Page 1

JUMO Dtrans T100

Screw-in RTD temperature probe

with transmitter

B 902815.0

Operating Instructions

2016-02-17/00495568

Page 2

Page 3

Contents

1 Introduction ............................................................... 4

2 Identifying the device version .................................. 5

2.1 Type designation .......................................................................................... 5

2.2 Scope of delivery .......................................................................................... 7

2.3 Accessories for programmable 2-wire transmitter ................................... 7

3 Installation ................................................................. 8

3.1 Connection diagram .................................................................................... 8

3.2 Connection example with power supply unit ............................................ 9

3.3 Connection example with supply isolator .................................................. 9

4 Setup program ......................................................... 10

4.1 Configurable parameters ........................................................................... 11

4.2 Software requirements .............................................................................. 12

4.3 Important information about Windows user administration .................. 12

4.4 Fine calibration ........................................................................................... 12

4.5 Connection arrangement ........................................................................... 13

5 Dimensions .............................................................. 15

5.1 Basic types .................................................................................................. 15

5.2 Process connection PA .............................................................................. 16

6 Technical data .......................................................... 19

Page 4

4

1 Introduction

The screw-in RTD temperature probe, which has a compact design,

consists of a protection tube with an integrated temperature sensor,

a process connection, and an attached housing for the transmitter

electronics. The built-in programmable 2-wire transmitter converts

the resistance value into a current signal.

The screw-in RTD temperature probe with programmable 2-wire

transmitter is used for measuring temperatures from -50 to +150 °C

(-58 to +302 °F), with an extension up to 260 °C (500 °F).

The range, fine calibration, measuring circuit monitoring etc. can all

be configured through the setup program.

The 4 to 20 mA or (reversed) 20 to 4 mA output signal that is

provided is linear with temperature. The instrument is designed for

industrial application and complies with the European standards for

assuring electromagnetic compatibility (EMC).

The transmitter must be protected from temperatures above

85 °C!

Product with an integrated transmitter is not intended for

export to the USA!

Page 5

5

2 Identifying the device version

2.1 Type designation

Order details: JUMO Dtrans T100

Screw-in RTD temperature probe with transmitter

- Product with an integrated transmitter is not intended for

export to the USA! -

(1) Basic type

902815/20 Screw-in RTD temperature probe

with programmable transmitter,

connection: M12 × 1 machine connector,

parts in contact with the medium

electrolytically polished;

surface roughness Ra ≤ 0.8 μm

902815/21 Screw-in RTD temperature probe

with programmable transmitter,

connection: M12 × 1 machine connector,

high-temperature version with extension,

parts in contact with the medium

electrolytically polished;

surface roughness Ra ≤ 0.8 μm

(2) Operating temperature in °C

x 370 -50 to +150 °C (max. transmitter temperature 85 °C)

x 386 -50 to +260 °C (max. transmitter temperature 85 °C)

(3) Measuring insert

x x 1013 1× Pt1000 in 4-wire circuit

(4) Tolerance class according to EN 60751

x x 2 Class A

(5) Protection tube diameter D in mm

xx 6 Ø6mm

(6) Fitting length EL in mm (EL 50 to 500)

x x 50 50 mm

x x 100 100 mm

x x 150 150 mm

x x 200 200 mm

x x ... Please specify in plain text (50 mm steps)

Page 6

6

2 Identifying the device version

(7) Process connection (PA)

xx 000 None

x x 103 G 3/8 (3/8" pipe) thread

x x 104 G 1/2 (1/2" pipe) thread

x x 380 G 1/2 (1/2" pipe) thread with CIP-compliant conical seal

with EHEDG certification

x x 601 Taper nipple with cap nut DN 10 DIN 11851 (milk pipe fitting)

x x 604 Taper nipple with cap nut DN 25 DIN 11851 (milk pipe fitting)

x x 605 Taper nipple with cap nut DN 32 DIN 11851 (milk pipe fitting)

