Page 1

AV-29W83 AV-29W93B

AV-29W93 AV-29W83B

SERVICE MANUAL

COLOUR TELEVISION

BASIC CHASSIS

CH

AV-29W83 /BK

AV-29W93 /BK

AV-29W93B /BK

POWER

MUTING

SYSTEM

CINEMA

COLOUR SOUND

SURROUND

ECO

SENSOR

DISPLAY

MENU

1/2

TV/VIDEO

123

OFF

TIMER

456

PICTURE

MODE

789

CHANNEL

RETURN+

SCAN

--

0-/

VOLUME

CHANNEL

RM-C1016

TV

RM-C1016-1H

[AV-29W83

/BK

MUTING

SYSTEM

CINEMA

COLOUR SOUND

SURROUND

DISPLAY

MENU

1/2

TV/VIDEO

123

OFF

TIMER

456

PICTURE

MODE

789

CHANNEL

RETURN+

SCAN

0-/

VOLUME

CHANNEL

RM-C1011

TV

RM-C1011-1H

[AV-29W93

]

POWER

ECO

SENSOR

--

/BK

]

[AV-29W93B

POWER

MUTING BASS

SYSTEM

CINEMA

COLOUR SOUND

SURROUND

ECO

SENSOR

DISPLAY

MENU

1/2

TV/VIDEO

123

OFF

TIMER

456

PICTURE

MODE

789

CHANNEL

RETURN+

SCAN

--

0-/

VOLUME

CHANNEL

RM-C1012

TV

RM-C1012-1H

/BK

POWER

BASS

MUTING

CINEMA

SYSTEM

SURROUND

COLOUR SOUND

SENSOR

DISPLAY

MENU

TV/VIDEO

123

OFF

TIMER

456

PICTURE

MODE

789

CHANNEL

RETURN+

SCAN

0-/

VOLUME

CHANNEL

RM-C1015

TV

RM-C1015-1H

[AV-29W83B

]

AV-29W83B /VT

AV-29W83 /VT

POWER

MUTING

SYSTEM

CINEMA

COLOUR SOUND

SURROUND

ECO

--

/VT

RM-C1014-1H

]

[AV-29W83

DISPLAY

TV/VIDEO

TIMER

PICTURE

MODE

CHANNEL

SCAN

OFF

CHANNEL

MENU

123

456

789

RETURN+

0-/

VOLUME

RM-C1014

TV

ECO

SENSOR

--

/VT

]

CONTENTS

a SPECIFICATIONS....................................................................................................................................2

a OPERATING INSTRUCTIONS (APPENDIX)

a SAFETY PRECAUTIONS ........................................................................................................................ 3

a FEATURES .............................................................................................................................................. 4

a FUNCTIONS ............................................................................................................................................. 5

a SPECIFIC SERVICE INSTRUCTIONS .................................................................................................... 6

a SERVICE ADJUSTMENTS ....................................................................................................................14

a STANDARD CIRCUIT DIAGRAM (APPENDIX) .................................................................................. 2-1

a PA RTS LIST ...........................................................................................................................................41

COPYRIGHT © 2002 VICTOR COMPANY OF JAPAN, LTD.

No. 52070

Nov. 2002

Page 2

AV-29W83 AV-29W93B

AV-29W93 AV-29W83B

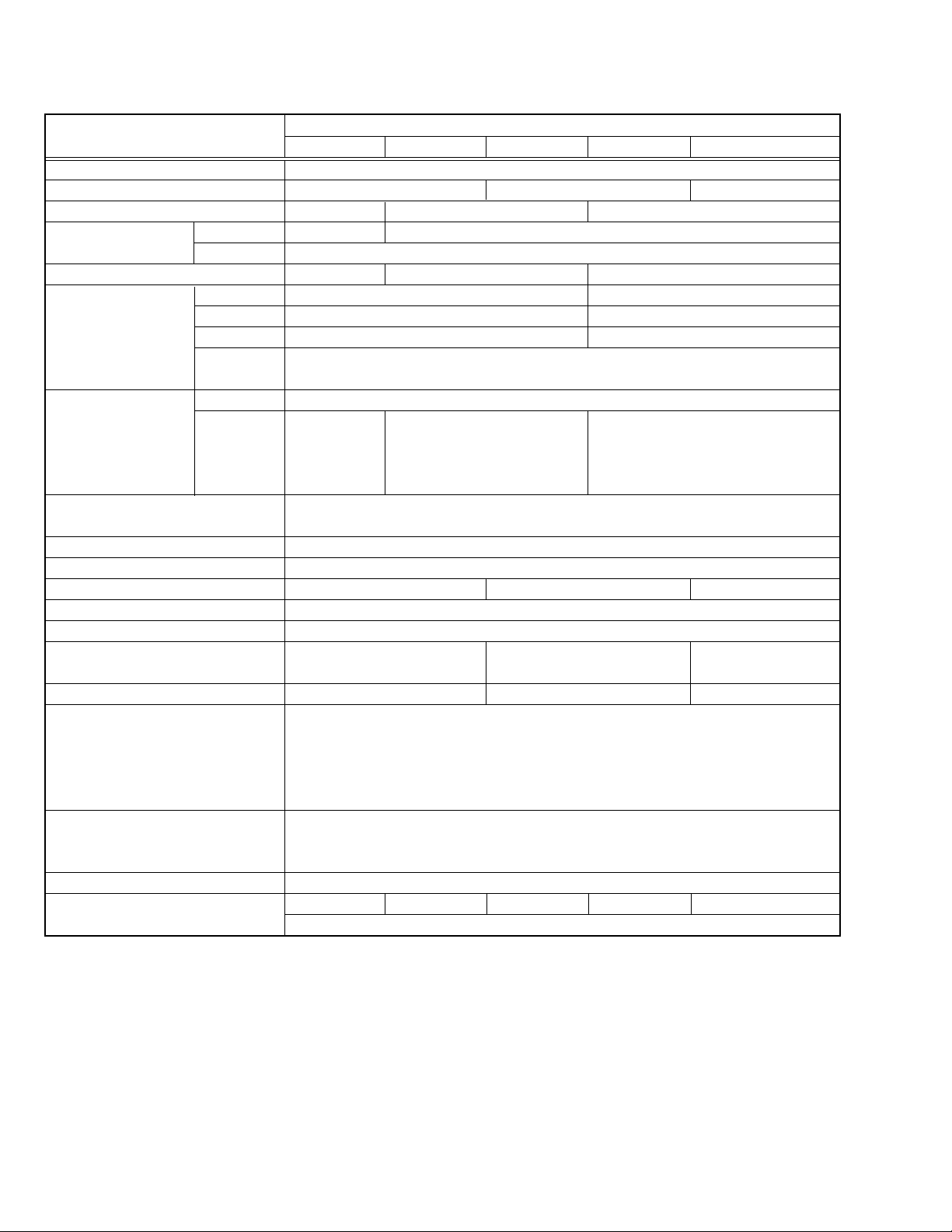

SPECIFICATIONS

Items

Dimensions (W × H × D)

Mass 45kg 47kg 45kg

TV RF System B, G B, G, I, D, K, K1, M B, G, D, K, K1, M

Colour System TV Mode PAL / SECAM PAL / SECAM / NTSC3.58 / NTSC4.43

VIDEO Mode PAL / SECAM / NTSC3.58 / NTSC4.43

Stereo System Playback Only A2/NICAM (B / G, I, D / K) System Playback Only

Receiving Frequency VHF (VL) 46.25MHz – 140.25MHz (AS0 – S6) 46.25MHz – 168.25MHz (AS0 – S6)

VHF (VH) 147.25MHz – 423.25MHz (S7 – S36) 175.25MHz – 463.25MHz (S7 – S36)

UHF 431.25MHz – 863.25MHz (S37 – CHINA 57) 471.25MHz – 863.25MHz (S37 – CHINA 57)

CATV ● Cable TVs of Mid (X-Z, S1-S10)

Intermediate VIF Carrier 38.0MHz

Frequency

SIF Carrier 32.0MHz (6.0MHz) 32.5MHz (5.5MHz)

Colour Sub Carrier Frequency PAL (4.43MHz), SECAM (4.40625MHz / 4.25MHz)

Aerial Input Terminal 75Ø Unbalanced

Power Input AC120 – 240V, 50 / 60Hz

Power Consumption 175W

Picture Tube Visible size : 69cm measured diagonally

High Voltage 32kV+1/ –1.5kV (at cut-off in service mode)

Speaker 6.5 × 13cm Oval type × 2 6.5 × 13cm Oval type × 2 6.5 × 13cm Oval type × 2

Audio Output 7W + 7W 7W + 7W +13W 7W + 7W

Video / Audio Input (1 / 2 / 3) Video(1,3) : 1Vp-p, 75Ø (RCA pin jack)

Video/ Audio Output 1Vp-p, 75Ø (RCA pin jack)

Headphone Jack Stereo mini jack (3.5φ)

Remote Control Unit RM-C1016-1H

AV-29W83/BK

81.2cm x 58.42cm x 51.8cm

Super (S11-S20) & Hyper (S21-S41) bands receivable

32.5MHz (5.5MHz)

NTSC (3.58MHz / 4.43MHz)

(Max.)

Audio(1,2,3) : 500mVrms ( -4dBs ), High Impedance (RCA pin jack)

Component Input ( Input 2 )

Y:1Vp-p positive (negative sync provided, when terminated with 75Ø)

CB/CR : 0.7Vp-p 75Ø

500mVrms(-4dBs)

Low impedance (400Hz when modulated 100%) (RCA pin jack)

(Battery size: AA/R06/UM-3 × 2)

AV-29W93/BK AV-29W93B/BK AV-29W83B/VT AV-29W83/VT

31.5MHz (6.5MHz) 31.5MHz (6.5MHz)

32.5MHz (5.5MHz) 33.5MHz (4.5MHz)

33.5MHz (4.5MHz)

/ 116W

(Avg.)

RM-C1011-1H

Design & specifications are subject to change without notice.

Contents

212W

(Max.)

/ 133W

(Avg.)

φ 13cm (BASS BLASTER UNIT)

RM-C1012-1H RM-C1015-1H RM-C1014-1H

175W (Max.) / 116W (Avg.)

2No. 52070

Page 3

SAFETY PRECAUTIONS

AC VOLTMETER

(HAVING 1000Ω/V,

OR MORE SENSITIVITY)

PLACE THIS PROBE

ON EACH EXPOSED

METAL PAR T

1500Ω 10W

0.15µF AC-TYPE

GOOD EARTH GROUND

1. The design of this product contains special hardware, many circuits

and components specially for safety purposes. For continued protection, no changes should be made to the original design unless

authorized in writing by the manufacturer. Replacement parts must

be identical to those used in the original circuits. Service should be

performed by qualified personnel only.

2. Alterations of the design or circuitry of the products should not be

made. Any design alterations or additions will void the manufacturer's warranty and will further relieve the manufacturer of responsibility for personal injury or property damage resulting therefrom.

3. Many electrical and mechanical parts in the products have special

safety-related characteristics. These characteristics are often not

evident from visual inspection nor can the protection afforded by

them necessarily be obtained by using replacement components

rated for higher voltage, wattage, etc. Replacement parts which have

these special safety characteristics are identified in the parts list of

Service manual. Electrical components having such features are

identified by shading on the schematics and by (!) on the parts

list in Service manual. The use of a substitute replacement which

does not have the same safety characteristics as the recommended

replacement part shown in the parts list of Service manual may

cause shock, fire, or other hazards.

4. Don't short between the LIVE side ground and ISOLATED (NEU-

TRAL) side ground or EARTH side ground when repairing.

Some model's power circuit is partly different in the GND. The difference of the GND is shown by the LIVE : ( ) side GND, the ISOLATED (NEUTRAL) : ( ) side GND and EARTH : ( ) side GND.

Don't short between the LIVE side GND and ISOLATED (NEUTRAL)

side GND or EARTH side GND and never measure the LIVE side

GND and ISOLATED (NEUTRAL) side GND or EARTH side GND

at the same time with a measuring apparatus (oscilloscope etc.).

If above note will not be kept, a fuse or any parts will be broken.

5. If any repair has been made to the chassis, it is recommended that

the B1 setting should be checked or adjusted (See ADJUSTMENT

OF B1 POWER SUPPLY).

6. The high voltage applied to the picture tube must conform with that

specified in Service manual. Excessive high voltage can cause an

increase in X-Ray emission, arcing and possible component damage, therefore operation under excessive high voltage conditions

should be kept to a minimum, or should be prevented. If severe

arcing occurs, remove the AC power immediately and determine

the cause by visual inspection (incorrect installation, cracked or

melted high voltage harness, poor soldering, etc.). To maintain the

proper minimum level of soft X-Ray emission, components in the

high voltage circuitry including the picture tube must be the exact

replacements or alternatives approved by the manufacturer of the

complete product.

AV-29W83 AV-29W93B

AV-29W93 AV-29W83B

8. When service is required, observe the original lead dress. Extra

precaution should be given to assure correct lead dress in the high

voltage circuit area. Where a short circuit has occurred, those components that indicate evidence of overheating should be replaced.

Always use the manufacturer's replacement components.

