Page 1

A

SER VICE MANUAL

COLOR TELEVISION

V-T2122

BASIC CHASSIS

GA2

AV-T2122

!!

/AR

CONTENTS

SPECIFICATIONS

!

SAFETY PRECAUTIONS

!

FEATURES

!

FUNCTIONS

!

SPECIFIC SERVICE INSTRUCTIONS

!

SERVICE ADJUSTMENTS

!

PARTS LIST

!

★

OPERATING INSTRUCTIONS

★

STANDARD CIRCUIT DIAGRAM (APPENDIX)

1

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

COPYRIGHT © 2001 VICTOR COMPANY OF JAPAN, LTD.

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・

・・・・・・・・・・

・・・

・・・・・・

・・

・・・・

10

29

2-1

2

3

4

4

6

No.51866

Aug.2001

Sept. 2001

Page 2

A

V-T2122

SPECIFICATIONS

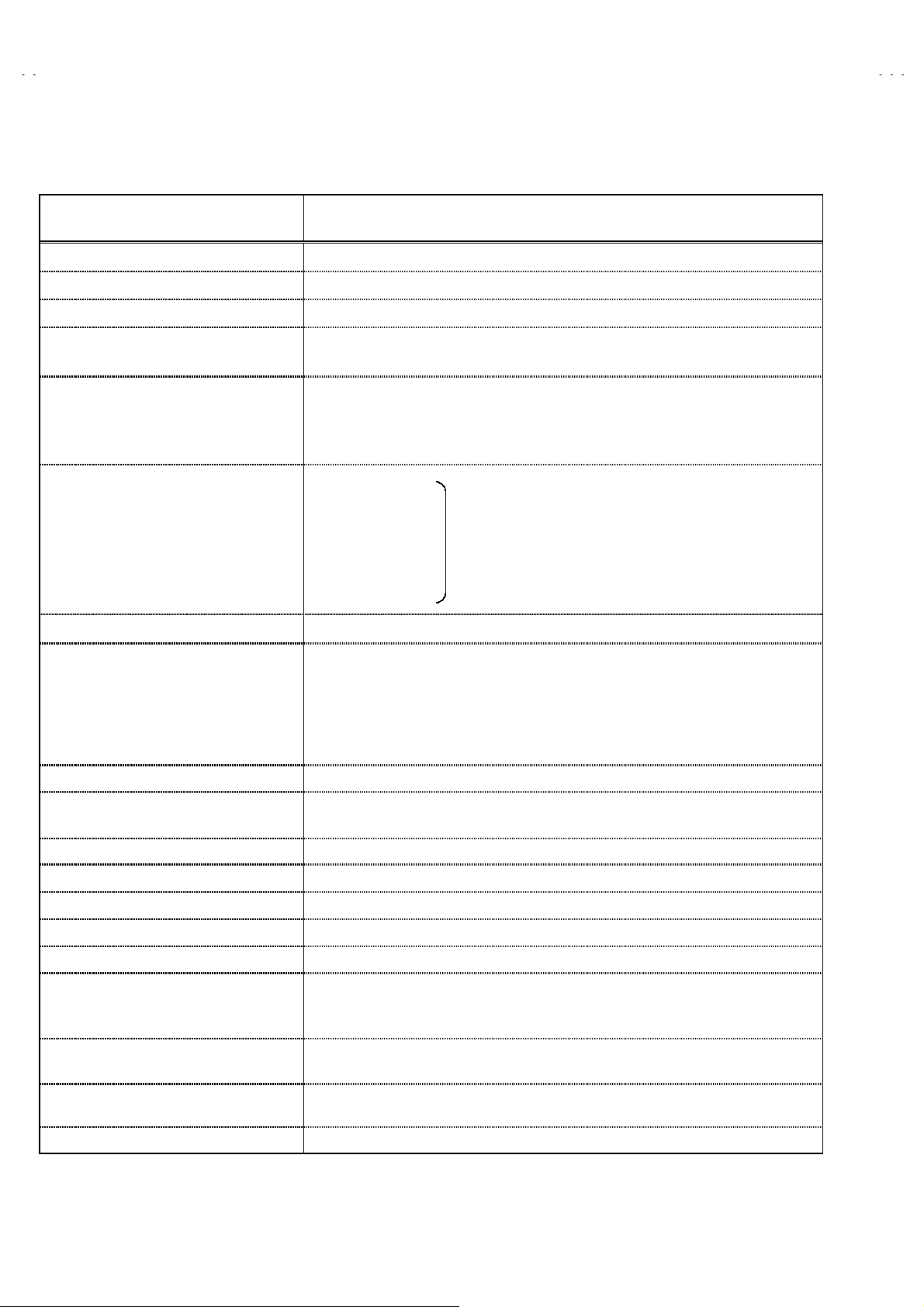

Items Contents

Dimensions (W

Mass

TV RF System

Color/ Sound System

TV Receiving Channels and Frequency

VL Band

VH Band

UHF Band

CATV Receiving Channels and Frequency

Low Band

High Band

Mid Band

Super Band

Hyper Band

Ultra Band

Sub Mid Band

TV/CATV Total Cha nne l

Intermediate Frequency

Video IF Carrier

Sound IF Carrier

Color Sub Carrier

××××H××××

D)

61.9cm×45.8cm×48.7cm

22.0kg

CCIR (M)&(N)

NTSC-M / PAL-M / PAL-N

MTS (Multi Channel Sound)

(02~06) 55.25MHz~83.25MHz

(07~13) 175.25MHz~211.25MHz

(14~69) 471.25MHz~801.25MHz

(02~06)

(07~13)

(14~22)

(23~36)

(37~64)

(65~94, 100~125)

(01, 96~99)

181 Channels

45.75MHz

41.25MHz (4.5MHz)

NTSC-M : 3.579545MHz

PAL-M : 3.57561149MHz

PAL-N : 3.58205625MHz

(55.25MHz~799.25MHz)

Antenna te rminal

Power Input

Power Consumption 87W(max.) / 63W(Avg.)

Picture Tube

High Voltage (at zero been current) 26.5kV±1.0kV

Speaker

Audio Power Output

Input

Video input

Audio input

Variable Audio Output

Headphone Jack / Earphone Jack

Remote Control Unit

75Ω(VHF/UHF) Terminal, F-Type Connector

Rated Volta ge : 120V~240V AC, 50Hz/60Hz

Operating Voltage : 90V~260V AC, 50Hz/60Hz

Visible size: 51 cm measured diagonally

6×12cm oval type×2

1.5W+1.5W (Stereo)

(Front / Rear)

1Vp-p 75Ω (RCA pin jack)

500mVrms (-4dBs),High Impedance (RCA pin jack)

More then 0~1550mVrms (+6dBs)

Low Impedance (400Hz when modula ted 100%) (RCA pin jack)

3.5mm stereo

mini jack (Headphone Jack)

RM-C373 (AA/R6/UM-3 battery×2)

Design & specification are subject to change without notic e.

2

No.51866

Page 3

A

SAFETY PRECAUTIONS

V-T2122

1. The design of this product contains special hardware, many

circuits and components specially for safety purposes. For

continued protection, no changes should be made to the original

design unless authorized in writing by the manufacturer.

Replacement parts must be identical to those used in the original

circuits. Service should be performed by qualified personnel

only.

2. Alterations of the design or circuitry of the products should not be

made. Any design alterations or additions will void the

manuf act urer's warr an t y and wil l fur t h er reli ev e t h e manufacturer

of responsi bility f or person al injury or pr operty dam age res ulting

therefrom.

3. Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics are

often not evident f rom visual i nspection nor can t he protect ion

afford ed by them n ecess arily be obt ained by using rep lacem ent

compon ents rated f or higher voltag e, watt ag e, etc. R epl acem ent

parts which have these special safety characteristics are

identified in the parts list of Service manual.

compon ents hav in g su ch feat ures are id entif ied by s hadin g

on the sche matics and by (

manual.

have the same safety characteristics as the recommended

replac ement part shown i n the p arts list of S ervic e manu al may

cause shock, fire, or other hazards.

The us e of a subst itute replacement which does n ot

) on the parts list in Service

!!!!

Electrical

4.

Don't short b etween the LIV E side groun d and ISOLATED

(NEUTRAL) side ground or EARTH side ground when

repairing.

Some model's power circuit is partly different in the GND. The

difference of the GN D is sh ow n by the LIV E : (") side GND, the

ISOLATED(NEUTRAL ) : (#) side GND and EARTH : ($) side

GND. Don't short between the LIVE side GND and

ISOLATED(NEUTRAL) side GND or EARTH side GND and

never meas ure with a measuri ng apparatus (osc illoscope etc .)

the LIVE side GND and ISOLATED(NEUTRAL) side GND or

EARTH side GND at the same time.

If above not e wi ll n ot be kept, a fuse or any parts w ill be broken.

5. If any repair has been made to the chassis, it is recommended

that the B1 setting should be checked or adjusted (See

ADJUSTMENT OF B1 POWER SUPPLY).

6. The hig h voltage app lied t o the picture t ube must c onform wit h

that specified in Service manual. Excessive high voltage can

cause an increase in X-Ray emission, arcing and possible

component damage, therefore operation under excessive high

voltag e conditions s hould b e kept to a mi nimum, or sh ould be

prevented. If severe arcing occurs, remove the AC power

immediately and determine the cause by visual inspection

(incorrect install ation, crack ed or melted high volt age harness ,

poor solderi ng, etc.). To maintain the pr oper minimum le vel of

soft X-Ray emission, components in the high voltage circuitry

including the picture tube must be the exact replacements or

alternatives approved by the manufacturer of the complete

product.

7. Do not check high voltage by drawing an arc. Use a high voltage

meter or a high voltage probe with a VTVM. Discharge the

picture tube before attempting meter connection, by connecting

a clip l ead to th e g roun d fr am e and c on necti ng t h e oth er end of

the lead through a 10k" 2W resistor t o the an ode button .

8. W hen servic e is requir ed, obser ve the origin al lead dress . Extr a

precaut ion shou ld be gi ven to assure c orrect l ead dr ess in t he

high voltage circuit area. Where a short circuit has occurred,

those comp onents that in dicat e evidenc e of over heating should

be replaced. Always use the manufacturer's replacement

components.

9.

Isolation Check

(Saf ety for Electrical Shock Hazard)

After re-assembling the product, always perform an isolation

check on the exposed metal parts of the cabinet (antenna

termin als , vid eo/ au dio input and output term inals, Con trol knobs,

metal c abinet, s crewhead s, earph one j ack, contr ol shafts, etc.)

to be sure the product is safe to operate without danger of

electrical shock.

(1)

Dielectric Stren gt h Test

The isol ation b etween th e AC pr imar y circuit and all metal parts

expos ed t o th e user, p ar tic u larly any exp osed metal part h avi ng a

return p ath to the chassis should withst and a voltage of 3000V

AC (r.m.s .) for a period of on e s ec on d.

(. . . . W ithstand a voltag e of 1100 V AC ( r.m.s.) to an applianc e

rated up t o 120V, and 3000V AC (r. m.s.) t o an appl iance rat ed

200V or mor e, f or a peri od of on e s ec on d.)

This method of test requires a test equipment not generally found

in the service trade.

(2)

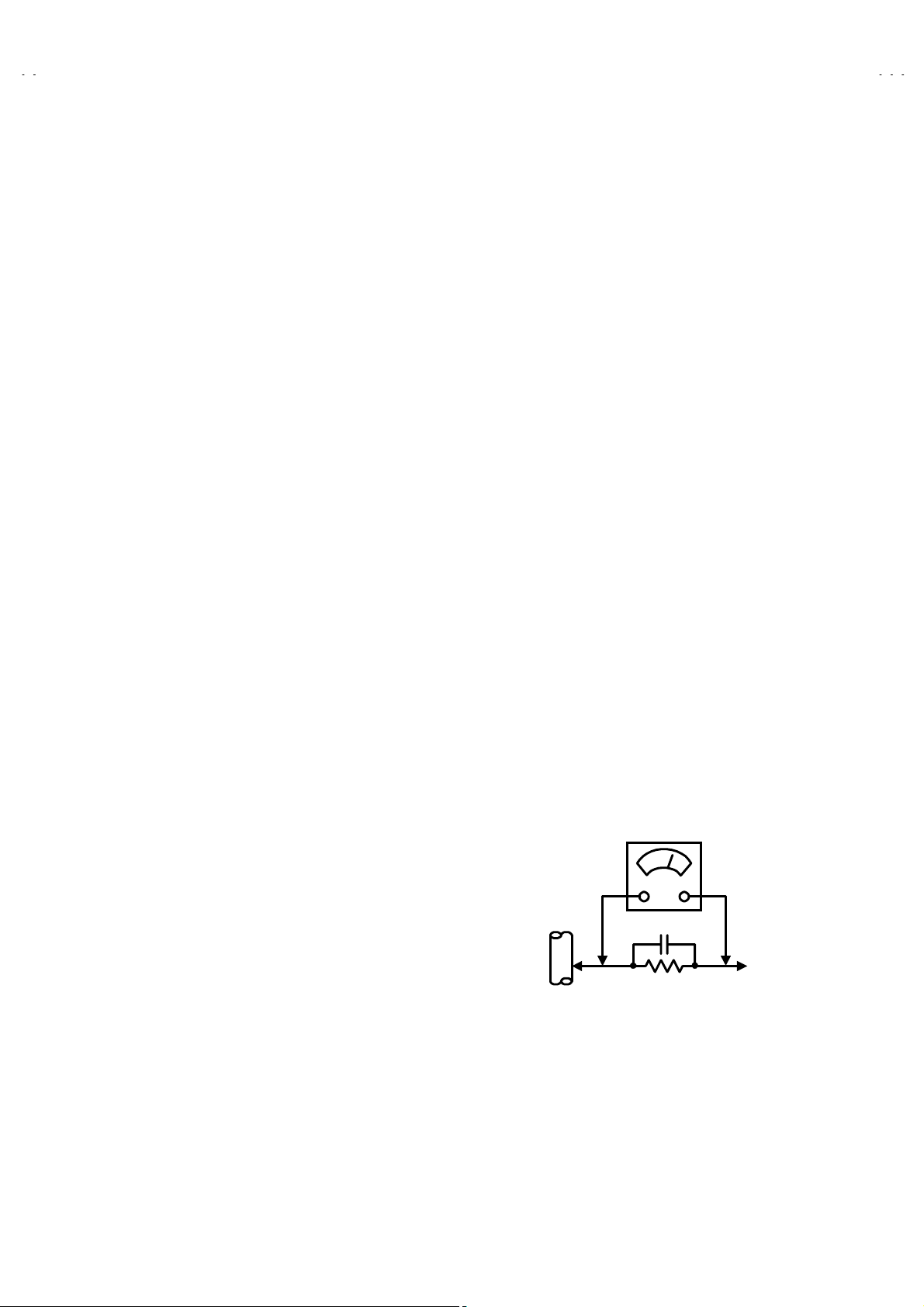

Leak age Current Check

Plug the AC lin e c or d dir ec t l y int o t he AC outlet ( d o not use a line

isolation transformer during this check.). Using a "Leakage

Current Tester", measure the leakage current from each exposed

metal part of the cabinet, particularly any exposed metal part

having a return path to the chassis, to a known good earth

ground ( water pipe, etc. ). An y leak age c urr ent mus t not exceed

0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.2mA AC

(r.m.s.).