x x 611 Clamping nipple (clamp) DN 10/20 according to DIN 32676

x x 613 Clamping nipple (clamp) DN 25/40 (1"/1.5") according to DIN 32676

x x 616 Clamping nipple (clamp) DN 50 (2") according to DIN 32676

x x 617 Clamping nipple (clamp) 2.5" similar according to DIN 32676

x x 681 Weld-in ball socket with clamping thread

x x 682 Weld-in socket with CIP-compliant conical seal

x x 684 Varivent connection DN 15/10 with EHEDG certification

x x 685 Varivent connection DN 32/25 with EHEDG certification

x x 686 Varivent connection DN 50/40 with EHEDG certification

x x 840 Ball weld-in pocket (material 316 Ti)

x x 997 JUMO PEKA with EHEDG certification

(8) Protection tube material

x x 24 Stainless steel 316 L (mat. ref. 1.4404 or 1.4435)

x x 26 Stainless steel 316 Ti (mat. ref. 1.4571) (upon request)

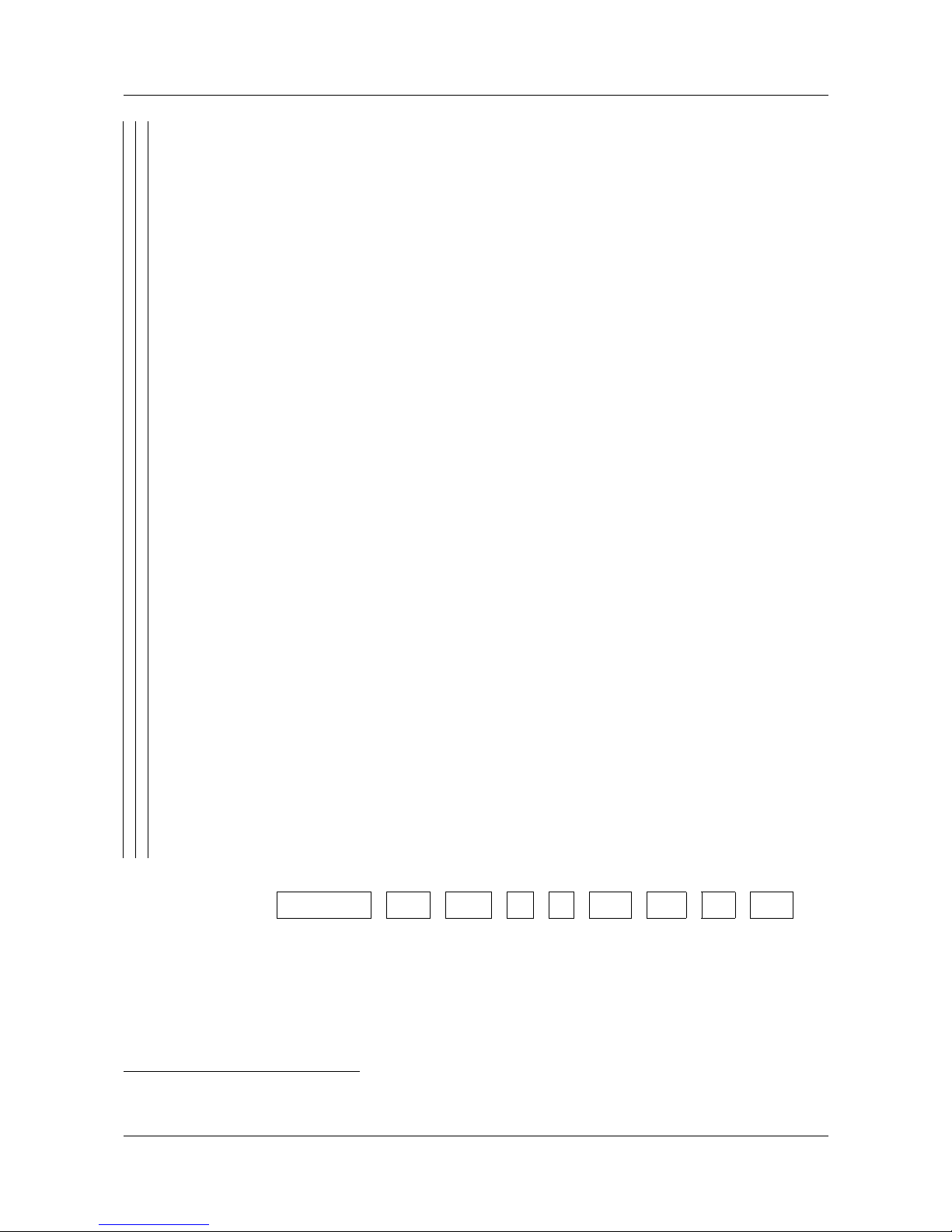

(9) Extra codes

xx 000 None

x x 100 Customer-specific configuration (specifications in plain text)

x x 310 Protection tube stepped down from 6 mm dia. to 3.3 mm dia.

x x 810 Weld-in socket (only for process connection 380)

(1) (2) (3) (4) (5) (6) (7) (8) (9)

Order code - - - - - - - / ,...

a

Order example 902815/20 - 370 - 1013 - 2 - 6 - 100 - 104 - 24 / 000

a

List extra codes in sequence, separated by commas.

Page 7

7

2 Identifying the device version

2.2 Scope of delivery

- 1 Operating Instructions B 902815.0

2.3 Accessories for programmable 2-wire transmitter

- Setup program on CD-ROM, multilingual,

part no. 00485016

- Configuration cable,

4-pole, with plug and socket M12 × 1

and RJ-45 Western plug,

part no. 00484692

- PVC connecting cable,

4-pole with M12 × 1 socket, length 2 meters,

part no. 00404585

- 5-pole contact box M12 × 1, straight,

without connecting cable to be patched by the customer,

part no. 00419130

- 5-pole contact box M12 × 1, angled,

without connecting cable to be patched by the customer,

part no. 00419133

- PC interface with USB/TTL converter and USB cable,

part no. 00456352

- Transmitter supply units 1-way and 4-way (data sheet 707500)

- Ex-i power supply / input isolating amplifier for electrical isolation

of standard signals and voltage supply

for 2-wire transmitter (data sheet 707530)

