Page 1

AV14BJ8ENS / AV14BM8ENS

AV14BJ8EPS / AV14BM8EPS

AV14BJ8EES / AV14BM8EES

SERVICE MANUAL

COLOUR TELEVISION

AV14BJ8ENS / AV14BM8ENS AV14BJ8EPS / AV14BM8EPS AV14BJ8EES / AV14BM8EES

AV14BJ8 AV14BM8

CONTENTS

! SPECIFICATIONS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

!

SAFETY PRECAUT IONS

!

FEATURES・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

! MAIN DIFFERENCE LIST ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

!

SPECIFIC SERVICE INSTRUCTIONS

! SERVICE ADJUSTMENTS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

! PARTS LIST ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

★ STANDARD CIRCUIT DIAGRAM・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

1

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

COPYRIGHT © 2002 VICTOR COMPANY OF JAPAN, LTD.

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 5

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・ 13

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・ 2

・・・・・・

・・・・・・・・・ 5

・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・ 23

・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・2- 1

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

No.519 99

Apr. 2002

4

6

Page 2

A

V14BJ8ENS / AV14BM8ENS

A

A

V14BJ8EPS / AV14BM8EPS

V14BJ8EES / AV14BM8EES

SPECIFICATIONS

Content

It em AV14BJ8 ENS

Dimens ions ( W

Mass 9.2 kg 9.8 kg

TV RF System B/G (ENS models) B /G , L/ L’ ( EPS models) B/G , D /K (EES models)

Colour Sy stem

Sound System Mono

Teletext System WST (W orld Standard system)

Receiving Frequency

Intermediate Frequency

Colour Sub Carrier Freq.

Power Input AC 220V~240V , 50Hz

Power Consumpti on 75 W , 8W (Sta nd by)

Aerial Input Term 75 Ωun ba lanc ed, C oaxial

Picture Tube Size Visi ble s ize : 3 4cm, Meas ur ed diagon ally

Hi g h Volt age 25 .5 kV ( at z ero beam current )

Speaker 5cm ×9cm Ova l type×2 Φ8cm round type×2

Au dio Output 8W 3W

REAR TERMINAL(AV1) 21 -pin E uro c onnecto r

FRONT T ERMINAL Video 1Vp- p 75Ω( RCA pin ja ck )

Headphone jack Mini j ac k (φ3. 5m m )

Remote Control Unit VE-300 17763 (RM-C 11 00) , (A A/R 0 6 dry b attery×2)

××××H××××

D ) 44 6mm×3 30mm×3 77mm 37 4mm×3 32mm×3 91mm

PAL, NTSC3.58 / NTSC4.43(Only EXT mode)----ENS model

PAL , SECAM , NTSC3.58 / NTSC4.43(Only EXT mode)----EPS,EES models

VHF (VL) 46 .25 MHz ~ 168. 25 MH z

(VH) 17 5.25MHz ~ 46 3.2 5MHz

UHF 47 1.2 5MHz ~ 86 3.2 5MHz

CATV S1 -S 20& S2 1- S41 &S 75- S7 9 E NS models

S1 -S 20& S2 1- S41 &S 75- S7 9 E PS mo de ls

S1-S20&S21-S41 EES models

VIF Carrier 38 .9 MHz (B/G , D/K , L) / 3 3.9MHz (L’)

SIF Car rier 33.4MHz (5 .5MHz:B/G) / 32. 9MHz (6.0MHz:D/ K ) /32. 4MHz (6.5MHz:L ) /40.4MHz (6.5MHz:L’ )

PAL 4.43MHz

SE CAM 4.2 5MH z / 4.40 62 5MHz

NT S C 3.58MHz / 4.43MHz

Au di o 50 0mVr ms( - 4dBs ) , High Impedance ( RCA pin jack )

AV14 BJ8EPS

AV14 BJ8EES

AV 14 BM 8 EN S

AV 14 BM 8 EPS

AV 14 BM 8 EES

De sign & speci fications are su bject to change wi th ou t no tice.

2

No.51999

Page 3

A

S

A

S

A

S

■■■■21-pin Euro connector (SCART socket) : AV-1

(P-P= Peak to Peak, S-W= Sync tip to white peak, B-W= Blanking to white peak)

V14BJ8ENS / AV14BM8EN

V14BJ8EPS / AV14BM8EP

V14BJ8EES / AV14BM8EE

Pin No.

1

2

3

4

5

6

7

8

9

10 SCL3 NC

11 G input 70 0mV

12 SDA3 NC

13 GND (R) ○

14 GND (YS) ○

15

16

17 GND(VIDEO output) ○

18

19

20

21

AUDIO R o utput 50 0mVr ms( N omina l),

AUDIO R i n put 50 0mVrms(Nom i na l),

AUDIO L o utp ut 50 0mVrms(Nom i na l),

AUDIO GND ○

GND (B) ○

AUDIO L input 500mVrms(Nominal),

B in pu t

FUNCTON SW

(SLOW SW)

GND (G) ○

R / C input

Ys i n put

GND(VIDEO input)

VIDEO output

VIDEO / Y inp ut

COM MON G ND ○

Signal Designation Matching Value AV-1

Low impedance

High i mpeda nce

Low impedance

High i mpeda nce

70 0mV

Low : 0-3V, High : 8-12V, High

impedance

R : 700mV

C : 300mV

Low : 0 - 0.4, High : 1 - 3V, 75

1V

1V

, 75Ω○

B- W

, 75Ω○

B- W

, 75Ω

B- W

Ω

, 75

P- P

Ω○

(Nega tive goin g sync ), 75 Ω○

P- P

(Nega tive goin g sync ), 75 Ω○

P- P

○

(TV OUT)

○

○

(TV OUT)

○

○

○

(only R)

○

(TV)

[Pin assignmen t]

No.51999

3

Page 4

A

V14BJ8ENS / AV14BM8ENS

A

A

V14BJ8EPS / AV14BM8EPS

V14BJ8EES / AV14BM8EES

SAFETY PRECAUTIONS

1. The des ign of th is pr od uct con ta in s s p eci al hardware , ma ny

circuit s and components specially for safety pur poses. For

con tinu ed pr ot ection, n o chan ges sh ould b e ma de to the o rig inal

d esi gn un less a uthori zed i n writi n g by th e manu facturer.

Replacement p arts m ust b e ident ic al to thos e used in th e or igin al

ci rcu it s. Se r vic e sh ou ld be performed b y q ua lifie d per sonnel

on ly.

2. Alte rations of t he desig n or cir cuitry of t he pr od ucts s h ould not be

made. Any design alterations or additions will void the

manufact urer 's warr a nt y and w ill f urth er r elieve t he ma nu factu rer

of r esp ons ibility for per sonal inj ury or p roperty dam ag e r esul t in g

th erefr om.

