Page 1

SERVICE MANUAL

HD MEMORY CAMERA

YF320<Rev.002>20102SERVICE MANUAL

GC-FM1AUS, GC-FM1BUS, GC-FM1VUS,

GC-FM1AEU, GC-FM1BEU, GC-FM1VEU,

GC-FM1BAA, GC-FM1BAC

MODEL

GC-FM1AUS

GC-FM1BUS

GC-FM1VUS

GC-FM1AEU

GC-FM1BEU

GC-FM1VEU

GC-FM1BAA

GC-FM1BAC

COPYRIGHT © 2010 Victor Company of Japan, Limited

Lead free solder used in the board (material : Sn-Ag-Cu, melting point : 219 Centigrade)

BODY COLOR

BLUE

BLACK

PURPLE

BLUE

BLACK

PURPLE

BLACK

BLACK

GC-FM1AUSG, GC-FM1BUSG, GC-FM1VUSG,

GC-FM1AEUG, GC-FM1BEUG, GC-FM1VEUG,

GC-FM1BAAG, GC-FM1BACG [C0X370]

TABLE OF CONTENTS

1 PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

5 TROUBLE SHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

SERIES

C0X3

COPYRIGHT © 2010 Victor Company of Japan, Limited

No.YF320<Rev.002>

2010/2

Page 2

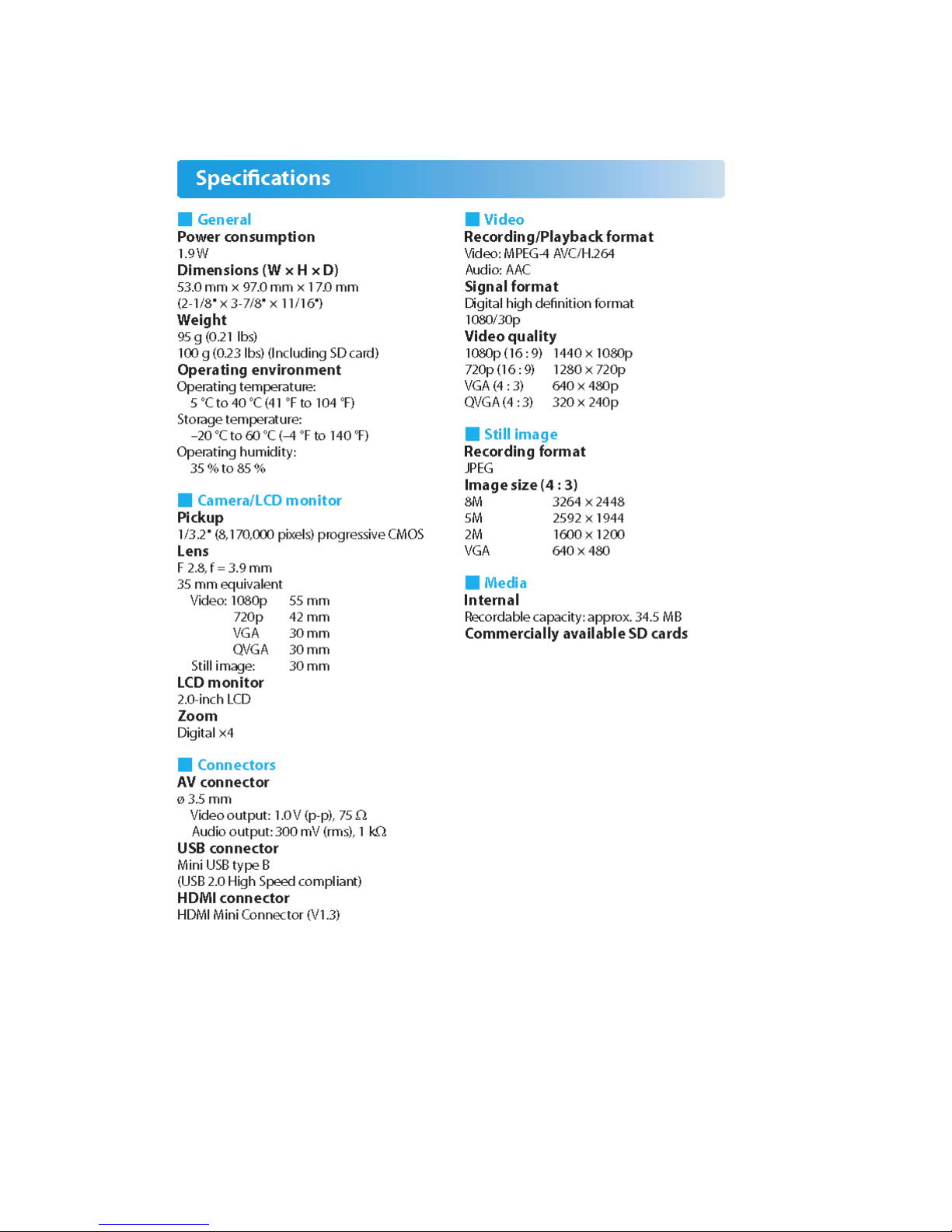

SPECIFICATION

1-2 (No.YF320<Rev.002>)

Page 3

SECTION 1

r

PRECAUTIONS

1.1 SAFETY PRECAUTIONS

Prior to shipment from the factory, JVC products are strictly

inspected to conform with the recognized product safety and

electrical codes of the countries in which they are to be

sold.However,in order to maintain such compliance, it is equally

important to implement the following precautions when a set is

being serviced.

1.1.1 Precautions during Servicing

(1) Locations requiring special caution are denoted by labels

and inscriptions on the cabinet, chassis and certain parts of

the product.When performing service, be sure to read and

comply with these and other cautionary notices appearing

in the operation and service manuals.

(2) Parts identified by the symbol and shaded ( ) parts

are critical for safety.

Replace only with specified part numbers.

NOTE :

Parts in this category also include those specified to

comply with X-ray emission standards for products

using cathode ray tubes and those specified for

compliance with various regulations regarding

spurious radiation emission.

(3) Fuse replacement caution notice.

Caution for continued protection against fire hazard.

Replace only with same type and rated fuse(s) as

specified.

(4) Use specified internal wiring. Note especially:

• Wires covered with PVC tubing

• Double insulated wires

• High voltage leads

(5) Use specified insulating materials for hazardous live parts.

Note especially:

• Insulation Tape

• PVC tubing

•Spacers

• Insulation sheets for transistors

• Barrier

(6) When replacing AC primary side components (transformers,

power cords, noise blocking capacitors, etc.) wrap ends of

wires securely about the terminals before soldering.

emission. Consequently, when servicing these products,

replace the cathode ray tubes and other parts with only the

specified parts. Under no circumstances attempt to modify

these circuits.Unauthorized modification can increase the

high voltage value and cause X-ray emission from the

cathode ray tube.

