Page 1

AV32X25EUS / AV32X250EU

S

Y

Y

Y

AV32X25EIGY / AV32X25EKG

AV28X25EUS / AV28X25EIG

SERVICE MANUAL

COLOUR TELEVISION

AV28X25EKG

BAS IC CHASSIS

AV32X25EUS / AV32X250EUS

AV32X25EIGY / AV32X25EKGY

AV28X25EUS / AV28X25EIGY

AV28X25EKGY

MF

ⅡⅡⅡⅡ

CONTENTS

! SPECIFICATIONS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

! SAFE TY PRECAUT IONS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

!

FEATURES・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

!

MAIN DIFFERENCE LIST ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

! FUNCTIONS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

!

SPECIFIC SERVICE INSTRUCTIONS

! SERVICE ADJUSTMENTS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

!

PARTS LIST

★

OPERATING INSTRUCTIONS

★

STAND ARD CIRCUIT DIAGRAM

1

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

COPYRIGHT © 2002 VICTOR COMPANY OF JAPAN, LTD.

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 2

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・ 4

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・ 6

・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・ 6

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・ 7

・・・・

・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・ 14

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

33

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

2- 1

8

No.519 94

Jun. 2002

Page 2

A

V32X25EUS / AV32X250EUS

A

A

A

(

(

y)

y)

V32X25EIGY / AV32X25EKGY

V28X25EUS / AV28X25EIGY

V28X25EKGY

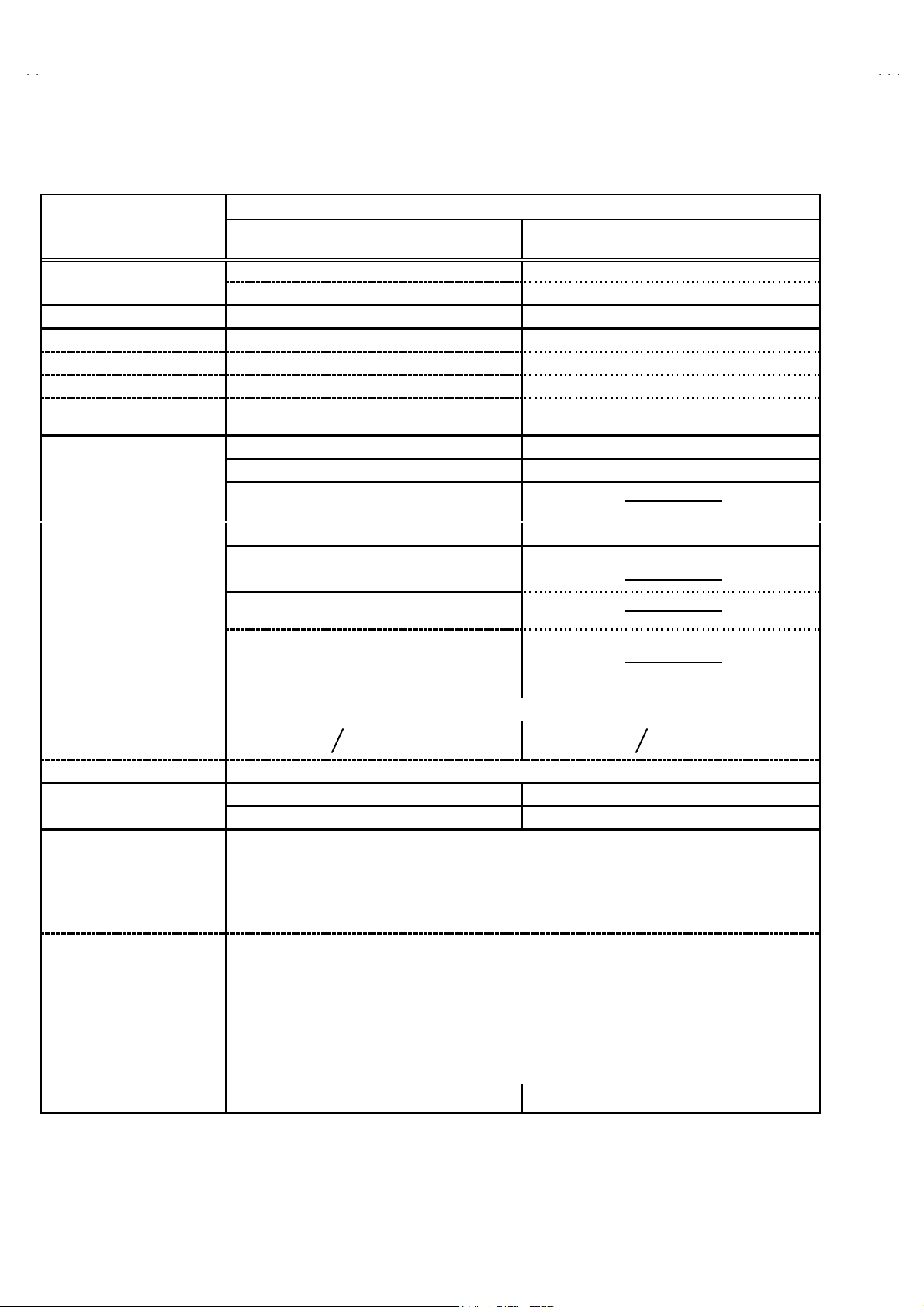

SPECIFICATIONS

Item

AV32 X2 5E US / AV3 2X2 50 EUS / AV28X25E US

Content

AV32 X2 5EIG Y / AV28 X25EIG Y

AV32 X2 5EK GY / AV 28X 25EKGY

32 ”) : 85. 5cm×55.0cm×56 .8c m

(28 ”) : 78. 0cm×50.9cm×49 .9c m

Mass (32 ”) : 54. 2k g / (28” ) : 40.2kg (32”) : 54. 2kg / ( 28” ) : 40. 2k g

TV RF Syste m CCIR ( B /G, D/ K, L, L’,I) CCIR ( I )

Colour Sy stem PA L / SEC A M / NTSC ( Only in EXT mo de ) PA L / NTSC (On ly in EXT mode)

Stere o Sy st em

Teletext System Fastext (UK syst em) / TOP (German syst em)

Receiving Frequency

Intermediate Frequency

Colour Sub Carr ier Fr eq.

Power Input

Power Consumpti on

Aerial Input Term

Picture Tube

Hi gh Vo l t ag e 31.0kV (at zero beam current)

Speake r

Au dio Output 7.5 W + 7.5 W

EX T-1 /EXT -2/E XT-3 ( I N/ OUT)

EXT-4 (Input)

A2 (B /G, D/ K) / NICAM (B/G, I, D/K, L) NICAM ( I )

WST(world standard system)

VHF : 47 MHz ~ 470MHz VHF : 47MHz ~ 470MHz ( EI model )

UHF : 470MHz ~ 86 2MHz UHF : 47 0MHz ~ 86 2 MHz ( EK / E I model )

• Fr enc h c able TV c han n el of br oa dcas t

fr eq ue ncies 1 16~ 1 72MH z & 220~ 46 9MH z

VIF Carr ier : 3 8.9MHz(B/G, D / K, I , L ) / 33.95MHz VIF C arr ier : 3 8. 9MHz

SIF Car r i er : 33 .4MH z(5.5 MHz : B/G ) SIF Carrier : 32.9MHz (6.0MHz )

32 .9 MHz( 6. 0MHz : I )

32 . 4MHz(6. 5MHz : L, D/K)

40.45 MHz ( 6 .5MH z : L ’)

PAL : 4.43 MHz PAL : 4. 43MH z

SE CAM : 4.40625MHz / 4.25MHz

NT S C : 3.58MHz / 4.43MHz NT S C : 3.58MHz / 4.43MHz

AC 2 20V~2 40V , 50Hz

187W (Max)

(32") (28 ” ) (32") (28”)

132W (Avg)

75 Ωun ba l anc ed, C oaxial

(32 ”) : V i ew ab l e ar e a 7 6cm ( meas ured di ag on ally)(32”) : V iewable are a 7 6cm ( meas ured di agon all

(28 ”) : V i ew ab l e ar e a 6 6cm ( meas ured di ag on ally)(28”) : V iewable are a 6 6cm ( meas ured di agon all

1.0kV

+

-1. 5kV

13 cm ×6.5cm , Ova l type×2

21 -p in E ur o c onnector (SCART s o cket)×3

Vide o : Vp-p 75Ω(RC A pin jack)

Au di o (L /R ) : 50 0m Vr ms(- 4d Bs), High Im pe dance (RC A p in j ac k)

S / Vide o Y : 1Vp- p P OSITI VE ( N eg ative sy nc Pr ovide d, when termi nat ed wit h 75Ω)

C : 0 .3V p-p ( B urst si gn al, wh en terminat ed with 75Ω)

178W (Max)

125W ( Av g)

32”) : 85. 5cm×55.0cm× 56 .8cmDimensions ( W××××H××××D )

(28”) : 78. 0cm×50.9cm×49 .9cm

Fastext (UK system)

WST(world standard system)

187W (Max)

132W (Avg)

178W (Max)

125W (Avg)

AUDIO OUT (Va riable)

Headphone jack

Remote Control Unit

0~1Vrms, Low Impedance (RCA pin jack×2)

St ereo min i jac k (φ3.5mm )

RM-C54 (AAA/ R 03 dry cel l batt er y×2) R M-C 55 (AAA/R0 3 dry cell b att er y×2)

De sign & sp eci fic ations are subje ct to cha ng e wi thout notic e .

2

No.51994

Page 3

A

V32X25EUS / AV32X250EU

S

A

A

A

V32X25EIGY / AV32X25EKGY

V28X25EUS / AV28X25EIGY

V28X25EKGY

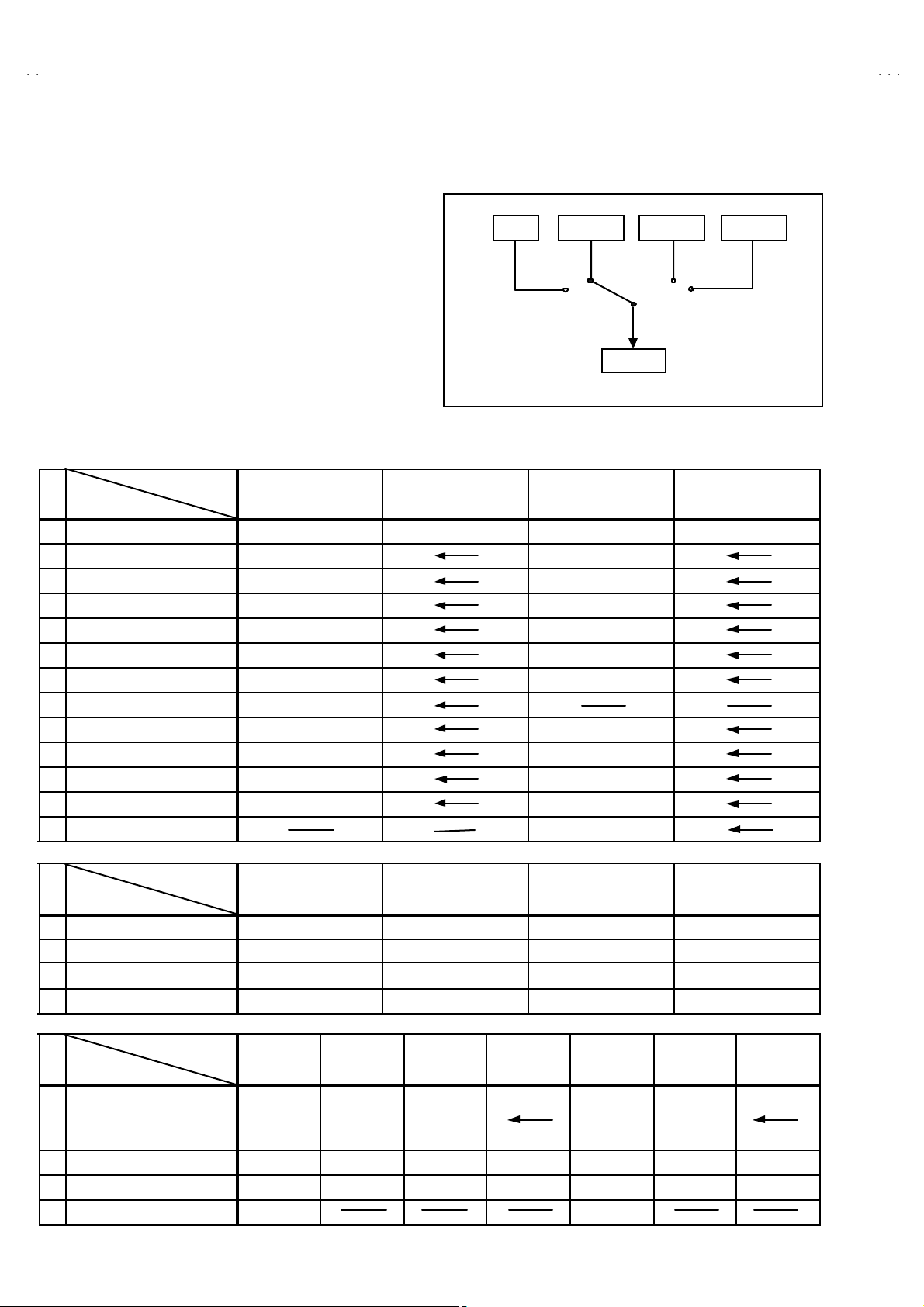

■■■■21-pin Euro connector (SCART socket) : EXT-1 / EXT-2 / EXT-3

(P-P= Peak to Peak, B-W= Blanking to white peak)

Pin

Signal Designation Matching Value EXT-1 EXT-2 EXT-3

No .