Page 8

8

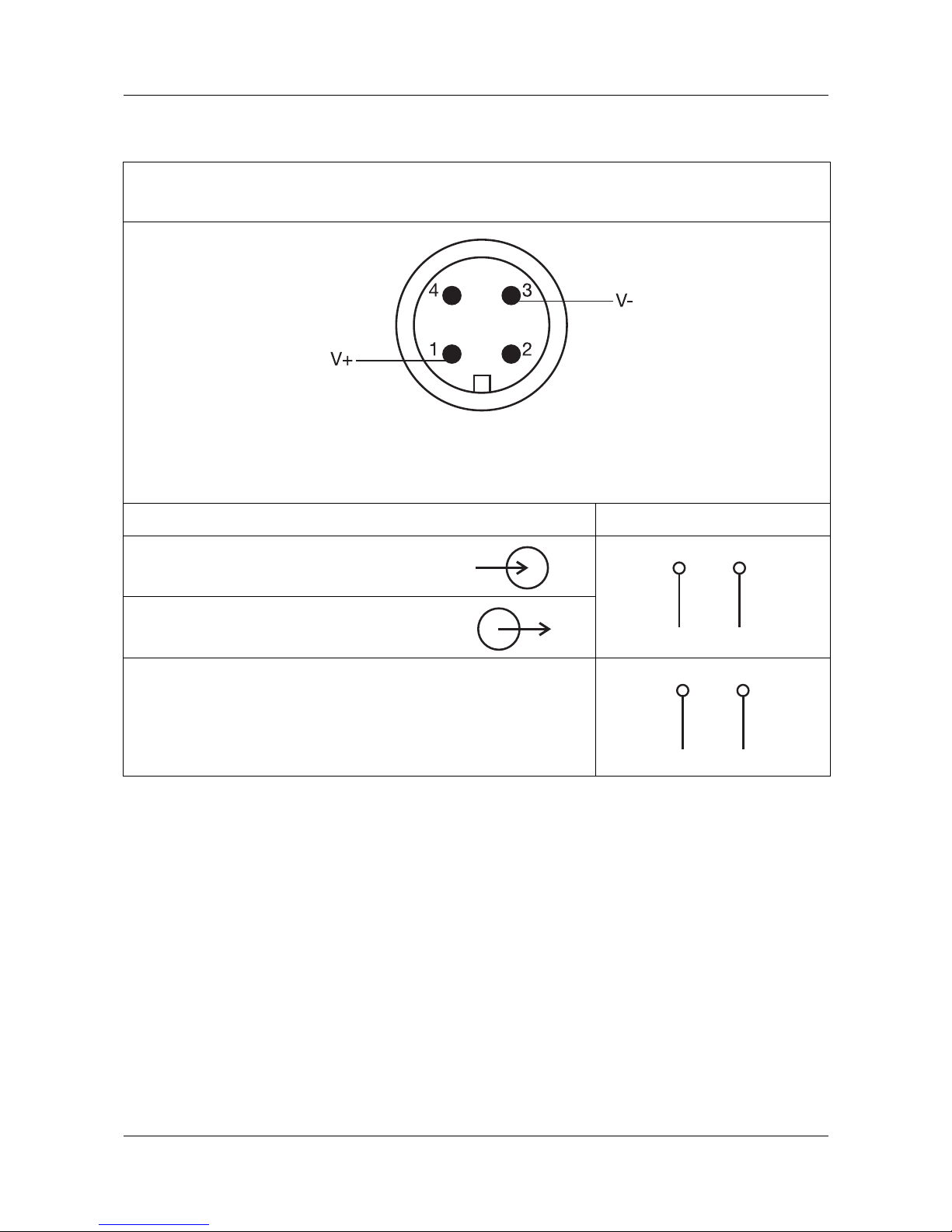

3 Installation

3.1 Connection diagram

M12 × 1 machine connector, 4-pole

according to IEC 60947-5-2

Warning

Do not connect pin 2 and pin 4 to the voltage!

Electrical connection Pin

Voltage supply

8to35VDC

Current output

4to20mA

Setup communication

via special configuration cable

(for configuration only,

continuous operation is not permissible)

V

Caution

After the machine connector has been plugged in correctly,

care must be taken that the prescribed voltage supply is

applied and the pins are assigned correctly during

connection. If this is not observed, the device will be

destroyed.

+

-

1 3

V+ V-

2 4

Page 9

9

3 Installation

3.2 Connection example with power supply unit

3.3 Connection example with supply isolator

Page 10

10

4 Setup program

Configuration from a PC

The setup program is available for configuring the programmable 2wire transmitter from a PC. The connection is made using a special

configuration cable with a M12 × 1 machine connector and M12 × 1

socket, and a RJ-45 Western plug. In addition, you will also need the

PVC connecting cable, 2 meters long. The PC interface with USB/TTL

converter and USB cable is needed for connecting up to a PC (see

accessories for the programmable 2-wire transmitter).

In order to configure the 2-wire transmitter, it must be

connected to the voltage supply.

If no power supply unit or supply isolator is available, the

transmitter can be configured using a 9 V battery as a power

source.

Page 11

11

4 Setup program

4.1 Configurable parameters

Setup

level

Parameter Value range Factory

setting

Hardware Device type - Meas. point

ID

TAG number - -

Measuring

range

°C or °F,

configurable

Offset

Range start

Range end

-50

+150 °C

or +260 °C

with extension

0.0 °C

0.0 °C

100.0 °C

Analog

output

Reversion of the

output

Signal on probe

break or shortcircuit

4to20mA/

20 to 4 mA

<3.8 mA/>21 mA

4to20mA

>21 mA

Further

parameters

Filter time constant

Unit

0 s/ ... / ... 125 s

°C/°F

0.1 s

°C

Page 12

12

4 Setup program

4.2 Software requirements

- Microsoft Windows XP or higher

4.3 Important information about Windows user

administration

If more than one user is administered by the computer, then the

user who is logged in should be the one who will subsequently be

working with the program. The user must have administrator rights

during the installation of the software. After installation, the rights

can be restricted again. If this is disregarded, it is not possible to

ensure a correct and complete installation.

