Page 1

JUMO dTRON 304/308/316

Compact Controller with program function

Type 703043

Type 703041 Type 703042 Type 703044

B 70.3041.0

Operating Manual

2010-04-30/00442056

Page 2

)

E

Please read this operating manual before commissioning the instrument. Keep the manual in a

place which is accessible to all users at all times.

Your comments are appreciated and may help us in improving this manual.

All necessary settings are described in this operating manual. Manipulations not described in the

manual or expressly forbidden will jeopardize your warranty rights. Please contact the nearest subsidiary or the head office, should you encounter problems.

This manual is valid from instrument software version 192.02.05.

It appears by simultaneously pressing the and keys.

When accessing the inner parts of the unit and returning modules, assemblies or components,

please observe the regulations accordings to EN 61340-5-1 and EN 61340-5-2 „Protection of electrostatic sensitive devices“. Only use ESD packaging for transport.

Please note that we cannot accept any liability for damage caused by ESD.

ESD=Electro Static Discharge

Page 3

Contents

1 Introduction 7

1.1 Description .................................................................................................... 7

1.2 Typographical conventions ......................................................................... 8

2 Identifying the instrument version 9

2.1 Type designation .......................................................................................... 9

2.2 Scope of delivery ........................................................................................ 10

2.3 Accessories ................................................................................................ 10

3 Mounting 11

3.1 Mounting site and climatic conditions ..................................................... 11

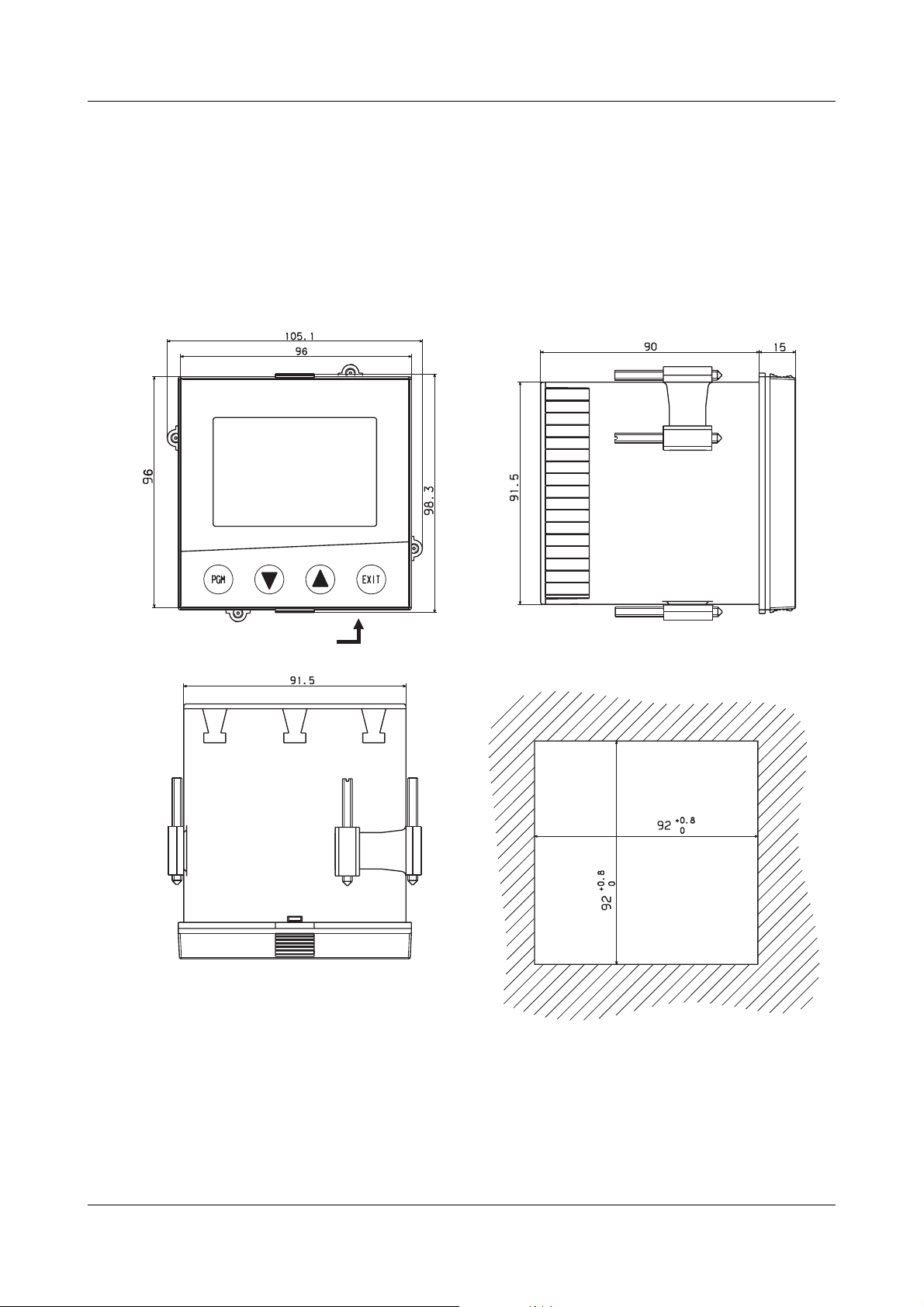

3.2 Dimensions ................................................................................................. 11

3.2.1 Type 703044 ................................................................................................. 11

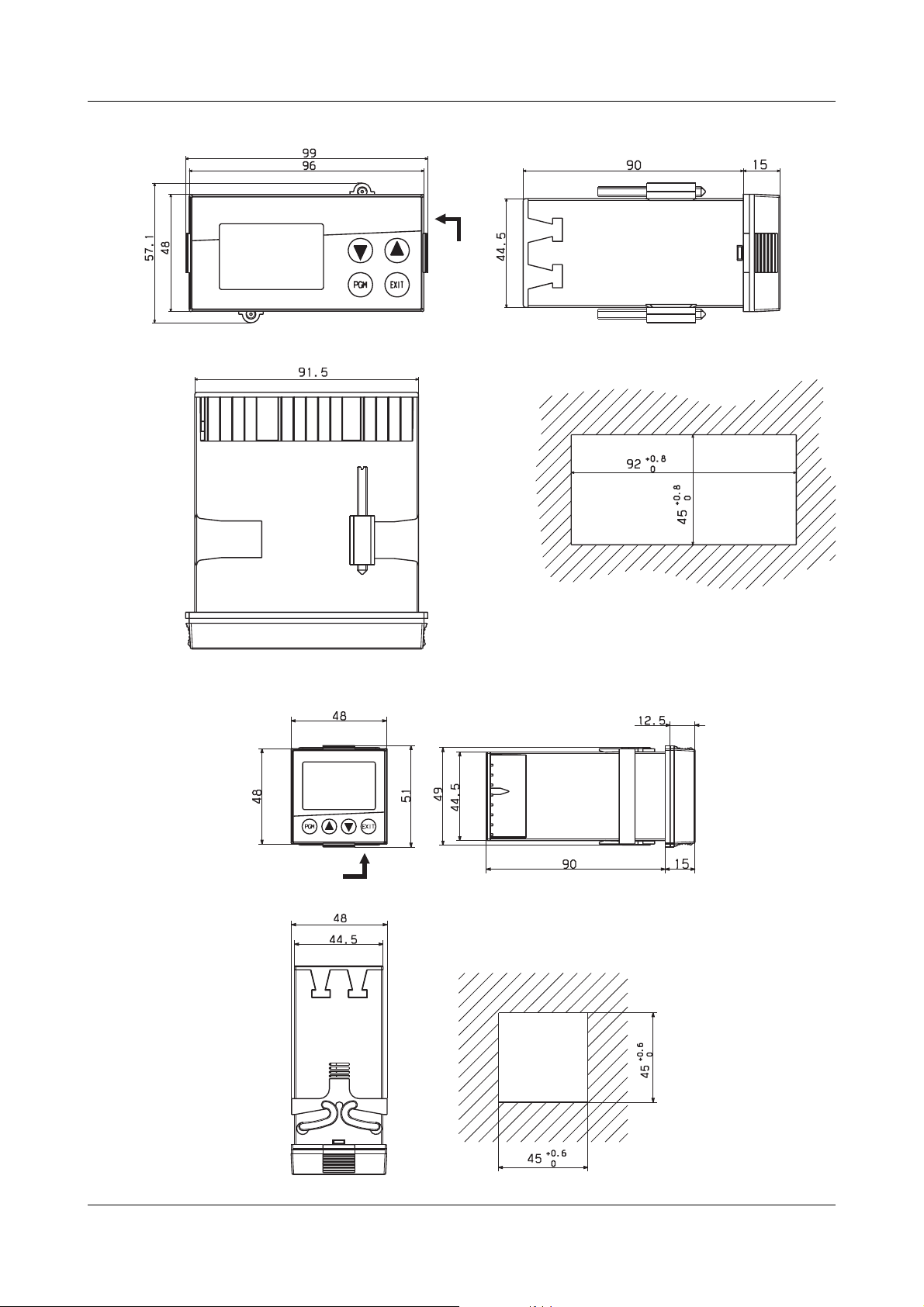

3.2.2 Type 703042/43 ............................................................................................ 12

3.2.3 Type 703041 ................................................................................................ 12

3.3 Side-by-side mounting .............................................................................. 13

3.4 Fitting in position ........................................................................................ 13

3.5 Removing the controller module .............................................................. 14

4 Electrical connection 15

4.1 Installation notes ........................................................................................ 15

4.2 Electrical isolation ...................................................................................... 16

4.3 Connection diagrams ................................................................................. 17

4.3.1 Type 703041 ................................................................................................. 17

4.3.2 Type 703042/43/44 ...................................................................................... 20

4.3.3 Termination resistor for the RS422/485 serial interface ............................... 24

4.3.4 Connection of the PROFIBUS-DP connector .............................................. 24

Page 4

Contents

5 Operation 25

5.1 Displays and controls ................................................................................ 25

5.2 Level concept ............................................................................................. 26

5.3 Level inhibit ................................................................................................. 27

5.4 Entries and operator prompting ............................................................... 28

5.5 Fixed-setpoint controller (ex-factory) ....................................................... 29

5.6 Program controller ..................................................................................... 30

5.6.1 Entering programs ........................................................................................ 30

5.6.2 Operation ..................................................................................................... 32

5.6.3 Shifting the program profile .......................................................................... 33

6 Operator level 35

7 Parameter level 37

8 Configuration 39

8.1 Analog inputs “InP” .................................................................................... 41

8.1.1 Customized fine tuning ................................................................................ 43

8.2 Controller “Cntr” ........................................................................................ 45

8.3 Generator “Pro” .......................................................................................... 47

8.4 Limit comparators “LC” ............................................................................. 50

8.5 Outputs “OutP” ........................................................................................... 54

8.6 Binary functions “binF” .............................................................................. 56

8.7 Display “diSP” ............................................................................................. 59

8.8 Timer “tFct” ................................................................................................ 61

8.9 Interfaces “IntF” ......................................................................................... 62

9 Tuning (optimization) 63

9.1 Autotuning (self-optimization) ................................................................... 63

9.2 Check of the tuning .................................................................................... 66

Page 5

Contents

10 Extra codes 67

10.1 Math and logic module .............................................................................. 67

10.2 Difference, humidity or ratio controller .................................................... 67

11 Retrofitting of modules 69

12 Appendix 71

12.1 Technical data ............................................................................................. 71

12.2 Alarm messages ......................................................................................... 74

13 Index 75

Page 6

Contents

Page 7

1.1 Description

The controller series consists of four freely programmable instruments in different DIN

formats for controlling temperature, pressure and other process variables.

As a temperature controller TR

generating plants to control the temperature of liquids or gases (mode of action: 1B).

The high-contrast, multicolor LCD display for process value, setpoint and operator

prompting contains two four-digit 7-segment displays, two single-character 16segment displays, display of the active setpoints, six status indicators, and displays

for the unit, ramp function and manual operation.

Just four keys on the front panel are needed for operation, parameterization and

configuration. The instruments can be used as 2-state, 3-state, modulating or

continuous controllers. The controller software includes a program or ramp function,

parameter set changeover, two autotuning (self-optimization) procedures, a math and

logic module, as well as 4 limit comparators.

Linearizations for the usual transducers are stored, and a customer-specific

linearization table can be programmed.

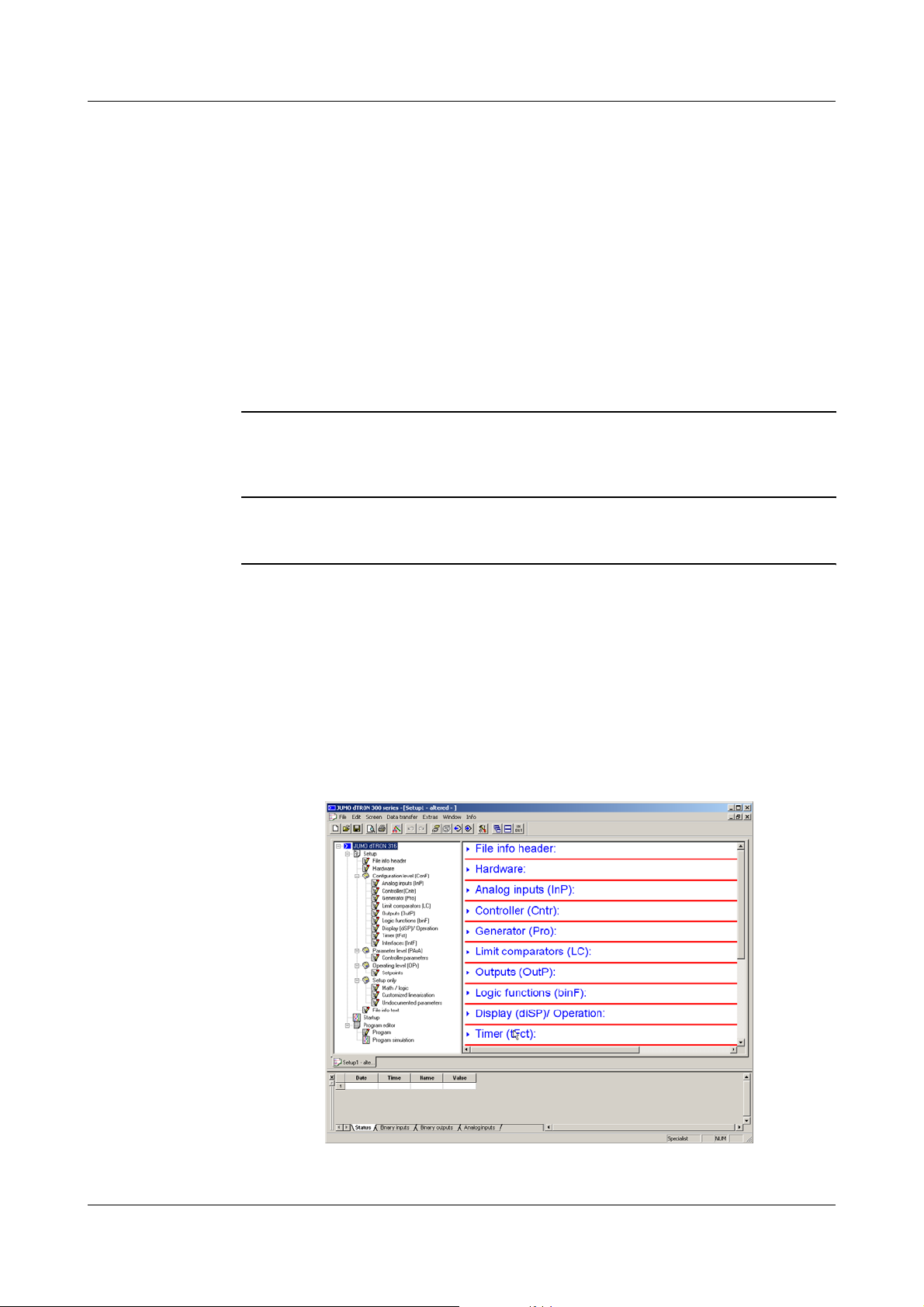

A setup program is available for user-friendly configuration from a PC.

