JVC AV-N48P55 Service Manual

SERVICE MANUAL

REAR PROJECTION TELEVISION

YA16620046

AV-N48P55/H,

AV-N56P55

[AV-N56P55]

/H

BASIC CHASSIS

RP

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-58

COPYRIGHT © 2004 Victor Company of Japan, Limited

No.YA166

2004/6

SPECIFICATION

Items Contents

AV-N48P55 AV-N56P55

Dimensions (W × H × D) 120cm × 124cm × 60.8cm

(47-1/4" × 49" × 24")

Mass 82 kg ( 181 lbs ) 93.2 kg ( 205.7 lbs )

TV RF System CCIR (M)

Color System NTSC

Sound System BTSC system (Multi Channel Sound)

Teletext System Closed caption (T1-T4 / CC1-CC4)

Receiving Channels

and Frequency

CATV

Receiving Channels

and Frequency

TV / CATV Total Channel 180 Channels

Intermediate

Frequency

Color Sub Carrier 3.58MHz

Power Input AC 120V, 60Hz

Power Consumption 248W (Max)

Screen Transparent screen (unitized fresnel lens / double lenticular lens)

Screen Size 48" (122cm) Measured diagonally

Projection Tube 17cm (6.7") tube × 3 ( R/G/B )

High Voltage 31kV+1.0kV/-1.3kV (at zero beam current)

Speaker 13cm round type × 2

Audio Power Output 10W+10W

Antenna Terminal 75Ω unbalanced, F-type connector × 1

External Input

(1/2/3/4)

Audio Output (FIX) 500mV(rms) (-4dBs), low impedance (1kHz when modulated 100%)

AV Compulink lll 3.5mm mini jack × 1

Remote Control Unit RM-C1257G (AA/R6/UM-3 battery × 2)

Design & specifications are subject to change without notice.

Component Video

VHF Low

VHF High

UHF

CATV 54MHz~804MHz

Video IF

Sound IF

[INPUT-1/2]

720p/1080i

480i/480p

S-Video

[INPUT-1/3/4]

Video

Audio

02ch~06ch : 54MHz~88MHz

07ch~13ch : 174MHz~216MHz

14ch~69ch : 470MHz~806MHz

Low Band : 02~06

High Band : 07~13

Mid Band : A~I by 14~22

Super Band : J~W by 23~36

Hyper Band : W+1~W+28 by 37~64

Ultra Band : W+29~W+58, W+59~W+84 by 65~94, 100~125

Sub Mid Band : A-8, A-4~A-1 by 01, 96~99

45.75MHz

41.25MHz (4.5MHz)

16:9 ratio (W:106.3 cm, H:59.8 cm)

RCA pin jack × 6

Y : 1V (p-p) (Sync signal: ±0.35V, 3-value sync.), 75Ω

Pb/Pr : ±0.35V, 75Ω

Y : 1V (p-p) Positive (Negative sync provided), 75Ω

Pb/Pr : 0.7V, 75Ω

Mini-DIN 4pin × 3

Y: 1V (p-p) positive (negative sync provided), 75Ω

C: 0.286V(p-p) (burst signal)

1V (p-p) positive (negative sync provided), 75Ω (RCA pin jack × 4)

500mV(rms) (-4dBs), high impedance (RCA pin jack × 9)

(RCA pin jack × 2)

136.8cm × 138.6cm × 66.7cm

(53-7/8" × 54-5/8" × 26-3/8")

56" (142cm) Measured diagonally

16:9 ratio (W:124 cm, H:69.8 cm)

1-2 (No.YA166)

SECTION 1

PRECAUTION

1.1 SAFETY PRECAUTIONS

(1) The design of this product contains special hardware, many

circuits and components specially for safety purposes. For

continued protection, no changes should be made to the original

design unless authorized in writing by the manufacturer.

Replacement parts must be identical to those used in the original

circuits. Service should be performed by qualified personnel only.

(2) Alterations of the design or circuitry of the products should not be

made. Any design alterations or additions will void the

manufacturer's warranty and will further relieve the manufacturer

of responsibility for personal injury or property damage resulting

therefrom.

(3) Many electrical and mechanical parts in the products have special

safety-related characteristics. These characteristics are often not

evident from visual inspection nor can the protection afforded by them

necessarily be obtained by using replacement components rated for

higher voltage, wattage, etc. Replacement parts which have these

special safety characteristics are identified in the parts list of Service

manual. Electrical components having such features are

identified by shading on the schematics and by ( ) on the

parts list in Service manual. The use of a substitute replacement

which does not have the same safety characteristics as the

recommended replacement part shown in the parts list of Service

manual may cause shock, fire, or other hazards.

(4) Use isolation transformer when hot chassis.

The chassis and any sub-chassis contained in some products are

connected to one side of the AC power line. An isolation

transformer of adequate capacity should be inserted between the

product and the AC power supply point while performing any

service on some products when the HOT chassis is exposed.

(5) Don't short between the LIVE side ground and ISOLATED (NEU-

TRAL) side ground or EARTH side ground when repairing.

Some model's power circuit is partly different in the GND. The difference of the GND is shown by the LIVE : ( ) side GND, the ISOLATED (NEUTRAL) : ( ) side GND and EARTH : ( ) side GND.

Don't short between the LIVE side GND and ISOLATED (NEUTRAL)

side GND or EARTH side GND and never measure the LIVE side

GND and ISOLATED (NEUTRAL) side GND or EARTH side GND at

the same time with a measuring apparatus (oscilloscope etc.). If

above note will not be kept, a fuse or any parts will be broken.

(6) If any repair has been made to the chassis, it is recommended that

the B1 setting should be checked or adjusted (See B1 POWER

SUPPLY check).

(7) The high voltage applied to the picture tube must conform with that

specified in Service manual. Excessive high voltage can cause an

increase in X-Ray emission, arcing and possible component

damage, therefore operation under excessive high voltage

conditions should be kept to a minimum, or should be prevented.

If severe arcing occurs, remove the AC power immediately and

determine the cause by visual inspection (incorrect installation,

cracked or melted high voltage harness, poor soldering, etc.). To

maintain the proper minimum level of soft X-Ray emission,

components in the high voltage circuitry including the picture tube

must be the exact replacements or alternatives approved by the

manufacturer of the complete product.

(8) Do not check high voltage by drawing an arc. Use a high voltage

meter or a high voltage probe with a VTVM. Discharge the picture

tube before attempting meter connection, by connecting a clip lead

to the ground frame and connecting the other end of the lead

through a 10k

(9) When service is required, observe the original lead dress. Extra

precaution should be given to assure correct lead dress in the high

voltage circuit area. Where a short circuit has occurred, those

components that indicate evidence of overheating should be

replaced. Always use the manufacturer's replacement

components.

Ω 2W resistor to the anode button.

(10) Isolation Check (Safety for Electrical Shock Hazard)

After re-assembling the product, always perform an isolation

check on the exposed metal parts of the cabinet (antenna

terminals, video/audio input and output terminals, Control knobs,

metal cabinet, screw heads, earphone jack, control shafts, etc.) to

be sure the product is safe to operate without danger of electrical

shock.

a) Dielectric Strength Test

The isolation between the AC primary circuit and all metal parts

exposed to the user, particularly any exposed metal part having a

return path to the chassis should withstand a voltage of 1100V AC

(r.m.s.) for a period of one second.

(. . . . Withstand a voltage of 1100V AC (r.m.s.) to an appliance rat-

ed up to 120V, and 3000V AC (r.m.s.) to an appliance rated 200V

or more, for a period of one second.) This method of test requires

a test equipment not generally found in the service trade.

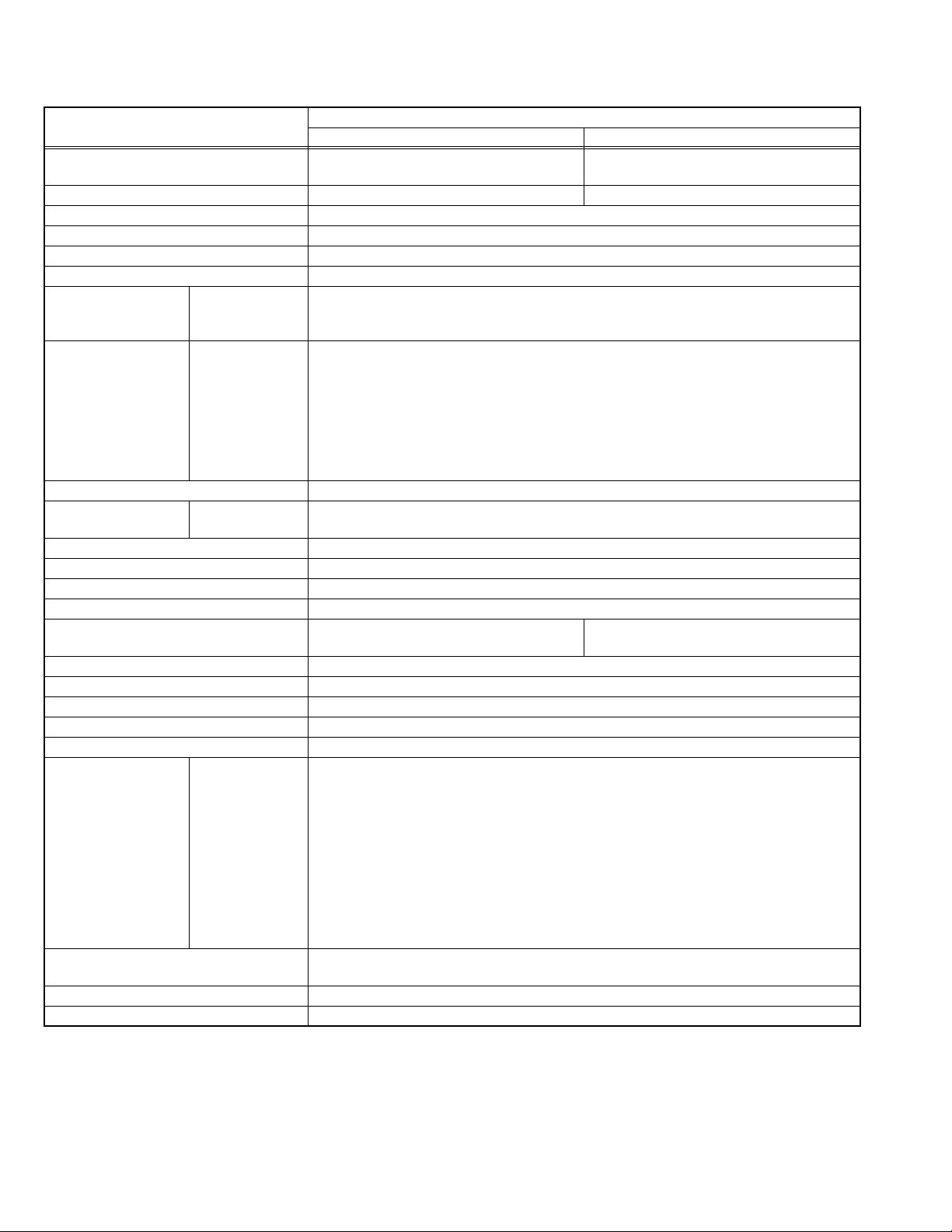

b) Leakage Current Check

Plug the AC line cord directly into the AC outlet (do not use a line

isolation transformer during this check.). Using a "Leakage

Current Tester", measure the leakage current from each exposed

metal part of the cabinet, particularly any exposed metal part

having a return path to the chassis, to a known good earth ground

(water pipe, etc.). Any leakage current must not exceed 0.5mA AC

(r.m.s.).

However, in tropical area, this must not exceed 0.2mA AC (r.m.s.).

Alternate Check Method

Plug the AC line cord directly into the AC outlet (do not use a

line isolation transformer during this check.). Use an AC

voltmeter having 1000

following manner. Connect a 1500

a 0.15

µF AC-type capacitor between an exposed metal part

Ω per volt or more sensitivity in the

Ω 10W resistor paralleled by

and a known good earth ground (water pipe, etc.). Measure the

AC voltage across the resistor with the AC voltmeter. Move the

resistor connection to each exposed metal part, particularly any

exposed metal part having a return path to the chassis, and

measure the AC voltage across the resistor. Now, reverse the

plug in the AC outlet and repeat each measurement. Any

voltage measured must not exceed 0.75V AC (r.m.s.). This

corresponds to 0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.3V AC

(r.m.s.). This corresponds to 0.2mA AC (r.m.s.).

AC VOLTMETER

(HAVING 1000 /V,

OR MORE SENSITIVITY)

0.15 F AC-TYPE

PLACE THIS PROBE

1500 10W

(11) High voltage hold down circuit check.

GOOD EARTH GROUND

ON EACH EXPOSED

ME TAL PAR T

After repair of the high voltage hold down circuit, this circuit shall

be checked to operate correctly.See item "How to check the high

voltage hold down circuit".