4.4 Fine calibration

Fine calibration means adjustment of the output signal. Fine

calibration is carried out with the aid of the setup program. Using

the setup program, the 4 mA value (zero) and 20 mA value (full

scale) can be calibrated separately.

Page 13

13

4 Setup program

4.5 Connection arrangement

Use

- The PC interface with USB/TTL converter is only designed for

service use over a limited period, such as the transfer of setup

data.

- It links JUMO devices to a PC through an electrically isolated

connection. The RJ-45 Western plug is specially adapted to

JUMO devices, and is not suitable for third-party equipment.

Make the connections for the setup program as described below:

1. First connect the USB type A plug (a) to the PC/laptop and then

connect the USB type B plug (b) to the PC interface with USB/

TTL converter (c).

This ensure a safe grounding on the PC/laptop side.

2. Connect the RJ-45 Western plug (d) of the configuration cable

(e) to the PC interface with USB/TTL converter (c) and the

M12 × 1 socket (f) to the JUMO Dtrans T100 (g).

3. Connect the M12 × 1 socket (i) of the PVC connecting cable (j)

to the M12 × 1 plug (h) of the configuration cable (e).

4. Connect the 8 to 35 V DC voltage supply to the PVC

connecting cable (j).

Do not confuse the RJ-45 socket with an ISDN or network

connection.

Remove the modular cable (not required for this setup,

therefore not shown in the diagram) of the PC interface with

USB/TTL converter, including two adapters (socket and

plug) – will be needed for other devices.

Page 14

14

4 Setup program

Diagram 1: Connection arrangement for setup with JUMO

Dtrans T100

PC/laptop connection

(setup program

Part no. 00485016)

white

black

brown (+) PIN 1

blue (-) PIN 3

approx. 600

PC interface with USB/TTL converter

Part no. 00456352

(with USB cable)

USB type A plug

USB type B plug

RJ-45 Western plug

M12 socket

Configuration cable

Part no. 00484692

JUMO Dtrans T100

M12 socket

M12 plug

PVC 4-pole connecting cable

Part no. 00404585

8—35 VDC

(a)

(b)

(c)

(d)

approx. 2000

approx. 600

(h)

(e)

(f)

( i ) ( j )

(g)

