Page 1

40302200T90Z001K000

V5.00/EN/00519462

JUMO dTRANS p20 DELTA

Differential pressure transmitter

Operating Manual

Page 2

Page 3

3

GEFAHR!

The device is suitable for measuring pressure in gases and liquids without solids content.

In the SIL version (functional safety), this device is used in safety-related systems for minimum,

maximum and area monitoring that fulfil the requirements of the series of standards DIN EN

61508:2011.

A failure of the device or other devices connected to it, e.g. due to an operating error, can lead to

dangerous malfunctions of the whole plant.

Therefore please also observe the corresponding safety manual from the device series.

HINWEIS!

Read this operating manual before putting the device into service. Keep the operating manual in a place

that is accessible to all users at all times.

All necessary settings are described in this operating manual. Nevertheless, should problems be encountered during startup please do not make any unauthorized manipulations. This could endanger your

rights under the warranty!

Please contact the nearest branch office or the head office.

Page 4

4

Page 5

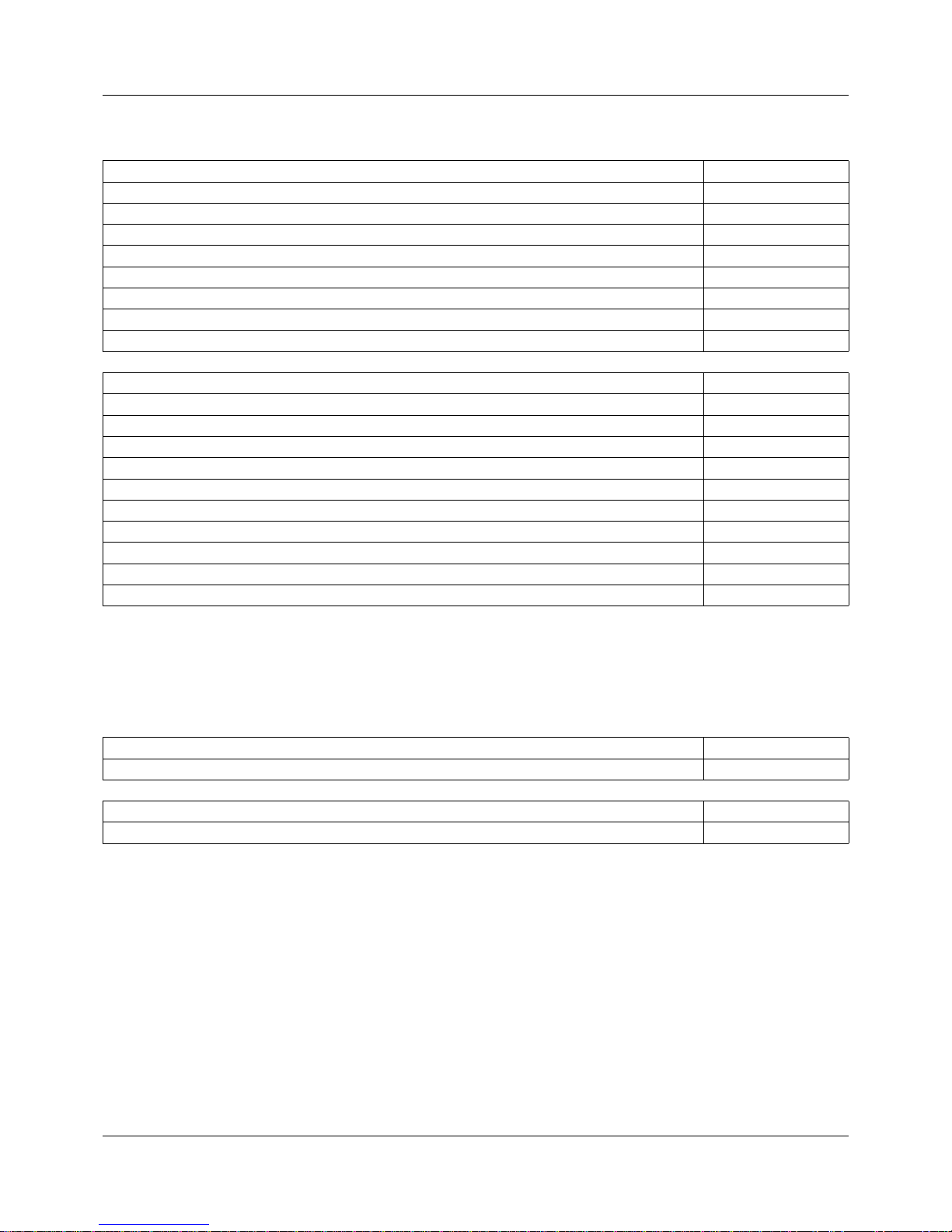

Contents

Contents

1 Safety information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 Areas of application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Identifying the device version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 Nameplate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Order details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3 Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.4 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.5 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.3 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.4 Voltage supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.5 Mechanical features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.6 Environmental influences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.7 Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.8 Approvals/approval marks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.1 Before mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.2 Unscrew the front ring or case lid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.3 Rotating the LCD (display) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.4 Rotating the housing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.5 Pressure connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.6 Bracket for wall and pipe mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.7 Level measurement with a diaphragm seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.7.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.7.2 Measuring arrangement in open or closed containers with ± measuring ranges . . . . . . . . . . . 29

5.7.3 Measuring arrangement in open and closed containers with a measuring range of 0 to 1 bar. . 30

5.8 Level measurement without a diaphragm seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.8.1 Measuring arrangement in open or closed containers with ± and 0 to 1 bar measuring rang-

es . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.8.2 Measuring arrangement for steam layering and ± measuring ranges . . . . . . . . . . . . . . . . . . . 32

5.8.3 Measuring arrangement for steam layering and a measuring range of 0 to 1 bar . . . . . . . . . . 33

5.9 Assembly in the explosion area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Page 6

Contents

6 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.1 Installation notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.2 Device with cable gland . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.3 Device with M12 connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.4 Electrical connection in Ex areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.4.1 Connection diagram "Ex" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.1 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.2 Operation with rotary knob or with setup programm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.3 The level concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.3.1 The display level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.3.2 The parameter level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

8 Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.1 Data flow diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.2 Description of the possible configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

8.3 Level measurement configuration with a pressure specification - recommended (tank emp-

ty, tank full) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.4 Level measurement configuration without a pressure specification . . . . . . . . . . . . . . . . . . . . . 58

8.4.1 With a diaphragm seal in closed containers with a measuring range of 0 to 1 bar. . . . . . . . . . 58

8.4.2 With a diaphragm seal in closed containers with ± measuring ranges . . . . . . . . . . . . . . . . . . . 60

8.4.3 Without a diaphragm seal in closed containers with ± measuring ranges or 0 to 1 bar . . . . . . 62

8.4.4 For steam layering with ± measuring ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

8.4.5 For steam layering with a measuring range of 0 to 1 bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

9 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

9.1 Overcoming errors and malfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

10 HART® 7 specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

10.1 Device identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

10.2 Variable codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

10.3 HART® commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

10.4 Burst mode commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

10.5 Performance data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

11 Declaration of conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

12 Examination certificate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

13 China RoHS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Page 7

7

1 Safety information

1 Safety informat ion

General

This manual contains information that must be observed in the interest of your own safety and to avoid

material damage. This information is supported by symbols which are used in this manual as indicated.

Please read this manual before starting up the device. Store this manual in a place that is accessible to

all users at all times.

If difficulties occur during startup, please do not intervene in any way that could jeopardize your warranty

rights!

Warning symbols

DANGER!

This symbol indicates that personal injury from electrocution may occur if the appropriate precaution-

ary measures are not taken.

CAUTION!

This symbol in connection with the signal word indicates that material damage or data loss will occur

if the respective precautionary measures are not taken.

Note symbols

NOTE!

This symbol refers to important information about the product, its handling, or additional benefits.

Page 8

8

2 General information

2 General information

2.1 Areas of application

The device with HART® interface combines maximum precision with simple operation. It is used to measure the system pressure of gases, steams, and liquids. The integrated LCD display shows measured

values and device data.