An RS422/485 or a Profibus-DP interface can be used to integrate the instrument into

a data network.

The electrical connection is made at the back of the instrument, via screw terminals.

1 Introduction

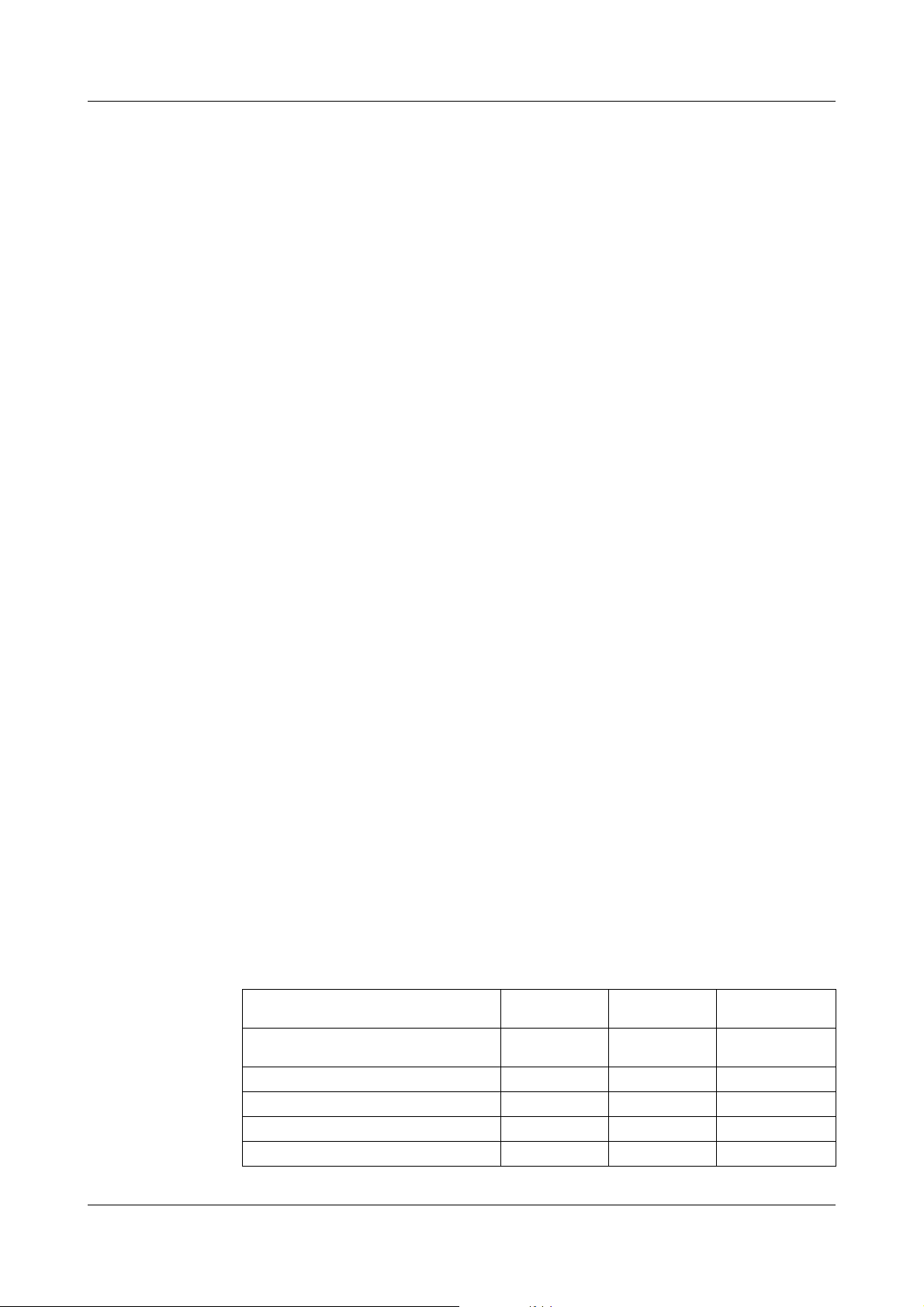

1

according to EN 14597 the devices are used in heat-

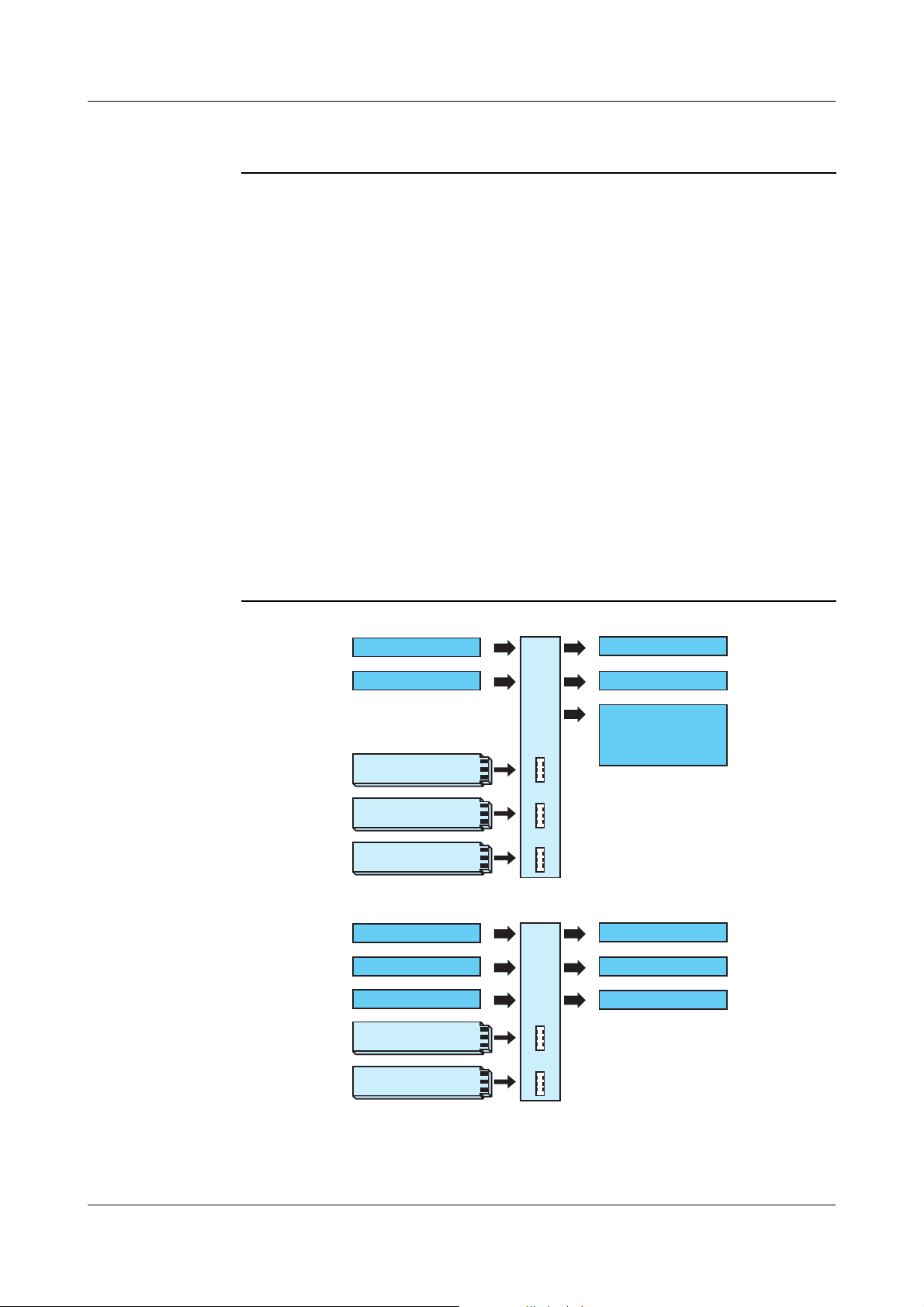

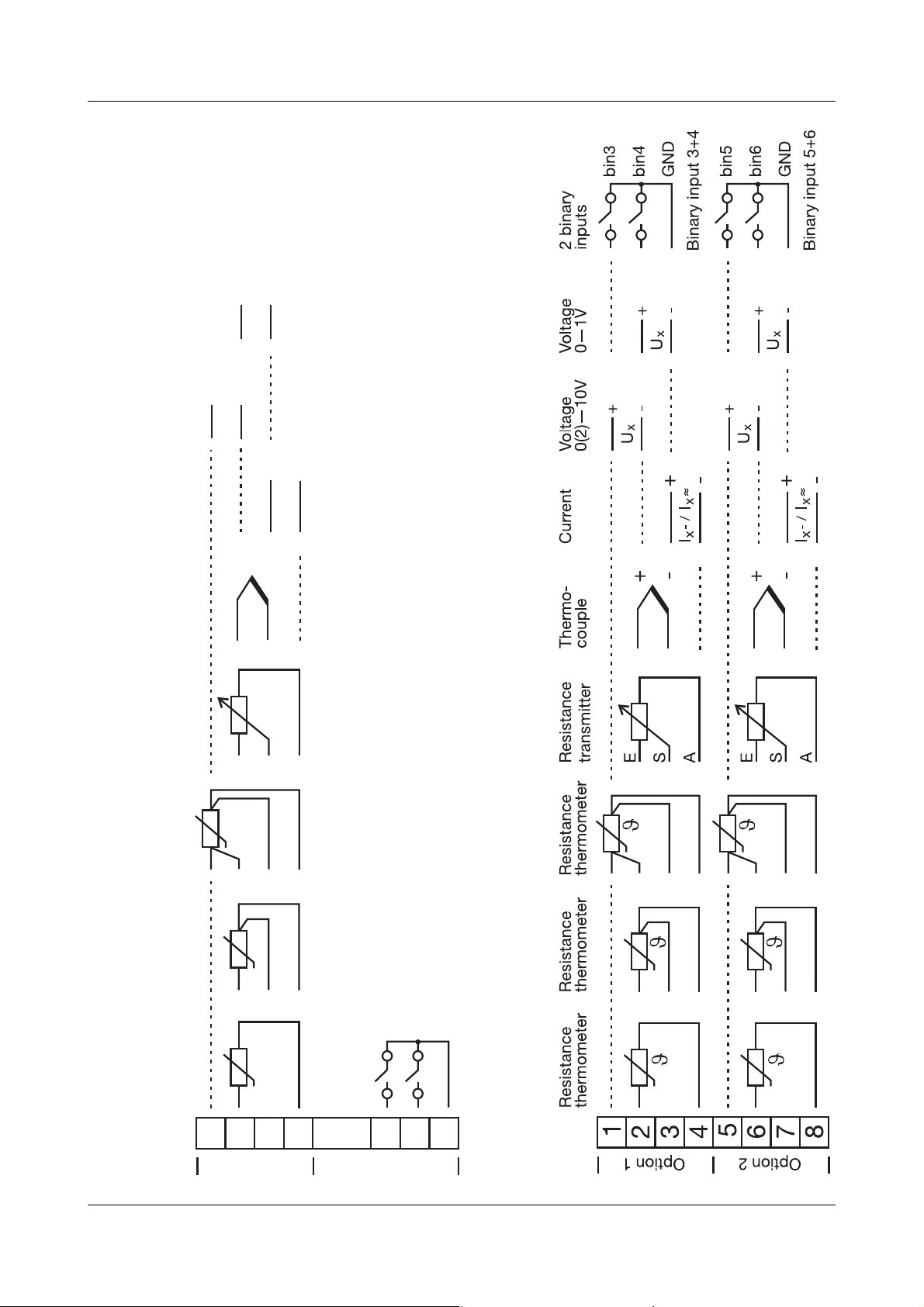

Analog input

2 binary inputs

Option 1

Option 2

Option 3

Analog input

Binary input

Binary input

Option 1

Type 703042/43/44

2 relays (changeover)

2 logic outputs

Supply voltage

17 V / 20 mA

for 2-wire

transmitter

Type 703041 (48mm x 48mm)

2 relays (make)

or

or

Logic output

Logic output

Option 2

1. For more detailed explanation, see EN 14597

7

Page 8

1 Introduction

1.2 Typographical conventions

Warning signs

Note signs

V

*

E

H

v

Danger This symbol is used when there may be danger to

personnel if the instructions are ignored or not followed

correctly!

Caution This symbol is used when there may be damage to

equipment or data if the instructions are ignored or not

followed correctly!

Caution This symbol is used where special care is required when

handling components liable to damage through

electrostatic discharge.

Note This symbol is used when your special attention is drawn

to a remark.

Reference This symbol refers to further information in other operating

instructions, chapters or sections.

H

Representation Menu items Texts from the setup program are shown in italics, for

Action

instruction

Blinking

display

This symbol indicates that an action to be performed is

described.

The individual steps are marked by this asterisk, e.g.

h Press

example: edit program.