1 AUDIO R o ut put 50 0m Vr ms( N om i na l),

Low impedance

2 AUDIO R in put 500m Vr ms( Nominal),

High i m pe dance

3 AUDIO L o utput 50 0m Vr ms( N om i na l),

Low impedance

4 AUDIO G ND ○○○

5 GND (B)

6 AUDIO L input 500mVrms(Nominal),

High i m pe dance

7B input 700mV

8 FUNCTON SW

(SLOW SW)

9 GND (G)

10 SCL3 NC ○ NC

11 G in put 70 0mV

12 SDA3 NC ○ NC

13 GND (R)

14 GND (YS) ○○NC

15 R / C input R : 700mV

16 Ys i n put

17 GND(VIDEO output) ○○○

18 GND(VIDEO input) ○○○

19 VID EO outpu t 1V

20 VIDEO / Y inp ut 1V

21 COMMON G ND ○○○

Low : 0-3V, High : 8-12V, High

impedance

C : 300mV

Low : 0 - 0.4, High : 1 - 3V, 75Ω○ ○

, 75Ω○○NC

B- W

, 75Ω○○NC

B- W

, 75Ω

B- W

, 75Ω

P- P

(Nega tiv e g oi n g s ync ), 75 Ω○

P- P

(Nega tiv e g oi n g s ync ), 75 Ω○ ○ ○

P- P

○

(TV OUT)

○○○

○

(TV OUT)

○○○

○○○

○○○

○○○

○○○

○

(only R)

(TV)

○

(LINE O UT)

○

(LINE O UT)

○○

○

(LINE O UT)

NC

NC

(only C )

NC

NC

[Pin assignment]

No.51994

3

Page 4

A

V32X25EUS

A

A

V32X250EUS

V28X25EUS

SAFETY PRECAUTIONS

1. T he des ign of th is prod uct con ta in s sp ecial har d ware , many

circuit s and components specially for safety purposes. For

con tinu ed pr ot ection , n o c han g es sh ou ld b e ma de to the o rig i nal

d esi gn un les s a uth or i zed i n w riti n g by th e ma nu fact urer.

Replacem en t par ts must b e id ent ic al to thos e u sed in th e or i gin al

ci rcu its. S ervi ce sho ul d b e p erformed by qu alif ied p ers onnel

on ly.

2. Al te rati on s of t he desig n or circui tr y of t he pr oducts sh oul d not be

made. Any design alterations or additions will void the

manu fact ur er 's warrant y and w i ll f urth er r elieve t he ma nufac tu rer

of r esp onsi b ility for perso nal inj ur y or p rop erty d amag e r esul t ing

th erefr om.

3. M an y el ectrical an d m ec h ani cal parts i n th e pr od uc ts ha ve

special safety-related characteristics. T hese characteristics are

oft en no t e v i den t f r om vi s ua l insp ecti on nor ca n t he pr o tect ion

aff or de d by them nece ssarily b e ob tai n ed by us ing rep lacem en t

com po ne nts rated f or hi g he r vo l tag e, watt ag e, etc. R ep l acement

p arts whic h ha v e th ese s p ecial s afet y ch ar ac t er ist ics ar e

ide ntified i n the parts li st of S ervice manua l. El ectric al

components having such features are identified by shading

on t he sche mat ic s and by (!!!! ) on the parts list in Service

manual. The us e of a s ub sti tu te rep lacem en t which do es n ot

h ave th e s ame saf ety ch ar act er ist ics as t he reco mmen de d

replac em ent part shown in th e p ar ts list of S er v ice m an ual m ay

cause shock, fire, or other hazards .

4. Don't short between the LIVE side ground and ISOLATED

(NEUTRAL) side ground or EARTH side ground when

repairing.

Some model's power circuit is partly different in the GND. The

diff er enc e of th e GND is s ho wn b y th e LIV E : (") side GND , the

ISO LATE D(N EUTRAL) : (#) si de GND and EARTH : ($) side

GND. Do n't s h or t bet we en th e LIV E sid e GN D an d

ISO LATE D(N EUTRAL) side GND or EART H side GND an d

n ever m ea sur e w it h a mea sur i ng appa r atus ( osci lloscop e etc.)

th e LI VE sid e GND and IS OLA T ED(NE UTR AL ) side G ND or

EARTH side GND at the s ame time.

If above note will not be kep t, a fuse or any parts will b e broken.

5. If any repair has been made to the chassis, it is recommended

th at t he B1 s et ting shou ld b e ch ecked or adju ste d ( Se e

ADJUST M ENT OF B 1 POW E R SUPPL Y).

6. The high vol ta ge app lie d t o th e pi ctu r e tu be must con form with

th at s p ec ifi ed i n S er v ice m an ual. E xcessi ve h igh voltag e can

cau s e an i ncre ase in X-Ray em i ssi on , ar c i ng an d possible

component damage, therefore operation under excessive high

voltage conditions should be kept to a minimum, or should be

preve nt ed. If s evere arc in g occurs, remove t he AC pow er

immed i ate ly and de termine th e ca use by vis ua l insp ect ion

(inc or r ect install at ion, cr ac ked or melte d high volt age har n es s,

p oor so ldering, et c .) . To m ai nt ain the p rope r min imu m l e v el of

sof t X- R ay emis si on, c omp on en ts in th e hi gh voltag e circui tr y

incl ud i ng t he pic t ur e tu be must b e t he e xact r ep lac em e nts or

alte rn at ives ap prove d by the ma nuf act urer of th e c om pl et e

prod uct.

7. Do n ot c hec k high volt ag e b y draw ing an arc. Use a high volt ag e

meter or a hi g h v ol tag e pr ob e wit h a V TVM. D isc ha rg e th e

picture tube before attempting meter connection, by connecting

a cl i p lead to the grou nd frame a nd c onn ecting th e oth er end of

the lead through a 10kΩ 2W resi sto r to the an od e butt on .

8. W hen service is r equ ire d, ob ser ve th e or i gina l lea d dress. Ex tr a

prec aut ion sh ould b e g i ven t o as sure cor r ec t l ea d dres s in th e

high vol tag e ci r cuit a r ea. W here a s hor t c ircui t h as occu rre d,

th ose co mponent s tha t indic a te evi de nc e of ove r hea ting sho uld

b e r e pl aced. A l wa ys us e th e ma nuf act ur er 's r ep lac em en t

components.

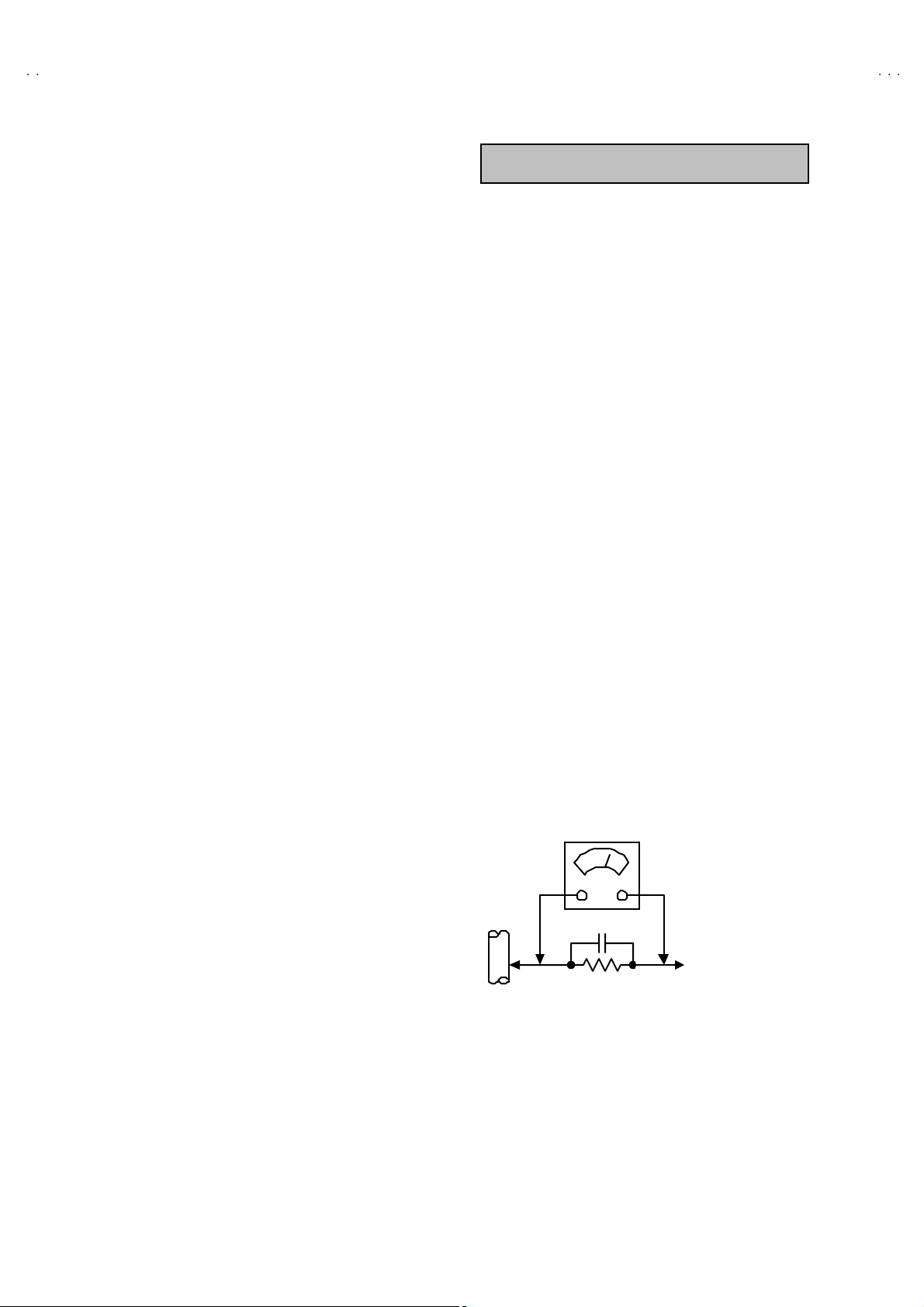

9. Isolation Check

(1) Di electric Strength Test

(2) Leakage Current Check

AV32X25EUS / AV32X250EUS / AV28X25EUS

(Safety for Electrical Shock Hazard)

Af ter r e- as s embling th e p r odu c t, alw ays per f orm an is olat io n

ch ec k on the ex po sed me tal p ar ts of t he c abin et ( a nte nn a

ter m ina ls, video /au dio inpu t and ou tput t erminals, C on trol kn obs,

metal cabin et, s crewhe ad s, ea r ph one j ac k, contr ol shaf ts , etc.)

to be s u re the p r odu c t i s s af e t o o pe r ate with ou t d an ger of

elect rical shoc k.

The i so l ati on be tween the AC pr im a ry ci rcu i t an d all metal p ar ts

exp osed t o th e us er, p arti c ularly an y expos ed met al p art having a

retu rn p ath to t he chass is s ho ul d withs tan d a vol t age of 3 000 V

AC (r.m.s.) for a period of one second.

(. . . . W it hstan d a vo lt ag e of 110 0V A C (r.m. s .) to an ap plianc e

rate d up to 12 0V , an d 3 00 0V AC ( r .m. s.) to an ap pl i an c e rat ed

200V or more, for a period of one second.)

This meth od of test requires a t est equipment n ot g enerally found

in t he s er vic e trade.

Plug th e AC l in e c ord d irect ly into th e AC ou tlet (do n ot use a line

isol ati o n transf ormer du ring this ch eck.) . U s in g a " Lea kag e

Curr ent Teste r", me asure th e lea kage cu rre nt f rom each exp osed

metal p ar t of the c a bi ne t, p art icularly any expos ed me tal part

h avi ng a re turn pa th to t he c h assis , t o a k n ow n go od ea rt h

grou nd (wa ter pi p e, e tc.) . An y l eaka ge curren t m ust n ot e xc eed

0.5mA AC (r.m.s.).

Howev e r, i n tropic al ar ea , th is mus t no t exc e ed 0.2 mA AC

(r.m.s.).

"""" Altern at e Che ck M ethod

Plug th e AC l in e c ord d irect ly into th e AC ou tlet (do n ot use a line

isol ati o n transformer during t his c he ck.). Use an AC v o lt me ter

h avi ng 1 000 oh ms pe r volt or m or e sens it i vity i n th e fo llowi ng

mann er . C on nec t a 1 500Ω 10W res ist or par a lle le d b y a 0 .1 5µF

AC-type c apa cit or bet ween an expo sed met al pa rt a nd a kno wn

g ood e ar th gr o un d ( water pi pe , etc.). Meas ure th e AC vo lt ag e

acr oss th e r es ist or with th e AC vo l tm eter . M ove th e r esis tor

con nec tion to e ach ex p os e d me tal par t, p art ic ularly any exp osed

metal p ar t hav in g a r etu rn pat h to t he chass is, an d m easu re th e

AC vol tag e ac ro s s the r es ist or . Now, re ver s e th e plu g in th e AC

ou tl et and r e peat eac h mea suremen t. Any volt ag e me as u re d

must no t e xceed 0 .7 5V AC (r .m.s.). This c orre spo nds to 0 .5mA

AC (r.m.s.).

Howeve r, in tropica l area, this must not exceed 0.3V AC ( r.m.s.).

This corresponds to 0.2mA AC (r.m.s.).

