rod on the

lifter unit.

With the rod mounted, place the lifter unit on the chassis "R"

assembly.

2. Combine the chassis "L" and "R" assemblies so that the hook

section (h) of the chassis "L" assembly is inserted into the

notch of the chassis "R" assembly by sliding it from the front

side.

3. After engaging, secure with the two screws (18).

4. Attach the tension spring between the lifter unit and the

chassis.

Lower Rod

Fig. 38

Set last (lifter side)

18

h

Slide to engage

Notch

Attached

Fig. 39

i

Combine with R chassis

i

Set first

(chassis side)

Tension Spring

Proper

orientation

Fig. 40

Page 13

Mounting the Top Plate

1. Mount the upper rod on the lifter side (j) and set it on the rear

of the top plate, then mount the other end of the upper rod to

(k).

2. Check that the five points (l, m, n, o and p) are correctly

positioned.

When mounting section (q), set it so that section (D) of the

lifter unit is pinched by the bending section of the top plate.

3. Secure the top plate with six fixing screws (19).

k

Upper Rod

Fig. 41

19

19

Expanded view of mounting "q"

(D)

Lifter Unit

Section "p"

Fig. 43

19

Fig. 42

p

l

m n

q

Fig. 44

Page 14

Mounting the Front Slider and Rear Slider

1. Position the unit with the rear side facing down, then rotate

the third gear in the direction of the arrow (clockwise) until the

lift arm comes to the position at which the holes are exposed,

as shown in Fig. 45-1.

2. Mount the front slider from the top.

Rotate the third gear counterclockwise until the hole of the

slider is lined up with the right hole of the stud, as shown in

Fig. 45-2.

3. Mount the E-washer on the shaft.

4. Position the unit with the front side facing down, then mount

the rear slider. Check that the (r), (s) and (t) positions are

correctly mounted as shown in Fig. 46.

5. Rotate the third gear in the direction of the arrow

(counterclockwise) until the lifter unit is at the top position.

Check after mounting

Front Slider

E-Washer

Stud

Position so that the

stud and right hole

are lined up

Fig. 45-2

Rotate the third gear to

move the slider

Fig. 45-1

Fig. 45

Set so the holes

are exposed

Rotate until the

holes are lined up

r s t

Fig. 46

Rotate the third

gear to move the

slider

Page 15

Mounting the Sensor PCB Assembly

1. Attach the longer spring to the white resin, and attach the

shorter spring temporarily to the sensor assembly bracket.

2. Mount the sensor assembly so that the shaft of the lift arm is

inserted into the longer hole on the white resin located on the

back of the sensor PCB assembly.

3. Attach the shorter spring to the hook of the lift arm.

Sensor assembly fixing screws

Attach

temporarily

Mounting the Main PC Board Assembly

1. Rotate the third gear clockwise until section (E) of the front

slider and the third hole from the right are lined up.

(Be sure to set properly. If incorrectly set, the switches on the

PCB assembly may be damaged.)

2. After they are correctly positioned, mount the main PCB

assembly.

Shorter

spring

Shorter

spring

Longer

spring

Fig. 47

Position so that the slider hole and third hole

from the right are lined up

(E)