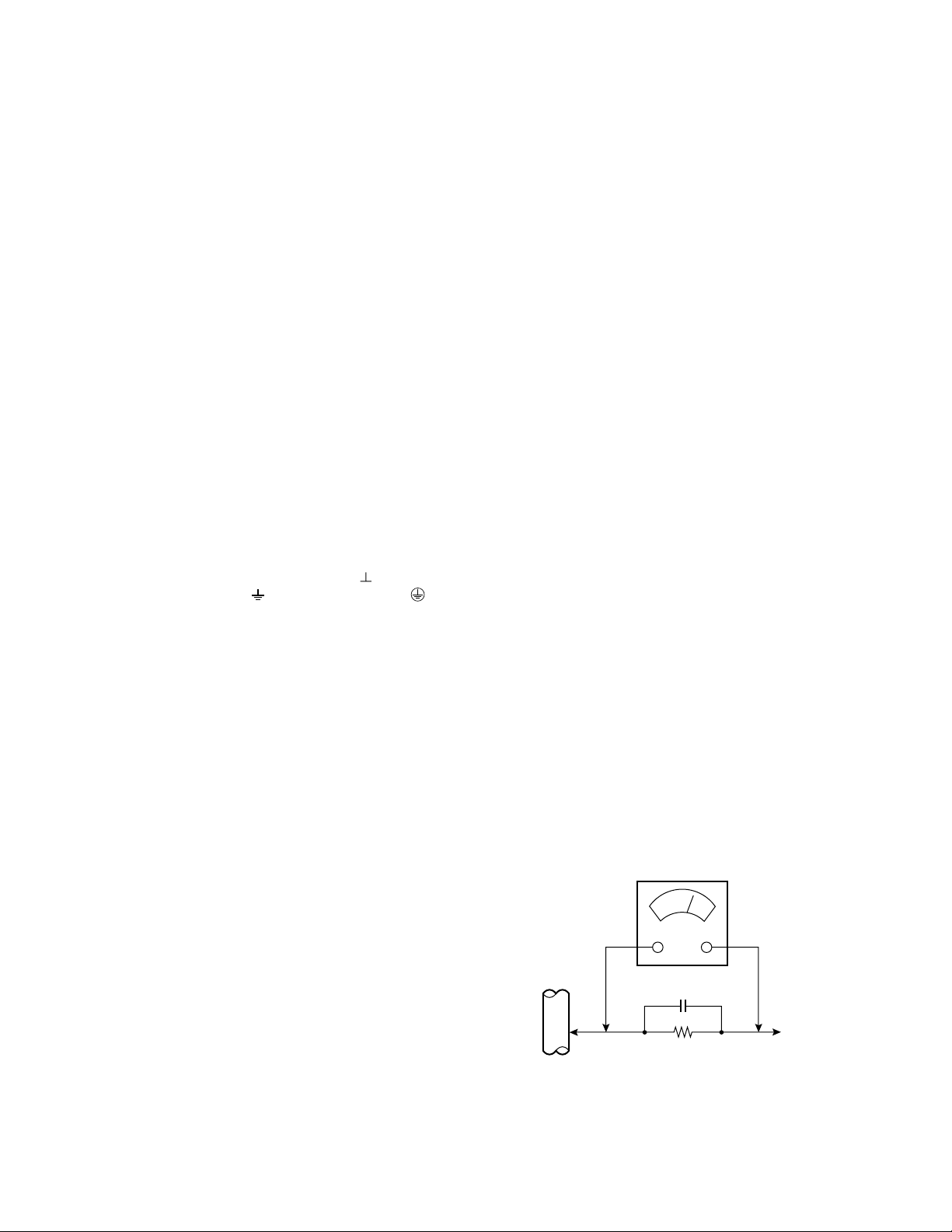

9. Isolation Check

(Safety for Electrical Shock Hazard)

After re-assembling the product, always perform an isolation check

on the exposed metal parts of the cabinet (antenna terminals, video/

audio input and output terminals, Control knobs, metal cabinet, screw

heads, earphone jack, control shafts, etc.) to be sure the product is

safe to operate without danger of electrical shock.

(1) Dielectric Strength Test

The isolation between the AC primary circuit and all metal parts

exposed to the user, particularly any exposed metal part having a

return path to the chassis should withstand a voltage of 3000V AC

(r.m.s.) for a period of one second.

(. . . . Withstand a voltage of 1100V AC (r.m.s.) to an appliance rated

up to 120V, and 3000V AC (r.m.s.) to an appliance rated 200V or

more, for a period of one second.)

This method of test requires a test equipment not generally found in

the service trade.

(2) Leakage Current Check

Plug the AC line cord directly into the AC outlet (do not use a line

isolation transformer during this check.). Using a "Leakage Current

Tester", measure the leakage current from each exposed metal part

of the cabinet, particularly any exposed metal part having a return

path to the chassis, to a known good earth ground (water pipe, etc.).

Any leakage current must not exceed 0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.2mA AC (r.m.s.).

● Alternate Check Method

Plug the AC line cord directly into the AC outlet (do not use a line

isolation transformer during this check.). Use an AC voltmeter having 1000 ohms per volt or more sensitivity in the following manner.

Connect a 1500Ø 10W resistor paralleled by a 0.15µF AC-type capacitor between an exposed metal part and a known good earth

ground (water pipe, etc.). Measure the AC voltage across the resistor with the AC voltmeter. Move the resistor connection to each exposed metal part, particularly any exposed metal part having a return path to the chassis, and measure the AC voltage across the

resistor. Now, reverse the plug in the AC outlet and repeat each

measurement. Any voltage measured must not exceed 0.75V AC

(r.m.s.). This corresponds to 0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.3V AC (r.m.s.).

This corresponds to 0.2mA AC (r.m.s.).

7. Do not check high voltage by drawing an arc. Use a high voltage

meter or a high voltage probe with a VTVM. Discharge the picture

tube before attempting meter connection, by connecting a clip lead

to the ground frame and connecting the other end of the lead through

a 10kØ 2W resistor to the anode button.

No. 52070 3

Page 4

AV-29W83 AV-29W93B

AV-29W93 AV-29W83B

FEATURES

s New chassis design enables use of an interactive on-screen control.

s Pure flat CRT produces fine textured picture in every detail.

s Wide range voltage (120V ~ 240V) for AC power input.

s With AUDIO/VIDEO/COMPONENT input terminals.

2

C bus control utilizes single chip ICs.

s I

s By means of AUTO PROGRAM, the TV stations can be selected

automatically and the TV channels can also be rearranged automatically.

s Built-in DIGITAL ECO MODE (ECONOMY, ECOLOGY).

In accordance with the brightness in a room, the brightness and/or

contrast of the picture can be adjusted automatically to make the

optimum picture which is easy on the eye.

s Built-in OFF TIMER & RETURN +.

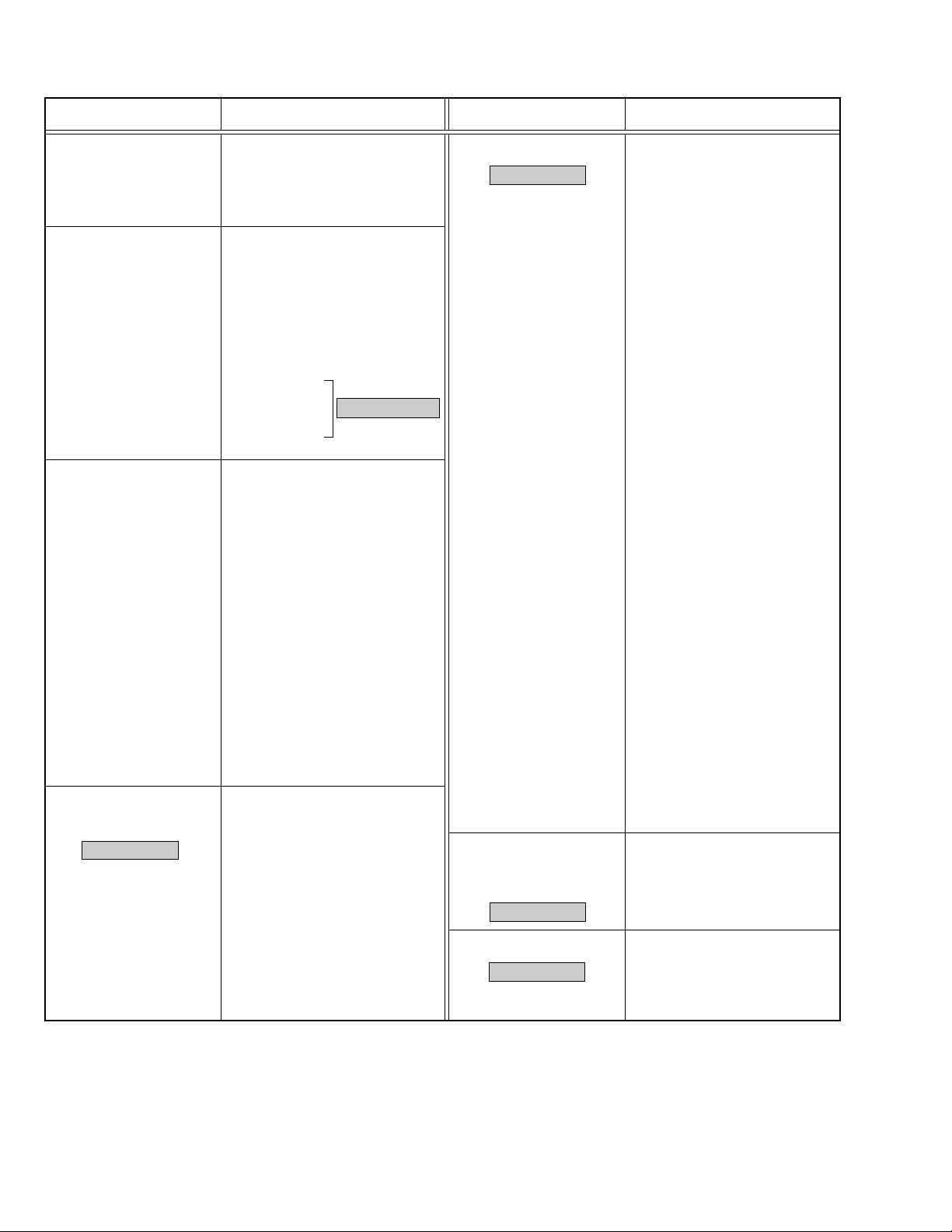

MAIN DIFFERENCE LIST

[AV-29W83

!

Part Name

! MAIN PWB SCH-1118A-BK SCH-1119A-BK SCH-1120A-BK

! REAR COVER GG10192-001B-H GG10192-004B-H

FRONT CABINET ASS’Y GG10189-008A-H GG10189-005A-H

REMOTE CONTROL UNIT RM-C1016-1H RM-C1011-1H RM-C1012-1H

/BK, AV-29W93/BK, AV-29W93B/BK]

MODEL No.

AV-29W83/BK AV-29W93/BK AV-29W93B/BK

[AV-29W83B/VT, AV-29W83/VT]

!

Part Name

! MAIN PWB SCH-1312A-CK SCH-1310A-V2

! REAR COVER GG10192-003B-HK GG10192-002B-HK

FRONT CABINET ASS’Y GG10189-007A-HK GG10189-009A-HK

! RATING LABEL GG20016-023A-E GG20016-022A-E

REMOTE CONTROL UNIT RM-C1015-1H RM-C1014-1H

MODEL No.

AV-29W83B/VT AV-29W83/VT

4No. 52070

Page 5

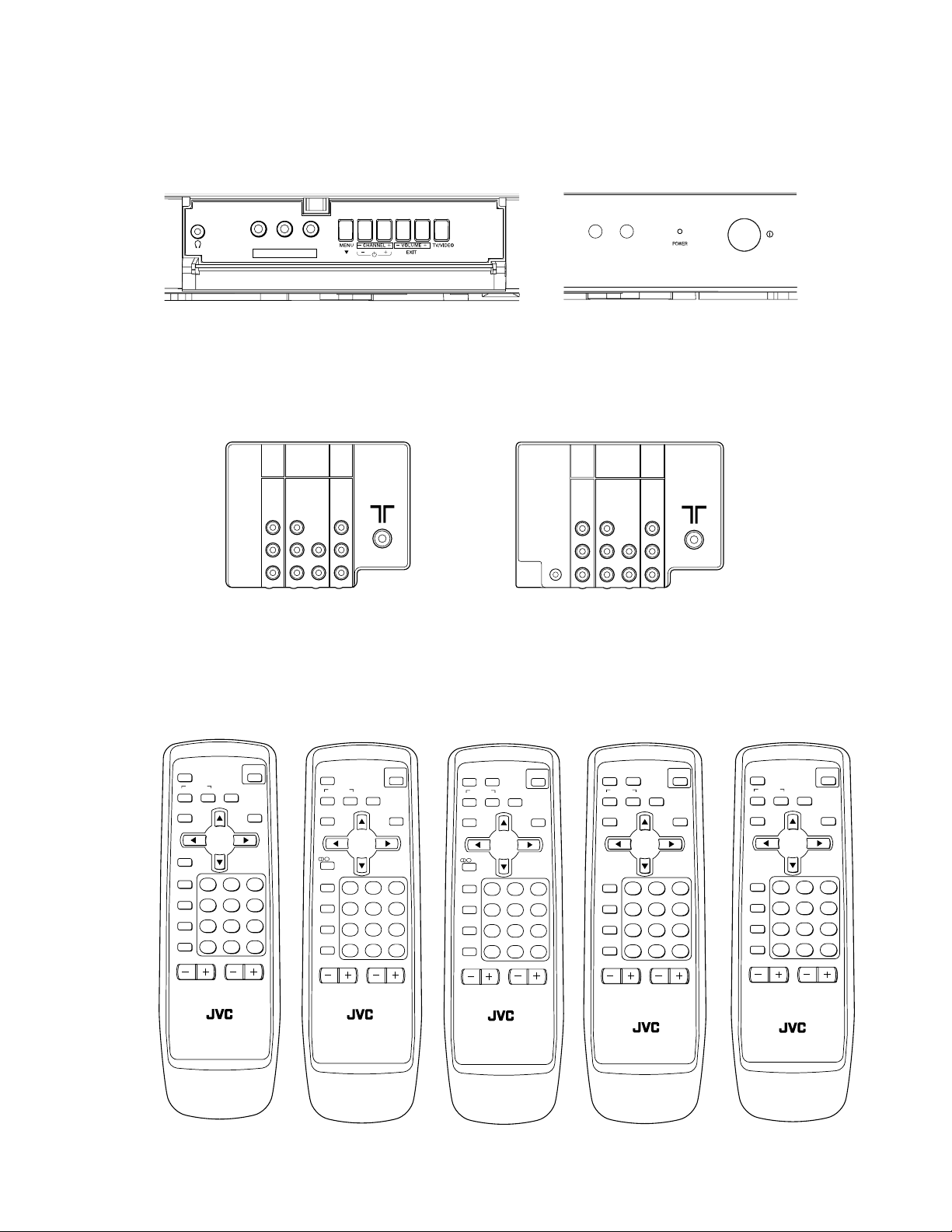

FUNCTIONS

a FRONT PANEL

L/MONOVR

IN (VIDEO-3)

a REAR PANEL

L/MONOVR

IN (VIDEO-3)

