Page 1

A

R

A

A

Y

SER VICE MANUAL

COLOUR TELEVISION

V28L2EUG

V28L2EUBL

V28L2EUG

BASIC CHASSIS

AV28L2EUGR

AV28L2EUBL

AV28L2EUGY

MF

CONTENTS

SPECIFICATIONS

!

SAFETY PRECAUTIONS

!

FEATURES

!

MAIN DIFFERENCE LIST

!

SPECIFIC SERVICE INSTRUCTIONS

!

SERVICE ADJUSTMENTS

!

PARTS LIST

!

★

OPERATING INSTRUCTIONS

★

STANDARD CIRCUIT DIAGRAM

1

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

COPYRIGHT © 2001 VICTOR COMPANY OF JAPAN, LTD.

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ ・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・

・・・・・・

2

4

5

5

6

12

31

2-1

No.51778

May. 2001

Page 2

A

V28L2EUGR

A

A

Y

V28L2EUBL

V28L2EUG

SPECIFICATIONS

Item Content

Dimensions ( W

Mass

TV RF System

Colour System

Stereo System

Teletext System

Receiving Frequency

Intermediate Frequency

Colour Sub Carrier Freq.

Power Input

Power Consumption

Aerial Input Term

Picture Tube

High Voltage

Speaker

Audio Output

EXT-1/EXT-2/EXT-3 (IN/OUT)

EXT-4 (Input) Video

D )

××××H××××

VIF Carrier

SIF Carrier

SECAM

Audio(L/R)

S / Video

VHF

UHF

PAL

NTSC

800mm×500mm×498mm

41.0kg

CCIR ( B/G, D/K, L, L’, I )

PAL / SECAM / NTSC (Only in EXT mode)

A2 (B/G, D/K) / NICAM (B/G, I, D/K, L)

Fastext (UK system) / TOP (German system)

WST(Standard system)

47MHz ~ 470MHz

470MHz ~ 862MHz

French cable TV channel of broadcast frequencies 116~172MHz & 220~469MHz

!

38.9MHz (B/G, D/K, I, L) / 33.95MHz (L’)

33.4MHz (5.5MHz : B/G)

32.9MHz (6.0MHz : I ) / 32.4MHz (6.5MHz : L, D/K) / 40.45MHz (6.5MHz : L’)

4.43MHz

4.40 625MHz / 4.25MHz

3.58MHz / 4.43MHz

AC 220V~240V , 50Hz

183W(Max) / 127W(Avg),

75Ωunbalanced, Coaxial

Visible size : 66cm, Measured diagonally

+

31.0kV (at zero beam current)

20cm×4cm, Oval type×2 with BOX

7.5W + 7.5W

21-pin Euro connector (SCART socket)×3

1Vp-p 75Ω(RCA pin j ac k)

500mVrms(-4dBs), High Impedance (RCA pin jack)

Y : 1Vp-p POSITIVE (Negative sync Provided, when terminated with 75Ω)

C : 0.3Vp-p (Burst signal, when terminated with 75Ω)

1.0kV

-1.5kV

AUDIO OUT (Variable)

Headphone jack

Remote Control Unit

0~1Vrms, Low Impedance (RCA pin jack×2)

Stereo mini jack (φ3.5mm )

RM-C54 (AAA/R03 dry cell battery×2)

Design & specifications are subject to change without notice

2

.

No.51778

Page 3

A

R

A

A

Y

■■■■

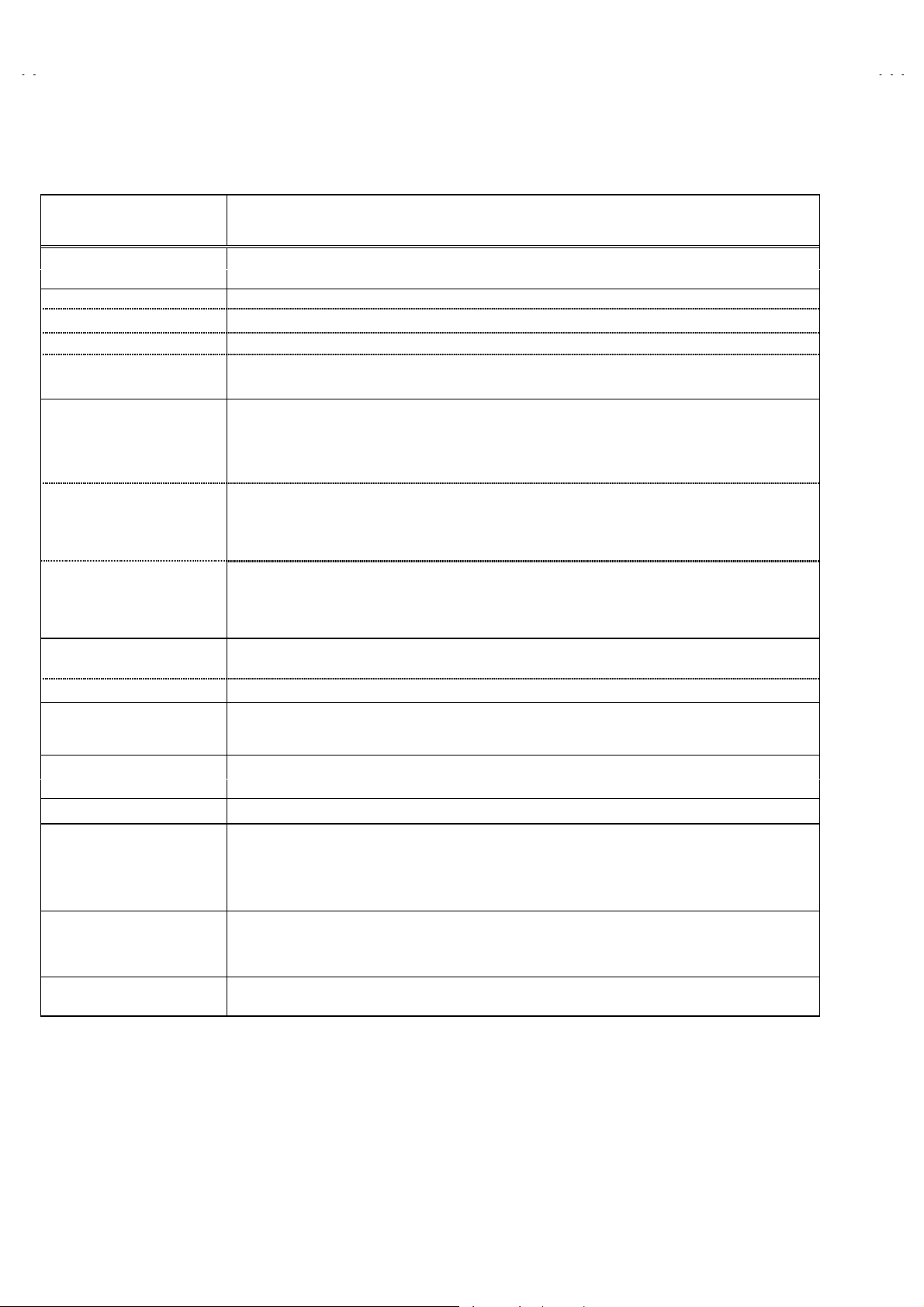

21-pin Euro connector (SCART socket) : EXT-1 / EXT-2 / EXT-3

(P-P= Peak to Peak, B -W= Bl ank ing to white peak)

Pin

Signal Designation Matching Value EXT-1 EXT-2 EXT-3

No.

1 AUDIO R output 500mVrms(Nominal),

Low impedance

2 AUDIO R input 500mVrms(Nominal),

High impedance

3 AUDIO L output 500mVrms(Nominal),

Low impedance

4 AUDIO GND

5 GND (B)

6 AUDIO L input 500mVrms(Nominal),

High impedance

7B input

8 FUNCTON SW

(SLOW SW)

9 GND (G)

10 SCL3 NC

11 G input

12 SDA3 NC

13 GND (R)

14 GND (YS)

15 R / C input

16 Ys input

17 GND(VIDEO output)

18 GND(VIDEO input)

19 VIDEO out pu t

20 VIDEO / Y input

21 COMMON GND

700mV

Low : 0-3V, High : 8-12V, High

impedance

700mV

R : 700mV

C : 300mV

Low : 0 - 0.4, High : 1 - 3V, 75

1V

1V

, 75

Ω○○

B-W

, 75

Ω○○

B-W

, 75

Ω

B-W

, 75

Ω

P-P

(Neg ati ve g oin g s ync ) , 75

P-P

(Neg ati ve g oin g s ync ) , 75

P-P

Ω○ ○

Ω○

Ω○ ○ ○

○

(TV OUT)

○○○

○

(TV OUT)

○○○

○○○

○○○

○○○

○○○

○○○

○○

○

(only R)

○○○

○○○

(TV)

○○○

○

(LINE OUT)

○

(LINE OUT)

○

○

○○

○

(LINE OUT)

V28L2EUG

V28L2EUBL

V28L2EUG

NC

NC

NC

NC

NC

NC

NC

(only C)

NC

NC

Pin assignment

[

]

No.51778

3

Page 4

A

V28L2EUGR

A

A

Y

V28L2EUBL

V28L2EUG

SAFETY PRECAUTIONS

1. The design of this product contains special hardware, many

circuits and components specially for safety purposes. For

continued protection, no changes should be made to the original

design unless authorized in writing by the manufacturer.

Replacement parts must be identical to those used in the original

circuits. Service should be performed by qualified personnel

only.

2. Alterations of the design or circuitry of the products should not be

made. Any design alterations or additions will void the

manuf act urer's warr anty and will fur t her reliev e the manuf actur er

of responsi bility f or person al injury or pr operty dam age res ulting

therefrom.

3. Many electrical and mechanical parts in the products have

special safety-related characteristics. These char acteristics are

often not evident f rom visual i nspection nor can t he protect ion

afford ed by them n ecess arily be obt ained by using rep lacem ent

compon ents rated f or higher voltag e, watt ag e, etc. R epl acem ent

parts which have these special safety characteristics are

identified in the parts list of Service manual.

compon ents hav in g su ch feat ures are id entif ied by s hadin g

on the sche matics and by (

manual.

have the same safety characteristics as the recommended

replac ement part shown i n the p arts list of S ervic e manu al may

cause shock, fire, or other hazards.

The us e of a subst itute replacement which does not

) on the parts list in Service

!!!!

Electrical

4.

Don't short b etween the LIV E side groun d and ISOLATED

(NEUTRAL) side ground or EARTH side ground when

repairing.

Some model's power circuit is partly different in the GND. The

difference of th e GND is sh own by the LI VE : (") side GND, the

ISOLATED(NEUTRAL ) : (#) side GND and EARTH : ($) side

GND. Don't short between the LIVE side GND and

ISOLATED(NEUTRAL) side GND or EARTH side GND and

never meas ure with a measuri ng apparatus (osc illoscope etc .)

the LIVE side GND and ISOLATED(NEUTRAL) side GND or

EARTH side GND at the same time.

If above not e wi ll n ot be kept, a fuse or any parts w ill be broken.

5. If any repair has been made to the chassis, it is recommended

that the B1 setting should be checked or adjusted (See

ADJUSTMENT OF B1 POWER SUPPLY).

6. The hig h voltage app lied t o the picture t ube must c onform wit h

that specified in Service manual. Excessive high voltage can

cause an increase in X-Ray emission, arcing and possible

component damage, therefore operation under excessive high

voltag e conditions s hould b e kept to a mi nimum, or sh ould be

prevented. If severe arcing occurs, remove the AC power

immediately and determine the cause by visual inspection

(incorrect inst allation, cracked or m elted high voltage harness,

poor solderi ng, etc.). To maintain the pr oper minimum le vel of

soft X-Ray emission, components in the high voltage circuitr y

including the picture tube must be the exact replacements or

alternatives approved by the manufacturer of the complete

product.

