Page 1

SERVICE MANUAL

COLOUR TELEVISION

AV-29LS2

AV-29LX2

AV-2968TEE

BASIC CHASSIS

CH

AV-29LS2

AV-29LX2

POWER

MUTING

SYSTEM

COLOUR SOUND

ECO

SENSOR

DISPLAY

MENU

TV/TEXT

I/II

TV/VIDEO

123

OFF

TIMER

456

PICTURE

MODE

789

CHANNEL

RETURN+

SCAN

--

0-/

CHANNEL

VOLUME

TEXT

HOLD

INDEX

SIZE

REVEAL

SUBPAGE CANCEL

STORE MODE

TV

RM-C1020

RM-C1020-1H

[AV-29LS2]

RM-C1024-1H

[AV-29LX2]

[AV-29LX2

MUTING

SYSTEM

COLOUR SOUND

DISPLAY

TV/VIDEO

OFF

TIMER

PICTURE

MODE

CHANNEL

SCAN

CHANNEL

MENU

123

456

789

RETURN+

0-/

VOLUME

RM-C1024

TV

POWER

ECO

SENSOR

--

RM-C1023-1H

[AV-2968TEE]

/A

]

MUTING

SYSTEM

COLOUR SOUND

DISPLAY

MENU

TV/VIDEO

123

OFF

TIMER

456

PICTURE

MODE

789

CHANNEL

RETURN+

SCAN

0-/

VOLUME

CHANNEL

TEXT

REVEAL

INDEX

HOLD

SUBPAGE CANCEL

STORE MODE

RM-C1023

AV-29LX2 /A

AV-2968TEE

POWER

ECO

SENSOR

TV/TEXT

--

SIZE

TV

CONTENTS

a SPECIFICATIONS....................................................................................................................................2

a OPERATING INSTRUCTIONS (APPENDIX)

a SAFETY PRECAUTIONS ........................................................................................................................3

a FEATURES ..............................................................................................................................................4

a FUNCTIONS.............................................................................................................................................5

a SPECIFIC SERVICE INSTRUCTIONS ....................................................................................................6

a SERVICE ADJUSTMENTS....................................................................................................................14

a STANDARD CIRCUIT DIAGRAM (APPENDIX) .................................................................................. 2-1

a PARTS LIST ...........................................................................................................................................41

COPYRIGHT © 2002 VICTOR COMPANY OF JAPAN, LTD.

No. 52062

Sep. 2002

Page 2

AV-29LS2

AV-29LX2

AV-2968TEE

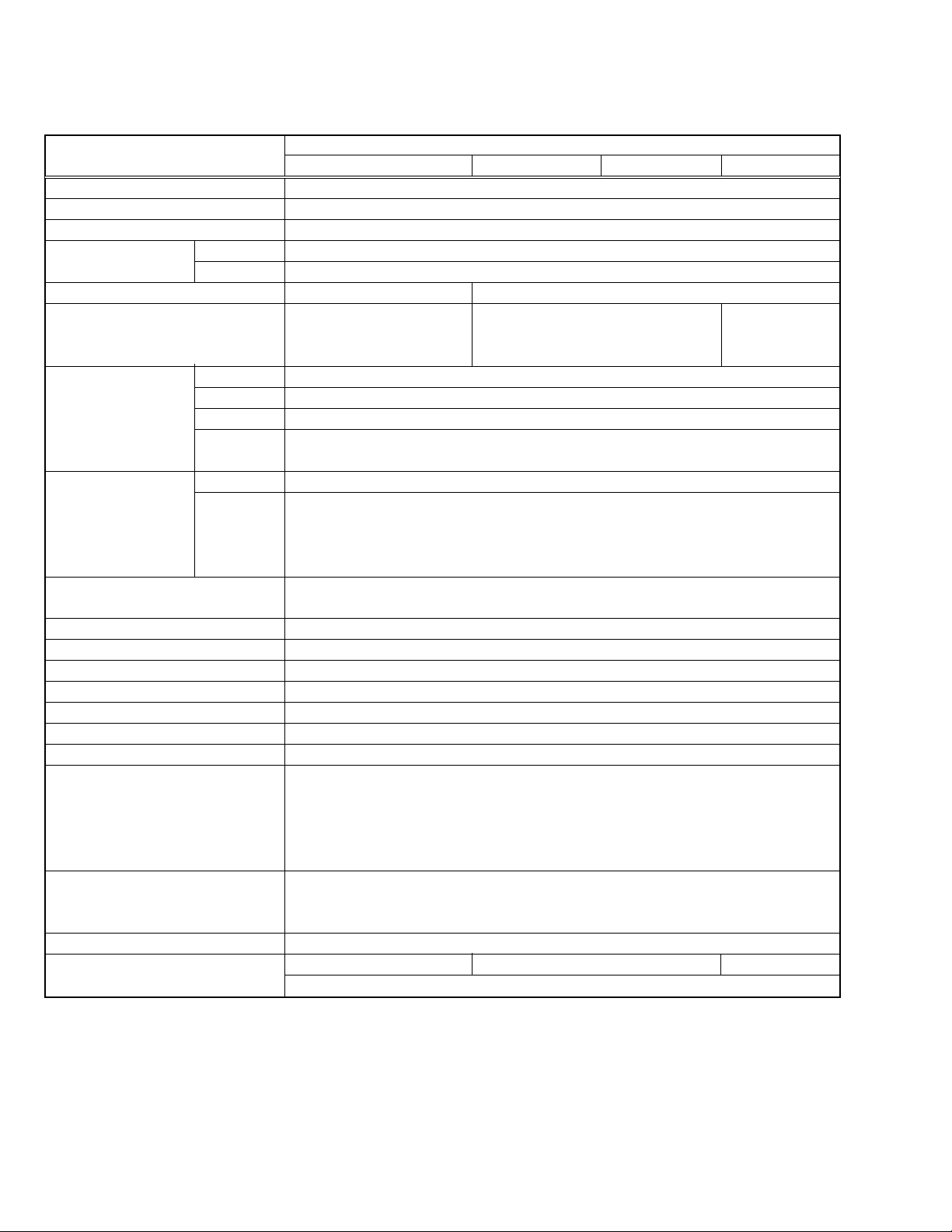

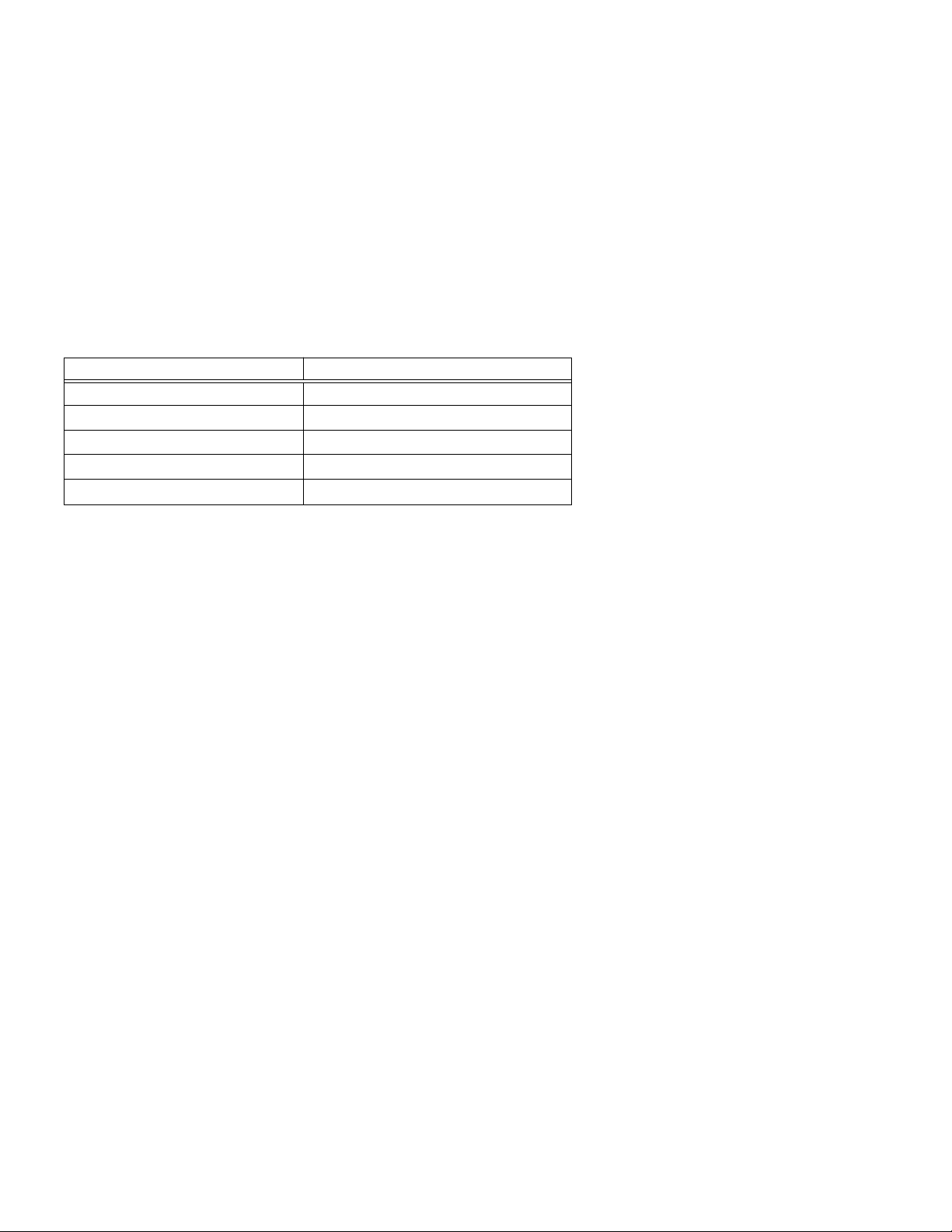

SPECIFICATIONS

Items

AV-29LS2 AV-29LX2 AV-29LX2/A

Dimensions (W × H × D)

Mass 47kg

TV RF System B, G, I, D, K, K1, M

Colour System TV Mode PAL / SECAM / NTSC3.58 / NTSC4.43

VIDEO Mode PAL / SECAM / NTSC3.58 / NTSC4.43

Stereo system A2 / NICAM (B/G, I, D/K) system Playback only

Teletext system

FLOF(Fastext), Q — Q

WST(World Standard Text)

Receiving Frequency VHF (VL) 46.25MHz – 140.25MHz (AS0 – S6)

VHF (VH) 147.25MHz – 423.25MHz (S7 – S36)

UHF 431.25MHz – 863.25MHz (S37 – CHINA 57)

CATV ● Cable TVs of Mid (X-Z, S1-S10)

Intermediate VIF Carrier 38.0MHz

Frequency 31.5MHz (6.5MHz)

SIF Carrier 32.0MHz (6.0MHz)

Colour Sub Carrier Frequency PAL (4.43MHz), SECAM (4.40625MHz / 4.25MHz)

Aerial Input Terminal 75Ø Unbalanced

Power Input AC110 – 240V, 50 / 60Hz

Power Consumption 175W

Picture T ube Visible size : 68cm measured diagonally

High V oltage 32.0kV +1/ – 1.5kV (at cut-off in service mode)

Speaker 5 × 12cm Oval type ×2

Audio Output 7W + 7W

Video / Audio Input (1 / 2 / 3) Video(1,3) : 1Vp-p, 75Ø (RCA pin jack)

Video/Audio Output 1Vp-p, 75Ø (RCA pin jack)

Headphone Jack Stereo mini jack (3.5φ)

Remote Control Unit RM-C1020-1H RM-C1024-1H RM-C1023-1H

73.2cm × 58.8cm × 51.8cm

Super (S11-S20) & Hyper (S21-S41) bands receivable

32.5MHz (5.5MHz)

33.5MHz (4.5MHz)

NTSC (3.58MHz / 4.43MHz)

(Max.)

/ 116W

(Avg.)

Audio(1,2,3) : 500mVrms ( -4dBs ), High Impedance (RCA pin jack)

Component Input ( Input 2 )

Y:1Vp-p positive (negative sync provided, when terminated with 75Ø)

CB/CR :0.7Vp-p 75Ø

500mVrms(-4dBs)

Low impedance (400Hz when modulated 100%) (RCA pin jack)

(Battery size: AA/R06/UM-3 × 2)

Contents

AV-2968TEE

Design & specifications are subject to change without notice.

2No. 52062

Page 3

SAFETY PRECAUTIONS

AC VOLTMETER

(HAVING 1000Ω/V,

OR MORE SENSITIVITY)

PLACE THIS PROBE

ON EACH EXPOSED

METAL PART

1500Ω 10W

0.15µF AC-TYPE

GOOD EARTH GROUND

1. The design of this product contains special hardware, many circuits

and components specially for safety purposes. For continued protection, no changes should be made to the original design unless

authorized in writing by the manufacturer. Replacement parts must

be identical to those used in the original circuits. Service should be

performed by qualified personnel only.

2. Alterations of the design or circuitry of the products should not be

made. Any design alterations or additions will void the manufacturer's warranty and will further relieve the manufacturer of responsibility for personal injury or property damage resulting therefrom.

3. Many electrical and mechanical parts in the products have special

safety-related characteristics. These characteristics are often not

evident from visual inspection nor can the protection afforded by

them necessarily be obtained by using replacement components

rated for higher voltage , wattage, etc. Replacement parts which have

these special safety characteristics are identified in the parts list of

Service manual. Electrical components having such features are

identified by shading on the schematics and by (!) on the parts

list in Service manual. The use of a substitute replacement which

does not have the same safety char acteristics as the recommended

replacement part shown in the parts list of Ser vice manual may

cause shock, fire, or other hazards.

4. Don't short between the LIVE side ground and ISOLA TED (NEU-

TRAL) side ground or EARTH side ground when repairing.

Some model's power circuit is partly different in the GND . The diff erence of the GND is shown by the LIVE : (

LA TED (NEUTRAL) : (

Don't short between the LIVE side GND and ISOLA TED (NEUTRAL)

side GND or EARTH side GND and never measure the LIVE side

GND and ISOLATED (NEUTRAL) side GND or EARTH side GND

at the same time with a measuring apparatus (oscilloscope etc.).

If above note will not be kept, a fuse or any parts will be broken.

5. If any repair has been made to the chassis, it is recommended that

the B1 setting should be checked or adjusted (See ADJUSTMENT

OF B1 POWER SUPPLY).

6. The high voltage applied to the picture tube must conf orm with that

specified in Service manual. Excessive high voltage can cause an

increase in X-Ray emission, arcing and possible component damage, therefore operation under excessive high voltage conditions

should be kept to a minimum, or should be prevented. If severe

arcing occurs, remove the AC power immediately and determine

the cause by visual inspection (incorrect installation, cracked or

melted high voltage harness, poor soldering, etc.). To maintain the

proper minimum level of soft X-Ray emission, components in the

high voltage circuitry including the picture tube must be the exact

replacements or alternatives approved by the manufacturer of the

complete product.

) side GND and EAR TH : ( ) side GND .

) side GND, the ISO-

AV-29LS2

AV-29LX2

AV-2968TEE

8. When service is required, observe the original lead dress. Extra

precaution should be given to assure correct lead dress in the high

voltage circuit area. Where a short circuit has occurred, those components that indicate evidence of overheating should be replaced.

Always use the manufacturer's replacement components.

9. Isolation Check

(Safety for Electrical Shock Hazard)

After re-assembling the product, always perf orm an isolation check

on the exposed metal parts of the cabinet (antenna terminals, video/

audio input and output terminals, Control knobs, metal cabinet, screw

heads, earphone jack, control shafts, etc.) to be sure the product is

safe to operate without danger of electrical shock.

(1)Dielectric Strength Test

The isolation between the AC primary circuit and all metal parts

exposed to the user, particularly any exposed metal part having a

return path to the chassis should withstand a voltage of 3000V AC

(r.m.s.) for a period of one second.

(. . . . Withstand a v oltage of 1100V AC (r .m.s .) to an appliance rated

up to 120V, and 3000V AC (r.m.s.) to an appliance rated 200V or

more, for a period of one second.)

This method of test requires a test equipment not generally found in

the service trade.

