Page 1

SERVICE MANUAL

COLOR TELEVISION

AV-14F13

AV-14F33

BASIC CHASSIS

GA2

RM-C372GY

[AV-14F13/PH]

RM-C373GY

[AV-14F33/PH]

AV-14F13

AV-14F33

/PH

/PH

CONTENTS

! SPECIFICATIONS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

!

SAFETY PRECAUT IONS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

!

FEATURES・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

! MAIN DIFFERENCE LIST ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

!

FUN CTIONS

! SPECIFIC SERVICE INSTRUCTIONS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

! SERVICE ADJUSTMENTS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

!

PARTS LIST ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

★ OPERATING INSTRUCTIONS

★ STAND ARD CIRCUIT DIAGRAM (APPENDIX) ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

1

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

COPYRIGHT © 2002 VICTOR COMPANY OF JAPAN, LTD.

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 2

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・ 3

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・ 5

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・ 8

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・ 15

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 33

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・ ・ 4

・・ ・・・ ・

・・

・・・・

・・・・・ 2- 1

・・・・・・・・・・

6

No.520 21

Jul. 2002

Jul. 200 2

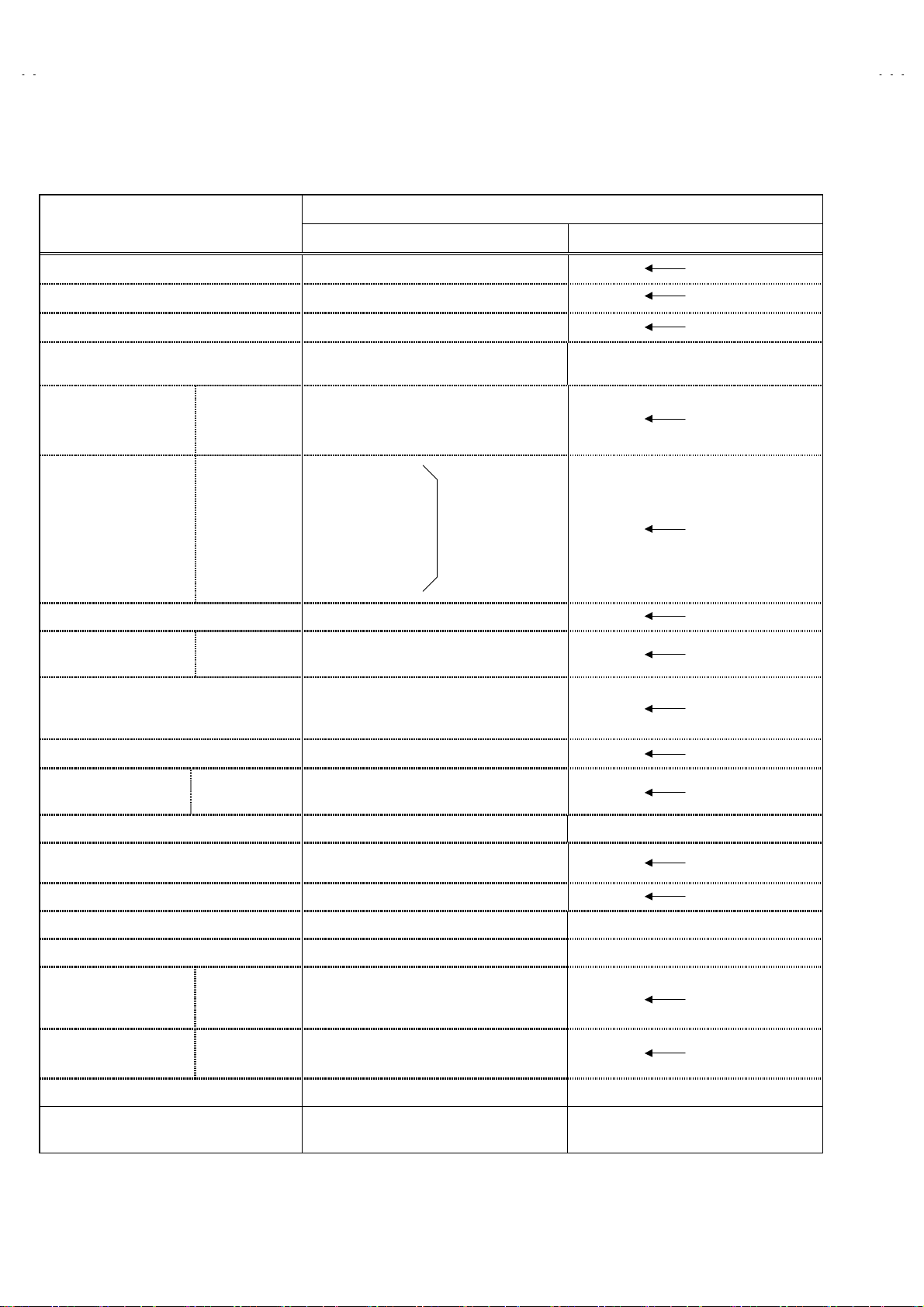

Page 2

A

V-14F13

A

V-14F33

SPECIFICATIONS

Items

Dimensions (W××××H××××D) 462mm×340.5mm×375mm

Mass 10kg

TV RF System CCIR (M)&(N)

Color / Sound System NTSC / PAL-M / PAL-N NTSC / PAL-M / PAL-N

TV Receiving Channels

and Frequency

CATV Receiv ing Channels

and Frequency

TV/CATV Total Channel 181 Channels

Intermediate Frequency Video IF Carrier

VL Band

VH Band

UHF Band

Low Band

High Band

Mid Band

Super Band

Hyper Band

Ultra Band

Sub Mid Band

Sound IF Carrier

(02~06) 54MHz~88MHz

(07~13) 174MHz~216MHz

(14~69) 470MHz~806MHz

(02~06)

(07~13)

(14~22)

(23~36)

(37~64)

(65~94, 100~125)

(01, 96~99)

45.75MHz

41.25MHz (4.5MHz)

AV-14F13

/PH AV-14F33/PH

(54MHz~804MHz)

Contents

BTSC (Multi Channel Sound)

Color Sub Carrier NTSC : 3.579545MHz

PAL-M : 3.57561149MHz

PAL-N : 3.58205625MHz

Antenna terminal

Power Input Rated Voltage

Oper ating Voltage

Power Consumption 42W 44W

Picture Tube (measured diagonally) Picture tube 36cm

High Voltage

Speaker

Audio Power Output 2W (monaural) 1.5W+1.5W (stereo)

Input Video input

Audio input

Output Video output

Audio output

Headphone Jack Stereo mini jack (dia. 3.5mm, Sound is Monaural) Stereo mini jack (dia. 3.5mm, Sound is Stereo)

Remote Control Unit RM-C372GY

75Ω(VHF/UHF) Terminal, F-Type Connector

110V~240V AC, 50Hz/60Hz

90V~260V AC, 50Hz/60Hz

Visible aria 34cm

22.5kV±1.0kV (at zero beam current)

5cm×12cm Oval type×2 (monaural) 5×12cm Oval type×2 (stereo)

1Vp-p, 75Ω (RCA pin jack)

500mVrms (-4dBs), High impedance

(RCA pin jack)

1Vp-p, 75Ω

500mVrms (-4dBs), Low impedance

RM-C373GY

(AA/R6/UM-3 battery×2)

(AA/R6/UM-3 battery×2)

Design & specifications are subject to change without notice.

2

No.52021

Page 3

A

A

SAFETY PRECAUTIONS

V-14F13

V-14F33

1. The design of this product contains special hardware, many

circuits and components specially for s afety purposes. For

continued protection, no changes should be made to the original

design unless authorized in writing by the manuf acturer.

Replacement parts must be identical to those used in the original

circuits. Service should be performed by qualified personnel

only.

2. Alterations of the design or circuitr y of the products should not be

made. Any design alterations or additions will void the

manufacturer's warrant y and will further relieve the manuf acturer

of responsibility for personal injury or property damage resulting

theref r om.

3. Many electric al and mechanical parts in the pr oducts have

special safety-related characteristics. These characteristics are

often not evident from visual inspection nor can the protection

afforded by them necessarily be obtained by using replacement

components rated for higher voltage, wattage, etc. Replacement

parts which have these special safety characteristics are

identified in the parts list of Service manual. Electrical

components having such feat ures are identified by shading

on the schematics and by (!!!!) on the parts list in Service

manual. The use of a substitute replacement which does not

have the s ame safety characteristics as the recommended

replacement part shown in the parts list of Service manual may

cause shock, fire, or other hazards.

4. Don't short between the LIVE side ground and ISOLATE D

(NEUTRAL) side ground or EARTH side ground when

repairing.

Some model's power circuit is partly different in the GND. The

differenc e of the GND is shown by the LIVE : (") side GND, the

ISOLATED(NEUTRAL) : (#) side GND and EARTH : ($) side

GND. Don't short between the LIVE side GND and

ISOLATED(NEUTRAL) side GND or EARTH side GND and

never meas ure with a measuring apparatus (oscillosc ope etc.)

the LIVE side GND and ISOLATED(NEUTRAL) side GND or

EARTH side GND at the s ame time.

If above note will not be kept, a fuse or any parts will be broken.

5. If any repair has been made to the chassis, it is recommended

that the B1 setting should be checked or adjusted (S ee

ADJUSTMENT OF B1 POWER SUPPLY).

6. The high voltage applied to the picture tube must conform with

that specified in Ser vice manual. Excessive high voltage can

cause an incr ease in X-Ray emission, arcing and possible

component damage, therefore operation under excessive high

voltage conditions should be kept to a minimum, or should be

prevented. If severe arcing occurs, remove the AC power

immediately and determine the cause by visual inspection

(incorrect installation, cracked or melted high voltage harness,

poor soldering, etc.). To maint ain the proper minimum level of

soft X-Ray emission, components in the high voltage circuitry

including the picture tube must be the exact replacements or

alternatives approved by the manufacturer of the c omplete

product.

7. Do not check high voltage by drawing an arc. Use a high volt age

meter or a high voltage probe with a VTVM. Discharge the

picture tube before attempting meter connection, by connecting

a clip lead to the ground fr ame and c onnecting the other end of

the lead through a 10kΩ 2W resistor to the anode button.

8. When servic e is required, observe the original lead dress. Extra

precaution should be given to assure c orrect lead dr ess in the

high voltage circuit area. W here a short circuit has occurred,

those components that indicate evidence of overheating should

be replaced. Always use the manufacturer's replacement

components.

9. Isolation Check

(Safety for Electrical Shock Hazard)

After re-assembling the product, always perform an isolation

check on the exposed metal parts of the cabinet (antenna

terminals, video/audio input and out put terminals, Control knobs,

metal cabinet, screw heads, earphone jack, control shafts, etc.)

to be sure the product is safe to operate without danger of

electrical shoc k.

(1) Dielectr ic Strength Test

The isolation between the AC primary circuit and all metal parts

exposed to the user, particularly any exposed metal part having a

return path to the chass is should withstand a voltage of 3000V

AC (r.m.s.) for a period of one second.

