Page 1

SERVICE MANUAL

COLOUR TELEVISION

YA08020052

AV-20RM4SE,

AV-21RM4SE,

AV-21RM4SN,

AV-21RM4SP

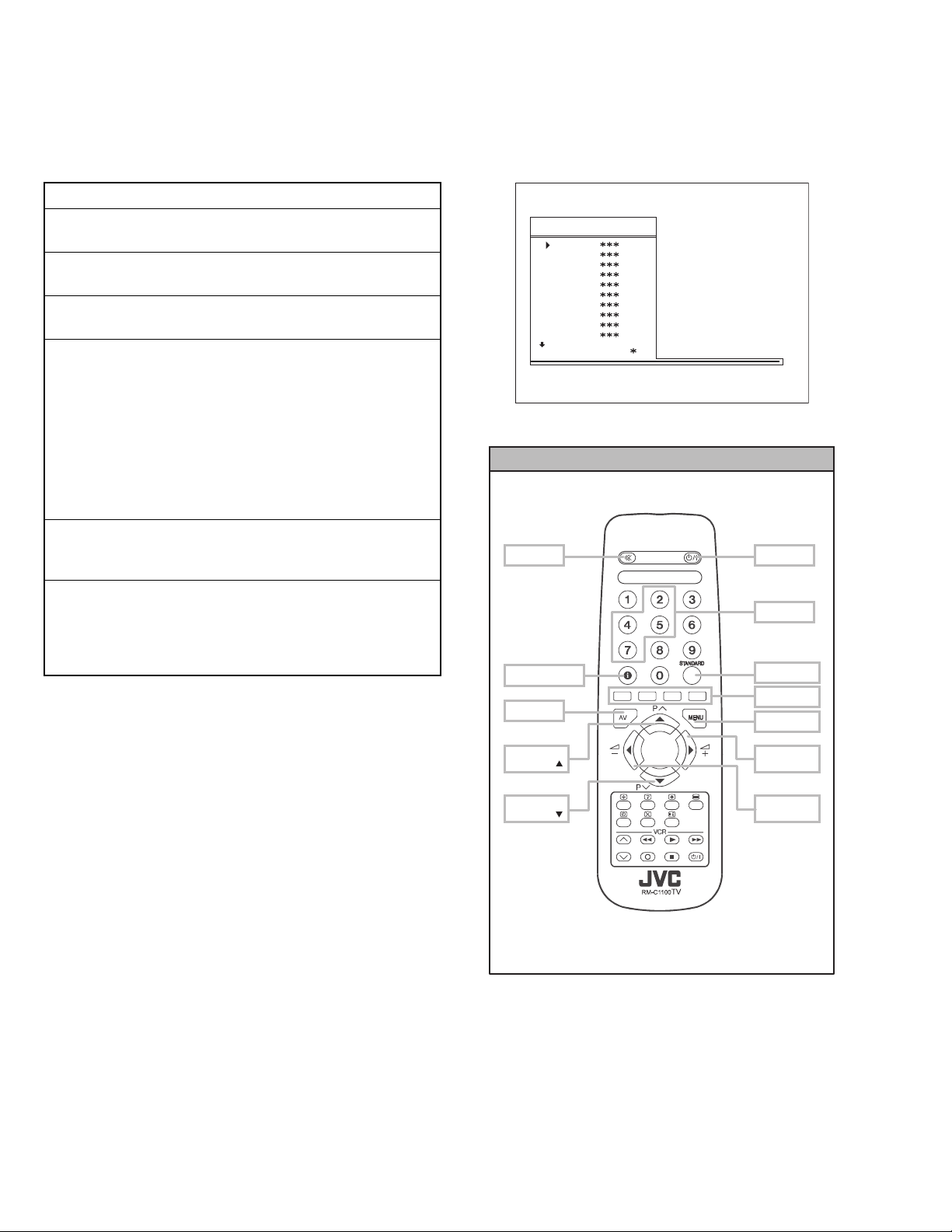

RM-C1100 TV

[AV-21RM4]

TABLE OF CONTENTS

1 PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2 SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

4 ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

COPYRIGHT © 2005 Victor Company of Japan, Limited

No.YA080

2005/2

Page 2

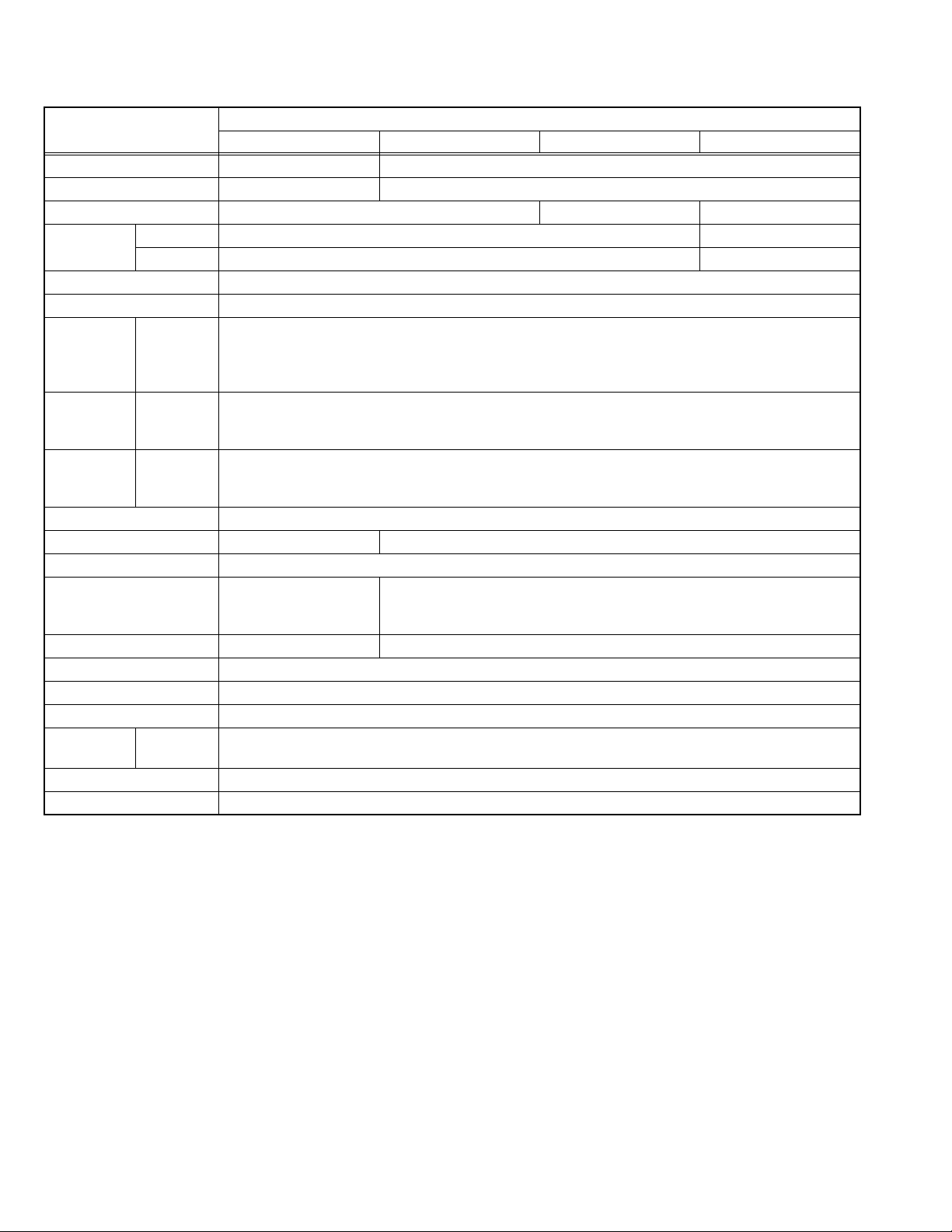

SPECIFICATION

Item

Dimensions ( W × H × D )

Mass 18kg 21kg

TV RF System B/G, L B/G, D/K B/G

Colour System

Sound System A2 / NICAM

Teletext System TOP / WST

Receiving

Frequency

Intermediate

Frequency

Colour Sub

Carrier

Frequency

Power Input AC220V - AC240V, 50Hz

Power Consumption

Aerial Input Terminal 75Ω unbalanced, coaxial

Picture Tube Size Visible size : 48cm (20"),

High Voltage

Speaker 5.7cm × 12.6cm, Oval type × 2

Audio Output 5.5W (10%THD)

EXT-1 Input / Output 21-pin Euro connector (SCRAT socket) × 1

EXT-2 Input Video

Headphone Jack Mono mini jack 3.5mm × 1

Remote Control Unit VE-30017763 (RM-C1100), (AA/R06 dry battery × 2)

Design & specifications are subject to change without notice.

TV Mode PAL / SECAM PAL

Video Mode PAL / SECAM / NTSC 3.58 / NTSC 4.43

VHF(VL)

VHF(VH)

UHF

CATV

VIF

SIF

PAL

SECAM

NTSC

Audio(L/R)

AV-20RM4SE AV-21RM4SE AV-21RM4SP AV-21RM4SN

60.6cm × 47.5cm × 49.0cm

46.25MHz - 168.25MHz

175.25MHz - 463.25MHz

471.25MHz - 863.25MHz

S01 - S41 / S75 - S79 (B/G), S01 - S20 / S75 - S77(L)

38.9MHz

33.4MHz (5.5MHz:B/G)

32.4MHz (6.5MHz:L)

4.43MHz

4.40625MHz / 4.25MHz

3.58MHz / 4.43MHz

85W (Max) / 4W (Standby)

Measured diagonally

(H:41.2cm × V:31.2cm)

26kV (in cut-off service mode)

1V(p-p) 75Ω, RCA pin jack × 1

500mV(rms) (-4dBs), High Impedance, RCA pin jack × 2

60.6cm × 47.5cm × 47.0cm

85W (Max) / 3W (Standby)

Visible size : 51cm (21"), Measured diagonally

(H:41.6cm × V:31.5cm)

28kV (in cut-off service mode)

Content

PAL / NTSC 3.58 / NTSC 4.43

1-2 (No.YA080)

Page 3

SECTION 1

PRECAUTION

1.1 SAFETY PRECAUTIONS [EXCEPT FOR UK]

(1) The design of this product contains special hardware,

many circuits and components specially for safety

purposes. For continued protection, no changes should be

made to the original design unless authorized in writing by

the manufacturer. Replacement parts must be identical to

those used in the original circuits. Service should be

performed by qualified personnel only.

(2) Alterations of the design or circuitry of the products should

not be made. Any design alterations or additions will void

the manufacturer's warranty and will further relieve the

manufacturer of responsibility for personal injury or

property damage resulting therefrom.

(3) Many electrical and mechanical parts in the products have

special safety-related characteristics. These

characteristics are often not evident from visual inspection

nor can the protection afforded by them necessarily be

obtained by using replacement components rated for

higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in

the parts list of Service manual. Electrical components

having such features are identified by shading on the

schematics and by ( ) on the parts list in Service

manual. The use of a substitute replacement which does

not have the same safety characteristics as the

recommended replacement part shown in the parts list of

Service manual may cause shock, fire, or other hazards.

(4) Don't short between the LIVE side ground and

ISOLATED (NEUTRAL) side ground or EARTH side

ground when repairing.

Some model's power circuit is partly different in the GND.

The difference of the GND is shown by the LIVE : ( ) side

GND, the ISOLATED (NEUTRAL) : ( ) side GND and

EARTH : ( ) side GND.

Don't short between the LIVE side GND and ISOLATED

(NEUTRAL) side GND or EARTH side GND and never

measure the LIVE side GND and ISOLATED (NEUTRAL)

side GND or EARTH side GND at the same time with a

measuring apparatus (oscilloscope etc.). If above note will

not be kept, a fuse or any parts will be broken.

(5) If any repair has been made to the chassis, it is

recommended that the B1 setting should be checked or

adjusted (See B1 POWER SUPPLY check).

(6) The high voltage applied to the picture tube must conform

with that specified in Service manual. Excessive high

voltage can cause an increase in X-Ray emission, arcing

and possible component damage, therefore operation

under excessive high voltage conditions should be kept to

a minimum, or should be prevented. If severe arcing

occurs, remove the AC power immediately and determine

the cause by visual inspection (incorrect installation,

cracked or melted high voltage harness, poor soldering,

etc.). To maintain the proper minimum level of soft X-Ray

emission, components in the high voltage circuitry

including the picture tube must be the exact replacements

or alternatives approved by the manufacturer of the

complete product.

(7) Do not check high voltage by drawing an arc. Use a high

voltage meter or a high voltage probe with a VTVM.

Discharge the picture tube before attempting meter

connection, by connecting a clip lead to the ground frame

and connecting the other end of the lead through a 10kΩ

2W resistor to the anode button.

(8) When service is required, observe the original lead dress.

Extra precaution should be given to assure correct lead

dress in the high voltage circuit area. Where a short circuit

has occurred, those components that indicate evidence of

overheating should be replaced. Always use the

manufacturer's replacement components.

(9) Isolation Check (Safety for Electrical Shock Hazard)

After re-assembling the product, always perform an

isolation check on the exposed metal parts of the cabinet

(antenna terminals, video/audio input and output terminals,

Control knobs, metal cabinet, screw heads, earphone jack,

control shafts, etc.) to be sure the product is safe to operate

without danger of electrical shock.

a) Dielectric Strength Test

The isolation between the AC primary circuit and all metal

parts exposed to the user, particularly any exposed metal

part having a return path to the chassis should withstand a

voltage of 3000V AC (r.m.s.) for a period of one second. (.

. . . Withstand a voltage of 1100V AC (r.m.s.) to an

appliance rated up to 120V, and 3000V AC (r.m.s.) to an

appliance rated 200V or more, for a period of one second.)

This method of test requires a test equipment not generally

found in the service trade.

b) Leakage Current Check

Plug the AC line cord directly into the AC outlet (do not use

a line isolation transformer during this check.). Using a

"Leakage Current Tester", measure the leakage current

from each exposed metal part of the cabinet, particularly

any exposed metal part having a return path to the chassis,

to a known good earth ground (water pipe, etc.). Any

leakage current must not exceed 0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.2mA AC

(r.m.s.).

Alternate Check Method

Plug the AC line cord directly into the AC outlet (do not

use a line isolation transformer during this check.). Use

an AC voltmeter having 1000Ω per volt or more

sensitivity in the following manner. Connect a 1500Ω

10W resistor paralleled by a 0.15µF AC-type capacitor

between an exposed metal part and a known good earth

ground (water pipe, etc.). Measure the AC voltage

across the resistor with the AC voltmeter. Move the

resistor connection to each exposed metal part,

particularly any exposed metal part having a return path

to the chassis, and measure the AC voltage across the

resistor. Now, reverse the plug in the AC outlet and

repeat each measurement. Any voltage measured must

not exceed 0.75V AC (r.m.s.). This corresponds to

0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.3V AC

(r.m.s.). This corresponds to 0.2mA AC (r.m.s.).

AC VOLTMETER

(HAVING 1000 /V,

OR MORE SENSITIVITY)

0.15 F AC-TYPE

PLACE THIS PROBE

1500 10W

GOOD EARTH GROUND

ON EACH EXPOSED

ME TAL PAR T

(No.YA080)1-3

Page 4

1.2 SAFETY PRECAUTIONS [FOR UK]

(1) The design of this product contains special hardware and many circuits and components specially for safety purposes. For

continued protection, no changes should be made to the original design unless authorized in writing by the manufacturer.

Replacement parts must be identical to those used in the original circuits. Service should be performed by qualified personnel

only.

(2) Alterations of the design or circuitry of the product should not be made. Any design alterations or additions will void the

manufacturer's warranty and will further relieve the manufacturer of responsibility for personal injury or property damage

resulting therefrom.

(3) Many electrical and mechanical parts in the product have special safety-related characteristics. These characteristics are often

not evident from visual inspection nor can the protection afforded by them necessary be obtained by using replacement

components rated for higher voltage, wattage, etc. Replacement parts which have these special safety characteristics are

identified in the Parts List of Service Manual. Electrical components having such features are identified by shading on the

schematics and by ( ) on the Parts List in the Service Manual. The use of a substitute replacement which does not have the

same safety characteristics as the recommended replacement part shown in the Parts List of Service Manual may cause shock,

fire, or other hazards.

(4) The leads in the products are routed and dressed with ties, clamps, tubing’s, barriers and the like to be separated from live parts,

high temperature parts, moving parts and / or sharp edges for the prevention of electric shock and fire hazard. When service is

required, the original lead routing and dress should be observed, and it should be confirmed that they have been returned to

normal, after re-assembling.

WARNING

(1) The equipment has been designed and manufactured to meet international safety standards.

(2) It is the legal responsibility of the repairer to ensure that these safety standards are maintained.

(3) Repairs must be made in accordance with the relevant safety standards.

(4) It is essential that safety critical components are replaced by approved parts.

(5) If mains voltage selector is provided, check setting for local voltage.

