Compressor

JUN-AIR® is a registered trademark of Gast Manufacturing, Inc. and Gast Group Ltd. ©Copyright 2015 Gast Manufacturing, Inc. All rights reserved.

WWW.JUN-AIR.COM

ISO 9001 CERTIFIED

Model 86/87R System

86R-4B, 87R-4B, 87R-15B, 87R-25B

6190755

6190755 (Rev A) 86/87R Compressor System User Guide

Table Of Contents

Section Page Number

Declaration of Conformity 3

Operating Manual 4

Diagrams / Schematics 8

Exploded Views 11

Parts and Accessories 19

Technical Data & Specifications 21

Pictures & Illustrations 26

2

We reserve the right to make any alterations which may be due to any technical improvements

© 2015, JUN-AIR

Printed in the USA

86/87R Compressor System User Guide 6190755 (Rev A)

Declaration of Conformity

Konformitätsbescheinigung

Certi cat de Conformité

Declaración de Conformidad

Conformiteitsverklaring

Overensstemmelseserklæring

GB e manufacturer Gast Manufacturing, Inc. declares that the compressor is in conformity with:

• 2009/105/EC Council Directive relating to Simple Pressure Vessels

• 2006/42/EC Machinery Directive

• 2004/108/EC EMC Directive

• 2006/95/EC Low Voltage Directive

• 2011/65/EU RoHS 2 Directive

• 2012/19/EU WEEE Directive

• 1907/2006 and 340/2008 REACH Regulation

DE Der Hersteller Gast Manufacturing, Inc. bescheinigt, dass der Kompressor entspricht:

• 2009/105/EC Richtlinie der einfachen Druckbehälter

• 2006/42/EC Richtlinie zur Sicherheit von Maschinen

• 2004/108/EC Richtlinie der Elektromagnetischen Verträglichkeit

• 2006/95/EC Richtlinie für Niederspannung

• 2011/65/EU RoHS Directive

• 2012/19/EU WEEE Directive

• 1907/2006 and 340/2008 REACH Regulativ

FR Le fabricant Gast Manufacturing, Inc. déclare que le compresseur est conforme aux directives suivantes:

• 2009/105/EC Directive relative aux appareils à pression simple

• 2006/42/EC Directive sur la sécurité des machines

• 2004/108/EC Directive sur la compatibilité électro-magnétique

• 2006/95/EC Directive sur les basses-tensions

• 2011/65/EU Directive RoHS

• 2012/19/EU Directive DEEE

• 1907/2006 et 340/2008 Réglementation REACH

ES El fabricante Gast Manufacturing, Inc. declara que el compresor está conforme con:

• 2009/105/EC Directiva en relación a recipientes a presión simple

• 2006/42/EC Directiva de Seguridad de maquinaria

• 2004/108/EC Directiva de Compatibilidad eléctrica magnética

• 2006/95/EC Directiva de baja tensión

• 2011/65/EU Directiva de RoHS

• 2012/19/EU Directiva de WEEE

• 1907/2006 and 340/2008 Reglamento REACH

NL De fabrikant Gast Manufacturing, Inc. verklaart dat de compressor in overeenstemming is met:

• 2009/105/EC Richtlijn voor eenvoudige drukvaten

• 2006/42/EC Machinerichtlijn

• 2004/108/EC Richtlijn inzake Electromagnetische Compatibilitet

• 2006/95/EC Laagspanningsrichtlijn

• 2011/65/EU RoHS Richtlijn

• 2012/19/EU WEEE Richtlijn

• 1907/2006 and 340/2008 REACH Verordening

DK Producenten Gast Manufacturing, Inc. bekræ er hermed at kompressoren er i overensstemmelse med:

• 2009/105/EC Direktivet vedrørende simple trykbeholdere

• 2006/42/EC Maskindirektivet

• 2004/108/EC EMC-direktivet

• 2006/95/EC Lavspændingsdirektivet

• 2011/65/EU RoHS Direktivet

• 2012/19/EU WEEE Direktivet

• 1907/2006 and 340/2008 REACH Forordningen

© 2015, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

3

6190755 (Rev A) 86/87R Compressor System User Guide

Operating manual

Information

Please note that you can find the pictures and figures we

are referring to in the back of the manual

Important - read this first!

Please read the following information and operating instructions included with this product

before use. This information is for your safety and it is important that you follow these

instructions. It will also help prevent damage to the product. Failure to operate the unit in

accordance with the instructions or using JUN-AIR unauthorized spare parts can cause

damage to the unit and could cause serious injury.

CAUTION: To reduce risk of electric shock

• Only authorized service agents should carry out service. Removing parts or

attempting repairs can create an electric shock. Refer all servicing to qualified service

agents.

• If this unit is supplied with a three-pin plug, connect with a properly earthed outlet

only.

WARNING: To reduce risk of electrocution

• Do not use this unit with electrical voltages other than stated on the rating plate.

• Never leave this product unattended when plugged in.

• Always unplug this unit immediately after use.

• Store in a dry place.

• Do not use this product in or near liquid or where it can fall or be pulled into water or

other liquids.

• Do not reach for this product if it has fallen into liquid. Unplug immediately.

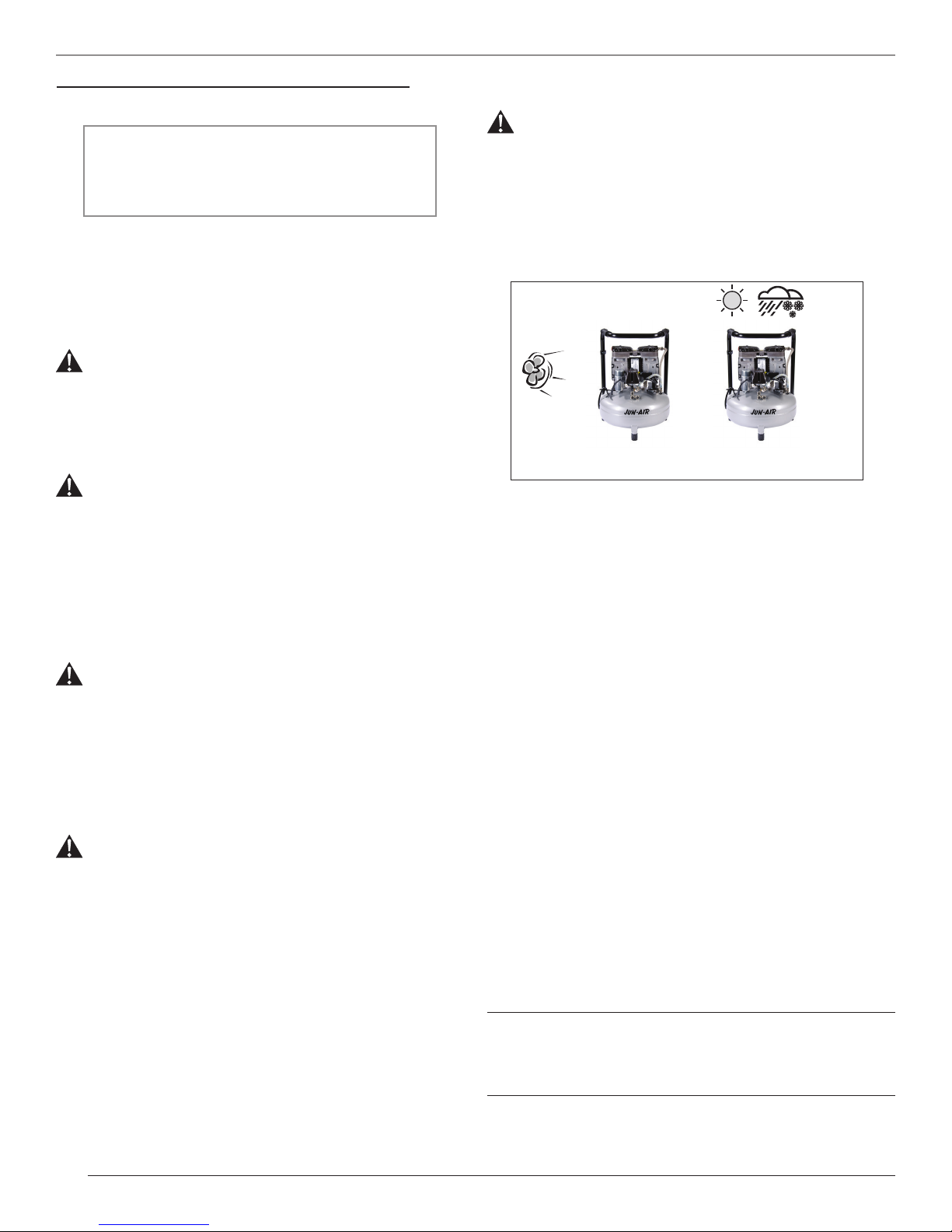

• This unit is not weatherproof. Never operate outdoors in the rain or in a wet area.