Alternate Check Method

""""

Plug the AC lin e c or d dir ec t l y int o t he AC outlet ( d o not use a line

isolati on transform er during t his check. ). Use an AC voltmet er

having 1000 ohms per volt or more sensitivity in the following

manner. Connect a 1 500" 10W resistor paralleled by a 0.15#F

AC-typ e capacitor betw een an expos ed metal part and a know n

good earth ground (water pipe, etc.). Measure the AC voltage

across the resistor with the AC voltmeter. Move the resistor

connect ion t o each exp os ed met al p art, part icul arl y any exp osed

metal part h avin g a return p ath to th e chassis , and meas ure th e

AC voltag e across the res istor. N ow, re vers e the plug in the AC

outlet and repeat each measurement. Any voltage measured

must not exceed 0.75V AC (r.m.s.). This corresponds to 0.5mA

AC (r.m.s.).

However , i n t ropical area, this m us t not exc eed 0.3V AC (r.m.s .).

This corresponds to 0.2mA AC (r.m.s.).

0.15μF AC-TYPE

1500

GOOD EARTH GROUND

"

AC VOLTMETER

(HAVING 1000

OR MORE SENSITIVITY)

10W

"

/V,

PLACE THIS PROBE

ON EACH EXPOSED

METAL PART

No.51866

3

Page 4

A

V-T2122

FEATURES

New chassis desi gn enabl es us e of a main b oard with simp lif ied

"

circuitry.

Provided with mi niatur e tun er (TV /C ATV).

"

PLL synthesizer system TV/CATV tota ling 181 channels.

"

Multifunctional remote control permits picture adjustment.

"

With AUDIO. VIDEO INPUT terminal.

"

FUNCTIONS

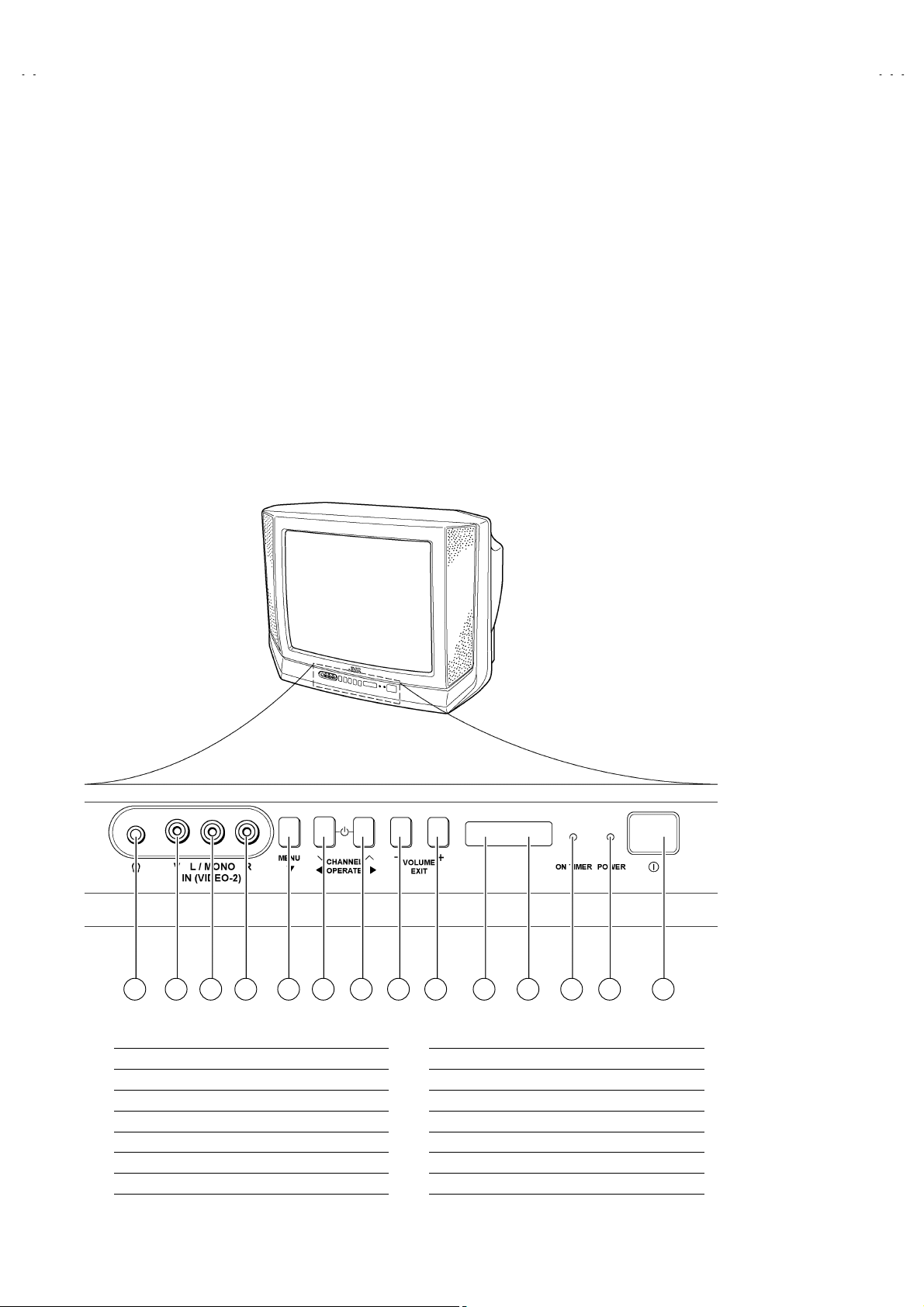

Front control

■■■■

Adopti on of the VIDEO STATUS func ti on.

"

Adoption of the ON/OFF TIMER function.

"

With 75ΩV/U in common (F-Type) ANT Terminal.

"

SLEEP TIMER for sett ing in real ti me.

"

Wide range voltage (90V~260V) AC power input.

"

Variable audio ou t p ut terminal.

"

1 2 3 4 5 6 7 8 9 10 11 12 13 14

HEADPHONE JACK Teminal

①

VIDEO INPUT Teminal

②

AUDIO L INPUT Tem inal

③

AUDIO R INPUT Teminal

④

MENU Button

⑤

CHANNEL ∨Button

⑥

CHANNEL ∧Button

⑦

4

No. 51866

VOLUME - Buttom

⑧

VOLUME + Buttom

⑨

ECO sensor

⑩

Remote control sensor

⑪

ON TIMER lamp

⑫

POWER lamp

⑬

MAIN POWER SW Button

⑭

Page 5

A

■

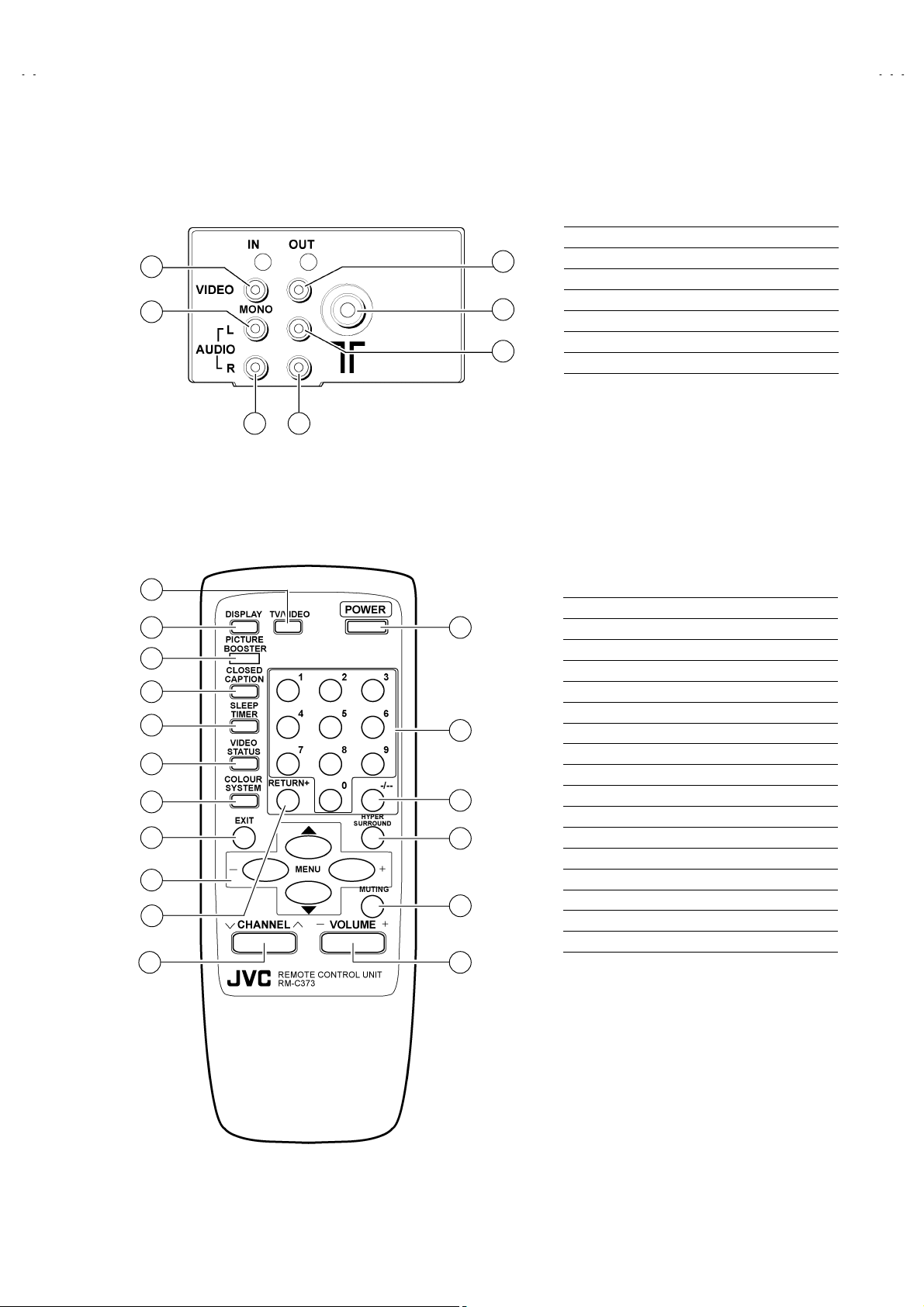

■Rear terminal

■■

2

3

4 7

■

■Remote control unit ( RM-C373)

■■

V-T2122

ANT Terminal

①

VIDEO INPUT Terminal

5

1

6

②

AUDIO L INPUT Terminal

③

AUDIO R INPUT Terminal

④

VIDEO OUTPUT Terminal

⑤

AUDIO L OUTPUT Terminal

⑥

AUDIO R OUTPUT Terminal

⑦

11

10

1

TV / VIDEO key

①

DISPLAY key

2

3

4

5

6

7

8

9

12

13

14

15

16

17

②

PICTURE BOOSTER key

③

CLOSED CAPTION key

④

SLEEP TIMER key

⑤

VIDEO STATUS key

⑥

COLOUR SYSTEM key

⑦

EXIT key

⑧

MENU (▲/▼& +/-)key

⑨

RETURN+ key

⑩

CHANNEL key

⑪

POWER key

⑫

Number (CH.) key

⑬

- /- - key

⑭

HYPER SURROUND key

⑮

MUTING key

⑯

VOLUME key

⑰

No. 51866

5

Page 6

A

V-T2122

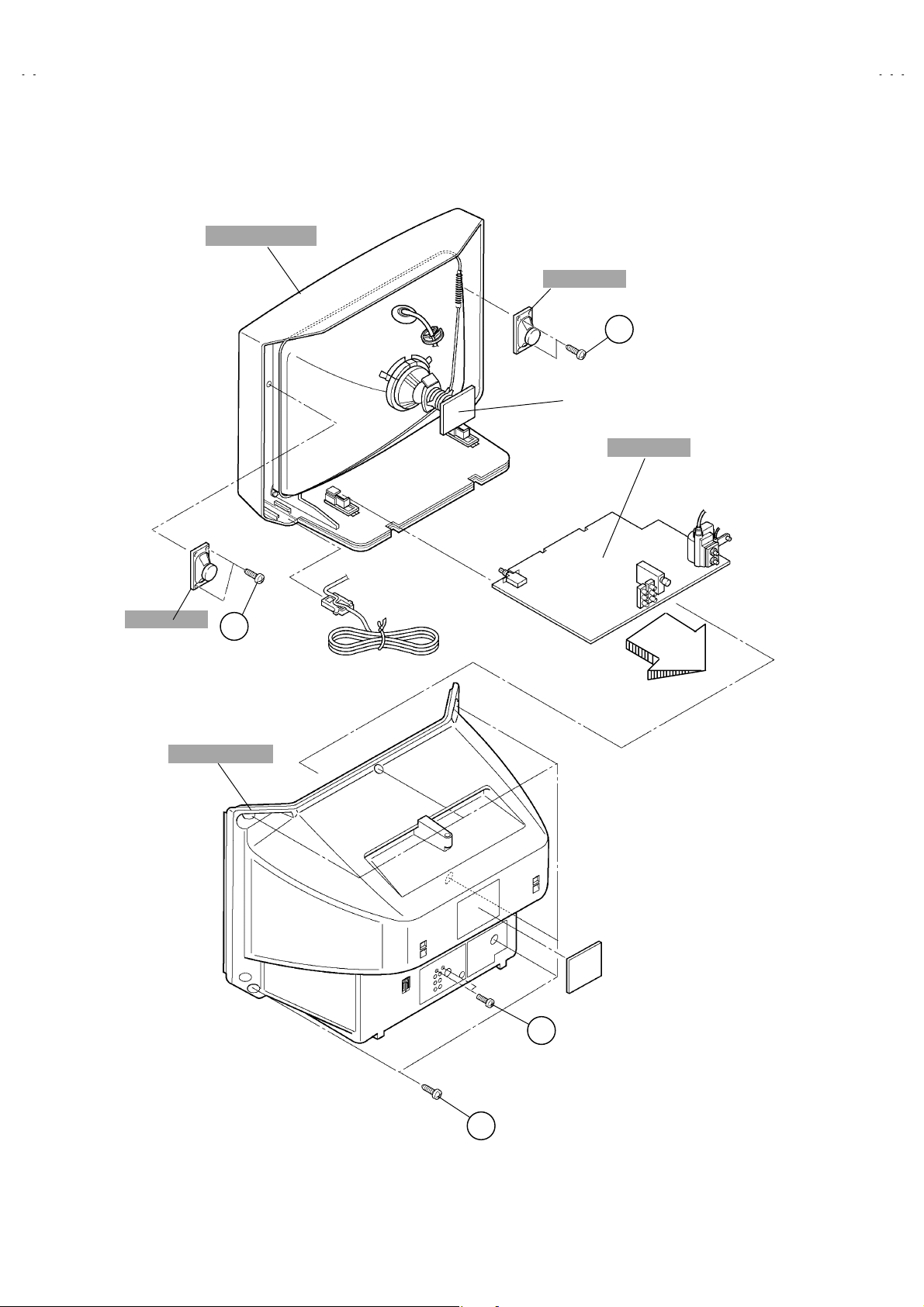

SPECIFIC SERVICE INSTRUCTIONS

DISASSEMBLY PROCEDURE

REMOVING THE REAR COVER

1. Unplug the power supply cord.

2. Remove the 6 screws marked

3. Withdraw the rear cover toward you.

REMOVING THE MAIN PW BOARD

Afte r removing the rear cover.

