Page 1

S

S

B

SERVICE MANUAL

COLOUR TELEVISION

AV32H20EUS

AV28H20EUS

AV32H20EU

AV28H20EU

AV28H20EU

BASIC CHASSIS

ⅡⅡⅡⅡ

MF

AV28H20EUB

CONTENTS

! SPECIFICATIONS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

!

SAFETY PRECAUT IONS

! FEATU RES・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

! MAIN DIFFERENCE LIST ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

!

SPECIFIC SERVICE INSTRUCTIONS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

! SERVICE ADJUSTMENTS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

!

PARTS LIST

★

OPERATING INSTRUCTIONS

★

STAND ARD CIRCUIT DIAGRAM

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 2

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・ 5

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・ 12

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・ 5

・・・・・・

・・・・・・・・・・・・・ 6

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

4

31

2- 1

1

COPYRIGHT © 2002 VICTOR COMPANY OF JAPAN, LTD.

No.519 45

May 2002

Page 2

A

V32H20EUS

A

A

V28H20EUS

V28H20EUB

SPECIFICATIONS

Item

Dimensions ( W××××H××××D ) 85 5m m ×5 50mm×5 68mm 78 0m m ×5 09mm ×499m m

Mass 53 .6 kg 40 .2 kg

TV RF System

Colour Syst em PA L / SEC A M / N TSC (Only in EXT mode)

Stere o Sy st em A2 (B /G,D/K )/ NICAM ( B/G, I,D /K,L )

Teletext System FLOF (Fastext)

Receiving Frequency

French CATV 116MHz ~ 1 72MHz / 22 0MHz ~ 469MHz

Intermediate Fr equency

VIF Carrier 38.9MHz ( B/G , I ,L)/ 33.95 MHz (L’)

SIF Carrier 33.4MHz ( 5 .5MHz :B/ G) / 32.9MHz ( 6.0MHz:I ) / 32.4MHz ( 6. 5MHz:L , D/K) / 40.4 5MHz (6.5MHz:L ’)

Colour Sub Carrier Freq.

SE CAM 4.40625MHz/4.25MHz

Power Input 220 – 240 V AC, 50Hz 220 – 240 V AC, 50Hz

Power Consumption 187W(Max) / 138W(Avg), standby : 2.6W 178W(Max) / 125W(Avg), standby : 2.6W

Aerial Input Term

Pictur e Tube Visi bl e siz e : 7 6cm, M eas ured dia gon ally Visi bl e size : 66cm , Meas ured dia gonal ly

Hi gh Vo l t ag e

CCIR (B/G ,D/K,I ,L, L ’)

TOP (German syst em)

WST(W orld Stan dard system)

VHF 47 MHz ~ 47 0M Hz

UHF

470MHz ~ 8 62MHz

PAL 4.43MHz

NT S C 3.58MHz / 4.43MHz

75Ωun ba l anc ed, C oaxial

1kV

+

-1. 5kV

31.0kV (at zero beam current)

AV 32 H 20 EU S AV 28 H 20 EU S / AV28 H2 0E UB

Content

Speake r (16c m×4c m) ov al typ e ×2

Au dio Output 7.5 W + 7.5 W

EX T-1/EXT - 2/E XT-3

(Input / Output)

S / Video

EXT-4 (Input) Video

Au di o (L /R )

S / Video

AUDIO OUT (Vari able)

Headphone jack

Remote Control Unit RM-C 54 H (AAA/R0 3 dr y batte ry×2) : (A V32H 20 EUS, A V28H20 EU S)

21 -p i n E uro c onnec to r

(SCART socket)

p-p

Y : 1V

C : 0.3V

1V p- p 7 5Ω( RCA pin jack )

50 0m Vr ms( -4dB s ), H i gh Im pe dance ( RCA pin jack )

Y : 1V

C : 0.3V

0~1Vrm s , Low Im p ed ance

(RCA pi n ja ck×2)

St ereo min i jac k (φ3.5mm )

RM-C 50( A AA/R0 3 d r y bat tery×2) : (AV28H20EUB)

POSITIVE (Negative sync Provided, when terminated with 75Ω)

p-p

(Burst signal, when terminated with 75Ω)

p-p

POSITIVE (Negative sync Provided, when terminated with 75Ω)

p-p

(Burst signal, when terminated with 75Ω)

De sign & speci f icatio ns ar e su bje ct to cha ng e wi thout no t ice.

2

No.51945

Page 3

A

V32H20EUS

A

A

V28H20EUS

V28H20EUB

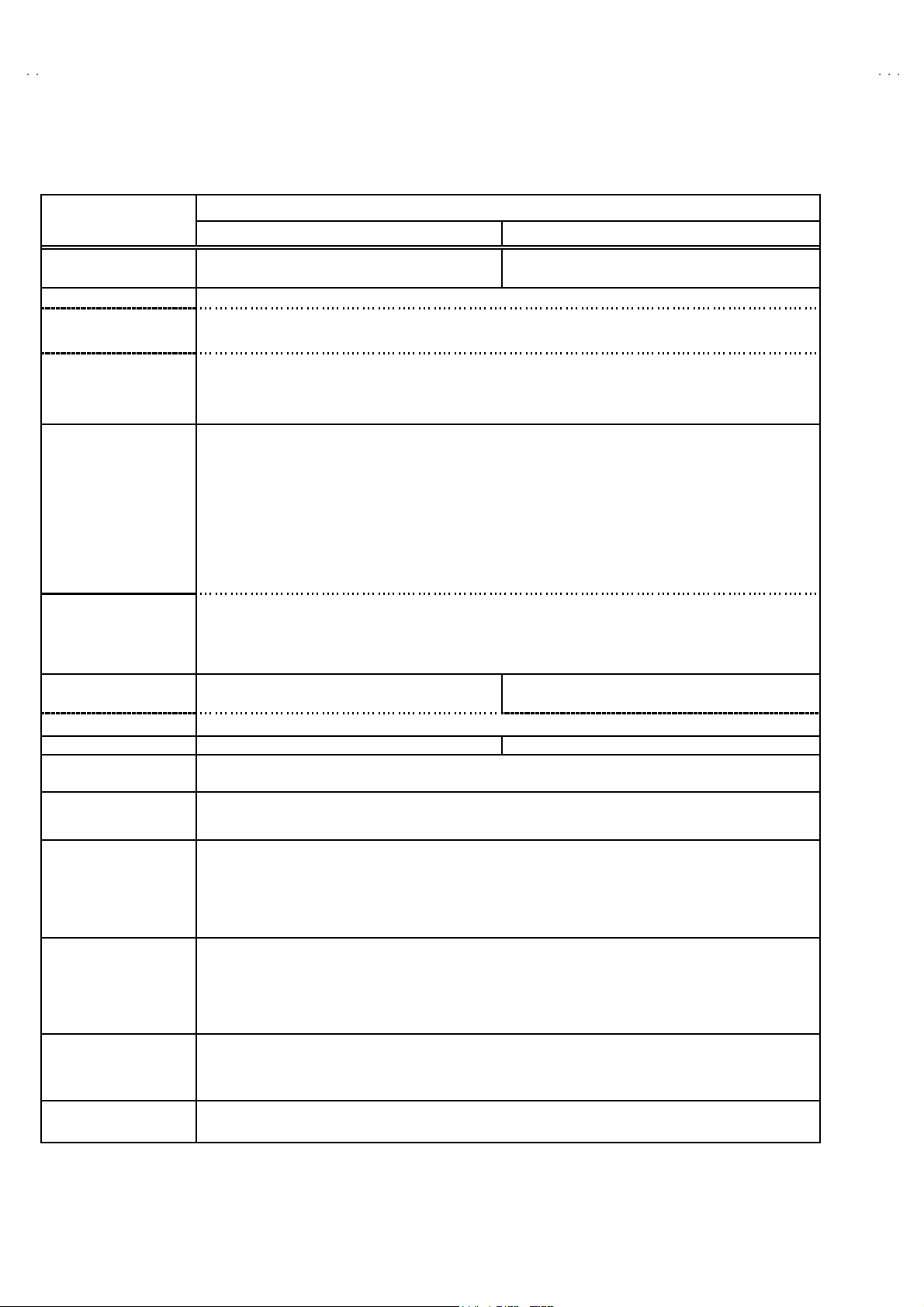

■■■■21-pin Euro connector (SCART socket) : EXT-1 / EXT-2 / EXT-3

(P-P= Peak to Peak, B-W= Blanking to white peak)

Pin

Signal Designation Matching Value EXT-1 EXT-2 EXT-3

No .

1 AUDIO R o utput 50 0m Vr ms(Nomina l) ,

Low impedance

2 AUDIO R i n put 50 0m Vr ms(Nomina l) ,

High i m pe danc e

3 AUDIO L outp ut 50 0m Vr ms(Nomina l),

Low impedance

4 AUDIO GN D ○○○

5 GND (B)

6 AUDIO L input 500mVrms(Nominal),

High i m pe danc e

7B input 700mV

8 FUNCTION SW

(SLOW SW)

9 GND (G)

10 SCL3 NC ○ NC

11 G in put 70 0mV

12 SDA3 NC ○ NC

13 GND (R)

14 GND (YS) ○ NC NC

15 R / C input R : 700mV

16 Ys i n put

17 GND(VIDEO output) ○○○

18 GND(VIDEO input) ○○○

19 VID EO outpu t 1V

20 VIDEO / Y inp ut 1V

21 COMMON GN D ○○○

Low : 0-3V, High : 8-12V, High

impedance

C : 300mV

Low : 0 - 0.4, High : 1 - 3V, 75Ω○

, 75Ω○○NC

B- W

, 75Ω○○NC

B- W

, 75Ω

B- W

, 75Ω

P- P

(Nega ti ve g oi n g s ync ), 75Ω○

P- P

(Nega ti ve g oi n g s ync ), 75Ω○ ○ ○

P- P

○

(TV OUT)

○○○

○

(TV OUT)

○○○

○○○

○○○

○○○

○○○

○

(only R)

(TV)

○

(LINE OUT)

○

(LINE OUT)

○

NC NC

○

(LINE OUT)

NC

NC

○

(only C )

NC

[Pin assignment]

No.51945

3

Page 4

A

V32H20EUS

A

A

V28H20EUS

V28H20EUB

SAFETY PRECAUTIONS

1. T he des i gn of th is pr od uct con ta ins speci al har d ware , many

circuit s and components specially for saf ety purposes. For

con tinu ed pr ot ecti on , n o chan g es sh ould b e ma de to the o rig i nal

d esign un less a uth or ized in writi n g by th e manu fac t urer .

Replacem ent p arts m ust b e i d entic al to thos e u sed in th e or i gi n al

ci rcu its. S er v i ce sho ul d b e p er for m ed by qu alif ied p ers on nel

on ly.

2. Alte r ation s of the desi g n or circui tr y of t he prod ucts s h oul d not be

made. Any design alterations or additions will void the

manu fac t urer 's warra nt y and will f urth er r el i eve t he ma nufac tu rer

of r esp onsib ili ty for per s o na l injury or pr operty d am ag e res ul t ing

th erefr om.

3. M an y el ectr i cal an d mech anic a l p ar ts i n th e pr od uc ts ha v e

special safety-related chara cteristics. T hese characteristics are

oft en no t e vi den t f r om v i sua l insp ecti on nor ca n t he pro tect io n

aff orde d by th em nece ssarily be ob tain ed b y u s in g r ep l ac em en t

com po nents rated for hig he r vo l tag e, watt age, etc . R ep lac em en t

p arts whic h have th ese sp ecial s afet y ch ar act erist ics ar e

ide ntified in the parts list of Ser vic e manua l. El ectric al

components having such features are ide ntified by shading

on the sche mat ic s and b y (

manual. The us e of a sub sti tu te r ep lac em en t which do es n ot

h ave th e sam e s af ety c h ar ac t erist ics as t he reco mmen ded

replac ement par t sh ow n i n th e parts list of Ser v i ce man ual m ay

cause shock, fire, or other hazards.

!!!!

) on the parts list in Service

4. Don't shor t between the LIVE s ide ground and ISOLATED

(NE UTRAL) side ground or EARTH side ground when

repairing.

