Page 1

T1600 Internet Routing Node Upgrade

Guide

28 April 2008

Part Number: 530-021924-01

Revision 2

This guide provides procedures for upgrading an operational T640 Internet routing

node to a T1600 Internet routing node. These procedures include preparing the site,

replacing hardware, and verifying operation.

NOTE: Before you upgrade, the T640 routing node must be running JUNOS Release

8.5 or later.

Contents

T1600 Routing Node Overview .......................................................................3

T1600 Upgrade Kit ..........................................................................................5

Power Supplies .........................................................................................6

Three-Input 240-A Power Supplies .....................................................6

T1600-SIBs ...............................................................................................9

T1600 Routing Node Upgrade Overview .......................................................10

Verifying the Hardware Version of the Rear Fan Tray ...................................11

Preparing the Site ..........................................................................................12

Typical Power Distribution ......................................................................12

Provisioning Additional Power for the T1600 Routing Node ...................13

Replacing the Rear Fan Tray .........................................................................13

Removing the Rear Fan Tray ..................................................................14

Installing a Rear Fan Tray .......................................................................15

Upgrading the DC Power Supplies .................................................................17

Preparing the DC Power Cables ..............................................................17

Tools and Parts Required ........................................................................17

Removing a Two-Input 160-A Power Supply ...........................................18

Setting the Input Mode Switch on a Three-Input 240-A Power

Supply ..............................................................................................21

■ 1

Page 2

T1600 Routing Node Upgrade Guide

Installing a Three-Input 240-A Power Supply ..........................................22

Replacing the Cable Restraint on a Three-Input 240-A Power Supply ......23

Removing the Standard Cable Restraint from a Three-Input 240-A

Power Supply .............................................................................24

Installing the Optional Cable Restraint on a Three-Input 240-A Power

Supply ........................................................................................24

Connecting a Three-Input 240-A Power Supply .......................................25

Powering On a Three-Input 240-A Power Supply ....................................26

Upgrading SIBs ..............................................................................................27

Overview of Upgrading the SIBs .............................................................28

Preparing to Upgrade the SIBs ................................................................29

Tools Required ........................................................................................30

Removing a Standard SIB or SIB Version B .............................................30

Installing a T1600-SIB .............................................................................32

Verifying the Installation of a T1600-SIB .................................................33

Preparing to Exit Upgrade Mode .............................................................33

Exiting Upgrade Mode ............................................................................34

Verifying Operation ................................................................................35

Removing the Upper Front Fan Tray .............................................................39

Replacing the Craft Interface .........................................................................40

Removing the Craft Interface ..................................................................40

Installing the Craft Interface ....................................................................41

Installing the Upper Front Fan Tray ...............................................................42

Attaching the T1600 Agency Label ................................................................42

Registering Your T1600 Upgrade ...................................................................43

T1600 Routing Node Environmental Specifications .......................................43

T1600 Routing Node DC Power Specifications ..............................................44

Power System Electrical Specifications ...................................................44

Three-Input 240-A Power Supply Specifications ......................................45

DC Power Cable Specifications ...............................................................46

Preventing Electrostatic Discharge Damage ..................................................47

List of Technical Publications ........................................................................48

Documentation Feedback ..............................................................................54

Requesting Technical Support .......................................................................55

Revision History ............................................................................................56

2 ■

Page 3

T1600 Routing Node Overview

The T1600 Internet routing node is a complete routing system that provides Gigabit

Ethernet, SONET/SDH, and other high-speed interfaces for large networks and network

applications, such as those supported by Internet service providers (ISPs). The routing

node accommodates up to eight Flexible PIC Concentrators (FPCs), which can each

be configured with a variety of network media types. The T1600 routing node provides

up to 800 gigabits per second (Gbps), full duplex (1600 Gbps of any-to-any,

non-blocking, half-duplex switching).

The routing node architecture cleanly separates control operations from packet

forwarding operations. This design eliminates processing and traffic bottlenecks,

permitting the routing node to achieve high performance.

■ Control operations in the routing node are performed by the host subsystem,

which runs JUNOS Internet software to handle routing protocols, traffic

engineering, policy, policing, monitoring, and configuration management.

■ Forwarding operations in the routing node are performed by the Packet

Forwarding Engines, which consist of hardware, including ASICs, designed by

Juniper Networks. Application-specific integrated circuits (ASICs) are a definitive

part of the routing node design; these ASICs enable the routing node to achieve

data forwarding rates that match current fiber-optic capacity. The T1600 routing

node provides up to a total of 1600 million packets per second (Mpps) of

forwarding.

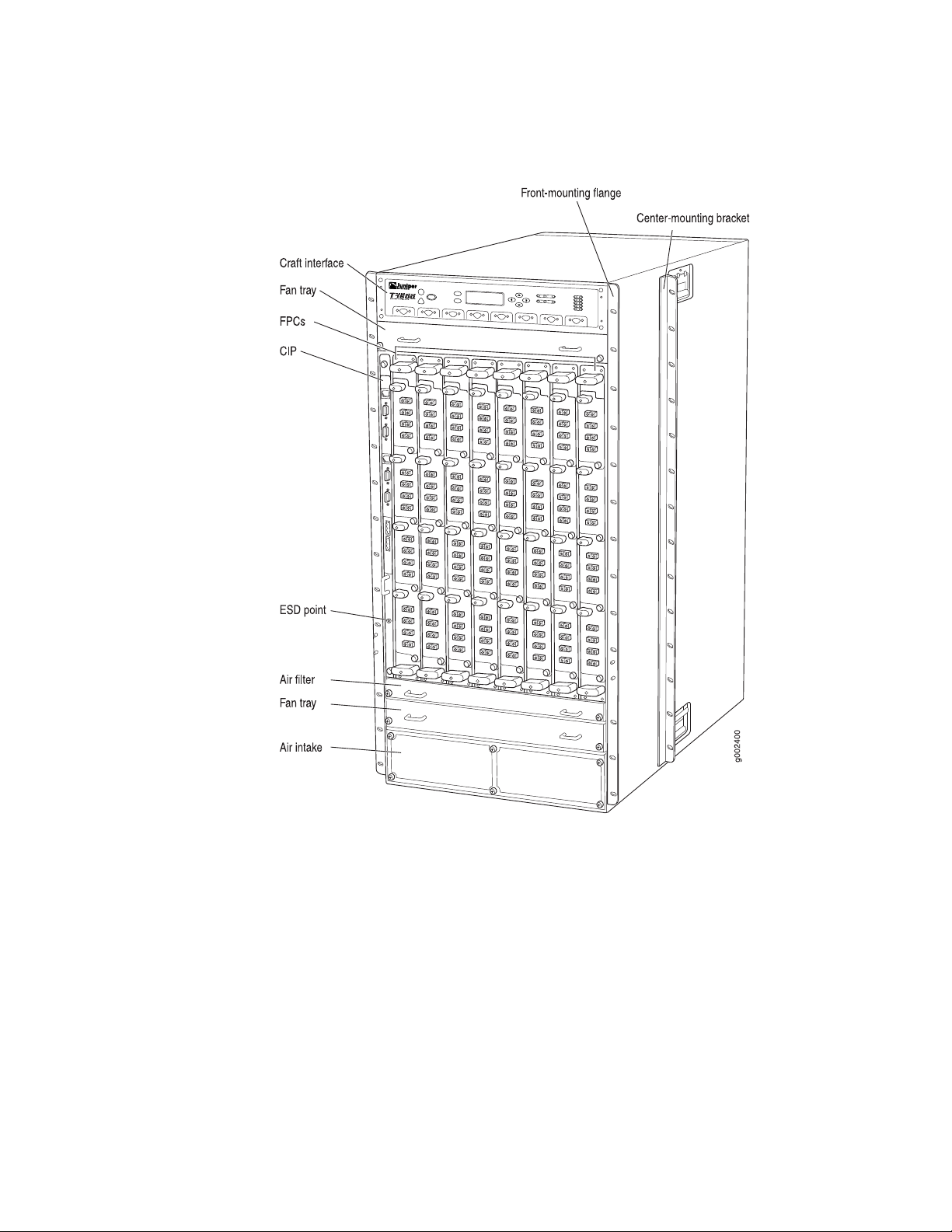

T1600 Routing Node Overview

Figure 1 on page 4 and Figure 2 on page 5 illustrate the front and rear of a T1600

routing node.

T1600 Routing Node Overview ■ 3

Page 4

T1600 Routing Node Upgrade Guide

Figure 1: Front View of the T1600 Routing Node

4 ■ T1600 Routing Node Overview

Page 5

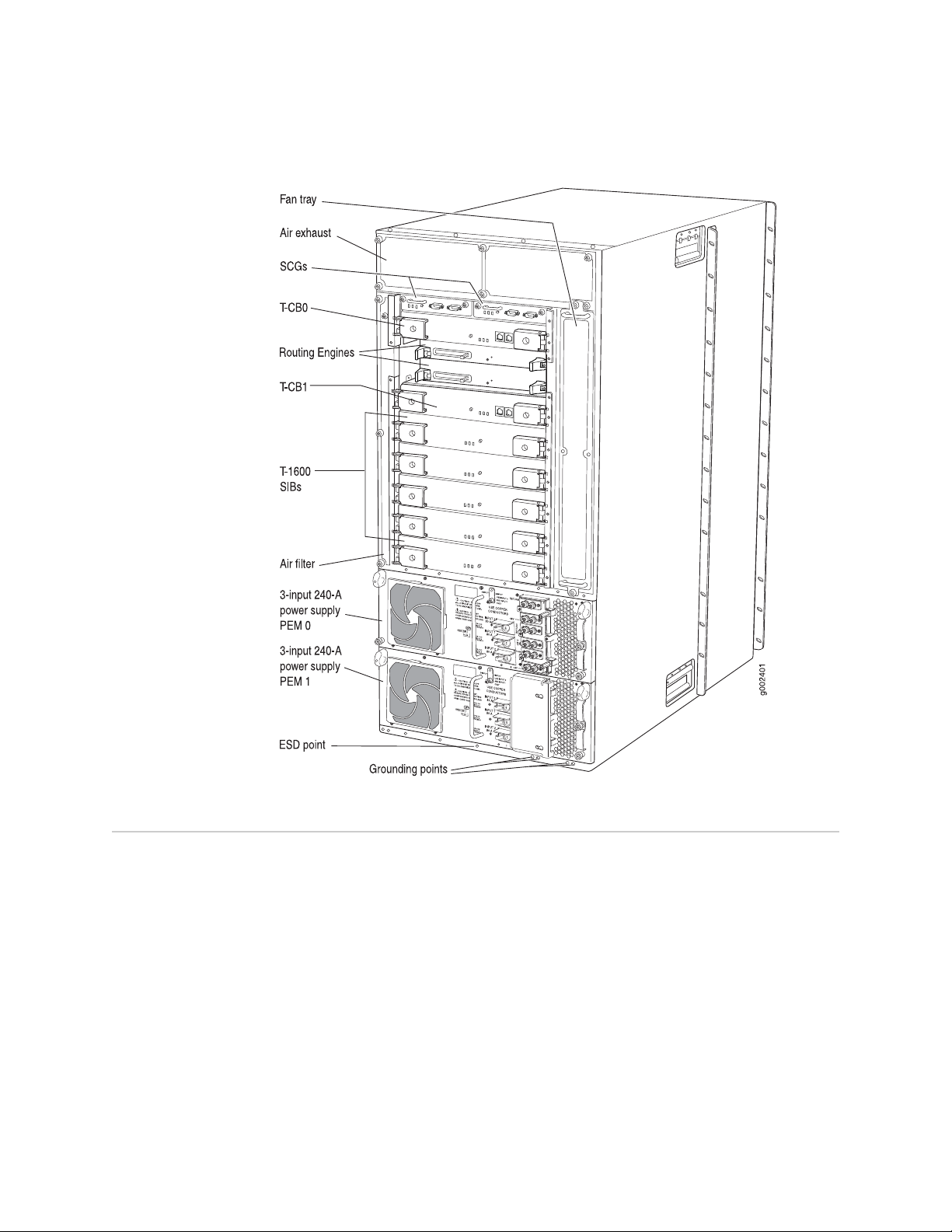

Figure 2: Rear View of the T1600 Routing Node

T1600 Upgrade Kit

T1600 Upgrade Kit

To upgrade a T640 routing node to a T1600 routing node, you install the following

hardware components:

■ Two redundant, load-sharing, three-input 240-A power supplies that connect to

the rear of the midplane

■ Five T1600-SIBs

■ One T1600 craft interface panel

You can order these components individually or order a T1600 upgrade kit that

contains all the components. You must supply four additional DC power cables.