3. Many e lectr i cal an d m ech anica l parts i n th e pr od ucts ha v e

special safety-related characteristics. T hese characteristics are

oft en no t evi den t f r om vi sual i nspecti on n or ca n t he pr o tect ion

aff or de d by th em nece ssar ily b e ob tai n ed b y us ing rep l acemen t

com po ne nts rated f or higher vo ltag e, w att ag e, etc. Rep l acemen t

p arts wh ic h ha ve th ese sp ecial s afet y c h aract er ist ics are

ide ntified in the parts list of S ervic e manua l. El ec tric al

components having su ch features are identified by shading

on the sch e mat ic s an d b y (!!!! ) on the parts list in Service

manual. The us e of a s ub stitute replac ement which do es n ot

h ave the sam e saf ety ch ar act er ist ics as t he r eco mm en de d

replac em ent par t shown i n th e p ar ts lis t of Ser vic e manual m ay

cause shock, fire, or other hazards.

4. Don't shor t between the LIVE s ide ground and ISOLATE D

(NEUTRAL) side ground or EARTH side ground when

repairing.

Some model's power circuit is partly different in the GND. The

diff er enc e of th e GND i s sh ow n by t he LI VE : (") side GND , the

ISO LATE D(NEU TR AL) : (#) side GND an d EA RTH : ($) side

GND. Don't short between the LIVE side GND and

ISO LATE D(NEU TR AL) s ide GN D or EARTH sid e GND an d

n ever m ea sur e w it h a m ea sur i ng a ppa ratus ( osci lloscop e etc.)

th e LI VE sid e GND an d IS OL AT ED(NE UTRAL ) side GND or

EARTH side GND at the same tim e.

If above note will not be kep t, a fuse or any parts will be broken.

5. If any repair has been made to the chassis, it is recommended

th at t he B1 set ting shou l d b e ch ecked or adju s te d ( Se e

ADJUSTMEN T OF B 1 POW E R SUPPL Y).

6. The high vol ta ge app lied t o th e pi cture tu be must c on for m wit h

th at s p eci fi ed in S ervi ce m an ual . E xcessive h i gh volt ag e c a n

cau se an incr e ase i n X- Ray em ission , arc ing and possib le

component damage, therefore operation under excessive high

voltage conditions should be kept to a minimum, or should be

preve nt ed. If s evere arc ing occurs , r emove t he AC power

immed i ate l y and de term i ne th e cause b y visua l insp ect ion

(inc orrec t in stall at i on, crac ke d or m elte d high v o lt age harness,

p oor so ld ering, et c.). To mai nt ai n the p r ope r minimu m level of

sof t X- Ray em ission, c omp on en ts in the high v oltag e ci rcui tr y

including t he pict ur e tu be must be t he e xac t r ep lacem e nts or

alternat ives ap prove d b y th e ma nuf act urer of th e c om plet e

product.

7. Do not c heck hi gh vol t age b y draw ing an arc . U se a hi gh volt age

meter or a hig h v ol tag e pr ob e wit h a VTV M. Dischar g e the

picture tube before attempting meter connection, by connecting

a cl ip lead to th e ground f ra me a nd c onn ectin g the oth er end of

the lead through a 10kΩ 2W resi stor to the an od e b utt on .

8. W hen service is r equ ired, ob ser ve th e origi na l lea d dr ess. E xtra

prec aut i on should b e g i ven t o ass ure cor rect l ea d dr ess in th e

high voltag e ci r cui t a r ea. W here a s hor t cir cuit has occu rred,

th ose co mp on ent s tha t i ndica te ev ide nce of ove r hea ti ng should

b e replac e d. A l ways u se the manuf act urer's replac ement

components.

9. Isolation Check

(Safety for Electrical Shock Hazard)

Af ter re- ass emb ling the p r odu ct, al ways per f orm an i solat ion

ch eck on the expo sed metal p ar ts of t he c abinet (ante nn a

ter mina ls, vid eo /au di o input and ou tpu t termi n als, C on tr ol kn obs,

metal cabinet, screwheads, earphone jack, control shafts, etc.)

to be sure the product i s s af e t o o pe r ate with ou t d an ger of

elect rical shoc k.

(1) Di electric Strength Test

The isolation be tween the A C pr ima ry ci rcu i t an d all me tal p ar ts

exp osed t o th e user, p articularly any e xp osed met al part havi ng a

retu rn path to t he chas s is s ho uld withs tan d a v olt age of 3 000 V

AC (r.m.s.) for a period of one sec ond.

(. . . . Withs tan d a voltage of 1 10 0V AC (r.m. s.) to an appli anc e

rate d up to 12 0V , and 3000V AC (r.m.s.) to an ap plian ce rat ed

200V or more, for a period of one second.)

This method of test requires a t est equipment not g enerally found

in the ser vice trad e.

