JUMO Quantrol LC100/LC200/LC300

Universal PID Controller Series

B 702030.0

Operating Manual

2013-09-23/00600571

Content

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Device documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.3 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2 Installation - Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Identifying the device version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Excerpt from the technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4 Installation notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.5 Electrical isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.6 Connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 Operation - Configuration - Parameterization . . . . . . . . . . . . . . . . . . . 13

3.1 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1.1 Display and operating elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1.2 Self-optimization, setpoint and manual mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1.3 Ramp function/firing curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1.4 Level concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1.5 Operator level (OPr) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3.2 Configuration (ConF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2.1 Analog input (InP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.2.2 Controller (Cntr) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2.3 Ramp function/firing curve (rAFC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2.4 Limit value monitoring (Li1, Li2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2.5 Timer (tFCt) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.2.6 Outputs (OutL, OutA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2.7 Binary functions (binF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2.8 Display and operation (diSP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2.9 Interface (IntF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.3 Parameterization (PArA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4 Supplement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.1 Additional information about installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.1.1 Device representation including dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.1.2 Cleaning the device front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2 Additional information about the device functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2.1 Entries and operator prompting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2.2 Analog input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.2.3 Analog output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.2.4 Ramp function and firing curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.2.5 Timers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2.6 Limit value monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3

Content

4.2.7 Self-optimization (TUNE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.3 Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.4 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

4

1 Introduction

1.1 Device documentation

Data sheet T 702030 (as a PDF document)

The data sheet contains general information about the device and forms the basis for planning

and purchase decision.

Brief instructions B 702030.7 (printed in DIN A6 format)

These brief instructions contain the most important information about installation, the electrical

connection as well as operation, parameterization and configuration of the device. The brief instructions are supplied with every device. For further information, please refer to the operating manual B 702030.0 available as a PDF document.

Operating manual B 702030.0 (as a PDF document)

This operating manual contains all information about installation, the electrical connection as well

as operation, parameterization and configuration of the device.

Interface description B 702030.2.0 (as a PDF document)

It contains information about the RS485 interface, the Modbus protocol and the communication

with other devices.

All PDF documents can be downloaded under www.jumo.net.

1.2 Safety information

This manual contains information that must be observed in the interest of your own safety and to

avoid damage to assets. This information is supported by symbols which are used in this manual

as follows.

Please read this manual before starting up the device. Keep the manual in a place accessible to

all users at all times.

All necessary settings are described in this manual. Manipulations not described in this manual

or expressly forbidden will jeopardize your warranty rights.

Warning signs

DANGER!

This symbol indicates that Injury or death caused by electrical shock can occur, if the

respective protective measures have not been taken.

CAUTION!

This symbol in combination with the signal word indicates that damage to assets or data

loss will occur if suitable precautions are not taken.

READ DOCUMENTATION!

This symbol – placed on the device – indicates that the associated device documentation has to be observed. This is necessary to recognize the kind of the

potential hazards as well as to take the measures to avoid them.

5

1 Introduction

?

Note signs

TIP!

This symbol refers to Important information about the product or its handling or additional

use.

REFERENCE!

This symbol refers to Further information in other sections, chapters or manuals.

1.3 Scope of delivery

• Controller (including seal and fastening elements)

• Brief instructions B 702030.7 in DIN A6 format

6

2 Installation - Electrical Connection

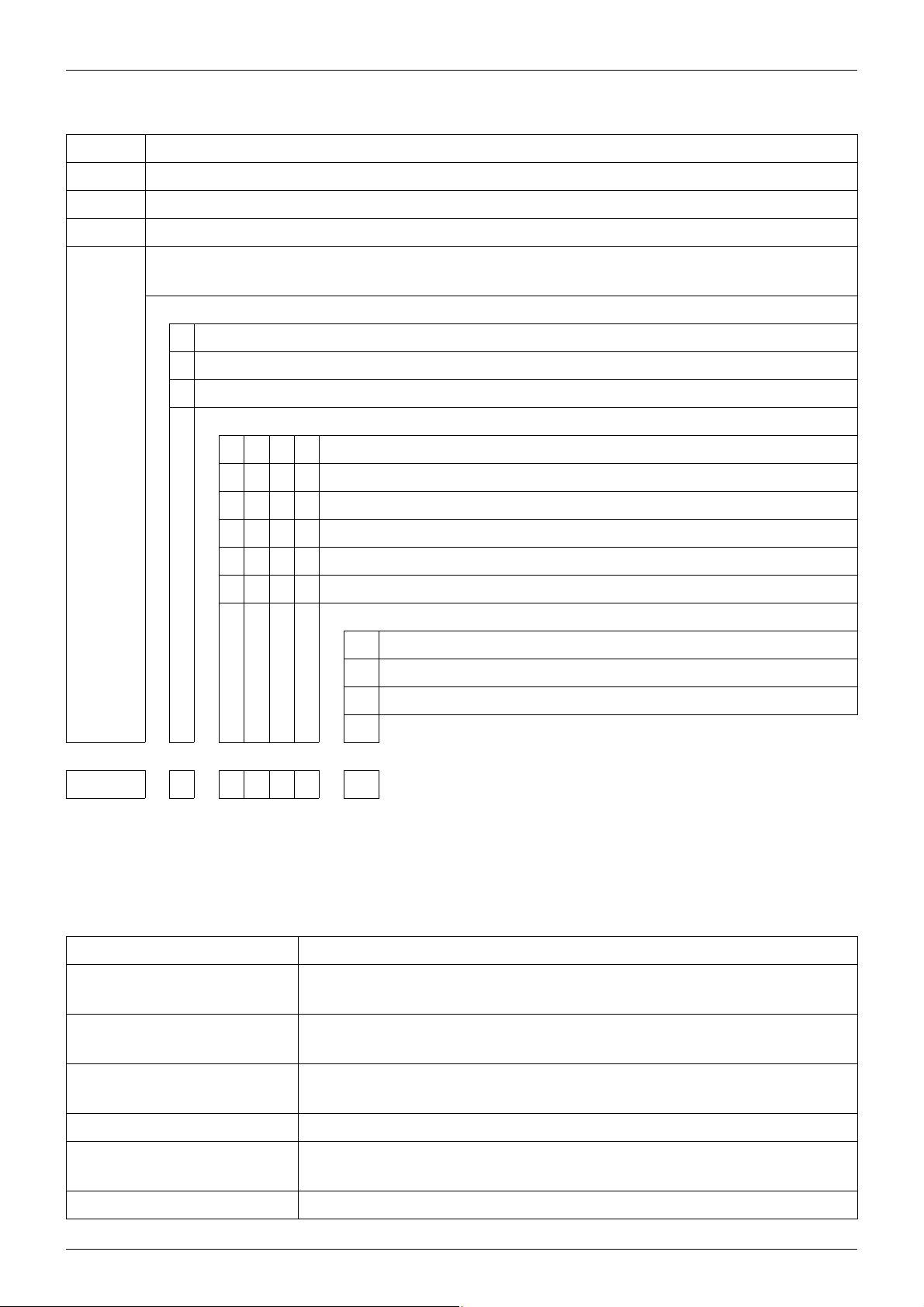

2.1 Identifying the device version

Basic type

702031 Quantrol LC100 (format 48 mm x 48 mm)

702032 Quantrol LC200 (format 48 mm x 96 mm, portrait format)

702034 Quantrol LC300 (format 96 mm x 96 mm)

All types including 1 analog input (universal), 1 binary input (for potential-free contact; can be used as an alternative to analog input 0 to 10 V), 1 relay output (N/O)

Basic type extension

8 Standard, with factory settings

9 Customer-specific programming (on request)

1234Options (3 and 4 not for LC100)

000011111 relay output (N/O)

22221 logic output

3 - - - 1 analog output (configurable)

- 4 - - 1 RS485 interface

Voltage supply

23 AC 110 to 240 V +10/-15 %, 48 to 63 Hz

25 AC/DC 20 to 30 V, 48 to 63 Hz

/- - Order code

702034 / 8 - 3412-23 Example

2.2 Excerpt from the technical data

Case

Case type Plastic case for panel mounting as per IEC 61554 (indoor use)

Dimensions (front) LC100: 48 mm x 48 mm; LC200: 48 mm x 96 mm (portrait format);

LC300: 96 mm x 96 mm

Panel cut-out LC100: 45 mm x 45 mm; LC200: 45 mm x 92 mm;

LC300: 92 mm x 92 mm

Minimum spacing

horizontal / vertical

Depth behind panel LC100: max. 95 mm; LC200/LC300: max. 80 mm

Ambient / storage

temperature range

Ambient conditions rel. humidity < 90% annual average, without condensation

LC100: 11 mm / 30 mm (65 mm with USB cable);

LC200/LC300: 22 mm / 30 mm (65 mm with USB cable)

-5 to +55 °C / -40 to +70 °C

7

2 Installation - Electrical Connection

Site altitude up to 2000 m above sea level

Operating position any

Protection type as per DIN EN 60529, at the front IP 65, at the rear IP 20

Weight (fully equipped) LC100: approx. 150 g; LC200: approx. 200 g;

LC300: approx. 300 g

Electrical data

Voltage supply (switch

mode PSU)

Electrical

safety

Power consumption max. 14 VA

Electrical connection on the rear via screw terminals; with core-end ferrule of a pipe

Conductor cross section fine-strand 0.25 to 1.5 mm

Tightening torque 0.5 Nm

Electromagnetic

compatibility

Interference emission Class A - Only for industrial use Interference immunity Industrial requirements

Setup interface USB socket, type Mini-B 5-pole

AC 110 to 240 V +10/-15 %, 48 to 63 Hz

AC/DC 20 to 30 V, 48 to 63 Hz

as per DIN EN 61010, part 1

overvoltage category III, pollution degree 2

shape, open cable lug or pin cable lug

2

as per DIN EN 61326-1

8

2 Installation - Electrical Connection

1.