The version with explosion protection "Ex ia (intrinsically safe)" allows the device to be installed up to

zone 0.

The housing and sensors are manufactured from high-grade stainless steel. Diaphragm seals can also

be connected for specific process technology applications (see data sheets 409772 to 409784).

The device is programmable and therefore readily adaptable to a variety of different measurement tasks.

An easy-to-use setup program is available as an accessory to enable operation via the interfaces. A rotary knob makes manual operation on-site very convenient and quick.

The pressure transmitter with 4 to 20 mA and HART® protocol was evaluated with regard to functional

safety and is certified by TÜV Nord according to DIN EN 61508/-1/-2, edition 2.0. These measuring devices are suitable for monitoring process level and process pressure up to SIL2. Further details can be

found in the Safety Manual.

Use in "Ex-area"

In the Ex ia version, the device is permitted for use in the "Ex-area" if it has a corresponding identification

marking on the nameplate.

Functional safety use

In the SIL version, the device is permitted for use according to IEC 61508 if it has a corresponding identification marking on the nameplate.

Application areas

The device can be used for various applications, e.g.

• For level measurements in pressurized containers

• For foam formation

• In containers with mixers or sieve installations

• For liquid gases

• For default level measurements

• For flow measurements

Measured process variables

Differential pressure

Calculated process variables

•Flow

• Filling level (level, volume, or mass)

Page 9

9

2 General information

2.2 Scope of delivery

Operating Manual

The operating manual describe the mounting, the electrical connection, the startup and operation of the

device.

Safety manual (option)

The safety manual describes the safe application with the installation according to IEC 61508.

Calibration certificate

The device is supplied with a calibration certificate and a setup print-out.

These documents contain information about the set parameters and/or the measured parameters for the

respective device.

If the calibration certificate is lost or if you need another copy, the calibration certificate can be requested

from the manufacturer by specifying the device's F number (see nameplate). You will find the supplier's

address on the back cover of the manual.

Setup program (option)

The setup program is available as an option: part no. 00537577

All the device's parameters can be conveniently checked and adjusted using the setup program - there

are also additional functions, e.g.:

• Recording the measured values

• Graphical view of temperature and pressure

• Detailed diagnostic messages

• Display of the complete order code and the device configuration (for follow-up orders)

The setup program accesses the device via

• the JUMO interface (standard) or

• the HART® interface (optional)

DANGER!

The JUMO interface must not be used in the Ex-area!

The device may only be operated using the rotary knob or the HART® interface!

PC interface cable (option)

Available as an accessory: PC interface cable with USB/TTL converter and two adapters (USB transmitter cable), part no. 00456352.

The device can be connected to a PC's USB port via the JUMO interface with the PC interface cable.

HART® modem (option)

Available as an accessory: HART® modem for USB, part no. 00443447.

The device can be connected to a PC's USB® port via the HART® interface with the HART® modem.

Input isolating amplifier (option)

Available as an accessory: Input isolating amplifier for Ex-applications, HART®-capable, part no.

00577948.

Devices with explosion protection ATEX Ex ia must be connected via an input isolating amplifier for use

in the Ex-area!

Page 10

2 General information

10

Diaphragm seal (option)

Available as an accessory: see data sheets 409770 to 409786.

Diaphragm seals are used for adjusting to particular applications if conventional pressure connections

cannot be used.

CAUTION!

Diaphragm seals are installed by default and must not be removed from the device!

Valve manifolds (option)

Available as an accessory: see data sheet 409706.

Additional JUMO accessories (option)

Additional accessories available: see data sheet 409700 (shut-off valves, measurement device holders,

transition pieces, seals, etc.).

Page 11

11

3 Identifying the device version

3 Identifying th e device version

3.1 Nameplate

Housing

Sample identification marking on the device housing

Date of manufacture

The date of manufacture (year and calendar week) of the device is encoded in the manufacturing number. The numbers 12 to 15 identify the year of manufacture (here 15 for 2015) and the calendar week

(here 12).

(1) Fabrication number (2) Output signal

(3) Voltage supply (4) Nominal measuring range

(5) Default measuring range (6) Part number

(7) Type (8) SIL version

(8)

(1)

(7)

(6)

(5)

(4)

(3)

(2)

Page 12

3 Identifying the device version

12

3.2 Order details

(1) Basic type

403022 JUMO dTRANS p20 DELTA – differential pressure transmitter

(2) Basic type extension

0 None

2SIL

a

3 SIL, customer-specific

a

9 Special version

(3) Explosion protection

0 None

1 ATEX Ex ia

b

(4) Housing

1 Short, stainless steel, with M12 connection

c

2 Long, stainless steel, with cable fitting

3 Precision casting, with cable fitting

(5) Electrical connection

36 Round plug M12 × 1

82 Plastic cable fitting

93 Metal cable fitting

(6) Cover material

20 CrNi (stainless steel)

85 Plastic

(7) Display

0 None

1 With display (LCD)

(8) Operation

0 None

1 With control knob

(9) Input – nominal measuring range

530 -10 to +10 mbar DP

d, e, f

532 0 to 1 bar DP

531 -1to+1bar DP

e

533 -1to+6bar DP

534 -1to+100bar DP

(10) Output

405 4 to 20 mA, two-wire, without SIL

410 4 to 20 mA, two-wire with HART® protocol

(11) Process connection

511 2× pressure connection 1/4-18 NPT according to DIN EN 837

998 Diaphragm seal process connection

(12) Process connection material

20 CrNi (stainless steel)

80 Tantalum

82 NiMo

(13) Measuring system, filling medium

Page 13

13

3 Identifying the device version

01 Silicon oil

02 Halogenized oil for oxygen application

(14) Extra codes

000 None

100 Customer-specific factory setting

g

226 With GOST/EAC approval

h

624 Oil and grease free

633 Mounting brackets for 2" tube

634 With TAG number

635 With NACE manufacturer's declaration

i

681 Expanded admissible ambient temperature

f

694 Increased nominal pressure PN 420 bar

932 With HART® version 5, always with SIL version (basic type extension 2 and 3)

a

SIL version always with LCD display (display 1), connection 4 to 20 mA (output 410) and HART® version 5 (extra

code 932)

b

ATEX Ex ia does not apply in connection with a cable fitting made out of plastic (process connection material 82)

and the connection 4 to 20 mA (output 405).

c

The short housing is only available with a round plug M12 × 1 (electrical connection 36).

d

This input is only available with a process connection made out of stainless steel (process connection 20).

e

The inputs are not available with an increased nominal pressure (extra code 694).

f

Without SIL

g

Please specify the setting you want in plain text. For default setting see “Accuracy” section in the data sheet.

h

Upon request

i

Only with NiMo (process connection material 82); not for pressure ranges -10 to +10 mbar and -1 to +1 bar

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10) (11) (12) (13) (14)

Order code /-----------/

Order example 403022 / 0 - 0 - 2 - 82 - 20 - 1 - 1 - 532 - 405 - 511 - 20 - 1 / 000

Page 14

3 Identifying the device version

14

3.3 Accessories

3.4 Software

Designation Part no.

PC interface with USB/TTL converter

a

00456352

HART® modem USB

b

00443447

4-pole cable box, straight, M12 × 1 with 2 m PVC cable 00404585

4-pole cable box, angled, M12 × 1 with 2 m PVC cable 00409334

5-pole cable box, straight, M12 × 1, without a cable 00419130

5-pole cable box, angled, M12 × 1, without a cable 00419133

SET oval flange 1/2“ NPT/accessory set 7/16-20UNF 00543775

Mounting brackets, set includes screws 7/16-20UNF 00543777

Designation Data sheet

Valve manifolds 409706

Diaphragm seal with dairy pipe fitting DIN 11851 409772

Diaphragm seal with clamp connection 409774

Diaphragm seal with DRD flange or VARIVENT® socket 409776

Diaphragm seal with ISS/SMS/RJT socket and (grooved) union nut 409778

Membrane diaphragm seal 4MDV-10 409780

Diaphragm seal with screw-in thread DIN ISO 228/1 or ANSI B1.201 409782

Diaphragm seal with flange connection DIN EN 1092-1 with sealing strip form B1 409784

Diaphragm seal with flange connection according to ANSI B 16.5 with sealing strip form RF 409786

Ex-i repeater power supply/input isolating amplifier 707530

a

The PC interface cable is the connection between the JUMO interface of the differential pressure transmitter and

the USB interface of a PC.

b

The HART® modem is the connection between the HART® interface of the differential pressure transmitter and

the USB interface of a PC.