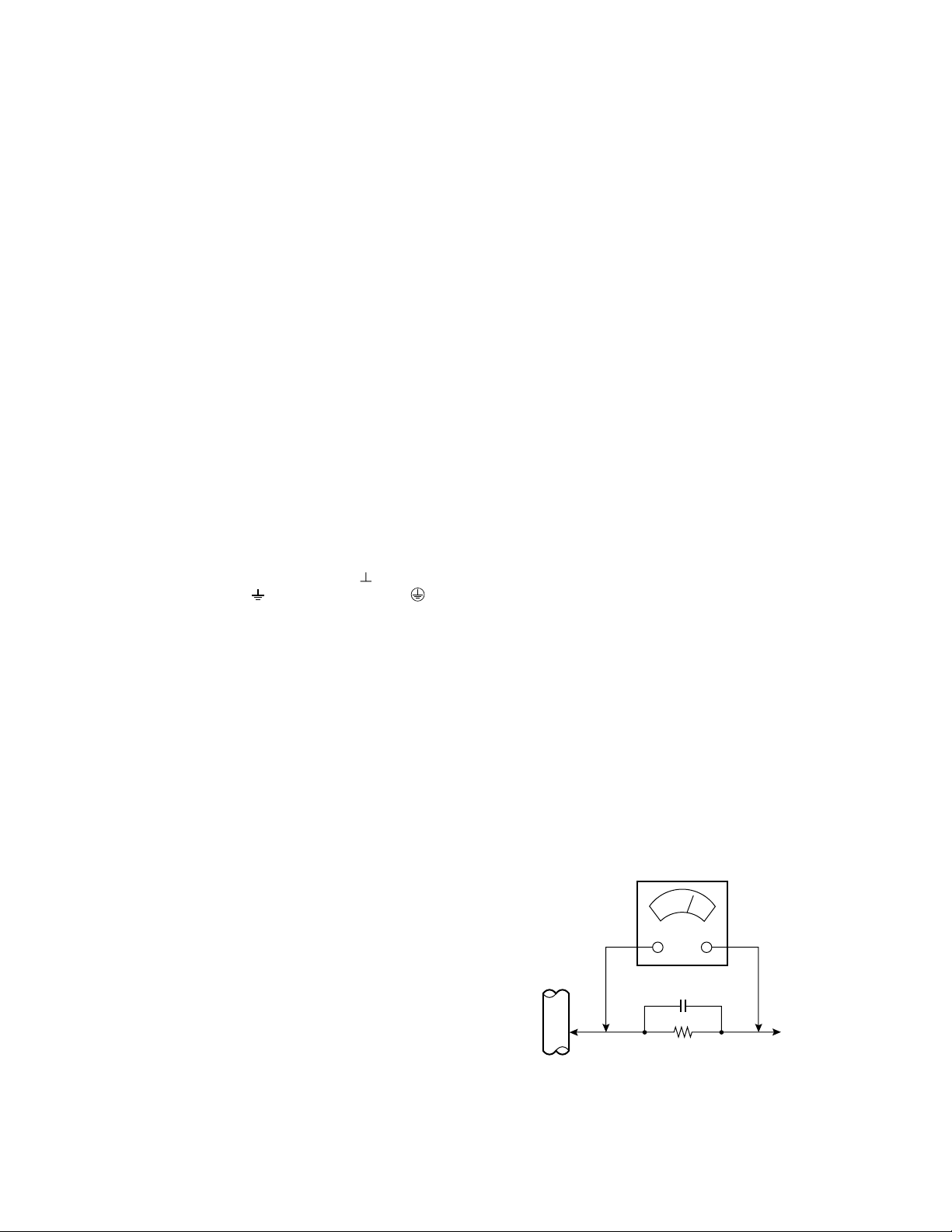

(2)Leakage Current Check

Plug the AC line cord directly into the AC outlet (do not use a line

isolation transformer during this check.). Using a "Leakage Current

Tester", measure the leakage current from each exposed metal part

of the cabinet, particularly any exposed metal part having a return

path to the chassis, to a known good earth ground (water pipe, etc.).

Any leakage current must not exceed 0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.2mA AC (r.m.s.).

● Alternate Check Method

Plug the AC line cord directly into the AC outlet (do not use a line

isolation transformer during this check.). Use an AC voltmeter having 1000 ohms per volt or more sensitivity in the following manner.

Connect a 1500Ø 10W resistor paralleled by a 0.15µF AC-type capacitor between an exposed metal part and a known good earth

ground (water pipe, etc.). Measure the A C v oltage across the resistor with the AC voltmeter. Move the resistor connection to each exposed metal part, particularly any exposed metal part having a return path to the chassis, and measure the AC voltage across the

resistor. Now, reverse the plug in the AC outlet and repeat each

measurement. Any voltage measured must not exceed 0.75V AC

(r.m.s.). This corresponds to 0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.3V AC (r.m.s.).

This corresponds to 0.2mA AC (r.m.s.).

7. Do not check high voltage by drawing an arc. Use a high voltage

meter or a high voltage probe with a VTVM. Discharge the picture

tube before attempting meter connection, by connecting a clip lead

to the ground frame and connecting the other end of the lead through

a 10kØ 2W resistor to the anode button.

No. 52062 3

Page 4

AV-29LS2

AV-29LX2

AV-2968TEE

FEATURES

s New chassis design enables use of an interactive on-screen control.

s Pure flat CRT produces fine textured picture in every detail.

s Wide range voltage (110V ~ 240V) for AC power input.

s With AUDIO/VIDEO/COMPONENT input terminals.

2

s I

C bus control utilizes single chip ICs.

s By means of AUTO PROGRAM, the TV stations can be selected

automatically and the TV channels can also be rearranged automatically.

s Built-in DIGITAL ECO MODE (ECONOMY, ECOLOGY).

In accordance with the brightness in a room, the brightness and/or

contrast of the picture can be adjusted automatically to make the

optimum picture which is easy on the eye.

s Built-in OFF TIMER & RETURN +.

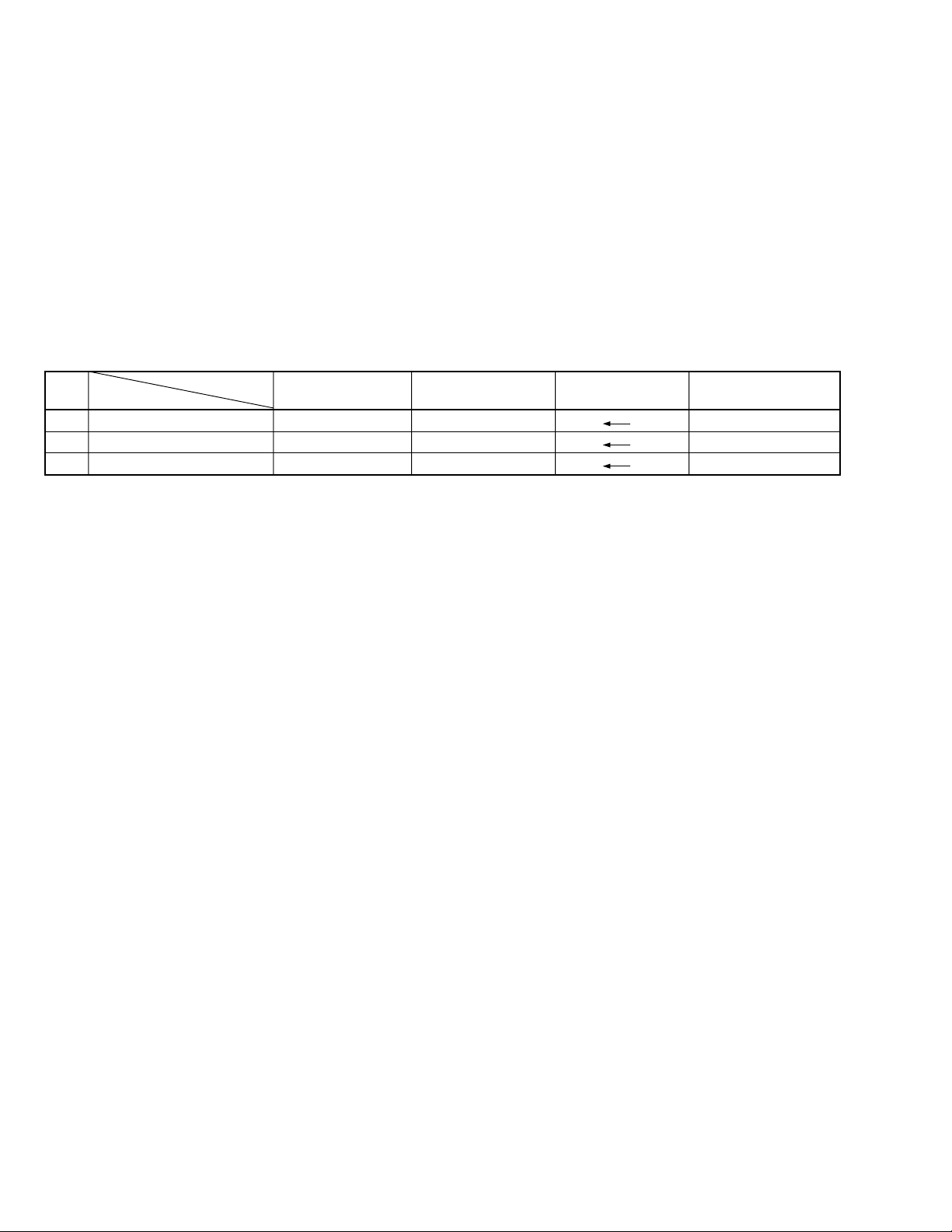

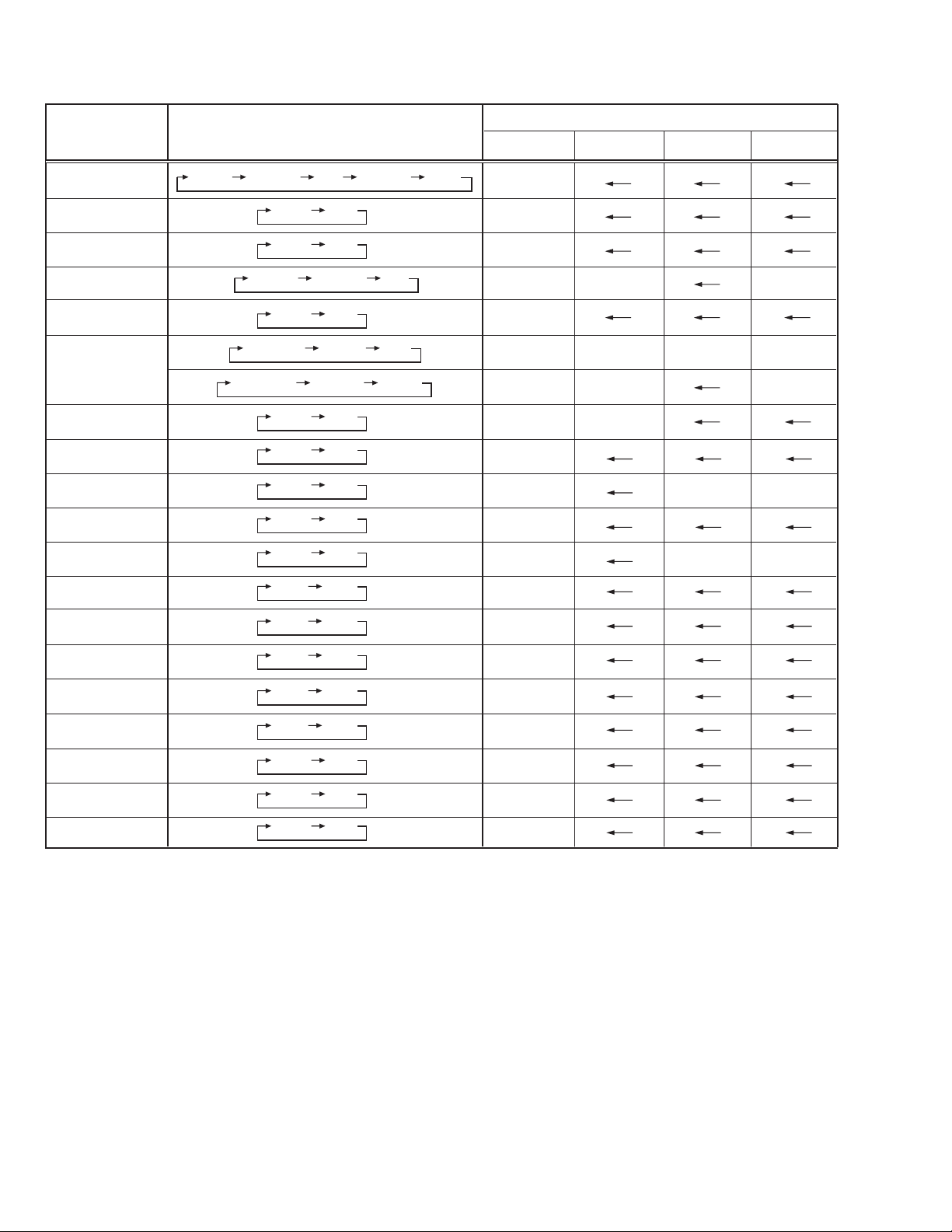

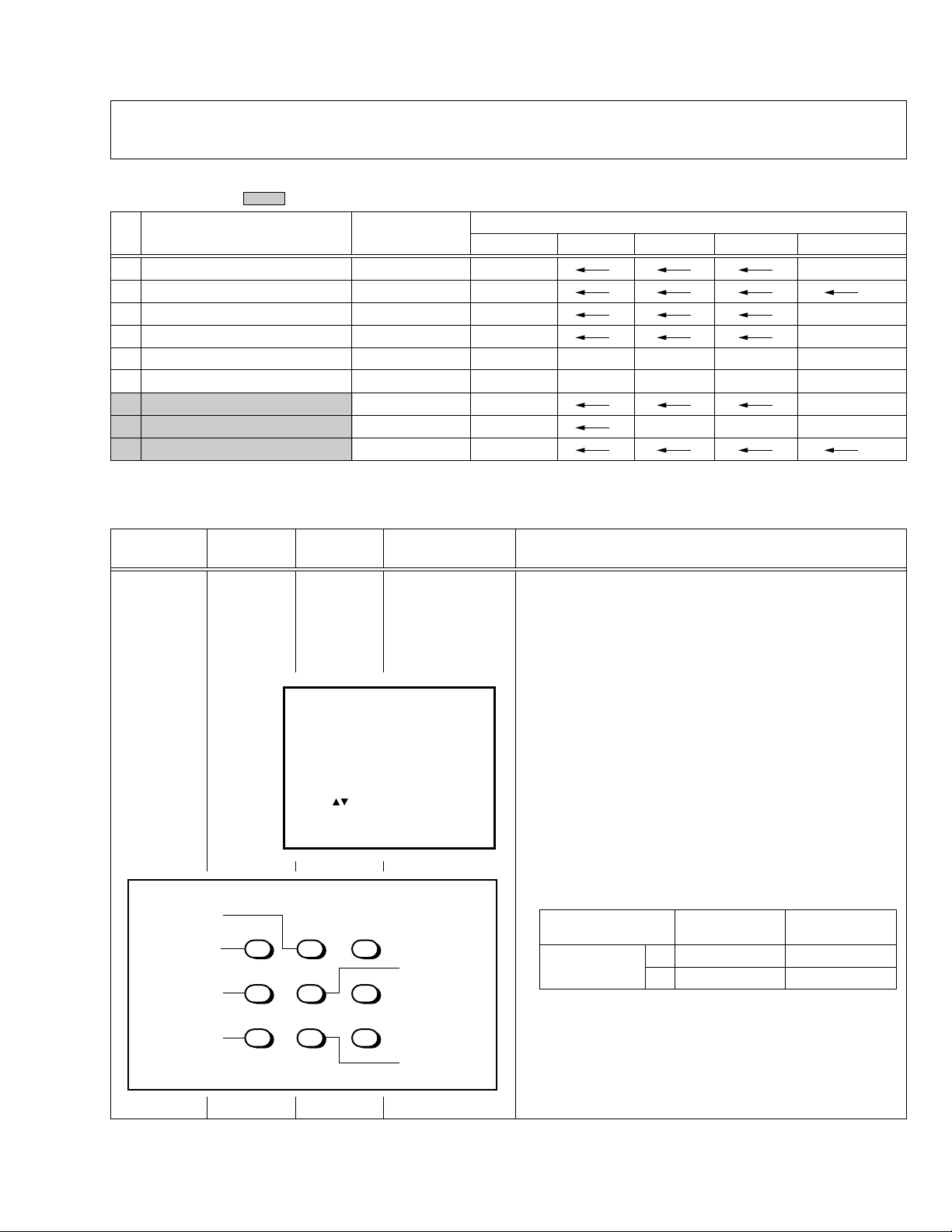

MAIN DIFFERENCE LIST

!

Part Name

! MAIN PWB SCH-1108A-H2 SCH-1095A-H2 SCH-1104A-H2

FRONT CABINET ASS’Y LC11193-020A-H LC11193-018A-H LC11193-021A-H

REMOTE CONTROL UNIT RM-C1020-1H RM-C1024-1H

MODEL No.