Some model's power circuit is partly different in the GND. The

diff erenc e of th e G ND i s sho wn b y th e LIVE : (") side GND, the

ISO LATE D(N EU TR AL) : (#) si de G ND and EART H : ($) side

GND. D o n't sh ort b et ween th e LIV E s i d e GND an d

ISO LATE D(N EU TR AL) si de GND or EAR TH side GN D an d

n ever mea sure w it h a mea sur i ng a ppa r atus ( osci l lo scop e etc.)

th e LI VE sid e GN D an d IS OLA TED(NE UTRAL ) s ide G ND or

EARTH sid e GND at the s ame time.

If above not e will not be kept, a fuse or any parts will be broken.

5. If any repair has been made to the chassis, it is recommended

th at t he B1 set ting shou l d b e c h ec ked or adju ste d ( Se e

ADJUSTM ENT OF B 1 POW E R SUPPLY).

6. The hi gh vol ta ge app lie d t o th e pi ctu r e tu be mu s t c on form with

th at sp ecifi ed i n S ervi ce man ual . E xc essi ve h i gh volt ag e c a n

cau se an i ncr e ase i n X- R ay em iss i on , arci ng an d possi b le

component damage, therefore operation under excessive high

voltage conditions should be kept to a minimum, or should be

preve nt ed. If s ever e arc ing occur s, r emov e t he AC power

immed iate l y and de ter m i ne th e ca us e b y vi sua l insp ec t ion

(incor r ec t in stal lat i on, cr ac ke d or melte d hi gh vo lt age harn ess,

p oor so ld er ing, et c.) . T o m ai nt ain the prope r mi n imu m le vel of

sof t X- R ay em iss i on, c omp on en ts i n th e hi gh voltag e c i r cuitr y

incl ud i ng t he pict ure tu be must be t he e xact r ep lacem e nts or

alte rn at ives ap pr ove d b y th e manuf ac t urer of th e c omplet e

prod uct.

7. Do not c hec k hi gh volt ag e by dr aw i ng an arc. Use a hi gh volt age

meter or a hig h v oltag e pr ob e wit h a V TVM . Discha rg e th e

picture tube before attempting meter connection, by connecting

a cl i p le ad to th e gr ou nd f rame and conn ecti n g th e oth er end of

the lead through a 10kΩ 2W resi sto r to the anod e butt on .

8. When se r vic e is r equ ire d, ob serve th e or i gina l lea d dr ess. E x tr a

prec aut i on sh ou ld b e given t o assur e cor r ect l ea d dress in th e

high vol tag e circui t a rea. W her e a s hor t c i r cuit h as occ u rr e d,

th ose co mpon ent s tha t indica te evide nce of ove r hea ting should

b e r e place d. A lways u s e th e manuf act ur er 's rep lacem ent

components.

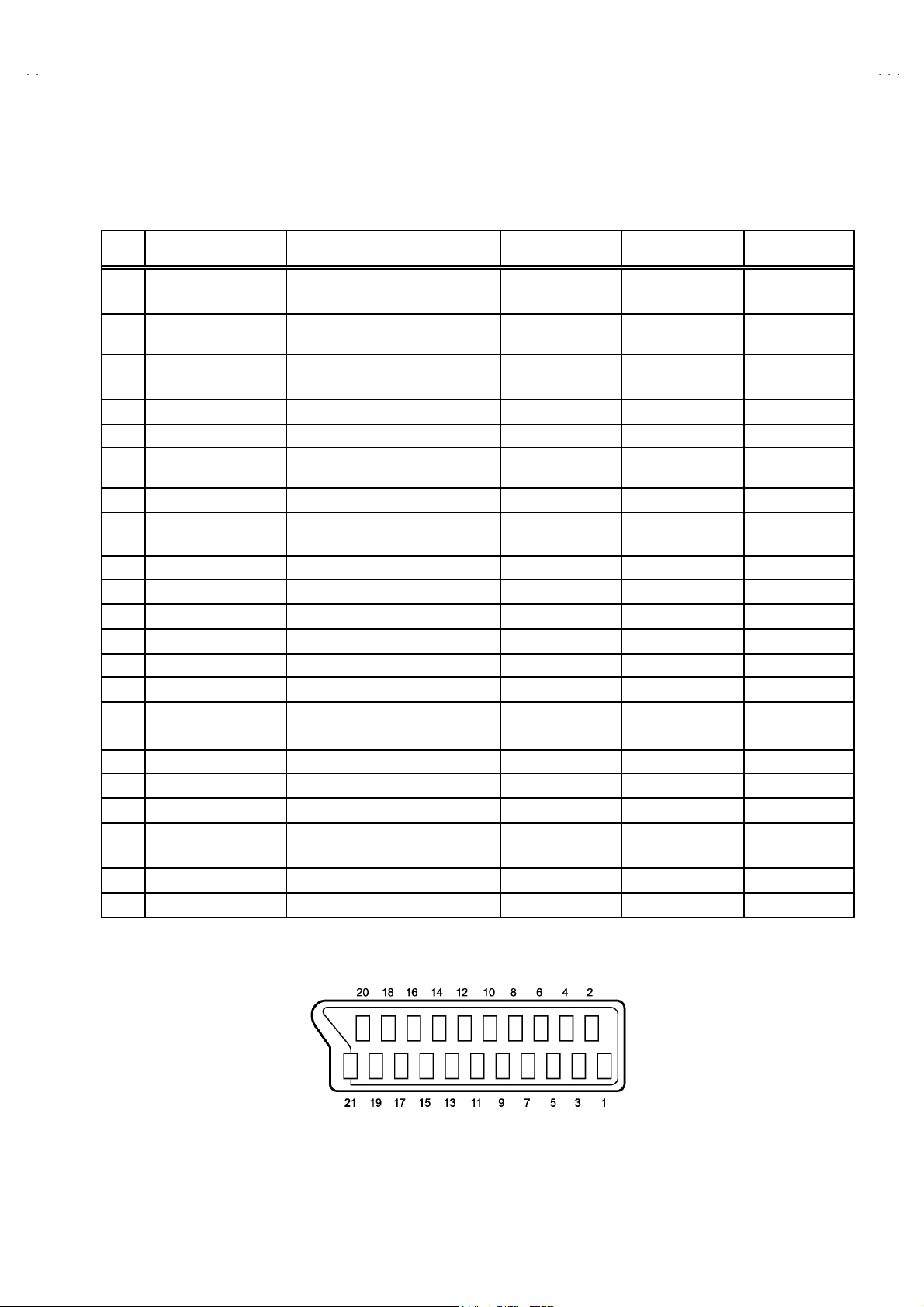

9. Isol ation Check

(1) Dielectric Strength Test

(2) Leakage Current Check

(Safety for Electrical Shock Hazard)

Af ter r e- ass embl in g th e p r odu ct, always per f orm an i solat io n

ch eck on the expo s ed me tal p ar ts of t he cabin et ( a nte nn a

ter m i na ls, vid eo /au dio i npu t and outpu t t ermi n al s, C on trol kn obs,

metal cabin et, sc r ew he ad s, ea rph one j ack, con tr ol s haf ts, etc.)

to be su re th e p r odu ct is s af e t o o pe rate with ou t d an ger of

elect rical shoc k.

The iso lation be tw een the AC pr im a ry ci rcu it an d al l me tal p arts

exp osed t o the us er, p ar ticular ly an y e xpos ed met al p art having a

retu rn p ath to t he c hass is sho uld withs tan d a vol t age of 3000 V

AC (r.m. s.) for a period of one sec ond.

(. . . . W it hstan d a v o lt age of 110 0V A C (r .m. s.) t o an ap plianc e

rate d up to 12 0V , an d 3 00 0V AC ( r.m. s.) to an ap pl i an c e r at ed

200V or more, for a period of one second.)

This meth od of test r equi res a test equipment n ot g enerall y fou nd

in t he serv ic e trad e.

Plug th e AC l in e c ord d irect ly into the A C ou tlet ( d o not use a lin e

isol ati o n transf orm er du r ing this ch eck.). U sin g a " Lea kag e

Current T este r", me as ur e th e l ea k ag e cu rr e nt f rom eac h ex p os ed

metal p ar t of the cabine t, p art icu lar ly any e x pos ed me tal p art

h aving a re turn pa th to the ch assis , to a kn own go od ea rt h

grou nd (w a ter pip e, e tc.). An y l eaka ge c ur r en t must n ot e xceed

0.5mA AC (r.m.s.).

Howev e r, in trop ic al ar ea , th is mu st no t ex ce ed 0.2 mA AC

(r.m.s.).

""""

Alte rn at e Che ck M et hod

Plug th e AC l in e c ord d irect ly into the A C ou tlet ( d o not use a lin e

isol ati o n tran sfor m er dur i ng this c he c k.). Use an AC vo lt meter

h aving 1 00 0 oh ms pe r vol t or mor e s ens it i vity i n th e fo llowi ng

mann er . C on nec t a 1 50 0Ω 10W res ist or par a lle le d b y a 0 .1 5µF

AC-type c apa cit or bet ween an expo sed met al pa rt and a kno wn

g ood e ar th gr o und (water pi pe , etc.) . M eas ur e th e A C volt ag e

acr os s th e res ist or wi th th e AC vo l tm eter. Move th e r es i stor

con nec tion to e ach exp ose d me tal part, p art i cularly any exp osed

metal p ar t havi n g a r etu rn pat h to the ch assis, and m easu r e th e

AC vol tag e ac ros s the res ist or. No w , re v er se th e pl u g in th e AC

ou tl et and re pe at eac h mea suremen t. An y vol t ag e me asu re d

must no t e xc eed 0 .7 5V AC (r.m. s.) . This c orre spo nds to 0 .5mA

AC (r.m. s.).

Howeve r, in tropica l area, this must n ot exce ed 0 .3V AC ( r .m.s.).

This corresponds to 0.2mA AC (r.m.s.).

AC VOLT MET ER

(HAVING 1000 Ω /V,

OR MOR E SENSIT IVITY)

0.15μF AC-T YPE

PLACE THIS PROBE

1500 Ω 10W

GOOD EARTH GROUND

ON E A C H EX PO SE D

ME T AL PA RT

4

No.51945

Page 5

A

A

A

FEATURES

V32H20EUS

V28H20EUS

V28H20EUB

"

New c hassi s d esign ena bl e us e of an inte rac tive on screen

control.

"

The TELETEXT SYSTEM has a built-in FASTEXT (UK system),

TOP (Germ an syst em) and W ST (world stan dard system)

system.

"

Be caus e th is TV un i t corr esp on ds t o m ultipl e x br oa dca s t, u ser s

can enjoy music programs and sporting events with live realism.

In ad dition , BI LIN GU AL pro gr am s can be h ear d in th ei r or i g in al

language.

