Page 1

Original Operating Manual

1.951.3727-V2 en 01/14

High Temperature Circulator

HT60-M2 HT60-M3

C.U.-cooling unit

JULABO GmbH

77960 Seelbach / Germany Tel. +49 (0) 7823 / 51-0 Fax +49 (0) 7823 / 24 91 info@julabo.de www.julabo.de

19513727-V2.docx Print date: 13.01.14

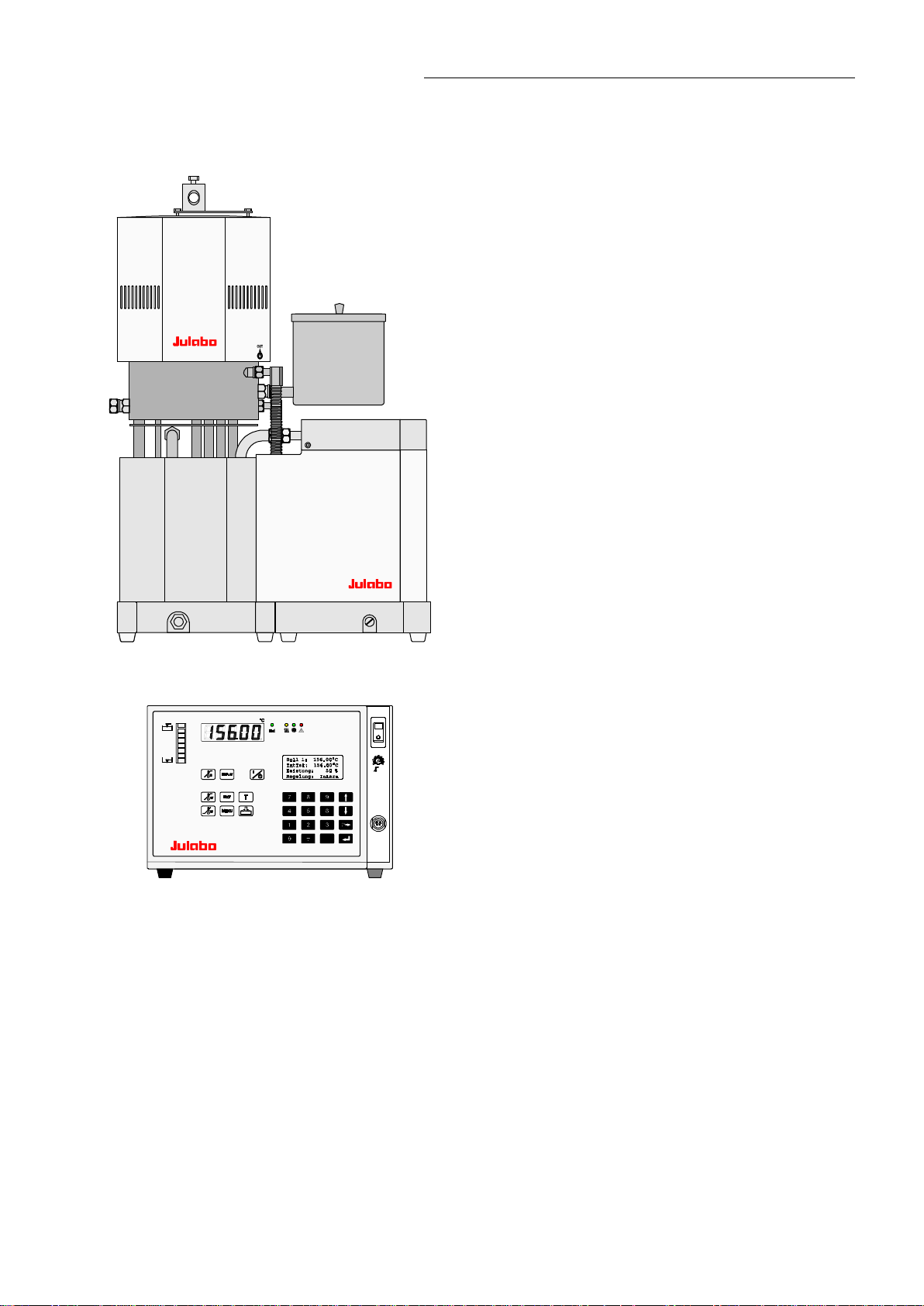

Forte HT with cooling unit

Page 2

Operating manual

Congratulations!

You have made an excellent choice.

JULABO thanks you for the tr ust y ou hav e plac ed in us.

This operati ng manual has been designed t o help you gain an understanding of the operation and possible

applicati ons of our ci rculators. For optimal utili z ation of all functions, we recommend that you thoroughly study

this manual prior to beginning operation.

The JULABO Quality Management System

Temperature cont rol devices f or research and indu stry are dev eloped, pr oduced, and

distribut ed ac c or ding to the requirements of ISO 9001 and ISO 14001. Certificate

Registrati on No. 01 100044846

Unpacking and inspecting

Unpack the instrument and accessories and inspect them for possible transport damage. Dam age shoul d be

reported to the responsible carrier, rail way, or postal authority, and a damage report should be requested. These

instructions must be followed fully for us to guarantee our full support of your claim for protecting against loss

from concealed damage. The form required for filing such a claim will be provided by the carrier.

Printed in Germany Changes without prior notification reserved

Important: keep operating manual for future use

2

Page 3

TABLE OF CONTENTS

HT60-M2 / HT60-M3

OPERATING MANUAL .................................................................................................................... 5

1. INTENDED USE ....................................................................................................................... 5

1.1. Description ................................................................................................................... 5

2. OPERATOR RESPONSIBILITY – SAFETY INSTRUCTIONS .................................................... 6

2.1. Disposal ....................................................................................................................... 7

2.2. EC Conformity .............................................................................................................. 8

2.3. Warranty conditions .................................................................................................... 12

2.4. Technical specifications .............................................................................................. 13

2.5. Cooling water connection ............................................................................................ 16

3. OPERATING CONTROLS AND FUNCTIONAL ELEMENTS ................................................... 17

M2 or M3 – control electronic .................................................................................................. 17

HT60 High Temperatur e Cir c ulator with C.U.-cooling unit (option) ........................................... 20

4. SAFETY NOTES FOR THE USER .......................................................................................... 22

4.1. Explanation of safety notes ......................................................................................... 22

4.2. Explanation of other notes .......................................................................................... 22

4.3. Safety instructions ...................................................................................................... 22

5. PREPARATIONS .................................................................................................................... 25

5.1. Setup .......................................................................................................................... 25

5.2. Installation .................................................................................................................. 26

5.3. Bath fluids .................................................................................................................. 28

5.4. Tubing ........................................................................................................................ 29

5.5. Power connection ....................................................................................................... 30

5.6. Filling / draining .......................................................................................................... 30

5.7. Degasifying................................................................................................................. 32

5.8. Countercooling ........................................................................................................... 34

6. OPERATING PROCEDURES ................................................................................................. 35

6.1. Switching on / Selecting the language ......................................................................... 35

7. MANUAL OPERATION ........................................................................................................... 36

7.1. Start - Stop ................................................................................................................. 36

7.2. Setting the temperatures ............................................................................................. 36

7.3. Warning functions ....................................................................................................... 37

7.4. Setting the safet y tem per ature (with shutdown function) .............................................. 38

7.5. Internal / external c ontrol ............................................................................................ 39

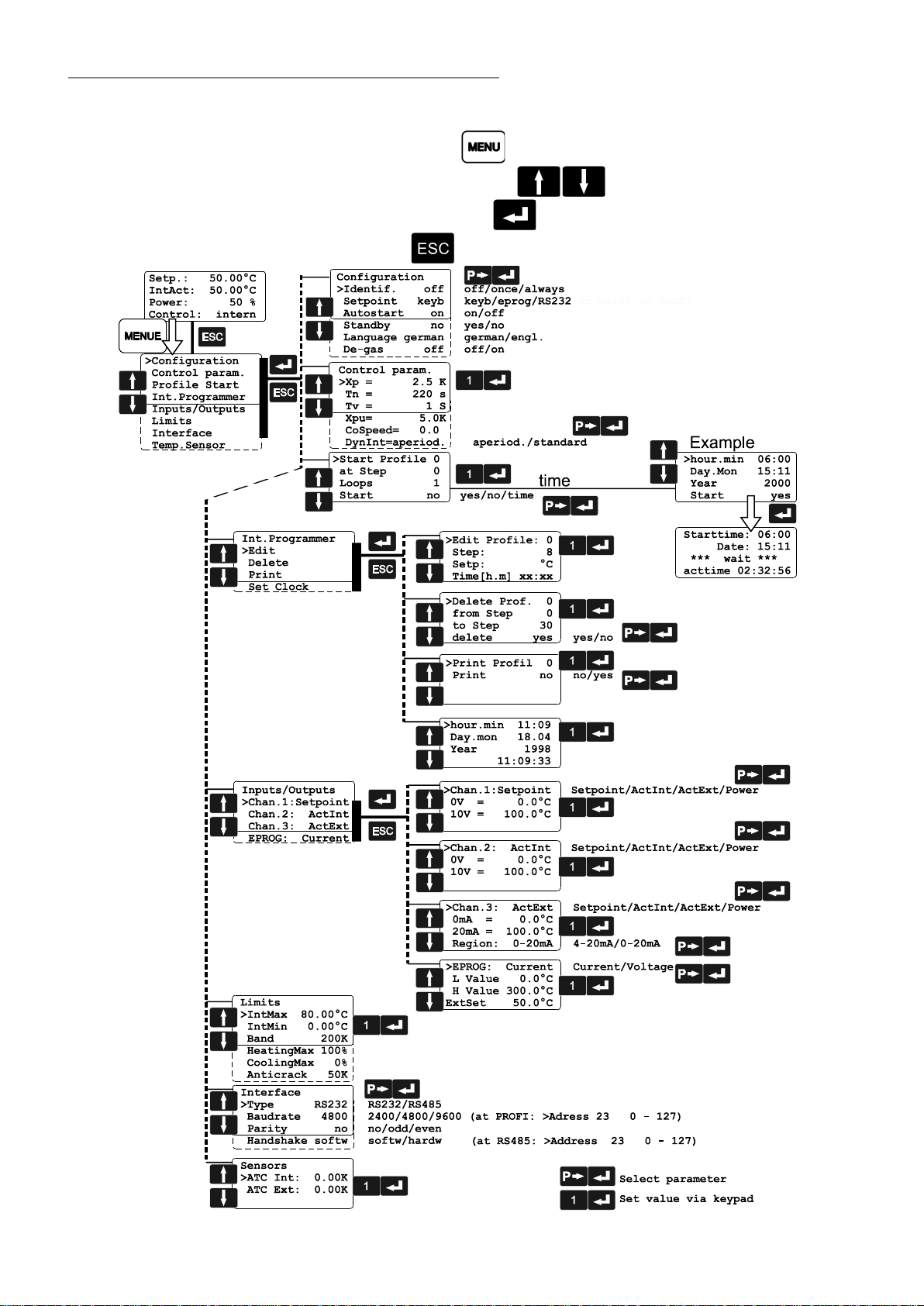

8. MENU FUNCTIONS ................................................................................................................ 40

8.1. Configuration .............................................................................................................. 41

8.2. Control parameters ..................................................................................................... 44

8.3. Start of a profile .......................................................................................................... 47

8.3.1. I nterrupting a profile ................................................................................................. 49

8.4. Integrated progr ammer ............................................................................................... 50

8.5. Analog input s/outputs ................................................................................................. 53

8.6. Limits .......................................................................................................................... 56

3

Page 4

Operating manual

8.7.

Interface ..................................................................................................................... 57

8.8. Sensors ...................................................................................................................... 57

9. TROUBLES HOOT IN G GU IDE / ERROR MESSAGES ............................................................ 59

10. ELECTRICAL CONNECTIONS ............................................................................................... 61

11. REMOTE CONTROL .............................................................................................................. 63

11.1. S etup for remote control ............................................................................................. 63

11.2. Com munication with a PC or a superordinat ed data system ........................................ 64

11.3. List of commands........................................................................................................ 65

11.4. Status messages / error messages ............................................................................. 68

12. CLEANING / REPAIRING THE UNIT ...................................................................................... 70

4

Page 5

HT60-M2 / HT60-M3

Operating manual

1. Intended use

The High Temperatur e Cir c ulators HT60-M2 and HT60-M3 are to be employed especially for closed tempering

circuits in the laboratory, the technical institution or the production, like e.g. for distillation plants, reaction vessels,

autoclaves, injection moulding tools.

JULABO circulators are not suitable for direct t em per ature c ontrol of foods, semi-luxury foods

and tobacco, or pharm ac eutical and medical products. Dir ec t t em per ature control means

unprotected cont ac t of the object with the bath medium (bath fl uid) .

1.1. Description

The structure of the High Temperature Circulator HT60 is sub-div ided in three zones:

• The cold zone (on t op) wit h the electronics for controlling and monitoring, the tem per ature c ontrol and the

pump motor.

• The cooling z one with the cooling coil, the fl oat f or the lev el indication, a temperature sensor for monitoring

the temperatur e, t he c onnec tion for inert-gas, the connecti on for the expansion vessel as well as an overfl ow

nozzle. At thi s place t he temper ature monitoring is independant from the other safety devices.

• The heati ng zone (down) with the heating element , t he pum p, t he temper ature sensors and the flow nozzl e

The C.U.-cooling unit can be installed firmly and fulfills two tasks.

• The temperature of the tempering liquid in the cooling zone is supervised. If it is necessary the cooling water

is led through the integr ated cooling coil in order to reduce the temperature (without C.U.-cooling unit the

cooling coil c an be connect ed dir ec tly to the cooling water).

• With a separate cooling circuit through the C.U.-cooling unit a rapid cooli ng of t he temper ing liquid becomes

possible.

The M2 or M3 control electronics is connected to the HT60-circulator via a control cable.

• The local oper ation of the control electronics M2 / M3 is effected via a splash-water protected keypad. The

Microprocessor technology allows to set three different temperatur e v alues, to store and to indicate them via

the digi tal display LCD – the worki ng temperature and the values for t he excess and lower t em per ature

warning functi ons.

• With the integrated programmer the instructions for setpoint and time for six different temperature pr ofiles

can be stored and call ed in.

• Via an analog i nterface REG+E-PROG an analog programmer can be connec ted for the setpoint.

• At the same tim e this interface is provided with three analog outputs for the recorder. For the best resol ution

the output settings can be adjusted via the menu delete surfac e - should just be Menu.

The remote control via the digital RS232/RS485 int erface according to NAMUR allows the m ost m oder n

process technology without additional interface.

• The excess temper ature protection i s a safety equi pm ent which does not depend on t he control circle. Its

safety value is shown and can be adjusted by the MULTI-DISPLAY (LED).

• The level of liquid is acquired in the cooling z one, indicated to the control el ectr onic s via the control cable.

There they are made vi sibl e by an 8-grade level indication.

5

Page 6

Operator responsibi lity – Safety instructions

2. Operator responsibility – Safety instructions

The products of JULABO ensure safe operation when installed, operated, and mai ntained according to common

safety regulati ons. This section explains the pot ential dangers that m ay arise when operating the circulator and

also specifies the m ost im por tant safety precautions to precl ude these dangers as far as possible.

The operator is responsible for the qualific ation of the personnel operating the units.

The personnel operating the units should be regul arl y instruct ed about the dangers inv olv ed with their job

activiti es as well as m easures to avert these dangers.

Make sure all persons tasked with operating, install ing, and maintaining the unit hav e r ead and under stand

the safety information and oper ating instructions.

When using hazardous mat eri als or materials that could become hazardous, the circ ulator may be operated

only by persons who are absolutel y familiar with these materi als and the ci r c ulator. These persons must be

fully aware of p ossible r isks.

If you have any questions concerning the operation of your unit or the information in this manual, please cont ac t

us!

Contact:

Safety instructions for the operator:

Avoid strikes to t he housi ng, vibrations, damage to the operating-element panel ( k ey pad, display), and

contamination.

Make sure the product is checked for proper condition regular ly (depending on the conditions of use).

Regularly check ( at least every 2 years) the proper condition of the mandatory, warning, pr ohibition and

safety labels.

Make sure that the mains power supply has l ow im pedanc e to avoid any negativ e eff ects on the instr um ents

being operated on the same mains.

This unit is designed f or oper ation in a controlled electromagnetic environment. This means that transmitti ng

devices (e.g., cellular phones) should not be used in the immediate vicinity.

Magnetic radiation may affect other devic es with c om ponents sen si tive to magnetic fields (e.g., monitors).

We recommend maintai ning a mi nim um distanc e of 1 m.

Permissible am bient temperature: max. 40 °C, min. 5 °C.

Permissible r elative humidity: 50% (40 °C).

Do not store the unit in an aggressive atmosphere. Protect t he unit f r om cont ami nation.

Do not expose the unit to sunlight.

JULABO GmbH

Eisenbahnstraße 45

77960 Seelbach / Germany

Tel. +49 (0) 7823 / 51-0

Fax +49 (0) 7823 / 24 91 www.julabo.de

info@julabo.de

Appropriate operation

Only qualified per sonnel is authorized to confi gur e, install, maintain, or repair the circulator.

Persons who operate the cir c ulator must be trained in the partic ular tasks by qualified personnel. The

summarized user guidance ( short manual) and the specification table with inform ation on individual parameters

are sufficient for this.

6

Page 7

HT60-M2 / HT60-M3

is not permitted!

Use

The bath can be filled with flammable materials. Fire hazard!

There might be chemic al danger s dependi ng on the bath medium used.

Observe all warnings f or the used m aterials (bath fluids) and t he r espect ive instructions (safety data sheets).

Insufficient ventilation may result in the formation of explosive mixtures. Only use the unit in well ventilated

areas.

Only use recommended m aterials (bath fluids). Only use non-acid and non c or r oding materials.

When using hazardous mat eri als or materials that could become hazardous, the operator must affix the

enclosed safety labels (1 + 2) to the front of the unit so they are highly visible:

1

2

or

2

Particular care and at tention is necessary because of the wide operat ing range.

There are thermal danger s: B ur n, scald, hot steam, hot parts and surfac es that can be touched.

Observe the instruc tions in the manuals for instruments of a different make that you connec t t o the cir c ulator,

particularly the corresponding safety instr uc tions. Also observe the pi n assignment of plugs and technical

specifications of the products.

Warning label W00: Colors: yellow, black

Danger area. Attention! Observe instructions.

(operating manual, safety data sheet)

Mandatory label M 018: Colors: blue, white

Carefully read the user i nformation prior to begi nning operation.

Scope: EU

Semi S1-0701 Table A1-2 #9

Carefully read the user i nformation prior to begi nning operation.

Scope: USA, NAFTA

Warning label W26: Colors: yellow, black

Hot surface warning.

(The label is put on by JULABO)

2.1. Disposal

The product may be used with oil as bath fluid. These oils fully or partially consist of mineral oil or synthetic oil.

For disposal, f ollow the instructions in the materi al safety data sheets.

Valid in EU countries

See the current official journal of the European Union – WEEE directive.

Directive of t he European Par liament and of the Council on waste electrical and electronic

equipment (WEEE ).

This directive r equir es el ec trical and electr onic equipment marked with a crossed-out trash

can to be disposed of separately in an environmentally friendly manner.

Contact an authoriz ed waste m anagement company in your countr y .