DANGER: To reduce risk of explosion or fire

• During spraying with combustible liquids risk of explosion may arise, particularly in

closed rooms

• Do not use this product in or near explosive atmospheres or where aerosol products

are being used.

• Do not pump any other gases other than atmospheric air.

• Do not pump combustible liquids or vapours with this product; do not use it in or

near areas with combustible or explosive liquids or vapours.

• Do not use this unit near naked flames.

CAUTION: To prevent injury

• Compressed air can be dangerous; do not direct airflow at a persons head or body.

• Always keep the system out of reach of children.

• Never operate this product if it has a damaged power lead or plug, if it has been

dropped or damaged, or if it has fallen into water. Return the product to a service

centre for examination and repair.

• Keep the electrical cable away from hot surfaces.

• Ensure all openings are kept free of restriction and never place the system on a soft

surface where the openings may be blocked. Keep all openings free from dust, dirt

and other particles.

• Never insert fingers or any other objects into fans.

• This unit is thermally protected and can automatically restart when the overload

resets.

• Wear safety glasses, when servicing this product.

• Use only in well ventilated areas.

• This product may only be connected to units or tools with a max. pressure higher or

equal to that of the system.

• The surface of the system can get hot. Do not touch system system during

operation.

Failure to observe the above safety precautions could result in severe bodily injury,

including death in extreme cases.

IMPORTANT: General directions for use

• Protect the system against rain, moisture, frost and dust.

• The system is constructed and approved for a max. pressure as stated under

Technical Specifications.

• Do not operate system at ambient temperatures exceeding 40°C/104°F or falling

below 5°C/41°F.

• If the supply lead on the system is defective, an authorized JUN-AIR distributor or

other qualified personnel must carry out the repair.

GOOD BAD

Min. 5°C/41°F • Max. 40°C/104°F

Warranty

Provided that the operational instructions, maintenance, and service have been carried

out, your JUN-AIR system is guaranteed against faulty material or workmanship for 2

years.

The air receiver is guaranteed for 5 years.

The guarantee does not cover damage caused by violence, misuse, incorrect repairs or

use of unoriginal spare parts.

Costs of transportation of parts/equipment are not covered by the guarantee.

JUN-AIR’s Conditions for Sale and Delivery will generally apply.

Gast Manufacturing, Inc. A/S reserves the right to change technical specifications/

constructions.

Contents of box

Your system should be delivered in a clean and undamaged box. If not, contact

your distributor immediately. The box should contain the following:

• 1 86/87R-XB system

• 1 system operating manual & 1 filter/regulator manual

• Individually packaged or attached filter/regulator

• 100 cm x 6 mm tube for filter/regulator autodrain line

Installation

Your JUN-AIR system is very easy to operate. Observe the following simple

instructions and you will get many years’ service from your unit.

• Visually inspect unit for shipping damage, contact your supplier

immediately if you think the unit may have been damaged.

Warning!

To avoid the risk of electric shock, do not install the system in

areas where it may get in contact with water or other liquids. In

which case protection is required.

0

• Use only pressure pipes tolerating a constant temperature of min. 150

Ensure that the pressure pipes have a sufficient internal diameter to avoid

pressure loss in the system. Check for leaks.

C.

4

We reserve the right to make any alterations which may be due to any technical improvements

© 2015, JUN-AIR

Printed in the USA

86/87R Compressor System User Guide 6190755 (Rev A)

• Install product on a rigid level surface maintaining a minimum of 6 in/15

cm clearance all around the unit and a 12 in/30 cm clearance above the

system.

• Sufficient cooling from the surroundings is important. Place the system

in a dustfree, dry and cool, yet frostfree, room. Do not install in a closed

cupboard, unless adequate openings for ventilation are available on top

and bottom (minimum 500 cm²/77.5 in² each). If the system is placed

under a table, a minimum of 12 cm/5 in free height must be available

above the system or an opening of Ø30cm/11.8 inches, corresponding

to the top of the system, may be cut in the table. Ensure that the system

stands firmly on the floor.

• The intake air may be supplied from another place (for instance outside).

Ensure that hoses for the intake are sufficient to avoid performance loss

and that any alternate filter used has the same micron rating (50μm) as the

JUN-AIR intake filter.

Electrical installation

Warning!

Incorrect electrical connection may result in electric shock. The

electrical connection must be carried out in accordance with

local electrical regulations and by qualified electrical engineers.

Note!

Earthing of all AC models must be ensured during installation. The capacitor

must be earthed, as failure to do so may cause electric shock when touched.

Plug the system into an earthed socket of nominal voltage and ensure that

fusing is adequate.

Adjustment of pressure switch

Warning!

If maximum pressure is exceeded, reduced lifetime may result.

Contact JUN-AIR for information on operation at higher

pressure.

• All systems may run at 100% continuous operation, but 50% operation is

recommendable to prolong lifetime.

• The system should be sized so that the tank is capable of supplying air

100% of the time and the compressors only run at 50%.

• Do not lubricate the oil-less system with oil, as this will destroy important

components.

• Start the system using the 0/1 switch on the pressure switch. The system

will automatically switch off at the preset pressure. If the system does not

start it may be due to pressure in the receiver, and the system will then

start automatically when the pressure reduces to approx. 6 bar/87 psi.

• Adjustment of pressure (see back of manual)

A: Max. pressure adjustment (cut-out)

B: Differential adjustment (cut-in)

The cut-in pressure (normally 6 bar) is set by adjustment of differential

screw B. Turn clockwise to reduce cut-in pressure. The cut-out pressure is

set by even adjustment of the two screws A. (Cut-in pressure + differential

= cut-out pressure). Turn clockwise to increase cut-out pressure. The

switch is normally factory set for operation at 6-8 bar (approx. 90-120 psi).

Fault finding and repair

AC models

• For electrical connection, refer to schematic in back of this manual.

• Check system serial number label for frequency and voltage to ensure

that it corresponds to the voltage and frequency used for the system. The

voltage stated on the system plate: 120/240V (/) means that the system

can operate at 120V or 240V, but this requires recoupling of the internal

wiring from the electrical system (see the electrical diagrams). 220-230V

(-) means that the system may operate within the range of 220V to 230V

without recoupling of the internal wiring.

• Capicitor is wired to motor via terminal box on side of motor.

• Accessorries are wired through the system pressure switch.

Operation

• If the temperature of the system is extremely low (for instance after

transportation or stocking), allow system to get to room temperature before

switching on the system.

• Do not use system for compression of liquids and dangerous gasses,

such as petrol vapour and solvents.

Important

This system is only suitable for atmospheric air.

• Do not remove protection covers during operation as it may cause electric

shock or risk of other personal injury (ie: terminal box, pressure switch).

• Ensure that system is correct for air supply flow required, see Technical

Specifications.

• Open the outlet cock on the receiver and connect equipment.

Important!

Switch off and isolate from electrical supply before removing

any parts from the system. Empt y air receiver of air before

dismantling parts of system unit’s pressure system.

1. System does not start:

a) No power from mains. Check fuses and plug.

b) Breakage or loose joints in electrical connections.

c) Defective capacitor.

d) The thermal protection has switched off the pump due to overheating.

When cooled the pump will automatically turn on at a suitable

operation temperature. Go through the points in step 5.

e) The system has not been unloaded and there is back pressure. Make

sure that the system is unloaded each time it stops.

f) The pump is locked.

g) Pressure in the air receiver is too high for activation of the pressure

switch. The pressure switch makes circuit only when pressure has

dropped to preset start pressure. Empty receiver.

2. System does not start, makes a buzzing sound followed by a

clicking noise (cannot start against high pressure):

a) Leaky non-return valve. Remove the flexible pressure pipe and clean

to find out whether air leaks from the valve. If so, clean or replace.

3 System works, but pressure does not increase:

a) Intake filter clogged. Replace.

b) Leaks in fittings, tubes or pneumatic equipment. Check with soapy water

or by letting unit stay overnight with disconnected mains. Pressure drop is

not to exceed 1 bar.

c) Cups are worn out. Check and replace if neccessary.

d) Defective valve plate. Contact your JUN-AIR distributor.

e) Burr or failure in non-return valve which is creating a flow restriction.