COMPONENT

VIDEO-1

(

VIDEO-2

INPUT

INPUT

AV-29W83 AV-29W93B

AV-29W93 AV-29W83B

[AV-29W93B/BK, AV-29W83B/VT][AV-29W83/BK, AV-29W93/BK, AV-29W83/VT]

COMPONENT

)

OUTPUT

VIDEO-1

INPUT

(

VIDEO-2

INPUT

)

OUTPUT

V

Y

L

C

/

MONO

R

a REMOTE CONTROL UNIT

RM-C1016-1H

[AV-29W83/BK]

MUTING

SYSTEM

COLOUR SOUND

DISPLAY

1/2

TV/VIDEO

OFF

TIMER

PICTURE

MODE

CHANNEL

SCAN

CHANNEL

POWER

CINEMA

SURROUND

ECO

SENSOR

MENU

123

456

789

RETURN+

0-/

VOLUME

--

V

/

V

L

B

L

/

MONO

RRC

R

RM-C1011-1H

[AV-29W93/BK]

MUTING

SYSTEM

COLOUR SOUND

DISPLAY

1/2

TV/VIDEO

OFF

TIMER

PICTURE

MODE

CHANNEL

SCAN

CHANNEL

POWER

CINEMA

SURROUND

ECO

SENSOR

MENU

123

456

789

RETURN+

0-/

VOLUME

Y

V

BASS

SPEAKER

L

/

MONO

OUT

R

RM-C1012-1H

[AV-29W93B/BK]

MUTING BASS

SYSTEM

COLOUR SOUND

DISPLAY

1/2

TV/VIDEO

OFF

TIMER

PICTURE

MODE

CHANNEL

--

SCAN

CHANNEL

POWER

CINEMA

SURROUND

ECO

SENSOR

MENU

123

456

789

RETURN+

0-/

VOLUME

--

V

/

V

L

C

B

L

/

MONO

R

C

R

R

RM-C1015-1H

[AV-29W83B/VT]

POWER

BASS

MUTING

COLOUR SOUND

DISPLAY

TV/VIDEO

PICTURE

CHANNEL

SYSTEM

123

OFF

TIMER

456

MODE

789

RETURN+

SCAN

CHANNEL

SURROUND

MENU

CINEMA

0-/

VOLUME

ECO

SENSOR

RM-C1014-1H

[AV-29W83

MUTING

SYSTEM

COLOUR SOUND

DISPLAY

TV/VIDEO

OFF

TIMER

PICTURE

MODE

CHANNEL

--

SCAN

CHANNEL

/VT]

POWER

CINEMA

SURROUND

ECO

SENSOR

MENU

123

456

789

RETURN+

0-/

VOLUME

--

RM-C1016

TV

RM-C1011

TV

RM-C1012

TV

RM-C1015

TV

RM-C1014

TV

No. 52070 5

Page 6

AV-29W83 AV-29W93B

AV-29W93 AV-29W83B

SPECIFIC SERVICE INSTRUCTIONS

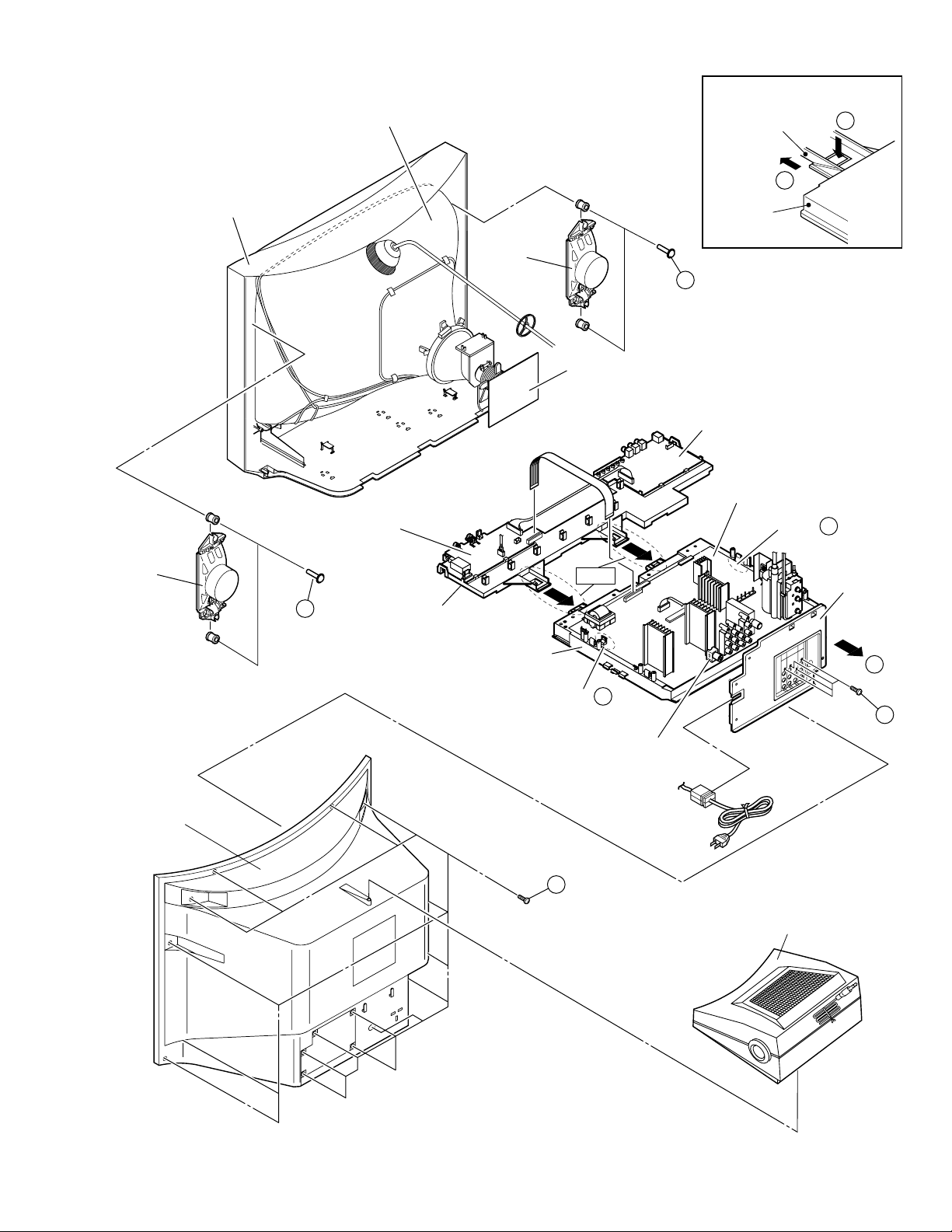

DISASSEMBLY PROCEDURE

REMOVING THE TWIN PORT BASS BLASTER UNIT

[AV-29W93B

1. Unplug the power supply cord.

2. Disconnect the Twin Port Bass Blaster Unit’s cord from the rear of

the TV set.

3. Remove the Twin Bass Blaster Unit by pulling it upwards.

[REMARK]

After removing the Twin Port Bass Blaster Unit, proceed to the fol-

•

lowing procedure.

/BK, AV-29W83B/VT only]

REMOVING THE REAR COVER

1. Unplug the power supply cord.

2. Remove the 16 screws marked

3. Withdraw the Rear cover toward you.

[CAUTION]

When reinstalling the rear cover, carefully push it inward after in-

•

serting the Main PWB into the rear cover groove.

as shown in Fig.1.

Å

REMOVING THE CHASSIS (CHASSIS BASE AND

CONTROL BASE)

After removing the rear cover.

•

1. Slightly raise the both sides of the chassis by hand and remove the

2 claws marked ı under the chassis from the front cabinet as shown

in Fig.1.

2. Withdraw the chassis backward.

(If necessary, take off the wire clamp, connector’s etc.)

When conducting a check with power supplied, be sure to confirm

*

that the CRT earth wire is connected to the CRT SOCKET PWB

and the Main PWB.

REMOVING THE SPEAKER

After removing the rear cover.

•

1. Remove the 2 screws marked ˝ as shown in Fig.1.

2. Withdraw the speaker backward.

3. Follow the same steps when removing the other hand speaker.

CHECKING THE MAIN PW BOARD

1. To check the back side of the Main PWB.

1) Pull out the chassis. (Refer to REMOVING THE CHASSIS).

2) Erect the chassis vertically so that you can easily check the back

side of the Main PWB.

[CAUTION]

When erecting the chassis, be careful so that there will be no con-

•

tacting with other PW Board.

Before turning on power, make sure that the CRT earth wire and

•

other connectors are properly connected.

When repairing, connect the Deg. coil to the DEG. connector on the

•

Main PWB.

WIRE CLAMPING AND CABLE TYING

1. Be sure to clamp the wire.

2. Never remove the cable tie used for tying the wires together.

Should it be inadvertently removed, be sure to tie the wires with a

new cable tie.

REMOVING THE AV TERMINAL BOARD

After removing the rear cover.

•

1. Remove the 4 screws marked Ç as shown in Fig.1.

2. When you pull out the AV Terminal board in the direction of arrow

marked Î as shown in Fig.1, it can be removed.

REMOVING THE CONTROL BASE

After removing the rear cover and the chassis.

•

1. While pushing down the 2 claws marked ´ as shown in Fig. 2 and

pull out the Control base in the direction of arrow marked Ï as

shown in Fig. 2, the control base can be removed.

(If necessary, take off the wire, connector’s etc.)

6No. 52070

Page 7

PICTURE TUBE

AV-29W83 AV-29W93B

AV-29W93 AV-29W83B

[FRONT SIDE]

CONTROL BASE

F

E

SPEAKER

FRONT CABINET

FRONT CONTROL

PWB (1/2)

(X2)

G

CONTROL BASE

SPEAKER

CHASSIS

BASE

CRT

SOCKET PWB

Fig.2

CHASSIS

BASE

Fig.2

(X2)

G

FRONT CONTROL PWB (2/2)

MAIN PWB

CLAW B

AV TERMINAL

BOARD

D

REAR COVER

Fig.1

CLAW B

(For AV-29W93B

AV-29W83B

A

(×16)

/VT

/BK

,

only)

TWIN PORT

BASS BLASTER UNIT

(For AV-29W93B

/BK

, AV-29W83B

/VT

C

(×4)

only)

No. 52070 7

Page 8

AV-29W83 AV-29W93B

AV-29W93 AV-29W83B

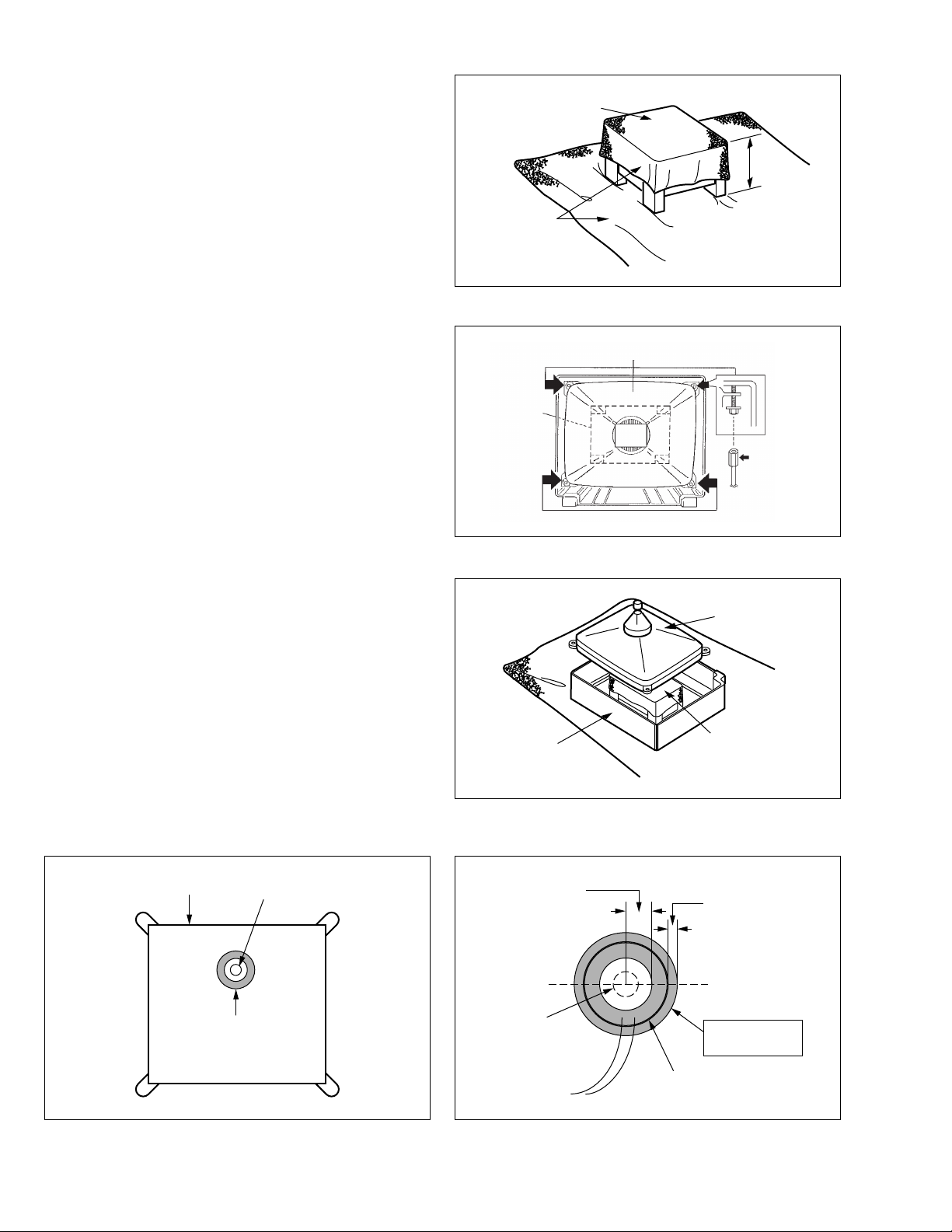

REMOVING THE CRT

* Replacement of the CRT should be performed by 2 or more persons.