Description Part no.

JUMO setup dTRANS p20 series 00537577

JUMO dTRANS p20 series, DD (device description) Upon request

JUMO dTRANS p20 series, DTM (device type manager) Upon request

Page 15

15

3 Identifying the device version

3.5 Dimensions

Type 403022/0-0-1

(short, stainless steel, with M12 connection)

Type 403022/0-0-2

(long, stainless steel, with cable fitting)

A M20 × 1.5 cable fitting

Type 403022/0-0-3

(precision casting, with cable fitting)

For extra code 694

(increased nominal pressure PN420)

A M20 × 1.5 cable fitting A M20 × 1.5 cable fitting

B M8 for mounting

86.5

138

104

63.5

54

87

94

127

191

7/16-20 UNF

1/4-18 NPT

41.3

ø73

51

A

A

145

182

109

66

57

119

ø73

A

B

Page 16

16

4 Technical data

4 Technical data

4.1 General Information

Reference conditions DIN EN 60770 and DIN EN 61298

Ambient temperature 22 °C ±5 K

Air pressure 1000 hPa (±25 hPa)

Voltage supply DC 24 V

Burden 50 Ω

Sensor system Silicon sensor with stainless steel separating diaphragm

Pressure transfer medium

For measuring system filling medi-

um 1

Silicon oil

For measuring system filling medium 2

Halogenized filling oil

Admissible load changes > 10 million

Position

Mounting position Any

Calibration position Device upright, process connection at the bottom

Zero offset depending on position ≤ 1 mbar

A zero offset is possible on-site or via setup

Display

a

LCD, two-line with bar graph

Alignment Display unit rotatable in 90° steps

Housing rotatable ±160°

Size Display 22 × 35 mm, font size 7 mm/5-digits

Color Black

Portrayable measuring units

Input pressure inH

2

O, inHg, ftH2O, mmH2O, mmHg, psi, bar, mbar, kg/cm2, kPa, torr, MPa,

mH

2

O

Measured value % or scaled with freely adjustable measuring unit

Output current mA

Sensor temperature °C, °F

Additional display data Minimum pressure, maximum pressure, error, overrange, underrange, operat-

ing hours

Operation

On-site With rotary knob and LCD

Setup program Via interface

Interface

Standard JUMO interface

b

For output 410 (4 to 20 mA with

HART®)

JUMO interfaceb and HART® interface

a

optional; SIL version only available with display

b

The JUMO interface may not be used in a potentially explosive area! In such a case the device can be operated

via the rotary knob or the HART® interface.

Page 17

17

4 Technical data

4.2 Input

4.3 Output

4.4 Voltage supply

Nominal pressure

Nominal measuring

range

-10to+10mbar

DP

a

-1to+1bar DP 0to1bar DP -1to+6bar DP -1to+100bar

DP

Nominal pressure (bar) PN2 PN210 PN210, optionally PN420

a

Without SIL

analog output

For output 405 (4to20mA) 4to20mA, 2-wire

For output 410

(4 to 20 mA with HART®)

4 to 20 mA, two-wire with HART® version 7

(optionally with HART® version 5, extra code 932, always with SIL version)

Jump response time T60 ≤ 190 ms without attenuation

Attenuation Adjustable 0 to 100 s

Burden

For output 405 (4 to 20 mA) Burden ≤ (U

B

-12V)÷0.022A

For output 410

(4 to 20 mA with HART®)

Burden ≤ (U

B

-12 V) ÷ 0.022 A; additional: min. 250 Ω, max. 1100 Ω

For version

Explosion protection 0 (none) DC 12 to 36 V

Explosion protection 1 (ATEX Ex ia) DC 12 to 28 V

The voltage supply must be intrinsically safe and must not exceed the following

maximum values:

Ui ≤ DC 28 V

Ii ≤ 115 mA

Pi ≤ 750 mW

Ci = 6 nF

Li = 105 µH

Page 18

4 Technical data

18

4.5 Mechanical features

Process connection

Materials

Membranes

For process connection 20

(stainless steel)

Stainless steel 316 L

For process connection 82

(HASTELLOY®)

HASTELLOY® C276, material-no. 2.4819

For process connection 80 (tantalum)

Tantalum

Flange Stainless steel 316

Seal PTFE

Housing

Materials

For housing 1 (short, stainless

steel)

Stainless steel 1.4404

For housing 2 (long, stainless steel) Stainless steel 1.4404, VMQ

For housing 3 (precision casting) Stainless steel 1.4408

For material lid 20 (stainless steel) Precision casting 1.4408, seal FPM

For material lid 85

(plastic)

PA, seal FPM

For electrical connection 36

(round plug M12 × 1)

Brass, nickel-plated

For electrical connection 82

(cable fitting, plastic)

PA

For electrical connection 93

(cable fitting, metal)

Brass, nickel-plated

For operation 0

(without control knob)

-

For operation 1 (with control knob) PA

Explosion protection

For

Explosion protection 0 (without) The device is not approved for use in an Ex-area.

Explosion protection 1 (ATEX Ex ia) EC-type examination certificate SEV 09 ATEX 0138 X

II 1G Ex ia IIC T4 Ga

II 1D Ex ia IIIC T105 °C Da

Weight

Type 403022/0-0-1 (housing, short) Approx. 3.0 kg

Type 403022/0-0-2 (housing, long) Approx. 3.3 kg

Type 403022/0-0-3 (housing, preci-

sion casting)

Approx. 4.0 kg

For extra code 694 (increased nominal pressure)

The weight of the device increases by approximately 3.8 kg.

Page 19

19

4 Technical data

4.6 Environmental influences

Admissible temperatures

Operation Version Tempera-

ture class

Maximum medium temperature

Ambient

temperature

a

Increased

ambient

temperature

(extra code

681)

a, b, c

Standard 110 °C -40 to +85 °C -50 to +85 °C

II 1G Ex ia T4 100°C -40to+60°C -50to+60°C

II 1D Ex ia T105°C 100°C -40to+60°C -50to+60°C

Storage -40 to +85 °C

Admissible humidity

Operation 100 % including condensation on the device outer case

Storage 90 % without condensation

Admissible mechanical load

Vibration strength 2 g, 10 to 500 Hz according to DIN EN 60770-3

Shock resistance 15 g for 6 ms according to IEC 60068-2-29

Electromagnetic compatibility According to EN 61326

Interference emission Class B

d

Interference immunity Industry

Protection type

For version

Explosion protection 0 (without) IP66/67 according to DIN EN 60529

Explosion protection 1 (ATEX Ex ia) IP66 according to DIN EN 60529

a

Under -20 °C limited function: stationary use, increased danger of cable break, display without function; under 30 °C operation of the device not possible.

b

In the range from -40 to -50 °C the device must be permanently in operation. Furthermore, the lid with the device

inspection glass must additionally be protected against mechanical impact and shock effects. Please contact

JUMO for further details.

c

Without SIL

d

The product is suitable for industrial use as well as for households and small businesses.