© 2015, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

5

6190755 (Rev A) 86/87R Compressor System User Guide

4. Loud noise from system:

a) Dirt or failure in non-return valve. Clean or replace.

5. System gets very hot:

a) Leaks. See above

b) Too high ambient temperature. Ensure adequate ventilation if the

vacuum pump is installed in a cabinet.

c) Overloaded. Ensure system is correct model for work load.

6. System starts when no air is being tapped:

a) Leaks. Step 3 - b

7. System does not switch on against pressure or does not switch

off at max. pressure:

a) Defective pressure switch. Replace.

Non-return valve Maintenance (NRV)

· Once a year.

· Switch off system on the main switch and pull out the plug.

· Pull the ring at the end of the safety valve (see back of manual).

Warning:

Loud noise!

· Let pressure fall to 0 bar. The pressure is to be read on the pressure

gauge for receiver pressure (see back of manual).

· If the system is mounted with a TÜV-approved safety valve, the receiver is

emptied by loosening the screw at the end of the safety valve

· Dismount non-return valve from receiver

· Disassemble non-return valve and remove O-ring from piston

· Clean non-return valve.

· Mount new O-rings and re-assemble non-return valve (Two O-rings in non-

return valve)

WARNING: To Avoid Serious Burns:

Do not touch surface during

operation.

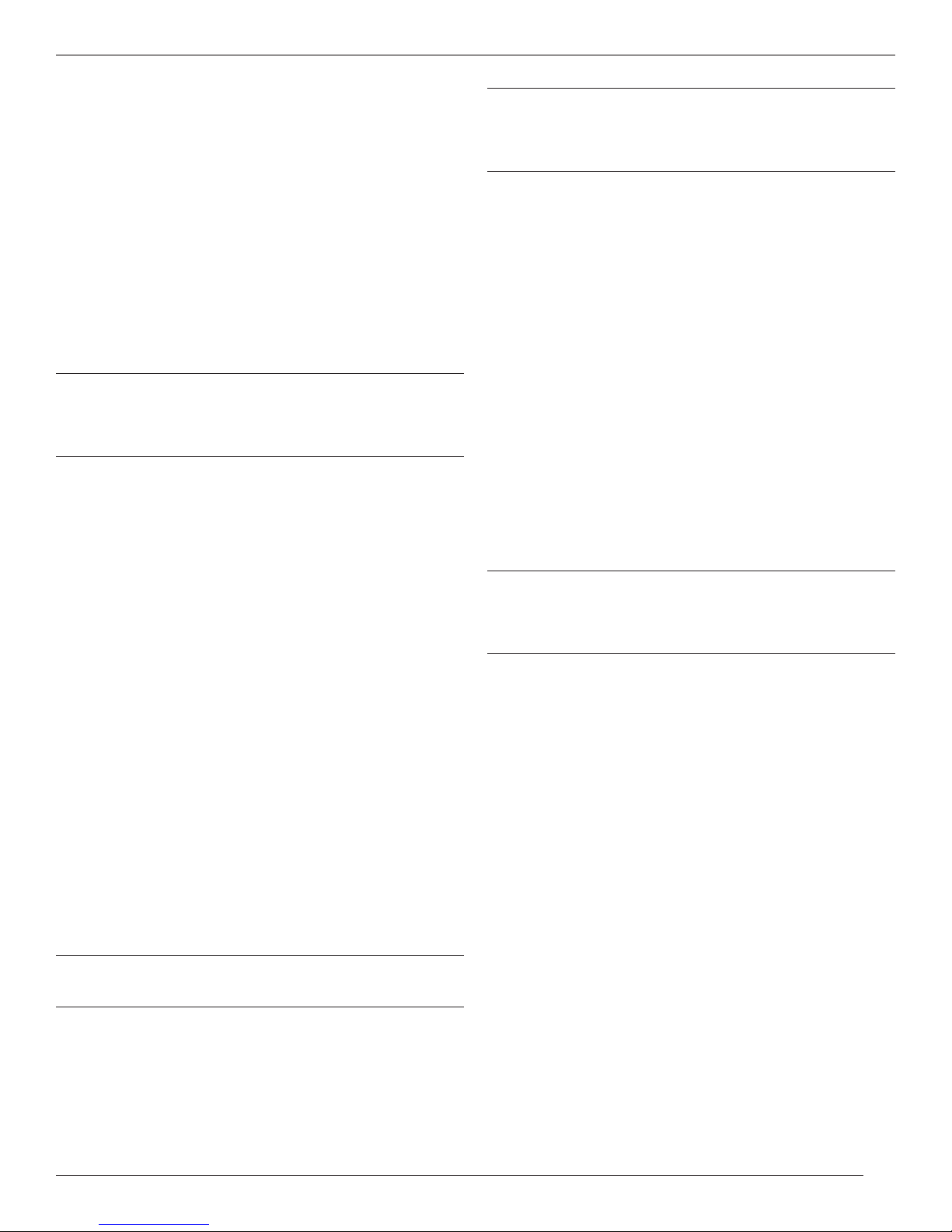

Preventive maintenance

Weekly

Drain condensate from air receiver. If

equipped with autodrain, this will take

place automatically, however, drain

bottle has to be emptied.

If compressor is fitted with outlet filter,

check and empty for water by pressing

the black button at the bottom. If fitted

with autodrain, this will take place

automatically.

Check motor, air tubes, hoses and

equipment for leaks, and check the

pumping time.

Clean unit or wipe with a soft, damp

cloth. If necessary, use paraffin on rag

to remove sticky adhesions. Dust and

dirt prevent cooling.

Check intake filter. Clean or replace if

necessary. Minimum every 2000 hours

Replace silencer (intake filter), if

necessary

Check the O-ring in the non-return

valve and replace, if necessary.

Note! Empty receiver of air before

dismounting.

Check filter regulator, clean or replace

as neccessary

Test the safety valve by gently pulling

the ring with pressure in the receiver.

Filters and non-return valves should be serviced every 2000 hours. The JUN-AIR basic service kit (identified in the accessories

portion of this manual) can be purchased to accommodate.

The comprehensive service kit includes components to maintain the system’s compressor (cups, valves, o-rings, cylinders) as well as

the systems filter elements, unloader valve, silencer, & NRV.

Comprehensive service kits should be utilized every 8000 hours.

Any solenoid accessories on the system should be serviced every 12000 hours.