Disposal with household waste ( unsort ed waste) or simi lar collections of munici pal waste

7

Page 8

Operator responsibi lity – Safety instructions

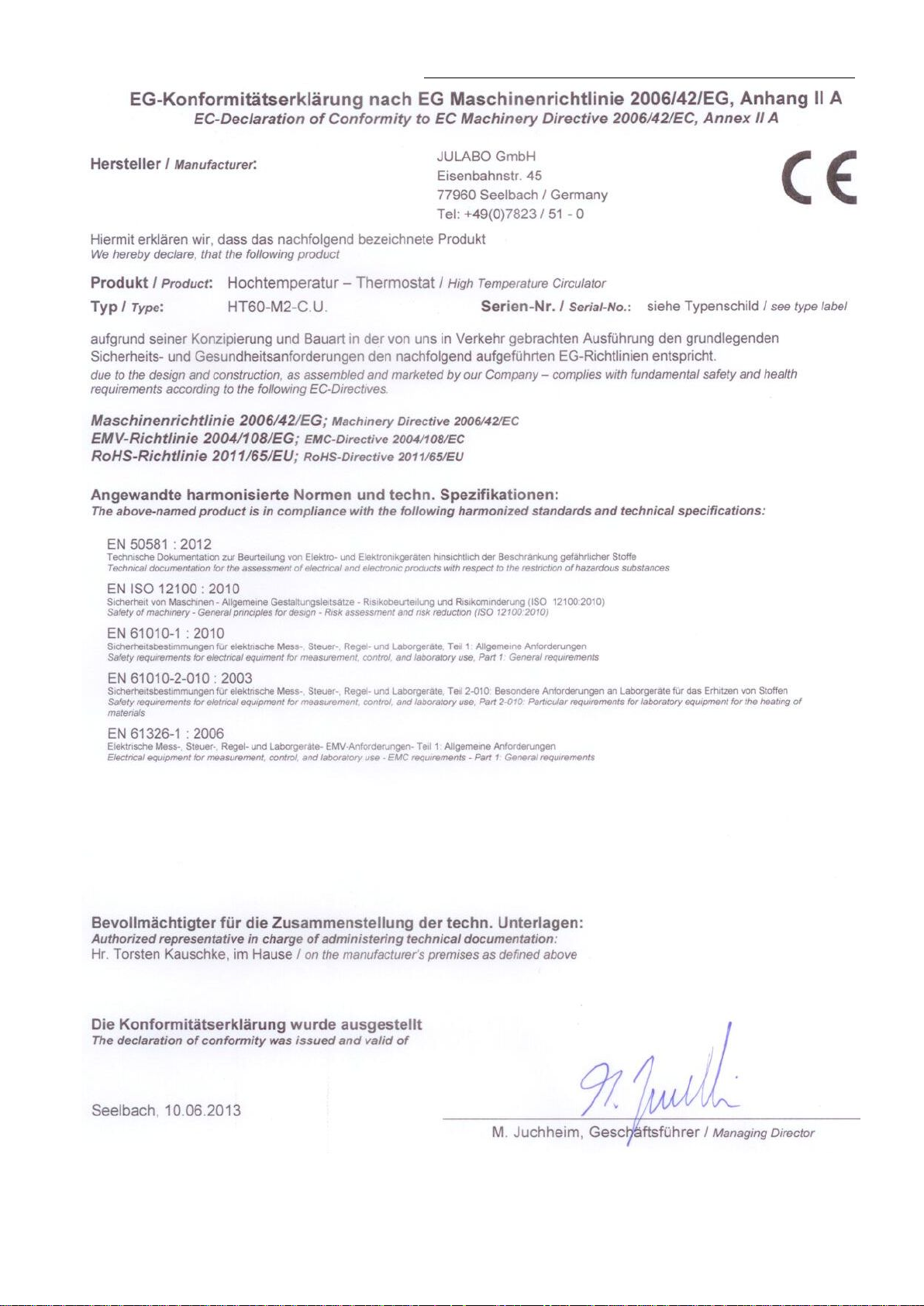

2.2. EC Conformity

8

Page 9

HT60-M2 / HT60-M3

9

Page 10

Operator responsibi lity – Safety instructions

10

Page 11

HT60-M2 / HT60-M3

11

Page 12

Operator responsibi lity – Safety instructions

2.3. Warranty conditions

JULABO GmbH warrants its products agai nst defects in material or in workmanship, when used under

appropriate conditions and in accordance wit h appr opr iate operating instruc tions

for a period of ONE YEAR.

Extension of the warranty period – free of charge

With the ‘1PLUS warranty’ t he user rec eives a free of charge extensi on to the warranty of up to 24 months,

limited to a maximum of 10 000 worki ng hour s.

To apply for this ext ended warrant y the user must register the unit on t he J ULABO web site

indicati ng the seri al no. The extended warranty will apply from the dat e of JULA BO GmbH’s original invoice.

JULABO GmbH reserves the right to decide the validity of any warranty cl aim . In case of f aults arising either

due to faulty materials or workmanship, parts will be r epair ed or r eplac ed free of charge, or a new replacement

unit will be suppli ed.

Any other compensation claims are excluded from this guarantee.

www.julabo.de,

12

Page 13

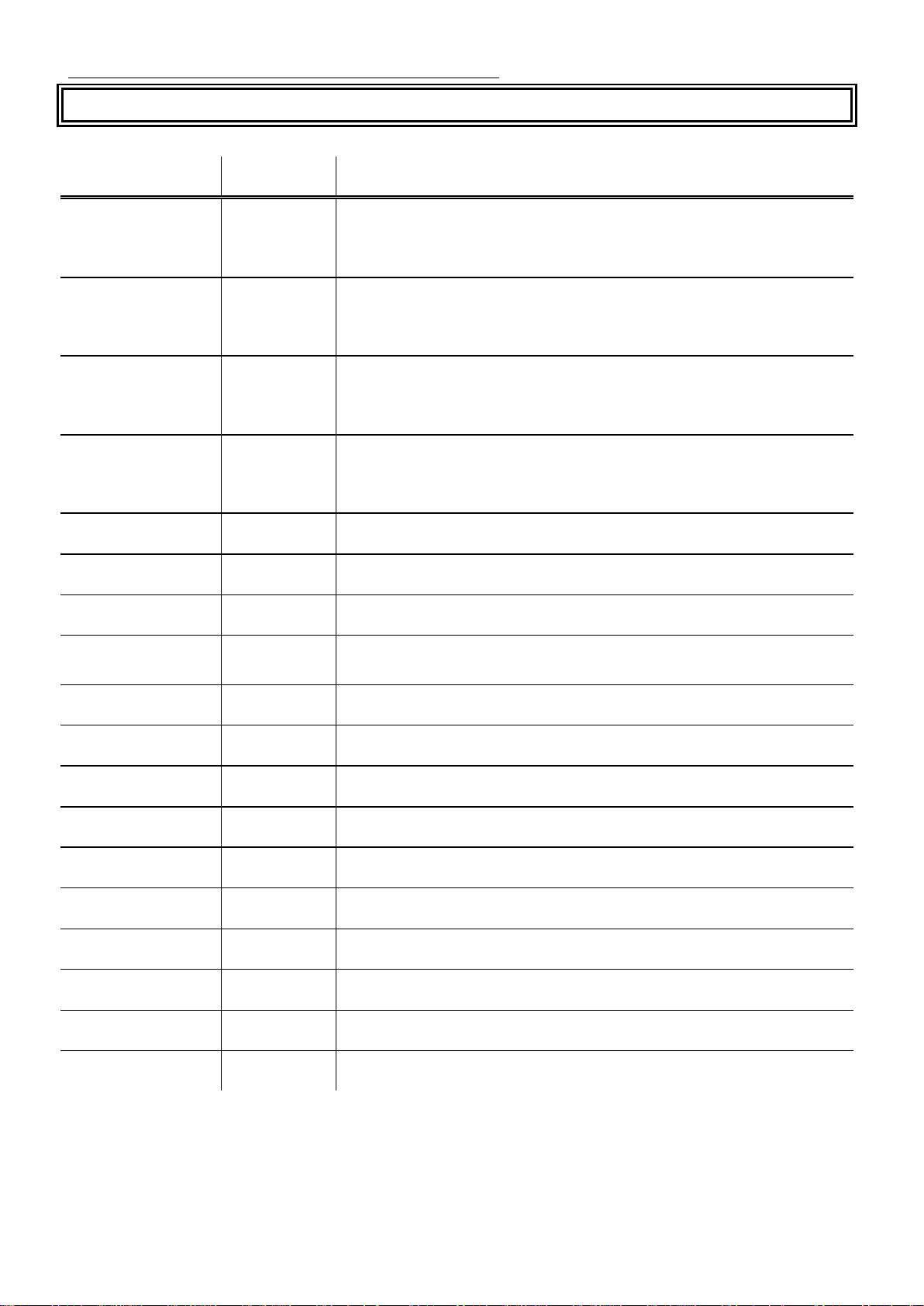

2.4. Technical specifications

HT60-M2 HT60-M2 & C.U.

Working temperature range

°C

70 ... 400 40 … 400

Temperature stability external

°C

±0,01 ... ±0.1

Display accurac y

%

±0.5 ±1Digit

Temperature selec tion

digital

via keypad

indicati on on LCD DIALOG -DISPLAY (°C/°F)

remote control via PC

indication on monitor

Temperature indication

Multi-Display (LED)

DIALOG-Display (LCD)

Resolution

°C

0.01

Absolute Temperature Calibration

(ATC 1)

°C

±9.99

(ATC 2)

°C

±9.99

Temperature control

ICC - Intelligent Cascade Control,

self-optimizing

Cascade, parameter c an be c alled-in and modified

Heater wattage (at 3x400 V)

kW

7.0

C.U.-cooling unit:

at 2 l/min flow of cooling water

Pressure pump:

Max. pressure max. at 0 liters

bar

0.8 … 1.2

Flow rate max. at 0 bar

l/min

14 … 18

Electrical connections:

See page 15

Filling volume

litre

2

Overall dimensi ons (W x Dx H) M2 / M3

cm

25x25x18 25x25x18

Weight

kg

29 37

Ambient temperature

°C

5 ... 40

400V/3PNPE/50Hz

Current draw

A

10.5 (at 400 V) 10,5 (400V) & 1 (230V)

HT60-M2 / HT60-M3

Temperature <IntAct>

Cooling capacity

Overall dimensi ons (W x Dx H) HT60 cm 23x23x58 43x23x58

Mains power connection

All measurements have been carried out at:

rated voltage and frequency ambient temperatur e: 20 °C

Technical changes without prior notification reserved.

°C

kW

V / Hz 365-440V/3PNPE/50Hz & 207-253V/50-60Hz

----- 350 250 150 75

----- 12 8 4 1

13

Page 14

Operator responsibility – Safety instructions

HT60-M3 HT60-M3 & C.U.

Working temperature range

°C

70 ... 400 40 … 400

Temperature stability external

°C

±0,01 ... ±0.1

Display accurac y

%

±0.5 ±1Digit

Temperature selec tion

digital

via keypad

indicati on on LCD DIALOG -DISPLAY (°C/°F)

remote control via PC

indication on monitor

Temperature indication

Multi-Display (LED)

DIALOG-Display (LCD)

Resolution

°C

0.01

Absolute Temperature Calibration

(ATC 1)

°C

±9.99

(ATC 2)

°C

±9.99

Temperature control

ICC - Intelligent Cascade Control,

self-optimizing

Cascade, parameter c an be c alled-in and modified

Heater wattage (at 3x400 V )

kW

6.0

C.U.-cooling unit:

at 2 l/min flow of cooling water

Pressure pump:

Max. pressure max. at 0 liters

bar

0.8 … 1.2

Flow rate max. at 0 bar

l/min

14 … 18

Electrical connections:

See page 15

Filling volume

litre

2

Overall dimensi ons (W x Dx H) M2 / M3

cm

25x25x18 25x25x18

Weight

kg

29 37

Ambient temperature

°C

5 ... 40

208/3PPE/60Hz

Current draw

A

18 (at 208 V) 18 (208V) & 1 (230V)

Temperature <IntAct>

Cooling capacity

°C

kW

----- 350 250 150 75

----- 12 8 4 1

Overall dimensi ons (W x Dx H) HT60 cm 23x23x58 43x23x58

Mains power connection

V / Hz 180-228V/3PPE/60Hz &207-253V/50-60Hz

All measurements have been carried out at:

rated voltage and frequency ambient temperature: 20 °C

Technical changes without prior notification reserved.

14

Page 15

HT60-M2 / HT60-M3

Electrical connections:

Computer interf ac e RS232 or RS485 or Profi

Programmer input 0 - 10 V / 0 - 20 mA

Temperatur rec or der outputs Channel 1 / 2 0 - 10 V /

Channel 3 0 - 20 mA / 4 - 20 mA

Stand-by input

External alarm devic e Switching capaci ty max. 30 W / 40 VA

Switching voltage max. 125 V∼/−

Switching cur r ent max. 1 A

External measurem ent and controlsensor Pt100, 4-lead technique

Safety installations according to IEC 61010-2-010:

Excess temperatur e pr otection adjustable fr om 0 °C to 420 °C

Low liquid level protection float switch

Liquid level indication optical 8-graded

Rèpartition par cl asse selon DIN 12876-1 Classe III FL

Supplementary safety installations

High temperat ur e warning func tion optical + audible (in intervals)

Low temperature warning function optical + audible (in intervals)

Supervision of the worki ng sensor plausibility c ontrol

Reciprocal sensor monitoring between

working and safety sensors difference >100 K

Alarm indicati on optical + audi ble ( permanent)

Environmental conditions according to IEC 61 010-1:

• Use only indoor.

• Altitude up t o 2000 m - normal zero.

• Ambient tem per ature: see Technical specific ations

• Air humidity:

Max. rel. humidity 80 % for temper atures up to +31 °C,

linear decrease down to 50 % relative humidity at a temperature of +40 °C

• Max. mains fluctuations of ±10 % are permissible.

• Overvoltage category II

• Pollution degr ee 2

Caution:

The unit is not for use in expl osive environment

Protection class according to IEC 60 529: IP31

The unit corresponds to Class I

Standards for interference resistance accor ding to EN 61326-1

This unit is an ISM device classified in Group 1 (using high frequency for internal purposes) Class A (industr ial

and commercial range).

15

Page 16

Operator responsibi lity – Safety instructions

• Avoid putrid water.

pH

7.5 to 9.0

Sulfate [SO4 2- ]

< 100 ppm

Hydrocarbonate [HCO 3-]/sulfate [SO4 2-]

> 1 ppm

Hardness [Ca 2+, Mg 2+]/[HCO 3-]

> 0 .5 °dH

Alkalinity

60 ppm < [HCO 3-] < 300 ppm

Conductivity

< 500 μS/cm

Chloride (Cl -)

< 50 ppm

Phosphate (PO4 3-)

< 2 ppm

Ammonia (NH3)

< 0.5 ppm

Free chlorine

< 0.5 ppm

Trivalent iron ions (Fe 3+)

Carbon dioxide ( CO2)

< 10 ppm

Hydrogen sulfide ( H2S )

< 50 ppm

Content of oxygen

Algae growth

impermissible

Suspended solids

impermissible

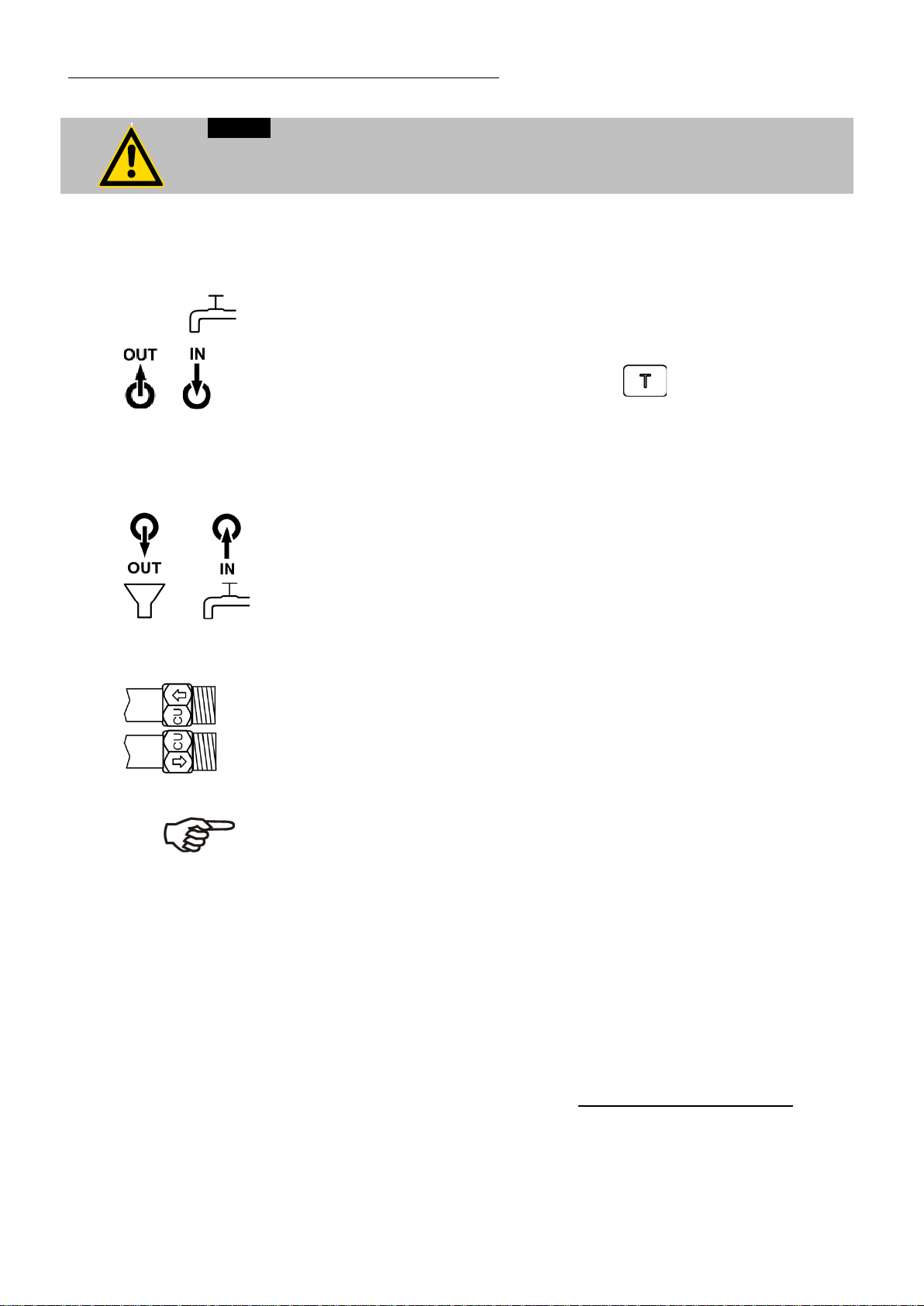

2.5. Cooling water connection

Cooling water pressure (IN / OUT ) max. 4.5 bar

Differenc e pressure (I N - O U T ) 2.0 to 4.5 bar

Rate of flow typical 2 l/min

Cooling water tem per ature <20 °C

Notice:

Danger of corrosion of heat exchanger due to unsuitable quality of cooling water.

• Due to its high content of lime, hard water i s not suitable for cooling and causes scale in

the heat exchanger.

• Ferrous water or water containing ferrous particles will cause form ation of rust even in

heat exchangers made of stainless steel.