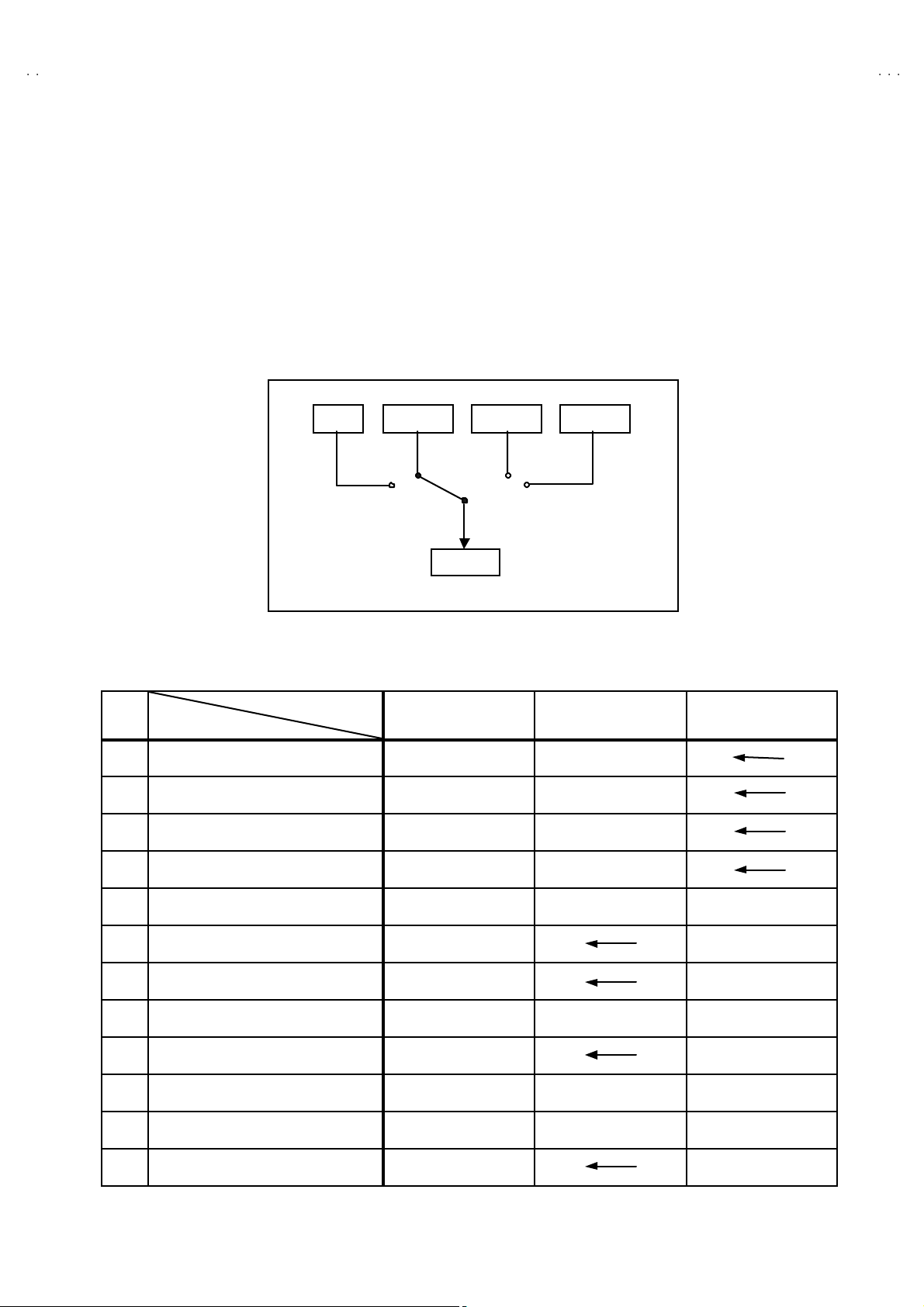

TV EXT-1 EXT-3

EXT-2

"

Users can make VCR dubbing of picture and sound by controlling

th e AV sel ec tor to s e le c t an o pti o na l so urc e at th e EXT- 2 outp ut

sh own i n figu re.

EXT-4

MAIN DIFFERENCE LIST

Model Name

!

Par t Name

MAIN PWB ASSY SMF-1401A-U2 SMF-1402A-U2

POWER & DEF PWB ASSY SMF-2401A-U2 SMF-2402A-U2

CRT SOCKET PWB ASSY SMF-3401A-U2 SMF-3402A-U2

FRONT C ONT ROL PW B ASSY SMF- 84 01A- U2 SMF- 8402 A- U2

!

FRONT C AB I NET A SS Y LC10 376- 020A -U LC 1066 2-02 3A-U LC 1066 2-02 4A-U

!

DOOR LC 20 265- 017A -U LC 20 265- 024A -U

!

POWE R KNOB LC 30 578- 007B-U LC 3057 8- 00 4A -U

!

REAR COVER LC10378-004B-U LC10664-003B-U LC10664-001E-U

JV C MA RK LC 40 354- 003A-C LC 4035 4- 00 1C- C

!

RATING LABEL LC20379-027A-U LC20379-026A-U LC20379-025A-U

AV32 H20E US AV28 H2 0E US AV28 H20E UB

EURO LABEL AEM 10 52-0 63 -E AEM 1052 -064 -E AEM 10 52-0 96 -E

REMOTE CONTROL UNIT RM -C54H-1C RM-C50-1C

No.51945

5

Page 6

A

V32H20EUS

A

A

V28H20EUS

V28H20EUB

SPECIFIC SERVICE INSTRUCTIONS

DISASSEMBLY PROCEDURE

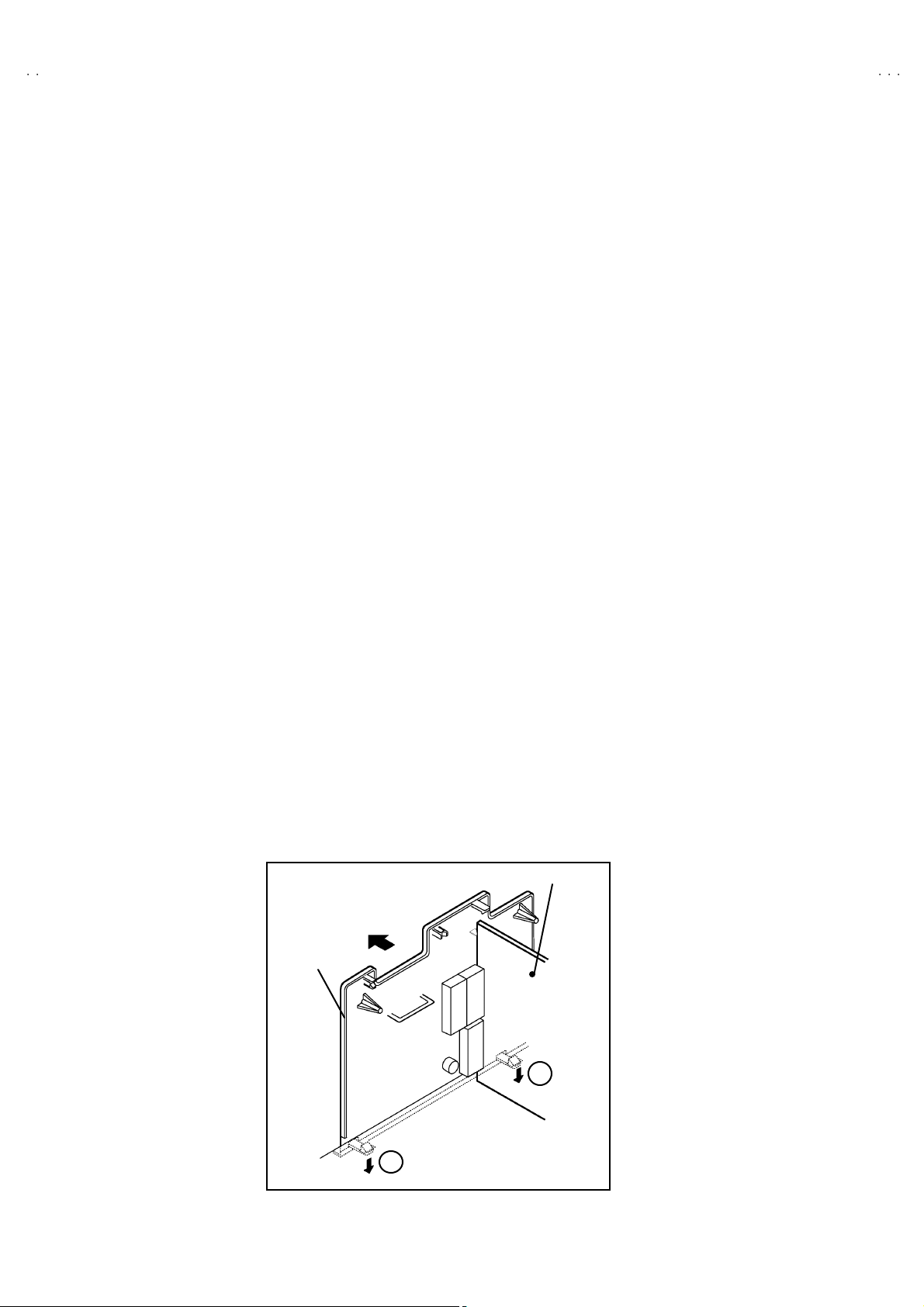

REMOVING THE REAR COVER

1. Unplug t he po we r c ord.

2. Rem ov e t he 12 (28 ” m od el s), 13 ( 32 ” m ode l) scr ews ma r ked A

as s hown in t he F i g. 1.

3. Withdr a w t he r ear co ver to wa rd you .

REMOVING THE CHASSIS

"

After removing the rear cover.

1. Sli ght ly rai se th e bo th si de s of the c hass i s by h and and r e mo ve

th e two c l aws u nd er th e b oth sid es of the chass i s fr om t he fro nt

cab inet .

2. Withdr a w t he chass is backw a rd .

(If necessary, take off the wire clamp, co nnectors etc.)

REMOVING THE SPEAKER

"

After removing the rear cover.

1. Remove t he 2 scr ew s m ar ked B, and r em ove th e sp eake r hold er

as s hown in Fi g. 1.

NOTE : When r em oving t he sc r ew s marked B of t he sp eake r

remove t he lo w er side sc r ew fi r s t, an d t hen remove th e

up per one .

2. Remove the 2 screws C a ttac hing th e sp eak er.

3. Fol l ow th e s am e st eps wh en rem oving the oth er ha nd spe ake r.

REMOVING THE AV TERMINAL BOARD

" After removing the rear cover.

1. Remove the 3 scr ew s m ar ked D as shown in t he F ig. 1 .

2. Remove the 2 cla ws mark ed E under the CHASSIS as shown in

Fig. 2.

3. Remove the AV TERMINAL BOARD slightly in the direction of

arrow F as shown in Fig. 2.

REMOVING THE POWER & DEF PWB

" After removing the rear cover.

"

After removing the rear CHASSIS.

1. Remove the 3 scr ew s marked G .

2. Rem ove the PO WER & DEF PW B.

CHECKIN G THE PW BOARD

To c h ec k the back s i de of th e PW B oard.

1) Pull out the ch assis. ( Refer to REMOVIN G TH E CH AS SIS ).

2) Erect the c hassis vertically so that you c an easily check the

b ack side of the PW B oard.

[CAUTION]

"

When erecting the chassis, be careful s o that there will be no

con tact ing with ot her PW Boar d.

"

Be fore tur n ing on po wer, ma ke sur e tha t the wire co nnecto r is

prop er l y con nected .

"

W hen co ndu cti ng a c h ec k wi th p ow er su pplied , b e sure to c onfir m

th at t he CRT E AR T H WI RE (B RAIDED AS S’Y) is co nne c ted t o

th e C R T SOC KE T PW b oard.

WIRE CLAMPIN G AND CABLE T Y ING

1. Be sur e t o clamp th e wire.

2. Never r em ove th e c able tie use d f or tying th e wires to ge the r.

Should it be inadver t ent ly removed , b e sure to tie th e wires wi th

a n ew c able tie.