AC VOLTMETER

(HAVING 1000 Ω/V,

OR MOR E SENSIT IVITY)

0.15μF AC-T YPE

PLACE THIS PROBE

1500 Ω 10W

GOOD EARTH GROUND

ON E A C H EX PO SE D

ME T AL PA RT

4

No.51994

Page 5

A

A

SAFETY PRECAUTIONS

V32X25EIGY / AV32X25EKGY

V28X25EIGY / AV28X25EKGY

AV32 X2 5EIG Y / AV32 X25EKGY

AV28 X2 5EIG Y / AV28 X25EKGY

1. The d esign of thi s pro du ct c ont ai ns spe c i al hard ware and ma ny

circuit s and components spe cially for saf ety pur poses. For

con tinu ed pr ot ection , n o c han g es sh ou ld b e ma de to the o rig i nal

d esi gn un les s a uth or i zed i n w riti n g by th e ma nu fact urer.

Replacem en t par ts must b e id ent ic al to thos e u sed in th e or i gin al

ci rcu its. S ervi ce sho ul d b e p erformed by qu alif ied p ers onnel

on ly.

2. Al te rati on s of the desig n or circ ui tr y of the pr od uc t should no t b e

made. Any design alterations or additions will void the

manu fact ur er 's warrant y and w i ll f urth er r elieve t he ma nufac tu rer

of r esp onsi b ility for perso nal inj ur y or p rop erty d amag e r esul t ing

th erefr om.

3. M an y electr ical a nd me cha nical p arts in the prod uct h av e spe ci al

saf ety- r el at ed charact erist ic s. Thes e ch aracter istic s are oft en not

evi d ent fr om visu al insp ecti o n no r c an th e pr otect ion af for de d by

th em n ecess ar y b e o bta in ed by using r e plac em ent c omponen ts

rate d for hi gh er v ol ta ge, watta ge, etc . R e pl acemen t p arts wh ic h

WARNING

h ave th ese spe ci al saf et y c harac teris tic s ar e i d ent if ied in th e

Pa rts Lis t of S ervi ce Manu al. El ectr ical compon en ts having suc h

fe atur es are i de nti fied by shad in g on the sche ma tic s a nd by (!)

on t he P arts Lis t i n the S ervi ce Man ual . T he use of a sub stitut e

replac em ent whic h d oes no t hav e th e s am e saf ety

ch ar ac ter i sti cs as the r e c om mend ed r epl ace m ent p art sho wn i n

th e Par ts Li st of Se rvice M an ual m ay cau se shock , fire, or ot her

hazards.

4. The lea ds in th e p r odu cts ar e r ou ted an d d res sed with t i es,

cl am ps, tu bi ng ’s , b ar ri e rs and t he like t o be s epa ra ted fr om live

p arts, high t em pe ra tur e pa rts, m oving par ts and / or sh ar p ed ge s

for t he p reven tion of e l ectr i c sh oc k and fire h azard. W he n

ser vice i s requ ired , the or igin al le ad r outi n g and dre ss s h ou ld b e

ob ser v ed , and it should b e co nfirmed t hat th ey h ave b ee n

retu rn ed to no rmal , aft er re- asse mb li n g.

1. The eq ui pm e nt has b een d esigned a nd manu fact ured to me et i nternati o nal saf ety stand ar ds.

2. It is t he l eg al r esp onsib ility o f th e re pa irer t o ensure th at thes e s afet y sta nd ar ds are m aint ai ne d.

3. Rep ai rs mu st b e m ad e in acc ordan ce with th e rel e vant saf ety st an dards .

4. It is essen tial t hat saf ety critical c ompon ents ar e replac ed by a pp ro v ed pa rt s.

5. If main s vol t age s elec tor i s p r ovide d, ch eck s etti n g for loca l voltag e.

No.51994

5

Page 6

A

V32X25EUS / AV32X250EUS

A

A

A

V32X25EIGY / AV32X25EKGY

V28X25EUS / AV28X25EIGY

V28X25EKGY

FEATURES

"

New c hass i s d esi gn ena ble us e of an interac tive on s creen

control.

"

The TELETEXT SYSTEM has a built-in FASTEXT (UK system),

TOP (German syst em) and WST (world standard system)

system.

"

Be caus e th is T V unit corr es p on ds t o multiple x br oa dc a st, u ser s

can enjoy music programs and sporting events with live realism.

In ad di tion , BI LINGUAL pr o gr am s can b e h ear d in th eir original

language.

"

Users can make VCR dubbing of picture and sound by controlling

th e AV se l ec to r t o s el ect a n opt ional s our ce at the E XT-2 ou tpu t

sh own i n fi gu re.

MAIN DIFFERENCE LIST

TV EXT-1 EXT-3

EXT-2

EXT-4

Model Name

!

Part Name

MAIN PW B ASSY SMF-1 40 4A-U2 SMF-1944A-U 2 SMF -1403A-U 2 SMF-194 3A- U2

POWE R & DEF PW B AS SY SM F-240 4A- U2 SMF-2403A-U 2

CRT SOCKE T PWB AS SY SMF-3404A-U 2 SM F-3 40 3A- U2

FRONT CONTROL PWB ASSY

SIDE CONTROL PWB AS SY SMF-8104A-U 2 SM F-8 10 3A- U2

!

ITC T U BE W76 ER F042 X04 4 W66 QD E993 X925

!

DEGA US SING COI L QQW 0066 -0 01 QQW 0100 -0 01

!

ROTATIO N CO IL QQW 0 130-001

!

FBT QQH 0127 -001 QQH0 126- 001

!

REAR COVE R LC1131 6- 00 1A- U LC1128 2- 00 1C - U

CUSH ION AS SY LC1137 3- 00 2A- U LC1131 8- 00 2A- U

PA CKING CASE AE M1002- 07 9-E AE M1002- A76 -E

CORNE R POST AE M3119- 00 3A- E

Model Name

!

Part Name

!

FR ON T CABINET AS SY LC1136 0- 00 4A- U LC1136 0- 00 3A- U LC1131 3- 00 4B- U LC1131 3- 00 3B- U

!

POWER CO RD QMPK160-185-JC QMPN130-185-JC QMPK160-185-JC QMPN130-185-JC

JVC M AR K LC4125 0- 00 2C - C LC4 1250- 001C - C LC4 1250- 002A- C LC4125 0- 00 1C - C

REMOTE CONTROL UNIT RM-C54H-1C RM-C55H-1C RM-C54H-1C RM-C55H-1C

AV32 X2 5EUS

AV32 X2 50EU S

AV32 X2 5EIG Y

SMF-8404A-U2 SMF-8403A-U2

AV32 X2 5EUS

AV32 X2 50EU S

AV32 X2 5EKGY

AV32 X2 5EIG Y

AV32 X2 5EKGY

AV28 X2 5EUS

AV28 X2 5EIG Y

AV28 X2 5EUS

AV28 X2 5EKGY

AV28 X2 5EIG Y

AV28 X2 5EKGY

Model Name

!

Part Name

!

INST BOOK

!

RATING LABEL

EURO LABEL

WARNING LABEL

!

6

AV32X25EU S AV32X250EUS AV32X25EIGY AV32X25EKGY AV 28X25EU S AV28X25EIGY AV28X25EKGY

LC T1184- 00 1A-U

LC T1185- 00 1A-U

LC T1186- 00 1A-U

LC1 141 4-00 3A- U LC1 137 2- 004A -U LC1136 4- 00 8A-U LC1136 4- 00 7A- U LC1 141 4- 00 4A-U LC1136 4- 01 0A-U LC1136 4- 00 9A- U

AEM1064-017-U AEM1064-020-U AEM1064-019-U AEM1064-018-U AEM1064-021-U AEM1064-023-U AEM1064-022-U

LC3 078 9-00 2B- U LC3 078 9-00 2B- U

LC T1185- 00 1A-U LCT11 87- 00 1A-U

LC T1184- 00 1A-U

LC T1185- 00 1A-U

LC T1186- 00 1A-U

LC T1187- 00 1A-U

No.51994

Page 7

A

S

A

A

A

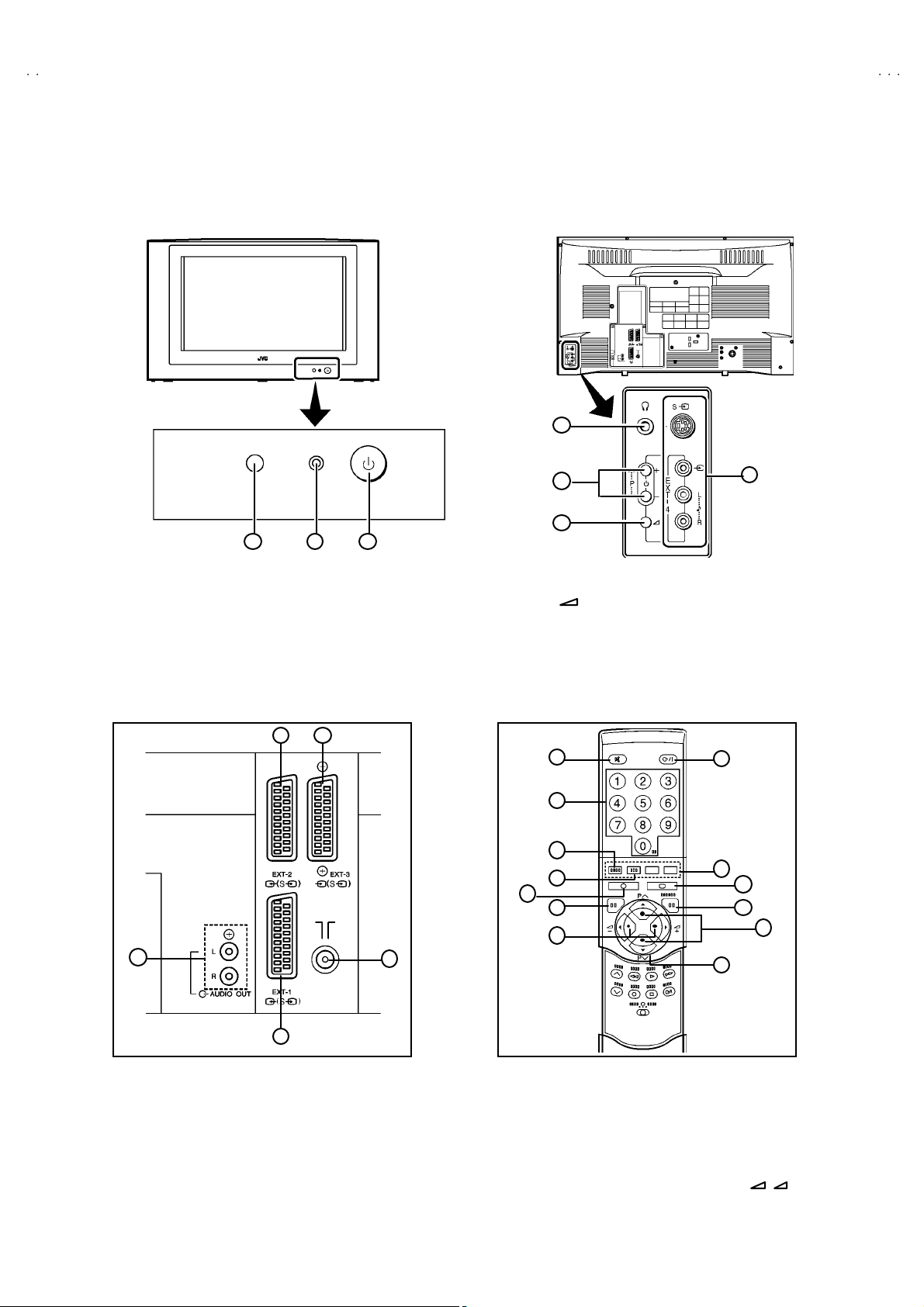

FUNCTIONS

(FRONT) (SIDE)

4

V32X25EUS / AV32X250EU

V32X25EIGY / AV32X25EKGY

V28X25EUS / AV28X25EIGY

V28X25EKGY

5

6

1 2

① R em ote co ntrol se nsor

② Power lamp

③ Main power butt on

3

∨/∧

⑤ P

buttons / -/+ bu ttons

⑥ (Volu me ) but ton

⑦ EXT-4 terminal

④ Headphone jack (mini jac k)

(REAR PANEL) (REMOTE CO NT ROL UNIT)