(. . . . Withstand a voltage of 1100V AC (r.m.s.) to an appliance

rated up to 120V, and 3000V AC (r.m.s.) to an appliance rated

200V or more, for a period of one second.)

This method of test requires a test equipment not generally found

in the s ervice trade.

(2) Leakage Current Check

Plug the AC line cord directly into the AC outlet (do not us e a line

isolation transformer during this check.). Using a "Leakage

Current T ester", measure the leakage c urrent from each expos ed

metal part of the cabinet, particularly any exposed metal part

having a return path to the chassis, to a known good earth

ground (water pipe, etc.). Any leakage current must not exceed

0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.2mA AC

(r.m.s.).

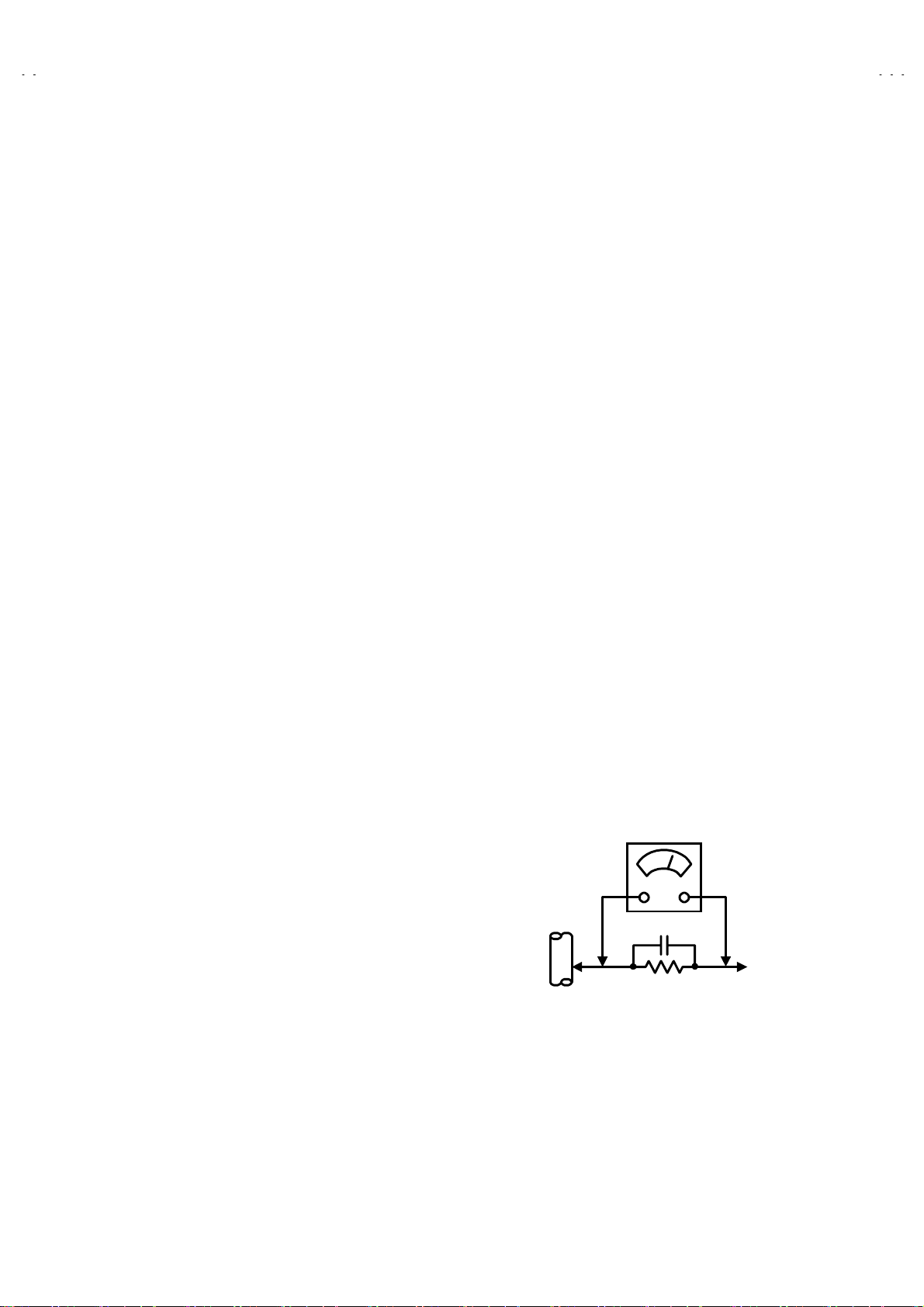

"""" Alternate Check Method

Plug the AC line cord directly into the AC outlet (do not us e a line

isolation transformer during this check.). Use an AC voltmeter

having 1000 ohms per volt or more sensitivity in the following

manner. Connect a 1500Ω 10W resistor paralleled by a 0.15µF

AC-type capacitor between an exposed metal part and a known

good earth ground (water pipe, etc.). Measure the AC voltage

across the resistor with the AC voltmeter. Move the resistor

connection to each exposed metal part, particularly any exposed

metal part having a return path to the chassis, and measure the

AC voltage across the resistor. Now, revers e the plug in the AC

outlet and repeat each measur ement. Any voltage measured

must not exceed 0.75V AC (r.m.s.). This corresponds to 0.5mA

AC (r.m.s.).

However, in tropical area, this must not exceed 0.3V AC (r.m.s.).

This corresponds to 0.2mA AC (r.m.s.).

AC VOLTMETER

(HAVING 1000 Ω/V,

OR MORE SENSITIVITY)

0.15μF AC-TYPE

PLACE THIS PROBE

1500 Ω 10W

GOOD EARTH GROUND

ON EACH EXPOSED

METAL PART

No.52021

3

Page 4

A

V-14F13

A

V-14F33

FEATURES

" New chassis design enables use of a main board with simplified

circuitry.

" Provided with miniature tuner (TV/CATV).

" PLL synthesizer system TV/CATV totaling 181 channels.

" Multifunctional remote control permits picture adjustment.

" Adoption of the VIDEO STATUS function.

" Adoption of the ON/OFF TIMER function.

" With 75ΩV/U in common (F-T ype) ANT Terminal.

" SLEEP TIMER for setting in real time.

" Wide range voltage (110V~240V) AC power input.

" With AUDIO / VIDEO INPUT & OUTPUT terminal.

" Closed-caption broadc ast c an be viewed.

4

No. 52021

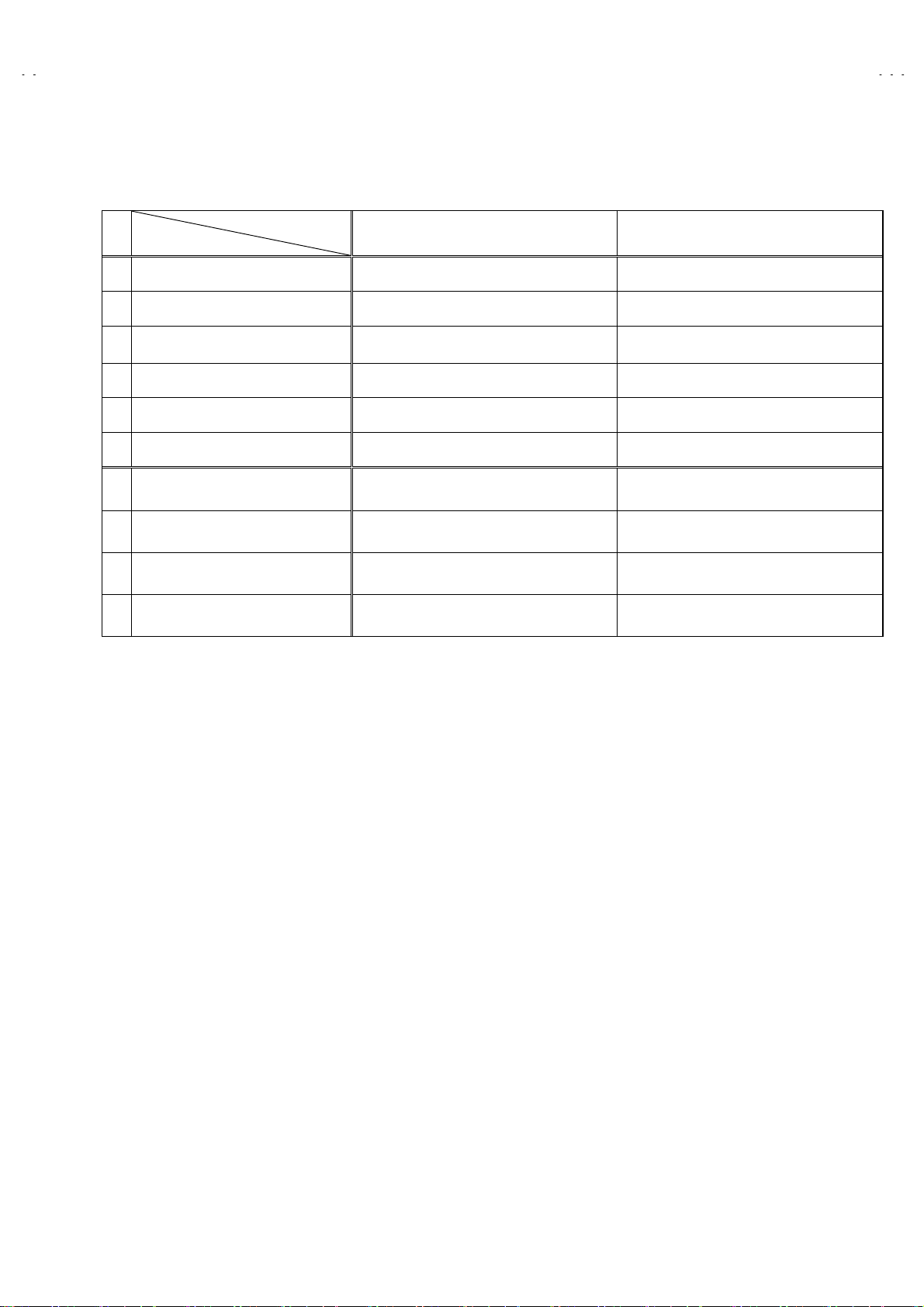

Page 5

A

A

MAIN DIFFERENCE LIST

Model Name

!

Part Name (Item)

MAIN PWB SGA-1066A SGA-1065A

FRONT CABINET LC-10831-028A-H LC-10831-027A-H

!

TERMINAL SHEET GG40021-002A-H GG40021-001A-H

SPEAKER CEBSS09D-05KJ2 CEBSS09D-03KJ2

!