1-4 (No.YA080)

Page 5

SECTION 2

SPECIFIC SERVICE INSTRUCTIONS

2.1 FEATURES

• It is a remote controlled color television.

• It can tune cable channels.

• Controlling the TV is very easy by its menu driven system.

• It has 1 Euroconnector sockets for external device.

• Front AV Input available.

• Simple teletext (Toptext, WST) system.

• It is possible to connect headphone.

• Direct channel access.

2.2 MAIN DIFFERENCE LIST

Item AV-20RM4SE AV-21RM4SE AV-21RM4SN AV-21RM4SP

MAIN PWB ASSY VE-20161051 VE-20161048 VE-20161045 VE-20161041

TV RF System B/G,D/K ← B/G B/G, L

Colour System (TV mode) PAL, SECAM ← PAL PAL, SECAM

TV RF System B/G,D/K ← B/G B/G, L

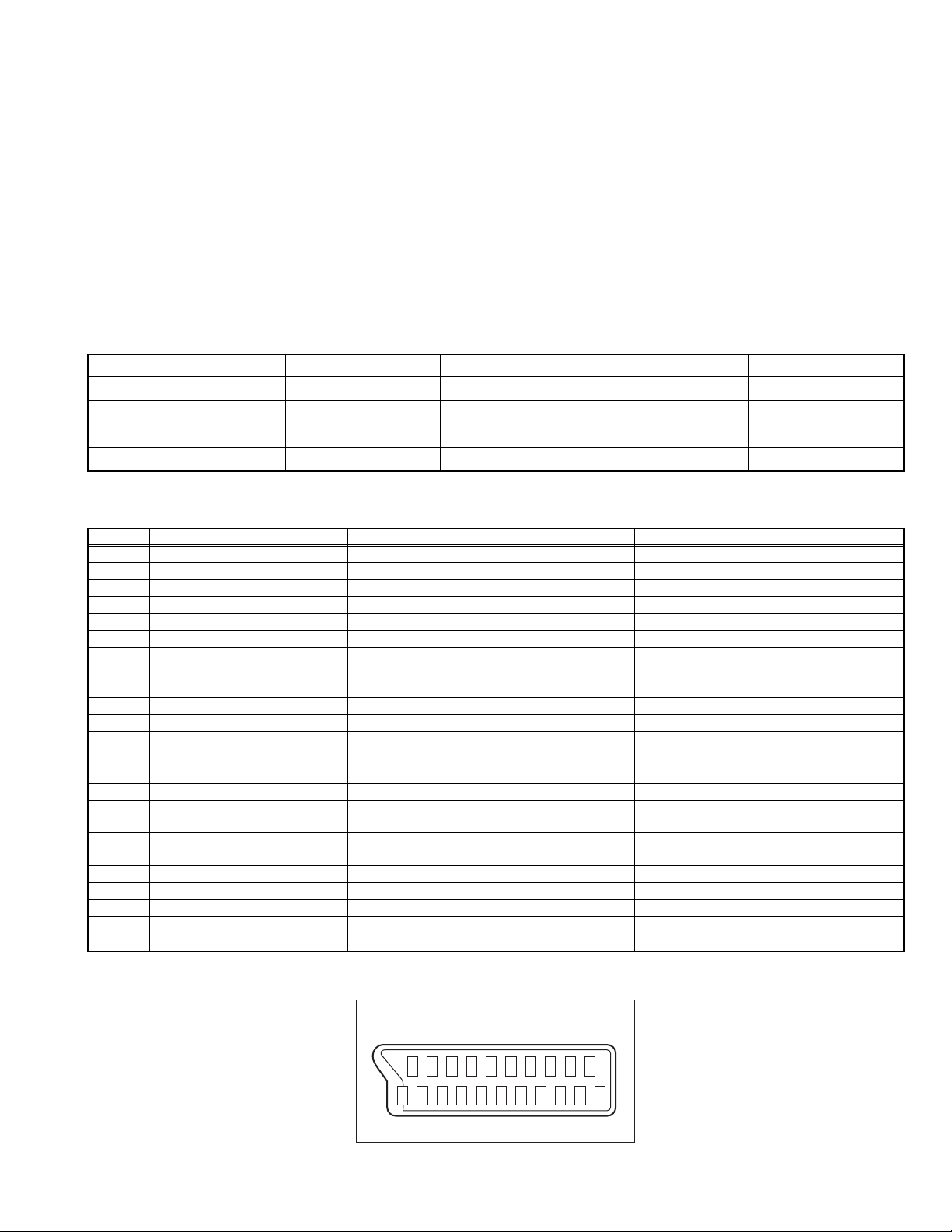

2.3 21-PIN EURO CONNECTOR (SCART) : EXT-1

Pin No. Signal designation Matching value EXT-1

1 AUDIO R output 500mV(rms) (Nominal), Low impedance Used (TV OUT)

2 AUDIO R input 500mV(rms) (Nominal), High impedance Used (R1)

3 AUDIO L output 500mV(rms) (Nominal), Low impedance Used (TV OUT)

4 AUDIO GND --- Used

5 GND (B) --- Used

6 AUDIO L input 500mV(rms) (Nominal), High impedance Used (L1)

7 B input 700mV

8 FUNCTION SW (SLOW SW) Low : 0V-3V

High : 8V-12V, High impedance

9 GND (G) --- Used

10 SCL / T-V LINK --- Not used

11 G input 700mV(B-W), 75 Ω Used

12 SDA3 --- Not used

13 GND (R) --- Used

14 GND (YS) --- Used

15 R / C input R : 700mV

C : 300mV

16 Ys input (FAST SW) Low : 0V-0.4V, 75 Ω

High : 1V-3V, 75 Ω

17 GND (VIDEO output) --- Used

18 GND (VIDEO input) --- Used

19 VIDEO output 1V

20 VIDEO / Y input 1V

21 COMMON GND --- Used

(P-P)

(P-P)

, 75 Ω Used

(B-W)

, 75 Ω

(B-W)

, 75 Ω

(P-P)

(Negative sync),75 Ω Used (TV OUT)

(Negative sync), 75 Ω Used

(P-P= Peak to Peak, B-W= Blanking to white peak)

• APS (Automatic Programming System).

• All programs can be named.

• Forward or backward automatic tuning.

• Sleep timer.

• Child Lock.

• Automatic sound mute when no transmission.

• 5 minutes after the broadcasting (closedown), the TV switches

itself automatically to stand-by mode.

Used

Used (R)

Used

Pin assignment

20 18 16 14 12 10 8 6 4 2

21 19 17 15 13 11 9 7 5 3 1

(No.YA080)1-5

Page 6

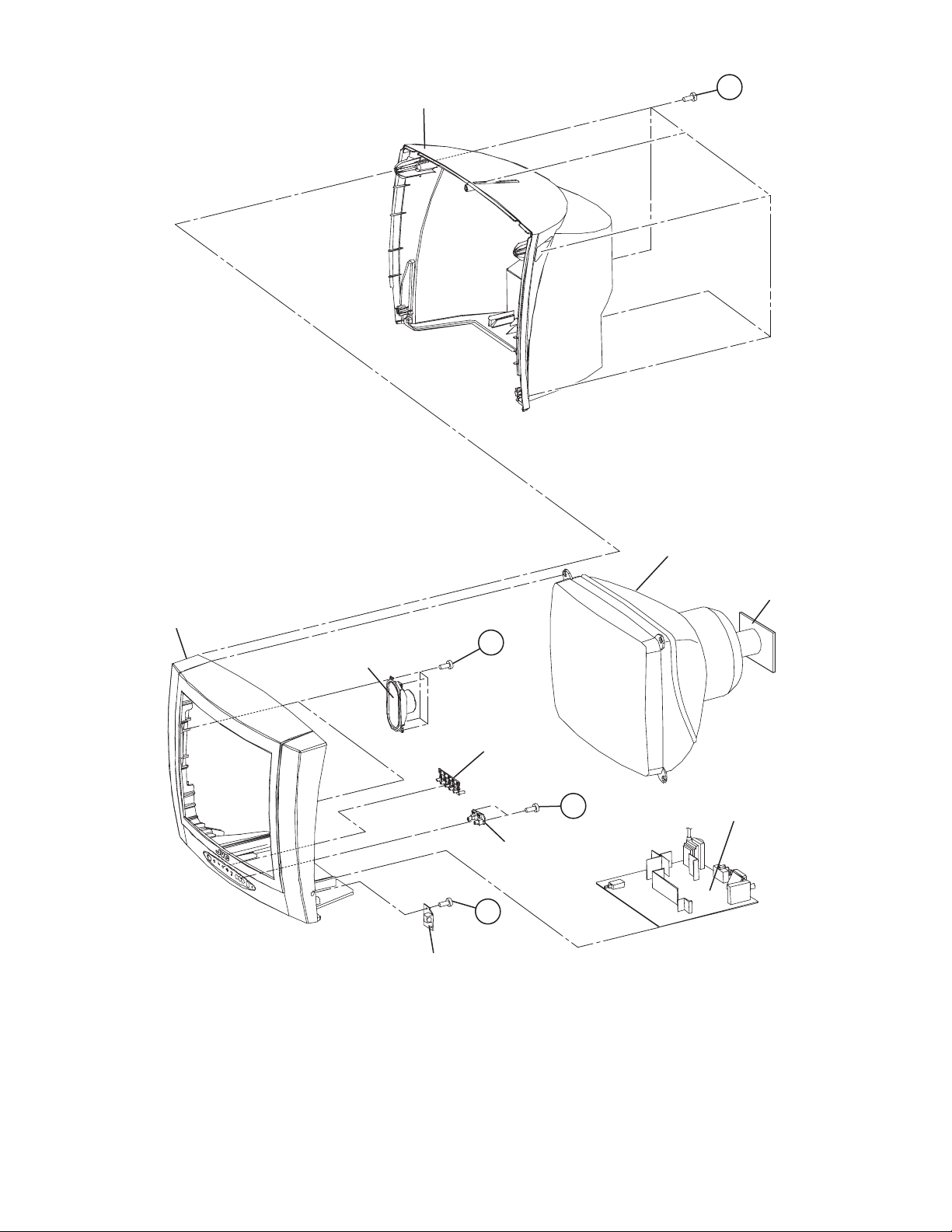

SECTION 3

DISASSEMBLY

3.1 DISASSEMBLY PROCEDURE

3.1.1 REMOVING THE REAR COVER

(1) Unplug the power cord.

(2) Remove the 6 screws [A].

(3) Withdraw the REAR COVER toward you.

3.1.2 REMOVING THE MAIN PWB

• Remove the REAR COVER.

(1) Slightly raise the both sides of the MAIN PWB by hand and

withdraw the MAIN PWB backward.

(If necessary, take off the wire clamp, connectors etc.)

3.1.3 REMOVING THE SPEAKER

• Remove the REAR COVER.

(1) Remove the 4 screws [B].

(2) Remove the speaker toward you.

3.1.4 REMOVING THE FRONT AV JACK PWB

• Remove the REAR COVER.

• Remove the MAIN PWB.

(1) Remove the 2 screws [C].

(2) Remove the FRONT AV JACK PWB.

3.1.6 CHECKING THE PW BOARD

• To check the back side of the PW Board.

(1) Pull out the PW Board. (Refer to REMOVING THE MAIN

PWB).

(2) Erect the PW Board vertically so that you can easily check

the back side of the PWB.

CAUTION:

• When erecting the PW Board, be careful so that there will be

no contacting with other PW Board.

• Before turning on power, make sure that the wire connector

is properly connected.

• When conducting a check with power supplied, be sure to

confirm that the CRT EARTH WIRE (BRAIDED ASS'Y) is

connected to the CRT SOCKET PWB.

3.1.7 WIRE CLAMPING AND CABLE TYING

(1) Be sure to clamp the wire.

(2) Never remove the cable tie used for tying the wires

together.

Should it be inadvertently removed, be sure to tie the wires

with a new cable tie.

3.1.5 REMOVING THE HEADPHONE JACK PWB

• Remove the REAR COVER.

• Remove the MAIN PWB.

(1) Remove the 1 screw [D].

(2) Remove the HEADPHONE JACK PWB.

1-6 (No.YA080)

Page 7

BACK COVER

A

(x6)

FRONT CABINET

SPEAKER

B

(x4)

FUNCTION

BUTTON

FRONT AV JACK PWB

D

(x1)

HEADPHONE JACK

PWB

PICTURE TUBE

CRT SOCKET PWB

(Within MAIN PWB)

C

(x2)

MAIN PWB

(No.YA080)1-7

Page 8

3.2 REPLACEMENT OF MEMORY IC

3.2.1 MEMORY IC

This model use a memory IC. This memory IC stores data for proper operation of the video and deflection circuits.

When replacing, be sure to use an IC containing this (initial value) data.

3.2.2 PROCEDURE FOR REPLACING MEMORY IC SERVICE MENU

PROCEDURE

1. Power off

Switch the power off and unplug the power cord from the outlet

2. Replace IC.

Be sure to use memory IC written with the initial data values.

3. Power on

Plug the power cord into the outlet and switch the power on.

4. SERVICE MENU setting

JVCAK30/37 B20

OSD

IF1

IF2

IF3

IF4

AGC

VLIN

RGBH

VSOF

VPOF

: 1 1 AVL

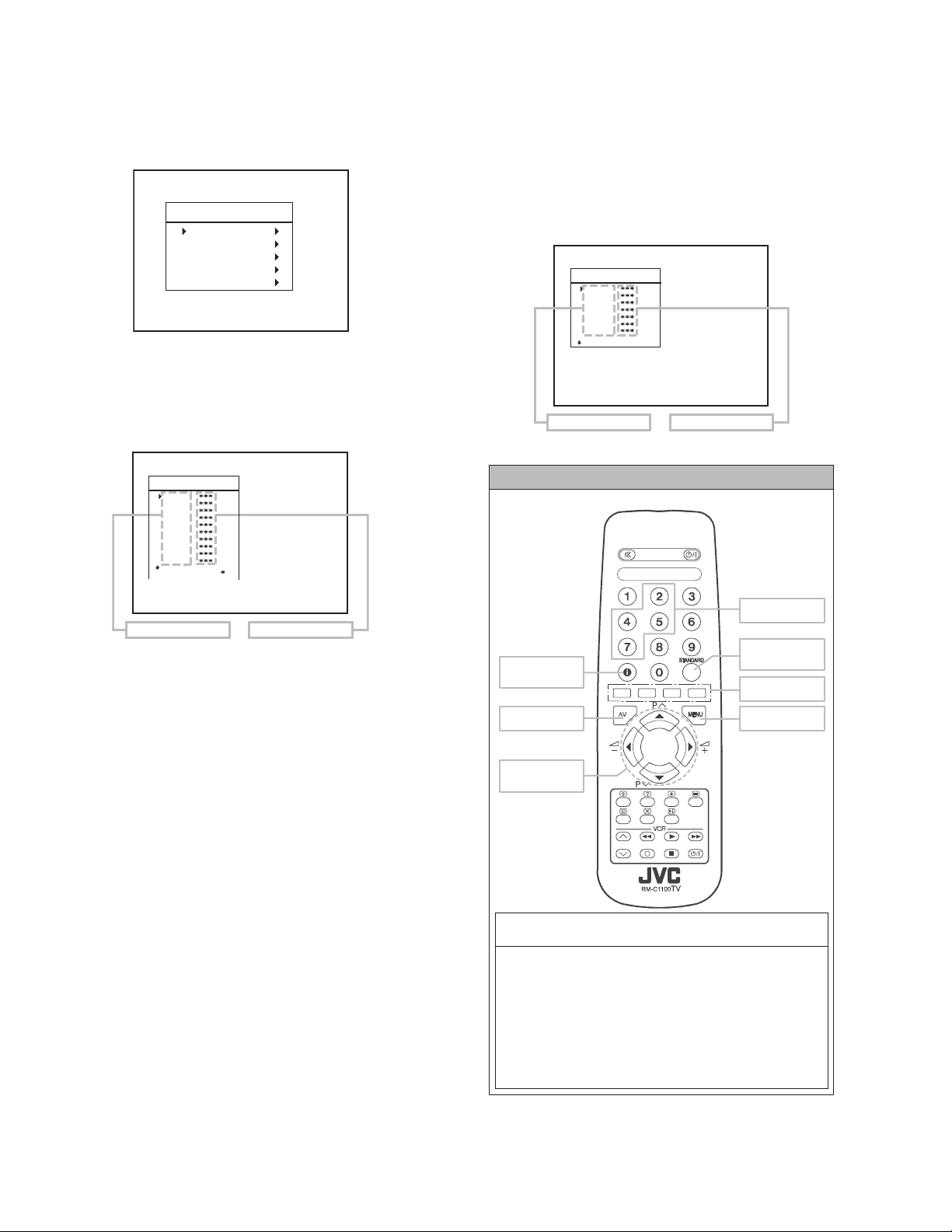

(1) Press [MENU] key and, while the displayed MENU screen,

press [4], [7], [2], [5] key on the remote control unit or press

[MUTING] key and [INFORMATION] key at the

simultaneously.