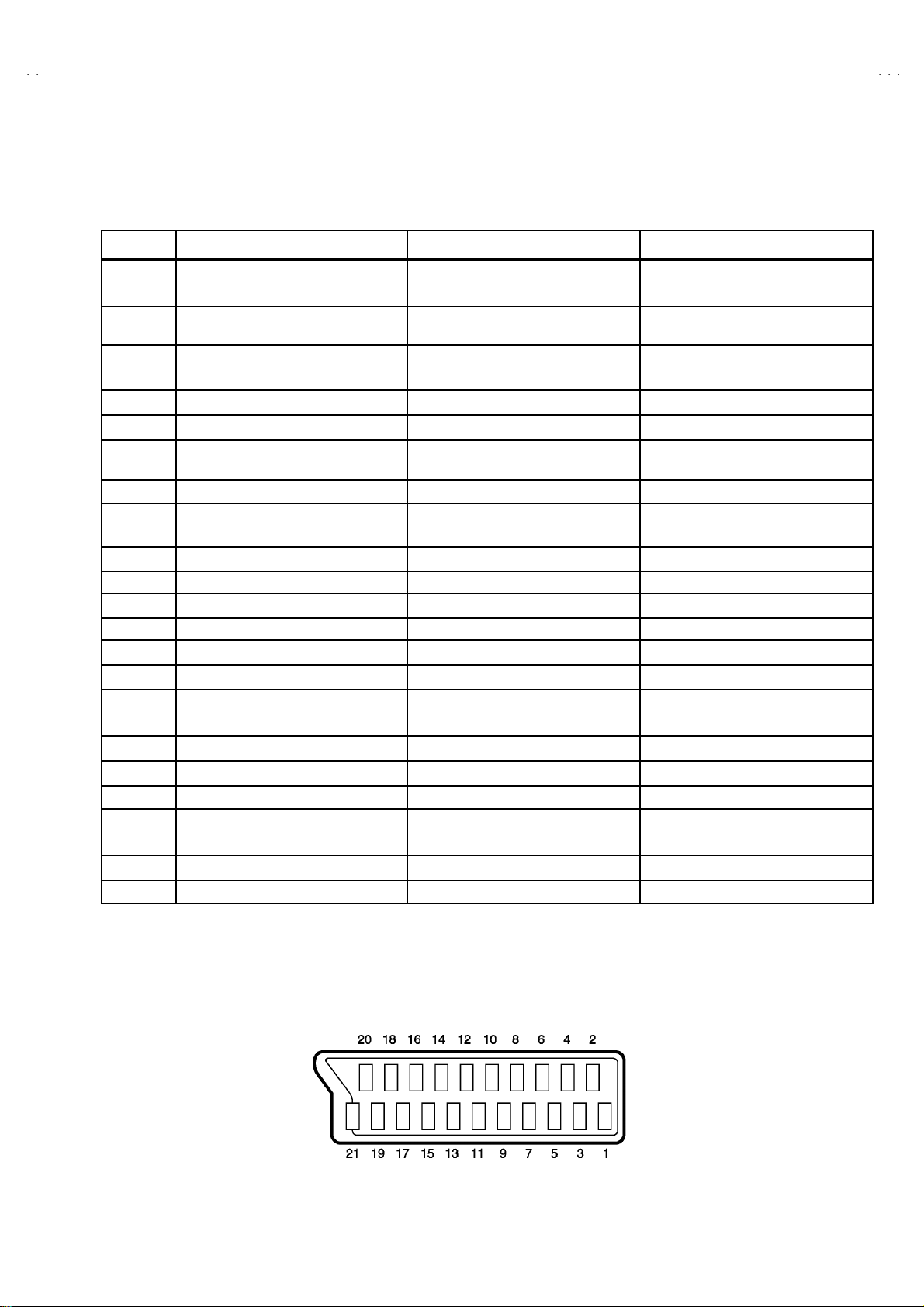

(2) Leakage Current Check

Plug th e A C lin e c ord d ir ect ly into th e A C ou tlet ( d o n ot use a lin e

isolation transf or m er du ring this ch eck.) . U si n g a " Lea kage

Curr ent Tester", me asure the lea kage cu rr e nt f rom each exp osed

metal part of the cabine t, p art icu l arly any e x pos ed me tal p ar t

h avi ng a r e tur n pa th to the ch assis , t o a kn own good earth

ground (wa ter pi p e, e tc.) . An y leaka ge curr en t m ust n ot e x ceed

0.5mA AC (r.m.s.).

However, in tropical ar ea , this must no t exceed 0.2 mA AC

(r.m.s.).

"""" Alternate Check Met ho d

Plug th e A C lin e c ord d ir ect ly into th e A C ou tlet ( d o n ot use a lin e

isolation transfor m er during this che c k.) . U se an AC voltmeter

h avi ng 1 00 0 oh ms pe r volt or m or e sens it i vity in the fo llow ing

manner. Con nec t a 1 50 0Ω 10W res ist or paralle le d b y a 0 .15µF

AC-type capacit or bet we en an expo s ed met al part a nd a kno wn

g ood e arth gro un d (water pi pe , etc.) . M eas ur e th e A C vo lt ag e

acr oss th e res ist or with th e AC v o ltmeter . M ove the res istor

con nec ti on to e ac h exp ose d metal part, p art icul arly a ny exposed

metal part havi n g a retu rn pat h to the chassis , an d m easu r e th e

AC vol tag e ac ross the res ist or. Now, rev erse th e pl u g i n th e AC

ou tlet and r e pe at eac h mea sur em en t. Any vol t ag e me asu red

must no t exc eed 0 .75V AC (r.m.s.). This c orre sponds to 0.5mA

AC (r.m.s.).

Howeve r, in tropical are a, this mu st n ot exceed 0.3V AC ( r .m.s.).

This corresponds to 0.2mA AC (r.m.s.).

AC VOLTMETER

(HAVING 1000 Ω/V,

OR MOR E SENSIT IVITY)

0.15μF AC-TYPE

PLACE THIS PROBE

1500 Ω 10W

GOOD EARTH GROUND

ON E A C H EX PO SE D

ME T AL PA R T

4

No.51999

Page 5

A

S

A

S

A

S

FEATURES

"

This TV set is monaural TV

" The TELETEXT S YSTEM has a built-in WST system.

"

Built-in CHILD LOCK function .

" Bu ilt-i n SLEEP TI ME R fun ction.

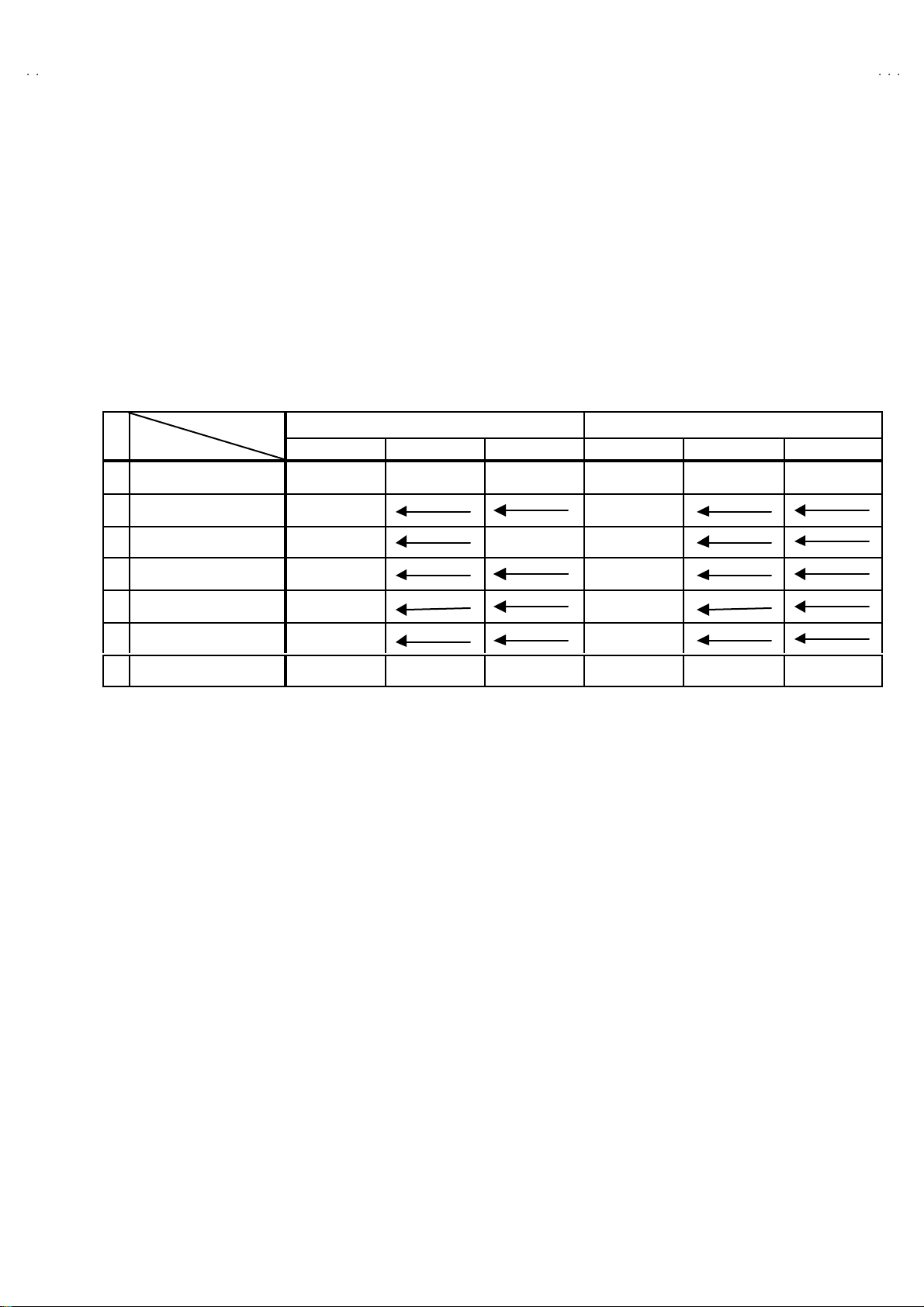

MAIN DIFFERENCE LIST

V14BJ8ENS / AV14BM8EN

V14BJ8EPS / AV14BM8EP

V14BJ8EES / AV14BM8EE

Model Name

!!!!