2.

1.

3.

2.

3.

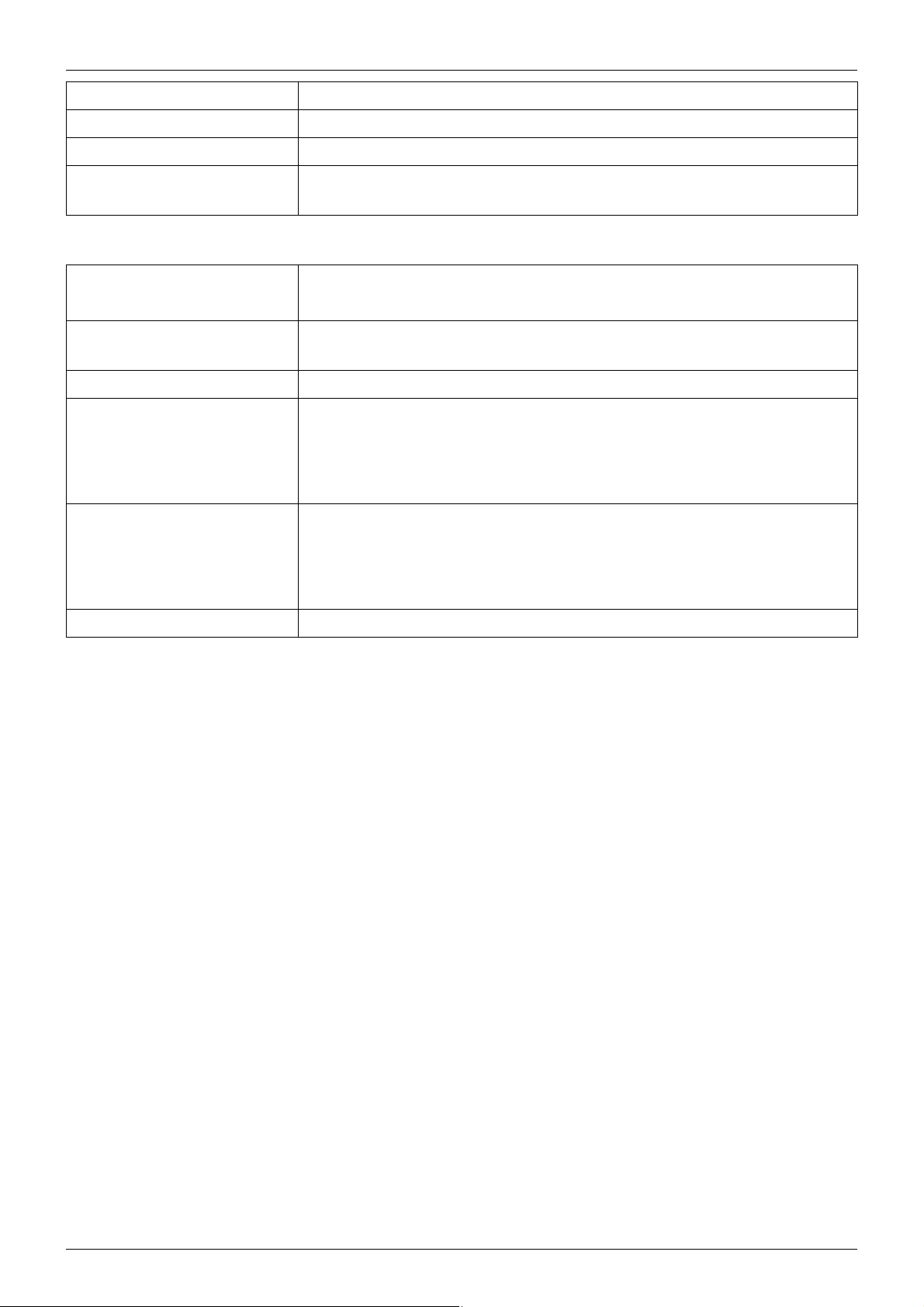

2.3 Installation

LC100 LC200 and LC300

Installation of LC100 Installation of LC200 and LC300

1. Insert the device from the front into the

panel cut-out and ensure that the seal is

correctly positioned.

2. Push the fastening frame from the panel

rear onto the device and press the

springs against the panel rear until the

lugs engage in their slots and it is

sufficiently fastened.

1. Insert the device from the front into the

panel cut-out and ensure that the seal is

correctly positioned.

2. Slide the mounting brackets from the

panel rear into the lateral openings and

push to the rear against the stop.

3. Place the mounting brackets against the

panel rear, and tighten evenly with a

screwdriver.

9

2 Installation - Electrical Connection

(4)

(3) (2) (1)

(7)

(6)(5) (8)

30 V AC

50 V DC

2300 V

AC

30 V AC

50 V DC

2300 V

AC

2.4 Installation notes

• The device is not suitable for installation in explosive areas (Ex areas).

• The choice of cable material, the installation and the electrical connection of the device must

conform to the requirements of DIN VDE 0100 "Installation of low-voltage power circuits"

and/or the appropriate local/national regulations (e.g. based on IEC 60364).

• At maximum load, the cables must be heat resistant up to at least 80 °C.

• The electrical connection must only be carried out by qualified personnel.

• The device is intended to be installed in electrical cabinets or systems. It shall be operated by

mains protected with a branch circuitry overcurrent protection device not more than 20 Amps.

For servicing/repairing a Disconnecting Device shall be provided to disconnect all conductors.

• The load circuit must be fused for the maximum relay current, in order to prevent the output

relay contacts from becoming welded in the event of a short circuit occurring at that point.

• The electromagnetic compatibility (EMC) meets the standards and regulations cited in the

technical data.

• Run input, output and supply cables separately and not in parallel with one another.

• Sensor and interface cables should be shielded cables with twisted conductors. Do not run

cables close to current-carrying components or cables. Ground the shielding on one side.

• Do not connect other consumers to the power terminals of the device.