This mark shows a fast

operating fuse, the

letters indicated below

show the rating.

A V

POWER CORD

REPLACEMENT WARNING.

Connecting the white line side of power

cord to "WHT" character side.

PWB

White line side

WHT

PW

(No.YA166)1-3

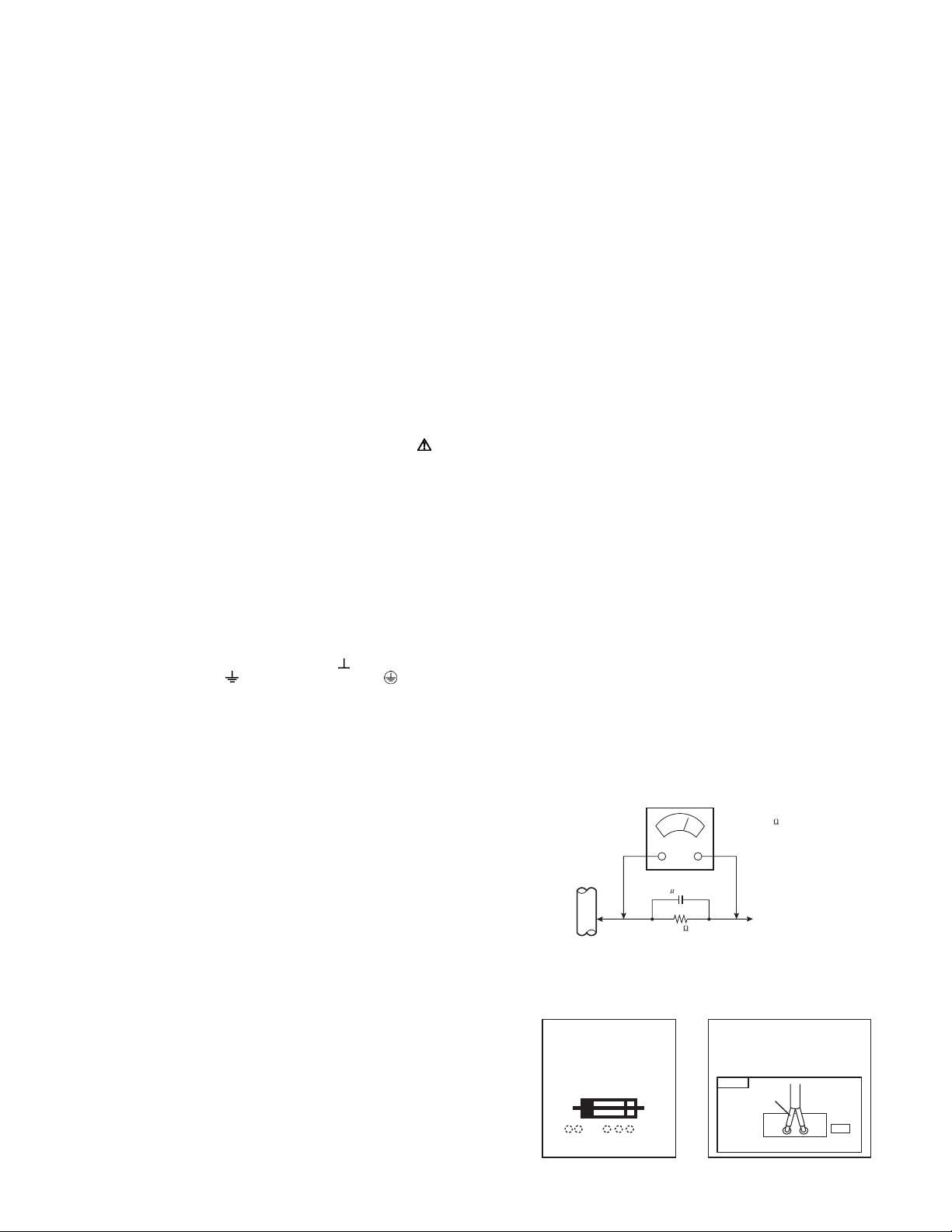

1.2 INSTALLATION

1.2.1 INSTALLATION SITE

(1) The rear of this set is provided with ventilation openings.

Install the set more than 5 cm from a wall and in a location

with good ventilation.

(2) Avoid the following types of locations.

a) Unstable locations (location must be able to

withstand heavy weight).

b) Locations subjected to direct sunlight.

c) Near stoves or other heating devices.

d) Locations subjected to humidity or oily smoke.

e) Dusty locations.

f) Locations with strong vibration.

1.2.2 INSTALLATION ADJUSTMENT

When installing, moving or changing the orientation of the set,

perform static convergence adjustment according to the

following procedure.

Adjusting CRT color convergence have MANUAL and RESET.

It adjust on the MENU screen.

NOTE :

Please have you TV on for at least 20 minutes before sing this

feature.

This adjustment will be needed only when the colors of the

characters/lines are separated and lack in distinction. If not,

please don't perform the adjustment.

MANUAL

(1) Press the [MENU] key, and select the

"CONVERGENCE" in the INITIAL SETUP menu with

[function up/down] key.

(2) Press the [function left/right] key, the CONVERGENCE

menu appears.

(3) Press the [function up/down] key, and select the

"MANUAL".

(4) Press the [function left/right] key, then CONVERGENCE

adjustment screen appear. [Fig.1]

• If all the crosses are white, no convergence

adjustment is needed.

(5) Select the location you want to adjust by using the

[number (2/4/5/6/8)] keys on the remote control unit.

[Fig.2]

(6) Press the [SELECT] key to change the color of the box

to the color of the cross you want to adjust (red or blue).

• You cannot adjust the green cross.

(7) Use the [function up/down] key and the [function left/

right] keys to adjust the position of the cross.

(8) Adjust the three colors crosses until they overlap and

appear as a single white cross.

(9) Press the [OK] key.

NOTE :

• When you adjust the convergence, make sure you

start with the center position (position 5), and work

your way around radial for best results.

• When you make the adjustment in the center

(positions 5), you are making the adjustment for the

whale screen. In other positions, you are making the

adjustment only in that area.

• You can reset the adjustment if you do not like the

results, See below.

(more than 5cm)

Wall

VENTILATION OPENING

(10) Press the [menu] key to end the convergence

adjustment procedure.

RESET

RESET in the CONVERGENCE menu resets all convergence

adjustments to the factory default setting.

Fig.1

2

5

8

64

Fig.2

1-4 (No.YA166)

SECTION 2

S-VIDEO

VIDEO

OPERATE

/ MONO

SPECIFIC SERVICE INSTRUCTIONS

2.1 FEATURES

• Rear Projection HDTV.

• 3-2 PULL DOWN : You can enjoy DVD movies at the highest picture quality.

• MOTION COMPENSATION : With this function, the seamless reproduction of dynamic motion on the screen has been realized.

• Bullet-in DSD (Digital Super Detail) circuit and 3 dimension Y/C separate circuit.

• Receive DTV broadcast (1080i / 720p / 480p / 480i)

• Built-in Component (Y / Pb / Pr) input.

• Built-in A.H.S. circuit.

2.2 FUNCTIONS

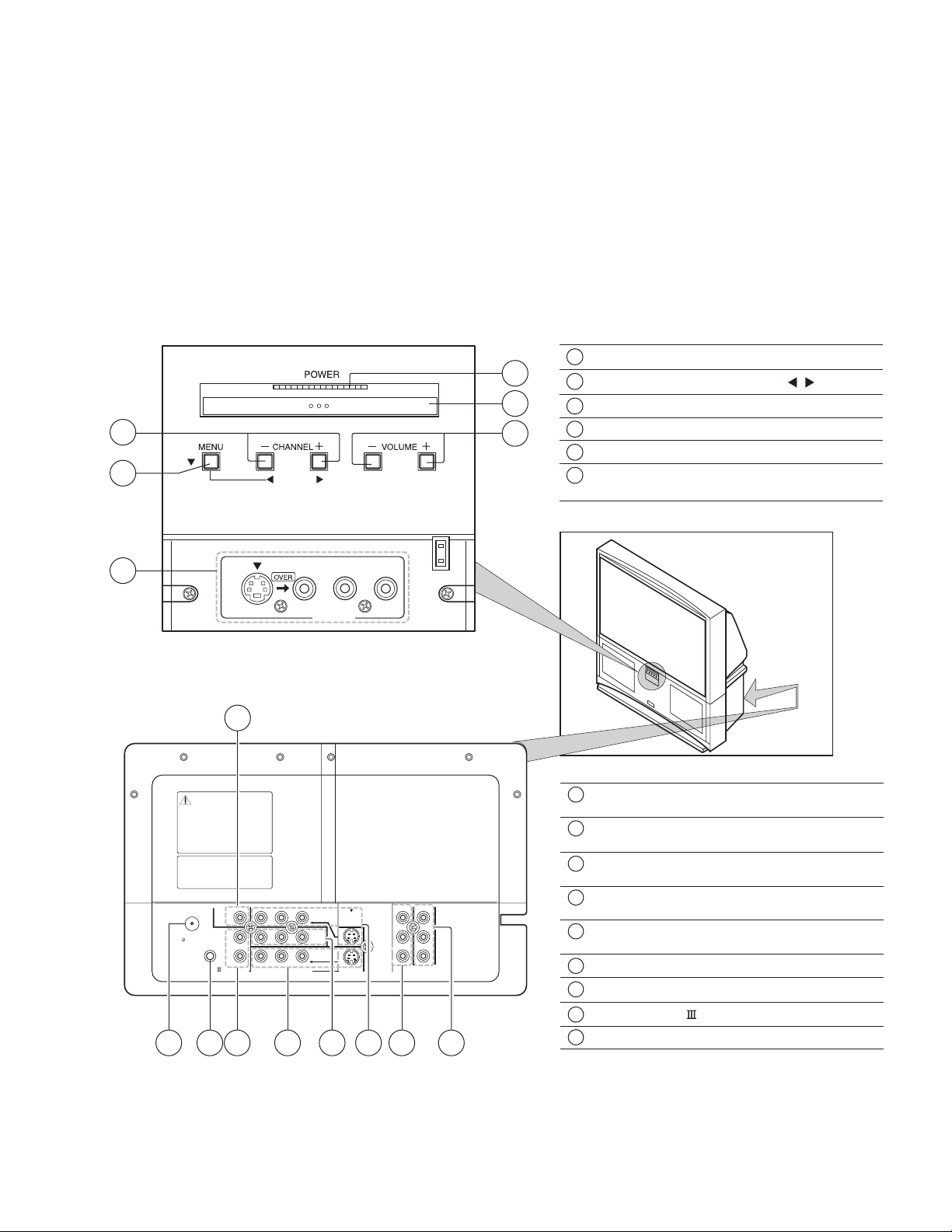

FRONT CONTROL KEY & TERMINAL

1

MENU button ( OPERATE ٕ )

5

4

2

1

OPERATE

3

2

CHANNERL -/+ button ( OPERATE / )

3

VOLUME -/+ button

4

MAIN POWER button

5

POWER LED (Blue)

6

INPUT4 terminal

( S-VIDEO / VIDEO / AUDIO )

6

REAR TERMINAL

UNPLUG THE POWER CORD FROM AC OUTLET

BEFORE REMOVING THE REAR COVER

When the rear cover is removed, follow "CAUTION AT DISASSEMBLY"

procedure in the service manual before plugging the TV's power

cord into an AC outlet. Failure to follow the procedure will result

in PERMANENT damage to some of the television features.

DÉBRANCHEZ LE CORDON DE LA PRISE DE COURANT

C.A. AVANT DE RETIRER LE COUVERCLE ARRIÈRE.

Une fois le couvercle arrière déposé suivez l procédure

« ATTENTION LORS DU DÉMONTAGE » décrite dans une

prise c.a. L'omission de suivre la procédure causera des

dommages PERMANENTS à certaines fonctions du téléviseur.

Licensed from BBE Sound, Inc. under USP4638258, 4482866

and 5510752.

BBE is a registered trademark of BBE Sound, Inc.

Sous licence de BBE Sound, Inc.

BBE est une marque de fabrique déposée de BBE Sound, Inc.

Autorizado con licencia de BBE Sound, Inc.

BBE es une marca comercial registrada de BBE Sound, Inc.