• Chlorinated water will cause pit ting corrosion in heat exchangers m ade of stainless steel.

• Due to their corrosive characteri stics, distilled water and dei onized water are unsuitable

and will cause corrosion of the bath.

• Due to its corrosive characteri stics, sea water is not suitable.

• Due to its microbiological ( bacter ial) components, which settle in the heat exchanger,

untreated and unpurified river water and water from c ooling towers is unsuitable.

• Avoid particulate matt er in cooling water.

Recommended quality of cooling water:

Manganese ions (Mn 2+)

< 0.5 ppm

< 0.05 ppm

< 0.1 ppm

16

Page 17

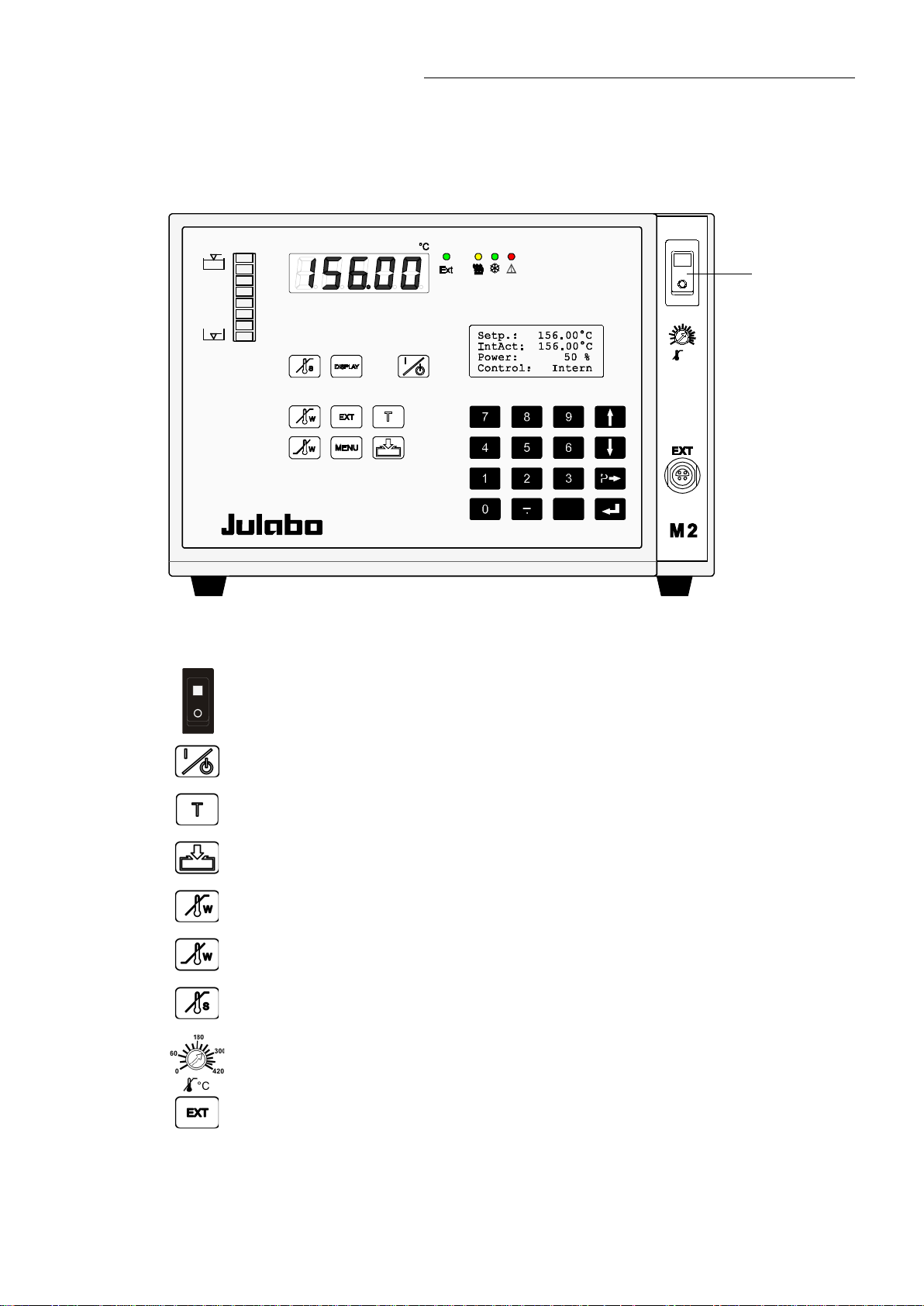

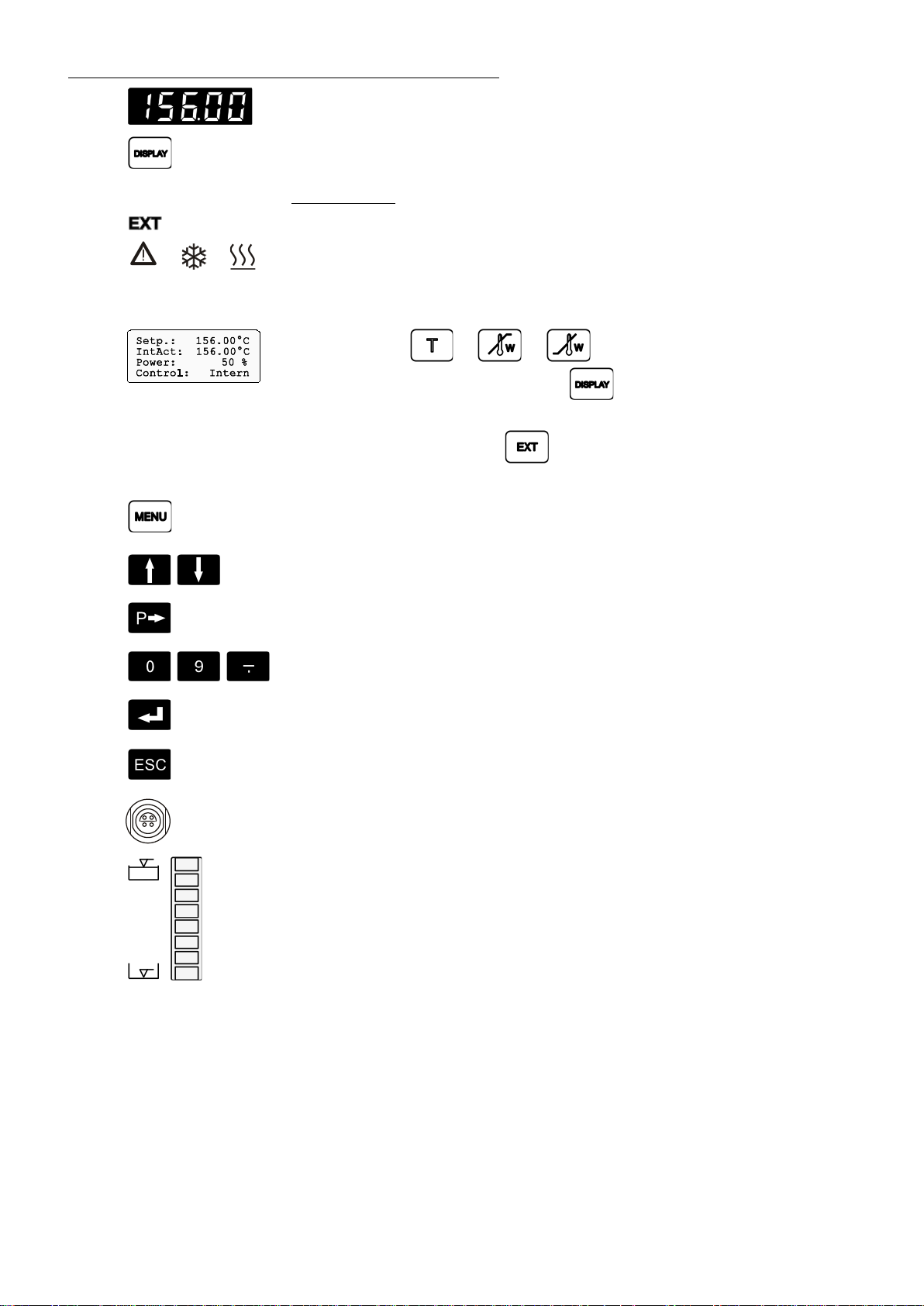

3. Operating controls and functional elements

1

-

ESC

P

0

60

180

300

420

°C

M2 or M3 – control electronic

HT60-M2 / HT60-M3

1

2

3

4

5

6

7

8

Mains power switch, illuminated

Start / stop key

Working temperature T

Key for automatic filling and aeration

High temperat ur e warning limit

Low temperature warning lim it

Safety temperature

Adjustable exc ess temperature protection ( safety temperature)

9

Control type: internal/external control

17

Page 18

Operating controls and functional elements

10

11

12

13

/ /

MULTI-DISPLAY (LED) temperature indication

Display of internal/external actual value

Indicator li ghts:

Temperature indication - external actual value

Alarm / Cooling / Heating

DIALOG-DISPLAY (LCD) for indication of:

Line 1: Setpoint or or

Line 2: Internal or exter nal actual value

Line 3: Heating power in %

Line 4: Control type: internal / external control

MENU key - for selecting the menu functions

14

15

16

17

18

19

EXT

20

Cursor keys - Select menu items

P-key Selecting paramet er s

Numeral keypad: numerals 0 to 9; minus / decimal point

Enter key 1) St or e v alue / param eter

2) Next lower menu level

Escape key 1) Cancel entries

2) Return to a higher menu level

Socket for exter nal m easurement and control sensor Pt100

8-grade liquid level indication

18

Page 19

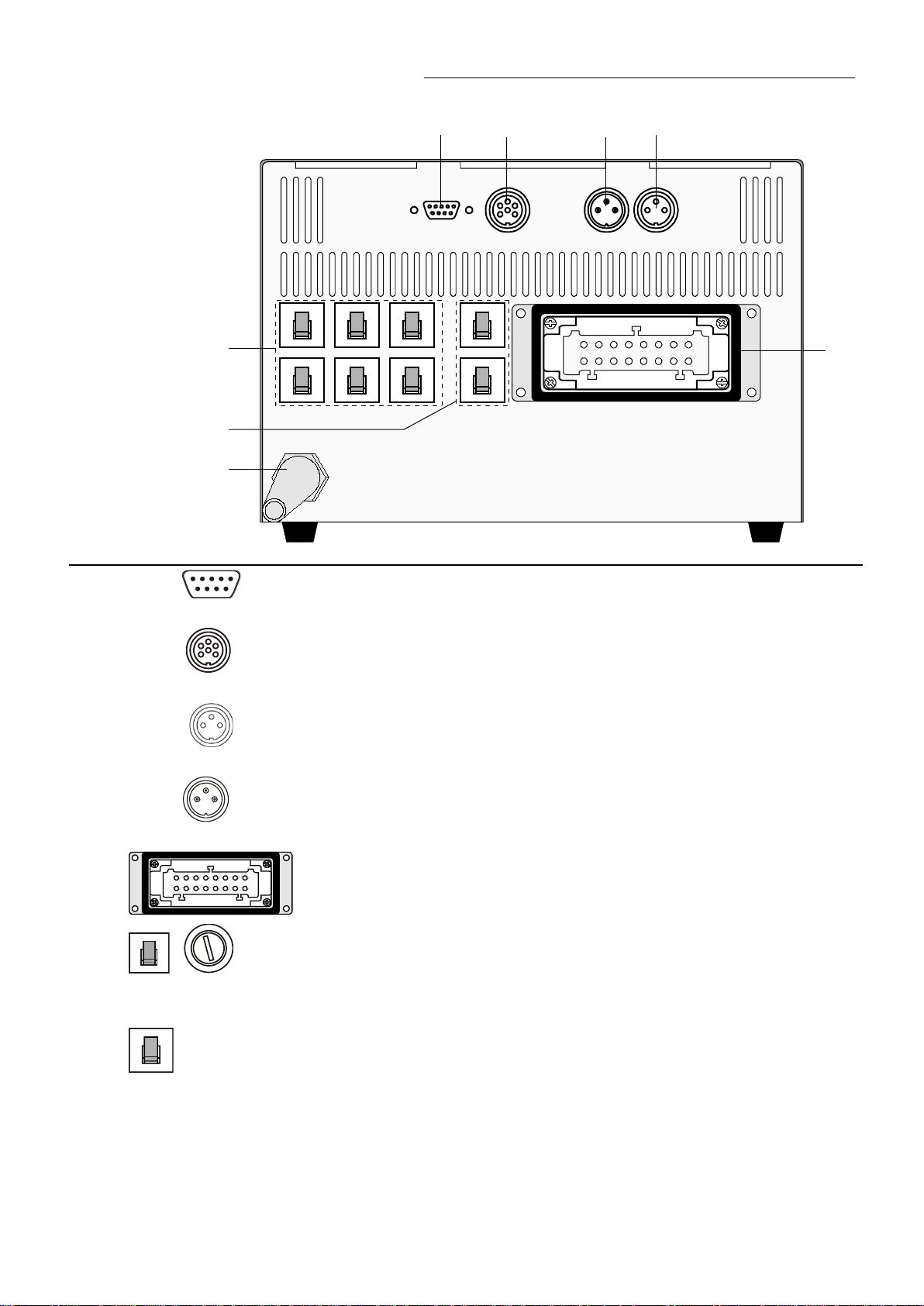

Rear view

30 31 32 33

1

8

916

4

A

M

P

HT60-M2 / HT60-M3

REG+E-PRO G STAND-BY ALARMSERIAL

30

31

32

36

37

38

SERIAL

REG+E-PROG

STAND-BY

16

A

M

P

16

A

M

P

16

A

M

P

16

A

M

P

16

A

M

P

16

A

M

P

4

A

M

P

4

A

M

P

8

HT60

916

1

MADE IN GERMANY

35

Interface RS232/RS485

Programmer input and temperature recorder out put

Stand-by input (f or ext er nal em er genc y switc h-off)

33

Alarm output (for exter nal alarm signal)

ALARM

35

Control exit Connector for contr ol cabl e of cir c ulator HT60

36

37

38 Mains power cable with pl ug

16

A

M

P

M2 – Mains circuit breaker s (resettable): 3x Mains fuses 16 A,

or

M2 – 3x fuse holder with fein-wire fuses T16A, 5x20 mm

M3 – Mains circuit breaker s (resettable): 6x Mains fuses 16 A,

Mains circuit break er s (resettable): Fuses 4 A, for C.U. -cool ing unit

19

Page 20

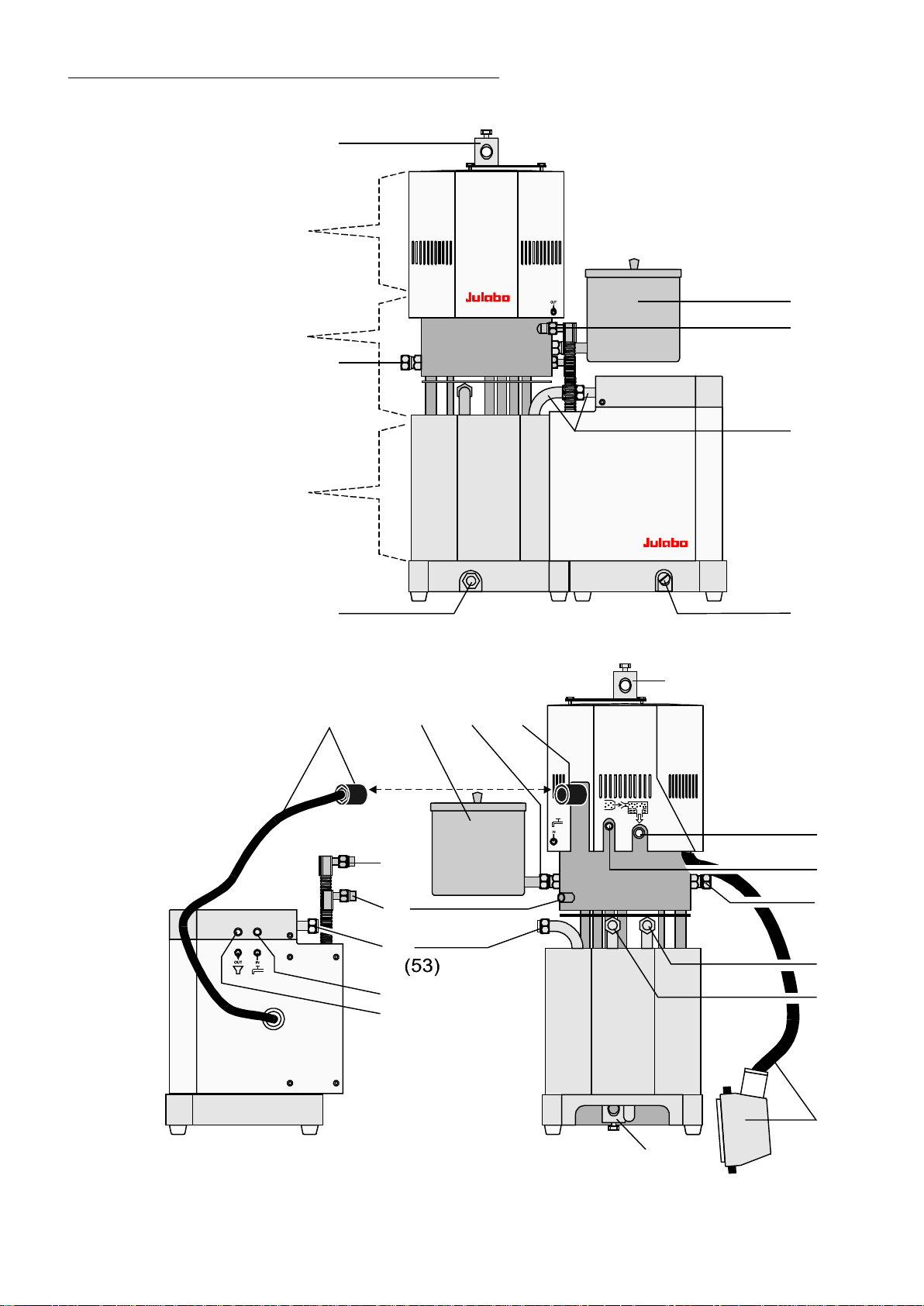

Operating controls and functional elements

HT60

CU

40

41

42

43

44

53

54

41

HT60 High Temperature Circulator with C.U.-cooling unit (option)

Front view:

Cold zone

Cooling zone

Heating zone

Rear view:

56

43 43a

44

45

52

46

47

40

56a

48

49

50

51

40

Presentation: Cooling unit divided from HT60

20

55

Page 21

40 Stand rod attac hm ent wit h mouting screw; ∅12; M8

41 Connector for liquid level indicator or

second expansion vessel; M16x 1 / ∠37°

42 Drain plug for bat h liquid; M16x1

43/43a Expansion vessel / Connector for expansion vessel; M16x1

(When filling it serves as funnel)

44/45

46/47

48

Cooling water connectors at the HT60, M12 / ∠37°

OUT – outlet (44), IN – inlet (45)

• Connection for cooling water or

• Connection for clocked cooling water with magnetic valv e or

• Connection for clocked cooling water out of t he CU-unit

Cooling water connectors at the C.U.-cooling unit; ∅10

IN –inlet, OUT – outlet

Overflow connector ∅15,5 / G ¼ ″ Internal thread

HT60-M2 / HT60-M3

49

50

51

52

53

54 Drain plug for cooling water; M10x1

55 Control cable wit h 16-c hannel plug for

56

56a

56a

Control cable wit h 6-c hannel plug for connection of the C.U.-cooling unit

Inert gas connector ∅10; M 8x 1 Internal thread

Pump connector f or ext er nal temper atur application

Return; 16x1

Pump connector f or ext er nal temper atur application

Feed ; 16x1

Pump connector f or C.U.-cooling unit - Return; M16x1

(Cooling circuit )

Pump connector f or C.U.-cooling unit - Feed; M16x1

(Cooling cir c uit )

connection of the M 2 or M3 control elec tronics

Control exit for C.U.-cooling unit

or

Control exit for magnet ic valve (for clocked cooling water)

21

Page 22

Safety notes for the user

surroundings can be dam aged.