7. Do not check high voltage by drawing an arc. Use a high voltage

meter or a high voltage probe with a VTVM. Discharge the

pictur e tube bef ore attempting met er connect ion, by connecting

a clip l ead to th e g roun d fr am e and c on necti ng t h e oth er end of

the lead through a 10k" 2W resistor t o the an ode button .

8. W hen servic e is requir ed, obser ve the origin al lead dress . Extr a

precaut ion shou ld be gi ven to assure c orrect l ead dr ess in t he

high voltage circuit area. W here a short circuit has occurred,

those comp onents that in dicat e evidenc e of over heating should

be replaced. Always use the manufacturer's replacement

components.

9.

Isolation Check

(Saf ety for Electrical Shock Hazard)

After re-assembling the product, always perform an isolation

check on the exposed metal parts of the cabinet (antenna

termin als , vid eo/ au dio inpu t an d output term inals, Con t r ol kn obs,

metal c abinet, s crewhead s, earph one j ack, contr ol shafts, etc.)

to be sure the product is safe to operate without danger of

electrical shock.

(1)

Dielectric Stren g th Test

The isol ation b etween th e AC pr imar y circuit and all metal parts

expos ed t o th e user, p ar tic u larly any exp osed met al part h avi ng a

return p ath to the chassis should withst and a voltage of 3000V

AC (r.m.s .) for a peri od of on e s ec ond.

(. . . . W ithstand a voltag e of 1100 V AC ( r.m.s.) to an applianc e

rated up t o 120V, and 3000 V AC (r. m.s.) t o an appl iance r ated

200V or mor e, f or a peri od of on e s ec on d.)

This method of test requires a test equipment not generally found

in the service trade.

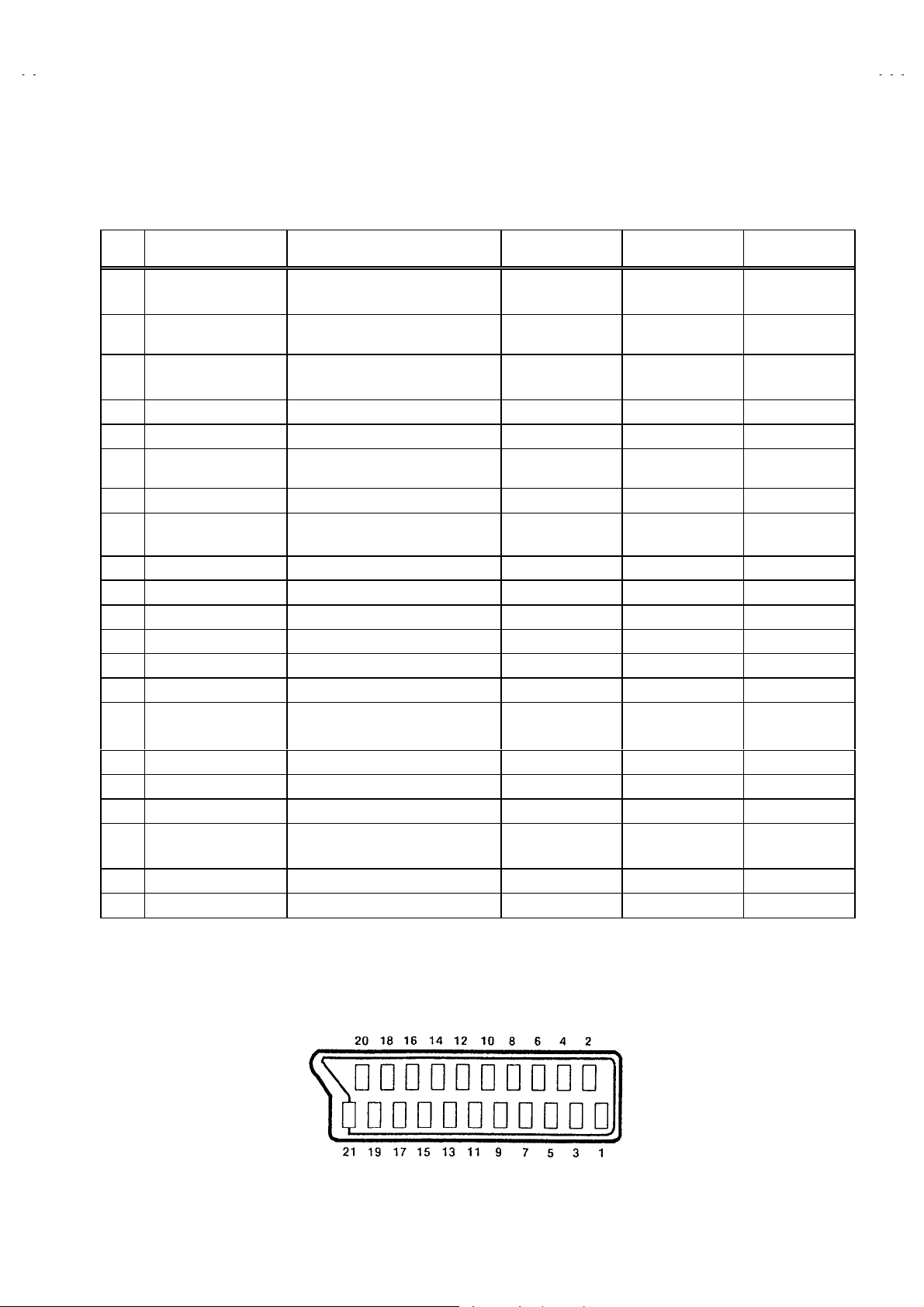

(2)

Leak age Current Check

Plug the AC lin e c or d dir ec t l y int o t he AC outl et (do not us e a lin e

isolation transformer during this check.). Using a "Leakage

Current Tester", measure the leakage current from each exposed

metal part of the cabinet, particularly any exposed metal part

having a return path to the chassis, to a known good earth

ground ( water pipe, etc. ). An y leak age c urr ent mus t not exceed

0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.2mA AC

(r.m.s.).

Alternate Check Method

""""

Plug the AC lin e c or d dir ec t l y int o t he AC outl et (do not us e a lin e

isolati on transform er during t his check. ). Use an AC voltmet er

having 1000 ohms per volt or more sensitivity in the following

manner. Connect a 1 500" 10W resistor paralleled by a 0.15#F

AC-typ e capacitor betw een an expos ed metal part and a know n

good earth ground (water pipe, etc.). Measure the AC voltage

across the resistor with the AC voltmeter. Move the resistor

connect ion t o each exp os ed met al p art, part icul arl y any exp osed

metal part h avin g a return p ath to th e chassis , and meas ure th e

AC voltag e across the res istor. N ow, re vers e the plug in the AC

outlet and repeat each measurement. Any voltage measured

must not exceed 0.75V AC (r.m.s.). This corresponds to 0.5mA

AC (r.m.s.).

However , i n t ropic al area, this m us t n ot exceed 0. 3 V A C (r. m.s .).

This corresponds to 0.2mA AC (r.m.s.).

0.15μF AC-TYPE

1500

GOOD EARTH GROUND

"

AC VOLTMETER

(HAVING 1000

OR MORE SENSITIVITY)

10W

"

/V,

PLACE THIS PROBE

ON EACH EXPOSED

METAL PART

4

No.51778

Page 5

A

R

A

A

Y

FEATURES

V28L2EUG

V28L2EUBL

V28L2EUG

New chassis design enable use of an interactive on screen

"

control.

The TELETEXT SYSTE M has a built-i n FAST EXT ( UK s ystem),

"

TOP (German system) and WST (world standard system)

system.

Pure FLAT CRT reproduce fine textured.

"

Digi Pure pro : Auto digi pure with motion picture compensation.

"

B ecause this TV uni t corresp onds t o multipl ex broadc ast, us ers

"

can enjo y music pr ograms an d spor ting ev ents wit h live real ism.

In additi on, BILINGUAL programs c an be heard in their original

language.

Built-in ECO (ECONOMY, ECOLOGY) MODE.

"

In accordance with the brightness in a room, the brightness

and/or contrast of the picture can be adjusted automatically to

make th e opti mu m pictur e wh ic h is eas y on th e ey e.

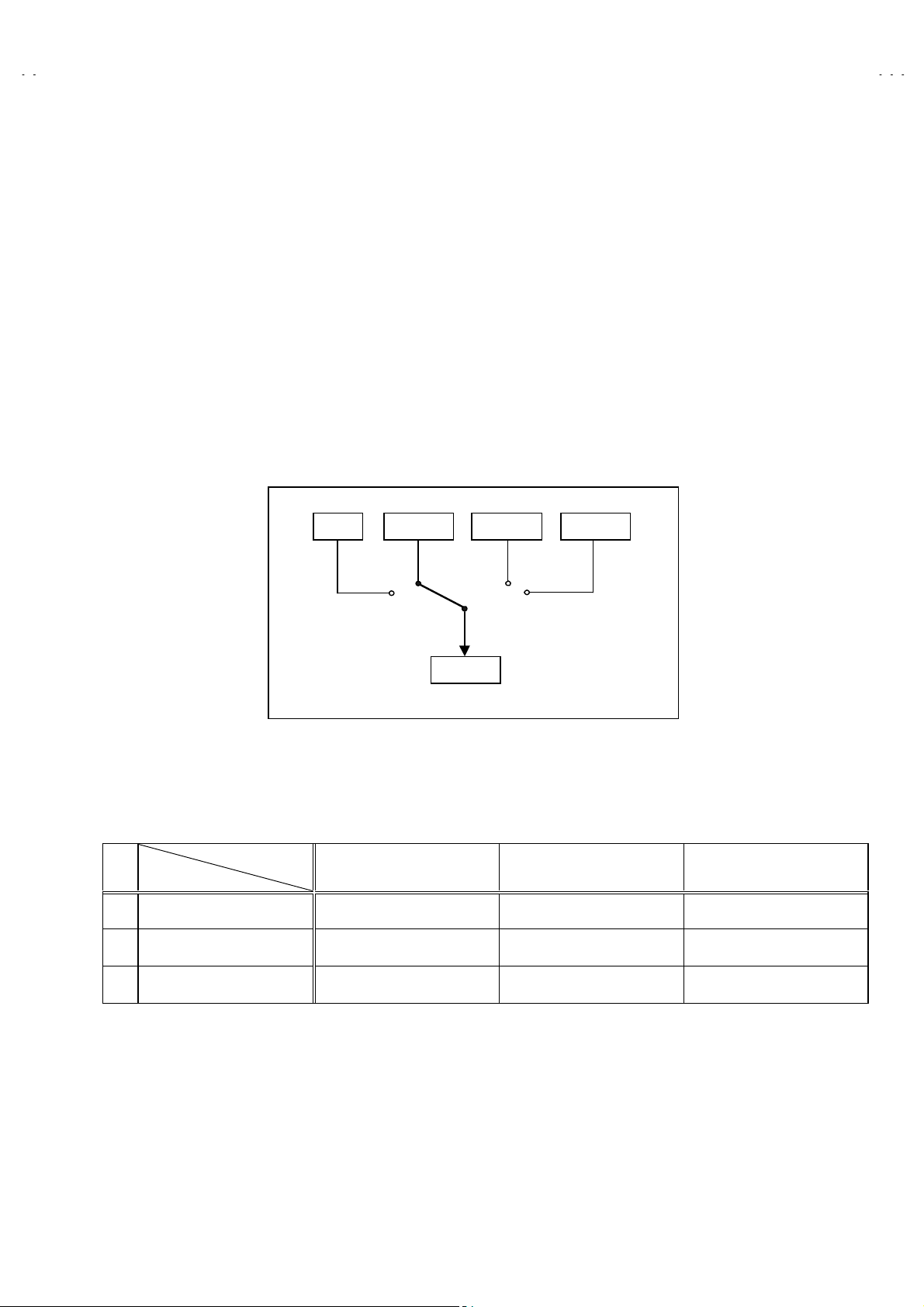

TV EXT-1 EXT-3

Users can make VCR dubbing of picture and sound by controlling

"

the AV select or to sel ect an opti onal sour ce at the E XT-2 output

shown in figure.

