Page 1

ENG-02030503-T

JVC Power Supply trouble shooting procedure

This procedure is based on GF Chassis. Minor differences could be seen in other chassis

Important Service manual information

Due to component tolerance production changes were made during manufacturing. Every

effort is made to inform those changes in the service manual. During troubleshooting,

Always refer to the service manual

Listed below are explanations of some of the abbreviations used in JVC service manual

1. (*): Refer to the NOTE

2. (BW): Bus wire is used instead of that particular component

3. (OPT): The specific component is optional and is not used in this model

4. (Y): Chassis configuration bus wire

5. Shaded: Safety related components. Do not substitute these components

Chassis Preparation

1. Remove the main PWB along with the Operation PWB from the television

2. Do not apply AC power to the PWB

3. Using a suitable resistor, discharge the electrolytic caps, C910 and C538

4. Visually inspect the PWB and replace if there are any burnt components

5. Connect a jumper wire between D922 Cathode and IC901 pin 4

6. Connect another jumper wire between the chassis’

cold ground (ex: E1) and hot ground (ex: IC901

heat sink)

7. In order to disconnect 130V supply from the flyback

transformer, remove L921.

Test Jig Preparation

Connect two long jumper wires from a 120V lamp

assembly as shown in figure

Use a 40W lamp.