PACKING CASE GG10056-079A-H GG10056-077A-H

REMOTE CONTROL UNIT RM-C372GY-1H RM-C373GY-1H

AV-14F13

/PH

AV-14F33

V-14F13

V-14F33

/PH

Color / Sound System NTSC / PAL-M / PAL-N

Power Consumption 42W 44W

Speaker

Audio Power Output 2W (monaural) 1.5W+1.5W (stereo)

5cm×12cm Oval type×2 (monaural) 5×12cm Oval type×2 (stereo)

NTSC / PAL-M / PAL-N

BTSC(Multi Channel Sound)

No. 52021

5

Page 6

A

V-14F13

A

V-14F33

FUNCTIONS

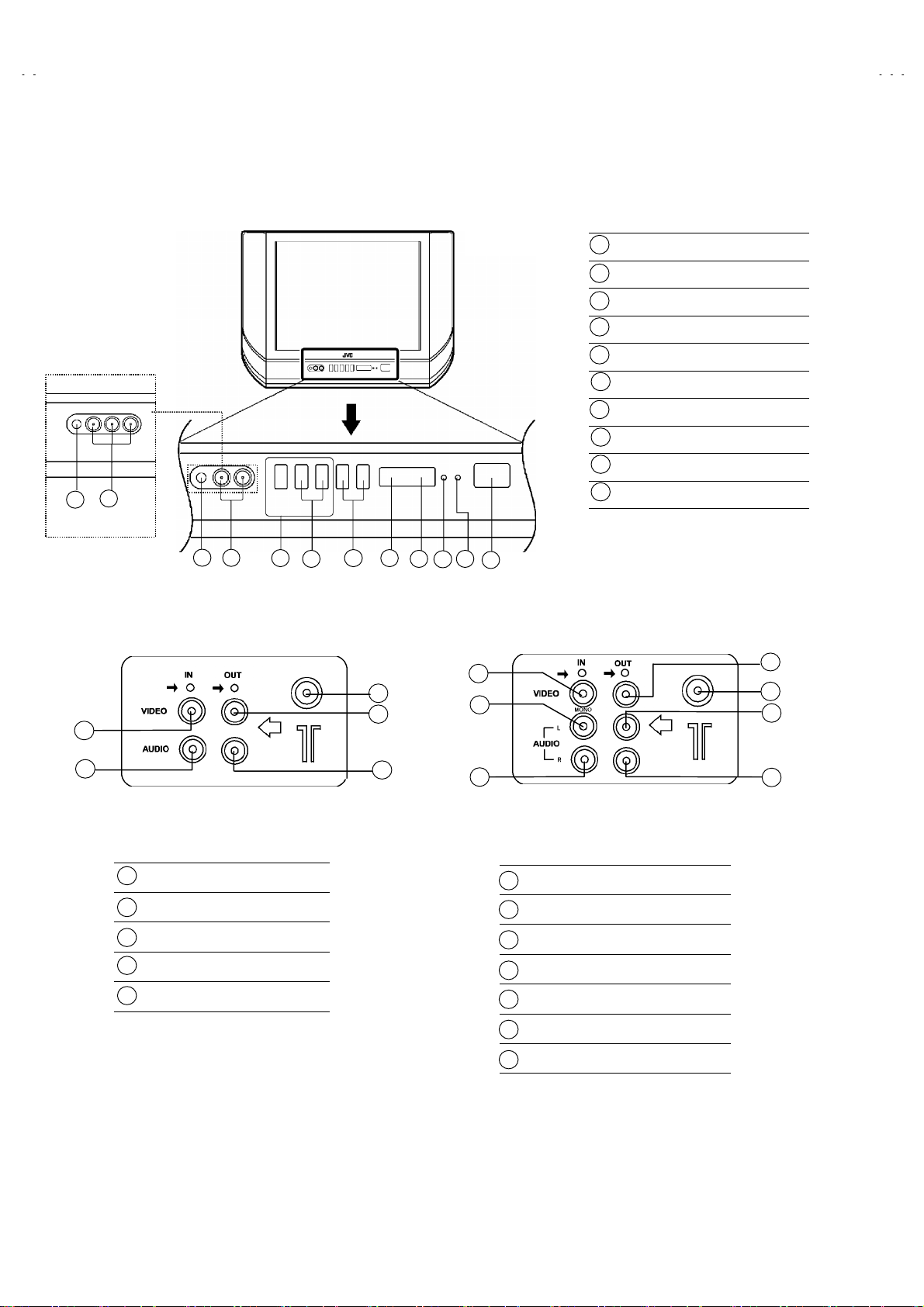

■ FRONT PANEL

9

10

[AV-14F33/PH]

10 9

■ REAR TERMINAL

2

[AV-14F13/PH]

1

3 4

2

5

1

4

7

6

8

2

3

1

MENU buttons

CHANNEL -/+ buttons

2

VOLUME -/+ buttons

3

AI ECO sensor

4

REMOTE CONTROL s ensor

5

ON TIMER lamp

6

POWER lamp

7

MAIN POW ER button

8

A/V INPUT terminal

9

HEADPHONE jack

10

5

1

6

3

[AV-14F13/PH]

1

ANT Terminal

2

VIDEO INPUT Terminal

3

AUDIO INPUT Terminal

4

VIDEO OUTPUT Terminal

5

AUDIO OUTPUT Terminal

5

4

[AV-14F33/PH]

ANT Terminal

1

VIDEO INPUT Terminal

2

AUDIO L/MONO INPUT Terminal

3

AUDIO R INPUT Terminal

4

VIDEO OUTPUT Terminal

5

AUDIO L OUTPUT Terminal

6

AUDIO R OUTPUT Terminal

7

7

6

No. 52021

Page 7

A

V-14F13

A

V-14F33

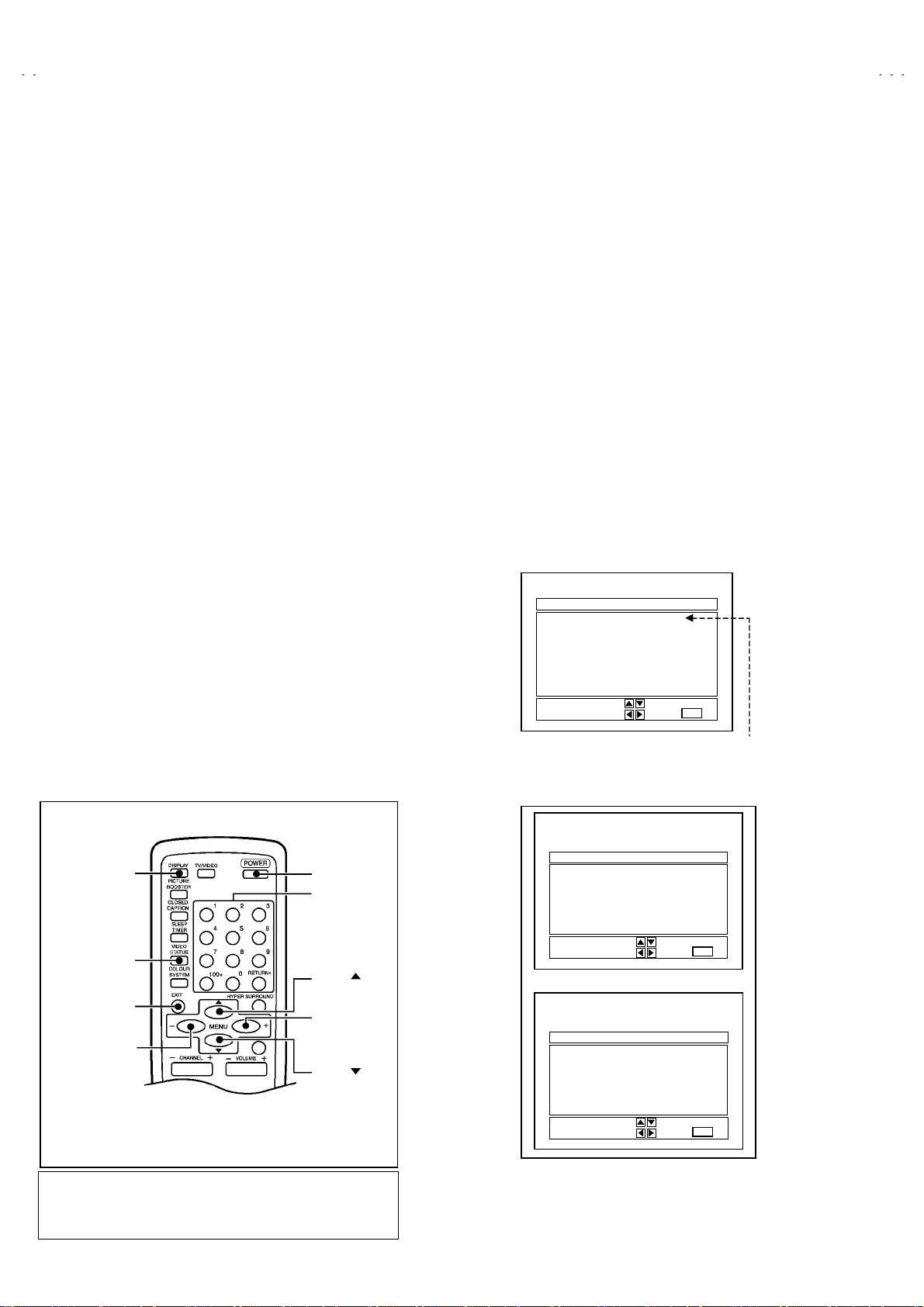

■ REMOTE CONTROL UNIT

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

TV/VIDEO key

1

DISPLAY key

2

PICTURE BOOSTER key

3

CLOSED CAPTION key

4

SLEEP TIMER key

5

VIDEO STATUS key

6

COLOUR SYSTEMkey

7

100+ key

8

EXIT key

9

CHANNEL-/+ key

10

POWER key

11

Number (CH.) key

12

RETURN+key

13

HYPER SURROUND key

14

[AV-14F33

15

MENU key

MENU ▲/▼ key

MENU -/+ key

16

MUTING key

/PH

Only]

This illustration is written about RM-373GY(AV-14F33/PH),

There are no key of HYPER SURROUND in the

RM-C372GY(AV-14F13/PH).