EXT-4

EXT-2

MAIN DIFFERENCE LIST

Model name

!!!!

Part name

FRONT FRAME LC11007-001B-U LC11007-002B-U LC11007-003A-U

!

RATING LABEL

!

EURO LABEL AEM1052-017-E AEM1052-014-E AEM1052-071-E

AV28L2EUGR AV28L2EUBL AV28L2EUGY

LC20380-008A-U

LC20379-008A-U

LC20380-012A-U

LC20379-012A-U

LC20380-023A-U

LC20379-019A-U

No.51778

5

Page 6

A

V28L2EUGR

A

A

Y

A

V28L2EUBL

V28L2EUG

SPECIFIC SERVICE INSTRUCTIONS

DISASSEMBLY PROCEDURE

REMOVING THE REAR COVER

1. Unplug the power cord.

2. Remove the 11 screws marked ”A” as shown in the Fig. 1.

3. Withdraw the rear cover toward you.

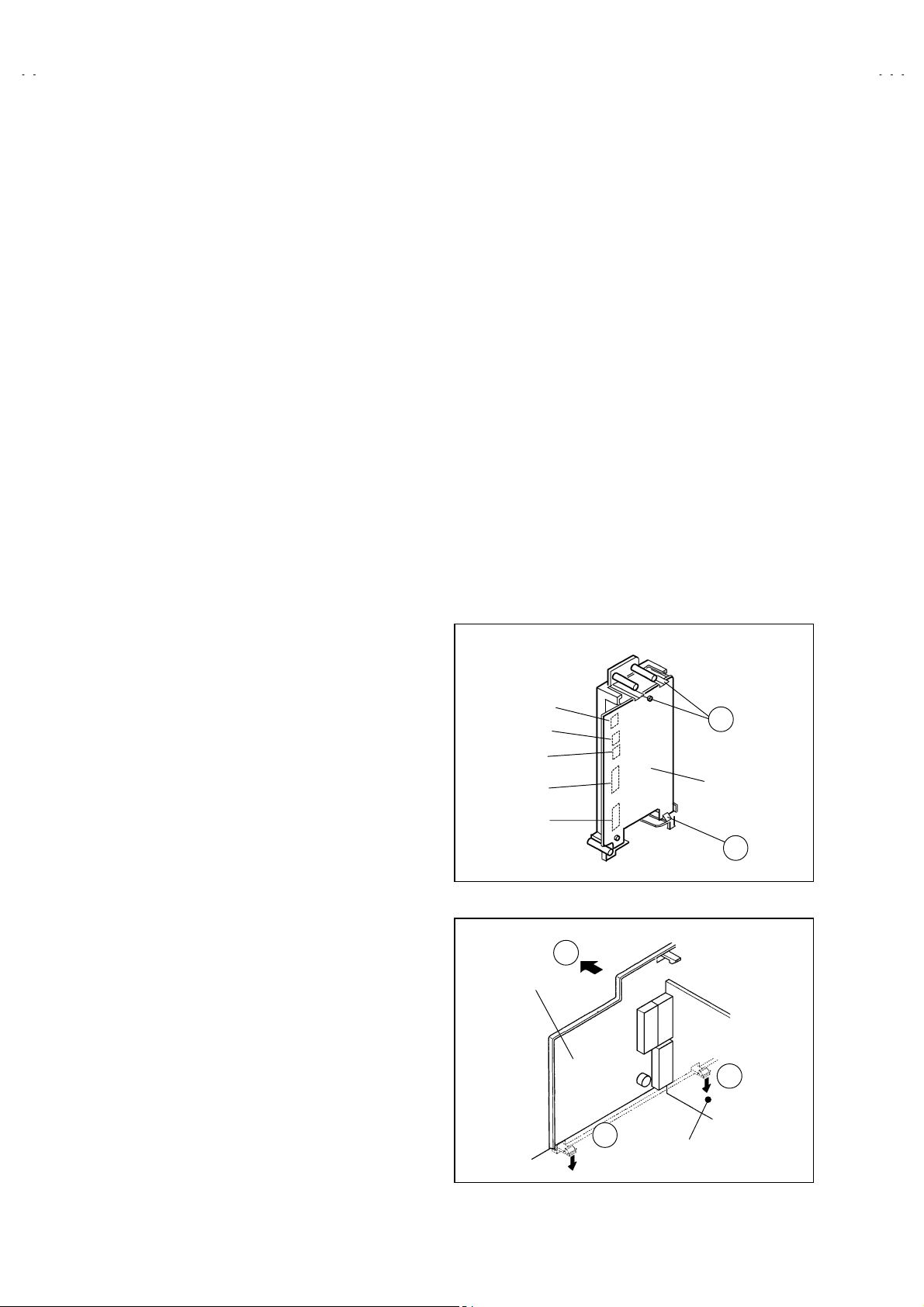

REMOVING THE SIDE C ON TRO L JACK ASSEMBLY

After removing the rear cover.

"

1. Remove the sc r ew m ark ed B as shown in the Fig.1.

2. While slight l y r aise the side control jack assembl y, remo ve th e 2

claws under the side control jack assembly.

3. Disconnect t he c onn ector “SR”, “SL”, “S”, “F” and “K” as shown

in Fig 2.

REMOVING THE SIDE CONTROL PWB

After removing the rear cover and side control jack assembly.

"

1. R emove the 3 c laws “C” f rom b ack s i d e of t h e s i d e co n tro l j ac k

assembly as shown in Fig.2.

2. Pull out the SIDE CONTROL PWB.

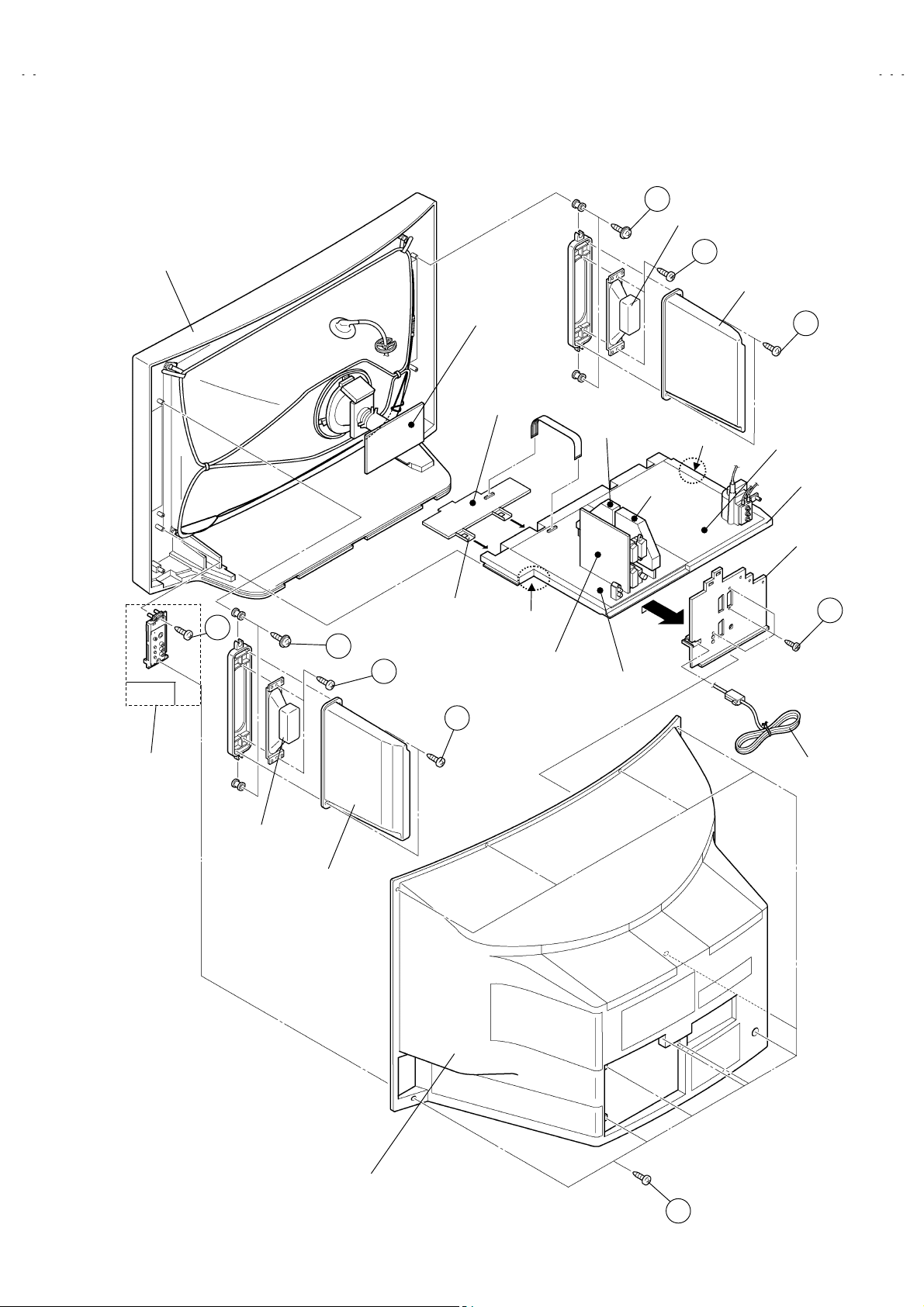

REMOVING THE CHASSIS

After removing the rear cover.

"

1. Slightly rais e the b ot h sid es of the c hass is b y h and and r em ove

the two c laws und er th e both s id es of the c has sis from the f r ont

cabinet.

2. Withdraw the chassis backward.

(If necessary, take off the wire clamp, connectors etc.)

REMOVING THE SPEAKER BOX

After removing the rear cover.

"

1. Remove the 2 screws marked ”D” as shown in Fig. 1.

: W hen removing t he screws marked D of th e speaker b ox

NOTE

assembly, remove the lower side screw first, and then

remove the upper one.

2. Remove the 2 screws “E” attaching the speaker box.

3. Remove the 2 screws “F” attaching the speaker.

4. Follow the same steps when removing the other hand speaker.

CHECKING THE PW BOARD

To check the back side of the PW Board.

1) Pull out the chassis. (Refer to REMOVING THE CHASSIS).

2) Erect t he ch assis vertic ally s o that you c an easi ly ch eck th e

back side of the PW Board.

[CAUTION]

When erecting the chassis, be careful so that there will be no

"

co n tac ti ng wit h oth e r PW B o ard .

Before turning on power, make sure that the wire connector is

"

properly connected.

When conducting a check with power supplied, be sure to confirm

"

that the CRT EARTH WIRE (BRAID ED ASS’Y) is conn ected to

the CRT SOCKET PW board.

WIRE CLAMPING AND CABLE TYING

1. Be sure to clamp the wire.

2. Never remove the cable tie used for tying the wires together.

Should it be inad ver tent l y remov ed, b e sur e to ti e th e wir es with

a new cable tie.