AV-29LS2 AV-29LX2 AV-29LX2

/A AV-2968TEE

RM-C1023-1H

4No. 52062

Page 5

FUNCTIONS

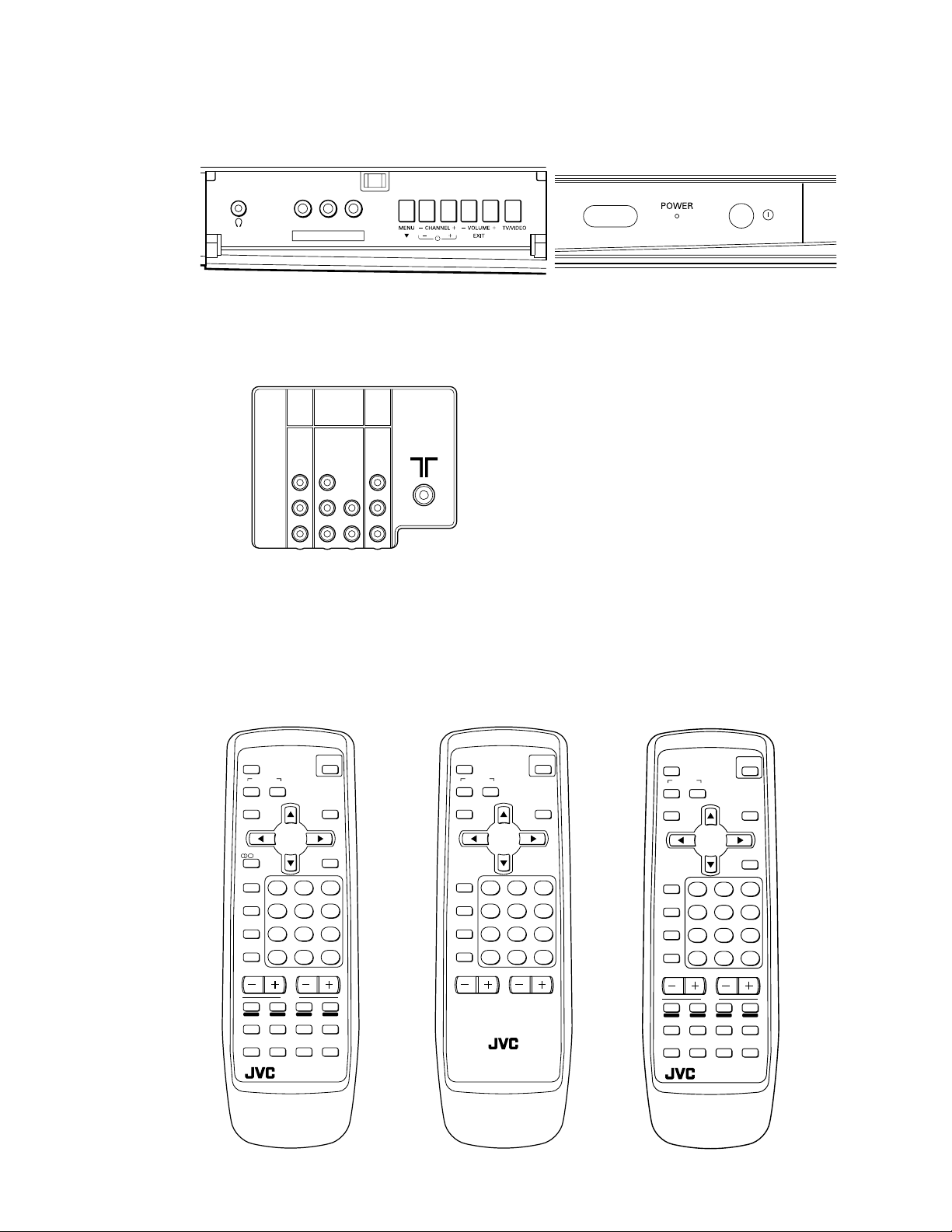

a FRONT PANEL

L/MONOVR

IN (VIDEO-3)

a REAR PANEL

VIDEO-1

INPUT

COMPONENT

(

)

VIDEO-2

INPUT

AV-29LS2

AV-29LX2

AV-2968TEE

OUTPUT

a REMOTE CONTROL UNIT

RM-C1020-1H

[AV-29LS2]

MUTING

SYSTEM

COLOUR SOUND

DISPLAY

MENU

I/II

TV/VIDEO

123

OFF

TIMER

456

PICTURE

MODE

789

CHANNEL

RETURN+

SCAN

CHANNEL

TEXT

HOLD

REVEAL

SUBPAGE CANCEL

STORE MODE

RM-C1020

V

L

/

R

MONO

0-/

VOLUME

INDEX

Y

/

V

C

B

C

R

POWER

ECO

SENSOR

TV/TEXT

SIZE

TV

V

L

L

/

MONO

R

R

RM-C1024-1H

[AV-29LX2]

[AV-29LX2

MUTING

SYSTEM

COLOUR SOUND

DISPLAY

TV/VIDEO

OFF

TIMER

PICTURE

MODE

CHANNEL

RETURN+

--

SCAN

CHANNEL

/A]

POWER

ECO

SENSOR

MENU

123

456

789

--

0-/

VOLUME

RM-C1024

TV

RM-C1023-1H

[AV-2968TEE]

MUTING

SYSTEM

COLOUR SOUND

DISPLAY

TV/VIDEO

OFF

TIMER

PICTURE

MODE

CHANNEL

RETURN+

SCAN

CHANNEL

REVEAL

HOLD

SUBPAGE CANCEL

STORE MODE

POWER

ECO

SENSOR

MENU

TV/TEXT

123

456

789

0-/

VOLUME

TEXT

INDEX

SIZE

RM-C1023

TV

--

No. 52062 5

Page 6

AV-29LS2

AV-29LX2

AV-2968TEE

SPECIFIC SERVICE INSTRUCTIONS

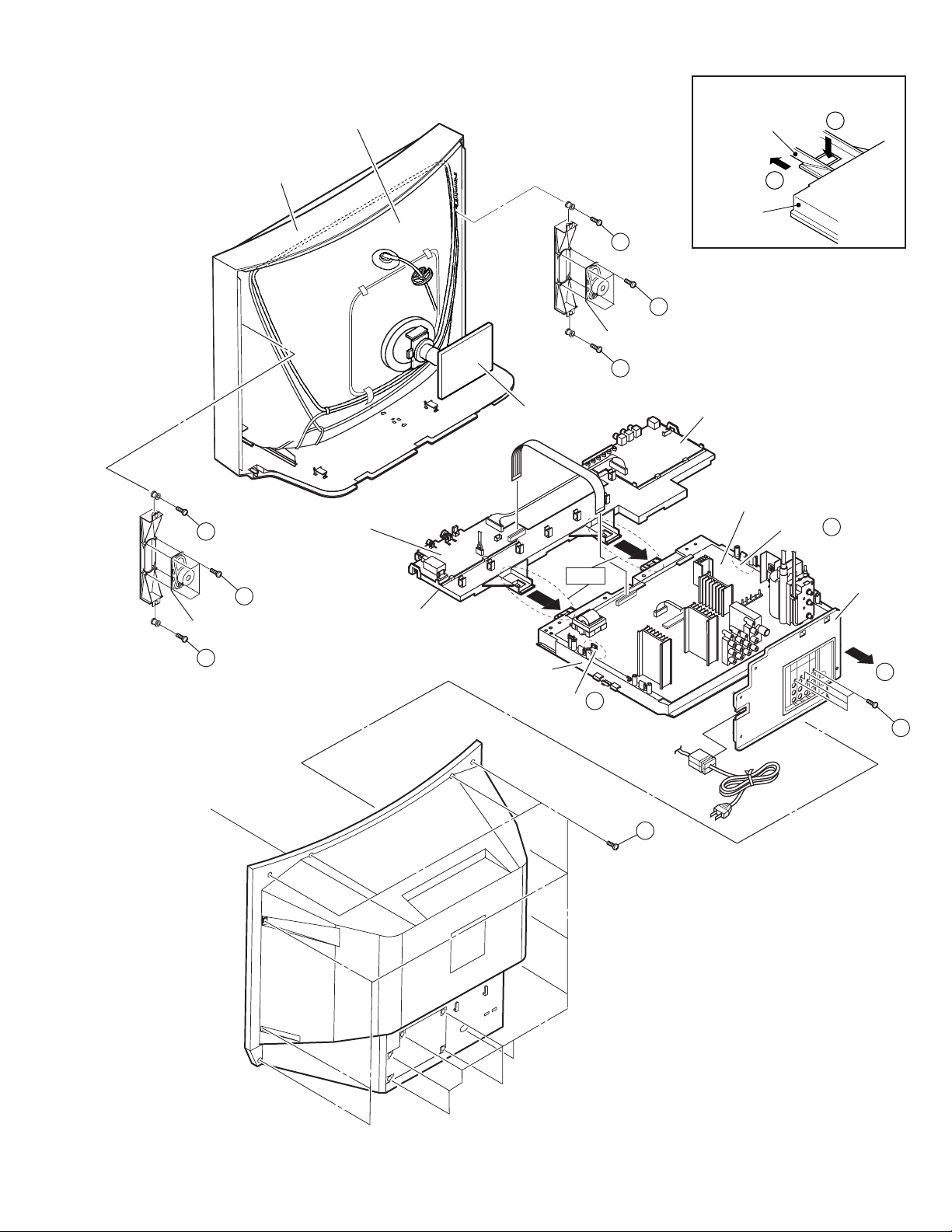

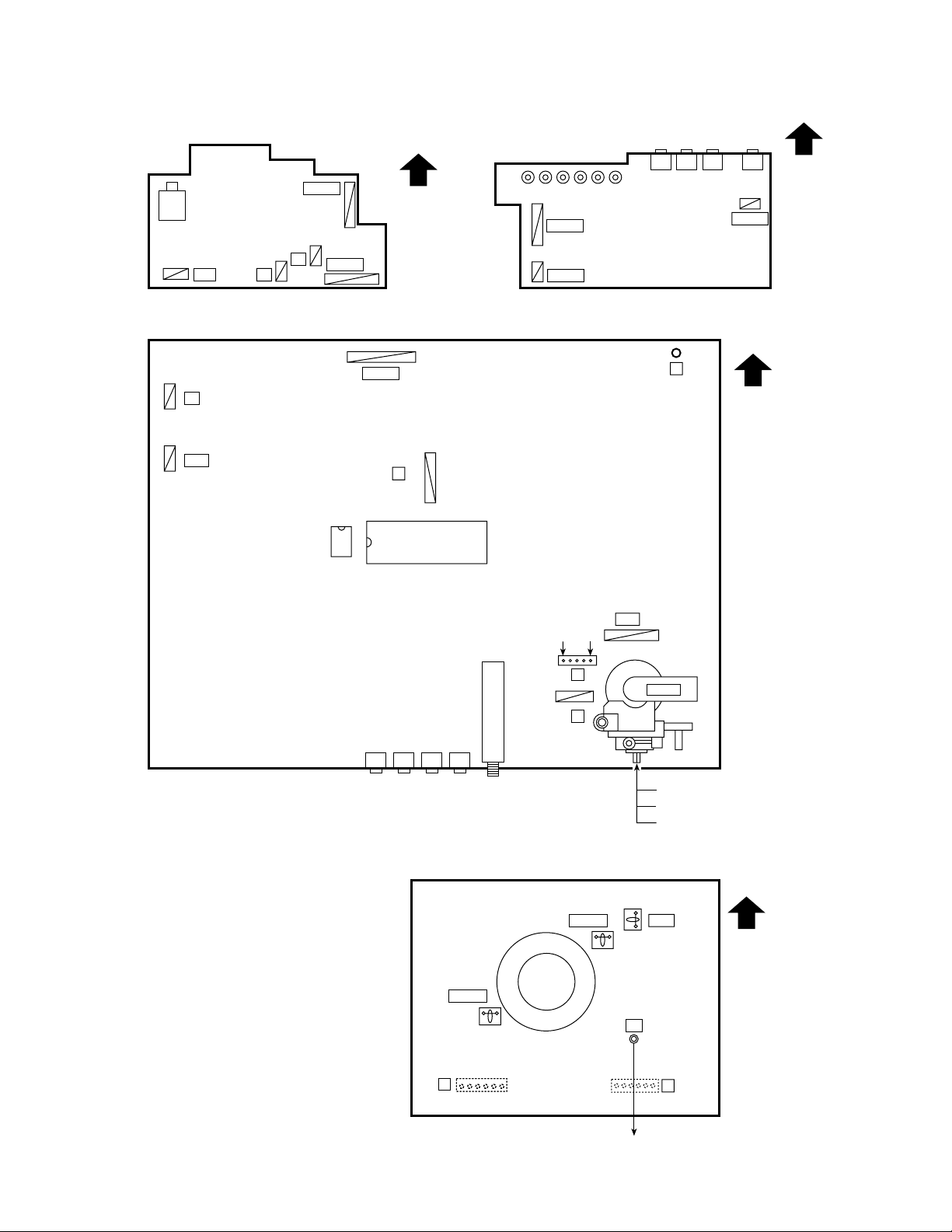

DISASSEMBLY PROCEDURE

REMOVING THE REAR COVER

1. Unplug the power supply cord.

2. Remove the 16 screws marked

3. Withdraw the Rear cover toward you.

[CAUTION]

When reinstalling the rear cover, carefully push it inward after in-

•

serting the Main PWB into the rear cover groove.

as shown in Fig.1.

Å

REMOVING THE CHASSIS (CHASSIS BASE AND

CONTROL BASE)

After removing the rear cover.

•

1. Slightly raise the both sides of the chassis by hand and remov e the

2 claws marked

in Fig.1.

2. Withdraw the chassis backward.

(If necessary, take off the wire clamp, connector’s etc.)

When conducting a check with power supplied, be sure to confirm

*

that the CRT earth wire is connected to the CRT SOCKET PWB

and the Main PWB.

under the chassis from the front cabinet as sho wn

ı

REMOVING THE AV TERMINAL BOARD

After removing the rear cover.

•

1. Remove the 4 screws marked

2. When you pull out the AV Terminal board in the direction of arrow

marked

as shown in Fig.1, it can be removed.

Î

as shown in Fig.1.

Ç

CHECKING THE MAIN PW BOARD

1. To check the back side of the Main PWB.

1) Pull out the chassis. (Refer to REMOVING THE CHASSIS).

2) Erect the chassis vertically so that you can easily check the back

side of the Main PWB.

[CAUTION]

When erecting the chassis, be careful so that there will be no con-

•

tacting with other PW Board.

Before turning on power, make sure that the CRT earth wire and

•

other connectors are properly connected.

When repairing, connect the Deg. coil to the DEG. connector on the

•

Main PWB.

WIRE CLAMPING AND CABLE TYING

1. Be sure to clamp the wire.

2. Never remove the cable tie used for tying the wires together.

Should it be inadvertently removed, be sure to tie the wires with a

new cable tie.

REMOVING THE CONTROL BASE

After removing the rear cover and the chassis.

•

1. While pushing down the 2 claws marked

pull out the Control base in the direction of arrow marked

shown in Fig. 2, the control base can be removed.

(If necessary, take off the wire, connector’s etc.)

as shown in Fig. 2 and

´

Ï

as

REMOVING THE SPEAKER

After removing the rear cover.

•

1. Remove the 4 scre ws marked

in Fig.1.

2. Withdraw the speaker backward.

3. Follow the same steps when removing the other hand speaker.

6No. 52062

and 2 scre ws marked Ó as sho wn

˝

Page 7

PICTURE TUBE

[FRONT SIDE]

CONTROL BASE

AV-29LS2

AV-29LX2

AV-2968TEE

E

FRONT CABINET

H

G

SPEAKER

(×4)

FRONT CONTROL

PWB (1/2)

CONTROL BASE

CRT

SOCKET PWB

Fig.2

H

G

SPEAKER

H

F

CHASSIS

BASE

Fig.2

(×4)

FRONT CONTROL PWB (2/2)

MAIN PWB

CLAW B

AV TERMINAL

BOARD

H

REAR COVER

CHASSIS

BASE

CLAW B

A

D

C

(×4)

(×16)

Fig.1

No. 52062 7

Page 8

AV-29LS2

AV-29LX2

AV-2968TEE

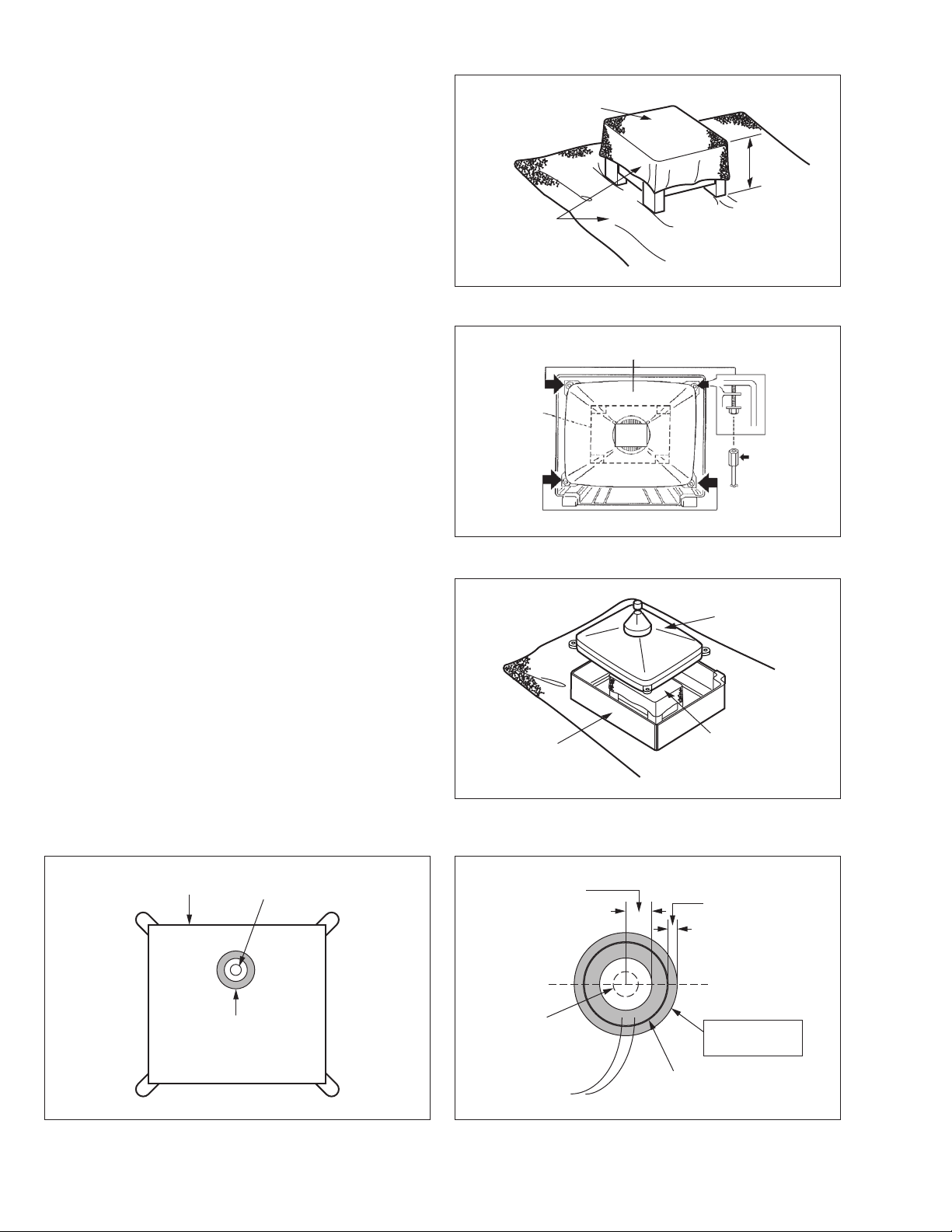

REMOVING THE CRT

* Replacement of the CRT should be perf ormed by 2 or more persons.