T1600 Upgrade Kit ■ 5

Page 6

T1600 Routing Node Upgrade Guide

NOTE: These components must be installed before you can install a T1600-FPC in

the T1600 routing node.

Power Supplies

Two redundant, load-sharing DC power supplies are located at the lower rear of the

chassis in slots PEM0 and PEM1 (top to bottom). For power specifications for the

system, power supplies, and power cables, see “T1600 Routing Node DC Power

Specifications” on page 44.

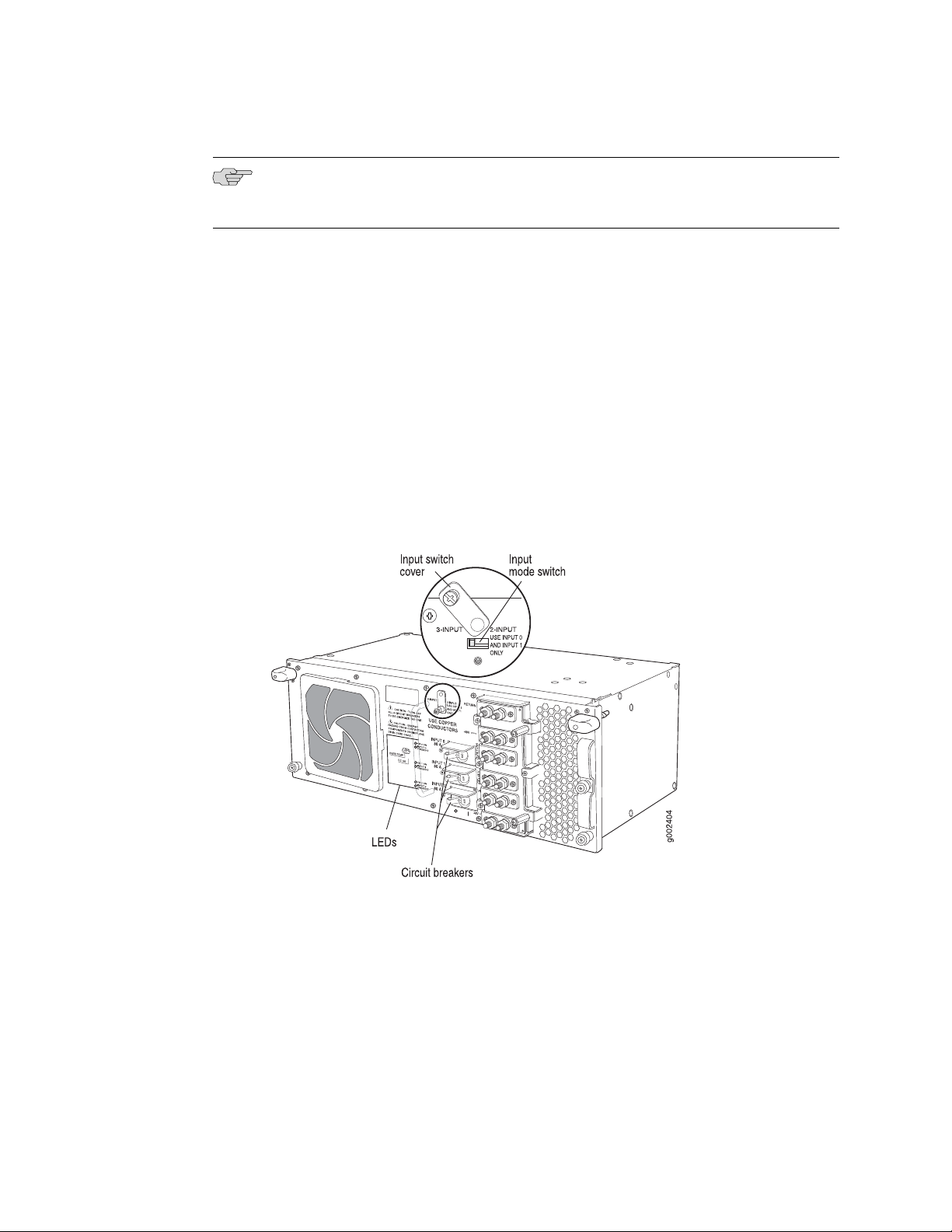

Three-Input 240-A Power Supplies

Each three-input 240-A power supply weighs approximately 25 lb. (11.3 kg) and

consists of three inputs, three 80-A circuit breakers, a fan, and LEDs to monitor the

status of the power supply. Figure 3 on page 6 shows the three-input 240-A power

supply.

Figure 3: Three-Input 240-A Power Supply

Three-Input 240-A Power Supply Inputs

The three-input 240-A DC power supply inputs are labeled INPUT 0, INPUT 1, and

INPUT 2, from top to bottom. Each input consists of –48 VDC and return—each with

its own 80-A circuit breaker. The input mode switch on the faceplate allows you to

set the DC power supply to either two-input or three-input mode mode. Three-input

mode is required for the T1600 routing node. Two-input mode is not currently

supported.

6 ■ T1600 Upgrade Kit

Table 1 on page 7 describes which components are powered by each input.

Page 7

T1600 Upgrade Kit

Table 1: Components Powered by Each Three-Input 240-A Power Supply Input

Two-Input ModeThree-Input ModeInput

INPUT 0

T1600-SIBs, T-CBs, fan trays, and

Routing Engines

FPCs in slots FPC0 and FPC1, SIBs, T-CBs,

fan trays, and Routing Engines

FPCs in slots FPC2 and FPC7FPCs in slots FPC4 through FPC7INPUT 1

FPCs in slots FPC0 through FPC3INPUT 2

Not applicable

Three-Input 240-A Power Supply Load Sharing and Fault Tolerance

When the routing node is operating normally and both power supplies are switched

on, load sharing between them occurs automatically. When one power supply fails

or is turned off, the other power supply immediately assumes the entire electrical

load for the system. A single power supply can provide full power for as long as the

routing node is operational. Table 2 on page 7 describes the behavior of the power

supply if one of the inputs fails.

Table 2: Fault Tolerance

Two-Input ModeThree-Input ModeInput

INPUT 0

INPUT 1

If this input fails, INPUT 0, INPUT 1,

and INPUT 2 shut down. The power

supply shuts down, and the other

power supply assumes the electrical

load for all three inputs.

If this input fails, INPUT 0 is

unaffected and INPUT 1 and INPUT 2

shut down. The other power supply

assumes the electrical load of INPUT 1

and INPUT 2.

If this input fails, INPUT 0 and INPUT 1

shut down. The power supply shuts

down, and the other power supply

assumes the electrical load of INPUT 0

and INPUT 1.

If this input fails, INPUT 0 is

unaffected and INPUT 1 shuts down.

The other power supply assumes the

electrical load of INPUT 1.

INPUT 2

If this input fails, INPUT 0 is

unaffected and INPUT 1 and INPUT 2

shut down. The other power supply

assumes the electrical load of INPUT 1

and INPUT 2.

Not applicable

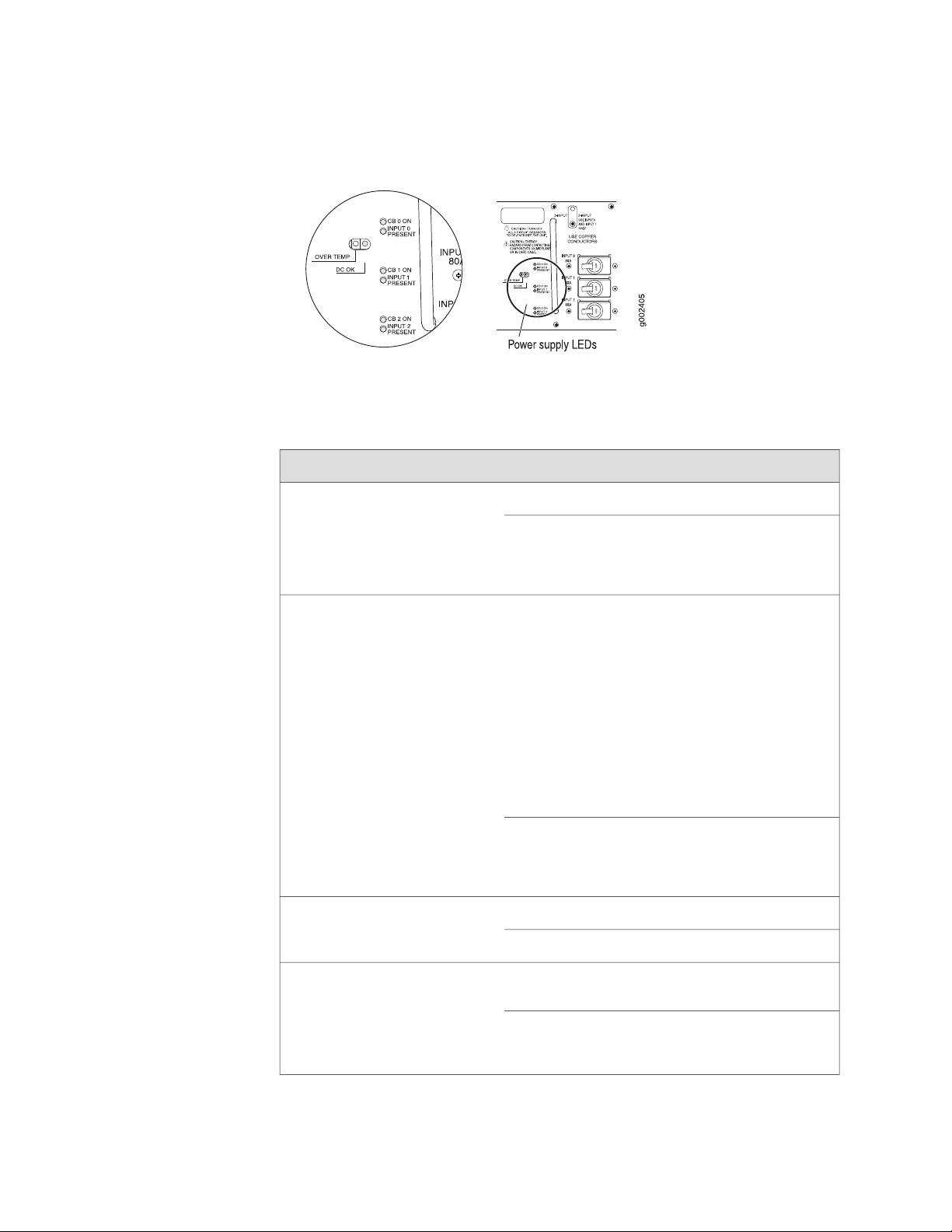

Three-Input 240-A Power Supply LEDs

LEDs on each power supply faceplate (see Figure 4 on page 8) indicate the status

of the power supply. In addition, a power supply failure triggers the red alarm LED

on the craft interface. Table 3 on page 8 describes the functions of the power supply

LEDs.

T1600 Upgrade Kit ■ 7

Page 8

T1600 Routing Node Upgrade Guide

Figure 4: Three-Input 240-A Power Supply LEDs

Table 3 on page 8 describes the three-input 240-A power supply LEDs.

Table 3: Three-Input 240-A Power Supply LEDs

DescriptionStateColorLED

CB ON—One per

input

DC OK—One per

power supply

INPUT

PRESENT—One

per input

Off

On steadilyBlue

Blinking

Circuit breaker is on.On steadilyGreen

Circuit breaker is not turned on, or

host subsystem has detected a

failure and has turned the circuit

breaker off.

When the power supply is correctly

set to three-input mode mode and

all three inputs are properly

energized, the DC OK LED indicates

that the power supply is

functioning normally.

When the power supply is correctly

set to two-input mode and INPUT 0

and INPUT 1 are both properly

energized, the DC OK LED indicates

that the power supply is

functioning normally.

Power supply is starting up, is not

functioning, is not properly

installed, or is not operating

properly.

Input is receiving voltage.On steadilyGreen

Input voltage is not present.Off

8 ■ T1600 Upgrade Kit

OVER

TEMP—One per

power supply

On steadilyAmber

Off

Power supply has exceeded

recommended temperature.