Monthly Annually 2000 Hours

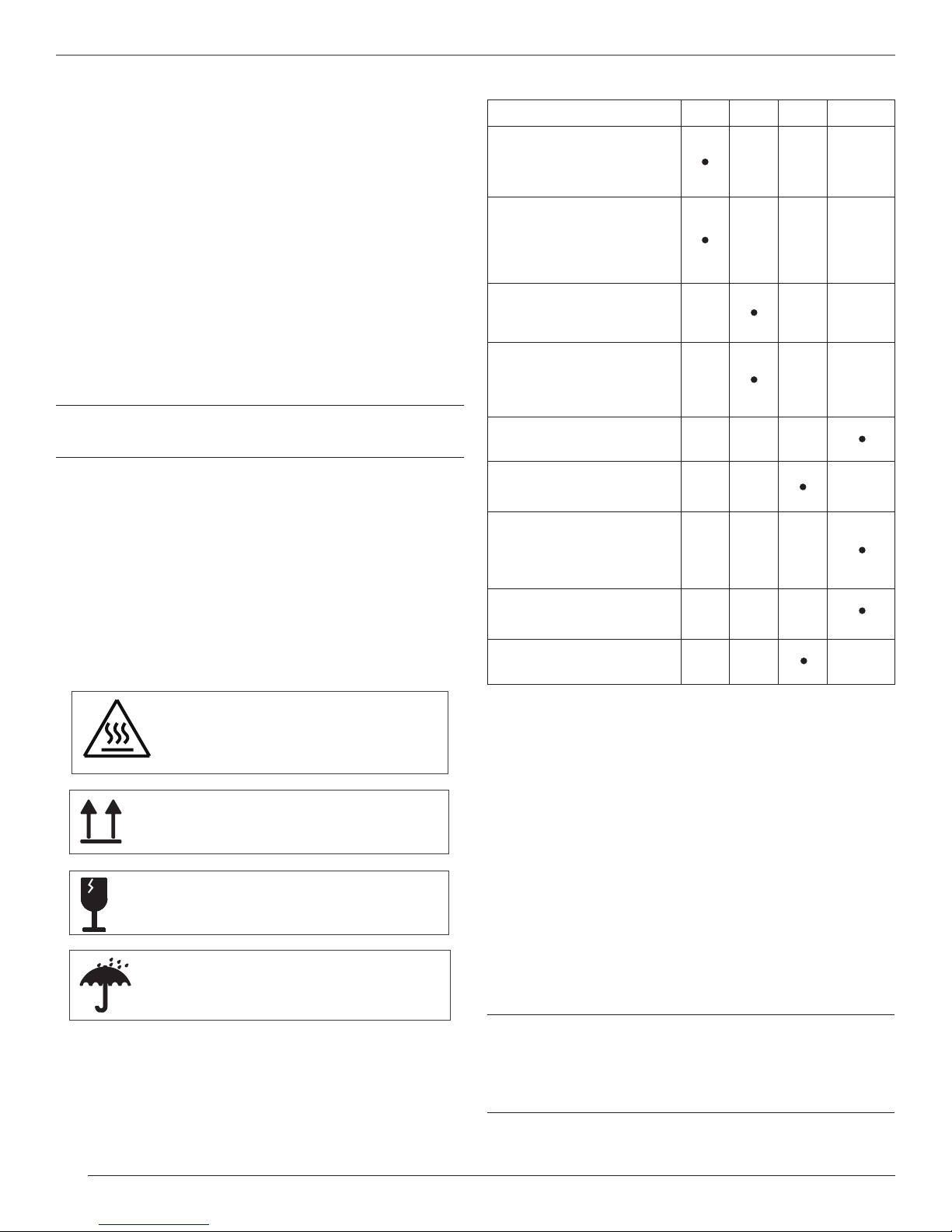

Indicates package should be handled with

these symbols pointing up.

FRAGILE: Handle package with care.

Indicates this package must be kept dry.

6

Check the Pumping Time

The pumping time indicates the condition of the compressor provided that

there are no leaks in the system where the compressed air may leak. Test the

compressor as follows:

1. Empty the air receiver of compressed air ( the pressure gauge shows 0 Bar)

2. Close the outlet on the air receiver and check that the drain cock is closed.

3. Start the compressor and note how long it takes until it switches off.

Ensure that the pressure in the air receiver is 8bar/120 psi as deviations may

indicate the wrong results (see technical Specifications for pumping time)

Important!

Always test the compressor when cold as the time indicated

refers to the pumping time of a cold compressor. The pumping

time of a warm compressor is much longer and consequently,

the result would be misleading.

© 2015, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

86/87R Compressor System User Guide 6190755 (Rev A)

Pressure vessel

Pressure tested at: All sizes:

Directions for use

Application Receiver for compressed air.

Receiver specifications See name plate.

Installation Tubes, etc. must be installed with

suitable materials.

Placement Observe the working temperature

of the receiver.

Ensure sufficient room for inspection

and maintenance.

The receiver must be kept in a

horizontal position.

Corrosion protection The surface treatment must be

maintained as required.

Internal inspection at least every

5 years.

Drain condensate at least once a week.

Alternation/repair No welding must be made on

pressurised parts.

Safety valve Ensures that PS rating will not be

exceeded.

Never adjust to a higher pressure

than PS.

The capacity of the valve must be

calculated in accordance with the

volume of air supplied by the

compressor.

(PS = Maximum working pressure

of the receiver. This is specified on the

system's serial number label.)

16.5 - 24BAR

© 2015, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

7

PROJECTION:

JUN-AIR

JUN-AIR

B

TLB

2

3

WEIGHT:

MATERIAL:

PROJECT NO:

TITLE

MADE FROM:

DG

8/7/14

APPROVED

DRAWN

B

SIZE

1 OF 1

DRAWING NUMBER

XB6782

SCALE

1:1

A

SHEET

REV

6

5

4

7

8

GAST /

PROPRIETARY INFORMATION

THIS DRAWING EMBODIES A PROPRIETARY DESIGN

OWNED BY IDEX,INC. AND IS SUBMITTED UNDER A

CONFIDENTIAL RELATIONSHIP. EXCEPT USES EXPRESSLY

GRANTED IN WRITING, ALL RIGHTS ARE RESERVED BY IDEX

INC.

COPYRIGHT © 2007 IDEX INC.

08/7/2014

-----

DATE

ECN

GEOMETRIC TOLERANCING PER: ASME Y14.5M-1994

DO NOT SCALE DRAWING

BY

DG

TOLERANCES UNLESS OTHERWISE SPECIFIED

WHERE USED:

SOURCE CODE:

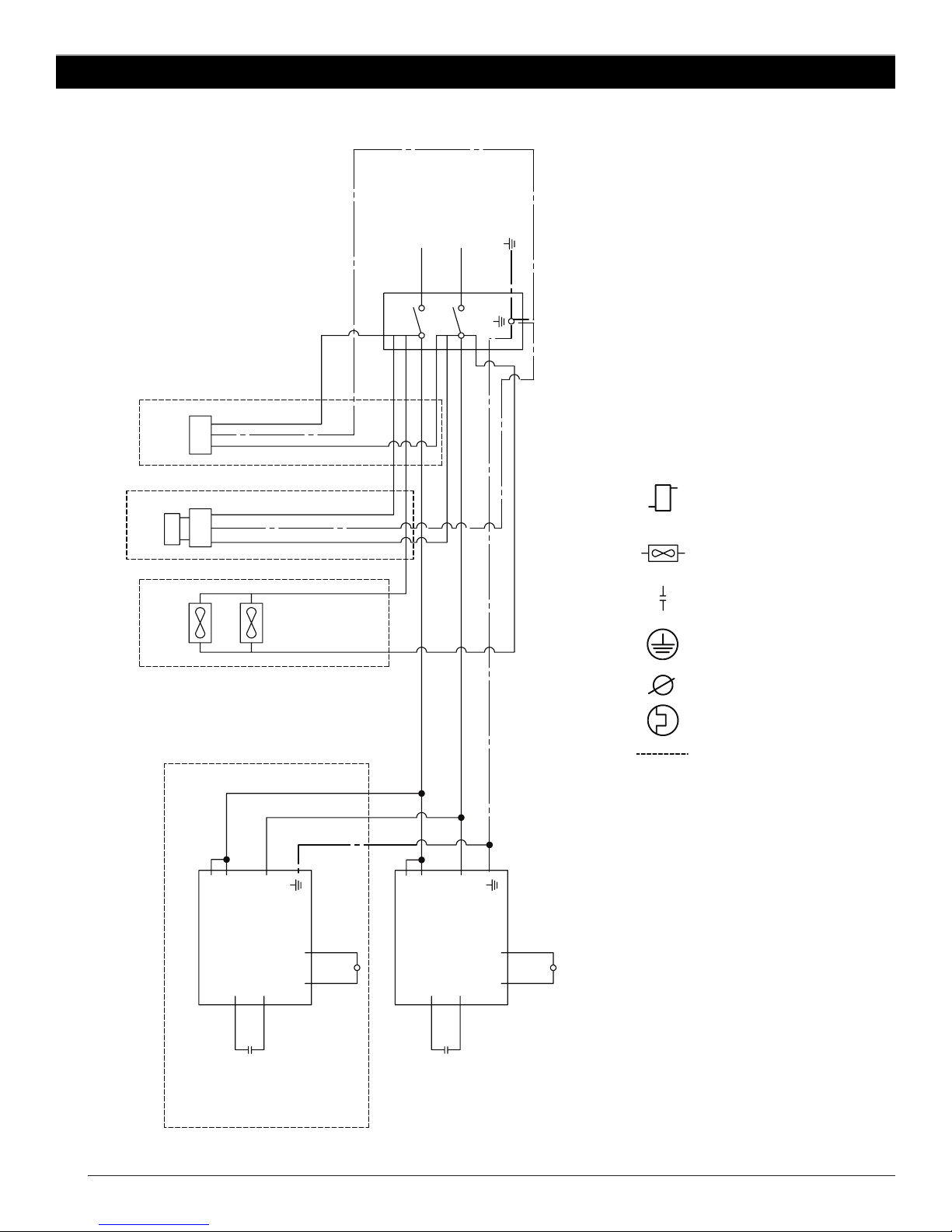

ELECTRICAL DRAWING 87R BASICS 120V

YELLOW/GREEN

(GREEN)

