Jun-Air 87R-4P Operation & Maintenance Manual

Part No. 6190900 (Rev B)

® Registered Trademark/™ Trademark of JUN-AIR Inc. ©Copyright 2017 JUN-AIR Manufacturing Inc. All Rights Reserved.

WWW.JUN-AIR.COM

ISO 9001 CERTIFIED

87R-4P Compressed

Air System

Operation & Maintenance Manual

6190900 (Rev B) 87R-4P Compressor System User Guide

WARNING

PLEASE READ THIS MANUAL COMPLETELY BEFORE INSTALLING AND USING

THIS PRODUCT. SAVE THIS MANUAL FOR FUTURE REFERENCE AND

KEEP IN THE VICINITY OF THE PRODUCT.

Dear Customer:

Congratulations on the purchase of your new JUN-AIR Industrial Compressed Air System.

This system’s intended purpose is for industrial and laboratory compression applications. It is to be used in

accordance with UL1450/CSA 22.2 standards, along with all applicable codes. The system utilizes an oil-less

rocking piston compressor that produces clean, dry, oil-free pressurized air flow when connected to an industrial or laboratory device. The tank ensures that a constant supply of air is available to the device.

A pressure regulator and safety relief valve are also included to ensure safe operation of the system. This

manual provides installation, operation and preventative maintenance guidelines that should be followed to

ensure correct/reliable performance of this system.

Please carry out all maintenance according to relevant instructions.

Section Page Number

Declaration of Conformity 3

Table of Symbols 4

System Features 5

Installation and Operation 7

Maintenance 11

Troubleshooting 21

Warranty Policy 22

2

We reserve the right to make any alterations which may be due to any technical improvements

© 2017, JUN-AIR

Printed in the USA

87R-4P Compressor System User Guide 6190900 (Rev B)

Declaration of Conformity

Konformitätsbescheinigung

Certificat de Conformité

Declaración de Conformidad

Conformiteitsverklaring

Overensstemmelseserklæring

GB The manufacturer Gast Manufacturing, Inc. declares that the compressor is in conformity with:

• 2014/68/EU Pressure Equipment Directive

• 2014/29/EU Council Directive relating to Simple Pressure Vessels

• 2006/42/EC Machinery Directive

• 2014/30/EU EMC Directive

• 2006/95/EC Low Voltage Directive

• 2011/65/EU RoHS 2 Directive

• 2012/19/EU WEEE Directive

• 1907/2006 and 340/2008 REACH Regulation

DE Der Hersteller Gast Manufacturing, Inc. bescheinigt, dass der Kompressor entspricht:

• 2014/68/EU Druckgeräterichlinie

• 2014/29/EU Richtlinie der einfachen Druckbehälter

• 2006/42/EC Richtlinie zur Sicherheit von Maschinen

• 2014/30/EU Richtlinie der Elektromagnetischen Verträglichkeit

• 2006/95/EC Richtlinie für Niederspannung

• 2011/65/EU RoHS Directive

• 2012/19/EU WEEE Directive

• 1907/2006 und 340/2008 REACH Regulativ

FR Le fabricant Gast Manufacturing, Inc. déclare que le compresseur est conforme aux directives suivantes:

• 2014/68/EU Directive équipements sous pression

• 2014/29/EU Directive relative aux appareils à pression simple

• 2006/42/EC Directive sur la sécurité des machines

• 2014/30/EU Directive sur la compatibilité électro-magnétique

• 2006/95/EC Directive sur les basses-tensions

• 2011/65/EU Directive RoHS

• 2012/19/EU Directive DEEE

• 1907/2006 et 340/2008 Réglementation REACH

ES El fabricante Gast Manufacturing, Inc. declara que el compresor está conforme con:

• 2014/68/EU Directiva de equipos a presión

• 2014/29/EU Directiva en relación a recipientes a presión simple

• 2006/42/EC Directiva de Seguridad de maquinaria

• 2014/30/EU Directiva de Compatibilidad eléctrica magnética

• 2006/95/EC Directiva de baja tensión

• 2011/65/EU Directiva de RoHS

• 2012/19/EU Directiva de WEEE

• 1907/2006 y 340/2008 Reglamento REACH

NL De fabrikant Gast Manufacturing, Inc. verklaart dat de compressor in overeenstemming is met:

• 2014/68/EU Richtlijn Drukapparatuur

• 2014/29/EU Richtlijn voor eenvoudige drukvaten

• 2006/42/EC Machinerichtlijn

• 2014/30/EU Richtlijn inzake Electromagnetische Compatibilitet

• 2006/95/EC Laagspanningsrichtlijn

• 2011/65/EU RoHS Richtlijn

• 2012/19/EU WEEE Richtlijn

• 1907/2006 en 340/2008 REACH Verordening

DK Producenten Gast Manufacturing, Inc. bekræfter hermed at kompressoren er i overensstemmelse med:

• 2014/68/EU Direktivet om trykbærenole udstyr

• 2014/29/EU Direktivet vedrørende simple trykbeholdere

• 2006/42/EC Maskindirektivet

• 2014/30/EU EMC-direktivet

• 2006/95/EC Lavspændingsdirektivet

• 2011/65/EU RoHS Direktivet

• 2012/19/EU WEEE Direktivet

• 1907/2006 og 340/2008 REACH Forordningen

© 2017, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

3

6190900 (Rev B) 87R-4P Compressor System User Guide

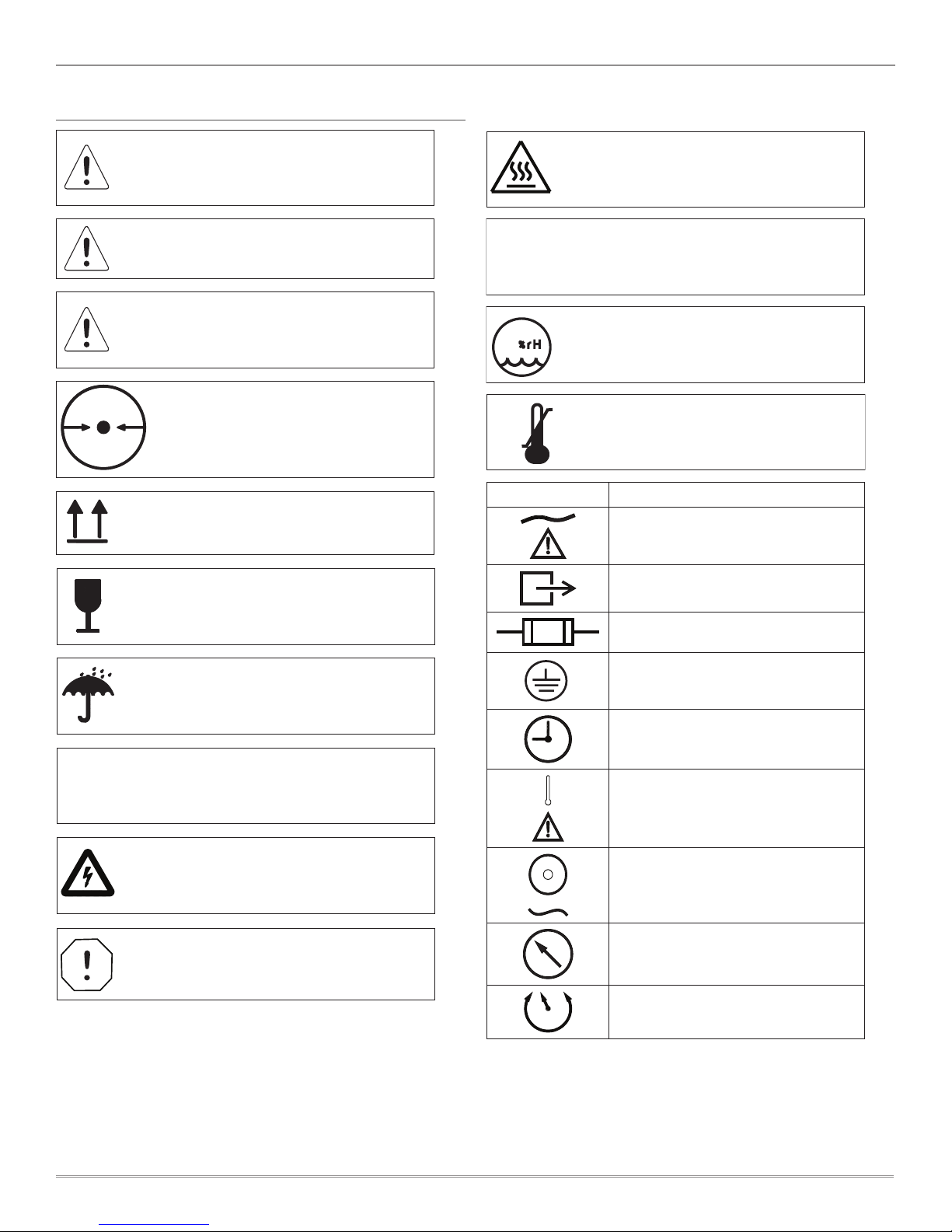

TABLE OF SYMBOLS

DANGER: Indicates an imminently hazardous

situation which will result in serious or fatal

injury if not avoided. This symbol is used only

in the most extreme conditions.

WARNING: Indicates a potentially hazardous

situation which could result in serious injury

if not avoided.

CAUTION: Indicates a potentially hazardous

situation which may result in minor or

moderate injury if not avoided. It may also be

used to alert against unsafe practices.

