Page 1

SRX5600 Services Gateway Hardware

Published

2020-12-07

Guide

Page 2

Juniper Networks, Inc.

1133 Innovation Way

Sunnyvale, California 94089

USA

408-745-2000

www.juniper.net

Juniper Networks, the Juniper Networks logo, Juniper, and Junos are registered trademarks of Juniper Networks, Inc. in

the United States and other countries. All other trademarks, service marks, registered marks, or registered service marks

are the property of their respective owners.

Juniper Networks assumes no responsibility for any inaccuracies in this document. Juniper Networks reserves the right

to change, modify, transfer, or otherwise revise this publication without notice.

SRX5600 Services Gateway Hardware Guide

Copyright © 2020 Juniper Networks, Inc. All rights reserved.

The information in this document is current as of the date on the title page.

ii

YEAR 2000 NOTICE

Juniper Networks hardware and software products are Year 2000 compliant. Junos OS has no known time-related

limitations through the year 2038. However, the NTP application is known to have some difficulty in the year 2036.

END USER LICENSE AGREEMENT

The Juniper Networks product that is the subject of this technical documentation consists of (or is intended for use with)

Juniper Networks software. Use of such software is subject to the terms and conditions of the End User License Agreement

(“EULA”) posted at https://support.juniper.net/support/eula/. By downloading, installing or using such software, you

agree to the terms and conditions of that EULA.

Page 3

Table of Contents

1

About the Documentation | xv

Documentation and Release Notes | xv

Using the Examples in This Manual | xv

Merging a Full Example | xvi

Merging a Snippet | xvii

Documentation Conventions | xvii

Documentation Feedback | xx

Requesting Technical Support | xx

Self-Help Online Tools and Resources | xxi

Creating a Service Request with JTAC | xxi

iii

Overview

SRX5600 Services Gateway System Overview | 23

SRX5600 Services Gateway Description | 23

Benefits of the SRX5600 Services Gateway | 24

SRX5600 Services Gateway FRUs | 24

SRX5600 Services Gateway Component Redundancy | 25

SRX5600 Chassis | 26

SRX5600 Services Gateway Chassis | 27

SRX5600 Services Gateway Physical Specifications | 29

SRX5600 Services Gateway Midplane Description | 30

SRX5600 Services Gateway Cable Manager Description | 31

SRX5600 Services Gateway Craft Interface Overview | 32

SRX5600 Services Gateway Craft Interface Alarm LEDs and Alarm Cutoff/Lamp Test

Button | 33

SRX5600 Services Gateway Craft Interface Host Subsystem LEDs | 34

SRX5600 Services Gateway Craft Interface Power Supply LEDs | 35

SRX5600 Services Gateway Craft Interface Card OK/Fail LEDs | 35

SRX5600 Services Gateway Craft Interface Fan LEDs | 35

SRX5600 Services Gateway Craft Interface Online Buttons | 36

Page 4

SRX5600 Services Gateway Craft Interface Alarm Relay Contacts | 39

SRX5600 Services Gateway Cooling System Description | 40

SRX3400 and SRX5600 Services Gateways Air Deflector Kits | 43

SRX5600 Power System | 45

SRX5600 Services Gateway Power System Overview | 45

SRX5600 Services Gateway AC Power Supply | 47

SRX5600 Services Gateway AC Power Supply Specifications | 49

SRX5600 Services Gateway AC Power Supply LEDs | 49

AC Power Cord Specifications for the SRX5600 Services Gateway | 50

AC Power Circuit Breaker Requirements for the SRX5600 Services Gateway | 53

SRX5600 Services Gateway DC Power Supply | 53

SRX5600 Services Gateway DC Power Supply Specifications | 54

SRX5600 Services Gateway DC Power Supply LEDs | 55

iv

DC Power Cable Specifications for the SRX5600 Services Gateway | 56

DC Power Cable Lug Specifications for the SRX5600 Services Gateway | 57

DC Power Circuit Breaker Requirements for the SRX5600 Services Gateway | 57

DC Power Source Cabling for the SRX5600 Services Gateway | 58

SRX5600 Services Gateway Chassis Grounding Point Specifications | 59

SRX5600 Services Gateway Grounding-Cable Lug Specification | 60

SRX5600 Host Subsystem | 61

SRX5600 Services Gateway Host Subsystem Description | 61

Switch Control Board SRX5K-SCB Overview | 62

Switch Control Board SRX5K-SCB Specifications | 63

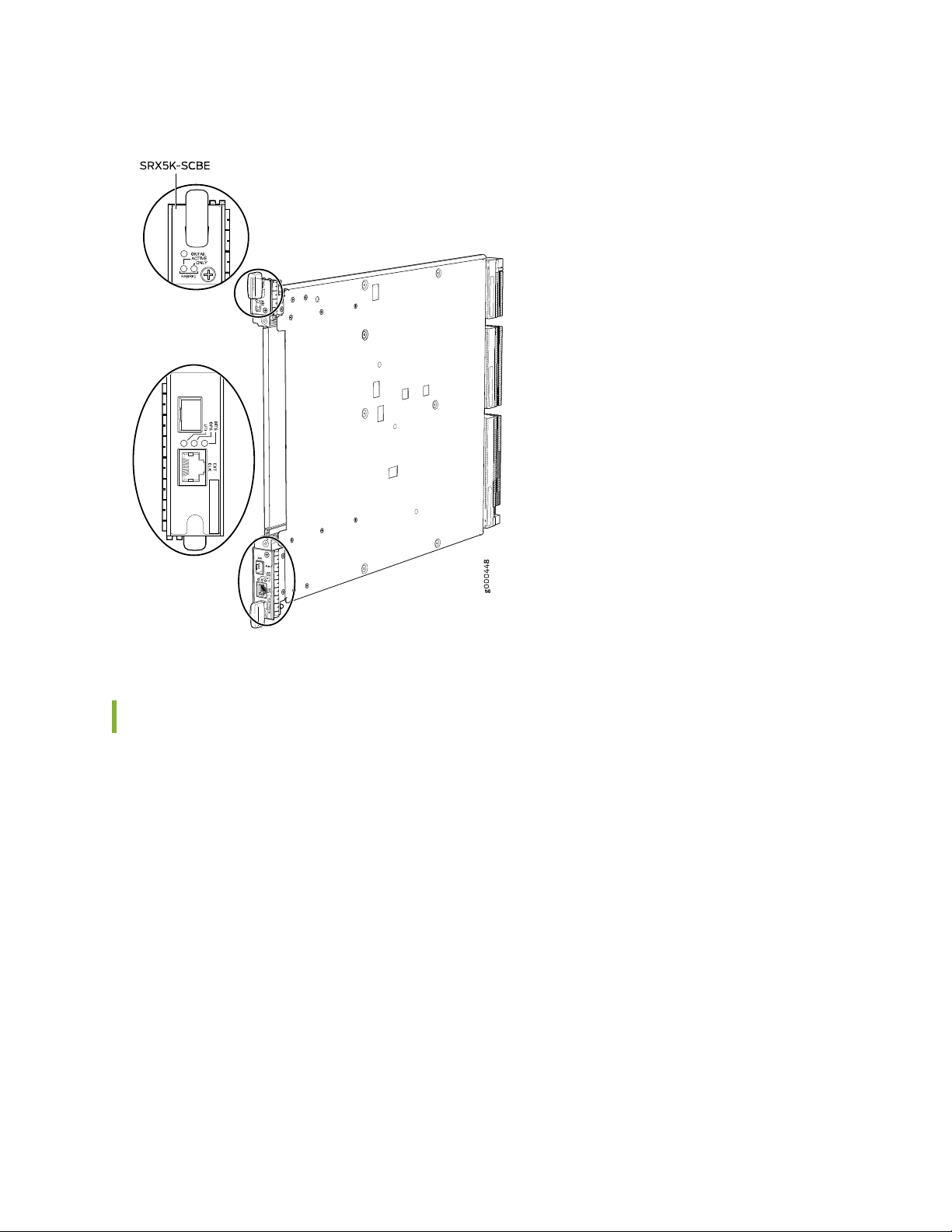

Switch Control Board SRX5K-SCBE Overview | 66

Switch Control Board SRX5K-SCBE Specifications | 67

SRX5K-SCBE LEDs | 69

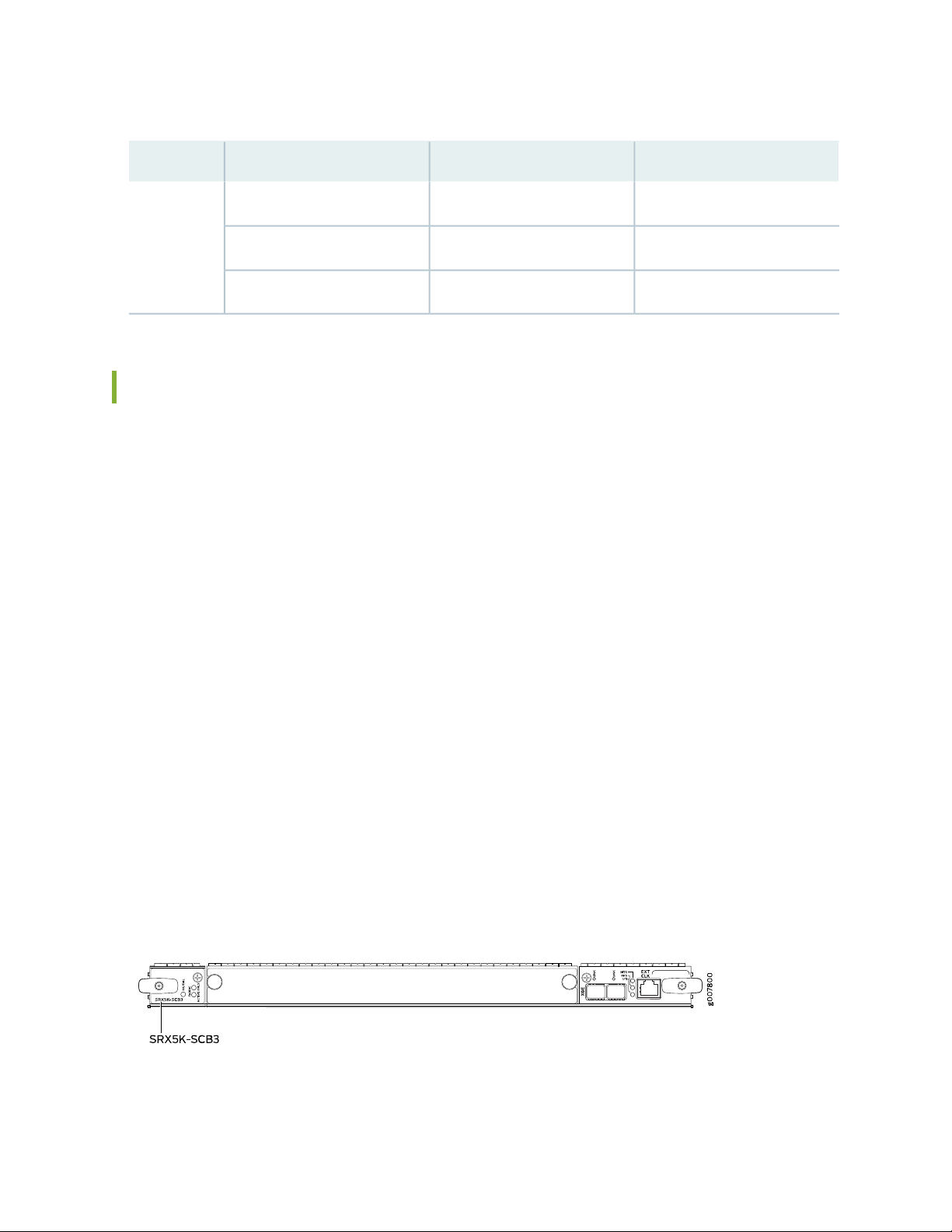

Switch Control Board SRX5K-SCB3 Overview | 70

Switch Control Board SRX5K-SCB3 Specifications | 71

SRX5K-SCB3 LEDs | 72

Switch Control Board SRX5K-SCB4 Overview | 73

Switch Control Board SRX5K-SCB4 Specifications | 74

SRX5K-SCB4 LEDs | 76

Page 5

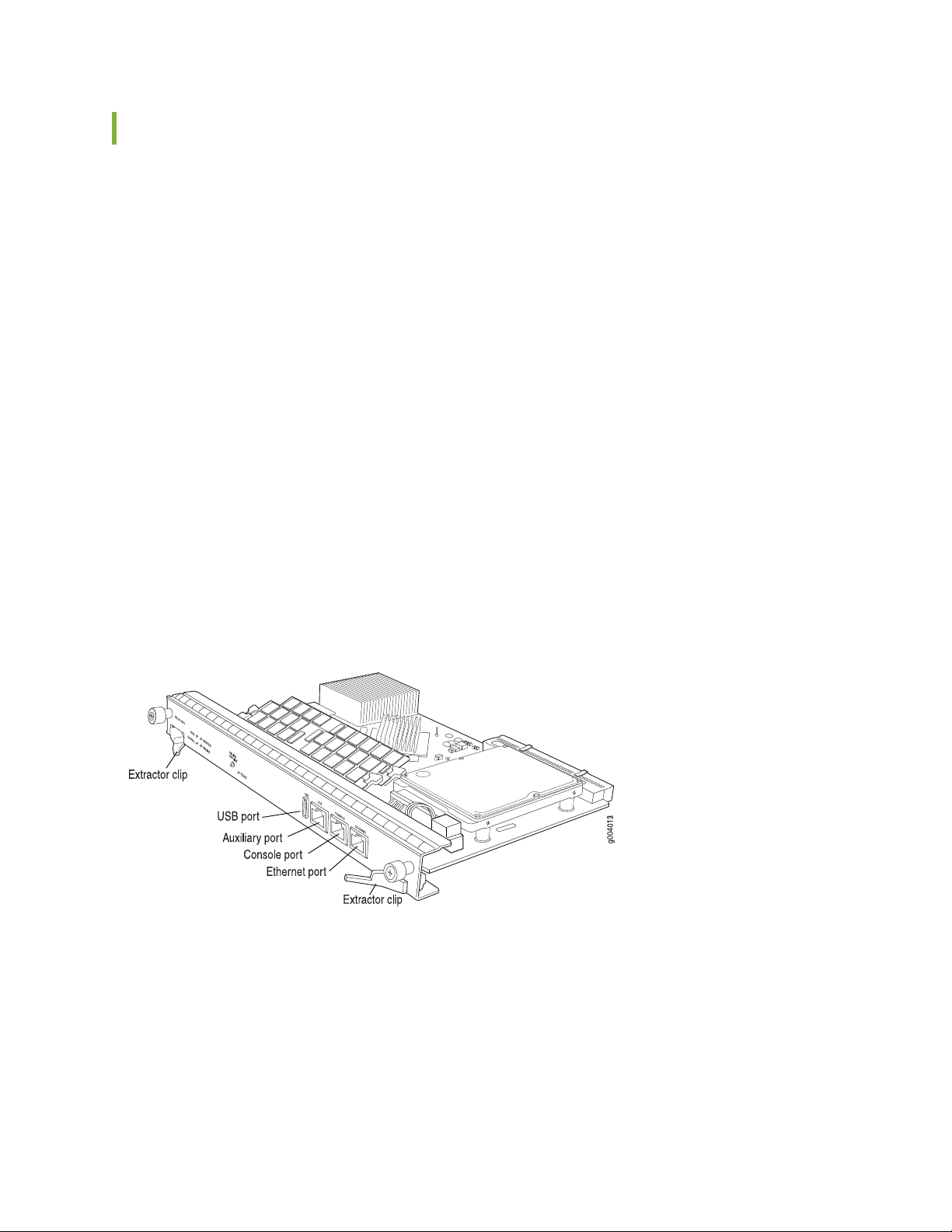

Routing Engine SRX5K-RE-1800X4 Overview | 77

SRX5K-RE-1800X4 Routing Engine Boot Sequence | 78

Routing Engine SRX5K-RE-1800X4 Specifications | 78

SRX5K-RE-1800X4 LEDs | 80

Routing Engine SRX5K-RE-13-20 Overview | 81

Routing Engine SRX5K-RE-13-20 Specifications | 82

Routing Engine SRX5K-RE3-128G Specifications | 85

SRX5K-RE3-128G Routing Engine Components | 87

SRX5K-RE3-128G Routing Engine LEDs | 88

SRX5K-RE3-128G Routing Engine Boot Sequence | 89

SRX5600 Line Cards and Modules | 89

SRX5400, SRX5600, and SRX5800 Services Gateway Card Overview | 90

SRX5600 Services Gateway Card Terminology | 91

v

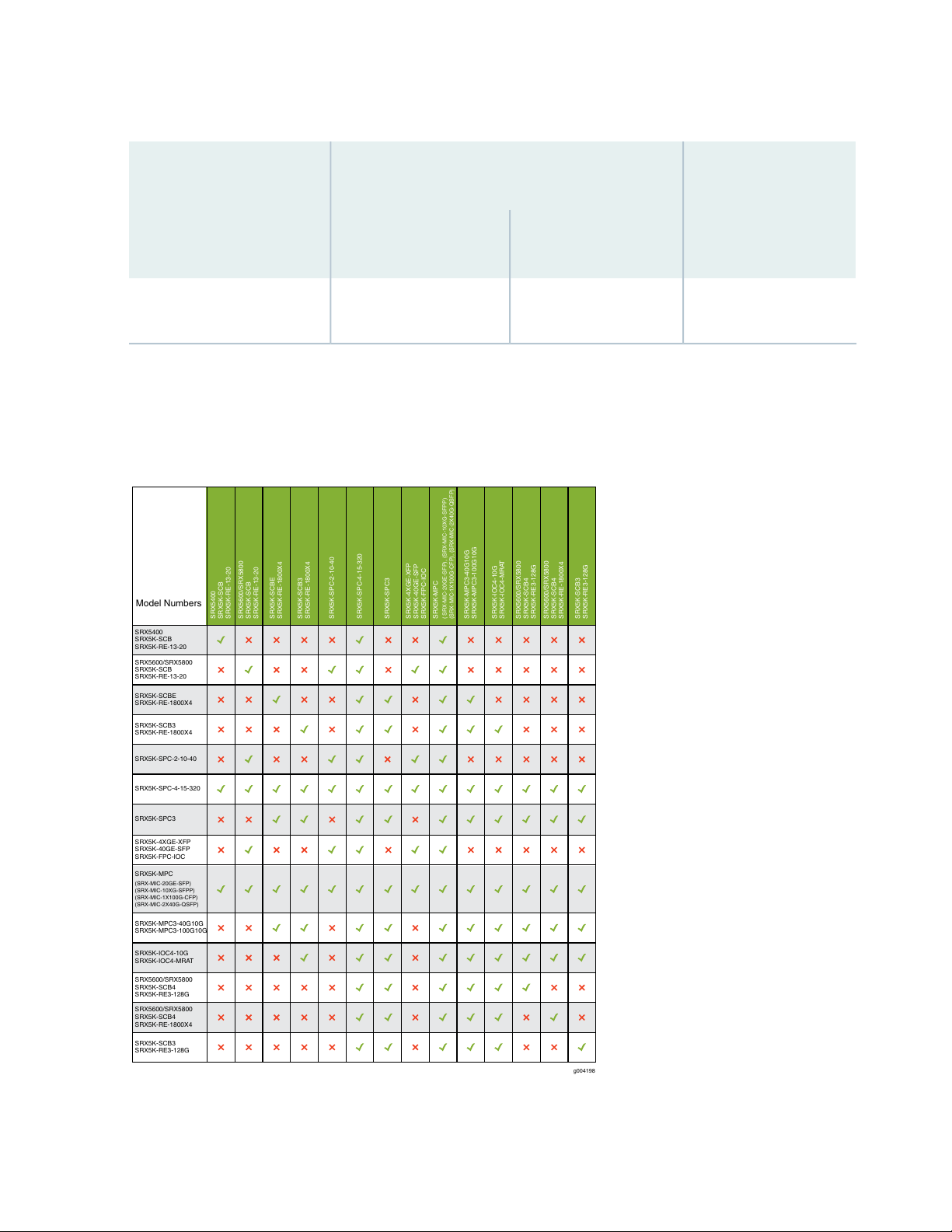

Cards Supported on SRX5400, SRX5600, and SRX5800 Services Gateways | 92

SRX5600 Services Gateway Card Cage and Slots | 96

SRX5600 Services Gateway SPC Description | 96

Services Processing Card SRX5K-SPC-2-10-40 Specifications | 97

Services Processing Card SRX5K-SPC-4-15-320 Specifications | 102

Services Processing Card SRX5K-SPC3 Specifications | 107

SRX5600 Services Gateway Interface Card Description | 111

Modular Port Concentrator (SRX5K-MPC) Specifications | 113

SRX5K-MPC3-40G10G Specifications | 116

SRX5K-MPC3-100G10G Specifications | 119

MIC with 20x1GE SFP Interfaces (SRX-MIC-20GE-SFP) | 122

MIC with 10x10GE SFP+ Interfaces (SRX-MIC-10XG-SFPP) | 128

MIC with 1x100GE CFP Interface (SRX-MIC-1X100G-CFP) | 133

MIC with 2x40GE QSFP+ Interfaces (SRX-MIC-2X40G-QSFP) | 135

SRX5K-IOC4-10G Specifications | 136

SRX5K-IOC4-MRAT Specifications | 139

I/O Card SRX5K-40GE-SFP Specifications | 143

I/O Card SRX5K-4XGE-XFP Specifications | 145

Flex I/O Card (SRX5K-FPC-IOC) Specifications | 147

Flex I/O Card Port Module SRX-IOC-16GE-SFP Specifications | 149

Flex I/O Card Port Module SRX-IOC-16GE-TX Specifications | 151

Page 6

Flex I/O Card Port Module SRX-IOC-4XGE-XFP Specifications | 152

2

Site Planning, Preparation, and Specifications

Site Preparation Checklist for the SRX5600 Services Gateway | 156

SRX5600 Site Guidelines and Requirements | 157

SRX5600 Services Gateway Environmental Specifications | 157

General Site Guidelines | 158

Site Electrical Wiring Guidelines | 159

Clearance Requirements for SRX5600 Services Gateway Airflow and Hardware

Maintenance | 160

SRX5600 Rack and Cabinet Requirements | 161

SRX5600 Services Gateway Rack Size and Strength Requirements | 161

Spacing of Rack Mounting Bracket Holes for the SRX5600 Services Gateway | 162

Connection to Building Structure for the SRX5600 Services Gateway Rack | 162

vi

SRX5600 Services Gateway Cabinet Size and Clearance Requirements | 162

SRX5600 Services Gateway Cabinet Airflow Requirements | 163

Calculating Power Requirements for the SRX5600 Services Gateway | 163

SRX5600 Network Cable and Transceiver Planning | 175

Routing Engine Interface Cable and Wire Specifications for the SRX5600 Services Gateway | 175