After removing the rear cover, chassis etc.,

•

1. Putting the CRT change table on soft cloth, the CRT change table

should also be covered with such soft cloth (shown in Fig. 3).

2. While keeping the surface of CRT down, mount the TV set on the

CRT change table balanced will as shown in Fig. 4.

3. Remove 4 screws marked by arrows with a box type screwdriver as

shown in Fig. 4.

Since the cabinet will drop when screws have been removed, be sure

•

to support the cabinet with hands.

4. After 4 screws have been removed, put the cabinet slowly on cloth

(At this time, be carefully so as not to damage the front surface of the

cabinet) shown in Fig. 5.

The CRT should be assembled according to the opposite sequence

•

of its dismounting steps.

* The CRT change table should preferably be smaller that the CRT sur-

face, and its height be about 35cm.

CRT CHANGE TABLE

CLOTH

CRT

CHANGE

TABLE

Fig. 3

CRT

APPROX.

35cm

BOX

TYPE

SCREW

DRIVER

COATING OF SILICON GREASE FOR ELECTRICAL INSULATION ON THE CRT ANODE CAP SECTION.

Subsequent to replacement of the CRT and HV transformer or repair

•

of the anode cap, etc. by dismounting them, be sure to coat silicon

grease for electrical insulation as shown in Fig. 6.

1. Wipe around the anode button with clean and dry cloth. (Fig. 6)

2. Coat silicon grease on the section around the anode button. At this

time, take care so that any silicon greases does not sticks to the

anode button. (Fig. 7)

夝 Silicon grease product No. KS - 650N

CRT

Anode button

CABINET

Approx.

20mm (Do not

coat grease on

this section

Fig. 4

CRT

CRT

CHANGE TABLE

Fig. 5

Silicon grease

should be coated

by 5mm or more

from the outside

diameter of anode

cap.

Silicon grease

coating

Fig. 6

8No. 52070

Anode button

(No sticking of

silicon grease)

Coating position

of silicon grease

Anode cap

Fig. 7

Page 9

REPLACEMENT OF MEMORY IC

1. MEMORY IC

This TV uses the following memory IC.

Memory IC: IC1702 on MAIN PW Board

The memory IC memorizes data for correctly operating the video

and deflection circuits. When replacing the memory IC, be sure to

use the same type IC written with the initial values of data. In other

words, use the specific IC listed in “PRINTED WIRING BOARD

PA RTS LIST”. For its mounting location, refer to “ADJUSTMENT

LOCATIONS”.

2. PROCEDURE FOR REPLACING MEMORY IC

(1) Power off

Switch the power off and unplug the power cord from the wall

outlet.

(2) Replacing the memory IC

Replace the memory IC with new one. Be sure to use the memory

IC written with the initial data values.

(3) Power on

Plug the power cord into the wall outlet and switch the power on.

(4) Check and setting of SYSTEM CONSTANT SET:

1) Press the DISPLAY key and the PICTURE MODE key on the

remote control unit simultaneously.

The SERVICE MENU screen will be displayed.(See Fig.1.)

2) In the SERVICE MENU, press the DISPLAY key and PICTURE MODE key simultaneously. Then, the SYSTEM CONSTANT SET screen will be displayed.(See Fig.2.)

3) Check whether the setting values of the SYSTEM CONSTANT

SET are the same as those indicated in Table1.

If the value is different, select the setting item with the MENU

&/^ key, and set the correct value with the MENU

4) Press the DISPLAY key twice to return to the normal screen.

(5) Receive channel setting

Refer to the OPERATING INSTRUCTIONS and set the receive

channels (channels preset).

(6) User setting

Check the user setting values in Table 2, and if setting value is

different, set the correct value.

For setting, refer to the OPERATING INSTRUCTIONS.

(7) Setting of SERVICE MENU

Ver ify the setting for each setting item in the SERVICE

MENU.(See Table 3.) If readjustment is necessary, perform adjustment referring to “SERVICE ADJUSTMENTS”.

NAME OF REMOTE CONTROL KEYS

POWER

CINEMA

SURROUND

ECO

SENSOR

MENU

TV/TEXT

123

456

789

--

0-/

VOLUME

TEXT

SIZE

DISPLAY

MENU

PICTURE

MODE

MUTING

SYSTEM

COLOUR SOUND

DISPLAY

I/II

TV/VIDEO

OFF

TIMER

PICTURE

MODE

CHANNEL

RETURN+

SCAN

CHANNEL

REVEAL

HOLD INDEX

SUBPAGE CANCEL

STORE MODE

*/T

MENU

MENU

MENU

key.

SERVICE MENU

SERVICE MENU

1. IF

3. DEF

5. PRESET

7. PLUG & PLAY (ON)

1-7 : SELECT DISPLAY : EXIT

******* **** ***** *****

**** **** *** ***

[AV-29W93

1. IF

3. DEF

5. PRESET

6. PLUG & PLAY (ON)

1-6 : SELECT DISPLAY : EXIT

******* **** ***** *****

**** **** *** ***

[AV-29W83

/BK

SERVICE MENU

/BK

, AV-29W83B

Fig. 1

SYSTEM CONSTANT-

SYSTEM CONSTANT SET 1

SYSTEM

COMB

TILT

TEXT

SUPER BASS

LANGUAGE

>? : SEL -+ : OPE

SYSTEM CONSTANT-

SYSTEM CONSTANT SET 2

MSP

BILINGUAL

B / B SOUND

TUNER

COLOUR AUTO

>? : SEL -+ : OPE

SYSTEM CONSTANT-

SYSTEM CONSTANT SET 3

LOCK 1 MHz

>? : SEL -+ : OPE

500 KHz

250 KHz

156. 25 KHz

31.25 KHz

SYSTEM CONSTANT-

SYSTEM CONSTANT SET 4

3D SURROUND

3CH VOL/TONE

AMP TUNER

>? : SEL -+ : OPE

Fig. 2

AV-29W83 AV-29W93B

AV-29W93 AV-29W83B

2. VC

4. VSM PRESET

6. A2NICAM

, AV-29W93B

/BK

2. VC

4. VSM PRESET

/VT,

AV-29W83

Ι

MULTI

YES

YES

ERCMI

YES

E/R/C/M/I

DISP : EXIT

II

YES

YES

NO

MU

YES

DISP : EXIT

III

: 040

: 040

: 040

: 030

: 030

DISP : EXIT

IV

YES

YES

NO

DISP : EXIT

]

/VT

]