I

I

I

I

I

I

I I I I I I I I I I I I I

I

I

IIIIIIIIIIII

I

X

I

I

I

I

I

I

I

I

I

8

Page 9

2 Identifying the instrument version

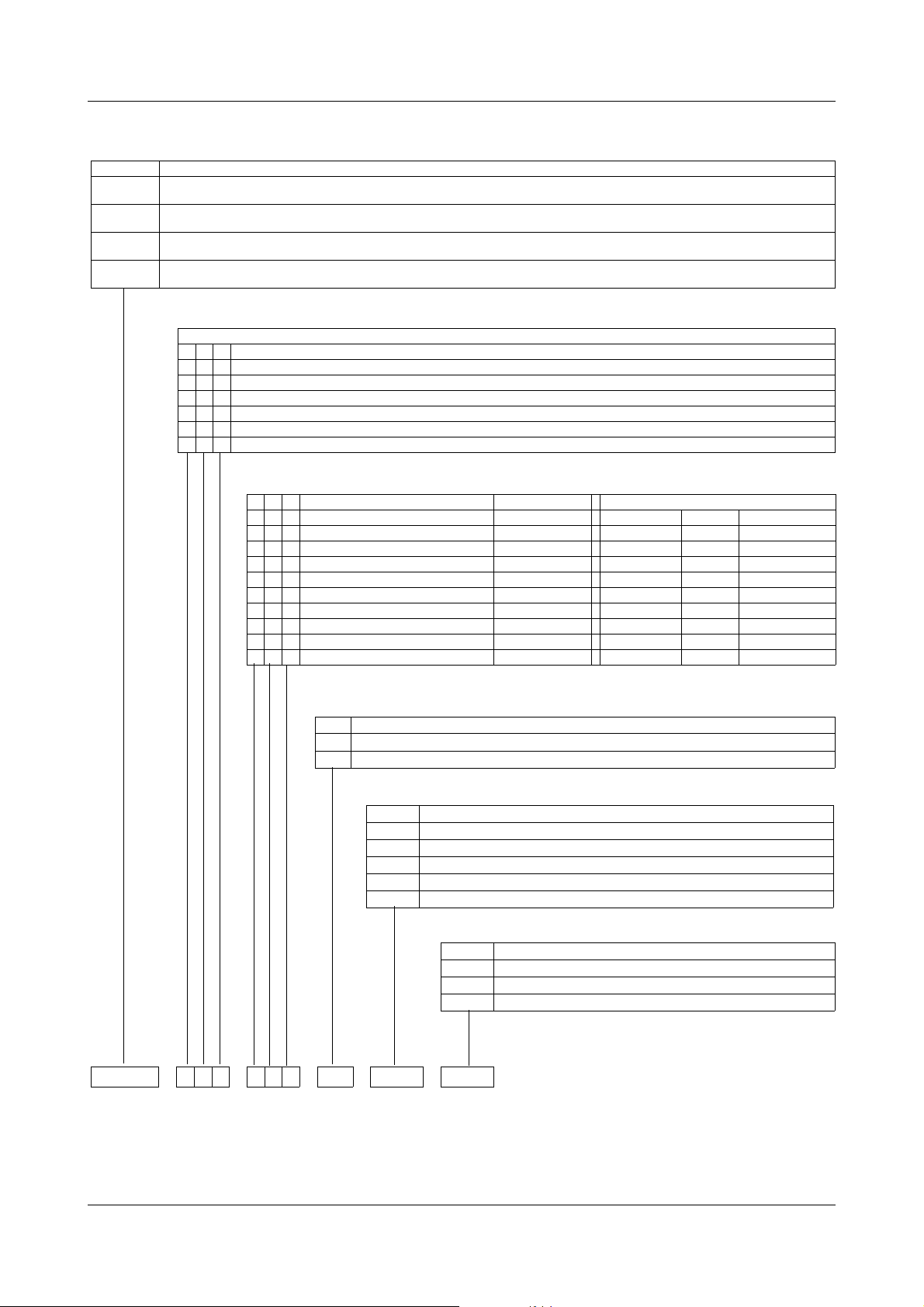

2.1 Type designation

Basic type

703041 JUMO dTRON 316, format 48mm x 48mm

703042 JUMO dTRON 308, format 48mm x 96 mm (portrait format)

703043 JUMO dTRON 308, format 96mm x 48 mm (landscape format)

703044 JUMO dTRON 304, format 96mm x 96mm

incl. 1 analog input, 2 relay outputs and 2 binary inputs or 2 logic outputs

incl. 1 analog and 2 binary inputs, 2 relays and 2 logic outputs

incl. 1 analog and 2 binary inputs, 2 relays and 2 logic outputs

incl. 1 analog and 2 binary inputs, 2 relays and 2 logic outputs

Basic type extensions

1 Basic type 1

Version

8 standard, with factory settings

9 programming to customer specification

logic outputs (2 are available as standard)

10/12V

20/18V

Type 703042/43/44

1. 2. 3. Option slot Max. number Max. number Option 1 Option 2

0 0 0 not used XX

1 1 1 analog input 2 (universal) 1 1 X X

2 2 2 relay (changeover) 2 1 X 3 3 3 2 relays (make contact) 2 1 X 4 4 4 analog output 2 2 X X

5 5 5 2 binary inputs 2 1 X X

6 6 6 solid-state relay 1 A 2 2 X X

7 7 7 RS422/485 interface 1 1 X X

8 8 8 Profibus-DP interface 1 1 X X

X = available in this option slot, - = not available in this option slot

Supply

2 3 110 — 240V AC -15/+10%, 48 — 63Hz

2 5 20 — 30V AC/DC, 48 — 63Hz

Extra codes

000none

214math and logic module

217ratio controller (requirement: 2 analog inputs)

218difference controller (requirement: 2 analog inputs)

2 1 9 humidity controller (requirement: 2 analog inputs)

Type 703041 (no option 3)

/1 – – / ,

703041 / 1 8 1 – 1 4 0 – 2 3 / 0 0 0 ,

Approvals

000none

056DIN EN 14597

dTRON 304 with GL approval on request

9

Page 10

2 Identifying the instrument version

2.2 Scope of delivery

- 1 controller

-1 seal

- mounting brackets

- Operating Manual B70.3041.0 in DIN A6 format

1 CD with demo software and PDF documents in DIN A4 format (operating manual

and further documentation) can be ordered separately.

The individual documents and programs are available for dowload from www.jumo.net

(the software can be enabled for a charge.)

2.3 Accessories

PC interface PC interface with TTL/RS232 converter and adapter (socket connector) for setup

program

Sales No. 70/00350260

USB interface PC interface with USB/TTL converter, adapter (socket conector) and adapter (pins)

Sales No. 70/00456352

Setup

program

Setup program with program editor and Startup

Sales No. 70/00445443

Hardware requirements:

- PC Pentium 100 or compatible

- 128 MB RAM, 30 MB free fixed disc memory

-CD ROM drive

- free serial or USB interface

Software requirements:

Microsoft

1

Windows 98/NT4.0/ME/2000/XP

10

1. Microsoft is a registered trademark of Microsoft Corporation

Page 11

3.1 Mounting site and climatic conditions

The conditions on the mounting site must meet the requirements specified in the

technical data. The ambient temperature on the mounting site can be from 0 to 55 °C,

with a relative humidity of not more than 90 %.

3.2 Dimensions

3.2.1 Type 703044

3 Mounting

Setup plug

Panel cut-out

11

Page 12

3 Mounting

3.2.2 Type 703042/43

Setup plug

Panel cut-out

3.2.3 Type 703041

Setup plug

Panel cut-out

12

Page 13

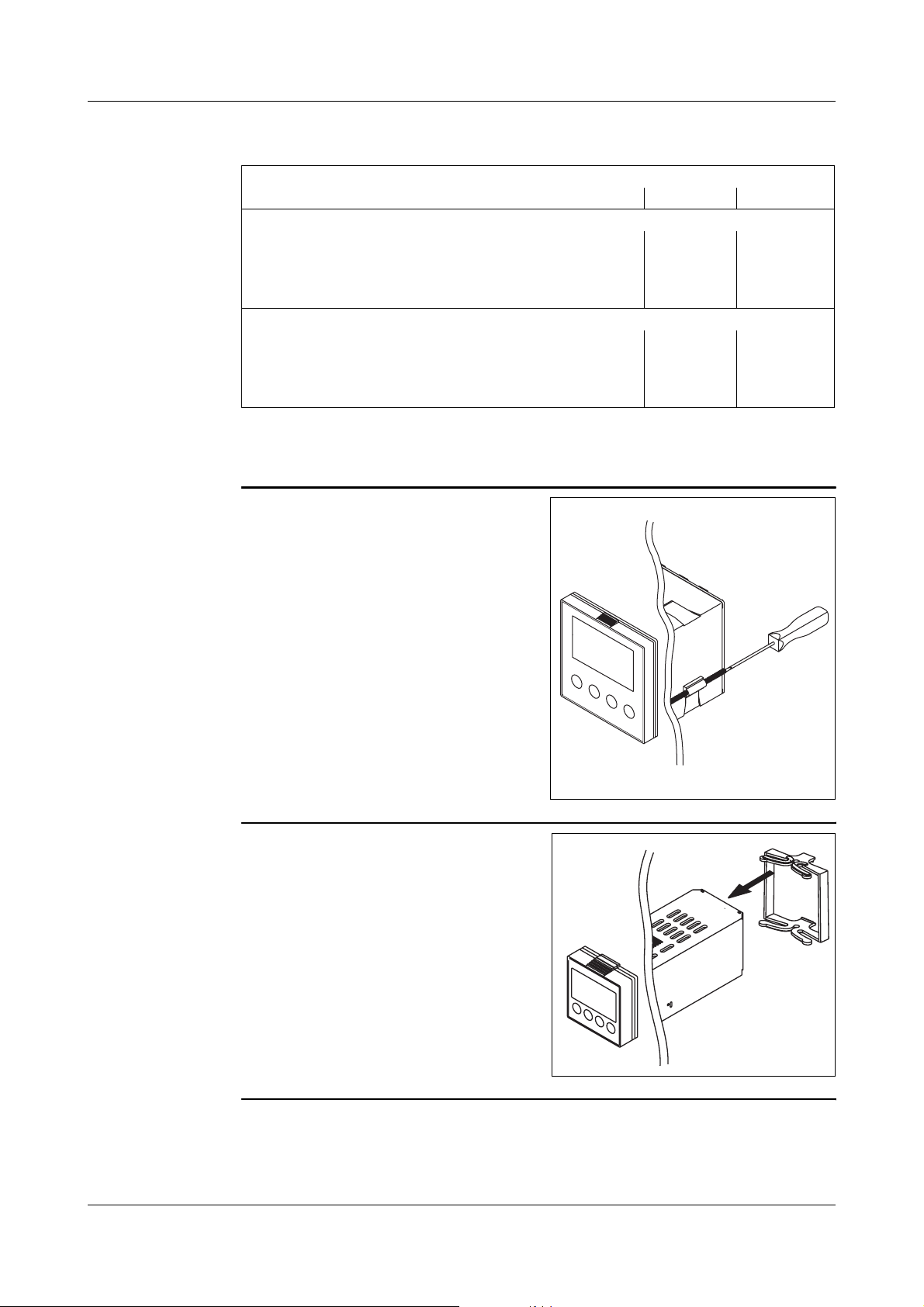

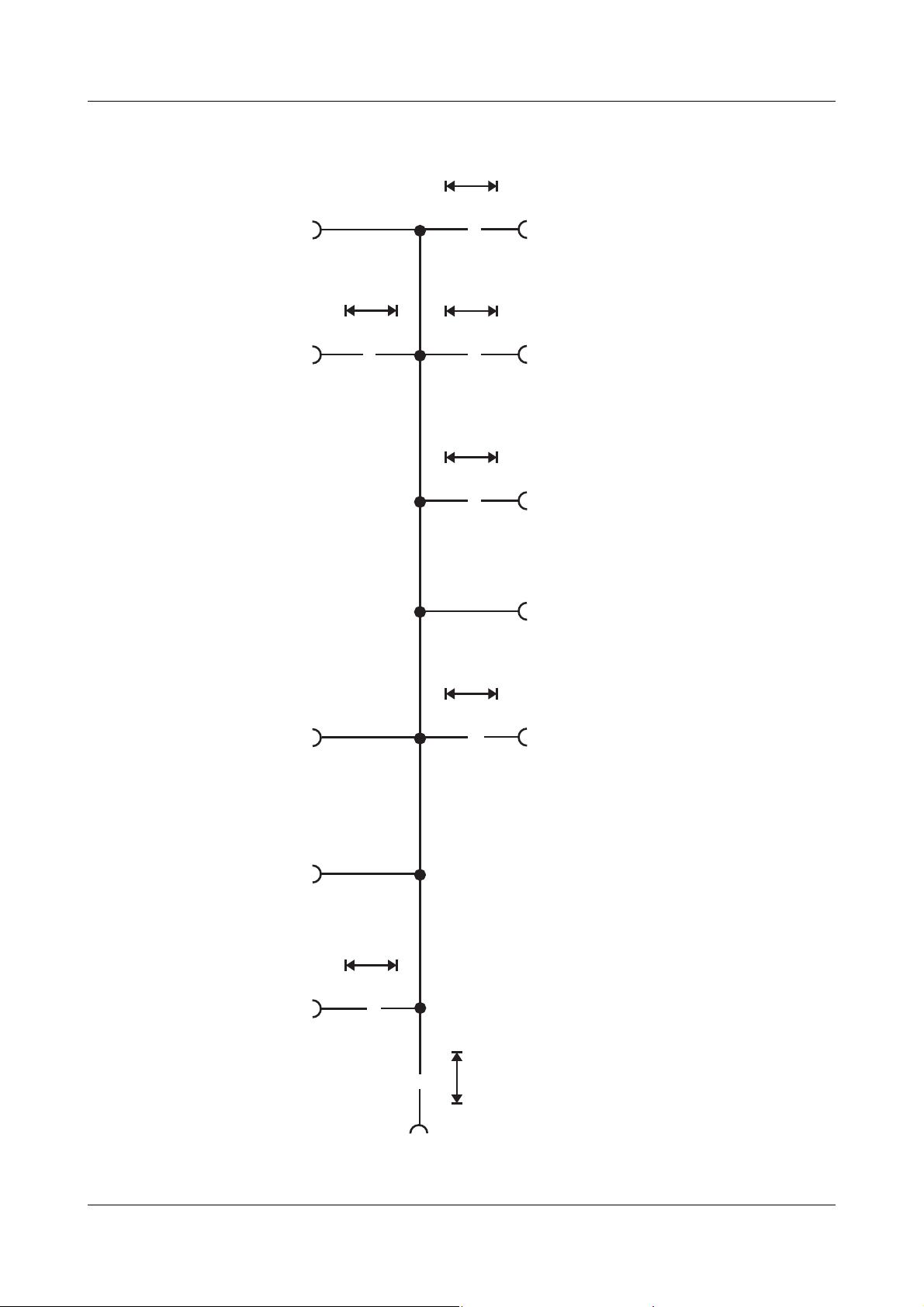

3.3 Side-by-side mounting

Minimum spacing of panel cut-outs

Type horizontal vertical

without setup plug:

703041 (48mm x 48mm)

703042 (portrait format: 48mm x 96mm))

703043 (landscape format: 96mm x 48mm)

703044 (96mm x 96mm)

with setup plug (see arrow):

703041 (48mm x 48mm)

703042 (portrait format: 48mm x 96mm))

703043 (landscape format: 96mm x 48mm)

703044 (96mm x 96mm)

3.4 Fitting in position

Type 703042/43/44 h Fit the seal that is supplied onto the

instrument body.

3 Mounting

11mm

11mm

30mm

11mm

11mm

11mm

65mm

11mm

30mm

30mm

11mm

30mm

65mm

65mm

11mm

65mm

h Insert the controller from the front into

the panel cut-out.

h From behind the panel, slide the

mounting brackets into the guides on

the sides of the housing.

The flat faces of the mounting brackets

must lie against the housing.

h Push the mounting brackets up to the

back of the panel, and tighten them

evenly with a screwdriver.

Type 703041 h Fit the seal that is supplied onto the

instrument body.

h Insert the controller from the front into

the panel cut-out.

h From the back of the panel, push the

mounting frame onto the instrument

body and press it against the back of

the panel, compressing the springs,

until the latches snap into the notches

provided and it is firmly fixed in position.

Care of the front

panel

The front panel can be cleaned with normal commercial washing, rinsing and cleaning

agents. It has a limited resistance to organic solvents (e.g. methylated spirits, white

spirit, P1, xylol etc.). Do not use high-pressure cleaning equipment.