Indicates the acceptable lowest barometric

372MM HG

.49 ATM

pressure conditions in which this unit

can be shipped.

Indicates package should be handled with

these symbols pointing up.

FRAGILE: Handle package with care.

WARNING: To Avoid Serious Burns.

Do not touch surface during operation.

ON

I

OFF

O

95

-28 °C

-18 °F

Indicates the ON and OFF position

for the equipment power switch.

Indicates the acceptable maximum

relative humidity for shipping.

+65 °C

+149 °F

Indicates the acceptable shipping

temperature range.

Symbol Description

A/C power

Air outlet port

Indicates this package must be kept dry.

INDUSTRIAL ELECTRICAL EQUIPMENT

With respect to electrical shock, fire, mechanical,

and other specified hazards only in accordance

with UL1450.

Electrical Shock Hazard.

Risk of electric shock present. Make sure power

is disconnected before attempting this procedure.

Equipment Alert: Indicates a potentially

hazardous situation that could result in

equipment damage if not avoided.

Fuse location

Ground

Hour meter

Over-temp indicator light

Power on indicator light

Pressure gauge

Pressure regulator valve

4

We reserve the right to make any alterations which may be due to any technical improvements

© 2017, JUN-AIR

Printed in the USA

87R-4P Compressor System User Guide 6190900 (Rev B)