75 (VHF/UHF)

AV COMPULINK

S-VIDEO

CENTER

CHANNEL

INPUT

6

R

L

AUDIO OUT

RL

AUDIO VIDEO

VIDEO

INPUT4

INPUT-3

INPUT-2

INPUT-1

L / MONO

OVER

OVER

S-VIDEO

R

COMPONENT VIDEO

51 2789 3

1

INPUT-1 terminal

( S-VIDEO / VIDEO / AUDIO )

2

INPUT-2 terminal

( VIDEO / AUDIO )

3

INPUT-3 terminal

( S-VIDEO / VIDEO / AUDIO )

4

INPUT-1INPUT-2

Y

Pb

Pr

4

INPUT-1 COMPONENT VIDEO terminal

( Y / Pb / Pr )

5

INPUT-2 COMPONENT VIDEO terminal

( Y / Pb / Pr )

6

CENTER CHANNEL INPUT terminal

7

AUDIO OUT terminal

8

AV COMPULINK

9

Antenna terminal ( VHF / UHF )

(No.YA166)1-5

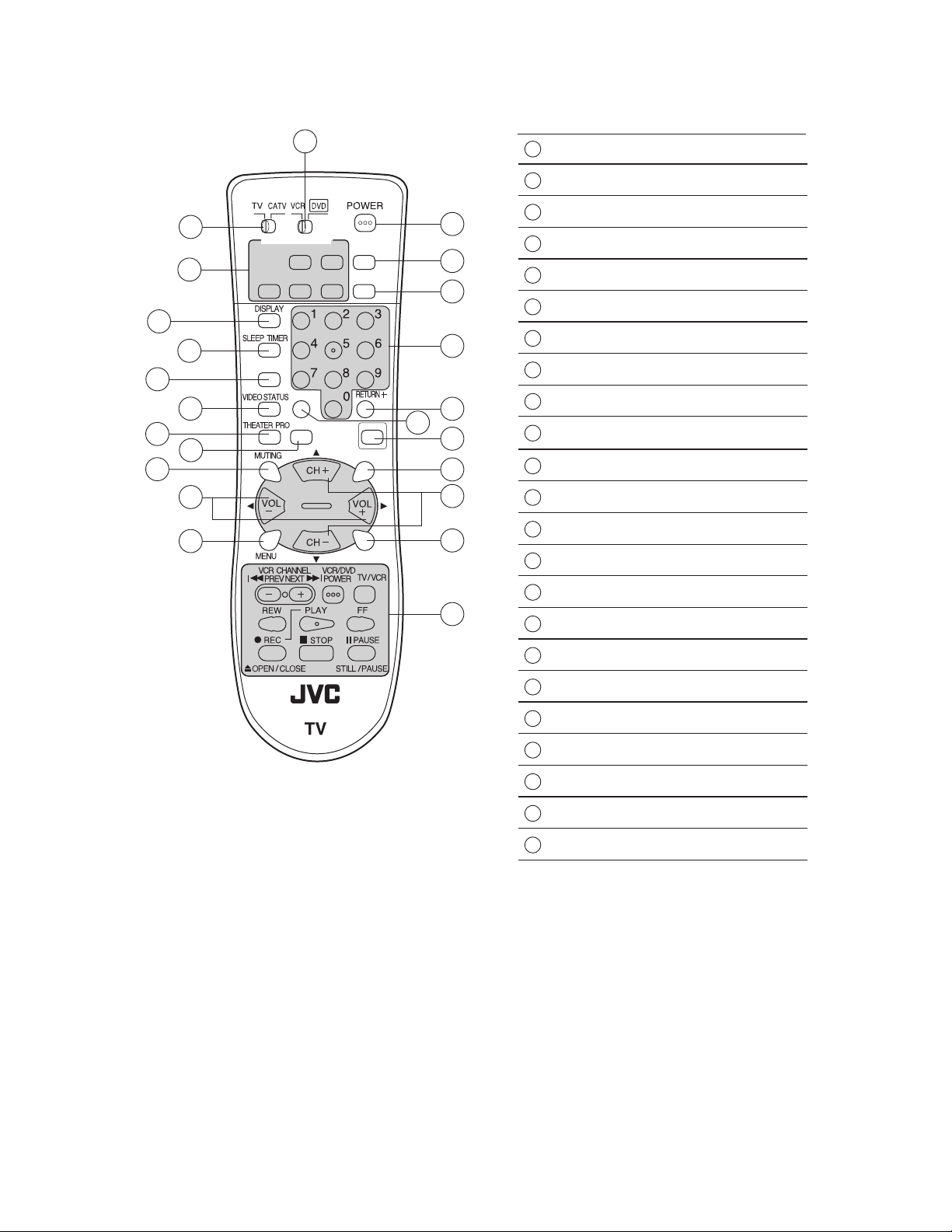

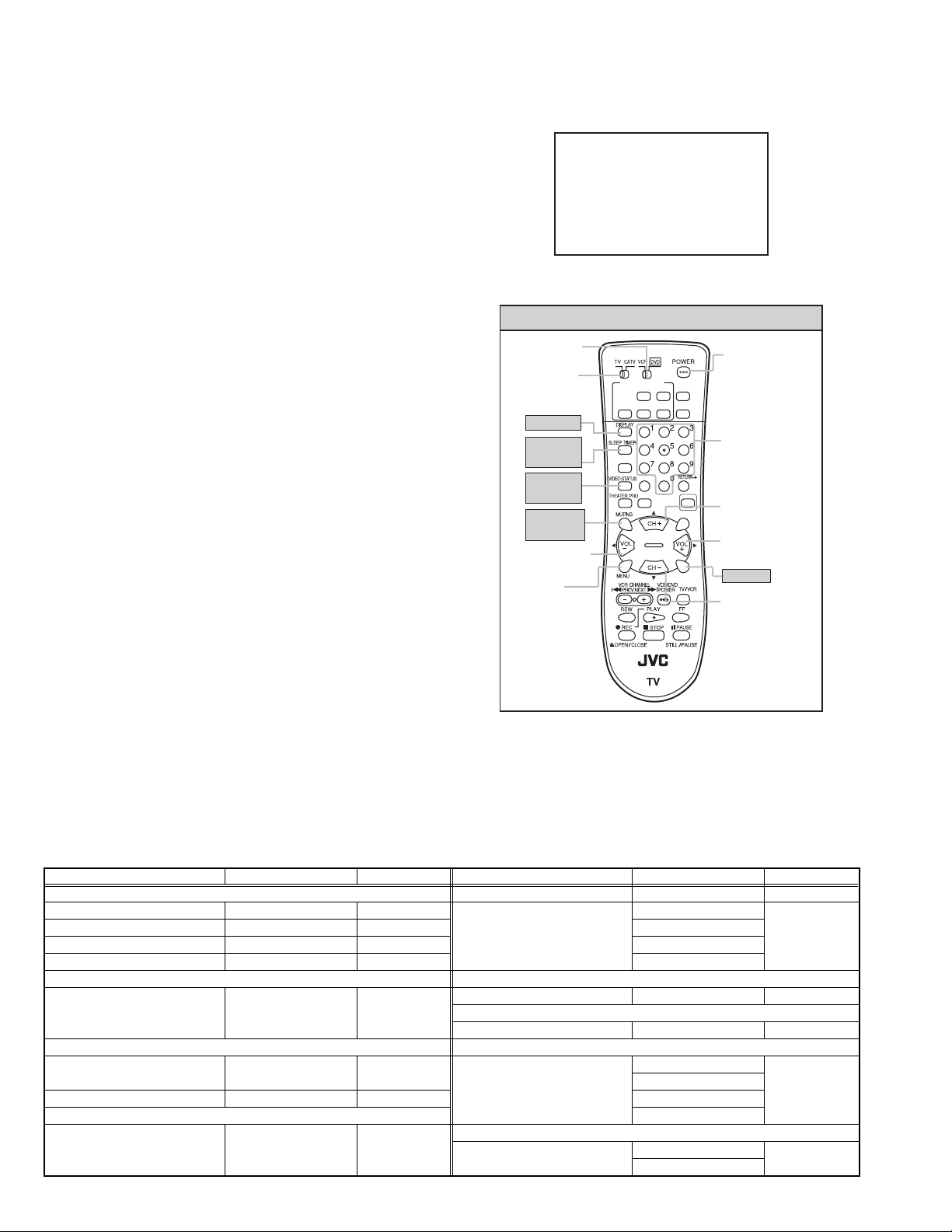

REMOTE CONTROL UNIT [RM-C1257G]

2

3

4

MULTI SCREEN

FREEZE

SWAP

SELECT

C.C.INDEXTWIN

INPUT

1

14

15

1

POWER key

2

VCR / DVD switch

3

TV / CATV switch

4

MULTI SCREEN operation keys

5

DISPLAY key

6

SLEEP TIMER key

5

7

6

SOUND

16

7

8

9

10

11

12

13

TUNE

ASPECT

LIGHT

OK

BACK

17

18

19

20

21

22

SOUND key

8

VIDEO STATUS key

9

THEATER PRO key

10

ASPECT key

11

MUTING key (memory key)

12

VOL+/- (/) keys

13

MENU key

14

C.C.(Closed Caption) key

RM-C1257G

23

15

INPUT key

16

Number (1~0) keys

17

RETURN+ key

18

TUNE key

LIGHT key

19

OK key

20

21

CH+/- (/) keys

22

BACK key

23

VCR / DVD operation keys

1-6 (No.YA166)

2.3 TECHNICAL INFORMATION

2.3.1 MAIN MICRO COMPUTER (CPU) FUNCTION (MN102H75K)

Pin No. Pin name I/O Function

1 NC O --------

2 /MICON_V I V.sync for OSD

3LB_PRO I

Low B protection detection

[Protection:H]

4 NC - --------

5 /RST I Main CPU reset [Reset:L]

6 NC O --------

7 /TEST I +3.3V

8 OSD_YS O OSD Ys (blanking)

9SDA4 I/OI

2

C bus (data) for JCC5055

10 NC O --------

11 A_MU O Audio muting [Muting:H]

12 /MICON_H I H sync for OSD

13 NC O --------

14 P46,OSDXI I Oscillation for OSD

15 P45,OSDXO O Oscillation for OSD

16 SDA2 I/O I

2

C bus (data) for MTS

17 AC-IN I AC for timer count

18 SCL2 O I

2

C bus (clock) for MTS

19 NC O --------

20 VCOI I LPF

21 PDO O LPF

22 /IP_RESET O Reset for DIST [Reset:L]

23 OSD_YM O OSD Ym (transparence)

24 OSD_B O OSD blue

25 POWER_LED O

Lighting for POWER LED

[HIGH / ON:H]

26 OSD_G O OSD green

27 OSD_R O OSD red

28 VREF I Reference voltage for OSD

29 IP_ERR I DIST program load detect.

30 IREF I Reference current for OSD

31 COMP I Phase adjust for OSD

32 AVDD I +3.3V

33 CLL I Clamp low level

34 VREFLS I Reference voltage for SUB CCD

35 SUB_CCD I

Video for sub closed caption

decoder

36 NC - --------

37 VSS I GND

38 MAIN_CCD I

Video for main closed caption

decorder

39 VREFHS I Reference voltage for MAIN CCD

40 CLH I Clamp high level

41 VDD/VPP I +3.3V

42 SCL4 O I

2

C bus (data) for JCC5055

Pin No. Pin name I/O Function

43 NC O --------

44 ON_TIM O

Lighting for on timer operating

[LOW / ON:H]

45 SBO 0 O Convergence control [RXD]

46 SBD 0 I Convergence control [TXD]

47 SBT1 I --------

48 AP_DATA - --------

49 BS_RST - --------

50 SQR - --------

51 BS1.5CTL - --------

52 NC O --------

53 NC O --------

54 DC_COTL O Black level DC reproduce control

55 NC O --------

56 NC O --------

57 NC O --------

58 /LOB_POW O LowB power control [Power on:L]

59 COMPULINK I AV COMPULINK III control

60 /POWERGOOD I Power condition check

61 /MECA_ON I Machine SW interrupt [Pushing:L]

62 /MAIN_POW O Main power control [Power on :L]

63 NC - --------

64 /B1 POW O B1 power control [Power on:L]

65 AFC I AFT voltage

66 X_RAY I

X-ray protection detection

[Protection : 2.0V]