After removing the rear cover, chassis etc.,

•

1. Putting the CRT change table on soft cloth, the CRT change table

should also be covered with such soft cloth (shown in Fig. 3).

2. While keeping the surface of CRT down, mount the TV set on the

CRT change table balanced will as shown in Fig. 4.

3. Remove 4 screws marked by arrows with a box type screwdriver as

shown in Fig. 4.

Since the cabinet will drop when screws have been remo ved, be sure

•

to support the cabinet with hands.

4. After 4 screws have been removed, put the cabinet slowly on cloth

(At this time, be carefully so as not to damage the front surface of the

cabinet) shown in Fig. 5.

The CRT should be assembled according to the opposite sequence

•

of its dismounting steps.

* The CRT change table should preferably be smaller that the CR T sur-

face, and its height be about 35cm.

CRT CHANGE TABLE

CLOTH

CRT

CHANGE

TABLE

Fig. 3

CRT

APPROX.

35cm

BOX

TYPE

SCREW

DRIVER

COA TING OF SILICON GREASE FOR ELECTRICAL INSULATION ON THE CRT ANODE CAP SECTION.

Subsequent to replacement of the CRT and HV transformer or repair

•

of the anode cap, etc. by dismounting them, be sure to coat silicon

grease for electrical insulation as shown in Fig. 6.

1. Wipe around the anode button with clean and dry cloth. (Fig. 6)

2. Coat silicon grease on the section around the anode button. At this

time, take care so that any silicon greases does not sticks to the

anode button. (Fig. 7)

夝 Silicon grease product No. KS - 650N

CRT

Anode button

CABINET

Approx.

20mm (Do not

coat grease on

this section

Fig. 4

CRT

CRT

CHANGE T ABLE

Fig. 5

Silicon grease

should be coated

by 5mm or more

from the outside

diameter of anode

cap.

Silicon grease

coating

Fig. 6

8No. 52062

Anode button

(No sticking of

silicon grease)

Coating position

of silicon grease

Anode cap

Fig. 7

Page 9

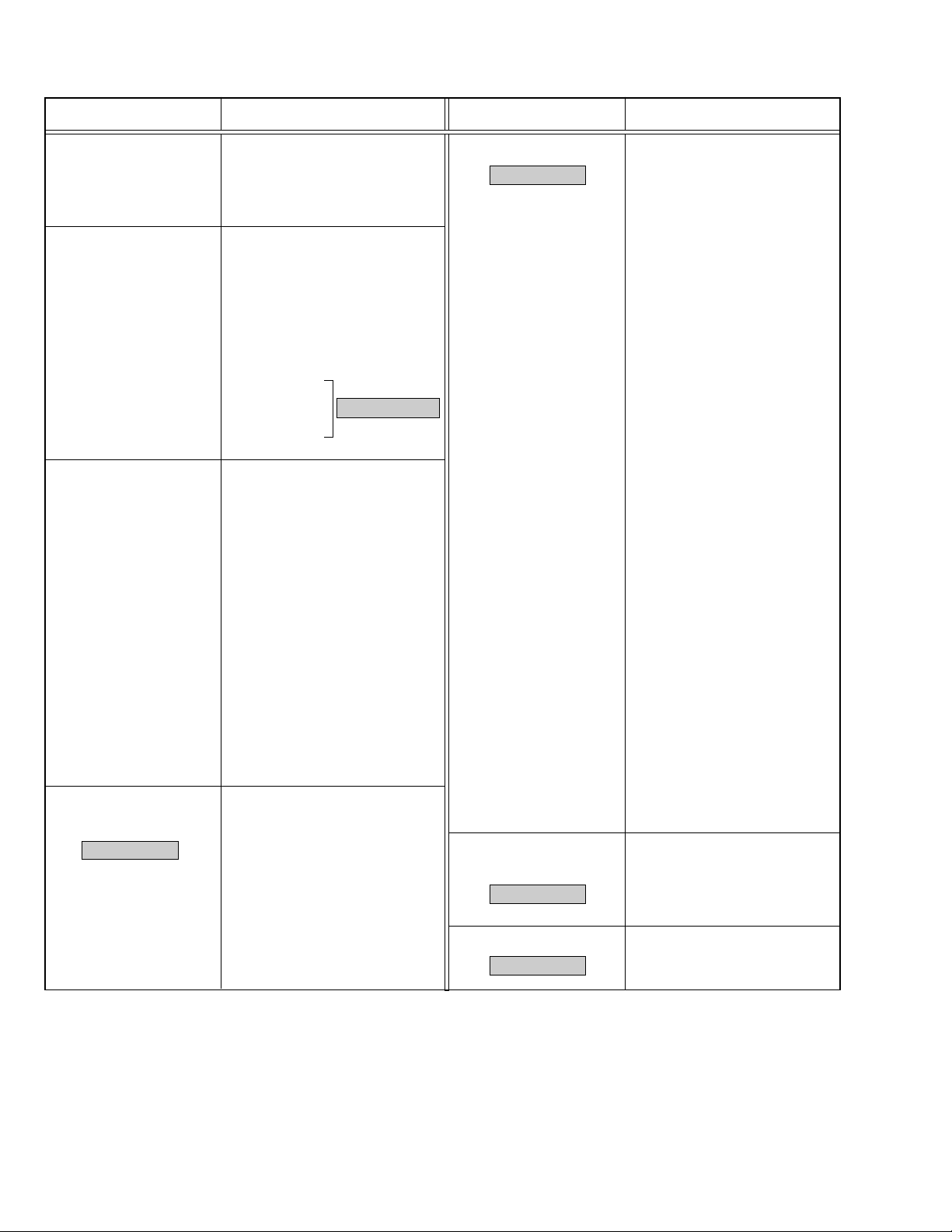

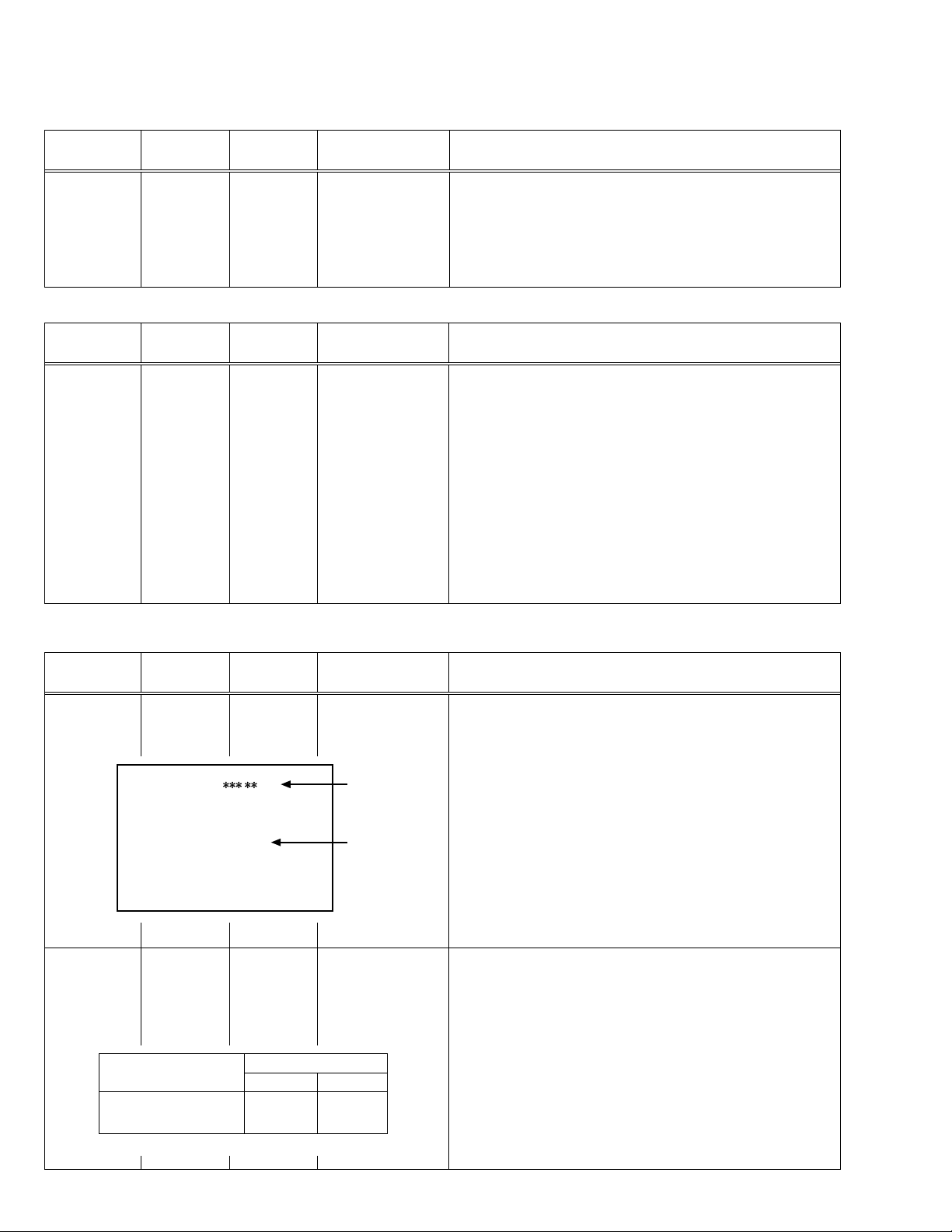

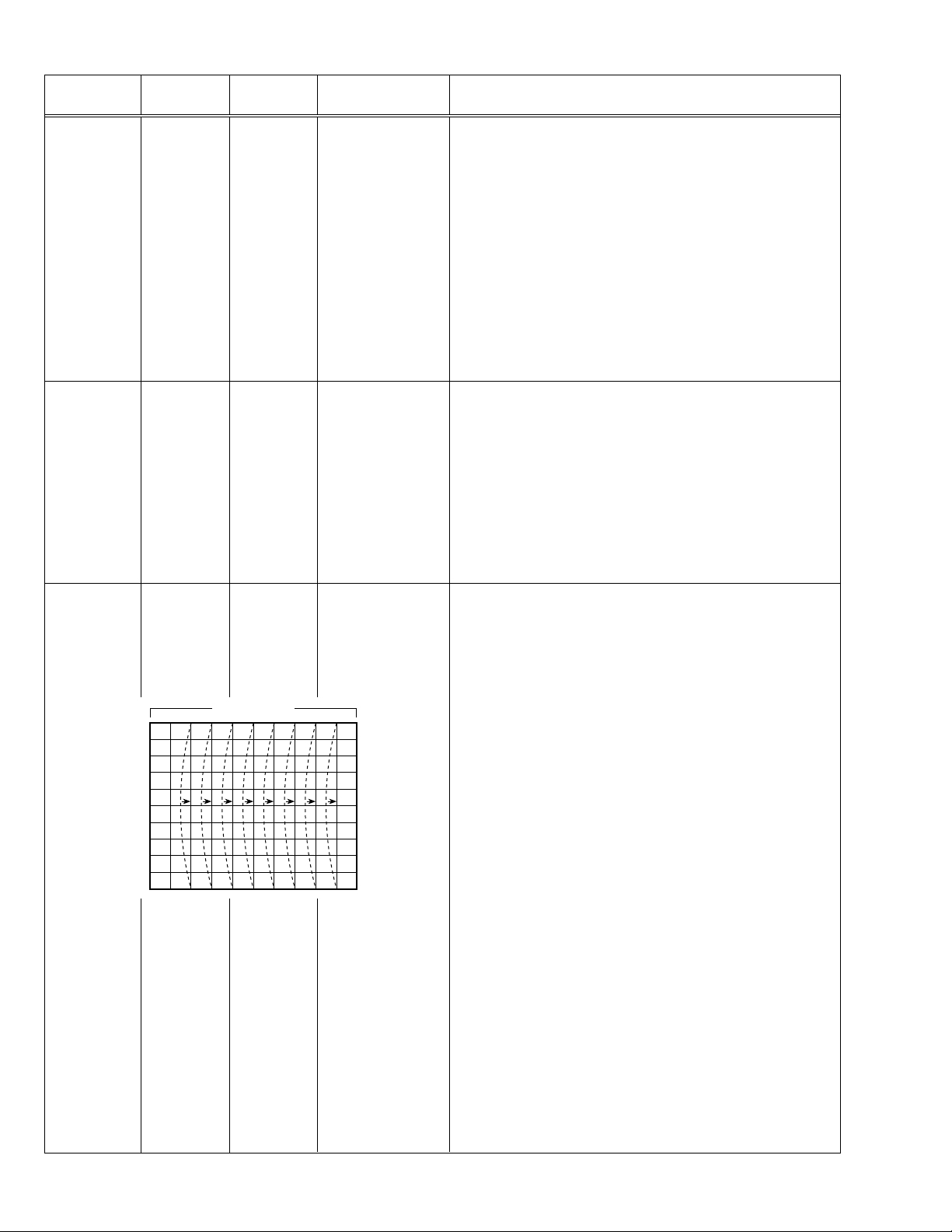

REPLACEMENT OF MEMORY IC

1. MEMORY IC

This TV uses the following memory IC.

Memory IC: IC1702 on MAIN PW Board

The memory IC memorizes data for correctly operating the video

and deflection circuits. When replacing the memory IC, be sure to

use the same type IC written with the initial values of data. In other

words, use the specific IC listed in “PRINTED WIRING BOARD

PARTS LIST”. For its mounting location, refer to “ADJUSTMENT

LOCATIONS”.

2. PROCEDURE FOR REPLACING MEMORY IC

(1) Power off

Switch the power off and unplug the power cord from the wall

outlet.

(2) Replacing the memory IC

Replace the memory IC with new one. Be sure to use the memory

IC written with the initial data values.

(3) Power on

Plug the power cord into the wall outlet and switch the po wer on.

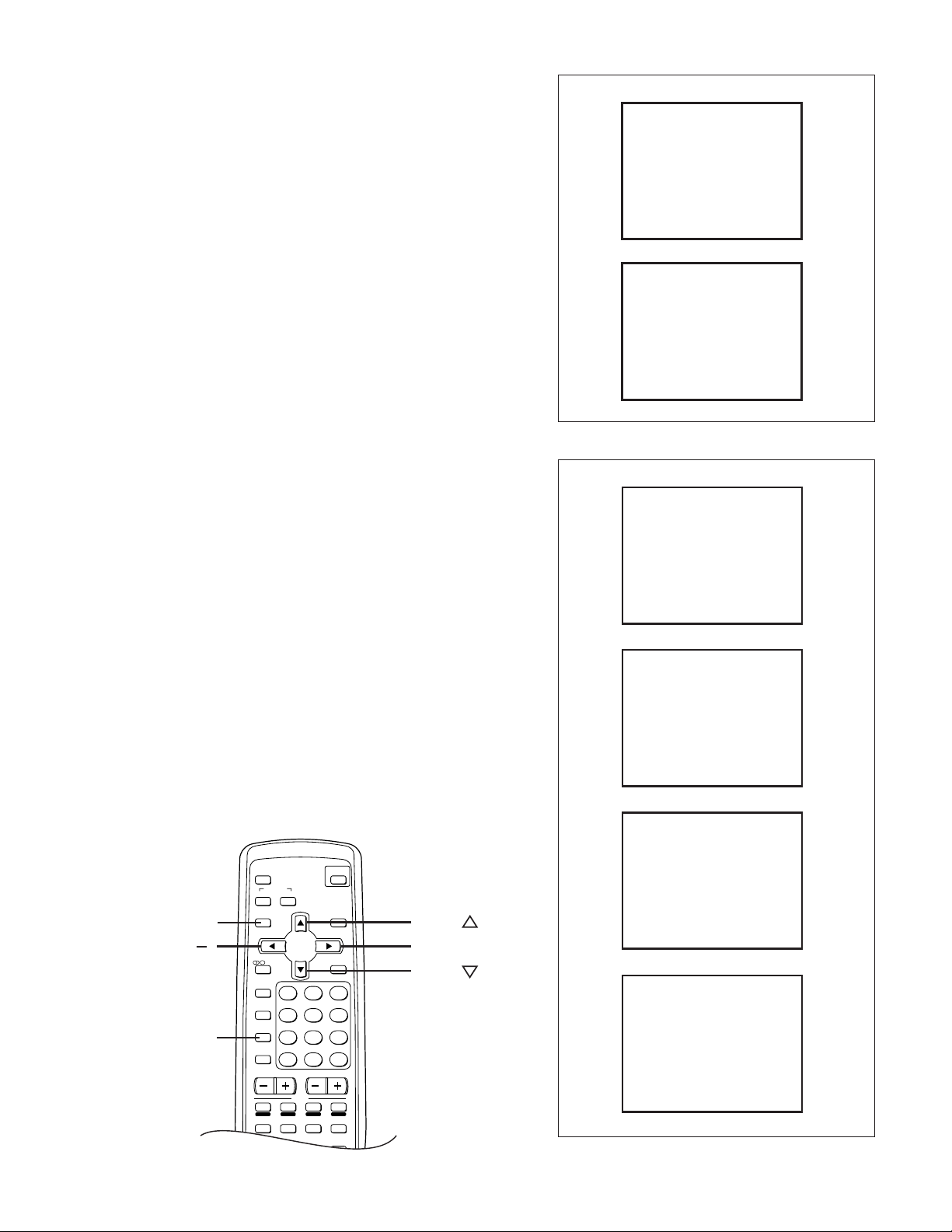

(4) Check and setting of SYSTEM CONSTANT SET:

1) Press the DISPLA Y k e y and the PICTURE MODE ke y on the

remote control unit simultaneously.