Fig.1

(2) The SERVICE MENU screen of Fig. 1 will be displayed.

(3) Verify what to set in the SERVICE MENU, and set

whatever is necessary (Fig.1). Refer to the SERVICE

SERVICE MENU SELECT KEY

ADJUSTMENT for setting.

(4) Press the [STANDARD] key to exit SERVICE MENU.

5. Receive channel setting

Refer to the OPERATING INSTRUCTIONS (USER'S GUIDE)

and set the receive channels (Channels Preset) as described.

MUTING

6. User settings

Check the user setting items according to after page.

Where these do not agree, refer to the OPERATING

INSTRUCTIONS (USER'S GUIDE) and set the items as

described.

INFORMATION

AV

POWER

NUMBER

STANDARD

COLOUR

MENU

1-8 (No.YA080)

ITEM

SELECT ( )

ITEM

SELECT ( )

Fig.2

VAL UE

SELECT (+)

VAL UE

SELECT (-)

Page 9

3.3 SETTING OF THE LAST MEMORY FOR SHIPMENT

3.3.1 USER SETTING VALUES

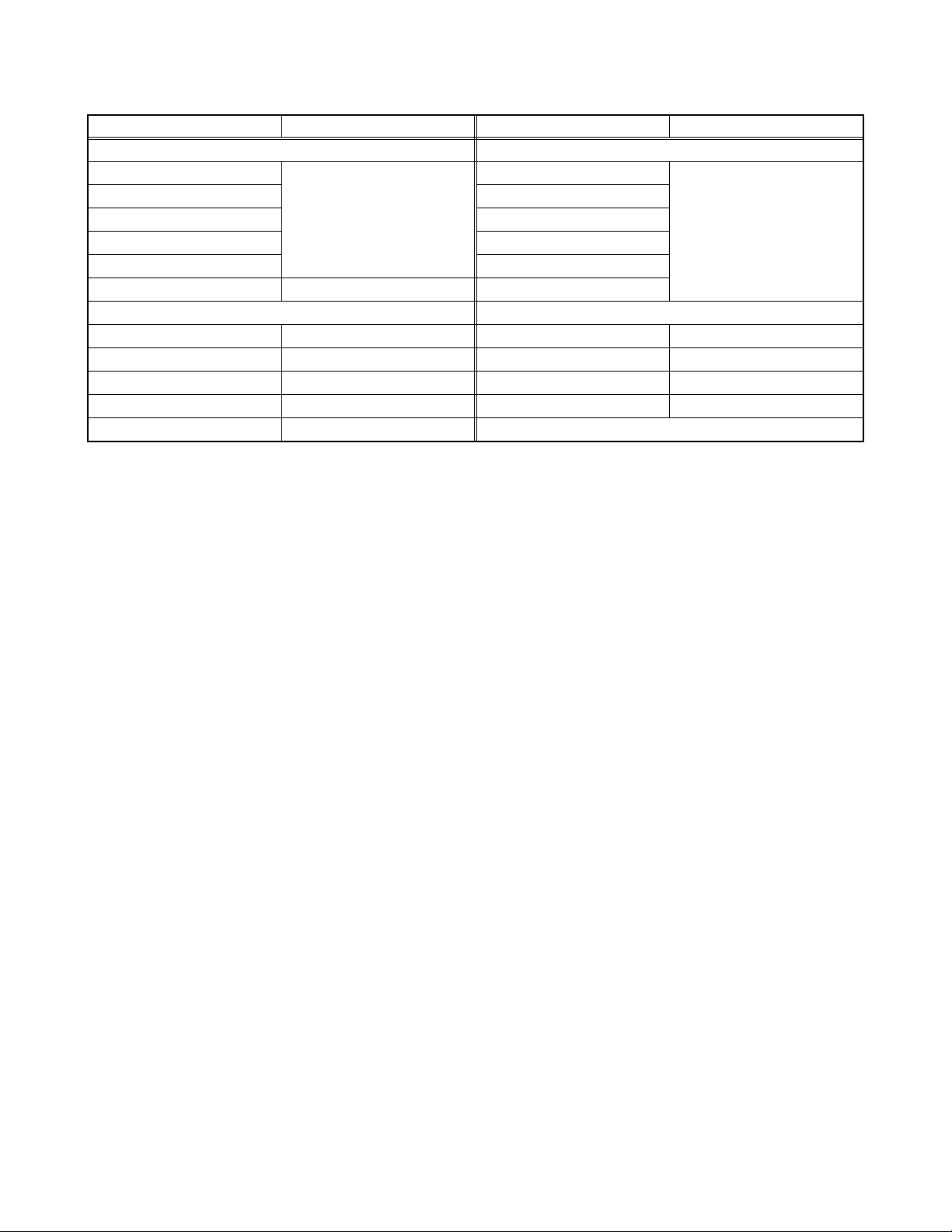

Setting item Setting value Setting item Setting value

PICTURE MENU INSTALL

BRIGHTNESS

CONTRAST BAND

COLOUR CHANNEL

SHARPNESS SEARCH

HUE(only NTSC) FINE TUNING

MODE AUTO STORE

SOUND MENU FEATURE MENU

BALANCE Center SLEEP TIMER OFF

BASS Center CHILD LOCK OFF

TREBLE Center LANGUAGE ENGLISH

MODE MONO AV-1 OUTPUT TV

EFFECT OFF

3.3.2 SETTING APS BIT IN SERVICE MENU

(1) Press the [INFORMATION] and [MUTING] keys enter service menu in TV mode simultaneously. Service Menu will appear.

(2) Press the []/[] key to select TX1(TELETEXT OPTION).

(3) Press the [7] key to set APS bit. (After this, bit 7 of TX1 will be "1")

(4) Press [STANDARD] key to exit service mode.

NOTE : DO NOT TURN OFF THE TV BY USING POWER BUTTON ON THE FRONT PANEL.

These adjust are automatically

restored when APS bit in

service menu is set.

The procedure for setting APS

bit is described below.

PROGRAMME

Refer to the INSTRUCTION

BOOK

(No.YA080)1-9

Page 10

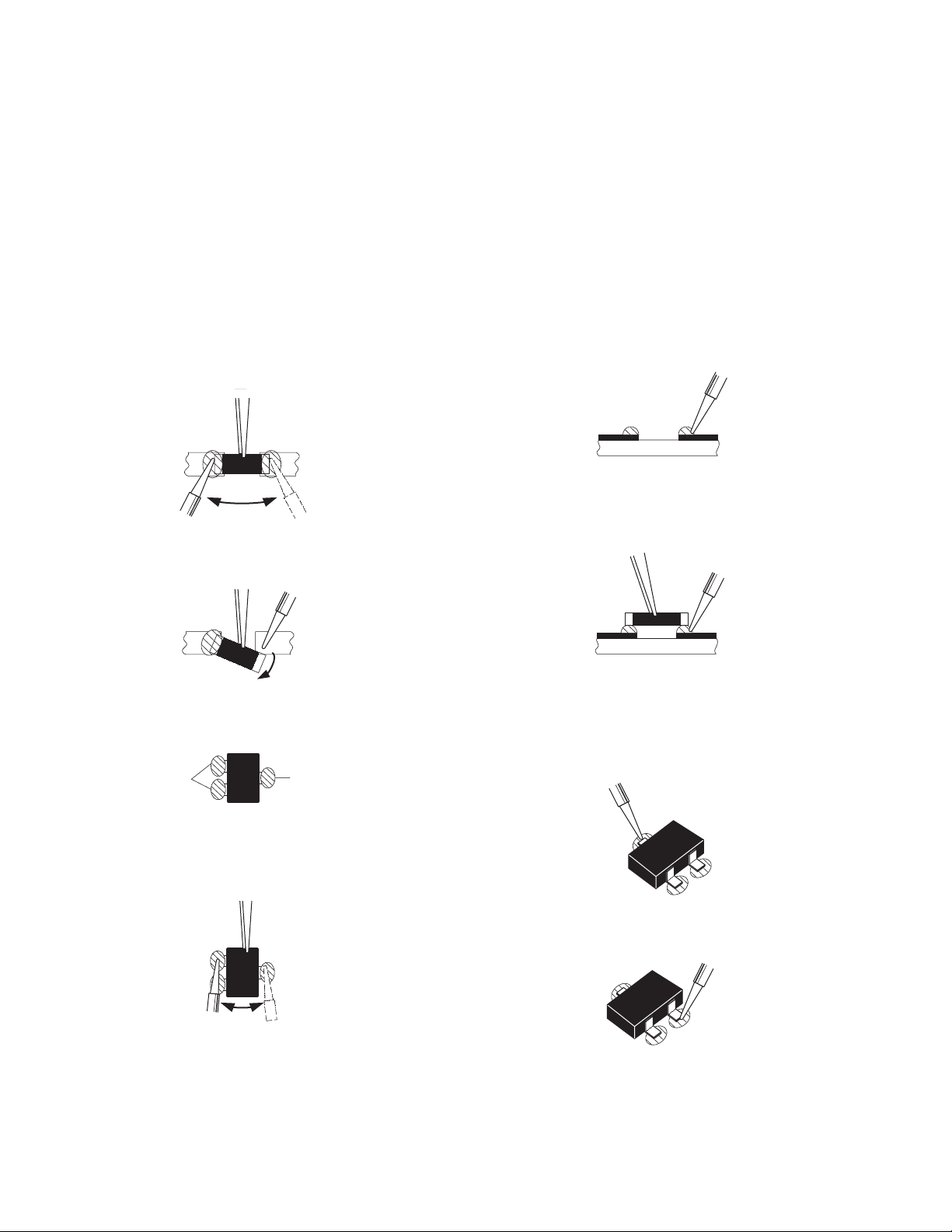

3.4 REPLACEMENT OF CHIP COMPONENT

3.4.1 CAUTIONS

(1) Avoid heating for more than 3 seconds.

(2) Do not rub the electrodes and the resist parts of the pattern.

(3) When removing a chip part, melt the solder adequately.

(4) Do not reuse a chip part after removing it.

3.4.2 SOLDERING IRON

(1) Use a high insulation soldering iron with a thin pointed end of it.

(2) A 30w soldering iron is recommended for easily removing parts.

3.4.3 REPLACEMENT STEPS

1. How to remove Chip parts

2. How to install Chip parts

[Resistors, capacitors, etc.]

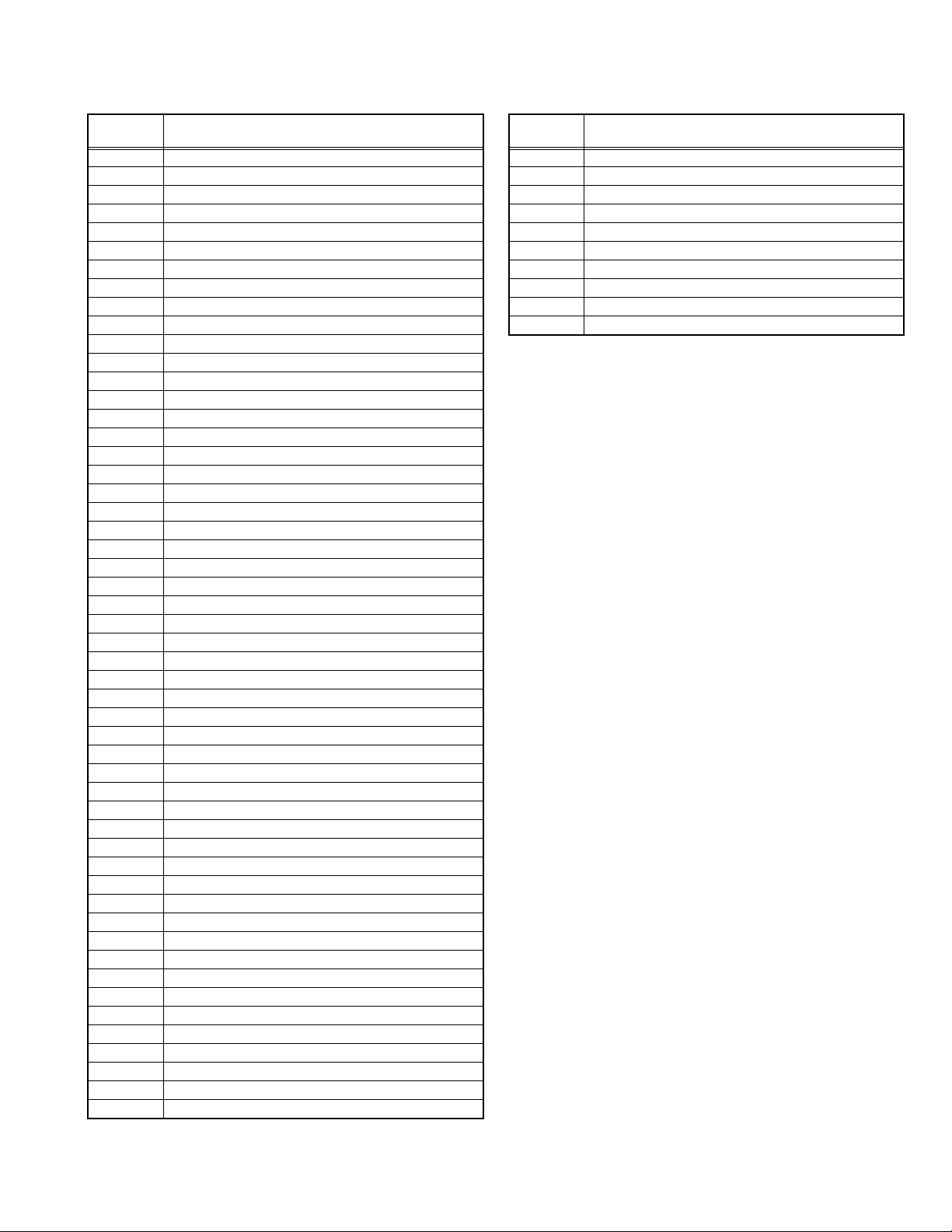

(1) As shown in the figure, push the part with tweezers and

alternately melt the solder at each end.

(2) Shift with the tweezers and remove the chip part.

[Transistors, diodes, variable resistors, etc.]

(1) Apply extra solder to each lead.

SOLDER

SOLDER

[Resistors, capacitors, etc.]

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the

solder. Then heat and melt the solder at both ends of the

chip part.

[Transistors, diodes, variable resistors, etc.]

(1) Apply solder to the pattern as indicated in the figure.

(2) Grasp the chip part with tweezers and place it on the

solder.

(3) First solder lead A as indicated in the figure.

(2) As shown in the figure, push the part with tweezers and

alternately melt the solder at each lead. Shift and remove

the chip part.

NOTE :

After removing the part, remove remaining solder from the

pattern.

1-10 (No.YA080)

A

B

C

(4) Then solder leads B and C.

A

B

C

Page 11

SECTION 4

ADJUSTMENT

4.1 ADJUSTMENT PREPARATION

(1) You can make the necessary adjustments for this unit with

either the Remote Control Unit or with the adjustment tools

and parts as given below.

(2) Adjustment with the Remote Control Unit is made on the

basis of the initial setting values, however, the new setting

values which set the screen to its optimum condition may

differ from the initial settings.

(3) Make sure that AC power is turned on correctly.

(4) Turn on the power for set and test equipment before use,

and start the adjustment procedures after waiting at least

30 minutes.

(5) Unless otherwise specified, prepare the most suitable

reception or input signal for adjustment.

(6) Never touch any adjustment parts which are not specified

in the list for this adjustment - variable resistors,

transformers, condensers, etc.

(7) Presetting before adjustment.