13

Page 14

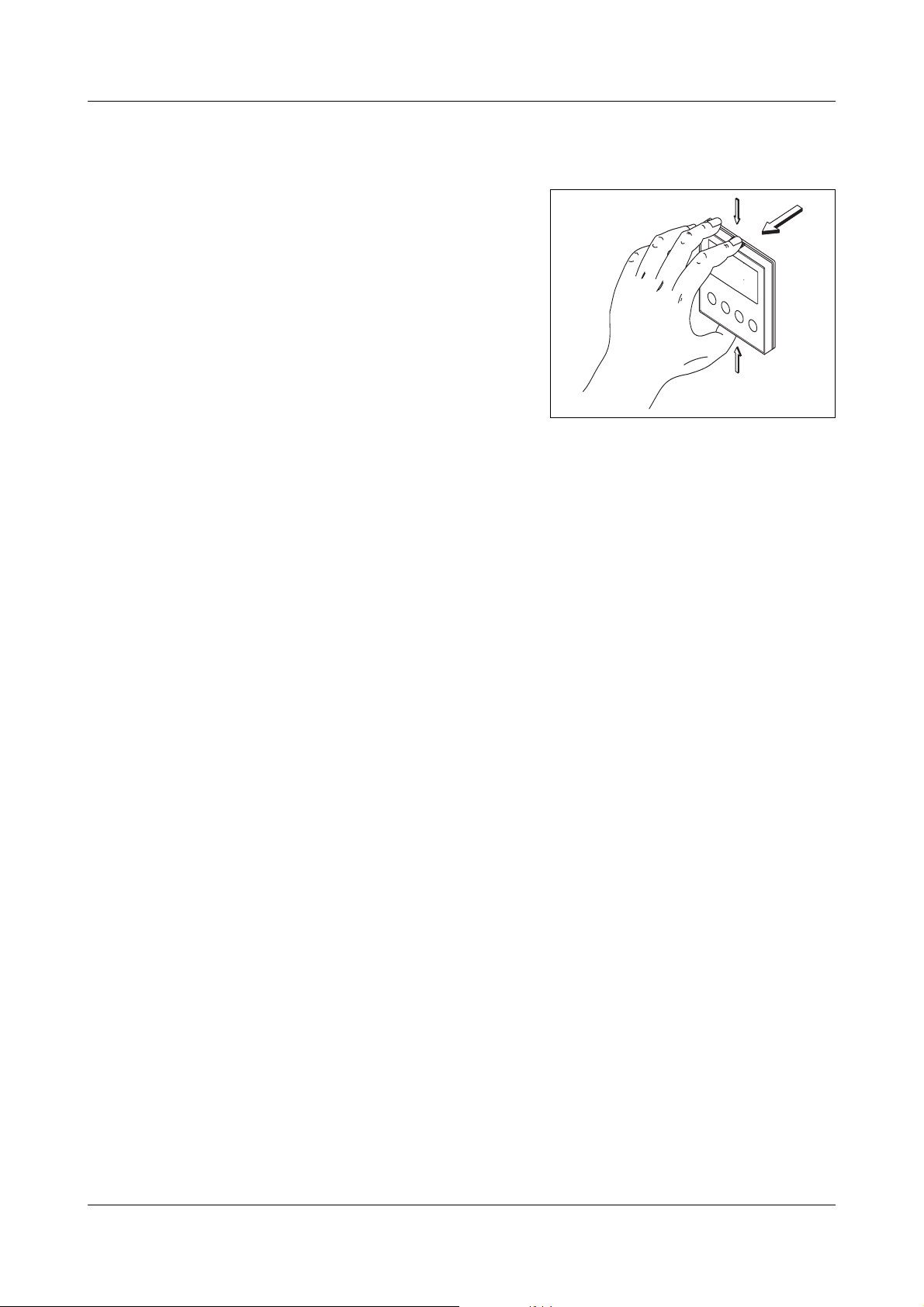

3 Mounting

3.5 Removing the controller module

The controller module can be removed from its housing for servicing.

h Press together the knurled areas

(top and bottom, or left and right for

landscape format) and pull out the

controller module.

H

When inserting the controller module, make sure that the latches (below the

knurled areas) snap into place.

14

Page 15

4.1 Installation notes

- The choice of cable, the installation and the electrical connection must conform to

the requirements of VDE 0100 “Regulations on the Installation of Power Circuits

with Nominal Voltages below 1000 V” or the appropriate local regulations.

- The electrical connection must only be carried out by qualified personnel.

- The instrument shall be operated by mains protected with a branch circuitry

overcurrent protection device not more than 20 Amps.

For servicing/repairing a Disconnecting Device shall be provided to disconnect all

conductors.

- The load circuit must be fused for the maximum relay current, in order to prevent

the output relay contacts becoming welded in the event of a short circuit.

- Electromagnetic compatibility conforms to the standards and regulations cited in

the technical data.

- Run input, output and supply cables separately and not parallel to one another.

- Sensor and interface cables should be shielded cables with twisted conductors.

Do not run them close to current-carrying components or cables. Ground the

shielding on one side.

- Do not connect any additional loads to the supply terminals of the instrument.

- The instrument is not suitable for use in areas with an explosion hazard (Ex areas).

- In addition to faulty installation, incorrect settings on the controller (setpoint, data

of the parameter and configuration levels, internal alterations) can also interfere

with the correct operation of dependent processes, or even cause damage. Safety

devices should always be provided that are independent of the controller (such as

overpressure valves or temperature limiters/monitors) and only capable of adjustment by specialist personnel. Please observe the relevant safety regulations for

such matters. Since adaptation (self-optimization) can not be expected to handle

all possible control loops, an unstable parameterization is theoretically possible.

The stability of the actual value that is produced should therefore be checked.

4 Electrical connection

.

The electrical connection must only be

carried out by specialist personnel.

V

H

Conductor cross-sections and core-end ferrules for installation

Without core-end ferrule 0.34mm

Core-end ferrule, no lip 0.25mm

Core-end ferrule, lip up to 1.5mm

Core-end ferrule, lip above 1.5mm

Twin ferrule with lip 0.25mm

The instrument version can be

identified by the type code.

Minimum

cross-section

2

0.25mm

2

1.5mm

Maximum

cross-section

2

2

2

2

2

2.5mm

2.5mm

1.5mm

2.5mm

1.5mm

2

2

2

2

2

Min. length of

core-end ferrule

10mm

(stripped)

10mm

10mm

12mm

12mm

15

Page 16

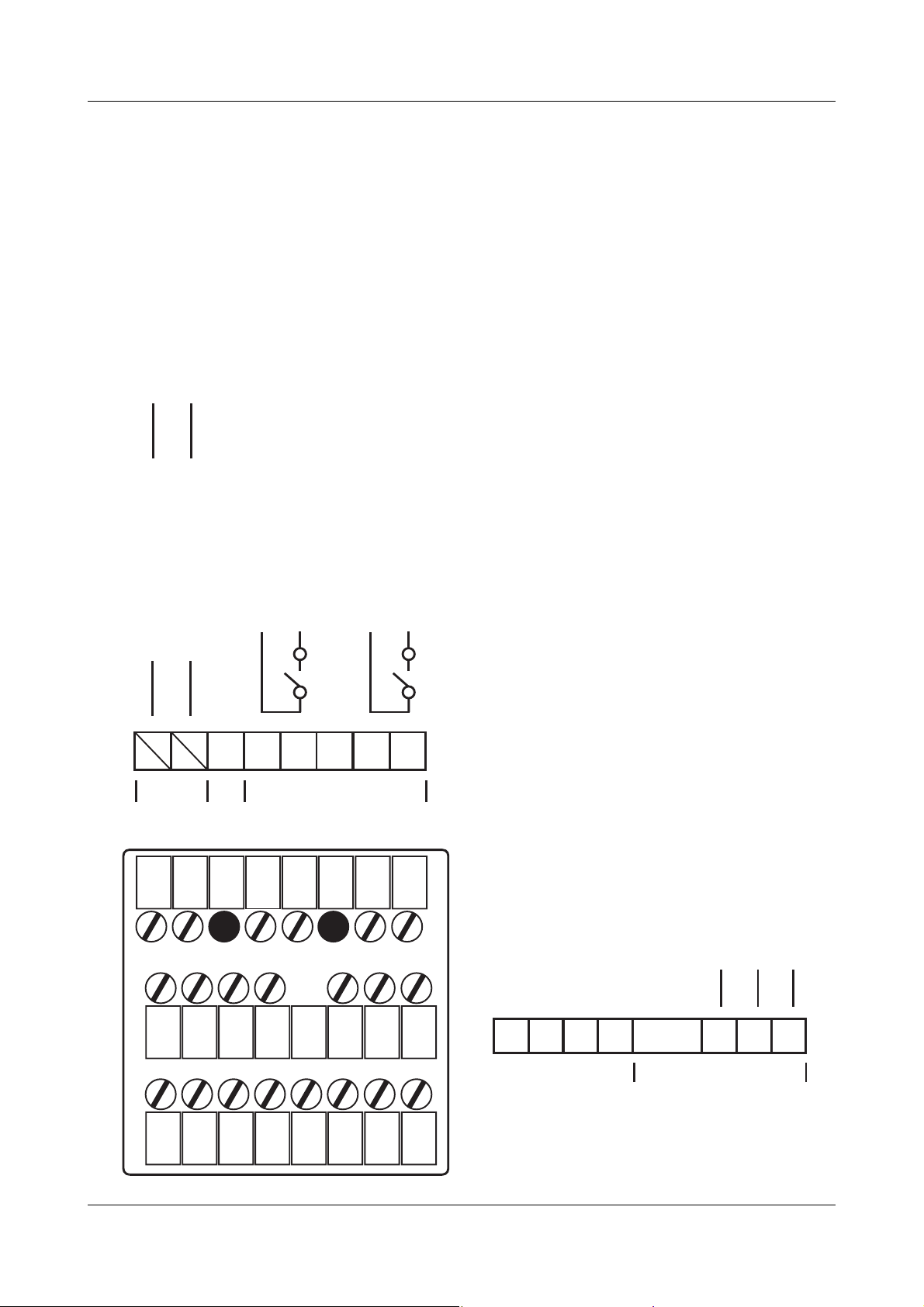

4 Electrical connection

4.2 Electrical isolation

3800 V AC

Input 1

Relay outputs

»

30 V AC

50 V DC

Input 2 Solid-state relay outputs

3800 V AC

»

»

30 V AC

50 V DC

Analog outputs

»

Logic outputs

30 V AC

50 V DC

Binary inputs

Setup

interface

RS422/485

PROFIBUS-DP

Supply voltage for

2-wire transmitter

»

30 V AC

50 V DC

»

»

3800 V AC

Supply voltage

16

Page 17

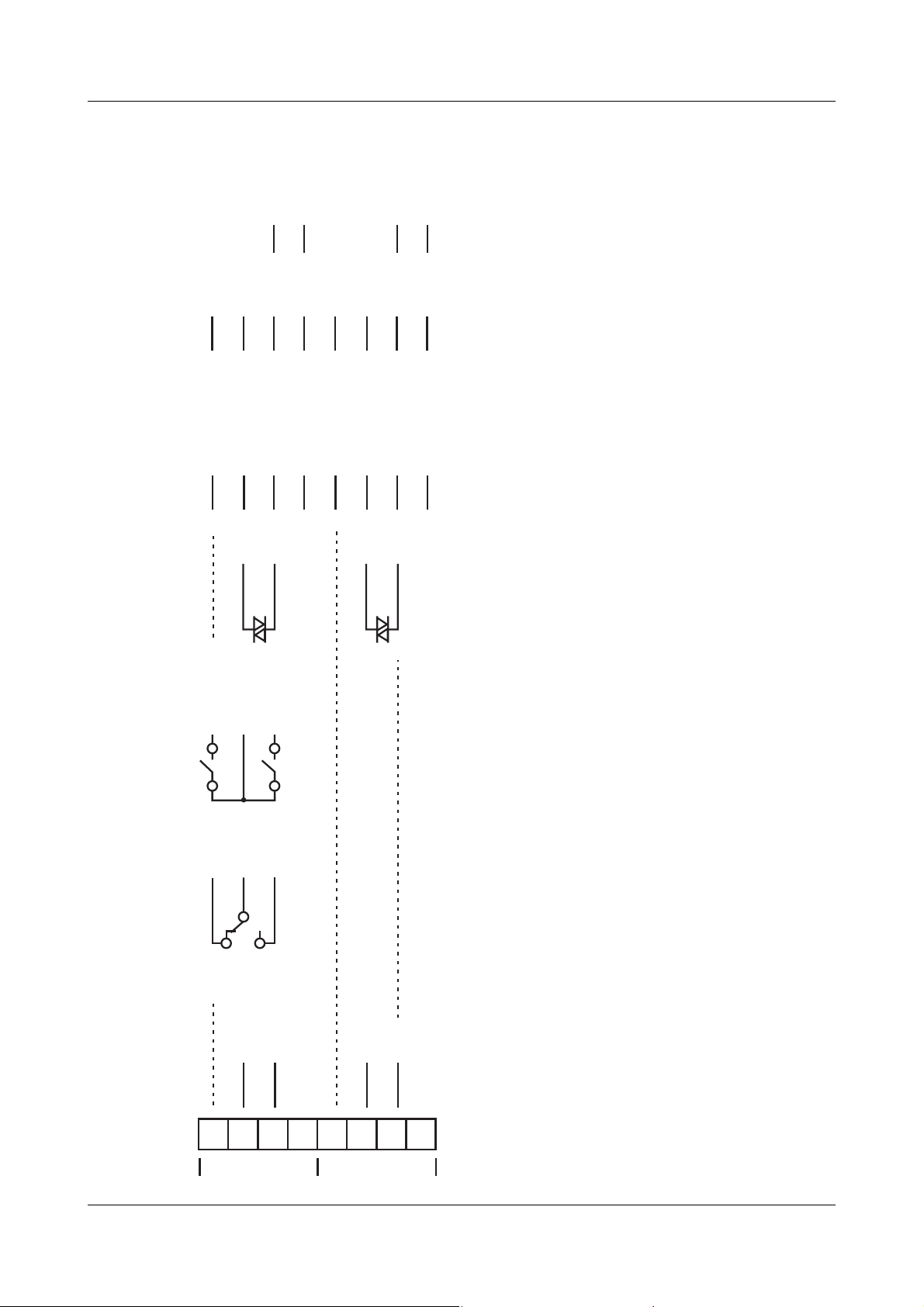

4.3 Connection diagrams

4.3.1 Type 703041

L-

L+

4 Electrical connection

Supply and outputs - terminal strip 3

3

110—240V AC 20—30V AC/DC

L1

L+

L1

N

L1(L+)

122

N

L-

3

Supply

3

N(L-)

230V/3A Binary output 1 (Out1)

P

S

5

4

6

230V/3A Binary output 2 (Out2)

P

S

7

8

Relays

8

3

4

4

5

6

6

7

7

8

Outputs - terminal strip 2

1

243

Logic output level 12V or 18V

(see type code)

As an alternative to binary inputs 1 and 2

(configurable)!

Binary output 3

Binary output 4

Out3 (+)

Out4 (+)

GND (-)

6

7

8

Logic

112

3

4

5

6

7

8

17

Page 18

4 Electrical connection

RxD/TxD +

RS485

PROFIBUS RS422

RxD +

RxD -

TxD +

VP (+5 V)

RxD/TxD-P (B)

RxD/TxD-N (A)

RxD/TxD -

TxD -

RxD +

DGND

VP (+5 V)

RxD/TxD +

RxD -

TxD +

RxD/TxD-P (B)

RxD/TxD-N (A)

RxD/TxD -

TxD -

DGND

Solid-state

relay

Out5

2 relays

(n.o. make)

Ö

Relay

(changeover)

Analog

output

Binary output 6

Binary output 5

(Out5)

Out8

Binary output 5+8

(Out5+Out8)

P

S

Binary output 5

(Out5)

-

+

x

/ I

x

U

Analog output 5

(Out5)

(not possible!) (not possible!)

+

x

/ I

x

U

(Out6)

-

Analog output 6

(Out6)

Note numbering of outputs.