67 SPRIT O NC

68 KEY2 I Front key scan 2 (CH+, VOL-/+)

69 KEY1 I Front key scan 1 (MENU, CH-)

70 SCL1 O I

71 SDA1 I/O I

2

C bus (clock) for EEP-ROM

2

C bus (data) for EEP-ROM

72 REMO I Remote control

73 NC O --------

74 VSS I GND

75 OSC2 O 4MHz oscillation for system clock

76 OSC1 I 4MHz oscillation for system clock

77 VDD I +3.3V

78 SCL0 O I

2

C bus (clock) for general

79 AP_CLK O --------

80 SDA0 I/O I

2

C bus (data) for general

81 NC O --------

82 NC O --------

83 NC - --------

84 P_MU O Picture muting [Muting:H]

(No.YA166)1-7

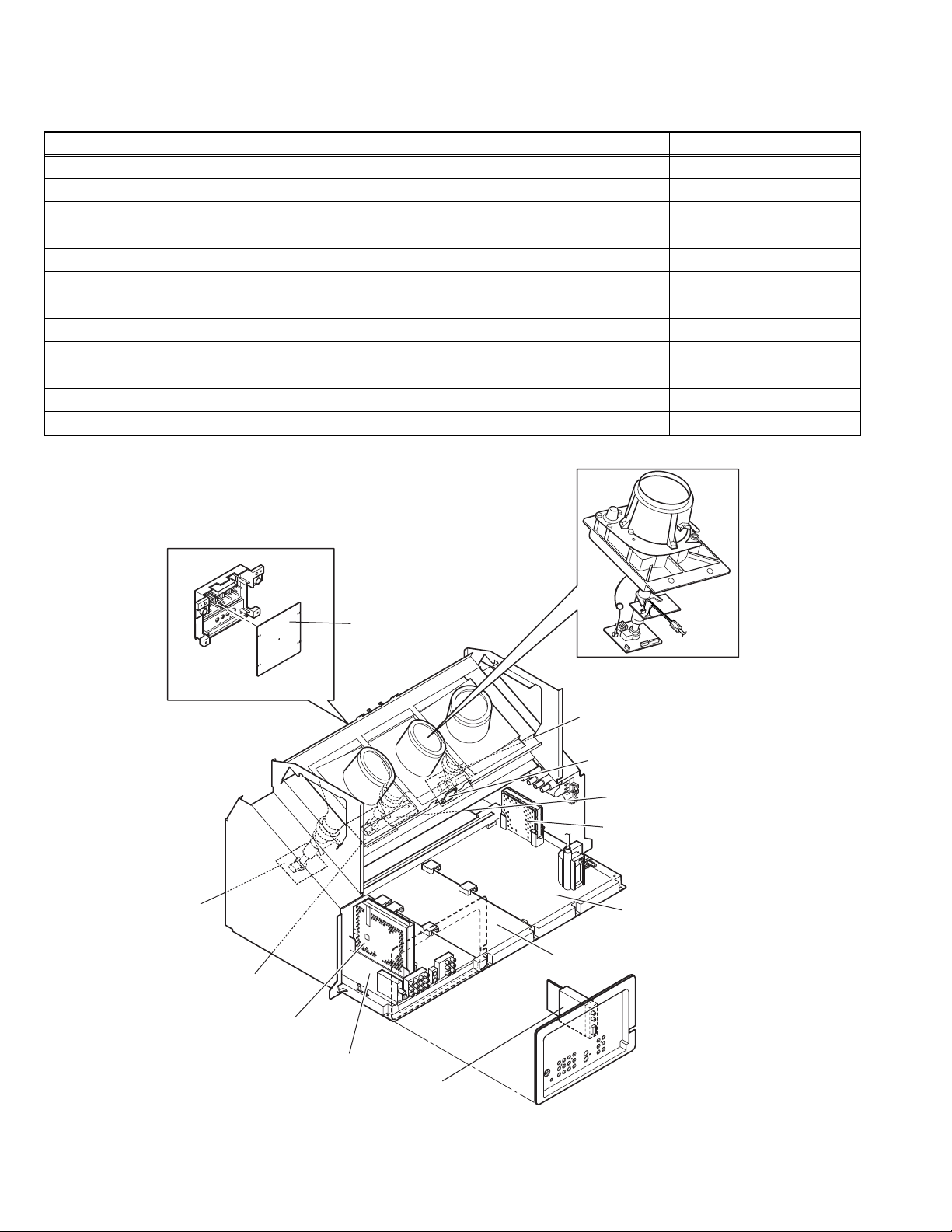

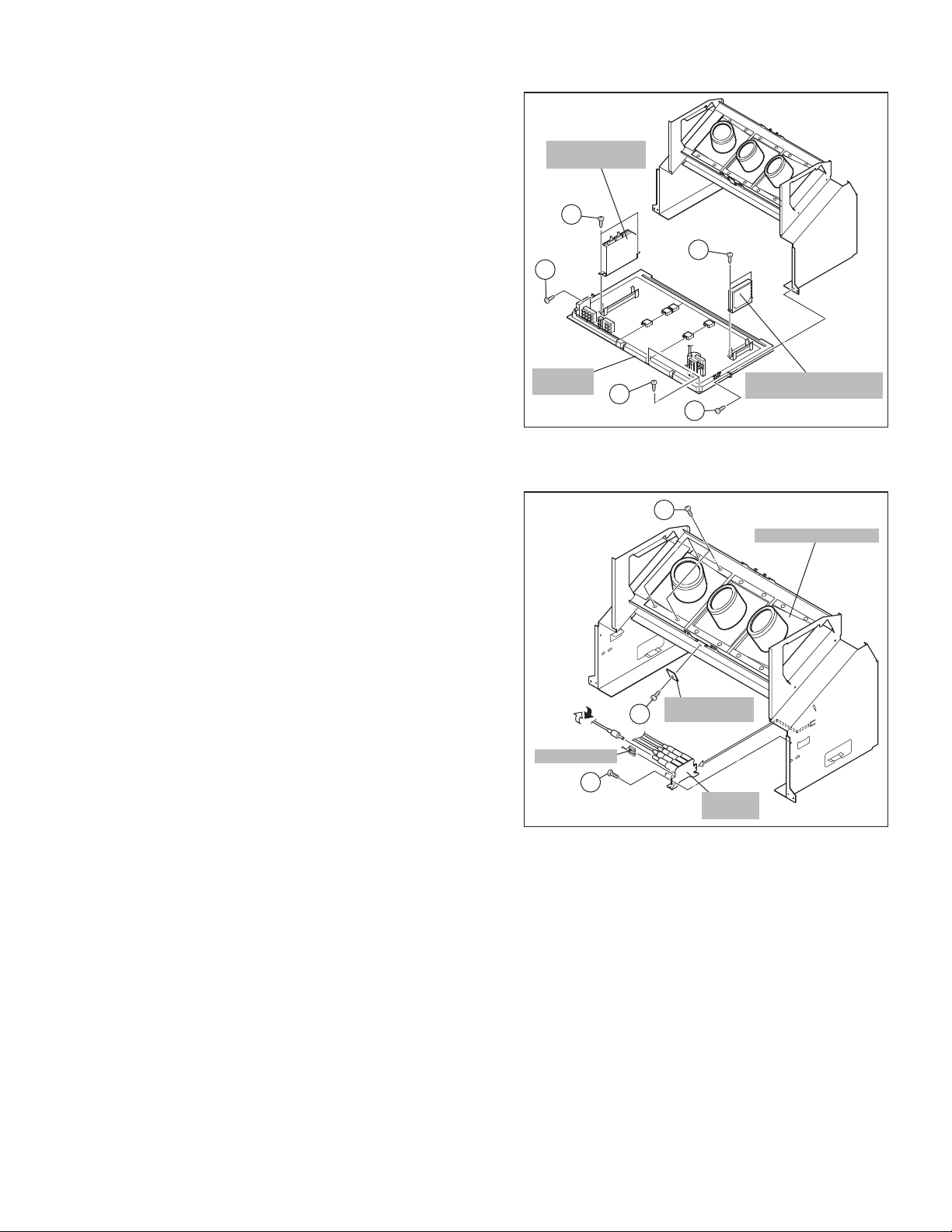

2.4 MAIN PARTS LOCATION

2.4.1 PWB ASS'Y ARRANGEMENT

The PWB ASS'Y is indicated below.

PWB ASS'Y name AV-N48P55H AV-N56P55H

MAIN PWB ASS'Y SRP-1015A-M2 SRP-1010A-M2

MI-COM & DIST MODULE PWB ASS'Y SRP0D001A-M2 ←

POWER PWB ASS'Y SRP-9010A-M2 ←

DEF / CONVERGENCE OUT PWB ASS'Y SRP-2012A-M2 ←

DIGITAL CONVERGENCE MODULE PWB ASS'Y SRP0K012A-M2 SRP0K013A-M2

DIGITAL INPUT MODULE PWB ASS'Y --- ---

FRONT CONTROL PWB ASS'Y SRP0L012A-M2 ←

REMOCON SENSOR PWB ASS'Y SRP-8001A-M2 ←

VM PWB ASS'Y SRP-7201A-M2 ←

R CRT SOCKET PWB ASS'Y SRP-3101A-M2 ←

G CRT SOCKET PWB ASS'Y SRP-3201A-M2 ←

B CRT SOCKET PWB ASS'Y SRP-3301A-M2 ←

PROJECTION UNIT

FRONT CONTROL ASS'Y

B CRT SOCKET

PWB

G CRT SOCKET

PWB

MI-COM & DIST

MODULE PWB

MAIN PWB

FRONT CONTROL

PWB

DIGITAL INPUT

MODULE PWB

[AV-65WP55]

R CRT SOCKET

PWB

REMOCON SENSOR

PWB

VM PWB

DIGITAL CONVERGENCE

MODULE PWB

DEF / CONVERGENCE

OUT PWB

POWER PWB

AV TERMINAL BOARD

1-8 (No.YA166)

(This figure is only MAIN UNIT)

2.5 SCREEN HANDLING CAUTIONS

2.5.1 SCREEN STORAGE

Store the SCREEN ASS'Y in a standing position in order to avoid deformation. If the screen is stored horizontally, there is risk of

deforming the screen face.

When necessary to place the SCREEN ASS'Y horizontally, position the screen side upwards and sure to place spacers between the

screen and resting site (floor or stand etc.) to prevent the screen from sagging.

2.5.2 SCREEN SURFACE

Since the screen surface is easily scratched or soiled, use ample care when handling.

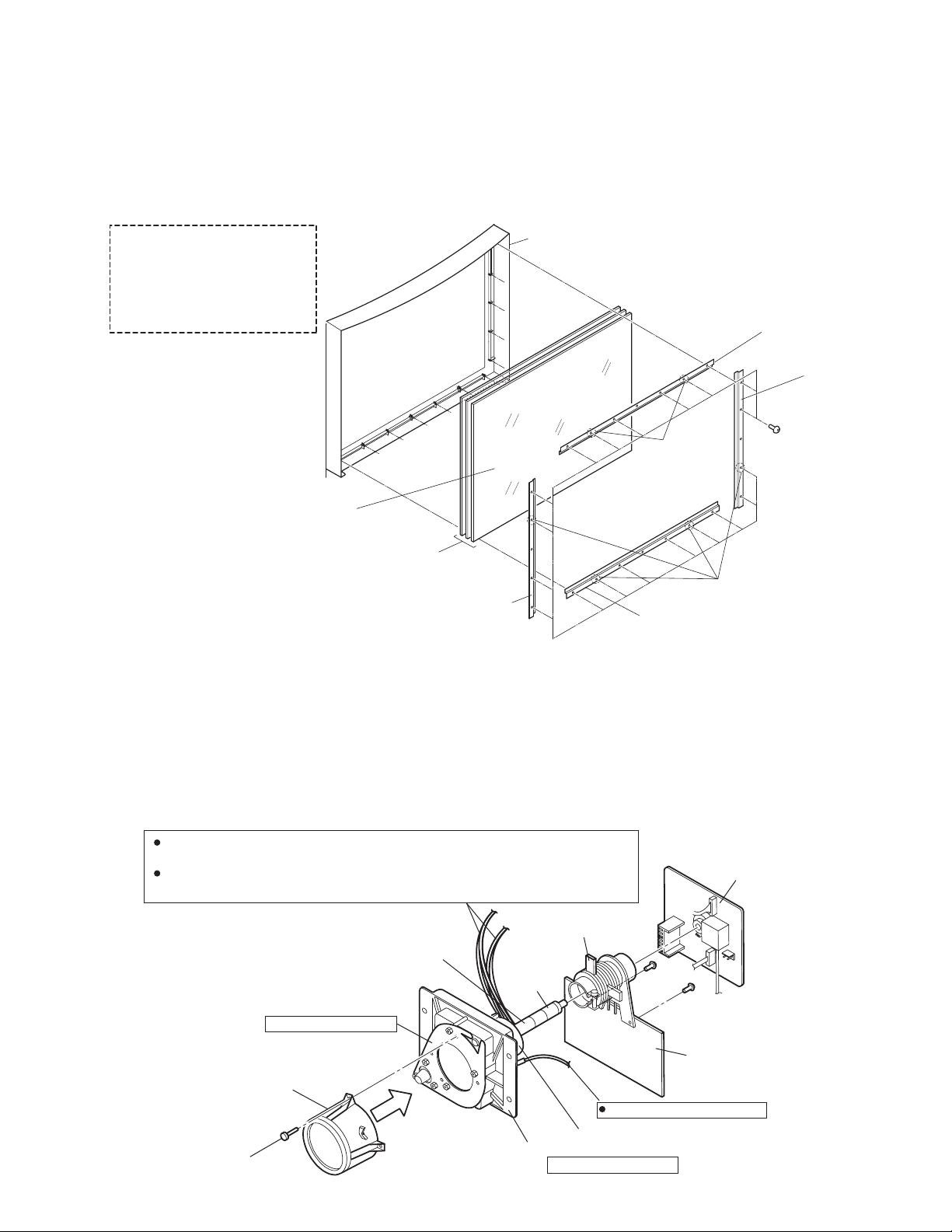

DISASSEMBLY PROCEDURE

If the screen or screen panel

need to

be replaced, remove the 14 (48

inch) /

20 (56 inch, 65 inch) screws A.