Fig. 48

Page 16

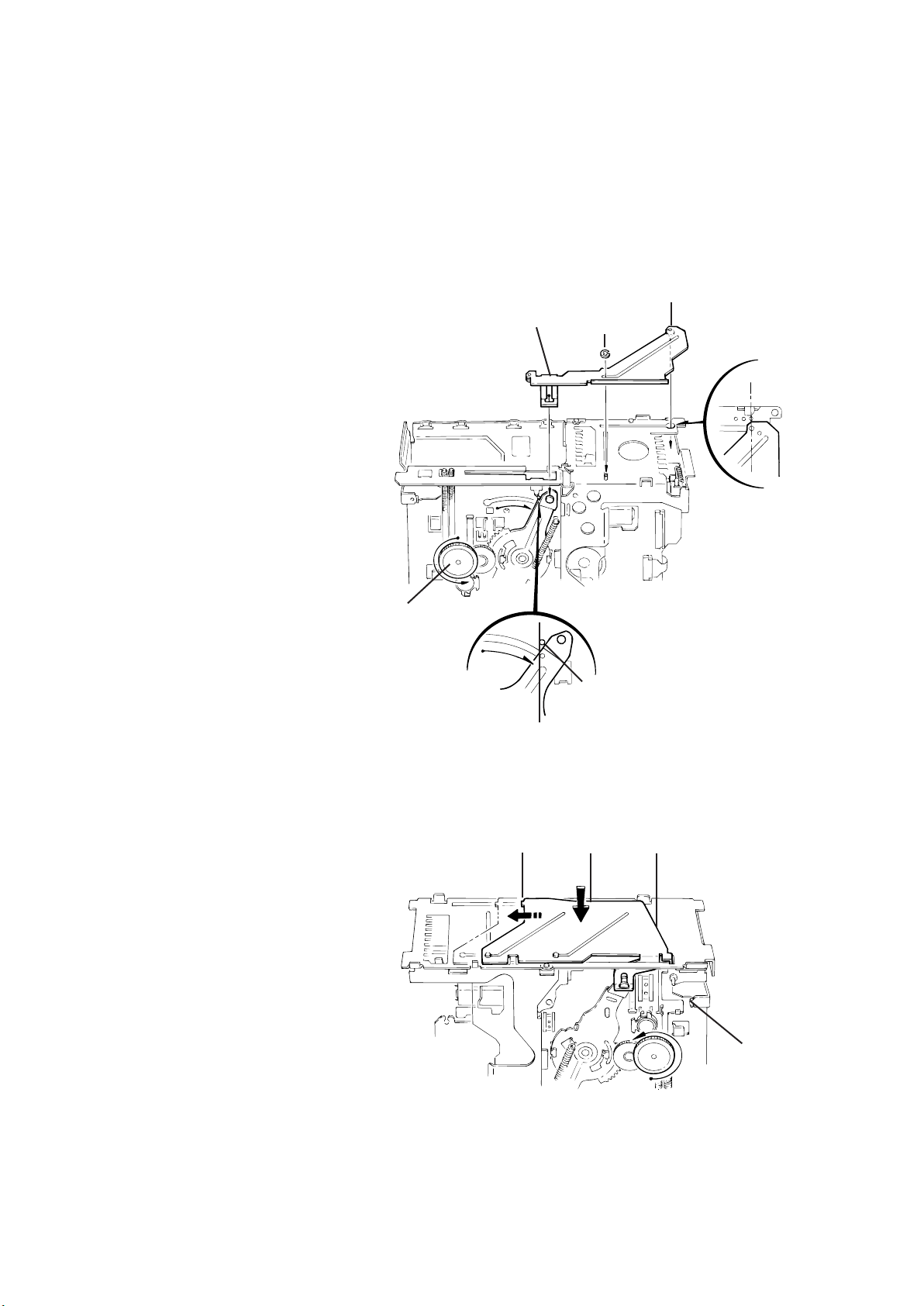

Pickup Replacement Procedure

1. Remove the bottom cover, front panel and top cover

from the exterior section.

2. Unplug the flexible ribbon wire from connector CN502

on the traverse mechanism PC board assembly.

3. Turn the rear slider and third gear in the lifter section

counterclockwise until the traverse mechanism

assembly is in the lowermost (bottom) position.

4. Unsolder the two wires (black and brown) connected

to the tray motor.

5. Remove the two screws (1) from the round holes on

the chassis R assembly to remove the lifter bracket

(L).

6. Remove the lower rod.

7. Short-circuit the grounding point on the traverse

mechanism PCB assembly of the lifter unit. Unsolder

the wires connected to the spindle motor (red, black)

and to the feed motor (blue, white) to lift the PCB

assembly.