Connector

SR

SL

S

F

K

(Back view)

Fig. 2

C

SIDE CONTROL

PWB

C

REMOVING THE AV TERMINAL BOARD

After removing the rear cover.

"

1. Remove the 3 screws marked ”G” as shown in the Fig. 1.

2. Remove the 2 cl aws mark ed “H” under the CH ASSIS as sh own

in Fig. 3.

3. Remove th e AV TERMIN AL BOARD slig htly in the direc tion of

arrow ”I” as shown in Fi g. 3.

6

No.51778

V TERMINAL

BOARD

I

H

H

AV SW PWB

Fig. 3

Page 7

A

R

A

A

Y

A

D

A

V28L2EUG

V28L2EUBL

V28L2EUG

SPEAKER

FRONT CABINET

Fig. 2

F

SPEAKER

CRT

SOCKET

PWB

FRONT

CONTROL

PWB

CONTROL

B

BASE

CLAW

MICON

PWB

CLAW

100Hz

PWB

D

F

V SW

PWB

MAIN PWB

BOX

E

POWER &

DEF. P WB

CHASSIS

V TERMINAL

BOARD

G

(×3)

E

SIDE

CONTROL

JACK

ASSEMBLY

SPEAKER

SPEAKER

BOX

REAR COVER

Fig. 1

A

POWER CORD

(×11)

No.51778

7

Page 8

A

V28L2EUGR

A

A

Y

A

A

A

A

A

V28L2EUBL

V28L2EUG

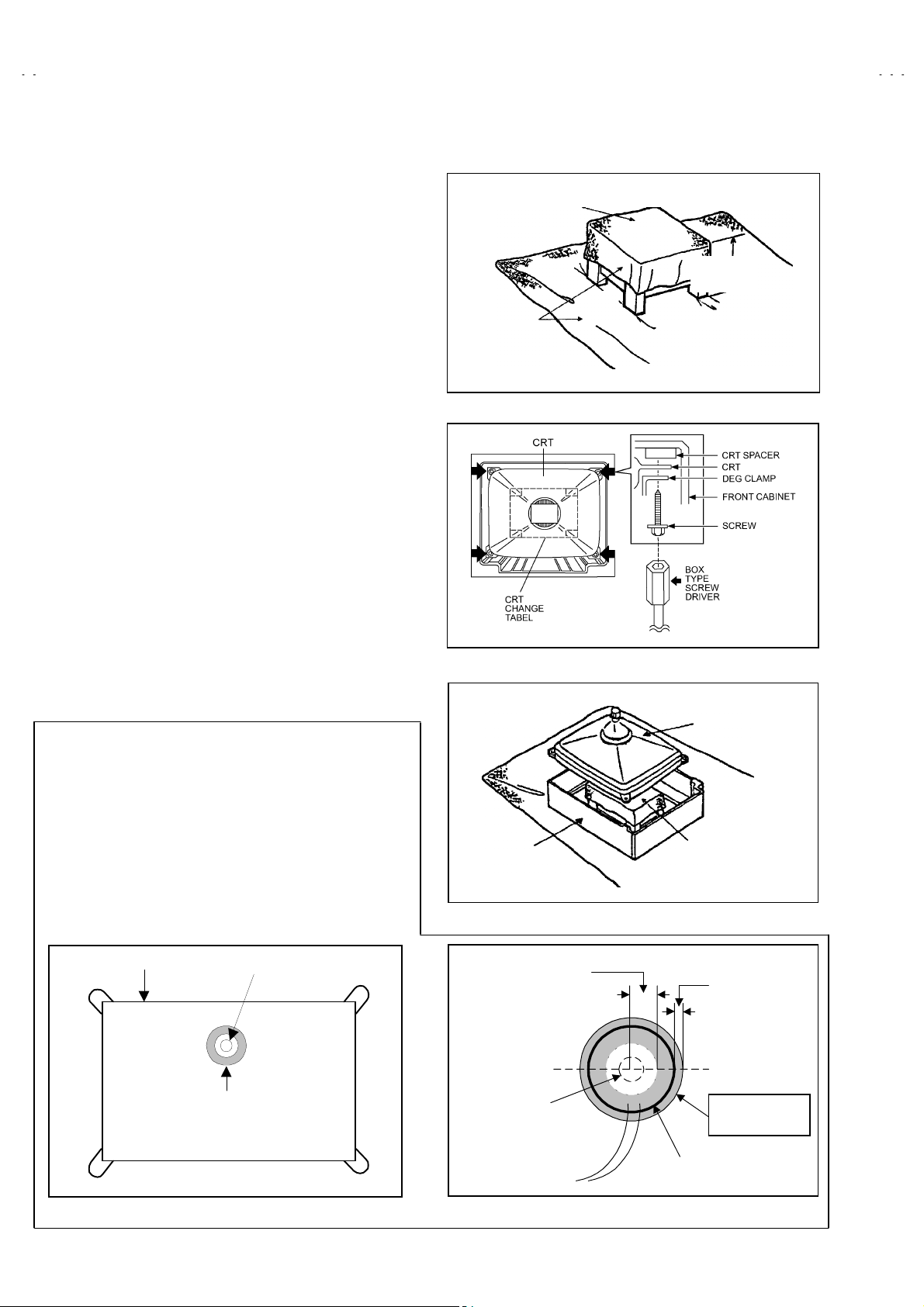

REMOVING THE CRT

Replacement of the CRT should be performed by 2 or more

$

persons.

After removing the cover, chassis etc.,

!

1. Putting the CRT change table on soft cloth, the CRT change table

should also be covered with such soft cloth (shown in Fig.4).

2. While keeping the surface of CRT down, mount the TV set on the

CRT change table balanced will as shown in Fig.5.

3. Remove 4 scr ews m ar k ed b y arrows with a box typ e sc r ew driver

as shown in Fig.5.

Since the cabi n et wi ll drop wh en s c rews have been rem o ved , be

!

sure to support the cabinet with hands.

4. After 4 sc rews have been removed, put th e cabinet sl owly on

cloth (At this time, be carefully so as not to damage the front

surface of the cabinet) shown in Fig.6.

The CRT should be assembled according to the opposite

!

sequence of its dis m oun ti ng steps.

T he CRT ch ang e t ab l e shoul d preferab ly be smaller th at th e CRT

$

surfac e, and its heig ht b e ab out 35cm.

About CRT Spacer

$

An appropriat e C R T s p ac er s h ou ld be used in the corres p on di ng

CRT in accordance with th e type of the CRT.

When a CRT is repl ac ed, s peci al att enti on s houl d be p aid to t his

matter.

CRT CHANGE TABLE

PPROX.

35cm

CLOTH

Fig. 4

COAT ING OF SILICON GREASE FO R ELECTRICAL

INSULATION ON THE CRT ANODE CAP SECTION.

Subsequ ent to rep lacemen t of t he CRT and HV transf ormer or

!

repair of the anode c ap, etc. by dismou nting them, be sure to

coat silicon greas e f or el ec trical insulati on as sh own in F i g. 7.

Wipe around the anode button with clean and dry cloth. (Fig.7)

Coat sil icon gr eas e on t he s ection arou nd the anod e but ton. A t

this ti me, t ak e c are s o th at an y si lic on gr eas es d os e not s tic k to

the anode button. (Fig.8)

Silicon grease product No. KS - 650N

★★★★

CRT

node button

Silicon gr ease

coating

CABINET

pprox.

20mm (Do not

coat grease on

this section

node button

(No sticking of

silicon grease)

Fig. 5

CRT

CRT

CHANGE TABLE

Fig. 6

Silicon gr ease

should b e c oat ed

by 5mm or mor e

from the outside

diamet er of

anode cap.

Coating positi on

of silicon grease

node cap

Fig. 7 Fig. 8

8

No. 51778

Page 9

A

R

A

A

Y

REPLACEMENT OF MEMORY ICs

1. Memory ICs

This TV use mem ory ICs . In the mem or y ICs, there ar e memor iz ed dat a

for cor rectl y op er ating th e vi deo an d def l ection cir cu its. W h en r epl acing

memory ICs, be sure to use ICs written with the initial values of data.

2. Procedure for replacing memory ICs

PROCEDURE

(1)

Power off

Switch th e p ow er off and unpl ug the p ow er c ord from the w all ou tl et.

SERVICE MENU

1. IF 2. V/C

3. AUDIO 4. DEF

5. VSM PRESET 6. STATUS

7. PIP 8.

9. SHIPPING (OFF) 0. BUS FREE

1-9 : SELECT : EXITi

Fig.1

V28L2EUG

V28L2EUBL

V28L2EUG

(2)

Replace ICs

.

Be sure to use memory ICs written with the initial data values.

(3)

Power on

Plug the power cord into the wall outlet and switch the power on.

(4)

Check and set SYSTEM CONSTANT SET:

It must not adjust with ou t sign al.

****

1) Press the INFORMATION key and the MUTING key of the

REMOTE CONTROL UNIT simultaneously.

2) T he SERVICE MEN U scr een of F ig . 1 wil l b e dis pl ayed.

3) While the SERVICE MENU is displayed, press the

INFORM ATION key and MUT ING key s imultan eousl y, and th e

SYSTEM CONSTANT SET screen of Fig. 2 wi ll b e dis pl ay ed.

4) Ch eck t he s etti ng valu es of th e SY STE M CON STA NT S ET of

Table 1. If the valu e is dif f erent , s elect the s et ting item wi th th e

FUNCTION UP/DOWN key, and set th e correct value with the

FUNCTION -/+ key.

5) Press the MENU(OK) key to memorize the setting value.

6) Press the INFORMATION key, and return to the normal screen.

(5)

Setting o f re ce iv e channel s

Set the receive channel.

For setting, refer to the OPERATING INSTRUCTIONS.

(6)

Setting of SERVICE MENU

Verif y the s etting items of th e

SERVICE MENU

wh ere neces sary .