No. 52070 9

Page 10

AV-29W83 AV-29W93B

AV-29W93 AV-29W83B

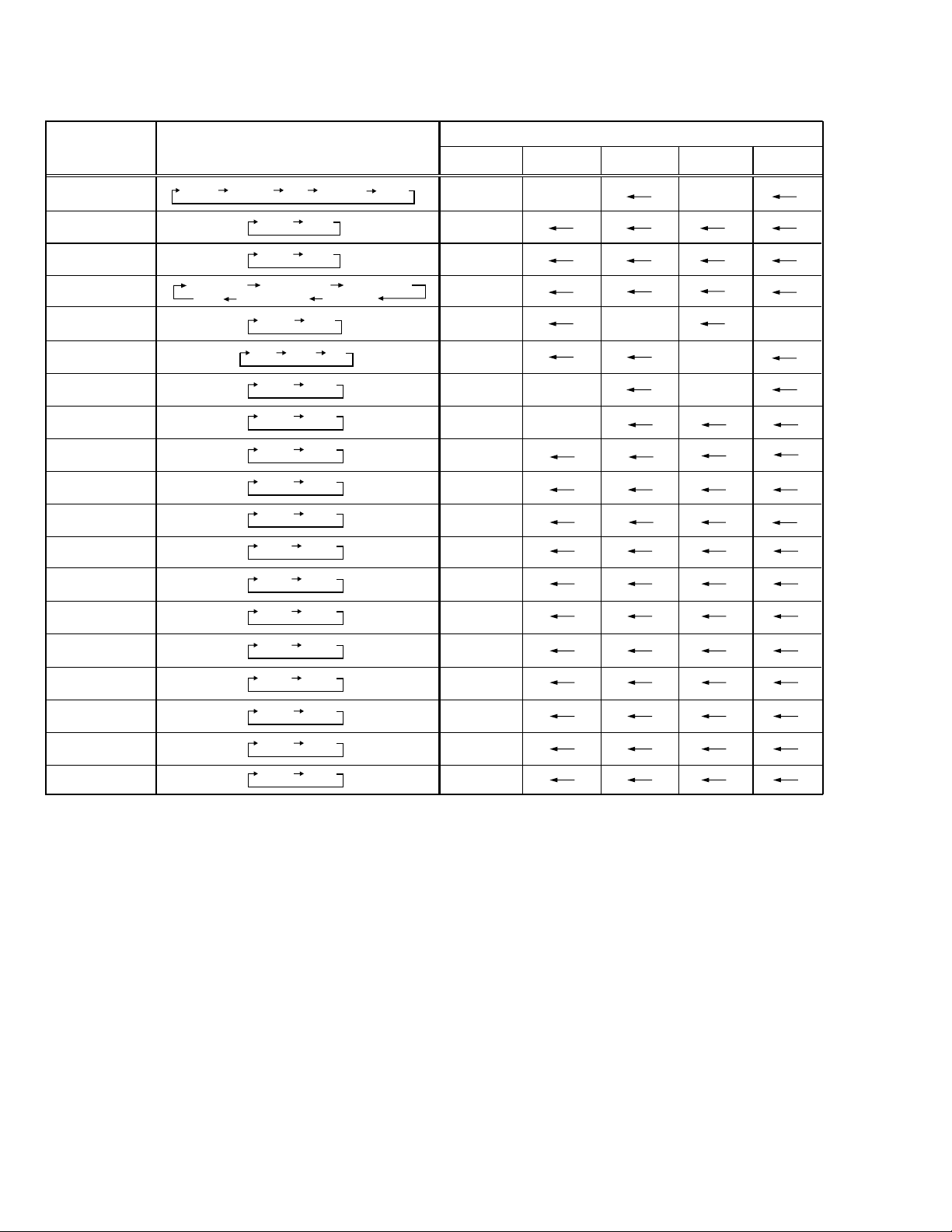

SETTING OF SYSTEM CONSTANT SET

Setting item Setting content

SYSTEM

COMB

TILT

TEXT

SUPER BASS

LANGUAGE

MSP

BILINGUAL

B/B SOUND

TUNER

COLOUR AUTO

LOCK 1MHz

500KHz

MULTI TRIPLE PAL SINGLE

YES NO

YES NO

EASTERN UKRANIAN RUSSIAN

NO PAN EURO ARABK

YES NO

E/T E/V E

YES NO

YES NO

YES NO

MU MA

YES NO

000 240

000 240

VIET

AV-29W83

SINGLE

YES

YES

NO

NO

E/T

YES

NO

MU

NO

040

040

/BK

AV-29W93

MULTI

YES

NO

Setting value

/BK

AV-29W93B

YES

AV-29W83B

/BK

VIET

E/V

NONO

AV-29W83

/VT

/VT

NO

250KHz

156.25KHz

31.25KHz

3D SURROUND

3CH VOL/TONE

AMP TUNER

000 240

000 240

000 240

YES NO

YES NO

YES NO

040

030

030

YES

YES

NO

Table 1

10 No. 52070

Page 11

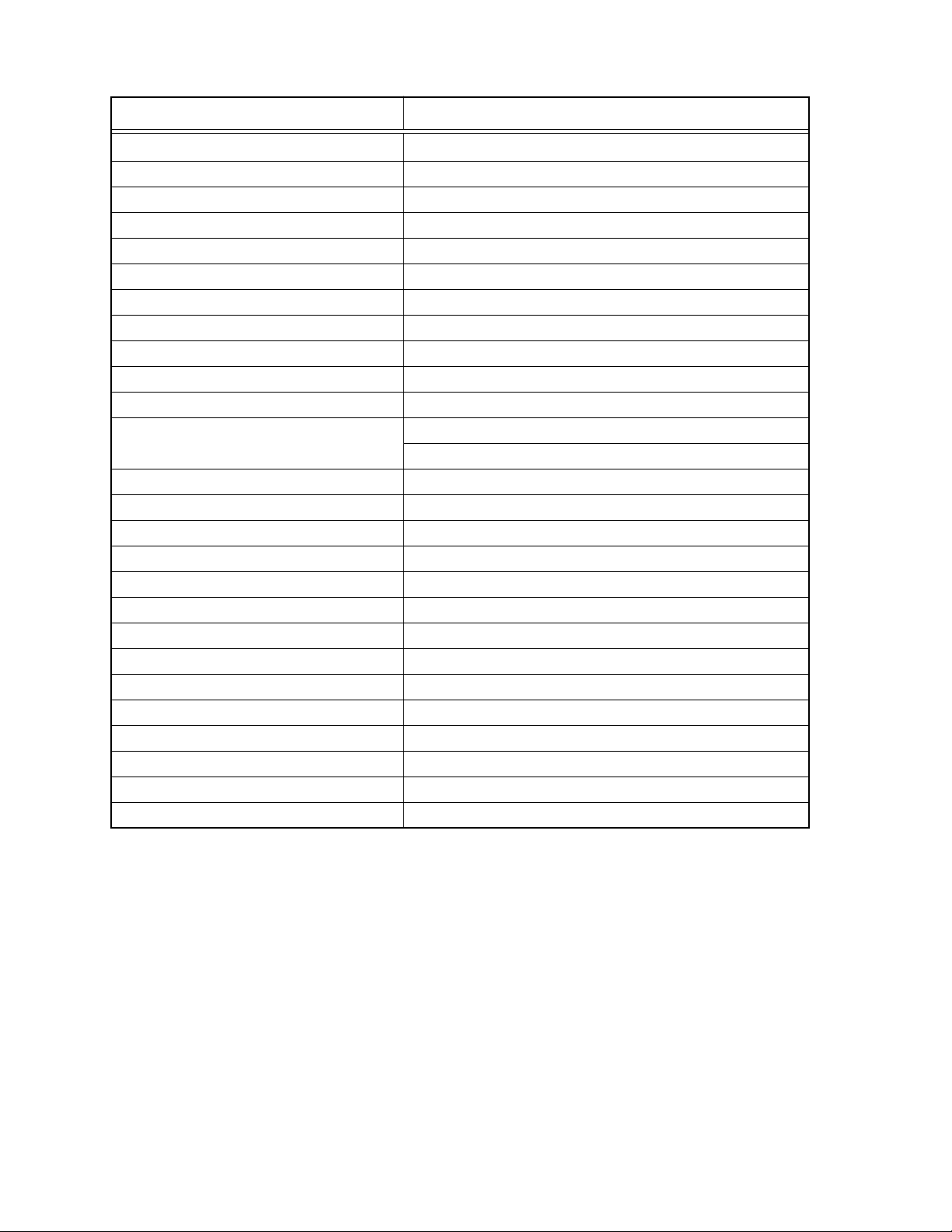

USER SETTING VALUES

Setting item Setting value

SUB POWER ON

CHANNEL POSITION 1 POSITION

CHANNEL PRESET REFER TO OPERATING INSTRUCTIONS

VOLUME 15 ± 2

TV/VIDEO TV

VNR OFF

COMPRESS (16:9) OFF

AUTO SHUTOFF OFF

CHILD LOCK OFF

BLUE BACK ON

VIDEO-2 SET VIDEO

LANGUAGE THAI [AV-29W83

VIET [AV-29W83B/VT, AV-29W83/VT only]

CINEMA SURROUND OFF

AI VOLUME ON

ON SCREEN DISPLAY POSITION INDICATION

COLOUR SYSTEM PAL

SOUND SYSTEM B/G

STEREO MODE STEREO [AV-29W93/BK, AV-29W93B/BK only]

PICTURE MODE-VSM BRIGHT

OFF TIMER 00

ECO SENSOR OFF

BASS CENTRE

TREBLE CENTRE

BALANCE CENTRE

SUPER BASS ON [AV-29W93B/BK, AV-29W83B/VT only]

BILINGUAL MODE 1/2 [AV-29W83/BK only]

/BK, AV-29W93/BK, AV-29W93B/BK only]

AV-29W83 AV-29W93B

AV-29W93 AV-29W83B

Tab le 2

No. 52070 11

Page 12

AV-29W83 AV-29W93B

AV-29W93 AV-29W83B

SERVICE MENU SETTING ITEMS

Service menu Setting item

1. IF 1. VCO

2. DELAY POINT

2. VC 1. CUTOFF(R/G)

2. DRIVE(R/G/B)

3. BRIGHT

4. CONT

5. COLOUR

6. TINT

7. SHARP

8. YDELAY

9. AMP T. SHARP

3. DEF 1. VER. SLOPE

2. VER. HEIGHT

3. VER. POSITION

4. VER. SCURVE

5. HOR. POSITION

6. HOR. WIDTH

7. EW-PIN

8. EW-TRAPEZ

9. UP CORNER

10. DW CORNER

11. HOR. PARALL

12. HOR. BOW

13. V. ZOOM

4. VSM PRESET 1. TINT

(BRIGHT/STD/SOFT) 2. COLOUR

Do not adjust

3. BRIGHT

4. PICTURE

5. DETAIL

Do not adjust

Service menu Setting item

5. PRESET 1. PSNS

Do not adjust

6. A2NICAM 1. ERROR LIMIT

[AV-29W93

/BK

, AV-29W93B

Do not adjust

/BK

2. ACL

3. MUS

4. MAT

5. FCO

6. BPS

7. IFLH

8. VID

9. STM

10. AFCW

11. VSW

12. FFI

13. AGC

14. CL

15. AKB

16. HBL

17. BKS

18. READ STATUS

19. VNR

20. PEAK

21. IVG

22. WPL

23. SOFT CLIPPER

24. IF PLL OFFSET

25. OVERSHOOT

26. HCO

27. HP2

28. AI VOLUME ADN

31. CCCLOOP

only]

2. A2 ID THR

3. SOUND SYSTEM

Table 3

12 No. 52070

6/7.

PLUG & PLAY(ON)

Do not adjust

Page 13

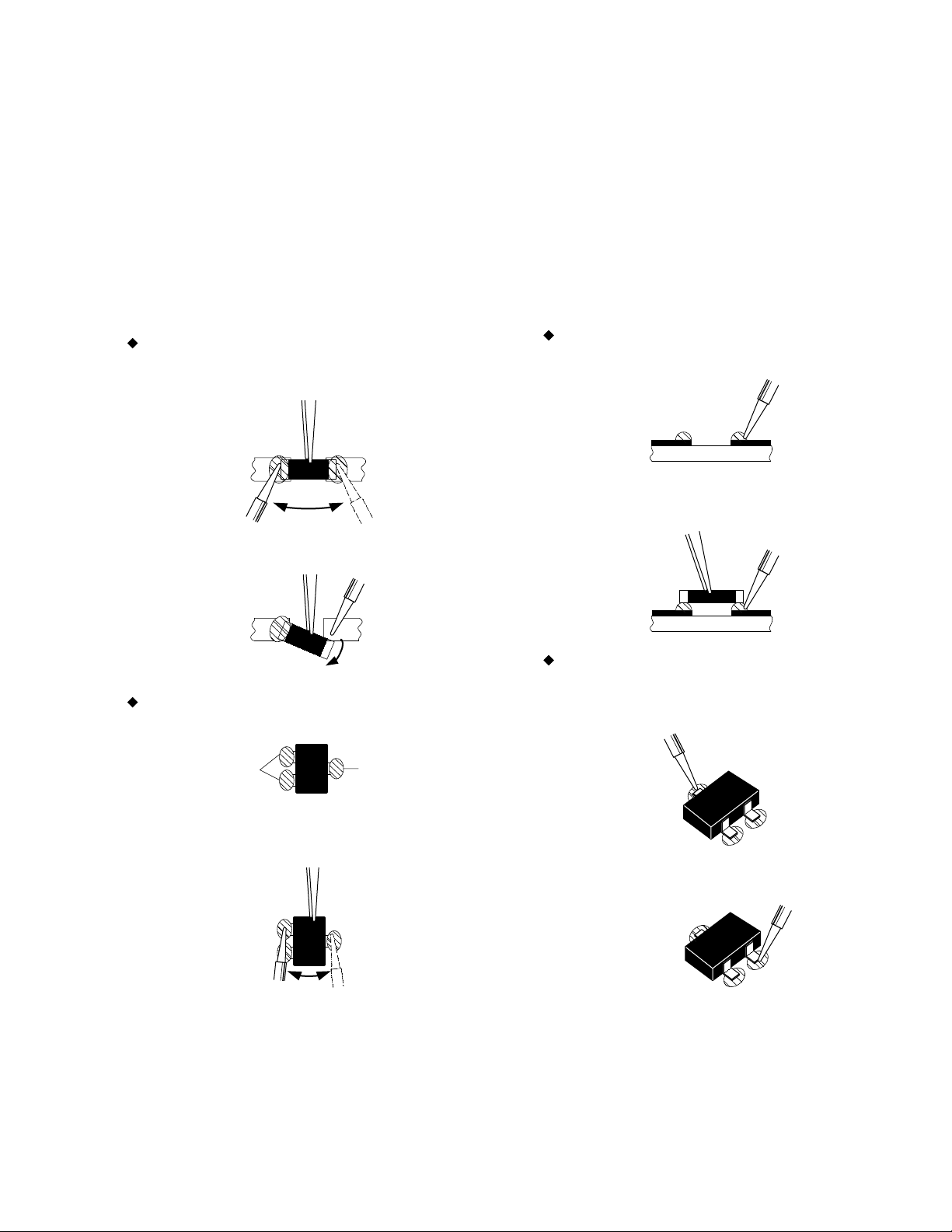

REPLACEMENT OF CHIP COMPONENT

CAUTIONS

a

1. Avoid heating for more than 3 seconds.

2. Do not rub the electrodes and the resist parts of the pattern.

3. When removing a chip part, melt the solder adequately.

4. Do not reuse a chip part after removing it.

SOLDERING IRON

a

1. Use a high insulation soldering iron with a thin pointed end of it.

2. A 30w soldering iron is recommended for easily removing parts.

REPLACEMENT STEPS

a

1. How to remove Chip parts

Resistors, capacitors, etc.

(1) As shown in the figure, push the part with tweezers and alter-

nately melt the solder at each end.

AV-29W83 AV-29W93B

AV-29W93 AV-29W83B

2. How to install Chip parts

Resistors, capacitors, etc.

(1) Apply solder to the pattern as indicated in the figure.

(2) Shift with tweezers and remove the chip part.

Transistors, diodes, variable resistors, etc.

(1) Apply extra solder to each lead.

SOLDER

(2) As shown in the figure, push the part with tweezers and alter-

nately melt the solder at each lead. Shift and remove the chip

part.

SOLDER

(2) Grasp the chip part with tweezers and place it on the solder.

Then heat and melt the solder at both ends of the chip part.

Transistors, diodes, variable resistors, etc.

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the solder.

(3) First solder lead A as indicated in the figure.

A

B

C

(4) Then solder leads B and C.

A

Note : After removing the part, remove remaining solder from the

pattern.

No. 52070 13

B

C

Page 14

AV-29W83 AV-29W93B

AV-29W93 AV-29W83B

SERVICE ADJUSTMENTS

ADJUSTMENT PREPARATION

1. You can make the necessary adjustments for this unit with either the remote control unit or with the adjustment equipment and parts

as given below.

2. Adjustment with the remote control unit is made on the basis of the initial setting values, however, the new setting values which set the

screen to its optimum condition may differ from the initial settings.

3. Make sure that AC power is turned on correctly.

4. Tu rn on the power for the set and test equipment before use, and start the adjustment procedures after waiting at least 30 minutes.

5. Unless otherwise specified, prepare the most suitable reception or input signal for adjustment.

6. Never touch any adjustment parts, which are not specified in the list for this adjustment-variable resistors, transformers, capacitors, etc.

7. Presetting before adjustment.

Unless otherwise specified in the adjustment instructions, preset the following functions with the remote control unit.

User mode setting position

•

Setting item Setting value

PICTURE MODE(VSM) BRIGHT

VNR OFF

BASS, TREBLE, BALANCE CENTRE

TINT, COLOUR, BRIGHT, DETAIL CENTRE

PICTURE MAXIMUM

MEASURING INSTRUMENT

1. DC voltmeter (or Digital voltmeter)

2. Oscilloscope

3. Signal generator (Pattern generator) [PAL/SECAM/NTSC]

4. Remote control unit

ADJUSTMENT ITEMS

B1 POWER SUPPLY

•

FOCUS ADJUSTMENT

•

IF CIRCUIT ADJUSTMENTS

•

Adjustment of VCO (CW)

Adjustment of DELAY POINT (AGC TAKE-OVER)

VC (VIDEO/CHROMA) CIRCUIT ADJUSTMENTS

•

Adjustment of WHITE BALANCE (Low light)

Adjustment of WHITE BALANCE (High light)

Adjustment of SUB BRIGHT

Adjustment of SUB CONTRAST

Adjustment of SUB COLOURAdjustment of SUB COLOURAdjustment of SUB TINTAdjustment of SUB TINT-

ΙΙ

Ι

ΙΙ

ΙΙΙΙ

ΙΙ

ΙΙΙΙ

ΙΙ

Ι

ΙΙ

ΙΙΙΙ

ΙΙ

ΙΙΙΙ

DEFLECTION CIRCUIT ADJUSTMENTS

•

Adjustment of V. SLOPE

Adjustment of V. POSITION

Adjustment of V. HEIGHT

Adjustment of H. POSITION

Adjustment of H. WIDTH

Adjustment of SIDE PIN

Adjustment of TRAPEZIUM

Adjustment of V. S-CURVE

Adjustment of CORNER

Adjustment of H. PARALLEL

Adjustment of H. BOW

VSM PRESET SETTING

•

PRESET SETTING

•

AUDIO ADJUSTMENT [AV-29W93/BK, AV-29W93B/BK only]

•

PURITY ADJUSTMENT

•

CONVERGENCE ADJUSTMENTS

•

Adjustment of STATIC CONVERGENCE

Adjustment of DYNAMIC CONVERGENCE

14 No. 52070

Page 15

ADJUSTMENT LOCATIONS

AV-29W83 AV-29W93B

AV-29W93 AV-29W83B

FRONT CONTROL PWB ASS’Y(1/2) FRONT CONTROL PWB ASS’Y(2/2)

POWER

SW.