Unless otherwise specified in the adjustment instructions,

preset the following functions with the remote control unit:

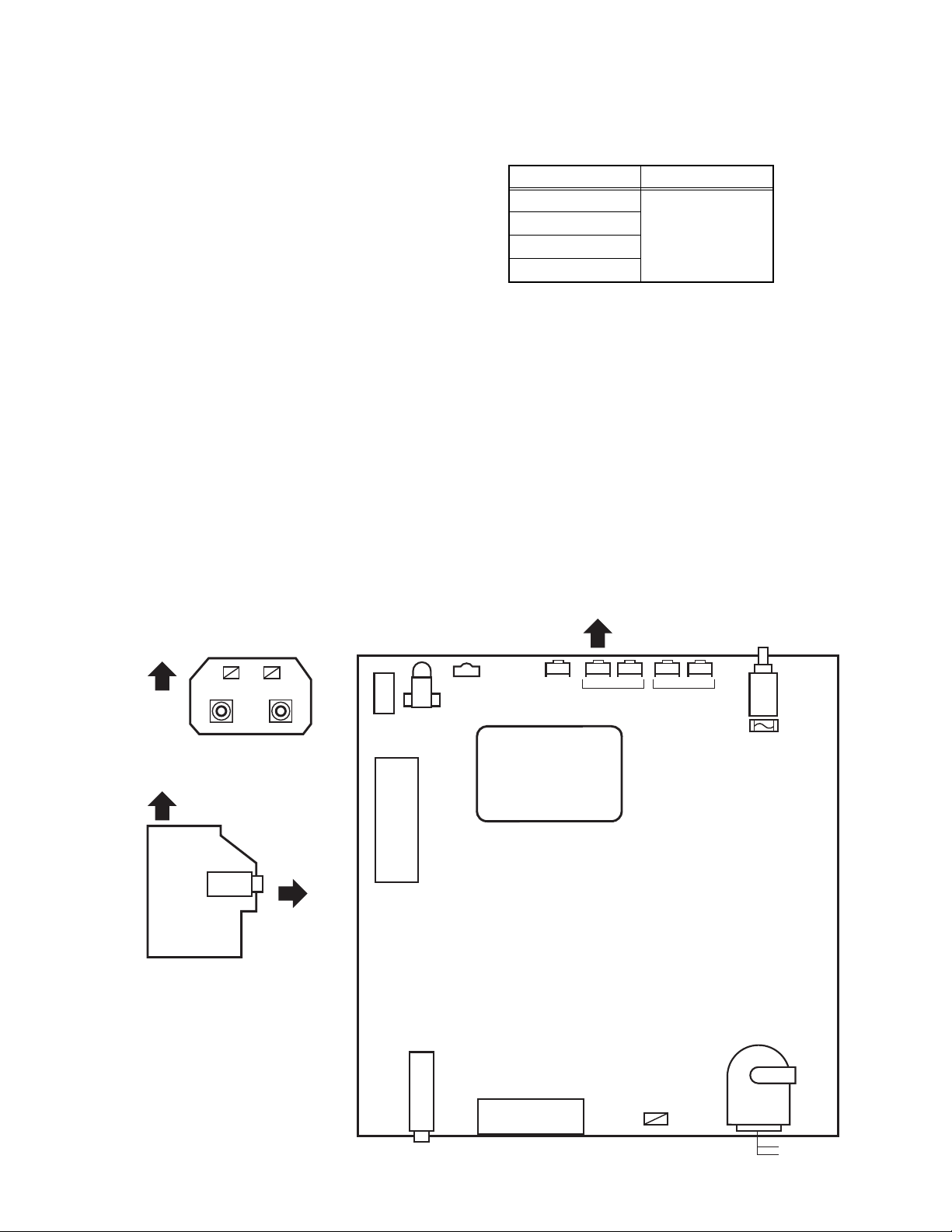

4.4 ADJUSTMENT LOCATIONS

Setting item Setting value

BRIGHTNESS

CONTRAST

COLOUR

Center

SHARPNESS

4.2 ADJUSTMENT EQUIPMENT

(1) DC voltmeter (or digital voltmeter)

(2) Signal generator (Pattern generator)

: [PAL / SECAM / NTSC]

(3) Remote control unit

4.3 ADJUSTMENT ITEM

• FOCUS ADJUSTMENT

• SCREEN ADJUSTMENT

• OSD HORIZONTAL POSITION ADJUSTMENT

• IF ADJUSTMENT

• AGC AUTOMATICALLY ADJUSTMENT

• DEFLECTION ADJUSTMENT

• WHITE BALANCE ADJUSTMENT

TOP

FRONT AV JACK PWB

TOP

HP

HEADPHONE JACK PWB

IC500

EEP ROM

IC501

MICOM

TUNER

LED

REMOCON

RECEIVER

MENU

AV-1(SCART)

FRONT

CH. / PROG.

PL602

(+) (-)(+) (-)

VOL.

MAIN

SW

FUSE

FBT

MAIN PWB

UPPER:FOCOUS

LOWER:SCREEN

(No.YA080)1-11

Page 12

4.5 BASIC OPERATION OF SERVICE MODE

4.5.1 HOW TO ENTER SERVICE MODE

(1) Press the MENU key.

(2) MENU screen will be displayed (fig.1).

MENU SCREEN

MENU

SOUND

PICTURE

FEATURE

INSTALL.

PROGRAM.

Fig.1

(3) While the MENU screen is displayed , press the [4], [7], [2],

[5] key or [INFORMATION] key and [MUTING] key

simultaneously.

(4) The SERVICE MENU screen will be displayed (fig.2).

SERVICE MENU

4.5.4 HOW TO ENTER THE GEOMETRY MENU

• This model is built-in GEOMETRY MENU for geometry

adjustment.

(1) Enter the SERVICE MODE.

(2) Press the [GREEN] key, geometry menu appears (Fig. 3).

(3) Press the []/[] key and select the adjustment item.

(4) Press the []/[] key and set the setting value.

GEOMETRY MENU

GEOMETRY

VSIZ

VPOS

VSCO

VCCO

HSIZ

HPOS

HPIN

AUTO

ADJUSTMENT ITEM SETTING VALUE

Fig.3

JVCAK30/37 B20

OSD

IF1

IF2

IF3

IF4

AGC

VLIN

RGBH

VSOF

VPOF

: 1 1 AVL

ADJUSTMENT ITEM SETTING VALUE

Fig.2

4.5.2 SELECTION OF ADJUSTMENT ITEMS

(1) Enter the SERVICE MODE.

(2) Press the []/[] key to select the adjustment item.

(3) Press the []/[] key to set the setting value.

4.5.3 HOW TO EXIT SERVICE MODE

(1) Press the [STANDARD] key.

REMOTE CONTROL UNIT key NAME

INFORMATION

Key

AV Key

FUNCTION

Key

NUMBER Key

STANDARD

Key

COLOUR Key

MENU Key

1-12 (No.YA080)

FUNCTION OF COLOUR key

RED key :

It switches the AVL to ON or OFF mode on service menu.

AVL word is visible on service menu when AVL is on.

GREEN key :

It switches to GEOMETRY adjust menu. Geometry

of the picture is adjusted in this menu.

YELLOW key :

It switches to VERTICAL SCAN DISABLE mode.

It is useful to adjust screen voltage.

BLUE key :

It is used to adjust AGC and IF automatically on service menu.

Page 13

4.5.5 ADJUSTMENT ITEM

4.5.5.1 SERVICE MENU 4.5.5.2 GEOMETRY MENU

Adjustment

item

OSD HORIZONTAL POSITION OF OSD

IF1 IF COARSE ADJUSTMENT

IF2 IF FINE ADJUSTMENT

IF3 IF COARSE ADJUSTMENT FOR L-PRIME

IF4 IF FINE ADJUSTMENT FOR L-PRIME

AGC AUTOMATIC GAIN CONTROL

VLIN VERTICAL LINEARITY

RGBH RGB MODE HORIZONTAL SHIFT OFFSET

VSOF VERTICAL SIZE OFFSET for 60Hz

VPOF VERTICAL POSITION OFFSET for 60Hz

HSOF HORIZONTAL SIZE OFFSET for 60Hz

HPOF HORIZONTAL POSITION OFFSET for 60Hz

HTOF HORIZONTAL TRAPEZOID OFFSET for 60Hz

WR WHITE POINT ADJUSTMENT FOR RED

WG WHITE POINT ADJUSTMENT FOR GREEN

WB WHITE POINT ADJUSTMENT FOR BLUE

BR BIAS FOR RED

BG BIAS FOR GREEN

APR AUTOMATIC RGB PEAK REGULATION THRESHOLD

BRI BRIGHTNESS

CON CONTRAST

COL COLOUR

SHA SHARP

HUE HUE

VOL VOLUME

WR-R WHITE POINT ADJUSTMENT for RED (RGBmode)

WG-R WHITE POINT ADJUSTMENT for GREEN (RGBmode)

WB-R WHITE POINT ADJUSTMENT for BLUE (RGBmode)

FMP1 FM PRESCALER WHEN AVL IS OFF

NIP1 NICAM PRESCALER WHEN AVL IS OFF

SCP1 SCART PRESCALER WHEN AVL IS OFF

SEC1 SECAM PRESCALER WHEN AVL IS OFF

FMP2 FM PRESCALER WHEN AVL IS ON

NIP2 NICAM PRESCALER WHEN AVL IS ON

SCP2 SCART PRESCALER WHEN AVL IS ON

SEC2 SECAM PRESCALER WHEN AVL IS ON

F1H

F1L

F2H

F2L

BS1 BAND SWITCHING BYTE FOR VHF1

BS2 BAND SWITCHING BYTE FOR VHF3

BS3 BAND SWITCHING BYTE FOR UHF

CB CONTROL BYTE

OP1 PERIPHERAL OPTIONS

OP2 RECEPTION STANDARD OPTIONS

OP3 VIDEO OPTIONS

OP4 TV FEATURES

OP5 CHANNEL TABLES

TX1 TELETEXT OPTIONS

GEOM GEOMETRY OPTIONS

OP8 PIP PRESET CHANGE

HIGH BYTE OF VHF1-VHF3 CROSS-OVER FREQUENCY

LOW BYTE OF VHF1-VHF3 CROSS-OVER FREQUENCY

HIGH BYTE OF VHF3-UHF CROSS-OVER FREQUENCY

LOW BYTE OF VHF3-UHF CROSS-OVER FREQUENCY

Description

Adjustment

item

VSIZ VERTICAL SIZE for 50Hz

VPOS VERTICAL POSITION for 50Hz

VSCO VERTICAL S-CORRECTION for 50Hz

VCCO VERTICAL CORNER CORRECTION for 50Hz

HSIZ HORIZONTAL SIZE for 50Hz

HPOS HORIZONTAL POSITION for 50Hz

HPIN HORIZONTAL PINCUSHION for 50Hz

HCCO HORIZONTAL CORNER CORRECTION for 50H

HTRP HORIZONTAL TRAPEZOID for 50Hz

VZSZ VERTICAL ZOOM SIZE for 50Hz

Description

(No.YA080)1-13

Page 14

4.6 ADJUSTMENTS PROCEDURE

r

4.6.1 FOCUS ADJUSTMENT

Item

FOCUS

adjustment

Measuring

instrument

Signal

generator

Remote

control unit

4.6.2 SCREEN ADJUSTMENT

Item

SCREEN

adjustment

Measuring

instrument

Remote

control unit

Test point Adjustment part Description

FOCUS VR

[On the FBT]

(1) Receive a PAL crosshatch signal.

(2) Adjust FOCUS VR on the FBT as thin as possible.

FOCUS VR

SCREEN VR

FBT

Test point Adjustment part Description

SCREEN VR

[On the FBT]

(1) Enter the SERVICE MODE.

(2) Press the [YELLOW] key to disable vertical scan.

(3) Adjust SCREEN VR. on the FBT as thin as possible.

(4) Press [YELLOW] key again to enable vertical scan.

(5) Press [STANDARD] key to leave service menu.

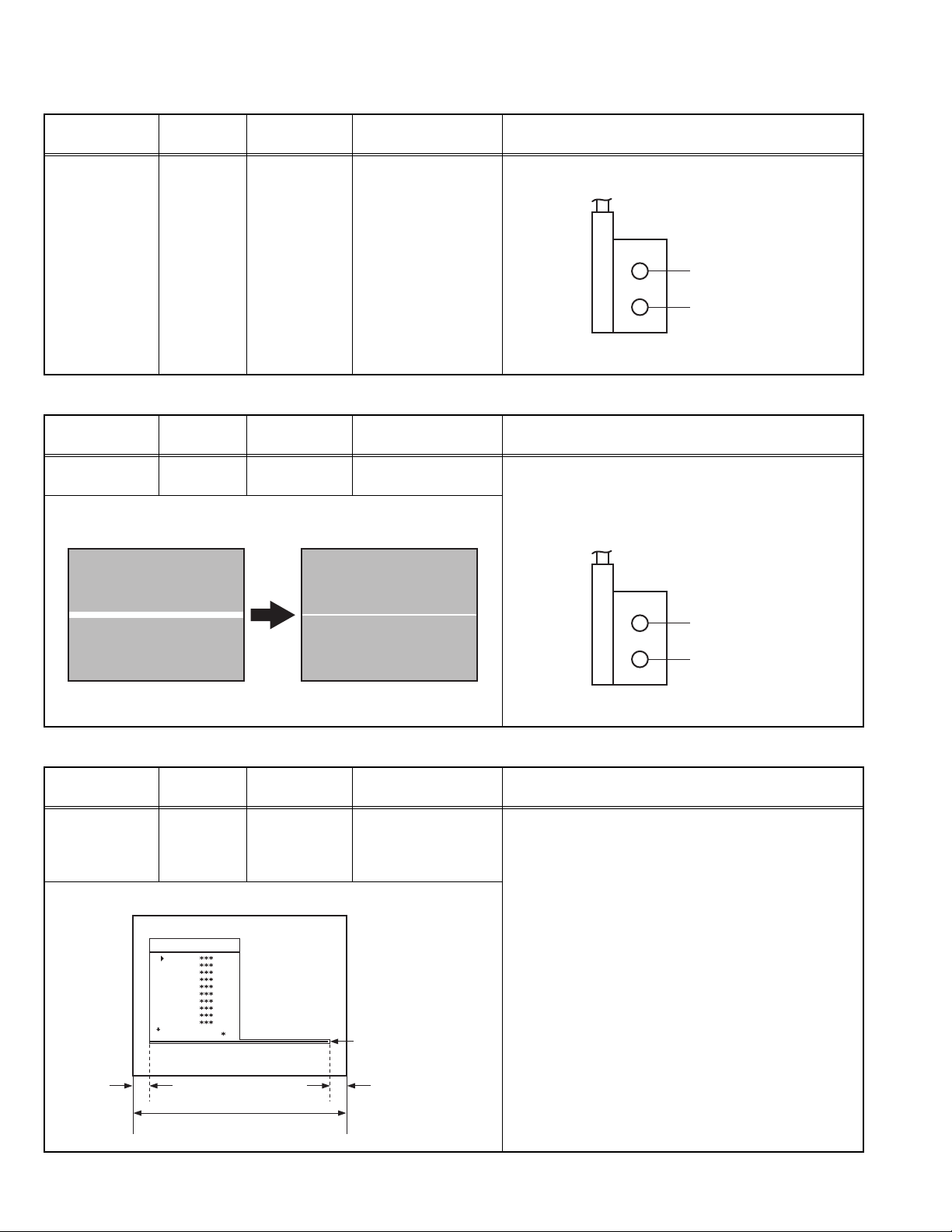

4.6.3 OSD ADJUSTMENT

Item

OSD

HORIZONTAL

Measuring

instrument

Remote

control unit

POSITION

adjustment

SERVICE MENU SCREEN

JVCAK30/37 B20

OSD

IF1

IF2

IF3

IF4

AGC

VLIN

RGBH

VSOF

VPOF

: 1 1 AVL

FOCUS VR

SCREEN VR

FBT

Test point Adjustment part Description

OSD (1) Enter the SERVICE MODE.

(2) Select OSD with the []/[] key.

(3) Adjust the OSD horizontal position with the []/[]

key, which shifts the reference bar on the bottom of

the SERVICE MENU horizontally, so that the OSD is

positioned on the screen center. (X=X')

Reference ba

XX'

1-14 (No.YA080)

Screen size

Page 15

4.6.4 IF ADJUSTMENT

Item

Measuring

instrument

Test point Adjustment part Description

IF adjustment Remote

control unit

4.6.5 AGC AUTOMATICALLY ADJUSTMENT

Item

AGC

AUTOMATICALLY

Measuring

instrument

Remote

control unit

Test point Adjustment part Description

adjustment

JVCAK30/37 B20

OSD

IF1

IF2

IF3

IF4

AGC

VLIN

RGBH

VSOF

VPOF

: 1 1 AVL

IF1

IF2

IF3

IF4

(1) Receive a PAL colour bar pattern.

(2) Enter the SERVICE MODE.

(3) Select IF 1 with the []/[] key.

(4) Press [BLUE] key during IF 1 is highlighted, IF 1 and

IF 2 values are adjusted automatically by software.

(5) If the standard is L-prime, IF 3 and IF 4 values are

adjustment automatically when [BLUE] key is

pressed during IF 1 is highlighted.

AGC (1) Receive a 60dBµV RF signal level.

(2) Enter the SERVICE MODE.

(3) Select AGC with the []/[] key.

(4) Press [BLUE] key.

(5) The adjustment will be done automatically by

software.

(6) See the AGC indicator on SERVICE MENU, it must

be "1".

(7) Check that picture is normal at 90dBµV signal level.