Test Instruments

1. Variable DC Power Supply (0~30V; 3A)

2. Digital Multimeter

3. Alligator clips

4. Test jig as shown in picture

Caution

Before replacing any components, turn off or disconnect all power supplies and

discharge any charged caps

Test Jig

Page 2

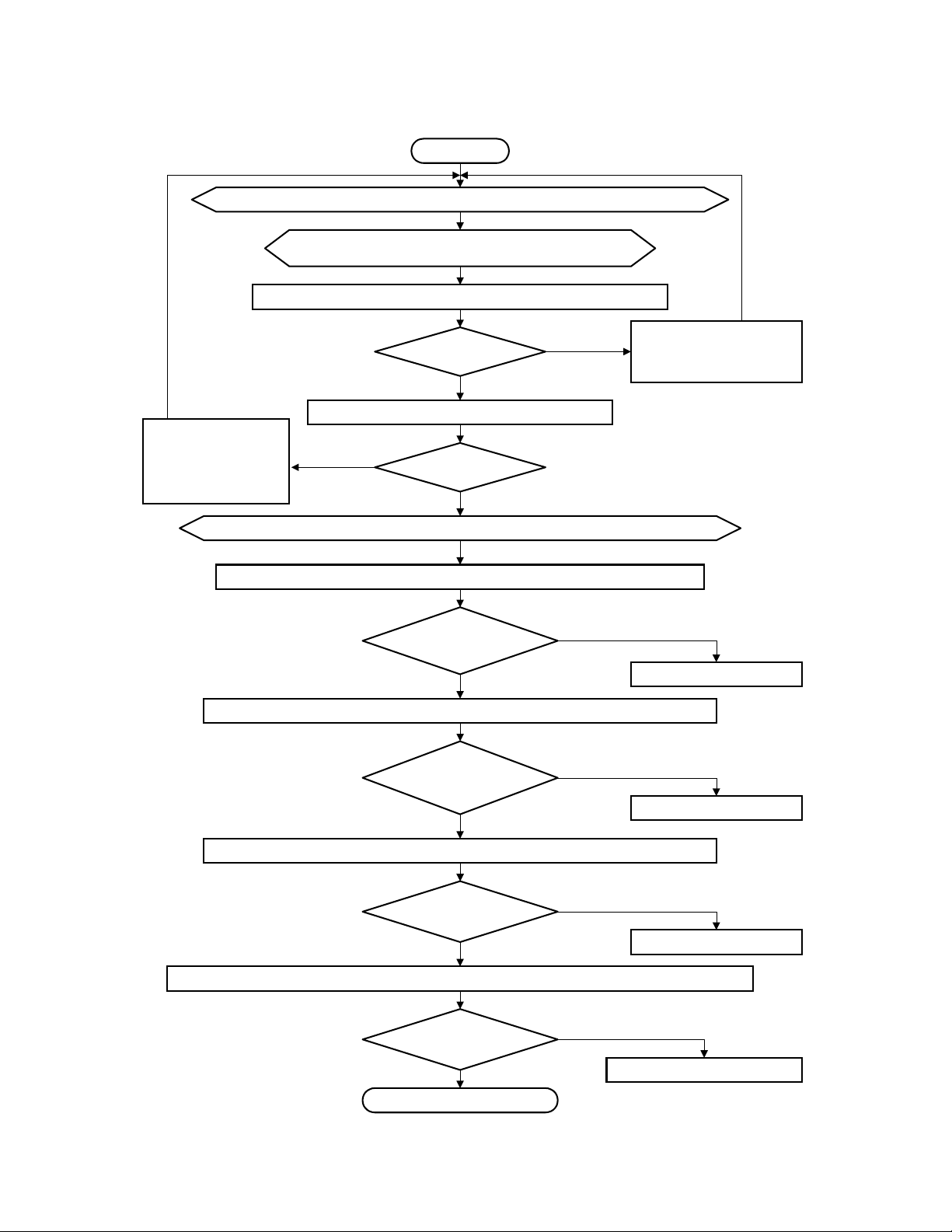

Overall

Start

Follow procedures listed in page 1 and prepare the chassis for troubleshooting

Using the external power supply, connect 7.0V DC

between D922 Cathode and the chassis' ground

Observe the Current readings on the power supply's current meter

Trouble shoot, and if

defective, replace CPU

or 5V regulator

components

On the external power supply, increase the DC voltage from 7.0V DC to

Press the Power On/Off button and confirm the Power indicator operation

During Power On/Off operation, measure DC voltage on IC901(STR-F6626) Pin1

Less than

Measure DC on IC701 (CPU) Pin61 and Pin22

No

5 ~ 5.5V DC

Power Off: not lit

Power On:lit

Power Off: approx

Power On:

1.0A

Yes

Yes

Yes

Yes

0V

2.5V

No

No

No

Trouble shoot and replace

any shorted components

13.0V DC

Goto Page 3 (CPU basic)

Goto Page 4 (Feedback)

Refer to the Schematic. At Q923 collector or a convinient location, measure 13V

Power Off:0V

Power On: 13V

Yes

Refer to the schematic. Measure the collector of both relay driver transistors (Q921 and Q922)

Power Off: 13V

Power On: 0V

Yes

Goto Page 7, Page 8

No

Goto Page 5 (SW 13)

No

Goto Page 6 (Relay control)