18

Type 703041 continued

Outputs and interfaces - terminal strip 1 (option board)

1

243

Option 1

5

687

Option 2

H

v Chapter 8.5 “Outputs “OutP””

Page 19

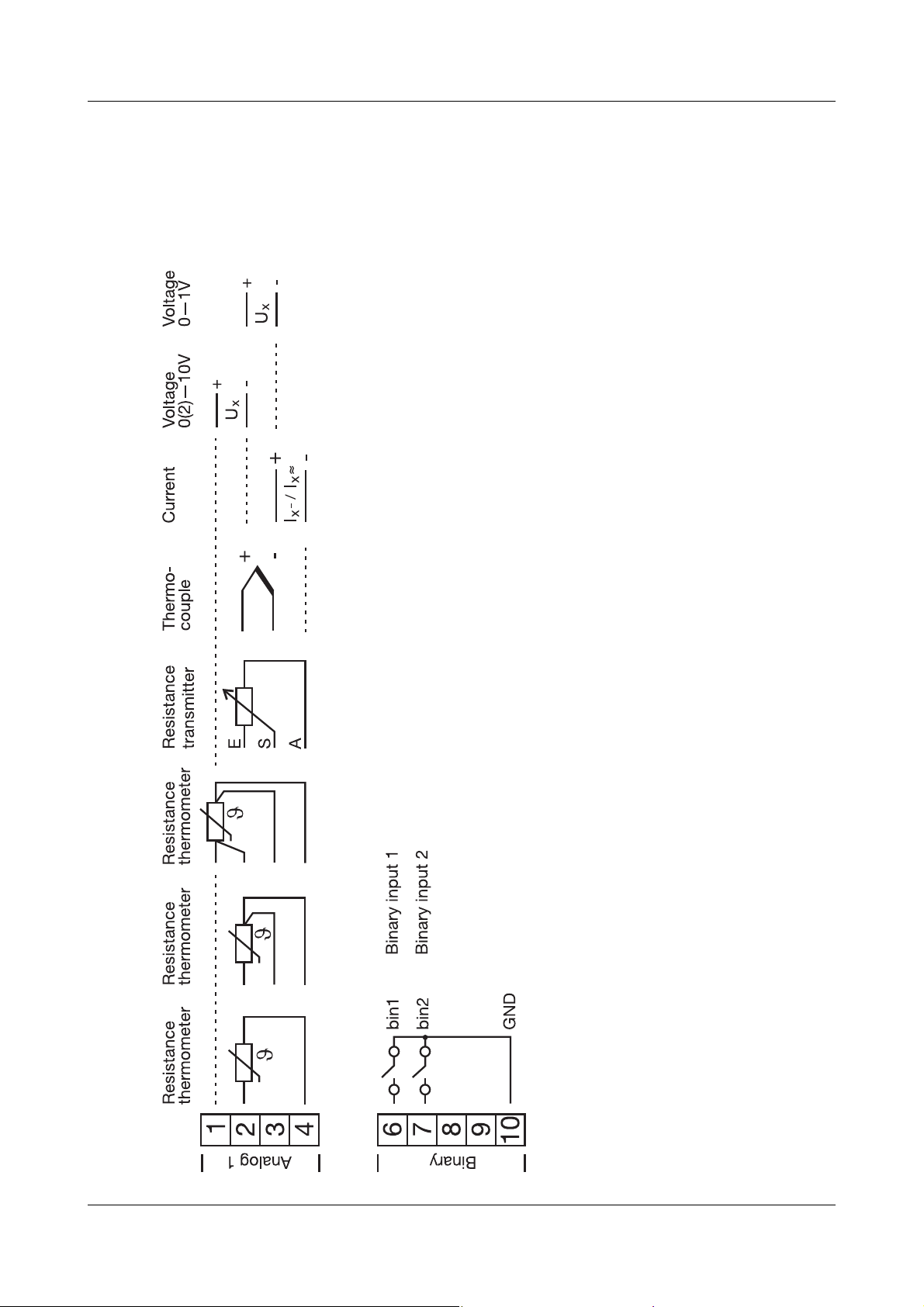

Voltage

0—1V

Voltage

0(2)—10V

Current

4 Electrical connection

-

+

x

U

-

+

x

U

-

+

~

~

x

I

- /

x

I

Thermo-

couple

Resistance

transmitter

E

Resistance

thermometer

Resistance

thermometer

-

+

As an alternative to binary outputs 3 and 4

S

A

(configurable)!

Binary input 1

Binary input 2

bin2

bin1

GND

Resistance

thermometer

1

243

Analog 1

Type 703041 continued

Analog input 1 and binary inputs 1+2 - terminal strip 2

6

Logic

7

8

Analog input 2 and binary inputs 3...6 - terminal strip 1 (option boards)

19

Page 20

4 Electrical connection

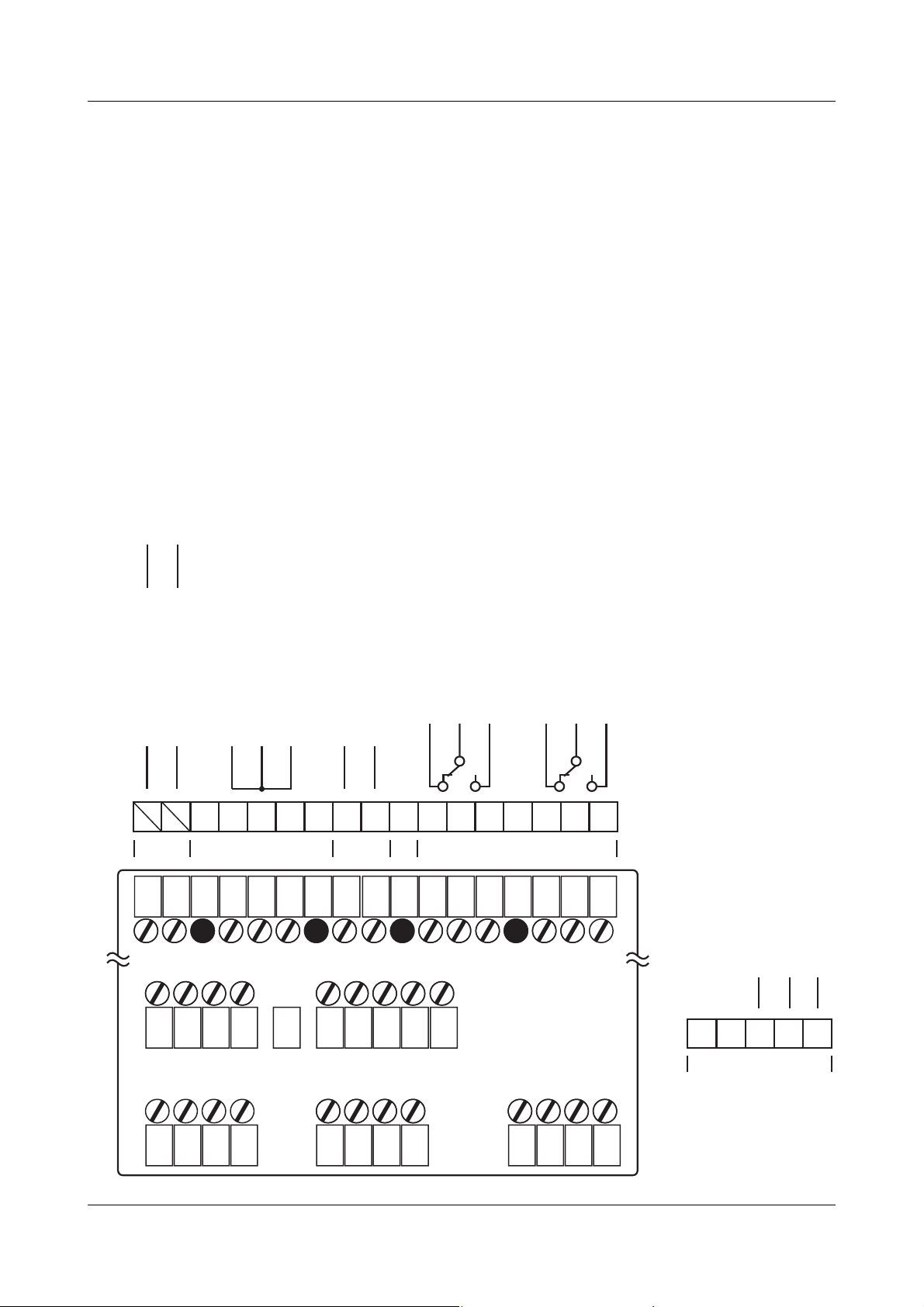

4.3.2 Type 703042/43/44

L-

L+

Supply and outputs - terminal strip 3

2

3

110—240V AC 20—30V AC/DC

L1

L1L+N

L1(L+)

1

N

L-

Supply

N(L+)

2

Supply for 2-wire transmitter

(off-load voltage approx. 25V)

17V/20mA

+

-

=

U

5

4

4

3

4

6

5

6

6

8

=

8

9

U

9

7

8

Binary output 1 (Out1)

230V/3A

Ö

P

S

13

12

11

11

12

13

9

10

Binary output 2 (Out2)

230V/3A

Ö

P

S

16

16

17

17

15

Relays

15

Outputs - terminal strip 2

6

Logic output level 12V or 18V

(see type code)

Binary output 3

Binary output 4

Out3 (+)

Out4 (+)

GND (-)

7

8

9

10

Logic

20

1

1

2

3

4

5

6

7

8

9

10

11

12

Page 21

RS485

PROFIBUS RS422

RxD/TxD +

RxD +

RxD -

TxD +

VP (+5 V)

RxD/TxD-P (B)

RxD/TxD-N (A)

RxD/TxD -

TxD -

DGND

RxD +

VP (+5 V)

RxD/TxD +

RxD/TxD -

RxD -

TxD +

TxD -

RxD/TxD-P (B)

RxD/TxD-N (A)

DGND

4 Electrical connection

RxD/TxD +

RxD/TxD -

RxD +

RxD -

TxD +

TxD -

VP (+5 V)

RxD/TxD-P (B)

RxD/TxD-N (A)

DGND

Solid-state

relay

Out5

2 relays

(n.o. make)

Ö

Relay

(changeover)

Analog

output

Binary output 6

Binary output 5

(Out5)

Out8

Binary output 5+8

(Out5+Out8)

P

S

Binary output 5

(Out5)

-

+

x

/ I

x

U

Analog output 5

(Out5)

Out6

Ö

P

+

x

/ I

x

U

(Out6)

Out9

Binary output 6+9

(Out6+Out9)

S

Binary output 6

(Out6)

-

Analog output 6

(Out6)

Out7

Ö

P

+

Binary output 7

(Out7)

Out0

Binary output 7+10

(Out7+Out0)

S

Binary output 7

(Out7)

-

x

/ I

x

U

Analog output 7

(Out7)

Note numbering of outputs.

1

243

ype 703042/43/44 continued

Outputs and interfaces - terminal strip 1 (option boards)

Option 1

5

687

Option 2

9

101211

Option 3

H

v Chapter 8.5 “Outputs “OutP””

21

Page 22

4 Electrical connection

22

Type 703042/43/44 continued

Analog input 1 and binary inputs 1+2 - terminal strip 2

Page 23

4 Electrical connection

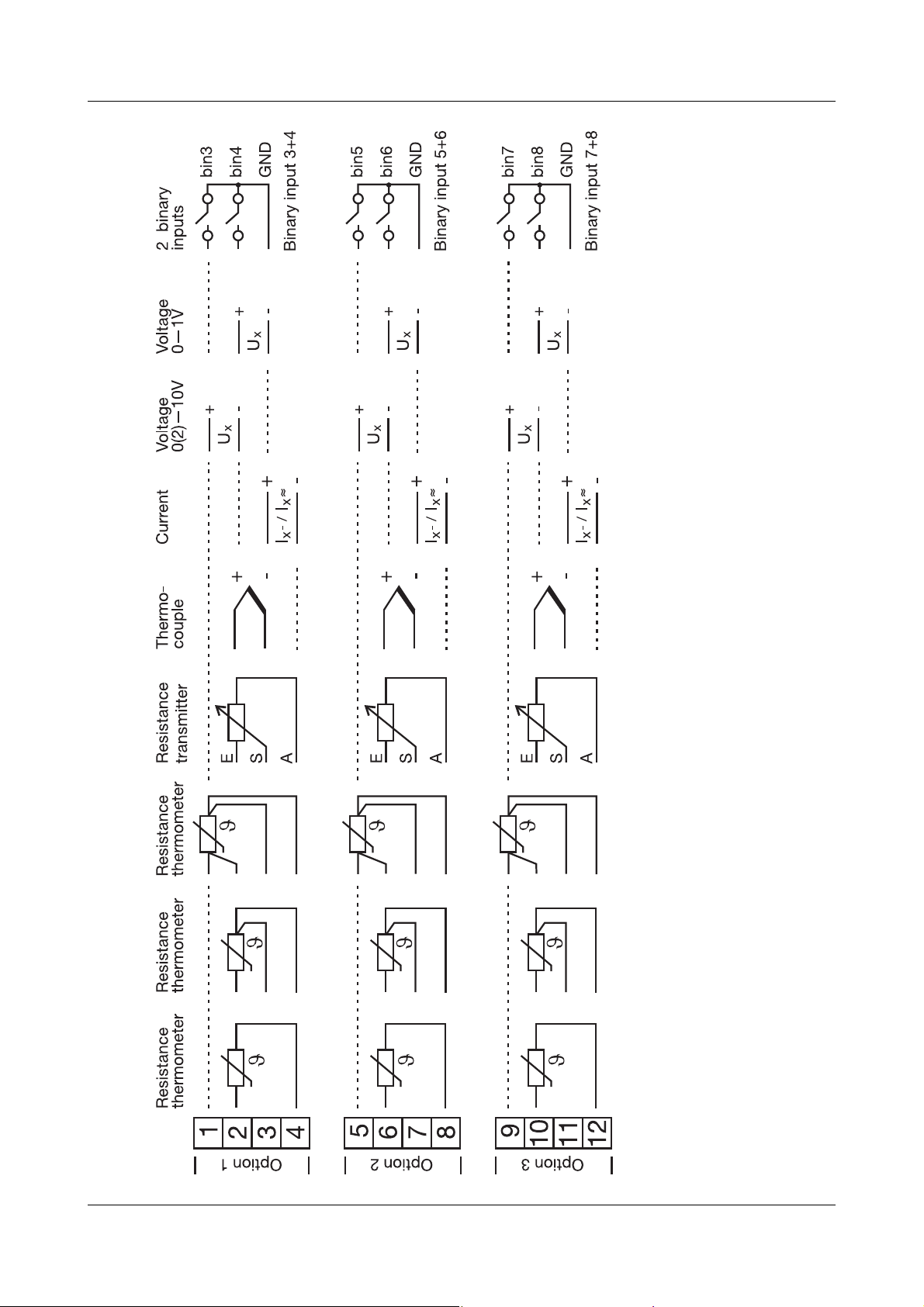

Analog input 2 and binary inputs 3...8 - terminal strip 1 (option boards)