Signal Loss in Multimode and Single-Mode Fiber-Optic Cable for the SRX5600 Services

Gateway | 176

Attenuation and Dispersion in Fiber-Optic Cable for the SRX5600 Services Gateway | 176

Calculating Power Budget for Fiber-Optic Cable for the SRX5600 Services Gateway | 177

Calculating Power Margin for Fiber-Optic Cable for the SRX5600 Services Gateway | 178

SRX5600 Alarm and Management Cable Specifications and Pinouts | 179

Alarm Relay Contact Wire Specifications for the SRX5600 Services Gateway | 180

Console Port Cable and Wire Specifications for the SRX5600 Services Gateway | 180

RJ-45 Connector Pinouts for the SRX5600 Services Gateway Routing Engine Ethernet Port | 180

RJ-45 Connector Pinouts for the SRX5600 Services Gateway Routing Engine Auxiliary and

Console Ports | 181

Page 7

Initial Installation and Configuration

3

Overview of Installing the SRX5600 Services Gateway | 184

Unpacking the SRX5600 | 185

Tools and Parts Required to Unpack the SRX5600 Services Gateway | 185

Unpacking the SRX5600 Services Gateway | 185

Verifying the SRX5600 Services Gateway Parts Received | 187

Installing the SRX5600 Mounting Hardware | 189

Installing the SRX5600 Services Gateway Mounting Hardware for a Rack or Cabinet | 189

Moving the Mounting Brackets for Center-Mounting the SRX5600 Services Gateway | 192

Installing the SRX5600 Using a Mechanical Lift | 193

Tools Required to Install the SRX5600 Services Gateway with a Mechanical Lift | 193

Installing the SRX5600 Services Gateway Using a Mechanical Lift | 194

vii

Installing the SRX5600 Without a Mechanical Lift | 196

Overview of Installing the SRX5600 Services Gateway Without a Mechanical Lift | 196

Tools Required to Install the SRX5600 Services Gateway Without a Mechanical Lift | 197

Removing Components from the SRX5600 Chassis Before Installing It Without a Lift | 197

Removing the Power Supplies Before Installing the SRX5600 Services Gateway Without

a Lift | 197

Removing the Fan Tray Before Installing an SRX5600 Services Gateway Without a Lift | 198

Removing Cards Before Installing an SRX5600 Services Gateway Without a Lift | 199

Installing the SRX5600 Services Gateway Chassis in the Rack Manually | 202

Reinstalling Components in the SRX5600 Services Gateway Chassis After Installing It Without

a Lift | 204

Reinstalling Power Supplies After Installing the SRX5600 Services Gateway Without a

Lift | 204

Reinstalling the Fan Tray After Installing the SRX5600 Services Gateway Without a Lift | 205

Reinstalling SCBs After Installing the SRX5600 Services Gateway Without a Lift | 206

Reinstalling IOCs, Flex IOCs, and SPCs After Installing the SRX5600 Services Gateway

Without a Lift | 207

Page 8

Connecting the SRX5600 to External Devices | 208

4

Tools and Parts Required for SRX5600 Services Gateway Connections | 208

Connecting the SRX5600 Services Gateway to a Management Console or an Auxiliary

Device | 209

Connecting the SRX5600 Services Gateway to a Network for Out-of-Band Management | 210

Connecting an SRX5600 Services Gateway to an External Alarm-Reporting Device | 211

Connecting Network Cables to SRX5600 Services Gateway IOCs and Port Modules | 212

Connecting the SRX5600 to Power | 214

Tools and Parts Required for SRX5600 Services Gateway Grounding and Power

Connections | 214

Grounding the SRX5600 Services Gateway | 215

Connecting Power to an AC-Powered SRX5600 Services Gateway | 216

Powering On an AC-Powered SRX5600 Services Gateway | 218

Connecting Power to a DC-Powered SRX5600 Services Gateway | 219

viii

Powering On a DC-Powered SRX5600 Services Gateway | 221

Powering Off the SRX5600 Services Gateway | 223

Performing the Initial Software Configuration for the SRX5600 | 224

SRX5600 Services Gateway Software Configuration Overview | 224

Initially Configuring the SRX5600 Services Gateway | 225

Performing Initial Software Configuration Using J-Web | 230

Configuring Root Authentication and the Management Interface from the CLI | 230

Configuring Interfaces, Zones, and Policies with J-Web | 232

Maintaining Components

Maintaining the SRX5600 Chassis | 237

Routine Maintenance Procedures for the SRX5600 Services Gateway | 237

Replacing the SRX5600 Services Gateway Craft Interface | 237

Disconnecting the Alarm Relay Wires from the SRX5600 Services Gateway Craft

Interface | 237

Removing the SRX5600 Services Gateway Craft Interface | 238

Installing the SRX5600 Services Gateway Craft Interface | 239

Page 9

Connecting the Alarm Relay Wires to the SRX5600 Services Gateway Craft Interface | 240

Maintaining the SRX5600 Cooling System | 241

Maintaining the Fan Tray on the SRX5600 Services Gateway | 241

Replacing the SRX5600 Services Gateway Fan Tray | 242

Removing the SRX5600 Services Gateway Fan Tray | 242

Installing the SRX5600 Services Gateway Fan Tray | 243

Maintaining the Air Filter on the SRX5600 Services Gateway | 244

Replacing the SRX5600 Services Gateway Air Filter | 245

Removing the SRX5600 Services Gateway Air Filter | 245

Installing the SRX5600 Services Gateway Air Filter | 246

Maintaining the SRX5600 Power System | 247

Maintaining SRX5600 Services Gateway Power Supplies | 247

Replacing an SRX5600 Services Gateway AC Power Supply | 248

ix

Removing an SRX5600 Services Gateway AC Power Supply | 249

Installing an SRX5600 Services Gateway AC Power Supply | 250

Replacing an SRX5600 Services Gateway AC Power Supply Cord | 251

Disconnecting an SRX5600 Services Gateway AC Power Supply Cord | 252

Connecting an SRX5600 Services Gateway AC Power Supply Cord | 252

Replacing an SRX5600 Services Gateway DC Power Supply | 253

Removing an SRX5600 Services Gateway DC Power Supply | 253

Installing an SRX5600 Services Gateway DC Power Supply | 254

Replacing an SRX5600 Services Gateway DC Power Supply Cable | 257

Disconnecting an SRX5600 Services Gateway DC Power Supply Cable | 257

Connecting an SRX5600 Services Gateway DC Power Supply Cable | 258

Upgrading an SRX5600 Services Gateway from Standard-Capacity to High-Capacity Power

Supplies | 259

Page 10

Maintaining the SRX5600 Host Subsystem | 263

Maintaining the SRX5600 Services Gateway Host Subsystem and SCBs | 263

Taking the SRX5600 Services Gateway Host Subsystem Offline | 265

Operating and Positioning the SRX5600 Services Gateway SCB Ejectors | 266

Replacing an SRX5600 Services Gateway SCB | 266

Removing an SRX5600 Services Gateway SCB | 267

Installing an SRX5600 Services Gateway SCB | 268

Replacing the SRX5600 Services Gateway Routing Engine | 270

Removing the SRX5600 Services Gateway Routing Engine | 270

Installing the SRX5600 Services Gateway Routing Engine | 271

Low Impact Hardware Upgrade for SCB3 and IOC3 | 274

In-Service Hardware Upgrade for SRX5K-RE-1800X4 and SRX5K-SCBE or SRX5K-RE-1800X4

and SRX5K-SCB3 in a Chassis Cluster | 292

Maintaining the SRX5600 Line Cards and Modules | 296

x

Maintaining Interface Cards and SPCs on the SRX5600 Services Gateway | 297

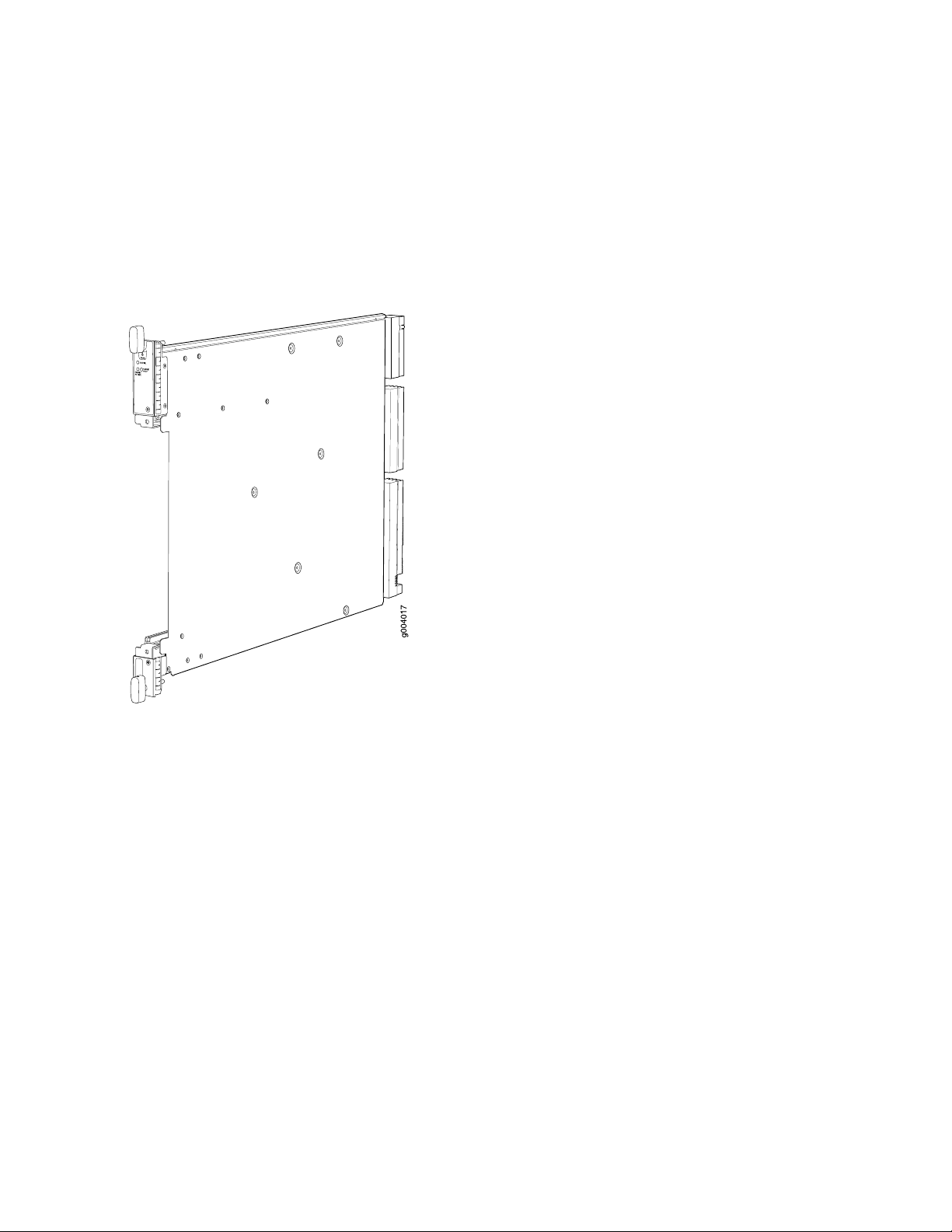

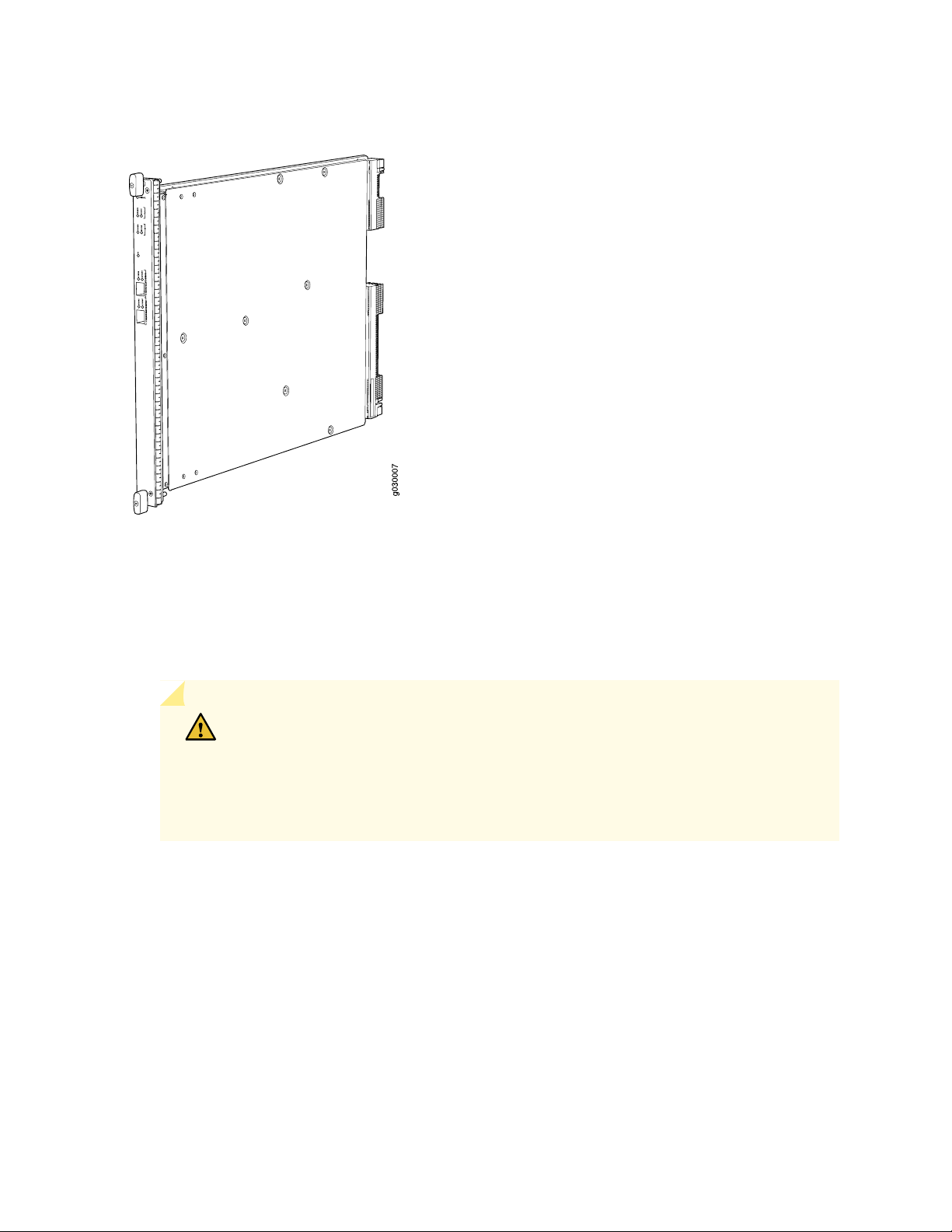

Holding an SRX5600 Services Gateway Card | 299

Storing an SRX5600 Services Gateway Card | 301

Replacing SRX5600 Services Gateway IOCs | 302

Removing an SRX5600 Services Gateway IOC | 302

Installing an SRX5600 Services Gateway IOC | 304

Replacing SRX5600 Services Gateway Flex IOCs | 307

Removing an SRX5600 Services Gateway Flex IOC | 307

Installing an SRX5600 Services Gateway Flex IOC | 310

Replacing SRX5600 Services Gateway SPCs | 312

Removing an SRX5600 Services Gateway SPC | 312

Installing an SRX5600 Services Gateway SPC | 314

Replacing SPCs in an Operating SRX5400, SRX5600, or SRX5800 Services Gateways Chassis

Cluster | 317

In-Service Hardware Upgrade for SRX5K-SPC3 in a Chassis Cluster | 320

Maintaining MICs and Port Modules on the SRX5600 Services Gateway | 323

Replacing SRX5600 Services Gateway MICs | 324

Removing an SRX5600 Services Gateway MIC | 324

Installing an SRX5600 Services Gateway MIC | 326

Page 11

Replacing SRX5600 Services Gateway Port Modules | 328

5

Removing an SRX5600 Services Gateway Port Module | 328

Installing an SRX5600 Services Gateway Port Module | 330

Replacing SRX5600 Services Gateway MPCs | 332

Removing an SRX5600 Services Gateway MPC | 333

Installing an SRX5600 Services Gateway MPC | 335

Maintaining the SRX5600 Cables and Connectors | 337

Maintaining SRX5600 Services Gateway Network Cables | 337

Replacing the Management Ethernet Cable on the SRX5600 Services Gateway | 339

Replacing the SRX5600 Services Gateway Console or Auxiliary Cable | 340

Replacing an SRX5600 Services Gateway Network Interface Cable | 341

Removing an SRX5600 Services Gateway Network Interface Cable | 341

Installing an SRX5600 Services Gateway Network Interface Cable | 343

xi

Replacing SRX5600 Services Gateway XFP and SFP Transceivers | 345

Removing an SRX5600 Services Gateway SFP or XFP Transceiver | 345

Installing an SRX5600 Services Gateway SFP or XFP Transceiver | 347

Replacing the SRX5600 Services Gateway Cable Manager | 348

Removing the SRX5600 Services Gateway Cable Manager | 348

Installing the SRX5600 Services Gateway Cable Manager | 349

Replacing a Routing Engine in an SRX Series High-End Chassis Cluster | 350

Replacing a Routing Engine: USB Flash-Drive Method | 350

Replacing a Routing Engine: External SCP Server Method | 357

Replacing the Routing Engine: File Transfer Method | 364

Troubleshooting Hardware

Troubleshooting the SRX5600 | 371

Troubleshooting the SRX5600 Services Gateway with the Junos OS CLI | 371

Troubleshooting the SRX5600 Services Gateway with Chassis and Interface Alarm

Messages | 372

Chassis Component Alarm Conditions on SRX5400, SRX5600, and SRX5800 Services

Gateways | 372

Backup Routing Engine Alarms | 387

Troubleshooting the SRX5600 Services Gateway with Alarm Relay Contacts | 389

Troubleshooting the SRX5600 Services Gateway with the Craft Interface LEDs | 389

Page 12

Troubleshooting the SRX5600 Services Gateway with the Component LEDs | 390

6

7

Troubleshooting the SRX5600 Services Gateway Cooling System | 391

Troubleshooting SRX5600 Services Gateway Interface Cards | 391

Troubleshooting SRX5600 Services Gateway MICs and Port Modules | 393

Troubleshooting SRX5600 Services Gateway SPCs | 394

Troubleshooting the SRX5600 Services Gateway Power System | 395

Behavior of the SRX5400, SRX5600, and SRX5800 Services Gateways When the SRX5K-SCBE