S901

PW

FRONT

CN002

R

W

CN001

S804

S805

S806 S802

CN002

CN00A

S803S801

J304 J303 J302

CN003

MAIN PWB ASS’Y

FRONT

Z

W

DEG

CN001

1

T

6

IC702

IC701

FRONT

J801

S801 : CH UP +

S802 : CH DOWN –

S803 : MENU

S804 : TV/VIDEO

S805 : VOL UP+

S806 : VOL DOWN –

(J805: For AV-29W93B/BK, AV-29W83B/VT only)

J804J801J805 J802 J803

AV IN/OUT

TU001

CRT SOCKET PWB ASS’Y

TP-47G

GND B1

5

S

61

U

TP-47B

HV

16

1

HVT

UPPER : FOCUS (F1)

MIDDLE : FOCUS (F2)

LOWER : SCREEN

(SOLDER SIDE)

TOP

TP-E

E1

61

T

16

CRT EARTH

(BRAIDED ASS'Y)

U

No. 52070 15

Page 16

AV-29W83 AV-29W93B

AV-29W93 AV-29W83B

BASIC OPERATION IN SERVICE MENU

1. TOOL OF SERVICE MENU OPERATION

Operate the SERVICE MENU with the remote control unit.

2. SERVICE MENU ITEMS

With the SERVICE MENU,various settings (adjustments)can be made,and they are broadly classified in the following items of settings:

1.IF ......................................For entering/adjusting the setting values (adjustment values)of the IF circuit.

•

2.VC ....................................For entering/adjusting the setting values (adjustment values)of the VIDEO/CHROMA circuit.

•

3.DEF ..................................For entering/adjusting the setting values (adjustment values)of the DEFLECTION circuit.

•

4.VSM PRESET ..................For setting the values of STANDARD,SOFT and BRIGHT.

•

5.PRESET ........................... For setting the values of the preset.

•

6.A2NICAM .........................For entering/adjusting the setting values (adjustment values)of the multiplicity sound circuit. [AV-29W93/BK,

•

6/7. PLUG & PLAY (ON) ..... This is not used for service.

•

3. BASIC OPERATION IN SERVICE MENU

(1) How to enter SERVICE MENU

Press the DISPLAY key and the PICTURE MODE key on the remote control unit simultaneously.

The SERVICE MENU screen will be displayed. (See Fig. 1 on the next page.)

(2) Selection of SUB MENU SCREEN

Press one of the keys 1 to 7 on the remote control unit,and select the SUB MENU SCREEN from the SERVICE MENU. (See Fig.1 on the next

page.)

(VSM:video status memory)

AV-29W93B

/BK only]

SERVICE MENU → SUB MENU 1. IF

2. VC

3. DEF

4. VSM PRESET

5. PRESET

6. A2NICAM [AV-29W93/BK, AV-29W93B/BK only]

6/7. PLUG & PLAY (ON)

(3) Method of Setting

*Once the setting values are set,they are memorized automatically.

*It must not adjust without inputting a signal.

1) 1. IF

[1.VCO ]

(a) 1 Key......................... Select 1. IF.

(b) 1 Key......................... Select 1. VCO.

(c) DISPLAY Key ............ When this is pressed twice, you will return to the SERVICE MENU.

Under normal conditions, no adjustment is required.

[2.DELAY POINT ]

(a) 1 Key......................... Select 1. IF.

(b) 2 Key......................... Select 2.DELAY POINT.

(c) MENU

(d) DISPLAY Key............ When this is pressed twice, you will return to the SERVICE MENU.

2) 2. VC, 3. DEF, 4. VSM PRESET, 5. PRESET and 6. A2NICAM

(a) 2 ~6 Keys.................. Select one from 2. VC, 3. DEF, 4. VSM PRESET, 5. PRESET and 6. A2NICAM.

(b) MENU &/^ key........ Select setting items.

(c) MENU

(d) DISPLAY Key............ When this is pressed, you will return to the SERVICE MENU.

*/T

Key ........ Adjust the setting value.

*/T

Key ........ Adjust the setting values of the setting items.

•

Use the number keys on the remote control unit for setting of WHITE BALANCE.

•

For the setting, refer to each item concerned.

3) 6/7. PLUG & PLAY (ON)

This is not used for service.

(4) Release of SERVICE MENU

After completing the setting, return to the SERVICE MENU by pressing the DISPLAY key, then again press the DISPLAY key to return to the

normal screen.

16 No. 52070

Page 17

AV-29W83 AV-29W93B

AV-29W93 AV-29W83B

SERVICE MENU

SERVICE MENU

1. IF

3. DEF

5. PRESET

7. PLUG & PLAY (ON)

1-7 : SELECT DISPLAY : EXIT

******* **** ***** *****

**** **** *** ***

[AV-29W93

1. IF

3. DEF

5. PRESET

6. PLUG & PLAY (ON)

1-6 : SELECT DISPLAY : EXIT

******* **** ***** *****

**** **** *** ***

[

AV-29W83

/BK

SERVICE MENU

/BK

,

AV-29W83B

, AV-29W93B

2. VC

4. VSM PRESET

6. A2NICAM

/BK

2. VC

4. VSM PRESET

/VT

,

AV-29W83

SUB MENU 1. IF

IF

1. VCO

2. DELAY POINT

1-2 : SELECT DISPLAY : EXIT

]

/VT

]

SUB MENU 2. VC

V/C

1. CUTOFF

50 Hz

MENU 89: SELECT

MENU

-

/+: OPERATE

AUTO

(R)

(G)

DISPLAY : EXIT

1. CUTOFF (R/G)

2. DRIVE (R/G/B)

**

**

3. BRIGHT

4. CONT

5. COLOUR

6. TINT

7. SHARP

8. YDELAY

9. AMP T.SHARP

VCO (CW)

-

Setting item

TOO HIGH

ABOVE REFERENCE

BELOW REFERENCE

TOO LOW

DELAY POINT UHF

AGC TAKE-OVER

/+: OPERATE

MHz

*****

DISPLAY : EXIT

**

DISPLAY : EXIT

SUB MENU 6. A2NICAM

[AV-29W93

1. ERROR LIMIT

MENU 89: SELECT

MENU

/BK

C AD BITS

NICAM ERROR

-

/+: OPERATE

1. ERROR LIMIT

2. A2 ID THR

3. SOUND SYSTEM

, AV-29W93B

DISPLAY : EXIT

Setting item

SUB MENU 5. PRESET

PRESET 50Hz

1. PSNS

MENU 89: SELECT

-

/+: OPERATE

MENU

/BK

]

MHzA2NICAM

*****

****

******

****

PALB/G

*

DISPLAY : EXIT

1. PSNS

2. ACL

3. MUS

4. MAT

5. FCO

6. BPS

7. IFLH

8. VID

9. STM

SUB MENU 3. DEF

DEF

4 : 3

PAL

1. VER. SLOPE

50Hz

MENU 89: SELECT

-

/+: OPERATE

MENU

**

DISPLAY : EXIT

SUB MENU 4. VSM PRESET

STANDARD

TINT

COLOUR

BRIGHT

PICTURE

DETAIL

MENU 89: SELECT

-

/+: OPERATE

MENU

10. AFCW

11. VSW

12. FFI

13. AGC

14. CL

15. AKB

16. HBL

17. BKS

18. READ STATUS

19. VNR

Setting item

**

**

**

**

**

DISPLAY : EXIT

Fig. 1

No. 52070 17

1. VER. SLOPE

2. VER. HEIGHT

3. VER. POSITION

4. VER. SCURVE

5. HOR. POSITION

6. HOR. WIDTH

BRIGHT / STD / SOFT

Setting item

1. TINT

2. COLOUR

3. BRIGHT

PICTURE

4.

5. DETAIL

20. PEAK

21. IVG

22. WPL

23. SOFT CLIPPER

24. IF PLL OFFSET

25. OVERSHOOT

26. HCO

27. HP2

28. AI VOLUME ADN

31. CCCLOOP

4 : 3 / 16 : 9

Setting item

7. EW-PIN

8. EW-TRAPEZ

9. UP CORNER

10. DW CORNER

11. HOR. PARALL

12. HOR. BOW

13. V. ZOOM

Page 18

AV-29W83 AV-29W93B

AV-29W93 AV-29W83B

ADJUSTMENTS

B1 POWER SUPPLY

Item

Measuring

instrument

Test point Adjustment part Description

Check of

B1 POWER

Signal

generator

SUPPLY

DC voltmeter

FOCUS ADJUSTMENT

Item

Adjustment

of FOCUS

Measuring

instrument

Signal

generator

B1 (pin 1)

GND (pin 5)

[CN00S

connector

1. Receive a black and white signal.

2. Connect a DC voltmeter between B1 and GND

(between pins 1 and 5 of the connector CN00S).

3. Make sure that the voltage is DC134.5 ± 2V.

in MAIN

PWB]

Test point Adjustment part Description

FOCUS VR

[In HVT]

Notes:

• Set PICTURE MODE (VSM) to “BRIGHT”.

• The final adjustment of CONVERGENCE must be done after the

FOCUS adjustment. (CONVERGENCE is changed by FOCUS adjustment.)

When makes difference by FOCUS adjustment, should be reconfirming

PURITY adjustment.

1. Receive a cross-hatch signal.

2. While looking at the screen centre, adjust the FOCUS VR so that

the vertical and horizontal lines will be clear and in fine detail.

3. Make sure that the picture is in focus even when the screen gets

darkened.

IF CIRCUIT ADJUSTMENTS

Item

Adjustment

of VCO (CW)

Adjustment

of DELAY

POINT

(AGC

TAKE-OVER)

(AGC TAKE-OVER)

Measuring

instrument

Remote

control unit

VCO (CW)

TOO HIGH

ABOVE REFERENCE

BELOW REFERENCE

TOO LOW

Remote

control unit

Setting Initial setting value

(Adjustment time) NTSC 3.58 OTHERS

DELAY POINT

Test point Adjustment part Description

. MHz

DISPLAY : EXIT

VCO (CW)

fv

YELLOW

DELAY POINT

2630

Note:

• Under normal conditions, no adjustment is required.

1. Select 1. IF from the SERVICE MENU.

2. Select 1. VCO by pressing the 1 key on the remote control unit.

3. Receive a broadcast signal.

4. Check the characters colour of the BELOW REFERENCE displayed

to yellow.

5. Press the DISPLAY key three times to return to normal screen.

1. Receive a black and white broadcast signal (colour off).

2. Select 1. IF from the SERVICE MENU.

3. Select 2. DELAY POINT by pressing the 2 key on the remote con-

trol unit.

4. Adjust the MENU

*/T

key in order to eliminate any noise or beat

from the image. Any increase above the initial value produces noise

and any decrease below it produces beat.

5. Press the DISPLAY key three times to return to the normal screen.

6. Turn to other channels and make sure that there are no irregularities.

18 No. 52070

Page 19

AV-29W83 AV-29W93B

AV-29W93 AV-29W83B

VC (VIDEO/CHROMA) CIRCUIT ADJUSTMENTS

The setting (adjustment) using the remote control unit is made on the basis of the initial setting values.

The setting values which adjust the screen to the optimum condition can be different from the initial setting values.

Do not change the initial setting values of the setting (adjustment) items not listed in “ADJUSTMENT”.

•

[SUB MENU 2. VC] : Do not adjust.

Setting (Adjustment)

item

Variable range

PAL SECAM NTSC3.58 NTSC4.43 COMPONENT (V-2)

1 CUT-OFF (R/G) -32 – +31 0/0 -2/+14

2 DRIVE (R/G/B) -32 – +31 0/0/0

3 BRIGHT (TV/V-1/V-2/V-3) -32 – +31 -13/0/0/+1 0/0/-1/0

4 CONT -32 – +31 -10 —

COLOUR *1

5

COLOUR (TV/VIDEO) *2 -4/— -13/— —/-11 —/+1 —/0

-32 – +31

TINT (TV/VIDEO) *1

6

TINT (TV/VIDEO) *2 — — —/+6 —/+1 —

-32 – +31

-4 -13 -11 +1 —

——-15/+2 —/+1 —

7 SHARP (TV/VIDEO) -32 – +31 -28/-22 —/0

8Y DELAY (TV/VIDEO) -8 – +7 -7/+1 0/+1 0/0 0/+1

9 AMP T. SHARP -32 – +31 0

Initial setting value

*1: AV-29W93/BK, AV-29W93B/BK, AV-29W83B/VT, AV-29W83/VT *2: AV-29W83/BK

Item

Adjustment

of WHITE

Measuring

instrument

Signal

generator

Test point Adjustment part Description

1. CUTOFF (R)

CUTOFF (G)

Note:

• Set PICTURE MODE (VSM) to “BRIGHT”.

BALANCE

(Low light)

Remote

control unit

SCREEN VR

[In HVT]

1. Receive a PAL black and white signal (colour off).

2. Select 2. VC from the SERVICE MENU.

3. Select 1. CUTOFF (R) and (G) with MENU &/^ key, and set each

value to initial setting value with the 4 and 7 keys, or 5 and 8 keys on

V/C

1. CUTOFF

50 Hz

MENU 89: SELECT

MENU

(R)

(G)

-

/+: OPERATE

PAL

**

**

DISPLAY : EXIT

the remote control unit.

4. Press the 1 key on the remote control unit to produce a single hori-

zontal line.

5. Tu rn the SCREEN VR fully counterclockwise, then slowly turn it clockwise to where a red, blue or green colour is faintly visible.

6. Use the keys 4 and 7 or 5 and 8 on the remote control unit and

adjust the other 2 colours to where the single horizontal line appears white.

7. Tu rn the SCREEN VR to where the single horizontal line glows faintly.

8. Press the 2 key to return to 1. CUTOFF screen.

9. Press the DISPLAY key twice to return to the normal screen.

Setting (Adjustment) Variable Initial setting

Item range value

1. CUT OFF

R –32 — +31 0

G –32 — +31 0

H.LINE OFF

H.LINE ON

R. LEVEL (

REMOTE CONTROL UNIT

12 3

4

8

)

56

G. LEVEL (8)

R. LEVEL (

789

)

9

G. LEVEL (

)

9

No. 52070 19

Page 20

AV-29W83 AV-29W93B

AV-29W93 AV-29W83B

Item

Adjustment

of WHITE

BALANCE

(High light)

R. DRIVE (

R. DRIVE (

Measuring

instrument

Signal

generator

Test point Adjustment part Description

2. DRIVE (R)

DRIVE (G)

DRIVE (B)

Remote

control

unit

(R)

(G)

(B)

PAL

**

**

**

DISPLAY : EXIT

V/C

2. DRIVE

50 Hz

MENU 89: SELECT

-

/+: OPERATE

MENU

REMOTE CONTROL UNIT

12 3

4

8

) B. DRIVE (8)

789

)

9

56

G. DRIVE (8)

B. DRIVE (

G.DRIVE (

Notes:

• Proceed to the following adjustment after having completed the adjustment of LOW LIGHT WHITE BALANCE.