"

1. Slight l y raise both sid es of the MAIN PW Board by hand and w it hdraw it b ack w ard.

(If necessary, t ak e off the wire clam p and connec tors, etc.)

REMOVING THE SPEAKER

Afte r removing the rear cover.

"

1. Remove the 2 screws marked

2. Follow the same step for removing the other hand speaker.

CHECKING THE MAIN PW BOARD

1. To check the backside of the MAIN PW Board.

1) Pull out the MAIN PW Board. (Refer to REMOVING THE MAIN PWB).

2) Erect the chassis vertically so that you can easily check the backside of the MAIN PW Board.

and 2 screws marked

!"

!"

!"!"

.

$$$$

####.""""

[CAUTION]

When erecting the MAIN PW Board, be careful so that there will be no contacting with other PW Board.

"

Bef or e turni ng on power, m ak e sure that all connector s are properl y connected.

"

WIRE CLAMPING AND CABLE TYING

1. Be sure clamp the wire.

2. Never remove the cable tie used for tying the wires together.

Should it be inadvertently removed, be sure to tie the wires with a new cable tie.

6

No. 51866

Page 7

A

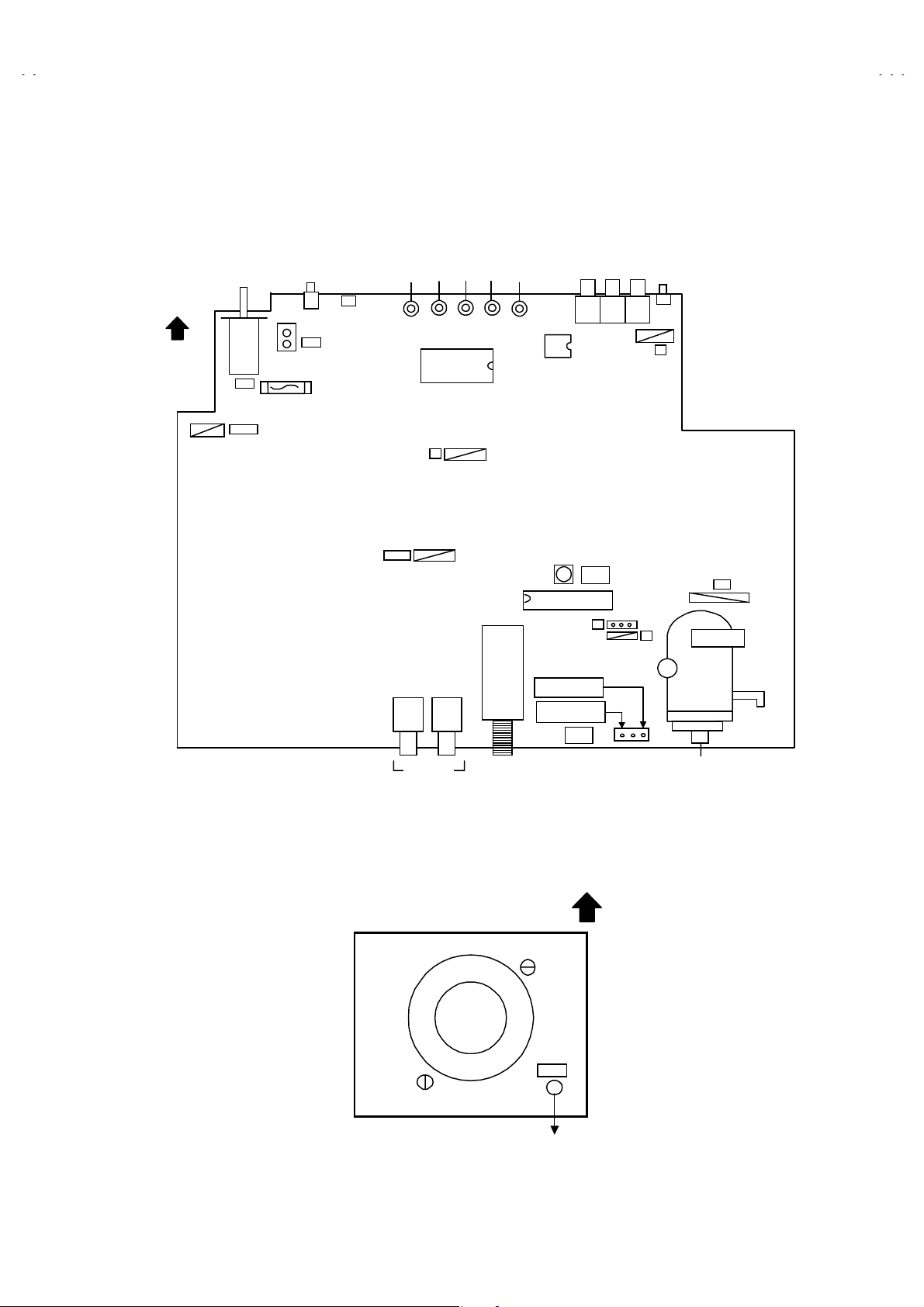

FRONT CABINET

SPEAKER

C

CRT SOCKET PWB

(Wit hin MAIN PWB )

MAIN PWB

V-T2122

(×2)

SPEAKER

REAR COVER

C

(×2)

(×2)

B

(×6)

A

No. 51866

7

Page 8

A

V-T2122

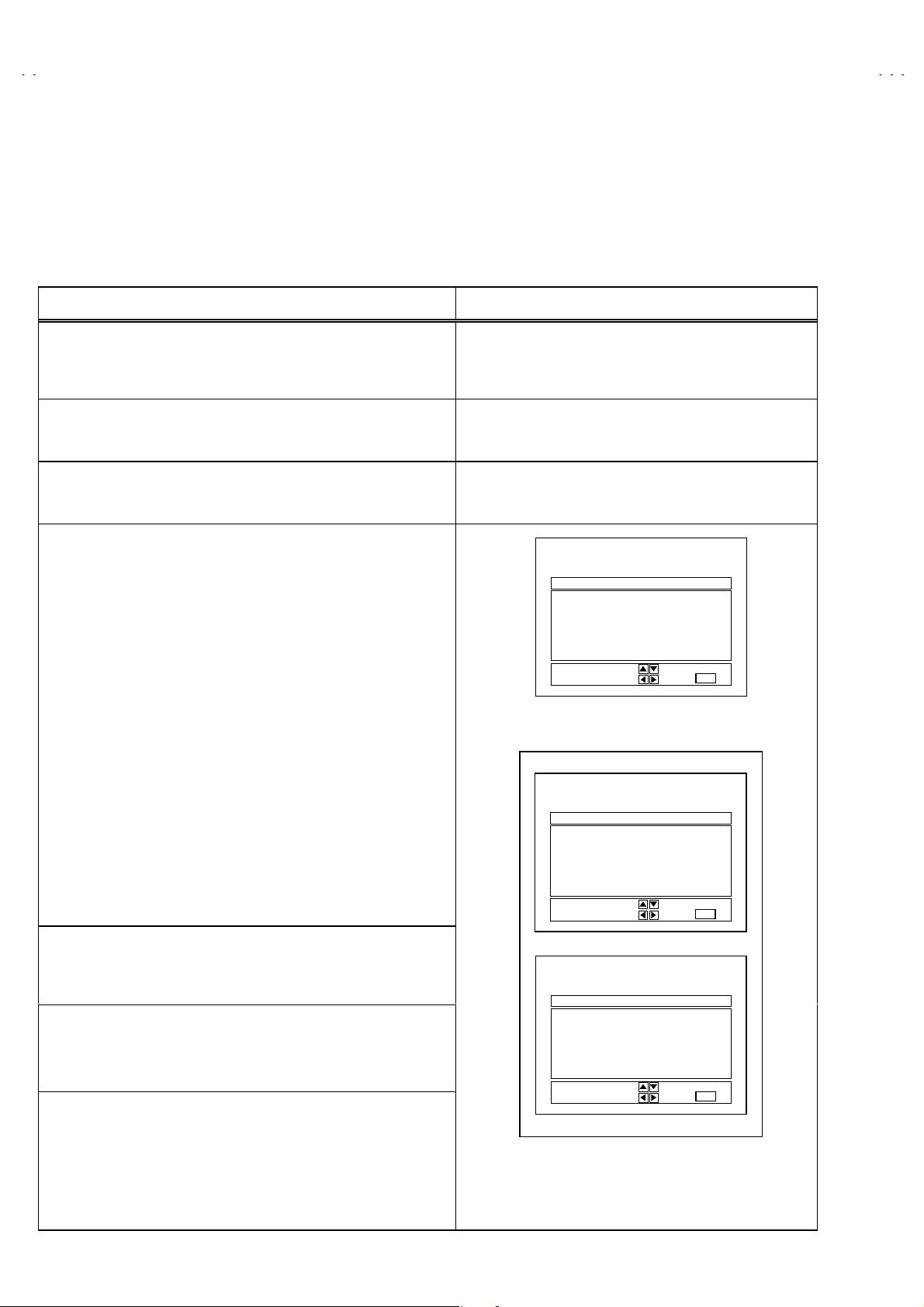

MEMORY I C REPLAC EMENT

1. Memory IC

This model uses a memory IC.

The memor y IC st or es dat a for proper op er at ion of video and deflecti on c irc uits.

When replacing, be sure to use an IC containing this (initial value) data.

2. Memory IC replacement pro cedu re

PROCEDURE SCREEN DISPLAY

(1)

Power off

Switch off the power and dis connect th e pow er c or d from the wall

outlet.

(2)

Replace the memory IC

.

Be sure to u se memo ry ICs written with the i nitial data values.

(3)

Power on

Connect the power cord to the wall outlet and switch on the power.

(4)

System constant check and setting

) Simul taneous ly press th e DISPLA Y key and V IDEO STAT US key

1

of the remote control unit.

) The SERVICE MENU screen of Fig.1 is displayed.

2

) While the SERVICE MENU is displayed, again simultaneously

3

press t h e D IS PLAY an d VIDEO S T ATUS k eys to dis play t h e Fig.2

SYSTEM CONSTANT screen.

) Refer to the SYSTEM CONSTANT table and check the setting

4

items. W here these diff er, select th e setting it em with the MENU

UP / DO WN key and adjust t he setting with the MENU LEFT /

RIGHT keys. (The letters of the selected item are displayed in

yellow.)

) A fter adj ustin g, r el ease t h e MENU LE FT / R IG HT key to st or e t he

5

setting value.

) Press the EXIT key twice to return the normal screen.

6

SERVICE MENU

PICTURE SOUND

VIDEO STATUS OTHERS

LOW LIGHT HI GH LIGHT

RF AFC CHK

VCO (CW) I2C BUS CTRL

SELECT BY

OPERATE BY

EXIT BY

EXIT

IT

Fig.1

SYSTEM CONSTANT

VIDEO : 2

AUDIO : MTS

VARI. OUT : NO

GAME : YES

CINEMA : YES

(5)

Receive chann el s et ting

SELECT BY

OPERATE BY

EXIT BY

EXIT

Refer to the OPERATING INSTRUCTIONS (USER’S GUID E) and

set the receive channels (Channels Preset) as de scribed.

SYSTEM CONSTANT

(6)

User setti n gs

Check th e us er s ett in g i t ems according t o Table 2-1 and 2- 2.

CCD : YES

RETURN+ : YES

SURROUND : YES

Where these do not agree, refer to the OPERATING

INSTRUCTIONS (USER’S GUIDE) and set the items as described.

(7)

SERVICE MENU setting

M37272MA-

SELECT BY

OPERATE BY

×××

×××

××××××

SP

EXIT BY

EXIT

Verify what to set in the SERVICE MENU, and set whatever is

necessary. (Fig.1) Refer to the SERVICE ADJUSTMENT for setting.

Fig.2

8

No.51866

Page 9

A

SETTING OF SYSTEM CONSTANT SET

Setting item Setting content Setting value

V-T2122

VIDEO 2

AUDIO MTS

VARI. OUT NO

GAME YES

CINEMA YES

CCD YES

RETURN +

SURROUND YES

MONO PH.MONO MTS

12

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

Table 1

YES

USER SETTING VALUES

1.Settin g of FUN CTION

Setting item Setting value Setting item Setting value

MAIN POWER OFF DISPLAY OFF

SUB POWER ON SLEEP TIMER 0 MIN

CHANNEL CH 02 VIDEO STATUS ESTANDAR

CAPTION OFF(CC1/T1) PICTURE BOOSTER OFF

VOLUME 10 COLOR SYSTEM AUTO

TV/VIDEO TV HYPER SURROUND OFF

Table 2-1

2.Setting of MENU

Setting item Setting value

TINTE ESTANDAR ALTAVOCES SI

COLOR ESTANDAR CHILD LOCK NO

CONTRASTE ESTANDAR TEMPORIZADOR NO

BRILLO ESTANDAR LISTA DE CANAIS SET OPTIONALLY

DETALLE ESTANDAR AJUSTE CODIGO DE ACCESO Unnecessary to Set

GRAVES CENTER PANTALLA AZUL NO

AGUDOS CENTER FONDO NEGRO SI (SIM)

BALANCE CENTER IDIOMA ESP.

MTS ESTÉREO SUBTITULOS OCULTOS NO(CC1/T1)

Table 2-2

Setting item Setting value

No.51866

9

Page 10

A

V-T2122

SERVICE ADJUSTMENTS

ADJUSTMENT PREPARATION

1. You can make t he n ec essary adju st ments for this un it wit h eit her the r em ote contro l u nit or with th e adj ust ment equ ip ment and

part s as given below.