IF INDICATOR AGC INDIXATOR NON

:11

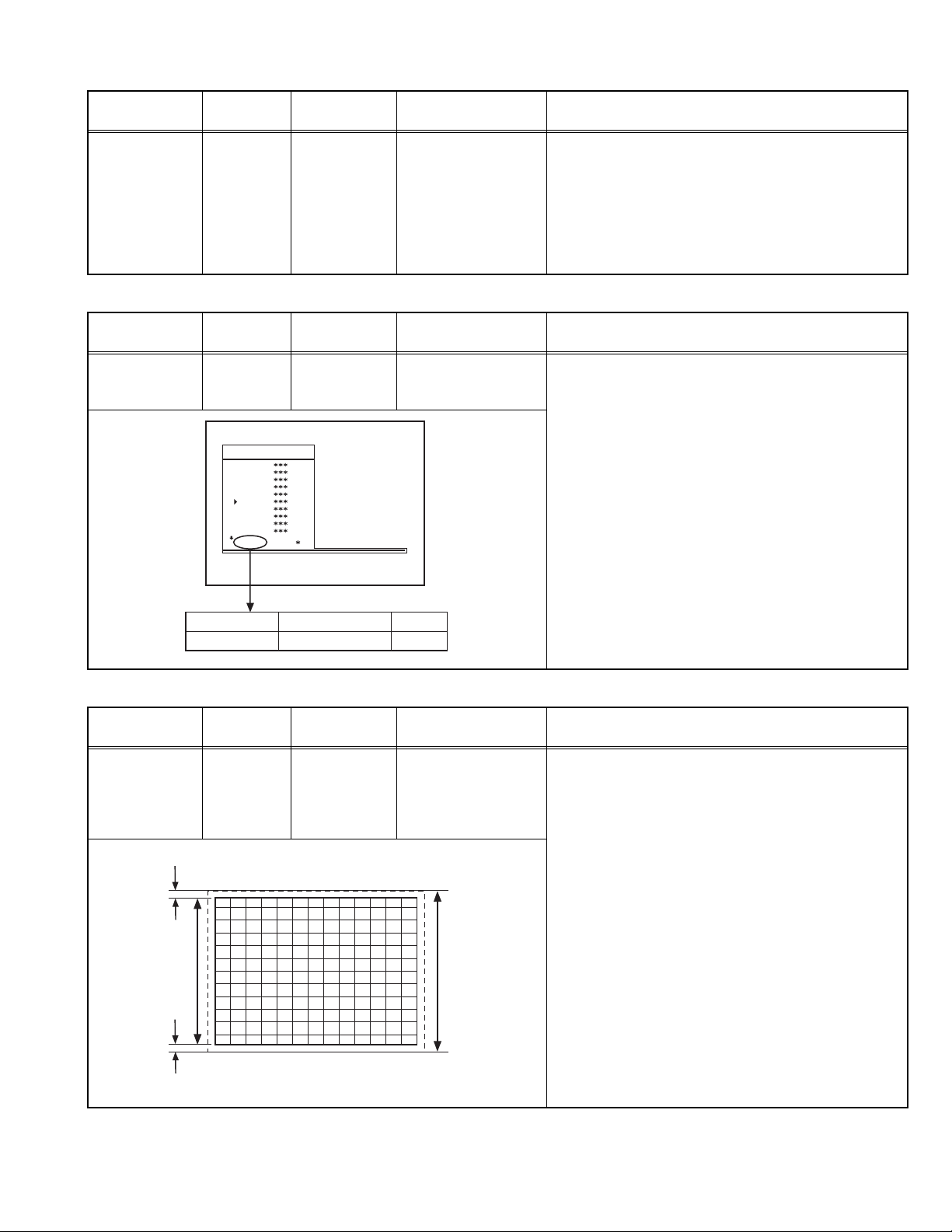

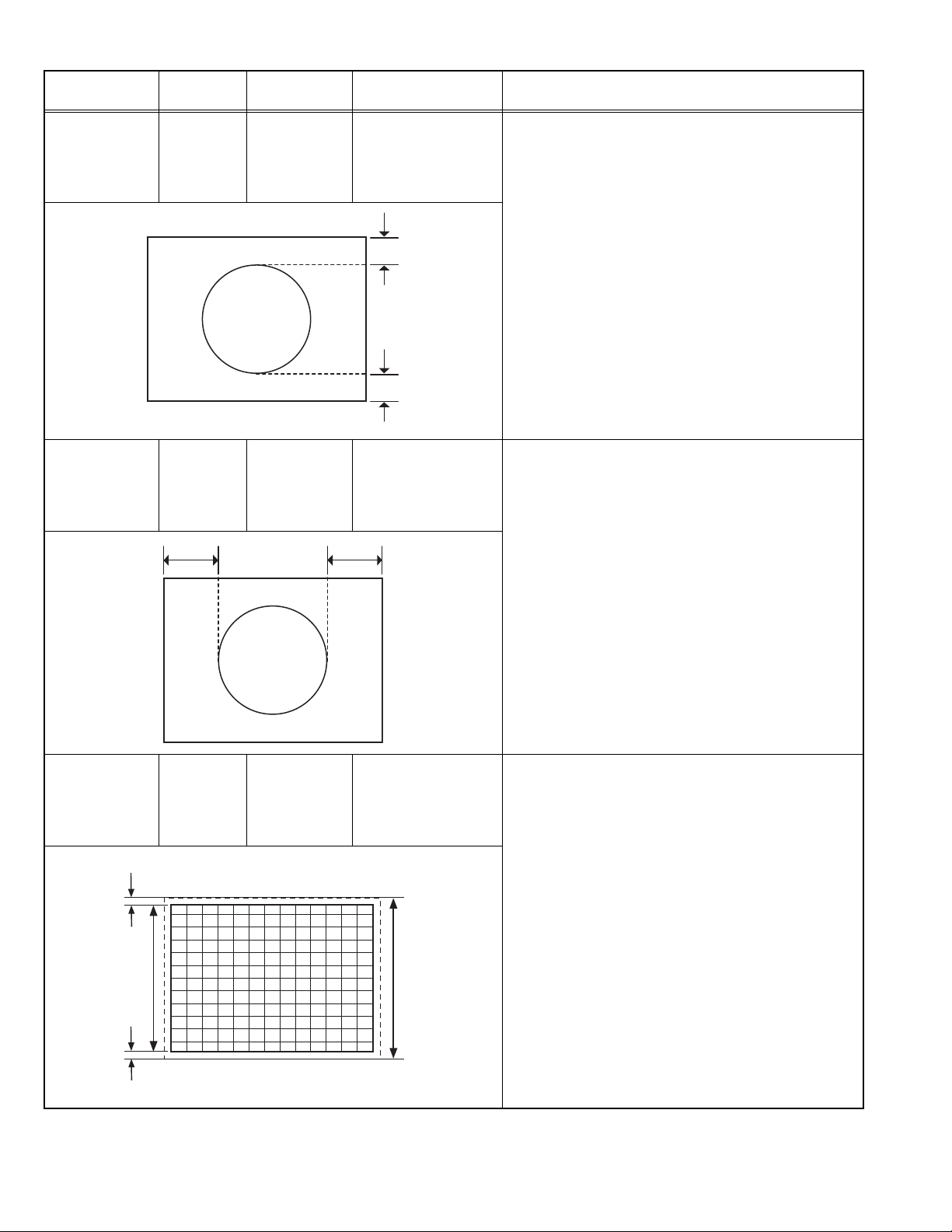

4.6.6 DEFLECTION ADJUSTMENT

Item

VERTICAL

SIZE OFFSET

Measuring

instrument

Signal

generator

(60Hz)

adjustment

Remote

control unit

Very close

Screen

size

Test point Adjustment part Description

VSOF (1) Receive a NTSC crosshatch pattern of vertical

frequency 60Hz.

(2) Enter the SERVICE MODE.

(3) Select VSOF with the []/[] key.

(4) Adjust VSOF with the []/[] key until the horizontal

black lines on both the upper and lower part of the

pattern become very close to the upper and lower

horizontal sides of picture size and nearly about to

disappear.

(5) Check and readjust VSOF item if the adjustment

becomes improper after some other geometric

Picture

size

100%

adjustments are done.

Very close

(No.YA080)1-15

Page 16

Item

VERTICAL

POSITION

OFFSET

(60Hz)

adjustment

Measuring

instrument

Signal

generator

Remote

control unit

Test point Adjustment part Description

VPOF (1) Receive a NTSC circle pattern of vertical frequency

60Hz.

(2) Enter the SERVICE MODE.

(3) Select VPOF with the []/[] key.

(4) Adjust VPOF with the []/[] key until the picture is

vertically centered. (C=D)

(5) Check and readjust vertical position item if the

C

adjustment becomes improper after some other

geometric adjustments are done.

D

HORIZONTAL

POSITION

OFFSET

(60Hz)

adjustment

VERTICAL

SIZE

(50Hz)

adjustment

Very close

Screen

size

Signal

HPOF (1) Receive a NTSC circle pattern signal of vertical

generator

Remote

control unit

EF

Signal

VSIZ (1) Receive a PAL crosshatch pattern of vertical

generator

Remote

control unit

Picture

size

100%

frequency 60Hz.

(2) Enter the SERVICE MODE.

(3) Select HPOF with the []/[] key.

(4) Adjust HPOF with the []/[] key until the circle

pattern is horizontally centered. (E=F)

(5) Check and readjust a horizontal position item if the

adjustment becomes improper after some other

geometric adjustments are done. Press the [MENU]

key and memorize the set value.

frequency 50Hz.

(2) Enter the SERVICE MODE.

(3) Press the [GREEN] key to enter the GEOMETRY

MENU.

(4) Select VSIZ (Vertical size) with the []/[] key.

(5) Adjust VSIZ with the []/[] key until the horizontal

black lines on both the upper and lower horizontal

sides of picture size and nearly about to disappear.

(6) Check and readjust VSIZ item if the adjustment

becomes improper after some other geometric

adjustments are done.

Very close

1-16 (No.YA080)

Page 17

Item

VERTICAL

POSITION

(50Hz)

adjustment

Measuring

instrument

Signal

generator

Remote

control unit

Test point Adjustment part Description

VPOS (1) Receive a PAL circle pattern signal of vertical

frequency 50Hz.

(2) Enter the GEOMETRY MODE.

(3) Select VPOS (Vertical position) with the []/[] key.

(4) Adjust VPOS with the []/[] key until the circle

pattern is vertically centered. (A=B)

(5) Check and readjust VPOS item if the adjustment

A

becomes improper after some other geometric

adjustments are done.

B

HORIZONTAL

POSITION

(50Hz)

adjustment

VERTICAL

LINEARITY

adjustment

Signal

generator

Remote

control unit

CD

Signal

generator

Remote

control unit

HPOS (1) Receive a PAL circle pattern signal of vertical

VLIN (1) Receive a PAL circle pattern .

frequency 50Hz.

(2) Enter the GEOMETRY MODE.

(3) Select HPOS (Horizontal position) with the []/[]

key.

(4) Adjust HPOS with the []/[] key until the circle

pattern is horizontally centered. (C=D)

(5) Check and readjust HPOS item if the adjustment

becomes improper after some other geometric

adjustments are done.

(2) Enter the SERVICE MODE.

(3) Select VLIN with the []/[] key.

(4) Adjust VLIN with the []/[] key until circle as round

as possible.

(No.YA080)1-17

Page 18

Item

RGB MODE

HORIZONTAL

SHIFT

adjustment

Measuring

instrument

Signal

generator

Remote

control unit

Test point Adjustment part Description

AB

4.6.7 WHITE BALANCE ADJUSTMENT

Item

WHITE

BALANCE

(Low light)

adjustment

WHITE

BALANCE

(High light)

adjustment

Measuring

instrument

Signal

generator

Remote

control unit

Signal

generator

Remote

control unit

Test point Adjustment part Description

RGBH (1) Input R/G/B circle pattern signal via video input

terminal.

(2) Press [AV] key, force the TV to RGB mode.

(3) Enter the SERVICE MODE.

(4) Select RGBH with the []/[] key.

(5) Adjust RGBH with the []/[] key until the circle

pattern is horizontally centered. (A=B)

(6) Check and readjust RGBH item if the adjustment

becomes improper after some other geometric

adjustments are done.

WR

WG

WB

BR

BG

(1) Receive a black & white signal (colour off).

(2) Enter the SERVICE MODE.

(3) Select WR / WG / WB with the []/[] key

respectively.

(4) Adjust WR / WG / WB with the []/[] key,

respectively, until the white part turns to pure white

without any other colour.

(1) Receive a black & white signal (colour off).

(2) Enter the SERVICE MODE.

(3) Select BR / BG with the []/[] key respectively.

(4) Adjust BR / BG with the []/[] key, respectively

until the white part of screen make white colour.

1-18 (No.YA080)

Page 19

SECTION 5

TROUBLESHOOTING

This service manual does not describe TROUBLESHOOTING.

(No.YA080)1-19

Page 20

Victor Company of Japan, Limited

AV & MULTIMEDIA COMPANY VIDEO DISPLAY CATEGORY 12, 3-chome, Moriya-cho, kanagawa-ku, Yokohama, kanagawa-prefecture, 221-8528, Japan

(No.YA080)

Printed in Japan

VPT

Page 21

AV-20RM4SE, AV-21RM4SE

AV-21RM4SN, AV-21RM4SP

STANDARD CIRCUIT DIAGRAM

CONTENTS

BLOCK DIAGRAM

CIRCUIT DIAGRAMS

MAIN PWB CIRCUIT DIAGRAM

HEADPHONE JACK PWB CIRCUIT DIAGRAM

FRONT AV JACK PWB CIRCUIT DIAGRAM

PATTERN DIAGRAMS

MAIN PWB PATTERN

HEADPHONE JACK PWB PATTERN

FRONT AV JACK

PWB PATTERN

USING P.W. BOARD

P.W.B ASS'Y name

MAIN PWB

FRONT AV JACK PWB

HEADPHONE JACK PWB

AV-20RM4SE

VE-20161051

VE-20166161

VE-20165426

AV-21RM4SE

VE-20161048

2-3

2-5

2-18

2-19

2-21

2-23

2-24

AV-21RM4SN AV-21RM4SP

VE-20161045 VE-20161041

(No.YA080)2-1

Page 22

2-2(No.YA080)

Page 23

BLOCK DIAGRAM

L

TU201

PLL/VST TUNER

SERVICE

CONNECTOR

IC500

EEPROM

(MEMORY)

I2 C

IC501

CONTROLLER

AUDIO

IF

OUT

IC403

VIDEO PROCESSOR

IC401(MONO)

AUDIO AMP

R

IC701

HP AMP

CRT

IC900

RGB AMP

AC IN

KEYPAD

IR

SENSOR

IC800

SMPS

+115V B+

+12V

+8V

+5V

+5V STBY

VIDEO

SWITCHING

CIRCUITS

SCART1

FAV

IC600

VER AMP

Q603

HOR DRIVE

VER. DEFL.

HOR. DEFL.

TR601

FBT

2-4(No.YA080)(No.YA080)2-3

Page 24

CIRCUIT DIAGRAMS

MAIN PWB CIRCUIT DIAGRAM (1/7)

MAIN PWB ASS'Y (1/7)

VE-20161045 (AV-21RM4SN)

VE-20161041 (AV-21RM4SP)

VE-20161048 (AV-21RM4SE)

VE-20161051 (AV-20RM4SE)

(No.YA080)2-5 2-6(No.YA080)

Page 25

MAIN PWB CIRCUIT DIAGRAM (2/7)

MAIN PWB ASS'Y (2/7)

VE-20161045 (AV-21RM4SN)

VE-20161041 (AV-21RM4SP)

VE-20161048 (AV-21RM4SE)

VE-20161051 (AV-20RM4SE)

2-8(No.YA080)(No.YA080)2-7

Page 26

MAIN PWB CIRCUIT DIAGRAM (3/7)

MAIN PWB ASS'Y (3/7)

VE-20161045 (AV-21RM4SN)

VE-20161041 (AV-21RM4SP)

VE-20161048 (AV-21RM4SE)

VE-20161051 (AV-20RM4SE)

(No.YA080)2-9 2-10(No.YA080)

Page 27

MAIN PWB CIRCUIT DIAGRAM (4/7)

MAIN PWB ASS'Y (4/7)

VE-20161045 (AV-21RM4SN)

VE-20161041 (AV-21RM4SP)

VE-20161048 (AV-21RM4SE)

VE-20161051 (AV-20RM4SE)

FBT

2-12(No.YA080)(No.YA080)2-11

Page 28

MAIN PWB CIRCUIT DIAGRAM (5/7)

SW TRANSFORMER

MAIN PWB ASS'Y (5/7)

VE-20161045 (AV-21RM4SN)

VE-20161041 (AV-21RM4SP)

VE-20161048 (AV-21RM4SE)

VE-20161051 (AV-20RM4SE)

POWER REG.