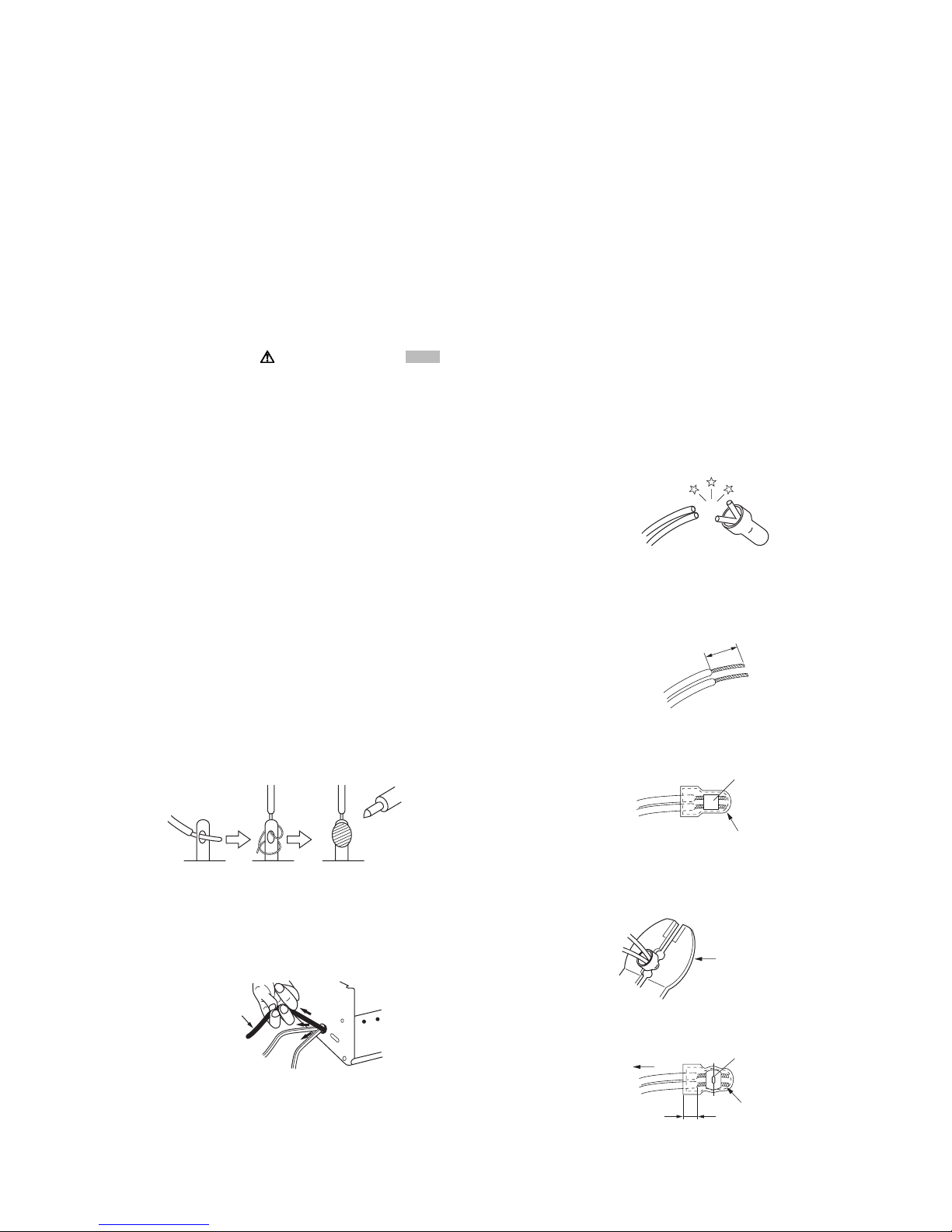

(12) Crimp type wire connectorIn such cases as when replacing

the power transformer in sets where the connections

between the power cord and power trans former primary

lead wires are performed using crimp type connectors, if

replacing the connectors is unavoidable, in order to prevent

safety hazards, perform carefully and precisely according

to the following steps.

• Connector part number :E03830-001

• Required tool : Connector crimping tool of the proper

type which will not damage insulated parts.

• Replacement procedure

a) Remove the old connector by cutting the wires at a

point close to the connector.Important : Do not

reuse a connector (discard it).

cut close to connector

Fig.1-1-3

b) Strip about 15 mm of the insulation from the ends

of the wires. If the wires are stranded, twist the

strands to avoid frayed conductors.

15 mm

Fig.1-1-4

c) Align the lengths of the wires to be connected.

Insert the wires fully into the connector.

Metal sleeve

Fig.1-1-1

(7) Observe that wires do not contact heat producing parts

(heatsinks, oxide metal film resistors, fusible resistors, etc.)

(8) Check that replaced wires do not contact sharp edged or

pointed parts.

(9) When a power cord has been replaced, check that 10-15

kg of force in any direction will not loosen it.

Power cord

Fig.1-1-2

(10) Also check areas surrounding repaired locations.

(11) Products using cathode ray tubes (CRTs)In regard to such

products, the cathode ray tubes themselves, the high

voltage circuits, and related circuits are specified for

compliance with recognized codes pertaining to X-ray

Connector

Fig.1-1-5

d) As shown in Fig.1-1-6, use the crimping tool to crimp

the metal sleeve at the center position. Be sure to

crimp fully to the complete closure of the tool.

1.2

5

2.0

5.5

Crimping tool

Fig.1-1-6

e) Check the four points noted in Fig.1-1-7.