FRONT PANEL

SCREEN BRACKET

(TOP)

SCREEN

BRACKET

(LEFT)

A

(x 14) [48 inch]

(x 20) [56 inch, 65 inch]

Leave the screen with protector, fresnel

lens and double lenticular lens

attached. If cannot be disassembled

further.

SCREEN

SCREEN BRACKET

(RIGHT)

56 inch

65 inch only

56 inch

65 inch only

SCREEN BRACKET

(BOTTOM)

2.6 PROJECTION UNIT REPLACEMENT

2.6.1 ADJUSTMENT DURING REPLACEMENT

When replacing the three R, G and B projection units, first replace the R and B units and perform focus / screen / raster centering

adjustments with reference to the G unit. Then replace the G unit and perform G focus / screen / convergence adjustment. Finally

perform R & B . Convergence adjustments. Use care to simultaneously removes all three-projection units.

2.6.2 DISASSEMBLY CAUTION

The projection units include locations that are not to be disassembled during service. When replacing projection unit parts,

disassemble to the state indicated in the figure below.

The figure indicates screws and wires that are not to be removed. Use care not to remove these.

Deflection yoke wires : to connector on DEF / CONVERGENCE OUT PWB ASS'Y.

[R="RHV", G="GHV", B="BHV"]

Convergence yoke wires : to connector on DEF / CONVERGENCE OUT PWB ASS'Y.

[R="R", G="G", B="B"]

2/4 POLE

Check that tape is applied to the CRT neck.

If absent, the deflection yoke can dislodge.

Do not remove screws

LENS ASS'Y

LENS ASS'Y SCREW ( x 4)

MAGNET

TAPE

CRT ASS'Y (COUPLER ASS'Y)

Do not disassembly

R CRT SOCKET PWB ASS'Y

G CRT SOCKET PWB ASS'Y

B CRT SOCKET PWB ASS'Y

VM PWB (G only)

ANODE wires : to DIVIDER

DEF. / CONVER. YOKE

(No.YA166)1-9

SECTION 3

DISASSEMBLY

3.1 DISASSEMBLY PROCEDURE

• Make sure that the power cord is pulled out from the AC wall

socket.

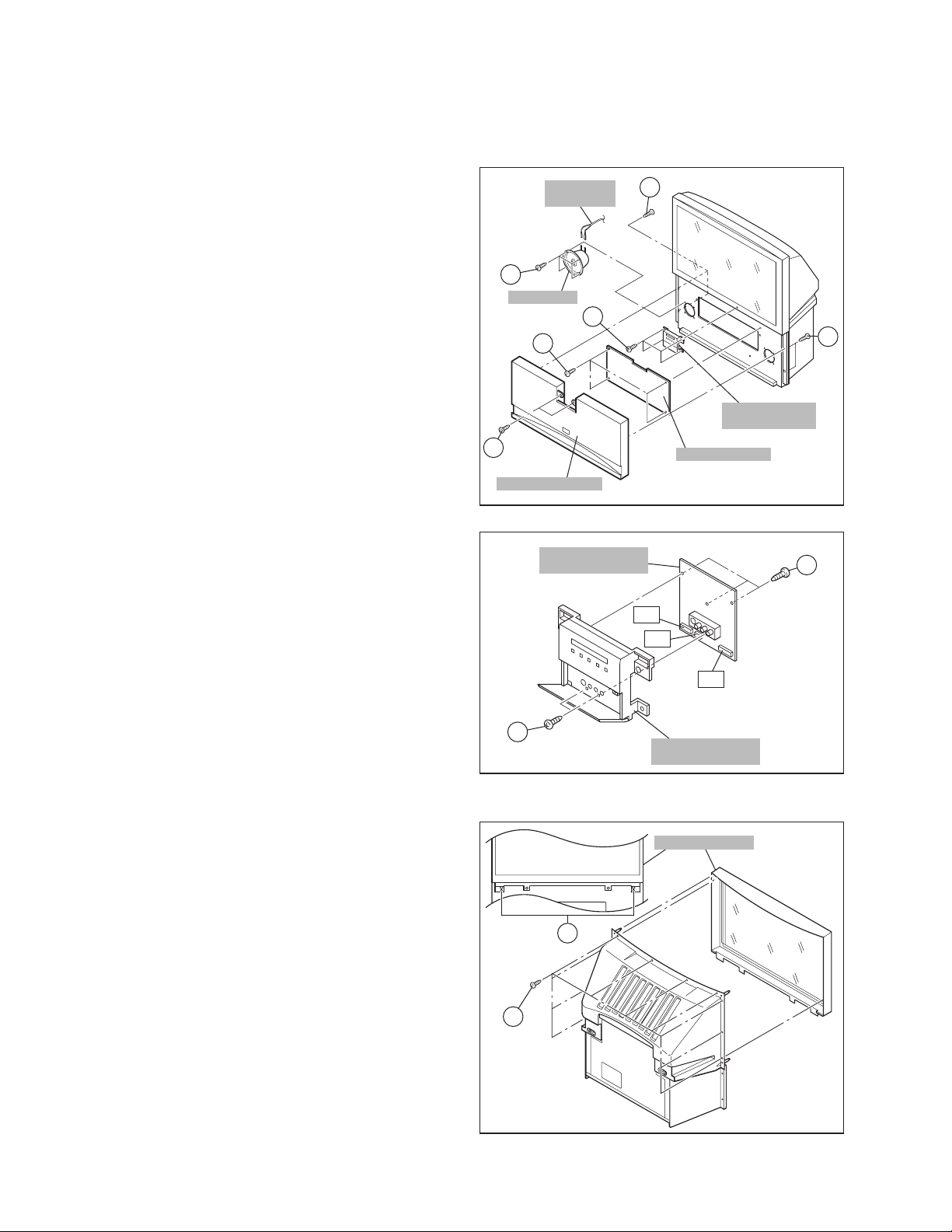

3.1.1 SPEAKER GRILLE

(1) Remove 4 screws [ A ] from rear side.

(2) Open the door of the FRONT CONTROL BOX and remove

2 screws [ B ] from front side.

(3) Take out the SPEAKER GRILLE.

3.1.2 SPEAKER

• Take out the SPEAKER GRILLE

(1) Remove 4 screws [ C ].

(2) Take out the SPEAKER.

(3) Disconnect the speaker wire from speaker terminal.

*Remove the both side SPEAKER same manner.

3.1.3 FRONT BOARD

• Take out the SPEAKER GRILLE.

(1) Remove 4 screws [ D ].

(2) Take out the FRONT BOARD.

3.1.4 FRONT CONTROL BOX

• Take out the SPEAKER GRILLE.

(1) Remove 4 screws [ E ].

(2) Disconnect the connector [BH], [R], [BG] on the FRONT

CONTROL PWB.

(3) Take out the FRONT CONTROL BOX.

3.1.5 FRONT CONTROL PWB

• Take out the SPEAKER GRILLE.

• Take out the FRONT CONTROL BOX.

(1) Remove 2 screws [ F ].

(2) Remove 3 screws [ G ] from rear side of FRONT

CONTROL BOX.

(3) Take out the FRONT CONTROL PWB.

SPEAKER

C

SPEAKER

D

B

SPEAKER GRILL

CONTROL PWB

WIRE

FRONT

A

E

A

FRONT

CONTROL BOX

FRONT BOARD

Fig.1

G

BG

R

BH

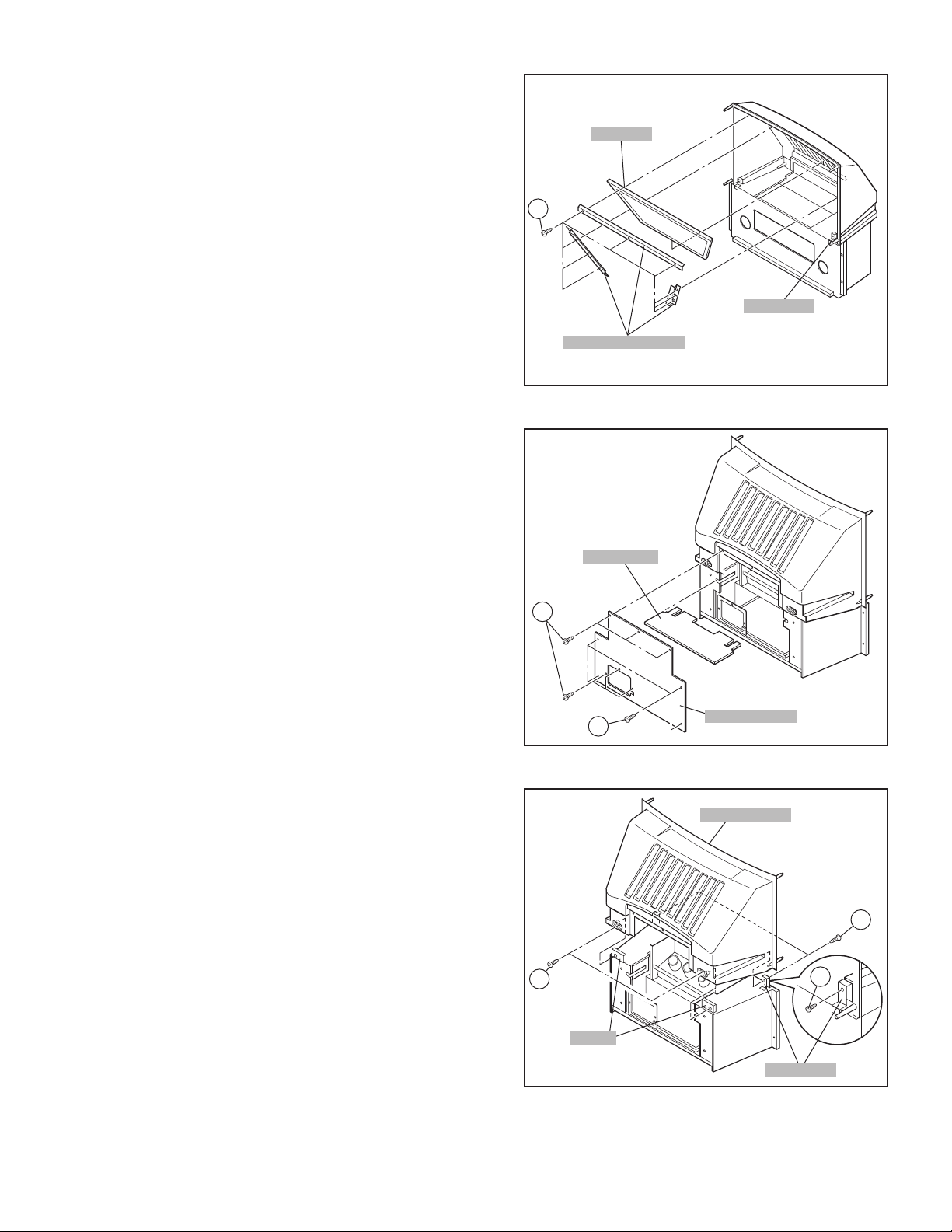

3.1.6 SCREEN ASS'Y

• Take out the SPEAKER GRILLE.

• Take out the FRONT CONTROL BOX.

(1) Remove 2 screws [ H ] attaching the FRONT BRACKET.

(2) Remove 10 screws [ I ] from rear side.

(3) Take out the SCREEN ASS'Y.

NOTE :

• Please place the SCREEN ASS'Y on a flat table

without fail.

• Because of the large size, at least two parsons are

recommended for removal and reassemble.

• Use care not to scratch the screen during work.

• During assembly, be sure to engage the left and right

tabs with the cabinet mounting positions.

• When than sporting the SCREEN ASS'Y, avoid

grasping the top of the screen panel, instead grasp the

left and right areas.

3.1.7 MIRROR

F

FRONT

CONTROL BOX

Fig.2

SCREEN ASS'Y

H

I

Fig.3

1-10 (No.YA166)

• Take out the SPEAKER GRILLE.

• Take out the FRONT CONTROL BOX.

• Take out the SCREEN ASS'Y.

(1) Remove 9 screws [ J ] attaching the mirror brackets of the

upper, left and right side.

(2) Raise slightly to disengage of the mirror from the bottom

bracket. (If necessary, loosen the screws attaching the

bottom bracket)

(3) Take out the MIRROR.

NOTE :

• The MIRROR is frontcoated. Do not touch the front of

the MIRROR.

• At least 2 persons are recommended for removable

and reassemble.

3.1.8 REAR PANEL

(1) Remove 6 screws [ K ].

(2) Remove 4 screws [ L ].

(3) Take out the REAR PANEL.

3.1.9 PARTITION

• Take out the REAR PANEL.

(1) Pull out the PARTITION backward.