AV SW PWB

AV TERMINAL

BOARD

E

E

Fig . 2

6

No.51945

Page 7

A

A

A

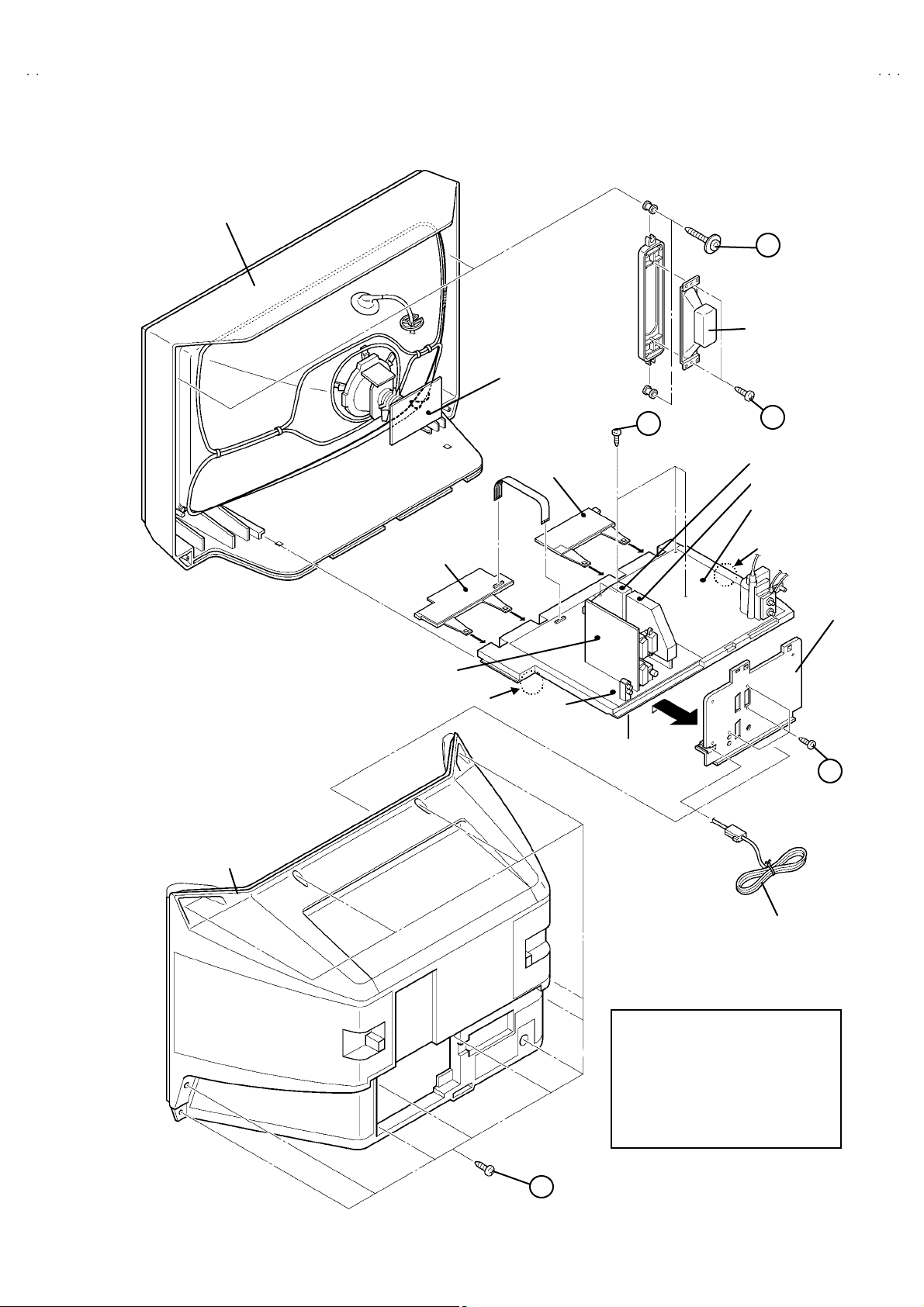

FRONT CABINET

(

)

(×3)

(

)

(

)

FRONT

C ONT RO L

PWB(1/2 )

CRT

SOCKET

PWB

FRONT

C ONT RO L

PWB(2/2 )

V32H20EUS

V28H20EUS

V28H20EUB

B

×

2

SP EAKER

C

G

×

3

×

2

MICOM PWB

100Hz PWB

POWER & DEF.

PWB

CLAW

REAR COVER

AV TERMINAL

BOARD

AV SW

PWB

CLAW

MAIN

PWB

CHASSIS

D

POWER CORD

Thi s expl o de d vi ew des cribe s ab out

AV 28H2 0EUS / AV28 H20EUB.

Alth ou gh AV 32 H 20E US are sl i ght ly

diff erent from t his f ig ur e, you c an use

th e e xpl od ed vi ew f or disass em bl i ng

th e A V32 H 20E U S in sam e ste p as

AV 28H2 0EUS / AV28 H20E UB.

(×12 : 28” mod el s)

A

(×13 : 32” mod el )

Fig . 1

No.51945

7

Page 8

A

V32H20EUS

A

A

V28H20EUS

V28H20EUB

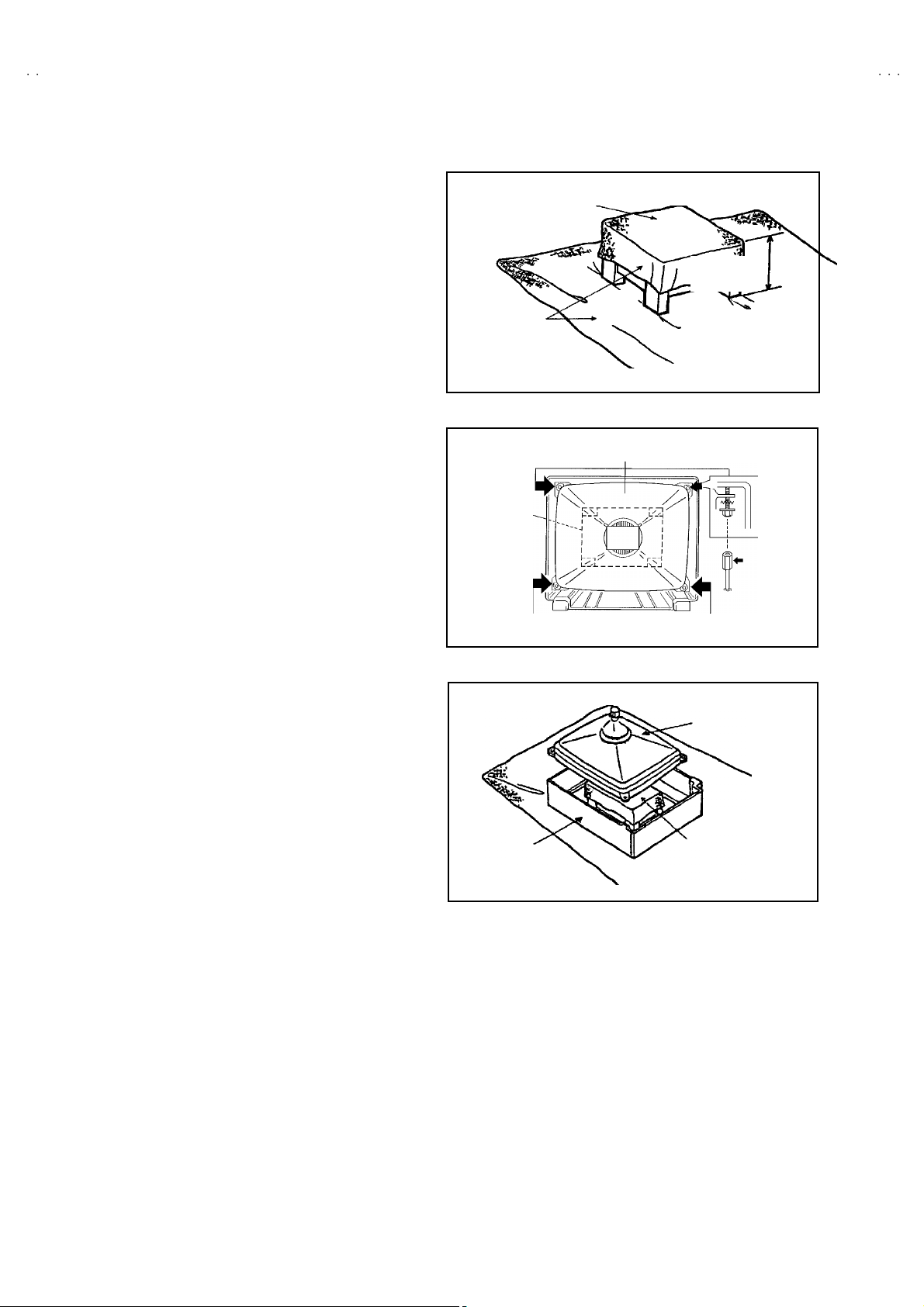

REMOVING THE CRT

∗

Replacem en t of th e CRT s ho ul d be p er for m ed b y 2 or mor e

p ers ons.

• After removing the cover, chassis etc.,

1. Putti ng the CRT chan ge table o n sof t cl oth , th e C R T cha nge ta ble

sh ould al so b e c over e d w i th s uch soft clot h (s ho wn i n Fig. 3) .

2. W hile kee pin g the s urfac e of C RT down , mou nt the TV s et o n t he

CRT change table balanced will as shown in Fig.4.

3. R em ov e 4 sc rews mark e d by arro ws with a box ty p e scr e w dri ver

as s hown in Fig. 4.

• Si nc e the cab i net will drop w h en scr ews h ave b een rem o ve d, be

sure t o su pp ort t he cabinet with hands.

4. After 4 screws have been removed, put the cabinet slowly on

cloth (At th is time, be ca refully so as not to damage th e front

sur fac e of th e c abin et) s h ow n i n Fig.5 .

• The CRT sh ould b e ass embled accor di n g to th e o pp osi te

sequence of its dismounting steps.

∗

The C RT cha ng e t able sh ould pr ef erab ly b e smaller that th e CRT

sur fac e, and its h ei gh t be abo ut 35c m.

CRT CHANGE TABLE

AP PROX.

35 cm

CLOTH

Fig. 3

CRT

CRT

CHANGE

TABLE

BOX

TYPE

SCREW

DRI VER

CABINET

Fig. 4

CRT

CRT

CHANGE TABLE

Fig. 5

8

No. 51945

Page 9

A

A

A

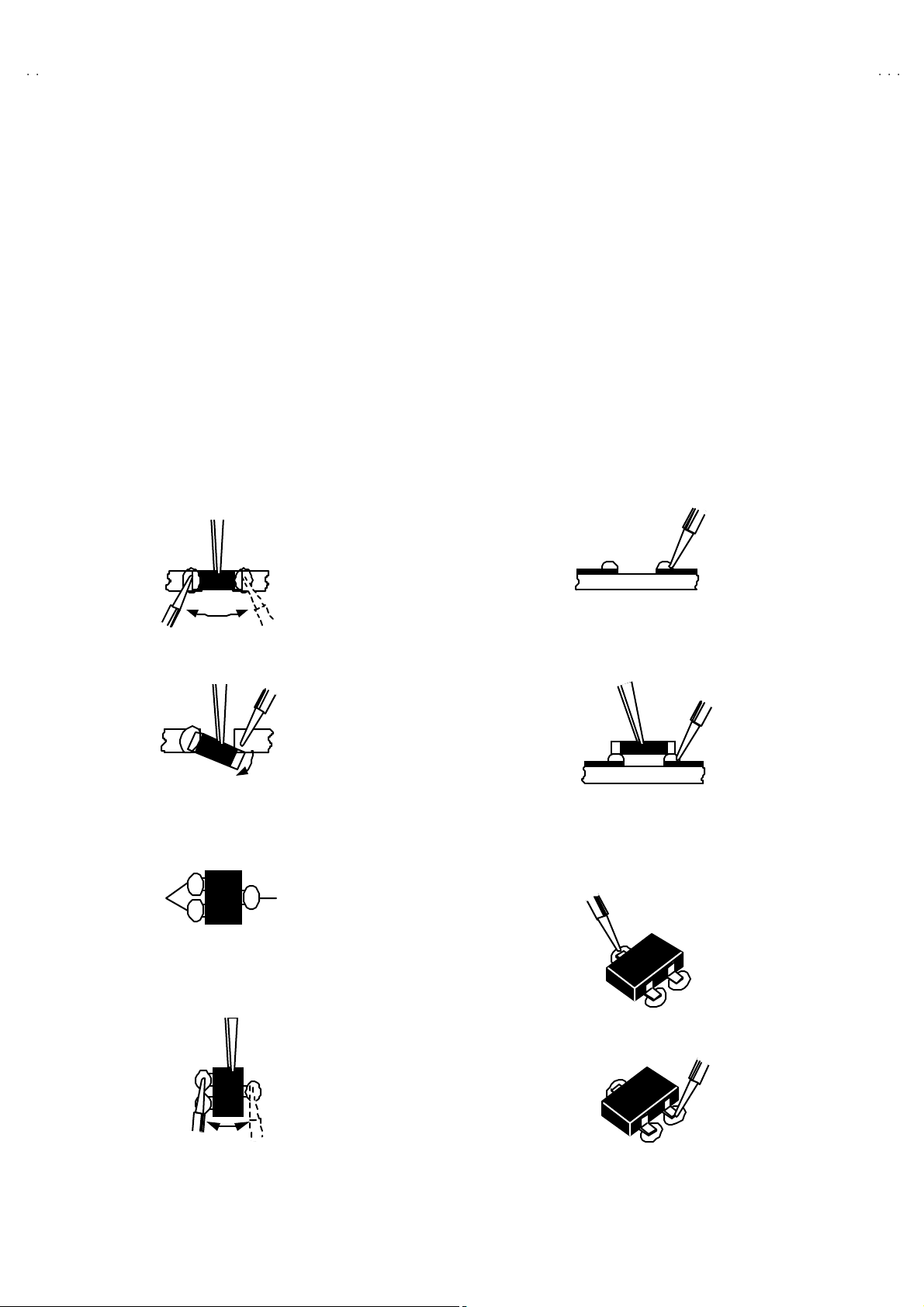

REPLACEMENT OF CHIP COMPONENT

! CAUTIONS

1. Avoid heating for more than 3 seconds.

2. Do n ot ru b the elect ro des an d the r esist p arts of the p att ern.

3. W hen r em oving a chip par t, mel t th e s older ad equately.

4. Do n ot reuse a ch ip p ar t afte r re mo v ing it .

! SOLDERING IRON

1. Use a hig h i ns ulatio n s ol der i ng i r on with a thi n poin ted e nd of it.

2. A 3 0 w s older i ng iron is r ec ommend ed for easily r em oving p ar ts.

!