Type 703042/43/44 continued

23

Page 24

4 Electrical connection

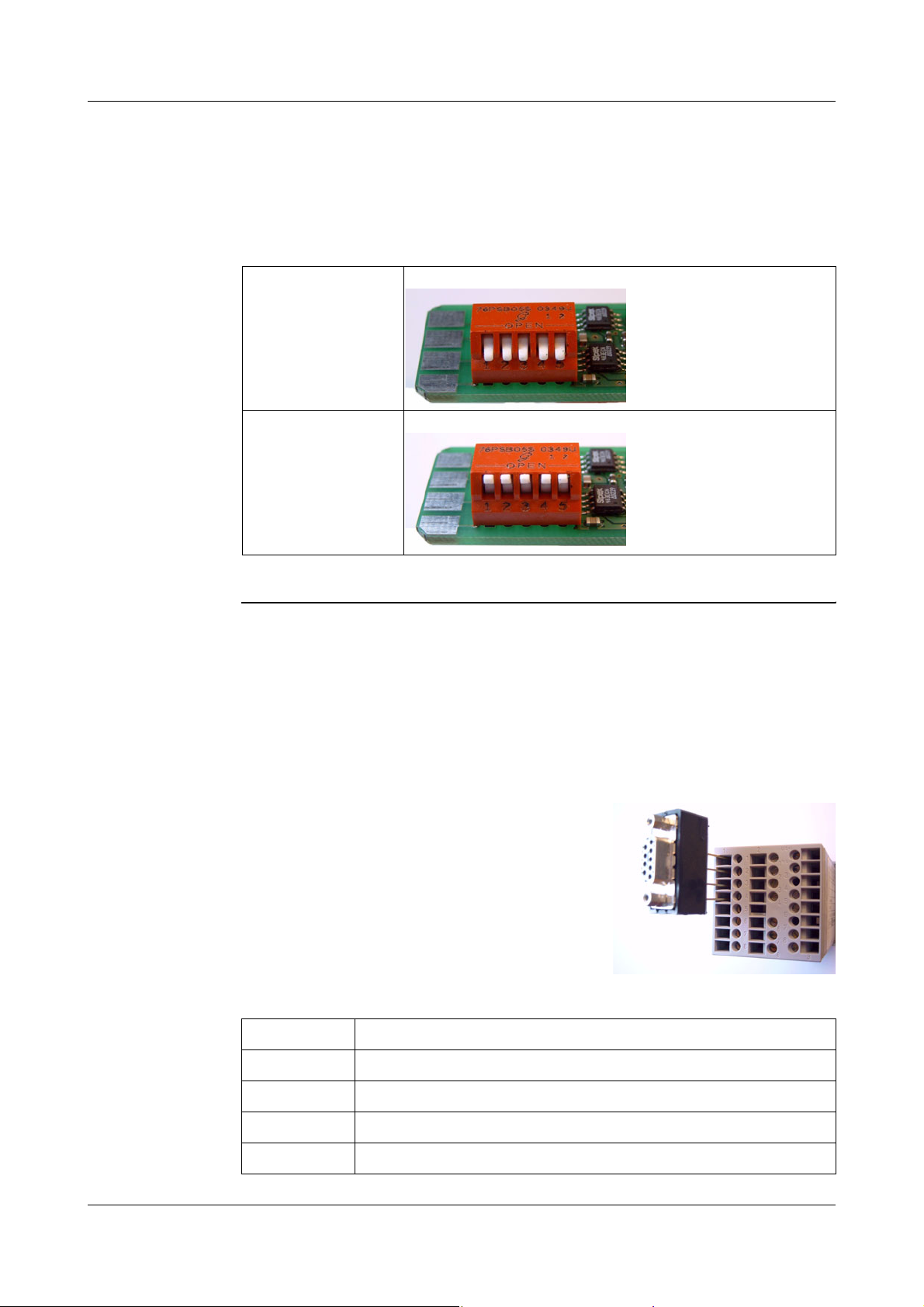

4.3.3 Termination resistor for the RS422/485 serial interface

For fault-free operation of several devices in a line structure, their internal termination

resistors must be activated at the start and end

h Pull plug-in module out towards the front by pressing on the knurled areas

h Using a ballpoint pen, press all the white switches into the same direction

.

Bus termination

resistor active:

No bus termination

(ex-factory)

h Re-insert the module back into the housing

Check h Press the

To the right of the green “VErS” display, “ON” is shown for active and “OFF“ for inactive termination resistors.

h Push all 5 switches down

h Push all 5 switches up

P + I keys

4.3.4 Connection of the PROFIBUS-DP connector

Mounting the

adapter

Assignment of

the 9-pole

D-SUB socket

h Identify option slot with the PROFIBUS-DP interface by means of the

type code (in the case of pre-configured devices)

In this example, the PROFIBUS-DP

interface is in option slot 1

H

Pin: Signal Designation

1: VP Supply voltage positive

2: RxD/TxD-P Receive/Transmit data positive

3: RxD/TxD-N Receive/Transmit data negative

4: DGND Ground

To fit the D-SUB adapter, open the housing

of the adapter; otherwise the terminal

screws are hided by the adapter.

24

Page 25

5.1 Displays and controls

(1)

5 Operation

(2)

(3)

(4)

(1) 7-segment display (factory setting: process value)

four-digit, red, decimal place is configurable

(automatic adjustment on display overflow)

(2) Active setpoint (factory setting: SP1)

SP1, SP2, SP3, SP4 (SP=setpoint); green;

(3) 7-segment display (factory setting: setpoint)

four-digit, green; decimal place is configurable;

also used for operator prompting (display of parameter and level symbols)

(4) Keys

(5) Indication

yellow, for

- switch status of binary outputs 1 —6 (display lights up = on)

- ramp/program function is active

PGM

EXIT

(6)

(5)

- manual operation is active

(6) 16-segment display for the unit °C/°F and text

two-digit, green; configurable; symbols for h, min, %

In addition, the current segment number (program), the parameter set or any

two-place letter/number combination can be displayed through the setup

program.

The displays are configurable.

v Chapter 8.7 “Display “diSP””

25

Page 26

5 Operation

5.2 Level concept

The parameters for making the settings on the instrument are arranged at different

levels.

Time-out

H

v Chapter 6 “Operator level”

v Chapter 7 “Parameter level”

v Chapter 8 “Configuration”

v Setup/Display - Operation/Time-out

User data “USEr” The setup program can be used to display and edit up to 8 freely chosen parameters

at this level.

v Setup / Configuration level / Display - Operation/ User data

The user can assign a symbol for the representation of each parameter. Otherwise the

default symbol will be used. Permissible symbols are the letters and numbers that can

be presented by a 7-segment display.

If no key is pressed for 180sec, the instrument returns to normal display.

26

Page 27

5.3 Level inhibit

The access to the individual levels can be prevented.

Code Operator level,

0 enabled enabled enabled

1 enabled enabled inhibited

2 enabled inhibited inhibited

3 inhibited inhibited inhibited

5 Operation

Parameter level Configuration level

user level,

program editor

h Go to code entry with

h Alter code with

h Enter code with

h Return to normal display with

The parameter and configuration levels can also be inhibited via the binary function.

v Chapter 8.6 “Binary functions “binF””

P (display blinks!)

P and D (simultaneously for >5sec).

I and D. Ex-factory: all levels enabled.

X or automatically after approx. 180sec

27

Page 28

5 Operation

5.4 Entries and operator prompting

Entering values When entries are made within the levels, the parameter symbol is shown in the lower

display.

Select parameter

Alter parameter

P

ID/

h Select parameter with

I or D

I I I I I I I I I I I I I

I

I

I

I

I

I

I

I

I

IIIIIIIIIIII

I

I

h Change to entry mode with P (lower display blinks!)

h Alter value with

I and D

The value alters dynamically with the duration of the key stroke.

h Accept the setting with

P, or automatically after 2sec

or

h Cancel entry with

X.

The value is not accepted.

Entering times When entering times (e.g. timer time), the time unit is shown in addition.

Select parameter

Alter parameter

I

I

I

I

I

I

D

I

I

P

ID/

I I I I I I I I I I I I I

I

I

I

I

I

I

I

I

IIIIIIIIIIII

I

I

I

I

I

I

I

I

I

I

D

I

28

The highest time unit of the display is shown for the unit.

If, for instance, “h” is shown for the hour, then the time format for the value is hh:mm.

h Select parameter with

I or D

h Change over to the entry mode using P (lower display blinks!)

h Alter value with

I and D

The value alters dynamically with the duration of the key stroke.

h Accept the setting with

P or automatically after 2sec

or

h Cancel entry with

X.

The value is not accepted.

Page 29

5.5 Fixed-setpoint controller (ex-factory)

5 Operation

Normal display

Altering the

setpoint

Manual mode In manual mode, the controller output can be altered by hand.

In normal display:

h Alter the present setpoint with

(the value is accepted automatically)

h Change to manual mode with

The output appears in the lower display. The hand symbol and the unit “%” light up in

addition.

h Alter the output with

In the case of a modulating controller, the actuator is opened or closed using the keys.

The various levels can be accessed from the manual mode.

h Finish manual mode with

The output entry on a changeover is configurable. The manual mode can be inhibited.

v Chapter 8.2 “Controller “Cntr””

I and D

Manual mode

I and D

X (> 2 sec)

X (>2 sec)

Additional operating options for the fixed-setpoint controller can be implemented via

the binary functions.

v Chapter 8.6 “Binary functions “binF””

On overrange/underrange and probe break, the controller automatically changes over

to manual mode.

29

Page 30

5 Operation

5.6 Program controller

Condition as

delivered

The instrument must be configured as a program controller/generator. Furthermore, a

program must be entered beforehand, to operate the instrument as a program

controller/generator.

5.6.1 Entering programs

Function A setpoint profile can be implemented with a maximum of 8 program segments.

Entry on the

instrument

The instrument must be configured as a program controller/generator.

v Chapter 8.3 “Generator “Pro”” (Function)

Configurable time base: mm:ss, hh:mm und dd:hh (s=seconds, m=minutes, h=hours,

d=days).

v Chapter 8.3 “Generator “Pro”” (unit)

The settings for segment setpoints (SPP1 — SPP8) and segment times (tP1 — tP8)

are made in the program editor.

30

Page 31

5 Operation

The program segments (up to eight) are defined by the segment setpoint and the segment time.

P

D

D

D

P

P

P

I I I I I I I I I I I I I

I

I

I

I

I

I

I

I

I

I I I I I I I I I I I I I

I

I

I

I

I

I

I

I

IIIIIIIIIIII

I

I I I I I I I I I I I I I

I

I

I

I

I

I

I

I

I

IIIIIIIIIIII

IIIIIIIIIIII

I

I

I

I

I

I

D

I

I

I

I

I

I

I

I

I

I

I

D

I

I

I

I

I

I

I

I

I

I

D

I

I

I

Entry through

setup program

Additional

functions via the

setup program

P

I

I I I I I I I I I I I I I

I

I

I

I

I

I

I

I

I

The setup program (accessory) features a user-friendly program editor, with a

graphical presentation of the program profile.

- Start at the process value

- Response to over/underrange

- Repeat program

- Setpoint input (ramp/step)

- Process is controlled to the most recent setpoint

- Delay time

- Program editor/management with graphical preview

- Up to four control contacts can be programmed segment by segment

- Parameter sets can be assigned segment by segment

IIIIIIIIIIII

I

I

I

I

I

I

D

I

I

I

31

Page 32

5 Operation

5.6.2 Operation

Normal display

Altering the setpoint

Normal display No program run in normal display, the controller controls to the selected setpoint.

Altering the

setpoint

From normal display:

h Change to setpoint input with

h Alter the present setpoint with I and D

(the value is accepted automatically)

Program is running

Program pause

D

Starting the

program

Canceling the

program

Pausing the

program

From normal display:

h Start program with

(the ramp symbol lights up!)

A delay time can be configured through the setup program. When the delay time has

elapsed, “

When the program is running:

h Cancel program with

When the program is running:

h Pause program with

(the lower display blinks!)

h Continue with

The program is canceled in the event of a power failure.

Additional program control functions via binary functions.

v Chapter 8.6 “Binary functions “binF””

Strt” is shown in the lower display, and then the program is processed.

I

I

X (>2 sec)

X (>2 sec)

32

Page 33

5.6.3 Shifting the program profile

The function “External setpoint with correction” can be used to shift the program

profile upwards or downwards (configurable through the setup program only).

The external setpoint is defined via an analog signal.

v Chapter 8.2 “Controller “Cntr””

5 Operation

33

Page 34

5 Operation

34

Page 35

Access

6 Operator level

The four setpoints are displayed and edited here, and additional process variables are

shown in accordance with the configuration.

Symbol Meaning

SP 1

SP 2

SP 3

SP 4

SPr

InP1

InP2

F1

F2

y

trun

trES

t1

t2

Setpoint 1 (editable)

Setpoint 2 (editable)

Setpoint 3 (editable)

Setpoint 4 (editable)

Ramp setpoint (only if configured)

Measurement of analog input 1

Measurement of analog input 2 (only if available)

Calculated result of math formula 1

(and for difference, ratio and humidity controller)

Calculated result of math formula 2 (only if available)

Controller output

Program run time (only with program controller/generator)

Residual program time (only with program controller/generator)

Timer run time 1 (only if configured)

Timer run time 2 (only if configured)

35

Page 36

6 Operator level

Definition of the program times

w

(2)(1)

(4)

(3)

tx

t

(1) Program run time (3) Segment run time

(2) Residual program time (4) Residual segment time

36

Page 37

7 Parameter level

General Two parameter sets (PAr1 and PAr2) can be stored.

Access

The level can be inhibited.

Applications - Parameter set switching via binary function

v Chapter 8.6 “Binary functions “binF””

- Allocating parameter sets to program segments (only through the setup program)

v Program editor/Program

Example Setting a 2-state controller with PI action:

Pb1=12°C (proportional band)

rt=160sec (reset time; I component)

dt=0sec (derivative time, D component)

37

Page 38

7 Parameter level

PArA ➔ PAr1 ( PAr2)

Display Value range Factory

Proportional

band

Derivative time

Reset time

Cycle time

Contact

spacing

(dead band)

Switching

differential

PB 1

Pb 2

dt

rt

CY1

CY2

db

HyS1

HyS2

0…9999 0 Size of the proportional band

0…9999 0

0…9999 s 80 s Influences the differential component of

0…9999 s 350 s Influences the integral component of the

0.0…999.9s 20 s With a switched output, the cycle time

0.0…999.9 s 20 s

0.0…999.9 0 The spacing between the two control

0.0…999.9 1 Hysteresis for switching controllers

0.0…999.9 1

Description

setting

The gain of the controller decreases with

increasing proportional band.

With Pb 1,2 = 0 the controller structure is

ineffective (limit comparator response).

Continuous controllers: Pb1,2 must be >0.

the controller output signal.

The effect of the D component increases

with increasing derivative time.

controller output signal.

The effect of the I component decreases

with increasing reset time.

should be chosen so that a) the pulsed

energy flow to the process does not cause

any impermissible PV fluctuations and b)

the switching elements are not overloaded.

contacts for 3-state or modulating

controllers.

with Pb1,2 = 0.

Actuator time

Working point

Output limiting

38

tt

Y0

Y1

Y2

The parameters Pb2, Cy2, HyS2 refer to the second controller output for a 3-state

controller.

The decimal place of some parameters depends on the decimal place setting in the

displays.

H

5…3000 s 60 s Actuator time range used by the control

valve for modulating controllers.

-100…+100% 0% Output for P and PD controllers

(when x = w then y = Y0).

0…100% 100% Maximum output limiting.

-100…+100 % -100% Minimum output limiting.

(only effective with PB>0!)

The parameter display on the instrument depends on the controller type

selected.

v Chapter 8.2 “Controller “Cntr””

Page 39

8 Configuration

General The following applies to the representation of parameters and functions at the

configuration level:

The parameter is not displayed or can not be selected if

- the equipment level does not permit the function assigned to the parameter.

Example: Analog output 2 can not be configured if

analog output 2 is not implemented in the instrument.

Access

H

Some parameters can only be programmed through the setup program. These

are marked in the symbol column with “(setup)”.

The symbol (appears in the display) that corresponds to the menu item is

shown in the chapter headings (e.g. 8.1 Analog inputs “InP”).

H

Levels can be inhibited.

v Chapter 5.3 “Level inhibit”

39

Page 40

8 Configuration

Analog selector With some parameters, you can choose from a series of analog values. To provide you

with an overview, this selection is listed below.

0 no function 21 program run time in sec

1 analog input 1 22 residual program time in sec

2 analog input 2 23 segment run time in sec

3 process value 24 residual segment time in sec

4 present setpoint 25 timer run time for timer 1 in sec

5 ramp end value 26 timer run time for timer 2 in sec

6 program setpoint 27 residual run time for timer 1 in sec

7 math 1 28 residual run time for timer 2 in sec

8 math 2 29 present segment end value

9 setpoint 1 30 analog marker (Profibus)

10 setpoint 2 31 reserved

13 controller output level 32 reserved

14 controller output 1 33 reserved

15 controller output 2

Definition of the program times

w

(2)(1)

(4)

(3)

t

x

t

(1) Program run time (3) Segment run time

(2) Residual program time (4) Residual segment time

40

Page 41

8.1 Analog inputs “InP”

8 Configuration

Configuration

Analog inputs

Controller

Generator

Limit comparators

Outputs

Binary functions

Display

Timer

Interfaces

Sensor type

InP: Analog input

Depending on the instrument version, up to two analog inputs are available.