Power supply is within the

recommended temperature or the

power supply is not on.

Page 9

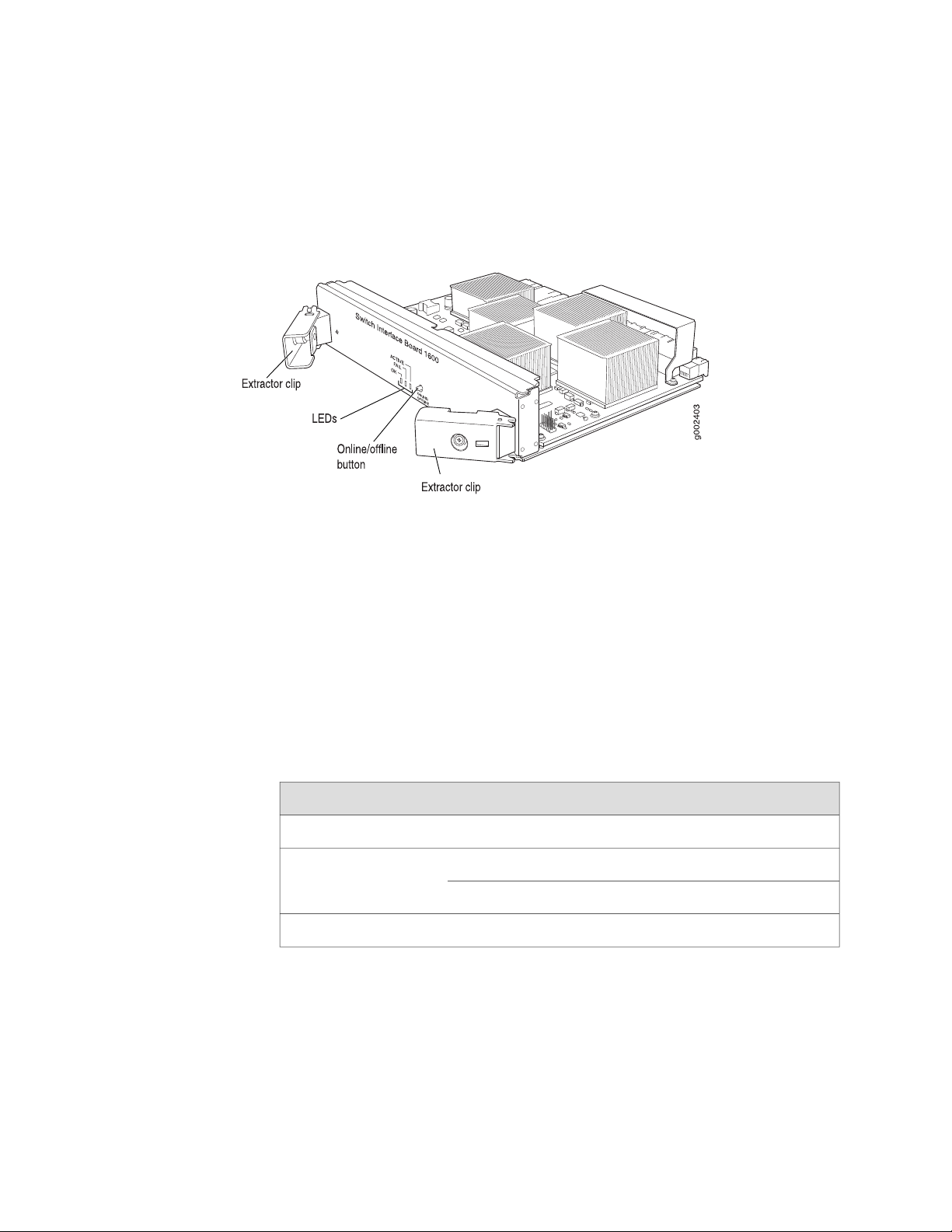

T1600-SIBs

T1600 Upgrade Kit

Figure 5 on page 9 shows a T1600-SIB.

Figure 5: T1600-SIB

Each T1600-SIB consists of the following components:

■ Switch fabric ASICs.

■ High-speed links to each FPC.

■ SIB online/offline button, located on the SIB faceplate.

■ Three LEDs located on the SIB faceplate that display the status of the SIB.

Table 4 on page 9 describes the functions of the SIB LEDs. If all three LEDs are

off, the SIB is not receiving power. The craft interface has three additional LEDs

that show the status of each T1600-SIB. The OK and FAIL LEDs are replicated on

the craft interface.

Table 4: SIB LEDs

DescriptionStateColorLabel

ACTIVE

OK

FAIL

SIB is in active mode.On steadilyGreen

SIB is functioning normally.On steadilyGreen

SIB is starting up.Blinking

SIB has failed.On steadilyAmber

Each SIB weighs approximately 6.5 lb (3 kg).

T1600 Upgrade Kit ■ 9

Page 10

T1600 Routing Node Upgrade Guide

T1600 Routing Node Upgrade Overview

NOTE: The T640 routing node can be upgraded while the routing node is powered

on and operational.

NOTE: During the SIB upgrade:

■ The routing node should not experience packet loss if the traffic is less than

50 percent per Packet Forwarding Engine in each FPC.

■ The routing node might experience some packet loss if the traffic is more than

50 percent per Packet Forwarding Engine in each FPC, depending on the

operational environment.

For more information, contact your customer support representative.

To upgrade the T640 routing node, use the following procedures:

1. If you have not already done so, install JUNOS Release 8.5 or later in the T640

routing node.

2. Verify that the required hardware version of the rear fan tray is installed. If

needed, order a new rear fan tray.

3. Prepare the site. Provision additional power as needed.

4. Remove one two-input 160-A power supply.

5. Install a three-input 240-A power supply.

6. Replace the other power supply.

7. Upgrade the existing standard SIBs to T1600-SIBs.

8. Remove the upper fan tray.

9. Replace the craft interface.

10. Reinstall the upper fan tray.

11. Verify the installation of components.

12. Attach the T1600 agency label.

13. Register your T1600 upgrade.

NOTE: Do not install T1600-FPC4s until after all upgrade procedures are completed.

10 ■ T1600 Routing Node Upgrade Overview

Page 11

Verifying the Hardware Version of the Rear Fan Tray

Verifying the Hardware Version of the Rear Fan Tray

The rear fan tray, model number FAN-REAR-TX-T640-S, has eight fans and is required

to support the additional thermal power generation of the T1600 routing node. Model

number RHTREARTRAY-T-S has five blowers and does not provide sufficient cooling

for the T1600 routing node. To verify that FAN-REAR-TX-T640-S is installed:

1.

Issue the show chassis environment command:

In this example, the output shows that the rear fan tray has five blowers,

indicating that RHTREARTRAY-T-S is installed. The last five lines of the output

for the fans each include Blower in the description.

user@host> show chassis environment

Fans Top Left Front fan OK Spinning at normal speed

Top Left Middle fan OK Spinning at normal speed

Top Left Rear fan OK Spinning at normal speed

Top Right Front fan OK Spinning at normal speed

Top Right Middle fan OK Spinning at normal speed

Top Right Rear fan OK Spinning at normal speed

Bottom Left Front fan OK Spinning at normal speed

Bottom Left Middle fan OK Spinning at normal speed

Bottom Left Rear fan OK Spinning at normal speed

Bottom Right Front fan OK Spinning at normal speed

Bottom Right Middle fan OK Spinning at normal speed

Bottom Right Rear fan OK Spinning at normal speed

Fourth Blower from top OK Spinning at normal speed

Bottom Blower OK Spinning at normal speed

Middle Blower OK Spinning at normal speed

Top Blower OK Spinning at normal speed

Second Blower from top OK Spinning at normal speed

In this example, the output shows that the rear fan tray has eight fans, indicating

that FAN-REAR-TX-T640-S is installed. The last eight lines of the output for the

fans each begin with Rear Tray and include fan in the description.

Fans Top Left Front fan OK Spinning at normal speed

Top Left Middle fan OK Spinning at normal speed

Top Left Rear fan OK Spinning at normal speed

Top Right Front fan OK Spinning at normal speed

Top Right Middle fan OK Spinning at normal speed

Top Right Rear fan OK Spinning at normal speed

Bottom Left Front fan OK Spinning at normal speed

Bottom Left Middle fan OK Spinning at normal speed

Bottom Left Rear fan OK Spinning at normal speed

Bottom Right Front fan OK Spinning at normal speed

Verifying the Hardware Version of the Rear Fan Tray ■ 11

Page 12

T1600 Routing Node Upgrade Guide

Bottom Right Middle fan OK Spinning at normal speed

Bottom Right Rear fan OK Spinning at normal speed

Rear Tray Top fan OK Spinning at normal speed

Rear Tray Second fan OK Spinning at normal speed

Rear Tray Third fan OK Spinning at normal speed

Rear Tray Fourth fan OK Spinning at normal speed

Rear Tray Fifth fan OK Spinning at normal speed

Rear Tray Sixth fan OK Spinning at normal speed

Rear Tray Seventh fan OK Spinning at normal speed

Rear Tray Bottom fan OK Spinning at normal speed

2. If RHTREARTRAY-T-S is installed, order FAN-REAR-TX-T640-S and install it before

installing the three-input 240-A power supplies.

Preparing the Site

The following sections describe how to prepare your site so that you can install

upgrade components.

■ Typical Power Distribution on page 12

■ Provisioning Additional Power for the T1600 Routing Node on page 13

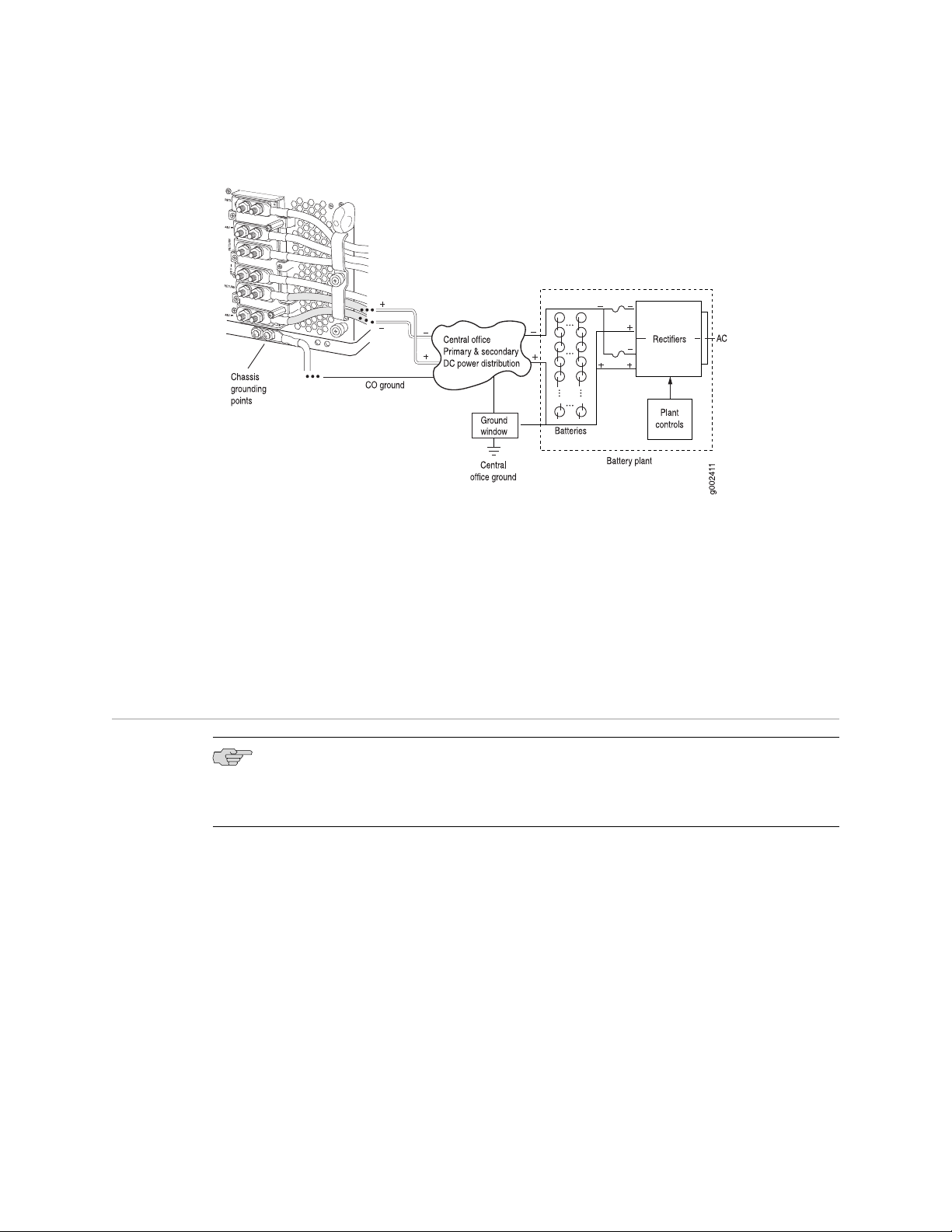

Typical Power Distribution

Most sites distribute DC power through a main conduit that leads to frame-mounted

DC power distribution panels, one of which might be located at the top of the rack

that houses the T1600 routing node. A pair of cables (one input and one return)

connects each set of terminal studs to the power distribution panel.