and SRX5K-RE-1800X4 in a Chassis Cluster Fail | 401

Contacting Customer Support and Returning the Chassis or Components

Returning the SRX5600 Chassis or Components | 404

Contacting Customer Support | 404

Return Procedure for the SRX5600 Services Gateway | 405

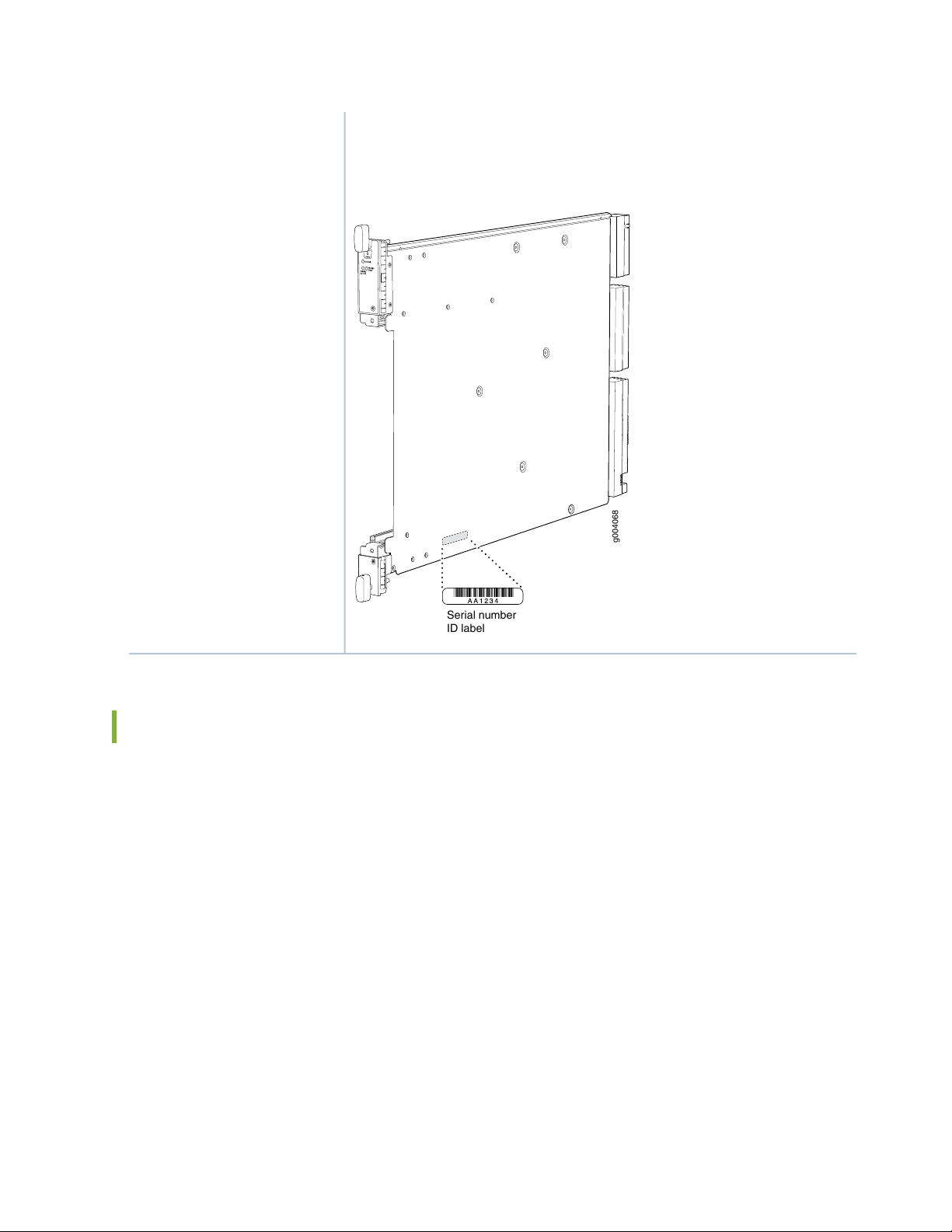

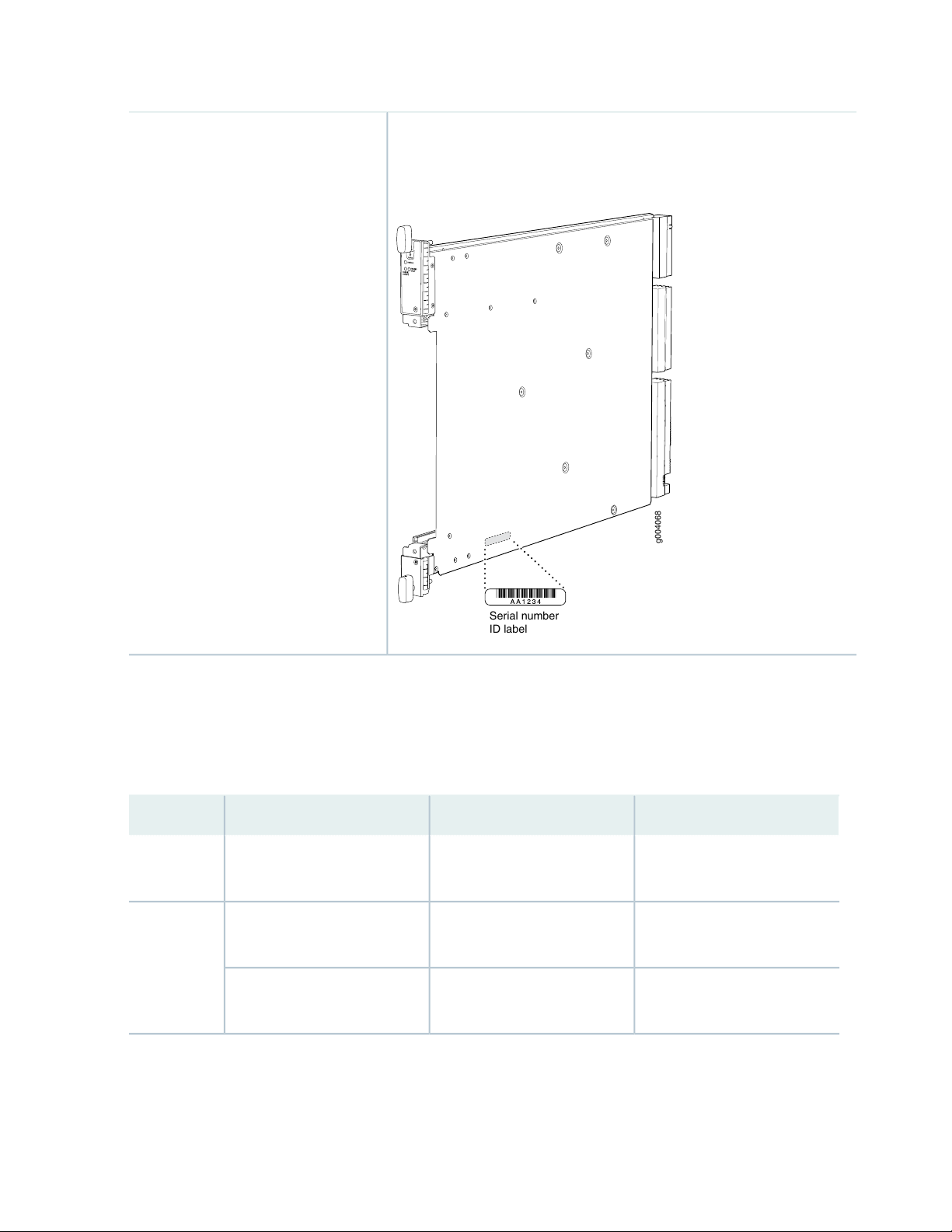

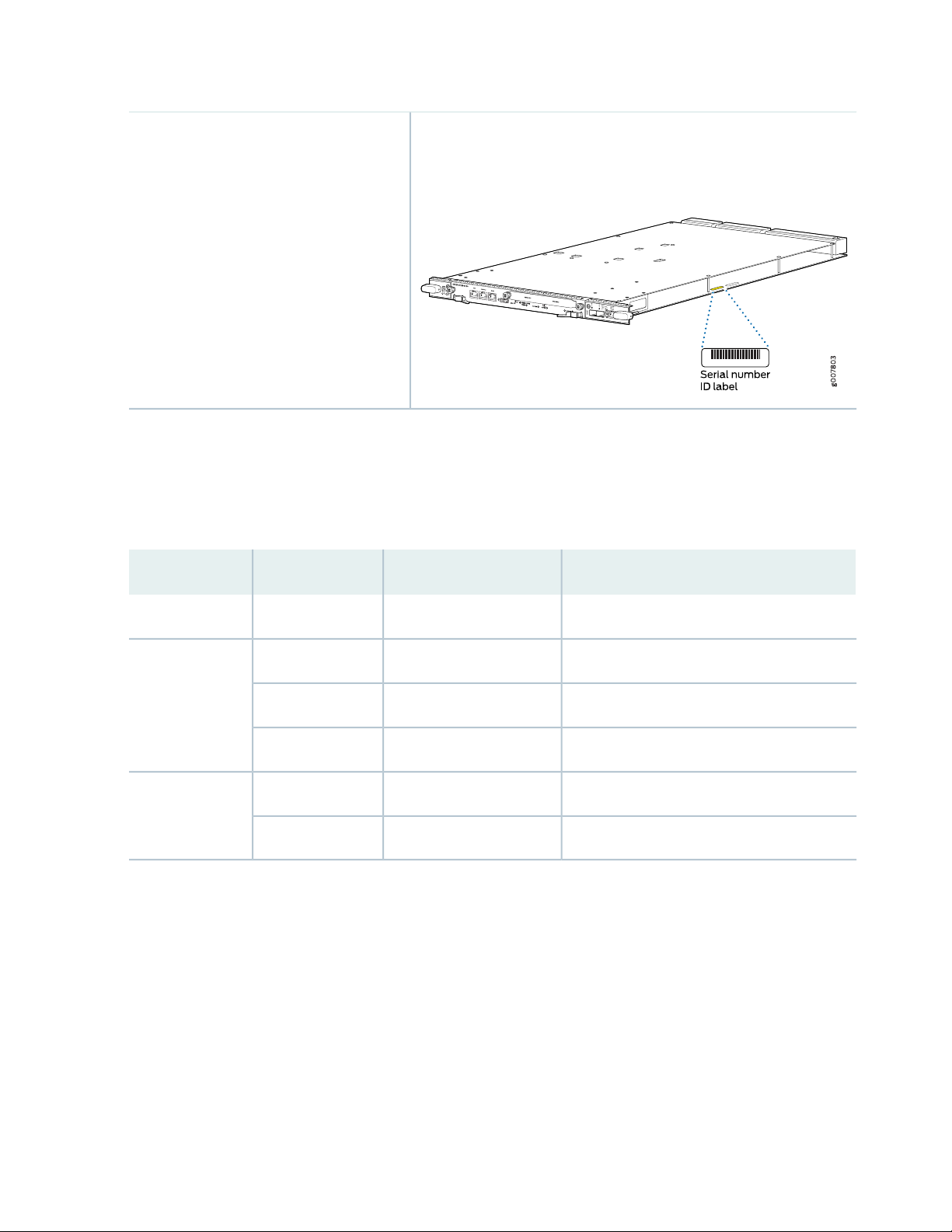

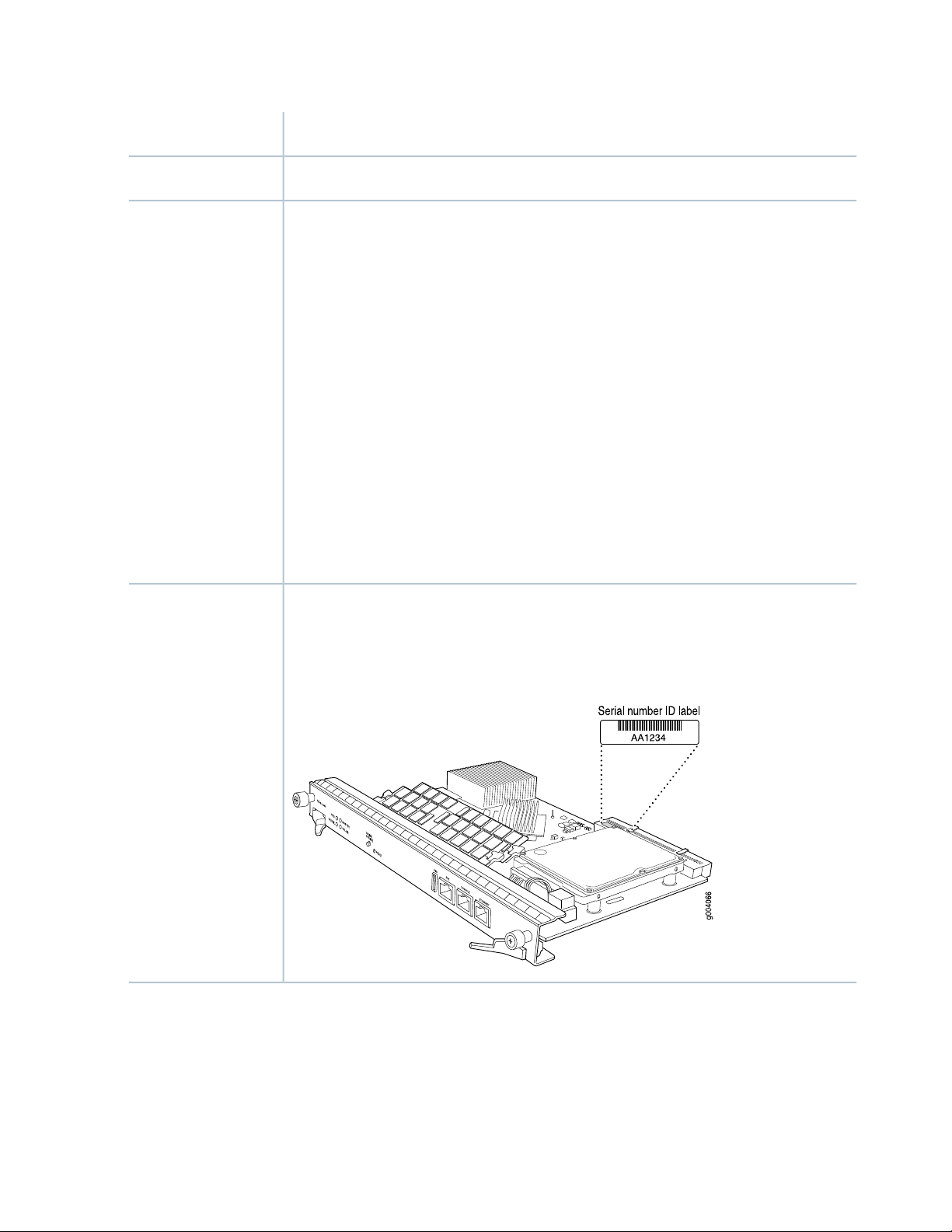

Listing the SRX5600 Services Gateway Component Serial Numbers with the CLI | 406

xii

Locating the SRX5600 Services Gateway Chassis Serial Number Label | 407

Locating the SRX5600 Services Gateway Power Supply Serial Number Labels | 407

Locating the SRX5600 Services Gateway Craft Interface Serial Number Label | 408

Information You Might Need to Supply to JTAC | 409

Required Tools and Parts for Packing the SRX5600 Services Gateway | 409

Packing the SRX5600 Services Gateway for Shipment | 410

Packing SRX5600 Services Gateway Components for Shipment | 411

Safety and Compliance Information

General Safety Guidelines and Warnings | 414

Definitions of Safety Warning Levels | 415

Restricted Access Area Warning | 419

Fire Safety Requirements | 421

Fire Suppression | 421

Fire Suppression Equipment | 422

Qualified Personnel Warning | 423

Warning Statement for Norway and Sweden | 423

Installation Instructions Warning | 424

Page 13

Chassis and Component Lifting Guidelines | 424

Ramp Warning | 425

Rack-Mounting and Cabinet-Mounting Warnings | 425

Grounded Equipment Warning | 431

Laser and LED Safety Guidelines and Warnings | 432

General Laser Safety Guidelines | 432

Class 1 Laser Product Warning | 433

Class 1 LED Product Warning | 434

Laser Beam Warning | 435

Radiation from Open Port Apertures Warning | 436

Maintenance and Operational Safety Guidelines and Warnings | 437

xiii

Battery Handling Warning | 438

Jewelry Removal Warning | 439

Lightning Activity Warning | 441

Operating Temperature Warning | 442

Product Disposal Warning | 444

General Electrical Safety Guidelines and Warnings | 445

Prevention of Electrostatic Discharge Damage | 446

AC Power Electrical Safety Guidelines | 447

AC Power Disconnection Warning | 449

DC Power Electrical Safety Guidelines | 450

DC Power Electrical Safety Guidelines | 450

DC Power Disconnection Warning | 452

DC Power Grounding Requirements and Warning | 454

DC Power Wiring Sequence Warning | 456

DC Power Wiring Terminations Warning | 459

DC Power Disconnection Warning | 462

DC Power Grounding Requirements and Warning | 464

DC Power Wiring Sequence Warning | 466

Page 14

DC Power Wiring Terminations Warning | 469

Multiple Power Supplies Disconnection Warning | 472

TN Power Warning | 473

Action to Take After an Electrical Accident | 473

SRX5600 Services Gateway Agency Approvals | 474

SRX5600 Services Gateway Compliance Statements for EMC Requirements | 475

Canada | 475

European Community | 475

Israel | 476

Japan | 476

United States | 476

xiv

Statements of Volatility for Juniper Network Devices | 477

Page 15

About the Documentation

IN THIS SECTION

Documentation and Release Notes | xv

Using the Examples in This Manual | xv

Documentation Conventions | xvii

Documentation Feedback | xx

Requesting Technical Support | xx

Use this guide to install hardware and perform initial software configuration, routine maintenance, and

troubleshooting for the SRX5600 Services Gateway.

xv

After completing the installation and basic configuration procedures covered in this guide, refer to the

Junos OS documentation for information about further software configuration.

Documentation and Release Notes

To obtain the most current version of all Juniper Networks®technical documentation, see the product

documentation page on the Juniper Networks website at https://www.juniper.net/documentation/.

If the information in the latest release notes differs from the information in the documentation, follow the

product Release Notes.

Juniper Networks Books publishes books by Juniper Networks engineers and subject matter experts.

These books go beyond the technical documentation to explore the nuances of network architecture,

deployment, and administration. The current list can be viewed at https://www.juniper.net/books.

Using the Examples in This Manual

If you want to use the examples in this manual, you can use the load merge or the load merge relative

command. These commands cause the software to merge the incoming configuration into the current

candidate configuration. The example does not become active until you commit the candidate configuration.

Page 16

If the example configuration contains the top level of the hierarchy (or multiple hierarchies), the example

is a full example. In this case, use the load merge command.

If the example configuration does not start at the top level of the hierarchy, the example is a snippet. In

this case, use the load merge relative command. These procedures are described in the following sections.

Merging a Full Example

To merge a full example, follow these steps:

1. From the HTML or PDF version of the manual, copy a configuration example into a text file, save the

file with a name, and copy the file to a directory on your routing platform.

For example, copy the following configuration to a file and name the file ex-script.conf. Copy the

ex-script.conf file to the /var/tmp directory on your routing platform.

system {

scripts {

commit {

file ex-script.xsl;

}

}

}

interfaces {

fxp0 {

disable;

unit 0 {

family inet {

address 10.0.0.1/24;

}

}

}

}

xvi

2. Merge the contents of the file into your routing platform configuration by issuing the load merge

configuration mode command:

[edit]

user@host# load merge /var/tmp/ex-script.conf

load complete

Page 17

Merging a Snippet

To merge a snippet, follow these steps:

1. From the HTML or PDF version of the manual, copy a configuration snippet into a text file, save the

file with a name, and copy the file to a directory on your routing platform.

For example, copy the following snippet to a file and name the file ex-script-snippet.conf. Copy the

ex-script-snippet.conf file to the /var/tmp directory on your routing platform.

commit {

file ex-script-snippet.xsl; }

2. Move to the hierarchy level that is relevant for this snippet by issuing the following configuration mode

command:

[edit]

user@host# edit system scripts

[edit system scripts]

xvii

3. Merge the contents of the file into your routing platform configuration by issuing the load merge

relative configuration mode command:

[edit system scripts]

user@host# load merge relative /var/tmp/ex-script-snippet.conf

load complete

For more information about the load command, see CLI Explorer.

Documentation Conventions

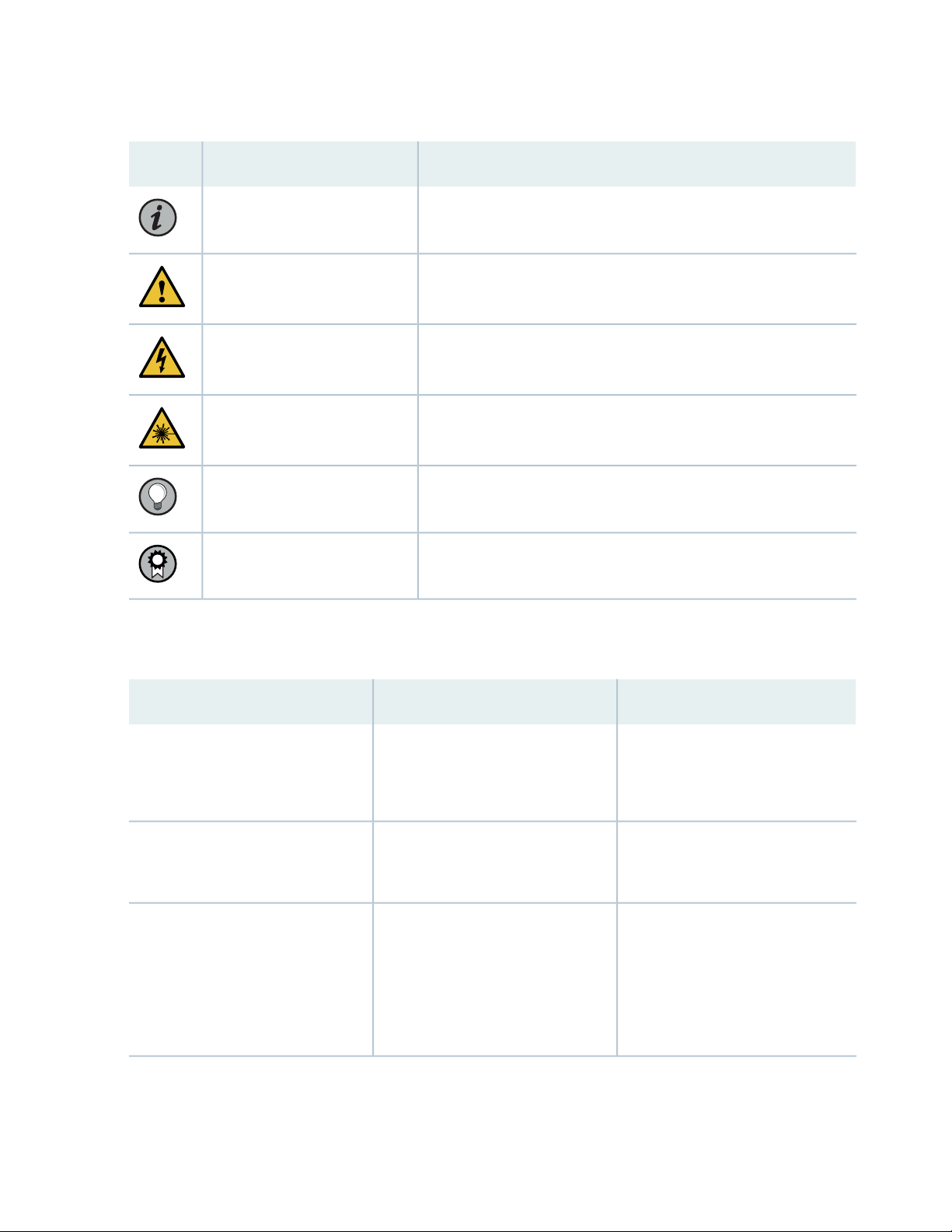

Table 1 on page xviii defines notice icons used in this guide.