Part Name ENS EPS EES ENS EPS EES

MAIN PWB VE -2 00 962 09 VE -2 00 962 08 VE -2 00 962 07 VE -2 00 962 05 VE -2 00 962 62 VE -2 00 962 10

HE ADPHONE JACK

PWB

!

FRONT CABINET VE-2 0067676 VE-2 0089085

LENS ( FRONT PANEL) VE -2 00 677 13 VE -200 78589

!

SP EAKE R VE -300 01951 VE -3 00109 42

BACK COVER VE -2 00 802 04 VE -200 80407

!

INST BOOK

!

VE -2 00781 06 VE -2 00939 33

VE -5 00264 09 VE-500 26405 VE-50026402 VE-50026409 VE-50026405 VE-50026402

AV 14 BJ 8

AV 14 BM 8

No.51999

5

Page 6

A

V14BJ8ENS / AV14BM8ENS

A

A

V14BJ8EPS / AV14BM8EPS

V14BJ8EES / AV14BM8EES

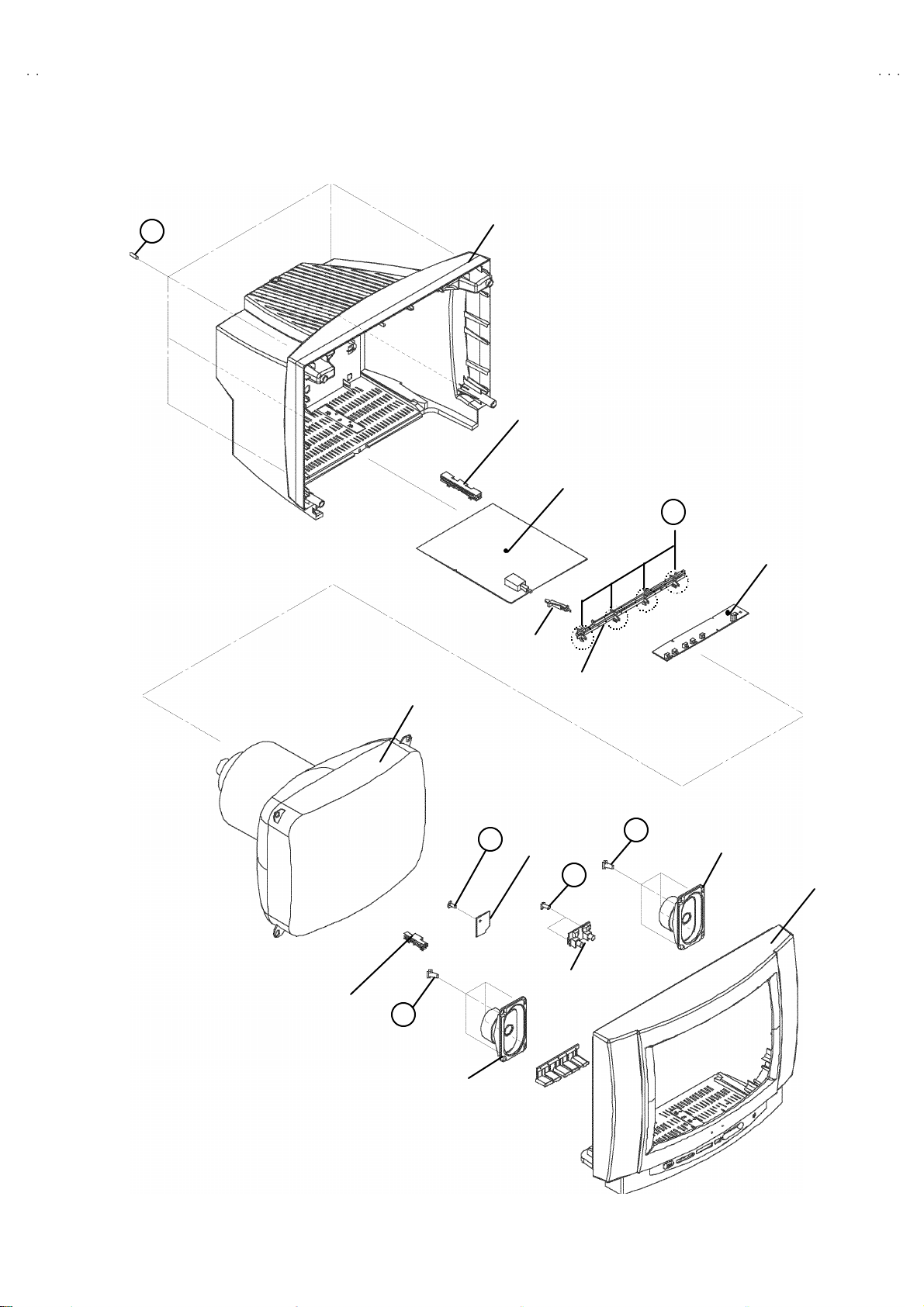

SPECIFIC SERVICE INSTRUCTIONS

DISASSEMBLY PROCEDURE

AV14BJ8ENS / EPS / EES

REMOVING THE REAR COVE R

1. Unplug t he po we r c ord.

2. Remove the 5 screws marked A as shown i n the F ig. 1.

3. Withdra w t he r ear co ver to ward y ou .

REMOVING THE MAIN PWB

" Removing the rear cover.

1. Slight ly rai se t he bo th sid es of th e chassis b y h and an d withd raw

th e M AIN PW B ba ckw ard.

(If n ecess ary, take off the wire clamp, co nnectors etc.)

REMOVING THE SPEAKER

" Removing the rear cover.

1. Remov e t he 4 scr ews m arked B, and remov e sp eak er as s hown

in Fig. 1.

REMOVING THE FRONT CONTR OL BOARD

" Removing the rear cover.

"

Removing th e MAIN PWB

1. R emove th e 4 c laws mark ed C from bott om si de att ac h ing t he

CHASSIS BRACKET as shown in the Fig. 1.

2. Remove th e CHASS IS BR ACKET up war d.

3. Pu ll out the FRO NT CO NTROL PW B.

REMOVING THE FRONT AV JACK PWB

"

Removing the rear cover.

" R emoving th e rea r MA IN PW B .

"

Removing the FRONT CONTROL PWB

1. Remove th e 2 scr ews m ar ked D.

2. R emove the FRON T AV JACK PW B .

REMOVING THE HP JACK PWB

" Removing the rear cover.

"

Removing th e MAIN PWB

1. R emove the 1 scr ew s m ar ked E .

2. Remove the HP JACK PWB

CHECKING THE PW BOARD

To c h eck the b ack side of th e PW B oar d.