The DC power supply in slot PEM0 must be powered by a dedicated power feed

derived from feed A, and the DC power supply in slot PEM1 must be powered by a

dedicated power feed derived from feed B. This configuration provides the commonly

deployed A/B feed redundancy for the system.

Figure 6 on page 13 shows a typical DC source cabling arrangement.

12 ■ Preparing the Site

Page 13

Replacing the Rear Fan Tray

Figure 6: Typical DC Source Cabling to the T1600 Routing Node

Provisioning Additional Power for the T1600 Routing Node

For a maximally configured T1600 routing node, we recommend that you provision

at least 64 A @ –48 VDC for each power supply input in the system.

We recommend that you provision a facility circuit breaker for each DC power supply

input rated for at least 125% of the continuous current that the input draws at

–48 VDC.

Replacing the Rear Fan Tray

NOTE: If the rear fan tray (model number FAN-REAR-TX-T640-S) is already installed,

replacing the rear fan tray is not necessary. Proceed to “Upgrading the DC Power

Supplies” on page 17.

The rear fan tray is hot-insertable and hot-removable. To replace a fan tray, use the

following procedures:

■ Removing the Rear Fan Tray on page 14

■ Installing a Rear Fan Tray on page 15

Replacing the Rear Fan Tray ■ 13

Page 14

T1600 Routing Node Upgrade Guide

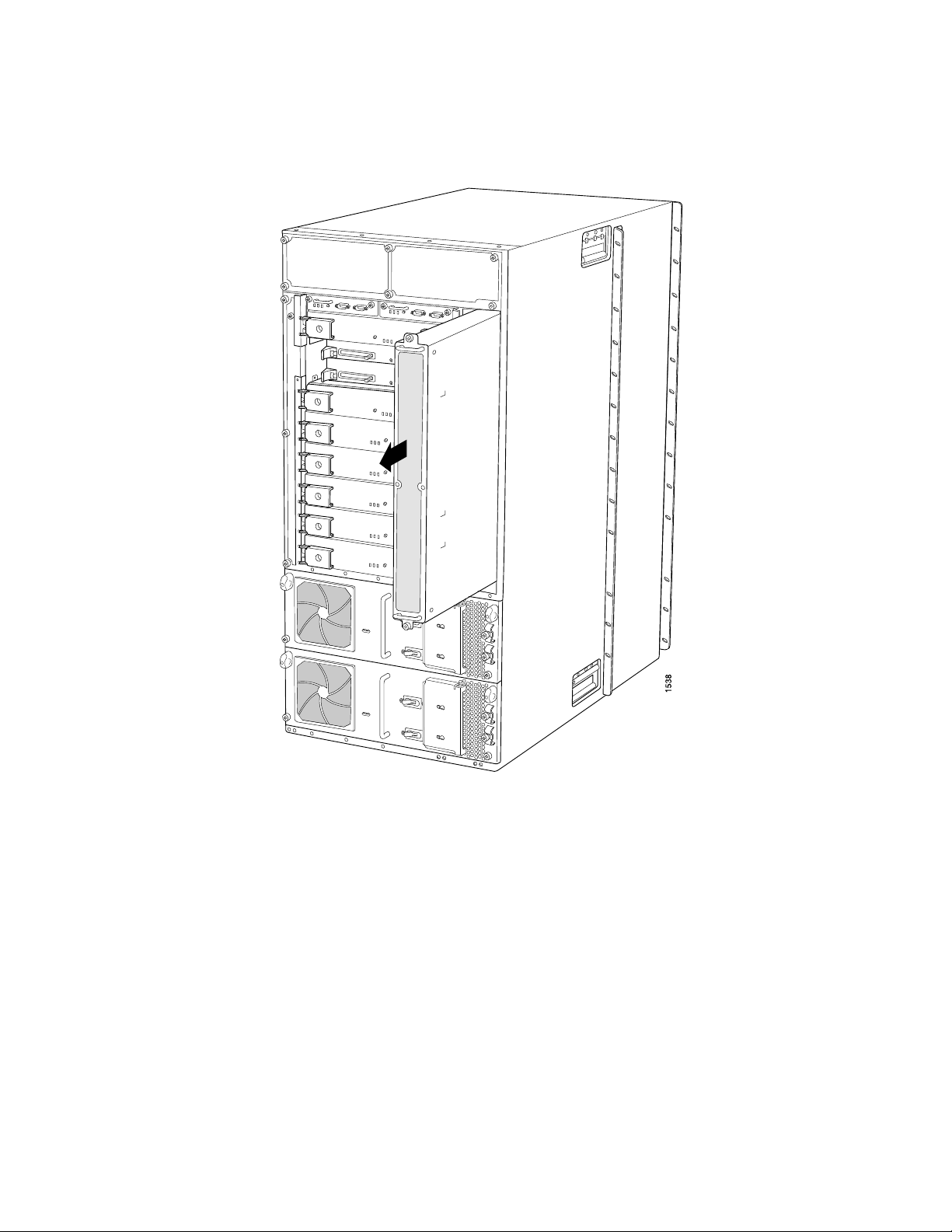

Removing the Rear Fan Tray

The rear fan tray is mounted vertically on the right side of the rear of the chassis.

The rear fan tray (model number RHTREARTRAY-T-S) weighs about 12 lb (5.4 kg).

To remove the rear fan tray, follow this procedure (see Figure 7 on page 15):

1. Attach an electrostatic discharge (ESD) grounding strap to your bare wrist and

connect the strap to one of the ESD points on the chassis. See “Preventing

Electrostatic Discharge Damage” on page 47.

2. Loosen the captive screws on the top and bottom of the fan tray faceplate, using

a Phillips (+) screwdriver, number 2.

3. Grasp the handles and pull the fan tray halfway out of the chassis.

WARNING: To avoid injury, keep tools and your fingers away from the fans as you

slide the fan tray out of the chassis. The fans might still be spinning.

4. When the fans stop spinning, grasp the handles and pull the fan tray completely

out of the chassis.

CAUTION: To maintain proper cooling, do not operate the T1600 routing node with

the rear fan tray removed for more than one minute.

14 ■ Replacing the Rear Fan Tray

Page 15

Figure 7: Removing the Rear Fan Tray

Replacing the Rear Fan Tray

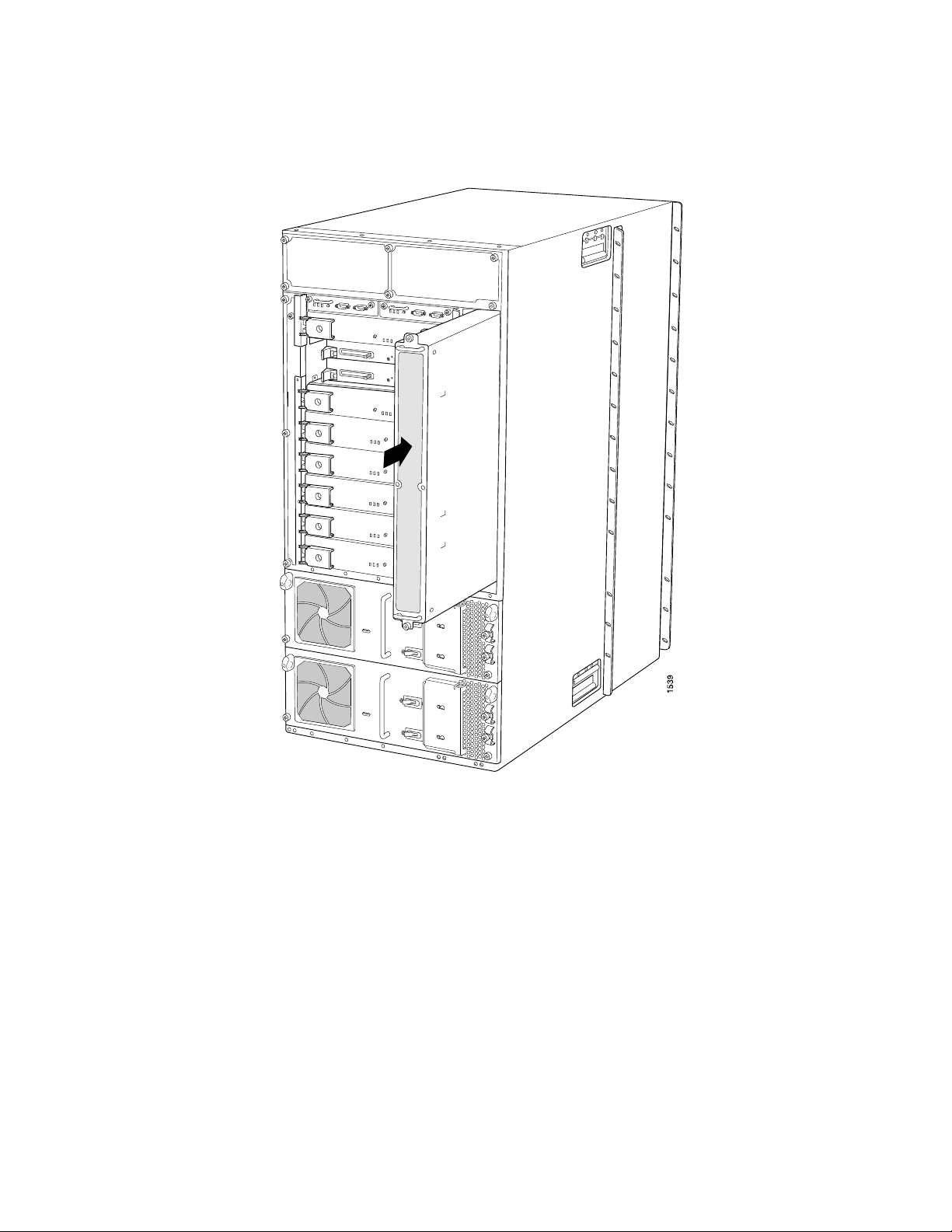

Installing a Rear Fan Tray

The rear fan tray (model number FAN-REAR-TX-T640-S) weighs about 10 pounds

(4.5 kg). To install a replacement rear fan tray, follow this procedure (see

Figure 8 on page 16):

1. Attach an electrostatic discharge (ESD) grounding strap to your bare wrist and

connect the strap to one of the ESD points on the chassis. See “Preventing

Electrostatic Discharge Damage” on page 47.

2. Grasp the fan tray by its handles and insert it straight into the chassis.

3. Tighten the captive screws on the fan tray faceplate to secure it in the chassis,

using a Phillips (+) screwdriver, number 2.

Replacing the Rear Fan Tray ■ 15

Page 16

T1600 Routing Node Upgrade Guide

Figure 8: Installing a Rear Fan Tray

16 ■ Replacing the Rear Fan Tray

Page 17

Upgrading the DC Power Supplies

NOTE: You must upgrade both power supplies. Follow these procedures for one

power supply, then immediately upgrade the other power supply. Mixing a two-input

160-A power supply and a three-input 240-A power supply is supported only during

the upgrade.