BLUE

PRESSURE SWITCH

BROWN

BLUE

BROWN

GROUND

(N)

(L1)

ORANGE

RED

YELLOW

BROWN

30

μF

CAPACITOR

M

L

IN

OUT

MOTOR 1

WHITE

BLUE

COOLER

BOX

AUTOMATIC

DRAIN

PRESSURE

RELIEF

30

μF

CAPACITOR

MOTOR 2

BLACK

INSULATE

GREEN

GREEN

INSULATE

(N)

(L1)

ORANGE

RED

YELLOW

BROWN

WHITE

BLUE

BLACK

1

2 3

4

5

6

6190755 (Rev A) 86/87R Compressor System User Guide

86/87R- XB Wiring Schematics

120VAC - 60Hz

PRESSURE

RELIEF

IN

(L1)

BLACK

L

M

120V/60Hz

(L2)

WHITE

YELLOW/GREEN

PRESSURE SWITCH

Legend

IN

: AUTO DRAIN

OUT

AUTOMATIC

DRAIN

OUT

: FAN

:CAPACITOR

COOLER

BOX

(L2)

(L1)

BLUE

WHITE

BLACK

MOTOR 2

RED

MOTOR 1

BLACK

BLUE

(L1)

BLACK

WHITE

(L2)

WHITE

(GREEN)

GROUND

RED

:EARTH

:TERMINAL CLIP

:MOTOR PROTECTION

:ADDITIONAL FEATURES

BROWN

YELLOW

30 μFCAPACITOR

ORANGE

8

YELLOW

ORANGE

BROWN

30 μFCAPACITOR

© 2015, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

PROJECTION:

JUN-AIR

JUN-AIR

B

TLB

3

C

A

B

WEIGHT:

MATERIAL:

PROJECT NO:

TITLE

MADE FROM:

DG

DG

8/7/14

APPROVED

DRAWN

B

SIZE

1 OF 1

DRAWING NUMBER

XB6790

SCALE

1:1

A

SHEET

REV

D

6

5

4

7

8

E

F

GAST /

PROPRIETARY INFORMATION

THIS DRAWING EMBODIES A PROPRIETARY DESIGN

OWNED BY IDEX,INC. AND IS SUBMITTED UNDER A

CONFIDENTIAL RELATIONSHIP. EXCEPT USES EXPRESSLY

GRANTED IN WRITING, ALL RIGHTS ARE RESERVED BY IDEX

INC.

COPYRIGHT © 2007 IDEX INC.

08/7/2014

-----

DATE

ECN

GEOMETRIC TOLERANCING PER: ASME Y14.5M-1994

08/15/2014

DO NOT SCALE DRAWING

BY

DG

TOLERANCES UNLESS OTHERWISE SPECIFIED

WHERE USED:

SOURCE CODE:

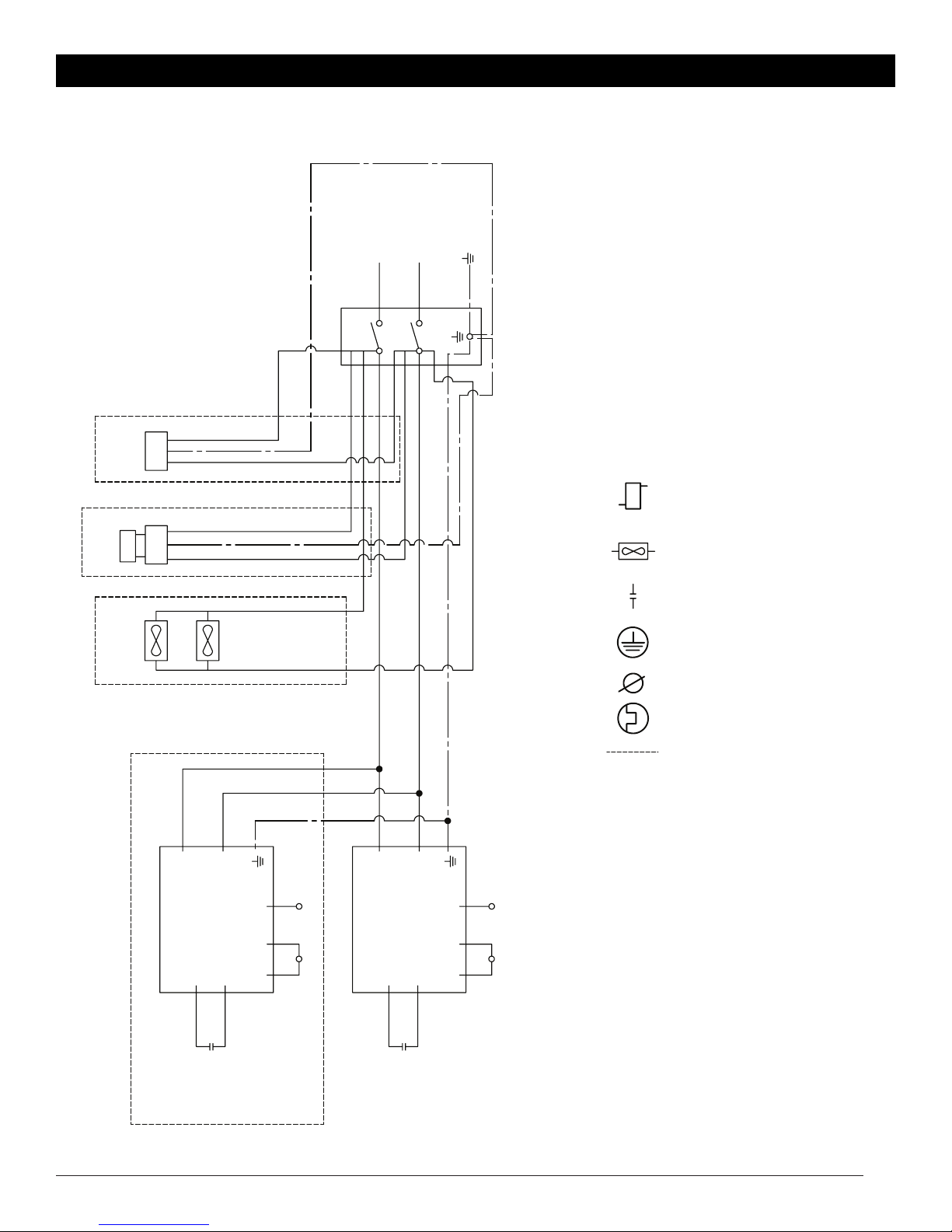

ELECTRICAL DRAWING 87R BASICS 230V

YELLOW/GREEN

(GREEN)

BLUE

PRESSURE SWITCH

BROWN

BLUE

BROWN

GROUND

(N)

(L1)

ORANGE

RED

YELLOW

BROWN

30

μF

CAPACITOR

M

L

IN

OUT

MOTOR 1

WHITE

BLUE

COOLER

BOX

AUTOMATIC

DRAIN

PRESSURE

RELIEF

30

μF

CAPACITOR

MOTOR 2

BLACK

INSULATE

GREEN

GREEN

INSULATE

(N)

(L1)

ORANGE

RED

YELLOW

BROWN

WHITE

BLUE

BLACK

1

2 3

4

5

6

86/87R Compressor System User Guide 6190755 (Rev A)

86/87R- XB Wiring Schematics

120VAC / 230VAC - 50Hz or 60Hz

230V/50-60Hz

(N)

(L1)

BLUE

PRESSURE

RELIEF

AUTOMATIC

DRAIN

BROWN

L

M

IN

OUT

YELLOW/GREEN

PRESSURE SWITCH

Legend

IN

: AUTO DRAIN

OUT

: FAN

:CAPACITOR

COOLER

BOX

MOTOR 2

(N)

(L1)

WHITE

YELLOW

BLUE

BROWN

GREEN

ORANGE

RED

BLACK

INSULATE

MOTOR 1

BROWN

(L1)

WHITE

YELLOW

BLUE

(N)

BLUE

BROWN

(GREEN)

GROUND

GREEN

ORANGE

RED

BLACK

INSULATE

:EARTH

:TERMINAL CLIP

:MOTOR PROTECTION

:ADDITIONAL FEATURES

30 μFCAPACITOR

© 2015, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

30 μFCAPACITOR

9

6190755 (Rev A) 86/87R Compressor System User Guide

PROJECTION:

JUN-AIR

JUN-AIR

WEIGHT:

MATERIAL:

PROJECT NO:

TITLE

MADE FROM:

DG

TLB

8/7/14

APPROVED

DRAWN

B

SIZE

DRAWING NUMBER

XB6787

SCALE

A

SHEET

REV

GAST /

PROPRIETARY INFORMATION

THIS DRAWING EMBODIES A PROPRIETARY DESIGN

OWNED BY IDEX,INC. AND IS SUBMITTED UNDER A

CONFIDENTIAL RELATIONSHIP. EXCEPT USES EXPRESSLY

GRANTED IN WRITING, ALL RIGHTS ARE RESERVED BY IDEX

INC.