1) Pu ll out th e PW B oar d. ( R ef er to R EM OV ING TH E MA IN

PWB).

2) Er ect th e PW B oard vert ic al ly so t ha t you c an easil y ch eck

th e b ack side of the PW B oar d.

[CAUTION]

" When erecting t he PW Board, be careful so that there will be no

con tact in g with ot her PW Board.

" Be for e tur n in g on po wer, mak e sur e tha t the wire co nn ector is

properl y con nec ted .

" W hen conducti ng a check wi th p ower su ppl ied, b e sur e to c onfi rm

th at t he CRT E AR TH W I RE (B RA ID ED AS S’Y) is co nne c ted t o

th e CRT SOC KE T PW b oar d.

WIRE CLAMPING AND CABLE TYING

1. Be sure t o cla mp th e wire.

2. N ever r em o ve the c abl e tie use d for tying th e wire s to ge the r.

Should it be inadvertently rem oved, b e sure to tie th e wires with

a n ew c able tie.

6

No.51999

Page 7

A

S

A

S

A

S

REAR COVER

(×1)

(×4)A(×5)

V14BJ8ENS / AV14BM8EN

V14BJ8EPS / AV14BM8EP

V14BJ8EES / AV14BM8EE

PWB

GUIDE RAIL

CRT

ON/OFF

BRACKET

E

HP JACK PWB

MAI N

PWB

CHAS SIS

BRACKET

D

(×2)

CLAW

C

FRONT

C ONT RO L

PWB

B

SP EAKE R

FRONT CABINET

FRONT AV PWB

PWB

GUIDE RAIL

B

(×4)

SP EAKE R

Fig. 1

No.51999

7

Page 8

A

V14BJ8ENS / AV14BM8ENS

A

A

V14BJ8EPS / AV14BM8EPS

V14BJ8EES / AV14BM8EES

DISASSEMBLY PROCEDURE

AV14BM8 ENS / EPS / EES

REMOVING THE REAR COVE R

1. Unplug t he po we r c ord.

2. Remove the 4 screws marked A as shown i n the F ig. 2.

3. Withdra w t he r ear co ver to ward y ou .

REMOVING THE MAIN PWB

"

Removing the REAR COVER.

1. Slight ly r aise t he bot h si d es of th e c hass is b y hand and

withdr aw th e MAIN PWB .

(If n ecess ary, take off the wire clamp, co nnectors etc.)

REMOVING THE FRONT AV JACK PWB

"

Removing the REAR COVER.

" R emove t he MA IN PW B.

1. Remov e th e 2 scr ews m arked B.

2. Remov e t he FRONT AV JACK PWB.

REMOVING THE HP JACK BOARD

"

Removing the REAR COVER.

"

Removing th e MAIN PWB

1. Remov e th e 1 scr ews m arked C.

2. Remove the HP JACK PWB.

CHECKING THE PW BOARD

To c h eck the b ack side of th e PW B oar d.

1) Pu ll out th e PW B oar d. ( R ef er t o R EM OVI NG THE MA IN

PWB).

2) Er ect th e PW Board v ert ic ally so t hat you ca n e asil y ch eck

th e b ack side of the PW B oar d.

[CAUTION]

" When erecting t he PW Board, be careful so that there will be no

con tact in g with ot her PW Board.

" Be for e tur n in g on po wer, mak e sur e tha t the wire co nn ector is

properl y con nec ted .

" W hen conducti ng a check wi th p ower su ppl ied, b e sur e to c onfi rm

th at t he CRT E AR TH W I RE (B RA ID ED AS S’Y) is co nne c ted t o

th e CRT SOC KE T PW b oar d.

WIRE CLAMPING AND CABLE TYING

1. Be sure to cl amp th e wire.

2. Never remo ve th e c able tie used f or tyi ng the w i res to gether.

Sh ould it be ina dvert ent l y re m oved , be sur e t o ti e th e wires with

a n ew c able tie.

8

No.51999

Page 9

A

V14BJ8ENS / AV14BM8EN

S

A

S

A

S

(

)

(

)B(×2)

V14BJ8EPS / AV14BM8EP

V14BJ8EES / AV14BM8EE

A

A

(×4)

(×4)

REAR COVER

REAR COVER

MAI N PWB

MAI N PWB

FUNCTION BOTTOM

FUNCTION BOTTOM

CRT

CRT

C

C

×

×

1

1

FRONT AV PWB

FRONT AV JACK

PWB

HP JACK PWB

HP JACK PWB

SP EAKE R

SP EAKE R

B

(×2)

FRONT CABINET

FRONT CABINET

Fig. 2

Fig. 2

No.51999

9

Page 10

A

V14BJ8ENS / AV14BM8ENS

A

A

V14BJ8EPS / AV14BM8EPS

V14BJ8EES / AV14BM8EES

REPLACEMENT OF CHIP COMPONENT

! CAUTIONS

1. Avoid heating for more than 3 seconds.

2. D o n ot ru b t he el ect rodes an d t he resi st p arts of th e p att ern.

3. W hen r em ovi ng a c hip par t, mel t th e s older adequ ately.

4. D o n ot reuse a ch ip part afte r re moving it.

! SOLDERING IRON

1. U se a hig h ins ulati o n s older ing ir on with a t hin pointed end of it .

2. A 3 0w s older ing ir on is r ec omm end ed for easil y r emoving par ts.

!

REPLACEMENT ST EPS

1. How to remove Chip parts

####

Resistors, capacito rs , etc

(1) As sh own in t he fig ur e, pu sh th e pa rt with tweezer s and

alternat ely m elt the sol de r at each end.

(2) Shift wi th tweeze rs an d r emove th e ch ip part.

#### Tr ans isto rs, dio des, va ria bl e resistors, etc

(1) Apply e xtra solder to ea ch lead.

SOLDE R SOLDE R

2. How to install Chip parts

####

Resistors, capa cit ors , et c

(1) Apply sold er to the pattern as i ndic ated in the fi gure.

(2) Gras p t he chip p art with twee z ers and pl ac e i t on the s ol d er.

The n hea t and melt the so ld er at b oth ends of t he chip part.

#### T ran s ist ors, diodes , varia bl e r esist or s, et c

(1) Apply sold er to the pattern as i ndic ated in the fi gure.

(2) Gras p th e chip p art wit h t we eze rs and plac e it on th e solder .

(3) First solder lead A as indicated in the figu re.

A

(2) As sh own in t he fig ur e, pu sh th e pa rt with tweezer s and

alternat ely m elt th e sold er a t each l e ad . Shift an d remov e t he

chip part.

(4) The n so ld er leads B and C.

Note : After remo ving t he part , remove remaining solder from the

pattern.

10

No.51999

C

A

C

B

B

Page 11

A

S

A

S

A

S

MEMORY IC REPLACEMENT

VALUE

VALUE

ITEM

ITEM

MENU

FUNCTION

1. Memory IC

This model use a memory IC.

Thi s memo r y IC st or es d ata for proper op er atio n of the video

an d d ef l ection circuits.

When replacing, be sure to use an IC containing this (initial

valu e) d ata.