Page 20

4 Technical data

20

4.7 Accuracy

Including non-linearity, hysteresis, non-repeatability, zero point and final value deviation (corresponds to

measurement deviations according to IEC 61298-2), calibrated at vertical installation position with the

process connection at the bottom

Differential pressure

Nominal measuring range -10 to +10 mbar

DP

a

-1to+1bar DP 0to1bar DP -1to+6bar DP -1to+100bar

DP

Default measuring range 0 to 10 mbar 0 to 1 bar 0 bar to 6 bar 0 bar to

100 bar

Smallest MSP

b

1 mbar

c

5mbar

c

0.350 bar 2.5 bar

Turndown ratio (r)

d

r ≤ 20 r ≤ 400 r ≤ 200 r ≤ 20 r ≤ 40

Non-linearity for reference

conditions

0.1 %

for r ≤ 2

0.07 %

for r ≤ 10

0.07 %

for r ≤ 5

r × 0.05 %

for 2 ≤ r ≤ 20

r × 0.007 %

for 10 ≤ r ≤ 400

r × 0.007 %

for 10 ≤ r ≤ 400

r × 0.014 %

for 5 ≤ r ≤ 20

r × 0.014 %

for 5 ≤ r ≤ 40

Accuracy in %

of the set MSP

at 20 °C

0.2 %

for r ≤ 2

0.1 %

for r ≤ 10

0.1 %

for r ≤ 5

r×0.1%

for 2 ≤ r ≤ 20

r × 0.01 %

for 10 ≤ r ≤ 400

r × 0.01 %

for 10 ≤ r ≤ 200

r × 0.02 %

for 5 ≤ r ≤ 20

r × 0.02 %

for 5 ≤ r ≤ 40

Accuracy in %

of the set MSP

Range: 20 to 85 °C

0.5 %

for r ≤ 2

(only to 60 °C)

0.2 %

for r ≤ 10

0.2 %

for r ≤ 5

r × 0.25 %

for 2 ≤ r ≤ 20

(only to 60 °C)

r × 0.02 %

for 10 ≤ r ≤ 400

r × 0.02 %

for 10 ≤ r ≤ 200

r × 0.04 %

for 5 ≤ r ≤ 20

r × 0.04 %

for 5 ≤ r ≤ 40

Accuracy in %

of the set MSP

Range: -40 to +20 °C

1.0 %

for r ≤ 2

0.6 %

for r ≤ 10

0.6 %

for r ≤ 5

r×0.5%

for 2 ≤ r ≤ 20

r × 0.06 %

for 10 ≤ r ≤ 400

r × 0.06 %

for 10 ≤ r ≤ 200

r × 0.12 %

for 5 ≤ r ≤ 20

r × 0.12 %

for 5 ≤ r ≤ 40

Accuracy in %

of the set MSP

Range: 60 to 85 °C

2.0 %

for r ≤ 2

2.0 %

for r ≤ 2

2.0 %

for r ≤ 2

r×1.0%

for 2 ≤ r ≤ 20

Influence of the static pressure P (bar) in %

from the nominal measuring

range

≤ 1 % ≤ P × 0.0005 % ≤ P × 0.0003 % ≤ P × 0.0025 % ≤ P × 0.001 %

Long-term stability in %

as of the nominal measuring

range

≤ 0.6 %/year ≤ 0.1 %/year ≤ 0.2 %/year

a

Without SIL

b

MSP = measuring span

c

For the calibration certificate from JUMO the smallest MSP is 10 mbar. MSPs smaller than 10 mbar can be adjusted

by the user.

d

r = span of the nominal measuring range ÷ adjusted measuring span

Page 21

21

4 Technical data

4.8 Approvals/approval marks

Approval

mark

Test facility Certificates/certification

numbers

Inspection basis Valid for

ATEX Electrosuisse SEV 09 ATEX 0138 X EN 60079-0 403022/x-1-...

EN 60079-11

EN 60079-26

EAC RU RU C-DE.ME92.B.00440 - Extra code 226

SIL TÜV Nord (German

Technical Inspection

Agency)

No. SEBS-A.

140944/16 V1.0

DIN EN 61508/-1/-2 Basic type extension 2

and 3

Page 22

22

5 Mounting

5 Mounting

5.1 Before mounting

DANGER!

Depressurize the plant before installing the device!

The device may only be opened in the potentially explosive area when disconnected from the

power supply!

NOTE!

Select a freely accessible and low-vibration installation location, preferably near the measuring point.

Ensure that the admissible ambient temperature is adhered to (take possible heat radiation into account).

The device can be installed above or below the pressure sensing point.

5.2 Unscrew the front ring or case lid

Plastic cover ring

The front ring (1) and the rear housing cover (2) can be unscrewed.

The bezel and the rear case lid can be removed using a screwdriver, or similar.

(1) Front ring (plastic)

(2) Housing cover (plastic)

(1)

(2)

Page 23

23

5 Mounting

NOTE!

Only tighten by hand!

(1) Bezel

(1)

(1)

Page 24

5 Mounting

24

5.3 Rotating the LCD (display)

Installation position

The rated position of the device is vertically upright.

Depending on the conditions of the measuring point, the device can be installed in any other position.

The LCD display can be rotated in 90° steps depending on the desired installation position.

1. To unscrew the bezel, see chapter 5.2 "Unscrew the front ring or case lid", page 22.

2. Lift out the electronics module using a narrow (small) screwdriver.

3. Rotate the electronics module into the desired position (90° steps) and insert again.

4. Screw on the bezel so that it is hand-tight.

Page 25

25

5 Mounting

5.4 Rotating the housing

The housing can be rotated by ±160°.

1. Loosen the threaded pin using a 1.5 mm hex wrench.

2. Rotate the housing to the desired position.

3. Screw on the threaded pin again until it is tight.

Page 26

5 Mounting

26

5.5 Pressure connection

Seals

Operating conditions (for example material compatibility) must be considered when selecting the seal.

Checking for seal tightness

The pressure connection must be checked for seal tightness once established.

CAUTION!

If shut-off valves are used incorrectly, this can lead to personal injury or significant material damage!

Observe the correct order when opening or closing the valves!

The device must not be vented when used in toxic media!

Differential pressure

NOTE!

The connection for the higher pressure is labeled with "H".

Page 27

27

5 Mounting

5.6 Bracket for wall and pipe mounting

Mounting example

(Part no. 00543777)

Page 28

5 Mounting

28

5.7 Level measurement with a diaphragm seal

The device is ideally suited for level measurements in open and closed containers.

5.7.1 General information

A device with a capillary and diaphragm seals is a closed system that is filled with oil under vacuum.

• Remove membrane protection before installation

• Do not open closed system

• Do not touch or clean the diaphragm seal membranes with hard or sharp tools

• Bending radius of the capillaries: ≥ 100 mm

• Install capillaries such that they are free from vibration in order to avoid pressure fluctuations and

device faults; avoid shaking during operation

• To ensure correct measuring results, do not install the capillaries in the vicinity of heating or cooling

lines; capillaries should preferably have the same temperature on both sides during operation; isolate the capillary in case of large temperature differences

• The length of the capillaries and the diaphragm seal connections used (material, diameter) should

be the same for the duplex diaphragm seal system

NOTE!

The filling oil influences the temperature application range and the response time of a diaphragm seal

system. The medium and ambient temperature, as well as the process pressure are therefore decisive

when selecting the filling oil.

Take note of the maximum possible temperature and pressures during commissioning/cleaning of the

tank.

Pay attention to the tolerability of the filling oil with the requirements of the medium. For example, only

filling oils that do not pose a health risk may be used in the food industry.

NOTE!

The level measurement is only ensured between the top edge of the lower diaphragm seal and the bottom edge of the upper one.

In vacuum applications it is recommended to install the device below the lower diaphragm seal. This prevents a vacuum load on the diaphragm seal caused by presence of the filling oil in the capillaries.

Page 29

29

5 Mounting

5.7.2 Measuring arrangement in open or closed containers with ± measuring ranges

The device must be installed according to the following diagram:

1. Always connect the minus side diaphragm seal via a capillary above the maximum filling level (MINUS input is at top).

2. Always connect the plus side diaphragm seal (marked "H") via a capillary at the bottom process connection (PLUS input is at bottom).

3. The level measurement is only ensured between the top edge of the lower diaphragm seal and the

bottom edge of the upper one.

4. The device can be placed (in terms of height) anywhere between the lower and upper diaphragm

seal.

5. In vacuum applications it is recommended to install the device below the lower diaphragm seal. This

prevents a load on the diaphragm seal membrane caused by the filling oil in the capillaries.