REPLACEMENT STEPS

1. How to remove Chip parts

####

Resi st o rs, capacitors , etc

(1) As sh own in the f ig ur e, pu sh th e pa rt w ith tw ee zer s and

alte rn at ely melt the s ol de r at eac h end.

(2) Sh if t with tweeze rs and r em ove th e c h i p p art.

#### Tran s istor s, diodes , variabl e r esistor s, etc

(1) Ap pl y e xt ra so ld er to eac h le ad .

SOLDE R SOLDE R

V32H20EUS

V28H20EUS

V28H20EUB

2. How to install Chip parts

####

Resi st o rs, ca pacit ors , etc

(1) Apply sold er to the pattern as indic ate d in the figure.

(2) Gr asp the c h i p p art with tw ee zer s and pl ac e it on th e s old er.

The n hea t and me lt th e so lder a t both ends of t he chi p part.

#### Tran s istor s, diodes , variabl e r esistor s, etc

(1) Apply sold er to the pattern as indic ate d in the figure.

(2) Gr asp th e ch ip p art wit h t we ezers an d pl ac e it on th e so l der .

(3) First s older lead A as i ndica ted in the fi gure.

A

(2) As sh own in the f ig ur e, pu sh th e pa rt w ith tw ee zer s and

alte rn at ely melt th e sol d er at each le ad . S hi ft an d r em ove the

chip part.

(4) The n so lder le ads B and C.

Note : A fte r re moving t he part, r emove rem ain ing solder fr o m the

pattern.

C

A

C

No.51945

B

B

9

Page 10

A

V32H20EUS

A

A

V28H20EUS

V28H20EUB

REPLACEMENT OF MEMORY ICs

1. Memory ICs

This TV use memory ICs. In the memory ICs, there are memorized data

for correctly op er atin g th e video an d def l ection circ u its . Wh en r ep lac i ng

memory ICs, be s ure t o us e IC s wr itte n with the i ni tial values of da ta.

2. Procedure for replacin g memory ICs

PROCEDURE

(1) Power off

Switch the p ow er of f and un plug th e pow er cor d f ro m t he ou tlet.

(2) R epla ce ICs.

Be sure to use memory ICs written with the initial data values.

(3) Powe r o n

Plug th e pow er c ord int o th e outl et a nd s wit ch t he powe r on .

(4) Check and s et SY STEM CONSTANT SET :

It must not adjust wit hout s ign al.

****

1) Pr es s th e INFO RMATI ON ke y and the MUT ING key of th e

REMO TE CONTROL UNIT simultaneous ly.

2) The SERVICE MENU screen of Fig. 1 will be displayed.

3) W hile th e S ERVICE ME NU is d is playe d, pr es s th e

INFORMATION key and MUTING key s imultaneously, and the

SYSTEM CONSTANT SET screen of Fig. 2 will be displayed.

4) Check th e se tti ng va lu es of the S YSTEM CONSTA NT SET of

Table 1. If the valu e is dif fere nt, sel ect th e s etting item with th e

FUNCTION UP/ DOWN ke y, and s et the corr ect va lue with th e

FUNCTION -/+ ke y.

5) Press the MENU key to memorize the setting value.

6) Pr ess t he IN F OR M ATION ke y t wice, a nd r etu rn t o th e no rmal

screen.

SE RV ICE MEN U

1. IF 2. V/C

3. A UDI O 4. D EF

5. VSM P RESET 6. S TAT US

7. P IP 8. ---

9. SHIPPING (OFF) 0. BUS FREE

1 -9 : SE LE CT

SYS TE M C ONS TA NT S ET

1. DESTINATION EU

- /+ : STORE i : EXIT

OK

Fig.1

Fig.2

i

: EXI T

NAME OF REMOTE CONTROL KEY

(5) Se tt in g of re ceive chann e ls

Names of key

ke y

Se t th e r ec eiv e ch anne l.

For setting , r ef er to the OPE RATING INS TRUCTIONS.

(6) U ser se tting s

INFORMATI ON

MU T I N G

iiii

Check th e us er s ett ing values of T ab le 2, and if sett in g value is

diff erent , set th e c orrec t val u e.

For setting , r ef er to the OPE RATING INS TRUCTIONS.

(7) Setting of SERVICE MENU

Ve rif y the set ting it ems of the SE R VICE ME NU of Tab l e 3, and rese t

ME NU

FUNCTION UP/ DO WN

OK

▼

▼

where n ecessary.

For setting , r ef er to the SE RVIC E ADJUSTMENTS.

FUNCTION -/+

▼

▼

10

No. 51945

Page 11

A

V32H20EUS

A

A

V28H20EUS

V28H20EUB

SETT ING VALU ES OF SYST EM CO NS TANT SE T (TABLE 1)

Setting item Setting content Setting value Setting item Setting content Setting value

DESTIN A TION EU DOLB Y NO

CRT TYPE 16:9 BBE YE S

EKEU EI

4:316 :9

YE SNO

YE SNO

PURITY NO PROGRESSIVE NO

PICTURE TILT YES TDA9178 NO

DIGIP URE PRO NO TONE IC NO

PIP NO FLAT YE S

PIC&TE XT NO

1TUNERNO

NO

YE SNO

YE SNO

YE SNO

2TUNER

YE S

NO

YE SNO

YE SNO

YE S

YE SNO

USER SETTING VALUES (TABLE 2)

PICTURE SE TTING EXT SET TI NG

TINT COOL

CONTRAST / BRIGHT

SHAR P / COLO UR

PICTURE FEATURES FEATURE S

DIGITAL VNR AUTO

COLO UR S YSTE M T V : Acco rd in g t o pr eset CH

4:3 AUTO ASPECT PA NORAMIC

SOUND SET TING INSTALL

BA SS / T REBL E / BALANCE LANGUAGE ENGLISH

HYPE R S OU ND

BB E

REFER to VSM PRESET

EXT : AUTO

CENTER

OFF

ON

ID

S-IN

DUBBING

SLEEP TIMER

BLUE BA CK

EDIT/MANUAL PRESET CH only

BLANK

BLANK

EXT- 1→EX T-2

OFF

ON

The others : BLA NK

SERVICE MENU SETING ITEMS (TABLE 3)

Setting item Setting value Setting item Setting value

1. IF

2. V / C

3.A UD IO

(Do not adjust)

9.S HIPPI NG

(Do not adjust)

1. V CO

2. ATT ON /OFF

1. RGB BLK

2. W D R R

3. W D R G

4. W D R B

5. BRIGHT

6. CONTRAST

7. COLO UR

8. HUE

9. SHAR P

10. VC O A DJ .

11 . VID AGC

12 . SY C SL I

13 . A M OV I E

1. ER R LI MIT

2. A2 ID THR

3. Q-PEA K

ON/OFF

4. DEF.

5. VSM P RESET

COOL

NORMA L

WARM

6.S TATUS

(Do not a dju st)

1. V-SHIF T

2. V-SIZE

3. H-CENT

4. H-S IZ E

5. TR APE Z

6. EW - PIN

7. COR-P IN

8. COR-UP

9. COR-LO

10. ANGLE

11 . BOW

12. V-S.CR

13 . V- LIN

1. CONT.

2. BRIGHT

3. SHAR P

4. COLO UR

5. HUE

6. W D R R

7. W D R G

8. W D R B

VP S

PDC

**** : Do not adjust

No. 51945

11

Page 12

A

V32H20EUS

A

A

V28H20EUS

V28H20EUB

SERVICE ADJUSTMENTS

BEFORE STARTING SERVICE ADJUSTMENT

1. Ther e ar e 2 w ays of ad ju st in g this TV: One is wi th t h e

REMOTE CONTROL UNI T and the other is the conventional

method using adjustment parts and components.

2. The setting (adjustment) us ing the REMOTE CONTROL

UNIT is made on the ba sis of th e initial se tting values . Th e

se tting va lu es whic h adjust the sc ree n to the o p t imum

condition can be different from the initial setting values.

3. M ak e s ure th at conn ect i on i s c orrec t ly ma de t o AC p ower

source.

4. T ur n on th e powe r of th e TV a nd m easu r in g i nstr um en t for

warmin g up f or at least 30 min ut es bef ore sta rt in g adju stm ent .

5. If th e r ec ei ve or i np ut sig nal is not sp eci fi ed , use t he m ost

ap pr op ri a te s ig na l f or a dj ust me nt.

6. Nev er tou ch p ar ts ( s uch as var i ab le r es ist ors, tr an s for m er s an d

condensers) not shown in the adjustment items of this service

adjustment.

7. Pr ep ar atio n f or ad j ustm en t (pr es etti n g) :

Unles s oth erw is e sp eci fi ed in th e a dj us t ment it em s , p res e t th e

follo win g fu nct ions with th e REMOTE CONTROL UNIT.

"

Setti ng positi on

PICTURE MODE (VSM) NORMAL

SLEEP TIMER OFF

TONE BALAN CE CENTER

ZO OM FULL

MEASURING INSTRUMENT AND FIXTURES

1. DC voltmet er (or digit al voltmeter)

2. Oscilloscope

3. Si gn al g en erat or (Patt er n g en er at or) [ PAL / SE CA M / N TSC]

4. Remote control unit

ADJUSTMENT ITEMS

●

Check ing i t ems.

●

Adjustm en t of FOCU S & SC R EEN

●

VS M p r es et adju st s etti n g.

●

VIDEO / CHROMA circ uit adjustment.

●

DEFLECTION c ircuit adjustment.

●

AUDIO circuit adjustment. (Do not adjust)

12

No. 51945

Page 13

A

A

A

ADJUSTMENT LOCATIONS

(

)

5

)

)

FRONT

FRONT CONTROL PWB (1/2

REMOCO NLED

F90 1POWER SW

PW

CN002

FRONT CONTROL PWB (2/2

JJ

UP DOWN

SP R

VLHPR

F

SP L

V32H20EUS

V28H20EUS

V28H20EUB

S

FRONT

AV SEL PW B

MAIN PWB POWE R&DE F PWB

CN001

TUNER

CN002

MIC OM

100Hz

CN013

W DEG

CN004

CN005

HV

CN006

CN014

FRONT

HVT

X

1

CRT SOCKET PWB

TP-E

SOLDER SIDE

T P- 47B

TOP

E1

FOCUS

SCREEN

1pin:B1( TP-91)

2pin:NC

3pin:X-ray

4pin:X-ray

5pin:T P-E

28"MODEL

FOCUS 1

FOCUS 2

CN014

CN013

TP-Y

32"MODEL

No. 51945

SCREEN

13

Page 14

A

V32H20EUS

A

A

y

y

V28H20EUS

V28H20EUB

BASIC OPERATION SERVICE MENU

1. TOOL OF SERVICE MENU OPE RATION

Operate the SERVICE MENU with the REMOTE CONTROL UNIT.

2. SE RVICE MENU ITEM S

With the SERVI CE MENU, var i ou s sett ings ( ad ju s tm en ts) c an b e m ade , a nd th ey are b r oad ly classif i ed i n th e f ol lowing ite ms of set tings

(adjus tments ):

(1) 1. IF ・・・・・・・・・・・・・・・・・・・・ ・・・ This m ode adjust s the se tting values of the IF circu it.

(2) 2.V /C ・・・・・・・ ・・・・・・・・・・・・・ ・・ This m ode adjust s th e se tti ng valu es o f th e VIDEO / CHROMA circu it.