COPYRIGHT © 2007 IDEX INC.

08/7/2014

DATE

GEOMETRIC TOLERANCING PER: ASME Y14.5M-1994

08/15/2014

BY

DG

TOLERANCES UNLESS OTHERWISE SPECIFIED

WHERE USED:

SOURCE CODE:

PNEUMATICS DRAWING 86/87R BASICS

COMPRESSED AIR OUTLET

TO WASTE

TO WASTE

M

M

2x 86/87R

TANK

PRESSURE

REGULATED

PRESSURE

FILTER

5

μm

1

2 3

4

5

6

7

86/87R- XB Pneumatic Schematic

M

2x 86/87R

M

TO WASTE

Legend

:WORKING PIPE

:STEERING PIPE

:PIPE COUPLING

M

:COMPRESSOR

:TANK

:INLET FILTER

:PRESSURE GAUGE

:PRESSURE SWITCH

TANK

PRESSURE

REGULATED

PRESSURE

μm

FILTER

5

TO WASTE

:SAFETY VALVE

:NON RETURN VALVE

:FILTER MANUAL DRAIN

:VALVE FOR PRESSURE RELIEF

:REDUCTION VALVE

:VALVE

:MUFFLER

:FILTER WITH AUTOMATIC DRAIN

:OPTIONAL

:TIMED AUTO DRAIN

:2/2 PRESSURE RELIEF

10

COMPRESSED AIR OUTLET

We reserve the right to make any alterations which may be due to any technical improvements

© 2015, JUN-AIR

Printed in the USA

86/87R Compressor System User Guide 6190755 (Rev A)

DATE

DESCRIPTION

PART NUMBER

1760420 - EXPLODED

SHEET 1 OF 1

REFERENCE ONLY

2/20/2015

1760420

86R-4B 230V/50Hz CE

86/87R- XB Exploded Views

86R-4B 230V - 50Hz

6341101

6973090

6973105

6975002

7164200

5416100

5418000

5130000

4071039

6340500

3051000

7024002

6243710 O-RING

86R135-101T-N270X

6341800

6357100

7540000

5960000

B

5427002

5427003

A

5031000

B

7190000

7071000

A

7565000

5414500

5424000

5427001

7156000

5130000

6290200

B300A

5237700

6341800

6355000

8008302

6390025

6320200

A-A 6457020

B-B 6420000

5320226

COMPLETE

6253704

6252010

5935011

6372700

© 2015, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

6320200

6296850

6253000

6390000

6314000

6392145

11

6190755 (Rev A) 86/87R Compressor System User Guide

DATE

DESCRIPTION

PART NUMBER

1760421 - EXPLODED

SHEET 1 OF 1

REFERENCE ONLY

1760421

86R-4B 230V/60Hz UL

86/87R- XB Exploded Views

86R-4B 120V/230V - 60Hz

5130000

6293100

6294600

6341101

6973090

6973105

6975002

7164200

5417000

5418000

B

5427002

5427003

B

6294600

6293100

5075000

7190000

A

7071000

7565000

5414500

5424000

5427001

7156000

5237700

4071039

6340500

3050005

7024002

6243710 O-RING

86R135-101T-N270X

6341800

6357100

7540000

5960000

6253704

6252010

5935011

6372700

5130000

6341800

6355000

8008302

6390025

6320200

6290200

A

A-A 6457020

B-B 6420000

B300A

6253000

6390000

6314000

6392145

5320226

COMPLETE

6320200

6296850

12

We reserve the right to make any alterations which may be due to any technical improvements

© 2015, JUN-AIR

Printed in the USA

86/87R Compressor System User Guide 6190755 (Rev A)

DATE

DESCRIPTION

PART NUMBER

1760400 - EXPLODED

SHEET 1 OF 1

REFERENCE ONLY

2/20/2015

1760400

87R-4B 230V/50Hz CE

86/87R- XB Exploded Views

87R-4B 230V - 50Hz

5130000

4071039

6341101

6973090

6973105

6975002

7164200

5416100

5418000

6340500

3051000

5031000

B

5427002

5427003

B

7190000

7071000

A

7565000

5414500

5424000

5427001

7156000

5237700

5130000

6341800

6355000

8008302

6390025

6320200

6290200

B300A

87R642-104RT-N470X

6341800

6357100

7540000

5960000

6253704

6252010

5935012

6372700

A

6390000

6314000

A-A 6457028

B-B 6420000

5320226

COMPLETE

7024002

6243710 O-RING

6320200

6296850

6253000

© 2015, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

13

6190755 (Rev A) 86/87R Compressor System User Guide

DATE

DESCRIPTION

PART NUMBER

1760401 - EXPLODED

SHEET 1 OF 1

REFERENCE ONLY

1760401

87R-4B 230V/60Hz UL

86/87R- XB Exploded Views

87R-4B 120V/230V - 60Hz

6293100

6294600

6341101

6973090

6973105

6975002

7164200

5417000

5418000

5130000

B

5427002

5427003

B

6294600

6293100

5075000

7190000

A

5424000

5427001

7156000

7071000

7565000

5414500

5237700

4071039

6340500

3050005

87R642-104RT-N470X

6341800

6357100

7540000

5960000

6253704

6252010

5935012

6372700

5130000

6290200

A

6390000

6314000

6341800

6355000

8008302

6390025

6320200

B300A

A-A 6457028

B-B 6420000

5320226

COMPLETE

7024002

6243710 O-RING

6320200

6296850

6253000

14

We reserve the right to make any alterations which may be due to any technical improvements

© 2015, JUN-AIR

Printed in the USA

86/87R Compressor System User Guide 6190755 (Rev A)

DATE

DESCRIPTION

PART NUMBER

1760430 - EXPLODED

SHEET 1 OF 1

REFERENCE ONLY

1760430

87R-15B 230V/50Hz CE

86/87R- XB Exploded Views

87R-15B 230V - 50Hz

B300A

6253704

5427001

5427002

5130000

4071039

5427003

6340500

A-A 6457020

8111962

6346300

7156100

5130000

5414500

7566200

7180000

7566000

7024002

A

6243710 O-RING

6290200

5424000

A

5340000

6296850

5935012

6392145

6296851

6392145

87R642-104RT-N470X

5237700

6341800

6355000

8008302

6390025

6320200

6392350

6392202

7540000

B

B

5960000

6372700

7020002

6243715 O-RING

7025005

6243715 O-RING

7070000

5031000

6341101

7190000

6973090

6975002

B-B 6420000

5419500

© 2015, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

5416100

7180000

7071350

7566000

3210005

6250000

15

6190755 (Rev A) 86/87R Compressor System User Guide

DESCRIPTION

PART NUMBER

1760431 - EXPLODED

SHEET 1 OF 1

REFERENCE ONLY

1760431

87R-15B 230V/60Hz UL

86/87R- XB Exploded Views

87R-15B 120V/230V - 60Hz

A

B300A

6253704

5427001

5427002

5130000

4071039

5427003

6340500

A-A 6457020

B-B 6420000

8111962

6346300

7156100

5130000

5414500

7566200

7180000

7566000

6290200

7024002

6243710 O-RING

5424000

B

A

B

5340000

6296850

5935012

6392145

6392145

87R642-104RT-N470X

6296851

5237700

6341800

6355000

8008302

6390025

6320200

6392350

6392202

7540000

5960000

6372700

7020002

6243715 O-RING

7025005

6243715 O-RING

7070000

5075000

6293100

6294600

6341101

7190000

6973090

6975002

5417000

5419500

16

7180000

7071350

7566000

3210098

6250000

© 2015, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

86/87R Compressor System User Guide 6190755 (Rev A)