6. For the device configuration, see chapter 8 "Configuration", page 51.

h (filling level) 4 to 20 mA

H

-

+

max.

p

2

min.

p

1

h

Page 30

5 Mounting

30

5.7.3 Measuring arrangement in open and closed containers with a measuring range

of 0 to 1 bar

The device must be installed according to the following diagram:

1. Always connect the minus side diaphragm seal via a capillary at the bottom process connection (MI-

NUS input is at bottom).

2. Always connect the plus side diaphragm seal (marked "H") via a capillary above the maximum filling

level (PLUS input is at top).

3. The level measurement is only ensured between the top edge of the lower diaphragm seal and the

bottom edge of the upper one.

4. The device can be placed (in terms of height) anywhere between the lower and upper diaphragm

seal.

5. In vacuum applications it is recommended to install the device below the lower diaphragm seal. This

prevents a load on the diaphragm seal membrane caused by the filling oil in the capillaries.

6. For the device configuration, see chapter 8 "Configuration", page 51.

NOTE!

There must be no zero point adjustment performed after the installation when the tank is empty.

h (filling level) 4 to 20 mA

H

+

-

max.

p

2

min.

p

1

h

Page 31

31

5 Mounting

5.8 Level measurement without a diaphragm seal

The device is ideally suited for level measurements in open and closed containers.

5.8.1 Measuring arrangement in open or closed containers with ± and 0 to 1 bar measuring ranges

The device must be installed according to the following diagram:

1. Always connect the minus side (zero) via a differential pressure pipe at the top process connection

(MINUS input is at top).

2. Always connect the plus side (marked "H") via a differential pressure pipe below the maximum filling

level (PLUS input is at bottom).

3. If possible, install the device below the lower measurement connection so that the lower differential

pressure pipe is always filled with liquid.

4. It is a good idea to mount cutters and drain valves in order to catch and remove deposits, pollutants

or liquid in the differential pressure pipes

5. For the device configuration, see chapter 8 "Configuration", page 51.

NOTE!

Applies for ± measuring ranges or a measuring range from 0 to 1 bar.

It is recommended to install the device behind a shut-off valve in order to allow easy cleaning and functional testing.

h (filling level) 4 to 20 mA

H

-

+

p

2

p

1

H

max.

min.

h

Page 32

5 Mounting

32

Do not install the device in the following positions:

- in the filling flow

- in the tank outlet

- at a position in the tank that could be affected by the mixer pressure pulses

With media that can harden upon cooling, the measuring device must be incorporated in the insulation.

5.8.2 Measuring arrangement for steam layering and ± measuring ranges

The device must be installed according to the following diagram:

1. Always connect the minus side (zero) via a differential pressure pipe at the top process connection

(MINUS input is at top).

2. Always connect the plus side (marked "H") via a differential pressure pipe below the maximum filling

level (PLUS input is at bottom).

3. If possible, install the device below the lower measurement connection so that the lower differential

pressure pipe is always filled with liquid.

4. For level measurement in closed containers with steam layering, a condensing vessel ensures a

filled differential pressure pipe and thus constant pressure on the minus side.

5. Fill up the differential pressure pipe in a cold state with water via the condensing vessel or via the

valve block.

6. For the device configuration, see chapter 8 "Configuration", page 51.

(1) Condensing vessel

h (filling level) 4 to 20 mA

H

-

+

p

2

p

1

H

max.

min.

h

(1)

Page 33

33

5 Mounting

NOTE!

Install the condensing vessel at the same height as the extraction support and at the same distance to

the measuring device.

5.8.3 Measuring arrangement for steam layering and a measuring range of 0 to 1 bar

The device must be installed according to the following diagram:

1. Always connect the plus side (marked "H") via a differential pressure pipe on the upper process con-

nection (PLUS input is at top).

2. Always connect the minus side (zero) via a differential pressure pipe below the maximum filling level

(MINUS input is at bottom).

3. If possible, install the device below the lower measurement connection so that the lower differential

pressure pipe is always filled with liquid.

4. For level measurement in closed containers with steam layering, a condensing vessel ensures a

filled differential pressure pipe and thus constant pressure on the minus side.

5. Fill up the differential pressure pipe in a cold state with water via the condensing vessel or via the

valve block.

6. For the device configuration, see chapter 8 "Configuration", page 51.

(1) Condensing vessel

h (filling level) 4 to 20 mA

H

+

-

p

2

p

1

H

max.

min.

h

(1)

Page 34

5 Mounting

34

NOTE!

Install the condensing vessel at the same height as the extraction support.

Page 35

35

5 Mounting

5.9 Assembly in the explosion area

(1) Hazardous (Ex) area Zone 0/20

(2) Non-hazardous area

(3) Burden (optional for HART® interface)

(4) Voltage supply device with isolating converter for connecting explosion-protected transmitters

+

+

-

+

-

-

(1) (2)

(3)

(4)

Page 36

36

6 Installation

6

Installation

6.1 Installation notes

DANGER!

The electrical connection must only be carried out by qualified personnel.

Ground the device!

Conductor cross-sections and ferrules

6.2 Device with cable gland

General information

DANGER!

For connection to devices in Ex areas see chapter 6.4 "Electrical connection in Ex areas",

page 41.

• Permissble cable diameter for devices with cable gland made of: 6to12mm

• Max. wire cross-section 1.5 mm

2

• Lay signal lines separate from cables with voltages of > 60 V.

Use a shielded cable with twisted wires.

Avoid the vicinity of large electrical systems.

The full specification as per HART® version 5.1, will only be achieved with a shielded cable.

The device must be completely disconnected from the mains voltage if there is a risk of contact with live

parts during work on the equipment.

The electromagnetic compatibility meets standard EN 61326.

The device is suitable for use in SELV or PELV electrical circuits according to protection rating 3.

For connecting devices with Ex-approval, see chapter 6.4 "Electrical connection in Ex areas", page 41.

In addition to a faulty installation, incorrectly set values could also impair the orderly function of the down-

stream process or lead to other damage.

Permissible cross-section

Without ferrule 0.2to1.5mm

2

(for rigid cable only) AWG 24 to 16

With ferrule 0.25 to 0.75 mm

2

(for rigid or flexible cable)

Page 37

37

6 Installation

Connection

1. Unscrew the housing cover from behind, see chapter 5.2 "Unscrew the front ring or case lid",

page 22

2. Ground the device.

3. To connect the connecting cables, see the following illustration.

(1) The Connecting cable must extend at least 5 mm into the housing

(2) Tighten the screw fitting by hand until you encounter resistance

(3) Tighten the screw connection with a wrench:

Plastic 4.5 Nm approx.

Metal 8 Nm approx.

(1)

(2)

(3)

Page 38

6 Installation

38

Terminal assignment

Operation and test

Connection Terminal assignment

82 (plastic),

93 (metal)

Cable fitting

Voltage supply 1 L+

DC 12 to 36 V for non-Ex-version 2 LDC 12 to 28 V for Ex-version

Output 1 L+

4to20mA, 2-wire 2 LLoad-independent current: 4 to 20 mA

In voltage supply

Test connection for current output TEST +

Internal resistance of the ammeter ≤ 10 Ω TEST Test connection for HART® HART +

The burden must be present! HART Functional ground 3

(1) Total burden: Burden ≤ (UB-12 V) ÷ 0.022 A;

for HART® in addition: min. 250 Ω, max. 1100 Ω

(2) Display or recording device, controller, PLC, etc.

(3) Voltage supply:

for non Ex version DC 12 to 36 V

for Ex version DC 12 to 28 V

(4) HART® modem

(5) PC or Notebook

(6) Inherent resistance of ammeter ≤ 10 Ω

231

+

-

HART -

HART +

Test +

Test -

+

-

(1) (2) (3)

(4) (5)

(6)

Page 39

39

6 Installation

6.3 Device with M12 connector

DANGER!

For connection of the device in an Ex area see chapter 6.4 "Electrical connection in Ex areas",

page 41!

Connect the device to ground using pin 4 of the device connector (1), see "Terminal

assignment ", page 40.