2. Memory IC replacement procedure

(1) Power off

Switch of f t he p ower an d di scon nec t th e po we r co rd fr om

the wall outlet.

V14BJ8ENS / AV14BM8EN

V14BJ8EPS / AV14BM8EP

V14BJ8EES / AV14BM8EE

SE RVICE M ENU

Fig.1

(2) Replace the memory IC

Init ial value must be enter ed i nto the new IC.

(3) Power on

Connect the po wer cor d to t he wall out let an d s wi tch on t he

power.

(4) SERVICE MENU setting

1) Press MENU key an d, whil e th e di spla y ed MENU

screen, press 4, 7, 2, 5 k ey on the rem ote c o ntr ol unit.

2) The SERV ICE M EN U scree n of Fi g.1 i s d isp layed.

3) Veri f y what to set in th e SERV IC E MENU, and set

whatever is necessary (Fi g.1 ). Ref er to the SE RVICE

ADJU STMENT for settin g.

4) Press the MENU key to exit SERVICE MENU.

(5) Receive c hannel setting

Refe r to th e OPERATING INSTR UCTIO NS (USER ’S

GUIDE) and s et the rec e ive channels (Chan nel s P reset ) as

described.

(6) U ser se tting s

Check the us er sett ing items acc ording to aft er pa ge .

Where th ese d o no t agree, r efer to t he OPE RA TING

INSTRUCT IONS (USER’S GUIDE) and set the it ems as

described.

SERVICE MENU SELECT KEY

POWER

NUMBER

SELECT(▲)

SELECT(-)

SELECT(+)

SELECT(▼)

Fig.2

No. 51999

11

Page 12

A

V14BJ8ENS / AV14BM8ENS

A

A

V14BJ8EPS / AV14BM8EPS

V14BJ8EES / AV14BM8EES

SETTING OF THE LAST MEMORY FOR SHIPMENT

■■■■ USER SETTING VALUES

Setting Item Setting Value Setting Ite m Setting Value

SOUND MENU FEATURE MENU

VOL UME 09 SLEEP TIME R OFF

AV L NO CHILD LO CK OFF

PICTURE MENU LANG UAGE ENGL ISH

BRIGHTNES S

COLO UR

CONTRAST

SHAR PNESS

HUE (only NTSC)

Default va lu e : 31 ( all)

12

No. 51999

Page 13

A

S

A

S

A

S

SERVICE ADJUSTMENTS

ADJUSTMENT PREPARATION

1. You can make the necessa ry ad justme nts f or this unit wit h

either the Remote Control Unit or With the adjustment tools

and par ts as give n below.

2. Ad justment with the Remote Control Uni t is made on the

basis of the initial setting v alues, however, the new setting

values which set the screen to its opti mum condition may

differ from t he init ial settin gs.

3. Make sure t hat AC power i s turned on c orrec tl y.

4. Turn on th e power for s et an d test eq ui p me nt bef or e use, and

start t he ad justm en t p rocedures aft er w aiting at least 30 m in ut es.

5. U nl ess o the r wise s pec if ied, prepare t he most s u it ab le rec ep ti on

or inp ut signal for adjust m ent.

6. N ever tou c h any ad j ustment p arts wh ic h ar e n ot s p eci fi ed in t he

list for this adjustment - variable res istors, transformers,

condensers, etc.

7. Pr es etting before ad justm en t.

Unles s ot herwi se spec if i ed i n t he a dj ustme nt ins tr uct ions, pr eset

th e f ollowin g f unctions with th e r e mote c ontrol un it :

BRIGHTNES S

CONTRAST

COLO UR

SHAR PNESS

V14BJ8ENS / AV14BM8EN

V14BJ8EPS / AV14BM8EP

V14BJ8EES / AV14BM8EE

CENTER

ADJUSTMENT EQUIPMENT

1. DC voltmeter (or digital voltmeter)

2. Signal g ener at or (P att ern g ener at or) [PAL/SECAM/NTSC]

3. Remote control unit

MAIN PARTS LOCATIONS

TOP

TOP

TOP

ADJUSTMENT ITEM

!

SCR EEN A DJU ST MEN T

! IF AD JU STM EN T

!

OSD HORIZONTAL ADJUSTMENT

! AGC AUTOMATI CALLY A DJU STM ENT

! DEFLECTION CI RCUIT ADJUSTMENT

!

WHITE BALANCE ADJUSTMENT

FRONT

FRONT

No. 51999

13

Page 14

A

V14BJ8ENS / AV14BM8ENS

A

A

U

y

A

y

V14BJ8EPS / AV14BM8EPS

V14BJ8EES / AV14BM8EES

BASIC OPERATION SERVICE MENU

■■■■ HOW TO ENTER THE SERVICE M ENU

1) Press the MENU key.

2) ME NU sc reen of Fig .1 w ill b e d isp l ayed .

MENU SCRE EN

MEN

SOUND

PICTURE

FEATURE

INSTALL

PROGRAM

Fig.1

3) W hile th e MENU scr ee n is d is played , press the 4,7 ,2 ,5 k ey a nd the

SERV ICE MENU screen of (Fig.2) will be displayed

SE RVICE M ENU

NUMBER key

V ke

REMOTE CONTROL UNI T key NAME

STANDARD

key

COLO UR key

MENU key

FUNCTION

ke

ADJ USTMENT ITEM

Fig.2

■

SEL ECTION OF ADJUSTMENT ITEMS

1) Enter th e SERVICE ME NU

2) Press the FUNC TION / ke y and s elect the SET TING VALUE.

3)

Press the FUNCTION / ke y and s et the settin g value.

SETTING VALUE

■ HOW TO EXIT SERVICE MODE

1) Press the MENU Key on REMOTE CONTROL UNIT.