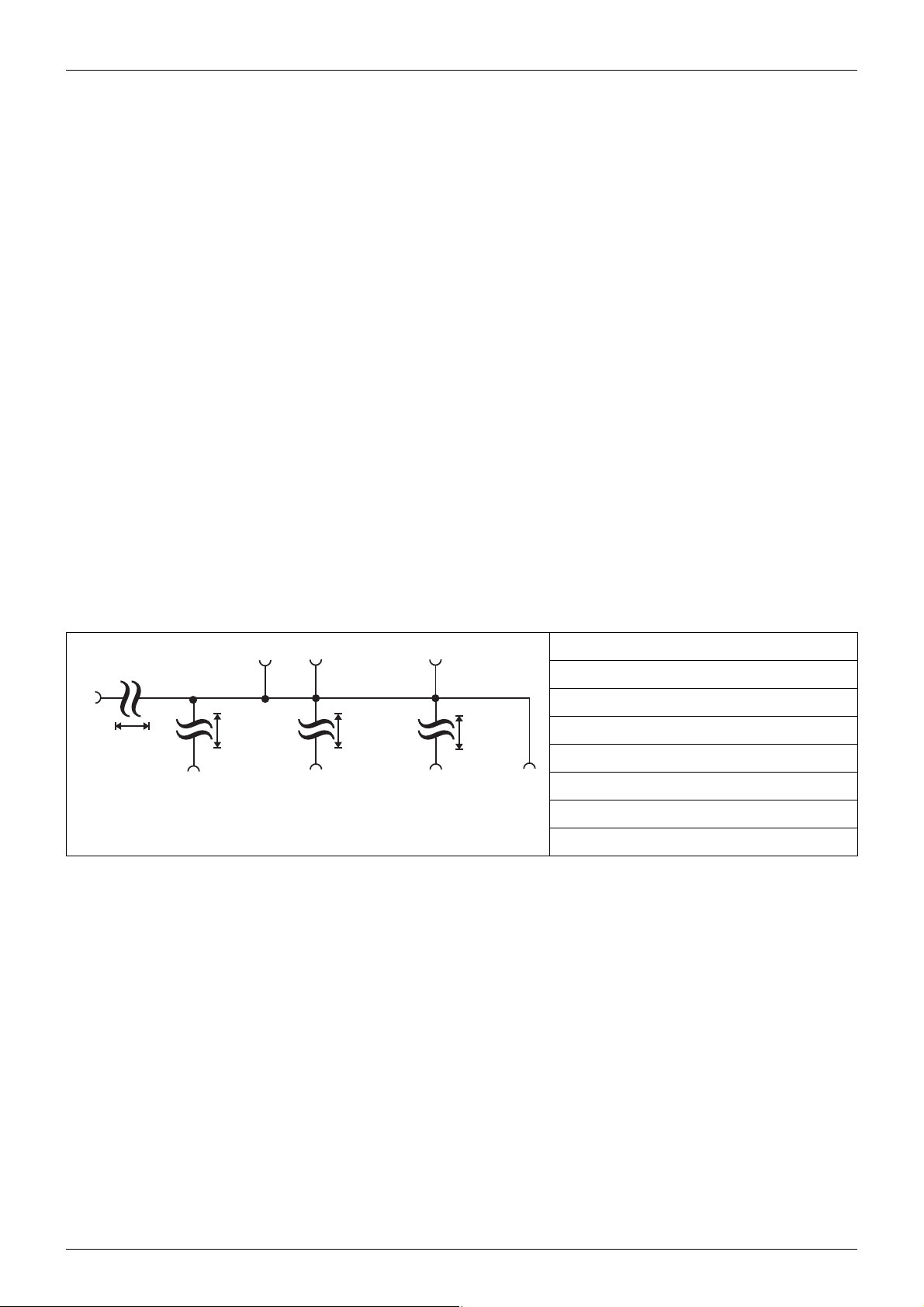

2.5 Electrical isolation

(1) Analog input

(2) Binary input

(3) Setup interface (USB)

(4) Voltage supply

(5) RS485 interface

(6) Analog output

(7) Relay outputs

(8) Logic outputs

10

2 Installation - Electrical Connection

13

14

76

12

11

10

9

8

N(L-)

5

L1(L+)

4

USB

N(L-)

L1(L+)

14

15

16

17

18

19

5

11

10

13

12

4

7

8

9

USB

N(L-)

L1(L+)

5

11

10

4

7

8

9

14

15

16

17

18

19

13

12

USB

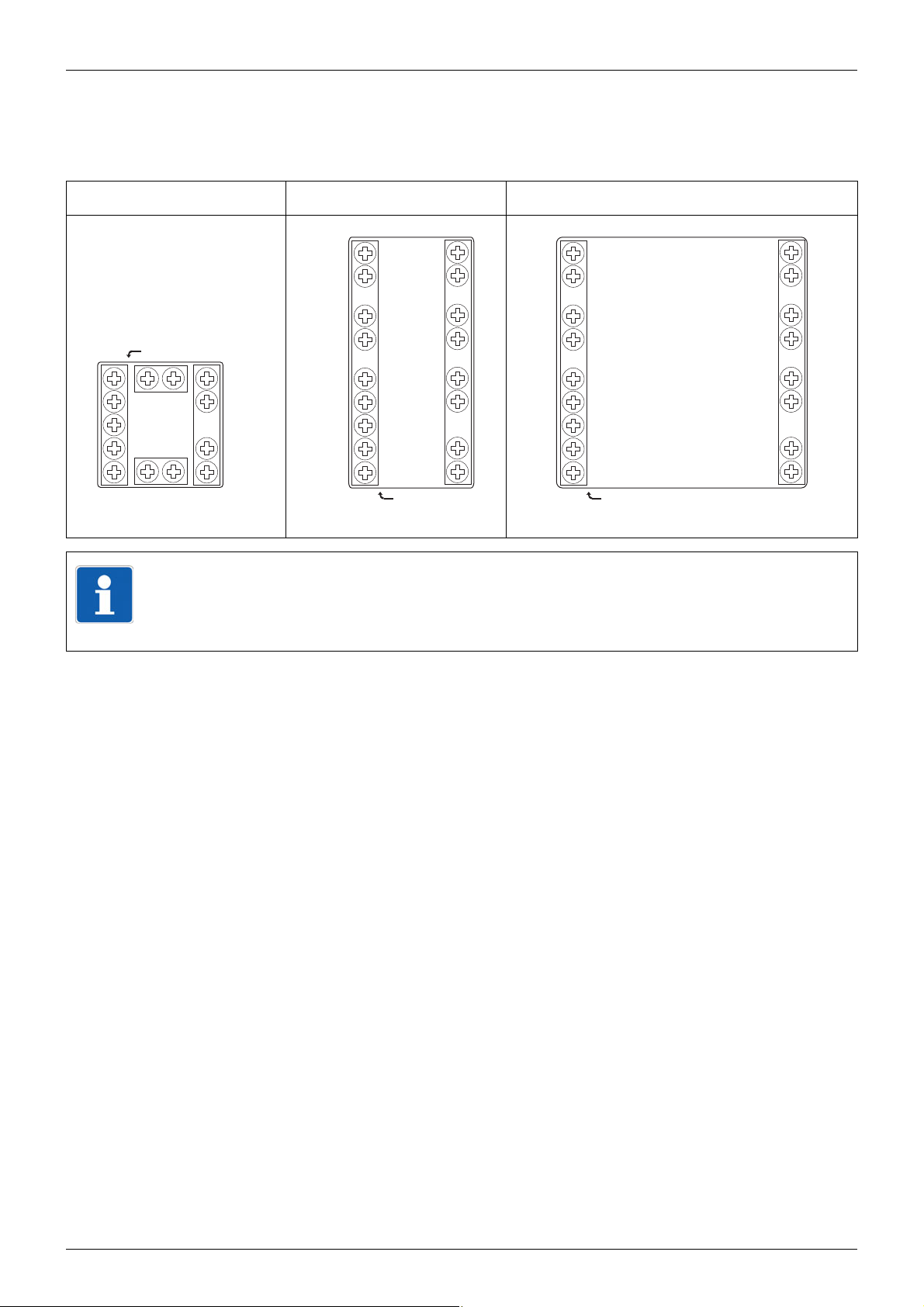

2.6 Connection diagram

The terminal strips on the device rear are equipped with screw terminals. Please refer to the technical data for specifications concerning the conductor cross section.

LC100 LC200 LC300

TIP!

The USB interface (socket Mini-B, 5-pole) is labeled on the device with "SETUP“

and is located on the case top of the LC100 and on the case bottom of the LC200

and LC300. It is used for connection to a PC that is running the setup program.