Indicates usage ti ps and other useful information.

valid safety instructions for working places must be followed.

short moment for example).

4. Safety notes for the user

4.1. Explanation of safety notes

In addition to the safety warnings listed above, warnings are posted t hr oughout the manual.

These warnings are designat ed by an ex cl am ation mark inside an equilateral triangle.

“Warning of a dangerous situation (Attenti on! Please follow the documentation).”

The danger is classifi ed usi ng a si gnal word.

Read and follow these im por tant instructions.

Warning:

Describes a possibl y highly danger ous sit uation. If these instruc tions are not followed, serious

injury and danger t o life could result.

Caution:

Describes a possibl y danger ous sit uation. If this is not avoided, slight or minor injuri es could

result. A warning of possibl e pr oper ty damage may also be contai ned in the t ex t.

Notice:

Describes a possibl y harmf ul si tuation. If this is not avoided, the pr oduc t or anything in its

4.2. Explanation of other notes

Note!

Draws attention to something special.

Important!

4.3. Safety instructions

Follow the safet y recommendations to prevent damage to persons or propert y . Further, the

• Only connect the unit to a power socket with earthing contact (PE – protective earth)!

• The power supply plug serves as safe disconnecti ng devi c e from the line and must be

always freely accessible.

• Place the i nstr um ent on an even surface on a pad made of non-flammable material.

• Do not stay in the area below the unit.

• Make sure you read and understand al l instructions and safety precauti ons li sted in this

manual before install ing or operating your unit.

• Set the safet y tem per ature.

• Never operate the unit without bath fluid in the bath.

• Pay attention to the thermal expansion of bath oil during heating to avoid overflowing of

the fluid.

• Prevent water f r om penetr ating into the hot bath oil.

• Do not drain the bat h fluid while it is hot!

Check the temperature of the bath fluid prior to drai ning (by switching the unit on for a

22

Page 23

HT60-M2 / HT60-M3

method of decontamination.

• Employ suitable connecting tubing.

• Avoid sharp bends in t he tubing, and maintain a suffi ci ent distance from surrounding walls.

• Make sure that the tubing is securely attached.

• Regularly check the tubing for material defects (e.g. for cracks).

• Never operate damaged or leaking equipm ent.

• Always turn off the unit and disconnect the mains cable f r om the power source before

performing any servi c e or mai ntenance pr oc edur es, or before moving the unit.

• Always turn off the unit and disconnect the mains cable f r om the power source before

cleaning the unit.

• Transport the unit with care.

• Sudden jolts or drops may cause damages in the interior of the unit.

• Observe all warning labels.

• Never rem ov e warning l abels.

• Never operate equipment with damaged mai ns power cables.

• Repairs are to be car ri ed out only by qualified servi c e personnel.

Some parts of the bath cover and the pump c onnec tions may become extremely warm during

continuous operation. Therefore, ex er ci se parti c ular caution when touching these part s.

Caution:

The temperatur e contr olling i.e. of fluids in a react or constit utes normal temperature system

practice.

We do not know which substances are contained within these vessels.

Many substances are:

• inflamm able, easily ignited or explosive

• hazardous to health

• environmentally unsafe

i.e.: dangerous

The user alone is responsible for the handling of these substances!

The following questions shall help to recognize possible dangers and to r educ e the risks to a

minimum.

• Are all tubes and electrical cables connected and installed?

Note:

sharp edges, hot surfac es i n oper ation, moving machine parts, etc.

• Do dangerous steams or gases arise when heating?

Is an exhaust needed when working?

• What to do when a dangerous substance was spilled on or in the unit?

Before starting to work, obtain informati on c onc er ning the substanc e and determine the

Notice:

When you have finished the appl ication, it is recommended to keep on ci r c ulating the liquid in

the bath or the external system for some time. Simultaneously set the working temperatur e to

+20 °C to allow the temperatur e in the system to decrease slowly.

Thus fractional ov er -heating of the bath liquid is prevented.

23

Page 24

Safety notes for the user

Notice:

Check the safety installations at least twice a year!

• Excess temperature protecti on according to IEC 61010-2-010

With a screw driver turn back the adjustable excess temper ature protection until the shutdown point (act ual temper ature).

• Low level prot ec tion

To check the function of the float of this unit it cannot be operated manually.

The 5-graded level display shoul d therefore be observed whenv er r efilling.

If the bath liquid thickens or cracks, the instrument shoul d be cl eaned and c hec k ed by

qualified per sonnel .

24

Page 25

5. Preparations

HT60

CU

-

ESC

P

M2

0

60

180

300

420

EXT

°C

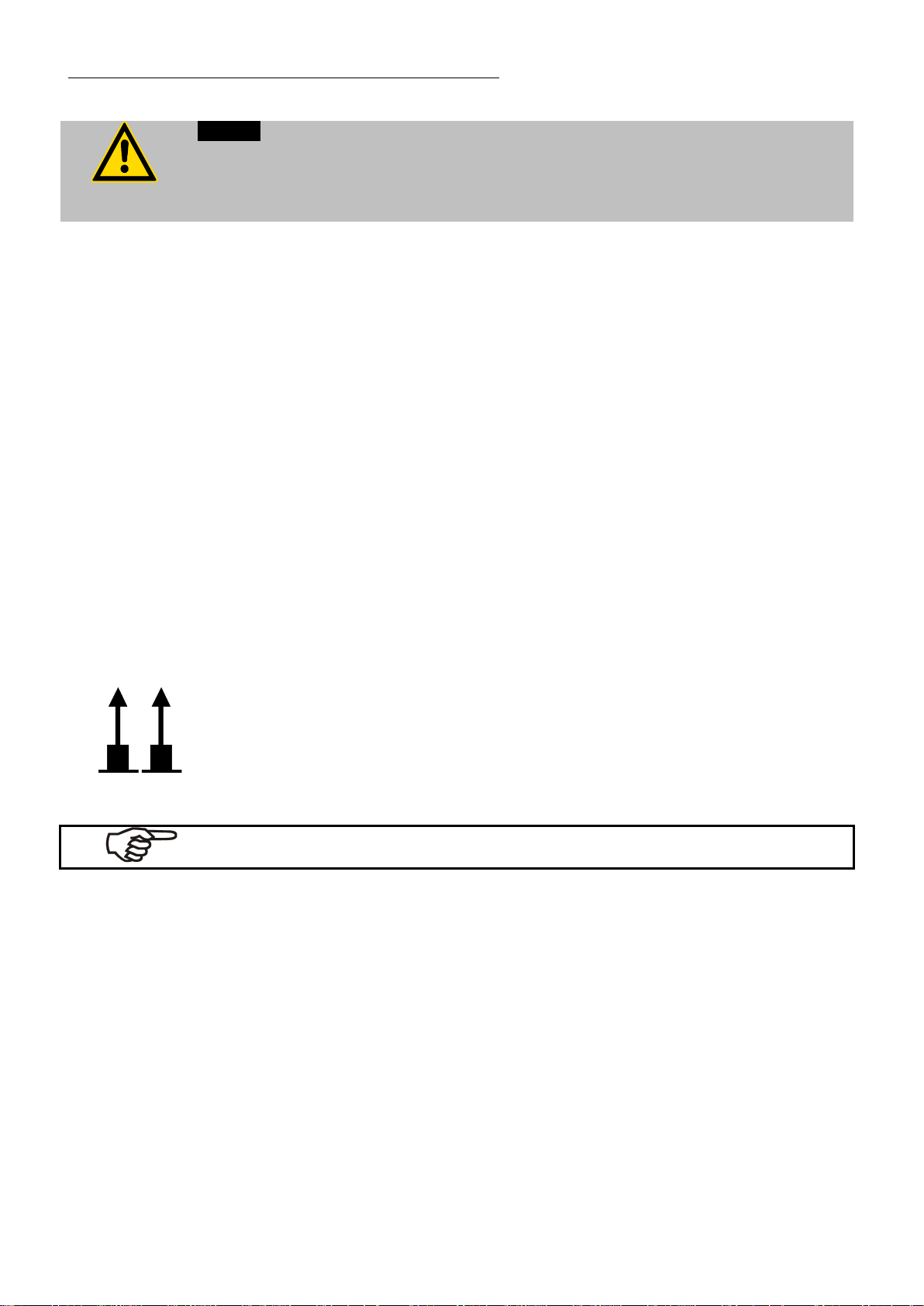

5.1. Setup

HT60-M2 / HT60-M3

High temperature circulator HT60 as well as

High temperature circulator HT60 with CU cooling

unit:

as a desktop unit

• Place the circulator on an even surf ac e on a pad

made of non-flammable material.

as a stand-mounted unit

• Place the unit in an vertical position.

• A wall distance of at least 15 cm m ust be

maintained for v entilation, allowing internal heat to

be conducted away from the unit.

JULABO Order-No.

9790100 C.U. cooling unit

M2 or M3 remote control electronics:

• The unit should be set up at a dry location.

• Place the unit in an upri ght position and do not

obstruct the ventilation Ambient temperatures

above 40 °C result in a fail ur e of the uni t.

• Do not set up the unit in the imm ediate vicinity of

heat sources and do not expose to sun light.

25

Page 26

Preparations

(see 8.6. Limits).

44

45

56

52

60

62

61

64

63

K11

K14

56a

5.2. Installation

Caution:

Installation of the C.U.-unit / Installation of the magnetic valve

• Always turn off the unit and disconnect the mains cable (38) from the power source

• The control c able with plug (56) of the C.U.-cooling unit or the magnetic valve always

Control of the C.U.-cooling unit or the magnetic valve.

before installing the unit.

have to be connected or disconnected in absence of current.

• With the C.U.-cooling unit or the magnetic valve the menupoint

–CoolingMax- has to be adjusted to a value of > 0 (Recommendation: 100%). So the

automatic al contr ol of the cooling can become active

Installation of the C.U.-unit

JULABO Order-No. 9790100 C.U. cooling unit

• Use the leader pi ns (62) to fix

the assembly sheet (60) into the

base (61) of the circulator and

fasten with hexagon screws

(63).

• Push the C.U.-cooling unit to the

circulator and screw it ti ghtly at

the points (64).

• Connect the cooling circulation

for the oil (52, 53) (open end

wrench SW19). When doing t his

hold the tube at positi on K 11

with an open end wrench SW21.

26

• Connect the cooling water (44, 45) (open end wrench SW15)

When doing this hold the t ube at position (K14) with an open end

wrench (SW14)

• Fix the control c able (56) at the control exit (56a) and screw it tightly.

Cooling capacity at 2 l/min flow of cooling water.

Temperature <IntAct> [°C] 350 250 150 75

Cooling capacity [kW] 12 8 4 1

Page 27

HT60-M2 / HT60-M3

5051

43

45

41

56

Installation of the magnetic valve

JULABO Order-No. 8 980 704 3 Magnetic valve

• Fix the expansi on tank (43) to the connection (41) ( open

end wrench SW19)

• Screw the magnetic valve to the entry for cooling water

(45). Respect the fl ow dir ec tion (arrow)

Connect the cooli ng water to the magnetic valve and to the

outflow of cooling water (44) by means of tubes 8 mm ID.

• Fix the control c able (56) at the control exit (56a) and srew

tightly.

Notice:

When using pressure sensitive glass vessels, it is absolutely necessary to work with

an adapter to reduce the pump pressure.

Caution:

Securely attach all tubing to prev ent slipping.

Adapter to reduce the pump pressure

JULABO Order-No. 8 970 802

With this adapter t he pum p pressure at the pump connection

(51) can be reduced from 1,2 bar to

0,8 bar

Assembly

• Fix the adapt er t o r educ e the pump pr essure to t he pump

–0,1

.

connections (50, 51) ( open end wrench SW19).

27

Page 28

Preparations

If a bath fluid with a fire point of ≤65 °C is used, only supervised operati on is possible.

No liability for use of other bath fluids!

Setp.: xxx.xx°C

hot cooling zone

5.3. Bath fluids

Caution:

Carefully read the safety data sheet of the bath liqui d used, particularly with regar d to the fire

point!

Recommended bath fluids

Co

ntact: see page 6.

Caution:

Fire or other dangers when using bath fluids that are not recommended:

See website for list of recommended bath fluids.

Please contact J ULA BO before usi ng other than recommended bath liquids.

JULABO assumes no liabili ty for damage caused by the selecti on of an unsuitable bath fluid.

Unsuitable bath fluids are fluids which, e.g.,

• are highly viscous

(much higher than 30 mm2 x s-1 at the respective working t em per ature)

• have a low viscosit y and hav e creep char ac teristics

• have corr osive characteristic s or

• tend to crac k.

ATTENTION: The maximum permissible viscosity is 30 mm

Caution:

The use of water in purified or unpur ified form is not allowed.

Examples: Tap water, distilled water, water-glycol mixture, CaCl2-brine

2

x s

-1

.

Tempering liquid

The circulator c an only be oper ated in closed tempering cir c uits. The contact of the

tempering liquid with atmospherical oxygen only takes place in the not-flowed cooling

zone. A safety equipment with definitely adjusted temperature value (170° C ±5 °C)

works independantly from the control circuit and supervises the temperature in the

cooling zone. From 160 °C on the warning >hot cooling zone< is shown in li ne 4 of

the DIALOG-DISPLAY (LCD).

Important notice

IntAct: xx.xx°C

Power xx %

Control: intern

If the temperature of the liquid r eac hes the safety temperature (170 ° C) , a com plete

shutdown of the controlled heating device is effec ted. So it becomes possible to use

tempering liquids with a flashpoint from 190° C on.

From a working temperature of 200°C on always work with counter-cooling.

28

Page 29

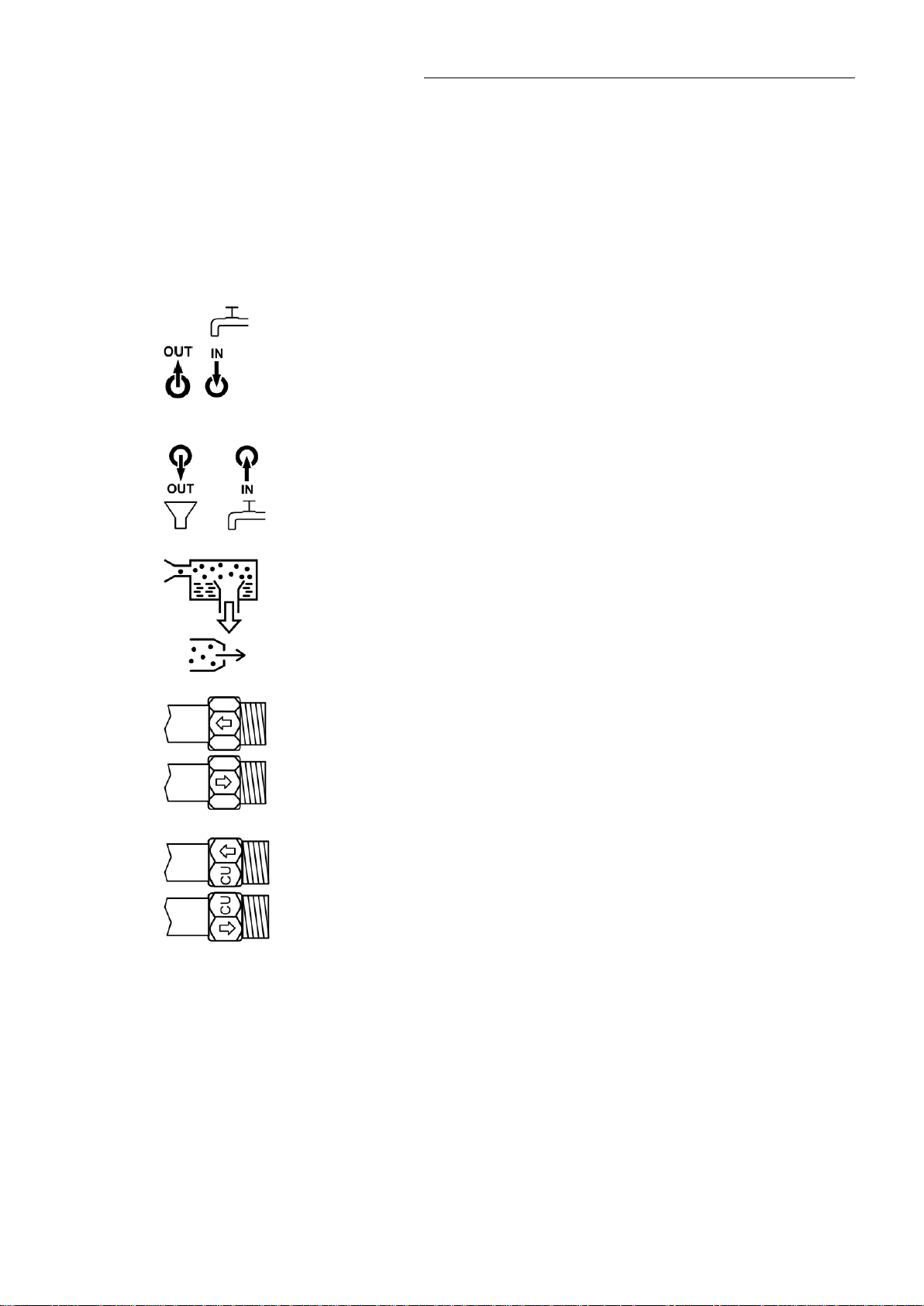

5.4. Tubing

8 930 214

3.0 m

8 930 223

3.0 m

Regularly check the tubing for material defects (e.g. for cracks)..

Recommended tubing:

Metal tubing, t ri ple insul ated, M16x1, Temperature range -100 °C ... + 350 ° C

Order No. Length

HT60-M2 / HT60-M3

8 930 209

8 930 210

8 930 211

Metal tubing, insulated, M16x1, Temperature range -50 °C ... +200 °C

Order No. Length

8 930 220

8 930 221

8 930 222

Pressure max. 6.0 bar at +20 °C

4.6 bar at +200 °C

3.8 bar at +350 °C

Warning:

Tubes:

At high working temper atures the tubing used for temperatur e application and cooling water

supply represents a danger sourc e.

A failure of the counter-cooling, e.g. t hr ough br ok en tubes can cause higher temperat ur es i n

the cooling zone. Due to a damaged temper ing tube hot tempering liquid can be pumped out

within a short tim e.

These are possible results:

• Danger of fire

• Danger of ex plosi on

• Burning of peopl e’s skin

• Diffi c ulties in breathing due to hot atmosphere

JULABO supplies the met al tubes with assem bly instructions

(No. 1.950.0013). There all the instruction f or assembly are indicated. They absolut ely have

to be respected.

Safety recommendat ions

• Employ suitable connecting tubing.

• Make sure that t he tubes are securel y attached.

• Avoid sharp bends in t he tubing, and maintain a suffici ent distance from surrounding

walls.