(No.YA080)2-13 2-14(No.YA080)

Page 29

MAIN PWB CIRCUIT DIAGRAM (6/7)

MAIN PWB ASS'Y (6/7)

VE-20161045 (AV-21RM4SN)

VE-20161041 (AV-21RM4SP)

VE-20161048 (AV-21RM4SE)

VE-20161051 (AV-20RM4SE)

2-16(No.YA080)(No.YA080)2-15

Page 30

MAIN PWB CIRCUIT DIAGRAM (7/7)

MAIN PWB ASS'Y (7/7)

VE-20161045 (AV-21RM4SN)

VE-20161041 (AV-21RM4SP)

VE-20161048 (AV-21RM4SE)

VE-20161051 (AV-20RM4SE)

(No.YA080)2-17 2-18(No.YA080)

Page 31

HEADPHONE JACK PWB CIRCUIT DIAGRAM

FRONT AV JACK PWB CIRCUIT DIAGRAM

HEADPHONE JACK PWB

VE-20165426

FRONT AV JACK PWB

VE-20166161

2-20(No.YA080)(No.YA080)2-19

Page 32

PATTERN DIAGRAMS

MAIN PWB PATTERN

FRONT

()

CRT SOCKET PWB PATTERN

(Within MAIN PWB)

()

TOP

()

(No.YA080)2-21 2-22(No.YA080)

Page 33

HEADPHONE JACK PWB PATTERN

TOP

(No.YA080)2-23

Page 34

FRONT AV JACK PWB PATTERN

TOP

2-24(No.YA080)

Page 35

PARTS LIST

CONTENTS

USING P.W. BOARD & REMOTE CONTROL UNIT ................................................................................................... 3-1

EXPLODED VIEW PARTS LIST ................................................................................................................................. 3-2

EXPLODED VIEW ....................................................................................................................................................... 3-3

PRINTED WIRING BOARD PARTS LIST [AV-20RM4SE] ......................................................................................... 3-4

MAIN P.W. BOARD ASS’Y (VE-20161051)........................................................................................................ 3-4

FRONT AV JACK P.W. BOARD ASS’Y (VE-20166161) [COMMON)] ............................................................... 3-6

HEADPHONE JACK P.W. BOARD ASS’Y (VE-20165426)[COMMON] ............................................................ 3-6

PRINTED WIRING BOARD PARTS LIST [AV-21RM4SE] ......................................................................................... 3-7

MAIN P.W. BOARD ASS’Y (VE-20161048) ....................................................................................................... 3-7

PRINTED WIRING BOARD PARTS LIST [AV-21RM4SN] ....................................................................................... 3-10

MAIN P.W. BOARD ASS’Y (VE-20161045) ..................................................................................................... 3-10

PRINTED WIRING BOARD PARTS LIST [AV-21RM4SP] ....................................................................................... 3-13

MAIN P.W. BOARD ASS’Y (VE-20161041) ..................................................................................................... 3-13

PACKING PARTS LIST ............................................................................................................................................. 3-16

PACKING ................................................................................................................................................................... 3-17

USING P.W. BOARD & REMOTE CONTROL UNIT

P.W.B ASS’Y name AV-20RM4SE AV-21RM4SE AV-21RM4SN AV-21RM4SP

MAIN P.W.B (with CRT SOCKET P.W.B) VE-20161051 VE-20161048 VE-20161045 VE-20161041

FRONT AV JACK P.W.B VE-20166161 ←←←

HEADPHONE JACK P.W.B VE-20165426 ←←←

REMOTE CONTROL UNIT

VE-30017763

(RM-C1100)

←←←

(No.YA080)3-1

Page 36

EXPLODED VIEW PARTS LIST

[ AV-20RM4SE ]

Ref.No. Part No. Part Name Description Local

V01 VE-30002748 PICTURE TUBE(ITC) Inc. DY, PC MAGNET

L01 VE-30002119 DEG COIL&EARTH CB.

TR601 VE-30017788 TRF FBT within MAIN PWB

1 VE-20160402 BUTTON ON/OFF

2 VE-35000013 SPRING ON/OFF SWITCH

3 VE-20004338 LENS PRE-AMP

4 VE-20167108 LENS

5 VE-20056446 LENS LED

6 VE-20165665 FRONT CABINET

7 VE-20160401 BUTTON FUNCTION

8 VE-40013593 LOGO JVC

9 VE-30026953 SPEAKER (x2) 16

10 VE-20160396 BACK COVER

11 VE-35010702 SCREW (4x20) (x6)

12 VE-20165670 LABEL

13 VE-30029498 POWERCORD 2.2MT

14 VE-20004520 CABLE HOLDER

15 VE-20004646 FOOT RUBBER (x2)

[ AV-21RM4SE , AV-21RM4SN , AV-21RM4SP ]

Ref.No. Part No. Part Name Description Local

V01 VE-30002749 PICTURE TUBE (ITC) Inc. DY, PC MAGNET

L01 VE-30002124 DEG COIL&EARTH CB.

TR601 VE-30017788 TRF FBT within MAIN PWB

1 VE-20160402 BUTTON ON/OFF

2 VE-35000013 SPRING ON/OFF SWITCH

3 VE-20053831 LENS PRE-AMP

4 VE-20167108 LENS

5 VE-20056446 LENS LED

6 VE-20165671 FRONT CABINET

7 VE-20160401 BUTTON FUNCTION

8 VE-40013593 LOGO JVC

9 VE-30026953 SPEAKER (x2) 16Ω 10W (57x126MM)

10 VE-20160396 BACK COVER

11 VE-35010702 SCREW (4x20) (x6)

12 VE-20165678 LABEL AV-21RM4SN

12 VE-20165569 LABEL AV-21RM4SP

12 VE-20165675 LABEL AV-21RM4SE

13 VE-30029498 POWER CORD 2.2MT

14 VE-20004520 CABLE HOLDER

15 VE-20004646 FOOT RUBBER (x2)

Ω

10W (57x126MM)

3-2(No.YA080)

Page 37

EXPLODED VIEW

13

10

11

(x6)

12

L01

V01

CRT SOCKET PWB

(within MAIN PWB)

9

6

14

8

2

1

3

4

7

FRONT AV JACK

PWB

TR601

MAIN PWB

5

15

HEADPHONE JACK

PWB

(No.YA080)3-3

Page 38

PRINTED WIRING BOARD PARTS LIST [AV-20RM4SE]

MAIN P.W. BOARD ASS’Y (VE-20161051)

Ref No. Part No. Part Name Description Local

IC118 VE-30023137 IC

IC401 VE-30013986 IC

IC403 VE-30026922 IC

IC500 VE-20161050 IC (MEMORY)

IC501 VE-20091454 IC (MICOM)

IC502 VE-30001670 PREAMPLIFIER

IC600 VE-30015306 IC

IC800 VE-30011968 IC

IC801 VE-30015087 IC

IC803 VE-30001500 IC

IC804 VE-30001622 IC

IC806 VE-30014346 IC

IC900 VE-30025172 IC

Q101 VE-30001457 TRANSISTOR

Q103 VE-30001457 TRANSISTOR

Q104 VE-30001457 TRANSISTOR

Q105 VE-30001457 TRANSISTOR

Q301 VE-30001458 TRANSISTOR

Q302 VE-30001457 TRANSISTOR

Q406 VE-30001457 TRANSISTOR

Q503 VE-30001457 TRANSISTOR

Q504 VE-30001458 TRANSISTOR

Q601 VE-30013656 TRANSISTOR POWER

Q603 VE-30001448 TRANSISTOR H.OUT

Q604 VE-30001457 TRANSISTOR

Q606 VE-30001457 TRANSISTOR

Q801 VE-30001386 TRANSISTOR

Q802 VE-30001457 TRANSISTOR

Q804 VE-30001454 TRANSISTOR

D101 VE-30007760 DIODE ZENER

D102 VE-30007760 DIODE ZENER

D103 VE-30007760 DIODE ZENER

D104 VE-30007762 DIODE ZENER

D106 VE-30001377 DIODE ZENER

D300 VE-30001285 DIODE

D301 VE-30001285 DIODE

D405 VE-30007763 DIODE ZENER

D407 VE-30001284 DIODE

D408 VE-30001285 DIODE

D409 VE-30007760 DIODE ZENER

D410 VE-30007760 DIODE ZENER

D411 VE-30007760 DIODE ZENER

D501 VE-30001285 DIODE

D505 VE-30001285 DIODE

D506 VE-30001284 DIODE

D509 VE-30001279 LED

D512 VE-30001285 DIODE

D513 VE-30001339 DIODE ZENER

D602 VE-30001329 DIODE

D603 VE-30001285 DIODE

D608 VE-30001318 DIODE

D609 VE-30001318 DIODE

D610 VE-30001318 DIODE

D611 VE-30001285 DIODE

D614 VE-30001318 DIODE

D615 VE-30001285 DIODE

D616 VE-30009699 DIODE ZENER

D619 VE-30009699 DIODE ZENER

D620 VE-30003722 DIODE ZENER

D800 VE-30001318 DIODE

D801 VE-30001347 DIODE ZENER

D802 VE-30001318 DIODE

D803 VE-30001315 DIODE

D804 VE-30001285 DIODE

D805 VE-30001315 DIODE

D806 VE-30001315 DIODE

D808 VE-30007681 DIODE

D809 VE-30001329 DIODE

D810 VE-30009366 DIODE

D811 VE-30001329 DIODE

D812 VE-30001285 DIODE

D813 VE-30001329 DIODE

D837 VE-30001329 DIODE

D838 VE-30001329 DIODE

D889 VE-30001384 TRANSISTOR

D890 VE-30001329 DIODE

D893 VE-30001329 DIODE

D894 VE-30001329 DIODE

D900 VE-30001318 DIODE

Ref No. Part No. Part Name Description Local

D901 VE-30001318 DIODE

D902 VE-30001318 DIODE

D903 VE-30001344 DIODE ZENER

C101 VE-30016654 CAP SMD 100NF 16V K R

C108 VE-30000371 CAP EL 22UF 50V M

C114 VE-30016654 CAP SMD 100NF 16V K R

C142 VE-30000384 CAP EL 2.2UF 50V M

C143 VE-30012583 CAP SMD 1.5NF 50V K

C144 VE-30012583 CAP SMD 1.5NF 50V K

C145 VE-30012589 CAP SMD 4.7NF 50V K

C155 VE-30012560 CAP SMD 100PF 50V J

C159 VE-30012560 CAP SMD 100PF 50V J

C160 VE-30000387 CAP EL 33UF 50V M

C166 VE-30012559 CAP SMD 10PF 50V D

C201 VE-30000400 CAP EL 47UF 50V M

C205 VE-30000371 CAP EL 22UF 50V M

C206 VE-30012610 CAP SMD 10NF 50V J

C207 VE-30012610 CAP SMD 10NF 50V J

C300 VE-30000400 CAP EL 47UF 50V M

C302 VE-30000092 CAP MKT 220NF 63V J

C408 VE-30012586 CAP SMD 22NF 50V K

C409 VE-30000345 CAP EL 10UF 50V M

C410 VE-30000384 CAP EL 2.2UF 50V M

C411 VE-30000345 CAP EL 10UF 50V M

C412 VE-30012586 CAP SMD 22NF 50V K

C413 VE-30000362 CAP EL 1UF 50V M

C414 VE-30012585 CAP SMD 2.2NF 50V K R

C415 VE-30012581 CAP SMD 1NF 50V K R

C416 VE-30000362 CAP EL 1UF 50V M

C417 VE-30000362 CAP EL 1UF 50V M

C418 VE-30012586 CAP SMD 22NF 50V K

C419 VE-30000413 CAP EL 4.7UF 50V M

C420 VE-30000100 CAP MKT 330NF 63V J

C422 VE-30000400 CAP EL 47UF 50V M

C423 VE-30000400 CAP EL 47UF 50V M

C424 VE-30000345 CAP EL 10UF 50V M

C425 VE-30012586 CAP SMD 22NF 50V K

C426 VE-30016654 CAP SMD 100NF 16V K R

C427 VE-30016654 CAP SMD 100NF 16V K R

C429 VE-30012589 CAP SMD 4.7NF 50V K

C431 VE-30000362 CAP EL 1UF 50V M

C432 VE-30012586 CAP SMD 22NF 50V K

C433 VE-30000345 CAP EL 10UF 50V M

C434 VE-30016654 CAP SMD 100NF 16V K R

C435 VE-30016654 CAP SMD 100NF 16V K R

C436 VE-30000109 CAP MKT 470NF 63V J

C437 VE-30016654 CAP SMD 100NF 16V K R

C438 VE-30016654 CAP SMD 100NF 16V K R

C439 VE-30016654 CAP SMD 100NF 16V K R

C440 VE-30000074 CAP MKT 100NF 63V J

C441 VE-30012582 CAP SMD 10NF 50V K R

C443 VE-30000362 CAP EL 1UF 50V M

C444 VE-30000384 CAP EL 2.2UF 50V M

C448 VE-30012586 CAP SMD 22NF 50V K

C449 VE-30012567 CAP SMD 220PF 50V J

C452 VE-30012581 CAP SMD 1NF 50V K R

C454 VE-30012573 CAP SMD 47PF 50V J

C455 VE-30012573 CAP SMD 47PF 50V J

C456 VE-30012573 CAP SMD 47PF 50V J

C459 VE-30012575 CAP SMD 4.7PF 50V C CH

C460 VE-30000345 CAP EL 10UF 50V M

C502 VE-30000396 CAP EL 47UF 16V M

C504 VE-30012586 CAP SMD 22NF 50V K

C505 VE-30012589 CAP SMD 4.7NF 50V K

C510 VE-30012586 CAP SMD 22NF 50V K

C511 VE-30012566 CAP SMD 22PF 50V J

C513 VE-30000371 CAP EL 22UF 50V M

C514 VE-30012586 CAP SMD 22NF 50V K

C515 VE-30012579 CAP SMD 82PF 50V J

C517 VE-30012586 CAP SMD 22NF 50V K

C518 VE-30012586 CAP SMD 22NF 50V K

C519 VE-30000352 CAP EL 100UF 16V M

C520 VE-30012560 CAP SMD 100PF 50V J

C521 VE-30012562 CAP SMD 15PF 50V J

C522 VE-30012562 CAP SMD 15PF 50V J

C523 VE-30012585 CAP SMD 2.2NF 50V K R

C525 VE-30012566 CAP SMD 22PF 50V J

C530 VE-30012589 CAP SMD 4.7NF 50V K

C531 VE-30000384 CAP EL 2.2UF 50V M

C532 VE-30012586 CAP SMD 22NF 50V K

C536 VE-30000074 CAP MKT 100NF 63V J

C541 VE-30000109 CAP MKT 470NF 63V J

C542 VE-30000205 CAP CER 150PF 50V J SL

3-4(No.YA080)

Page 39

Ref No. Part No. Part Name Description Local

Ref No. Part No. Part Name Description Local

C543 VE-30000205 CAP CER 150PF 50V J SL

C545 VE-30012607 CAP SMD 150PF 50V J

C603 VE-30000384 CAP EL 2.2UF 50V M

C604 VE-30000345 CAP EL 10UF 50V M

C608 VE-30000107 CAP MKT 47NF 250V J

C610 VE-30000355 CAP EL 100UF 50V M

C611 VE-30000092 CAP MKT 220NF 63V J

C613 VE-30016085 CAP EL 10UF 63V 105°

C615 VE-30000359 CAP EL 1000UF 16V M

C616 VE-30000352 CAP EL 100UF 16V M

C618 VE-30007100 CAP MKP 10NF 1600Vdc / 1250Vpp %3.5

C619 VE-30000131 CAP MKP 100NF 250V J

C623 VE-30000404 CAP EL 47UF 160V M (HR) 105°

C624 VE-30000350 CAP EL 10UF 250V M

C627 VE-30000152 CAP MKP 330NF 250V J

C628 VE-30018380 CAP EL 3.3UF 160V M 105°

C631 VE-30000410 CAP EL 470UF 50V M

C632 VE-30000100 CAP MKT 330NF 63V J

C633 VE-30016085 CAP EL 10UF 63V 105°

C634 VE-30000409 CAP EL 470UF 25V M

C635 VE-30000100 CAP MKT 330NF 63V J

C636 VE-30000387 CAP EL 33UF 50V M

C638 VE-30012581 CAP SMD 1NF 50V K R

C639 VE-30000431 CAP CER 100PF 1KV M

C641 VE-30000345 CAP EL 10UF 50V M

C642 VE-30012609 CAP SMD 68NF 50V K

C643 VE-30000116 CAP MKT 68NF 63V J

C644 VE-30000362 CAP EL 1UF 50V M

C801 VE-30000094 CAP MKT 220NF 275V M AC

C802 VE-30000094 CAP MKT 220NF 275V M AC

C803 VE-30000433 CAP CER 1NF 1KV M B

C804 VE-30000433 CAP CER 1NF 1KV M B

C808 VE-30000295 CAP CER 100NF 50V Z F

C809 VE-30000418 CAP EL 100UF 400V M

C810 VE-30000387 CAP EL 33UF 50V M

C811 VE-30000161 CAP MKP 47NF 630Vdc / 622Vpp J

C812 VE-30009208 CAP CER 470PF 1KV K

C813 VE-30000295 CAP CER 100NF 50V Z F

C816 VE-30000447 CAP CER 4.7NF 4KV M E

C817 VE-30000198 CAP CER 120PF 500V J SL

C818 VE-30016654 CAP SMD 100NF 16V K R

C819 VE-30012609 CAP SMD 68NF 50V K

C824 VE-30000433 CAP CER 1NF 1KV M B

C826 VE-30000404 CAP EL 47UF 160V M (HR) 105°

C827 VE-30000411 CAP EL 4700UF 16V M

C828 VE-30000295 CAP CER 100NF 50V Z F

C829 VE-30000407 CAP EL 470UF 16V M

C830 VE-30000382 CAP EL 2200UF 16V M

C832 VE-30000295 CAP CER 100NF 50V Z F

C833 VE-30000409 CAP EL 470UF 25V M

C834 VE-30000295 CAP CER 100NF 50V Z F

C836 VE-30000431 CAP CER 100PF 1KV M

C838 VE-30000352 CAP EL 100UF 16V M

C839 VE-30000352 CAP EL 100UF 16V M

C840 VE-30000352 CAP EL 100UF 16V M

C843 VE-30000431 CAP CER 100PF 1KV M

C848 VE-30000352 CAP EL 100UF 16V M

C849 VE-30000352 CAP EL 100UF 16V M

C850 VE-30000352 CAP EL 100UF 16V M

C855 VE-30000407 CAP EL 470UF 16V M

C857 VE-30012573 CAP SMD 47PF 50V J

C858 VE-30007308 CAP CER 220PF 1KV K

C862 VE-30000367 CAP EL 1UF 250V M

C863 VE-30000433 CAP CER 1NF 1KV M B

C907 VE-30000434 CAP CER 1NF 2KV K B

C908 VE-30000415 CAP EL 4.7UF 250V M

C912 VE-30000075 CAP MKT 100NF 250V K (DC)