The SERVICE MENU screen will be displayed.(See Fig.1.)

2) In the SERVICE MENU, press the DISPLAY key and PICTURE MODE key simultaneously. Then, the SYSTEM CONSTANT SET screen will be displayed.(See Fig.2.)

3) Check whether the setting values of the SYSTEM CONSTANT

SET are the same as those indicated in Table1.

If the value is different, select the setting item with the MENU

&/^ key, and set the correct value with the MENU

4) Press the DISPLAY key twice to return to the normal screen.

(5) Receive channel setting

Refer to the OPERATING INSTRUCTIONS and set the receive

channels (channels preset).

(6) User setting

Check the user setting values in Table 2, and if setting value is

different, set the correct value.

For setting, refer to the OPERATING INSTRUCTIONS.

(7) Setting of SERVICE MENU

Verify the setting for each setting item in the SERVICE

MENU.(See Table 3.) If readjustment is necessary, perform adjustment referring to “SERVICE ADJUSTMENTS”.

NAME OF REMOTE CONTROL KEYS

POWER

ECO

SENSOR

MENU

TV/TEXT

123

456

789

--

0-/

VOLUME

TEXT

HOLD INDEX

SIZE

DISPLAY

MENU

PICTURE

MODE

MUTING

SYSTEM

COLOUR SOUND

DISPLAY

I/II

TV/VIDEO

OFF

TIMER

PICTURE

MODE

CHANNEL

RETURN+

SCAN

CHANNEL

REVEAL

SUBPAGE CANCEL

STORE MODE

*/T

MENU

MENU

MENU

AV-29LS2

AV-29LX2

AV-2968TEE

SERVICE MENU

SERVICE MENU

1. IF

3. DEF

5. PRESET

7. PLUG & PLAY (ON)

1-7 : SELECT DISPLAY : EXIT

******* **** ***** *****

**** **** *** ***

1. IF

3. DEF

5. PRESET

6. PLUG & PLAY (ON)

1-6 : SELECT DISPLAY : EXIT

******* **** ***** *****

**** **** *** ***

[AV-29LX2, AV-29LX2/A, AV-2968TEE]

2. VC

4. VSM PRESET

6. A2NICAM

[AV-29LS2]

SERVICE MENU

2. VC

4. VSM PRESET

Fig. 1

key.

SYSTEM CONSTANT-

SYSTEM CONSTANT SET 1

SYSTEM

COMB

TILT

TEXT

SUPER BASS

LANGUAGE

>? : SEL -+ : OPE

SYSTEM CONSTANT-

SYSTEM CONSTANT SET 2

MSP

BILINGUAL

B / B SOUND

TUNER

COLOUR AUTO

>? : SEL -+ : OPE

SYSTEM CONSTANT-

SYSTEM CONSTANT SET 3

LOCK 1 MHz

>? : SEL -+ : OPE

500 KHz

250 KHz

156. 25 KHz

31.25 KHz

MULTI

YES

YES

ERCMI

YES

E/R/C/M/I

DISP : EXIT

YES

YES

NO

MU

YES

DISP : EXIT

: 040

: 040

: 040

: 030

: 030

DISP : EXIT

Ι

II

III

+

SYSTEM CONSTANT-

SYSTEM CONSTANT SET 4

3D SURROUND

3CH VOL/TONE

AMP TUNER

>? : SEL -+ : OPE

Fig. 2

YES

YES

NO

DISP : EXIT

IV

No. 52062 9

Page 10

AV-29LS2

AV-29LX2

AV-2968TEE

SETTING OF SYSTEM CONSTANT SET

Setting item Setting content

SYSTEM

COMB

TILT

TEXT

SUPER BASS

LANGUAGE

MSP

BILINGUAL

B/B SOUND

TUNER

COLOUR AUTO

LOCK 1MHz

MULTI TRIPLE PAL SINGLE VIET

YES NO

YES NO

ERCMI ERAPU NO

YES NO

E/R/C/M/I E/R/C E/C

E/R/A/P/U E/R/A/P E/R/U

YES NO

YES NO

YES NO

MU MA

YES NO

000 240

AV-29LX2AV-29LS2

MULTI

YES

YES

ERCMI NO

NO

E/R/C/M/I

–

NO

NO

MU

NO

040

E/R/A/P E/R/A/P/U

–

NOYES

Setting value

––

YES

YES

/A

AV-2968TEEAV-29LX2

ERAPU

NO

NO

500KHz

250KHz

156.25KHz

31.25KHz

3D SURROUND

3CH VOL/TONE

AMP TUNER

000 240

000 240

000 240

000 240

YES NO

YES NO

YES NO

040

040

030

030

NO

YES

NO

Table 1

10 No. 52062

Page 11

USER SETTING VALUES

Setting item Setting value

SUB POWER ON

CHANNEL POSITION 1 POSITION

CHANNEL PRESET REFER TO OPERATING INSTRUCTIONS

VOLUME 15 ± 2

TV/VIDEO TV

VNR OFF

COMPRESS (16:9) OFF

AUTO SHUTOFF OFF

CHILD LOCK OFF

BLUE BACK ON

VIDEO-2 SET VIDEO

LANGUAGE ENG

AI VOLUME ON

ON SCREEN DISPLAY POSITION INDICATION

COLOUR SYSTEM PAL

SOUND SYSTEM B/G

STEREO MODE STEREO [AV-29LS2 only]

PICTURE MODE-VSM BRIGHT

OFF TIMER 00

ECO SENSOR OFF

BASS CENTRE

TREBLE CENTRE

BALANCE CENTRE

Table 2

AV-29LS2

AV-29LX2

AV-2968TEE

No. 52062 11

Page 12

AV-29LS2

AV-29LX2

AV-2968TEE

SERVICE MENU SETTING ITEMS

Service menu Setting item

1. IF 1. VCO

2. DELAY POINT

2. VC 1. CUTOFF(R/G)

2. DRIVE(R/G/B)

3. BRIGHT

4. CONT

5. COLOUR

6. TINT

7. SHARP

8. YDELA Y

9. AMP T. SHARP

3. DEF 1. VER. SLOPE

2. VER. HEIGHT

3. VER. POSITION

4. VER. SCURVE

5. HOR. POSITION

6. HOR. WIDTH

7. EW-PIN

8. EW-TRAPEZ

9. UP CORNER

10. DW CORNER

11. HOR. PARALL

12. HOR. BOW

13. V. ZOOM

4. VSM PRESET 1. TINT

(BRIGHT/STD/SOFT) 2. COLOUR

Do not adjust

3. BRIGHT

4. PICTURE

5. DETAIL

Do not adjust

Service menu Setting item

5. PRESET 1. PSNS

Do not adjust

6. A2NICAM 1. ERROR LIMIT

[AV-29LS2 only] 2. A2 ID THR

Do not adjust

2. ACL

3. MUS

4. MAT

5. FCO

6. BPS

7. IFLH

8. VID

9. STM

10. AFCW

11. VSW

12. FFI

13. A GC

14. CL

15. AKB

16. HBL

17. BKS

18. READ STATUS

19. VNR

20. PEAK

21. IVG

22. WPL

23. SOFT CLIPPER

24. IF PLL OFFSET

25. OVERSHOOT

26. HCO

27. HP2

28. AI VOLUME ADN

31. CCCLOOP

3. SOUND SYSTEM

Table 3

12 No. 52062

6/7.

PLUG & PLAY(ON)

Do not adjust

Page 13

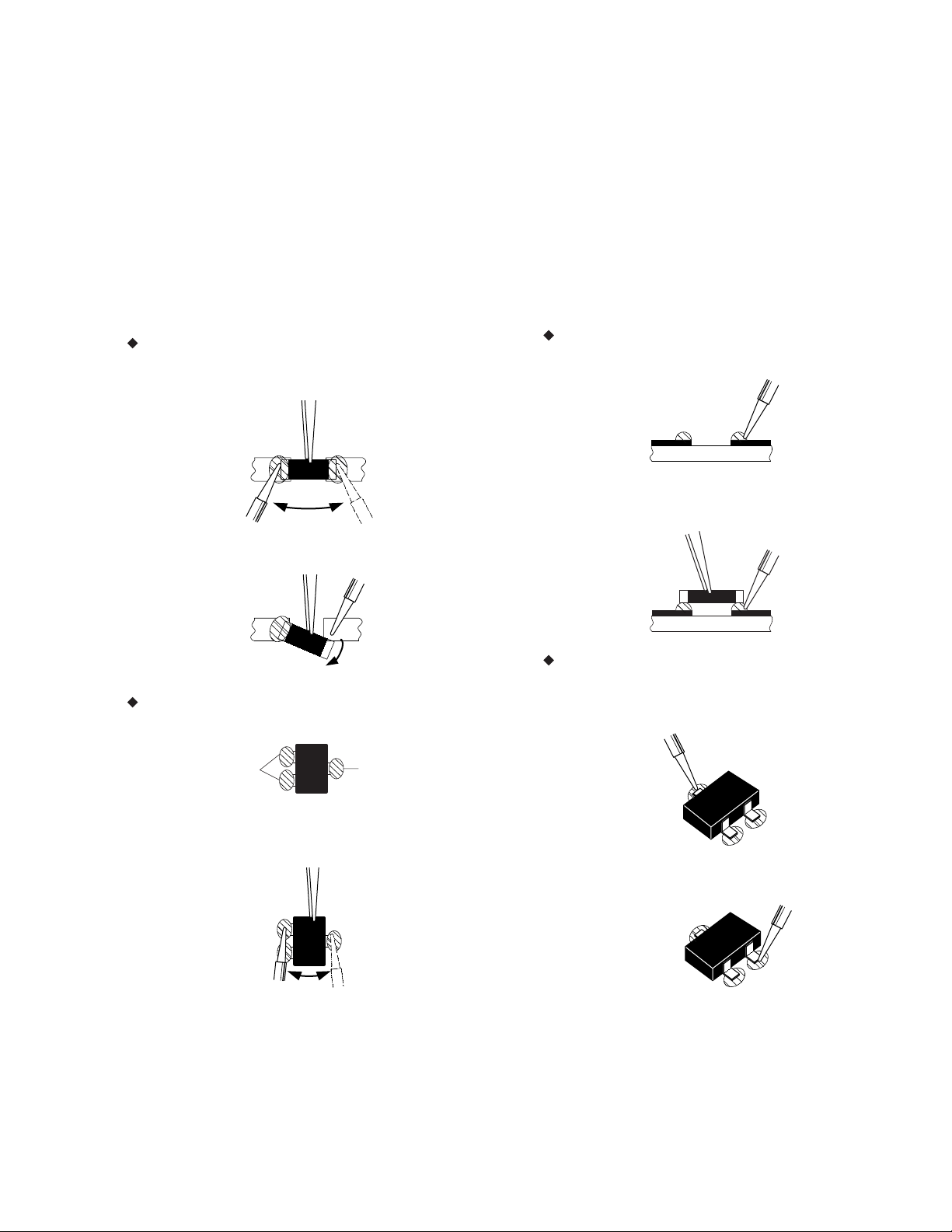

REPLACEMENT OF CHIP COMPONENT

CAUTIONS

a

1. Avoid heating for more than 3 seconds.

2. Do not rub the electrodes and the resist parts of the pattern.

3. When removing a chip part, melt the solder adequately.

4. Do not reuse a chip part after removing it.

SOLDERING IRON

a

1. Use a high insulation soldering iron with a thin pointed end of it.

2. A 30w soldering iron is recommended for easily remo ving parts.

REPLACEMENT STEPS

a

1. How to remove Chip parts

Resistors, capacitors, etc.

(1) As shown in the figure, push the part with tweezers and alter-

nately melt the solder at each end.

AV-29LS2

AV-29LX2

AV-2968TEE

2. How to install Chip parts

Resistors, capacitors, etc.

(1) Apply solder to the pattern as indicated in the figure.

(2) Shift with tweezers and remove the chip part.

Transistors, diodes, variable resistors, etc.

(1) Apply extra solder to each lead.

SOLDER

(2) As shown in the figure, push the part with tweezers and alter-

nately melt the solder at each lead. Shift and remove the chip

part.

SOLDER

(2) Grasp the chip part with tweezers and place it on the solder.

Then heat and melt the solder at both ends of the chip part.

Transistors, diodes, variable resistors, etc.

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the solder.

(3) First solder lead

(4) Then solder leads B and C.

A as indicated in the figure.

A

B

C

A

Note : After removing the part, remove remaining solder from the

pattern.

No. 52062 13

B

C

Page 14

AV-29LS2

AV-29LX2

AV-2968TEE

SERVICE ADJUSTMENTS

ADJUSTMENT PREPARATION

1. You can make the necessary adjustments for this unit with either the remote control unit or with the adjustment equipment and parts

as given below.

2. Adjustment with the remote control unit is made on the basis of the initial setting values, howe ver , the new setting v alues which set the

screen to its optimum condition may differ from the initial settings.

3. Make sure that AC power is turned on correctly.

4. Turn on the power for the set and test equipment before use, and start the adjustment procedures after waiting at least 30 minutes.

5. Unless otherwise specified, prepare the most suitable reception or input signal for adjustment.

6. Never touch any adjustment parts, which are not specified in the list for this adjustment-variable resistors, transformers, capacitors, etc.

7. Presetting before adjustment.

Unless otherwise specified in the adjustment instructions, preset the following functions with the remote control unit.

User mode setting position

•

Setting item Setting value

PICTURE MODE(VSM) BRIGHT

VNR OFF

BASS, TREBLE, BALANCE CENTRE

TINT, COLOUR, BRIGHT, DETAIL CENTRE

PICTURE MAXIMUM

MEASURING INSTRUMENT

1. DC voltmeter (or Digital voltmeter)

2. Oscilloscope

3. Signal generator (Pattern generator) [PAL/SECAM/NTSC]

4. Remote control unit

ADJUSTMENT ITEMS

B1 POWER SUPPLY

•

FOCUS ADJUSTMENT

•

IF CIRCUIT ADJUSTMENTS

•

Adjustment of VCO (CW)

Adjustment of DELAY POINT (AGC TAKE-OVER)

VC (VIDEO/CHROMA) CIRCUIT ADJUSTMENTS

•

Adjustment of WHITE BALANCE (Low light)

Adjustment of WHITE BALANCE (High light)

Adjustment of SUB BRIGHT

Adjustment of SUB CONTRAST

Adjustment of SUB COLOUR-Ι

Adjustment of SUB COLOUR-ΙΙ

Adjustment of SUB TINT-Ι

Adjustment of SUB TINT-ΙΙ

DEFLECTION CIRCUIT ADJUSTMENTS

•

Adjustment of V. SLOPE

Adjustment of V. POSITION

Adjustment of V. HEIGHT

Adjustment of H. POSITION

Adjustment of H. WIDTH

Adjustment of SIDE PIN

Adjustment of TRAPEZIUM

Adjustment of V. S-CURVE

Adjustment of CORNER

Adjustment of H. PARALLEL

Adjustment of H. BOW

VSM PRESET SETTING

•

PRESET SETTING

•

AUDIO ADJUSTMENT [AV-29LS2 only]