A suitable connection is provided by a

• 4-pin cable box, straight, M12 × 1, with 2 m PVC cable, part no. 00404585, or a

• 4-pin cable box, angled, M12 × 1, with 2 m PVC cable, part no. 00409334, or a

5-pin cable box, straight, M12 × 1, without cable, part no. 00419130, or a

• 5-pin cable box, angled, M12 × 1, without cable, part no. 00419133

For pin configuration see below.

General information

• Lay signal lines separate from cables with voltages of > 60 V

• Use a shielded cable with twisted wires

• Avoid the vicinity of large electrical systems

• The full specification as per HART®, will only be achieved with a shielded cable.

(1) Device connector

(1)

Page 40

6 Installation

40

Terminal assignment

Operation

Connection Terminal assignment Color

coding

a

a

The color coding is only valid for A-coded standard cables!

36

round plug M12 × 1

Voltage supply 1 L+ Brown

DC 12 to 36 V for non-Ex-version 3 L- Blue

DC 12 to 28 V for Ex-version

Output 1 L+ Brown

4to20mA, 2-wire 3 L- Blue

Load-independent current: 4 to 20 mA

In voltage supply

Functional ground 4 Black

(1) Total burden: Burden ≤ (UB-12 V) ÷ 0.022 A;

for HART® in addition: min. 250 Ω, max. 1100 Ω

(2) Display or recording device, controller, PLC, etc.

(3) Voltage supply:

for non Ex version DC 12 to 36 V

for Ex version DC 12 to 28 V

(4) HART® modem

(5) PC or Notebook

(1) (2) (3)

(4) (5)

2

3

1

+

-

4

+

-

Page 41

41

6 Installation

6.4 Electrical connection in Ex areas

General information

The relevant regulations must be observed during electrical connection; furthermore, in the potentially

explosive area the minimum requirements according to Directive 1999/92/EC apply, for example:

• Regulation for the project planning, selection and installation of electrical plants in potentially explo-

sive areas (IEC/EN 60079-14)

• EU type examination certificate

NOTE!

Only certified measuring devices may be used in intrinsically safe electrical circuits,!

NOTE!

The intrinsically safe electrical circuit must be restricted to overvoltage category I, as stipulated in

IEC 60664-1. The electrical circuit supply is only to be provided by a certified, intrinsically safe power

source with a protection level of "ia".

NOTE!

In particular, equipment used in potentially explosive areas where hybrid mixtures are present must be

checked. Hybrid mixtures are explosive mixtures of flammable gases, vapors, or mists with flammable

dusts. The operator is responsible for checking that the equipment is suitable for such uses.

DANGER!

Only the HART® modem may be used in the explosion-proof area!

The JUMO interface must not be used!

The device's voltage supply must be intrinsically safe and must not exceed the following maximum

values:

U

i

: DC 28 V

I

i

: 115 mA

Pi: 750 mW

Page 42

6 Installation

42

NOTE!

Connecting the HART® communicator or the HART® modem is optional.

A minimum burden must be present on the signal circuit in order to facilitate error-free communication,

see the previous pages.

The burden is usually already integrated when using input isolating amplifiers.

Page 43

43

6 Installation

6.4.1 Connection diagram "Ex"

(1) Potentially explosive area zone 0/20

(2) Non-potentially explosive area

(3) Burden for HART® ≤ (U

B

-12 V) ÷ 0.022 A;

additional: min. 250 Ω, max. 1100 Ω

The current limiting resistor integrated in the input isolating amplifier must be included in this cal-

culation.

(4) Input isolating amplifier for connecting explosion-proof devices

(5) Indicating device or recorder, controller, PLC, etc.

(6) Further devices

(7) Burden for HART® min. 250 Ω, max. 1100 Ω

The current limiting resistor integrated in the input isolating amplifier must be included in this cal-

culation.

(8) HART® modem

(9) PC or laptop

(10) HART® communicator, intrinsically safe

+

+

-

+

-

-

(1) (2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

Page 44

44

7 Operation

7 Operation

7.1 Display

(1) Socket for JUMO setup interface (behind a cover)

(2) Measured value

(3) Measuring unit

(4) Overrange

(5) Percentage control of the measuring range

(6) Underrange

(1)

(2)

(3)

(4)(5)(6)

Page 45

45

7 Operation

7.2 Operation with rotary knob or with setup programm

The device is operated either

• with the rotary knob (1) or

• via the optional setup program or

• via the HART® interface, e.g. with a handheld or PC

program.

NOTE!

Alternatively, for operation via a rotary knob, all actual values and parameters can very easily be displayed or adjusted by means of the setup program.

Furthermore, the setup program offers an array of useful additional functions, e.g.:

• Recording the measured values

• Graphical view of temperature and pressure

• Detailed diagnostic messages

• Display of the complete order code and the device configuration (can be printed out, e.g. for project

documents or follow-up orders)

The setup program can address the device via the following interfaces:

• JUMO setup interface

The PC interface cable with USB/TTL converter (USB transmitter cable) is required to connect the

PC to the device, part no. 00456352

• HART® interface

A HART® modem is required to connect the PC to the device, part no. 00443447

Rotating and pressing

(1) Rotary knob

(1)

Rotate

Select parameter or set values

Press

Confirm parameter or values

Page 46

7 Operation

46

7.3 The level concept

Two levels

Operation is on two levels:

NOTE!

After the device is turned on, it is on the display level. You can go to the parameter level through the

following operation.

Display level

(Normal display)

Parameter level

Cancel

or timeout

> 3 s

> 3 s

Parameter

Save

> 3 s

Select

< 1 s

Search

Page 47

47

7 Operation

7.3.1 The display level

The measured pressure and other values are displayed at the display level. The output current is shown

in % as a bar chart in the third line of the display.

It is not possible to change parameters at the display level!

Action Display

(example)

Explanation

Displays the pressure with measuring unit

Displays the measured value in %

or

measured value scaled with a choice of measuring unit

Displays the calculated output current in mA.

Displays the sensor temperature in °C or °F.

Displays the stored minimum pressure in the selected measuring unit

Displays the stored maximum pressure

Displays the pressure value and the sensor temperature in the

selected measuring units

Page 48

7 Operation

48

7.3.2 The parameter level

The device parameters can be displayed and changed at the parameter level.

Action Display

(example)

Explanation Selection

a

P min Reset by

Stored minimum

pressure

> 3 seconds

P max Reset by

Stored maximum

pressure

> 3 seconds

P0 Den 0.01 to 1.00 to 99.99

"Density"

Density correction

P1 Uni inH2O

inHG

ftH2O

mmH2O

mmHG

PSI

bar

mbar

kg/cm2

kPa

TORR

MPa

mH2O

"Unit"

Pressure measuring

unit

P2 mA 4.00 to 20.00 mA

Measuring range

Lower range value

P3 mA 4.00 to 20.00 mA

Measuring range

Upper range value

P4 sec 0.00 to 100.0 s

Attenuation

P5 RS Nominal measuring range

"Range start"

Measuring range

Lower range value

Page 49

49

7 Operation

P6 RE Nominal measuring range

"Range end"

Measuring range

Upper range value

P7 Zero Current pressure

Zero point adjust-

ment

P8 mA 3.60 to 4.00 to 21.60 mA

Current generator

P9 Err ErLo = 3.6 mA

ErHi = 21.6 mA

LASt = last value

Current in case of

malfunction

P10 Key 0 = no lock

LA = all, interface released

L0 = all, without measurement start

LS = alle, ohne Messanfang und -ende

LALL = alle, inkl. Schnittstelle

Key lock

P11 Chr Lin = linear

SLin = linear bis Beginn Radizierung

SoFF = off until start of square root extraction

Characteristic line

"Characteristic"

P12 % 5.0 to 9.4 to 15.0 %

vom Ausgangsstrom

Insertion point of

Radizierung

P13 SWV Editing not possible

Software version

P14 Uni °C/°F

Temperature mea-

suring unit

P15 OFF Nominal measuring range

Pressure value offset

(zero offset)

Action Display

(example)

Explanation Selection

a

Page 50

7 Operation

50

P16 SCS -9999 to 0 to +9999

Scaling start

„Scaling start“

P17 SCE -9999 to 100 to +9999

Scaling end

„Scaling end“

P18 SCD Auto = automatic

0 = no decimal place

1 = 1 decimal place

2 = 2 decimal places

3 = 3 decimal places

Decimal place scaling

„Scaling decimal

point“

P19 % % (default setting)

kg/sec

kg/min

kg/h

t/min

t/h

l/sec

l/min

l/h

m3/sec

m3/min

m3/h

L

m3

UsrTEXT

Scaling unit

P20 h Editing not possible

Operating hours

a

Default settings are shown in bold.