Not easily pulled free

Wire insulation recessed

more than 4 mm

Crimped at approx. cente

of metal sleeve

Conductors extended

Fig.1-1-7

(No.YF320<Rev.002>)1-3

Page 4

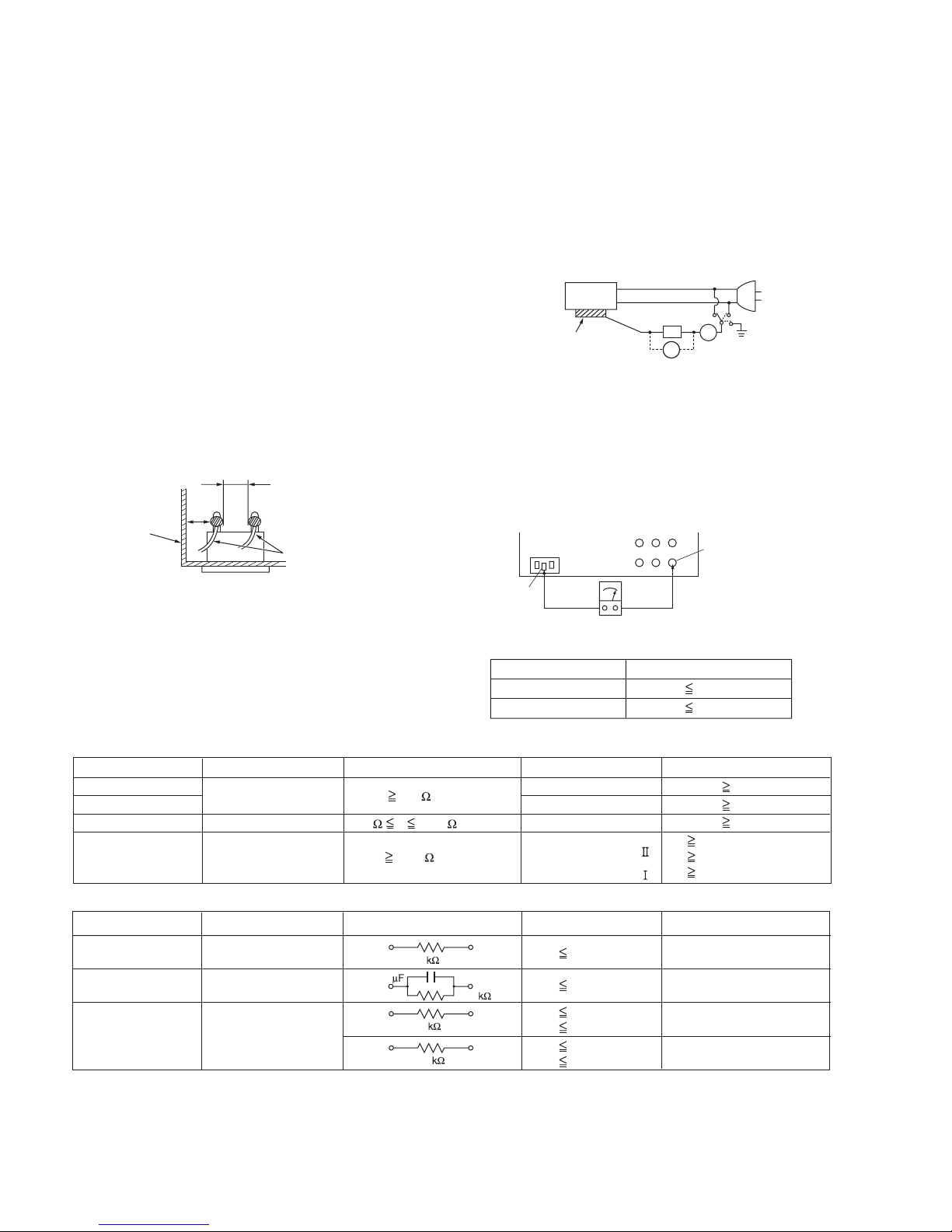

1.1.2 Safety Check after Servicing

Examine the area surrounding the repaired location for damage

or deterioration. Observe that screws, parts and wires have been

returned to original positions, Afterwards, perform the following

tests and confirm the specified values in order to verify

compliance with safety standards.

(1) Insulation resistance test

Confirm the specified insulation resistance or greater

between power cord plug prongs and externally exposed

parts of the set (RF terminals, antenna terminals, video and

audio input and output terminals, microphone jacks,

earphone jacks, etc.).See table 1 below.

(2) Dielectric strength test

Confirm specified dielectric strength or greater between

power cord plug prongs and exposed accessible parts of

the set (RF terminals, antenna terminals, video and audio

input and output terminals, microphone jacks, earphone

jacks, etc.). See Fig.1-1-11 below.