32

5

4

1

2

3

4

5

6

7

8

9

13

7

10

11

12

1

① EXT-1(IN/OUT) Terminal

② EXT-2(IN/OUT) Terminal

③

EXT-3(IN/OUT) Terminal

④

Aerial Sock et

⑤

Au di o out put t erm ina l

① Mu ting K ey

② Number Key

③

ZOOM Key

④

Hyper Sound Key

⑤

Information Key

⑥ TV Key

⑧ St and by (p ower) Key

⑨ Colour Key

⑩

TEXT Key

⑪

K/MENU Key

⑫

PR Channel ∨/∧Key

⑬

FUNCTION ( / / P∧/ P∨) Key

+ -

⑦ Volume -/+ Key

No. 51994

7

Page 8

A

V32X25EUS / AV32X250EUS

A

A

A

V32X25EIGY / AV32X25EKGY

V28X25EUS / AV28X25EIGY

V28X25EKGY

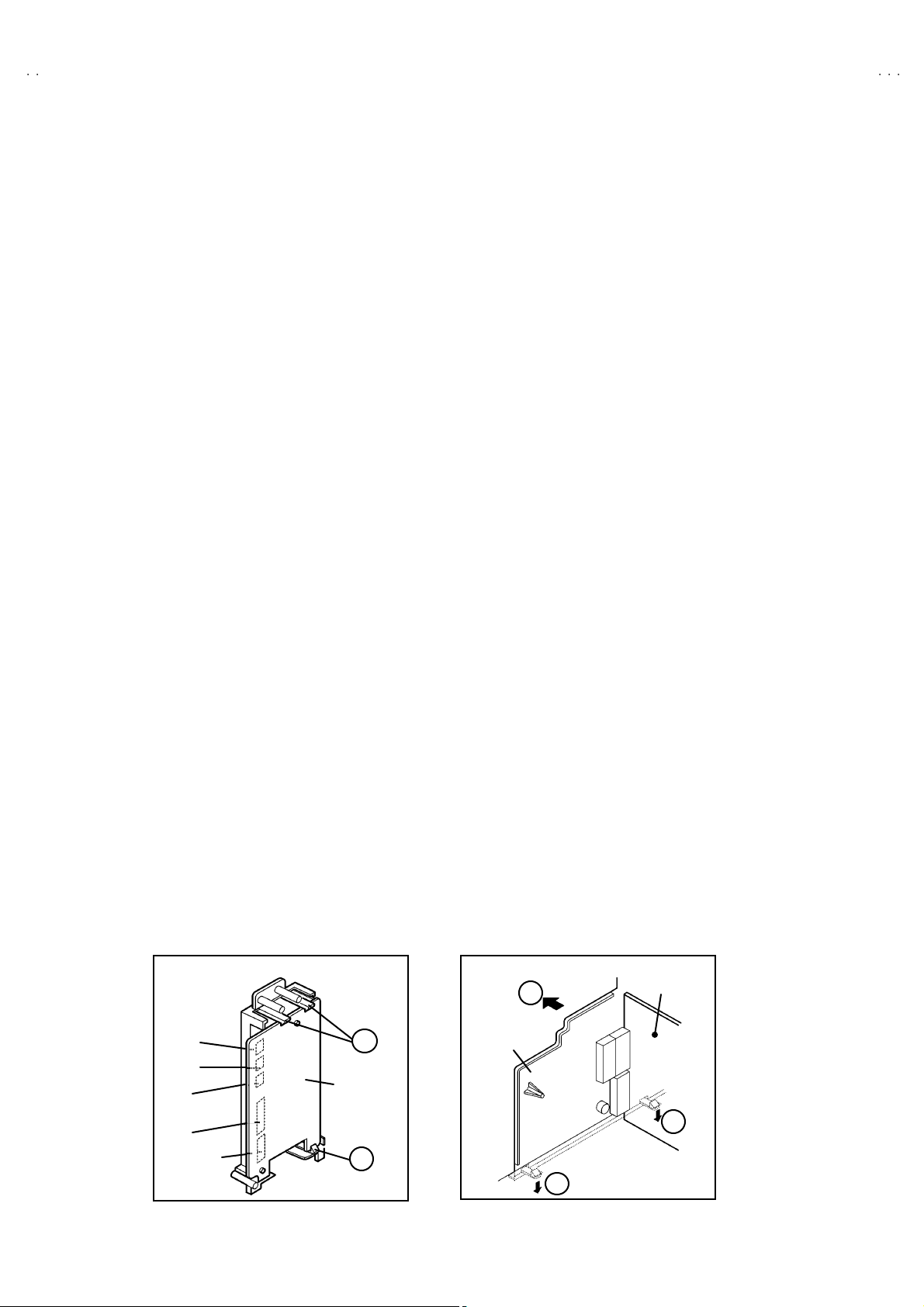

SPECIFIC SERVICE INSTRUCTIONS

DISASSEMBLY PROCEDURE

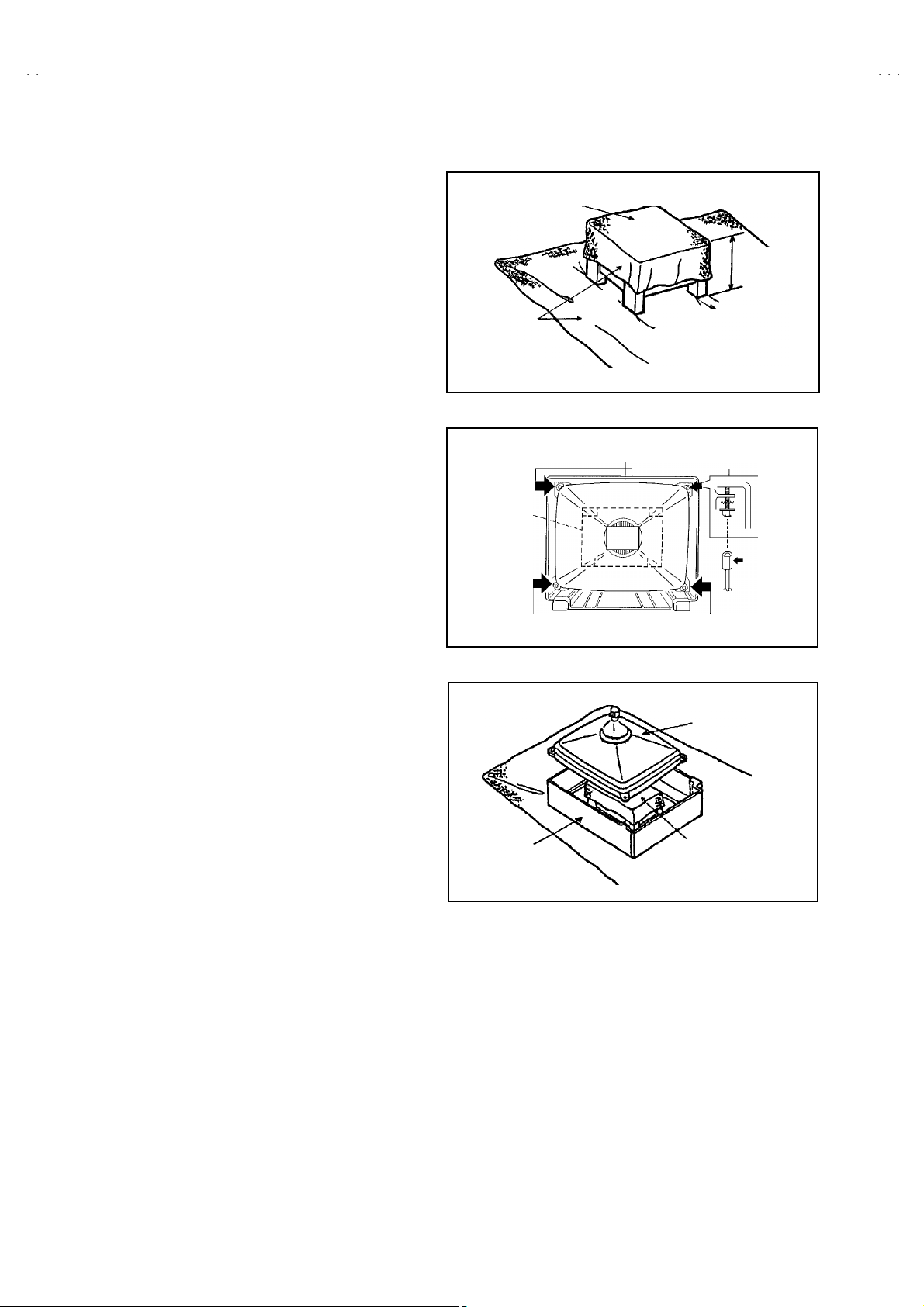

REMOVING THE REAR COVER

1. Unp lu g t he po we r c ord.

2. Remove the 13 screws marked A as s hown i n t he F i g. 1.

3. W i thdr a w t he rear cover towa rd you .

REMOVING THE SIDE CONTROL JACK ASSEMBLY

"

After removing the rear cover.

1. Remove the screw marked B as shown in the Fi g.1 .

2. W hile s l ight l y r ai s e th e side c ontr o l jack asse mb ly, r em ov e th e 2

claws under the side control jack assembly.

3. Disc onn ect th e c onn ecto r “SR ”, “ SL”, “ S”, “F” and “CN01 6” as

shown in Fig 2.

REMOVING THE SIDE CONT ROL PWB

"

Af ter remov i ng th e re ar cov er an d sid e co ntr ol j ac k ass embly.

1. Remove th e 3 claws C from b ack side of the side control jack

asse mb l y as s hown in Fi g. 2.

2. Pu ll out the SI DE C ON T RO L PW B.

REMOVING THE CHASSIS

" After removing the rear cover.

1. Slight l y r ai se th e bo th si de s of th e c hassis by h and and re mo v e

th e tw o c laws u nd er the b oth sid es of the chass is from t he fr o nt

cab inet .

2. W i thdr a w t he chass is back w a rd .

(If n ecessary, take off the wire clamp, connecto rs etc.)

REMOVING THE POWER & DEF. PWB

"

After removing the CHASSIS.

1. Remove the 3 sc r ews m arked D a s sh own in the Fig.1 .

2. Remove the PO W ER & D EF. PW B upper .

(If n ecess ary, ta ke o ff the wire c lamp, co nnectors, etc.)

REMOVING THE SPEAKER

" After removing the rear cover.

1. R em ove t he 2 scr ew s marked E, and rem ove the sp eake r hold er

as s hown in F i g. 1.

NOTE : When rem oving th e scr ew s marked E of t he sp eaker ho lder

remove t he lower si de s cr ew fir s t, an d t hen r em ov e the

up per one .

2. Remove the 2 screws F a tta ching th e sp ea ker.

3. Follow th e s ame st eps wh en r em oving th e oth er ha nd spe aker.

REMOVING THE AV TERMINAL BOARD

"

After removing the rear cover.

1. R em ove th e 3 scr ew s marked G as show n i n t he F ig . 1 .

2. Remove the 2 claws marked H under the CHASSIS as shown in

Fig. 3.

3. Remove the AV TERMINAL BOARD slightly in the directio n of

arrow I as shown in Fi g. 3.

CHECKIN G THE PW BOARD

To c h eck the b ack side of th e PW Boar d.

1) Pull out the chassis. (R efer to REMOVING THE CHASSIS).

2) Erect t he c hassis vertically so that you c an easily check the

b ack side of th e PW Boar d.

[CAUTION]

"

When erecting the chassis, be caref ul s o that there will be no

con tact ing with ot her PW Boar d.

"

Be fore tur n in g on pow er , ma k e sur e tha t the wire co nn ecto r i s

prop er ly c on nec ted .

"

W hen condu cting a check with p ow er supplied , be sur e to c onfi r m

th at t he CRT E ARTH W I RE (BRAID ED AS S’Y) i s co nne cted t o

th e C R T SOC KE T PW b oar d.

WIRE CLAMPIN G AND CABLE T YING

1. Be sure t o clamp th e wire.

2. N ever rem ove th e c able tie use d f or ty i ng th e wires to ge the r.

Sh oul d it be i n adve rt ent ly remove d, b e sure to ti e th e wir es wit h

a n ew c able ti e.

I

Connector

SR

SL

S

F

CN0 16

C

SI DE

C ONT RO L

PWB

C

(Back view)

Fig . 2

8

No.51994

AV TERMINAL

BOARD

H

Fig . 3

AV SW PWB

H

Page 9

A

S

A

A

A

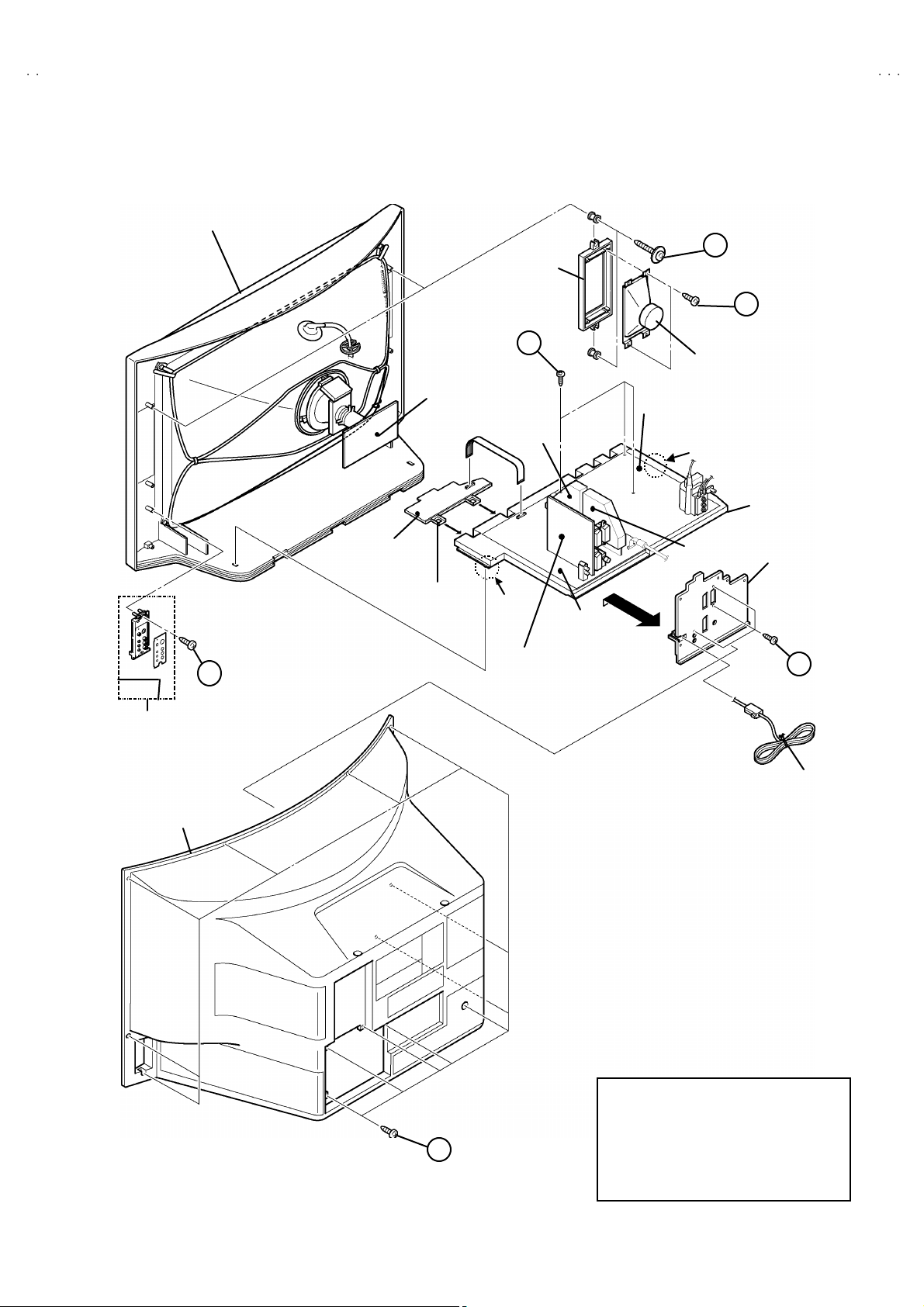

FRONT CABINET

(

)

(×3)

(×2)

(

)

SP EAKER

HOLDER

V32X25EUS / AV32X250EU

V32X25EIGY / AV32X25EKGY

V28X25EUS / AV28X25EIGY

V28X25EKGY

E

F

×

2

Fig.2

SI DE C ONTR OL

JACK ASSEMBLY

D (×3)

CRT

SOCKET

PWB

FRONT

C ONT RO L

PWB

C ONT RO L

BAS E

B

MICOM

PWB

CLAW

MAI N

PWB

AV SW

PWB

POWER & DEF.