11

2 Installation - Electrical Connection

+

-

U

+

-

x

I

x

+

-

xIx

U

,

-

+

U

+

-

x

RxD/TxD

+

-

AC/DC

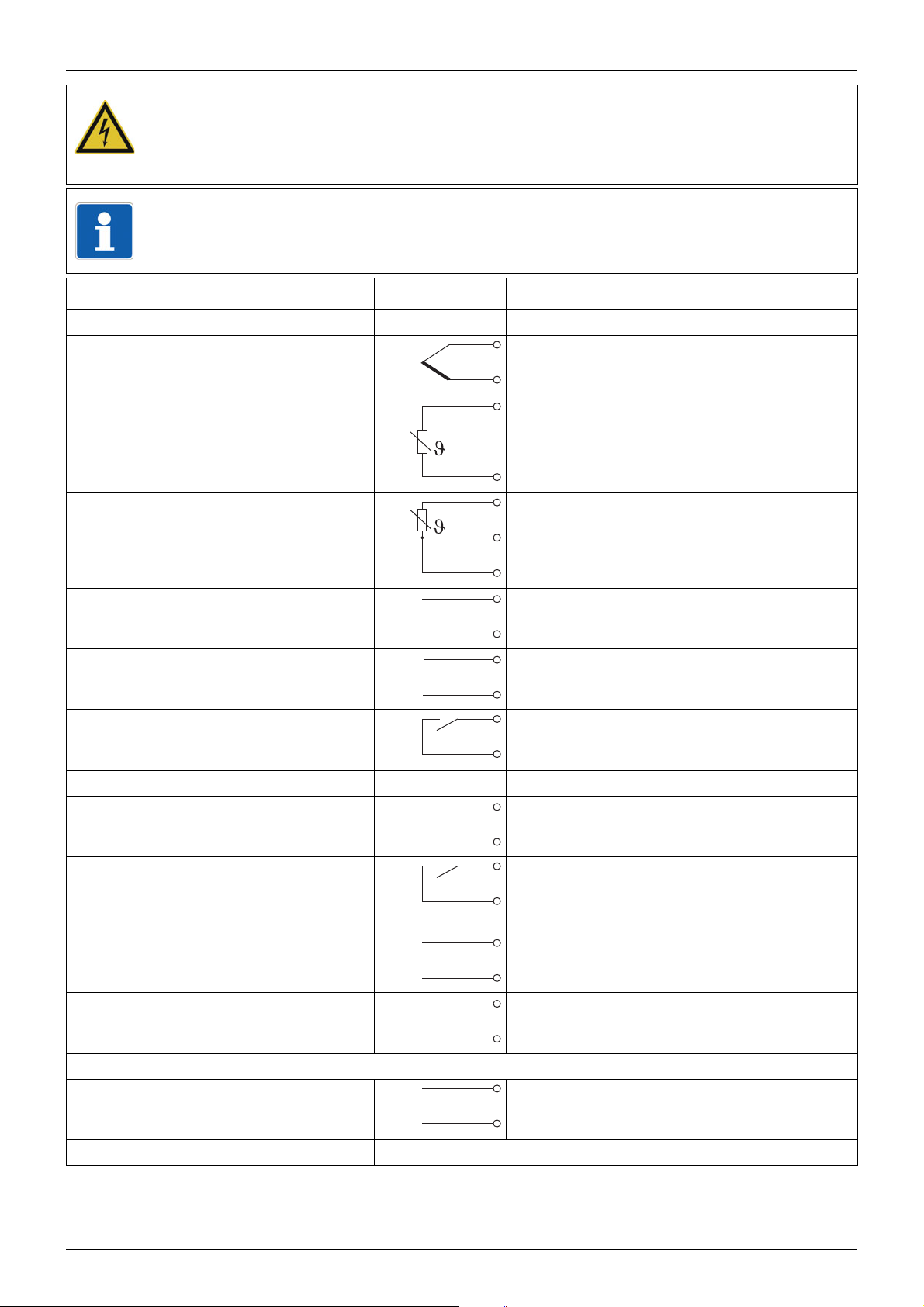

DANGER!

The electrical installation may carry voltage.

Risk of electrocution.

The electrical connection must only be performed by qualified personnel.

TIP!

Prior to starting the electrical connection, check that the device version complies

with the order code.

Connections Symbol LC100 LC200/LC300

Analog input

Thermocouple 9 10

811

RTD temperature probe, 2-wire 10 9

811

RTD temperature probe, 3-wire 10 9

910

811

Voltage

DC 0 to 10 V

Current

DC 0(4) to 20 mA

Binary input

for potential-free contact

Output:12312345

Analog output

DC 0 to 10 V, DC 0(4) to 20 mA

Relay output (N/O)

(max. 3 A at AC 230 V, resistive

load)

Logic output (DC 0/14 V) 13 7 12 14 16 18

RS485 interface 714

12 7

11 8

910

811

11 7

12 8

13 12

14 13

4136 412141618

5147 513151719

14 6 13151719

615

Output 1 as standard; Outputs 2 to 5 optional (options 1 to 4)

Voltage supply L1 (L+) L1 (L+)

N (L-) N (L-)

Setup interface USB socket, type Mini-B 5-pole

12

3 Operation - Configuration - Parameterization

(H)

(G)

(E)

(F)

(A)

(B) (C) (D)

t

w/x

t1

rASL

t2

SP1

t

w

SP2

SP1

w/x

rASL

x

t1

t2 t3 t4

t1

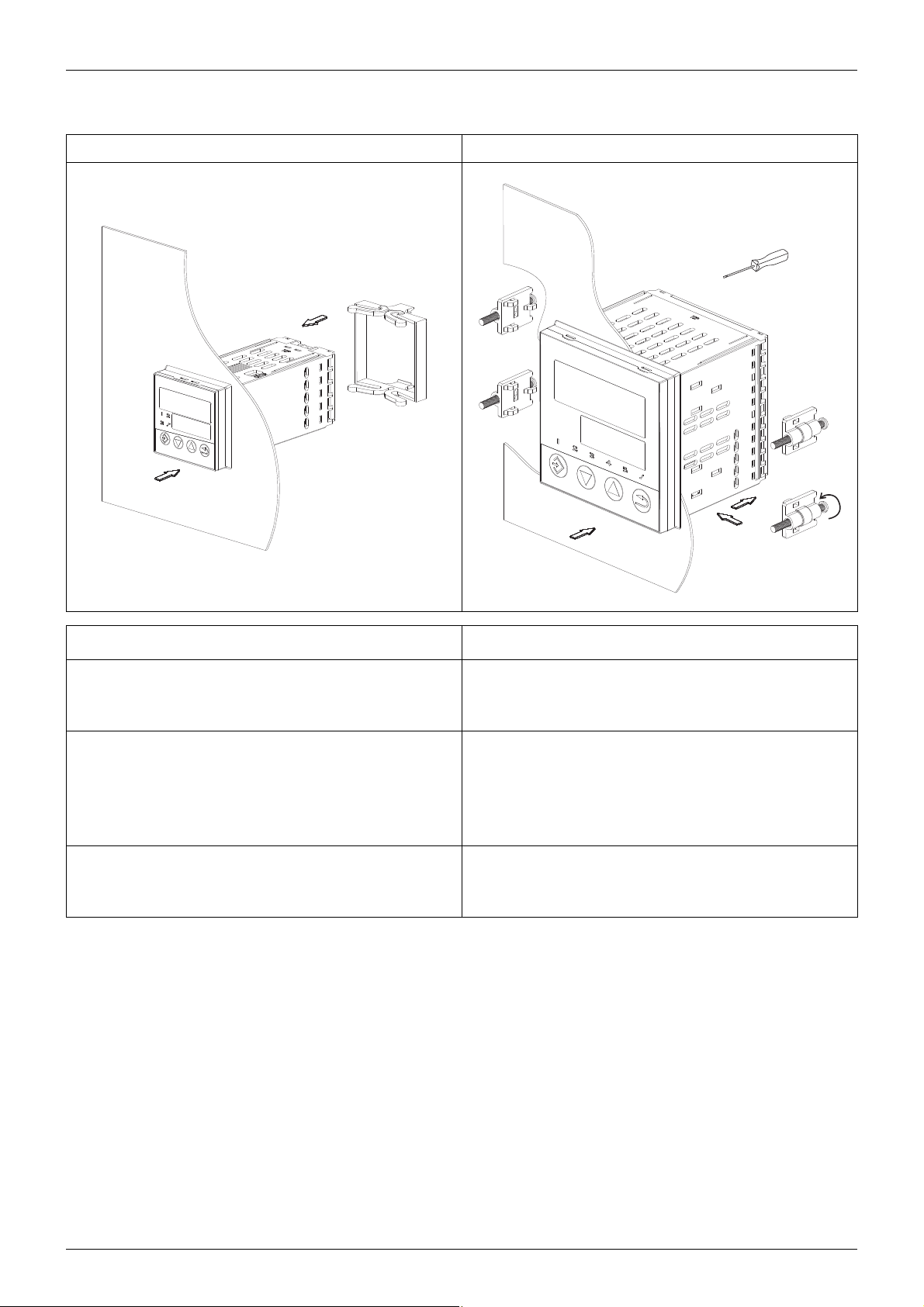

3.1 Operation

3.1.1 Display and operating elements

(A) Programming / one level deeper

(B) Value reduction / previous parameter

(C) Value increase / next parameter

(D) Function key / leave level

(E) Red 7-segment display (factory-set: Actual

value); 4-digit, configurable decimal place (automatic adjustment in the case of display overflow)

(F) Green 7-segment display (factory-set: Setpoint);

4-digit, configurable decimal place; also display

of level and parameter symbols

The software version is displayed on

the device when simultaneously pressing keys (A) and (C).

(G) LED 1 to 3(5): Switching position of binary output

(LED is lit = output active)

(H) LED ramp function or firing curve

3.1.2 Self-optimization, setpoint and manual mode

On the basis of the Normal display, the following Functions are available:

Start of self-optimization: Simultane-

ously press keys (B) and (C) (> 2 s)

Abort of self-optimization: Simulta-

neously press keys (B) and (C)

Change setpoint using keys (B) and

(C)

Function key (D) (> 2 s) is used to

Change-over to manual mode and to

exit the manual mode

"tUnE“ flashes in the lower display.

No parameters are changed by the abort.

The longer the key is kept pressed, the faster the set

point value changes. The value will be automatically

applied.