MIRROR

J

BRACKET

MIRROR BRACKET

Fig.4

PARTITION

3.1.10 REAR COVER

• Take out the SPEAKER GRILLE.

• Take out the FRONT CONTROL BOX.

• Take out the SCREEN ASS'Y.

(1) Remove 2 screws [ M ].

(2) Remove 2 screws [ N ] from front side.

(3) Slightly pull for backside to disengage of the REAR COVER

from hooks.

(4) Take out the REAR COVER.

NOTE :

• Because of the large size, at least two persons are

recommended for removal and reassemble.

K

L

REAR PANEL

Fig.5

REAR COVER

N

M

HOOK

N

Fig.6

BRACKET

(No.YA166)1-11

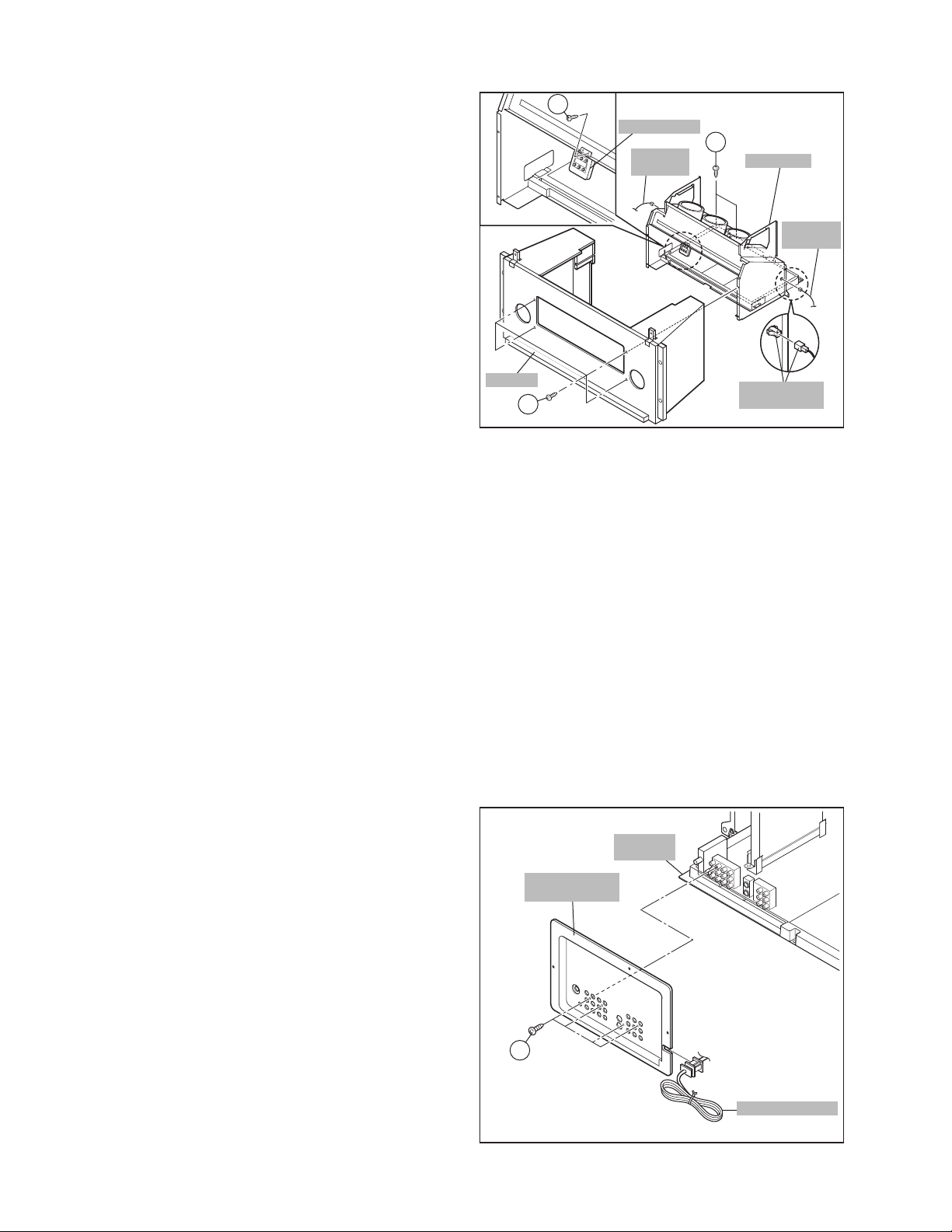

3.1.11 MAIN UNIT

• Take out the SPEAKER GRILLE.

• Take out the FRONT PANEL.

• Take out the REAR PANEL.

(1) Remove 4 screws [ O ] from front side.

(2) Take out the connector [BH], [R], [BG] on the FRONT

CONTROL PWB.

(3) Remove 2 screws [ P ] attaching the MAIN CHASSIS and

BODY.

(4) Pull out the MAIN UNIT rear side.

NOTE :

• Except for confirmation of projection of images on the

screen and audio output through the speakers, the

removed MAIN UNIT is still workable in the same state

as if it is still built in the TV set. Therefore, the MAIN

UNIT can be removed, if necessary, for board

diagnosis, electric testing, etc. apart from confirmation

of screen images and audio output.

• When wire clamps are removed during work, use care

to restore them precisely to their original positions.

Performance can be affected if these are not returned

to the original positions.

• Because of the large size, at least two persons are

recommended for removal and reassemble.

• When carrying the MAIN UNIT, use care not to drop,

shock or shake it.

• Do not stain or damage the lens of the PROJECTION

UNIT.

• Do not look the projection side of a PROJECTION

UNIT when the image is projected.

BODY

Q

FOCUS PACK

P

SPEAKER

WIRE

O

MAIN UNIT

SPEAKER

WIRE

SPEAKER

CONNECTOR

Fig.7

3.1.11.1 CHECKING THE P.W. BOARD

When checking the MAIN PWB, POWER PWB, DEF &

CONVERGENCE OUT PWB, etc., raise the MAIN UNIT with the

front side down for the make of convenience.

3.1.12 FOCUS PACK

• Take out the MAIN UNIT.

(1) Remove 1 screw [ Q ].

(2) Take out the FOCUS PACK.

(3) Take out 9 wires connecting the FOCUS PACK.

3.1.13 AV TERMINAL BOARD

• Take out the REAR PANEL.

(1) Remove 4 screws [ R ].

(2) Pull out the POWER CORD CLAMP from AV TERMINAL

BOARD right side.

(3) Disconnect the connector [AU], [DC], [Q] and [SR] on the

DIGITAL INPUT MODULE PWB.

(4) Take out the AV TERMINAL BOARD.

MAIN

CHASSIS

AV TERMINAL

BOARD

R

1-12 (No.YA166)

POWER CORD

Fig.8

3.1.14 MAIN CHASSIS

• Take out the REAR PANEL.

(1) Remove 2 screws [ S ].

(2) Remove 2 screws [ P ].

(3) Pull out the MAIN CHASSIS for backside.

NOTE:

If necessary, remove the anode wires, connectors,

respectively.

3.1.15 MI-COM & DIST MODULE PWB

• Take out the REAR PANEL.

• Take out the MAIN CHASSIS.

(1) Disconnect the connector [ CN000E ], [ CN000Y ] on the

MI-COM & DIST MODULE PWB.

(2) Remove 2 screws [ T ].

(3) Take out the MI-COM & DIST MODULE PWB.

MI-COM & DIST

MODULE PWB

T

U

S

3.1.16 DIGITAL CONVERGENCE MODULE PWB

• Take out the REAR PANEL.

• Take out the MAIN CHASSIS.

(1) Remove 2 screws [ U ].

(2) Take out the DIGITAL CONVERGENCE MODULE PWB.

3.1.17 PROJECTION UNIT

• Take out the SPEAKER GRILLE.

• Take out the FRONT CONTROL BOX.

• Take out the REAR PANEL.

• Take out the MAIN UNIT.

(1) Take out the CRT SOCKET PWB.

(2) Remove 4 screws [ V ].

(3) Pull out the PROJECTION UNIT upward.

NOTE :

• Refer to "PROJECTION UNIT REPLACEMENT" on page

1-12 when taking out and replacing the PROJECTION

UNIT.

• When wire clamps are removed during work, use care

to restore them precisely to their original positions.

Performance can be affected if these are not returned

to the original positions.

3.1.18 HV DIVIDER

• Take out the REAR PANEL.

(1) Remove 1 screw [ W ].

(2) Take out the HV DIVIDER.

*Wires of the transformer (FBT) and CRT of each

PROJECTION UNIT can be removed by turning the

connector portions.

NOTE :

• If necessary, remove the anode wires, and replacing

the HV DIVIDER, take care to correctly engage the

connector.

MAIN

CHASSIS

Turn

CONNECTOR

Pull

W

DIGITAL CONVERGENCE

P

MODULE PWB

S

Fig.9

V

PROJECTION UNIT

REMOCON

X

SENSOR PWB

HV

DIVIDER

Fig.10

3.1.19 REMOCON SENSOR PWB

• Take out the REAR PANEL.

(1) Disconnect the connector [ R ].

(2) Remove 1 screw [ X ].

(3) Take out the REMOCON SENSOR PWB.

(No.YA166)1-13

3.2 MEMORY IC REPLACEMENT

3.2.1 MEMORY IC

This memory IC stores data for proper operation of the video and

deflection circuits.

When replacing, be sure to use an IC containing this (initial

value) data.

3.2.2 MEMORY IC REPLACEMENT PROCEDURE

(1) Power off

Switch off the power and disconnect the power cord from

the wall outlet.

(2) Replace the memory IC

Initial value must be entered into the new IC.

(3) Power on

Connect the power cord to the wall outlet and switch on the

power.

(4) SERVICE MENU setting

Before entering the SERVICE MENU, confirm that the setting

of TV/CATV SW of the REMOTE CONTROL UNIT is at the

"TV" side and the setting of VCR/DVD SW of the REMOTE

CONTROL UNIT is at the "VCR" side. If the switches have not

been properly set, you cannot enter the SERVICE MENU.

a) Press [SLEEP TIMER] key and, while the indication

of SLEEP TIMER 0 MIN is being displayed, press

[DISPLAY] key and [VIDEO STATUS] key (Fig.2)

simultaneously.

b) The SERVICE MENU screen of Fig.1 is displayed.

c) Verify what to set in the SERVICE MENU, and set

whatever is necessary (Fig.1).

Refer to the SERVICE ADJUSTMENT for setting.

d) Press the [BACK] key twice to return normal screen.

(5) Receive channel setting

Refer to the OPERATING INSTRUCTIONS (USER'S GUIDE)

and set the receive channels (Channels Preset) as described.

(6) User settings

Check the user setting items according to after page.

Where these do not agree, refer to the OPERATING

INSTRUCTIONS (USER'S GUIDE) and set the items as

described.

SERVICE MENU SELECT KEY

VCR/DVD

switch

TV/CATV

switch

DISPLAY

SLEEP

TIMER

VIDEO

STATUS

MEMORY

(MUTING

FUNCTION

(LEFT)

MENU

SERVICE MENU

1.PICTURE/SOUND

2.YC SEP

3.WHITE BALANCE

4.MEMORY SETUP

5.RF AFC

6.CONVER A

Fig.1

MULTI SCREEN

SWAP

FREEZE

SELECT

SOUND

TUNE

ASPECT

RM-C1257G

Fig.2

7.CONVER B

8.IP

9.DSD

0.HDMI

C.C.INDEXTWIN

INPUT

LIGHT

OK

BACK

POWER

NUMBER

FUNCTION

(UP)

FUNCTION

(RIGHT)

BACK

FUNCTION

(DOWN)