GF chassis Power Supply troubleshooting procedure Page: 2

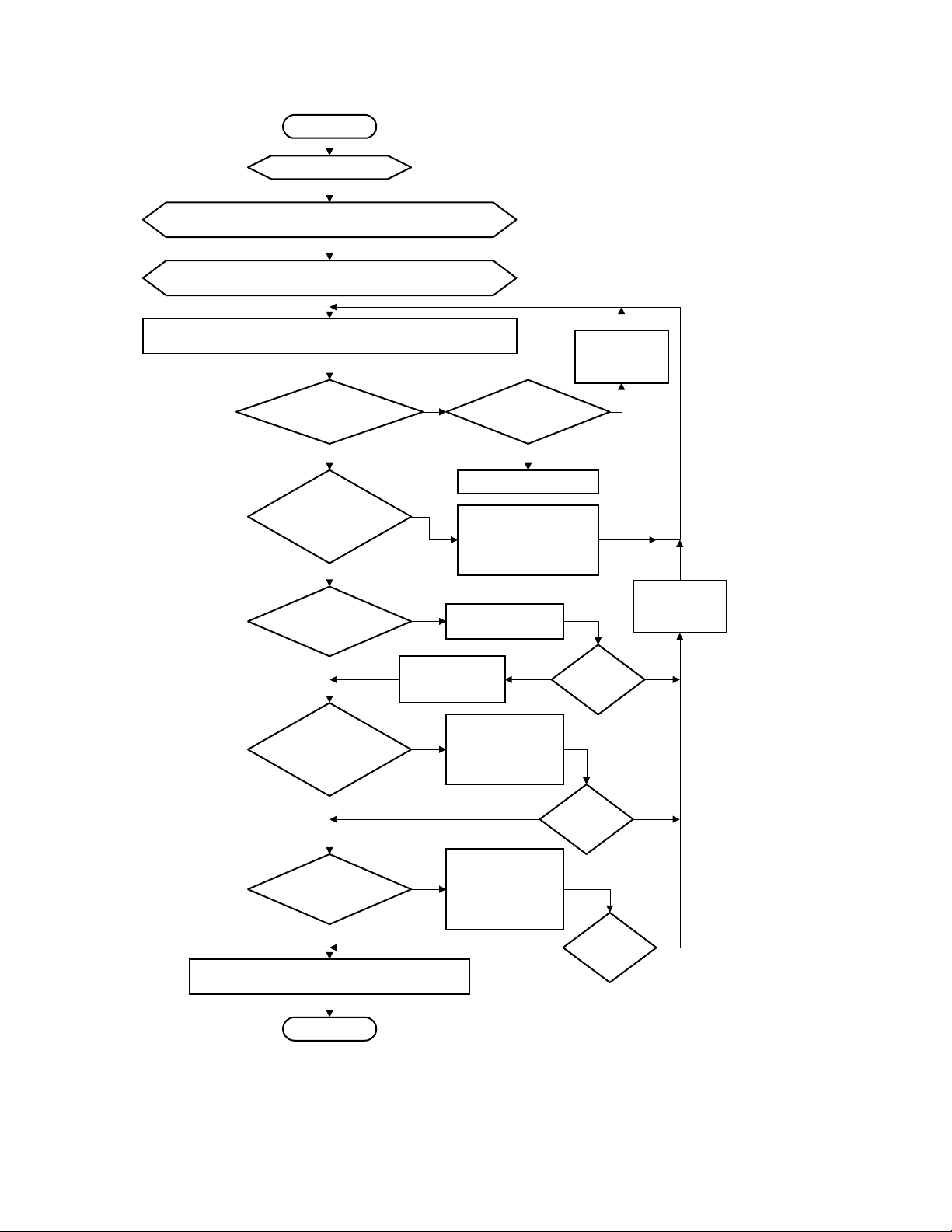

Page 3

Start

Goto Page 2

Follow procedures listed in

for troubleshooting and

OK

page 1.

Prepare the chassis

Confirm CPU Vcc.

CPU basic

(Before this test, Start with Page 2)

Using the external power supply, connect

between D922 Cathode and the chassis' ground

Press the Power On/Off button and confirm the Power indicator

operation

Power Off:

Power On:

CPU pin7:

Power Off:

Power On:

CPU pin54:

>4.5V

Yes

not lit

lit

No

5V

0V

No

13.0V DC

Yes

couple of seconds

Goto Page 2 (Overall)

Trouble shoot power

Yes

No

If IC703 pin2 is

5V, Replace

IC703 (RST)

indicator LED or

related components

Measure IC703

(reset IC) pin1

Flashes after

No

No

Troubleshoot if

there is >0V on

CPU pin 14

Yes

IC701 (CPU)

> 4.0V

Yes

Replace

CPU pin 62, 63

5.0V 12MHz

Oscillation

Yes

CPU pin 4, 5

5.0V

Yes

Trouble shoot power indicator LED or related

components

Replace CF701,

C718, and C717.