•

PURITY ADJUSTMENT

•

CONVERGENCE ADJUSTMENTS

•

Adjustment of STATIC CONVERGENCE

Adjustment of DYNAMIC CONVERGENCE

14 No. 52062

Page 15

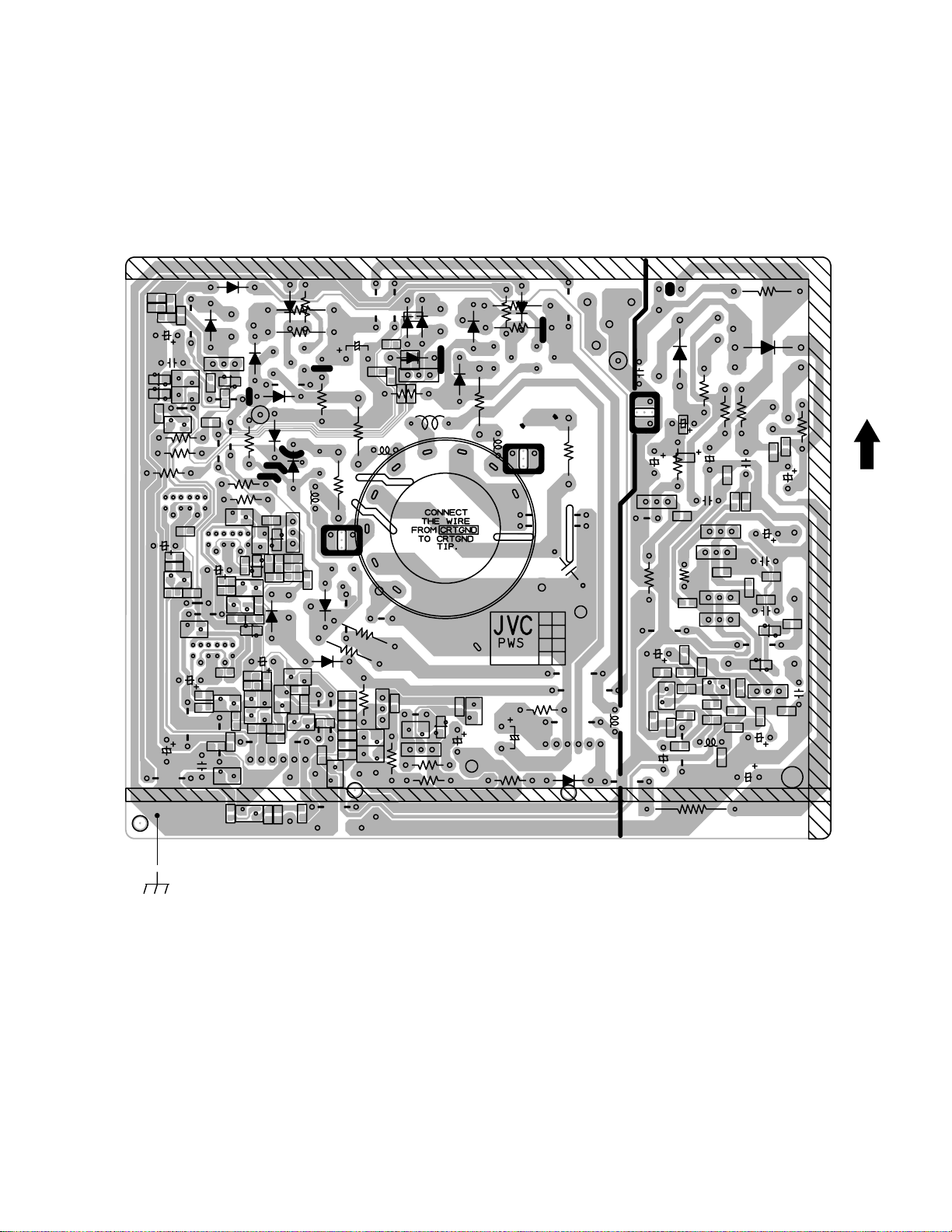

ADJUSTMENT LOCATIONS

E1

TOP

CRT EARTH

(BRAIDED ASS'Y)

U

TP-47B

TP-47G

HV

61

GND B1

UPPER : FOCUS (F1)

MIDDLE : FOCUS (F2)

IC702

CRT SOCKET PWB ASS’Y

(SOLDER SIDE)

1

16

FRONT

FRONT

FRONT

AV IN/OUT

HVT

MAIN PWB ASS’Y

FRONT CONTROL PWB ASS’Y(1/2) FRONT CONTROL PWB ASS’Y(2/2)

J304 J303 J302

S804

S805

S806 S802

S803S801 J801

CN003

CN002

CN00A

CN001

CN002

PW

POWER

SW.

W

R

S901

S801 : CH UP +

S802 : CH DOWN –

S803 : MENU

S804 : TV/VIDEO

S805 : VOL UP+

S806 : VOL DOWN –

1

1

6

16

5

S

U

LOWER : SCREEN

TU001

J804J801 J802 J803

IC701

Z

CN001

W

T

DEG

TP-E

T

61

T

61

AV-29LS2

AV-29LX2

AV-2968TEE

No. 52062 15

Page 16

AV-29LS2

AV-29LX2

AV-2968TEE

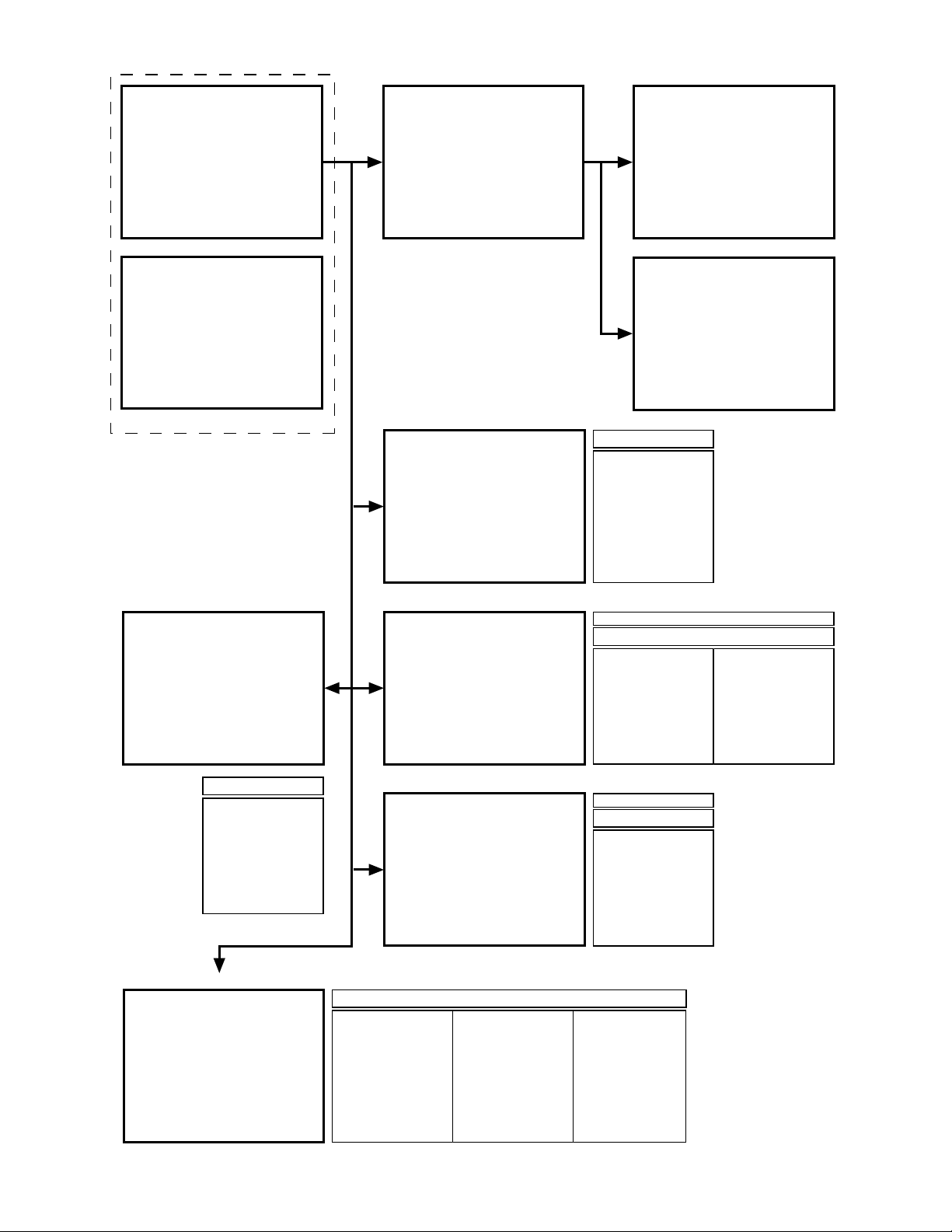

BASIC OPERATION IN SERVICE MENU

1. TOOL OF SERVICE MENU OPERATION

Operate the SERVICE MENU with the remote control unit.

2. SERVICE MENU ITEMS

With the SERVICE MENU,various settings (adjustments)can be made,and they are broadly classified in the following items of settings:

1.IF......................................For entering/adjusting the setting values (adjustment values)of the IF circuit.

•

2.VC ....................................For entering/adjusting the setting values (adjustment values)of the VIDEO/CHROMA circuit.

•

3.DEF..................................For entering/adjusting the setting values (adjustment values)of the DEFLECTION circuit.

•

4.VSM PRESET..................For setting the values of STANDARD,SOFT and BRIGHT.

•

5.PRESET...........................For setting the values of the preset.

•

6.A2NICAM .........................For entering/adjusting the setting values (adjustment values)of the multiplicity sound circuit. [AV-29LS2 only]

•

6/7. PLUG & PLAY (ON) .....This is not used for service.

•

3. BASIC OPERATION IN SERVICE MENU

(1) How to enter SERVICE MENU

Press the DISPLAY key and the PICTURE MODE key on the remote control unit simultaneously.

The SERVICE MENU screen will be displayed. (See Fig. 1 on the next page.)

(2) Selection of SUB MENU SCREEN

Press one of the keys 1 to 7 on the remote control unit,and select the SUB MENU SCREEN from the SER VICE MENU.(See Fig.1 on the next

page.)

(VSM:video status memory)

SERVICE MENU → SUB MENU 1. IF

2. VC

3. DEF

4. VSM PRESET

5. PRESET

6. A2NICAM [AV-29LS2 only]

6/7. PLUG & PLAY (ON)

(3) Method of Setting

*Once the setting values are set,they are memorized automatically.

*It must not adjust without inputting a signal.

1) 1. IF

[1.VCO ]

(a) 1 Key......................... Select 1. IF.

(b) 1 Key......................... Select 1. VCO.

(c) DISPLAY Key............ When this is pressed twice, you will return to the SERVICE MENU.

Under normal conditions, no adjustment is required.

[2.DELAY POINT ]

(a) 1 Key......................... Select 1. IF.

(b) 2 Key......................... Select 2.DELA Y POINT.

(c) MENU

(d) DISPLAY Key............ When this is pressed twice, you will return to the SERVICE MENU.

2) 2. VC, 3. DEF, 4. VSM PRESET, 5. PRESET and 6. A2NICAM

(a) 2 ~6 Keys.................. Select one from 2. VC, 3. DEF, 4. VSM PRESET, 5. PRESET and 6. A2NICAM.

(b) MENU &/^ key........ Select setting items.

(c) MENU

(d) DISPLAY Key............ When this is pressed, you will return to the SERVICE MENU.

*/T

Key ........ Adjust the setting value.

*/T

Key ........ Adjust the setting values of the setting items.

•

Use the number keys on the remote control unit for setting of WHITE BALANCE.

•

For the setting, refer to each item concerned.

3) 6/7. PLUG & PLAY (ON)

This is not used for service.

(4) Release of SERVICE MENU

After completing the setting, return to the SERVICE MENU by pressing the DISPLAY key, then again press the DISPLAY ke y to return to the

normal screen.

16 No. 52062

Page 17

SERVICE MENU

AV-29LS2

AV-29LX2

AV-2968TEE

SUB MENU 1. IF

SERVICE MENU

1. IF

3. DEF

5. PRESET

7. PLUG & PLAY (ON)

1-7 : SELECT DISPLAY : EXIT

******* **** ***** *****

**** **** *** ***

2. VC

4. VSM PRESET

6. A2NICAM

[AV-29LS2]

SERVICE MENU

1. IF

3. DEF

5. PRESET

6. PLUG & PLAY (ON)

1-6 : SELECT DISPLAY : EXIT

******* **** ***** *****

**** **** *** ***

2. VC

4. VSM PRESET

[AV-29LX2, AV-29LX2 /A, AV-2968TEE ]

IF

1. VCO

2. DELAY POINT

1-2 : SELECT DISPLAY : EXIT

SUB MENU 2. VC

V/C

AUTO

1. CUTOFF

50 Hz

MENU 89: SELECT

MENU -/+: OPERATE

(R)

(G)

DISPLAY : EXIT

**

**

Setting item

1. CUTOFF (R/G)

2. DRIVE (R/G/B)

3. BRIGHT

4. CONT

5. COLOUR

6. TINT

7. SHARP

8. YDELAY

9. AMP T.SHARP

VCO (CW)

TOO HIGH

ABOVE REFERENCE

BELOW REFERENCE

TOO LOW

DELAY POINT UHF

AGC TAKE-OVER

-

/+: OPERATE

MHz

*****

DISPLAY : EXIT

**

DISPLAY : EXIT

SUB MENU 6. A2NICAM

[AV-29LS2]

1. ERROR LIMIT

C AD BITS

NICAM ERROR

MENU 89: SELECT

MENU

-

/+: OPERATE

DISPLAY : EXIT

Setting item

1. ERROR LIMIT

2. A2 ID THR

3. SOUND SYSTEM

SUB MENU 5. PRESET

PRESET 50Hz

1. PSNS

MENU 89: SELECT

-

/+: OPERATE

MENU

DISPLAY : EXIT

*****

******

PALB/G

*

MHzA2NICAM

****

****

1. PSNS

2. ACL

3. MUS

4. MAT

5. FCO

6. BPS

7. IFLH

8. VID

9. STM

SUB MENU 3. DEF

DEF

4 : 3

PAL

1. VER. SLOPE

50Hz

MENU 89: SELECT

-

/+: OPERATE

MENU

**

DISPLAY : EXIT

SUB MENU 4. VSM PRESET

STANDARD

TINT

COLOUR

BRIGHT

PICTURE

DETAIL

MENU 89: SELECT

MENU

-

/+: OPERATE

10. AFCW

11. VSW

12. FFI

13. AGC

14. CL

15. AKB

16. HBL

17. BKS

18. READ STATUS

19. VNR

**

**

**

**

**

DISPLAY : EXIT

Setting item

1. VER. SLOPE

2. VER. HEIGHT

3. VER. POSITION

4. VER. SCURVE

5. HOR. POSITION

6. HOR. WIDTH

BRIGHT / STD / SOFT

Setting item

1. TINT

2. COLOUR

3. BRIGHT

PICTURE

4.

5. DETAIL

20. PEAK

21. IVG

22. WPL

23. SOFT CLIPPER

24. IF PLL OFFSET

25. OVERSHOOT

26. HCO

27. HP2

28. AI VOLUME ADN

31. CCCLOOP

4 : 3 / 16 : 9

Setting item

7. EW-PIN

8. EW-TRAPEZ

9. UP CORNER

10. DW CORNER

11. HOR. PARALL

12. HOR. BOW

13. V. ZOOM

Fig. 1

No. 52062 17

Page 18

AV-29LS2

AV-29LX2

AV-2968TEE

ADJUSTMENTS

B1 POWER SUPPLY

Item

Measuring

instrument

Test point Adjustment part Description

Check of

B1 POWER

SUPPLY

Signal

Generator

DC V oltmeter

FOCUS ADJUSTMENT

Item

Adjustment

of FOCUS

Measuring

instrument

Signal

generator

B1 (pin 1)

GND (pin 5)

[CN00S

connector

in MAIN

PWB]

Test point Adjustment part Description

FOCUS VR

[In HVT]

1. Receive a black and white signal.

2. Connect a DC voltmeter between B1 and GND

(between pins 1 and 5 of the connector CN00S).

3. Make sure that the voltage is DC134.5 ± 2V.

Notes:

•Set PICTURE MODE (VSM) to “BRIGHT”.

•The final adjustment of CONVERGENCE must be done after the

FOCUS adjustment. (CONVERGENCE is changed by FOCUS adjustment.)

When makes difference by FOCUS adjustment, should be reconfirming

PURITY adjustment.

1. Receive a cross-hatch signal.

2. While looking at the screen centre, adjust the FOCUS VR so that

the vertical and horizontal lines will be clear and in fine detail.

3. Make sure that the picture is in focus even when the screen gets

darkened.

IF CIRCUIT ADJUSTMENTS

Item

Adjustment

of VCO (CW)

Adjustment

of DELAY

POINT

(AGC

TAKE-OVER)

(AGC TAKE-O VER)

Measuring

instrument

Remote

control unit

VCO (CW)

TOO HIGH

ABOVE REFERENCE

BELOW REFERENCE

TOO LOW

Remote

control unit

Setting Initial setting value

(Adjustment time) NTSC 3.58 OTHERS

DELAY POINT

Test point Adjustment part Description

. MHz

DISPLAY : EXIT

VCO (CW)

fv

YELLOW

DELAY POINT

2630

Note:

•Under normal conditions, no adjustment is required.

1. Select 1. IF from the SERVICE MENU.

2. Select 1. VCO by pressing the 1 key on the remote control unit.

3. Receive a broadcast signal.

4. Check the characters colour of the BELOW REFERENCE displayed

to yellow.

5. Press the DISPLAY key three times to return to normal screen.

1. Receive a black and white broadcast signal (colour off).

2. Select 1. IF from the SERVICE MENU.

3. Select 2. DELAY POINT by pressing the 2 key on the remote con-

trol unit.

4. Adjust the MENU

from the image. An y increase above the initial v alue produces noise

and any decrease below it produces beat.

5. Press the DISPLA Y key three times to return to the normal screen.

6. Turn to other channels and make sure that there are no irregularities.

*/T

key in order to eliminate any noise or beat

18 No. 52062

Page 19

AV-29LS2

AV-29LX2

AV-2968TEE

VC (VIDEO/CHROMA) CIRCUIT ADJUSTMENTS

The setting (adjustment) using the remote control unit is made on the basis of the initial setting values.

The setting values which adjust the screen to the optimum condition can be different from the initial setting values.

Do not change the initial setting values of the setting (adjustment) items not listed in “ADJUSTMENT”.