3.2.3 SERVICE ADJUSTMENT ITEM

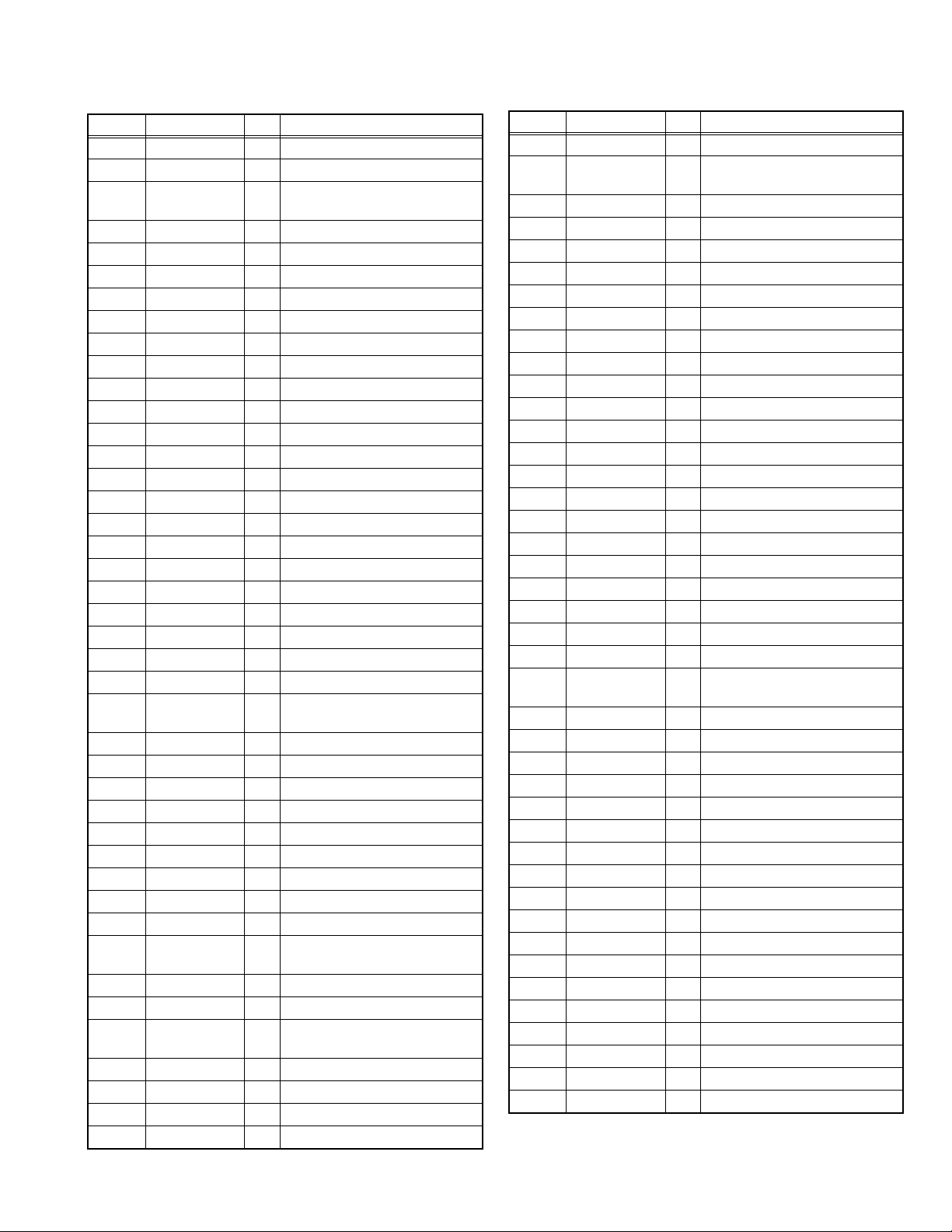

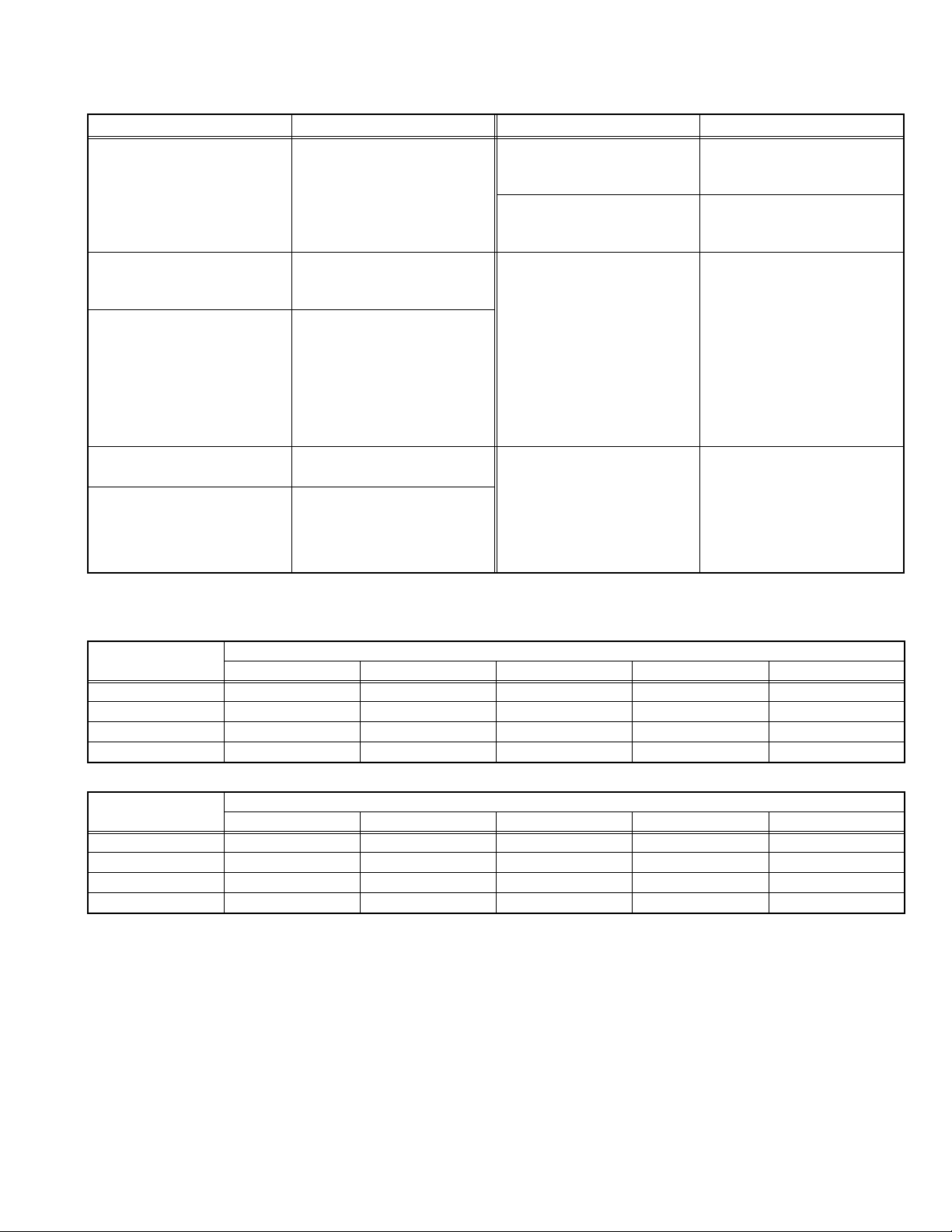

Setting item Item No. Remark Setting item Item No. Remark

1.PICTURE/SOUND 6.CONVER A

AUDIO A01~A27 Convergence adjustment CPA01~CPA11

VIDEO S01~S99 CCA01~CCA12

DEFLECTION D01~D32 CDA01~CDA07

FACTORY setting F01~F70 CBA01~CBA94

2.YC SEP 7.CONVER B

YC separation setting YCM001~YCM185

YCS001~YCS114 Do not adjust

Convergence adjustment ------

8.IP

DIST process setting IPA001~IPA042 Do not adjust

3.WHITE BALANCE 9.DSD

LOW LIGHT/HIGH LIGHT

adjustment

BR, DRV R, DRV B,

CUT R, CUT G, CUT B

DSD process setting DSA001~DSA053

DSB001~DSB053

4.MEMORY SETUP ------ Do not adjust DSC001~DSC044

5.RF AFC DSD001~DSD017

TUNER RF AFT setting TUNER, AFC,FINE

Do not adjust

0.HDMI

Digital input setting HDM001~HDM080

RHD001~RHD170

1-14 (No.YA166)

Do not adjust

Do not adjust

Do not adjust

3.2.4 FACTORY SHIPPING SETTING

USER SETTING

Setting item Setting value Setting item Setting value

POWER

CHANNEL

VOLUME

INPUT

DISPLAY

ASPECT

VIDEO STATUS

SOUND

SPLIT SOURCE LEFT SIDE : CA 02

POSITION ADJUSTMENT

XDS ID

CONVERGENCE

POWER INDICATOR

Off

CABLE-02

10

TV

OFF

REGULAR

DYNAMIC

A.H.S OFF

RIGHT SIDE : INPUT1

Center

ON

AUTO

HIGH

TINT / COLOR / PICTURE/

BRIGHT / DETAIL

COLOR TEMPERATURE

DIG. NOISE CLEAR

VSM (Velocity Scan Modulation)

NATURAL CINEMA

BASS / TREBLE / BALANCE

MTS

ON / OFF TIMER

LANGUAGE

NOISE MUTING

FRONT PANEL LOCK

CLOSED CAPTION

FRONT PANEL LOCK

V1 SMART INPUT

VIDEO INPUT LABEL

AUTO SHUT OFF

DIGITAL-IN

DIGITAL AUDIO

CHANNEL SUMMARY

V-CHIP

AUTO DEMO

Refer to setting of Video status

memory at shipping factory

setting

LOW

OFF

ON

AUTO

Center

STEREO

OFF

ESP

ON

OFF

OFF ( CC1 / T1 )

OFF

OFF

BLANK

OFF

SIZE 1

DIGITAL

Refer to Last memory

(CH. summary)

OFF

OFF

VIDEO STATUS MEMORY

(NTSC / 480i / 480p)

Item

STANDARD 0 0 0 0 0

THEATER 0 0 0 0 0

DYNAMIC 0 0 +10 0 +5

GAME 0 0 -10 0 0

(720p / 1080i)

Item

STANDARD 0 0 0 0 0

THEATER 0 0 0 0 0

DYNAMIC 0 0 +5 0 +10

GAME 0 0 -10 0 0

TINT COLOR PICTURE BRIGHT DETAIL

TINT COLOR PICTURE BRIGHT DETAIL

Setting value

Setting value

(No.YA166)1-15

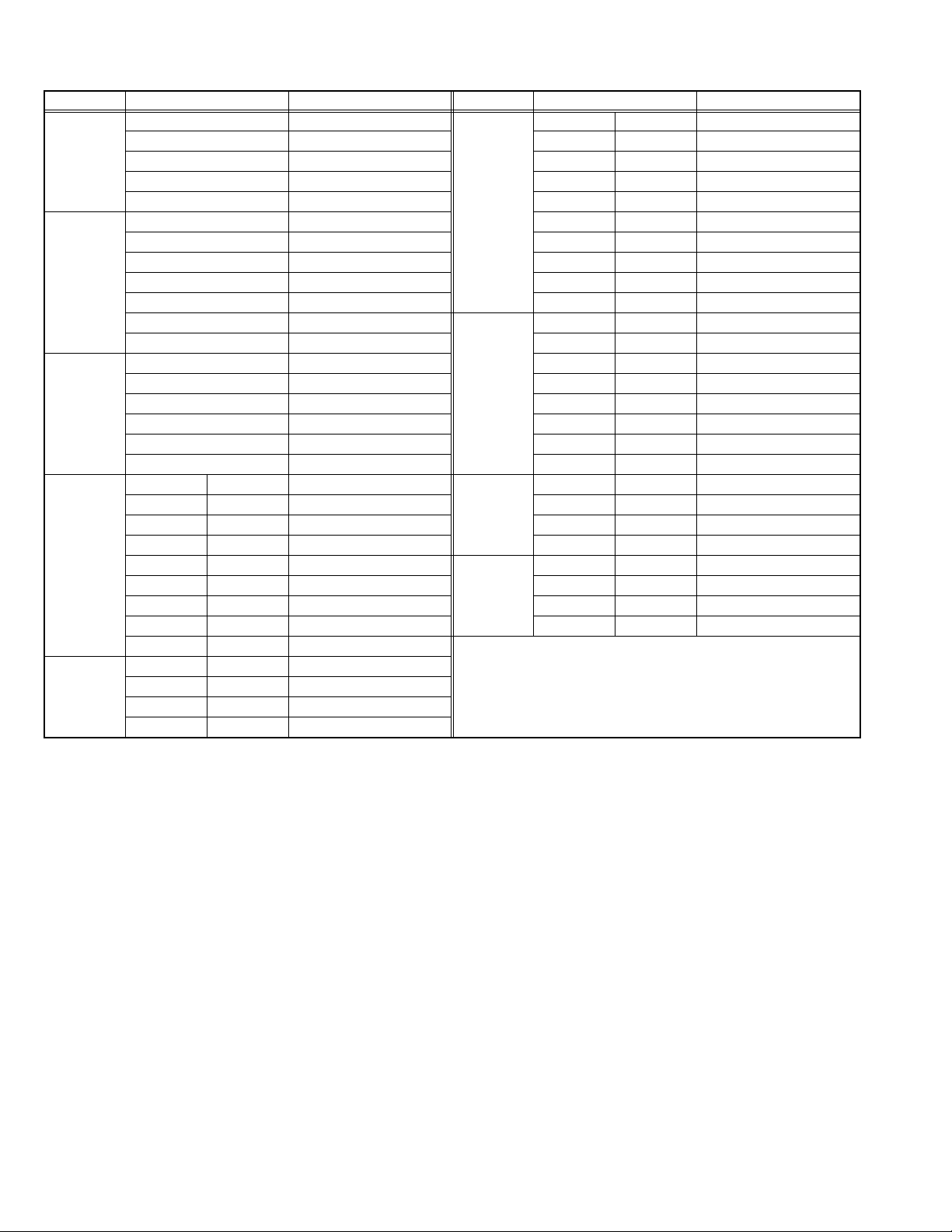

CHANNEL SETTING (CHANNEL SUMMARY)