•

0.5 m

1.0 m

1.5 m

0.5 m

1.0 m

1.5 m

29

Page 30

Preparations

5.5. Power connection

Caution:

1. Connect control cable (55) with control exit (35) of the control electronics M2 / M3 and

latch the saftey loop.

Lengthening piec e for control cable, 5 m - JULABO Order-No. 8 980 125

2. If available screw the C. U.-cooling unit tightly to the control exit (56a) of the HT60 by

means of the control cable ( 56) .

3. Connect the mains plug (38) of t he c ontrol electronics to a power socket wit h ear thing

contact (PE – protective earth)!

• The available supply voltage and the power frequenc y hav e to be com par ed with the

specifications on the type plate.

Voltage differences of ± 10 % are allowed.

• The power supply plug serves as a safe disconnecting devi c e from the line and must

always be easily acc essible.

• Never operate the unit with a damaged mains power cable.

• Regularl y check the mains power cables for damage.

• We disclaim all li ability for damage caused by incor r ec t line voltages!

5.6. Filling / draining

Caution:

• The lines of t he exter nal system should be well cleaned in or der to av oid soil par ticles

30

(sand, metal chips) f r om bei ng ri nsed i nto the circulator. Danger for magnetic valves and

the pump.

• The tempering liquid must not contai n water!

Preparing the tempering liquid:

Heat the oil up to 110C in an open bath to boil off any water.Tempering time

approximately 1 hour.

In case of high temperatures water parts in the tempering liquid can cause damages

in the HT circulator!

Recommendation :

After each refilling a degasifying of the tempering liquid should be made.

Page 31

HT60-M2 / HT60-M3

43

48

49

50

51

55

52

43a

41

Store and dispose the used bath fluid according to the laws for environment al pr otection.

Filling

1. Attach a tube at the overflow nozzle (48) and lead it into a

suitable vessel.

2. Remove the screw plugs from the pump c onnec tion (50,

51) and connect it to the exter nal system by means of

metal tubes (open end wrench SW 19)

3. Remove the screw plug from the connec tion (43a) and

srew on the expansion tank (43)

4. Always close tightl y the connec tions which have not been

used (e.g. 41 or 52, 53) wit h screw plugs, the drai n plug

(42) is also important.

5. Connect the mains supply (see above) and switch on the

mains switch (1).

6. Fill the unit by pouring the fluid into the expansion tank ,

which is connected to the cooling zone.

7. Operate key

Internally a valve opens the passage to the heating zone.

With a reduced no. of rotati ons the pum p m otor pumps the

tempering liquid into the externally connected consumer.

8. Slowly refill temper ing liquid until two or three segm ents of the level indication

light up. The necessary quantity of li quid then is in the tempering system.

9. If the minimum level liquid remains under, a low level alarm E01 can be caused.

By a short switching-off and switc hing-on again at the mains switc h ( 1) the alarm

status is cancell ed.

Afterwards again refill the tempering liquid and operate the key until two or

three segments of t he lev el indic ation lighten.

10. Operate key in order to finish the filling process.

Notice:

• Do not drain the bat h fluid while it is hot or cold !

Check the temperature of the bath fluid prior to drai ning (by switching the unit on for a

short moment, for example).

•

Draining

1. Cool the fluid below 40C and then tur n off the mains switch.

2. Place the circulat or to t he table edge and put under a suitable vessel to uptak e the

used tempering liquid.

3. For emptying unscrew the drain nut (42) on the front of the HT30 and have t he

tempering liquid run into a suitable vessel.

31

Page 32

Preparations

Setp. : 37.00°C

Setp.: 20.00°C

IntAct: 50.40°C

Power 0 %

Control: intern

Enter temperatur

Setp.: 250.00°C

IntAct: 80.00°C

Power 10 %

Control: intern

degasing aktiv

Setp.: 250.00°C

IntAct: 250.00°C

Power 50 %

Control: intern

degased->Enter

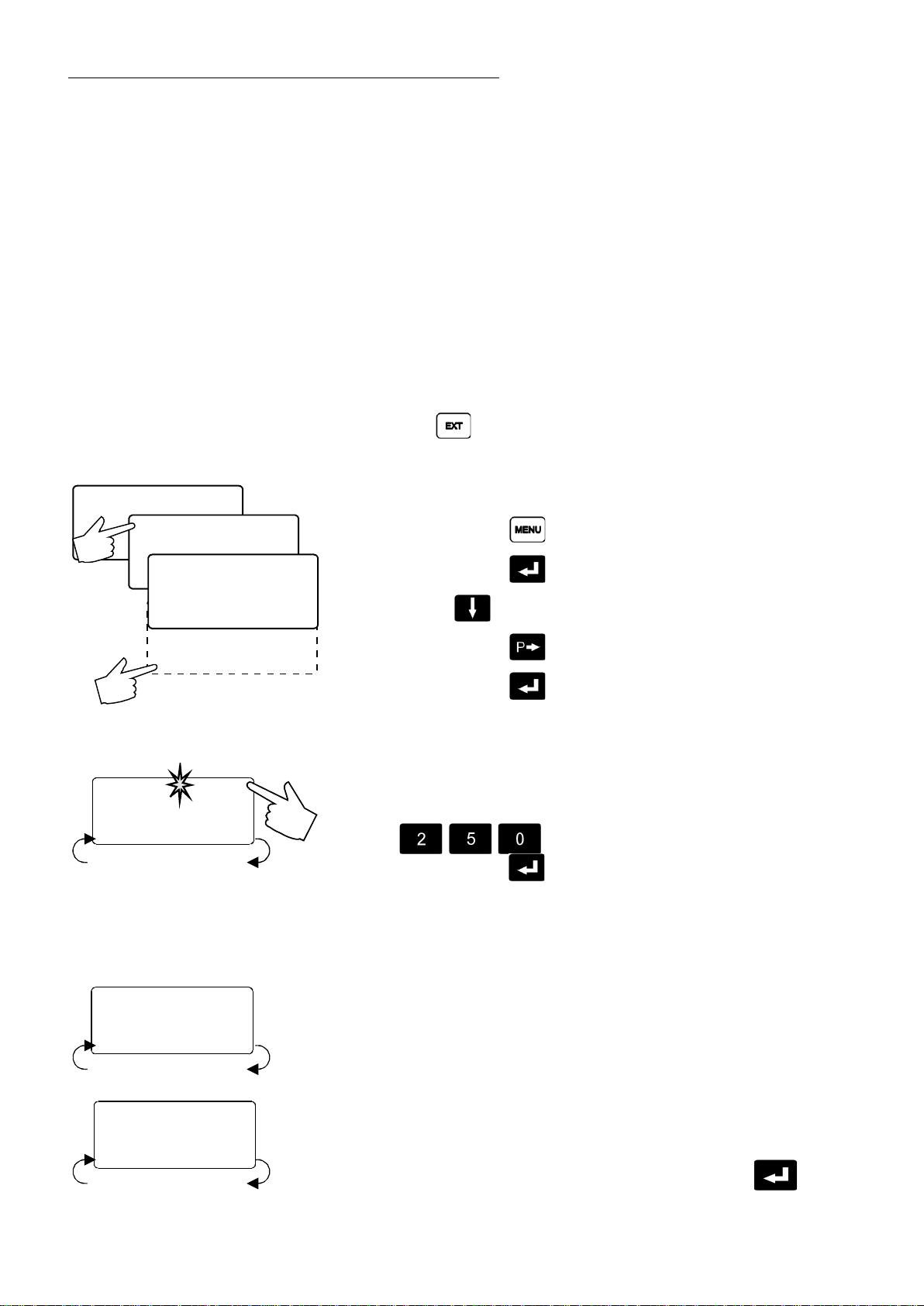

5.7. Degasifying

ExtAct: ---.--°C

Power: 0 %

Control: intern

>Configuration

Control param.

Configuration

Identif. xxxxxx

Setpoint xxxxx

Autostart xxx

Standby xxxx

Language engl.

>De-Gas on

During the filling pr oc ess the pump fluidizes air bubbl es i nto the

tempering liqui d. I n the aut om atic degasifying mode those and other light

solvent substances are sl owly dr ained from the oil via the breather tube.

Notice:

In the automatic degasifying mode the breather tube between heati ng

and cooling zone is opened agai n and again. Hot gases and selfextending tem peri ng liquid therefore get int o the cooling zone. Therefore

in case of a target temperat ur e whic h is hi gher than 150°C a countercooling in the cooling zone should be possible.

(See 5.8. Countercooling)

• Switch on the control electronics by the mains switch (1)

• With key switch to „internal control“.

• Operate the foll owing k ey s one aft er the ot her as described i n or der

to get into the degasifyi ng m ode or to leave it. On the DIALOGDISPLAY (LCD) the differ ent actions can be followed-up.

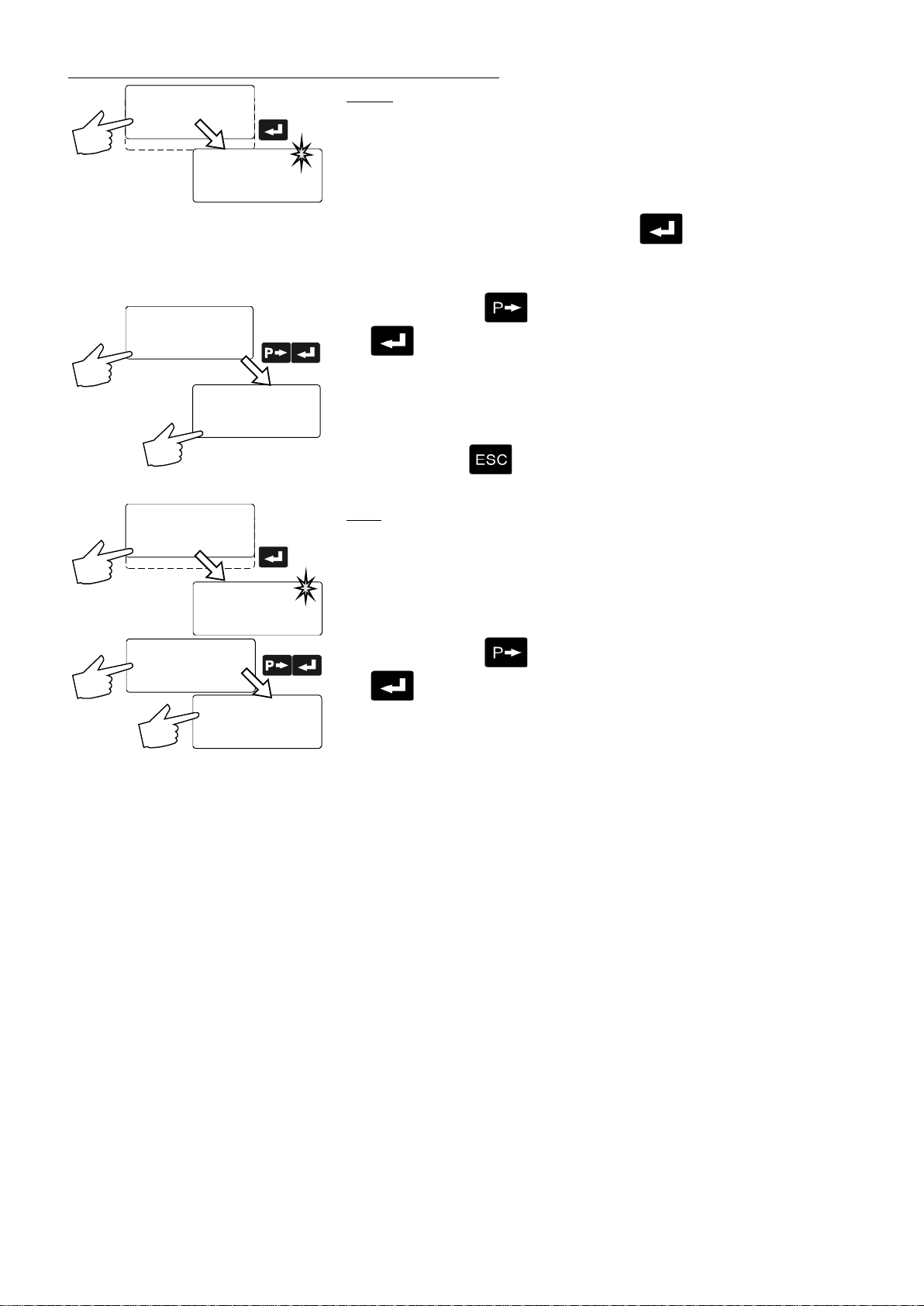

1. MENUE-key 1x

2. Enter-key 1x

3. Cursor-key 5x

4. P-key 1x

5. Enter-key 1x

6. Now in line 4 of the DIALOG-DISPLAY there is the demand to set a

temperature value ( „ E nter temperature“)

Example: 250°C

For this operat e the following keys

With the Enter-key the value is stored

and

at the same time the degasifyi ng m ode is start ed.

(Also see „Temperatur e setting“ page 20)

7. The temperatur e is autom atically increased step by step by 2°C.

Each time there is a standsti ll of approximately one minute. In line 4

of the DIALOG-DISPLAY ( LCD) the degasifying mode is indicated by

blinking.

8. When the target tem per ature is reached, the degasifying mode is

finshed.

A signal tone sounds in i nterv als and in line 4 of the DIALOG-

32

DISPLAY there is the demand t o oper ate the Enter-key.

Page 33

HT60-M2 / HT60-M3

Setp.: 250.00°C

IntAct: 250.00°C

Power 50 %

Control: intern

Overtmp:305.00°C

ExtAct: xxxxxx°C

Power: x %

Control: xxxxxx

9. The DIALOG-DISPLAY (LCD) shows the standard indication, the

circulator regul ates to the last adjusted setpoint (in the example 250

°C) with the last adjusted control parameters.

The circulator is ready for use!

Stopping the degasifying:

• By operating the Start/Stop-key the degasifying mode can be

stopped at any tim e.

• The degasifying mode can also be left via the menu level .

Proceeding as point 1 – 5.

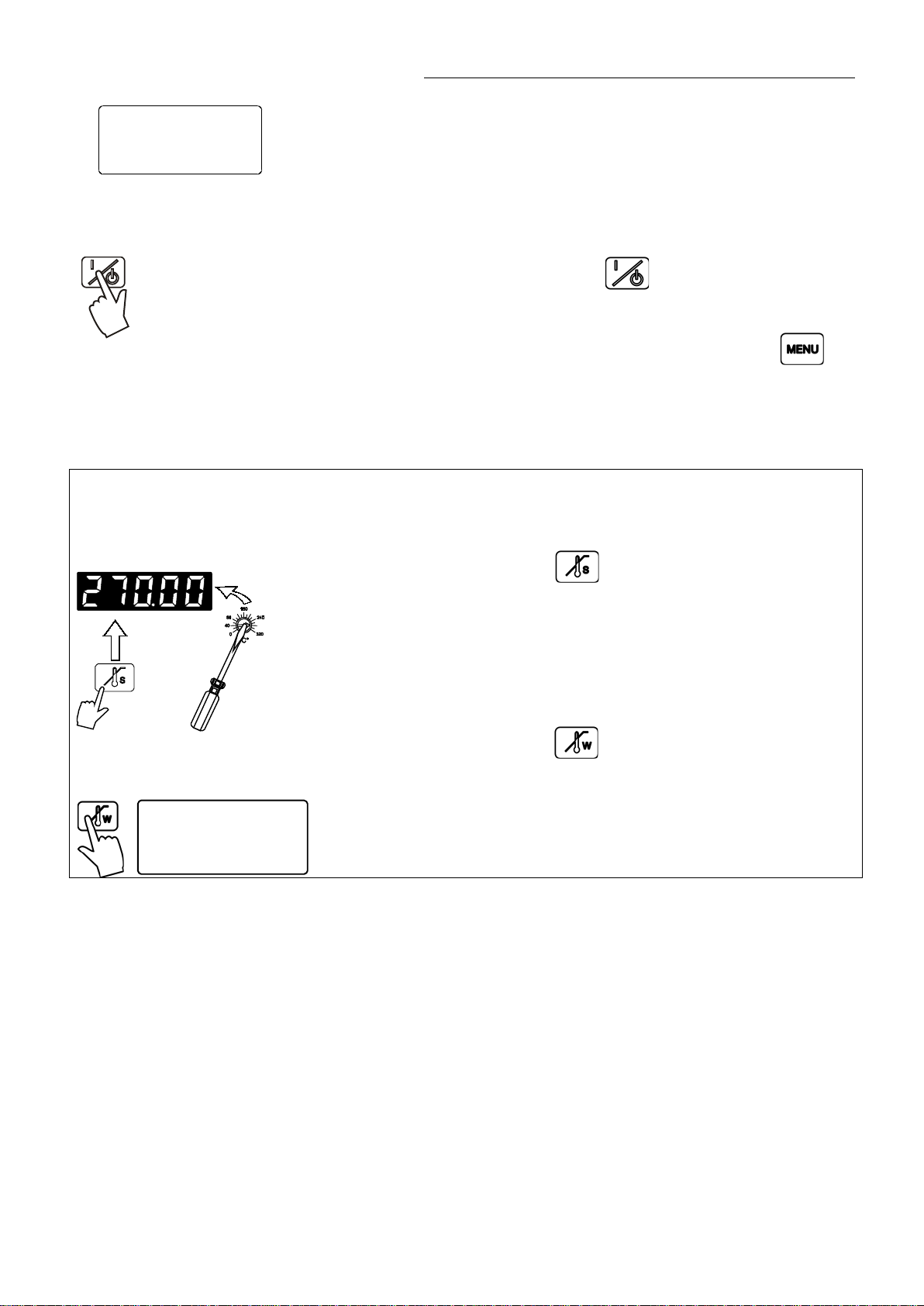

Important !

To avoid swi tching-off due to the exc ess temperature protection or –

warning both settings should be checked and,.if necessary , adjusted.

• Operate t he setpoint-key .

The MULTI-DISPLAY (LE D) shows the present setpoint temperature

(Example: 270.00°C).

(„Safety temperature“ see page 38)

• Operate t he setpoint key .

The DIALOG-DISPLAY (LCD) shows the present setpoint

temperature (Examples: 305.00°C)

(„Warning functions“ see page 37)

33

Page 34

Preparations

Tube connecti ons 10 mm ID

5.8. Countercooling

Caution:

Securely attac h all tubing to prevent slipping.

From a working temperat ur e of 200° C on always work with c ounter-cooling.

On the HT60-circ ulator we distinguish two diff er ent cooling devices:

(Cooling water see page 16)

1. A cooling coil in the cooli ng z one for cooling water.

Without C.U.-cooling unit

The cooling wate is directl y c onnec ted to the connections (44, 45).

HT60

(45) (44)

Thread M2 / M3 2 / ∠37 +

Barbed fittings 8 mm ID

CU

(47) (46)

HT60 Returnf ( 52)

HT60 Feed (53 )

Thread M2 / M3 6x1

Flow of cooling water: app. 2 l/min at >150 °C.

or

A magnetic valve f or clock ed c ooling water is connected to the

connection (44)

When required the cont r ol exi t opens and cl ose s the magnetic valve.

JULABO Order no.. 8 980 704 Magnetic valve

With assembled C.U.-cooling unit

the cooling water i s connected to the connections (47, 46)

The flow of cooling water is controlled automatic ally .

2. A cooling coil in the C.U. -c ooling unit for rapid cool-down of the

tempering liquid

Via the pump connections (52, 53) the tempering liquid is led through

the CU-unit.