(3) Clearance distance

When replacing primary circuit components, confirm

specified clearance distance (d), (d') between soldered

terminals, and between terminals and surrounding metallic

parts. See Fig.1-1-11 below.

d

Chassis

d'

Power cord

primary wire

(4) Leakage current test

Confirm specified or lower leakage current between earth

ground/power cord plug prongs and externally exposed

accessible parts (RF terminals, antenna terminals, video

and audio input and output terminals, microphone jacks,

earphone jacks, etc.).

Measuring Method : (Power ON)Insert load Z between

earth ground/power cord plug prongs and externally

exposed accessible parts. Use an AC voltmeter to

measure across both terminals of load Z. See Fig.1-1-9

and following Fig.1-1-12.

ab

Externally

exposed

accessible part

Z

V

c

A

Fig.1-1-9

(5) Grounding (Class 1 model only)

Confirm specified or lower grounding impedance between

earth pin in AC inlet and externally exposed accessible

parts (Video in, Video out, Audio in, Audio out or Fixing

screw etc.).Measuring Method:

Connect milli ohm meter between earth pin in AC inlet and

exposed accessible parts. See Fig.1-1-10 and grounding

specifications.

AC inlet

Exposed accessible part

Fig.1-1-8

Earth pin

MIlli ohm meter

Grounding Specifications

Region

USA & Canada

Europe & Australia

Grounding Impedance (Z

Z 0.1 ohm

Z 0.5 ohm

)

Fig.1-1-10

AC Line Voltage

100 V

100 to 240 V

110 to 130 V

110 to 130 V

200 to 240 V

Region

Japan

USA & Canada

Europe & Australia

Insulation Resistance (R

R 1 M /500 V DC

1 M R 12 M /500 V DC

R 10 M /500 V DC

)

Dielectric Strength

AC 1 kV 1 minute

AC 1.5 kV 1 minute

AC 1 kV 1 minute

AC 3 kV 1 minute

AC 1.5 kV 1 minute

(

Class

(

Class

Clearance Distance (d), (d'

d, d' 3 mm

d, d' 4 mm

d, d' 3.2 mm

d 4 m m

)

d' 8 m m (Power cord

d' 6 m m (Primary wire

)

Fig.1-1-11

AC Line Voltage

100 V

110 to 130 V

110 to 130 V

220 to 240 V

Region

Japan

USA & Canada

Europe & Australia

Load Z

1

0.15

1.5

2

50

Leakage Current (i)

i 1 mA rms

i 0.5 mA rms

i 0.7 mA peak

i 2 mA dc

i 0.7 mA peak

i 2 mA dc

a, b, c

Exposed accessible parts

Exposed accessible parts

Antenna earth terminals

Other terminals

Fig.1-1-12

NOTE :

These tables are unofficial and for reference only. Be sure to confirm the precise values for your particular country and locality.

)

)

)

1-4 (No.YF320<Rev.002>)

Page 5

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

1.This camcorder has a built-in battery. The battery cannot be replaced by the user.

During disassembly/assembly, be careful not to get electrical

shock by touching and turning ON the power button, or not to

damage the circuits by short-circuiting.