The power supplies are located at the lower rear of the chassis. Each power supply

is hot-insertable and hot-removable. When one power supply is powered down or

removed, the other power supply automatically assumes the entire electrical load

for the routing node. To upgrade each two-input 160-A power supply to a three-input

240-A power supply, use the following procedures:

■ Preparing the DC Power Cables on page 17

■ Tools and Parts Required on page 17

■ Removing a Two-Input 160-A Power Supply on page 18

■ Setting the Input Mode Switch on a Three-Input 240-A Power Supply on page 21

■ Installing a Three-Input 240-A Power Supply on page 22

■ Replacing the Cable Restraint on a Three-Input 240-A Power Supply on page 23

■ Connecting a Three-Input 240-A Power Supply on page 25

■ Powering On a Three-Input 240-A Power Supply on page 26

Upgrading the DC Power Supplies

Preparing the DC Power Cables

The accessory box shipped with the installation kit includes the cable lugs that attach

to the terminal studs of each power supply (see Figure 25 on page 46).

CAUTION: Before the power supply installation begins, a licensed electrician must

attach cable lugs to the power cables that you supply. A cable with an incorrectly

attached lug can damage the power supply.

Tools and Parts Required

To upgrade the power supplies, you need the following tools and parts:

■ Four additional DC power cables (two cables for each power supply)

■ Electrostatic discharge (ESD) grounding wrist strap

■ 7/16-in. nut driver or pliers

Upgrading the DC Power Supplies ■ 17

Page 18

T1600 Routing Node Upgrade Guide

CAUTION: Do not substitute a metric nut driver or wrench. A tool that does not fit

the nuts exactly can damage them. If a 7/16-in. tool is not available, use pliers or an

adjustable wrench.

■ Phillips (+) screwdrivers, numbers 1 and 2

■ Flashlight

■ Non-conductive sharp object to set the input-mode switch

■ Wire cutters

Removing a Two-Input 160-A Power Supply

To remove a two-input 160-A power supply, follow this procedure:

1. Switch off the external circuit breakers to the power supply being removed. Make

sure that the voltage across the DC power source cable leads is 0 V and that there

is no chance that the cables might become active during the removal process.

2. Attach an electrostatic discharge (ESD) grounding strap to your bare wrist and

connect the strap to one of the ESD points on the chassis. See “Preventing

Electrostatic Discharge Damage” on page 47.

3.

Switch both circuit breakers on the power supply faceplate to the off position (O).

Figure 9: Two-Input 160-A Power Supply

NOTE: After powering off a power supply, wait at least 60 seconds before turning it

back on.

4. Remove the clear plastic cover protecting the terminal studs on the faceplate.

18 ■ Upgrading the DC Power Supplies

Page 19

CAUTION: You must ensure that power connections maintain the proper polarity.

The power source cables might be labeled (+) and (–) to indicate their polarity. There

is no standard color coding for DC power cables. The color coding used by the external

DC power source at your site determines the color coding for the leads on the power

cables that attach to the terminal studs on each power supply.

5. Using a 7/16-in. nut driver or pliers, remove the nuts and washers from the

terminal studs (see Figure 10 on page 19).

Figure 10: Disconnecting Power Cables From the DC Power Supply

Upgrading the DC Power Supplies

6. Remove the cable lugs from the terminal studs.

7. Loosen the captive screws on the cable restraints on the right edge of the power

supply faceplate.

8. Carefully move the power cables out of the way.

9. Loosen the captive screws on the lower corners of the power supply faceplate

completely.

10. Twist the ejector handles on the upper corners of the faceplate counterclockwise

to unseat the power supply.

WARNING: Do not touch the power connectors on the rear of the power supply (see

Figure 11 on page 20). They can contain dangerous voltages.

Upgrading the DC Power Supplies ■ 19

Page 20

T1600 Routing Node Upgrade Guide

Figure 11: Rear of the Power Supply Showing Midplane Connectors

11. Grasp the handle on the power supply faceplate and pull firmly. Slide it halfway

out of the chassis (see Figure 12 on page 21).

CAUTION: Each two-input 160-A power supply weighs approximately 23 lb (10.5 kg).

Be prepared to support the full weight of the power supply as you remove it from

the routing platform.

12. Place one hand underneath the power supply to support it and slide it completely

out of the chassis.

CAUTION: Do not leave a power supply slot empty for more than a short time while

the routing node is operational. For proper airflow, the power supply must remain

in the chassis or a blank panel must be used in an empty slot.

20 ■ Upgrading the DC Power Supplies

Page 21

Figure 12: Removing a Power Supply

Upgrading the DC Power Supplies

Setting the Input Mode Switch on a Three-Input 240-A Power Supply

NOTE: Do not set the input mode switch if the power supply is installed in the chassis.

If the power supply is already installed, you must remove it before setting the input

mode switch.

To set the input mode switch:

1. Using a screwdriver, loosen the captive screw holding the metal cover over the

input mode switch (see Figure 13 on page 22).

2. Rotate the metal cover away from the input mode switch to expose the switch.

3. Check the setting of the input mode switch. Use a flashlight, if necessary. In

3-INPUT mode, the switch is located all the way to the left.

4. Use a sharp, nonconductive object to slide the switch all the way to the left to

set the power supply to three-input mode.

CAUTION: Do not use a pencil, because fragments can break off and cause damage

to the power supply.

5. Rotate the metal cover over the input mode switch, and use a screwdriver to

tighten the captive screw.

Figure 13 on page 22 shows the input mode switch.

Upgrading the DC Power Supplies ■ 21

Page 22

T1600 Routing Node Upgrade Guide

Figure 13: Three-Input 240-A Power Supply

Installing a Three-Input 240-A Power Supply

Each three-input 240-A power supply weighs approximately 25 lb (11.3 kg). To install

a three-input 240-A power supply, follow this procedure:

1. Make sure that the voltage across the DC power source cable leads is 0 V and

that there is no chance that the cables might become active during installation.

2. Attach an electrostatic discharge (ESD) grounding strap to your bare wrist and

connect the strap to one of the ESD points on the chassis. See “Preventing

Electrostatic Discharge Damage” on page 47.

3.

Switch the circuit breakers on the power supply faceplate to the OFF position (O).

4. Using both hands, slide the power supply into the chassis until you feel resistance

(see Figure 14 on page 23).

5. Twist the ejector handles at the upper corners of the power supply faceplate

clockwise until they stop.

6. Tighten the captive screws at the lower corners of the power supply faceplate

to secure the power supply in the chassis.

22 ■ Upgrading the DC Power Supplies

Page 23

Figure 14: Installing a Three-Input 240-A Power Supply

Upgrading the DC Power Supplies

Replacing the Cable Restraint on a Three-Input 240-A Power Supply

Each three-input 240-A power supply is shipped with the standard cable restraint

shown in Figure 15 on page 23. Two optional cable restraints are shipped in the

accessory box for the T1600 routing node and in the T1600 upgrade kit.

If your DC power cables are too large or inflexible to fit into the standard cable

restraint, we recommend that you remove the standard cable restraint and install

the optional cable restraint (see Figure 16 on page 24) on each three-input 240-A

power supply.

Figure 15: Three-Input 240-A Power Supply with the Standard Cable Restraint

Upgrading the DC Power Supplies ■ 23

Page 24

T1600 Routing Node Upgrade Guide

Figure 16: Three-Input 240-A Power Supply with the Optional Cable Restraint

To replace the cable restraint on a three-input 240-A power supply, use the following

procedures:

■ Removing the Standard Cable Restraint from a Three-Input 240-A Power

Supply on page 24

■ Installing the Optional Cable Restraint on a Three-Input 240-A Power

Supply on page 24

Removing the Standard Cable Restraint from a Three-Input 240-A Power Supply

The cable restraint is located on the right edge of the power supply faceplate. To

remove the standard cable restraint, follow this procedure:

1. Loosen the captive screw on the standard cable restraint.

2. Remove the cable restraint from the power supply.

Installing the Optional Cable Restraint on a Three-Input 240-A Power Supply

To install the optional cable restraint, follow this procedure:

1. Align the two captive screws on the optional cable restraint with the two threaded

holes located at the right edge of the power supply faceplate.

2. Fasten the captive screws.

24 ■ Upgrading the DC Power Supplies

Page 25

Connecting a Three-Input 240-A Power Supply

To connect a three-input 240-A power supply to the power sources, follow this

procedure:

1. Attach an electrostatic discharge (ESD) grounding strap to your bare wrist and

connect the strap to one of the ESD points on the chassis. See “Preventing

Electrostatic Discharge Damage” on page 47.

2. Verify that a licensed electrician has attached cable lugs to the power cables that

you supply.

3. Verify that the voltage across the DC power source cables leads is 0 V and that

there is no chance that the cables might become active during installation. If

needed, switch off the external circuit breakers.

4.

Verify that the circuit breakers on the power supply faceplate are in the OFF

position (O).

5. Remove the clear plastic cover protecting the terminal studs on the faceplate.

Upgrading the DC Power Supplies

6. Remove the nut and washer from each power terminal stud.

CAUTION: You must ensure that power connections maintain the proper polarity.

The power source cables might be labeled (+) and (–) to indicate their polarity. There

is no standard color coding for DC power cables. The color coding used by the external

DC power source at your site determines the color coding for the leads on the power

cables that attach to the terminal studs on each power supply.

7. Attach the lugs on the DC source power cables to the terminal studs.

a.

Attach the positive (+) DC source power cable lugs to the RETURN (return)

terminals.

b.

Attach the negative (–) DC source power cable lugs to the –48V (input)

terminals.

Secure the cable lugs to the terminal studs, first with a washer, then with a nut

(see Figure 17 on page 26). Use a 7/16-in. (11-mm) nut driver or wrench to

tighten the nut. Apply between 23 lb-in. (2.6 Nm) and 25 lb-in. (2.8 Nm) of torque

to each nut.

NOTE: For power supplies set to 3-INPUT mode (required for the T1600 routing node),

connect two DC power cables to each of the three inputs.

8. Loosen the captive screw or screws on the cable restraint on the right edge of

the power supply faceplate.

9. Route the DC power cables through the cable restraint.

10. Tighten the cable restraint captive screw or screws to hold the power cables in

place.

Upgrading the DC Power Supplies ■ 25

Page 26

T1600 Routing Node Upgrade Guide

11. Verify that the ground and power cabling are correct, that they are not touching

12. Replace the clear plastic cover over the terminal studs on the faceplate.

Figure 17: Connecting Power Cables to the Power Supply

or blocking access to other hardware components, and that they do not drape

where people could trip on them.

Powering On a Three-Input 240-A Power Supply

To power on a three-input 240-A power supply, follow this procedure:

1. Attach an electrostatic discharge (ESD) grounding strap to your bare wrist and

connect the strap to one of the ESD points on the chassis. See “Preventing

Electrostatic Discharge Damage” on page 47.

2. Switch on the external circuit breakers to provide voltage to the DC power source

cables.

3.

Verify that the INPUT PRESENT LEDs on the power supply faceplate are lit steadily,

indicating that the inputs are receiving power.

4.

Switch the circuit breakers on the power supply to the ON position (|).

26 ■ Upgrading the DC Power Supplies

Page 27

Upgrading SIBs

NOTE: After a power supply is powered on, it can take up to 60 seconds for status

indicators—such as the LEDs on the power supply, the show chassis command

display, and messages on the LED display on the craft interface—to indicate that the

power supply is functioning normally. Ignore error indicators that appear during the

first 60 seconds.

5.

Verify that the CB ON LEDs on the power supply faceplate are lit steadily. The

CB ON LEDs blink momentarily, then light steadily to indicate that the circuit

breakers are on.

6.

Verify that the DC OK LED on the power supply faceplate is lit steadily, indicating

that the power supply is correctly installed and is functioning properly.

NOTE: After powering on a power supply, wait at least 60 seconds before turning it

off. If the system is completely powered off when you power on the power supply,

the Routing Engine boots as the power supply completes its startup sequence. If the

Routing Engine finishes booting and you need to power off the system again, first

issue the CLI request system halt command.

Upgrading SIBs

After powering off a power supply, wait at least 60 seconds before turning it back

on.

To convert an operational T640 routing node to a T1600 routing node, you upgrade

the standard SIBs or SIBs version B in the T640 routing node to T1600-SIBs. You

repeat the upgrade procedures for each of the five SIBs in the routing node.

NOTE: During the SIB upgrade:

■ The routing node should not experience packet loss if the traffic is less than

50 percent per Packet Forwarding Engine in each FPC.

■ The routing node might experience some packet loss if the traffic is more than

50 percent per Packet Forwarding Engine in each FPC, depending on the

operational environment.