2. Adjustment with the remot e contro l un it i s m ade on t he b a si s of the initial set t i ng values, h owever, th e new sett i n g values which

set the screen to its optimum condition may differ from the initial settings.

3. Make sure that AC power is turned on correctly..

4. Turn on the power for the set and test equipment before use, and start the adjustment procedures after waiting at least 30 minutes

5. Unless otherwise specified, prepare the most suitable reception or input signal for adjustment.

6. Never touch any adjustment parts, which are not specified in the list for this adjustment-variable resistors, transformers, condensers, etc .

7. Presetti ng b ef or e ad jus t m ent .

Unless otherwise specified in the adjustment instructions, preset the following functions with the remote control unit.

VIDEO STATUS ESTANDAR

GRAVES, AGUDOS, BALANCE CENTER

$$$$

ADJUSTMENT EQUIPMENT

1. DC voltmet er ( or di gi tal voltmeter)

2. Oscilloscope

3. Signal generator ( Pattern generator ) [NTSC%M]![PAL-M] [PAL-N ]

4. Remote control unit

5. TV audio multiplex signal generator

6. Frequency counter

ADJUSTMENT ITEMS

B1 POWER SUPPLY

●

IF VCO adjustment

●

RF AGC adjustment

●

FOCUS ad jus tment

●

DEFLECT IO N ad jus t m ent

●

V. HEIGHT, V. POSITION, V. LIN., V S CR adjustment

H. POSITION adjustment

VIDEO / CHROMA adjustment

●

WHITE BALANCE (Low light) adjustment

WHIT E BALAN C E (H i gh li ght) adjus t m ent

SUB BRIGHT adjustment

SUB CONTRAST adjustment

SUB COLOR adjustment

SUB TINT adjustment

●MTS adjus t m en t

INPUT LEVEL adjustment

STEREO VCO adjustment

SAP VCO adjustment

FILTER check

SEPARATION adjust ment

10

No.51866

Page 11

A

ADJUSTMENT LOCATIONS

(

)

FRONT

VOL+

V-T2122

CH-CH+VOL-

MENU

SW

DEG.

F901

PW

MPX

T

5 1

AV IN OUT

IC701

TUNER

IC704

T111

CW

IC101

B1(TP-91)

GND(TP-E)

B1

S

MAIN P WB

HV

3

1

X

U

T522

3

1

UPPER : FOCUS

LOWER : SCREEN

CRT SOCKET PWB

TOP

(Within MAIN PWB ASS'Y)

TP-47B

E1

TP-E

SOLDER SIDE

No.51866

CRT EARTH

(BRAIDED ASS'Y)

11

Page 12

A

V-T2122

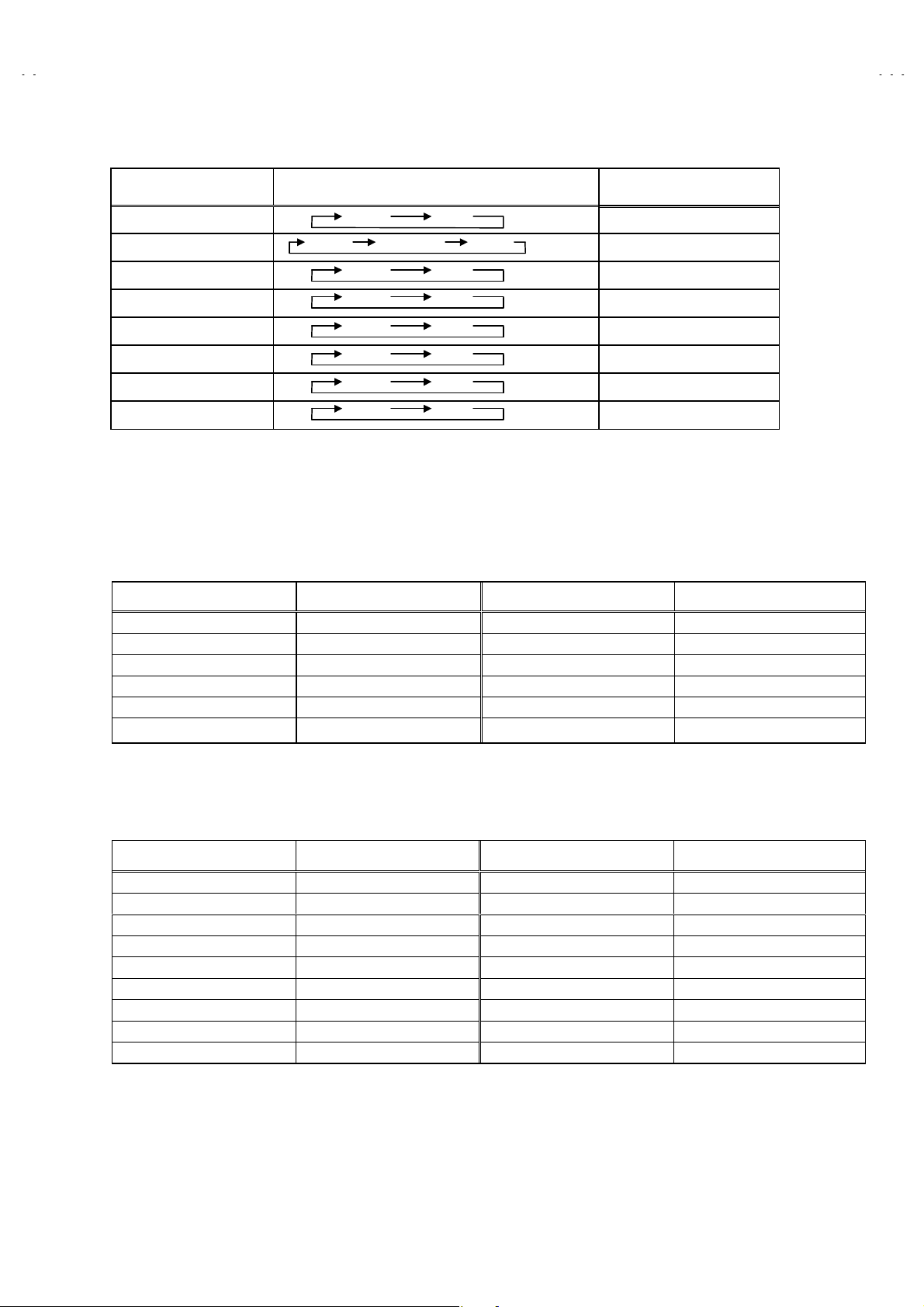

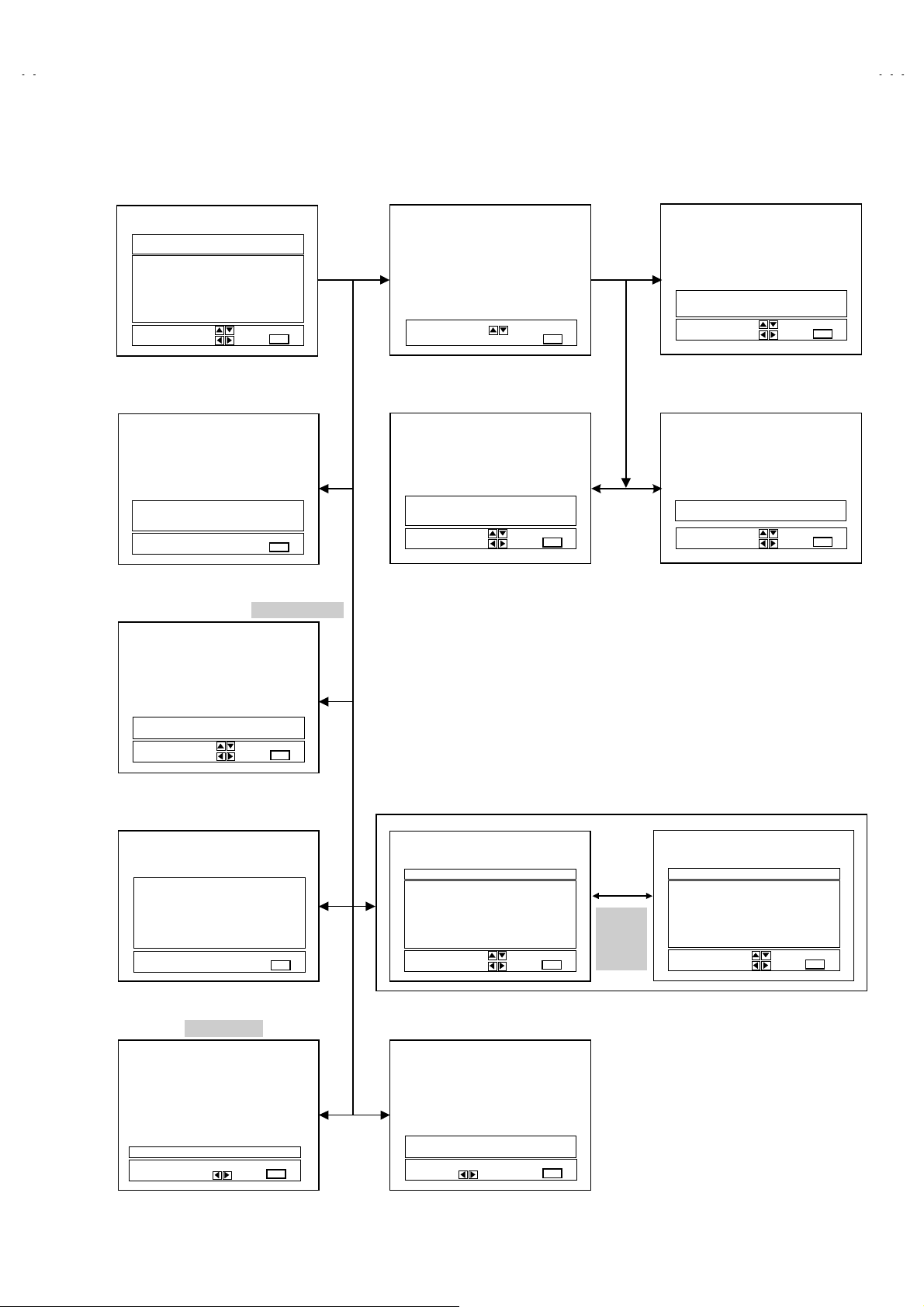

BASIC OPERATION OF SERVICE MENU

1. Operate the SERVICE MENU with the REMOTE CONTROL UNIT.

2. In general

(1) PICTURE

(2) SOUND

(3) VIDEO STATUS

(4) OTHERS

(5) LOW LIGHT

(6) HIGH LIGHT

(7) RF AFC CHK

(8) VCO (CW)

(9) I

3. Basic Opera ti o ns of th e SER VI C E M EN U

(1) How to enter the SERVICE MENU.

(2) SERVICE MENU screen selection

basic sett ing

!!!!

・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・

2

C BUS CTRL

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

(adjustments) items or verifications are performed in the SERVICE MENU.

!!!!

This set the setting values (adjustment values) of the VIDEO/CHROMA and DEFLECTION circuits.

This set the setting values (adjustment values) of the AUDIO circuit.

・・・・・・・・・・・・・

This is used when the THEATER and GAME MODE is adjusted.

This is used when the OTHERS MODE is adjusted.

This sets the setting values (adjustment values) of the WHITE BALANCE circuit.

This sets the setting values (adjustment values) of the WHITE BALANCE circuit.

This is used when the RF AFC CHK MODE is verified.

This is used when the IF VCO is adjusted.

・・・・・・・・・・・・・・・

This is used when ON/OFF of the I2C BUS CTRL is set.

[Do not adjust]

[Fixed ON]

Press the DISPL A Y k ey and V IDEO ST AT US k e y!of the remote control unit at the same time to enter the SERVICE MENU screen

shown in figure page la ter.

Press the UP / DOWN key of the MENU to select any of the following items.

(The lett ers of t h e sel ec t ed it ems are disp l ayed in y ell ow .)

PICTURE

●

VIDEO STATUS

●

LOW LIGHT

●

RF AFC CHK

●

VCO (CW)

●

SOUND

●

OTHERS

●

HIGH LIGHT

●

I2C BUS CTRL

●

①

(3) Enter the any setting ( adjustment ) mode

PICTURE, SOUND and OTHERS mode

"

1) If select any of PICTURE, SOUND or OTHERS items, and the LEFT / RIGHT key is pressed from SERVICE MENU ( MAIN

MENU ), the screen ② will be dis p layed as sh ow n in fi gure page later.

2) T hen the U P / DOWN k ey is pr ess ed, th e PICT UR E m ode sc r een ③ or th e SOUND m ode s cr een ④ or the OTHERS mode

screen ⑤ is displayed, and the PICTURE, SOUND or OTHERS setting can be performed.

VIDEO STATUS, LOW LIGHT, HIGH LIGHT, RF AF C

"

CHK,

VCO (CW) and I

!!!!

!!!!

2

C BUS CTRL mode

1) If select any of VIDEO STATUS / LOW LIGHT / HIGH LIGHT / RF AFC CHK / VCO (CW) / I2C BUS CTRL items, and the LEFT

/ RIGHT k ey is pr essed fr om SER V I CE ME NU ( MAIN MENU ), t h e sc reens ⑥ ⑦ ⑧ ⑨ ⑩ ⑪ w ill b e displ ayed as sh own in

figure page later.

2) Then the s ett in gs or verificat i ons c an b e performed.

12

No.51866

Page 13

A

V-T2122

)

)

y

①①①①

SERVICE MENU (MAIN MENU

SERVICE MENU

PICTURE SOUND

VIDEO STATUS OTHERS

LOW LIGHT HIGH LIGHT

RF AFC CHK

VCO (CW

SELECT BY

OPERATE BY

⑧⑧⑧⑧

HIGH LIGHT MODE

HIGH LIGHT

***

*** ***

******

⑨⑨⑨⑨

RF AFC CHK MODE

I2C BUS CTRL

EXIT BY

EXIT

***

******

EXIT BY

EXIT

[DO NOT ADJUST]

②②②②

SCREEN

SELECT BY EXIT BY

④④④④

SOUND MODE

1. NOISE

STATUS

SELECT BY

OPERATE BY

EXIT

***

***

******

****

****

********

EXIT BY

EXIT

③③③③

PICTURE MODE

1. PICTURE

*****

***** ****

**********

SELECT BY

OPERATE BY

⑤⑤⑤⑤

OTHERS MODE

1. OSD HP

SELECT BY

OPERATE BY

***

***

******

****

********

EXIT BY

EXIT

***

***

******

EXIT BY

EXIT

RF AFC ON

FINE

SELECT BY

OPERATE BY

⑩⑩⑩⑩

VOC (CW) MODE

TOO HIGH

ABOVE REFERENCE

BELOW REFERE NCE

TOO LOW

SYNC : YES

⑪⑪⑪⑪

I2C BUS CTRL MODE

[FIXED ON]

I2C BUS ON

OPERATE BY

EXIT BY

**

**

****

EXIT BY

EXIT

EXIT BY

EXIT

EXIT

CINEMA

TINT G DRIVE

COLOR B DRIVE

PICTURE R CUT.