14

No. 51999

Page 15

A

V14BJ8ENS / AV14BM8EN

S

A

S

A

S

V14BJ8EPS / AV14BM8EP

V14BJ8EES / AV14BM8EE

■

ADJUSTMENT ITEM & INITIAL (Recommended) SETTING VALUE in the SERVICE MENU

ADJ USTMENT ITEM DE SCRIPTION INITIAL VALUE

OSP HORIZONTAL POSI TION OF OS D 064

IF1 IF COARS E ADJU STM ENT 001

IF2 IF FINE ADJUSTMENT 076

IF3 IF COARS E ADJU STM ENT FOR L- P RIME 003

IF4 IF FINE AD JUST MENT FOR L-PRIME 063

AGC AUTOMATIC GA IN CO NT ROL 033

VLIN VERTIC A L LINEARITY 044

VS 1A VE RTICAL SIZE f or 50HZ / 4:3 037

VS 1B VE RTICAL SIZE f or 50HZ / 16:9 059

VP 1 VE RTICAL POSITIO N for 50H

HP1 HORIZON TAL P OSITION for 50H

VS 2A VE RTICAL SIZE f or 60HZ / 4:3 008

VS 2B VE RTICAL SIZE f or 60HZ / 16:9 037

VP 2 VE RTICAL POSITIO N for 60H

HP2 HORIZON TAL P OSITION for 60H

RGBH RGB MODE HORIZONTAL SHI FT OFFSET 031

WR W H ITE POINT ADJUSTMENT FO R RE D 040

WG W HITE POINT ADJU STMENT FO R GREEN 04 0

WB W HITE POINT AD JU STME NT FOR BLUE 04 0

BR BIA S FOR RED 031

BG BIAS FOR G REEN 031

AP R AU TOM ATIC R GB PEA K REGUL ATION THRESHOLD 01 0

FMP1 FM PRESCALER W HEN AV L IS OFF 009

NIP1 NIC AM PRESC A LER W HEN A VL IS OF F 02 0

SCP1 SC ART P RESCALE R WH EN AVL IS O FF 01 3

FMP2 FM PRESCALER W HEN AV L IS ON 01 3

NZP2 FM PRESC A LER W HEN AV L IS ON 01 6

SCP2 F M PRESCALER W HEN AV L IS ON 01 3

F1H HIGH BYTE OF VHF1-VHF3 CROSS-OVER FREQUENCY 0000 1001

F1L LOW BYTE O F VHF1- VHF3 CROSS -O VER FREQ UENCY 10 01 00 10

F2H HIGH BYTE OF VHF3-UHF CROSS-OVER FREQUENCY 00011011

F2L LOW BYTE O F VHF3- UHF CR OS S-OVER F REQ UE NCY 10 00 00 10

BS 1 BAND SW ITCHIN G B YTE FOR VHF1 00 00 00 11

BS 2 BAND SW ITCHIN G B YTE FOR VHF3 00 00 01 10

BS 3 BAND SW ITCHIN G B YTE FOR UHF 10 00 01 01

CB CONTROL BYTE 10 00 11 10

OP1 PERIPHERAL OPTIONS 01 10 11 01

OP2 RECEPTI ON STANDARD OPTIONS 01 011000

OP3 VIDEO OPTI ONS 11 1101 01

OP4 TU FEATURRES 01 10 10 11

OP5 C HANNEL TA BLES 11 01 10 11

TX1 TELE TEXT OPTIONS 00 00 01 10

Z

Z

Z

Z

00 8

03 5

01 3

02 3

DO NOT ADJUST

No. 51999

15

Page 16

AV14BJ8ENS / AV14BM8ENS

r

AV14BJ8EPS / AV14BM8EPS

AV14BJ8EES / AV14BM8EES

ADJUSTMENTS

■

■ SCREEN ADJUSTMENT

■■

Item

SCREEN

adjustment

■

■ ADJUSTMENT

■■

Measuring

instrument

Remote

control unit

Test point Adjustment part Description

SCREEN VR

[On the FBT]

1. Enter SERVICE MENU.

2. Press YELLOW key to disable vertical scan.

3. Adjust SCREEN VR. on the FBT for a thin horizontal line like a

figure.

4. Press YE LLOW key again to enable vertical scan.

5. Press MENU key to leave service menu.

Item

IF adjustment Remote

■

■ OSD HORIZONTAL POSITION ADJUSTMENT

■■

Item

HORIZONTAL

POSITION OF

OSD

adjustment

Measuring

instrument

control unit

Measuring

instrument

Remote

control unit

Test point Adjustment part Description

IF 1

IF 2

IF 3

IF 4

Test point Adjustment part Description

OSD

SERVICE MENU SCREEN

1. Enter SERVICE MENU.

2. Select IF 1 with FUNCTION ( / ) key

3. Press BLUE key during IF 1 is highlighted, IF 1 and IF 2 values

are adjusted automatically by software.

4. If the standard is L-prime, IF 3 and IF 4 values are adjustment

automatically when BLUE key is pressed during IF 1 is

highlighted.

1. Enter SERVICE MENU.

2. Select OSD with FUNCTION ( / ) key

3. Adjust the OSD horizontal position with the FUNCTION ( / )

key, which shifts the reference bar on the bottom of the

SERVICE MENU horizontally, so that the OSD is positioned on

the screen center. (X=X’)

16

Reference ba

X X’

Screen s ize

No. 51999

Page 17

A

S

A

S

A

S

■■■■ AGC AUTOMAT ICALLY ADJUSTMENT

S

Item

AG C

AUTOMATICAL LY

adjust ment

& check

Measuring

instrume nt

Remote

control unit

ERVICE MENU SCREEN

Test point Ad justment part Des cription

AG C 1. En ter SERVIC E MENU.

■■■■ DEFLECTION C IRCUIT

Item

VERT ICAL

LINEARITY

adjust ment

Measuring

instrume nt

Signal

gener ator

Remote

control unit

Test point Ad justment part Des cription

VLIN 1. Receive a PAL B/G circle pattern.

V14BJ8ENS / AV14BM8EN

V14BJ8EPS / AV14BM8EP

V14BJ8EES / AV14BM8EE

2. Receive a 60dBμV RF signal level.

3. Se lect AG C from SE RVICE MENU .

4. Pr ess BLUE ke y on th e r emot e co ntrol uni t.

5. Then the adjustment will be done automatically by software.

6. Se e the AGC ind ic ator on SERVICE MENU , i t m ust be “1” .

7. C heck th at p ict ure i s norm al a t 90 dB μV signal level.

:11

IF INDICATOR AGC INDICATOR NONE

2. En ter SERVIC E MENU.

3. Select VLIN wi th the FUNCTION ( / ) key.

4. Ad just VL IN w it h t he F UNCTION ( / ) key until circle as

round as p ossible.

5. Pr ess the ME NU key and mem oriz e th e s et value.

VERTICAL

SIZ E

adjust ment

(50Hz , 4: 3)

very close

Scr een

size

very close

Signal

gener ator

Remote

control unit

VS1A 1. Rec eive a PA L B/G ci r cl e p att ern of ve rtica l fr equ en cy 5 0Hz.

2. En ter SERVIC E MENU.

3. Select VS1A w ith th e FUNCTION ( / ) key.

4. Ad just VS1 A with the FUNCTION ( / ) key un til horizontal

blac k lin es on b oth the u pp er a nd l ow er p ar t of th e ci r cl e

pattern become very close to the upper and lower horizontal

si des of pic tu re si ze and nearl y about to disa ppear .

5. Chec k and readjus t VS 1A item if t he ad justm en t b ec om es

impr ope r aft er some oth er geomet ric adjus t m ents are d one.

Picture

size

10 0%

No. 51999

17

Page 18

A

V14BJ8ENS / AV14BM8ENS

A

A

g

V14BJ8EPS / AV14BM8EPS

V14BJ8EES / AV14BM8EES

Item

VERTICAL

SIZ E

adjust ment

(50Hz , 16 :9)

16 :9

format

screen

size

VERTICAL

POSITION

adjust ment

(50Hz )

Measurin

instrume nts

Signal

gener ator

Remote

control unit

16:9 S CREEN

Signal

gener ator

Remote

control unit

Test point Ad justment part Des cription

VS1B 1. R eceive a PAL B/G c ross-h atch p att er n of ver tical frequ enc y

50 Hz.

2. En ter SERVIC E MENU.

3. Select VS 1B with the FUNCTION ( / ) key.

4. Press GREEN key to switch t o 16:9 screen mode.

5. Ad just VS1 B with t he FUNCTION ( / ) key unti l the s creen

become 16:9 format.