Page 18

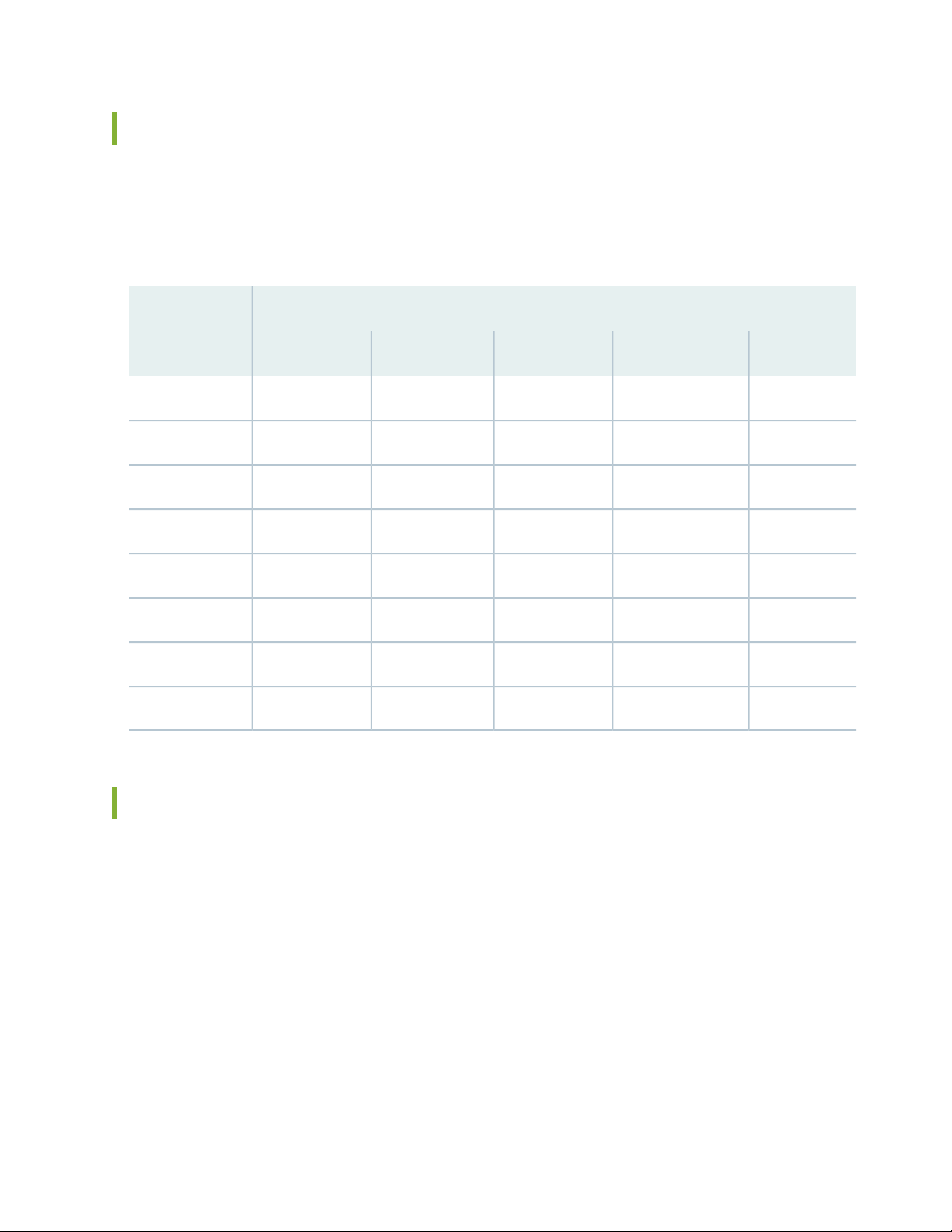

Table 1: Notice Icons

xviii

DescriptionMeaningIcon

Indicates important features or instructions.Informational note

Caution

Indicates a situation that might result in loss of data or hardware

damage.

Alerts you to the risk of personal injury or death.Warning

Alerts you to the risk of personal injury from a laser.Laser warning

Indicates helpful information.Tip

Alerts you to a recommended use or implementation.Best practice

Table 2 on page xviii defines the text and syntax conventions used in this guide.

Table 2: Text and Syntax Conventions

ExamplesDescriptionConvention

Fixed-width text like this

Italic text like this

Represents text that you type.Bold text like this

Represents output that appears on

the terminal screen.

Introduces or emphasizes important

•

new terms.

Identifies guide names.

•

Identifies RFC and Internet draft

•

titles.

To enter configuration mode, type

the configure command:

user@host> configure

user@host> show chassis alarms

No alarms currently active

A policy term is a named structure

•

that defines match conditions and

actions.

Junos OS CLI User Guide

•

RFC 1997, BGP Communities

•

Attribute

Page 19

Table 2: Text and Syntax Conventions (continued)

xix

ExamplesDescriptionConvention

Italic text like this

Text like this

< > (angle brackets)

| (pipe symbol)

Represents variables (options for

which you substitute a value) in

commands or configuration

statements.

Represents names of configuration

statements, commands, files, and

directories; configuration hierarchy

levels; or labels on routing platform

components.

variables.

Indicates a choice between the

mutually exclusive keywords or

variables on either side of the symbol.

The set of choices is often enclosed

in parentheses for clarity.

Configure the machine’s domain

name:

[edit]

root@# set system domain-name

domain-name

To configure a stub area, include

•

the stub statement at the [edit

protocols ospf area area-id]

hierarchy level.

The console port is labeled

•

CONSOLE.

stub <default-metric metric>;Encloses optional keywords or

broadcast | multicast

(string1 | string2 | string3)

# (pound sign)

[ ] (square brackets)

Indention and braces ( { } )

; (semicolon)

GUI Conventions

Indicates a comment specified on the

same line as the configuration

statement to which it applies.

Encloses a variable for which you can

substitute one or more values.

Identifies a level in the configuration

hierarchy.

Identifies a leaf statement at a

configuration hierarchy level.

rsvp { # Required for dynamic MPLS

only

community name members [

community-ids ]

[edit]

routing-options {

static {

route default {

nexthop address;

retain;

}

}

}

Page 20

Table 2: Text and Syntax Conventions (continued)

xx

ExamplesDescriptionConvention

Bold text like this

> (bold right angle bracket)

Represents graphical user interface

(GUI) items you click or select.

Separates levels in a hierarchy of

menu selections.

In the Logical Interfaces box, select

•

All Interfaces.

To cancel the configuration, click

•

Cancel.

In the configuration editor hierarchy,

select Protocols>Ospf.

Documentation Feedback

We encourage you to provide feedback so that we can improve our documentation. You can use either

of the following methods:

Online feedback system—Click TechLibrary Feedback, on the lower right of any page on the Juniper

•

Networks TechLibrary site, and do one of the following:

Click the thumbs-up icon if the information on the page was helpful to you.

•

Click the thumbs-down icon if the information on the page was not helpful to you or if you have

•

suggestions for improvement, and use the pop-up form to provide feedback.

E-mail—Send your comments to techpubs-comments@juniper.net. Include the document or topic name,

•

URL or page number, and software version (if applicable).

Requesting Technical Support

Technical product support is available through the Juniper Networks Technical Assistance Center (JTAC).

If you are a customer with an active Juniper Care or Partner Support Services support contract, or are

Page 21

covered under warranty, and need post-sales technical support, you can access our tools and resources

online or open a case with JTAC.

JTAC policies—For a complete understanding of our JTAC procedures and policies, review the JTAC User

•

Guide located at https://www.juniper.net/us/en/local/pdf/resource-guides/7100059-en.pdf.

Product warranties—For product warranty information, visit https://www.juniper.net/support/warranty/.

•

JTAC hours of operation—The JTAC centers have resources available 24 hours a day, 7 days a week,

•

365 days a year.

Self-Help Online Tools and Resources

For quick and easy problem resolution, Juniper Networks has designed an online self-service portal called

the Customer Support Center (CSC) that provides you with the following features:

Find CSC offerings: https://www.juniper.net/customers/support/

•

Search for known bugs: https://prsearch.juniper.net/

•

xxi

Find product documentation: https://www.juniper.net/documentation/

•

Find solutions and answer questions using our Knowledge Base: https://kb.juniper.net/

•

Download the latest versions of software and review release notes:

•

https://www.juniper.net/customers/csc/software/

Search technical bulletins for relevant hardware and software notifications:

•

https://kb.juniper.net/InfoCenter/

Join and participate in the Juniper Networks Community Forum:

•

https://www.juniper.net/company/communities/

Create a service request online: https://myjuniper.juniper.net

•

To verify service entitlement by product serial number, use our Serial Number Entitlement (SNE) Tool:

https://entitlementsearch.juniper.net/entitlementsearch/

Creating a Service Request with JTAC

You can create a service request with JTAC on the Web or by telephone.

Visit https://myjuniper.juniper.net.

•

Call 1-888-314-JTAC (1-888-314-5822 toll-free in the USA, Canada, and Mexico).

•

For international or direct-dial options in countries without toll-free numbers, see

https://support.juniper.net/support/requesting-support/.

Page 22

1

CHAPTER

Overview

SRX5600 Services Gateway System Overview | 23

SRX5600 Chassis | 26

SRX5600 Services Gateway Cooling System Description | 40

SRX3400 and SRX5600 Services Gateways Air Deflector Kits | 43

SRX5600 Power System | 45

SRX5600 Host Subsystem | 61

SRX5600 Line Cards and Modules | 89

Page 23

SRX5600 Services Gateway System Overview

IN THIS SECTION

SRX5600 Services Gateway Description | 23

Benefits of the SRX5600 Services Gateway | 24

SRX5600 Services Gateway FRUs | 24

SRX5600 Services Gateway Component Redundancy | 25

SRX5600 Services Gateway Description

23

The SRX5600 Services Gateway is a high-performance, highly scalable, carrier-class security device with

multi-processor architecture.

The SRX5600 Services Gateway is 8 rack units (U) tall. Three of these devices can be stacked in a single

floor-to-ceiling rack, for increased port density per unit of floor space.

The services gateway provides eight slots that you can populate with two Switch Control Boards (SCBs)

and six other cards of the following types:

Services Processing Cards (SPCs) provide the processing capacity to run integrated services such as

•

firewall, IPsec, and IDP.

Modular PIC Concentrators (MPCs) provide Ethernet interfaces that connect the services gateway to

•

your network.

I/O cards (IOCs) provide Ethernet interfaces that connect the services gateway to your network.

•

Flex IOCs are similar to IOCs, but have slots for port modules that allow you greater flexibility in adding

•

different types of Ethernet ports to your services gateway.

For detailed information about the cards supported by the services gateway, see the SRX5400, SRX5600,

and SRX5800 Services Gateway Card Reference at www.juniper.net/documentation/.

Page 24

Benefits of the SRX5600 Services Gateway

The next generation SPCs and IOCs on the SRX5600 Services Gateway support up to 570 IMIX Gbps

•

firewall throughput, 180 million concurrent sessions, and 460 Gbps IPS.

The ability to support unique security policies per zone and ability to scale with the growth of the network

infrastructure, makes the SRX5600 an ideal deployment for consolidation of services in large enterprise,

service provider, or mobile operator environments.

IPS Capabilities - Juniper Networks IPS capabilities offer several unique features such as Protocol decodes,

•

Zero-day protection, Active/active traffic monitoring, and packet capture logging per rule assure the

highest level of network security.

Content Security UTM Capabilities - The UTM services offered on the SRX5000 line of Services Gateways

•

include industry-leading antivirus, antispam, content filtering, and additional content security services.

The UTM services provide sophisticated protection from:

Antivirus experts against malware attacks that can lead to data breaches and lost productivity.

•

Advanced persistent threats perpetrated through social networking attacks and the latest phishing

•

scams with sophisticated e-mail filtering and content blockers.

24

Lost productivity and the impact of malicious URLs and extraneous or malicious content on the network

•

to help maintain bandwidth.

Advanced Threat Prevention (ATP) - Juniper Sky ATP, a SaaS-based service, and the Juniper ATP

•

Appliance, an on-premises solution:

Protects enterprise users from a spectrum of advanced malware that exploits “zero-day” vulnerabilities.

•

Proactively blocks malware communication channels.

•

The Juniper ATP Appliance includes support for cloud-based e-mail services such as Office 365 and

•

Google Mail, and detects threats in SMB traffic.

Single pane-of-glass management with Security Director and JSA Series integration.

•

SRX5600 Services Gateway FRUs

Field-replaceable units (FRUs) are services gateway components that can be replaced at the customer site.

The services gateway uses the following types of FRUs:

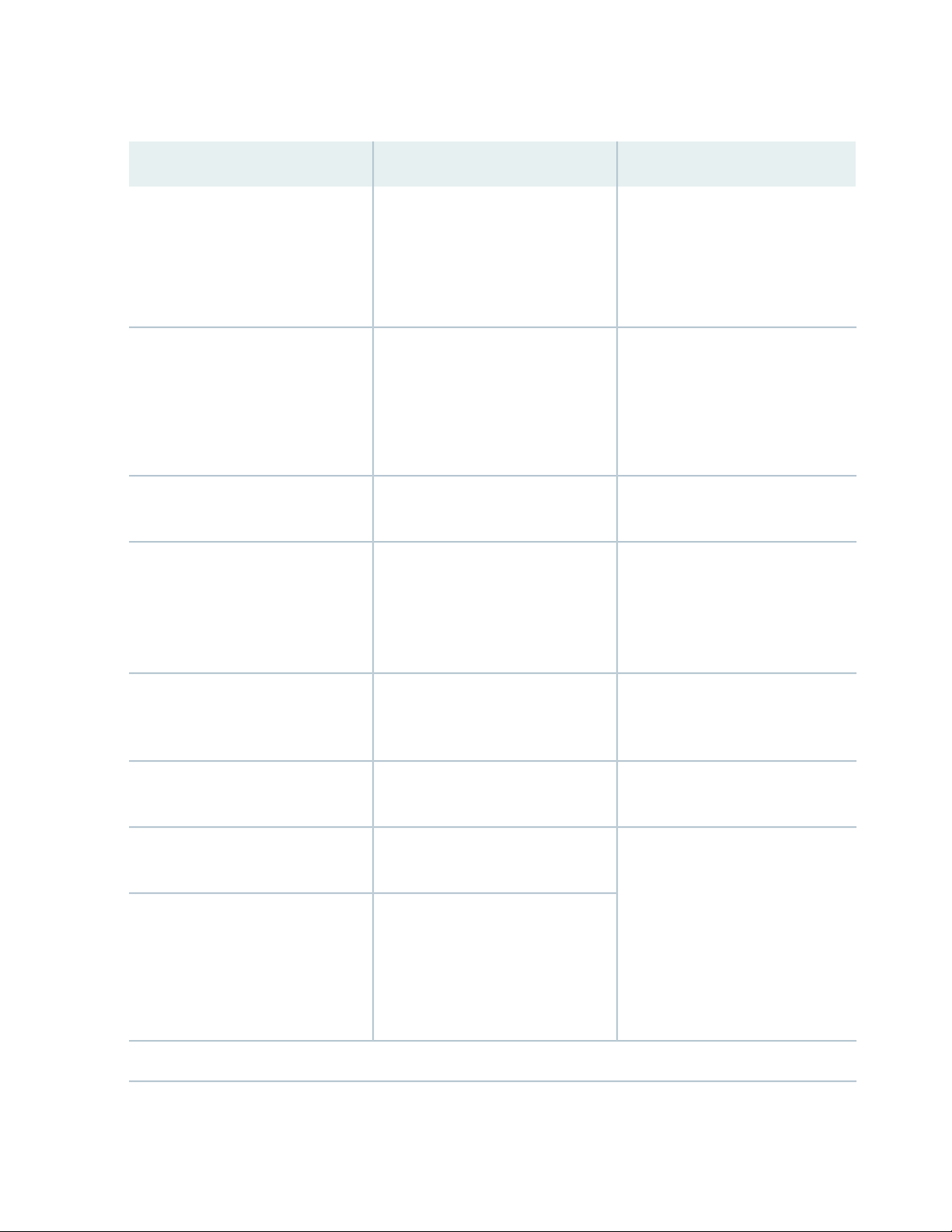

Table 3 on page 25 lists the FRUs of the services gateway and the action to perform to install, remove, or

replace an FRU.

Page 25

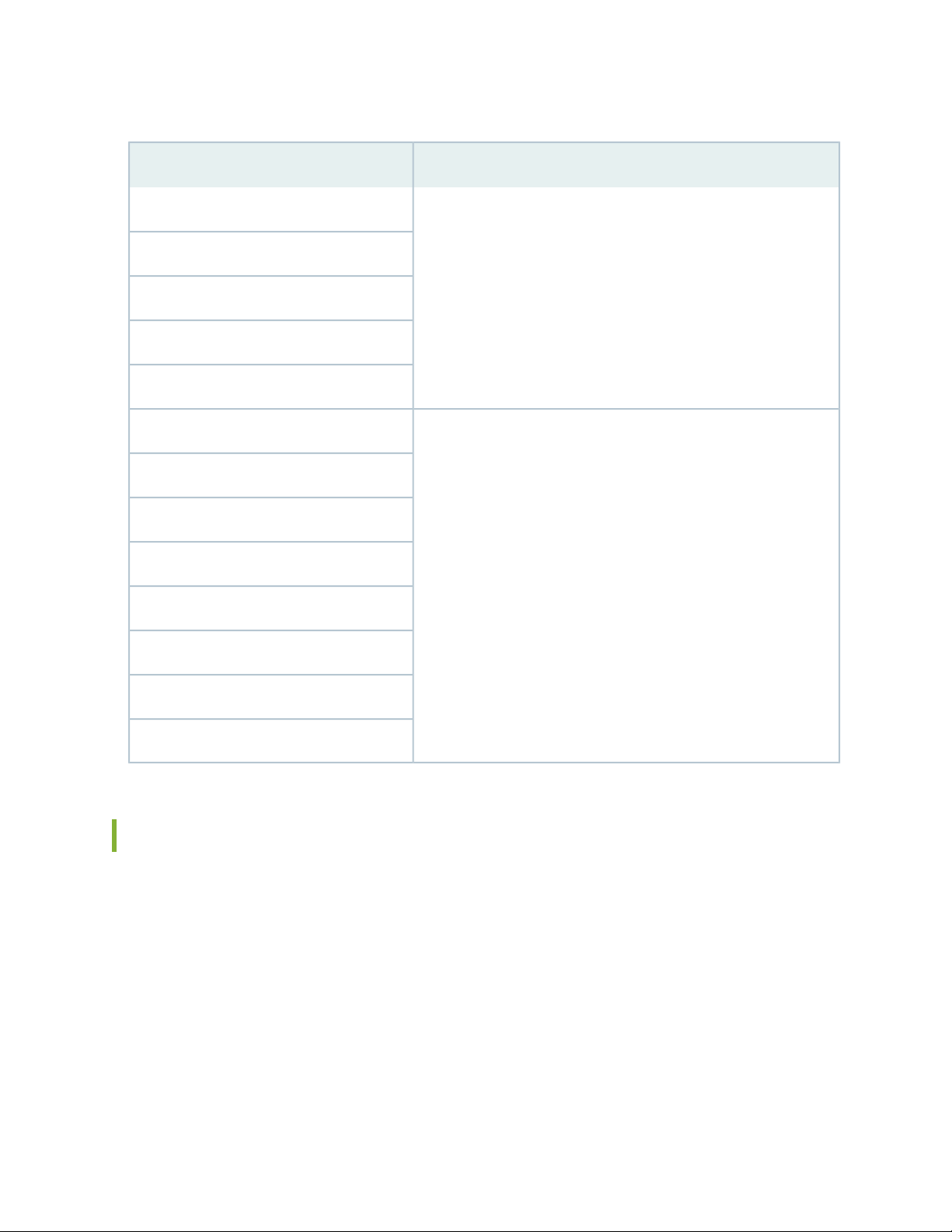

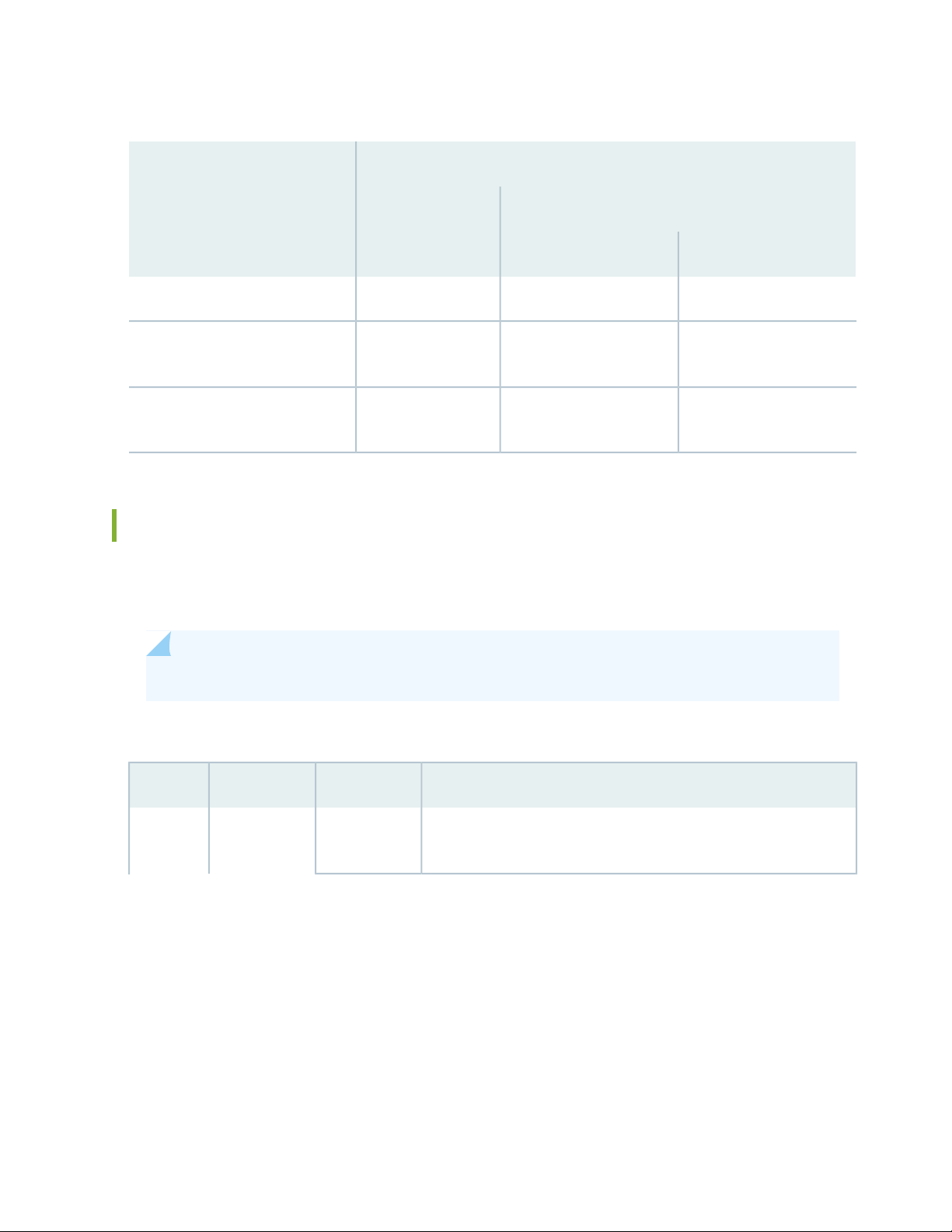

Table 3: Field-Replaceable Units

25

ActionField-Replaceable Units (FRUs)

Air filter

Fan tray

Craft interface

AC and DC power supplies (if redundant)

SFP and XFP transceivers

IOCs

Flex IOCs

Port modules of the Flex IOCs

Routing Engine

SCBs

SPCs

You need not power off the services gateway to install, remove, or

replace any of these FRUs.