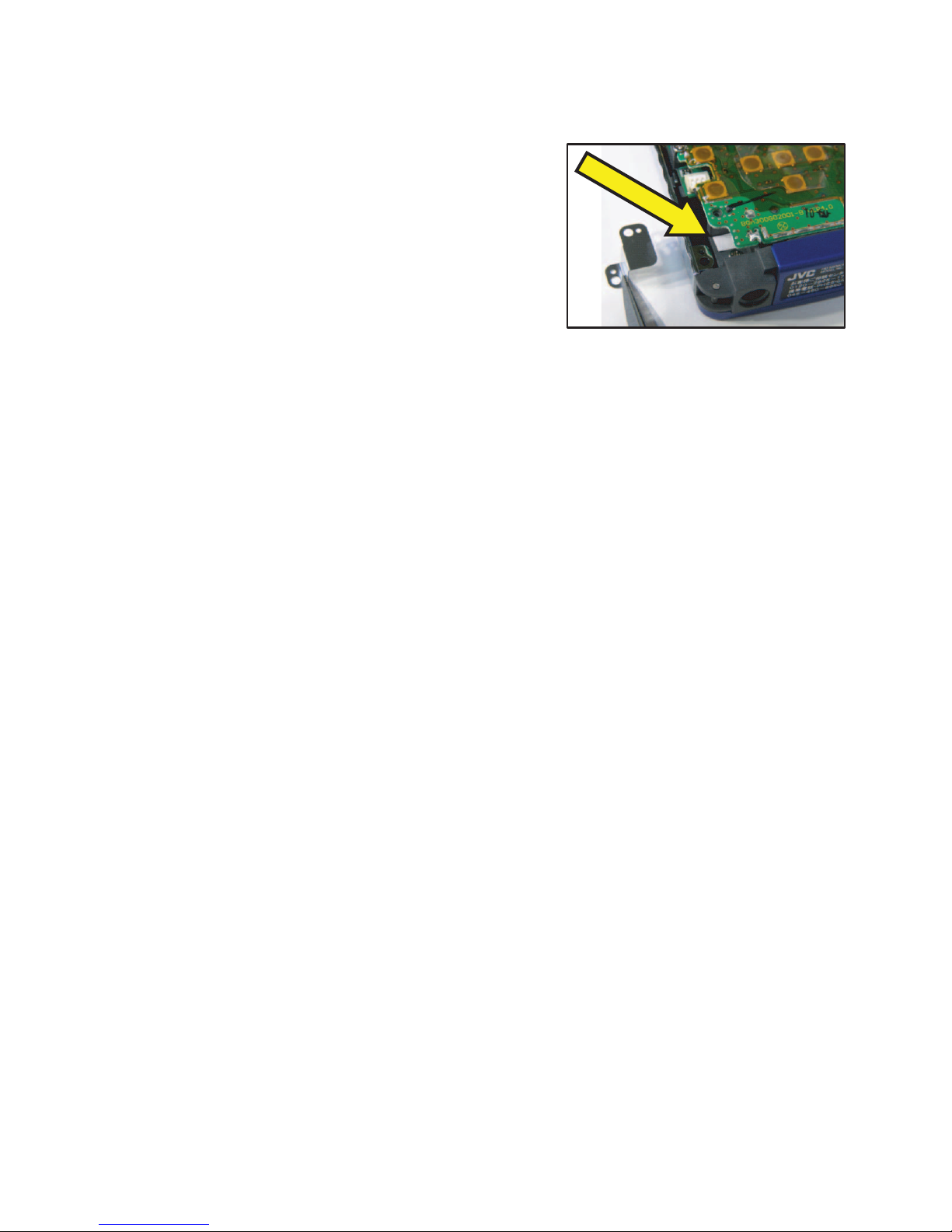

2.A water damage/submersion indicator (white) is affixed inside.(Refer to the picture in the right.)

When the battery is damaged by the water or submerged, the indicator turns to red.

3.When loading the battery to the main unit, be careful with the loading direction.

4.There is no adjustment needed after replacement of any parts.

5. Returning to the Factory Preset resets the following settings.

• File/ folder numbers

• Internal memory (image storage area) format

• Time setting

• Resolution setting

Procedure

(1) Download FN_Reset.dat from JS-NET.

Uploaded in "Special Tool" in "Service Support Software".

factory preset file for GC-FM1(31KB)

(2) Copy FN_Reset.dat to the SD card route.

(3) Insert the SD card into the slot on the main unit.

(4) Turn ON the power of the main unit.

(5) The power turns OFF automatically in about 1 second.

(6) Remove the SD card from the slot on the main unit.

NOTE

• If the remaining battery is less than half the capacity, a warning message appears and the reset cannot be performed.

• If a USB cable is connected for battery charging, the reset cannot be performed.

6. The firmware updated procedure is as follows.

(1) Download the relevant update file from JS-NET.

(2) Copy the update file to the SD card route.

(3) Insert the SD card into the slot on the main unit, then turn ON the power.

(4) An update screen appears.

(5) Selecting YES starts the update.

(6) When an update normal finish screen appears, turn OFF the power.

(7) Remove the SD card from the slot on the main unit.