BRIGHT G CUT.

DETAIL B CUT.

SELECT BY

OPERATE BY

BRIGHT

***

*** ***

******

***

*** ***

******

***

*** ***

******

***

*** ***

******

***

*** ***

******

⑦⑦⑦⑦

LOW LIGHT MODE

BRIGHT

***

*** *** ***

******

***

***

******

*** ***

*** ****** ***

EXIT BY

EXIT

EXIT BY

EXIT

⑥⑥⑥⑥

VIDEO STATUS MODE

***

******

***

******

***

******

***

******

***

******

STATUS

Press

VIDEO

Ke

GAME

TINT G DRIVE

COLOR B DRIVE

PICTURE R CUT.

BRIGHT G CUT.

DETAIL B CUT.

SELECT BY

OPERATE BY

***

*** ***

******

***

*** ***

******

***

*** ***

******

***

*** ***

******

***

*** ***

******

EXIT BY

EXIT

***

******

***

******

***

******

***

******

***

******

No.51866

13

Page 14

A

V-T2122

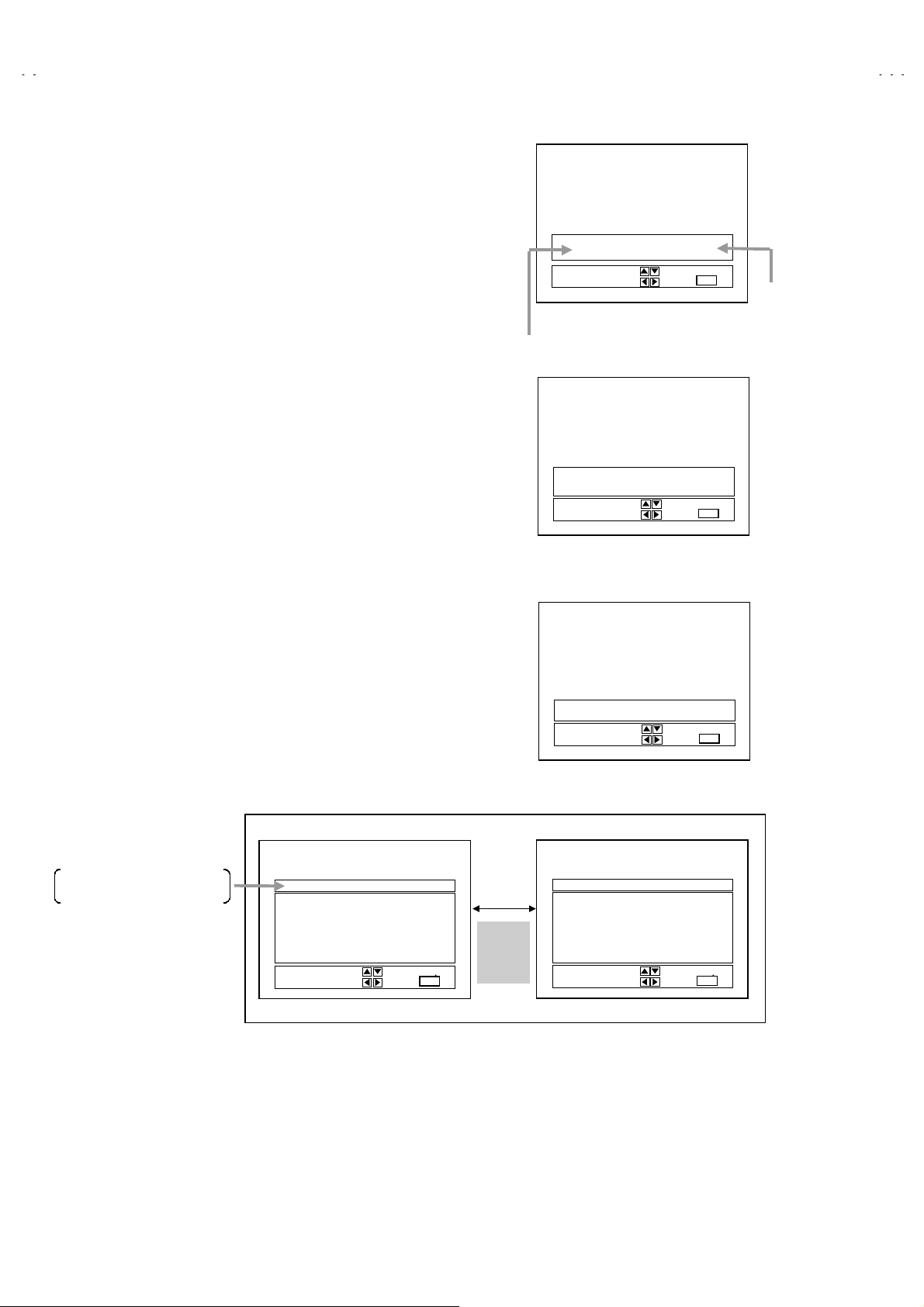

(4) Setting method

1) UP / DOWN key of the MENU

Select the SETTING ITEM.

2) LEFT / RIGHT key of the MENU

Setting (adjust) the SETTING VALUE of the SETTING ITEM.

When the key is released the SETTING VALUE will be stored

(memorized).

3) EXIT key

Returns to the previous screen.

(PICTURE MODE ONLY)

[NOTE]

When the IN ITIAL SET TING VALUE is t urned to yell ow, you can adj ust the

values but you cannot adjust the values when it is turned to red.

(Because the signal conditions, etc. are not met.)

(5) Releasing SERVICE MENU

1) After returni ng to the SERVICE MENU upon c ompletion of t he setting

(adjust m ent ) w or k, pr ess the EXIT key ag ain.

1. PICTURE

*****

***** ****

**********

SELECT BY

OPERATE BY

PICTURE MODE

SETTING

ITEM

1. NOISE

STATUS

SELECT BY

OPERATE BY

***

***

******

****

********

EXIT BY

EXIT

***

***

******

****

****

********

EXIT BY

EXIT

IT

IT

INITIAL

SETTING VALUE

↓ (Adjus t)

SETTING VALUE

The s ettings f or LOW LIGHT and H IGH LIGHT are descr ibed in t he W HITE

★

BALANCE page of ADJUSTMENT.

The setting for VCO (CW) are described in the IF VCO page of ADJUSTMENT.

★

The letter of the

Items are dis played in y ell ow .

selected

CINEMA

TINT G DRIVE

COLOR B DRIVE

PICTURE R CUT.

BRIGHT G CUT.

DETAIL B CUT.

SELECT BY

OPERATE BY

***

*** ***

******

***

*** ***

******

***

*** ***

******

***

*** ***

******

***

*** ***

******

EXIT BY

EXIT

***

******

***

******

***

******

***

******

***

******

I

T

Press

VIDEO

STATUS

Key

SOUND MODE

1. OSD HP

SELECT BY

OPERATE BY

OTHERS MODE

GAME

TINT G DRIVE

COLOR B DRIVE

PICTURE R CUT.

BRIGHT G CUT.

DETAIL B CUT.

SELECT BY

OPERATE BY

***

*** ***

******

***

*** ***

******

***

*** ***

******

***

*** ***

******

***

*** ***

******

***

***

******

EXIT BY

EXIT

EXIT BY

EXIT

***

******

***

******

***

******

***

******

***

******

IT

I

T

VIDEO STATUS MODE

14

No.51866

Page 15

A

V-T2122

INITIAL SETTING VALUE OF SERVICE MENU

1. Adjustment of the SERVICE MENU is ma de on the basis of the initi al sett ing values; however, the new setting values

which set the screen in its optimum condition may differ from the initial setting.

2. Do not change the initial Setting Values of the Setting (Adjustment) items not listed In “ADJUSTMENT”.

PICTURE MODE

""""

The four settin g items i n the vi deo mod e No.8 E XT PIC., No.9 E XT BR I., No. 10 EXT C OL. a n d No.11 E XT T IN T are linked to th e it ems in

#

the TV MO DE No.1 PICT U R E, No.2 BR IG H T , N o.5 CO L . N T S C and No.6 T IN T , r es pectively. When the setting items i n the TV mod e are

adjust ed, th e val u es in the s et t in g items in the vid eo mode are revis ed au tomatic ally to t h e same valu es i n t h e TV mode. (The initial setting

values given in ( ) are off-set values.)

When the f our it ems (No.8, 9, 10 and 11) ar e adj us ted in the vid eo mode, the s etting valu es in eac h it em ar e re vised independently.

#

No. Setting item Variable range

1. PICTURE

2. BRIGHT

3. COL. PALM

4. COL. PALN

5. COL. NTSC

6. TINT

7. TV DTL

8. EXT PIC.

9. EXT BRI.

10. EXT COL.

11. EXT TINT

12. EXT DTL

13. P/N KILL 0 / 1

14. Y S CONT

15. TV Y-DL

16. EXT Y-DL

17. WPL SW 0 / 1

18. Y GAMMA 0 / 1

19. P/N G P 0 / 1

20. COL. L SW 0 / 1

21. CO L. LMT.

22. PN C. ATT

23. OFST. SW 0 / 1

24. OFSET. B-Y

25. OFSET. R-Y

26. C-TOF SW 0 / 1

27. TV T FO

28. TV T Q

29. EXT T FO

30. EXT T Q

0~127

0~127

0~127

0~127

0~127

0~127

0~63

25

±

25

±

25

±

25

±

0~63

0~31

0~7

0~7

0~3

0~3

0~15

0~15

0~3

0~3

0~3

0~3

Initial setting value No. Set ting item Variable r ange Initial setting valu e

65

64

70

70

80

65

38

(0)

(+5)

(0)

+1

35

1

31

1

2

0

0

0

1

1

1

0

8

8

1

1

0

0

0

31. C-TRAP 0 / 1

32. C-TR. FO

33. C-TRAP Q

34. FIX B/W 0 / 1

35. APA P. FO

36. DC TRAN.

37. B. ST. SW

38. B. ST. PO. 0 / 1

39. ABL GAIN

40. ABL PO

41. HALF T.

42. DRV G SW 0 / 1

43. NT. COMB 0 / 1

44. COIN DET

45. NOISE L

46. VCD MODE 0 / 1

47. V AGC SP 0 / 1

48. H POS. 50

49. H BLK. 50

50. V POS. 50

51. V SIZE50

52. V S CR50

53. V LIN. 50

54. H POS. 60

55. H BLK. 60

56. V POS. 60

57. V SIZE60

58. V S CR60

59. V LIN. 60

60. RF AGC

0~3

0~3

0~3

0~7

0~7

0~7

0~7

0~2

0~3

0~3

0~31

0~7

0~7

0~127

0~127

0~31

0~31

0~7

0~7

0~127

0~127

0~31

0~255

0

2

0

0

1

7

0

0

4

0

1

0

1

3

3

0

0

7

0

0

87

28

4

12

0

0

88

48

4

160

No.51866

15

Page 16

A

V-T2122

SOUND MODE

"

No. Setting item Variable range Initial setting value

1. NOISE 0 / 1 1

2. IN LEVEL

3. FH MON. 0 / 1 0

4. ST VCO

5. PILOT 0 / 1 0

6. FILTER

7. LOW SEP.

8. HI SEP.

9. 5FH MON . 0 / 1 0

10. SAP VCO

11. IN GAIN 0 / 1 0

12. FIL. OFF

VIDEO STATUS MODE

"

No.Setting (Adjustment) item Variable range

1. TINT

0~63

0~63

0~63

0~63

0~63

0~63

10

±

20

±

Initial settin g val ue

CINEMA GAME

00

20

25

30

22

23

26

0

2. COLOR

3. PICTURE

4. BRIGHT

5. DETAIL

6. G DRIVE

7. B DRIVE

8. R CUT.

9. G CUT.

10. B CUT

20

±

20

±

20

±

15

±

-99~+50

-99~+50

10

±

10

±

10

±

-3 -3

-10 -10

00

0-5

-22 0

-54 0

00

00

00

16

No.51866

Page 17

A

OTHERS MODE!

"

No. Setting (Adjustment) item Variable range Initial setting value

!

!!

V-T2122

1. OSD HP

2. OSD VP

3. H CK SW 0 / 1 0

LOW LIGHT MODE!

"

Setting (Adjustment) item Variable range Initial setting value

R CUTOFF 0~255 20

G CUTOFF 0~255 20

B CUTOFF 0~255 20

HIGH LIGHT MODE!

"

Setting (Adjustment) item Variable range Initial setting value

G DRIVE

B DRIVE

!

!!

!

!!

0~31

0~15

0~255

0~255

23

12

128

128

RF AFC CHECK MODE!

"

Setting (Adjustment) item Variable range Initial setting value

RF AFC ON / OFF ON

FINE

2

C BUS CTRL MODE!

I

"

Setting (Adjustment) item Variable range Initial setting value

I2C BUS ON / OFF

!

!!

(DO NOT ADJUST)

-77~+77

!

!!

± **

[Fixed ON]

No.51866

17

Page 18

A

V-T2122

■■■■

ADJUSTMENTS

!!!!

B1 POWER SUPPLY

Item

Check of

B1 POWER

SUPPLY

Measuring

instrument

DC Voltmeter B1 (

IF VCO ADJUSTMENT

Item

IF VCO

adjustment

Measuring

instrument

Signal

generator

TOO HIGH

ABOVE REFERENCE

BELOW REFERE NCE

TOO LOW

SYNC : YES

Test point Adjustment ite m Description

B1

Connector

pin)

1

(TP-91)

TP-E(#)

(

B1

Connector

pin)

3

Test point Adjustment ite m Description

CW TRANSF. (T111)

[VCO (CW)] mode

YELLOW

1. Rec eive a bl ac k and whit e sig n al (color off) . (NT S C)

2. Connect the DC voltmeter to B1 connector 1 pin (TP-91)

and TP-E(#) (B1 connector 3 pin).

3. Confirm that the voltage is DC134.5V±2V.

Under normal conditions, no adjustment is required.

"

1. Rec eive a br oadcast. ( use channels w ith out offs et frequenc y).

2. Select the VCO(CW) mode from the SERVICE MENU.

3. Confirm the color change (yellow) from “TOO HIGH” to

TOO LOW”by CW TRAN SF. and “SYNC : YES” being

“

shown on the screen. Then, adjust CW TRANSF. until

BELOW REFERENCE” mark turns yellow and confirm

“

again “ SYNC : YES” being shown on the screen.