Action Display

(example)

Explanation Selection

a

Page 51

51

8 Configuration

8 Configuration

8.1 Data flow diagram

Display

selected

values

Pressure

value A/D

Linearized

pressure

Filter/

attenuation

P4 Sec

Zero point

adjustment

P7 Zero

P15 Off

Density

correction

P0 Den

Measuring

range

P5 RS

P6 RE

P2 mA

P3 mA

Characteristic

line

P11 Chr

Current

output

P9 Err

P8 mA

Current

value

D/A

Temperature

value

A/D

Linearized

temperature

Temperature

unit

P14 Unit

Drag indicator

P min

P max

relevant for output signal mA

relevant for Display

fixed values, not changeable

Fixed values without

configuration

possibility

P10 Key

P13 SWV

P20 h

Scaling

P16 SCS

P17 SCE

P18 SCD

P19 %

Pressure unit

P1 unit

Temperature value

Pressure min/max

Scaled output

Pressure value

Current output

Page 52

8 Configuration

52

8.2 Description of the possible configurations

CAUTION!

The set value should remain at the value 1 and should be changed in exceptional cases.

CAUTION!

No further density corrections may be configured. No other values may be entered under P5 RS.

CAUTION!

No further density corrections may be configured. No other values may be entered under P6 RE.

P0 Den Density correction

Configuration of the density of the medium to be measured

This may, for example, be relevant for the level measurement in order to display the correct

filling height from the measured pressure.

P1 Uni Pressure measuring unit

The pressure value unit can be configured here. The pressure value unit is shown on the

display and can be taken from the HART® protocol.

P2 mA Measuring range lower range value

Configuration of the device (measuring range) with pressure specification

If the tank is empty, the start point (zero point) of the pressure/level measurement can be

set here. The advantage of this procedure: The device is immediately configured for the application (e.g. tank).

P3 mA Measuring range upper range value

Configuration of the device (measuring range) with pressure specification

If the tank is full, the end point (full) of the pressure/level measurement can be set here. The

advantage of this procedure: The device is immediately configured for the application (e.g.

tank).

P4 Sec Attenuation

Time constant defined in seconds

Depending on the default setting, it is ensured that the measured value responds with a de-

lay to short, fast pressure changes.

P5 RS Measuring range lower range value

Configuration of the device (measuring range) without pressure specification

Any values can be entered here as the lower range value. It is important when, for example,

a differential pressure measurement with a diaphragm seal is attached to an application

(e.g. filling level) and no configuration with a pressure specification can be performed.

There is a calculation example available under chapter 8.4 "Level measurement configuration without a pressure specification", page 58.

Page 53

53

8 Configuration

CAUTION!

No further density corrections may be configured. No other values may be entered under P2 mA.

CAUTION!

No further density corrections may be configured. No other values may be entered under P3 mA.

CAUTION!

Only perform this configuration if it is certain that the zero point is actually present on the device

(e.g. after installing or correcting the position of the device). Otherwise a zero offset can also be

configured with this. The zero offset is stored as an offset (P15).

Zero point adjustment is not possible with absolute pressure sensors.

P6 RE Measuring range upper range value

Configuration of the device (measuring range) without pressure specification

Any values can be entered here as the upper range value. It is important when, for example,

a differential pressure measurement with a diaphragm seal is attached to an application

(e.g. filling level) and no configuration with a pressure specification can be performed.

There is a calculation example available under chapter 8.4 "Level measurement configuration without a pressure specification", page 58.

P7 Zero Zero point adjustment (only for relative pressure)

The applied pressure is stored as a zero point.

P8 mA Current generator

The device outputs a freely adjustable current value. The analog output has no reference

to the pressure measurement. The actual pressure measurement continues to be performed in the background and can be queried via the interfaces. If the current generator

was manually started via P8, this is represented by an icon next to P8 and can also be

stopped again by exiting P8.

P9 Err Current in case of malfunction

Option for setting which fault current the device should output in case of a malfunction. The

default value is set to 21.6 mA according to NAMUR NE 43.

P10 Key Key lock

This makes it possible to set a keypad lock in different stages. This is a safety feature to

prevent accidental, but also intentional configuration changes to the device.

Page 54

8 Configuration

54

P11 Chr Characteristic line

This point is not relevant for relative/absolute pressure measurement and should therefore

not be configured. It can be used with the differential pressure measurement to implement

a flow measurement.

With P11, the characteristic line of the preset value Lin = pressure proportional can be reconfigured to a square root extraction characteristic line SLin or SOff = flow proportional.

For the flow measurement, parameter P12 = insertion point relevant, below the characteristic line for low flow suppression either linearly connected (SLin) or completely disabled

(SOff).

P12 % Insertion point of the square root extraction

This point is not relevant for relative/absolute pressure measurement and should therefore

not be configured. It can be used with the differential pressure measurement to implement

a flow measurement. The insertion point of the square root extraction sets the start point for

the flow measurement.

P13 SWV Software version

For information only

No configuration option

P14 Uni Temperature measuring unit

The temperature value can be read on the display or via the HART® signal. There is no

option to transmit the temperature value via a 4 to 20 mA signal. The temperature unit can

be configured here.

Page 55

55

8 Configuration

P15 Off Pressure value offset

The offset value of the pressure value (relative or absolute pressure) is shown in figures

here (e.g. after the zero point adjustment). The values listed there should only be corrected

in exceptional cases as it is possible to manually readjust an offset there. Please contact

the manufacturer for this.

P16 SCS Scaling start

Configuration option to show the pressure value assignment on other physical values/units.

For example, the pressure value applied on the device can be scaled to liters and other

units (see P19). The scaling start is set here (e.g. 0).

P17 SCE Scaling end

Configuration option to show the pressure value assignment on other physical values/units.

For example, the pressure value applied on the device can be scaled to liters and other

units (see P19). The scaling end is set here (e.g. 100).

P18 SCD Decimal place scaling

Configuration option to show the pressure value assignment on other physical values/units.

For example, the pressure value applied on the device can be scaled to liters and other

units (see P19). The scaling decimal place is set here.

P19 % Scaling unit

Configuration option to show the pressure value assignment on other physical values/units.

The scaling unit is set here.

P20 h Operating hours

For information only

No configuration option

Page 56

8 Configuration

56

8.3 Level measurement configuration with a pressure specification - recommended (tank empty, tank full)

The following description applies to level measurements of all measuring ranges with or without a diaphragm seal.

With rotary knob operation (parameter level)

Swap from display level to parameter level, see chapter 7.3 "The level concept", page 46

The following configuration steps should be taken:

Swap from parameter level to display level

With JUMO setup program

P1 Measuring unit, e.g. mbar

P2 Measuring range lower range value: 4 mA (configuration with empty tank)

P3 Measuring range upper range value: 20 mA (configuration with full tank)

P4 Attenuation: 0

P14 Temperature measuring unit (only for displaying or as HART® signal): °C

P16 Scaling start: scaling on the tank, e.g. in liters: 0

P17 Scaling end: scaling on the tank, e.g. in liters: 200

P19 Scaling unit: L (liters)

Extras Extras: Online operation_measuring start with pressure transmitter (zero) – with emp-

ty tank

Confirm transfer.

Extras Extras: Online operation_measuring end with pressure transmitter (span) – with full

tank

Confirm transfer.

Page 57

57

8 Configuration

NOTE!

No zero point adjustment should be performed when configuring the level measurement with a pressure

specification.

Page 58

8 Configuration

58

8.4 Level measurement configuration without a pressure specification

8.4.1 With a diaphragm seal in closed containers with a measuring range of 0 to 1 bar

NOTE!