H

The approval according to DIN EN 14597 requires the usage of probes, also

approved to DIN EN 14597, in the specified temperature ranges.

v see data sheets T90.1006 and T90.2006

Analog input 1 InP1 ➔

Analog input 2

Symbol Value/selection Description

SEnS

InP2 ➔

0

no function

1

Resistance thermometer in 3-wire circuit

2

Resistance thermometer in 2-wire circuit

3

Resistance thermometer in 4-wire circuit

4

Thermocouple

5

Resistance transmitter

6

Heater current 0— 50mA AC (analog input 2 only)

7

0—20mA

8

4—20mA

9

0—10V

10

2—10V

11

0—1V

Linearization

Lin

factory-set on analog input 2: no function

0

Linear

1

Pt100

2

Pt500

3

Pt1000

4

KTY11-6

5

W5Re_W26Re C

6

W3Re_W25Re D

7

NiCr-Con E

8

Cu-Con T

9

Fe-Con J

10

Cu-Con U

11

Fe-Con L

12

NiCr-Ni K

13

Pt10Rh-Pt S

14

Pt13Rh-Pt R

15

Pt30Rh-Pt6Rh B

16

NiCrSi-NiSi N

17

W3Re_W26Re

18

customized linearization

For customized linearization, a maximum of 10 knee-points

can be implemented, or a 5th order polynomial function

programmed (only through the setup program).

For the linearization “KTY11-6”, the resistance is 2kΩ at 25 °C

(only through the setup program).

Factory settings are shown bold.

41

Page 42

8 Configuration

Analog input 1 InP1 ➔

Analog input 2 InP2 ➔

Symbol Value/selection Description

Measurement offset

Display start

Display end

OFFS

SCL

SCH

-1999… 0… +9999 The measurement offset is used to correct a measured value

-1999…0…+9999 On transducers with standard signal and on potentiometers, a

-1999…

100

…+9999

by a certain amount upwards or downwards.

Examples:

Measured Displayed

value offset value

294.7 +0.3 295.0

295.3 - 0.3 295.0

The controller uses the corrected value (= displayed

value) for its calculation. This value is not the same as

the actually measured value. If incorrectly applied, this

A

can result in impermissible values of the control

variable.

Special case: 2-wire circuit

If the input is connected to a resistance thermometer in 2-wire

circuit, then the lead resistance is set in ohms here.

display value is assigned to the physical signal.

Example: 0 — 20mA 0 — 1500°C.

Filter time constant

Fine tuning

start value

Fine tuning

end value

Heater current

monitoring (output)

KTY correction value

at 25°C

The range of the physical signal can be 20 % wider or

narrower without generating an out-of-range signal.

dF

FtS

FtE

HEAt

(setup) 0

1. Both parameters can be activated/deactivated with setup program.

0…0.6…100 s To adjust the digital input filter (0sec = filter off).

1

-1999… 0…+9999 v See “Customized fine tuning” on Page 43.

1

-1999…1…+9999

…

2000…4000 Ω Resistance at 25°C/77°F for linearization “KTY 11-6”

Factory settings are shown bold.

63% of the alterations are acquired after 2x filter time constant

at a signal step change.

When the filter time constant is large:

- high damping of disturbance signals

- slow reaction of the process value display

to process value changes

- low limit-frequency (2nd order low-pass filter)

If these values are altered by mistake, then this setting

has to be canceled, using the procedure described

under “Customized fine tuning”.

A

These values can not be accepted by another

instrument.

0

No function

1…10

Binary output 1—10 (controller output)

The heater current is measured via a current transformer with

standard signal output and can be monitored by linking analog

output 2 to limit comparator 1.

The input signal range is 0 — 50mA AC (see probe type:

“Heater current”) and must be scaled correspondingly (display

start/end).

The heater current is measured when the heating contact is

closed. For this purpose, the binary output which controls the

heating contact (not the binary output for the alarm) has to be

selected here.

42

Page 43

Analog inputs (general)In12 ➔

Symbol Value/selection Description

Temperature unit

Sampling cycle time

Supply frequency (setup) 50Hz

Unit

CycL

60Hz

Factory settings are shown bold.

8.1.1 Customized fine tuning

8 Configuration

01deg. Celsius

deg. Fahrenheit

Unit for temperature values

0

50msec

1

90msec

2

150msec

3

250msec

Adaptation of the conversion time of the input circuitry to the

supply frequency

Activate FtS and

FtE with setup

program

Ex-factory, both parameters are not visible at the device and have to be activated first.

h Connect the device to the PC and start the setup program

h Establisch a connection to the device

h Make a double click on Undocumented parameters

h Click on check box at Parameter 17 (a tick shall appear)

h Save the setup file and execute Data transfer to device

Now the parameters FtS and FtE are visible in the Configuration level.

Principle The customised fine tuning (= fine adjustment) is used to correct the values displayed

by the device. This may be necessary, for example, after a system validation, if the

displayed values no longer coincide with the actual values at the point where the

measurement is taken.

Using a reference measuring instrument, two measured values are determined which

should be as far apart as possible (start value, end value). Ensure that the measuring

conditions are stable. Enter the reference value found as the start value (FtS) or end

value (FtE) on the device to be adjusted.

43

Page 44

8 Configuration

Caution:

A

Example The temperature inside an oven is measured with a resistance thermometer and

If start value and/or end value deviate from the factory-set values (FtS=0 and FtE=1), a

fine adjustment has already been done before. In this case the fine adjustment has to

be reset (see below).

Repeating fine adjustment without doing a reset before means that an already adjusted characteristic curve is used. This leads to wrong values.

displayed on a device. The reading on the device deviates from the actual temperature

as a result of the sensor temperature drifting. At 20°C the device reads 15°C, at 80°C

it shows 70°C (exaggerated example for better understanding).

Sensor

15°C / 70°C

Display on the device

20°C / 80°C

Actual temperature at

20°C / 80°C

reference measuring instrument

(e. g. thermometer)

Oven

Procedure h Determine lower measurement value (as low as possible and constant) with a refe-

rence measuring instrument;

Example: Oven temperature 20°C (= room temperature)

h Set start value at the device to this lower measurement value;

Example: Set start value (FtS) to 20

h Increase temperature and determine higher measurement value (as high as posible

and constant) with reference measuring instrument;

Example: Increase oven temperature to 80°C

h Set end value at the device to this higher measurement value;

Example: Set end value (FtE) to 80

Characteristic

curve

The following diagram shows the changes in the characteristic curve caused by the

fine adjustment (point of intersection with the x axis as well as ascent)

Special case: Offset

If the deviation between measured value

and displayed value at the low and high

measuring point is identical, an offset cor-

80

70

Display

(Instrument)

rection is sufficient (ascent remains

After fine

adjustment

Before fine

adjustment

unchanged). In this case, fine adjustment

is not required.

v Chapter 8.1 “Analog inputs “InP””

Parameter OFFS

20

15

Measurement

(Reference)

20 80

Reset

fine adjustment

44

In order to reset fine adjustment, the same value hast to be given to start value (FtS)

and end value (FtE) (e. g. set both parameters to 0). This automatically sets the start

value to 0 and the end value to 1 (factory setting).

Page 45

8.2 Controller “Cntr”

8 Configuration

Configuration

Analog inputs

Controller

Generator

Limit comparators

Outputs

Binary functions

Display

Timer

Interfaces

Controller type

Control action

Cntr: Controller

The following are set here: controller type, input variables of the controller, the setpoint

limits, conditions for manual mode and the presettings for autotuning (selfoptimization).

Symbol Value/selection Description

Configuration

0

CtyP

CAct

no function

1

2-state controller

2

3-state controller

3

Modulating controller

4

Continuous controller

01Direct

Inverse

Inhibit manual mode

Manual output

Range output

Setpoint low

Setpoint high

InHA

HAnd

rOut

SPL

SPH

inverse:

The controller output Y is > 0 when the process value is

smaller than the setpoint (e. g. heating).

direct:

The controller output Y is > 0 when the process value is larger

than the setpoint (e. g. cooling).

01enabled

inhibited

If the manual mode is inhibited, changing over to “manual” is

not possible from the keys or via the binary input.

-100…101 Defines the controller output level after changing over to

-100…0…101 Output on over/underrange.

-1999…+9999 Setpoint limiting prevents the input of values outside the

-1999…+9999

manual mode.

101 = last output

For modulating controller:

101 = actuator is stationary;

0 = actuator closes; 100 = actuator opens

101 = last output

For modulating controller:

101 = actuator is stationary;

0 = actuator closes; 100 = actuator opens

defined range.

H

The setpoint limits are not effective with setpoint input

via the interface.

The correction value is limited for external setpoint with

correction.

Factory settings are shown bold.

45

Page 46

8 Configuration

Symbol Value/selection Description

Inputs

Controller process

value

External setpoint

Output feedback

Method of tuning

Inhibit tuning

Output of tuning 1

Output of tuning 2

Controller standby

output

Step size

CPr

ESP

FEEd

Autotuning

tyPt

InHt

Ott1

Ott2

SOut

StSI

(analog selector)

Analog inp. 1

(analog selector)

switched off

(analog selector)

switched off

-100…0…+100% Initial output with step response

10…30…100% Step size with step response

Factory settings are shown bold.

Defines the source for the process value of the control

channel.

Activates the external setpoint input and defines the source

for the external setpoint.

External setpoint with correction:

External setpoint + setpoint 1 = present setpoint

The external setpoint is corrected up or down from the keypad

(setpoint 1). The display shows the present setpoint.

Defines the source for output feedback for a modulating

controller.

v See “Analog selector” on Page 40.

01Oscillation method

Step response method

v Chapter 9.1 “Autotuning (self-optimization)”

01enabled

inhibited

If autotuning is inhibited, it can not be started via the keys or

the binary function.

0

Relay

1

Solid-state + logic

2

Continuous

The type of the physical output for the signal of the controller

outputs 1 and 2 has to be defined.

Analog selector

46

0 no function 21 program run time in sec

1 analog input 1 22 residual program time in sec

2 analog input 2 23 segment run time in sec

3 process value 24 residual segment time in sec

4 present setpoint 25 timer run time for timer 1 in sec

5 ramp end value 26 timer run time for timer 2 in sec

6 program setpoint 27 residual run time for timer 1 in sec

7 math 1 28 residual run time for timer 2 in sec

8 math 2 29 present segment end value

9 setpoint 1 30 analog marker (Profibus)

10 setpoint 2 31 reserved

11 setpoint 3 32 reserved

12 setpoint 4 33 reserved

13 controller output level

14 controller output 1

15 controller output 2

Page 47

8.3 Generator “Pro”

8 Configuration

Configuration

Analog inputs

Controller

Generator

Limit comparators

Outputs

Binary functions

Display

Timer

Interfaces

Function

Pro: (Program) Generator

The basic function of the instrument is defined here. The instrument can be operated

as a fixed-setpoint controller with or without a ramp function, or warm-up ramp for

hot-channel equipment, program controller or program generator.

Symbol Value/selection Description

General

0

Fnct

Fixed-setpoint controller

1

Ramp function

2

Program controller

3

Program generator

4

Hot-channel controller

Ramp function:

A rising or a falling ramp function can be implemented. The

ramp end value is determined by the setpoint input and can be

altered from the I and D keys, just as for a fixed-setpoint

controller.

The ramp function can be paused or canceled via the binary

functions.

v Chapter 8.6 “Binary functions “binF””

H

Factory settings are shown bold.

The ramp function is interrupted on a probe break, or

for manual mode. The outputs react as for overrange/

underrange (configurable).

Program generator:

Is used, for instance, to output the setpoint profile via a

continuous output without a control function.

Settings for the program generator are not evaluated with

regard to the process value (e. g. start at process value,

continue, tolerance band).

47

Page 48

8 Configuration

Symbol Value/selection Description

Unit of slope

Ramp slope

Tolerance band

Unit

rASL

toLP

Ramp function Program

0

°C/min mm:ss

1

°C/hour hh:mm

2

°C/day dd:hh

s=seconds; m=minutes; h=hours;d=days

Unit of ramp slope in °C per time unit, or format of segment

times for program controller/generator.

0…9999 Value of slope for ramp function

0…999 0=off

For a program controller/generator and ramp function, the

process value can be monitored by applying a tolerance band

around the setpoint profile.

If the upper or lower limit is infringed, a tolerance limit signal is

generated, which is internally processed or produced via an

output.

Example:

Signal is produced

when process value is

20 °C larger or smaller

than

setpoint.

toLP=40

Processing the tolerance limit signal, see:

v Chapter 8.5 “Outputs “OutP””

v Chapter 8.6 “Binary functions “binF””

Program

Program start (setup) Program start

Range response (setup) Continue

Response to

power-on

Program repeat (setup) none

Setpoint input (setup) Ramp

Control to the

most recent setpoint

Delay time (setup) 0…9999 min Delays the program start by an adjustable time.

(setup) No start

(setup) inactive

start at the process

pause program

automatic start

Defines whether the program starts with the first program

setpoint or whether the present process value is accepted as

value

the first program setpoint.

Defines the response to over/underrange

Defines whether the program starts on connecting the supply

voltage.

The “Cyclic” setting has the effect of continuously repeating

cyclic

the program.

Setpoint ramp Setpoint step

Step

w

A01

If active, the process is controlled to the most recent program

active

setpoint after the program has ended.

A02

t

Basic status

Control contacts (setup) SK1

SK2

SK3

SK4

Factory settings are shown bold.

48

Strt” is shown in the lower display.

“

The four control contacts can be activated in the basic status

(when the program is not running).

Page 49

8 Configuration

Hot-channel

controller

The warm-up ramp for hot-channel equipment is used, for example, for the gentle

operation of ceramic heater elements. Damage can be avoided by allowing moisture

to evaporate slowly from the hygroscopic heater elements during the warm-up phase

(t

— t2).

0

The present setpoint is accepted as the start value for the ramp at time t

time period t

setpoint SPP2. Within this period, the ramp setpoint is increased linearly. This is

followed by the programmable dwell time tP2 (t

controlled to the present setpoint (factory setting: setpoint 1 (SP1)).

The hot-channel function, with the settings for the ramp function and the program, is

implemented through the setup program.

Relevant settings:

— t1, the programmed ramp slope rASL is used to approach the hold

0

— t2), after which the process is

1

. Within the

0

Setup/Generator/General

- Ramp slope rASL with time unit

- Tolerance band (optional)

Setup/Generator/Program

- Configure program start to “Start at process value”

- Define response after power-on; the warm-up ramp either starts automatically

when switching on the supply voltage, or by pressing the

Setup/Parameter level/Controller parameters

- Output limiting for parameter sets 1 and 2 (optional)

Setup/Program editor/Program

- Set parameter set 2 for segment 1 (segment setpoint and time are not taken into

account)

- Configure segment 2 with segment setpoint (= hold setpoint SPP2), segment time

(= dwell time tP2) and parameter set 2

Setup/Display - Operation/ User data

- Relevant parameters can optionally be placed in the user data (operator level)

I key.

49

Page 50

8 Configuration

8.4 Limit comparators “LC”

Configuration

Analog inputs

Controller

Generator

Limit comparators

Outputs

Binary functions

Display

Timer

Interfaces

Limit comparator

functions (lk)

LC: Limit comparator

Limit comparators (threshold monitors, limit contacts) can be used to monitor an input

variable (process value for the limit comparator) against a fixed limit or another

variable (the setpoint for the limit comparator). When a limit is exceeded, a signal can

be output or an internal controller function initiated.