7. The screw tightening torque is 0.108N*m (1.1kgf*cm) throughout the assembly procedure.

8. When the battery performance deteriorates, the following phenomena are observed.

• Abnormally long charging time

Normally, a completely empty battery finishes charging in about 3 hours. When the charging does not complete after about 6 hours

(twice the normal charging time), a battery trouble is considered.

If the charging does not complete after 12 hours, the charge LED blinks indicating an error.

• Abnormally short charging time

When a completely empty battery finishes charging in 10 to 20 minutes, battery abnormality is considered.

• Abnormally short discharge (usable) time

Although it varies according to environment, a fully charged new battery can record for about 70 minutes. If the battery becomes

empty (discharged) in several minutes, the battery capacity is considered to be extremely low.

9. Simple battery failure detection

When the voltage measures 2[V] or over between the (+) and (-) terminals, and the resistance measures 50[kΩ] to 150[kΩ] between

the (T) terminal and the GND, the battery is considered as a non defective battery.

(This does not indicate capacity decline. Use this measurement just as reference for detecting battery failure.)

(No.YF320<Rev.002>)1-5

Page 6

1-6 (No.YF320<Rev.002>)

Fig.2-1

Page 7

Fig.2-2

(No.YF320<Rev.002>)1-7

Page 8

1-8 (No.YF320<Rev.002>)

Fig.2-3

Page 9

SECTION 3

DISASSEMBLY

NOTE)The screw tightening torque is 0.108N·m (1.1kgf·cm) throughout the assembly procedure.

S1 : SCREW 1.7 x 4.0

S2 : SCREW 1.4 x 4.0

1

SCREW

(S1)

SCREW

(S1)

SCREW

(S1)

SCREW

(S1)

2 NOTE2

3 NOTE3

SCREW

(S1)

Unplug the battery power connector as shown

in the picture.

LCD

SCREW

(S1)

SCREW

(S2)4

PO

Pull the SPEAKER WIRES through the rib.

(No.YF320<Rev.002>)1-9

Page 10

4 NOTE4

Connector-Battery Wire

SCREW

(S1)

SCREW

(S1)

SCREW

(S1)

FPC Connector

B toB Connector

5 NOTE5

Place the SPEAKER WIRES as shown in the picture.

SCREW

(S1)

SCREW(S1)

SCREW

(S1)

Be careful with the FOCUS SWITCHING LEVER positioning.

Move both the LENS LEVER and the FOCUS SWITCHINGLEVER to the direction of the arrows before assembly.

SCREW

(S1)

SCREW

(S1)

Connector-Battery Wire

Connector-Battery Wire

6 NOTE6

SCREW

SCREW

SCREW

(S1)

(S1)

SCREW

(S1)

(S1)

SCREW

SCREW

(S1)

(S1)

1-10 (No.YF320<Rev.002>)

Place the battery wires within the guide as shown

in the picture.

Page 11

7 NOTE7

Push here to remove the battery.

This service manual does not describe ADJUSTMENT.

Be careful not to load the battery in a wrong direction.

SECTION 4

ADJUSTMENT

SECTION 5

TROUBLE SHOOTING

This service manual does not describe TROUBLE SHOOTING.

(No.YF320<Rev.002>)1-11

Page 12

Victor Company of Japan, Limited

Digital Imaging Products Business Division Imaging Products Operation 12, 3-chome, Moriya-cho, Kanagawa-ku, Yokohama-city, Kanagawa-prefecture, 221-8528, Japan

(No.YF320<Rev.002>)

Printed in Japan

VSE

Page 13

REVISION INFORMATION

HD MEMORY CAMERA

GC-FM1AUS, GC-FM1BUS, GC-FM1VUS,

GC-FM1AEU, GC-FM1BEU, GC-FM1VEU,

GC-FM1BAA, GC-FM1BAC

■ OVERVIEW

Parts have been added.

The additional parts are as follows:

Symbol Part No. Part Name

M1MM 25 1SM422700 GAP FILL TAPE

■ DETAILS

COVER SECTION

Title Line No.YF320<Rev.001> No.YF320<Rev.002> Description

Revision Rev.001 Rev.002

Issue Date 2009/10 2010/02

Copyright COPYRIGHT (C) 2009 Victor Company

of Japan, Limited

PARTS LIST

MODEL No. LIST

Model No. No.YF320<Rev.002>

GC-FM1AEU 04

GC-FM1AUS 01

GC-FM1BAA 07

GC-FM1BAC 08

GC-FM1BEU 05

GC-FM1BUS 02

GC-FM1VEU 06

GC-FM1VUS 03

FINAL ASSEMBLY [M1MM]

Symbol or

!