Next, short-circuit the grounding point on the pickup

main unit and unplug the pickup flexible PCB from

CN501.

8. Remove the three fixing screws (2) from the round

holes on the chassis R assembly to remove the

traverse mechanism PCB assembly.

9. Remove the pickup shaft holder fixing screw (3) to

remove the pickup assembly.

Lifter Bracket (L)

Main PCB

Assembly

1

Unsolder

Grounding Point

Third Gear

Feed Motor

Assembly

1

CN502

Fig. 49

Unsolder

Note: When replacing the pickup, be sure to

apply countermeasures against static

electricity (grounding the operation table,

wrist band and soldering iron). To remove

it, first short-circuit the grounding point on

the mechanism PCB, then lift the

mechanism PCB assembly with CN501

connected. Next, short-circuit the

grounding point on the pickup main unit,

then unplug the pickup flexible PCB from

connector CN501.

When reassembling, perform in the reverse order.

2

Traverse

Mechanism

PCB Assembly

Tray Motor

Assembly

2

2

CN501

Fig. 50

Spindle Motor

Shaft Holder

3

Pickup Assembly

Fig. 51

Page 17

10. Remove the two rack arm fixing screws (4).

Pull out the feed slide shaft.

Remove the shaft holder fixing screw (5).

11. When mounting the lifter bracket after replacing the pickup,

shift the lifter unit lever approx. 30 mm towards the inside,

then mount the lifter bracket.

5

Grounding Point

Pickup

Feed Slide Shaft

Rack Arm

4

Fig. 52

3

Shaft Holder

Middle Gear

Shift approx. 30 mm

Shift approx. 30 mm

Enlarged

Diagram

Fig. 54

Fig. 53

Lifter Unit Lever

Page 18

JC12 Forced Eject Procedures

Magazine eject does not function.

RESET (Press EJECT for 3 sec.)

YES

Completed

Check that the trays remain no more

than 10 mm inside the magazine.

Improperly positioned

Remove the dampers and the top

cover to take out the mechanism.

Remove the item(s) causing the

disc-jam through the clearance at

the top of the lifter.

Are trays stored in

the magazine?

Check visually.

Remove the bottom cover

NO

Is the disc set in the playing

position?

Rotate the third gear clockwise and

unchuck the disc.

Disconnect the tray from the hook.

NO

NO

YES

YES

Peel off the sticker on the left side

of the unit. Insert a screwdriver

and press the internal lever to

forcibly eject the magazine.

Completed

Remove the lifter bracket (L) and

return the tray to the magazine.

Place the unit with its left side

facing down and apply a slight

shock, then return the tray to the

magazine.

Rotate the third gear clockwise

until the lifter level is below the 9th

tray position.

Press the magazine lock lever to

eject the magazine.

Completed

Page 19

Page 20

CH-X1200 Error Code

The following error codes can be displayed and stored in up to 3 memorieswhen the KD-MX3000 is used with

the controller. Refer to the KD-MX3000service manual regarding error code indication.

The error code indication when using the earlier controller is the same asthe CH-X99,KD-MK88 and other

12CD changer models.

CH-1 error code table

Generating condition Description Error code

Tray extension

error

Tray retraction

error

Lifter raise error

Lifter lower error

Chuck error

Unchuck error

Eject error

Initialize error

Tray-in switch time out

(Tray-in switch Low, Tray-out switch High)

Tray-out switch High)

Tray-out switch Low)

MAG-in switch Low to High

Tray-out switch Low)

Tray-out switch High)

Tray-out switch Low)

Wait position time out

Wait position time out

Wait position time out

Play position time out

Play position time out

Wait position time out

Eject position time out

MAG in switch time out

Mechanism switch time out

Tray stops part way E1 03 00 11

Tray stops part way E1 03 00 12Tray-out switch time out (Tray-in switch High,

Tray-in switch faulty or other defect E1 03 00 13Tray-in switch time out (Tray-in switch Low,