RF AGC AD JUS TMENT

RF AGC

adjustment

FOCUS ADJUST MENT

FOCUS

adjustment

Signal

generator

EXIT BY

EXIT

IT

No.60 RF AGC

FOCUS VR

[In HVT]

1. Rec eive a br oadcast.

2. S elect “No.60 RF AGC” of the PICT URE mode in SERVICE

MENU.

3. Press the MUTE key and turn off color.

4. W ith the M ENU L EFT k ey, g et nois e in t he scr een pic ture. ( 0

side of sett in g value)

5. Press the MENU R IGHT k ey and s top wh en n ois e dis app ears

from the screen.

6. Change to other channels and make sure that there is no

irregularity.

7. Press the MUTE key and get color out.

1. Receive a crosshatch signal.

2. While looking at the screen, adjust FOCUS VR s o that the

vertic al and hor i z ont al lines will be cl ear and in fine detail.

3. Make sure t hat the pictur e is in focus even when the sc reen

gets dark en ed.

18

No.51866

Page 19

A

DEFLECTI ON AD JUSTMENT

r

%

(

)

(

)

The setting (adjustment) using the REMOTE CONTROL UNIT is made on the basis of the initial setting values.

The setting values which adjust the screen to the optimum condition can be different from the initial setting values.

V-T2122

Item

V. HEI GHT,

V. POSITION,

V. LIN.

V. S CR

adjustment

Screen

size

92%

Measuring

instrument

Signal

generator

Test point Adjustment ite m Description

[60Hz]

No.56 V POS. 60

No.57 V SIZE 60

No.58 V S CR60

No.59 V. LIN. 60

1. Receive a crosshatch signal.(NTSC or PAL-M)

2. C onfirm that the value of PICTURE MODE “No.56 V PO S.

60” is 0.

3. C onfirm th e initial setting value of t he “No.57 V SIZE 60”,

No.58 V S CR60” and “No.59 V LIN. 60”.

4. Adjust the vertical screen size to 92% with the PICTURE

MODE “No. 57 V SIZE 60”.

5. Adjust the PICTURE MODE “No.59 L LIN. 60” and “No.58

V S CR60” to get the best vertical linearity.

NOTE :

The PICTURE MODE “No.56 V POS. 60” is fixed on value 0.

[50Hz]

No.50 V POS.50

No.51 V SISE 50

No.52 V S CR50

No.53 V LIN.50

1. Receive a crosshatch signal. (PAL-N)

2. Confirm the initial setting value of the “No.50 V POS.50”,

“No.51 V SIZE 50” , “No.52 V S CR 50” and “No.53 V LIN.50”.

3. Adjust the vertical screen size to 92% with the PICTURE

MODE “No.51 V SIZE50”.

4. Adjus t the P ICT URE MO DE “ No. 53 V LIN. 50” and “N o.52 V S

Scree s ize

CR50” to get the best vertical linearity.

5. Adjust the PICTURE MODE “No.50 V POS.50” so that the

vertic al cent er lin e com es clos e to th e CRT vertic al cent er as

much as possible.

Readjust V SIZE, V LIN., V S CR if necessary.

Pictu

size

100

"

100%

No.54 H PO S .60

[60Hz]

1. Rec eive a cr osshatc h sig n al. ( NTSC or PAL-M)

H. POSITION

adjustment

Picture size

Signal

generator

2. Select the “No.54 H POS. 60” of the PICTURE mode in

SERVICE MENU.

3. Confirm the initial setting value of the "No.54 H POS. 60".

4. Adjust the “No.54 H POS. 60” until the screen will be

horizontally centered.

[50Hz]

No.48 H PO S .50

1. Receive a crosshatch signal. (PAL-N)

2. Select the “No.48 H POS. 50” of the PICTURE mode in

SERVICE MENU.

3. Confirm the initial setting value of the "No.48 H POS. 50".

4. Adjust the “No.48 H POS. 50” until the screen will be

horizontally centered.

No.51866

19

Page 20

A

V-T2122

VIDEO / CHROMA !!!!ADJUSTMENT

The setting (adjustment) using the REMOTE CONTROL UNIT is made on the basis of the initial setting values.

The setting values which adjust the screen to the optimum condition can be different from the initial setting values.

Do not change the initial setting values of the setting items not listed in “ADJUSTMENT”.

Item

WHITE

BALANCE

(Low Light)

adjustment

Measuring

instrument

Signal

generator

Remote

control unit

REMOTE CONTROL UNIT

H.LINE OFF EXITH.LINE ON

1111

R CUTOFF G CUTOFF

4444

7777

R CUTOFF

2222 3333

5555 6666

8888

Test point Adjustment ite m Description

BRIGHT

1. Rec eive a bl ac k and whit e sig n al (color off) .

2. Select the LOW LIGHT mode from the SERVICE MENU.

R CUTOFF

G CUTOFF

B CUTOFF

SCREEN VR

3. Confirm th e In itial s ett in g val ue of “ BRIGHT ” , “R C UTOFF” , “ G

CUTOFF” and “B CUTOFF”.

4. Displ ay a single h orizont al line by pr essing t he

remote control unit.

5. Turn the screen VR all the way to th e le ft.

6. T urn the screen VR gradual ly to the right fr om the left until

either one of the red, blue or green colors appears faintly.

7. Adjust the two colors which did not appear until the single

horizontal line tha t is displayed becomes white using the

keys of the remote control unit.

⑨⑨⑨⑨

8. Turn the sc reen VR un til the si ngl e hor iz ontal li ne is dis play ed

B CUTOFF

faintly.

9. Press the

key to return to the regular screen.

②②②②

9999

[LOW LIGHT] MODE

B CUTOFFG CUTOFF

R CUTOFF

G CUTOFF

BRIGHT

B CUTOFF

key of the

①①①①

to

④④④④

WHITE

BALANCE

(High Light)

adjustment

Signal

generator

Remote

control unit

Remote Control Unit

key : H.LINE ON

①

key : H.LINE OFF

②

key : EXIT

③

key : G DRIVE

⑤

key : B DRIVE

⑥

key : G DRIVE

⑧

key : B DRIVE

⑨

***

***

******

*** *** ***

*** *** ***

*** *** ****** *** ***

EXIT BY

EXIT

IT

G DRIVE

B DRIV E

BRIGHT

BRIGHT

1. Rec eive a bl ac k and whit e sig n al (color off) .

2. Select the HIGH LIGHT mode in the SERVICE MENU.

3. Confirm the initial setting value of “G DRIVE” and “B DRIVE”.

4. Adjust the screen color to white with the

⑤⑤⑤⑤, ⑥⑥⑥⑥, ⑧⑧⑧⑧

and

⑨⑨⑨⑨

keys of the remote control unit.

[HIGH LIGHT] MODE

▲

G DRIVE

▲

▼

▼

HIGH LIGHT

***

******

B DRIVE

***

******

******

EXIT BY

EXIT

IT

20

No.51866

Page 21

A

V-T2122

Item

SUB BR I GHT

adjustment

SUB

CONTRAST

adjustment

SUB COLOR

adjustment

Measuring

instrument

Remote

control unit

Remote

control unit

Remote

control unit

Test point Adjustment ite m Description

No.2 BRIGHT

No.1 PICTURE

No.3 COL. PALM

1. Rec eive a br oadcast.

2. Select “No.2 BRIGHT” of the PICTURE mode in SERVICE

MENU.

3. Confirm the initial setting value of the “No.2 BRIGHT” .

4. If the brightness is not the b est with the initial settin g value,

make fin e adjustm ent of th e “No.2 BRIG HT” until you get th e

optimu m bri ghtness.

1. Rec eive a br oadcast.

2. S elect “No.1 PICTURE” of the PICTURE mode in S ERVICE

MENU.

3. Confirm the initial setting value of the “No.1 PICTURE”.

4. If the contrast is not the best with the initial setting value, make

fine adjustment of the “No.1 PICTURE” until you get the

optimum contrast.

[PAL-M]

1. Rec eive a PA L -M c olor b ar sig nal.

2. S elect “No.3 COL. PALM” of t he PICTURE mode in SERVICE

MENU.

3. Confirm the initial setting value of the “No.3 COL. PALM”.

4. If th e color is not th e best wit h the init ial setti ng value, make

fine adjustment until you get the best color.

SUB TINT

adjustment

Remote

control unit

No.4 C O L . P A LN

No.5 C O L . NTSC

No. 6 TINT

[PAL-N]

1. Rec eive a PA L -N c olor b ar sig n al.

2. Select “N o.4 C OL. PA LN” of the P ICT URE mod e in S ER VICE

MENU.

3. Confirm the initial setting value of the “No.4 COL. PALN”.

4. If th e color is not th e best wit h the init ial setti ng value, make

fine adjustment until you get the best color.

[NTSC]

1. Receive a NTSC color bar signal.

2. Select “No.5 COL. NTSC” of the PICTURE mode in SERVICE

MENU.

3. Confirm the initial setting value of the “No.5 COL. NTSC”.

4. If th e color is not th e best wit h the init ial setti ng value, make

fine adjustment until you get the best color.

1. Receive a NTSC color bar signal.

2. Select “No. 6 TINT” of the PICTURE mode in SERVICE

MENU.

3. Confirm the initial setting value of the “No. 6 TINT”.

4. If the tint is not the best with the ini tial setti ng valu e, mak e fine

adjust m ent un t il you get t h e bes t tint.

No.51866

21

Page 22

A

V-T2122

MT S ADJUSTME NT

Item

INPUT LEVEL

adjustment

STEREO VCO

adjustment

Measuring

instrument

Signal

generator

Frequency

counter

Test point Adjustment part Desc ription

1. Select the “No.2 IN LEVEL” of the SOUND mode in SE RVICE

MENU.

2. Verify that the “No.2 IN LEVEL” is set at its initial setting

value.

1. Receive a NTSC RF signal (non modulated sound signal) from

the anten n a t ermi n al.

2. Select the “No.3 FH MON” of SOUND mode in SERVICE

MENU, change the setting value from 0 to 1.

3. Connect the frequency connector to pin 2 of MPX

connector.

4. Select the “No.4 ST VCO”.

5. Confirm the initial setting value of the “No.4 ST VCO”.

6. Adj ust the “No.4 ST VCO” so th at the frequ ency count er wil l

displ ay 15. 73kHz±0.1kHz.

7. Select the “No.3 FH MON” of the SOUND mode, and reset the

setting v al u e fr om 1 to 0.

MPX

Connector

2 pin TVR

[M AI N PWB]

No.2 IN LEVEL

No.3 FH MON

No.4 ST VCO

!

SAP VCO

adjustment

FILTER

check

Signal

generator

Frequency

counter

MPX

Connector

4 pin SDA

3 pin GND

2 pin TVR

[M AI N PWB]

No.9 5FH MON.

No.10 SAP VCO.

No.6 FILTER

1. Rec eive a NTSC RF si gn al ( n on m od ul ated sound si gn al) fr om

the anten n a t ermi n al.

2. Connect between pin 4 of MPX connector and GND (pin

3 of MPX connector) through 1MΩ resistor.

3. Select the “No.9 5FH MON.” of the SOUND mode in SERVICE

MENU, and reset the setting value from 0 to 1.

4. Connect the frequency connector to pin 2 (R.OUT) of

MPX connector.

5. Select the “No.10 SAP VCO”.

6. Confirm the initial setting value of “No.10 SAP VCO”.

7. Adjus t th e “N o.10 SA P VCO ” s o th at th e f r equenc y c onnec tor

will display 78.67kHz±0.5kHz.

8. Select the “No.9 5FH MON.” of the SOUND mode, and reset

the setting value from 1 to 0.

1. Select the “No.6 FILTER” of the SOUND mode in SERVICE

MENU.

2. Verify that the “No.6 FILTER” is set at its initial setting value.

22

No.51866

Page 23

A

V-T2122

Item

SEPARATION

adjustment

L-Channel

signal wave form

Measuring

instrument

TV audio

multiplex

signal

generator

Oscilloscope

Test point Adjustment part Desc ription

MPX

Connector

1 pin TVL

2 pin TVR

[M AI N PWB]

R-Channel

crosstalk port i on

Minimum

No.7 LOW SEP.

No.8 HI SEP.

1. Input a s tereo L sig nal (30 0Hz) fr om the TV Au dio multi plex

signal g en er at or to the antenna terminal.!(NTSC)

2. Connect an oscilloscope to pin 2 (R.OUT) of MPX

connector, and display one cycle portion of the 300Hz signal.

3. Select the “No.7 LOW SEP.” of the SOUND mode in SERVICE

MENU.

4. Confirm the initial setting value of the “No.7 LOW SEP.”.

5. Adjus t the “No.7 LOW SEP.” so that the stroke element of the

300Hz sig n al wi ll b ec om e minimum .

6. Ch ang e t h e c onn ect ion of the osc illosc op e to pin 1 (L.OUT )

of MP X connect or , and en large th e volt ag e axis.

7. Ch ange th e signal t o 3kHz, and si milarly adjust the “N o.8 HI

SEP.”.

!

1 cy cl e

No.51866

23

Page 24

A

V-T2122

(

)

PURITY, CONVERGENCE

PURITY ADJUSTMENT

1. Demagnetize CRT with the dema gnetizer.

2. Loosen the retainer screw of the deflection yoke.

3. R emo ve t h e w ed g es.

4. Input a green r aster signal fr om the sign al generat or, and t urn

the screen to green raster.

5. Move the defl ec ti on yoke back w ar d.

6. Brin g the long l ug of the pur ity magnets on the sh ort lug an d

position them horizontally. (Fig.2)

7. Adj us t the gap b etween t w o l ugs s o th at th e G R EE N R AS T E R

will come into the center of the screen. (Fig.3)

8. Move the defl ection yoke forwar d, and fix the position of the

deflection yoke so that the whole screen will become green.

9. Insert the wedge to the top side of the deflection yoke so that it

will not move.

WEDGE

CRT

P/C M A GNETS

$

P : PURITY MAGNET

4 : 4 POLES

6 : 6 POLES

(con ver g ence magnet s )

(con ver g ence magnet s )

Fig.1

PURITY MAGNETS

DEFLECTION

YOKE

P

46

P / C

MAGNETS

10. Input a crosshatch signa l.

11. Verify that the screen is hori z ont al.

12. Inp ut red and blu e raster si gnals, and make su re that pur ity is

properly adjust ed.

Long lug

Short lug

FRONT VIEW

Bring the long lug over the short lug

and position them horizontally.