4 limit comparators are available.

Limit comparators can have different switching functions.

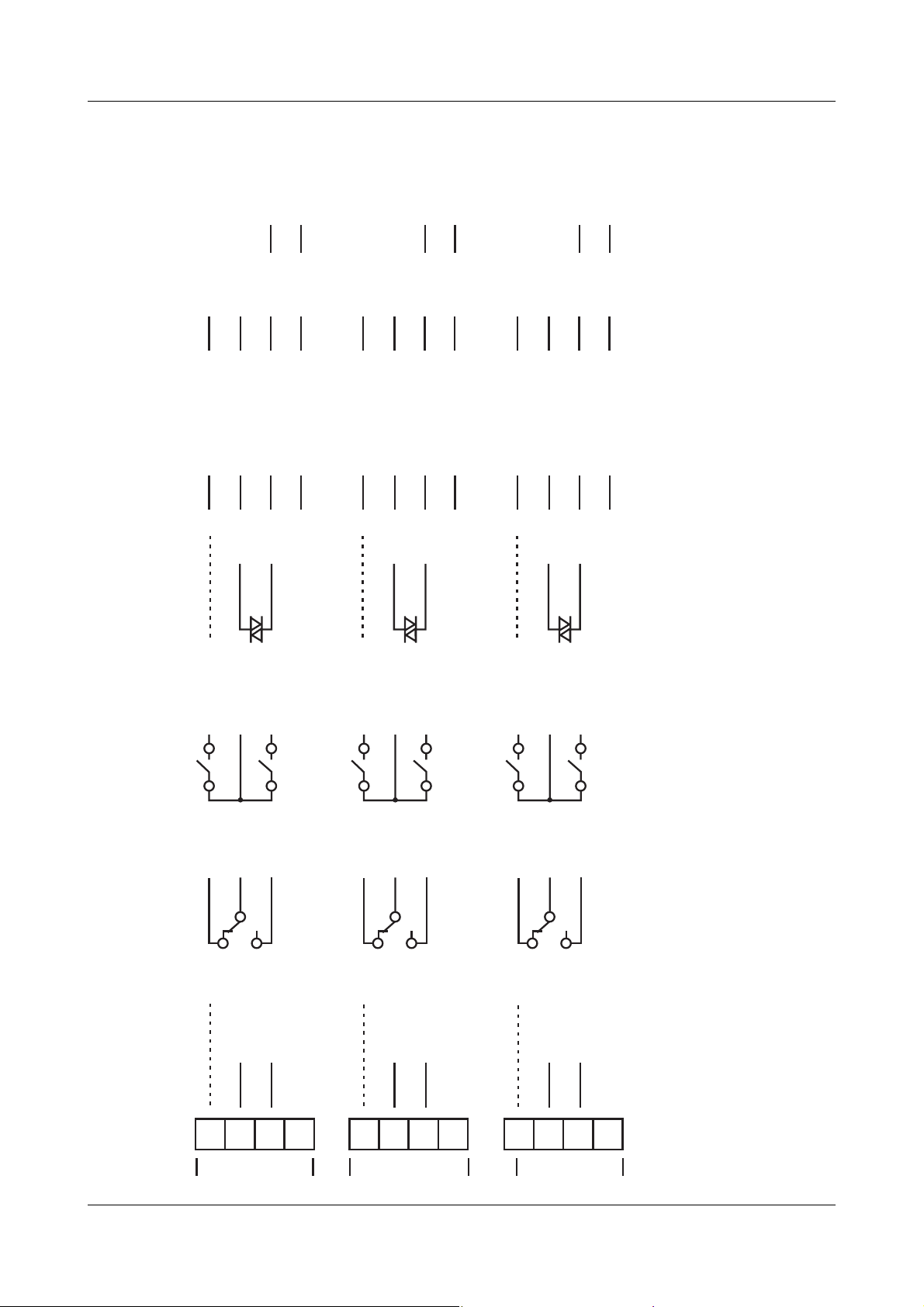

The hysteresis functions “asymmetrical, left” and “asymmetrical, right” can only be set

through the setup program. The “symmetrical” hysteresis function is used as

standard.

Hysteresis function

asymmetrical, left symmetrical asymmetrical, right

lk1

lk2

lk3

lk4

lk5

lk6

50

Page 51

8 Configuration

In the case of the limit comparator functions lk7 and lk8, the measurement that is set

is monitored with respect to a fixed value AL.

Hysteresis function

asymmetrical, left symmetrical asymmetrical, right

lk7

lk8

Limit comparator 1 LC1 ➔

LC2 ➔

0

no function

1

lk1

2

lk2

3

lk3

4

lk4

5

lk5

6

lk6

7

lk7

8

lk8

Function

Limit comparator 2

Limit comparator 3 LC3 ➔

Limit comparator 4 LC4 ➔

Symbol Value/selection Description

Fnct

Limit value

Switching differential

AL

HySt

-1999…0…+9999 Limit value to be monitored

Limit range for lk1 and lk2: 0 — 9999

0…1…9999 Switching differential

Factory settings are shown bold.

51

Page 52

8 Configuration

Action/

range response

Limit comparator 1

Limit comparator 2 LC2 ➔

Limit comparator 3 LC3 ➔

Limit comparator 4

Symbol Value/selection Description

AcrA

LC1 ➔

LC4 ➔

0

absolute/off

1

relative/off

2

absolute/on

3

relative/on

Defines the switching action of the limit comparators and the

switch status for an overrange or underrange.

Action:

Defines the switching action of the limit comparators on a

setpoint change or power-on.

absolute:

At the time of alteration, the limit comparator acts according

to its function.

relative:

The limit comparator is in the OFF status.

An alteration of the limit value or the (limit comparator)

setpoint could cause the limit comparator to switch ON. Such

a reaction will be suppressed, and this condition is maintained

until the (limit comparator) process value has moved out of

the switch-on region (gray area).

Example:

Monitoring the (controller) process value x with function lk4

Setpoint alteration w1→w2

a) Initial condition

Switch-on delay

Switch-off delay

t0n

t0FF

b) Condition at the time of the alteration

The limit comparator remains OFF, although the process value

is within the switch-on region.

c) Stabilized condition

The limit comparator again operates in accordance with its

function.

This function also prevents a limit comparator from being

triggered during the approach phase.

0…9999 Delays the switch-on edge by a definable time period

0… 9999s Delays the switch-off edge by a definable time period

Factory settings are shown bold.

52

Page 53

Limit comparator 1 LC1 ➔

Limit comparator 2 LC2 ➔

Limit comparator 3 LC3 ➔

Limit comparator 4

Symbol Value/selection Description

Acknowledgement

Pulse time

Limit comparator PV

Limit comparator SP

Hysteresis function (setup) symmetrical

AcnL

tPuL

LCPr

LCSP

0… 9999s The limit comparator is automatically reset after an adjustable

(analog selector)

process value

(analog selector)

present setpoint

asymmetrical, left

asymmetrical, right

Factory settings are shown bold.

LC4 ➔

8 Configuration

0

no acknowledgement

1

acknowledgement; only with inactive limit comparator

2

acknowledgement; always possible

For settings with acknowledgement, the limit comparator is

latching, which means it remains ON, even when the switchon condition is no longer present.

The limit comparator must be reset via the D + X keys or

binary signal.

time period.

see circuit diagrams

see circuit diagrams (only with lk1—lk6)

see circuit diagrams

v Chapter 12.2 “Alarm messages”

Analog selector

0 no function 21 program run time in sec

1 analog input 1 22 residual program time in sec

2 analog input 2 23 segment run time in sec

3 process value 24 residual segment time in sec

4 present setpoint 25 timer run time for timer 1 in sec

5 ramp end value 26 timer run time for timer 2 in sec

6 program setpoint 27 residual run time for timer 1 in sec

7 math 1 28 residual run time for timer 2 in sec

8 math 2 29 present segment end value

9 setpoint 1 30 analog marker (Profibus)

10 setpoint 2 31 reserved

11 setpoint 3 32 reserved

12 setpoint 4 33 reserved

13 controller output level

14 controller output 1

15 controller output 2

53

Page 54

8 Configuration

8.5 Outputs “OutP”

Configuration

Analog inputs

Controller

Generator

Limit comparators

Outputs

Binary functions

Display

Timer

Interfaces

Numbering of the

outputs

OutP: Outputs

Configuration of the instrument outputs are subdivided into analog outputs (OutA;

max. 2) and binary outputs (OutL; max. 9). Binary outputs are relay, solid-state relay

and logic outputs. Display and numbering of the outputs depends on the assignment

of the option slots.

The switching states of the binary outputs 1—6 are shown in the display.

Standard for all instrument versions:

(Binary) output 1 (Out1) = relay

(Binary) output 2 (Out2) = relay

(Binary) output 3 (Out3) = logic output

(Binary) output 4 (Out4) = logic output

Extended numbering for the option slots:

Slot Plug-in board with

1 analog output

Option 1 Output 5 (Out5) Output 5 (Out5) Output 5+8 (Out5/Out8)

Option 2 Output 6 (Out6) Output 6 (Out6) Output 6+9 (Out6/Out9)

Option 3 Output 7 (Out7) Output 7 (Out7) Output 7+10 (Out7/Out0)

Plug-in board with

1 binary output

(relay or solid-state

relay)

Plug-in board with

2 binary outputs

(2 relays)

Binary output 1

...

Binary output 10

Binary outputs 0utL

Symbol Value/selection Description

0

0ut1

...

0ut0

Factory settings are shown bold.

no function

1

Controller output 1 (ex-factory with Out1)

2

Controller output 2

5

Binary input 1

6

Binary input 2

7

Binary input 3

8

Binary input 4

9

Binary input 5

10

Binary input 6

11

Binary input 7

12

Binary input 8

13

Limit comparator 1

14

Limit comparator 2

15

Limit comparator 3

16

Limit comparator 4

17

Control contact 1

18

Control contact 2

19

Control contact 3

20

Control contact 4

21

Logic formula 1

22

Logic formula 2

23

Timer 1 active

24

Timer 2 active

25

Program active

26

Program end signal

27

Tolerance limit signal

28

Manual mode on/off

29

Binary marker

30

Any binary value from storage address (only through setup)

31

always active

54

Page 55

Function

Type of signal

Range output

Analog outputs 0utA ➔ Output 5 0ut5 ➔

Output 6 0ut6 ➔

Output 7 0ut7 ➔

Symbol Value/selection Description

Fnct

S iGn

r0ut

(analog selector)

switched off

0…101% Signal on going above/below range

Function of the output

Physical output signal

0

0—10V

1

2—10V

2

0—20mA

3

4—20mA

101 = last output signal

8 Configuration

H

Zero point

End value

0Pnt

End

-1999…0…+9999 A physical output signal is assigned to the value range of an

-1999…

100

…+9999

output variable.

Ex-factory, the setting corresponds to an output level of

0 — 100% for controller outputs.

No changes of the ex-factory setting are required for

continous controllers with only one output.

H

Example (function as a transducer):

An analog output (0 — 20mA) is to be used to put out the

process value (value range 150 to 500 °C), that means:

150 to 500°C

Offset (setup) -1999…0…+9999 The offset is used to correct the output signal by a certain

Factory settings are shown bold.

amount upwards or downwards.

Examples:

Original Output

value Offset value

294.7 +0.3 295.0

295.3 - 0.3 295.0

If the output is a controller output, the controller

switches over to manual mode and produces the

output level defined in chapter “Controller Cntr”

under rOut.

Chapter 8.2 “Controller “Cntr””

Setting for controller outputs for cooling

With 3-state controllers, the following settings must

be predefined:

zero: 0 / end value: -100

0 — 20mA; Zero point: 150 / End value: 500

Analog selector

0 no function 21 program run time in sec

1 analog input 1 22 residual program time in sec

2 analog input 2 23 segment run time in sec

3 process value 24 residual segment time in sec

4 present setpoint 25 timer run time for timer 1 in sec

5 ramp end value 26 timer run time for timer 2 in sec

6 program setpoint 27 residual run time for timer 1 in sec

7 math 1 28 residual run time for timer 2 in sec

8 math 2 29 present segment end value

9 setpoint 1 30 analog marker (Profibus)

10 setpoint 2 31 reserved

11 setpoint 3 32 reserved

12 setpoint 4 33 reserved

13 controller output level

14 controller output 1

15 controller output 2

55

Page 56

8 Configuration

8.6 Binary functions “binF”

Configuration

Analog inputs

Controller

Generator

Limit comparators

Outputs

Binary functions

Display

Timer

Interfaces

Switching action

binF: Binary functions

Functions are assigned here to the binary signals of the binary inputs and limit

comparators.

In addition, the functions for control contacts, tolerance limit signal and program end

signal are defined for program controllers/generators.

In the case of a fixed-setpoint controller, functions can be assigned to the ramp end

signals.

Edge-triggered

functions

State-triggered

functions

The functions are arranged in two groups:

The binary function reacts to switch-on edges.

The following functions are edge-triggered:

- Start/stop of autotuning

- Acknowledge limit comparators

- Program start/cancel

-Start timer

- Segment change

The binary function reacts to switch-on or switch-off states.

- All remaining functions

56

Page 57

Binary input 1

...

Binary input 8

Limit comparator 1

...

Limit comparator 4

Timer 1

Timer 2

Logic 1

Logic 2

Control contact 1

...

Symbol Value/selection Description

0

b in1

b in8

LC1

LC4

tF1

tF2

Lo1

Lo2

CC1

no function

1

Start autotuning

2

Cancel autotuning

3

Change to manual mode

4

Controller off (controller outputs are switched off)

5

Inhibit manual mode

6

Hold ramp

7

Cancel ramp

8

Setpoint changeover

9

Parameter set switching

10

Key inhibit

11

Level inhibit

12

Display “off” with key inhibit

13

Acknowledge limit comparators

14

Inhibit program start

15

Start program

16

Pause program

17

Cancel program

18

Segment change

19

Start timer 1

20

Start timer 2

21

Cancel timer 1

22

Cancel timer 2

8 Configuration

Control contact 4

Tolerance limit signal

Program end signal

Setpoint and

parameter set

switching

CC4

toLS

PrES

Factory settings are shown bold.

Level inhibit:

The parameter and configuration levels are inhibited.

In addition, the start of autotuning is inhibited.

Program end signal:

The signal is active after approx. 1 second (pulse). For longer

signals, the program end signal can be used to start a timer.

Text display:

If the binary function is active, a configurable text is shown in

the lower display. The text can be uniquely defined (only

through the setup program).

Type 703041:

The settings for the binary inputs 1+2 have priority over those

for the logic outputs.

A binary function can be used to switch between setpoint 1 and setpoint 2 or

parameter set 1 and parameter set 2.

Setpoint switching Parameter set switching Binary signal

Setpoint 1 active Parameter set 1 active 0/contact open

Setpoint 2 active Parameter set 2 active 1/contact closed

In order to switch between the four possible setpoints, two binary functions must be

configured to “setpoint switching”. The states of the two binary functions are

designated Z1 and Z2 and switch the setpoints over as shown in the table below:

Setpoint Z2 Z1

Setpoint 1 00

Setpoint 2 01

Setpoint 3 10

Setpoint 4 11

0 = contact open /OFF 1 = contact closed /ON

57

Page 58

8 Configuration

The states Z1 and Z2 are assigned to the

binary functions in descending order (see

list on the right), i. e. the first binary

function selected in the list is Z1.

Example:

The setpoint is to be selected via a binary

input and the state of one limit comparator.