For setting, refer to the SERVICE ADJUSTMENTS.

of Table 2, and reset

SYSTEM CONSTANT SET

1. DESTINATION EU

OK

+ : STORE : EXIT

i

Fig.2

2. CRT TYPE 16 : 9

3. PURITY NO

4. PICTURE TILT YES

5. DIGIPURE PRO YES

6. PIP NO

7. PIC & TEXT YES

8. DOLBY NO

9. BBE YES

10. PROGRESSIVE YES

11. TDA9178 YES

12. TONE IC NO

13. FLAT YES

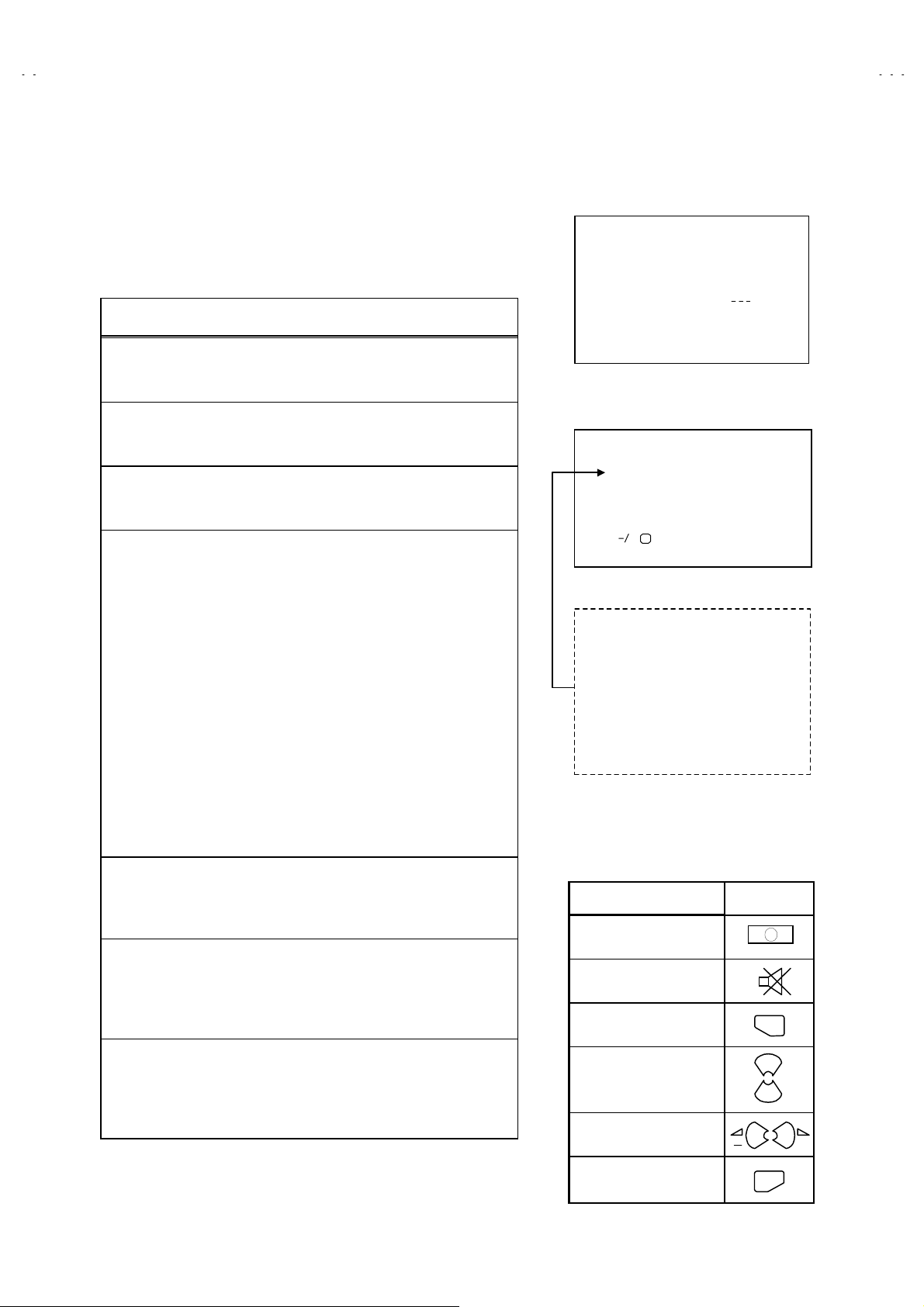

NAME OF REMOTE CONTROL KEY

Names of key

INFORMATION

key

iiii

MUTING

MENU

OK

(7)

User setti n gs

Check th e us er s ett in g values of T abl e 3, and if setti ng v al ue is

different, set the correct value.

FUNCTION UP/DOWN

▼

▼

For setting, refer to the OPERATING INSTRUCTIONS.

▼

TV

▼

+

9

FUNCTION -/+

TV

No. 51778

Page 10

A

V28L2EUGR

A

A

Y

V28L2EUBL

V28L2EUG

SETTIN G VALUES OF SYSTEM CONSTANT SET (TABLE 1)

Setting item Setting content Setting value

1. DESTINATION EU

2. CRT TY P E 16 : 9

3. PURITY NO

4. PICTURE TILT YES

5. DIGIPURE PRO YES

6. PIP NO

7. PIC & TEXT YES

8. DOLBY NO

9. BBE YES

10. PROGRESSIVE YES

11. TDA9178 YES

12. TONE IC NO

13. FLAT YES

EK EU EI

16 : 9 4 : 3

YES NO

YES NO

YES NO

1 TUNER

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

2 TUNER

NO

SERVICE MENU SETTING ITEMS (TABLE 2)

Setting item Setting value Setting item Setting value

1. IF 1. VCO 4. DEF. 1. V-SHIFT

2. V-SIZE

3. H-CENT

4. H-SIZE

5. TRAPEZ

2. V / C 1. RGB BLK

2. WDR R

3. WDR G

4. WDR B

5. BRIGHT

6. CONTRAST

7. COLOUR

8. HUE

9. SHARP

10. VCO ADJUSTMENT

11. VIDEO AGC

12. SYNC SLICE

5. VSM PRESET

COOL

NORMAL

WARM

6. EW-PIN

7. COR-PIN

8. COR-UP

9. COR-LO

10. ANGLE

11. BOW

12. V-S.CR

13. V.LIN

1. CONT.

2. BRIGHT

3. SHARP

4. COLOUR

5. HUE

6. WDR R

7. WDR G

8. WDR B

3. AUDIO

(Do not adjust)

10

1. ERR LIMIT

2. A2 ID THR

6. STATUS

No. 51778

(Do not adjust)

VPS

PDC

Page 11

A

R

A

A

Y

USER SETTING VALUES (TABLE 3)

Setting item Setting value Setting item Setting value

SUB POWER ON VOLUME Appropriate sound volume

SHIPPING CHANNEL PR1 DISPLAY INDICATED

V28L2EUG

V28L2EUBL

V28L2EUG

PRESET CHANNEL

PICTURE SETTING EXT SETTING

TINT

CONTRAST

BRIGHT

SHARP

COLOUR

ECO MODE

PICTURE FEATURES FEATURES

DIGITAL VNR

DIGIPURE PRO

COLOUR SYSTEM

AUTO ASPECT

SOUND SETTING INSTALL

BASS

TREBLE

BALANCE

TV SPEAKER

HYPER SOUND

BBE

See ; OPERATING

INSTRUCTIONS.

COOL

REFER to VSM SETTING

REFER to VSM SETTING

REFER to VSM SETTING

REFER to VSM SETTING

OFF

AUTO

AUTO

TV : According to preset CH

EXT : AUTO

PANORAMIC

CENTER

CENTER

CENTER

L / R

OFF

ON

ZOOM MODE PANORAMIC

ID

DUBBING

SLEEP TIMER

BLUE BLACK

CHILD LOCK

DECODER (EXT-2)

LANGUAGE

EDIT

BLANK

EXT-1→EXT-2

OFF

ON

ID : No.0000, ALL CH : OFF

ALL CH : OFF

ENGLISH

PR CHANNEL ONLY

OTHERS : BLANK

No. 51778

11

Page 12

A

V28L2EUGR

A

A

Y

V28L2EUBL

V28L2EUG

SERVICE ADJUSTMENTS

BEFORE STARTING SERVICE ADJUSTMENT

1.

There are 2 ways of adjusting this TV: One is with the

REMOTE CONTRO L UNIT and t he oth er is t he conv ention al

method using adjustment parts a nd components.

2.

The setting (adjustment) using the REMOTE CONTROL

UNIT is ma de on t he b asis of th e initi al se tting v alue s. The

setting values which adjust the screen to the optimum

condition can be different from the initial setting values.

3. Make sure that connection is correctly made to AC power

source.

4. Turn on the power of the TV and measuring instrument for

warming up for at least 30 minutes before starting adjustment.

5. If the receive or input signal is not specified, use the most

appropriate signal for adjustment.

6. N ever touc h parts ( suc h as vari able r esist ors, tr ansf ormers and

condens ers) not show n in the adj ustment i tems of this s ervice

adjustment.

7. Preparation for adjustment (presetting):

Unless oth erwise sp ecified in t he adjust ment items , preset t he

following functions with the REMOTE CONTROL UNIT:

Setting position

"

PICTURE MODE (VSM) NORMAL

SLEEP TIMER OFF

BALANCE CENTER

ECO OFF

ZOOM PANORAMIC

MEASURING INSTRUMENT AND FIXTURES

1. DC voltmeter (or digital voltmeter)

2. Oscilloscope

3. Signal generator (Pattern generato r) [PAL / SECAM / NTSC]

4. Remote control unit

ADJUSTMENT ITEMS

Checking items.

●

Adjustment of FOCUS.

●

VSM preset s etti ng.

●

VIDEO / CHROMA circuit adjustment.

●

DEFLECTION circuit adjustment.

●

AUDIO circuit adjustment.

●

(Do not adjust)

12

No. 51778

Page 13

A

R

A

A

Y

ADJUSTMENT LOCATIONS

)

SIDE CONTROL PWB

TOP

V28L2EUG

V28L2EUBL

V28L2EUG

SR

FRONT

FRONT

FRONT CONTROL PWB

F901

PW

POWER SW

MAIN PWB POWER&DEF PWB

CN002

S

L

MICON PWB

AV SW PWB

CN006

TUNER

CN007

HEAD

PHONE

S-IN

E

X

T

CN102

W

4

SL

S

F

K

FRONT

W DEG

CN004

CN005

TOP

OUT

EXT 1 2 3

AUDIO

IN-OUT IN

CRT SOCKET PWB

TP-47G

TP-E

CN013

100Hz PWB

ANT IN

TP-47R

CN003

CN013

(SOLDER SIDE)