17

VOLUME-/+ key

No. 52021

7

Page 8

A

V-14F13

A

V-14F33

SPECIFIC SERVICE INSTRUCTIONS

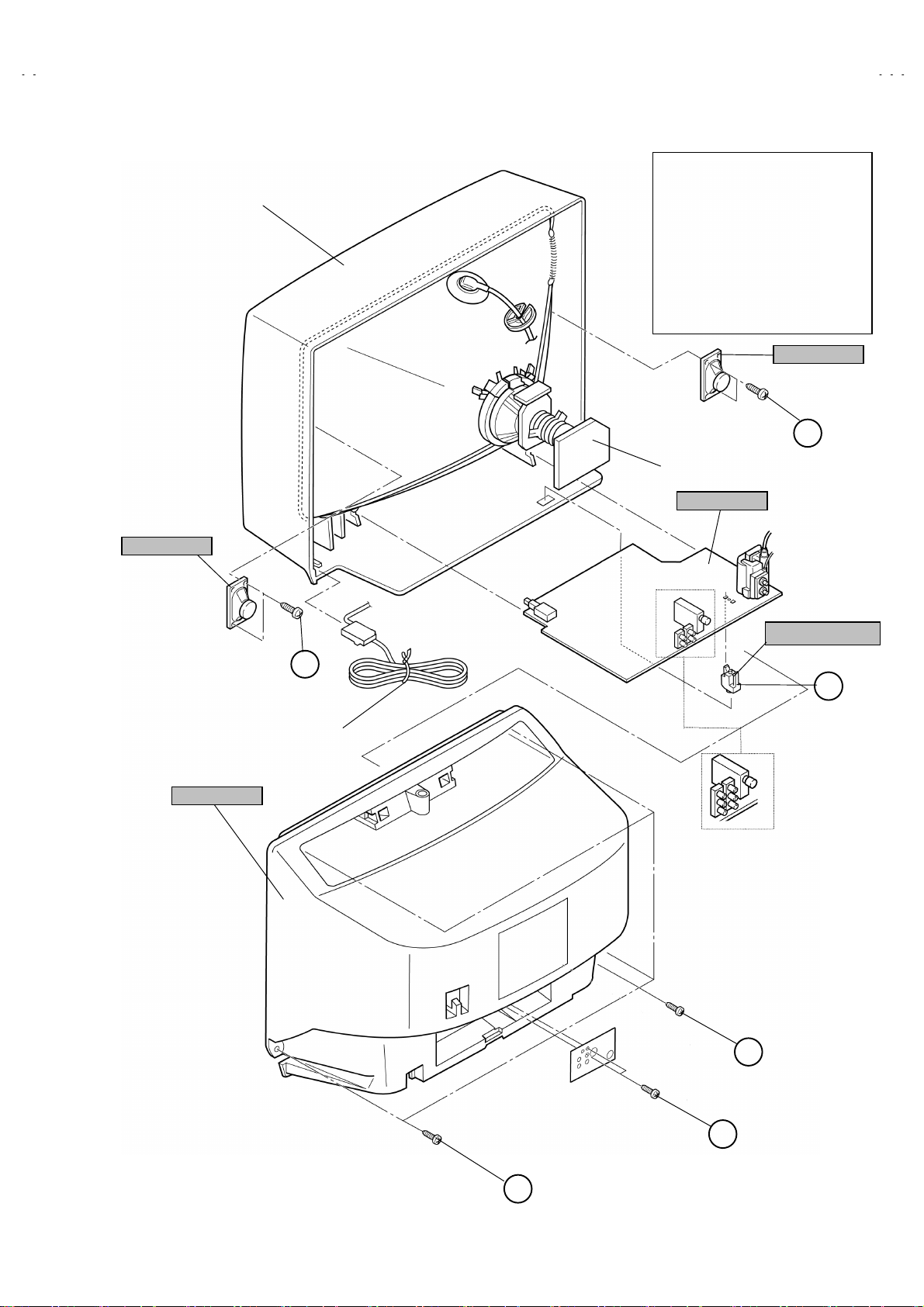

DISASSEMBLY PROCEDURE

REMOVING THE REAR COVER

1. Unplug the power plug.

screws marked

2. As shown in figure, remove the

""""

.

marked

3. As shown in figure, remove the

4. Withdr aw the r ear cover toward you.

[CAUTION]

" When reinstalling the rear cover, c arefully push it inward after

inserting the MAIN PW B into the rear cover groove.

4

screws marked

2

REMOVING THE MAIN PW BOARD

" After removing the rear cover.

1. Slightly raise the both side of the MAIN PW BOARD by hand, and

from the front cabinet.

$%

remove the PWB stopper marked

2. W ithdraw the MAIN PW BOARD backward.

(If necessary, remove the wire clamp, c onnectors etc.)

$%

$%$%

and a screw

!!!!

####

REMOVING THE SPEAKER

" After removing the rear cover.

screws marked

1. As shown in figure, remove the

remove the speaker.

2

&&&&

CHECKING THE MAIN PW BOARD

1. To check the back side of the PW board.

(1) Pull out the MAIN PW board. (Refer to REMOVING THE MAIN

PW Boar d)

(2) Erect the PW Board vertic ally s o that you can easily c heck the

back side of the PW Board.

[CAUTION]

" When erecting the PW Board, be careful so that there will be no

contact ing with other PW Board.

" Before turning on power, make sure that the CRT earth wire

and other connector are properly connected.

WIRE CLAMPING AND CABLE TYING

1. Be sure to clamp the wire.

2. Never remove the cable tie us ed for tying the wires together.

Should it be inadver tently removed, be sure to tie the wires with

a new cable tie.

, then

8

No. 52021

Page 9

A

A

FRONT CABINET

V-14F13

V-14F33

This exploded view describes

/PH

about AV-14F13

Although AV-14F 33

different from this figure, you

can use the exploded view for

disassembling the AV-14F33

in the same step as for the AV-

/PH.

14F13

CRT SOCKET PWB

MAIN PWB

.

/PH

is slightly

SPEAKER

E

(××××2)

/PH

SPEAKER

REAR COVER

E

(××××2)

POWER CORD

AV-14F13/PH

PWB STOPPER

D

AV-14F33/PH

(××××1)

B

(××××2)

C

(××××4)

A

No. 52021

9

Page 10

A

V-14F13

A

V-14F33

MEMORY IC REPLACEMENT

1. Memory IC

This model uses a memory IC.

The memory IC stores data for proper operation of video and deflection circuits.

When replacing, be sure to use an IC containing this (initial value) data.

2. Memory IC replacement procedure

(1) Power off

Switch off the power and disconnect the power cord from the wall

outlet.

(5) Receive channel setting

Refer to the OPERATING INSTRUCTIONS (USER’S GUIDE)

and set the receive channels (Channels Preset) as described.

(2) Replace the memory IC.

Be sure to use memory ICs written with the initial data values.

(3) Power on

Connect the power cord to the wall outlet and switch on the

power.

(4) System constant check and setting

1) Simultaneously press t he DISPLAY key and VIDEO STATUS

key of the remote control unit.

2) The SERVICE MENU screen of Fig.1 is displayed.

3) While the SERVICE MENU is displayed, again simultaneously

press the DISP LAY and VIDEO STATUS keys to display the

Fig.2 SYSTEM CONSTANT screen.

4) Refer to the SYSTEM CONSTANT table and check the setting

items. W here these differ, s elect the s etting item with the

MENU UP / DOWN key and adjust the setting value with the

MENU LEFT / RIGHT keys.

5) After adjusting, release the MENU LEFT / R IGHT key to store

the setting value.

6) Press the EXIT key twice to r eturn the nor mal screen.

NAME OF REMOTE CONTROL KEYS

(6) User settings

Check the user setting items according t o Table 2.

Where these do not agree, refer to the OPERATING

INSTRUCTIONS (USER ’ S GUIDE) and set the items as

described.

(7) SERVICE MENU setting

Verify what to s et in the SERVICE MENU, and set whatever is

necessary. (Fig.1) Refer to the SERVICE ADJUSTMENT for

setting.

SERVICE MENU

PICTURE SOUND

VIDEO STATUS OTHERS

LOW LIGHT HIGH LIGHT

RF AFC CHK

VCO (CW) I2C BUS CTRL

SETUP TOUR(OFF)

Fig.1

EXIT BY

EXIT

IT

[ AV-14F33/PH Only ]

SELECT BY

OPERATE BY

DISPLAY

Key

VIDEO STATUS

Key

EXIT

Key

MENU -

(LEFT) Key

This illustration is written about RM-C373GY(AV-14F33/PH),

There are no key of HYPER SURROUND in the RM-C372GY

(AV-14F13/PH).

10

POWER Key

NUMBER Key

MENU

(UP) Key

MENU +

(RIGHT) Key

MENU

(DOWN) Key

No.52021

SYSTEM CONSTANT

VIDEO :

AUDIO :

VARI. OUT : NO

GAME : YES

CINEMA : YES

SELECT BY

OPERATE BY

SYSTEM CONSTANT

CCD : YES

RETURN+ : YES

SURROUND :

M37272M8-

SELECT BY

OPERATE BY

×××

×××

××××××

SP

****

***

***

******

***

***

******

Fig.2

EXIT BY

EXIT

EXIT BY

EXIT

Page 11

A

A

TABLE 1(System Constant Setting)

Setting item Setting content

VIDEO 1 2

AUDIO MONO MTS

MONO MONO MTS

12

AV-14F13/PH AV-14F33/PH

Setting value

V-14F13

V-14F33

VARI. OUT NO NO

GAME YES YES

CINEMA YES YES

CCD YES YES

RETURN+ YES YES

SURROUND NO YES

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

TABLE 2 (User setting value)

Setting item Setting value

" Setting of FUNCTION

MAIN POWER OFF

SUB POWER ON

CHANNEL CH 02 (AIR)

PICTURE BOOSTER OFF

VOLUME 10

TV/VIDEO TV

CAPTION OFF (CC1/T1)

DISPLAY POSITION INDICATION

SLEEP TIMER 0

VIDEO STATUS STANDARD

HYPER SURROUND OFF [ AV-14F33

COLOR SYSTEM AUTO PAL

SETUP TOUR ON

" Setting of MENU

TINT

COLOR

PICTURE STANDARD

BRIGHT

DETAIL

BASS CENTER

TREBLE CENTER

BALANCE CENTER

MTS STEREO

SET CLOCK Unnecessary to set : (000)

ON/OFF TIMER NO

CHANNEL SUMMARY necessary to set

NOISE MUTING OFF

BACK GROUND BLACK

CLOSED CAPTION CC1 / T1 ( OFF at shipping )

LANGUAGE ENG.

/PH

Only ]

[ AV-14F33

/PH

Only ]

No.52021

11

Page 12

A

V-14F13

A

V-14F33

INITIAL SETTING VALUE OF SERVICE MENU

1. Adjustment of the SERVICE MENU is made on the basis of the initial setting values; however, the new setting values which set the

screen in its optimum condition may differ from the initial setting.

2. Do not change the initial Setting Values of the Setting (Adjustment) items not listed In “ADJUSTMENT”.

PICTURE MODE (1/2)

""""

" The four setting items in the video mode No.8 EXT PIC., No.9 E XT BRI., No.10 EXT COL. and No.11 EXT TINT are linked to the items in

the TV MODE No.1 PICTURE, No.2 BRIGHT, No.5 COL. NTSC and No.6 TINT, respectively. W hen the setting it ems in the TV mode are

adjusted, the values in the setting it ems in t he video mode are revis ed automatic ally to the same values in the TV mode.(The initial setting

values given in ( ) are off-set values.)

" When the four items (No.8, 9, 10 and 11) are adjusted in the video mod e, the setting values in each item are revised independently.