(3) 3.AUDIO・・・・・・・ ・・・・・・・・・・・・ This mode adjusts the setting values of the multiplicity SOUND circuit.

(4) 4. DEF ・・・・・・・ ・・・・・・・・・・・・・・ T his m ode adjust s th e setti ng valu es o f th e DE FLECTION ci r c ui t f or eac h as pect m od e gi ven be lo w .

FULL (100/120Hzi)

PA NO RA MIC ( 100 /12 0H z i )

SUBTITLE (100/120Hzi)

COMP RE SS (F ixed va lu e) (100 /1 20Hzi)

(5) 5.V SM PR ESE T

(VSM : Video Status Memory)

3. BASIC OPERATION OF SERVICE MENU

(1) Ho w to enter SERVICE MENU

Press the “INFORM ATI ON” key and th e “MUT ING” ke y of the

REMO TE CONTROL UNIT simultaneous ly, and the

SERVICE MENU screen of Fig.1 will be displayed.

(2) Selection of SUB MENU SCREEN

Press one of keys 1~5 of the REMOTE CONTROL UNIT

an d sele ct th e S UB MENU SCREEN (See F i g. 3 ), fo rm the

SERVICE MENU.

SERVICE MENU → SUB MENU

・・・・・・・ ・・・・・・

1. IF

2. V / C

3. AUDIO

4. DEF.

5. VSM PRESE T

6. STATUS

7. PI P

8. ---

9. SHIP PING (OFF )

0. BUS FREE

Thi s m od e adjust s th e in iti a l s ett in g va l ues of CO OL, NORMAL an d WAR M .

SE RVICE MENU

SE RVIC E ME N U

1. IF 2. V/C

3. AUDIO 4. DEF

5. VS M PRES ET 6. ST ATU S

7. PIP 8. ---

9. SH I PP I NG (OF F) 0 . BUS F R EE

****

: Do not adjust

1- 9 : SEL ECT

NAME OF REMOTE CONTROL KEY

Names of ke

INFORMA TION

MU T I N G

ME N U

FUNCTION UP/DOWN

FUNCTION -/+

Fig.1

Fig.2

i

: EXI T

ke

iiii

OK

▼

▼

▼

▼

14

No. 51945

Page 15

A

A

A

SE RVICE MENU

SERVICE ME NU

1. I F 2. V /C

3. AUDIO 4. DEF

5. VSM PRESET 6. STATUS

7. PIP (O FF) 8. - - -

9. SHIPPING (OFF) 0. BUS FREE

1-9 : SELE CT : E X ITi

V32H20EUS

V28H20EUS

V28H20EUB

1. V- SHIFT

2. V- SIZE

3. H-CENT

4. H-SIZE

5. TRAPEZ

6. EW -PIN

7. COR-PIN

8. COR-UP

9. COR-LO

10. A NGLE

11. B OW

12.V- S.C R

13.V-LIN

DE F *** Hz FULL

1. V- SHIFT

: STORE i : EXIT

OK

- / +

4. DEF

***

1.IF(VCO)

IF SER VICE M ENU

1. VCO

2. ATT ON/ O FF

1-2 : SELECT i : EXIT

2. V/C

PAL

****

1. RGB_BLK

OK

- / +

V/C

: STORE i : EXIT

Do no t move

1. RGB BLK

2. WDR R

3. WDR G

4. WDR B

5. BRIGHT

6. CONTRAST

7. COLOUR

8. HUE

9. SHARP

10. VCO ADJ

11. VID AGC

12. SYC SLI

13. A MO VIE

COOL

NORMAL

WARM

1. CONT.

2. BRIGHT

3. SHARP

4. COLOUR

5. HUE

6. WDR R

7. WDR G

8. WDR B

5. VSM PRESET

VSM PRESET NORMAL

1.CONT

OK

- / +

: STORE i : EXIT

***

- / +

Fig.3 SUB MENU SCREE N

No. 51945

3. AUDIO

AUDIO

1. ERR LIMIT 100H

ERROR RATE =

OK

: STORE i : EXIT

* ** *** **

Do no t adjust

1. ERR L IMIT

2. A2 ID THR

3. Q P EAK

15

Page 16

A

V32H20EUS

A

A

V28H20EUS

V28H20EUB

(3) M eth od of Set ting

1) Meth od of Set ting 1.IF

[VCO] ・・・・・・・ ・・・・・・・・・・・・・ ・・・・・・・・・・・・ ・・・ It must n ot adjust witho ut signal.

① 1 K ey・・・・・・・ ・・・・・・・・・・・・・ ・・・・・・・・・・・・ Select 1.IF.

② 1 K ey・・・・・・・ ・・・・・・・・・・・・・ ・・・・・・・・・・・・ Sele ct 1.VCO(CW)

Make sure that the arrow position between the ABOVE REF and BELOW REF.

③ INFOR MAT ION Key ・・・・・・・ ・・・・・・・・・・・・ Return t o th e SERVICE MENU screen.

2) Meth od of s ett in g 2.V/C, 3.AUDI O, 4.DEF and 5 .VSM PRESET.

① 2 ~5 K ey・・・・・・・・・・・・・・・・・・・・ ・・・・・・・・・ Select one from 2.V/C, 3.AUDIO, 4.DEF an d 5.VSM PRESET.

②

FUNCTION UP / D OWN ( / ) Key

③

FUNCTION - /+ ( / ) Ke y

④

ME NU K ey

⑤

INFORM ATION K ey

・・・・・・・ ・・・・・・・・・・・・・ ・・・・・・・

・・・・・・・ ・・・・・・・・・・・・

・・・・・・・ ・・・・・・

・・・・・

Select s etting items.

Set ( ad just) th e se tting values of the settin g items.

Memorize th e s etting value.

(Bef ore st orin g t he sett in g values in m emor y, do not pres s th e C H , T V, POWE R ON /

OFF k e y - if you d o, the value s will n ot be s tor ed in me mo r y. )

Retu rn t o the SE R VICE ME NU scr een.

3) Do not setting 6.STATUS , 7.PIP, 8.--- , 9.SHIPPING(OFF) & 0.BUS FREE.

(4) R ele ase o f SER V ICE M ENU

1) Af ter co mpl eti ng the s e tting , ret urn t o t he SERVICE ME NU, then agai n p ress th e I NFOR M ATIO N ke y.

16

No. 51945

Page 17

A

A

A

ADJUSTMENTS

y

CHECK ITEM

Item

B1

Powe r Suppl

che ck

Measuring

instrume nt

Signal

generator

DC v oltm et er

Remote

control unit

Test point Ad justment part Description

TP-91(B1)

TP-E(####)

[X connector

on POWER

DE F PW B ]

1.R G B BL K 1. Rec ei ve a an y broa dca st.

2. Pu sh t he “ZOOM ” k e y an d s elec t the FU LL mode .

3. Se lect 2. V/ C from the SERVICE MENU.

4. Se lect 1. RGB BLK with f un cti on UP / DOWN ( / ) key.

5. Press the function + ( ) key to find th e cut off screen (Bla ck

screen).

6. Con nect a D C voltmet er t o TP- 9 1(B 1) a nd TP-E( #).

7. Make sure t hat th e volt age is D C 13 9.9 ±2.0V.

8. Pr ess the function – ( ) key t o retu rn to service menu..

V32H20EUS

V28H20EUS

V28H20EUB

Hi gh Vo l t ag e

che ck

Signal

generator

DC volunteer

Remote

control unit

VCO chec k Remo t e

control unit

IF S ERVICE MEN U

1. VCO

2. ATT ON/OFF

1-2 : SELECT

TO O HI GH

ABOVE REF

JUST REF

BELOW REF

TO O LO W

VCO(CW)

MAI N

CRT anode

Chass is

GND

i : EXIT

****

MHz

i : EXIT

1.R G B BL K 1. Rec ei ve a an y broa dca st.

2. Pu sh t he “ZOOM ” k e y an d s elec t the FU LL mode .

3. Se lect 2. V/ C from the SERVICE MENU.

4. Se lect 1. RGB BLK with f un cti on UP / DOWN ( / ) key.

5. Press the function + ( ) key to find th e cut off screen (Bla ck

screen).

6. Connect a DC voltmeter t o CRT ANODE and chassis GND.

7. Make sure t hat th e volt age is D C 3 1.0kV .

8. Pr ess the function – ( ) key t o retu rn to service menu.

1. VC O

"

U nd er n orma l c ondi tions , no ad just ment is r e quir ed .

" Conf irm at ion a dj ust me nt.

1. Se lect 1.IF f rom the SERVICE M ENU .

2. Then se lect 1.VC O fr om th e IF S ERVICE MENU.

3. Recei ve an y bro adc ast.

←←←←

) p ositi on be tween th e AB OVE REF . an d

(Do not move)

4. Chec k t he arrow (

BE LOW REF.

+1kV

-1.5kV

No. 51945

17

Page 18

A

V32H20EUS

A

A

V28H20EUS

V28H20EUB

FOCU S & SCREEN ADJUSTMENT

Item

FOCUS

adjust me nt

[28” M ODEL]

Measuring

instrume nt

Signal

generator

HVT

Test point Ad justment part Description

FOCUS VR

SCREEN VR

FOCUS VR

[In HVT]

[28”MODEL]

1. Recei ve a cross -hatc h sign al .

2. Press the “ZOOM” ke y and select the FULL mode.

3. While watc hing th e scr een, a dj us t th e F OC US VR to m ak e th e

ver tic al and hori zo nta l l in es as f in e a nd sha rp as possib le.

4. Make sure th at when the sc re en is dar k e ned , the li nes r e mai n

in good focus.

FOCUS

adjus tme nt

[32” M ODEL]

SCREEN

Ad j ust men t

Signal

generator

FOCUS 1

HVT

Signal

generator

1. RGB BLK

- / +

OK

0 0 0 0 0 1 0 0

FOCUS 2

V/C

: STORE i : EXIT

PAL

00

FOCUS2(F2)

FOCUS1(F1)

SCREEN1(S1)

FOCUS 1

FOCUS 2

[In HVT]

SCREEN VR

[In HVT]

CLOW

status

[32”MODEL]

1. Rec ei ve a cross - h atch signa l.

2. Pu sh t he “ZOOM ” k e y an d s elec t the FU LL mode .

3. By turnin g th e FOCU S2 VR , and a djust t he pict ure s o tha t th e

“ “ part vertical lin e may become thinnest.

4. By turnin g th e FOCU S1 VR , and a djust t he pict ure s o tha t th e

3rd h or i zont al line fr om the upp er m ay bec ome un i for m at th e

line c ent er an d its periph ery.

5. Carry out adjustm ent b y rep eat in g the ste ps 3 an d 4 ab ove .

6. Make sure th at when the sc re en is dar k e ned , the li nes r e mai n

in good focus.

1 Pr ess a wh ol e b la c k s i gn al

2 Press the “ZOOM” key and s elect the FULL mode.

3 Se lect 2 . V/ C from th e SERVICE MENU.

4 T ur n t he SC REEN V R c l ockw is e f r om th e f ul l co unt er

cl ockw is e pos i ti on and st op i t a t th e po i nt w h ere “ C LOW ” stat us

(mark e d i n F i g.) c h ang es f rom 1 t o 0 to 1 ( which i s

ind icated at th e 3 rd colu mn from the right.)

5 The n turn th e SCREEN V R cou nt erclo ckwis e, an d st op wher e

th e “ C LOW ” stat us ch anges 1 t o 0

* “CLOW ” : c ontr o l l oop ou t of w indo w.

SERVICE MODE SCREEN

18

No. 51945

Page 19

A

A

A

VSM PR ESET AD JUST SET TIN G

g

Item

VS M PRESET

se tting

COOL +16 0 -10 +1 0 -27 -12 0

Measurin

instrume nt

Remote

control unit

1.CONT. 2.BRIGHT 3.SHARP 4.COLOUR 5. HUE 6.WDR R 7.WDR G 8.WDR B

Test point Ad justment part Description

1. C ONT .

2. BR I G HT

3. SHARP

4. COLOUR

5. HUE

6. W DR R

7. W DR G

8. W DR B

V32H20EUS

V28H20EUS

V28H20EUB

1. S elect COOL with the MENU key of the remote control unit.

2. Selec t 5 .VS M P RESET from th e S ERVICE ME NU.

3. Ad just t he FUNCTIO N UP/DOWN ( / ) and -/+ ( / )ke y to

bring th e set va l ues of 1.CONT ~ 8. W DR B to the val ues

sh own i n the ta bl e.