The heat is drained via t he cooli ng water ( 47) .

Comments:

• With an assembl ed C.U.-cooling unit the menu-poi nt CoolingMax has

to be set to a value of >0. So, the automatic control of the cooling can

become activ e.

• In the C.U.-unit water and oil temperature are supervised at each

outflow.

The oil flow-through is interrupted

when the oil temperature is app. 150 °C and

the water temperatur e is app. 80 °C.

C.U.-cooling unit:

Cooling capacity at 2 l/min flow of cooling water.

Temperature <IntAct> [°C] 350 250 150 75

Cooling capacity [kW] 12 8 4 1

34

Page 35

6. Operating procedures

Soll : 37.00°C

ExtIst: ---.--°C

Leistung: 0 %

Regelung: intern

>Konfiguration

Regelparameter

Proggeber Start

Programmgeber

Konfiguration

Identif. xxxxxx

Sollwert xxxxx

Autostart xxx

Standby xxxx

>Sprache xxxxxxx

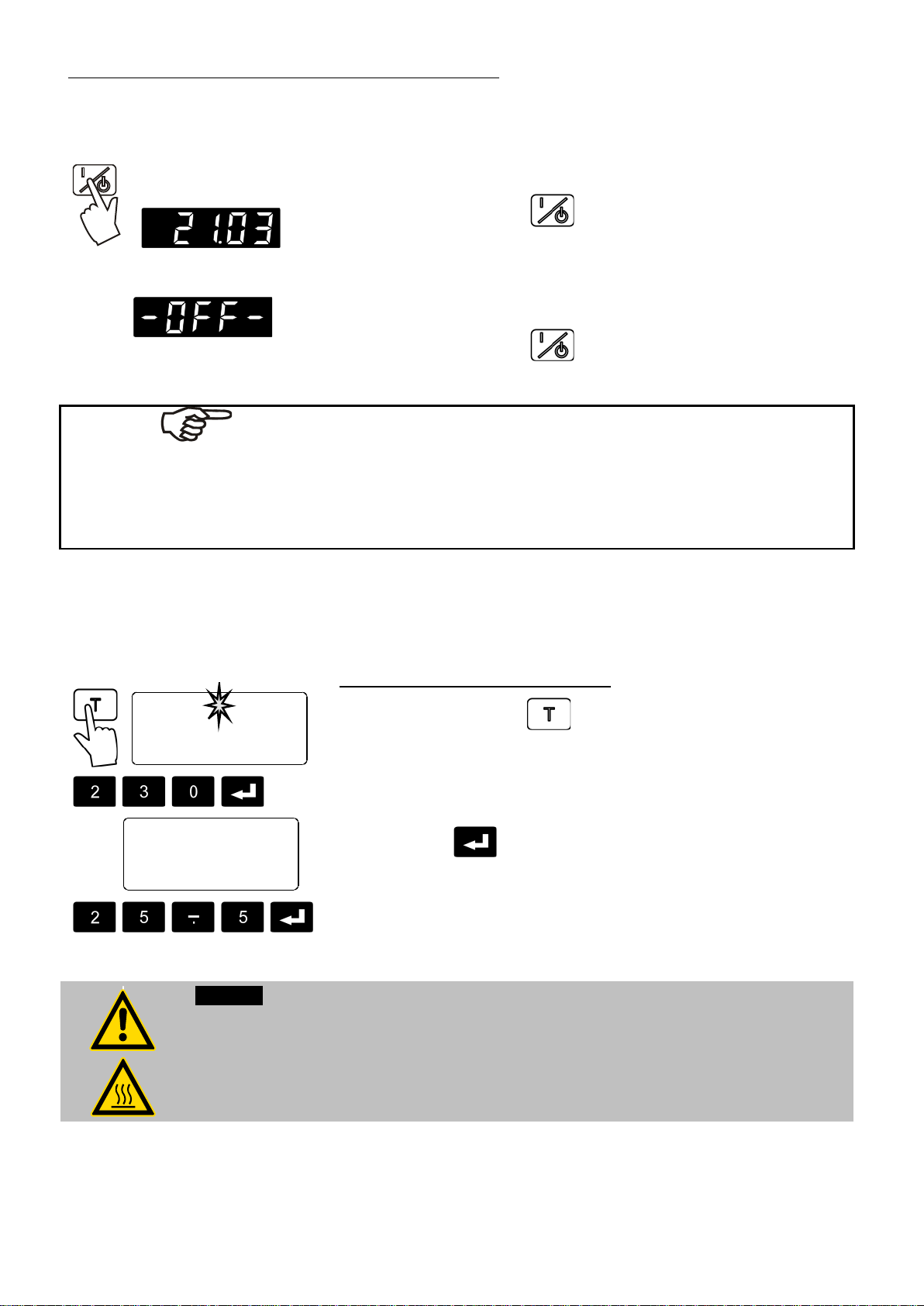

6.1. Switching on / Selecting the language

Switching on:

Turn on the mains power switch.

The unit perform s a self-test.

JULABO

HT-30/60

Controller

V 4.01-J

All segments of the 5-digit MULTI-DISPLAY (LED), all indicator lights

and the DIALOG-DISPLAY (LCD) will illuminate.

Then the software ver si on ( ex am ple: V 4.01-J) appears. The display

"OFF" indic ates the unit is ready to operate (standby mode).

The high temperatur e ci r c ulator enters the operati ng mode activated

before switching the programmable controller off:

keypad control mode (manual operation) or

remote control mode (oper ation via personal computer).

HT60-M2 / HT60-M3

Selecting the language:

There are two options for the language of the DIALOG-DISPLAY (LCD):

German or English. Select the desired language in the MENUE level

under the confi gur ation submenu.

Press the respectiv e k ey s in the following order:

1. MENUE key 1 x

2. Enter key 1 x

3. Cursor key 4 x

4. P key 1 x

5. Enter key 1 x

6. Escape key 2 x

The DIALOG-DISPLAY (LCD) helps to follow up the individual settings.

(example: swap the language from German to English.)

35

Page 36

Manual operation

The MULTI-DISPLAY (LE D) indi c ates the message "OFF".

the circulator m ay be restarted.

Setp.: 50.00°C

ExtAct: xxxxxx°C

Power xx %

Control: xxxxxx

Setp.: 230.00°C

ExtAct: xxxxxx°C

Power xx %

Control: xxxxxx

7. Manual operation

7.1. Start - Stop

Start:

• Press the start/stop key .

The MULTI-DISPLAY (LE D) indi c ates the actual bath temperat ur e.

(example: 21.03 °C)

Stop:

• Press the start/stop key .

The unit also enters the safe operating state "OFF" or "r OFF after a

mains power interruptanc e. The temperature values enter ed v ia the

keypad remain in mem ory. With the programmable controller in k ey pad

control mode, press the start /stop key to restart operation.

With the programmable controller in remote control m ode, t he per sonal

computer must fir st r esend the par am eters set via the interface befor e

7.2. Setting the temperatures

This setting may be car ri ed out wit h the high temperature circulator being

in operating state S tart or Stop!

Setting the working temperature "T":

1. Pr ess the set point key .

The value previousl y set appear s on the DIALOG-DISPLAY (LCD)

(example: 50.00° C) .

A flashing segment indicates that a value needs to be entered.

2. Use the key pad to enter the new value (example: 230.00 °C).

3. Pr ess enter to store the selected value.

Warning:

In case of high temperat ur es some par ts of the High Temperature Circul ators can get high

surface temper atures when working continuousl y .

Attention when touching !

During operation do not touch the heating and the cooling zone.

(example 2: 25.50 ° C).

36

Page 37

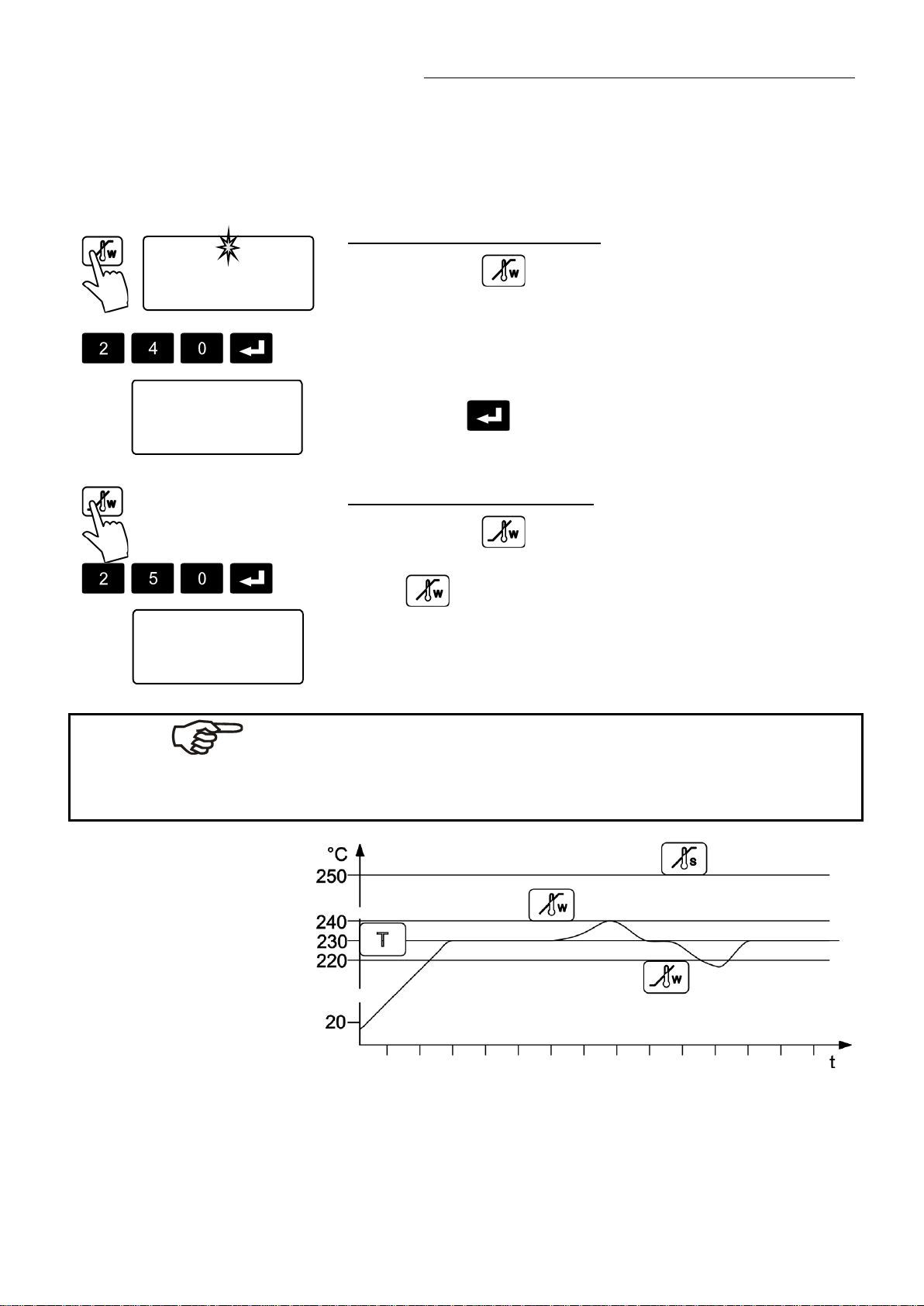

7.3. Warning functions

Overtmp:240.00°C

ExtAct: xxxxxx°C

Power: x %

Control: xxxxxx

Subtemp:220.00°C

ExtAct: xxxxxx°C

Power: x %

Control: xxxxxx

)) )) ))

HT60-M2 / HT60-M3

More protection for your samples in the bath!

An audible signal sounds in intervals when the actual temperature value

exceeds one of the set limits (patented).

Overtmp:305.00°C

ExtAct: xxxxxx°C

Power: x %

Control: xxxxxx

Setting the high temperature limit:

1. Pr ess the key .

The value previousl y set appeear s on the DIALOG-DISPLAY (LCD)

(example: 305.00° C) . A flashing segment indicates that a value

needs to be entered.

2. Use the key pad to enter the new value

(example: 240.00 ° C) .

3. Pr ess enter to store the value.

Setting the low temperature limit:

1. Pr ess the key .

2. F ollow the instructions

3. for ( example: 220.00 °C).

Note:

The warning functions wil l only be triggered when the actual bath

temperature, after star t f r om the „OFF “ or „rOFF “ mode, li es within the set

limits for 3 seconds.

37

Page 38

Manual operation

!

A L A R M !

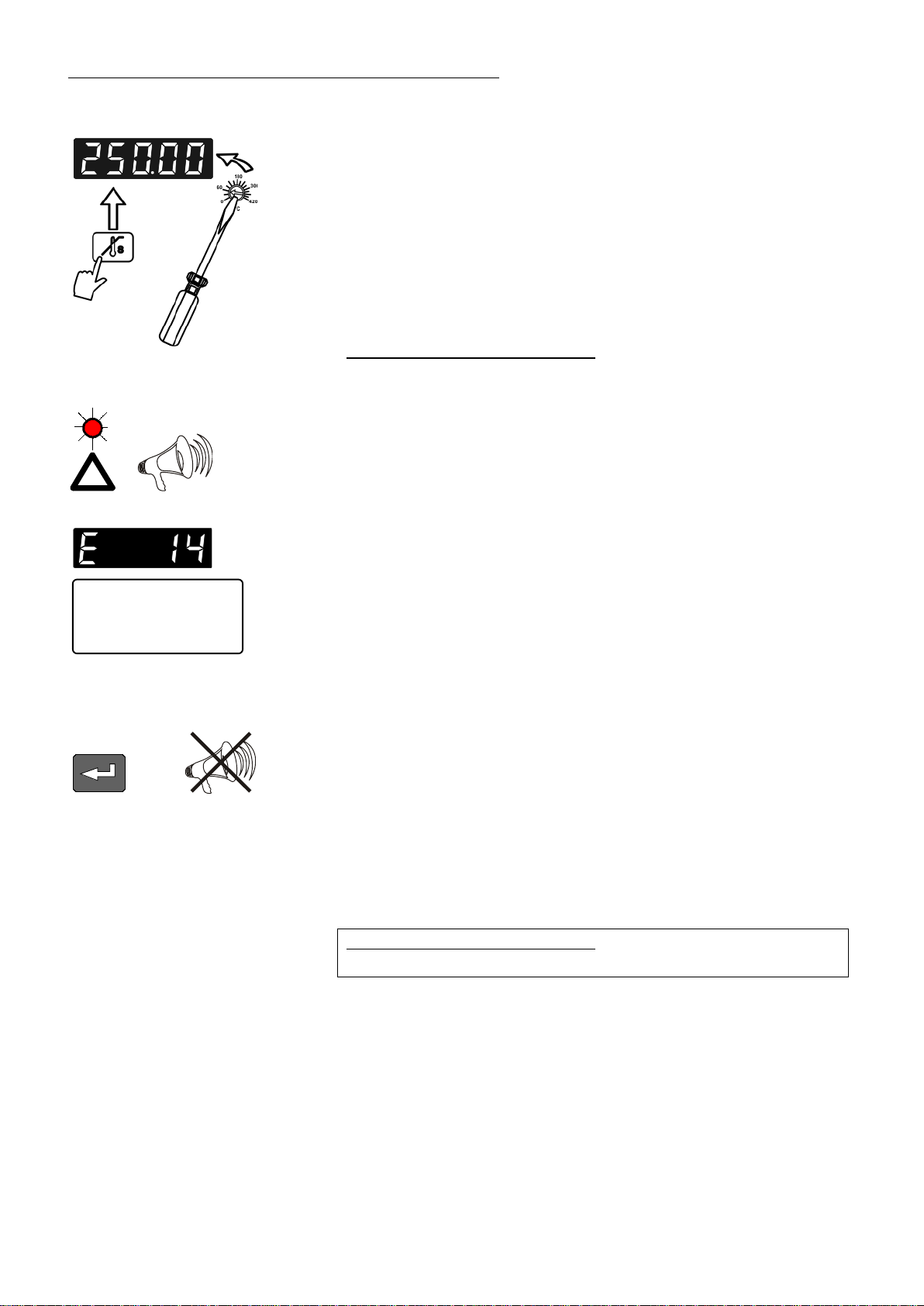

7.4. Setting the safety temperature (with shutdown function)

+

ExtAct: xxx.xx°C

Temp/level alarm

⇒

(excess temper ature protection)

• Press the key to indicate the saf ety temper ature value on the MULTIDISPLAY and using a screwdriver simultaneously t ur n the setti ng

screw to the desired value

(example: 250 °C).

Setting range: 0 °C t o 420 °C

in 2 °C steps

Safety device in the heating zone:

The safety device works independent ly from the control circuit and

supervises the temperature in the heating zone.

If the temperat ur e of the bath liquid reaches the safety temperature, a

complete shutdown of the controlled heating devic e is effected.

The alarm is indicated by optical and audible signal s (continuous tone).

On the MULTI-DISPLAY (LED) and DIALOG-DISPLAY (LCD) appears

the error message "E 14".

Cancel the alarm state (see page 60)

Recommendation:

• Set the safet y tem per ature at 20 °C above the working temperatur e

setpoint.

• From time to time the safety device has to be c hec k ed.

With a screw driver turn back the adjustable overtemperat ur e

protecti on until the shut-down point (actual tem per ature).

Safety device in the cooling zone:

See „Important noti c e“ page 28

38

Page 39

7.5. Internal / external control

Setp.1: 37.00°C

ExtAct: xxxxxx°C

Power: x %

Control: extern

Setp.: 230.00°C

ExtAct: xxxxxx°C

Power: x %

Control: intern

Setp.: 37.00°C

IntAct: 26.05°C

Power: x %

Control: xxxxxx

Setp.: 37.00°C

IntAct: 25.22°C

Power: x %

Control: xxxxxx

4

1

3

2

HT60-M2 / HT60-M3

EXT

The High Temperatur e Cir c ulator offers the possibili ty of int er nal

temperature control in a primary bath vessel or ext er nal contr ol dir ec tly in

an external system.

Setup for external control:

Connect a Pt100 sensor to the socket „ E XT“ of t he programmable

controller, if nec essary perform a calibrati on usi ng the „ATC Ext:“ function

(see 8.8. Sensors) and then securely fix the sensor in the external

system.

Switching from internal to external control:

• Press the key

type.

• The DIALOG-DISPLAY (LCD) indic ates the effective control type.

in operating state “OFF “ to sel ect the control

• Press the start/stop key .

Caution:

Place the external sensor into the bath medium and securely fix the sensor.

Temperature indication:

• Both actual temperatures are indicated at the same time:

1) on the MULTI-DISPLAY (LED)

2) on the DIALOG-DISPLAY (LCD).

• Press the key to swap the values on the displ ay s.

The indicator li ght „Ext “ r efers to the indication on the MULTIDISPLAY (LED).

39

Page 40

Menu functions

Press escape to return to the previous menu level.

8. Menu functions

• Press the MENU key to enter the menu level.

• Use the up/down cursor keys to select the desired

submenu and press enter .