TP-47B

CN014

CN014

HV

HVT

FOCUS 1 VR

FOCUS 2 VR

SCREEN VR

X

1

5

1pin:B1(TP-91

2pin:NC

3pin:X-RAY

4pin:X-RAY

5pin:GND

CN006

C2

E1

No. 51778

13

Page 14

A

V28L2EUGR

A

A

Y

V28L2EUBL

V28L2EUG

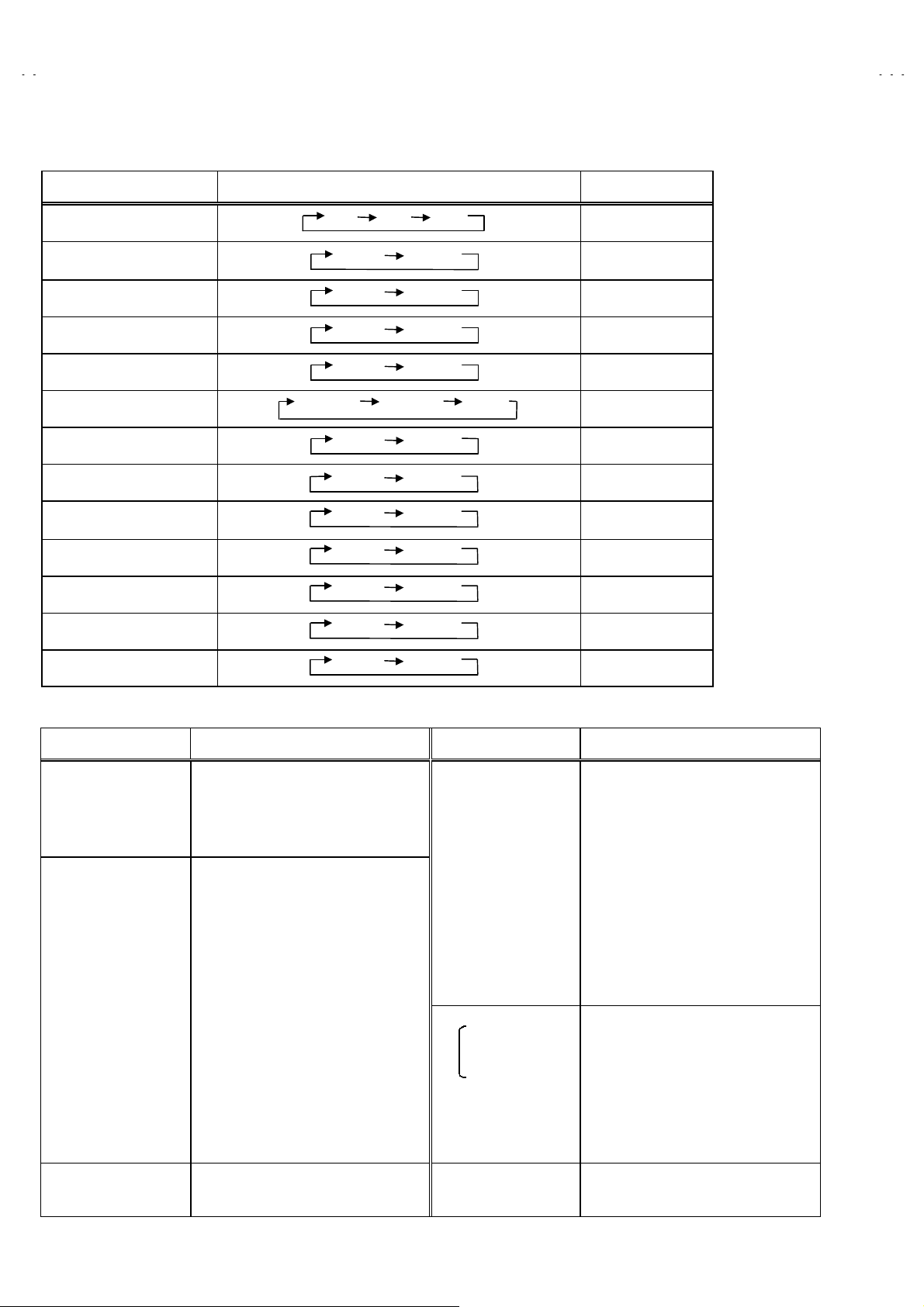

BASIC OPERATION SERVICE MENU

1. TOOL OF SERVICE MENU OPERATION

Operate the SERVICE MENU with the REMOTE CONTROL UNIT.

2. SERVICE MENU ITEMS

With the S ERVIC E MENU, vari ous s ettings (adjust ments ) can be made, and the y are br oadly c lassif ied in th e f ollowing items of settings

(adjustments):

(1)

(2)

(3)

(4)

1. IF

・・・・・・・・・・・・・・・・・・・・・・・

2.V/C

・・・・・・・・・・・・・・・・・・・・・・

3.AUDIO

4.DEF

・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

This mode adjusts the setting values of the IF circuit.

This mode adjusts the setting values of the VIDEO / CHROMA circuit.

This mode adjusts the s etting val u es of the multi pl ic it y SOUND circui t.

This mode adjusts the setting values of the DEFLECTION circuit for each aspect mode given below.

ASPECT V. FREQ.

FULL 100Hzi / 60HzP / 120Hzi

PANORAMIC

SUBTITLE

↑

↑

(5)

5.VSM PRESET

・・・・・・・・・・・・・

This mod e adj us ts the initial s ett in g values of COO L,N OMAL an d W A RM.

(VSM : Video Status Memory)

3. BASIC OPERATION OF SERVICE MENU

(1)

How to enter SERVICE MENU

Press the INFORMATION key and the MUTING key of the

REMOTE CONTROL UNIT simultaneously, and the

SERVICE ME NU sc r een of Fi g. 1 wi ll b e dis pl ay ed.

(2)

Selection of SUB MENU SCREEN

Press one of keys 1~5 of the REMOTE CONTROL UNIT

and select the SUB MENU SCR EEN (See Fi g. 3), f orm the

SERVICE MENU.

SERVICE MENU → SUB MENU

1. IF

2. V / C

3. AUDIO

4. DEF.

5. VSM PRESET

6. STATUS

7. PIP

8. - - -

9. SHIPPING (OFF)

0. BUSS FRE E

DO NOT

WORK

SERVICE MENU

SERVICE MENU

1. IF 2. V/C

3. AUDIO 4. DEF

5. VSM PRESET 6. STATUS

7. PIP 8.

9. SHIPPING (OFF) 0. BUS FREE

1-9 : SELECT : EXI Ti

Fig.1

NAME OF REMOTE CONTROL KEY

Names of key

INFORMATION

MUTING

MENU

FUNCTION UP/DOWN

FUNCTION -/+

TV

key

iiii

OK

▼

▼

TV

▼

▼

+

Fig.2

14

No. 51778

Page 15

A

R

A

A

Y

(

)

(**)

1. V-SHIFT

)

2. V-SIZE

3. H-CENT

4. H-SIZE

5. H-TRAPEZ

6. EW-PIN

7. COR-PIN

8. COR-UP

9. COR-LO

10. ANGLE

11. BOW

12. V-S.CR

13. V.LIN

SUB MENU 4. DE F

DEF FULL

1. V-SHIFT

: STORE i : EXIT

OK

- / +

SERVICE MENU

SERVICE MENU

1. IF 2. V/C

3. AUDIO 4. DEF

5. VSM PRESET 6. STATUS

7. PIP 8. - - -

9. SHIPPING

1-9 : SELECT i : EXIT

**

**

Hz

****

***

OFF)0. BUS FREE

IF SERVICE MENU

1. VCO

2. ATT ON/OFF

1-2 : SELECT i : EXIT

SUB MENU 1.IF (CW)

**

**....**

VCO (CW

MAIN

TOO HIGH

ABOVE REF

JUST REF

BELOW REF

TOO LOW

**

MHz

****

****

i : EXIT

V28L2EUG

V28L2EUBL

V28L2EUG

Do Not move.

COOL

NORMAL

WARM

1. CONT.

2. BRIGHT

3. SHARP

4. COLOUR

5. HUE

6. WDR R

7. WDR G

8. WDR B

SUB MENU 5. VSM PRESET

VSM PRESET NORMAL

1.CONT

- / +

: STORE i : EXIT

OK

***

Fig. 3 SUB MENU SCREEN

SUB MENU 2. V/C

PAL

V/C

1. RGB. BLK

- / +

SUB MENU 3. AUDIO (Do not adjust

- / +

: STORE i : EXIT

OK

AUDIO

1. ERR LIMIT 10H

C AD BITS =

: STORE i : EXIT

OK

****

********

1. RGB BLK

2. WDR R

3. WDR G

4. WDR B

5. BRIGHT

6. CONTRAST

7. COLOUR

8. HUE

9. SHARP

10.VCO ADJUSTMENT

11. VIDEO AGC

12. SYNC SLICE

1.ERR LIM IT

2. A2 ID THR

No. 51778

15

Page 16

A

V28L2EUGR

A

A

Y

V28L2EUBL

V28L2EUG

(3)

Method of Setting

Method of Sett i ng

"

[VCO]

1 Key

①

1 Key

②

INFORMATION ( ) Key

③

1.IF

・・・・・・・・・・・・・・・・・・・・・・・・・・・・ *

・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・

i

・・・・・・

It must not adjust without sig n al.

Select 1.IF.

Select 1. VC O (CW)

Check the arrow position between ABOVE REF. and BELOW REF.

Return to the SERVICE MENU screen.

Method of setting

"

5 Key

①2~

FUNCTION UP/DOWN Key

②

FUNCTION -/+

③

MENU (OK) Key

④

INFORMATION ( ) Key

⑤

Can not setting

"

(4)

Release of SERVICE MENU

1) After completing the setting, return to the SERVICE MENU, then again press the INFORMATION (OK) key.

2.V/C, 3.AUDIO, 4.DEF

・・・・・・・・・・・・・・・・・・・・・・

・・・・・

・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・

i

6. STATUS, 7. PIP, 8. --- , 9. SHIPPING(ON) & 0. BUS FREE.

・・・・・・

and

5.VSM PRESET.

Select on e from

Select setting items.

Set (adjust) the setting values of the setting items.

Memorize the setting value.

(Before storing the setting values in memory, do not press the CH, TV, POWER ON / OFF key -

if you do, the values will not be stored in memory.)

Return to the

2. V/C, 3. AUDIO, 4. DEF

SERVICE MENU

screen.

and

5. VSM PRESET

.

16

No. 51778

Page 17

A

R

A

A

Y

ADJUSTMENT

)

CHECKING ITEM

V28L2EUG

V28L2EUBL

V28L2EUG

Item

Measuring

instrument

Check of B 1

Power Supply

Signal

Generator

DC voltmeter

Remote

Control unit

Check of Hi gh

Voltage

Signal

Generator

DC volunteer

Remote

Control unit

Check of VC O Remote

control unit

IF SERVICE MENU

1. VCO

2. ATT ON/OFF

Test point Adjustment part Descrip tion

TP-91(B1)

TP-E(

)

####

[X connector

on POWER

DEF P WB]

1. RGB BLK

1. Receive any br oad cast.

2. Press the ZOOM key and select the FULL mode.

3. Select 2. V/C from the SERVICE MENU.

4. Select 1. RGB BLK with function UP / DOWN key.

5. Pr ess the f uncti on +( ) key t o find t he cut off sc reen (B lack

screen).

6. Connect a DC voltmeter to TP-91(B1) and TP-E(#).

7. Make sure that the voltage is DC139.9 ±2.0V.

8. Press the function – ( ) key to return to service menu.

CRT anode

1. RGB BLK

1. Receive any br oad cast.

2. Press the ZOOM key and select the FULL mode.

Chassis GND

3. Select 2. V/C from the SERVICE MENU.

4. Select 1. RGB BLK with function UP / DOWN key.

5. Pr ess the f uncti on +( ) key t o find t he cut off sc reen (B lack

screen).

6. Connect a DC voltmeter to CRT ANODE and chassis GND.

7. Make sure that the voltage is DC 31.0kV .

8. Press the function – ( ) key to return to service menu.

1. VCO

Under norm al c ond iti ons , no adjus t m ent is r equ ired.

"

Confirmation adjustment.

"

1. Select 1.IF from the SERVICE MENU.

2. Then select 1.VCO from the IF SERVICE MENU.

3. Receive any broadcast .

(Do not move)

4. Check the arrow ( ) p osition b etween the ABOVE R EF. and

BELOW REF.

+1kV

-1.5kV

1-2 : SELECT

TOO HIGH

ABOVE REF

JUST REF

BELOW REF

TOO LOW

VCO(CW

MAIN

i: EXIT

****

MHz

i : EXIT

No. 51778

17

Page 18

A

V28L2EUGR

A

A

Y

g

V28L2EUBL

V28L2EUG

ADJUSTMENT OF FOCUS & SCREEN

Item

Adjustment of

FOCUS

HVT

Adjustment of

SCREEN VR

Measuring

instrument

Signal

generator

FOCUS 1 VR

FOCUS 2 VR

SCREEN VR

Signal

generator

1. RGB BLK

- / +

Test point Adjustment part Descrip tion

FOCUS 2 VR

V/C

: STORE i : EXIT

OK

0 0 0 0 0 1 0 0

PAL

00

FOCUS 1 VR

FOCUS 2 VR

[In HVT]

FOCUS 1 VR

SCREEN VR

(In HVT)

CLOW

status

1. Receive a cross-hatch signal.

2. By t urning the FOC US 2 VR, adjus t the to make th e vertic al

lines as fin e an d sh arp as p oss ib le.

3. By turning the F OC US 2 V R, ad jus t the pic t ure so t h at the 5t h

vertic al line f rom left side of th e c ross-h atch pic tur e bec omes

thinnest.

4. By turning the FOCUS 1 VR, adjust the 3rd horizontal line from

the upper s id e may b ecome unif orm at th e line c ent er and its

periphery.

5. Carry out adjus t m ent by r ep eat ing the st eps 3 and 4 ab ou t .

6. Make sure that wh en th e sc r een is d ark ened, t he l ines rem ain

in good foc us .