Fig.2

GREEN RASTER

CENTER

Fig.3

24

No.51866

Page 25

A

STATIC CONVERGENCE ADJUSTMENT

1. Input a crosshatch signal.

2. Using 4- pole conver gence magn ets, overlap th e red and bl ue

lines in the center of the screen (Fig.1) and turn them to

magenta (red/blue).

3. Using 6-pole convergence magnets, overlap the

magent a(red/bl ue) and green lines in th e center of th e screen

and turn them to white.

4. R epeat 2 and 3 above, an d m ak e best conver gence.

DYNAMIC CONVERGENCE ADJUSTMENT

1. Move t he defl ecti on yok e up an d d own and ov erl ap the lin es i n

the periphery. (Fig. 2)

2. Move the deflection yoke left to right and overlap the lines in the

periphery. (Fig. 3)

3. R epeat 1 and 2 above, an d m ak e best conver gence.

(FRONT VIEW)

(FRONT VIEW)

BLUE

GREEN

RED

RED

Fig.1

GREEN

V-T2122

BLUE

RED

GREEN

BLUE

After ad jus t m ent , fi x the w ed g e at th e ori gi nal positi on.

●

Fasten the retainer screw of the deflection yoke.

Fix the 6 magnets w ith glue.

(FRONT VIEW)

GREEN

RED

BLUE

BLUE

GREEN RED

Fig.2

BLUE

Fig.3

GREEN

RED

RED

GREEN

BLUE

BLUE

GREEN

RED

No.51866

25

Page 26

A

V-T2122

HOW TO CHECK THE HIGH VOLTAGE HOLD DOWN CIRCUIT

1. HIGH VOLTAGE HOLD DOWN CIRCUIT

After rep air i ng the hi gh voltage h old down circ uit sh ow n in Fi g. 1.

This circuit shall be checked to operate correctly.

2. CHECKI NG OF THE HIGH VOLTAGE HOLD DOWN CIRCUIT

(1) Turn the POWER SW ON.

(2) As shown in Fig.2, set the resistor (between X connector 1 & 3 ).

(3) Make sure that the screen picture disappears.

(4) Tempor arily unplug the power c or d.

(5) Remove the resistor (between X connector 1 & 3 ).

(6) Again plug the power cord, make sure that the normal picture is displayed on the screen.

B1

Q941

Q942

IC701

27 28

Q511

H-Vcc

D510

3

D562

IC201

H-OUT

4

R563

3 2 1

R562

Fig. 1

Q521

C561

Q522

T521

Fig. 2

X

FR561

D561

T522

HVT

10

4

HEATER

26

RESISTOR

D562

17.2k

R563

RESISTOR

RESISTORRESISTOR

1% 1/4W

ΩΩΩΩ±±±±

3 2 1 X

R562

Fig. 2

No.51866

CONNECTOR

FR561

C561

D561

Page 27

A

SELF CHECK FUNCTIONS

1. Outline

This model includes protector functions for Over-current, X-ray and CRT NECK which cutoff the sub-power in the event of a malfunction and

inform of the malfunction by flashing POWER/ON TIMER LED.

The malfunction is detected according to the state of the control line input connected to the main CPU.

2. Self check items

Check ite m Det e cte d contents Detection method Abnorma lit y stat e

V-T2122

Over-c urrent prot ector Oper ati on of over-current

protection circuit

X-ray protector Operation of X-ray protection

circuit

CRT NECK protector When the vertical circuit S-

correction capacitor C413 is

shorted, detect the potential

drop of the C413, and prevent

the burn damage to the CRT

NECK.

The main CPU detects at

1second intervals.

If NG is detected f or mor e than

1ms, a malfunction is interpreted

The main CPU detects at

1second intervals.

If NG is detected f or mor e than

1ms, a malfunction is interpreted

The main CPU detects at

1second intervals.

If NG is detected f or mor e than

1ms, a malfunction is interpreted

During an abn ormality the subpower is cutoff. The remote

controll er p ow er k ey op eration is

not recognized and sub-power

off is main tained until the power

cord is unpl ug g ed an d

reinserted.

During an abnormality the subpower is cutoff. The remote

controll er p ow er k ey op eration is

not recognized and sub-power

off is maintained until the power

cord is unplugged and

reinserted.

During an abnormality the subpower is cutoff. The remote

controll er p ow er k ey op eration is

not recognized and sub-power

off is maintained until the power

cord is unplugged and

reinserted.

3. Self check indicating function

The self check function begins detection about 5

seconds after power is sup pl i ed.

In the event a malfunction is detected, the sub-power is

cutoff immediately.

At this time, the POWER/ON TIMER LED flashes to

inform of the malfun ction .

Item LED flashing intervals P riority of detection

OCP/X-ray

NECK

POWER

supplied

Red and gr een LED fl ash al ternat el y at

0.5 second intervals

Red and gr een LED fl ash al ternat el y at

1.0 second intervals

No.51866

About 5 seconds

after

Detection

start

Malfuction is

detected

SUB-POWER OFF

Flashing

POWER /

ON TIMER LED

1

2

27

Page 28

A

V-T2122

REPLACEMENT OF CHIP COMPONENT

CAUTIONS

!

1. Avoid heating for more than 3 seconds.

2. Do not rub the electrodes and the resist parts of the pattern.

3. When removing a chip part, melt the solder adequately.

4. Do not r euse a chip part after removi ng it.

SOLDERING IRON

!

1. Use a high ins ul ation sold er in g iron with a thin p ointed end of it.

2. A 30w soldering iron is recommended for easily removing parts.

REPLACEMEN T STEPS

!

How to remove Chip parts

1.

Resistors, capa citors, etc.

%

(1) As sh own in th e figure, pus h the p art with t weezers and

alternately melt t h e s old er at eac h en d.

2. How to install Chip part s

Resistors, capa citors, etc.

%

(1) Apply solder to the pattern as indicated in the figure.

(2) S hif t wi th tweezers an d rem ove the chip p ar t.

Transistors, diodes, variable resistors, etc.

%

(1) Apply extra solder to each lead.

SOLDER

(2) As sh own in th e figure, pus h the p art with t weezers and

alternat ely melt th e solder at each l ead. Shift and remov e

the chip part.

SOLDER

(2) Grasp the chip part with tweezers and place it on the

solder. Then h eat and m elt the sold er at both en ds of the

chip part.

Transistors, diodes, variable resistors, etc.

%

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the

solder.

(3) First solder lead

(4) Then solder leads

as indicated in the figure.

A

A

C

and C.

B

B

A

B

Note

!

28

: After removing the part, remove remaining solder from

the pa ttern.

No.51866

C

Page 29

V

ICTOR COMPANY OF JAPAN, LIMITED

HOME AV NETWORK BUSINESS UNIT 12, 3-chome, Moriya-cho, Kanagawa-ku, Yokohama, Kanagawa-prefecture, 221-8528, Japan

4

AVT2122AR-CK #3

Printed in Japan

VP 0109

DP7051

Page 30

A

PARTS LIST

CAUTION

V-T2122

The parts identified by the

!

the safety .

The parts not indicated in this P arts Lis t and those which are fill ed w ith lin es

!

P. W. Board Ass'y will not be supplied, but those which are filled with the Parts No. in the Parts No. columns will be supplied.

!

symbol are important for the safety. Whenever replacing these parts, be sure to use specified ones to secure

!

in the Parts No. columns will not be supplied.

ABBREVIATIONS OF RESISTO RS, CAPACITO RS AND TOLE RANCES

RESISTORS CAPACITORS

C R Ca rbon Resistor C CAP. Ceramic Capacitor

F R Fusible Resistor E CAP. Electrolytic Capacitor

P R Plate Resistor M CAP. Mylar Capacitor

V R

HV R High Voltage Resistor MF CAP. Metalized Film Capacitor

MF R Metal Film Resistor MM CAP. Metalized Mylar Capacitor

MG R Metal Glazed Resistor MP CAP. Metalized Polystyrol Capacitor

MP R Metal Plate Resistor PP CAP. Polypropylene Capacitor

OM R Metal Oxide Film Resistor

Variable Resisto

r

HV CAP. High Voltage Capacitor

PS CAP

.

Polystyrol Capacitor

CMF R Coating Metal Film Resistor TF CAP. Thin Fi l m Capacito r

UNF R Non-Flammable Resistor MPP CAP. Metalized Polypropylene Capacitor

CH V R Chip Variable Resistor TAN. CAP. Tantalum Capacitor

CH MG R Chip Metal Glazed Resistor CH C CAP. Chip Ceramic Capacitor

COMP. R Composition Resistor BP E CAP. Bi-Polar Electrolytic Capacitor

LPTC R

Linear Positive Temperature Coefficient

Resistor

CH AL E CAP. Chip Aluminum Electrolytic Capacitor

CH AL BP CAP.

CH TAN. E CAP.

CH AL BP E CAP.

Chip Aluminum Bi-Polar Capacitor

Chip Tantalum Electrolytic Capacitor

Chip Tantalum Bi-Polar Electrolytic Capacitor

TOLERANCES

FGJKMNRHZP

1%

±

2%

±

5%

±

10%

±

20%

±

±

30%

+30%

-10%

+50%

-10%

+80%

-20%

+100%

-0%

No.51866

29

Page 31

A

V-T2122

CONTENTS

EXPLODED VIEW PARTS LIST

!

EXPLODED VIEW

!

PRINTED WIRING BOARD PARTS LIST

!

MAIN PW BOARD ASS'Y (SGA-1019A-R2) (With CRT SOCKET PW BOARD)

"

PACKING / PACKING PARTS LIST

!

REMOTE CONTROL UNIT PARTS LIST

!

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

EXPLODED VIEW PA RTS LI ST

!"#$%&$ '()*+% &$ '()*+% (," -"./)0 1*0& 2

!

345 67589: 4;7< => '?:@A!9+@A B9C: D ?2/$-EF+': +G6H %9@F +I9- H9

!

845 JJI444 ;K44 5 -9H$:L?8

!

@57MM JJN44> 4K44 M N$3$@! 6%OP $

!

++5 8:54>Q=K4> =6KN R P!L%@+:6B? %9@

!

++M 8:M4MQMK44 =6KN :L%@!L8+R%LB

!

++> 8:>4;5SK44 56KN 8$9$-$89%O

!

++= :G=S44;K44 TK: U3:+G6!R

++7 8:>4;5TK44 5:KN 9$9$+I?%-LI

!

++; 8:>4;5;K44 =6KN 'LI9!+R%LB

!

++T :G>4S;5K4S = O'!?%H

++S 6=S=7TK=KO O'!?%H

++Q :NHB445;K4 BKHO B!6?-9-+I?!9

+54 :G>;;M >KB4 5KN :N6OO?O+!6?8 C×MD

!

+55 J6O44> TK44 5 O'96R9! C×MDO'45K4M

!

+5M :G=T44 7K64 5KN 'LI9!+:L!-+:86 G'

!

+5> JG'!57 4KM4 4KU: 'LI9!+:L!-

!

+5= 8:54== SK44 >6KN R !96!+:L39!

!

+57 8:>4=; MK44 T6K- !6@?%H+86B98

!

+5; JEOBOP >454 V @6''?%H+O: !9I C×MD

+5T JEOBOP H=45 ;V @6''?%H+O: !9I C×;D

+5S 8:>4S5 QK44 56 @9!G?%68+O N99@

!

30

31

32

36

36

30

No.51866

Page 32

A

V-T2122

EXPLODED VIEW

!

L01

!

10

!

V01

8

11

CRT SOCKET PWB

9

(Within MAIN PWB)

!

10

!

4

!

!

5

MAIN PWB

!!

2

3

7

6

!

T1522

!

1

!

11

!

14

!

12

!

13

18

!

16

!

15

(×2)

17

(×6)

No.51866

31

Page 33

A

V-T2122

PRINTED WIRING BOARD PA RTS LIST

MAIN P.W. BOARD ASS’Y (SGA-1019A-R2)

OW,X&Y+%&$ '()*+%&$ '()*+%(," -"./)01*0&2

!

++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

!9O?O@L!

!5445 %!O64MUK7;>< GH+! 7;Z"+5[54I+++U

!544>K4= %!O64MUK4!4< GH+! 4$4"+5[54I+++U

!5447 J!@4MQUK=!T GP+! =$T

!544; %!O64MUKSM4< GH+! SM

!5545 %!O64MUK7;M< GH+! 7$;Z"+5[54I+++U

!554M %!O64MUK5SM< GH+! 5$SZ

!554> J!95M5UK545E :+! 544"++5[MI+++U

!554= %!O64MUK544< GH+! 54"+5[54I+++U

!5547 %!O64MUKMT4< GH+! MT

!5555 %!O64MUK>Q=< GH+! >Q4Z

!555M %!O64MUK>>=< GH+! >>4Z"+5[54I+++U

!555> %!O64MUK545< GH+! 544

!555; %!O64MUK575< GH+! 574

!55>5 %!O64MUK54M< GH+! 5Z"+5[54I+++U

!55>M %!O64MUK>>5< GH+! >>4

!55>> %!O64MUK54M< GH+! 5Z"+5[54I+++U

!55>= %!O64MUKMT5< GH+! MT4

!55>7 %!O64MUK=T5< GH+! =T4

!55;5 %!O64MUK>>M< GH+! >$>Z

!55;M %!O64MUK4!4< GH+! 4$4"+5[54I+++U

!55;> %!O64MUK54>< GH+! 54Z

!55;= %!O64MUK54M< GH+! 5Z"+5[54I+++U

!55;7 %!O64MUKMT>< GH+! MTZ"+5[54I+++U

!55;; %!O64MUK54>< GH+! 54Z

!55;T %!O64MUK54M< GH+! 5Z

!55;S %!O64MUK545< GH+! 544"+5[54I+++U

!55;Q %!O64MUK7;5< GH+! 7;4

!55T4 %!O64MUK5M>< GH+! 5MZ"+5[54I+++U

!55T5 %!O64MUK57>< GH+! 57Z"+5[54I+++U

!5M45 %!O64MUKSM5< GH+! SM4

!5M4M %!O64MUK54M< GH+! 5Z

!5M4> %!O64MUKSM5< GH+! SM4

!5M4= %!O64MUK;S5< GH+! ;S4

!5M47 %!O64MUK57M< GH+! 5$7Z"+5[54I+++U

!5M5> %!O64MUK>Q5< GH+! >Q4"+5[54I+++U

!5M57 %!O64MUKSM=< GH+! SM4Z

!5M5; %!O64MUK4!4< GH+! 4$4"+5[54I+++U

!5M5T %!O64MUK;S=< GH+! ;S4Z"+5[54I+++U

!5MM4 %!O64MUK4!4< GH+! 4$4

!5M75K7M %!O64MUKT74< GH+! T7

!5M7> %!O64MUK;S4< GH+! ;S

!5M7= J!95M5UK545E :+! 544

!5M77 %!O64MUK545< GH+! 544"+5[54I+++U

!5>45 %!O64MUK54M< GH+! 5Z"+5[54I+++U

!5>4> %!O64MUKMM>< GH+! MMZ

!5>4= %!O64MUKMM>< GH+! MMZ"+5[54I+++U

!5>4T %!O64MUK54>< GH+! 54Z"+5[54I+++U

!5>4S %!O64MUK=TM< GH+! =$TZ

!5>4Q %!O64MUK54>< GH+! 54Z

!5>55 %!O64MUKMT>< GH+! MTZ

!5>5M %!O64MUK4!4< GH+! 4$4

!5>5= %!O64MUK4!4< GH+! 4$4"+5[54I+++U

!5>=5 %!O64MUK5M5< GH+! 5M4"+5[54I+++U

!5>=MK=> %!O64MUK>>>< GH+! >>Z

!5>75K7> %!O64MUK575< GH+! 574"+5[54I+++U

!5>7=K7; %!O64MUK>>5< GH+! >>4"+5[54I+++U

!5>7TK7Q %!O64MUK545< GH+! 544

!5>;4K;M J!V454TK57MV :+! 5$7Z"+++5[MI+++R

!5>;>K;7 J!84MQUK5M> LG+! 5MZ"++++MI+++U

!5>;;K;S %!O64MUKMTM< GH+! M$TZ

!5=45 %!O64MUK54>< GH+! 54Z"+5[54I+++U

!5=4M %!O64MUK;SM< GH+! ;$SZ"+5[54I+++U

!5=4> %!O64MUK4!4< GH+! 4$4

!5=4= %!O64MUK54M< GH+! 5Z"+5[54I+++U

!5=47 %!O64MUKMM5< GH+! MM4

!5=4;K4S %!O64MUK=TM< GH+! =$TZ

!5=54 %!O64MUK4!4< GH+! 4$4"+5[54I+++U

!5=5> J!95M5UK>Q5E :+! >Q4"++5[MI+++U

++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

"

++++MI+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

++5[MI+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

OW,X&Y+%&$ '()*+%&$ '()*+%(," -"./)01*0&2

!