No

Measure Pin 62

Replace if any

components on

No

Pin4 and Pin5 and

check again

Yes

shorted

5.0V 12MHz

Yes

No

No

5.0V

Goto Page2

GF chassis Power Supply troubleshooting procedure Page: 3

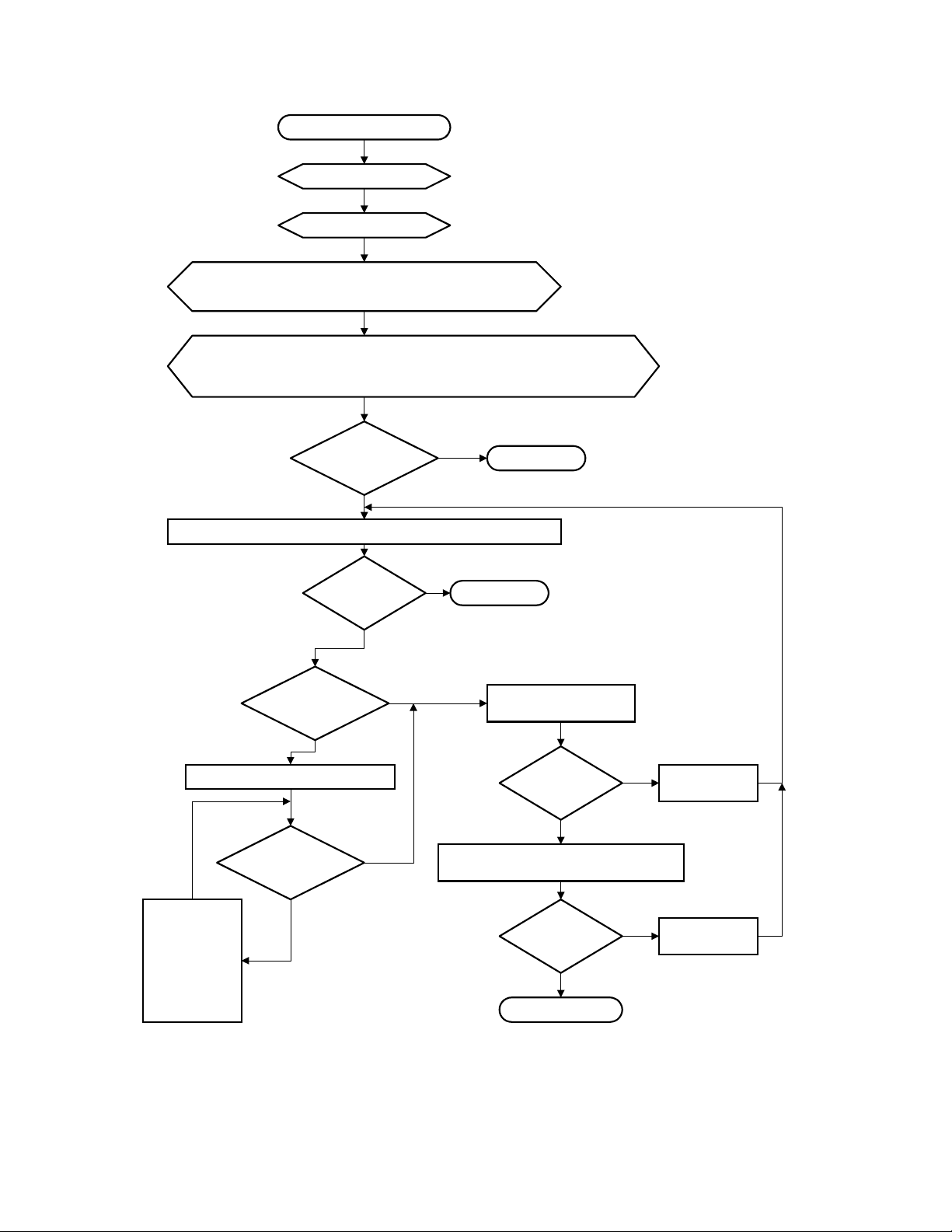

Page 4

Feed back test

Goto Page 2

OK

Follow procedures listed in

for troubleshooting and Confirm CPU Vcc.