• Set PICTURE MODE (VSM) to “BRIGHT”.

1. Receive a PAL black and white signal (colour off).

2. Select 2. VC from the SERVICE MENU.

3. Select 2. DRIVE (R), (G) and (B) with MENU &/^ key, and set

each value to initial setting value with the 4 to 9 keys on the remote

control unit.

4. Use the keys 4 to 9 to produce a white screen.

5. Press the DISPLAY key twice to return to the normal screen.

Setting (Adjustment) Variable Initial setting

Item range value

R –32 — +31 0

2. DRIVE G –32 — +31 0

B –32 — +31 0

)

9

)

9

Adjustment

of

SUB BRIGHT

Adjustment

of

SUB

CONTRAST

Remote

control unit

Remote

control unit

3. BRIGHT

4. CONT

Notes:

• Proceed to the following adjustment after having completed the adjustments of LOW LIGHT WHITE BALANCE and HIGH LIGHT WHITE

BALANCE.

• Set PICTURE MODE (VSM) to “BRIGHT”.

1. Receive a broadcast.

2. Select 2. VC from the SERVICE MENU.

3. Select 3. BRIGHT with the MENU &/^ key.

4. Set the initial setting value with the MENU

*/T

key.

5. If the brightness is not best with the initial setting value, make fine

adjustment until you get the best brightness.

6. Press the DISPLAY key twice to return to the normal screen.

Notes:

• Proceed to the following adjustment after having completed the adjustment of SUB BRIGHT.

• Set PICTURE MODE (VSM) to “BRIGHT”.

1. Receive a broadcast.

2. Select 2. VC from the SERVICE MENU.

3. Select 4. CONT with the MENU &/^ key.

4. Set the initial setting value with the MENU

*/T

key.

5. If the contrast is not best with the initial setting value, make fine

adjustment until you get the best contrast.

6. Press the DISPLAY key twice to return to the normal screen.

20 No. 52070

Page 21

AV-29W83 AV-29W93B

AV-29W93 AV-29W83B

Item

Adjustment

of

SUB

COLOUR-I

Measuring

instrument

Remote

control unit

Test point Adjustment part Description

5. COLOUR

[Method of adjustment without measuring instrument]

Notes:

• Proceed to the following adjustment after having completed the adjustment of SUB CONT.

• Set PICTURE MODE (VSM) to “BRIGHT”.

– PAL COLOUR –

1. Receive a PAL broadcast.

2. Select 2. VC from the SERVICE MENU.

3. Select 5. COLOUR with the MENU &/^ key.

4. Set the initial setting value for PAL COLOUR with the MENU

5. If the colour is not best with the initial setting value, make fine adjustment until you get the best colour.

6. Press the DISPLAY key twice to return to the normal screen.

– SECAM COLOUR –

7. Receive a SECAM broadcast.

8. Press the COLOUR SYSTEM button on the remote control unit to

select the SECAM colour system.

9. Make fine adjustment of SECAM COLOUR in the same way as for

“PAL COLOUR”.

– NTSC 3.58 COLOUR –

10. Receive a NTSC 3.58MHz broadcast.

11. Press the COLOUR SYSTEM button on the remote control unit to

select the NTSC 3.58 colour system.

12. Make similar fine adjustment of NTSC 3.58 COLOUR in the same

way as for “PAL COLOUR”.

– NTSC 4.43 COLOUR –

When adjustment is done for NTSC 3.58 COLOUR, appropriate

values are automatically set for NTSC 4.43 COLOUR.

*/T

key.

Adjustment

of

SUB

COLOUR-II

Signal

generator

Oscilloscope

Remote

control unit

Cy

Y

W

TP-47G

TP-E (H)

[CRT

SOCKET

PWB]

Mg

G

5. COLOUR [Method of adjustment using measuring instrument]

Notes:

• Proceed to the following adjustment after having completed the adjustment of SUB CONT.

• Set PICTURE MODE (VSM) to “BRIGHT”.

– PAL COLOUR –

1. Receive a PAL colour bar signal (full field colour bar 75% white).

2. Select 2. VC from the SERVICE MENU.

3. Select 5. COLOUR with the MENU &/^ key.

4.

Set the initial setting value of PAL COLOUR with the MENU */Tkey.

5. Connect the oscilloscope between TP-47G and TP-E.

6.

Adjust PAL COLOUR to set the value (A) in the figure to +14V (V

W-G

).

– SECAM COLOUR –

B

7. Receive a SECAM colour bar signal (full field colour bar 75% white).

8. Press the COLOUR SYSTEM button on the remote control unit to

R

(A)

(–)

0V

(+)

select the SECAM colour system.

9.

Set the initial setting value of SECAM COLOUR with the MENU */Tkey.

10. Adjust SECAM COLOUR to set the value (A) in the figure to +6V

(VW-G).

– NTSC 3.58 COLOUR –

11. Receive a NTSC 3.58 colour bar signal (full field colour bar 75% white).

12. Press the COLOUR SYSTEM button on the remote control unit to

select the NTSC 3.58 colour system.

13.

Set the initial setting value of NTSC 3.58 COLOUR with the MENU

*/Tkey.

14. Adjust NTSC 3.58 COLOUR to set the value (A) in the figure to

+3V (VW-G).

– NTSC 4.43 COLOUR –

When adjustment is done for NTSC 3.58 COLOUR, appropriate

values are automatically set for NTSC 4.43 COLOUR.

No. 52070 21

Page 22

AV-29W83 AV-29W93B

AV-29W93 AV-29W83B

Item

Adjustment

of

SUB TINT-I

Measuring

instrument

Signal

generator

Remote

control unit

Test point Adjustment part Description

6. TINT [Method of adjustment without measuring instrument]

Notes:

• Proceed to the following adjustment after having completed the adjustment of SUB CONT.

• Set PICTURE MODE (VSM) to “BRIGHT”.

– NTSC 3.58 TINT –

1. Receive a NTSC 3.58 colour bar signal (full field colour bar 75%

white).

2. Press the COLOUR SYSTEM button on the remote control unit to

select the NTSC 3.58 colour system.

3. Select 2. VC from the SERVICE MENU.

4. Select 6. TINT with the MENU &/^ key.

5. Set the initial setting value of NTSC 3.58 with the MENU

6. If you cannot get the best tint with the initial setting value, make fine

adjustment until you get the best tint.

7. Press the DISPLAY key twice to return to the normal screen.

– NTSC 4.43 TINT –

When adjustment is done for NTSC 3.58 TINT, appropriate values are

automatically set for NTSC 4.43 TINT.

*/T

key.

Adjustment

of

SUB TINT-II

Signal

generator

Oscilloscope

Remote

control unit

(B)

Cy

W

Y

TP-47G

TP-E (H)

[CRT

SOCKET

PWB]

B

Mg

R

G

6. TINT [Method of adjustment using measuring instrument]

Notes:

• Proceed to the following adjustment after having completed the adjustment of SUB CONT.

• Set PICTURE MODE (VSM) to “BRIGHT”.

– NTSC 3.58 TINT –

1. Receive a NTSC 3.58 colour bar signal (full field colour bar 75%

white).

2. Press the COLOUR SYSTEM button on the remote control unit to

select the NTSC 3.58 colour system.

3. Select 2. VC from the SERVICE MENU.

4. Select 6. TINT with the MENU &/^ key.

5. Set the initial setting value of NTSC 3.58 with the MENU

6. Connect the oscilloscope between TP-47G and TP-E.

(–)

0V

(+)

7.

Adjust NTSC 3.58 TINT to set the value (B) in the figure to +1V (V

8. Press the DISPLAY key twice to return to the normal screen.

– NTSC 4.43 TINT –

When adjustment is done for NTSC 3.58 TINT, appropriate values are

automatically set for NTSC 4.43 TINT.

*/T

key.

W-Cy

).

22 No. 52070

Page 23

AV-29W83 AV-29W93B

AV-29W93 AV-29W83B

DEFLECTION CIRCUIT ADJUSTMENTS

The setting (adjustment) using the remote control unit is made on the basis of the initial setting values.

The setting values which adjust the screen to the optimum condition can be different from the initial setting values.

Note:

Proceed to the following adjustment after having completed the adjustments of SUB BRIGHT and SUB PICTURE.

[SUB MENU 3. DEF]

Setting

(Adjustment)

item

Variable range

50Hz

4:3

60Hz

1. VER. SLOPE –32 — +31 +2 0 0 0 —

2. VER. HEIGHT –32 — +31 +31 0 –26 –29 —

3. VER. POSITION –32 — +31 –3 –1 –3 +2 —

4. VER. SCURVE –32 — +31 –10 0 –10 0 —

5. HOR. POSITION –32 — +31 0 +7 0 +7 +7

6. HOR. WIDTH –32 — +31 +11 –1 +11 –1 —

7. EW-PIN –32 — +31 –12 –1 –13 –12 —

8. EW-TRAPEZ –32 — +31 –4 0 0 –1 —

9. UP CORNER –32 — +31 –20 0 0 0 —

10. DW CORNER –32 — +31 –19 0 0 0 —

11. HOR. PARALL –32 — +31 0 0 0 0 —

12. HOR. BOW –32 — +31 0 0 0 0 —

13. V.ZOOM –32 — +31 –1 –1 +14 +14 —

Initial setting value

COMPRESS(16:9)

50Hz

60Hz

COMPONENT

DVD (50Hz)

[COMPRESS (16:9) : OFF, fv: 50Hz mode]

Item

Adjustment

of

Measuring

instrument

Signal

generator

Test point Adjustment part Description

V. SLOPE

Remote

control unit

A

B

Adjustment

of

Signal

generator

V. POSITION

Remote

control unit

1. VER. SLOPE 1. Receive a PAL circle pattern signal of vertical frequency 50Hz.

2. Select 3. DEF from the SERVICE MENU.

3. Select 1. VER. SLOPE with the MENU &/^ key.

4. Set the initial setting value of 1. VER. SLOPE with the MENU

*/T

key.

5. Adjust 1. VER. SLOPE to make “A = B” with the MENU

Blanking

line

*/T

3. VER. POSITION 6. Select 3. VER. POSITION with the MENU &/^ key.

7. Set the initial setting value of 3. VER. POSITION with the MENU

*/T

key.

8. Adjust 3. VER. POSITION to make “A = B” with the MENU

A

*/T

key.

key.

(to be continued)

B

No. 52070 23

Page 24

AV-29W83 AV-29W93B

AV-29W93 AV-29W83B

Item

Adjustment

of

V. HEIGHT

Screen

size

91%

Adjustment

of

H. POSITION

Measuring

instrument

Signal

generator

Remote

control unit

Signal

generator

Remote

control unit

Test point Adjustment part Description

2. VER. HEIGHT

13. V. ZOOM

9. Receive a PAL cross-hatch signal.

10. Select 2. VER. HEIGHT with the MENU &/^ key.

11. Set the initial setting value of 2. VER. HEIGHT with the MENU

*/T

key.

12. Select 13. V. ZOOM with the MENU &/^ key.

13. Set the initial setting value of 13. V. ZOOM with the MENU

14. Adjust 13. V. ZOOM and make the vertical screen size 91% of the

picture size with the MENU

Picture

size

100%

*/T

key.

5. HOR. POSITION 15. Receive a PAL circle pattern signal.

16. Select 5. HOR. POSITION with the MENU &/^ key.

17.

Set the initial setting value of 5. HOR. POSITION with the MENU

*/T

key.

18. Adjust 5. HOR POSITION to make “C=D” with the MENU

*/T

*/T

key.

key.

Adjustment

of

H. WIDTH

CD

Signal

6. HOR. WIDTH 19. Receive a PAL cross-hatch signal.

generator

Remote

control unit

Screen size 91%

20. Select 6. HOR. WIDTH with the MENU &/^ key.

21. Set the initial setting value of 6. HOR. WIDTH with the MENU

*/T

key.

22. Adjust 6. HOR. WIDTH and make the horizontal screen size 91%

of the picture size with the MENU

*/T

key.

(to be continued)

Picture size 100%

24 No. 52070

Page 25

AV-29W83 AV-29W93B

AV-29W93 AV-29W83B

Item

Adjustment

of

SIDE PIN

Adjustment

of

TRAPEZIUM

Measuring

instrument

Signal

generator

Remote

control unit

Signal

generator

Remote

control unit

Test point Adjustment part Description

7. EW-PIN 23. Select 7. EW-PIN with the MENU &/^ key.

24. Set the initial setting value of 7. EW-PIN with the MENU

25. Adjust 7. EW-PIN so that the first vertical lines at the left and right

edges on the screen are straight.

Straight

8. EW-TRAPEZ 26. Select 8. EW-TRAPEZ with the MENU &/^ key.

27. Set the initial setting value of 8. EW-TRAPEZ with the MENU

*/T

key.

28. Adjust 8. EW-TRAPEZ so that the vertical lines at the left and right

edges on the screen are in parallel.

*/T

key.

Adjustment

of

V.S-CURVE

Signal

generator

Remote

control unit

Parallel

4. VER. SCURVE 29. Select 4. VER. SCURVE with the MENU &/^ key.

30. Set the initial setting value of 4. VER. SCURVE with the MENU

*/T

key.

31. Adjust 4. VER. SCURVE so that the spaces of each line on TOP,

CENTRE and BOTTOM become uniform.