For more information, contact your customer support representative.

■ Overview of Upgrading the SIBs on page 28

■ Preparing to Upgrade the SIBs on page 29

■ Tools Required on page 30

■ Removing a Standard SIB or SIB Version B on page 30

■ Installing a T1600-SIB on page 32

Upgrading SIBs ■ 27

Page 28

T1600 Routing Node Upgrade Guide

■ Verifying the Installation of a T1600-SIB on page 33

■ Preparing to Exit Upgrade Mode on page 33

■ Exiting Upgrade Mode on page 34

■ Verifying Operation on page 35

Overview of Upgrading the SIBs

To replace the standard SIBs or SIB version B in a T640 routing node with T1600-SIBs,

follow these procedures:

1. Identify the spare SIB.

2. Upgrade the spare SIB.

a. Remove the spare SIB using the procedure“Removing a Standard SIB or SIB

Version B” on page 30.

b. Install a T1600-SIB in the slot where the spare SIB was located. See “Installing

a T1600-SIB” on page 32

3. Remove one of the remaining standard SIBs or SIB version B and install a

T1600-SIB. Then, repeat the procedures for each of the remaining SIBs.

28 ■ Upgrading SIBs

Page 29

Preparing to Upgrade the SIBs

To prepare to upgrade the SIBs, follow this procedure:

1. The T640 routing node must contain five standard SIBs or SIBs version B before

the upgrade. Verify that four SIBs are in the Online state and one SIB is in the

Spare state. Display the status of the SIBs by issuing the show chassis sibs

command:

user@host> show chassis sibs

Slot State Uptime

0 Spare 255 days, 31 minutes, 12 seconds

1 Online 255 days, 31 minutes, 12 seconds

2 Online 255 days, 31 minutes, 12 seconds

3 Online 255 days, 31 minutes, 12 seconds

4 Online 255 days, 31 minutes, 12 seconds

Upgrading SIBs

To bring a SIB online, issue the request chassis sib online operational mode

command. To install additional SIBs, use the standard installation procedure

described in the T640 Internet Routing Node Hardware Guide.

NOTE: Do not proceed with the upgrade until all five SIBs are present and operational.

2. Enter configuration mode.

user@host> configure

3.

Include the fabric upgrade-mode statement in the configuration at the [edit chassis]

hierarchy level.

user@host# set chassis fabric upgrade-mode

4. Commit the configuration:

■ If GRES is enabled, commit the configuration on both the master and the

backup Routing Engines:

user@host# commit synchronize

■ If GRES is not enabled, commit the configuration on the master Routing

Engine:

user@host# commit

5. Exit configuration mode.

Upgrading SIBs ■ 29

Page 30

T1600 Routing Node Upgrade Guide

user@host# exit

Tools Required

To upgrade the SIBs, you need the following tools and parts.

■ Electrostatic discharge (ESD) grounding wrist strap

■ Phillips (+) screwdrivers, numbers 1 and 2

Removing a Standard SIB or SIB Version B

To remove a standard SIB or SIB version B, follow this procedure:

1. Attach an electrostatic discharge (ESD) grounding strap to your bare wrist and

connect the strap to one of the ESD points on the chassis. See “Preventing

Electrostatic Discharge Damage” on page 47.

2. Take the SIB offline by using one of the following methods:

■

Press and hold the ONLINE/OFFLINE button on the SIB faceplate for about

five seconds until the OK LED is not lit.

■

Issue the request chassis sib offline command. For example:

user@host> request chassis sib offline slot 0

NOTE: When you bring an active SIB offline, the spare SIB becomes active and

transitions to the Online state.

3. Loosen the captive screws (using a Phillips (+) screwdriver, number 2) on the

ejector handles on each side of the SIB faceplate.

4. Flip the ejector handles outward to unseat the SIB.

5. Grasp both ejector handles, pull firmly, and slide the SIB about three-quarters of

the way out of the chassis.

6. Place one hand underneath the SIB to support it and slide it completely out of

the chassis. Place the SIB on the antistatic mat.

CAUTION: Do not stack hardware components on one another after you remove

them. Place each component on an antistatic mat resting on a stable, flat surface.

30 ■ Upgrading SIBs

Page 31

Figure 18: Removing a SIB from a T640 Routing Node

Upgrading SIBs

Figure 19: Standard SIB Supported in a T640 Routing Node

Upgrading SIBs ■ 31

Page 32

g002406

T1600 Routing Node Upgrade Guide

Installing a T1600-SIB

Each SIB weighs approximately 6.5 lb (3 kg). To install a T1600-SIB, follow this

procedure (see Figure 20 on page 32):

1. Attach an electrostatic discharge (ESD) grounding strap to your bare wrist and

2. Place one hand underneath the T1600-SIB to support it. With the other hand,

3. Carefully align the sides of the T1600-SIB with the guides inside the chassis.

4. Slide the T1600-SIB into the chassis, carefully ensuring that it is correctly aligned.

5. Grasp both ejector handles and press them inward to seat the T1600-SIB. Ensure

connect the strap to one of the ESD points on the chassis. See “Preventing

Electrostatic Discharge Damage” on page 47.

hold one of the ejector handles on the T1600-SIB faceplate.

that the ejector handle tabs are properly mated inside their corresponding chassis

slots. You might have to close and open the handles a few times before the tabs

catch the slots.

6. Tighten the captive screws on the ejector handles.

7. Bring the T1600-SIB online using one of the following methods:

■

Press and hold the ONLINE/OFFLINE button on the T1600-SIB faceplate. The

green OK LED on the faceplate begins to blink. Hold the button down until

the LED blinks.

■ Issue the following CLI command on the routing node:

user@host> request chassis sib online slot 0

Figure 20: Installing a T1600-SIB in a T1600

32 ■ Upgrading SIBs

Page 33

Verifying the Installation of a T1600-SIB

To verify that the T1600-SIB is functioning normally, follow this procedure:

1. Check the LEDs on the T1600-SIB faceplate.

■

The green OK LED should light steadily a few minutes after the T1600-SIB

is installed.

■

If the FAIL LED is lit steadily, remove and install the T1600-SIB again. Make

sure that the T1600-SIB is seated properly. If the FAIL LED still lights steadily,

the T1600-SIB is not functioning properly. Contact your customer support

representative.

2.

Verify that four T1600-SIB are in the Online state and one SIB is in the Spare

state. Display the status of the T1600-SIB by issuing the show chassis sibs

command:

user@host> show chassis sibs

Upgrading SIBs

Slot State Uptime

0 Spare 0 days, 30 minutes, 12 seconds

1 Online 0 days, 25 minutes, 45 seconds

2 Online 0 days, 20 minutes, 28 seconds

3 Online 0 days, 15 minutes, 7 seconds

4 Online 0 days, 10 minutes, 52 seconds

To bring a T1600-SIB online, issue the request chassis sib online operational

mode command.

Preparing to Exit Upgrade Mode

After all five T1600-SIBs have been installed, use the following commands to exit

upgrade mode :

1. Determine if GRES is enabled.

user@host> show system switchover

Graceful switchover: On

Configuration database: Ready

Kernel database: Ready

2.

Verify that the Routing Engines are operating properly by issuing the show chassis

routing-engine command.

user@host> show chassis routing-engine

Routing Engine status:

Slot 0:

Current state Master

Election priority Master (default)

Temperature 32 degrees C / 89 degrees F

CPU temperature 33 degrees C / 91 degrees F

Upgrading SIBs ■ 33

Page 34

T1600 Routing Node Upgrade Guide

Exiting Upgrade Mode

Use the following commands to exit upgrade mode:

DRAM 2048 MB

Memory utilization 8 percent

CPU utilization:

User 0 percent

Background 0 percent

Kernel 2 percent

Interrupt 0 percent

Idle 98 percent

Model RE-4.0

Serial ID P13004101110

Start time 2007-04-30 08:38:22 PDT

Uptime 2 days, 2 hours, 22 minutes, 43 seconds

Load averages: 1 minute 5 minute 15 minute

0.02 0.02 0.00

1. Enter configuration mode.

user@host> configure

2.

Delete the fabric upgrade-mode statement in the configuration at the [edit chassis]

hierarchy level.

user@host# delete chassis fabric upgrade-mode

3. Commit the configuration:

■ If GRES is enabled, commit the configuration on both the master and the

backup Routing Engines:

user@host# commit synchronize

■ If GRES is not enabled, commit the configuration on the master Routing

Engine:

user@host# commit

4. Exit configuration mode.

user@host# exit

34 ■ Upgrading SIBs

Page 35

Upgrading SIBs

Verifying Operation

Use the following commands to verify proper operation of the T1600 routing node:

1.

Verify that the model number is now T1600 by issuing the show version

command.

user@host> show version

Hostname: myhost

Model: t1600

JUNOS Base OS boot [8.5R1]

JUNOS Base OS Software Suite [8.5R1]

JUNOS Kernel Software Suite [8.5R1]

JUNOS Crypto Software Suite [8.5R1]

JUNOS Packet Forwarding Engine Support (M/T Common) [8.5R1] JUNOS Packet Forwarding Engine Support

(T-Series) [8.5R1] JUNOS Online Documentation [8.5R1] JUNOS Routing Software Suite [8.5R1]

2.

Verify that no alarms are present by issuing the show chassis alarms command.

user@host> show chassis alarms

No alarms currently active

3. Verify that the LEDs and indicators on the craft interface show that the routing

node is operating properly by issuing the show chassis craft-interface command.

user@host> show chassis craft-interface

FPM Display contents:

+--------------------+

|Myhost router |

|Up: 0+22:34 |

| |

|Temperature OK |

+--------------------|

Front Panel System LEDs:

Routing Engine 0 1

-------------------------OK * *

Fail . .

Master * .

Front Panel Alarm Indicators:

----------------------------Red LED .

Yellow LED .

Major relay .

Minor relay .

Front Panel FPC LEDs:

FPC 0 1 2 3 4 5 6 7

------------------------------------

Red . . . . . . . .

Green * * * * * * * *

CB LEDs:

Upgrading SIBs ■ 35

Page 36

T1600 Routing Node Upgrade Guide

CB 0 1

-------------Amber . .

Green * *

Blue * .

SCG LEDs:

SCG 0 1

-------------Amber . .

Green * *

Blue * .

SIB LEDs:

SIB 0 1 2 3 4

--------------------------

Red . . . . .

Green * * * * *

4. Verify that all FPCs in the routing node are detected and online by issuing the

show chassis fpc and show chassis hardware commands.

user@host> show chassis fpc

Temp CPU Utilization (%) Memory Utilization (%)

Slot State (C) Total Interrupt DRAM (MB) Heap Buffer

0 Online 41 6 0 1024 6 49

1 Online 35 4 0 1024 4 49

2 Online 35 4 0 1024 4 49

3 Online 31 1 0 1024 2 49

4 Online 33 1 0 1024 2 49

5 Online 56 9 0 2048 5 24

6 Online 35 4 0 1024 4 49

7 Online 32 1 0 1024 2 49

user@host> show chassis hardware

Hardware inventory:

Item Version Part number Serial number Description

Chassis JN1090E5DAHA T1600

Midplane REV 02 710-017247 RC0094 T640 Backplane

FPM GBUS REV 09 710-002901 WE0156 T640 FPM Board

FPM Display REV 05 710-021387 DE4543 T1600 FPM Display

CIP REV 06 710-002895 WD8691 T-series CIP

PEM 0 Rev 06 740-017906 TE27790 Power Entry Module 3x80

PEM 1 Rev 06 740-017906 TE27779 Power Entry Module 3x80

SCG 0 REV 14 710-003423 WF1874 T640 Sonet Clock Gen.

SCG 1 REV 14 710-003423 WF1881 T640 Sonet Clock Gen.