NOT1 VE-30000352 CAP EL 100UF 16V M

X403 VE-30000074 CAP MKT 100NF 63V J

R101 VE-30012509 RES SMD 1/16W 100K J

R104 VE-30000594 RES CF 1/4W 22K J

R105 VE-30000792 RES CF 1/4W 75R J

R108 VE-30000723 RES CF 1/4W 47K J

R109 VE-30012713 RES SMD 1/16W 75R J

R110 VE-30012713 RES SMD 1/16W 75R J

R113 VE-30012713 RES SMD 1/16W 75R J

R114 VE-30012713 RES SMD 1/16W 75R J

R115 VE-30012713 RES SMD 1/16W 75R J

R116 VE-30012987 RES SMD 1/16W 56R J

R117 VE-30012713 RES SMD 1/16W 75R J

R118 VE-30000792 RES CF 1/4W 75R J

R122 VE-30000792 RES CF 1/4W 75R J

R123 VE-30000792 RES CF 1/4W 75R J

R125 VE-30012657 RES SMD 1/16W 1K J

R126 VE-30012695 RES SMD 1/16W 470R J

R127 VE-30000459 RES CF 1/4W 100R J

R128 VE-30000471 RES CF 1/4W 10K J

R129 VE-30012713 RES SMD 1/16W 75R J

R130 VE-30000594 RES CF 1/4W 22K J

R132 VE-30000723 RES CF 1/4W 47K J

R133 VE-30000718 RES CF 1/4W 4.7K J

R135 VE-30012657 RES SMD 1/16W 1K J

R153 VE-30012657 RES SMD 1/16W 1K J

R201 VE-30012674 RES SMD 1/16W 27K J

R202 VE-30012692 RES SMD 1/16W 4.7K J

R204 VE-30000459 RES CF 1/4W 100R J

R206 VE-30000459 RES CF 1/4W 100R J

R301 VE-30000471 RES CF 1/4W 10K J

R302 VE-30000471 RES CF 1/4W 10K J

R303 VE-30012641 RES SMD 1/16W 10K J

R305 VE-30012641 RES SMD 1/16W 10K J

R306 VE-30012509 RES SMD 1/16W 100K J

R417 VE-30012510 RES SMD 1/16W 100R J

R418 VE-30012510 RES SMD 1/16W 100R J

R419 VE-30012649 RES SMD 1/16W 150R J

R420 VE-30000466 RES CF 1/4W 1K J

R421 VE-30012650 RES SMD 1/16W 15K J

R422 VE-30012659 RES SMD 1/16W 2.2K J

R423 VE-30012712 RES SMD 1/16W 8.2K J

R424 VE-30000712 RES CF 1/4W 470R J

R425 VE-30000583 RES CF 1/4W 220R J

R426 VE-30012659 RES SMD 1/16W 2.2K J

R427 VE-30012674 RES SMD 1/16W 27K J

R428 VE-30000792 RES CF 1/4W 75R J

R431 VE-30012674 RES SMD 1/16W 27K J

R432 VE-30012657 RES SMD 1/16W 1K J

R433 VE-30012667 RES SMD 1/16W 220K J

R437 VE-30000466 RES CF 1/4W 1K J

R438 VE-30000466 RES CF 1/4W 1K J

R439 VE-30012657 RES SMD 1/16W 1K J

R440 VE-30012714 RES SMD 1/16W 820R J

R441 VE-30012656 RES SMD 1/16W 18K J

R442 VE-30000466 RES CF 1/4W 1K J

R446 VE-30012714 RES SMD 1/16W 820R J

R447 VE-30012714 RES SMD 1/16W 820R J

R448 VE-30012683 RES SMD 1/16W 330K J

R449 VE-30012662 RES SMD 1/16W 2.7K J

R450 VE-30000712 RES CF 1/4W 470R J

R454 VE-30000594 RES CF 1/4W 22K J

R455 VE-30012656 RES SMD 1/16W 18K J

R458 VE-30012662 RES SMD 1/16W 2.7K J

R459 VE-30012510 RES SMD 1/16W 100R J

R460 VE-30012510 RES SMD 1/16W 100R J

R461 VE-30012510 RES SMD 1/16W 100R J

R469 VE-30000670 RES CF 1/4W 330K J

R470 VE-30012683 RES SMD 1/16W 330K J

R475 VE-30012510 RES SMD 1/16W 100R J

R476 VE-30012707 RES SMD 1/16W 680R J

R477 VE-30014022 RES SMD 1/16W 47R J

R502 VE-30012695 RES SMD 1/16W 470R J

R503 VE-30012707 RES SMD 1/16W 680R J

R504 VE-30012679 RES SMD 1/16W 3.9K J

R505 VE-30012673 RES SMD 1/16W 270R J

R506 VE-30012506 RES SMD 1/16W 1.5K J

R507 VE-30012657 RES SMD 1/16W 1K J

R508 VE-30000706 RES CF 1/4W 47R J

R509 VE-30012641 RES SMD 1/16W 10K J

R510 VE-30000622 RES CF 1/4W 270R J

R511 VE-30012657 RES SMD 1/16W 1K J

R512 VE-30012504 RES SMD 1/16W 1.2K J

R513 VE-30000459 RES CF 1/4W 100R J

R514 VE-30000459 RES CF 1/4W 100R J

R515 VE-30012692 RES SMD 1/16W 4.7K J

R516 VE-30012692 RES SMD 1/16W 4.7K J

R517 VE-30012692 RES SMD 1/16W 4.7K J

R518 VE-30000471 RES CF 1/4W 10K J

R519 VE-30012698 RES SMD 1/16W 5.6K J

R525 VE-30000583 RES CF 1/4W 220R J

R526 VE-30012641 RES SMD 1/16W 10K J

R527 VE-30000718 RES CF 1/4W 4.7K J

R528 VE-30012698 RES SMD 1/16W 5.6K J

R530 VE-30012698 RES SMD 1/16W 5.6K J

R531 VE-30012692 RES SMD 1/16W 4.7K J

R532 VE-30012659 RES SMD 1/16W 2.2K J

R533 VE-30012644 RES SMD 1/16W 12K J

R534 VE-30000526 RES CF 1/4W 1.5K J

R535 VE-30000718 RES CF 1/4W 4.7K J

R536 VE-30000471 RES CF 1/4W 10K J

R537 VE-30012641 RES SMD 1/16W 10K J

R545 VE-30012644 RES SMD 1/16W 12K J

R546 VE-30000590 RES CF 1/4W 2.2K J

R547 VE-30012659 RES SMD 1/16W 2.2K J

R548 VE-30012641 RES SMD 1/16W 10K J

(No.YA080)3-5

Page 40

Ref No. Part No. Part Name Description Local

Ref No. Part No. Part Name Description Local

R555 VE-30012659 RES SMD 1/16W 2.2K J

R556 VE-30012657 RES SMD 1/16W 1K J

R559 VE-30000470 RES CF 1/2W 10K J

R560 VE-30012669 RES SMD 1/16W 22K J

R561 VE-30012692 RES SMD 1/16W 4.7K J

R562 VE-30000471 RES CF 1/4W 10K J

R564 VE-30012641 RES SMD 1/16W 10K J

R601 VE-30000752 RES CF 1/4W 56K J

R602 VE-30000536 RES CF 1/4W 150K J

R605 VE-30000504 RES CF 1/4W 120K J

R612 VE-30012692 RES SMD 1/16W 4.7K J

R613 VE-30012692 RES SMD 1/16W 4.7K J

R618 VE-30012662 RES SMD 1/16W 2.7K J

R619 VE-30012641 RES SMD 1/16W 10K J

R623 VE-30000607 RES CF 1/4W 2.2R J

R624 VE-30001161 RES MO 2W 39R J

R625 VE-30000900 RES MF 1/4W 1.8K J

R627 VE-30000910 RES MF 1/2W 1.8R G

R628 VE-30000650 RES CF 1/4W 33R J

R630 VE-30000828 RES CF 1/4W 8.2M J

R631 VE-30000885 RES MF 1/4W 1.5K J

R633 VE-30000706 RES CF 1/4W 47R J

R634 VE-30012641 RES SMD 1/16W 10K J

R637 VE-30000621 RES CF 1/2W 270R J

R638 VE-30000612 RES CF 1/4W 2.4K J

R639 VE-30000718 RES CF 1/4W 4.7K J

R640 VE-30012662 RES SMD 1/16W 2.7K J

R641 VE-30012649 RES SMD 1/16W 150R J

R645 VE-30016868 RES MO 3W 2.2K J

R646 VE-30000500 RES CF 1/4W 12K J

R647 VE-30000466 RES CF 1/4W 1K J

R648 VE-30001254 RES FUSE 1/2W 0.68R J

R649 VE-30000775 RES CF 1/4W 6.8K J

R650 VE-30000744 RES CF 1/4W 560R J

R654 VE-30000705 RES CF 1/2W 47R J

R655 VE-30000705 RES CF 1/2W 47R J

R657 VE-30012656 RES SMD 1/16W 18K J

R658 VE-30001161 RES MO 2W 39R J

R659 VE-30001123 RES MO 2W 220R J

R660 VE-30012669 RES SMD 1/16W 22K J

R661 VE-30012674 RES SMD 1/16W 27K J

R662 VE-30000712 RES CF 1/4W 470R J

R663 VE-30000459 RES CF 1/4W 100R J

R665 VE-30012708 RES SMD 1/16W 68K J

R801 VE-30000982 RES MF 1/4W 4.7K J

R803 VE-30012692 RES SMD 1/16W 4.7K J

R804 VE-30000536 RES CF 1/4W 150K J

R805 VE-30000843 RES MF 1/4W 10R J

R806 VE-30000982 RES MF 1/4W 4.7K J

R807 VE-30001159 RES MO 1W 0.33R J

R809 VE-30007784 RES MO 5W 33K J

R810 VE-30001257 RES MG 1/2W 4.7M J

R811 VE-30000594 RES CF 1/4W 22K J

R813 VE-30000718 RES CF 1/4W 4.7K J

R814 VE-30012662 RES SMD 1/16W 2.7K J

R815 VE-30000452 RES CF 1/4W 10R J

R817 VE-30001037 RES MF 1/4W 99K F

R818 VE-30000925 RES MF 1/4W 2.2K F

R819 VE-30000466 RES CF 1/4W 1K J

R821 VE-30000470 RES CF 1/2W 10K J

R828 VE-30001260 RES WW 5W 2.2R J

R829 VE-30000718 RES CF 1/4W 4.7K J

R830 VE-30012657 RES SMD 1/16W 1K J

R831 VE-30012669 RES SMD 1/16W 22K J

R835 VE-30016802 RES WW 5W 5.6R J RAD

R900 VE-30006712 FERRITE BEAD

R901 VE-30006712 FERRITE BEAD

R902 VE-30006712 FERRITE BEAD

R903 VE-30000525 RES CF 1/2W 1.5K J

R904 VE-30000525 RES CF 1/2W 1.5K J

R905 VE-30000525 RES CF 1/2W 1.5K J

R906 VE-30000525 RES CF 1/2W 1.5K J

R919 VE-30001213 RES FUSE 1/4W 1R J

J107 VE-30000683 RES CF 1/4W 390R J

J108 VE-30000712 RES CF 1/4W 470R J

J271 VE-30000712 RES CF 1/4W 470R J

S142 VE-30012673 RES SMD 1/16W 270R J

J282 VE-30001992 FIXED COIL 10UH

J313 VE-30001994 FIXED COIL 22UH

L201 VE-30001979 FIXED COIL 1UH

L402 VE-30001992 FIXED COIL 10UH

L404 VE-30001990 FIXED COIL 6.8UH

L405 VE-30026042 ADJ.COIL

L601 VE-30001990 FIXED COIL 6.8UH

L603 VE-30002149 LINEARITY COIL 50UH

L803 VE-30001984 FIXED COIL 2.2UH

L807 VE-30001992 FIXED COIL 10UH

L810 VE-30001992 FIXED COIL 10UH

TR601 VE-30017788 TRF FBT

TR802 VE-30013683 TRF SMPS (170-270V)

F801 VE-30001731 FUSE 2.5A

J281 VE-30006712 FERRITE BEAD

L101 VE-30001971 FERRITE SMD

L103 VE-30001971 FERRITE SMD

L110 VE-30001971 FERRITE SMD

L111 VE-30001971 FERRITE SMD

L112 VE-30001971 FERRITE SMD

L113 VE-30001971 FERRITE SMD

L114 VE-30001971 FERRITE SMD

L116 VE-30001971 FERRITE SMD

L210 VE-30001971 FERRITE SMD

L211 VE-30001971 FERRITE SMD

L401 VE-30001971 FERRITE SMD

L403 VE-30001971 FERRITE SMD

L406 VE-30001971 FERRITE SMD

L604 VE-30001971 FERRITE SMD

L802 VE-30001971 FERRITE SMD

L805 VE-30001971 FERRITE SMD

L806 VE-30001971 FERRITE SMD

PL101 VE-30015053 SOCKET SCART

PL903 VE-30001855 SOCKET CRT

SG900 VE-30000428 SPARK GAP 300V

SG901 VE-30000428 SPARK GAP 300V

SG902 VE-30000428 SPARK GAP 300V

SW501 VE-30002178 SWITCH TACT

SW502 VE-30002178 SWITCH TACT

SW503 VE-30002178 SWITCH TACT

SW504 VE-30002178 SWITCH TACT

SW505 VE-30002178 SWITCH TACT

SW801 VE-30017848 SWITCH ON/OFF

TH800 VE-30001270 PTC 9 OHM

TR801 VE-30002100 LINE FILTER

TU201 VE-30009637 TUNER WSP (PLL)

X401 VE-30001749 XTAL

X402 VE-30015592 XTAL

X501 VE-30002851 XTAL

Z402 VE-30012544 FILTER SAW

FRONT AV JACK P.W. BOARD ASS’Y (VE-20166161)

Ref No. Part No. Part Name Description Local

D1201 VE-30001350 DIODE ZENER 12V

D1203 VE-30001350 DIODE ZENER 12V

PL1204 VE-30001882 RCA JACK 1P WHITE

PL1203 VE-30001884 RCA JACK 1P YELLOW

HEADPHONE JACK P.W. BOARD ASS’Y

(VE-20165426)

Ref No. Part No. Part Name Description Local

D100 VE-30001371 DIODE ZENER

D101 VE-30001371 DIODE ZENER

C100 VE-30000330 CAP CER 4.7NF 50V K B

C101 VE-30000330 CAP CER 4.7NF 50V K B

R100 VE-30000492 RES CF 1/4W 120R J

R101 VE-30000492 RES CF 1/4W 120R J

R102 VE-30000744 RES CF 1/4W 121R J

R103 VE-30000744 RES CF 1/4W 121R J

JK1 VE-30001900 JACK HEADPHONE HP01

3-6(No.YA080)

Page 41

PRINTED WIRING BOARD PARTS LIST [AV-21RM4SE]

MAIN P.W. BOARD ASS’Y (VE-20161048)

Ref No. Part No. Part Name Description Local

IC118 VE-30023137 IC

IC401 VE-30013986 IC

IC403 VE-30026922 IC

IC500 VE-20121218 IC (MEMORY)

IC501 VE-20091454 IC (MICOM)