TOP

CENTRE

(to be continued)

BOTTOM

No. 52070 25

Page 26

AV-29W83 AV-29W93B

AV-29W93 AV-29W83B

Item

Adjustment

of

CORNER

Adjustment

of

H. PARALLEL

Measuring

instrument

Signal

generator

Remote

control unit

Signal

generator

Remote

control unit

Test point Adjustment part Description

9. UP CORNER

10. DW CORNER

11. HOR. PARALL 37. Select 11. HOR. PARALL with the MENU &/^ key.

32. Select 9. UP CORNER with the MENU &/^ key.

33. Set the initial setting value of 9. UP CORNER with the MENU

*/T

key.

34. Select 10. DW CORNER with the MENU &/^ key.

35. Set the initial setting value of 10. DW CORNER with the MENU

*/T

key.

36. Adjust 9. UP CORNER and 10. DW CORNER so that the vertical

lines at the four corners on the screen are straight.

38. Set the initial setting value of 11. HOR. PARALL with the MENU

*/T

key.

39. Adjust 11. HOR. PARALL to optimize the parallelogram distortion.

Adjustment

of

H. BOW

Signal

generator

Remote

control unit

Straight

12. HOR. BOW 40. Select 12. HOR. BOW with the MENU &/^ key.

41. Set the initial setting value of 12. HOR. BOW with the MENU

T

key.

42. Adjust 12. HOR. BOW to optimize the horizontal arc distortion.

43. Press the DISPLAY key twice to return to the normal screen.

*/

26 No. 52070

Page 27

[COMPRESS (16 : 9) : OFF, fv: 60Hz mode ]

Item

Measuring

instrument

Test point Adjustment part Description

AV-29W83 AV-29W93B

AV-29W93 AV-29W83B

Adjustment

of

V. SLOPE

Signal

generator

Remote

control unit

1. VER. SLOPE 1. Receive a NTSC circle pattern signal of vertical frequency 60Hz.

2. Select 3. DEF from the SERVICE MENU.

3. Select 1. VER. SLOPE with the MENU &/^ key.

4. Set the initial setting value of 1. VER. SLOPE with the MENU

*/T

key.

*/T

5. Adjust 1. VER. SLOPE to make “A = B” with the MENU

A

Blanking

line

B

key.

Adjustment

of

V. POSITION

Signal

generator

Remote

control unit

3. VER. POSITION 6. Select 3. VER. POSITION with the MENU &/^ key.

7. Set the initial setting value of 3. VER. POSITION with the MENU

*/T

key.

8. Adjust 3. VER. POSITION to make “A = B” with the MENU

A

(to be continued)

B

*/T

key.

No. 52070 27

Page 28

AV-29W83 AV-29W93B

AV-29W93 AV-29W83B

Item

Adjustment

of

V. HEIGHT

Screen

size

91%

Adjustment

of

H. POSITION

Measuring

instrument

Signal

generator

Remote

control unit

Signal

generator

Remote

control unit

Test point Adjustment part Description

2. VER. HEIGHT

13. V. ZOOM

9. Receive a NTSC cross-hatch signal.

10. Select 2. VER. HEIGHT with the MENU &/^ key.

11. Set the initial setting value of 2. VER. HEIGHT with the MENU

*/T

key.

12. Select 13. V. ZOOM with the MENU &/^ key.

13. Set the initial setting value of 13. V. ZOOM with the MENU

14. Adjust 13. V. ZOOM and make the vertical screen size 91% of the

picture size with the MENU

Picture

size

100%

*/T

key.

5. HOR. POSITION 15. Receive a NTSC circle pattern signal.

16. Select 5. HOR. POSITION with the MENU &/^ key.

17.

Set the initial setting value of 5. HOR. POSITION with the MENU

*/T

key.

18. Adjust 5. HOR POSITION to make “C=D” with the MENU

*/T

*/T

key.

key.

Adjustment

of

H. WIDTH

CD

Signal

6. HOR. WIDTH 19. Receive a NTSC cross-hatch signal.

generator

Remote

control unit

Screen size 91%

20. Select 6. HOR. WIDTH with the MENU &/^ key.

21. Set the initial setting value of 6. HOR. WIDTH with the MENU

*/T

key.

22. Adjust 6. HOR. WIDTH and make the horizontal screen size 91%

of the picture size with the MENU

*/T

key.

(to be continued)

Picture size 100%

28 No. 52070

Page 29

AV-29W83 AV-29W93B

AV-29W93 AV-29W83B

Item

Adjustment

of

SIDE PIN

Adjustment

of

TRAPEZIUM

Measuring

instrument

Signal

generator

Remote

control unit

Signal

generator

Remote

control unit

Test point Adjustment part Description

7. EW-PIN 23. Select 7. EW-PIN with the MENU &/^ key.

24. Set the initial setting value of 7. EW-PIN with the MENU

25. Adjust 7. EW-PIN so that the first vertical lines at the left and right

edges on the screen are straight.

Straight

8. EW-TRAPEZ 26. Select 8. EW-TRAPEZ with the MENU &/^ key.

27. Set the initial setting value of 8. EW-TRAPEZ with the MENU

*/T

key.

28. Adjust 8. EW-TRAPEZ so that the vertical lines at the left and right

edges on the screen are in parallel.

*/T

key.

Adjustment

of

V.S-CURVE

Signal

generator

Remote

control unit

Parallel

4. VER. SCURVE 29. Select 4. VER. SCURVE with the MENU &/^ key.

30. Set the initial setting value of 4. VER. SCURVE with the MENU

*/T

key.

31. Adjust 4. VER. SCURVE so that the spaces of each line on TOP,

CENTRE and BOTTOM become uniform.

TOP

CENTRE

(to be continued)

BOTTOM

No. 52070 29

Page 30

AV-29W83 AV-29W93B

AV-29W93 AV-29W83B

Item

Adjustment

of

CORNER

Adjustment

of

H. PARALLEL

Measuring

instrument

Signal

generator

Remote

control unit

Signal

generator

Remote

control unit

Test point Adjustment part Description

9. UP CORNER

10. DW CORNER

11. HOR. PARALL 37. Select 11. HOR. PARALL with the MENU &/^ key.

32. Select 9. UP CORNER with the MENU &/^ key.

33. Set the initial setting value of 9. UP CORNER with the MENU

*/T

key.

34. Select 10. DW CORNER with the MENU &/^ key.

35. Set the initial setting value of 10. DW CORNER with the MENU

*/T

key.

36. Adjust 9. UP CORNER and 10. DW CORNER so that the vertical

lines at the four corners on the screen are straight.

38. Set the initial setting value of 11. HOR. PARALL with the MENU

*/T

key.

39. Adjust 11. HOR. PARALL to optimize the parallelogram distortion.

Adjustment

of

H. BOW

Signal

generator

Remote

control unit

Straight

12. HOR. BOW 40. Select 12. HOR. BOW with the MENU &/^ key.

41. Set the initial setting value of 12. HOR. BOW with the MENU

T

key.

42. Adjust 12. HOR. BOW to optimize the horizontal arc distortion.

43. Press the DISPLAY key twice to return to the normal screen.

*/

30 No. 52070

Page 31

[COMPRESS (16 : 9) : ON, fv: 50Hz mode ]

Item

Measuring

instrument

Test point Adjustment part Description

AV-29W83 AV-29W93B

AV-29W93 AV-29W83B

Adjustment

of

V. HEIGHT

Screen

size

Signal

generator

Remote

control unit

Screen size

13. V. ZOOM

2. VER. HEIGHT

Vertical

amplitude

1. Receive a PAL cross-hatch signal of vertical frequency 50Hz.

2. Select COMPRESS from the MENU and set COMPRESS to ON.

3. Select 3. DEF from the SERVICE MENU.

4. Set the initial setting value of 13. V. ZOOM with the MENU

*/T

key.

5. Select 2. VER. HEIGHT with the MENU &/^ key.

6. Set the initial setting value of 2. VER. HEIGHT with the MENU

*/T

key.

7. Adjust 2. VER. HEIGHT to set the vertical amplitude of the image to

305mm.

Adjustment

of

V. SLOPE

Signal

generator

Remote

control unit

1. VER. SLOPE 8. Receive a PAL circle pattern signal of vertical frequency 50Hz.

9. Select 3. DEF from the SERVICE MENU.

10. Select 1. VER. SLOPE with the MENU &/^ key.

11. Set the initial setting value of 1. VER. SLOPE with the MENU

*/T

key.

12. Adjust 1. VER. SLOPE to make “A = B” with the MENU

A

Blanking

line

B

(to be continued)

*/T

key.

No. 52070 31

Page 32

AV-29W83 AV-29W93B

AV-29W93 AV-29W83B

Item

Adjustment

of

SIDE PIN

Adjustment

of

TRAPEZIUM

Measuring

instrument

Signal

generator

Remote

control unit

Signal

generator

Remote

control unit

Test point Adjustment part Description

7. EW-PIN 13. Receive a PAL cross-hatch signal.

14. Select 7. EW-PIN with the MENU &/^ key.

15. Set the initial setting value of 7. EW-PIN with the MENU

16. Adjust 7. EW-PIN so that the first ver tical lines at the left and right

edges on the screen are straight.

Straight

8. EW-TRAPEZ 17. Select 8. EW-TRAPEZ with the MENU &/^ key.

18. Set the initial setting value of 8. EW-TRAPEZ with the MENU

*/T

key.

19. Adjust 8. EW-TRAPEZ so that the vertical lines at the left and right

edges on the screen are in parallel.

*/T

key.

Adjustment

of

CORNER

Signal

generator

Remote

control unit

Parallel

9. UP CORNER

10. DW CORNER

20. Select 9. UP CORNER with the MENU &/^ key.

21. Set the initial setting value of 9. UP CORNER with the MENU

*/T

key.

22. Select 10. DW CORNER with the MENU &/^ key.

23. Set the initial setting value of 10. DW CORNER with the MENU

*/T

key.

24. Adjust 9. UP CORNER and 10. DW CORNER so that the vertical

lines at the four corners on the screen are straight.

25. Press the DISPLAY key twice to return to the normal screen.

32 No. 52070

Page 33

[COMPRESS (16 : 9) : ON, fv: 60Hz mode ]

Item

Measuring

instrument

Test point Adjustment part Description

AV-29W83 AV-29W93B

AV-29W93 AV-29W83B

Adjustment

of

V. HEIGHT

Screen

size

Signal

generator

Remote

control unit

Screen size

13. V. ZOOM

2. VER. HEIGHT

Vertical

amplitude

1. Receive a NTSC cross-hatch signal of vertical frequency 60Hz.

2. Select COMPRESS from the MENU and set COMPRESS to ON.

3. Select 3. DEF from the SERVICE MENU.

4. Set the initial setting value of 13. V. ZOOM with the MENU

*/T

key.

5. Select 2. VER. HEIGHT with the MENU &/^ key.

6. Set the initial setting value of 2. VER. HEIGHT with the MENU

*/T

key.

7. Adjust 2. VER. HEIGHT to set the vertical amplitude of the image to

305mm.

Adjustment

of

V. SLOPE

Signal

generator

Remote

control unit

1. VER. SLOPE 8. Receive a NTSC circle pattern signal of vertical frequency 60Hz.

9. Select 3. DEF from the SERVICE MENU.

10. Select 1. VER. SLOPE with the MENU &/^ key.

11. Set the initial setting value of 1. VER. SLOPE with the MENU

*/T

key.

12. Adjust 1. VER. SLOPE to make “A = B” with the MENU

A

Blanking

line

B

*/T

key.

(to be continued)

No. 52070 33

Page 34

AV-29W83 AV-29W93B

AV-29W93 AV-29W83B

Item

Adjustment

of

SIDE PIN

Adjustment

of

TRAPEZIUM

Measuring

instrument

Signal

generator

Remote

control unit

Signal

generator

Remote

control unit

Test point Adjustment part Description

7. EW-PIN 13. Receive a NTSC cross-hatch signal.

14. Select 7. EW-PIN with the MENU &/^ key.

15. Set the initial setting value of 7. EW-PIN with the MENU

16. Adjust 7. EW-PIN so that the first ver tical lines at the left and right

edges on the screen are straight.

Straight

8. EW-TRAPEZ 17. Select 8. EW-TRAPEZ with the MENU &/^ key.

18. Set the initial setting value of 8. EW-TRAPEZ with the MENU

*/T

key.

19. Adjust 8. EW-TRAPEZ so that the vertical lines at the left and right

edges on the screen are in parallel.

*/T

key.

Adjustment

of

CORNER

Signal

generator

Remote

control unit

Parallel

9. UP CORNER

10. DW CORNER

20. Select 9. UP CORNER with the MENU &/^ key.

21. Set the initial setting value of 9. UP CORNER with the MENU

*/T

key.

22. Select 10. DW CORNER with the MENU &/^ key.

23. Set the initial setting value of 10. DW CORNER with the MENU

*/T

key.

24. Adjust 9. UP CORNER and 10. DW CORNER so that the vertical

lines at the four corners on the screen are straight.

25. Press the DISPLAY key twice to return to the normal screen.

34 No. 52070

Page 35

[VIDEO - 2 SET : COMPONENT, fv: 50/60Hz mode]

VSM preset

VSM mode BRIGHT STANDARD SOFT

Setting item

1. TINT

SETTING VALUE

2. COLOUR

SETTING VALUE

3. BRIGHT

SETTING VALUE

4. PICTURE

30

15

15

15

15 7

15 11

SETTING VALUE

5. DETAIL

SETTING VALUE

[Setting Values for SUB MENU 4. VSM PRESET]

Item

Measuring

instrument

Test point Adjustment part Description

AV-29W83 AV-29W93B

AV-29W93 AV-29W83B

Adjustment

of

H. POSITION

Signal

5. HOR. POSITION 1. Receive a PAL circle pattern signal to VIDEO-2 terminal.

generator

Remote

control unit

CD

2. Select VIDEO-2 SET from the MENU and set VIDEO-2 SET to

COMPONENT.

3. Select 3. DEF from the SERVICE MENU.