1. Press a whole black signal .

2. Press the ZOOM key and select the FLL mode.

3. Select 2. V/C from the SERVICE MENU.

4. Rotate the SCREEN VR clockwise from the full

counterclockwise position and stop it at the point where

“CLOW” status (marked in Fig.) changes from 1 to 0 (which

is indicated at the 3rd

“CLOW” : control l oop ou t of wi nd ow .

*

column from the right.)

SERVICE MODE SCREEN

VSM PRESET SETTING

Item

Setting of

VSM PRESET

Settin

item

COOL

NORMAL

WARM

Measuring

instrument

Remote

control unit

VSM preset

mode

1.CONT. 2.BRIGHT 3.SHARP 4.COLOUR 5.HUE 6.WDR R 7.WDR G 8.WDR B

+16 0 -12 0 0 -25 -12 0

Test point Adjust m ent part Description

1. CONT.

2. BRI GHT

3. SHARP

4. COLOUR

5. HUE

6. WDR R

7. WDR G

8. WDR B

1. Select 5.VSM PRESET from the SERVICE MENU.

2. Select COOL with the MENU key of the remote control unit.

3. Adjust the FUNCTION UP/DOWN and -/+ key to bring the set

val ues of 1 .CON T.~ 8. W DR B to the values shown in th e

table.

4. Press the MEN U k ey and mem ori z e t h e s et value.

5. Respectively select the VSM PRESET mode for NORMAL and

WAR M, and m ak e sim il ar ad jus t m ent as in 3 above.

6. Press the MEN U k ey and mem ori z e t h e s et value.

Refer to OPERATING INSTRUCTIONS for the PICTURE

$

MODE.

00-1200000

-13 0 -12 -1 0 +5 0 0

SETTING VALUES OF VSM PRESET

18

No. 51778

Page 19

A

R

A

A

Y

VIDEO/CHROMA CIRCUIT ADJUSTM E NT

The setting (adjustment) using the REMOTE CONTROL UNIT is made on the basis of the initial setting values.

The setting values which adjust the screen to the optimum condition can be different from the initial setting values.

V28L2EUG

V28L2EUBL

V28L2EUG

Colour system

Setting item

1.RGB BLK 7.COLOUR

2.WDR R

3.WDR G

4.WDR B

5.BRIGHT

6.CONTRAST

Item

Adjustment

of WHITE

BALANCE

(High-Light)

Measuring

instrument

Signal

generator

Remote

control unit

Initial setting val ue Init i al settin g val ue

PAL SECAM

000

000

%

-012

000

000

Test point Adjustment part Desc ription

2.WDR R

3.WDR G

NTSC

Setting item

8.HUE

9.SHARP

10.VCO ADJUSTM ENT

11.V IDE O AG C

12.SYNC SLICE

Set the PICTURE MODE to NORMAL.

"

1. Receive a black an d whi te sign al (c olour off ).

2. Select 2. V/C from the SERVICE MENU.

3. Modify 2. WDR R and 3.WDR G data to adjust the white

4. Press the MENU k ey an d m em or i z e th e set value.

5. Change the contrast and brightness with the remote control up

marked

"

Colour system

PAL SECAM NTSC

000 000 000

%

+007

Automatically optimized

%

000

%

+007

balance ( high light ).

& down from low–light to high –l ight and ch ec k that the tracki n g

of the white balance is good.

:Do not adjust

%

after adjus tment

020

Adjustment

of

SUB BR I GHT

Adjustment

Of SU B

CONTRAST.

Remote

control unit

Remote

control unit

5.BRIGHT

6.CONTRAST

No. 51778

1. Receive any broad cast.

2. Select 2.V/C from the SERVICE MENU.

3. Select 5.BRIGHT with the FUNCTION UP/DOWN key.

4. Set the initial setting value with the FUNCTION -/+ key.

5. If the brightness is not the best with th e initial setting value,

make fin e adj us tm en t unt il y ou g et t h e bes t br ig ht n ess .

6. Press the MENU k ey an d m em or i z e th e set value.

1. Receive any broad cast.

2. Select 2.V/C from the SERVICE MENU.

3. Select 6.CONTRAST with the FUNCTION UP/DOWN key.

4. Set the initial setting value with t h e FUNCTION - or + key.

5. If the contrast is not the best with the initial setting value, make

fine adjustment until you get the best contrast.

6. Press the MENU k ey an d m em or i z e th e set value.

19

Page 20

A

V28L2EUGR

A

A

Y

V28L2EUBL

V28L2EUG

Item

Adjustment

of SUB

COLOUR

ⅠⅠⅠⅠ

Measuring

instrument

Remote

control unit

Test point Adjustment p art Description

key

CH.

MENU

( OK ) key

7.COLOUR

(PAL/SECAM/NTSC)

PAL COLOUR (PAL COLOUR)

SECAM COLOUR (SECAM COLOUR)

NTSC COLOUR

[Method of adjustment without measuring instrument]

1. Receive PAL broadcast.

2. Select 2.V/C from the SERVICE MENU.

3. Select 7.COLOUR with the FUNCTION UP/DOWN key.

4. Set the initial setting value for PAL COLOUR with the

FUNCTION - or + key.

5. If the col our is not th e bes t with th e initi al set val ue, mak e fin e

adjust m ent un t il you get t h e bes t c ol our .

6. Press the MENU k ey an d m em or i z e th e set value.

1. R ec eive a SEC AM broadcast.

2. Make fine adjustment of SECAM COLOUR in the same

manner as for ab ov e.

(NTSC 3.58 COLOUR)

1. Input a NTSC 3. 58MHz C OMPOSIT E VIDEO s ignal fr om the

EXT terminal.

2. M ake similar fine adjustment of NTSC 3.58 COLOUR in the

same manner as for above.

(

INFORMATION

i

FUNCTION

) key

key

(NTSC 4.43 COLOUR)

1. R ec eive a NTSC 4.43MHz CO MPOSITE VIDEO signal from

the EXT terminal.

2. Make similar fine adjustment of 4.43 COLOUR in the same

manner as for ab ov e.

20

No. 51778

Page 21

A

V28L2EUG

R

A

A

Y

V28L2EUBL

V28L2EUG

Item

Adjustment

of SUB

COLOUR

ⅡⅡⅡⅡ

W

Measuring

instrument

Signal

generator

Oscilloscope

Remote

control unit

Cy Mg B

Test point Adjustment p art Description

TP-47B

TP-E(

[CRT

SOCKET

PWB ]

(A)

7.COLOUR

(PAL/SECAM/NTSC)

)

####

PAL COLOUR (PAL COLOUR)

SECAM COLOUR (SECAM COLOUR)

(-)

NTSC COLOUR

0

(+)

[Method of adjustment using measuring instrument]

1. Receive a PAL full field colour bar signal(75% white).

2. Select 2.V/C from the SERVICE MENU.

3. Select 7.COLOUR with the FUNCTION UP/DOWN key.

4. Set the initial setting value of PAL COLOUR with the

FUNCTION - or + key.

5. C onn ect th e osc i lloscope between T P-47B and TP -E

6. Adjust PAL COLOUR and bring the value of

illustr ation to

blue (B)).

7. Pr ess the ME NU k ey an d memori z e the settin g val ue.

1. Receive a SECAM full field colour bar signal(75% white).

2. Set the initial setting value of SECAM COLOUR with the

FUNCTION -/+ key.

3. Adjust SECAM COLOUR and bring the value of

illustr ation to

4. Pr ess the ME NU k ey an d memori z e the settin g val ue.

(NTSC 3.58 COLOUR)

1. Input a NT SC 3. 58MH z CO MPOSIT E VI DEO si gnal (f ull f ield

colour bar with 75% white) from the EXT terminal.

2. Set the initial s etting value of NTSC 3.58 COLOUR with th e

FUNCTION -/+ key.

3. Adjust NTS C 3.58 CO LOUR and bring t he val ue of

illustr ation to

4. Pr ess the ME NU k ey an d memori z e the settin g val ue.

(volt age diff erenc e between w hite (w) an d

+5V

(W~B).

+4V

(W~B).

+6V

(A)

(A)

(A)

in the

of the

of t h e

(NTSC 4.43 COLOUR)

1. Input a NT SC 4. 43MH z CO MPOSIT E VI DEO si gnal (f ull f ield

colour bar with 75% white) from the EXT terminal.

2. S et the initi al s etting val ue of NTSC 4.43 COLO UR with the

FUNCTION -/+ key.

3. Adjust NTS C 4.43 CO LOUR and bring t he val ue of

illustr ation to

4. Pr ess the ME NU k ey an d memori z e the settin g val ue.

+6V

(W~B).

No. 51778

(A)

of t h e

21

Page 22

A

V28L2EUGR

A

A

Y

V28L2EUBL

V28L2EUG

Item

Adjustment

of

SUB HUE

Adjustment

of

SUB HUE

ⅠⅠⅠⅠ

ⅡⅡⅡⅡ

Measuring

instrument

Remote

control unit

Signal

generator

Oscilloscope

Remote

control unit

Test point Adjustment p art Description

8.HUE [Method of adjustment without measuring instrument]

TP-47B

TP-E(

####

[CRT

SOCKET

PWB]

NTSC 3.58 HUE

NTSC 4.43 HUE [NTSC 4.43 HUE]

8.HUE [Method of adjustment using measuring instrument]

)

NTSC 3.58 HUE [NTSC 3.58 HUE]

[NTSC 3.58 HUE]

1. Input a NTSC 3.58MH z COMPO SITE VI DEO sign al (full f ield

colour bar with 75% white) from the EXT terminal.

2. Select 2.V/C from the SERVICE MENU.

3. Select 8.HUE with the FUNCTION UP/DOWN key.

4. Set the initial setting value of NTSC 3.58 HUE with the

FUNCTION -/+ key.

5. If you cannot get the best hue with the initial s etting value,

make fin e adj us tm en t unt il y ou g et t h e bes t hu e.

6. Press the MEN U k ey and mem ori z e t h e s et value.

1. When NTSC 3.58 is set, NTSC 4.43 will be automatically set at

the respective values.

1. Input a N TSC 3.58 MHz CO MPOSITE V IDEO sign al (full f ield

colour bar with 75% white) from the EXT terminal.

2. Select 2.V/C from the SERVICE MENU.

3. Select 8.HUE with the FUNCTION UP/DOWN key.

4. Set the initial setting value of NTSC 3.58 HUE with the

FUNCTION - or + key.

5. C onn ect t h e osc i ll oscope bet w een TP -47B and TP- E

6. Adjust NTSC 3.58 HUE to bring the value of

illustr ation to

magenta(Mg)).

7. Press the MEN U k ey and memor i z e t h e s etting valu e

・・・・・・・・・・・・・・・・・

(voltage differenc e between white (W) and

-3V

(NTSC only)

(B)

in the

NTSC 4.43 HUE [NTSC 4.43 HUE]

(B)

W

Cy Mg B

Adjustment

of VCO

for colour

decoder

Signal

generator

Remote

control unit

22

(-)

0

(+)

10. VCO

No. 51778

1. When NTSC 3.58 is set, NTSC 4.43 will be automatically set at

the respective values.

1. Input a P AL full f ield colour bar si gnal (75% white) f rom the

EXT terminal.

2. Select 2. V/C from the SERVICE MENU.

3. Select 10. VCO adjustment with the FUNCTION UP/DOWN

key.

4. Press the OK key th en autom at ically opt i mi z ed.

Page 23

A

R

A

A

Y

DEFLECTION CIRCUIT ADJUST MENT

There are 4 as pect modes (

and ( 3 ) 120Hz i mode

When the 10 0 Hz FUL L mo d e ha s bee n est ablished, the set ting of other modes wil l be do n e aut o matically .