The filling oil in the diaphragm seal used has an influence on the configuration of the device and therefore always needs to be considered in the calculation.

Range start (4 mA):

Measuring range lower range

value P5

[mbar] = H ×

oil

×g×0.01

Range end (20 mA):

Measuring range upper range

value P6

[mbar] = (H ×

oil

-h×

liq

) × g × 0.01

Legend:

H [mm] = Vertical distance of the diaphragm seal

h [mm] = Max. level of the measured liquid, 0 < h ≤ H

oil

[g/cm3] = 0.96, density of the oil in the capillary

liq

[g/cm3] = Density of the measured liquid

g[m/s

2

] = 9.81, gravitational acceleration

Example:

Tank height = 10 m

H [mm] = 9000

h [mm] = 8000

liq

[g/cm3] = 1.00, density of the water, 4 °C

Measuring range lower range

value P5

[mbar] = 9000 × 0.96 × 9.81 × 0.01 = 847.6

Measuring range upper range

value P6

[mbar] = (9000 × 0.96 - 8000 × 1.00) × 9.81 × 0.01 = 62.8

H

+

-

max.

p

2

min.

p

1

Dp

h

Page 59

59

8 Configuration

With rotary knob operation (parameter level)

Swap from display level to parameter level, see chapter 7.3 "The level concept", page 46

The following configuration steps should be taken:

Swap from parameter level to display level

With JUMO setup program

Data transfer from the device

P1 Unit, e. g. mbar

P4 Attenuation: 0

P5 Measuring range lower range value: 847.6, see example calculation

P6 Measuring range upper range value: 62.8, see example calculation

P14 Temperature measuring unit (only for displaying or as HART® signal): °C

P16 Scaling start: scaling on the tank, e.g. in liters: 0

P17 Scaling end: scaling on the tank, e.g. in liters: 200

P19 Scaling unit: L (liters)

Editing Maintenance

The following dialog window opens: "Maintenance":

P01 Measuring unit, e.g. mbar

P04 Attenuation: 2.5

P05 Measuring range lower range value: 847.6, see example calculation

P06 Measuring range upper range value: 62.8, see example calculation

P11 Characteristic line: linear

P14 Temperature measuring unit (only for displaying or as HART® signal): °C

P16 Scaling start: scaling on the tank, e.g. in liters: 0

P17 Scaling end: scaling on the tank, e.g. in liters: 200

P18 Maximum decimal place: automatic

P19 Scaling unit: L (liters)

Page 60

8 Configuration

60

After entering the desired values: Start data transfer to device.

CAUTION!

A zero point adjustment should generally not be performed (e.g. when the tank is empty) in a

measuring range of 0 to 1 bar.

8.4.2 With a diaphragm seal in closed containers with ± measuring ranges

Range start (4 mA):

Measuring range lower range

value P5

[mbar] = (H ×

oil

-h×

liq

) ×g × 0.01

Range end (20 mA):

Measuring range upper range

value P6

[mbar] = H ×

oil

×g×0.01

Legend:

H [mm] = Vertical distance of the diaphragm seal

h [mm] = Max. level of the measured liquid, 0 < h ≤ H

oil

[g/cm3] = 0.96, density of the oil in the capillary

liq

[g/cm3] = Density of the measured liquid

g[m/s

2

] = 9.81, gravitational acceleration

Example:

Tank height = 10 m

H [mm] = 9000

h [mm] = 8000

liq

[g/cm3] = 1.00, density of the water, 4 °C

Measuring range lower range

value P5

[mbar] = (9000 × 0.96 - 8000 × 1.00) × 9.81 × 0.01 = 62.8

Measuring range upper range

value P6

[mbar] = 9000 × 0.96 × 9.81 × 0.01 = 847.6

H

-

+

max.

p

2

min.

p

1

Dp

h

Page 61

61

8 Configuration

With rotary knob operation (parameter level)

Swap from display level to parameter level, see chapter 7.3 "The level concept", page 46

The following configuration steps should be taken:

Swap from parameter level to display level

With JUMO setup program

Data transfer from the device

P1 Unit, e. g. mbar

P4 Attenuation: 0

P5 Measuring range lower range value: 62.8, see example calculation

P6 Measuring range upper range value: 847.6, see example calculation

P14 Temperature measuring unit (only for displaying or as HART® signal): °C

P16 Scaling start: scaling on the tank, e.g. in liters: 0

P17 Scaling end: scaling on the tank, e.g. in liters: 200

P19 Scaling unit: L (liters)

Editing Maintenance

The following dialog window opens:

P01 Measuring unit, e.g. mbar

P04 Attenuation: 2.5

P05 Measuring range lower range value: 62.8, see example calculation

P06 Measuring range upper range value: 847.6, see example calculation

P11 Characteristic line: linear

P14 Temperature measuring unit (only for displaying or as HART® signal): °C

P16 Scaling start: scaling on the tank, e.g. in liters: 0

P17 Scaling end: scaling on the tank, e.g. in liters: 200

P18 Maximum decimal place: automatic

P19 Scaling unit: L (liters)

Page 62

8 Configuration

62

NOTE!

No zero point adjustment should be performed after configuring the level measurement without a pressure specification (for ± measuring range).

8.4.3 Without a diaphragm seal in closed containers with ± measuring ranges or 0 to

1 bar

The device is ideally suited for level measurements in open and containers.

With rotary knob operation (parameter level)

Swap from display level to parameter level, see chapter 7.3 "The level concept", page 46

The following configuration steps should be taken:

Swap from parameter level to display level

P1 Unit, e. g. mbar

P4 Attenuation: 0

P5 Measuring range lower range value: 0

P6 Measuring range upper range value: 2.00 (2 m water column in this example)

P7 Zero point adjustment, set device to zero, e.g. if tank is empty

P11 Characteristic line: linear

P14 Temperature measuring unit (only for displaying or as HART® signal): °C

P16 Scaling start: scaling on the tank, e.g. in liters: 0

P17 Scaling end: scaling on the tank, e.g. in liters: 200

P19 Scaling unit: L (liters)

Page 63

63

8 Configuration

With JUMO setup program

Data transfer from the device

After entering the desired values: Data transfer to device

Zero point adjustment, set device to zero, e.g. if tank is empty

Editing Maintenance

The following dialog window opens:

P01 Measuring unit, e.g. mbar

P04 Attenuation: 0

P05 Measuring range lower range value: 0

P06 Measuring range upper range value: 2.00 (2 m water column in this example)

P11 Characteristic line: linear

P14 Temperature measuring unit (only for displaying or as HART® signal): °C

P16 Scaling start: scaling on the tank, e.g. in liters: 0

P17 Scaling end: scaling on the tank, e.g. in liters: 200

P18 Maximum decimal place: automatic

P19 Scaling unit: L (liters)

Extras Extras: Online operation_sensor zero point calibration

Page 64

8 Configuration

64

8.4.4 For steam layering with ± measuring ranges

(1) Condensing vessel

I Vertical distance from tank to measuring device input

L Vertical distance from condensing vessel to measuring device input

Range start (4 mA):

Measuring range lower range

value P5

[mbar] = (L - I) ×

vap

×g×0.01

Range end (20 mA):

Measuring range upper range

value P6

[mbar] = ([L - I] + H) ×

vap

×g×0.01

Legend:

H [mm] = Max. filling level height

h [mm] = Max. level of the measured liquid, 0 < h ≤ H

L [mm] = Vertical distance from tank to measuring device input

(low pressure)

I [mm] = Vertical distance from condensing vessel to measuring

device input (high pressure)

vap

[g/cm3] = 1.00, density of the water, 4 °C

liq

[g/cm3] = Density of the measured liquid

g[m/s

2

] = 9.81, gravitational acceleration

Example:

H

-

+

p

2

p

1

H

max.

min.

h

(1)

L

I

Page 65

65

8 Configuration

With rotary knob operation (parameter level)

Swap from display level to parameter level, see chapter 7.3 "The level concept", page 46

The following configuration steps should be taken:

Swap from parameter level to display level

CAUTION!

No zero point adjustment may be performed for this configuration of the level measurement

With JUMO setup program

Data transfer from the device