M1MM 25 ------------ 1SM422700 GAP FILL TAPE (Addition) 1 01,02,03,04,05,06,07,08

<Rev.001> <Rev.002>

Part No.

COPYRIGHT (C) 2010 Victor Company

of Japan, Limited

Part Name Description Qty Models

COPYRIGHT © 2010 Victor Company of Japan, Limited

YF320-R002

2010/02

Page 14

Victor Company of Japan, Limited

Digital Imaging Products Business Division Imaging Products Operation 12, 3-chome, Moriya-cho, Kanagawa-ku, Yokohama-city, Kanagawa-prefecture, 2218528, Japan

(YF320-R002)

Printed in Japan

No.YF320<Rev.001> VSE

Page 15

PARTS LIST

1.EXPLODED VIEW

1.1 FINAL ASSEMBLY <M1>

3-1

Page 16

2.PARTS LIST

2.1.FINAL ASSEMBLY<M1>

Symbol

No.

Part No. Part Name Q'ty

1 QA300-SVC001 FRONT COVER ASSY Including MIC 1

1 QA301-SVC001 FRONT COVER ASSY (BLUE) Including MIC 1

1 QA302-SVC001 FRONT COVER ASSY (PURPLE) Including MIC 1

2 QA300-SVC004 FRAME ASSY 1

3 QA300-SVC003 DOOR ASSY 1

3 QA301-SVC003 DOOR ASSY (BLUE) 1

3 QA302-SVC003 DOOR ASSY (PURPLE) 1

4 QA300-SVC005 SUB PCB ASSY 1

5 QA300-SVC002 REAR COVER ASSY 1

5 QA301-SVC002 REAR COVER ASSY (BLUE) 1

5 QA302-SVC002 REAR COVER ASSY (PURPLE) 1

6 QA300-SVC006 MAIN PCB ASSY 1

7 QA300-SVC007 MONITOR FRAME ASSY 1

8 XB00L00SN001 LITHIUM ION BATTERY 1

9 UDULCDTPD001 TFT LCD MODULE 1

10 1SM421928 STRAP PIN 1

11 1SM321303 OBI B 1

12 1SM422200 DATA PLATE (US) 1

12 1SM422292 DATA PLATE (US) BLUE 1

12 1SM422293 DATA PLATE (US) PURPLE 1

12 1SM422201 DATA PLATE (EU) 1

12 1SM422294 DATA PLATE (EU) BLUE 1

12 1SM422295 DATA PLATE (EU) PURPLE 1

12 1SM422203 DATA PLATE (AA) 1

12 1SM422204 DATA PLATE (AC) 1

12 1SM422202 DATA PLATE (JP) 1

12 1SM422296 DATA PLATE (JP) BLUE 1

12 1SM422297 DATA PLATE (JP) PURPLE 1

14 1SM421925 DOOR SHAFT 1

15 1SM421926 DOOR SP 1

16 1SM321363 EARTH PLATE 1

17 1SM321383 GND PLATE 1

18 1SM321448 GND PLATE B 1

19 1SM422341 THERMAL CONDITION SHEET A 1

20 1SM422360 THERMAL CONDITION SHEET C 1

23 1SM420609 SCREW.B-TIGHT 1.4*4.0 M3PAN+NI 4

24 1SM421116 SCREW.B-TIGHT 1.7*4.0 M3PAN+NI 14

2.2.ACCESSORY<M5>

Symbol

No.

Part No. Part Name Q'ty

-

WUU102SCP001 USB CABLE 1

- WPU122SCP001 AV CABLE 1

- 1SM422120 STRAP 1

- 1SM321404 BASIC USER GUIDE (US) * 1

- 1SM321423 BASIC USER GUIDE (EU) * 1

- 1SM321424 BASIC USER GUIDE (AA) * 1

- 1SM321425 BASIC USER GUIDE (AC) * 1

- 1SM321426 BASIC USER GUIDE (JP) * 1

* For more details on the operations, refer to the “Detailed User Guide” in the internal memory. (p. 4)

Loading...

Loading...