Power off the services gateway to install, remove, or replace any of

these FRUs.

MPCs

MICs

SRX5600 Services Gateway Component Redundancy

The following major hardware components are redundant:

SCBs—The host subsystem consists of a Routing Engine installed in an SCB. The device must have one

•

host subsystem installed. You can install a second SCB for redundancy. If a second SCB is installed, the

host subsystem SCB functions as the primary and the other functions as the backup. If the SCB of the

host subsystem fails, the other SCB takes over as the primary.

Power supplies—In the low-line (110 V) AC power configuration, the device contains three or four AC

•

power supplies, located horizontally at the rear of the chassis in slots PEM0 through PEM3 (left to right).

Each AC power supply provides power to all components in the device. When three power supplies are

present, they share power almost equally within a fully populated system. Four AC power supplies

Page 26

provide full power redundancy. If one power supply fails or is removed, the remaining power supplies

instantly assume the entire electrical load without interruption. Three power supplies provide the

maximum configuration with full power for as long as the device is operational.

In the high-line (220 V) AC power configuration, the device contains two or four AC power supplies

located horizontally at the rear of the chassis in slots PEM0 through PEM3 (left to right). Each AC power

supply provides power to all components in the device. When two or more power supplies are present,

they share power almost equally within a fully populated system. Four AC power supplies provide full

power redundancy. If one power supply fails or is removed, the remaining power supplies instantly

assume the entire electrical load without interruption. Two power supplies provide the maximum

configuration with full power for as long as the device is operational.

In the DC configuration, two power supplies are required to supply power to a fully configured device.

One power supply supports approximately half of the components in the device, and the other power

supply supports the remaining components. The addition of two power supplies provides full power

redundancy. If one power supply fails or is removed, the remaining power supplies instantly assume the

entire electrical load without interruption. Two power supplies provide the maximum configuration with

full power for as long as the device is operational.

26

Cooling system—The cooling system has redundant components, which are controlled by the host

•

subsystem. If one of the fans fails, the host subsystem increases the speed of the remaining fans to

provide sufficient cooling for the services gateway indefinitely.

SRX5600 Chassis

IN THIS SECTION

SRX5600 Services Gateway Chassis | 27

SRX5600 Services Gateway Physical Specifications | 29

SRX5600 Services Gateway Midplane Description | 30

SRX5600 Services Gateway Cable Manager Description | 31

SRX5600 Services Gateway Craft Interface Overview | 32

SRX5600 Services Gateway Craft Interface Alarm LEDs and Alarm Cutoff/Lamp Test Button | 33

SRX5600 Services Gateway Craft Interface Host Subsystem LEDs | 34

SRX5600 Services Gateway Craft Interface Power Supply LEDs | 35

SRX5600 Services Gateway Craft Interface Card OK/Fail LEDs | 35

SRX5600 Services Gateway Craft Interface Fan LEDs | 35

Page 27

SRX5600 Services Gateway Craft Interface Online Buttons | 36

SRX5600 Services Gateway Craft Interface Alarm Relay Contacts | 39

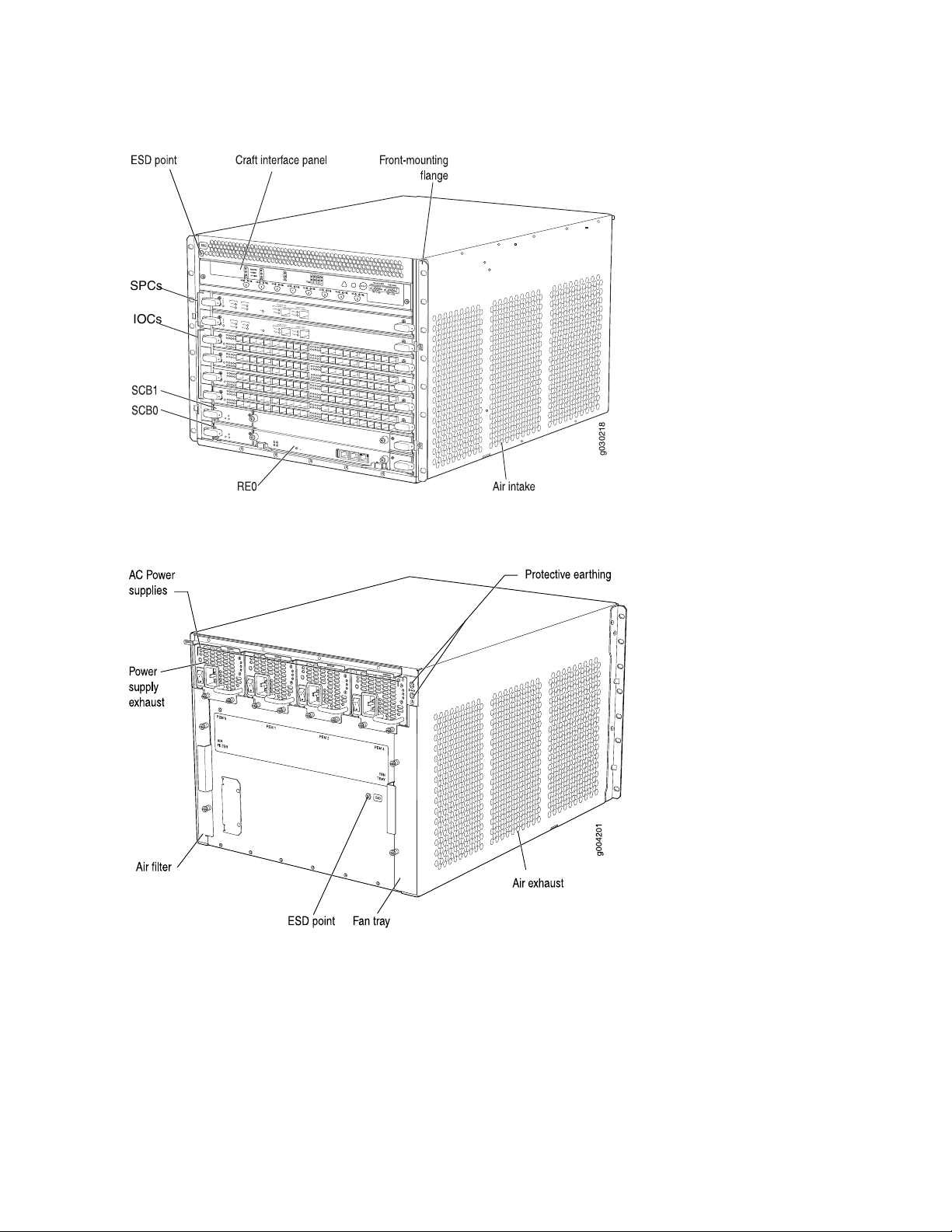

SRX5600 Services Gateway Chassis

The services gateway chassis is a rigid sheet metal structure that houses all the other components (see

Figure 1 on page 28, Figure 2 on page 28, and Figure 3 on page 29). The chassis measures 14.0 in. (35.6 cm)

high, 17.45 in. (44.3 cm) wide, and 24.5 in. (62.2 cm) deep (from the front to the rear of the chassis). The

chassis installs in standard 800-mm (or larger) enclosed cabinets, 19-in. equipment racks, or telco open-frame

racks. Up to five services gateways can be installed in one standard (48 U) rack if the rack can handle their

combined weight, which can be greater than 1100 lb (500 kg). See “SRX5600 Services Gateway Physical

Specifications” on page 29 for physical specifications for the SRX5600 Services Gateway.

27

CAUTION: Before removing or installing components of a services gateway, attach

an ESD strap to an ESD point and place the other end of the strap around your bare

wrist. Failure to use an ESD strap can result in damage to the services gateway.

WARNING: The services gateway must be connected to earth ground during normal

operation.

Page 28

Figure 1: Front View of a Fully Configured Services Gateway Chassis

STATUS

SPU0

SERVICE

STATUS

SPU1

SERVICE

HA

OK/FAIL

CHASSISCLUSTER

CONTROL0

ENABLE

LINK/ACT

CHASSISCLUSTER

CONTROL1

ENABLE

LINK/ACT

STATUS

SPU0

SERVICE

STATUS

SPU1

SERVICE

HA

OK/FAIL

CHASSISCLUSTER

CONTROL0

ENABLE

LINK/ACT

CHASSISCLUSTER

CONTROL1

ENABLE

LINK/ACT

SPCs

g030218

IOCs

28

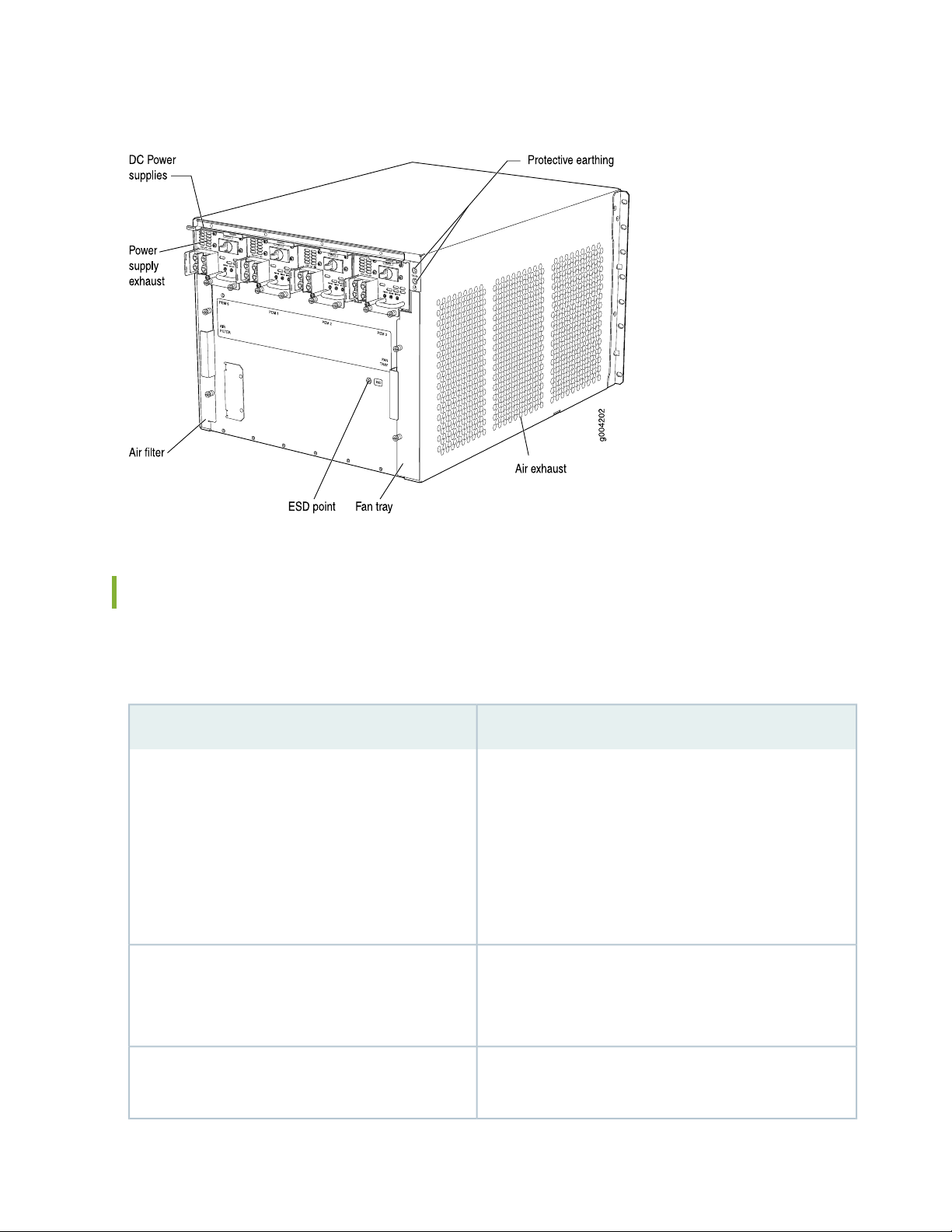

Figure 2: Rear View of a Fully Configured AC-Powered Services Gateway Chassis

Page 29

Figure 3: Rear View of a Fully Configured DC-Powered Services Gateway Chassis

29

SRX5600 Services Gateway Physical Specifications

Table 4 on page 29 summarizes the physical specifications for the services gateway chassis.

Table 4: Physical Specifications

ValueDescription

Chassis dimensions

Services Gateway weight

14.0 in. (35.6 cm) high

17.45 in. (44.3 cm) wide

24.5 in. (62.2 cm) deep (from front-mounting bracket to

chassis rear)

Total depth (including cable management system):

27.75 in. (70.5 cm)

Chassis with midplane, fan tray, air filter, and cable

management system: 65.5 lb (29.7 kg)

Maximum configuration: 220 lb (100 kg)

Routing Engine weight

SRX5K-RE-13-20: 2.4 lb (1.1 kg)

SRX5K-RE-1800X4: 2.4 lb (1.1 kg)

Page 30

Table 4: Physical Specifications (continued)

30

ValueDescription

SCB weight

supported on devices with SRX5K-SCB and

SRX5K-RE-13-20)

SRX5K-SCB: 9.6 lb (4.4 kg)

SRX5K-SCBE: 9.6 lb (4.4 kg)

SRX5K-SCB3: 10.14 lb (4.6 kg)

13.1 lb (5.9 kg)MPC weight (with two MICs)

13.1 lb (5.9 kg)IOC weight

1.1 lb (0.5 kg)Craft interface weight

4.2 lb (1.9 kg)Fan tray weight

1.0 lb (0.5 kg)Air filter weight

0.3 lb (0.14 kg)Cable management weight

3.8 lb (1.7 kg)Standard-capacity DC power supply weight (only

6.2 lb (2.8 kg)High-capacity DC power supply weight

5.0 lb (2.3 kg)Standard-capacity AC power supply weight (only

supported on devices with SRX5K-SCB and

SRX5K-RE-13-20)

6.6 lb (3.0 kg)High-capacity AC power supply weight

SRX5600 Services Gateway Midplane Description

The midplane is located toward the rear of the chassis and forms the rear of the card cage (see

Figure 4 on page 31). IOCs, Flex IOCs, SPCs, and SCBs install into the midplane from the front of the

chassis, and the power supplies install into the midplane from the rear of the chassis. The cooling system

components also connect to the midplane.

Page 31

The midplane performs the following major functions:

Data path—Data packets are transferred across the midplane between the IOCs and SPCs through the

•

fabric ASICs on the SCBs.

Power distribution—The power supplies are connected to the midplane, which distributes power to all

•

the services gateway components.

Signal path—The midplane provides the signal path to the IOCs, SCBs, SPCs, Routing Engine, and other

•

system components for monitoring and control of the system.

The enhanced midplane supports Junos OS Release15.1X49-D10. It provides greater per-slot fabric

performance and signal integrity, along with error-free high speed data transfer, and it reduces cross-talk.

The midplane supports link speeds up to 10 Gbps and is not field replaceable.

Figure 4: Midplane

31

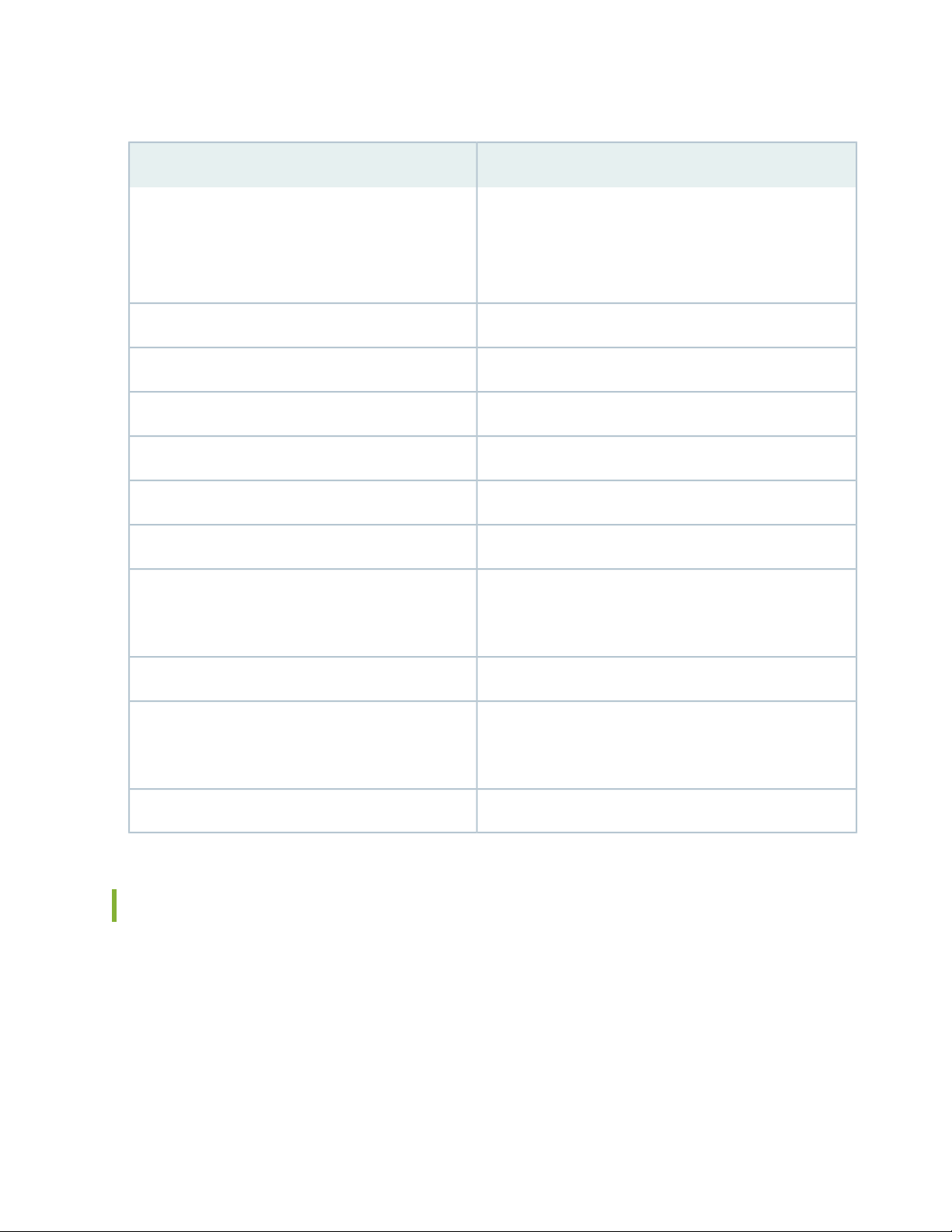

SRX5600 Services Gateway Cable Manager Description

The cable management system (see Figure 5 on page 32 and Figure 6 on page 32) consists of plastic

dividers located on the left and right sides of each IOC slot. The cable management system allows you to

route the cables outside the services gateway and away from the IOCs.