Using the external power supply, connect 13.0V DC

between D922 Cathode and chassis ground

page 1.

Prepare the chassis

Low Voltage (BL) control &

Photo coupler (PC901)

(Before this test, Start with Page2

Press the Power On/Off button.

indicator function,

(A)

measure DC voltage on IC901 (regulator)

Power Off:approx 2.5V

Power On: 0V

Power Off: >3V

Power On:

Power Off: 0V

Power On: 1~2V

Power Off: .7V

Power On: 0V

After confirming the Power

IC901(1)

No

CPU pin53:

0V

Yes

Q944 (C):

Yes

Q942 (C):

Yes

pin1

Goto Page 2 (Overall)

Yes

Desolder CPU

pin53 and measure

voltage on the print

No

No

Q542 (C):

13V

No

Yes

Replace

IC701 (CPU)

> 4.0V

Check 5V supply,

R757 and Q944

Goto (A)

Check D560, D561,Q542,

No

Q541. Replace if bad.

Goto (A)

Check D931 and Q944.

Replace if bad.

Goto (A)

Check Q942, 943.

Replace if bad.

Goto (A)

Yes

No

D942 (C):

Power Off: 7.5V

Power On: 6.8V

Yes

No

Check D942.

Replace if bad.

Goto (A)

Continued on Page 5

GF chassis Power Supply troubleshooting procedure Page: 4

Page 5

Continued from Page 4

Low Voltage (BL) control & Photo coupler (PC901)

(Before this test, Start with Page2)

(B)

PC901(pin2):

Power Off: 0V

Power On: 13V

Yes

PC901(pin3):

Power Off: 2~3V

Power On: 0V

Yes

Goto Page2 (Overall)

SW13 Test

Goto Page 2

OK

No

Desolder

IC941 pin2.

No

Desolder

IC901 pin1.

SW13V check

(Before this test, Start with Page2)

PC901(pin2):

Power Off: 0V

Power On: 13V

No

PC901(pin2):

Power Off: 0V

Power On: 13V

No

Yes

Check Q943 and PC901.

Replace if bad.

Yes

Check PC901, D903,

R903, 904, 905.

Replace if bad.

Replace

IC941

Goto (B)

Goto (B)

Replace

IC901

Goto (B)

Goto (B)

Using the external power supply, connect

between D922 Cathode and the chassis' ground

Press the Power On/Off button to confirm the 13V sw circuit

Q923 (C)

Power Off:

Power On:

Q924 (C)

Power Off:

Power On:

Check Q924, R924.

If good, Goto Page4 (A)

0V

13V

No

13V

<.5V

No

13.0V DC

Yes

Yes

Goto Page 2 (Overall)

or shorted components

Check Q923

at Q923 collector.

GF chassis Power Supply troubleshooting procedure Page: 5

Page 6

Relay Control Test

Goto Page 2

Follow procedures listed in

for troubleshooting and

OK

Prepare the chassis

page 1.

Confirm CPU Vcc.

Relay Control Test

(Before this test, Start with Page2

Using the external power supply, connect

between D922 Cathode and chassis ground

(C)

Yes

If relay does not

click, replace relay

No

Check D928, Q922 and relay

Replace if bad.

Goto (C)

Q922(C)

Power Off: 13V

Power On: .6V

No

CPU pin52

Power Off: >3.0V

Power On: 0V

Yes

Q927(C)

Power Off: 0V

Power On: 1.3V

Yes

Q922(C)

Power Off: 13V

Power On: .6V

Yes

13.0V DC

Desolder CPU

pin52 and measure

No

voltage on the print

No

Q542 (C):

13V

Yes

Replace

IC701 (CPU)

Yes

> 4.0V

No

Check 5V supply, R756, Q927, and Q928

Replace if bad.