•

[SUB MENU 2. VC] : Do not adjust.

Setting (Adjustment)

item

Variable range

PAL SECAM NTSC3.58 NTSC4.43 COMPONENT (V–2)

1 CUT-OFF (R/G) -32 – +31 0/0 -2/+14

2 DRIVE (R/G/B) -32 – +31 0/0/0

3 BRIGHT (TV/V-1/V-2/V-3) -32 – +31 -13/0/0/+1 —/—/-1/—

4 CONT -32 – +31 -10 —

5 COLOUR -32 – +31 -4 -13 -11 +1 0

6 TINT (TV/VIDEO) -32 – +31 — — -15/+2 —/+1 —

7 SHARP (TV/VIDEO) -32 – +31 -28/-22 —/0

8Y DELAY (TV/VIDEO) -8 – +7 -7/+1 0/+1 0/0 —/+1

9 AMP T. SHARP -32 – +31 0

Initial setting value

Item

Adjustment

of WHITE

BALANCE

(Low light)

H.LINE OFF

H.LINE ON

R. LEVEL (

Measuring

instrument

Signal

generator

Remote

control unit

MENU : SELECT

MENU -/+: OPERATE

REMOTE CONTROL UNIT

12 3

4

8

)

56

Test point Adjustment part Description

1.CUTOFF (R)

CUTOFF (G)

Note:

•Set PICTURE MODE (VSM) to “BRIGHT”.

SCREEN VR

[In HVT]

1. Receive a PAL black and white signal (colour off).

2. Select 2. VC from the SERVICE MENU.

3. Select 1. CUTOFF (R) and (G) with MENU &/^ key, and set each

value to initial setting value with the 4 and 7 keys, or 5 and 8 keys on

the remote control unit.

4. Press the 1 key on the remote control unit to produce a single hori-

zontal line.

5. Turn the SCREEN VR fully counterclockwise , then slowly turn it clock-

1. CUTOFF

50 Hz

V/C

(R)

(G)

PAL

**

**

wise to where a red, blue or green colour is faintly visible.

DISPLAY : EXIT

6. Use the keys 4 and 7 or 5 and 8 on the remote control unit and

adjust the other 2 colours to where the single horizontal line appears white.

7. Turn the SCREEN VR to where the single horizontal line glows f aintly .

8. Press the 2 key to return to 1. CUTOFF screen.

9. Press the DISPLAY key twice to return to the normal screen.

Setting (Adjustment) Variable Initial setting

Item range value

G. LEVEL (8)

1. CUT OFF

R –32 — +31 0

G –32 — +31 0

R. LEVEL (

789

)

9

G. LEVEL (

)

9

No. 52062 19

Page 20

AV-29LS2

AV-29LX2

AV-2968TEE

Item

Adjustment

of WHITE

BALANCE

(High light)

R. DRIVE (

Measuring

instrument

Signal

generator

Test point Adjustment part Description

2.DRIVE (R)

DRIVE (G)

DRIVE (B)

Remote

control

unit

V/C

1. DRIVE

50 Hz

MENU 89: SELECT

MENU

(R)

(G)

(B)

-

/+: OPERATE

PAL

**

**

**

DISPLAY : EXIT

REMOTE CONTROL UNIT

12 3

4

8

) B. DRIVE (8)

789

)

9

56

G. DRIVE (8)

B. DRIVE (

G.DRIVE (

Notes:

•Proceed to the following adjustment after having completed the adjustment of LOW LIGHT WHITE BALANCE.

•Set PICTURE MODE (VSM) to “BRIGHT”.

1. Receive a PAL black and white signal (colour off).

2. Select 2. VC from the SERVICE MENU.

3. Select 2. DRIVE (R), (G) and (B) with MENU &/^ key, and set

each value to initial setting value with the 4 to 9 keys on the remote

control unit.

4. Use the keys 4 to 9 to produce a white screen.

5. Press the DISPLAY key twice to return to the normal screen.

Setting (Adjustment) Variable Initial setting

Item range value

R –32 — +31 0

2. DRIVE G –32 — +31 0

B –32 — +31 0

)R. DRIVE (

9

)

9

Adjustment

of

SUB BRIGHT

Adjustment

of

SUB

CONTRAST

Remote

control unit

Remote

control unit

3. BRIGHT

4. CONT

Notes:

•Proceed to the following adjustment after having completed the adjustments of LOW LIGHT WHITE BALANCE and HIGH LIGHT WHITE

BALANCE.

•Set PICTURE MODE (VSM) to “BRIGHT”.

1. Receive a broadcast.

2. Select 2. VC from the SERVICE MENU.

3. Select 3. BRIGHT with the MENU &/^ key.

4. Set the initial setting value with the MENU

*/T

key .

5. If the brightness is not best with the initial setting value, make fine

adjustment until you get the best brightness.

6. Press the DISPLAY key twice to return to the normal screen.

Notes:

•Proceed to the following adjustment after having completed the adjustment of SUB BRIGHT.

•Set PICTURE MODE (VSM) to “BRIGHT”.

1. Receive a broadcast.

2. Select 2. VC from the SERVICE MENU.

3. Select 4. CONT with the MENU &/^ key.

4. Set the initial setting value with the MENU

*/T

key .

5. If the contrast is not best with the initial setting value, make fine

adjustment until you get the best contrast.

6. Press the DISPLAY key twice to return to the normal screen.

20 No. 52062

Page 21

AV-29LS2

AV-29LX2

AV-2968TEE

Item

Adjustment

of

SUB

COLOUR-I

Measuring

instrument

Remote

control unit

Test point Adjustment part Description

5. COLOUR

[Method of adjustment without measuring instrument]

Notes:

•Proceed to the following adjustment after having completed the adjustment of SUB CONT.

•Set PICTURE MODE (VSM) to “BRIGHT”.

– PAL COLOUR –

1. Receive a PAL broadcast.

2. Select 2. VC from the SERVICE MENU.

3. Select 5. COLOUR with the MENU &/^ key.

4. Set the initial setting value for PAL COLOUR with the MENU

5. If the colour is not best with the initial setting value, make fine ad-

justment until you get the best colour.

6. Press the DISPLAY key twice to return to the normal screen.

– SECAM COLOUR –

7. Receive a SECAM broadcast.

8. Press the COLOUR SYSTEM button on the remote control unit to

select the SECAM colour system.

9. Make fine adjustment of SECAM COLOUR in the same way as for

“PAL COLOUR”.

– NTSC 3.58 COLOUR –

10. Receive a NTSC 3.58MHz broadcast.

11. Press the COLOUR SYSTEM button on the remote control unit to

select the NTSC 3.58 colour system.

12. Make similar fine adjustment of NTSC 3.58 COLOUR in the same

way as for “PAL COLOUR”.

– NTSC 4.43 COLOUR –

When adjustment is done for NTSC 3.58 COLOUR, appropriate

values are automatically set for NTSC 4.43 COLOUR.

*/T

key.

Adjustment

of

SUB

COLOUR-II

Signal

generator

Oscilloscope

Remote

control unit

Cy

Y

W

TP-47G

TP-E (H)

[CRT

SOCKET

PWB]

Mg

R

G

5. COLOUR [Method of adjustment using measuring instrument]

Notes:

•Proceed to the following adjustment after having completed the ad-

justment of SUB CONT.

•Set PICTURE MODE (VSM) to “BRIGHT”.

– PAL COLOUR –

1. Receive a PAL colour bar signal (full field colour bar 75% white).

2. Select 2. VC from the SERVICE MENU.

3. Select 5. COLOUR with the MENU &/^ key.

4.

Set the initial setting value of PAL COLOUR with the MENU */Tkey.

5. Connect the oscilloscope between TP-47G and TP-E.

6.

Adjust P AL COLOUR to set the v alue (A) in the figure to +15V (V

W-G

).

– SECAM COLOUR –

B

7. Receive a SECAM colour bar signal (full field colour bar 75% white).

8. Press the COLOUR SYSTEM button on the remote control unit to

select the SECAM colour system.

(A)

(–)

0V

(+)

9.

Set the initial setting value of SECAM COLOUR with the MENU */Tkey .

10. Adjust SECAM COLOUR to set the value (A) in the figure to 0V

(VW-G).

– NTSC 3.58 COLOUR –

11. Receive a NTSC 3.58 colour bar signal (full field colour bar 75% white).

12. Press the COLOUR SYSTEM button on the remote control unit to

select the NTSC 3.58 colour system.

13.

Set the initial setting value of NTSC 3.58 COLOUR with the MENU

*/Tkey .

14. Adjust NTSC 3.58 COLOUR to set the value (A) in the figure to

+6V (VW-G).

– NTSC 4.43 COLOUR –

When adjustment is done for NTSC 3.58 COLOUR, appropriate

values are automatically set for NTSC 4.43 COLOUR.

No. 52062 21

Page 22

AV-29LS2

AV-29LX2

AV-2968TEE

Item

Adjustment

of

SUB TINT -I

Measuring

instrument

Signal

generator

Remote

control unit

Test point Adjustment part Description

6. TINT [Method of adjustment without measuring instrument]

Notes:

•Proceed to the following adjustment after having completed the ad-

justment of SUB CONT.

•Set PICTURE MODE (VSM) to “BRIGHT”.

– NTSC 3.58 TINT –

1. Receive a NTSC 3.58 colour bar signal (full field colour bar 75%

white).

2. Press the COLOUR SYSTEM button on the remote control unit to

select the NTSC 3.58 colour system.

3. Select 2. VC from the SERVICE MENU.

4. Select 6. TINT with the MENU &/^ key.

5. Set the initial setting value of NTSC 3.58 with the MENU

6. If you cannot get the best tint with the initial setting value, make fine

adjustment until you get the best tint.

7. Press the DISPLAY key twice to return to the normal screen.

– NTSC 4.43 TINT –

When adjustment is done for NTSC 3.58 TINT, appropriate values are

automatically set for NTSC 4.43 TINT.

*/T

key .

Adjustment

of

SUB TINT -II

Signal

generator

Oscilloscope

Remote

control unit

(B)

Cy

W

Y

TP-47G

TP-E (H)

[CRT

SOCKET

PWB]

B

Mg

R

G

6. TINT [Method of adjustment using measuring instrument]

Notes:

•Proceed to the following adjustment after having completed the ad-

justment of SUB CONT.

•Set PICTURE MODE (VSM) to “BRIGHT”.

– NTSC 3.58 TINT –

1. Receive a NTSC 3.58 colour bar signal (full field colour bar 75%

white).

2. Press the COLOUR SYSTEM button on the remote control unit to

select the NTSC 3.58 colour system.

3. Select 2. VC from the SERVICE MENU.

4. Select 6. TINT with the MENU &/^ key.

5. Set the initial setting value of NTSC 3.58 with the MENU

6. Connect the oscilloscope between TP-47G and TP-E.

(–)

0V

(+)

7.

Adjust NTSC 3.58 TINT to set the v alue (B) in the figure to +2V (V

8. Press the DISPLAY key twice to return to the normal screen.

– NTSC 4.43 TINT –

When adjustment is done for NTSC 3.58 TINT, appropriate values are

automatically set for NTSC 4.43 TINT.

*/T

key .

W-Cy

).

22 No. 52062

Page 23

DEFLECTION CIRCUIT ADJUSTMENTS

The setting (adjustment) using the remote control unit is made on the basis of the initial setting values.

The setting values which adjust the screen to the optimum condition can be different from the initial setting values.

Note:

Proceed to the following adjustment after having completed the adjustments of SUB BRIGHT and SUB PICTURE.

[SUB MENU 3. DEF]

Setting

(Adjustment)

item

Variable range

50Hz

4:3

60Hz

1. VER. SLOPE –32 — +31 +2 0 0 0 —

2. VER. HEIGHT –32 — +31 +31 0 –26 –29 —

3. VER. POSITION –32 — +31 –3 –1 –3 –1 —

4. VER. SCURVE –32 — +31 –10 0 –10 0 —

5. HOR. POSITION –32 — +31 0 +7 0 +7 +7

6. HOR. WIDTH –32 — +31 11 –1 11 –1 —

7. EW-PIN –32 — +31 –12 –1 –13 –12 —

8. EW-TRAPEZ –32 — +31 –4 0 0 –1 —

9. UP CORNER –32 — +31 –20 0 0 0 —

10. DW CORNER –32 — +31 –19 0 0 0 —

11. HOR. PARALL –32 — +31 0 0 0 0 —

12. HOR. BOW –32 — +31 0 0 0 0 —

13. V.ZOOM –32 — +31 –1 –1 14 14 —

Initial setting value

COMPRESS(16:9)

50Hz

60Hz

COMPONENT

DVD (50Hz)

AV-29LS2

AV-29LX2

AV-2968TEE

[COMPRESS (16:9) : OFF, fv: 50Hz mode]

Item

Adjustment

of

Measuring

instrument

Signal

generator

Test point Adjustment part Description

V. SLOPE

Remote

control unit

A

B

Adjustment

of

Signal

generator

V. POSITION

Remote

control unit

1. VER. SLOPE 1. Receive a PAL circle pattern signal of vertical frequency 50Hz.

2. Select 3. DEF from the SERVICE MENU.

3. Select 1. VER. SLOPE with the MENU &/^ key.

4. Set the initial setting value of 1. VER. SLOPE with the MENU

*/T

key .

5. Adjust 1. VER. SLOPE to make “A = B” with the MENU

Blanking

line

*/T

3. VER. POSITION 6. Select 3. VER. POSITION with the MENU &/^ key.

7. Set the initial setting value of 3. VER. POSITION with the MENU

*/T

key.

8. Adjust 3. VER. POSITION to mak e “A = B” with the MENU

A

*/T

key .

key .

(to be continued)

B

No. 52062 23

Page 24

AV-29LS2

AV-29LX2

AV-2968TEE

Item

Adjustment

of

V. HEIGHT

Screen

size

91%

Adjustment

of

H. POSITION

Measuring

instrument

Signal

generator

Remote

control unit

Signal

generator

Remote

control unit

Test point Adjustment part Description

2. VER. HEIGHT

13. V. ZOOM

9. Receive a PAL cross-hatch signal.

10. Select 2. VER. HEIGHT with the MENU &/^ key.

11. Set the initial setting value of 2. VER. HEIGHT with the MENU

*/T

key .

12. Select 13. V . ZOOM with the MENU &/^ key.

13. Set the initial setting value of 13. V . ZOOM with the MENU

14. Adjust 13. V . ZOOM and make the vertical screen size 91% of the

picture size with the MENU

Picture

size

100%

*/T

key .

5. HOR. POSITION 15. Receive a PAL circle pattern signal.

16. Select 5. HOR. POSITION with the MENU &/^ key.

17.

Set the initial setting value of 5. HOR. POSITION with the MENU

*/T

key.

18. Adjust 5. HOR POSITION to mak e “C=D” with the MENU

*/T

*/T

key.

key .

Adjustment

of

H. WIDTH

CD

Signal

6. HOR. WIDTH 19. Receive a PAL cross-hatch signal.

generator

Remote

control unit

Screen size 91%

20. Select 6. HOR. WIDTH with the MENU &/^ key.

21. Set the initial setting value of 6. HOR. WIDTH with the MENU

*/T

key .

22. Adjust 6. HOR. WIDTH and make the horizontal screen size 91%

of the picture size with the MENU

*/T

key .

(to be continued)

Picture size 100%

24 No. 52062

Page 25

AV-29LS2

AV-29LX2

AV-2968TEE

Item

Adjustment

of

SIDE PIN

Adjustment

of

TRAPEZIUM

Measuring

instrument

Signal

generator

Remote

control unit

Signal

generator

Remote

control unit

Test point Adjustment part Description

7. EW-PIN 23. Select 7. EW-PIN with the MENU &/^ key.

24. Set the initial setting value of 7. EW-PIN with the MENU

25. Adjust 7. EW-PIN so that the first vertical lines at the left and right

edges on the screen are straight.

Straight

8. EW-TRAPEZ 26. Select 8. EW-TRAPEZ with the MENU &/^ key.

27. Set the initial setting value of 8. EW-TRAPEZ with the MENU

*/T

key .

28. Adjust 8. EW -TRAPEZ so that the vertical lines at the left and right

edges on the screen are in parallel.

*/T

key .

Adjustment

of

V.S-CURVE

Signal

generator

Remote

control unit

Parallel

4. VER. SCURVE 29. Select 4. VER. SCURVE with the MENU &/^ key.

30. Set the initial setting value of 4. VER. SCURVE with the MENU

*/T

key .

31. Adjust 4. VER. SCURVE so that the spaces of each line on TOP,

CENTRE and BOTTOM become uniform.

TOP

CENTRE

(to be continued)

BOTTOM

No. 52062 25

Page 26

AV-29LS2

AV-29LX2

AV-2968TEE

Item

Adjustment

of

CORNER

Adjustment

of

H. PARALLEL

Measuring

instrument

Signal

generator

Remote

control unit

Signal

generator

Remote

control unit

Test point Adjustment part Description

9. UP CORNER

10. DW CORNER

11. HOR. PARALL 37. Select 11. HOR. PARALL with the MENU &/^ key.

32. Select 9. UP CORNER with the MENU &/^ key.

33. Set the initial setting value of 9. UP CORNER with the MENU

*/T

key .

34. Select 10. DW CORNER with the MENU &/^ key.

35. Set the initial setting value of 10. DW CORNER with the MENU

*/T

key .