Page 32

Figure 5: Cable Manager

Figure 6: Cable Management System Installed on the Device

32

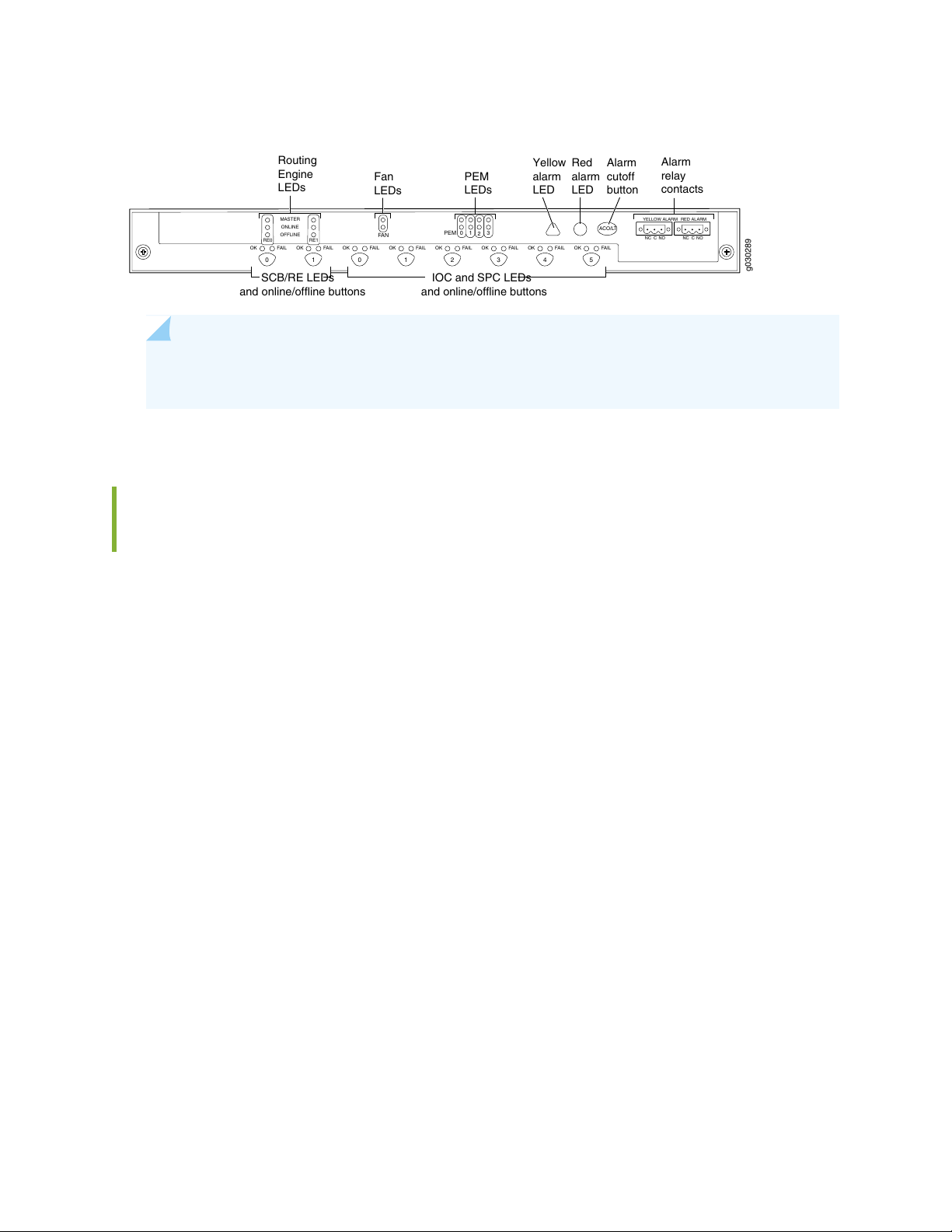

SRX5600 Services Gateway Craft Interface Overview

The craft interface shows you status and troubleshooting information at a glance and lets you perform

many system control functions. It is hot-insertable and hot-removable. The craft interface is located on

the front of the services gateway above the upper fan tray. See Figure 7 on page 33.

Page 33

Figure 7: Front Panel of the Craft Interface

0

OK FAIL1OK FAIL0OK FAIL1OK FAIL2OK FAIL3OK FAIL4OK FAIL5OK FAIL

ACO/LT

RE0 RE1

YELLOW ALARM RED ALARM

NC NOC NC NOC

Alarm

relay

contacts

Yellow

alarm

LED

Red

alarm

LED

Alarm

cutoff

button

IOC and SPC LEDs

and online/offline buttons

SCB/RE LEDs

and online/offline buttons

g030289

PEM

FAN

0 1

2

3

MASTER

ONLINE

OFFLINE

PEM

LEDs

Fan

LEDs

Routing

Engine

LEDs

NOTE: At least one SCB must be installed in the services gateway for the craft interface to

obtain power.

SRX5600 Services Gateway Craft Interface Alarm LEDs and Alarm

33

Cutoff/Lamp Test Button

Two large alarm LEDs are located at the upper right of the craft interface. The circular red LED lights to

indicate a critical condition that can result in a system shutdown. The triangular yellow LED lights to indicate

a less severe condition that requires monitoring or maintenance. Both LEDs can be lit simultaneously. A

condition that causes an LED to light also activates the corresponding alarm relay contact on the craft

interface.

To deactivate the red and yellow alarms, press the button labeled ACO/LT (for “alarm cutoff/lamp test”),

which is located to the right of the alarm LEDs. Deactivating an alarm turns off both LEDs and deactivates

the device attached to the corresponding alarm relay contact on the craft interface.

Table 5 on page 34 describes the alarm LEDs and alarm cutoff button in more detail.

Page 34

Table 5: Alarm LEDs and Alarm Cutoff/Lamp Test Button

DescriptionStateColorShape

34

On steadilyRed

On steadilyYellow

––

Critical alarm LED—Indicates a critical condition that can cause the

device to stop functioning. Possible causes include component removal,

failure, or overheating.

Warning alarm LED—Indicates a serious but nonfatal error condition,

such as a maintenance alert or a significant increase in component

temperature.

Alarm cutoff/lamp test button—Deactivates red and yellow alarms.

Causes all LEDs on the craft interface to light (for testing) when pressed

and held.

SRX5600 Services Gateway Craft Interface Host Subsystem LEDs

The host subsystem has three LEDs, located in the middle of the craft interface, that indicate its status.

The LEDs labeled RE0 show the status of the Routing Engine and SCB in slot 0 .

The LEDs labeled RE1 show the status of the Routing Engine and SCB in slot 1. Table 6 on page 34 describes

the functions of the host subsystem LEDs.

Table 6: Host Subsystem LEDs

DescriptionStateColorLabel

Host is functioning as the master.On steadilyGreenMASTER

Host is online and is functioning normally.On steadilyGreenONLINE

Host is installed but the Routing Engine is offline.On steadilyRedOFFLINE

Host is not installed.Off

Page 35

SRX5600 Services Gateway Craft Interface Power Supply LEDs

Each power supply has two LEDs on the craft interface that indicate its status. The LEDs, labeled 0 through

3, are located near the middle of the craft interface next to the PEM label. Table 7 on page 35 describes

the functions of the power supply LEDs on the craft interface.

Table 7: Power Supply LEDs on the Craft Interface

DescriptionStateColorLabel

Power supply is functioning normally.On steadilyGreenPEM

Power supply has failed or power input has failed.On steadilyRed

SRX5600 Services Gateway Craft Interface Card OK/Fail LEDs

35

Each slot in the card cage has a pair of LEDs on the craft interface that indicates the status of the card

installed in it. The card LEDs are located along the bottom edge of the craft interface and are labeled 0

and 1 for the slots reserved for SCBs and 0 through 5 for the remaining slots.

Table 8 on page 35 describes the functions of the OK and Fail LEDs.

Table 8: Card OK/Fail LEDs

DescriptionStateColorLabel

The card is functioning normally.On steadilyGreenOK

The card is transitioning online or offline.Blinking

The card is not online.Off

The card has failed.On steadilyRedFAIL

SRX5600 Services Gateway Craft Interface Fan LEDs

Each fan LED is located on the top left of the craft interface. Table 9 on page 36 describes the functions

of the fan LEDs.

Page 36

Table 9: Fan LEDs

DescriptionStateColorLabel

Fan tray is functioning normally.On steadilyGreenOK

Fan tray has failed.On steadilyRedFAIL

SRX5600 Services Gateway Craft Interface Online Buttons

The craft interface has a row of Online/Offline buttons along its lower edge. Each button corresponds to

one slot in the card cage. The Online/Offline buttons are only supported for slots containing MPC interface

cards. You can install MPCs into slots:

SRX5400–Any slot except bottom slot 0

•

36

SRX5600–Any slot except bottom slots 0 or 1

•

SRX5800–Any slot except center slots 0 or 1

•

NOTE: The Online/Offline buttons are not supported for removal and replacement of SPCs or

SCB.

CAUTION: While traffic is passing through the Services Gateway, particularly if the

device is configured as part of a high availability (HA) cluster, we strongly recommend

that you do not push any of the Online/Offline buttons.

To take an MPC offline using the Online/Offline buttons:

1. Press and hold the corresponding card’s Online/Offline button on slot 1 on the craft interface. The

green OK/FAIL LED next to the button begins to blink. Hold until both the button’s LED and the MPC’s

LED are off.

2. Issue the CLI show chassis fpc command to check the status of installed MPCs. As shown in the sample

output, the value Offline in the column labeled State indicates that the MPC in slot 1 is now offline:

user@host> show chassis fpc

Page 37

Slot State (C) Total Interrupt DRAM (MB) Heap Buffer

0 Online 35 4 0 1024 13 25

1 Online 47 3 0 1024 13 25

2 Online 37 8 0 2048 18 14

An MPC can also be taken offline via CLI command:

user@host> request chassis fpc slot 2 offline

node0:

-------------------------------------------------------------------------Offline initiated, use "show chassis fpc" to verify

{primary:node0}

user@host> show chassis fpc

37

node0:

------------------------------------------------------------------------- Temp CPU Utilization (%) Memory Utilization (%)

Slot State (C) Total Interrupt DRAM (MB) Heap Buffer

0 Online 35 7 0 1024 13 25

1 Online 46 4 0 1024 13 25

2 Offline ---Offlined by cli command---

After pushing MPC online button:

user@host> show chassis fpc

Temp CPU Utilization (%) Memory Utilization (%)

Slot State (C) Total Interrupt DRAM (MB) Heap Buffer

0 Online 34 5 0 1024 13 25

1 Online 46 3 0 1024 13 25

2 Offline ---Offlined by button press---

To bring an MPC back online using the Online/Offline buttons:

1. Press and hold the corresponding card’s Online/Offline button on slot 1 on the craft interface. The

green OK/FAIL LED next to the button and the MPC’s LED begins to blink. Hold until both the button’s

LED and the MPC’s LED are green and steady.

Page 38

2. Issue the CLI show chassis fpc command to check the status of installed MPCs. As shown in the sample

output, the value Online in the column labeled State indicates that the MPC in slot 1 is functioning

normally:

Verify if the MPC is offline:

user@host> show chassis fpc

node0:

------------------------------------------------------------------------- Temp CPU Utilization (%) Memory Utilization (%)

Slot State (C) Total Interrupt DRAM (MB) Heap Buffer

0 Online 37 23 0 2048 19 14

1 Offline ---Offlined by cli command-- 2 Online 49 37 0 1024 14 25

The command output indicates the MPC is offline.

Bring the MPC online for the first time by using the following CLI command:

38

user@host> request chassis fpc slot 1 online

node0:

-------------------------------------------------------------------------Online initiated, use "show chassis fpc" to verify

Verify that the MPC is online:

user@host> request chassis fpc slot 1 online node 0

node0:

-------------------------------------------------------------------------FPC 1 already online

The command output indicates the MPC is online.

Confirm that the MPC in the chassis is online:

user@host> show chassis fpc

node0:

------------------------------------------------------------------------- Temp CPU Utilization (%) Memory Utilization (%)

Slot State (C) Total Interrupt DRAM (MB) Heap Buffer

0 Online 37 6 0 2048 19 14

Page 39

1 Online 44 11 0 1024 23 29

2 Online 49 22 0 1024 14 25

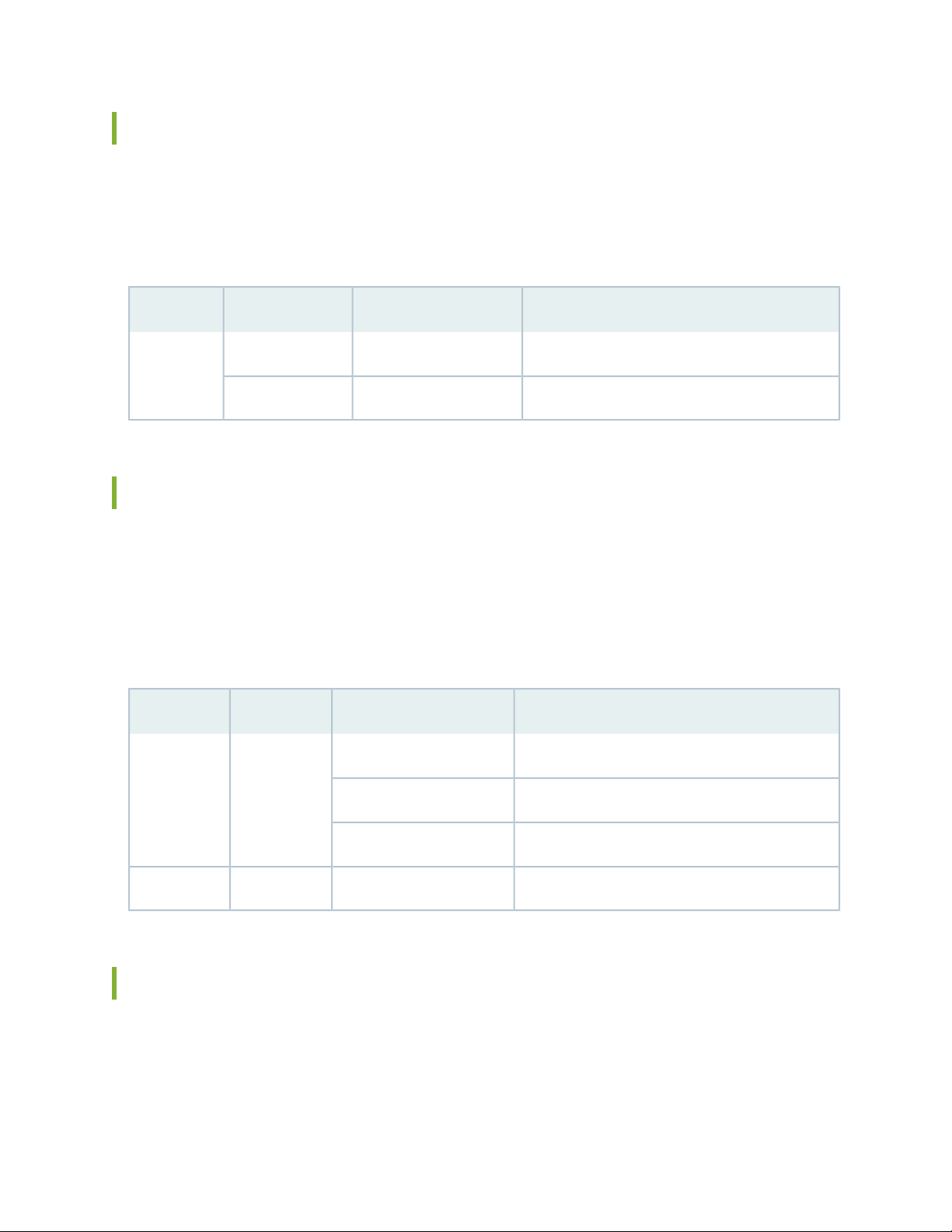

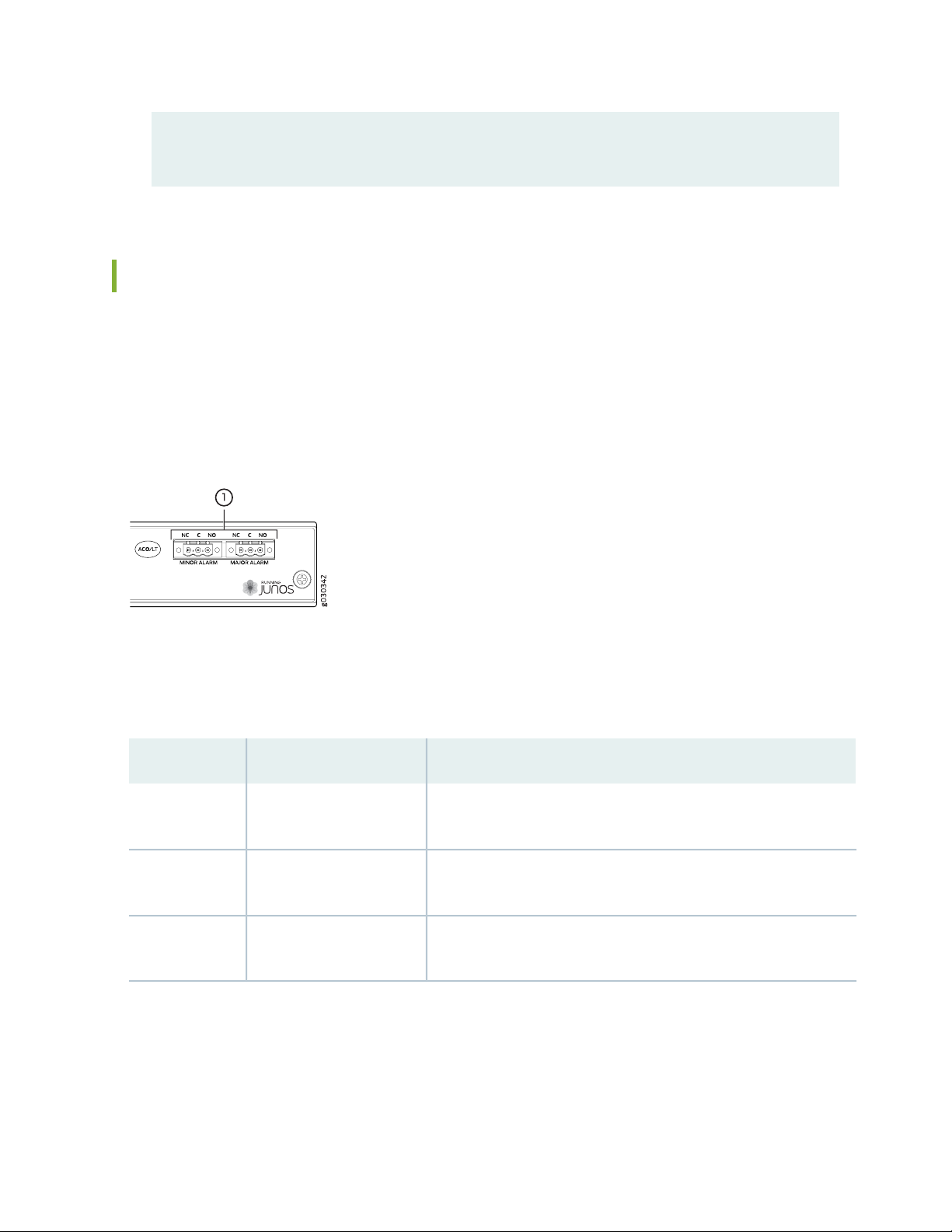

SRX5600 Services Gateway Craft Interface Alarm Relay Contacts

The craft interface has two alarm relay contacts for connecting the device to external alarm devices (see

Figure 8 on page 39). Whenever a system condition triggers either the major or minor alarm on the craft

interface, the alarm relay contacts are also activated. The alarm relay contacts are located on the upper

right of the craft interface.

Figure 8: Alarm Relay Contacts

39

The alarm relay contacts consist of two sets of connectors, one set for each of the two alarms (major and

minor). For each alarm color there are three connectors. Table 10 on page 39 describes the functions of

the connectors.

Table 10: Alarm Relay Contact Functions

FunctionContact NameContact Label

Normally ClosedNC

Current InC

Normally OpenNO

Connects the alarm relay to an external alarm-reporting device that

activates when the circuit between C and NC is closed.

Connects the alarm relay to the current source for the external

alarm-reporting device.

Connects the alarm relay to an external alarm-reporting device that

activates when the circuit between C and NC is open.

Table 11 on page 40 shows the electrical specifications for the alarm relay contacts.

Page 40

Table 11: Alarm Relay Contact Electrical Specifications

g030297

Current Type

DCAC

30250Maximum Voltage

8 AMaximum Current

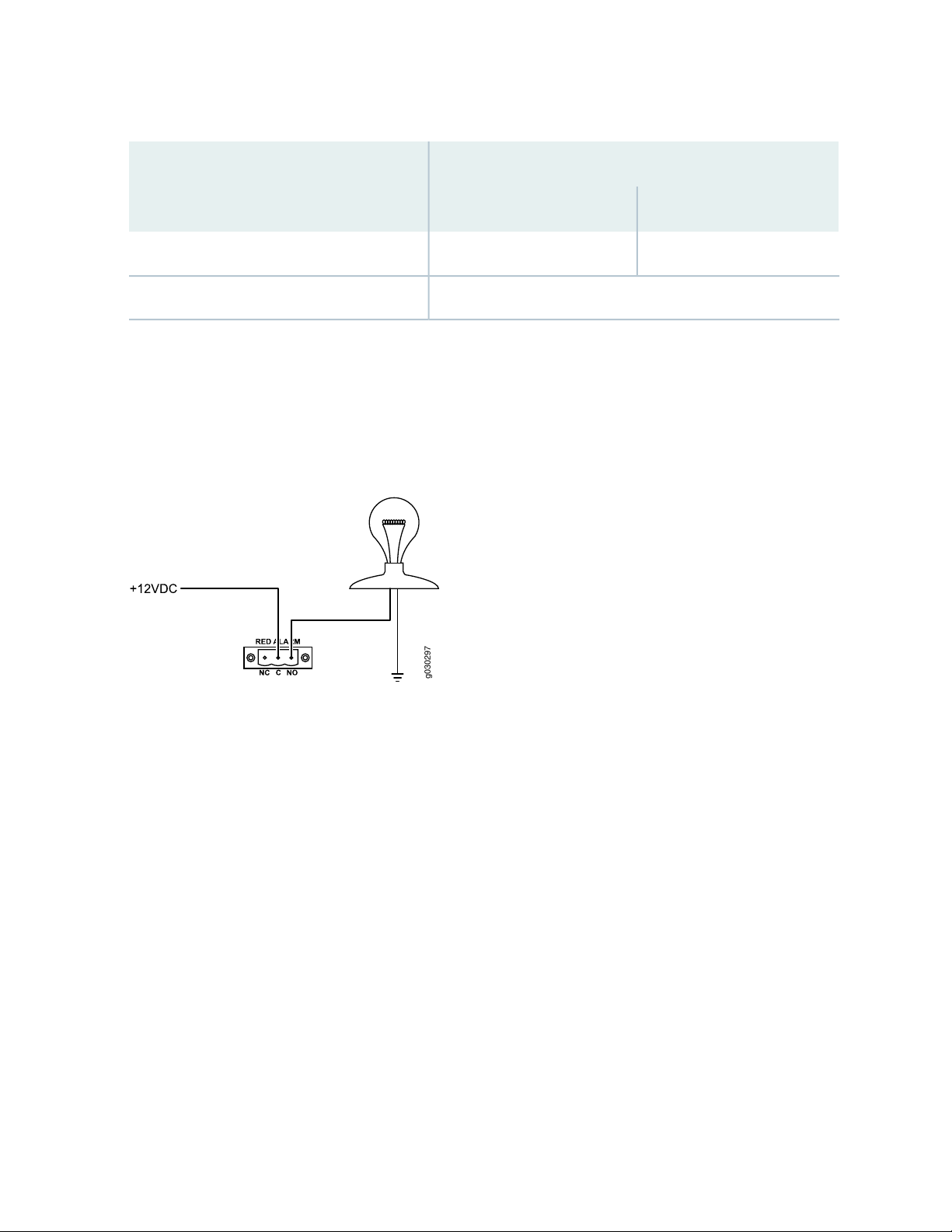

Figure 9 on page 40 shows an example wiring diagram for a simple alarm reporting device. In this case the

device is a 12-volt light bulb that illuminates when the device encounters a condition that activates the

major alarm LED and relay contacts. The alarm relay contacts can also be used to activate other devices

such as bells or buzzers.