PWB

SI DE

SP EAKER

CLAW

10 0Hz

PWB

CHAS SIS

AV TERMINAL

BOARD

G

POWER CORD

REAR COVER

A

×

13

Fig . 1

No.51994

Thi s expl o de d vi ew d escr i bes a bo ut 32”

models.

Alth ou gh 2 8” m ode ls ar e sli gh tly di ffe r ent

fr om th is f igur e, you can use the exp lod ed

vi ew f or di sass emb l ing t he 28 ” mod els in

same step as 32” models.

9

Page 10

A

V32X25EUS / AV32X250EUS

A

A

A

V32X25EIGY / AV32X25EKGY

V28X25EUS / AV28X25EIGY

V28X25EKGY

REMOVING THE CRT

∗

Replacem en t of the CR T sho ul d be p erformed b y 2 or m or e

p ers ons.

• After removing the cover, chassis etc.,

1. Putti ng the C R T c hange table on sof t cl oth , th e CRT c ha ng e tabl e

sh ould al so b e c overe d with s uch soft c lot h ( sho wn in Fi g. 8).

2. W hile kee pin g th e s urf ac e of C RT down , m ou nt the TV s et on t he

CRT change table balanced will as shown in Fig.9.

3. R em ove 4 sc re ws mar ked by arr o ws wi th a box typ e scr ew d ri ve r

as s hown in Fig. 9.

• Si nc e th e cab i net wi ll dr op w he n s crews h ave be en r em ove d, b e

sure t o su pp ort t he cab inet with h ands.

4. After 4 screws have been removed, put the cabinet slowly on

cloth (At this ti me, be carefully so as not to damage th e front

sur fac e of th e c abin et) sh own in Fig. 10.

• T he CR T sh oul d b e ass embled acc or di n g to th e o pp os i te

sequence of its dismounting steps.

∗

The C RT chang e t able sh ould pr ef erab l y b e small er t hat th e CRT

sur fac e, and i ts h ei gh t b e abo ut 35c m.

CRT CHAN GE TABLE

AP PROX.

35 cm

CLOTH

Fig. 8

CRT

CRT

CHA NGE

TABLE

BOX

TYPE

SCREW

DRI VER

CABINET

Fig. 9

CRT

CRT

CHANGE TA BLE

Fig. 10

10

No. 51994

Page 11

A

S

A

A

A

REPLACEMENT OF CHIP COMPONENT

! CAUTIONS

1. Avoid heating for more than 3 seconds.

2. D o n ot rub t he elec t ro des an d t he resi st p ar ts of the p att er n.

3. W hen rem oving a c hip par t, mel t th e s older adequ atel y.

4. D o n ot reuse a ch ip p ar t after removi ng it .

! SOLDERING IRON

1. U se a hig h ins ulati o n s older ing iron with a t hin po in ted end of it.

2. A 3 0w s older ing i r on is r ec ommended for easily r em ovi ng par ts.

!

REPLACE MENT STEPS

1. How to remove Chip parts

####

Resi st ors, ca pa cit o rs , etc

(1) As sh own in t he f igure, pu s h th e pa rt with tw ee zers and

alte rn at ely m elt th e sol de r at each en d.

(2) Sh if t w i th tweez e rs and r emo ve th e ch i p p ar t.

#### Trans ist o rs, dio des , va ria bl e r esistor s, etc

(1) Ap pl y e xt ra so ld er to each le ad .

SOLDE R SOLDE R

V32X25EUS / AV32X250EU

V32X25EIGY / AV32X25EKGY

V28X25EUS / AV28X25EIGY

V28X25EKGY

2. How to install Chip parts

####

Resi st ors, ca pa cit o rs , etc

(1) Apply sold er to th e p att ern a s indic ate d in the fig ure.

(2) Gr asp t he c h i p p art with twee zer s and pl ac e it on the s old er.

The n hea t and me lt th e so lder a t b oth ends of t he chip part.

#### T rans isto rs, dio d es , va ria bl e r esistor s, etc

(1) Apply sold er to th e p att ern a s indic ate d in the fig ure.

(2) Gr asp th e chip part w it h t we eze rs and p lace it on the so lder .

(3) First solder lead A as indica ted in t he figu re.

A

(2) As sh own in t he f igure, pu s h th e pa rt with tw ee zers and

alte rn at ely m elt th e sol d er at eac h le ad . S hift an d r em ov e the

chip part.

(4) Then so ld er l e ads B and C.

Note : A fte r re moving t he part , remove r emaining solder fr o m the

pattern.

C

A

C

No.51994

B

B

11

Page 12

A

V32X25EUS / AV32X250EUS

A

A

A

V32X25EIGY / AV32X25EKGY

V28X25EUS / AV28X25EIGY

V28X25EKGY

REPLACEMENT OF MEMORY ICs

1. Memory ICs

This TV use memory ICs. In the memory ICs, there are memorized data

for cor r ec tl y op er ati n g th e vid eo and def l ecti on circu its . W h en r ep lac ing

memory IC s , b e sure t o us e ICs writte n with th e ini ti al values of da ta.

2. Procedure f or replacing memory ICs

PROCE DURE

(1) Powe r off

Switch the p ower of f and un pl ug the p ower cord f ro m t he ou tlet.

(2) R ep la ce ICs.

Be sure to use memory ICs written with the init ial data values.

(3) Po we r o n

Plug th e pow er c ord i nt o the ou tlet a nd switch t he power on .

(4) C heck an d s et SY STEM CO NSTA NT SET :

It must not adjus t without signal.

****

1) Pr ess th e IN FO RMATI ON ke y and th e MUTING key of th e

REMOTE CONTROL UNIT simultaneously.

2) The SERVICE MENU screen of Fig. 1 will be displayed.

3) While th e S ER VICE ME NU is d is playe d, pres s th e

INFORMATION key and MUTING key s imultaneously, and the

SYSTEM CONSTANT SET screen of Fig. 2 will be display ed.

4) Check th e s e tting va lues of the S YSTEM CON STA NT SET of

Table 1. If the valu e is differe nt, se lect the s ettin g item with th e

FUNCTION U P/ DOWN ke y, an d s et t he c orrect value with the

FUNCTION - /+ ke y.

5) Press the MENU key to memorize the sett ing value.

6) Press t he INFORMATION ke y t wice, a nd retu rn t o th e normal

screen.

SE RV ICE MEN U

1. IF 2. V/C

3. A UDI O 4. D EF

5. VSM P RESET 6. S TAT US

7. P IP 8. -- -

9. SHIPPING (OFF) 0. BUS FREE

1 -9 : SE LE CT

SYS TE M C ONS TA NT S ET

1. DESTINATION EU

- /+ : STORE i : EXIT

OK

Fig.1

Fig.2

i

: EXI T

NAME OF REMOTE CONTROL KEY

(5) Setting o f re ceive chann e ls

Names of key

ke y

Se t th e r ec eive ch anne l.

For setting , refer to the OPE RATING IN S TRUC TIONS.

(6) U ser se ttings

INFORMATION

MU T I N G

iiii

Check th e us er sett in g values of T ab le 2, and i f sett in g v alue is

diff er ent , set the c orr ec t val u e.

For setting , refer to the OPE RATING IN S TRUC TIONS.

(7) Setting of SERVICE MENU

Ve rif y the set ti ng it ems of th e SE RVICE MENU of Tab le 3, and r ese t

ME NU

FUNCTION UP/ DOWN

OK

▼

▼

where n ecessary.

For setting , refer to the SE RVIC E ADJU STM ENTS.

FUNCTION -/+

▼

▼

12

No. 51994

Page 13

A

V32X25EUS / AV32X250EU

S

A

A

A

AV32X25EKGY

AV32X25EIGY

V32X25EIGY / AV32X25EKGY

V28X25EUS / AV28X25EIGY

V28X25EKGY

SETT ING VALU ES OF SY ST EM CO NS TANT SE T (TABLE 1)

Setting item Setting content Setting value Setting item Setting content Setting value

AV32X25EUS

AV 32X 250E US

DESTIN A TION

CRT TYPE 16:9 BBE YE S

EKEU EI

4:316 :9

AV28X25EUS

AV28X25EKGY

AV28X25EIGY

EU

PIC&TE XT NO

EK

DOLB Y NO

EI

NO

YE SNO

YE SNO

YE S

PURITY NO PROGRESSIVE NO

PICTURE TILT YES TDA9178 NO

DIGIP URE PRO NO TONE I C NO

PIP NO FLAT YE S

NO

1TUNERNO 2TUNER

YE SNO

YE SNO

YE S

NO

YE SNO

YE S

YE SNO

YE SNO

USER SETTING VALUES (TABLE 2)

PICTURE SE TTING EX T SETTI NG

TINT COOL

CONTRAST / BRIGHT

SHAR P / COLO UR

PICTURE FEATURES FEATURES

DIGITAL VNR AUTO

COLO UR S YST E M T V : Acco rdin g t o pr eset C H

4:3 AUT O ASPECT PA NO RAMIC

SOUND SETTING INSTALL

BA SS / T REBLE / BA LANCE LANGUAGE ENGLISH

HYPE R S OU ND

BB E

REFER to VSM PRESET

EXT : AUTO

CENTER

OFF

ON

ID

S-IN

DUB BING

SLEEP TIMER

BLUE BA CK

EDIT/MANUAL PRES ET CH only

BLANK

BLANK

EXT- 1→EX T-2

OFF

ON

The others : BLANK

SERVICE MENU SETING ITEMS (TAB LE 3)

Setting item Setting value Setting item Setting value

1. IF

2. V / C

3.A UDIO

(Do not adjust)

9.S HIPPI NG

(Do not adjust)

1. V CO

2. ATT ON /OFF

1. RGB BL K

2. W D R R

3. W D R G

4. W D R B

5. BRIGHT

6. CONTRAST

7. COLO UR

8. HUE

9. SHAR P

10. VC O A DJ .

11 . VID AGC

12 . SY C SL I

13 . A M OV I E

1. ER R LI MIT

2. A2 ID THR

3. Q-PEA K

ON/OFF

4. DEF.

5. VSM P RESET

COOL

NORMAL

WARM

6.S TATUS

(Do not a djust)

1. V-SHIF T

2. V-SIZE

3. H-CENT

4. H-S IZ E

5. TR APE Z

6. EW - PIN

7. COR-PIN

8. COR-UP

9. COR-LO

10. ANGLE

11 . BOW

12. V-S.CR

13 . V- LIN

1. CONT.

2. BRIGHT

3. SHAR P

4. COLO UR

5. HUE

6. W D R R

7. W D R G

8. W D R B

VP S

PDC

**** : Do not adjust

No. 51994

13

Page 14

A

V32X25EUS / AV32X250EUS

A

A

A

V32X25EIGY / AV32X25EKGY

V28X25EUS / AV28X25EIGY

V28X25EKGY

SERVICE ADJUSTMENTS

BEFORE STARTING SERVICE ADJUSTMENT

1. T here ar e 2 w ays of adjusting this TV: One is wi th the

REMOTE CONTROL UNI T and the other is the conventional

method using adjustment parts and components.

2. The setting (adjustment) using the REMOTE CONTROL

UNIT is made on th e ba sis o f the initial setting va lues . Th e

se tting va lues whic h a dj ust the sc ree n to t h e optimu m

condition can be differ ent from the initial setting values.

3. M ak e s ure th at conn ect ion i s c orrec t l y made t o AC p ower

source.

4. T ur n on th e powe r of th e TV a nd m easu r in g instrument for

warmi n g u p for at l east 30 m in ut es b ef ore sta rt in g adj u s tm ent .

5. If th e r ec ei ve or inp ut sig nal is not sp eci fi ed , use t he most

ap pr op ria te s igna l f or a dj ust me nt.

6. Never touch p arts ( s uch as v ar iab le resist or s, tr an s for m er s an d

condensers) not shown in the adjustment items of this service

adjustment.

7. Pr ep arati o n for adj ustmen t ( pr es etti n g) :

Unles s oth er w is e s p ec ified i n th e a djust ment it em s , p rese t th e

follo wi n g functions with th e REM OTE CO NT ROL UNI T.