The output level (%) is displayed in the lower display

and can be changed with the keys (B) and (C).

(The controller automatically changes to manual mode

in the event of overrange/underrange and probe

break.)

3.1.3 Ramp function/firing curve

Ramp function (start after mains ON or with

the binary function)

t1:

Start (actual

value)

t2:

Setpoint setting

was reached

LED (H): Is lit with the ramp function active LED (H): Flashes in phase 1 (t1 to t2), is lit in

Firing curve (start with the binary function or

using the function key)

t1:

Start

t2:

SP1 -> SP2

(automatically)

t3:

Timer start

t4:

Timer end

phases 2 and 3 (t2 to t4)

OFF (F): Firing curve not active

13

3 Operation - Configuration - Parameterization

ConF

> 2s

PArA

(11)

OPr

(1) (3)

(4)

(2)

(5)

(6)

(14)

(12)

(10)

(13)

3.1.4 Level concept

The parameters for device setting are organized at different levels.

(1) Changeover from normal display to the levels

(2) Changeover between levels

(3) Changeover to the operator level (setpoints,

process values, timer value and time)

(4) Changeover to the parameter level (controller

parameters)

(5) Changeover to configuration level (analog input,

controller, ramp function, limit value monitoring,

timer, outputs, binary functions, display and

operation, interface)

(6) Return to the normal display

(10) Navigation principle:

If no key is pressed for 180 s (factorysetting), the device will return to its

(11) - one level deeper

(12) - next parameter / increase value

normal display. This time period can

be configured.

(13) - previous parameter / reduce value

(14) - one level back

The various levels are also accessible in manual mode.

Level inhibit (factory-setting: all levels are free):

Code Operator

level

0 free free free

1 free free inhibited

2 free inhibited inhibited

3 inhibited inhibited inhibited

Parameter

level

Configuration level

1. Simultaneously press (A) and (B) (> 5 s)

2. Press (A) (display flashes)

3. Enter code using (B) or (C)

4. Use (D) to return to the normal display

(or automatically after 180 s)

(key designation in brackets;

see chapter 3.1.1)

3.1.5 Operator level (OPr)

Depending on the configuration, the following parameters are available:

Symbol Description Symbol Description

SP1 Setpoint 1 (can be edited) rASL Ramp rate (for firing curve; can be

edited)

SP2 Setpoint 2 (can be edited) SPr Current ramp setpoint (for ramp

function or firing curve)

t1 Timer value (if timer or firing curve

tL Timer run time (if timer or firing

tr Residual timer run time (if timer or

14

are inactive; can be edited)

curve are active)

firing curve are active)

InP1 Measured value at analog input

y Output level

3 Operation - Configuration - Parameterization

3.2 Configuration (ConF)

TIP!

The device will map out parameters unless the equipment level permits the function

assigned to the parameter. Factory settings appear in bold in the following table.

Analog selector

With some parameters in the configuration level, the user can choose from a series of analog

values. The following list contains all available signals.

Value Description Value Description

0 Switched off 7 Setpoint 2

1 Analog input 8 Output level display

(-100 % to +100 %)

2 Actual value 9 Controller output 1 (e.g. heating,

output level 0 to +100 %)

3 Current setpoint 10 Controller output 2 (e.g. cooling,

output level 0 to -100 %)

4 Ramp end value 11 Timer run time (time unit of the

timer)

5 (reserved) 12 Timer residual time (time unit of the

timer)

6Setpoint 1

3.2.1 Analog input (InP)

ConF

-> InP ->

Parameters Value Description Value Description

Probe type

SEnS

0 Pt100 3-wire 9 NiCr-Ni K

1 Pt1000 3-wire 10 Pt10Rh-Pt S

2 Pt100 2-wire 11 Pt13Rh-Pt R

3 Pt1000 2-wire 12 NiCrSi-NiSi N

4 KTY 2 wire 13 NiCr-CuNi E

RTD temperature probe: Thermocouples:

5 Cu-50 3-wire Standard signals:

Thermocouples: 14 0 to 20 mA

6 Cu-CuNi T 15 4 to 20 mA

7 Fe-CuNi J 16 0 to 10 V

8 Fe-CuNi L

When selecting "0 to 10 V“, binary input

bin1 is inactive.

15

3 Operation - Configuration - Parameterization

Parameters Value Description

Measured value

offset

OFFS

Display start

SCL

Display end

SCH

Filter time constantdF0.0 ...

Temperature unit

Unit

(Setup program: Adjustable resistance of the KTY at 25 °C.)

-1999 ...

0 ...

+9999

-1999 ...

0 ...

+9999

-1999 ...

100 ...

+9999

0.6 ...

100.0 (s)

1 deg. Celsius

2 deg. Fahrenheit

The measured value is corrected through this value (offset),

prior to being used as a controller input value and in the analog

selector.

On transducers with standard signal, a display value is

assigned to the physical signal.

Example: 0 to 20 mA = 0 to 1500 °C

Adaptation of the digital input filter (0 = Filter OFF)

3.2.2 Controller (Cntr)

The actual value is provided for the controller by the analog input.

ConF -> Cntr ->

Parameters Value Description

Controller type

CtyP

Action

CACt

Output value,

manual mode

HAnd

Output level at

Out-of-Range

rOut

Setpoint limit start

SPL

Setpoint limit end

SPH

1 2-state controller

2 3-state controller

3 Continuous controller

0 Direct: (The output level of the controller is > 0 when the actual

value exceeds the setpoint, e.g. cooling).

1 Inverse: (The output level of the controller is > 0 when the

actual value is smaller than the setpoint, e.g. heating.)

-100 ...

0 ...

+101

-100 ...

0 ...

+100

-1999 ...

+9999

-1999 ...

+9999

Output level after switching to manual mode

101 = last output value

Output level in the event of overrange or underrange

The setpoint limitation prevents the entry of values exceeding

the default range.

The setpoint limits are not effective when entering setpoints

via the interface. The correction value is limited for external

setpoints with offset.

(Setup program: Manual mode and self-optimization can be inhibited.)

16

3 Operation - Configuration - Parameterization

3.2.3 Ramp function/firing curve (rAFC)

The device can be operated as a fixed value controller with and without ramp function. In addition, a firing curve is supported.

ConF -> rAFC ->

Parameters Value Description

Function

FnCt

Ramp rate

rASL

(Setup program: For the firing curve, timer value, time unit and setpoint can also be set here.)

0 Ramp function/firing curve switched off

1 Ramp function Kelvin/Minute

2 Ramp function Kelvin/Hour

3 Ramp function Kelvin/Day

4 Firing curve Kelvin/Minute

5 Firing curve Kelvin/Hour

6 Firing curve Kelvin/Day

0 ...

999

Value of the ramp rate (only for function = 1 to 6)

3.2.4 Limit value monitoring (Li1, Li2)

The device is equipped with two functions for limit value monitoring (Li 1, Li 2) each with eight

different alarm functions (AF1 to AF8). The two output signals are available for binary functions.

ConF -> LiI , Li2 ->

Parameters Value Description

Alarm function

FnCt

Limit value

AL, AL2

Switching

differential

HySt

0 Limit value monitoring switched off

1 AF1: Limit value above and below the setpoint (monitoring

range); symmetric or asymmetric

2 AF2: As AF1, output signal inverted

3 AF3: Limit value below the setpoint

4 AF4: As AF3, output signal inverted

5 AF5: Limit value above the setpoint

6 AF6: As AF5, output signal inverted

7 AF7: Fixed limit value (setpoint independent)

8 AF8: As AF7, output signal inverted

-1999 ...

0 ...

+9999

0 ... 1 ...

9999

Limit value to be monitored

For asymmetrical limit value: AL is below the setpoint, AL2 is

above the setpoint.

Limit value range for AF1 and AF2: 0 to 9999

Switching differential in respect to the limit value

17

3 Operation - Configuration - Parameterization

Parameters Value Description

Response at

Out-of-Range /

symmetry of limit

value

ACrA

Switch-on

delay

0 Off / symmetric (only AL is active)

1 On / symmetric (only AL is active)

2 Off / asymmetric (AL and AL2 are active)

3 On / asymmetric (AL and AL2 are active)

Switching state in the event of overrange or underrange ("Out-

of-Range“) / symmetry of alarm functions AF1, AF2

0 ... 9999 Switch-on delay of the output signal (in seconds)

tOn

Actual value

AFPr

Setpoint value

AFSP

2 Signal to be monitored; 2 = actual value

"Analog selector", page 15

3 Setpoint for limit value monitoring (reference signal for AF1 to

AF6); 3 = current setpoint

"Analog selector", page 15

3.2.5 Timer (tFCt)

The timer provides an output signal available for the binary functions. This signal can be used,

e.g. to realize a time-limited control or a time-dependent setpoint changeover.