Routing Engine 0 REV 06 740-014082 1000688671 RE-A-2000

Routing Engine 1 REV 06 740-014082 1000688739 RE-A-2000

CB 0 REV 06 710-007655 KB9648 Control Board (CB-T)

CB 1 REV 15 710-002728 HR8130 T-series Control Board

FPC 0 REV 10 710-010845 JZ2728 FPC Type 4

CPU REV 04 710-011481 JT8139 FPC CPU-Enhanced

PIC 0 REV 05 750-017405 DF3515 4x 10GE (LAN/WAN) XFP

Xcvr 0 REV 01 740-014279 KB405P1 XFP-10G-LR

Xcvr 1 REV 01 740-014289 C701XU05U XFP-10G-SR

MMB 0 REV 01 710-016606 JW7943 ST-MMB

36 ■ Upgrading SIBs

Page 37

FPC 1 REV 03 710-013035 DF5574 FPC Type 3-ES

CPU

FPC 2 REV 04 710-013560 WF7206 E2-FPC Type 3

CPU REV 03 710-013563 WE9007 FPC CPU-Enhanced

PIC 0 REV 16 750-007141 NF5528 10x 1GE(LAN), 1000 BASE

Xcvr 0 REV 01 740-011782 P8P085F SFP-SX

PIC 1 REV 12 750-009567 WF3566 1x 10GE(LAN),XENPAK

Xcvr 0 REV 02 740-013170 T07C94489 XENPAK-LR

PIC 2 REV 11 750-009567 CW9479 1x 10GE(LAN),XENPAK

Xcvr 0 REV 02 740-013170 T06F90331 XENPAK-LR

PIC 3 REV 07 750-012793 WF5106 1x 10GE(LAN/WAN) IQ2

Xcvr 0 REV 01 740-014279 KB405Q8 XFP-10G-LR

MMB 0 REV 06 710-010171 WF6759 MMB-5M3-288mbit

MMB 1 REV 06 710-010171 WF6800 MMB-5M3-288mbit

FPC 3 REV 04 710-013553 JW1482 E2-FPC Type 1

CPU REV 02 710-013563 JY4119 FPC CPU-Enhanced

PIC 0 REV 10 750-012266 JX5515 4x 1GE(LAN), IQ2

Xcvr 0 REV 01 740-011613 PAM2Y9H SFP-SX

Xcvr 1 REV 01 740-011613 PAM2Y99 SFP-SX

Xcvr 2 REV 01 740-011613 AM07287E42 SFP-SX

Xcvr 3 REV 01 740-011613 PAJ4SQL SFP-SX

PIC 1 REV 04 750-011209 HY3332 Adaptive Services-II

PIC 2 REV 03 750-011750 JH4537 Adaptive Services-II FIPS

MMB 1 REV 05 710-008923 JS8106 MMB 3M 288-bit

FPC 4 REV 04 710-013558 JX5622 E2-FPC Type 2

CPU REV 02 710-013563 JT5841 FPC CPU-Enhanced

PIC 3 REV 21 750-001901 HZ6258 4x OC-12 SONET, SMIR

MMB 1 REV 05 710-010171 JY3756 MMB-5M3-288mbit

FPC 5 REV 10 710-010845 JZ2728 FPC Type 4

CPU REV 04 710-011481 JT8139 FPC CPU-Enhanced

PIC 0 REV 01 750-010850 JA0329 1x OC-768 SONET SR

MMB 0 REV 01 710-016606 JW7943 ST-MMB

FPC 6 REV 10 710-010845 JZ2729 FPC Type 4

CPU REV 04 710-011481 JT8138 FPC CPU-Enhanced

PIC 0 REV 01 750-010850 JA0324 1x OC-768 SONET SR

MMB 0 REV 01 710-016606 JW7942 ST-MMB

FPC 7 REV 05 710-013558 WF4779 E2-FPC Type 2

CPU REV 03 710-013563 WF4663 FPC CPU-Enhanced

PIC 0 REV 09 750-011800 KA2397 8x 1GE(LAN), IQ2

Xcvr 0 REV 01 740-007326 P5S0PD9 SFP-SX

Xcvr 1 REV 01 740-007326 P5S0PD6 SFP-SX

Xcvr 2 REV 01 740-011613 PAJ4SQV SFP-SX

Xcvr 3 REV 01 740-011613 PAM2Y94 SFP-SX

Xcvr 5 REV 01 740-011613 P9R0AJV SFP-SX

Xcvr 7 REV 01 740-013111 70191002 SFP-T

MMB 1 REV 06 710-010171 WF4050 MMB-5M3-288mbit

SPMB 0 REV 10 710-003229 JZ1095 T-series Switch CPU

SPMB 1 REV 09 710-003229 HR8670 T-series Switch CPU

SIB 0 REV 05 710-013074 DE7894 SIB-I8-SF

SIB 1 REV 05 710-013074 DE7916 SIB-I8-SF

SIB 2 REV 05 710-013074 DE7890 SIB-I8-SF

SIB 3 REV 05 710-013074 DE7883 SIB-I8-SF

SIB 4 REV 05 710-013074 DE7913 SIB-I8-SF

Upgrading SIBs

5.

Verify that all interfaces in the routing node are up by issuing the show interfaces

terse command:

user@host> show interfaces terse

Upgrading SIBs ■ 37

Page 38

T1600 Routing Node Upgrade Guide

Interface Admin Link Proto Local Remote

xe-0/0/0 up up

xe-0/0/1 up down

xe-0/0/2 up down

xe-0/0/3 up down

ge-2/0/0 up down

ge-2/0/1 up down

ge-2/0/2 up down

ge-2/0/3 up down

ge-2/0/4 up down

ge-2/0/5 up down

ge-2/0/6 up down

ge-2/0/7 up down

ge-2/0/8 up down

ge-2/0/9 up down

ge-2/1/0 up up

ge-2/2/0 up up

pc-2/3/0 up up

pc-2/3/0.16383 up up inet 10.0.0.1 --> 10.0.0.51

10.0.0.6 --> 0/0

xe-2/3/0 up down

ge-3/0/0 up up

pc-3/0/0 up up

pc-3/0/0.16383 up up inet 10.0.0.1 --> 10.0.0.64

10.0.0.6 --> 0/0

ge-3/0/1 up up

ge-3/0/2 up down

ge-3/0/3 up up

gr-3/1/0 up up

ip-3/1/0 up up

mt-3/1/0 up up

pd-3/1/0 up up

pe-3/1/0 up up

sp-3/1/0 up up

sp-3/1/0.16383 up up inet 10.0.0.1 --> 10.0.0.65

vt-3/1/0 up up

gr-3/2/0 up up

ip-3/2/0 up up

mt-3/2/0 up up

pd-3/2/0 up up

pe-3/2/0 up up

sp-3/2/0 up up

sp-3/2/0.16383 up up inet 10.0.0.1 --> 10.0.0.66

vt-3/2/0 up up

so-4/3/0 up up

so-4/3/1 up down

so-4/3/2 up down

so-4/3/3 up down

so-5/0/0 up up

so-5/1/0 up up

so-5/1/1 up up

so-5/1/2 up down

so-5/1/3 up down

ge-7/0/0 up up

pc-7/0/0 up up

pc-7/0/0.16383 up up inet 10.0.0.1 --> 10.0.0.128

10.0.0.6 --> 0/0

ge-7/0/1 up up

ge-7/0/2 up down

ge-7/0/3 up up

ge-7/0/4 up down

38 ■ Upgrading SIBs

Page 39

Removing the Upper Front Fan Tray

ge-7/0/5 up down

ge-7/0/6 up down

ge-7/0/7 up up

bcm0 up up

bcm0.0 up up inet 10.0.0.4/8

inet6 fe80::200:ff:fe00:4/64

fec0::a:0:0:4/64

tnp 4

dsc up up

em0 up up

em0.0 up up inet 10.0.0.4/8

inet6 fe80::200:1ff:fe00:4/64

fec0::a:0:0:4/64

tnp 4

fxp0 up up

fxp0.0 up up inet 192.168.168.34/22

gre up up

ipip up up

lo0 up up

lo0.0 up up inet 10.255.168.34 --> 0/0

127.0.0.1 --> 0/0

iso 47.0005.80ff.f800.0000.0108.0001.0102.5516.8034

inet6 abcd::10:255:168:34

fe80::2a0:a5ff:fe5e:59f5

lo0.16384 up up inet 127.0.0.1 --> 0/0

lo0.16385 up up inet

lsi up up

mtun up up

pimd up up

pime up up

tap up up

After you have verified operation, you can install T1600-FPC4s.

Removing the Upper Front Fan Tray

NOTE: Remove the front upper fan tray to make the craft interface easier to replace

and to avoid injury and damaging the equipment.

The upper front fan tray is located above the FPC card cage. The fan tray weighs

about 18.6 lb (8.4 kg). To remove the upper front fan tray, follow this procedure (see

Figure 21 on page 40):

1. Attach an electrostatic discharge (ESD) grounding strap to your bare wrist and

connect the strap to one of the ESD points on the chassis. See “Preventing

Electrostatic Discharge Damage” on page 47.

2. Loosen the captive screws on the corners of the fan tray faceplate.

3. Grasp the handles and pull the fan tray halfway out of the chassis.

Removing the Upper Front Fan Tray ■ 39

Page 40

T1600 Routing Node Upgrade Guide

WARNING: To avoid injury, keep tools and your fingers away from the fans as you

slide the fan tray out of the chassis. The fans might still be spinning.

4. When the fans stop spinning, place one hand under the fan tray to support it

Figure 21: Removing a Front Fan Tray

and pull the fan tray completely out of the chassis.

Replacing the Craft Interface

The craft interface is hot-insertable and hot-removable. When you install the craft

interface, allow several minutes for the display to reflect the current state of the

T1600 routing node. Before you remove the craft interface, remove the front upper

fan tray. For instructions on removing a front fan tray, see “Removing the Upper

Front Fan Tray” on page 39

To replace the craft interface, use the following procedures:

■ Removing the Craft Interface on page 40

■ Installing the Craft Interface on page 41

Removing the Craft Interface

The craft interface is located on the front of the chassis above the FPC card cage.

The craft interface weighs approximately 2 lb (0.9 kg). To remove the craft interface,

follow this procedure (see Figure 22 on page 41):

1. Attach an electrostatic discharge (ESD) grounding strap to your bare wrist and

connect the strap to one of the ESD points on the chassis. See “Preventing

Electrostatic Discharge Damage” on page 47.

2. Completely loosen the screws at the four corners of the craft interface.

3. Insert the blade of a flat-blade screwdriver into the slot on one side of the craft

interface, then gently pry that side out from the chassis.

40 ■ Replacing the Craft Interface

Page 41

Replacing the Craft Interface

4. Repeat Step 3 for the other side of the craft interface.

5. Grasp the craft interface by the top and bottom edges and carefully pull it straight

out of the chassis.

Figure 22: Removing the Craft Interface

Installing the Craft Interface

To install the craft interface, follow this procedure (see Figure 23 on page 42):

1. Attach an electrostatic discharge (ESD) grounding strap to your bare wrist and

connect the strap to one of the ESD points on the chassis. See “Preventing

Electrostatic Discharge Damage” on page 47.

2. Grasping the craft interface by the top and bottom edges, press it into place.

3. Tighten the screws at the corners of the craft interface.

NOTE: When you install the craft interface in an operating T1600 routing node, allow

several minutes for the LEDs on the craft interface to reflect the current state of the

T1600 routing node.

After you install the replacement craft interface, immediately reinstall the upper front

fan tray.

Replacing the Craft Interface ■ 41

Page 42

T1600 Routing Node Upgrade Guide

Figure 23: Installing a Replacement Craft Interface

Installing the Upper Front Fan Tray

To install the upper front fan tray, follow this procedure (see Figure 24 on page 42):

1. Attach an electrostatic discharge (ESD) grounding strap to your bare wrist and

connect the strap to one of the ESD points on the chassis. See “Preventing

Electrostatic Discharge Damage” on page 47.

2. Grasp the fan tray by its handles and insert it straight into the chassis.

3. Tighten the captive screws on each side of the fan tray faceplate to secure it in

the chassis.

Figure 24: Installing a Front Fan Tray

Attaching the T1600 Agency Label

To attach the T1600 agency label, follow this procedure:

1. Locate the T640 agency label on the side of the chassis.

42 ■ Installing the Upper Front Fan Tray

Page 43

2. Peel the protective backing off the T1600 agency label.

3. Apply the T1600 agency label on top of the T640 agency label.

Registering Your T1600 Upgrade

You must register the T1600 upgrade with Juniper upon completion of the upgrade.

To register your upgrade:

1. Log on to the Juniper Customer Support Center at

http://www.juniper.net/customers/support/.

2.

Click on Update Install Base.