•

40

Page 41

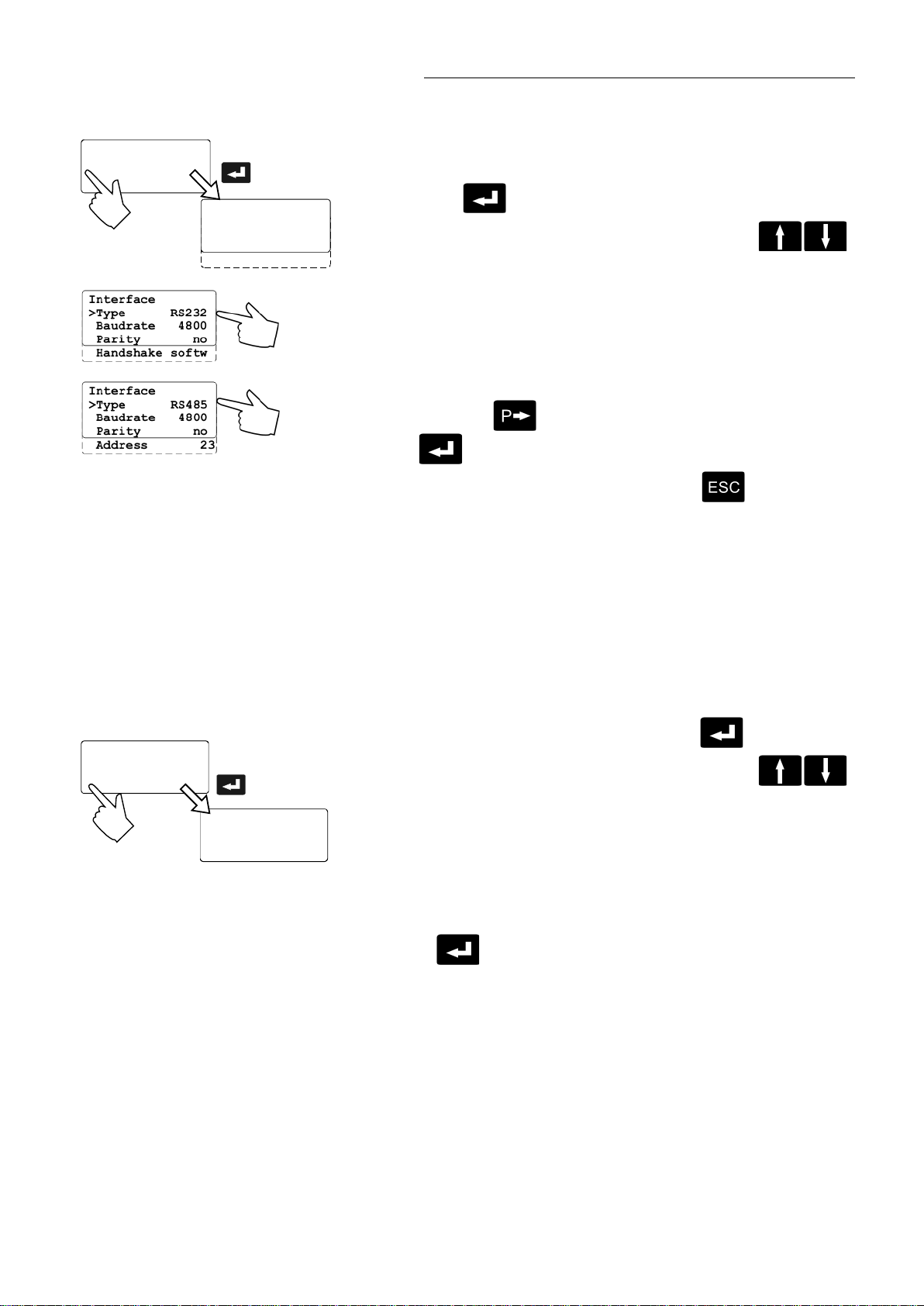

8.1. Configuration

>Configuration

Control param.

Profile Start

Int.Programmer

Inputs/Outputs

Limits

Interface

Temp.Sensor

Configuration

>Identif. off

Setpoint keyb

Autostart on

Standby no

Language engl.

Degas off

HT60-M2 / HT60-M3

By means of the configur ation functions, operati on of t he High

Temperature Circ ulator can be optimized for the curr ent application.

• Press enter to select the configurat ion submenu.

• Use the up/down cursor keys to select the desired

option. A flashing line indicates that a value needs to be entered.

• Press the P-key t o sel ect the param eter and press enter

.

• Press escape to return the previous menu level.

Identification

When performing an ident ification for the controlled system (temperat ur e

applicati on system), the control paramet er s Xp, Tn and Tv will be

automatic ally determined and stored.

Possible parameters:

off - no identification.

The control parameters ascertained duri ng the last identification are

used for control pur poses.

once - single identification

The High Temperatur e Cir c ulator performs a single identification of

the controll ed system after start.

After the identificati on pr oc ess the parameter is automati c ally set to

“off“.

always - continual identification

The High Temperatur e Cir c ulator performs an identification of the

controlled system whenever a new setpoint is to be reached.

NOTE: Use this setting only when the tem per ature application

system changes permanent ly.

Note:

Requirement f or an identification of the contr olled system:

• The High Temperature Circulator must heat to a setpoint temperat ur e

at least 10 °C above the prev ious setpoi nt using the adjusted heating

power.

41

Page 42

Menu functions

Setp.: 50.00°C

In

Po

Co

Eprog: 50.00°C

In

Po

Co

RS232: 50.00°C

IntAct: 50.00°C

Power 50 %

Control: intern

• When the adjusted control par am eters Xp, Tn and Tv are too high,

this requirem ent may not be given with respect to on how much the

setpoint temper ature has to change. In this case, pri or to carry ing out

an identification in the „OFF“ state, set the contr ol par am eters to

lower values.

Recommended setting for internal control:

Xp = 1.0 °C

Tn = 80 s

Tv = 8 s

Setpoint

The programmabl e contr oller provides three possibilities for the setpoint

selection. The selec ted mode is indicated on the DIALOG-DISPLAY

(LCD).

Possible parameters:

keyb- via keypad (worki ng temperature T) or via the integrated

programmer.

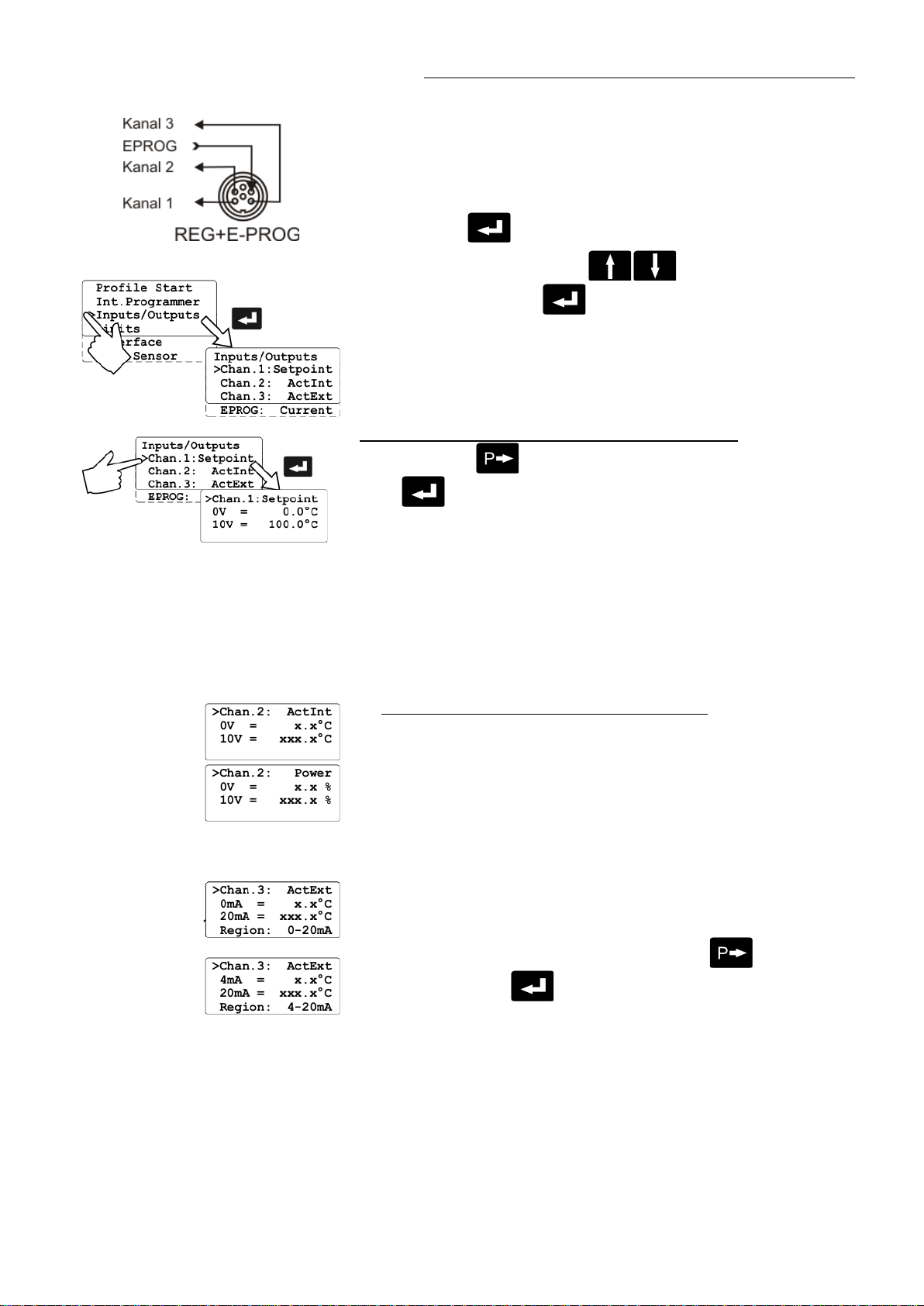

eprog - via the analog interface REG+E-PROG (31) through an external

programmer.

REG+E-PROG

RS232 - via the serial RS 232/RS485 interface (30) through a PC or

superordinated data sy stem.

SERIAL

Autostart

Note:

The M2 / M3 control electronic has been configured and supplied by

JULABO according to N. A.M.U.R. recommendations. This means for the

start mode, that t he unit must enter a safe operating state after a power

failure (non-aut om atic start mode). This safe operati ng state is indicated

by „OFF“ or „rOFF“, resp. on the MULTI-DISPLAY (LED). A complete

shutdown of the main functional elements such as heater and circulation

pump is effected simultaneously.

Should such a safety standard not be r equired, the AUTOSTART

function (autom atic start mode) may be activated, thus allowing the start

of the programmable c ontroller directly by pressing the mains power

switch or using a tim er.

Possible parameters:

on - AUTOSTART on

off - AUTOSTART off

42

Page 43

Warning:

For supervised or unsupervised operation with the AUTOSTART function, av oid any

STAND-BY

hazardous situation to persons or propert y .

The High Temperatur e Cir c ulator does no longer conform to N.A.M.U.R. recommendations.

Take care you fully observ e the safety and warning functions of the programmable

controller.

HT60-M2 / HT60-M3

Stand-by input

External stand-by for em er genc y switc h-off

(connector - see page 6)

Possible parameters:

no - stand-by input is ignored

yes - stand-by input is active

Language

There are two options for the language of the DIALOG-DISPLAY (LCD):

German or English.

Possible parameters:

German (deutsch)

English (engl.)

Degasifying

During the filling pr oc ess the pump fluidizes air bubbl es i nto the

tempering liquid. In an automatic degasifyi ng m ode those and other light

solvent substances are let out via a breather tube.

Adjustable param eters:

off – Degasifying mode switched off

on – Degasifying mode switched on

(Also see page 32)

43

Page 44

Menu functions

Configuration

>Control param.

Profile Start

Int.Programmer

Inputs/Outputs

Limits

Interface

Temp.Sensor

Control param.

>Xp = 2.5 K

Tn = 220 s

Tv = 1 S

Xpu= 5.0K

CoSpeed= 0.0

DynInt=aperiod

8.2. Control parameters

Xp =

When performing an ident ification for the controlled system (temperatur e

applicati ons system ) ( see page 41), the control parameters Xp, Tn, and

Tv will be automatic ally determined and stored.

Each parameter may be manually set via the keypad if necessary, to

allow optimum control performance.

• Press enter to select the submenu „cont r ol par am eters“.

• Use the up/down cursor keys to select the desired

option. A flashing segment indicates that a new val ue needs to be

entered.

• Use the numeral keypad to set the value and then set with enter

(example: Xp = 2.5 °C).

• or at >DynInt<

Press the P-key to select the parameter and pr ess enter

.

• Press escape to return to the previous menu level.

Proportional range >Xp<

The proporti onal r ange is the r ange below the selected temperature

value in wich the the cont r ol ci rcuit r educ es the heating power from 100

% to 0 %.

Resetting time >Tn< (Integral component)

Compensation of the rem aining control deviati on due to proportional

regulati on. An insufficient resetting time may cause instabili ties to occur.

Excessive resett ing time will unnecessaril y prolong compensation of the

control differ enc e.

Lead time >Tv< (Differential component)

The differenti al c om ponent reduces the control settli ng time. An

insuffici ent lead time will prolong the time requir ed to compensate for

disturbance eff ec ts and cause high overshooting during run-up. An

excessive lead time could cause instabilities (oscillations) to occur .

44

Page 45

HT60-M2 / HT60-M3

JULABO

HT-30/60

Controller

V 4.01-J

Note:

The parameters >Xpu<, >CoSpeed< and >Dynamik< are only

supported from the programme version V4 xx.

If the control electronics (V 4.xx) M2 respectively M3 is

combined with an older v er si on of t he HT60 cir c ulators, these

parameters are not av ailable. They are not indicated in the

menu.

Proportional range >Xpu<

The proporti onal r ange Xpu of the cascaded controller is only

needed for external control.

>DynInt< - Dynamics

This parameter aff ec ts the march of temperature only in case

of internal control ( see page 39).

Adjustable param eter:

standard The t em per ature rises quicker, howev er can

overshoot up to 5 %. If a ramp is defined, the

march of temperatur e oft en follows this ramp.

aperiod. The temperature rises chronologically without

overshoot.

With both adjustment s a sufficient temperatur e stability is

reached after approx imately the same time.

>CoSpeed< 0 up to 5

This parameter aff ec ts the march temperature only in case of

external control ( see page 39).

The adjustment aff ec ts the calculation of the control parameter

when identifying and so the c ontrol course.

45

Page 46

Menu functions

°C

t

heat-up curves:

°C

t

°C

t

°C

t

°C

t

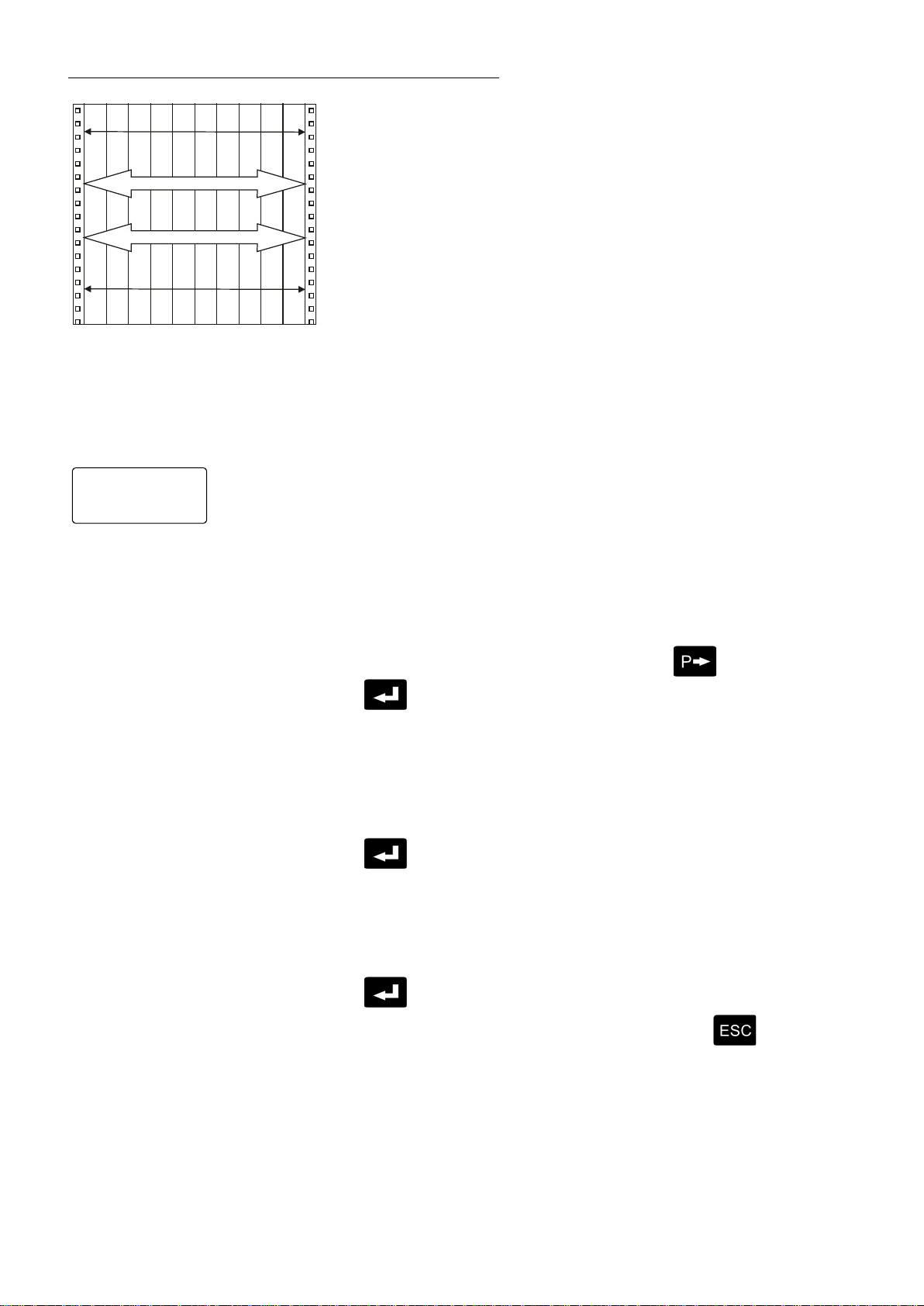

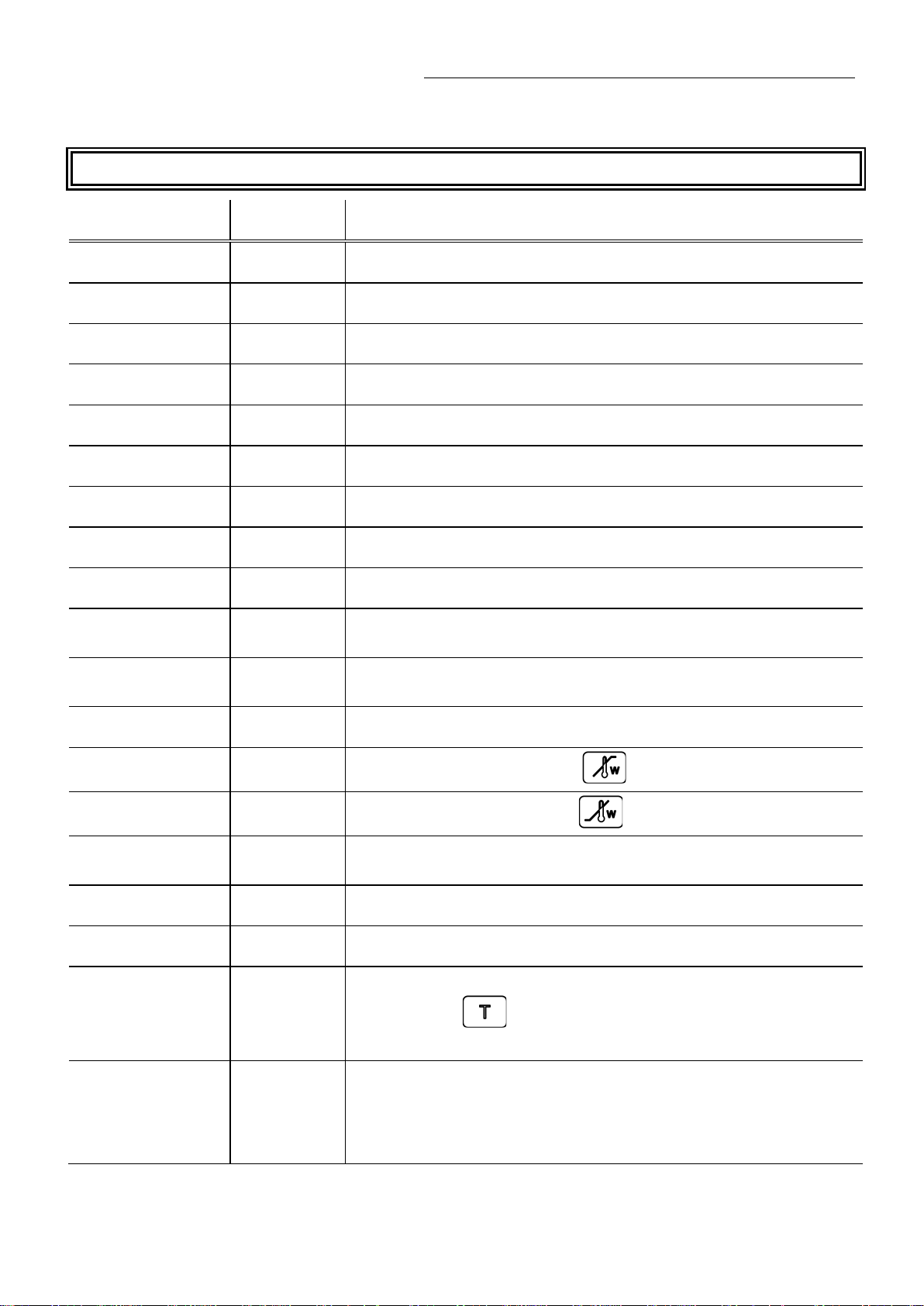

Optimization instructions for the PID control parameters:

The heat-up curve r ev eals i nappr opr iate control settings.