Figure 9: Example Alarm Reporting Device

40

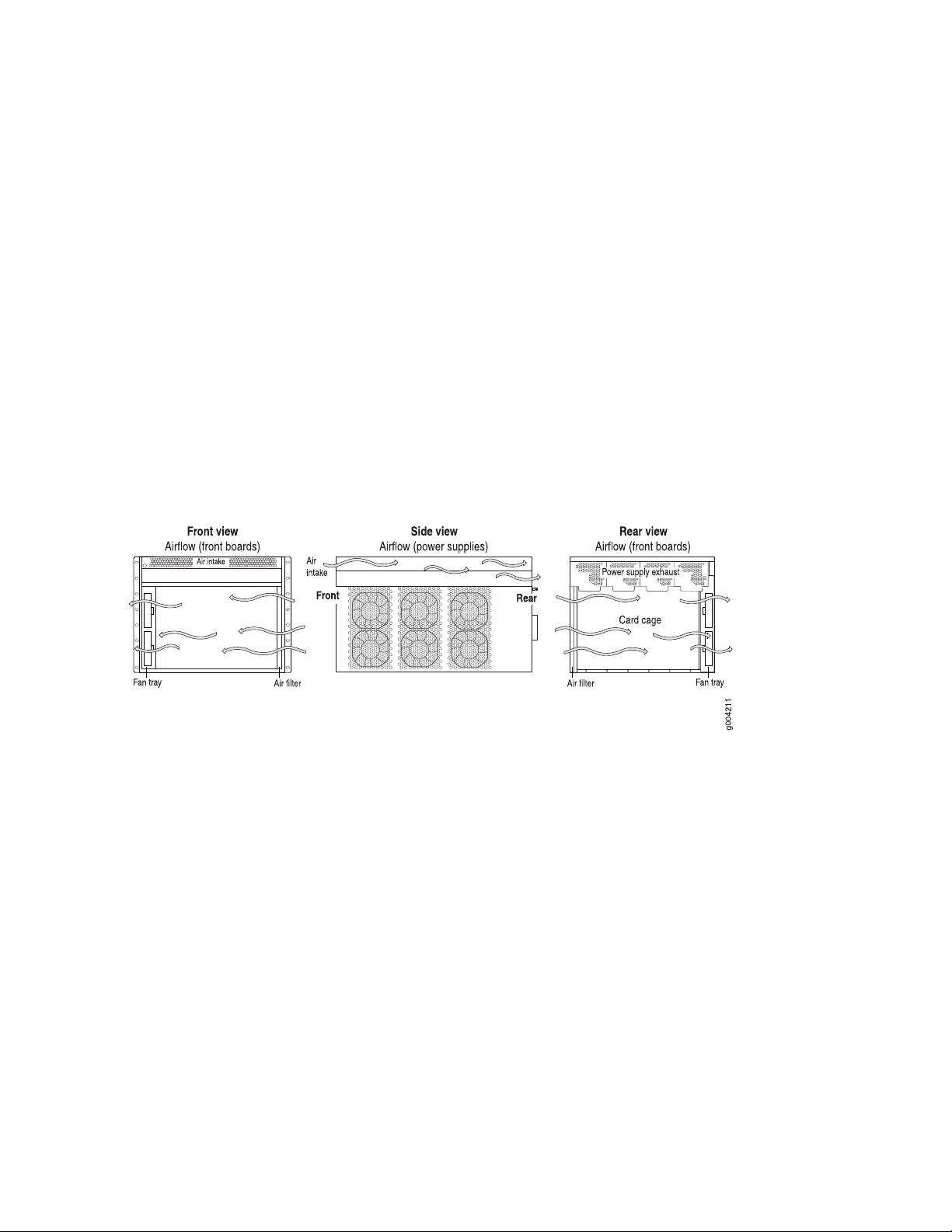

SRX5600 Services Gateway Cooling System Description

The cooling system consists of the following components:

Fan tray

•

Air filter

•

The cooling system components work together to keep all services gateway components within the

acceptable temperature range (see Figure 10 on page 41, Figure 11 on page 42, and Figure 12 on page 42).

The device has one fan tray and one air filter that install vertically in the rear of the device.

Page 41

Two types of fan trays are available:

The standard capacity fan tray has six fans that operate at 432 cubic feet per minute (CFM) at full speed

•

and is adequate for services gateways in which standard-capacity power supplies are installed.

The high-capacity fan tray has six fans that operate at 579 cubic feet per minute (CFM) at full speed and

•

is required when high-capacity power supplies are installed.

High-capacity fan trays satisfy cooling requirements for high-capacity power supplies and for high-density

SPCs, and must be upgraded for proper cooling.

The air intake to cool the chassis is located on the side of the chassis next to the air filter. Air is pulled

through the chassis toward the fan tray, where it is exhausted out the side of the system. The air intake

to cool the power supplies is located in the front of the device above the craft interface. The exhaust for

the power supplies is located on the rear bulkhead power supplies.

Each fan has an LED that displays its status. The fan LEDs are located on the top left of the craft interface.

Figure 10: Airflow Through the Chassis

41

The host subsystem monitors the temperature of the services gateway components. When the device is

operating normally, the fans function at lower than full speed. If a fan fails or the ambient temperature

rises above a threshold, the speed of the remaining fans is automatically adjusted to keep the temperature

within the acceptable range. If the ambient maximum temperature specification is exceeded and the system

cannot be adequately cooled, the Routing Engine shuts down the system by disabling output power from

each power supply.

Page 42

Figure 11: Fan Tray

42

Figure 12: Air Filter

RELATED DOCUMENTATION

Maintaining the Fan Tray on the SRX5600 Services Gateway | 241

Maintaining the Air Filter on the SRX5600 Services Gateway | 244

Troubleshooting the SRX5600 Services Gateway Cooling System | 391

Page 43

Replacing the SRX5600 Services Gateway Fan Tray | 242

Replacing the SRX5600 Services Gateway Air Filter | 245

SRX5600 Services Gateway Craft Interface Fan LEDs | 35

SRX3400 and SRX5600 Services Gateways Air Deflector Kits

Optional air deflector kits are available that let you install the SRX3400 and SRX5600 Services Gateways

in a hot aisle/cold aisle ventilation environment. These kits convert the services gateway from side-to-side

ventilation into front-to-back ventilation. The air deflectors contain no additional fans, so they require no

additional electrical power.

The air deflector kits consist of four main components: two intake/exhaust boxes and two side plenums.

The two intake/exhaust boxes are identical to each other, as are the side plenums.

43

The intake/exhaust boxes are installed above and below the services gateway to direct intake air from the

air space in front of the services gateway into the side plenum mounted on the intake side of the device.

The intake air plenum directs air into the services gateway, and the exhaust air plenum collects the exhaust

air on the opposite side of the device. The exhaust plenum directs the exhausted air into the intake/exhaust

boxes above and below the unit, where it is expelled into the air space behind the services gateway.

The air deflector kit requires additional space around the services gateway, increasing its overall height

and width as described in Table 12 on page 43.

Table 12: Services Gateway and Air Deflector Dimensions

SRX5600 Services GatewaySRX3400 Services GatewaySpecification

8 U (14 in. or 35.6 cm)3 U (5.25 in. or 13.3 cm)Services gateway height

6 U (10.5 in. or 26.7 cm)4 U (7 in. or 17.8 cm)Additional height required for air

deflector kit

14 U (24.5 in. or 62.2 cm)7 U (12.25 in. or 31.1 cm)Total height of services gateway and air

deflector kit

17.5 in. (44.5 cm)17.5 in. (44.5 cm)Services gateway chassis width

Additional width required for air deflector

kit

5.6 in. (14.2 cm) per side

11.2 in. (28.4 cm) total

5.6 in. (14.2 cm) per side

11.2 in. (28.4 cm) total

Page 44

Table 12: Services Gateway and Air Deflector Dimensions (continued)

g036126

g030308

SRX5600 Services GatewaySRX3400 Services GatewaySpecification

28.7 in. (72.9 cm)28.7 in. (72.9 cm)Total width of services gateway and air

deflector kit

Figure 13 on page 44 and Figure 14 on page 44 show the SRX3400 and SRX5600 Services Gateways,

respectively, installed in typical four-post mounting racks with the air deflector kit parts in place.

Figure 13: SRX3400 Services Gateway Air Deflector Kit

44

Figure 14: SRX5600 Services Gateway Air Deflector Kit (Services Gateway Chassis Contents Omitted

for Clarity)

RELATED DOCUMENTATION

Page 45

SRX3400 Services Gateway Chassis

SRX5600 Services Gateway Chassis | 27

SRX5600 Power System

IN THIS SECTION

SRX5600 Services Gateway Power System Overview | 45

SRX5600 Services Gateway AC Power Supply | 47

SRX5600 Services Gateway AC Power Supply Specifications | 49

SRX5600 Services Gateway AC Power Supply LEDs | 49

AC Power Cord Specifications for the SRX5600 Services Gateway | 50

45

AC Power Circuit Breaker Requirements for the SRX5600 Services Gateway | 53

SRX5600 Services Gateway DC Power Supply | 53

SRX5600 Services Gateway DC Power Supply Specifications | 54

SRX5600 Services Gateway DC Power Supply LEDs | 55

DC Power Cable Specifications for the SRX5600 Services Gateway | 56

DC Power Cable Lug Specifications for the SRX5600 Services Gateway | 57

DC Power Circuit Breaker Requirements for the SRX5600 Services Gateway | 57

DC Power Source Cabling for the SRX5600 Services Gateway | 58

SRX5600 Services Gateway Chassis Grounding Point Specifications | 59

SRX5600 Services Gateway Grounding-Cable Lug Specification | 60

SRX5600 Services Gateway Power System Overview

The services gateway uses either AC or DC power supplies. The services gateway is configurable with

two, three, or four AC power supplies or two or four DC power supplies. The power supplies are located

horizontally at the rear of the chassis in slots PEM0 through PEM3 (left to right). The power supplies

connect to the midplane, which distributes the different output voltages produced by the power supplies

to the services gateway components, depending on their voltage requirements. Each power supply is

cooled by its own internal cooling system.

Page 46

CAUTION: The services gateway cannot be powered from AC and DC power supplies

simultaneously. The first type of power supply detected by the services gateway when

initially powered on determines the type of power supply allowed by the services

gateway. All installed power supplies of the other type are disabled by the services

gateway. If you install a power supply of the other type while the services gateway is

operating, the services gateway disables the power supply and generates an alarm.

Redundant power supplies are hot-removable and hot-insertable. When you remove a power supply from

a services gateway that uses a nonredundant power supply configuration, the services gateway might shut

down depending on your configuration.

Depending on the types of power supplies installed and their input voltages, the power distribution in the

services gateway chassis is either shared or zoned. Table 13 on page 46 summarizes the available power

supply types, their output capacities, and their redundancy and power distribution schemes. For detailed

power supply specifications, see “SRX5600 Services Gateway AC Power Supply Specifications” on page 49

or “SRX5600 Services Gateway DC Power Supply Specifications” on page 54.

46

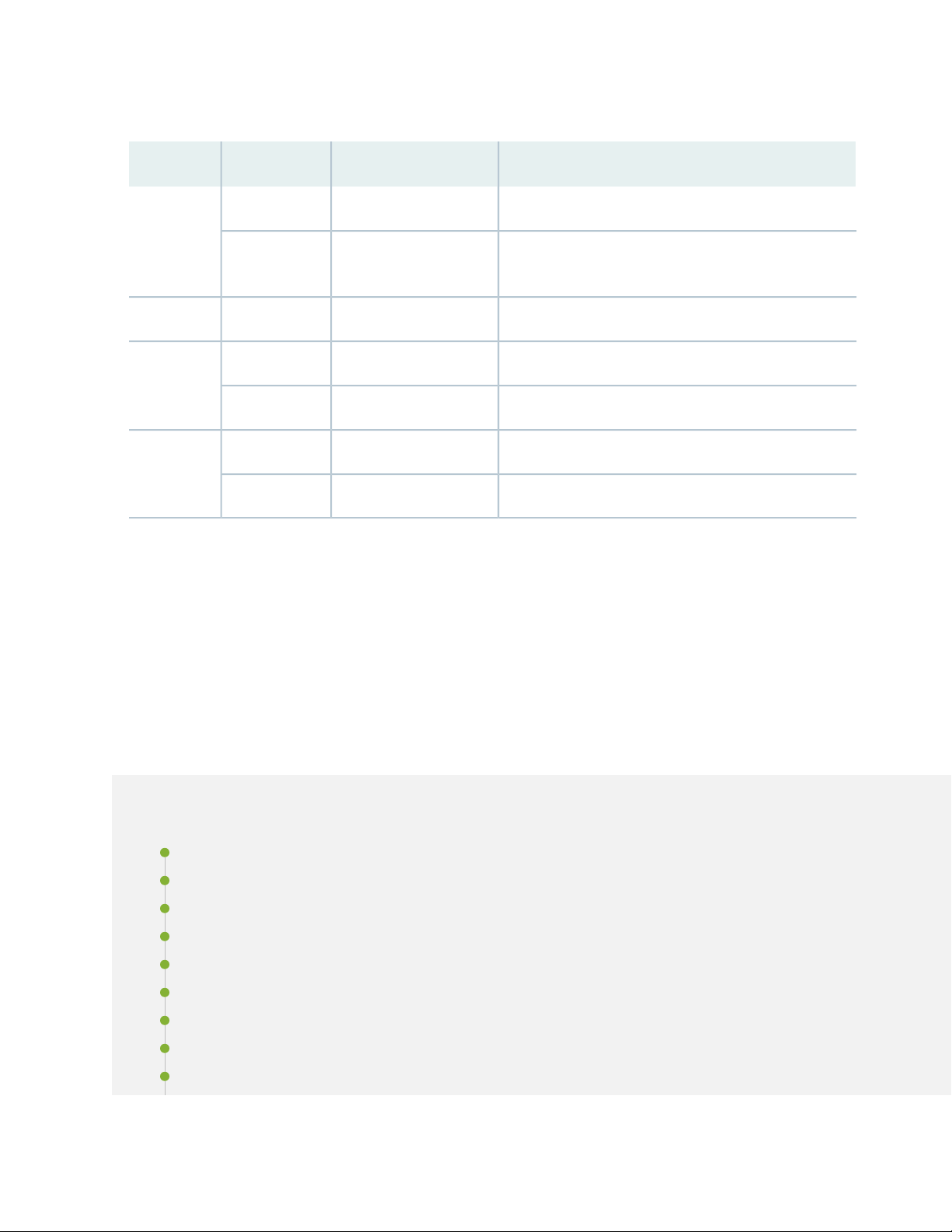

Table 13: Power Supply Type Summary

Power Supply

Type

standard-capacity

standard-capacity

Power

DistributionRedundancyMaximum OutputInput Condition (If Any)

Shared3+11027 WLow-line (110 V Input)AC

2+21590 WHigh-line (220 V Input)

3+11167 WLow-line (110 V Input)AC high-capacity

2+22050 WHigh-line (220 V Input)

Zoned2+2 (1+1 per zone)1600 WDC

2+2 (1+1 per zone)2240 WDIP=0 (60 A Input)DC high-capacity

2+2 (1+1 per zone)2440 WDIP=1 (70 A Input)

NOTE: The services gateway must be running Junos OS Release 12.1X44-D10 or later in order

to use high-capacity AC or DC power supplies.

Page 47

When AC power supplies are installed, the power distribution is shared. All of the power supply power to

all of the components in the services gateway chassis. The power supplies share the load almost equally.

In the low-line (110VAC input) configuration, three power supplies are required to support the services

gateway electrical requirements, and you can install an additional power supply that takes over in case

any of the other three fail. In the high-line (220VAC input) configuration, two power supplies are required

to support the services gateway electrical requirements, and you can install one or two additional power

supplies that will over in case any of the others fail. In the two-PEM high-line configuration, slots PEM0

and PEM1 or PEM2 and PEM3 are used.

When DC power supplies are installed, the power distribution is zoned. The chassis is divided into two

zones numbered 0 and 1. Each zone is powered by one or two power supplies. Two power supplies are

required to support the services gateway electrical requirements, and you can install two additional power

supplies so that each zone has an extra power supply that takes over in case the first power supply fails.

Table 14 on page 47

Table 14: SRX5600 Services Gateway Power Distribution (DC Power Supplies)

Provide Power To:Power SuppliesZone

47

PEM0 or PEM2Zone 0

PEM1 or PEM3Zone 1

Bottom slots 0 and 1 for SCBs

•

Card slots 0 and 1 for SPCs or interface cards (IOCs, Flex

•

IOCs, or MPCs)

Card slots 2 through 5 for SPCs or interface cards (IOCs, Flex

•

IOCs, or MPCs)

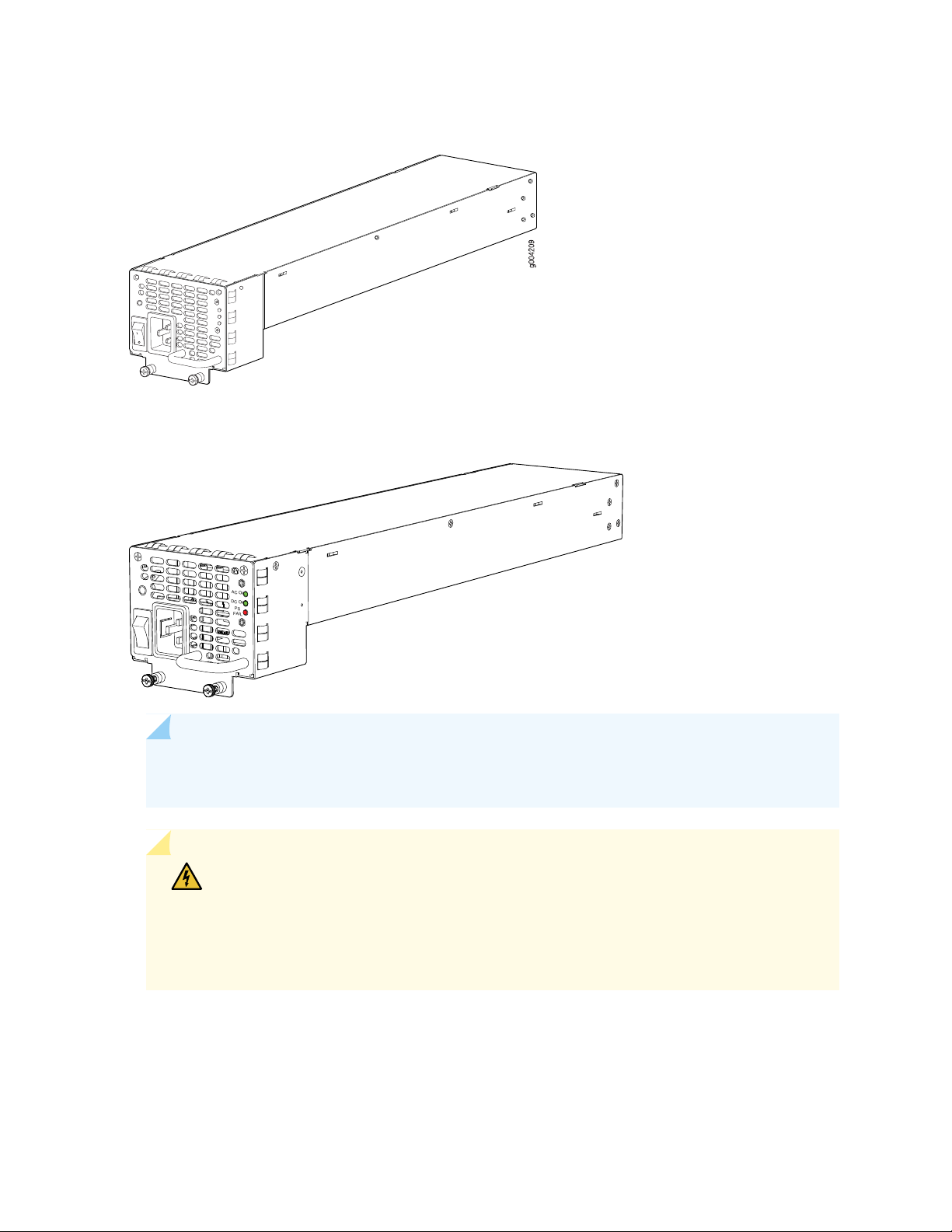

SRX5600 Services Gateway AC Power Supply

Each AC power supply consists of one AC appliance inlet, an AC switch, a fan, and LEDs to monitor the

status of the power supply. Figure 15 on page 48 and Figure 16 on page 48 show the power supplies. For

standard-capacity power supplies, each inlet requires a dedicated AC power feed and a dedicated

15 A (250 VAC)circuit breaker. For high-capacity power supplies, each inlet requires a dedicated AC power

feed and a dedicated 16 A @ 100 VAC or 16 A @ 200 VAC circuit breaker, or as required by local code.