IC502 VE-30001670 PREAMPLIFIER

IC600 VE-30015306 IC

IC800 VE-30011968 IC

IC801 VE-30015087 IC

IC803 VE-30001500 IC

IC804 VE-30001622 IC

IC806 VE-30014346 IC

IC900 VE-30025172 IC

Q101 VE-30001457 TRANSISTOR

Q103 VE-30001457 TRANSISTOR

Q105 VE-30001457 TRANSISTOR

Q301 VE-30001458 TRANSISTOR

Q302 VE-30001457 TRANSISTOR

Q406 VE-30001457 TRANSISTOR

Q504 VE-30001458 TRANSISTOR

Q601 VE-30013656 TRANSISTOR POWER

Q603 VE-30001448 TRANSISTOR H.OUT

Q801 VE-30001386 TRANSISTOR

Q804 VE-30001454 TRANSISTOR

D101 VE-30007760 DIODE ZENER

D102 VE-30007760 DIODE ZENER

D103 VE-30007760 DIODE ZENER

D104 VE-30007762 DIODE ZENER

D106 VE-30001377 DIODE ZENER

D300 VE-30001285 DIODE

D301 VE-30001285 DIODE

D405 VE-30007763 DIODE ZENER

D407 VE-30001284 DIODE

D408 VE-30001285 DIODE

D409 VE-30007760 DIODE ZENER

D410 VE-30007760 DIODE ZENER

D411 VE-30007760 DIODE ZENER

D501 VE-30001285 DIODE

D505 VE-30001285 DIODE

D506 VE-30001284 DIODE

D509 VE-30001279 LED

D512 VE-30001285 DIODE

D513 VE-30001339 DIODE ZENER

D602 VE-30001329 DIODE

D603 VE-30001285 DIODE

D608 VE-30001318 DIODE

D609 VE-30001318 DIODE

D610 VE-30001318 DIODE

D611 VE-30001285 DIODE

D614 VE-30001318 DIODE

D615 VE-30001285 DIODE

D616 VE-30009699 DIODE ZENER

D619 VE-30009699 DIODE ZENER

D620 VE-30003722 DIODE ZENER

D800 VE-30001318 DIODE

D801 VE-30001347 DIODE ZENER

D802 VE-30001318 DIODE

D803 VE-30001315 DIODE

D804 VE-30001285 DIODE

D805 VE-30001315 DIODE

D806 VE-30001315 DIODE

D808 VE-30007681 DIODE

D809 VE-30001329 DIODE

D810 VE-30009366 DIODE

D811 VE-30001329 DIODE

D812 VE-30001285 DIODE

D813 VE-30001329 DIODE

D837 VE-30001329 DIODE

D838 VE-30001329 DIODE

D889 VE-30001384 TRANSISTOR

D890 VE-30001329 DIODE

D893 VE-30001329 DIODE

D894 VE-30001329 DIODE

D900 VE-30001318 DIODE

D901 VE-30001318 DIODE

D902 VE-30001318 DIODE

D903 VE-30001344 DIODE ZENER

C101 VE-30016654 CAP SMD 100NF 16V K R

C108 VE-30000371 CAP EL 22UF 50V M

Ref No. Part No. Part Name Description Local

C114 VE-30016654 CAP SMD 100NF 16V K R

C142 VE-30000384 CAP EL 2.2UF 50V M

C143 VE-30012583 CAP SMD 1.5NF 50V K

C144 VE-30012583 CAP SMD 1.5NF 50V K

C145 VE-30012589 CAP SMD 4.7NF 50V K

C155 VE-30012560 CAP SMD 100PF 50V J

C159 VE-30012560 CAP SMD 100PF 50V J

C160 VE-30000387 CAP EL 33UF 50V M

C166 VE-30012559 CAP SMD 10PF 50V D

C201 VE-30000400 CAP EL 47UF 50V M

C205 VE-30000371 CAP EL 22UF 50V M

C206 VE-30012610 CAP SMD 10NF 50V J

C207 VE-30012610 CAP SMD 10NF 50V J

C300 VE-30000400 CAP EL 47UF 50V M

C302 VE-30000092 CAP MKT 220NF 63V J

C408 VE-30012586 CAP SMD 22NF 50V K

C409 VE-30000345 CAP EL 10UF 50V M

C410 VE-30000384 CAP EL 2.2UF 50V M

C411 VE-30000345 CAP EL 10UF 50V M

C412 VE-30012586 CAP SMD 22NF 50V K

C413 VE-30000362 CAP EL 1UF 50V M

C414 VE-30012585 CAP SMD 2.2NF 50V K R

C415 VE-30012581 CAP SMD 1NF 50V K R

C416 VE-30000362 CAP EL 1UF 50V M

C417 VE-30000362 CAP EL 1UF 50V M

C418 VE-30012586 CAP SMD 22NF 50V K

C419 VE-30000413 CAP EL 4.7UF 50V M

C420 VE-30000100 CAP MKT 330NF 63V J

C422 VE-30000400 CAP EL 47UF 50V M

C423 VE-30000400 CAP EL 47UF 50V M

C424 VE-30000345 CAP EL 10UF 50V M

C425 VE-30012586 CAP SMD 22NF 50V K

C426 VE-30016654 CAP SMD 100NF 16V K R

C427 VE-30016654 CAP SMD 100NF 16V K R

C429 VE-30012589 CAP SMD 4.7NF 50V K

C431 VE-30000362 CAP EL 1UF 50V M

C432 VE-30012586 CAP SMD 22NF 50V K

C433 VE-30000345 CAP EL 10UF 50V M

C434 VE-30016654 CAP SMD 100NF 16V K R

C435 VE-30016654 CAP SMD 100NF 16V K R

C436 VE-30000109 CAP MKT 470NF 63V J

C437 VE-30016654 CAP SMD 100NF 16V K R

C438 VE-30016654 CAP SMD 100NF 16V K R

C439 VE-30016654 CAP SMD 100NF 16V K R

C440 VE-30000074 CAP MKT 100NF 63V J

C441 VE-30012582 CAP SMD 10NF 50V K R

C443 VE-30000362 CAP EL 1UF 50V M

C444 VE-30000384 CAP EL 2.2UF 50V M

C448 VE-30012586 CAP SMD 22NF 50V K

C449 VE-30012567 CAP SMD 220PF 50V J

C452 VE-30012581 CAP SMD 1NF 50V K R

C454 VE-30012573 CAP SMD 47PF 50V J

C455 VE-30012573 CAP SMD 47PF 50V J

C456 VE-30012573 CAP SMD 47PF 50V J

C459 VE-30012575 CAP SMD 4.7PF 50V C CH

C460 VE-30000345 CAP EL 10UF 50V M

C502 VE-30000396 CAP EL 47UF 16V M

C504 VE-30012586 CAP SMD 22NF 50V K

C505 VE-30012589 CAP SMD 4.7NF 50V K

C510 VE-30012586 CAP SMD 22NF 50V K

C511 VE-30012566 CAP SMD 22PF 50V J

C513 VE-30000371 CAP EL 22UF 50V M

C514 VE-30012586 CAP SMD 22NF 50V K

C515 VE-30012579 CAP SMD 82PF 50V J

C517 VE-30012586 CAP SMD 22NF 50V K

C518 VE-30012586 CAP SMD 22NF 50V K

C519 VE-30000352 CAP EL 100UF 16V M

C520 VE-30012560 CAP SMD 100PF 50V J

C521 VE-30012562 CAP SMD 15PF 50V J

C522 VE-30012562 CAP SMD 15PF 50V J

C523 VE-30012585 CAP SMD 2.2NF 50V K R

C525 VE-30012566 CAP SMD 22PF 50V J

C530 VE-30012589 CAP SMD 4.7NF 50V K

C531 VE-30000384 CAP EL 2.2UF 50V M

C532 VE-30012586 CAP SMD 22NF 50V K

C536 VE-30000074 CAP MKT 100NF 63V J

C541 VE-30000109 CAP MKT 470NF 63V J

C542 VE-30000205 CAP CER 150PF 50V J SL

C543 VE-30000205 CAP CER 150PF 50V J SL

C545 VE-30012607 CAP SMD 150PF 50V J

C603 VE-30000384 CAP EL 2.2UF 50V M

C604 VE-30000345 CAP EL 10UF 50V M

C608 VE-30000107 CAP MKT 47NF 250V J

C610 VE-30000355 CAP EL 100UF 50V M

(No.YA080)3-7

Page 42

Ref No. Part No. Part Name Description Local

Ref No. Part No. Part Name Description Local

C611 VE-30000092 CAP MKT 220NF 63V J

C613 VE-30016085 CAP EL 10UF 63V 105°

C615 VE-30000359 CAP EL 1000UF 16V M

C616 VE-30000352 CAP EL 100UF 16V M

C618 VE-30000180 CAP MKP 9.1NF 2000Vdc/ 1700Vpp %3.5

C619 VE-30000138 CAP MKP 150NF 250V J

C623 VE-30000404 CAP EL 47UF 160V M (HR) 105°

C624 VE-30000350 CAP EL 10UF 250V M

C627 VE-30000154 CAP MKP 390NF 250V J

C628 VE-30018380 CAP EL 3.3UF 160V M 105°

C631 VE-30000410 CAP EL 470UF 50V M

C632 VE-30000100 CAP MKT 330NF 63V J

C633 VE-30016085 CAP EL 10UF 63V 105°

C634 VE-30000409 CAP EL 470UF 25V M

C635 VE-30000100 CAP MKT 330NF 63V J

C636 VE-30000387 CAP EL 33UF 50V M

C638 VE-30012581 CAP SMD 1NF 50V K R

C639 VE-30000431 CAP CER 100PF 1KV M

C641 VE-30000345 CAP EL 10UF 50V M

C642 VE-30012609 CAP SMD 68NF 50V K

C643 VE-30000116 CAP MKT 68NF 63V J

C644 VE-30000362 CAP EL 1UF 50V M

C801 VE-30000094 CAP MKT 220NF 275V M AC

C802 VE-30000094 CAP MKT 220NF 275V M AC

C803 VE-30000433 CAP CER 1NF 1KV M B

C804 VE-30000433 CAP CER 1NF 1KV M B

C808 VE-30000295 CAP CER 100NF 50V Z F

C809 VE-30000418 CAP EL 100UF 400V M

C810 VE-30000387 CAP EL 33UF 50V M

C811 VE-30000161 CAP MKP 47NF 630Vdc / 622Vpp J

C812 VE-30009208 CAP CER 470PF 1KV K

C813 VE-30000295 CAP CER 100NF 50V Z F

C816 VE-30000447 CAP CER 4.7NF 4KV M E

C817 VE-30000198 CAP CER 120PF 500V J SL

C818 VE-30016654 CAP SMD 100NF 16V K R

C819 VE-30012609 CAP SMD 68NF 50V K

C824 VE-30000433 CAP CER 1NF 1KV M B

C826 VE-30000404 CAP EL 47UF 160V M (HR) 105°

C827 VE-30000411 CAP EL 4700UF 16V M

C828 VE-30000295 CAP CER 100NF 50V Z F

C829 VE-30000407 CAP EL 470UF 16V M

C830 VE-30000382 CAP EL 2200UF 16V M

C832 VE-30000295 CAP CER 100NF 50V Z F

C833 VE-30000409 CAP EL 470UF 25V M

C834 VE-30000295 CAP CER 100NF 50V Z F

C836 VE-30000431 CAP CER 100PF 1KV M

C838 VE-30000352 CAP EL 100UF 16V M

C839 VE-30000352 CAP EL 100UF 16V M

C840 VE-30000352 CAP EL 100UF 16V M

C843 VE-30000431 CAP CER 100PF 1KV M

C848 VE-30000352 CAP EL 100UF 16V M

C849 VE-30000352 CAP EL 100UF 16V M

C850 VE-30000352 CAP EL 100UF 16V M

C855 VE-30000407 CAP EL 470UF 16V M

C857 VE-30012573 CAP SMD 47PF 50V J

C858 VE-30007308 CAP CER 220PF 1KV K

C862 VE-30000367 CAP EL 1UF 250V M

C863 VE-30000433 CAP CER 1NF 1KV M B

C907 VE-30000434 CAP CER 1NF 2KV K B

C908 VE-30000415 CAP EL 4.7UF 250V M

C912 VE-30000075 CAP MKT 100NF 250V K (DC)

NOT1 VE-30000352 CAP EL 100UF 16V M

X403 VE-30000074 CAP MKT 100NF 63V J

R101 VE-30012509 RES SMD 1/16W 100K J

R104 VE-30000594 RES CF 1/4W 22K J

R105 VE-30000792 RES CF 1/4W 75R J

R108 VE-30000723 RES CF 1/4W 47K J

R109 VE-30012713 RES SMD 1/16W 75R J

R110 VE-30012713 RES SMD 1/16W 75R J

R113 VE-30012713 RES SMD 1/16W 75R J

R114 VE-30012713 RES SMD 1/16W 75R J

R115 VE-30012713 RES SMD 1/16W 75R J

R116 VE-30012987 RES SMD 1/16W 56R J

R117 VE-30012713 RES SMD 1/16W 75R J

R118 VE-30000792 RES CF 1/4W 75R J

R122 VE-30000792 RES CF 1/4W 75R J

R123 VE-30000792 RES CF 1/4W 75R J

R125 VE-30012657 RES SMD 1/16W 1K J

R126 VE-30012695 RES SMD 1/16W 470R J

R127 VE-30000459 RES CF 1/4W 100R J

R128 VE-30000471 RES CF 1/4W 10K J

R129 VE-30012713 RES SMD 1/16W 75R J

R130 VE-30000594 RES CF 1/4W 22K J

R132 VE-30000723 RES CF 1/4W 47K J

R133 VE-30000718 RES CF 1/4W 4.7K J

R135 VE-30012657 RES SMD 1/16W 1K J

R153 VE-30012657 RES SMD 1/16W 1K J

R201 VE-30012674 RES SMD 1/16W 27K J

R202 VE-30012692 RES SMD 1/16W 4.7K J

R204 VE-30000459 RES CF 1/4W 100R J

R206 VE-30000459 RES CF 1/4W 100R J

R301 VE-30000471 RES CF 1/4W 10K J

R302 VE-30000471 RES CF 1/4W 10K J

R303 VE-30012641 RES SMD 1/16W 10K J

R305 VE-30012641 RES SMD 1/16W 10K J

R306 VE-30012509 RES SMD 1/16W 100K J

R417 VE-30012510 RES SMD 1/16W 100R J

R418 VE-30012510 RES SMD 1/16W 100R J

R419 VE-30012649 RES SMD 1/16W 150R J

R420 VE-30000466 RES CF 1/4W 1K J

R421 VE-30012650 RES SMD 1/16W 15K J

R422 VE-30012659 RES SMD 1/16W 2.2K J

R423 VE-30012712 RES SMD 1/16W 8.2K J

R424 VE-30000712 RES CF 1/4W 470R J

R425 VE-30000583 RES CF 1/4W 220R J

R426 VE-30012659 RES SMD 1/16W 2.2K J

R427 VE-30012674 RES SMD 1/16W 27K J

R428 VE-30000792 RES CF 1/4W 75R J

R431 VE-30012674 RES SMD 1/16W 27K J

R432 VE-30012657 RES SMD 1/16W 1K J

R433 VE-30012667 RES SMD 1/16W 220K J

R437 VE-30000466 RES CF 1/4W 1K J

R438 VE-30000466 RES CF 1/4W 1K J

R439 VE-30012657 RES SMD 1/16W 1K J

R440 VE-30012714 RES SMD 1/16W 820R J

R441 VE-30012656 RES SMD 1/16W 18K J

R442 VE-30000466 RES CF 1/4W 1K J

R446 VE-30012714 RES SMD 1/16W 820R J

R447 VE-30012714 RES SMD 1/16W 820R J

R448 VE-30012683 RES SMD 1/16W 330K J

R449 VE-30012662 RES SMD 1/16W 2.7K J

R450 VE-30000712 RES CF 1/4W 470R J

R454 VE-30000594 RES CF 1/4W 22K J

R455 VE-30012656 RES SMD 1/16W 18K J

R458 VE-30012662 RES SMD 1/16W 2.7K J

R459 VE-30012510 RES SMD 1/16W 100R J

R460 VE-30012510 RES SMD 1/16W 100R J

R461 VE-30012510 RES SMD 1/16W 100R J

R469 VE-30000670 RES CF 1/4W 330K J

R470 VE-30012683 RES SMD 1/16W 330K J

R475 VE-30012510 RES SMD 1/16W 100R J

R476 VE-30012707 RES SMD 1/16W 680R J

R477 VE-30014022 RES SMD 1/16W 47R J

R502 VE-30012695 RES SMD 1/16W 470R J

R503 VE-30012707 RES SMD 1/16W 680R J

R504 VE-30012679 RES SMD 1/16W 3.9K J

R505 VE-30012673 RES SMD 1/16W 270R J

R506 VE-30012506 RES SMD 1/16W 1.5K J

R507 VE-30012657 RES SMD 1/16W 1K J

R508 VE-30000706 RES CF 1/4W 47R J

R509 VE-30012641 RES SMD 1/16W 10K J