6. Chec k and re adj us t VS1 B i tem if th e adjustm ent be com es

impr ope r aft er some oth er geomet ric adjus t m ents are d one.

Picture

size

10 0%

VP 1 1. Recei ve a PA L B/G circ le patt er n si g nal of vert ic al f re qu enc y

50 Hz.

2. En ter SERVIC E MENU.

3. Select VP1 with the FUNCT ION ( / ) key.

4. Adjust VP 1 with the FU NCTION ( / ) key unti l the circle

pattern is vertically centered.(A=B)

5. Chec k and re ad ju st V P1 ite m if t he ad j ustmen t bec om es

impr ope r aft er some oth er geomet ric adjus t m ents are d one.

A

HORIZONTAL

POSITION

adjus tment

(50Hz )

18

Signal

Generator

Remote

control unit

C

B

HP1 1. R eceiv e a PA L B/G ci rc le p att er n sig nal of vertical freque ncy

50 Hz.

2. En ter SERVIC E MENU.

3. Select HP1 with the FUNCTION ( / ) key.

4. Adjust HP1 wi th the FUNCTIO N ( / ) key until the ci rcle

p atter n i s h orizo ntal ly cente r ed.( C=D)

D

5. Chec k and re ad ju st HP 1 it em if the a djust me nt bec om es

impr ope r aft er some oth er geomet ric adjus t m ents are d one.

No. 51999

Page 19

A

V14BJ8ENS / AV14BM8EN

S

A

S

A

S

g

V14BJ8EPS / AV14BM8EP

V14BJ8EES / AV14BM8EE

Item

VERTICAL

SIZ E

adjus tment

(60Hz , 4: 3)

Very clos e

Scr een

size

Very clos e

Measurin

instrume nts

Signal

gener ator

Remote

control unit

Test point Ad justment part Des cription

VS2A 1. R eceive a PAL B/G cross- h atch p att ern of ver ti cal frequ enc y

60Hz.

2. Enter SE RVICE M ENU.

3. Select VS 2A wi th the FUNCTION ( / ) key.

4. Ad just VS2A wi th t he FUNCTION ( / ) key un ti l th e

h oriz o nt al blac k l ines on b oth t he upp er and low er p art of the

circle pattern become very close to the upper and lower

h oriz o nt al sid es of pic tur e si ze and nearl y about to disap pear .

5. Check a nd r e adjus t VS2A item if the adju s tm ent be comes

impr ope r aft er some oth er geomet ric adjus t m ents are d one.

Picture

size

10 0%

VERT ICAL

SIZ E

adjust ment

(60Hz , 16 :9)

16 :9

format

screen

size

Signal

gener ator

Remote

control unit

16:9 S CREEN

VS 2B 1. R eceive a PAL B/G cross- h atch p att ern of ver ti cal frequ enc y

60Hz.

2. Enter SE RVICE M ENU.

3. Select VS 2B wi th the FUNCTION ( / ) key.

4. Press GREEN key to swi tch t o 16:9 screen m ode.

5. Adjust VS2B with t he FUNCTION ( / ) key until the s creen

become 16:9 format.

6. Check a nd r e adjus t VS2B item if the adju s tm ent be comes

impr ope r aft er some oth er geomet ric adjus t m ents are d one.

Picture

size

10 0%

No. 51999

19

Page 20

A

V14BJ8ENS / AV14BM8ENS

A

A

g

V14BJ8EPS / AV14BM8EPS

V14BJ8EES / AV14BM8EES

Item

VERTICAL

POSITION

adjus tment

(60Hz )

HORIZONTAL

POSITION

adjus tment

(60Hz )

Measurin

instrume nts

Signal

gener ator

Remote

control unit

Signal

gener ator

Remote

control unit

C

Test point Ad justment part Des cription

VP2 1. Recei ve a PA L B/G circ le patt er n si g nal of vert ic al f re qu enc y

60Hz.

2. En ter SERVIC E MENU.

3. Select VP2 with the FUNCT ION ( / ) key.

4. Adjust VP 2 with the FU NCTION ( / ) key unti l the circle

pattern is vertically centered.(A=B)

5. Chec k and re ad ju st V P2 ite m if t he ad j ustmen t bec om es

A

B

HP2 1. R eceiv e a PA L B/G ci rc le p att er n sig nal of vertical freque ncy

D

impr ope r aft er some oth er geomet ric adjus t m ents are d one.

60Hz.

2. En ter SERVIC E MENU.

3. Select HP2 with the FUNCTION ( / ) key.

4. Adjust HP2 wi th the FUNCTIO N ( / ) key until the ci rcle

p atter n i s h orizo ntal ly cente r ed.( C=D)

5. Chec k and re ad ju st HP 2 it em if the a djust me nt bec om es

impr ope r aft er some oth er geomet ric adjus t m ents are d one.

R GB M ODE

HORIZONTAL

SHIFT

OFF SET

adjus tment

20

Signal

gener ator

Remote

control unit

E

RGBH 1. Input R/G/B circle pattern signal via video inpu t te r minal.

2. Pr ess AV k ey on the r emo te control u nit.

3. En ter SERVIC E MENU.

4. Select RGBH with th e FUNCTION ( / ) key.

5. Adjust RGBH with the FUNCTION ( / ) key until the circle

p atter n i s h orizo ntal ly cente r ed.( E=F)

6. Chec k and r ead ju st RGBH it em i f the adj ustment be com es

F

impr ope r aft er some oth er geomet ric adjus t m ents are d one.

No. 51999

Page 21

A

S

A

S

A

S

■■■■ WHITE BALANCE ADJUS TM ENT

Item

WHITE

BALANCE

adjust ment

(Low light)

Measuring

instrume nt

Signal

gener ator

Remote

control unit

Test point Ad justment part Des cription

Recom mended value 04 0 04 0 04 0

V14BJ8ENS / AV14BM8EN

V14BJ8EPS / AV14BM8EP

V14BJ8EES / AV14BM8EE

WR

WG

WB

It em WR WG W B

1. R ecei ve a bla ck & wh it e si gn al (co l our of f) .

2. En ter SERVIC E MENU.

3. Select WR / WG / WB w ith t he ( / ) key, respecti ve ly.

4. Adju st W R / W G / WB with the FUNCTION ( / ) key,

resp ectively, unt il the whit e part tu rns to pure whit e witho ut any

other color..

WHITE

BALANCE

adjust ment

(Hi gh light)

Signal

gener ator

Remote

control unit

BR

BG

It em BR BG

Recom mended value 04 0 040

1. R ecei ve a bla ck & wh it e si gn al (co l our of f)

2. En ter SERVIC E MENU.

3. Select BR / BG with the FUNCTION ( / ) key r espectively.

4. Ad just BR / BG with the FUNCTION ( / ) key r espectively

un til the whi te part of screen make whi te colo ur.

No. 51999

21

Page 22

A

V14BJ8ENS / AV14BM8ENS

A

A

V14BJ8EPS / AV14BM8EPS

V14BJ8EES / AV14BM8EES

< M E M O >

22

No. 51999

Loading...

Loading...