3. Follow the instructions provided in this link.

After your T600 upgrade is registered, allow up to 45 days for restocking of the new

hardware configuration to support any Next Day or Same Day contracts. Juniper

Networks will provide Best Effort support until restocking of the upgraded product

is complete.

Registering Your T1600 Upgrade

Registering Your T1600 Upgrade ■ 43

Page 44

T1600 Routing Node Upgrade Guide

T1600 Routing Node Environmental Specifications

Table 5 on page 44 specifies the environmental specifications required for normal

T1600 routing node operation.

Table 5: T1600 Routing Node Environmental Specifications

ValueDescription

No performance degradation to 10,000 ft (3048 m)Altitude

Relative humidity

Temperature

Seismic

Maximum thermal output

Normal operation ensured in relative humidity range of 5% to

90%, noncondensing

Normal operation ensured in temperature range of 32°F (0°C) to

104°F (40°C)

Nonoperating storage temperature in shipping crate: –40°F (–40°C)

to 158°F (70°C)

Designed to meet Telcordia Technologies Zone 4 earthquake

requirements

28,500 BTU/hour est (8350 W)

NOTE: These specifications are estimates and subject to change.

T1600 Routing Node DC Power Specifications

This section contains specifications for the power system, power supply, and DC

power cables.

■ Power System Electrical Specifications on page 44

■ Three-Input 240-A Power Supply Specifications on page 45

■ DC Power Cable Specifications on page 46

Power System Electrical Specifications

Table 6 on page 45 lists the power system electrical specifications.

44 ■

Page 45

Table 6: Power System Electrical Specifications

SpecificationItem

T1600 Routing Node DC Power Specifications

DC input voltage

Three-Input 240-A Power Supply Specifications

Table 7 on page 45 lists the power supply electrical specifications.

Table 7: Power Supply Electrical Specifications

DC input voltage

Operating range: –40.0 to –72 VDC

NOTE: If the input voltage from the DC power

source drops below –37.5 to –39.5 VDC, the

routing platform automatically shuts down.

During automatic shutdown, the circuit remains

active. When the input voltage returns to –43.0

to –44.0 VDC, the router automatically starts

up again and the system returns to normal

operation within 30 minutes. No operator

intervention is required.

174 A @ –48 VDC (nominal)DC system current rating

8350 WDC system input power

SpecificationItem

Nominal –48 VDC, –60 VDC

Operating range: –40.0 to –72.0 VDC

Input DC current rating

NOTE: If the input voltage from the DC power

source drops below -37.5 to -39.5 VDC, the

routing platform automatically shuts down.

During automatic shutdown, the circuit

remains active. When the input voltage returns

to –43.0 to –44.00 VDC, the router

automatically starts up again and the system

returns to normal operation within 30 minutes.

No operator intervention is required.

Input 0: 46 A @ –48 VDC (nominal)

Input 1: 64 A @ –48 VDC (nominal)

Input 2: 64 A @ –48 VDC (nominal)

T1600 Routing Node DC Power Specifications ■ 45

Page 46

T1600 Routing Node Upgrade Guide

NOTE: If you plan to operate a maximally configured T1600 routing node, we

recommend that you provision at least 64 A @ –48 VDC for each power supply input

in the system. Although Input 0 requires less power, we recommend provisioning

the same amount of power for each input to avoid the possibility of connecting the

lower-powered DC cable to Input 1 or Input 2.

Use a facility circuit breaker rated for 80 A (–48 VDC) minimum for each power

supply input. Doing so enables you to operate the T1600 routing node in any

configuration without upgrading the power infrastructure. You must provision a

circuit breaker for each DC power supply input rated for at least 125% of the

continuous current that the system draws at –48 VDC.

DC Power Cable Specifications

Table 8 on page 46 summarizes the specifications for the DC power cables, which

you supply. For two of the inputs on each power supply, use the DC power cables

and lugs that were connected to the two-input 160-A power supply. Four additional

DC power cables are required. The accessory box shipped with the T1600 upgrade

kit includes four cable lugs that attach to the terminal studs of the additional third

input on each three-input 240-A power supply (see Figure 25 on page 46).

Figure 25: DC Power Cable Lug

Table 8: DC Power Cable Specifications

Quantity and SpecificationCable Type

Power

Four 4-AWG (21.2 mm2), minimum 90°C wire, or as permitted by the local

code

46 ■ T1600 Routing Node DC Power Specifications

Page 47

Preventing Electrostatic Discharge Damage

Many T1600 routing node hardware components are sensitive to damage from static

electricity. Some components can be impaired by voltages as low as 30 V. You can

easily generate potentially damaging static voltages whenever you handle plastic or

foam packing material or if you move components across plastic or carpets. Observe

the following guidelines to minimize the potential for electrostatic discharge (ESD)

damage, which can cause intermittent or complete component failures:

■ Always use an ESD wrist strap or ankle strap, and verify that it is in direct contact

with your skin.

CAUTION: For safety, periodically check the resistance value of the ESD strap. The

measurement should be in the range of 1 to 10 Mohms.

■ When handling any component that is removed from the chassis, verify that the

equipment end of your ESD strap is attached to one of the ESD points on the

chassis, which are shown in Figure 1 on page 4 and Figure 2 on page 5.

Preventing Electrostatic Discharge Damage

■ Avoid contact between the component and your clothing. ESD voltages emitted

from clothing can still damage components.

■ When removing or installing a component, always place it component-side up

on an antistatic surface, in an antistatic card rack, or in an electrostatic bag (see

Figure 26 on page 47). If you are returning a component, place it in an

electrostatic bag before packing it.

Figure 26: Placing a Component into an Electrostatic Bag

Preventing Electrostatic Discharge Damage ■ 47

Page 48

T1600 Routing Node Upgrade Guide

List of Technical Publications

Table 9 on page 48 lists the software and hardware guides and release notes for

Juniper Networks J-series, M-series, MX-series, and T-series routing platforms and

describes the contents of each document. Table 10 on page 52 lists the books included

in the Network Operations Guide series. Table 11 on page 53 lists the manuals and

release notes supporting JUNOS software with enhanced services. All documents are

available at http://www.juniper.net/techpubs/.

Table 12 on page 54 lists additional books on Juniper Networks solutions that you

can order through your bookstore. A complete list of such books is available at

http://www.juniper.net/books.

Table 9: Technical Documentation for Supported Routing Platforms

DescriptionBook

JUNOS Software for Supported Routing Platforms

Access Privilege

Explains how to configure access privileges in user classes by using

permission flags and regular expressions. Lists the permission flags

along with their associated command-line interface (CLI) operational

mode commands and configuration statements.

Class of Service

CLI User Guide

Feature Guide

High Availability

MPLS Applications

Multicast Protocols

Multiplay Solutions

Provides an overview of the class-of-service (CoS) functions of the

JUNOS software and describes how to configure CoS features,

including configuring multiple forwarding classes for transmitting

packets, defining which packets are placed into each output queue,

scheduling the transmission service level for each queue, and

managing congestion through the random early detection (RED)

algorithm.

Describes how to use the JUNOS command-line interface (CLI) to

configure, monitor, and manage Juniper Networks routing

platforms. This material was formerly covered in the JUNOS System

Basics Configuration Guide.

Provides a detailed explanation and configuration examples for

several of the most complex features in the JUNOS software.

Provides an overview of hardware and software resources that

ensure a high level of continuous routing platform operation and

describes how to configure high availability (HA) features such as

nonstop active routing (NSR) and graceful Routing Engine

switchover (GRES).

Provides an overview of traffic engineering concepts and describes

how to configure traffic engineering protocols.

Provides an overview of multicast concepts and describes how to

configure multicast routing protocols.

Describes how you can deploy IPTV and voice over IP (VoIP)

services in your network.

48 ■ List of Technical Publications

Page 49

Table 9: Technical Documentation for Supported Routing Platforms (continued)

DescriptionBook

List of Technical Publications

MX-series Solutions Guide

Network Interfaces

Network Management

Policy Framework

Protected System Domain

Routing Protocols

Describes common configuration scenarios for the Layer 2 features

supported on the MX-series routers, including basic bridged VLANs

with normalized VLAN tags, aggregated Ethernet links, bridge

domains, Multiple Spanning Tree Protocol (MSTP), and integrated

routing and bridging (IRB).

Provides an overview of the network interface functions of the

JUNOS software and describes how to configure the network

interfaces on the routing platform.

Provides an overview of network management concepts and

describes how to configure various network management features,

such as SNMP and accounting options.

Provides an overview of policy concepts and describes how to

configure routing policy, firewall filters, and forwarding options.

Provides an overview of the JCS 1200 platform and the concept of

Protected System Domains (PSDs). The JCS 1200 platform, which

contains up to six redundant pairs of Routing Engines running

JUNOS software, is connected to a T320 router or to a T640 or

T1600 routing node. To configure a PSD, you assign any number

of Flexible PIC concentrators (FPCs) in the T-series routing platform

to a pair of Routing Engines on the JCS 1200 platform. Each PSD

has the same capabilities and functionality as a physical router,

with its own control plane, forwarding plane, and administration.

Provides an overview of routing concepts and describes how to

configure routing, routing instances, and unicast routing protocols.

Secure Configuration Guide for Common Criteria

and JUNOS-FIPS

Services Interfaces

Software Installation and Upgrade Guide

System Basics

VPNs

JUNOS References

Provides an overview of secure Common Criteria and JUNOS-FIPS

protocols for the JUNOS software and describes how to install and

configure secure Common Criteria and JUNOS-FIPS on a routing

platform.

Provides an overview of the services interfaces functions of the

JUNOS software and describes how to configure the services

interfaces on the router.

Describes the JUNOS software components and packaging and

explains how to initially configure, reinstall, and upgrade the JUNOS

system software. This material was formerly covered in the JUNOS

System Basics Configuration Guide.

Describes Juniper Networks routing platforms and explains how

to configure basic system parameters, supported protocols and

software processes, authentication, and a variety of utilities for

managing your router on the network.

Provides an overview and describes how to configure Layer 2 and

Layer 3 virtual private networks (VPNs), virtual private LAN service

(VPLS), and Layer 2 circuits. Provides configuration examples.

List of Technical Publications ■ 49

Page 50

T1600 Routing Node Upgrade Guide

Table 9: Technical Documentation for Supported Routing Platforms (continued)

DescriptionBook

Hierarchy and RFC Reference

Interfaces Command Reference

Routing Protocols and Policies Command

Reference

System Basics and Services Command Reference

System Log Messages Reference

J-Web User Guide

J-Web Interface User Guide

Describes the JUNOS configuration mode commands. Provides a

hierarchy reference that displays each level of a configuration

hierarchy, and includes all possible configuration statements that

can be used at that level. This material was formerly covered in

the JUNOS System Basics Configuration Guide.

Describes the JUNOS software operational mode commands you

use to monitor and troubleshoot interfaces.

Describes the JUNOS software operational mode commands you

use to monitor and troubleshoot routing policies and protocols,

including firewall filters.

Describes the JUNOS software operational mode commands you

use to monitor and troubleshoot system basics, including

commands for real-time monitoring and route (or path) tracing,

system software management, and chassis management. Also

describes commands for monitoring and troubleshooting services

such as class of service (CoS), IP Security (IPSec), stateful firewalls,

flow collection, and flow monitoring.

Describes how to access and interpret system log messages

generated by JUNOS software modules and provides a reference

page for each message.

Describes how to use the J-Web graphical user interface (GUI) to

configure, monitor, and manage Juniper Networks routing

platforms.

JUNOS API and Scripting Documentation

JUNOScript API Guide

JUNOS XML API Configuration Reference

JUNOS XML API Operational Reference

NETCONF API Guide

JUNOS Configuration and Diagnostic Automation

Guide

Hardware Documentation

Describes how to use the JUNOScript application programming

interface (API) to monitor and configure Juniper Networks routing

platforms.

Provides reference pages for the configuration tag elements in the

JUNOS XML API.

Provides reference pages for the operational tag elements in the

JUNOS XML API.

Describes how to use the NETCONF API to monitor and configure

Juniper Networks routing platforms.

Describes how to use the commit script and self-diagnosis features

of the JUNOS software. This guide explains how to enforce custom

configuration rules defined in scripts, how to use commit script

macros to provide simplified aliases for frequently used

configuration statements, and how to configure diagnostic event

policies.

50 ■ List of Technical Publications

Page 51