No. Setting ( Adjustment) item Variable range Initial setting value

1. PICTURE

2. BRIGHT

3. COL. PALM

4. COL. PALN

5. COL. NTSC

6. TINT

7. TV DTL

8. EXT PIC.

9. EXT BRI.

10. EXT COL.

11. EXT TINT

12. EXT DTL

13. P/N KILL 000 / 001 001

14. Y S CONT

15. TV Y-DL

16. EXR Y-DL

17. WPL SW 000 / 001

18. Y GAM MA 000 / 001

19. P/N G P. 000 / 001

20. COL. L SW 000 / 001

21. COL. LMT.

22. PN C. ATT

23. OFST. SW 000 / 001 000

24. OFSET. B-Y

25. OFSET. R-Y

26. C-TOF SW 000 / 001 001

27. TV T FO

28. TV T Q

29. EXT T FO

30. EXT T Q

31. C-TRAP 000 / 001 000

32. C-TR. FO

33. C-TRAP Q

34. FIX B/W 000 / 001

35. APA P. FO

36. DC TRAN.

37. B. ST. SW 000 / 001

38. B. ST. PO.

39. ABL GAIN

40. ABL PO.

000~127

000~127

000~127

000~127

000~127

000~127

000~063

±025

±025 (±000)

±025

±025

000~063

000~031

000~007

000~007

000~003

000~003

000~015

000~015

000~003

000~003

000~003

000~003

000~003

000~003

000~003

000~007

000~001

000~007

000~007

: Do not adjust in this area.

040

064

070

070

072

065

028

(±000)

(±000)

(+001)

030

031

001

002

000

000

000

001

001

001

008

008

001

000

000

000

002

000

000

001

006

000

000

004

000

12

No.52021

Page 13

A

A

PICTURE MODE (2/2)

"

No. Setting ( Adjustment) item Vari able range Initial setting value

V-14F13

V-14F33

41. HALF T.

42. DRV G SW 000 / 001

43. NT. COMB 000 / 001

44. COIN DET

45. NOISE L.

46. VCD MODE 000 / 001 000

47. V AGC SP 000 / 001 000

48. H POS. 50

49. H BLK. 50

50. V POS. 50

51. V SIZE50

52. V S CR50

53. V LIN. 50

54. H POS. 60

55. H BLK. 60

56. V POS. 60

57. V SIZE60

58. V S CR60

59. V LIN. 60

60. RF AGC

SOUND MODE

"

No. Setting ( Adjustment) item Vari able range Initial setting value

[ AV-14F33

/PH

Only ]

000~002

000~003

000~003

000~031

000~007

000~007

000~127

000~127

000~031

000~031

000~007

000~007

000~127

000~127

000~031

000~255

001

000

001

001

003

007

000

000

024

018

004

012

000

000

028

046

004

183

1. NOISE 000 / 001 001

2. IN LEVEL

3. FH MON. 000 / 001 000

4. ST VCO

5. PILOT 000 / 001 000

6. FILTER

7. LOW SEP.

8. HI SEP.

9. 5FH MON. 000 / 001 000

10. SAP VCO

11. IN GAIN 000 / 001 000

12. FIL. OFF.

VIDEO STATUS MODE

"

No. Setting (Adjustment) item Variable range

1. TINT

2. COLOR

3. PICTURE

4. BRIGHT

5. DETAIL

6. G DRIVE

7. B DRIVE

8. R CUT.

9. G CUT.

10. B CUT.

000~063

000~063

000~063

000~063

000~063

000~063

±010 (±000)

Initial setting value

CINEMA GAME

±20 (±0) (±0)

±20 -3 -3

±20 -10 -10

±20 (±0) (±0)

±15 (±0) -5

-99~+50 -22 (±0)

-99~+50 -54 (±0)

±10 (±0) (±0)

±10 (±0) (±0)

±10 (±0) (±0)

020

025

030

022

023

026

No.52021

13

Page 14

A

V-14F13

A

V-14F33

OTHERS MODE

"

No. Setting ( Adjustment) item Vari able range Initial setting value

1. OSD HP

2. OSD VP

3. H-CK SW 000 / 001 000

LOW LIGHT MODE

"

No. Setting ( Adjustment) item Vari able range Initial setting value

1. R CUTOFF

2. G CUTOFF

3. B CUTOFF

HIGH LIGHT MODE

"

No. Setting ( Adjustment) item Vari able range Initial setting value

1. G DRIVE

2. B DRIVE

RF AFC CHK MODE

"

No. Setting ( Adjustment) item Vari able range Initial setting value

000~031

000~015

000~255

000~255

000~255

000~255

000~255

023

012

020

020

020

128

128

1. RF AFC ON / OFF ON

2. FINE

2

C BUS CTRL MODE

I

"

No. Setting ( Adjustment) item Vari able range Initial setting value

1. I2C BUS ON / OFF [Fixed ON]

-77~+77

± **

(DO NOT ADJUST)

14

No.52021

Page 15

A

A

SERVICE ADJUSTMENTS

ADJUSTMENT PREPARATION

1. You can make the necessary adjust ments for this unit with

either the Remote Control Unit or With the adjustment tools

and parts as given below.

2. Adjustment with the Remote Control Unit is made on the

basis of the initial setting values, however, the new setting

values which set the screen to its optimu m condition may

differ from the initial settings.

3. Make sure that connection is correctly made to AC power

source.

4. Turn on t he power of the set and equipment before use, and

start the adjustment procedures after waiting at least 30 minutes.

5. Unless otherwis e specified, prepare the most suitable reception

or input signal for adjustment.

6. Never touch any adjustment parts, which are not specified

in the list for this adju stment VRs, transforms, condensers,

etc.

7. Preparation for adjustment

Unless otherwis e specified in the adjustment instructions, preset

the following functions with the REMOTE CONTROL UNIT.

User mode position

VIDEO STATUS STANDARD

TINT / COLOR / PICTURE

BRIGHT / DETAIL

BASS / TREBLE / BALANCE

MTS

HYPER SURROUND

SETUP TOUR ON

V-14F13

V-14F33

STANDARD

CENTER

[AV-14F33/PH Only]

STEREO

[AV-14F33/PH Only]

OFF

[AV-14F33/PH Only]

ADJUSTMENT EQUIPMENT

1. DC voltmeter (or digital voltmeter)

2. Oscill oscope

3. Signal generator (Pattern generator) [NTSC / PAL-M / PAL-N ]

4. Remote cont rol un it

5. TV audio multiplex signal generator.

6. Frequ ency c ounter.

ADJUSTMENT ITEMS

Adjustment item Adjustment item

B1 POWER SUPPLY

IF VCO adjustment VIDEO / CHROMA adjustment

RF AGC adjustment

FOCUS adjustment PURITY / CONVERGENCE adjustment.

DEFLECTION adjustment

MTS circuit adjustment [AV-14F33/PH Only]

No.52021

15

Page 16

A

V-14F13

A

V-14F33

BASIC OPERATION IN SERVICE MENU

1. TOOL OF SERVICE MENU OPERATION

Operate the SERVICE MENU with the REMOTE CONTROL UNIT.

2. SERVICE MENU ITEMS

In general basic setting (adjustments) items or verifications are performed in the SERVICE MENU.

(1) PICTURE・・・・・・・・・・・・・・・・・・・ This set the setting values (adjustment values) of the VIDEO/CHROMA and DEFLECT ION circuits.

(2) SOUND [ AV-14F33/PH ] ・・・・・ This set the setting values (adjustment values) of the AUDIO circuit.

(3) VIDEO STATUS ・・・・・・・・・・・・・ This is used when the THEATER and GAME MODE is adjusted.

(4) OTHERS ・・・・・・・・・・・・・・・・・・・ This is us ed when the OTHERS MODE is adjusted.

(5) LOW LIGHT・・・・・・・・・・・・・・・・・ This sets the s etting values (adjustment values) of the W HITE BALANCE circuit.

(6) HIGH LIGHT ・・・・・・・・・・・・・・・・ This sets the s etting values (adjustment values) of the W HITE BALANCE circuit.

(7) RF AFC CHK・・・・・・・・・・・・・・・・ This is us ed when the RF AFC CHK MODE is verified. [Do not adjust]

(8) VCO (CW) ・・・・・・・・・・・・・・・・・・ This is us ed when the IF VCO is adjusted.

2

(9) I

C BUS CTRL・・・・・・・・・・・・・・・ This is us ed when ON/OFF of the I2C BUS CTRL is set. [Fixed ON]

(10)

SETUP TOUR OFF・・・・・・・・・・ It should be able to select mode (LANGUAGE and SET CLOCK).

[Should be OFF]

3. Basic Operations of the SERVIC E MENU

(1) How to enter the SERVICE MENU.

Press the DISPLAY key and VIDEO STATUS key of the remote control unit

at the s ame time to enter the SERVICE MENU screen ①

shown in figure page later.

(2) SERVICE M ENU scr een selection

Press the UP / DOW N key of the MENU to select any of the

following items.

(The letters of the selected items are displayed in yellow.)

SERVICE MENU

PICTURE SOUND

VIDEO STATUS OTHERS

LOW LIGHT HIGH LIGHT

RF AFC CHK

VCO (CW) I2C BUS CTRL

SETUP TOUR(OFF)

SELECT BY

OPERATE BY

EXIT BY

EXIT

IT

(3) Enter the any setting ( adjustment ) mode

[AV-14F33/PH Only]

" PICTURE, SOUND and OTHERS mode

1) If select any of PICTURE, SOUND or OTHERS items, and the LEFT / RIGHT key is pressed from SERVICE MENU ( MAIN

MENU ), the screen ② will be displayed as shown in figure page later.

2) Then the UP / DOW N key is pressed, the PICTURE mode screen ③ or the SOUND mode screen ④ or the OTHERS mode

screen ⑤ is displayed, and the PICTURE, SOUND or OTHERS setting can be performed.

" VIDEO STATUS, LOW LIGHT, HIGH LIGHT, RF AFC CHK, VCO (CW) and I

1) If select any of VIDEO STATUS / LOW LIGHT / HIGH LIGHT / RF AFC CHK / VCO (CW ) / I

2

C BUS CTRL mode

2

C BUS CTRL items, and the LEFT

/ RIGHT key is pr essed from SERV ICE MENU ( MAIN MENU ), the screens ⑥ ⑦ ⑧ ⑨ ⑩ ⑪ will be displayed as shown in

figure page later.

2) Then the settings or verifications can be perf ormed.

" SETUP TOUR OFF mode

1) If select of SETUP TOUR OFF item from SERVICE MENU , and you c an change the ON or OFF(should be OFF).

(Should be OFF)

% If it is ON, then you turn the TV power off, when you are turn the TV pow er on again.

The JVC is logo will be shown about 15 seconds automatically.

2) MENU -/+ Key ・・・・・・・・・・・・・ Select Language.

3) MENU ▼ Key・・・・・・・・・・・・・ Auto Search.

16

No.52021

Page 17

A

A

(4) Setting method

1) UP / DOWN key of the MENU

Select the SETTING ITEM.

2) LEFT / RIGHT key of the MENU

Setting (adjust) the SETTING VALUE of the SETTING ITEM.

When the key is released the SETTING VALUE will be stored

(memorized).

3) EXIT key

Returns to the previous screen.