Page 15

15

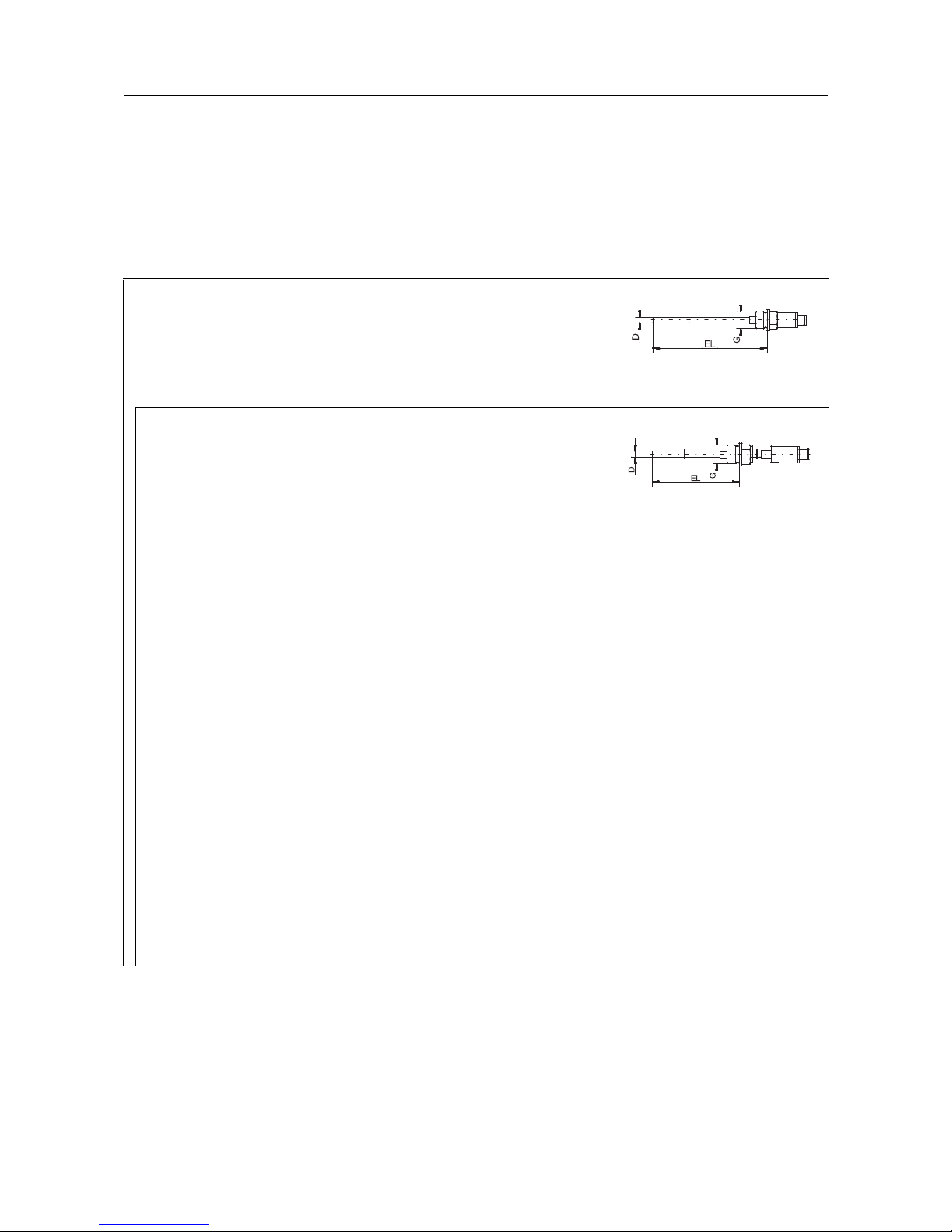

5 Dimensions

5.1 Basic types

Basic type 902815/20... Basic type 902815/21...

with extension

Page 16

16

5 Dimensions

5.2 Process connection PA

Screw fitting Screw fitting with

CIP-compliant conical seal

Clamping nipple

according to DIN 32676 (clamp)

PA G

103 3/8

104 1/2

PA

380

PA DN D1 PA DN D1

- - Ø 25 613 40/1.5" Ø 50.5

611 10/20 Ø 34 616 50/2" Ø 64

613 25/1" Ø 50.5 617 2.5" Ø 77.5

Page 17

17

5 Dimensions

Weld-in ball socket

with clamping nipple

Taper nipple

with cap nut

according to DIN 11851

(milk pipe fitting)