DATE

DESCRIPTION

PART NUMBER

1760410 - EXPLODED

SHEET 1 OF 1

REFERENCE ONLY

1760410

87R-25B 230V/50Hz CE

86/87R- XB Exploded Views

87R-25B 230V - 50Hz

B300A

6253704

5427001

5427002

5130000

4071039

5427003

6340500

A-A 6457020

B-B 6420000

8111962

6346300

7156100

5130000

5414500

7566200

7180000

7566000

5420000

7024002

A

6243710 O-RING

6290200

5424000

A

5340000

6296850

B

B

5935012

6392145

6296851

6392145

87R642-104RT-N470X

5237700

6341800

6355000

8008302

6390025

6320200

6392350

6392202

7540000

5960000

6372700

7020002

6243715 O-RING

7025005

6243715 O-RING

7070000

5031000

6341101

7190000

6973090

6975002

5416100

7180000

7071350

7566000

© 2015, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

3410010

6250000

17

6190755 (Rev A) 86/87R Compressor System User Guide

6290200

DATE

DESCRIPTION

PART NUMBER

1760411 - EXPLODED

SHEET 1 OF 1

REFERENCE ONLY

1760411

87R-25B 230V/60Hz UL

86/87R- XB Exploded Views

87R-25B 120V/230V - 60Hz

A

B300A

6253704

5427001

5427002

5130000

4071039

5427003

6340500

A-A 6457020

B-B 6420000

8111962

6346300

7156100

5130000

5414500

7566200

7180000

7566000

5420000

7024002

6243710 O-RING

5424000

B

A

B

5340000

6296850

5935012

6392145

6392145

87R642-104RT-N470X

6296851

5237700

6341800

6355000

8008302

6390025

6320200

6392350

6392202

7540000

5960000

6372700

7020002

6243715 O-RING

7025005

6243715 O-RING

7070000

5075000

6293100

6294600

6341101

7190000

6973090

6975002

5417000

7180000

7071350

7566000

18

3411399

6250000

© 2015, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

86/87R Compressor System User Guide 6190755 (Rev A)

Parts & Accessories List

Part no. Description

4071030 5 micron outlet filter/regulator with manual drain

4071055 .01 micron outlet filter with manual drain

4071065 FILTER 0.01UM W/AUTODRAIN

4071210 SPARE PARTS KIT F/5micron Filter

4071220 SPARE PARTS KIT Regulator

4071230 SPARE PARTS KIT Filter/Regulator

4071240 SPARE PARTS KIT F/0.01micron Filter

4797100 Tank Auto Drain kit with drain bottle 120V

4900001 NON RETURN VALVE KIT

5471005 86/87R-XB Basic Service Kit

5471006 87R-XB Comprehensive Service Kit

5471007 86R-4B Comprehensive Service Kit

5612300 Drain Bottle Kit

4797600 Tank Auto Drain kit with drain bottle 230V

86R135-101-N270X 86R135-101T-N270X: 86R-4B Compressor individually packaged for resale

87R642-103R-N470X 87R642-104RT-N470X: 87R-XB Compressor individually packaged for

resale

© 2015, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

19

6190755 (Rev A) 86/87R Compressor System User Guide

Part no. Description

3050005 TANK - 4L CE/UL w/inspection

3051000 4L TANK CE

3210005 TANK - 15B CE

3210098 Tank – 15B CE/ASME 16 Bar

3410010 TANK - 25B CE

3411399 TANK - 25B ASME

4071039 Filter regulator 5u w/automati

4141800 RAPID FITTING ELBOW 1/8"XO6

4146457 RAPID FITTING 06-06MM PIPE

5031000 Pressure switch MDR 2/11

5075000 Pressure switch MDR 21/11 UL

5130000 GAUGE +40 - 0-16BAR 1/8"DOWN

5237700 CAPACITOR 30UF/370V AC

5320226 Handle 86/87R-4B

5340000 Handle 87R-25/15B

5414500 Non return valve f/lubicated

5416100 SAFETY VALVE 12 BAR 177 PSI

5417000 SAFETY VALVE 9 BAR/135 PSI

5418000 DRAIN COCK 1/4" 4L

5419500 DRAIN COCK 1/4" 15L

5420000 DRAIN COCK 1/4" 25L

5424000 OUTLET COCK 1/4"

5427001 Nipple for connecting Fil/reg

5427002 Nipple for connecting Fil/reg

5427003 Connector for Fil/reg

5935011 Squeeze Box 86R single

5935012 Squeeze Box 87R Dual

5960000 CABLE RELIEF

6243710 O-RING F/OF PLUG

6243715 O-ring O7x1, 5 Viton (for 1 /

6250000 SOCKET 25 MM BLACK

6253704 Rubber Base f/82R

6290200 PLASTIC HANDLE BLACK 025MM

6293100 NUT PG16 BRASS

6294600 PG-NIPPLE M16 UL/CSA

6296850 CABLE RELEIF HEYCO 1327 ELBOW

6296851 Cable relief Heyco 1226 OF300

*6314000 M6x10 HHCS ZINC PLATE

*6320200 COUNTER NUT M8 FLAT FZB

6340500 1/8 PIPE PLUG x 7mm LONG

*6341040 M4x25 SHCS ZINC PLATE

Part no. Description

*6341101 SCREW F/UNLOADER VALVE M5X6

*6341800 M6x10 SHCS

*6346300 M8x20 FLAT HEAD ZINC PLATE

*6355000 WASHER 6.5X13X1.25MM

*6357100 Washer O18xO6.4x1.6 FZB

*6372500 LOCK NUT M4

*6372700 LOCK NUT M8 FZB

*6390000 STAR WASHER TYPE A M6

*6390025 Star washer type A M8

*6391800 SCREW PH FZB 4X12

*6391900 M2.2x12 PAN HD SHEET MTL ZINC

*6392145 SCREW GROUND

*6392202 M6 x 12MM FLAT HEAD ZINC

*6392350 M8x25 FLAT HEAD ZINC

6420000 FLEX PIPE 1/8" 20 (22)

6457020 Teflon hose 1/4" 20 cm with el

6457024 Teflon hose 1/4" 24 cm with el

6457028 Teflon hose 1/4" 28 cm with el

**6973090 Unloader valve

**6973105 Needle f/unloader valve 16.4 m

**6975002 Silencer f/unload valve OF300

7020002 Double nipple 1/8" w/o-ring

7024002 Double nipple 1/4 in w/o-ring

7025000 DOUBLE NIPPLE 1/4"X1/8"

7025005 Double nipple 1/4"x1/8" w/o-ri

7070000 CONN. PIECE F/NON-RETURN VALVE

7071000 T-PIECE 1/8"

7071350 Tee-connector 1/4" (2xexternal

7156000 EXTENSION PIECE F/COCK SHORT

7156100 EXTENSION PIECE F/COCK LONG

7164200 CROSS CONNECTOR

7180000 ELBOW 1/4" INT/EXT KRG

7190000 ELBOW 1/8"

7540000 BUSH F/5960000

7555000 Coupling nut 1/8"

7565000 BUSHING 1/4"EXT X 1/8"INT

7566200 BUSHING 1/4"X1/4" L = 35 MM

8008302 BRACKET

8111962 MOUNTING BRACKET F/ 87R-25B

B300A FILTER PLASTIC 1/4 NPT

* Not available for resale

** Only available in service kit

20

We reserve the right to make any alterations which may be due to any technical improvements

© 2015, JUN-AIR

Printed in the USA

86/87R Compressor System User Guide 6190755 (Rev A)

Technical Data & Specifications

Specifications

87R-25B 87R-15B

120 V 230 V 230 V 120 V 230 V 230 V

Frequency HZ 60 50 60 60 50 60

Displacement @ 0 Bar

FAD @ 8 bar

Max Current A 5,7 2,5 2,8 5,7 2,5 2,8

Weight

Pumping Time

0-8 bar/0-120psi

Noise level

Dimensions (LxWxH)

Motor

Max Pressure

Tank Size

Thermal Protection Yes Yes

Duty Cycle 100% 100%

Relative Humidity % 20 - 80%* 20 - 80%*

Ambient Temperature 5/40°C 5/40°C

l/min 91 82 91 91 82 91

CFM 3,2 2,9 3,2 3,2 2,9 3,2

l/min 34 28 34 34 28 34

CFM 1,2 1 1,2 1,2 1 1,2

kg 32 27 32 29 22 29

lbs 70 59 70 61 48,5 61

sec 185 205 185 115 125 115

dB(a)/1m

mm

in

63 61 63 63 61 63

388 x 380 x 619

15,3 x 15,0 x 24,4

388 x 380 x 548

15,3 x 15,0 x 21,6

HP 1/2 1/2

KW 0,37 0,37

bar 8 8

psi 120 120

liters 25 15

gallons 6,6 4

* Non-Condensing

The figures in the tables are based on the unit working in a clean environment at an ambient

temperature of 20°C, relative humidity of 50% and operating at sea level. The performance of the

product will be adversely effected at high altitudes. JUN-AIR reserves the right to make technical

modifications to these units as needed.