Check D560, D561,Q542,

No

Q541. Replace if bad.

Check Q927 and Q922.

Goto (C)

Goto (C)

Replace if bad.

Goto (C)

Q921(C)

Power Off: 13V

Yes

If degauss relay does not

click on and off, replace relay

Power On:

0.6V(momentarily)

No

Q928(C)

Power Off: 0V

Power On: 5V

No

Check Q928

Yes

Check Check D933, C932,

D927, Q921, and D926

GF chassis Power Supply troubleshooting procedure Page: 6

Page 7

Run DC Test

Goto Page 2

OK

Remove all jumpers and the external power supply from

the chassis. Connect multimeter common probe to SW

transformer pin3 (live ground)

Run DC Regulator Test

(Before this test, Start with Page2

Using the external power supply, connect

between D914 Cathode and

IC901 pin4

13.0V

Yes

Check R914,

D913, D914.

Replace if bad.

live ground

20.0V DC

No

Refresh circuit Test

Remove all jumpers and the external power supply from

the chassis. Connect multimeter common probe to SW

transformer pin3 (live ground)

Using the external power supply, connect

between D910 Cathode and

live ground

20.0V DC

Check Q912,

D916, D918.

Replace if bad.

Refresh circuit Test

(Before this test, Start with Page2

No

IC901 pin1

5V

Yes

Check D910, R914.

Replace if bad.

Check Q911, D911, D912.

Replace if bad.

Goto Page8

GF chassis Power Supply troubleshooting procedure Page: 7

Page 8

Regulator Test

Goto Page 2

OK

Switching and Regulation test

(Before this test,

Start with Page2

Remove all jumpers and the external power supply from the chassis.

Connect the

Remove L921.

test jig (See page1) across C924

Using a jumper, Short

(100MFD160V)

between the cold ground and live ground

Using the external power supply, connect

AC lead. (

Check D922

Positive to the nutral pin

between D921(cathode) and the chassis' cold ground

D922 (C)

7.0V

No

IC901 pin4

11.0V

Yes

Yes

IC901 pin3

100~150Vp-p

oscillation

30.0V DC

). Connect the jig (see page1)

Yes

No

to the television's

Goto Page9

D902 (A)

30V

No

Yes

Check for reverse Power supply. Check

F901, VA901, or related components.

Check for shorted IC901 or

shorted components on Pin4.

Replace if any

Replace if bad.

Replace if

defective

NG

No

Check

R903/4/5

OK

Replace IC901

D922 (C)

7.0V

No

Goto Page 2

Yes

Goto Page9

GF chassis Power Supply troubleshooting procedure Page: 8

Page 9

Regulator Test

Goto Page 2

OK

Goto Page 8

OK

Switching and Regulation test

(Before this test,

Start with Page2

Remove L921.

Using a jumper, Short

between the cold ground and live ground

Using the external power supply, connect

AC lead. (

Positive to the nutral pin

between D921(cathode) and the chassis' cold ground

D922 (C)

7.0V

Yes

Press the power button, to turn the power on

Power

LED Lights

Yes

On the jig,

bulb ights

Yes

30.0V DC

). Connect the jig (see page1)

No

No

Goto Page3

to the television's

Goto Page8

Measure the voltage at

D921 Cathode

No

Replace IC941 and power ON

Replace any

shorted

components in

the switched

supplies.

Replace and

power ON

On the jig,

bulb ights

No

Yes

110~130V

Yes

Remove the bulb

measure the voltage at D921 cathode

from the jig and

135V

Yes

Finish

<90V

>135V

Replace IC941

Replace IC941

GF chassis Power Supply troubleshooting procedure Page: 9

Loading...

Loading...