The timer value is not saved during a mains failure. After the mains connection is restored, the

timer remains inactive.

ConF -> tFCt ->

Parameters Value Description

Function

FnCt

Start condition

Strt

Time unit

Unit

Timer value

t1

0 Timer switched off

1 Timer signal is "high“ while the timer is running

2 Timer signal is "low“ while the timer is running

0 Manual start via function key or binary signal (no restart after

mains failure)

1 Automatic start after mains ON (restart after mains failure);

manual start is also possible

0 mm:ss

1 hh:mm

2 hhh.h

00.00.

...

999.9.

Timer run time (in the time unit set)

Tolerance band

toLt

18

0 ...

9999

Tolerance band for timer start

The timer only starts once the actual value has reached the

tolerance band.

0 = Start without tolerance band

3 Operation - Configuration - Parameterization

3.2.6 Outputs (OutL, OutA)

The configuration of the device outputs is subdivided in binary outputs (OutL) and analog output

(OutA). The switching states of binary outputs 1 to 3 (5) are displayed by LEDs K1 to K3 (K5) (LED

is lit = output active).

Binary outputs

The device is equipped with a relay output (N/O, output 1) as standard and can be optionally

equipped with two (four) additional binary outputs (relay or logic output; outputs 2 to 5).

ConF -> OutL ->

Parameters Value Description

Output 1 ... 5

Out1

Out2

Out3

Out4

Out5

(Setup program: The output signal can be inverted.)

Analog output

The device can be optionally equipped with an analog output (output 2).

0 Output not active (factory setting for Out2 ... Out5)

1 Controller output 1 (factory setting for Out1)

2 Controller output 2

3 Binary input

4 Limit value monitoring 1

5 Limit value monitoring 2

6 Timer signal

ConF -> OutA ->

Parameters Value Description

Function

FnCt

Type of signal

9 Function of the output; 9 = Controller output 1

"Analog selector", page 15

Physical output signal

SiGn

Value at

Out-of-Range

rOut

Zero point

0Pnt

End value

End

0 0 ... 20 mA

1 4 ... 20 mA

2 0 ... 10 V

0 ... 101 Signal (in percent) at overrange or underrange

101 = last output signal

-1999 ...

0 ...

+9999

-1999 ...

100 ...

+9999

Value range of the output variable for the physical output sig-

nal

19

3 Operation - Configuration - Parameterization

3.2.7 Binary functions (binF)

The binary signals of the binary output, the limit value monitoring and the timer can be used to

trigger different functions.

The binary functions for start and abort react to the rising flank of the triggering signal, all other

binary functions are state-dependent controlled and active with "High".

ConF -> binF ->

Parameters Value Description

Binary input

bin1

Limit value monitoring 1 and 2

LiI, Li2

Timer signal

tF1

0 Signal without function

1 Start self-optimization

2 Abort self-optimization

3 Change to manual mode

4 Switch off controller (controller outputs inactive)

5 Switch on controller

6 Inhibit manual mode

7 Stop ramp/firing curve

8 Abort ramp/firing curve

9 Restart ramp, start/abort firing curve

10 Switch over from setpoint 1 to setpoint 2

11 Lock keypad

12 Inhibit parameter and configuration level,

inhibit self-optimization start

13 Switch off the display

14 Start timer

15 Abort timer

16 Stop timer

17 Start/abort timer

3.2.8 Display and operation (diSP)

Both displays and the function key can be individually adapted to the respective requirements.

ConF -> diSP ->

Parameters Value Description

Upper display

diSU

Lower display

diSL

2 Display value for the upper display; 2 = Actual value

"Analog selector", page 15

3 Display value for the lower display; 3 = current set point

value

"Analog selector", page 15

20

3 Operation - Configuration - Parameterization

Parameters Value Description

Display change

when timer is

started

diSt

Time-out

tout

Decimal place

dECP

Function key, press

briefly (< 2 s)

tAS

(Setup program: The function of pressing the function key longer (> 2 s) can also be configured.)

0 No display change

1 Residual timer time

2 Timer run time

0 ...

180 ...

255

0 No decimal place

1 One decimal place

2 Two decimal places

0 No function

1 Start timer/firing curve

2 Abort timer/firing curve

3 Stop/continue timer/firing curve run

4 Start/abort timer/firing curve

5 Timer display (timer run time or residual timer time)

Time appears in the bottom display once the timer is started

Time period in seconds, after which the device automatically

returns to its normal display (if no key is pressed).

0 = Function switched off

3.2.9 Interface (IntF)

An optional RS485 interface can be used to integrate the device in a data network. When the

communication takes place via the setup interface, the RS485 interface is inactive.

ConF -> IntF ->

Parameters Value Description

Baud rate

bdrt

Device address

Adr

For further information about the RS485 interface, the Modbus protocol and the communication

with other devices, please refer to the interface description B 702030.2.0 available as a PDF

document under www.jumo.net.

0 9600 baud

1 19200 baud

0 ...

1 ...

254

Address in data network

21

3 Operation - Configuration - Parameterization

3.3 Parameterization (PArA)

Enter the controller parameters here.

PArA ->

Parameters Value Description

Proportional band

PB1, PB2

Derivative time

1

dt

Reset time

rt

Cycle time

Cy1, Cy2

Contact spacing

1

db

0 ...

9999

0 ...

80 ...

9999 (s)

0 ...

350 ...

9999 (s)

0.0 ...

20.0 ...

999.9 (s)

0.0 ...

999.9

Range of the proportional band

The larger the proportional band the lower the controller ampli-

fication.

The controller structure is not effective with Pb = 0 (behavior

identical to limit value monitoring). For the continuous control-

ler, ensure that Pb is > 0.

Influences the differential portion of the controller output signal

The larger the derivative time the higher the effectiveness of

the D portion.

0 = derivative time switched off (no D portion)

Influences the integral portion of the controller output signal

The larger the reset time the lower the effectiveness of the I

portion.

0 = reset time switched off (no I portion)

When using a switched output, the cycle time should be cho-

sen so that the energy flow to the process is as continuous as

is practicable without overloading the switching elements.

Spacing between the two control contacts of a 3-state control-

ler

Hysteresis

HyS1, HyS2

Working point

1

y0

Output level limiting

y1, y2

1

Only available for 3-state controllers (controller output 2)

The display of parameters depends on the controller type. For some parameters, the decimal

place depends on the device setting.

Factory settings appear in bold.

0.0 ...

1.0 ...

999.9

-100 ...

0 ...

+100

0 ...

100 (%)

-100 ...

+100 (%)

Hysteresis for a switching controller with proportional range

Pb = 0 (behavior identical to that for limit value monitoring)

The output level for P and PD controllers (if x = w then y = y0)

y1: Maximum output level limitation

y2: Minimum output level limitation

(only effective when Pb > 0)

22

4 Supplement

45

+0.6

45

+0.6

(1)

(2)

4.1 Additional information about installation

TIP!

The information given in this chapter is exclusively contained in this operating

manual provided as PDF document. It supplements the information contained in the

previous chapters of this operating manual as well as in the brief instructions added

to every device as a print out.

The ambient conditions at the installation site must meet the requirements specified in the technical data.

The device is not suitable for installation in explosive areas (Ex areas).

4.1.1 Device representation including dimensions

LC100

(1) Setup interface (USB)

on the device top

(2) Panel cut-out

23

4 Supplement

92

+0.8

45

+0.8

(1)

(2)

LC200

(1) Setup interface (USB)

on the device bottom

24

(2) Panel cut-out

LC300

92

+0.8

92

+0.8

(1)

(2)

4 Supplement

(1) Setup interface (USB)

(2) Panel cut-out

on the device bottom

Minimum spacing of panel cut-outs

Type without USB cable with USB cable

horizontal vertical horizontal vertical

LC100 11 mm 30 mm 11 mm 65 mm

LC200 22 mm 30 mm 22 mm 65 mm

LC300 22 mm 30 mm 22 mm 65 mm

4.1.2 Cleaning the device front

The device front panel can be cleaned with commercial cleaning and rinsing agents. It has a

limited resistance to organic solvents (such as ethyl alcohol, turpentine substitute, P1, xylol and

similar). Do not use high-pressure cleaning equipment.

25

4 Supplement

(1)

(2)

(3)

(C)

(B)

(C)

(B)

(A)

(1)

(2)

(3)

(C)

(B)

(C)

(B)

(A)

4.2 Additional information about the device functions

TIP!

The information given in this chapter is exclusively contained in this operating manual provided as a PDF document. It supplements the information contained in the

previous chapters of this operating manual as well as in the brief instructions added

to every device as a print out.

4.2.1 Entries and operator prompting

Value entry

When entries are made within the levels, the parameter symbol appears in the lower display.