Page 48

Figure 15: Standard-Capacity AC Power Supply

AC OK

DC OK

PS

FAIL

Figure 16: High-Capacity AC Power Supply

48

NOTE: The services gateway must be running Junos OS Release 12.1X44-D10 or later in order

to use high-capacity AC power supplies.

WARNING: The services gateway is pluggable type A equipment installed in a

restricted-access location. It has a separate protective earthing terminal (sized for UNC

1/4-20 ground lugs) provided on the chassis in addition to the grounding pin of the

power supply cord. This separate protective earthing terminal must be permanently

connected to earth.

Page 49

SRX5600 Services Gateway AC Power Supply Specifications

Table 15 on page 49 lists the AC power supply electrical specifications.

Table 16 on page 49 lists the AC power system electrical specifications.

Table 15: AC Power Supply Electrical Specifications

Specification

Item High-CapacityStandard-Capacity

49

Maximum output power

AC input current rating

1027 W (low line)

1590 W (high line)

14.5 A @ 110 VAC maximum

11.0 A @ 200 VAC maximum

Operating range: 100 - 240 VAC (nominal)AC input voltage

50 to 60 Hz (nominal)AC input line frequency

Table 16: AC Power System Specifications

Normal-Capacity

Low-Line (110V)Item

per power supply

Normal-Capacity

High-Line (220V)

1167 W (low line)

2050 W (high line)

16 A @ 110 VAC maximum

15.1 A @ 200 VAC maximum

High-Capacity

Low-Line (110V)

High-Capacity

High-Line (220V)

2+23+12+23+1Redundancy

2050 W1167 W1590 W1027 WOutput power (maximum)

4100 W3501 W3180 W3081 WOutput power (maximum)

per system

SRX5600 Services Gateway AC Power Supply LEDs

Each AC power supply faceplate contains three LEDs that indicate the status of the power supply (see

Table 17 on page 50). The power supply status is also reflected in two LEDs on the craft interface. In

addition, a power supply failure triggers the red alarm LED on the craft interface.

Page 50

Table 17: AC Power Supply LEDs

50

DescriptionStateColorLabel

AC power input voltage is below 78 VAC.OffAmberAC OK

AC power input voltage is within 78–264 VAC.OnGreen

OffGreenDC OK

On

On

DC power outputs generated by the power supply are not within the

normal operating ranges.

DC power outputs generated by the power supply are within the

normal operating ranges.

Power supply is functioning normally.OffRedPS FAIL

Power supply is not functioning normally and its output voltage is out

of regulation limits. Check AC OK and DC OK LEDs for more

information.

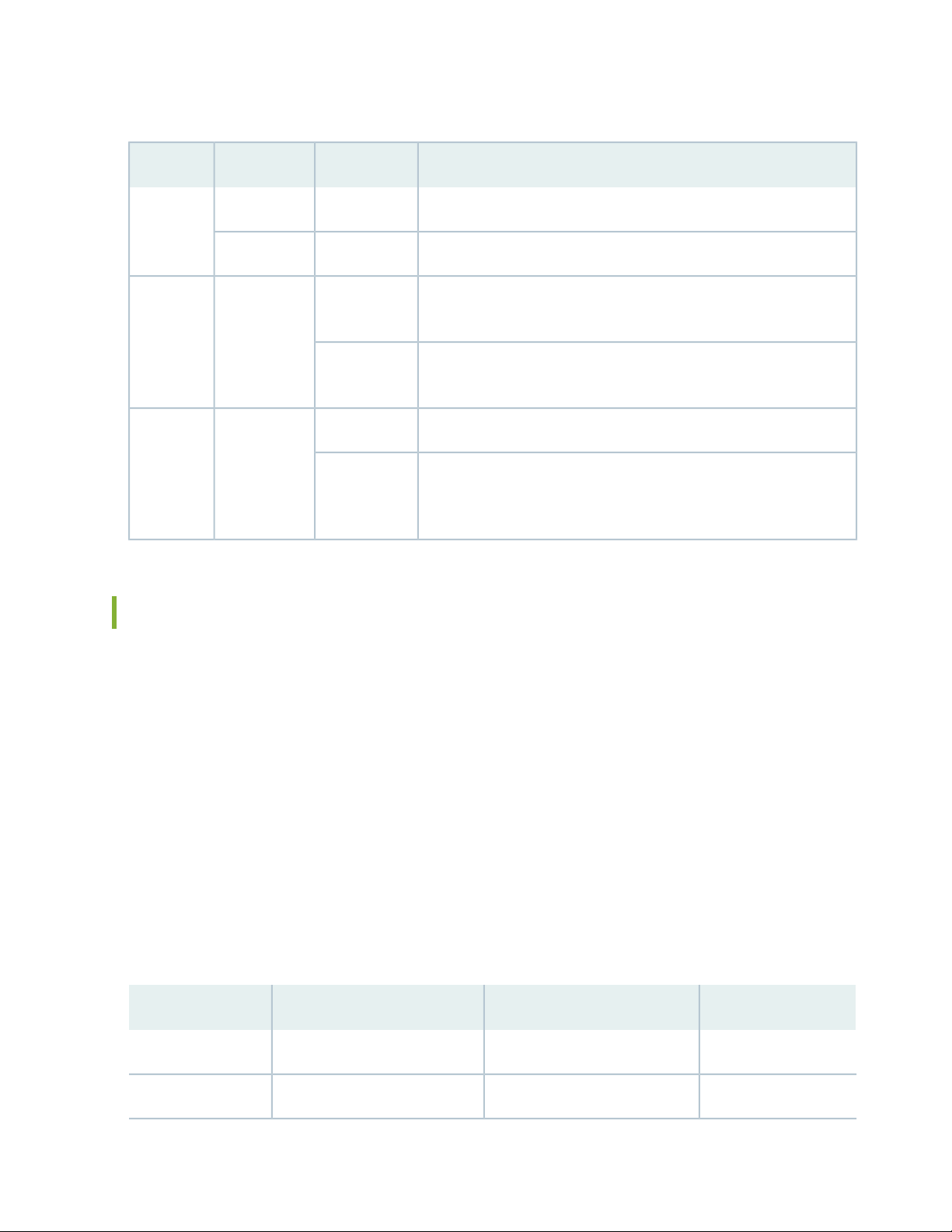

AC Power Cord Specifications for the SRX5600 Services Gateway

Each AC power supply has a single AC appliance inlet located on the power supply that requires a dedicated

AC power feed. Most sites distribute power through a main conduit that leads to frame-mounted power

distribution panels, one of which can be located at the top of the rack that houses the services gateway.

An AC power cord connects each power supply to the power distribution panel.

The services gateway is not shipped with AC power cords. You must order power cords separately using

the model number shown in Table 18 on page 50. The C19 appliance coupler end of the cord inserts into

the AC appliance inlet coupler, type C20 (right angle) as described by International Electrotechnical

Commission (IEC) standard 60320. The plug end of the power cord fits into the power source receptacle

that is standard for your geographical location.

Table 18 on page 50 provides specifications and Figure 17 on page 52 depicts the plug on the AC power

cord provided for each country or region.

Table 18: AC Power Cord Specifications

Plug TypeElectrical SpecificationModel NumberCountry

SAA/3/15240 VAC, 50 Hz ACCBL-M-PWR-RA-AUAustralia

CH2-16P220 VAC, 50 Hz ACCBL-M-PWR-RA-CHChina

Page 51

Table 18: AC Power Cord Specifications (continued)

Denmark, Italy,

Switzerland, and

United Kingdom)

51

Plug TypeElectrical SpecificationModel NumberCountry

CEE 7/7220 or 230 VAC, 50 Hz ACCBL-M-PWR-RA-EUEurope (except

CEI 23-16/VII230 VAC, 50 Hz ACCBL-M-PWR-RA-ITItaly

JIS 8303125 VAC, 50 or 60 Hz ACCBL-PWR-RA-JP15Japan

NEMA L6-20P220 VAC, 50 or 60 Hz ACCBL-M-PWR-RA-JP

NEMA 5-15P125 VAC, 60 Hz ACCBL-PWR-RA-US15North America

NEMA L5-15P125 VAC, 60 Hz ACCBL-PWR-RA-TWLK-US15

NEMA 6-20250 VAC, 60 Hz ACCBL-M-PWR-RA-US

NEMA L6-20P250 VAC, 60 Hz ACCBL-M-PWR-RA-TWLK-US

BS89/13240 VAC, 50 Hz ACCBL-M-PWR-RA-UKUnited Kingdom

Page 52

Figure 17: AC Plug Types

52

WARNING: The AC power cord for the services gateway is intended for use with the

services gateway only and not for any other use.

WARNING: To meet safety and electromagnetic interference (EMI) requirements and

to ensure proper operation, you must properly ground the services gateway chassis

before connecting power. See “Grounding the SRX5600 Services Gateway” on page 215

for instructions.

CAUTION: Power cords and cables must not block access to device components or

drape where people could trip on them.

NOTE: In North America, AC power cords must not exceed 4.5 m (approximately 14.75 ft) in

length, to comply with National Electrical Code (NEC) Sections 400-8 (NFPA 75, 5-2.2) and

210-52, and Canadian Electrical Code (CEC) Section 4-010(3). The cords listed in

Table 18 on page 50 are in compliance.

Page 53

AC Power Circuit Breaker Requirements for the SRX5600 Services Gateway

Each AC power supply has a single AC appliance inlet located on the power supply that requires a dedicated

AC power feed. We recommend that you use a customer site circuit breaker rated for 15 A (250 VAC)

minimum for each AC power supply, or as required by local code. Doing so enables you to operate the

services gateway in any configuration without upgrading the power infrastructure.

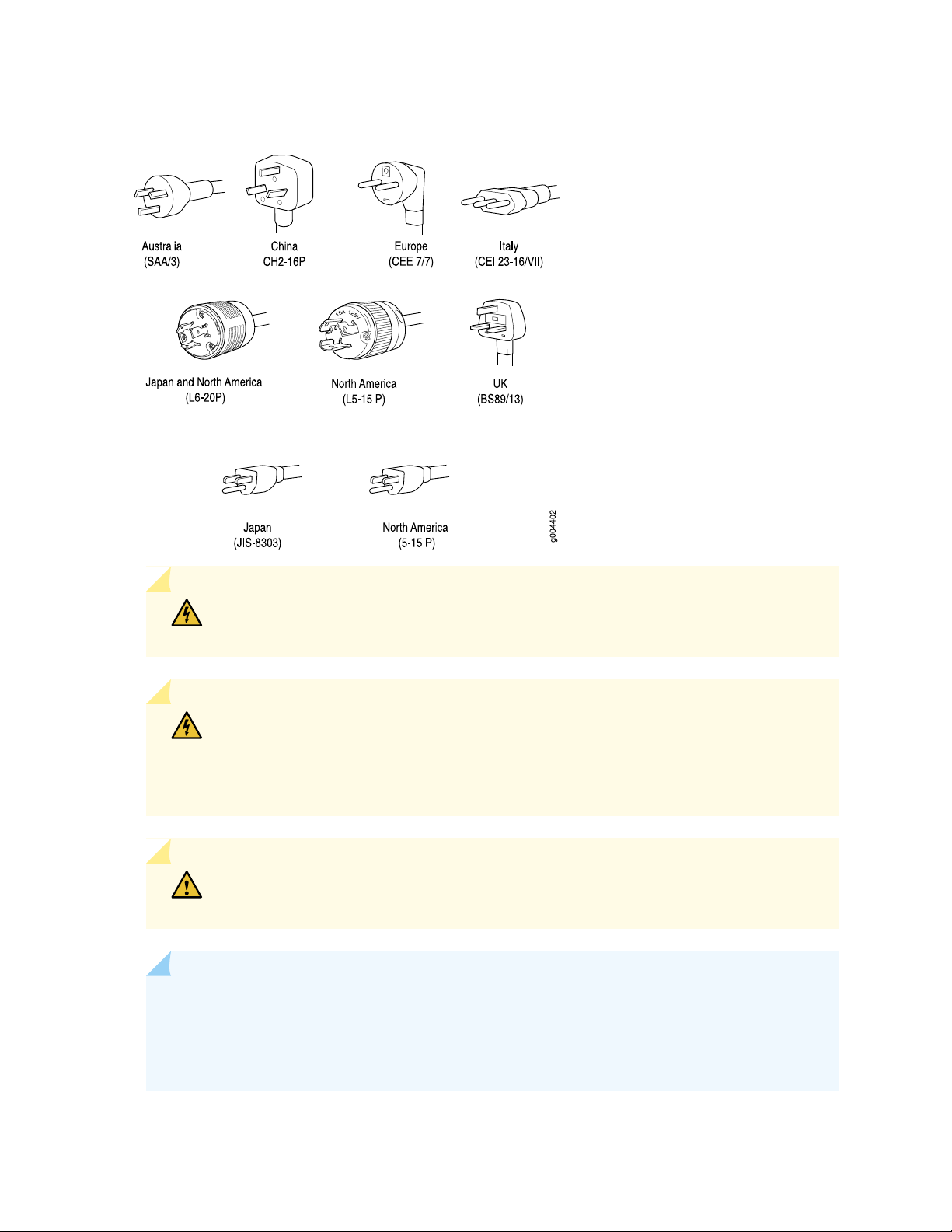

SRX5600 Services Gateway DC Power Supply

Each DC power supply consists of one DC input (–48 VDC and return), one 40 A (–48 VDC) circuit breaker,

a fan, and LEDs to monitor the status of the power supply. Two different DC power supply types are

available. Figure 18 on page 53 and Figure 19 on page 54 show the power supplies. Each DC power supply

has a single DC input (–48 VDC and return) that requires a dedicated facility circuit breaker.

For high-capacity power supplies, we recommend that you provision 60 A or 70 A per feed, depending

on the selected DIP switch setting.

53

Figure 18: Standard-Capacity DC Power Supply

Page 54

Figure 19: High-Capacity DC Power Supply Faceplate

g004725

NOTE: The services gateway must be running Junos OS Release 12.1X44-D10 or later in order

to use high-capacity DC power supplies.

54

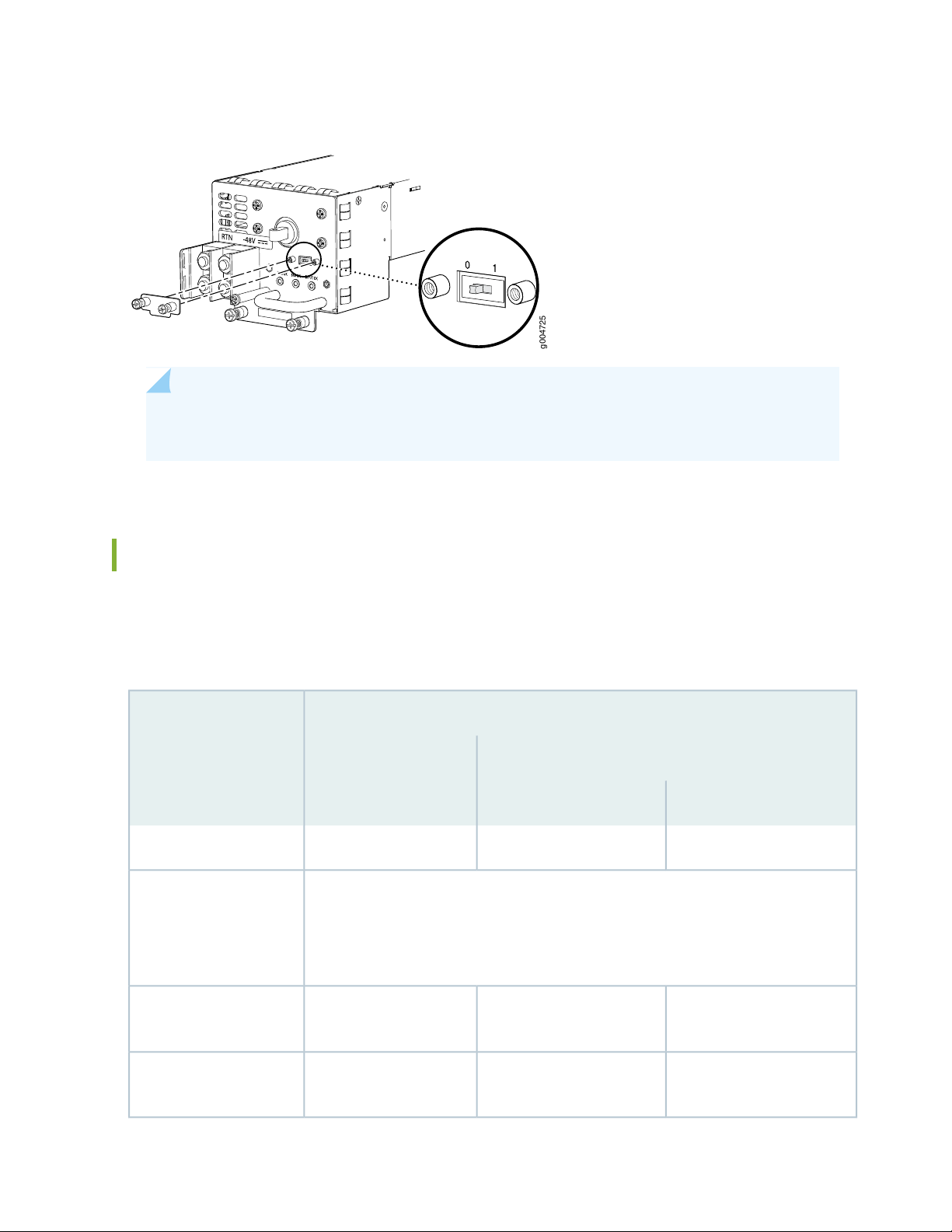

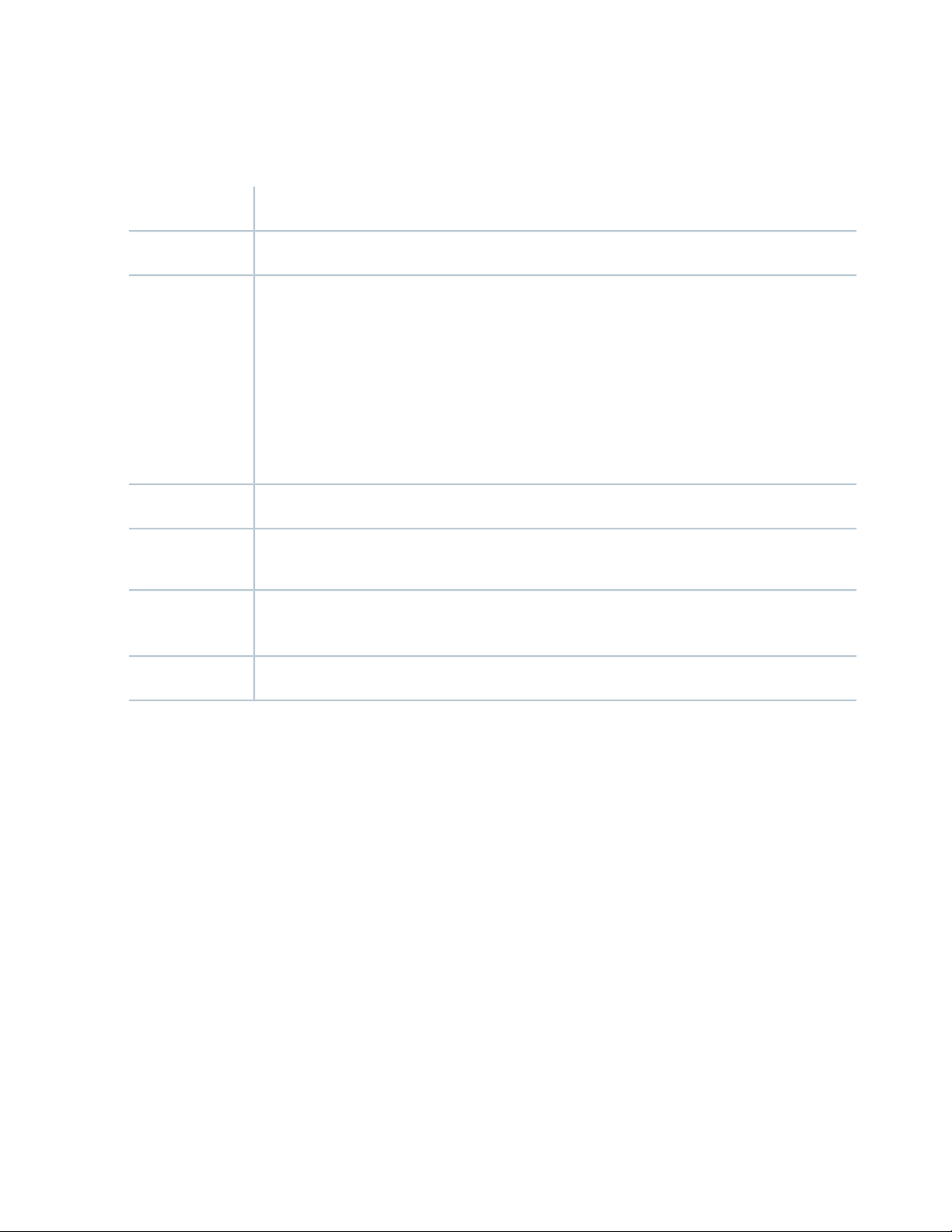

SRX5600 Services Gateway DC Power Supply Specifications

Table 19 on page 54 lists the DC power supply electrical specifications. Table 20 on page 55 lists the DC

power system specifications.

Table 19: DC Power Supply Electrical Specifications

Specification

High Capacity

Item

DC input voltage

DC input current rating

Standard-Capacity DIP=1 (70 A Input)DIP=0 (60 A Input)

Minimum: –40.5 VDC

Nominal: –48 VDC

Operating range: –40.5 to –72 VDC

33.3 A @ –48 V nominal

operating voltage

50 A @ –48 V nominal

operating voltage

2440 W2240 W1600 WMaximum output power

54.2 A @ –48 V nominal

operating voltage

Protector

NoneNone40 AInternal Supplementary

Page 55

Table 20: DC Power System Specifications