(example: working t em per ature T)

optimum setti ng

Inappropriat e settings may produce the following

Xp too low

Tv/Tn too low

Xp too high

or

Tv too high

Tv/Tn too high

or

Xp too high

46

Page 47

8.3. Start of a profile

Configuration

>Identif. off

Setpoint keyb

Autostart on

Configuration

Control param.

Profile Start

Int.Programmer

Inputs/Outputs

Limits

Interface

Temp.Sensor

Start Profile 0

at Step 0

Loops 1

>Start time

>hour.min 06:00

Day.Mon 15:11

Year 2000

Start yes

HT60-M2 / HT60-M3

1.

2.

The start menu of the High Temperature Circulator allows cal ling up and

defined starting of one of six previously stored t em per ature pr ofiles. This

start can be effected m anually or be released by an integrated timer.

Important:

In the menu configuration under menu point „setpoint“ operation has t o

be set via „key“.

There are two possibilities for manually starting a program:

1. Starting a program from the OFF stat us:

The programmer switches back to the OFF status at the end of the

program.

2. Starting a program from the operating status.

The programmer is started with the Start key , and the bath is

heated to the desired temperature, for example 100 ° C. At the end of

the program, the programmer switches to the operating status and

holds the bath temper ature stable at 100.00 °C.

• Press enter to select the submenu „Profile Start“.

• Use the up/down cursor keys

to select the desired

option.

A flashing segment indicates that a number needs to be entered.

Start Profile 0 to 5

at Step 0 to 60

Loops 1 to 99

Enter the desired num ber and set eac h entry with enter .

Start no / yes (manual start)

or

time (via integrated timer)

A flashing line indicates that a parameter needs to be enter ed.

Press the P-key to select the respectiv e par am eter and press

enter .

47

Page 48

Menu functions

>hour.min 06:00

Day.Mon 15:11

Year 2000

Start yes

Starttime: 06:00

Date: 15:11

*** wait ***

acttime 02:32:56

Setp. : xx.xx°C

IntAct: xx.xx°C

Prof. : x Stp: x

Remain: xx:xx:xx

Setp. : xx.xx°C

ExtAct: xx.xx°C

Prof. : x Stp: x

Remain: xx:xx:xx

Example: hour.mi n 6:00 h

• When selecting the paramet er time, a new menu level is called up

for entry of the start time.

A flashing segment indicates that a start time needs to be entered.

hour.min Start time

Day.Mon day and month

Year year

Set each entry with ent er .

Start no / yes

A flashing line indicates that the parameter „y es“ needs to be

entered.

Press the P-key to select the parameter and pr ess enter

.

• The High Temperature Circulator switches to waiting mode and a

flashing li ne „wait“ appear s on the DIALOG-DISPLAY (LCD). The

start time and act ual time ar e permanently indicated on the display.

Indication after starting the profile:

DIALOG-DISPLAY (LCD)

1st line: Setpoint of the programmer

2nd line: Actual temperature value

at internal control = IntAct: xxx.xx

at external control = ExtAct: xxx.xx

3rd line: Selected profile and the actual section

4th line: Rem aining time of the actual section

MULTI-DISPLAY (LED)

If the circulator is operat ed through the integrated programmer the

MULTI-DISPLAY (LED) swaps between the two actual values

(internal and external)

48

Page 49

8.3.1. Interrupting a profile

flashes on the DIALOG DISPLA Y (LCD).

Setp. : xx.xx°C

IntAct: xx.xx°C

Prof. : x Stp: x

** STAND-BY **

>Start Profile 0

at Step 0

Loops 1

Start yes

Setp. : xx.xx°C

IntAct: xx.xx°C

Prof. : x Stp: x

Remain: xx:xx:xx

AK 1 2 3 STAND-BY

HT60-M2 / HT60-M3

Setp. : xx.xx°C

IntAct: xx.xx°C

Prof. : x Stp: x

Remain: xx:xx:xx

*** pause ***

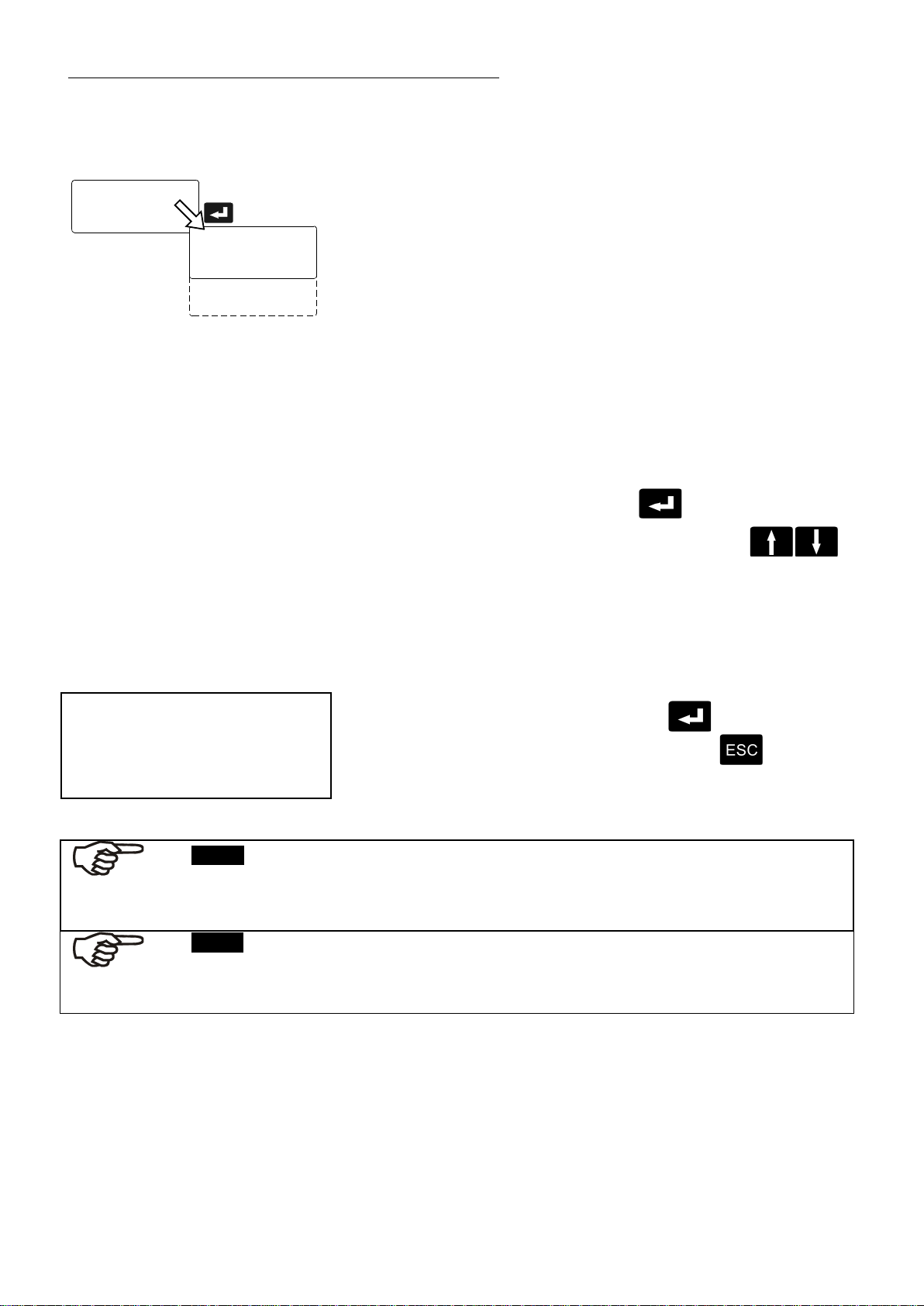

Interrupting a profile:

Press the start/stop key to interrupt or restart a profile.

The setpoint and time period set for the corresponding secti on ar e thus

stopped at the values presently achieved.

The programmabl e contr oller is put on hold and the message „pause“

• A profile can be interrupted or restarted by an external emergenc y

shut-off.(see page 6).

CAUTION:

This is not an actual emergency shut-off!

• The setpoint control and the timer are interrupted by breaking the

contact “AK”. The pr ogr ammer switches to the waiting position, while

displaying this condition with a blinking LCD displ ay .

Important:

To achieve this, the Stand-by c ondition must first be activ ated and

the Autostart function turned on.

(see page 43).

Warning:

Following a power inter r uption, it would be possible in thi s condition for the programmer to

restart automati c ally. The safety and warning functions of the programmer should always be

used to their fullest c apac ity.

See warning page 43

Termination of a profile:

A profile can be termi nated by pressing the escape key . The

programmer switches back to the Start menu.

• Press escape again to leave the menu or use the cursor keys

to remain in the Start menu.

The execution of another temperature profile can now be prepared if

necessary.

49

Page 50

Menu functions

Control param.

Profile Start

Int.Programmer

Inputs/Outputs

Limits

Interface

Temp.Sensor

Int.Programmer

>Edit

Delete

Print

Set Clock

Int.Programmer

Edit

Delete

Print

>Set Clock

>hour.min 11:09

Day.mon 18.04

Year 2001

11:09:33

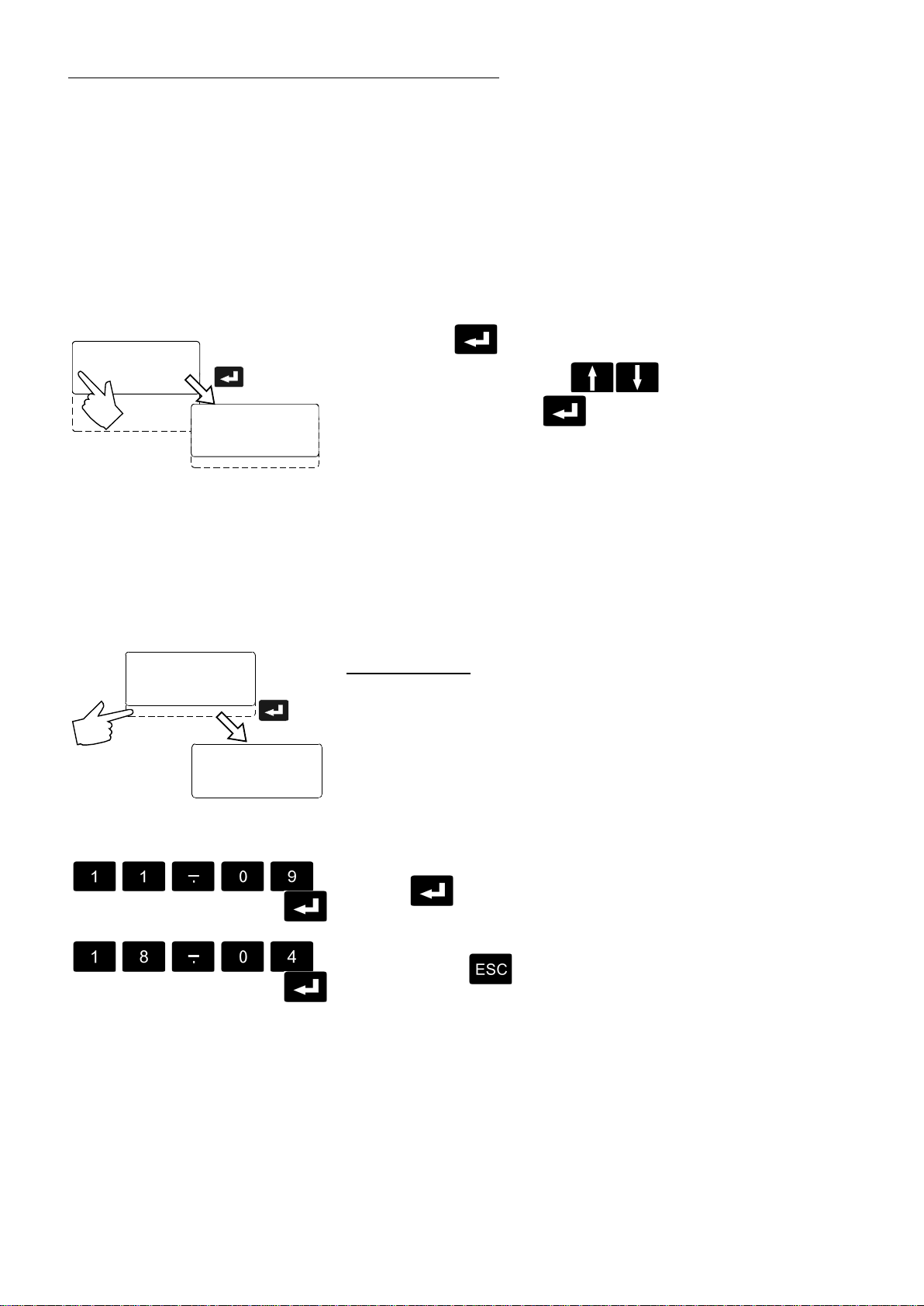

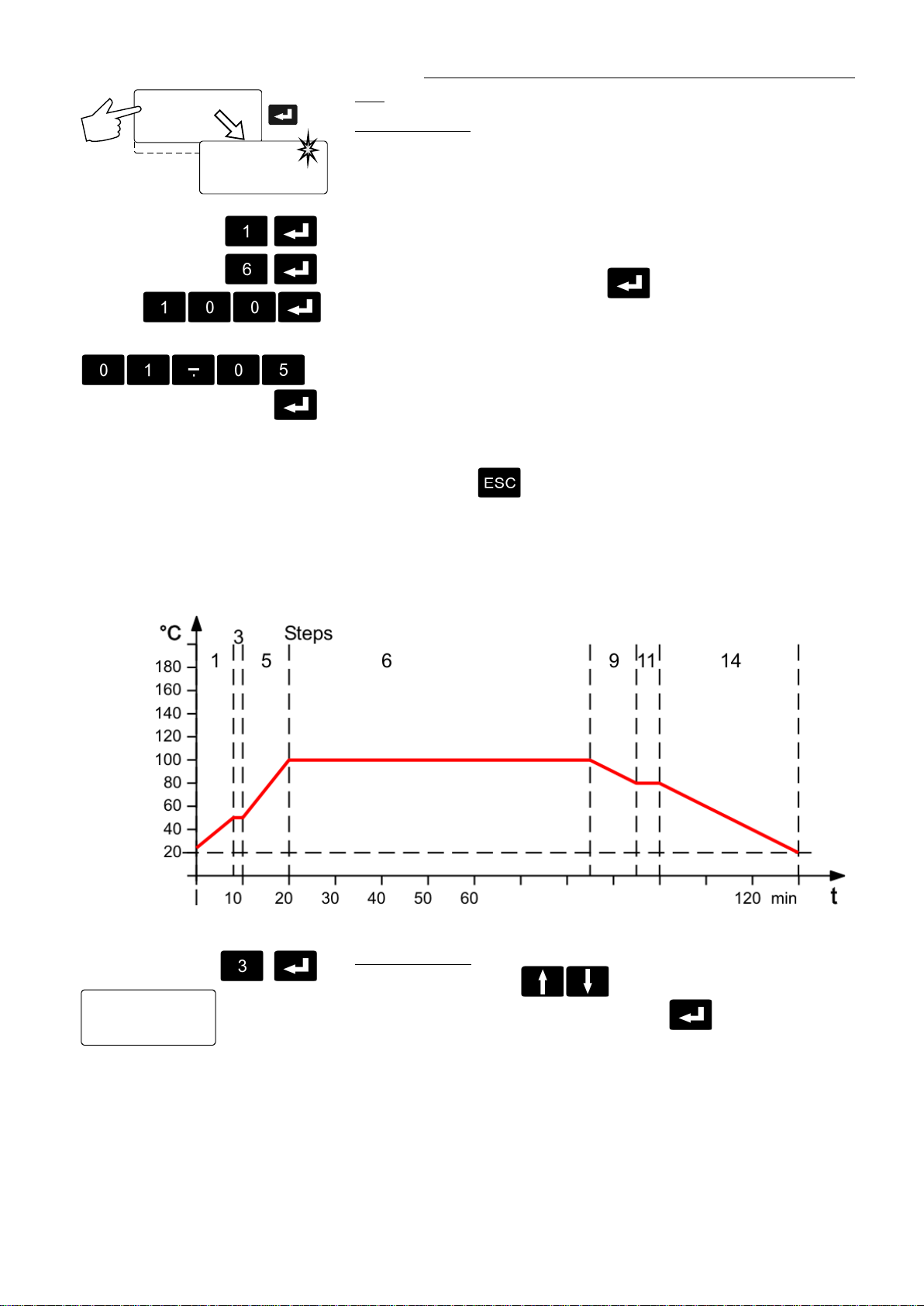

8.4. Integrated programmer

The integrated progr ammer allows any desired temperat ur e pr ogr am

sequences to be reali z ed. Suc h a temper ature sequence is called

profile. A profil e c onsi sts of individual sections defi ned by durat ion (t:)

and target temperature. Target temperature is the setpoint (T:), that is

achieved at the end of a secti on. T he pr ogr ammer uses time and