(1) Select parameter (lower

display - green)

(2) Change value (upper

display - red)

(3) Parameter flashes

Time entry

A decimal place is mapped in the centre and on the right to display times. The time unit can be

configured.

(1) Select parameter (lower

display - green)

(2) Change value (upper

display - red)

(3) Parameter flashes

Procedure

1. Select parameter with key (B) or (C)

2. Change-over to the input mode with key (A): The lower display flashes.

3. Change value with key (B) or (C)

The longer the key is kept pressed, the faster the value changes.

4. Apply setting with key (A) (value is automatically applied after 2 s) - or cancel entry using

key (D) (value will not be applied)

TIP!

When pressing function key (D) for more than 2 seconds, the device will return to

the normal display

26

4 Supplement

4.2.2 Analog input

Measured value offset

A measured value correction (offset) can be carried out to correct system specific deviations. The

offset value is added to the measured value with the correct prefix (the measured value is reduced by entering a negative offset value).

CAUTION!

Measured value offset: The controller uses the corrected value for calculation (= displayed value). When the measured value has been offset, the corrected value does

no longer correspond to the value measured at the measuring point.

Incorrect use can cause inadmissible values of the control variable.

Only carry out a measured value offset within the admissible range.

Filter time constant

The filter time constant serves to adapt the digital input filter (filter of second priority). At a step

change of the input signal, approx. 26 % of the change is detected after the elapse of a time period corresponding to the filter time constant dF (2 x dF: approx. 59 %; 5 x dF: approx. 96 %).

A high filter time constant means:

• High damping of interference signals

• Slow reaction of the actual value display to actual value changes

• Low limit frequency

4.2.3 Analog output

Zero point and end value

The factory setting corresponds to an output level of 0 ... 100 % for the continuous controller (controller output 1): zero point = 0, end value = 100

If the analog output is used as controller output 2 for the 3-state controller (e.g. for cooling), the

following setting is required: zero point = 0, end value = -100

If, for example, the actual value is to be put out, which can be within the range of 150 °C to

500 °C, select the limits so that they correspond to the minimum and maximum temperature:

zero point = 150, end value = 500

27

4 Supplement

t

w/x

t1

rASL

t2

SP1

t

w

SP2

SP1

w/x

rASL

x

t1

t2 t3 t4

t1

4.2.4 Ramp function and firing curve

Ramp function

This function allows the continuous change of the setpoint up to the ramp end value (setpoint

setting SP1 or SP2). Depending on the actual value at ramp start, this results in a rising or falling

ramp with identical gradient (adjustable ramp ratio rASL).

The ramp starts after mains ON (or through the binary

function) at time t1 and starts at the actual value. The setpoint

reached at time t2.

When switching over or changing the setpoint, the new

setpoint is also moved to at ramp ratio rASL.

SP1 (or SP2) is moved to at ramp ratio rASL and is

LED "Ramp“ (H): Is lit with active

ramp function (until it is cancelled)

TIP!

The ramp function is interrupted in the event of a probe break, probe short-circuit,

overrange/underrange or changeover to manual mode. Once the event is remedied

(or after switching to automatic mode), the ramp function continues at the current

actual value.

After the power supply is restored, the ramp function starts at the current actual

value.

Firing curve

For use in small kilns, a firing curve can be saved for controlled start-up and time-dependent

firing.

With this function, the parameters setpoint 1 (SP1), setpoint 2 (SP2), ramp rate (rASL) and timer

value (

t1) are automatically linked to each other.

The ramp can be stopped or aborted using the binary

function. When aborted, the setpoint setting

is used to control.

Phase 1 (t1 to t2): The firing curve is started by using the

function key or with the binary function (time t1) and

starts at the actual value. The setpoint

ramp ratio

rASL.

SP1 is moved to at

SP1 (or SP2)

LED "Ramp“ (H):

Flashes in phase 1,

is lit in phase 2 and 3

28

Phase 2 (t2 to t3): Once the current ramp value has

reached the setpoint SP1 (t2), the device automatically

switches over to setpoint

approaches the new setpoint (the ramp ratio is of no

importance).

Phase 3 (t3 to t4): The timer starts when the actual value

has reached the setpoint

the set time (timer value

(t4), the controller switches off (setpoint display = 0).

SP2 (w). The actual value (x)

SP2 (t3) and keeps running for

t1). Once the timer has elapsed

TIP!

S

SP1

w/x

t

t1

w/x

t

SP1

t1

S

tOLt

(A) (B)

SP2

SP1

w/x

t

SP2

SP1

w/x

t

SP2

w/x

t

P

S

t1

t1

t1

(C)

(A) (B)

tOLt

SP1

S

PP

The firing curve can only be started when the actual value is smaller than setpoint 1.

The firing curve is aborted in the event of a probe break, probe short-circuit, overrange/underrange or change-over to manual mode (controller switched off).

After the power supply is restored, the firing curve is not active (controller switched

off).

When the firing curve is not active, OFF appears in the lower display.

4.2.5 Timers

The following functions can be realized when using the binary functions.

Time-limited control

The control is switched off once the timer has elapsed (output level 0 %).

(A) Without tolerance band

(B) With tolerance band

SP1 Setpoint 1

4 Supplement

Time-dependent setpoint changeover

After the timer is started, the controller is automatically set to setpoint SP2. Once the timer has

elapsed, the controller automatically switches to SP1.

tOLt Tolerance band

t1 Timer value

S Start (manual)

(A) Manual start

(B) Automatic start after

power ON

(C) Manual start with

tolerance band

SP1 Setpoint 1

SP2 Setpoint 2

tOLt Tolerance band

t1 Timer value

PPower ON

S Start (manual)

29

4 Supplement

w

1

AL

x

HySt

0

AL

AL

HySt

0

1

w

x

AL

w

1

AL

x

HySt

0

AL2

AL

HySt

0

1

w

x

AL2

w

1

AL

x

HySt

0

AL

HySt

1

0

w

x

AL

w

1

x

HySt

0

AL

HySt

1

0

w

x

AL

1

x

HySt

0

AL

HySt

1

0

x

4.2.6 Limit value monitoring

The following representations show the function of limit value (AL, AL2) for the various alarm

functions AF1 to AF8. The hysteresis (HySt) is always symmetrical in relation to the limit value.

Limit value referring to setpoint w

AF1 symmetric AF2 symmetric

AF1 asymmetric AF2 asymmetric

AF3 AF4

AF5 AF6

Fixed limit value

AF7 AF8

4.2.7 Self-optimization (TUNE)

Self-optimization operates according to the oscillation method and determines the optimum parameters for a PID or PI controller.

The following parameters are optimized depending on the controller type configured (2-state, 3state, continuous controller) and the controller structure (parameterization):

Proportional band (Pb1, Pb2), derivative time (dt), reset time (rt), cycle time (Cy1, Cy2), filter time

constant (dF; parameter of the analog input).

30

4 Supplement

t

x

w

T

S

w

x

T

t

S

Depending on the value of the control deviation, the controller selects between two self-optimization methods:

Self-optimization in the startup-phase

Self-optimization at the

setpoint

wSetpoint

S Switching curve

T Start time of self-optimi-

zation

Prerequisites

The following prerequisites must be fulfilled to be able to start self-optimization:

• Self-optimization start is not inhibited by the binary function (binF)

• Controller is in the automatic mode, not in the manual mode

• No parameter level inhibit active via setup program

• Ensure that keys (B) and (C) are not pressed one after the other. They must always be pressed

simultaneously.

Furthermore, the following points should be taken into consideration, checked and, if necessary,

adjusted, prior to starting self-optimization:

• Is the suitable controller type configured?

• Check and/or adjust the control action of the controller

• Is it possible to sufficiently influence the actual value in the manual mode?

• Only for continuous controller: The function of the output (OutP -> OutA) must be configured

as controller output 1 and scaled to 0 ... 100 %. This means:

Function (FnCt) = Controller output 1 (9)

Zero point (0Pnt) = 0

End value (End) = 100

Depending on the controller type and parameter setting, the controller structures and specific parameters are optimized:

Controller type Parameter setting Optimized cont-

Optimized parameters

roller structure

2-state controller rt > 0; dt = 0; Pb1 = any PI Pb1, rt, Cy1, dF

all other settings PID Pb1, dt, rt, Cy1, dF

3-state controller rt > 0; dt = 0;

PI Pb1, Pb2, rt, Cy1, Cy2, dF

Pb1 = Pb2 = any

all other settings PID Pb1, Pb2, dt, rt, Cy1, Cy2,

dF

Continuous

controller

rt > 0; dt = 0; Pb1 = any PI Pb1, rt, dF

all other settings PID Pb1, dt, rt, dF

31

4 Supplement

Start of self-optimization

Simultaneously press keys (B) and (C) (> 2 s):

"tUnE“ flashes in the lower display.