Cover

Tank

Compressor

IEC plug

& fuse

Power supply

switch

Air

outlet

Output

pressure

regulator

Power

indicator

light

Over-temp

indicator

Hour

meter

Pressure

switch

5 µm

autodrain

filter

System

intake

filter

Drain

solenoid

Dump

solenoid

Compressor

intake

filter

Thermostat

Terminal

block

Heat

exchange

SYSTEM FEATURES

© 2017, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

5

6190900 (Rev B) 87R-4P Compressor System User Guide

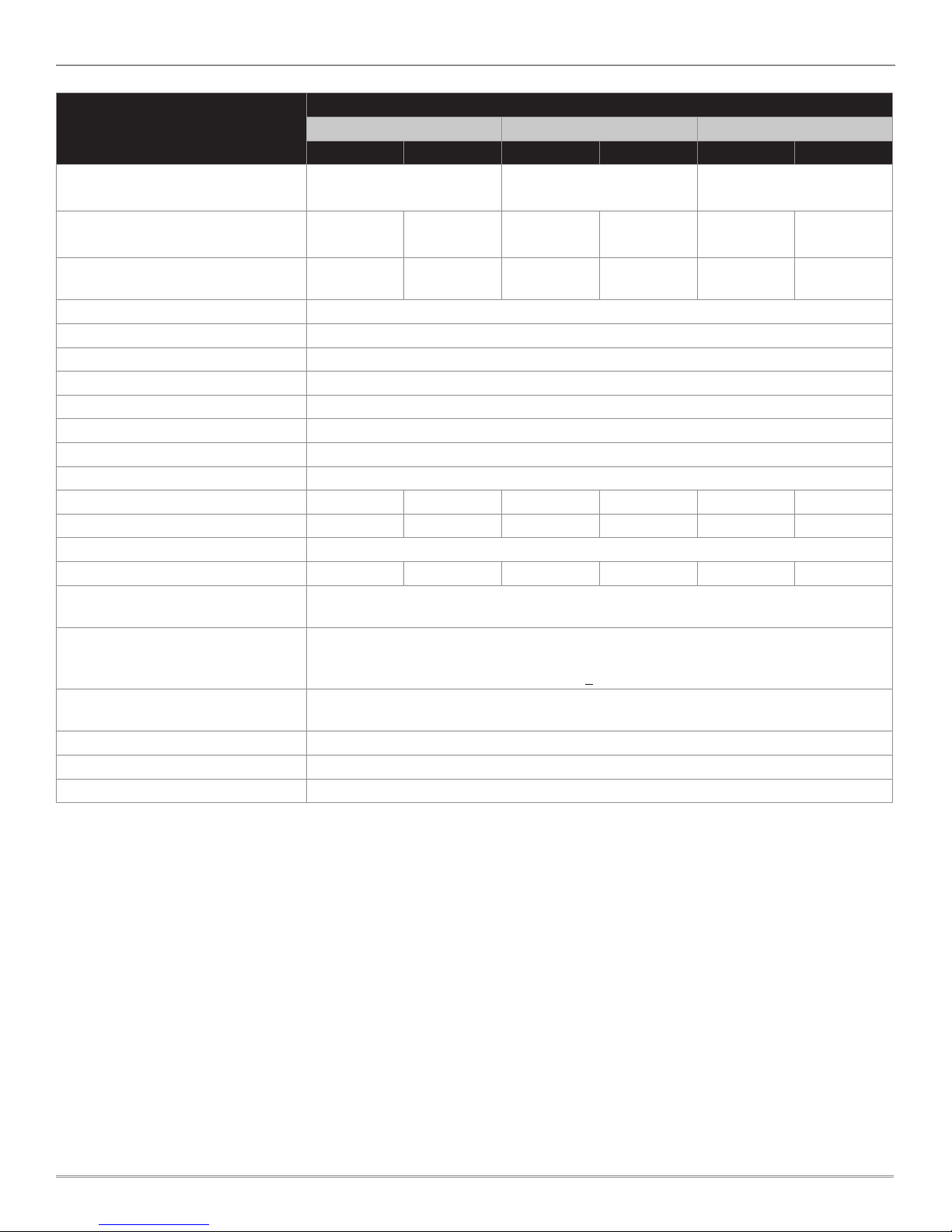

NO DRYER

Specifications

50Hz 60Hz 50Hz 60Hz 50Hz 60Hz

Model Numbers

100V 115V 230V

1770018 1770008

1770009 (NA)

1770010 (EU/UK)

Continuous System

Output Flow @ 4 bar (58 psi)

Continuous System

Output Flow @ 8 bar (116 psi)

Cut-in Pressure

Cut-out Pressure

1

1

46 SLPM

[1.6 SCFM]

27 SLPM

[1.0 SCFM]

51 SLPM

[1.8 SCFM]

31 SLPM

[1.1 SCFM]

46 SLPM

[1.6 SCFM]

27 SLPM

[1.0 SCFM]

6 bar [87 psi]

8 bar [116 psi]

51 SLPM

[1.8 SCFM]

31 SLPM

[1.1 SCFM]

46 SLPM

[1.6 SCFM]

27 SLPM

[1.0 SCFM]

51 SLPM

[1.8 SCFM]

31 SLPM

[1.1 SCFM]

Maximum Operational Pressure 8 bar [116 psi]

Dew Point Suppression

2

N/A

Air Filtration 5 µm

Safety Relief Valve Pressure 9.3 bar (135 psi)