"

Setti ng position

PICTURE MODE (VSM) NORMAL

SLEEP TIMER OFF

TONE BALAN CE CENTER

ZO OM FULL

MEASURING INSTRUMENT AND FIXTURES

1. DC voltmeter (or digital voltmet er)

2. Oscilloscope

3. Sign al g en erat or (Patt ern g en erat or) [ PAL / SE CA M / NTSC ]

4. Remote control unit

ADJUSTMENT ITEMS

●

Check ing i t ems.

●

Adjustment of FOCUS & SCREEN

●

VS M p r eset ad ju st s ettin g.

●

VIDEO / CHROMA circuit adjust ment.

●

DEFLECTION c ircuit adjustment.

●

AUDIO circuit adjustment. (Do not adjust)

14

No. 51994

Page 15

A

S

A

A

A

CN0

(

)

ay

CN00

U

SLSFCN016

ADJUSTMENT LOCATIONS

FRONT

FRONT CONTROL PWB

F8901

PW

PO WER SW

V32X25EUS / AV32X250EU

V32X25EIGY / AV32X25EKGY

V28X25EUS / AV28X25EIGY

V28X25EKGY

SIDE CONTROL PWB

TOP

HEAD

PH O NE

S-IN

E

UP

X

DOWN

MEN

T

4

CN001

W

SR

FRONT

AV SE L PW B

MAIN P WB POW ER &DE F PW B

CN001

TU NER

CN002

MICOM

100Hz

CN013

W DEG

4

CN005

HV

CN006

CN014

HVT

FRONT

X

1

5

TOP

CRT SOCKET PWB

TP-E

CN013

SOLDER SIDE

TP-47B

14

TP-Y

E1

FOC US

SC R EEN

28"MODEL

No. 51994

1pin:B1(TP-91)

2pin:NC

3pin:X-ray

4pin:X-r

5pin:TP-E

32"MODEL

FOC US 1

FOC US 2

SC R EEN

15

Page 16

A

V32X25EUS / AV32X250EUS

A

A

A

y

y

V32X25EIGY / AV32X25EKGY

V28X25EUS / AV28X25EIGY

V28X25EKGY

BASIC OPERATION SERVICE MENU

1. TOOL OF SERVICE MENU OPE RATION

Operate the SERVICE MENU with the REMOTE CONTROL UNI T.

2. SERVICE M ENU ITEMS

With the SERVI CE MEN U, various s ett ings ( ad ju stm en ts) can b e m ade , a nd th ey a re b r oad l y c las sified in th e f ol l ow i ng ite ms of set tings

(adjus tm ents ):

(1) 1. IF ・・・・・・・ ・・・・・・・・・・・・・ ・・・ This mode a djust s the se tting values of the IF circuit .

(2) 2.V /C ・・・・・・・・・・・・・・・・・・・・・・ This m ode adjust s th e se tting values of the VIDEO / CHRO MA circu it.

(3) 3.AUDIO・・・・・・・・・・・・・・・・・・・ This mode adjusts the setting values of the mult iplic ity SOUND circuit.

(4) 4. DEF ・・・・・・・・・・・・・・・・・・・・ ・ T hi s mode adj ust s th e se tti ng valu es o f th e DE FLECTION ci r c uit f or eac h as pect m od e g iven belo w .

FULL (100/120Hzi)

PA NO RA MIC ( 100 /1 2 0H z i )

SUBTITLE (100/120Hzi)

COMP RE SS (Fi x ed va lu e) ( 100 /1 20Hzi )

(5) 5.V SM PRESET

(VSM : Video Status Memory)

3. BASIC OPERATION OF SERVICE MENU

(1) Ho w to enter SERVICE MENU

Press the “INFORMATION” key and the “MUT ING” key of the

REMOTE CONTROL UNIT simultaneously, and the

SERVICE MENU screen of Fig.1 will be displayed.

(2) Selecti on of SUB MENU SCREEN

Press one of keys 1~5 of the REMOTE CONTROL UNIT

an d sel e ct th e S UB M EN U S C R EEN ( See F i g. 3 ), fo rm th e

SERV ICE MENU.

SERVICE MENU → SUB ME NU

・・・・・・・ ・・・・・・

1. IF

2. V / C

3. AUDIO

4. DE F.

5. VS M PRESE T

6. STATUS

7. PI P

8. ---

9. SHIP PING ( OF F)

0. BUS FREE

Thi s mod e adj ust s th e i n iti a l s etting values of CO OL, NORMAL an d W ARM.

SE RVICE M EN U

SE RVIC E ME N U

1. IF 2. V/C

3. AUDIO 4. DEF

5. VS M PRES ET 6. ST ATU S

7. PIP 8. ---

9. SH I PP ING ( OFF ) 0. BU S FR EE

****

: Do not adjust

1- 9 : SEL ECT

NAME OF REMOTE CONTROL KEY

Names of ke

INFORMATION

MU T I N G

ME N U

FUNCTION UP/DOWN

FUNCTION -/+

Fig.1

Fig.2

i

: EXI T

ke

iiii

OK

▼

▼

▼

▼

16

No. 51994

Page 17

A

S

A

A

A

SE RVICE M EN U

SERVICE MENU

1. I F 2. V/C

3. AUDIO 4. DE F

5. VSM PRESET 6. STATUS

7. PIP (OFF) 8. - - -

9. SHIPPING (OFF) 0. BUS FREE

1-9 : SELE CT : E XITi

V32X25EUS / AV32X250EU

V32X25EIGY / AV32X25EKGY

V28X25EUS / AV28X25EIGY

V28X25EKGY

1. V- SHIFT

2. V- SIZE

3. H-CE NT

4. H-S IZE

5. TRAPEZ

6. EW -PIN

7. COR-PIN

8. COR-UP

9. COR-LO

10. A NGLE

11. B OW

12.V- S.CR

13.V- LIN

DE F *** Hz FULL

1. V- SH I FT

: STORE i : EXIT

OK

- / +

4. DEF

***

1.IF(VCO)

IF SER VICE M ENU

1. VCO

2. ATT ON/ O FF

1-2 : SE LECT i : EXIT

2. V/C

PAL

****

1. RGB_BLK

OK

- / +

V/C

: STORE i : EXIT

Do no t move

1. RGB BLK

2. WDR R

3. WDR G

4. WDR B

5. BRIGHT

6. CONTRAST

7. COLOUR

8. HUE

9. SHARP

10. VCO ADJ

11. VID AGC

12. SYC SLI

13. A MO VIE

COOL

NORMAL

WARM

1. CONT.

2. BRIGHT

3. SHARP

4. COLOUR

5. HUE

6. WDR R

7. WDR G

8. WDR B

5. VSM PRESET

VSM PRESET NORMAL

1.CONT

OK

- / +

: STORE i : EXIT

***

- / +

Fig.3 SUB MENU SCREEN

No. 51994

3. AUDIO

AUDIO

1. ERR LIMIT 100H

ERROR RATE =

OK

: STORE i : EXIT

* ** *** **

Do no t adjust

1. ERR L IM IT

2. A2 ID TH R

3. Q P EAK

17

Page 18

A

V32X25EUS / AV32X250EUS

A

A

A

V32X25EIGY / AV32X25EKGY

V28X25EUS / AV28X25EIGY

V28X25EKGY

(3) Meth od of Set ting

1) Meth od of Set ting 1. IF

[VCO] ・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・ It mus t n ot adjust w itho ut signal.

① 1 K ey・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・ Se lect 1.IF.

② 1 K ey・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・ Se le ct 1 .VCO( CW)

Make sure that the arrow position between the ABOVE REF and BELOW REF.

③ INFORMATION Key ・・・・・・・ ・・・・・・・・・・・・ Return t o the SER VICE ME NU scre en.

2) Meth od of s ett in g 2.V/C, 3.AUDIO, 4 .DEF an d 5.VSM PRESET.

① 2~5 K ey・・・・・・・ ・・・・・・・・・・・・・ ・・・・・・・・・ Select one from 2.V/C, 3.AUDIO, 4.DEF an d 5.VSM PR ESET.

②

FUNCTION U P / DOWN ( / ) Ke y

③

FUNCTION -/+ ( / ) Key

④

ME NU Key

⑤

INFORM ATION K ey

・・・・・・・ ・・・・・・・・・・・・・ ・・・・・・・

・・・・・・・ ・・・・・・・・・・・・

・・・・・・・ ・・・・・・

・・・・・

Select s etting items.

Set ( ad just) th e se tting values of the settin g items.

Memorize the s ettin g va lue.

(Bef or e s t oring t he sett in g values in memory, do no t pr es s th e CH, TV, POWE R ON /

OFF k e y - if you do, t he value s will n ot be s tor ed in me mo r y. )

Retu rn t o th e SE R VICE ME NU scr ee n.

3) Do not setting 6.STATUS, 7. PIP, 8. --- , 9.SHIP PING(OFF) & 0.BUS FREE.

(4) Rele as e of SERV IC E M ENU

1) Af ter co mp l eti ng the se tting , ret urn t o t he SER VICE ME NU, th en ag ain p r ess the I NFORMATIO N key.

18

No. 51994

Page 19

A

S

A

A

A

ADJUSTMENTS

y

CHECK ITEM

Item

B1

Powe r Suppl

che ck

Measuring

instrume nt

Signal

generator

DC v oltm et er

Remote

control unit

V32X25EUS / AV32X250EU

V32X25EIGY / AV32X25EKGY

Test point Ad justment part Description

TP-91(B1)

TP-E(####)

[X connector

on POWER

DE F PW B ]

1.R G B BL K 1. R eceive a any broa dca st.

2. Pu sh t he “ZOOM ” ke y an d s el ect the FULL mode .

3. Select 2 . V/ C from the SER VICE ME NU .

4. Select 1 . RGB BLK wit h f un ction UP / DOW N ( / ) key.

5. Press the function + ( ) key to f ind the cut off screen (Black

screen).

6. C on nect a D C voltm et er t o TP-9 1(B 1) a nd T P- E( #).

7. M ake sur e that th e volt age is D C 13 9.9 ±2.0V.

8. Press the function – ( ) key t o retur n to service menu..

V28X25EUS / AV28X25EIGY

V28X25EKGY

Hi gh Vo l t ag e

che ck

Signal

generator

DC volunteer

Remote

control unit

VCO chec k Remot e

control unit

IF S ERVIC E MEN U

1. VCO

2. ATT ON/OFF

1-2 : SELECT

TO O HI GH

ABOVE REF

JUST REF

BELOW REF

TO O LO W

VCO( CW)

MAI N

CRT anode

Chass is

GND

i : EXIT

****

MHz

i : EXIT

1.R G B BL K 1. R eceive a any broa dca st.

2. Pu sh t he “ZOOM ” ke y an d s el ect the FULL mode .

3. Select 2 . V/ C from the SER VICE ME NU .

4. Select 1 . RGB BLK wit h f un ction UP / DOW N ( / ) key.

5. Press the function + ( ) key to f ind the cut off screen (Black

screen).

6. Connect a DC voltmeter to CRT ANODE and chassis GND.

7. M ake sur e that th e volt age is D C 3 1.0 kV .

8. Press the function – ( ) key t o retur n to service menu.

1. VC O

"

U nd er n orm a l c ondi ti ons, no ad just ment is r e qui r ed .

" Conf irmat io n a djust me nt.

1. Select 1 .IF f rom the SERV ICE MENU.

2. Then select 1 .VCO from th e IF S ERVICE MENU.

3. R eceiv e an y bro adc ast.

(Do not move)

4. C heck the arrow (

BE LOW REF.

) posi t io n betw een the A BOV E R E F. and

+1kV

-1.5kV

No. 51994

19

Page 20

A

V32X25EUS / AV32X250EUS

A

A

A

V32X25EIGY / AV32X25EKGY

V28X25EUS / AV28X25EIGY

V28X25EKGY

FOCU S & SCREEN ADJUSTM ENT

Item

FOCUS

adjust ment

[28” M OD EL ]

Measuring

instrume nt

Signal

gener ator

HVT

Test point Ad justment part Description

FOCUS V R

SCREE N VR

FOCUS VR

[In HV T]

[28”MODEL]

1. R eceiv e a cross -hatc h sign al.

2. Press the “ZOOM” key and s elect the FULL mode.

3. W hi l e w atc hing th e s cr een , a dj ust the F OC US VR to m ake th e

ver ti cal and ho rizo ntal l in es as f in e a nd sharp as possi b l e.

4. M ake sur e th at w hen the sc re en i s d arke ned , the lines r e main

in good focus.

FOCUS

adjus tment

[32” M OD EL ]

SCREE N

Ad j ust men t

Signal

gener ator

FOCUS 1

HVT

Signal

gener ator

1. RGB BLK

- / +

OK

0 0 0 0 0 1 0 0

FOCUS 2

V/C

: STORE i : EXIT

PAL

00

FOCUS2(F2)

FOCUS1(F1)

SCREEN1(S1)

FOCUS 1

FOCUS 2

[In HV T]

SCREEN VR

[In HV T]

CLOW

statu s

[32”MODEL]

1. R eceive a cross-h atc h si gna l.

2. Pu sh t he “ZOOM ” ke y an d s el ect the FULL mode .

3. By t ur ni n g th e FOC US2 VR , an d ad just th e pi cture so th at th e

“ “ part vertical line may become thinnest.

4. By t ur ni n g th e FOC US1 VR , an d ad just th e pi cture so th at th e

3rd h or izont al line from t he upp er m ay bec ome un ifor m a t th e

line c ent er an d its periph ery.

5. C ar r y out adjustm ent b y rep eat in g the s te ps 3 an d 4 ab ove .

6. M ake sur e th at w hen the sc re en i s d arke ned , the lines r e main

in good focus.