"

However , if the pi c tu re qu ali t y has n ot been opti miz e d , adj u st each mod e ag a in, respect ively.

The adjustment using the remote control unit is made on the basis of the initial setting values.

"

The setting values which adjust the screen to the optimum condition can be different from the initial setting values.

"

Setting item

1.V- SHIFT -4 +8 +1 0 +8 +2 0 0

2.V-SIZE +700000-15 0

3.H-CENT -23 +4 -4 0 0 0 0 0

・・・・・

・・・・・・・・・

・・・・・・・・・・

100Hz i 60Hz p 100Hz i 60Hz p 100Hz i

FULL,

①①①①

depending upon the kind of signal s ( vertic al frequency 100Hzi / 60HZp / 120Hzi ).

FULL PANORAMIC SUBTITLE COMPRESS

PANORAMIC,

②②②②

SUBTITLE,

③③③③

Initial settin g val ue

COMPRESS) of the ad jus tm ent ( 1 ) 100Hz i m od e, ( 2 ) 6 0 Hz p

④④④④

60Hz p

100Hz i

V28L2EUG

V28L2EUBL

V28L2EUG

120Hz i

4.H-SIZE -27-4-40000 0

5.TRAPEZ -17 +13 0 0 0 0 0 0

6.EW-PIN -45 0 0 0 0 0 0 0

7.COR-PIN0000000 0

8.COR-UP 0 0 0 0 0 0 0 0

9.COR-LO -10 0 0 0 0 0 0 0

10.ANGLE0000000 0

11.BOW 0000000 0

12.V-S.CR +6 0 +5 0 +7 0 0 0

13.V-LIN -4 +4 -11 0 -22 0 0 0

Screen tone : Do not move fixed value.

%

No. 51778

23

Page 24

A

V28L2EUGR

A

A

Y

V28L2EUBL

V28L2EUG

Item

Adjustment

of

V-SHIFT

Adjustment

of V-SIZE

Screen

size

Measuring

instrument

Signal

generator

Remote

control unit

Test point Adjustment p art Description

1. V- SHIFT

A

B

2.V-SIZE

Screen size

Picture

size

100%

[FULL mode]

1. Receive a circ l e pattern sig n al of vert ical fr equency 50H z.

2. Select 4.DEF from the SERVICE MENU.

3. Select 1.V-SHIFT with the FUNCTION UP/DOWN key.

4. Adjust V-SHIFT to make

5. Check the adjustment value above in other zoom mode.

If it is a wrong adjustm ent, re-adjus t in “PANORA MIC” mode

and adjus t b y 1. V-SH I FT.

6. Press the MENU k ey an d m em or i z e the set valu e.

7. Receive a cross-hatch signal.

8. Select 2.V-SIZE and set the initial setting value.

9. Adj ust V-S IZE and mak e sure that t he ver tic al screen siz e of

the picture size is in the bellow table.

10. Press the ME NU k ey an d m em o ri z e t h e s et value.

11. Input a NTSC VIDEO sign al (60Hz) from the EXT t er minal,

and make sure that the vertic al screen size is in the table

below.

12. Press the ME NU k ey an d m em o ri z e t h e s et value.

A = B

.

Picture size 100%

ASPECT

SCREEN

POSITION

TOP

BOTTOM 92% 87% 83%

24

FULL PANORAMIC

92% 87% 70%

[ SCREEN SIZE ]

SUB TITLE

No. 51778

Page 25

A

V28L2EUG

R

A

A

Y

V28L2EUBL

V28L2EUG

Item

Adjustment of

H.CENTER

Adjustment

of

H.SIZE

Measuring

instrument

Signal

generator

Remote

control unit

CD

Test point Adjustment p art Description

3.H-CENT.

4.H-SIZE

13. Receive a cir c l e patt er n s ig n al.

14. Select 3.H-CENT and set the initial setting value.

15. Adjust H-CENT to make

16. Press the MEN U k ey an d m em or i z e the set valu e.

17. Receive a cross-hatch signal.

18. Select 4.H-SIZE and set the initial setting value.

19. Adjust H -SIZE and make sur e t hat t he hori zontal s cr een s ize

of the picture size is in the bellow table.

20. Press the MEN U k ey an d m em or i z e the set valu e.

21. Input a NTSC VIDEO signal (60Hz) from the EXT terminal, and

make sure that the horizontal screen size is in the table below.

22. Press the MEN U k ey an d m em or i z e the set valu e.

C=D

.

ASPECT

MODE

H SIZE

Adjustment of

EW-PIN

FULL PANORAMIC

92% 95% 92%

[ SCREEN SIZE ]

6.EW-PIN

Straight

SUBTITLE

23. Select 6.E W-PIN and set the initial setting value

24. Adjus t EW- PIN and mak e th e 2nd . vertic al li n es at t he l eft and

right edg es of t h e s c reen straight . Als o m ak e s ur e that th e 3r d

vertical lines are straight.

25. Press the MEN U k ey an d m em or i z e the set valu e.

No. 51778

25

Page 26

A

V28L2EUGR

A

A

Y

V28L2EUBL

V28L2EUG

Item

Adjustment

of TRAPEZ

Adjustment of

CORNER

UP/ LOW

Measuring

instrument

Signal

generator

Remote

control unit

Signal

generator

Remote

control unit

Straight Straight

Test point Adjustment p art Description

5.TRAPEZ

Parallel

7.COR-PIN

8.COR-UP

9.COR-LO

26. Receive a cross-hatch signal.

27. Select 5.TRAPEZ with the FUNCTION UP/DOWN key.

28. Set the initial setting value of TRAPEZ with the FUNCTION or + key.

29. Adjust T RAPEZ and bring the VERTICAL lines at the right and

left edges of the screen parallel .

30. Press the MEN U k ey an d m em or i z e the set valu e.

31. Select 9.COR-LO with the FUNCTION UP / DOWN key.

32. Set the initial setting value of COR-LO with the FUNCTION –

or + key.

33. Adjust COR-LO, and bring the straight line at the low corner.

34. Select 8.COR-UP with the FUNCTION UP / DOWN key.

35. Set the initial setting value of COR-UP with the FUNCTION –

or + key.

36. Adjust COR-UP, and bring the straight line at the upper

corner.

37. If the extrem e upper & lower corners and a litt le pin or barr el,

chose 7.CO R -PIN and adj ust.

And adjust to get the straight. Store the set value.

Adjustment of

ANGLE

Signal

generator

Remote

control unit

26

10.ANGLE

No. 51778

In case where there is a parallelogrammical distortion of

"

images on the screen. (Fig. A)

38. Select 10.ANGLE with the FUNCTION UP / DOWN key.

39. Adjust ANGLE, and bring the VERTICAL lines straight.

40. Press the MEN U k ey an d m em or i z e the set valu e.

Fig. A

Page 27

A

V28L2EUG

R

A

A

Y

V28L2EUBL

V28L2EUG

Item

Adjustment

of BOW

Adjustment

of V-S.CR &

V.LINE

Measuring

instrument

Signal

generator

Remote

control unit

Test point Adjustment p art Description

11.BOW

Fig. C

12.V-S.CR

13.V.LIN.

TOP

CENTER

In c ase where t here is a bow-sh aped dist ortion of im ages on

"

the screen. (Fig.C)

41. Select 11.BOW with the FUNCTION UP/DOWN key.

42. Adjust BOW, and bring the VERTICAL lines straight.

43. Press the MEN U k ey an d m em or i z e the set valu e.

When the ver tic al linear ity has been deter iorat ed rem ark ably,

!

perform the following steps.

44. Receive a cross-hatch signal.

45. Select 13. V.LIN with the FUNCTION UP / DOWN key.

46. Set the initial setting value of 13. V.LIN with the FUNCTION

- / + key.

47. Select 12. V-S.CR. with the FUNCTION UP / DOWN key.

48. Set the initial setting value of 12. V-S.CR. with the FUNCTION

- / + key.

49. Adjust 13. V .LIN and 12. V -S.CR . so that th e spac es of each

line on TOP, C EN T E R , an d BOTTOM b ec om e u niform.

BOTTOM

NOTE : Do not adjust “PANORAMIC” & “SUBTITLE” mode.

At first t he adjus tm ent in 1 00Hz FUL L mo de sh ould b e done,

then th e data for th e other aspect mode is corrected in the

respect ive valu e at th e same tim e. And c onfirm t he defl ection

adjust ment initial s etting value in 12 0Hz (NTSC EXT mod e)

FULL mode. If the adjustment in 1 00Hz each aspect mod e has

been don e and st ored, the dat a for the s ame as pect m odes in

120Hz is c orrect ed in the r espect ive value. O nly th e data f or

the other as pect mode in 120Hz is c orr ec t ed f or itself.

No. 51778

27

Page 28

A

V28L2EUGR

A

A

Y

V28L2EUBL

V28L2EUG

AUDIO CIRCUIT ADJUSTMENT

Do not touch

"

If values had changed for the some reason, set the initial values in the following table.

3. AUDIO(Do not ad j ust)

1. ERR LIMIT 00H~FFH 10H

3. AUDIO

Sett ing item Variable ran ge fixed value

adjust m ent of t h e SER V IC E MENU as it req uires no ad jus tment.

2. A2 ID THR

00H~FFH

19H

28

No. 51778

Page 29

A

R

A

A

Y

REPLACEMENT OF CHIP COMPONENT

CAUTIONS

!

1. Avoid heating for more than 3 seconds.

2. Do not rub the electrodes and the resist parts of the pattern.

3. When removing a chip part, melt the solder adequately.

4. Do not reuse a chip part aft er r em ovi n g it.

SOLDERING IRON

!

1. Use a high insulat i on s old er in g iron with a thi n p oint ed end of it.

2. A 30w soldering iron is recommended for easily removing parts.

REPLACEMEN T STEPS

!

How to remove Chip parts

1.

Resistors, capacitors, etc

####

(1) As shown in the figure, push the part with tweezers and

alternately m elt th e s older at each en d.

(2) S hif t wi th tweezers and remo ve th e ch ip part.

Transistors, diodes, variable resistors, etc

####

(1) Apply extra solder to each lead.

V28L2EUG

V28L2EUBL

V28L2EUG

2. Ho w to install Chip parts

Resistors, capacitors, etc

####

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp th e chip part with tw eezers and pl ace it on th e sold er.

Then heat an d m elt t h e s old er at b oth en ds of th e chip part .

Transistors, diodes, variable resistors, etc

####

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the solder.

(3) First solder lead

as indicated in the figure.

A

SOLDER

(2) As shown in the figure, push the part with tweezers and

alternat el y melt t he s old er at each lead . Shif t and r emov e th e

chip part.

Note : After removing the part, remove remaining solder from the

pattern.

SOLDER

No.51778

A

C

(4) Then solder leads

A

C

and C.

B

B

B

29

Page 30

A

V28L2EUGR

A

A

Y

V28L2EUBL

V28L2EUG

30

No.51778

Page 31

A

V28L2EUG

R

A

A

Y

V28L2EUBL

V28L2EUG

No. 51778

47

Page 32

V

ICTOR COMPANY OF JAPAN, LIMITED

HOME AV NETWORK BUSINESS UNIT 12, 3-chome, Moriya-cho, Knagawa-ku, Yokohama, Kanagawa-prefecture, 221-8528, Japan

4

AV28L2EUGR-U #4

AV28L2EUBL-U #3

AV28L2EUGY-U #3

Printed in Japan

VP 0105

DP105851

Loading...

Loading...