© 2015, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

21

6190755 (Rev A) 86/87R Compressor System User Guide

Specifica-

tions

Frequency HZ 60 50 60 60 50 60

l/min 91 82 91 40 34 40

Displacement @

0 Bar

FAD @ 8 bar

Max Current A 5,7 2,5 2,8 2,1 1,7 1,1

Weight

Pumping Time

0-8 bar/0-120psi

Noise level

Dimensions

(LxWxH)

Motor

Max Pressure

Tank Size

Thermal Protection Yes Yes

Duty Cycle 100% 100%

Relative Humidity % 20 - 80%* 20 - 80%*

Ambient Temperature 5/40°C 5/40°C

CFM 3,2 2,9 3,2 1,41 1,20 1,41

l/min 34 28 34 15,0 12,5 15,0

CFM 1,2 1 1,2 0,53 0,44 0,53

kg 18 18 18 15,6 15,6 15,6

lbs 40 40 40 34,4 34,4 34,4

sec 32 37 32 80 90 80

dB(a)/1m

mm

in

HP 1/2 1/3

KW 0,37 0,25

bar 8 8

psi 120 120

liters 4 4

gallons 1,1 1,1

120 V 230 V 230 V 120 V 230 V 230 V

63 61 63 58 55 58

87R-4B 86R-4B

404 x 306 x 338

15,9 x 12,0 x13,3

404 x 306 x 338

15,9 x 12,0 x13,3

* Non-Condensing

The figures in the tables are based on the unit working in a clean environment at an ambient

temperature of 20°C, relative humidity of 50% and operating at sea level. The performance of the

product will be adversely effected at high altitudes. JUN-AIR reserves the right to make technical

modifications to these units as needed.

22

We reserve the right to make any alterations which may be due to any technical improvements

© 2015, JUN-AIR

Printed in the USA

86/87R Compressor System User Guide 6190755 (Rev A)

86R-4B-BXXXX English Performance

1.6

1.4

1.2

1.0

0.8

Flow (CFM)

0.6

0.4

0.2

0.0

0 20 40 60 80 100 120

Pressure (PSI)

86R-4B-BXXXX Metric Performance

45

40

35

50 Hz

60 Hz

30

25

20

Flow (LPM)

15

10

5

0

0 1 2 3 4 5 6 7 8 9

© 2015, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

50 Hz

60 Hz

Pressure (BAR)

23

6190755 (Rev A) 86/87R Compressor System User Guide

87R-XB-JXXXX English Performance

3.5

3.0

2.5

2.0

50 Hz

1.5

Flow (CFM)

1.0

0.5

60 Hz

0.0

0 20 40 60 80 100 120

Pressure (PSI)

87R-XB-JXXXX Metric Performance

100

90

80

70

60

50

Flow (LPM)

40

30

20

50 Hz

60 Hz

10

0

0 1 2 3 4 5 6 7 8 9

24

Pressure (BAR)

© 2015, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

86/87R Compressor System User Guide 6190755 (Rev A)

87R - 25 B Q2 - X XX X X X

Tank

Regulatory

Elec/region config

Accessory configuration

Compressor Configuration

Dryer Type

Enclosure Style

Receiver Size

Family & cylinders

Family & cylinders Receiver Size Enclosure Style Dryer Type

86R = single cylinder & small bore (low flow) 4, 15, 25, 40 B = Basic or Open Q = iQ dryer (2, 3, or 6 size)

87R = twin cylinder & large bore (high flow) M = Metal Cabinet A = Membrane Dryer

P = Plastic Cover

Compressor Accessory Elec/region config Regulatory Tank

A Single Cylinder, Low Stroke Manual tank drain, 5µ F/R manual drain,

B Single Cylinder, High Stroke (0.35") Manual tank drain, 5µ F/R auto drain,

C Single Cylinder, High Stroke (0.42") Bent

Valve (100psi max)

D Manual tank drain, 5µ F/R auto drain,

E Manual tank drain, 5µ F/R auto drain, no

F Manual tank drain, 5µ F/R auto drain,

G Dual Parallel Cylinder, Low Stroke 220-240 50 or 60 AU (AS-3112) ASME/CRN

H Dual Parallel Cylinder, High Stroke

(0.37")

J Dual Parallel Cylinder, High Stroke

(0.42") Bent Valves

K Auto tank drain, 5µ F/R auto drain, with

L Auto tank drain, 5µ F/R auto drain,

M Auto tank drain, 5µ Filter auto drain,

N Dual Staged Cylinders, Std Stroke Auto tank drain, 5µ Filter auto drain,

P Dual Independent Cylinders, Std Stroke

R

S Special compressor configuration OEM Specific Model Special voltage/plug Special Special

no bottle, pressure switch unloader

with bottle

Manual tank drain, 5µ F/R manual drain,

0.01µ Coalescing Filter, no bottle

0.01µ Coalescing Filter, with bottle

bottle, pressure switch unloader

0.01µ Coalescing Filter, no bottle

bottle

0.01µ Coalescing filter, with bottle

regulator, solenoid unloader, no bottle

regulator, solenoid unloader, with bottle

100/50 or 60 Japan

(NEMA 1-15 or 5-15)

120/50 or 60 NA (NEMA 5-15) CSA ASME

220-240 50 or 60 NA (NEMA 6-15) cULus ASME

220-240 50 or 60 EU (CEE 7/7) CE/cULus GB (china)

220-240 50 or 60 EU (CEE 7/7) &

GB adaptor

220-240 50 or 60 CH (NEMA 1-15

or AS-3112)

220-240 50 or 60 GB (IEC Type G) CE/UL

CE CE

Singapore

CCC CRN

cCSAus ASME/CE

None

© 2015, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

25

6190755 (Rev A) 86/87R Compressor System User Guide

Pictures / Illustrations References

Pressure Switch ’1’ on or ’0’ off Pressure Switch Adjustment

Safety Valve Non-Return Valve

B

A

Non-Return Valve Assembly ( A + B + C)

C

26

We reserve the right to make any alterations which may be due to any technical improvements

© 2015, JUN-AIR

Printed in the USA

86/87R Compressor System User Guide 6190755 (Rev A)

WARRANTY POLICY

If within the warranty time limits described below, the compressor system or any of its components fail under normal use and service, the original user-owner must contact an authorized JUN-AIR dealer with the product sale and service records. Should the dealer not be

able to complete the repair, the dealer may contact JUN-AIR for disposition. The product’s

model and serial number, the installation date and the JUN-AIR invoice number must be furnished. Transportation charges both ways must be paid by the dealer. If upon receipt at the

factory, an examination reveals faulty or defective original parts, materials, or workmanship,

JUN-AIR will, at its sole discretion, rebuild or replace. This warranty does not cover damages

caused by misuse, abuse, accident, or neglect. Unauthorized alterations or repairs made

outside our factory will cancel this warranty and charges for them will not be allowed.

COMPRESSOR SYSTEMS

All compressor systems sold and installed by authorized JUN-AIR dealers are warrantied to

be free from defects in parts, workmanship, and materials for 8,000 hours of operation or

two (2) years from date of purchase, whichever occurs first.

This warranty excludes normal expected service items such as but not limited to: filters/filter

kits, o-rings, and hoses. It also excludes add-on accessories that carry their own specific

manufacturer’s warranty.

Gast Manufacturing

P.O. Box 97

2300 M139 Highway

Benton Harbor, MI 49023-0097

Ph: 269-926-6171

Fax: 269-925-8288

Gast Group Limited

c/o IDEX Trading (Shanghai) Co., LTD

Room 3502-3505

No. 1027 Chang Ning Road,

Zhaofeng Plaza

Shanghai, China 200050

Phone +86-21-52415599

Fax +86-21-52418339

Gast Group Ltd.

Unit 11, The I O Centre

Nash Road

Redditch, B98 7AS

United Kingdom

Phone +44 (0)1527-504040

Fax +44 (0)1527-525262

www.JUN-AIR.com

© 2015, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

27

Loading...

Loading...