4. Pr ess the ME NU key a nd m em or iz e the s et va l ue.

5. Respectively s elect the VSM PRESET mode for NORMAL and

WAR M, an d make simi l ar a dj ust me nt as in 3 abo ve.

6. Pr ess the ME NU key a nd m em or iz e the s et va l ue.

* Refer t o OP ERATING I NS TRUC TION S for the PICTURE

MO DE .

32 ” NORMAL 00-1000000

WARM -13 0 -12 -1 0 +5 0 0

COOL +130 -120 0-28-120

28 ” NORMAL -30-1200000

WARM -13 0 -12 -1 0 +4 0 0

SE TTING VALU ES OF VSM PRESET

No. 51945

19

Page 20

A

V32H20EUS

A

A

V28H20EUS

V28H20EUB

VIDEO / CHROMA CIRCUIT ADJUSTMENT

The setting (adjustment) using the REMOTE CONTROL UNIT is made on the basis of the initial setting values.

The setting values which adjust the scr een to the optimum condition can be different from the initial setting values.

Setting item

(Adjustment item)

2. V/C PAL SE CAM NT SC

1.R G B BL K

2.WDR R 00 00

3.WDR G 00 00

4.WDR B (Do not adjust) -012

5. BR IG HT 00 00

6.CONTRAST 0060

7.COL O UR 00 00

8. HUE 00 20

9.SHARP (Do not adjust) 00 07

Initial setting value

10.VCO ADJ. (Do not adjust)

11 .VI D AGC (Do no t adjust) 00 00

12.SY C SLI ( Do not adjust) 00 07

13.A MOVIE (Do not adjust) 0001

****

: Do not adjust

20

No. 51945

Page 21

A

V32H20EUS

A

A

V28H20EUS

V28H20EUB

Item

WHITE

BALANCE

(High Light)

adjust me nt

SUB BRIGHT

adjus tme nt

Measuring

instrume nt

Signal

generator

Remote

control unit

Remote

control unit

Test point Ad justment part Description

2. W DR R

3. W DR G

4. W DR B

(Do not adjust)

5. BR I G HT 1. Rec ei ve an y br o adc ast.

" Se t th e P IC TURE MODE to NORMAL.

1. Recei ve a bl ack a nd w hi te sign al (col o ur of f).

2. Se le ct 2.V/C f r om the SE RV IC E M ENU.

3. M odi f y 2. W DR R and 3. WDR G d ata to adjust th e whi te

balance ( high light ).

4. Press the ME NU key a nd m em or iz e the s et va l ue.

5. Change the c ontras t a nd bri gh tnes s wi th th e rem ot e co ntr ol up

& d ow n from low–light to hi g h– light an d ch eck that th e tr acki ng

of th e white ba lanc e is g ood .

2. Se le ct 2.V/C f r om the SE RV IC E M ENU.

3. Se lect 5.BRIGHT with th e FU NCTION UP/DOW N ( / ) key.

4. Set the initial setting value with t he FUNCTION -/+ ( / )key.

5. If th e b ri gh tn ess is no t th e be st wi th th e initial se tti ng val ue ,

make fine adjustment until you get the best brightness.

6. Press the ME NU key a nd m em or iz e the s et va l ue.

SUB CONT.

Ad j ust men t

Remote

control unit

6.CO NT . 1. Rec eive any br o adcast.

2. Select 2 .V/C f rom the SE RVICE MENU .

3. Select 6.CONT with the FUNCTION UP/DOWN ( / ) key.

4. Set the initial s etting value with the FUNCTION - / + ( / )

key.

5. If the con tras t is n ot t he best w ith t he i ni tial s e tting va lu e, make

fine adjustment until you get the best contrast.

6. Pr ess the ME NU k ey a nd m emor iz e the s et va lue.

No. 51945

21

Page 22

A

V32H20EUS

A

A

ey

V28H20EUS

V28H20EUB

Item

SUB CO LO UR

adjus tme nt

instrume nt

Remote

ⅠⅠⅠⅠ

control unit

Measuring

Test point Ad justment part Description

7.COL O UR

(PAL~~~~NT S C)

PAL COLOUR (PAL COLOUR)

CH. key

SECAM COLOUR

MENU

( OK ) k ey

NTSC COLO UR

[Method of adjustm ent without measuring instrument]

1. Recei ve PA L br oadcast.

2. Select 2 .V/C f rom the SE RVICE MENU .

3. Se lect 7.COLOUR with th e FUNCTIO N UP/DOW N ( / ) ke y.

4. Set the initial setting value f or PAL COLOUR with the

FUNCTION - or + ( / ) key.

5. If t he co l our i s no t the bes t with th e in iti al set value, ma k e

fine adjustment until you get the best colour.

6. Pr ess the ME NU k ey a nd m emor iz e the s et va lue.

(SECAM C OLO UR)

1. Recei ve a SECAM b roadc ast.

2. Mak e fi n e a djustme nt of SE CA M C OLOUR in the s ame

mann er as fo r abo v e.

(NTSC 3.58 COLOUR)

1. Input a NTSC 3 .58MHz COMPOS ITE VIDEO sig na l from the

EXT t erminal .

2. Make si milar f in e ad jus tm en t of NT SC 3. 58 COLO UR in th e

sam e mann er as f or a bo ve .

FUNCTION k

( INFORMATI ON ) keyi

REMOTE CONTROL KEY

(NTSC 4.43COLOUR)

1. When NTSC 3.58 COLOUR set, NTSC 4.43 COLOUR will

automatically set.

22

No. 51945

Page 23

A

V32H20EUS

A

A

V28H20EUS

V28H20EUB

Item

SUB CO LO UR

adjus tme nt

Measuring

instrume nt

Signal

Ⅱ

Ⅱ

ⅡⅡ

generator

Oscilloscope

Remote

control unit

Test point Ad justment part Description

TP-47B

####

TP-E(

[CRT

SOCKET

PWB ]

7.COL O UR

(PAL~~~~NT S C)

)

PAL COLOUR (PAL COLOUR)

SECAM COLOUR

[Method of adjustm ent using measur ing instrument]

1. Recei ve a PAL fu ll f i el d co lour b ar s ign al ( 75% whi te ).

2. Select 2 .V/C f rom the SE RVICE MENU .

3. Se lect 7.COLO UR with th e FU NCTION UP/DOW N ( / ) ke y.

4. Set the initial setting value of PAL COLOUR with the

FUNCTION - or + ( / ) key.

5. Con nect th e osc illosc ope be tw ee n TP -4 7B an d T P- E( #).

6. Ad just P AL COLO UR an d br in g th e val u e of (A) in the

illustration to the values as shown giv en billow (Voltage

diff erenc e betwee n wh i te ( W) and blu e ( B) ) .

7. Pr ess the ME NU k ey a nd m emor iz e the s etti n g value.

VOLTAGE (W-B) +5V

(SECAM C OLO UR)

1. Recei ve a SECAM fu ll fi el d colour b ar sign al (75 % white ).

2. Set the initial setting value of SECAM CO LOUR with the

FUNCTION - /+ ( / ) key.

3. Adju s t SE CAM CO LOU R an d b rin g t he va lu e of (A) in t he

illu s tr ation t o th e values as s hown gi ven b ill ow ( Vol t ag e

diff erenc e betwee n wh i te ( W) and blu e ( B) ) .

4. Pr ess the ME NU k ey a nd m emor iz e the s etti n g value.

YG R

WCyMgB

NTSC COLO UR

(A)

(-)

(+)

VOLTAGE (W-B) +4V

(NTSC 3.58 COLOUR)

1. Input a NTSC 3.58MHz COMPOS ITE VIDEO sign al ( fu ll fie ld

colo ur bar with 75% whit e) from th e EXT t erminal.

2. Set th e ini ti al setti ng val ue of N T SC 3.58 COLO UR wit h th e

FUNCTION - /+ ( / ) key.

3. Ad ju st NTS C 3.5 8 C OLO UR a nd bring th e v alu e of (A) in the

illustration to the values as shown giv en billow (Voltage

diff erenc e betwee n wh i te ( W) and blu e ( B) ) .

4. Pr ess the ME NU k ey a nd m emor iz e the s etti n g value.

32” 28”

VOLTAGE (W-B) +5V +6V

(NTSC 4.43COLOUR)

0

1. When NTSC 3.58 COLOUR set, NTSC 4.43 COLOUR will

automatically set.

No. 51945

23

Page 24

A

V32H20EUS

A

A

V28H20EUS

V28H20EUB

Item

SUB HUEⅠⅠⅠⅠ

adjust me nt

Ad j ust men t

of

SUB HUE

ⅡⅡⅡⅡ

Measuring

instrume nt

Remote

control unit

Signal

generator

Oscilloscope

Remote

control unit

YGR

Test point Ad justment part Description

8.HUE [Method of adjustm ent without measuring instrument]

NTSC 3.58 HUE [NTSC 3.58 HUE]

1. Inp ut a NTSC 3.5 8 MH z COMPOSI TE V IDEO sign al (f ul l fi e ld

colo ur bar with 75% whit e) from th e EXT t erminal.

2. Select 2 .V/C f rom the SE RVICE MENU .

3. Se lect 8. HUE wi th t he FUNCTION UP /DOW N ( / ) ke y.

4. Se t the initia l sett in g value of N TSC 3. 58 H UE w i th th e

FUNCTION - /+ ( / ) key.

5. If you cannot get the best hue with the initial setting value,

make fine adjustment until you get the best hue.

6. Pr ess the ME NU k ey a nd m emor iz e the s et va lue.

NTSC 4.43 HUE (NTS C 4.43 HUE)

1. W hen NTS C 3 .58 is s et , NT SC 4.4 3 will be au tomat ic all y s et at

the respective values

TP-47B

TP-E(#### )

[CRT

SOCKET

PWB]

8. HUE [Method of adjustm ent using measur ing instrument]

NTSC 3.58 HUE [NTSC 3.58 HUE]

1. Inp ut a NTSC 3.5 8 MH z COMPOSI TE V IDEO sign al (f ul l fi e ld

colo ur bar with 75% whit e) from th e EXT t erminal.

2. Select 2 .V/C f rom the SE RVICE MENU .

3. Se lect 8. HU E wi th t he FUNCTION UP /DOW N ( / ) ke y.

4. Se t the initia l sett in g value of N TSC 3. 58 H UE w i th th e

FUNCTION - or + ( / ) key.

5. Con nect th e osc illosc ope be tw ee n TP -4 7B an d T P- E( #)

6. Adjust NTSC 3. 58 H UE t o bring th e val u e of (B) in the

illu s tr ation t o the values as s hown gi ven b i llo w ( volta ge

diff erenc e betwee n wh i te ( W) an d mag en ta ( Mg )) .

(B)

(-)

7. Press the MENU key and memoriz e the settin g value

0

WCyMgB

24

(+)

NTSC 4.43 HUE (NTSC 4.43 HUE)

1. W hen N T SC 3. 58 CO LOUR se t, NT SC 4 .43 COLO UR wil l

automatically set.

No. 51945

VOLTAGE (W-Mg) -8V -3V

32” 28 ”

Page 25

A

A

A

DEFLECTION CIRCUIT ADJUSTMENT

(

)

(

)

(

)

(

)

Th ere are 4 as pe ct mode s ( ①①①①FULL, ②②②②PANORAMIC, ③③③③ SUBTIT LE , ④④④④ COMPRES) of the adjustment ( 1 ) 100Hz i mode,

( 2 ) 120Hz i mode ・・・・・・

"

When the 100 Hz FU LL mode has be en establ ished, the se ttin g of oth er mode s will be done automatically.

Ho wever, if the picture quality has not been optimized, adjust each mode again, respectively.

" The adjustment using the remote control unit is made on the basis of the initial setting values.

"

The setting values which adjust the screen to the optimum condition can be different from the initial setting values.

・・・・ ・・ depending upon the kin d of signals ( vertical frequency 100Hzi / 120Hzi ).