1 Press a wh ol e b la ck sign al

2 Press the “ZOOM” key and s elect the FULL mode.

3 Se lect 2. V/ C fr om the SERVICE ME NU.

4 Turn t he SCR EEN V R cl ockw is e f r om th e f ull co unt er

cl ockw is e position an d st op it a t th e po i nt w h ere “ CLOW ” stat us

(mark e d i n Fig.) ch ang es f ro m 1 t o 0 to 1 (whic h is

ind icated at th e 3rd column from th e righ t.)

5 T he n turn th e SC RE EN V R cou nt erclock wis e, an d s t op where

th e “ C LOW ” stat us ch anges 1 t o 0

* “CLOW ” : c ontro l loop ou t of win do w.

SERVICE MODE SCREEN

20

No. 51994

Page 21

A

S

A

A

A

VSM PR ES ET AD JUS T S ET TIN G

g

Item

VS M PRESET

se tting

COOL +16 0 -12 +1 0 -27 -12 0

Measurin

instrume nt

Remote

control unit

1.CONT. 2.BRIG HT 3.SHARP 4.COLOUR 5.HUE 6.WDR R 7.WDR G 8.WDR B

Test point Ad justment part Description

1. C ONT .

2. BR IG HT

3. SHARP

4. COLOUR

5. HUE

6. W DR R

7. W DR G

8. W DR B

V32X25EUS / AV32X250EU

V32X25EIGY / AV32X25EKGY

V28X25EUS / AV28X25EIGY

V28X25EKGY

1. Select COOL with the MENU key of t he remote control uni t.

2. Se lect 5 .VS M P R ESET from th e S ER VICE ME NU.

3. Adjust t he FUNCTIO N UP/DOW N ( / ) and -/+ ( / ) ke y to

bring th e set values of 1.CON T ~ 8. W DR B to the val ues

sh own i n th e table.

4. Pr es s the ME NU key a nd m em or iz e the s et va lue.

5. Respectively select the VSM PRESET mode for NORMAL and

WARM, an d m ak e simil ar a dj ust me nt as in 3 abo v e.

6. Pr es s the ME NU key a nd m em or iz e the s et va lue.

* Refer t o OP ERATING I NS TRUCTIONS for the PICTURE

MO DE .

32 ” NORMA L 00-1200000

WARM -13 0 -12 -1 0 +5 0 0

COOL +130 -120 0-28-12 0

28 ” NORMA L -30-1200000

WARM -13 0 -12 -1 0 +4 0 0

SE TT ING VAL UES OF VSM PRESET

No. 51994

21

Page 22

A

V32X25EUS / AV32X250EUS

A

A

A

V32X25EIGY / AV32X25EKGY

V28X25EUS / AV28X25EIGY

V28X25EKGY

VIDEO / CHR OMA CIRCUIT ADJ USTMENT

The setting (adjustment) using the REMOTE CONTROL UNIT is made on the basis of the initial setting values.

The setting values which adjust the scr een to the optimum condition can be different from the initial setting values.

Setting item

(Adjustment item)

2. V/C PAL SE CAM NT SC

1.R G B BL K

2.WDR R 00 00

3.WDR G 0000

4.WDR B (Do not adjust) -012

5. BR IG HT 00 00

6.CONTRAST 00 60

7.COLO UR 00 00

8. HUE 00 20

9.SHARP (Do not adjust) 00 07

Initial set ting v al ue

10.VCO ADJ. (Do not adjust)

11.VID AGC (Do not adjust) 00 00

12.SY C SLI ( Do not adjust) 00 07

13.A MOVIE (Do not adjust) 00 01

****

: Do not adjust

22

No. 51994

Page 23

A

V32X25EUS / AV32X250EU

S

A

A

A

V32X25EIGY / AV32X25EKGY

V28X25EUS / AV28X25EIGY

V28X25EKGY

Item

WHITE

BALANCE

(Hi gh Light)

adjust ment

SUB BRIGHT

adjus tment

Measuring

instrume nt

Signal

gener ator

Remote

control unit

Remote

control unit

Test point Ad justment part Description

2. W DR R

3. W DR G

4. W DR B

(Do not adjust)

5. BR I G HT 1. Receive any bro adc ast.

" Set the P IC TURE MODE to NOR MAL.

1. Recei ve a bl ack a nd w hi te sign al (col o ur of f).

2. Select 2 .V/C f rom the SERVICE M EN U.

3. M odif y 2. W D R R a nd 3.WDR G da ta t o adj u s t t he white

balance ( high light ).

4. Pr ess the ME NU key a nd m em or iz e the s et va lue.

5. Cha nge th e c ontras t a nd bri gh tnes s w i th the rem ote co ntrol up

& d ow n fr om low–li ght to hig h– l i ght and ch eck that th e tracki ng

of th e whi te bal anc e is g ood .

2. Select 2 .V/C f rom the SERVICE M EN U.

3. Select 5.BRIGHT with the FUN CTI ON UP/DOWN ( / ) key.

4. Set the initial setting value with the FUNCTION -/+ ( / )key.

5. If th e b ri gh tness is not th e be st with th e initial se tting v alue ,

make fine adjustment until you get the best brightness.

6. Pr ess the ME NU key a nd m em or iz e the s et va lue.

SUB CONT.

Ad j ust men t

Remote

control unit

6.CO NT. 1. Recei ve an y bro adc ast.

2. Se lec t 2 .V/C f rom the SE RVICE MEN U.

3. Select 6.CONT with the FUNCTION UP/DOWN ( / ) key.

4. Set the initial setting value with the FUNCTION - / + ( / )

key.

5. If the contr ast is n ot t he be st with t he initial se tting va lue, ma k e

fine adjustment until you get the best contrast.

6. Pr ess the MENU key a nd mem or iz e the s et va lue.

No. 51994

23

Page 24

A

V32X25EUS / AV32X250EUS

A

A

A

ey

V32X25EIGY / AV32X25EKGY

V28X25EUS / AV28X25EIGY

V28X25EKGY

Item

SUB CO LO UR

adjus tment

instrume nt

Remote

ⅠⅠⅠⅠ

control unit

Measuring

Test point Ad justment part Description

7.COLO UR

(PAL~~~~NT S C)

PAL COLOUR (PAL CO LOUR)

CH. key

SECA M COLOUR

MENU

( OK ) k ey

NTSC COLOUR

[Method of adjustment without m easuring instrument]

1. R eceiv e PA L br oadcast.

2. Se lec t 2 .V/C f rom the SE RVICE MEN U.

3. Select 7 .COLOUR wi th th e FUNCTIO N UP/DOWN ( / ) ke y.

4. Set the initial setting value for PAL COLOUR with the

FUNCTION - or + ( / ) ke y.

5. If t he c o l our is no t the bes t wi th th e initial set v a lu e, make

fine adjustment until you get the best colour.

6. Pr ess the MENU key a nd mem or iz e the s et va lue.

(SECAM COLO UR)

1. R eceiv e a SECAM b roadc ast.

2. M ak e fi n e adj ustm e nt of SE CA M C OLOUR i n the s am e

mann er as for abo ve.

(NTSC 3.58 COLOUR)

1. Input a NTSC 3 .58 MHz C OMPOSITE V IDEO sig na l fr om the

EXT t erminal.

2. Make s i mil ar fine ad jus tm en t of NT SC 3. 58 COLO UR in th e

sam e mann er as f or a bove.

FUNCTION k

( INFORM ATI ON ) keyi

REMOTE CONTROL KEY

(NTSC 4.43COLOUR)

1. When NTSC 3.58 COLOUR set, NTSC 4. 43 COLOUR will

automatically set.

24

No. 51994

Page 25

A

V32X25EUS / AV32X250EU

S

A

A

A

V32X25EIGY / AV32X25EKGY

V28X25EUS / AV28X25EIGY

V28X25EKGY

Item

SUB CO LO UR

adjus tment

Measuring

instrume nt

Signal

Ⅱ

Ⅱ

ⅡⅡ

gener ator

Oscilloscope

Remote

control unit

Test point Ad justment part Description

TP-47B

####

TP-E(

[CRT

SOCKET

PWB ]

7.COLO UR

(PAL~~~~NT S C)

)

PAL COLOUR (PAL CO LOUR)

SECA M COLOUR

[Method of adjustment using measur ing instrument]

1. R eceiv e a PAL fu ll f iel d co lour b ar sign al ( 75% whi te ).

2. Se lec t 2 .V/C f rom the SE RVICE MEN U.

3. Select 7.COLO UR with th e FUNCTI ON UP/DOWN ( / ) ke y.

4. Set the initial setting value of PAL COLOUR with the

FUNCTION - or + ( / ) ke y.

5. C on nect th e osc ill osc ope be twee n T P -4 7B and T P- E( #).

6. Ad just P AL COLO UR an d br in g th e v alu e of ( A) in the

illu stration t o the values as shown given billow (Voltage

diff er enc e b etw ee n wh i te ( W ) and blu e ( B) ) .

7. Pr ess the MENU key a nd mem or iz e the s etti n g value.

VOLTAGE (W-B) +5V

(SECAM COLO UR)

1. R eceiv e a SECAM fu ll fi el d co lour b ar sign al ( 75 % whi te ).

2. Set the initial setting value of SECAM COLOUR with the

FUNCTION -/+ ( / ) key.

3. Adju st SE CAM COLOUR an d b ring th e v al u e o f (A) in t he

illu str ati on to th e values as s hown g i ven bill ow ( Vol t ag e

diff er enc e b etw ee n wh i te ( W ) and blu e ( B) ) .

4. Pr ess the MENU key a nd mem or iz e the s etti n g value.

YG R

WCyMgB

NTSC COLOUR

(A)

(-)

(+)

VOLTAGE (W-B) +4V

(NTSC 3.58 COLOUR)

1. Input a NTSC 3.5 8 MHz C OMPOSITE V IDEO sign al ( fu ll fie ld

colo ur bar with 75% whit e) fr om th e E XT t erminal.

2. Set th e initial s etting val ue of NT SC 3.58 C OLO UR wit h th e

FUNCTION -/+ ( / ) key.

3. Ad jus t N T SC 3.5 8 C OLOU R and br ing th e v a l ue of (A) in the

illu stration t o the values as shown given billow (Voltage

diff er enc e b etw ee n wh i te ( W ) and blu e ( B) ) .

4. Pr ess the MENU key a nd mem or iz e the s etti n g value.

32” 28”

VOLTAGE (W-B) +5V +6V

(NTSC 4.43COLOUR)

0

1. When NTSC 3.58 COLOUR set, NTSC 4.43 COLOUR will

automatically set.

No. 51994

25

Page 26

A

V32X25EUS / AV32X250EUS

A

A

A

g)

V32X25EIGY / AV32X25EKGY

V28X25EUS / AV28X25EIGY

V28X25EKGY

Item

SUB HUEⅠⅠⅠⅠ

adjust ment

Ad j ust men t

of

SUB HUEⅡⅡⅡⅡ

Measuring

instrume nt

Remote

control unit

Signal

gener ator

Oscilloscope

Remote

control unit

YGR

Test point Ad justment part Description

8.HUE [Method of adjustment without m easuring instrument]

NTSC 3.58 HUE [NTSC 3.58 HUE]

1. Input a N T SC 3.5 8 MHz COM POSI TE V IDE O si gn al (f ull fi e ld

colo ur bar with 75% whit e) fr om th e E XT t erminal.

2. Se lec t 2 .V/C f rom the SE RVICE MEN U.

3. Select 8 . HUE wi th t he FUNCT ION U P /DOW N ( / ) key.

4. Se t the ini ti a l sett in g value of NTSC 3. 58 HUE w ith th e

FUNCTION -/+ ( / ) key.

5. If you cannot get the best hue with the initial setting value,

make fine adjustment until you get the best hue.

6. Pr ess the MENU key a nd mem or iz e the s et va lue.

NTSC 4.43 HUE (NTSC 4.43 HUE)

1. W hen NTS C 3.58 i s set , NT SC 4.4 3 wi ll be au tom at ically s et at

the respective values

TP-47B

TP-E(#### )

[CRT

SOCKET

PWB]

8. HUE [Method of adjustm ent using measuring instrument]

NTSC 3.58 HUE [NTSC 3.58 HUE]

1. Input a N T SC 3.5 8 MHz COM POSI TE V IDE O si gn al (f ull fi e ld

colo ur bar with 75% whit e) fr om th e E XT t erminal.

2. Se lec t 2 .V/C f rom the SE RVICE MEN U.

3. Select 8 . HU E wi th t he FUNCT ION U P /DOW N ( / ) key.

4. Se t the ini ti a l sett in g value of NTSC 3. 58 HUE w ith th e

FUNCTION - or + ( / ) ke y.

5. C on nect th e osc ill osc ope be twee n T P -4 7B and T P- E( #)

6. Adjust N T SC 3. 58 HUE t o br i ng th e val u e of (B) in the

illu str ati on to the values as s hown given b illo w ( vol tage

diff er enc e b etw ee n wh i te ( W ) an d mag en ta (Mg)).

(B)

(-)

7. Press the MENU key and memoriz e the setting value

0

WCyMgB

(+)

NTSC 4.43 HUE (NTSC 4.4 3 HUE)

1. When NTSC 3.58 COLOUR set, NTSC 4.43 COLOUR will

automatically set.

26

No. 51994

VOLTAGE (W-M

32” 28 ”

-8V -3V

Page 27

A

V32X25EUS / AV32X250EU

S

A

A

A

(

)

(

)

(

)

(

)

V32X25EIGY / AV32X25EKGY

V28X25EUS / AV28X25EIGY

DEFLECTION CIRCUIT ADJUSTMENT

Th ere are 4 as pe ct mod e s ( ①①①①FULL, ②②②②PANORAMIC, ③③③③ SUBTIT LE , ④④④④ COMPRES) of the adjustment ( 1 ) 100Hz i mode,

( 2 ) 120Hz i mode ・・・・ ・・

"

When the 100Hz FULL mode has be en establ ished, th e settin g of other modes will be done automatica lly.