++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

!9O?O@L!

!5=5= J!<45HUK5!M GP+! 5$M"++++5I+++U

!5=5; %!O64MUK7;>< GH+! 7;Z"+5[54I+++U

!5=5S %!O64MUK7;>< GH+! 7;Z

!5=5Q %!O64MUKMM>< GH+! MMZ

!5=M5KMM %!O64MUK4!4< GH+! 4$4"+5[54I+++U

!5=M> %!O64MUK54>< GH+! 54Z

!5745 %!O64MUK4!4< GH+! 4$4"+5[54I+++U

!574> %!O64MUK54>< GH+! 54Z"+5[54I+++U

!574= %!O64MUK54=< GH+! 544Z

!5747 %!O64MUKSMM< GH+! S$MZ

!574; %!O64MUK54M< GH+! 5Z"+5[54I+++U

!5754 %!O64MUK4!4< GH+! 4$4

!575M %!O64MUK54>< GH+! 54Z

!575> %!O64MUK4!4< GH+! 4$4"+5[54I+++U

!575= %!O64MUK>>>< GH+! >>Z

!57M5 J!84>QUK7;M LG+! 7$;Z"++++>I+++U

!57M> %!O64MUKMMM< GH+! M$MZ

!57M= J!95M5UK54>E :+! 54Z

!57M; J!84MQUK57M LG+! 5$7Z

!57MQ %!O64MUK;M5< GH+! ;M4"+5[54I+++U

!57>M J!84>QUK=TM LG+! =$TZ

!57>> J!95M5UKMM4E :+! MM"++5[MI+++U

!57=> J!@4>QUK!=T GP+! 4$=T"++++>I+++U

!57== J!84>QUKMM> LG+! MMZ

!57;M J!65=:PK;S45E GP+! ;$SZ

!

!57;> J!65=:PK>T=5E GP+! >$T=Z"++5[=I+++P

!

!57S5 J!95M5UKMT>E :+! MTZ

!57SM J!95M5UK>Q>E :+! >QZ"++5[MI+++U

!57S= J!95M5UKMM>E :+! MMZ"++5[MI+++U

!5;4> %!O64MUK;SM< GH+! ;$SZ

!5;47 %!O64MUK>Q5< GH+! >Q4

!5;4T %!O64MUK;SM< GH+! ;$SZ

!5;4Q %!O64MUK>Q5< GH+! >Q4

!5;55 %!O64MUKMM>< GH+! MMZ"+5[54I+++U

!5;5> %!O64MUK>>>< GH+! >>Z"+5[54I+++U

!5;M4 %!O64MUK5S>< GH+! 5SZ

!5;MM %!O64MUK5S>< GH+! 5SZ"+5[54I+++U

!5;M; %!O64MUK57>< GH+! 57Z"+5[54I+++U

!5;MT %!O64MUK54=< GH+! 544Z

!5;MS %!O64MUK57>< GH+! 57Z

!5;MQ %!O64MUK54=< GH+! 544Z

!5;>5 %!O64MUK=T>< GH+! =TZ

!5;>7K>; J!95M5UKMT5E :+! MT4"++5[MI+++U

!5;75 %!O64MUK54M< GH+! 5Z"+5[54I+++U

!5;7M %!O64MUK>QM< GH+! >$QZ

!5;7> %!O64MUK57M< GH+! 5$7Z"+5[54I+++U

!5;7= %!O64MUK>>>< GH+! >>Z"+5[54I+++U

!5;77 %!O64MUK>>M< GH+! >$>Z

!5;7; %!364M-K57M< GP+! 5$7Z

!5;7S %!364M-K57>< GP+! 57Z

!5;;4 %!O64MUK75M< GH+! 7$5Z

!5;;QKT4 %!O64MUK=T5< GH+! =T4"+5[54I+++U

!5;T5 %!O64MUK54M< GH+! 5Z"+5[54I+++U

!5;TM %!O64MUK54M< GH+! 5Z

!5;T>KT= %!O64MUKSM>< GH+! SMZ"+5[54I+++U

!5;T7KT; %!O64MUK5S5< GH+! 5S4"+5[54I+++U

!5;TT %!O64MUK54>< GH+! 54Z

!5;TS %!O64MUKMM>< GH+! MMZ"+5[54I+++U

!5;TQ %!O64MUKMM>< GH+! MMZ"+5[54I+++U

!5;S4 %!O64MUKMM>< GH+! MMZ

!5;S5 %!O64MUKMM>< GH+! MMZ"+5[54I+++U

!5;SM %!O64MUK;S>< GH+! ;SZ"+5[54I+++U

!5;S7 %!O64MUK54M< GH+! 5Z

!5;S; %!O64MUK54M< GH+! 5Z"+5[54I+++U

!5;ST %!O64MUK54M< GH+! 5Z

!5;SS %!O64MUK54M< GH+! 5Z

!5;Q5 %!O64MUK54M< GH+! 5Z"+5[54I+++U

!5;QM %!O64MUK54M< GH+! 5Z"+5[54I+++U

++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

++5[MI+++U

"

++++MI+++U

"

++++>I+++U

"

++++>I+++U

"

++5[=I+++P

"

++5[MI+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++-

"

+5[54I+++-

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

32

No. 51866

Page 34

A

V-T2122

OW,X&Y+%&$ '()*+%&$ '()*+%(," -"./)01*0&2

!

++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

!9O?O@L!

!5T45 %!O64MUK7;>< GH+! 7;Z"+5[54I+++U

!5T4M %!O64MUKMM>< GH+! MMZ"+5[54I+++U

!5T4> %!O64MUK4!4< GH+! 4$4"+5[54I+++U

!5T4= %!O64MUK54>< GH+! 54Z"+5[54I+++U

!5T47 %!O64MUK54M< GH+! 5Z

!5T4; %!O64MUKSM>< GH+! SMZ

!5T4T %!O64MUK54>< GH+! 54Z

!5T4S %!O64MUK4!4< GH+! 4$4

!5T4Q %!O64MUK54>< GH+! 54Z

!5T54 %!O64MUK54M< GH+! 5Z"+5[54I+++U

!5T55 %!O64MUK54>< GH+! 54Z

!5T5M %!O64MUK4!4< GH+! 4$4"+5[54I+++U

!5T5> %!O64MUK54>< GH+! 54Z"+5[54I+++U

!5T5= %!O64MUK4!4< GH+! 4$4

!5T57 %!O64MUK=TM< GH+! =$TZ

!5T5; %!O64MUK4!4< GH+! 4$4

!5T5T %!O64MUK=TM< GH+! =$TZ

!5T5S %!O64MUK4!4< GH+! 4$4

!5T5Q %!O64MUK=T>< GH+! =TZ"+5[54I+++U

!5TM4 %!O64MUK;S>< GH+! ;SZ

!5TM5 %!O64MUK=T>< GH+! =TZ"+5[54I+++U

!5TM7 %!O64MUK54M< GH+! 5Z"+5[54I+++U

!5TM; %!O64MUK4!4< GH+! 4$4

!5TMT %!O64MUK54>< GH+! 54Z"+5[54I+++U

!5TMS %!O64MUK54M< GH+! 5Z

!5TMQ %!O64MUK547< GH+! 5G

!5T>M %!O64MUK54M< GH+! 5Z"+5[54I+++U

!5T>> %!O64MUK>>>< GH+! >>Z"+5[54I+++U

!5T>= %!O64MUK54M< GH+! 5Z

!5T>7 %!O64MUK54M< GH+! 5Z

!5T>; %!O64MUK5M=< GH+! 5M4Z

!5T>T %!O64MUK5S=< GH+! 5S4Z

!5T>S %!O64MUK54M< GH+! 5Z

!5T>Q %!O64MUK54M< GH+! 5Z"+5[54I+++U

!5T=4 %!O64MUK=TM< GH+! =$TZ

!5T=5 %!O64MUK54M< GH+! 5Z"+5[54I+++U

!5T=M %!O64MUK=TM< GH+! =$TZ"+5[54I+++U

!5T=> %!O64MUKMM>< GH+! MMZ

!5T== %!O64MUK54>< GH+! 54Z"+5[54I+++U

!5T=7 %!O64MUK57>< GH+! 57Z"+5[54I+++U

!5T=; %!O64MUK54>< GH+! 54Z

!5T=T %!O64MUK57>< GH+! 57Z

!5T=S %!O64MUK54>< GH+! 54Z"+5[54I+++U

!5T=Q %!O64MUK57>< GH+! 57Z

!5T74K75 %!O64MUK7;5< GH+! 7;4

!5T7MK7> %!O64MUK54>< GH+! 54Z

!5T7= %!O64MUK7;M< GH+! 7$;Z

!5T77K7; %!O64MUK54>< GH+! 54Z"+5[54I+++U

!5T7T %!O64MUK7;M< GH+! 7$;Z

!5T7S %!O64MUKMM>< GH+! MMZ

!5T7Q %!O64MUK54>< GH+! 54Z"+5[54I+++U

!5T;7 %!O64MUK5MM< GH+! 5$MZ"+5[54I+++U

!5T;; %!O64MUK54M< GH+! 5Z

!5TT5KTM %!O64MUKMM5< GH+! MM4

!5TS5KSM %!O64MUK;S5< GH+! ;S4"+5[54I+++U

!5TS>KS= %!O64MUKMM5< GH+! MM4

!5S45K4> %!O64MUKMM5< GH+! MM4

!5S55K5> %!O64MUK4!4< GH+! 4$4"+5[54I+++U

!5S57 %!O64MUK4!4< GH+! 4$4

!5S5; %!O64MUK54>< GH+! 54Z"+5[54I+++U

!5Q45 J!P54=RK>!Q A%P+! >$Q"+++54I+++R

!

!5Q4M J!84>QUK>Q> LG+! >QZ

!5Q54 J!95M5UK7;=E :+! 7;4Z"++5[MI+++U

!5Q55 J!95M5UK5S>E :+! 5SZ"++5[MI+++U

!5QM5 J!95M5UK;S5E :+! ;S4

!5QMM J!G47QUK!MM G'+! 4$MM"+++7I+++U

!5QM> J!@4MQUK!>Q GP+! 4$>Q"++++MI+++U

!5QM= J!95M5UK54>E :+! 54Z

!5QM7 J!95M5UK54ME :+! 5Z"++5[MI+++U

!5QM; J!95M5UK57ME :+! 5$7Z"++5[MI+++U

!5QMQ J!95M5UK>>ME :+! >$>Z

++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

+5[54I+++U

"

++++>I+++U

"

++5[MI+++U

"

++5[MI+++U

"

++5[MI+++U

OW,X&Y+%&$ '()*+%&$ '()*+%(," -"./)01*0&2

!

++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

!9O?O@L!

!5Q>M J!95M5UK=!TE :+! =$T"++5[MI+++U

!5Q=M %!O64MUKMM>< GH+! MMZ"+5[54I+++U

!5Q=> J!95M5UK57ME :+! 5$7Z"++5[MI+++U

!5Q== %!O64MUK54>< GH+! 54Z"+5[54I+++U

!5Q=7 %!O64MUK>>M< GH+! >$>Z

!5Q=; %!O64MUK5M>< GH+! 5MZ

!5Q=T J!95M5UK=T4E :+! =T

!5Q=S %!O64MUK57M< GH+! 5$7Z

!5Q=Q %!O64MUK57>< GH+! 57Z

!5Q74 %!O64MUK54>< GH+! 54Z"+5[54I+++U

!5Q75 %!O64MUK>>M< GH+! >$>Z

!5Q7M %!O64MUK=TM< GH+! =$TZ"+5[54I+++U

!5Q7Q %!O64MUK4!4< GH+! 4$4"+5[54I+++U

!5Q;5K;M J!@4MQUK5!S GP+! 5$S

!5Q;= J!95M5UKMTME :+! M$TZ

!5Q;7 J!95M5UK=T>E :+! =TZ

!5Q;; %!O64MUKMM>< GH+! MMZ

!5Q;T J!H45HUK;S5 LG+! ;S4

!5QS5 J!V447TKSM7 :+! S$MG"+++5I+++U

!

++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

:6'6:?@L!

:5445 J9@%5NGK54;V 9+:6'$ +++54#P+++74 3 +++G

:544T J9@%5:GK=TTV 9+:6'$ ++=T4#P+++5; 3 +++G

:544SK4Q J9@%5:GK54TV 9+:6'$ ++544#P+++5; 3 +++G

:5455 %:BM5NRK54>< :+:6'$ 4$45

:5545K4M %:BM5NRK54>< :+:6'$ 4$45#P+++74 3 +++R

:554> %-:M5NUK;S4< :+:6'$ ;S1P+++7 4 3 +++U