Weld-in socket

with CIP-compliant conical seal

PA

681

PA DN D1 D2 D3 D4 L1 L2

601 10 Ø 22 Ø 18

RD 28 × 1/8

Ø389 18

604 25 Ø 44 Ø 35

RD 52 × 1/6

Ø6313 21

605 32 Ø 50 Ø 41

RD 58 × 1/6

Ø7013 21

28

EL

15

41

D

30Ø

G1/2

18Ø

PA

682

Page 18

18

5 Dimensions

Varivent connection Ball weld-in pocket

JUMO PEKA PA 997

Process connection adapter

see data sheet 409711

PA DN D1

684 15/10 Ø 31

685 32/25 Ø 50

686 50/40 Ø 68

PA

840

Varivent Clamp Aseptic Weld-in

socket

DN 25/32 DN 25/32/40 DN 40 Ø 55 mm

DN 40-125 DN 50 DN 50 -

-- NKS DN40-

Page 19

19

6 Technical data

Input

Measurement input Pt1000 temperature sensor,

EN 60751, class A,

4-wire circuit

Measuring ranges Basic type 902815/20... : -50 to +150 °C

Basic type 902815/21... : -50 to +260 °C

with extension

Tolerance limits 0.15 + 0.002 × |t|, class A

|t| is the numerical value for the

temperature in °C without taking the sign

into account

Response time Water 0.4 m/s protection tube standard

t

0.5

= 5 s; t

0.9

= 12 s

Water 0.4 m/s protection tube stepped

t

0.5

= 2 s; t

0.9

= 5 s

Air 3.0 m/s protection tube standard

t

0.5

= 40 s; t

0.9

= 110 s

Air 3.0 m/s protection tube stepped

t

0.5

= 21 s; t

0.9

= 70 s

Input

Shortest span 10 K

Sampling rate 1 measurement per second

Input filter 1st order digital filter;

filter constant is adjustable

within the range 0 to 125 s

Measuring circuit monitoring

Underrange Linear drop down to 3.8 mA

(according to

NAMUR recommendation 43)

Page 20

20

6 Technical data

Overrange Linear rise up to 20.5 mA

(according to

NAMUR recommendation 43)

Probe short-circuit/

probe or lead break

≤ 3.6 mA or ≥ 21.0 mA (configurable)

Current limiting

on probe short-circuit

or probe break

≤ 25 mA

Output

Output signal Proportional DC current

4to20mA, 20to4mA

Transfer characteristic Linear with temperature

Maximum burden (R

B

)RB = (Ub - 8 V) devided by 23 mA,

max. 600 Ω

Burden error ≤ ±0.02 % per 100 Ω

The % value refers to the range end value

20 mA

Settling time on a

temperature change

≤ 5s

Settling time after a

switch-on or reset

≤ 5s

Measuring accuracy

of electronics

0.1 °C or 0.08 %

The % value refers to the measuring span

that was set, the larger value applies

Electrical data

Voltage supply

(U

b

)

DC 8 to 35 V (pin 1 = +, pin 3 = -),

operation solely with SELV or PELV-

transmitter supply

(according to DIN EN 61140)

Protection rating III (according to DIN 61140)

Page 21

21

6 Technical data

Galvanic isolation Without galvanic isolation between sensor

and output

Leakage resistance > 100 MΩ at DC 100 V measured at room

temperature between connection

terminals and case

Reverse polarity

protection

Yes

Voltage supply error ≤ ±0.01 % per V deviation from 24 V

The % value refers to the range end value

20 mA

Environmental influences

Ambient temperature

range for head

-30 to +85 °C

Storage temperature

range

-30 to +90 °C

Ambient

temperature error

≤ ±(15 ppm/°C × (range end value +200) +

50 ppm/°C × measuring range set) × Δυ

Δυ = deviation of ambient temperature

from the reference temperature

Calibration/reference

conditions

DC 24 V at 25 °C ±5 °C (77 °F ±9 °F)

Climatic conditions According to IEC 60068-2-30

(rel. humidity ≤ 95 % with condensation)

Vibration strength According to IEC 60068-2-6

(according to GL characteristics)

Electromagnetic

compatibility (EMC)

- interference emission

- interference immunity

DIN EN 61326

class B

industrial requirements

Protection type IP67 according to DIN EN 60529

with machine connector plugged in

Page 22

22

6 Technical data

Page 23

Page 24

JUMO GmbH & Co. KG JUMO Instrument Co. Ltd. JUMO Process Control, Inc.

Street address:

Moritz-Juchheim-Straße 1

36039 Fulda, Germany

Delivery address:

Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

E-mail: mail@jumo.net

Internet: www.jumo.net

JUMO House

Temple Bank, Riverway

Harlow - Essex CM20 2DY, UK

Phone: +44 1279 63 55 33

Fax: +44 1279 63 52 62

E-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

E-mail: info.us@jumo.net

Internet: www.jumousa.com

Loading...

Loading...