・・・・ ・・・・・・ ・・

V32H20EUS

V28H20EUS

V28H20EUB

Initial setting value (AV32H20EUS)

Initial setting value

Setting item Adjustment nam e

1. V- SH IF T Vert ic al cent er -001 +001 00 00 00 00 +012 00 00 0000 00 00

2. V- SIZE Ve rt ic al heig ht +002 -001 +002 00 00 +008 00 00 - 014 00 00

3. H-CENT Hor i zont al cente r -005 +004 - 002 0000 00 00 00 00 00 00 00 00

4. H-S IZE Horizont al width 0000 -004 -003 0000 0000 00 00 0000 00 00

5. TRAPE Z Tr ap ez oida l di sto rt ion c orrec tion -013 - 002 - 003 0000 -002 0000 00 00 00 00

6. EW - PIN Si de pin cor r ectio n - 041 0000 00 00 0000 0000 00 00 00 00 00 00

7. COR-PIN Corner Pin 0000 0000 0000 0000 0000 0000 00 00 00 00

8. COR -UP Cor ne r P in c orr ect ion Up si de 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

9. COR - LO Corne r P i n c orrect ion Lo w s id e 0000 00 00 00 00 00 00 00 00 00 00 00 00 00 00

10 .AN GL E An gl e c orre c ti on 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

11.BOW Bo w-shaped distortion correction 0000 0000 0000 0000 0000 0000 00 00 00 00

12.V- S.CR

Do not adjust

13 .V- LIN

Do not adjust

Ve rt ic al height c orr ection 00 00 0000 00 00 00 00 +012 00 00 00 00 00 00

Ve rt ic al Lin eari ty -007 0000 00 00 00 00 - 017 0000 00 00 00 00

FULL PANORAMIC SUBTITLE COMPRE SS

10 0Hzi 12 0Hzi 100Hzi 120Hzi 100Hz i 12 0Hzi 100H zi 60P

**** : Fixed value

Initial setting value (AV28H20EUS, AV28H20EUB)

Initial setting value

Setting item Adjustment nam e

1. V- SH IF T Vert ic al cent er -002 +002 00 00 00 00 +011 00 00 0000 00 00

2. V- SIZE Ve rt ic al heig ht +006 00 00 +003 00 00 + 009 00 00 - 015 00 00

3. H-CENT Hor i zont al cente r -013 +004 - 003 0000 + 001 00 00 00 00 00 00

4. H-S IZE Horizont al width -002 - 004 -004 0000 00 00 00 00 00 00 00 00

5. TRAPE Z Tr ap ez oida l di sto rt ion c orrec tion -023 0000 - 003 00 00 0000 00 00 00 00 00 00

6. EW - PIN Si de pin cor r ectio n - 042 0000 00 00 0000 0000 00 00 00 00 00 00

7. COR-PIN Corner Pin 0000 0000 0000 0000 0000 0000 00 00 00 00

8. COR -UP Cor ne r P in c orr ect ion Up si de 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

9. COR - LO Corne r P i n c orrect ion Lo w s id e 0000 00 00 00 00 00 00 00 00 00 00 00 00 00 00

10 .AN GL E An gl e c orre c ti on 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

11.BOW Bo w-shaped distortion correction 0000 0000 0000 0000 0000 0000 00 00 00 00

12.V- S.CR

Do not adjust

13 .V- LIN

Do not adjust

Ve rt ic al height c orr ection + 002 00 00 00 00 00 00 +010 00 00 0000 00 00

Ve rt ic al Lin eari ty -005 0000 00 00 00 00 - 015 0000 00 00 00 00

FULL PANORAMIC SUBTITLE COMPRE SS

10 0Hzi 12 0Hzi 100Hzi 120Hzi 100Hz i 12 0Hzi 100H zi 60P

No. 51945

25

Page 26

A

V32H20EUS

A

A

V28H20EUS

V28H20EUB

Item

V-SHIF T

Ad j ust men t

Measuring

instrume nt

Signal

generator

Remote

control unit

Test point Ad justment part Description

1. V- S HI FT [FULL mode]

1. Receive a cir c l e p att ern s ig na l of ve rt ic al fr eque ncy 5 0H z.

2. Select 4 .DEF f rom t he SERVI CE M ENU.

3. Select 1.V-SHIFT with the FUNCTION UP / DOWN ( / ) key.

4. Ad just V-SHIFT to make A = B.

5. Check the ad j ustm en t val u e abo ve in o the r zoom mode . If i t i s a

wrong adjustment, re-adjust in PANORAMIC mode and adjust

A

B

by 1.V-SHIFT.

6. Pres s the ME NU key a nd m emor iz e th e s et va lue.

V-SIZ E

adjust me nt

Screen size

Scr e en

size

Picture size 100%

ASPECT MODE FULL PANORAMIC SUBTITLE

SCREEN

TOP

SCREEN

BOTTOM

92 % 87 % 70%

92 % 87 % 83%

[ SCREEN SIZE ]

2.V-SI ZE 1. R ecei v e a cross - h atch signa l.

2. Select 2.V-SIZE and set the initial s etting valu e.

3. Ad ju st V- S IZE a nd m ak e s ure t hat th e vert ic al sc r een siz e of

4. Pr ess the ME NU k ey a nd m emor iz e the s et va lue.

5. Input a NTSC VID EO si g nal ( 60 Hz) fr om the E XT ter m in al ,

6. Press the MENU key and memoriz e the set value

Picture

size

10 0%

th e p ict ur e s ize is in t he bellow t able.

an d m ake sure th at t he ver t ic al sc r een s iz e is i n th e ta ble

below.

26

No. 51945

Page 27

A

V32H20EUS

A

A

V28H20EUS

V28H20EUB

Item

H. CENTER

adjus tme nt

H.S IZ E

adjus tme nt

Measuring

instrume nt

CD

90 %

Test point Ad justment part Description

3. H-CENT. 1. Recei ve a c ircle p atter n s igna l.

2. Select 3.H-CENT and set the initial s etting value.

3. Ad ju s t H - CE NT to ma ke C=D.

4. Press the MENU key a nd m emoriz e th e s et va lue.

90 %

4. H- SIZ E 1. Receive a circle pattern signal.

2. Select 4.H-SIZE and set the initial setting value.

3. Ad jus t H- S IZE an d m ake su re th at th e ho ri zo nta l scr e en si ze

4. Press the MENU key a nd m emoriz e th e s et va lue.

5. Inp ut a N T SC V IDEO sign al (6 0H z) f r om th e EXT ter m i na l,

6. Press the MENU key a nd m emoriz e th e s et va lue.

of th e p ict ure s i ze is in th e b ellow t abl e .

an d m ake su re tha t th e h orizo nt al scr een si ze of the each

ASPECT mode is in the below table.

AS PE CT

H SI Z E

EW-PIN

adjus tme nt

MODE

FULL PANORAMIC SUBTITLE

92 % 95 %

[ SCR EEN S IZ E ]

6.E W-PI N 1. Se le ct 6 .EW - PIN an d s et t he ini tial s etti ng valu e

Straight

92 %

2. Ad jus t EW -PIN an d m ak e th e 2nd .v e rt ic al lines at th e l eft a nd

right ed ges of the s cree n str a i ght . A ls o make sur e th at th e 3rd

vertical lines are straight.

3. Press the MENU key a nd m emoriz e th e s et va lue.

No. 51945

27

Page 28

A

V32H20EUS

A

A

V28H20EUS

V28H20EUB

Item

TR APEZIU M

adjus tme nt

COR. UP/LO

adjus tme nt

Straight Straight

Measuring

instrume nt

Signal

generator

Remote

control unit

Signal

generator

Remote

control unit

Test point Ad justment part Description

5. TRA PEZ 1. R eceiv e a cross - h atch s igna l.

2. Select 5.TRAPEZ with the FUNCTION UP/DOWN ( / ) key.

3. Se t th e in it ial sett ing value of TRAPEZ with th e FU NCTION

- or + ( / ) key.

Paralle l

7.COR-PIN

8.COR-UP

9.COR-LO

4. Ad ju st TRAPE Z an d b r in g the VE RTICA L l i nes at th e ri gh t a nd

left edges of the scr een par al l el .

5. Pr ess the ME NU k ey a nd m emor iz e the s et va lue.

1. Se lect 8.COR-UP wit h the FUNCTION UP / DOW N ( / )

key.

2. Set the initial setting value of COR.-UP with the FUNCTION

- or + ( / ) key.

3. Ad ju st C OR - UP , an d br in g t he st raight l i ne a t the u pp er c orne r.

4. Se lect 9.COR-LO with th e FUNCTION UP / D OWN ( / )

key.

5. Set the initial setting value of COR-LO with the FUNCTION

- or + ( / ) key.

6. Ad ju st C OR - LO, an d brin g t he s tr aigh t l i ne at the l ow co rner .

7. Pr ess the ME NU k ey a nd m emor iz e the s et va lue.

8. If the e xt re am e u pper & low er c or n er s are a l itt le pi n or ba rrel

ch ose 7.C OR -P IN an d adju st.

9. Press the MENU key and memoriz e the set value

ANGLE

adjus tme nt

Fig. A

28

10. ANGLE • In case where ther e is a para lle logrammi cal dis tort ion of

images o n t he screen. (F ig.A )

1. Se lect 10.ANGLE with the FUNCTION UP / DOW N ( / )

key.

2. Ad ju st AN GE L, an d b ri n g t he VERTICAL l i nes str ai gh t..

3. Pr ess the ME NU k ey a nd m emor iz e the s et va lue.

No. 51945

Page 29

A

V32H20EUS

A

A

V28H20EUS

V28H20EUB

Item

BOW

adjus tme nt

V-S.CR

&

V. LI NE AR IT Y

adjus tme nt

Measuring

instrume nt

Test point Ad justment part Description

11.B OW • In case where there is a bow-shaped distortion of images

on the sc ree n. ( Fig.B)

1. Se lect 11.BOWwith th e FU NCTIO N UP/DOW N ( / ) key.

2. Ad ju st BO W, an d b ri n g t he VERTICAL l i nes str ai gh t.

3. Pr ess the ME NU k ey a nd m emor iz e the s et va lue.

Fig. B

12.V- S.CR

13.V- LIN

TOP

• Whe n the vertica l li neari ty h a s been det e riorat ed

remark ably, perform the following steps

1. Rec ei ve a cross - h atch signa l.

2. Se lect 13.V-LIN wit h t he FUNCTION UP/ DOW N ( / )k ey.

3. Set the initial setting value of 13.V-LIN with the FUNCTION

- / + ( / ) key.

4. Select 1 2.V -S .COR with t he FUNCTION UP / DOW N ( / )

key.

5. Se t th e in it ial sett ing value of 12.V-S.COR with th e FU NCTION

- / + ( / ) key.

6. Ad ju st 13 .V-LI N an d 12.V -S.COR so tha t th e s p ac es of eac h

line on TO P, CE NTE R and BO T T OM bec ome u ni fo rm.

.

CENTER

BOT TOM

No. 51945

NO T E : Do not ad just PA NO RAMIC & SUBTIT LE mode.

At first the adjustment in 100Hz FULL mode should be done,

th en th e d at a f or the ot her asp ec t mo de is cor rec t ed in the

resp ecti ve value a t t he s am e time. A nd co nfir m th e d efl ec ti o n

ad justmen t in iti a l setti ng va lue i n 12 0Hz (NT SC EXT m od e)

FU LL m od e. If the adj u s tm en t in 10 0H z eac h asp ec t mode h as

b een don e and sto re d, th e d ata f or th e s am e as pect m od es i n

12 0Hz i s c or re cte d i n the res pect i ve va lue. Onl y t he da ta fo r th e

oth er as pect mod e in 12 0Hz i s co rrect ed f or its elf.

29

Page 30

A

V32H20EUS

A

A

V28H20EUS

V28H20EUB

AUDIO CIRCU IT ADJ USTMENT

"

Do not tou ch 3. AUDIO a djust ment of t he SER V ICE MEN U as it re qu ir e s no ad justmen t.

If values ha d ch an ge d for th e s o me r eas on, s et the ini tial values in t he fol l ow i ng ta bl e.

3. AUDIO (Do not adjust)

Setting item Variabl e range fixed value

1. ER R LI MIT 00 0H~FF0H 100H

2. A2 ID THR 00H~FFH 19H

3. Q-P EA K 00 00 H ~7FFFH ---

30

No. 51945

Loading...

Loading...