Self-optimization is completed when the display automatically changes to the normal display.

The duration of self-optimization depends on the control process.

Abort of self-optimization

Simultaneously press keys (B) and (C)

No parameters are changed by the abort.

32

4.3 Error messages

Display Cause Fault remedy

4 Supplement

-1999

(flashing!)

9999

(flashing!)

PErr Firing curve start is impos-

Overrange / underrange covers the following events:

• Probe break/short-circuit

• Measured value outside the probe measuring range

• Display overflow

No keyboard operations are possible during device initialization (all displays are switched on, the

upper 7-segment display flashes).

Underrange of the displayed value.

Overrange of the displayed

value.

sible because

the actual value is ≥ than

the setpoint 1

Is the medium being measured within the

range (too hot? too cold?)

Check probe for break and short-circuit.

Check the probe connection and the termi-

nals.

Check cable.

Check that the connected probe complies

with the configured probe type

The firing curve can be started when

the actual value is < than the setpoint 1

33

4 Supplement

4.4 Technical Data

Thermocouple input

Designation Standard Measuring range

Fe-CuNi „L“

Fe-CuNi „J“

Cu-CuNi „T“

NiCr-Ni „K“

NiCr-CuNi „E“

NiCrSi-NiSi „N“

Pt10Rh-Pt „S“

Pt13Rh-Pt „R“

EN 60584

EN 60584

EN 60584

EN 60584

EN 60584

EN 60584

EN 60584

-150 to +900 °C

-200 to +1200 °C

-200 to +400 °C

-200 to +1372 °C

-200 to +1000 °C

-100 to +1300 °C

-40 to +1768 °C

-40 to +1768 °C

Cold junction: KTY internal

a

The specifications refer to an ambient temperature of 20°C.

b

Including measuring accuracy at the internal cold junction.

The accuracy values refer to the measuring range.

RTD temperature probe input

Designation,

Measuring range Measuring

connection type

a

Measuring

accuracy

≤ 0.4 %

≤ 0.4 %

≤ 0.4 %

≤ 0.4 %

≤ 0.4 %

≤ 0.4 %

≤ 0.4 %

≤ 0.4 %

accuracy

b

temperature

influence

≤ 100 ppm/ K

≤ 100 ppm/ K

≤ 100 ppm/ K

≤ 100 ppm/ K

≤ 100 ppm/ K

≤ 100 ppm/ K

≤ 100 ppm/ K

≤ 100 ppm/ K

Ambient

Ambient

a

temperature

influence

Pt100 DIN EN 60751

2-wire connection

3-wire connection

Pt1000 DIN EN 60751

2-wire connection

3-wire connection

KTY, R25 = 1000 Ω

2-wire connection

KTY, R25 = 2000 Ω

2-wire connection

Cu-50

3-wire connection

-200 to +650 °C

-200 to +650 °C

-50 to +150 °C

-50 to +80 °C

-50 to +200 °C

≤ 50 ppm/K

≤ 0.4 %

≤ 0.4 %

≤ 50 ppm/ K

≤ 0.4 %

≤ 0.4 %

≤ 50 ppm/ K

≤ 1.0 %

≤ 50 ppm/ K

≤ 1.0 %

≤ 50 ppm/ K

≤ 1.0 %

Probe wire resistance: max. 30 Ω per wire with 3-wire circuit

Measured current: Pt100 approx. 1 mA; Pt1000 and KTY approx. 100 μA

Lead compensation: Not required for 3-wire circuit. For a 2-wire circuit, the lead resistance can

be compensated by correcting the actual value.

a

The accuracy values refer to the measuring range.

34

Input for standard signals

4 Supplement

Measuring range Measuring

a

Voltage 0 to 10 V

accuracy

≤ 0.4 % ≤ 150 ppm/K

Ambient

temperature influence

Input resistance > 650 kΩ

Current 0(4) to 20 mA

≤ 0.4 % ≤ 100 ppm/K

voltage drop > 2.2 V

a

The accuracy values refer to the maximum measuring range.

Binary input

Input for potential-free contact open = inactive;

closed = active

Measuring circuit monitoring

In the event of a fault, the outputs adopt a defined (configurable) status.

Measuring probe Overrange /

underrange

Probe /

cable short circuit

Probe /

cable break

Thermocouple • - •

RTD

•••

temperature probe

Voltage 0 to 10 V - - Current 4 to 20 mA • • •

Current 0 to 20 mA - - -

• = detected - = not detected

Outputs

Relay (N/O)

Contact rating

Contact life

max. 3 A at 230 V AC resistive load

150,000 operations at nominal load

350,000 operations at 1 A

310,000 operations at 1 A and cos ϕ > 0.7

Logic output 0/14V / 20 mA max.

Voltage (option)

Output signal

Load resistance

Accuracy

Current (option)

Output signals

Load resistance

Accuracy

0 to 10 V

> 600 Ω

< 0.5 %

0 to 20 mA / 4 to 20 mA

< 450 Ω

< 0.5 %

35

4 Supplement

Controller

Controller type 2-state controller, 3-state controller, continuous controller

Controller structures P/PI/PD/PID

Sampling time 250 ms

A/D converter 16 bit resolution

Timers

Accuracy 0.8 % ± 10 ppm/K ± 250 ms

Electrical data

Voltage supply (switch

mode PSU)

Electrical

safety

Power consumption max. 14 VA

Electrical connection on the rear via screw terminals; with core-end ferrule of a pipe

Conductor cross section fine-strand 0.25 to 1.5 mm

Tightening torque 0.5 Nm

Electromagnetic

compatibility

Interference emission Class A - Only for industrial use Interference immunity Industrial requirements

Setup interface USB socket, type Mini-B 5-pole

Requirements for core-end ferrules and cable lugs

Core-end ferrule pipe shape, without plastic sheath as per DIN 46228 part 1,

Cable lug open crimp cable lug, dimensionally adapted to DIN 46237 for

Pin cable lug as per DIN 46231

With UL applications use of the cable lugs or ferrules acc. to UL 486A-B (UL listed or

AC 110 to 240 V +10/-15 %, 48 to 63 Hz

AC/DC 20 to 30 V, 48 to 63 Hz

as per DIN EN 61010, part 1

overvoltage category III, pollution degree 2

shape, ope-n cable lug or pin cable lug

2

as per DIN EN 61326-1

with plastic sheath as per DIN 46228 part 4

closed crimp cable lugs

recognized)

Case

Case type plastic case for panel mounting as per IEC 61554 (indoor use)

Dimensions (front) LC100: 48 mm x 48 mm; LC200: 48 mm x 96 mm (portrait format);

LC300: 96 mm x 96 mm

Panel cut-out LC100: 45 mm x 45 mm; LC200: 45 mm x 92 mm;

LC300: 92 mm x 92 mm

Minimum spacing

horizontal / vertical

Depth behind panel LC100: max. 95 mm; LC200/LC300: max. 80 mm

Ambient / storage

temperature range

Ambient conditions rel. humidity < 90% annual average, without condensation

36

LC100: 11 mm / 30 mm (65 mm with USB cable);

LC200/LC300: 22 mm / 30 mm (65 mm with USB cable)

-5 to +55 °C / -40 to +70 °C

4 Supplement

Site altitude up to 2000 m above sea level

Operating position any

Protection type as per DIN EN 60529, at the front IP 65, at the rear IP 20

Weight (fully equipped) LC100: approx. 150 g; LC200: approx. 200 g;

LC300: approx. 300 g

Interface

Interface type RS485

Protocol Modbus RTU

Baud rate 9600, 19200

Data format 8 data bits, no parity bit, 1 stop bit

Device address 0 to 254

No. of subscribers max. 32

7-segment displays

Digit height

LC100, LC200 upper display: 10 mm; lower display: 7 mm

LC300 upper display: 20 mm; lower display: 13 mm

Color upper display: red; lower display: green

Places 4 (including decimal places)

Decimal places 0, 1, 2 (configurable)

Display range -1999 to 9999

Approvals/approval marks

Approval marks Inspection

authority

c UL us Underwriters

Laboratories

Certificate / Inspection number

E201387 UL 61010-1,

Inspection/test

basis

CAN/CSA C22.2

No. 61010-1

Valid for

all versions

37

4 Supplement

38

JUMO GmbH & Co. KG JUMO Instrument Co. Ltd. JUMO Process Control, Inc.

Street address:

Moritz-Juchheim-Straße 1

36039 Fulda, Germany

Delivery address:

Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO House

Temple Bank, Riverway

Harlow - Essex CM20 2DY, UK

Phone: +44 1279 63 55 33

Fax: +44 1279 63 52 62

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Loading...

Loading...