Band CH display Setting Band CH display Setting

VHF LOW 2 USED SUPER N 27 NOT USED

3 NOT USED O 28 USED

4 USED P 29 NOT USED

5 USED Q 30 NOT USED

6 USED R 31 USED

VHF HIGH 7 USED S 32 USED

8 NOT USED T 33 NOT USED

9 USED U 34 NOT USED

10 NOT USED V 35 NOT USED

11 USED W 36 USED

12 NOT USED SUBMID A-7 93 NOT USED

13 USED A-6 94 NOT USED

UHF 14 USED A-5 95 NOT USED

36 USED A-4 96 USED

41 NOT USED A-3 97 USED

46 NOT USED A-2 98 USED

63 USED A-1 99 NOT USED

69 USED A-8 01 NOT USED

MID A 14 USED HYPER W+11 47 USED

B 15 USED W+12 48 USED

C 16 USED W+17 53 USED

D 17 USED W+23 59 USED

E 18 USED ULTRA W+29 65 NOT USED

F 19 NOT USED W+51 NOT USED

G 20 NOT USED W+78 NOT USED

H 21 USED W+84 NOT USED

I 22 NOT USED

SUPER J 23 NOT USED

K 24 USED

L 25 NOT USED

M 26 NOT USED

1-16 (No.YA166)

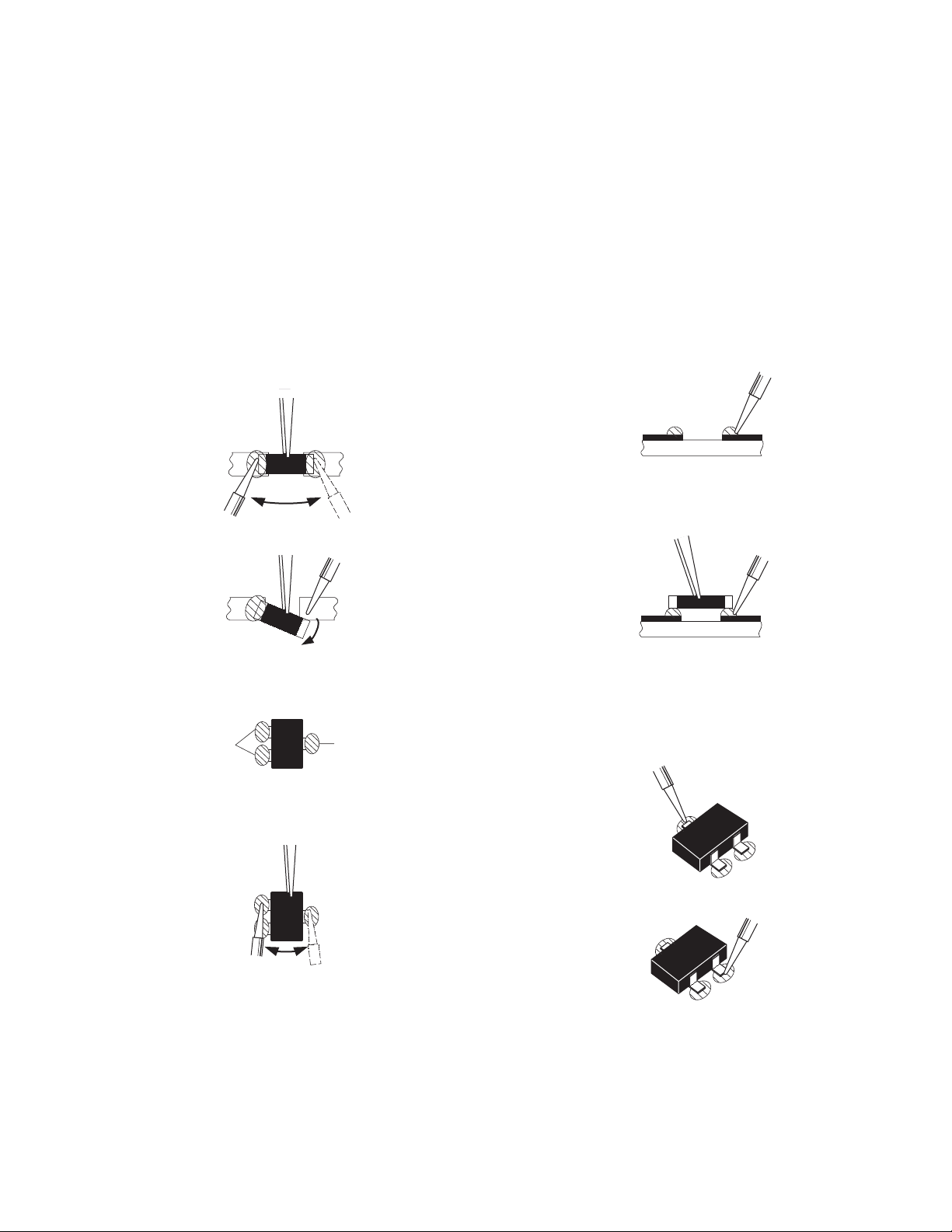

3.3 REPLACEMENT OF CHIP COMPONENT

3.3.1 CAUTIONS

(1) Avoid heating for more than 3 seconds.

(2) Do not rub the electrodes and the resist parts of the pattern.

(3) When removing a chip part, melt the solder adequately.

(4) Do not reuse a chip part after removing it.

3.3.2 SOLDERING IRON

(1) Use a high insulation soldering iron with a thin pointed end of it.

(2) A 30w soldering iron is recommended for easily removing parts.

3.3.3 REPLACEMENT STEPS

1. How to remove Chip parts

2. How to install Chip parts

[Resistors, capacitors, etc.]

(1) As shown in the figure, push the part with tweezers and

alternately melt the solder at each end.

(2) Shift with the tweezers and remove the chip part.

[Transistors, diodes, variable resistors, etc.]

(1) Apply extra solder to each lead.

SOLDER

SOLDER

[Resistors, capacitors, etc.]

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the

solder. Then heat and melt the solder at both ends of the

chip part.

[Transistors, diodes, variable resistors, etc.]

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the

solder.

(3) First solder lead A as indicated in the figure.

(2) As shown in the figure, push the part with tweezers and

alternately melt the solder at each lead. Shift and remove

the chip part.

NOTE :

After removing the part, remove remaining solder from the

pattern.

A

B

C

(4) Then solder leads B and C.

A

B

C

(No.YA166)1-17

SECTION 4

ADJUSTMENT

4.1 ADJUSTMENT PREPARATION

(1) You can make the necessary adjustments for this unit with

either the Remote Control Unit or with the adjustment tools

and parts as given below.

(2) Adjustment with the Remote Control Unit is made on the

basis of the initial setting values, however, the new setting

values which set the screen to its optimum condition may

differ from the initial settings.

(3) Make sure that AC power is turned on correctly.

(4) Turn on the power for set and test equipment before use,

and start the adjustment procedures after waiting at least

30 minutes.

(5) Unless otherwise specified, prepare the most suitable

reception or input signal for adjustment.

(6) Never touch any adjustment setting value which are not

specified in the list for this adjustment.

(7) Presetting before adjustment

Unless otherwise specified in the adjustment instructions,

preset the following functions with the remote control unit.

4.2 MEASURING INSTRUMENT AND FIXTURES

(1) DC voltmeter (or digital voltmeter)

(2) Oscilloscope

(3) Signal generator (Pattern generator)

[NTSC / 480i / 480p / 720p / 1080i / HDMI]

(4) TV audio multiplex signal generator

(5) Remote control unit

SETTING POSITION

Setting item Setting position

VIDEO STATUS STANDARD

TINT / COLOR / PICTURE /

BRIGHT / DETAIL

0

COLOR TEMPERATURE LOW

DIG. NOISE CLEAR OFF

NATURAL CINEMA AUTO

VSM OFF

BASS / TREBLE / BALANCE Center

A.H.S OFF

ASPECT FULL

VERTICAL POSITION Center

ON/OFF TIMER OFF

AUTO SHUTOFF OFF

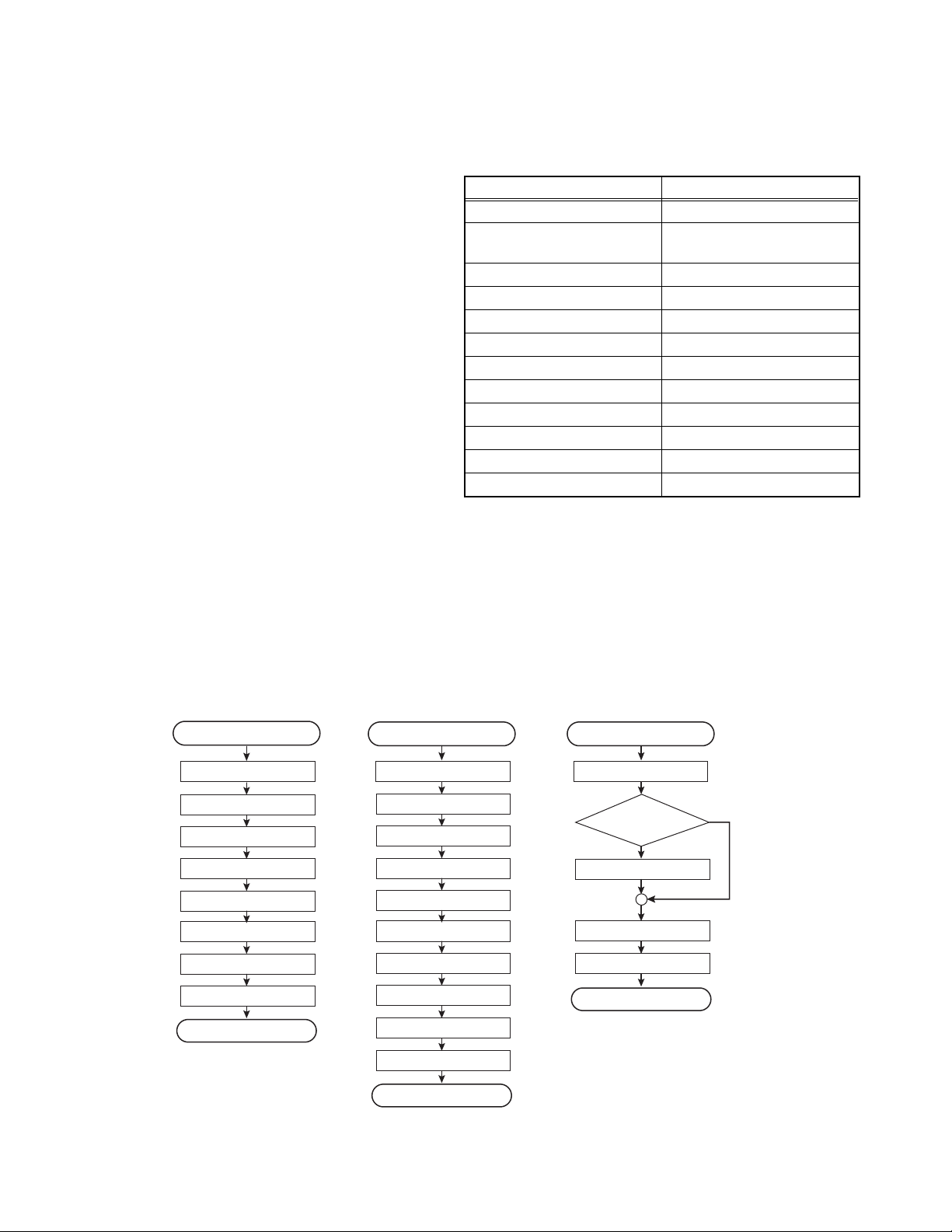

4.3 ADJUSTMENT FLOWCHART

WHEN REPLACING SCREEN AND PROJECTION UNIT

• Contains only the main adjustments. Also confirm other adjustments as required.

1 Projection unit

Install projection tube

LENS FOCUS

BEAM SPOT

CRT FOCUS

SCREEN & LOW LIGHT

DEFLECTION

CONVERGENCE

(match to unreplaced tube)

HIGH LIGHT

END

3 Projection unit

Install projection tube

LENS FOCUS

BEAM SPOT

CRT FOCUS

SCREEN & LOW LIGHT

DEFLECTION

G CONVERGENCE

R CONVERGENCE

B CONVERGENCE

HIGH LIGHT

END

SCREEN

LENS FOCUS

G convergence

disturbed

Y

G CONVERGENCE

R CONVERGENCE

B CONVERGENCE

END

N

1-18 (No.YA166)

Loading...

Loading...