[NOTE] (PICTURE MODE ONLY)

When the INITIAL SETTING VALUE is turned to yellow, you can adjust the

values but you cannot adjust the values when it is turned to red.

(Becaus e the signal c onditions, etc. are not met.)

(5) Releasing SERVICE MENU

1) After returning to the SERVICE MENU upon c ompletion of the setting

(adjustment) work, press the EXIT key again.

SETTING

ITEM

1. PICTURE

********

******** ****

****************

SELECT BY

OPERATE BY

SETTING

VALUE

***

***

******

****

********

EXIT BY

EXIT

PICTURE MODE

1. NOISE

STATUS

********

********

******** ********

SELECT BY

OPERATE BY

***

***

******

EXIT BY

EXIT

V-14F13

V-14F33

IT

IT

★ The settings for LOW LIGHT and HIGH LIGHT are described in the W HITE

BALANCE page of ADJUSTMENT.

★ The setting for VCO (CW) are described in the IF VCO page of ADJUSTMENT.

The letter of the

selected

Items are displayed in yellow.

CINEMA

TINT G DRIVE

COLOR B DRIVE

PICTURE R CUT.

BRIGHT G CUT.

DETAIL B CUT.

SELECT BY

OPERATE BY

***

*** ***

******

***

*** ***

******

***

*** ***

******

***

*** ***

******

***

*** ***

******

EXIT BY

EXIT

***

******

***

******

***

******

***

******

***

******

Press

VIDEO

STAT US

Key

SOUND MODE

[ AV-14F33

1. OSD HP

SELECT BY

OPERATE BY

/PH

Only ]

OTHERS MODE

GAME

TINT G DRIVE

COLOR B DRIVE

PICTURE R CUT.

BRIGHT G CUT.

DETAIL B CUT.

SELECT BY

OPERATE BY

***

*** ***

******

***

*** ***

******

***

*** ***

******

***

*** ***

******

***

*** ***

******

EXIT BY

***

***

******

EXIT BY

EXIT

EXIT

***

******

***

******

***

******

***

******

***

******

IT

VIDEO STATUS MODE

No.52021

17

Page 18

A

V-14F13

A

V-14F33

SERVICE MENU FLOW CHART

①

①

SERVICE MENU (MAIN MENU)

① ①

SERVICE MENU

PICTURE SOUND

VIDEO STATUS OTHERS

LOW LIGHT HIGH LIGHT

RF AFC CHK

VCO (CW) I2C BUS CTRL

SETUP TOUR OFF

SELECT BY

OPERATE BY

EXIT BY

EXIT

②

②

SCREEN

② ②

SELECT BY EXIT BY

EXIT

③

③

PICTURE MODE

③ ③

1. PICTURE

********

******** ****

****************

SELECT BY

OPERATE BY

***

***

******

****

********

EXIT BY

EXIT

ON / OFF

⑧

⑧

HIGH LIGHT MODE

⑧ ⑧

⑨

⑨

RF AFC CHK MODE

⑨ ⑨

RF AFC ON

FINE

SELECT BY

OPERATE BY

⑩

⑩

⑩ ⑩

HIGH LIGHT

***

*** ***

******

VCO (CW) MODE

AV-14F33 Only

***

******

EXIT BY

EXIT

DO NOT ADJUST

***

***

******

EXIT BY

EXIT

④

④

SOUND MODE

④ ④

1. NOISE

STATUS

SELECT BY

OPERATE BY

AV-14F33 Only

***

***

******

********

********

****************

EXIT BY

EXIT

⑥

⑥

VIDEO STATUS MODE

⑥ ⑥

⑤

⑤

OTHERS MODE

⑤ ⑤

1. OSD HP

SELECT BY

OPERATE BY

***

***

******

EXIT BY

EXIT

CINEMA

TOO HIGH

ABOVE REFERENCE

BELOW REFERE NCE

TOO LOW

SYNC : YES

⑪

⑪

I2C BUS CTRL MODE

⑪ ⑪

I2C BUS ON

OPERATE BY

EXIT BY

EXIT

FIXED ON

EXIT BY

EXIT

I

T

TINT G DRIVE

COLOR B DRIVE

PICTURE R CUT.

BRIGHT G CUT.

DETAIL B CUT.

SELECT BY

OPERATE BY

BRIGHT

18

***

*** ***

******

***

*** ***

******

***

*** ***

******

***

*** ***

******

***

*** ***

******

EXIT BY

⑦

⑦

LOW LIGHT MODE

⑦ ⑦

BRIGHT

***

*** *** ***

*** ***

***

***

******

*** ***

*** ****** ***

EXIT BY

No.52021

EXIT

EXIT

***

******

***

******

***

******

***

******

***

******

Press

VIDEO

STATUS

Key

GAME

TINT G DRIVE

COLOR B DRIVE

PICTURE R CUT.

BRIGHT G CUT.

DETAIL B CUT.

SELECT BY

OPERATE BY

***

*** ***

******

***

*** ***

******

***

*** ***

******

***

*** ***

******

***

*** ***

******

EXIT BY

EXIT

***

******

***

******

***

******

***

******

***

******

Page 19

A

A

ADJUSTMENT LOCATIONS

V-14F13

V-14F33

FRONT

S901

POWER

SW

CRT SOCKET PWB

(Within MAIN PWB ASS'Y)

(SOLDER SIDE)

MAIN PWB

PW

F901

TOP

TP-E

E1

TP-47B

T

U

CRT EARTH

(BRAIDED ASS'Y)

AV-14F13/PH : MONO

AV-14F33/PH : STEREO

AV IN

S

IC701

IC704

MEMORY IC

DEG.

AV-14F33/PH : STEREO

T

MPX

[Only AV-14F33/PH]

AV IN OUT

AV-14F13/PH : MONO

15

T111

HV

TUNER

CW

X

3Pin:GND(TP-E)

ANT

1Pin:B1(TP-91)

U

1

3

B1

HVT

UPPER : FOCUS

LOWER : SCREEN

No.52021

19

Page 20

A

V-14F13

A

V-14F33

■■■■ ADJUSTMENTS

B1 POWER SUPPLY

Item

Measurin g

instrument

Check of

DC Voltmeter B1 (

B1 POWER

SUPPLY

IF VCO ADJUSTMENT

Item

IF VCO

adjustment

Measurin g

instrument

Signal

generator

TOO HIGH

ABOVE REFERENCE

BELOW REFERENCE

TOO LOW

SYNC : YES

Test point Adjustment item Description

B1

Connector

1

pin)

(TP-91)

1. Receive a black and white signal (color off). (NTSC)

2. Connect a DC voltmeter to TP-91(B1) and TP-E(#).

3. Confirm that the voltage is DC134.5V±2V.

TP-E(#)

(

B1

Connector

3

pin)

Test point Adjustment item Description

CW TRANSF. (T111)

[ VCO (CW) ] mode

" Under normal conditions, no adjustment is required.

1. Receive a broadcast. (use channels without offset frequency).

2. Select the VCO(CW ) mode from the SERVICE MENU.

3. Confirm the color change (yellow) from TOO HIGH to TOO

LOW by CW TRANSF.(T111) and S YNC : YES being s hown

on the screen. Then, adjust CW TRANSF.(T111) until BELOW

REFERENCE mark turns yellow and confirm again SYNC :

YES being shown on the screen.

YELLOW

EXIT BY

EXIT

IT

RF AGC ADJUSTMENT

RF AGC

adjustment

No. Setting item

60 RF AGC

FOCUS ADJUSTMENT

FOCUS

adjustment

Signal

generator

Variable

range

000~255

No.60 RF AGC 1. Receive a br oadcast.

2. Select No.60 RF AGC of the PICTURE mode in SERVICE

MENU.

3. Press the MUTE key and turn off color.

4. With the MENU LEFT key, get noise in the screen picture. (0

Initial setting

value

183

side of setting value)

5. Press the MENU RIGHT key and stop when noise disappears

from the screen.

6. Change to other channels and make sure that there is no

irregularity.

7. Press the MUTE key and get color out.

FOCUS VR

[ In HVT ]

1. Receive a crosshatch signal.

2. While looking at the screen, adjust FOCUS VR so that the

vertical and horizontal lines will be clear and in fine detail.

3. Make sure that the pictur e is in focus even when the screen

gets darkened.

20

No.52021

Page 21

A

A

DEFLECTION ADJUSTMENT

V-14F13

V-14F33

Item

V. HEIGHT,

V. POSITION,

V. LIN.

V. S CR

adjustment

No. Setting item

56 V POS.60

57 V SIZE 60

58 V S CR60

59 V. LIN60

Screen

size

(92%)

Measurin g

instrument

Signal

generator

Test point Adjustment item Description

[60Hz]No.56 V POS. 60

Variable

range

000~007

000~127

000~127

000~31

Scree size

No.57 V SIZE 60

No.58 V S CR60

No.59 V. LIN. 60

Initial setting

value

000

028

046

004

No.50 V POS.50

No.51 V SIZE 50

No.52 V S CR50

No.53 V LIN. 50

Picture

size

(100%)

1. Receive a crosshatch signal.(NTSC or PAL-M)

2. Confir m that the value of PICTURE MODE N o.56 V POS. 60 is

0.

3. Confirm the initial s etting value of the N o.57 V SIZE 60, No.58

V S CR60 and No.59 V LIN. 60.

4. Adjust the vertical screen size to 92% with the PICTURE

MODE No.57 V SIZE60.

5. Adjust the PICTURE MODE No.59 L LIN. 60 and No.58 V S

CR60 to get the best vertic al linearity.

NOTE :

The PICTURE MODE N o.56 V POS. 60 is fixed on value 0.

[50Hz]

1. Receive a crosshatch signal. (PAL-N)

2. Confirm the initial setting value of the No.50 V POS.50, No.51

V SIZE 50, No.52 V S CR 50 and No.53 V LIN.50.

3. Adjust the vertical screen size to 92% with the PICTURE

MODE No.51 V SIZE50.

4. Adjust the PICTURE MODE No.53 V LIN.50 and No.52 V S

CR50 to get the best vertic al linearity.

5. Adjust the PICTURE MODE No.50 V POS.50 so that the

vertical center line c omes close to the CRT vert ical center as

much as possible.

" Readjust V SIZE , V LIN ., V S CR if necessary.

No. Setting item

Variable

range

Initial setting

value

H. POSITION

adjustment

No. Setting item

54 H POS.60

No. Setting item

48 H POS.50

Signal

generator

Picture size

Variable

range

000~031

Variable

range

000~031

(100%)

Initial setting

value

012

No.48 H POS.50

Initial setting

value

007

50 V POS.50

51 V SIZE 50

52 V S CR50

53 V LIN.50

[60Hz]No.54 H POS.60

1. Receive a cross hatch signal. (NTSC or PAL-M)

2. Select the No.54 H POS. 60 of the PICTURE mode in

SERVICE MENU.

3. Confirm the initial s etting value of the N o.54 H POS. 60.

4. Adjust the No.54 H POS. 60 until the screen will be horizontally

centered.