High Temperature Indication ≥ 60 °C [140 °F] in compressor chamber

Air Connections 1/4 in BSPP

Current, A 5.0 5.8 4.8 5.3 2.6 2.9

Power Consumption, W 450 550 500 600 550 650

Fuse Specifications 12.5 A, 250 Vac, time delay

Sound Level, dB(A) 46 48 46 48 46 48

Operating Ambient Conditions

10 °C to 40 °C [50 °F to 104 °F]

10 - 95% RH*

-28 °C to 65 °C [-18 °F to 149 °F]

Storage Ambient Conditions

10 - 95% RH*

Barometric pressure >372 mm-Hg [14.7 in-Hg]

System Dimensions

W x H x D

406 mm x 495 mm x 439 mm

[16 in W x 19.5 in D x 17.3 in H]

System Weight 29.5 kg [65 lb]

Shipping Weight 35.0 kg [77 lb]

Regulatory Certifications UL 1450 / CSA 22.2 / CE

1

The compressor switches on and off at the cut-in and cut-out pressures, respectively. The cut-in and cut-out pressures are adjustable.

2

Membrane dryer specifications are available upon request.

* Avoid conditions that promote condensation on the equipment.

6

We reserve the right to make any alterations which may be due to any technical improvements

© 2017, JUN-AIR

Printed in the USA

87R-4P Compressor System User Guide 6190900 (Rev B)

INSTALLATION AND OPERATION

Intended Use

To provide compressed air for use with industrial or laboratory devices as a primary or back-up air source.

JUN-AIR compressor systems meet or exceed the most

current and highest safety standards, which are:

• UL1450, 4th edition

• CSA C22.2 68

• ISO 9001:2008

• Ingress protection: IP50

• 2006 / 42 / EC Directive

• RoHS compliant

To ensure the safety potential of this equipment is

achieved, please:

Make sure your equipment is installed according to the

instructions provided in this manual and make sure the

installation checklist is completed prior to starting the

equipment.

DANGER

The equipment is not suitable for use in the presence

of a flammable anesthetic mixture or with oxygen or

nitrous oxide. DO NOT OPERATE THE EQUIPMENT IF

THESE CONDITIONS EXIST.

Unpacking

1. Cut the banding strap from the carton and remove the

lid and cardboard inserts.

2. Visually inspect the entire system for shipping damage

and verify that the following accessories have been

included: two (2) locking casters, two (2) non-locking

casters, four (4) vibration-isolation feet, four (4) studs,

four (4) washers, and one (1) power cable.

a. If the contents were damaged during shipping,

contact the freight carrier to file a claim.

b. If parts are missing, contact the supplier.

3. Use caution when removing the system from the

remaining packaging. Retain the packaging material for

future use, if necessary.

4. Install the casters or rubber mounting feet.

Before You Install...

Equipment Alert: Compressors are oil-less and

require NO lubrication.

Equipment Alert: The system must be installed in a

temperature-controlled and/or ventilated room to

ensure operational ambient temperature of 50 °F to

104 °F [10 °C to 40 °C]. A 12-inch clearance is required

on each side and top of unit to allow air flow.

Failure to do so could cause premature loss of

system performance and void warranty.

Transportation and Storage Conditions

• Temperature: -28 °C (-18 °F) to 65 °C (149 °F)

• Relative humidity: 10% to 95%

• Minimum barometric pressure: 372 mm•Hg

(14.7 in•Hg)

• Keep the system dry at all times.

• Do not stack units during shipment, installation, or usage.

Equipment Alert: Refer servicing to an authorized

service representative.

© 2017, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

Personal Safety

DANGER

Risk of fire or explosion when using flammable substances.

Do not operate the system in an area containing combustible

gases or anesthetic mixtures.

CAUTION

Never leave children unattended near the system when in use.

WARNING

Property damage and/or personal injury may result

if directions are not followed or if the manufacturer’s

replacement parts/accessories are not used.

WARNING

Only connect equipment suitable for the listed maximum

pressure of the system.

7

Loading...

Loading...