36. Adjust 9. UP CORNER and 10. DW CORNER so that the vertical

lines at the four corners on the screen are straight.

38. Set the initial setting value of 11. HOR. PARALL with the MENU

*/T

key.

39. Adjust 11. HOR. PARALL to optimiz e the par allelogram distortion.

Adjustment

of

H. BOW

Signal

generator

Remote

control unit

Straight

12. HOR. BOW 40. Select 12. HOR. BOW with the MENU &/^ key.

41. Set the initial setting value of Select 12. HOR. BOW with the MENU

*/T

key .

42. Adjust 12. HOR. BOW to optimize the horizontal arc distortion.

43. Press the DISPLAY key twice to return to the normal screen.

26 No. 52062

Page 27

[COMPRESS (16 : 9) : OFF, fv: 60Hz mode ]

Item

Measuring

instrument

Test point Adjustment part Description

AV-29LS2

AV-29LX2

AV-2968TEE

Adjustment

of

V. SLOPE

Signal

generator

Remote

control unit

1. VER. SLOPE 1. Receive a NTSC circle pattern signal of vertical frequency 60Hz.

2. Select 3. DEF from the SERVICE MENU.

3. Select 1. VER. SLOPE with the MENU &/^ key .

4. Set the initial setting value of 1. VER. SLOPE with the MENU

*/T

key .

5. Adjust 1. VER. SLOPE to make “A = B” with the MENU

A

Blanking

line

B

*/T

key .

Adjustment

of

V. POSITION

Signal

generator

Remote

control unit

3. VER. POSITION 6. Select 3. VER. POSITION with the MENU &/^ key.

7. Set the initial setting value of 3. VER. POSITION with the MENU

*/T

key.

8. Adjust 3. VER. POSITION to mak e “A = B” with the MENU

A

B

(to be continued)

*/T

key .

No. 52062 27

Page 28

AV-29LS2

AV-29LX2

AV-2968TEE

Item

Adjustment

of

V. HEIGHT

Screen

size

91%

Adjustment

of

H. POSITION

Measuring

instrument

Signal

generator

Remote

control unit

Signal

generator

Remote

control unit

Test point Adjustment part Description

2. VER. HEIGHT

13. V. ZOOM

9. Receive a NTSC cross-hatch signal.

10. Select 2. VER. HEIGHT with the MENU &/^ key.

11. Set the initial setting value of 2. VER. HEIGHT with the MENU

*/T

key .

12. Select 13. V . ZOOM with the MENU &/^ key.

13. Set the initial setting value of 13. V . ZOOM with the MENU

14. Adjust 13. V . ZOOM and make the vertical screen size 91% of the

picture size with the MENU

Picture

size

100%

*/T

key .

5. HOR. POSITION 15. Receive a NTSC circle pattern signal.

16. Select 5. HOR. POSITION with the MENU &/^ key.

17.

Set the initial setting value of 5. HOR. POSITION with the MENU

*/T

key.

18. Adjust 5. HOR POSITION to mak e “C=D” with the MENU

*/T

*/T

key.

key .

Adjustment

of

H. WIDTH

CD

Signal

6. HOR. WIDTH 19. Receive a NTSC cross-hatch signal.

generator

Remote

control unit

Screen size 91%

20. Select 6. HOR. WIDTH with the MENU &/^ key.

21. Set the initial setting value of 6. HOR. WIDTH with the MENU

*/T

key .

22. Adjust 6. HOR. WIDTH and make the horizontal screen size 91%

of the picture size with the MENU

*/T

key .

(to be continued)

Picture size 100%

28 No. 52062

Page 29

AV-29LS2

AV-29LX2

AV-2968TEE

Item

Adjustment

of

SIDE PIN

Adjustment

of

TRAPEZIUM

Measuring

instrument

Signal

generator

Remote

control unit

Signal

generator

Remote

control unit

Test point Adjustment part Description

7. EW-PIN 23. Select 7. EW-PIN with the MENU &/^ key.

24. Set the initial setting value of 7. EW-PIN with the MENU

25. Adjust 7. EW-PIN so that the first vertical lines at the left and right

edges on the screen are straight.

Straight

8. EW-TRAPEZ 26. Select 8. EW-TRAPEZ with the MENU &/^ key.

27. Set the initial setting value of 8. EW-TRAPEZ with the MENU

*/T

key .

28. Adjust 8. EW -TRAPEZ so that the vertical lines at the left and right

edges on the screen are in parallel.

*/T

key .

Adjustment

of

V.S-CURVE

Signal

generator

Remote

control unit

Parallel

4. VER. SCURVE 29. Select 4. VER. SCURVE with the MENU &/^ key.

30. Set the initial setting value of 4. VER. SCURVE with the MENU

*/T

key .

31. Adjust 4. VER. SCURVE so that the spaces of each line on TOP,

CENTRE and BOTTOM become uniform.

TOP

CENTRE

(to be continued)

BOTTOM

No. 52062 29

Page 30

AV-29LS2

AV-29LX2

AV-2968TEE

Item

Adjustment

of

CORNER

Adjustment

of

H. PARALLEL

Measuring

instrument

Signal

generator

Remote

control unit

Signal

generator

Remote

control unit

Test point Adjustment part Description

9. UP CORNER

10. DW CORNER

11. HOR. PARALL 37. Select 11. HOR. PARALL with the MENU &/^ key.

32. Select 9. UP CORNER with the MENU &/^ key.

33. Set the initial setting value of 9. UP CORNER with the MENU

*/T

key .

34. Select 10. DW CORNER with the MENU &/^ key.

35. Set the initial setting value of 10. DW CORNER with the MENU

*/T

key .

36. Adjust 9. UP CORNER and 10. DW CORNER so that the vertical

lines at the four corners on the screen are straight.

38. Set the initial setting value of 11. HOR. PARALL with the MENU

*/T

key.

39. Adjust 11. HOR. PARALL to optimiz e the par allelogram distortion.

Adjustment

of

H. BOW

Signal

generator

Remote

control unit

Straight

12. HOR. BOW 40. Select 12. HOR. BOW with the MENU &/^ key.

41. Set the initial setting value of Select 12. HOR. BOW with the MENU

*/T

key .

42. Adjust 12. HOR. BOW to optimize the horizontal arc distortion.

43. Press the DISPLAY key twice to return to the normal screen.

30 No. 52062

Page 31

[COMPRESS (16 : 9) : ON, fv: 50Hz mode ]

Item

Measuring

instrument

Test point Adjustment part Description

AV-29LS2

AV-29LX2

AV-2968TEE

Adjustment

of

V. HEIGHT

Screen

size

Signal

generator

Remote

control unit

Screen size

13. V . ZOOM

2. VER. HEIGHT

Vertical

amplitude

1. Receive a PAL cross-hatch signal of vertical frequency 50Hz.

2. Select COMPRESS from the MENU and set COMPRESS to ON.

3. Select 3. DEF from the SERVICE MENU.

4. Set the initial setting value of 13. V . ZOOM with the MENU

*/T

key .

5. Select 2. VER. HEIGHT with the MENU &/^ key.

6. Set the initial setting value of 2. VER. HEIGHT with the MENU

*/T

key .

7. Adjust 2. VER. HEIGHT to set the vertical amplitude of the image to

295mm.

Adjustment

of

V. SLOPE

Signal

generator

Remote

control unit

1. VER. SLOPE 8. Receive a PAL circle pattern signal of vertical frequency 50Hz.

9. Select 3. DEF from the SERVICE MENU.

10. Select 1. VER. SLOPE with the MENU &/^ key.

11. Set the initial setting value of 1. VER. SLOPE with the MENU

*/T

key.

12. Adjust 1. VER. SLOPE to make “A = B” with the MENU

A

Blanking

line

B

(to be continued)

*/T

key .

No. 52062 31

Page 32

AV-29LS2

AV-29LX2

AV-2968TEE

Item

Adjustment

of

SIDE PIN

Adjustment

of

TRAPEZIUM

Measuring

instrument

Signal

generator

Remote

control unit

Signal

generator

Remote

control unit

Test point Adjustment part Description

7. EW-PIN 13. Receive a PAL cross-hatch signal.

14 Select 7. EW-PIN with the MENU &/^ key.

15. Set the initial setting value of 7. EW -PIN with the MENU

16. Adjust 7. EW-PIN so that the first vertical lines at the left and right

edges on the screen are straight.

Straight

8. EW-TRAPEZ 17. Select 8. EW-TRAPEZ with the MENU &/^ key.

18. Set the initial setting value of 8. EW-TRAPEZ with the MENU

*/T

key .

19. Adjust 8. EW -TRAPEZ so that the vertical lines at the left and right

edges on the screen are in parallel.

*/T

key .

Adjustment

of

CORNER

Signal

generator

Remote

control unit

Parallel

9. UP CORNER

10. DW CORNER

20. Select 9. UP CORNER with the MENU &/^ key.

21. Set the initial setting value of 9. UP CORNER with the MENU

*/T

key .

22. Select 10. DW CORNER with the MENU &/^ key.

23. Set the initial setting value of 10. DW CORNER with the MENU

*/T

key.

24. Adjust 9. UP CORNER and 10. DW CORNER so that the vertical

lines at the four corners on the screen are straight.

25. Press the DISPLAY key twice to return to the normal screen.

32 No. 52062

Page 33

[COMPRESS (16 : 9) : ON, fv: 60Hz mode ]

Item

Measuring

instrument

Test point Adjustment part Description

AV-29LS2

AV-29LX2

AV-2968TEE

Adjustment

of

V. HEIGHT

Screen

size

Signal

generator

Remote

control unit

Screen size

13. V . ZOOM

2. VER. HEIGHT

Vertical

amplitude

1. Receive a NTSC cross-hatch signal of vertical frequency 60Hz.

2. Select COMPRESS from the MENU and set COMPRESS to ON.

3. Select 3. DEF from the SERVICE MENU.

4. Set the initial setting value of 13. V . ZOOM with the MENU

*/T

key .

5. Select 2. VER. HEIGHT with the MENU &/^ key.

6. Set the initial setting value of 2. VER. HEIGHT with the MENU

*/T

key .

7. Adjust 2. VER. HEIGHT to set the vertical amplitude of the image to

295mm.

Adjustment

of

V. SLOPE

Signal

generator

Remote

control unit

1. VER. SLOPE 8. Receive a NTSC circle pattern signal of vertical frequency 60Hz.

9. Select 3. DEF from the SERVICE MENU.

10. Select 1. VER. SLOPE with the MENU &/^ key.

11. Set the initial setting value of 1. VER. SLOPE with the MENU

*/T

key.

12. Adjust 1. VER. SLOPE to make “A = B” with the MENU

A

Blanking

line

B

(to be continued)

*/T

key .

No. 52062 33

Page 34

AV-29LS2

AV-29LX2

AV-2968TEE

Item

Adjustment

of

SIDE PIN

Adjustment

of

TRAPEZIUM

Measuring

instrument

Signal

generator

Remote

control unit

Signal

generator

Remote

control unit

Test point Adjustment part Description

7. EW-PIN 13. Receive a NTSC cross-hatch signal.

14 Select 7. EW-PIN with the MENU &/^ key.

15. Set the initial setting value of 7. EW -PIN with the MENU

16. Adjust 7. EW-PIN so that the first vertical lines at the left and right

edges on the screen are straight.

Straight

8. EW-TRAPEZ 17. Select 8. EW-TRAPEZ with the MENU &/^ key.

18. Set the initial setting value of 8. EW-TRAPEZ with the MENU

*/T

key .

19. Adjust 8. EW -TRAPEZ so that the vertical lines at the left and right

edges on the screen are in parallel.

*/T

key .

Adjustment

of

CORNER

Signal

generator

Remote

control unit

Parallel

9. UP CORNER

10. DW CORNER

20. Select 9. UP CORNER with the MENU &/^ key.

21. Set the initial setting value of 9. UP CORNER with the MENU

*/T

key .

22. Select 10. DW CORNER with the MENU &/^ key.

23. Set the initial setting value of 10. DW CORNER with the MENU

*/T

key.

24. Adjust 9. UP CORNER and 10. DW CORNER so that the vertical

lines at the four corners on the screen are straight.

25. Press the DISPLAY key twice to return to the normal screen.

34 No. 52062

Page 35

[VIDEO - 2 SET : COMPONENT, fv: 50/60Hz mode]

Item

Measuring

instrument

Test point Adjustment part Description

AV-29LS2

AV-29LX2

AV-2968TEE

Adjustment

of

H. POSITION

Signal

5. HOR. POSITION 1. Receive a PAL circle pattern signal to VIDEO-2 terminal.

generator

Remote

control unit

CD

2. Select VIDEO-2 SET from the MENU and set VIDEO-2 SET to

COMPONENT.

3. Select 3. DEF from the SERVICE MENU.

4. Select 5. HOR. POSITION with the MENU &/^ key.

5.

Set the initial setting value of 5. HOR. POSITION with the MENU

*/T

key .

6 Adjust 5. HOR POSITION to make “C=D” with the MENU

*/T

key .

7. Press the DISPLAY key twice to return to the normal screen.

VSM PRESET SETTING

Item

Setting of

VSM

PRESET

Measuring

instrument

Remote

control unit

SUB MENU 4. VSM PRESET

BRIGHT

TINT

COLOUR

BRIGHT

PICTURE

DETAIL

MENU 89: SELECT

MENU

-

/+: OPERATE

Test point Adjustment part Description

1. TINT

2. COLOUR

3. BRIGHT

4. PICTURE

5. DETAIL

1. Select 4. VSM PRESET from the SERVICE MENU.

2. Select BRIGHT with the PICTURE MODE key.

3. Adjust the MENU &/^ key and MENU

values of 1. TINT – 5. DETAIL to the values shown in the table.

4. Respectively select the VSM PRESET mode f or SOFT and STANDARD, and make similar adjustment as in 3 above.

5. Press the DISPLAY key twice to return to the normal screen.

[Setting Values for SUB MENU 4. VSM PRESET]

VSM preset

**

**

VSM mode BRIGHT STANDARD SOFT

Setting item

**

**

**

DISPLAY : EXIT

1. TINT

SETTING VALUE

2. COLOUR

SETTING VALUE

3. BRIGHT

SETTING VALUE

4. PICTURE

SETTING VALUE

5. DETAIL

SETTING VALUE

15

15

15

30

15 7

*/T

key to reset the set

15 11

No. 52062 35

Page 36

AV-29LS2

AV-29LX2

AV-2968TEE

PRESET SETTING

Do not adjust 5. PRESET in the SERVICE MENU as it requires no adjustment.

•

[SUB MENU 5. PRESET]

Setting item Variable range Initial setting value

1 PSNS 0/1 0

2ACL 0/1 0

3 MUS 0/1 0

4MAT 0/1 0

5 FCO 0/1 0

6 BPS 0/1 0

7 IFLH 0/1 0

8 VID 0/1 0

9 STM 0/1 0

10 AFCW 0/1 0

11 VSW 0/1 0

12 FFI 0/1 0

13 AGC 00/01/10/11 01

14 CL 50 – 95 50

15 AKB 0/1 0

16 HBL 0/1 0

17 BKS 0/1 1

18 READ STATUS — —

19 VNR 00 – 63 25

20 PEAK 0 – 3 1

21 IVG 0/1 1

22 WPL 0 – F 5

23 SOFT CLIPPER 0 – 3 0

24 IF PLL OFFSET 0 – 63 32

25 OVERSHOOT 0 – 3 3

26 HCO 0/1 0

27 HP2 0/1 0

28 AI VOLUME ADN 00/01/10/11 10

31 CCCLOOP 0 – 4 0

AUDIO ADJUSTMENT [AV-29LS2 only]

Do not adjust 6. A2NICAM (1.ERROR LIMIT, 2.A2 ID THR, 3.SOUND SYSTEM) in the SERVICE MENU as it requires no adjustment.

•

[SUB MENU 6. A2NICAM]

Setting item Variable range Initial setting value (fixed)

1. ERROR LIMIT

2. A2 ID THR

3. SOUND SYSTEM

(Do not adjust.)

(Do not adjust.)

(Do not adjust.)

000H – FF0H

00H – FFH

100H

0AH

36 No. 52062

Page 37

PURITY ADJUSTMENT

Note: The final adjustment of CONVERGENCE must be done after the

FOCUS adjustment. (CONVERGENCE is changed by FOCUS

adjustment.)

When makes difference by FOCUS adjustment, should be

reconfirming PURITY adjustment.

WEDGE

AV-29LS2

AV-29LX2

AV-2968TEE

DEFLECTION

YOKE

1. Demagnetize CRT with the demagnetizer.

2. Loosen the retainer screw of the deflection yoke.

3. Remove the wedges.

4. Input a green raster signal from the signal generator, and turn the

screen to green raster.

5. Move the deflection yoke backward.

6. Bring the long lug of the purity magnets on the short lug and position

them horizontally. (Fig. 2)

7. Adjust the gap between two lugs so that the GREEN RASTER will

come into the centre of the screen. (Fig. 3)

8. Move the deflection yoke forward, and fix the position of the deflection yoke so that the whole screen will become green.

9. Insert the wedge to the top side of the deflection yoke so that it will

not move.

10. Input a crosshatch signal.

11. Verify that the screen is horizontal.

P

CRT

4 6

P / C

MAGNETS

• P/C MAGNETS

P : PURITY MAGNET

4 : 4 POLES (convergence magnets)

6 : 6 POLES (convergence magnets)

Fig. 1

PURITY MAGNETS

Long lug