[50Hz]

1. Receive a crosshatch signal. (PAL-N)

2. Select the No.48 H POS. 50 of the PICTURE mode in

SERVICE MENU.

3. Confirm the initial s etting value of the N o.48 H POS. 50.

4. Adjust the No.48 H POS. 50 until the screen will be horizontally

centered.

000~007

000~127

000~127

000~31

000

024

018

004

No.52021

21

Page 22

A

V-14F13

A

V-14F33

VIDEO / CHROMA ADJUSTMENT

Item

WHITE

BALANCE

(Low Light)

adjustment

Measurin g

Test point Adjustment item Description

instrument

Signal

generator

Remote

control unit

[LOW LIGHT] MODE

R CUTOFF

G CUTOFF

BRIGHT

***

BRIGHT

BRIGHT

Remote Control Unit

H.LINE ON

1 2

R CUTOFF

4 5

R CUTOFF

7 8

***

******

*** *** ***

*** *** ***

*** *** ****** *** ***

H.LINE OFF

G CUTOFF

G CUTOFF

B CUTOFF

EXIT BY

EXIT

EXIT

3

B CUTOFF

6

B CUTOFF

9

BRIGHT

R CUTOFF

G CUTOFF

B CUT OFF

SCREEN VR

IT

1. Receive a black and white signal (color off).

2. Select the LOW LIGHT mode from the SERVICE MENU.

3. Confirm the Initial setting value of BRIGHT, R CUTOFF, G

CUTOFF and B CUTOFF.

4. Display a single horizontal line by pressing the ①①①① key of the

remote c ontrol unit.

5. Turn the screen VR all the way to the left.

6. Turn the scr een VR gradually to the right from the left until

either one of the red, blue or green colors appears faintly.

7. Adjust the two colors which did not appear until the single

horizontal line that is displayed becomes white using the ④④④④ to

⑨⑨⑨⑨ keys of the remote control unit.

8. Turn the scr een VR to where the single horizontal line glows

faintly.

9. Press the ②②②② key to return to the regular screen.

No. Setting item

2BRIGHT

1R CUTOFF

2G CUTOFF

3B CUTOFF

Variable

range

0~127

0~255

0~255

0~255

Initial setting

value

064

020

020

020

WHITE

BALANCE

(High Light)

adjustment

Signal

generator

Remote

control unit

[HIGH LIGHT] MODE

G DRIVE

HIGH LIGHT

B DRIVE

***

******

***

******

******

EXIT BY

EXIT

G DRIVE

B DRIVE

IT

1. Receive a black and white signal (color off).

2. Select the HIGH LIGHT mode in the SERVICE MEN U.

3. Confirm the initial s etting value of G DRIVE and B DRIVE.

4. Adjust the screen color to white with the⑤⑤⑤⑤, ⑥⑥⑥⑥, ⑧⑧⑧⑧ and ⑨⑨⑨⑨

keys of the remote control unit.

Remote Control Unit

H.LINE ON

No. Setting item

1 G DRIVE

2B DRIVE

H.LINE OFF

1 2

G DRIVE

4 5

G DRIVE

7 8

000~255

000~255

Variable

range

EXIT

3

B DRIVE

6

B DRIVE

9

Initial setting

value

128

128

22

No.52021

Page 23

A

V-14F13

A

V-14F33

Item

SUB BRIGHT

adjustment

No. Setting item

2BRIGHT

SUB

CONTRAST

adjustment

No. Setting item

1PICTURE

SUB COLOR

Adju stment

[ⅠⅠⅠⅠ]

Measurin g

instrument

Remote

control unit

Remote

control unit

Remote

control unit

Test point Adjustment item Description

No.2 BRIGHT 1. Receive a broadcast.

2. Select No.2 BRIGHT of the PICTURE mode in SERVICE

MENU.

3. Confirm the initial s etting value of the N o.2 BRIGHT.

Variable

range

000~127

Variable

range

000~127

Initial setting

value

064

No.1 PICTURE 1. Receive a broadc ast.

Initial setting

value

040

4. If the brightness is not the best with the initial setting value,

make fine adjustment of the No.2 BRIGHT until you get the

optimum brightness.

2. Select No.1 PICTURE of the PICTURE mode in SERVICE

MENU.

3. Confirm the initial s etting value of the N o.1 PICTURE.

4. If the contrast is not the best with the initial setting value, make

fine adjustment of the N o.1 PICTURE until you get the

optimum contrast.

[PAL-M]No.3 COL. PALM

1. Receive a PAL-M broadcast.

2. Select No.3 COL. PALM of the PICTURE mode in SERVICE

MENU.

3. Confirm the initial s etting value of the N o.3 COL. PALM.

4. If the color is not the best with the initial s etting value, make

fine adjustment until you get the best color.

No. Setting item Variable

3COL.PALM

4COL.PALN

5COL.NTSC

SUB TINT

adjustment

[ⅠⅠⅠⅠ]

No. Setting item

6TINT

Remote

control unit

range

000~127

000~127

000~127

Variable

range

000~127

[PAL-N]No.4 COL. PALN

Initial setting

value

070

070

072

No.5 COL. NTSC

No. 6 TINT 1. Receive a NTSC color bar signal.

Initial setting

value

065

1. Receive a PAL-N broadc ast.

2. Select No.4 COL. PALN of the PICTURE mode in SERVICE

MENU.

3. Confirm the initial s etting value of the N o.4 COL. PALN.

4. If the color is not the best with the initial s etting value, make

fine adjustment until you get the best color.

[NTSC]

1. Receive a NTSC broadcast.

2. Select No.5 COL. NTSC of the PICTURE mode in SERVICE

MENU.

3. Confirm the initial s etting value of the N o.5 COL. NTSC.

4. If the color is not the best with the initial s etting value, make

fine adjustment until you get the best color.

2. Select No. 6 TINT of the PICTURE mode in SERVCE MENU.

3. Confirm the initial s etting value of the N o. 6 TINT.

4. If the tint is not the best with the initial setting value, make fine

adjustment until you get the best tint.

No.52021

23

Page 24

A

V-14F13

A

V-14F33

Item

Adju stment

of SUB

COLOR-ⅡⅡⅡⅡ

W

Y

Cy

Measurin g

instrument

" Signal

generator

" Oscillo-

scope

" Remote

control

unit

G

R

Mg

Test point Adjustment item Description

B

TP-47B

TP-E(####)

[ CRT

SOCKET

PWB ]

( )

0V

(+)

(A)

3. COL. PALM

[Method of adjustment using measuring instrument]

(PAL-M COLOR)

1. Receive a PAL-M full field color bar signal (75% white).

2. Select the sub menu screen PICTURE from the SERVICE

MENU.

3. Select 3. COL. PALM with the MENU / key , and confirm

its initial setting value.

4. Connect the oscillosc ope between TP-47B and TP-E.

1. Adjust 3. COL. PALM to set the value (A) in the figure to +7V

(W & B), with the MENU -/+ key

(PAL-N COLOR)4. COL. PALN

1. Receive a PAL-N full field color bar signal (75% white).

2. In the sub menu screen PICTURE, select 4. COL. PALN with

the MENU / key, and conf irm its initial setting value.

3. Connect the oscillosc ope between TP-47B and TP-E.

4. Adjust 4. COL. PALN to set the value (A) in the figure to

+18V(W & B), with the MENU -/+ key.

Adju stment

of

SUB TINT-ⅡⅡⅡⅡ

W

Y

Cy

" Signal

generator

" Oscillo-

scope

Remote

control

unit

G

R

Mg

B

TP-47B

TP-E(####)

[ CRT

SOCKET

PWB ]

( )

0V

(+)

(B)

5. COL. NTSC

6.TINT 1. Receive a NTSC 3.58 color bar signal (full field color bar

(NTSC COLOR)

1. Receive a NTSC full field color bar signal ( 75% white).

2. In the sub menu screen PICTURE, select 5. COL. NTSC with

the MENU / key, and conf irm its initial setting value.

3. Connect the oscillosc ope between TP-47B and TP-E.

4. Adjust 5. COL. NTSC to set the value (A) in the figure to

+22V(W & B), with the MENU -/+ key.

[Method of adjustment using measuring instrument]

75%white).

2. Select the sub menu screen PICTURE from the SERVICE

MENU.

3. Select 6. TINT with the MENU / key, and c onfirm its initial

setting value.

4. Connect the oscillosc ope betweenTP-47B and TP-E.

5. Adjust 6. TINT to set the value (B) in the figure to +14V(W &

Mg), with the MENU -/+ key.

24

No.52021

Page 25

A

A

VIDEO STATUS ADJUSTMENT ( Do not adjust. Each value should be set to the initial value. )

V-14F13

V-14F33

Item

Setting

of

VIDEO

STAT US

Measurin g

Test point Adjustment item Description

instrument

Remote

control unit

SUB MENU : VIDEO STATUS

GAME

TINT G DRIVE

COLOR B DRIVE

PICTURE R CUT.

BRIGHT G CUT.

DETAIL B CUT.

SELECT BY

OPERATE BY

***

*** ***

******

***

*** ***

******

***

*** ***

******

***

*** ***

******

***

*** ***

******

EXIT BY

EXIT

***

******

***

******

***

******

***

******

***

******

IT

TINT

COLOR

PICTURE

BRIGHT

DETAIL

G DRIVE

B DRIVE

R CUT.

G CUT.

B CUT.

1. Select the sub menu screen VIDEO STATUS-CINEMA from

the SERVICE MENU.

2. Select TINT ~ B CUT. with the MENU / key, and reset

each value to the initial setting value with the MENU -/+

key.

3. Pr ess the VIDEO STAT US key on the remote control unit to

select VIDEO STATUS-GAME. (Each time you press the

VIDEO ST ATUS key, CINEMA and GAME alternates.)

4. Make similar settings as in 2 above.

No. Setting item

1TINT

2 COLOR

3PICTURE

4BRIGHT

5DETAIL

6 G DRIVE

7B DRIVE

8R CUT.

9G CUT.

10 B CUT

Variable

Range

CINEMA

±20 (±0) (±0)

±20

-30~+20

-3 -3

-10 -10

±20 (±0) (±0)

±15 (±0) (±0)

-99~+50

-99~+50

-22 -5

-54

±10 (±0) (±0)

±10 (±0) (±0)

±10 (±0) (±0)

GAME

(±0)

No.52021

25

Page 26

A

V-14F13

A

V-14F33

MTS CIRCUIT ADJUSTMENT

Item

INPUT

LEVEL

check

STEREO VCO

adjustment

No. Setting item

2IN LEVEL

3FH MON000 / 001 000

4ST VCO

SAP

VCO

adjustment

No. Setting item

95FH MON.000 / 001 000

10 SAP VCO.

6FILTER

7 LOW SEP.

8 HI SEP.

Measurin g

instrument

Signal

generator

Frequency

counter

Signal

generator

Frequency

counter

R OUT

[AUDIO OUT]

000~063

000~063

MPX

Connector

4 pin SDA

3 pin GND

[MAIN PWB]

R OUT

[AUDIO OUT]

[ AV-14F33

Test point Adjustment part Description

Variable

range

Variable

range

000~063

000~063

000~063

000~063

/PH

Only ]

No.2 IN LEVEL 1. Select the No.2 IN LEVEL of the SOUND mode in SERVICE

MENU.