E1 03 00 14 Magazine removed when tray partly extende

Tray motor inoperative E1 03 00 16Tray-in switch time out (Tray-in switch Low,

Tray retraction stops part way E1 03 00 17Tray-out switch time out (Tray-in switch High,

Tray-in switch faulty or other defect E1 03 00 18Tray-in switch time out (Tray-in switch Low,

Magazine removed when tray partly retracted E1 03 00 19MAG-in switch Low to High

E1 02 00 21Position motor inoperativeWait position time out

E1 02 00 22Position not stable in fine adjust mode

E1 02 00 23Other faultWait position time out

E1 02 00 26Position motor inoperative

E1 02 00 27Position not stable in fine adjust mode

E1 02 00 28Other faultWait position time out

E1 02 00 31Position motor inoperative

E1 02 00 32Position not stable in fine adjust modePlay position time out

E1 02 00 33Other fault

E1 02 00 36Position motor inoperativeWait position time out

E1 02 00 37Position not stable in fine adjust modeWait position time out

E1 02 00 38Other fault

E1 02 00 41Position motor inoperativeEject position time out

E1 02 00 42Eject position not attained

E1 02 00 43Magazine not ejected

E1 03 00 46Both Tray-in and Tray-out Low

E1 03 00 47Not stable at absolute positionAbsolute position time out

Note: The 1st error code is indicated by E1, while the 2nd and 3rd errorcodes are respectively indicated by E2 and E3.

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

1.Block Diagram

SBAD

FEO

FEN

VRO

RFRP

RFIS

RFGO

RFGC

AGCI

RFO

GND

RFN

+

13

14

-

+

15

16

17

+

18

19

-

+

+

-

PEAK

BOTTOM

-

+

+

-

SW1 LDC

-

+

SW2

3 STATE

DET

+

-

+

TEO

-

12

TEN

11

2VRO

10

TEB

9

8

SEL

7

LDO

6

MDI

-

20

21

-

+

+

-

I-I

I-I

TNI

5

4

TPI

+

22

-

23

-

+

+

+

+

24

FPI

3

FNI

2

LDC

SEL

SW1

SW2

1

Vcc

L

Hiz

H

ON

OFF

OFF

OFF

ON

ON

SW3

OFF

ON

ON

2.Function

Page 29

Page 30

Page 31

Page 32

Page 33

Printed Circuit Board

Main board

Volume board

8Pin connector board

Mechanism board

Main board

Volume board

8Pin connector board

Page 34

PARTS LIST

[ CH-X200 ]

* All printed circuit boards and its assemblies are not available as service parts.

Areas Suffix

E ----------- Continental Europe

J -------------- Northern America

U --------------------- Other Areas

No marks indicates all areas.

- Contents -

Exploded View of General Assembly and Parts List -------------------------------------CD Changer Mechanism Ass'y and Parts List ---------------------------------------------Electrical Parts List --------------------------------------------------------------------------------Packing Materials and Accessories Parts List ---------------------------------------------

3-2

3-4

3-7

3-10

Page 35

Exploded View of General Assembly and Parts List

4

20

34

To Changer

Mecha 'd'

d

Block No. M1MM

32

36

b

8

35

b

33

9

31

30

Page 36

Page 37

CD Changer Mechanism Ass'y and Parts List

E-CFD-931

E-LEN-320M

E-CFD-931

BOTOM SIDE

BOTOM SIDE

BOTOM SIDE

71

E-CFD-931

BOTOM SIDE

E-CFD-931

E-LEN-320M

Block No. M2MM

Grease No.: E-JC-525

BACK SIDE

BOTH SIDE

67

68

30

FRONT SIDE

To General

d

Assembly 'd'

70

69

E-LEN-320M

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Packing Materials and Accessories Parts List

Block No. M3MM

Block No. M4MM

Page 44

Page 45

Loading...

Loading...