However, if the picture quality has not been optimized, adjust each mode again, respectively.

" The adjustment using the remote control unit is made on the basis of the initial setting values.

"

The setti ng values which adj ust the screen to the optimum condition can be different from the initial s etting values.

・・・・ ・・ depending upon the kin d of signals ( vertical freque ncy 100Hzi / 120Hzi ).

・・・・ ・・・・・・ ・・

V28X25EKGY

Initial setting value (32”)

Initial set ting v al ue

Setting item Ad justment name

1. V- SH IF T Vert ic al cent er -002 + 008 00 00 00 00 + 006 00 00 00 00 00 00

2. V- SIZE Ve rt ic al he ig ht 00 00 + 002 00 00 00 00 +001 00 00 -014 00 00

3. H-CENT Hor i zont al ce nte r -012 + 004 -002 00 00 00 00 00 00 00 00 00 00

4. H-S IZE Horiz ont al width - 028 -004 -002 00 00 00 00 00 00 - 003 0000

5. TRAPE Z Tr ap ezoida l disto rti on c orrec tion -012 + 007 - 003 -002 -002 00 00 +002 00 00

6. EW - PIN Side p in correcti o n - 041 +001 00 00 -001 00 00 -002 00 00 00 00

7. COR -P IN C or ne r P i n 0000 + 006 00 00 00 00 0000 +002 00 00 00 00

8. COR -UP C or ne r P in c orr ect i on Up side 00 00 + 003 00 00 00 00 0000 00 00 00 00 0000

9. COR - LO Corne r P i n c orrect ion Low s id e - 005 -013 - 004 + 002 - 005 +003 00 00 00 00

10 .AN GL E An gle c orre cti on + 002 00 00 +001 00 00 + 002 00 00 0000 00 00

11.BOW Bow-sh ape d dis tortio n correc t ion 00 00 00 00 + 001 00 00 + 001 0000 00 00 00 00

12.V- S.CR

Do not adjust

13 .V- LIN

Do not adjust

Ve rt ic al height c or r ecti on 00 00 - 008 00 00 00 00 +007 00 00 00 00 00 00

Ve rt ic al Lin ear i ty - 007 +004 00 00 0000 - 015 0000 00 00 00 00

FULL PANORAMIC SUBTITLE COMPRESS

10 0Hzi 12 0Hzi 10 0Hzi 120Hzi 10 0Hzi 12 0Hzi 100H zi 60 P

**** : Fixed value

Initial setting value (28”)

Initial set ting v al ue

Setting item Ad justment name

1. V- SH IF T Vert ic al cent er -004 + 009 00 00 00 00 + 005 +001 00 00 00 00

2. V- SIZE Ve rt ic al he ig ht +005 00 00 00 00 00 00 + 001 00 00 - 015 00 00

3. H-CENT Hor i zont al ce nte r -007 + 004 -003 00 00 00 00 00 00 00 00 00 00

4. H-S IZE Horiz ont al width - 015 -004 -002 00 00 00 00 00 00 00 00 00 00

5. TRAPE Z Tr ap ezoida l disto rti on c orrec tion -022 + 009 - 004 00 00 00 00 + 006 00 00 00 00

6. EW - PIN Side p in correcti o n - 042 0000 00 00 0000 00 00 0000 00 00 00 00

7. COR -P IN C or ne r P i n 0000 + 010 00 00 00 00 0000 00 00 00 00 0000

8. COR -UP C or ne r P in c orr ect i on Up side 00 00 + 001 00 00 - 002 00 00 -008 00 00 00 00

9. COR - LO Corne r P i n c orrect ion Low s id e - 005 -007 00 00 00 00 0000 00 00 00 00 00 00

10 .AN GL E An gle c orre cti on 0000 00 00 00 00 00 00 00 00 0000 00 00 00 00

11.BOW Bow-sh aped distortion correction 0000 0000 0000 0000 0000 0000 00 00 00 00

12.V- S.CR

Do not adjust

13 .V- LIN

Do not adjust

Ve rt ic al height c or r ecti on +002 00 00 00 00 00 00 + 010 00 00 00 00 00 00

Ve rt ic al Lin ear i ty - 005 00 00 00 00 00 00 -015 00 00 00 00 00 00

FULL PANORAMIC SUBTITLE COMPRESS

10 0Hzi 12 0Hzi 10 0Hzi 120Hzi 10 0Hzi 12 0Hzi 100H zi 60 P

No. 51994

27

Page 28

A

V32X25EUS / AV32X250EUS

A

A

A

V32X25EIGY / AV32X25EKGY

V28X25EUS / AV28X25EIGY

V28X25EKGY

Item

V-SHIF T

Ad j ust men t

Measuring

instrume nt

Signal

gener ator

Remote

control unit

Test point Adjustment part Description

1. V- S HI FT [FULL mode]

1. Recei ve a cir cle p att ern si g nal of ve rt ic al fr eq uency 5 0Hz.

2. Sele ct 4 .DEF f rom t he SERVI CE M ENU.

3. Select 1.V-SHIFT with the FUNCTION UP / DOWN ( / ) key.

4. Adjust V-S HIFT to make A = B.

5. Check th e adj ustm en t v al u e ab ove in othe r zo om mo de . If it is a

wrong adjustment, re-adjust in PANORAMIC mode and adjust

A

B

by 1.V-SHIFT.

6. Press the MENU key a nd mem or iz e the s et value.

V-SIZ E

adjust ment

Screen size

Scr e en

size

Picture size 100%

AS PECT MODE FULL PANORAMIC SUBTITLE

SCREE N

TOP

SCREE N

BOTTOM

92 % 87 % 70%

92 % 87 % 83%

[ SCREEN SIZE ]

2.V-SI ZE 1. Receiv e a cros s-h atch si gna l.

2. Select 2.V-SIZE and set t he initial setting value.

3. Ad ju st V- S IZE a nd make s ure t hat th e vert ic al sc r een size of

4. Pr ess the MENU key a nd mem or iz e the s et va lue.

5. Input a N TSC VIDEO sig nal (60 Hz) fr om the E XT ter m in al ,

6. Press the MENU key and memoriz e the set value

Picture

size

10 0%

th e p ict ure s ize is i n t he bell ow t abl e.

an d m ake sur e that t he ver t ic al sc r een siz e i s i n th e ta ble

below.

28

No. 51994

Page 29

A

V32X25EUS / AV32X250EU

S

A

A

A

V32X25EIGY / AV32X25EKGY

V28X25EUS / AV28X25EIGY

V28X25EKGY

Item

H. CENTER

adjus tment

H.S IZ E

adjus tment

Measuring

instrume nt

CD

90 %

Test point Adjustment part Description

3.H-CENT. 1. Rec ei ve a c ircl e p at tern s ig na l.

2. Select 3.H-CENT and set the initial setting value.

3. Ad ju st H- CE NT to ma k e C=D.

4. Pr ess the ME NU key a nd mem or iz e the s et va lue.

90 %

4. H-SIZ E 1. Receive a circle pattern signal.

2. Select 4.H-SIZE and set the initial setting value.

3. Ad ju st H-S IZ E an d m ak e sure th at th e ho ri zonta l scr e en si ze

4. Pr ess the ME NU key a nd mem or iz e the s et va lue.

5. Inp ut a N TSC V ID EO si gn al (6 0H z) f r om th e EXT termina l,

6. Pr ess the ME NU key a nd mem or iz e the s et va lue.

of th e pict ur e size is in th e bel low t abl e .

an d m ake s u r e that th e h orizo nt al screen siz e of the each

ASPECT mode is in the below table.

AS PE CT

H SI Z E

EW-PIN

adjus tment

MODE

FULL PANORAMIC SUBTITLE

92 % 95 %

[ SCR EEN S IZE ]

6.E W-PI N 1. Select 6.EW - PIN and s et t he i ni ti al s etting val u e

Straight

92 %

2. Ad ju st EW - PIN an d make th e 2 nd .v e rt ic al li nes at th e left a nd

right ed ges of the scree n str a i ght . Als o m ake sur e th at th e 3r d

vertical lines are straigh t.

3. Pr ess the ME NU key a nd mem or iz e the s et va lue.

No. 51994

29

Page 30

A

V32X25EUS / AV32X250EUS

A

A

A

V32X25EIGY / AV32X25EKGY

V28X25EUS / AV28X25EIGY

V28X25EKGY

Item

TR APEZIU M

adjus tment

COR. UP/LO

adjus tment

Straight Straight

Measuring

instrume nt

Signal

gener ator

Remote

control unit

Signal

gener ator

Remote

control unit

Test point Adjustment part Description

5. TR A PEZ 1. Receiv e a cros s-hatch si gna l.

2. Select 5.TRAPE Z with the FUNCTION UP/DOWN ( / ) key.

3. Set th e initial sett ing value of TRAPEZ with the FUN CT ION

- or + ( / ) key.

Parallel

7.COR-PI N

8.COR-UP

9.COR-LO

4. Ad ju st TRAPE Z an d b ring the VERTIC A L l i nes at th e righ t a nd

left ed ges of the s creen p ar al lel .

5. Pr ess the MENU key a nd mem or iz e the s et va lue.

1. Se lect 8. CO R-UP with the FU NCTION UP / DOWN ( / )

key.

2. Set the init ial setting value of COR.-UP with the FUNCTION

- or + ( / ) key.

3. Ad ju st COR - UP , an d br in g t he st r ai ght line a t th e upp er corne r.

4. Se lect 9. CO R-LO with the FUNCTION UP / DOW N ( / )

key.

5. Set the init ial setting value of COR-LO with the FUNCTION

- or + ( / ) key.

6. Ad ju st COR - LO, and b rin g t he s tr ai gh t li ne at the l ow co rn er .

7. Pr ess the MENU key a nd mem or iz e the s et va lue.

8. If the e xtre am e u ppe r & lower c or n er s a re a litt l e pi n or ba rr el

ch ose 7.C OR -P IN an d adj u st.

9. Press the MENU key and memoriz e the set value

ANGL E

adjus tment

Fig. A

30

10. ANGLE • In c ase whe re th er e is a para lle logrammi cal dis tort ion of

images o n the scree n. ( Fig.A)

1. Se lect 10 .ANGLE with th e FU NCTION UP / DOW N ( / )

key.

2. Ad ju st AN GE L, an d b rin g t he VERT IC AL lines str aigh t..

3. Pr ess the MENU key a nd mem or iz e the s et va lue.

No. 51994

Page 31

A

V32X25EUS / AV32X250EU

S

A

A

A

V32X25EIGY / AV32X25EKGY

V28X25EUS / AV28X25EIGY

V28X25EKGY

Item

BOW

adjus tment

V-S.CR

&

V. LI NE AR IT Y

adjus tment

Measuring

instrume nt

Test point Adjustment part Description

11.B OW • In cas e where th ere is a bow-shaped distortion o f images

on the sc ree n. ( Fig.B)

1. Select 1 1.BOWwith th e FUNCTIO N UP/D OWN ( / ) key.

2. Ad ju st BO W, and b rin g t he VER T IC AL lines straigh t.

3. Pr ess the MENU key a nd mem or iz e the s et va lue.

Fig. B

12.V- S.CR

13.V- LIN

TOP

• Whe n the vertica l li n eari ty h a s b ee n dete riorated

remark ably, perform the following s teps

1. R eceive a cross-h atc h si gna l.

2. Select 1 3.V-LIN with the F UNCTION U P/ DOW N ( / )key.

3. Set the init ial setting value of 13.V-LIN with the FUNCTION

- / + ( / ) key.

4. Sele ct 1 2.V -S.COR wit h t he FUNCTION U P / DOWN ( / )

key.

5. Set th e initial sett ing value of 12.V- S.COR with th e FUNCTI ON

- / + ( / ) key.

6. Ad jus t 13 .V- LI N an d 12.V -S .COR so tha t th e sp aces of eac h

line on TO P, CENTE R and BOTT OM bec om e u ni fo rm.

.

CENTER

BOT TOM

No. 51994

NO T E : Do not adjust PA NO RAMIC & SUBTIT LE mode.

At first the adjustment in 100Hz FULL mode should be done,

th en th e d at a for th e ot her asp ec t mo de is c or rect ed in th e

resp ec ti ve value a t t he s ame time. A nd co nfirm th e defl ectio n

ad justmen t in itia l se tting value in 120Hz (NTSC EXT m od e)

FU LL m od e. If the adj u stm en t in 10 0Hz eac h asp ect mode h as

b een don e and sto re d, th e d ata f or th e s am e as pect m od es i n

12 0Hz i s correcte d in the res pect i ve va lue. Only t he da ta fo r th e

oth er as pect mod e i n 120H z is correct ed for its elf.

31

Page 32

A

V32X25EUS / AV32X250EUS

A

A

A

V32X25EIGY / AV32X25EKGY

V28X25EUS / AV28X25EIGY

V28X25EKGY

AUDIO CIRCU IT ADJUSTMENT

"

Do not tou ch 3. AUDIO a dj ust me nt of t he SERV ICE M EN U as it re qu ire s no ad j ustmen t.

If values ha d chan ge d f or the so me r eas on, set th e initi al values in t he f ollowing ta bl e.

3. AUDIO (Do not adjust)

Setting item Variable range fixed value

1. ER R LI M IT 00 0H~FF0H 100H

2. A2 ID THR 00H~FFH 19 H

3. Q-P EA K 0000 H~7FFFH ---

32

No. 51994

Loading...

Loading...