2. Verify that the No.2 IN LEVEL is set at its initial setting value.

No.3 FH MON

No.4 ST VCO

Initial setting

value

020

025

No.9 5FH MON.

No.10 SAP VCO.

Initial setting

value

026

030

022

063

1. Receive a NTSC RF signal (non modulated sound signal) from

the antenna terminal.

2. Select the No.3 FH MON of SOUND mode in SERVICE

MENU, change the setting value from 0 to 1.

3. Connect the frequency connector to R OUT RCA pin of the

AUDIO OUT

4. Select the No.4 ST VCO.

5. Confirm the initial setting value of the No.4 ST VCO.

6. Adjust the No.4 ST VCO so that the frequency c ounter will

display 15.73kHz±0.1kHz.

7. Select the No.3 FH MON of the SOUND mode, and reset the

setting value from 1 to 0.

1. Receive a NTSC RF signal (non modulated sound signal) from

the antenna terminal.

2. Connect between pin 4 of MP X connector and GND (pin

3 of MPX connector) through 1MΩ resistor.

3. Select the No.9 5FH MON. of the SOUND mode in SERVICE

MENU, and reset the setting value from 0 to 1.

4. Connect the frequency connector to R OUT RCA pin of the

AUDIO OUT.

5. Select the No.10 SAP VCO.

6. Confirm the initial setting value of No.10 SAP VCO.

7. Adjust the No.10 SAP VCO so that the frequency connector

will display 78.67kHz±0.5kHz.

8. Select the No.9 5FH MON. of the SOUND mode, and reset the

setting value from 1 to 0.

FILTER

check

SEPARATION

adjustment

L-Channel

signal waveform

1 cycle

26

TV audio

multiplex

signal

generator

Oscilloscope

L OUT

R OUT

[AUDIO OUT]

R-Channel

crosstalk portion

Minimum

No.6 FILTER

No.7 LOW SEP.

No.8 HI SEP.

1. Select the No.6 FILTER of the SOUND mode in SERVICE

MENU.

2. Verify that the No.6 FILTER is s et at its initial setting value.

1. Input a ster eo L signal (300Hz) from the TV Audio multiplex

signal generator to the antenna terminal. (NTSC)

2. Connect an oscilloscope to L OUT RCA pin of the AUDIO

OUT, and display one c ycle portion of the 300Hz signal.

3. Change the connection of the oscilloscope to R OUT RCA pin

of the AUDIO OUT, and enlarge the voltage axis.

4. Select the No.7 LOW SEP. of the SOUND mode in SERVICE

MENU.

5. Confirm the initial setting value of the No.7 LOW SEP.

6. Adjust the No.7 LOW SEP. so that the stroke element of the

300Hz signal will become minimum.

7. Change the signal to 3kHz, and similarly adjust the “No.8 HI

SEP.

No.52021

Page 27

A

A

PURITY / CONVERGENCE ADJUSTMENT

PURITY ADJUSTMENT

1. Demagnetize CRT with the demagnetizer.

V-14F13

V-14F33

2. Loosen the retainer screw of the deflection yok e.

3. Remove the wedges.

4. Input a green raster signal from the signal generator, and turn

the screen to green r aster.

5. Move the deflection yoke backward.

6. Bring the long lug of the purity magnets on the short lug and

position them horizontally. (Fig.2)

7. Adjust the gap between two lugs so that the GREEN RASTER

will come into the center of the scr een. (Fig.3)

8. Move the deflection yoke forward, and fix the position of the

deflection yoke so that the whole screen will become green.

9. Insert the wedge to the top side of the deflection yoke so that it

will not move.

WEDGE

CRT

# P/C MAGNETS

P : PURITY MAGNET

4 : 4 POLES

6 : 6 POLES

(convergence magnets)

(convergence magnets)

Fig.1

PURITY MAGNETS

DEFLECTION

YOKE

P

46

P / C

MAGNE TS

10. Input a crosshatch signal.

11. Verif y that the screen is horizontal.

12. Input red and blue raster signals, and make sure that purity is

properly adjusted.

Long lug

Short lug

(FRONT VIEW )

Bring the long lug over the short lug

and position them horizontally.

Fig.2

GREEN RASTER

CENTER

Fig.3

No.52021

27

Page 28

A

V-14F13

A

V-14F33

STATIC CONVERGENCE ADJUSTMENT

1. Input a crosshatch signal.

2. Using 4-pole convergence magnets, overlap the red and blue

lines in the center of the screen (Fig.1) and turn them to

magenta (red/blue).

3. Using 6-pole convergence magnets, overlap the

magenta(red/blue) and green lines in the center of the screen

and turn them to white.

4. Repeat 2 and 3 above, and make best convergence.

DYNAMIC CONVERGENCE ADJUSTMENT

1. Move the deflection yok e up and down and overlap the lines in

the periphery. (Fig. 2)

2. Move the deflection yok e left to right and overlap the lines in the

periphery. (Fig. 3)

3. Repeat 1 and 2 above, and make best convergence.

(FRONT VIEW )

(FRONT VIEW )

BLUE

GREEN

RED

RED

Fig.1

GREEN

BLUE

RED

GREEN

BLUE

●

After adjustment, fix the wedge at the original position.

Fasten the retainer screw of the deflection yoke.

Fix the 6 magnets with glue.

(FRONT VIEW )

GREEN

RED

BLUE

BLUE

GREEN RED

Fig.2

Fig.3

BLUE

GREEN

RED

RED

GREEN

BLUE

BLUE

GREEN

RED

28

No.52021

Page 29

A

A

HOW TO CHECK THE HIGH VOLTAGE HOLD DOWN CIRCUIT

1. HIGH VOLTAGE HOLD DOWN CIRCUIT

After repairing the high voltage hold down circuit shown in Fig. 1.

This circuit shall be checked to operate correctly.

2. CHECKING OF THE HIGH VOLTAGE HOLD DOWN CIRCUIT

(1) Turn the POWER SW ON.

(2) As shown in Fig.2, set the resistor (between X connector 1 & 3 ).

(3) Make sure that the screen picture disappears.

(4) Temporarily unplug the power cord.

(5) Remove the resistor (between X connector 1 & 3 ).

(6) Again plug the power cord, make sure that the normal picture is displayed on the screen.

B1

Q52

2

Q94

2

Q941

H-Vcc

IC201

3

H-OUT

4

T521

V-14F13

V-14F33

T522

HVT

10

IC701

27 28

Q511

D510

3 2 1

R562

D562

R563

Fig. 1

RESISTOR

RESISTOR

RESISTORRESISTOR

15.0kΩ±1% 1/4W

15.0kΩ±1% 1/4W

15.0kΩ±1% 1/4W15.0kΩ±1% 1/4W

3 2 1 X

Q521

Fig.2

X

FR561

4

D561

C561

HEATER

CONNECTOR

R562

D562

R563

Fig. 2

No.52021

C561

FR561

D561

29

Page 30

A

V-14F13

A

V-14F33

SELF CHECK FUNCTIONS

1. Outline

This model includes protector functions for Over-current, X-ray and CRT NECK which cutoff the sub-pow er in the event of a malfunction and

inform of the malfunction by flashing ON TIMER LED.

The malfunction is detected according to the state of the control line input connected to the main CPU.

2. Self check items

Check item Detected cont ents Detection method Abnormality state

Over-current protector An over-curr ent on the B1 line

and Audio-Vcc line is detected.

[ AV-14F13/PH ]

An over-current on the B1 line is

detected. [ AV-14F33/PH ]

X-ray protector Operation of X-ray protection

circuit

CRT NECK protector W hen the vertical circuit S-

correction capacitor C 413 is

shorted, detect the potential

drop of the C413, and prevent

the burn damage to the CRT

NECK.

The main CPU detects at

1 second intervals.

If NG is detected f or more than

1 ms, a malfunction is interpreted.

The main CPU detects at

1 second intervals.

If NG is detected f or more than

1 ms, a malfunction is interpreted.

The main CPU detects at

1 second intervals.

If NG is detected f or more than

1 ms, a malfunction is interpreted.

During an abnormality the subpower is cutoff. The remote

controller power key operation is

not recognized and sub-power

off is maintained until the power

cord is unplugged and

reinserted.

During an abnormality the subpower is cutoff. The remote

controller power key operation is

not recognized and sub-power

off is maintained until the power

cord is unplugged and

reinserted.

During an abnormality the subpower is cutoff. The remote

controller power key operation is

not recognized and sub-power

off is maintained until the power

cord is unplugged and

reinserted.

3. Self check indicating function

The self check function begins detection about 5

seconds aft er power is supplied.

In the event a malfunction is detected, the sub-power is

cutoff immediately.

At this time, the ON TIMER LED flashes to inform of

the malfunction.

Item LED ON / OFF intervals Priority of detection

OCP/X-ray every 0.5-second 1

NECK every 1.0-second 2

30

POWER

supplied

No.52021

About 5 seconds

after

Detection

start

Malfuction is

detected

SUB-POWER OFF

Flashing

ON TIMER LED

Page 31

A

A

REPLACEMENT OF CHIP COMPONENT

! CAUTIONS

1. Avoid heating f or more than 3 s econds.

2. Do not rub the electrodes and the resist parts of t he pattern.

3. When removing a chip part, melt the solder adequately.

4. Do not reuse a chip part after removing it.

! SOLDERING IRON

1. Use a high insulation soldering ir on with a thin pointed end of it.

2. A 30w soldering iron is recommended for easily removing parts.

! REPLACEMENT STEPS

1.

How to remove Chip parts

$ Resistor s, capacitors, etc.

(1) As shown in the figure, push the part with tweezers and

alternately melt the solder at each end.

V-14F13

V-14F33

2. How to install Chip parts

$ Resistor s, capacitors, etc.

(1) Apply solder to the pattern as indicated in the figur e.

(2) Shift with tweezers and remove the chip part.

$ Transistors, diodes, variable resistors, etc.

(1) Apply extra solder to each lead.

SOLDER

(2) As shown in the figure, push the part with tweezers and

alternately melt the solder at each lead. Shift and remove

the chip part.

SOLDER

(2) Grasp the chip part with tweezers and place it on the

solder. Then heat and melt the solder at both ends of the

chip part.

$ Transistors, diodes, variable resistors, etc.

(1) Apply solder to the pattern as indicated in the figur e.

(2) Grasp the chip part with tweezers and place it on the

solder.

(3) First solder lead

(4) Then solder leads

as indicated in the figure.

A

A

B

C

and C.

B

A

B

Note

: After removing the part, remove remaining solder from

the pattern.

No.52021

C

31

Page 32

A

V-14F13

A

V-14F33

32

No.52021

Loading...

Loading...